Patents

Literature

130results about How to "The pressing process is stable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

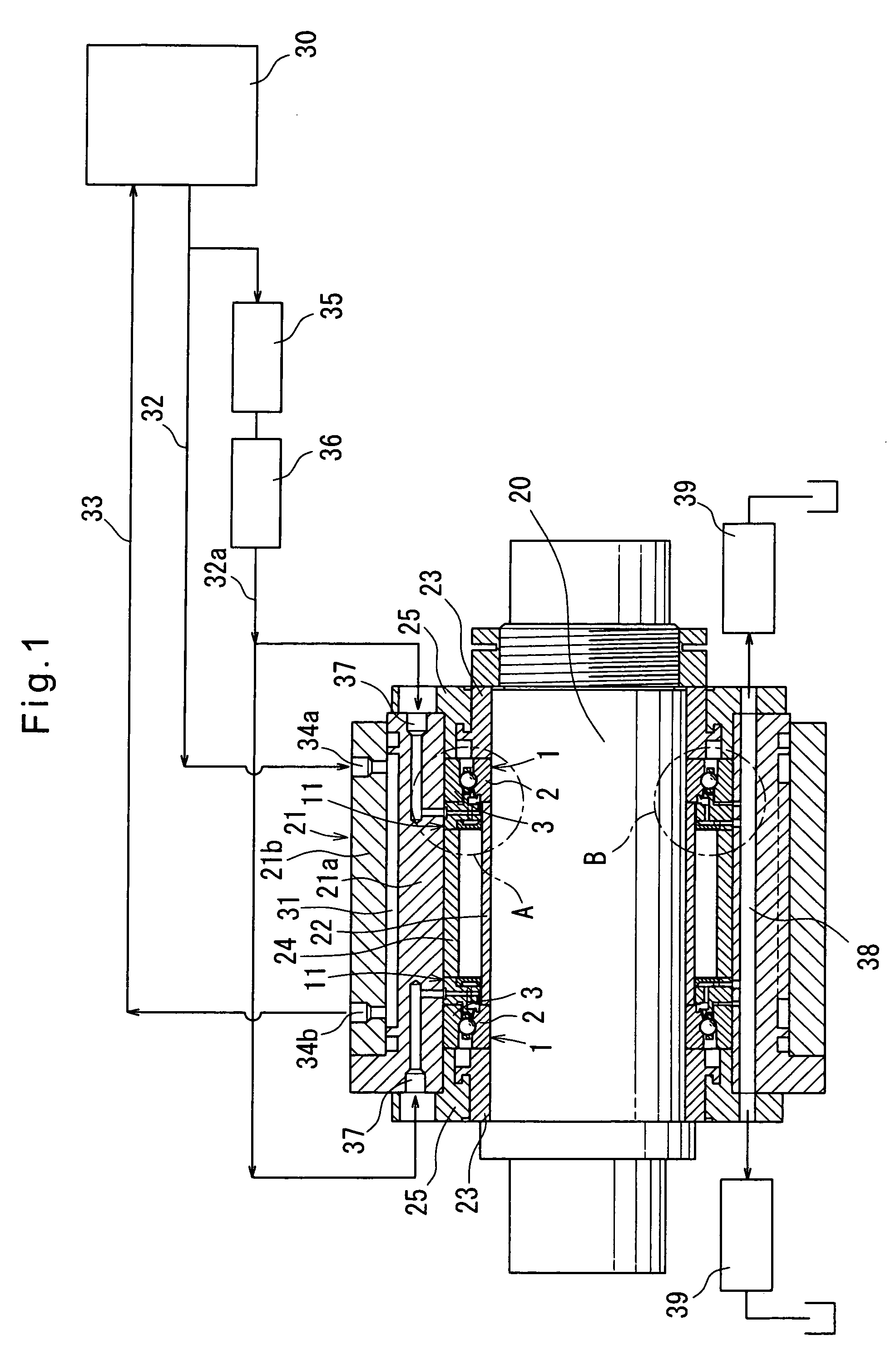

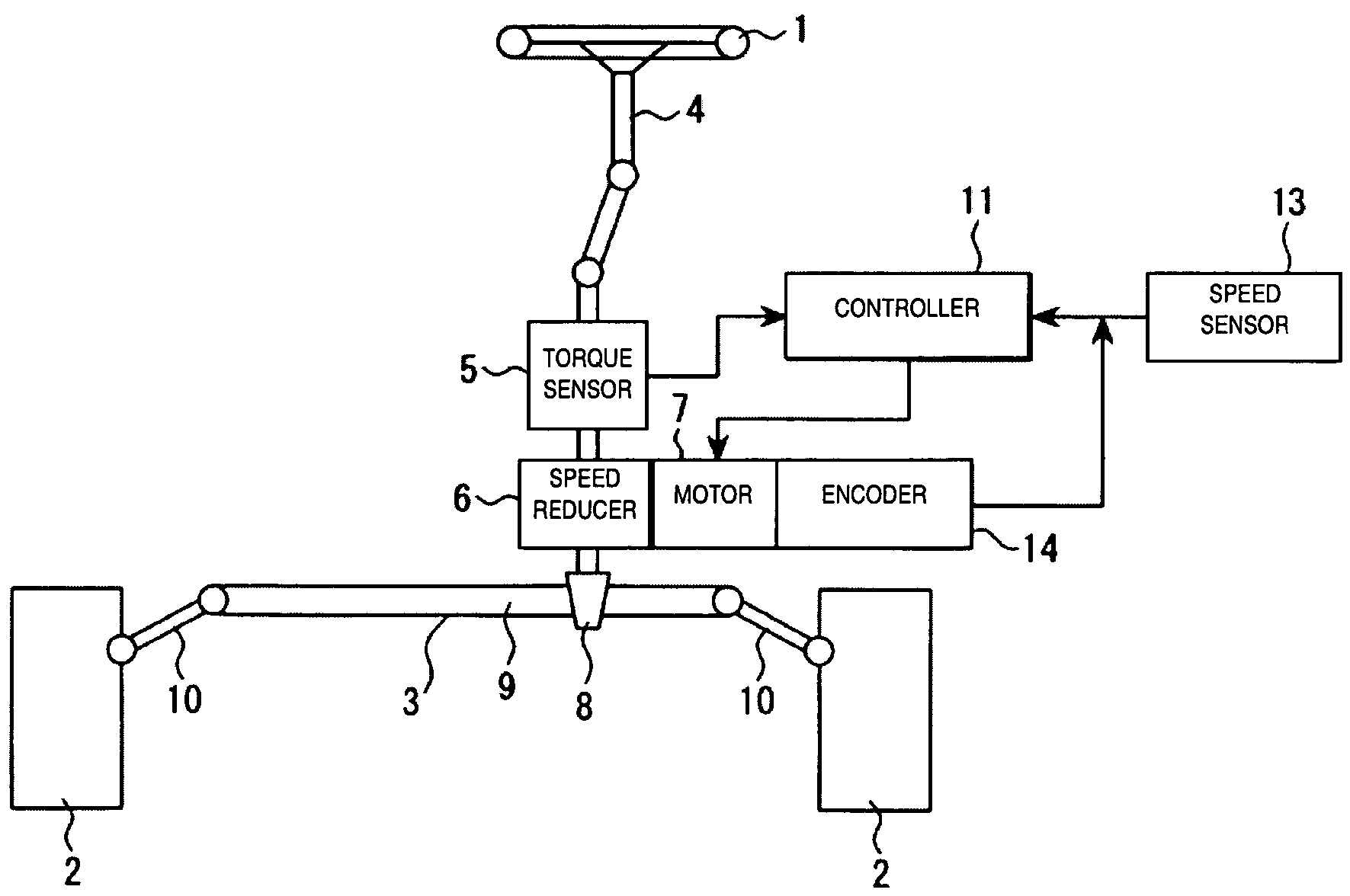

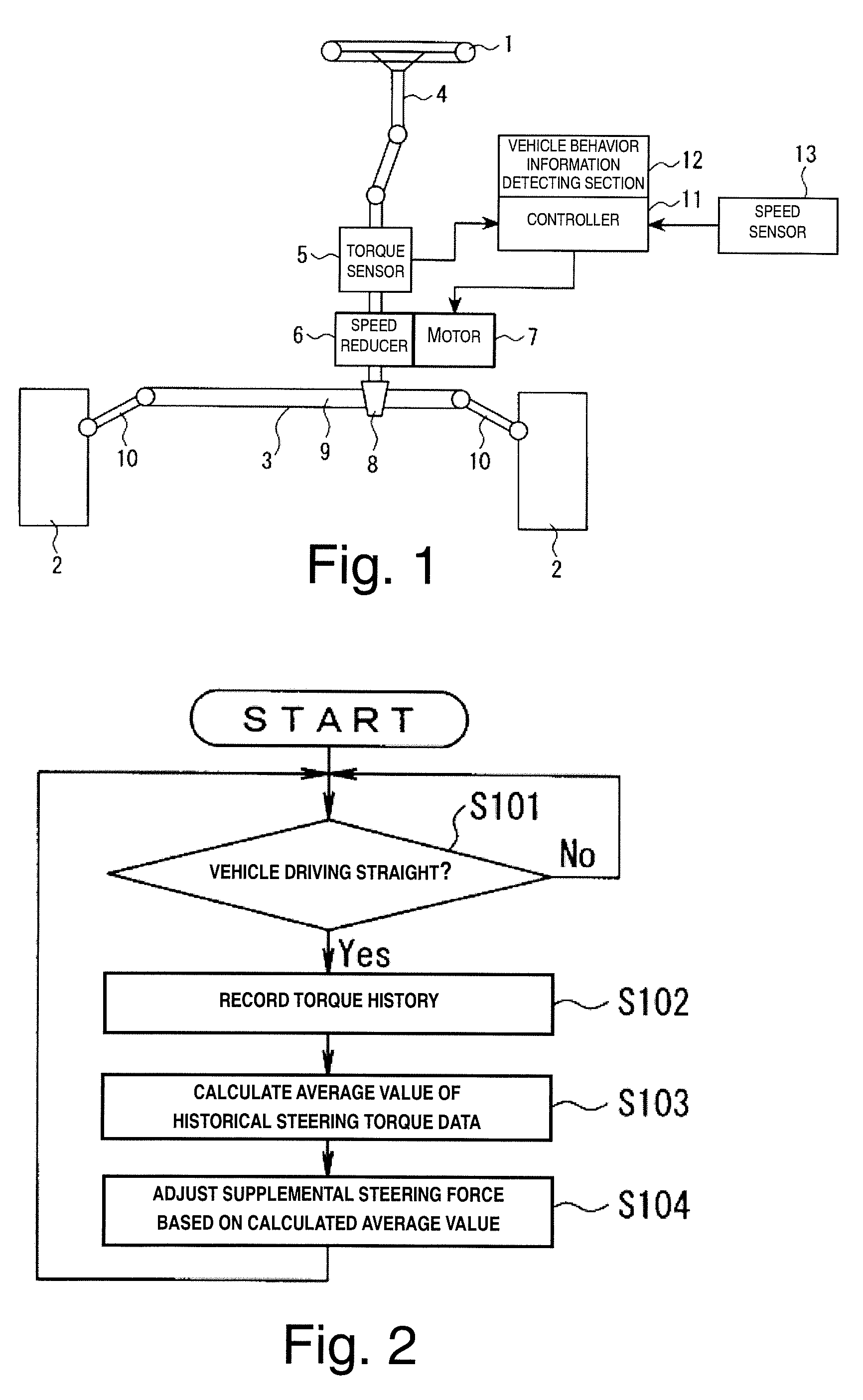

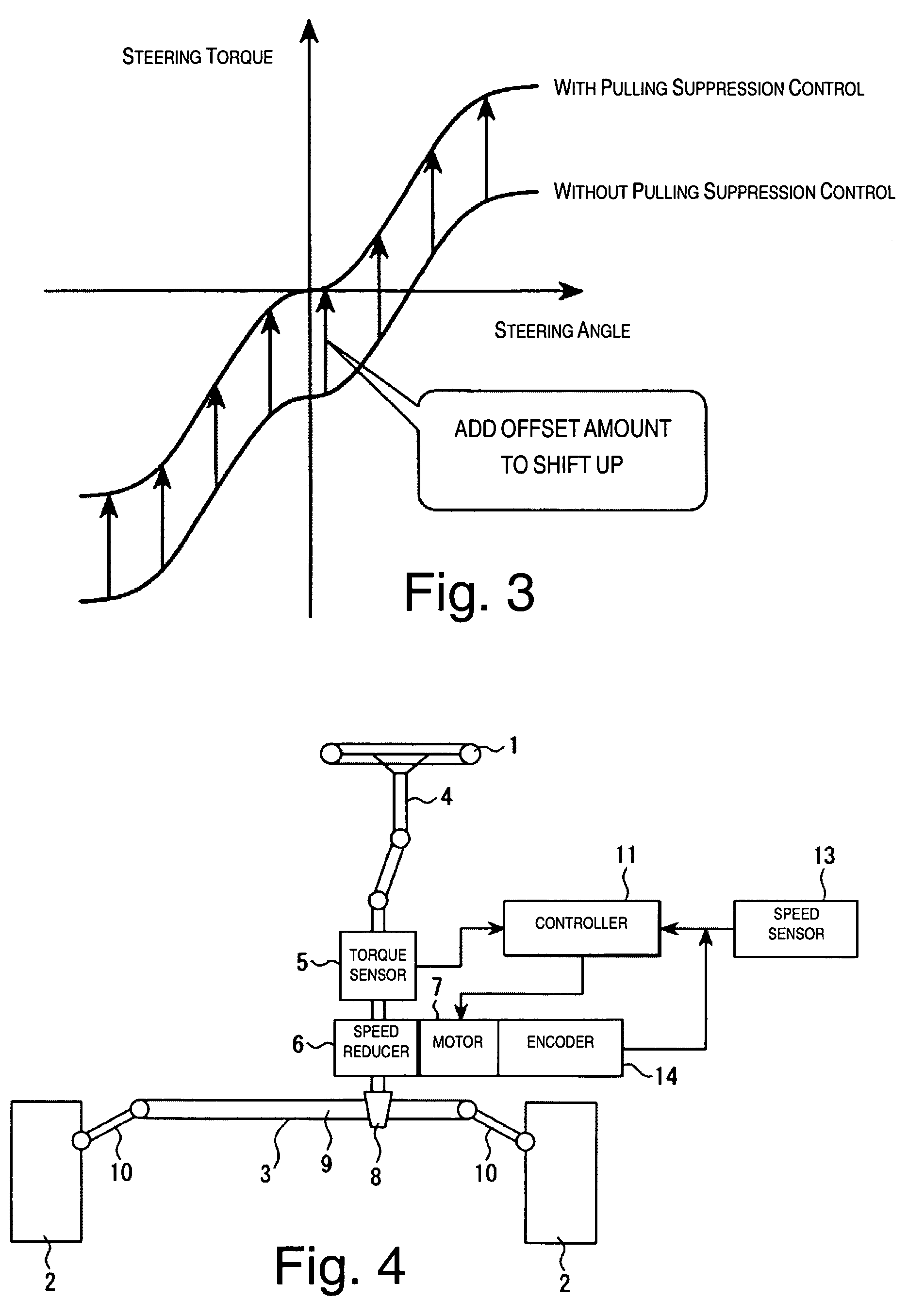

Vehicle steering apparatus and vehicle steering method

InactiveUS20070029129A1Easy loadingIncrease loadAutomatic steering controlElectrical steeringPull forceEngineering

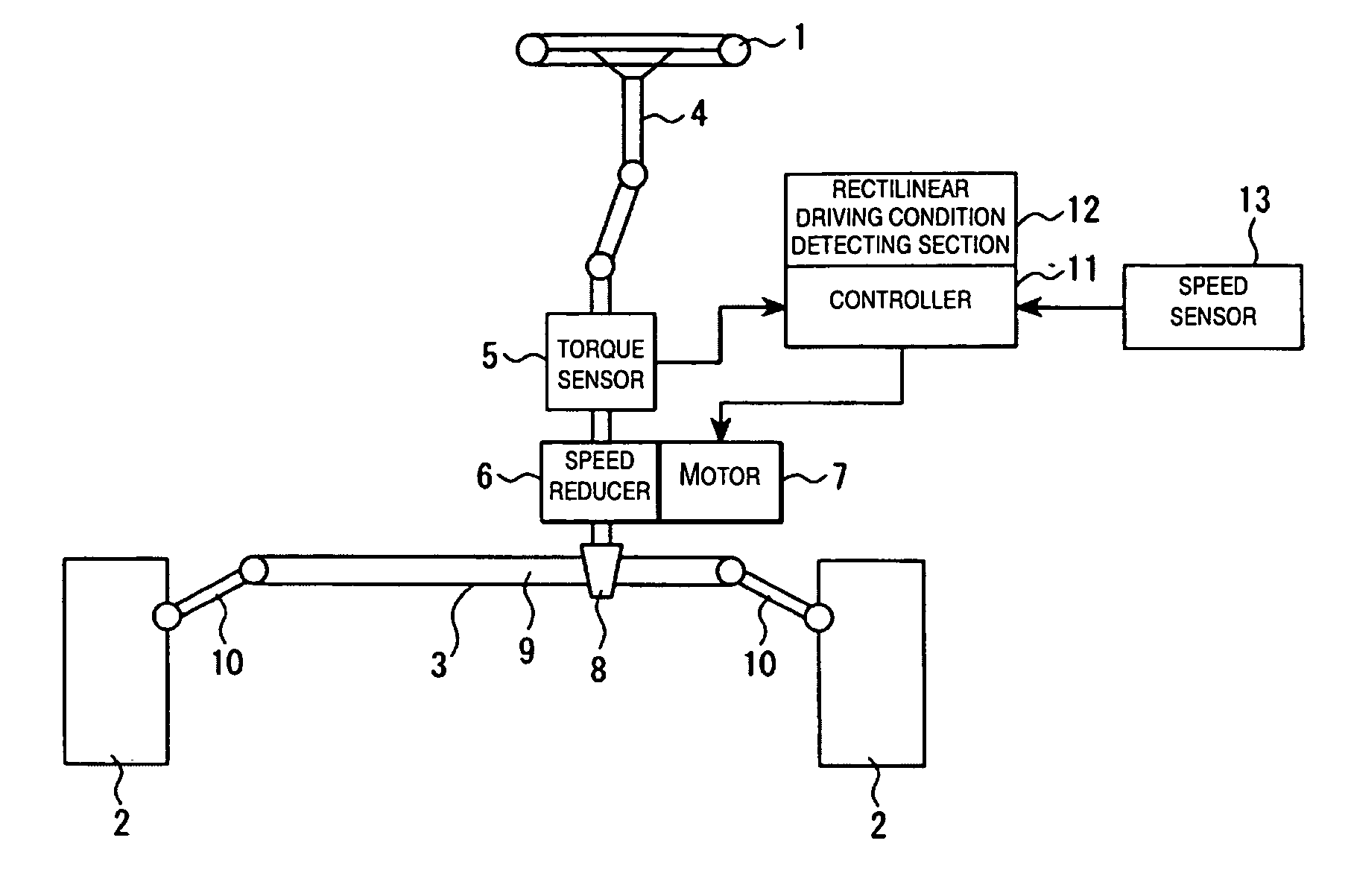

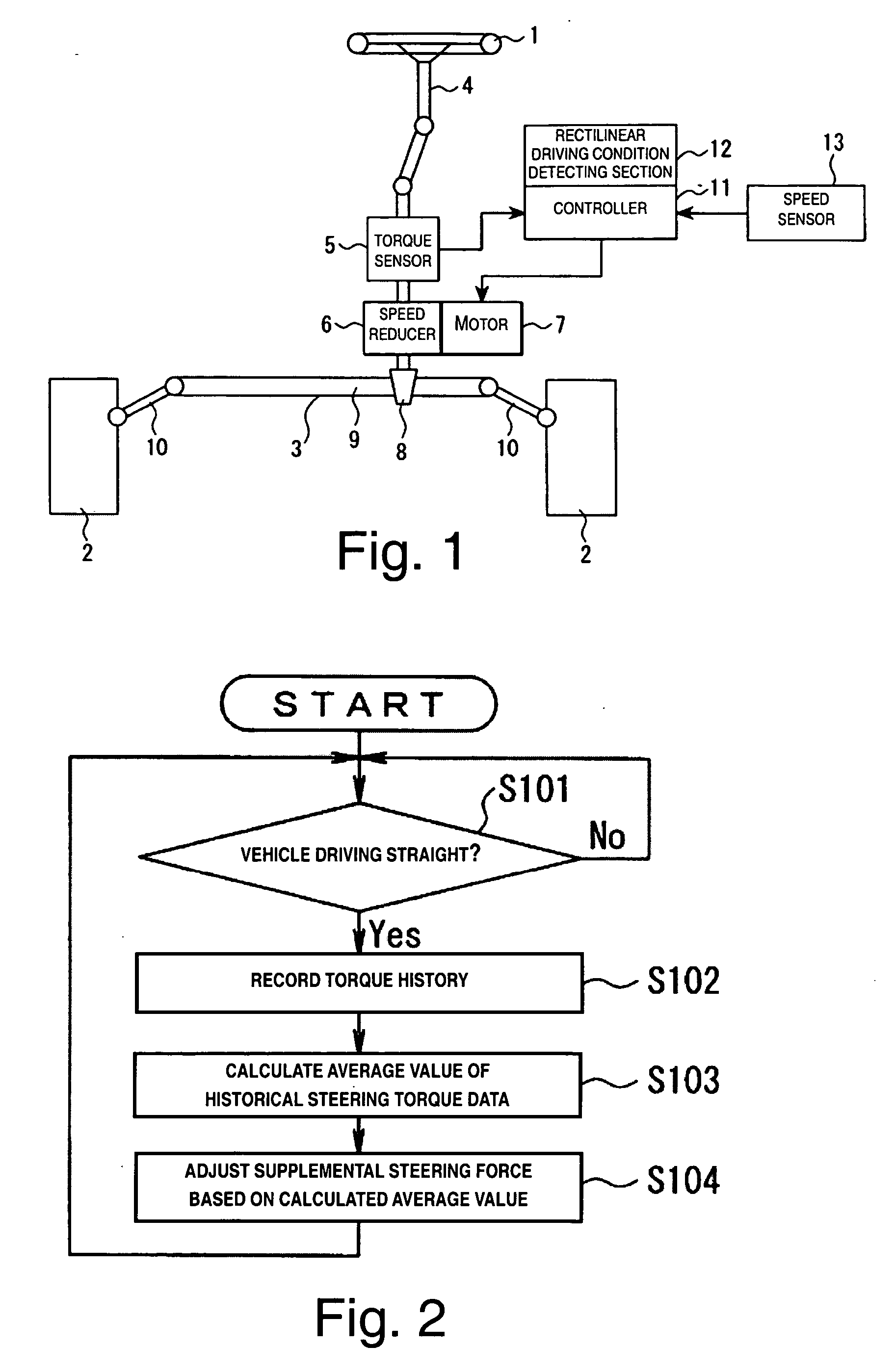

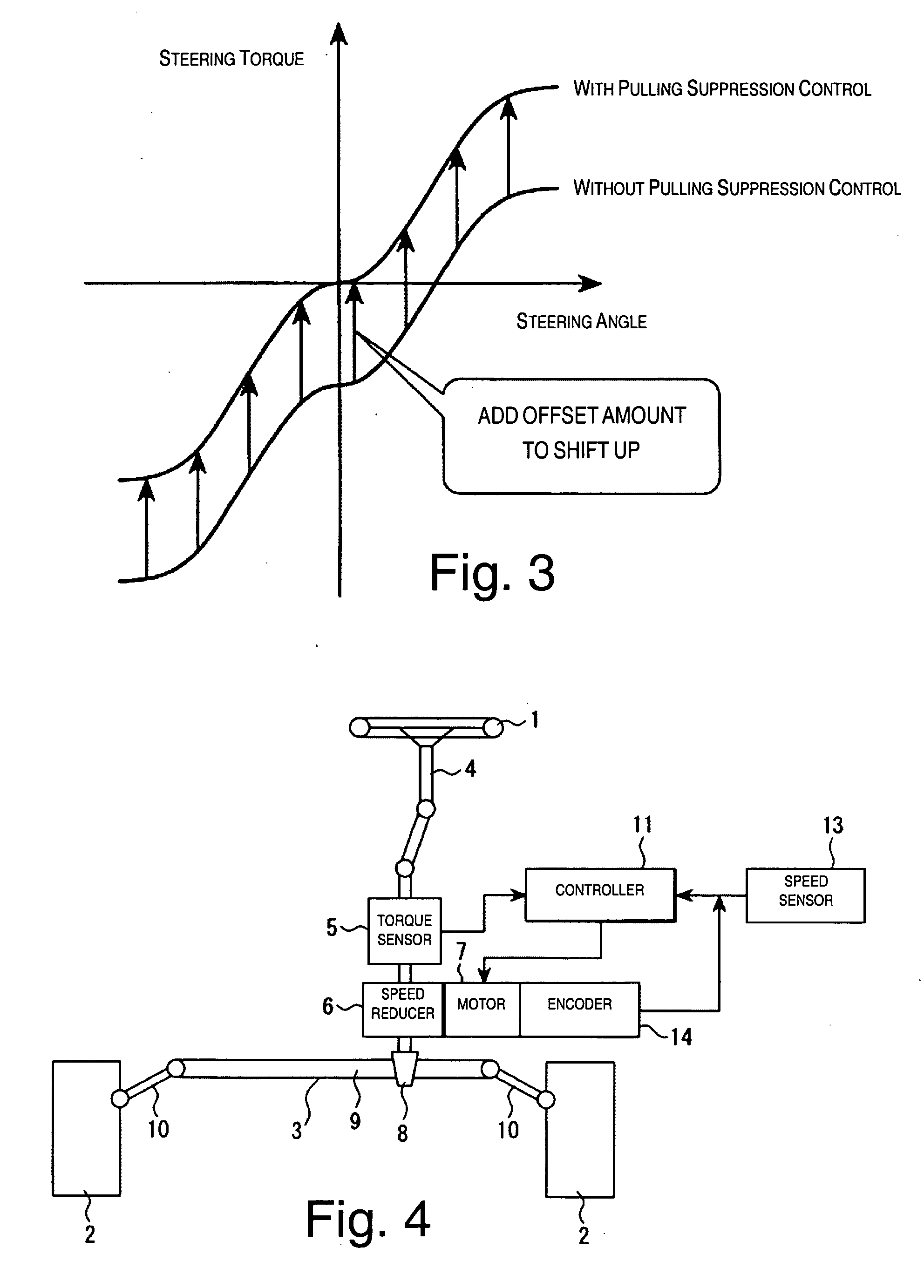

A vehicle steering apparatus includes a vehicle steering system and a supplemental steering force applying device. The supplemental steering force applying device is configured and arranged to apply a supplemental steering force to the vehicle steering system to reduce a steering load on the operator. The supplemental steering force applying device includes a steering torque detecting section, a rectilinear driving condition detecting section, a pulling suppression control section. The rectilinear driving condition detecting section is configured and arranged to detect a rectilinear driving condition of the vehicle. The pulling suppression control section is configured and arranged to adjust the supplemental steering force in a direction canceling a pulling force imparted on the vehicle during the rectilinear driving condition by using a pulling suppression force calculated based on historical data of the steering torque detected during the rectilinear driving condition.

