Patents

Literature

253results about How to "Quick press" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

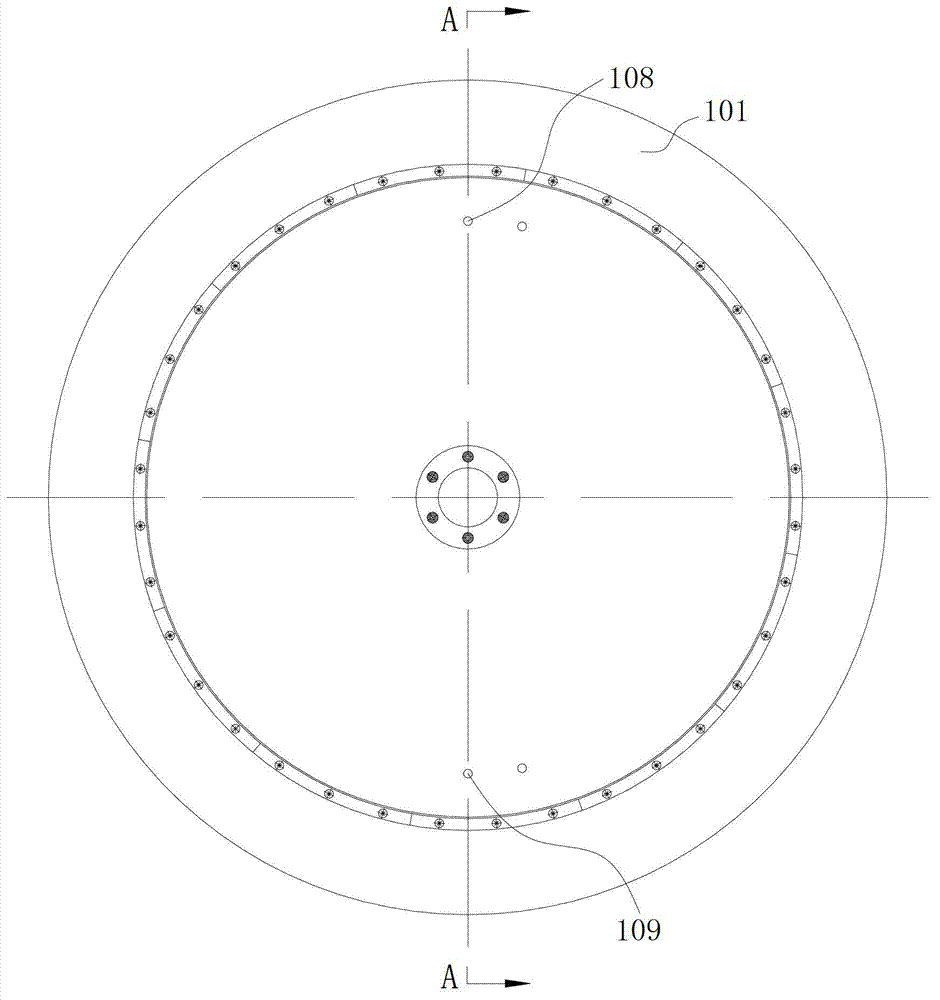

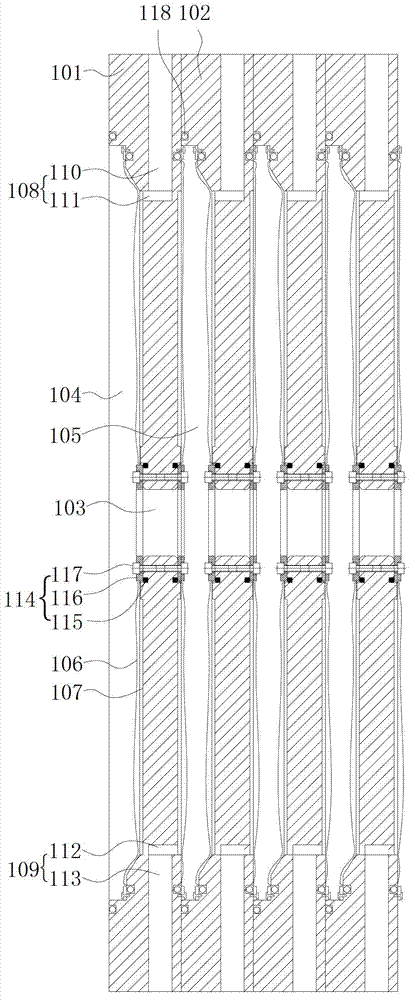

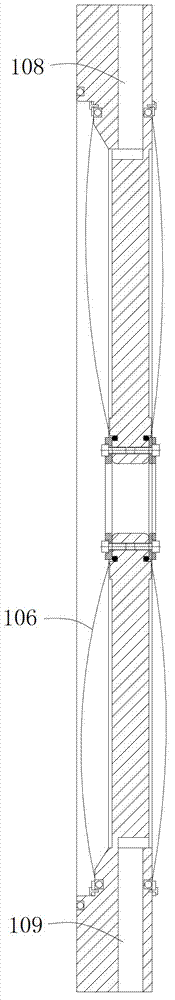

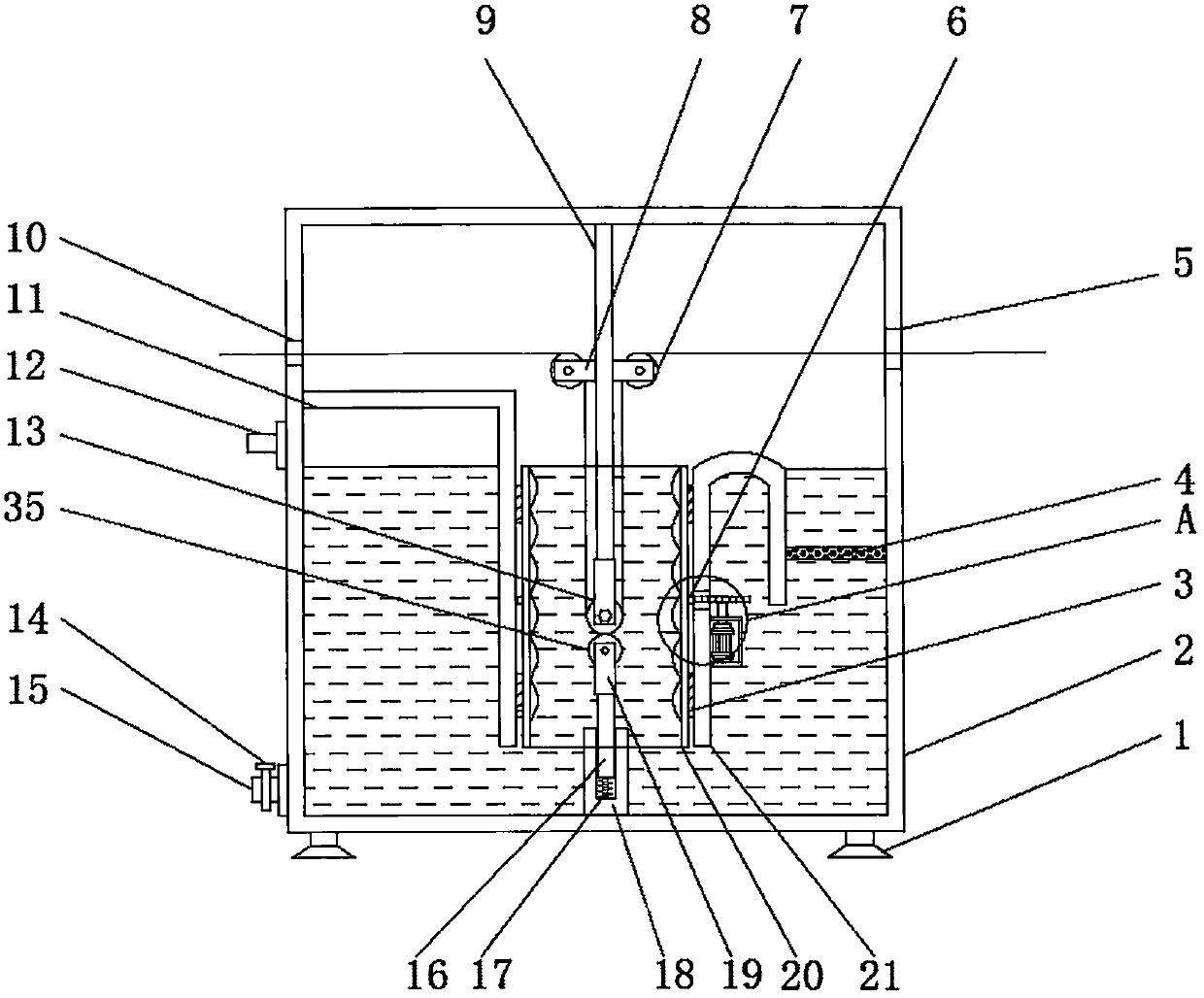

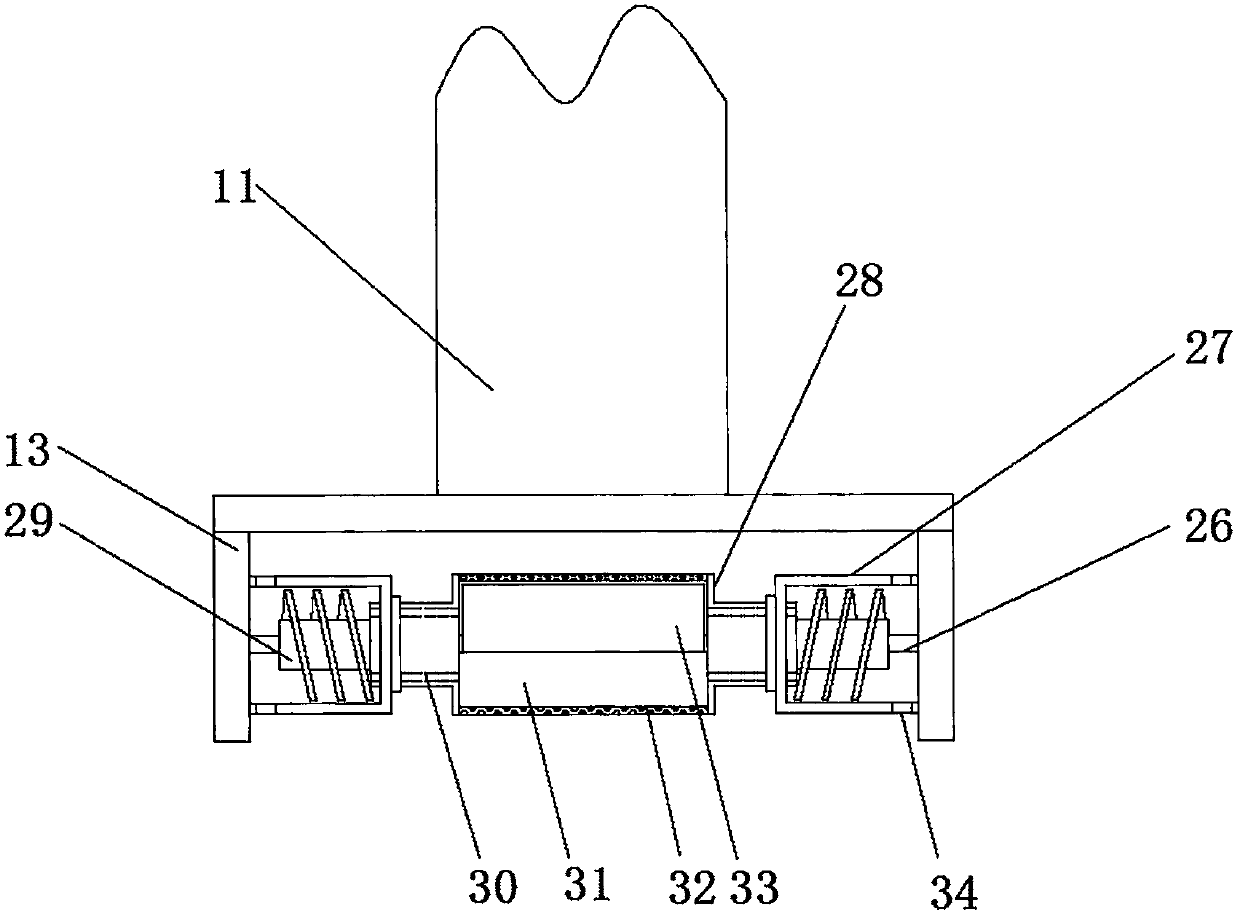

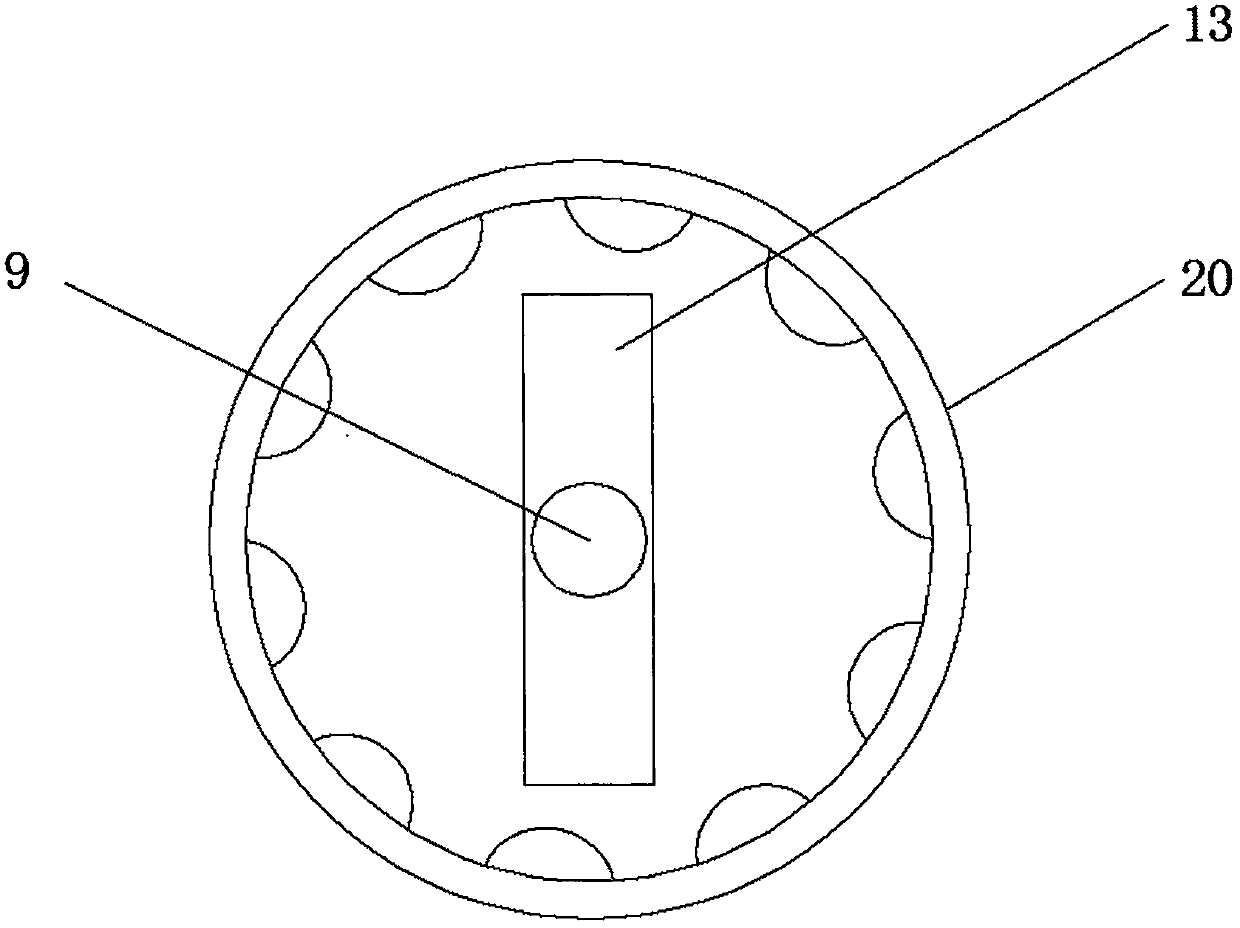

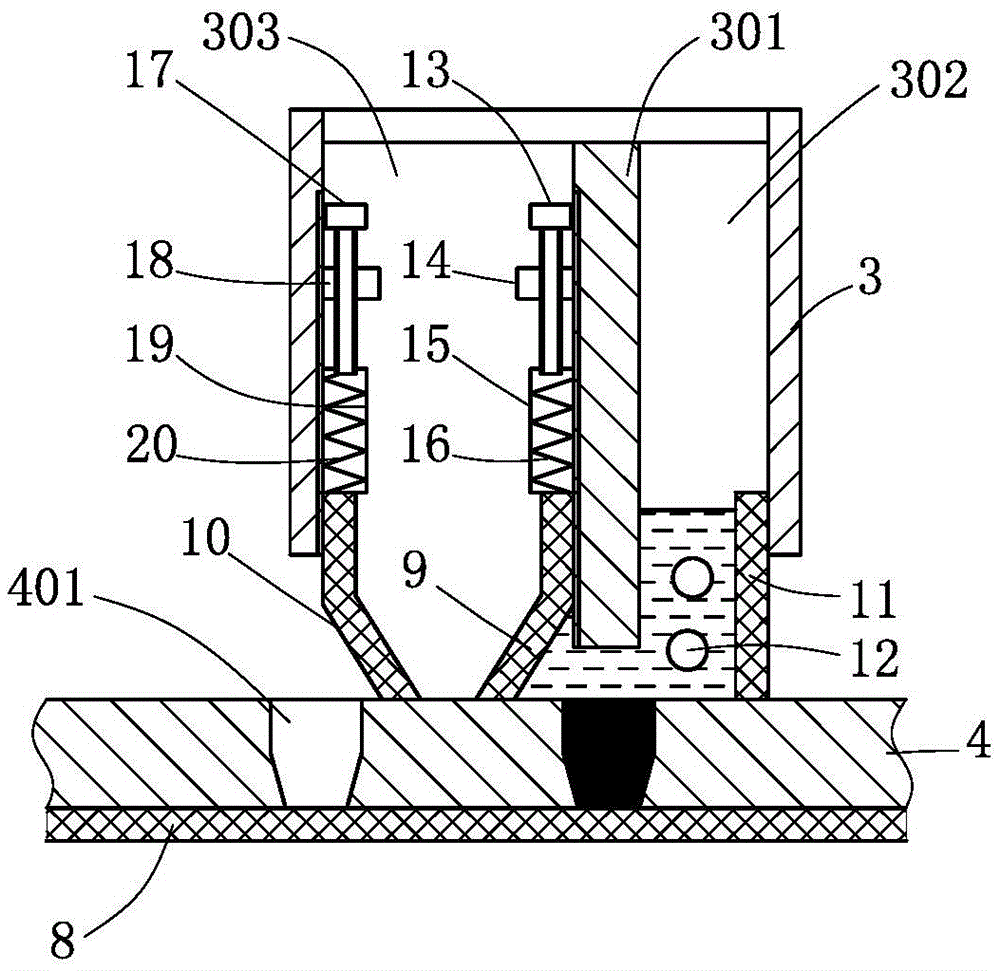

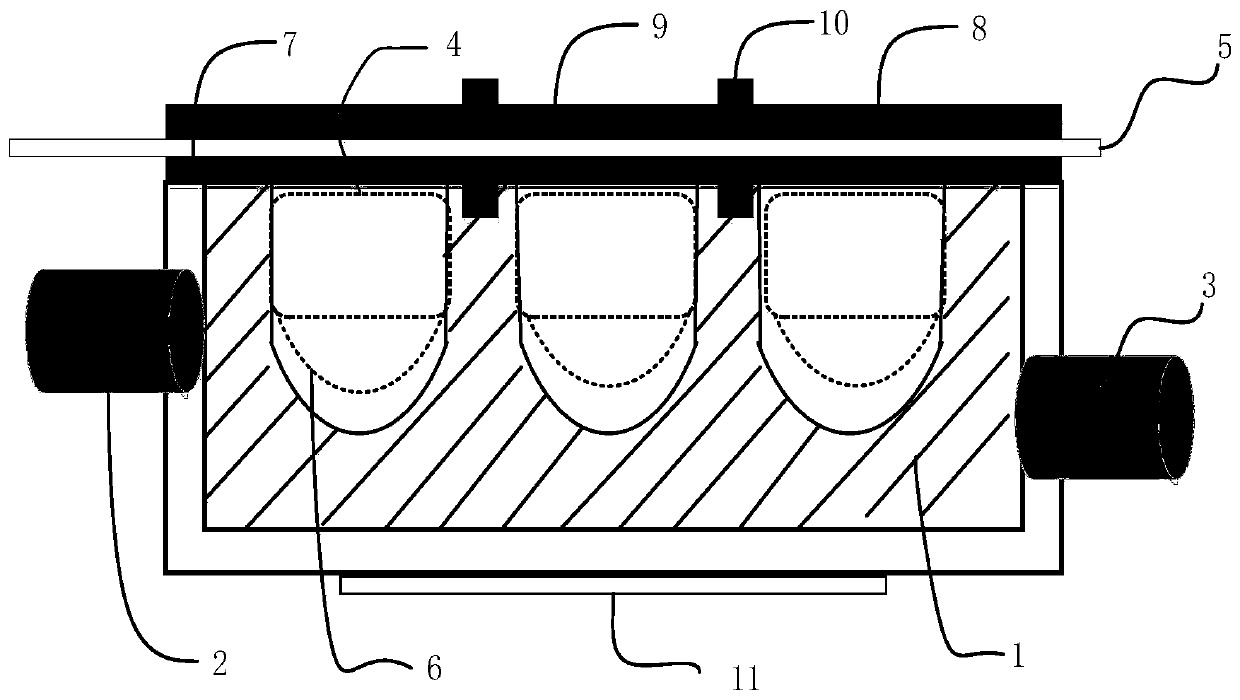

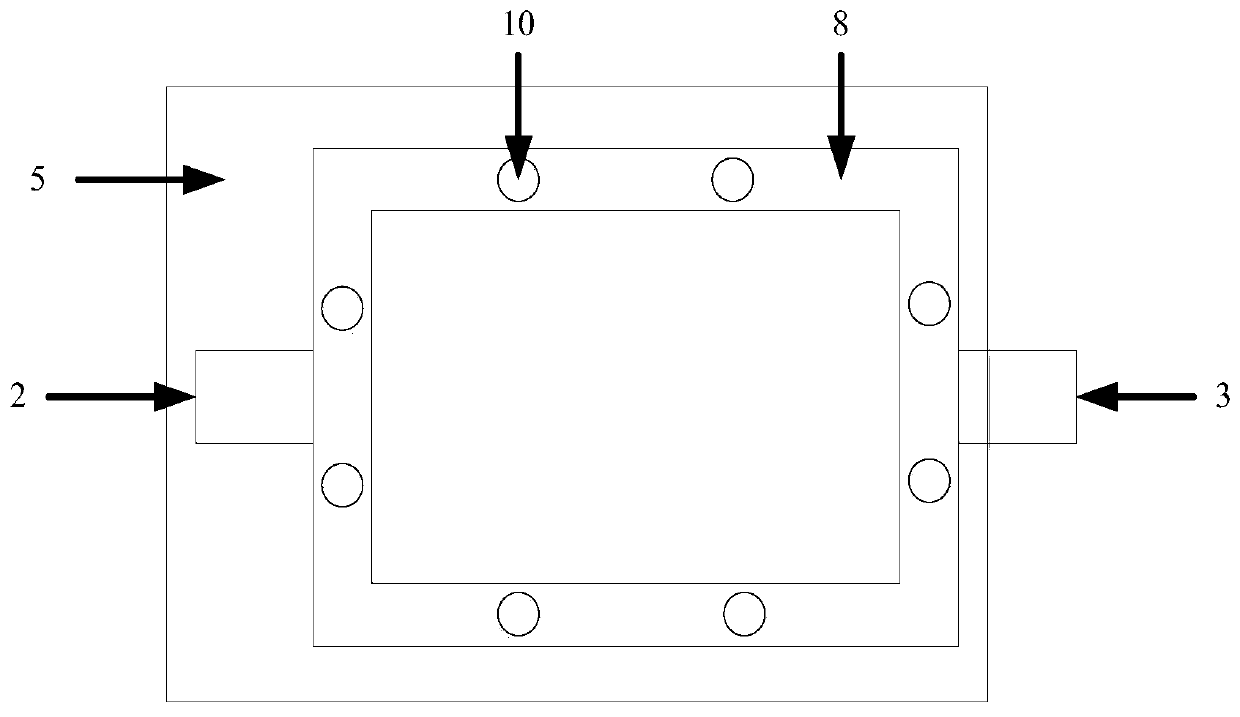

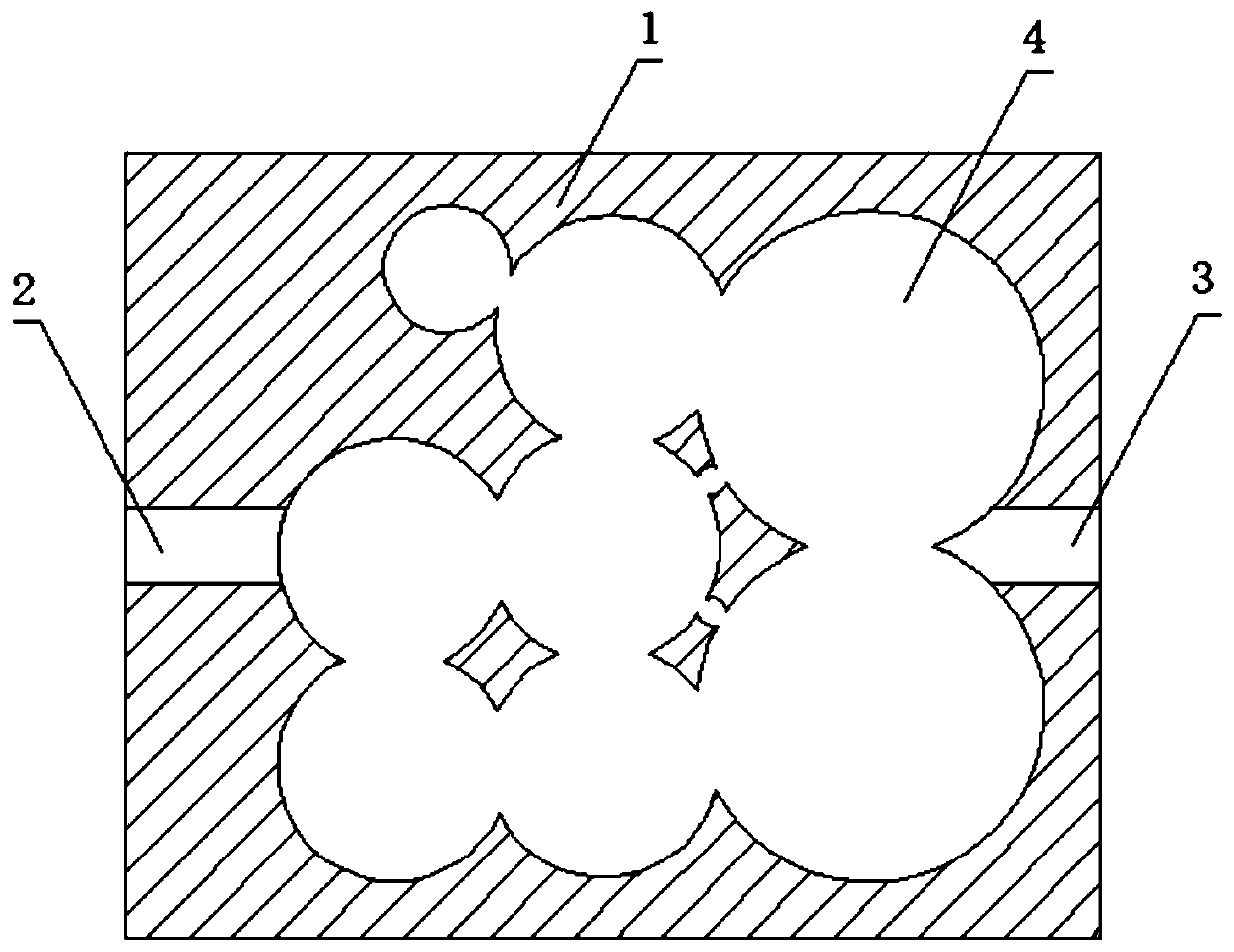

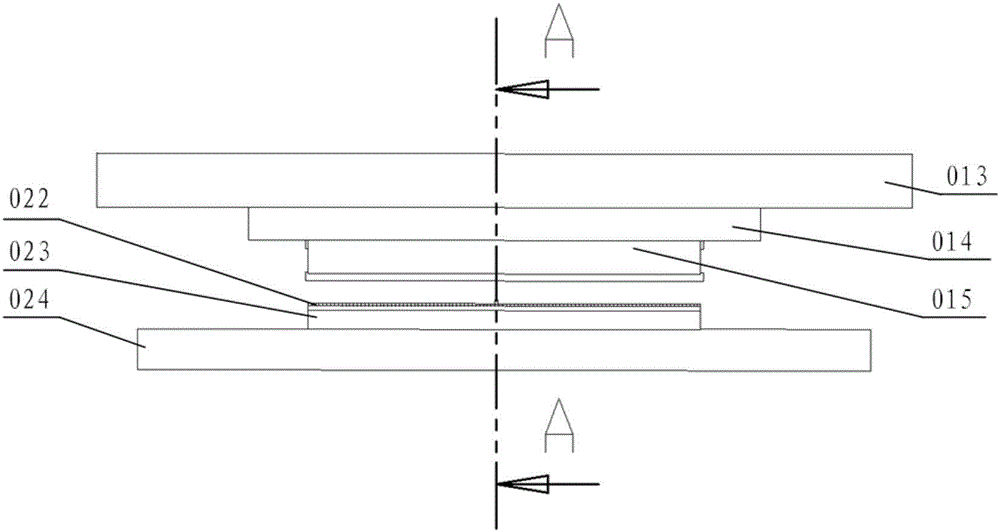

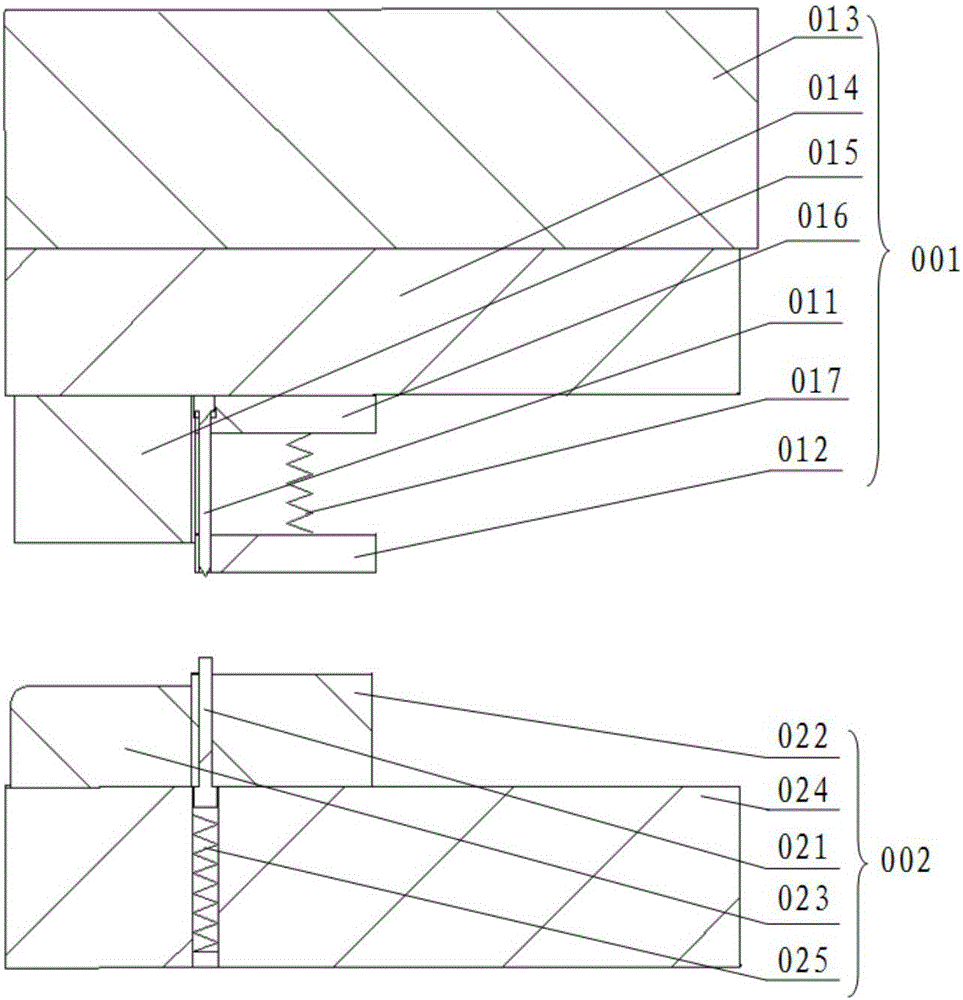

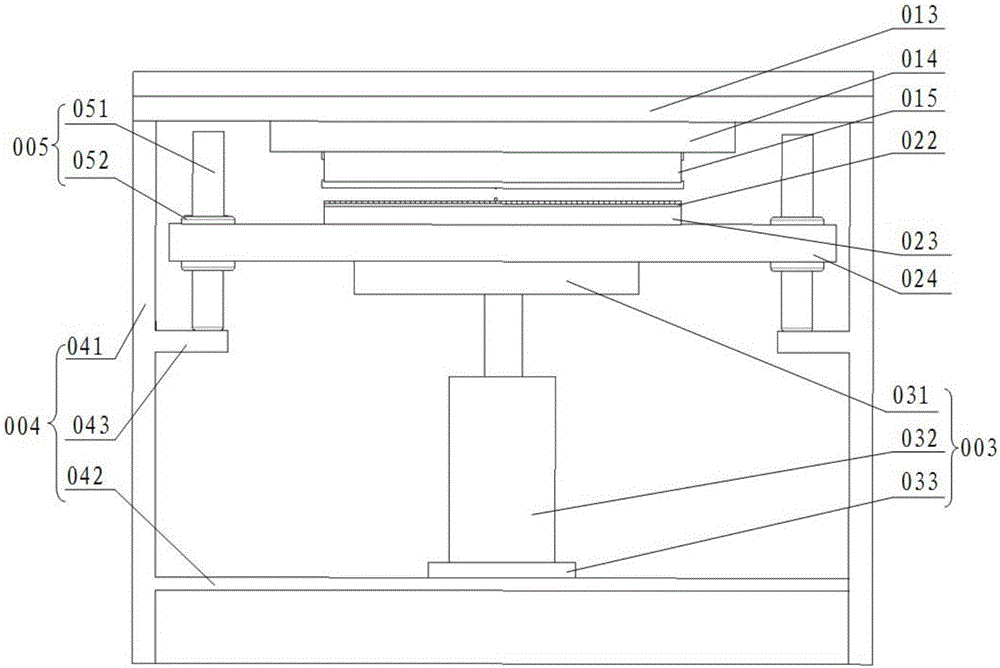

Pressure filter and pressure filtration method thereof

InactiveCN102814063AFew partsThe overall structure is simple and reliableFiltration separationPlate pressureFiltration

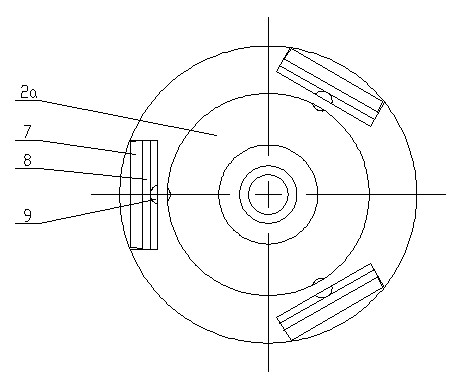

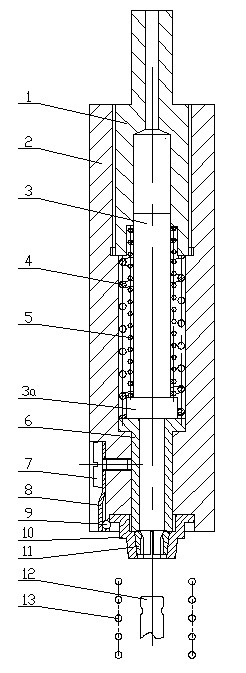

The present invention discloses a pressure filter, which comprises multiple groups of filter plates, wherein the adjacent filter plates are arranged in a contact manner, and each filter plate is provided with a material channel and a pressure filtration space with a variable volume and for accommodating a material. One end of the material channel is communicated with the pressure filtration space, and the other end is communicated with the pressure filtration space of the adjacent filter plate. Each filter plate is further provided with an air channel for communicating the filter plate pressure filtration space and a liquid channel for communicating the pressure filtration space of the adjacent filter plate. Filter screens are arranged on both sides of the filter plates and are positioned inside the adjacent pressure filtration space, wherein a filter cloth is covered outside the filter screen. The pressure filter of the present invention has characteristics of fewer components, simple and reliable structure, and low equipment maintenance workload. The present invention provides a pressure filtration method. According to the pressure filtration method of the present invention, two-stage pressure filtration and one-stage drying are adopted, wherein the first stage is that a driving pump is adopted to feed the material to carry out pressure filtration, the second stage is that high pressure air pressurizes the filter cloth to carry out pressure pressing, and the third stage is that the material is dried with high temperature air, such that pressure filtration efficiency is improved, and effects of automatic material unloading and filter cloth cleaning are achieved through the high pressure air.

Owner:FOSHAN JINKAIDI FILTRATION EQUIP CO LTD

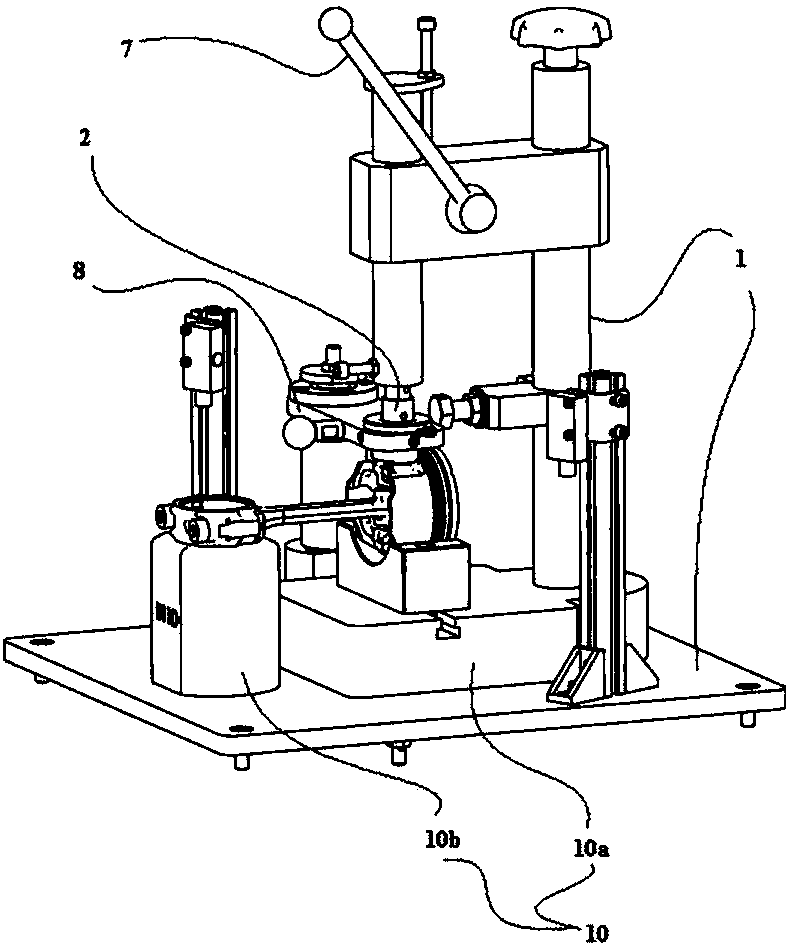

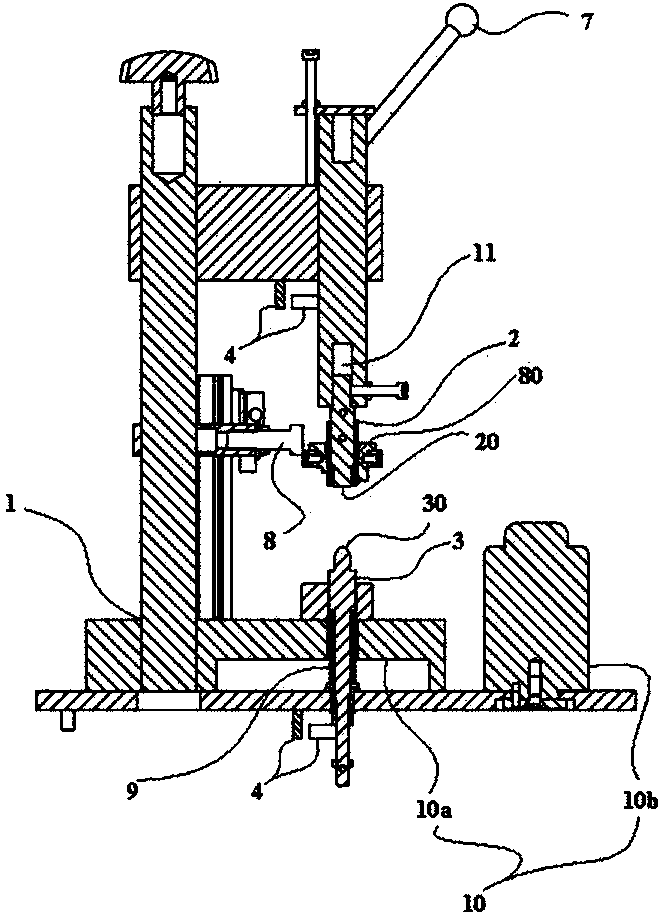

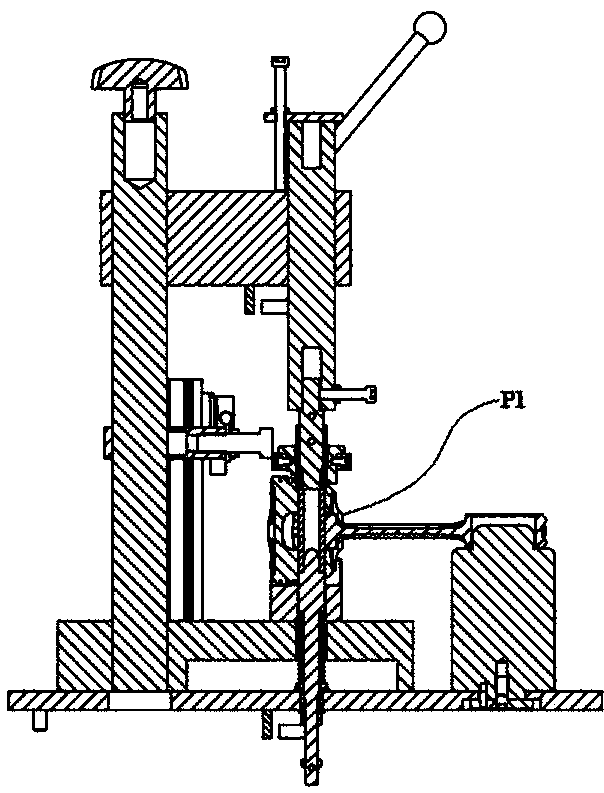

Engine piston pin snap ring press fitting tool

