Patents

Literature

48 results about "Fitting - action" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

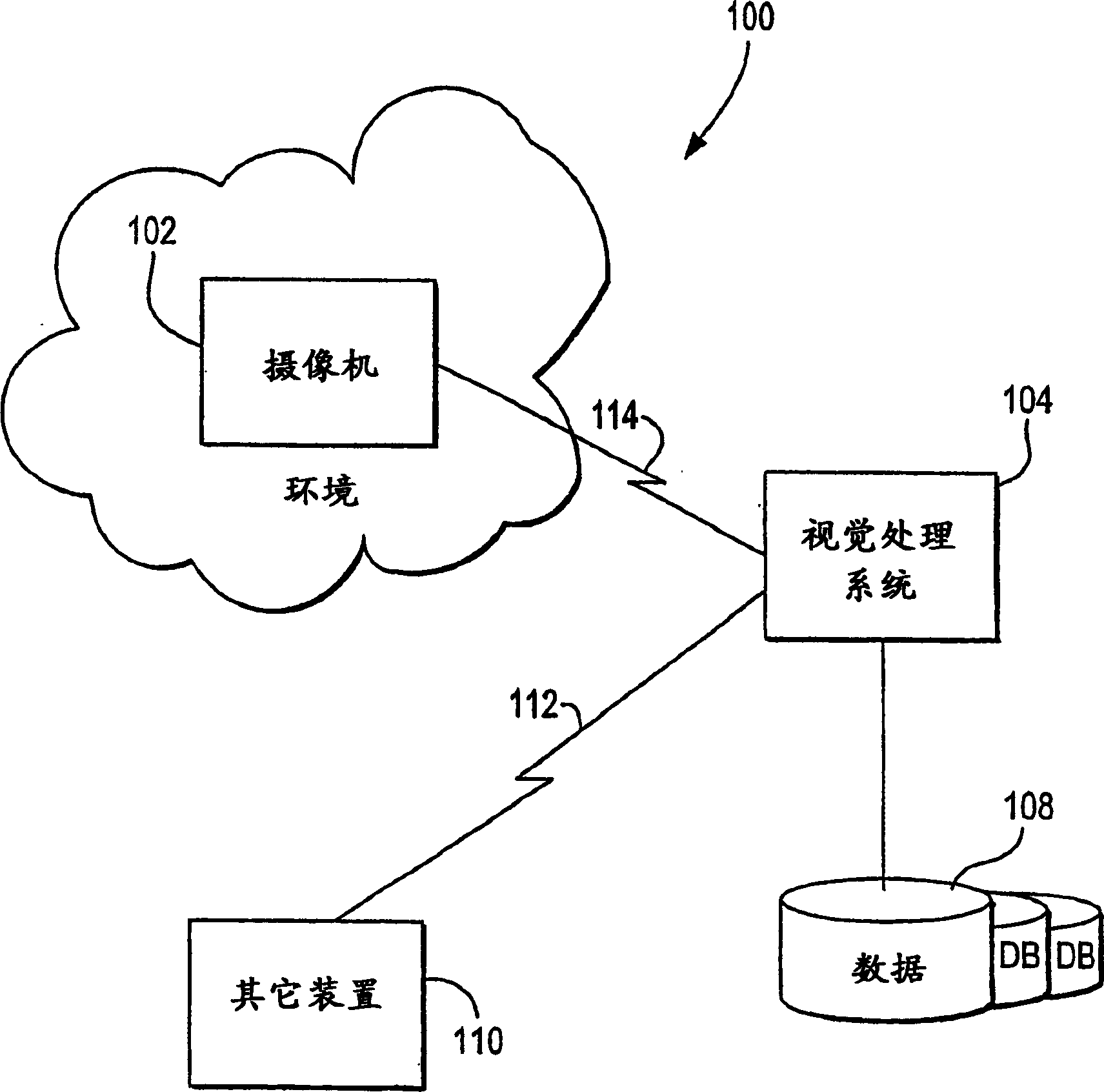

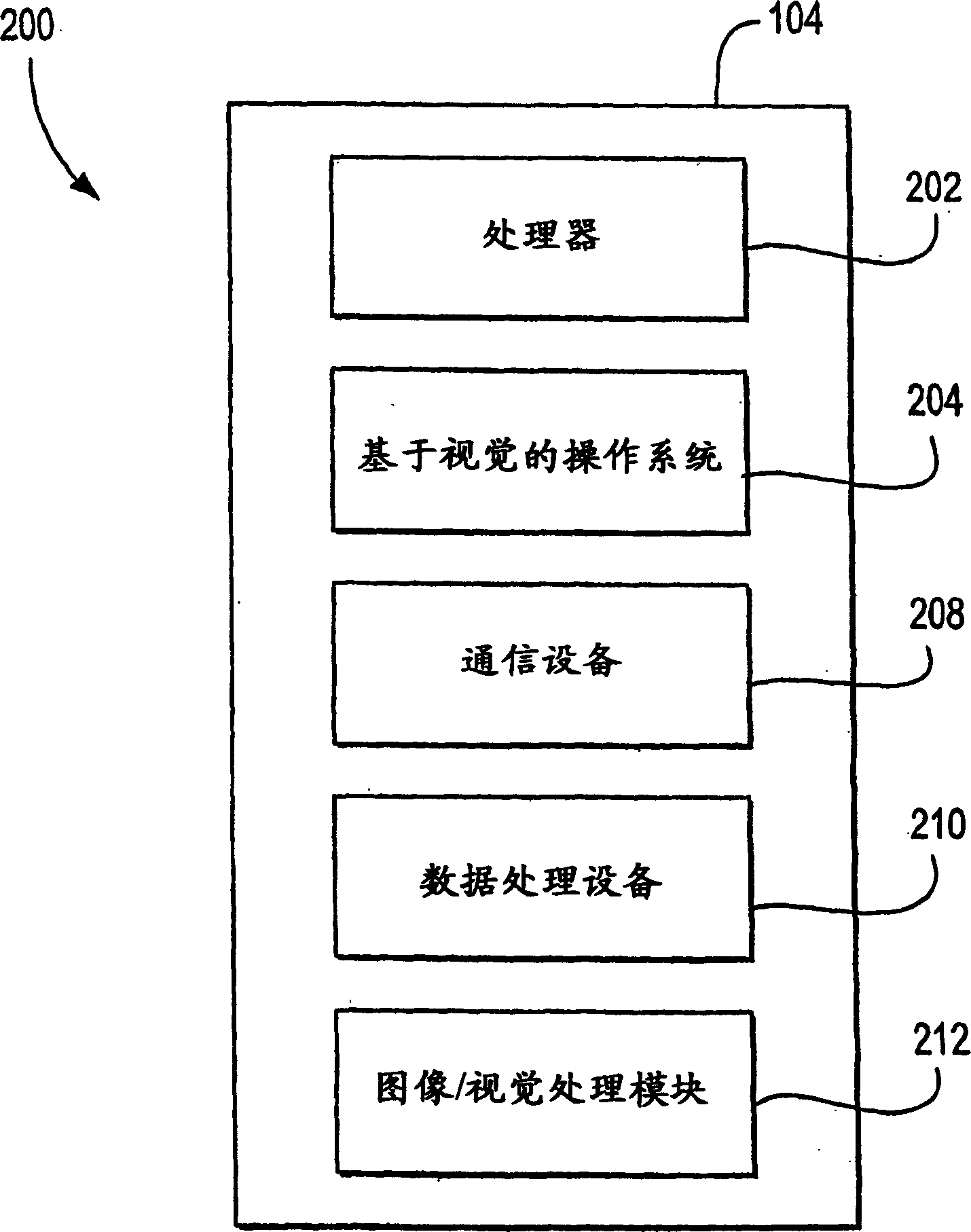

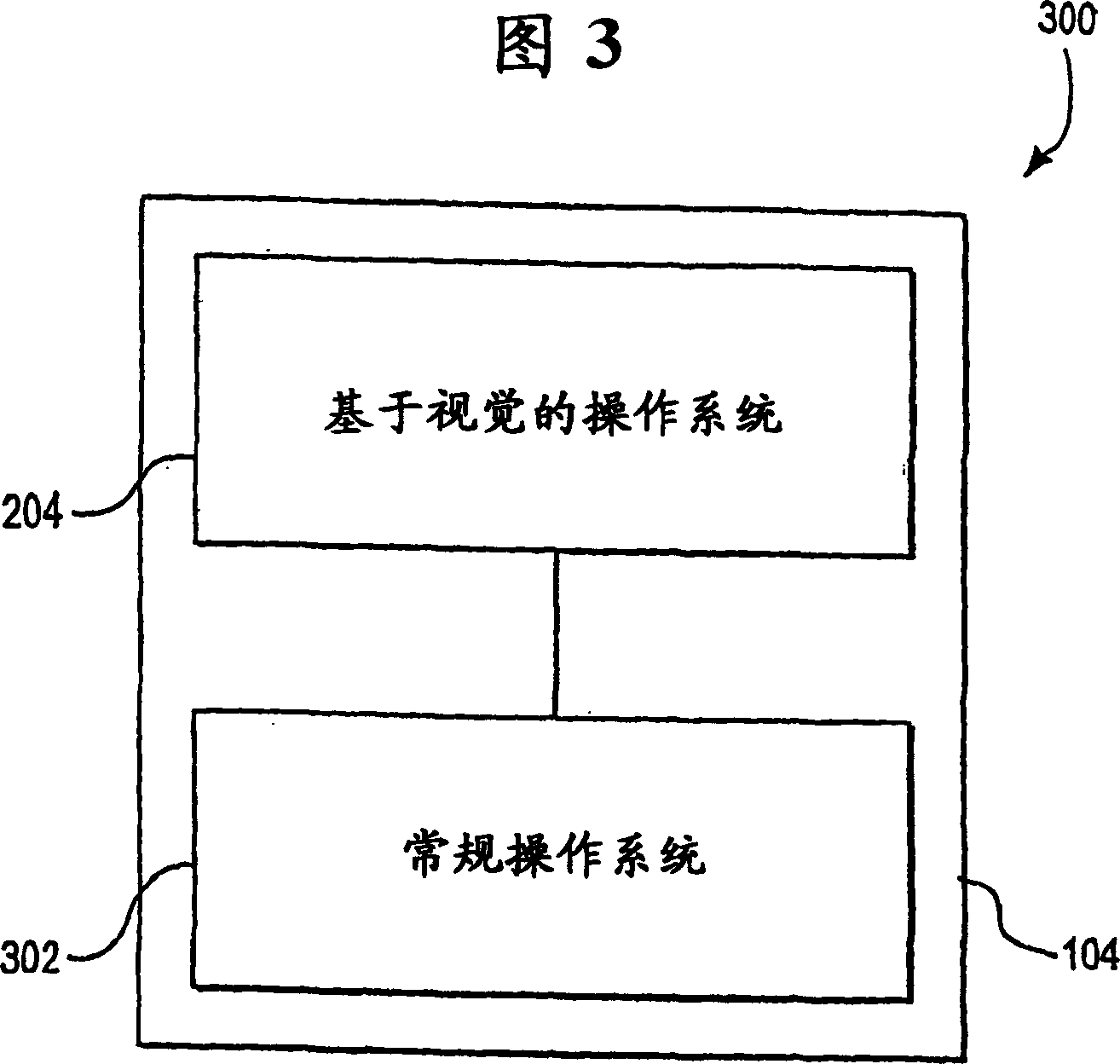

Vision-based operating method and system

InactiveCN1656503ADon't worry about granting accessImage analysisCharacter and pattern recognitionPattern recognitionOperational system

Embodiments of the present invention are directed to a method and apparatus for probabilistic image analysis. In one embodiment, an image is normalized and filtered. A determination is made regarding the likelihood of the image randomly matching characteristics of the reference image. If the likelihood is smaller than a threshold, the system determines that the image and the reference image match. In one embodiment, the likelihood is determined by using patches of skin in the images. In one embodiment, the likelihood is derived from the coherence of the optical flow computed between the two images. In one embodiment, the image is partitioned into a plurality of pixel regions. A pixel region in one image is mapped to a best-fit region in the other image. A neighbor region of the pixel region is mapped to a best-fit pixel region in the other image. The positional relationship between the pixel region and its neighbor is compared with the positional relationship between the two best-fit pixel regions.

Owner:IDENTIX

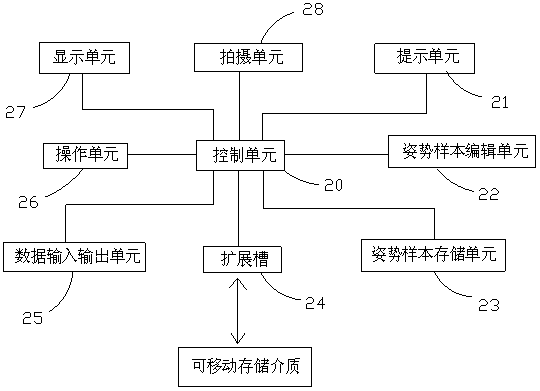

Digital camera with posture guiding function

InactiveCN102891958AImprove use valueImprove quality of lifeTelevision system detailsColor television detailsFitting - actionInput/output

The invention relates to a digital camera with a posture guiding function. The digital camera with the posture guiding function comprises a control unit, an image collecting unit, a display unit, an operating unit, a data input-output unit and a posture sample storage unit which is connected with the control unit and is used for storing at least one posture sample in advance; before shooting, the posture samples in the posture sample storage unit can be read through the control unit, and are displayed through the display unit for users to refer to in shooting. The digital camera disclosed by the invention can provide samples for shooting postures, and provide reference for users who are not good at posturing in shooting, can guide users to perform appropriate actions and expressions under different situations, and further can shoot perfect pictures.

Owner:BEIJING HUAQI PORTABLE DIGITAL

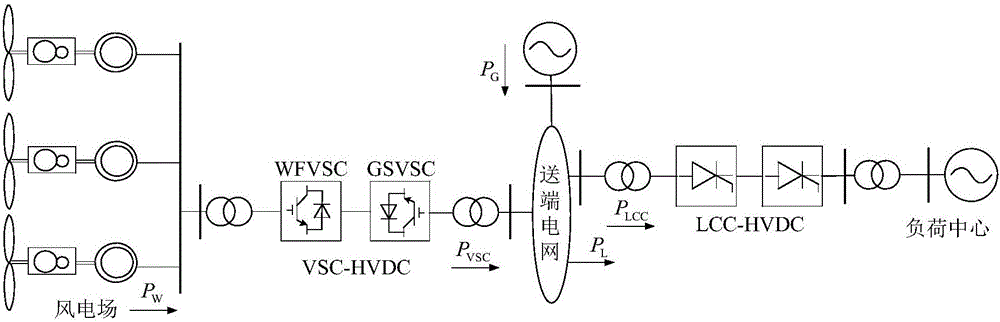

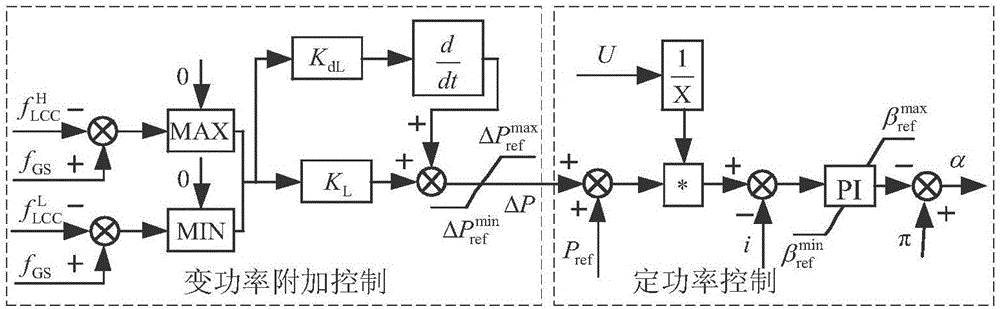

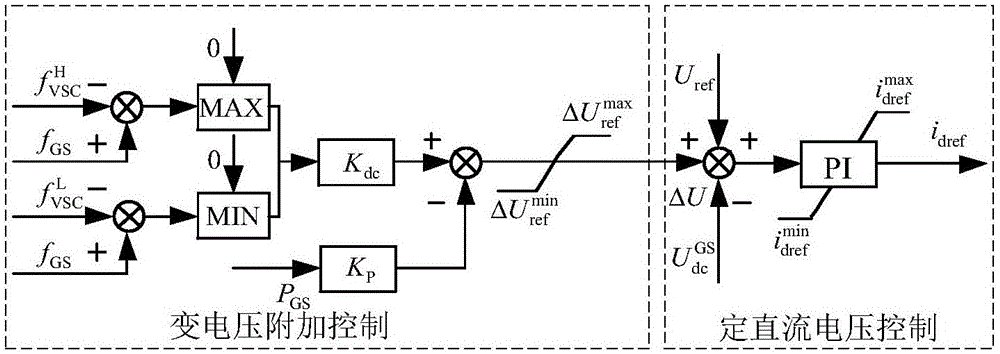

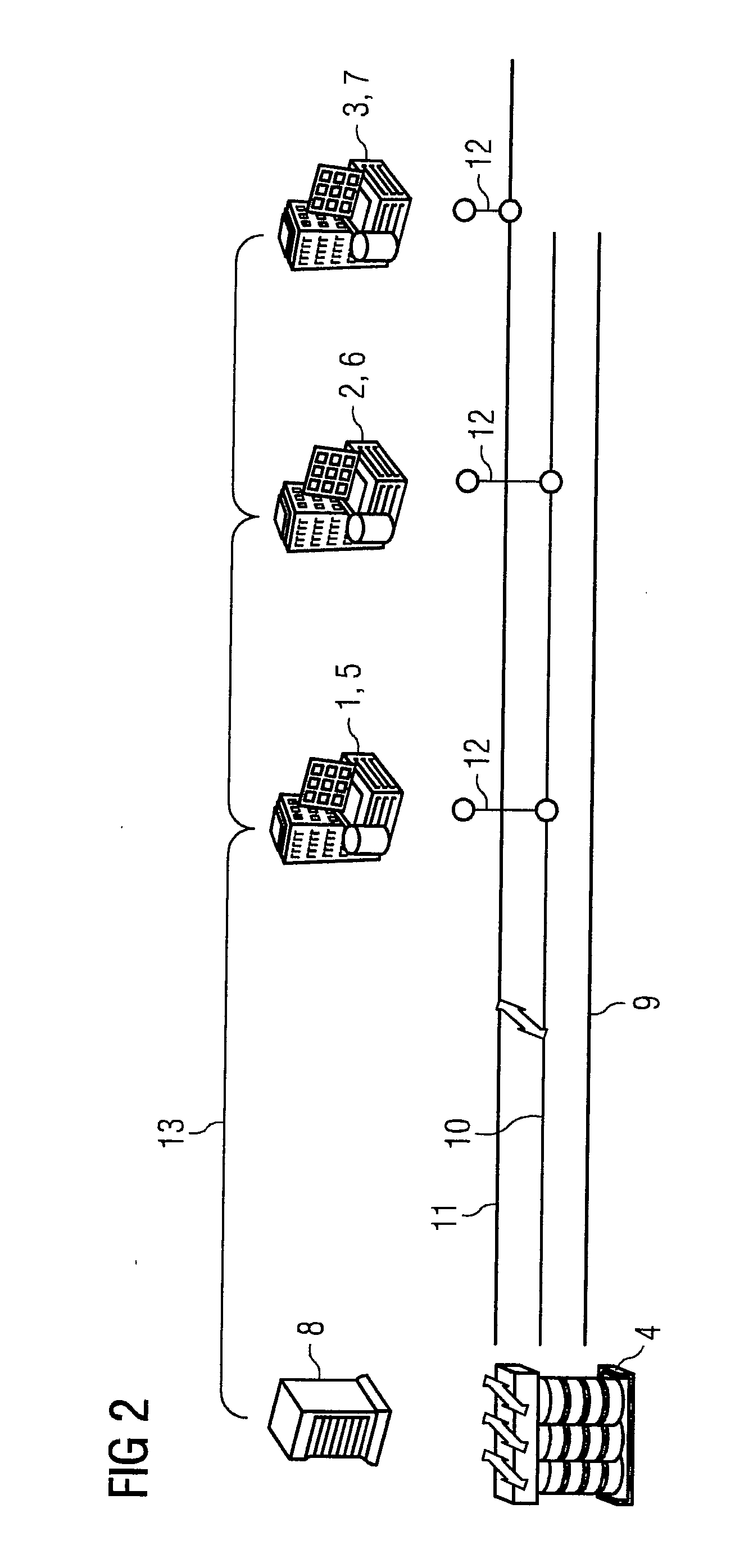

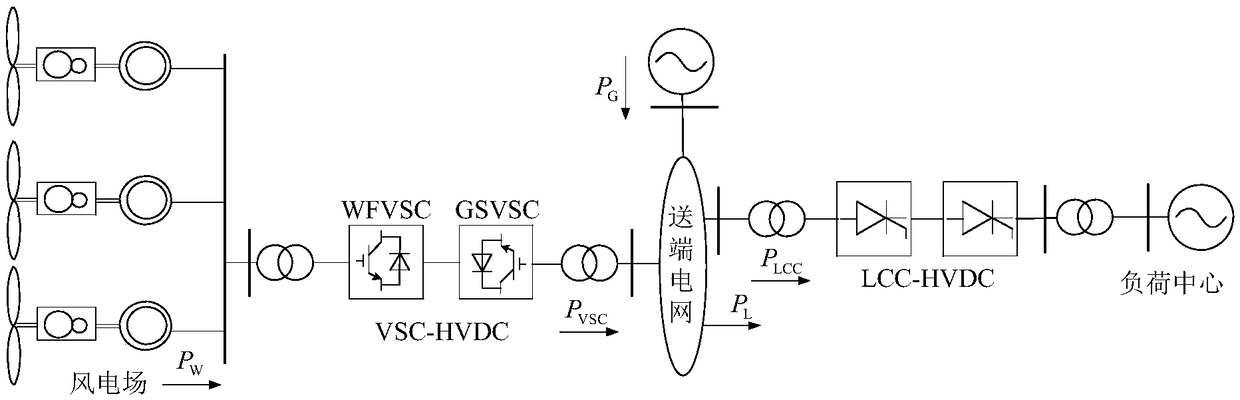

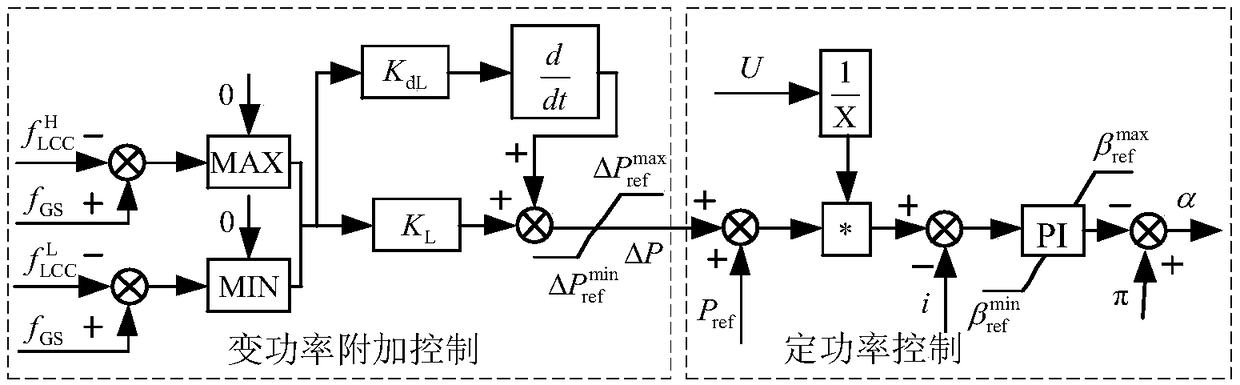

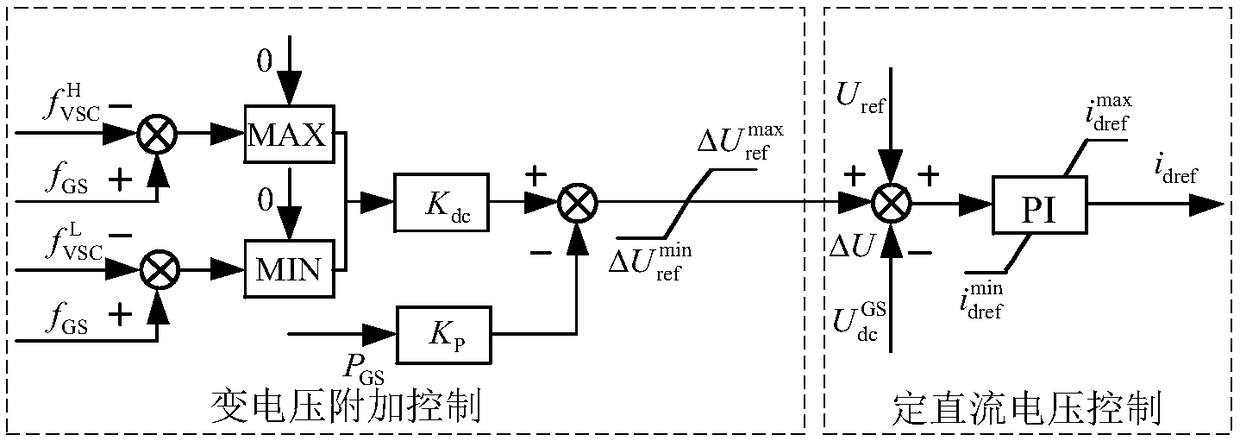

Wind farm direct current grid connection and direct current transmission source net coordination control method

ActiveCN106816887AReduce volatilityReasonable distribution of unbalanced powerElectric power transfer ac networkSingle network parallel feeding arrangementsTransmitted powerInertial control

The invention discloses a wind farm direct current grid connection and direct current transmission source net coordination control method. The wind farm direct current grid connection and direct current transmission source net coordination control method comprises steps that LCC-HVDC additional control is additionally provided, and power-frequency slope characteristics provided with dead zones and inertia control are introduced in LCC-HVDC rectifier station fixed power control, and then transmitted power is capable of responding to frequency of a sending-end power grid; VSC-HVDC additional control is additionally provided; draught fan additional control is additionally provided, and active-frequency slope characteristic and the inertial control are introduced in draught fans, and then active power output by the draught fans is capable of responding to changes of WFVSC side frequencies; coordination of controllers is additionally provided, proper motion dead zones are arranged, and then the various controllers are coordinated. By increasing the power-frequency statistic characteristic coefficient and the inertia response coefficient of the system of the sending-end power grid, the inertia of the sending-end power grid is increased, and the frequency stability of the system is improved.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID NINGXIA ELECTRIC POWER COMPANY +1

