Patents

Literature

102results about How to "Improve press fit accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

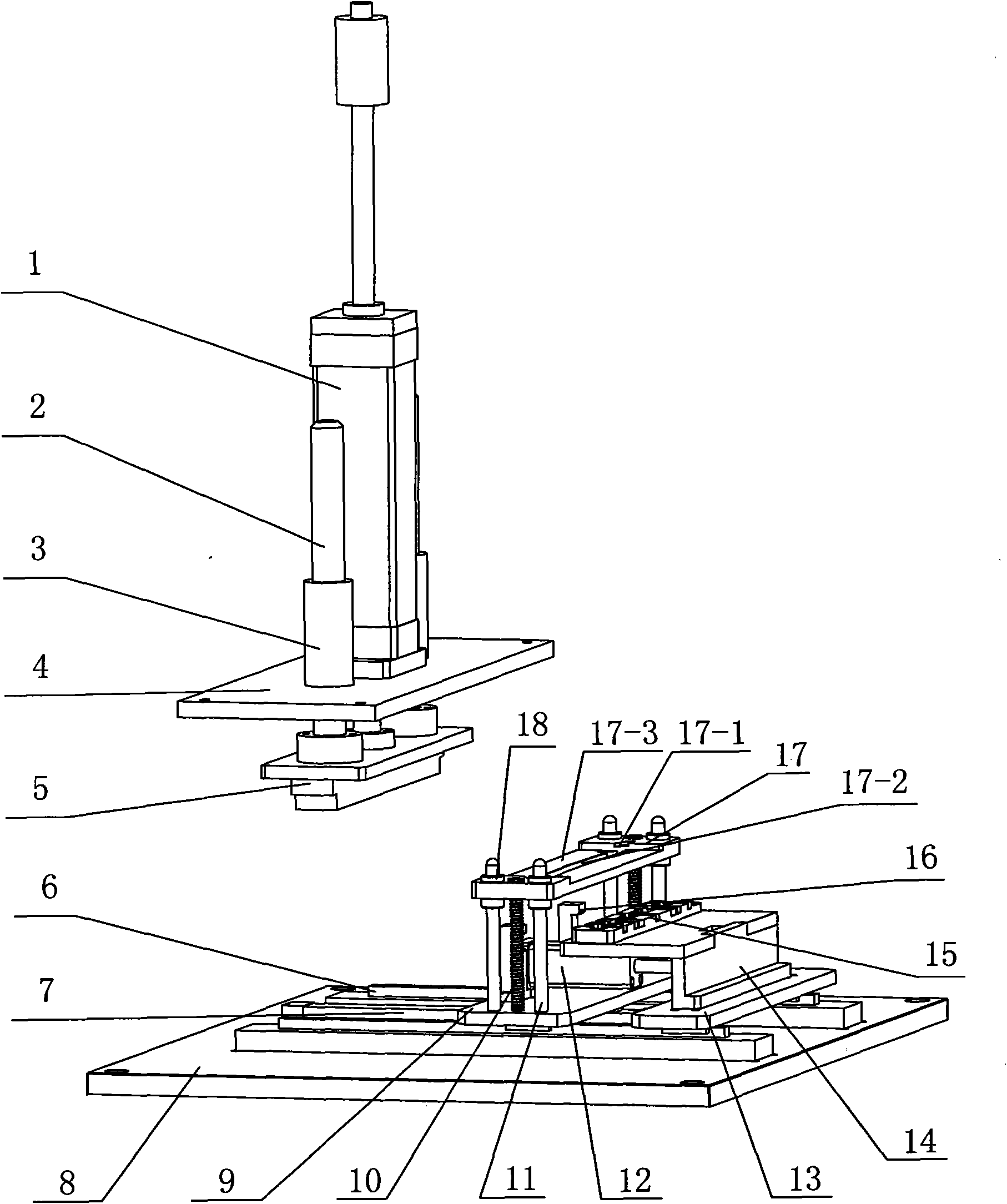

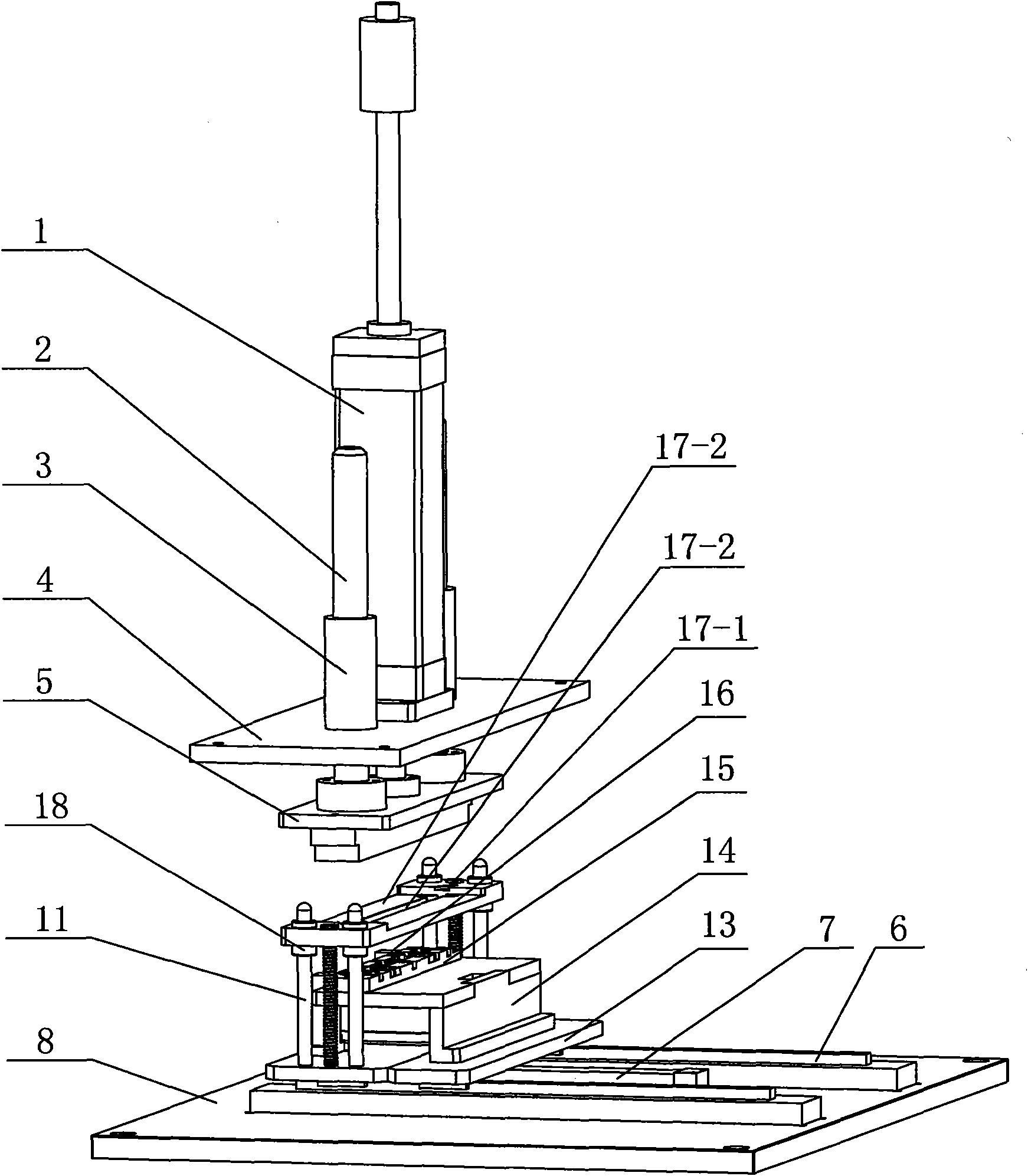

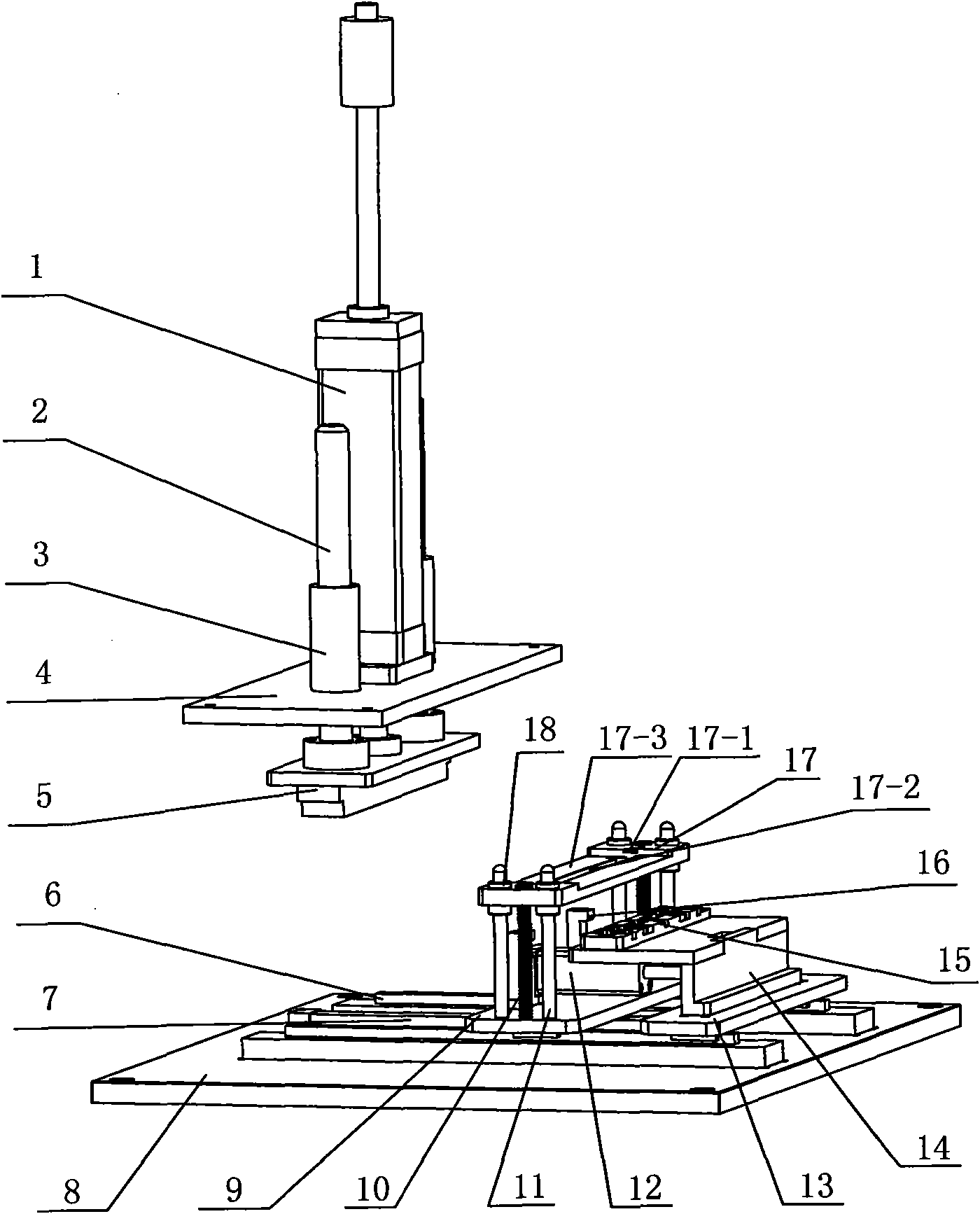

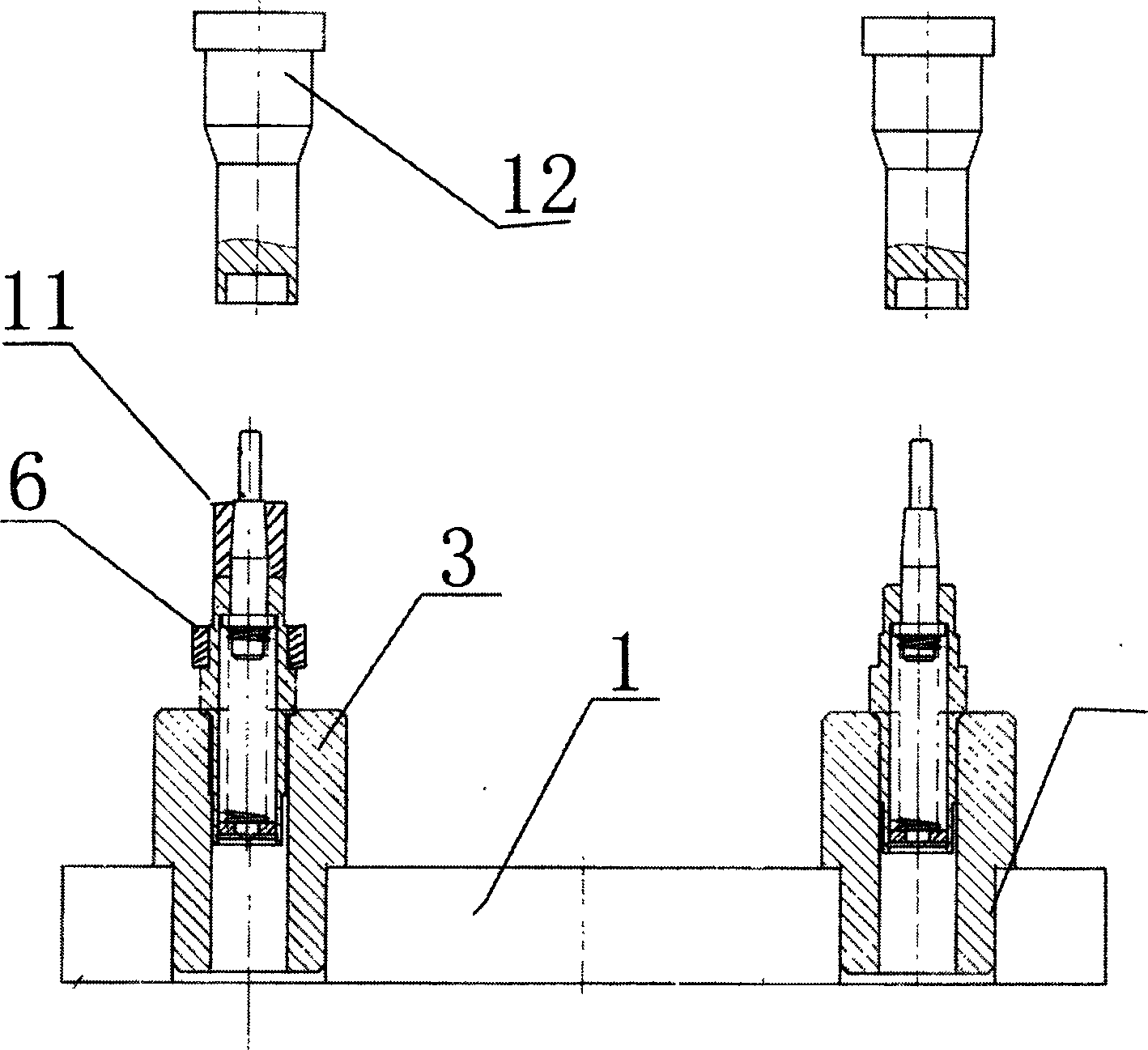

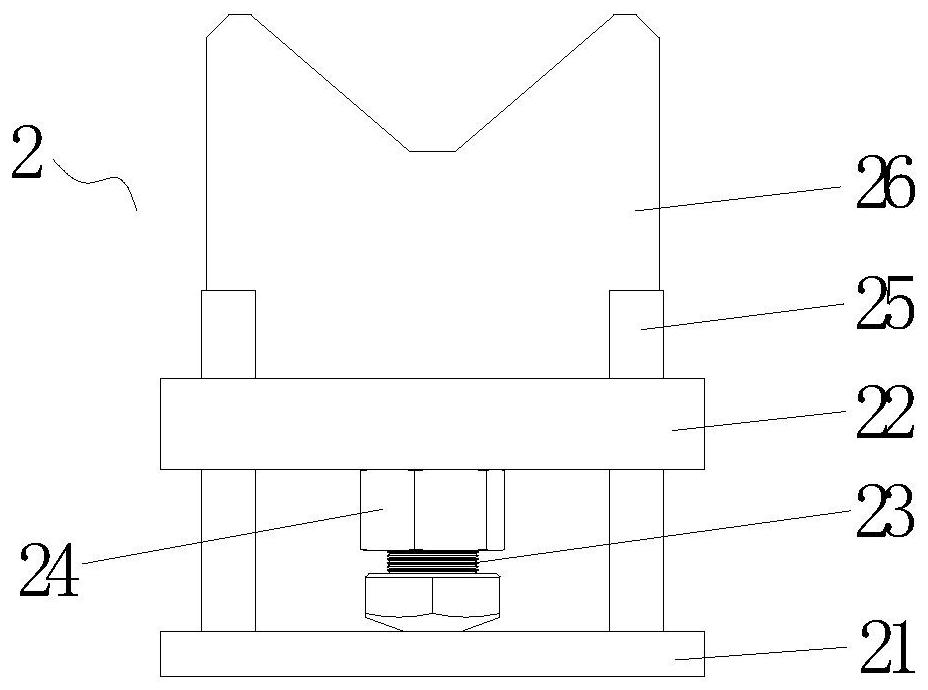

Lamp crimping and assembling mechanism

The invention relates to a lamp crimping and assembling mechanism, which comprises an upper crimping assembly and a lower crimping assembly, wherein a lower connecting base of the lower crimping assembly is provided with two linear guide tracks and a first cylinder in the transverse direction; a first sliding plate and a second sliding plate are arranged on the two linear guide tracks and are movable; the piston of the first cylinder is connected with the first sliding plate; at least two springs arranged on the first sliding plate are supported to a first limiting plate; the first limiting plate is provided with a mounting surface for mounting parts, a positioning groove and an H-shaped discharge notch arranged on the mounting surface; a second cylinder arranged on the first sliding plate is connected with a supporting plate arranged on the second sliding plate; a second limiting plate is arranged on the supporting plate; the second limiting plate is provided with a mounting surface for mounting parts and more than two spacing grooves; and the first sliding plate is provided with a positioning block for height positioning of the second limiting plate, and the positioning block is provided with a side positioning notch. The lamp crimping and assembling mechanism ensures that two parts can be placed in a staggered mode, can improve the assembly efficiency, and has accurate positioning, and safe and convenient operation.

Owner:CHANGZHOU XINGYU AUTOMOTIVE LIGHTING SYST

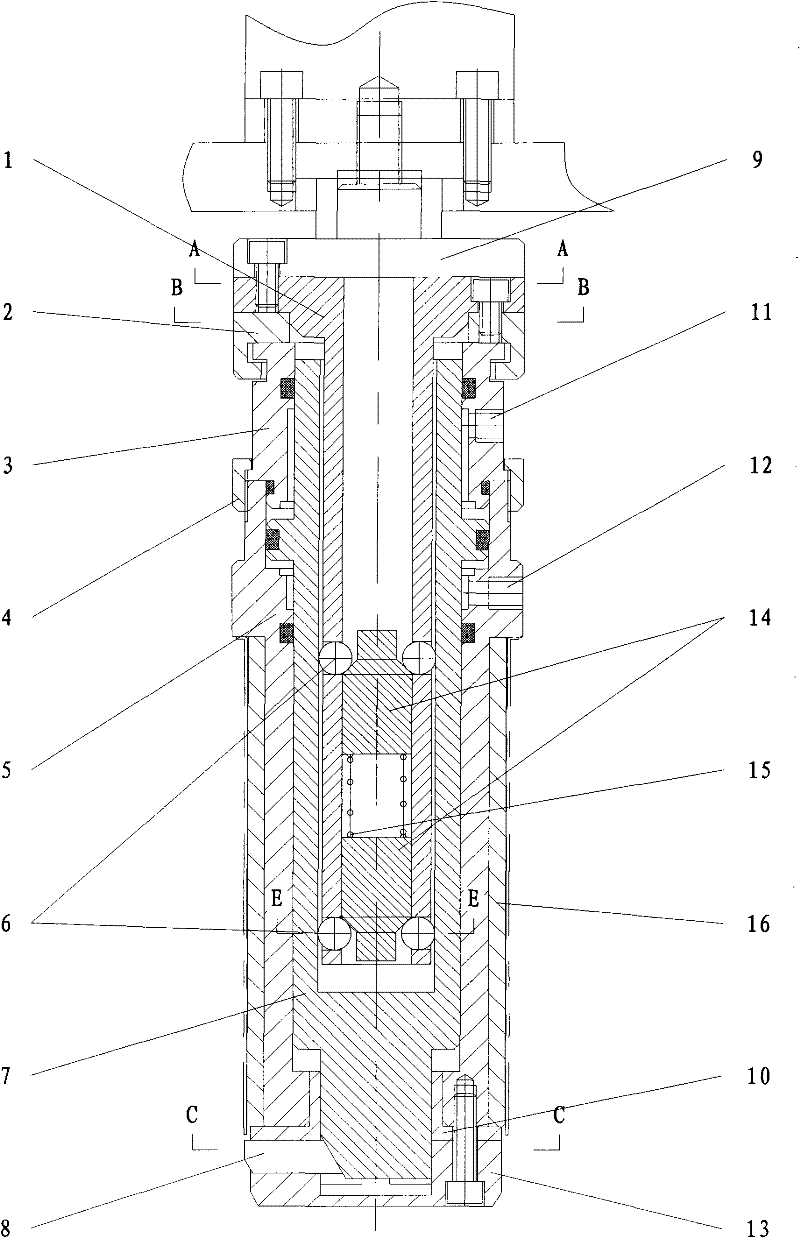

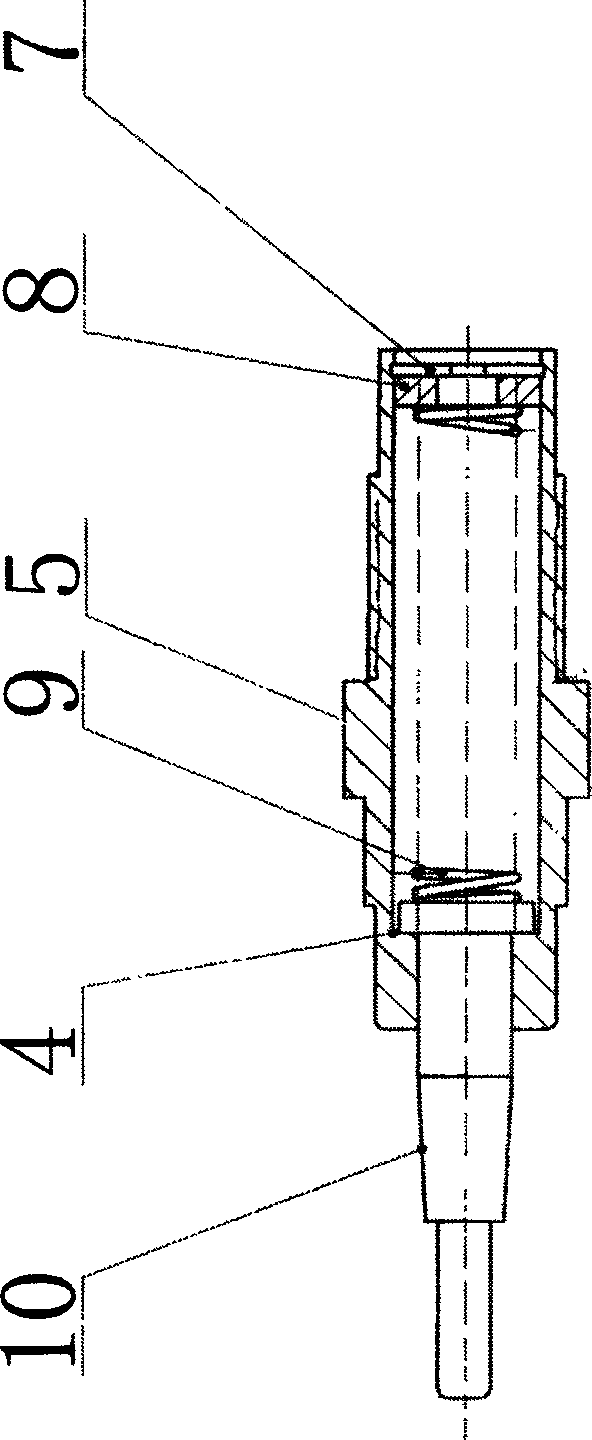

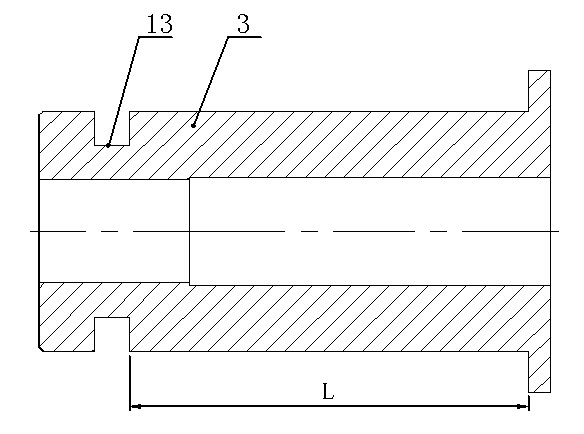

Pressing and mounting device for pressing and mounting thin-wall sleeve

ActiveCN101745799AEasy to operateImprove press fit accuracyMetal working apparatusThin walledEngineering

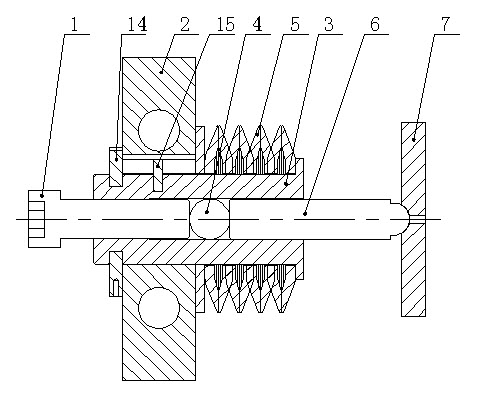

The invention relates to a device for pressing and mounting a thin-wall sleeve, which can solve the problem that the thin-wall sleeve is difficult to press and mount. The device comprises a press head, a basic shaft, a sliding sleeve, an upper floating retention sleeve, a lower floating retention sleeve, a copper sleeve and the like. The upper end face of the basic shaft is provided with a flange plate which is coaxially connected on a fixed fixture block by screws, an annular clamping groove of the fixed fixture block is clamped and hooped on a shaft journal at the upper part of the upper floating retention sleeve, the lower floating retention sleeve is coaxially positioned at the lower part of the upper floating retention sleeve, the upper floating retention sleeve and the lower floating retention sleeve are connected into a whole by the nuts of the retention sleeves, and the copper sleeve is sleeved and arranged on the lower floating retention sleeve. The sliding sleeve is arranged in the upper floating retention sleeve and the lower floating retention sleeve, and the middle part of the external diameter of the sliding sleeve is provided with a piston ring; and the lower half section of the sliding sleeve is provided with a solid shaft, and the end face of the solid shaft is provided with three centripetal tapered wedge T-shaped grooves which are uniformly distributed along a circumferential direction. The device has simple structure and convenient operation and can carry out pressing and mounting motions as long as the thin-wall sleeve is sleeved into the press head and a jack catch of a control button extends out, so that the parts of the thin-wall sleeve obtain higher pressing and mounting accuracy, and the effective guarantee is provided for enhancing the quality of a class of cylinder body.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