The invention provides an engine piston pin snap ring press fitting tool. The engine piston pin snap ring pressing fitting tool comprises a support and a press rod, wherein the press rod is fixed to the support and can be controlled to stretch, the support comprises a supporting seat, the position of the press rod corresponds to that of the supporting seat, an upper boss is arranged on the middle section of the press rod, and a displacement sensor used for detecting the displacement of the press rod is fixedly arranged beside the press rod and on the support. Through the adoption of the technical scheme, if a snap ring at the upper end of a piston is not assembled or the assembling of the snap ring is not in place, the displacement sensor at the upper end of the press rod senses whether the snap ring at the upper end of the piston is neglected or not or whether the assembling of the snap ring is in place or not through the moving of a press head of the press rod, the problems of error assembling and neglected assembling can be found out in time, the production rhythm can be improved, and manpower can be saved.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

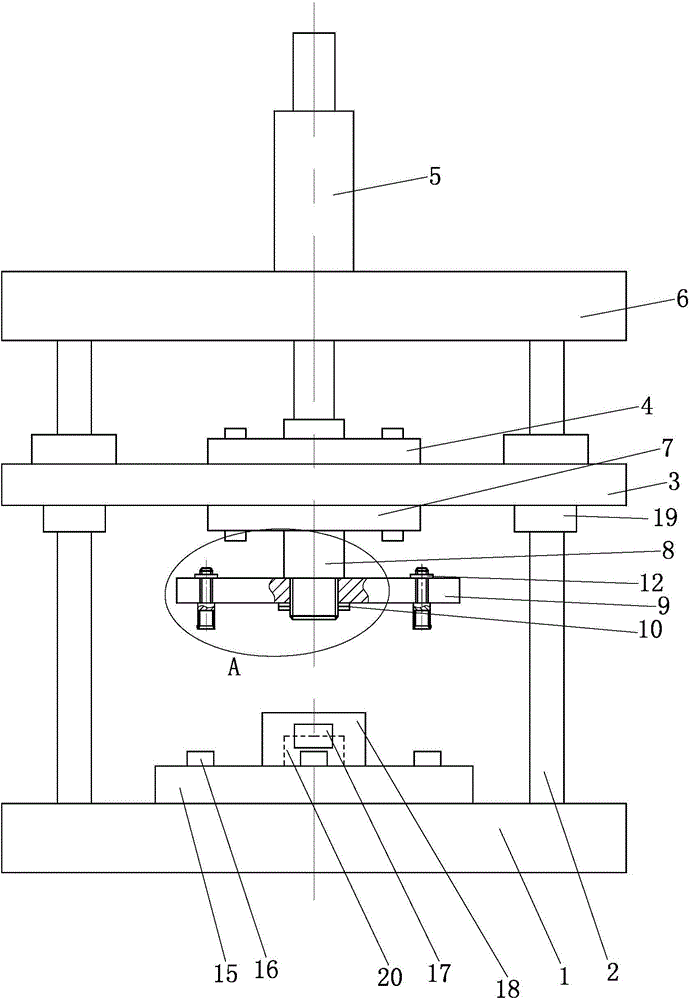

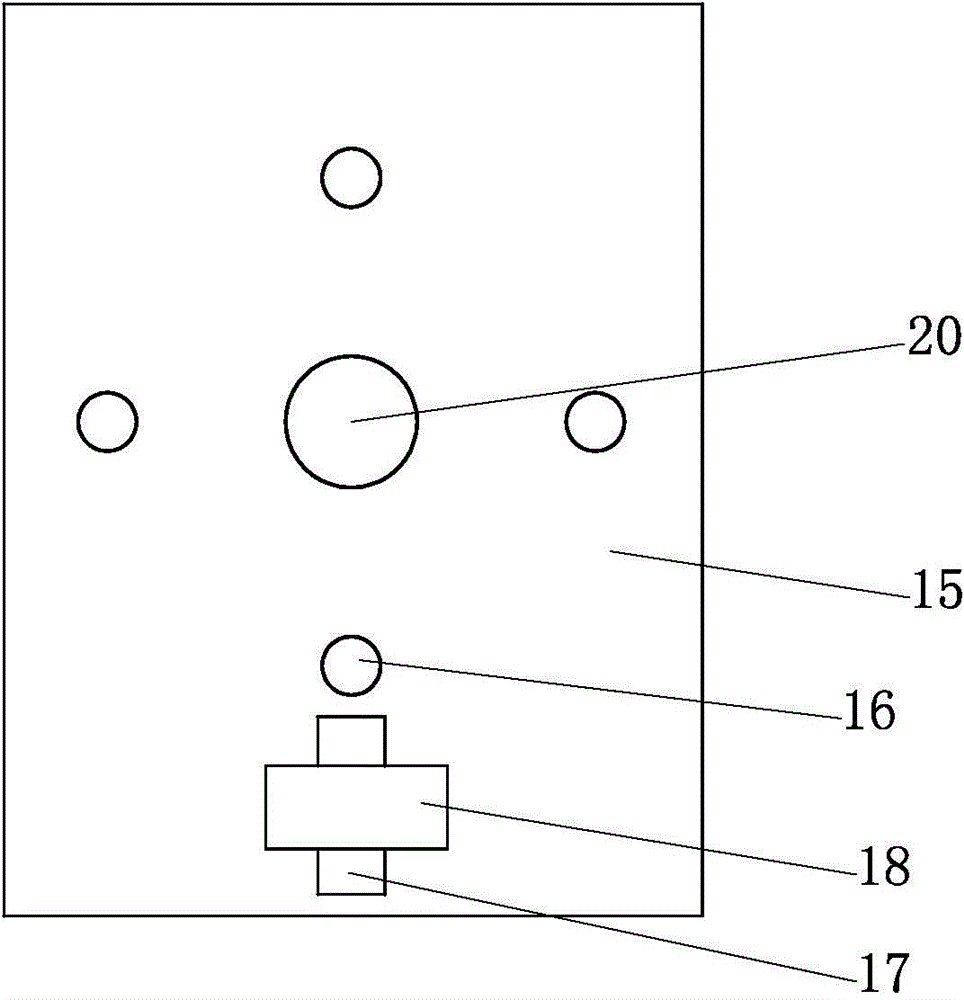

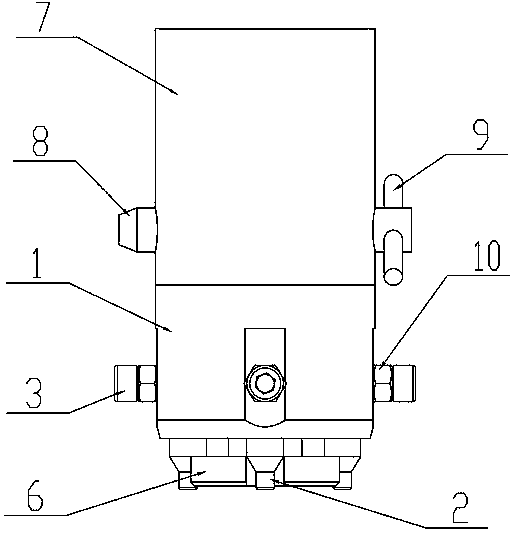

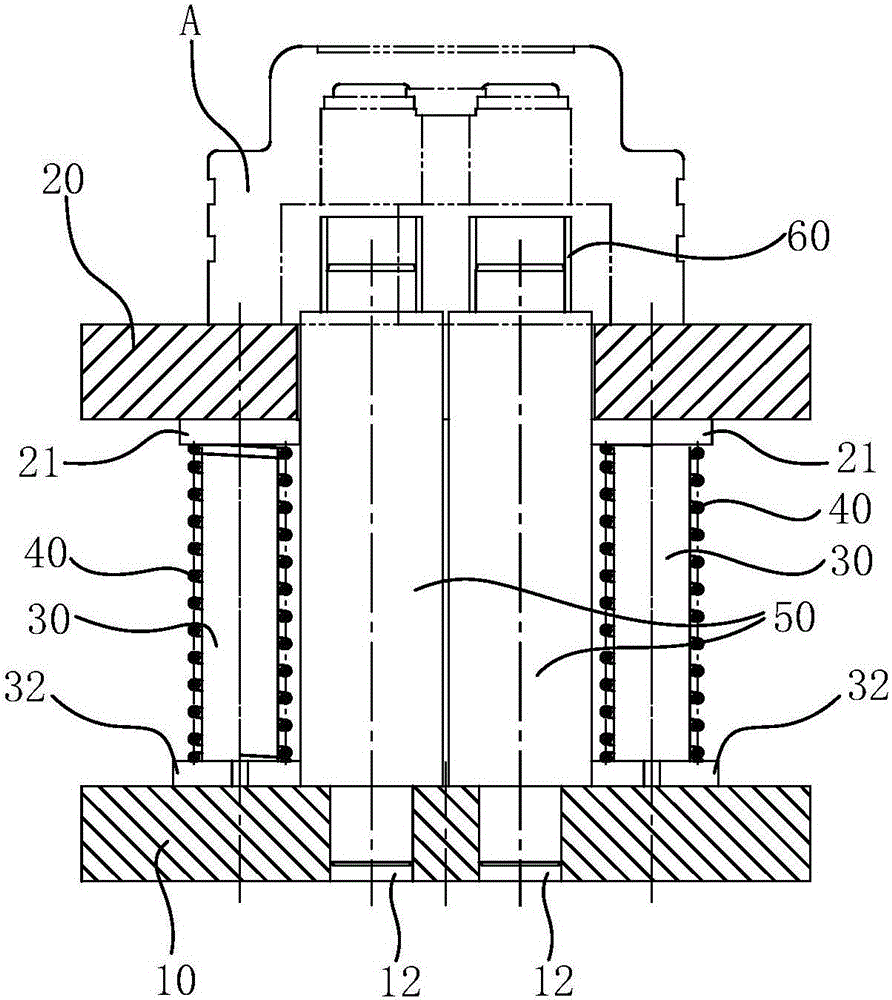

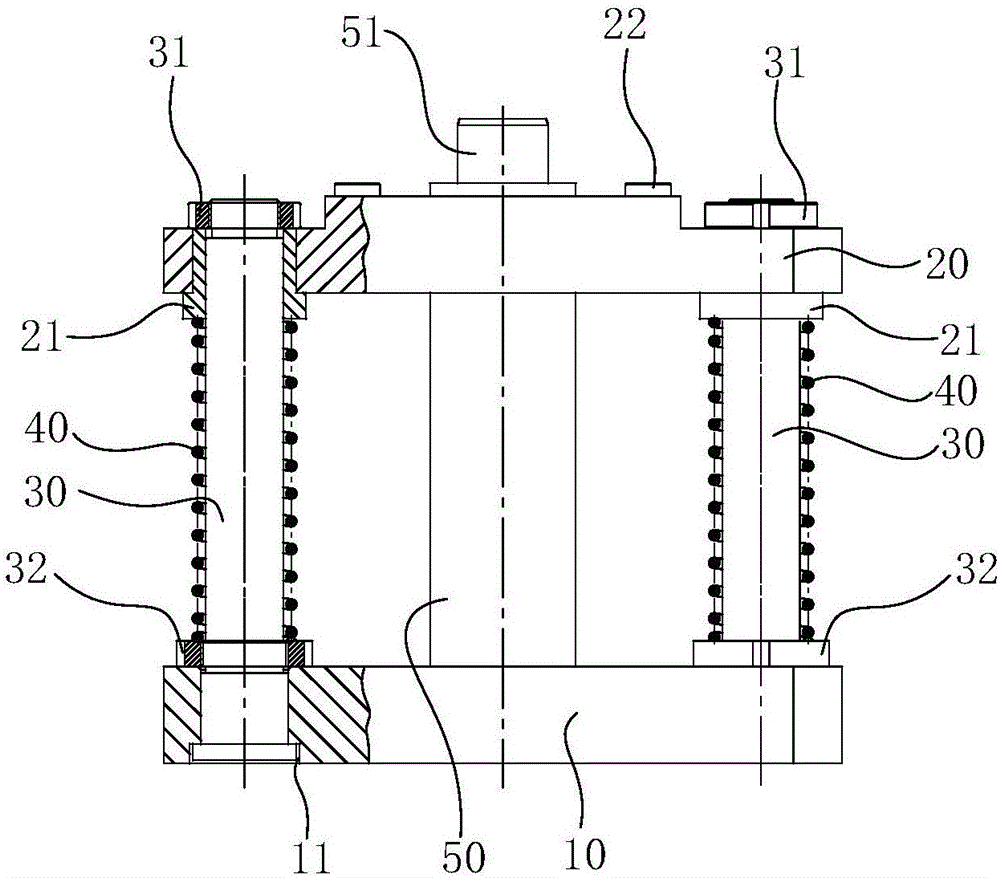

Flywheel clutch positioning pin pressing tool

The invention discloses a flywheel clutch positioning pin pressing tool. Four stand columns are fixedly arranged on the top face of a base, and a horizontal movable plate is connected among the four stand columns in a sliding mode. An upper connecting disc of the upper plate face of the horizontal movable plate is fixed to the lower end of a piston rod of a cylinder. The cylinder is installed on a top plate. The bottom face of the top face is fixed to the top ends of the four stand columns. A vertical shaft is fixedly arranged on the lower disc face of a lower connecting disc of the lower plate face of the horizontal movable plate. The small-diameter section of the vertical shaft is sleeved with a pressing disc and a double nut. Positioning pin connecting rods are circumferentially distributed on the pressing disc. The lower ends of the large-diameter sections of the positioning pin connecting rods are provided with positioning pin installation blind holes. A base plate is placed on the base and provided with a central positioning column and a positioning cushion block. Circumferential positioning blocks are arranged around the central positioning column. Clutch positioning pins can be accurately and rapidly pressed in pin holes in a flywheel, the flywheel clutch positioning pin pressing tool is high in automation degree and high in reliability, the clutch positioning pins at different circumferential positions can be pressed by rotating the pressing disc, and therefore the application range of the flywheel clutch positioning pin pressing tool is enlarged.