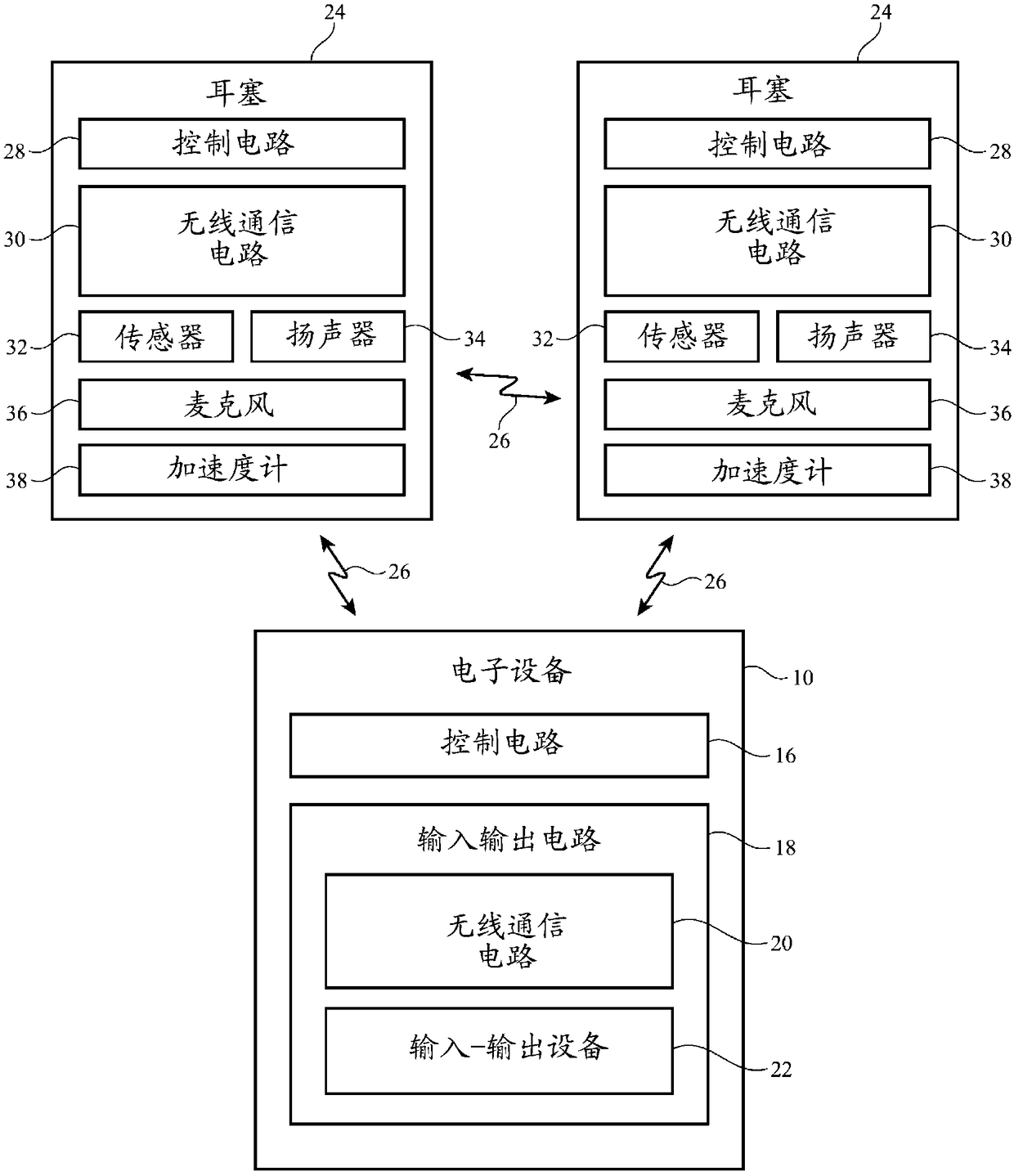

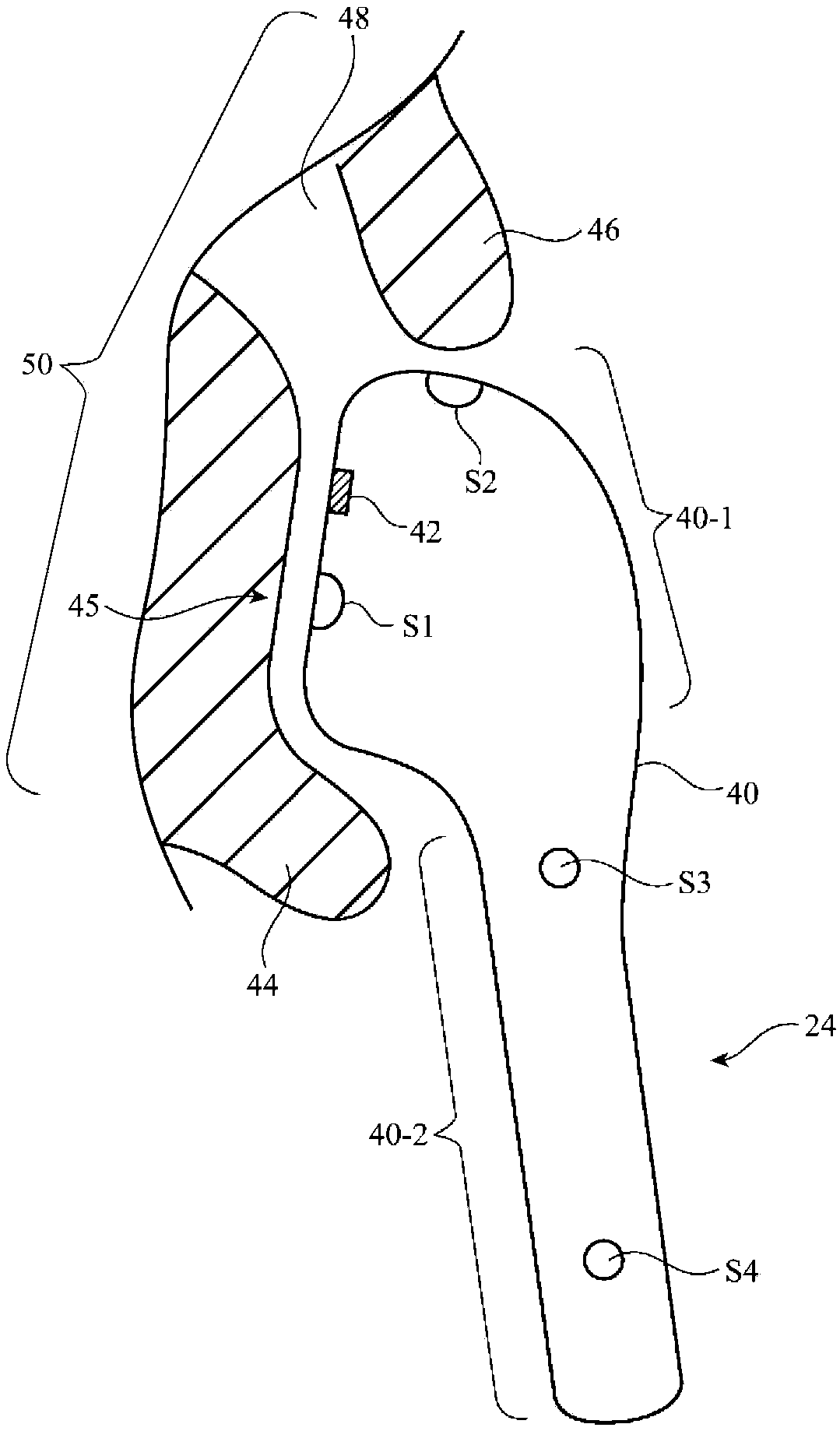

Wireless ear buds with proximity sensors

Owner:APPLE INC

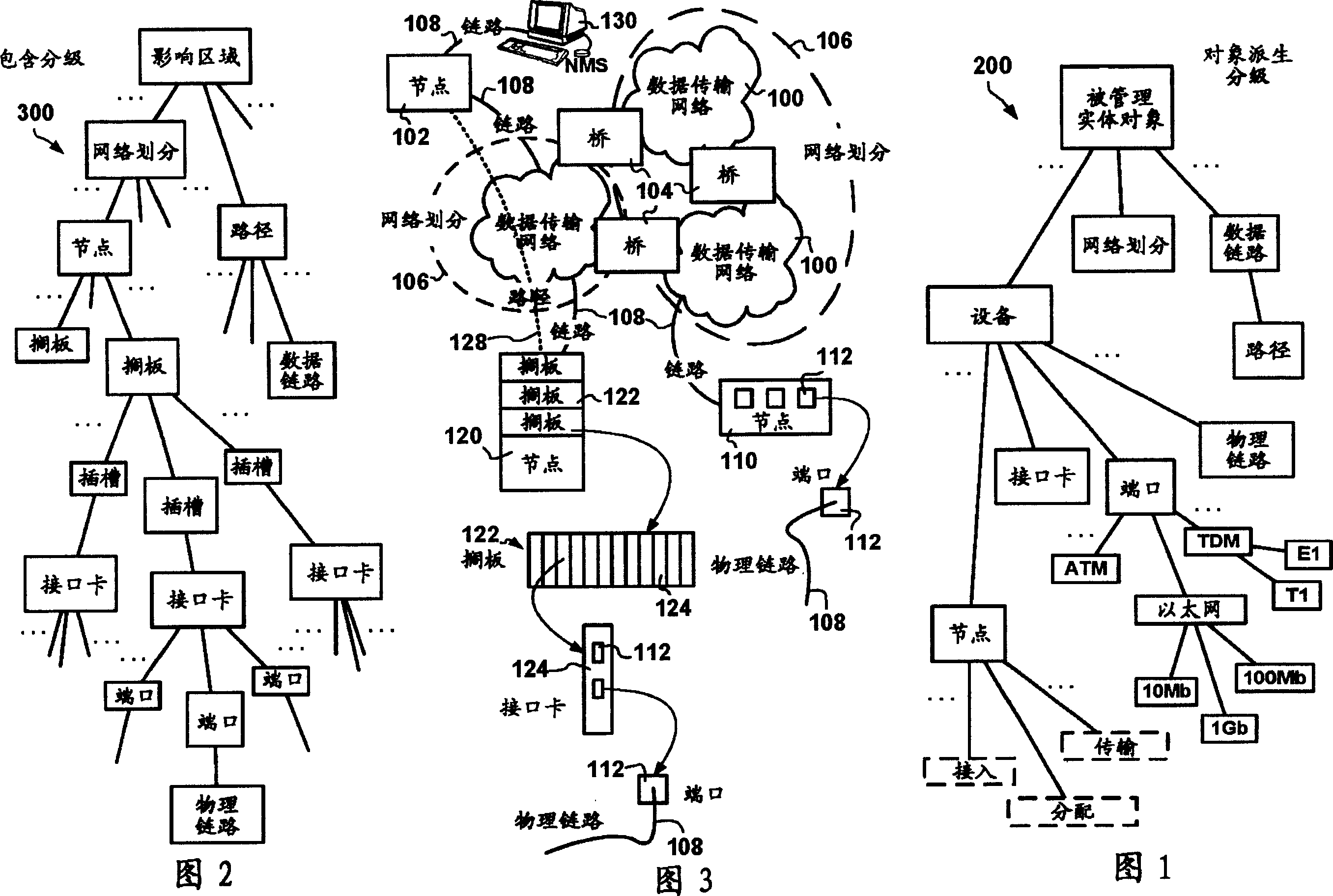

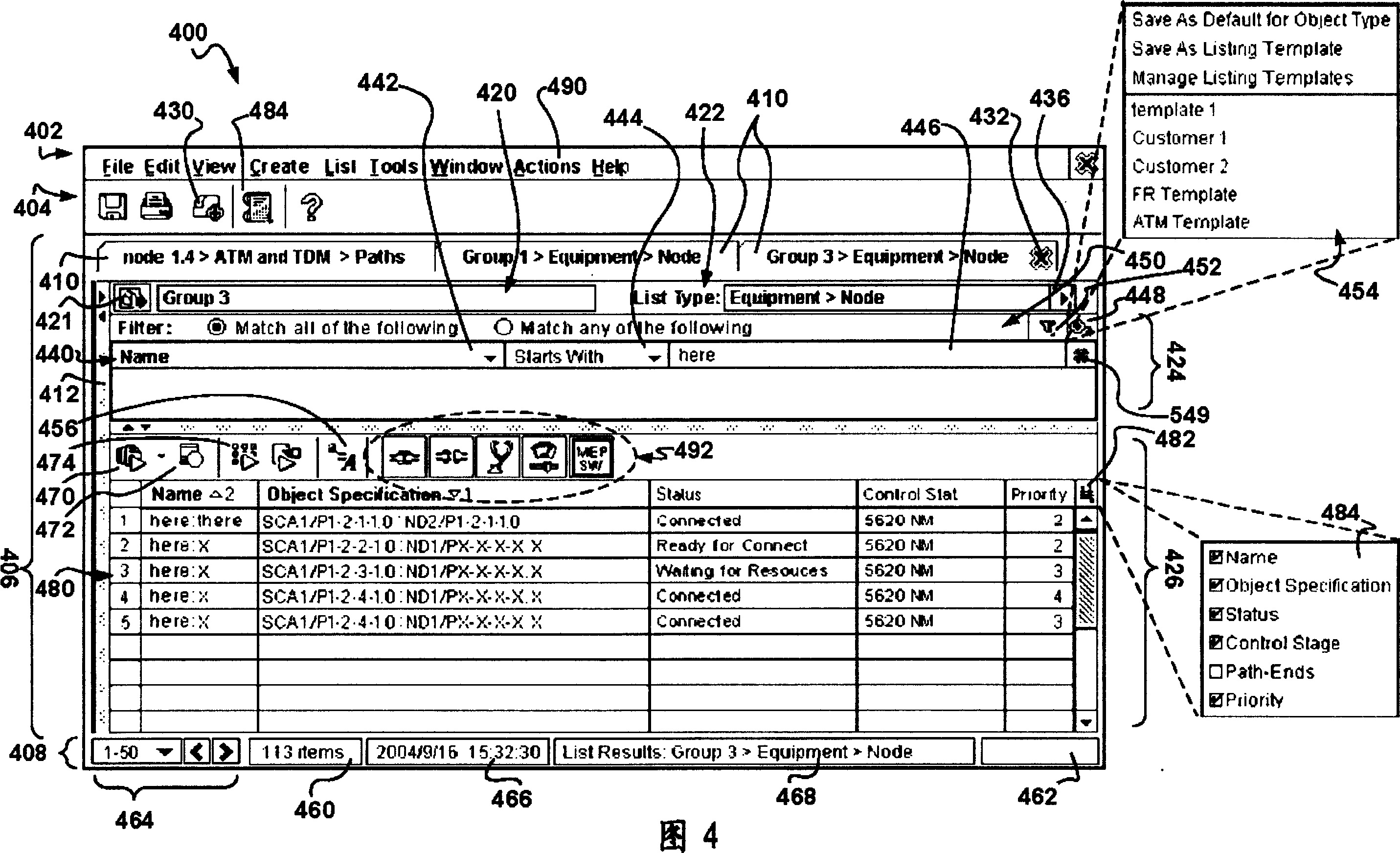

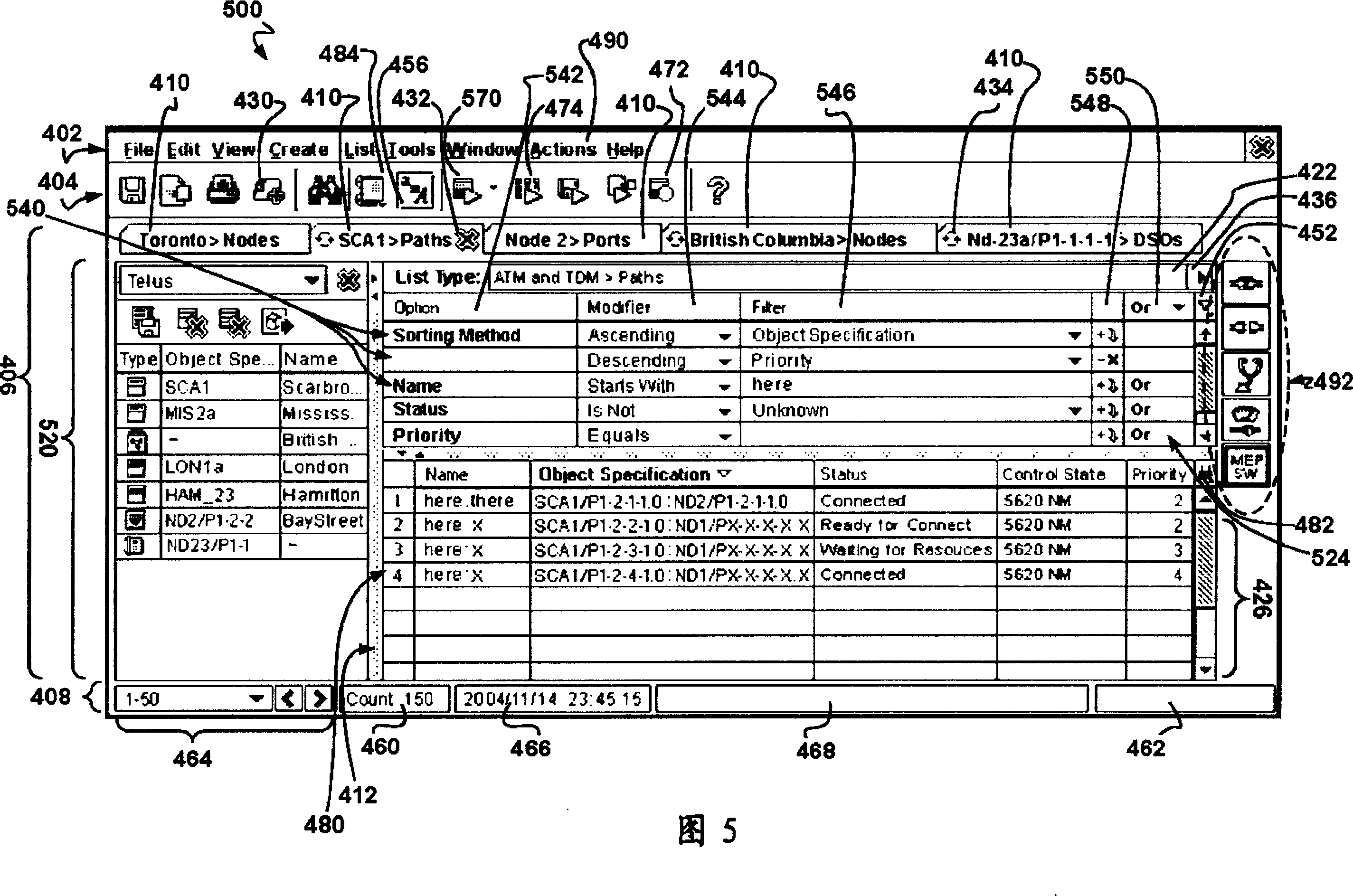

Graphical user interface for generic listing of managed objects

InactiveCN101013954AImprove inefficiencyImprove usabilityData switching by path configurationExecution for user interfacesGraphicsGraphical user interface

Graphical user interface for generic listing of managed objects and methods for efficiently filtering and sorting a large number of managed objects of different object types are presented. A single context-sensitive listing form is employed, the operation and display of which changes dynamically according to the selection of a target object. Whenever the user changes the selected target object, the items of a list type menu change to display the applicable list types. An action menu and / or a context-sensitive tool bar changes based on the selected target object to provide quick access selected object type specific actions. The solution allows users to paste objects into the listing form, perform complex filtering based on the object type used, provide a quick assessment of list filtering effectiveness, and invoke appropriate actions on managed object hits. Advantages of the solution include enhanced complex context-sensitive filtering and sorting capabilities, improved performance in dealing with large lists as well a reduction in window management.

Owner:ALCATEL LUCENT SAS

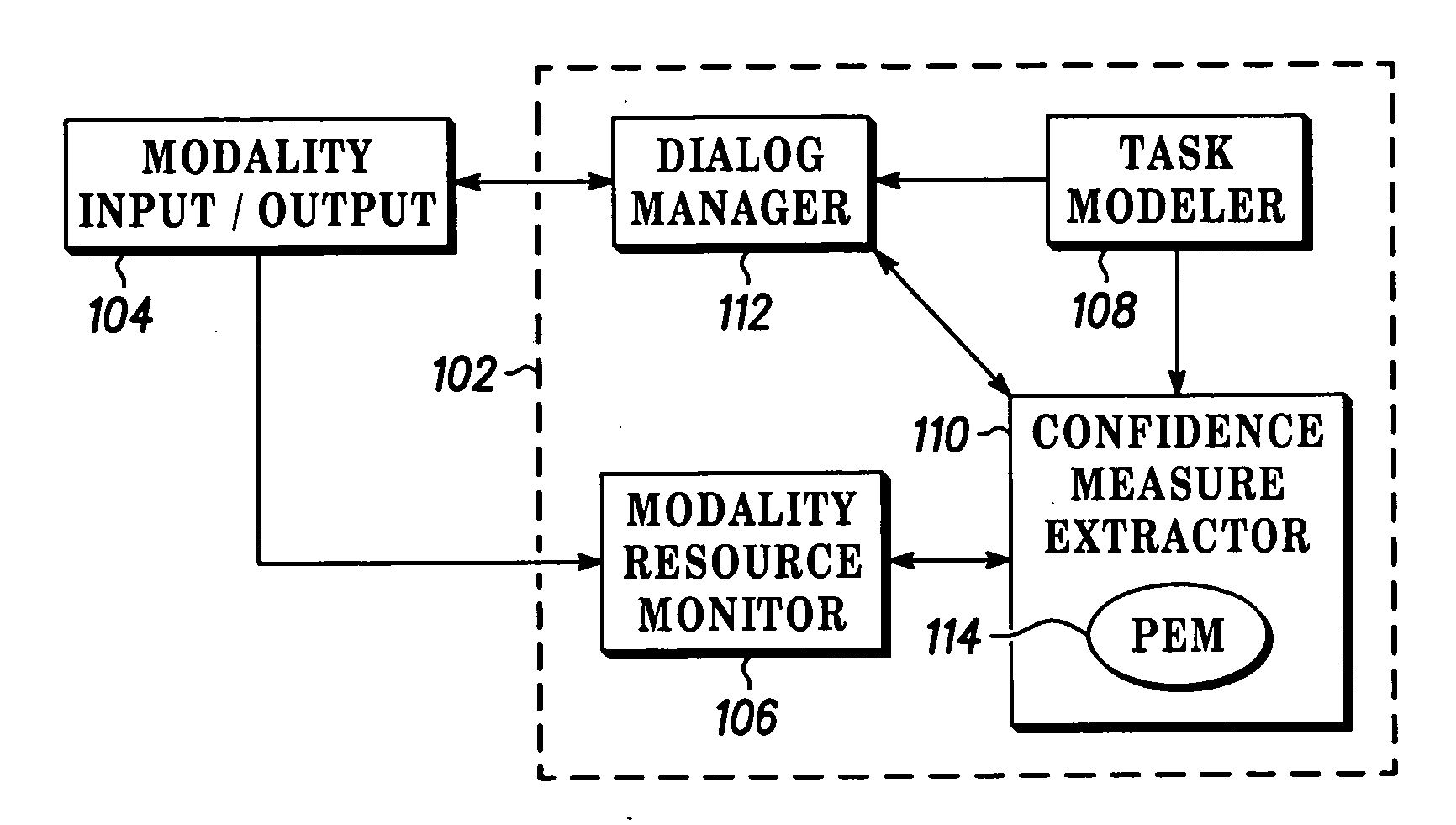

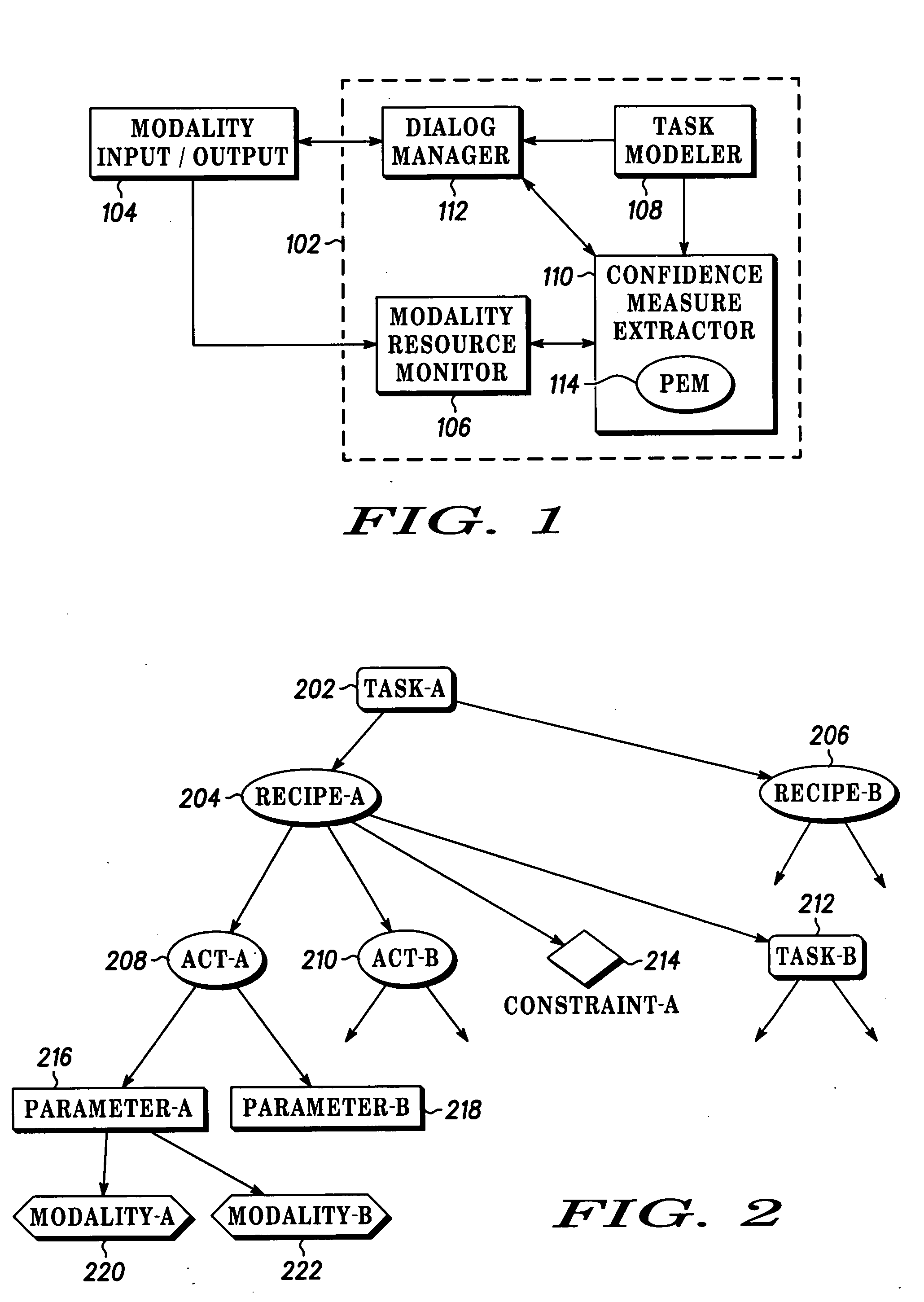

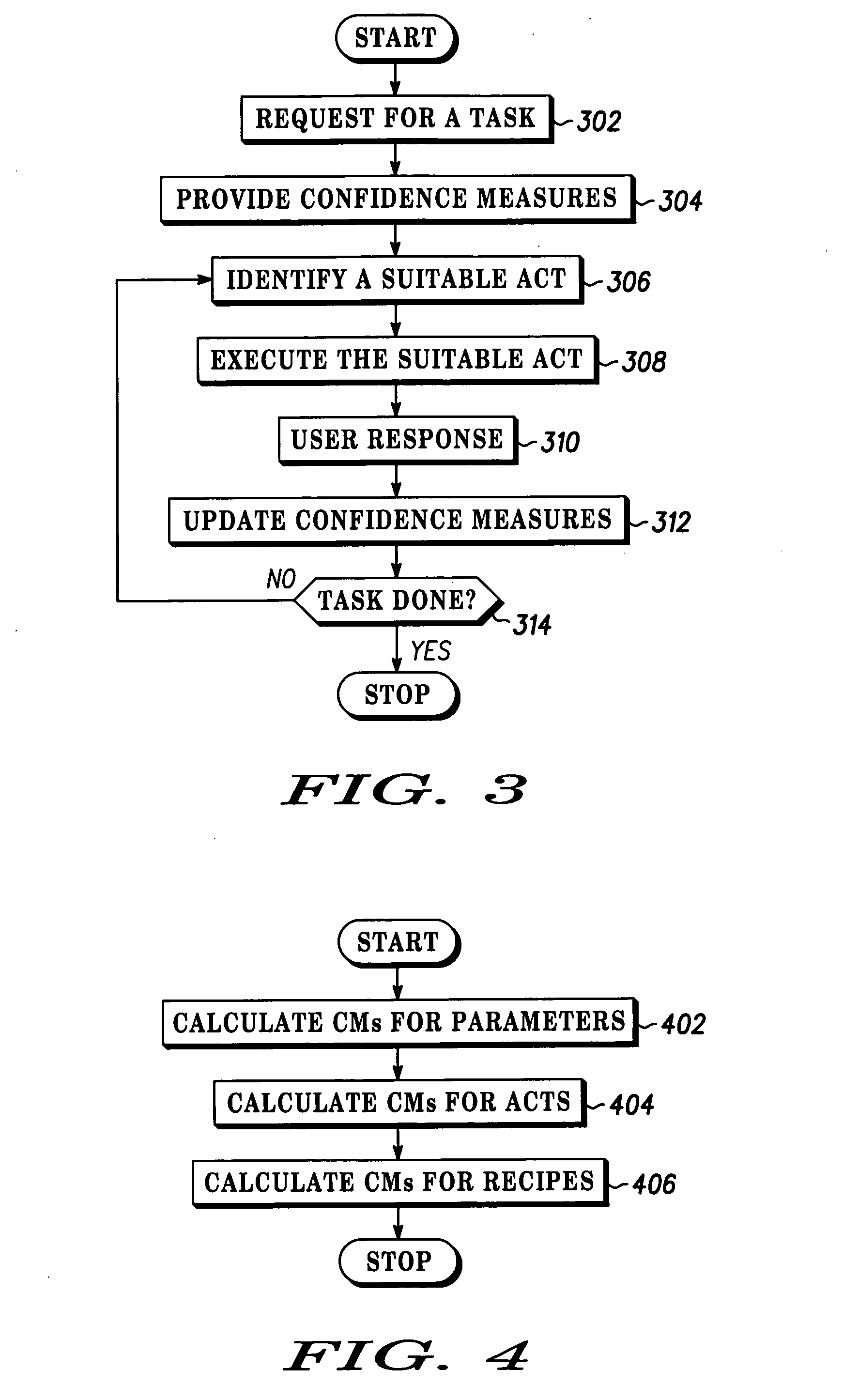

Multi-level confidence measures for task modeling and its application to task-oriented multi-modal dialog management

InactiveUS20050004788A1Maximize probabilitySpeech recognitionProgram controlTask completionDialog management

A method and system (102) is provided for a multi-modal task-oriented dialog management implemented on a computer-based system. The system (102) maximizes the probability of successful task completion after a task is requested (302). Every task is associated with a task model comprising recipes, acts, parameters and modalities. Confidence measures are calculated at various levels for each task. The confidence measures represent the probability of success of the action depending on the user preferences. The most suitable recipe, act, parameter and modality are selected at runtime using the provided confidence measures (304) to maximize the probability of task completion. After each act, confidence measures are modified (312) depending on the user response, and the next suitable act is accordingly selected. Optionally, a post evaluation module (PEM) is provided for monitoring the user response and modifying the formulation for the confidence measures calculation.

Owner:MOTOROLA INC

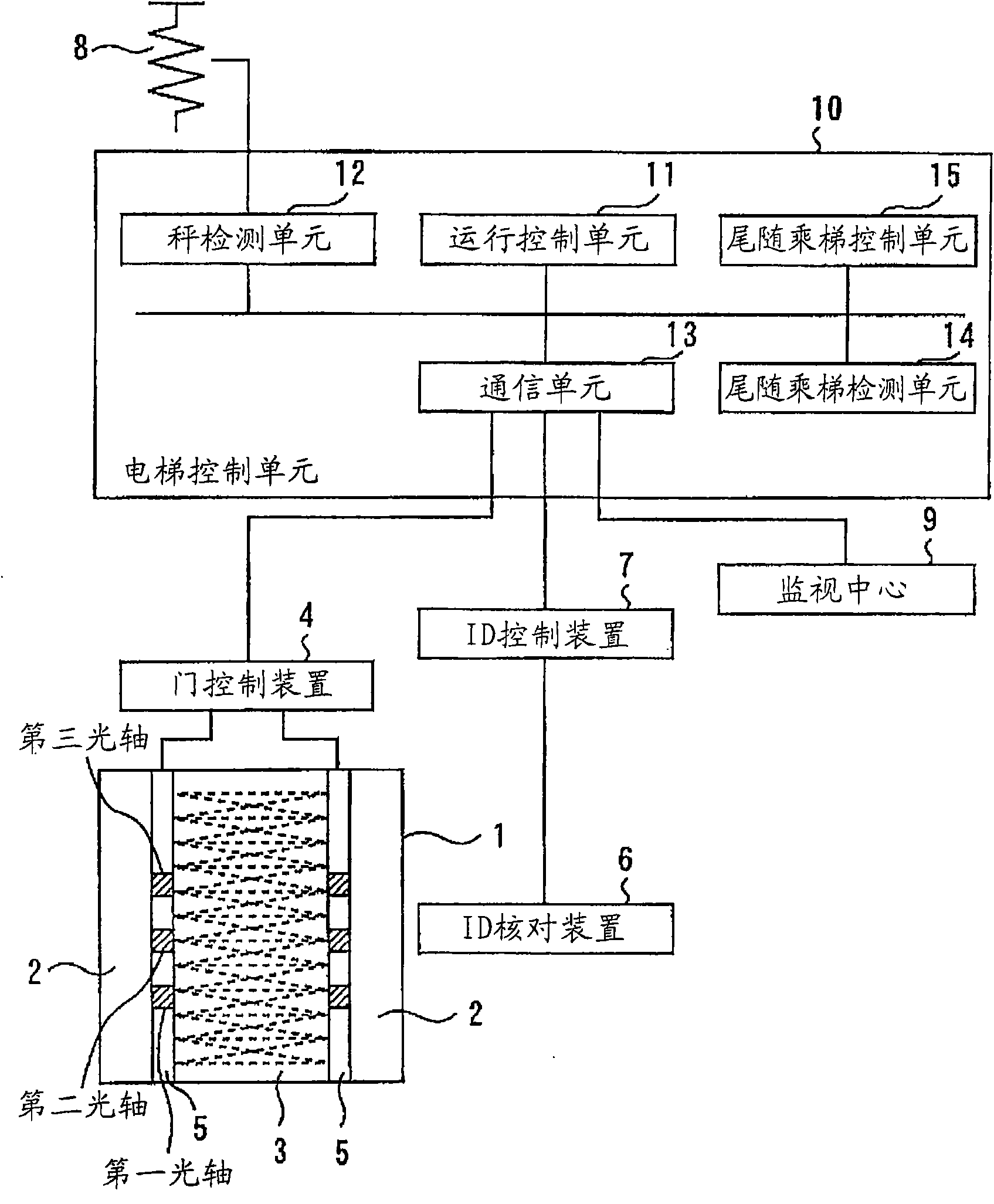

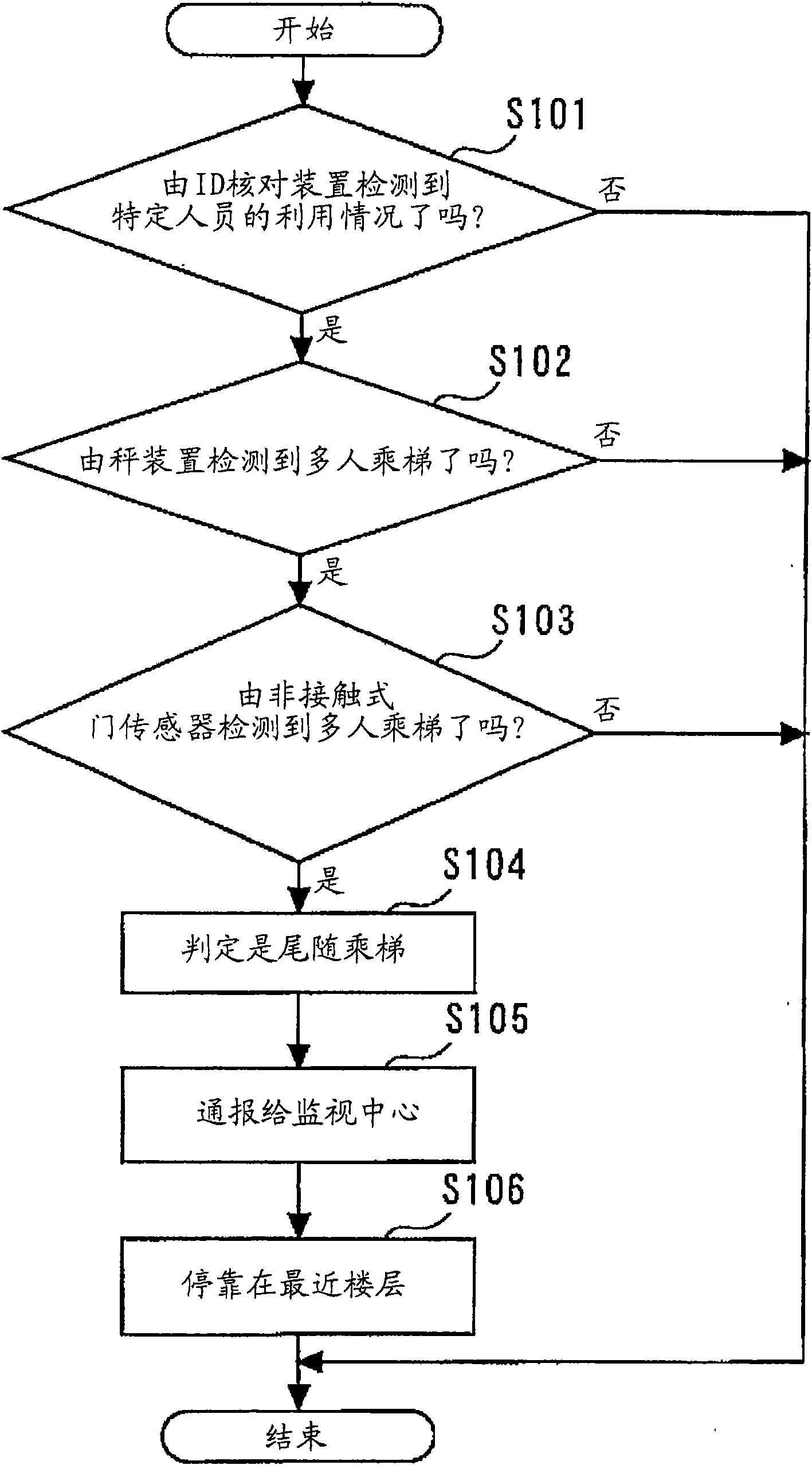

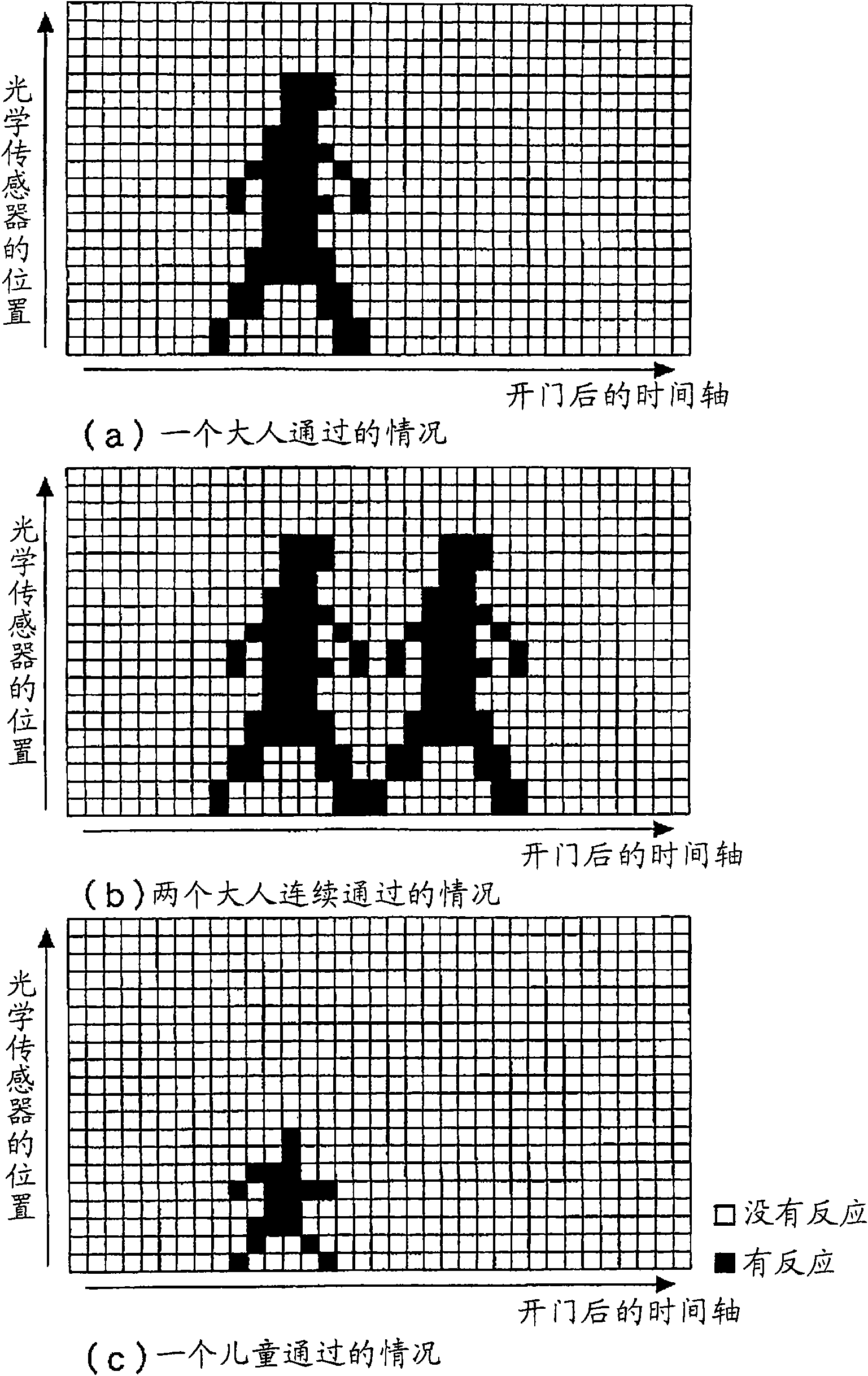

Controller for elevator

A controller for an elevator which can detect tailgating using a low-cost configuration and perform proper operation upon detection of tailgating. For this purpose, an ID checking device, a noncontacttype door sensor for detecting a user getting on a cage, and a weighing scale detection means for detecting a user in accordance with the deadweight of a cage are provided on the elevator. When use of the elevator by an identified person is detected by the ID checking device and when it is detected by both the noncontact type door sensor and the weighing scale detection means that a suspicious individual gets on a cage together with the identified person, it is judged that tailgating takes place. In the event of occurrence of tailgating, the controller controls the elevator to perform the specified operation for eliminating tailgating and for notifying occurrence of tailgating to the outside.

