Patents

Literature

116results about How to "Realize pressing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

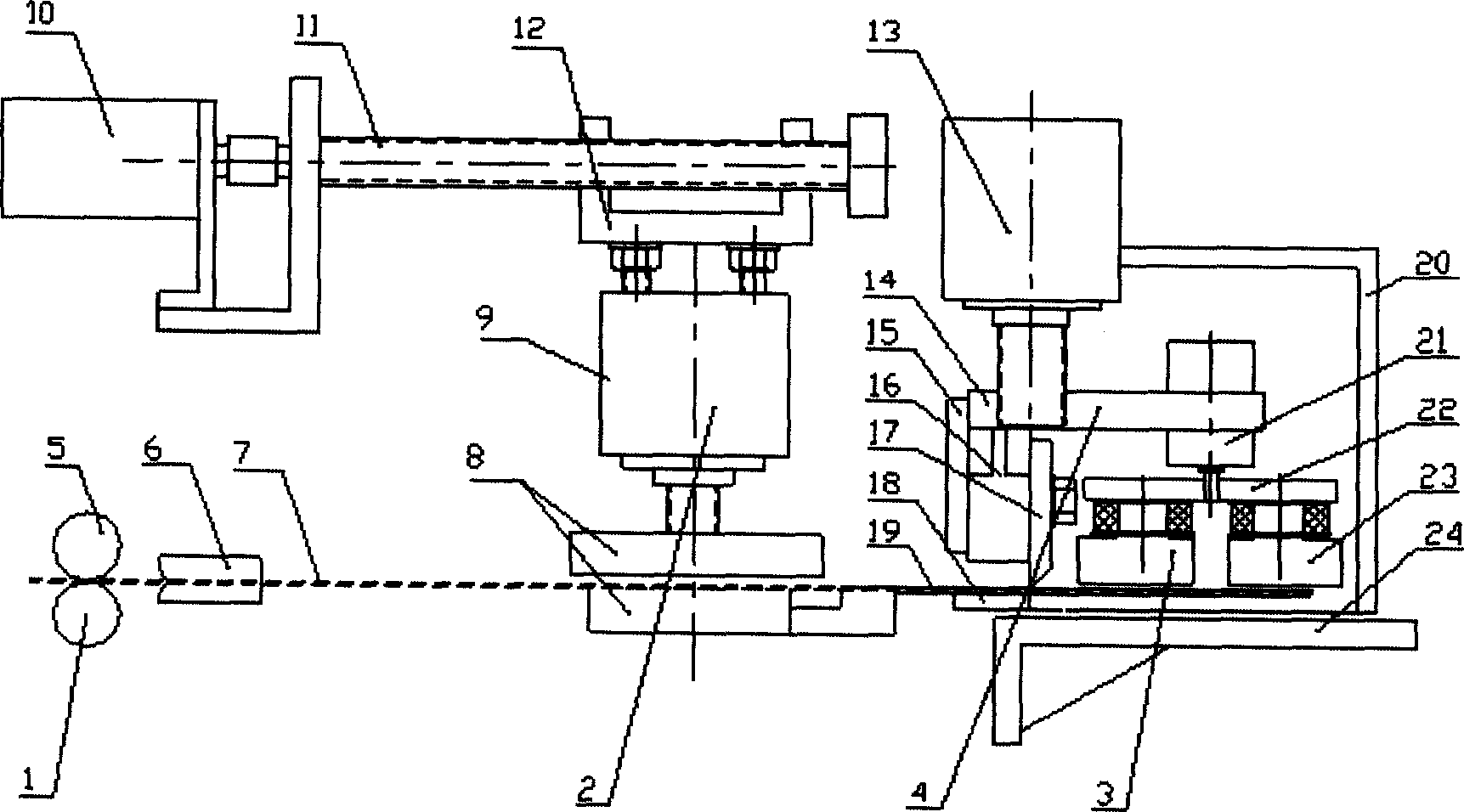

Feeding cutting and pressing binding device of flexible iron base thin belt material

InactiveCN1718365ARealize transferSimultaneous productionMetal-working feeding devicesOther manufacturing equipments/toolsBand shapeEngineering

A feeding, shearing and sticking machine for the flexible Fe-base thin band used for anti forge metallic labels is composed of a band shaping unit, a band piloting and feeding unit consisting of piloting plate, clamping plate, clamping cylinder, motor, etc, an electromagnetic sucking-transferring unit consisting of DC electromagnet and sucking plate, and a shearing-sticking unit consisting of shearing cylinder, shearing blade, lower sheering edge sticking cylinder, etc.

Owner:SHANGHAI JIAO TONG UNIV

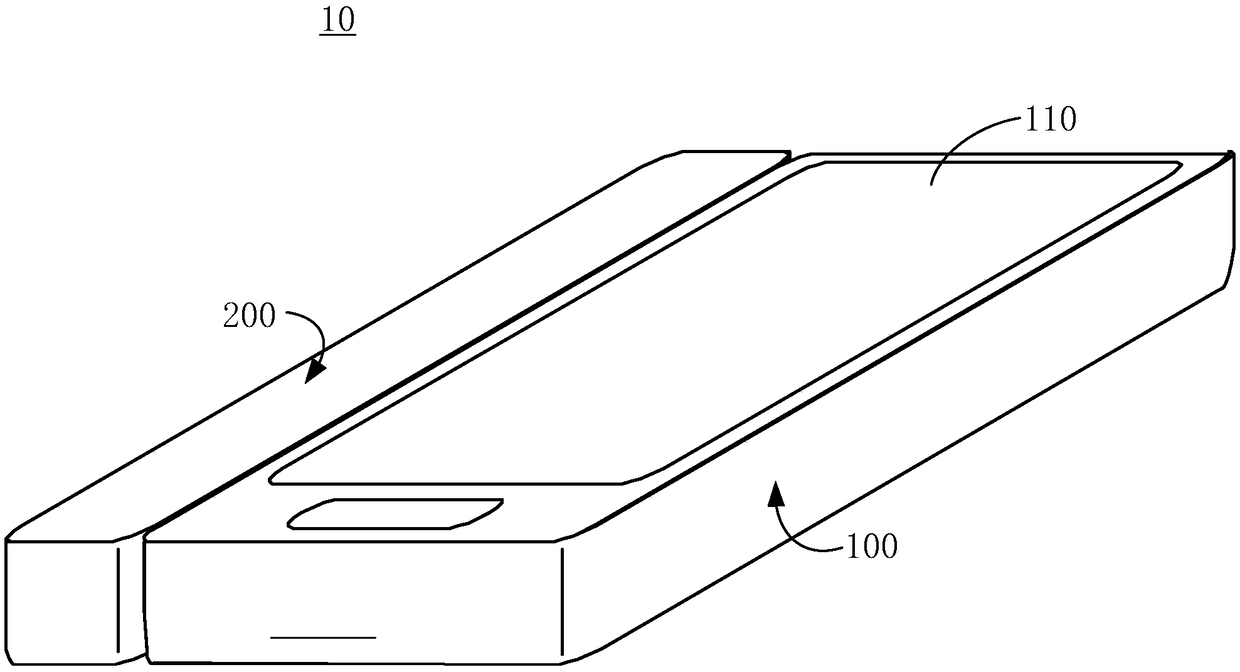

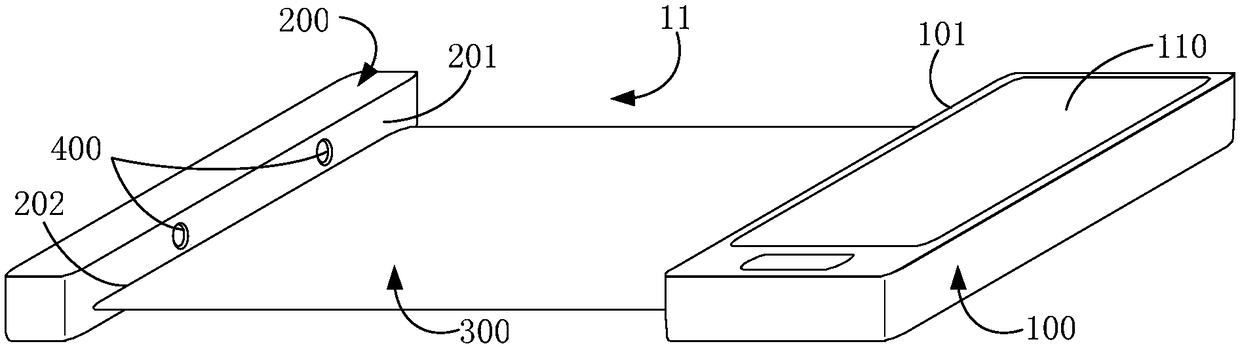

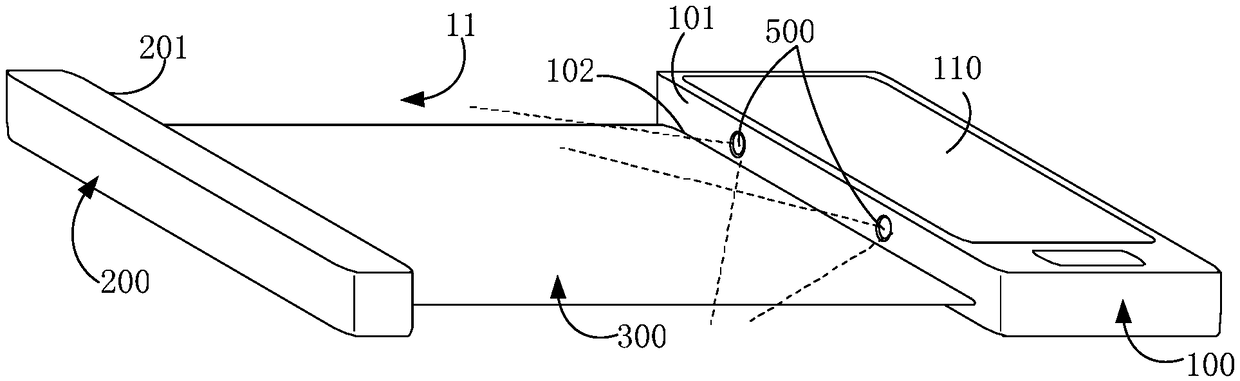

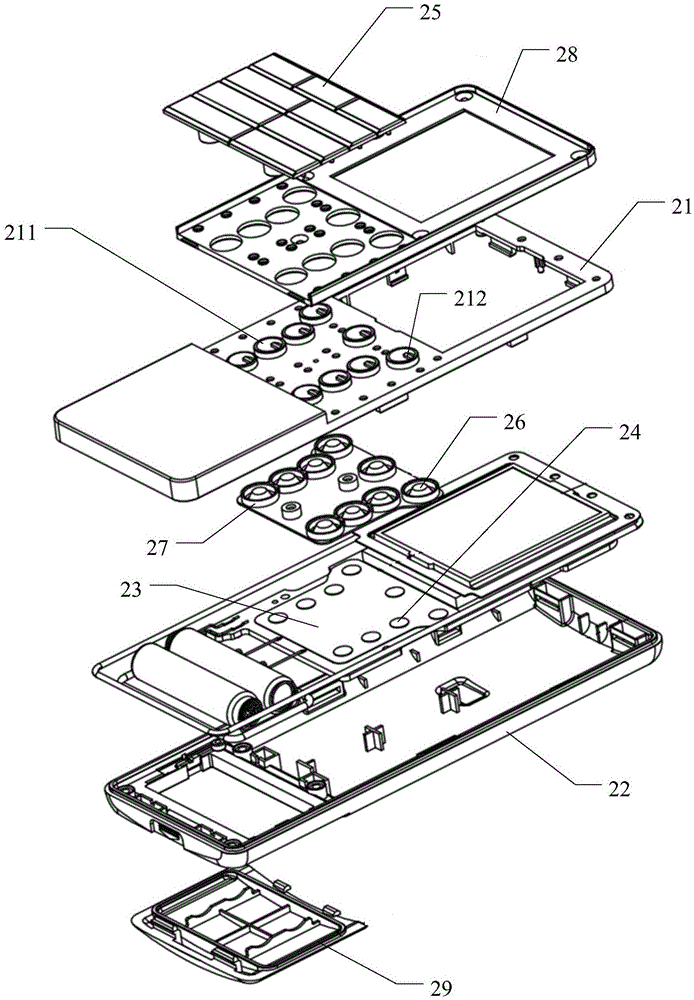

Electronic device

InactiveCN108632411AAvoid pressingAvoid shearing and other forcesInput/output for user-computer interactionGraph readingOperation modeComputer science

The invention relates to an electronic device with a combined state and an opened state. The electronic device comprises a main body; a secondary body which is set in opposite to the main body and canmove relative to the main body; a flexible screen, wherein one end of the flexible screen is set on the main body, and the other end of the flexible screen is set on the secondary body; and a gestureidentifier which is connected with the secondary body, wherein the gesture identifier is used for identifying a gesture, thereby carrying out non-touch screen operation on the flexible screen. When the electronic device is in the opened state, a gap exists between the main body and the secondary body, and the flexible screen is unfolded in the gap. When the electronic device is in the combined state, the gap between the main body and the secondary body is removed, and the flexible screen is stored in the main body or the secondary body. An icon on the flexible screen is operated through identification of the gesture identifier for the gesture. An operation mode is the non-touch screen operation. The flexible screen is effectively prevented from deformation under the touch screen effect. Adisplay effect of the electronic device is ensured. The user experience is improved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Film mounter and film mounting method thereof

InactiveCN105947280AQuality improvementAchieve regulationPackagingOptical elementsTectorial membraneSemi automatic

The invention discloses a film mounter and a film mounting method thereof. The film mounter comprises a film tearing device, a film mounting device and a plate feeding device. When the film mounter is used, plastic adhesive tape is wound on the film tearing device and moves at intervals, the sides, provided with protecting membranes, of films are attached to the plastic adhesive tape at intervals through a film feeding mechanism, vacuum is formed in a vacuum suction nozzle, and negative pressure is formed at the bottom of a film mounting bottom plate so as to adsorb the film on a film tearing plate onto the position under the film mounting bottom plate; under the cooperation of two correction assemblies, the position of the film is adjusted, people only need to place an LCD plate on a sliding block of the feeding device to achieve limiting, a wiping part is used for wiping the surface of the LCD plate, under the control of a fourth air cylinder, the sliding block automatically moves to the position under the film mounting bottom plate, high pressure is formed in the vacuum suction nozzle, and the LCD plate is covered with the film on the film mounting bottom plate; and in the resetting process of the fourth air cylinder, a first rubber sleeve on a rolling rod rolls the film, and the semi-automatic film mounting process of the LCD plate is achieved.