Owner:绿驰智能(深圳)有限公司

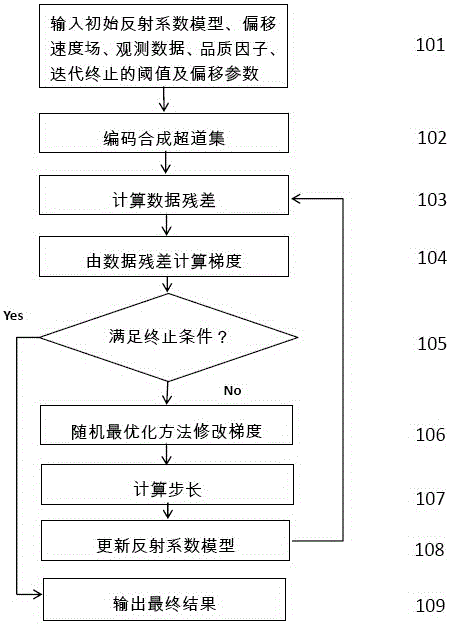

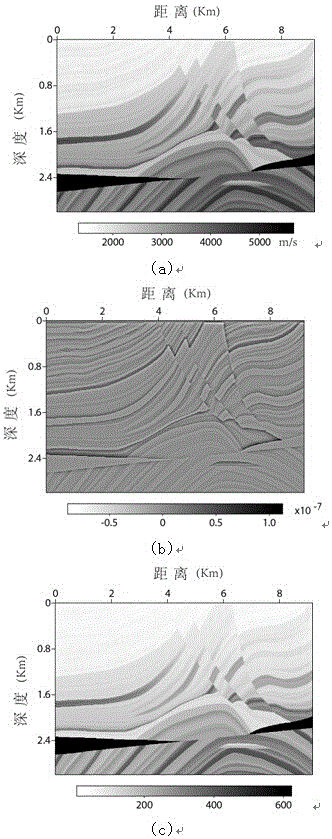

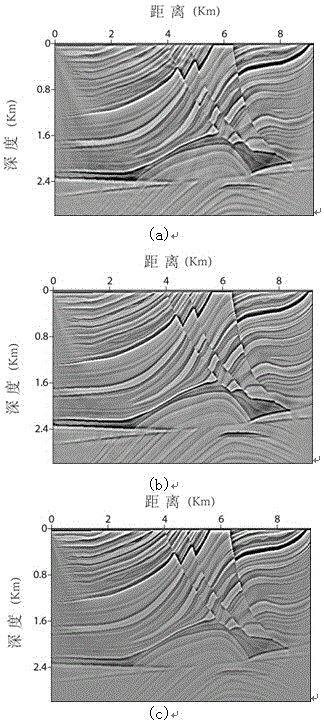

Multi-seismic resource sticky sound least square reverse time migration method based on stochastic optimization

ActiveCN106033124AQuick pressCompensation for absorption attenuationSeismic signal processingReverse timeLeast squares

The invention provides a multi-seismic resource sticky sound least square reverse time migration method based on stochastic optimization. The multi-seismic resource sticky sound least square reverse time migration method based on stochastic optimization comprises the steps that 1, field observation record and preset parameter synthesized supergather are read; 2, by adopting a current reflection coefficient model, a data residual error is calculated through multi-seismic resource excitation forward modelling supergather; 3, an update gradient is calculated according to the data residual error; 4, according to a stochastic optimization idea, the gradient is modified, and an update step length is calculated; 5, the reflection coefficient model is updated through the gradient and the update step length. According to the multi-seismic resource sticky sound least square reverse time migration method based on stochastic optimization, the stochastic optimization idea is popularized to sticky sound least square reverse time migration of phase encoding, stochastic fluctuation of the gradient is reduced through the gradient obtained before weighted averaging is conducted, and a good effect is obtained.

Owner:CHINA PETROLEUM & CHEM CORP +1

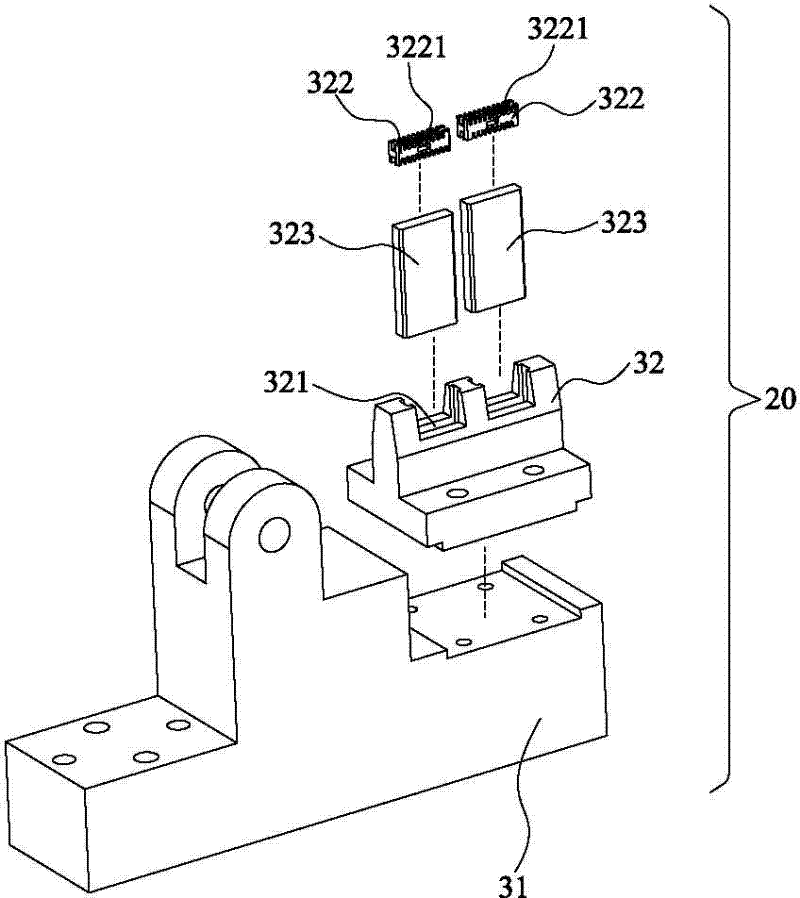

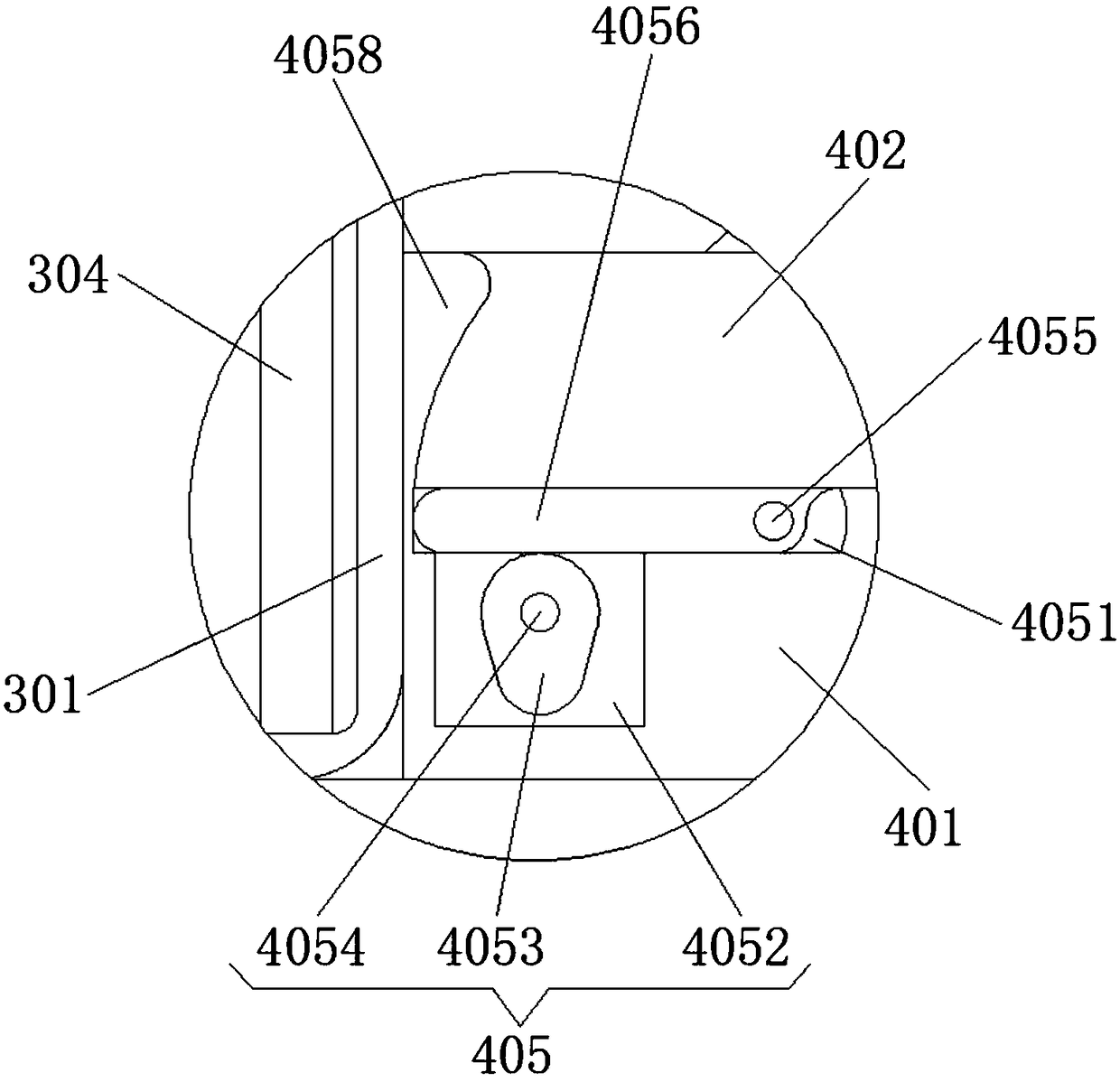

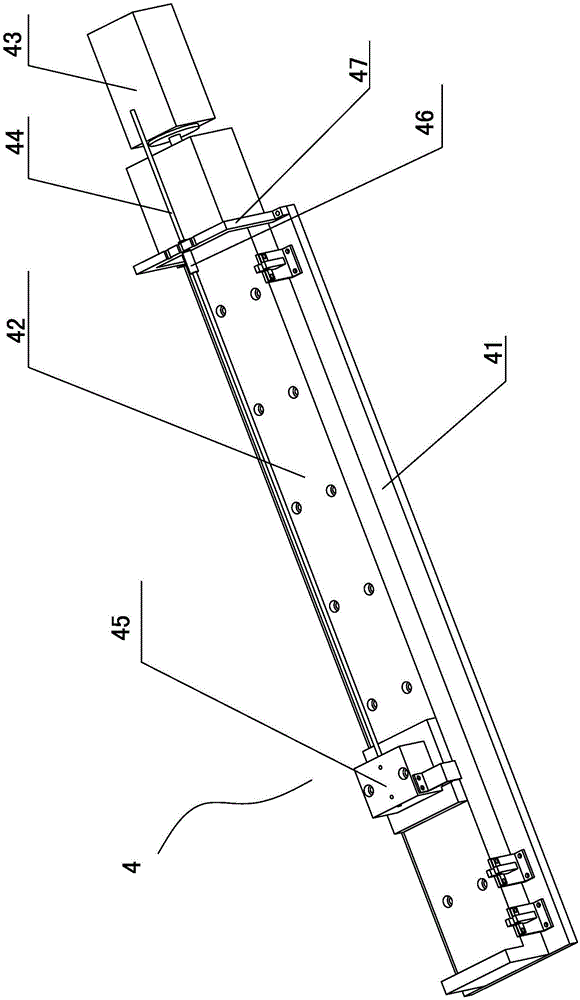

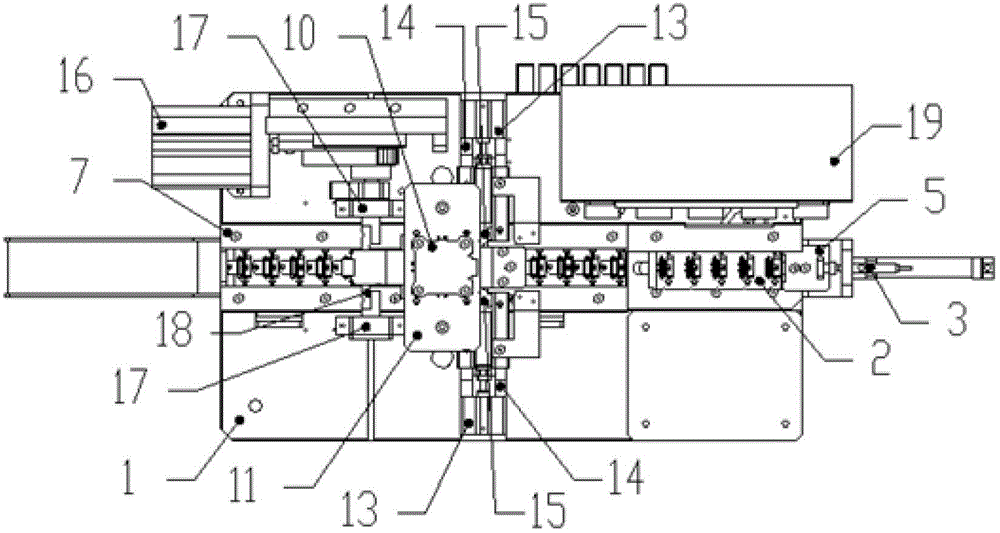

Clamp spring conveying press-in structure

The invention provides a clip-spring conveying press-in structure, which can quickly and accurately transport the circlip to the corresponding position of the bearing and quickly press-fit, such that the installation efficiency is improved, the installation is time-saving and labor-saving. The invention relates to a fixing device for positioning bearing, which is used for locating bearing and is provided with a pressure head on the upper part of the jig, and a vertical vibration machine is arranged on the bottom plate of the bracket. The base plate of the jig is arranged on the bottom plate of the bracket. The upper end surface of the vertical vibration machine is arranged with a straight-line clamping spring flow path, and the input end of the vertical vibration machine is connected with the discharging port of the feeding reel, wherein the input end of the upper charging reel is arranged with a clamping spring, and the product-in-place inductor is arranged toward the output end of the clamping spring flow path, the upper part of the pressure head is fixed to the piston end of the upper and lower cylinder, and the base of the upper and lower cylinder is fixed to the fixing plate of the upper and lower cylinder, and the bottom slider of the upper and lower cylinder fixing plates is embedded in two lines.

Owner:昆山嘉斯特自动化技术有限公司

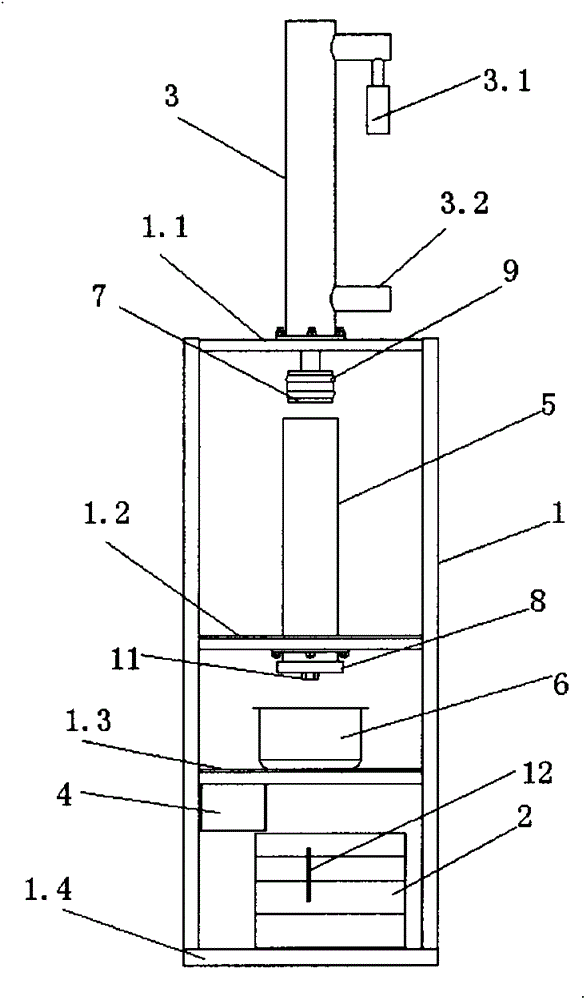

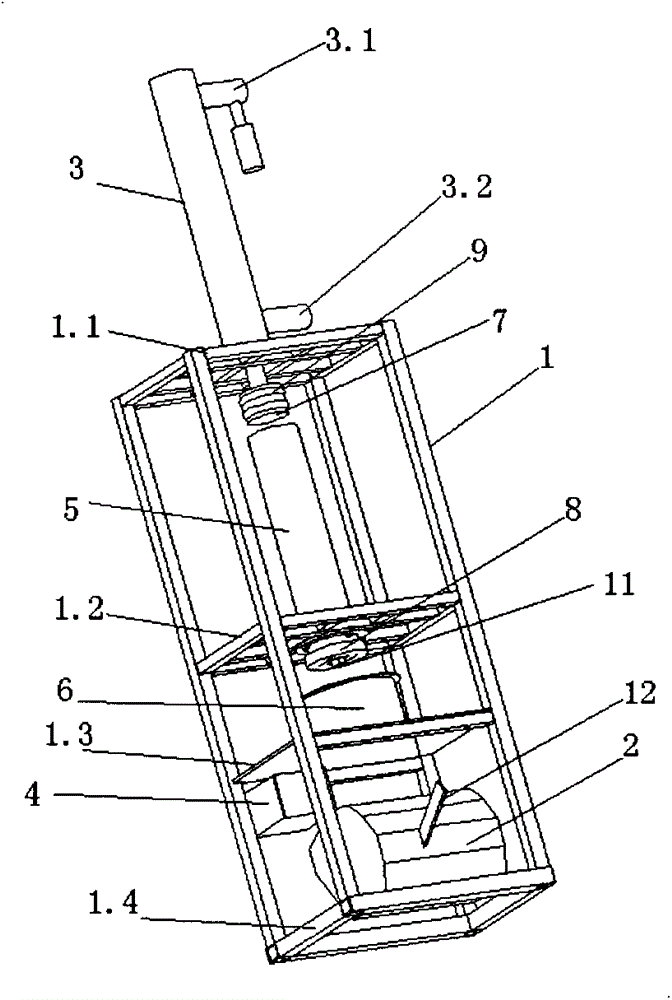

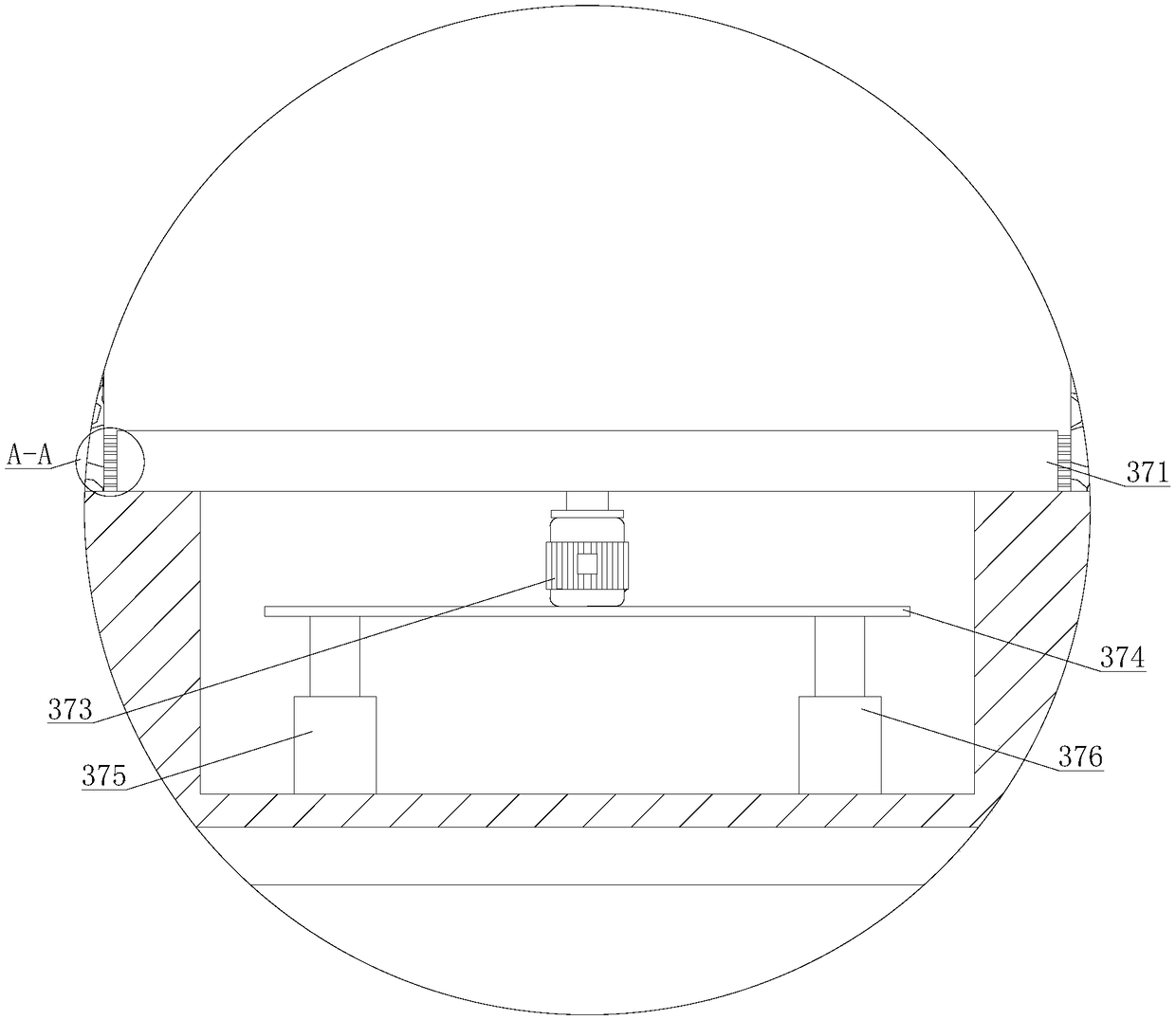

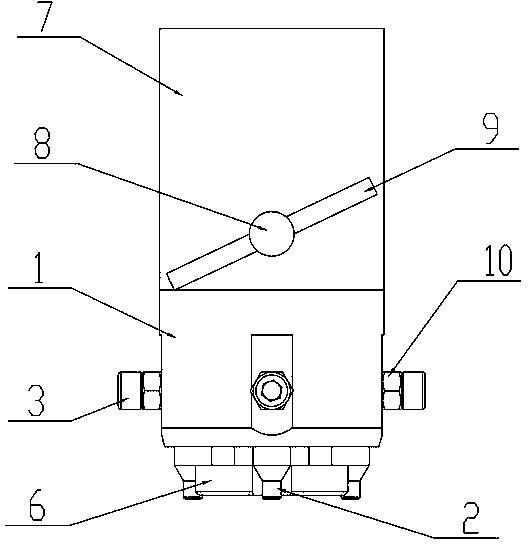

Electric hydraulic water squeezing machine

InactiveCN104055410AStructural design and simple operationFast pressingStrainersElectric machineryManufacturing efficiency

The invention discloses an electric hydraulic water squeezing machine, which comprises a square steel frame, a hydraulic pump, a hydraulic cylinder and a transformer, wherein the square steel frame is provided with an upper layer frame used for fixing the hydraulic cylinder, a middle layer frame used for fixing a squeezing cylinder, a lower layer frame used for containing a liquid storage barrel, and a bottom layer frame used for accommodating the hydraulic pump; a squeezing head is arranged at the downward telescopic end of the hydraulic cylinder; the lower end of the squeezing cylinder is screwed with a liquid outlet cover; an oil inlet and an oil outlet of the hydraulic cylinder are connected with an oil inlet valve and an oil outlet valve of the hydraulic pump through oil pipelines; the hydraulic pump is driven by a motor; the motor is connected with the transformer. The electric hydraulic water squeezing machine, provided by the invention, adopts the hydraulic pump to control a handle to control the hydraulic cylinder to rise or fall, so as to drive the squeezing head to perform squeezing operation quickly; the electric hydraulic water squeezing machine is simple in operation, high in squeezing speed, convenient to use and maintain, low in cost, and high in manufacturing efficiency.