Owner:MITSUBISHI ELECTRIC CORP

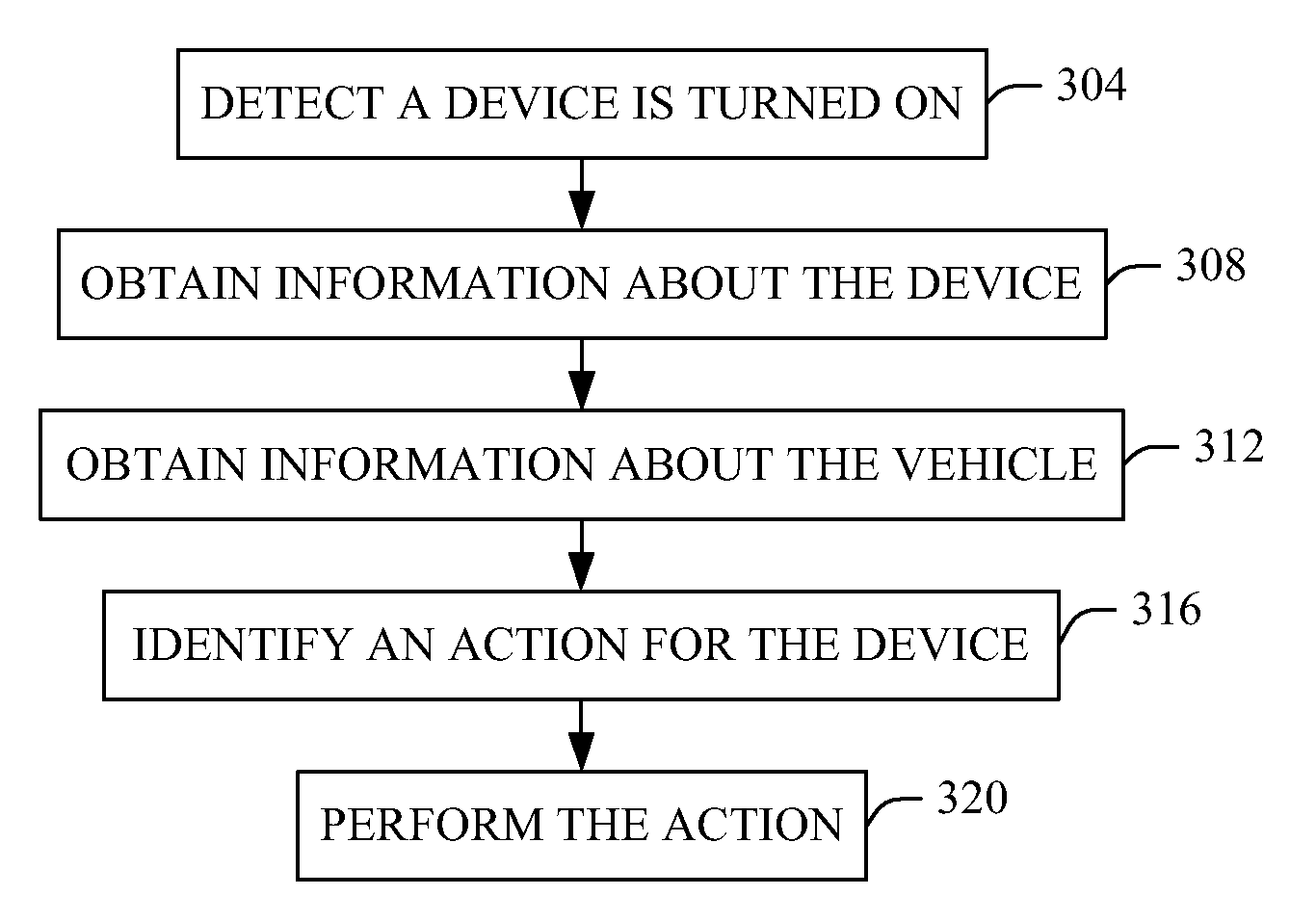

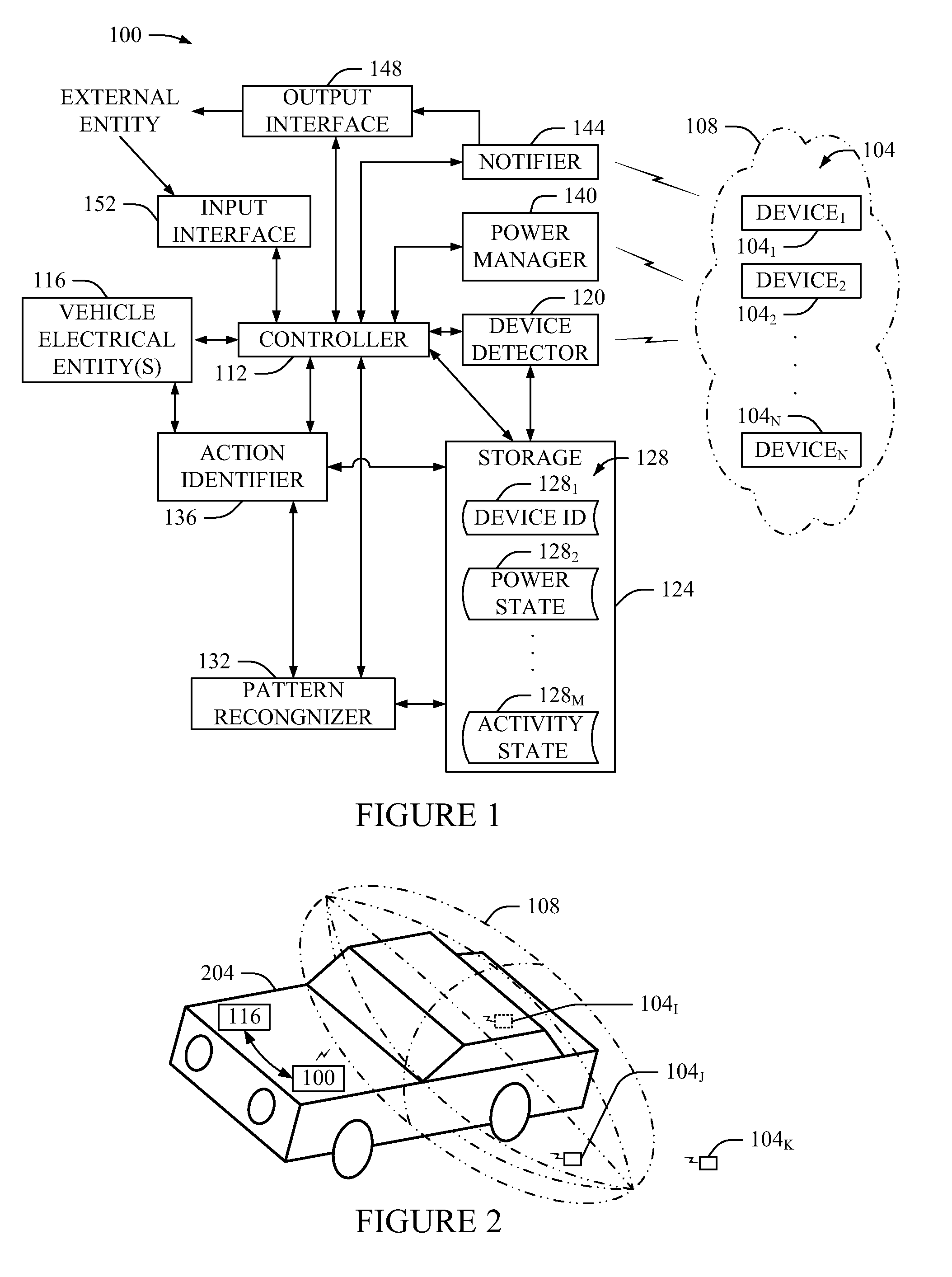

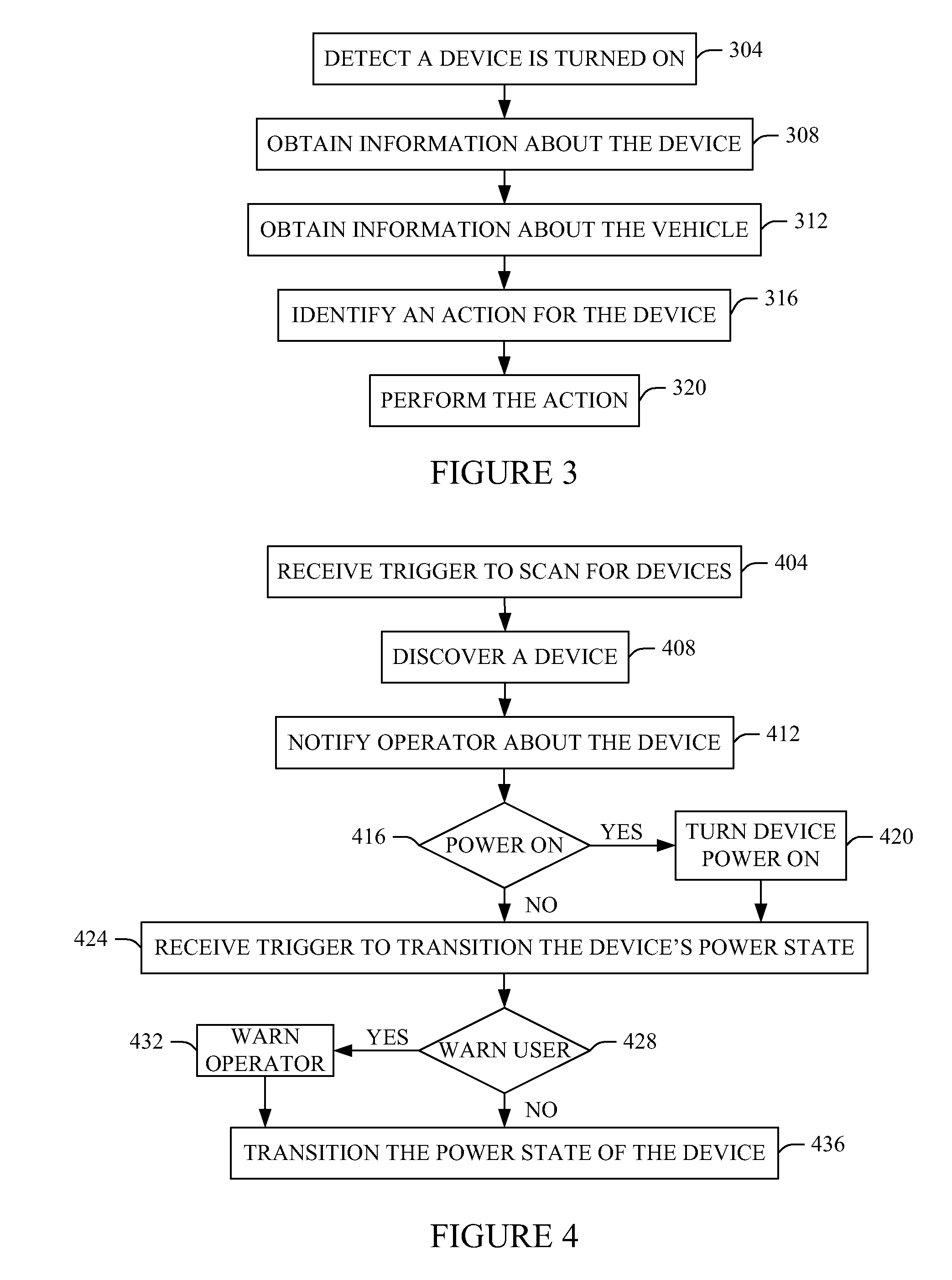

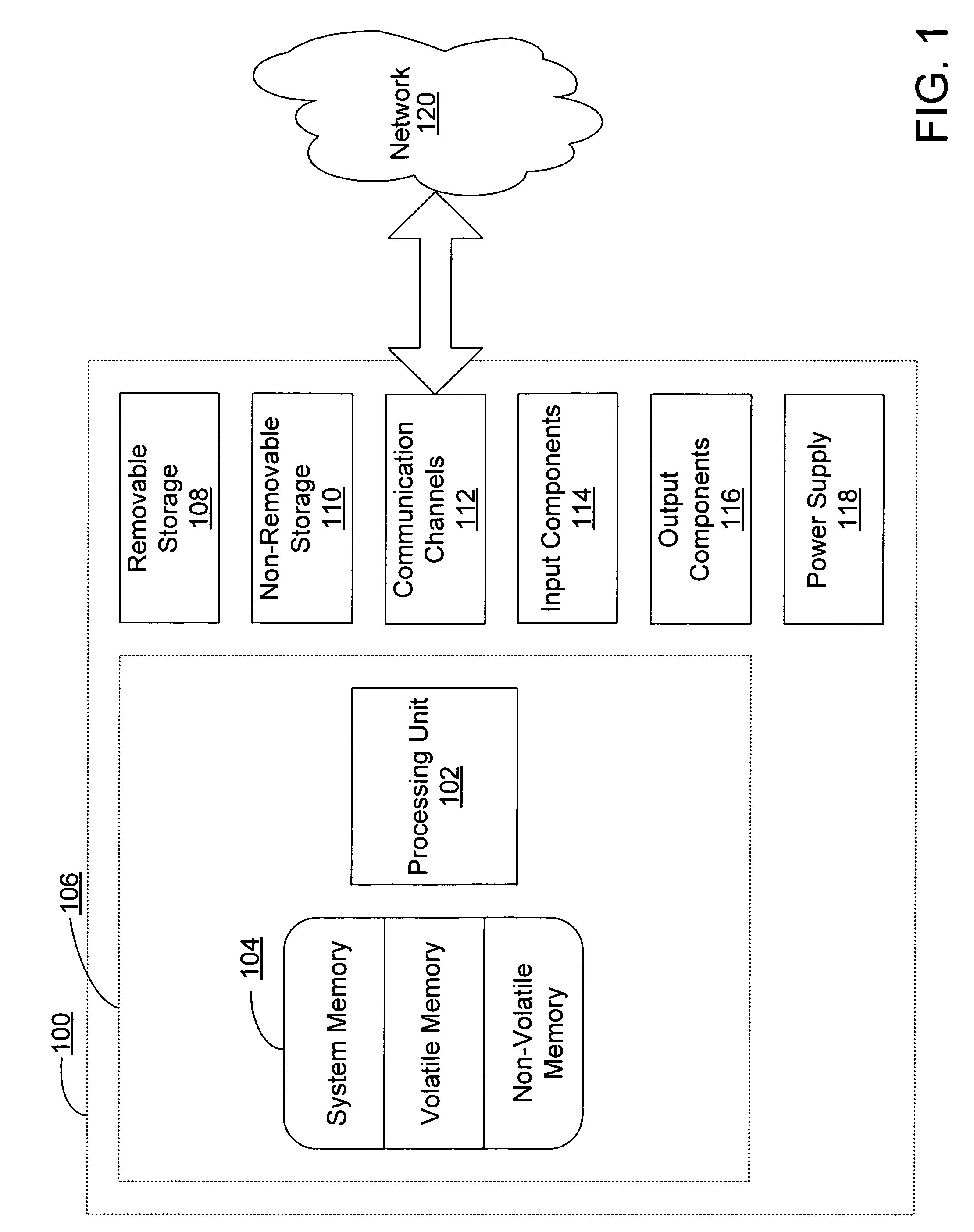

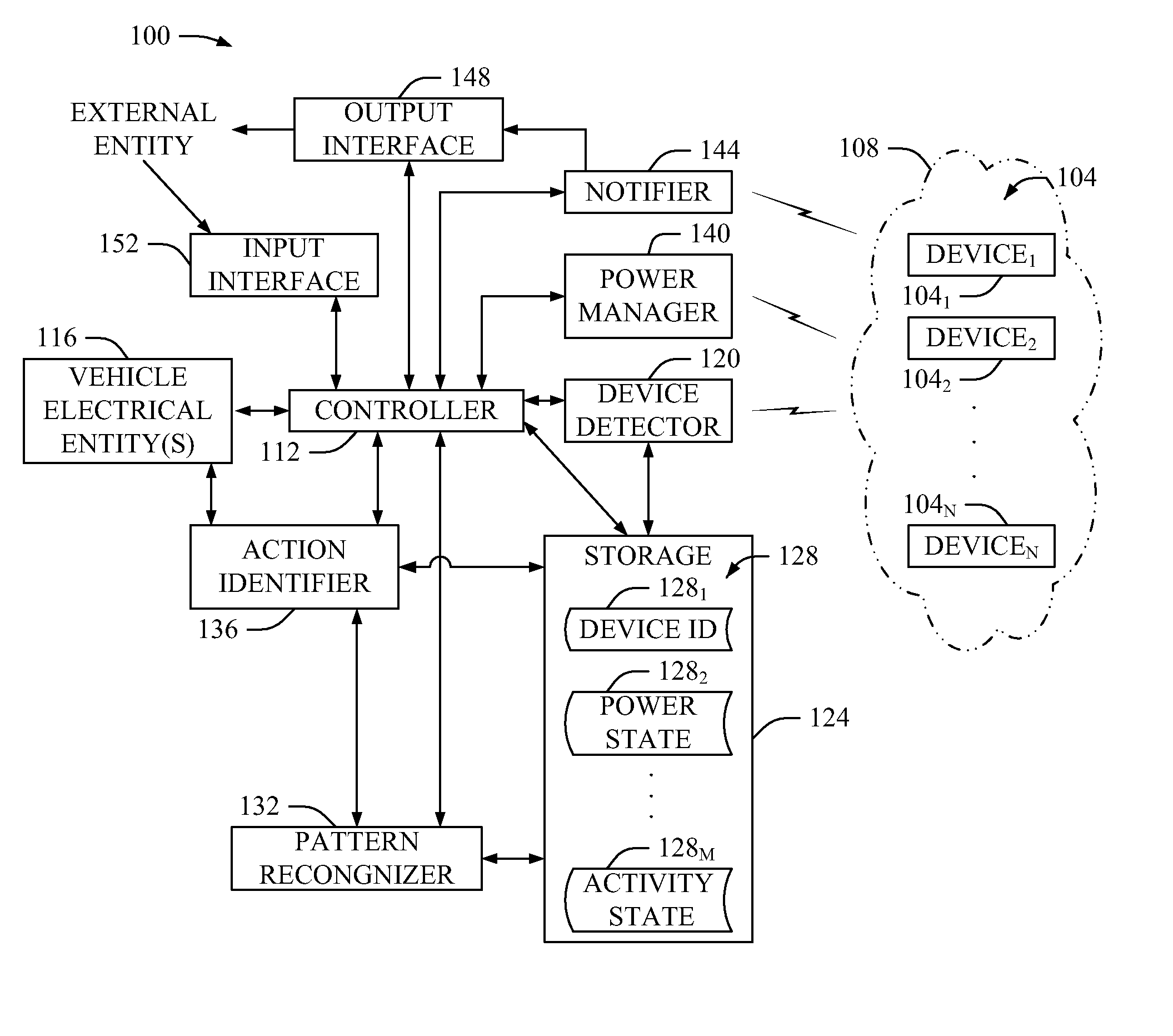

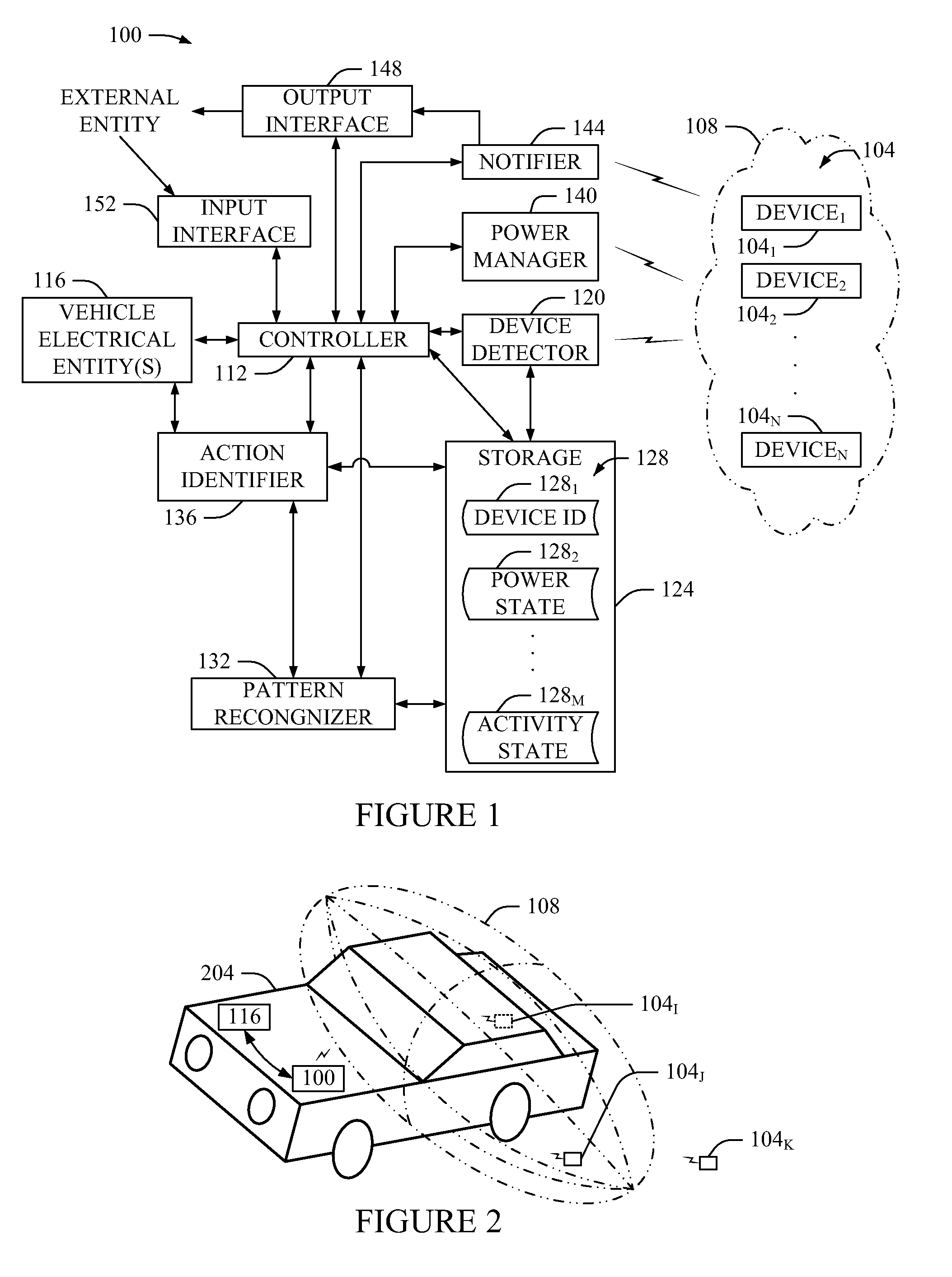

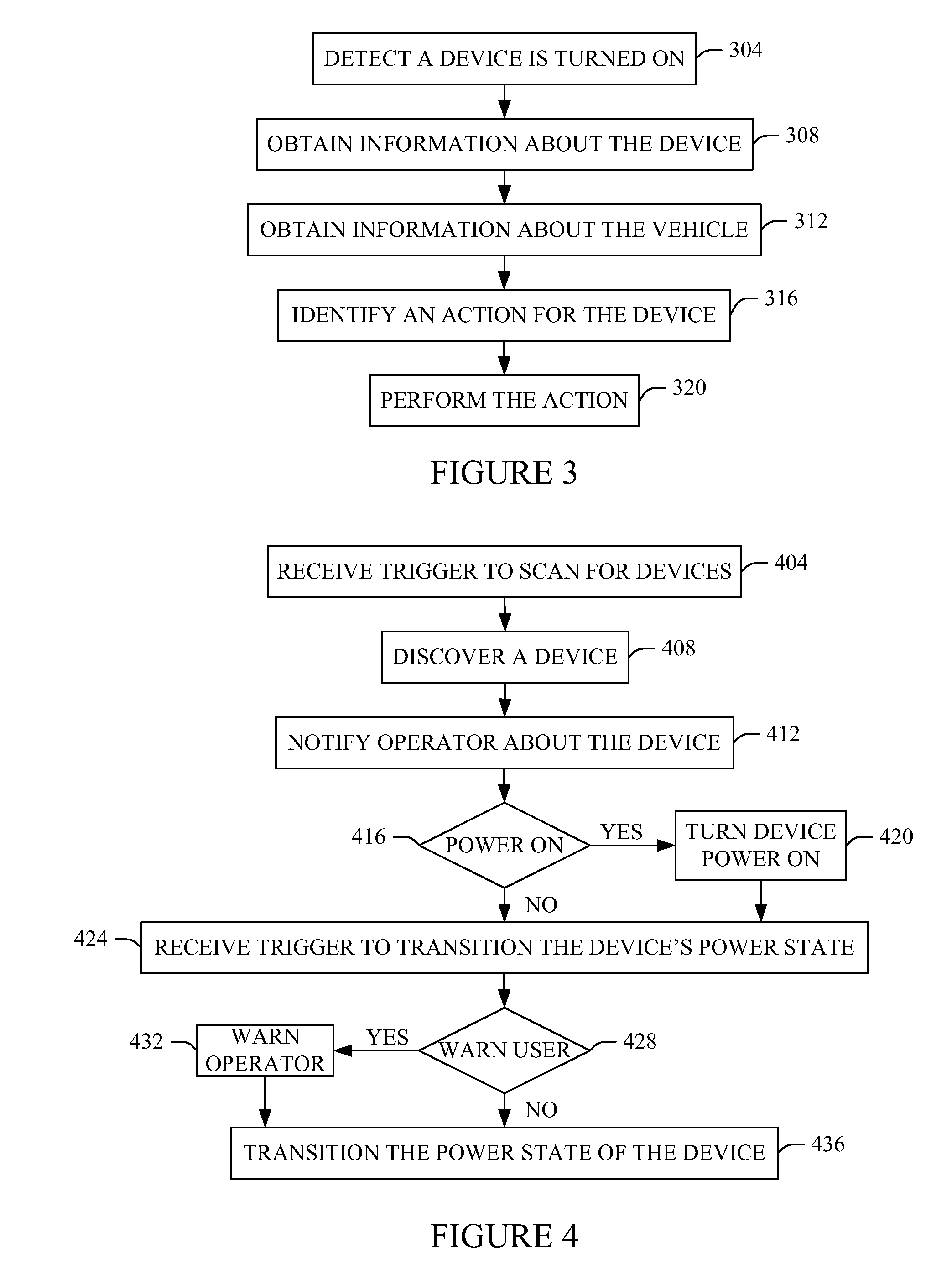

Vehicle method, system, and program product for managing electrical device power state

A system, method, and program product that manages the power state of a portable electrical device located within a monitored region about a vehicle. Information about the portable electrical device such as the power state of the portable electrical device is obtained and used to identify an action for the portable electrical device. Suitable actions include, but are not limited to, transitioning the power state of the portable electrical device and / or providing a notification about the portable electrical device. Other information such as the state of the ignition of the vehicle and / or the proximity of the driver and / or a passenger(s) with respect to the vehicle may additionally or alternatively be used to determine the action.

Owner:IBM CORP

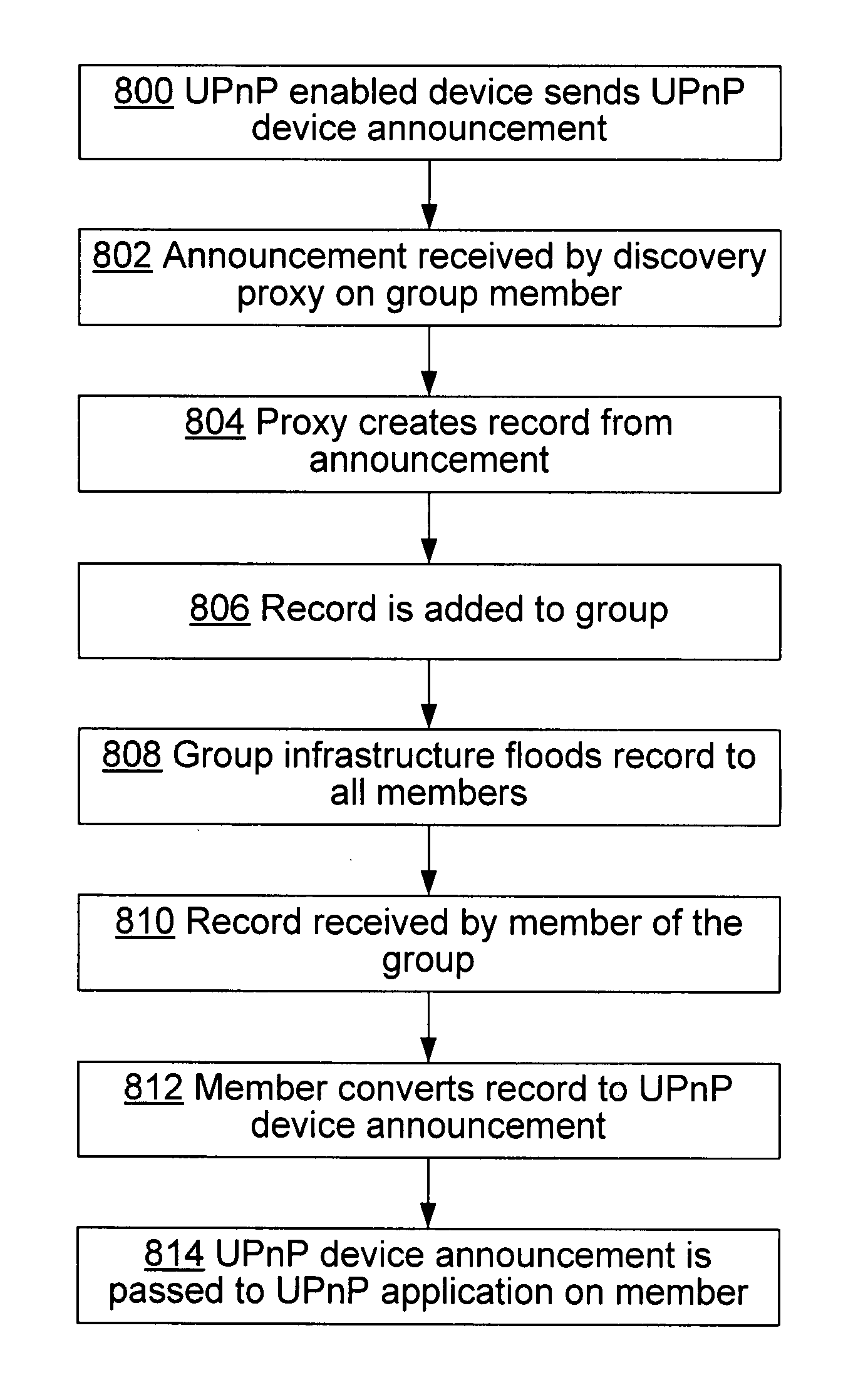

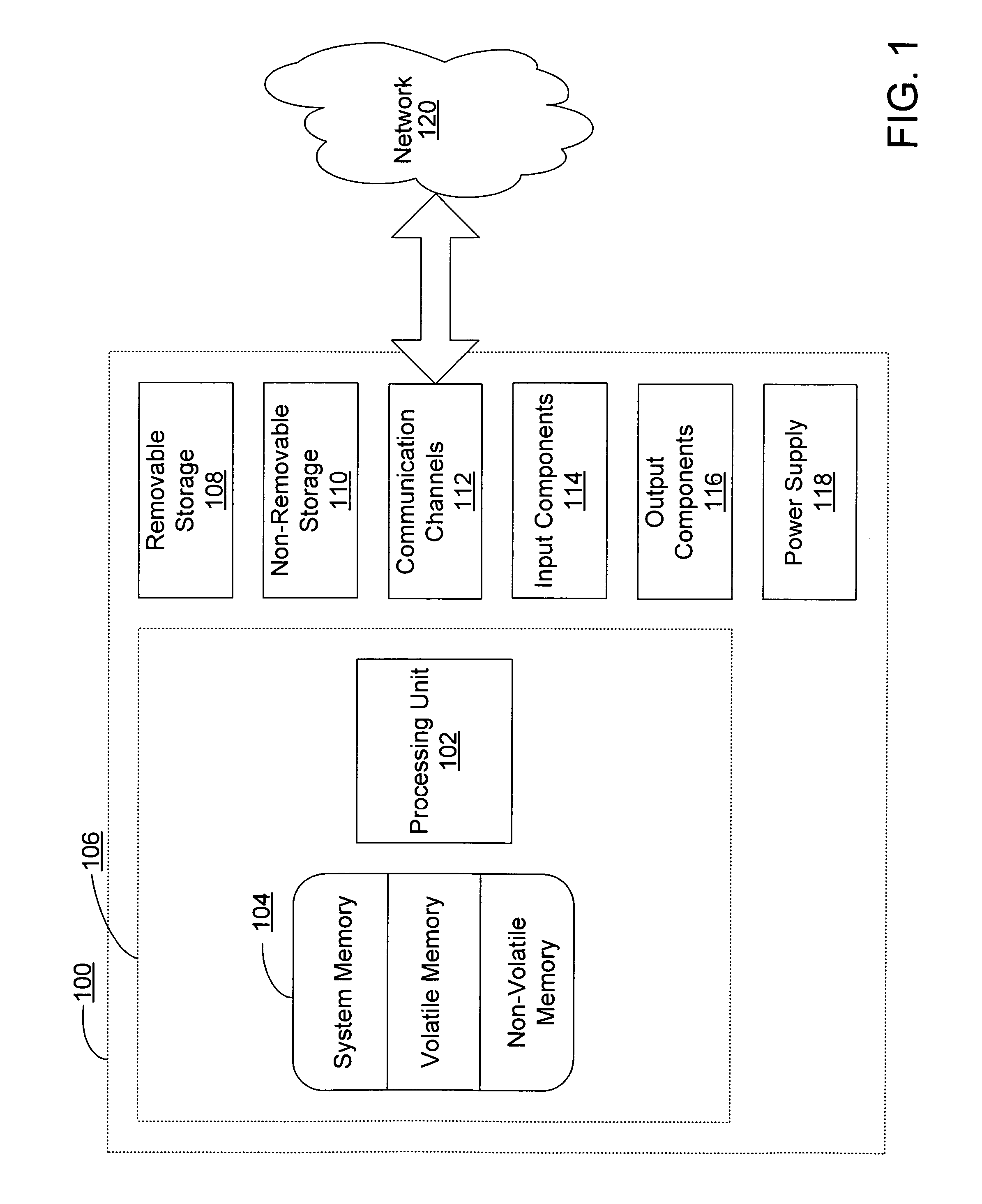

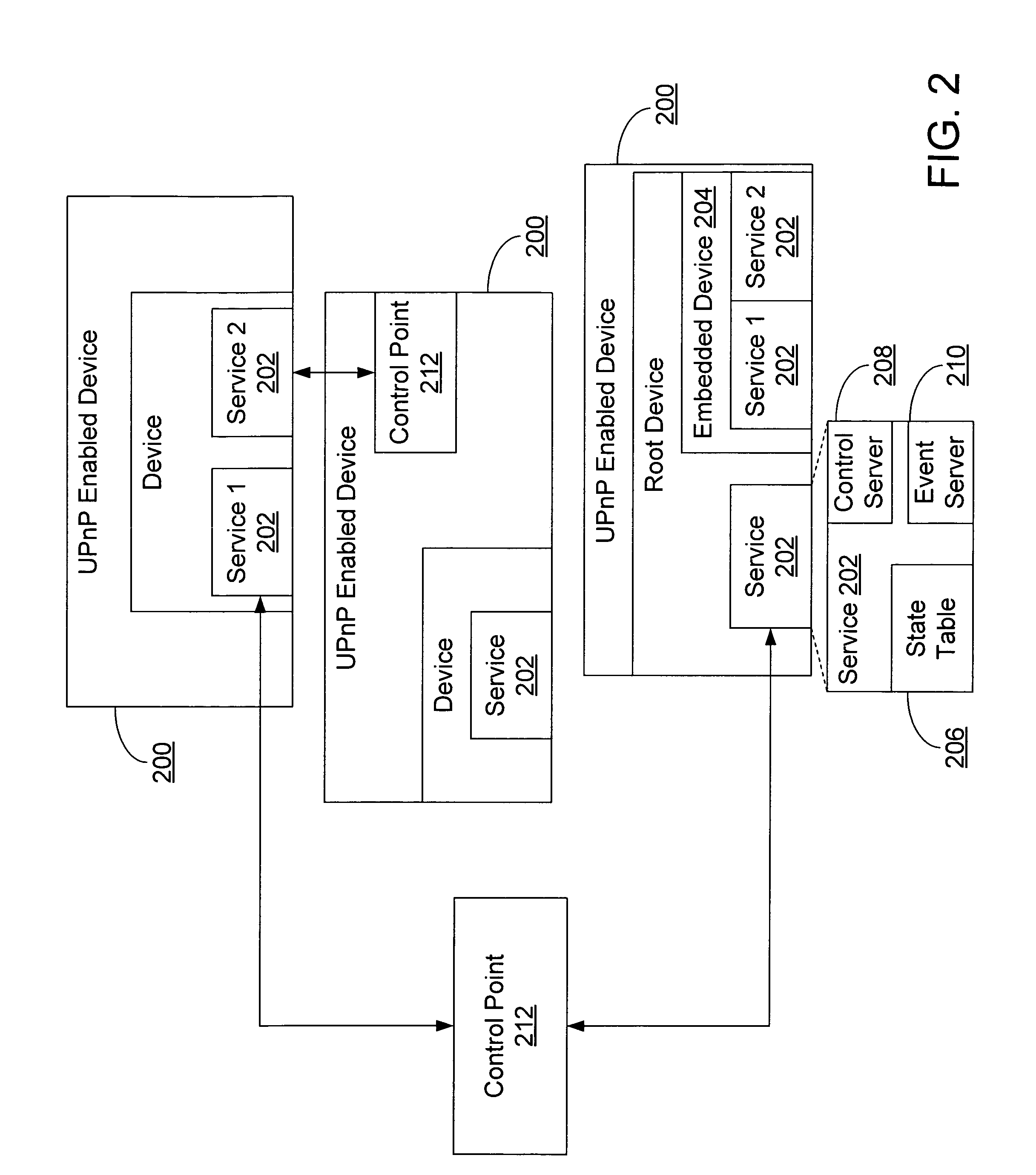

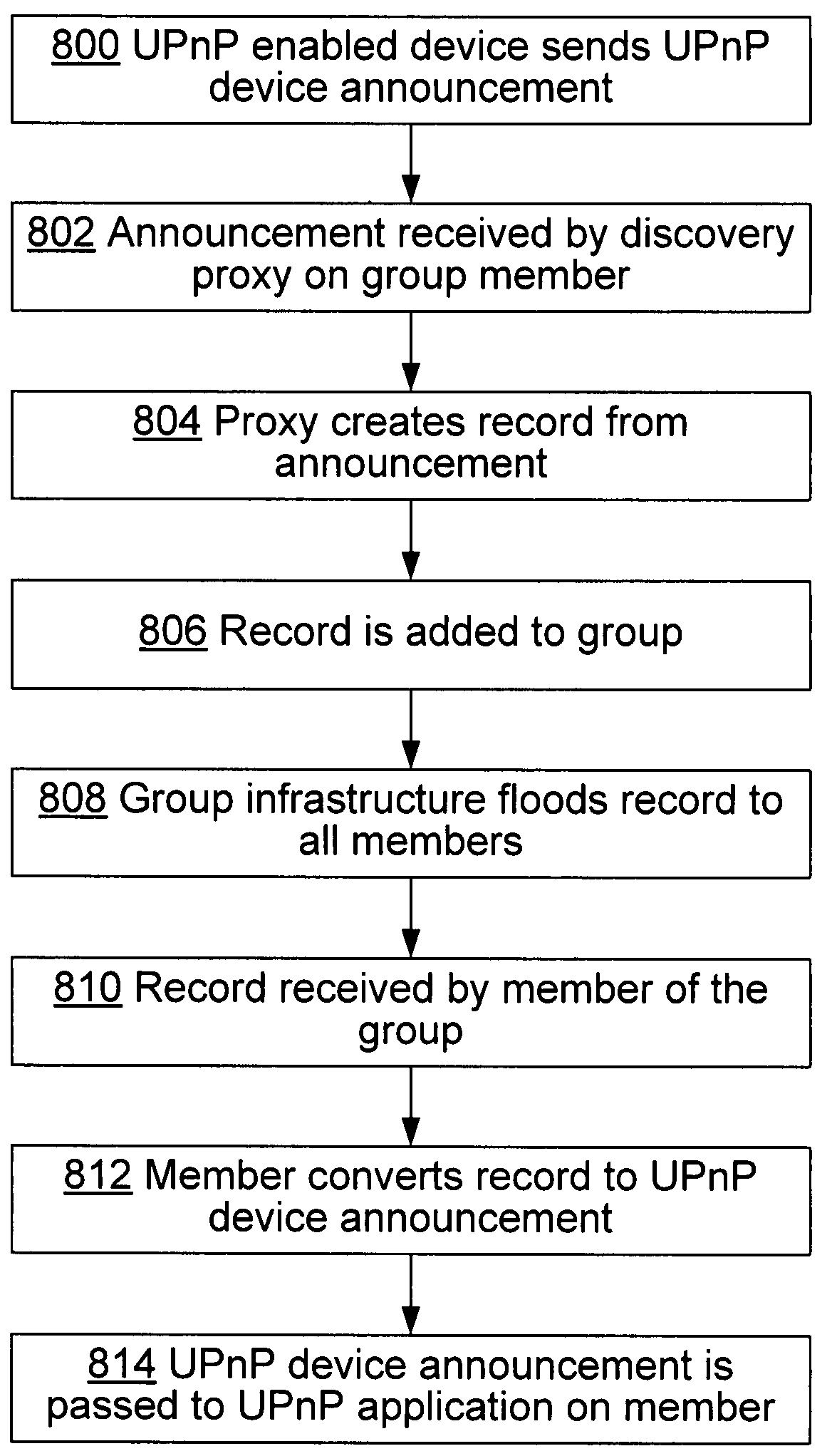

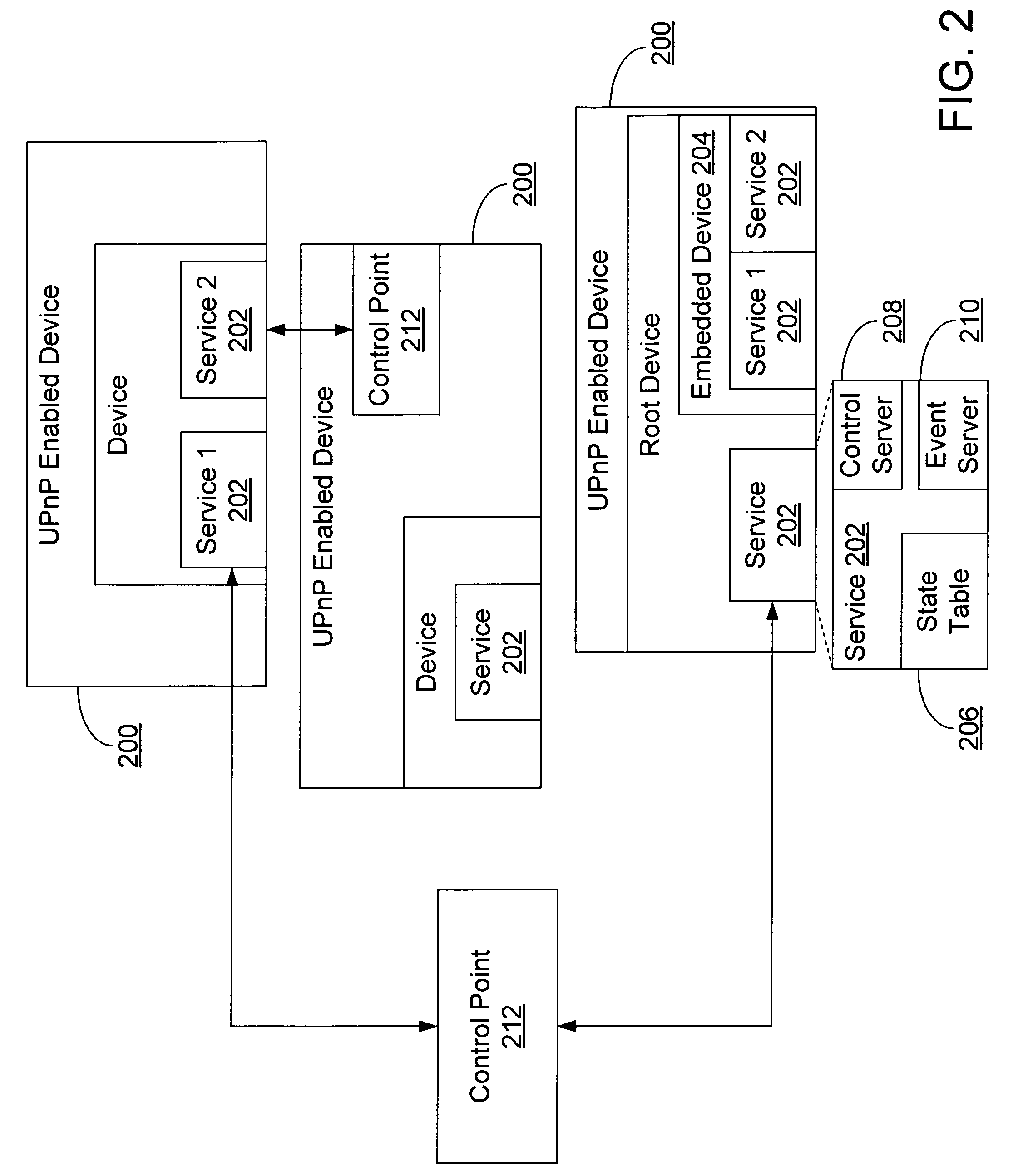

Scaling UPnP v1.0 device eventing using peer groups

InactiveUS7647394B2Effectively scaledFacilitate communicationDigital computer detailsTransmissionSemanticsComputer science