Owner:江苏华东文化科技融资租赁有限公司

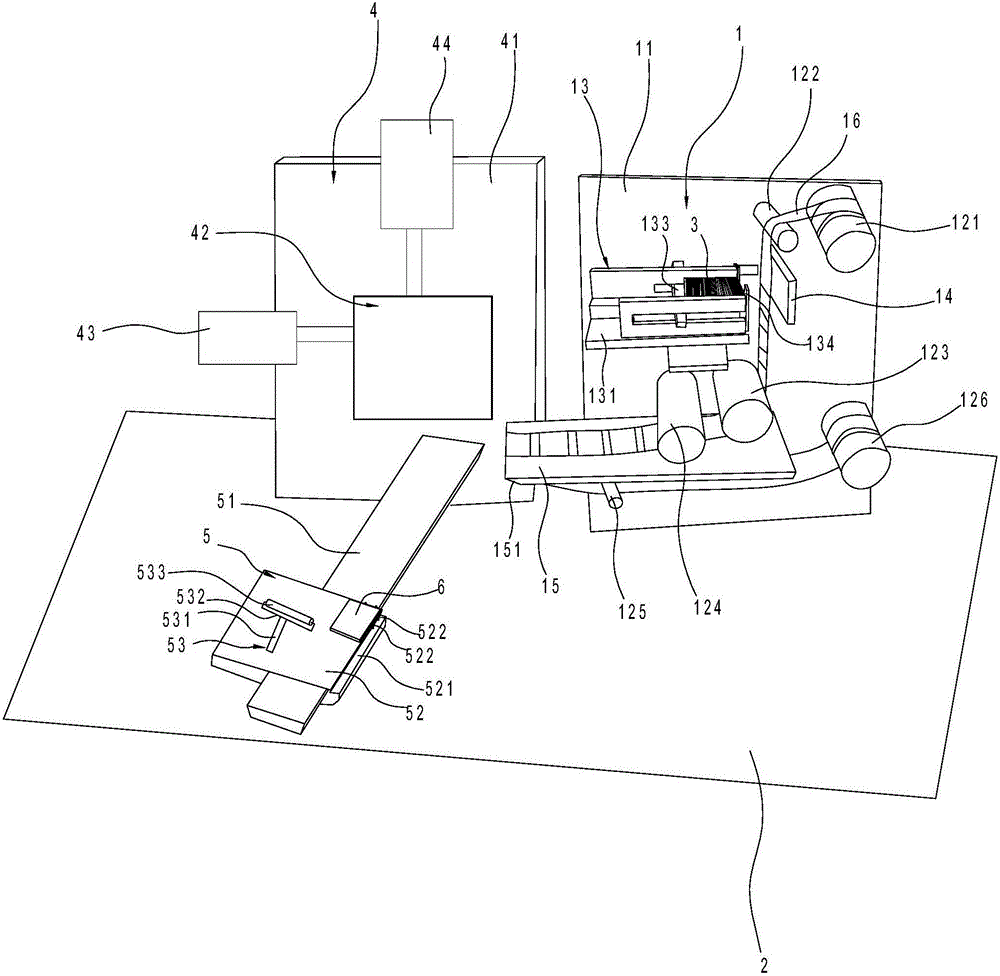

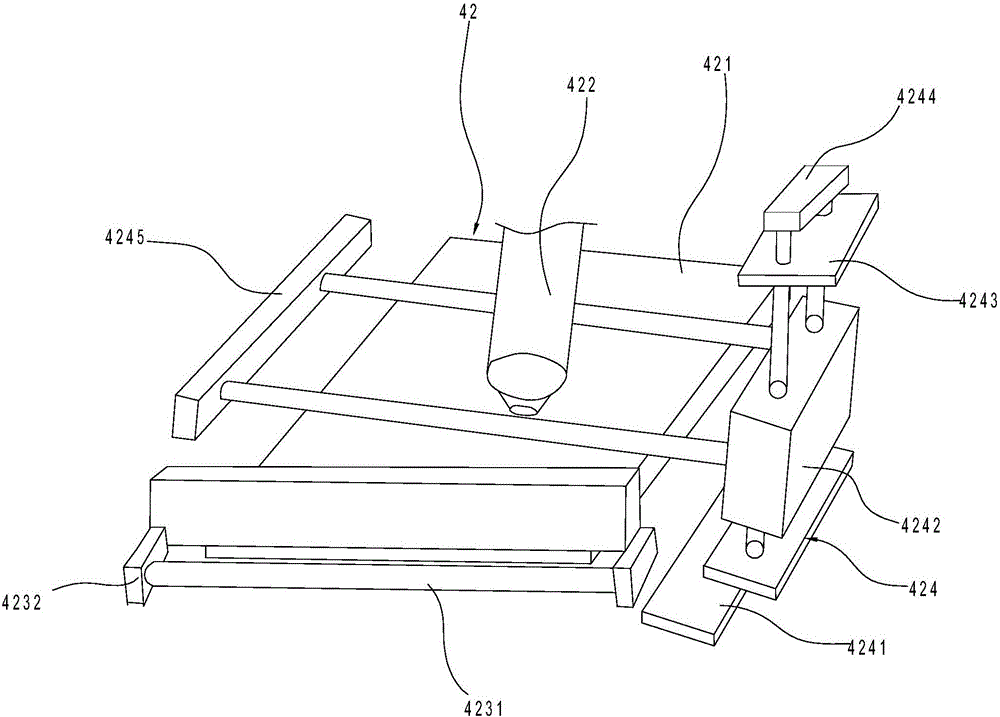

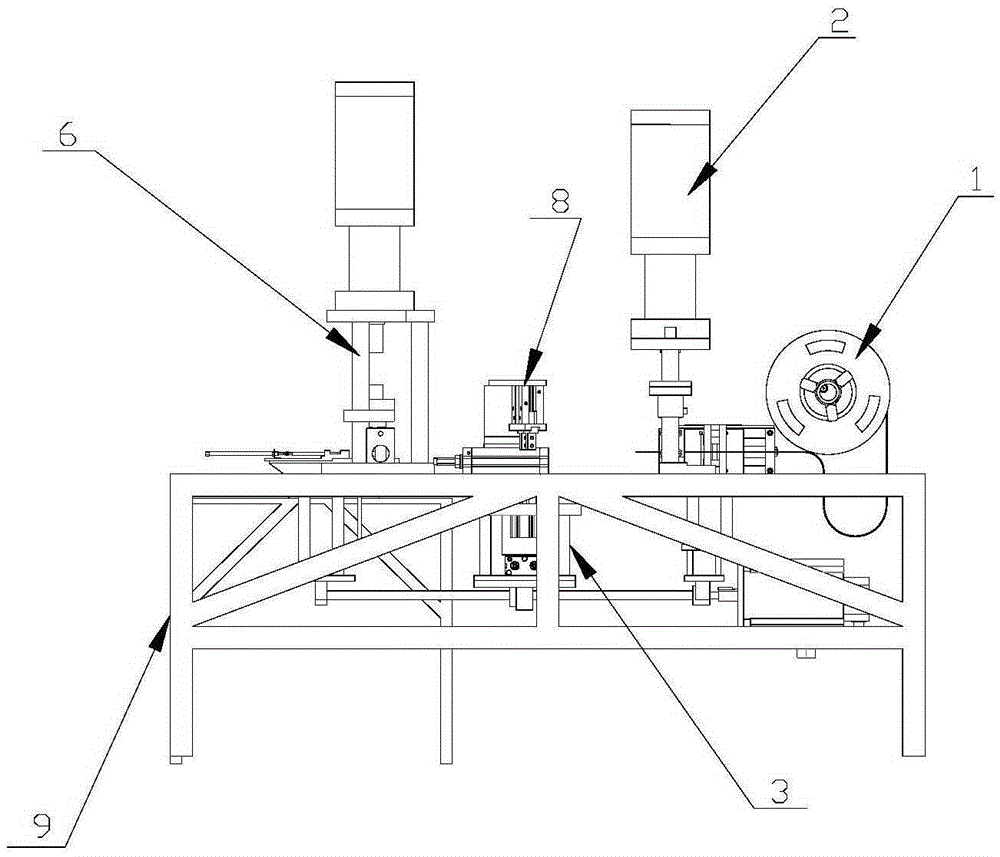

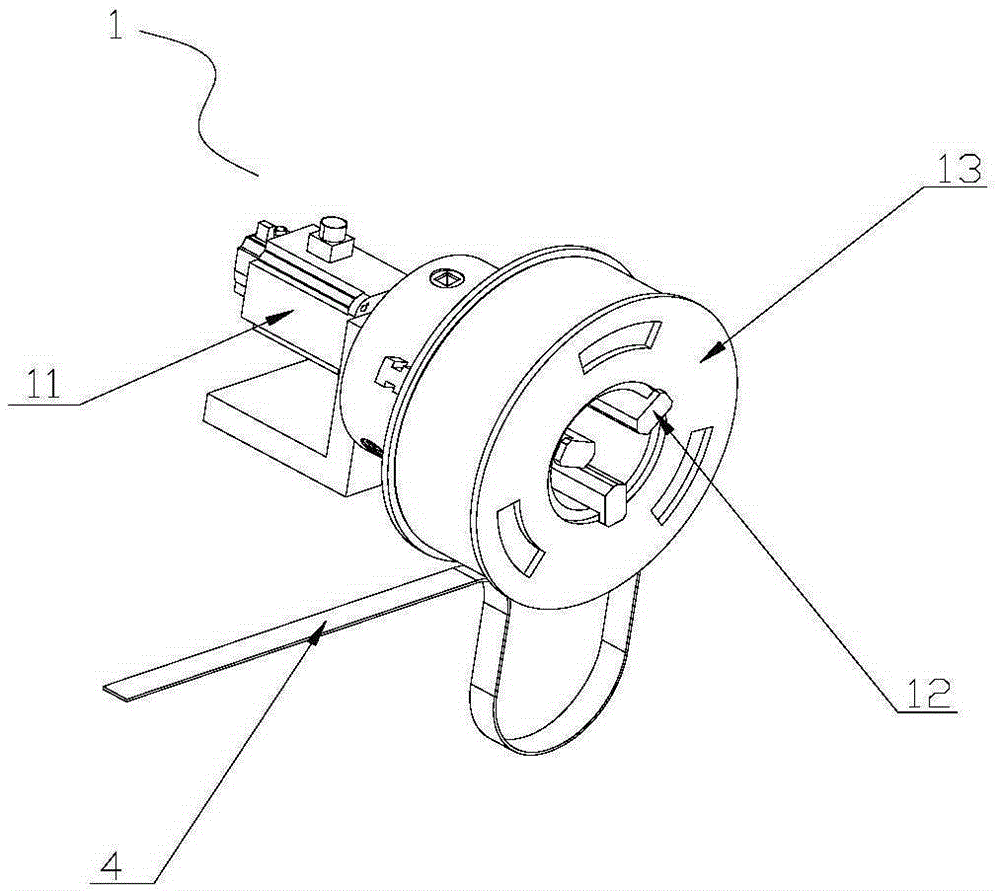

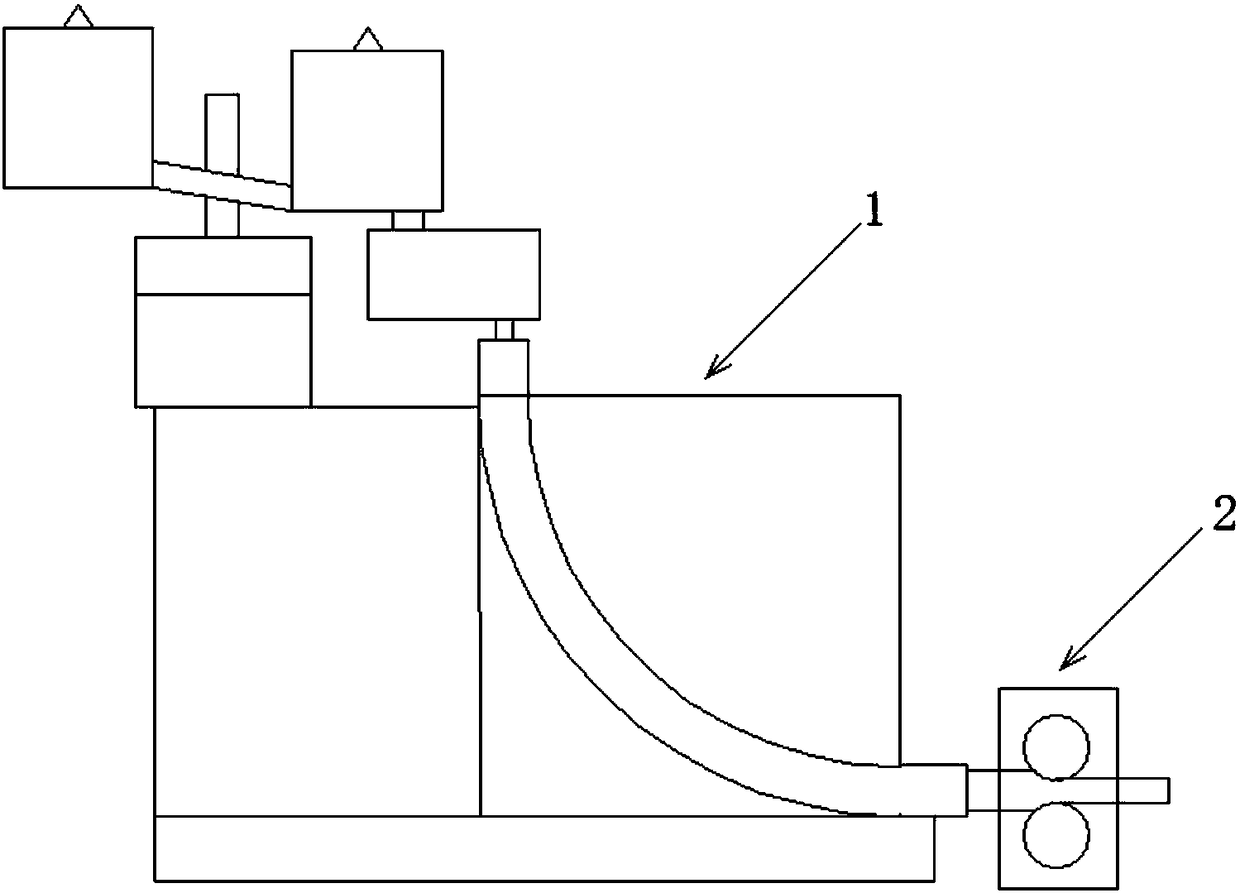

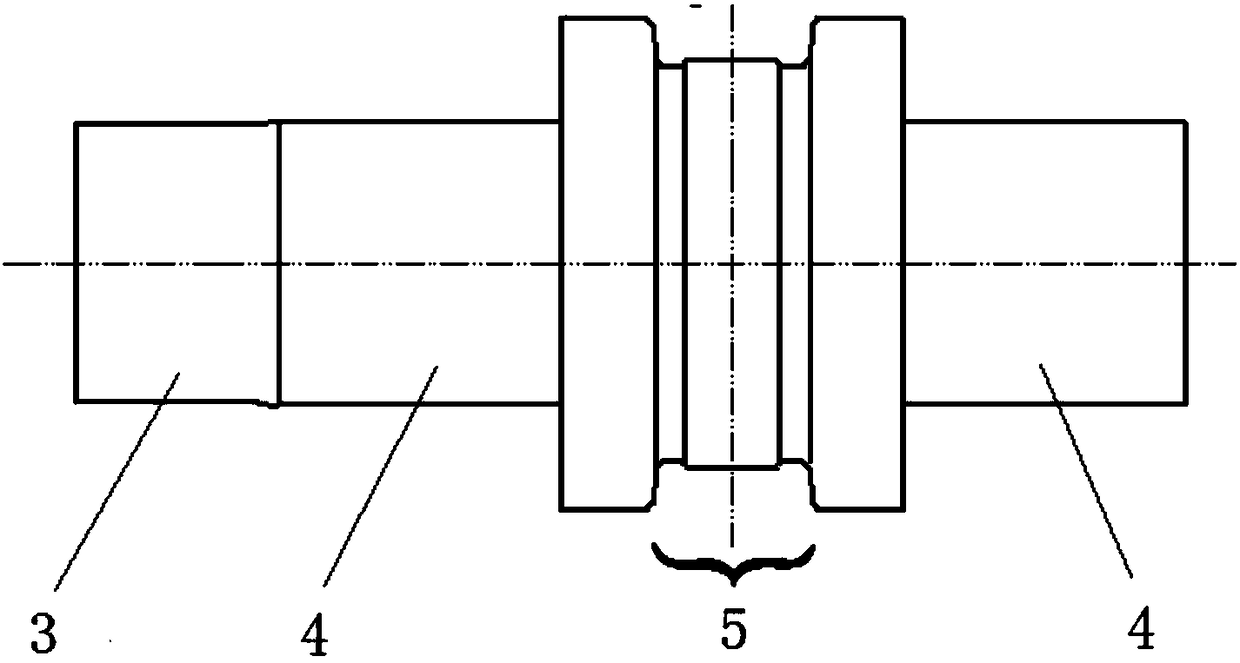

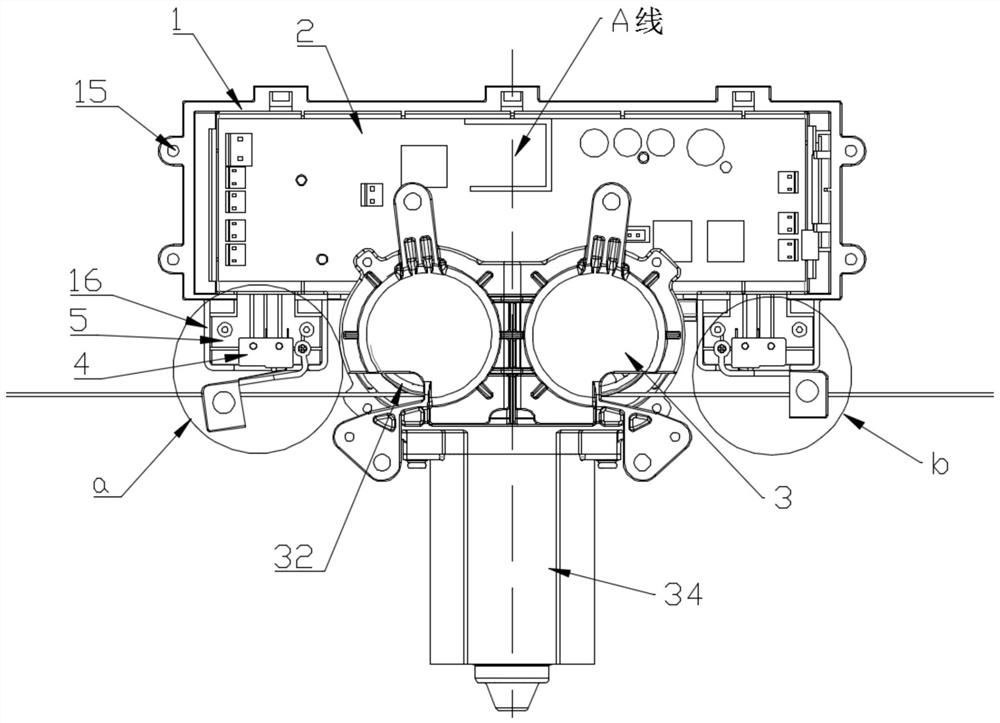

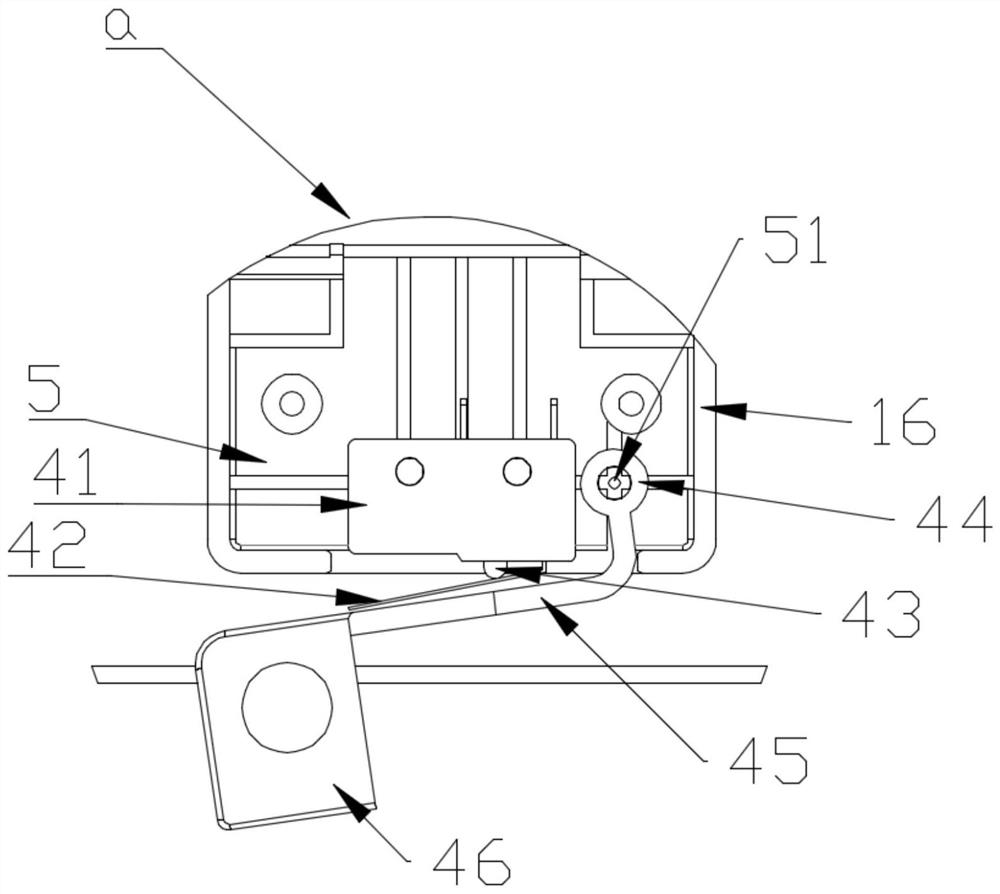

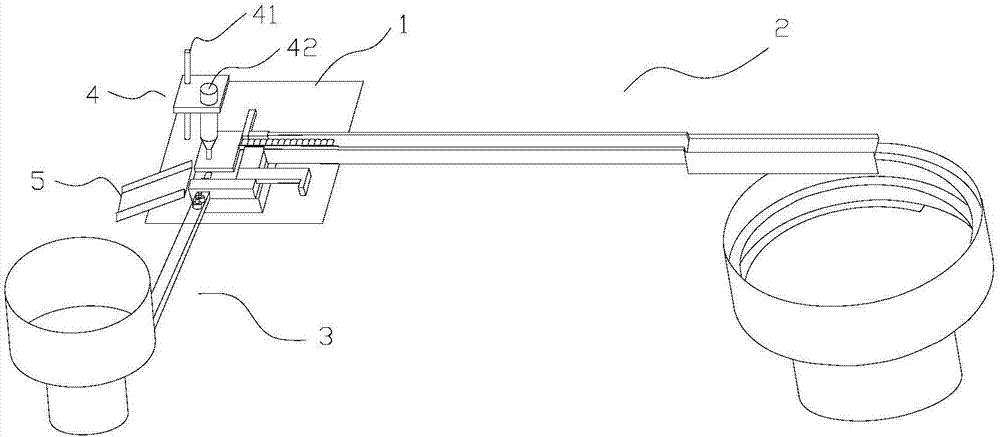

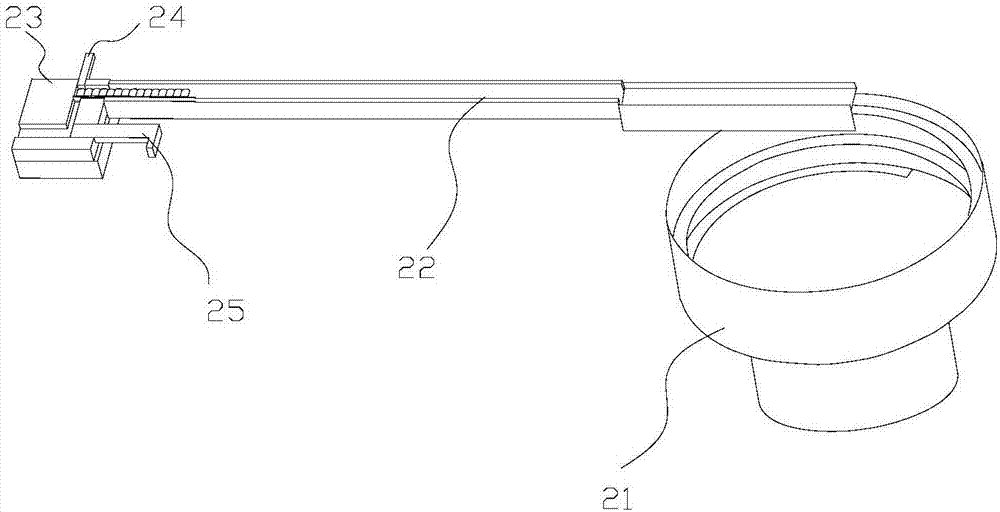

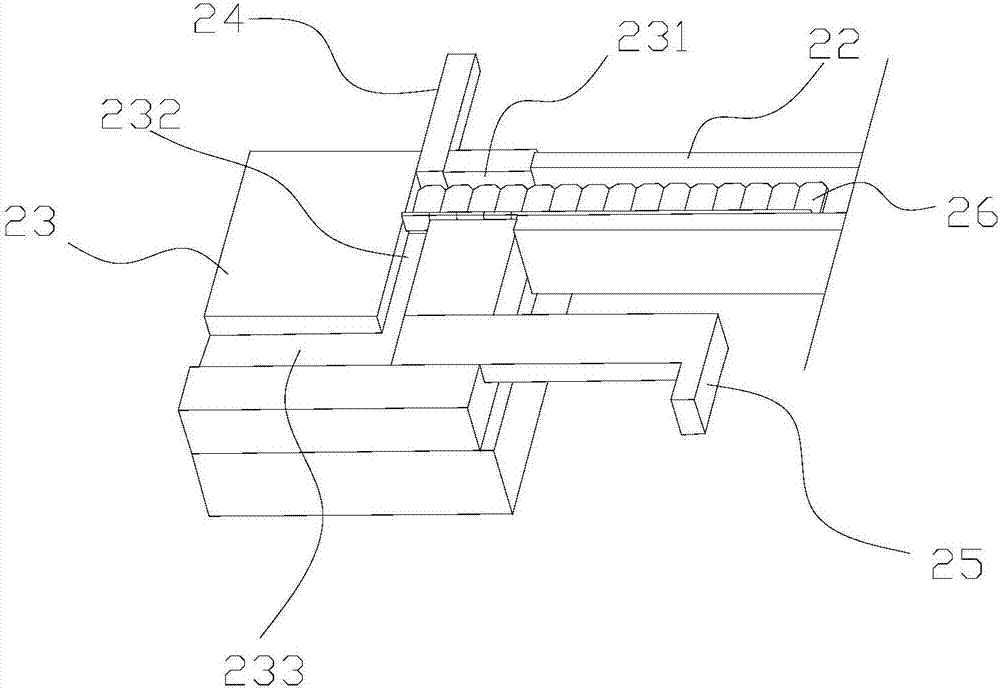

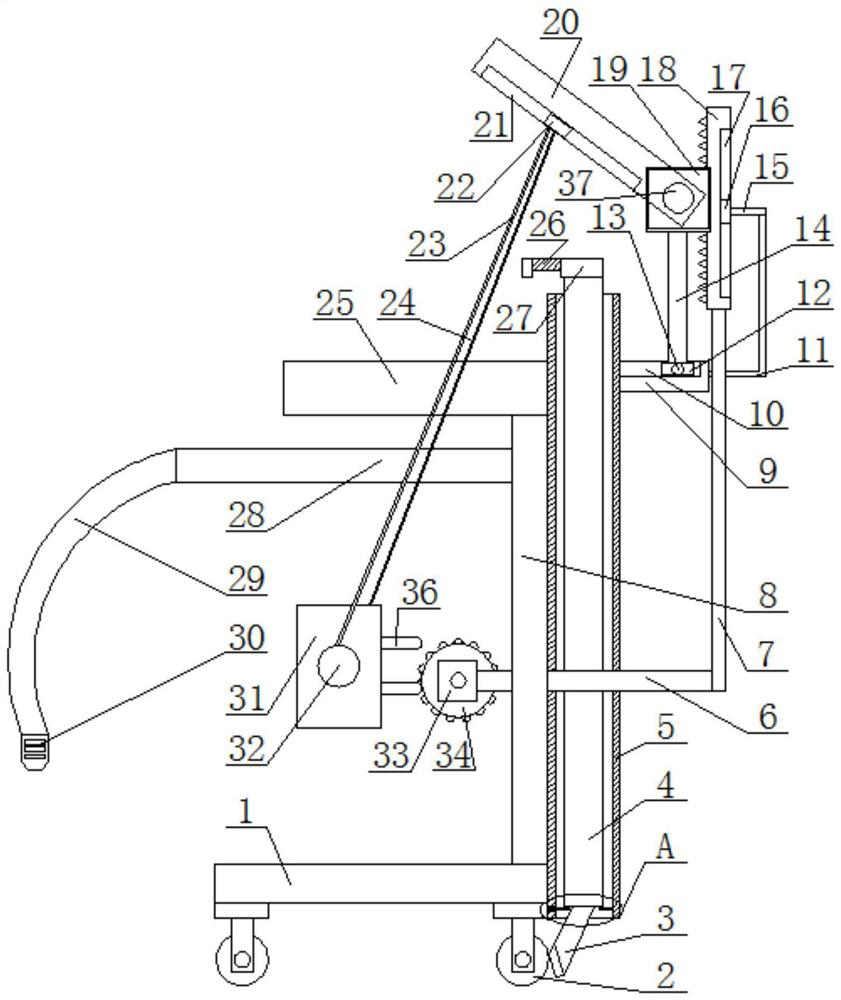

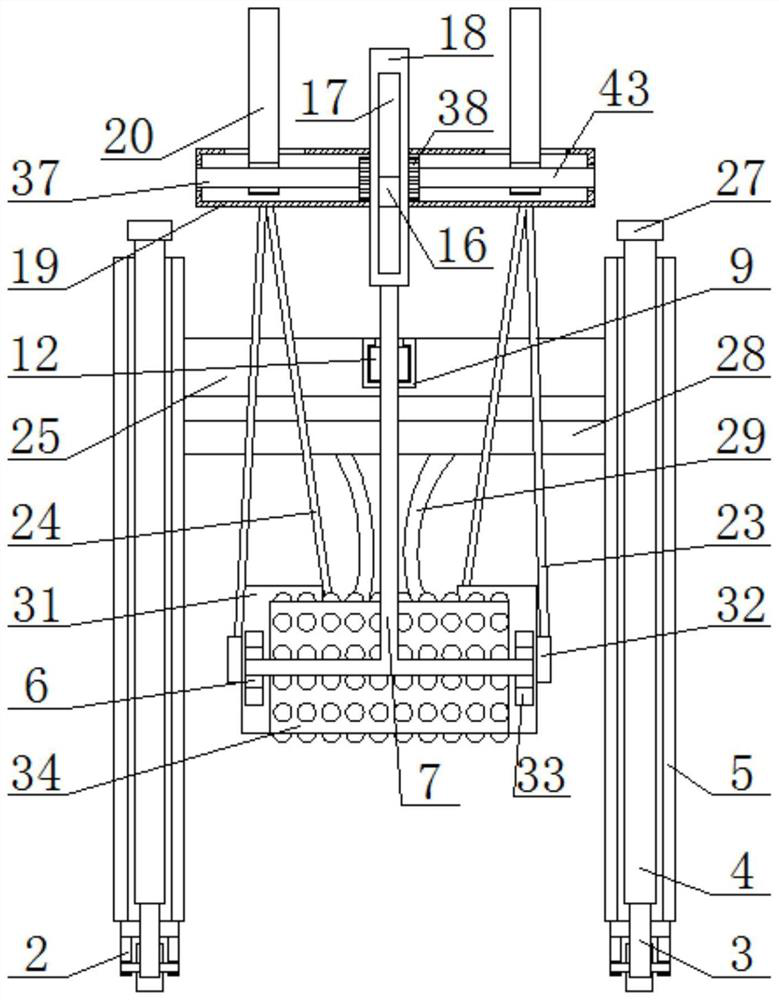

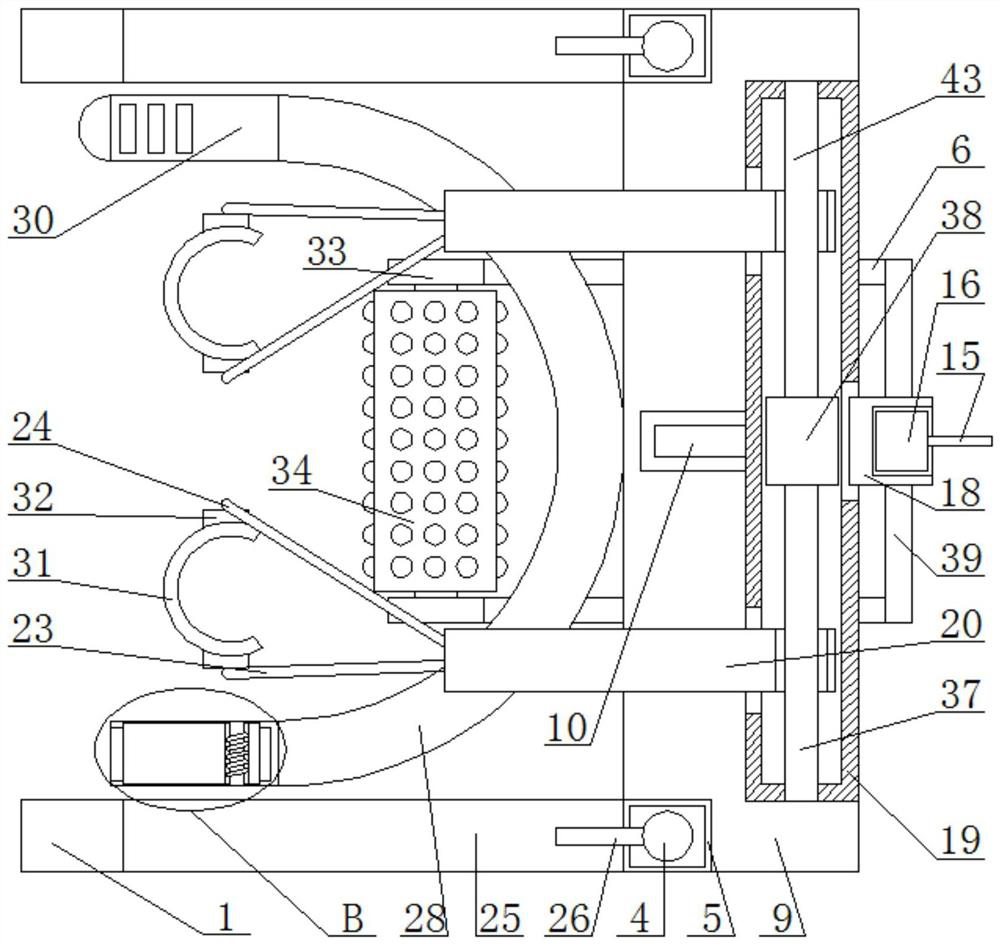

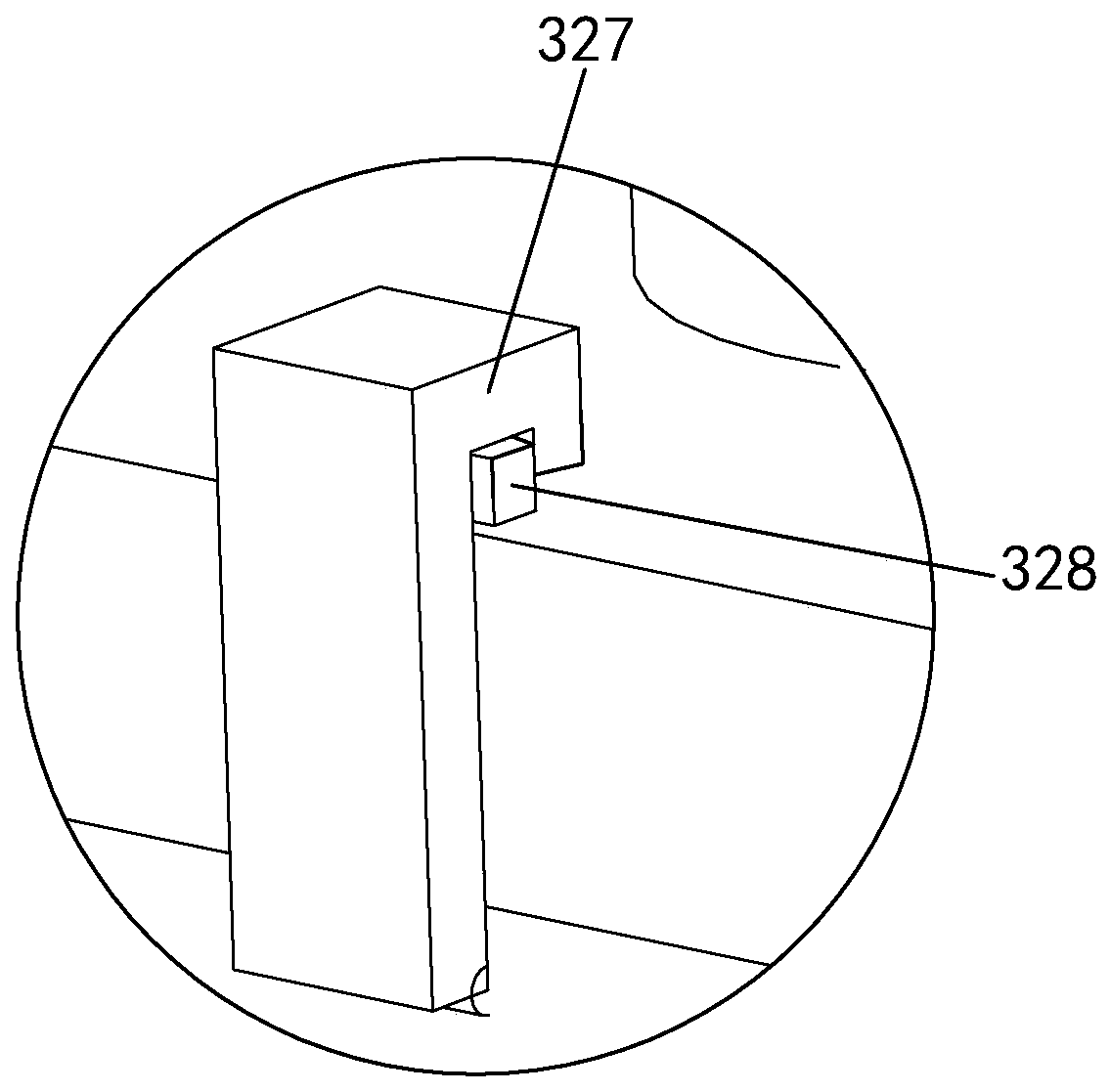

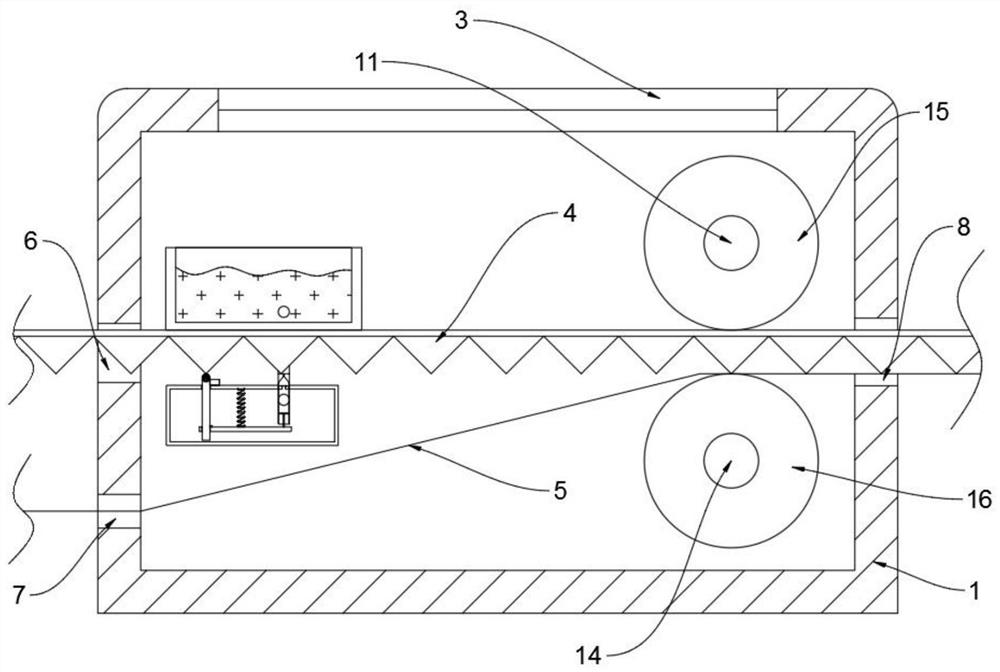

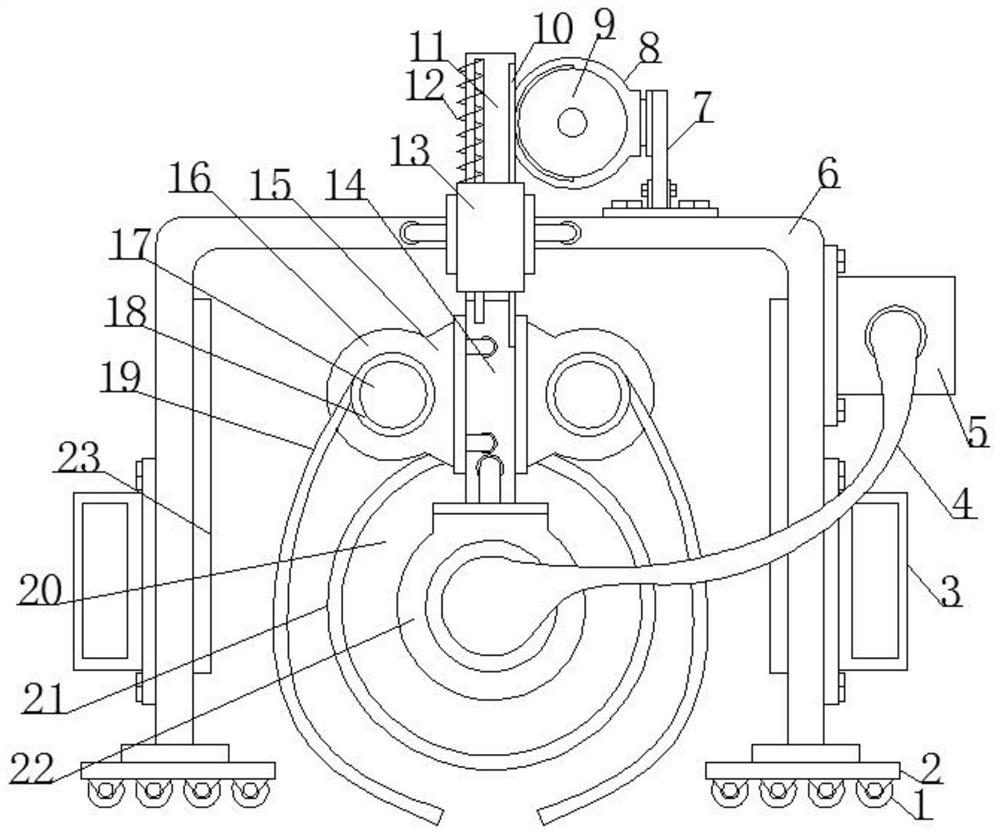

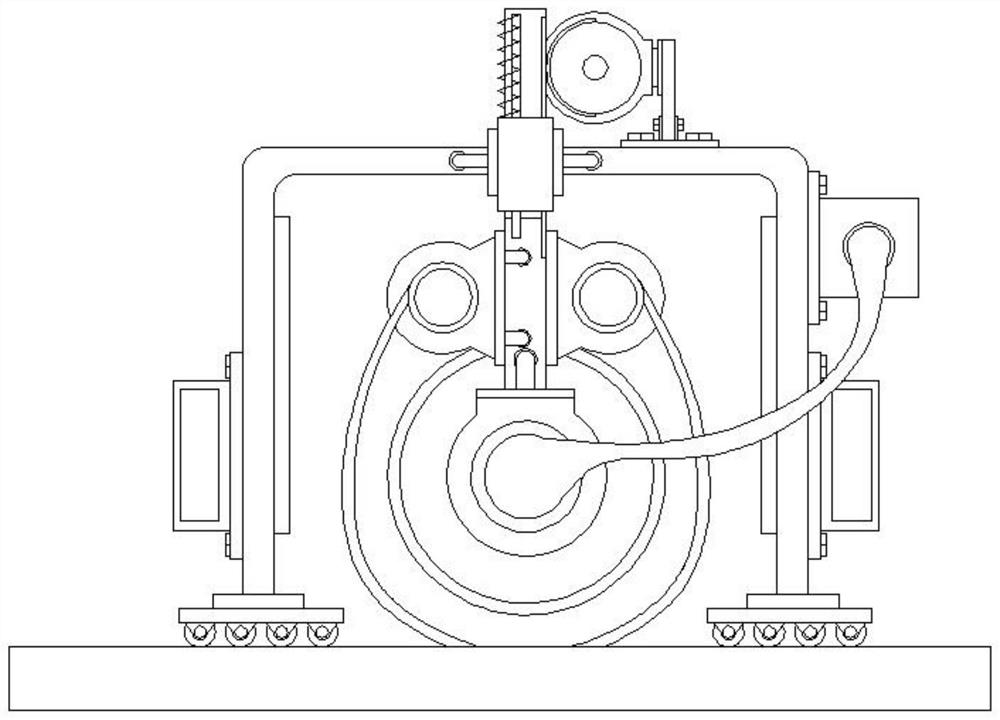

Automatic wire cutting and pressing machine for flat braided wire

ActiveCN105375235APrecise control of cutting line lengthRealize pressingLine/current collector detailsWire cuttingEngineering

Owner:INST OF INTELLIGENT MFG GUANGDONG ACAD OF SCI

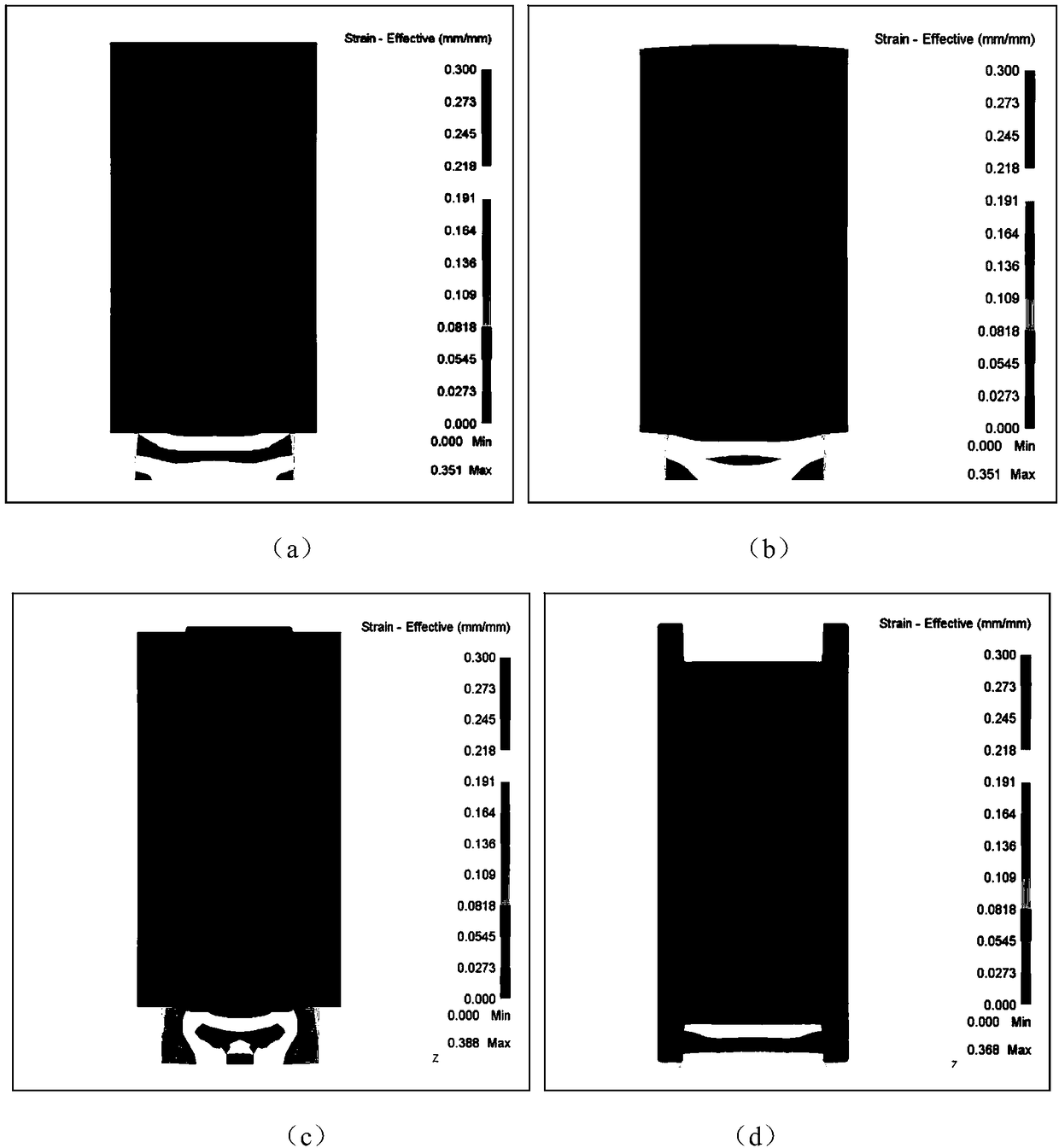

Curve design of rolling mill work roller for high-temperature large-rolling-reduction technology of large square billet and rectangular billet

ActiveCN108067501AEasy to compressGood shrinkage and lamination effectRollsMetal rolling arrangementsLiquid coreHot Temperature

The invention relates to the field of continuous casting billet high-temperature large-rolling-reduction rolling mills, in particular to roll shape curve design of a rolling mill work roller for a high-temperature large-rolling-reduction technology of a large square billet and a rectangular billet. The roll shape curve design is particularly applied to the single-pass hot core or liquid core high-temperature large-rolling-reduction rolling process of the large square billet or the rectangular billet. The work roller achieves optimal combination of a flanged roller shape and a box type hole shape, and optimization design of the geometrical characteristics of the work roller is conducted through calculation. The flange width coefficient of a combined roller is 0.4-0.8, and the flange heightof the combined roller is 5-45 mm. The radius of a box type inner fillet of the combined roller is 10-40 mm, the inclination angle of the side wall of the combined roller is 90-120 degrees, and the diameter of the work roller is 500-1000 mm. After the work roller in a combined roller shape is applied to the high-temperature large-rolling-reduction rolling technology, the shrinkage cavity press fiteffect, in the thickness direction and the extension direction, of the flanged roller and the shrinkage cavity press fit effect, in the width direction, of the box type hole shape can be highlightedat the same time. In this way, the casting billet core deformation permeability and the central shrinkage cavity three-direction press fit effect in the single-pass high-temperature large-rolling-reduction rolling deformation can be improved to a greater extent.