Owner:NISSAN MOTOR CO LTD

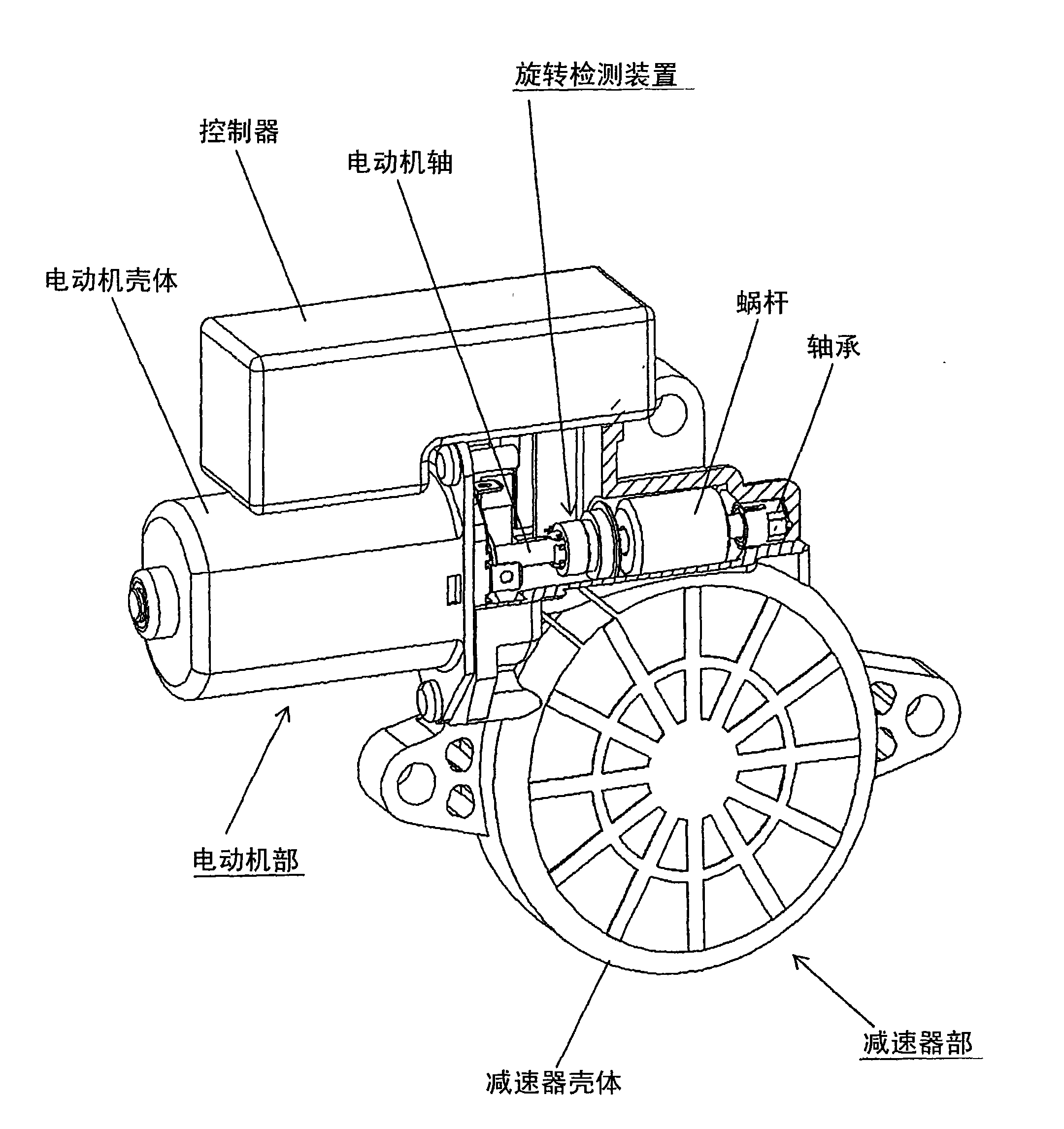

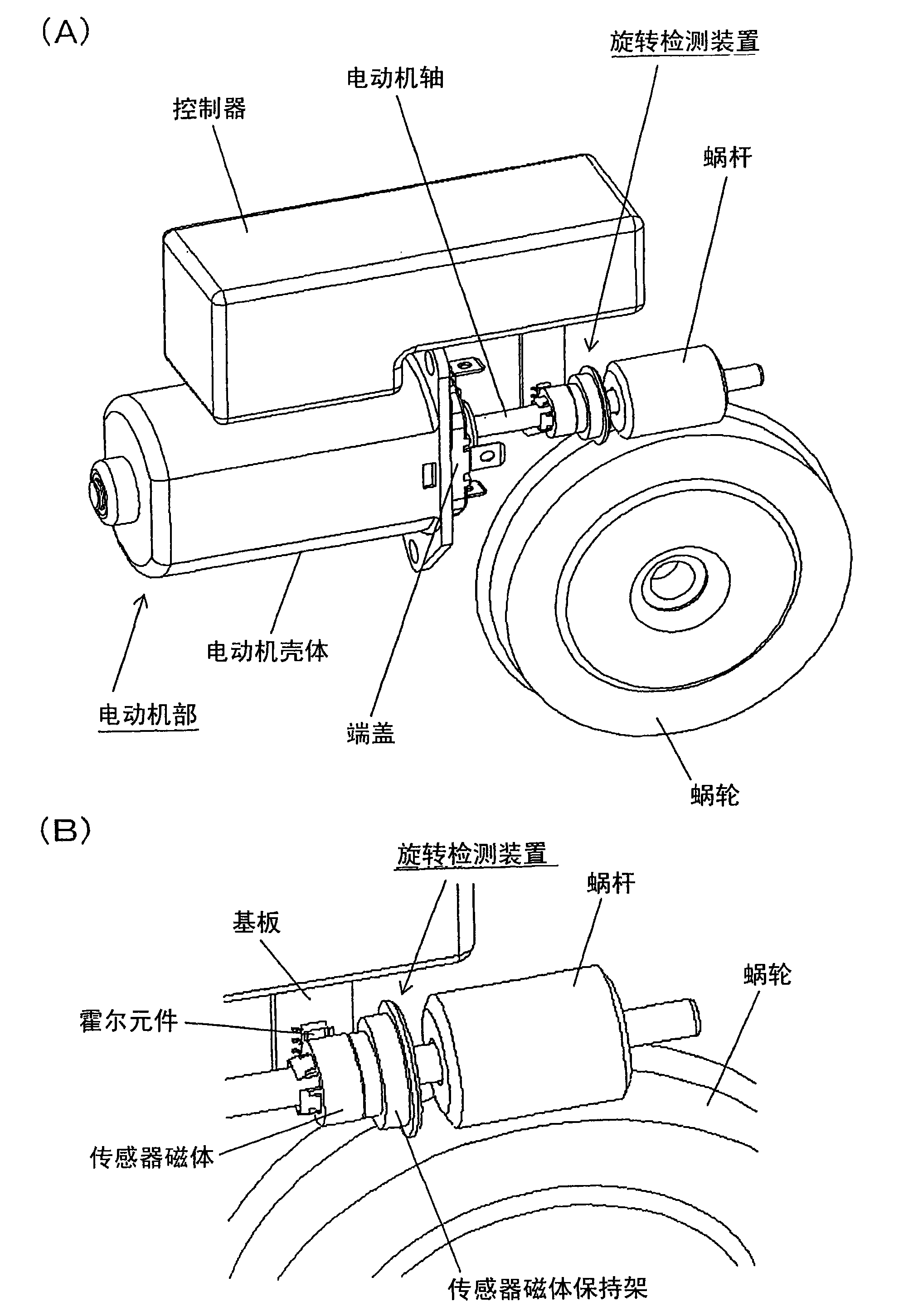

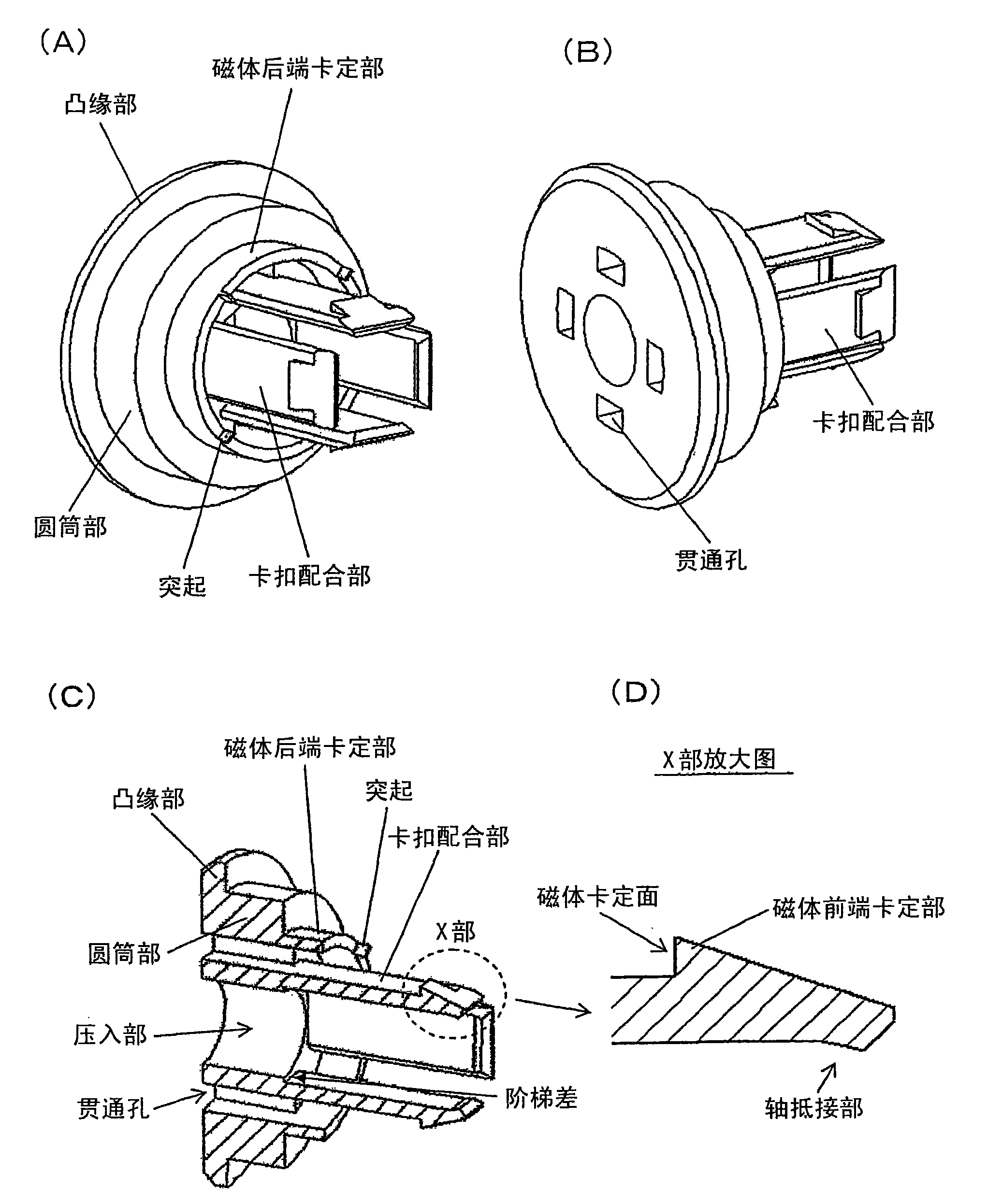

Sensor magnet holder, motor having the holder incorporated therein, and method of manufacturing the motor

ActiveCN101630888AAvoid crackingImprove resistance to movementManufacturing dynamo-electric machinesDC commutatorEngineeringMotor shaft

A sensor magnet holder is formed such that a cylindrical portion, a flange portion formed by increasing the diameter of one end part of the cylindrical portion, a magnet rear-end engagement portion formed at the other end part of the cylindrical portion, and four plate-like snap fit tongues are formed integral with one another. The cylindrical portion including the flange portion has, on its inner diametral side, a press fit portion to be press-fitted to a motor shaft. The four plate-like snap fit tongues have respective magnet front-end engagement portions formed on an outer diametral side of their tip portions. The four snap fit tongues are brought into contact with respective flat inner surfaces of the sensor magnet having four flat inner surfaces, by utilizing elasticity of the snap fit tongues. The sensor magnet is retained between the magnet rear-end engagement portion and the magnet front-end engagement portions.

Owner:MABUCHI MOTOR

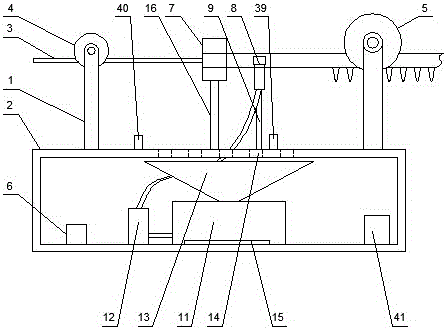

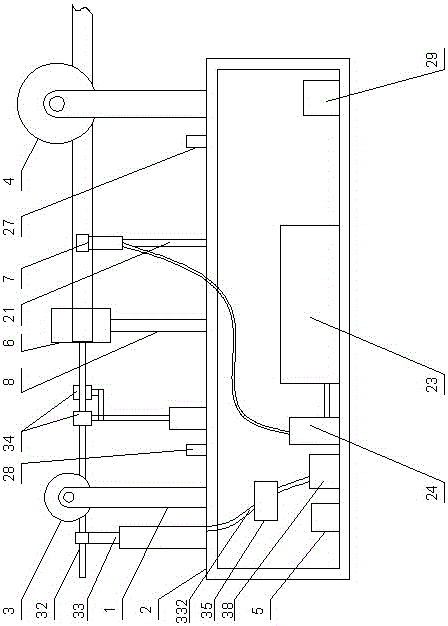

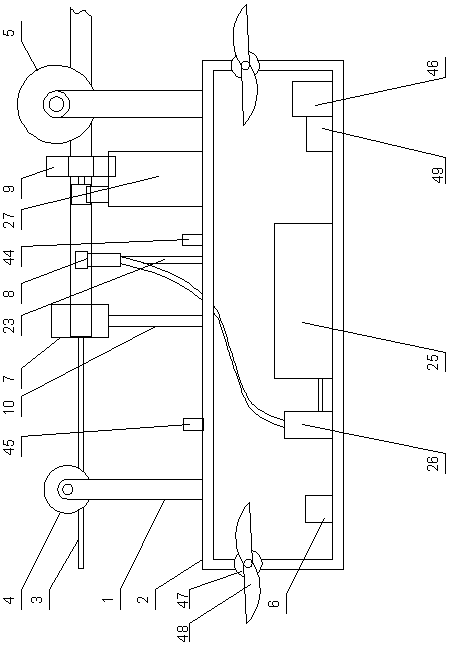

Ice and snow removing apparatus for power transmission line

The invention discloses an ice and snow removing apparatus for a power transmission line. The ice and snow removing apparatus comprises a walking mechanism and a rack connected below the walking mechanism through mechanical arms, wherein the walking mechanism comprises a back walking wheel which is clamped at a part, where icing is removed, of the power transmission line, and a front walking wheel which is clamped at a part, where icing is not removed, of the power transmission line; the rack is provided with a de-icing mechanism; a wireless controller is arranged on the left side of the interior of the rack; the de-icing mechanism comprises an icing smashing module and a water jet cutter cutting module from left to right in sequence; an opening is formed in the top of a water tank; an ice and snow receiving funnel is arranged on the opening; notches are formed in a position, corresponding to the ice and snow receiving funnel, of the top of the rack, and used for collecting ice blocks falling from the power transmission line; and a heating module is arranged at the bottom of the water tank and is in electric signal connection with the wireless controller. Water pressure of the water jet cutter cutting module can be adjusted according to the detected thickness of an icing layer, so that efficient de-icing can be realized during cutting the surface icing without being affected by the thickness of the icing layer, and a line is not damaged either.

Owner:STATE GRID HENAN ELECTRIC ZHOUKOU POWER SUPPLY +1

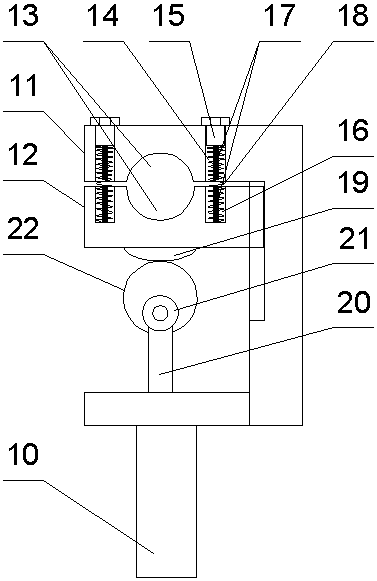

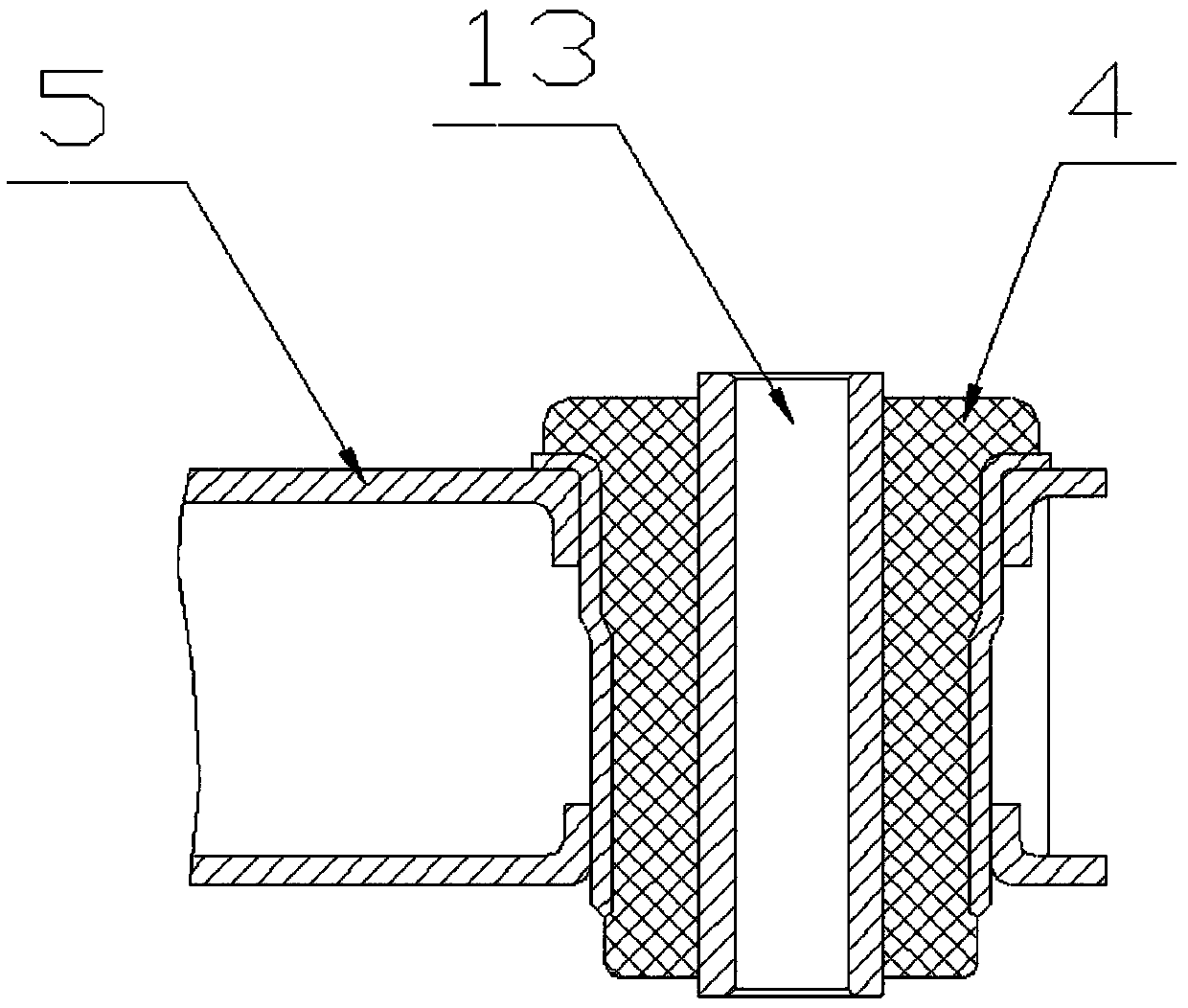

Tool for pressing small copper sleeve of engine connecting rod

The invention discloses a tool for pressing a small copper sleeve of an engine connecting rod. The tool comprises a liner plate, a pressing sleeve, and a base fixed on a press, wherein a guide post is arranged inside an unthreaded hole at one end of the base corresponding to the pressing sleeve; the guide post is a stepped shaft which is thick in lower part and thin in upper part; a rack is arranged at the lower end of the guide post; a gear shaft meshed with the rack is arranged at one side of the rack; a locating sleeve of which the upper end face is matched with an inclined plane of the copper sleeve and the diameter corresponds to the copper sleeve is arranged on the step of the guide post; a bush for pressing the copper sleeve is sleeved on the upper end of the guide post, wherein the lower end surface of the bush is matched with the inclined plane of the copper sleeve; a diamond locating pin matched with the aperture of a large end of the connecting rod is arranged at the other end of the base; an inner hole of the pressing sleeve is a step hole which is large in lower part and small in upper part; the aperture of the small end of the step hole is smaller than the guide post; and the lower end face of the pressing sleeve is the inclined plane matched with that of the small head of the connecting rod, and a locating pin is arranged at the position of the inclined plane on the lower end of the pressing sleeve, corresponding to the plane end of the small end of the connecting rod. The tool disclosed by the invention is accurate in positioning and convenient to operate, and the pressing efficiency is improved.

Owner:HEBEI HUABEI DIESEL ENGINE

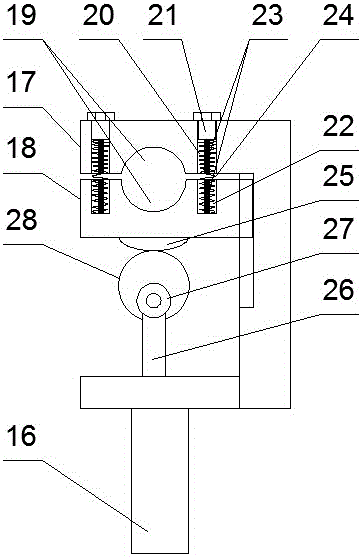

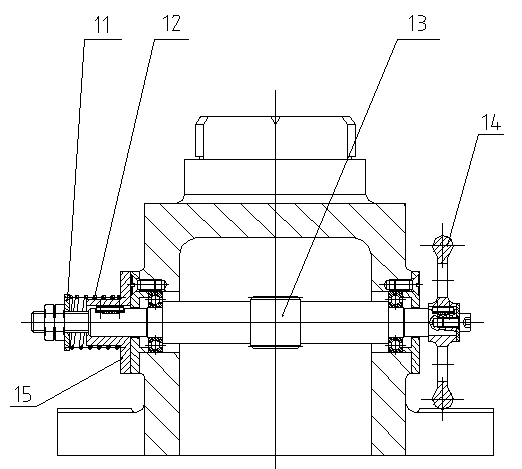

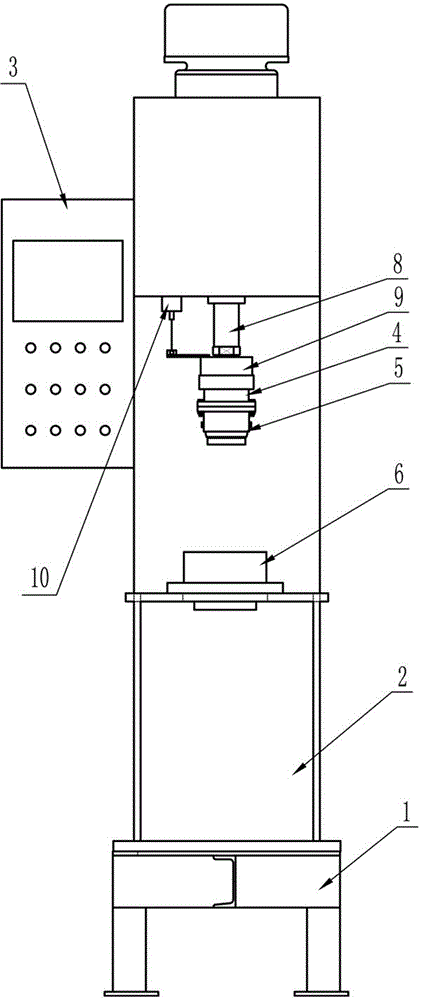

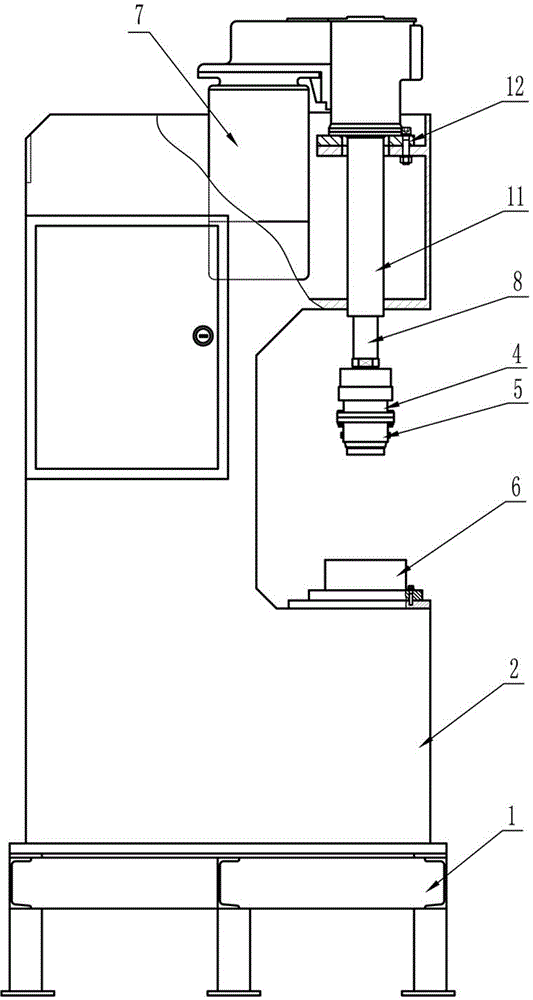

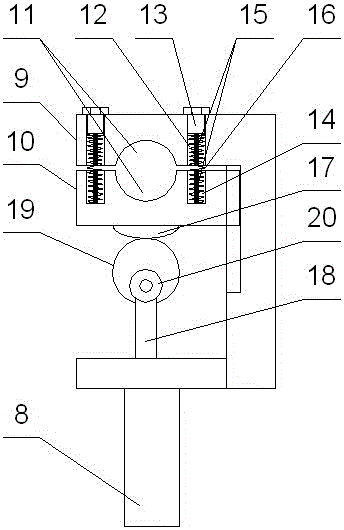

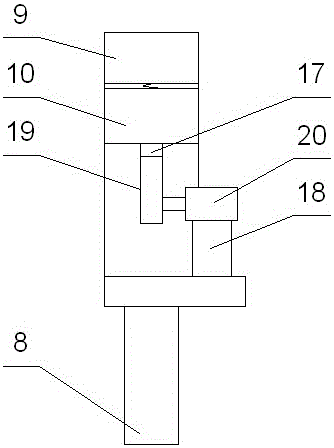

Vertical type bearing pressing machine

InactiveCN106141622ASmall footprintLarge operating spaceMetal working apparatusMotor driveBall bearing

The invention discloses a vertical type bearing pressing machine which comprises a base; a rack is arranged on the base; an operation panel is arranged on the rack; a pushing rod drive device is arranged on the top of the rack; the pushing rod drive device comprises a servo motor and a spiral pair; in use, the servo motor drives a lead screw of the spiral pair to rotate and move; a pushing rod is arranged on a nut support of the spiral pair; a guide sleeve is arranged on the outer part of the pushing rod; a central deviation correcting device is arranged on the pushing rod drive device; a quick-to-change pressure head is arranged on the central deviation correcting device; a clamp is arranged on the bottom of the rack; the central deviation correcting device comprises an upper connecting part and a lower connecting part; a thrust ball bearing is arranged between the two connecting parts; a rubber spring is arranged in an inner cavity of the lower connecting part; a bearing clamping mechanism is arranged on the quick-to-change pressure head; the central deviation correcting device is fixed onto a pressure sensor at the lower end of the pushing rod drive device; and the quick-to-change pressure head is connected onto the central deviation correcting device. The vertical type bearing pressing machine is simple in structure, is convenient to operate, is high in assembly precision, is high in efficiency and is high in practicability.