Disclosed is a method for scaling and extending the reach of UPnP device discovery and eventing by leveraging the use of a peer-to-peer network infrastructure. Peer-to-peer networking allows for the organization of a set of nodes into a group for efficient exchange of information and the group has an efficient and scalable mechanism for flooding data to all members in it. In one embodiment one PC in a peer group can receive device discovery announcements and subscribe for device event notifications. A discovery proxy and an eventing proxy running on the PC package the announcement and / or notification in a record and proceed to flood it to the group. The group flooding semantics route the notification to the subscribed controllers, which can subsequently take suitable action. Ultimately, this method produces a result whereby device discovery and eventing tasks can be fulfilled by locating the closest peer and obtaining the device announcements and notifications from that peer.

Owner:MICROSOFT TECH LICENSING LLC

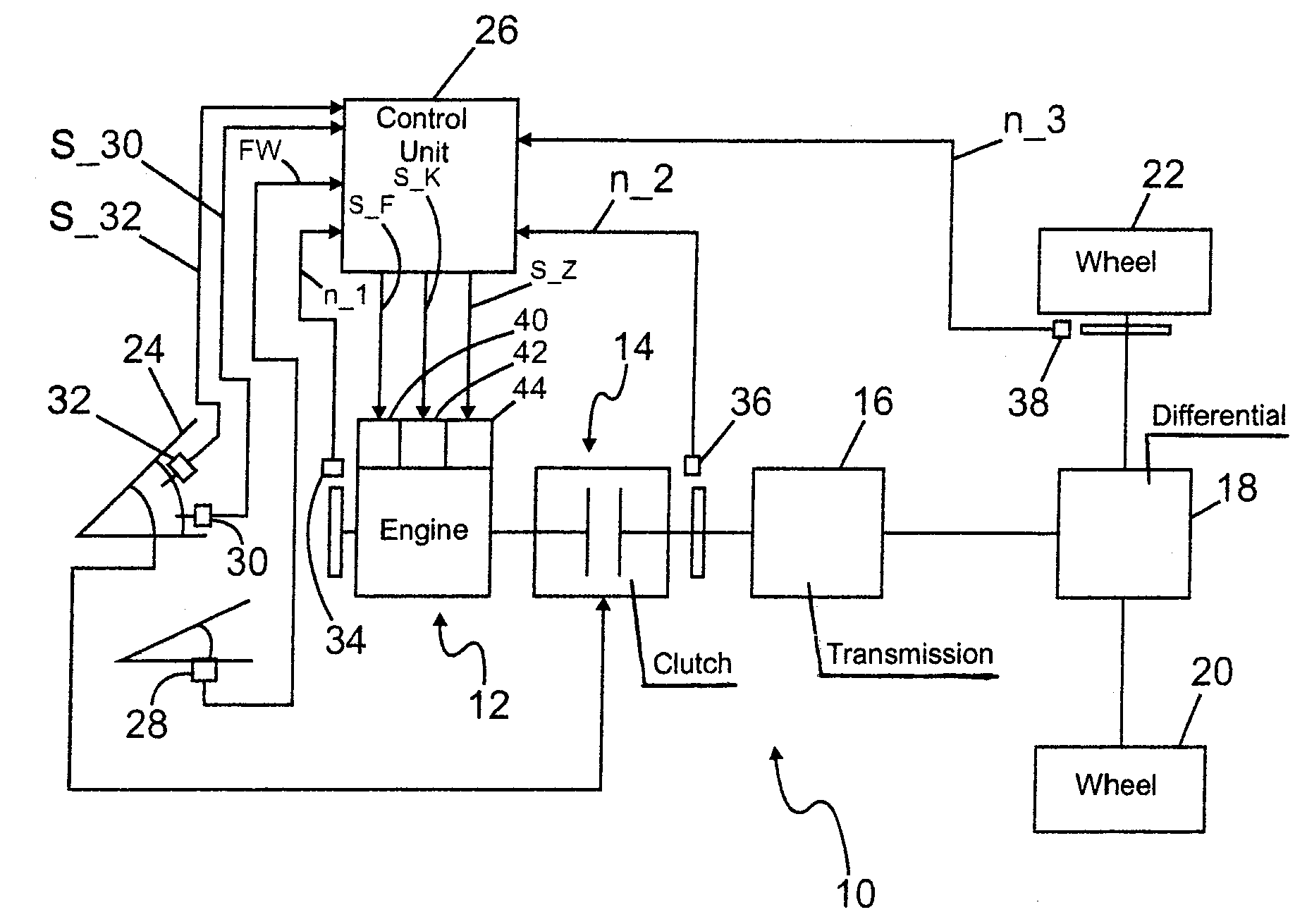

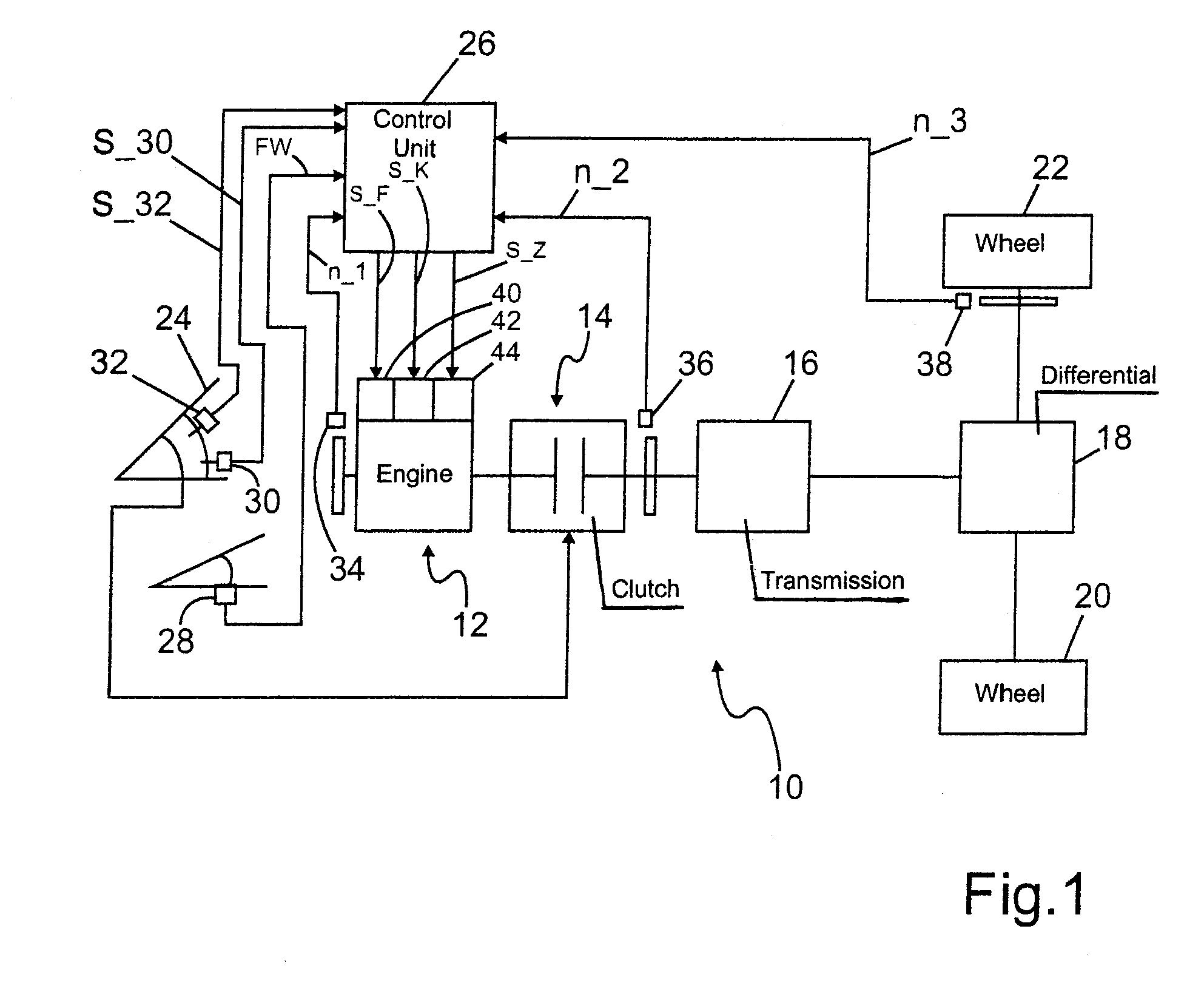

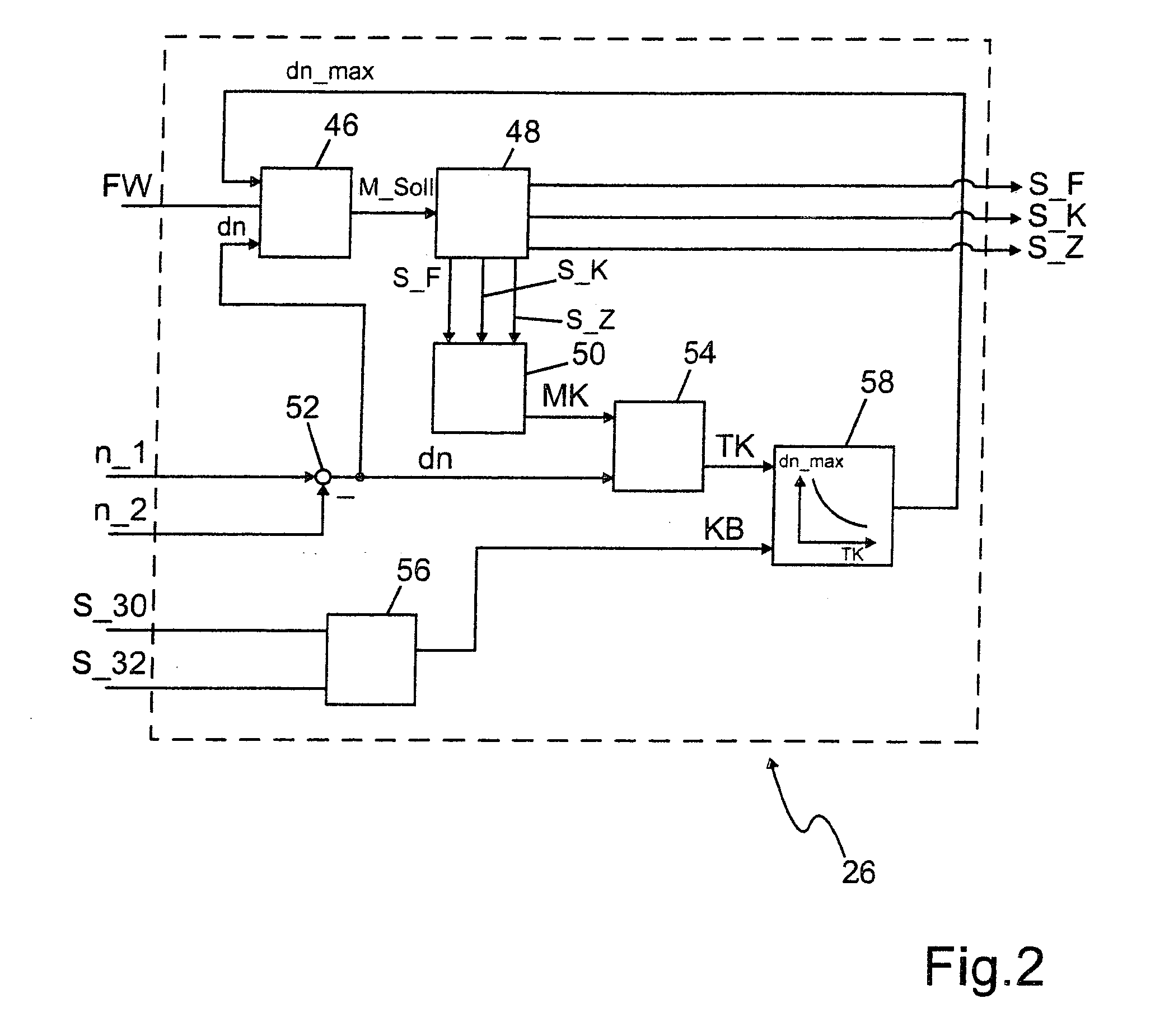

Method and Control Unit for Protecting a Clutch in a Drivetrain of a Motor Vehicle

InactiveUS20080147288A1High torqueSmall torque valueElectrical controlDigital data processing detailsMobile vehicleDriver/operator

A method controls an internal combustion engine in a drivetrain of a motor vehicle. The drivetrain has a variable-speed transmission and a friction clutch which is to be actuated by the driver. By use of the friction clutch a force-fitting action between the internal combustion engine and the variable-speed transmission is controlled, with it being possible for the clutch torque of the internal combustion engine to be reduced in order to protect the clutch from thermal overloading. A temperature of the clutch is determined, a limit value which is dependent on the determined temperature is determined and a rotational speed difference across the clutch is determined. The clutch torque is reduced if the rotational speed difference approaches or reaches or exceeds the temperature-dependent predetermined limit value. A control unit is set up to carry out a method of this type or to control its process.

