Patents

Literature

35results about How to "Optimizing the curing process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of artificial quartz stone composite color plate

The invention provides a preparation method of an artificial quartz stone composite color plate. The quartz stone composite color plate is prepared from quartz sand with different meshes, quartz powder, unsaturated polyester resin, a coupling agent, a curing agent, and an accelerant through the steps of batching, mixing, dyeing, distributing materials, performing vacuum vibration forming, curing by a drying oven as well as grinding and molding. During preparation of the quartz stone composite color plate, the treatment method of the raw materials is unique and the used equipment is improved by an inventor, so that the prepared quartz stone composite color plate has higher quality, the problems that flowing and blooming phenomena are liable to occur in the preparation process of the quartz stone composite color plate are solved, and outstanding contribution is made for the artificial quartz stone industry.

Owner:湖北赛典新材料科技有限公司

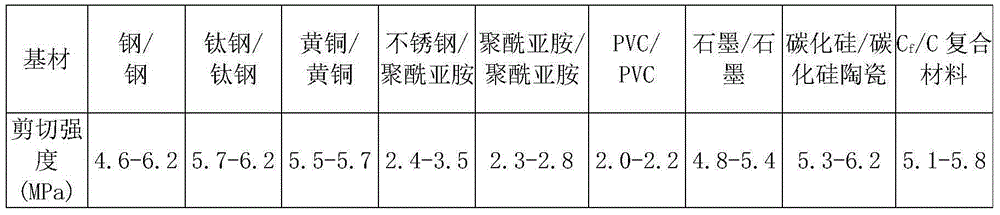

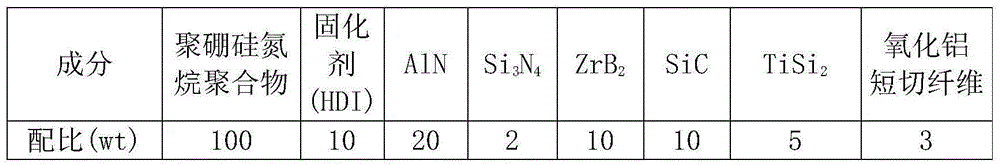

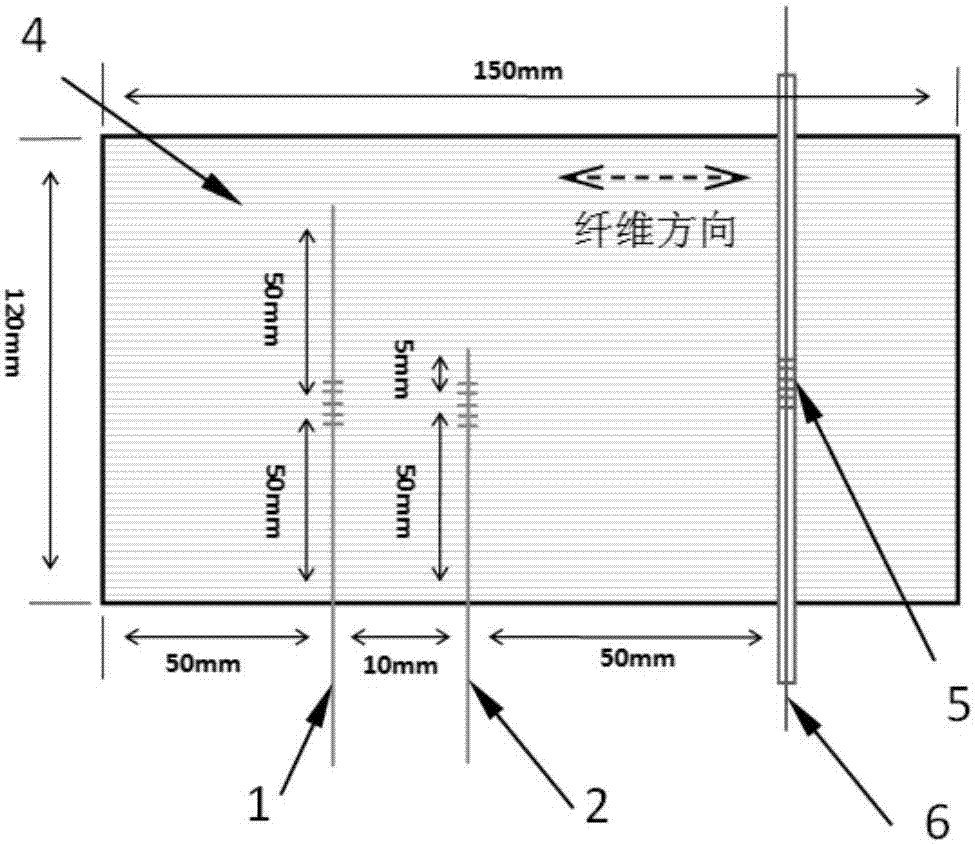

Room-temperature curing adhesive based on silazane and modified silazane polymer and preparation method thereof

ActiveCN105112010AOptimizing the curing processImprove temperature resistanceNon-macromolecular adhesive additivesOrganosiliconPhenol formaldehyde resin

The invention discloses room-temperature curing adhesive based on silazane and modified silazane polymer and a preparation method thereof. The silazane and the modified silazane polymer refer to one or more of polysilazane, polyborosilazane, polycarbosilazane, polysiloxazane and ceramic precursor polymer containing silicon-nitrogen bonds. The silazane-based ceramic precursor polymer can achieve room-temperature curing under the action of isocyanate, and room-temperature curing high-temperature-resistant organic silicone adhesive is prepared by compounding corresponding packing. The adhesive has high temperature resistance and still has quite high shearing strength at 1,000 DEG C. The adhesive has good thermostability, mechanical performance and adhesive performance, and the temperature resistance of the adhesive is superior to that of phenolic resin; compared with inorganic adhesive, the adhesive has excellent toughness.

Owner:INST OF CHEM CHINESE ACAD OF SCI

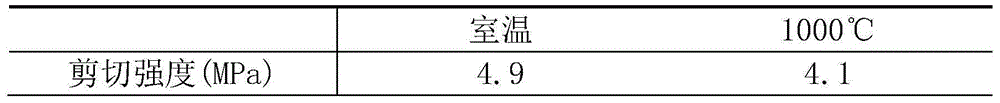

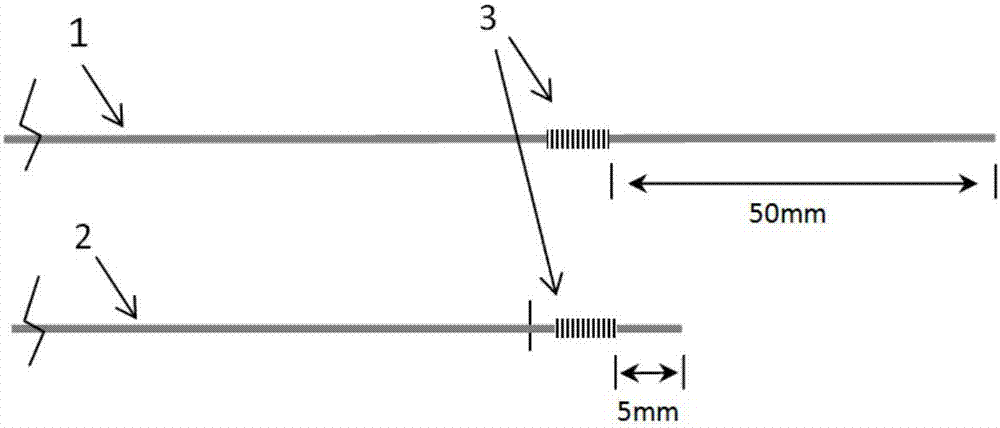

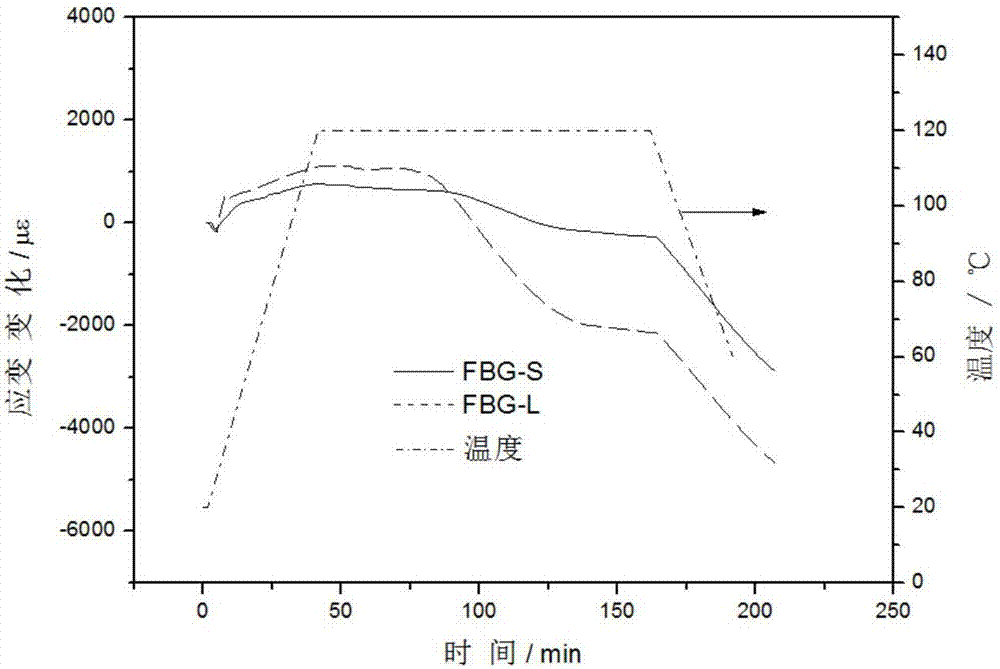

Method of monitoring effective chemical shrinkage rate of thermoset composite in real time

InactiveCN107367523ARealize real-time monitoringOptimizing the curing processMaterial thermal coefficient of expansionUsing optical meansGratingFiber Bragg grating

The invention provides a method of monitoring an effective chemical shrinkage rate of a thermoset composite in real time. The method comprises the following steps of: 1) selecting a truncated FBG (fiber bragg grating) group and a temperature reference grating, burying the truncated FBG group and the temperature reference grating in a unidirectional laminate of the thermoset composite, 3) performing curing molding, recording central wavelength variations of the truncated FBG group and the temperature reference grating in a curing process at the same time, 4) subtracting a central wavelength variation value of the temperature reference grating from central wavelength variation values of a long-tail FBG sensor and a short-tail FBG sensor, then dividing by a strain sensitivity coefficient to form strain variations of the long-tail FBG sensor and the short-tail FBG sensor, and 5) selecting a gel point and a glass transition point, and taking a strain variation value monitored by the long-tail FBG sensor between the gel point and the glass transition point at constant temperature stage in the curing process as the transverse effective chemical shrinkage rate of the composite, wherein the truncated FBG group comprises the long-tail FBG sensor and the short-tail FBG sensor. The method is simple, practicable and high in testing accuracy.