Owner:HUBEI UNIV OF AUTOMOTIVE TECH

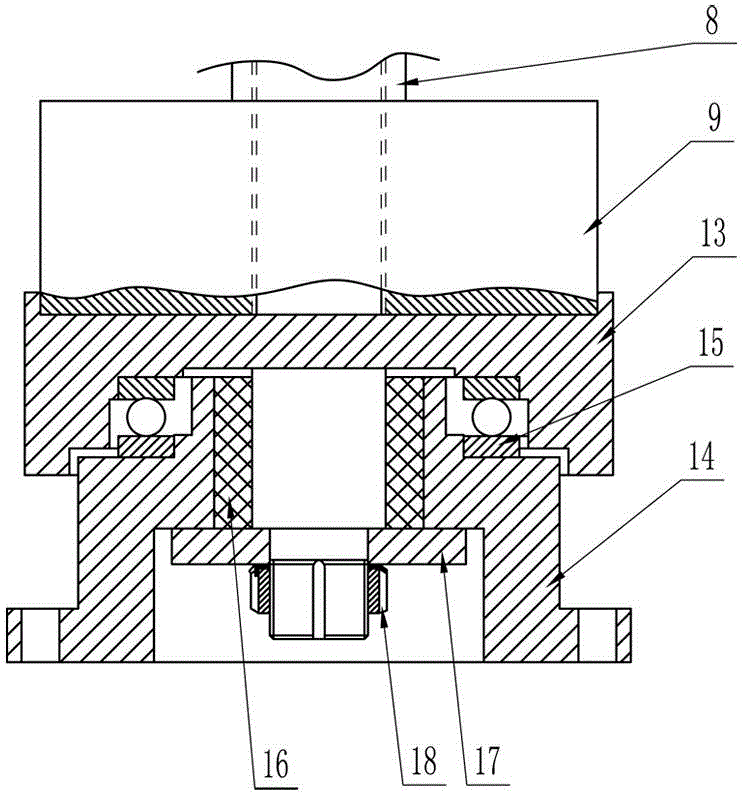

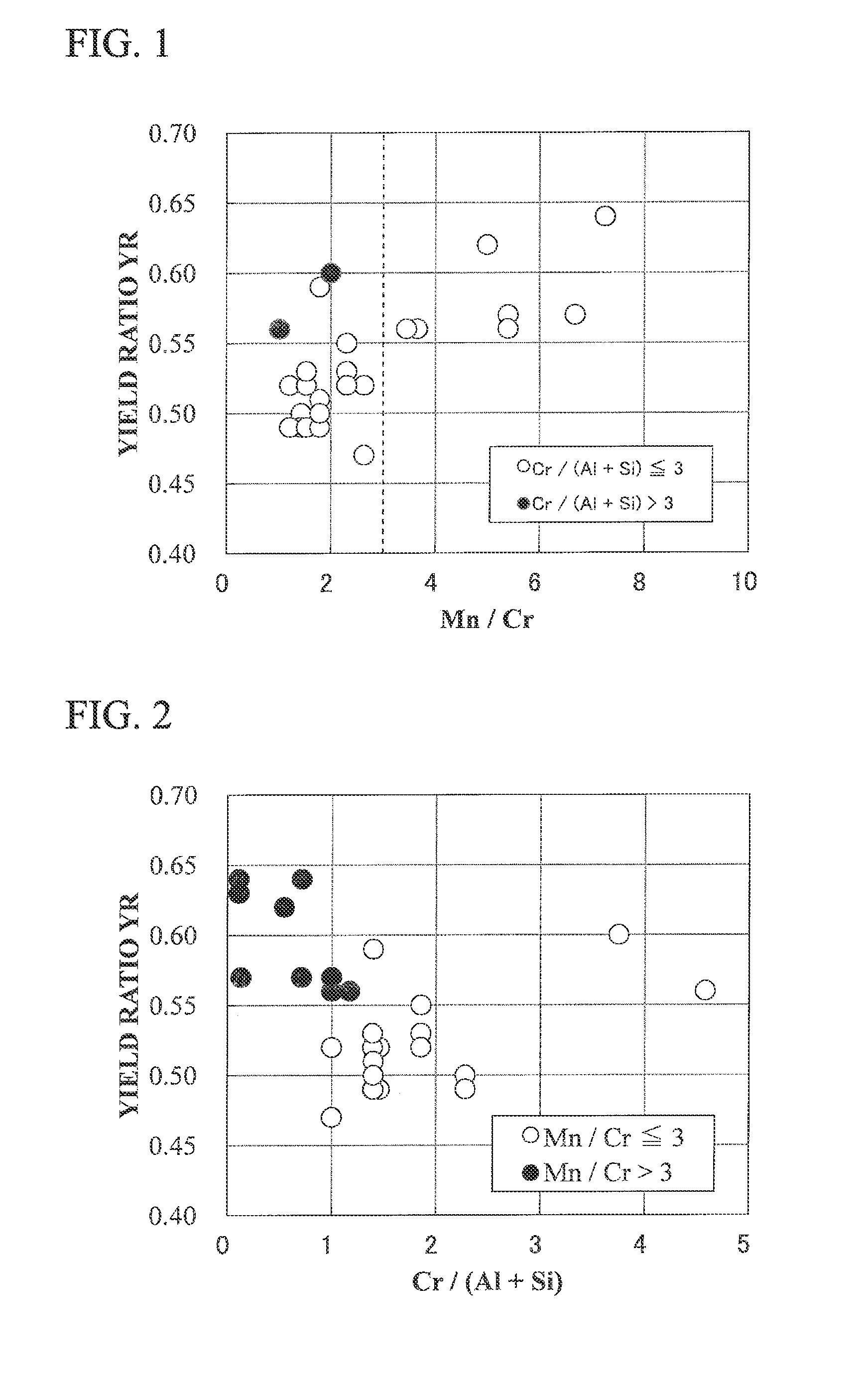

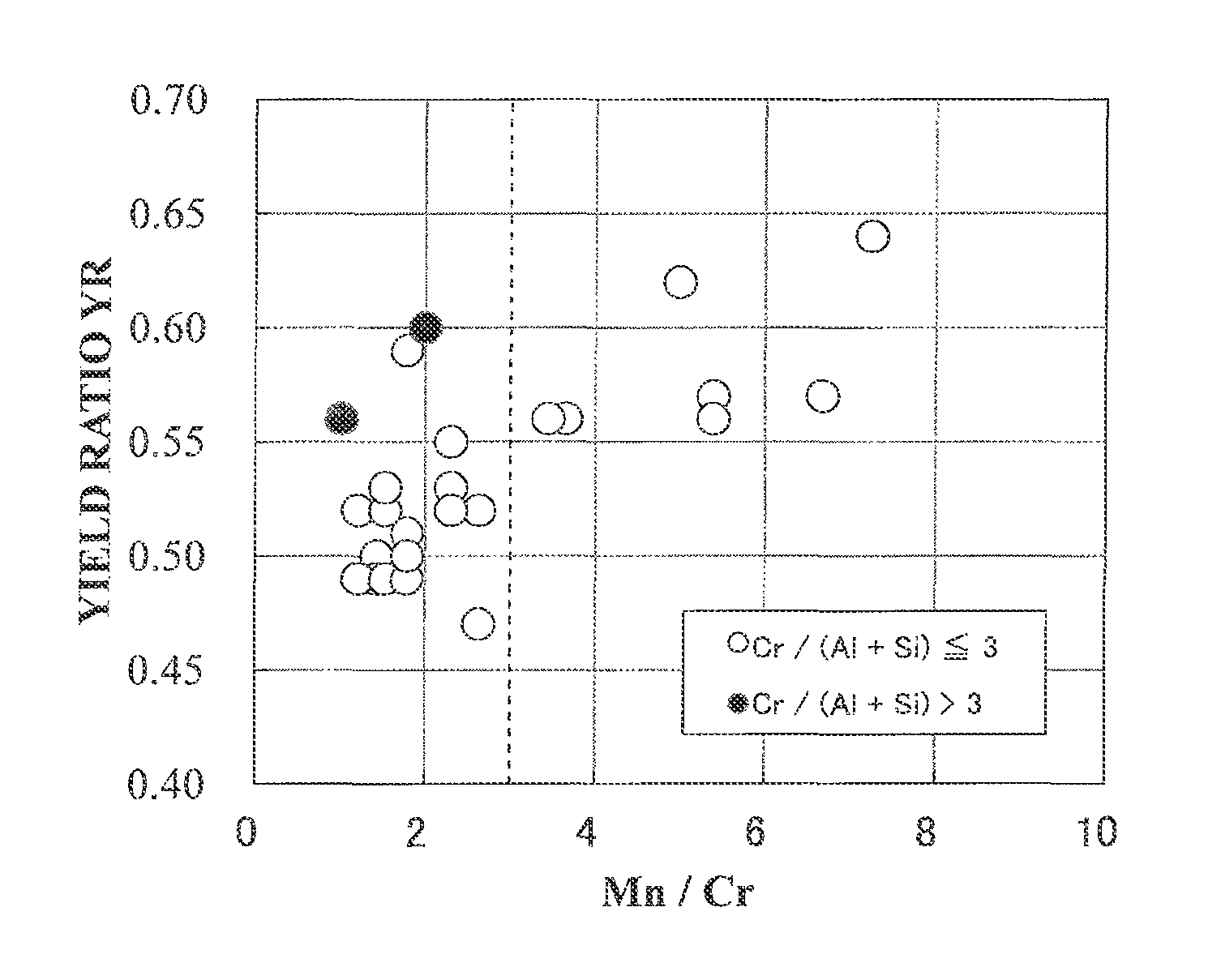

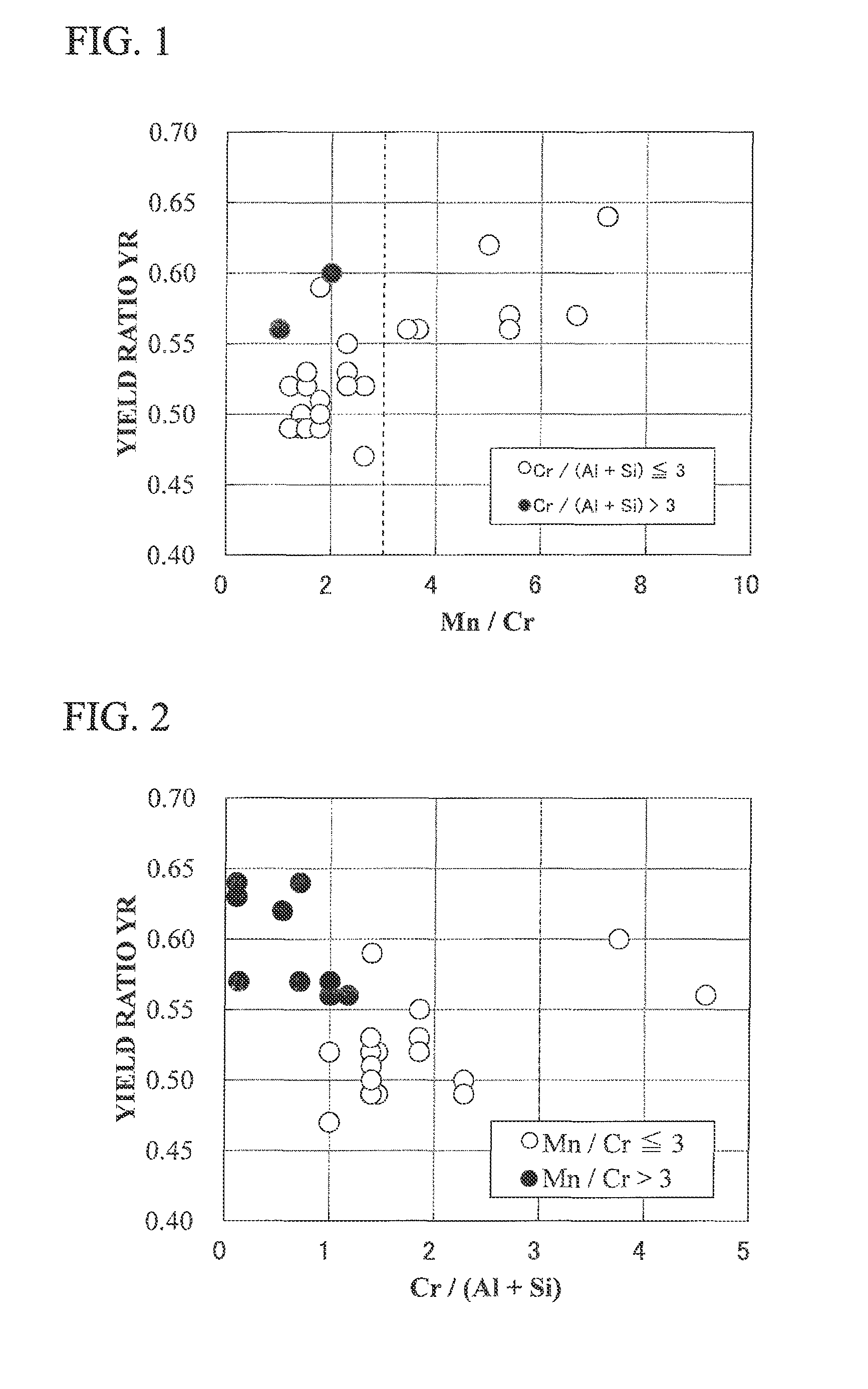

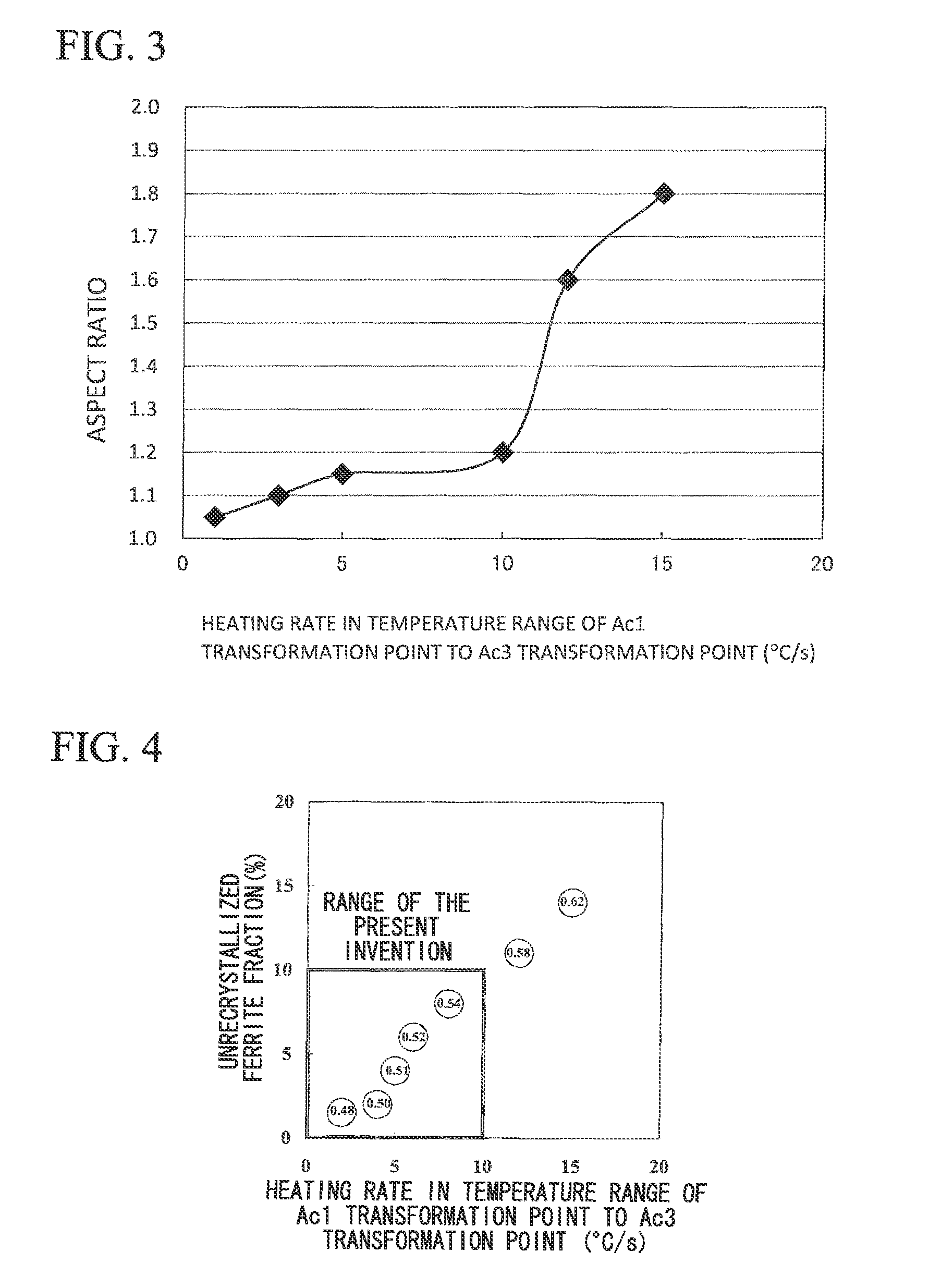

High-strength steel sheet having excellent processability and paint bake hardenability, and method for producing of high-strength steel sheet

InactiveUS20120282487A1Lower ratioLow strengthHot-dipping/immersion processesFurnace typesManganeseMaterials science

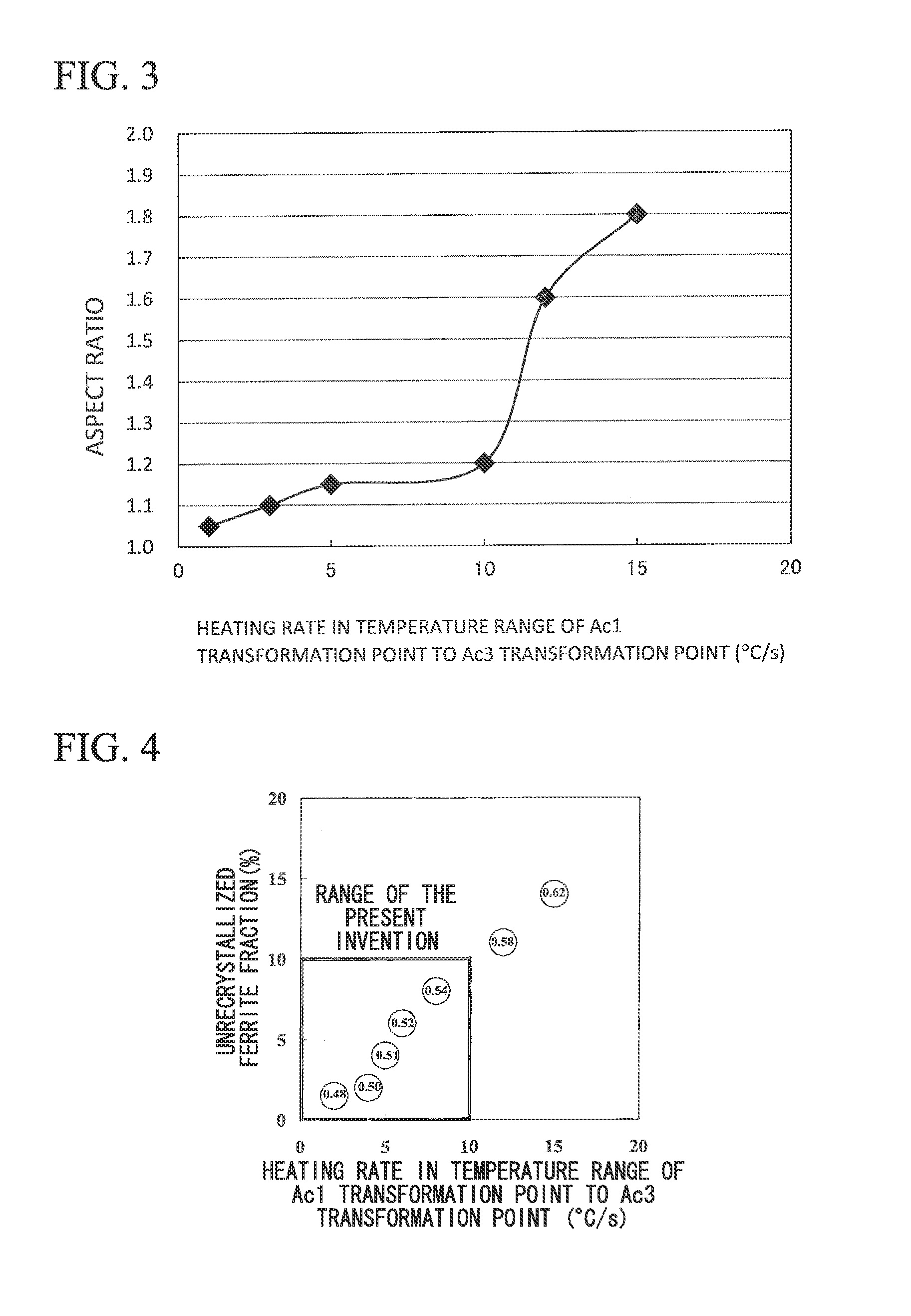

The high-strength steel sheet includes, by mass %: C: 0.01% to 0.10%; Si: 0.15% or less; Mn: 0.80% to 1.80%; P: 0.10% or less; S: 0.015% or less; Al: 0.10% to 0.80%; Cr: 0.01% to 1.50%; N: 0.0100% or less; and a balance consisting of iron and inevitable impurities, in which a metallic structure is composed of ferrite and a hard second phase, the area fraction of the ferrite is 80% or more, the area fraction of the hard second phase is 1% to 20%, the fraction of unrecrystallized ferrite in the ferrite is less than 10%, the ferrite grain sizes are 5 μm to 20 μm, and the fraction of the ferrite crystal grains having an aspect ratio of 1.2 or less in the entire ferrite crystal grains is 60% or more.

Owner:NIPPON STEEL CORP

On-line de-icing device for power transmission line

ActiveCN106329450AWon't stayReduce mutual consumptionOverhead installationComputer moduleEngineering

The invention discloses an on-line de-icing device for a power transmission line. The on-line de-icing device comprises a walking mechanism and a rack which is connected to the lower portion of the walking mechanism through mechanical arms. The walking mechanism comprises a rear walking wheel and a front walking wheel, wherein the rear walking wheel is clamped on the de-iced portion of the power transmission line, and the front walking wheel is clamped on the icing portion of the power transmission line, a de-icing mechanism is arranged on the rack and located between the rear walking wheel and the front walking wheel, a wireless controller is arranged on the left side inside the rack, and the walking mechanism is connected with the wireless controller through electric signals; the de-icing mechanism comprises an ice cover crashing module and a water jet cutter dividing module in sequence from left to right. The water pressure of the water jet cutter dividing module can be adjusted according to the detected thickness of an ice cover layer, so that the on-line de-icing device efficiently carries out de-icing without being affected by the thickness of the ice cover layer when the surface ice cover is divided, and also will not damage the line.

Owner:XICHUAN COUNTY POWER BUREAU

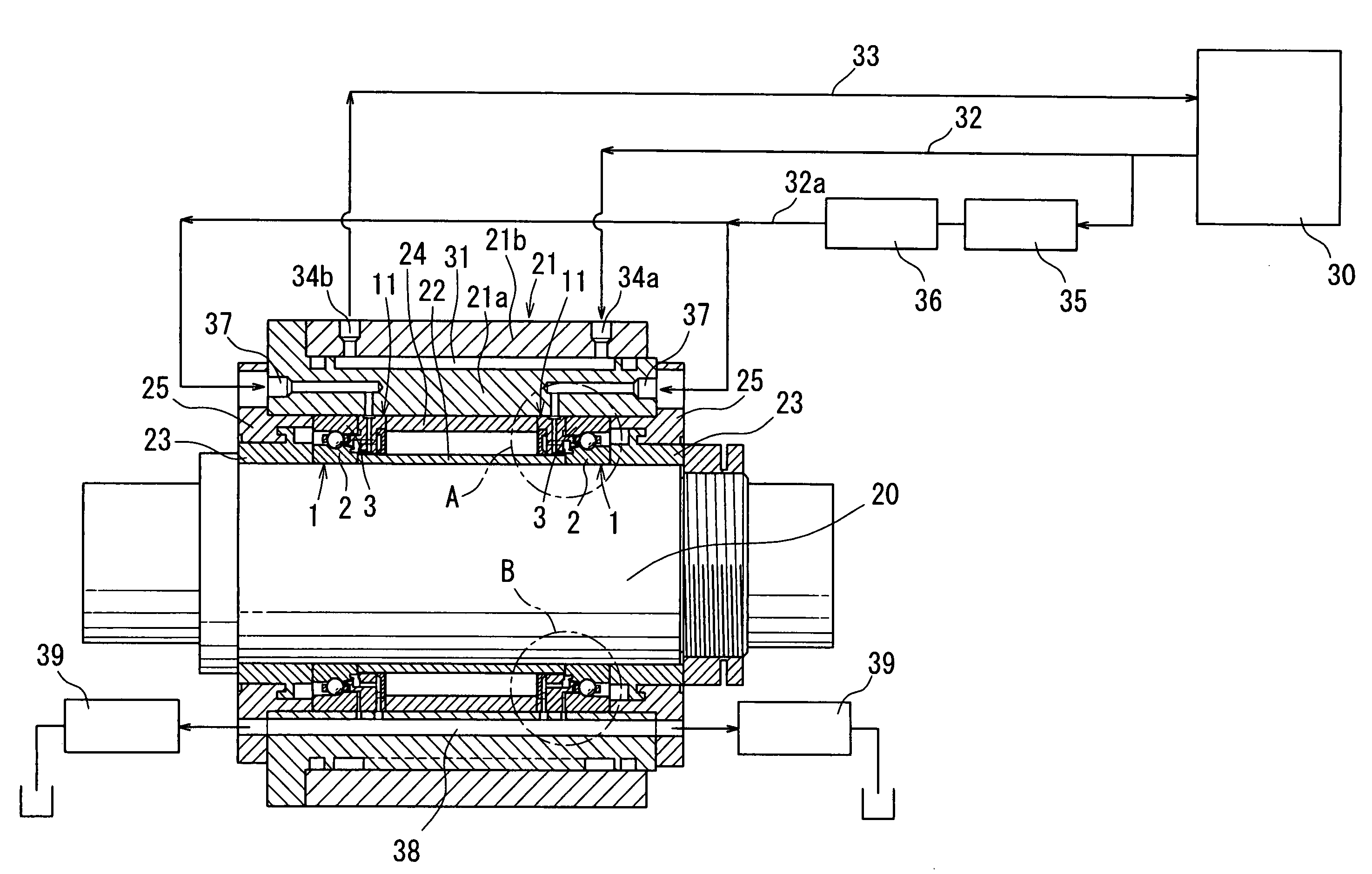

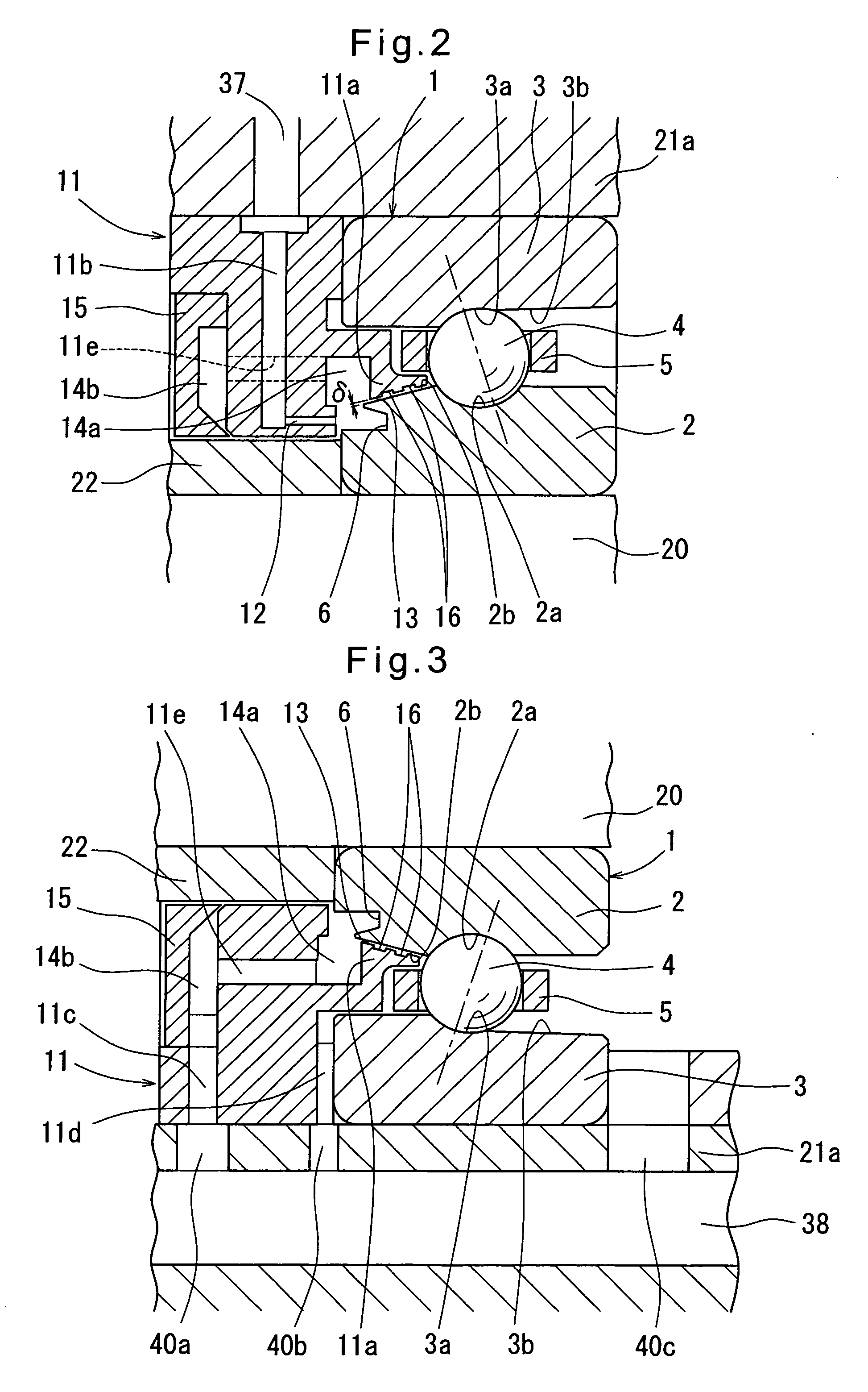

Lubricator for Rolling Bearings

InactiveUS20090148088A1Stably suppressReduce resistanceRolling contact bearingsBearing coolingBall bearingRolling-element bearing

The object is to provide a lubricator for rolling bearings which is also capable of cooling the inner ring and which can reduce the resistance of cooling oil when the oil is agitated during high-speed rotation of the bearing.On the back side of an angular ball bearing 1, a cooling oil introducing member 11 is provided which includes a nozzle 12 for discharging cooling oil toward a circumferential groove 6 formed in an end surface of an inner ring 2. The cooling oil introducing member 11 has an extension 11a formed with a seal portion 13 that faces a tapered surface 2b of the inner ring with a gap δ left therebetween. The gap δ of the seal portion is set at 0.2 mm or less to limit the amount of cooling oil that flows through the seal portion 13 into the bearing to a minimum, thereby reducing the resistance of cooling oil when the oil is agitated during high-speed rotation of the angular ball bearing 1.

Owner:NTN CORP

Vehicle steering apparatus and vehicle steering method

InactiveUS7753162B2Easy loadingIncrease loadAutomatic steering controlElectrical steeringPull forceSteering system

A vehicle steering apparatus includes a vehicle steering system and a supplemental steering force applying device. The supplemental steering force applying device is configured and arranged to apply a supplemental steering force to the vehicle steering system to reduce a steering load on the operator. The supplemental steering force applying device includes a steering torque detecting section, a rectilinear driving condition detecting section, a pulling suppression control section. The rectilinear driving condition detecting section is configured and arranged to detect a rectilinear driving condition of the vehicle. The pulling suppression control section is configured and arranged to adjust the supplemental steering force in a direction canceling a pulling force imparted on the vehicle during the rectilinear driving condition by using a pulling suppression force calculated based on historical data of the steering torque detected during the rectilinear driving condition.

Owner:NISSAN MOTOR CO LTD

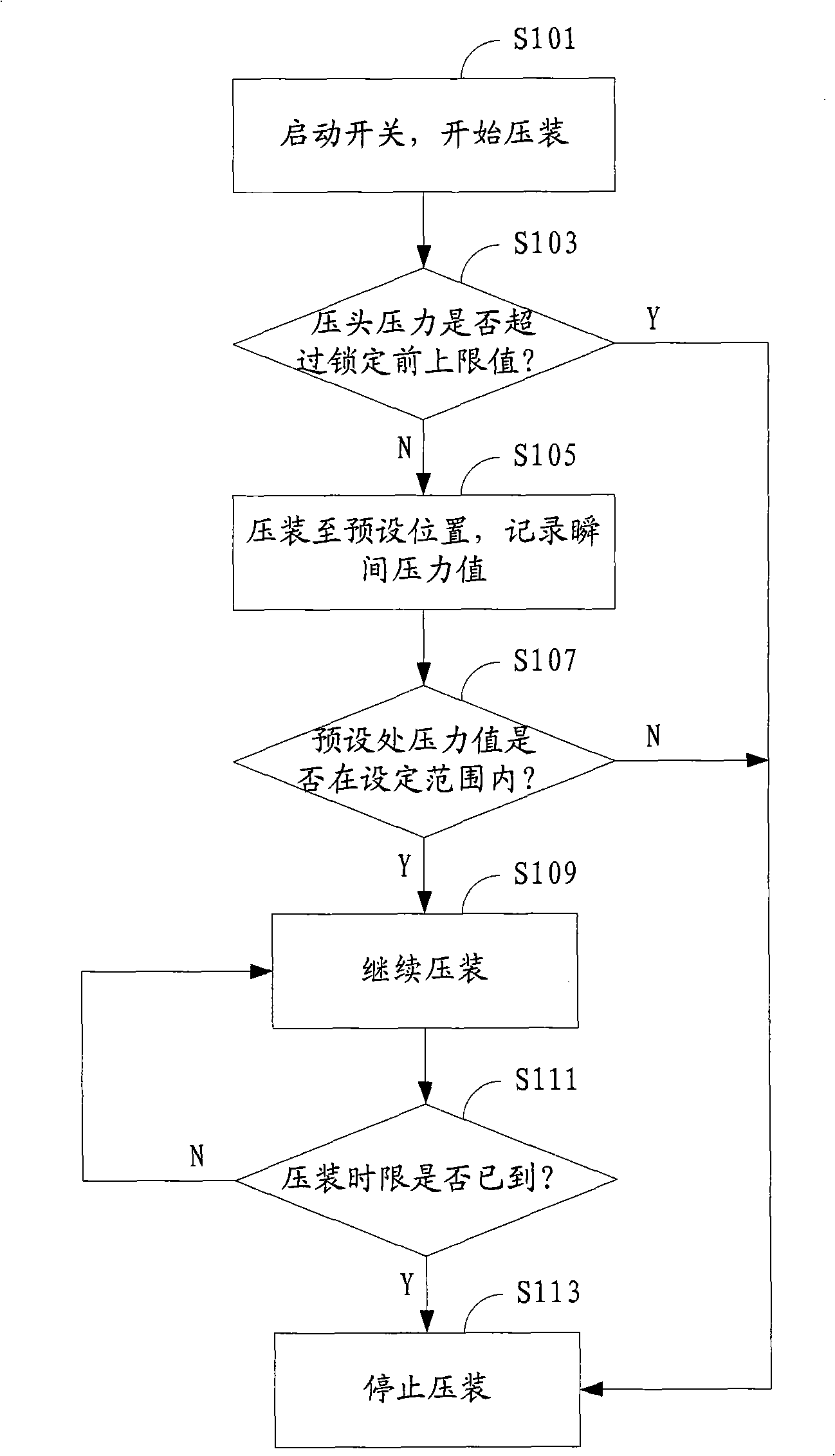

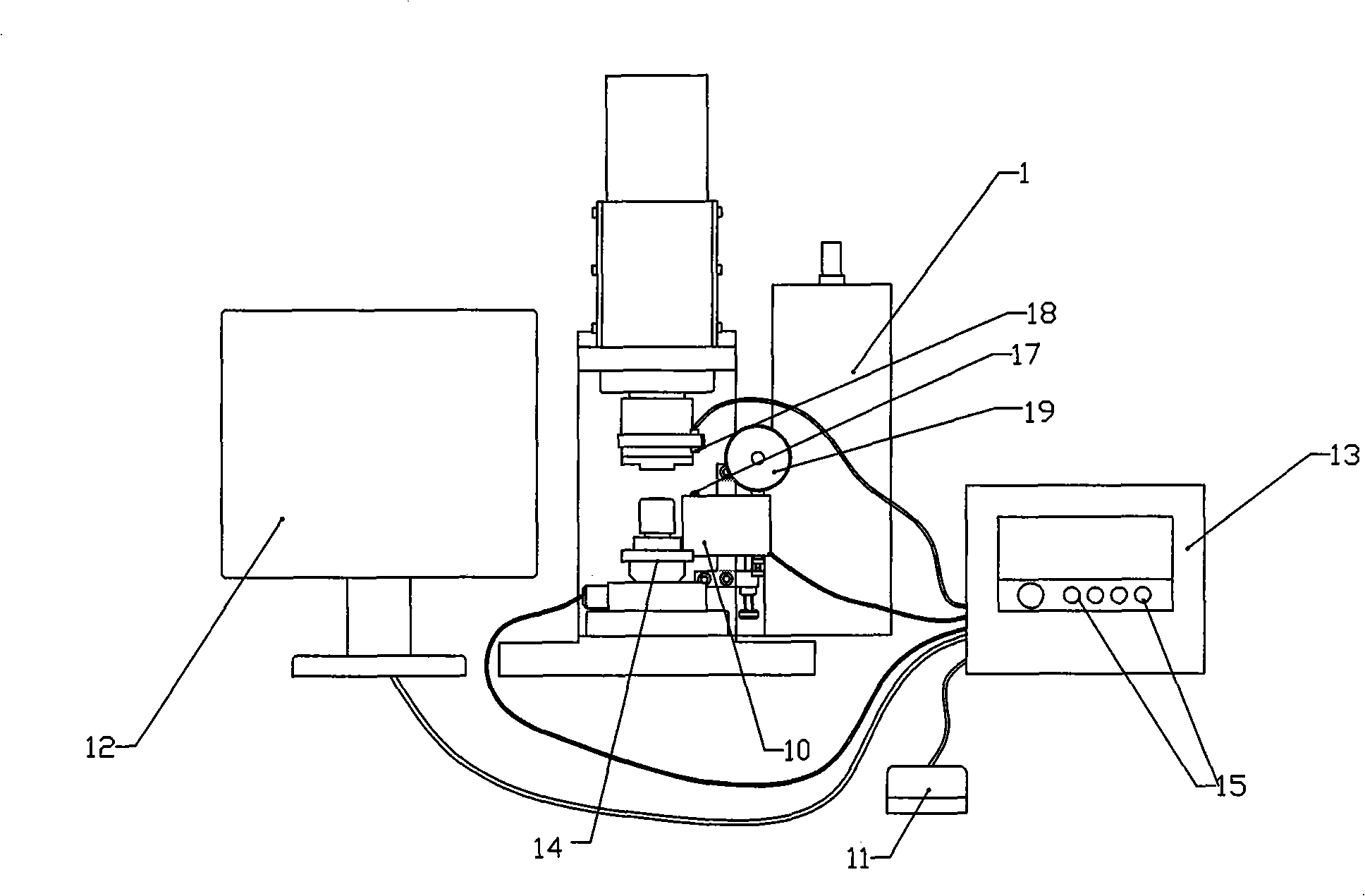

Method and equipment for automatically controlling press mounting of assembly part

InactiveCN101539648AReliably extract and storeEasy to extract and saveCoupling light guidesLower limitAutomatic control

The invention is suitable for the field of manufacturing optical active components and optical passive components in the optical communication technique, and provides a method and equipment for automatically controlling the press mounting of an assembly part. The method comprises: a switch is started to begin the process of press mounting; before a workpiece is pressed and mounted at a preset position by a pressure head, real-time collection of press mounting signal of the pressure head and detection that whether the press mounting signal exceeds a preset pre-locking upper limit value or not are carried out, if yes, press mounting is stopped immediately, if no, press mounting is continued; when the workpiece is pressed and mounted at the preset position by the pressure head, the instantaneously collected pressure value of the pressure head towards the workpiece is recorded and stored, and whether the pressure value is between a preset post-locking upper limit value and a post-locking lower limit value or not is judged; if yes, the press mounting is continued, if no, the press mounting is stopped immediately; and when the pressure head is downwards pressed, timing is started, and whether the counted time reaches the preset press mounting time limit or not is real time monitored in the process of press mounting, and if yes, the press mounting is stopped, if no, the press mounting is continued.