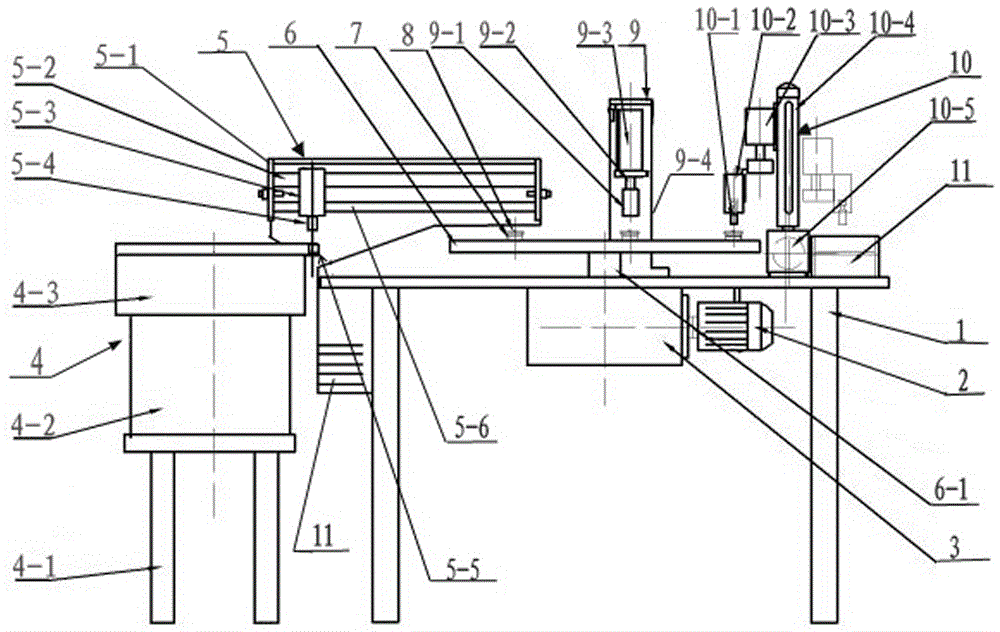

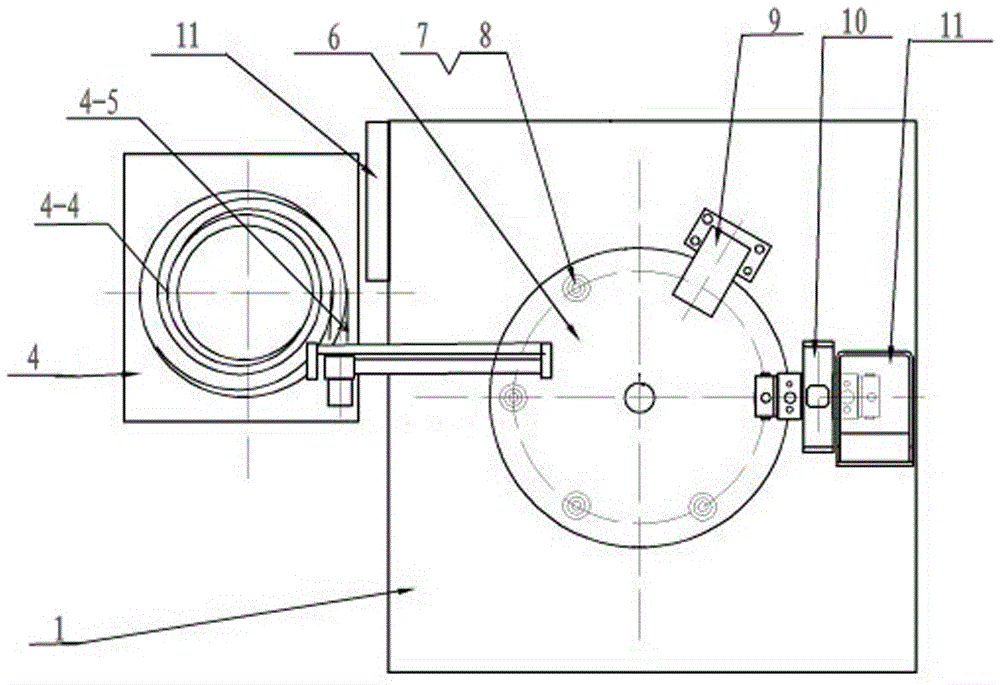

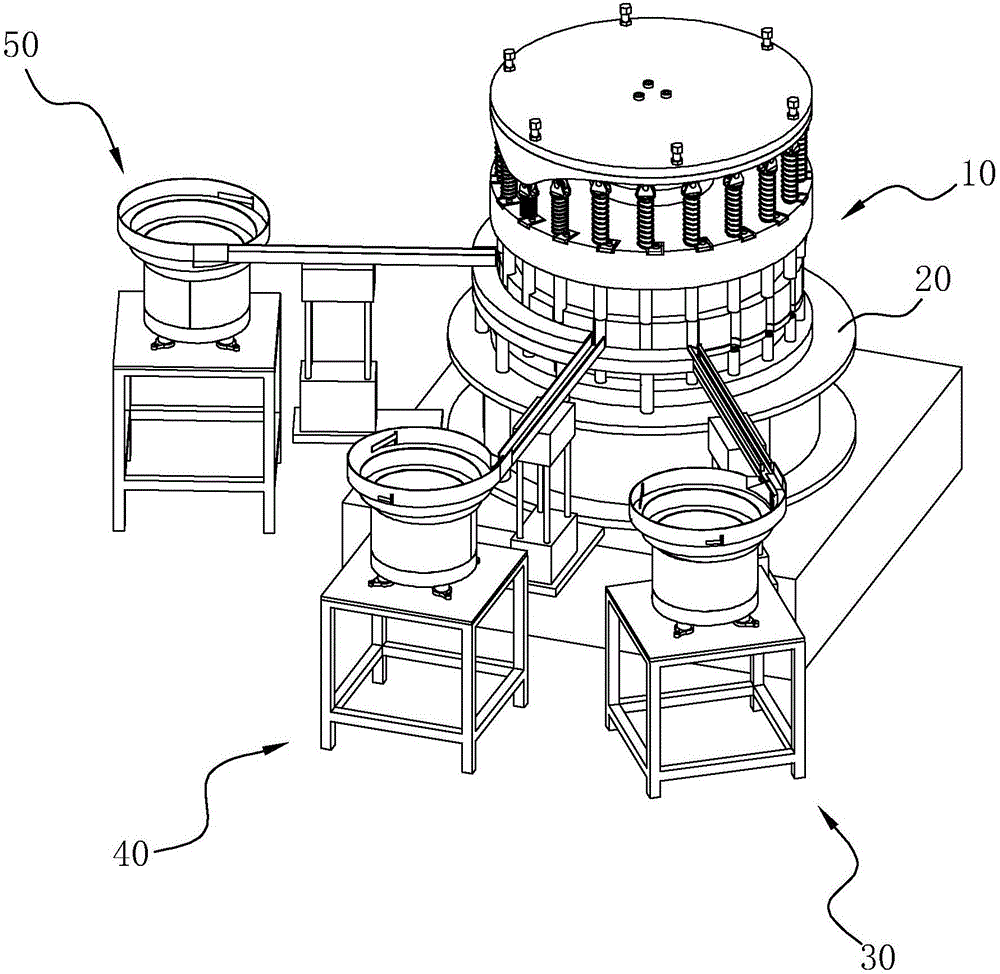

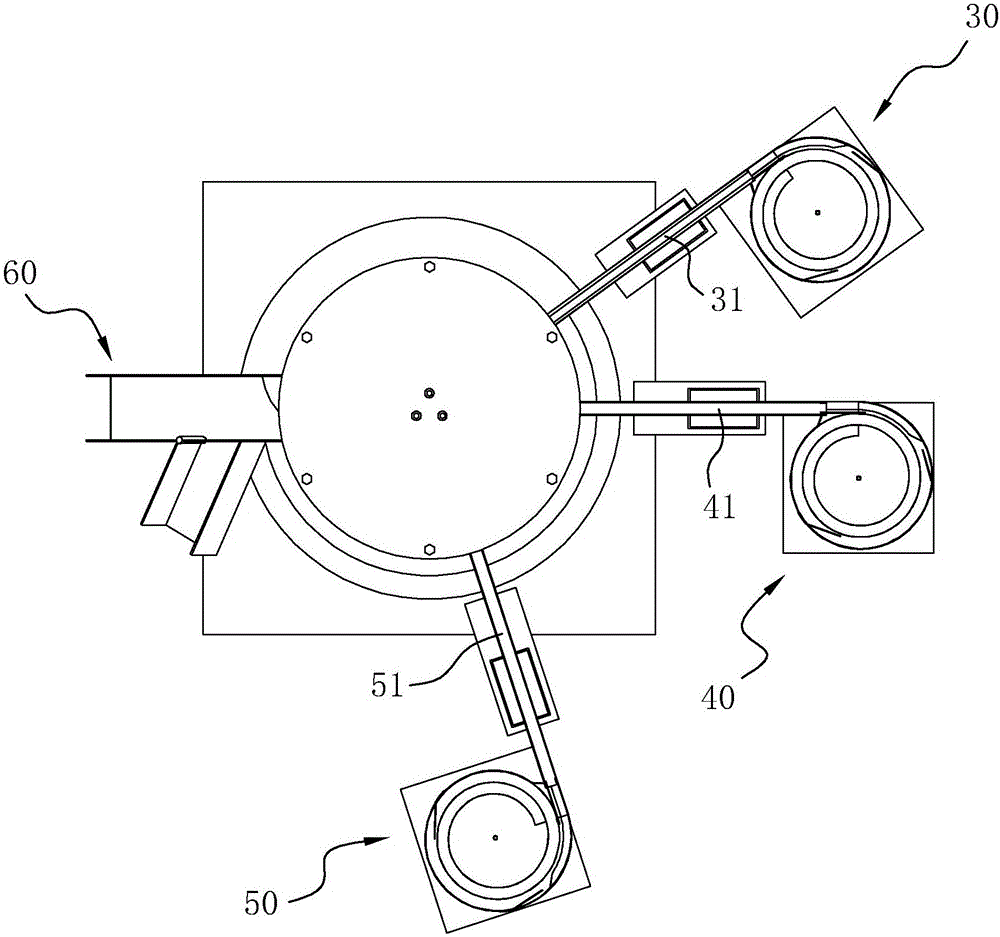

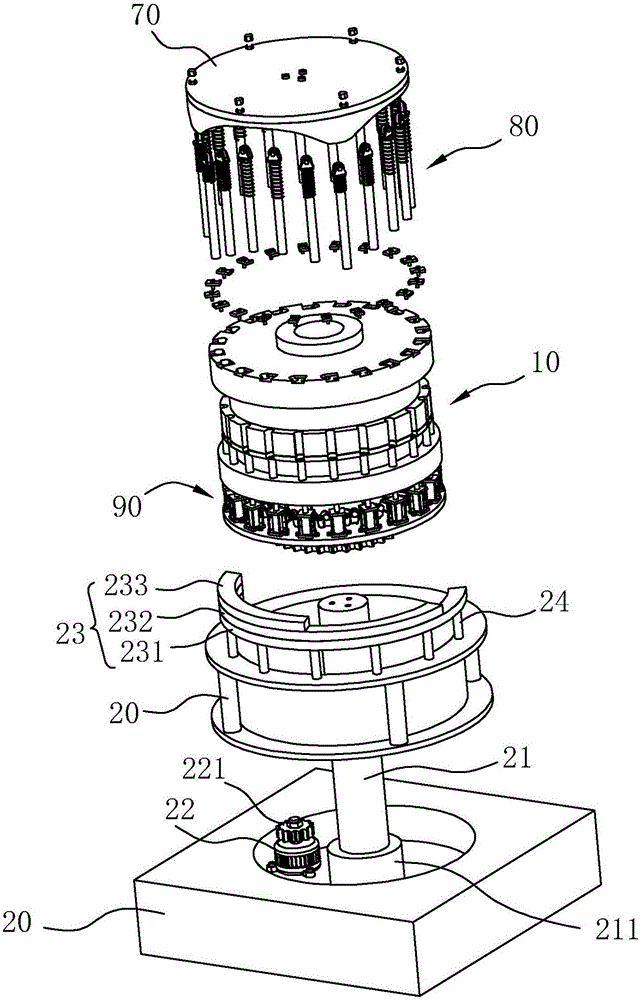

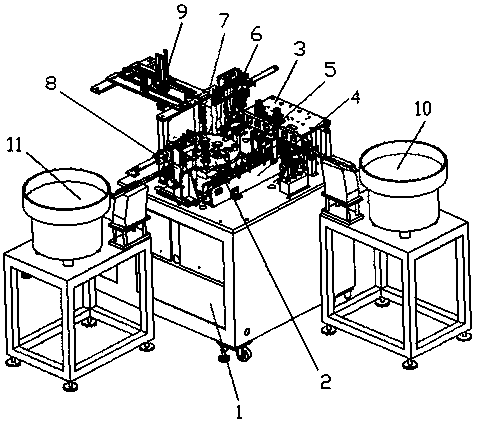

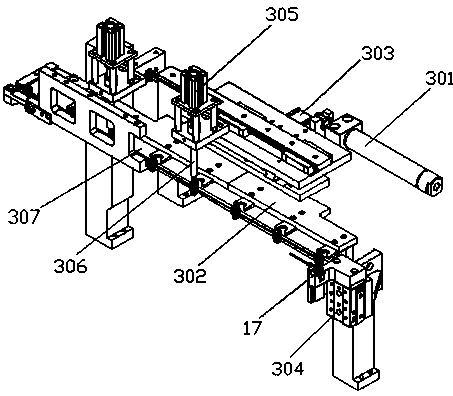

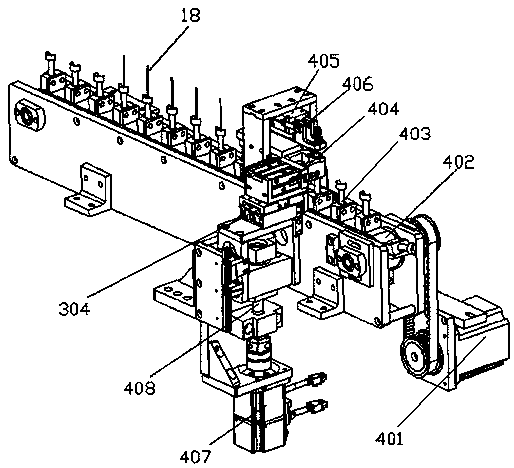

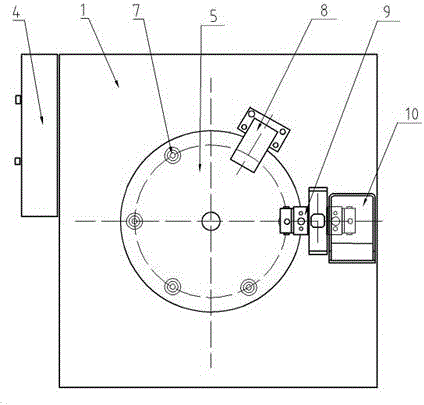

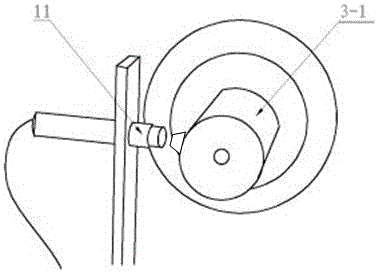

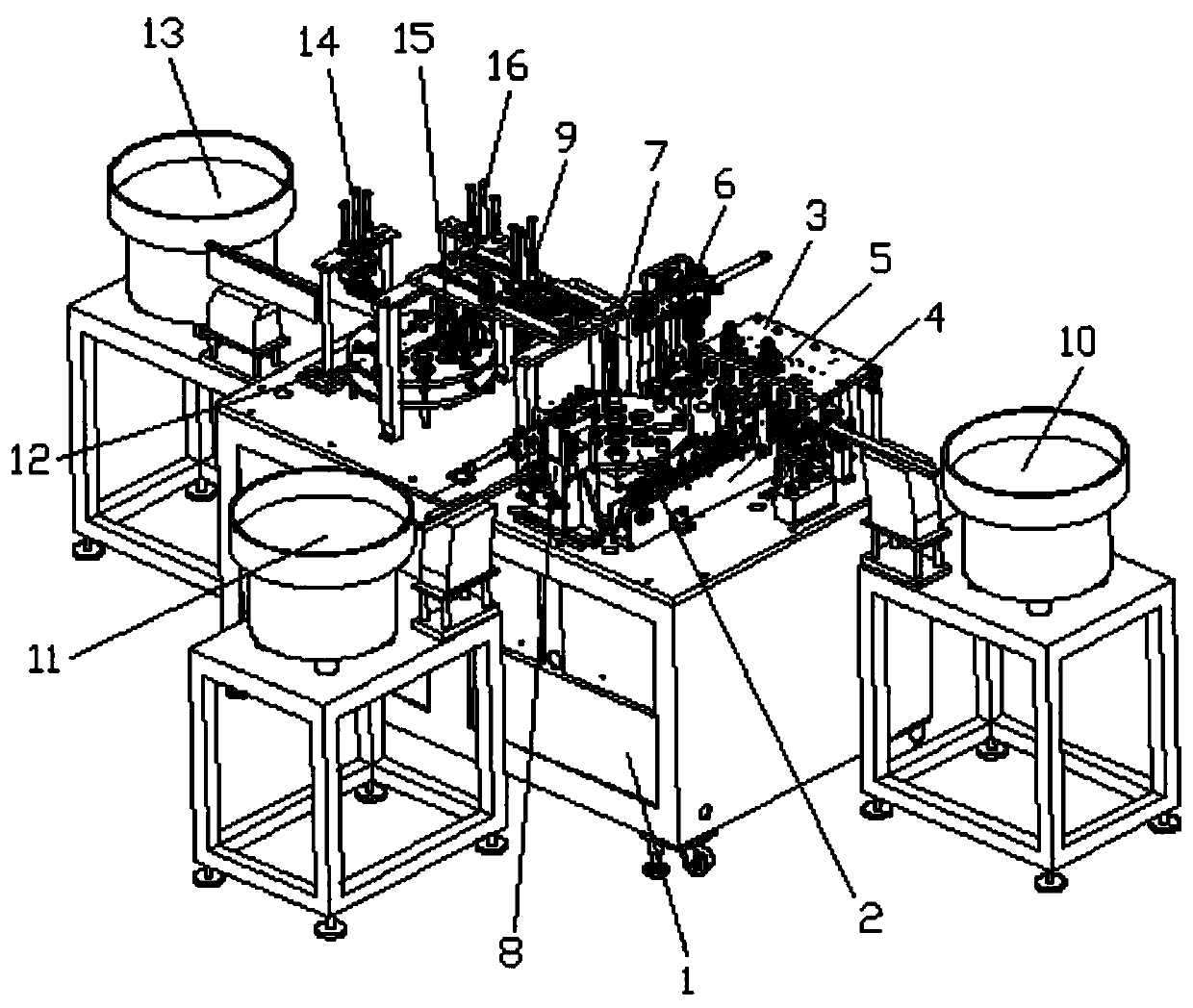

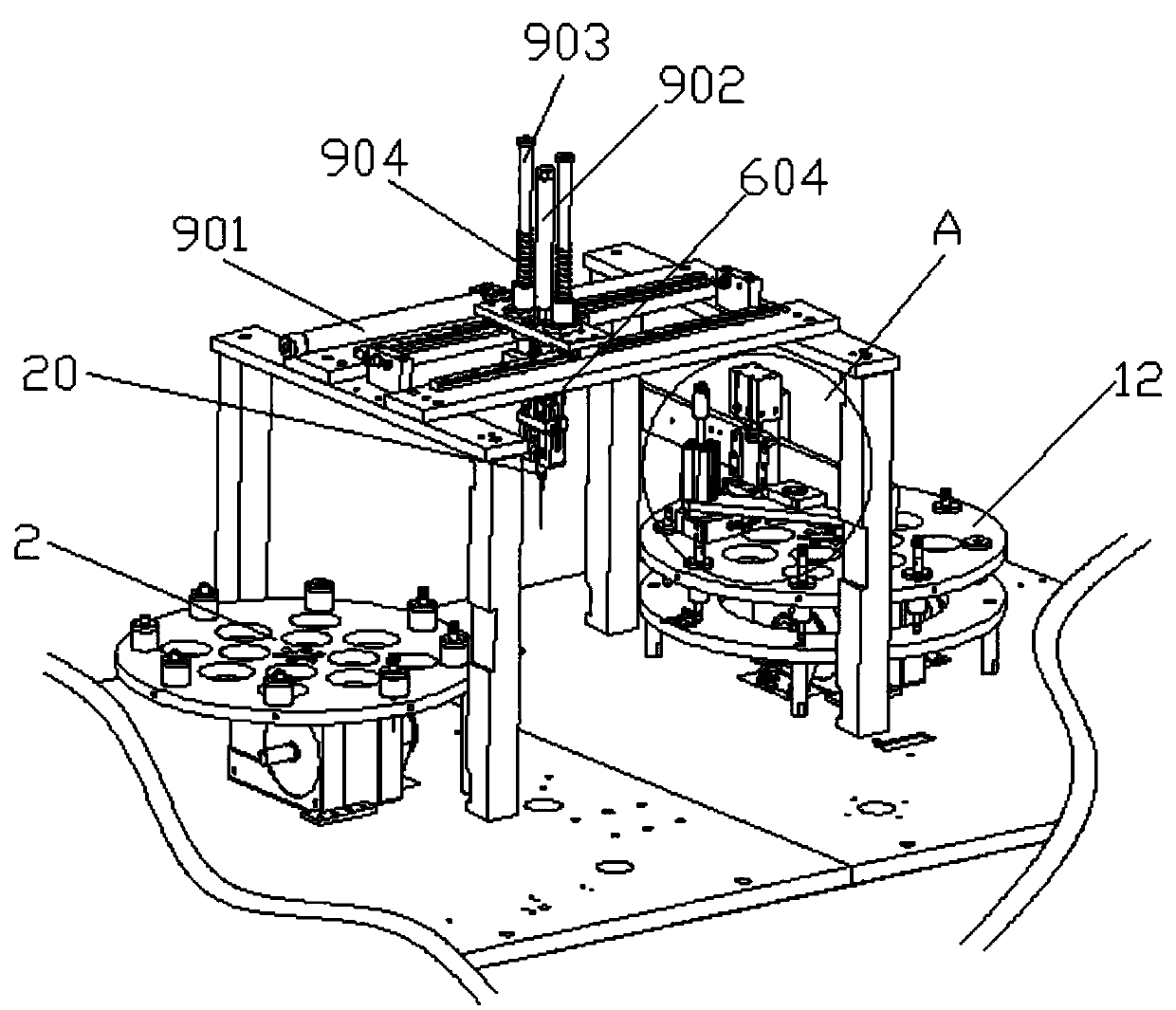

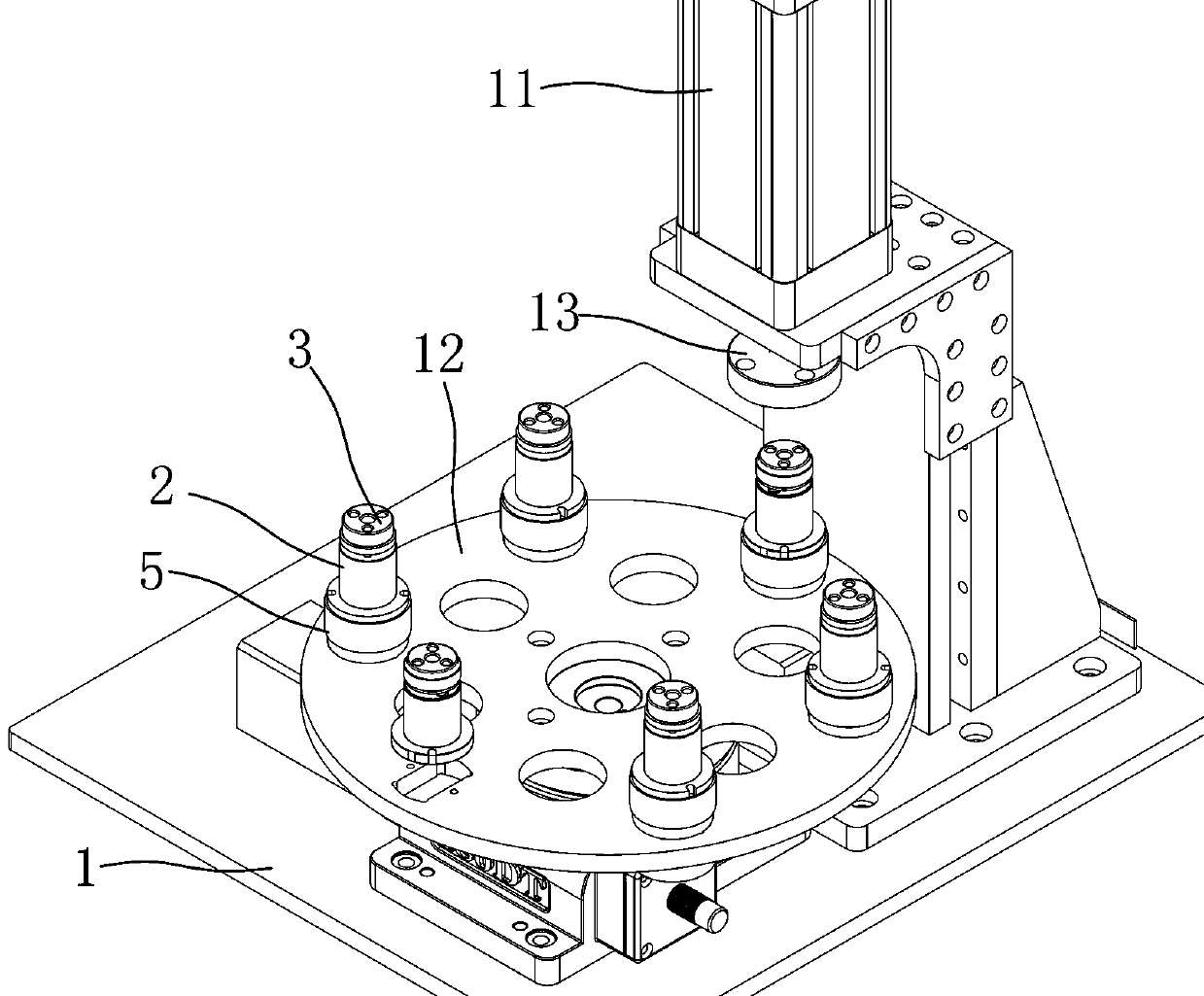

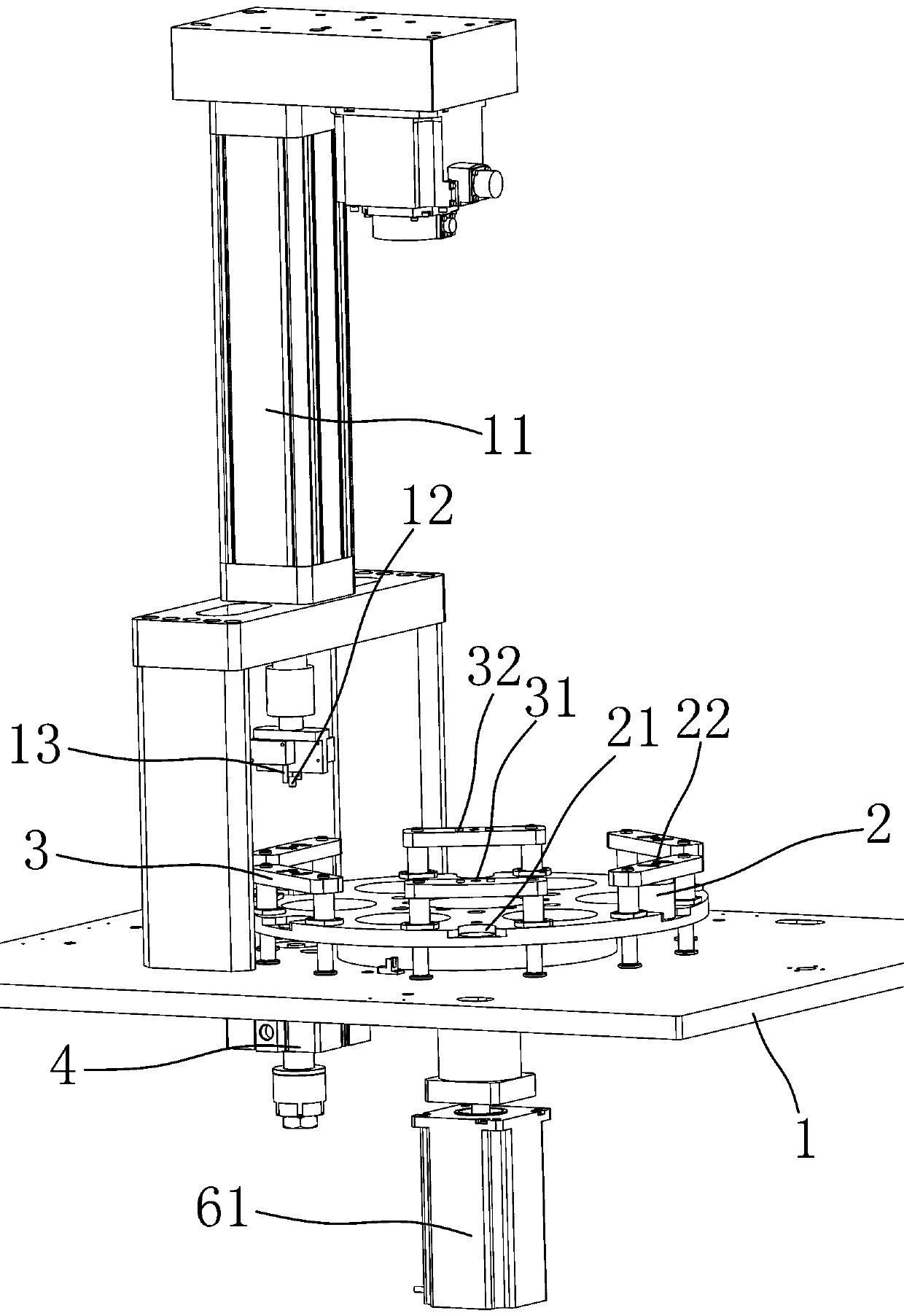

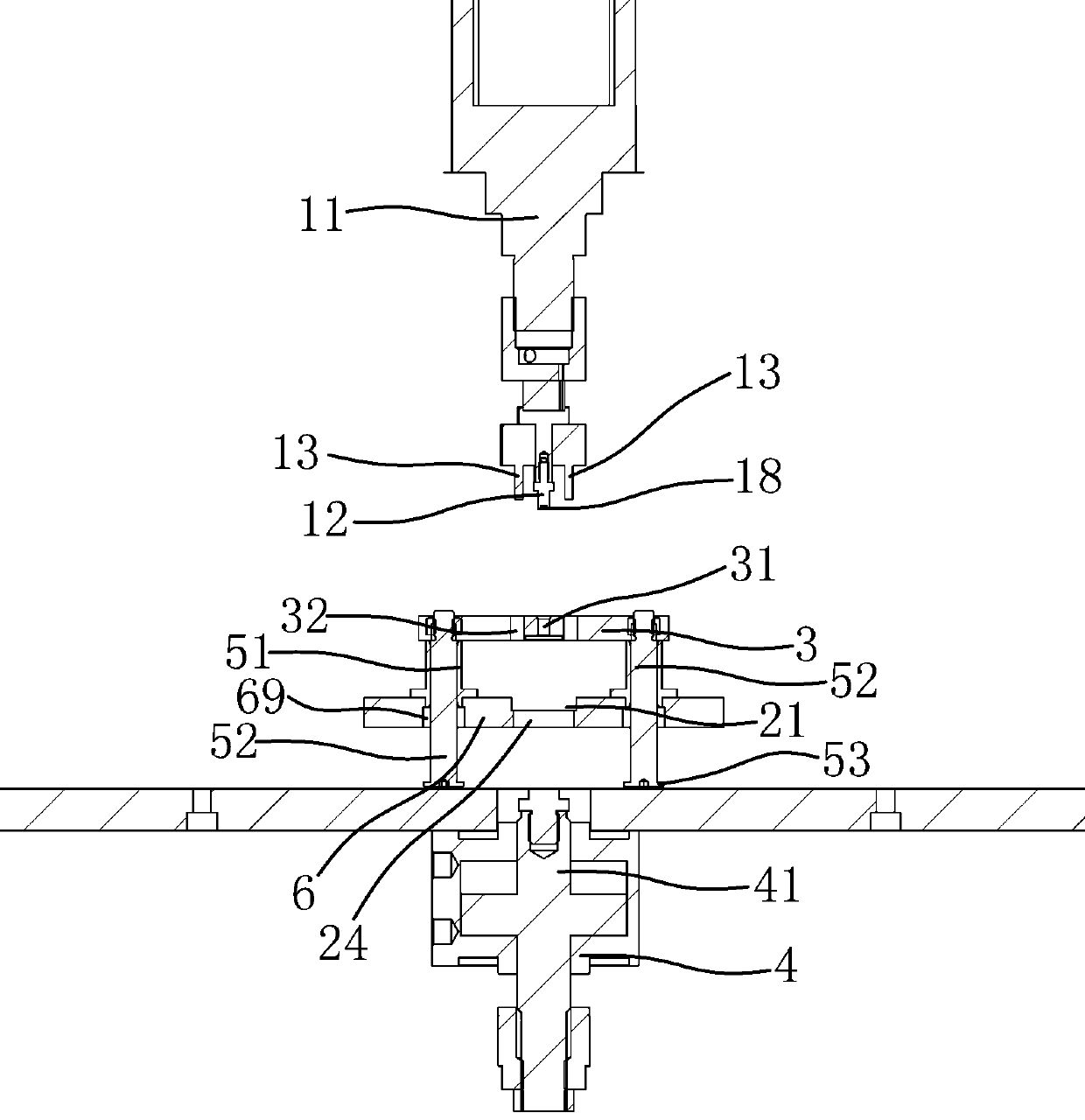

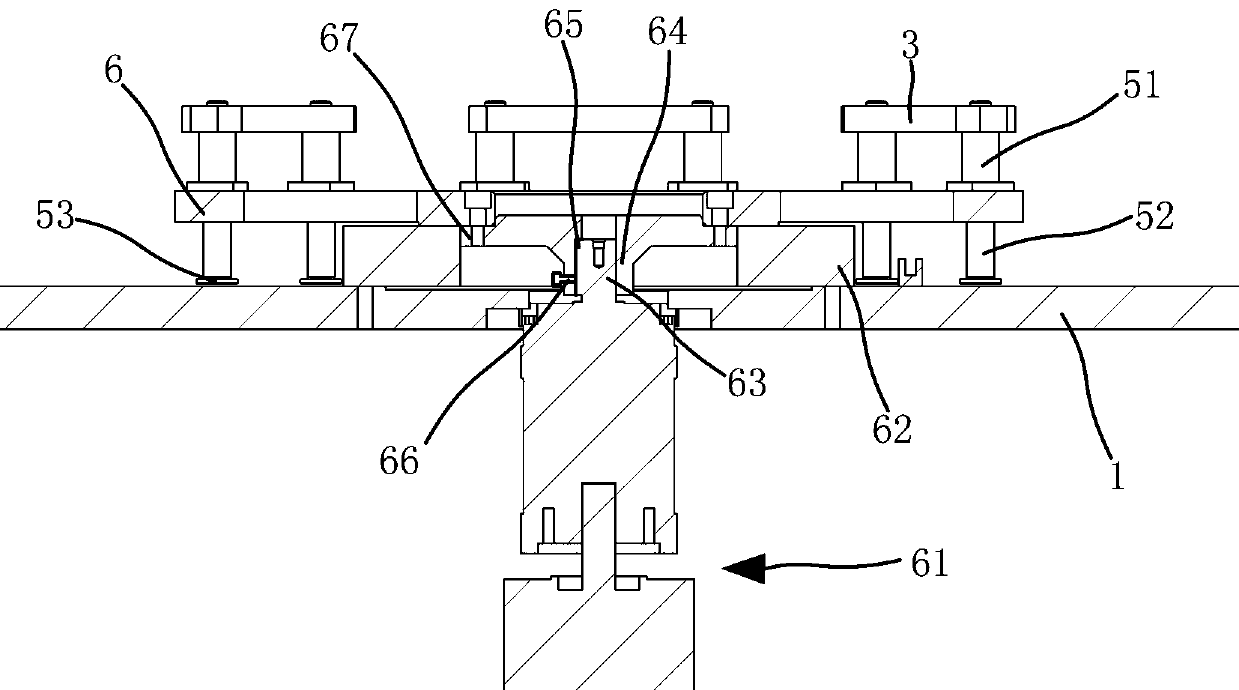

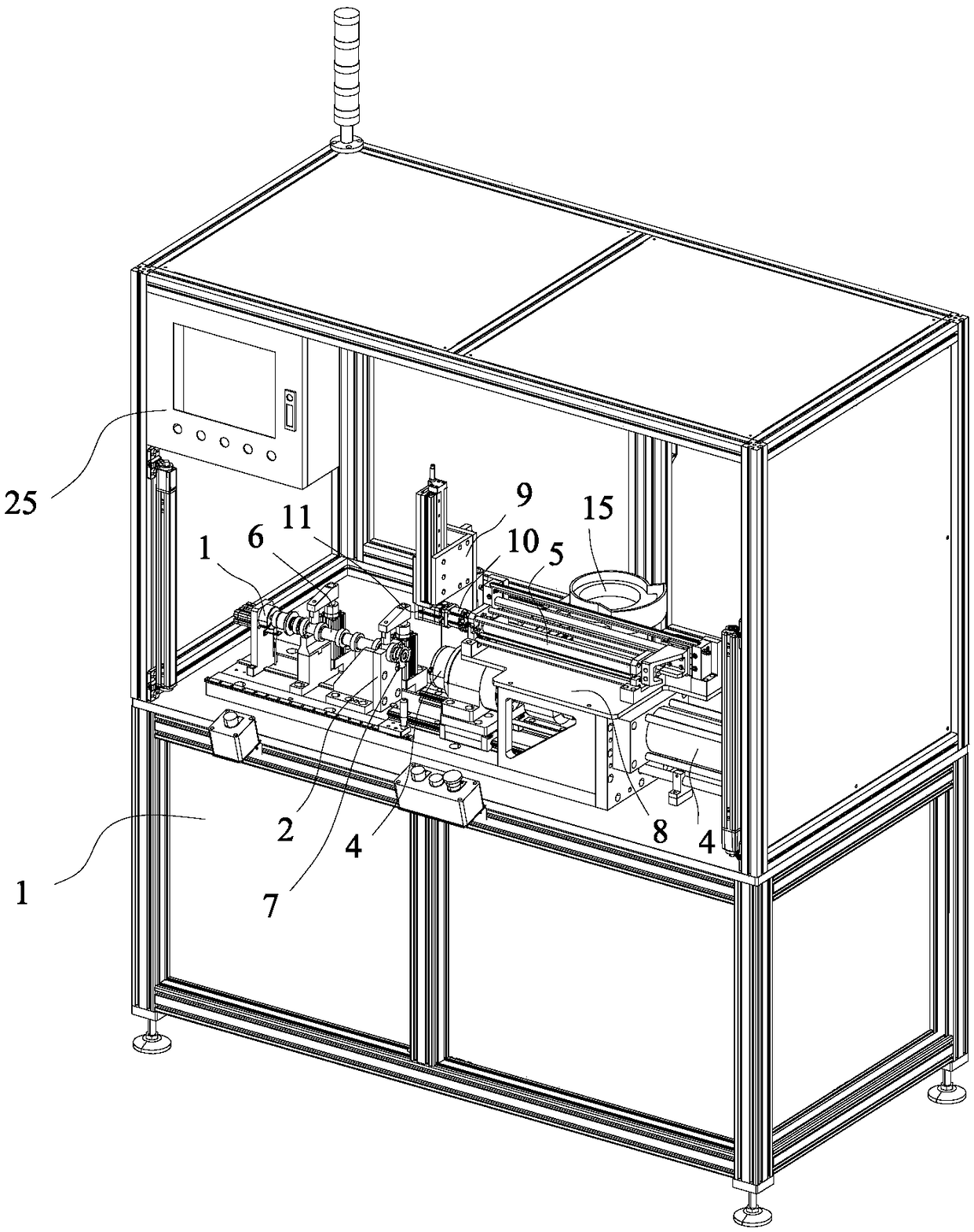

Automatic feeding and press fit machine of self-cleaning automobile shock absorber triple-linked part and control method thereof

The invention relates to an automatic feeding and press fit machine of a self-cleaning automobile shock absorber triple-linked part. The automatic feeding and press fit machine comprises a mechanical press fit part and an automatic control part, wherein the mechanical press fit part comprises a workbench, a splitter, a station rotary disc, a vibration feeding mechanism, a feeding mechanical hand, a pneumatic press fit mechanism, a pneumatic mechanical hand and a collection box; the station rotary disc is fixedly mounted on the surface of the workbench; a plurality of press fit stations and pressing dies are uniformly distributed on the station rotary disc; the splitter is arranged at the bottom of the surface of the workbench; an input shaft of the splitter is connected with a variable-frequency and variable-speed motor through a coupling; an output shaft of the splitter is connected with a rotating shaft of the station rotary disc; and the vibration feeding mechanism, the feeding mechanical hand, the pneumatic press fit mechanism and the collection box are arranged on one side of the workbench. The automatic feeding and press fit machine cooperates with an automatic control method to achieve automatic feeding and press fit of the self-cleaning shock absorber triple-linked part, can improve press fit speed and accuracy, and has the advantages that the operation time is shortened, the press fit accuracy is high, the action is reliable, the consistency is high, the comprehensive cost is low, and the like.

Owner:NANYANG XIJIAN AUTOMOBILE SHOCK ABSORBER

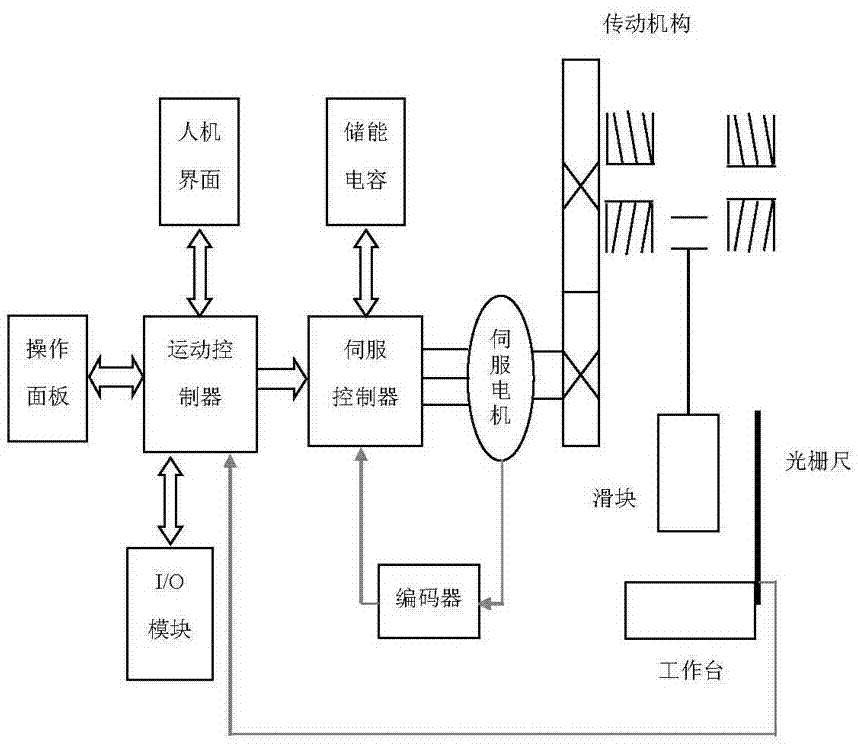

Servo press control system

InactiveCN106881903AShow location in real timeDisplay pressure in real timePressesProduction rateGrating

A servo press control system comprises a servo press. The servo press comprises a servo motor, a servo controller, a transmission mechanism, a sliding block, a workbench and a grating ruler, wherein the servo controller is in communication connection with a movement controller through a network, and an I / O interface module, an operation panel and a human-machine interface are connected to the movement controller; the input end of the servo controller is connected with a capacitive energy storage device, and the output end of