Method and device for continuously producing aqueous solution of long-carbon-chain nylon salt

A technology of long carbon chain and nylon salt, which is applied in the field of continuous production of long carbon chain nylon salt solution, and can solve the problems of low solubility and incompatibility with water of long carbon chain nylon salt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

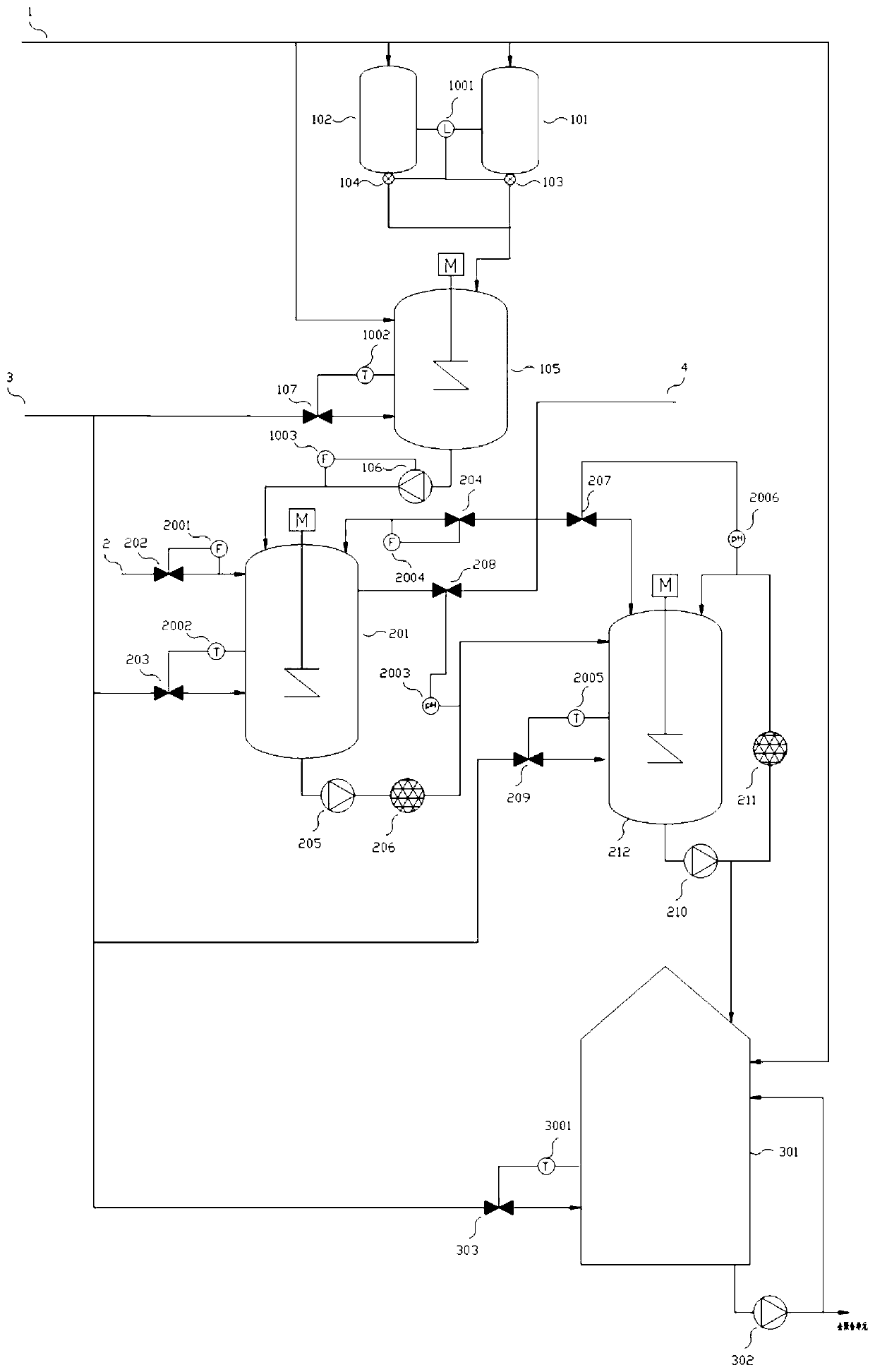

[0035] like figure 1As shown, a continuous production system for long carbon chain nylon salt is composed of a storage tank A 101, a storage tank B 102, a melting tank 105, a primary reaction kettle 201, a secondary reaction kettle 212 and a salt storage tank 301. There is a nitrogen pipe 1 on the upper part of the storage tank A 101 to provide nitrogen protection. There is a rotary valve A 103 at the bottom of the storage tank A 101 and a rotary valve B 104 at the bottom of the storage tank B 102 to feed materials to the melting tank 105 respectively. The level control system 1001 controls the feeding of long carbon chain diacids. When the storage tank B 102 reaches a low level, the rotary valve B 104 is stopped, and the rotary valve A 103 is started to continue feeding to the melting tank 105 . While tank A 101 is feeding melt tank 105, tank B 102 is recharged with long carbon chain diacids.

[0036] The temperature transmitter A 1002 monitors the temperature of the meltin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com