Owner:WUHAN UNIV OF TECH

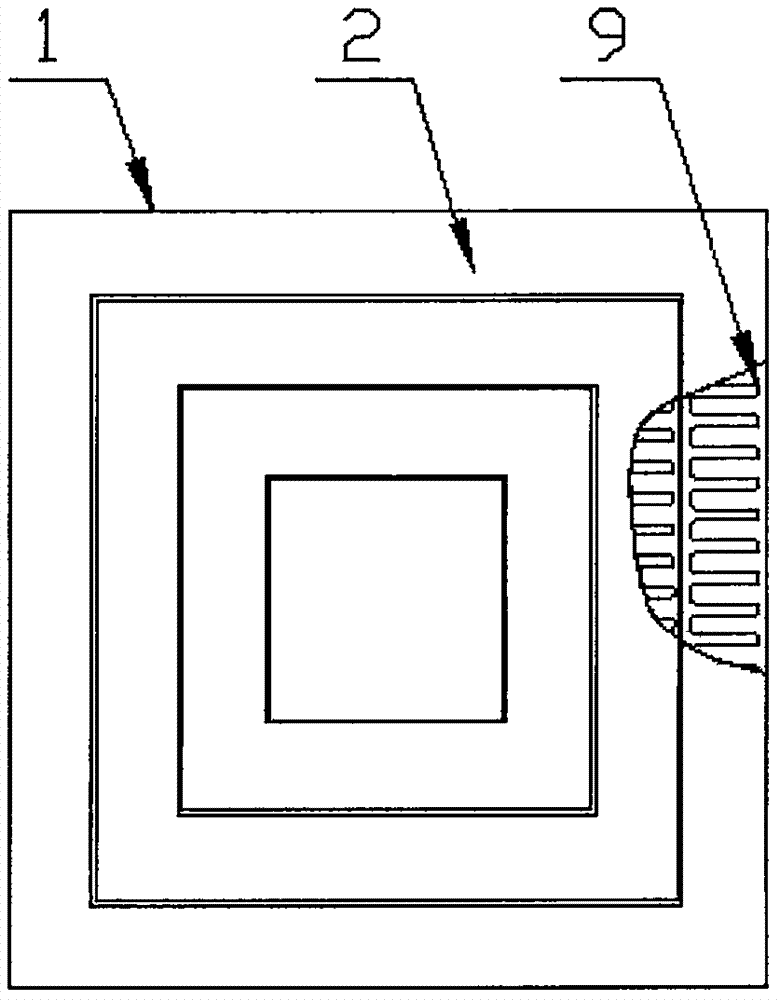

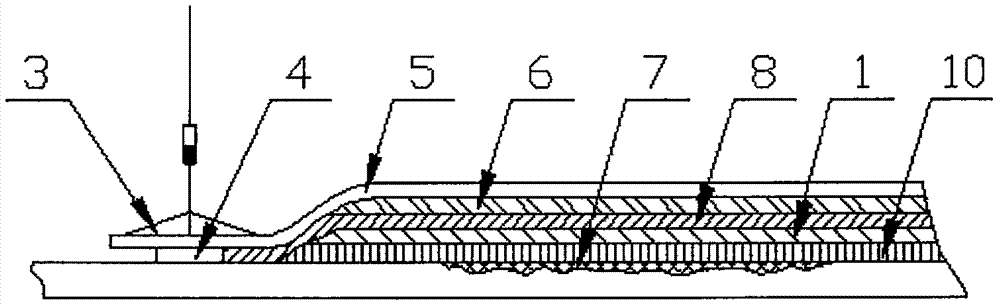

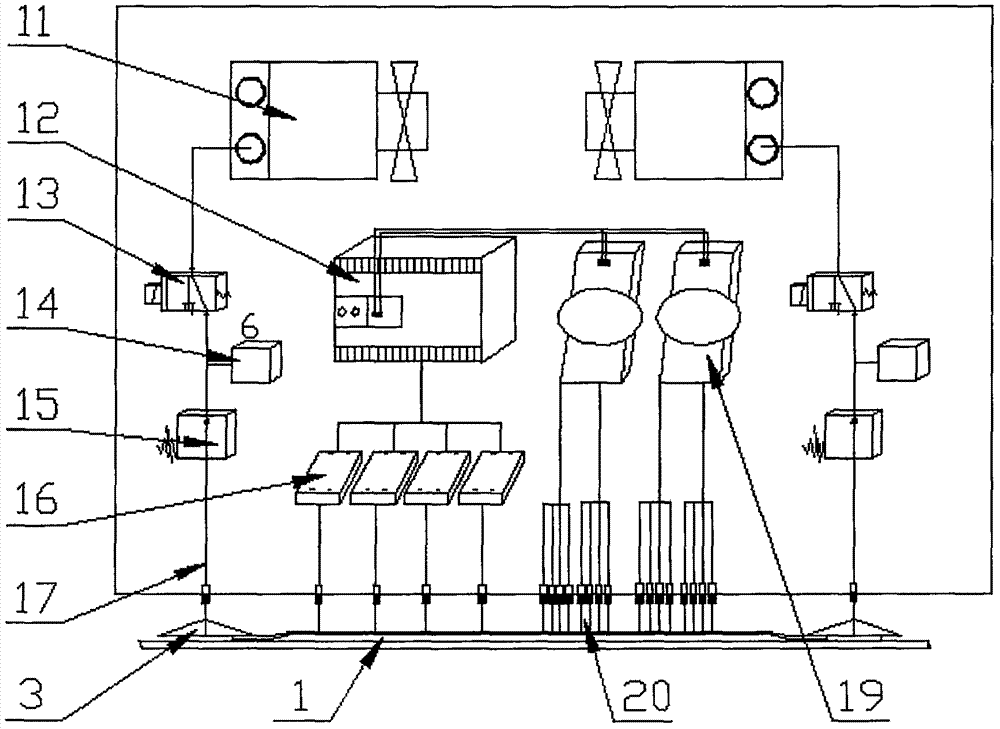

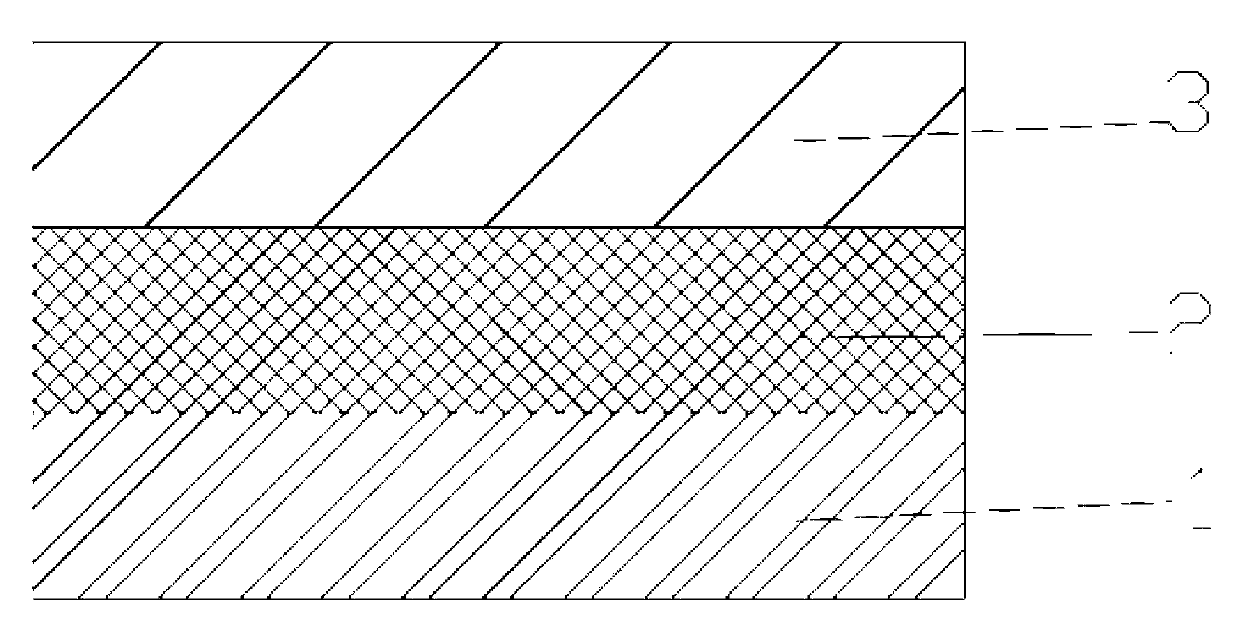

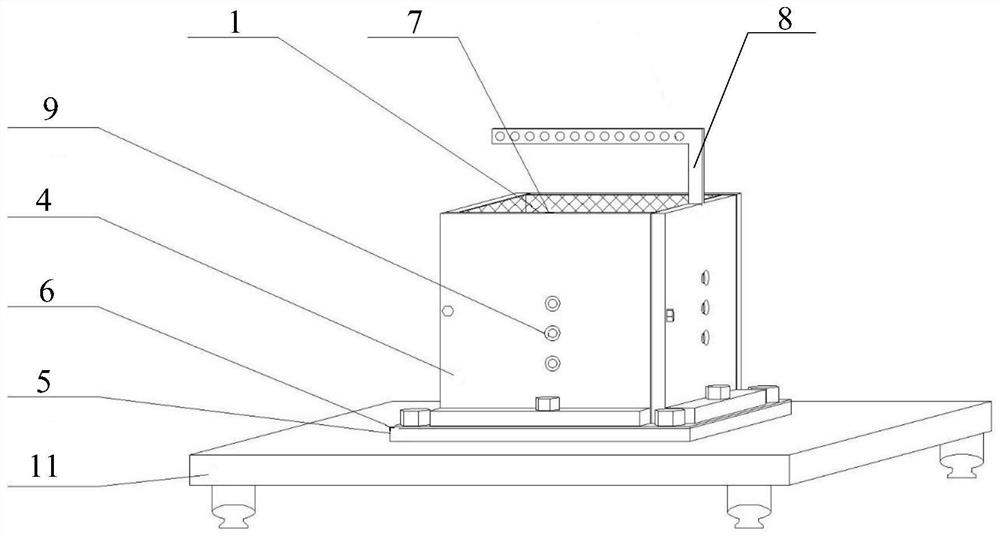

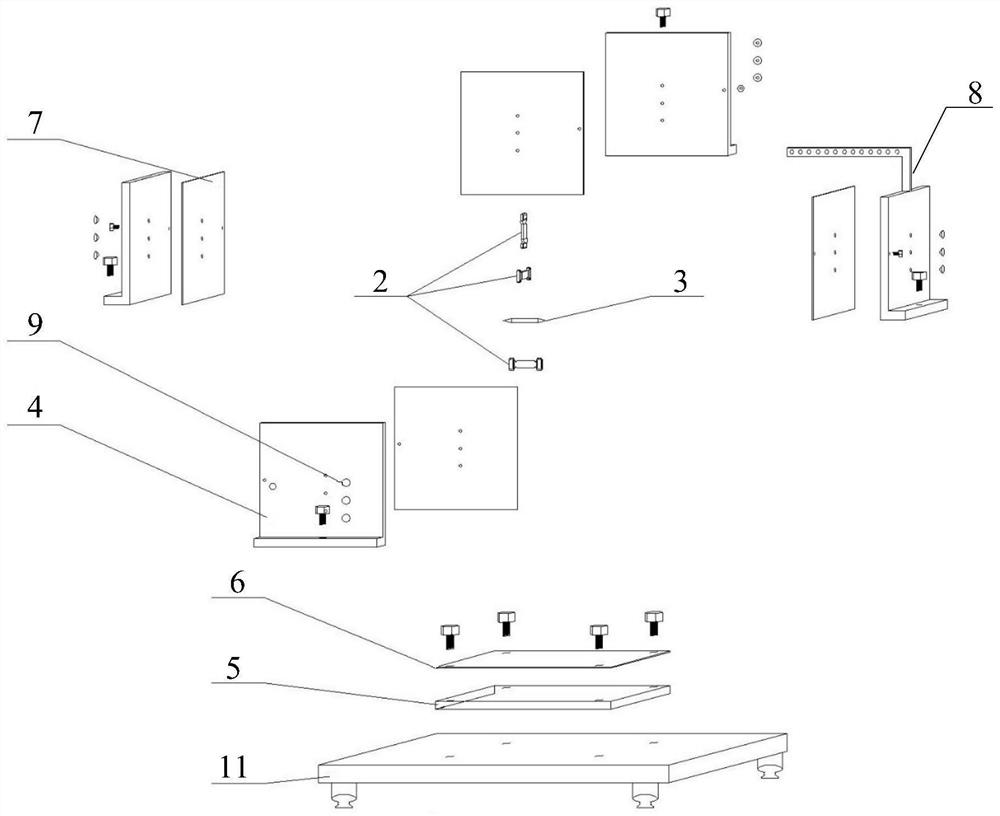

Monitoring and repairing method for curing and cementing of composite material

PendingCN107538771AUniform temperature fieldAvoid excessive temperature differenceDomestic articlesField conditionsDamage zone

The invention provides a method for monitoring and repairing composite material curing adhesive bonding, which belongs to the field of composite material adhesive bonding repair equipment. The method is based on a composite material curing adhesive repair instrument, which includes a body, and a curing source module is provided at the adhesive repair working surface of the body, and the curing source module provides energy for the composite material prepreg to cure, and the curing The source module is surrounded by multiple temperature zones from the inside to the outside. Each temperature zone is equipped with an independent curing source for providing energy to the temperature zone. The multiple temperature zones are used alone or in conjunction with each other, and according to The shape of the damaged area of the structure is determined, and the temperatures of multiple temperature zones are the same or different. The present invention is based on multi-area curing source control, establishes a uniform and stable temperature field under external field conditions, and solves the problem of avoiding excessive temperature differences. Based on the principle of heat conduction, the multi-area temperature field control technology is used to achieve uniform and stable bonding repair areas. temperature field while avoiding excessive temperature differences.

Owner:青岛东正浩机电科技有限公司

Nano-composite coating material

InactiveCN110157329AOptimizing the curing processHigh hardnessCoatingsPolymethyl methacrylateAluminium isopropoxide

The invention discloses a nano-composite coating material. The nano-composite coating material is prepared by taking aluminium isopropoxide (AIP) and siloxane with relatively low price are used as main raw materials, and the composite coating is prepared with combination of a sol-gel method, wherein pencil hardness of the composite coating on polycarbonate (PC) and polymethyl methacrylate (PMMA) reaches 6H or above, and adhesive force reaches 2. According to the invention, firstly, a composite coating is modified by tetraethyl orthosilicate (TEOS), and the research shows that through additionof a tetraethyl orthosilicate hydrolysis product, a polycondensation reaction between AIP hydrolysis products and organosiloxane hydrolysis products is further promoted, so that curing process of thecomposite coating can be optimized, and hardness and adhesive force of the coating can be improved; and then, the composite coating is modified by an alcohol-water mixture of the graphene-like molybdenum disulfide, so that wear resistance of the coating can be improved, and gas-liquid barrier performance of the coating can be improved.

Owner:LANZHOU CITY UNIV

Preparation method of C/SiC composite material

The invention provides a preparation method of a C / SiC composite material. The C / SiC composite material is prepared by preparing a porous C / C composite material by means of an infiltration method. Asa special high-activity porous body C / C is adopted to reactive infiltration, the mechanical property and the anti- ablation property of the material are improved. The preparation method can be also applied to rapid low-cost preparation of a ceramic-based composite material.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

Preparation method of hydrophobic material for antenna housing surface and application of hydrophobic material

ActiveCN108841263AOptimizing the curing processGood weather resistanceDomestic articlesCoatingsOXALIC ACID DIHYDRATERadar antennas

The invention discloses a preparation method of a hydrophobic material for an antenna housing surface and application of the hydrophobic material and relates to the preparation method and the application of the hydrophobic material. The problem that a hydrophobic material on the surface of a radar antenna housing is low in weather resistance and low in hydrophobic property is solved. The preparation method comprises the following steps: 1, modifying nano SiO2 by a silane coupling agent, namely uniformly mixing an oxalic acid solution and absolute ethyl alcohol, adding a KH-570 silane couplingagent, adding into SiO2 dispersion, reacting at a temperature of 70-80 DEG C, and performing vacuum drying to obtain the modified Nano-SiO2 powder; and 2, preparing resin, namely adding vinyl polytetrafluoroethylene into butyl acetate dispersion of the modified Nano-SiO2. The hydrophobic material is applied to the surface of the antenna housing to prepare a hydrophobic coating. The hydrophobic material applied to the surface of the antenna housing prepared in the invention has a static hydrophobic angle of more than 120 degrees, and after the artificial 1000 h weathering test, the hydrophobicangle is more than 110 degrees.