Owner:NORTHEASTERN UNIV

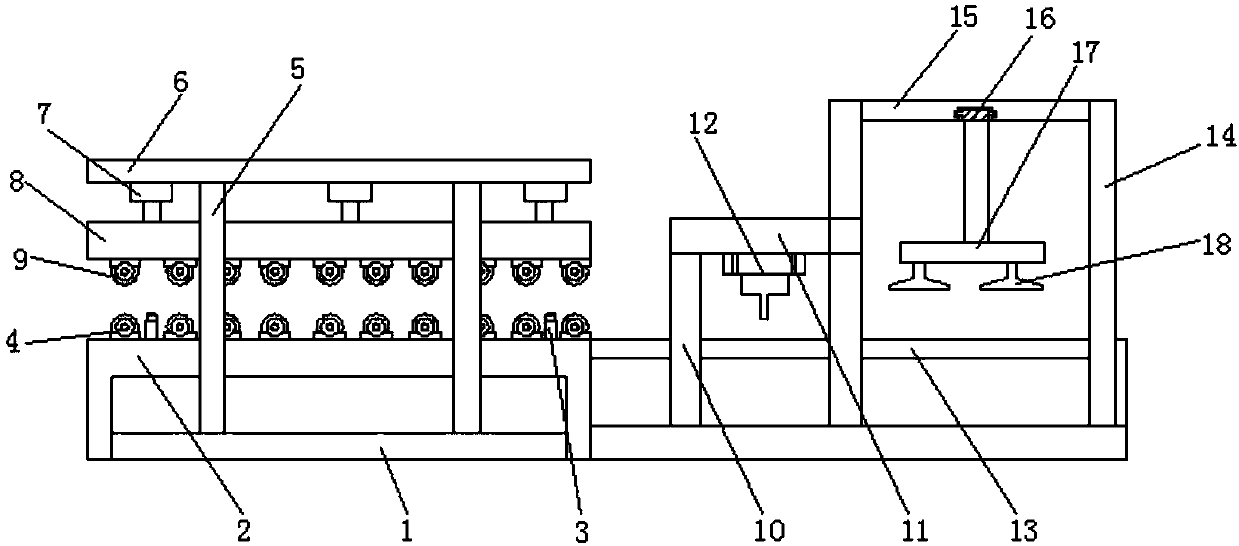

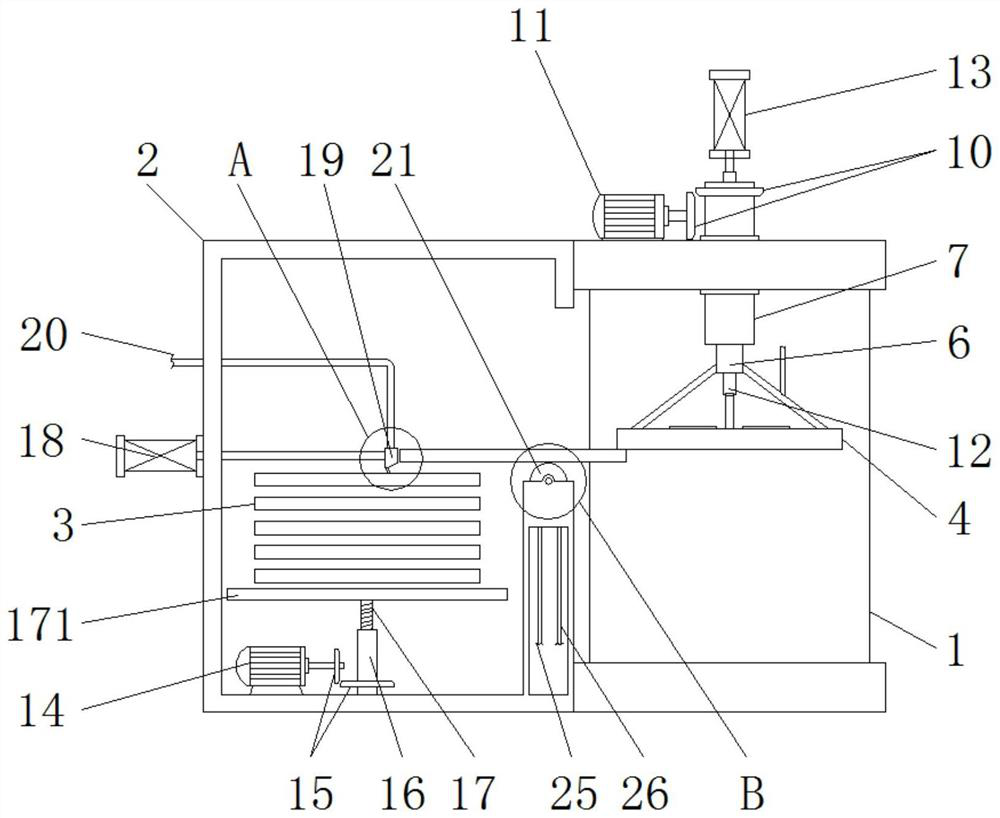

Assembly line for production of color steel sandwich panel

InactiveCN107825138ARealize automatic deliveryRealize pressingOther manufacturing equipments/toolsMetal working apparatusAssembly lineSandwich panel

The invention discloses an assembly line for production of a color steel sandwich panel. The assembly line comprises a base, and a transportation rack is welded on the base; first conveying rollers are arranged on the upper surface of the transportation rack at equal intervals; a fixed plate is fixed in the position, above the transportation rack, on the base through first supporting pillars; a lamination plate is fixed to the bottom of the fixed plate through telescopic cylinders; second conveying rollers are arranged at the bottom of the lamination plate at equal intervals; a cross beam is fixed to the position, on one side of the transportation rack, on the base through a second supporting pillar; and a cutting machine is fixed to the bottom of the cross beam through a telescopic rod. In the assembly line, the lamination plate is fixed through the telescopic cylinders, and lamination of the color steel sandwich panel is achieved; the second conveying rollers are arranged on the lamination plate, the lamination plate performs lamination of the color steel sandwich panel through the second conveying rollers, transportation of the color steel sandwich panel is not affected, and working efficiency is improved; and the cutting machine is arranged, the assembly line for production of the color steel sandwich panel has the function of cutting the color steel sandwich, the functionsare increased, and practicability is improved.