Owner:DR ING H C F PORSCHE AG

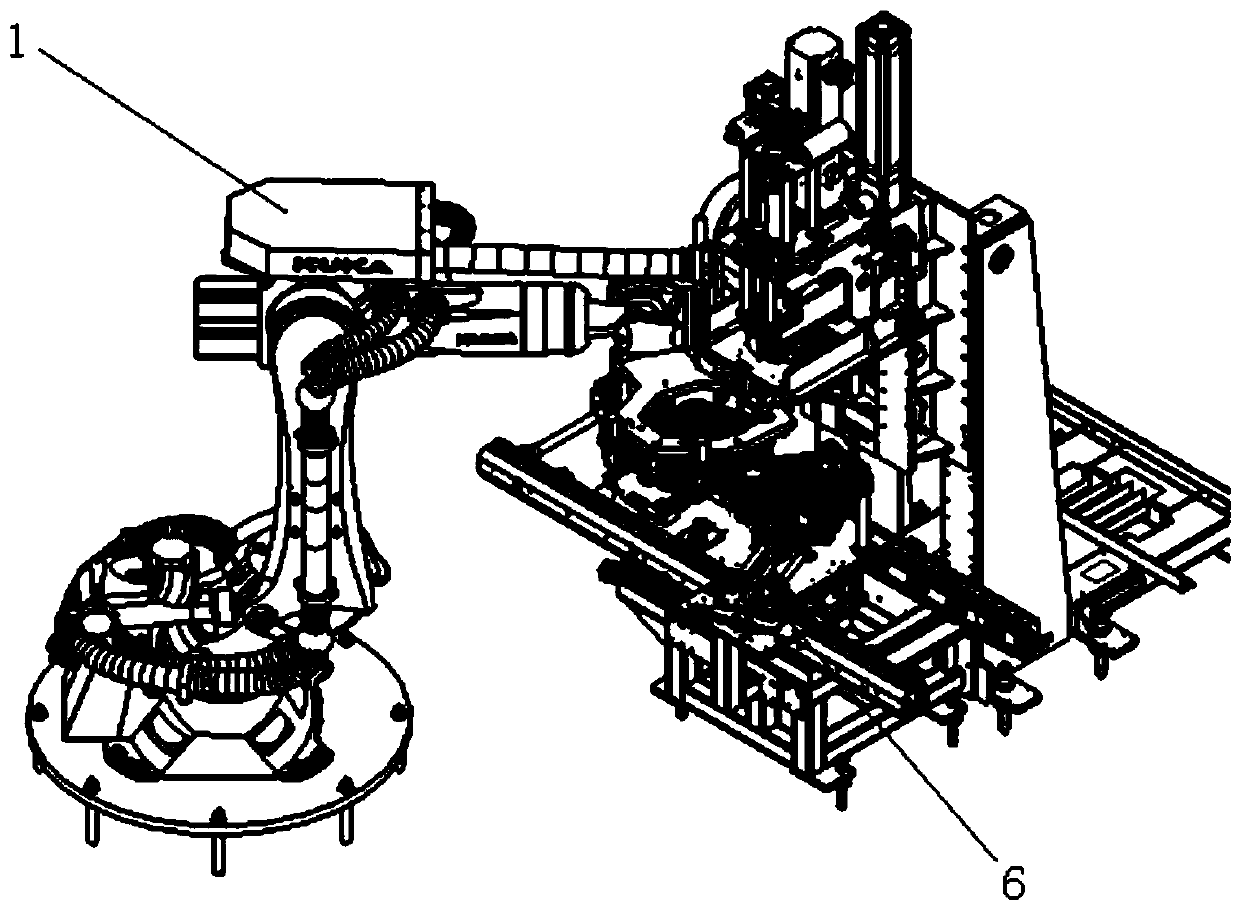

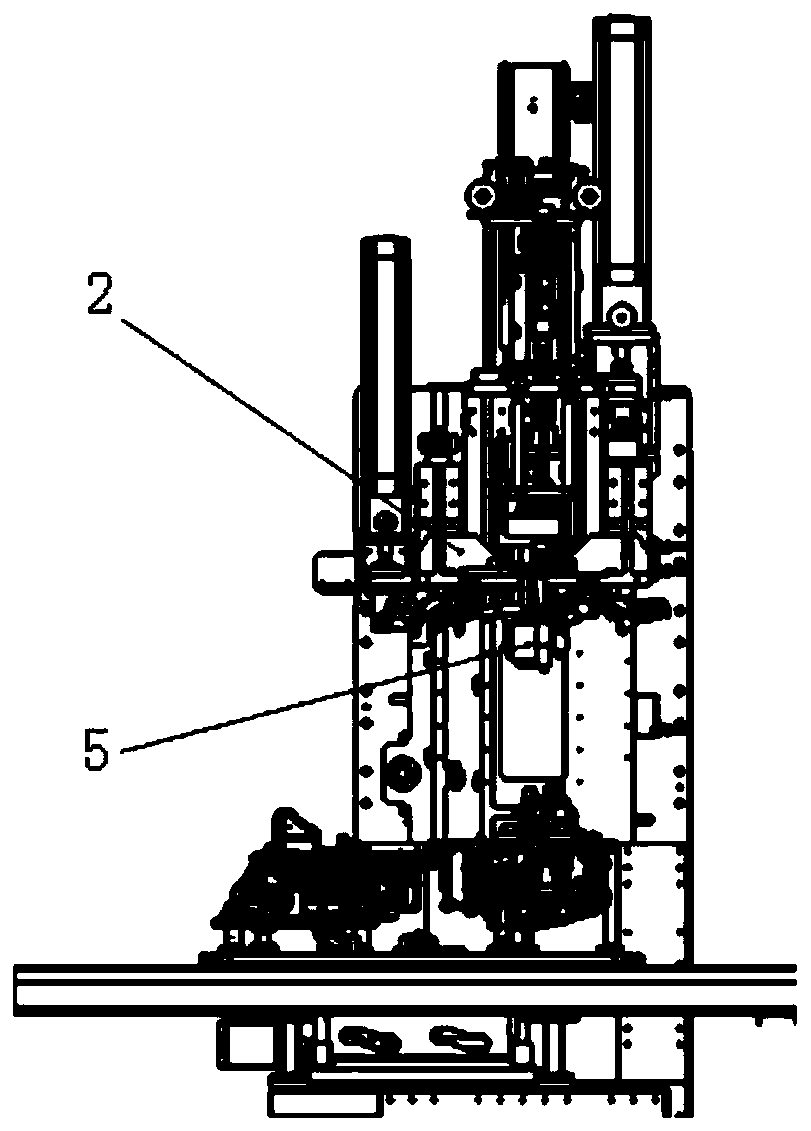

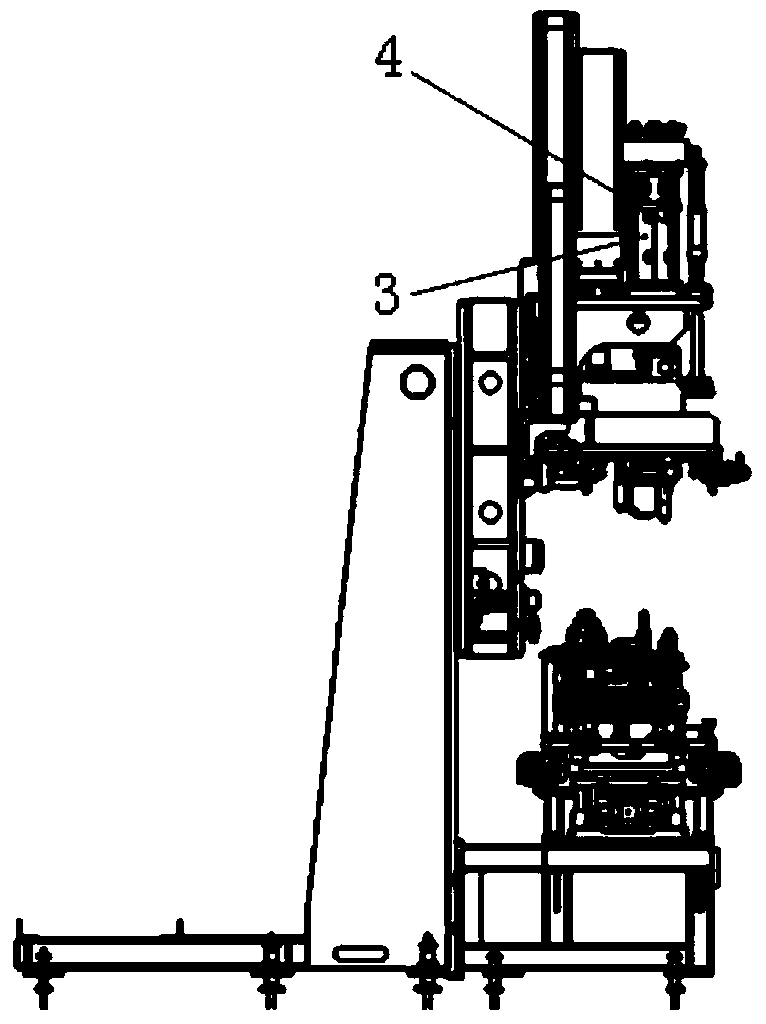

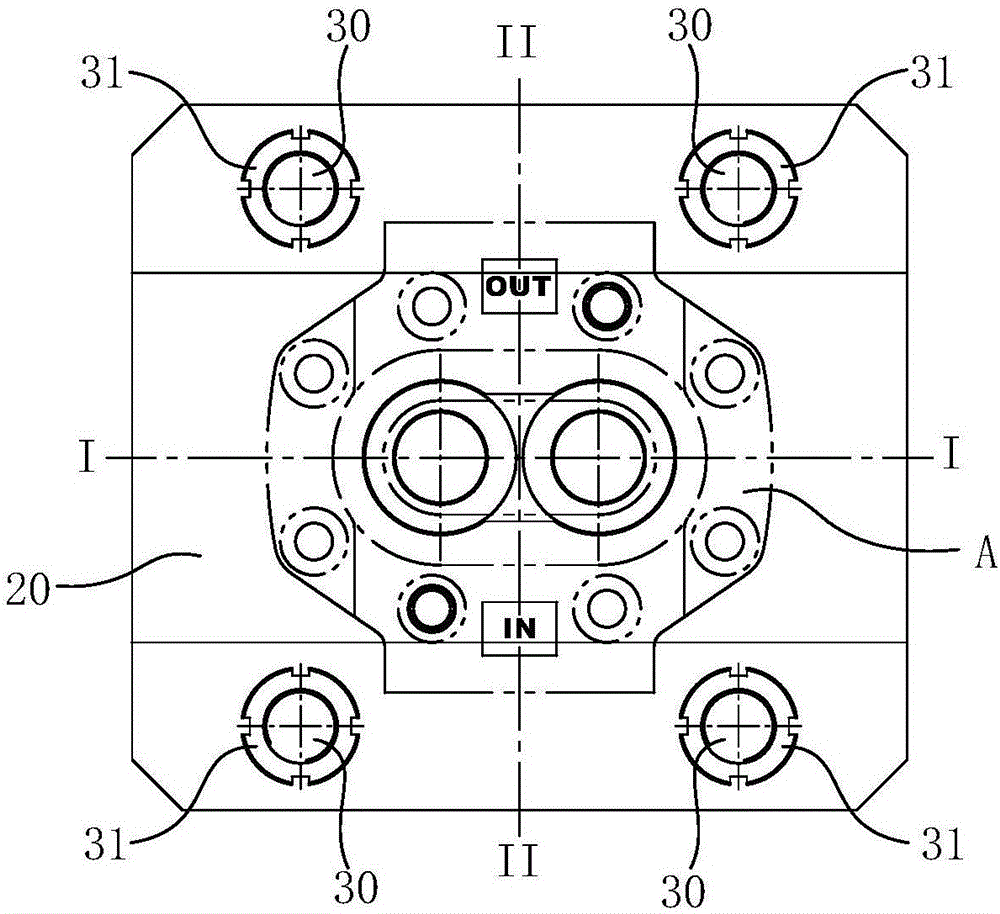

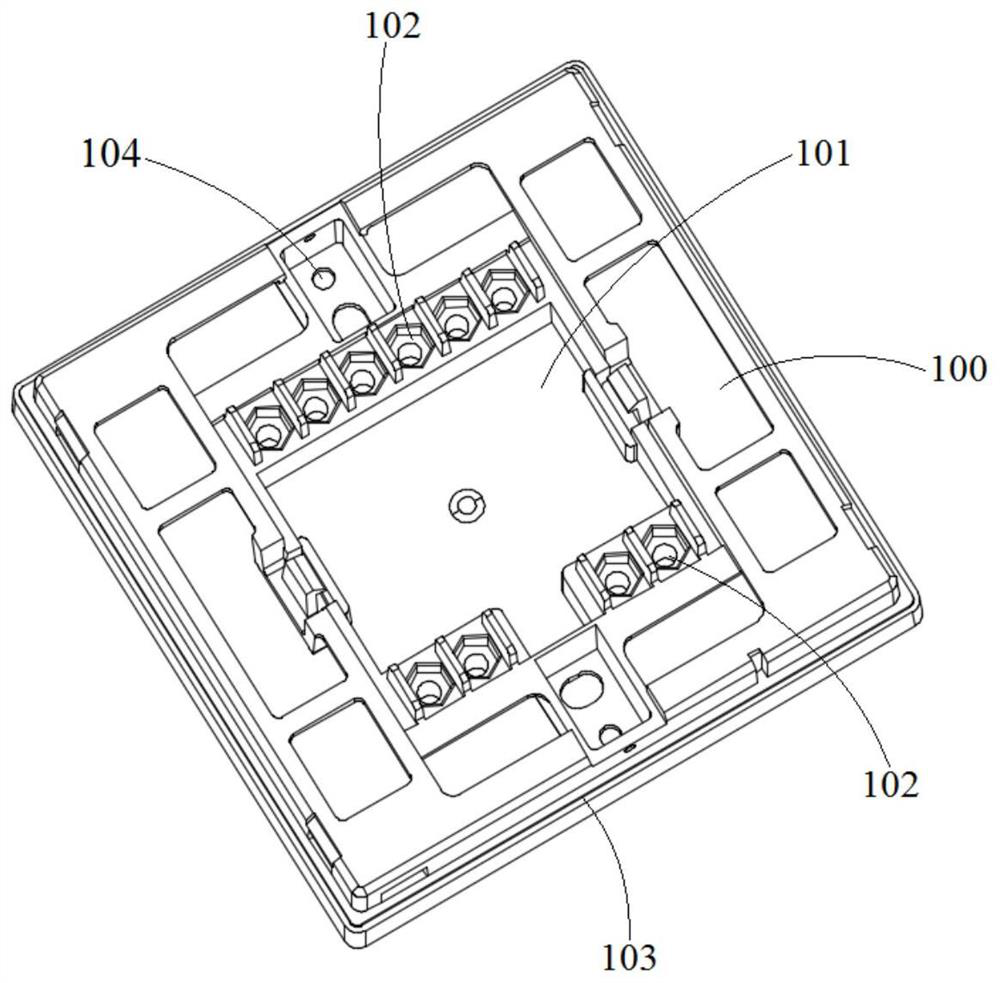

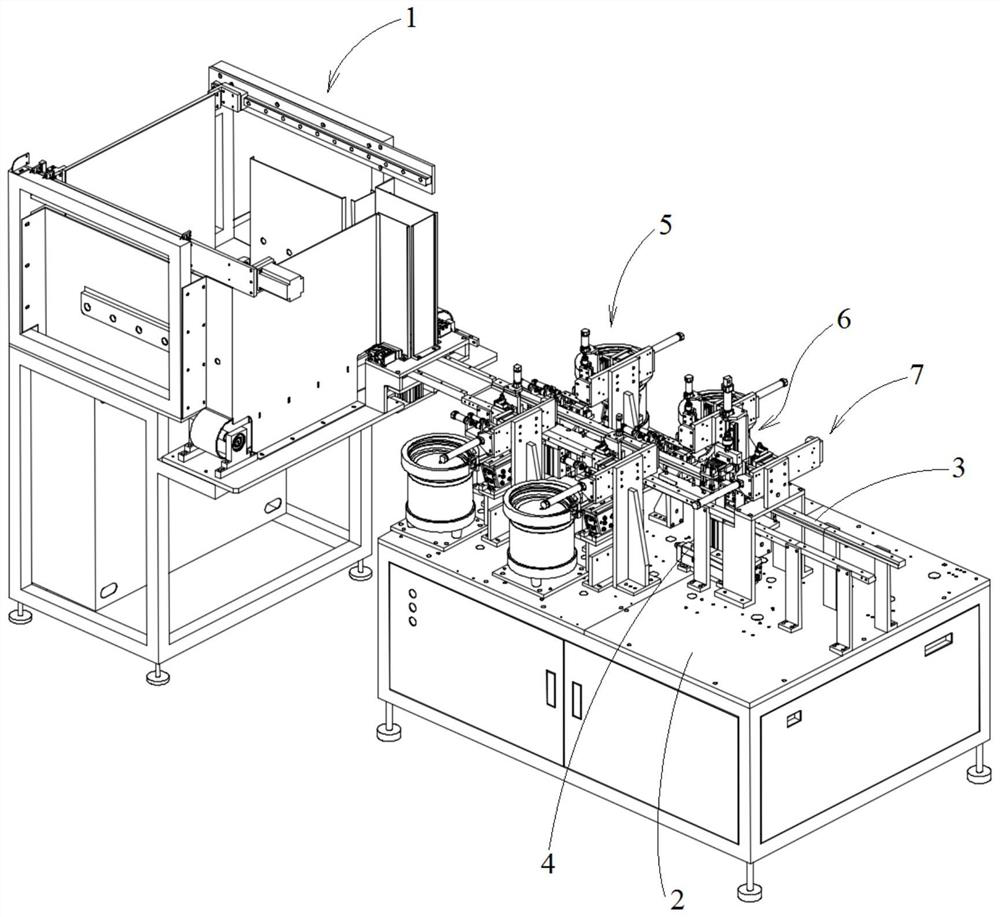

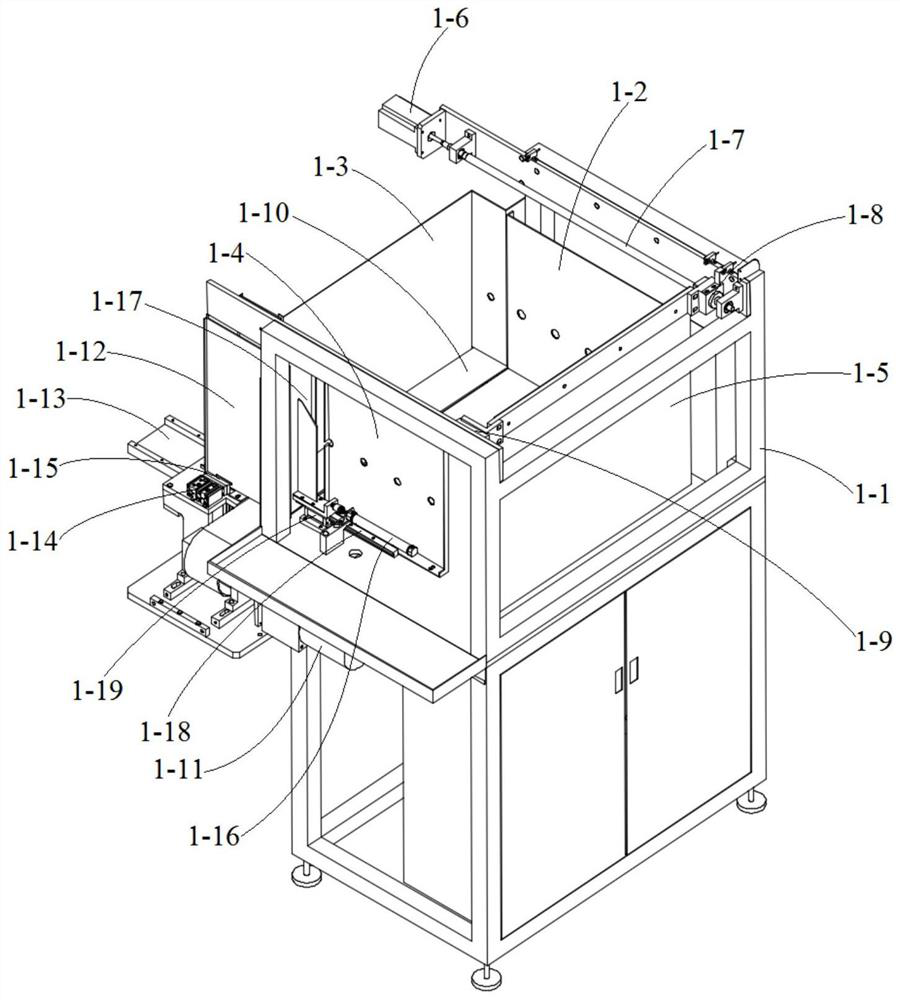

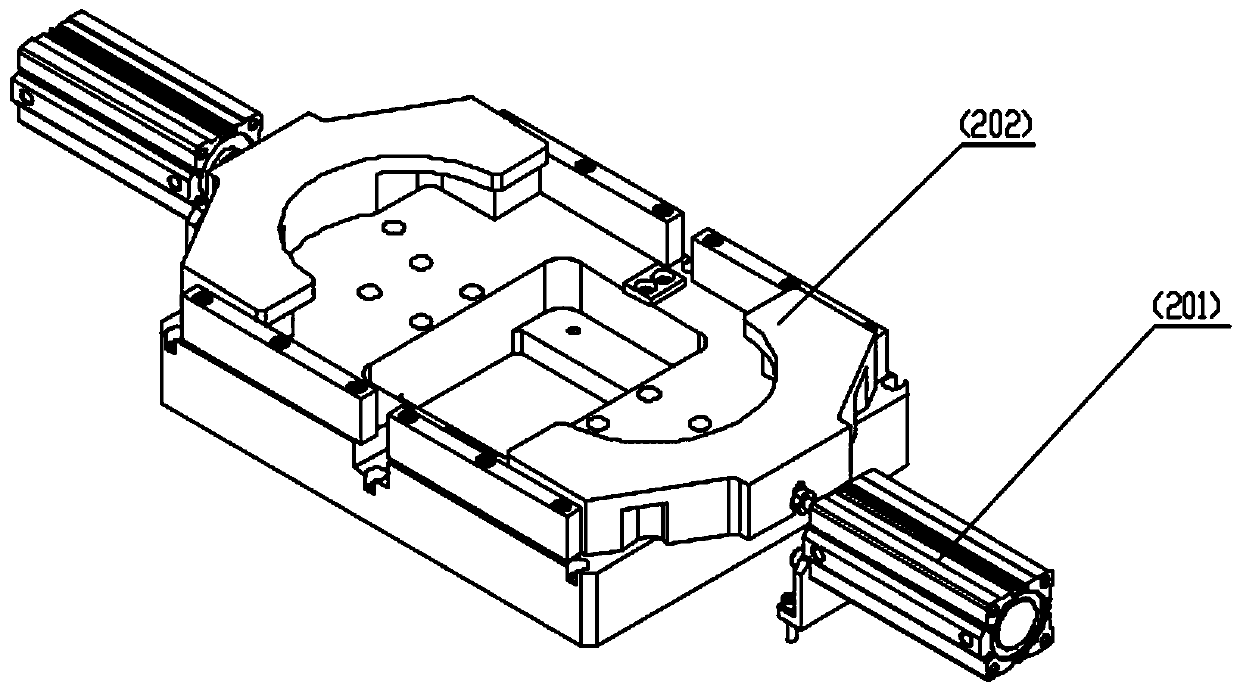

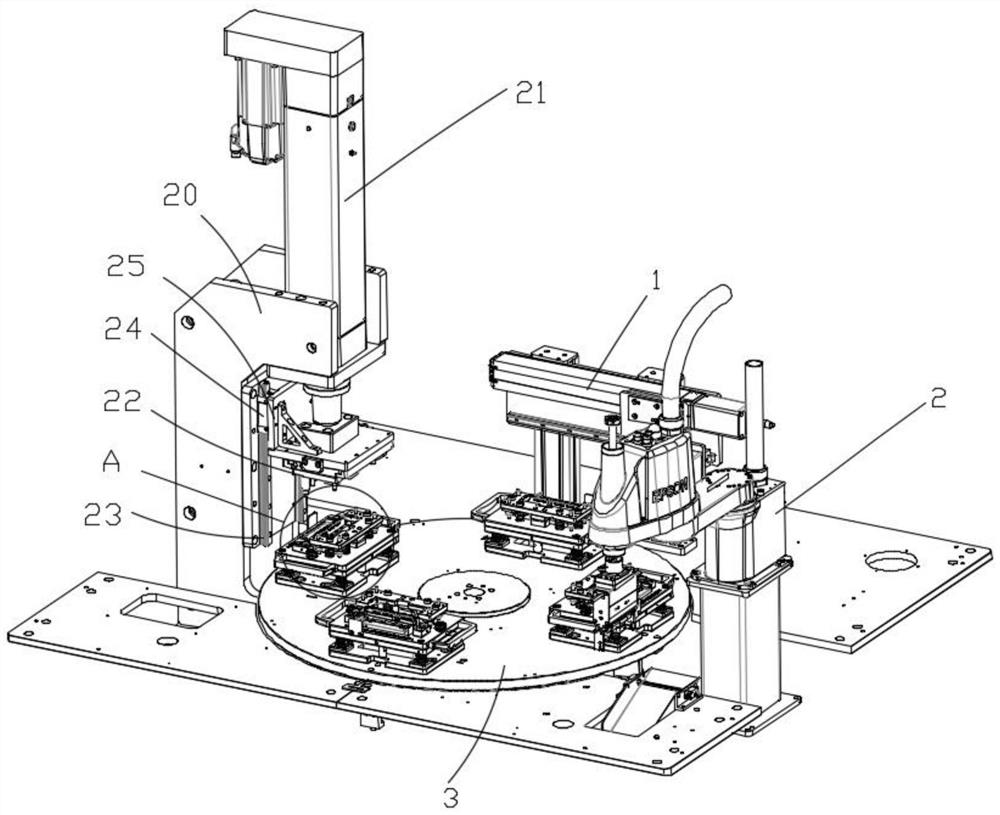

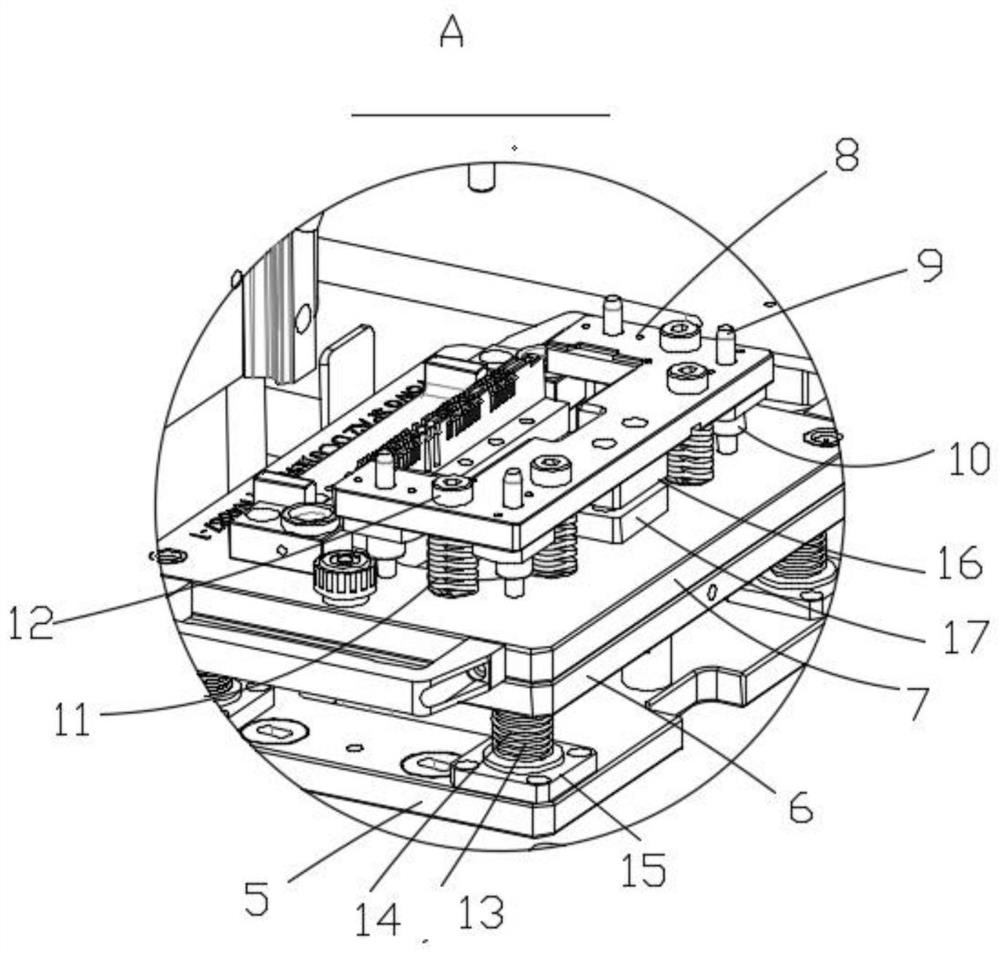

Automatic box closing assembly device

ActiveCN110961891APrevent rotationSave manpower and material resourcesMetal working apparatusControl engineeringEngineering

The invention discloses an automatic box closing assembly device. The automatic box closing assembly device is characterized by comprising an automatic feeding mechanism, a lifter press-fitting body mechanism, an input shaft holding mechanism, a hybrid shaft tensioning mechanism and a type position-changing mechanism. A robot is used for automatically feeding workpieces, the takt is saved, and themanual cost is reduced; a lifting air cylinder cooperates with a servo press machine, and therefore press-fitting action is smoother; the output shaft holding structure is changed, and therefore theholding mechanism is more flexible, the telescopic quantity is increased, wear is reduced, and the equipment maintenance failure rate is reduced; and the servo press machine cooperates with a tensionsensor, press fitting is precisely monitored to be achieved in place by adjusting the in-place positions of different shafts, and press-fitting reliability and stability are increased.

Owner:COMAU SHANGHAI ENG

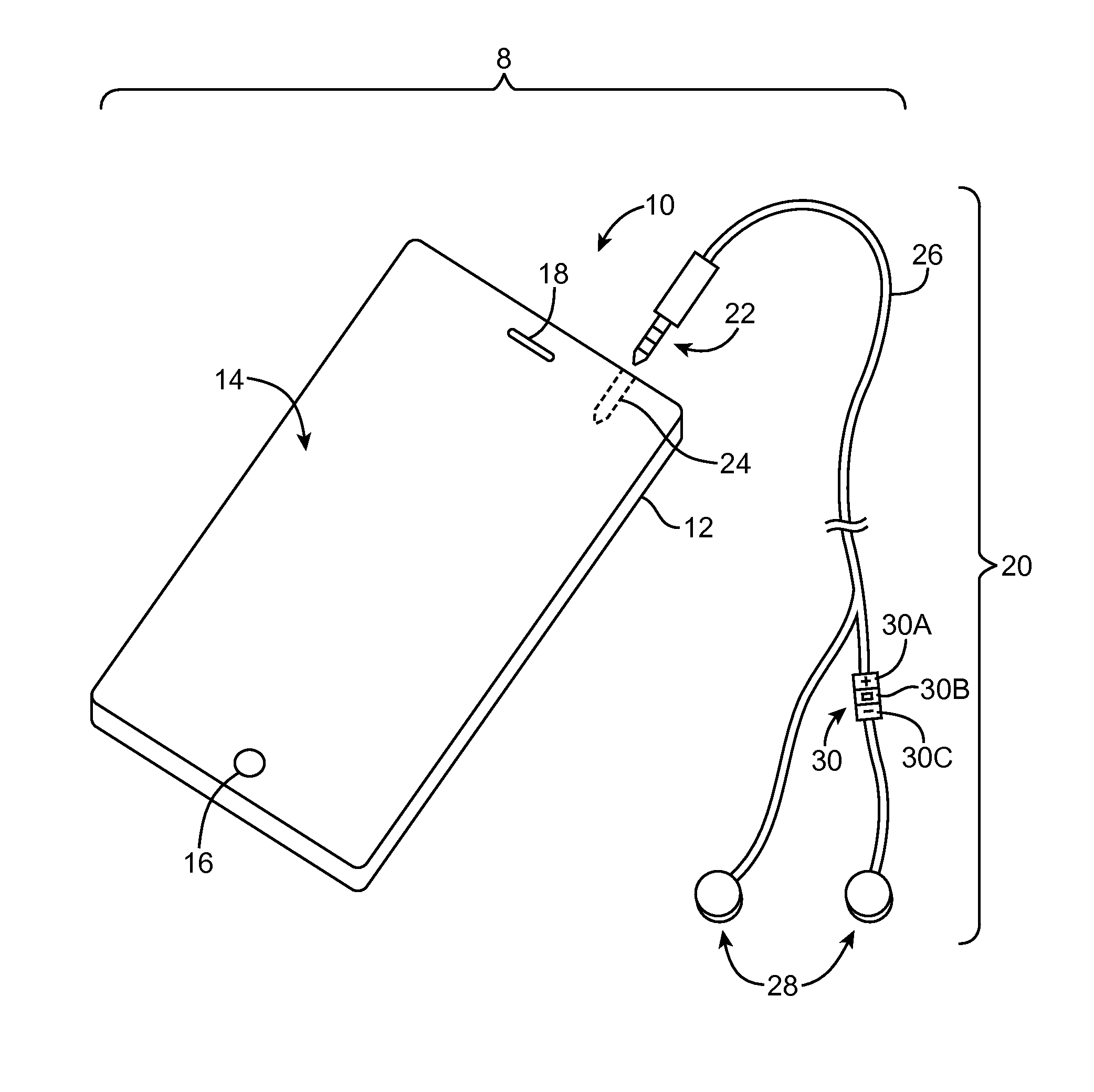

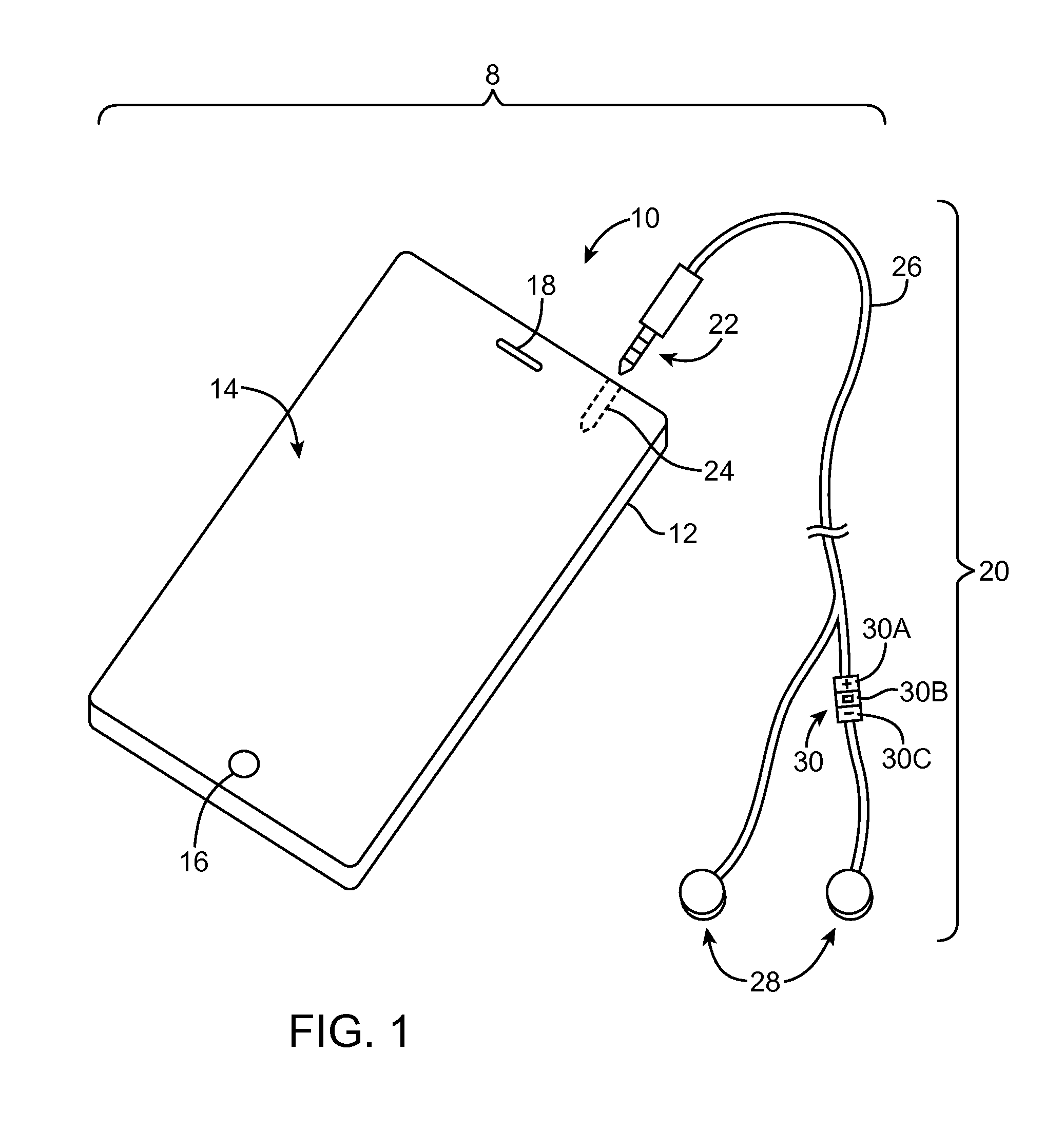

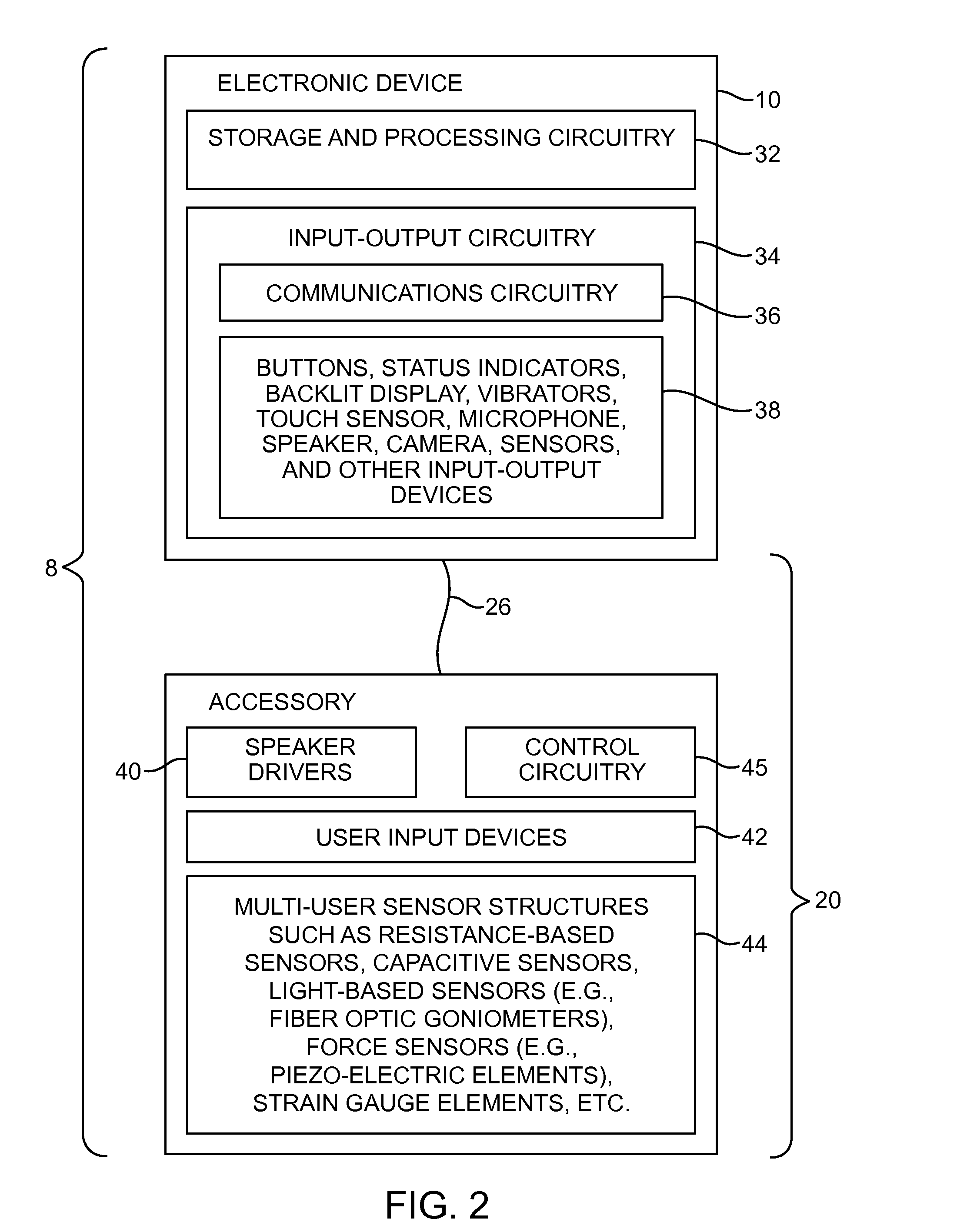

Earphones with cable orientation sensors

InactiveUS9049508B2Headphones for stereophonic communicationStereophonic circuit arrangementsHeadphonesLoudspeaker

An electronic device may be coupled to an accessory such as a pair of earphones. The earphones may have multi-user sensor structures that determine whether or not the earphones are being shared by multiple users. The multi-user sensor structures may include an angle sensor configured to measure an angle at the Y-junction of a cable associated with the pair of headphones. When the first and second speakers are both located in the ears of a single user, the electronic device may perform functions such as playing audio content. When one of the speakers is located in an ear of a first user while the other of the speakers is located in an ear of a second user, the electronic device can automatically take actions such as switching from stereo to mono playback, playing a different type of audio content to each earphone, or other suitable action.

Owner:APPLE INC

Scaling and extending UPnP v1.0 device discovery using peer groups

ActiveUS7640329B2Effectively scaledFacilitate communicationMultiple digital computer combinationsData switching networksSemanticsPeer-to-peer

Disclosed is a method for scaling and extending the reach of UPnP device discovery and eventing by leveraging the use of a peer-to-peer network infrastructure. Peer-to-peer networking allows for the organization of a set of nodes into a group for efficient exchange of information and the group has an efficient and scalable mechanism for flooding data to all members in it. In one embodiment one PC in a peer group can receive device discovery announcements and subscribe for device event notifications. A discovery proxy and an eventing proxy running on the PC package the announcement and / or notification in a record and proceed to flood it to the group. The group flooding semantics route the notification to the subscribed controllers, which can subsequently take suitable action. Ultimately, this method produces a result whereby device discovery and eventing tasks can be fulfilled by locating the closest peer and obtaining the device announcements and notifications from that peer.

Owner:MICROSOFT TECH LICENSING LLC

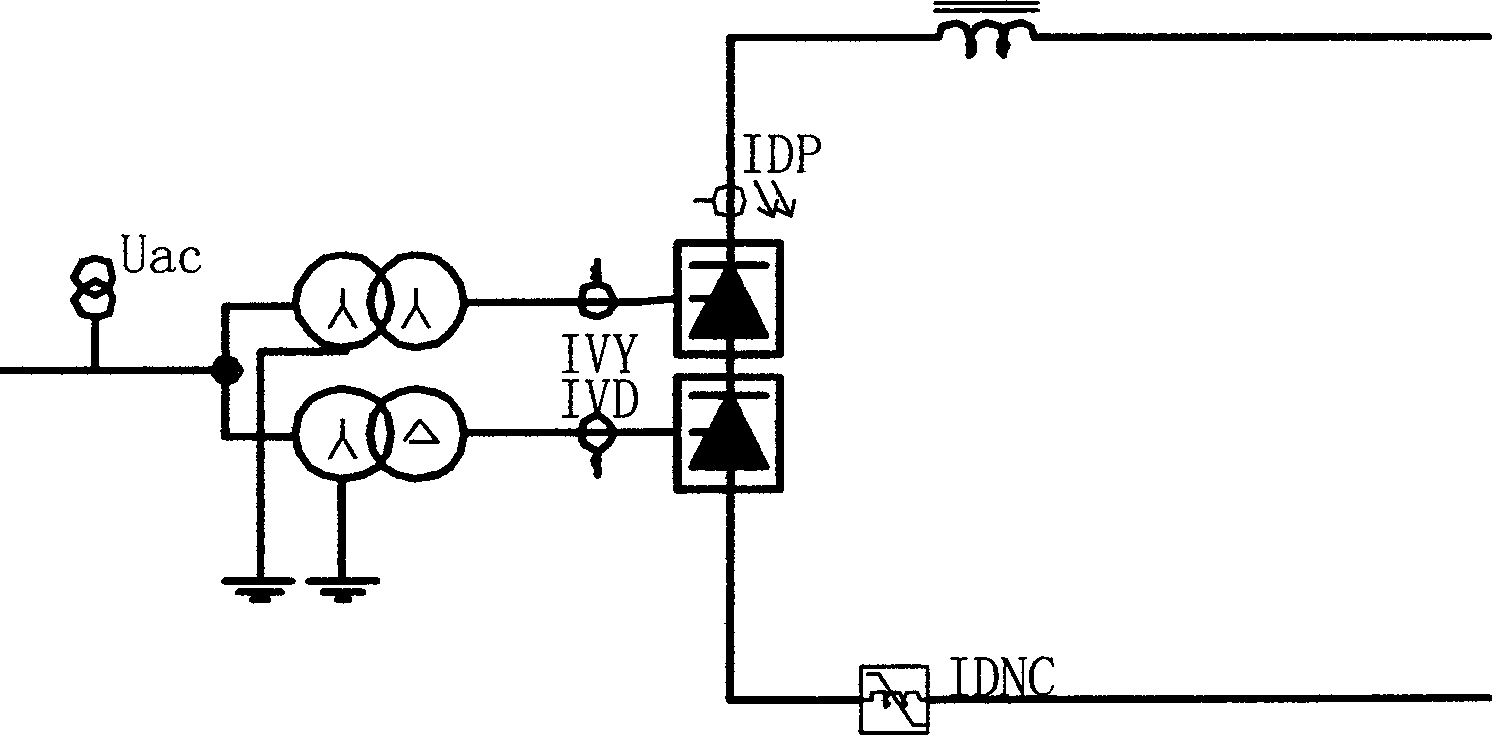

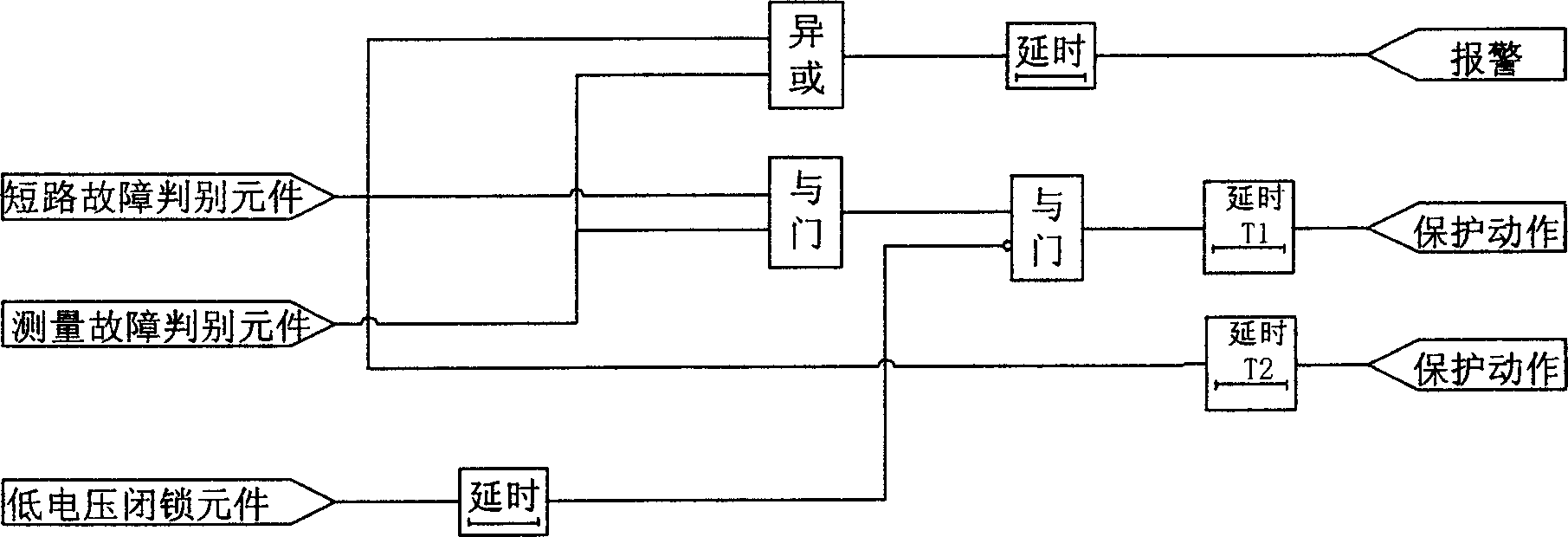

Short trouble protective method for converter valve assembly

ActiveCN1877945ADetect short circuit faultsGuaranteed reliabilityEmergency protective circuit arrangementsDc currentMedicine

The invention discloses a short-circuit accident protective method of converting valve group, which comprises the following judging expression formulas: |IVY|-IDP>Ivss+k*|IVY|, |IVD|-IDP>Ivss+k*|IVD|(2); |IVY|-IDNC>Ivss+k*|IVY|, |IVD|-IDNC>Ivss+k*|IVD|(3), wherein IVY and IVD is equivalent DC current; Ivss and k are constant; IDP is DC current for electrode bus valve side; IDNC is DC current for neutral bus valve side; if the conversing valve group occurs short circuit, (2) or (3) satisfies. The invention guarantees the reliability and safety for valve group, which avoids error movement in the measuring course.

Owner:NR ELECTRIC CO LTD

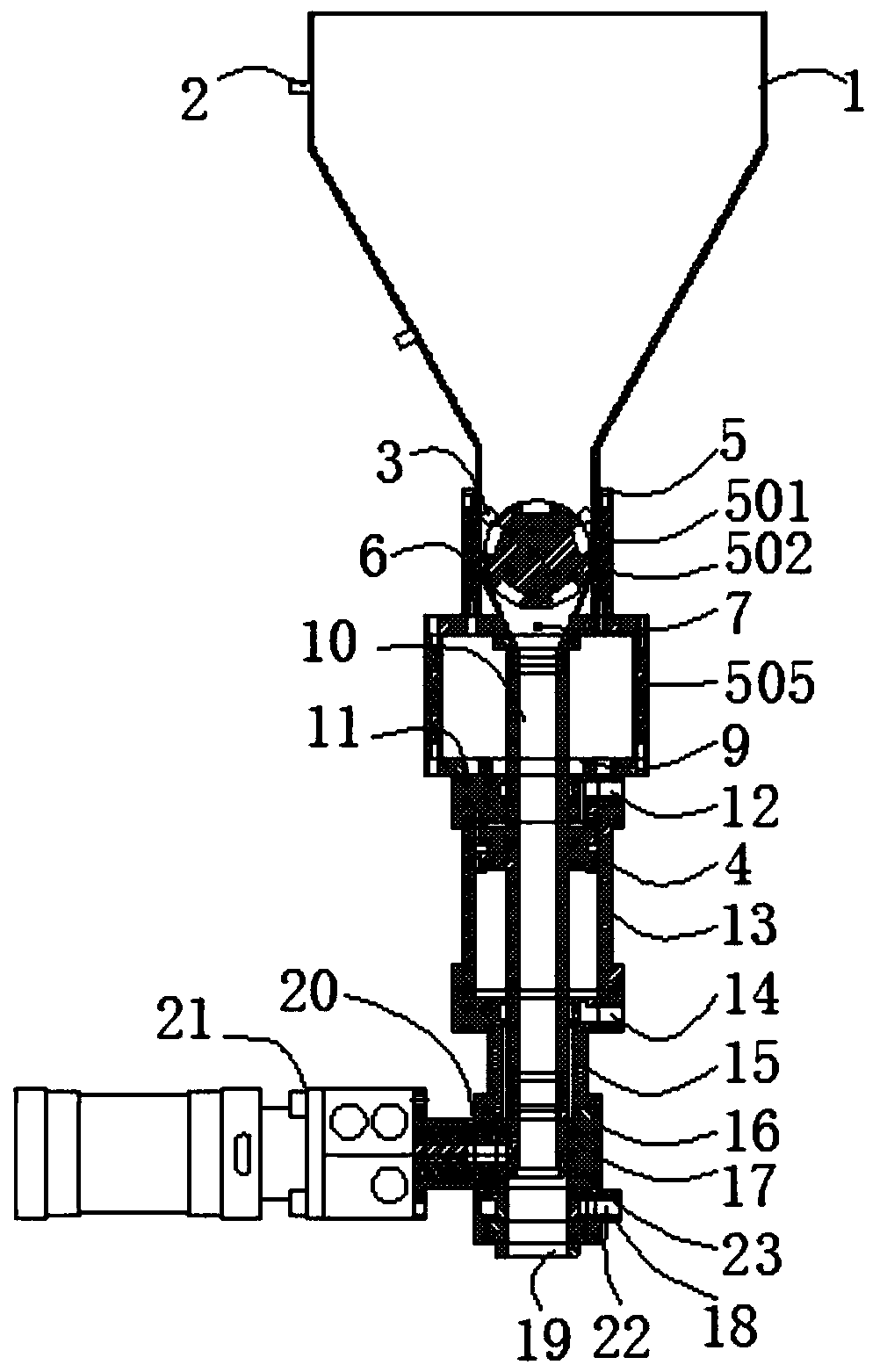

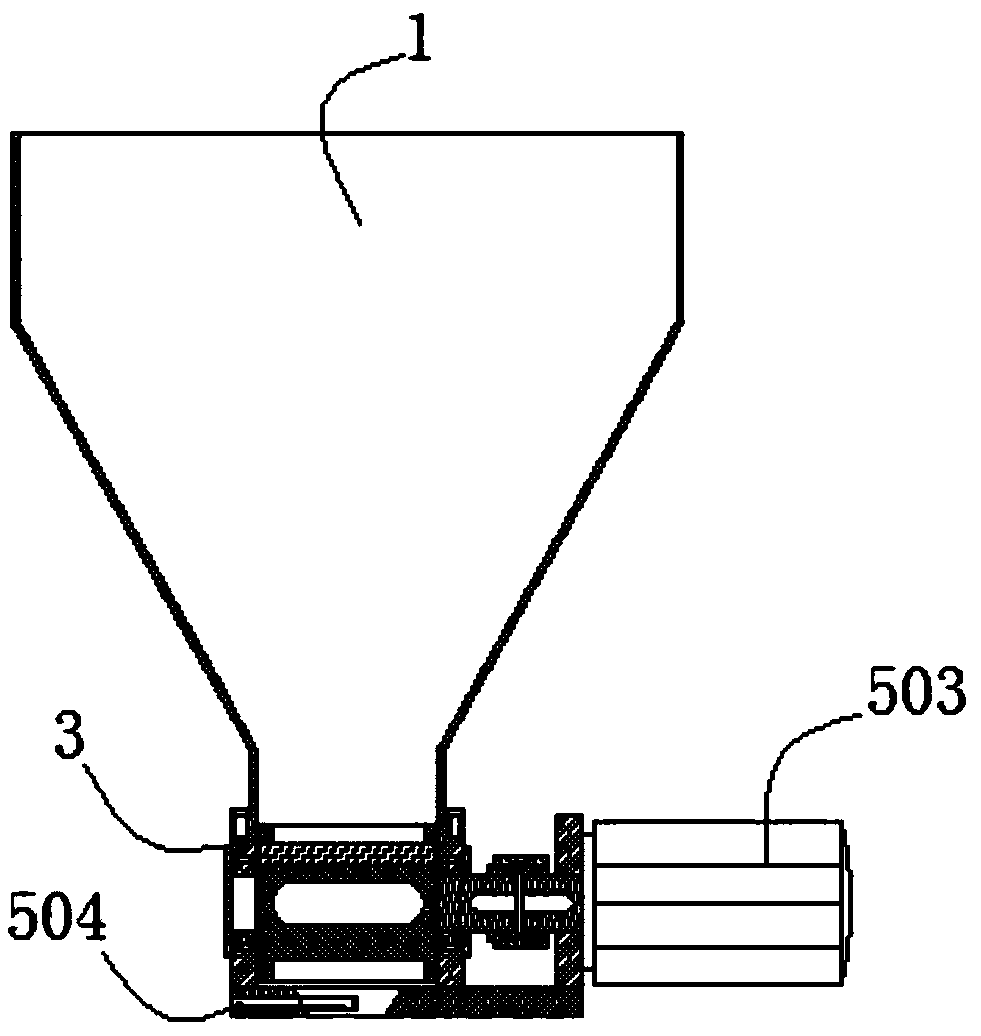

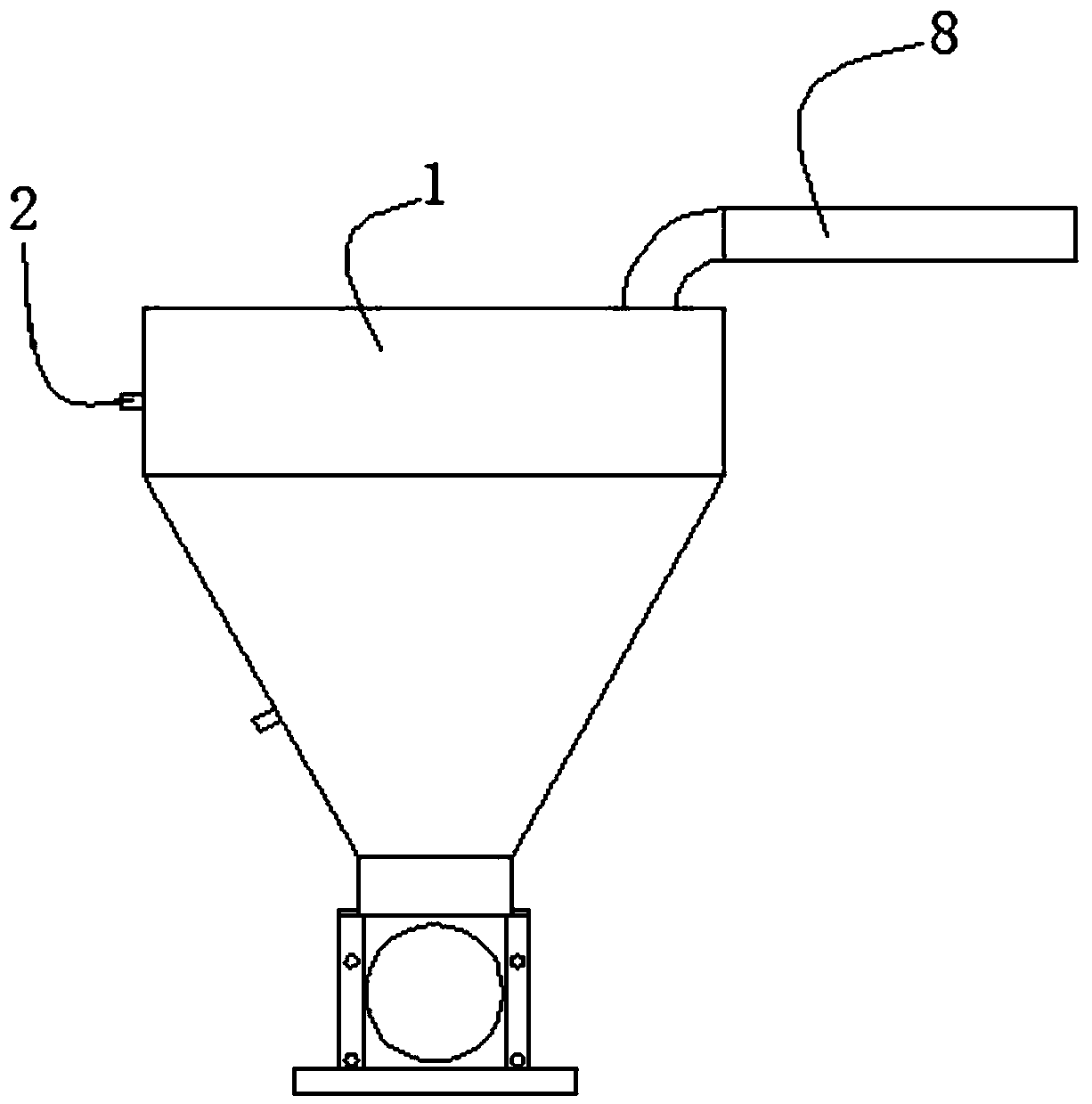

Polyurethane waste regenerating device

InactiveCN109436849ATo achieve the purpose of measuring workAdjust working speed in timePlastic recyclingLarge containersLevel sensorPulp and paper industry