Owner:HARBIN TOPFRP COMPOSITE

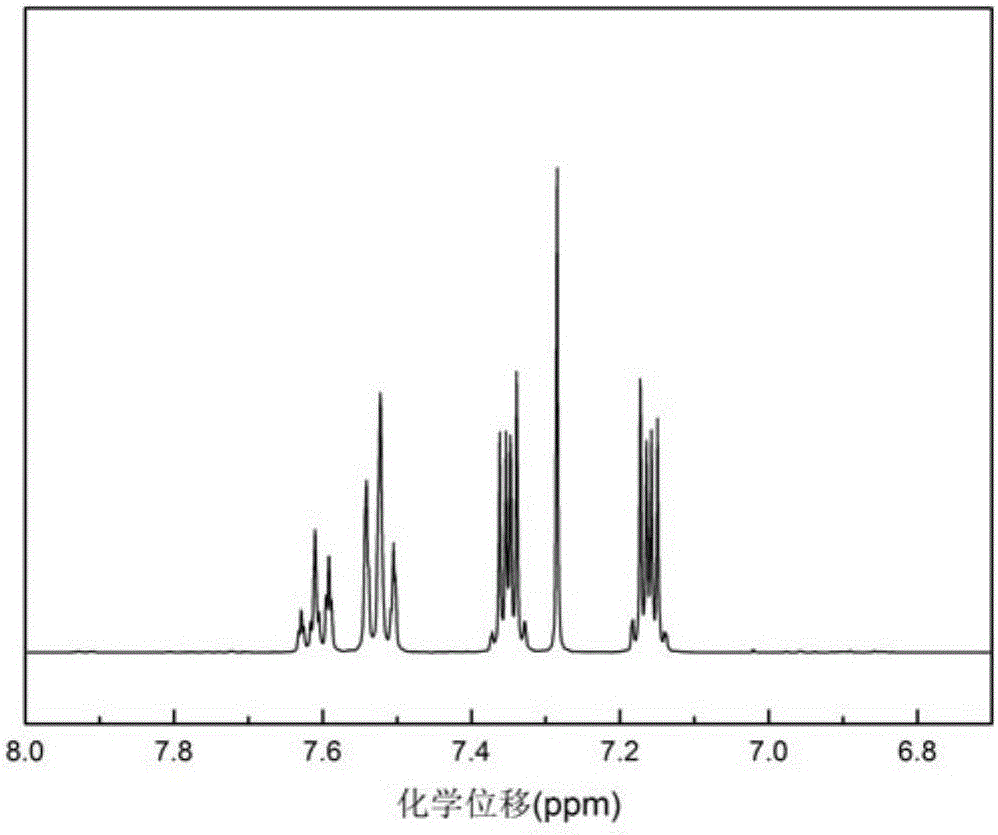

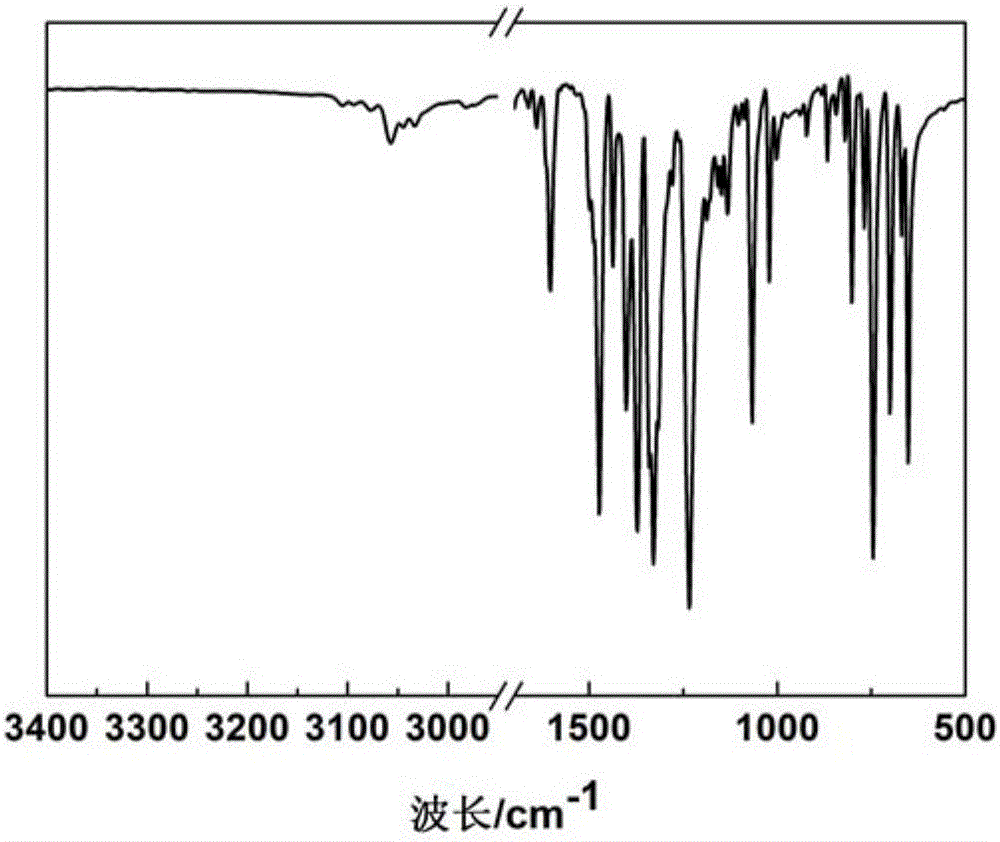

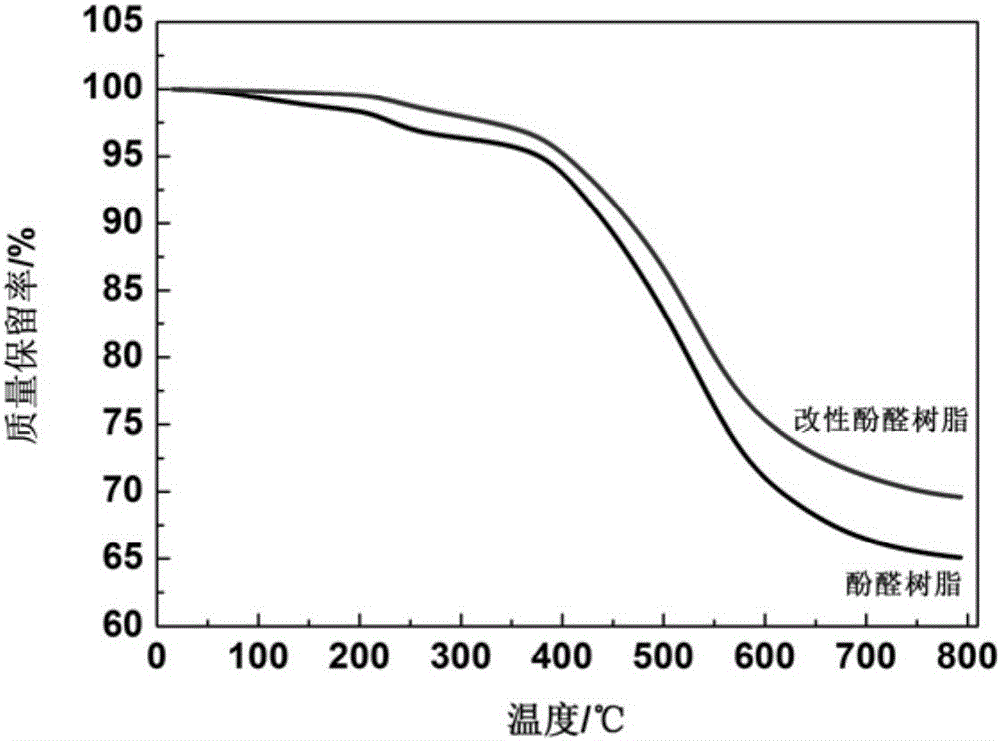

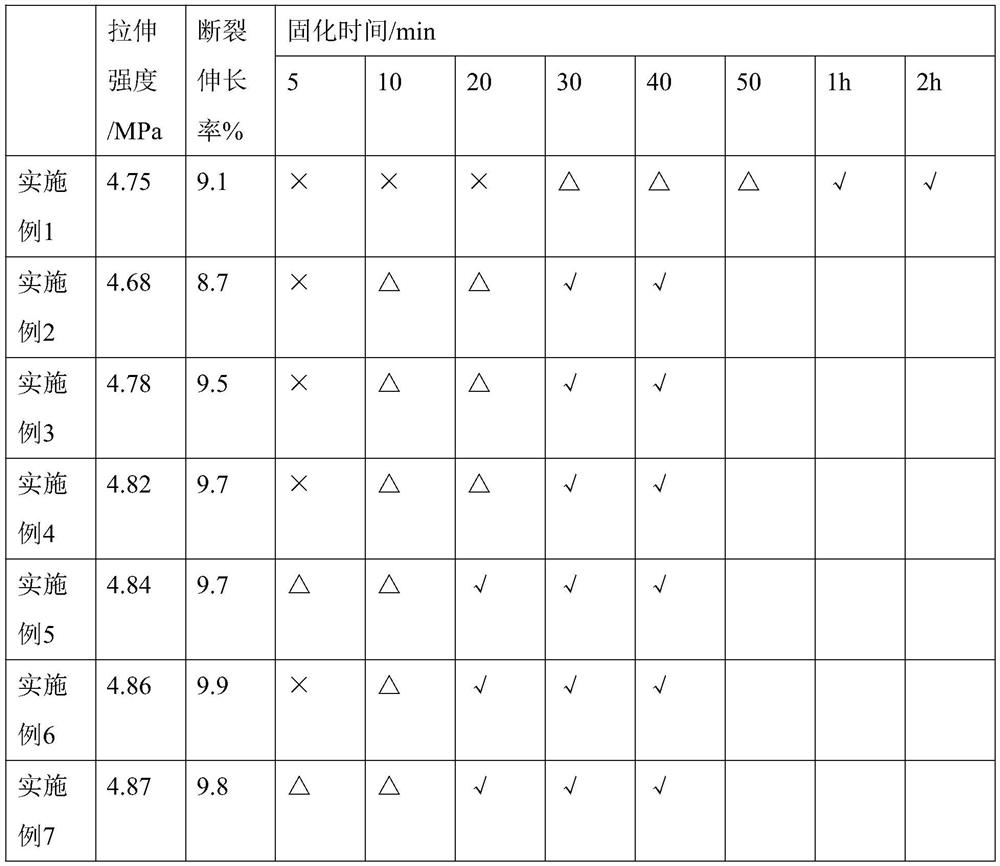

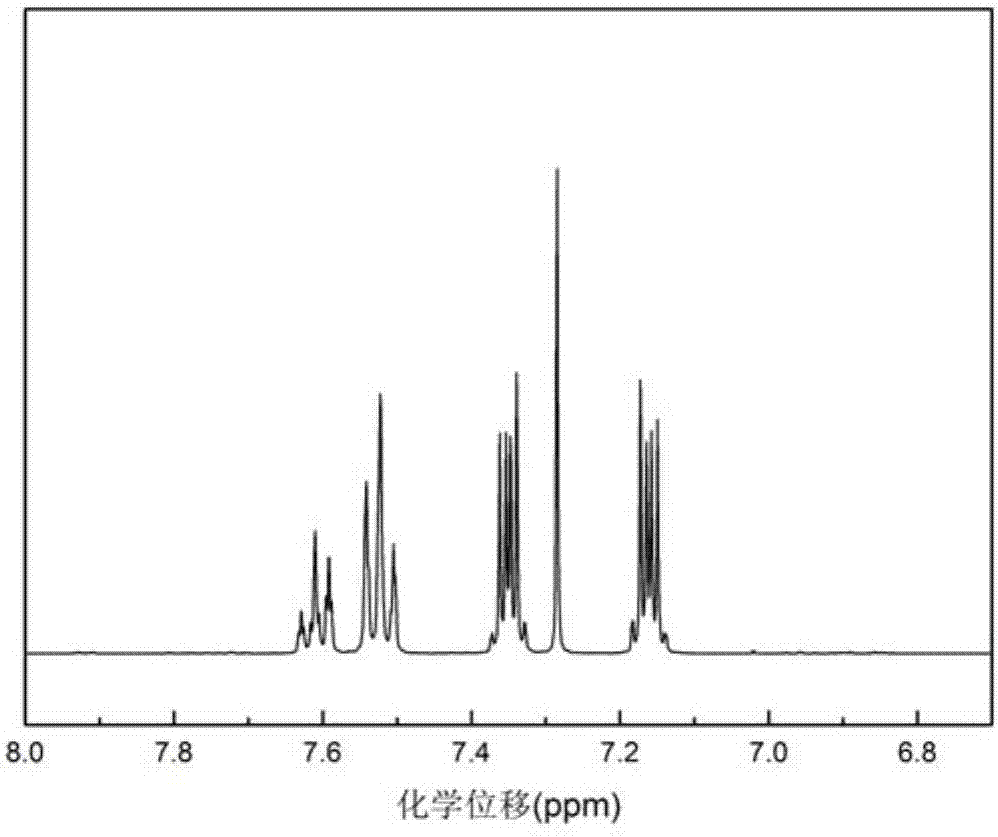

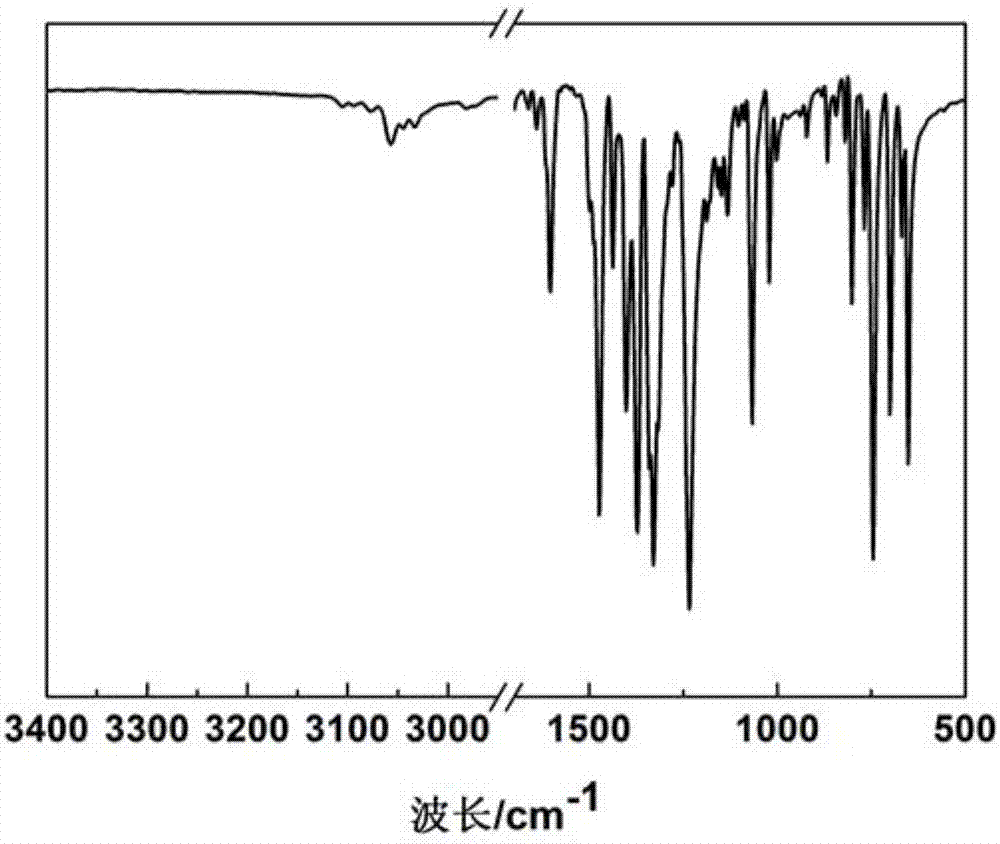

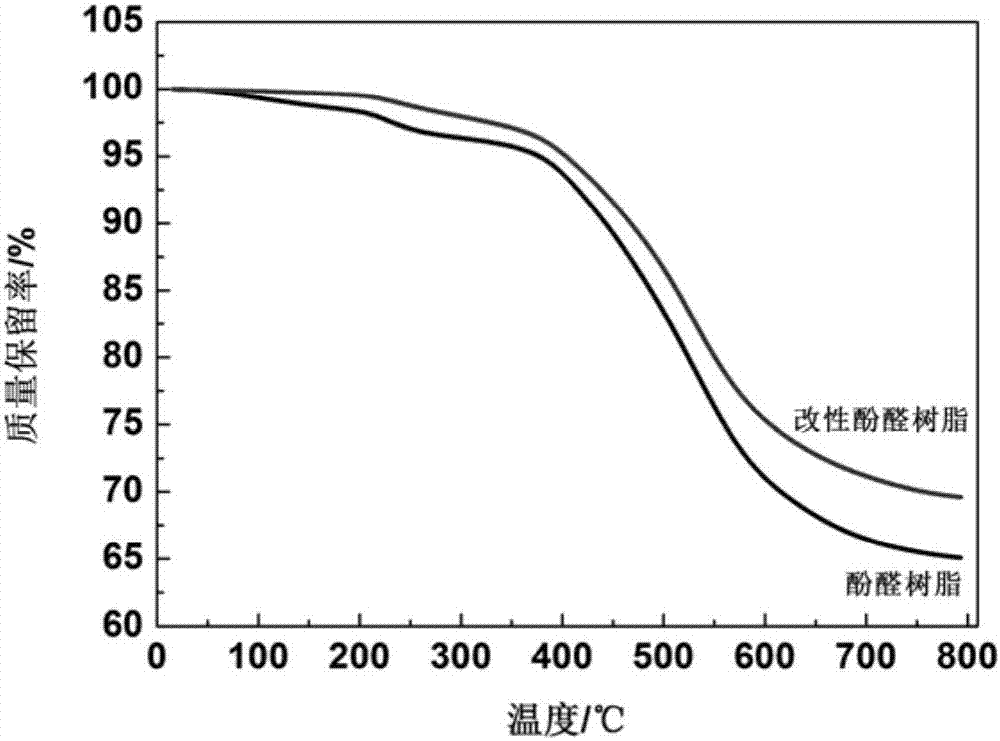

Preparation method of arylboronic acid catechol ester modified phenolic resin

A preparation method of arylboronic acid catechol ester modified phenolic resin comprises the steps that a boric acid catechol ester compound is added to phenolic resin under an inert atmosphere, heat treatment is performed at the temperature of 110 DEG C for 2 hours after even mixing, then curing is performed at the temperature of 160 DEG C for 2-4 hours to obtain the arylboronic acid catechol ester modified phenolic resin, wherein the mass of the boric acid catechol ester is 1-35% of the mass of the phenolic resin. The adverse influence brought by in-situ formation of a boric acid ester structure of an existing boric acid compound modified phenolic resin is overcome, and a composite material curing process is improved, so that a curing product has a compact structure and good properties, and cured resin has high thermal stability. The resin can be used as a high-performance composite material resin matrix, a carbon / carbon composite material, a high-temperature brake material, a frictional material, a heat insulation material, an adhesive, a coating and a flame retardant material and used in other high-tech fields.

Owner:XI AN JIAOTONG UNIV +1

High heat conductive epoxy sealant, and preparation method thereof

InactiveCN109705788AImprove thermal conductivityExpand the scope of applicationNon-macromolecular adhesive additivesEpoxy resin adhesivesCvd grapheneOxide

The invention provides a high heat conductive epoxy sealant. The high heat conductive epoxy sealant comprises following raw materials: epoxy resin, a high heat conductive filling material, a curing agent, an antifoaming agent, and a wetting dispersant; the epoxy resin is one or a mixture of two components selected from bisphenol A epoxy resin and bisphenol F epoxy resin; the high heat conductive filling material is one or a mixture of a plurality of components selected from silica, alumina, zinc oxide, copper powder, and graphene; the curing agent is one or a mixture of a plurality of components selected from dicyandiamide, imidazole, and carbamide. The heat conductive performance of the high heat conductive epoxy sealant is obviously better that that of commercially available products, and is as high as 2.0W / (m.k); cost is low, and the cost is 1 / 3 of that of foreign products; the high heat conductive epoxy sealant is a single component material; middle and low temperature curing can be realized; the curing technology is simple; product suitable range is wide; using is convenient; low temperature storage time can be longer than 6 months; the high heat conductive epoxy sealant is convenient to store; and waste is avoided.