Owner:FINETOP SCI &TECH

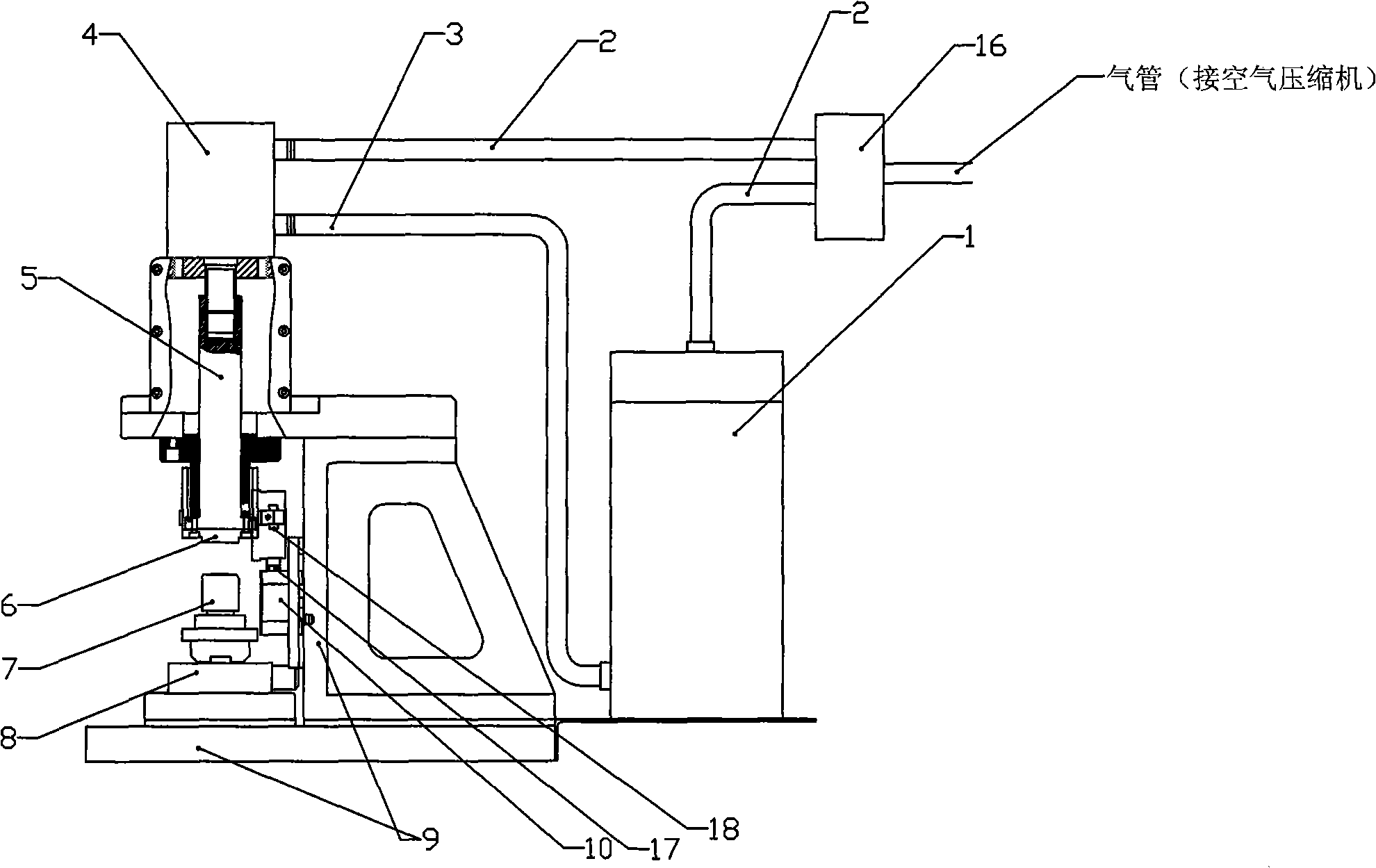

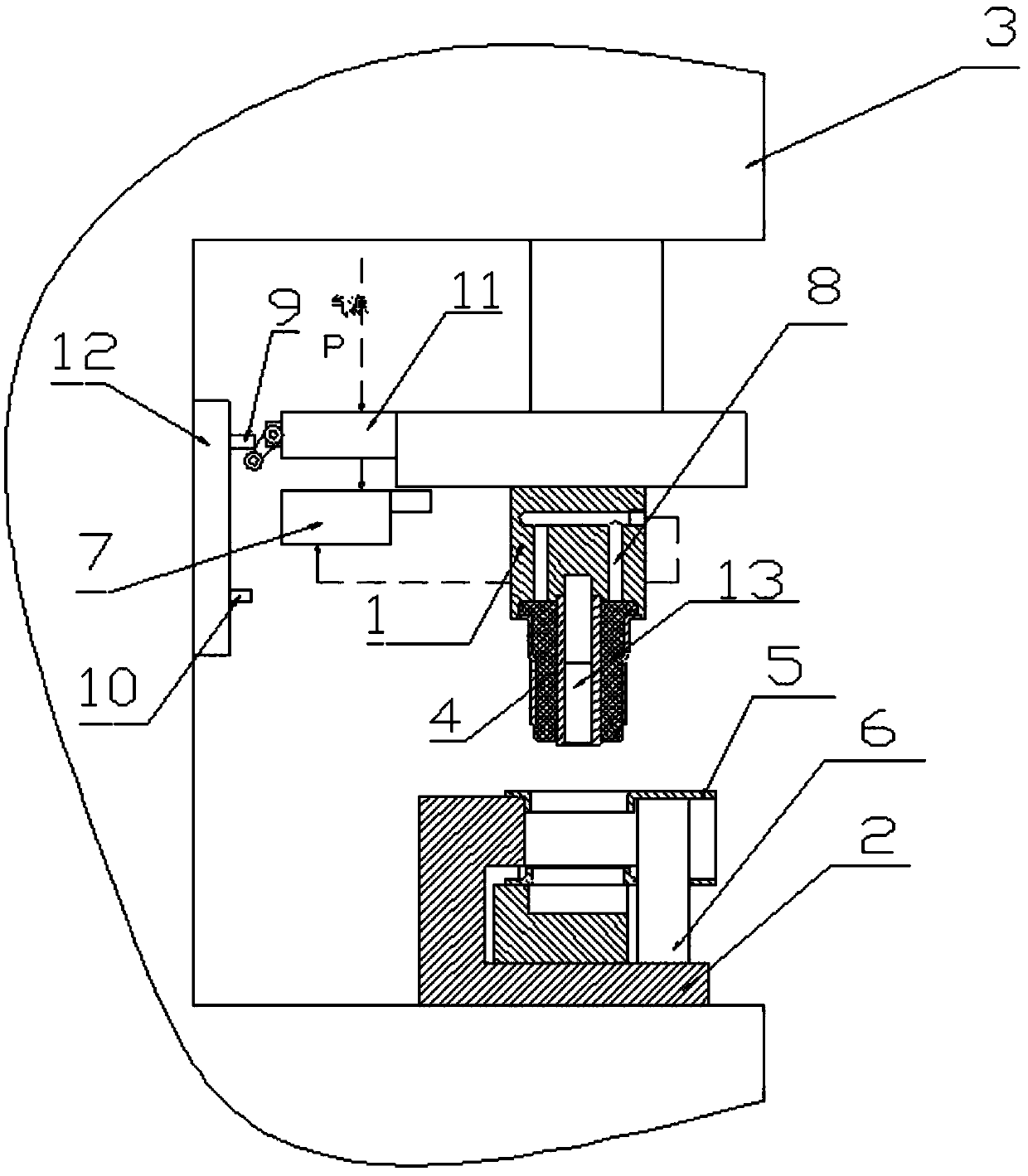

Mobile bearing press

ActiveCN102091928AMotion synchronizationAvoid damageMetal working apparatusField conditionsMobile bearing

The invention relates to a mobile bearing press which is used for a pressing axle reducer assembly bearing. A pneumatic pressing machine adopts a gas-liquid booster cylinder and is movably hung on a guiding rail, and a counter force rod mechanism is connected with the pneumatic pressing machine. When in pressing, a press block inlaid with a magnet is connected with a shaft by a screw, an outer ring of the bearing is adsorbed on the press block, a handle of the counter force rod mechanism is rotated, and a clamping jaw extends out to hook the inner end surface of a reducer shell bearing saddle hole so as to finish the bearing pressing under the action of the booster cylinder. Due to the pneumatic pressing and hanging, the whole press is light, can move freely on the preset guiding rail and cover a plurality of assembly trolleys, and can press bearings synchronously with the assembly line under the condition of occupying the space beside the assembly line as little as possible; the mobile bearing press can press bearings instead of manual beating, and improve the assembling quality of the assembly line; the mobile bearing press improves the traditional assembly line of bearing pressing and guarantees smooth and consistent pressing process under harsh requirements of the field conditions; and the mobile bearing press reduces the labor intensity of operators.

Owner:DONGFENG DANA AXLE

Forming mechanism of brick press

ActiveCN110883908AImprove molding qualityMany types of functionsDischarging arrangementShaping press ramBrickMolding machine

The invention discloses a forming mechanism of a brick press. The forming mechanism comprises a spreading mechanism for spreading raw materials, a prepressing mechanism for prepressing the raw materials, a main pressing mechanism for mainly pressing the raw materials, a demolding mechanism for demolding formed bricks, and a main bearing frame for bearing the spreading mechanism, the prepressing mechanism, the main pressing mechanism and the demolding mechanism. After the structure is adopted, compared with the prior art, the forming mechanism is provided with a brick making forming mold, the brick making forming mold sequentially passes through the spreading mechanism, the prepressing mechanism, the main pressing mechanism and the demolding mechanism, and the raw materials in the mold arepressed and formed in multiple processes. The forming mechanism is provided with the various processing mechanism, function types are rich, the raw materials in the mold can be spread, prepressed, mainly pressed, demolded and the like, the processing flow is finer, and therefore the forming quality of the bricks is improved.