Owner:邢福生

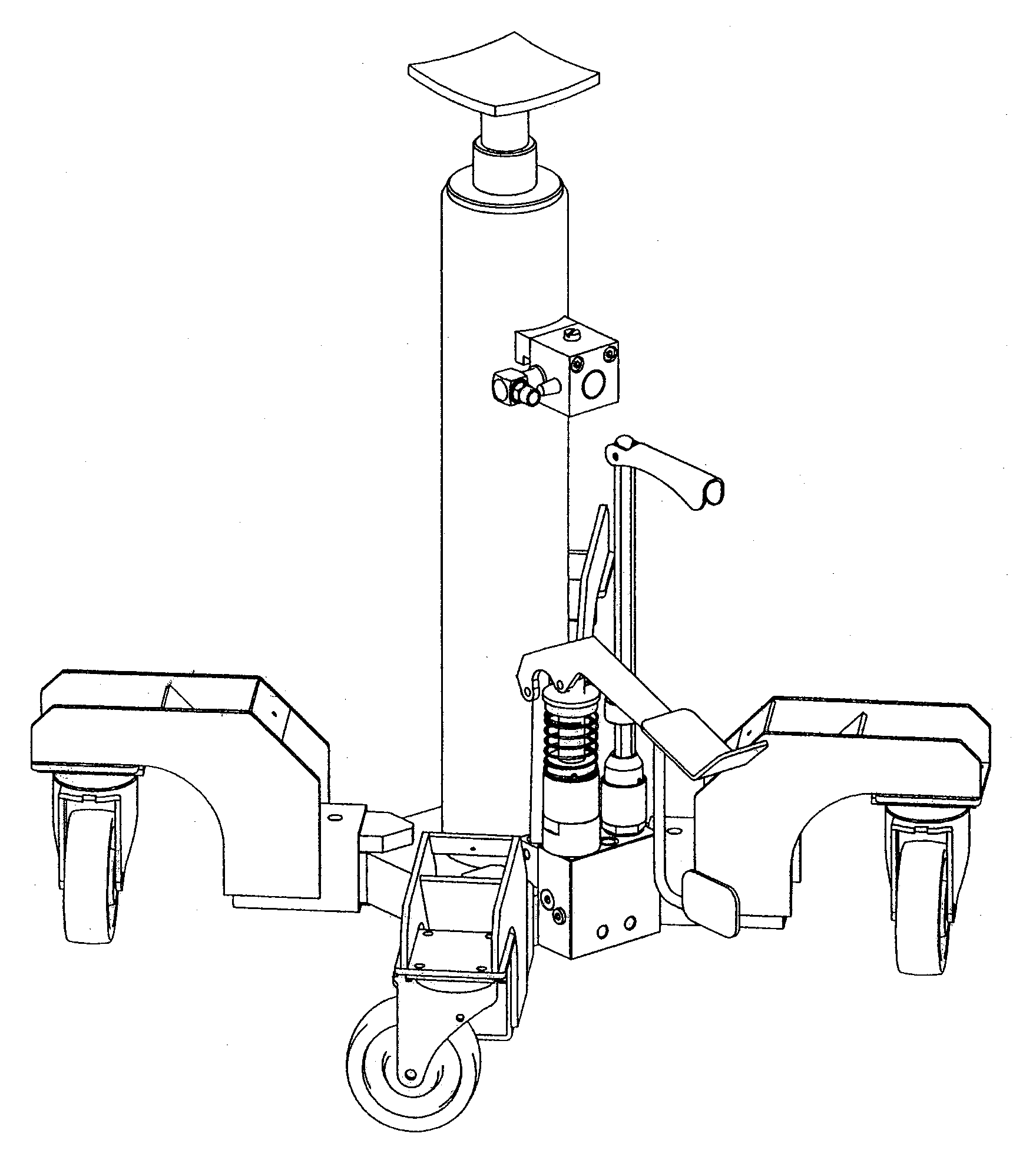

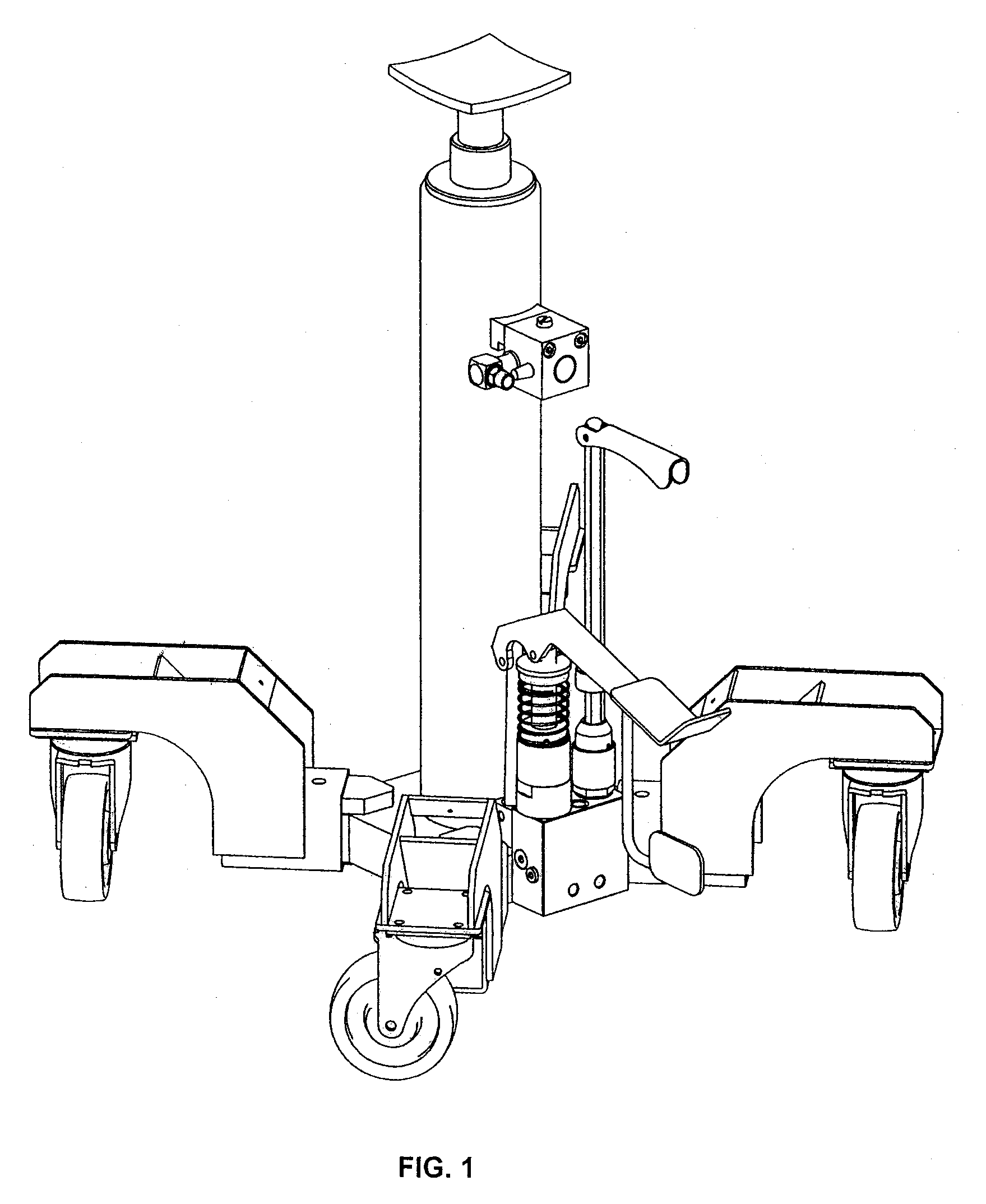

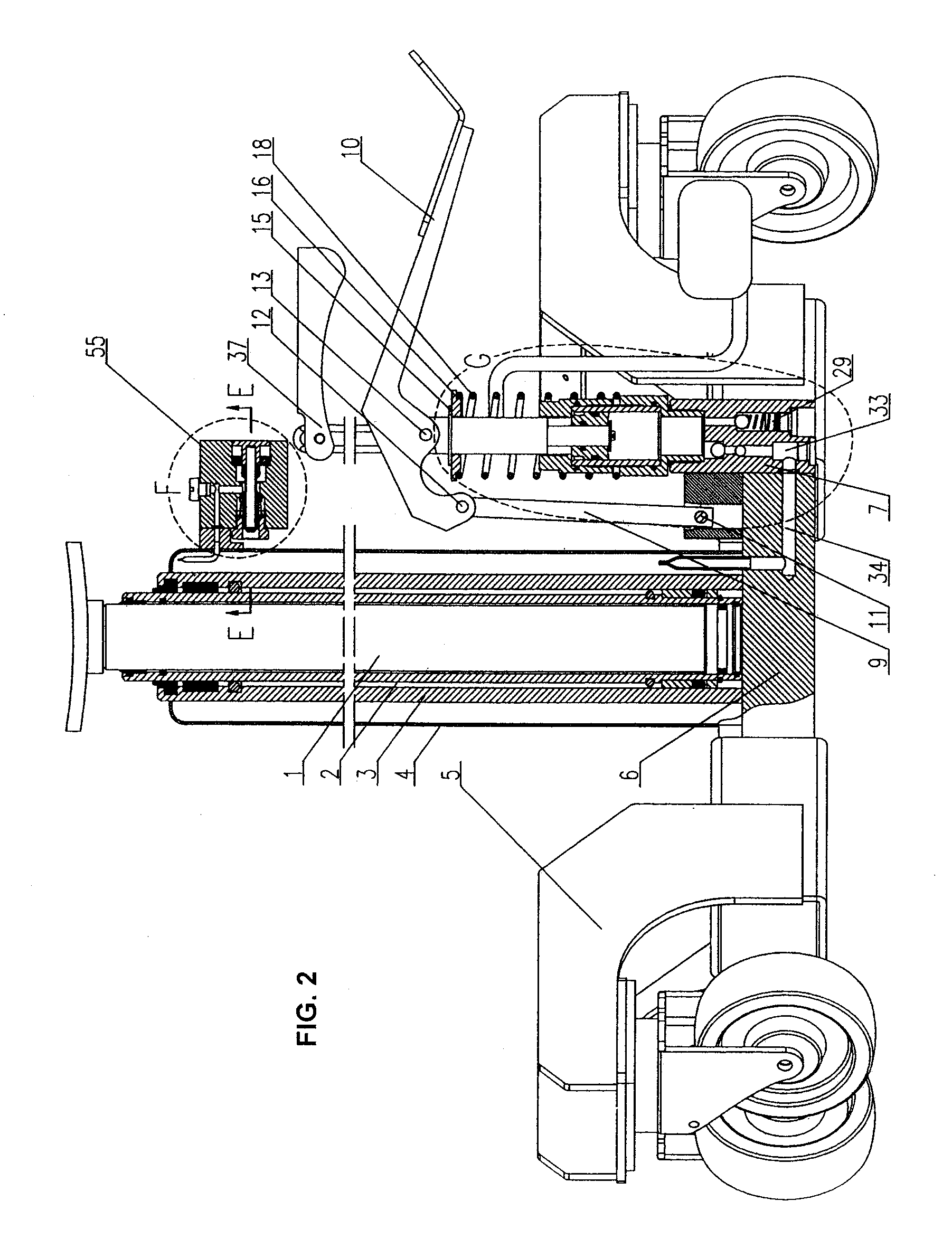

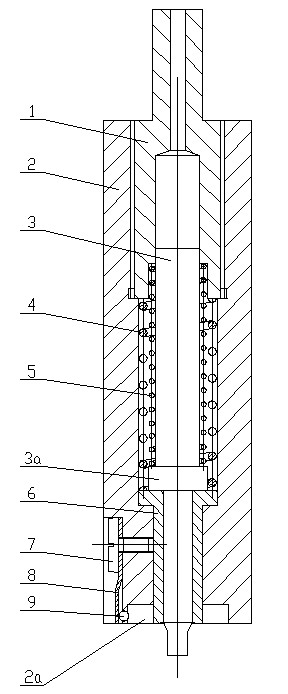

One kind of foot pedal hydraulic jack with two speed pump, and there is a pneumatic set to lift piston quickly on the jack

InactiveUS20090134375A1Simple structural designImprove reliabilityFluid couplingsServomotor componentsPiston ringFuel tank

This invention involves a type of pneumatic non-load quick dual-speed hydraulic jack, of which, the small of piston ring (17) of hydraulic pump cylinder integrates with pump body (19) and external ring of step pump core (14) to form movable assembly; the middle part of step pump core (14) is provided with pump core step interface (8); the step hole on the same axis of pneumatic valve block on special pneumatic valve structure is provided with washer (48), button (49), pneumatic valve core (45), compressed spring (68) and valve core securing seat (46). The available effect of this invention is stated as follows: the pump core interface used for conversion of hydraulic speed is characterized by the excellent process and low cost; the pneumatic valve parts specially provided for the jack can replace the hydraulic quick pump structure partially when the high-pressure air source is available. High-pressure air delivered to the oil reservoir of the external sleeve (4) will press the hydraulic oil into the oil chamber of oil cylinder, and thus facilitate the quick lift of jack piston under light load or empty load.

Owner:CHANGSHU TONGRUN AUTO ACCESSORY

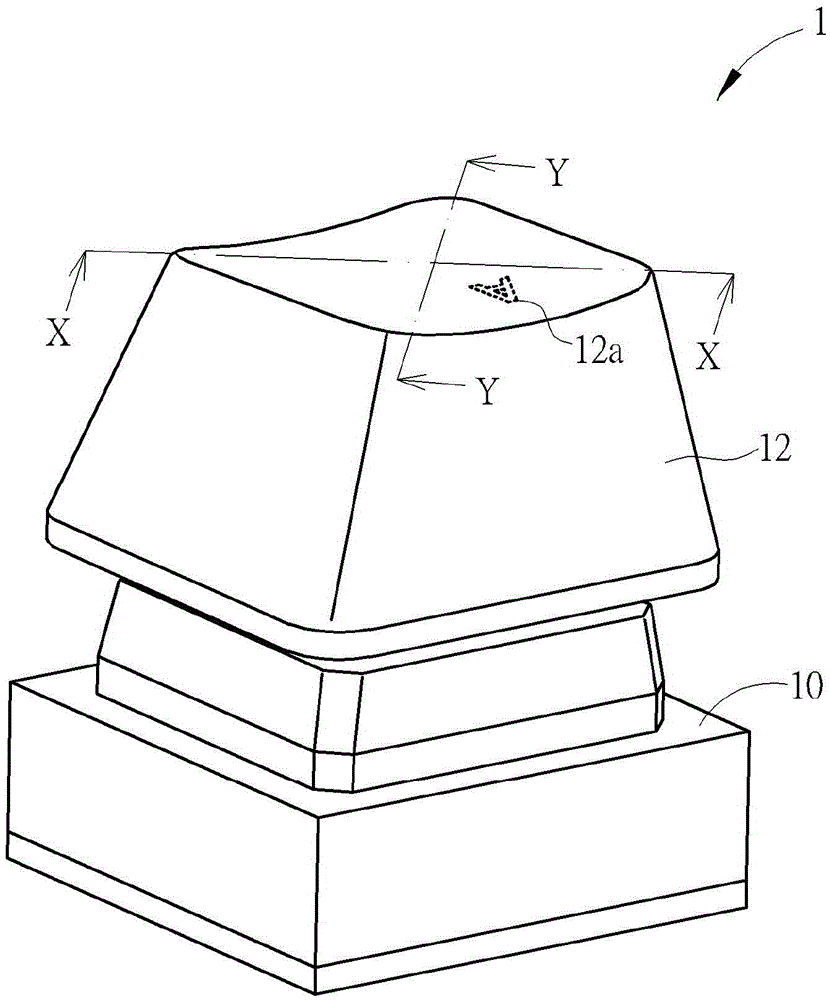

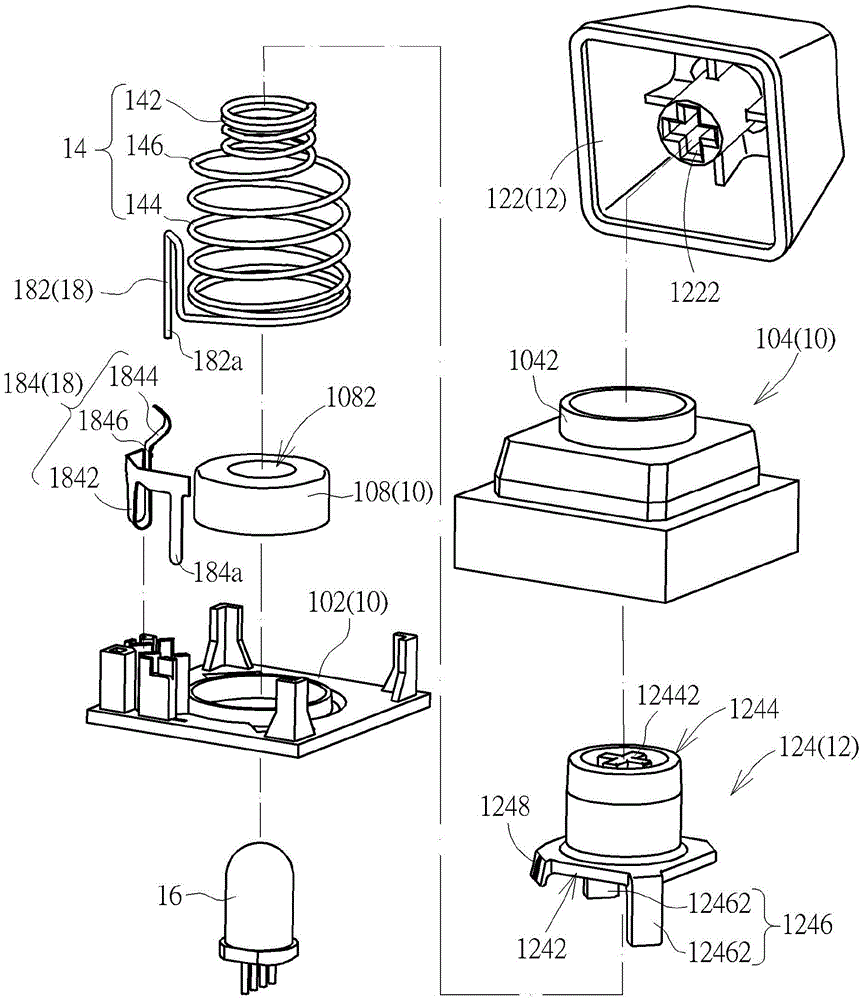

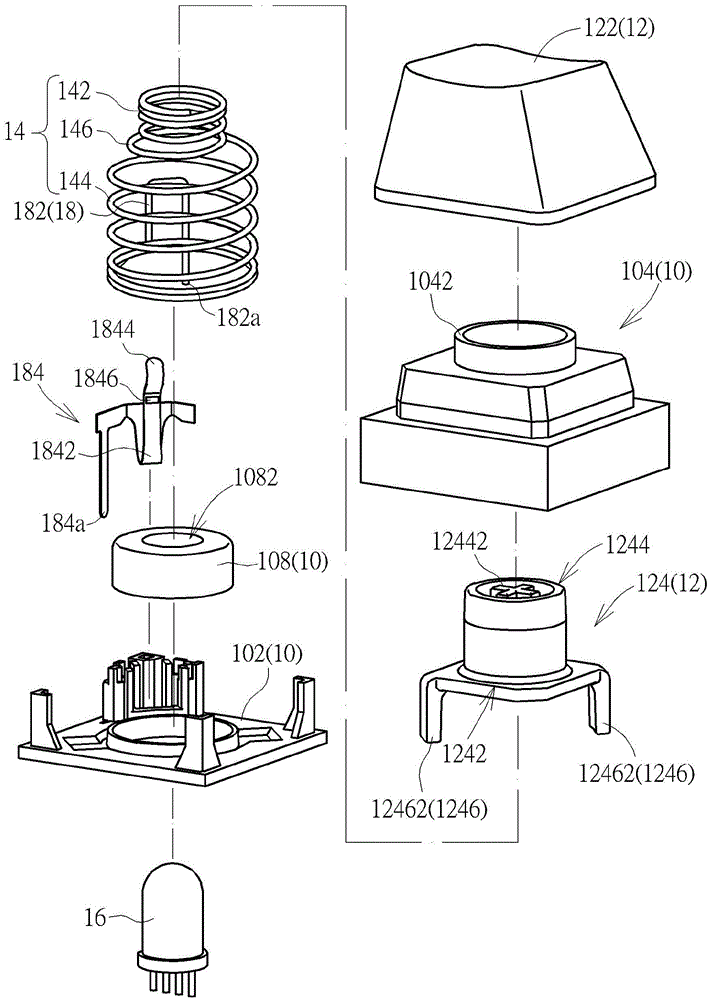

Key structure

InactiveCN105489428ASmall spring constantQuick pressElectric switchesTactile feedbackEngineeringMechanical engineering

The invention discloses a key structure. According to the key structure, a spring assembly composed of multiple springs connected in series supplies resilience force to a key cap. When the key cap moves towards a base of the key structure, one of the springs stops deformation after the key cap moves beyond a switching position, so that the elastic coefficient of the whole spring assembly is increased, and elasticity of the spring assembly can be enhanced. As a result, a user will feel feedback force which is light at first and heavy later in the process of pressing the key cap. The characteristic of the feedback force enables the user to press the key cap quickly, and the key cap can quickly rebound after being pressed. Further, a laterally actuated switch can be applied to the key structure, and influences of the resilience force of the switch on up-down action of the key cap can be reduced.