Owner:SHANGHAI JORLE FINE CHEM

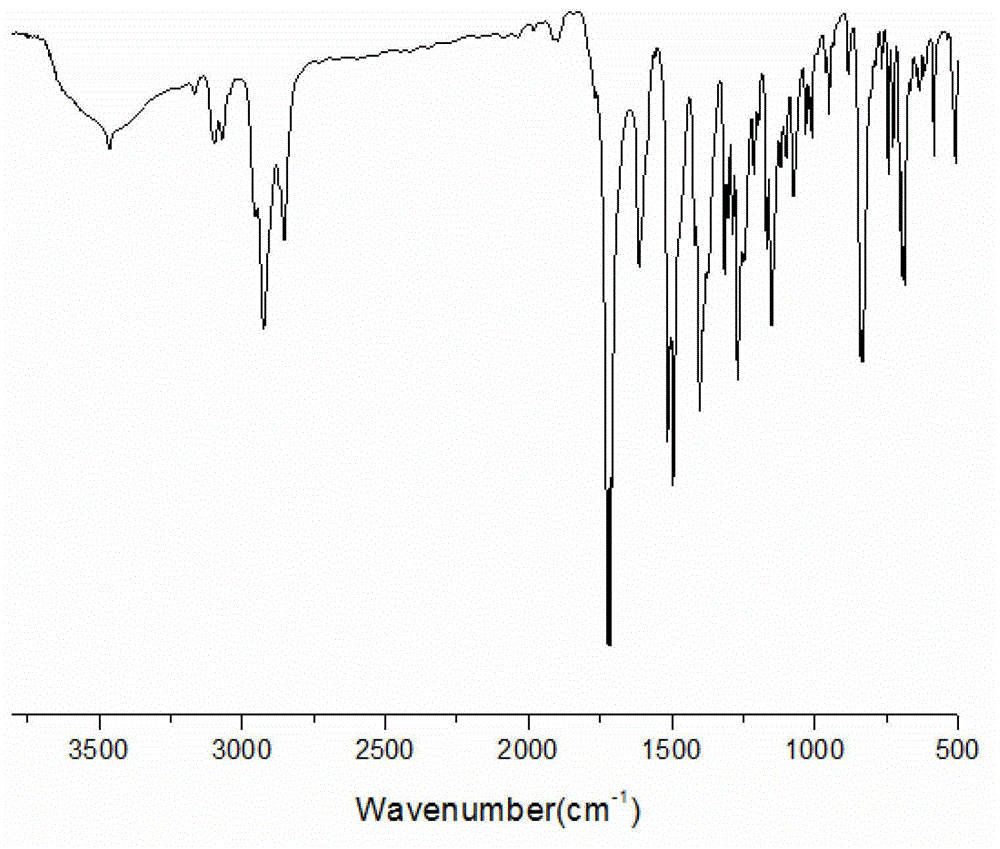

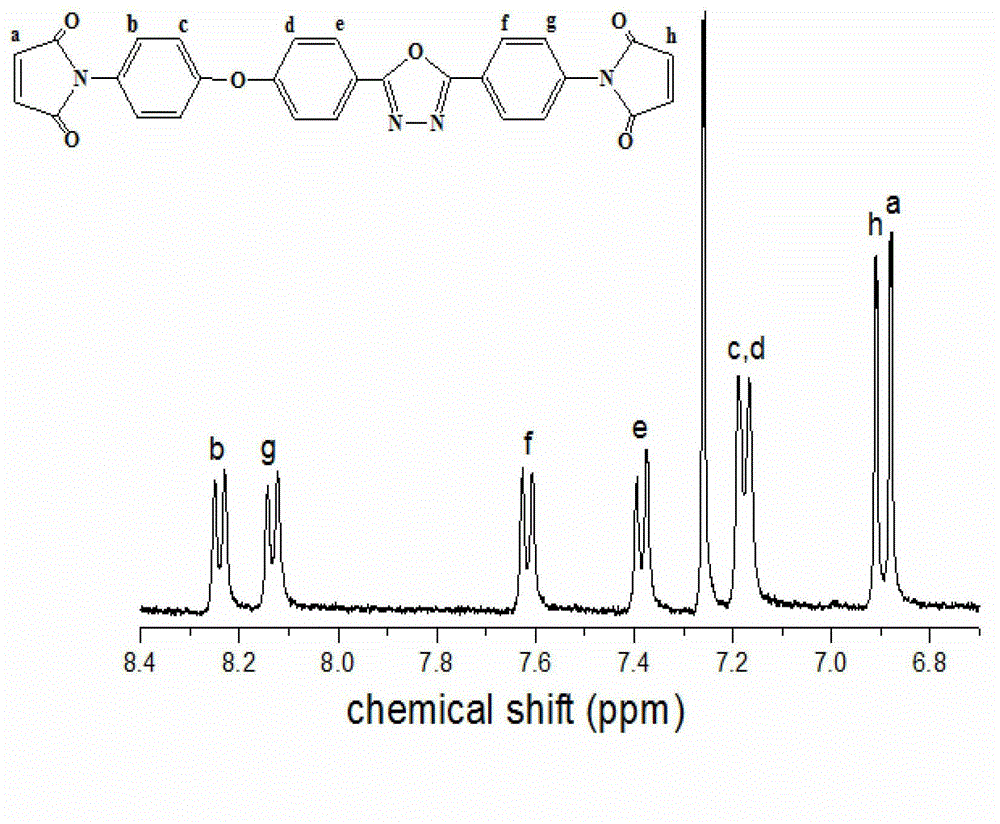

Asymmetric bismaleimide containing 1, 3, 4-oxadiazole structure and preparation method thereof

InactiveCN102942564AImprove heat resistanceImprove mechanical propertiesOrganic chemistrySolubilityImide

The invention discloses a novel asymmetric bismaleimide containing a 1, 3, 4-oxadiazole structure and a preparation method thereof, and mainly solves the problem of fused process difficulty caused by large rigidity, high melting point and poor solubility property of the bismaleimide. Substituents R1 and R2 in the bismaleimide structure are -H and C1-C6 saturated fatty alkyl. Asymmetric aromatic diamine containing the 1, 3, 4-oxadiazole structure reacts with maleic anhydride to generate bismaleamic acid, and imide cyclization reaction is performed in the present of catalysts and dehydrating agents to obtain the bismaleimide. According to the bismaleimide, the structure is asymmetric, double bonds at two ends are in different chemical environments, and the reactivity and the curing temperature are different, so that curing is more stable; the 1, 3, 4-oxadiazole structure is introduced, cured products are provided with superior heat resistance and mechanical properties and suitable for being used as matrices of high-performance polymer matrix composites.