the servo controller is connected with the servo motor; the servo motor is connected with the transmission mechanism; the sliding block is connected with the transmission mechanism; and the human-machine interface is in communication connection with the movement controller. According to the servo press control system, requirements for different technological curves for movement of the sliding block can be met according to different working conditions, and the torque requirement of the sliding block in a certain position is met; and the stroke of the sliding block can be adjusted according to different workpieces, and the sliding block does not need to move to the top dead center every time in all cycles, so that the cycle time is shortened, meaningless stroke is minimized, and productivity is greatly improved.

Owner:GUANGDONG HUST IND TECH RES INST +1

Emulsion pump automatic assembling device

The invention discloses an emulsion pump automatic assembling device which comprises a rack, a rotating working table arranged on the rack and driven by a driving mechanism to rotate, a pump body vibration disc, a pressing head vibration disc, a cover vibration disc and a discharging mechanism, wherein the pump body vibration disc, the pressing head vibration disc and the cover vibration disc are connected with the rotating working table and are apart from the rotating working table by a certain angle, and the discharging mechanism is used for outputting an emulsion pump finished product; and the rotating working table is provided with an upper press fit mechanism and a lower press fit mechanism which rotate synchronously, and a cam disc is further arranged on the rack, wherein the upper end of the upper press fit mechanism abuts against the cam face of the cam disc all the time, the upper press fit mechanism is synchronously driven by the rotating working table to slide in the axial direction of the rotating working table to be matched with the lower press fit mechanism, the upper press fit mechanism slides between a smooth section and a protrusion section of the cam disc in a circulation and alternation manner to achieve the axial lifting process of the upper press fit mechanism and the press fit process of a pressing head and a cover, and the finished product obtained after press fit is discharged from the discharging mechanism. The feeding and press fit processes are perfectly joined, the pause situation is avoided, the continuous assembly work is achieved, and the production efficiency is improved.

Owner:余姚市翔盛塑业有限公司

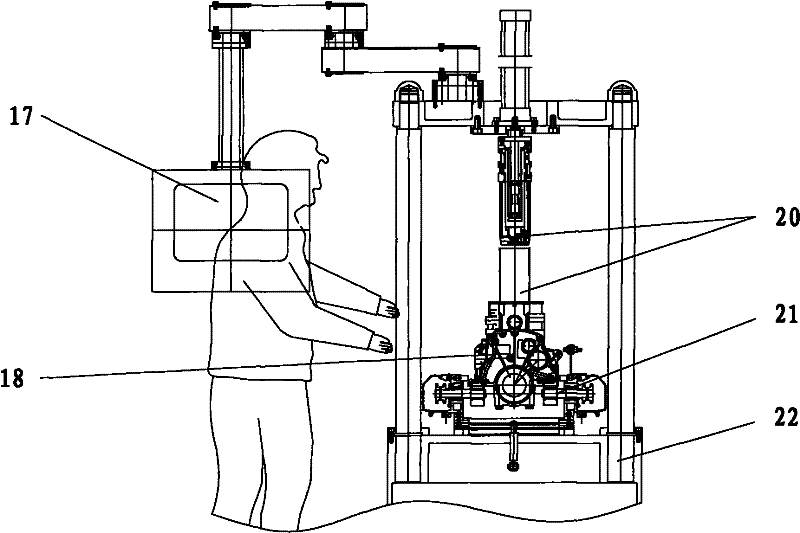

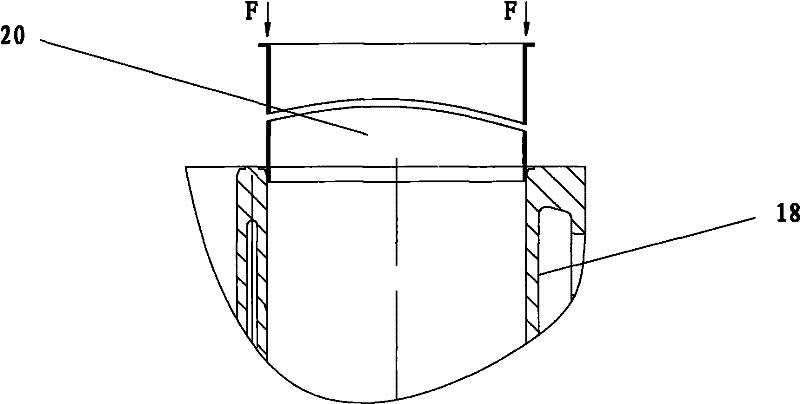

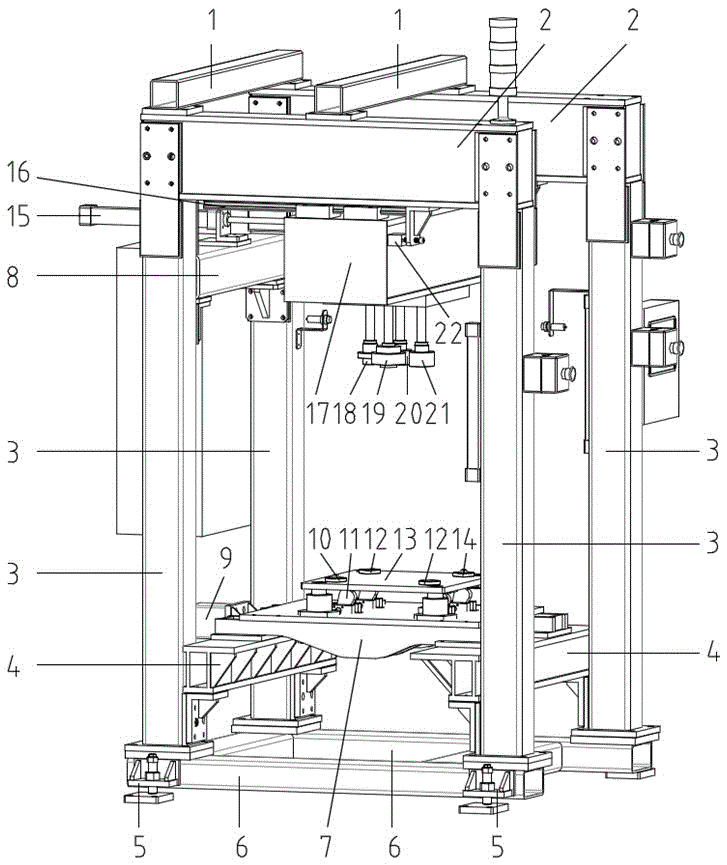

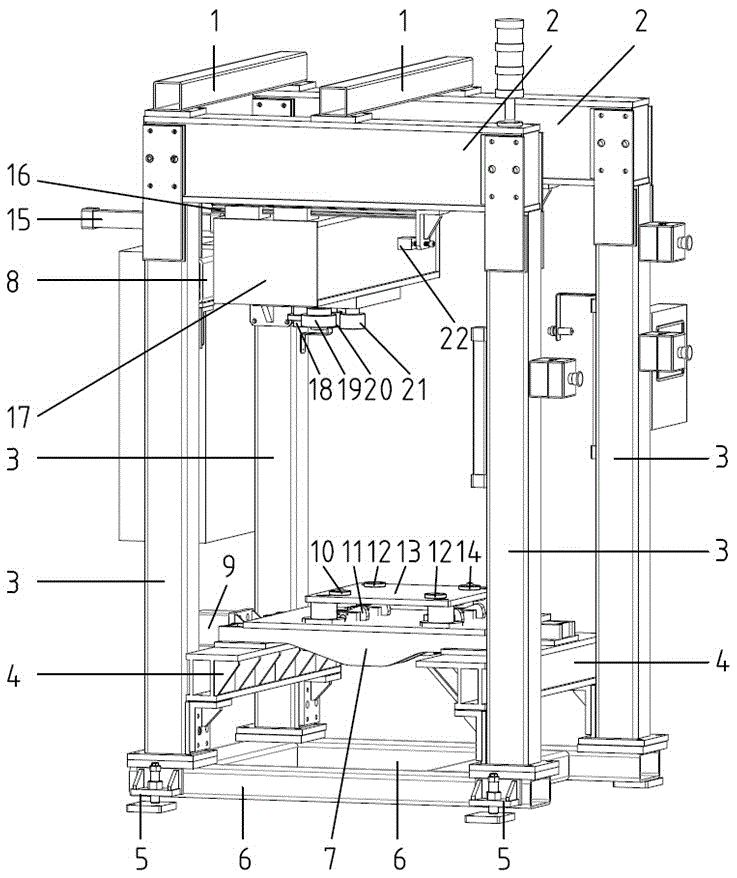

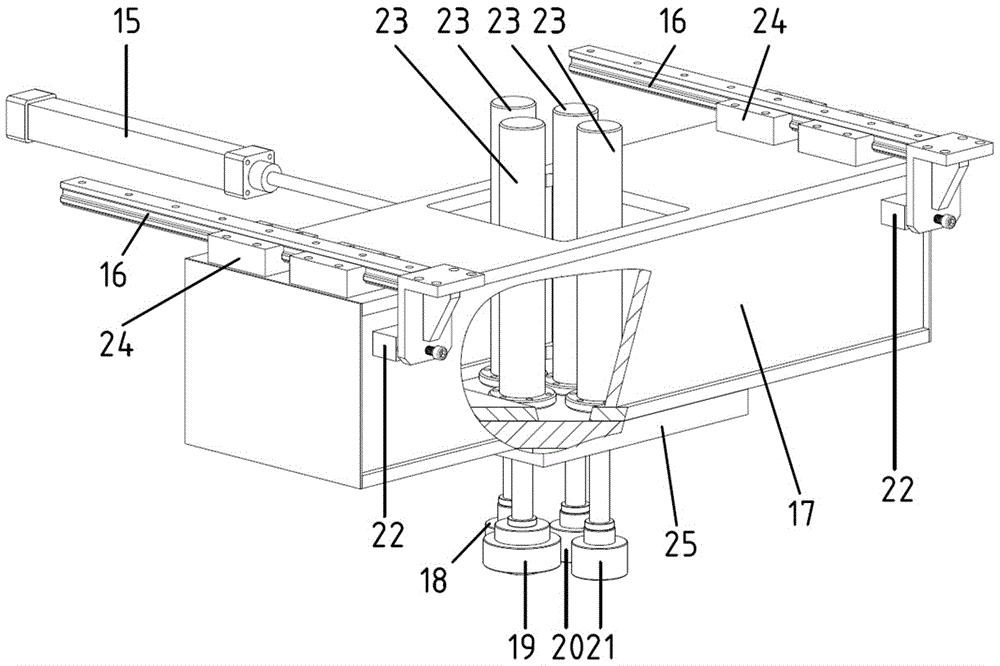

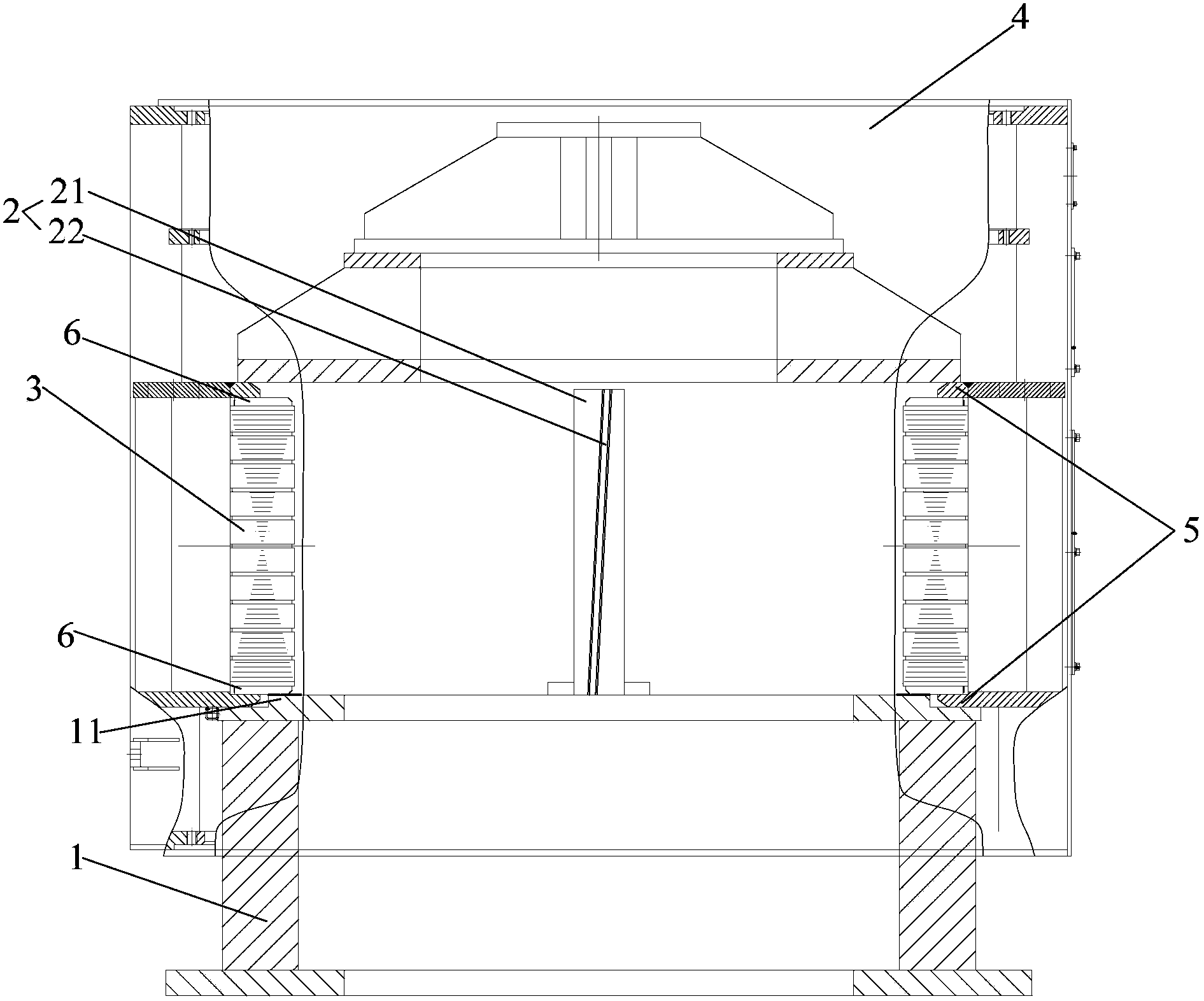

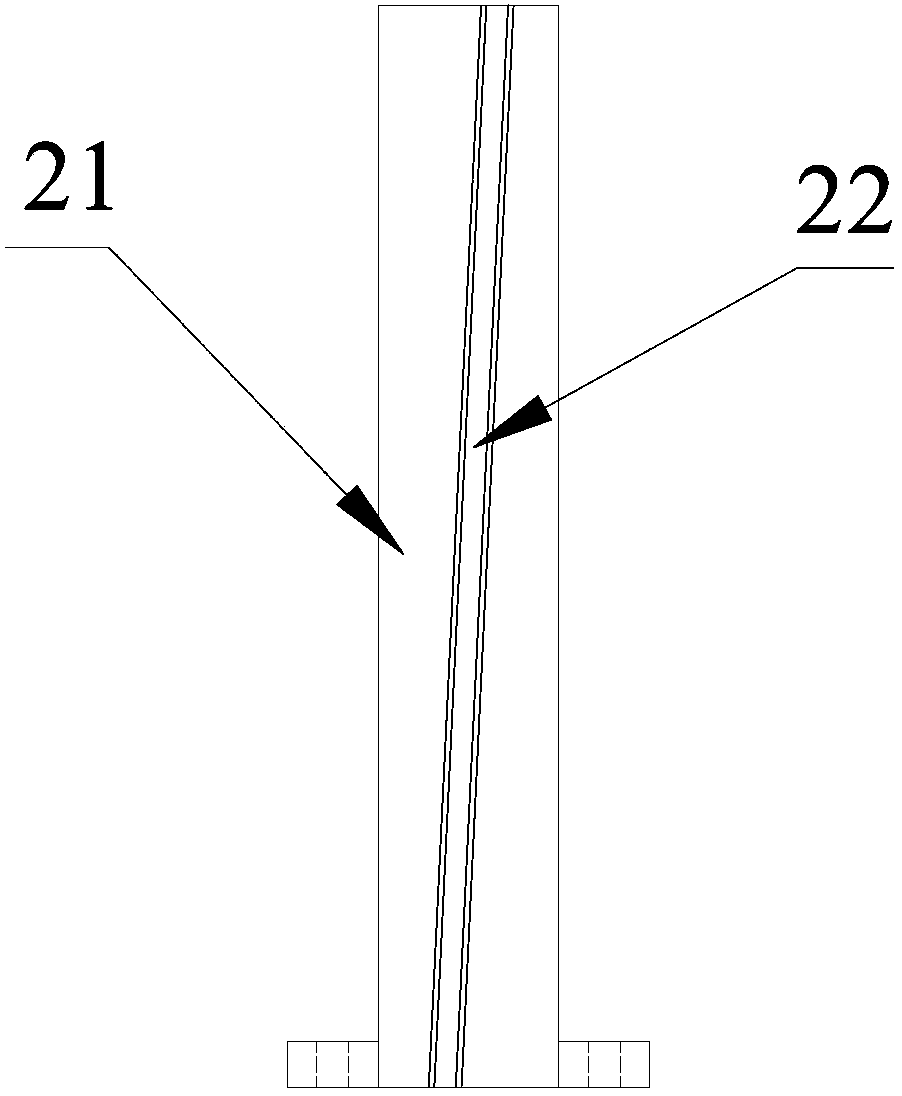

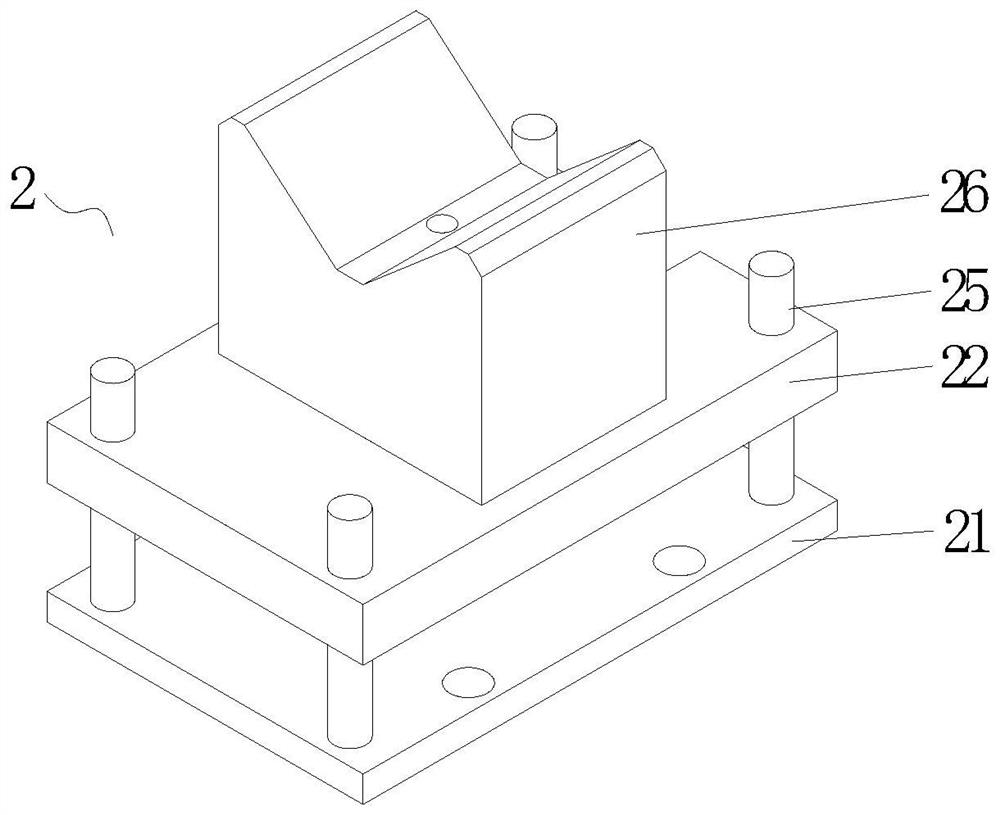

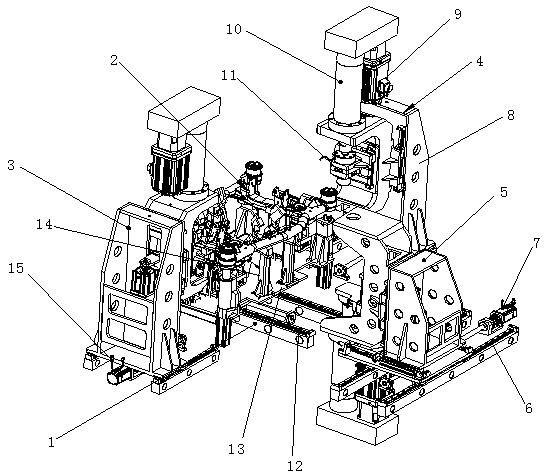

Combined pressing device for online assembly of forklift gearbox

ActiveCN105643244ASatisfy online pressingImprove press fit accuracyMetal working apparatusEngineeringMechanical engineering