Owner:天津贵和建设集团有限公司

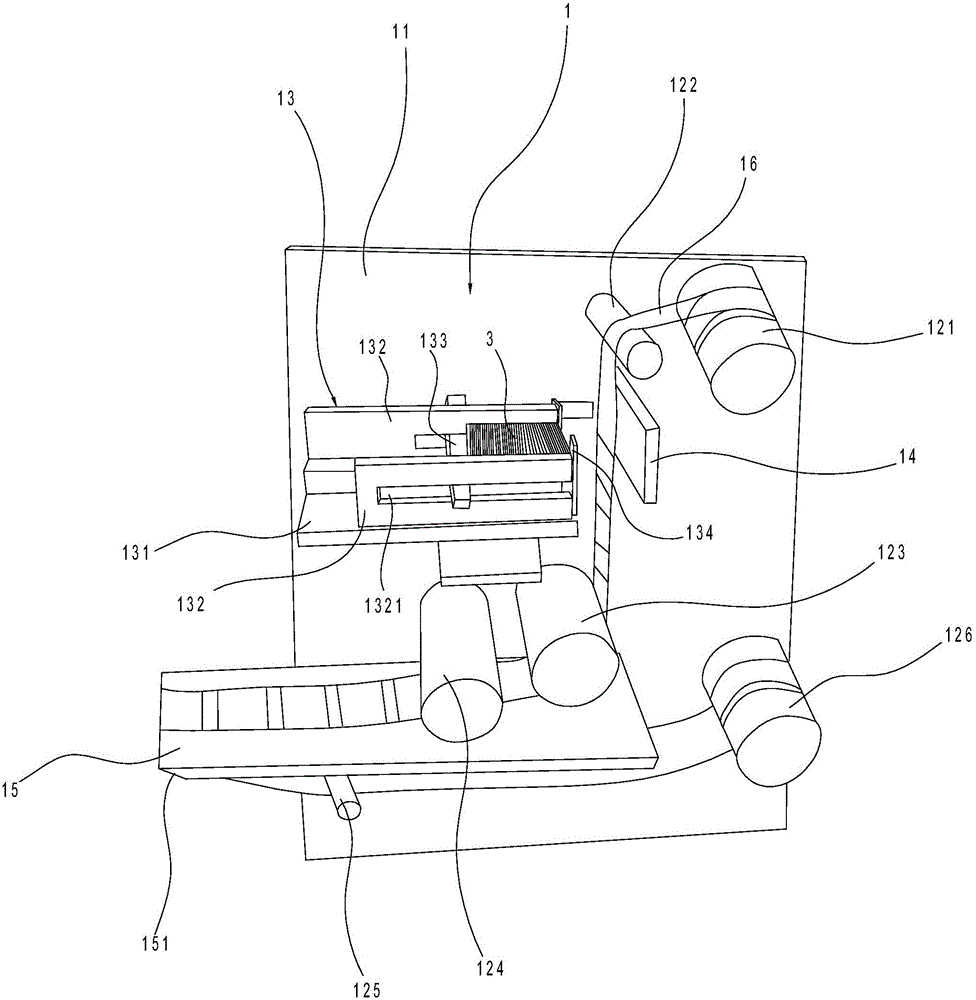

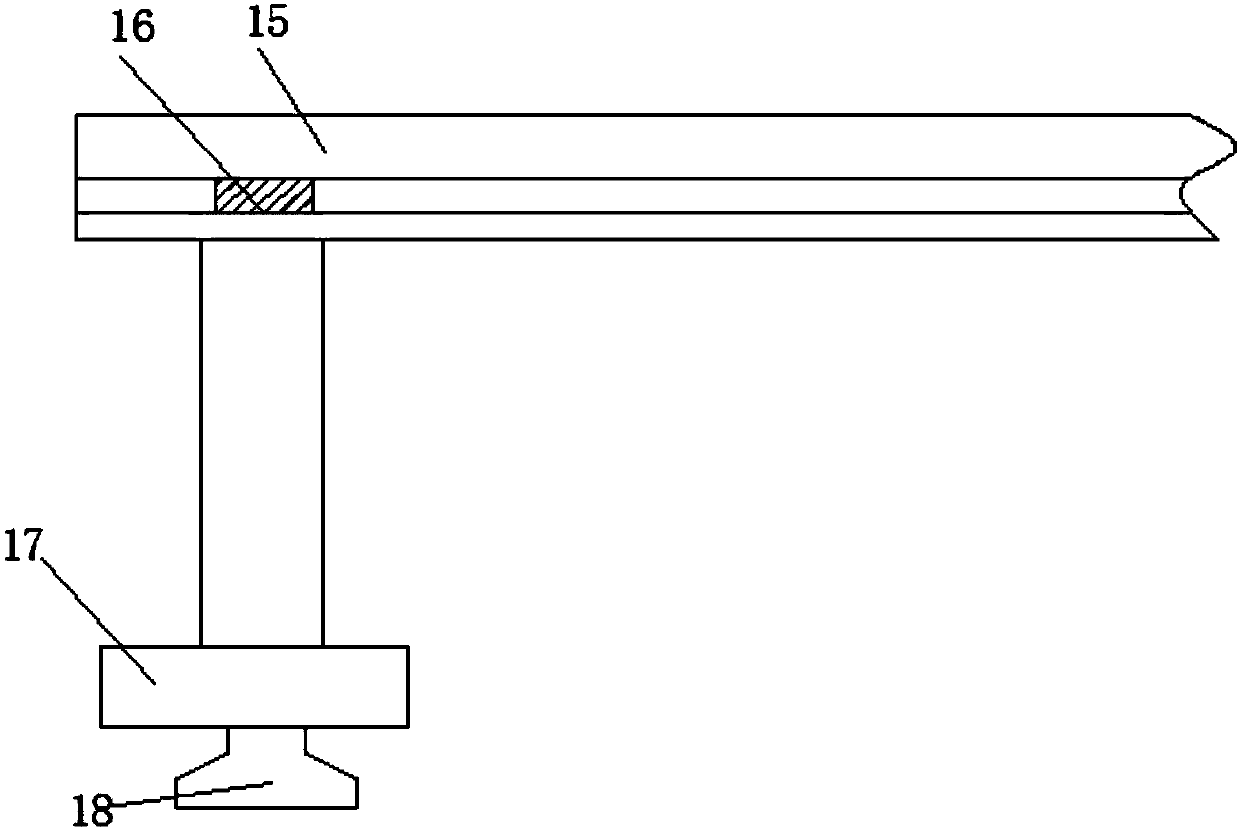

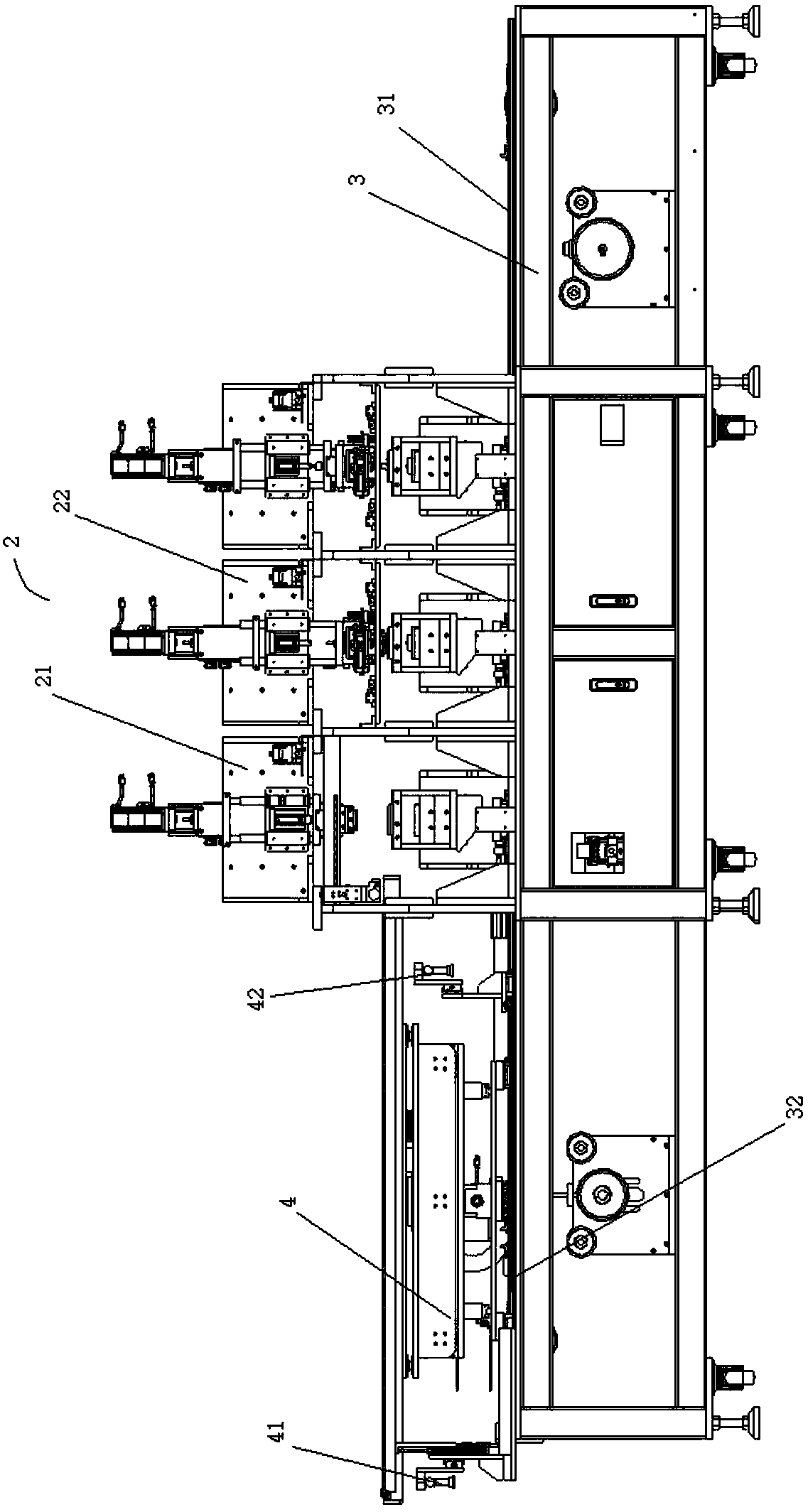

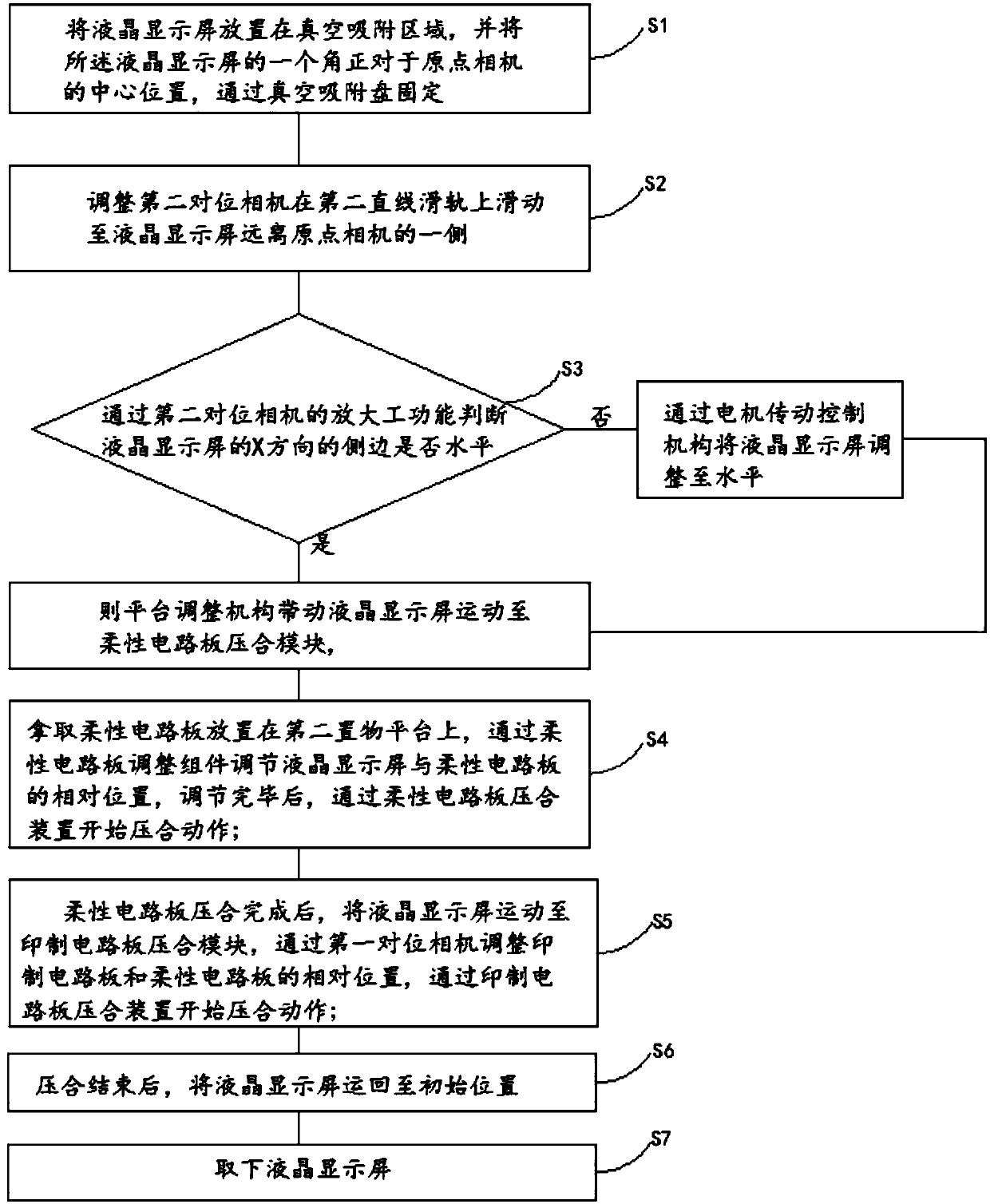

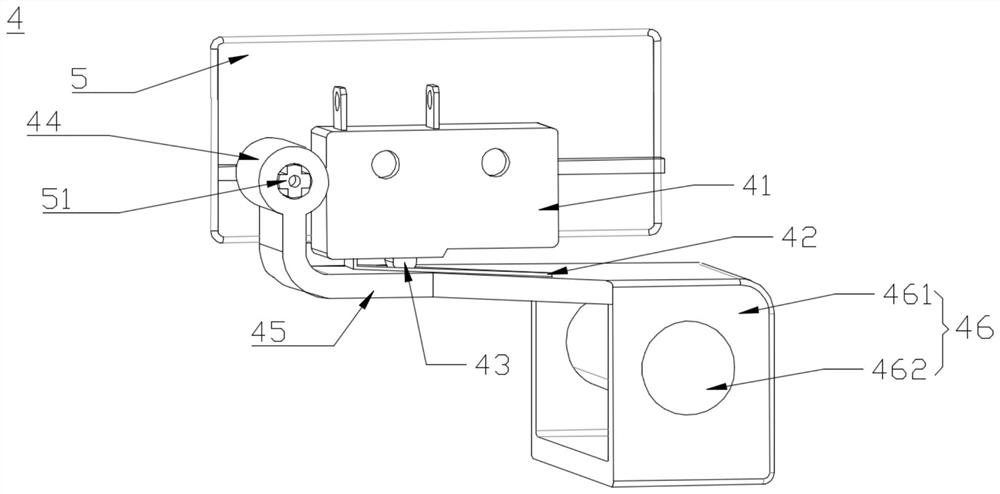

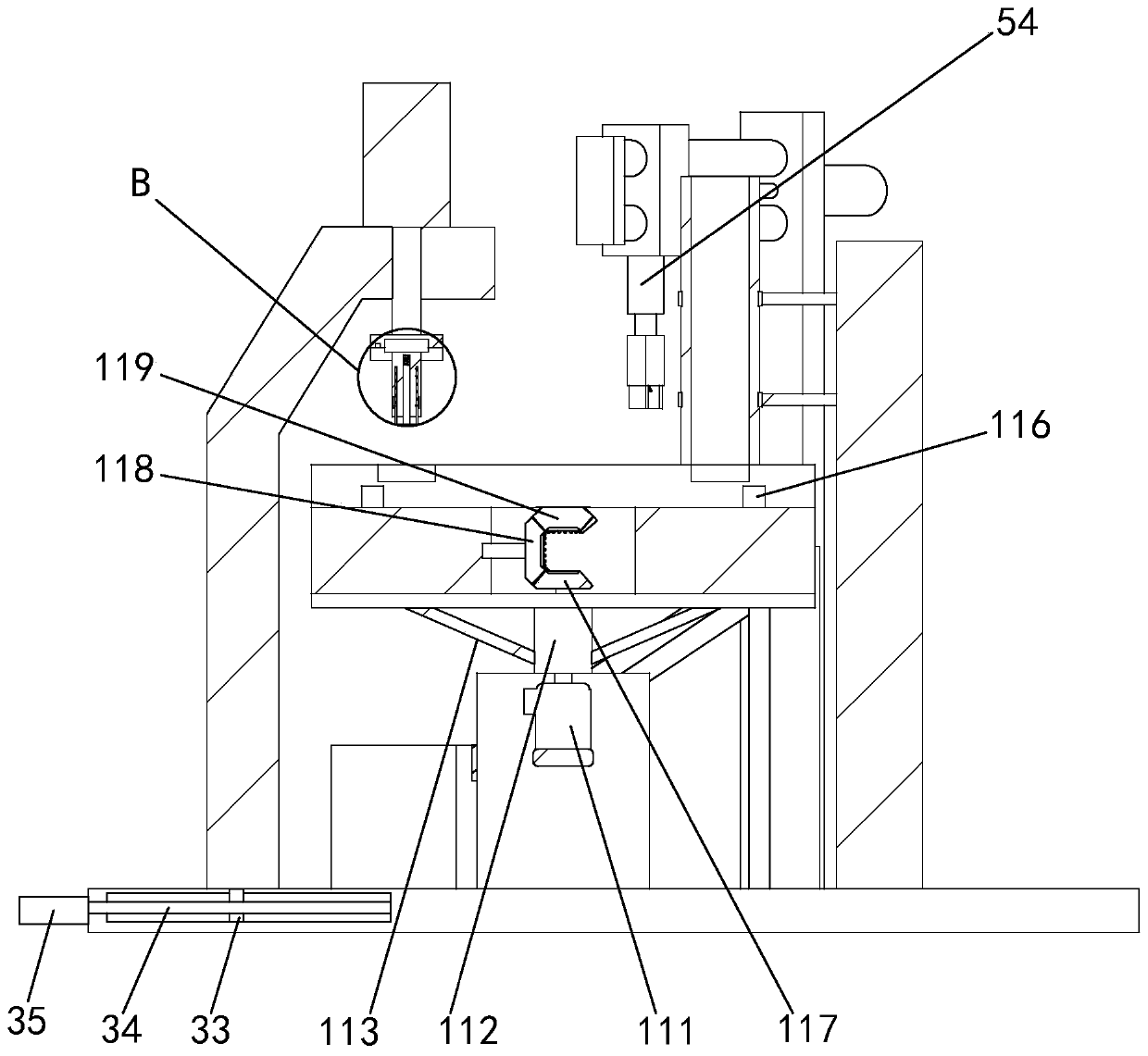

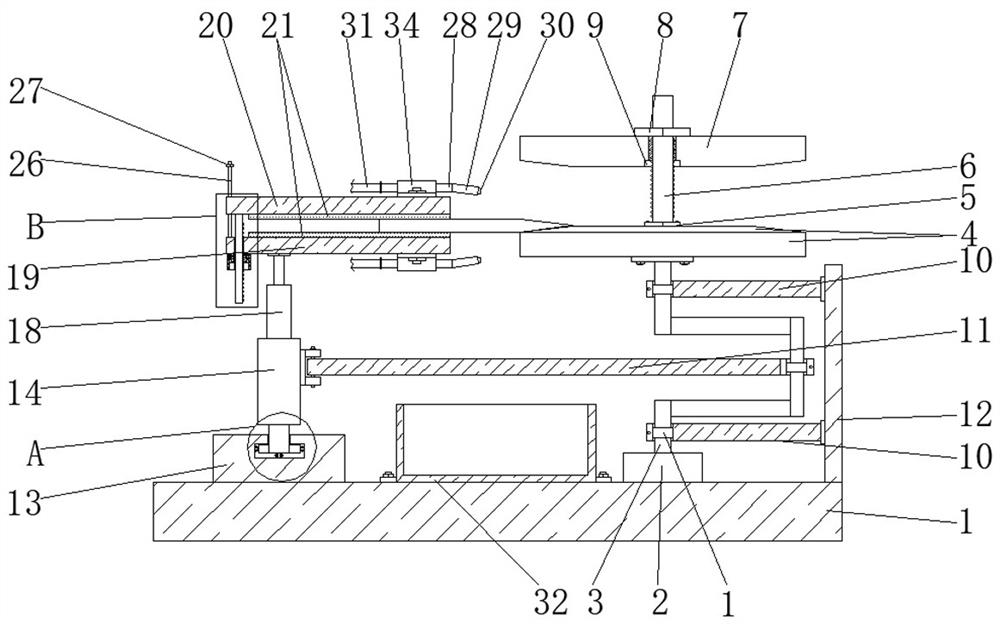

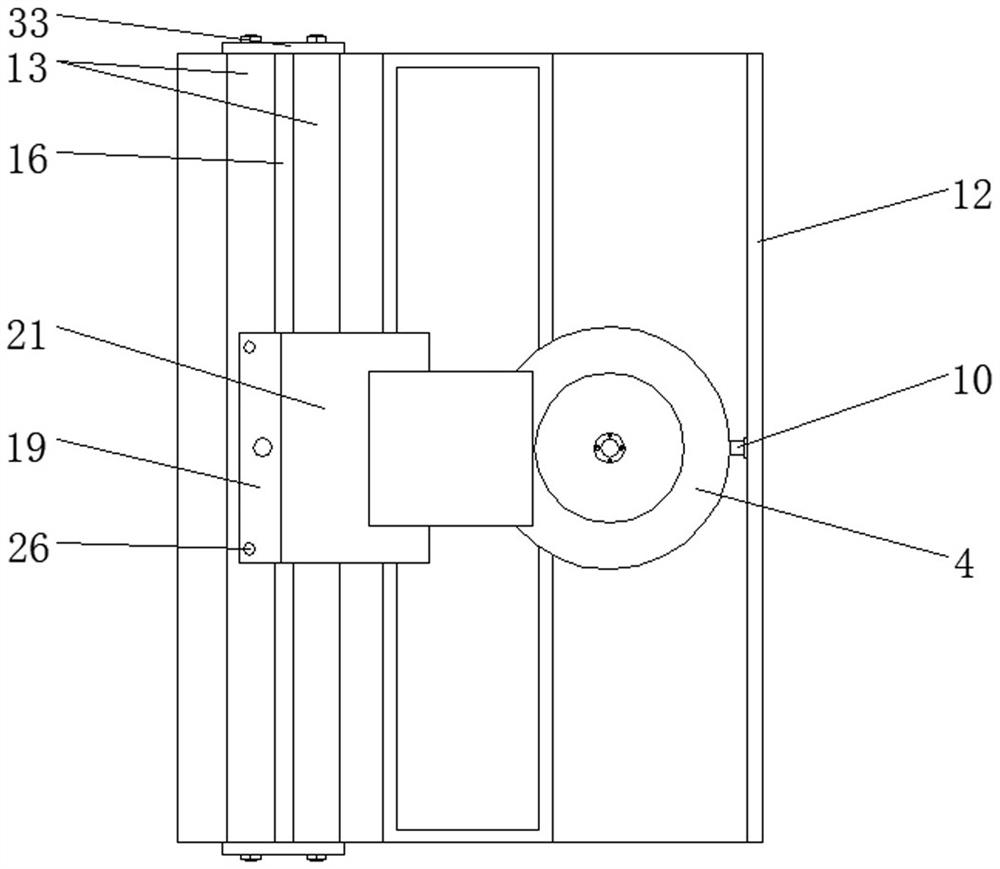

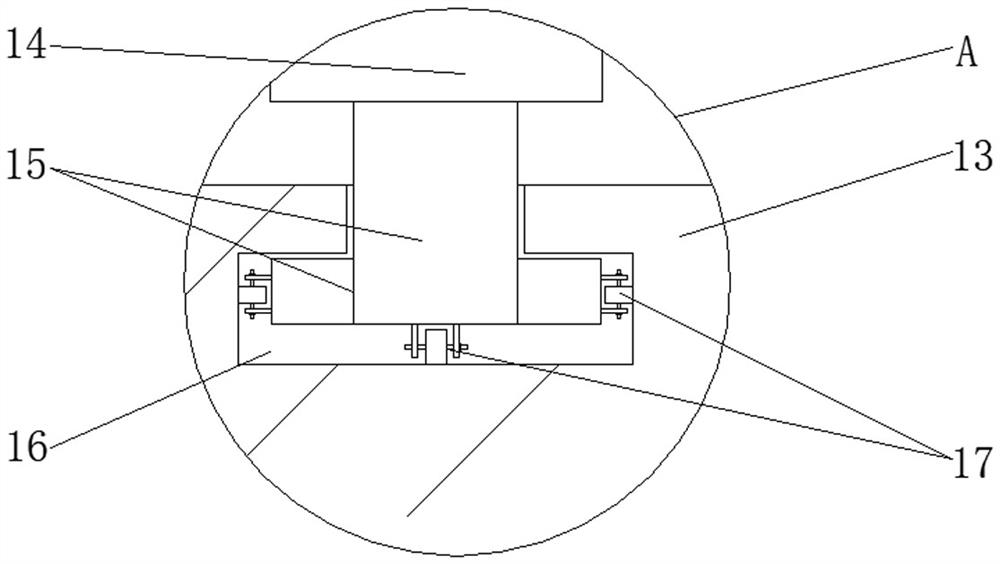

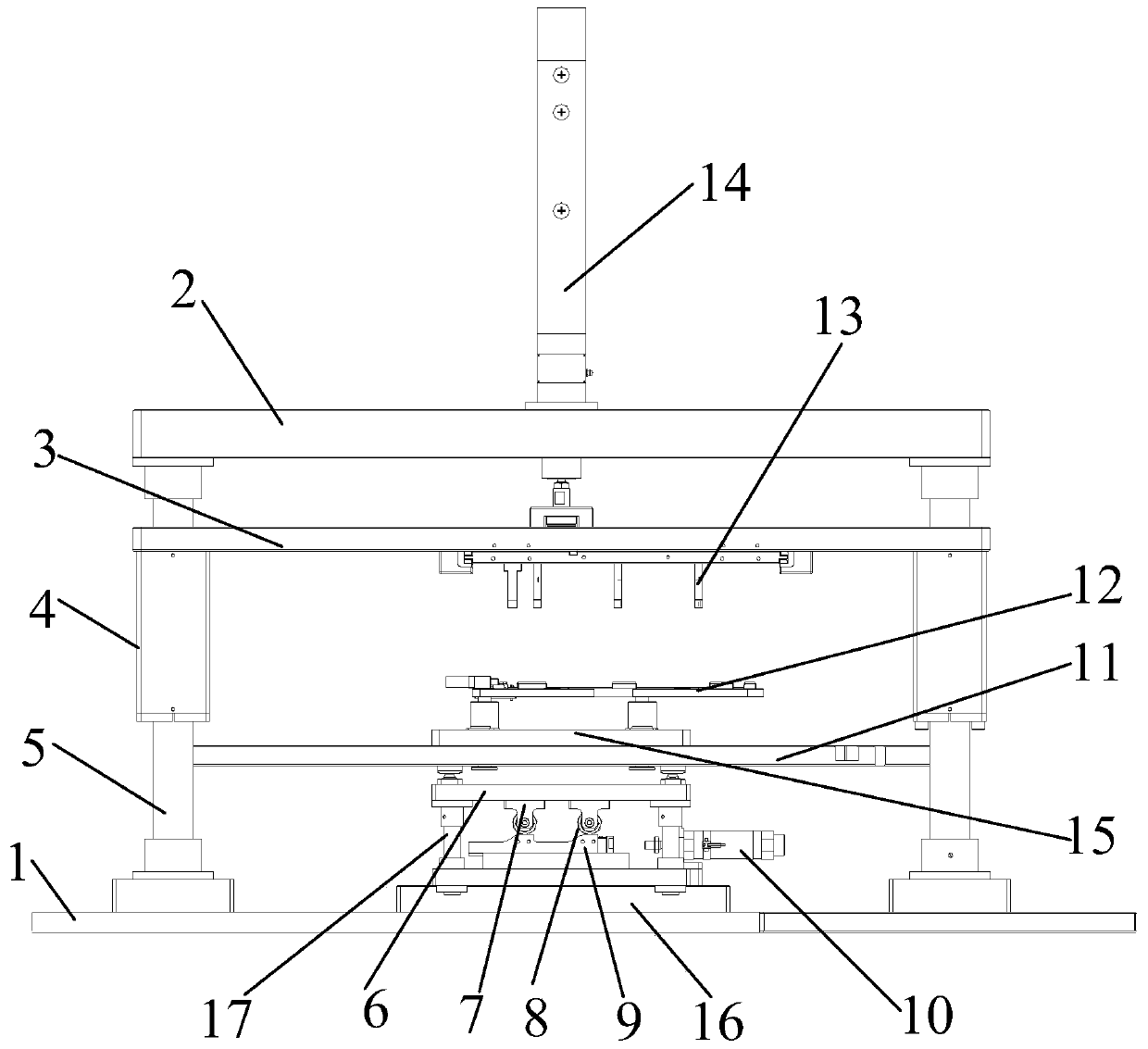

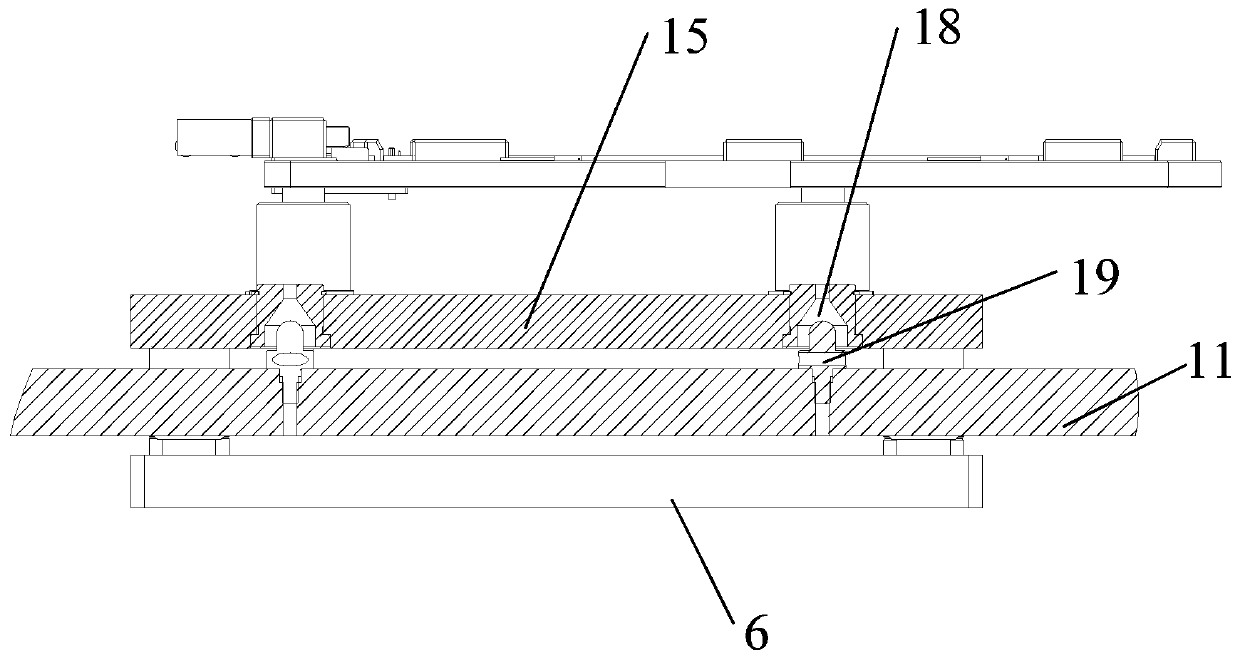

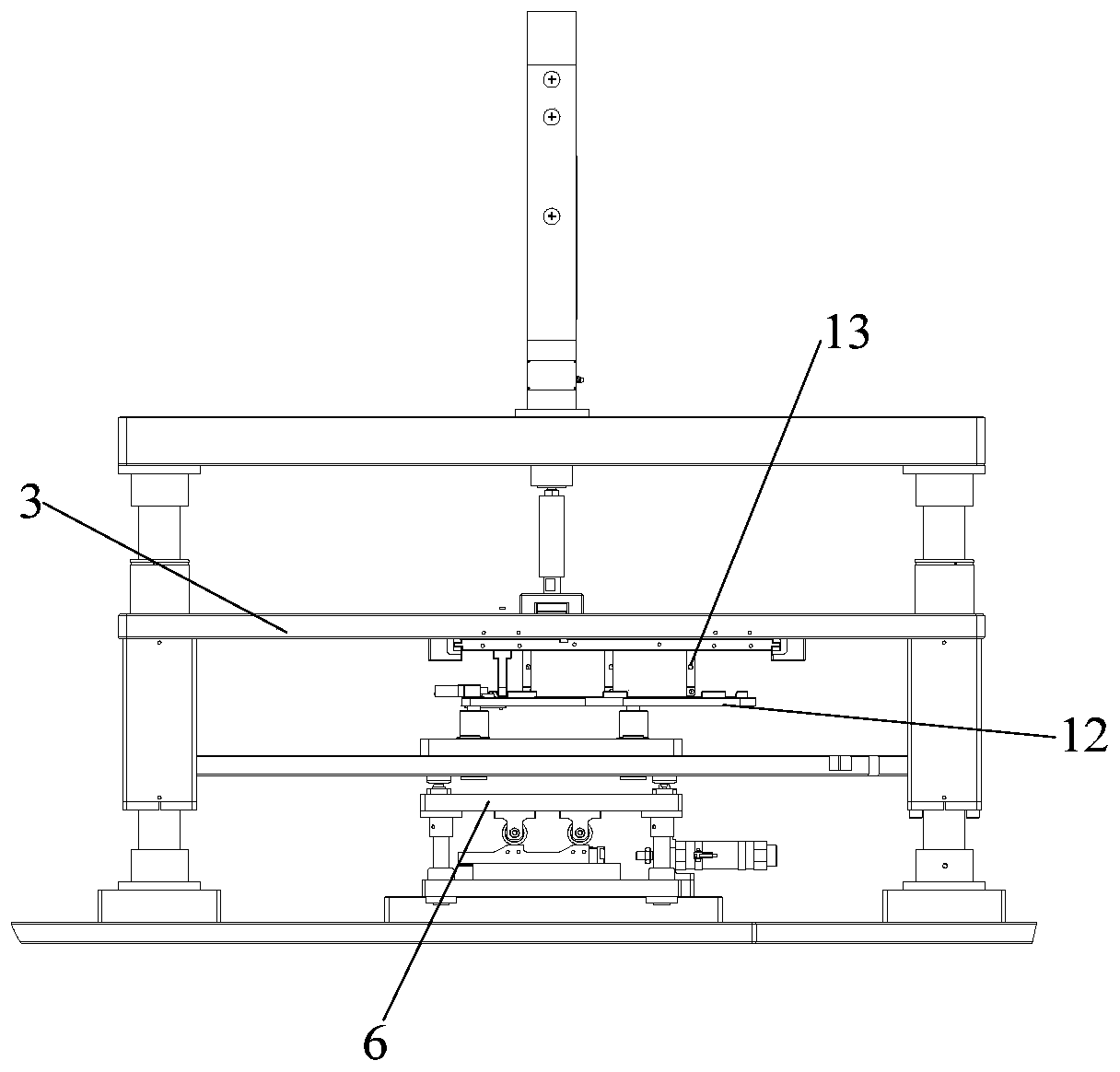

Liquid crystal display COF (chip on film) bonding semi-automatic device and pressing process thereof

ActiveCN107632424AAvoid bendingGuaranteed flatnessNon-linear opticsChip on filmLiquid-crystal display

The invention relates to the technical field of liquid crystal display panel manufacture, and discloses a liquid crystal display COF (chip on film) bonding semi-automatic device which comprises a vacuum absorption mechanism and a pressing mechanism. A gravity center of the vacuum absorption mechanism approaches to one side of the pressing mechanism, flatness of large-size liquid crystal displays is ensured, and the pressing mechanism comprises a printed circuit board pressing module and a flexible printed circuit board pressing module. According to the device, straightness of printed circuit boards is monitored by a first alignment camera, relative positions of the liquid crystal displays and the printed circuit boards are adjusted by a second alignment camera and a motor transmission control mechanism, relative positions of the liquid crystal displays and flexible printed circuit boards are adjusted by a flexible printed circuit board adjusting component, the device solves the problems that a Gate side and a Source side are difficultly and simultaneously pressed, large-size liquid crystal displays are difficultly pressed when the flatness of the liquid crystal displays is ensured,and position accuracy is difficultly ensured by manually adjusting the positions of the liquid crystal displays in the prior art.

Owner:苏州富强加能精机有限公司

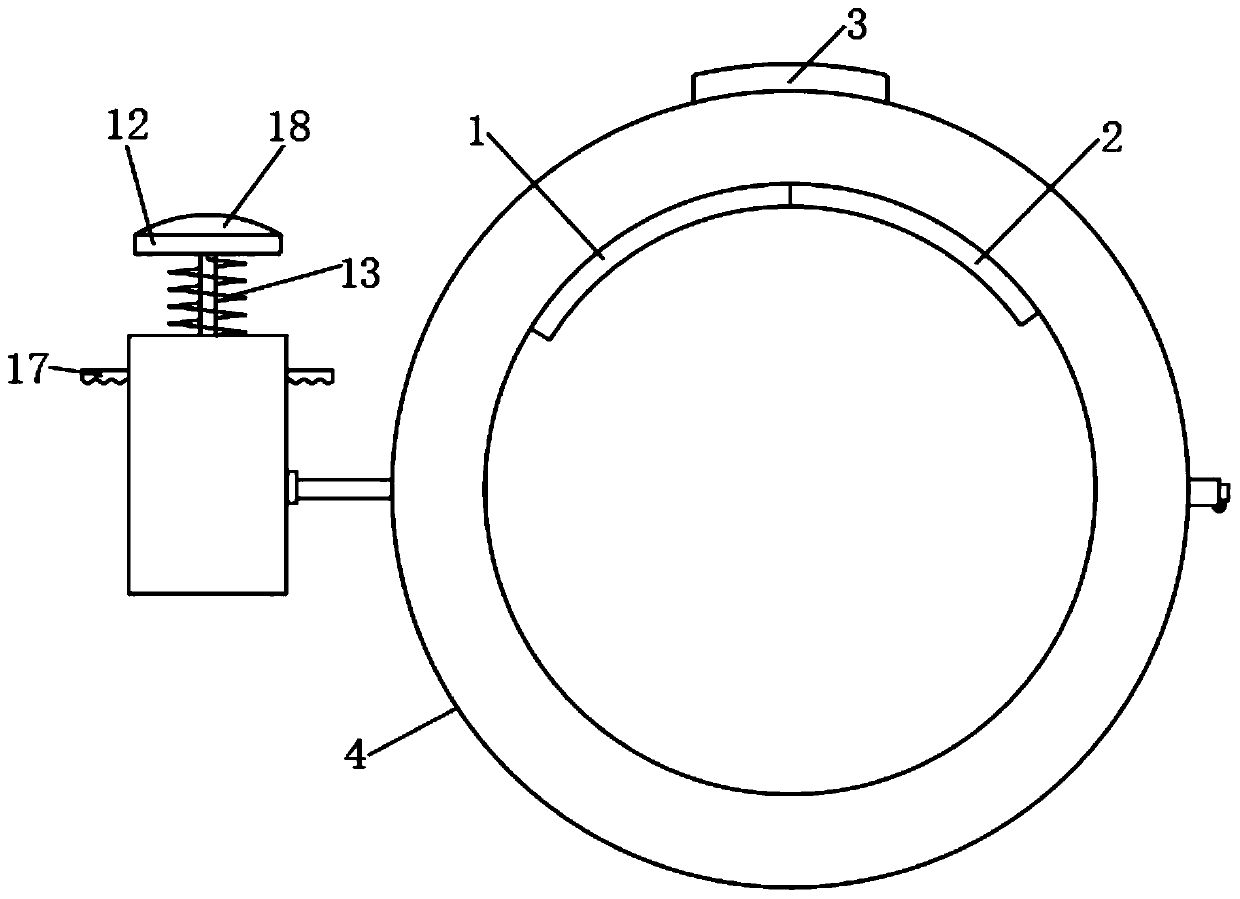

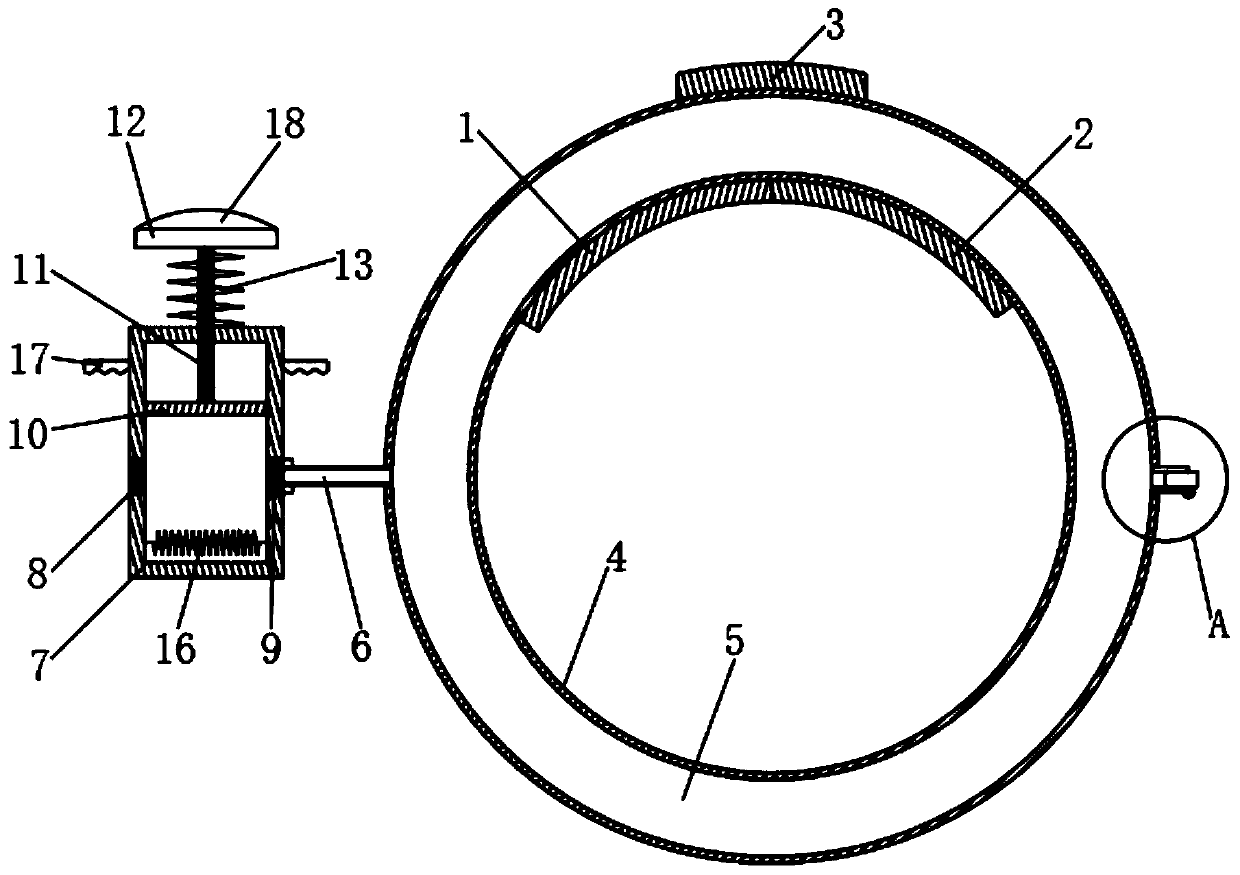

Postoperative puncture site pressing device for cerebrovascular intervention

InactiveCN110101428AQuick pressPlay a pressing effectTourniquetsEngineeringUltimate tensile strength

The invention discloses a postoperative puncture site pressing device for cerebrovascular intervention. The postoperative puncture site pressing device for the cerebrovascular intervention comprises asensing module, a monitoring module and an alarm module, wherein the opposite surfaces of the sensing module, the monitoring module and the alarm module are fixedly connected with a pressing device,the pressing device comprises an annular air bag and an air inlet shell, the inner ring surface of the annular air bag is fixedly connected to the surface of the sensing module and the monitoring module, and the outer ring surface of the annular air bag is fixedly connected to the surface of the alarm module, a through hole is formed in a left side of the annular air bag, and through the through hole, a connecting tube is in fixed sealed connection with the annular air bag. The postoperative puncture site pressing device for the cerebrovascular intervention, through the cooperative use of theabove structures, solves the problem that due to the fact that the adjustment of the pressing strength of a traditional presser is not convenient in the actual use process and it is necessary to pullout an adhesive tape several times and then perform re-bonding in order to achieve a suitable pressing strength, secondary damage to a puncture site is caused, the work efficiency is lowered, and inconvenience is brought to the use.

Owner:周林国

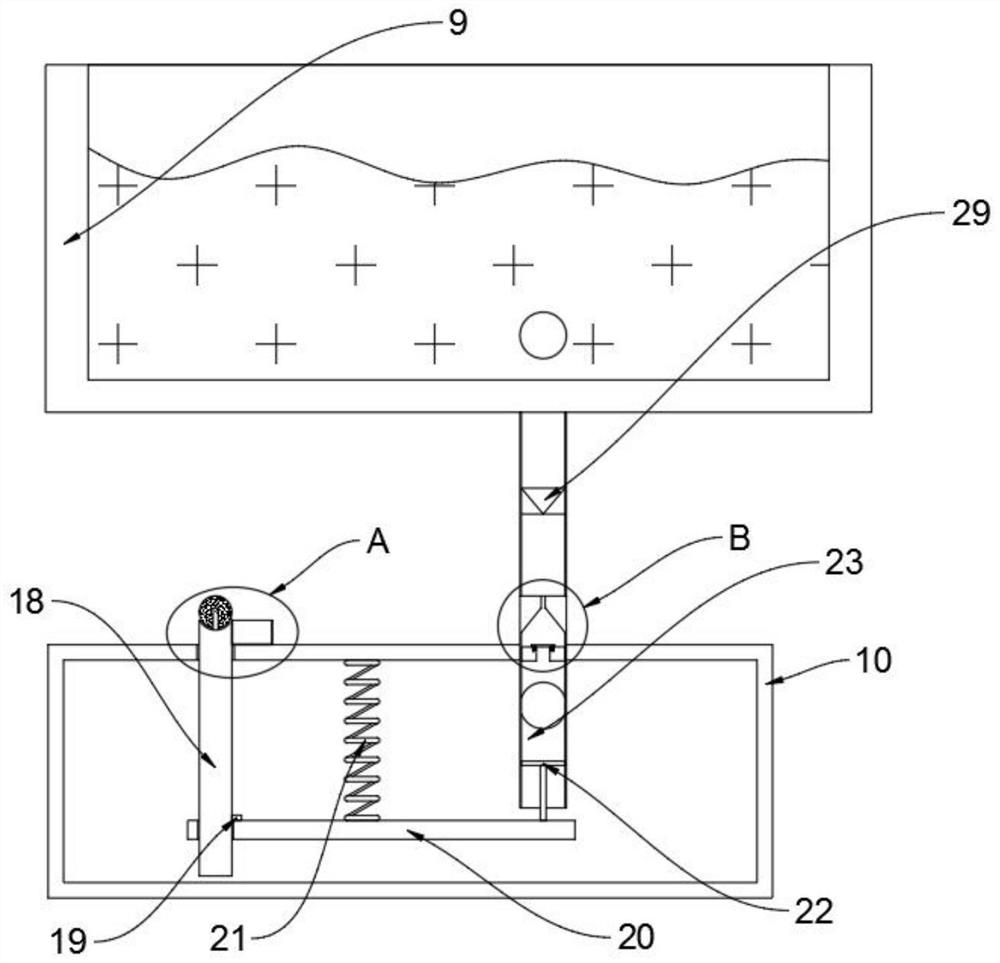

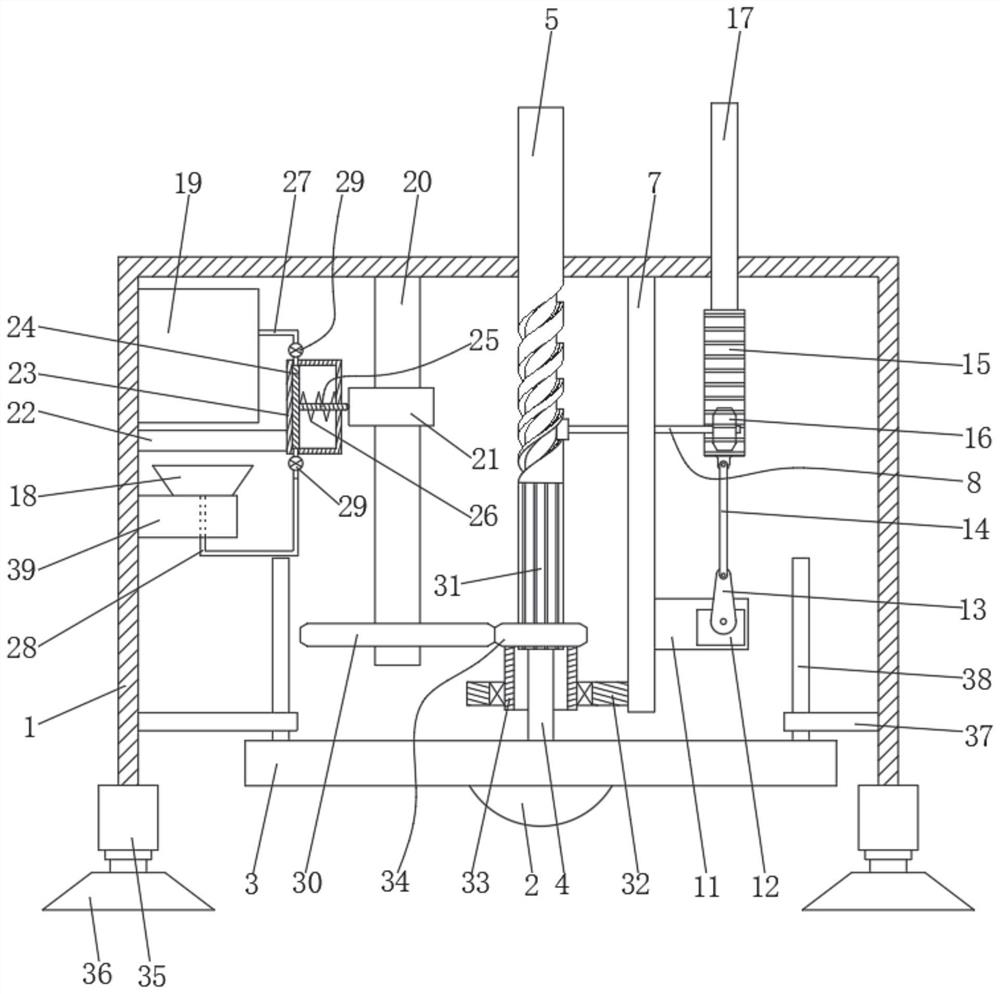

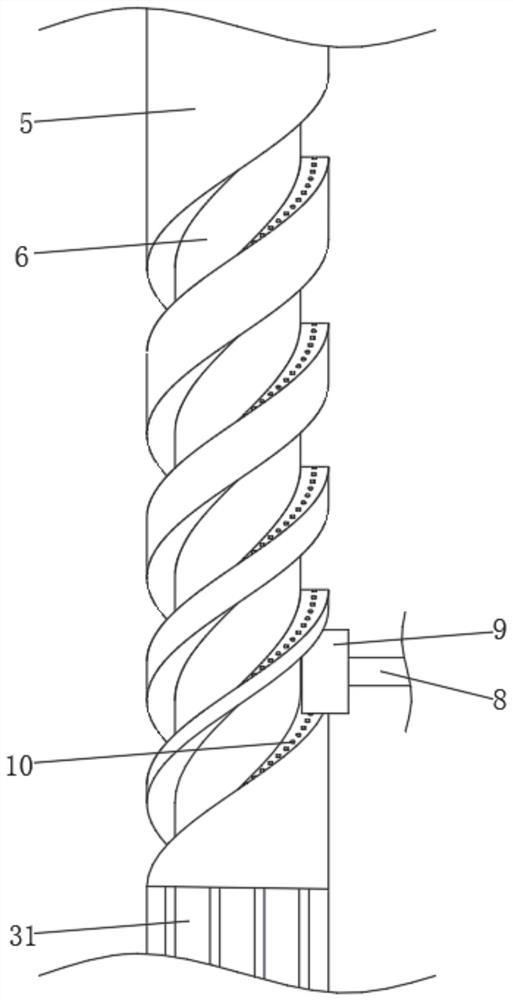

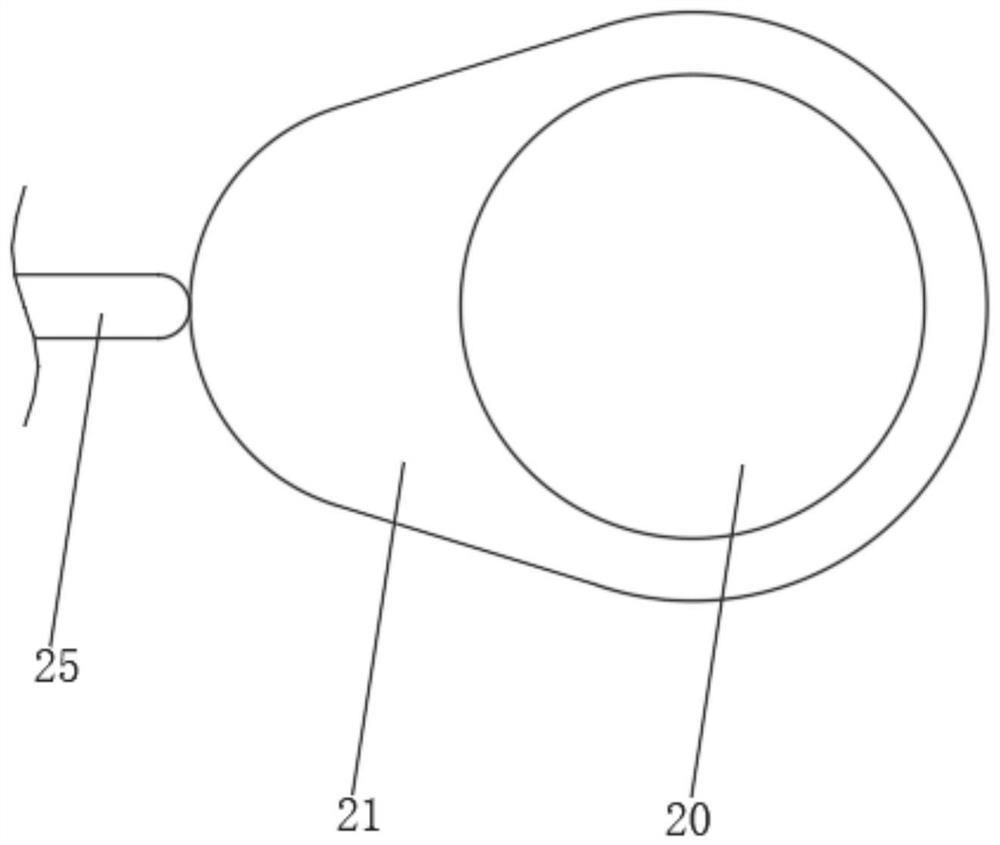

Multifunctional nursing equipment for cardiology department monitoring and using method thereof