Owner:DARFON ELECTRONICS (SUZHOU) CO LTD +1

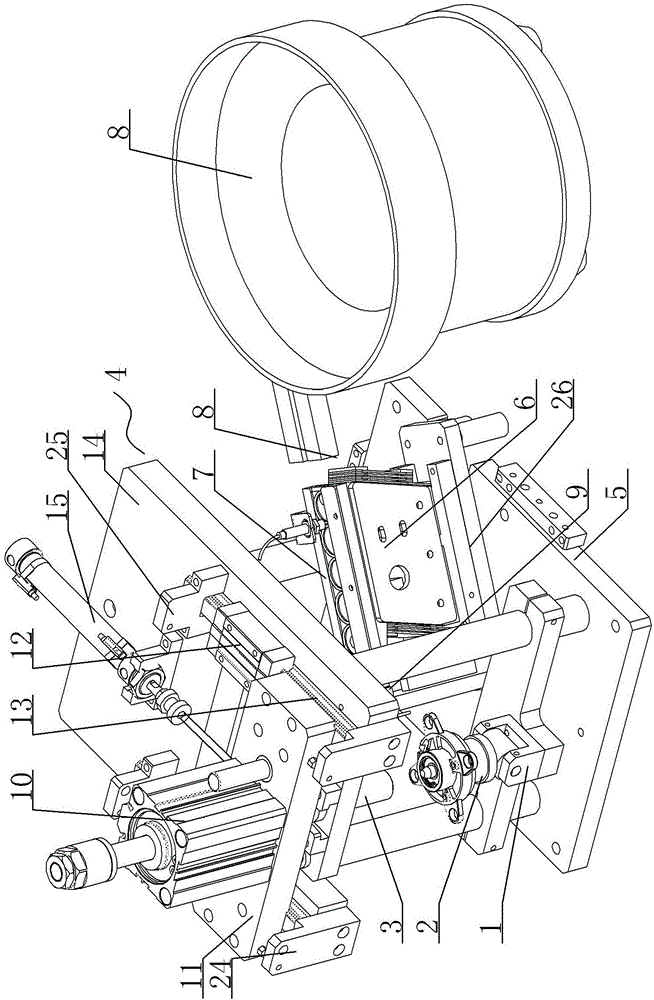

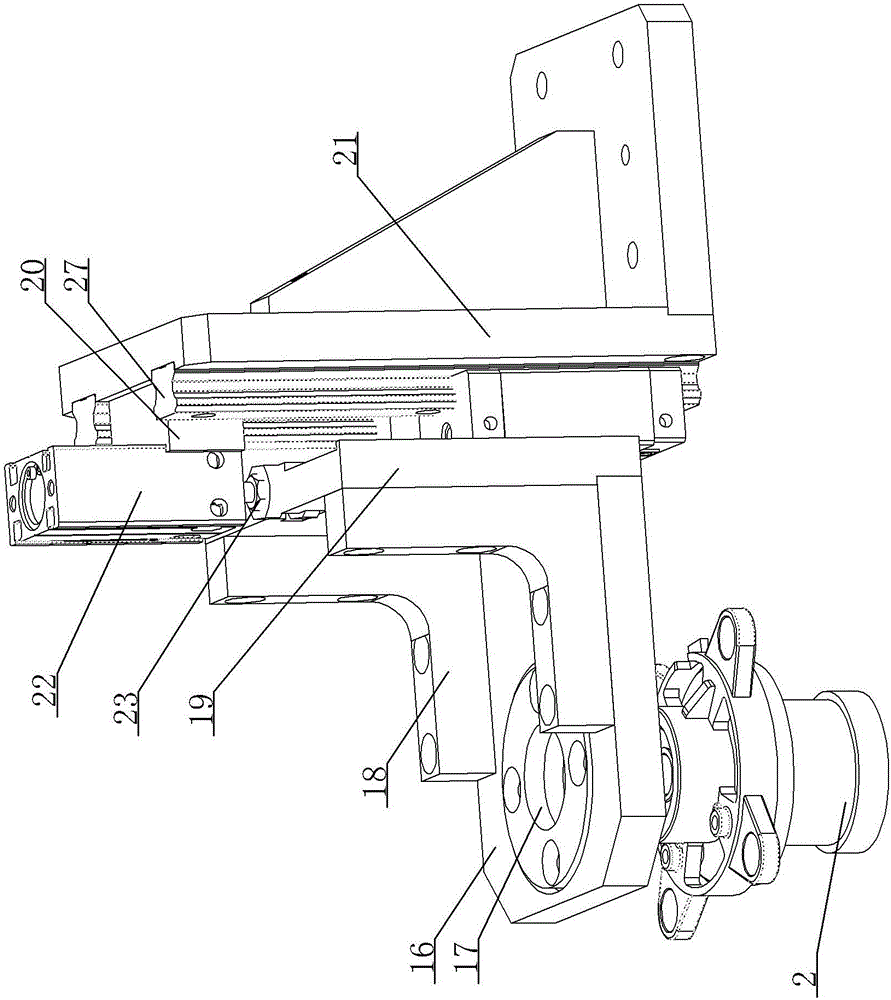

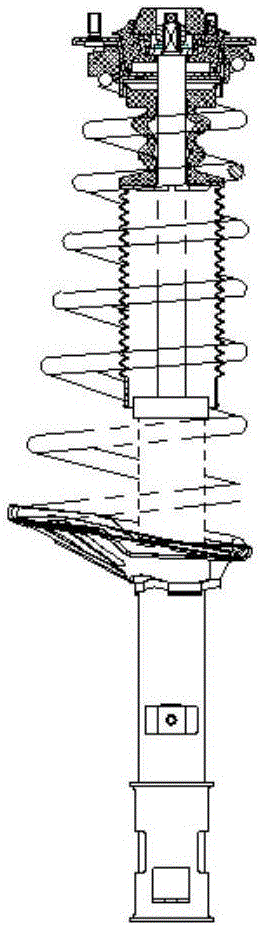

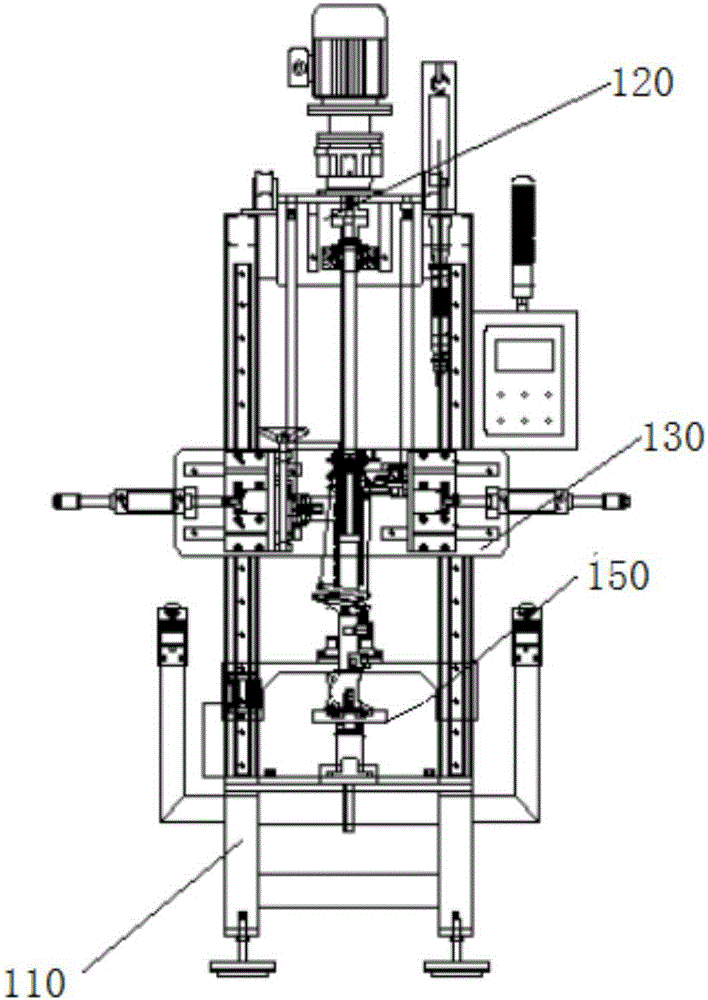

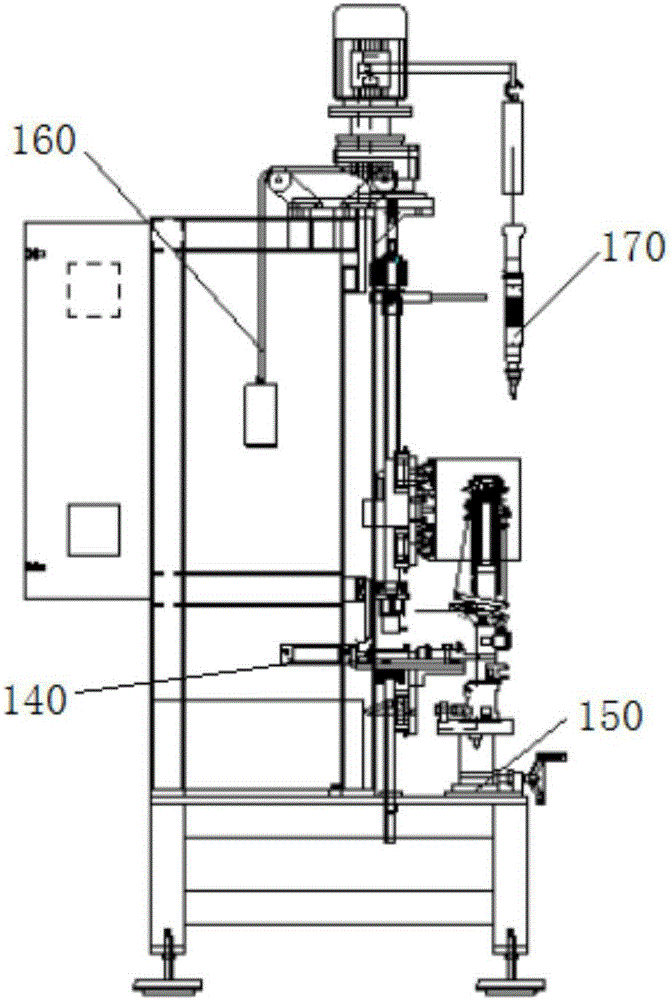

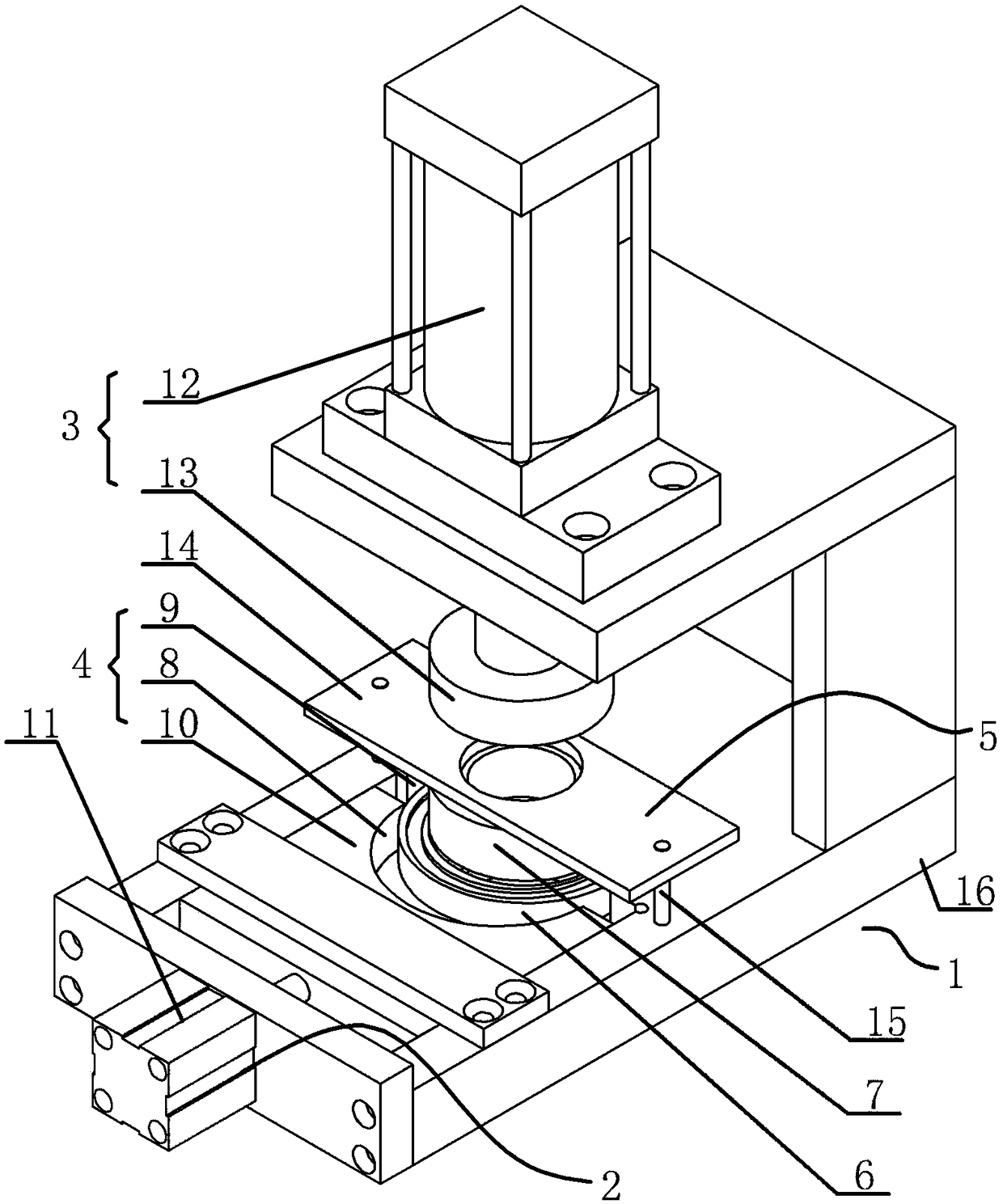

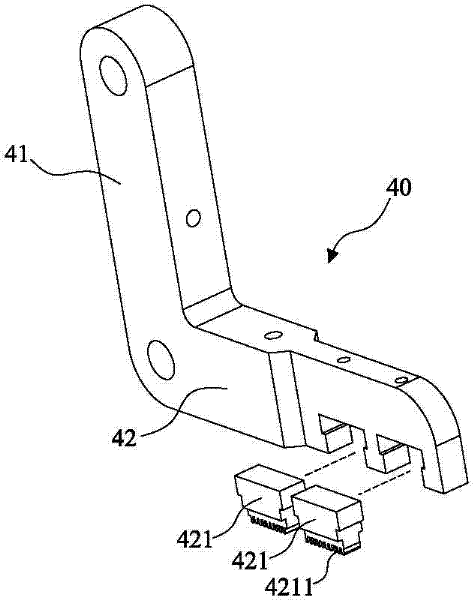

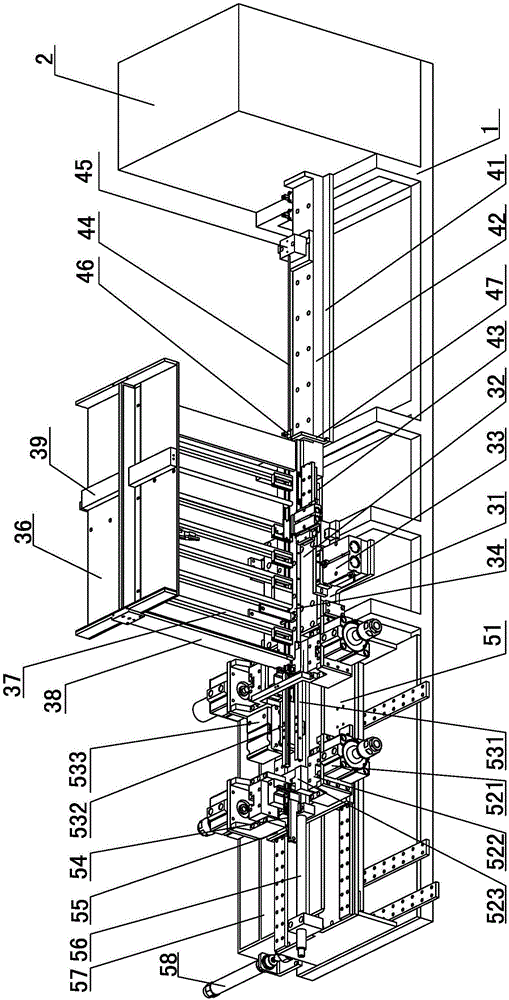

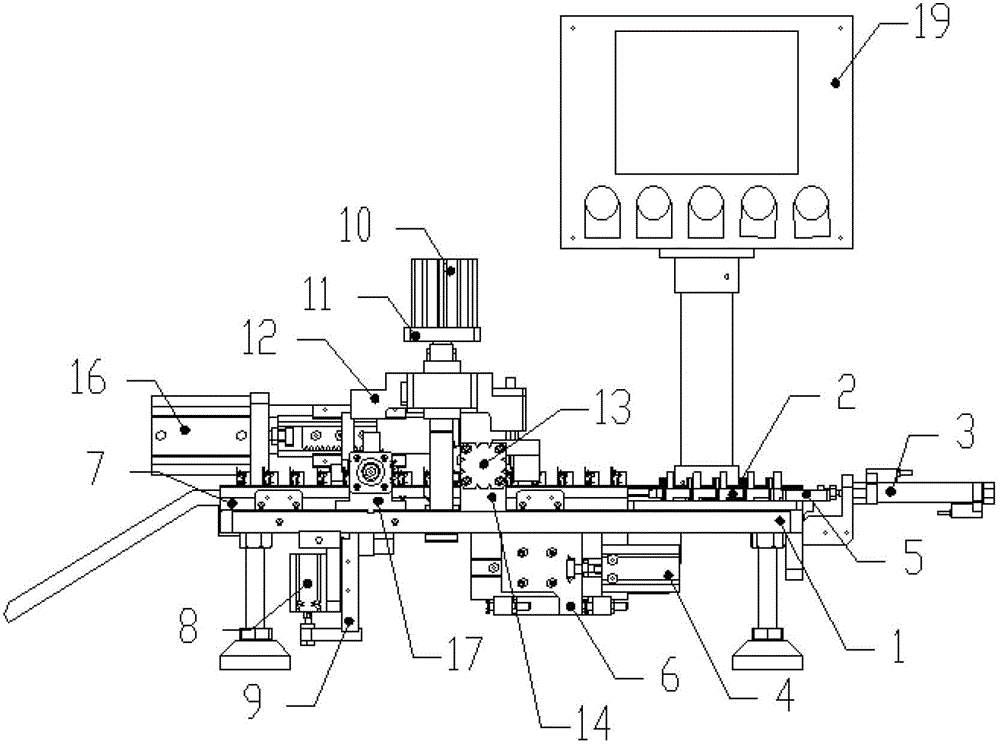

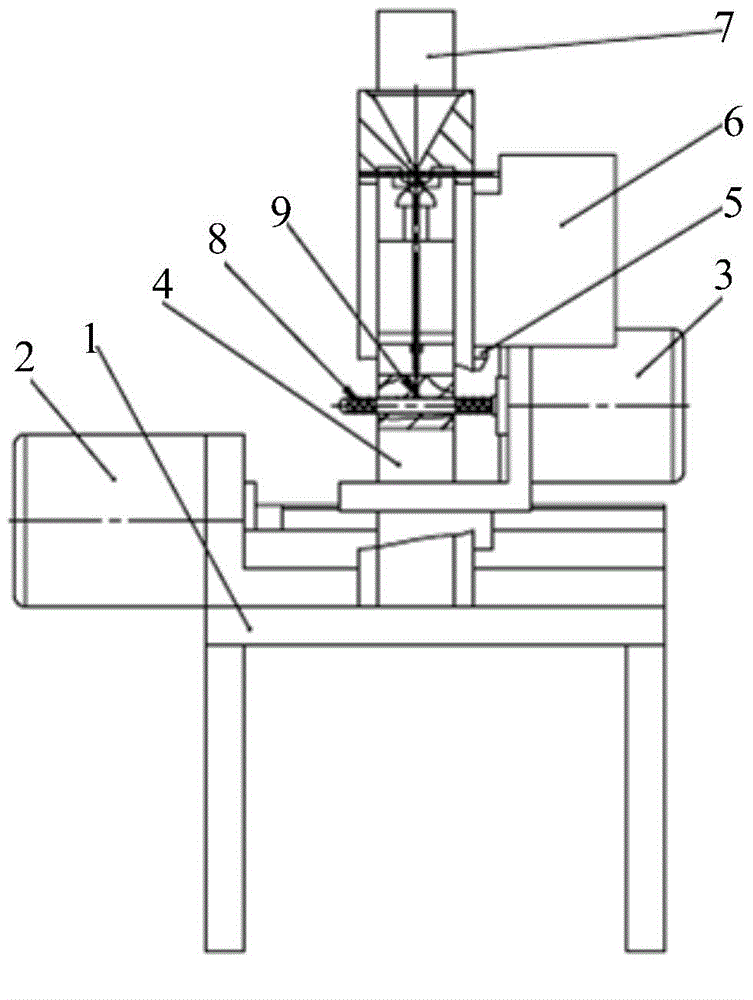

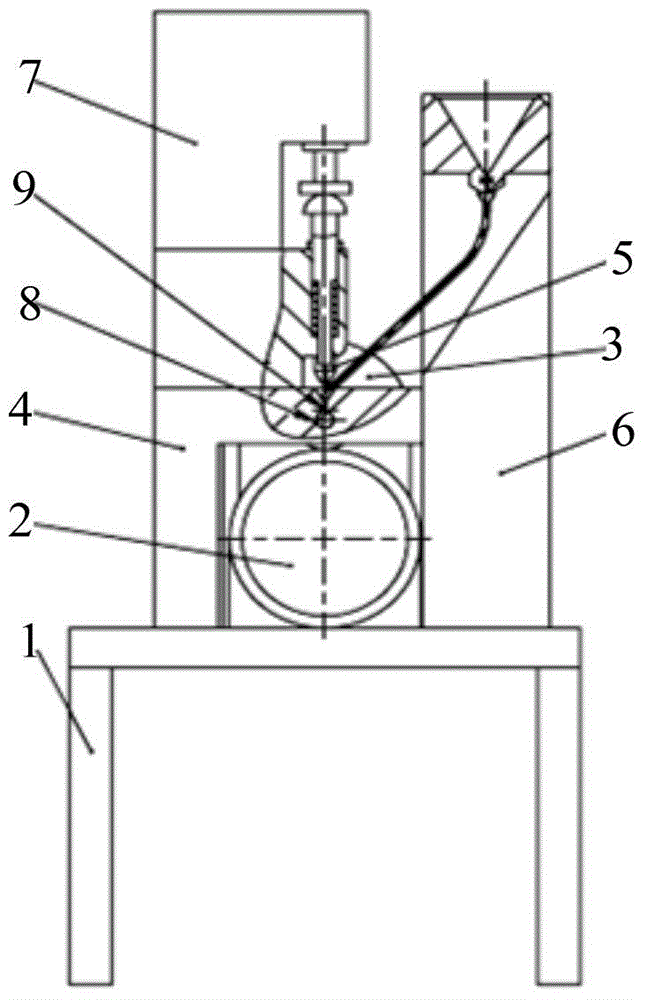

Press-fitting machine for shock absorber strut assemblies

InactiveCN106271550AQuick pressReliable structural clampingVehicle componentsMetal working apparatusEngineeringPiston rod

The invention discloses a press-fitting machine for shock absorber strut assemblies, which comprises a bottom tire assembly, a strut clamping and positioning mechanism, a clamping arm holding mechanism, a power transmission mechanism and an upper tooling positioning mechanism. The bottom tire assembly is used for fixing the bottom of a shock absorber strut assembly; the strut clamping and positioning mechanism is used for clamping a cylinder barrel of the shock absorber strut assembly; the clamping arm holding mechanism comprises two clamping arms which are oppositely arranged on the left and the right, the clamping arms are connected with air cylinders to drive spring-pressing plates of the clamping arms to move to the left and the right, and the two spring-pressing plates can compress a shock absorber spring; at least one of the two spring-pressing plates is connected with a height-adjusting mechanism, and the height-adjusting mechanism can drive the spring-pressing plate to move up and down to adjust the distance between the two spring-pressing plates in the vertical direction; the power transmission mechanism is connected with the clamping arm holding mechanism to drive the whole clamping arm holding mechanism to move up and down; and the upper tooling positioning mechanism is used for fixing a piston rod of the shock absorber.

