Tire bolt press fitting equipment capable of realizing multiple pressure head displacement

A technology of indenter and equipment, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problem of complex indenter switching operation and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

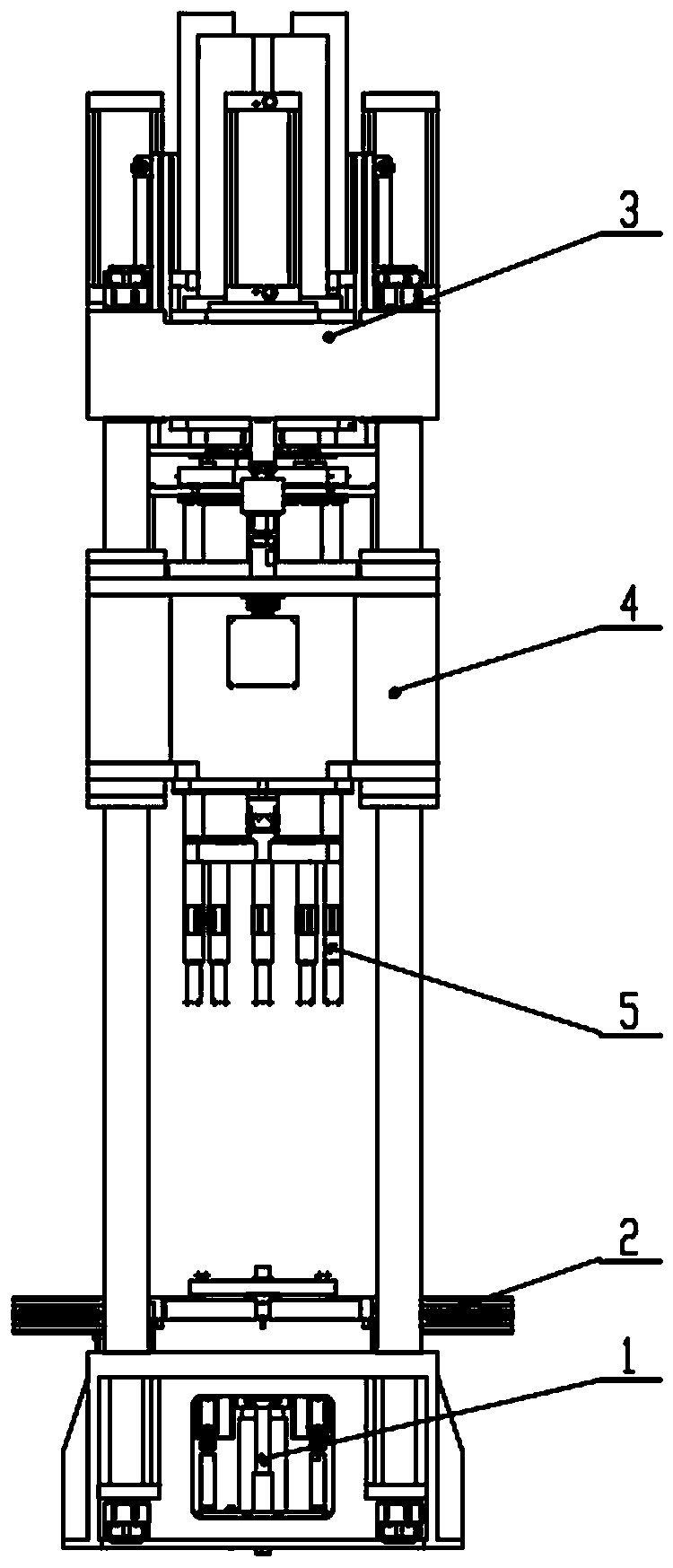

[0030] Such as Figures 1 to 6 As shown, a device for tire bolt pressing that can realize multi-indenter displacement

