Engine air valve locking plate pressure head

A technology of engine valves and pressure heads, which is applied in the field of fixtures and fixtures, can solve problems such as force skewing of locking pieces, prolonging assembly time, and insufficient pressing of locking pieces, so as to prevent free swing, improve assembly efficiency, and be easy to press and fit in place Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

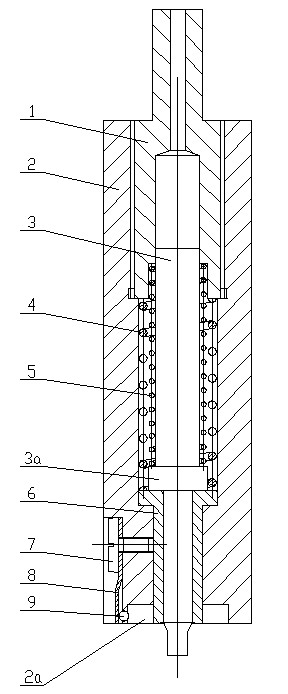

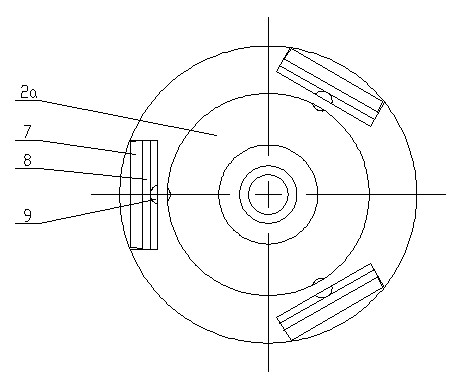

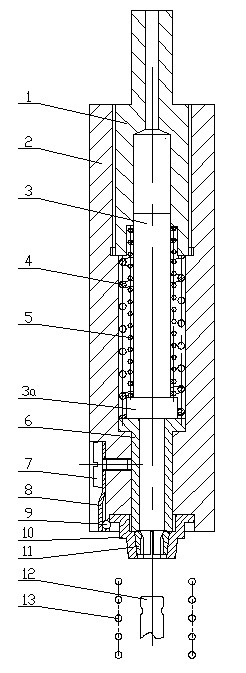

[0019] Such as figure 1 , figure 2 As shown, the present invention is made of guide screw plug 1, outer pressure head 2, guide positioning shaft 3, inner pressure head spring 4, positioning shaft spring 5, inner pressure head 6, bolt 7, reed 8 and steel ball 9, wherein The outer ram 2 is provided with a stepped inner hole along the direction of its axis, the upper inner hole of the outer ram 2 is a threaded section, the lower part of the guide screw plug 1 is put into the upper inner hole of the outer ram 2, through Threaded connections are held together. The top of the guide screw plug 1 is circular or square, which is compatible with the assembly hole of the lifting shaft of the press. A positioning groove 2a is provided in the middle of the bottom surface of the external pressure head 2, and an internal pressure head 6 is installed in the inner hole at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com