Owner:SHENYANG AEROSPACE UNIVERSITY +1

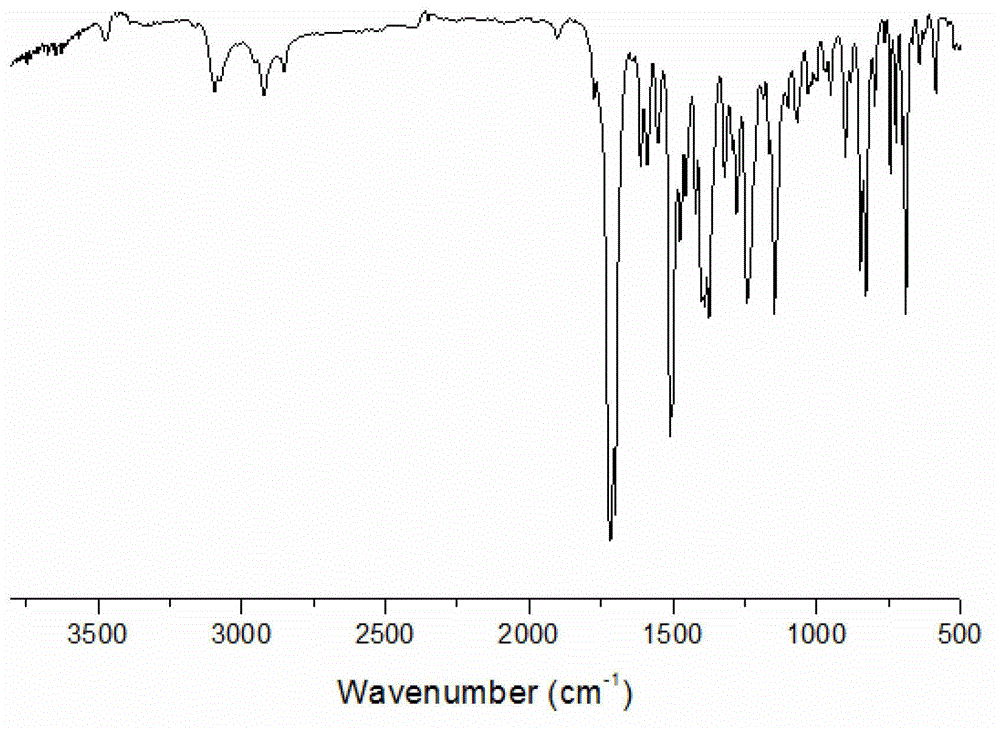

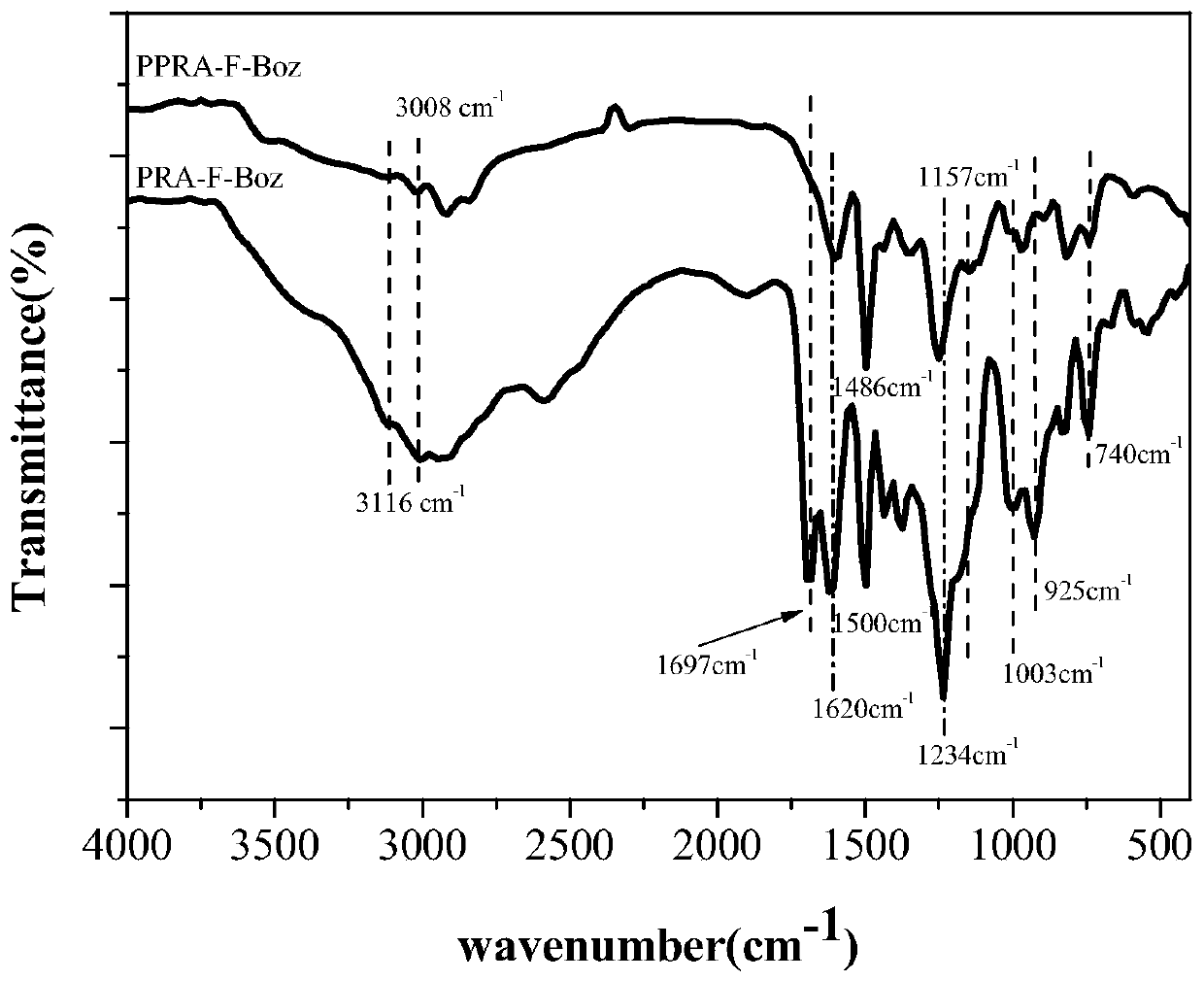

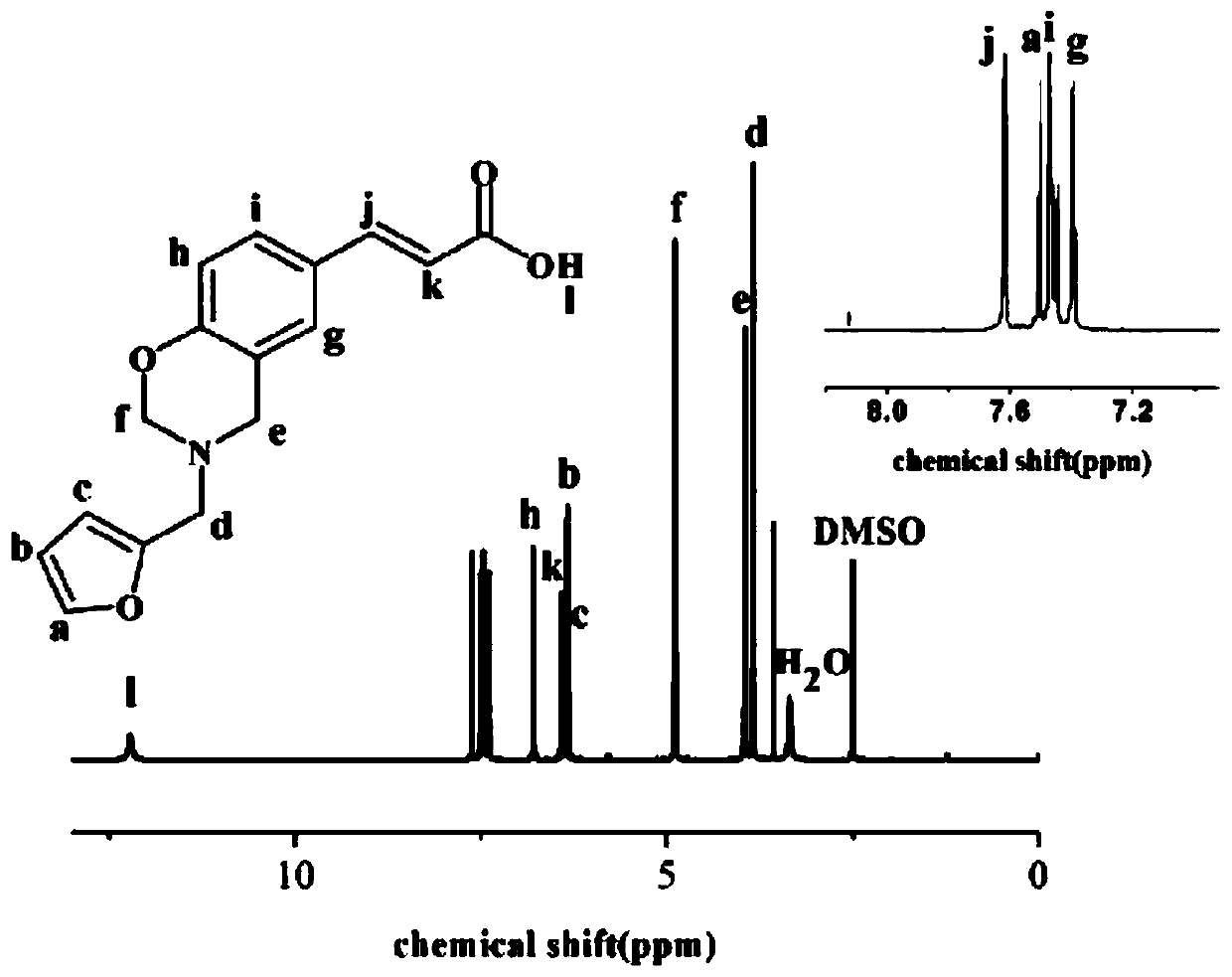

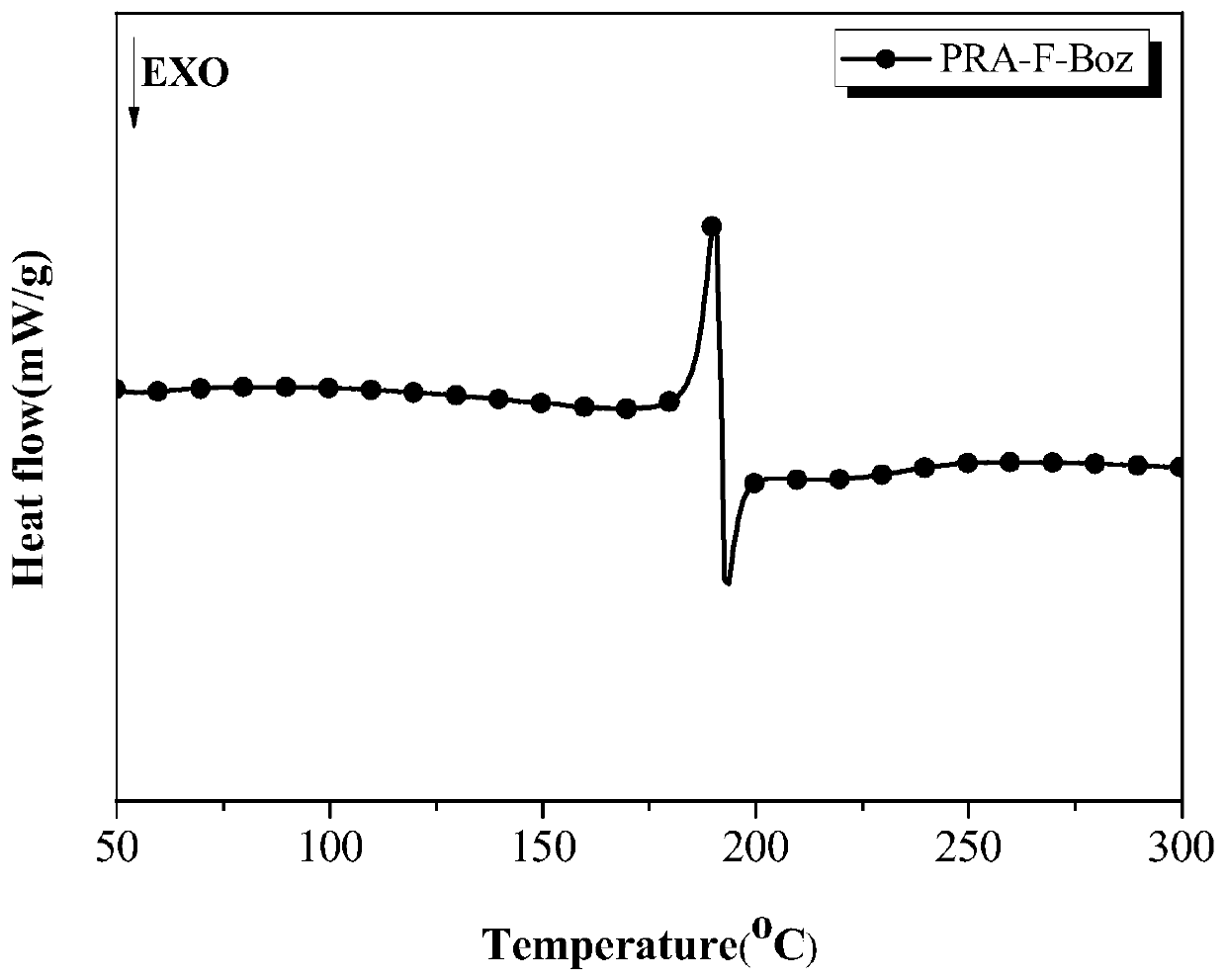

Monomer of benzoxazine resin, benzoxazine resin and preparation method of benzoxazine resin

ActiveCN111138423AGet rid of excessive dependenceThe synthesis process is simpleOrganic chemistryPolymer scienceCoumaric acid

The invention relates to a monomer of a benzoxazine resin, a benzoxazine resin and a preparation method of the benzoxazine resin, wherein the structural formula of the benzoxazine resin is representedby the following formula (II). According to the benzoxazine resin disclosed by the invention, p-coumaric acid and furfuryl amine are respectively used as a phenol source and an amine source, And PRAmolecules have phenolic hydroxyl structures similar to those of phenol, so that PRA serving as a bio-based polymer monomer can completely replace phenol or bisphenol A to be used for preparing high polymer materials such as a benzoxazine resin and the like; FA is also a common biomass fine chemical industry raw material produced from plant raw materials such as corncobs, cottonseed hulls, bagasseand the like in nature; and by taking p-coumaric acid as a phenol source and furfuryl amine as an amine source, excessive dependence of the traditional benzoxazine resin on petroleum products is eliminated.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

Organic titanium epoxy resin catalytic ester cyanate system

An ester cyanate resin system with organic titanium epoxy resin as catalyst is characterized by taking organic titanium modified epoxy resin as catalyst, which is obtained by reacting tetrabutyl titanate with hydroxyl in glycidol ether epoxy resin structure, and consisting of ester cyanate resin 70-99.99% and organic titanium epoxy resin catalyst 0.01-30%. It can improve curing process of resin system, lower curing temperature, shorten curing time and cost low.

Owner:AVIC COMPOSITES

Strong release-type connecting adhesive tape

InactiveCN102766417A"The connecting function is goodStrong release propertiesFilm/foil adhesivesCoatingsPolymer scienceLow mobility

The invention relates to the field of adhesive tape, and specifically provides a strong release-type connecting adhesive tape. The connecting adhesive tape comprises a layer of PET film, which is characterized in that one surface of the PET film is coated with a silica gel-water layer, and the other surface of the PET film is coated with a silicon fluoride coating. The connecting adhesive tape provided by the invention has good adhesive property on release paper with low surface energy, high temperature resistance, and strong release characteristics on the back, and can be reused for 8-10 times. The connecting adhesive tape provided by the invention has large shearing force in high temperature bonding, and will not break paper after connection. The release-type coating has extremely low mobility, good strong release type and solvent resistance. The connecting adhesive tape provided by the invention is mainly used for production of artificial leather and industrial adhesive tape.

Owner:广州市鸿鹄胶粘材料科技有限公司

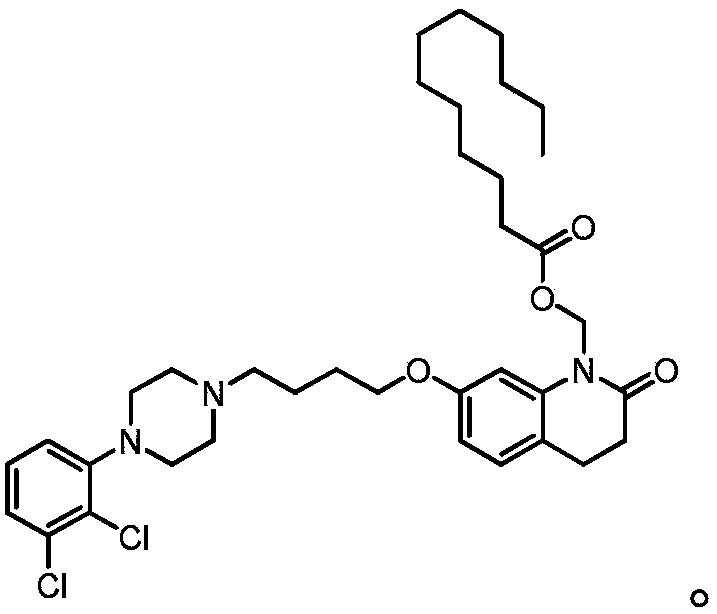

Preparation method of aripiprazole lauroxil

PendingCN110204488AImprove conversion rateResidue reductionOrganic chemistryAripiprazole lauroxilOrganic solvent

The invention belongs to the technical field of medicine synthesis methods, and provides a preparation method of aripiprazole lauroxil. The preparation method comprises the following steps: (1) carrying out a hydroxymethylation reaction: contacting and reacting aripiprazole, an aqueous formaldehyde solution having a mass concentration of 35-40 wt% and an alkali in an organic solvent to obtain hydroxymethyl aripiprazole; and (2) carrying out a lauroylation reaction: contacting and reacting the hydroxymethyl aripiprazole, an organic alkali and lauroyl chloride in a solvent which is immiscible with water at 20-30 DEG C, and then recrystallizing the obtained reaction product in a crystallization solvent to obtain the aripiprazole lauroxil. The method of the invention can improve the yield of the two-step reaction of hydroxymethylation and lauroylation and the purity of the product, and also can shorten the reaction time, simplify the post-treatment process and reduce the material cost.

Owner:SICHUAN KELUN PHARMA RES INST CO LTD

Preparation method and application of polyimide varnish

InactiveCN112608675AImprove mechanical propertiesExcellent electric heating performanceCoatingsSilicon-controlled rectifierPolymer science

The invention discloses a preparation method and the application of polyimide varnish. The method comprises the steps of dissolving the refined aromatic diamine and aliphatic diamine into the refined organic solvent, then adding the refined aromatic dianhydride in batches, and stirring and reacting for several hours under the protection of low-temperature inert gas to obtain polyimide varnish; after the varnish is filtered for multiple times, covering the surfaces of microelectronic devices with the varnish such as rectifiers, diodes, triodes, high-power silicon controlled rectifiers, high-voltage silicon stacks, thyristors and the like and large-scale integrated circuit patterns by adopting methods such as drop coating, roller coating, silk-screen printing and the like, and high-insulation, high-strength and then obtaining low-expansion electronic components through stepped heating and curing. The method has the advantages of accessible raw materials and simple operation, and is suitable for large-scale industrial production.