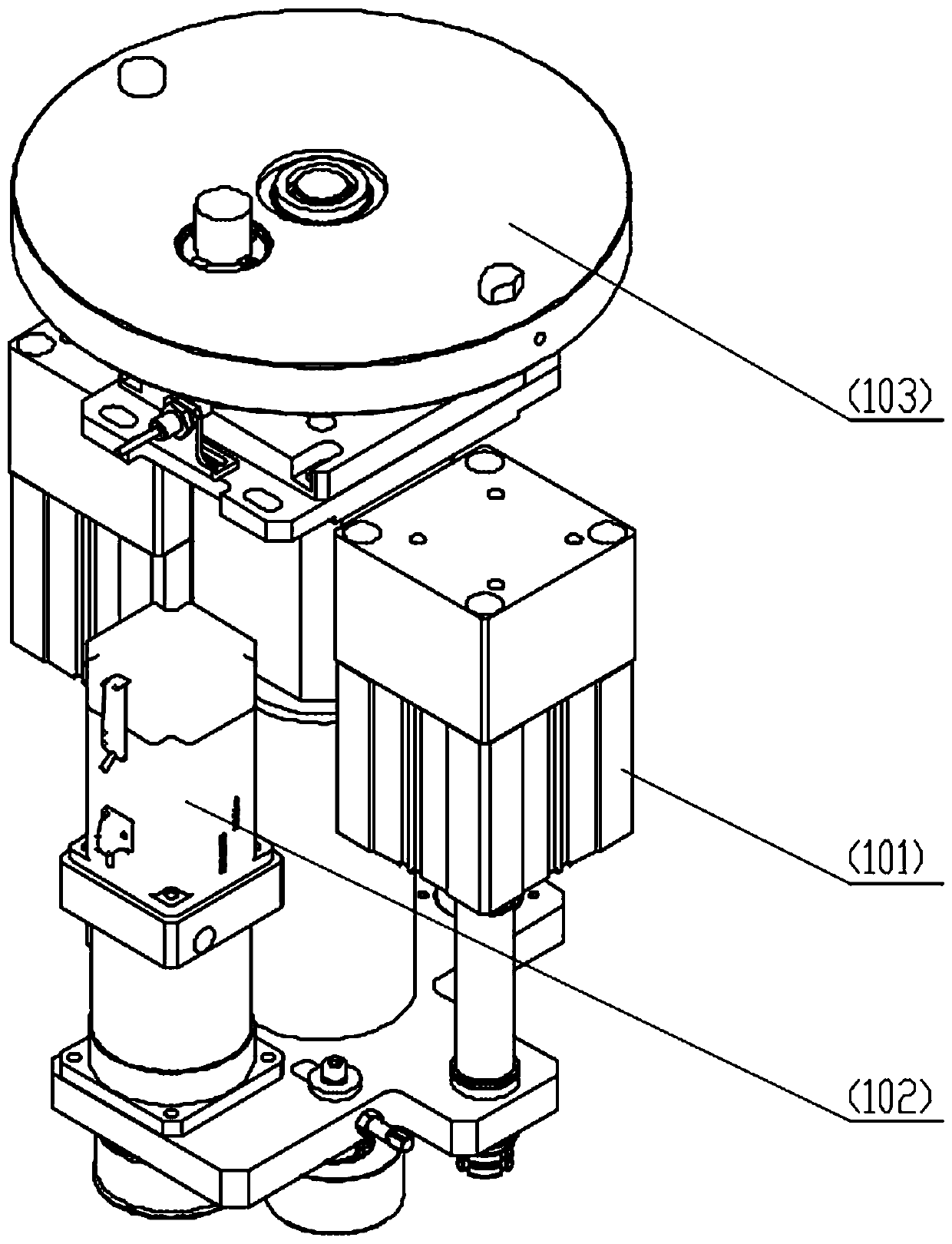

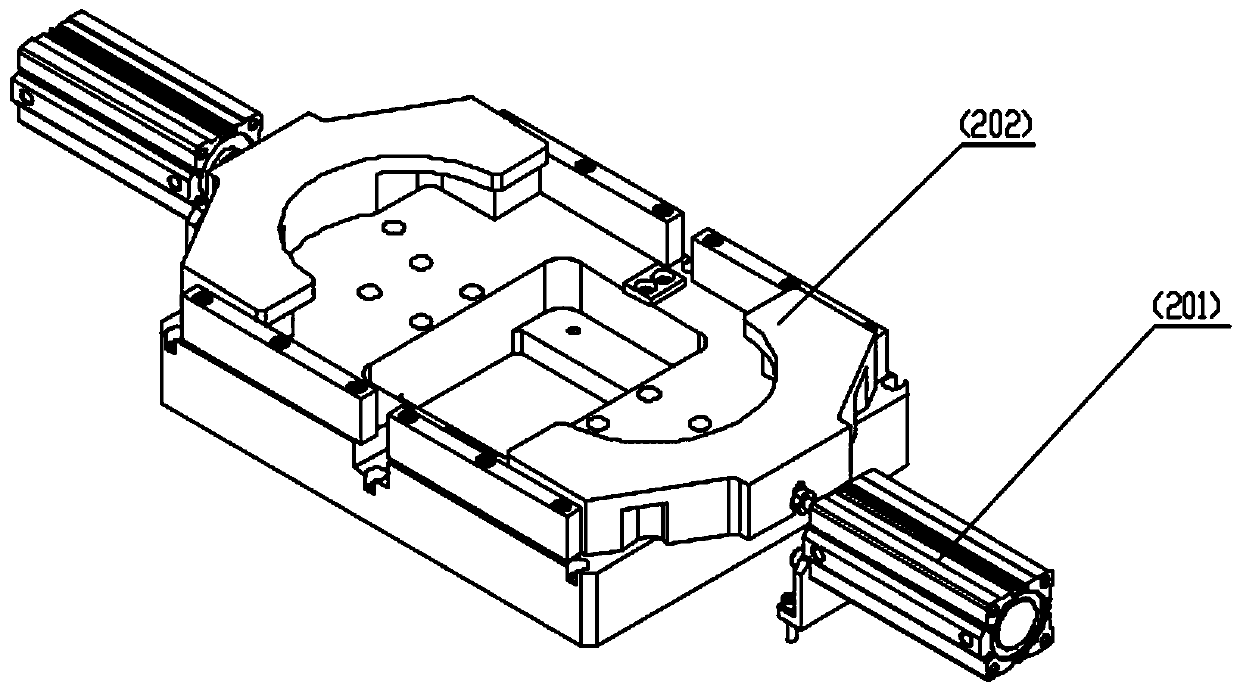

[0031] A device for tire bolt press-fitting that can realize multi-indenter displacement, including: a pallet lifting and positioning mechanism 1 installed on the equipment base, used for lifting and positioning the workpiece and adjusting the angle of the workpiece; installed on the equipment base The pad iron plate mechanism 2 is used to provide counter force support for the workpiece during the press-fitting process; the power and drive mechanism 3 installed on the upper seat of the equipment is used to drive the press-fitting mechanism up and down and drive the pressure head to press-fit the bolts; and The press-fit mechanism 4 connected with the power and the drive mechanism 3 is a combined member of the pressure head and the displacement mechanism, which is used to press the bolt; the displacement mechanism 5 installed in the press-fit mechanism 4 is us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com