InactiveCN112022676ARealize pressingImprove the pressing effectRespiratorsElectrotherapyNursing careEngineering

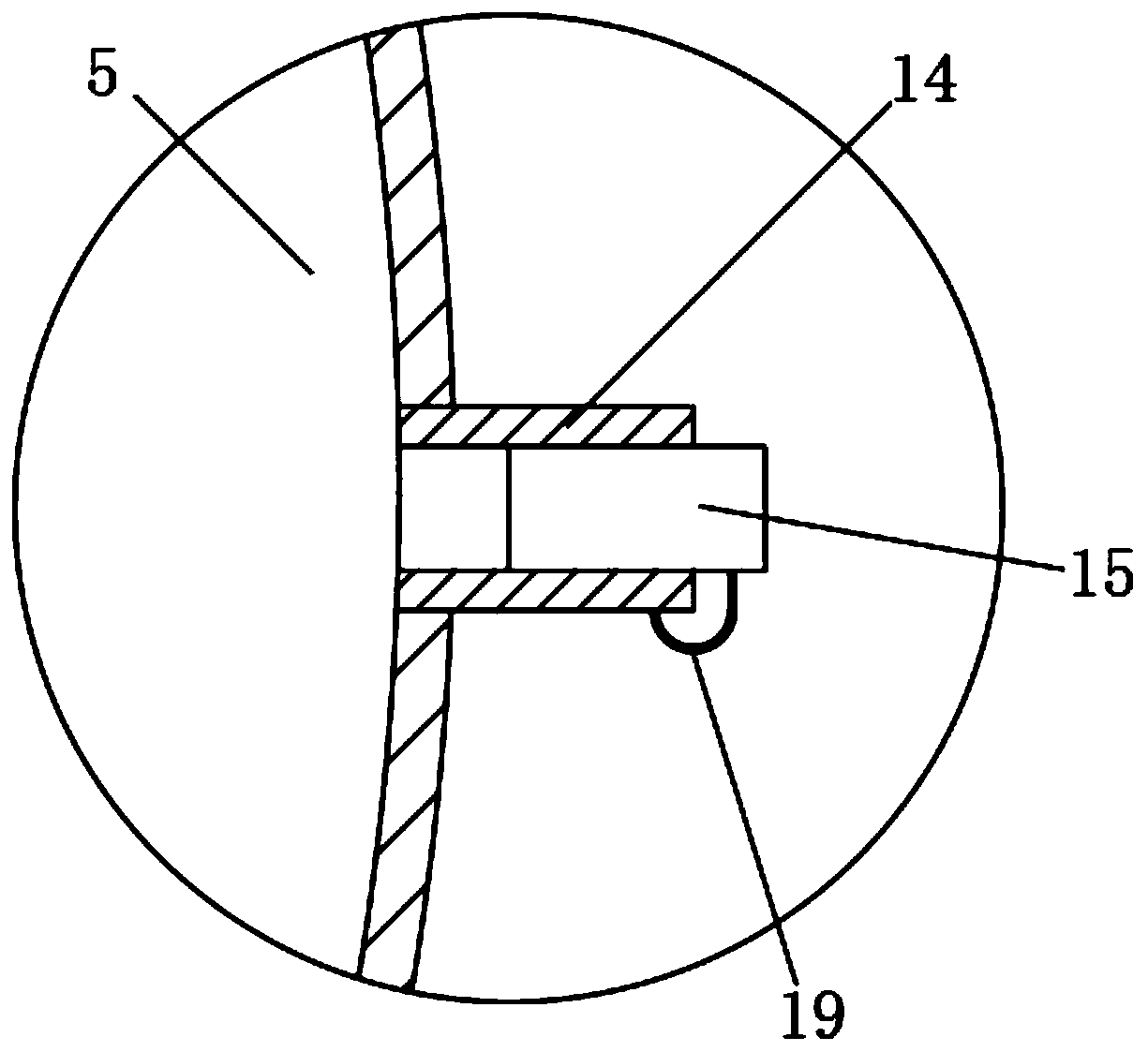

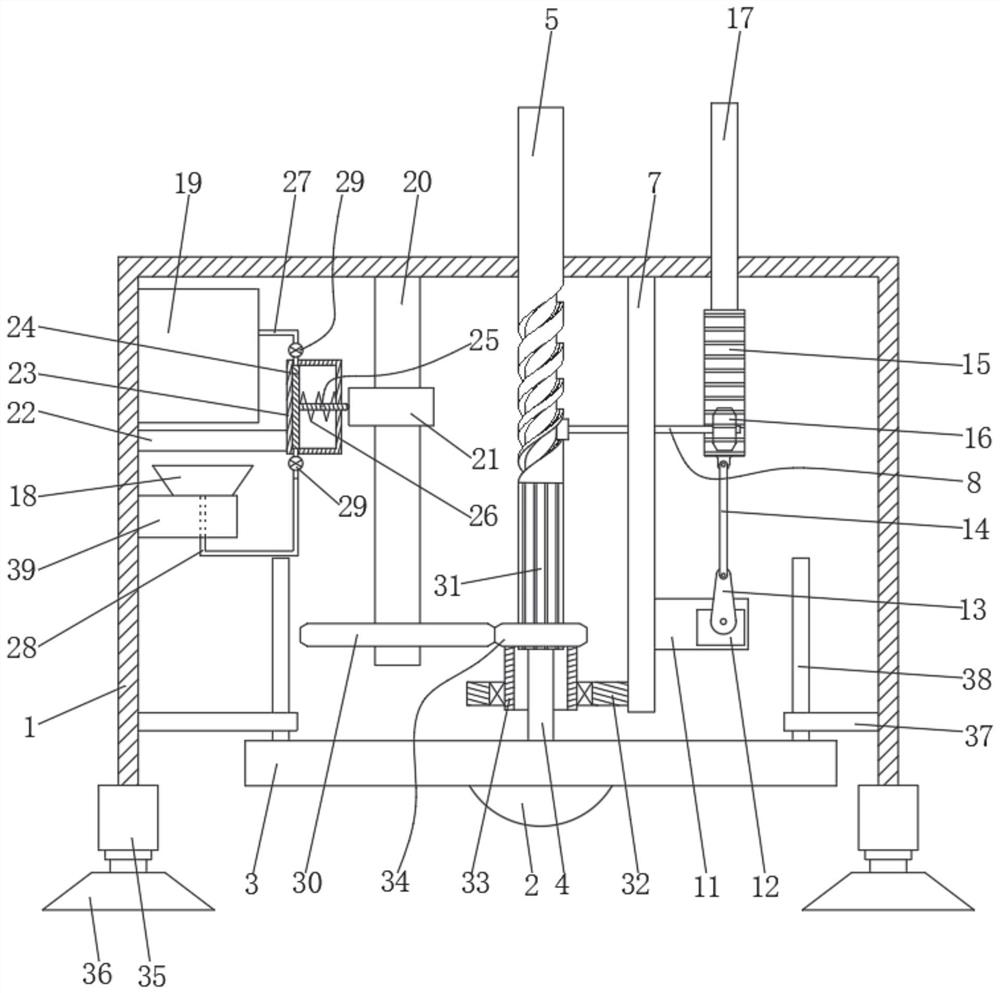

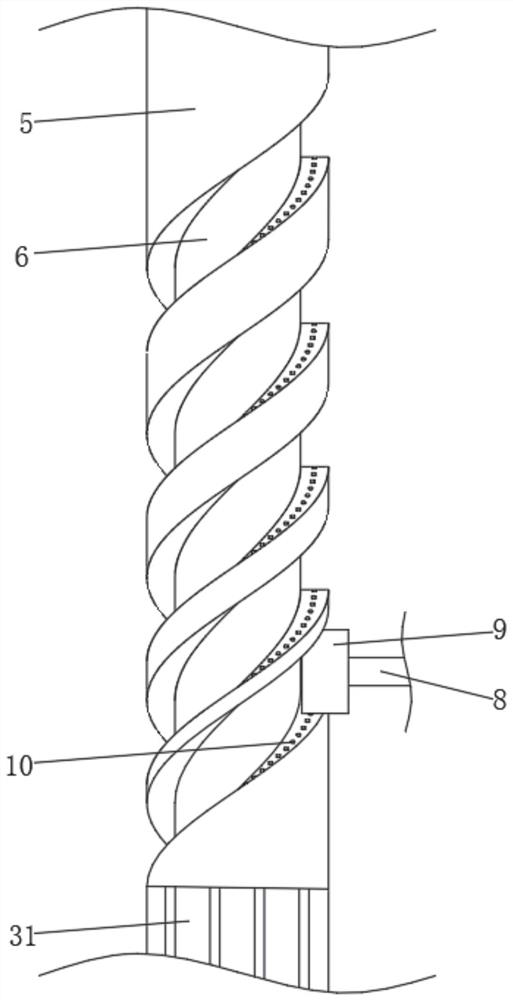

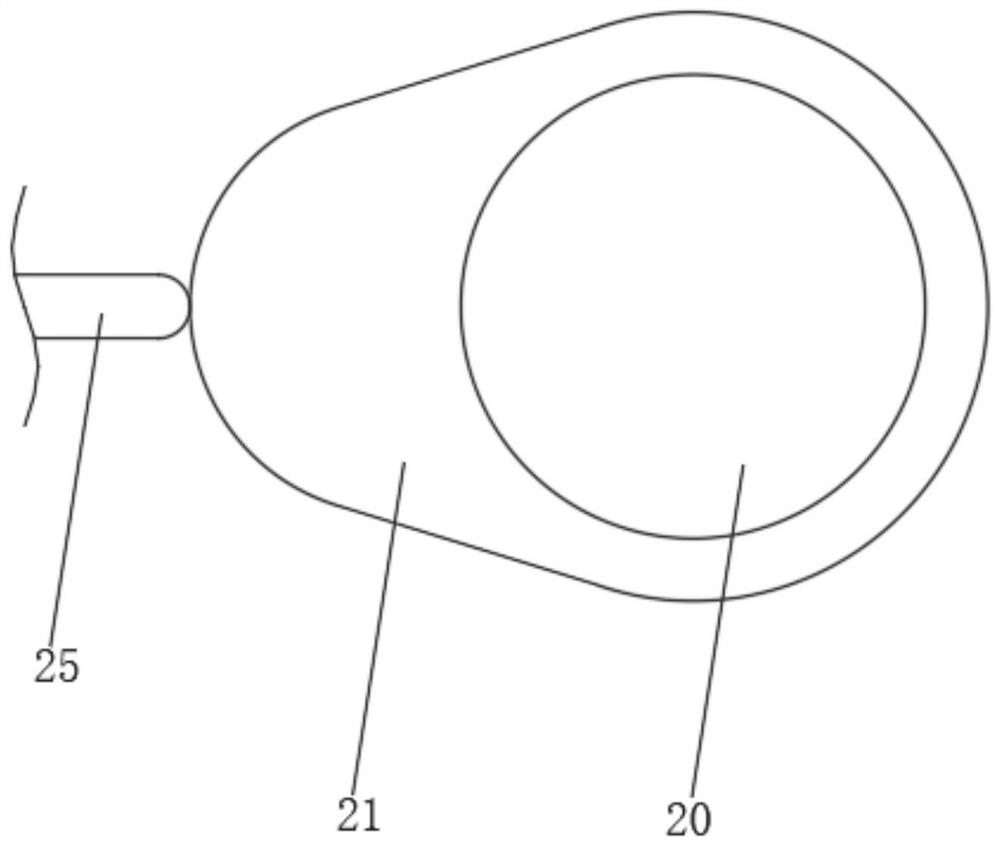

The invention discloses multifunctional nursing equipment for cardiology department monitoring and a using method thereof, and relates to the technical field of nursing equipment. The multifunctionalnursing equipment comprises a supporting frame; supporting height adjusting mechanisms are arranged on the lower surfaces, close to the two sides of the supporting frame, of the supporting frame; andthe multifunctional nursing equipment further comprises a vertically-moving pressing block of which the upper surface is fixedly connected with a fixing plate. A connecting shaft is rotatably connected to the upper surface of the fixing plate; a rotating shaft is fixedly connected to the upper end of the connecting shaft; a spiral groove is formed in the surface of the rotating shaft; the helix angle of the spiral groove is gradually increased from the position close to the pressing block; and the equipment further comprises a driving mechanism used for driving the rotating shaft to verticallymove while rotating. According to the equipment, the pressing block is driven to vertically move back and forth in a mechanical movement mode, the external chest of the heart of a patient is pressed,meanwhile, when the pressing block presses the external chest of the heart, a uniform acceleration displacement state can be kept, and then the impact force generated when the pressing block pressesthe external chest of the heart of the patient is increased; and the effect of pressing the external chest of the heart of the patient is indirectly improved.

Owner:AFFILIATED HOSPITAL OF NANTONG UNIV

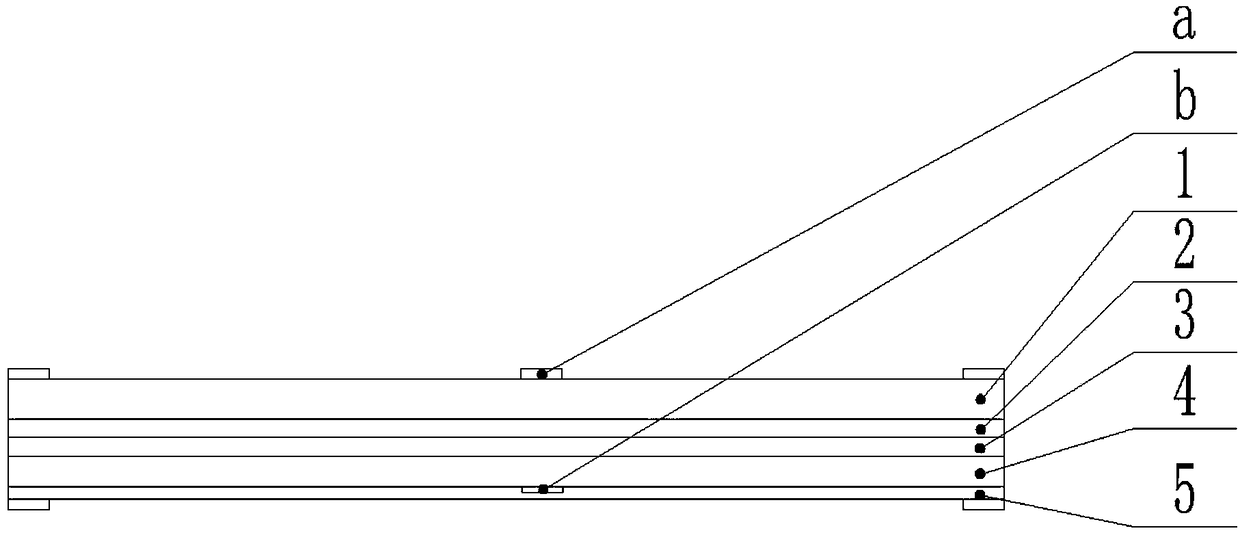

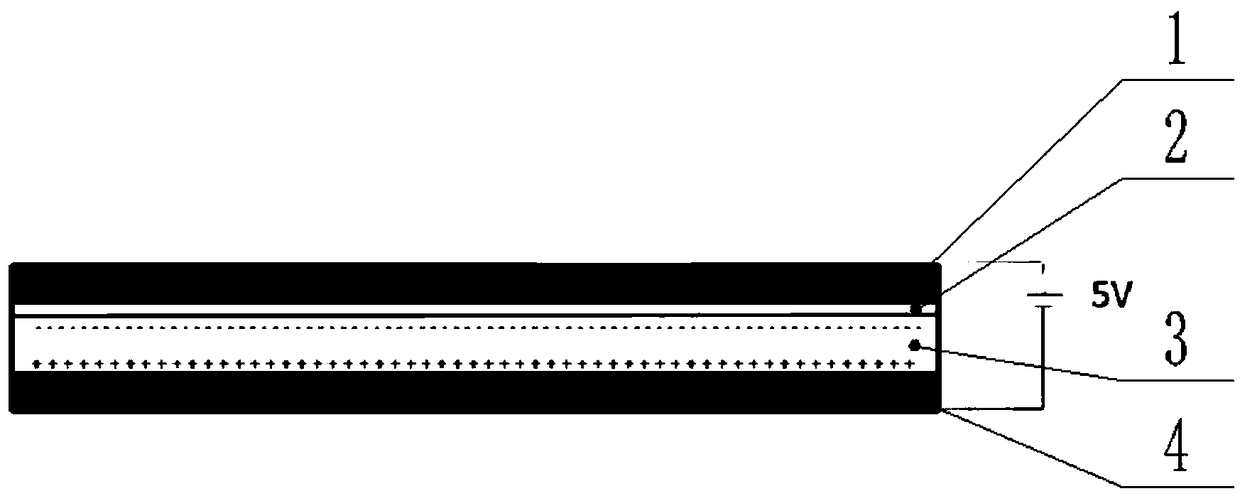

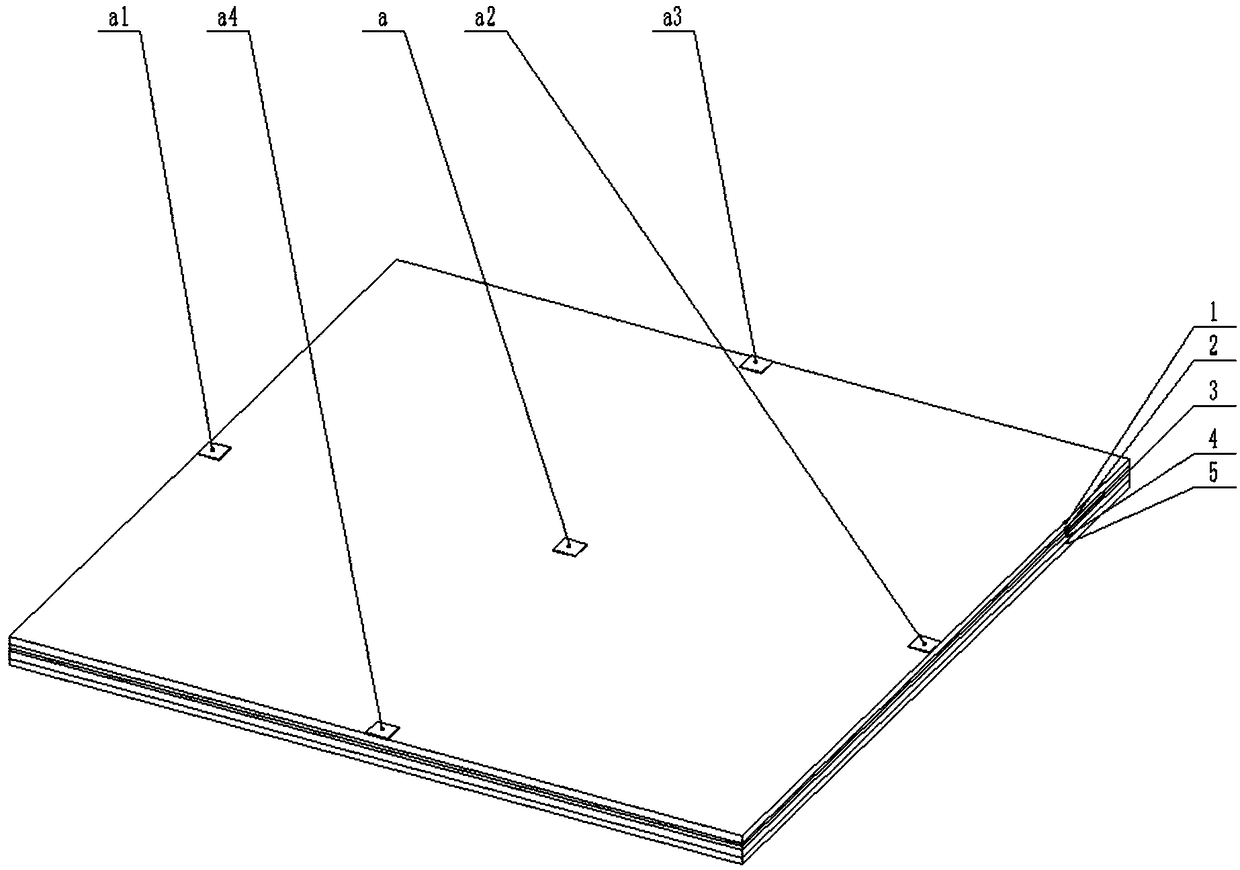

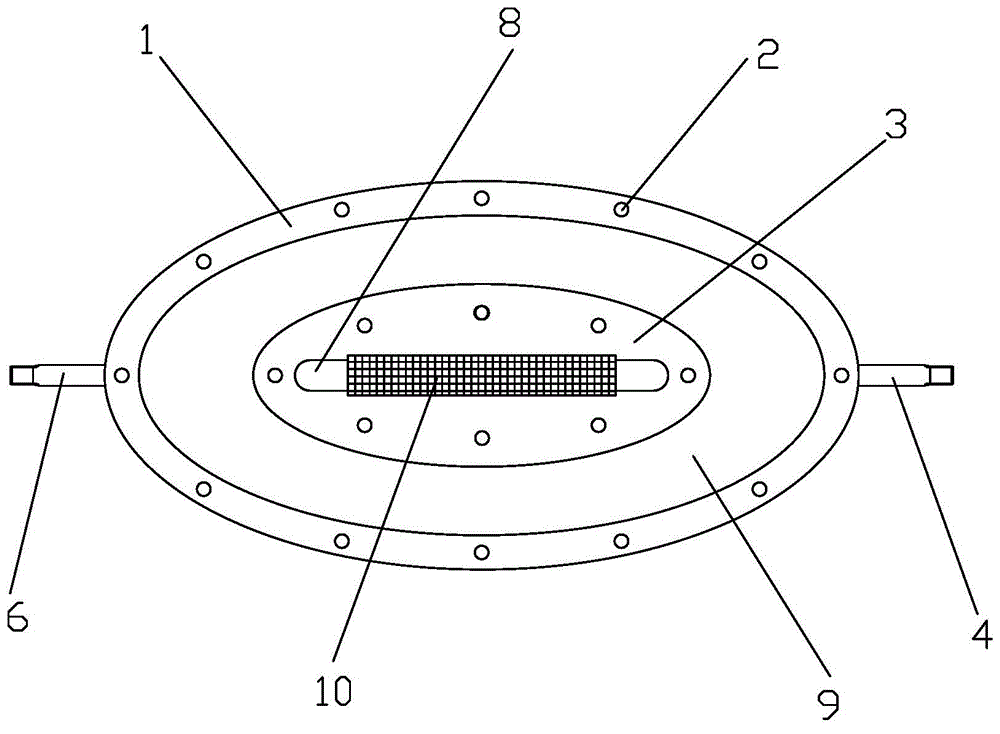

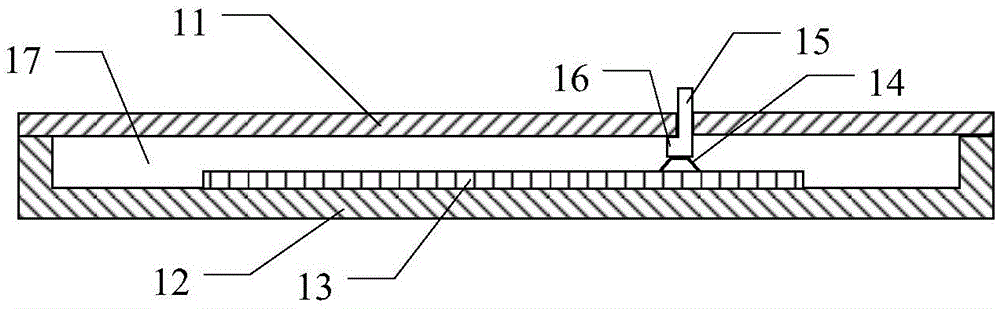

Non-array type super-capacitive tactile sensor and application

ActiveCN109323782AImprove flexibilityAchieve stretchForce measurementPositive pressureTactile sensor

The invention provides a non-array type super-capacitive tactile sensor and an application. The sensor comprises an upper electrode layer, a lower electrode layer, an ionic gel layer and an air layer,wherein the ionic gel layer and the air layer are located between the two electrode layers; the air layer is arranged between the upper electrode layer and the ionic gel layer; the ionic gel layer can collect positive and negative charges on the upper surface and the lower surface when being electrified; the upper electrode layer is connected with the positive electrode a of a power supply; thelower electrode layer is connected with the ground b; two groups of measuring electrodes are arranged on the upper surface of the upper electrode layer in transverse and longitudinal directions; eachgroup of the measuring electrodes comprises two measuring electrodes; and the distances between the two measuring electrodes and the center of the upper electrode layer are the same. The sensor adoptsa non-array type structure; the ionic gel layer and air are adopted as intermediate layers; large-area accurate positioning of a positive pressure is realized; and the upper electrode layer and the ionic gel layer are in contact with each other to form a super-capacitor when the positive pressure is received, so that the position of the positive pressure is determined.

Owner:HEBEI UNIV OF TECH

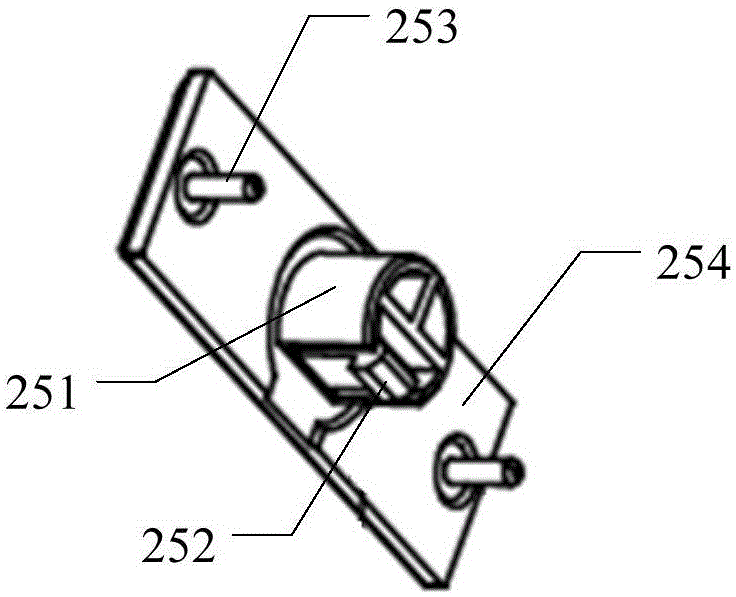

Rotary touch obstacle meeting mechanism, power integration mechanism and clothes drying machine

PendingCN111762709AReduce volumeRealize pressingOther drying apparatusWinding mechanismsEngineeringElectric wire

The invention discloses a rotary touch obstacle meeting mechanism, a power integration mechanism and a clothes drying machine. The obstacle meeting mechanism comprises a cover plate, a body part, an on-off elastic sheet and an abutting part. The cover plate is provided with a rotating shaft. The body part is arranged on the cover plate and is provided with a side wall. The on-off elastic sheet isconnected with the side wall and is provided with a contact portion in electric wire connection with the body part within the deformation range of the on-off elastic sheet. The abutting part comprisesa rotating portion, an abutting portion and a wire pressing portion, all of which are connected in sequence, the rotating portion is in pivotal joint with the rotating shaft, the joint of the rotating portion and the abutting portion is bent, and the abutting portion right faces the on-off elastic sheet, so that the abutting part half surrounding the body part. Under the action of external force,the wire pressing portion drives the abutting part to rotate with the rotating shaft as the axis, the butting portion moves towards the direction of the on-off elastic sheet so as to abut against theon-off elastic sheet, so that the on-off elastic sheet deforms elastically and is pressed towards the contact portion, and breakover of the body part is achieved. The size of the obstacle meeting mechanism can be reduced, detection precision and timeliness of the obstacle meeting mechanism can be improved, meanwhile, wires in the clothes drying machine are ordered, and the inner space of the clothes drying machine is saved.