The invention discloses a polyurethane waste regenerating device, and relates to the technical field of polyurethane waste regenerating. A storage groove and a metering mechanism are included, the outer wall of the storage groove is provided with a material level sensor, and a sealing shaft is arranged on the lower part of the interior of the storage groove; and the metering mechanism is arrangedat the bottom end of the storage groove, the bottom of the metering mechanism is provided with a feeding funnel, and the inner wall of the feeding funnel is provided with a second air inlet hole. Thepolyurethane waste regenerating device has the beneficial effects that through arrangement of metering grooves, a metering shaft material level sensor and the storage groove, the metering grooves areformed in the inner side of the outer wall of a metering shaft at equal distance; when materials fall into the storage groove, the materials continue to move downwards, through the close fitting action of the sealing shaft and the metering shaft, the materials can only enter the metering grooves on the inner side of the outer wall of the metering shaft, and then move down under the rotation actionof the metering shaft and the metering action of a metering device arranged on the inner side of the metering mechanism.

Owner:蚌埠中正聚氨酯发泡设备有限公司

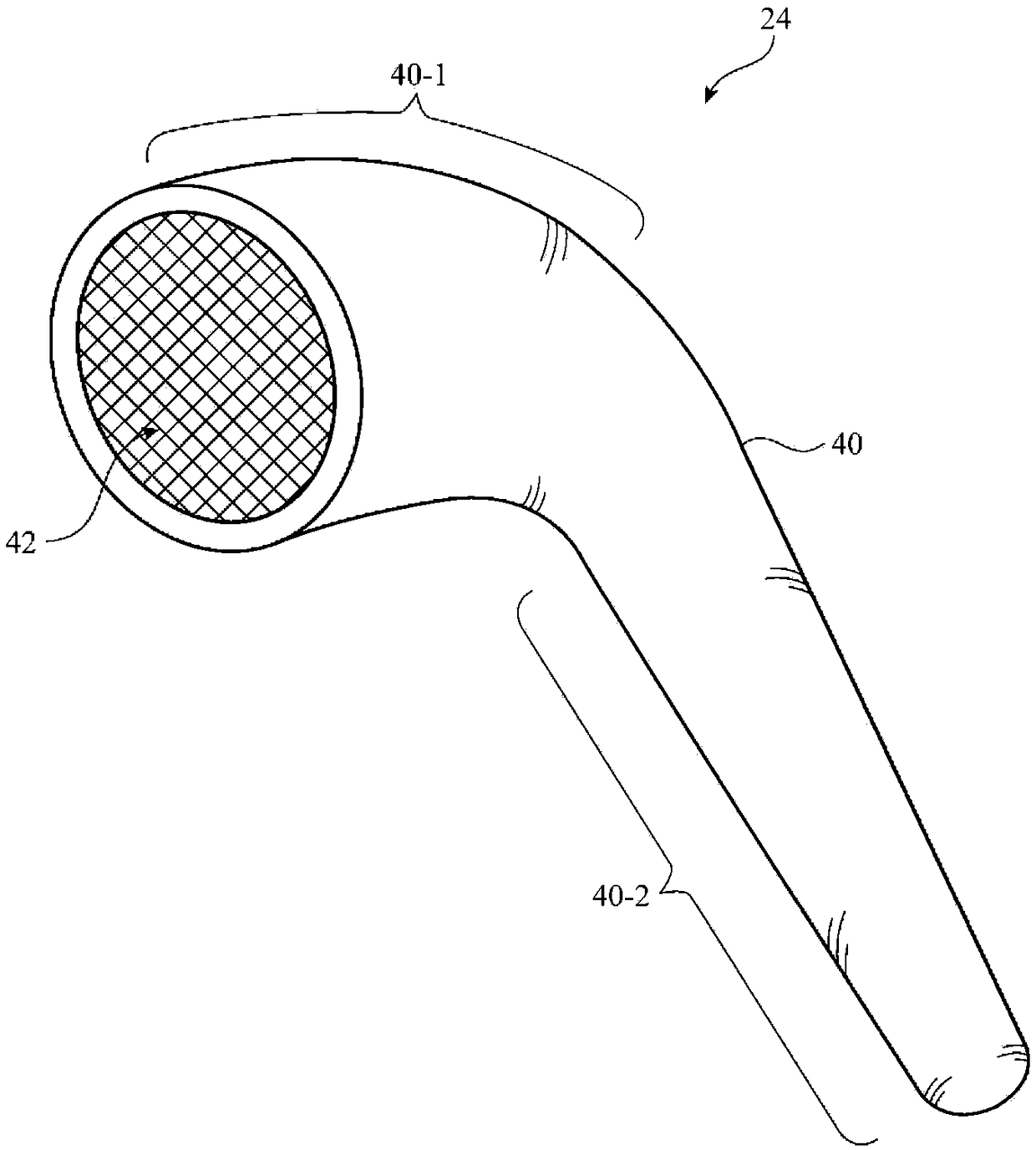

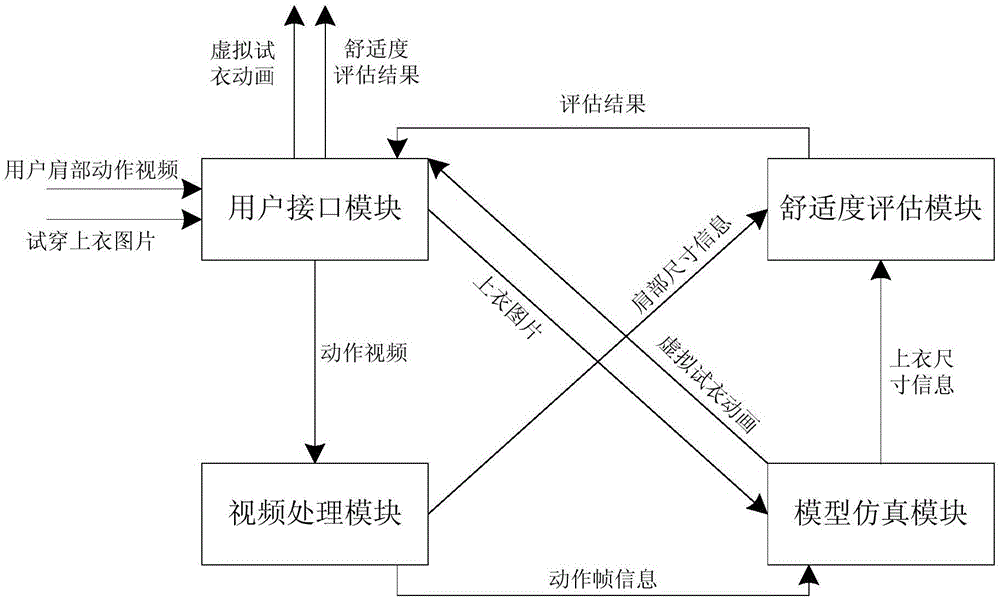

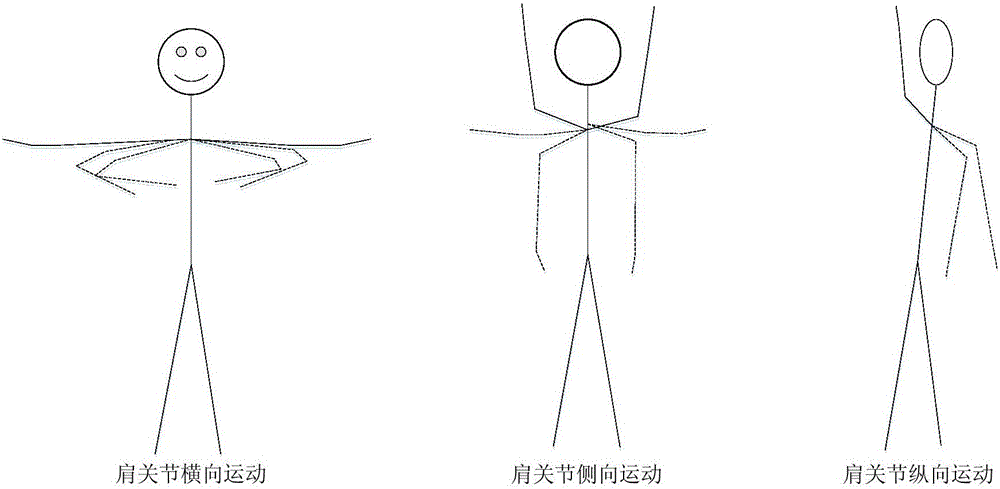

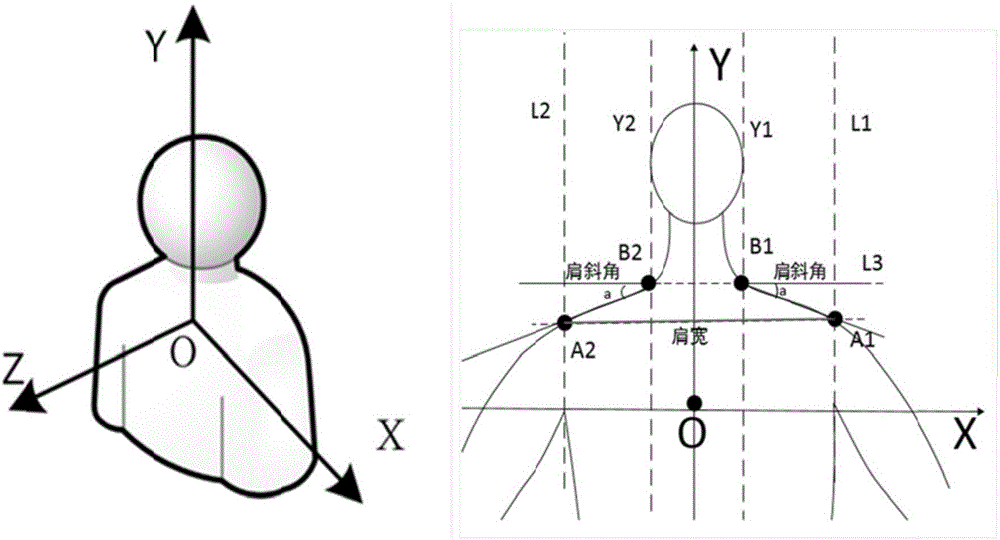

Shoulder fitting simulation wearing comfort assessment system and method

ActiveCN106530064ALow costShorten the timeBuying/selling/leasing transactions3D modellingShoulder widthVideo processing

The present invention discloses a shoulder fitting simulation wearing comfort assessment system and method. The system comprises four modules: a user interface module, a video processing module, a model simulation module and a comfort assessment module. The method comprises: firstly, photographing and uploading a video of a standard fitting action of a user shoulder by means of the user interface module, and entering information of a to-be-tried upper outer garment, such as a shoulder width size, a color and a material; then extracting a user shoulder parameter and key frame information by using the video processing module; completing dynamic simulation of a shoulder fitting effect in the model simulation module; and finally, giving a result of comfort detection in the comfort assessment module. The system provided by the present invention presents the shoulder fitting effect of a user, has authenticity, reliability and convenience, and can observe the dynamic wearing effect of the shoulder and back parts. The assessment result of shoulder comfort after a specified type of upper outer garment is put on can be directly obtained, and moreover, the system and method have low application cost and are beneficial for attracting customers, and can improve user experience of virtual fitting and reduce a sales return rate.

Owner:SOUTHEAST UNIV

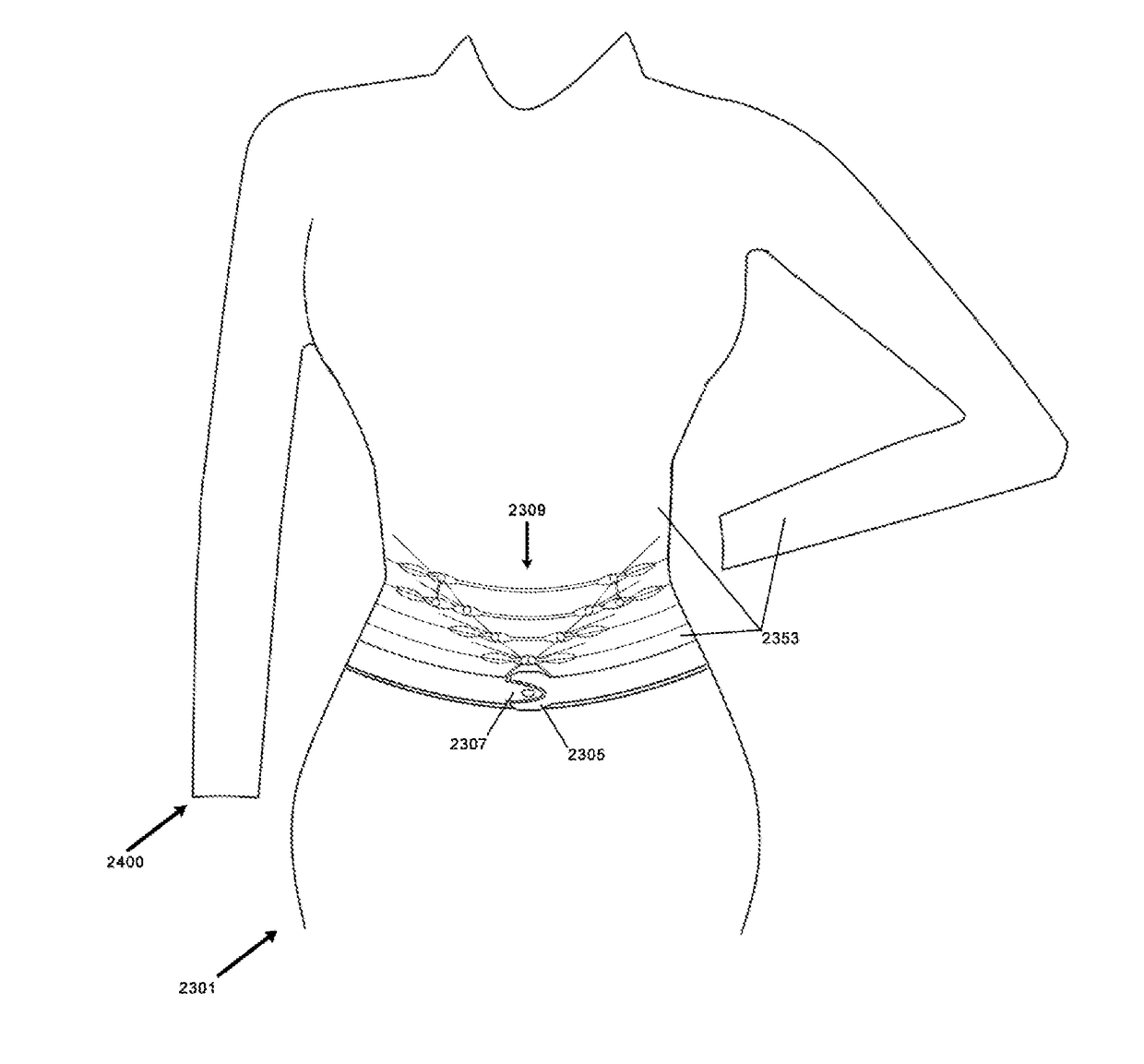

Self-Fitting Apparel with Cascading Closures

InactiveUS20170135428A1Quick wearMinimal effortGarment special featuresDumb-bellsEngineeringCustom-fit

New forms of self-fitting apparel devices and fasteners are disclosed. In some aspects of the invention, new donning-actuated fitting devices and fasteners are disclosed. In other aspects, these and other fitting devices and fasteners incorporate cascading implementation techniques, triggered by a single fastening, donning or fitting action. In some embodiments, these cascading fitting devices and fasteners include mutually-influencing magnetic and / or elastic subunits incorporated in a common semi-flexible substrate. The techniques of the invention are applicable to a wide variety of apparel types, incorporating many different materials, allowing rapid donning of clothing with minimum effort, and leading to an extraordinary custom-fit to a user's body or preferences.

Owner:BECKMAN CHRISTOPHER V

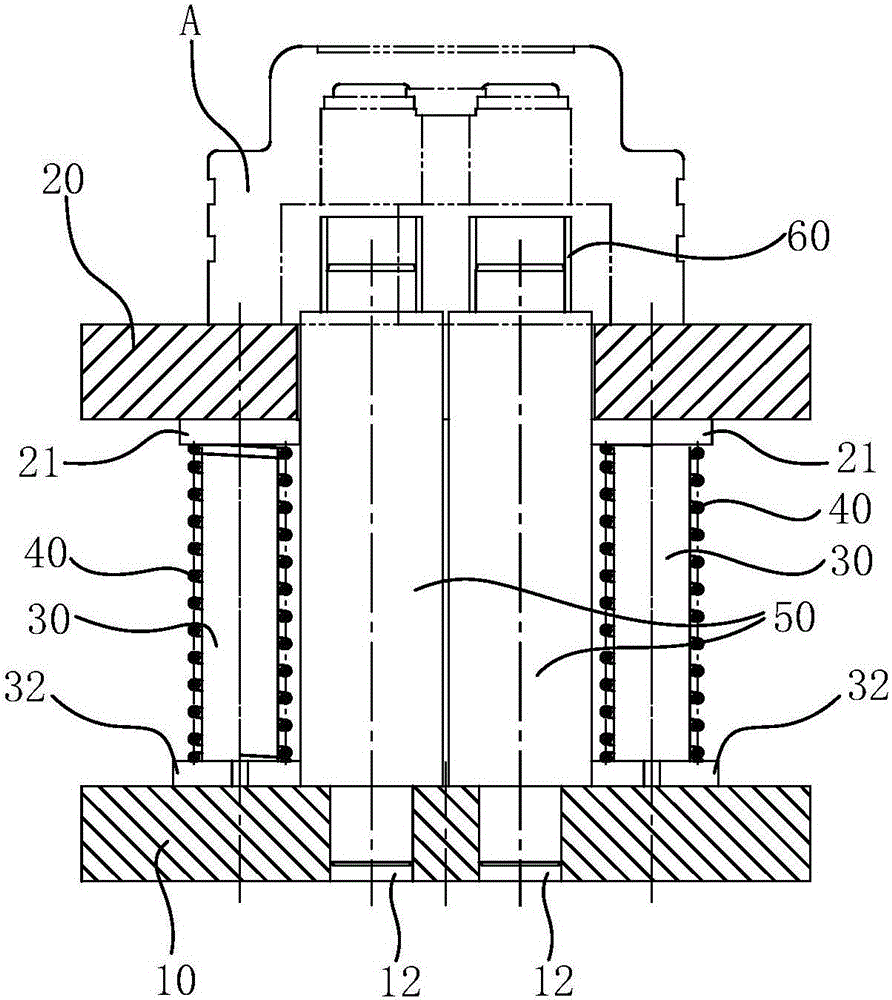

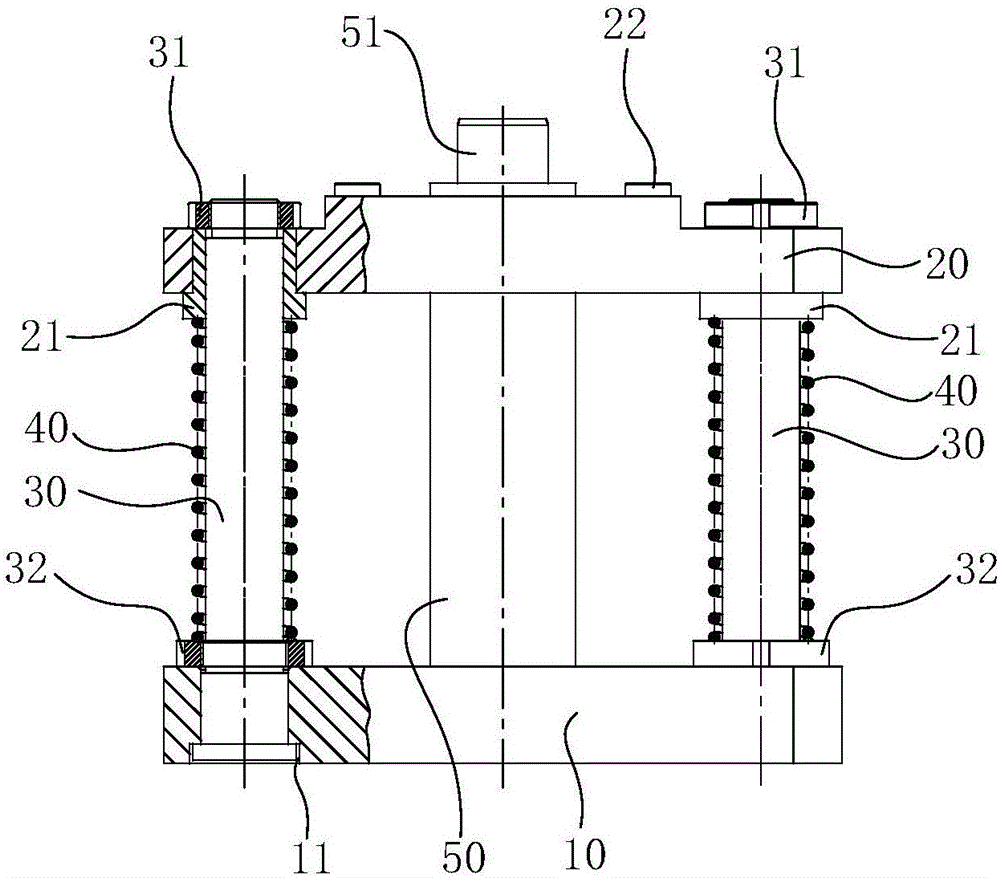

Lining press-fitting tool

InactiveCN106392585AQuick pressImprove press fit accuracyMetal working apparatusEngineeringHydraulic press

The invention relates to a lining press-fitting tool. The lining press-fitting tool comprises: a positioning plate is arranged above a bottom plate; a guide column is arranged between the positioning plate and the bottom plate; the lower end of the guide column is fixedly connected with the bottom plate; the upper end of the guide column stretches out of the positioning plate, and the guide column and the positioning plate form linear guide cooperation; a spring is arranged on the guide column in a sleeving way; the two ends of the spring abut against the upper plate surface of the bottom plate and the lower plate surface of the positioning plate correspondingly; two positioning pressure heads are arranged on the bottom plate and are parallel with the guide column; and the upper ends of the two positioning pressure heads stretch out of the positioning plate and are used for assembling a lining to be press-fitted. The lining to be press-fitted is arranged at the upper ends of the two positioning pressure heads and a workpiece is placed on the positioning plate of the tool, so that the upper ends, which stretch out of the positioning plate, of the positioning heads are positioned below a shaft hole of the workpiece; the tool is placed on a hydraulic press and the hydraulic press starts, so that a shaft sleeve is press-fitted on the workpiece; the workpiece is taken down after press fitting is finished, and the next press-fitting action is repeated; and the tool is convenient and safe, is quick in press fitting, and has high press-fitting precision and production efficiency.

Owner:HEFEI CHANGYUAN HYDRAULICS

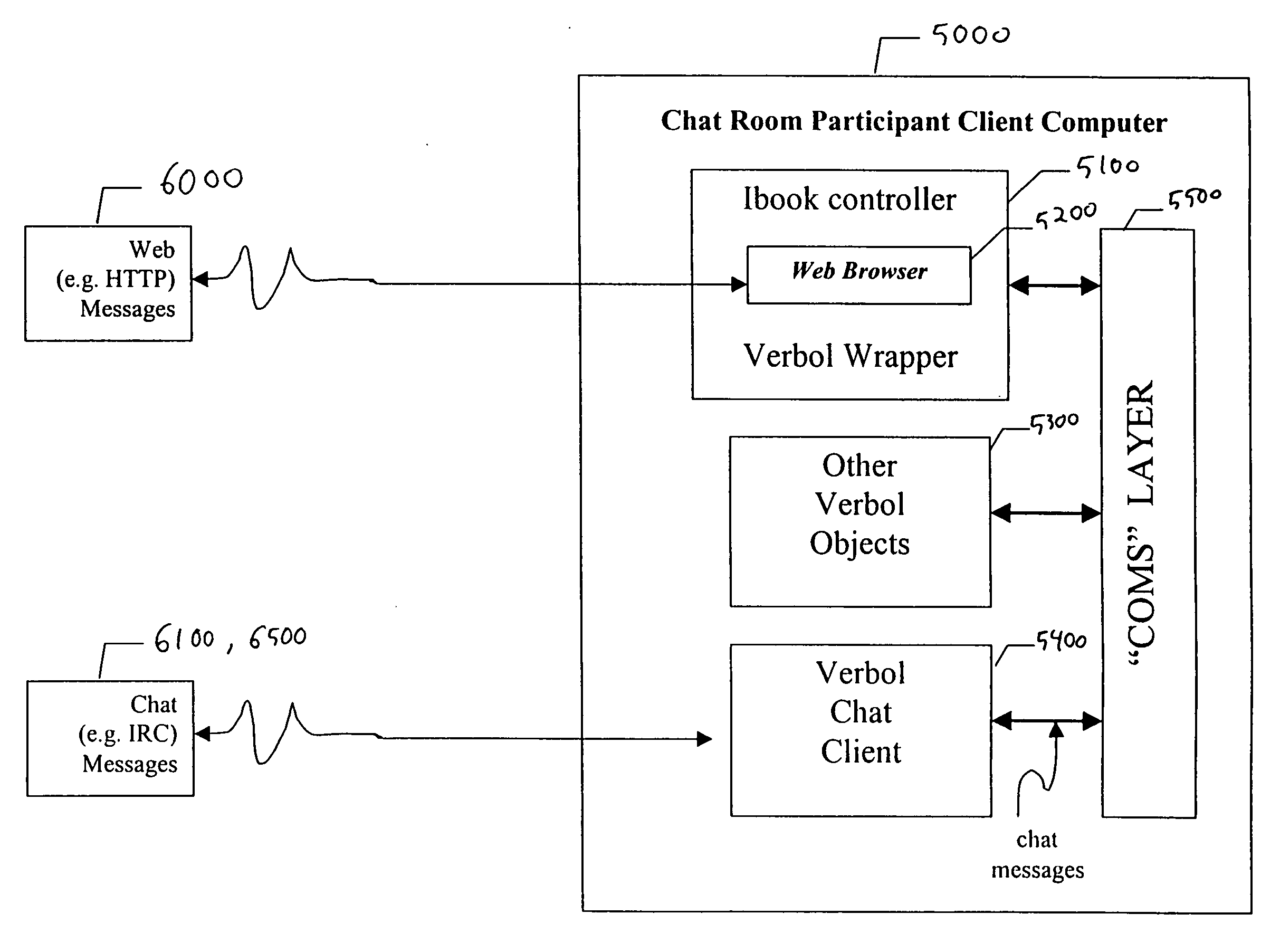

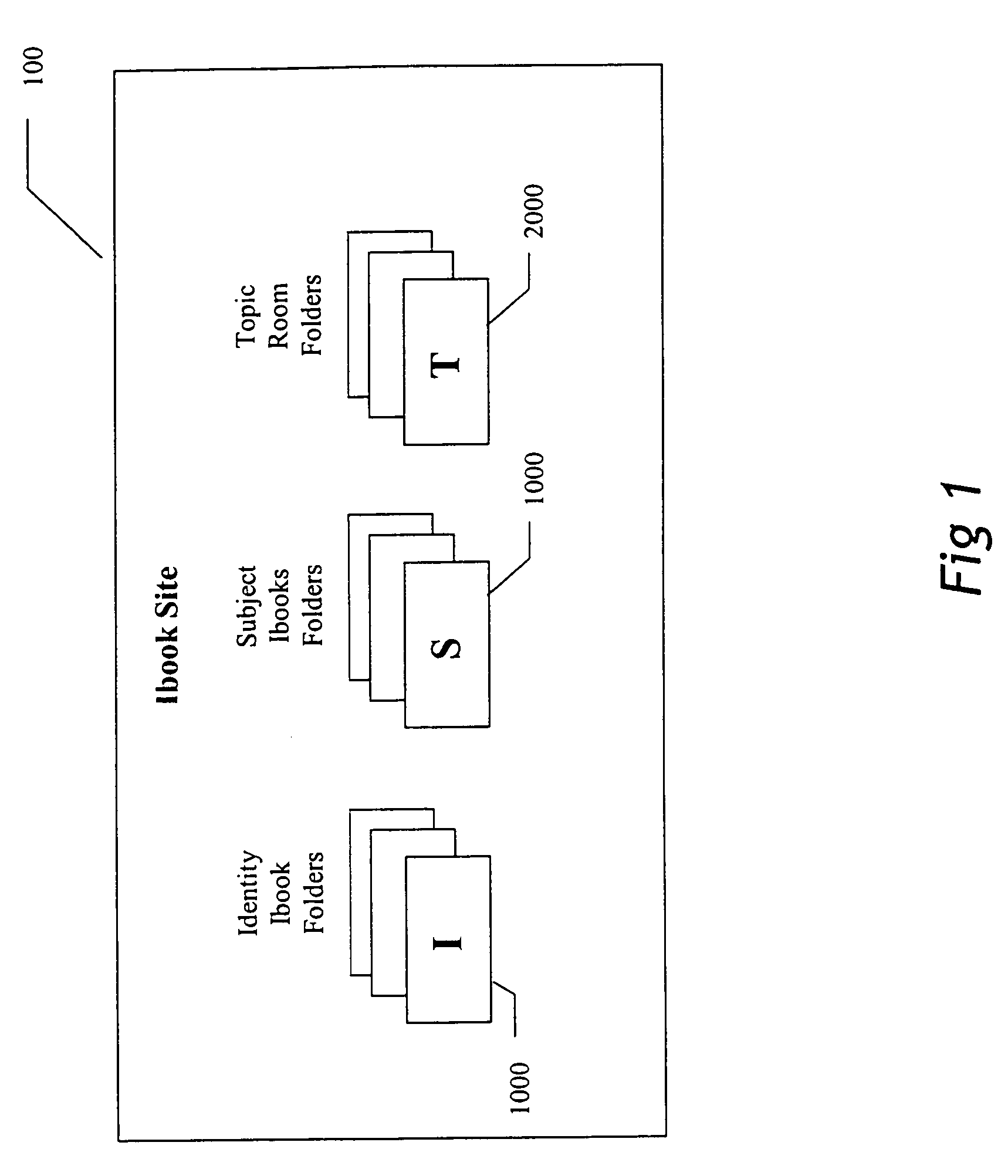

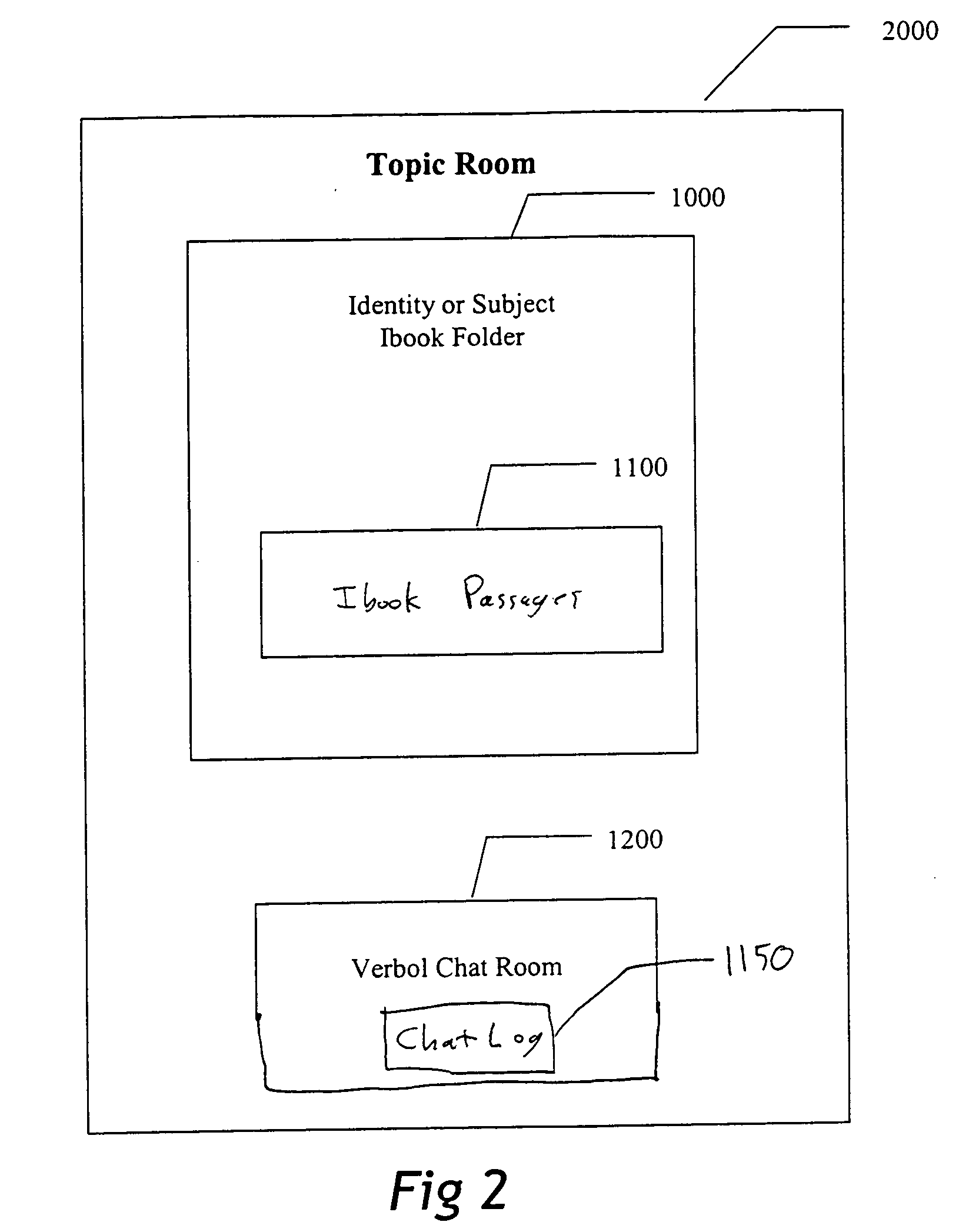

Interactive web collaboration systems and methods

InactiveUS20080228881A1Special service provision for substationNatural language data processingNon real timeChat room

A topic room is provided in which one or more individuals or other entities may collaborate on topics of mutual interest. Multiple individuals or participants may use the topic room to communicate in real or non-real time and may work together to create, browse, modify, comment on, and perform any other suitable action on content. A chat room within the topic room receives, records, and transmits the communications and all activity in the topic room to all participants as messages. Client processes at a participant's user equipment may listen to the messages and take particular actions. For example, one participant can follow another participant as that participant browses through material by using the messages received from that participant.

