Press-in device for bushing tube of shock absorber of automobile

A technology of automobile shock absorbers and press-in devices, which is applied in vehicle parts, transportation and packaging, metal processing, etc., can solve the problems of deformation of rubber products, time-consuming and labor-intensive problems, and achieve easy operation, improved work efficiency, and simple and reasonable structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

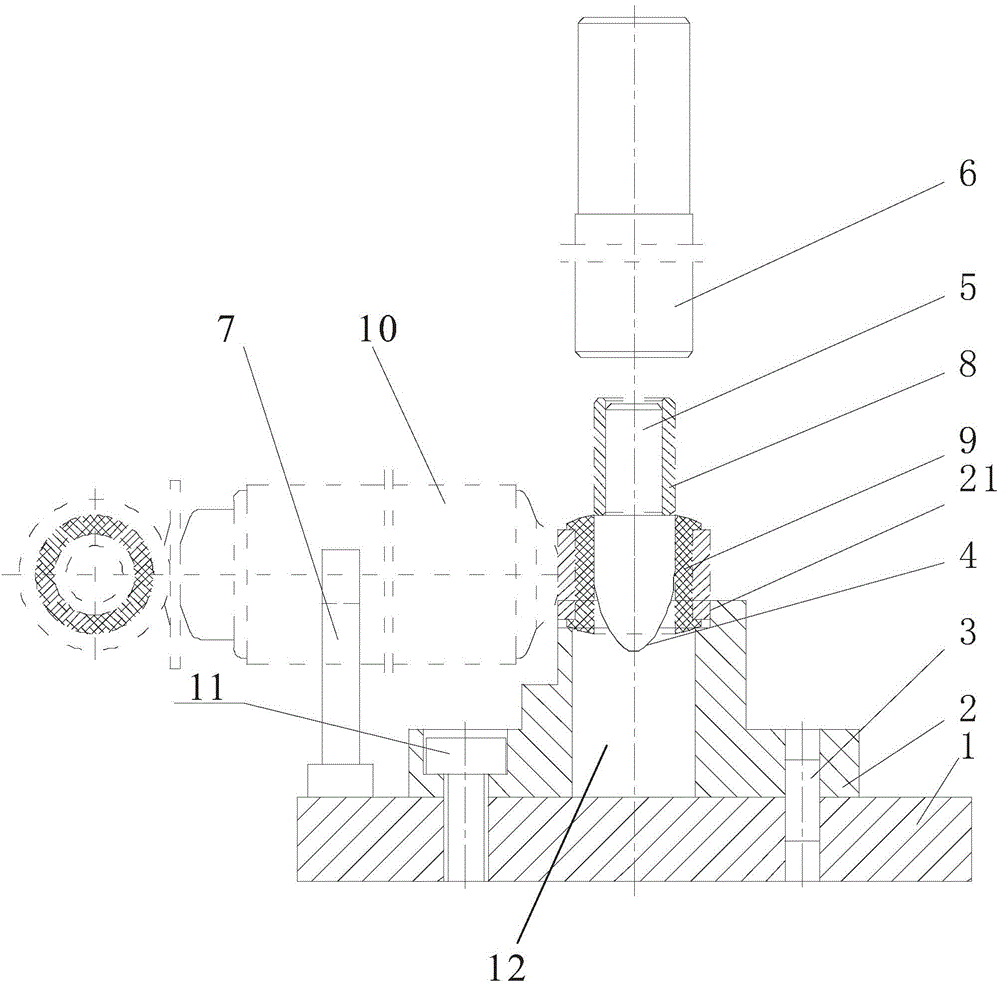

[0011] Such as figure 1 Shown is an automobile shock absorber bushing tube press-in device, including a base 1, a guide body 5 and a pressure head 6; a positioning plate 2 is fixed on the upper part of the base 1, and a cylindrical pin 3 and a screw are used between the two 11 is fixedly connected; the positioning plate 2 has a vertical through hole 12, and the upper top of the through hole 12 is provided with a positioning groove 21 for supporting the lifting ring; the guide body 5 includes a cylindrical body with a bushing tube 8 on the outside and the conical head 4 integrally structured with the cylindrical body; the maximum value of the outer diameter of the conical head 4 is the same as that of the bushing tube 8; the end of the indenter 6 is a cylinder.

[0012] One side of the base 1 is provided with a V-shaped or arc-shaped bracket 7 for supporting the shock absorber.

[0013] Working principle: put the shock absorber 10 on the bracket 7, place the lifting ring welde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com