Owner:武汉市美克亚胺科技有限责任公司

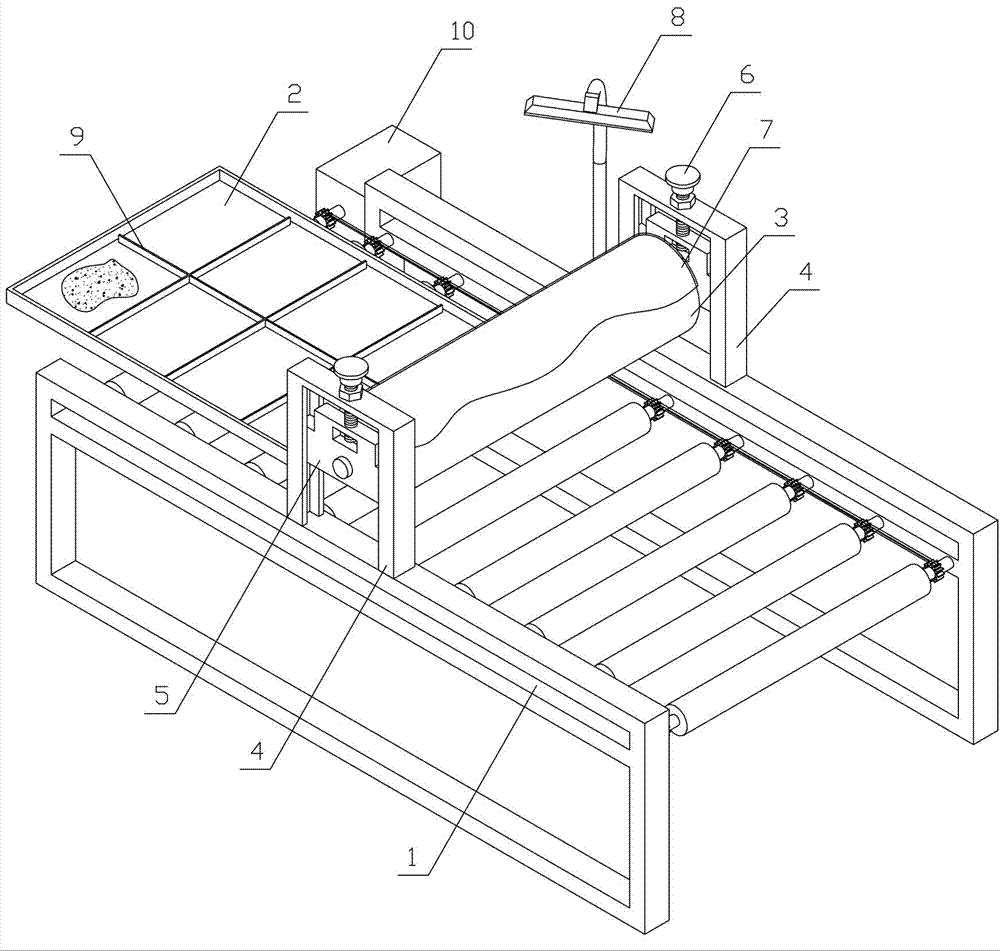

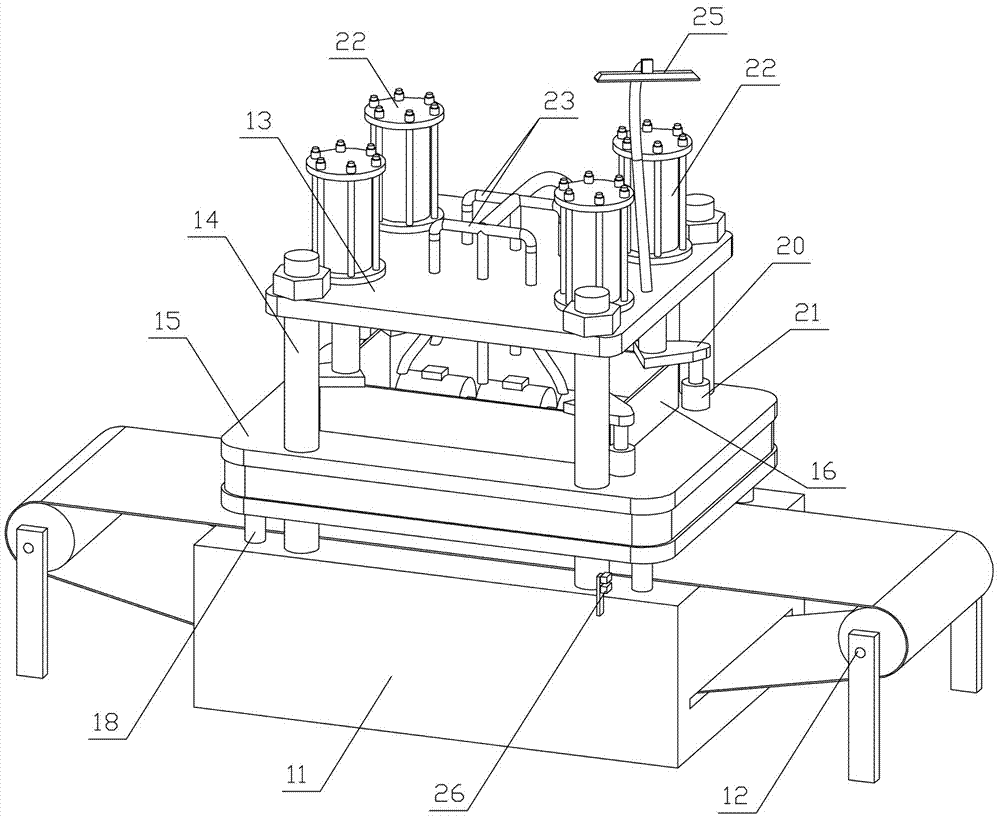

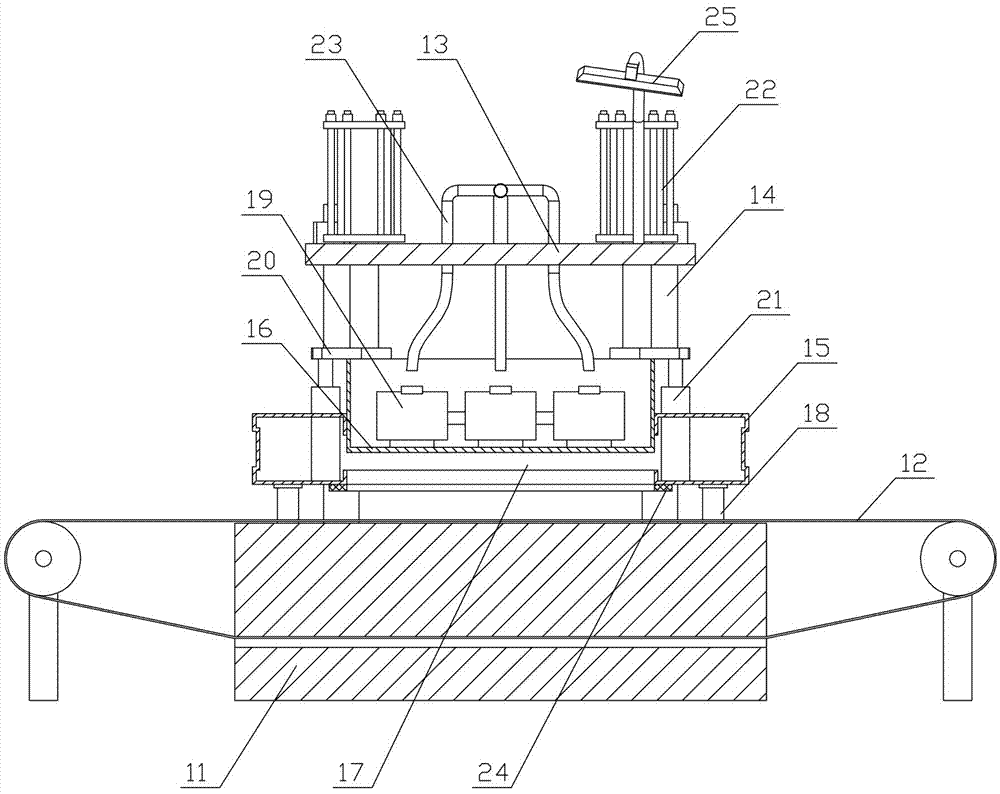

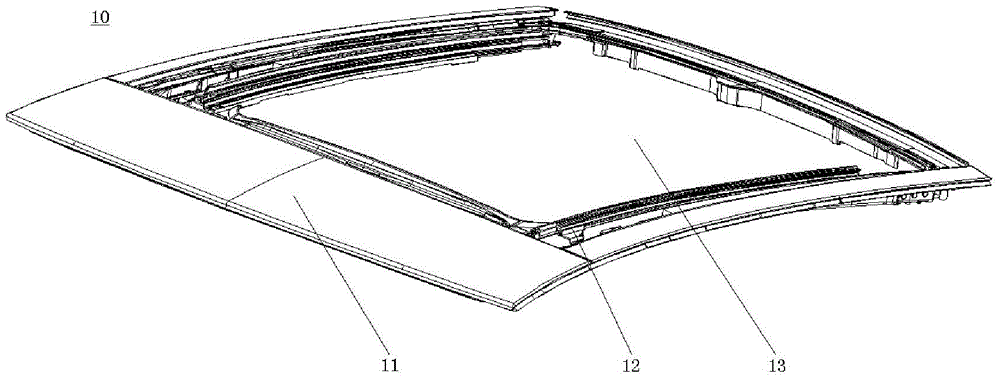

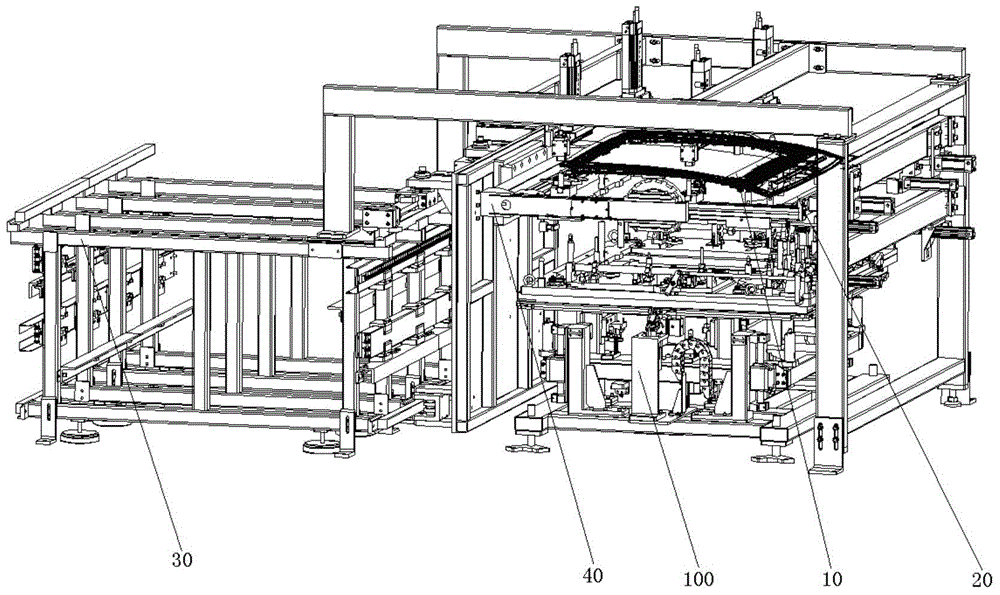

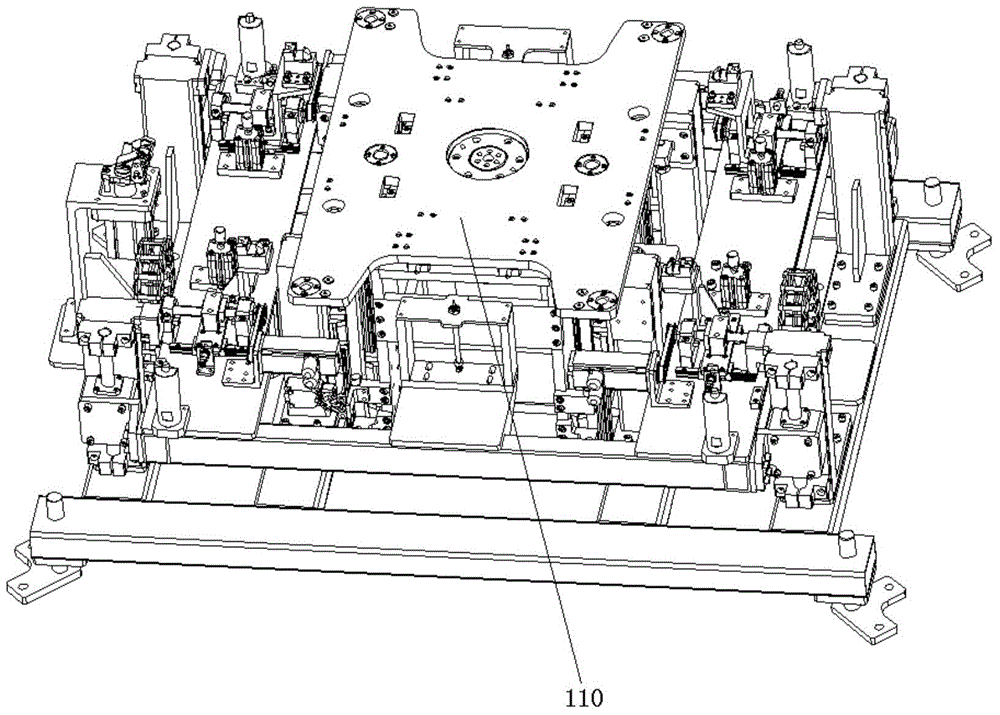

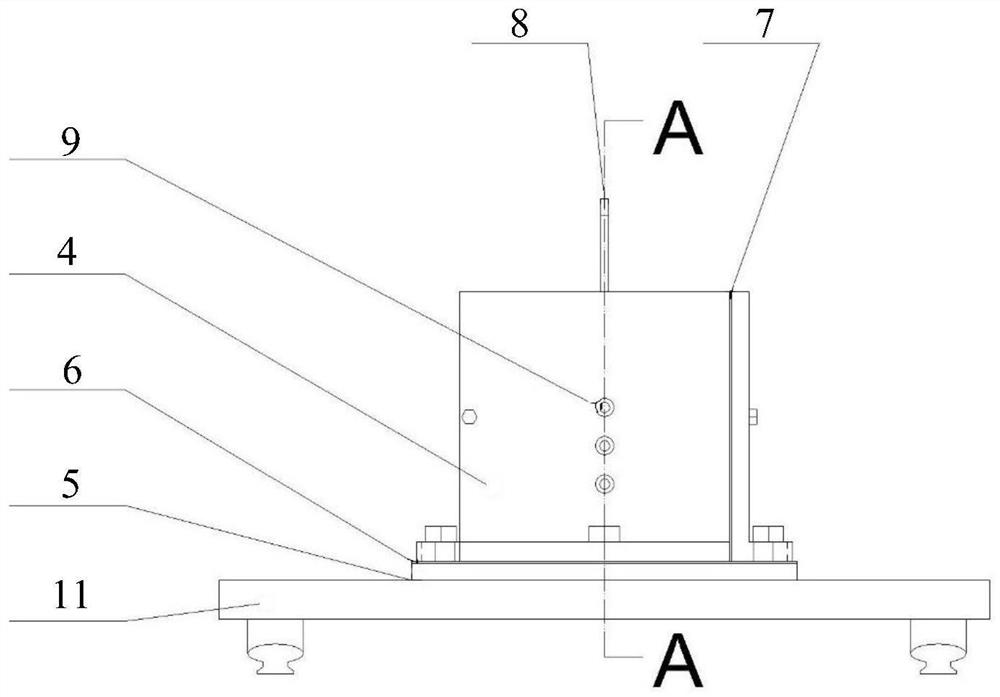

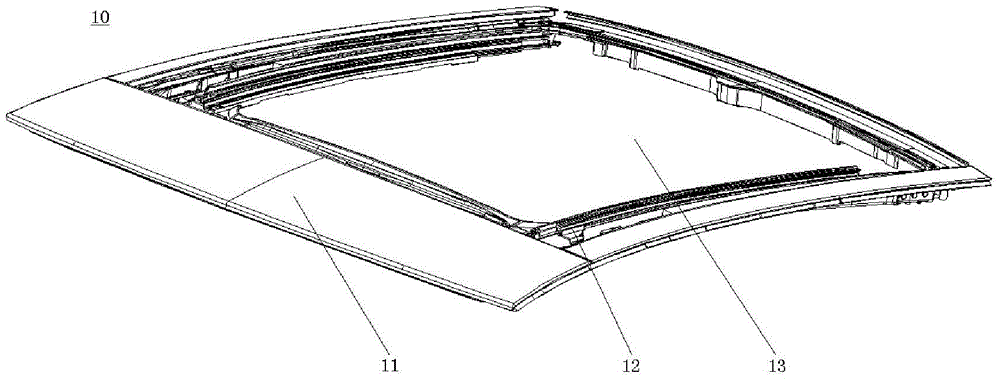

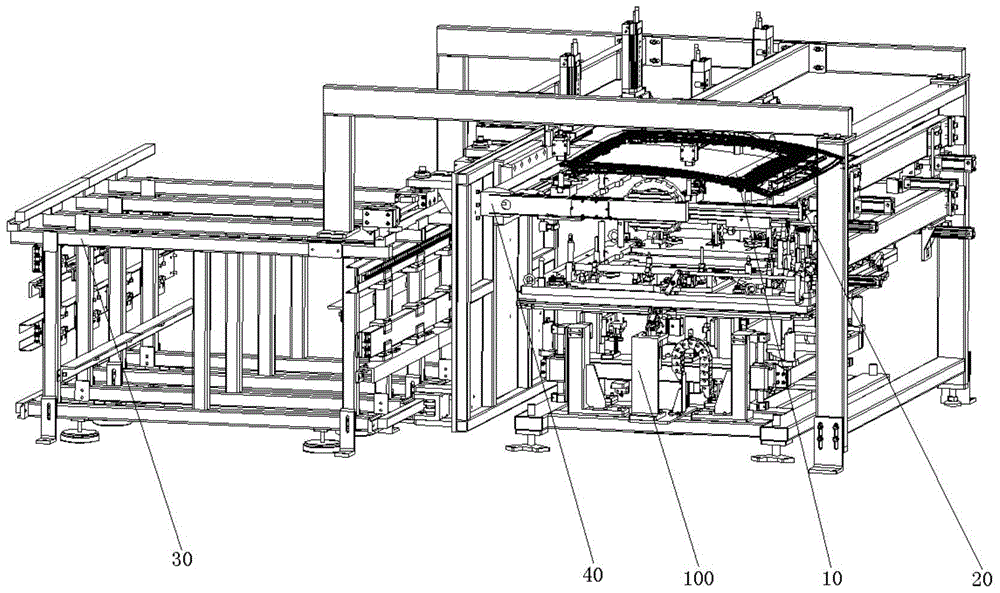

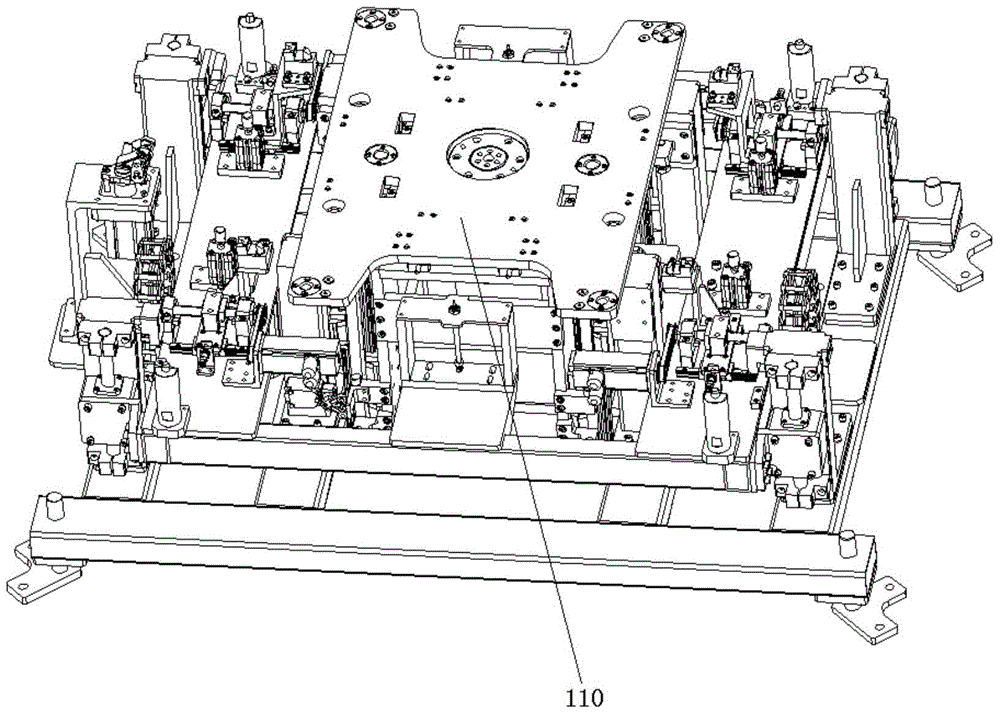

Self-adaptive hoisting device of skylight assembly production line

ActiveCN104555810ARapid positioningAvoid breakingAssembly machinesLifting framesProduction lineVibration attenuation

The invention provides a self-adaptive hoisting device of a skylight assembly production line. The self-adaptive hoisting device is characterized by comprising a tray, a hoisting mechanism and a return mechanism; the hoisting mechanism comprises a lifting air cylinder and a lifting platform, the lifting platform is fixed on the lifting air cylinder, and the lifting platform moves up and down along the lifting air cylinder; the tray is arranged on the lifting platform; the return mechanism comprises return air cylinders which are uniformly distributed on the periphery of the lifting air cylinder, located below the tray and used for applying a downward force to the tray. The self-adaptive hoisting device has advantages that a semi-finished product can be rapidly and self-adaptively positioned on a new workstation; the rapid fixation of the semi-finished product after being positioned on the new workstation can be facilitated. By simply improving the mechanical structure, rapid transportation of the skylight semi-finished product between a main production line and a curing production line can be realized; by adding a horizontal floating support, a vertical floating support and the like, the problem that the semi-finished product cannot be rapidly and self-adaptively positioned can be solved, a vibration attenuation effect also can be realized, the installation and assembling quality of the skylight can be greatly improved, and the production efficiency can be improved.

