A device for pressing tire bolts capable of realizing multi-pressure head displacement

A technology of indenter and equipment, which is applied in the direction of metal processing equipment, metal processing, manufacturing tools, etc., and can solve the problem of complex operation of indenter switching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

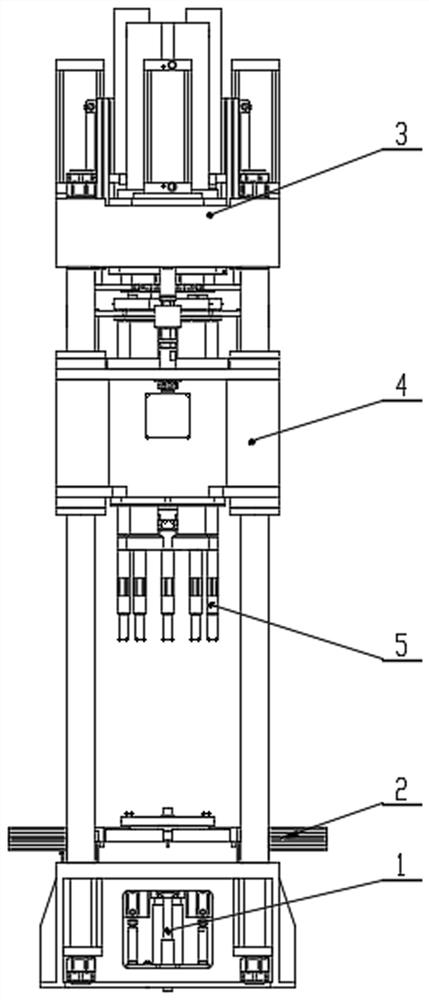

[0030] like Figures 1 to 6 As shown, a device for tire bolt pressing that can realize multi-indenter displacement

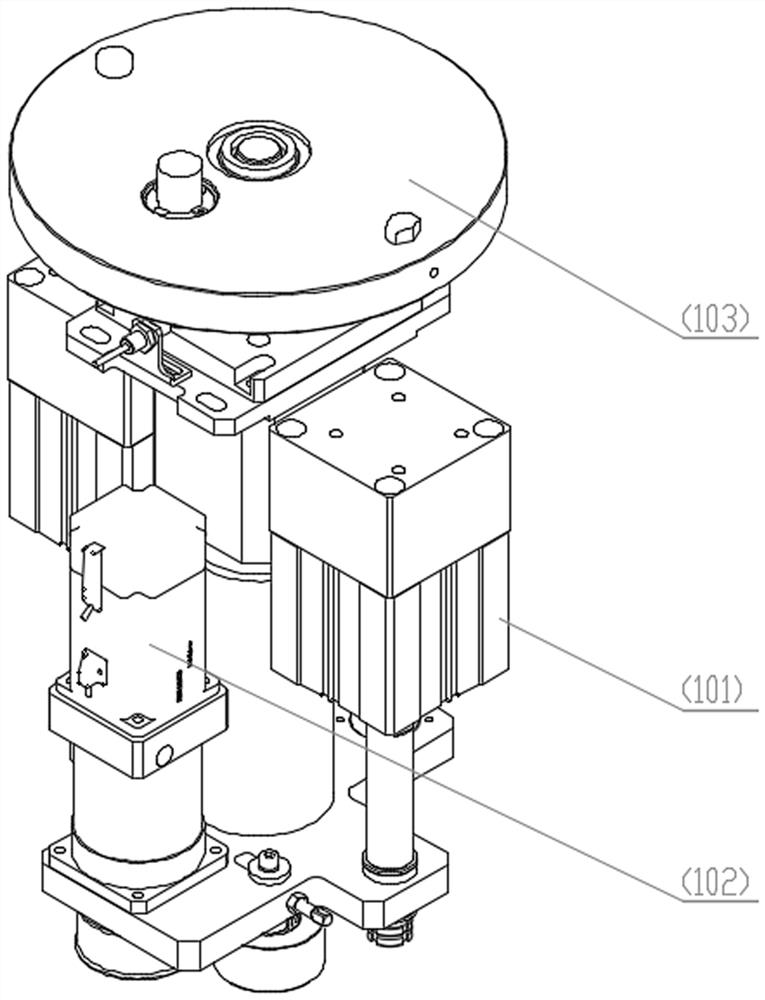

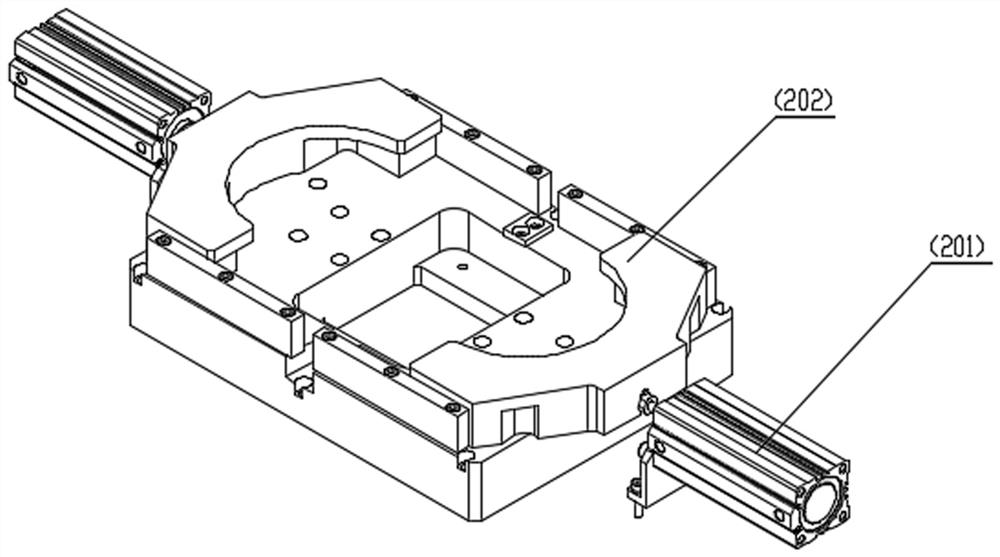

[0031] A device for tire bolt press-fitting that can realize multi-indenter displacement, including: a pallet lifting and positioning mechanism 1 installed on the equipment base, used for lifting and positioning the workpiece and adjusting the angle of the workpiece; installed on the equipment base The pad iron plate mechanism 2 is used to provide counter force support for the workpiece during the press-fitting process; the power and drive mechanism 3 installed on the upper seat of the equipment is used to drive the press-fitting mechanism up and down and drive the pressure head to press-fit the bolts; and The press-fit mechanism 4 connected with the power and the drive mechanism 3 is a combined member of the pressure head and the displacement mechanism, which is used to press the bolt; the displacement mechanism 5 installed in the press-fit mechanism 4 is used ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com