The invention relates to a combined pressing device for online assembly of a forklift gearbox. The combined pressing device comprises a machine frame, a movable pressing head mechanism and a lifting and positioning mechanism. The machine frame is a cubic frame. The movable pressing head mechanism is installed at the upper end of the machine frame and comprises an installation base and a first driving assembly. The installation base is located in the machine frame. Two or more pressing oil cylinders are arranged in the middle of the installation base. The telescopic ends of the pressing oil cylinders vertically face the lower end of the machine frame. The first driving assembly is arranged on the portion, corresponding to the installation base, of the machine frame. The first driving assembly is connected with the installation base and drives the installation base to move horizontally in the machine frame. The lifting and positioning mechanism is installed at the lower end of the machine frame and comprises a lifting plate and a second driving assembly. The lifting plate is located in the machine frame. The second driving assembly is located below the lifting plate. When the second driving assembly works, the lifting plate is driven to move upwards. The combined pressing device is high in pressing precision, an assembly space is provided for subsequent work after pressing, and damage to a conveying roller way is avoided.

Owner:ANHUI HELI CO LTD

Assembling machine for components of vehicle mounted antenna

InactiveCN107813140AHigh degree of automationImprove processing efficiencyAssembly machinesVehicle componentsDistribution controlTransfer mechanism

The invention relates to an assembling machine for components of a vehicle mounted antenna. The assembling machine comprises a frame and a power distribution control cabinet which is arranged inside the frame; the middle part of the upper end of the frame is provided with a base body rotating device; the base body rotating device is provided with a base body feeding device, a cable conveying device, a pressing device, a transporting device, a circular cover pressing mechanism and a transferring device in sequence along the rotation direction; the pressing device comprises a pen-shaped cylinderwhich is connected with a working position switching block; one end of the working position switching block is connected with front and rear pressing cylinders; the other end of the working positionswitching block corresponds to a circular cover conveying slide way; and a push cylinder is fixedly installed at the lower portion of the start end of the circular cover conveying slide way. The invention aims to provide the assembling machine for the components of the vehicle-mounted antenna, the periphery of the base body rotating device is provided with the base body feeding device, the cable conveying device, the pressing device, the circular cover pressing mechanism and the transferring device in sequence along the rotation direction so as to accomplish feeding, assembling and dischargingof a base body, a circular cover and a cable, and the assembling machine is high in automation degree and greatly improves the machining efficiency.

Owner:DONGGUAN UNIV OF TECH

Automatic press fit machine of automobile shock absorber triple-linked part and automatic control method thereof

ActiveCN106112521ARealize continuous automatic pressingHigh speedAssembly machinesVehicle componentsAutomatic controlCoupling

The invention relates to an automatic press fit machine of an automobile shock absorber triple-linked part. The automatic press fit machine comprises a mechanical press fit part and an automatic control part, wherein the mechanical press fit part comprises a workbench, a splitter, a variable-frequency and variable-speed motor, a station rotary disc, a pneumatic press fit mechanism, a pneumatic mechanical hand and a collection box; the station rotary disc is fixedly mounted on the surface of the workbench; a plurality of press fit stations and pressing dies embedded on the stations are uniformly distributed on the station rotary disc; the splitter is arranged at the bottom of the surface of the workbench; an input shaft of the splitter is connected with the variable-frequency and variable-speed motor through a coupling; an output shaft of the splitter is connected with a rotating shaft of the station rotary disc; and the pneumatic press fit mechanism, the pneumatic mechanical hand and the collection box are fixedly mounted on the working surface, corresponding to the stations, on the station rotary disc. The automatic press fit machine cooperates with an automatic control method to achieve continuous automatic press fit of the triple-linked part, can improve press fit speed and accuracy, and has the advantages that the operation is easy and convenient, the operation time is shortened, the press fit accuracy is high, the action is reliable, the comprehensive cost is low, and the like.

Owner:NANYANG XIJIAN AUTOMOBILE SHOCK ABSORBER

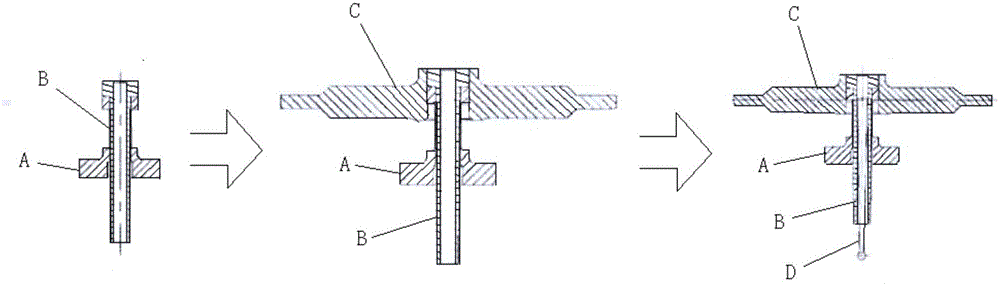

Press-fitting tool and press-fitting method

ActiveCN103475168AAchieve positioningAvoid misalignmentManufacturing stator/rotor bodiesPunchingEngineering

The invention provides a press-fitting tool which is used for press-fitting fan-shaped punching sheets of a skewed slot stator core and comprises a stator bracket and at least one skewed slot positioning device, wherein the skewed slot positioning devices are installed on the stator bracket and are matched with a skewed slot of a stator core to be press-fitted. When the fan-shaped punching sheets are press-fitted, the skewed slot positioning devices are used for positioning the fan-shaped punching sheets. Accordingly, the invention further provides a press-fitting method. With the press-fitting tool and the press-fitting method, the laminating precision of the skewed slot fan-shaped punching sheets and the press-fitting efficiency can be improved.

Owner:北京三一智能电机有限公司

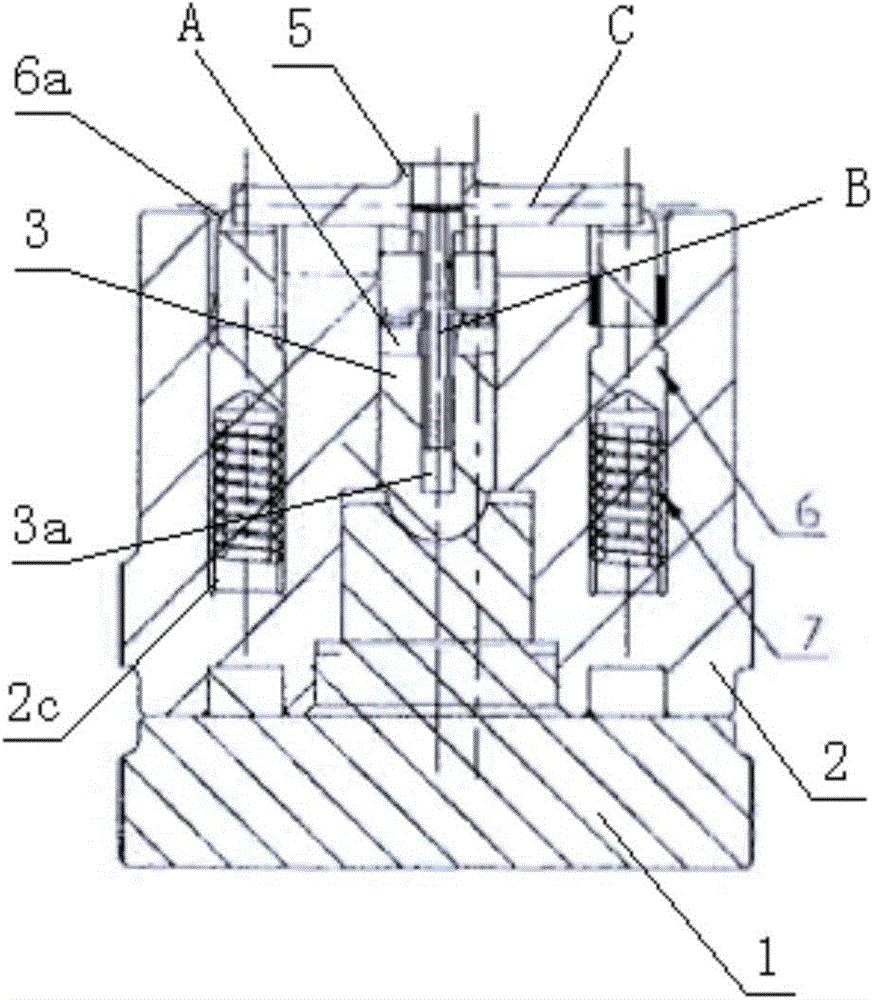

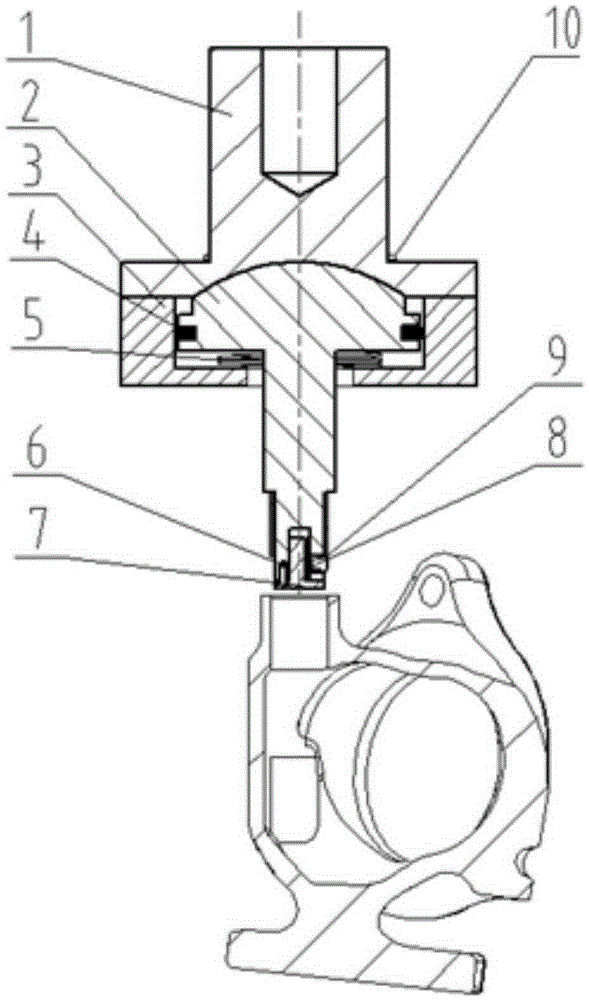

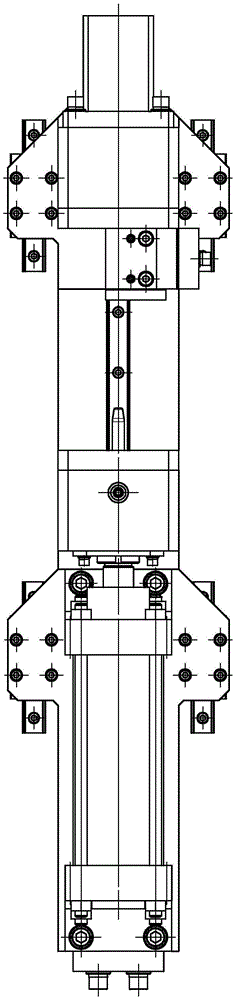

High-precision compression-configured device of electro-hydraulic servo valve armature component

InactiveCN104827441AAchieving sequential press-fittingReduce matching errorMetal-working hand toolsScrew threadServo

The invention discloses a high-precision compression-configured device of an electro-hydraulic servo valve armature component. The armature component comprises a baffle plate, a tube spring, an armature and a feedback rod which are subsequently arranged in a compression way. The compression-configured device comprises a central component, an adjusting pedestal, a tube spring auxiliary clamping guide mechanism and an armature floatation supporting and positioning mechanism, wherein a longitudinal through hole is formed in the central component; a positioning block used for placing a positioning plate is arranged in the through hole; a compression-configured hole for the tube spring to reach in is formed in the positioning block; the adjusting pedestal is matched with the longitudinal through hole in the central component through screw threads; the top part of the adjusting pedestal pushes against the positioning block to drive the positioning block to move up and down; the tube spring auxiliary clamping guide mechanism comprises at least two transverse through holes which are symmetrical about the longitudinal through hole; a slide positioning baffle block which can extend into the longitudinal through hole to push against the tube spring is glidingly formed in each transverse through hole; the armature floatation supporting and positioning mechanism comprises two elastic component mounting holes symmetrical about the longitudinal through hole left and right; an elastic component and an armature supporting and positioning block which is arranged on the elastic component are arranged in each elastic component mounting hole. The device can assist workers to configure the armature component in a compressing way, so that the compression-configured precision and the production efficiency are greatly improved.

Owner:WUJIANG TIANLONG MACHINERY

Press-fitting fixture for guide pipe and seat ring of air cylinder head

InactiveCN103831606AExtend exhaust lifePrecise positioningMetal working apparatusExhaust valveCylinder head

The invention discloses a press-fitting fixture for a guide pipe and a seat ring of an air cylinder head. The press-fitting fixture comprises a fixture seat and two pressing heads. Two locating holes are symmetrically formed in the fixture seat, two locating core devices are installed in the two locating holes respectively, and the seat ring and the guide pipe are connected to the locating core devices in a locating and sleeved mode. The lower portions of the pressing heads are connected with the air cylinder head to enable an air inlet valve of the air cylinder head and an exhaust valve of the air cylinder head to be located in the centers of the locating core devices respectively and correspondingly, and power mechanisms are connected to the two pressing heads. The fixture is simple in structure and convenient to operate, enables the guide pipe and the seat ring to be arranged in the air cylinder head in a press-fitting mode at a time, guarantees the press-fitting precision of the guide pipe and the seat ring, and is beneficial for prolonging the service life of the air inlet valve of the air cylinder head and the service life of the exhaust valve of the air cylinder head.

Owner:唐维刚

Automatic assembling machine for vehicle-mounted antenna

InactiveCN107892160AHigh degree of automationImprove processing efficiencyMetal working apparatusConveyor partsDistribution controlEngineering

The invention relates to an automatic assembly machine for vehicle-mounted antennas, which includes a frame and a power distribution control box arranged in the frame, a base body rotating device and a shield rotating device are correspondingly arranged on the upper end of the frame, and the periphery of the shield rotating device is sequentially arranged There are shield feeding device, transfer device and unloading device. The finished product assembly device is installed under the transfer device. The substrate rotating device is equipped with a substrate feeding device, a cable conveying device, a pressing device, a handling device and a round cover in sequence. Mechanism; the present invention completes the feeding, assembling and transporting of the base body, the round cover and the cable by sequentially setting the base body feeding device, the cable conveying device, the press-fitting device, the round cover pressing mechanism and the transfer device around the periphery of the base body rotating device. The shield transfer device is equipped with shield feeding device, finished product assembly device and unloading device sequentially around the periphery of the shield rotating device, so as to realize the feeding, assembly and finished product unloading of the shield, which has a high degree of automation and greatly improves the Processing efficiency.

Owner:DONGGUAN UNIV OF TECH

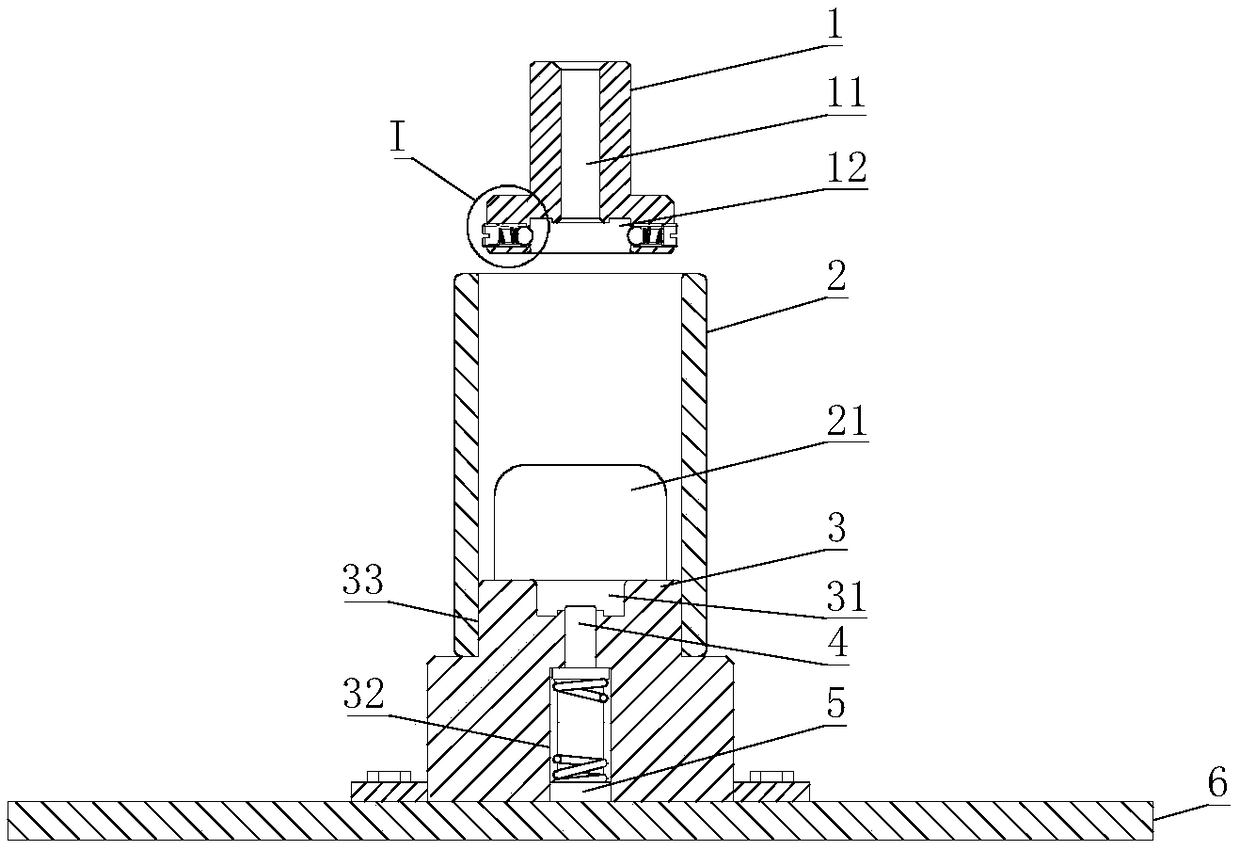

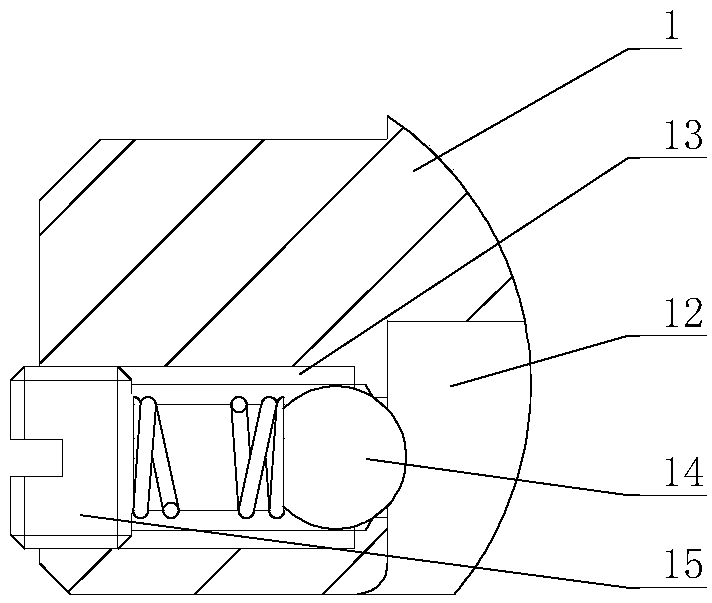

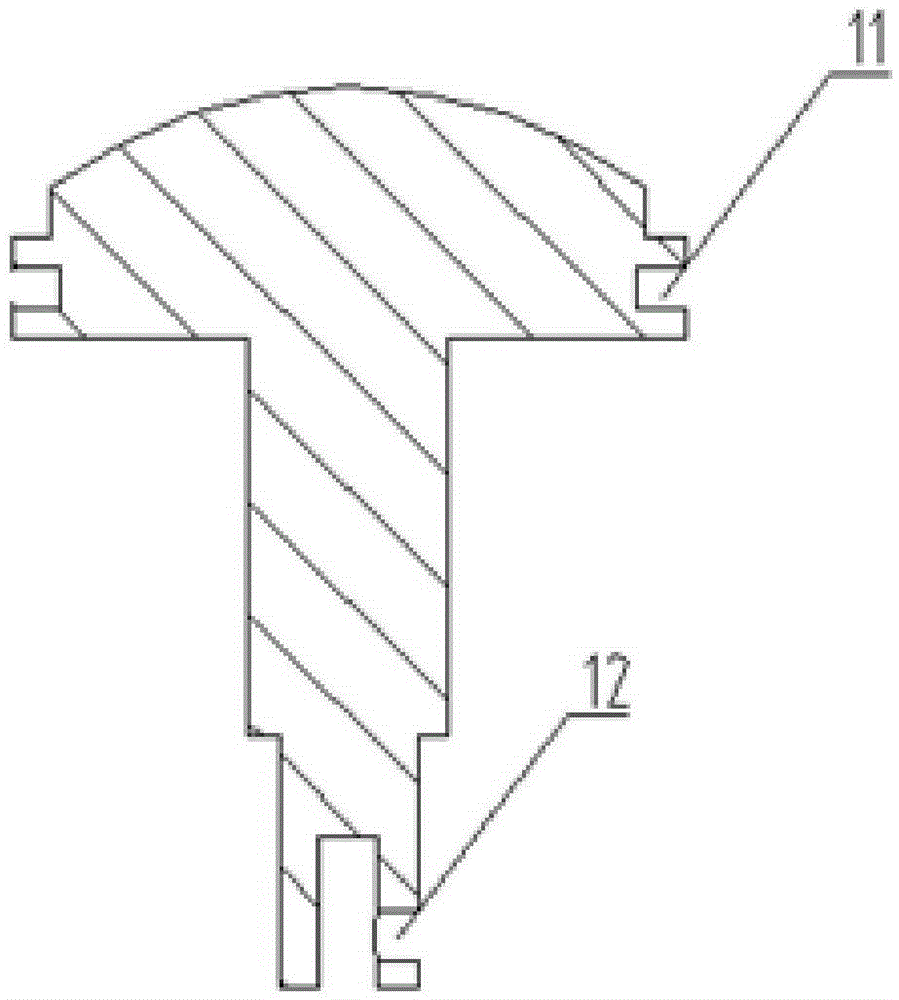

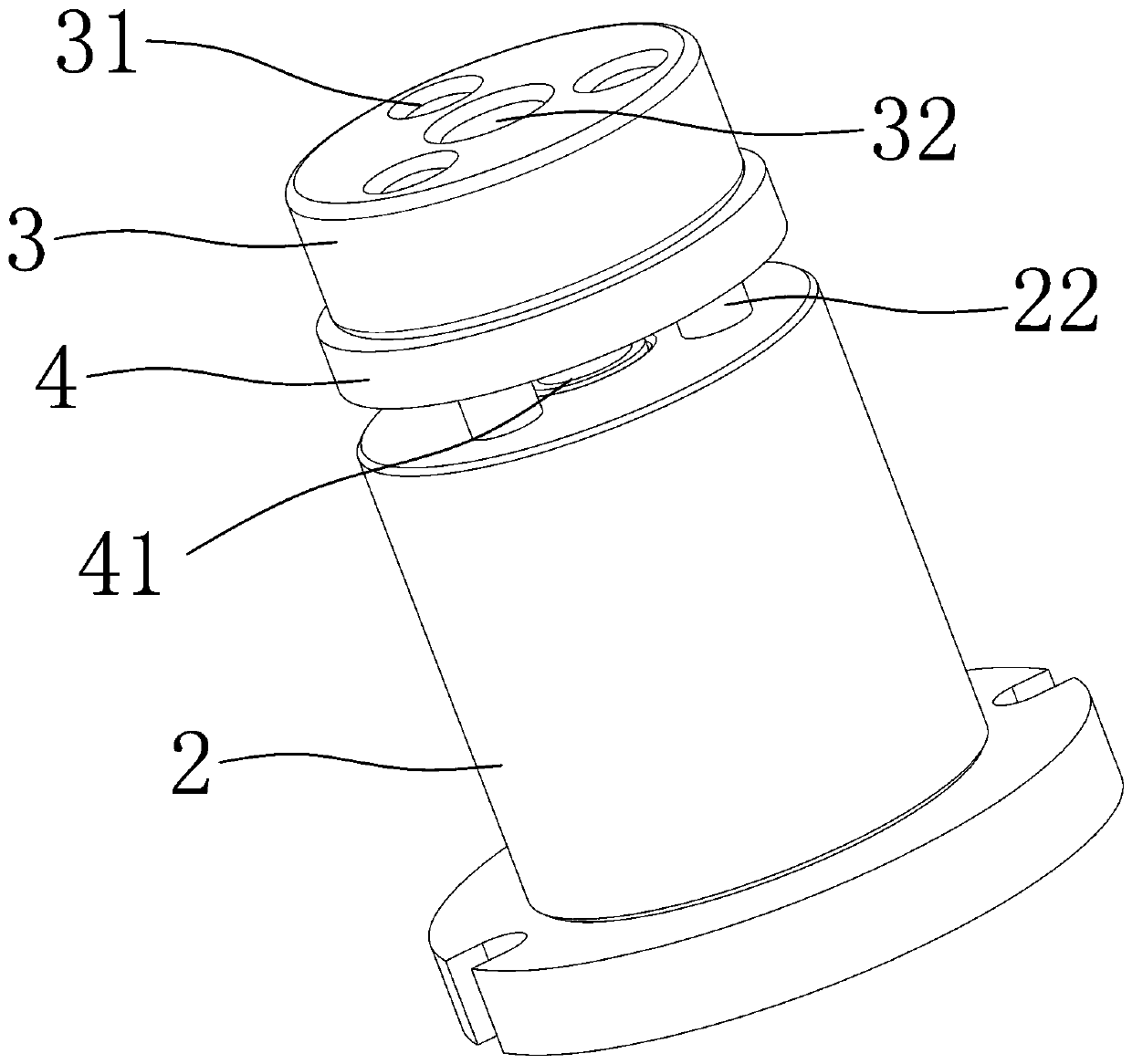

Tool for press fitting of motor rotor bearing

The invention relates to a tool for press fitting of a motor rotor bearing, and belongs to the technical field of motors. The tool for press fitting of the motor rotor bearing comprises a pressing head, a positioning part and a base, wherein a boss is arranged on the base, a groove B is coaxially arranged in the boss, the shape and size of the boss are consistent with those of an inner cavity of the positioning part, one end of the positioning part sleeves the boss, a groove A is formed in the pressing head, a through hole is coaxially formed in the groove A, and the pressing head is placed outside the positioning part. The tool is simple in structure, easy and convenient to operate, high in positioning precision, stable and reliable. A motor rotor does not incline, and the bearing in thepressing head and the base can be pressed on a middle shaft of the rotor at the same time, so that the efficiency is high. By means of a steel ball in the pressing head and a top column in the base, the coaxiality of the bearing and the middle shaft of the rotor during press fitting is effectively ensured, and the press fitting precision is high.