Owner:FUJIAN QUNFENG MACHINERY

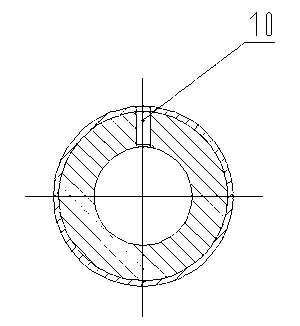

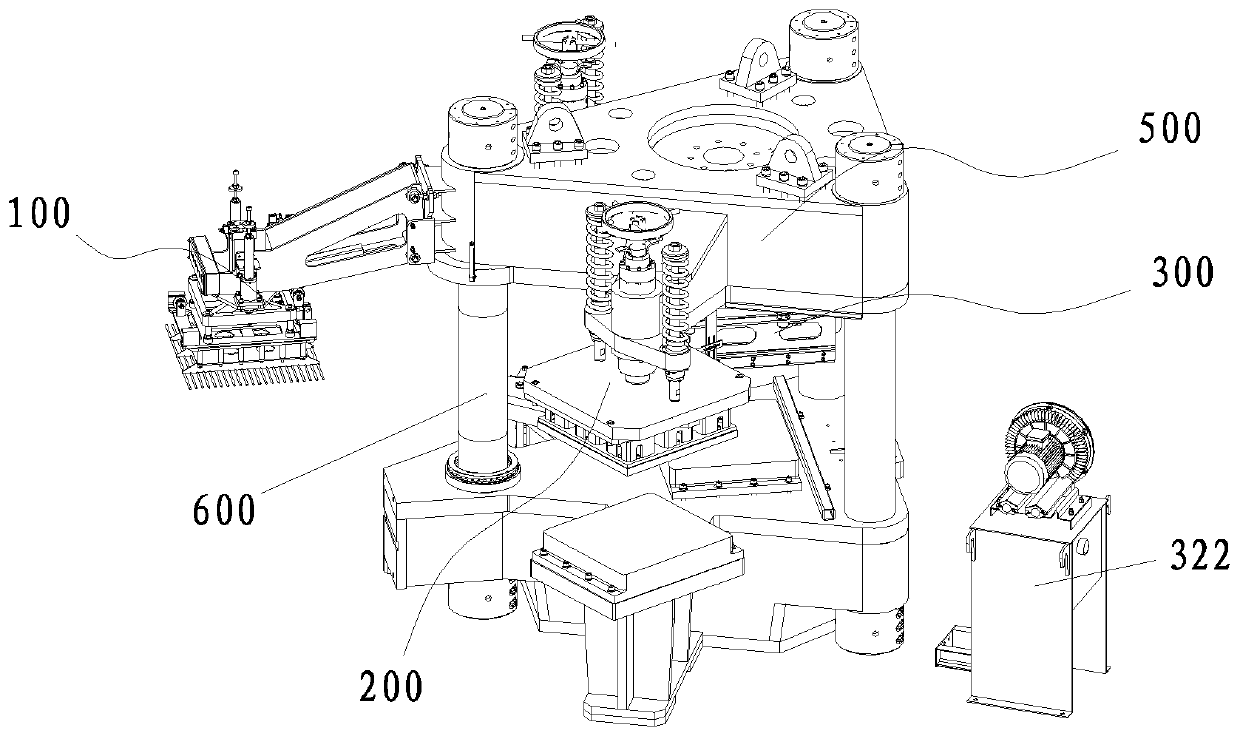

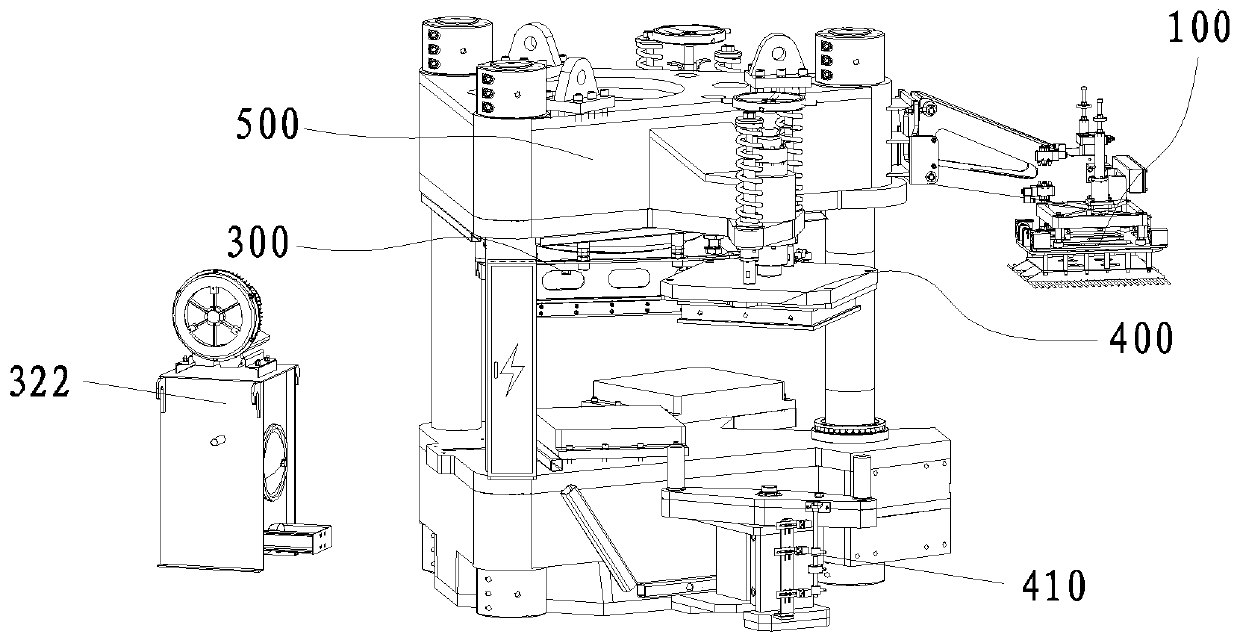

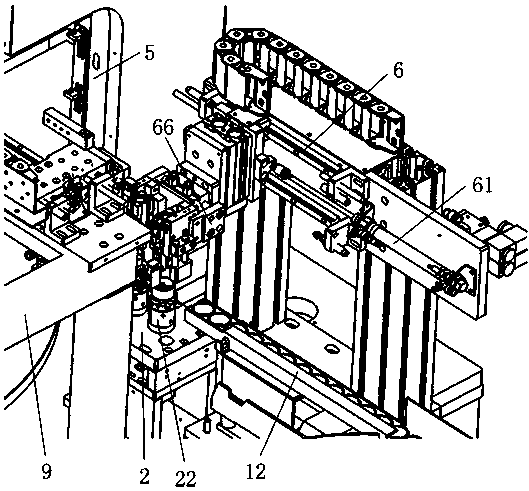

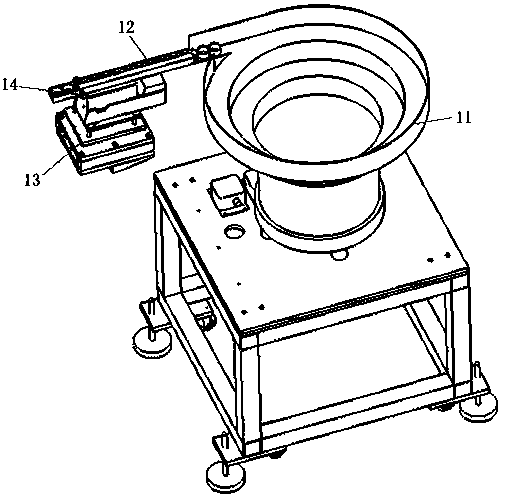

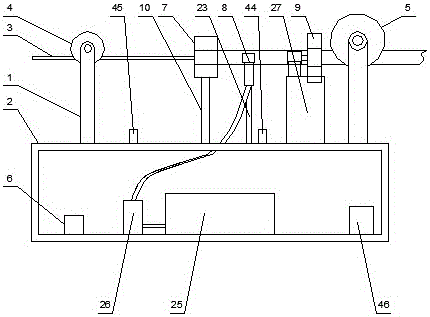

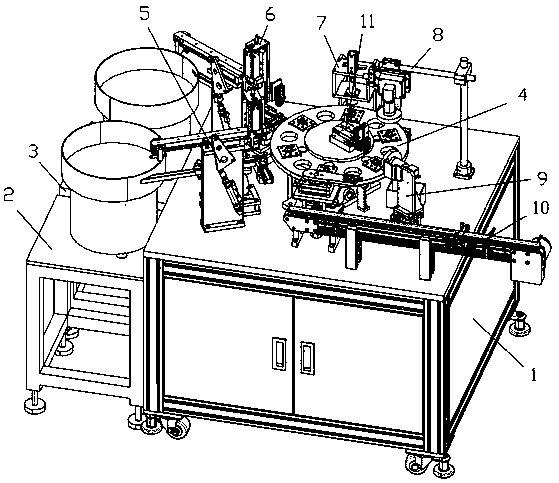

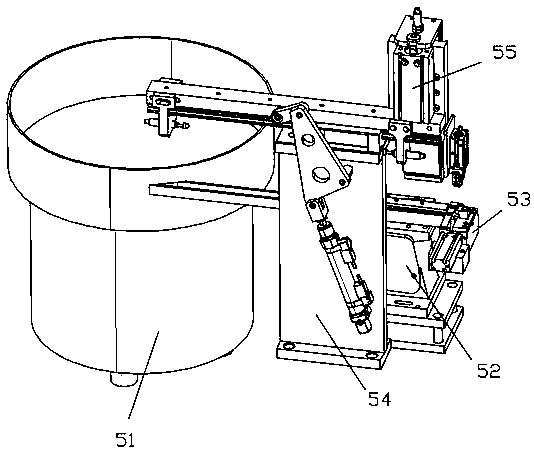

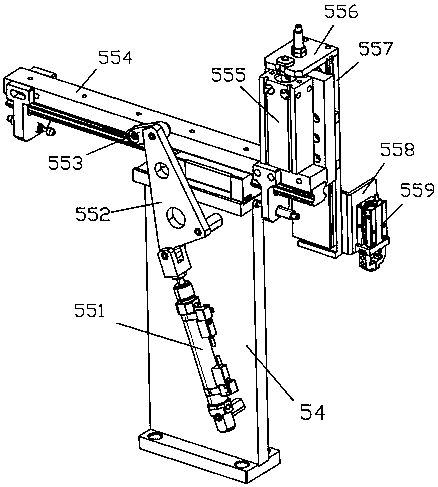

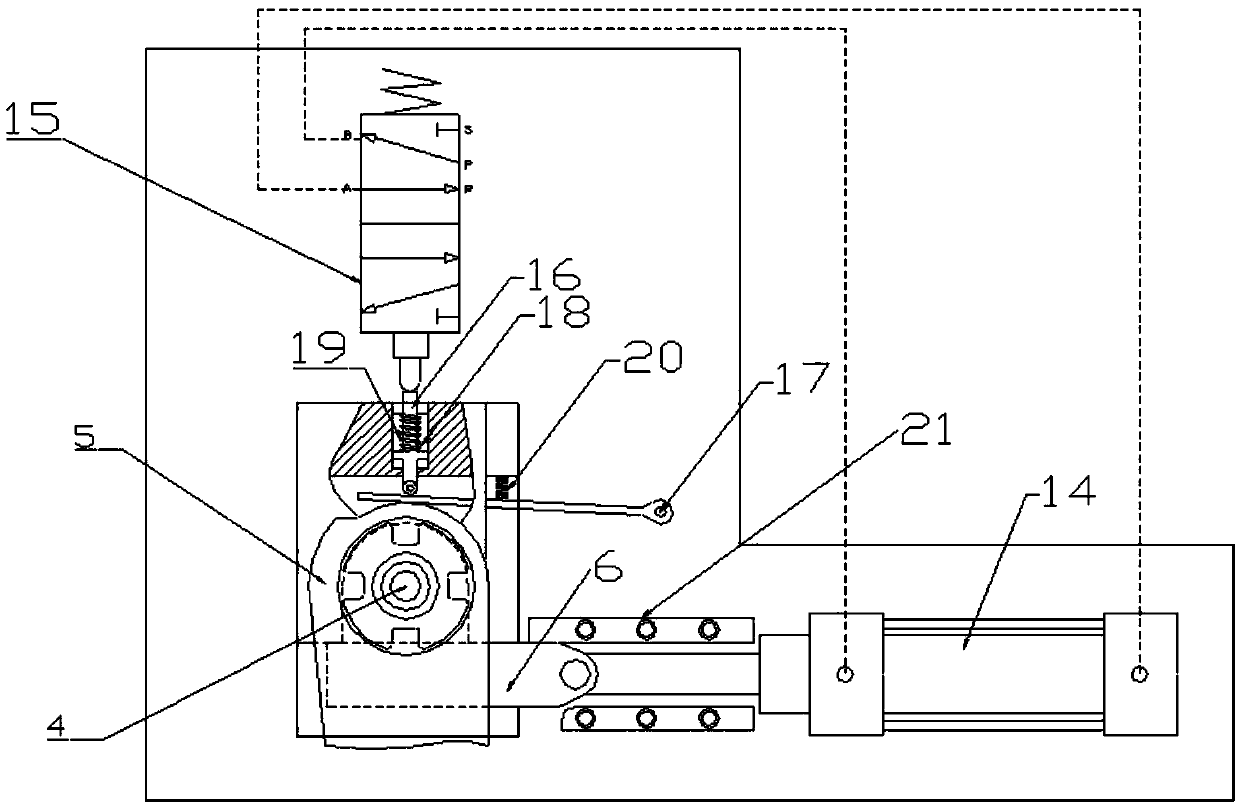

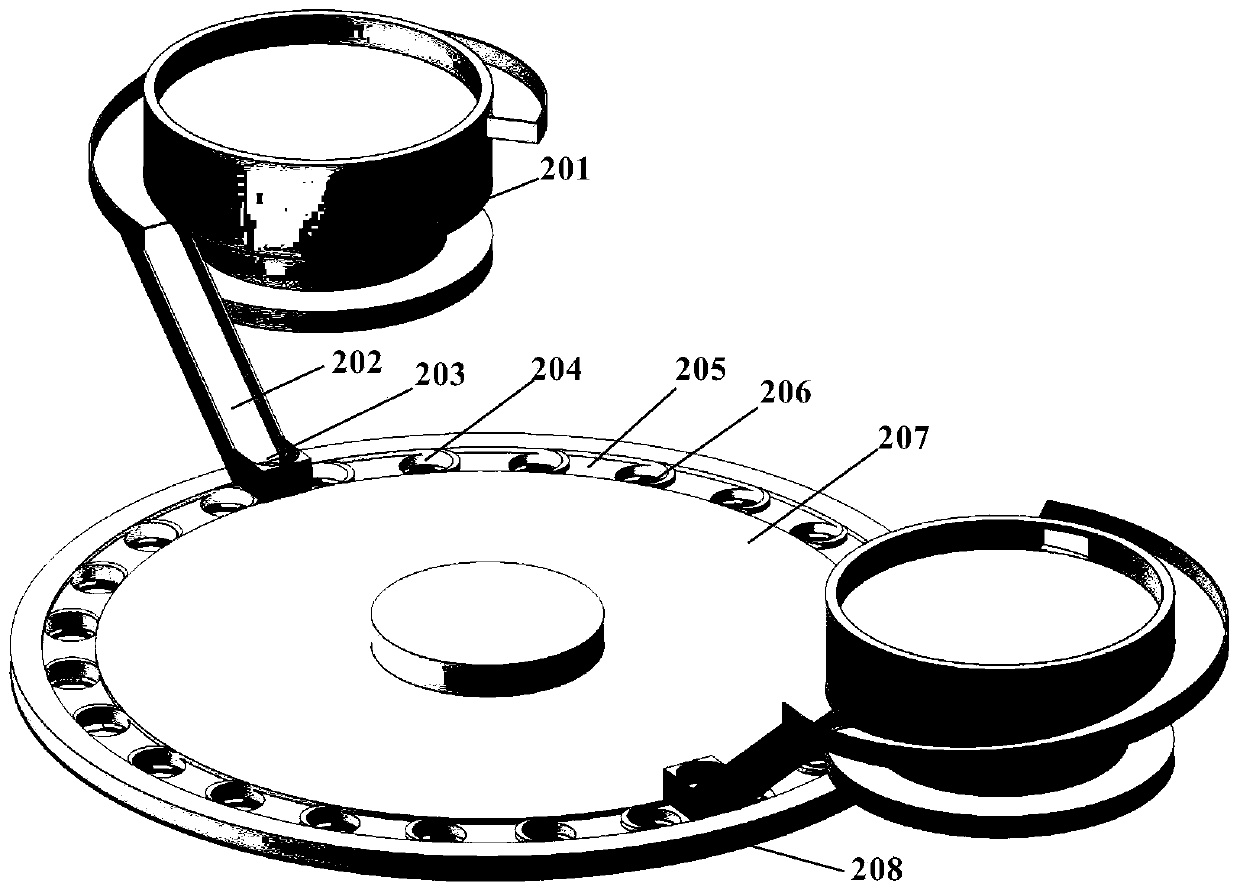

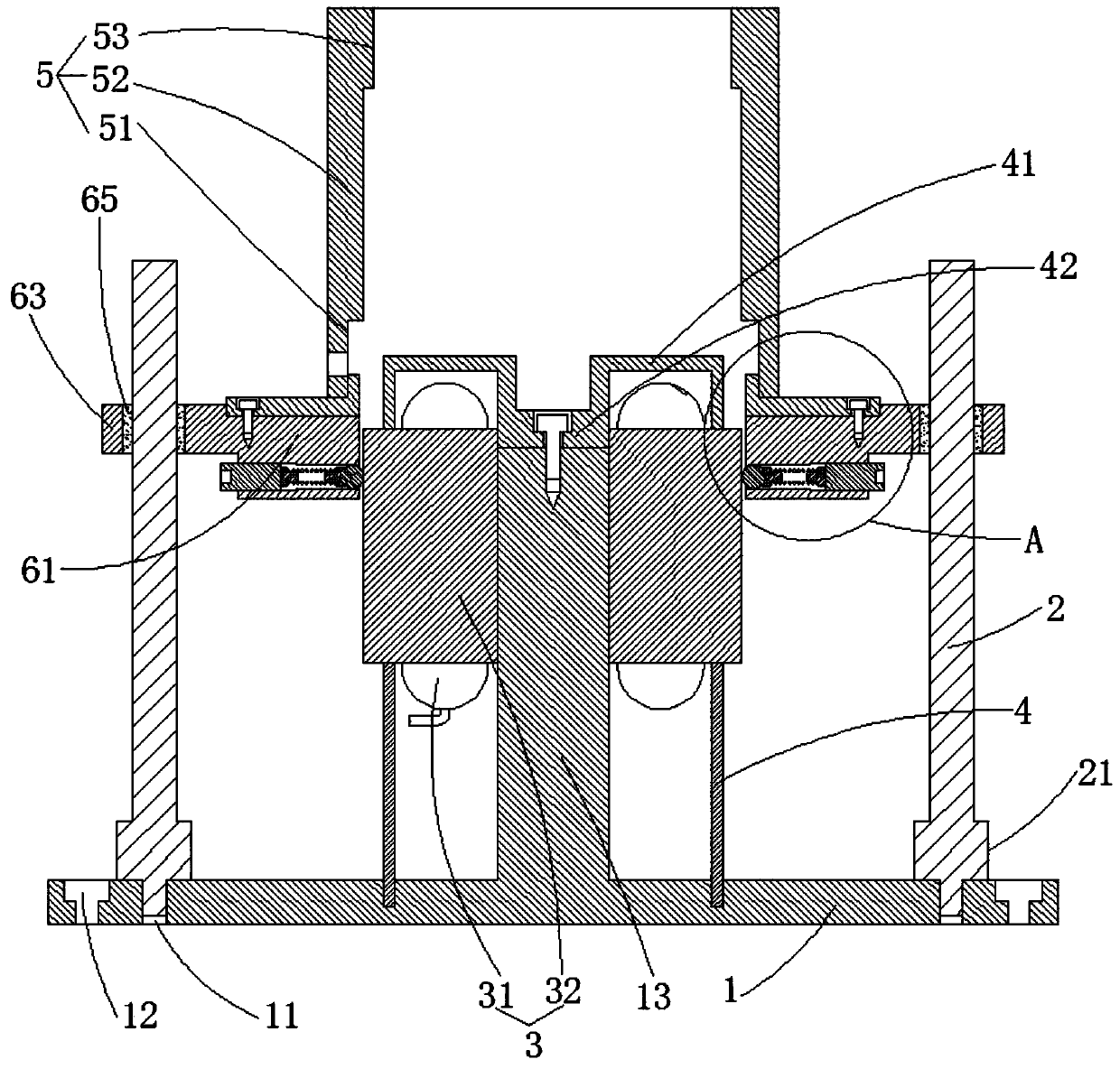

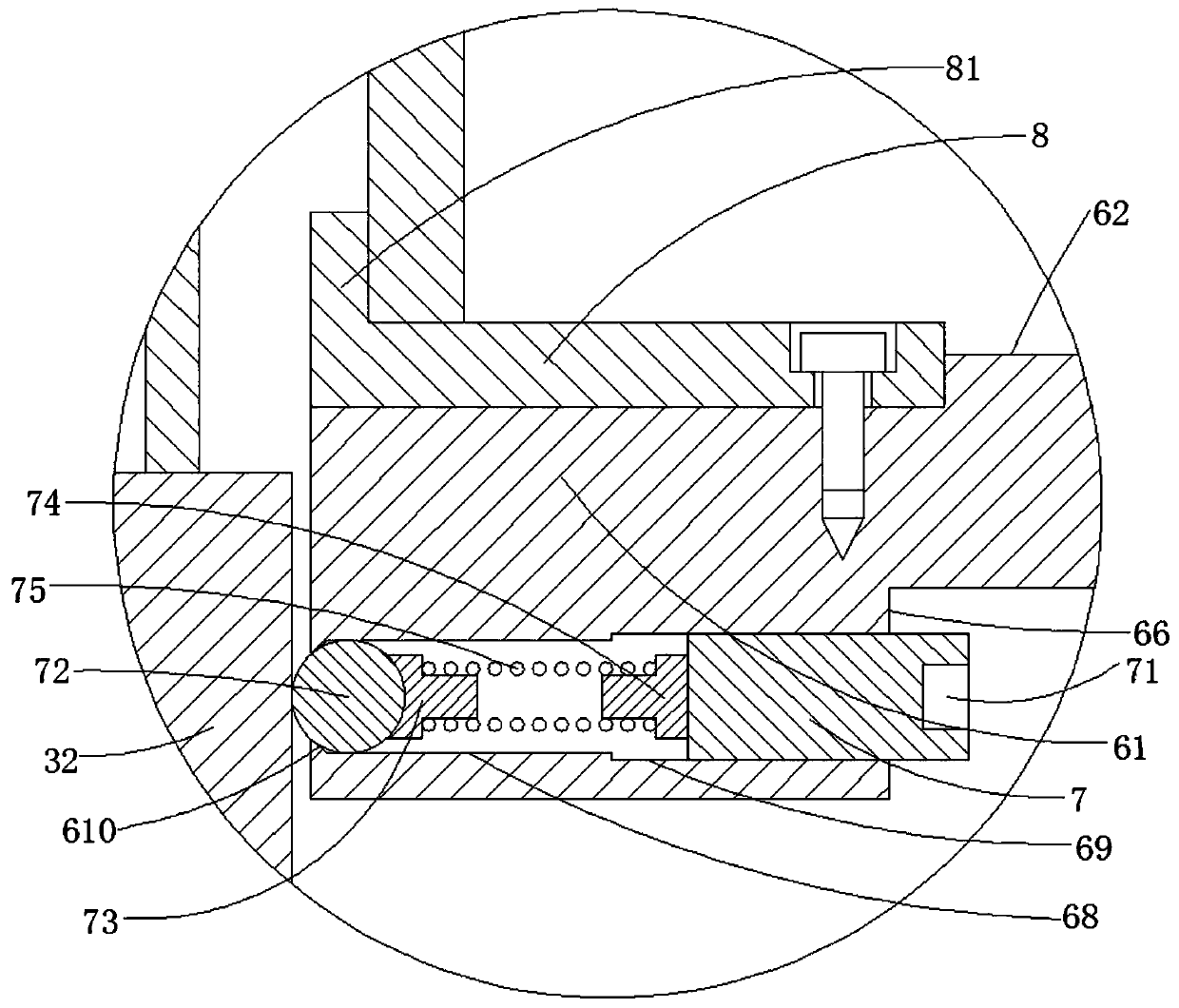

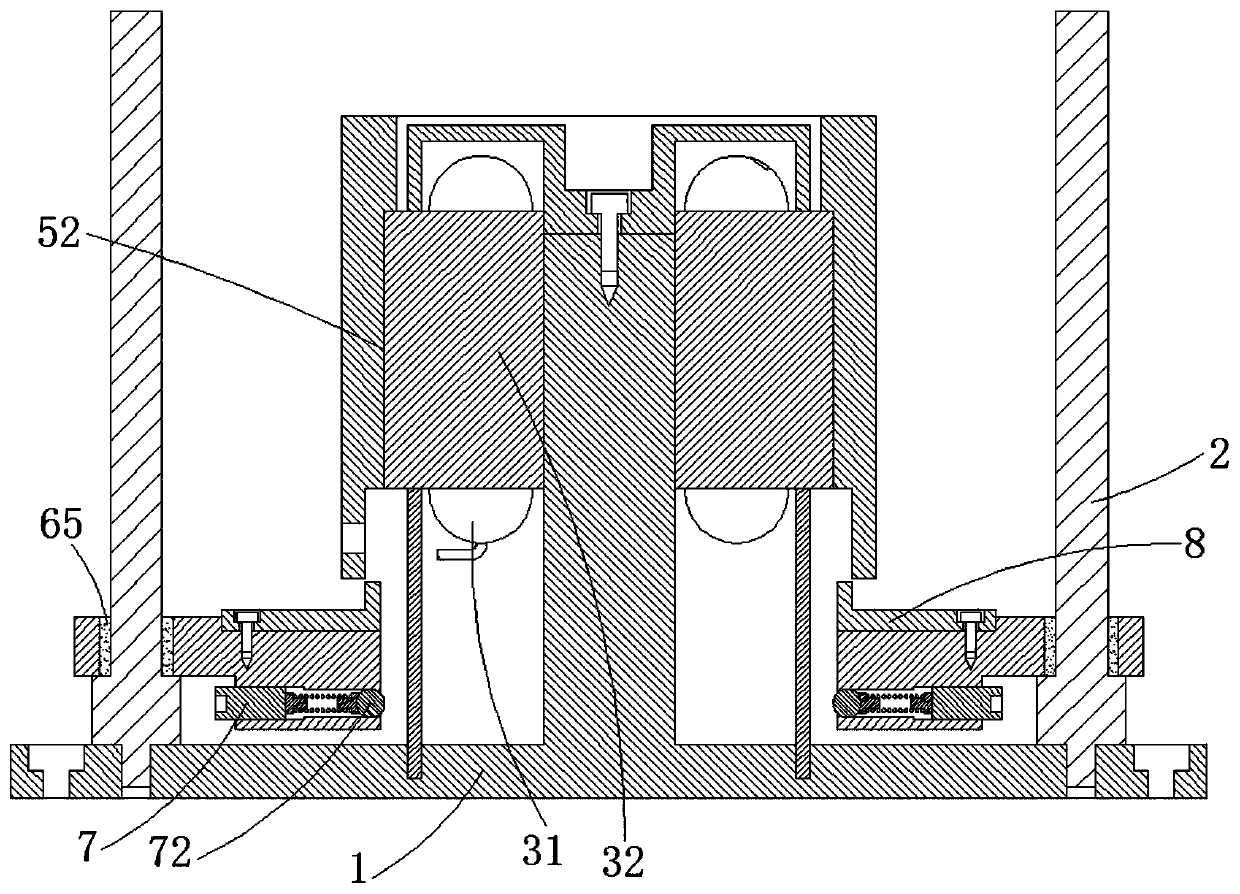

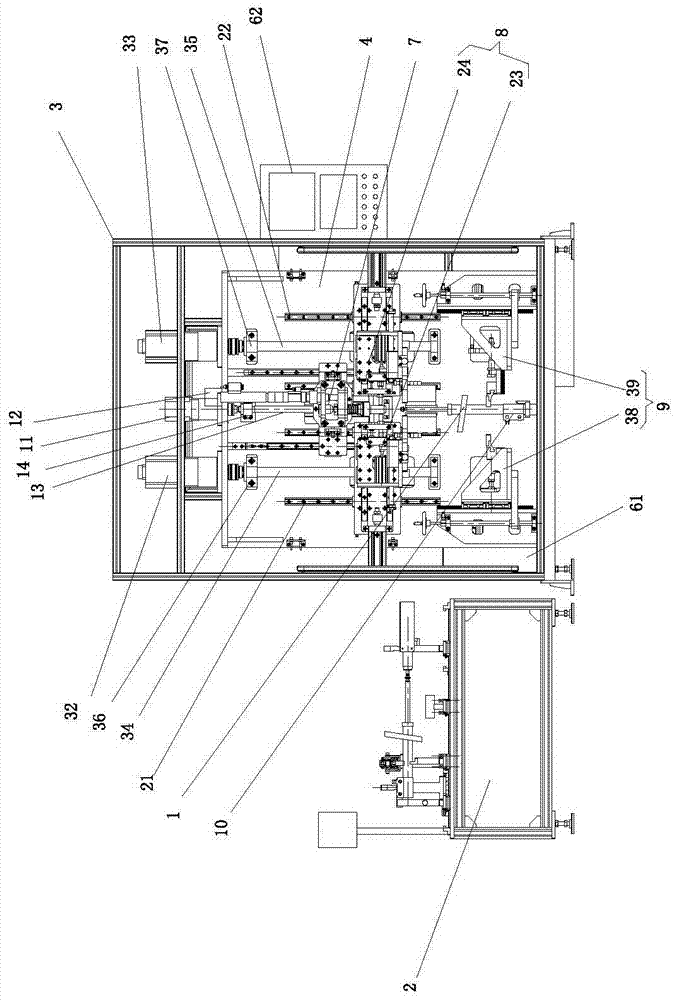

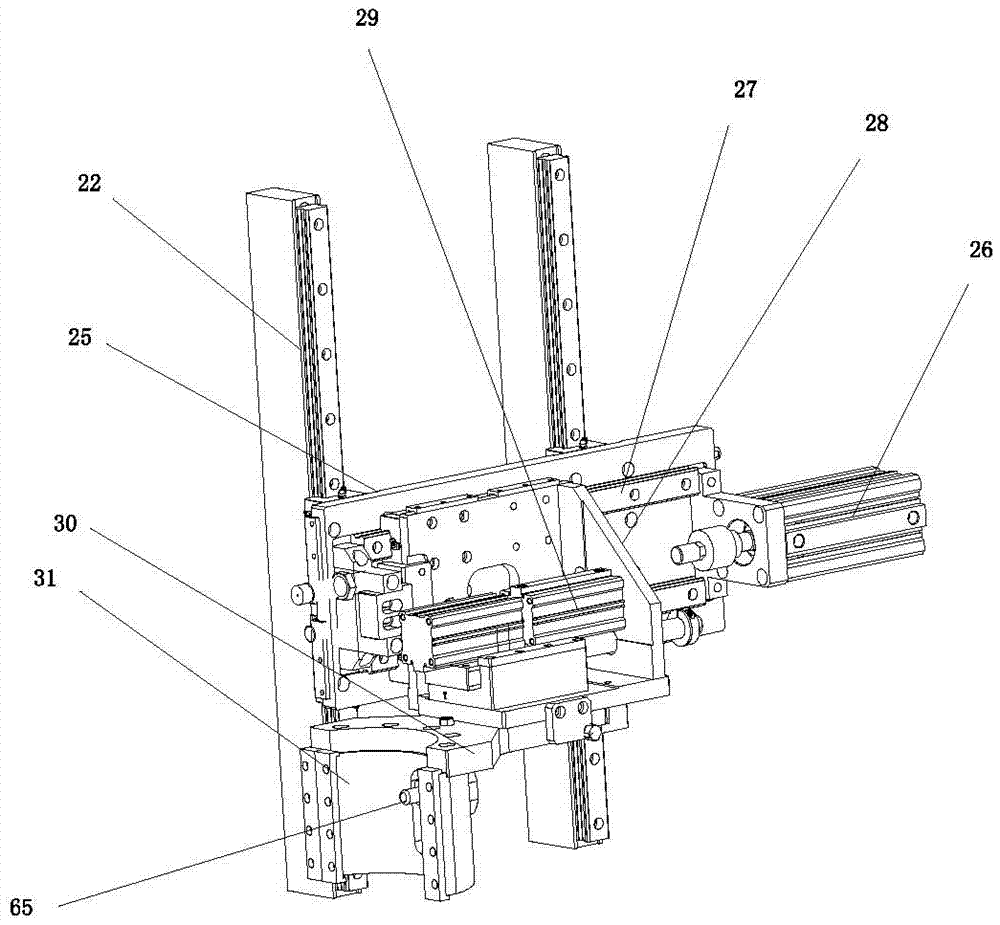

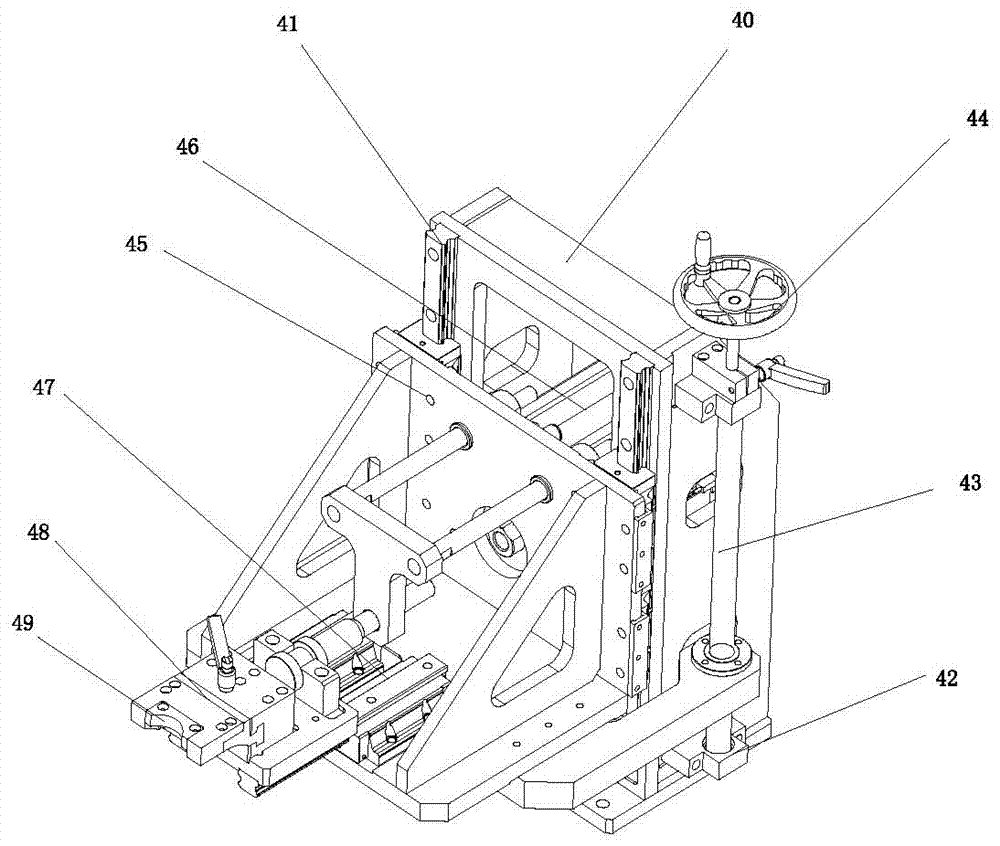

Automatic press fitting equipment for oil pump cooper sleeve

ActiveCN110977399APress fit correctlyEfficient pressingEdge grinding machinesMetal working apparatusEngineeringTransfer mechanism

The invention relates to the technical field of oil pump component assembly, and discloses automatic press fitting equipment for an oil pump cooper sleeve. The automatic press fitting equipment comprises a cooper sleeve feeding mechanism, a cooper sleeve gap recognition mechanism, an end cover feeding mechanism, a cooper sleeve discharging mechanism, a press fitting mechanism for pressing cooper sleeves into end covers, a transferring mechanism for transferring the cooper sleeves from the cooper sleeve feeding mechanism to the cooper sleeve gap recognition mechanism and a rotary disc mechanismfor undertaking material transferring in the whole press-fitting process; a plurality of end cover positioning jigs are arranged on the rotary disc mechanism, the transferring mechanism transfers twocooper sleeves each time, and the copper sleeve gap recognition mechanism carries out gap recognition on the two copper sleeves at the same time; and the copper sleeve discharging mechanism is used for transferring the two copper sleeves on the copper sleeve gap recognition mechanism to the end cover positioning jigs to be pre-assembled for press-fitting by the press fitting mechanism, and the press fitting mechanism simultaneously presses the two copper sleeves into two copper sleeve mounting holes of an end cover correspondingly. Gaps of the two copper sleeves are effectively detected at the same time, and the two copper sleeves are pressed in at a time by the press fitting mechanism, so that the copper sleeve press-fitting process is carried out efficiently and continuously without errors.

Owner:ZHUZHOU TORCH SPARK PLUG CO LTD

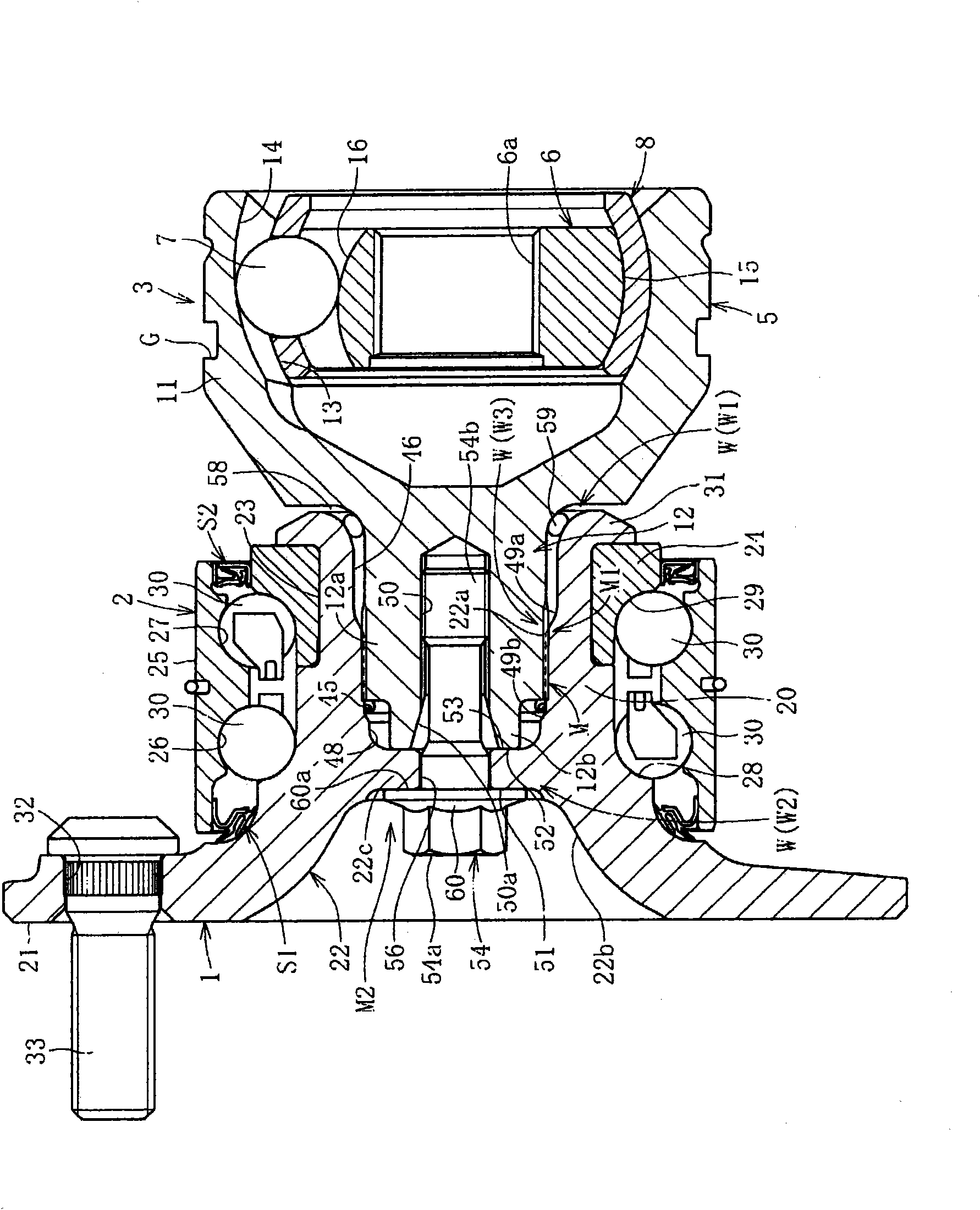

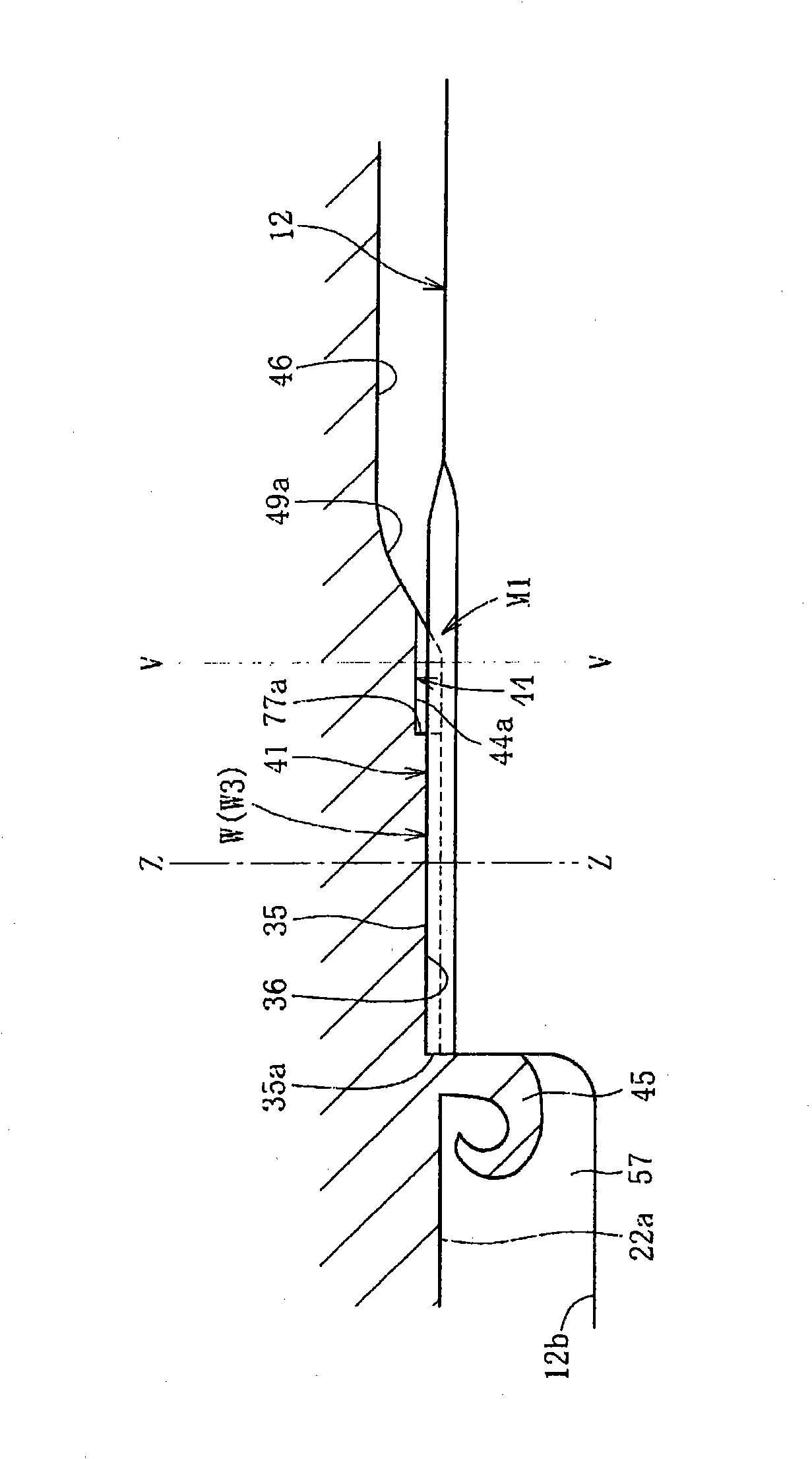

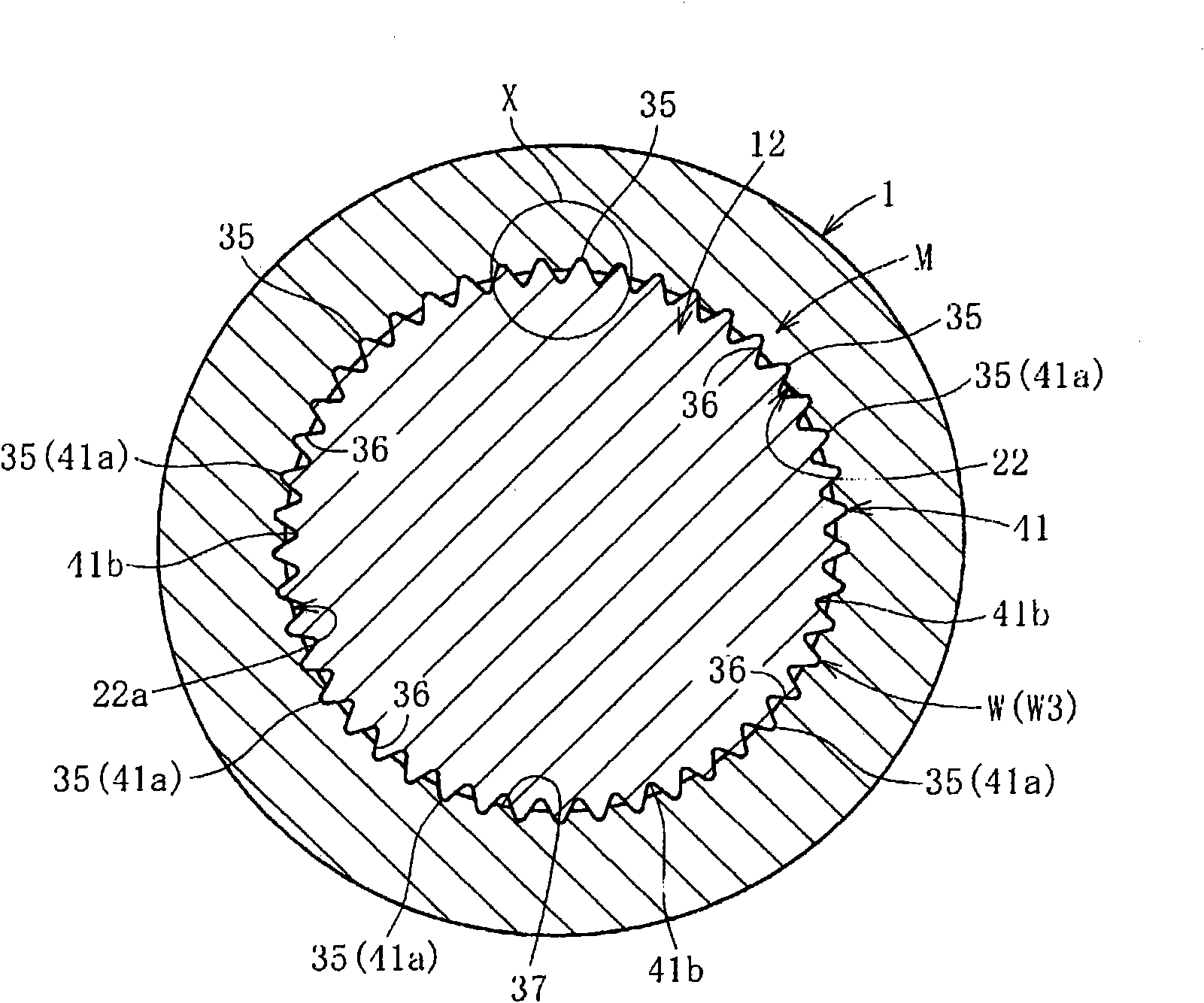

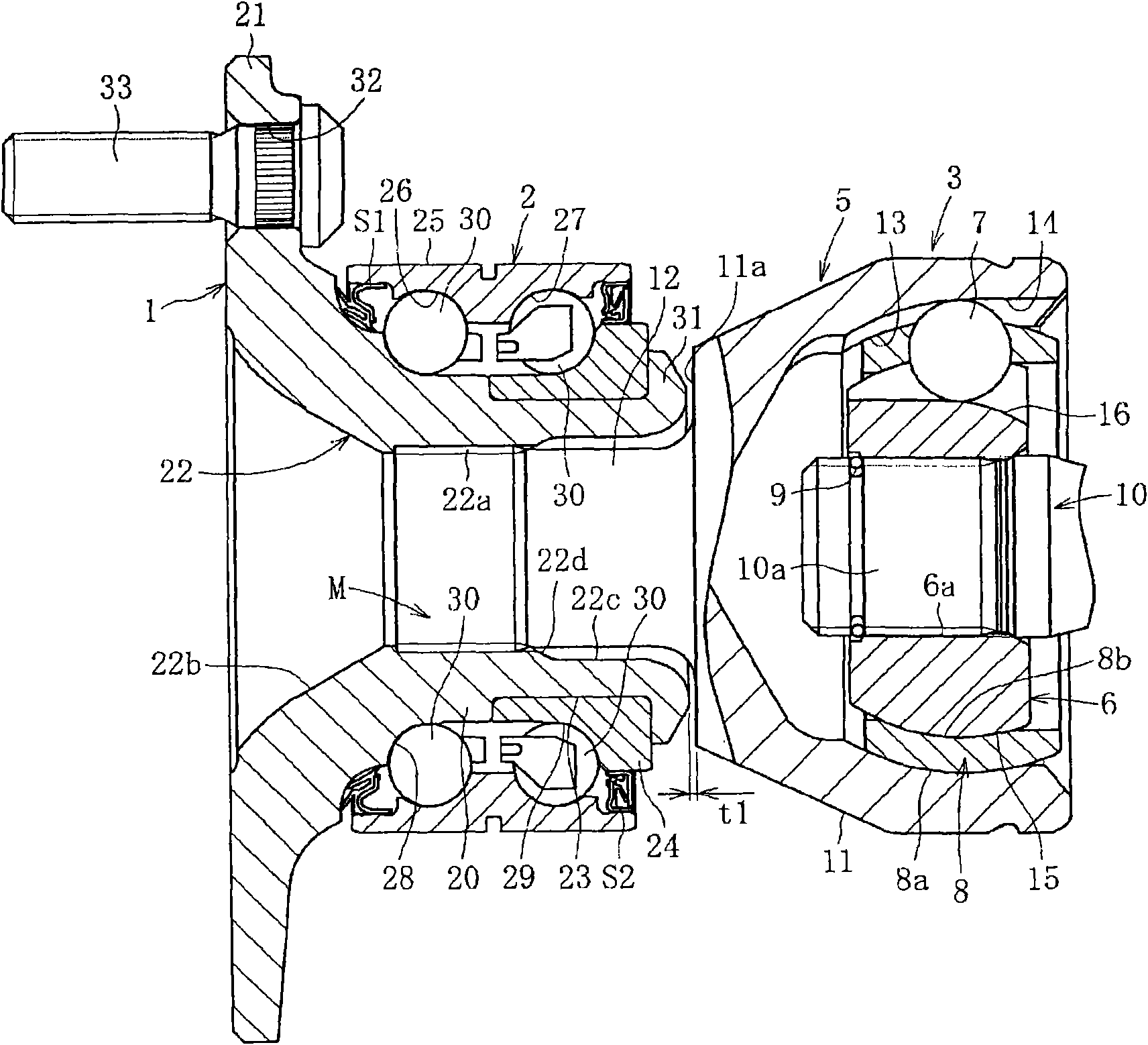

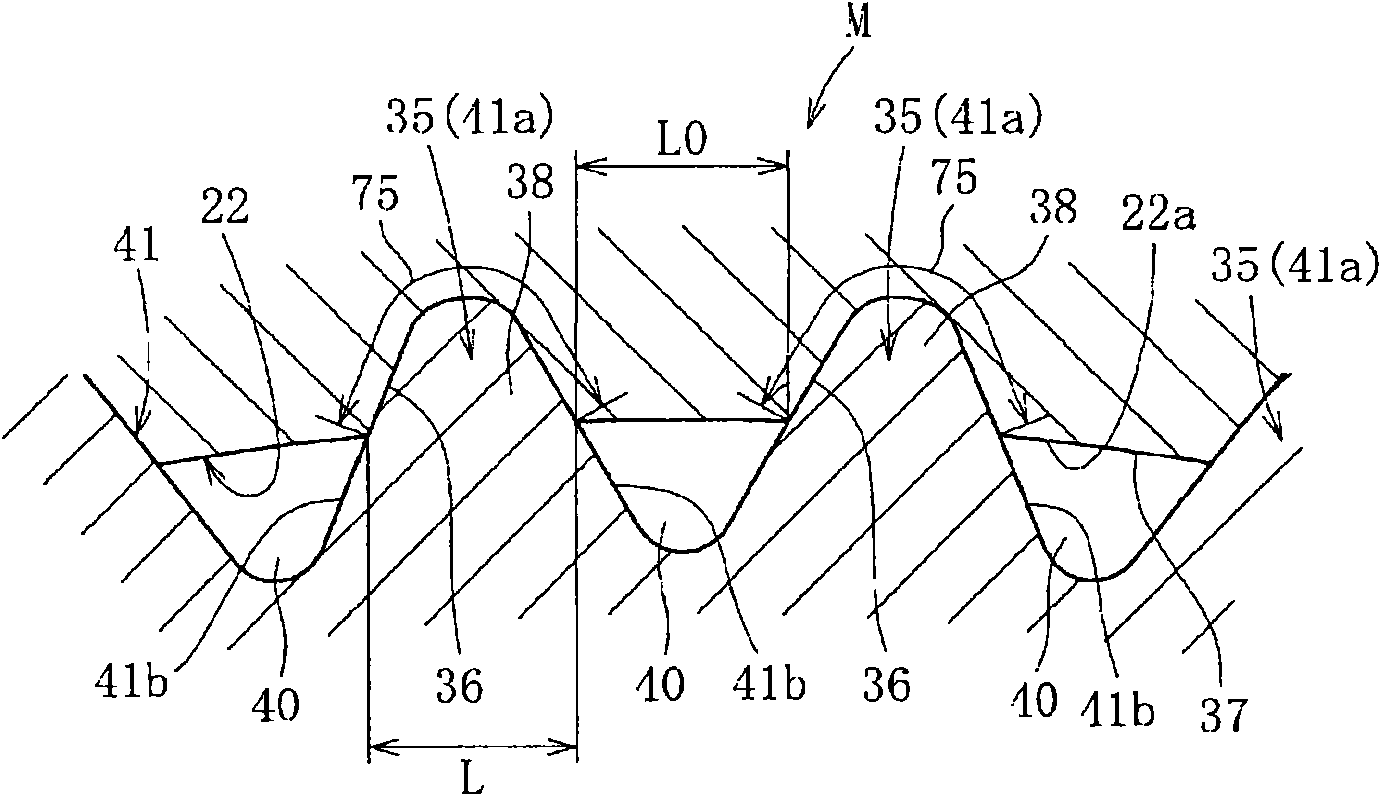

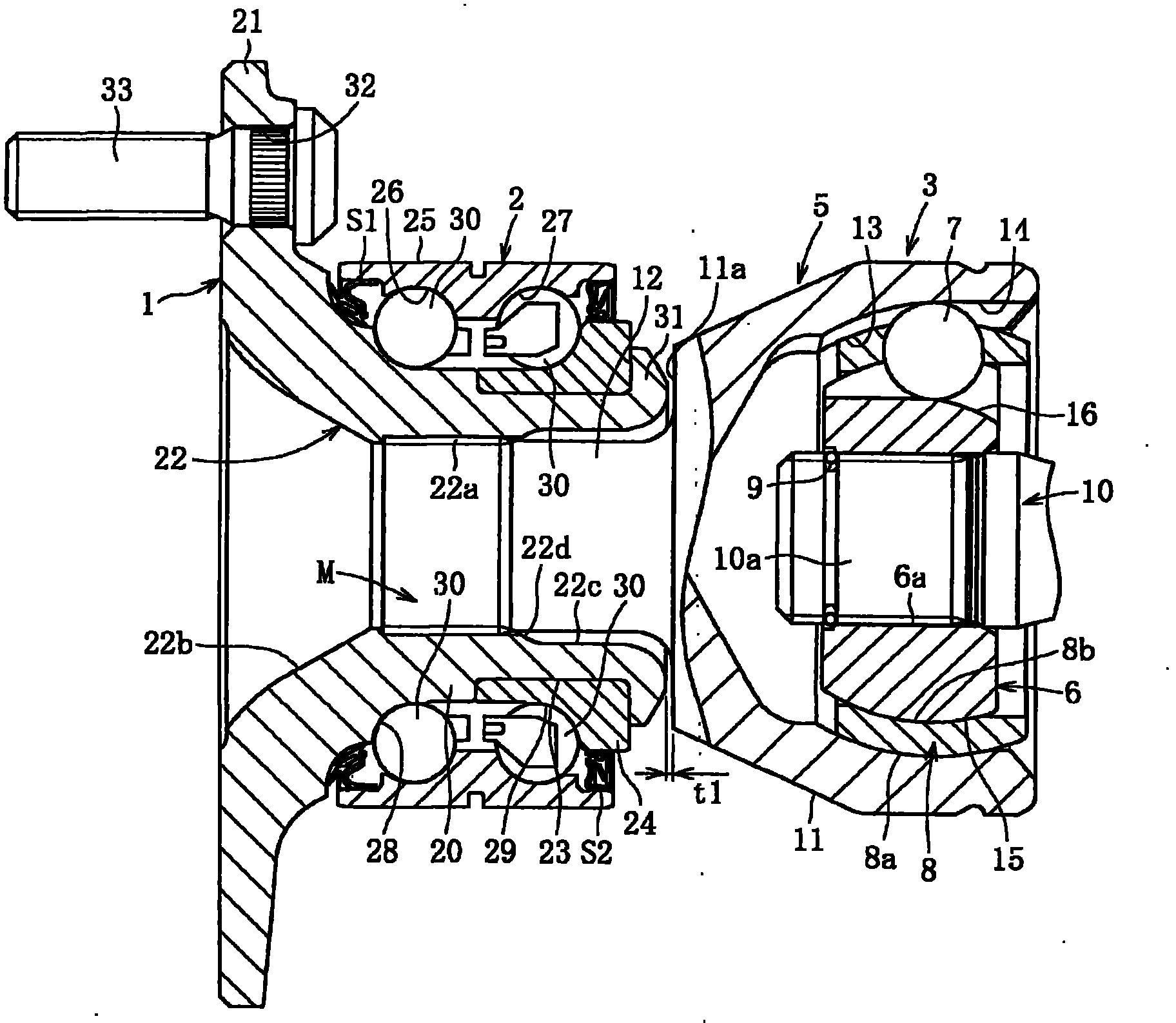

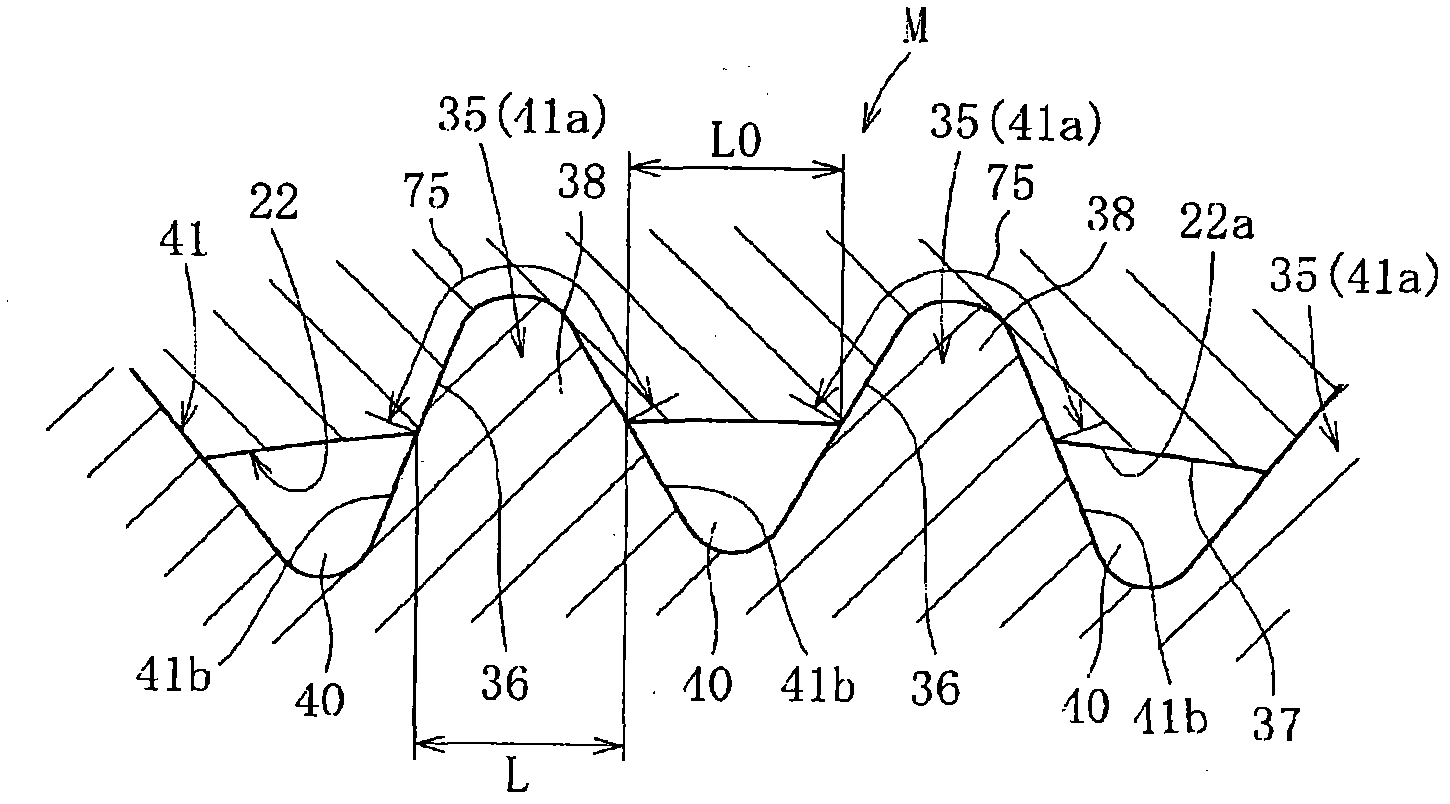

Bearing device for wheel

ActiveCN101827715AStable deliveryHigh strengthYielding couplingRolling contact bearingsJoint componentPull force

A bearing device for a wheel, in which circumferential play is minimized, a hub ring and an outer joint member of a constant velocity universal joint can be connected to each other with good workability, and the hub ring and the outer joint member are adapted to be separable from each other to provide the device with good maintainability. In the bearing device, the outer joint member of the constant velocity universal joint (3) has a shaft section (12) fitted into a hole (22) of the hub ring (1), and the hub ring (1) and the shaft section (12) are separably joined to each other by a ridge-groove fit structure (M). Axially extending ridges are formed on either of the outer diameter surface of the shaft section of the outer joint member and the inner diameter surface of the hole of the hub ring. The ridges are axially press-fitted into the other. As a result, grooves fitting on the ridges are formed in the other to form the ridge-groove fit structure in which the entire areas of fit and contact portions of the ridges and grooves are in intimate contact with each other. The ridge-groove fit structure (M) allows separation between the hub and the outer joint member by axially applied pulling force.