Owner:FIVER LLC

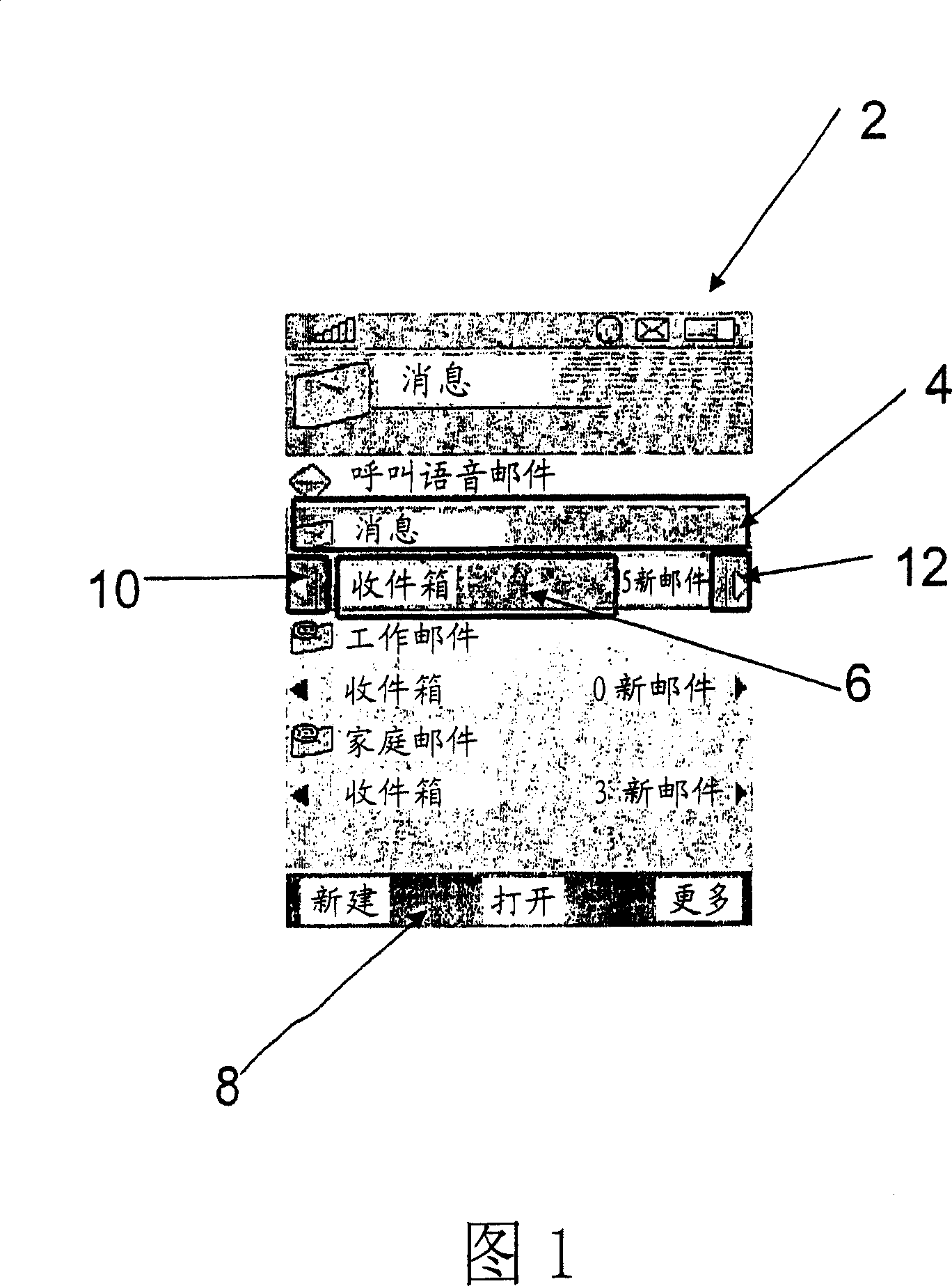

Displaying information in an interactive computing device

An interactive computing device comprises a display (2) includes fish-eye areas (4) and (6) for displaying information concerning a plurality of function items in the form of a list or table. The selection of an item results in an increase in the area of the display used to display the selected item, while leaving the area of the display used by non-selected items unchanged. The selection also results in the presentation within the increased area of the information provided in the list before the item was selected together with additional information pertaining to the selected item; and also results in the presentation within the increased fish-eye area of additional command options and related screen controls applicable only to selected items, rather than to the whole list or the non-selected items, the selection and activation of which causes the device to carry out the appropriate action.

Owner:UIQ TECH

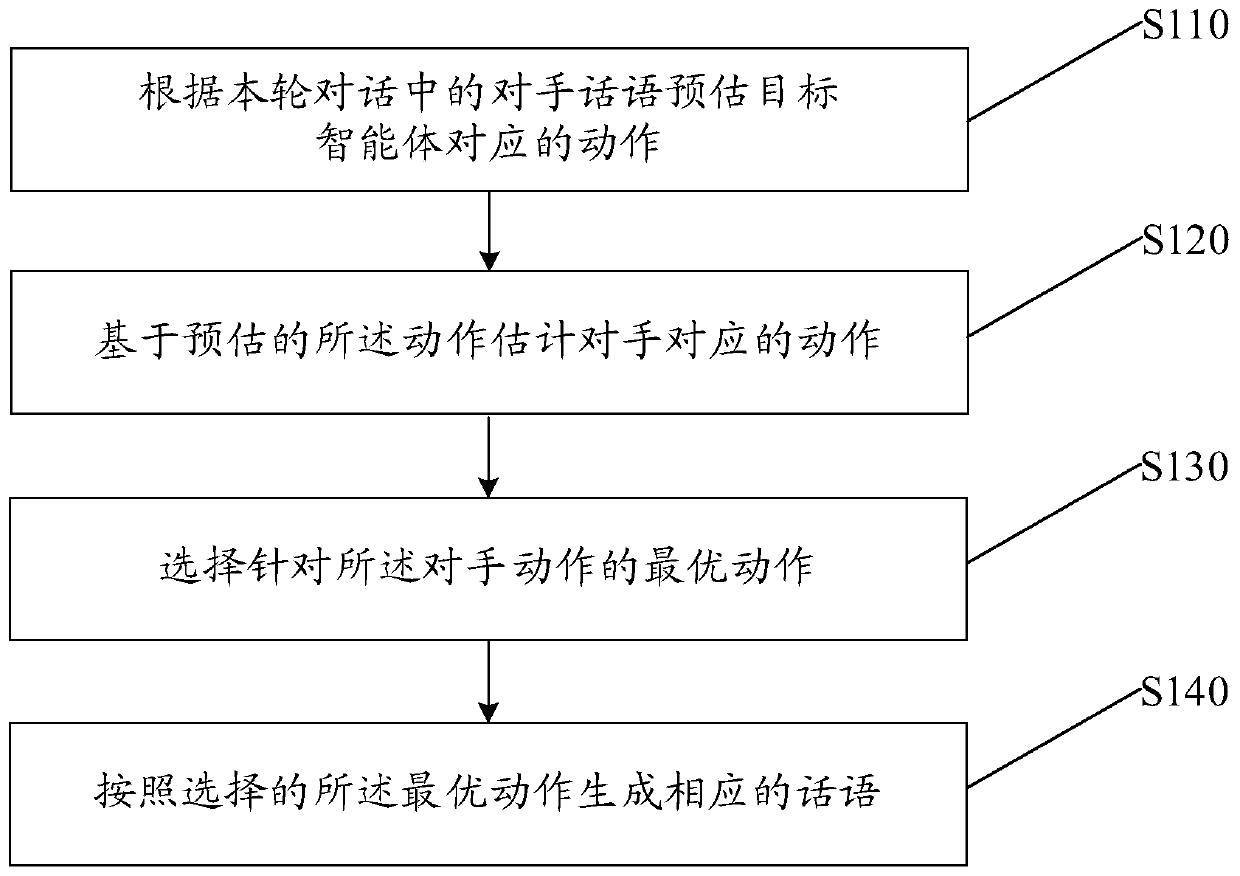

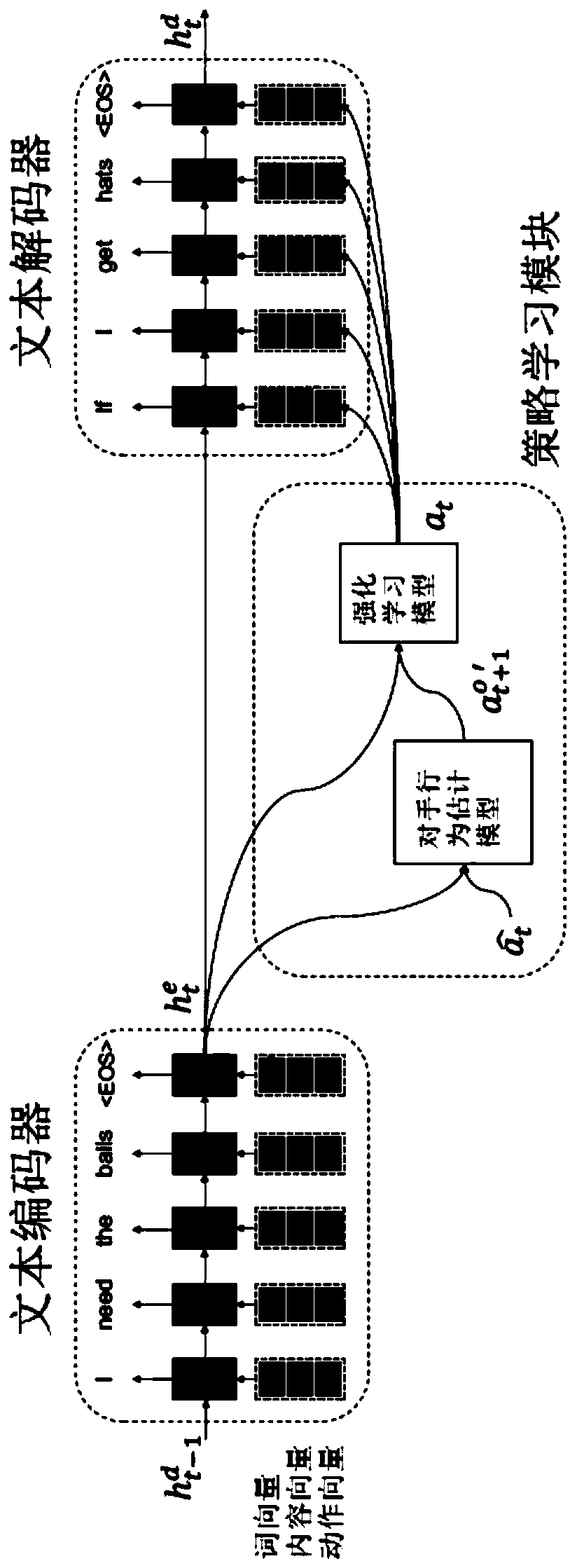

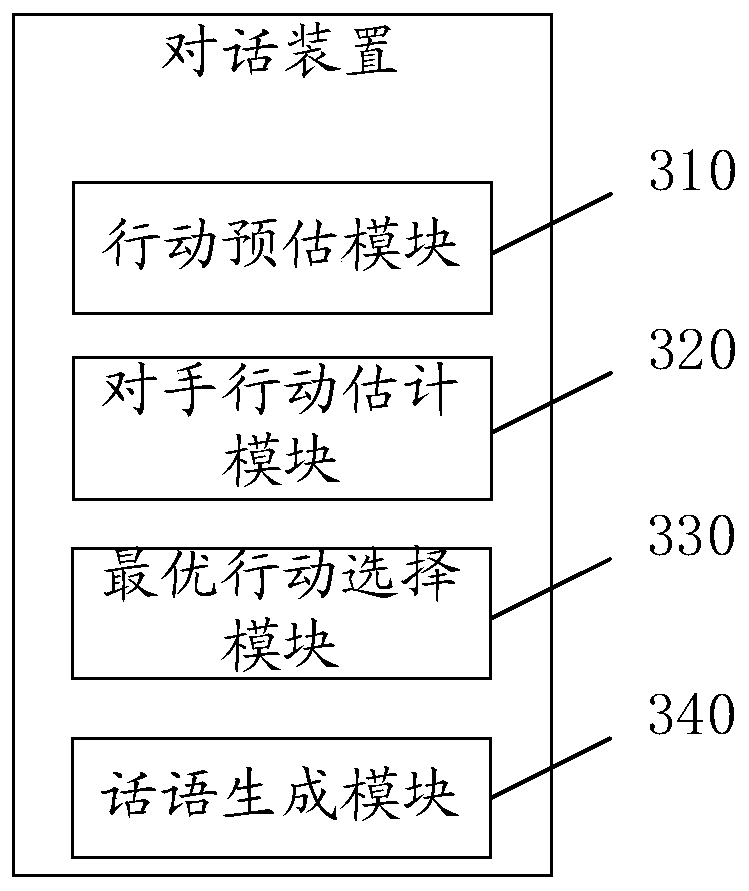

Dialogue method, medium, device and computing equipment

ActiveCN110569339AImprove instabilityDigital data information retrievalNeural architecturesDecision takingHuman–computer interaction

The embodiment of the invention provides a dialogue method. The dialogue comprises multiple rounds of dialogues between two parties of the dialogue, one party of the two parties of the dialogue is a target intelligent agent, the other party of the two parties of the dialogue is a user or an opponent intelligent agent, and the method comprises the following steps: estimating an action correspondingto the target intelligent agent according to opponent utterances in the dialogue of this round; estimating an action corresponding to the opponent based on the estimated action; selecting an optimalaction for the opponent action; and generating a corresponding utterance according to the selected optimal action. According to the method, the action of the opponent is estimated to select the more appropriate action and generate the corresponding utterance, so that the decision of the intelligent agent is forward-looking, the more appropriate dialogue can be generated, and better experience is brought to the user. In addition, the embodiment of the invention provides a dialogue device, a medium and computing equipment.

Owner:TSINGHUA UNIV

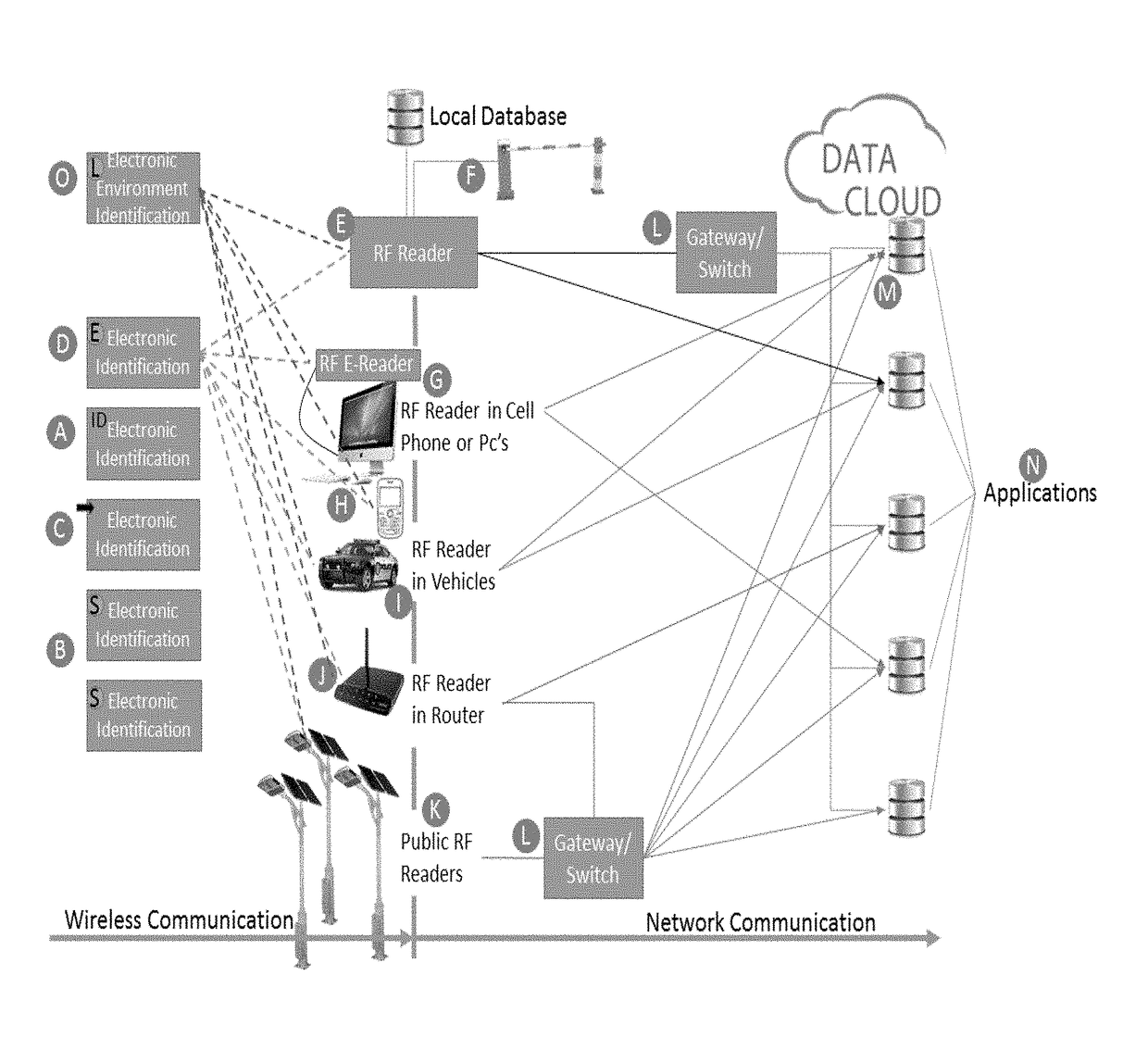

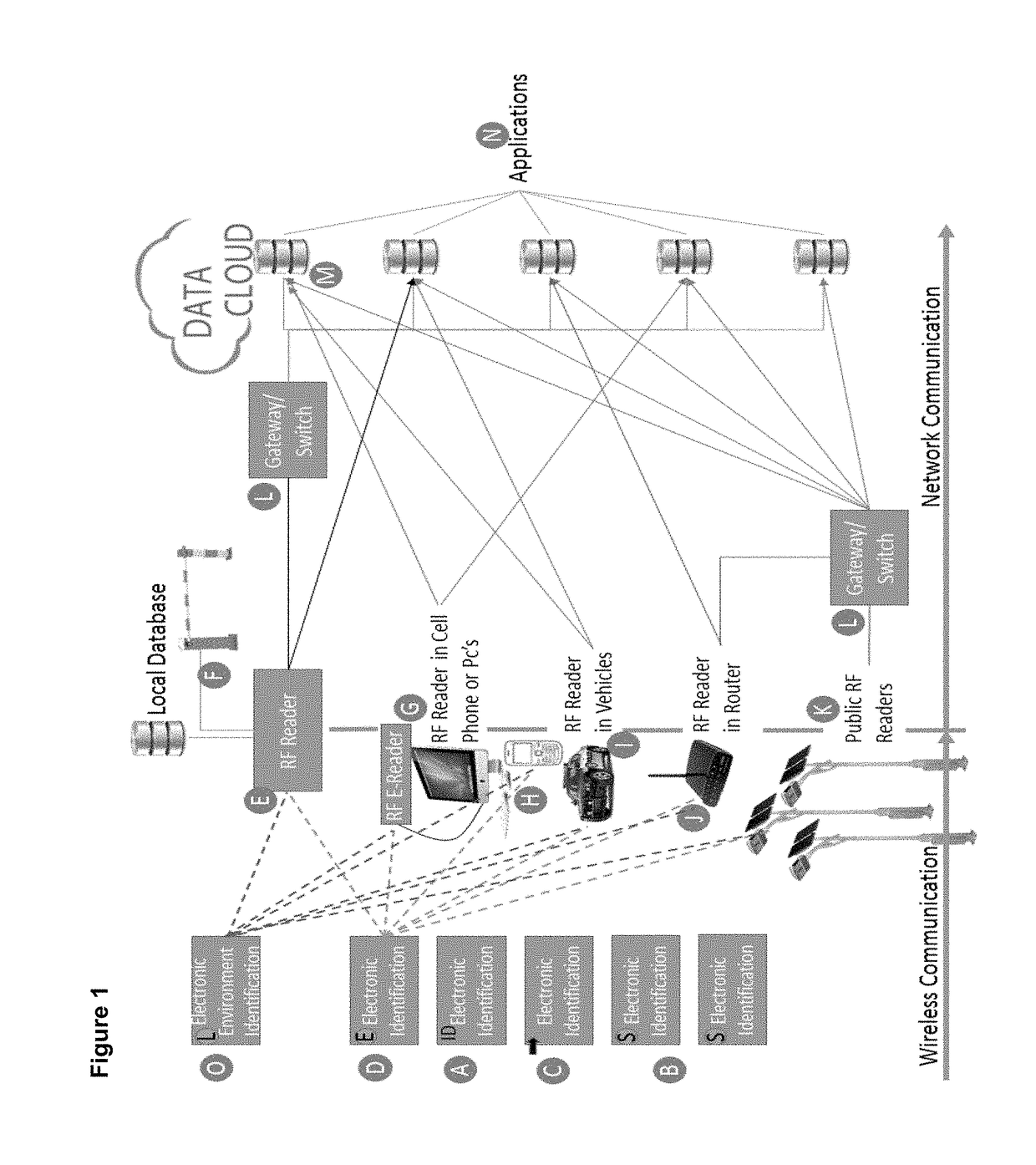

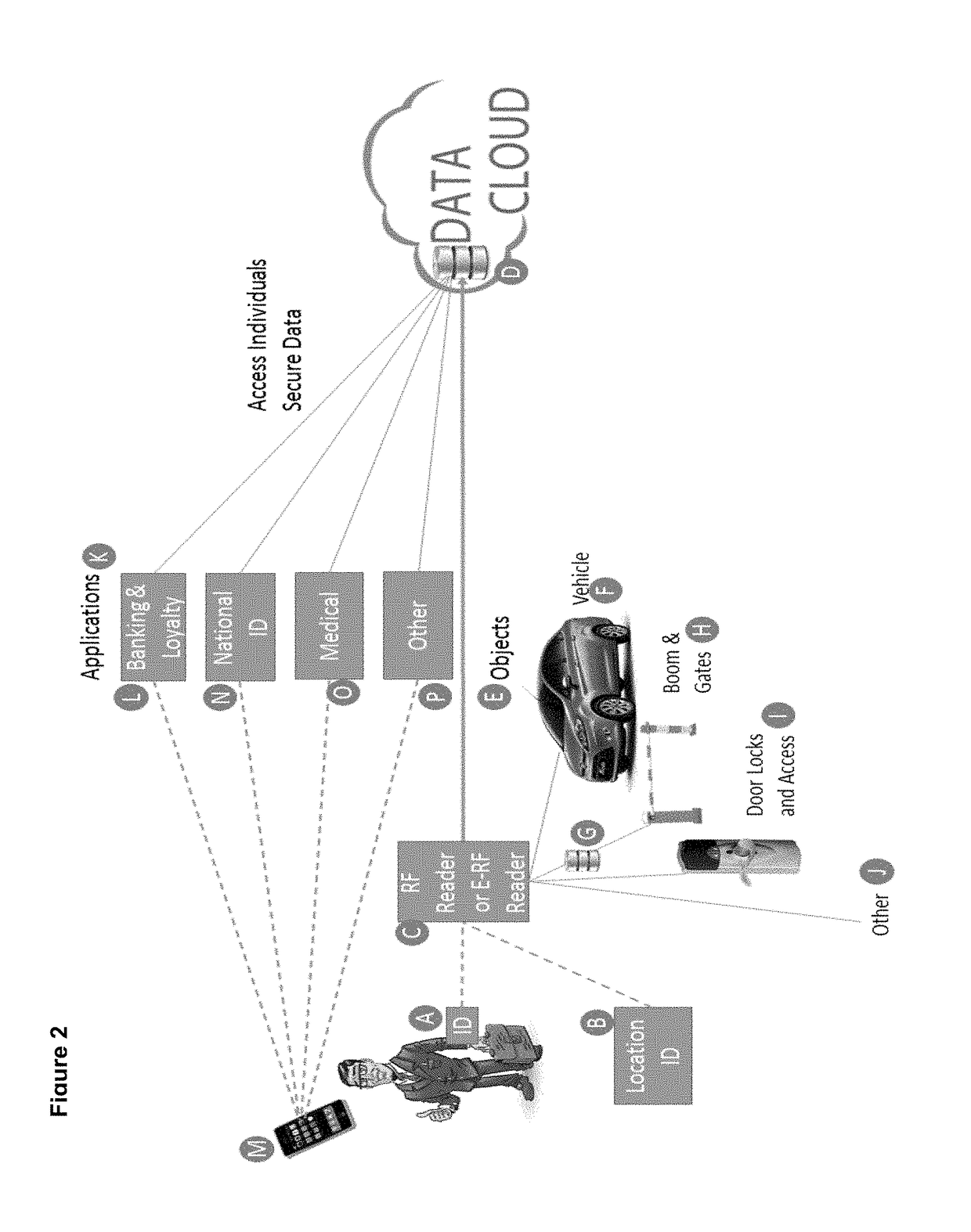

Method and apparatus for selecting a wireless reader action as a result of an output data received from a wireless identification device

ActiveUS20180157944A1Efficient processingCo-operative working arrangementsSensing record carriersIdentification deviceAuthentication server

A method and apparatus for selecting a wireless reader action comprising the steps of a wireless communication identification device which is a wireless identification device transmitting output data; the wireless reader thereafter receives the output data, wherein the output data comprises an instruction set how to process the output data; and the wireless reader processing the output data and performing a suitable action in compliance with said output data instructions. The wireless identification device comprises at least one of a unique data address and a unique variable encryption key, which is transmitted as part of the instruction set. Authentication of data and resulting permission to decrypt the wireless identification device output data is transmitted to at least one of an authentication server or user API, which processes the data, and generates an authentication code where the wireless identification device output data corresponds with authentication criteria.

Owner:BSMART DIGITAL LTD

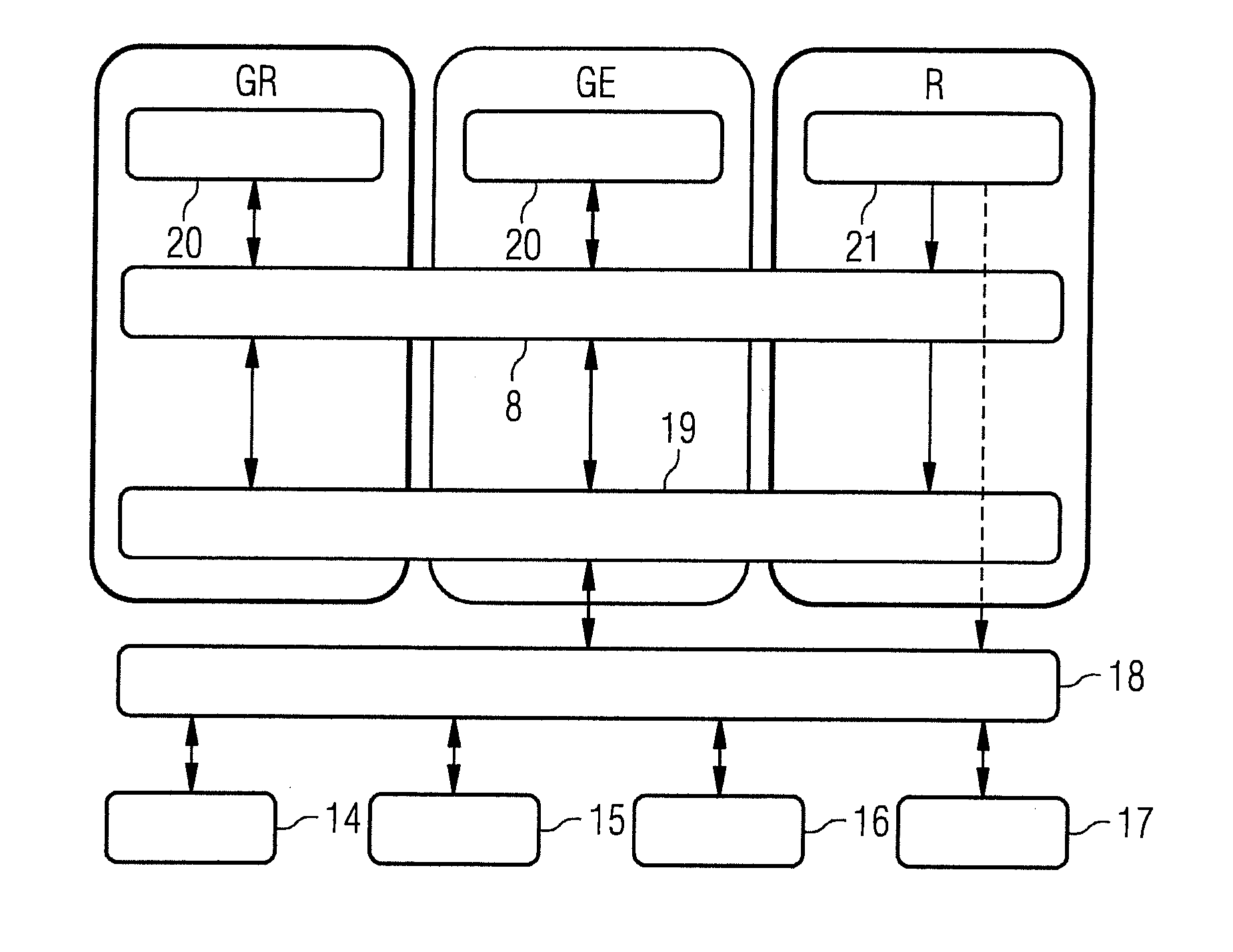

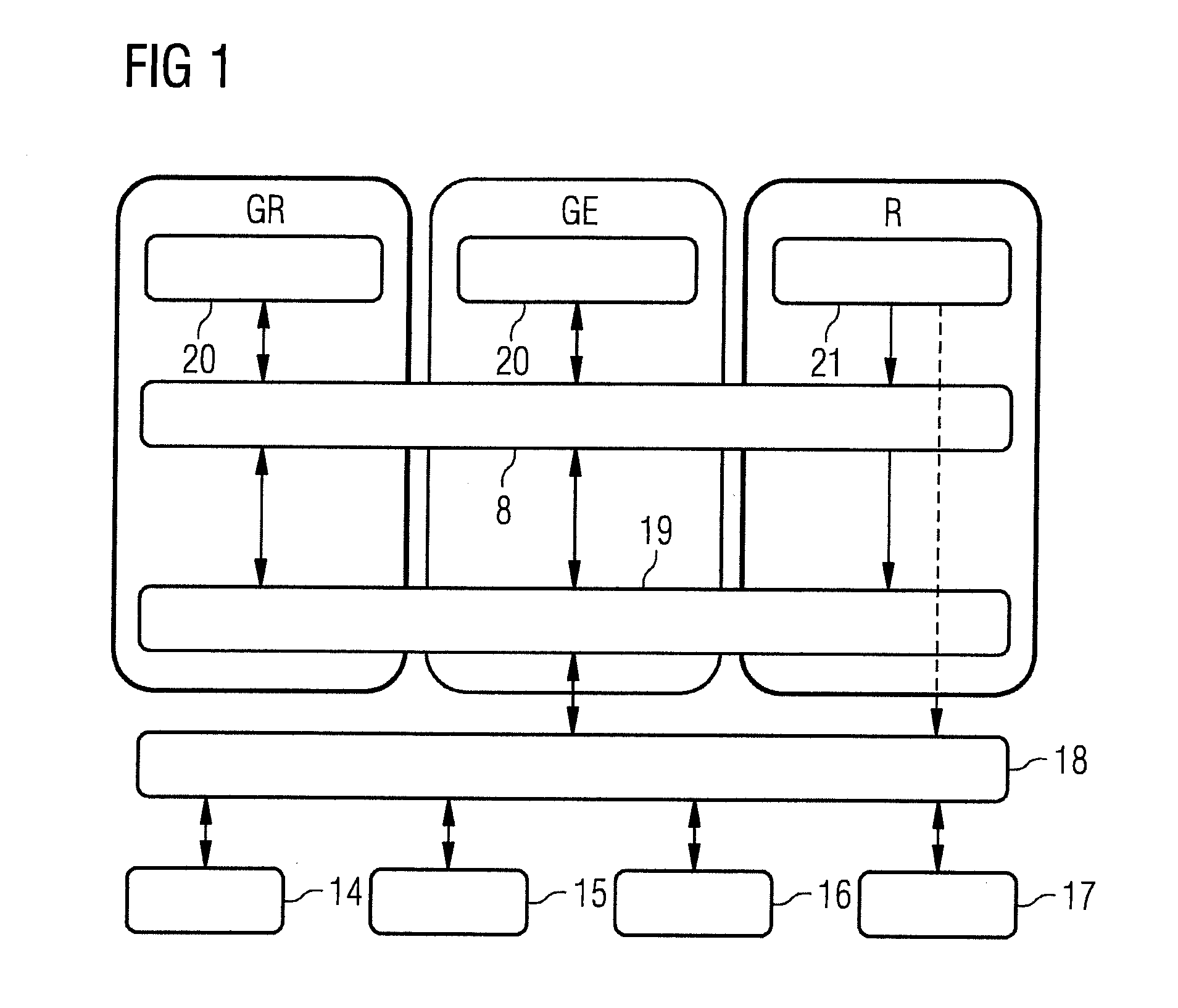

Network Regulation Upon Threshold Value Overshoots in a Low Voltage or Medium Voltage Network

ActiveUS20160363918A1Ensure qualityReduce the valueProgramme controlComputer controlLow voltageEngineering

A method for network regulation upon threshold value overshoots in a low voltage or medium voltage network, wherein control commands are transmitted from a central regulation unit of the low or medium voltage network to controllable components of the low voltage or medium voltage network, where upon occurrence of the threshold value overshoot, the central regulation unit calculates the necessary correction and transmits a suitable action instruction to at least one controllable component, with each action instruction, a probability factor is also transmitted which is incrementally raised if, given an insufficient reaction of the controllable components, the threshold value overshoot is not prevented and thus an action instruction must be transmitted anew, and the central regulation unit informs the network operator if the emergency reserves of the controllable components are insufficient to prevent the threshold value overshoot.