Owner:LIAONING UNIVERSITY OF TECHNOLOGY

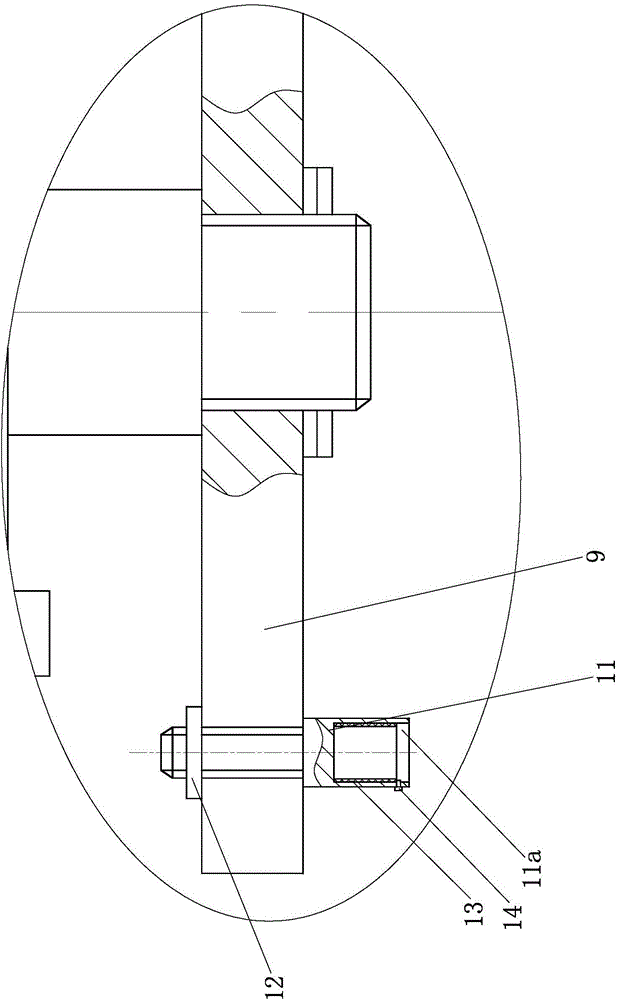

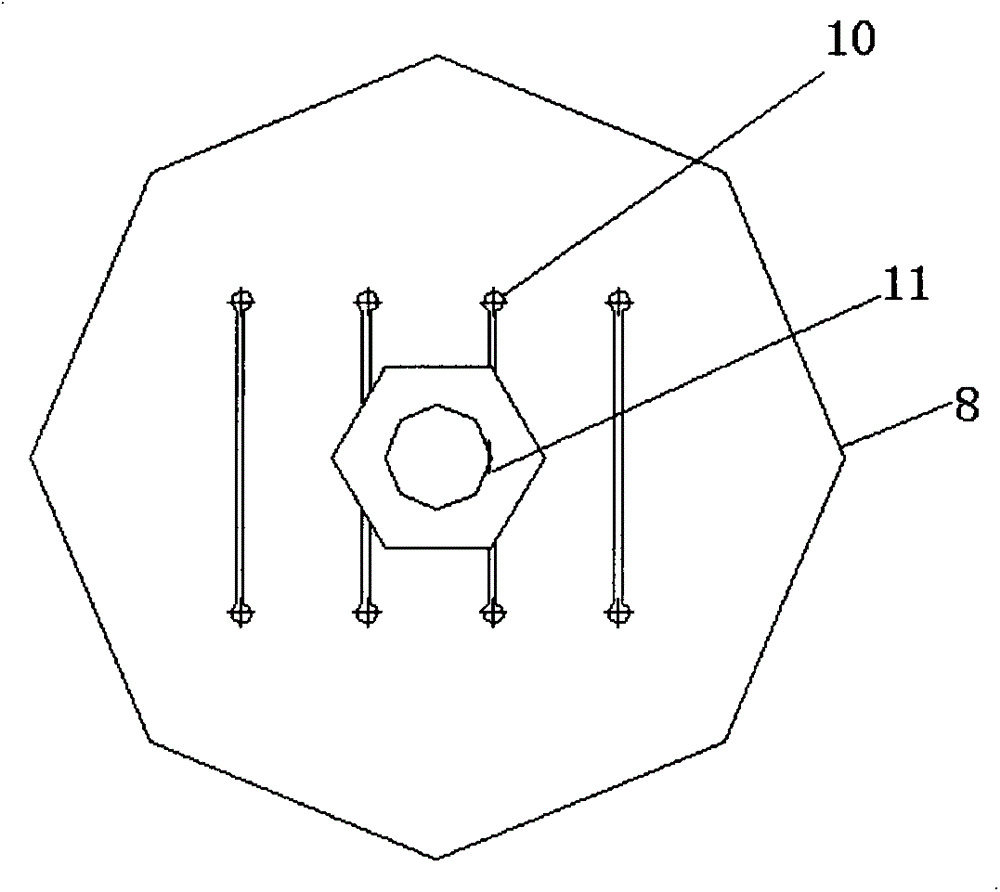

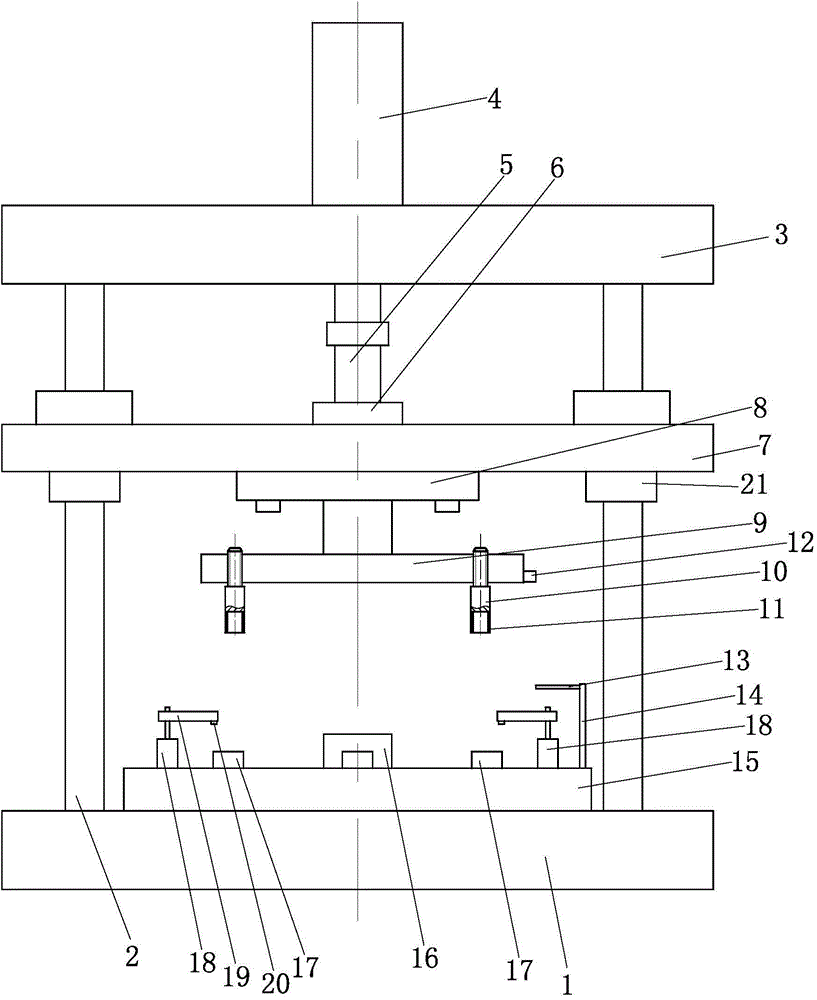

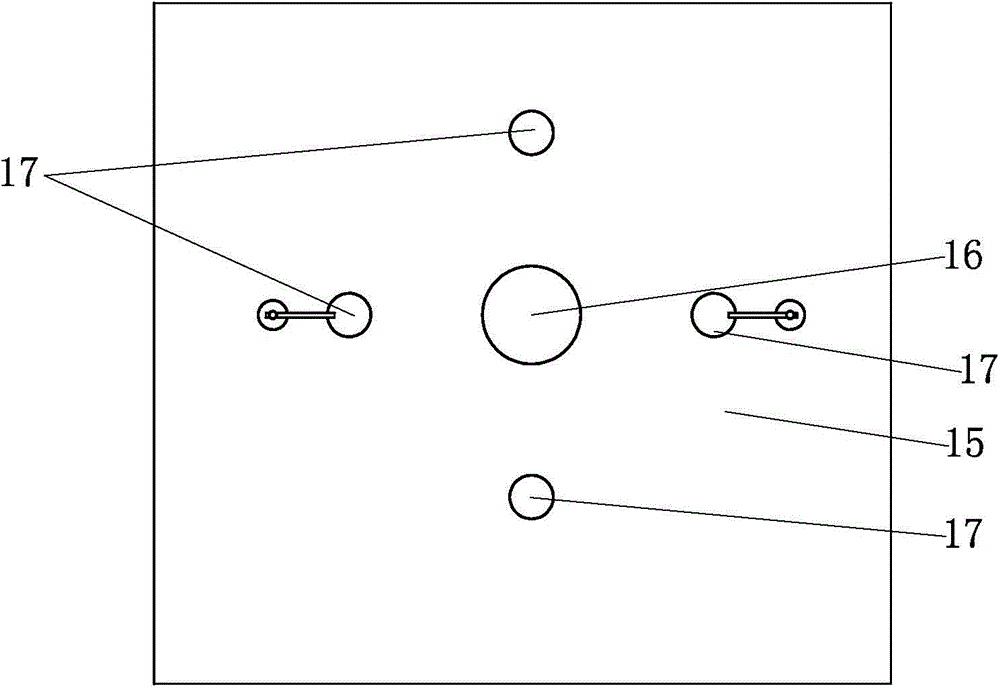

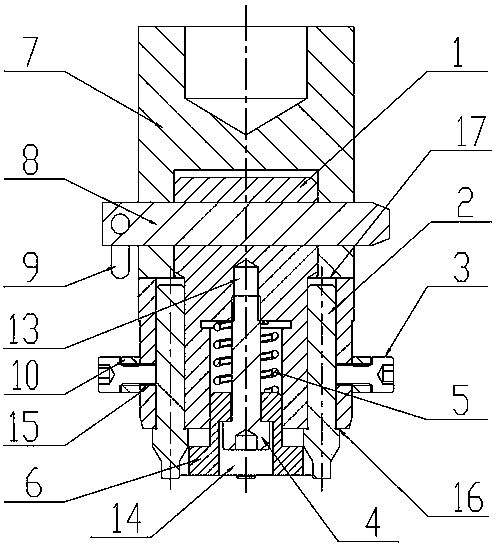

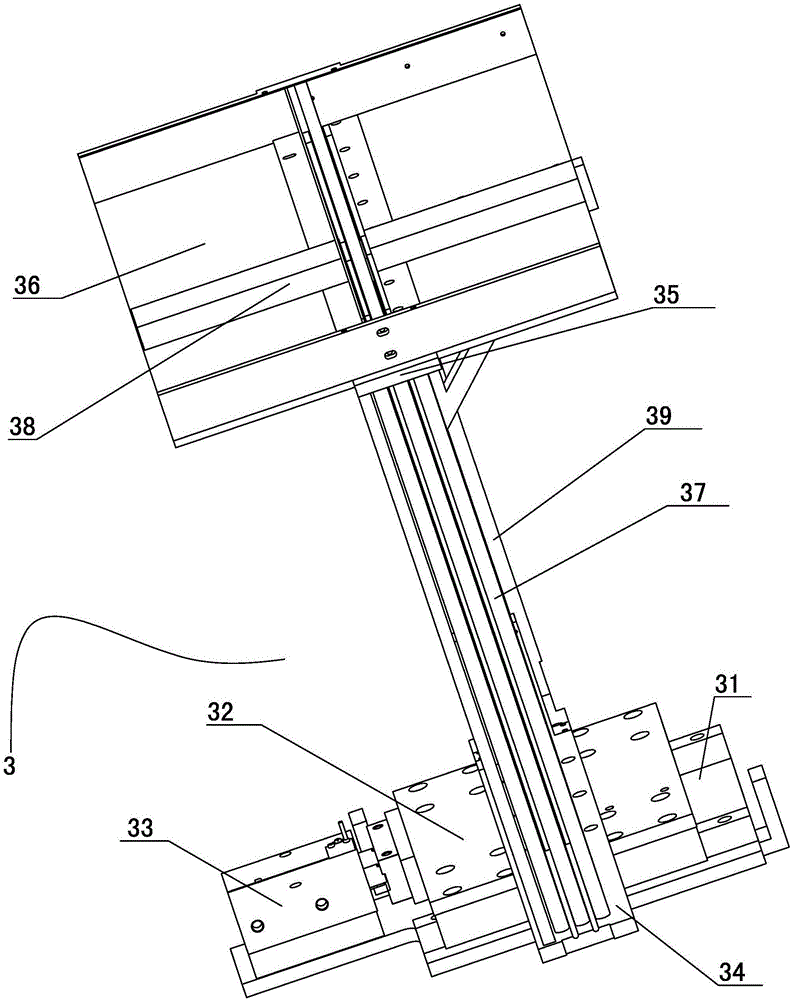

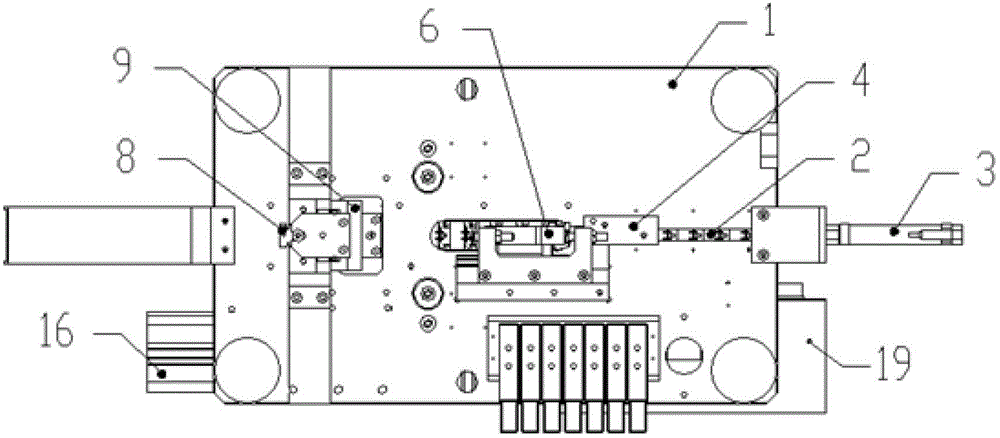

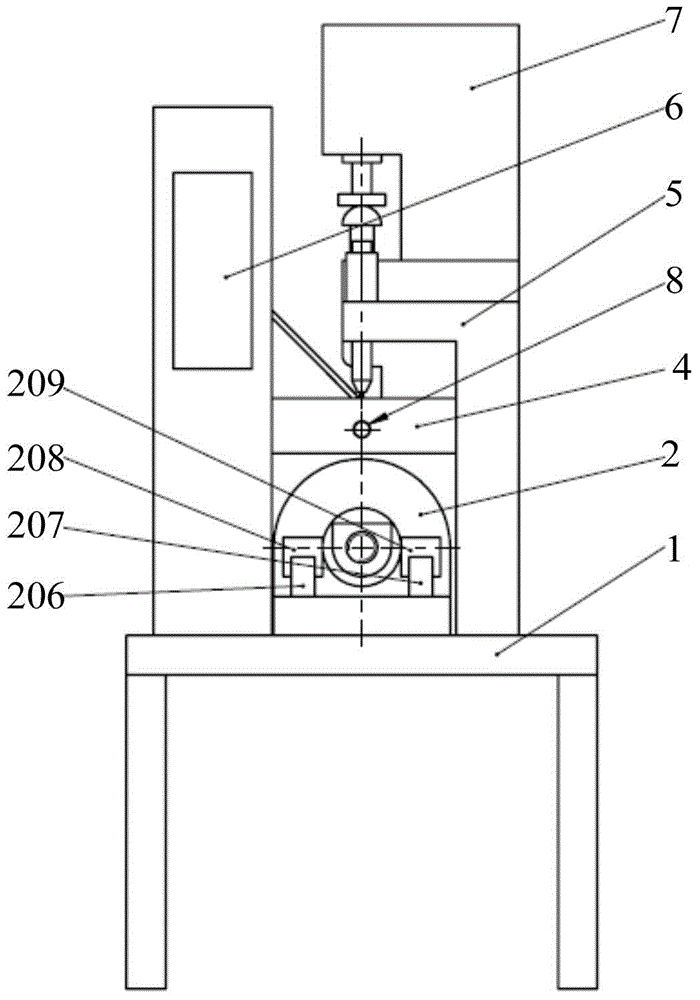

Press mounting device for locating pin of fly wheel clutch

The invention discloses a press mounting device for a locating pin of a fly wheel clutch. A base is fixedly provided with four vertical posts, the top ends of the four vertical posts are fixed with a top plate, a servo motor is arranged on the top plate, the lower end of an output shaft of the servo motor is connected with the upper end of the lead screw and a feed screw nut on the lead screw is simultaneously fixed with a lifting plate; the lower plate surface of the lifting plate is fixed with a support plate, and the lower end of the vertical section of the support plate is horizontally welded with a press mounting disk; the edge of the press mounting disk is provided with vertical threaded holes, each vertical threaded hole is connected with an outer threaded section of a press mounting rod, and a falling-prevention sleeve is fixed in a blind hole in the lower end of the press mounting rod; a proximity switch is fixedly arranged at a certain side of the press mounting disk, a position detection block matched with the proximity switch is fixed on a cushion plate, a central locating post and 4 locating cushion blocks are arranged at the top surface of the cushion plate and a fly wheel pressing device is arranged at the top surface of the cushion plate. According to the press mounting device for the locating pin of the fly wheel clutch, the locating pin of the clutch can be accurately and quickly pressed in a pin hole of a fly wheel; furthermore, the press mounting device is high in degree of automation and good in reliability; in addition, the press mounting depth can be precisely controlled.

Owner:CHONGQING MINFA AUTOMOBILE FITTINGS

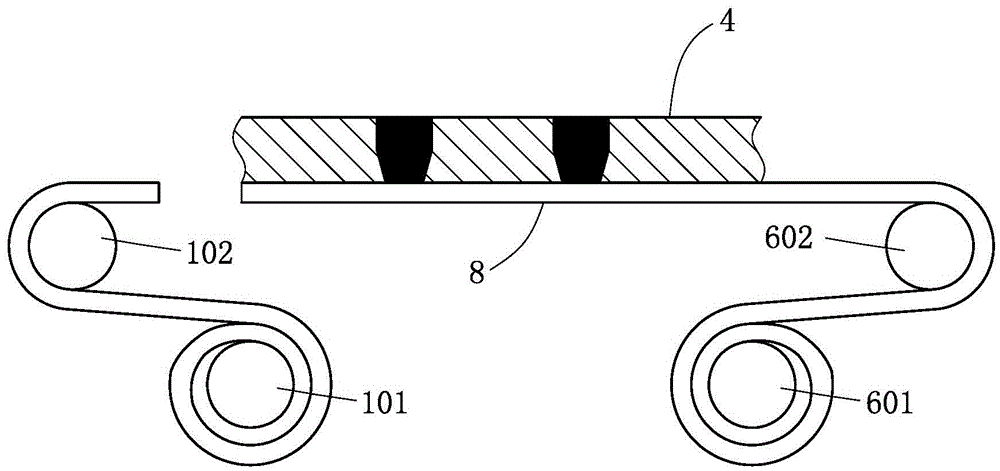

Textile fabric dyeing device with good dyeing uniformity

ActiveCN110878454AIncrease pressureIncrease contact areaTextile treatment machine arrangementsLiquid/gas/vapor treatment of indefinite length materialsPolymer scienceEngineering

The invention discloses a textile cloth dyeing device with good dyeing uniformity, which comprises a housing, a second guide roller support, a sleeve and an inner spiral pipe; a cloth feeding port isarranged at the top of one side of the housing, a cloth discharging port is arranged at the top of the other side of the housing, an L-shaped retainer is arranged on the inner wall of the housing below the cloth feeding port, and an n-shaped retainer is arranged in the housing at one side of the cloth feeding port. The second guide roller is driven to rotate through the transmission of cloth, a dye liquor is pressed into a cavity and is sprayed from a second outlet, the contact area between the cloth and the dye liquor is increased, and the dyeing efficiency is improved; in addition, the dye liquor inside the inner spiral pipe is rotated and surges upward; when the dye liquor rotates, the dye liquor can penetrate the cloth, so that the dyeing efficiency for the cloth is further improved, the cloth is uniformly dyed, and a dye in the dye liquor is prevented from precipitating; when the dye liquor surges upward, impurities floating on the surface of the dye liquor move to the other sideof the n-shaped retainer and are filtered so that the dye liquor is kept clean, the service life of the dye liquor is prolonged, and the cost is reduced.

Owner:JIANGSU SHUANGSHAN GRP

Engine air valve locking plate pressure head

InactiveCN101983833AInhibit sheddingPrevent free swingMetal working apparatusInternal pressureSteel ball

The invention discloses an engine air valve locking plate pressure head. A guide positioning shaft, an inner pressure head spring and a positioning shaft spring are arranged in an outer pressure head; a guide screw plug is arranged in an inner hole on the upper part of the outer pressure head, an inner pressure head is arranged in an inner hole on the lower part of the outer pressure head, and the bottom surface of the outer pressure head is provided with a positioning groove; and the peripheral wall of the positioning groove is provided with at least two positioning holes distributed uniformly according to the circumference, a steel ball is arranged in each positioning hole, each steel ball is provided with a reed, the upper part of the reed is fixed with the outer pressure head, and the lower part of the reed is pressed on the corresponding steel bal so that the small part of ball body of the steel ball is positioned in the positioning groove. The engine air valve locking plate pressure head has the advantages of simple operation, low labor intensity of workers and high work efficiency, and is not easy to damage an air valve, an air valve locking plate and an upper spring seat; and the upper spring seat and an air valve rod are positioned more accurately, and the locking plate is pressed in place more easily, so the locking plate is effectively prevented from falling in the running process of an engine, the locking plate is not popped up or inclined, and the assembly efficiency is improved.

Owner:力帆科技(集团)股份有限公司

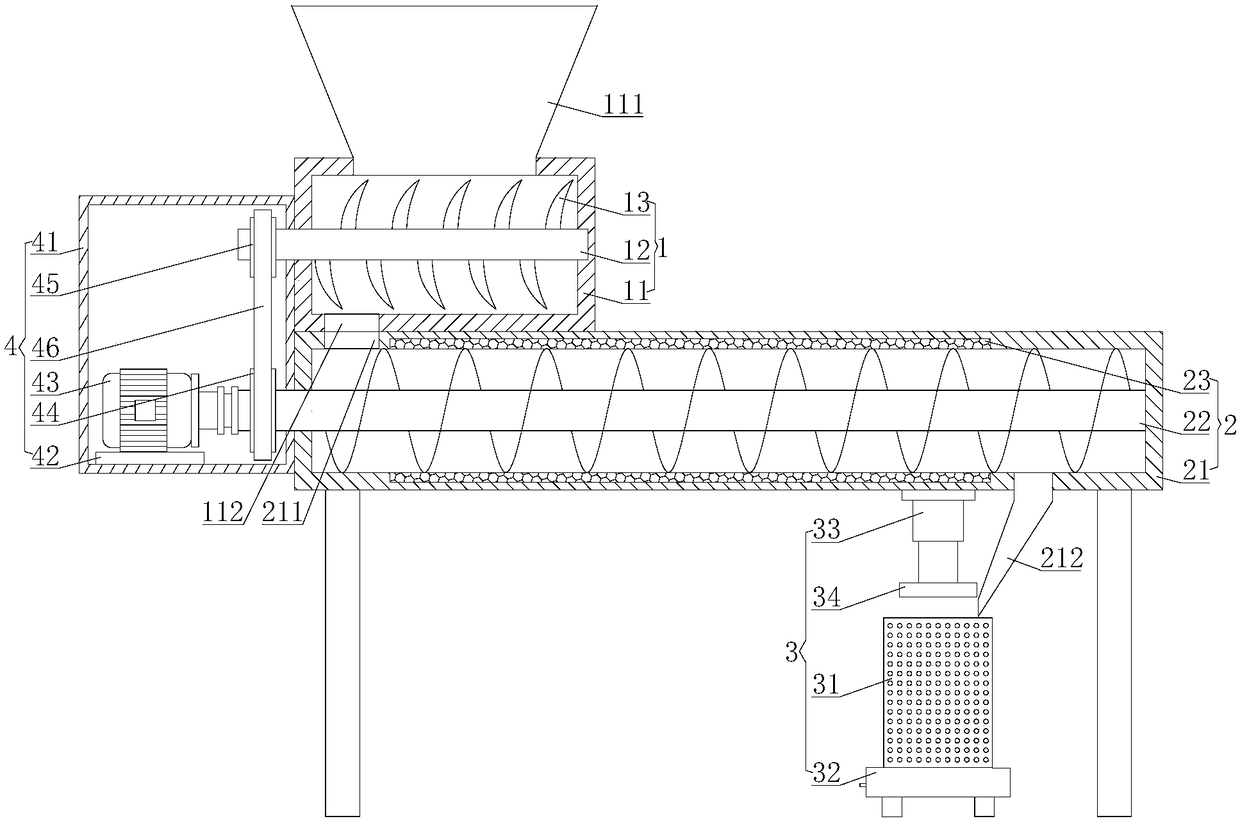

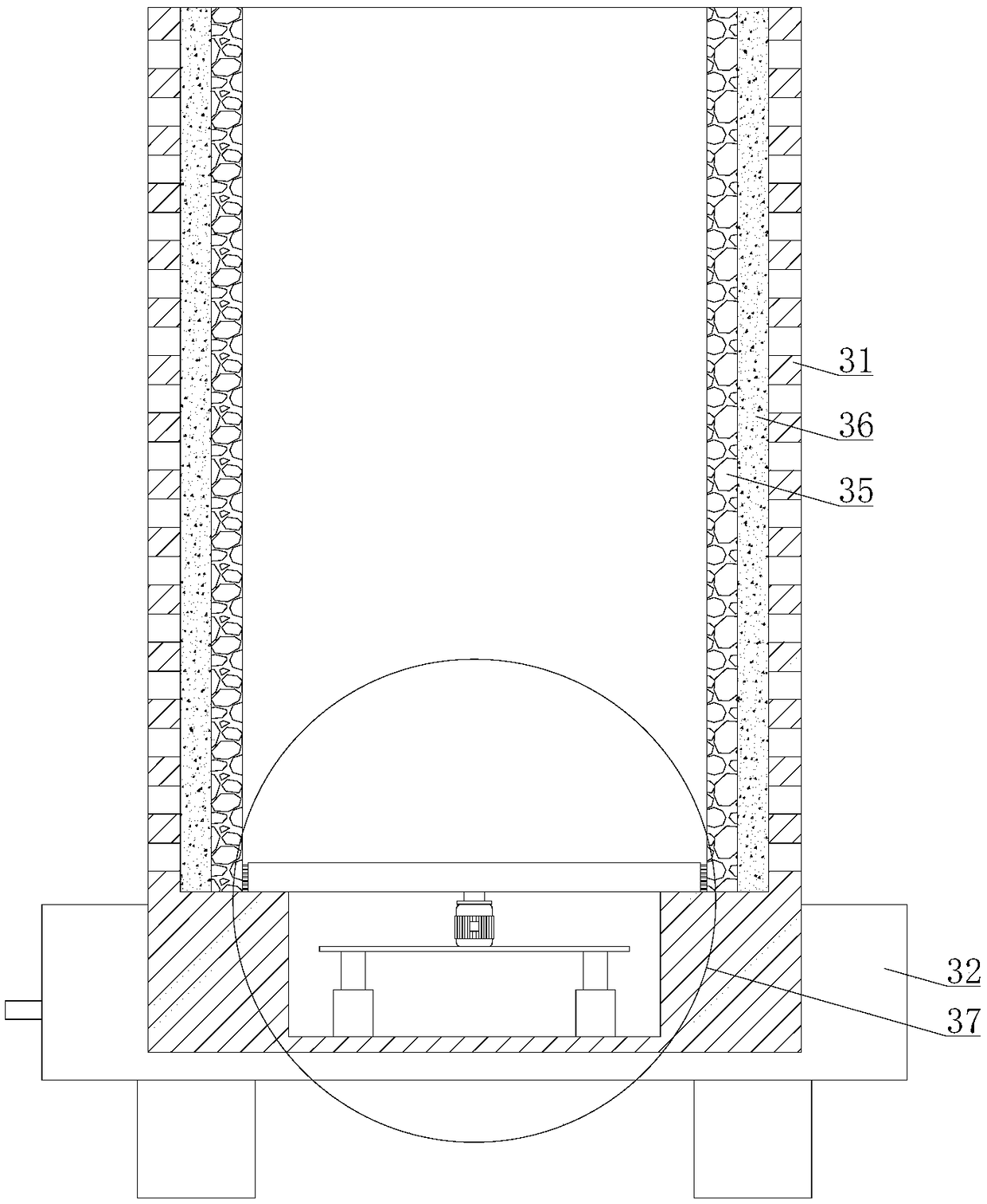

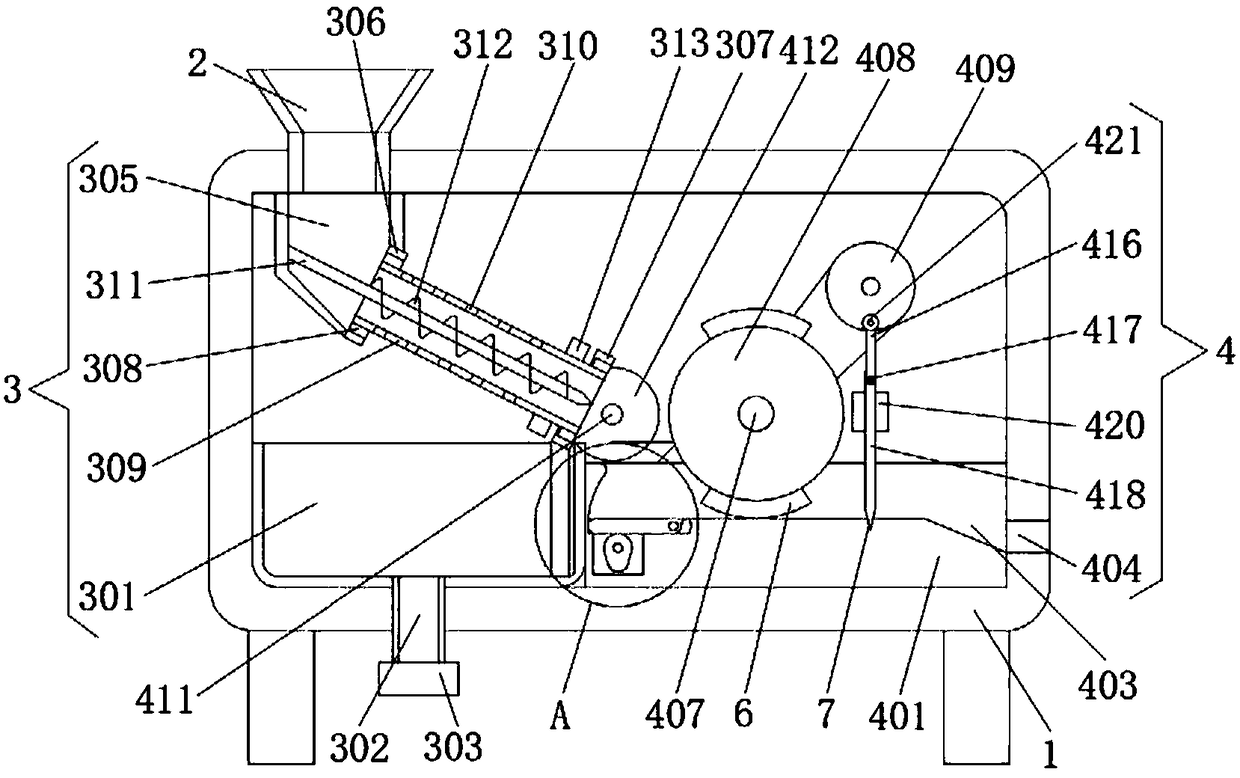

Crushing squeezer

InactiveCN109080191ANo manual delivery requiredSave human effortFatty-oils/fats productionGrain treatmentsVegetable oilSlag

The invention discloses a crushing squeezer, and belongs to the technical field of vegetable oil production. The crushing squeezer comprises a crushing mechanism, a heat treatment conveying mechanismand a squeezing mechanism. The crushing mechanism comprises a crushing bin, a rotating shaft and a crushing blade. The heat treatment conveying mechanism comprises a conveying bin, a spiral conveyingrod and a resistive heater. The squeezing mechanism comprises a squeezing barrel, an oil collecting plate, a squeezing oil cylinder, a squeezing block, a steel plate filter net, a filter cloth layer and an oil slag blockage clearing assembly. The oil slag blockage clearing assembly comprises a blockage clearing plate, a blockage clearing brush, a second motor, a mounting plate, a first electric telescopic rod and a second electric telescopic rod. According to the crushing squeezer, raw materials are crushed through the crushing mechanism and then enter the heat treatment conveying mechanism tobe heated and pretreated, and meanwhile the raw materials are conveyed to the squeezing mechanism to be squeezed; the whole operation process is completed integrally, meanwhile, the blockage clearingbrush is driven to rotate in the rotating process of the blockage clearing plate, so that the steel plate filter net is cleared, oil slag does not block the steel plate filter net any more, the squeezing efficiency is improved, and the productivity effect is improved.

Owner:ANHUI HUAYU FOOD

Assembling method of flexible bearing and cam

The invention provides an assembling method of a flexible bearing and a cam. According to the assembling method, the cam can be ensured to conveniently, rapidly and accurately pressed into an inner hole of the flexible bearing, the flexible bearing is not damaged, and the hidden danger of shortening the service life of a harmonic reducer is eliminated. The assembling method comprises the followingsteps that (1) according to the design, the cam is machined, and the machined cam is frozen; (2) according to the specification of the wave generator needing to be assembled, a corresponding assembling tool is machined, and the positioned cam is pressed into the flexible bearing which is subjected to deformation through a press-fitting part of the assembling tool; (3) the flexible bearing in thewave generator needing to be assembled is placed into a flexible bearing positioning cavity of a positioning part for positioning; (4) the frozen cam is taken out, and the cam is fixed through a cam positioning part; (5) a profiling part is used for carrying out pressure deformation on the flexible bearing to form an oval shape, and fixing is carried out; and (6) it is ensured that after the elliptical axis of the cam coincides with the corresponding elliptical axis of the flexible bearing, the positioned cam is pressed into the flexible bearing by the aid of a press machine.

Owner:ZHEJIANG UNIV KUNSHAN INNOVATION INST

Press-fitting centering device for turbine shell plugging cover

ActiveCN104289891AImprove line change efficiencyNot easy to wearMetal working apparatusLever pressingStructural engineering

The invention discloses a press-fitting centering device for a turbine shell plugging cover. The press-fitting centering device comprises a pressing cover, pressing heads, pressing rods and a pressing cover base. The pressing cover base is connected with the pressing cover through a first quick changing mechanism. The lower half part of the pressing cover is of a hollow structure in the axial direction. The hollow structure is internally provided with a second quick changing structure. The pressing heads capable of sliding in the axial direction of the inner wall of the hollow structure are arranged between the second quick changing mechanism and the hollow structure. The pressing heads and the pressing cover are in clearance fit. At least one long groove is formed in the lower half part of the pressing cover in the circumferential direction of the edge area. The pressing rods are arranged in the long grooves. The pressing rods are in clearance fit with the pressing cover. The pressing rods are fastened on the pressing cover through a third quick changing mechanism. Under the initial state, the tail ends of the pressing heads protrude out of the lower portions of the tail ends of the pressing rods. The press-fitting centering device has the advantages that quick replacing of the pressing cover, the pressing heads and the pressing rods can be achieved through the quick changing mechanisms, the production cost is saved, the working efficiency is improved, and the quality of products is guaranteed.

Owner:CRRC CHANGZHOU AUTO PARTS CO LTD +1

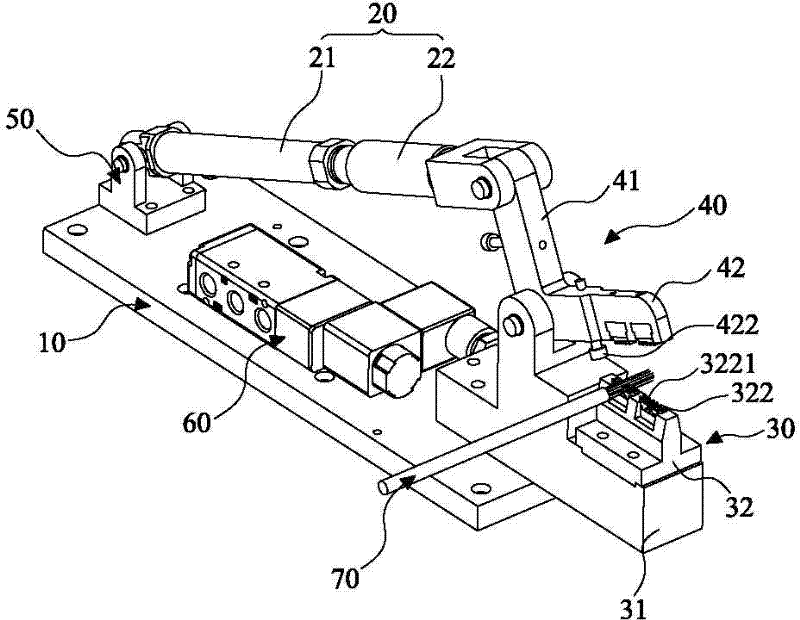

Connector cable pressing jig

InactiveCN102509987AQuick pressReduce crimping timeLine/current collector detailsCable carrierPiston rod

The invention discloses a connector cable pressing jig, which comprises a base, a cylinder, a pedestal and a corner pressing rod. A connecting seat is arranged at one end of the base, and the cylinder comprises a cylinder body and a piston rod, wherein the cylinder body is pivoted on the connecting seat. The pedestal is fixedly mounted on the base and comprises a pedestal body and a supporting seat, the supporting seat is provided with two grooves side by side, a cable carrier is placed in each groove, and the upper face and the lower face of each cable carrier are respectively provided with a plurality of cable slots. The corner pressing rod comprises a connecting arm and a pressing arm, one end of the connecting arm is pivoted to the end of the piston rod, the corner position of the corner pressing rod is pivoted to the pedestal, two detachable pressing blocks corresponding to the two cable carriers respectively are arranged on the pressing arm, each pressing block is provided with a plurality of pressing blocks, and cables are pressed to the bottom of the cable slots by the pressing blocks when being pressed. Therefore, by means of the structure, the connector cable pressing efficiency is improved, cable connecting stability is enhanced, and the connector cable pressing jig is simple in structure and convenient in assembly.

Owner:DONGGUAN KECHENDA ELECTRONICS TECH

Conveying device for textiles

The invention relates to the technical field of conveying devices, and particularly discloses a conveying device for textiles. The conveying device for the textiles comprises a roller storage barrel and a dividing plate, wherein empty rollers are arranged in the roller storage barrel; grooves are formed in the dividing plate; the bottom end of the roller storage barrel communicates with one groove; the grooves in the dividing plate rotate to communicate with the upper end of a batching rail; a first cavity and a second cavity are arranged on the batching rail; a pressing block is connected into the first cavity; and a baffle plate is connected into the second cavity. The conveying device for the textiles further comprises a piston chamber arranged under the first cavity, wherein the pistonchamber is connected with a piston; a piston rod is arranged on the piston and is connected to the bottom part of the pressing block; the piston chamber is divided into an upper chamber and a lower chamber; the second cavity communicates with the upper chamber; cavities are arranged in the empty rollers; center axes are arranged in the cavities along the axial directions; the empty rollers are divided into drive semi-rollers and adsorption semi-rollers; fans are arranged on the center axes; and through holes are formed in the adsorption semi-rollers. The conveying device for the textiles provided by the invention is used for batching and conveying cloth, and solves the problem that the cloth is easy to yellow and breed bacteria after contacting water for a long time.

Owner:嘉兴市雄辉纺织有限公司

Intermittent extrusion type steel material cuttings treatment device utilizing centrifugal pollution discharge

InactiveCN108582845AGood for cost recoveryReduce pollutionRotary centrifugesMaintainance and safety accessoriesCentrifugal forceCutting oil

The invention belongs to the technical field of metal scrap processing, and discloses an intermittent extrusion type steel material cuttings treatment device utilizing centrifugal pollution discharge.The intermittent extrusion type steel material cuttings treatment device utilizing centrifugal pollution discharge comprises a tank, wherein a discharge end communicating with a feeding hopper is fixed to the left end of a top wall of the tank; a centrifugal liquid removing mechanism is arranged in the tank and located on the lower side of the feeding hopper; and a cuttings compression mechanismis arranged in the tank and located on the right side of the centrifugal liquid removing mechanism. According to the intermittent extrusion type steel material cuttings treatment device utilizing centrifugal pollution discharge, through arranging the centrifugal liquid removing mechanism, cuttings oil on the cuttings can be thrown away through a centrifugal force formed by the rotation of a liquidthrowing cylinder so as to be recycled, so that the recycling cost of the enterprises is reduced, and the environment pollution is reduced.