Owner:GUANGDONG HOTATA TECH GRP

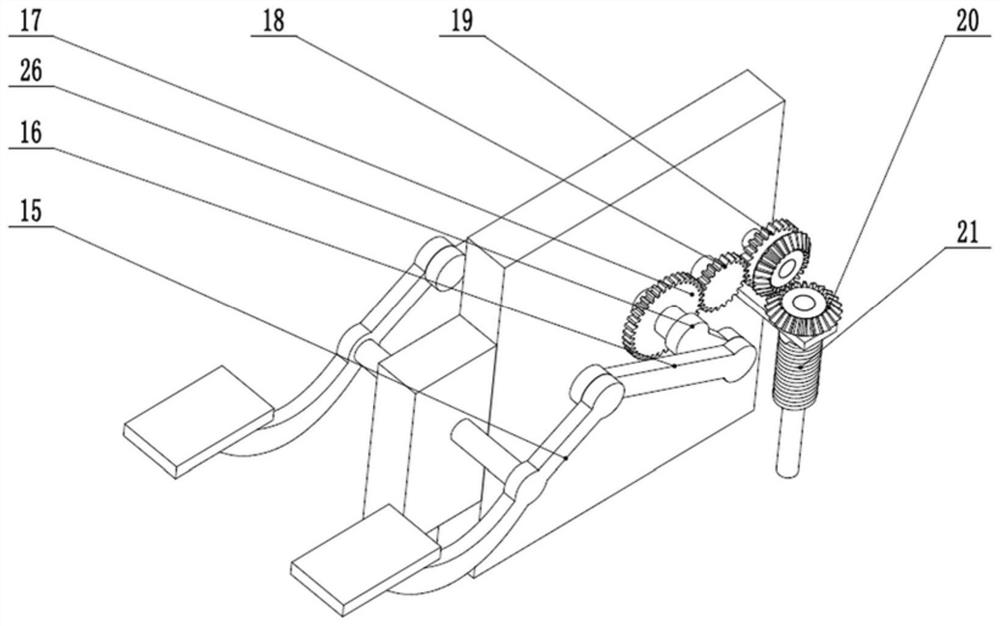

Spinal cord injury rehabilitation treatment device

PendingCN112618312ANovel structureIngenious ideaOperating chairsGymnastic exercisingPhysical medicine and rehabilitationSpinal cord injury rehabilitation

The invention relates to a spinal cord injury rehabilitation treatment device. The spinal cord injury rehabilitation treatment device comprises a bottom plate, wherein supports are evenly and fixedly connected to the periphery of the upper surface of the bottom plate, a supporting plate is fixedly connected to the top ends of the supports, and guardrails are fixedly connected to the left end and the right end of the upper surface of the supporting plate respectively. The spinal cord injury rehabilitation treatment device is characterized in that a leg transmission device is arranged in the center position of the front end of the upper surface of the bottom plate, and angle adjusting devices driven by the leg transmission device are arranged on the left side and the right side of the top end of the bottom plate. By arranging the transmission device, the legs of a patient are exercised, besides, the angle of a backrest is adjusted through the transmission device, the comfort degree of the patient during treatment is improved, besides, the massage strength is adjusted, massage treatment on the back and the neck of the patient is achieved through a massage device, the spine of the patient is pressed, Blood circulation of the patient is promoted, and rehabilitation of the patient is further facilitated. Through the arrangement of a gear shifting mechanism, the massage device is driven by a motor, and time and labor are saved.

Owner:甘肃省康复中心

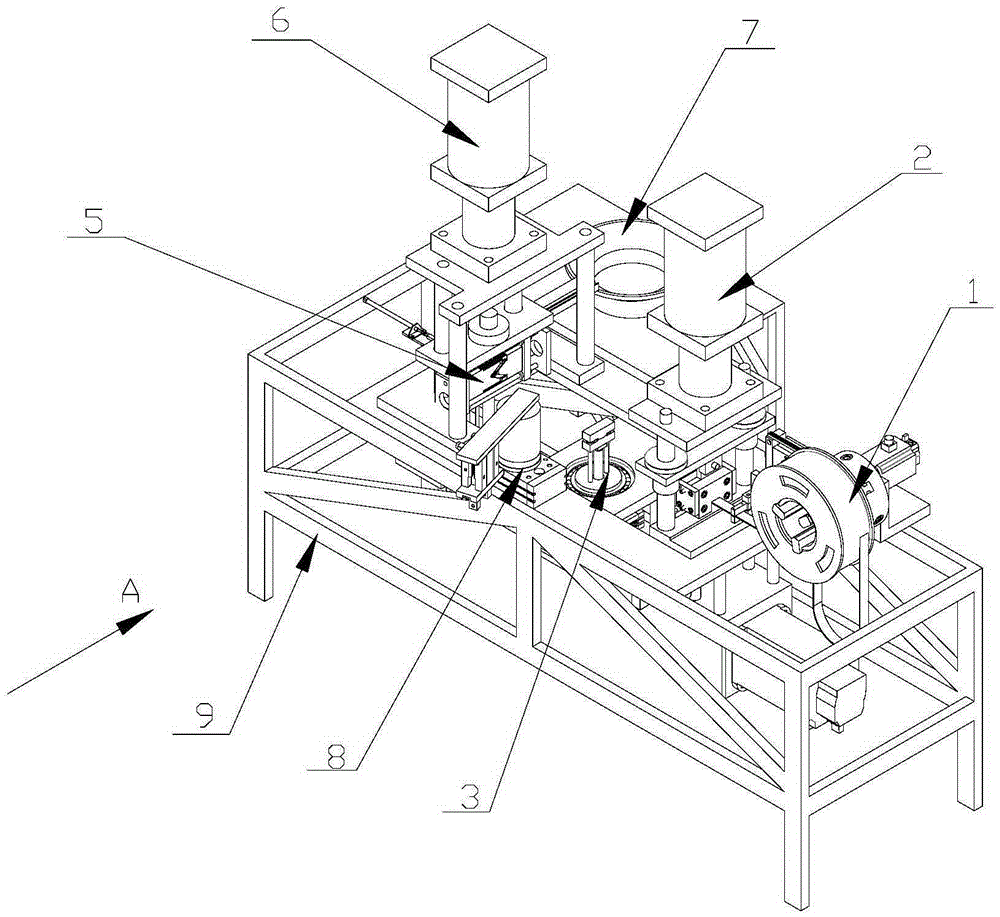

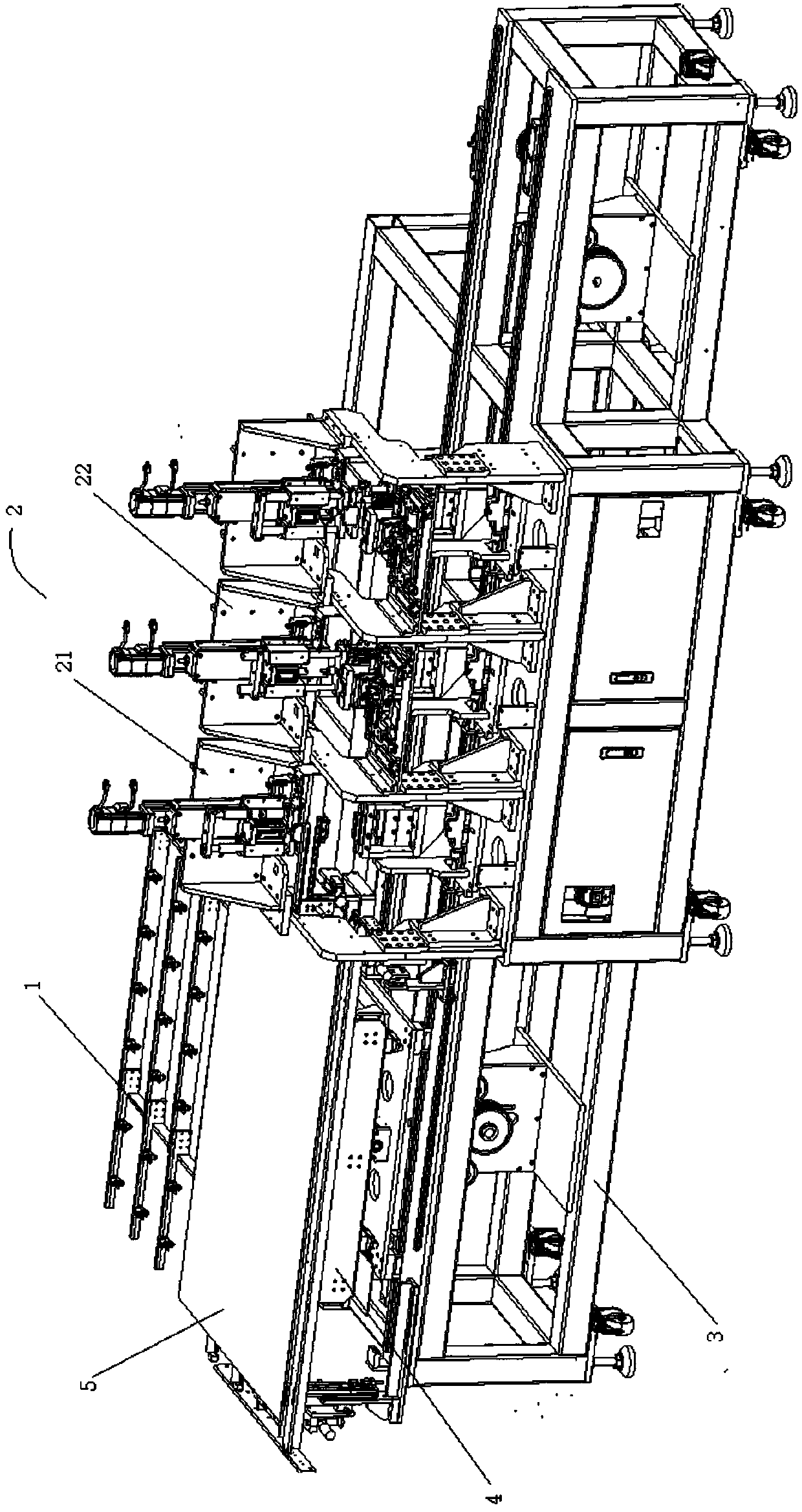

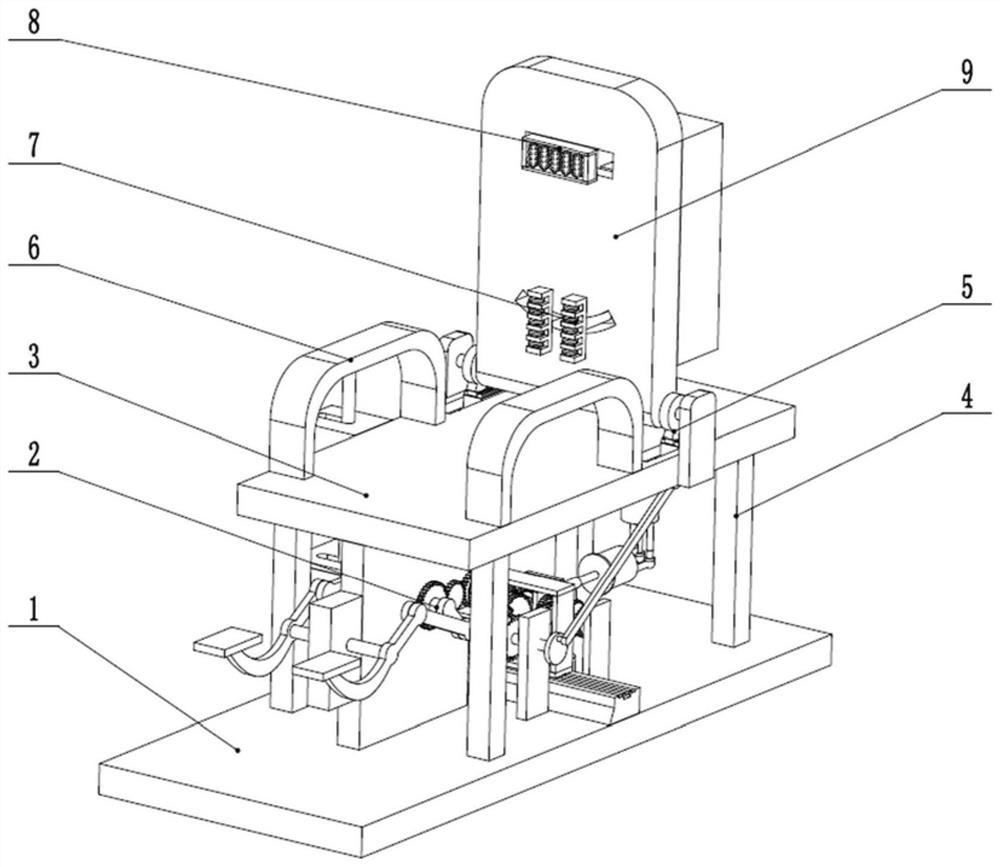

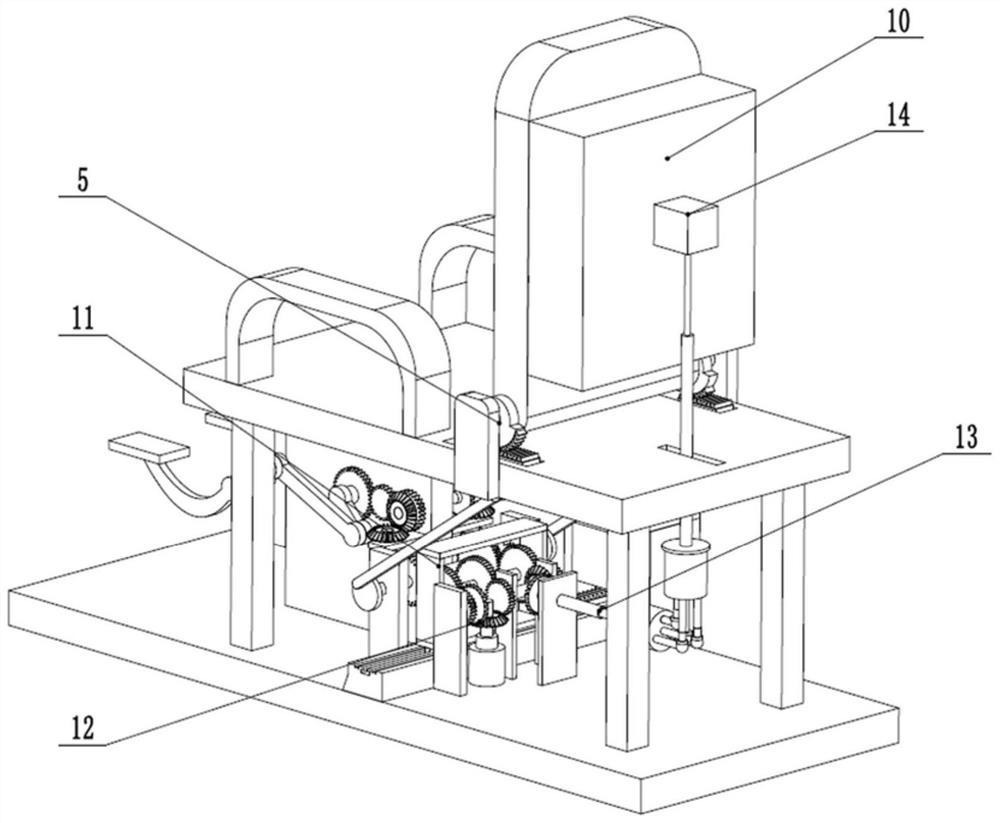

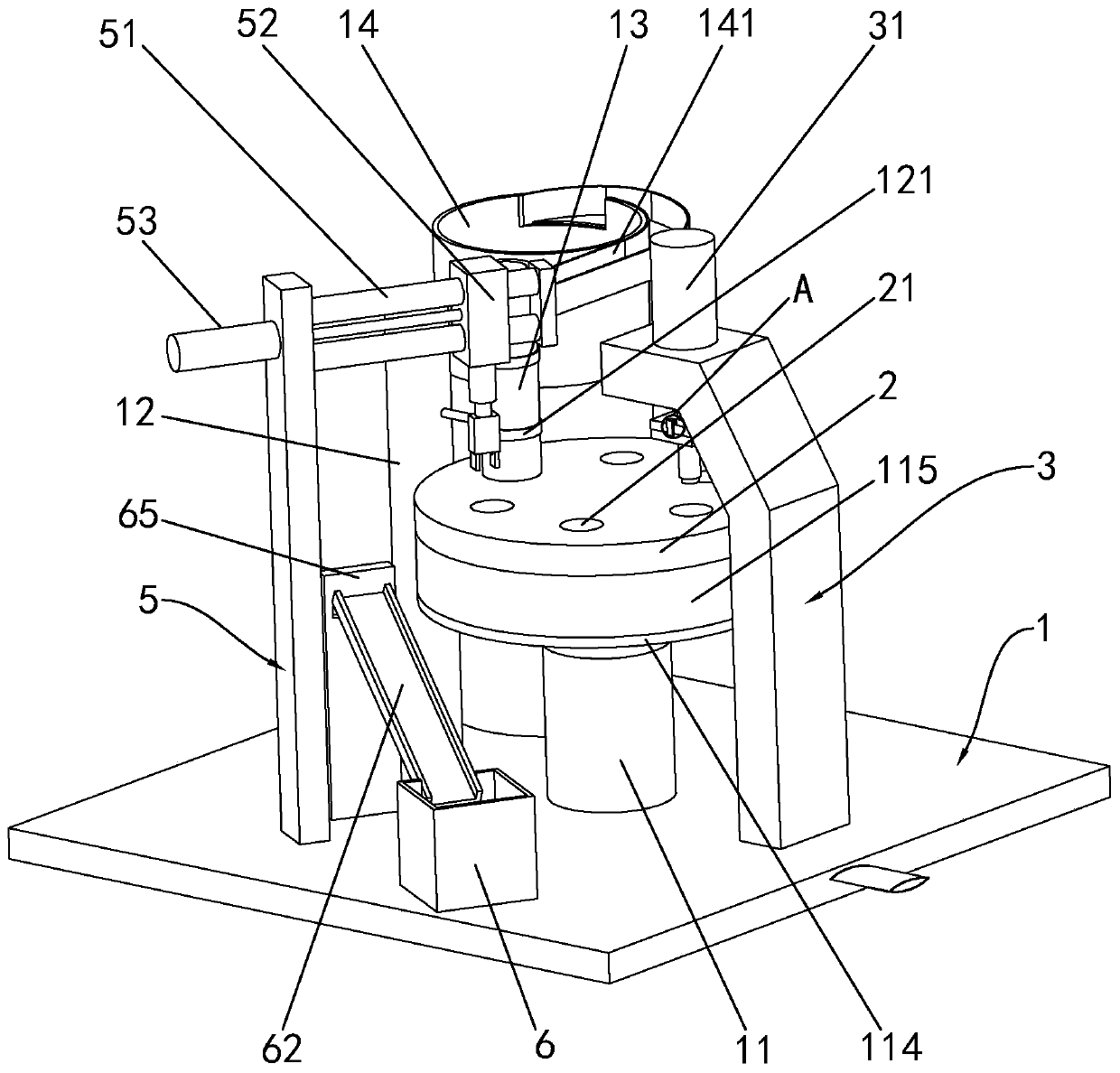

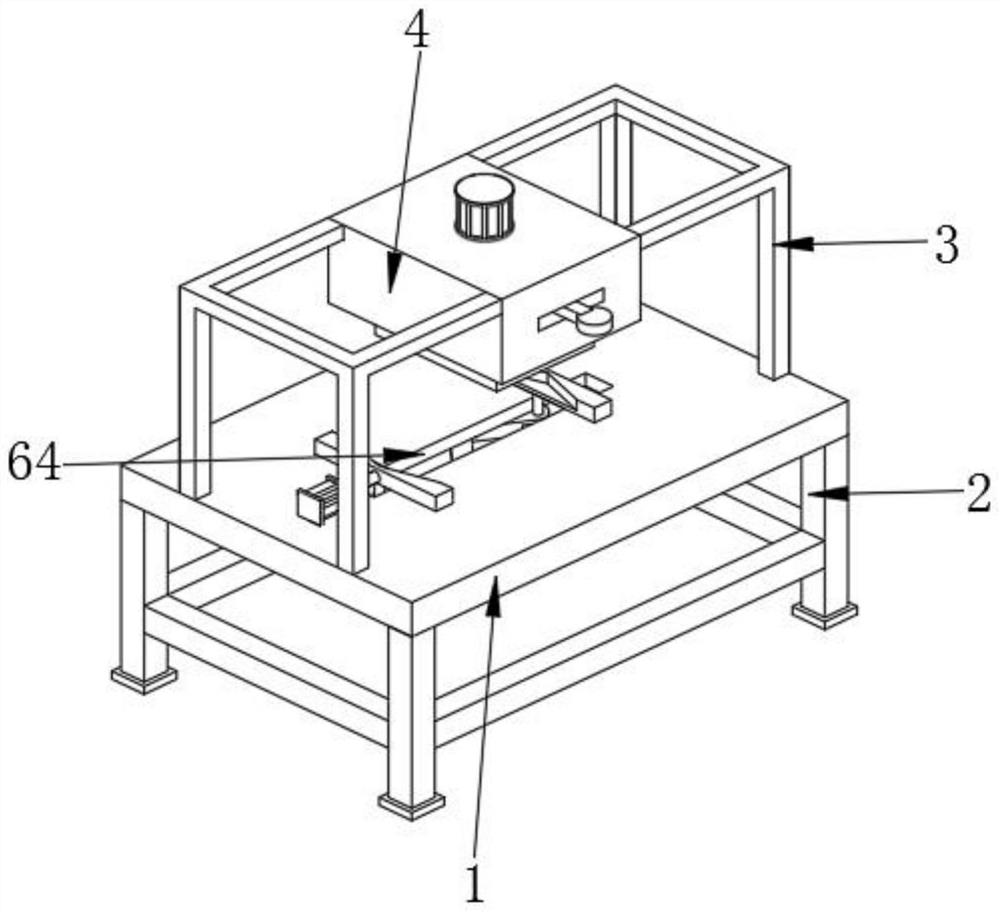

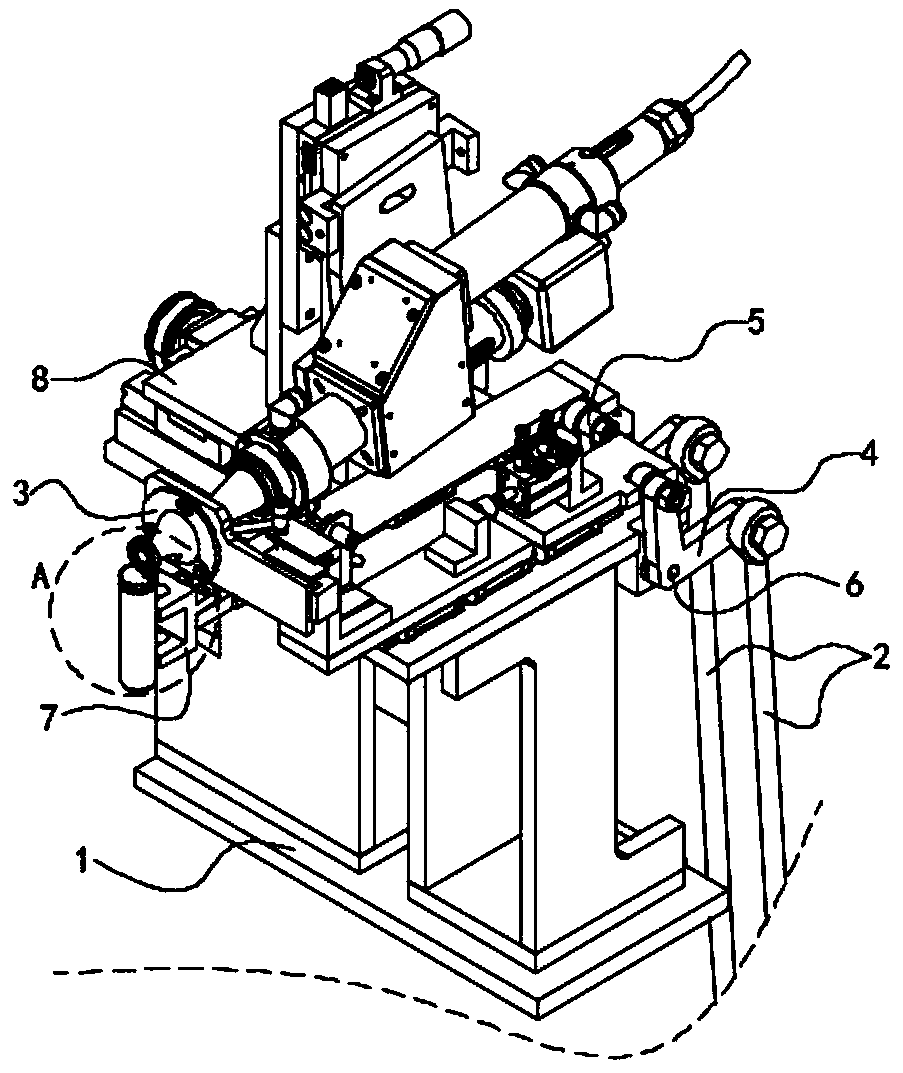

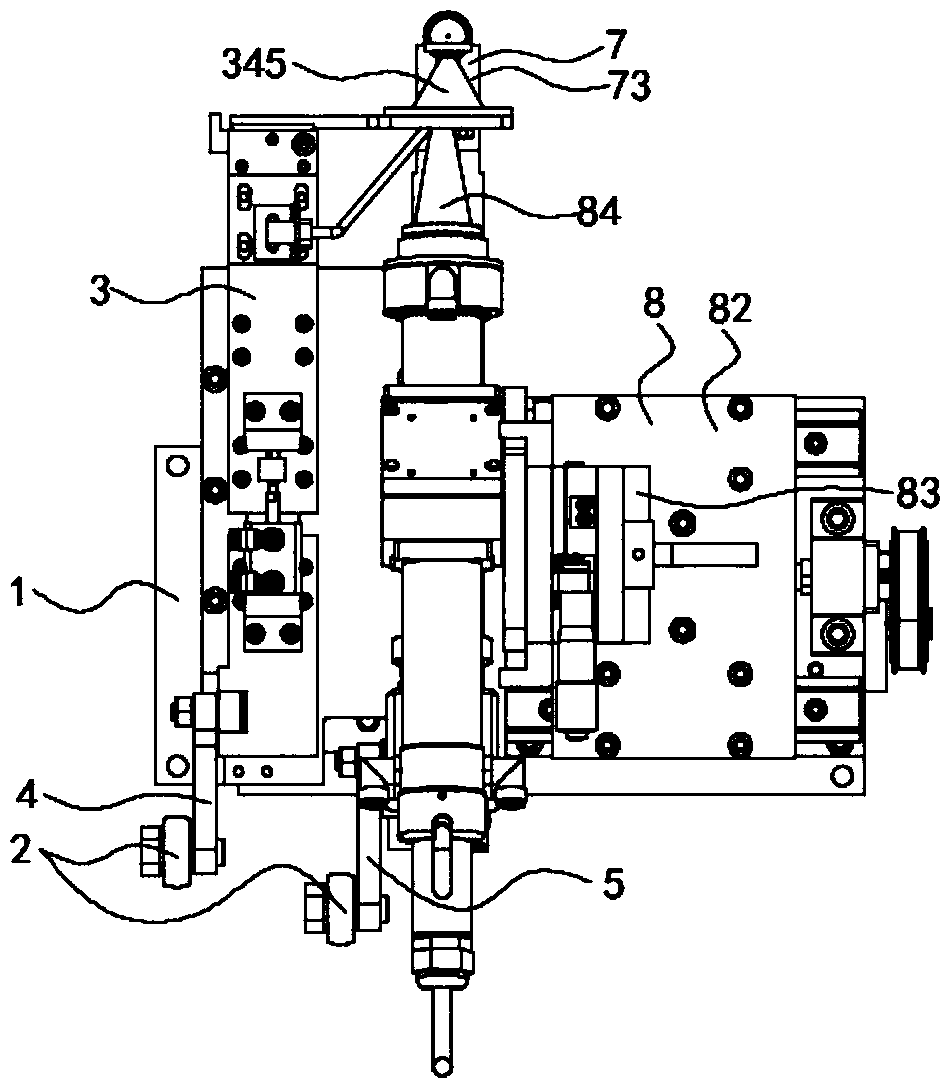

Stationary contact point automatic riveting machine

InactiveCN107297436ASimple structureRealize pressingMetal-working feeding devicesHeat exchange apparatusEngineeringMechanical engineering

The invention discloses a stationary contact point automatic riveting machine. The stationary contact point automatic riveting machine comprises a workbench, a stationary wafer feeding mechanism, a stationary contact point feeding mechanism and a riveting head, and the stationary wafer feeding mechanism, the stationary contact point feeding mechanism and the riveting head are arranged on the workbench; the stationary wafer feeding mechanism comprises a first vibration disc, a first feeding track, a shaping locating block, a first push block and a second push block; the stationary contact point feeding mechanism comprises a second vibration disc, a second feeding track, a top pillar, and a bevel push block; the riveting head is fixed to the workbench through a mounting frame. The stationary contact point automatic riveting machine is simple in structure, automatic feeding and riveting of stationary contact points and stationary wafers can be achieved, and the working efficiency of riveting is improved.