Owner:SIEMENS AG

Source-network coordination control method for wind farm flexible DC grid connection and DC output

ActiveCN106816887BReduce volatilityReasonable distribution of unbalanced powerElectric power transfer ac networkSingle network parallel feeding arrangementsTransmitted powerInertial control

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID NINGXIA ELECTRIC POWER COMPANY +1

Automatic press-fitting device for product embedded nuts

ActiveCN113649788AStable press fitImprove installation efficiencySortingMetal working apparatusProcess engineeringWorkbench

The invention discloses an automatic press-fitting device for product embedded nuts, and belongs to the field of automatic assembly equipment. The automatic press-fitting device comprises a product feeding mechanism, a workbench, a product conveying rail, a product moving mechanism and a nut feeding press-fitting mechanism, wherein the product conveying rail is horizontally erected on the workbench, one end of the product conveying rail is connected with a discharging port of the product feeding mechanism, the product moving mechanism is arranged below the product conveying rail, and the nut feeding press-fitting mechanism is arranged on the workbench and is located on the side of the product conveying rail. According to the automatic press-fitting device, automatic feeding and discharging of the nuts are realized by utilizing a nut staggered arrangement mechanism, automatic grabbing and press-fitting of the nuts are realized by utilizing a nut grabbing press-fitting mechanism, so that rapid and stable press-fitting of the plurality of nuts on a product is realized, the nut installation efficiency is high, the installation quality is good, the assembly efficiency of the product is greatly improved, the labor intensity of manual assembly is reduced, and the automatic press-fitting device has the advantages of being compact and ingenious in structural design, stable and reliable in press-fitting action, high in working efficiency and the like.

Owner:江苏墨新电子科技有限公司

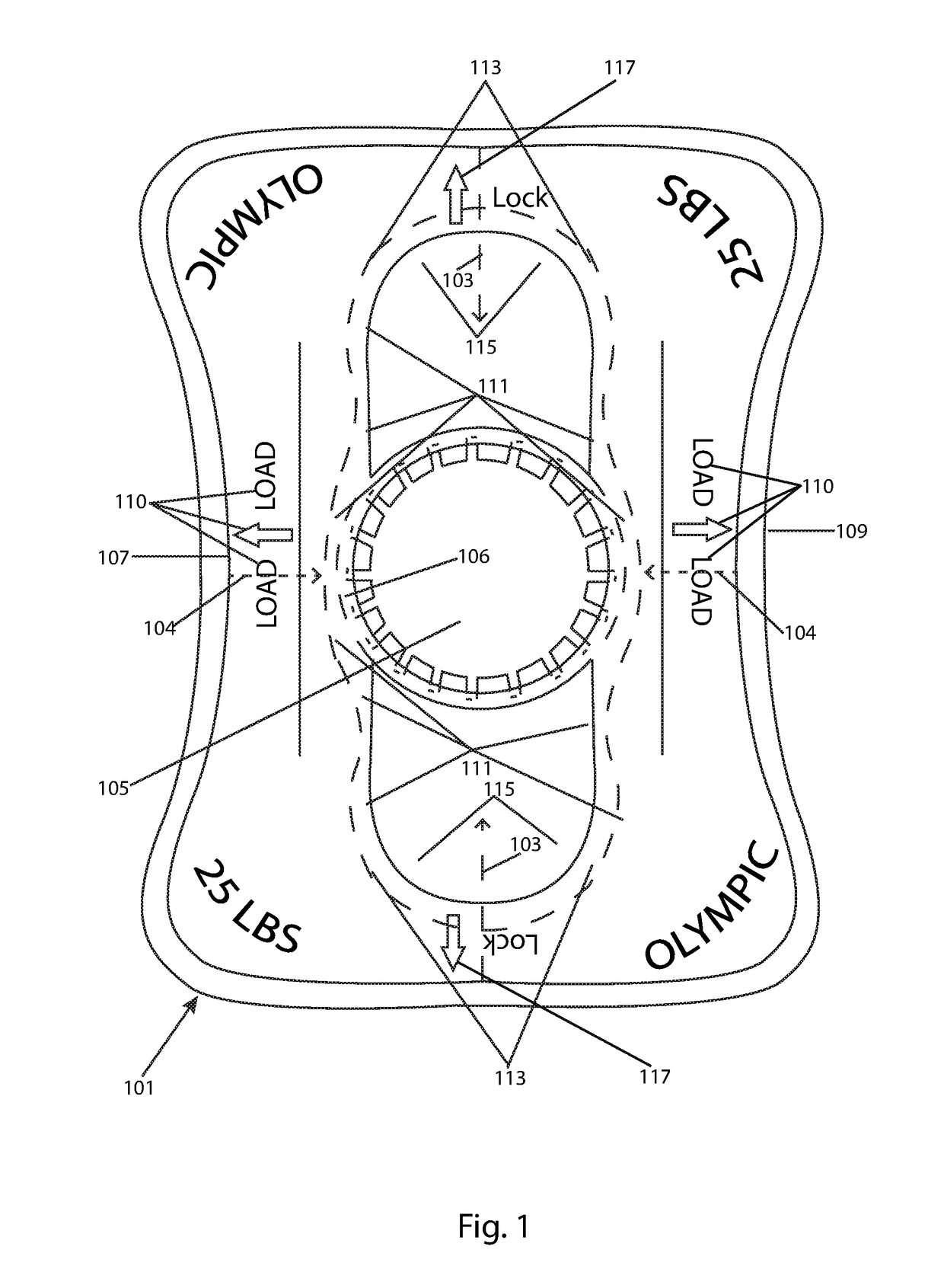

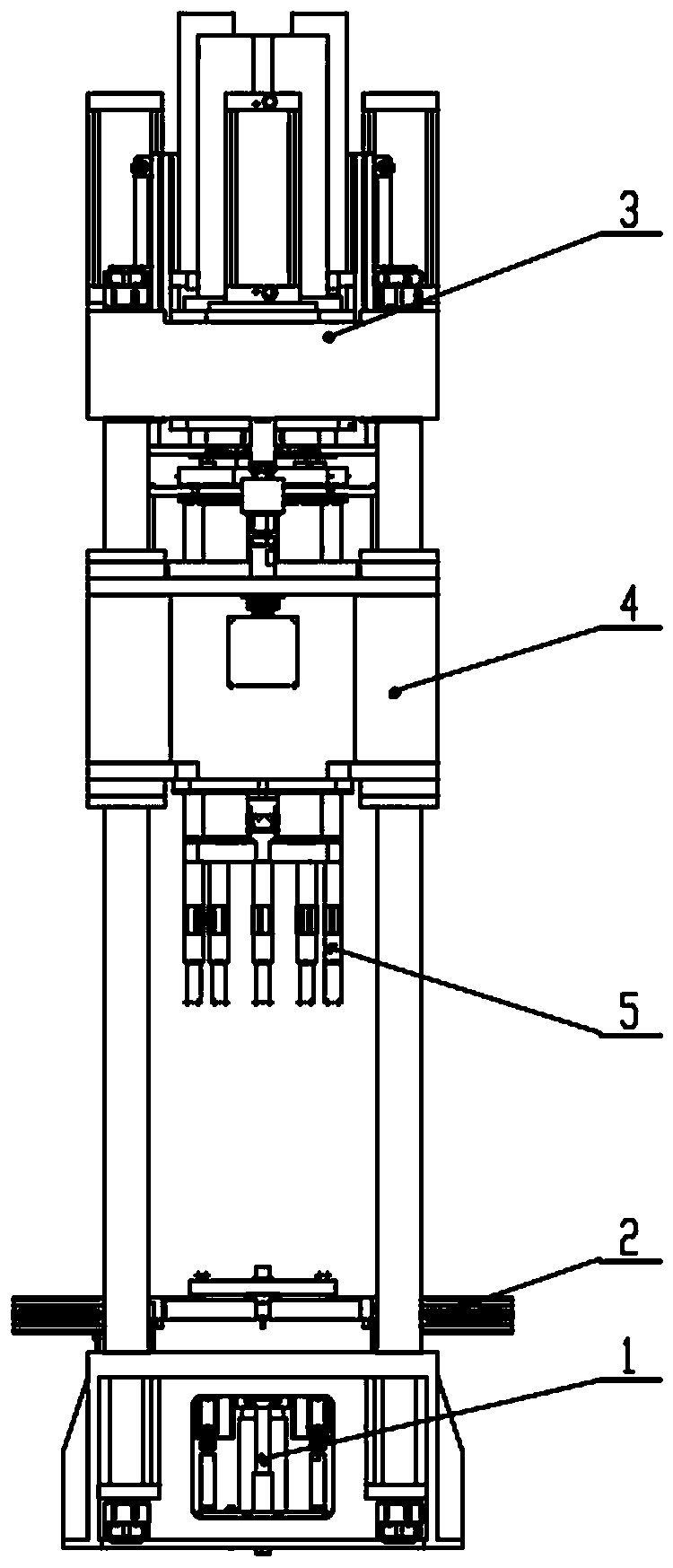

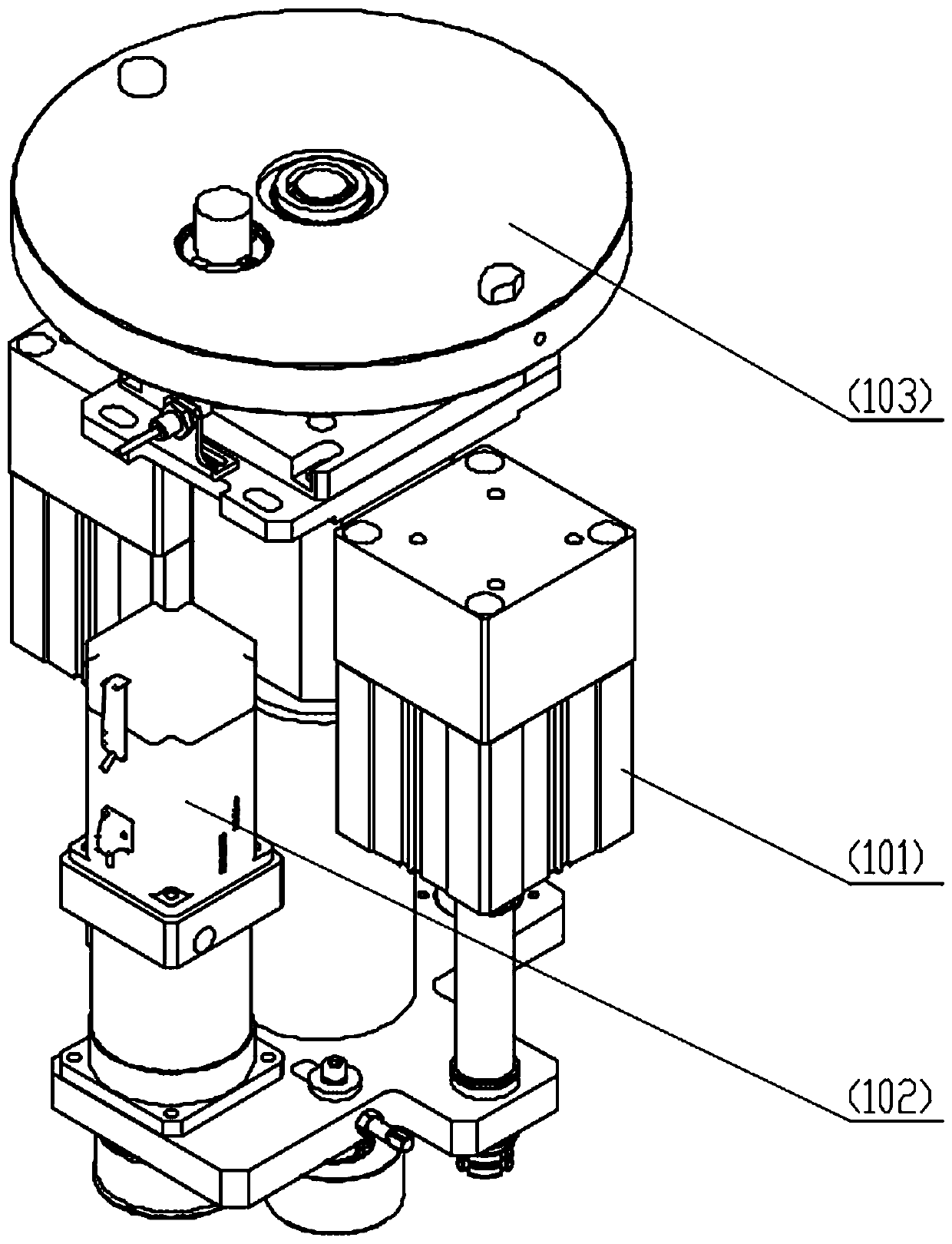

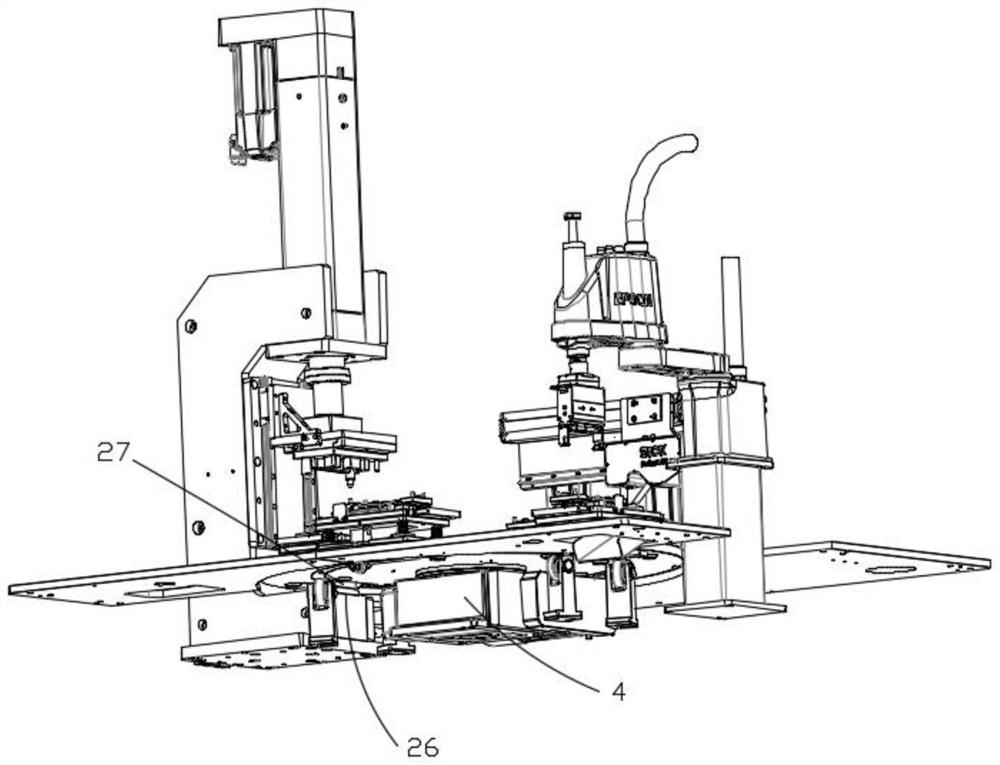

Tire bolt press fitting equipment capable of realizing multiple pressure head displacement

ActiveCN110666486AAutomatically complete the pressing actionMetal working apparatusEngineeringFitting - action

The invention discloses tire bolt press fitting equipment capable of realizing multiple pressure head displacement. The equipment comprises a tray lifting and positioning mechanism, a sizing block inserting plate mechanism, a power and driving mechanism, a press fitting mechanism, and a displacement mechanism, wherein the tray lifting and positioning mechanism is arranged on a base of the equipment and used for lifting and positioning a workpiece and adjusting the angle of the workpiece; the sizing block inserting plate mechanism is arranged on the base of the equipment and used for providingcounter force support for the workpiece in the press fitting process; the power and driving mechanism is installed on an upper seat of the equipment and used for driving the press fitting mechanism tolift and driving pressure heads to press bolts; the press fitting mechanism is connected with the power and driving mechanism, is a combined member of the pressure heads and the displacement mechanism and is used for pressing the bolts; and the displacement mechanism is arranged in the press fitting mechanism and used for switching the number and the position of the pressure heads according to different products. According to the equipment, the number and the position of the pressure heads can be easily switched by workers, and the whole set of press fitting actions can be automatically completed.

Owner:DALIAN KANGZHAN MACHINERY & ELECTRIC ENG

Managing electrical device power state

InactiveUS7956747B2Power managementEnergy efficient ICTElectrical and Electronics engineeringElectronic equipment

A system, method, and program product that manages the power state of a portable electrical device located within a monitored region about a vehicle. Information about the portable electrical device such as the power state of the portable electrical device is obtained and used to identify an action for the portable electrical device. Suitable actions include, but are not limited to, transitioning the power state of the portable electrical device and / or providing a notification about the portable electrical device. Other information such as the state of the ignition of the vehicle and / or the proximity of the driver and / or a passenger(s) with respect to the vehicle may additionally or alternatively be used to determine the action.

Owner:INT BUSINESS MASCH CORP

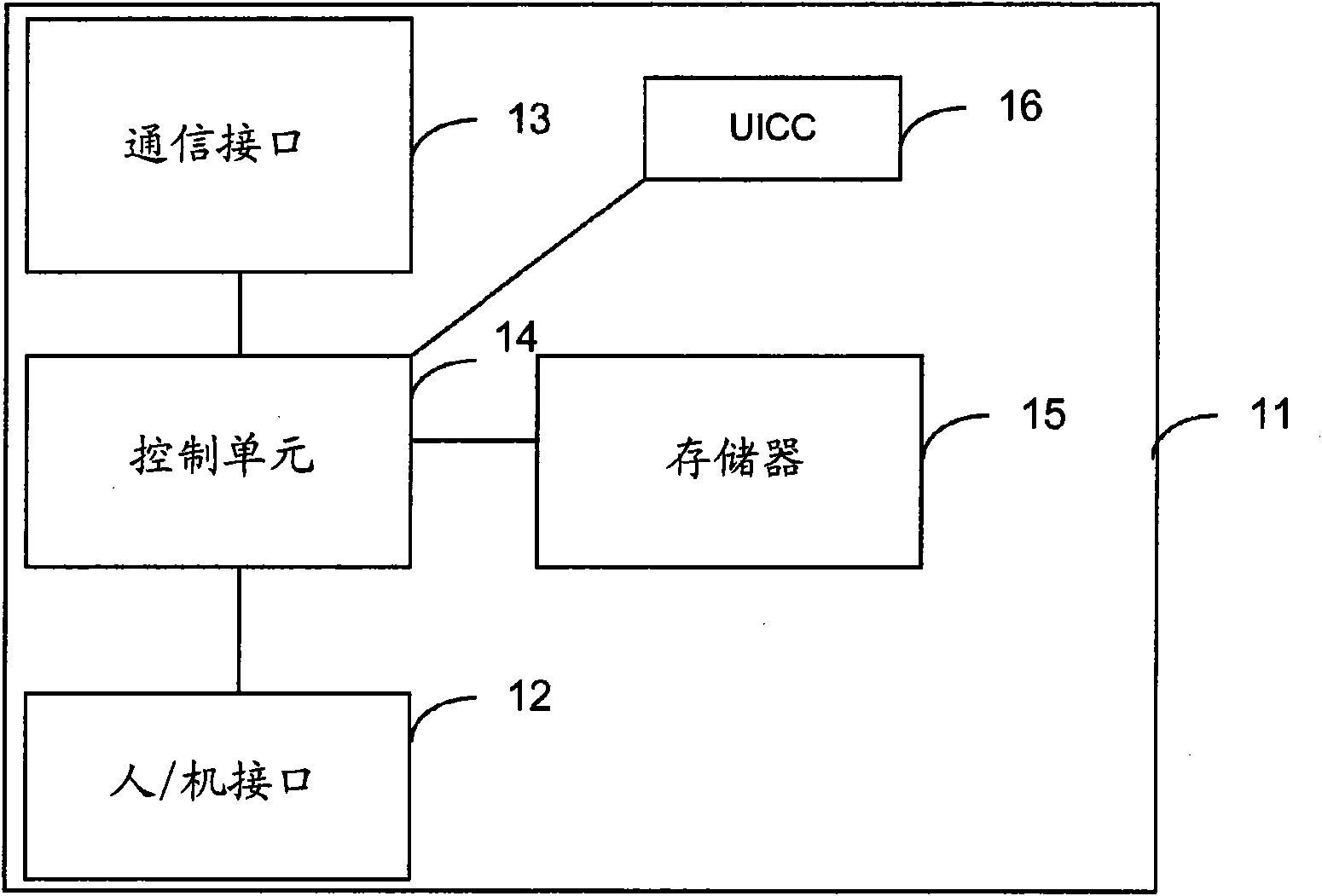

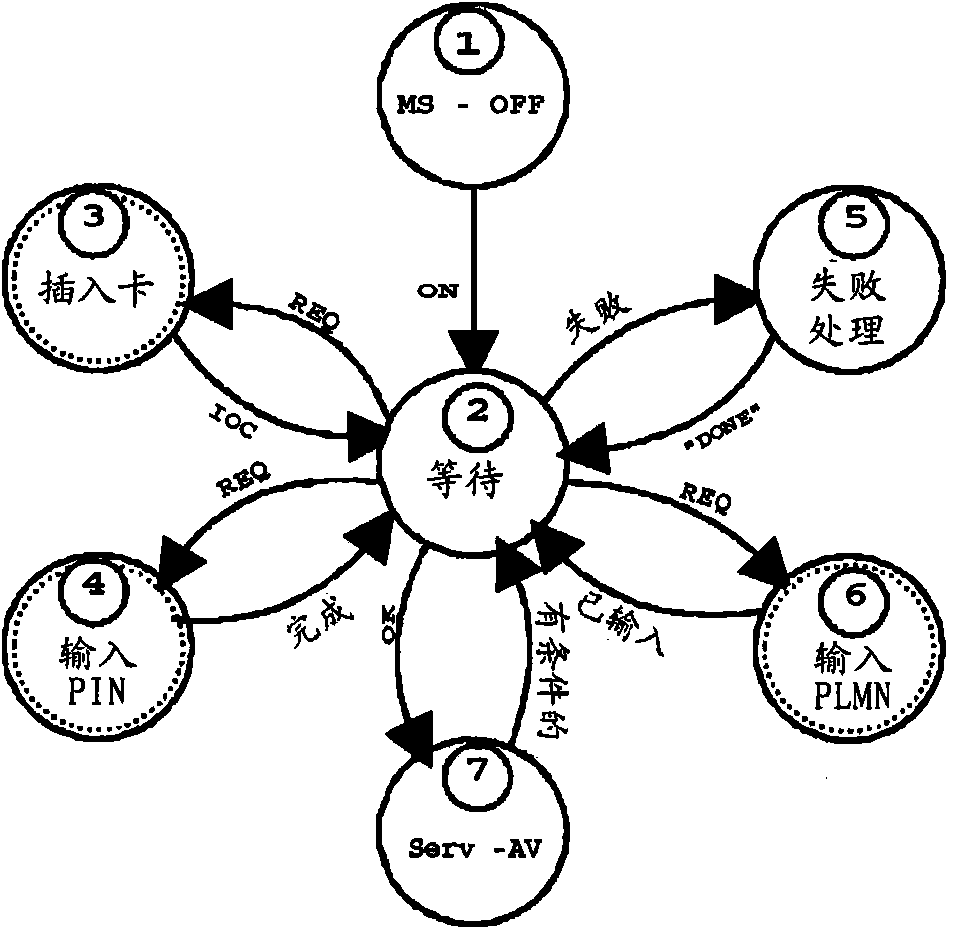

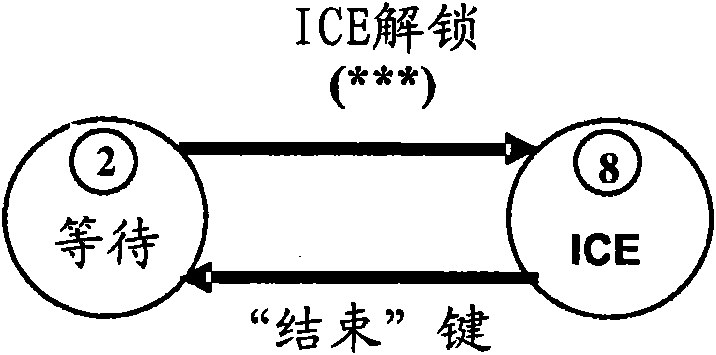

Mobile terminal having in case of emergency state and method for entering such state

The invention relates to a mobile terminal having an ''in case of emergency (ICE) state''. The In Case of Emergency (ICE) state is reachable by pressing a predefined code, suitably 'I', 'C, 'E' (which on most phones correspond to '4', '2', '3') and then an additional button e.g. the 'Send'-, 'Accept'- or 'Call' key. This action overrides 'keylock', 'phone lock' and use of 'PIN-code' etc similarly to the current emergency number handling. The action causes the ICE contact information to be displayed on the mobile phone or other suitable actions. If more than one contact is available in the ICE contact information storage, a list of alternative ICE contacts may be displayed. The invention also relates to a corresponding method and computer program product implementing the method.

Owner:TELEFON AB LM ERICSSON (PUBL)

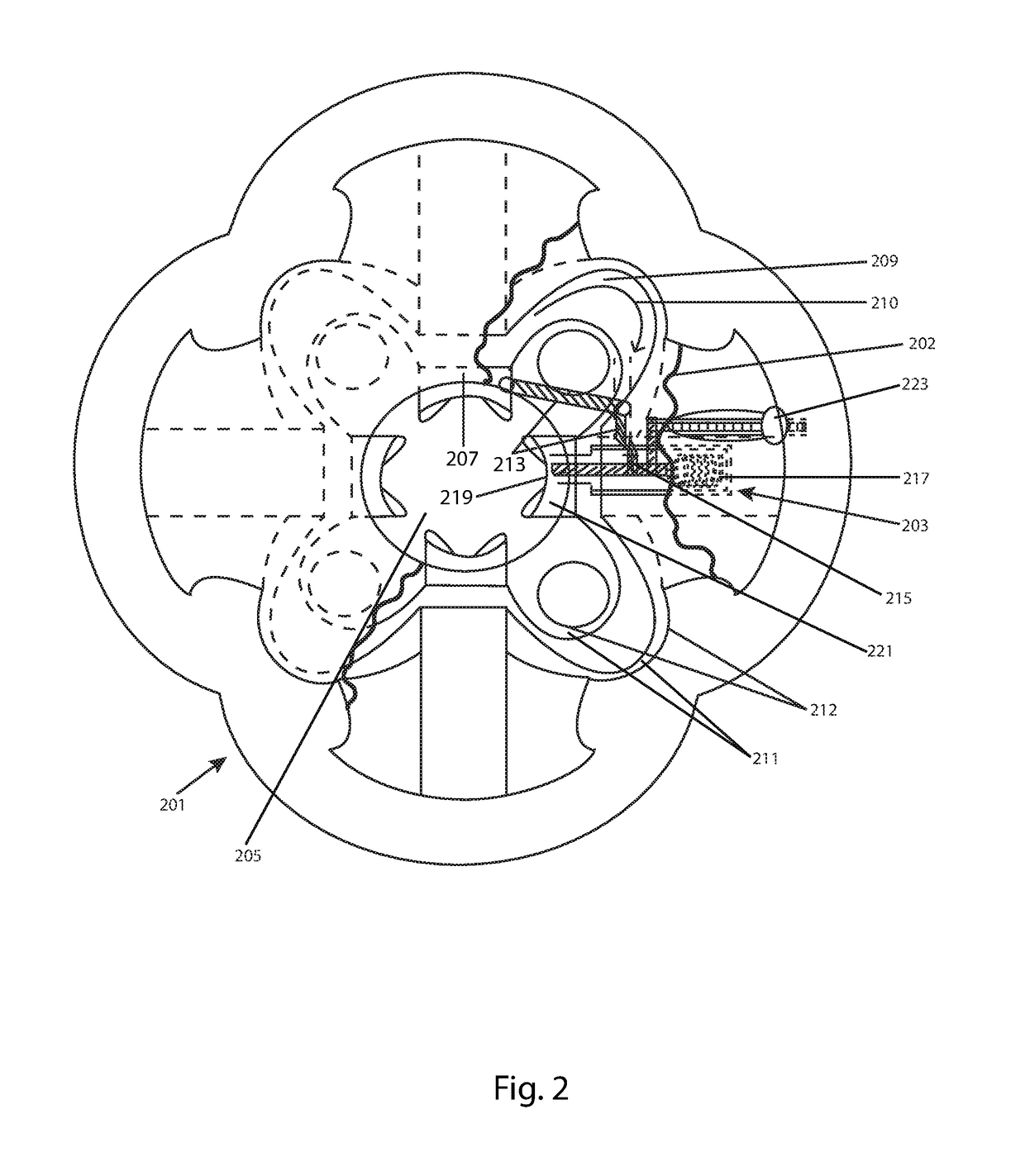

Connector press-fitting device

PendingCN113997044ASimple structureEasy to manufacture and installPrinted circuit manufactureMetal working apparatusFitting - actionEngineering

The invention discloses a connector press-fitting device which comprises a press-fitting mechanism, a rotary table mechanism, a plurality of connector carrier mechanisms, a height detection mechanism and an NG material taking mechanism, wherein the connector carrier mechanisms are distributed on the rotary table mechanism at intervals in a circumferential array mode and used for bearing connectors and PCBA boards. The press-fitting mechanism is fixed to the side face of the rotary table mechanism and used for achieving press-fitting action on the connector and the PCBA on the connector carrier mechanism, and the height detection mechanism and the NG material taking mechanism are fixed to the side face of the rotary table mechanism and used for detecting the height of pressed pins of the connector and the discharging process of NG materials. According to the connector press-fitting device, the automatic production process of press-fitting, detection and NG waste removal of the connector and the PCBA board is achieved, the press-fitting precision and the press-fitting efficiency are improved, and practicability is high.

Owner:江苏科伯瑞工业技术有限公司

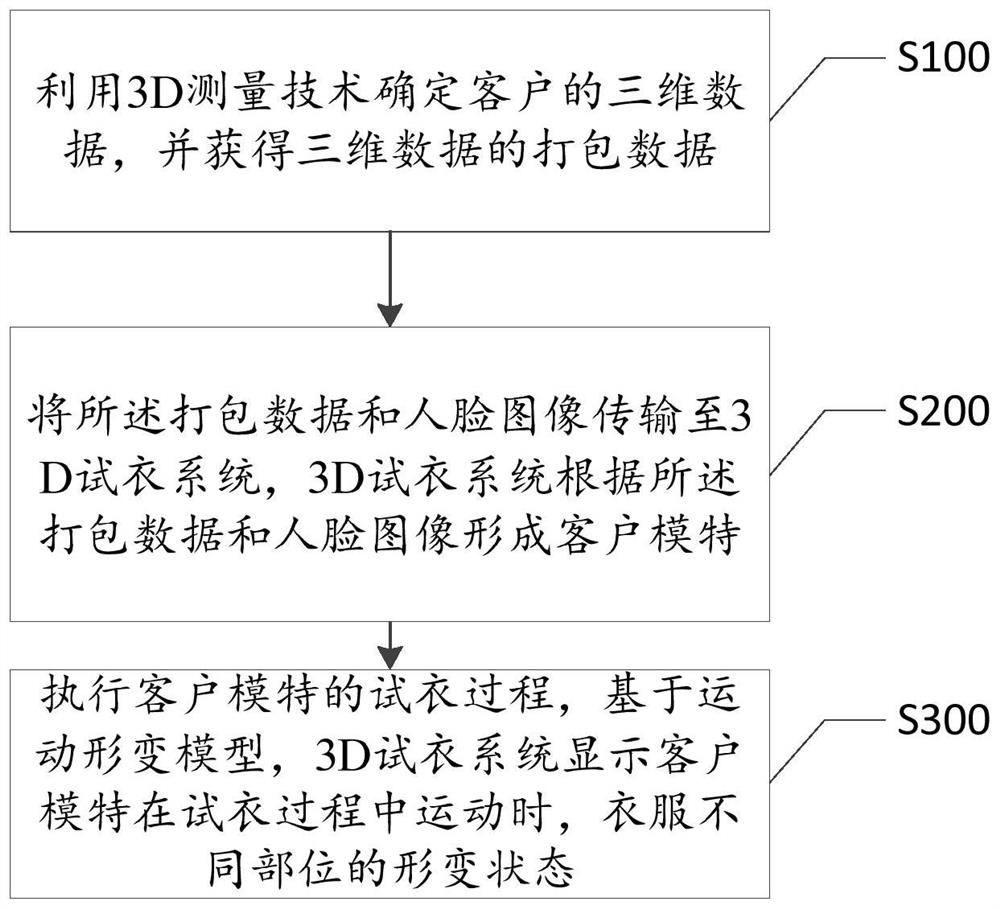

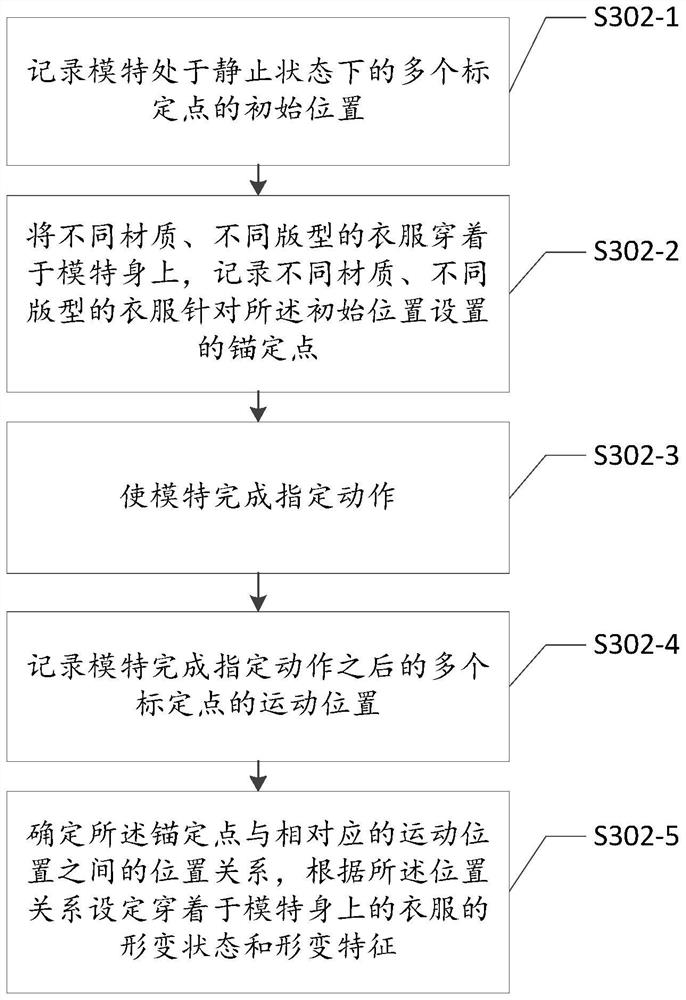

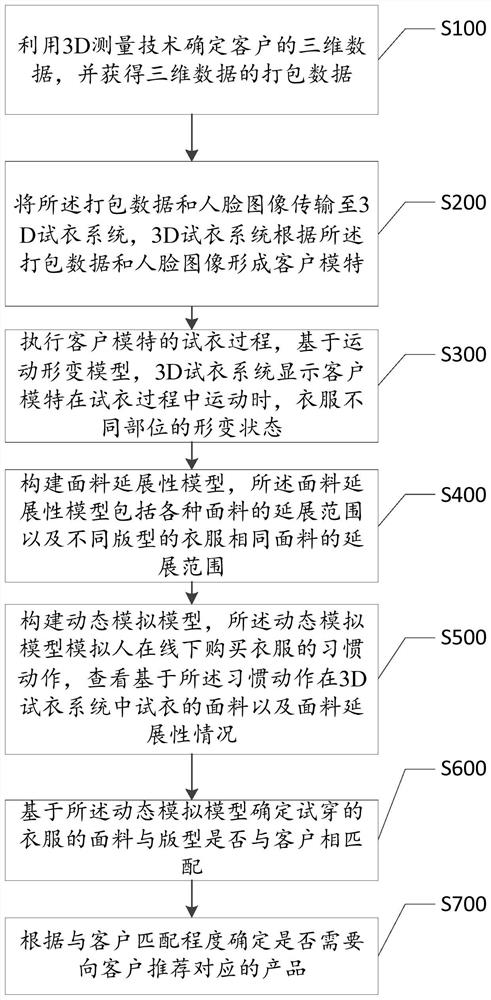

Method for restoring fitting action of customer by using 3D measurement technology

PendingCN114187068AImprove experienceBuying/selling/leasing transactions3D-image renderingComputer graphics (images)Image formation

The invention discloses a method for restoring the fitting action of a customer by using a 3D measurement technology, and the method comprises the steps: determining the three-dimensional data of the customer by using the 3D measurement technology, and obtaining the packaged data of the three-dimensional data; the packaged data and the face image are transmitted to a 3D fitting system, and the 3D fitting system forms a client model according to the packaged data and the face image; the fitting process of the customer model is executed, and based on the motion deformation model, the 3D fitting system displays deformation states of different parts of the clothes when the customer model moves in the fitting process. According to the embodiment, comfort is embodied through deformation, the actual clothes fitting habit is also met, the fitting comfort is simply and clearly embodied through the deformation state through the embodiment formed by fitting the fitting habit of people, dynamic information is provided, and the experience of customers in the virtual fitting process can be improved.

Owner:SHENZHEN SUPOIN INFORMATION SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com