Owner:GUIZHOU HUAFENG ELECTRICAL APPLIANCES

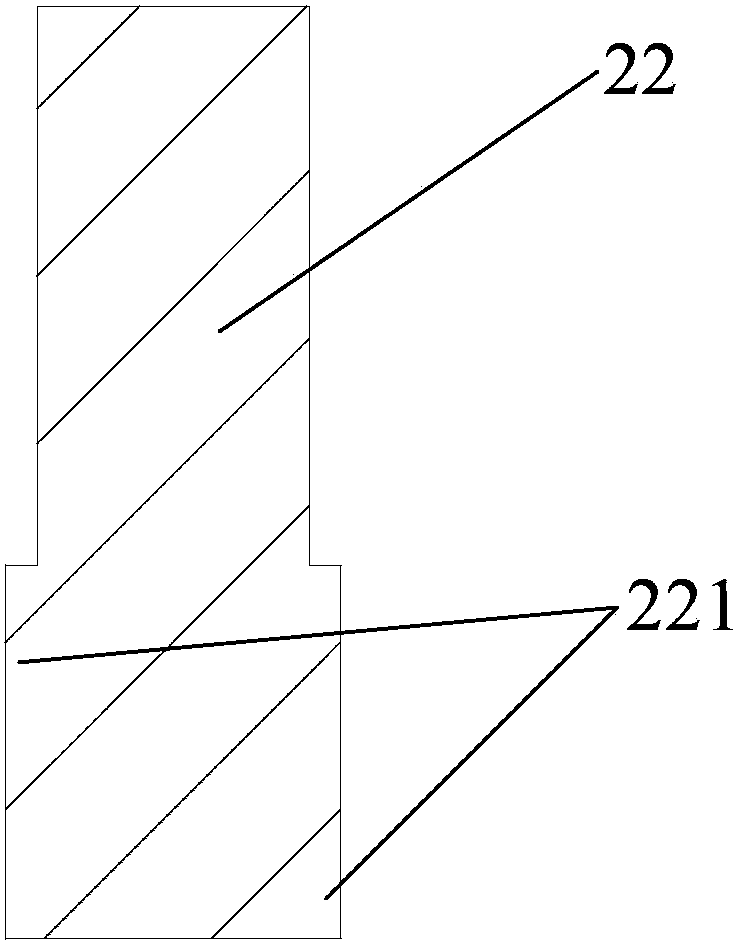

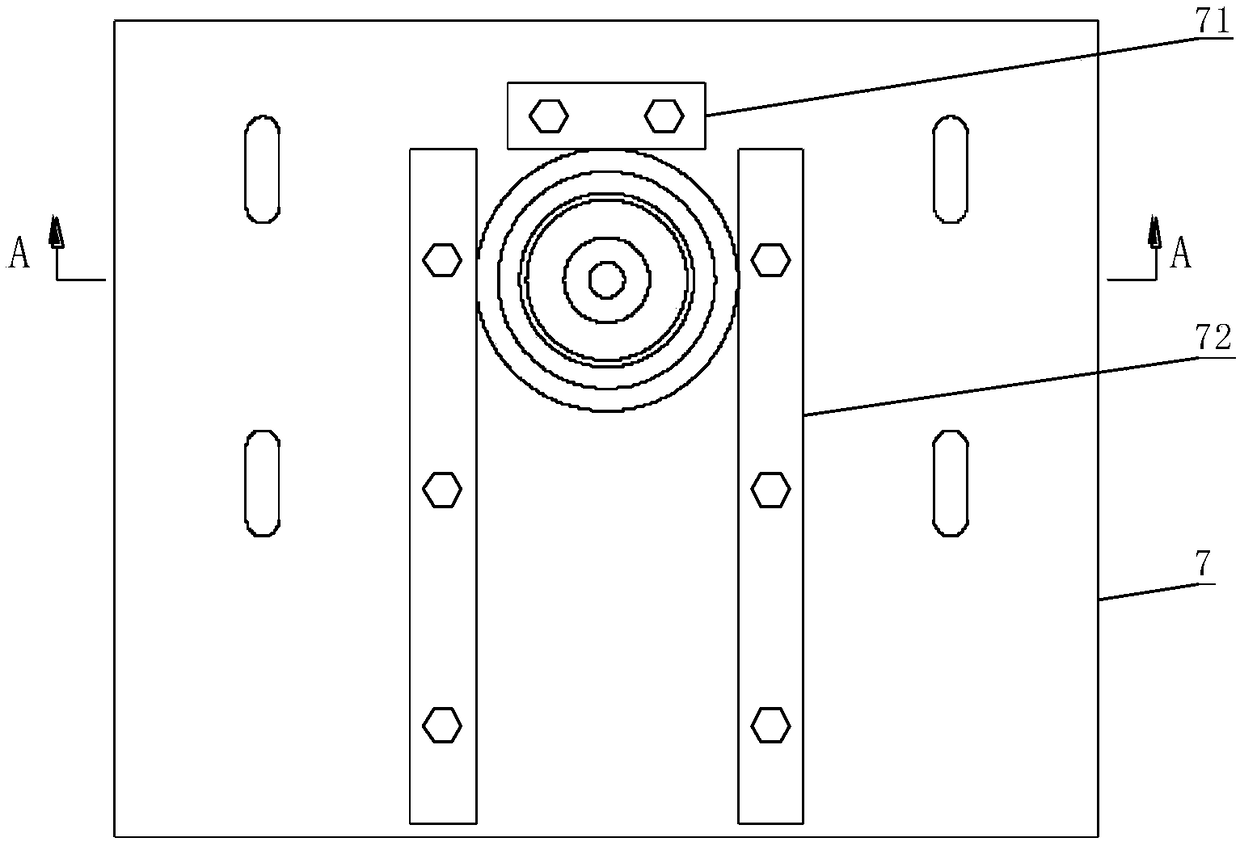

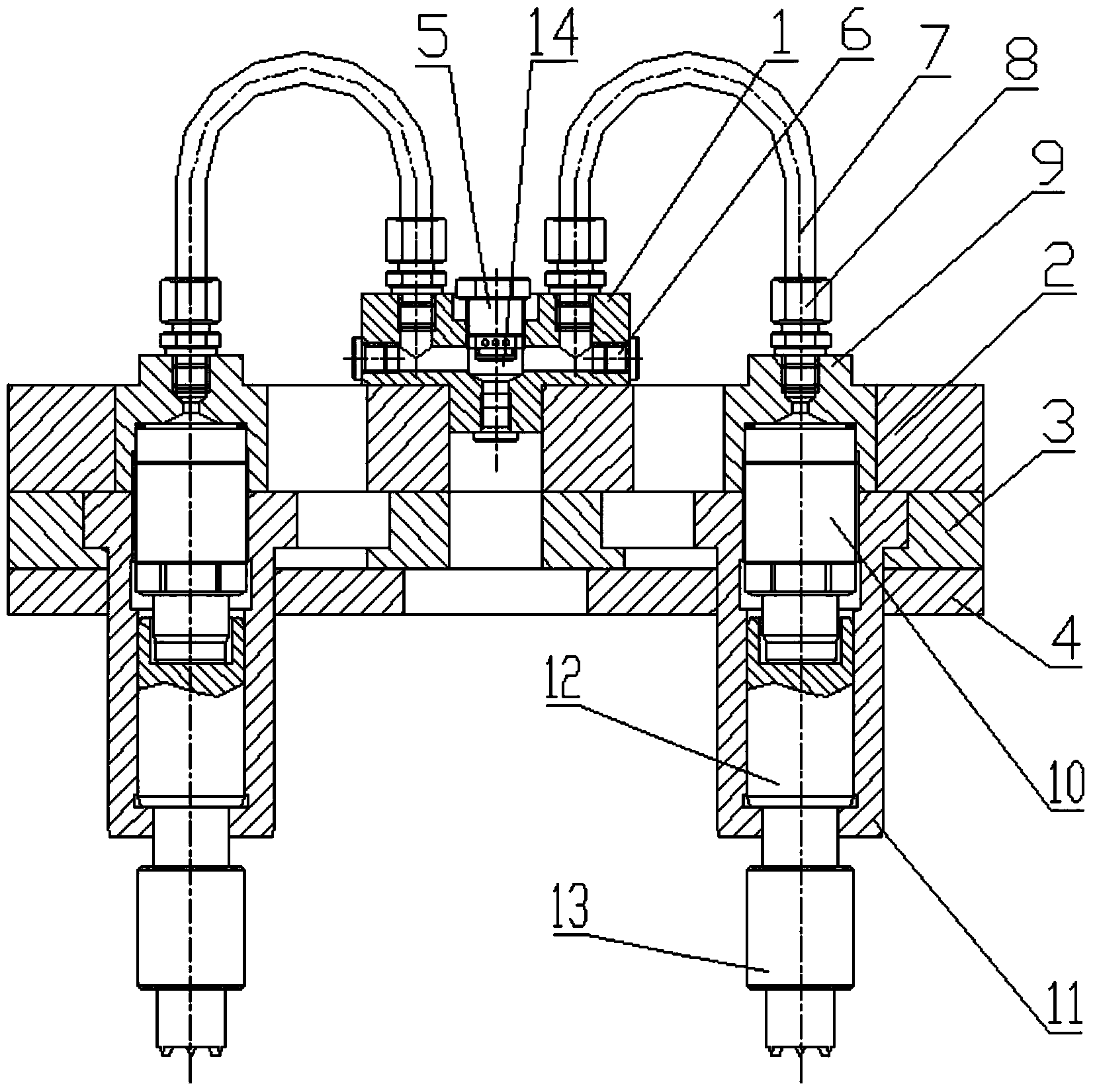

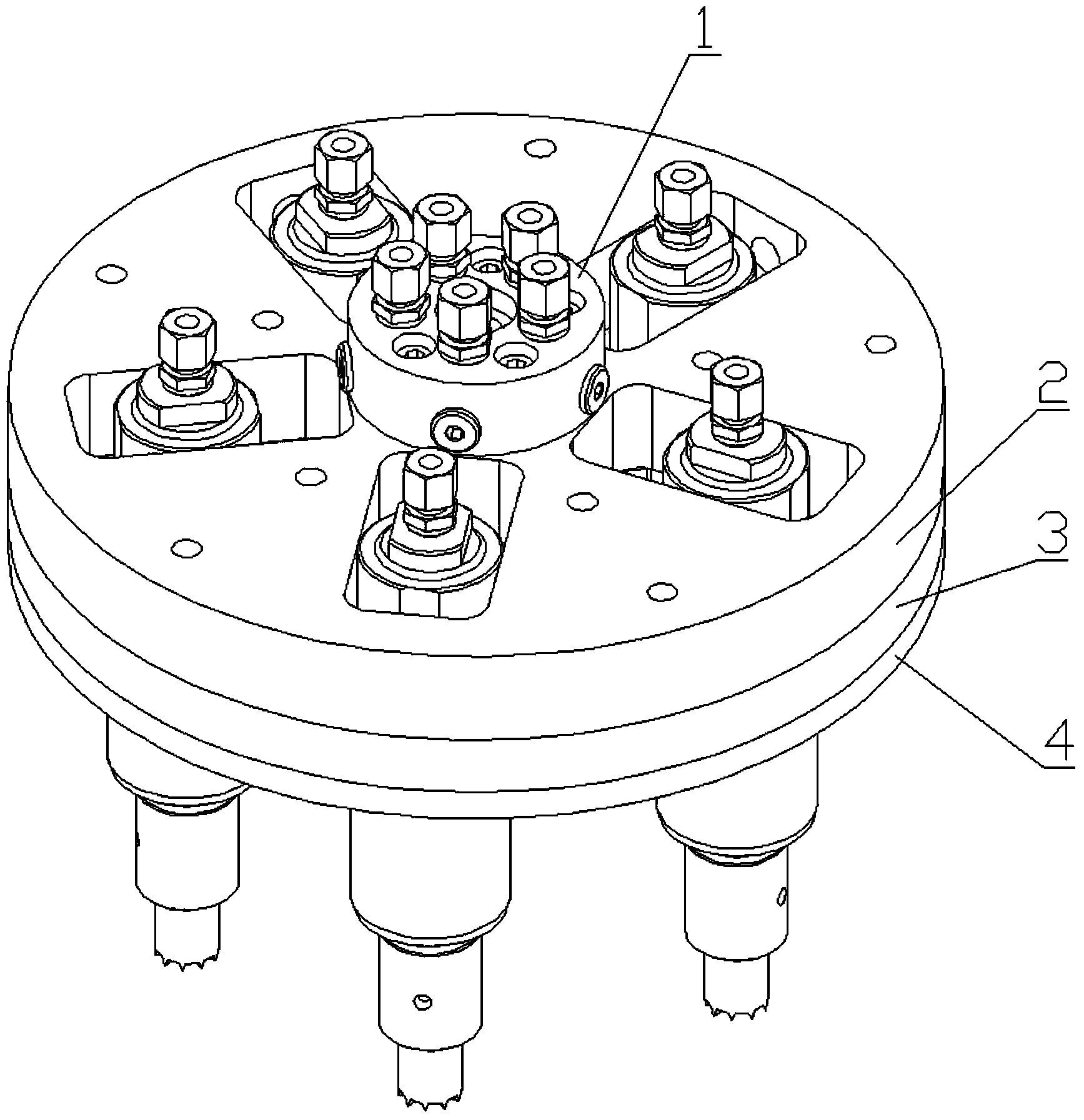

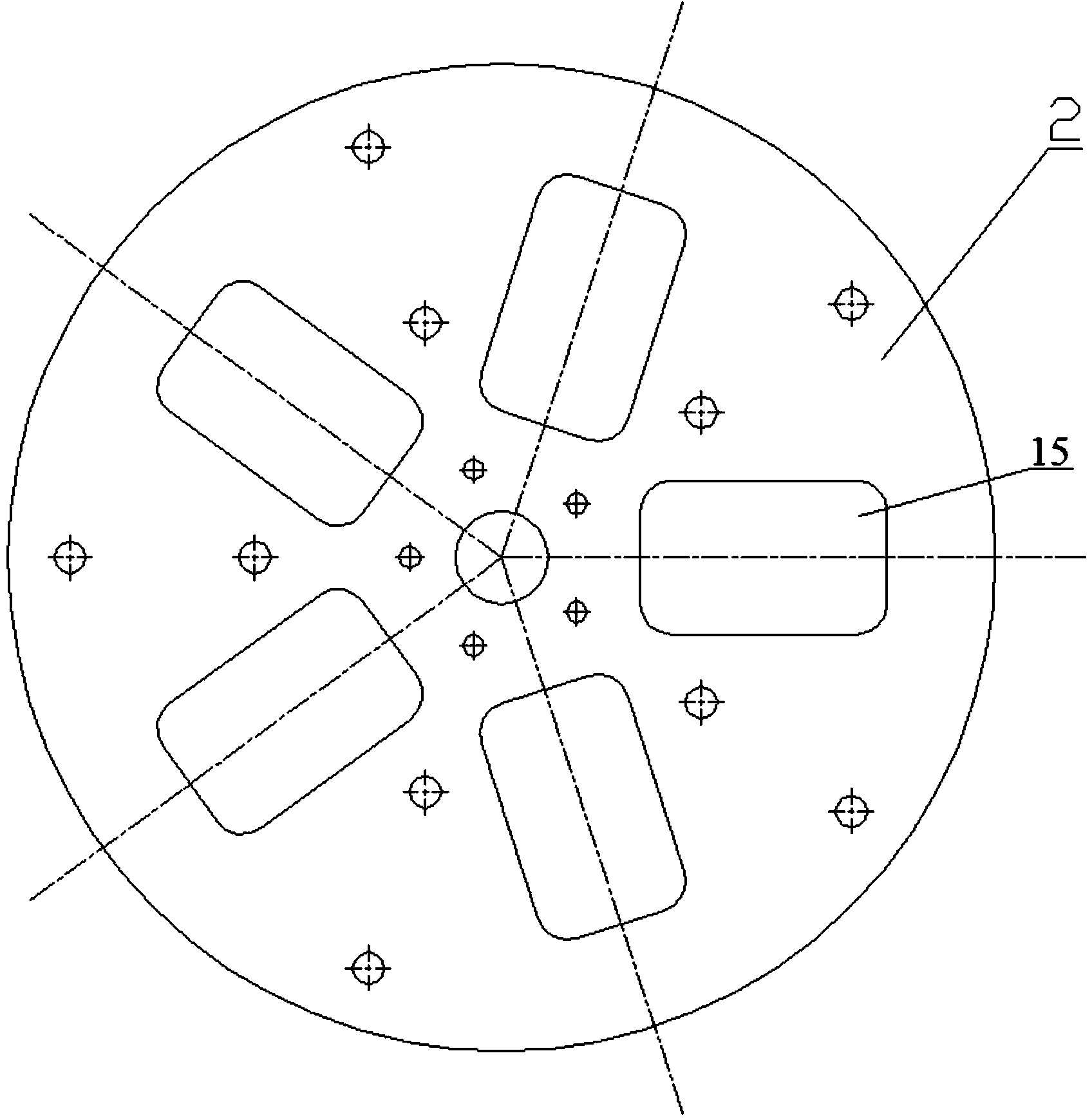

Floating pressure head device

InactiveCN103962828AUniform pressing force of the indenterImprove connectivityMetal working apparatusMechanical engineering

The invention discloses a floating pressure head device. The floating pressure head device comprises an oil distributing base, a base, an index plate, a positioning plate and multiple pressure head assemblies in a sequential overlaying mode. Multiple through installation grooves are formed in the base and the index plate. The pressure head assemblies are correspondingly arranged in the installation grooves. Each pressure head assembly can horizontally move in the corresponding installation groove. A cavity is formed in the oil distributing base, and the oil distributing base is provided with an oil filling port which leads to the cavity. A one-way valve is installed on the oil distributing base, and multiple oil outlets are respectively formed in the oil distributing base and lead to the cavity. Hydraulic hoses are correspondingly connected between the oil outlets and the pressure head assemblies. Hydraulic oil in all the pressure head assemblies is communicated, so that press fitting force of pressure heads of all the pressure head assemblies is even, press fitting is performed on each part in place, and press fitting precision is improved. Multiple parts can be pressed into the device in a one-off mode, so that time is saved, efficiency is improved, operation is convenient and cost is reduced, and the number of the pressure heads of all the pressure head assemblies can be designed according to workpieces.

Owner:HEFEI UNIV OF TECH

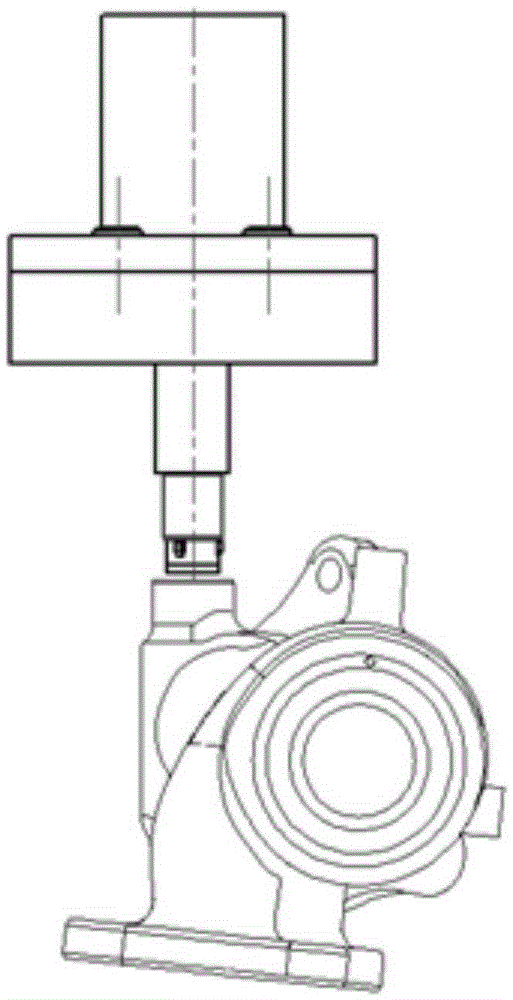

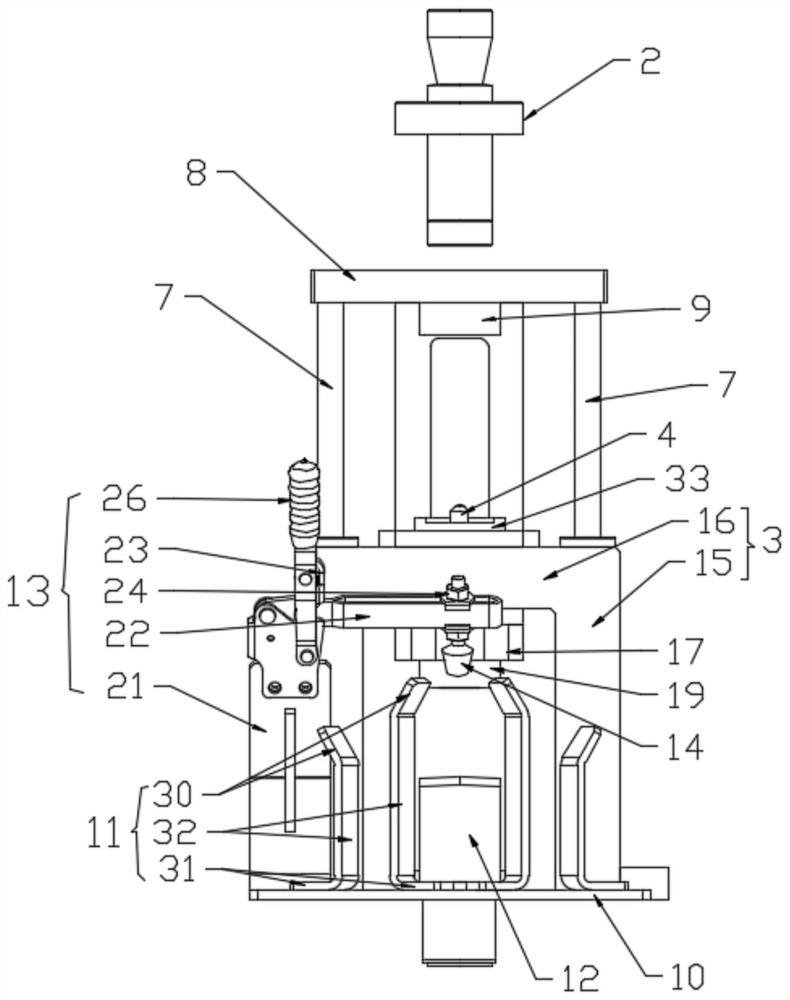

Floating press-fitting turbine shell bushing device and aligning positioning method

ActiveCN105415246AGuaranteed self-confidenceGuaranteed press fit rateWork holdersMetal working apparatusTurbochargerEngineering

The invention relates to a tool clamp, in particular to an aligning mounting device for a floating bushing of a turbocharger turbine shell. The floating press-fitting turbine shell bushing device comprises a connecting base which is directly connected to a press base body, a positioning rod which is matched with the connecting base, a fixed baffle block which is connected with the connecting base and the positioning rod, a small spring which guarantees the fixed baffle block and the positioning rod to tightly act, a fastening rod which is in bolted connection with the positioning rod, a guide block which is connected on the positioning rod, and a large spring which guarantees normal action of the guide block. According to the floating press-fitting turbine shell bushing device, interaction of force between springs is delicately utilized to guarantee self-centering of the device, so that the bushing and a component bushing hole are kept to be coaxial, and therefore, press-fitting precision is improved, the structure is simplified, the operation is simple, convenient and reliable, and a press-fitting qualified rate is guaranteed.

Owner:CRRC QISHUYAN INSTITUTE CO LTD +1

Press fitting device for spare part on planet carrier

PendingCN110253254AExtended service lifeIncrease productivityAssembly machinesMetal working apparatusEngineeringPositioning system

The invention aims at providing a press fitting device for a spare part on a planet carrier. The press fitting device for the spare part on the planet carrier is capable of improving the production efficiency. The device comprises a pressing machine which is arranged on a working platform, a positioning seat and a positioning block, wherein a plurality of first storing grooves are formed in the positioning seat and upwards penetrate through the positioning seat; first compressing springs and positioning pins are arranged in the first storing grooves; the upper end surface of the positioning seat is downwards sunken to form a second storing groove; a positioning column is arranged in the second storing groove and is used for positioning a sun gear; the inner diameter of the second storing groove is beyond the outer diameter of the sun gear; the positioning pins are used for supporting a wheel shaft; a plurality of through positioning holes are formed in the positioning block; the quantity and the position of the positioning hole are corresponding to those of wheel shaft fixing holes in the planet carrier; when the planet carrier is positioned on the positioning seat, and the positioning block is positioned on the planet carrier, the upper ends of the positioning pins extend into the positioning holes through the first compressing springs.