Owner:上海新松机器人有限公司

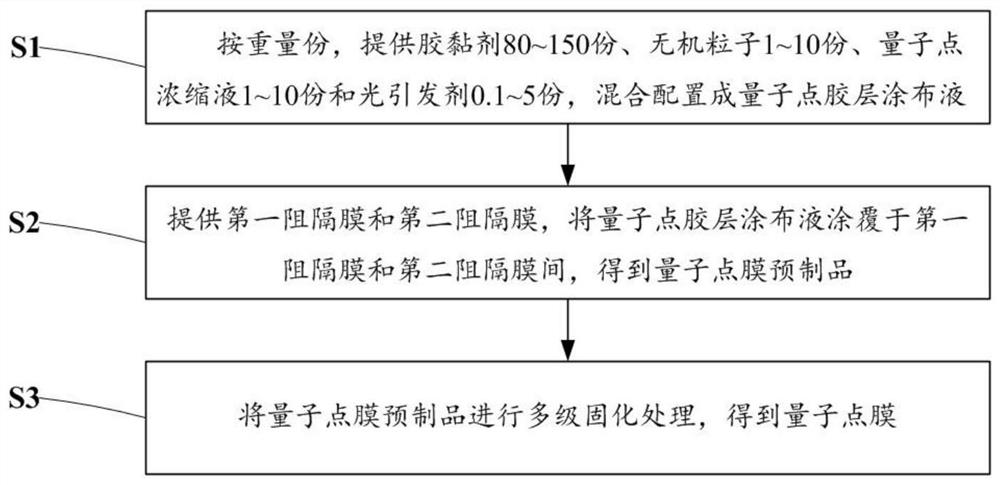

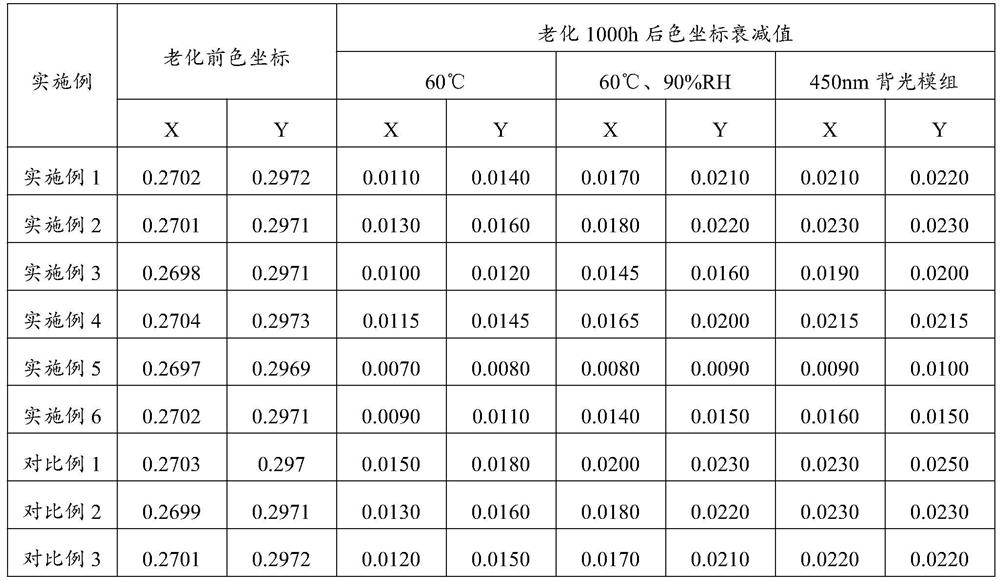

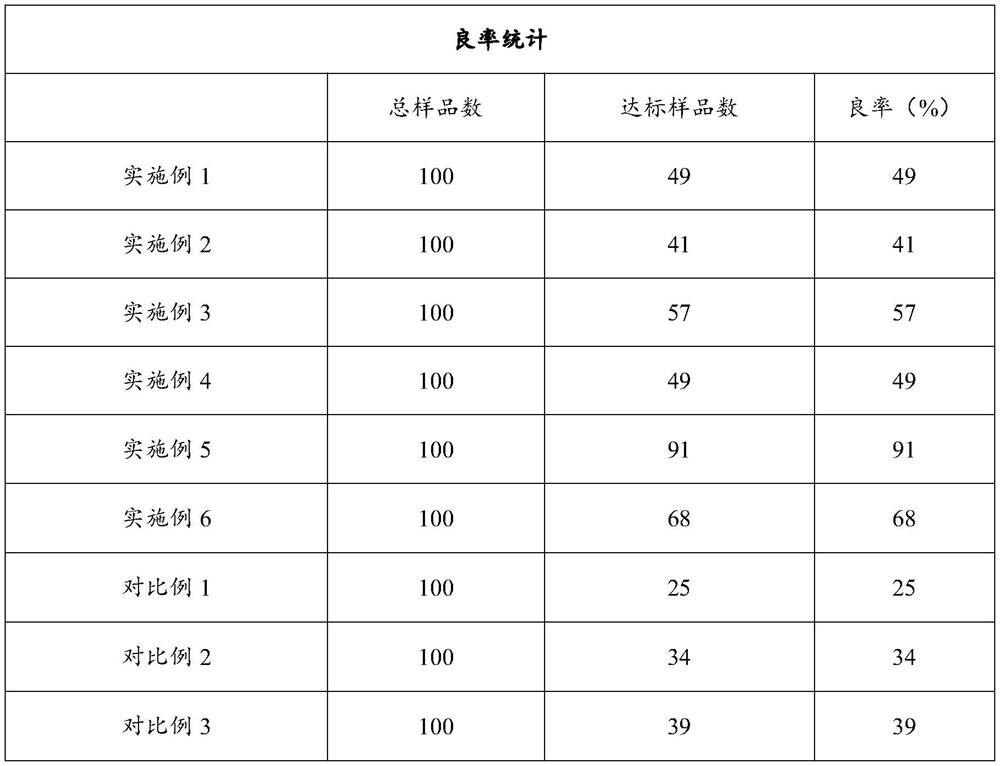

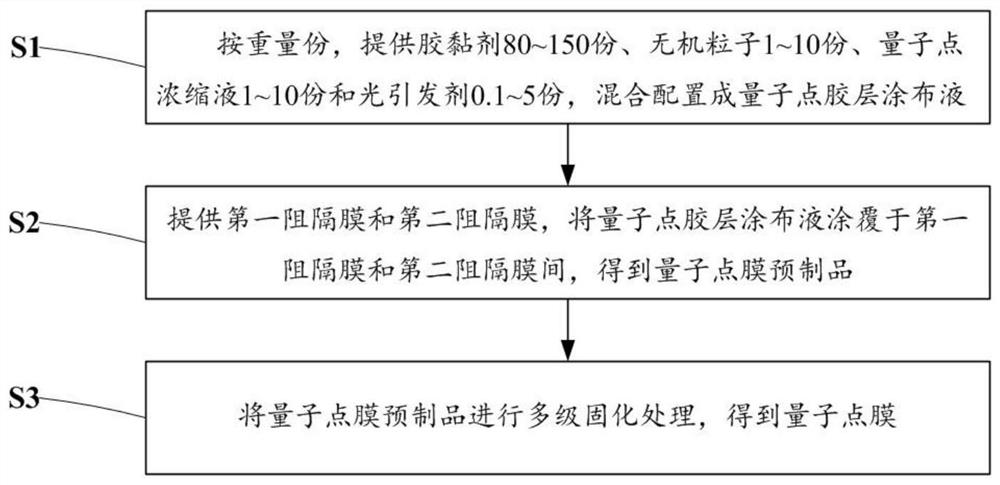

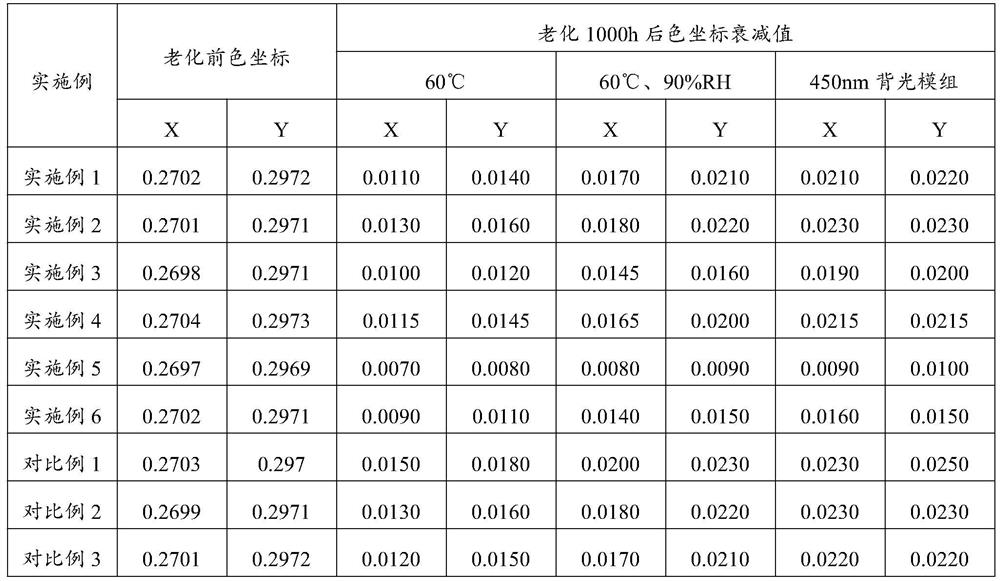

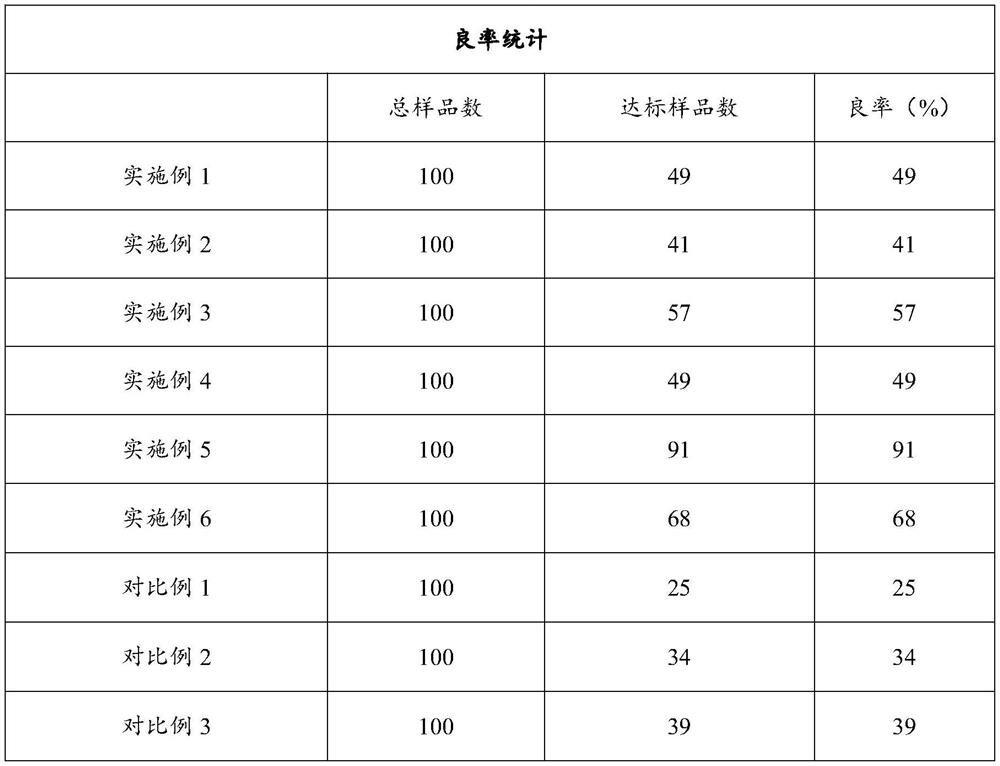

Quantum dot film with high luminous efficiency, and preparation process thereof

ActiveCN111647380AOptimizing the curing processImprove stabilityNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPhysicsPhotoinitiator

The invention discloses a quantum dot film with high luminous efficiency, and a preparation process thereof. The preparation process of the quantum dot film with high luminous efficiency comprises thefollowing steps: providing 80-150 parts by weight of an adhesive, 1-10 parts by weight of inorganic particles, 1-10 parts by weight of a quantum dot concentrated solution and 0.1-5 parts by weight ofa photoinitiator, and mixing to prepare a quantum dot adhesive layer coating solution; providing a first barrier film and a second barrier film, and coating the quantum dot adhesive layer coating liquid between the first barrier film and the second barrier film to obtain a quantum dot film prefabricated product; and carrying out multi-stage curing treatment on the quantum dot film prefabricated product to obtain the quantum dot film. The photoinitiator is matched with the multi-stage curing process, the curing process of the quantum dot film is optimized, the curing efficiency is improved, the influence on quantum dots is reduced, and finally, the stability of the optical performance of the quantum dot film and the yield in the production process of products are improved.

Owner:武汉华彩光电有限公司

Multifucntional insulating wire for live-wire work and its manufacturing process

InactiveCN1471111AOptimizing the curing processImprove waterproof functionInsulated cablesCable/conductor manufactureFluorocarbonSolubility

The invention includes following procedures. (1) Immersion fluid is prepared from water-solubility fluorocarbon surfactant, adhesive and contact agent. (2) Fabric thread is dipped in the immersion fluid at room temperature. (3) Picking off immersion fluid. (4) Solidifying. The continuous heating curve for solidifying procedure is from room temperature to 60 deg.C for 0.5-1 hr., 60 deg.C to 80 deg.C for 0.5-1 hr., 80 deg.C to 100 deg.C for 15 - 30 minutes and 100 deg.C to 200 deg.C for 10-15 deg.C. The constituent of immersion fluid is water 100 portions, fluorocarbon surfactant 3-7 portions, adhesive 2-7 portions and contact agent 0.5-1.2 portions. The invented rope, strip and cloth made from insulated threads reaches or exceeds the national standard of insulation property for hot-line work.

Owner:WENLING CITY ELECTRICITY INSULATED EQUIP CO LTD

Repairing process for aircraft skin surface defects

InactiveCN110877006AGood restorativeSimple construction processPretreated surfacesSpecial surfacesGlass fiberMechanical engineering

The invention provides a repairing process for aircraft skin surface defects. The process comprises the following steps: (1) surface treatment of parts; (2) epoxy putty preparation; (3) putty coating:the prepared epoxy putty is evenly brushed or scraped to the cleaned to-be-repaired part of metal parts through a banister brush or a scraper; (4) curing: the metal parts coated with the epoxy puttyis cured at room temperature or by heating; and (5) shape modification: after the putty is cured, the repaired part of the parts is polished. The repairing process for aircraft skin surface defects can well solve the surface defect problem of aluminum alloy, glass fiber reinforced plastic and other substrates, is simple and convenient to operate, can effectively avoid the problems of reworking, scrapping and the like of parts, reduces the production cost, shortens the delivery period, improves the product quality, and is suitable for popularization and application.

