Press-fitting machine for shock absorber strut assemblies

A technology of shock absorber and press-fitting machine, which is used in transportation and packaging, metal processing, metal processing equipment, etc., can solve problems such as spring release, and achieve the effect of reliable clamping and fast press-fitting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

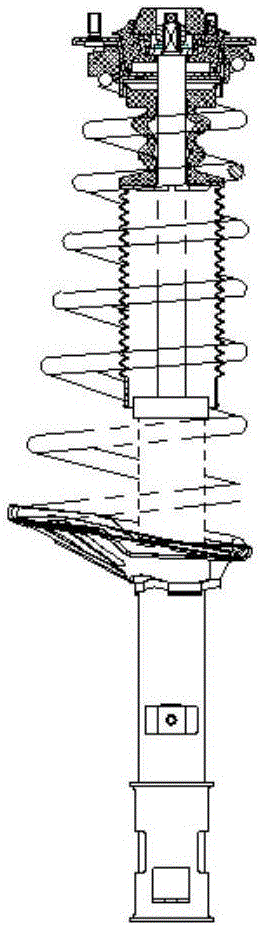

[0051] like figure 1 As shown, the shock absorber strut assembly is composed of a shock absorber and a spring element. The upper end is connected with the vehicle body or the frame, and the lower end is connected with the axle. When the body vibrates, the shock absorber strut assembly can quickly attenuate the vibration of the body. The resistance of oil movement itself is used to consume the resistance of vibration. It can guide the wheel shaft together with the control arm, support the elastic force of the coil spring, support the braking torque and stabilize the rod.

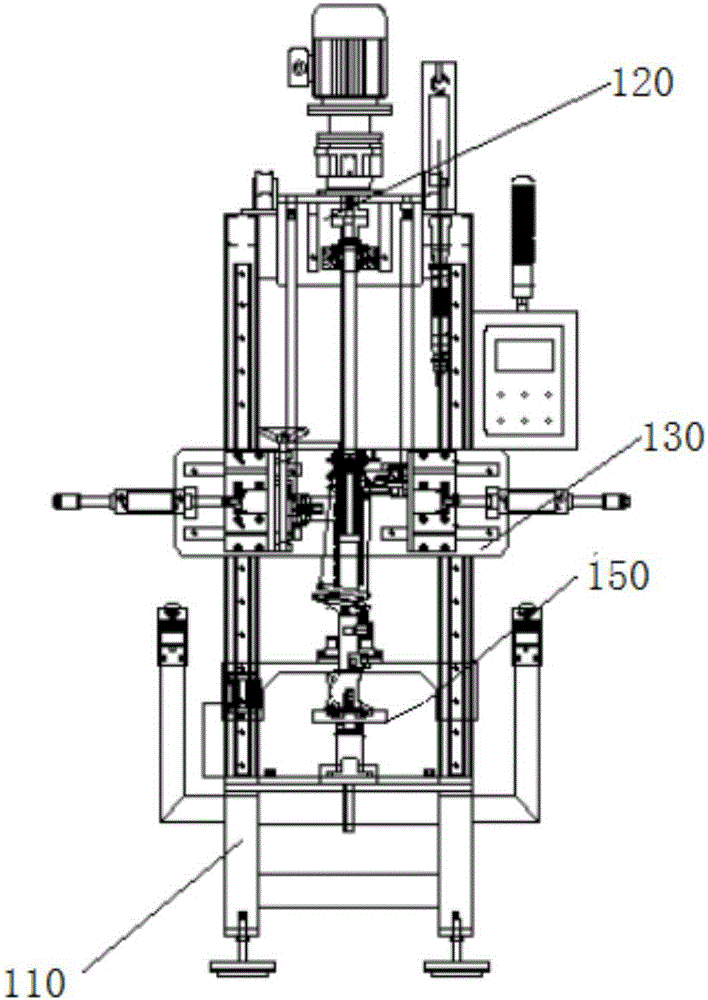

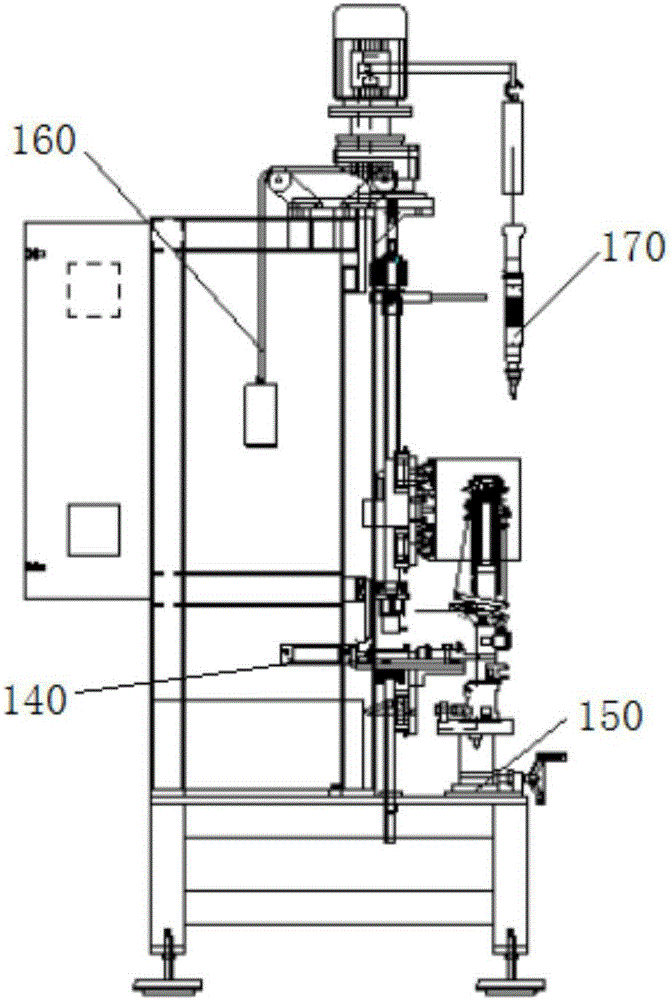

[0052] like figure 2 , image 3 As shown, the present invention provides a shock absorber strut assembly press assembly machine, including a frame 110, a power transmission mechanism 120, a clamping arm h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com