Owner:苏州明雪电子有限公司

Orthopedic leg auxiliary rehabilitation nursing device capable of adjusting training intensity

ActiveCN112774124ARealize pressingAchieve resistanceRoller massageMuscle exercising devicesPhysical medicine and rehabilitationOrthopedic department

The invention discloses an orthopedic leg auxiliary rehabilitation nursing device capable of adjusting training intensity, which comprises two bearing plates, vertical plates are fixedly connected to the top parts, close to the right side, of the two bearing plates, the two vertical plates are arranged front and back, a second connecting plate is fixedly connected to the top parts of the two vertical plates, a first connecting plate is fixedly connected to the center of the right side of the second connecting plate, a first sliding groove is formed in the first connecting plate, a first sliding block is arranged in an inner cavity of the first sliding groove, and the bottom of the first sliding block is movably connected with the inner cavity of the first sliding groove. Through mutual cooperation of mechanisms such as a handle, a first rope and a second rope, upward acting force can be provided for the bandage, then the legs can move upwards more easily, through mutual cooperation of mechanisms such as a T-shaped rod, a transverse rod and a massage rod, pressing of the legs can be achieved, and then people feel comfortable.

Owner:FIRST AFFILIATED HOSPITAL OF KUNMING MEDICAL UNIV

Motor end cover automatic press-fitting device

The invention discloses a motor end cover automatic press-fitting device. The motor end cover automatic press-fitting device comprises a base. A stand column is fixedly arranged on the upper end faceof the base. A rotary plate is arranged on the upper end face of the stand column. A main supporting frame is arranged on the base. The upper end of the main supporting frame is provided with a hydraulic cylinder. An auxiliary supporting frame is arranged on one side of the main supporting frame. The auxiliary supporting frame is provided with two guide rolls. A guide block is arranged on the guide rolls. The guide block is provided with a cylinder I. An output shaft of the cylinder I is connected with a material fixing block. The lower end of the material fixing block is provided with two clamping arms. A feed barrel is arranged on the base. The base is fixedly provided with a vibration tray. One side of the vibration tray is provided with a discharge passage. One end of the discharge passage is fixedly connected with the feed barrel. The motor end cover automatic press-fitting device is reasonable in structure and conveys an end cover in the vibration tray onto the rotary plate. Thehydraulic cylinder is started to conduct press-fitting on the end cover. The end cover subjected to press-fitting is clamped by the two clamping arms and is moved out from the rotary plate. Thus, themotor end cover automatic press-fitting device achieves the automatic press-fitting effect on the end cover.

Owner:杭州烽银电机制造有限公司

Automatic knife sharpener

ActiveCN111702567AImprove work efficiencyLow costGrinding wheel securing apparatusGrinding drivesRotational axisKnife sharpener

The invention discloses an automatic knife sharpener, and belongs to the technical field of knife sharpeners. The automatic knife sharpener comprises a base, a motor, a rotating shaft, an annular knife stone and a fixing block, the top end of the base is provided with the vertically arranged motor, the output end of the motor is connected with the rotating shaft, the top end of the rotating shaftis connected with the horizontally arranged annular knife stone through the fixing block, a clamping mechanism for fixing a blade is arranged above the base, the middle of the top end of the annular knife stone is connected with a first threaded rod through another fixing block, the first threaded rod is perpendicular to the annular knife stone, and the first threaded rod is sleeved with a press-fit knife stone parallel to the annular knife stone in a threaded mode. Through the arrangement that the rotating shaft is connected with a moving plate through a linkage structure, grinding equipmentcan achieve the dual effects of rotation of the knife stone and horizontal movement of the blade to be sharpened under the driving of one motor, and therefore the grinding equipment has the advantagesof being flexible to use and high in grinding efficiency under the condition of low cost.

Owner:山东立连智能设备有限公司

Press-fit device for new energy automobile battery control panel and connector

The invention relates to a press-fit device for a new energy automobile battery control panel and a connector. The press-fit device is characterized in that a stand column is arranged on a working table board, a movable cross beam is arranged on the stand column through a guide sleeve, a fixed cross beam is horizontally fixed on the top of the stand column, a servo press is arranged on the fixed cross beam, a lead screw of the servo press penetrates through the fixed cross beam to be in driving connection with the movable cross beam, pressing heads are distributed on the bottom surface of themovable cross beam, a rotating disc is arranged on a rotating table on the working table board, a control panel fixing plate is arranged on a tool bottom plate through a sliding shaft pin, a spring sleeves the sliding shaft pin, the lower end of the spring abuts against the tool bottom plate, the upper end of the spring abuts against the control panel fixing plate, a positioning supporting shaft on the tool bottom plate penetrates through a shaft hole in the rotating disc, the positioning pin fixing plate is arranged on a guide column through a sliding sleeve, a positioning pin on the positioning pin fixing plate is in contact with a positioning supporting shaft of the tool bottom plate in a direct facing mode, a cam roller mounting seat is arranged on the bottom surface, a protrusion is arranged on the working surface of an inclined wedge plate below a cam roller, the inclined wedge plate can move in a reciprocating mode. According to the press-fit device, the press-fit operation is automatically realized.

Owner:KERUI AUTOMATION TECH SUZHOU

Key ultraviolet sterilization system and working method

InactiveCN111729101AEasy to pressAvoid depositionLavatory sanitoryRadiationEngineeringDistance sensors

The invention discloses a key ultraviolet sterilization system and a working method. The key ultraviolet sterilization system comprises a key sterilization device and a control device, wherein the keysterilization device comprises a key seat, a key, a reset spring, a distance sensor and a light shielding plate; the control device comprises a sterilization seat, a sliding block, a driving device,a linkage mechanism and a controller; a sliding groove is formed in a side surface of the sliding block and comprises a first sliding groove, a buffer groove, a second sliding groove and a reset groove; an elastic sheet is arranged at the joint of the first sliding groove and the buffer groove on the sliding block; the middle of the elastic sheet protrudes towards the rear end of the sliding blockto form an arc; and the linkage mechanism comprises a driving rod, a fixing pin, a fixing rod, a connecting pin, a spring, a fixing block and a trigger switch, and further comprises a human body sensor. According to the working method, when the key is pressed by a hand, an ultraviolet sterilization lamp does not work, otherwise, the ultraviolet sterilization lamp works, and light shielding is carried out by utilizing the light shielding plate. According to the key ultraviolet sterilization system and the working method, the key can be pressed, the key can be sterilized after pressing is completed, and no harm is caused to a human body.

Owner:GUANGZHOU LEDIA LIGHTING CO LTD

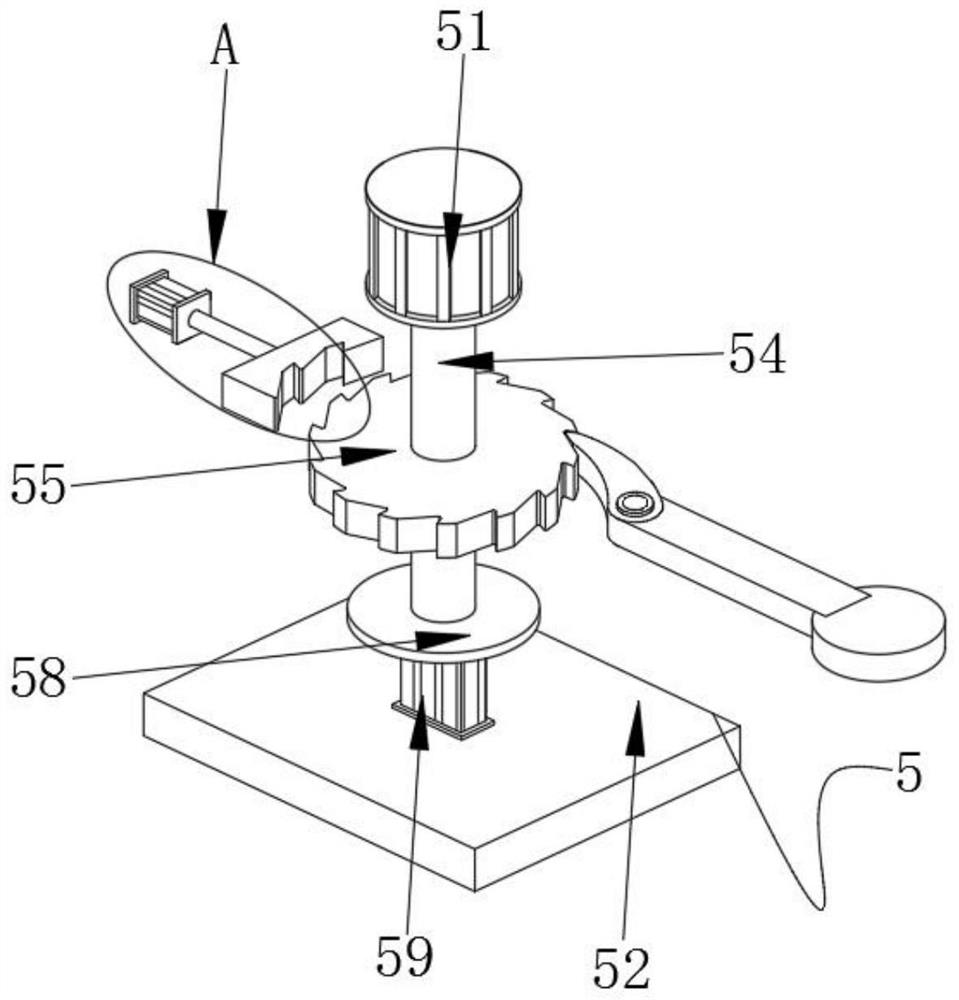

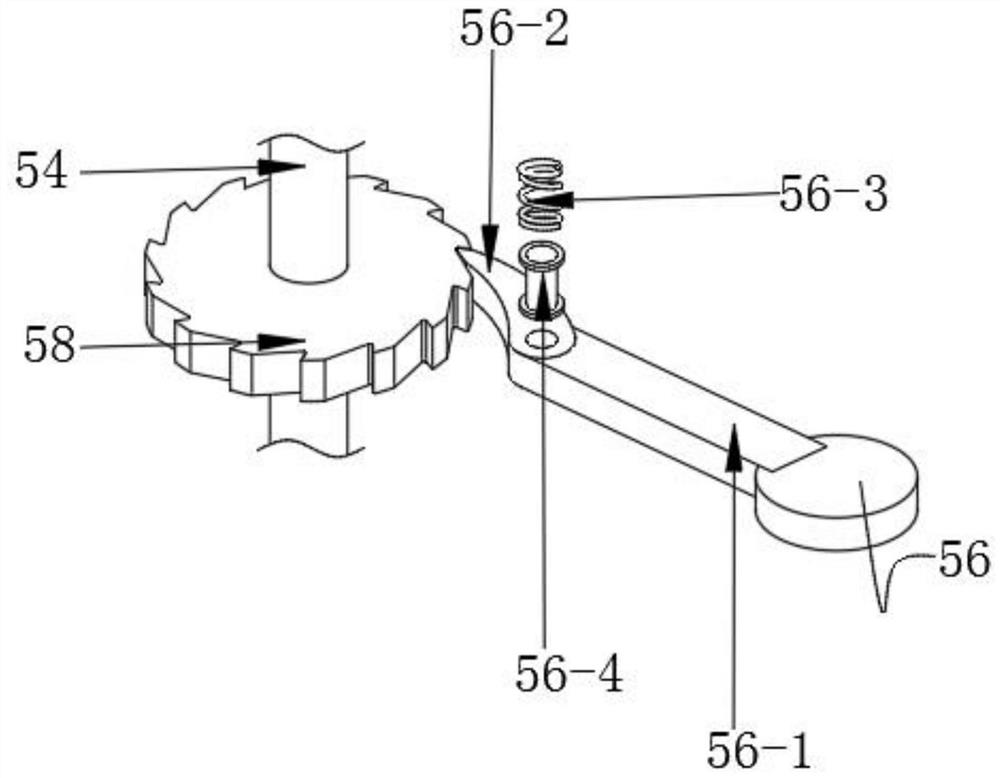

Servo motor iron core rapid assembly system and lossless installation method thereof

ActiveCN113922602AEasy to adjustImprove assembly speedManufacturing stator/rotor bodiesRatchetControl engineering

The invention discloses a servo motor iron core rapid assembly system and a lossless installation method thereof. The assembly system comprises an assembly table, the bottom of the assembly table is fixedly connected with a bottom frame, the top of the assembly table enables an assembly box to move through a telescopic support, and a steering adjusting mechanism is arranged in the assembly box, and a shell pre-pressing mechanism is arranged at the top of the assembly table, and the steering adjusting mechanism comprises a driving motor and a positioning plate. The invention relates to the technical field of servo motors. According to the iron core rapid assembly system of the servo motor and the lossless installation method thereof, the steering adjusting mechanism is arranged, a driving motor is used for driving a driving rotating shaft to rotate, so that a positioning plate at the bottom is adjusted at a large angle, and then a shifting rod drives a clamping block to rotate, therefore a limiting ratchet wheel is driven to slightly rotate, therefore, precise positioning of the iron core of the servo motor can be achieved, the assembly speed is improved, and product damage caused by collision in the assembly process is avoided.

Owner:杭州纳智电机有限公司

Corrugated paper gluing equipment

InactiveCN112318943AAvoid wastingSpray evenlyMechanical working/deformationPaperboardStructural engineering

The invention discloses corrugated paper gluing equipment which comprises a box body and a servo motor; a box door is rotatably connected to the top of the box body, a corrugated paper inlet is formedin the outer side wall of the box body in a penetrating mode, corrugated paper is slidably connected to the inner side wall of the corrugated paper inlet, a paperboard inlet is formed in the outer side wall of the box body in a penetrating mode, and a a paperboard is slidably connected to the inner side wall of the a paperboard inlet; and the outer side wall of the box body is provided with an outlet in a penetrating mode, and the inner side wall of the box body is fixedly connected with a glue storage box. According to the corrugated paper gluing equipment, glue can be sprayed on the bondingportions between the corrugated paper and the paperboard through movement of the corrugated paper, waste of glue is reduced, and the utilization rate of the glue is increased; and through rotation ofthe servo motor, same-speed reverse rotation of a first pressing roller and a second pressing roller is realized, the bonding portions between the paperboard and the corrugated paper are well pressed, meanwhile, pulling of the corrugated paper and the paperboard is also realized, the work efficiency is improved, and the resource waste is reduced.

Owner:黄丹

Automobile tire leakage prevention detection mechanism adaptive to tire inner diameter

ActiveCN112129464AEasy to installEasy to disassembleDetection of fluid at leakage pointElectric machineryControl theory

The invention discloses an automobile tire leakage prevention detection mechanism adaptive to a tire inner diameter. The automobile tire leakage prevention detection mechanism comprises a detection box, a reset spring, a fan and a tire body, wherein a support frame is fixed at the top of the detection box; a motor shaft is rotatably connected to the top of a motor; a sleeve is connected with a connecting shaft by virtue of a belt pulley mechanism; a movable cylinder penetrates through the interior of the sleeve; a movable rod is movably arranged at the bottom of the movable cylinder; the fan is installed on the inner side of the support frame by virtue of a bolt; the bottom of a fixed cylinder is connected with one end of a connecting pipe; a sleeve block is fixedly connected to the otherend of the connecting pipe; the tire body sleeves the outer side of a connecting plate; and an inner ring is arranged in the tire body. According to the automobile tire leakage prevention detection mechanism adaptive to the tire inner diameter, the same pair of tire clamping structures is suitable for tires with different inner diameters, so that the device can conveniently detect the air leakageof the tires with different specifications, and the tires are convenient to install and disassemble in the detection process.

Owner:浙江环艺电子科技有限公司

Multifunctional equipment for cardiology department monitoring, and using method thereof

InactiveCN112472574AImprove the pressing effectIncrease impactRespiratorsElectrotherapyNursing careEmergency medicine

The invention discloses multifunctional cardiology department monitoring equipment and a using method thereof, and relates to the technical field of nursing device. The multifunctional cardiology department monitoring equipment comprises a supporting frame, wherein supporting height adjusting mechanisms are arranged on the lower surface, close to the two sides of the supporting frame, of the supporting frame, the equipment further comprises a vertically-moving pressing block, a fixing plate is fixedly connected to the upper surface of the vertically-moving pressing block, a connecting shaft isrotatably connected to the upper surface of the fixing plate, a rotating shaft is fixedly connected to the upper end of the connecting shaft, a spiral groove is formed in the surface of the rotatingshaft, the helix rise angle of the spiral groove is gradually increased from the position close to the pressing block, and the equipment further comprises a driving mechanism used for driving the rotating shaft to vertically move while rotating. According to the invention, the pressing block is driven to vertically move back and forth in a mechanical movement mode so as to press the external chestof the heart of a patient, and when the pressing block presses the external chest of the heart, a uniform acceleration displacement state can be kept, so that the impact force generated when the pressing block presses the external chest of the heart of the patient is increased, and the effect of pressing the external chest of the heart of the patient is indirectly improved.

Owner:THE FIRST PEOPLES HOSPITAL OF NANTONG

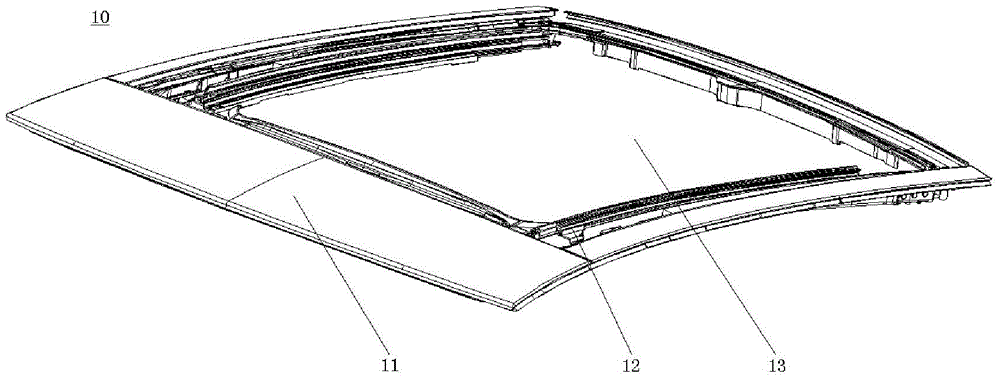

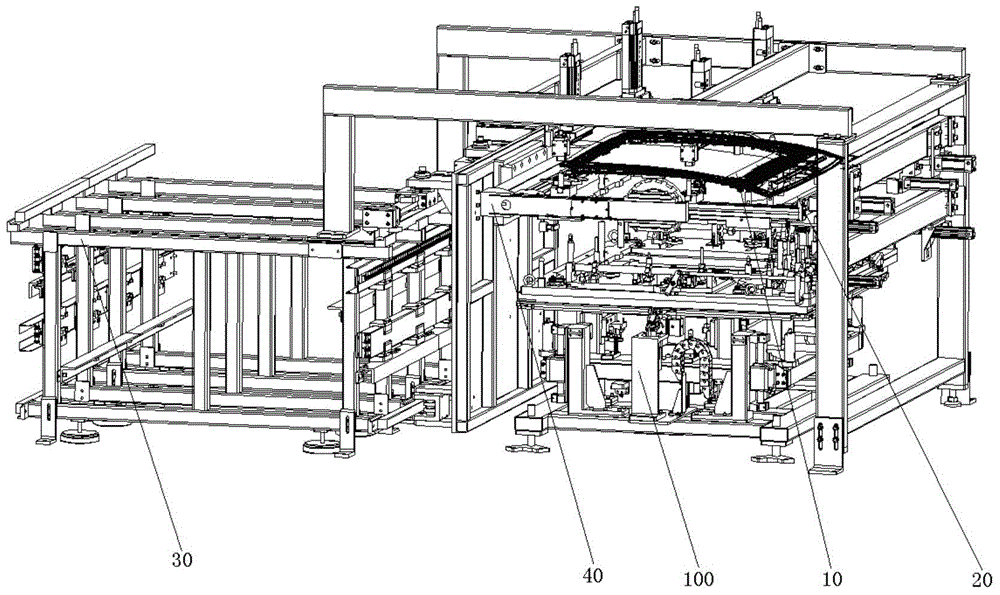

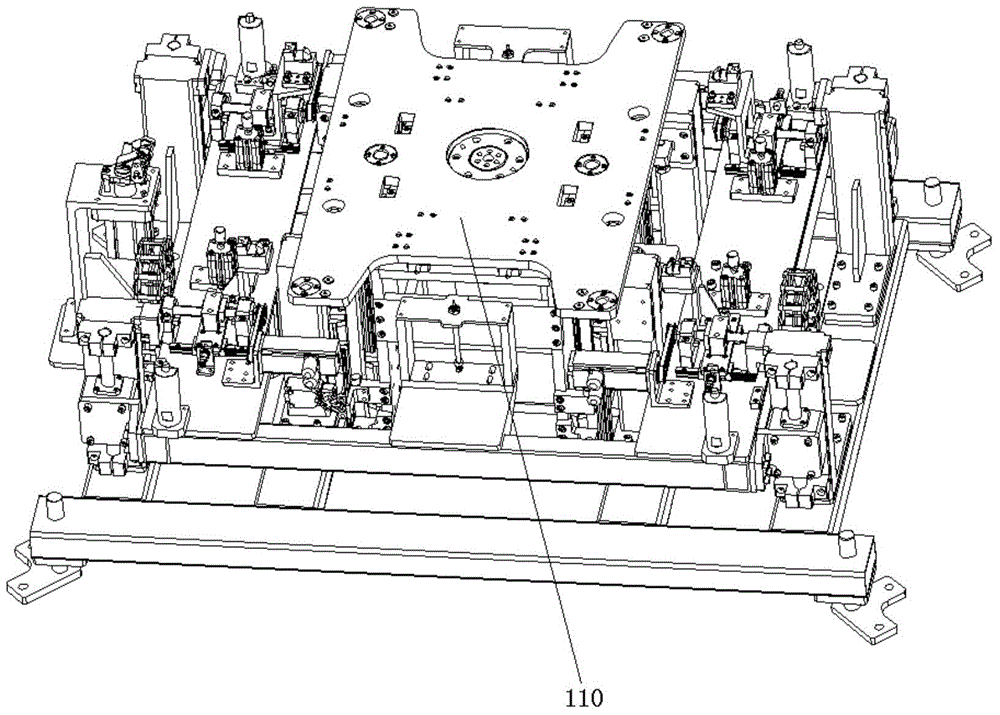

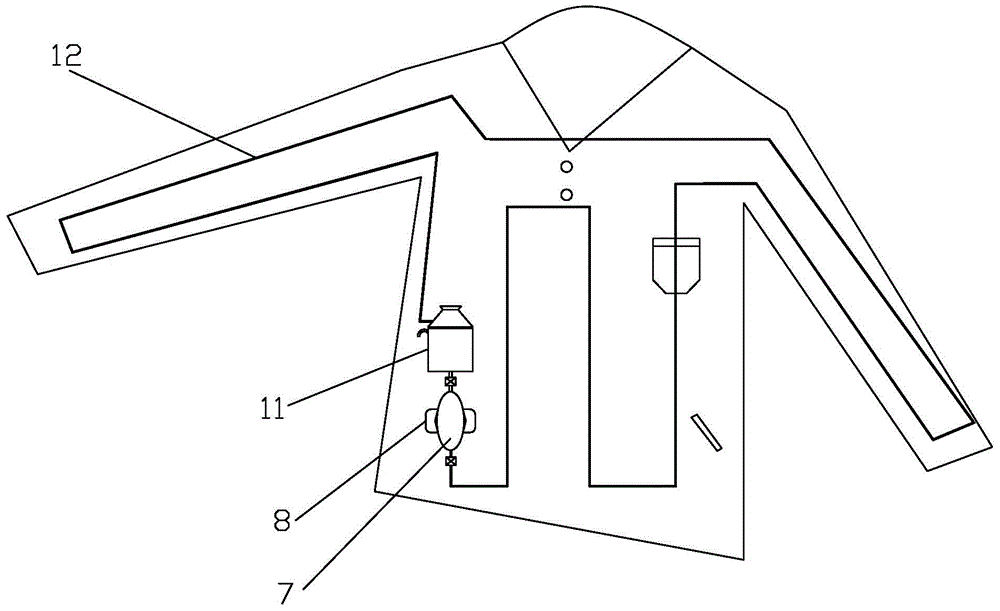

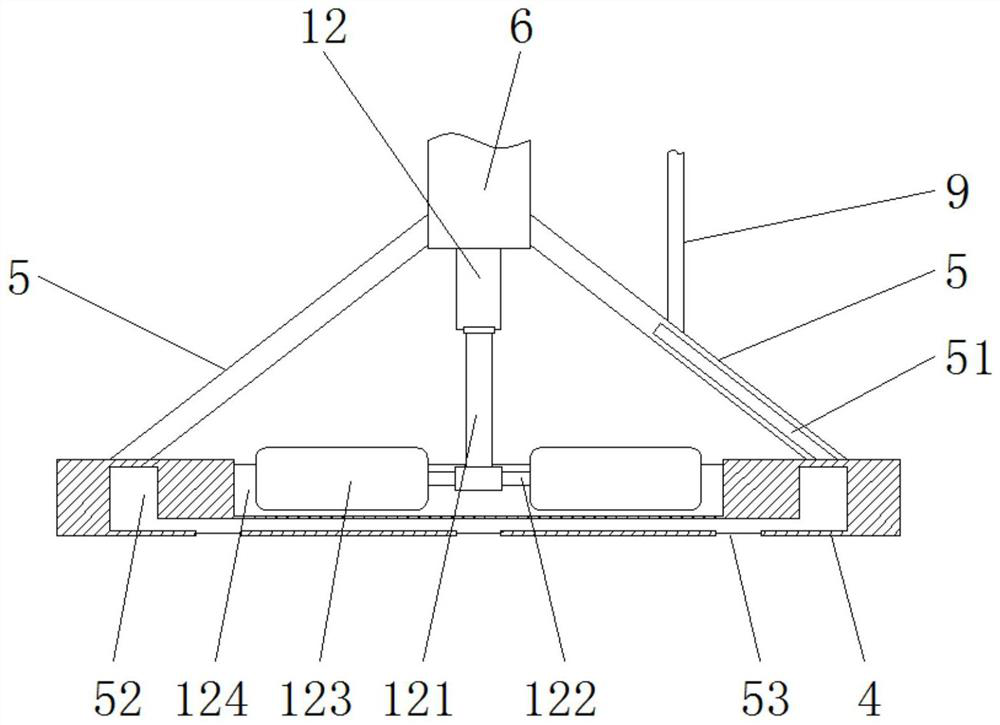

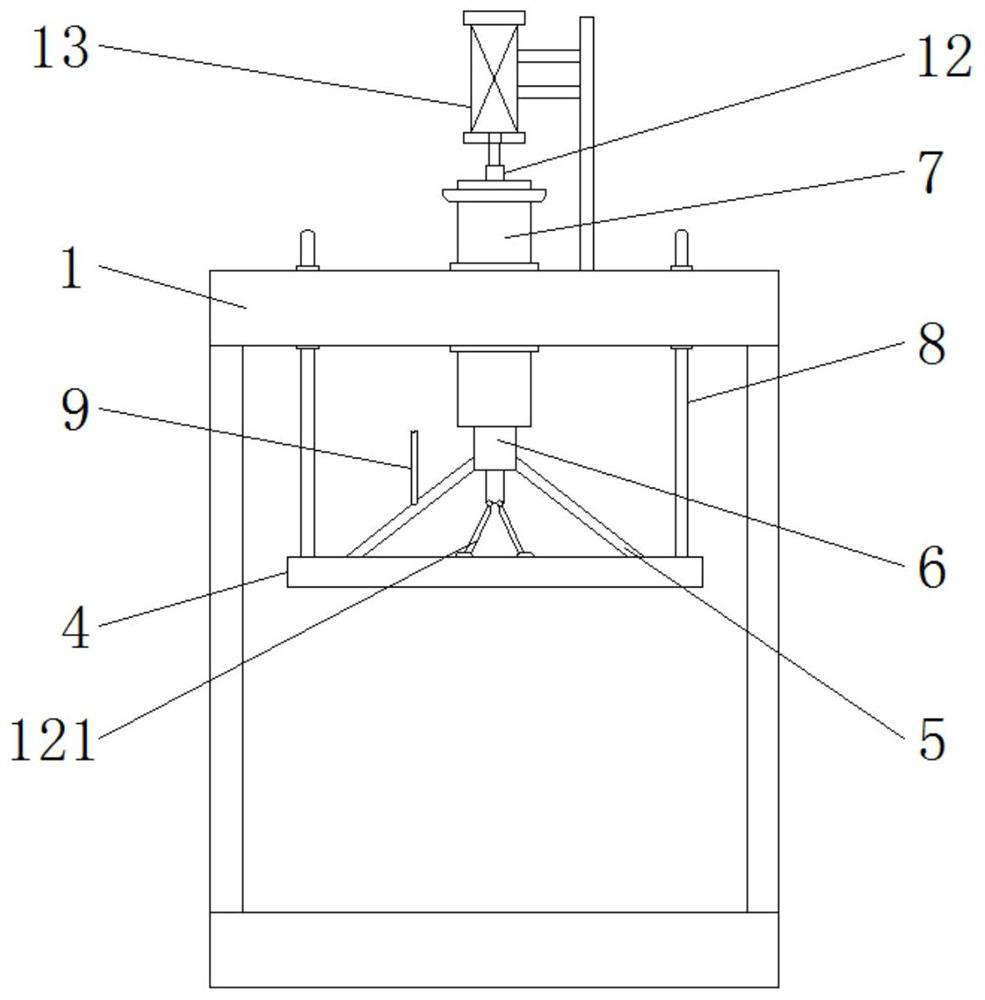

Self-adaptive hoisting device of skylight assembly production line

ActiveCN104555810ARapid positioningAvoid breakingAssembly machinesLifting framesProduction lineVibration attenuation

The invention provides a self-adaptive hoisting device of a skylight assembly production line. The self-adaptive hoisting device is characterized by comprising a tray, a hoisting mechanism and a return mechanism; the hoisting mechanism comprises a lifting air cylinder and a lifting platform, the lifting platform is fixed on the lifting air cylinder, and the lifting platform moves up and down along the lifting air cylinder; the tray is arranged on the lifting platform; the return mechanism comprises return air cylinders which are uniformly distributed on the periphery of the lifting air cylinder, located below the tray and used for applying a downward force to the tray. The self-adaptive hoisting device has advantages that a semi-finished product can be rapidly and self-adaptively positioned on a new workstation; the rapid fixation of the semi-finished product after being positioned on the new workstation can be facilitated. By simply improving the mechanical structure, rapid transportation of the skylight semi-finished product between a main production line and a curing production line can be realized; by adding a horizontal floating support, a vertical floating support and the like, the problem that the semi-finished product cannot be rapidly and self-adaptively positioned can be solved, a vibration attenuation effect also can be realized, the installation and assembling quality of the skylight can be greatly improved, and the production efficiency can be improved.

