Press fitting device for starting gear on motor shaft

A technology of press-fitting device and motor shaft, which is applied to electromechanical devices, manufacturing motor generators, electrical components, etc. High precision and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below according to the accompanying drawings and specific embodiments.

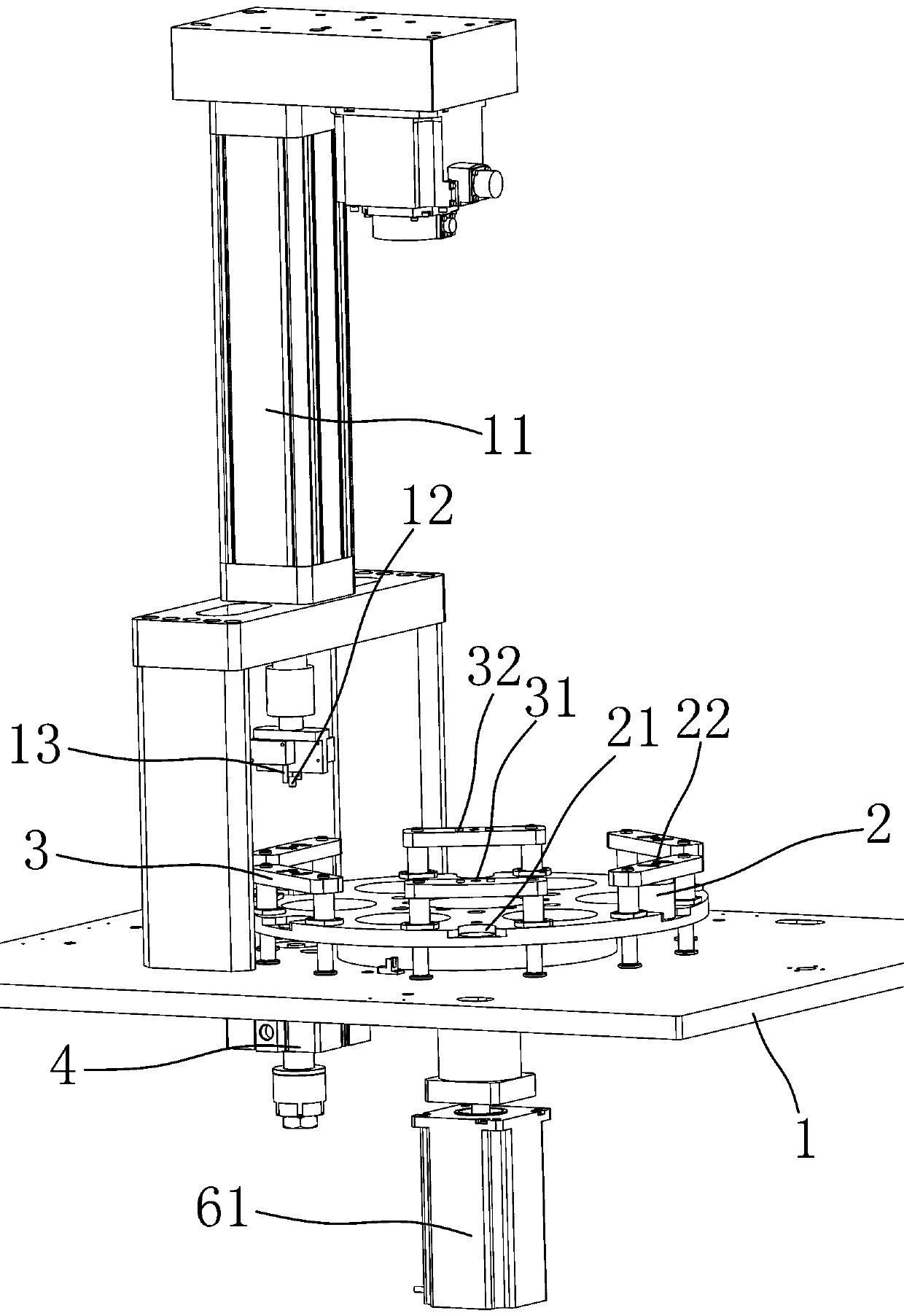

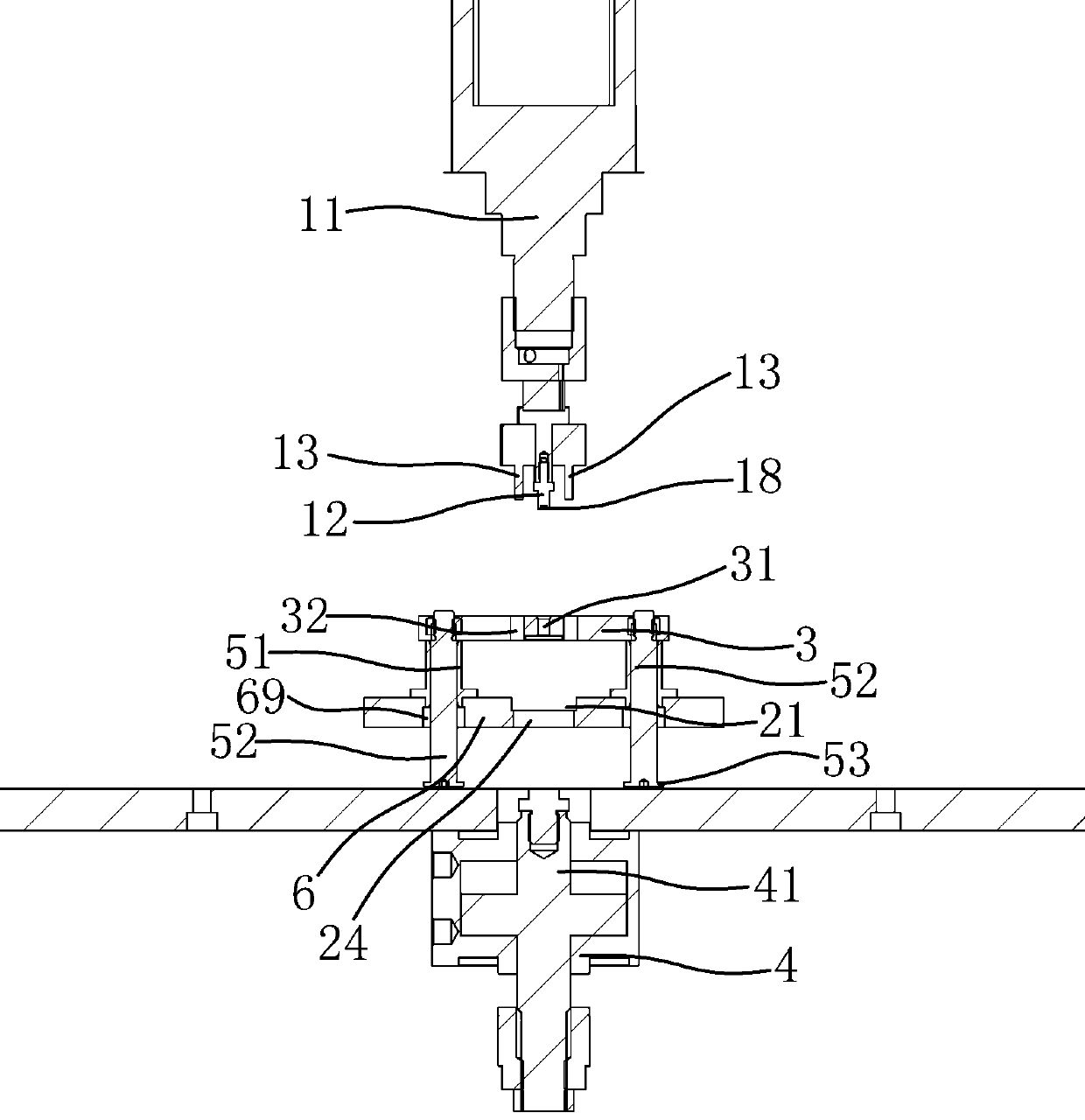

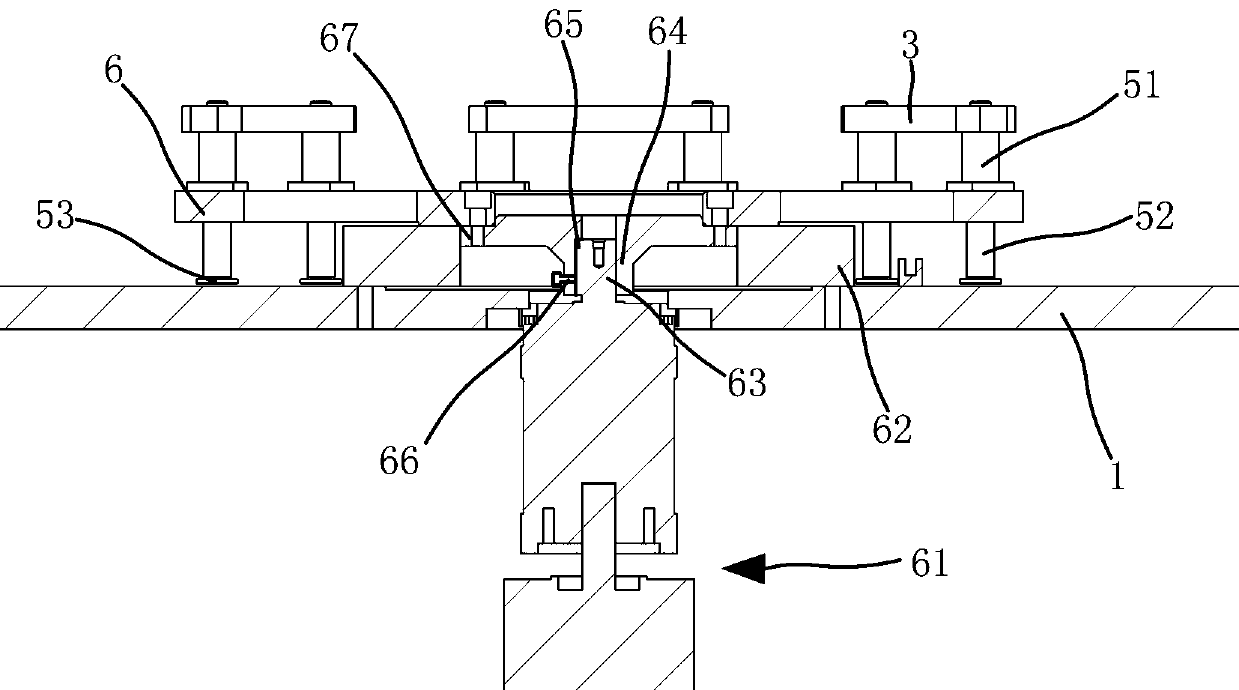

[0021] Depend on Figure 1 to Figure 4 As shown, a starting gear press-fitting device on a motor shaft of the present invention includes a base plate 1, a press 11 is arranged on the base plate 1, and a positioning position for positioning the motor 2 to be pressed is provided on the lower side of the press head 12 of the press 11. The positioning plate is formed with a positioning groove 21 for positioning and fixing the motor 2 to be pressed, and a pressing plate 3 is arranged above the positioning plate, and the pressing plate 3 is fitted up and down on the guide mechanism. The first relief groove 31, the positioning plate has a second relief groove 24 that penetrates up and down to give way to the lower end of the rotating shaft 23 of the press-fit motor 2, the positioning plate lower side is provided with a support mechanism 4, and the support me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com