Owner:HENGDIAN GRP INNUOVO ELECTRIC

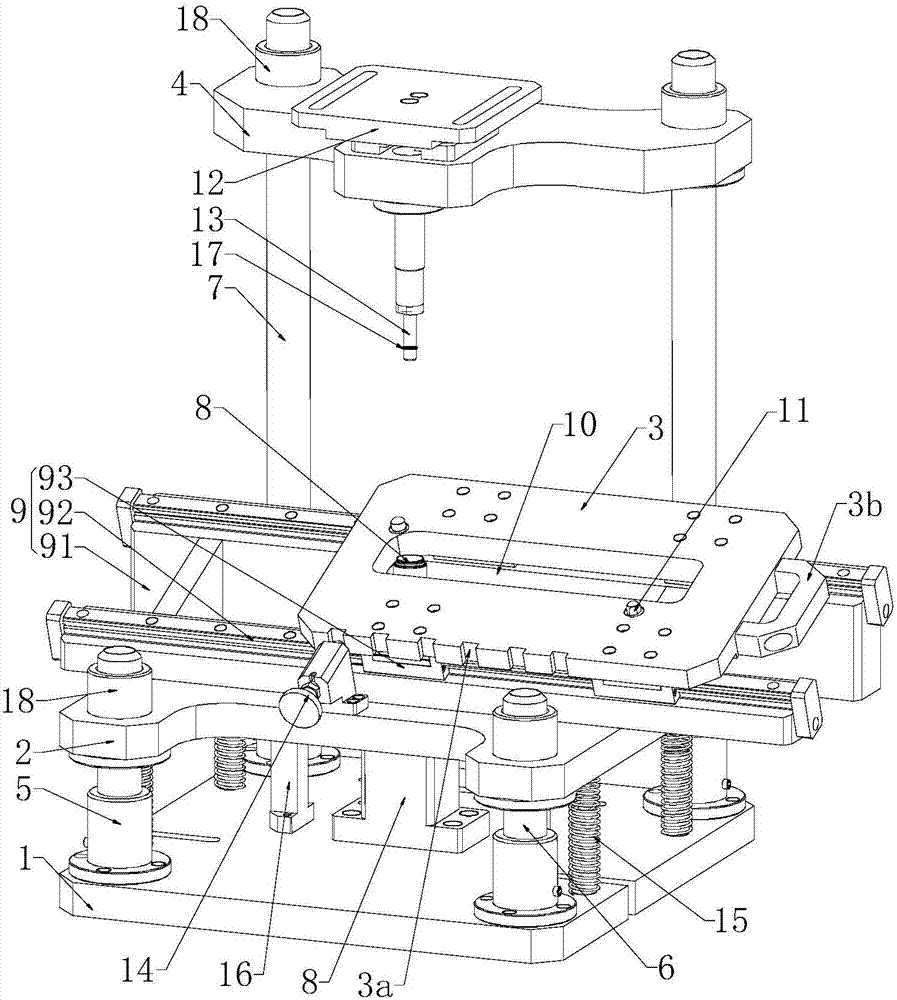

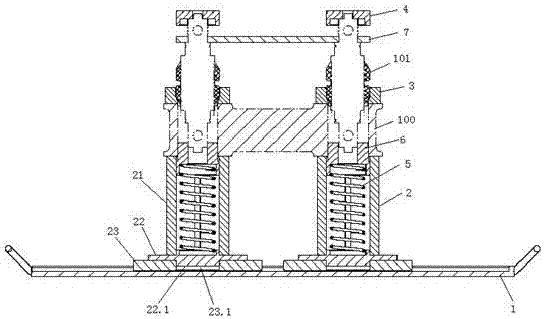

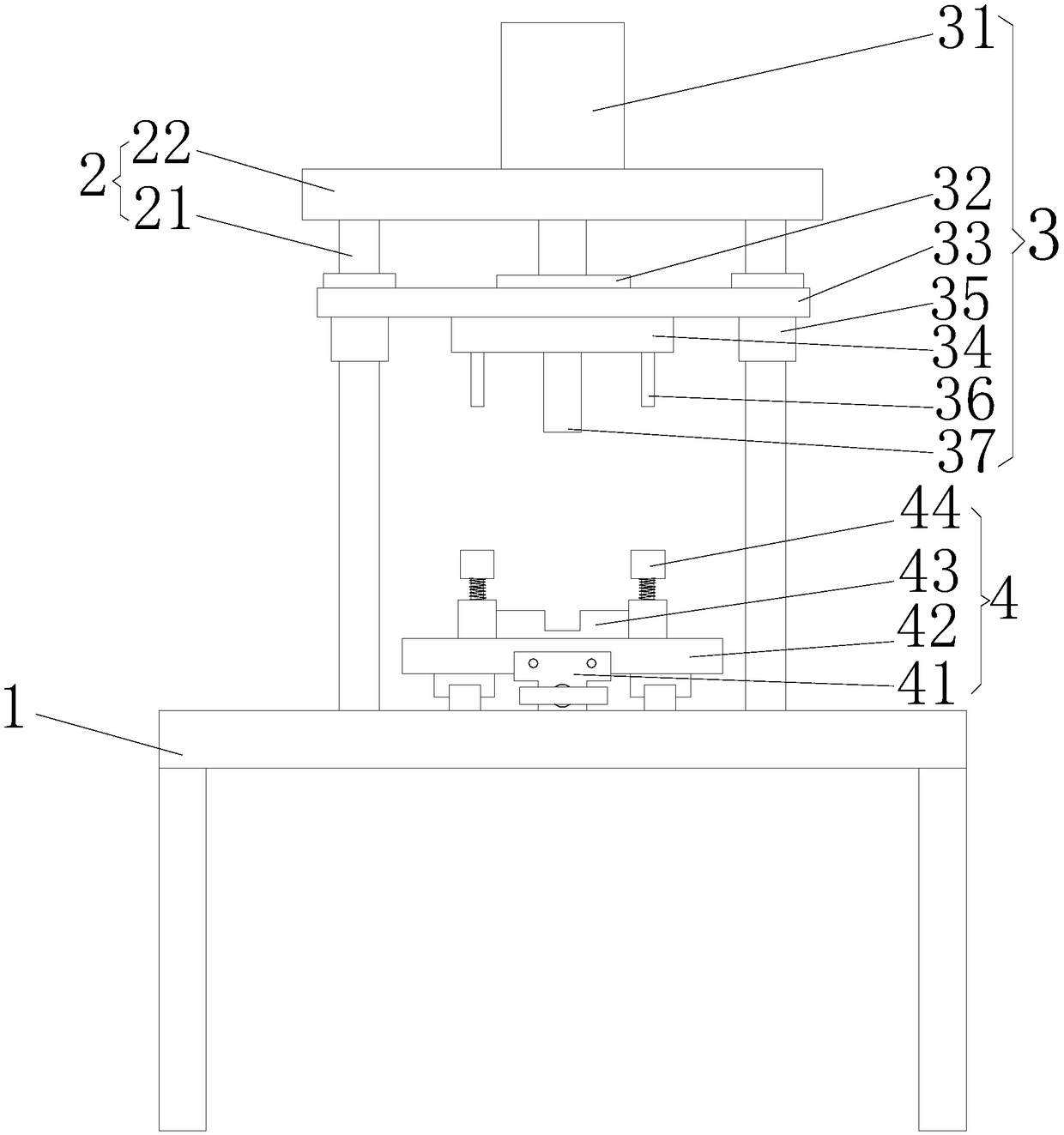

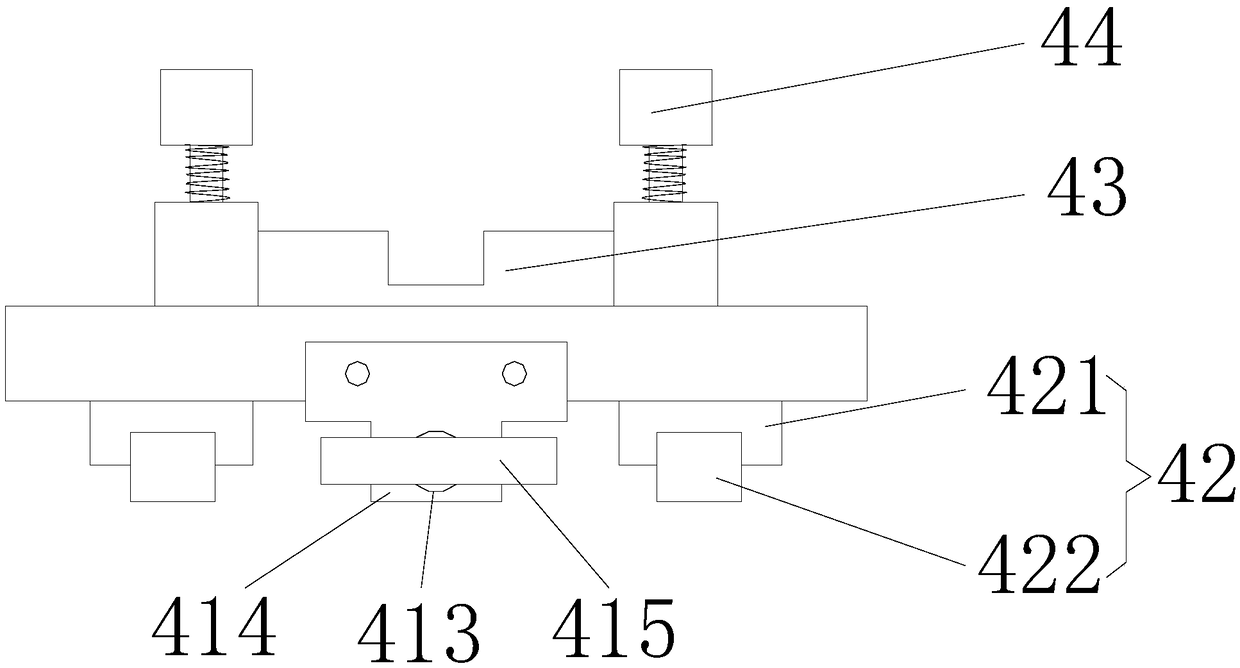

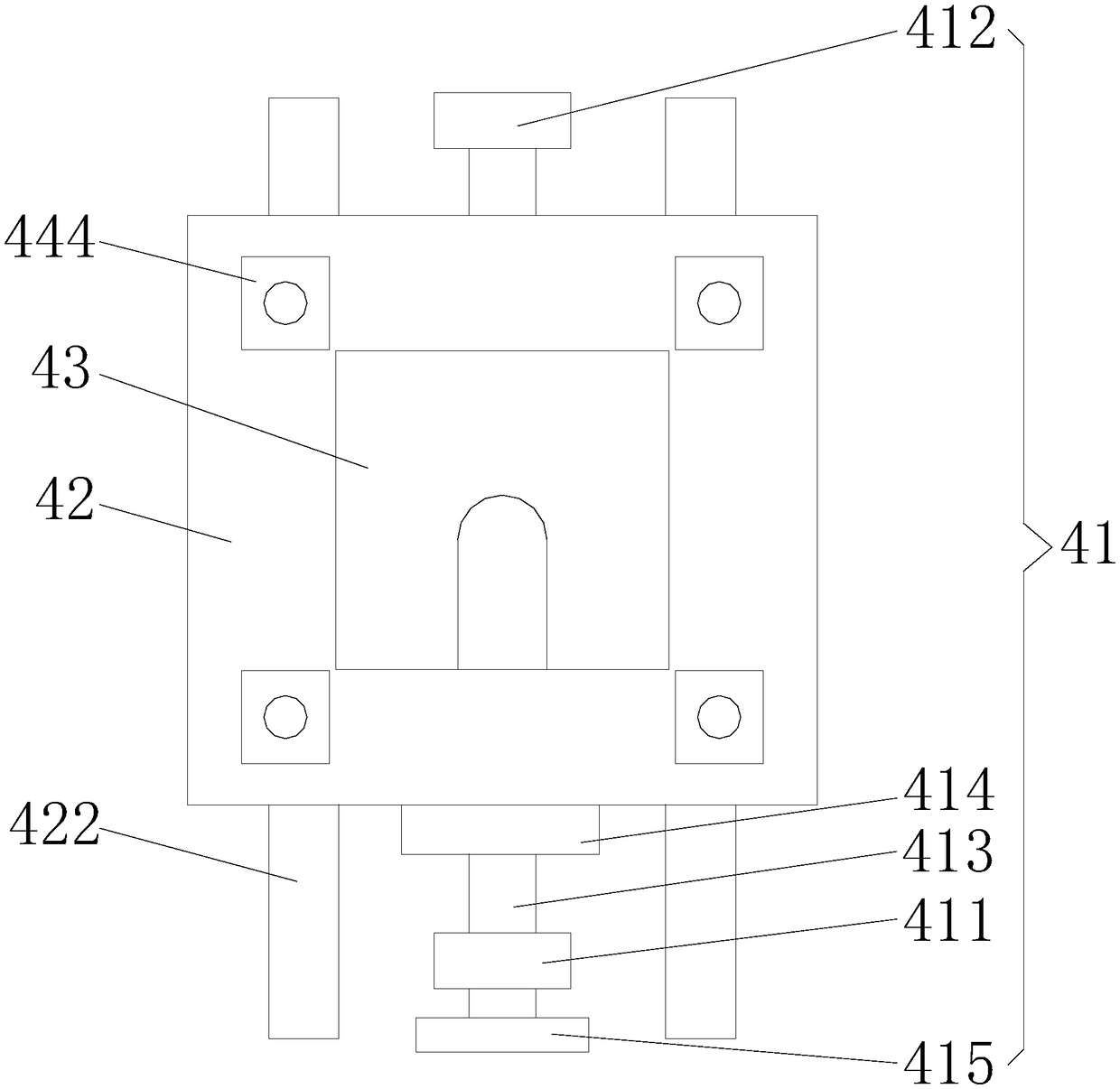

Pressing-mounting equipment for pressing-mounting of cylinder cover guide pipe and seat ring

PendingCN107971729AIncrease productivityPrecise positioningMetal working apparatusOutput deviceEngineering

The invention discloses pressing-mounting equipment for pressing-mounting of a cylinder cover guide pipe and a seat ring. The pressing-mounting equipment comprises a foot plate, a bottom plate, a supporting plate and a top plate; at least two short vertical columns and at least two long vertical columns are fixed to the foot plate through guiding sleeves; the bottom plate is supported on the shortvertical columns and the long vertical columns in sliding and sleeving modes; a positioning shaft is further fixed to the foot plate; the obliquely-arranged supporting plate is mounted above the bottom plate through a sliding supporting mechanism; and a machining groove is formed in the center of the supporting plate, and the upper portion of the positioning shaft extends into the machining groove; a positioning pin assembly is arranged on the supporting plate; the top plate is supported on the upper portions of the long vertical columns in sliding and sleeving modes, and a pressure transferassembly for being connected to a pressure output device is arranged in the middle of the top plate; and the lower end of the pressure transfer assembly is connected with a guide pipe fixing sleeve which corresponds to the positioning shaft in position. The pressing-mounting equipment has the remarkable effects that pressing-mounting work of the cylinder cover guide pipe and the seat ring is completed by the equipment instead of manual work, and the advantages of high pressing-mounting efficiency, low equipment input and good product quality are achieved.

Owner:CHONGQING SCI & TECH CO LTD YINGXI

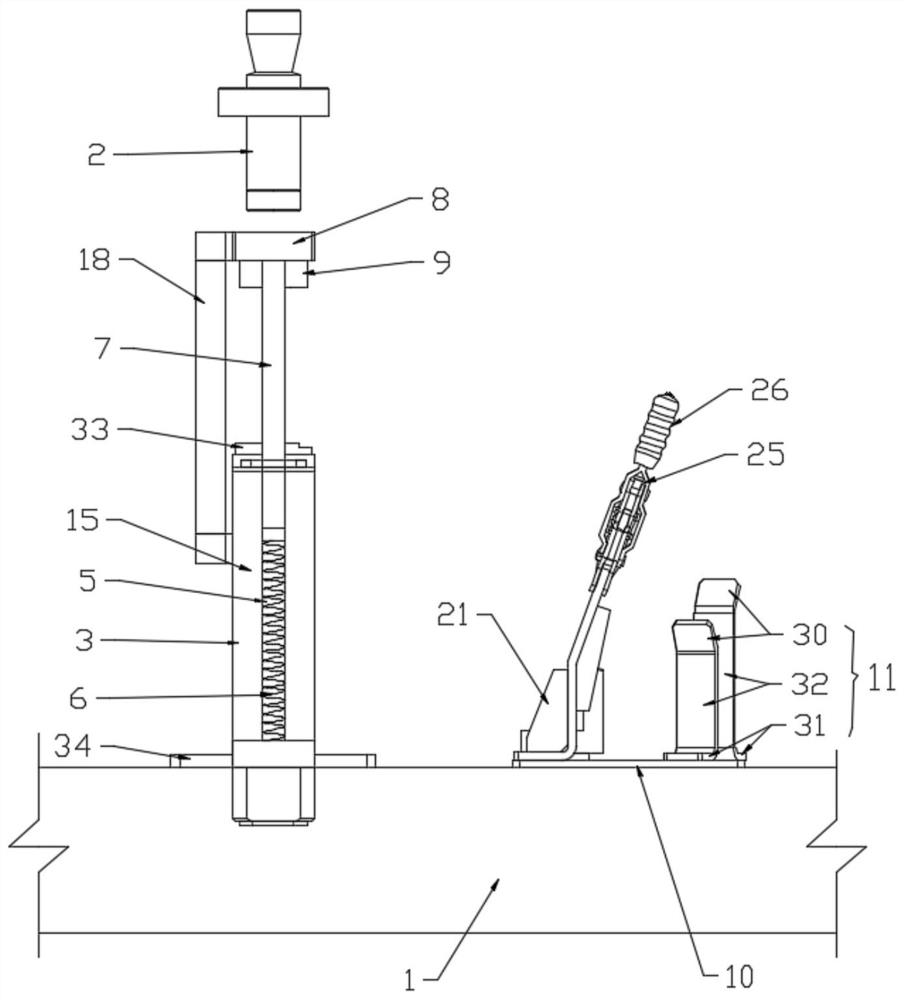

Lining press-fitting tool

InactiveCN106392585AQuick pressImprove press fit accuracyMetal working apparatusEngineeringHydraulic press

The invention relates to a lining press-fitting tool. The lining press-fitting tool comprises: a positioning plate is arranged above a bottom plate; a guide column is arranged between the positioning plate and the bottom plate; the lower end of the guide column is fixedly connected with the bottom plate; the upper end of the guide column stretches out of the positioning plate, and the guide column and the positioning plate form linear guide cooperation; a spring is arranged on the guide column in a sleeving way; the two ends of the spring abut against the upper plate surface of the bottom plate and the lower plate surface of the positioning plate correspondingly; two positioning pressure heads are arranged on the bottom plate and are parallel with the guide column; and the upper ends of the two positioning pressure heads stretch out of the positioning plate and are used for assembling a lining to be press-fitted. The lining to be press-fitted is arranged at the upper ends of the two positioning pressure heads and a workpiece is placed on the positioning plate of the tool, so that the upper ends, which stretch out of the positioning plate, of the positioning heads are positioned below a shaft hole of the workpiece; the tool is placed on a hydraulic press and the hydraulic press starts, so that a shaft sleeve is press-fitted on the workpiece; the workpiece is taken down after press fitting is finished, and the next press-fitting action is repeated; and the tool is convenient and safe, is quick in press fitting, and has high press-fitting precision and production efficiency.

Owner:HEFEI CHANGYUAN HYDRAULICS

Press-mounting tool and press-mounting method for axle-box pull rod

PendingCN107350774AAvoid Axial MisalignmentRealize high-precision pressingVehicle componentsMetal working apparatusEngineeringStructural engineering

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

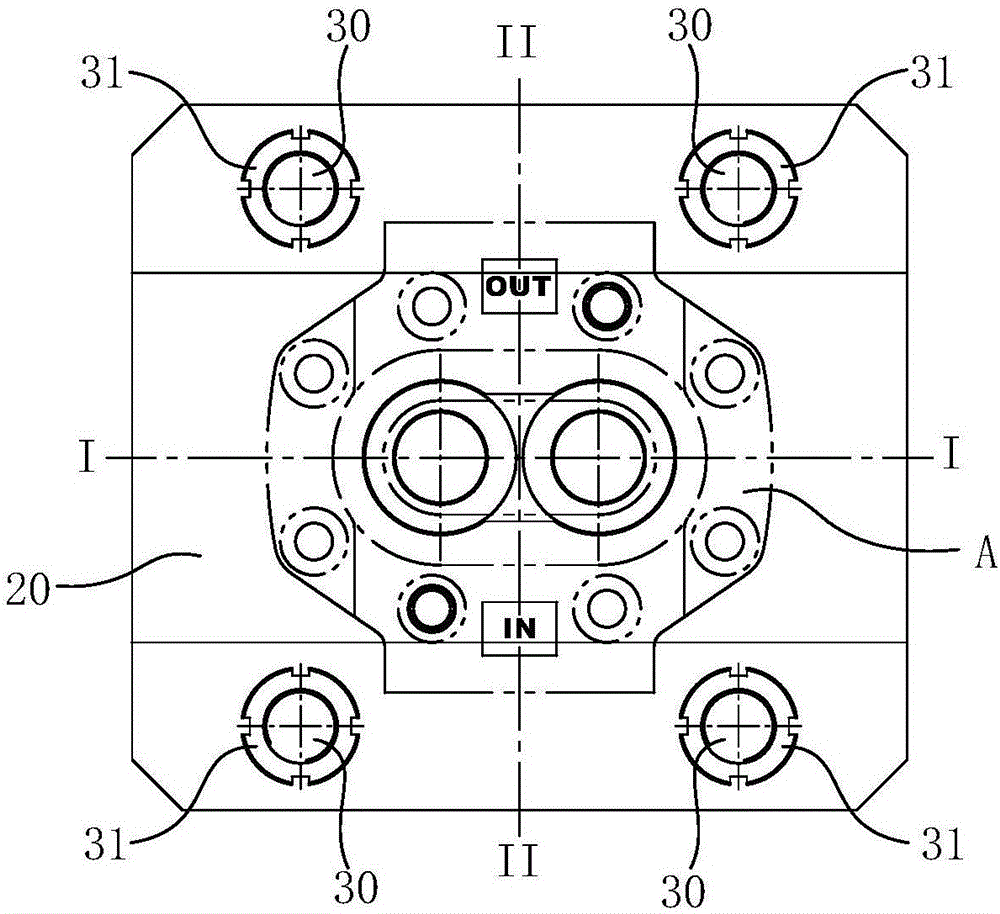

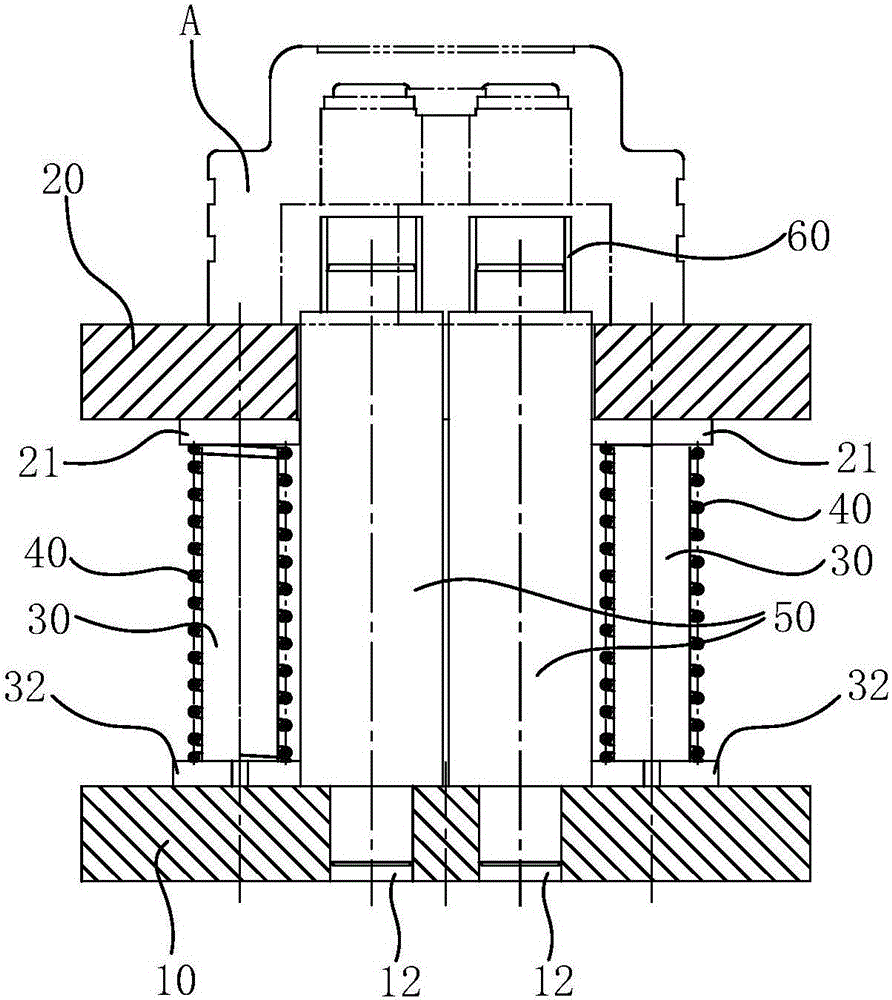

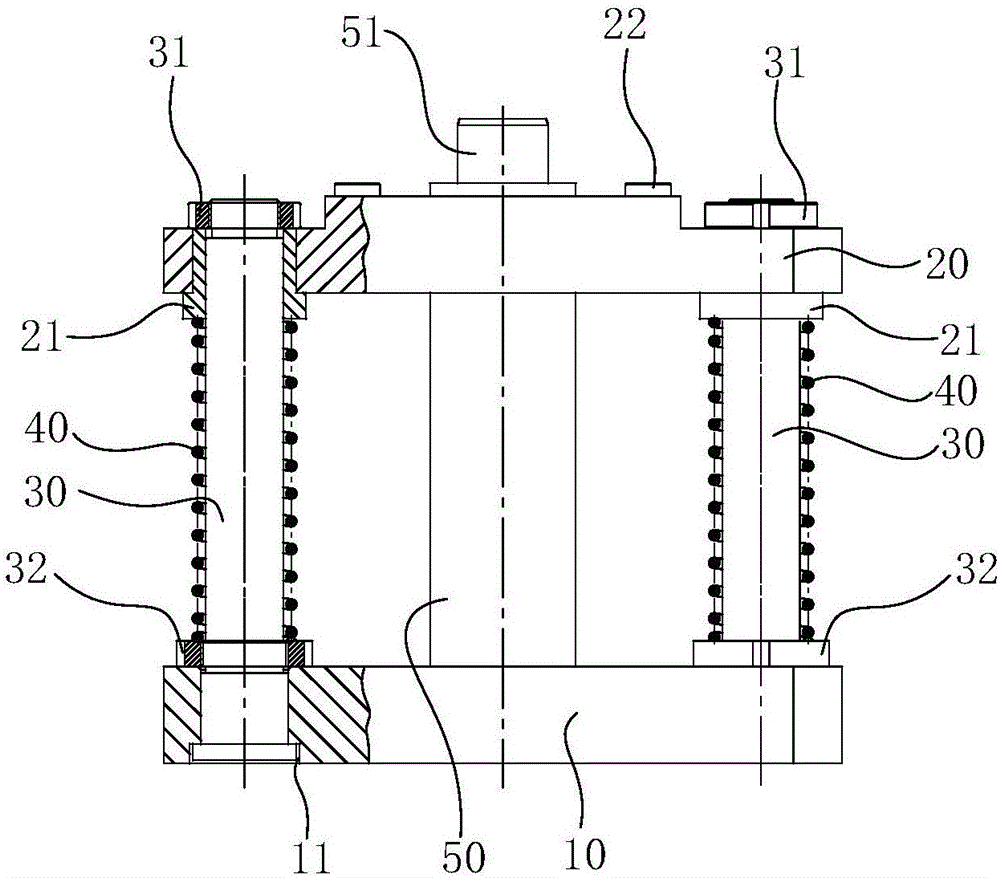

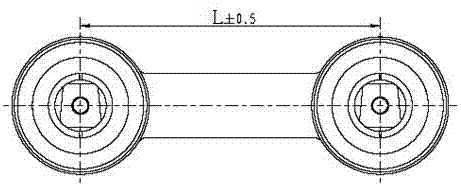

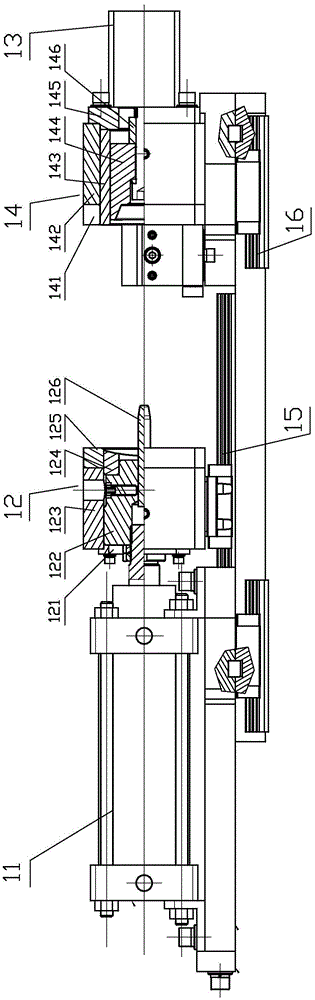

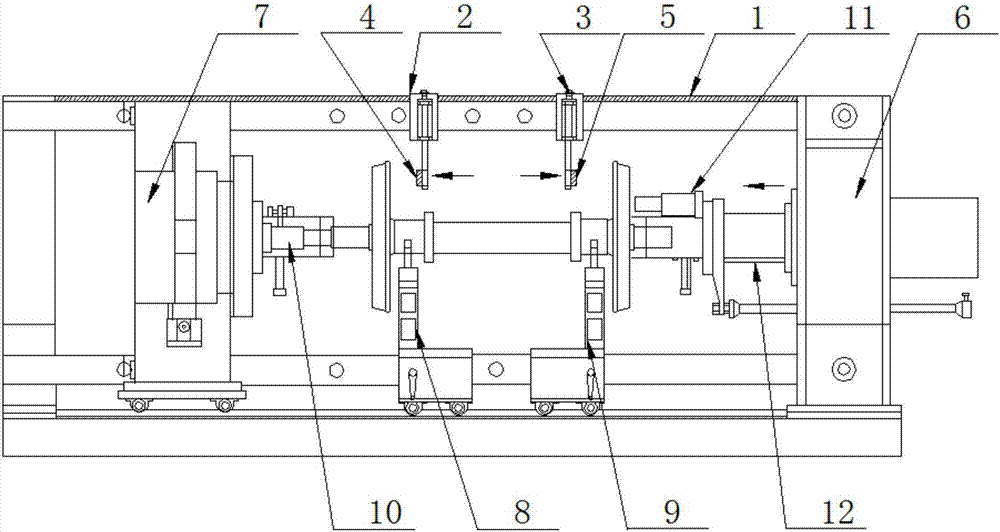

Horizontal bearing pressing system

InactiveCN112372579AImprove press fit accuracyImprove efficiencyMetal-working hand toolsEngineeringCylinder block

The invention relates to a horizontal bearing pressing system. The horizontal bearing pressing system comprises a base; a linear guide rail is fixedly installed in the middle of the base; two air cylinders are symmetrically installed on the two sides of the base; each air cylinder comprises a thrust rod; the end of the thrust rod away from the air cylinder body is fixedly connected with a press-fitting sleeve; three sliding blocks are connected to the linear guide rail in a sliding mode; limiting plates used for fixing the press-fitting sleeve are fixedly connected to the sliding blocks on thetwo sides; and a lifting V-shaped support used for horizontally supporting a rotor is fixedly connected to the sliding block in the middle. The horizontal bearing pressing system achieves simultaneous press-fitting of two bearings, is high in press-fitting precision, high in efficiency, low in cost and wide in application range, and is suitable for bearing press-fitting of different types of rotors and large-scale production lines. According to the invention, the linear guide rail and the sliding blocks which are high in precision are adopted, which ensures that the pressure in the bearing press-fitting process is always kept on the same straight line, and has an obvious effect of reducing shaft deformation caused by radial force borne by the rotor shaft in the press-fitting process.

Owner:湖北梨威机械设备有限公司

Press fitting device for starting gear on motor shaft

PendingCN110253257AImprove coaxialityImprove press fit accuracyManufacturing dynamo-electric machinesMetal working apparatusMotor shaftEngineering

The invention aims at providing a press fitting device for a starting gear on a motor shaft. The press fitting device for the starting gear on the motor shaft is good in coaxial effect of the starting gear and a rotating shaft and high in press fitting accuracy. According to the technical scheme, the device comprises a bottom plate, wherein a pressing machine is arranged on the bottom plate; a positioning plate for positioning a motor to be subjected to press fitting is arranged at the lower side of a pressing head of the pressing machine; a pressing plate is arranged at the upper part of the positioning plate; the pressing plate is arranged on a guide mechanism in an up-down sliding fitting manner; the pressing plate is provided with a first avoiding groove which up and down penetrates to avoid the starting gear; the positioning plate is provided with a second avoiding groove which up and down penetrates to avoid the lower end of a rotating shaft of the motor to be subjected to press fitting; a supporting mechanism comprises a lifting shaft is arranged at the lower side of the positioning plate; when the motor to be subjected to press fitting is positioned on the positioning plate, the rotating shaft of the motor to be subjected to press fitting is coaxial with the lifting shaft and the first avoiding groove.