Owner:NTN CORP

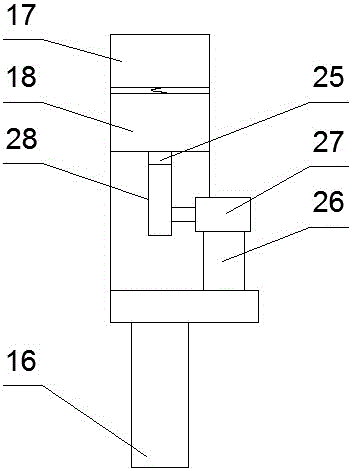

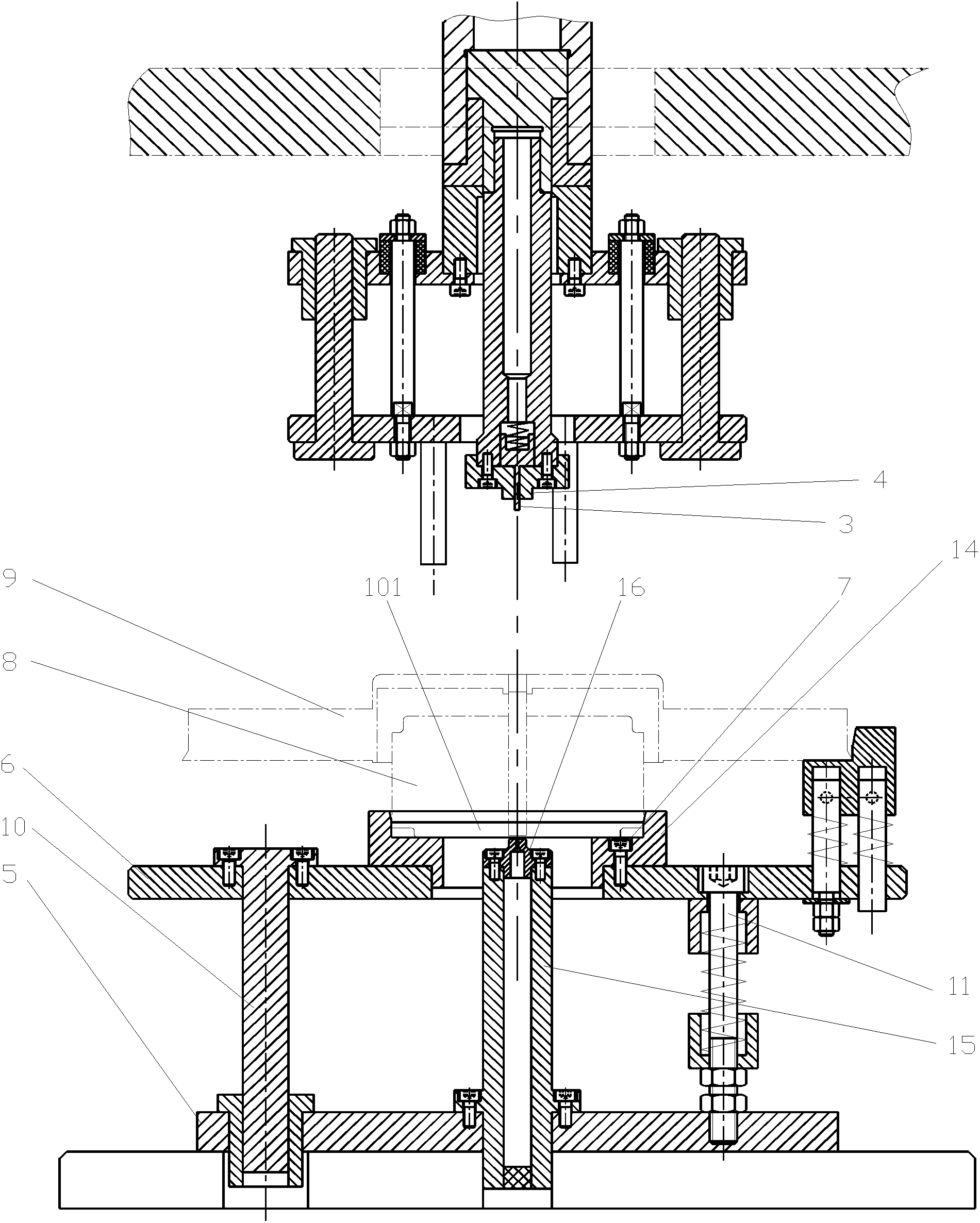

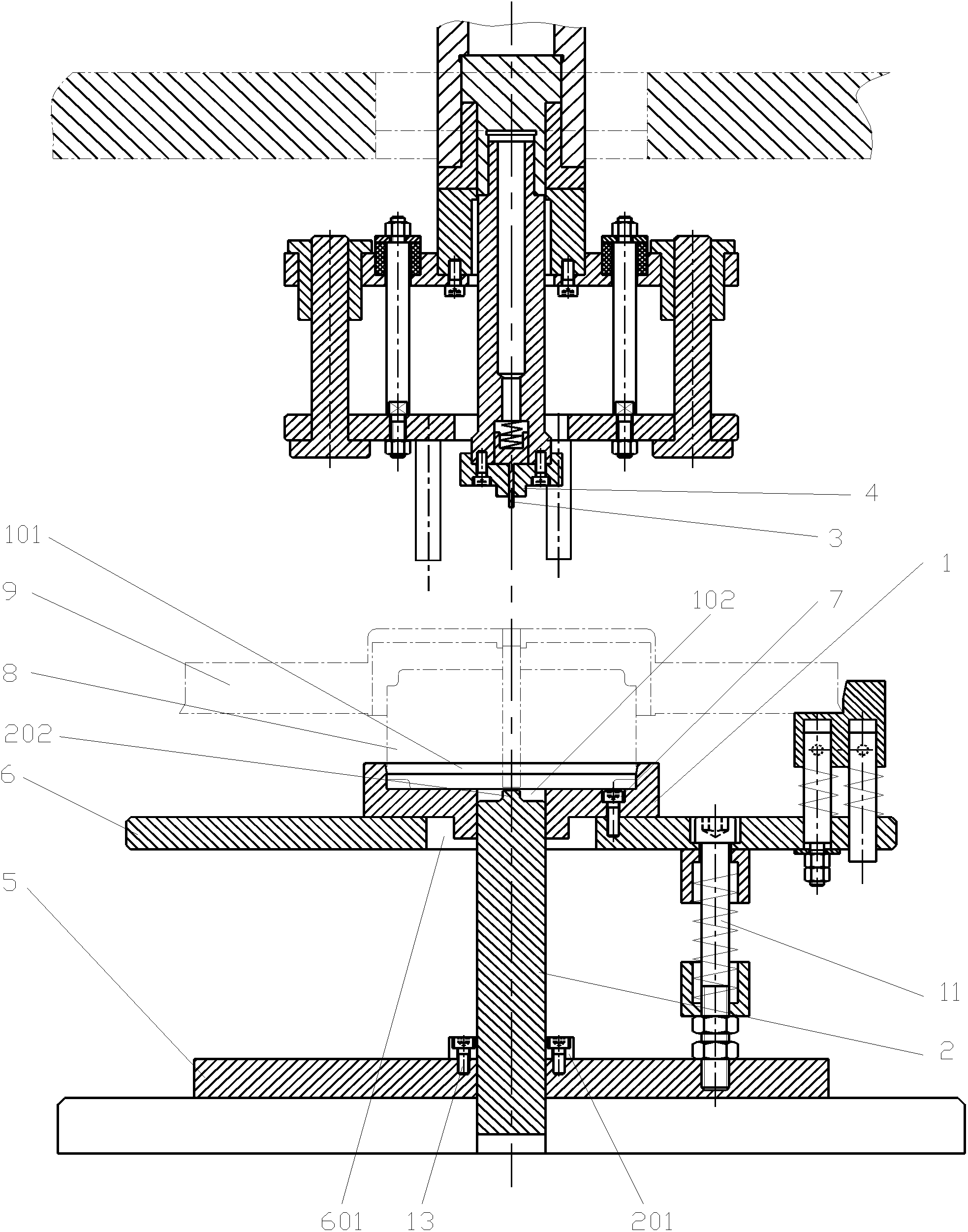

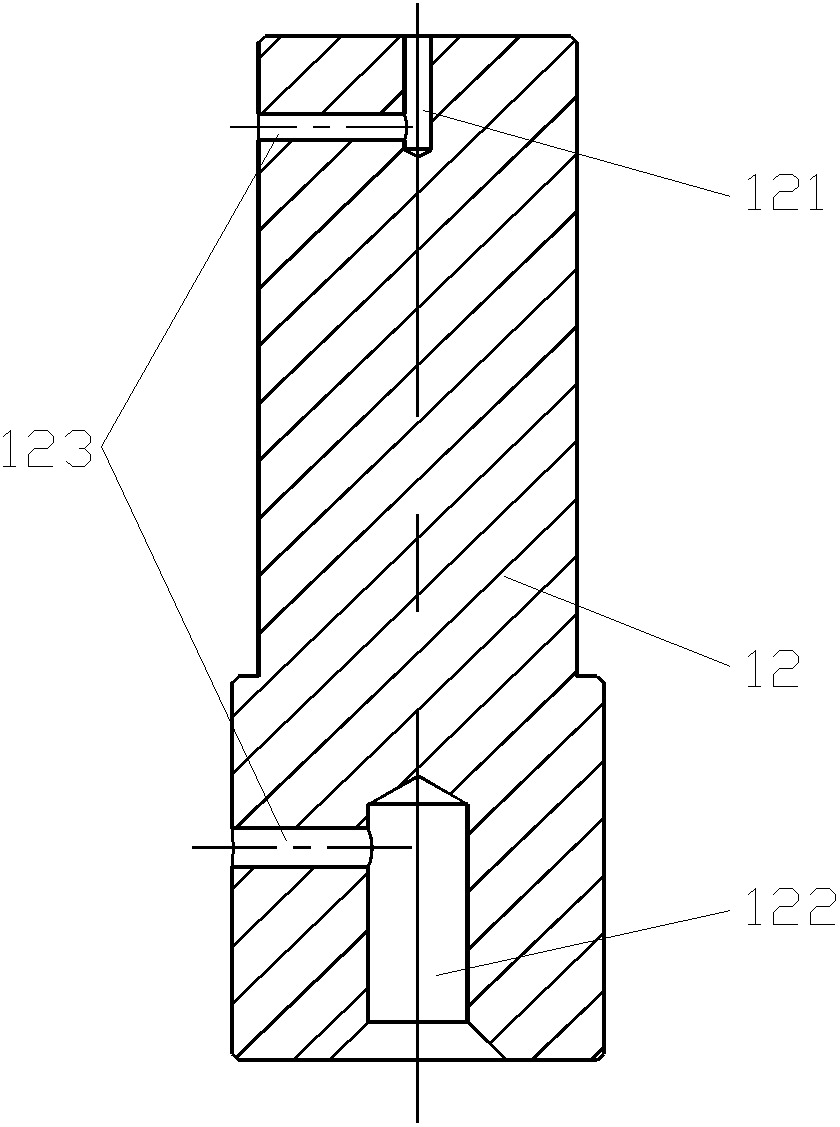

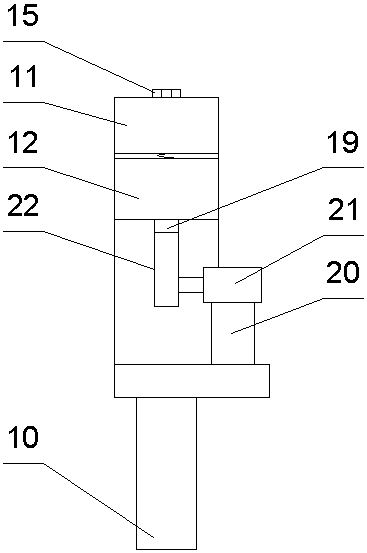

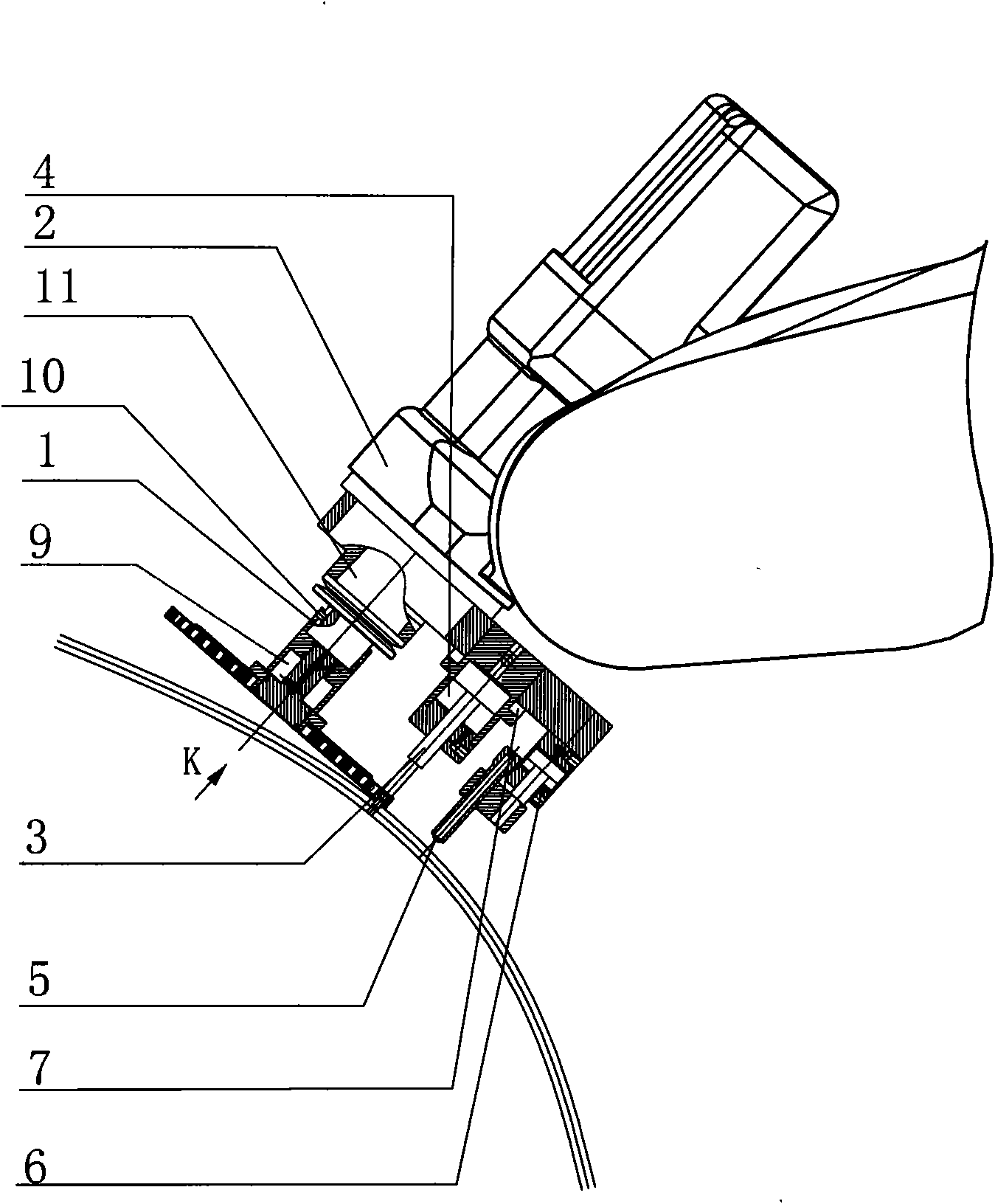

Improved structure of cooling fan compression joint device

ActiveCN102528426AGuaranteed positioning accuracyThe pressing process is stableMetal working apparatusEngineeringRejection rate

The invention relates to an improved structure of a cooling fan compression joint device. A liftable supporting plate is arranged in parallel above a horizontal base. The center of the supporting plate is provided with a mounting hole. A lower clamp which is of a step disk shape is arranged above the supporting plate. The small end of the lower clamp extends into the mounting hole. The outer diameter of the small end of the lower clamp is less than the aperture of the mounting hole on the supporting plate. The big end of the lower clamp is provided with a motor positioning cavity. The center of the small end of the lower clamp is provided with a through hole. The through hole is communicated with the motor positioning cavity. A vertical ejector rod is arranged in the through hole of the lower clamp. The ejector rod is in clearance fit with the through hole. The center of the end face of the upper end of the ejector rod protrudes to form an ejector head. An upper guide pin capable of vertically lifting and descending is coaxially arranged above the lower clamp. A device is provided with a vertical centering rod. The upper and lower end faces of the vertical centering rod are respectively provided with coaxial centering holes. The coaxiality of the upper guide pin and the lower clamp is detected before press mounting by utilizing the centering rod, so that the press mounting process is ensured stable, the interference is uniform, the pressure is reduced, the press mounting alarm is reduced and the rework rate and the rejection rate are reduced, and thus, the cost is reduced.

Owner:SHANGHAI BROSE AUTOMOTIVE COMPONENTS

Power transmission and transformation line crystal cleaning device

ActiveCN106410724AEasy to snapBack-off guaranteeOverhead installationElectric power transmissionEngineering

The invention discloses a power transmission and transformation line crystal cleaning device. The device comprises a walking mechanism and a rack connected below the walking mechanism by mechanical arms. A deicing mechanism is arranged on the rack. A wireless controller is arranged on the left side inside the rack, and the walking mechanism is in electrical signal connection with the wireless controller. The deicing mechanism is composed of an ice breaking module, a water jet segmenting module, and a pre-cutting module in sequence from left to right. The rack is equipped with an attitude adjustment module used for attitude adjustment and a balance detection module. First, ice is pre-cut by the pre-cutting module; then, the pre-cut ice is segmented by the water jet segmenting module; and finally, the pre-cut and segmented ice is removed from a power line by the ice breaking module. Moreover, the attitude adjustment module and the balance detection module ensure that the device can run smoothly even if there is ice which is hard to remove. The deicing effect of the device is enhanced.

Owner:XICHUAN COUNTY POWER BUREAU

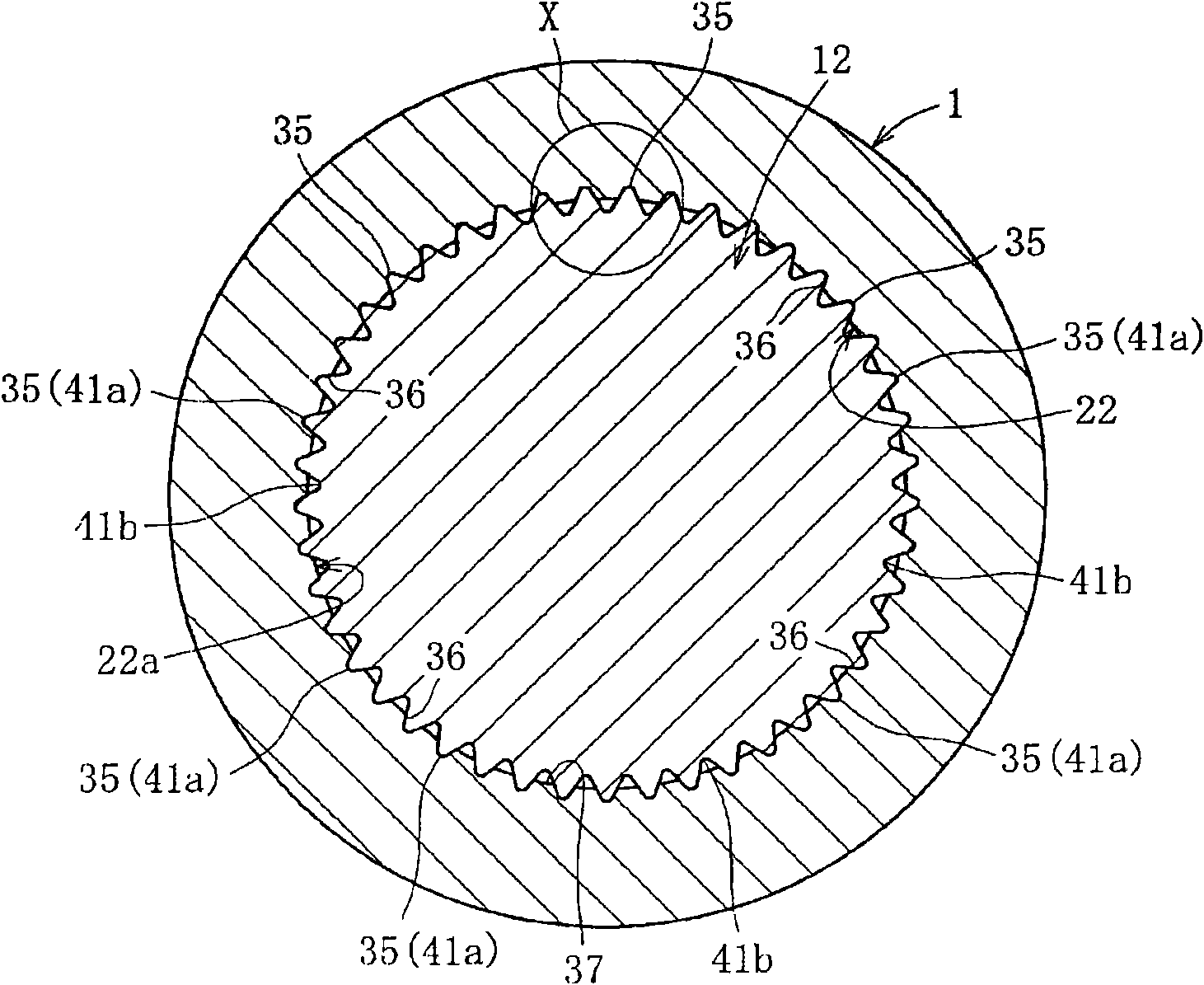

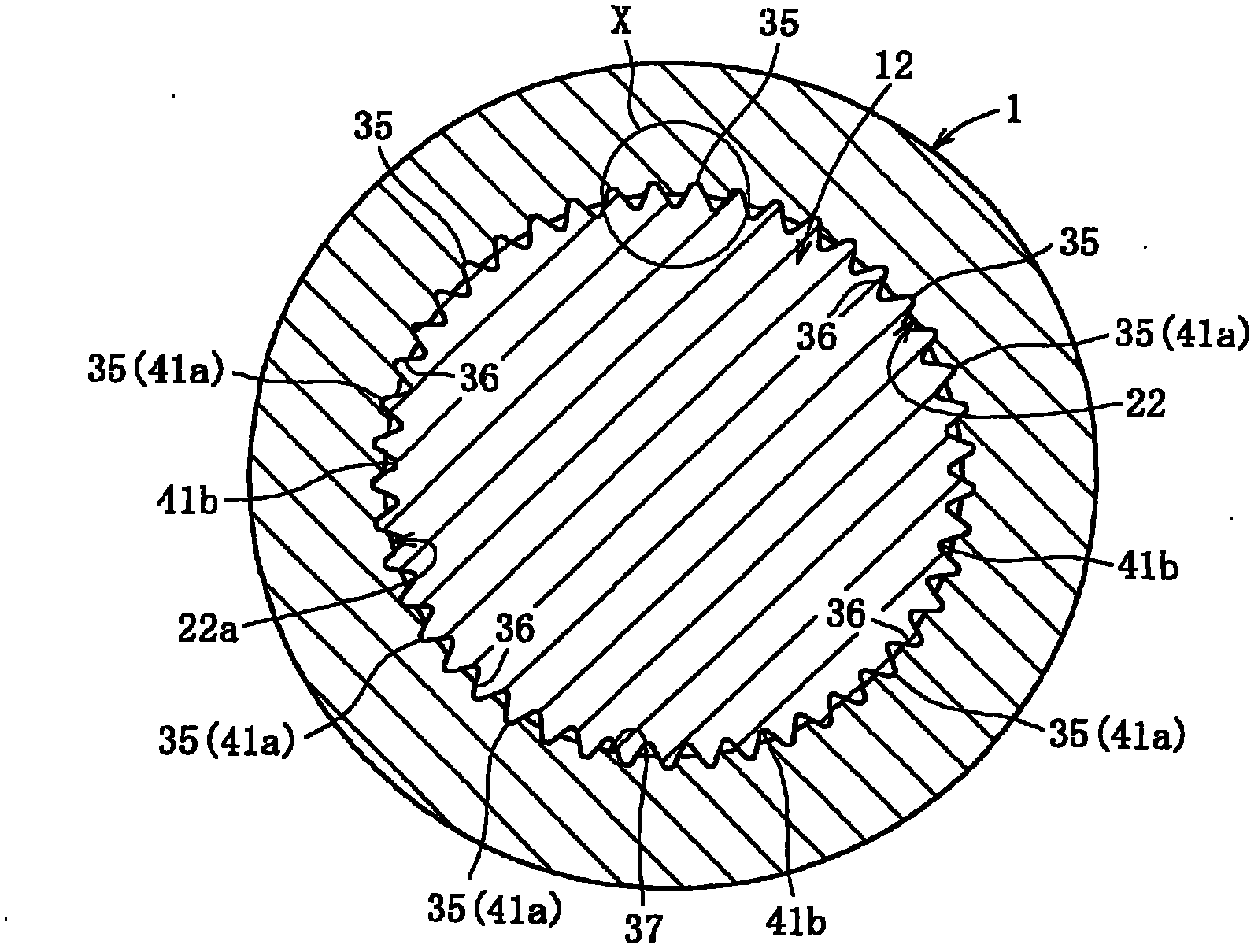

Bearing device for wheel

InactiveCN101641225ADoes not generate abnormal noiseHigh strengthRolling contact bearingsAxle unitsKnuckleEngineering

A bearing device for a wheel, in which circumferential play is suppressed, which facilitates connection between a hub ring and an outer coupling member, in which a reduction in NVH characteristics due to play at a joint between the hub ring and the constant velocity universal joint and by play between a bearing outer member and a knuckle is prevented, and which performs highly accurate transmission of rotational torque. The bearing device has a groove-ridge fitting structure (M) by which the hub ring (1) and a shaft section (12) of the outer coupling member of the constant velocity universal joint (3) are integrated together, and the shaft section (12) is fitted in a hole (22) of the hub ring (1). In the groove-ridge fitting structure (M), ridges (35) on the outer diameter surface of the shaft section (12) and grooves (36) in the inner diameter surface (37) of the hub ring (1) are fitted to each other in a fitting contact portion (38), and the ridges (35) and the grooves (36) are in intimate contact with each other in the entire fitting contact portion (38).