Owner:上海新松机器人有限公司

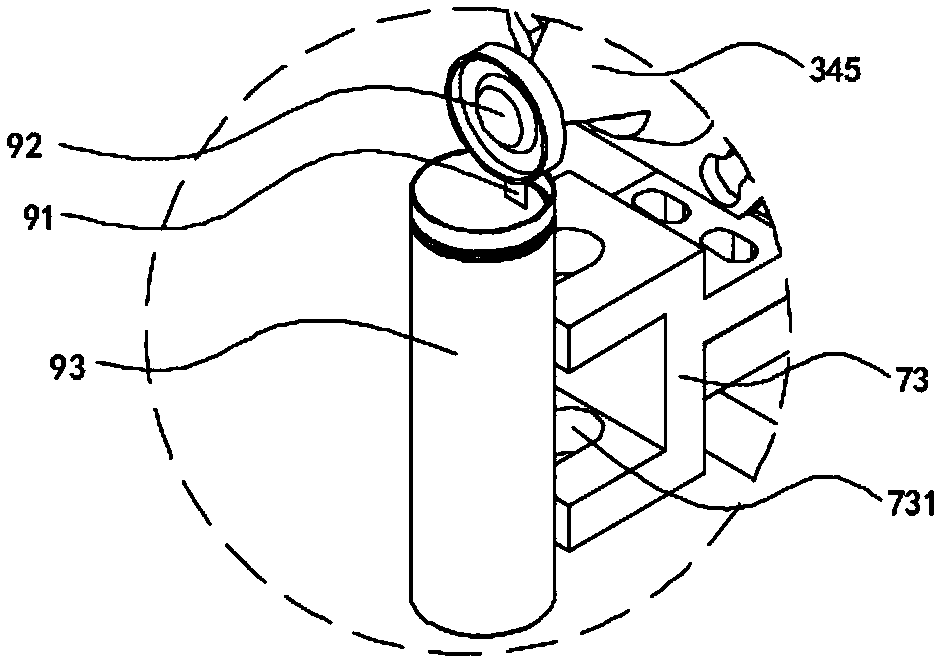

End cap welding mechanism

ActiveCN109048061AGuaranteed welding accuracyImprove welding efficiencyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringCam

The invention discloses an end cap welding mechanism. The end cap welding mechanism comprises a platen, wherein an electric cam push mechanism is arranged below the platen; a housing clamping mechanism is arranged above the platen; the two sides of the housing clamping mechanism are separately equipped with an end cap clamping mechanism and a laser welding mechanism; the electric cam push mechanism is equipped with a first transmission rod and a second transmission rod; the electric cam push mechanism slides up and down for driving the first transmission rod to swing around a first rotary shaft to drive the end cap clamping mechanism to move front and rear, so that a fitting block presses a lug to fit to an end cap; the electric cam push mechanism slides up and down for driving the secondtransmission rod to swing around the first rotary shaft to drive the housing clamping mechanism to move front and rear, so that the clamp clamps the housing; and the laser welding mechanism regulatesthe position of a laser unit through a horizontal transplanting platform and a laser unit transplanting mechanism, so that a laser spot of the laser unit is kept consistent with the lug and the end cap, and therefore, welding precision between the lug and the end cap is guaranteed.

Owner:HUIZHOU CHENGTAI AUTOMATION TECH CO LTD

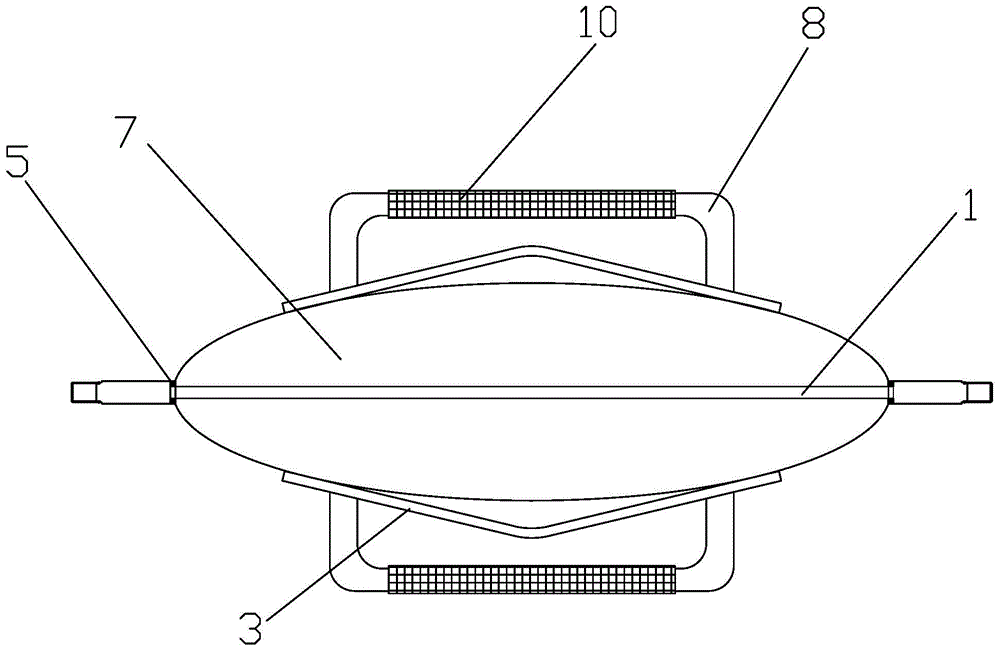

Water bag squeezing device for water circulation air-conditioning clothes

The invention discloses a water bag squeezing device for water circulation air-conditioning clothes. The water bag squeezing device comprises a water bag and a sealing metal ring wrapped in the water bag. Through holes are evenly formed in the sealing metal ring, and sealing nails used for fixing the water bag and the sealing metal ring are mounted at the positions, corresponding to the through holes, of the water bag. The upper surface and the lower surface of the water bag are each fixedly connected with a supporting plate, and the supporting plates are provided with handles used for squeezing or stretching the water bag. A water inlet pipe is mounted at one end of the water bag, a water outlet pipe is mounted at the other end of the water bag, and the water inlet pipe and the water outlet pipe are each provided with a sealing rubber ring. The water bag is composed of two anti-aging rubber sheets with the side portions being combined together in a hot-pressing mode. The handles are provided with antiskid sleeves. The water bag squeezing device is simple in structure, reasonable in design, economical and environmentally friendly, convenient to use, low in cost, convenient to maintain, good in sealing effect, capable of stretching or squeezing the water bag by stretching or squeezing the handles in the using process, convenient and fast.

Owner:SHAANXI ZIZHU ELECTRON

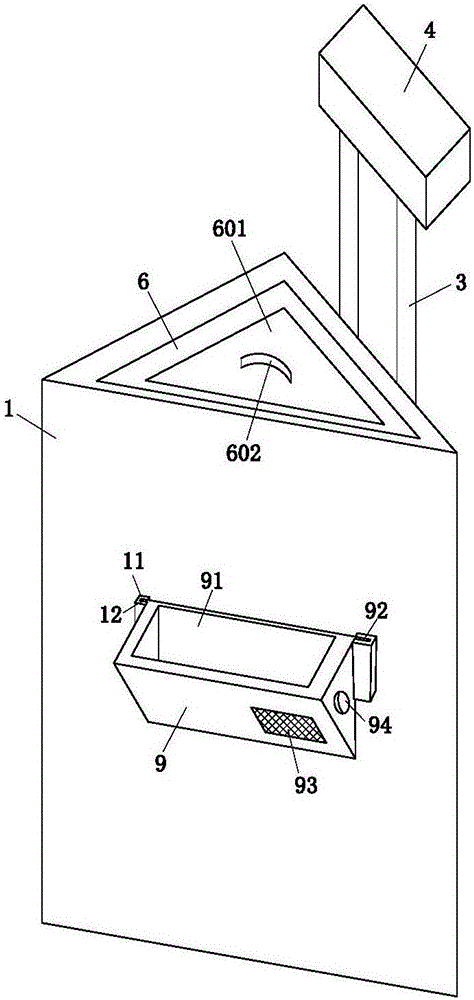

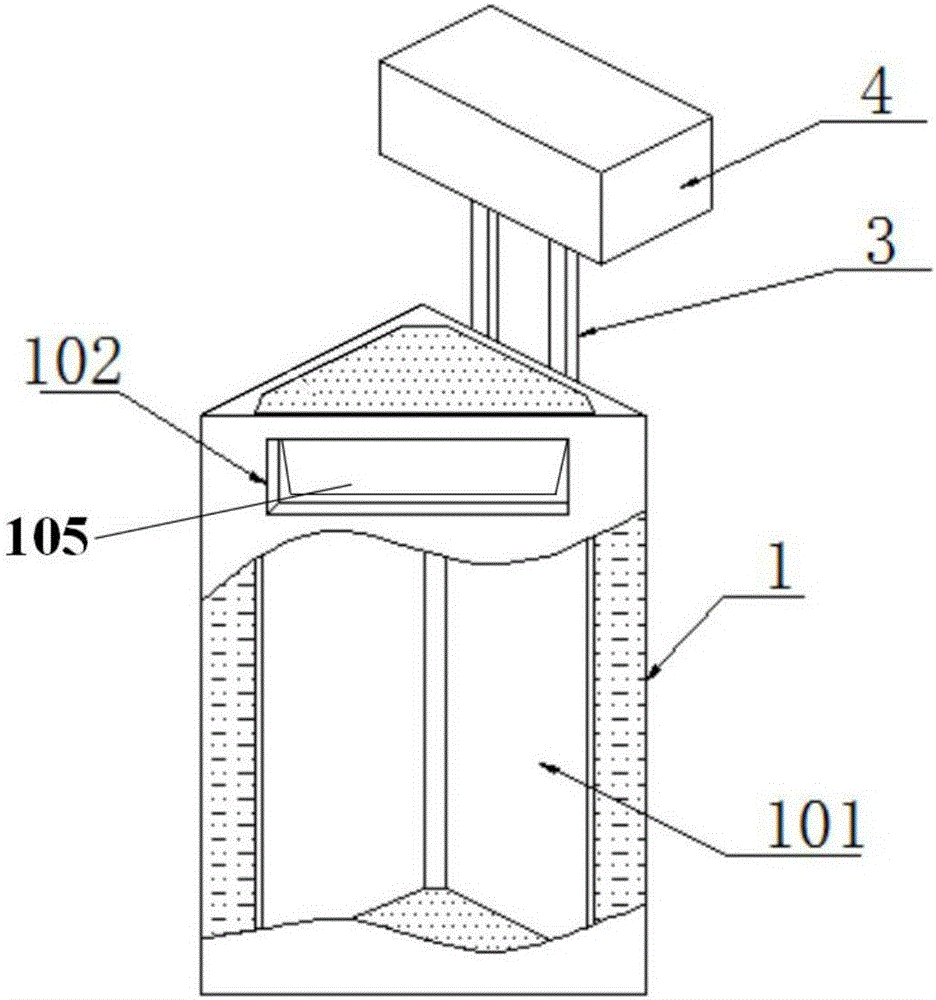

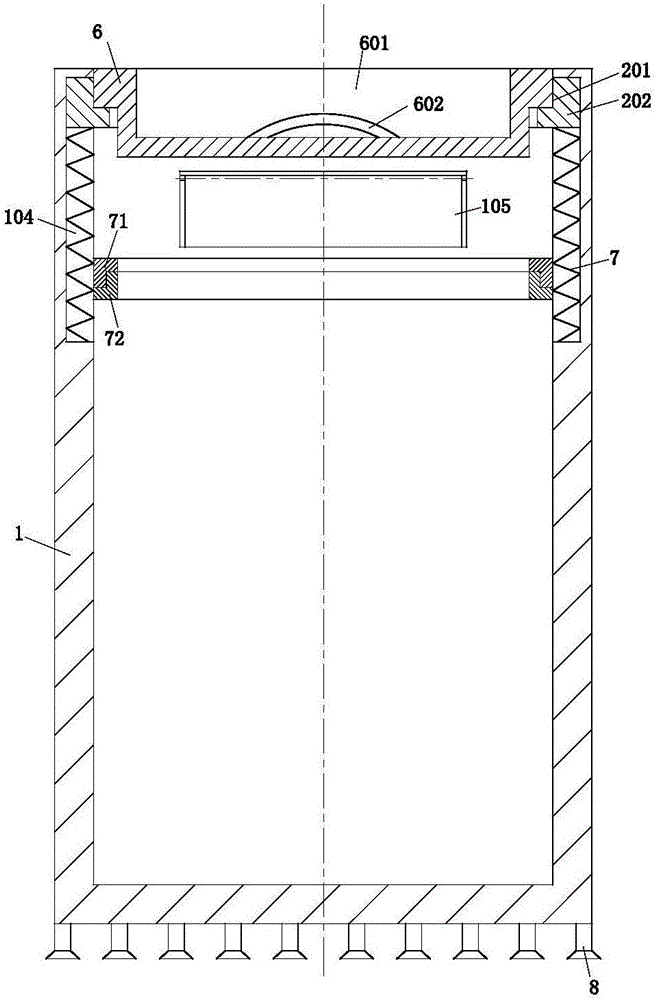

Toilet garbage can convenient to use

The invention relates to a garbage can, in particular to a toilet garbage can convenient to use. The toilet garbage can comprises a can body and a cover plate; the cross section of the appearance of the can body is in an equilateral right triangle shape, and an object storing cavity with the cross section being in an equilateral right triangle shape is arranged inside the can body; a putting opening of a rectangle structure is formed in the outer wall of the can body, and a baffle capable of overturning to the inner side of the putting opening is hinged to the upper portion of the putting opening; an inflator is arranged on the side wall of the can body and is communicated with the interior of the can body through an air pipe, and a supporting rod is connected to the top of the inflator; a box body is arranged at the top of the supporting rod; sliding grooves are formed in three corners of the object storing cavity, and springs are arranged inside the sliding grooves; a triangular connecting support is placed at the top ends of the springs and can slide vertically along the sliding grooves, a triangular stepped hole is formed in the middle portion of the connecting support, and a cover plate is placed in the stepped hole. The toilet garbage can convenient to use has the beneficial effects that the structure is small and exquisite, multiple functions are achieved, and the floor space is small; and use by people is facilitated.

Owner:平湖市浪涛卫浴科技股份有限公司

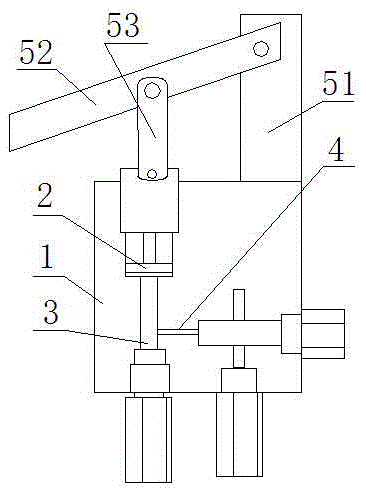

Hydraulic manual pump easy to operate

InactiveCN105626412ARealize pressingRealize liftingPositive displacement pump componentsPiston pumpsInlet channelEngineering

The invention discloses a hydraulic manual pump easy to operate. The hydraulic manual pump easy to operate comprises a valve body. A piston mechanism, an oil inlet channel and an oil outlet channel are arranged on the valve body, wherein the oil inlet channel and the oil outlet channel are connected with the piston mechanism. The oil inlet channel is connected with an oil inlet through an oil inlet control one-way valve. The oil outlet channel is connected with an oil outlet through an oil outlet control one-way valve. A piston pulling device is arranged on the piston mechanism. The piston pulling device comprises a fixing part arranged on the valve body, a pull rod with one end movably arranged on the fixing part, and a transmission rod used for being connected with the pull rod and the piston mechanism. The hydraulic manual pump is easy to operate.

Owner:CHENGDU FAREAST HIGH TECH CO LTD

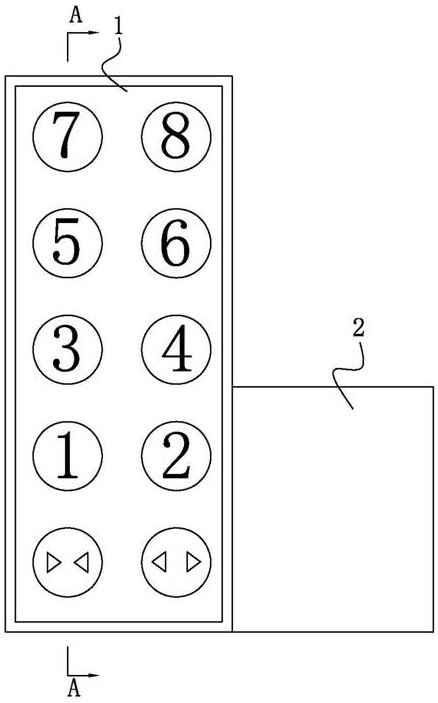

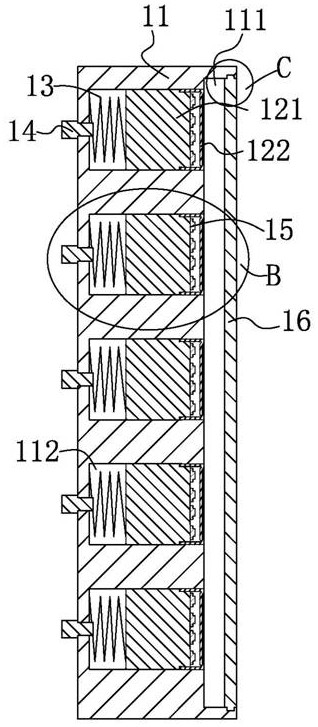

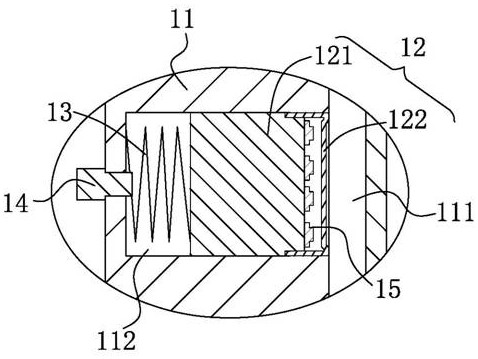

Remote controller

ActiveCN106535517AHigh sensitivityFeel goodCasings/cabinets/drawers detailsElectric switchesEngineering

Owner:ZHEJIANG MELLKIT INTERGRATED CEILING CO LTD

A bonding and pressing equipment for plywood production and processing

ActiveCN110480763BAchieve cleaning effectEasy to operatePlywood pressesVeneer pressesElectric machineryScrew thread

The invention discloses a bonding and pressing equipment for production and processing of plywood, which comprises a pressing machine and a panel body. A feeding box is installed on the side of the pressing machine, and horizontally distributed boxes are installed on the side of the feeding box. The second hydraulic rod, a glue roller is arranged below the connection between the feeding box and the pressing machine, and the glue roller is connected to the top of the box wall of the feeding box through the rotation of the roller shaft, and the roller shaft is connected to the third motor, A rubber delivery pipe and a rubber discharge pipe installed with a glue spraying head are arranged below the glue roller. The bonding and pressing equipment for plywood production and processing uses the motor to run the screw drive to achieve the purpose of pressing, and the operation of pressing is more convenient, and on this basis, the glue distribution between the boards is made more convenient through hydraulic power. Uniformity, improve the pressing effect, and can realize the cleaning and gluing operation of the board surface while the feeding box is feeding, and the design is more reasonable.

Owner:嘉兴宝龙新材料股份有限公司

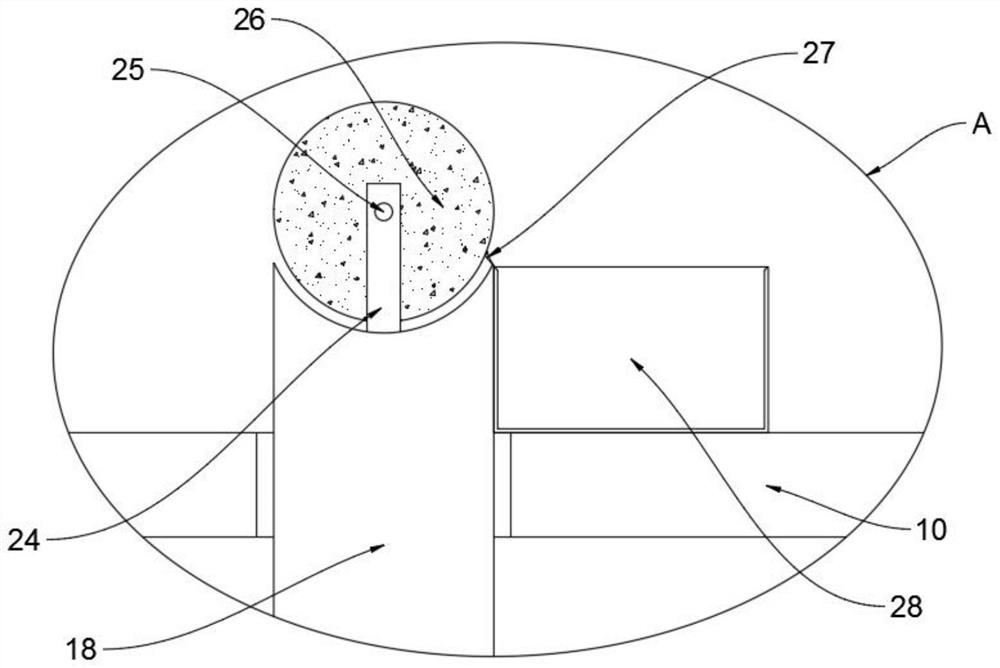

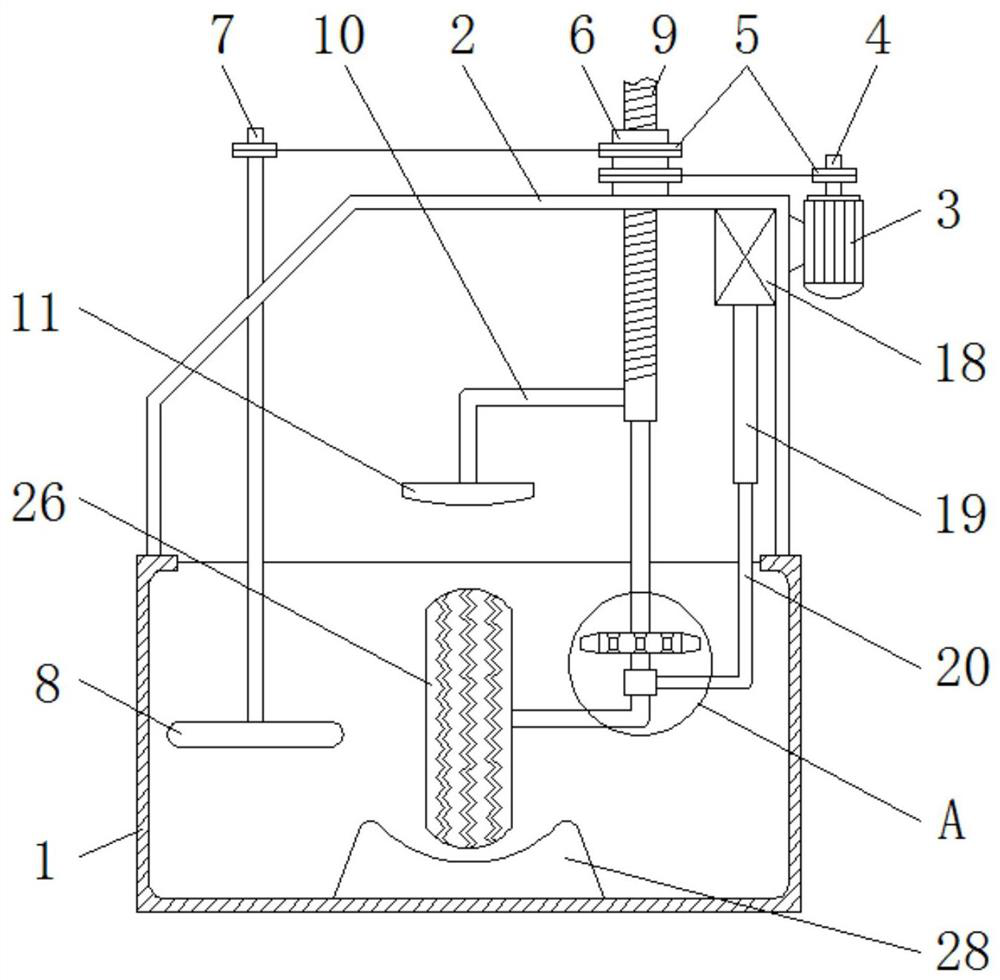

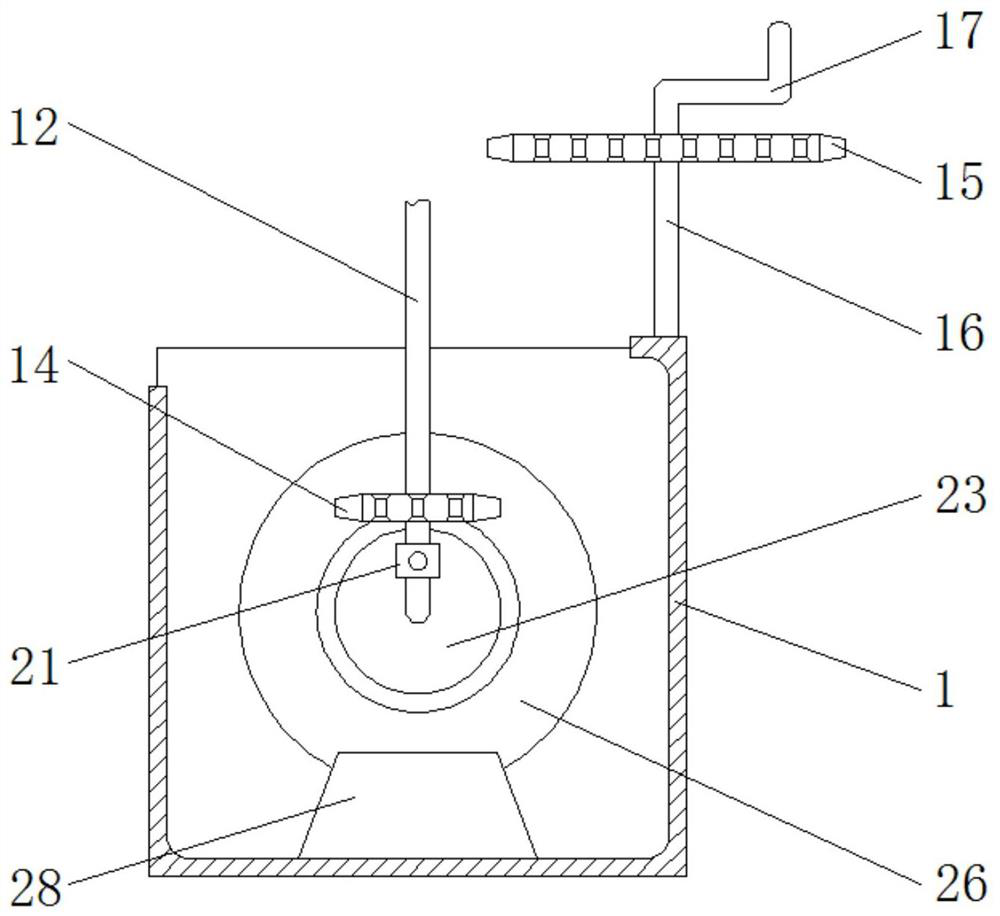

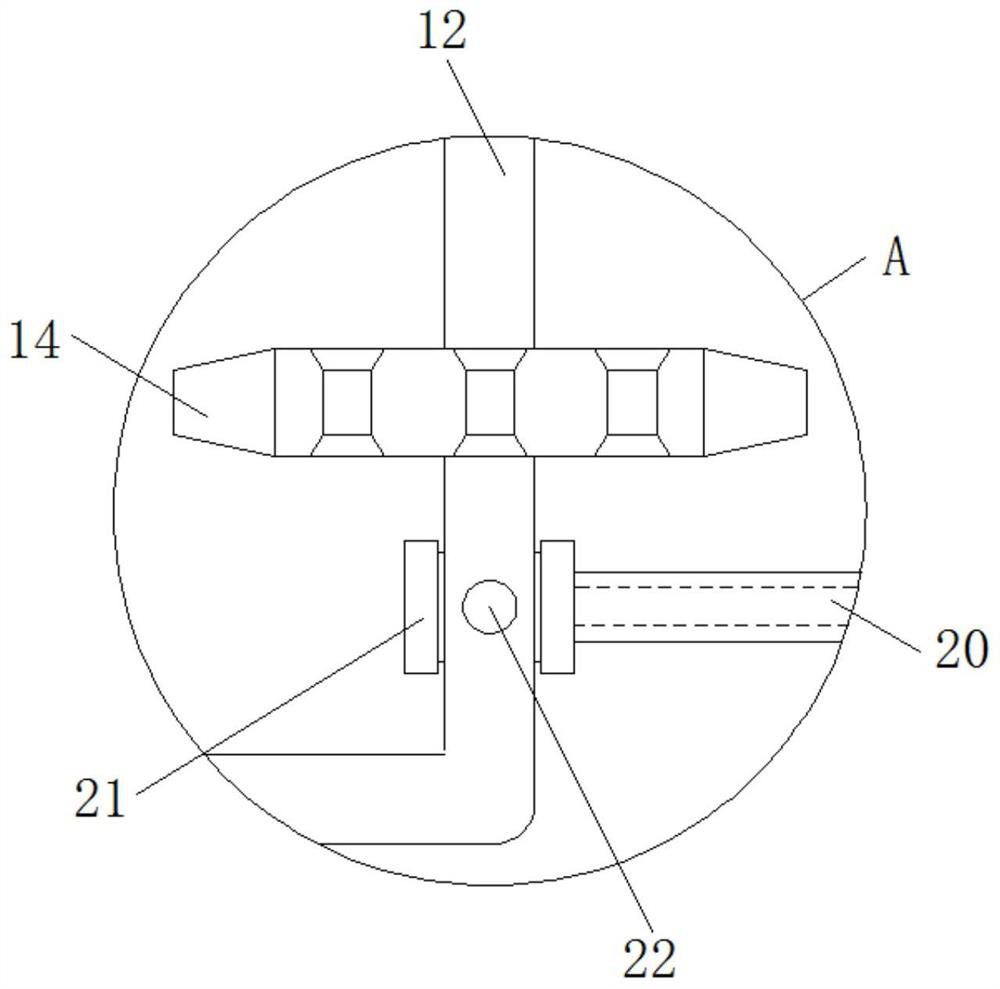

Building concrete slab strength detection device

PendingCN113310804AAchieve inflatableRealize pressingMaterial strength using tensile/compressive forcesGear wheelElectric machine

The invention aims to solve the problem of concrete strength detection, and discloses a building concrete slab strength detection device which comprises a support frame. Bottom plates are symmetrically mounted at the bottom end of the support frame, universal wheels are uniformly mounted on the bottom surfaces of the bottom plates, handles are symmetrically mounted on the left and right side surfaces of the support frame, a support rod is fixedly installed on the right side of the upper surface of the support frame, a first motor is fixedly installed at the top end of the support rod, a gear is installed in the middle of the first motor, a sleeve is fixedly installed in the middle of the top end of the support frame, a sliding frame is sleeved with the sleeve, a rack is welded to the right side face of the sliding frame, the left side wall of the sliding frame is sleeved with a spiral spring, a connecting rod is fixedly installed at the lower end of the sliding frame, a connecting ring is fixedly connected to the lower end of the connecting rod, and a pressing cylinder is installed in the middle of the connecting ring. The pull rope is reasonably poured in the concrete layer, and then the visual detection of the quality of the concrete slab is realized by pulling the pull rope.

Owner:胡斯楞

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com