Owner:当涂县金龙凤科技股份有限公司

Hot-pressing equipment for threads at two ends of automobile cable hose

InactiveCN106313495AQuick pressPressed deepScrew-threads articlesDomestic articlesScrew threadElectrical and Electronics engineering

Owner:NINGBO AUTO CABLE CONTROLS

Method and device for optimizing chemical nickel-palladium-gold coating

InactiveCN105543818AFast fillImprove printing efficiencyLiquid/solution decomposition chemical coatingElectronic industryPalladium

The invention discloses a method and device for optimizing a chemical nickel-palladium-gold coating and belongs to the technical field of electroplating. The device comprises a laminating mechanism, wherein the laminating mechanism is used for coating the lower surface of a steel mold plate with breathable cloth. A conveying belt used for conveying the steel mold plate is arranged on the downstream portion of the laminating mechanism. A rolling mechanism used for stripping the breathable cloth on the steel mold plate is arranged at the tail end of the conveying belt. A working table is arranged between the laminating mechanism and the rolling mechanism. A notch matched with the steel mold plate in shape is formed in the working table. A material box is arranged on the working table. A partition board is arranged in the material box. The material box is divided into a paste storage cavity and a sundry storage cavity by the partition board. A scraper is vertically arranged on the partition board. A file is arranged on the material box and located in the sundry storage cavity. A demolding mechanism used for discharging tin paste on the steel mold plate is arranged on the downstream portion of the rolling mechanism. By the adoption of the method and device for optimizing the chemical nickel-palladium-gold coating, the technical effects of pressing the tin paste in a mold hole of the steel mold plate evenly and rapidly and transferring the tin paste onto a printed circuit board (PCB) bonding pad are achieved, and the method and device are widely applied to the electronic industry.

Owner:WEIFANG UNIVERSITY

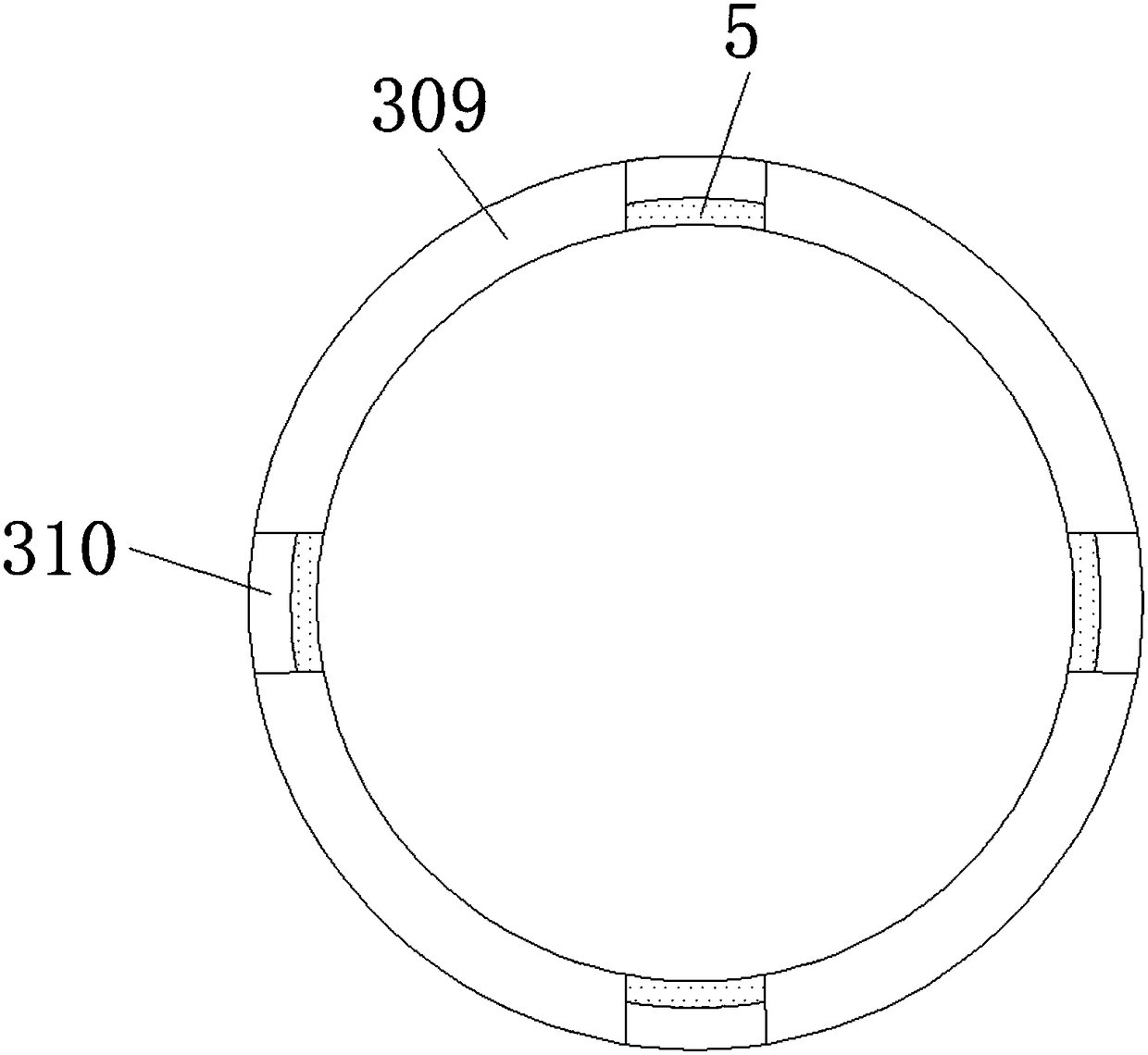

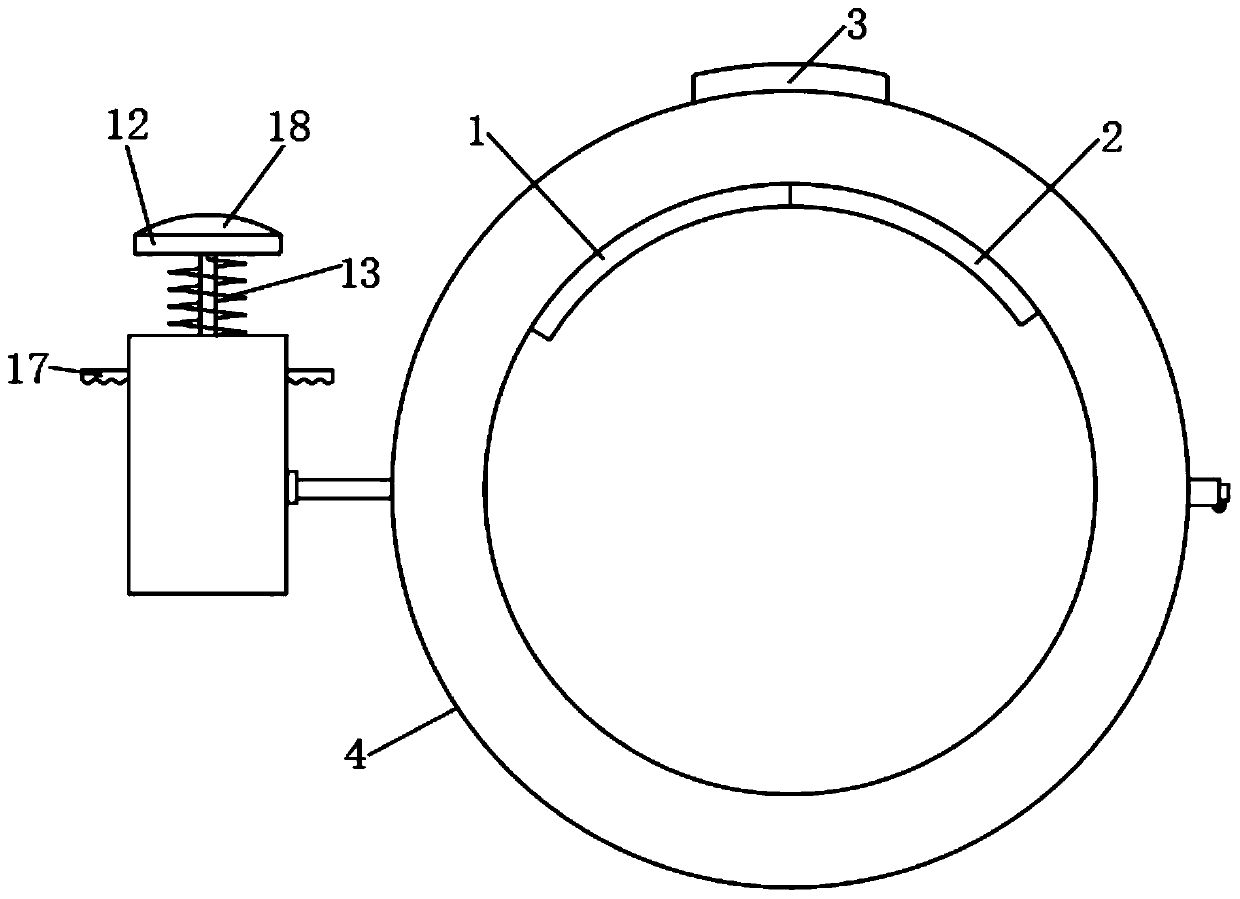

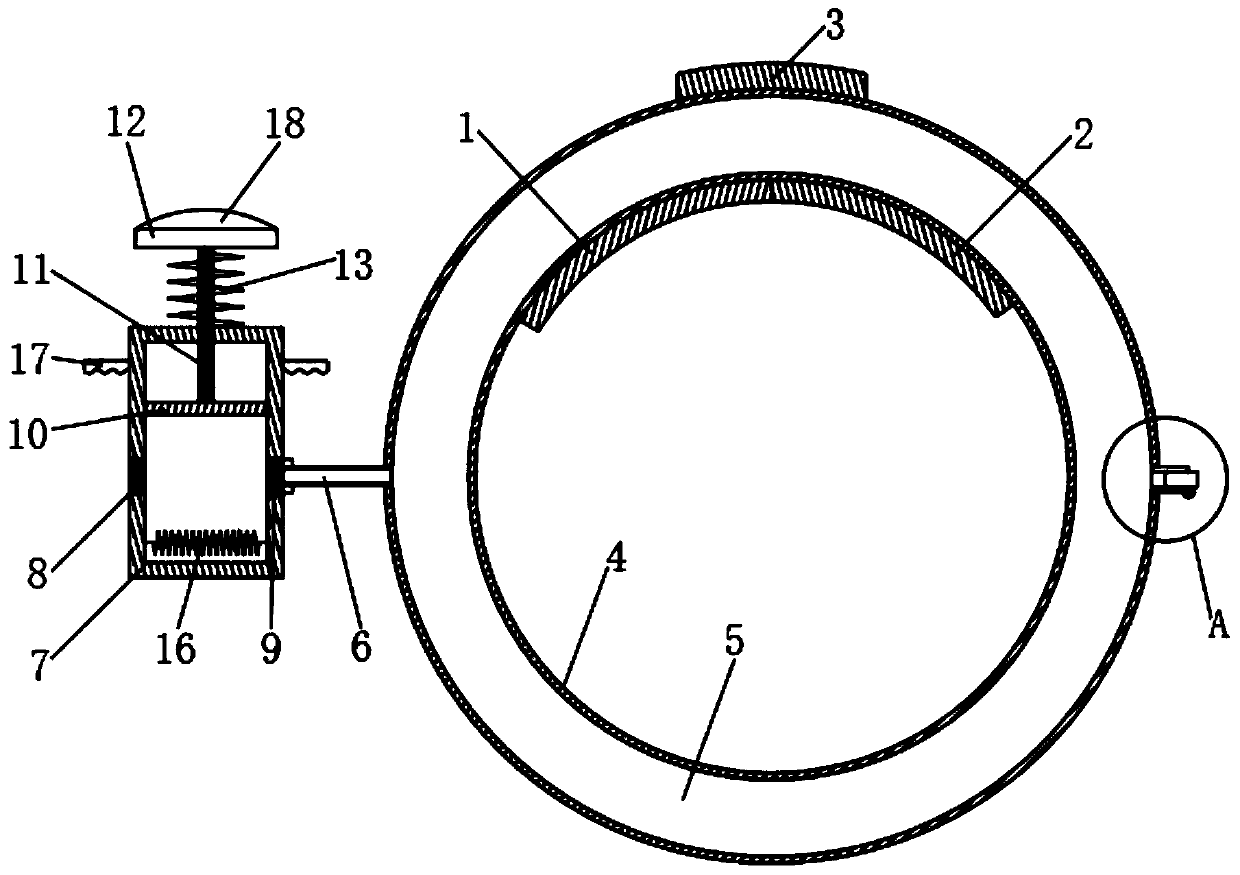

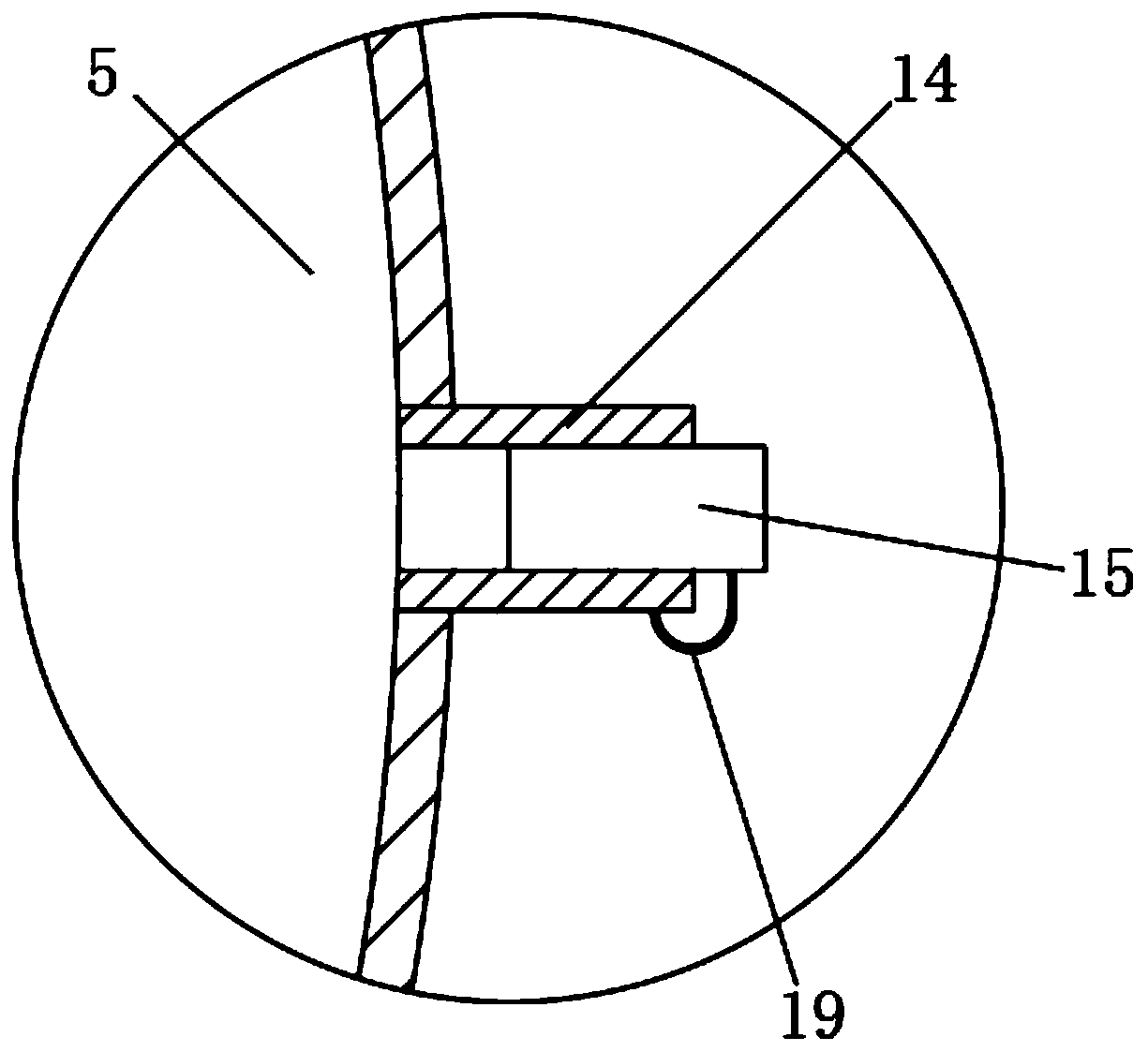

Postoperative puncture site pressing device for cerebrovascular intervention

InactiveCN110101428AQuick pressPlay a pressing effectTourniquetsEngineeringUltimate tensile strength

The invention discloses a postoperative puncture site pressing device for cerebrovascular intervention. The postoperative puncture site pressing device for the cerebrovascular intervention comprises asensing module, a monitoring module and an alarm module, wherein the opposite surfaces of the sensing module, the monitoring module and the alarm module are fixedly connected with a pressing device,the pressing device comprises an annular air bag and an air inlet shell, the inner ring surface of the annular air bag is fixedly connected to the surface of the sensing module and the monitoring module, and the outer ring surface of the annular air bag is fixedly connected to the surface of the alarm module, a through hole is formed in a left side of the annular air bag, and through the through hole, a connecting tube is in fixed sealed connection with the annular air bag. The postoperative puncture site pressing device for the cerebrovascular intervention, through the cooperative use of theabove structures, solves the problem that due to the fact that the adjustment of the pressing strength of a traditional presser is not convenient in the actual use process and it is necessary to pullout an adhesive tape several times and then perform re-bonding in order to achieve a suitable pressing strength, secondary damage to a puncture site is caused, the work efficiency is lowered, and inconvenience is brought to the use.

Owner:周林国

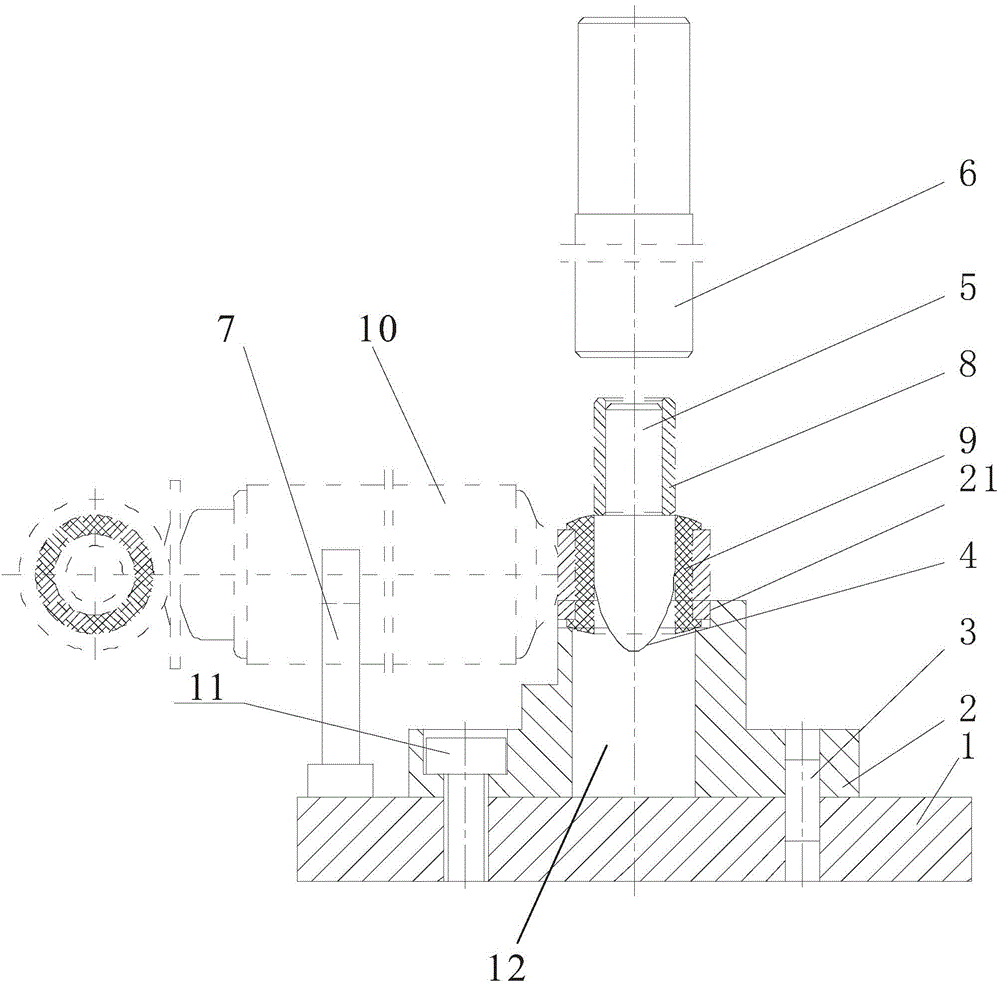

Press-in device for bushing tube of shock absorber of automobile

InactiveCN104690532AEasy accessQuick pressVehicle componentsMetal working apparatusEngineeringShock absorber

The invention discloses a press-in device for a bushing tube of a shock absorber of an automobile. The press-in device comprises a base, a guiding body and a press head, wherein a positioning disc is fixed at the upper part of the base; a vertical through hole is formed in the positioning disc, and a positioning groove for supporting a lifting ring is arranged at the top end of the through hole; the guiding body comprises a cylinder and a conical head, the cylinder is sleeved with the bushing tube, the cylinder and the conical head adopt an integrated structure, and the maximum value of the outer diameter of the conical head is identical with that of the bushing tube; one end of the press head is cylindrical. The press-in device is convenient to operate and simple and reasonable in structure, the rubber bushing tube can be pressed in an inner hole of a bushing of the lifting ring quickly, and the working efficiency is greatly improved.

Owner:天津市汉沽德源机械制造有限公司

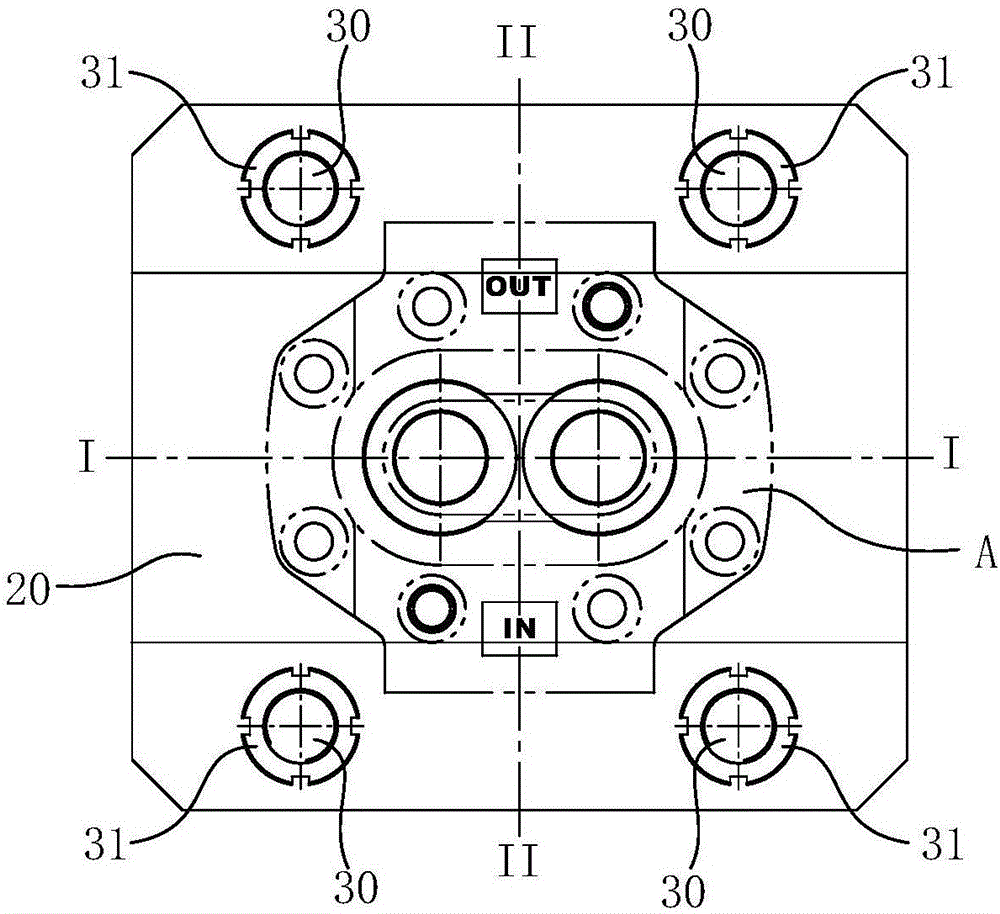

Multi-sensor electronic nose-based conformal gas chamber and gas testing system and method

ActiveCN110231366ASave spaceExpand the scope of detectionFlow control using electric meansMaterial analysis by electric/magnetic meansProcess engineeringGas chamber

The invention discloses a multi-sensor electronic nose-based conformal gas chamber and a gas testing system and method. A gas inlet and a gas outlet, which are oppositely arranged are formed in a sidewall of a mounting main body of the gas chamber; a plurality of detection ports for mounting gas sensors are formed in the upper end surface of the mounting main body; the gas chamber communicating with the gas inlet, the gas outlet and the plurality of detection ports is formed in a hollowed-cut in the mounting main body; the upper end surface of the mounting main body is sealed through a circuit board; a plurality of gas sensors matched with the detection ports are arranged on the lower end surface of the circuit board; the lower end of each gas sensor extends into the gas chamber through the corresponding detection port; and a chamber wall conformal with the gas sensors is arranged in the gas chamber. Gas detection is carried out on the basis of the conformal gas chamber, so that the volume of the gas chamber is fully utilized and the space of the gas chamber is effectively reduced. Compared with an electronic nose system with a regular gas chamber, the multi-sensor electronic nose-based conformal gas chamber has the advantages that the detection effect can be improved and the multi-sensor electronic nose-based conformal gas chamber can be effectively applied to various gas testing systems.

