Assembling method of flexible bearing and cam

A flexible bearing and assembly method technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of time-consuming and labor-intensive assembly methods, damage to flexible bearings, etc., to improve assembly quality, reduce positioning errors, and meet the transmission of working torque. the effect of the request

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

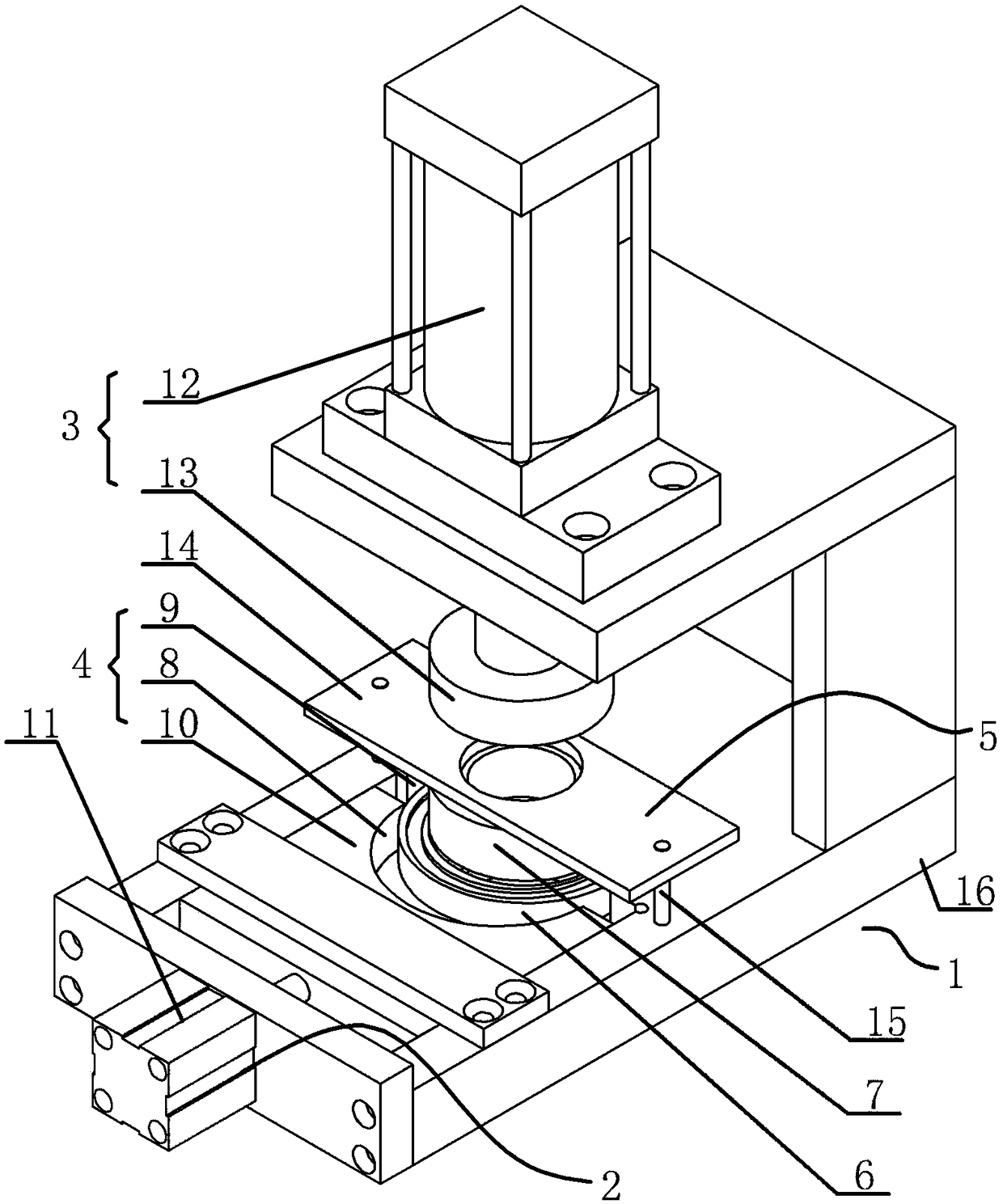

[0021] An assembly method of a flexible bearing and a cam:

[0022] (1) The elliptical axis positioning datum is reserved in the design of the cam, and the reserved elliptical axis is at least one of the major axis or the minor axis; then the cam is processed according to the design, and the processed cam is placed in an industrial freezer Freeze in the box, the freezing temperature is -62℃~-58℃, and the freezing time is not less than 8 hours;

[0023] (2) According to the specifications of the wave generator to be assembled, process the corresponding assembly tooling 1. The assembly tooling 1 includes a positioning part, a pressing part 2, and a pressing part 3. The positioning part includes a flexible bearing positioning part 4 and a cam positioning part 5. , the pressing part 2 is used to pressure deform the flexible bearing 6 into an oval shape and fix it, and the pressing part 3 presses the positioned cam 7 into the deformed flexible bearing 6;

[0024] (3) Put the flexi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com