Owner:HENGDIAN GRP INNUOVO ELECTRIC

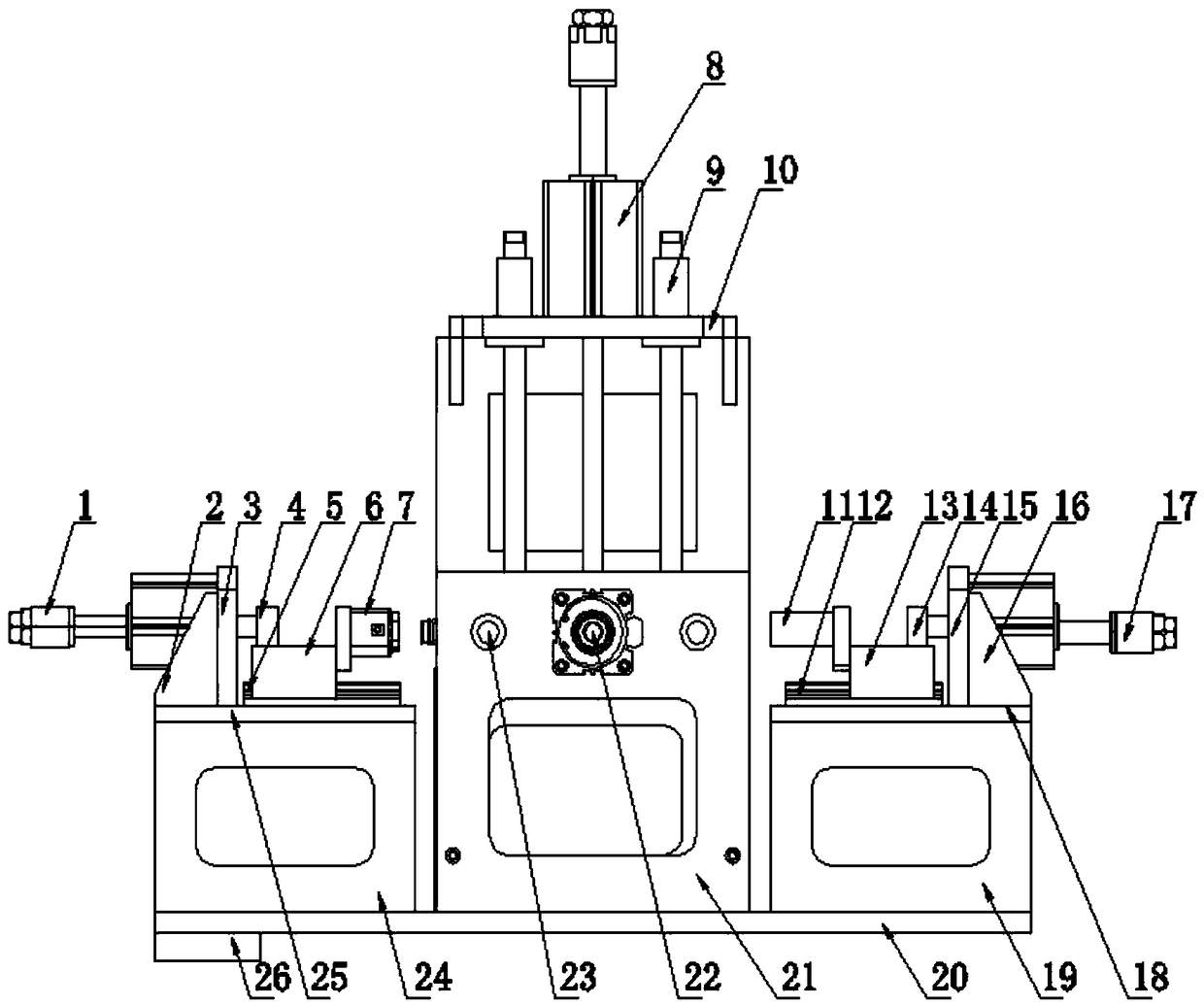

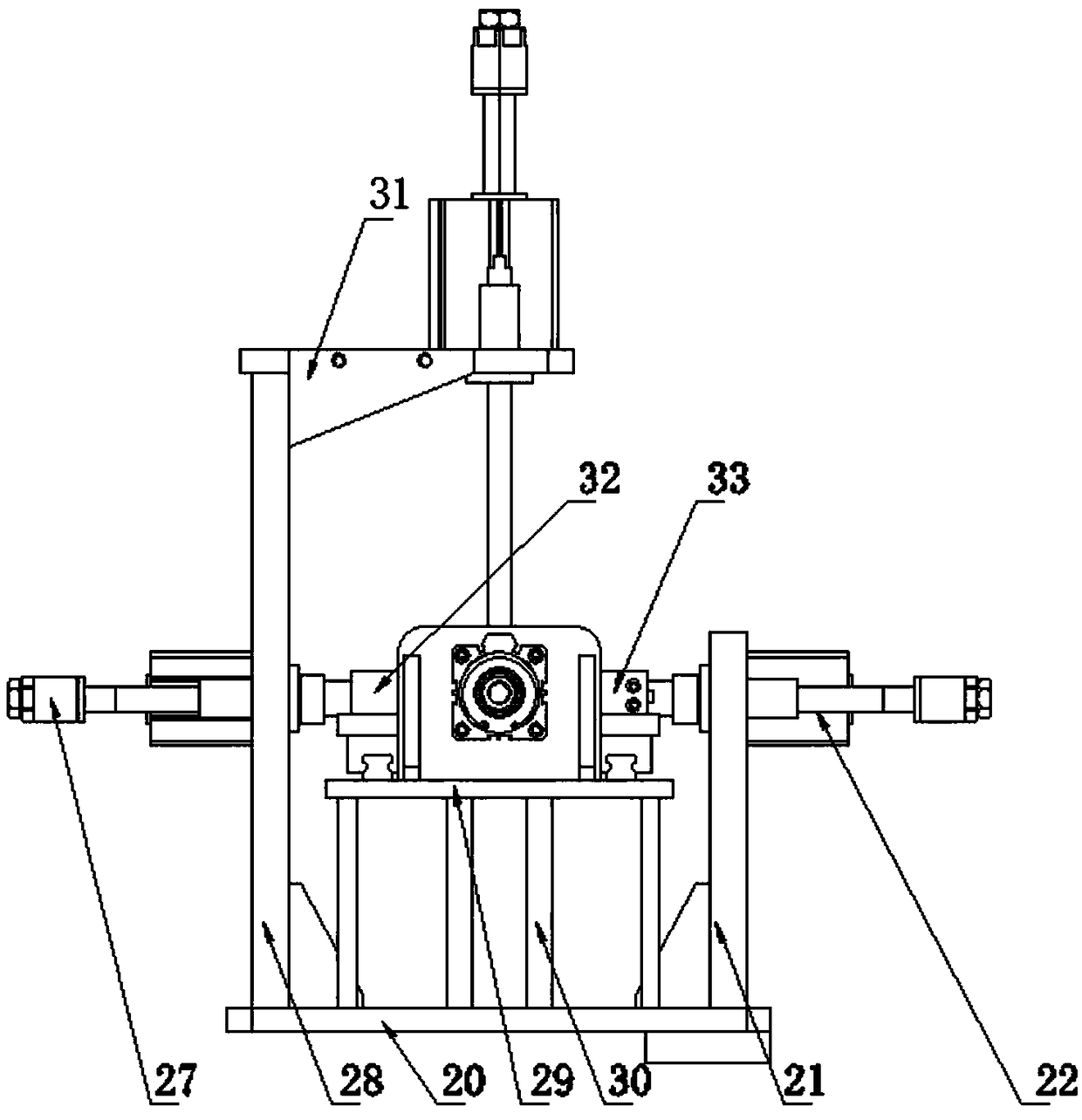

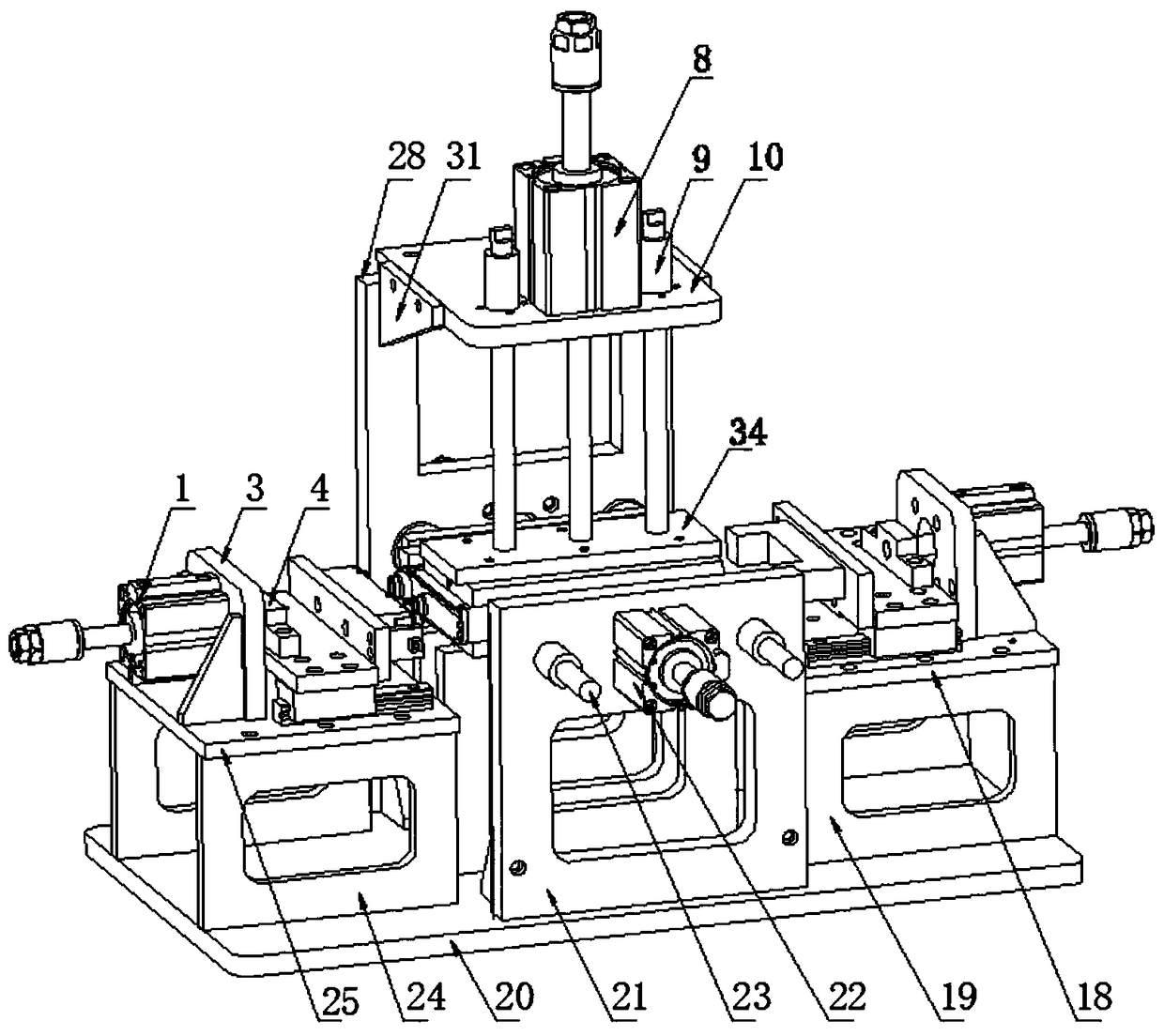

Transverse high-efficiency press fitting machine for automotive heat dissipator

InactiveCN108857390AEasy to fixImprove press fit accuracyAssembly machinesEngineeringMechanical engineering

The invention relates to a transverse high-efficiency press fitting machine for an automotive heat dissipator. A left press fitting air cylinder is fixedly mounted on a left supporting plate, a left slide block is slidably mounted on a left press fitting mechanism mounting rack, and a left pressure block is fixedly mounted at the right end of the left slide block; a right press fitting air cylinder is fixedly mounted on a right supporting plate, a right slide block is slidably mounted on a right press fitting mechanism mounting rack, and a right pressure block is fixedly mounted at the right end of the right slide block; a front positioning air cylinder is fixedly mounted on a front positioning plate, a front positioning block is arranged on the end part of the front positioning air cylinder, a back positioning air cylinder is fixedly mounted on a back positioning plate, a back positioning block is arranged on the end part of the back positioning air cylinder, a top plate is horizontally mounted at the top end of the back positioning plate, an upper positioning air cylinder is fixedly mounted on the top plate, and an upper positioning block is arranged on the end part of the upperpositioning air cylinder. The transverse high-efficiency press fitting machine provided by the invention is scientific and reasonable in structural design, so that a core body of the heat dissipator is stably fixed, the press fitting precision of a blanking cap and the core body of the heat dissipator and the product quality are improved, and the core bodies of the heat dissipator of different sizes can be processed by press fitting, so that the transverse high-efficiency press fitting machine is wide in application range.