Owner:CHONGQING UNIV

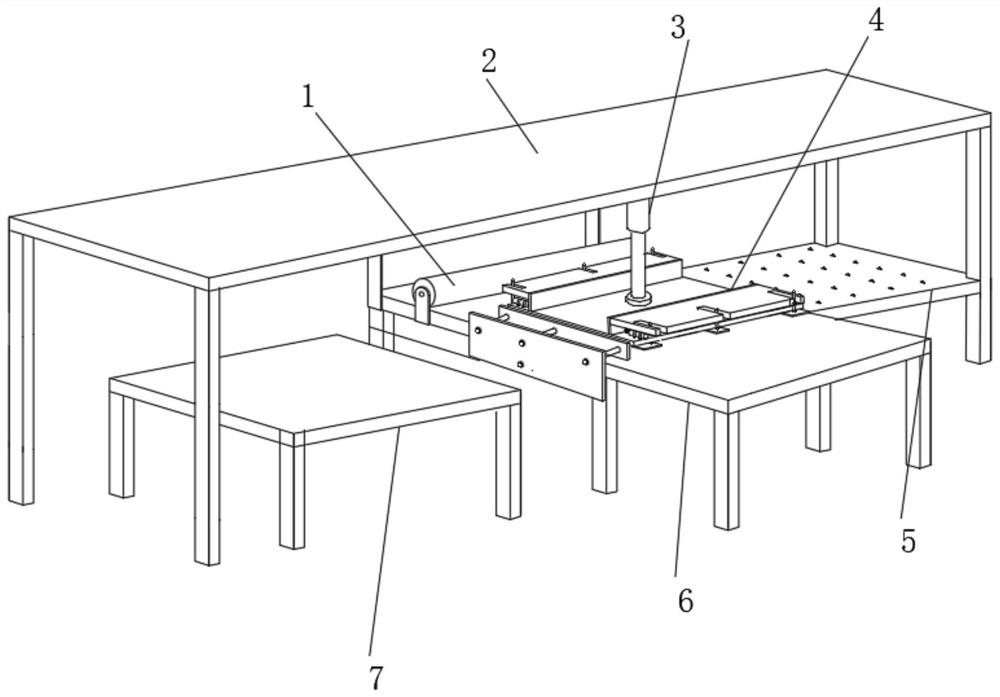

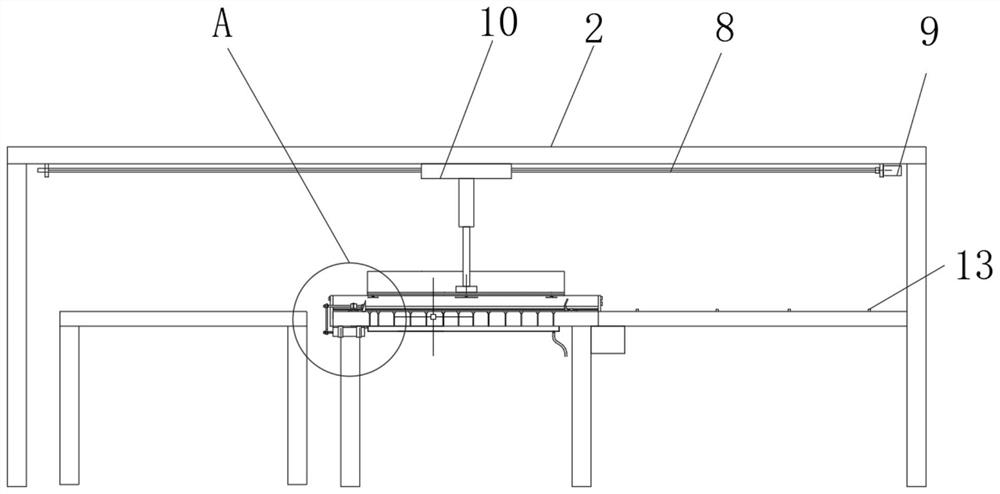

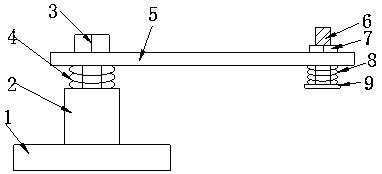

Lining press-fitting tool

InactiveCN106392585AQuick pressImprove press fit accuracyMetal working apparatusEngineeringHydraulic press

The invention relates to a lining press-fitting tool. The lining press-fitting tool comprises: a positioning plate is arranged above a bottom plate; a guide column is arranged between the positioning plate and the bottom plate; the lower end of the guide column is fixedly connected with the bottom plate; the upper end of the guide column stretches out of the positioning plate, and the guide column and the positioning plate form linear guide cooperation; a spring is arranged on the guide column in a sleeving way; the two ends of the spring abut against the upper plate surface of the bottom plate and the lower plate surface of the positioning plate correspondingly; two positioning pressure heads are arranged on the bottom plate and are parallel with the guide column; and the upper ends of the two positioning pressure heads stretch out of the positioning plate and are used for assembling a lining to be press-fitted. The lining to be press-fitted is arranged at the upper ends of the two positioning pressure heads and a workpiece is placed on the positioning plate of the tool, so that the upper ends, which stretch out of the positioning plate, of the positioning heads are positioned below a shaft hole of the workpiece; the tool is placed on a hydraulic press and the hydraulic press starts, so that a shaft sleeve is press-fitted on the workpiece; the workpiece is taken down after press fitting is finished, and the next press-fitting action is repeated; and the tool is convenient and safe, is quick in press fitting, and has high press-fitting precision and production efficiency.

Owner:HEFEI CHANGYUAN HYDRAULICS

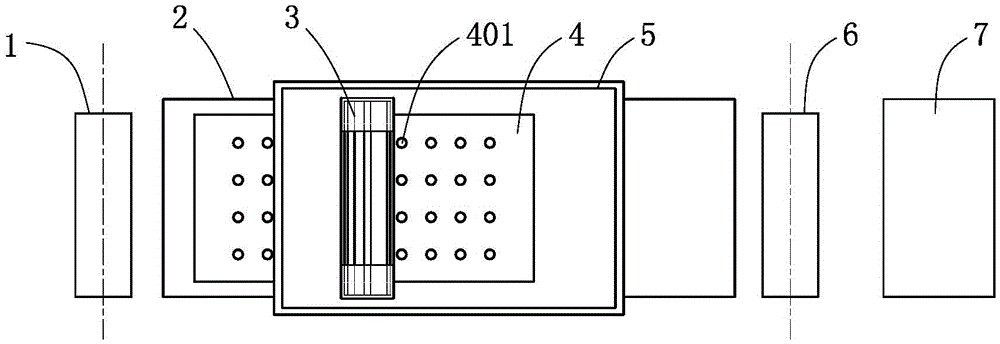

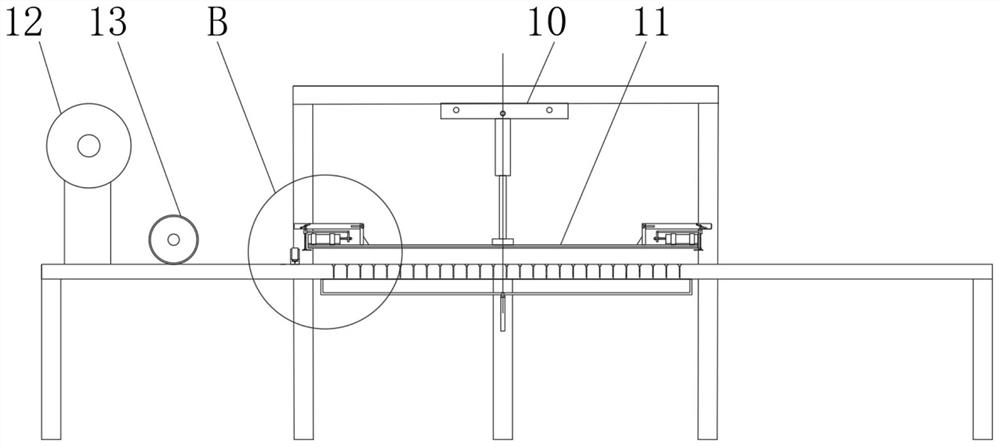

Copper-clad laminate production device for printed circuit board, and board pressing method thereof

ActiveCN113619252AGuaranteed contactSimple structureLamination ancillary operationsLaminationAir pumpElectric machinery

The invention discloses a copper-clad laminate production device for a printed circuit board, and a board pressing method thereof. The copper-clad laminate production device comprises a feeding roller, a top bracket, a pressing hydraulic rod, a material taking and pressing mechanism, a substrate placing platform, a composite platform, a finished product placing platform, a screw rod, a screw rod driving motor, a sliding block and a raw material winding drum, a plurality of needle holes distributed in a matrix shape are formed in the middle of the composite platform, the lower surface, corresponding to the needle holes, of the composite platform is connected with a sealing cover, and the sealing cover covers the end openings, located at the lower end of the composite platform, of all the needle holes. The copper foil and the zinc foil are adsorbed through an adsorption mechanism composed of the air pump and the sealing cover, then a substrate, the copper foil and the zinc foil are pressed through the material taking and pressing mechanism, the overall structure is simple, and pressing is rapid; and after pressing, the copper foil and the zinc foil are in contact, so that the product can be stored for a long time.

Owner:云南惠铜新材料科技有限公司

Press riveting device

ActiveCN104028991AAccurate riveting positionAvoid harmMetal working apparatusEngineeringMechanical engineering

The invention discloses a press riveting device. A carrier pushing positioning channel is arranged on a frame in a penetrating mode; a carrier pushing driving device can drive a carrier pushing device to convey carriers along the carrier pushing driving device; the carrier positioning driving device can drive a carrier positioning device to fix and position the carriers; a staggered riveting driving device can drive symmetrically-distributed staggered riveting blocks to move opposite to each other; rotating riveting blocks are rotatably positioned right above the carrier pushing positioning channel, and a rotating riveting driving device drives the rotating riveting blocks to rotate; a pressing shaping device which is slidingly positioned on the frame in a press mode is arranged right above the carrier pushing positioning channel; a pressing shaping driving device drives a pressing shaping device to act; a controller controls all the driving devices to act. The press riveting device achieves automated continuous operation and is high in pressing and riveting speed, accurate in riveting position of iron casings, free from damage to products, harmless for workers, high in production efficiency and low in production cost.

Owner:KUNSHAN FULIRUI ELECTRONICS TECH

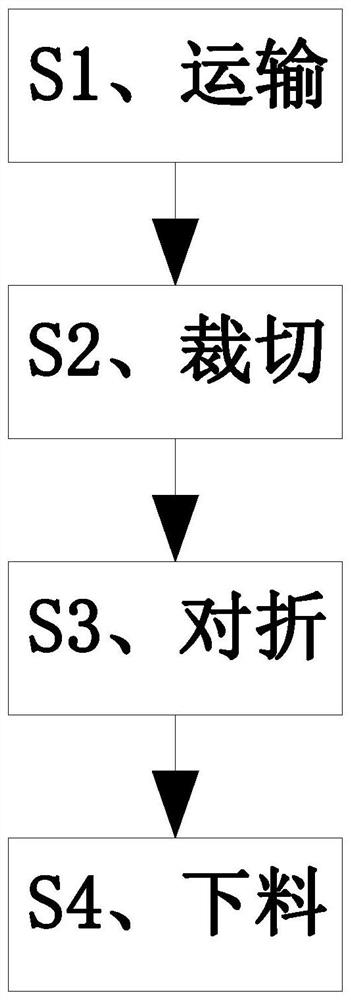

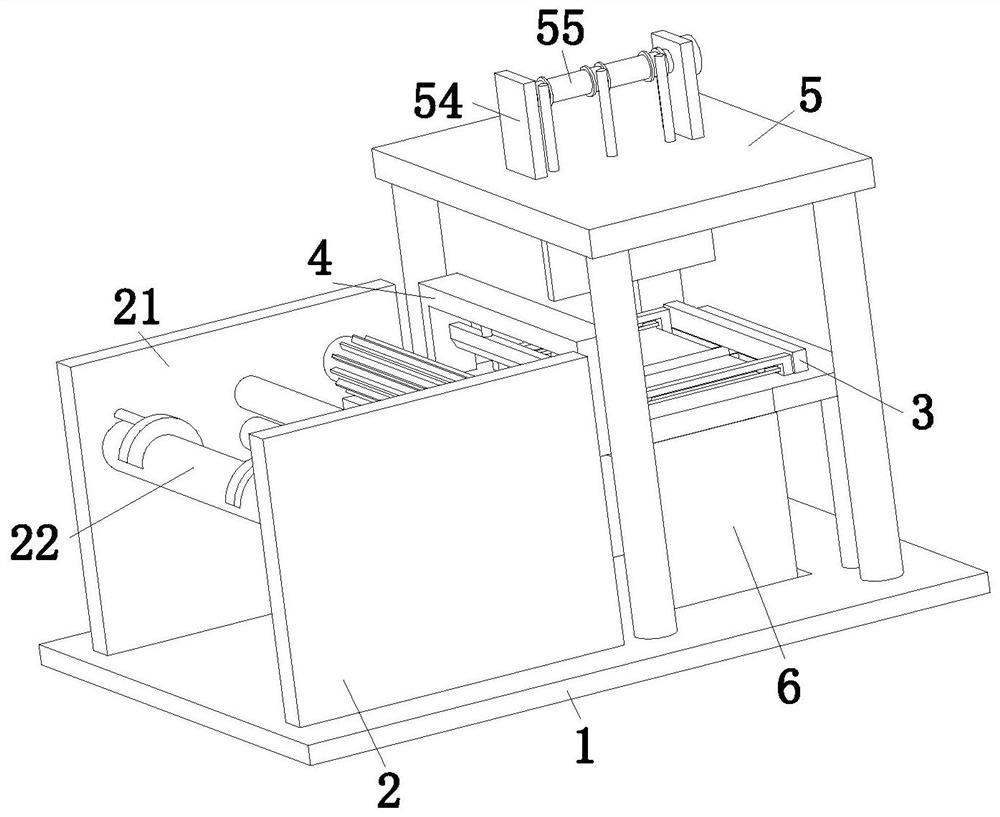

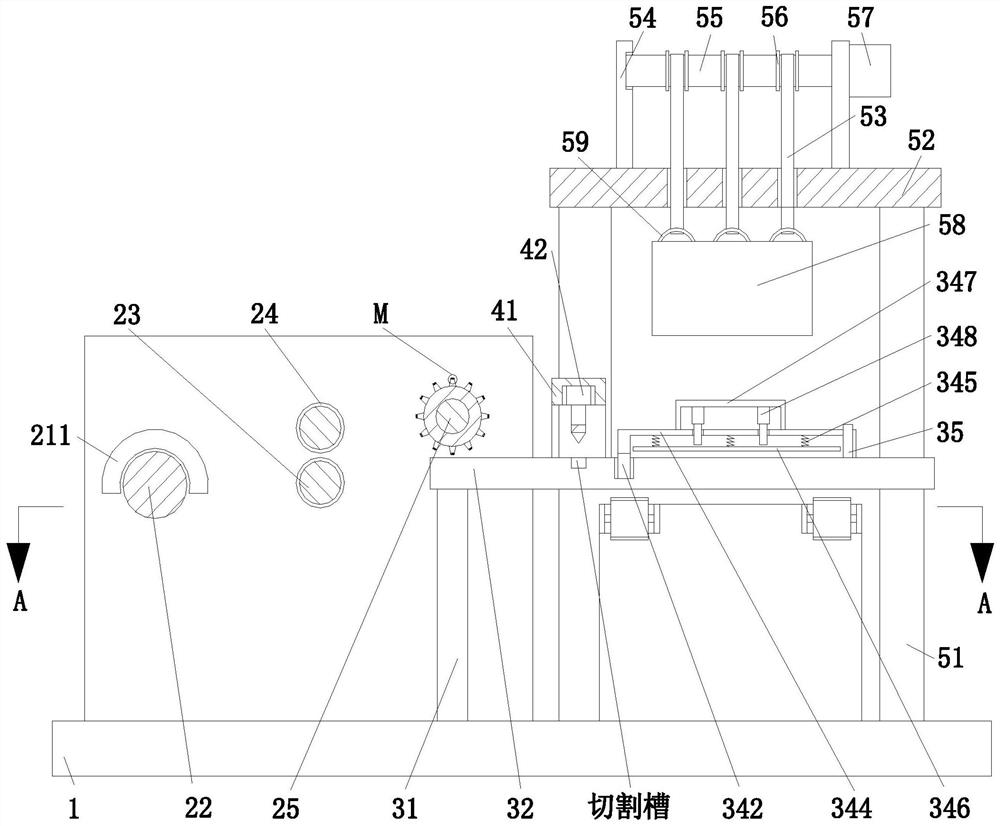

Manufacturing and processing method for aluminum foil packaging bag

InactiveCN112976686AImprove applicabilityImprove pass rateBag making operationsPaper-makingManufacturing engineeringMechanical engineering

The invention relates to a manufacturing and processing method for an aluminum foil packaging bag. The manufacturing and processing method comprises a workbench, a winding device, a fixing device, a cutting device, a moving device and a pressing device, wherein the fixing device comprises a supporting rod, a fixing structure plate, a first rectangular through groove, a moving frame and a limiting plate. According to the manufacturing and processing method, the workbench, the winding device, the fixing device, the cutting device, the moving device and the pressing device are arranged to cooperate with one another, firstly, the aluminum foil packaging bag needing to be manufactured and processed is placed on the winding device, the aluminum foil packaging bag is transported to the fixing device through the winding device, at the moment, the aluminum foil packaging bag is cut into a proper size through the cutting device, so that the applicability of the machine is improved; and at the moment, the aluminum foil packaging bag is rapidly folded in half through the moving device, so that the percent of pass of the machine is improved, the aluminum foil packaging bag is rapidly pressed through the pressing device while being folded in half, so that the working efficiency of the machine during pressing is improved.

Owner:梁星胜

Adjustable pressure plate for filter

Owner:南京幕府信息技术有限公司

Device for pressing developing point

The embodiment of the invention provides a device for pressing a developing point. The device comprises a frame, a longitudinal positioning mechanism, a circumferential positioning mechanism, a support seat, a scanning mechanism, a discharge mechanism and a pressure head mechanism. The longitudinal positioning mechanism is arranged on the frame and comprises a first sliding block and a second sliding block capable of sliding along a first direction. The circumferential positioning mechanism is arranged on the first sliding block and the second sliding block and comprises a positioning core shaft which is used for installing a workpiece and capable of rotating around a shaft center. The support seat is arranged on the frame and located above the longitudinal positioning mechanism. The positioning core shaft is arranged in a first through hole of the support seat in a penetrating mode. The scanning mechanism is arranged on the frame and comprises a scanning portion located between the support seat and the circumferential positioning mechanism. The discharge mechanism is arranged on the frame and comprises a discharge pipe, one end of which is located in a second through hole of the support seat. The first through hole is communicated with the second through hole. The pressure head mechanism is arranged on the support seat. The embodiment of the invention is capable of accurately and rapidly developing the developing point of a workpiece with the developing point to be pressed.

Owner:SHANGHAI BIO HEART BIOLOGICAL TECHNOLOGY CO LTD

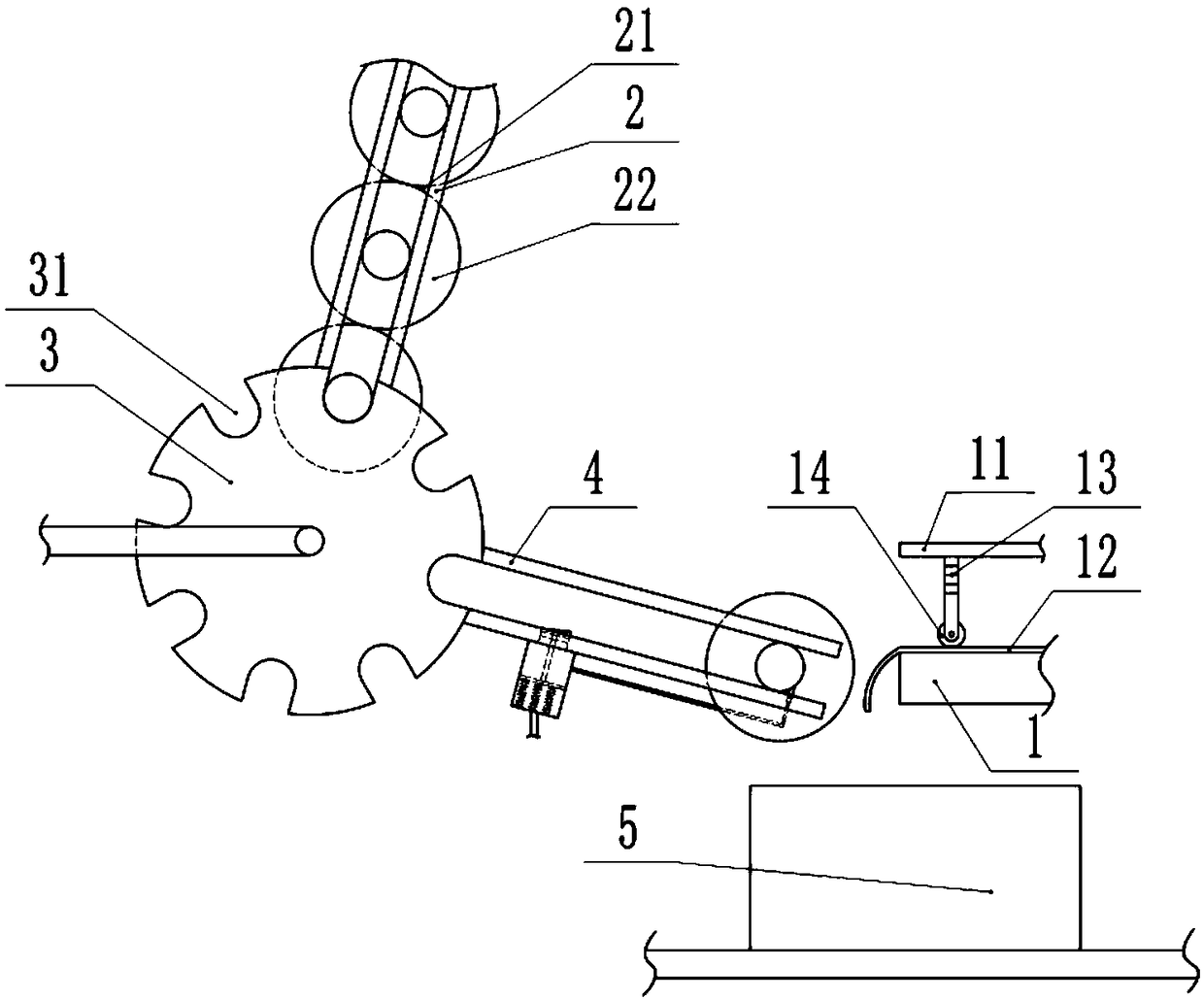

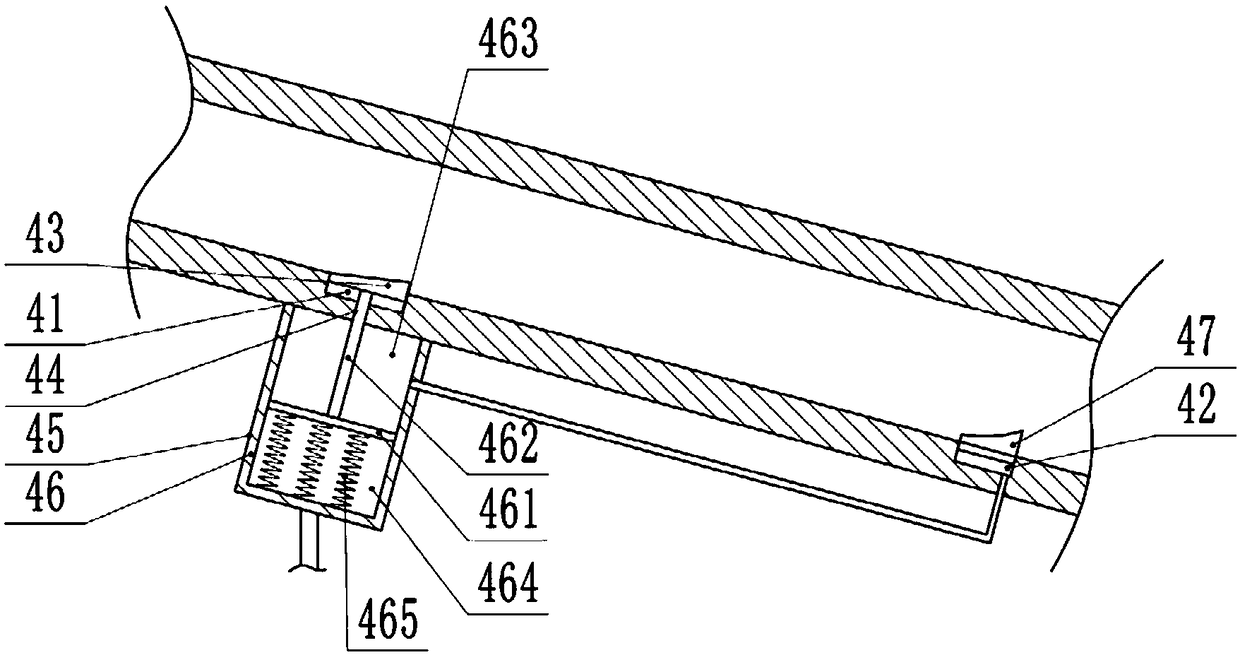

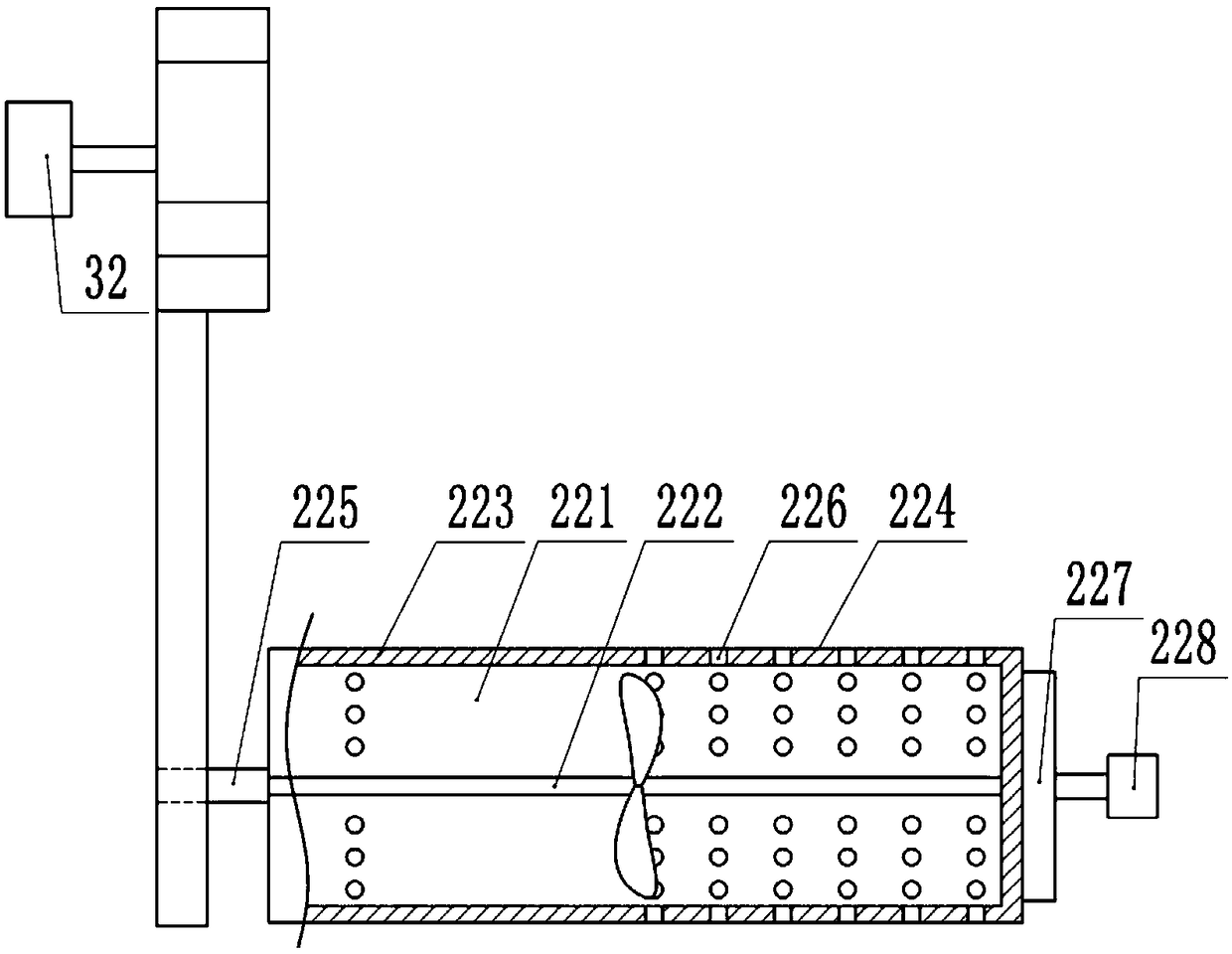

Saw blade press-fit mechanism and binding machine using same

ActiveCN106113580AImprove stabilityImprove efficiencyPerforating toolsContainer making machineryCartonEngineering

The invention discloses a saw blade press-fit mechanism and a binding machine using the same, and relates to the technical field of binding devices to solve the technical problems that in the prior art, saw blade fixation is instable and the installation efficiency is low. The saw blade press-fit mechanism comprises an upper press-fit assembly, a lower press-fit assembly and a drive assembly connected with the lower press-fit assembly. The upper press-fit assembly and the lower press-fit assembly are arranged in a spaced manner. The upper press-fit assembly comprises first punch pins and a material return plate. The lower press-fit assembly comprises a second punch pin. During use, a carton stretches into the space between the upper press-fit assembly and the lower press-fit assembly, the drive assembly drives the lower press-fit assembly to move upwards, a saw blade raw material moves upwards at the same time, and the lower press-fit assembly makes contact with the upper press-fit assembly to complete the press-fit action; at the same time, the first punch pins punch holes in the saw blade raw material and complete the action of cutting off the saw blade raw material; and then, the carton and the first punch pins are separated through the material return plate, and the second punch pin returns the rest of the saw blade raw material to the working position. The saw blade press-fit mechanism and the binding machine are mainly applied to production and manufacture of the saw blade press-fit mechanism and the binding machine using the saw blade press-fit mechanism.

Owner:江苏绿源健康铝箔科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com