Combined pyrolysis gasifier

A pyrolysis gasification, combined technology, applied in the gasification process, the manufacture of combustible gas, the petroleum industry, etc., can solve the problems of a large amount of combustible waste or straw, "dioxin" emission, aggravated greenhouse effect, etc. The effect of prolonging the time of pyrolysis and gasification, reducing energy consumption and prolonging residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

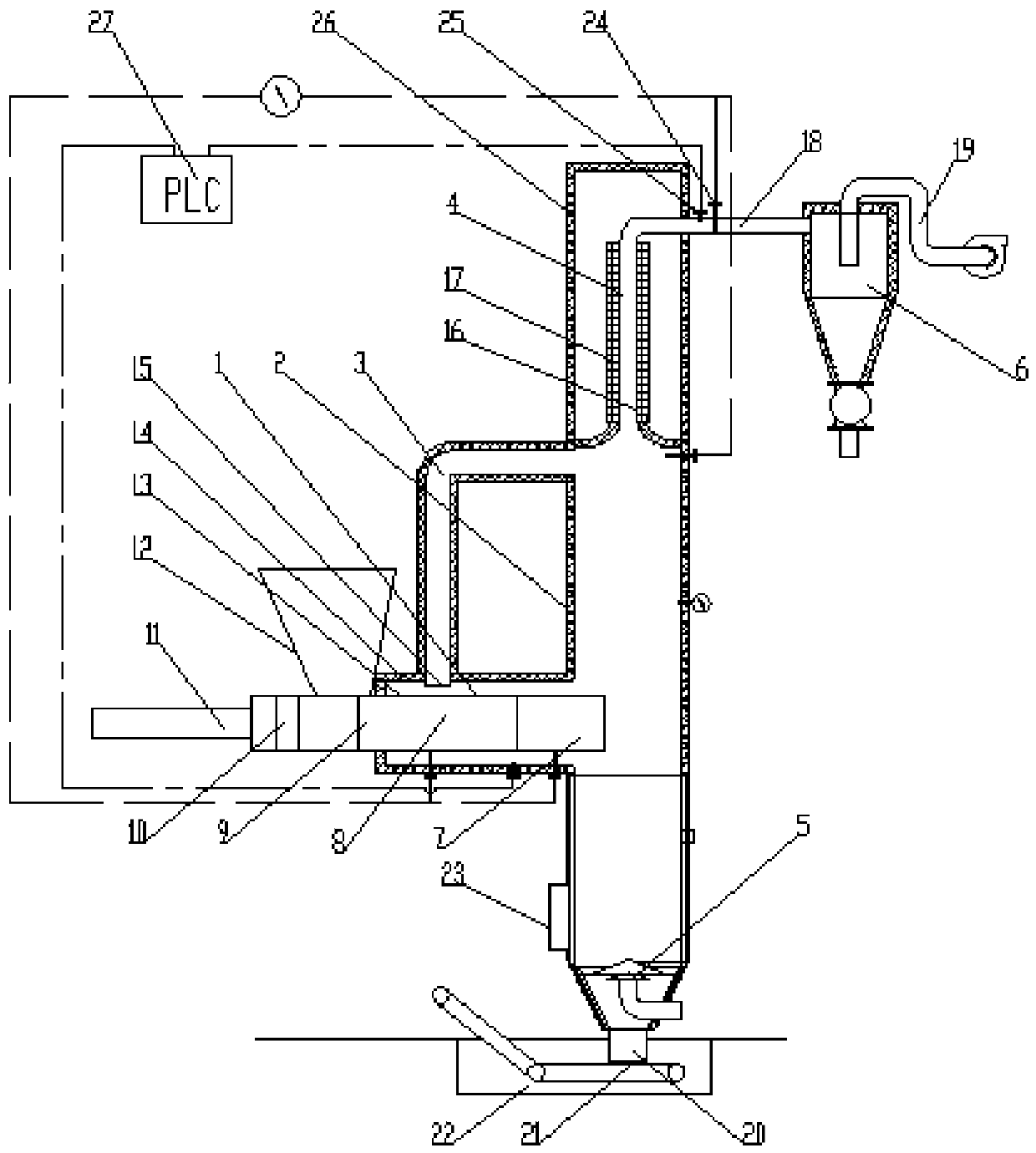

[0012] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0013] Such as figure 1 As shown, a combined pyrolysis gasification furnace includes a horizontal furnace body 1, a vertical furnace body 2, a water vapor extraction device 3, a tar thermal cracking catalytic device 4, a slagging device 5 and a cyclone dust removal device 6. The horizontal furnace body 1 is divided into a feed section 9, a drying section 8 and a pyrolysis gasification section 7 from left to right. The lengths of each section are respectively 1 / 3 of the total length of the horizontal furnace body 1. The hydraulic pushing device 11 and the pushing plate 10 communicate with the feed hopper 12 in the radial direction, the feeding section 9, the drying section 8 and the pyrolysis gasification section 7 form a horizontal inner layer furnace body 13, the drying section 8 and the pyrolysis section The gasification section 7 is also provided with an outer fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com