Owner:AVIC GUIZHOU AIRPLANE

Die, method and device for detecting internal stress of adhesive

PendingCN114486718AOptimizing post-curing process for adhesivesRealize internal stress monitoringPreparing sample for investigationForce measurement by measuring optical property variationStrain sensorAdhesive cement

The invention provides an adhesive internal stress detection mold, method and device, and relates to the technical field of detection, the adhesive internal stress detection mold comprises: a mold body, an internal cavity of which is used for containing an adhesive; and the at least one strain sensor is fixedly connected with the mold body, is immersed in the adhesive contained in the inner cavity, and is used for acquiring a strain signal of the adhesive. According to the scheme, internal stress monitoring in the adhesive curing process can be achieved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

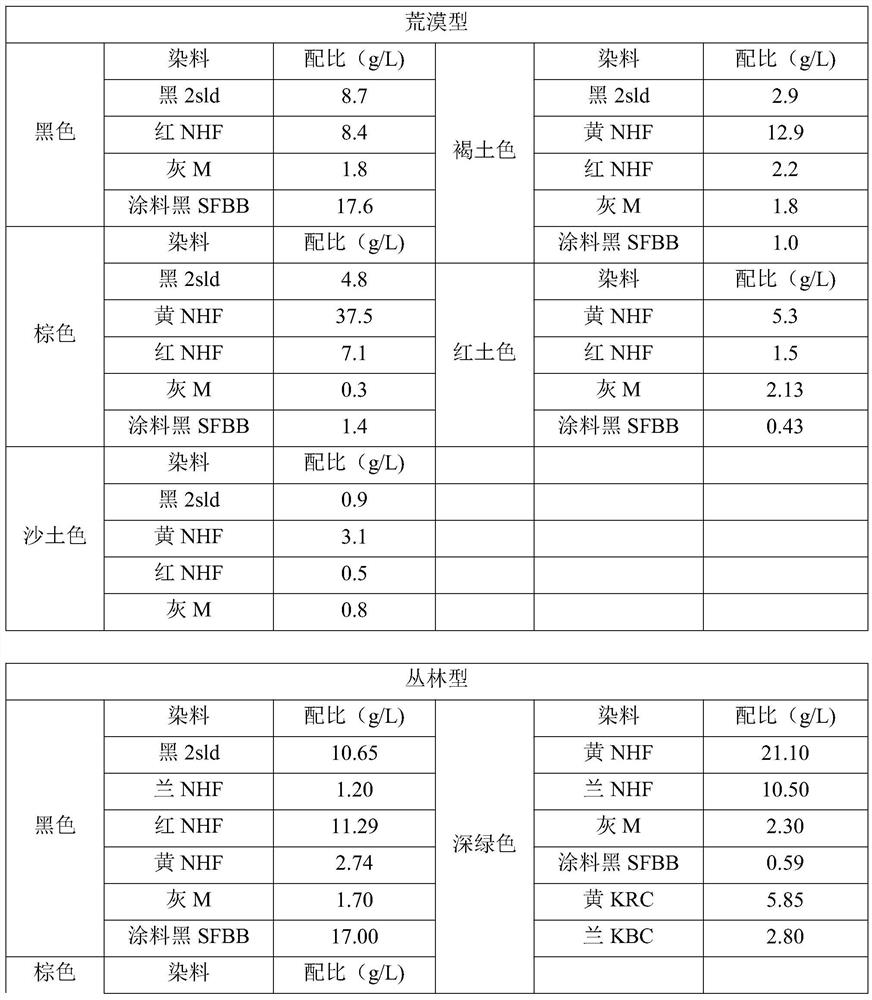

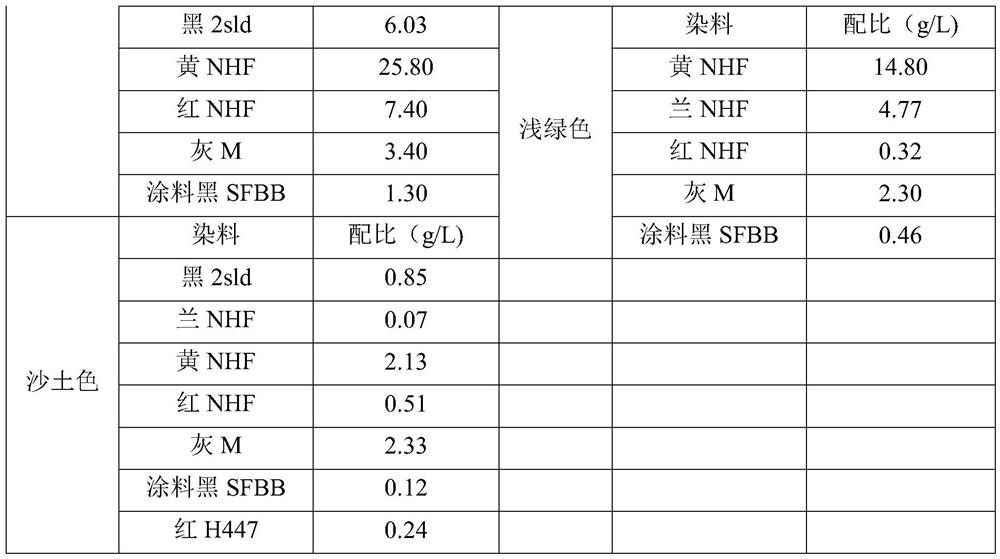

Polyamide pattern painting camouflage fabric printing process and fabric production and processing method

The invention relates to a polyamide pattern painting camouflage fabric printing process and a fabric production and processing method. The printing process is used for printing a pattern painting camouflage color, and vat grey M is added into color paste of the pattern painting camouflage color. The processing method comprises a coating finishing procedure, wherein coating finishing is performed on a waterproof set fabric printed with the pattern painting camouflage color, and a flame-retardant coating is completed according to a sequence of firstly performing bottom glue blade coating and calendaring, then performing middle glue blade coating and finally performing surface glue blade coating; during the bottom glue blade coating, the temperature of a drying oven is controlled to be close to the temperature of a cross-linking agent in a bottom glue formula, the vehicle speed is regulated and controlled, methylbenzene in polyurethane glue is completely volatilized, bottom glue is in a dried state, but part of the cross-linking agent does not completely react to form a net structure, more bottom glue is extruded into yarn gaps of a fabric during subsequent calendaring, and further the cross-linking agent reacts with the polyurethane glue and a curing process is finished. The color fastness of the fabric is stable, and the dark color migration phenomenon is reduced. The production and processing method meets the use requirements of novel equipment such as carrying tools and bulletproof vests.

Owner:北京邦维高科新材料科技股份有限公司

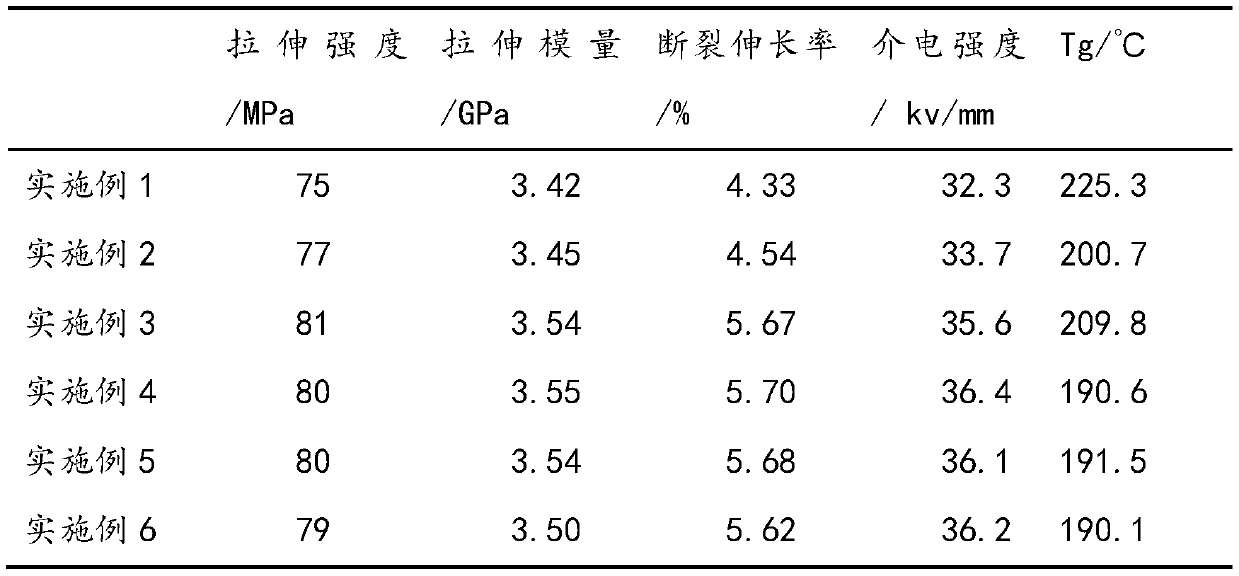

High-toughness insulating epoxy resin cured product as well as preparation method and application thereof

The invention provides a high-toughness insulating epoxy resin cured product as well as a preparation method and application thereof. The high-toughness insulating epoxy resin cured product comprisesthe following raw materials: matrix resin, a curing agent, a toughening agent and an accelerant, the matrix resin is a mixture of an epoxy resin and an inactive resin modifier containing a hydrophobicaliphatic chain and an aromatic ring, the toughening agent is a mixture of an active diluent and nanoparticles, andhydrogen bonds can be formed between the active diluent and the nanoparticles. Thelong hydrophobic aliphatic side chain and the aromatic ring in the inactive resin modifier can endow the product with extremely low viscosity, so that the viscosity of the epoxy resin is reduced, the compatibility between the epoxy resin and other components is improved, the flexibility is improved, excellent early water resistance, hardness performance and corrosion protection are provided, and excellent insulation and heat resistance are provided; the reactive diluent can react with the nanoparticles to form a damping branched chain and toughening suspension chain structure with the nanoparticles, so that the intermolecular distance of an epoxy resin system can be increased, and better toughness is provided.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +3

A kind of porous c/c composite material and its preparation method

ActiveCN108840698BHigh porosityUniform distribution of poresCeramicwarePore distributionCarbon matrix

The present invention proposes a porous C / C composite material and a preparation method thereof, which are obtained through a precursor impregnation-curing-cracking process, and the precursor is composed of resorcinol, formaldehyde and water. Under the action of saturated vapor pressure, the present invention forms pores by occupying water in the phenolic resin, and finally obtains a porous resin carbon matrix suitable for reactive infiltration with high porosity, uniform pore distribution and adjustable pore size distribution.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

Organic titanium epoxy resin catalytic ester cyanate system

An ester cyanate resin system with organic titanium epoxy resin as catalyst is characterized by taking organic titanium modified epoxy resin as catalyst, which is obtained by reacting tetrabutyl titanate with hydroxyl in glycidol ether epoxy resin structure, and consisting of ester cyanate resin 70-99.99% and organic titanium epoxy resin catalyst 0.01-30%. It can improve curing process of resin system, lower curing temperature, shorten curing time and cost low.

Owner:AVIC COMPOSITES

A quantum dot film with high luminous efficiency and its preparation process

ActiveCN111647380BOptimizing the curing processImprove stabilityNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesOptical propertyInorganic particle

The invention discloses a quantum dot film with high luminous efficiency and a preparation process thereof. The preparation process of the quantum dot film with high luminous efficiency comprises the following steps: in parts by weight, providing 80-150 parts of adhesive, 1-10 parts of inorganic particles, 1-10 parts of quantum dot concentrate and 0.1-5 parts of photoinitiator Parts, mixed and configured as a quantum dot layer coating solution; the first barrier film and the second barrier film are provided, and the quantum dot layer coating solution is coated between the first barrier film and the second barrier film to obtain a quantum dot film Preform: performing multi-stage curing treatment on the quantum dot film preform to obtain the quantum dot film. The present invention adopts the matching method of photoinitiator and multi-stage curing process, optimizes the curing process of quantum dot film, improves the curing efficiency and reduces the impact on quantum dots, and finally improves the stability of the optical properties of the quantum dot film and the stability of the product production process. yield.

Owner:武汉华彩光电有限公司

Insulating wire for live-wire work and its manufacturing process

InactiveCN1236457CReasonable formulaOptimizing the curing processInsulated cablesCable/conductor manufactureSolubilityRoom temperature

The invention includes following procedures. (1) Immersion fluid is prepared from water-solubility fluorocarbon surfactant, adhesive and contact agent. (2) Fabric thread is dipped in the immersion fluid at room temperature. (3) Picking off immersion fluid. (4) Solidifying. The continuous heating curve for solidifying procedure is from room temperature to 60 deg.C for 0.5-1 hr., 60 deg.C to 80 deg.C for 0.5-1 hr., 80 deg.C to 100 deg.C for 15 - 30 minutes and 100 deg.C to 200 deg.C for 10-15 deg.C. The constituent of immersion fluid is water 100 portions, fluorocarbon surfactant 3-7 portions, adhesive 2-7 portions and contact agent 0.5-1.2 portions. The invented rope, strip and cloth made from insulated threads reaches or exceeds the national standard of insulation property for hot-line work.

Owner:WENLING CITY ELECTRICITY INSULATED EQUIP CO LTD

Preparation method of efficient soft porcelain flexible face brick

The invention provides a curing method of a high-efficiency soft porcelain flexible facing brick. The curing method comprises the following steps: 1, preparing a mixed emulsion; 2, preparing mixed powder; 3, adding the mixed emulsion into the mixed powder, adding 5-15 parts of water, and stirring to obtain soft porcelain slurry; 4, injecting the slurry in the step 3 into a mold; and 5, curing. Wherein the curing step comprises microwave curing treatment, meanwhile, due to the fact that a certain temperature exists on the outer layer of the soft porcelain slurry, the whole curing process is carried out inside and outside the soft porcelain slurry at the same time, and in order to further improve the curing efficiency, a wave absorbing agent is further added into the soft porcelain slurry, and the curing efficiency is improved.

Owner:万卓(江苏)新材料有限公司

A kind of preparation method of aryl boric acid catechol ester modified phenolic resin

Owner:XI AN JIAOTONG UNIV +1

A kind of c/sic composite material preparation method

ActiveCN108892524BImprove mechanical propertiesImprove anti-ablation performanceCeramicwareMaterials preparationHigh activity

The invention provides a preparation method of a C / SiC composite material. The C / SiC composite material is prepared by preparing a porous C / C composite material by means of an infiltration method. Asa special high-activity porous body C / C is adopted to reactive infiltration, the mechanical property and the anti- ablation property of the material are improved. The preparation method can be also applied to rapid low-cost preparation of a ceramic-based composite material.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

Adaptive lifting device for sunroof assembly line

ActiveCN104555810BRealize the assemblyRealize pressingAssembly machinesLifting framesVibration attenuationProduction line

The invention provides a self-adaptive hoisting device of a skylight assembly production line. The self-adaptive hoisting device is characterized by comprising a tray, a hoisting mechanism and a return mechanism; the hoisting mechanism comprises a lifting air cylinder and a lifting platform, the lifting platform is fixed on the lifting air cylinder, and the lifting platform moves up and down along the lifting air cylinder; the tray is arranged on the lifting platform; the return mechanism comprises return air cylinders which are uniformly distributed on the periphery of the lifting air cylinder, located below the tray and used for applying a downward force to the tray. The self-adaptive hoisting device has advantages that a semi-finished product can be rapidly and self-adaptively positioned on a new workstation; the rapid fixation of the semi-finished product after being positioned on the new workstation can be facilitated. By simply improving the mechanical structure, rapid transportation of the skylight semi-finished product between a main production line and a curing production line can be realized; by adding a horizontal floating support, a vertical floating support and the like, the problem that the semi-finished product cannot be rapidly and self-adaptively positioned can be solved, a vibration attenuation effect also can be realized, the installation and assembling quality of the skylight can be greatly improved, and the production efficiency can be improved.

Owner:上海新松机器人有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com