Owner:TIANJIN YAXING RADIATOR

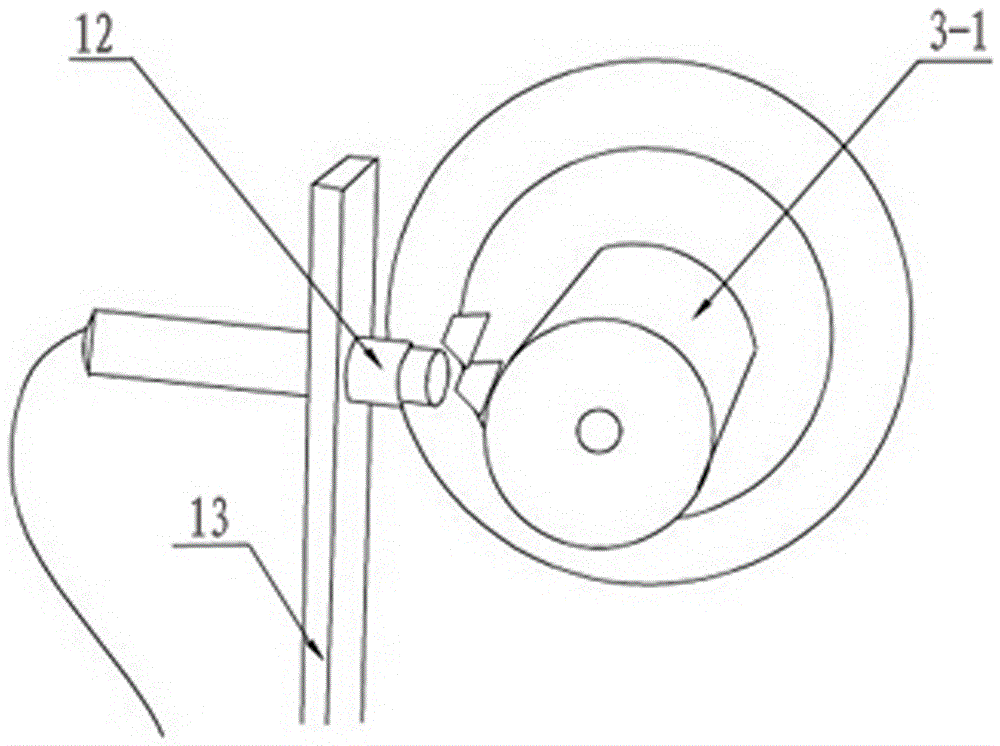

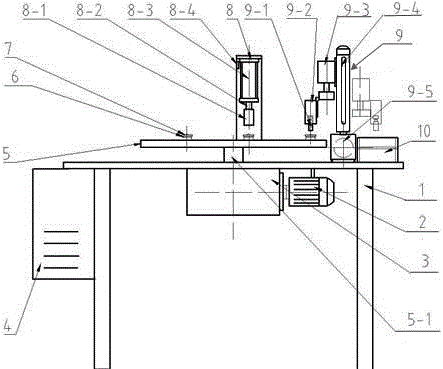

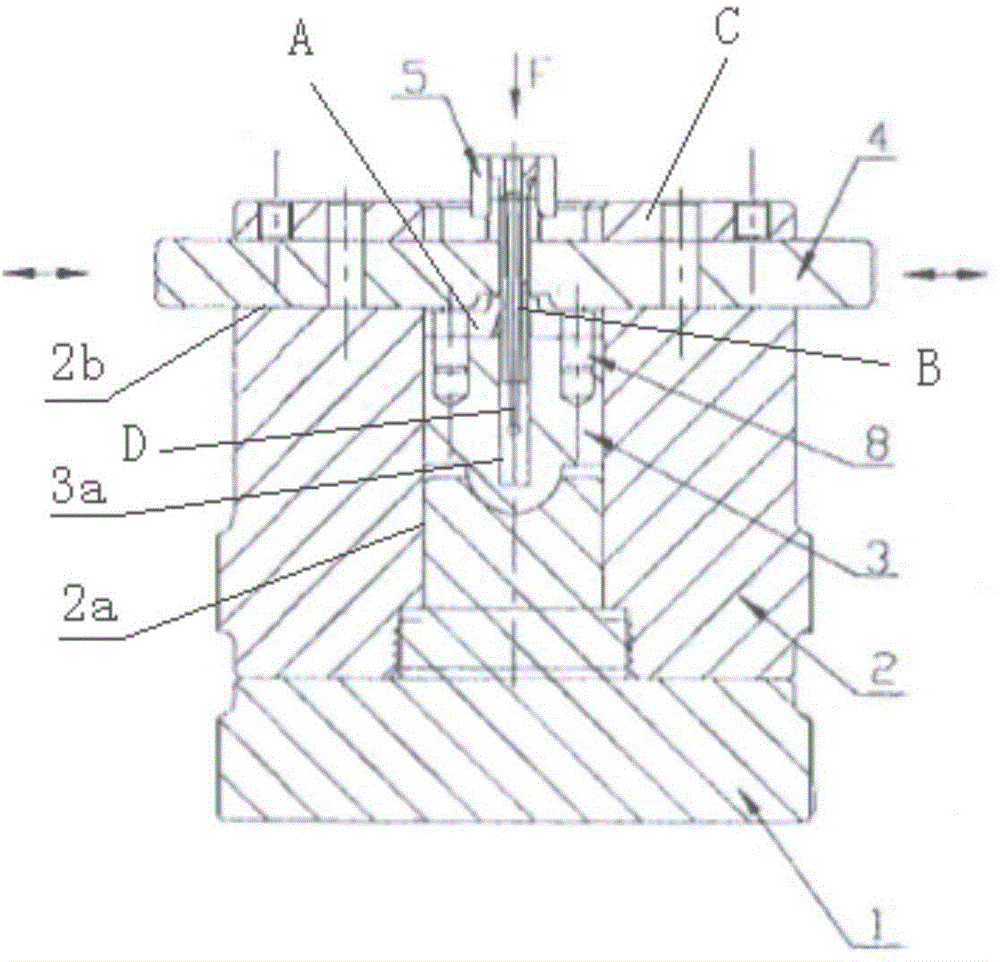

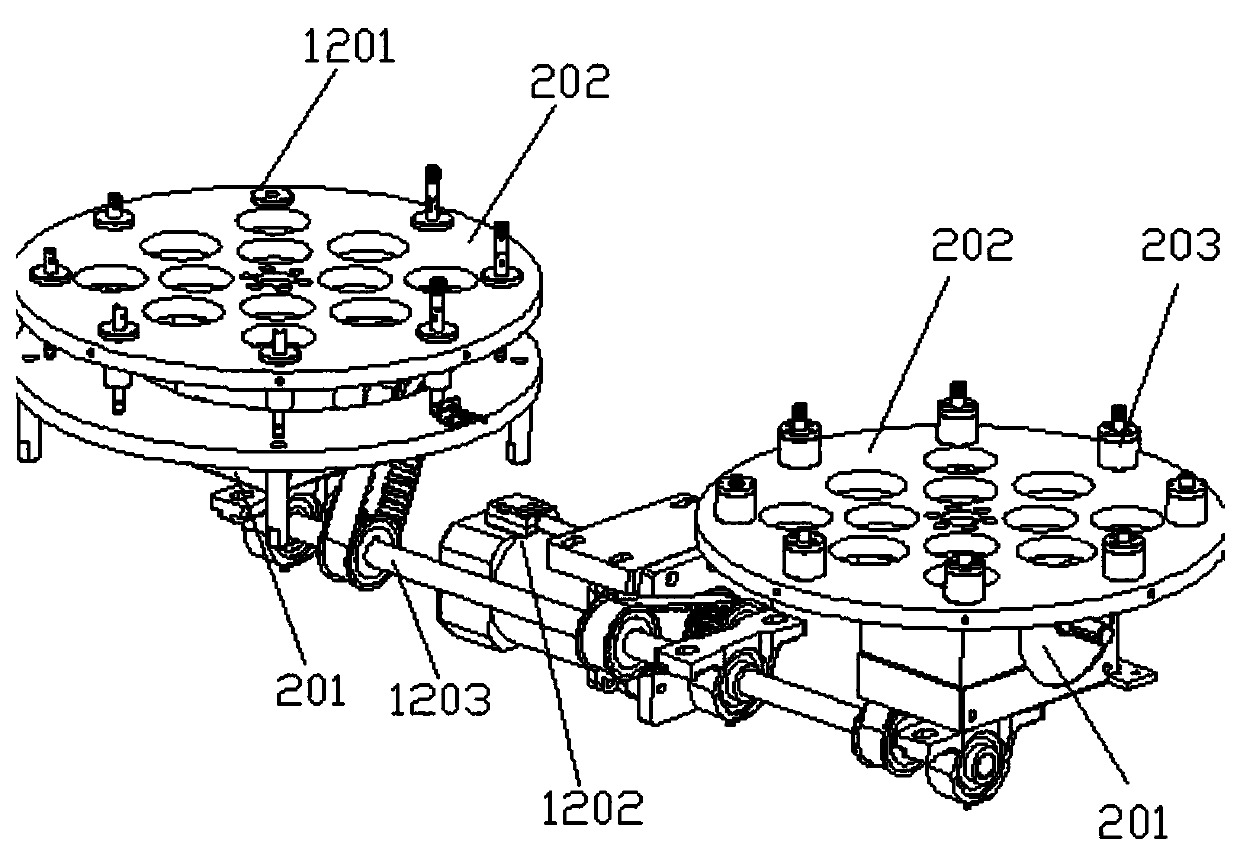

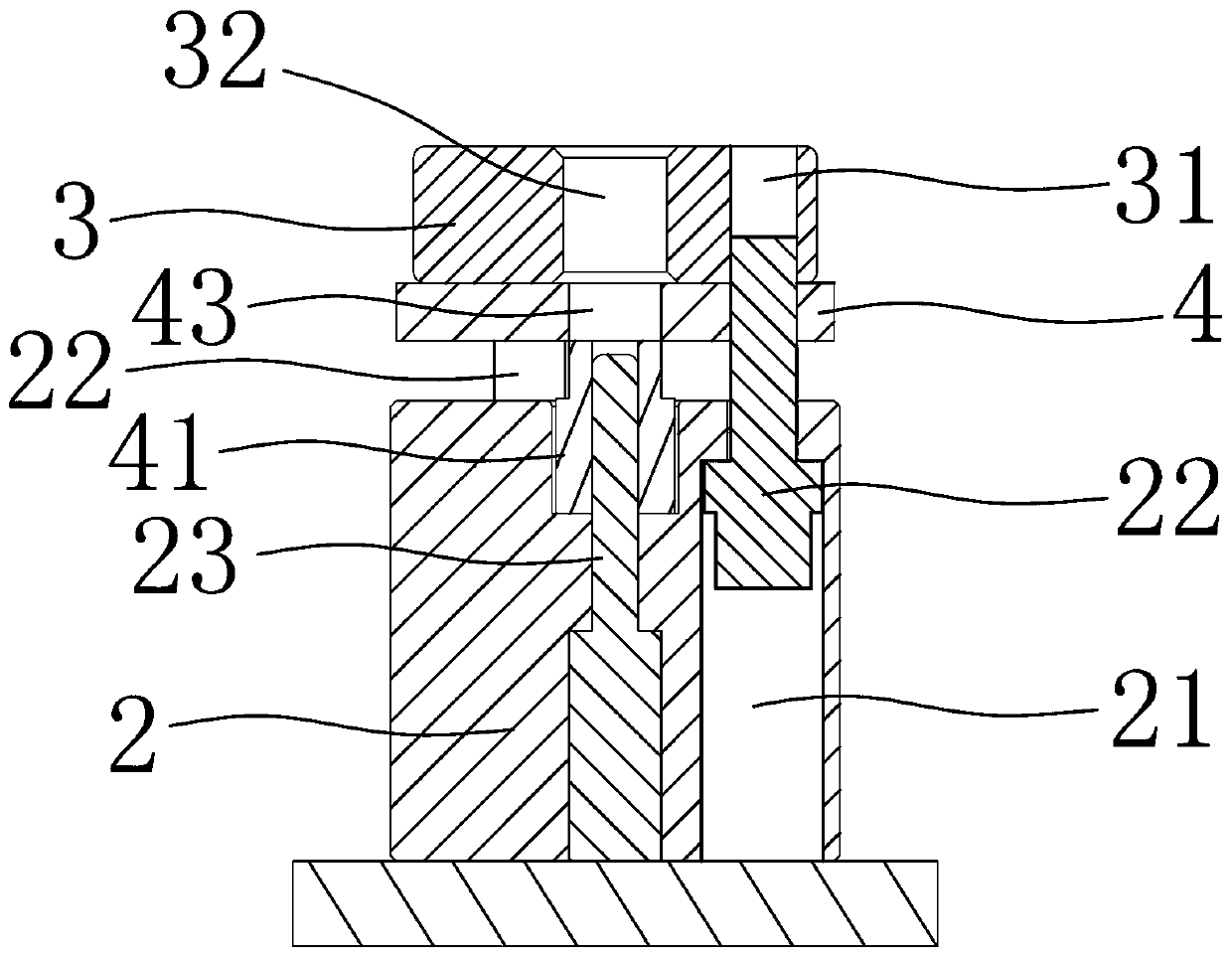

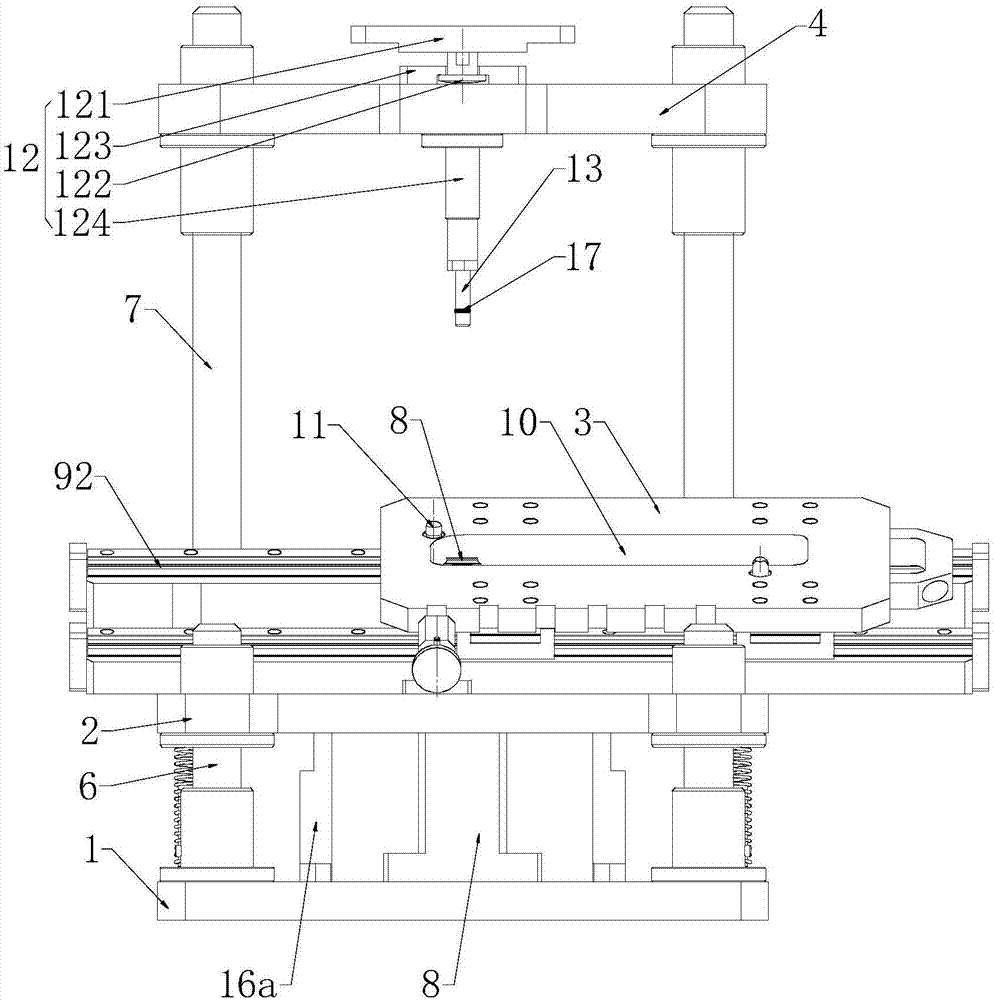

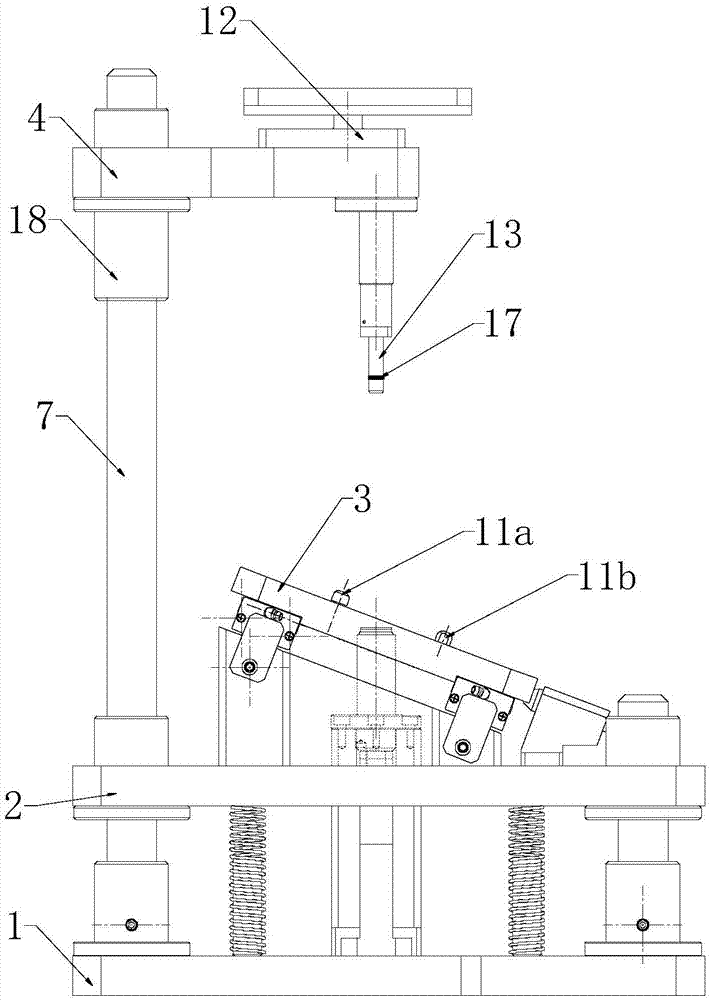

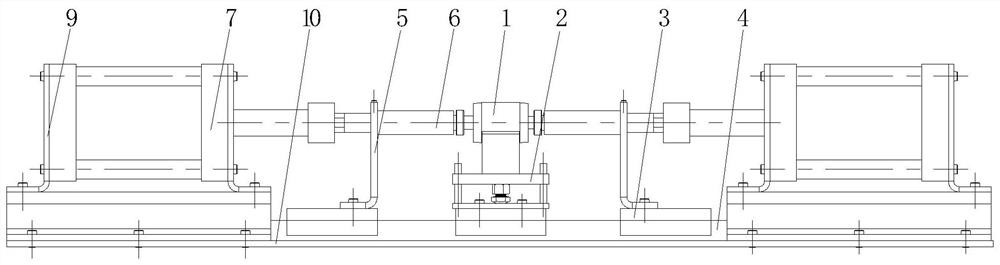

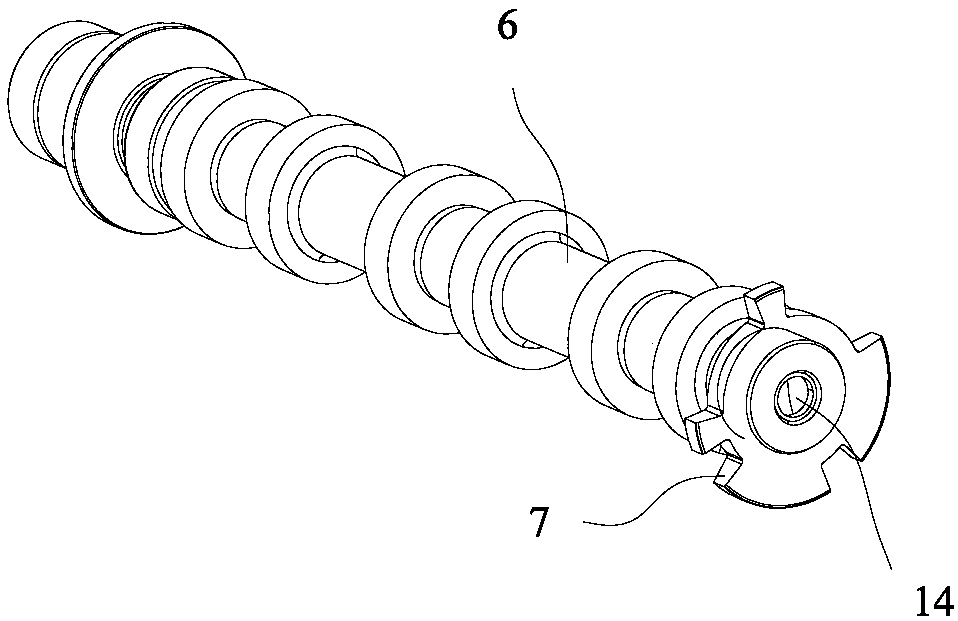

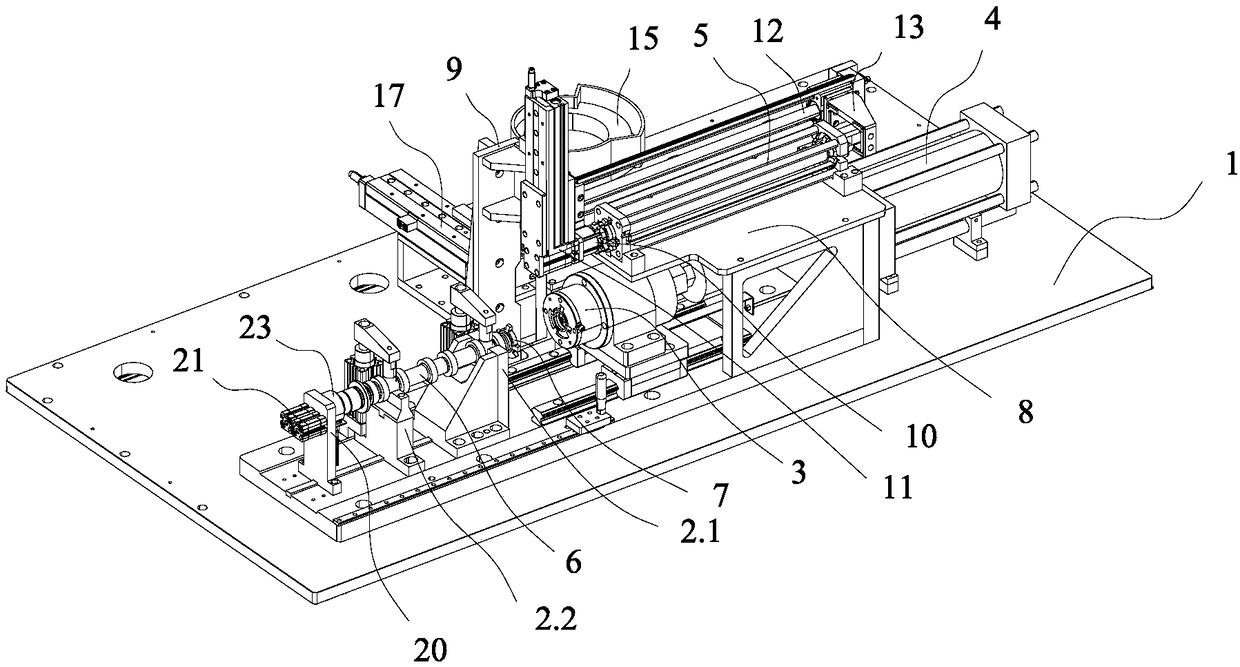

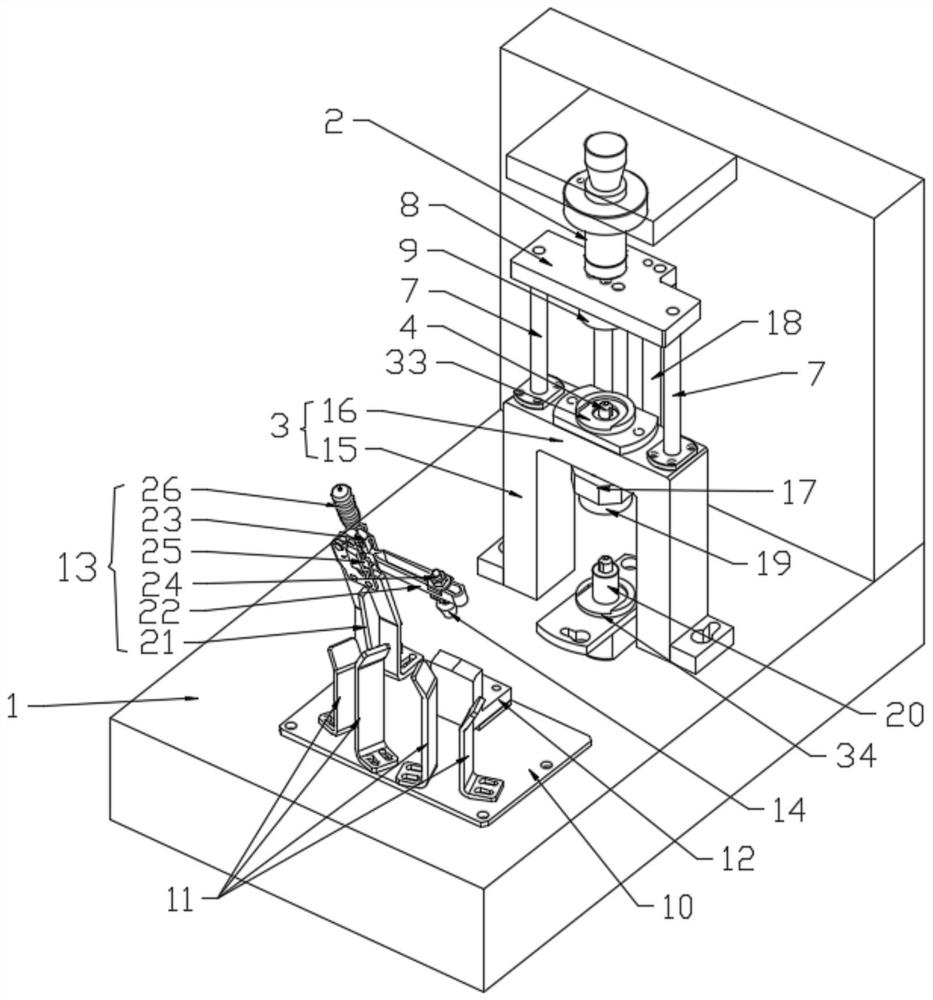

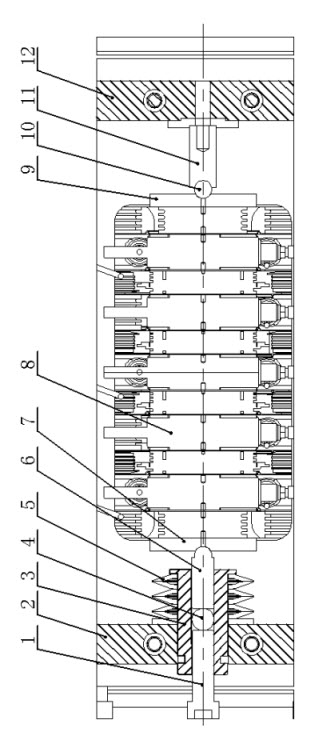

Camshaft assembly tooling

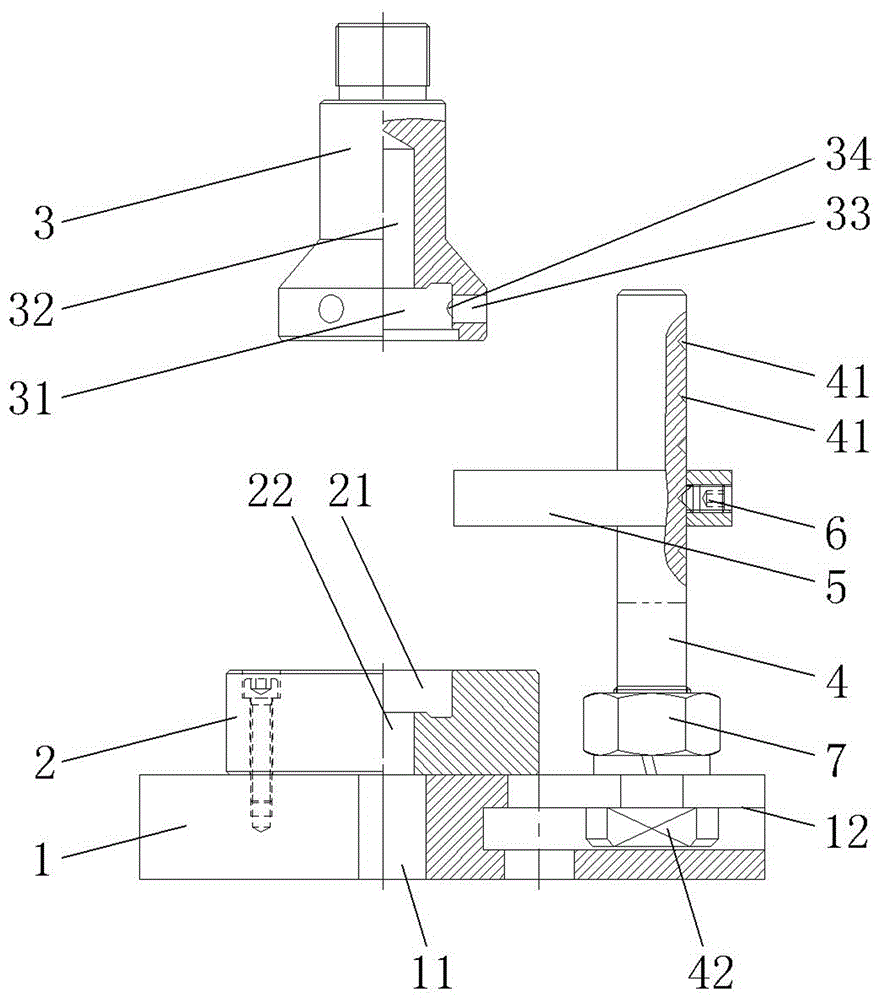

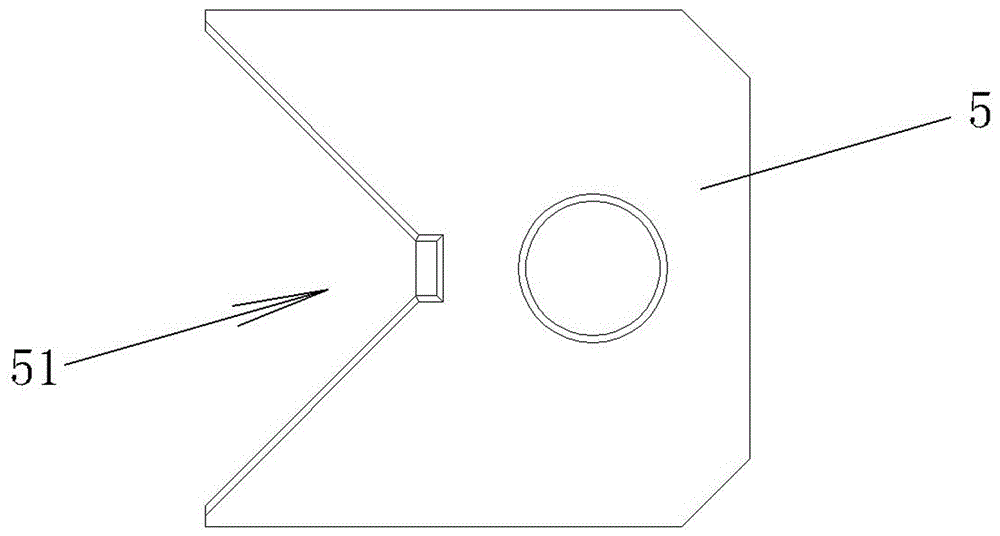

ActiveCN106217032BImprove press fit accuracyIncrease productivityCamsAssembly machinesEngineeringCamshaft

The invention discloses a camshaft assembly jig. The camshaft assembly jig comprises a base (1), a fixture (2), a press fitting part (3) and a power driving part (4), and further comprises a first installation rack (8), a second installation rack (9), a material rack (5), a grab hand (10) and a first driving mechanism (11),wherein the first installation rack (8) and the second installation rack (9) are arranged on the base (1), the material rack (5) is arranged on the first installation rack (8) and used for containing a plurality of signal wheels (7), the grab hand (10) is used for grabbing the signal wheels (7) in the material rack (5), the first driving mechanism (11) is arranged on the second installation rack (9) and used for driving the grab hand (10) to grab the signal wheels (7) and place the signal wheels (7) on the press fitting part (3), and the driving end of the first driving mechanism (11) is connected with the grab hand (10). According to the camshaft assembly jig, by adopting the structure, automatic feeding can be carried out when press fitting is carried out on a camshaft and a signal wheel, and therefore, the accuracy of press fitting and the production efficiency can be improved.

Owner:宁波圣龙智造凸轮轴有限公司

Rear axle lining press-fitting machine

ActiveCN105598667AEasy to put inEasy to take outMetal working apparatusHydraulic cylinderEngineering

The invention provides a rear axle lining press-fitting machine and relates to a press-fitting machine. The rear axle lining press-fitting machine comprises two sets of press-fitting devices which are symmetrically arranged, wherein each set of the press-fitting device comprises a main hydraulic cylinder, a main pressing head, a secondary hydraulic cylinder, a secondary pressing head, a main guide rail and a secondary guide rail; a stretching-out end of each main hydraulic cylinder is connected with the corresponding main pressing head; the bottom of each main pressing head is in sliding fit with the corresponding main slide rail; each main pressing head is connected with a lining; the stretching-out end of each secondary hydraulic cylinder is connected with the corresponding secondary pressing head; each secondary pressing head is in sliding fit with the corresponding secondary guide rail; and each secondary pressing head is connected with a rear axle assembly sleeve of the corresponding lining to be subjected to press fitting. With the adoption of the rear axle lining press-fitting machine, the operation of putting in and taking out a rear axle assembly becomes relatively easy; and the rear axle lining press-fitting machine has the characteristics of convenience for press fitting, high press fitting precision and efficiency, capability of displaying a working result in real time and simple structure, and is easy to popularize and use.

Owner:LIUZHOU LIUHE FANGSHENG MACHINERY

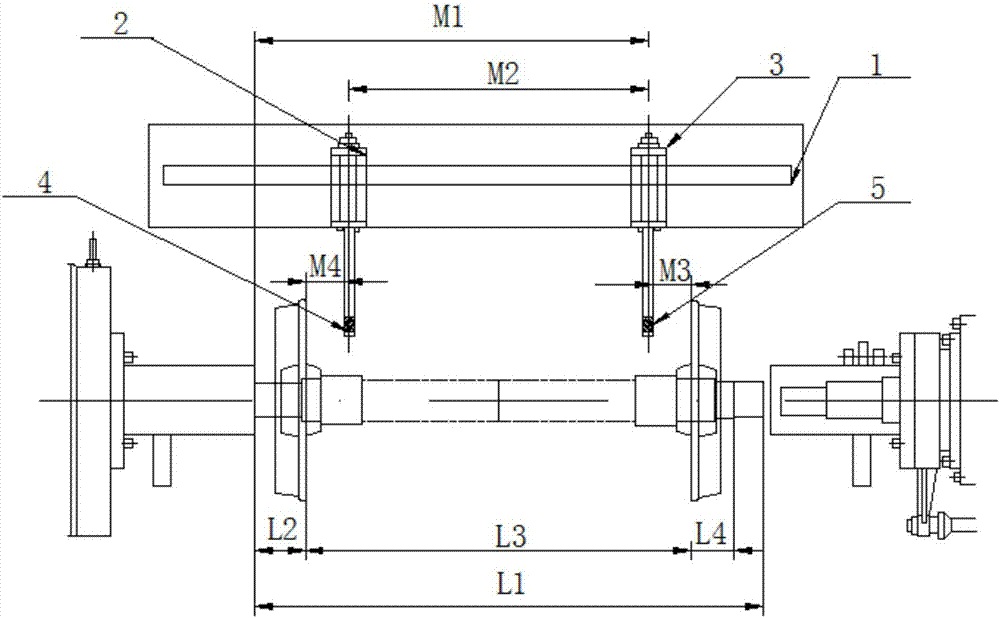

Wheel-set pressing-fit machine high-precision control and measurement control system

InactiveCN106949839AEliminate errorsImprove press fit accuracyUsing optical meansGratingControl system

The invention discloses a wheel-set pressing-fit machine high-precision control and measurement control system, which relates to the technical field of pressing-fit machines. The wheel-set pressing-fit machine high-precision control and measurement control system comprises a first grating scale, a left measuring rod, a right measuring rod, a left laser head, a right laser head, a primary stand column, a secondary stand column, a left wheel supporting trolley, a right wheel supporting trolley, a secondary pendulum bob, a primary pendulum bob and a second grating scale, wherein the first grating scale is arranged on one side of the left measuring rod and the right measuring rod, the lower end of the left measuring rod is provided with the left laser head, the lower end of the right measuring rod is provided with the right laser head, and the left measuring rod and the right measuring rod are each connected with a translation hydraulic oil cylinder; the left side of the primary stand column is sequentially provided with the right wheel supporting trolley, the left wheel supporting trolley and the secondary stand column, the secondary stand column is connected with the secondary pendulum bob, and the primary stand column is connected with the primary pendulum bob; and the second grating scale is arranged between the primary stand column and the primary pendulum bob. The wheel-set pressing-fit machine high-precision control and measurement control system does not need system calibration and test before pressing fit, thus a certain amount of errors caused by mechanical deformation amount in traditional pressing fit can be eliminated, thereby greatly improving pressing fit precision of equipment.

Owner:苏州瑞信轨道交通科技有限公司

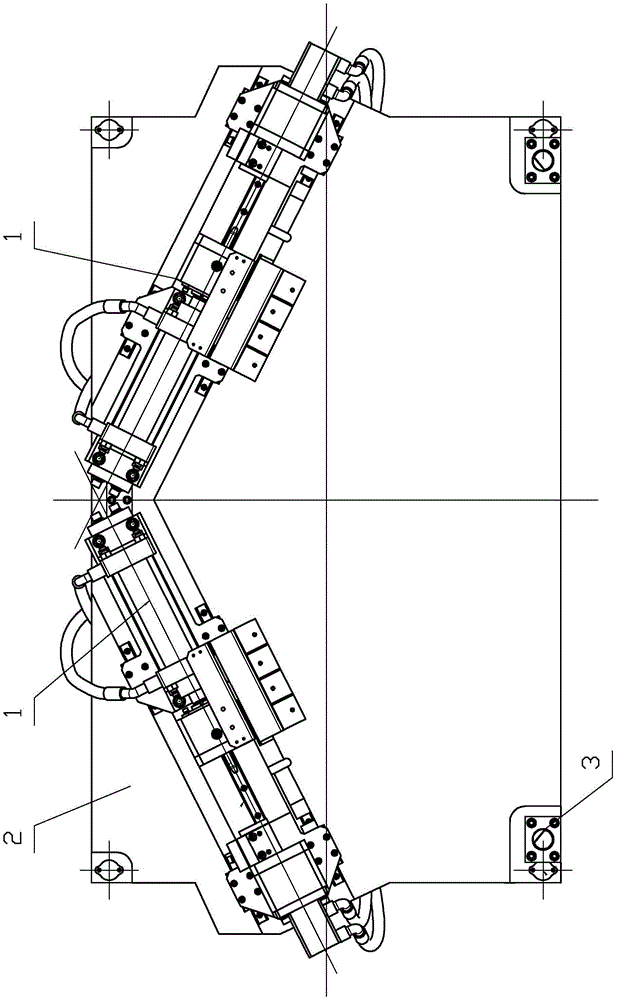

Automobile auxiliary frame bushing press-mounting equipment

PendingCN110315318AImprove press fit accuracyVehicle componentsMetal working apparatusVehicle frameEngineering

The invention provides automobile auxiliary frame bushing press-mounting equipment which comprises a frame transfer tool. An auxiliary frame to be machined is arranged at the upper end of the frame transfer tool, a left side bushing press-mounting mechanism and a right side bushing press-mounting mechanism are arranged on the two sides of the frame transfer tool, a bushing on the auxiliary frame is press-mounted through the left side bushing press-mounting mechanism and the right side bushing press-mounting mechanism, a suspension bushing press-mounting mechanism is arranged beside the frame transfer tool, the lower ends of the left side bushing press-mounting mechanism, the right side bushing press-mounting mechanism and the suspension bushing press-mounting mechanism are provided with sliding tracks correspondingly, the left side bushing press-mounting mechanism, the right side bushing press-mounting mechanism and the suspension bushing press-mounting mechanism slide front and back on the sliding tracks arranged at the lower ends of the left side bushing press-mounting mechanism, the right side bushing press-mounting mechanism and the suspension bushing press-mounting mechanism correspondingly, one sides of the lower ends of the left side bushing press-mounting mechanism, the right side bushing press-mounting mechanism and the suspension bushing press-mounting mechanism are provided with servo motors, and moving power is provided for the left side bushing press-mounting mechanism, the right side bushing press-mounting mechanism and the suspension bushing press-mounting mechanism through the servo motors.

Owner:安徽泓毅汽车技术股份有限公司

Thermostat-shell press-fitting device and operating method

InactiveCN109227096AThe pressing process is stableEven by forceMetal working apparatusEngineeringThermostat

The invention discloses a thermostat-shell press-fitting device and an operating method. The thermostat-shell press-fitting device comprises a support, a supporting mechanism, a press-fitting mechanism and a fixing mechanism, wherein the supporting mechanism and the fixing mechanism are fixed on the support, and the press-fitting mechanism is fixed on the supporting mechanism; the supporting mechanism comprises four sliding guiding columns and a supporting plate; the press-fitting mechanism comprises a driving air cylinder, a fixed plate, a sliding plate and an installing base; the fixing mechanism comprises an adjustable device, an installing bottom plate, a fixing clamp and buffering devices. The thermostat-shell press-fitting device and the operating method have the advantages that thepress-fitting device is more stable during press fitting, stress is even, the press-fitting accuracy and effect are improved, the service life of the thermostat-shell press-fitting device is also guaranteed, and the fixing clamp and a thermostat shell are conveniently replaced.

Owner:ANHUI QUANCHAI ENGINE

Rear overhang swing arm press-mounting tool

ActiveCN112621165AImprove press fit accuracyImprove pressing efficiencyMetal working apparatusEngineeringMachine

The invention discloses a rear overhang swing arm press-mounting tool. A supporting mechanism is arranged to provide stable support for an arm body of a rear overhang swing arm; a liner tube of the rear overhang swing arm is positioned through an upper positioning pin on a press-fitting mechanism, and the arm body of the rear overhang swing arm is pressed downwards through a pre-pressing mechanism; then a pushing mechanism pushes a connecting plate downwards to enable an upper pressing head to press bushings, and the press-mounting precision and the press-mounting efficiency are remarkably improved; a lower pressing head can be arranged below a horizontal part of a support, the lower pressing head and the upper pressing head press the front-hinged bushing and the rear-hinged bushing at the same time in the same direction, and a press-mounting machine does not need to be purchased independently; a pressure sensor is arranged, so that the press-mounting process is monitored, and press-mounting is automatically stopped when a set pressure value is reached; and in addition, the pre-pressing mechanism is adjusted, so that the rear overhang swing arm press-mounting tool is suitable for positioning, supporting and press-mounting of rear overhang swing arms of different shapes and models.

Owner:DONGFENG WUHAN IND

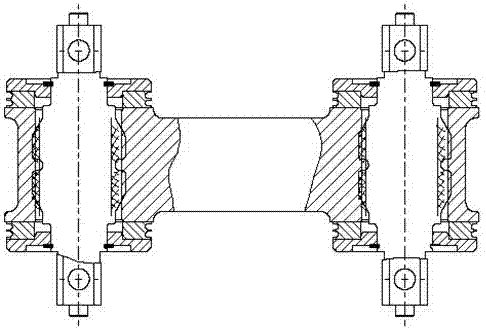

Mechanical press mounting structure of group large-power flat-plate power electronic device

ActiveCN101794767AEasy to controlImprove toleranceSemiconductor/solid-state device detailsSolid-state devicesMachine partsEngineering

The invention relates to a mechanical press mounting structure of a group large-power flat-plate power electronic device, which is technically characterized in that firstly, a left ejector pin is coaxially installed in a spring mandrel in a sliding mode, the spring mandrel is installed on a left support plate through a key pin which is mounted along the radial direction of the spring mandrel, a set of disk springs is mounted on the spring mandrel at the right end of the support plate, an annular groove is radially manufactured on the spring mandrel at the right end of the support plate, and a limiting chuck is mounted in the annular groove; secondly, a press mounting screw is coaxially engaged in the spring mandrel at the left side of the left ejector pin; and thirdly, the right end of the left ejector pin and a left pressure plate are in spherical pair installation, and the left end of the a right ejector pin and a right pressure plate are in spherical pair installation. In the mechanical press mounting structure, the disk springs are adopted as driving elements, the compression stroke of the disk springs are accurately controlled through machining parts and has nothing to do with the assembly precision; the mechanical pressing force is accurately controlled with constant pressure; and the structure has large latitude for the assembly length of power device series, eliminates the assembling clearance, has self-adaption for the length of the power device series in a certain range, and has high press mounting precision.

Owner:TIANJIN RES INST OF ELECTRIC SCI +1

Bearing press-fitting device

InactiveCN105856158AAchieve horizontalRealize regulationMetal-working hand toolsFixed bearingEngineering

The invention provides a bearing press-fitting device, belongs to the technical field of machinery, and aims to solve the problem that the bearings are dismounted and changed due to bearing noise generated in the assembling as the conventional bearing press-fitting devices are low in press-fitting precision. The bearing press-fitting device comprises a base, a lower die on the base and an upper die above the lower die, wherein a vertical concave cavity which is used for containing a rotor body is arranged in the lower die; a through hole I which is coaxial with the concave cavity and is used for containing a rotor lower rotation shaft is formed in the concave cavity; a containing cavity which is coaxial with the concave cavity and is used for containing a bearing is arranged in the upper die; a through hole II which is coaxial with the containing cavity and is used for containing a rotor upper rotation shaft is formed in the containing cavity; a fixing structure which is used for fixing the bearing is arranged in the containing cavity. The bearing press-fitting device has the advantages of being high in press-fitting precision and good in press-fitting effect.

Owner:LEO GRP ZHEJIANG PUMP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com