Owner:NTN CORP

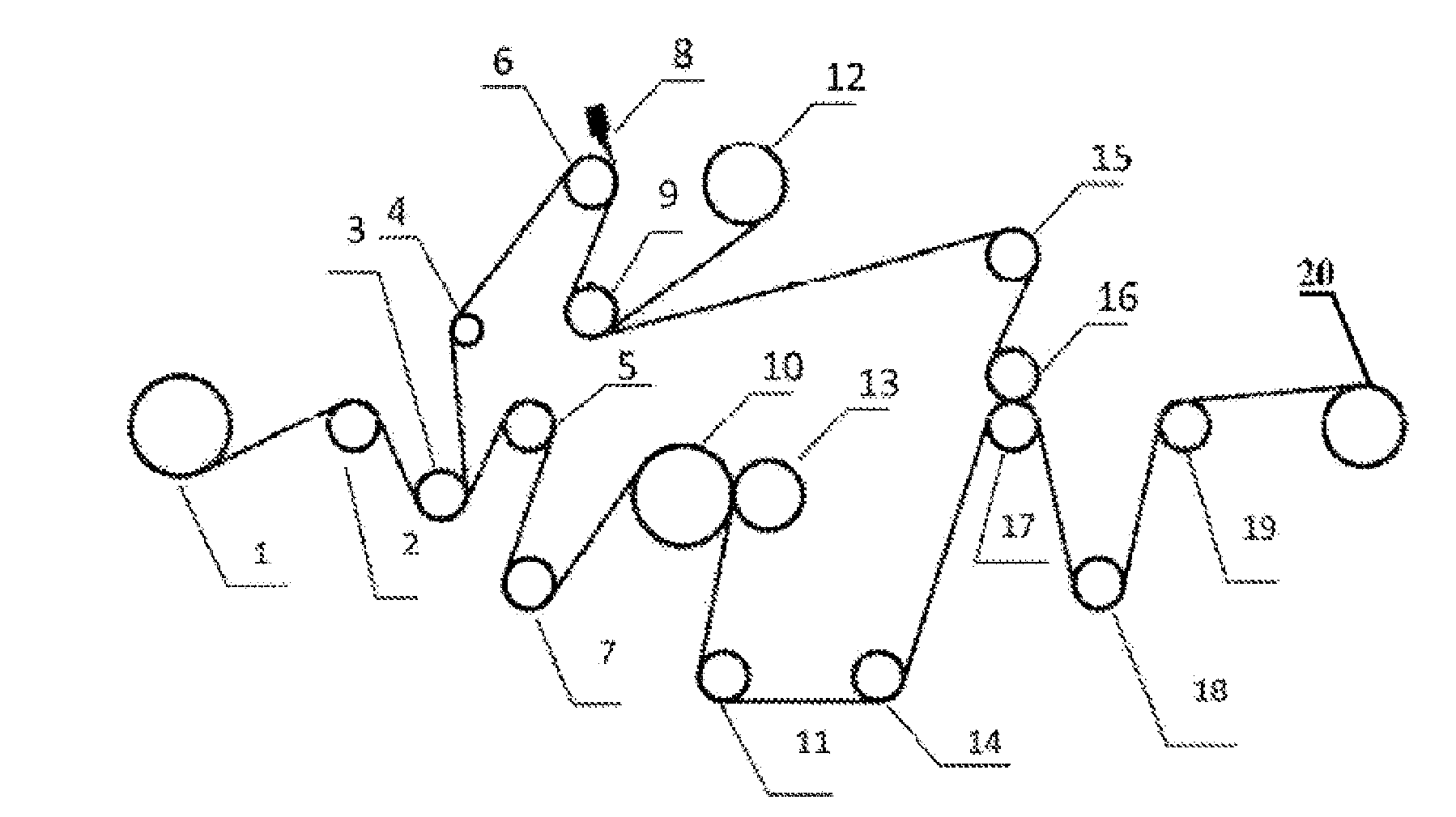

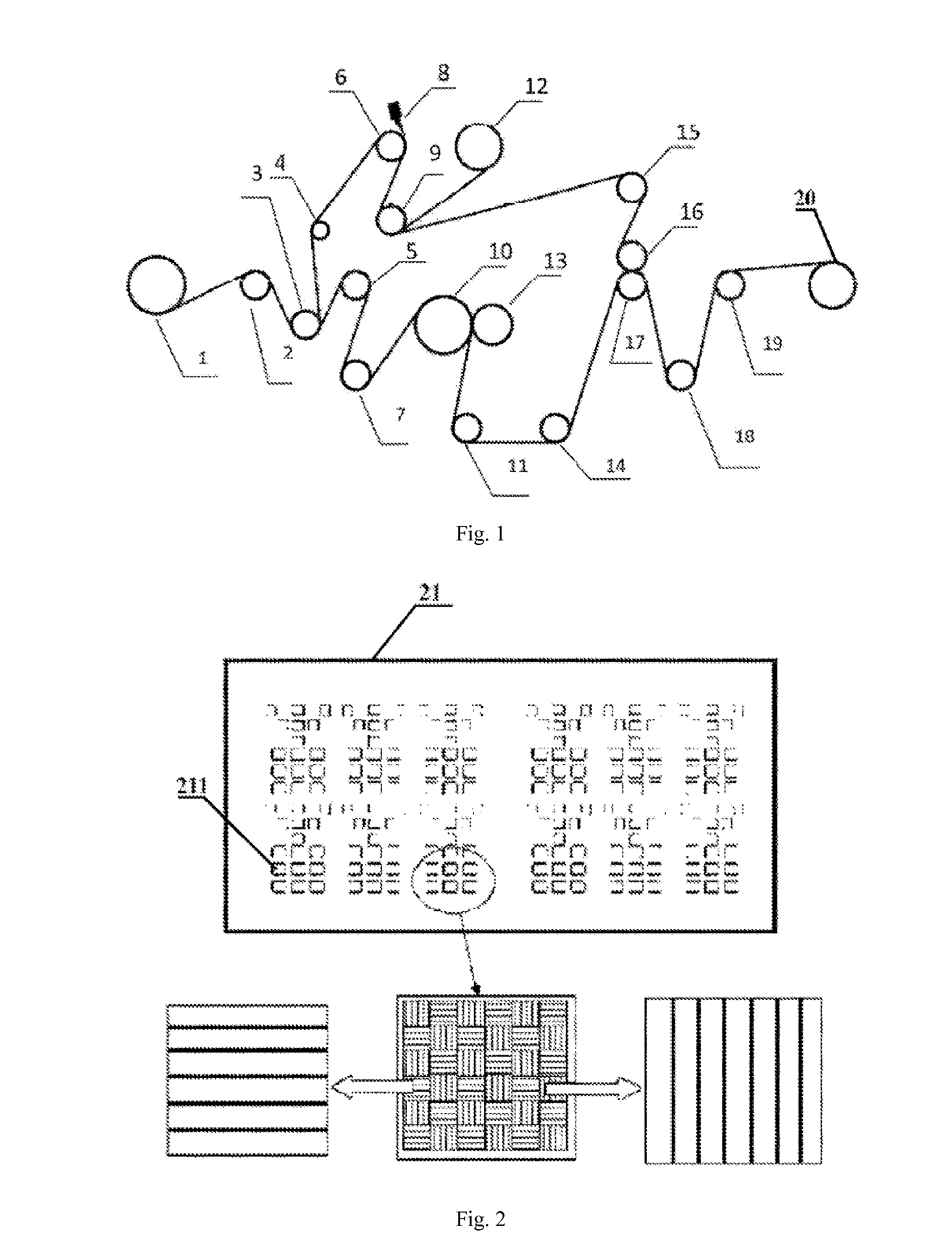

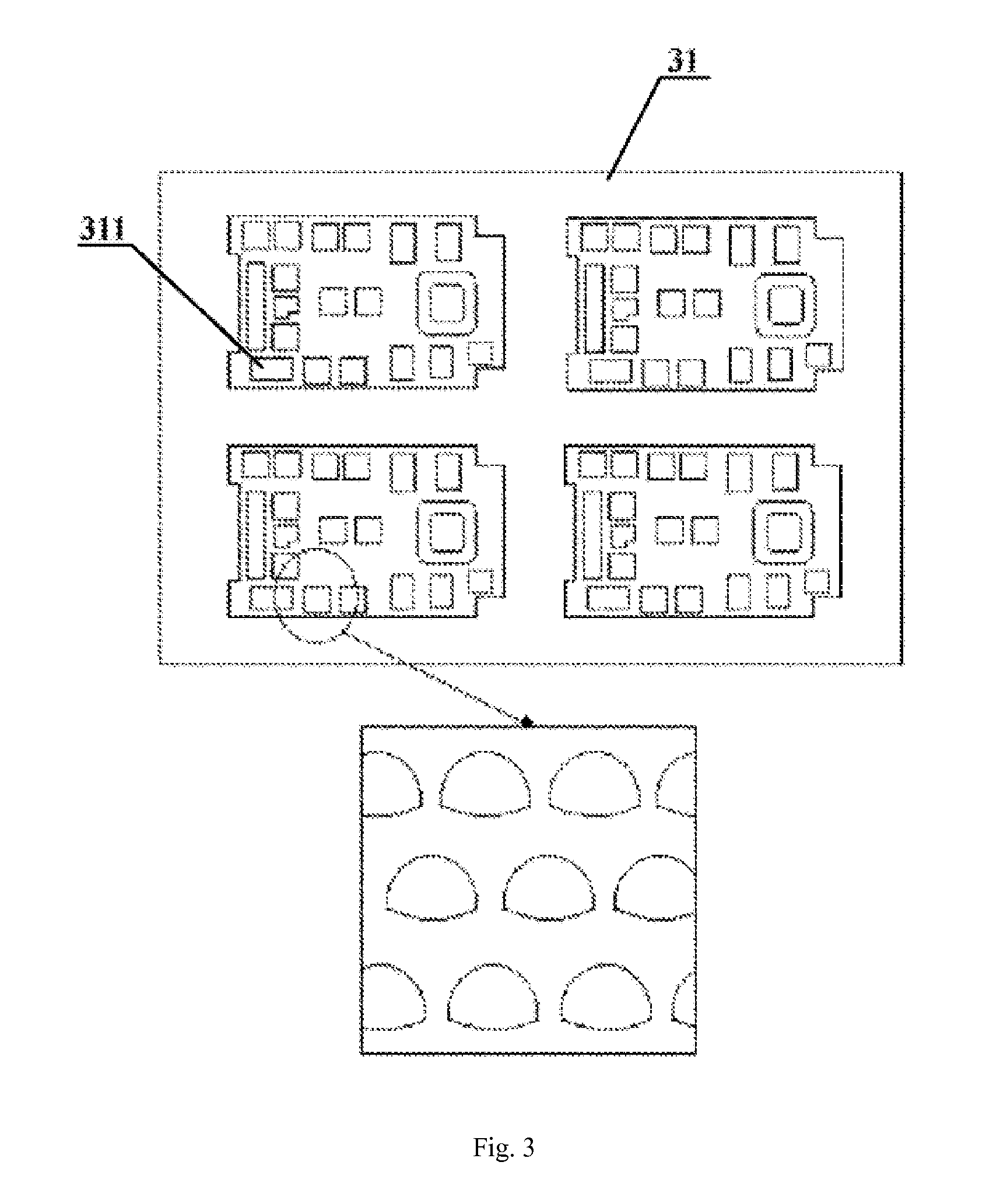

Apparatus for manufacturing light guide film

An apparatus for manufacturing a light guide film may comprise a feed roller, a receiving roller, a separating device, a hot press printing device and a recombining device. Firstly, the separating device may separate a protective layer from a substrate layer of the light guide film. Secondly, a surface of the substrate layer to be manufactured may be impressed with light guide dots by the hot press printing device, and the recombining device recombine the peeled protective layer to the substrate layer. And lastly, the finished light guide film is recycled by the receiving roller. The apparatus may have advantages such as high output and low cost, and it may manufacture a large dimensioned product.

Owner:SVG TECH GRP CO LTD +1

Power cable deicing device

The invention discloses a power cable deicing device. The power cable deicing device comprises a travel mechanism and a frame which is connected with the lower side of the travel mechanism through a robot arm. The travel mechanism comprises a rear travel wheel which is arranged at a part without icing on a power cable, and a front travel wheel which is arranged at a part with icing on the power cable. A deicing mechanism is arranged on the frame. The deicing mechanism is located between the rear travel wheel and the front travel wheel. A wireless controller is arranged on the left side of in the frame. The travel mechanism is in electrical signal connection with the wireless controller. The deicing mechanism comprises an icing breaking module, a water jet cutting module and a pre-cutting module in order from left to right. The water pressure of the water jet cutting module is adjusted according to the detected thickness of an icing layer. When icing on the surface is cut, deicing is efficiently carried out without the influence of the thickness of the icing layer, and a line is prevented from being damaged. The pre-cutting module is used to pre-cut the icing, and the icing is easily divided into small pieces when water jet cutting is carried out.

Owner:PINGDINGSHAN POWER SUPPLY ELECTRIC POWER OF HENAN

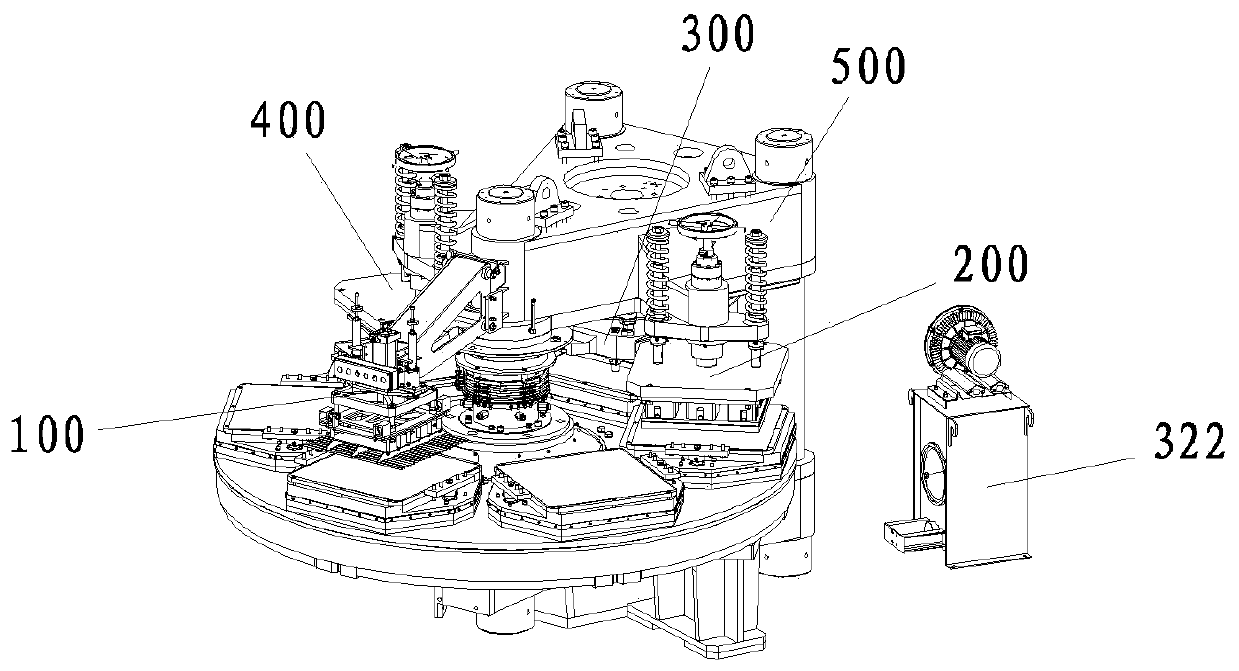

Automatic machining equipment for ceramic ferrules

ActiveCN111443434AImprove accuracyThe pressing process is stableCoupling light guidesManufacturing engineeringWorkbench

The invention relates to automatic machining equipment for ceramic ferrules. The automatic machining equipment comprises a workbench, wherein a vibrating disk bottom frame I and a vibrating disk bottom frame II are arranged on a left side of the workbench; and the vibrating disk bottom frame I is located on a front side of the vibrating disk bottom frame II. The automatic machining equipment is characterized in that a rotary carrying mechanism is arranged in the middle of an upper surface of the workbench; a sleeve feeding mechanism, a plug feeding mechanism, a press fitting mechanism, a firstappearance detection mechanism I, a second appearance detection mechanism II and a discharging mechanism are sequentially arranged on the periphery of the rotary carrying mechanism in the clockwise rotation direction of the rotary carrying mechanism; a defective product removing mechanism is arranged at an upper end of the rotary carrying mechanism; a material box is fixed to the position, corresponding to a carrying part of the rotary carrying mechanism, on the upper surface of the workbench; the material box is located on a front side of the appearance detection mechanism I; and the sleevefeeding mechanism is used for placing a sleeve on a product positioning seat of the rotary material loading mechanism. The automatic machining equipment is high in automation degree, improves the working efficiency, saves the labor cost, and has good market application value.

Owner:深圳市前海中剑辰星科技有限公司

Bearing device for wheel

InactiveCN102152711AStable deliveryHigh strengthYielding couplingRolling contact bearingsUniversal jointTorque transmission

Provided is a bearing device for a wheel that can realize prevention of a backlash in a circumferential direction and is excellent in workability of connection of a hub wheel and an outer joint member of a constant velocity universal joint. Further, provided is a bearing device for a wheel that can prevent deterioration in NVH characteristics, which is caused by the backlash occurring in a joint section between the hub wheel and the constant velocity universal joint or between an outer member and a knuckle, and can perform rotation torque transmission with high accuracy. The bearing device includes a recess-projection fitting structure (M) in which the hub wheel (1) and a shaft section (12), which is fitted in a hole (22) of the hub wheel (1) of the outer joint member of the constant velocity universal joint (3) are unitized together. In the recess-projection fitting structure (M), entire fitting regions among projections (35) on the outer surface of the shaft section (12) of the outer joint member and recesses (36), which fit on the projections, are brought into intimate contact with each other.

Owner:NTN CORP

Assembling device for lining pressing assembling

PendingCN109570969ASolve complexityAddress operational hazardsMetal working apparatusCushionEngineering

The invention relates to an assembling device for lining pressing assembling. An upper die, a lower die and a negative pressure device are included. The upper die is driven by a hydraulic machine to move downwards so that a lining can be pressed and assembled into a workpiece. The negative pressure device is connected with the lining through a pipeline, and the lining is adsorbed to the bottom ofthe upper die. The position, corresponding to the negative pressure device, on the side wall of the hydraulic machine is provided with a control mechanism for starting the negative pressure device inthe pressing assembling process and stopping the negative pressure device after pressing assembling is finished. A cushion block inserted in a groove in the side portion of the workpiece so as to support the workpiece for pressing assembling is arranged on one side of the bottom of the workpiece in a sliding manner, the outer side of the workpiece is provided with a pushing mechanism, and after the pushing mechanism drives the cushion block to be inserted in the groove in the side portion of the workpiece during workpiece inserting, the workpiece is supported; and the pushing mechanism drivesthe cushion block to disengage from the groove in the side portion of the workpiece when the workpiece is subjected to pressing assembling and extracted out of a cavity, and accordingly it is guaranteed that the workpiece is smoothly taken out. According to the device, the defects that during traditional lining pressing assembling, manual die operation is complex, operation is dangerous, efficiency is low, and manual lining placement positioning is instable are overcome.

Owner:WANXIANG QIANCHAO GUILIN CHASSIS PARTS

High-strength steel sheet having excellent processability and paint bake hardenability, and method for producing of high-strength steel sheet

InactiveUS8911567B2Lower ratioLow strengthHot-dipping/immersion processesFurnace typesImpurityArea fraction

The high-strength steel sheet includes, by mass %: C: 0.01% to 0.10%; Si: 0.15% or less; Mn: 0.80% to 1.80%; P: 0.10% or less; S: 0.015% or less; Al: 0.10% to 0.80%; Cr: 0.01% to 1.50%; N: 0.0100% or less; and a balance consisting of iron and inevitable impurities, in which a metallic structure is composed of ferrite and a hard second phase, the area fraction of the ferrite is 80% or more, the area fraction of the hard second phase is 1% to 20%, the fraction of unrecrystallized ferrite in the ferrite is less than 10%, the ferrite grain sizes are 5 μm to 20 μm, and the fraction of the ferrite crystal grains having an aspect ratio of 1.2 or less in the entire ferrite crystal grains is 60% or more.

