Vertical type bearing pressing machine

A technology for press-fitting machines and bearings, which is applied in the field of bearing press-fitting machines, can solve the problems of unsatisfactory mass production of automobiles, difficult control of assembly quality, and high labor intensity of workers, so as to improve assembly flexibility, stabilize the press-fitting process, and facilitate real-time monitoring Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing.

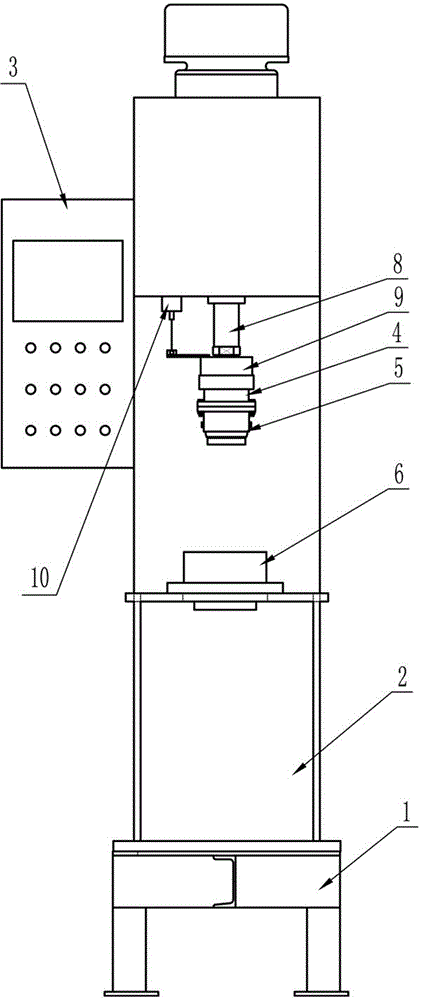

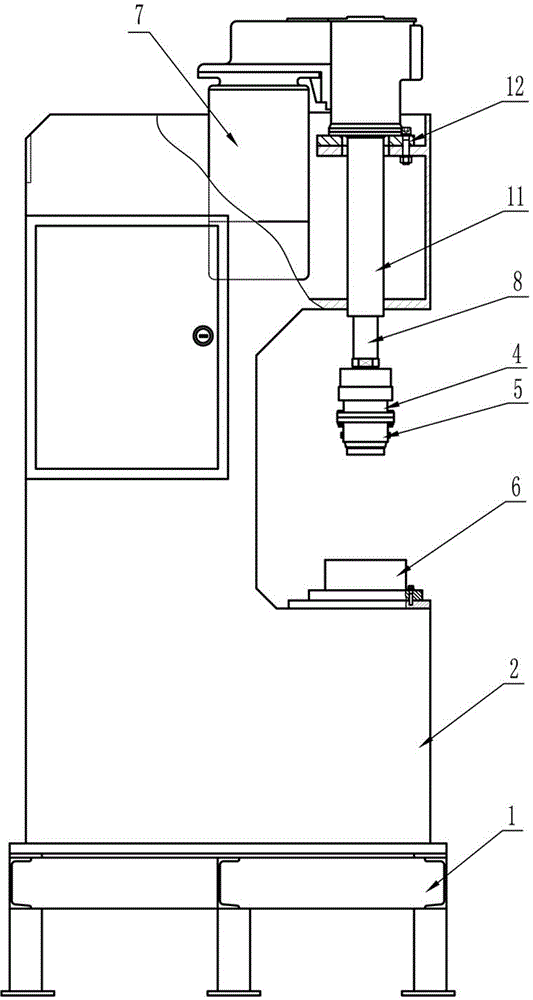

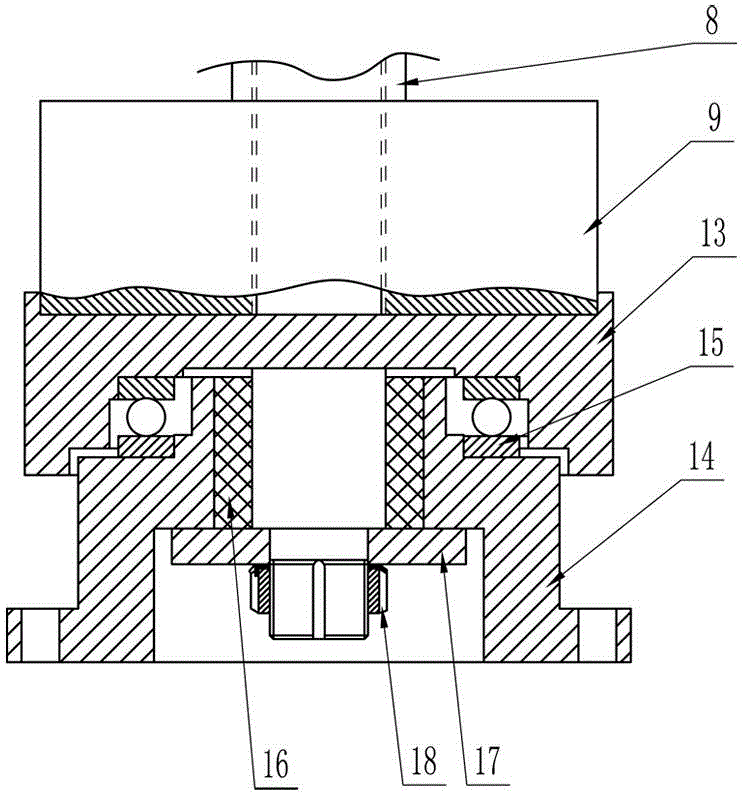

[0019] Such as figure 1 , figure 2 , image 3 As shown, a vertical bearing press-fitting machine includes a base 1, and a frame 2 is fixedly connected to the base 1 by bolts. The frame 2 is a C-shaped open structure, and an operation panel is provided on the side of the frame 2. 3. A push rod driving device is installed on the top of the frame 2. The push rod driving device includes a screw pair and a servo motor 7. During assembly, the servo motor 7 is vertically upwardly fixedly connected to the frame 2 through the connecting plate , the screw pair is made up of a screw rod and a nut, and the screw pair is fixedly connected to the frame 2 through the coupling flange 12; the output shaft of the servo motor 7 is fixedly connected with a first gear by a screw thread, and the screw pair is fixedly connected to the first gear by a screw thread. The screw is fixedly connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com