Owner:NIPPON STEEL CORP

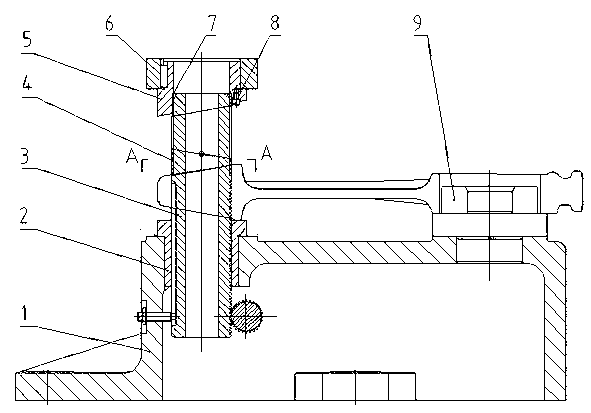

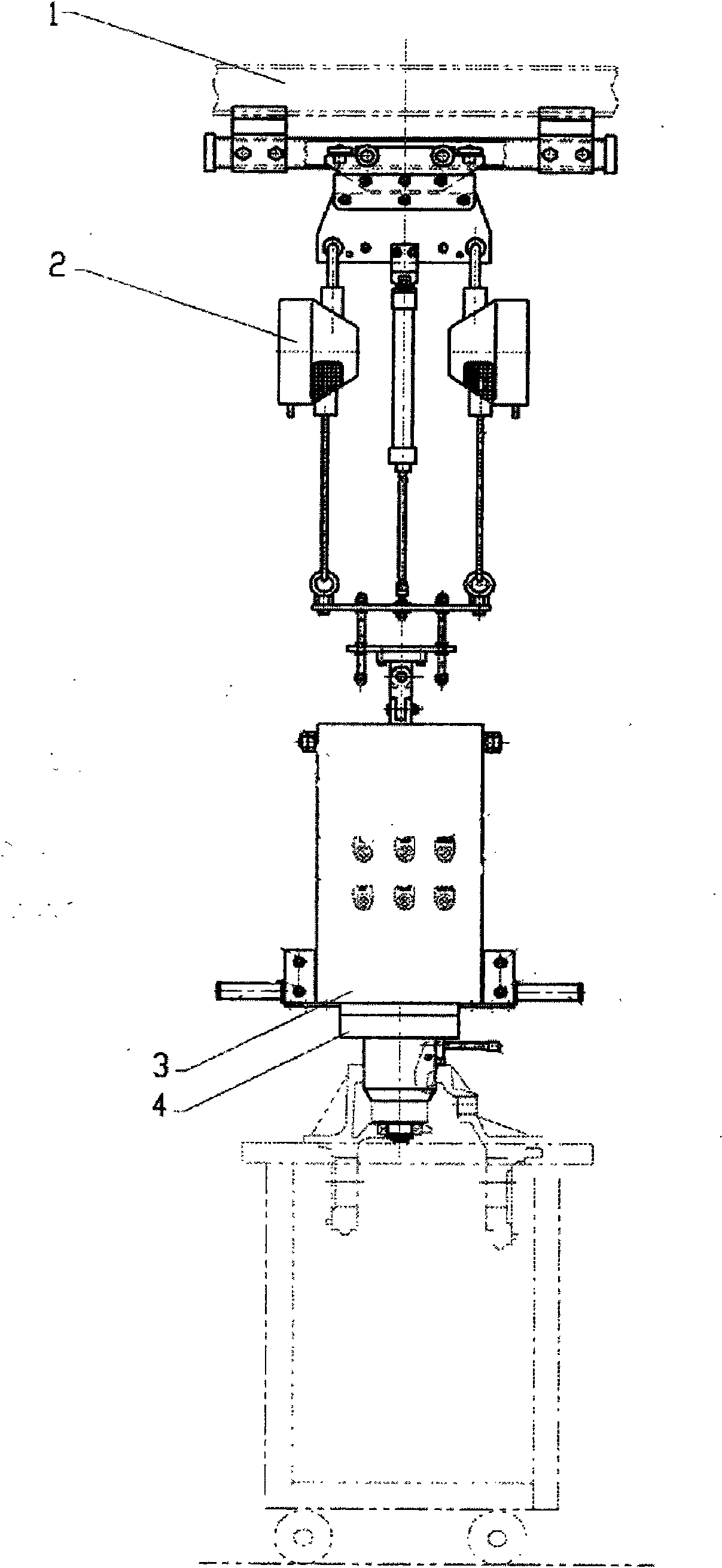

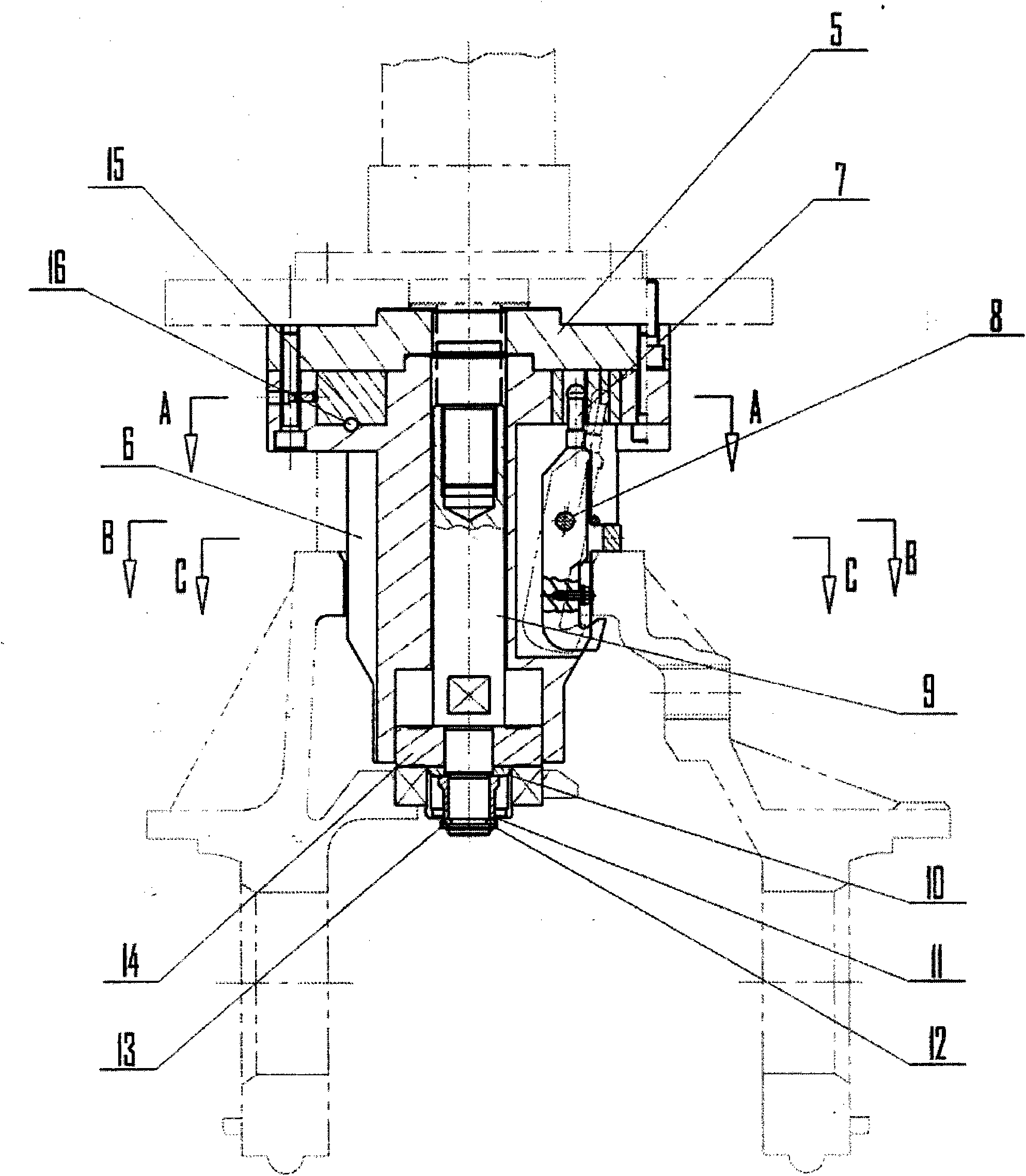

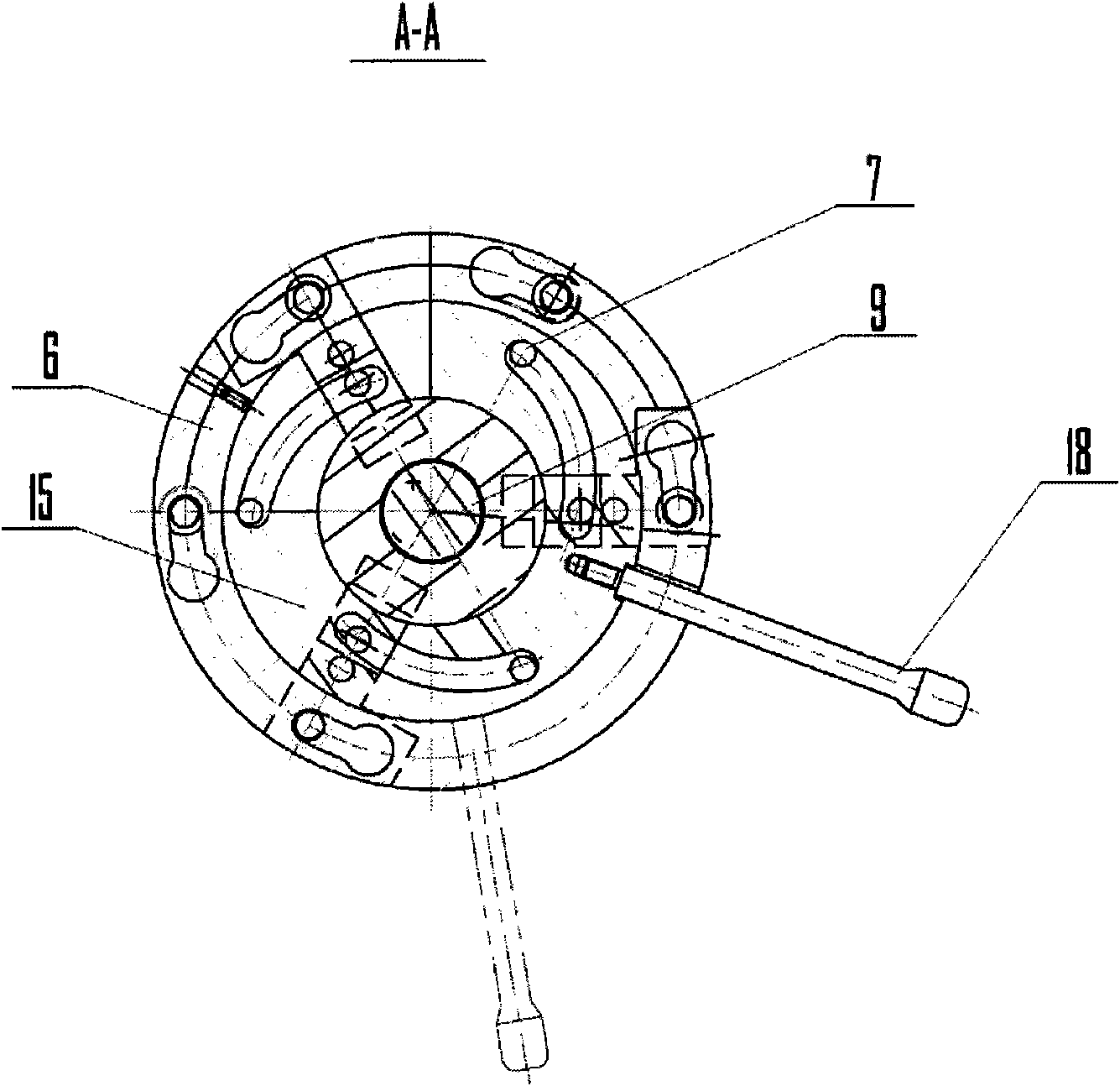

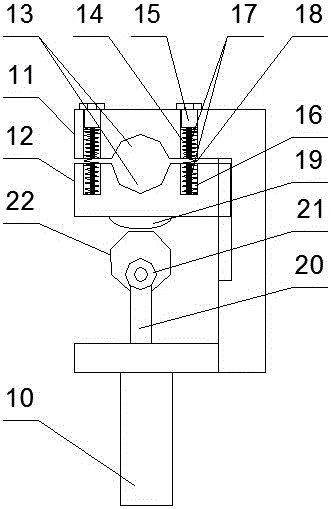

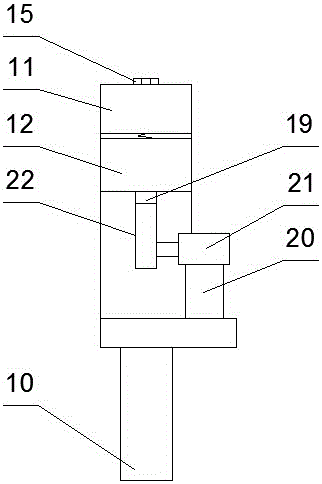

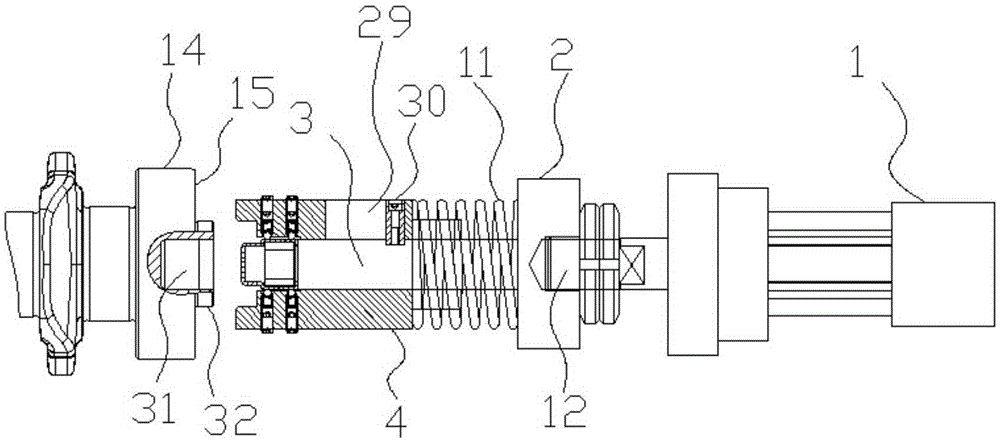

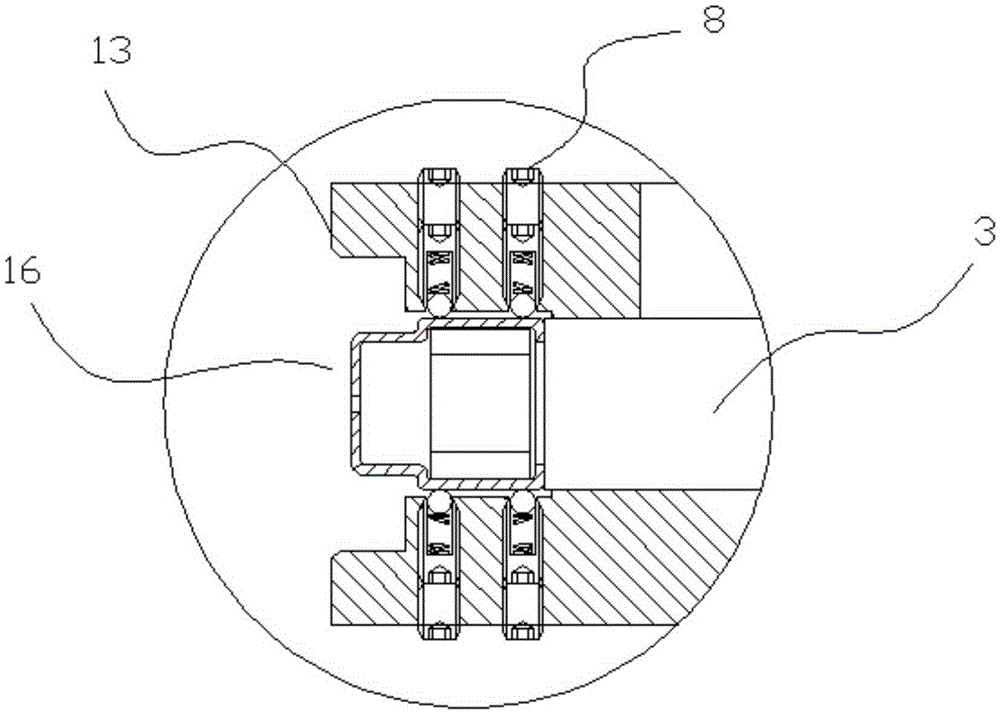

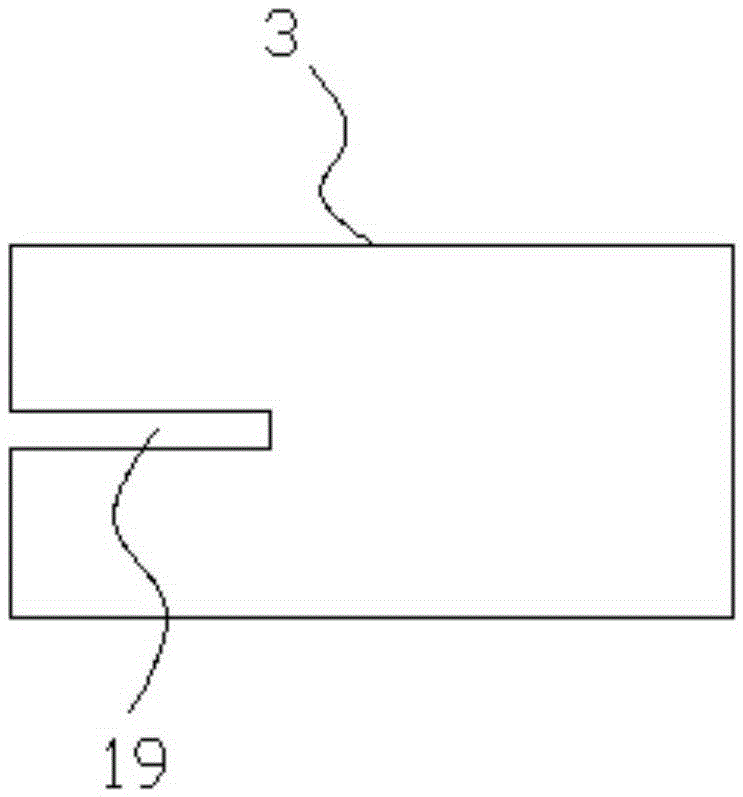

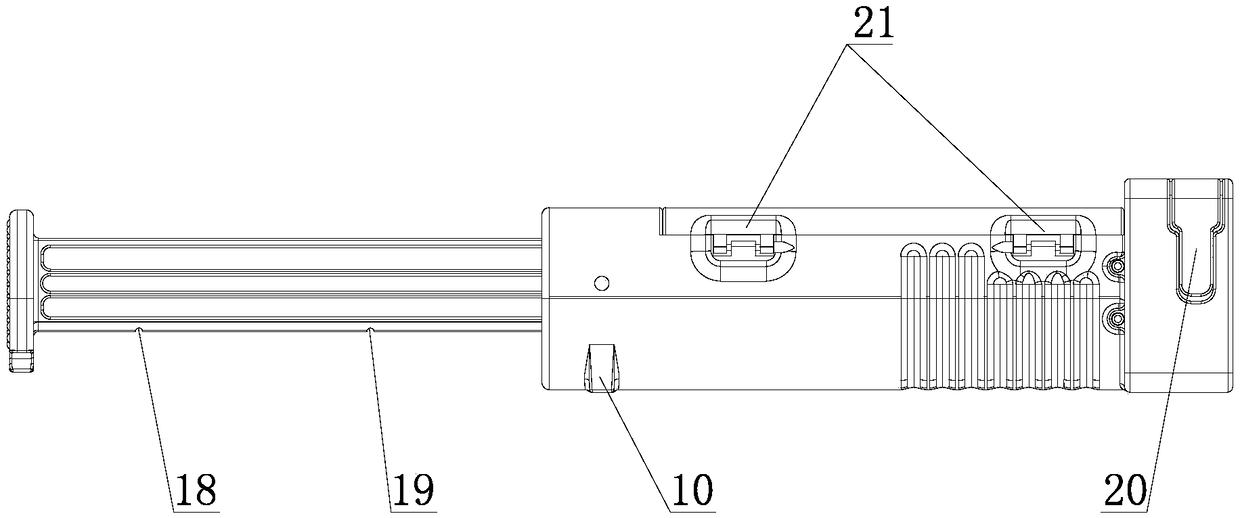

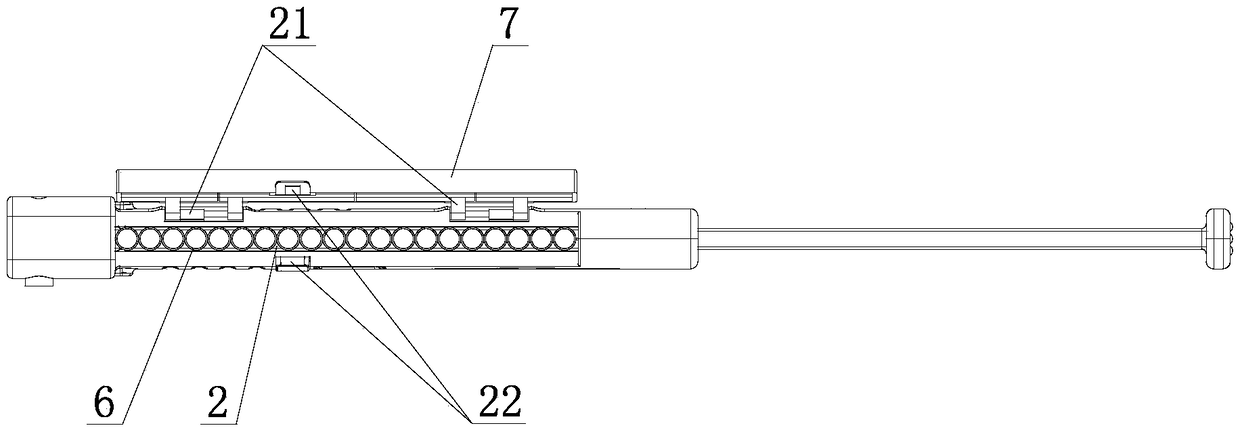

Press-fitting device for a stepped type needle roller bearing without inner ring

InactiveCN105666092ANot easy to tiltThe pressing process is stableCrankshaftsMetal working apparatusNeedle roller bearingSelf adaptive

The invention discloses a press-fitting device for a stepped type needle roller bearing without an inner ring. The press-fitting device is reasonable in structure and capable of effectively pressing the existing stepped type needle roller bearing without the inner ring to a bearing hole in the rear end of a crankshaft, centering and adaptive adjustment can be carried out during press-fitting, the press-fitting process is stable, and the bearing centering is good after assembling. The press-fitting device comprises a bearing press-fitting base and a dynamic electricity cylinder. The bearing press-fitting base comprises a force transmission seat and a bearing push rod. A piston rod of the dynamic electricity cylinder stretches towards the force transmission seat, and the bearing push rod is sleeved with an outer positioning sleeve; the outer positioning sleeve is provided with a plurality of self-adaptive positioning hole groups, each self-adaptive positioning hole group comprises two positioning holes penetrating through the side wall of the outer positioning sleeve, a fixing plunger is arranged on each positioning hole, and each fixing plunger is connected with a contact ball used for making contact with an outer ring of the needle roller bearing through an adjusting spring. An outer spring is arranged between the force transmission seat and the outer positioning sleeve and arranged on the bearing push rod in a sleeving mode. One end of the outer spring is connected with the force transmission seat, and the other end of the outer spring is connected with the outer positioning sleeve.

Owner:HUNAN LUOYOU ENGINE PARTS

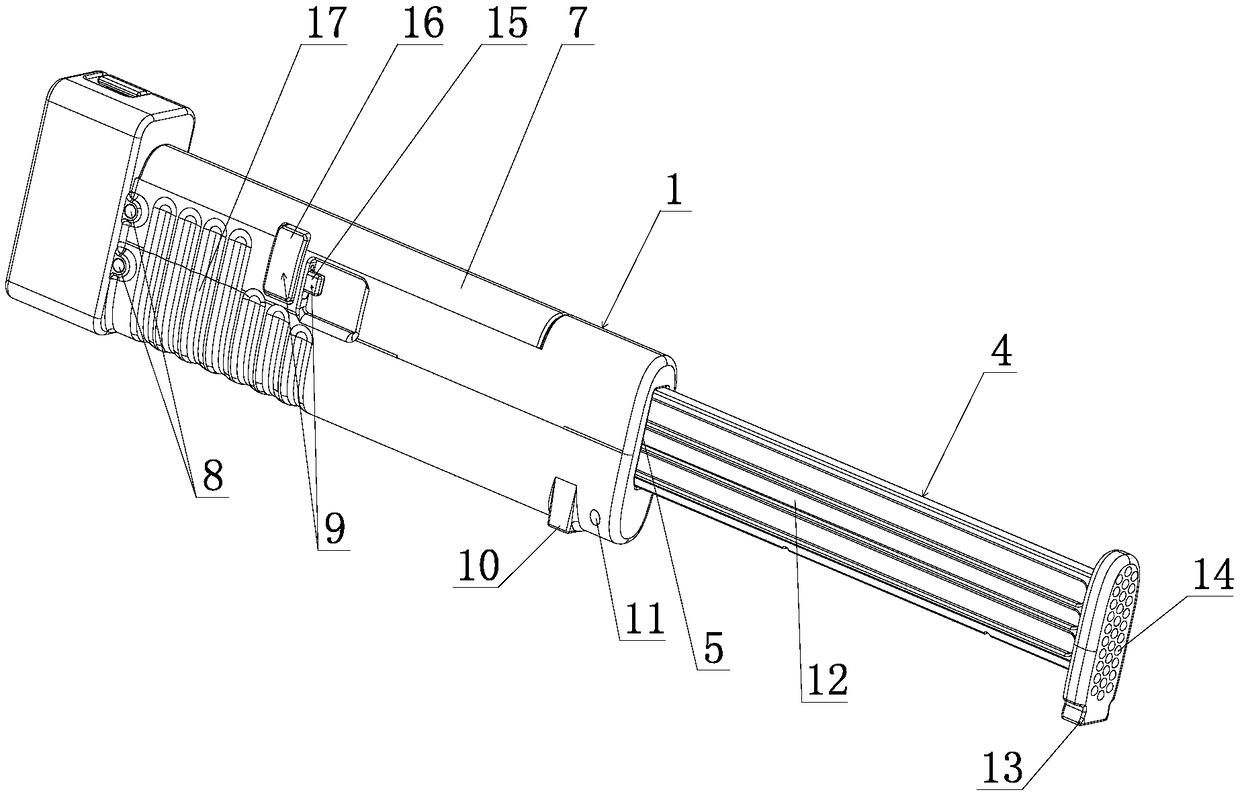

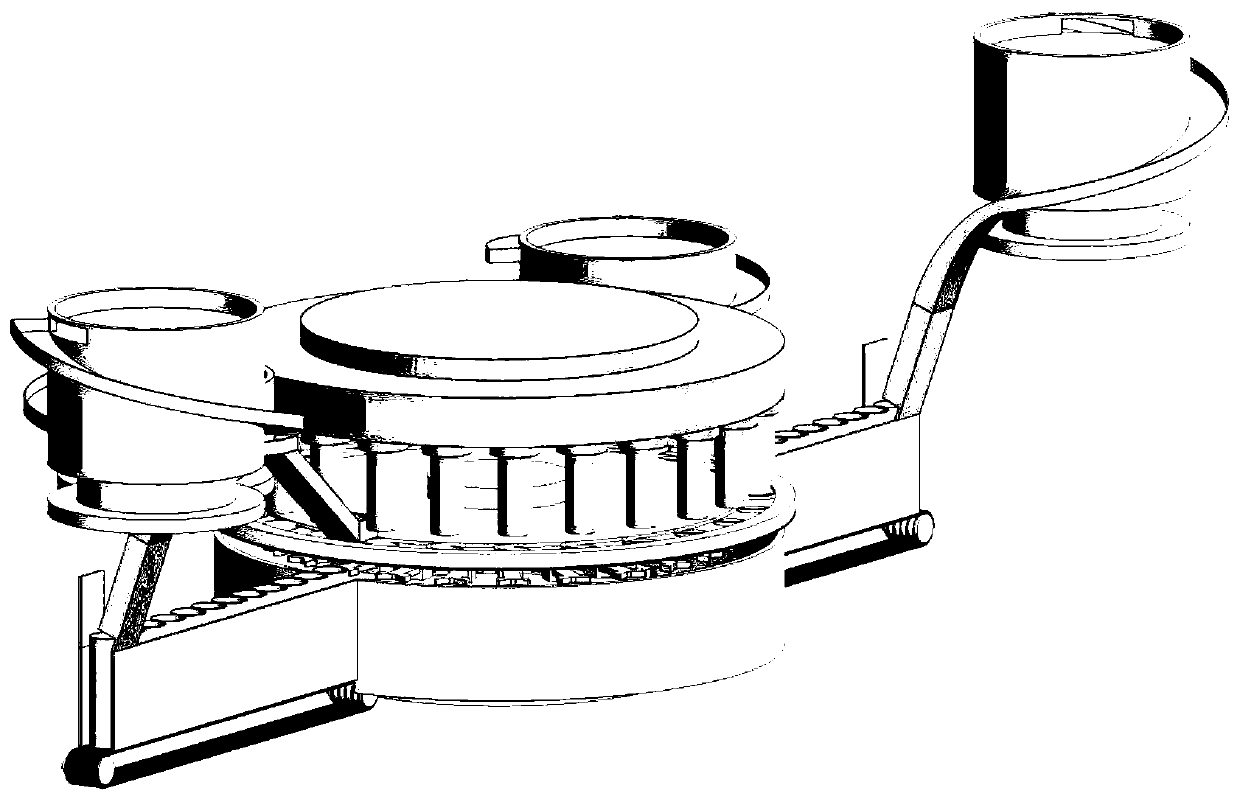

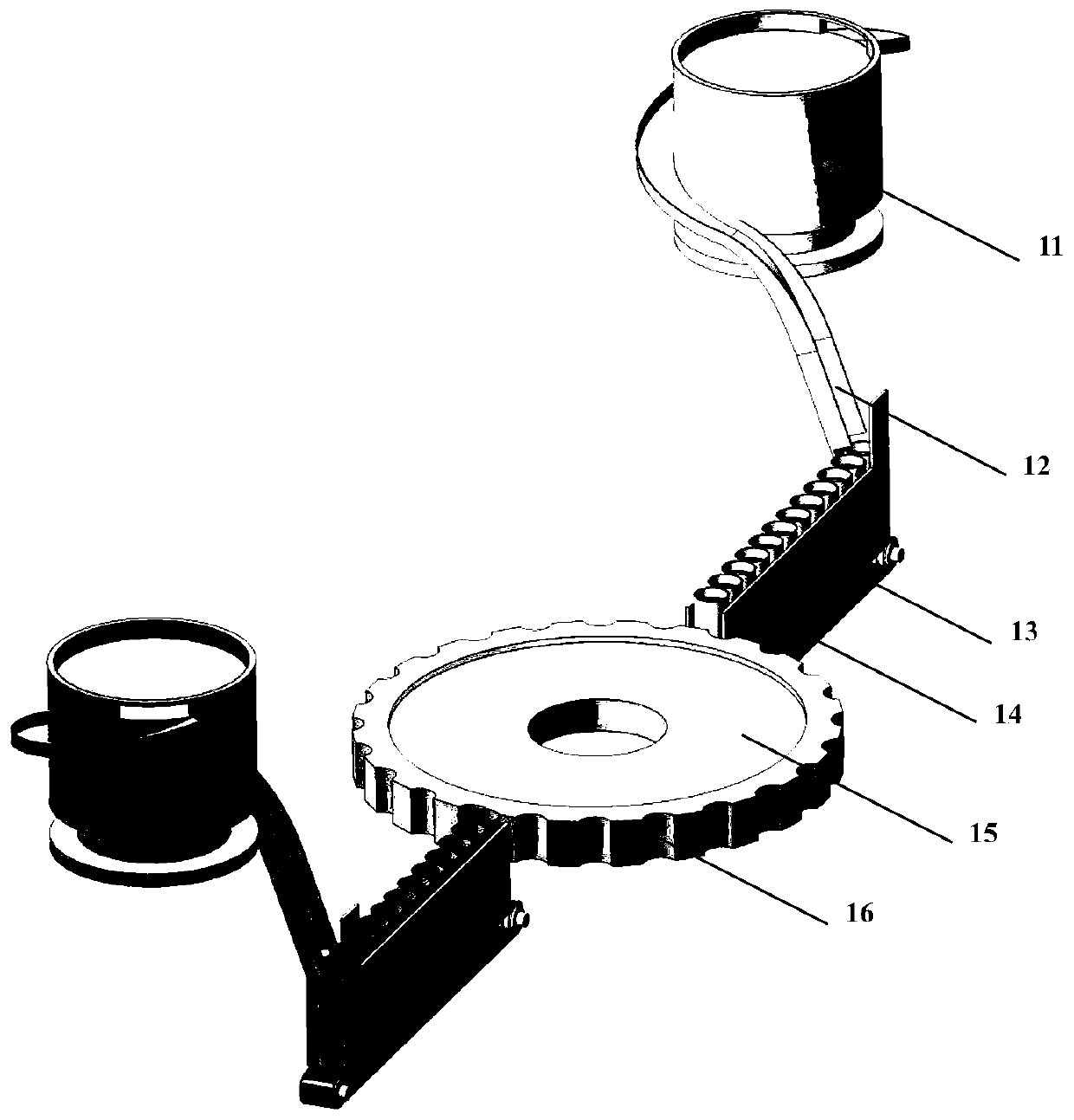

Cartridge magazine rapid reloading device

The invention discloses a cartridge magazine rapid reloading device. The device comprises a shell and a cartridge cavity which is formed in the shell and extends in the length direction of the shell.The device further comprises a cartridge magazine reloading inlet which is located at one end of the shell and communicates with the cartridge cavity. A push rod used for pressing cartridges which arearranged linearly into a cartridge magazine is in sliding fit with the interior of the cartridge cavity. The push rod extends out of a push enter and exit opening formed in a position of the shell, and the position is located at the end, away from the cartridge magazine reloading inlet, of the cartridge cavity. An opening used for loading cartridges therein is formed in the position, at the top of the cartridge cavity, of the shell and provided with a closing or opening top cover. The width of the cartridge cavity is equal to or greater than the maximum diameter of the cartridges, and the shape of the cross section of the bottom of the cartridge cavity is matched with the shape of the cartridges. The cartridge magazine rapid reloading device is simple in structure and low in cost, the push rod makes linear movement along the cartridge cavity, the mechanical performance of the device is ideal, operation is easy and convenient and saves labor, filling is rapid, the cartridge reloading time is greatly shortened, and the device is convenient to carry, high in practicability and wide in applicability.

Owner:NINGBO NUOCHI TRADE

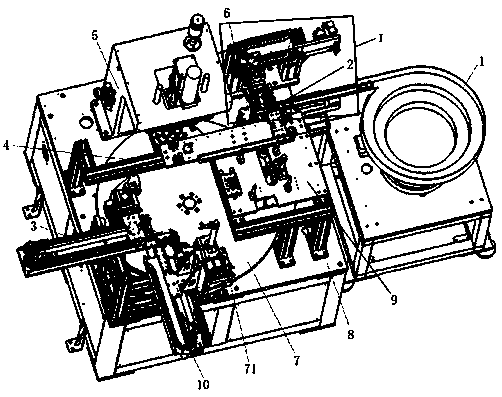

Automatic ammunition primer press fitting equipment

ActiveCN109839040AImprove press-fitting efficiency and operational stabilitySimple structureAmmunitionEngineeringCam

The invention discloses automatic ammunition primer press fitting equipment, and relates to the field of ammunition production. The automatic ammunition primer press fitting equipment comprises a shell case feeding module, a primer feeding module, a primer press fitting module and a shell case radial clamping module, wherein the shell case feeding module, the primer feeding module, the primer pressing fitting module and the shell case radial clamping module are arranged coaxially from top to bottom; the shell case feeding module comprises a shell case feeding device and a shell case conveyingdisc, and the shell case feeding device conveys shell cases into the shell case conveying disc one by one; the primer feeding module comprises a primer feeding device and a primer disc, a plurality ofcylindrical through holes are formed in the periphery of the primer disc, a supporting piece is arranged at the bottom of the primer disc and is connected with the primer disc through a first elasticpart, and the primer feeding device enables primers to fall into the supporting piece located at the bottoms of the cylindrical through holes; the primer press fitting module comprises a primer pressfitting disc and a primer pressing rod, and the primer is pressed into the shell case; and the shell case radial clamping module comprises a wedge cam and a radial clamping device, and the wedge camand the shell case conveying disc are coaxially arranged, and the radial clamping device is arranged on the shell case conveying disc. The automatic ammunition primer press fitting equipment improvesthe press fitting efficiency of the primer.

Owner:SHANGHAI JIAO TONG UNIV

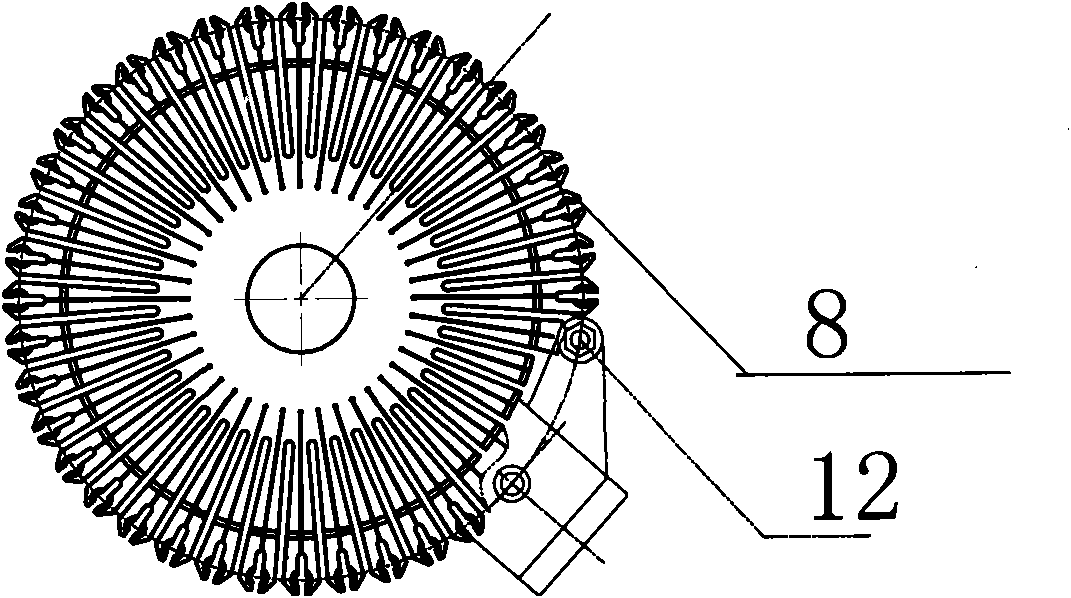

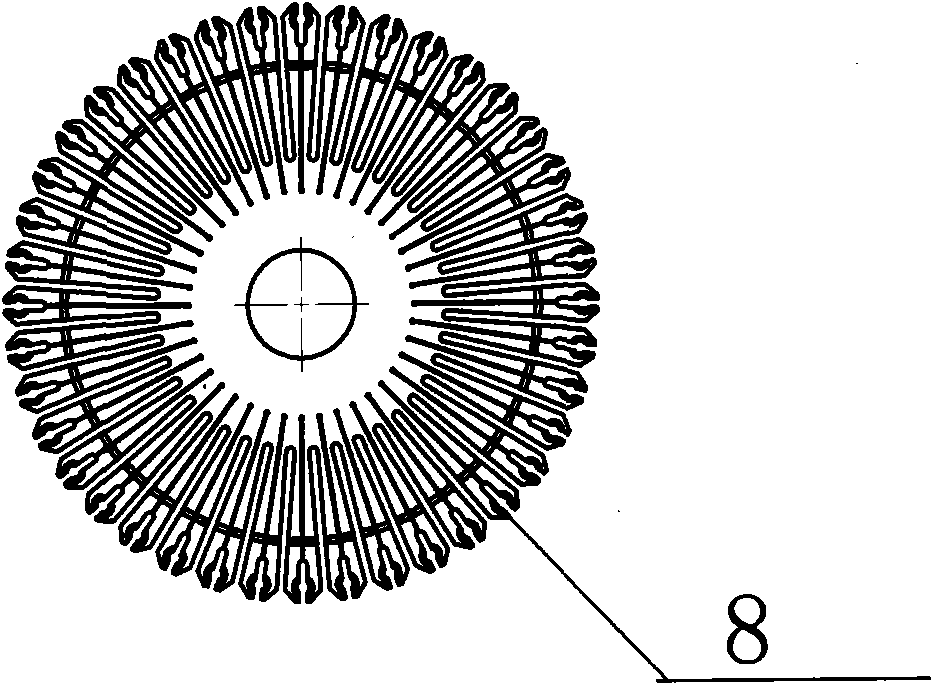

Drilling, pressing and riveting machine tool

ActiveCN101804563AReduce labor intensityImprove quality and efficiencyLiquid surface applicatorsOther manufacturing equipments/toolsNumerical controlSpray nozzle

The invention relates to a drilling, pressing and riveting machine tool. The existing drilling and riveting machine tool has the disadvantages of complicated automatic nailing system, poor reliability, difficult realization of normal direction drilling and riveting of high-curvature curve surfaces, overlarge size of a drilling and riveting head and difficult completion of automatic drilling and riveting in a narrow space. The drilling, pressing and riveting machine tool consists of a clamping mechanism (1), wherein the clamping mechanism (1) is arranged in a shaft hole formed at the front end of a machine tool main shaft or other dividing device (2), a press nail oil cylinder (4) and a glue coating steam cylinder (6) are arranged on a case of the machine tool main shaft or other dividing device (2), the press nail oil cylinder (4) is provided with a press nail propping rod (3), the glue coating steam cylinder (6) is provided with a glue coating spray nozzle (5), the back side of the press nail oil cylinder (4) is provided with a pressure sensor (7), the side surface of the press nail oil cylinder (4) is provided with a photoelectric or sensing identification device (12), and the case of the machine tool main shaft or other dividing device (2) is arranged at the tail end of a set of numerical control actuating unit. The invention is used for the riveting and interference matching screw connection technology in machinery manufacture industry.

Owner:HARBIN MEASURING & CUTTING TOOL GROUP CO LTD

Assembling tool for shell and stator of direct drive motor

ActiveCN110571986AEasy to fixReliable concentric positioning accuracyManufacturing stator/rotor bodiesInterference fitDrive motor

The invention discloses an assembling tool for a shell and a stator of a direct drive motor. The assembling tool comprises a base, guide rods, a support ring and a guide ring. The upper end of the base is connected with the guide rods. A base boss is arranged in the center of the upper end face of the base. The support ring is installed on the upper end face of the base. A stator is attached to the outer wall of the base boss. The lower end face of the stator abuts against the support ring in an attached mode. The guide ring comprises a mounting table, and a mounting table lower bulge is formed on the lower end face of the mounting table. Lower bulge through holes penetrating through the inner and outer walls are formed in the mounting table lower bulge. The inner end of each lower bulge through hole abuts against a ball. The inner ends of the balls are exposed out of the lower bulge through holes and abut against the outer wall of the stator. A heat insulation ring is arranged on theupper end face of the mounting table, and the heat insulation ring abuts against the shell in an attached mode. The shell includes a second shell body matched with the stator. The shell is pressed downwards to drive the guide ring to be pressed downwards along with the guide rod so that the second shell body can be pressed into the outer wall of the stator in an interference fit manner. In the invention, the stator is fixed reliably and firmly, the temperature of the shell will not decrease rapidly, and the assembly of the shell and the stator is premise, reliable and efficient.

Owner:HENAN NORMAL UNIV

PE pipe pressing tooling

The invention discloses a PE pipe pressing tooling and relates to the technical field of PE pipe machining. The PE pipe pressing tooling comprises a working table, a hydraulic cylinder, an upper pressing die and a lower pressing die. Guide supports are disposed on the two sides of the working table vertically and upwards; a fixing rack is disposed at the upper ends of the guide supports; the hydraulic cylinder is mounted on the fixing rack; the upper pressing die comprises a movable rod; the movable rod is connected with a piston rod of the hydraulic cylinder; the two ends of the movable rod are in sliding joint with the guide supports; a plurality of connecting rods are disposed at the lower end of the movable rod; the heights of the connecting rods are increased gradually from the connecting rods in the middle to the connecting rods on the two sides; rolling wheels are disposed at the lower ends of all the connecting rods; the lower pressing die comprises a fixing plate and a plurality of support frames arranged on the fixing plate; the heights of the support frames are reduced gradually from the support frames in the middle to the support frames on the two sides; the fixing plate is disposed on the working table; and PE pipes are mounted on the support frames. By means of the design, the structure is simple and reasonable, abrasion and scratches to the surfaces of the PE pipes are not prone to occur, the pipe bending efficiency is improved, and the quality of the PE pipes is guaranteed.

Owner:WUHU NEW UNIVERSAL ENVIRONMENTAL SCI TECH

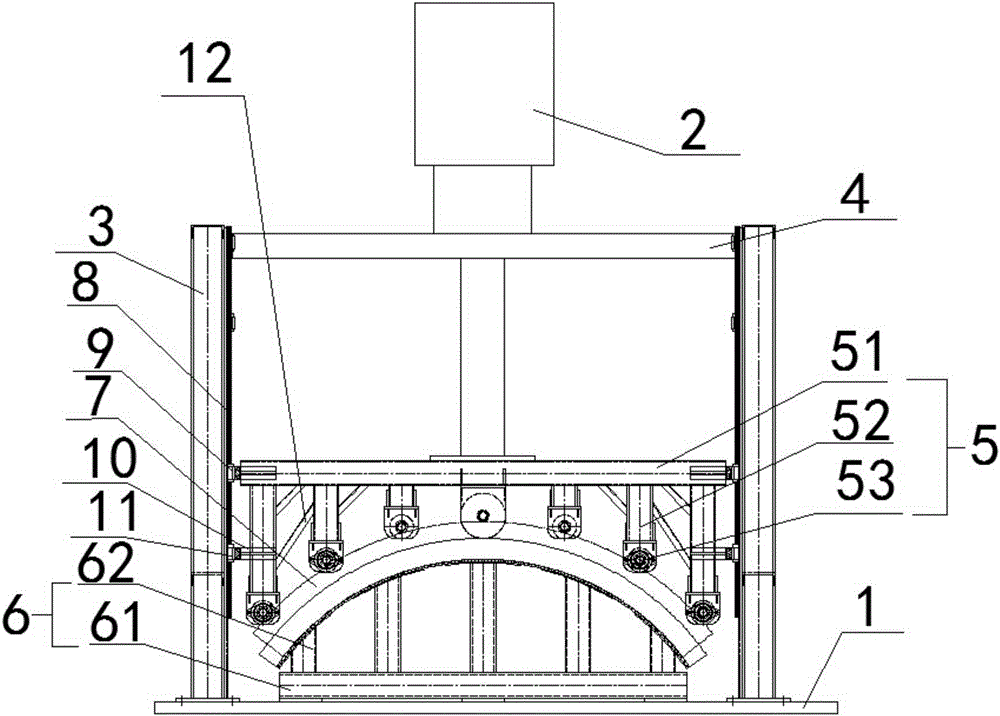

Vehicle suspension spring pressing equipment

ActiveCN106975908AEasy to fixThe pressing process is stableMetal working apparatusEngineeringPiston rod

The invention discloses vehicle suspension spring pressing equipment. The vehicle suspension spring pressing equipment comprises pressing equipment and workpiece detecting equipment; the pressing equipment includes a frame body; the frame body is provided with a frame plate, a tightening shaft motor module, a spring pressing motor module, a tightening mechanism, a spring pressing mechanism, a two-side clamping mechanism and a workpiece lower positioning base mechanism; a piston rod workpiece is fixedly connected with the workpiece lower positioning base mechanism, and is clamped through the two-side clamping mechanism; a spring module needing to be pressed is placed on the piston rod workpiece; the spring pressing mechanism wraps the spring module and the piston rod workpiece, and presses the spring module and the piston rod workpiece; and the tightening mechanism tightens the spring module and the piston rod workpiece to finish automatic pressing operation.

Owner:广州市嘉特斯机电制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com