Patents

Literature

349results about How to "No bending" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

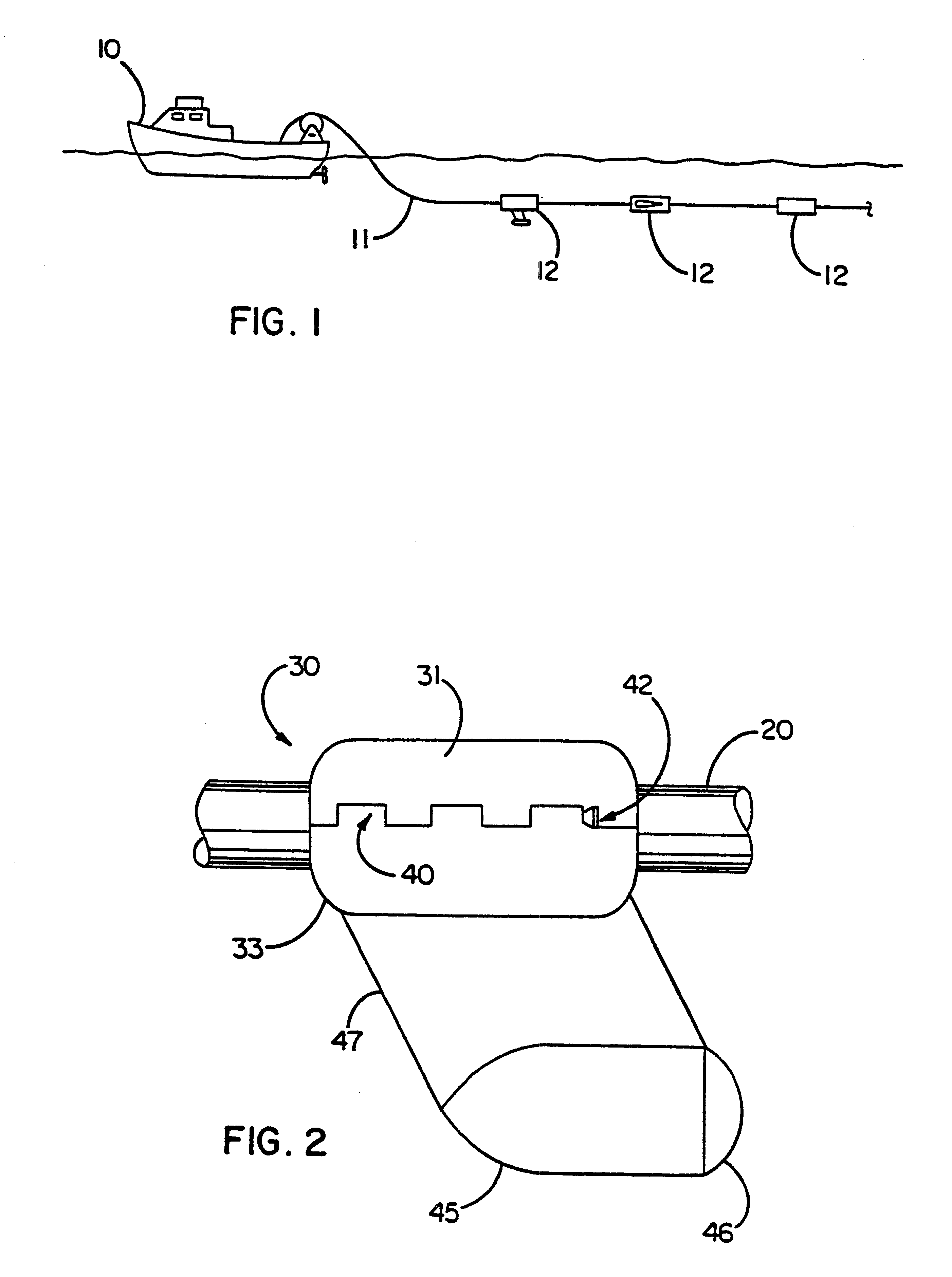

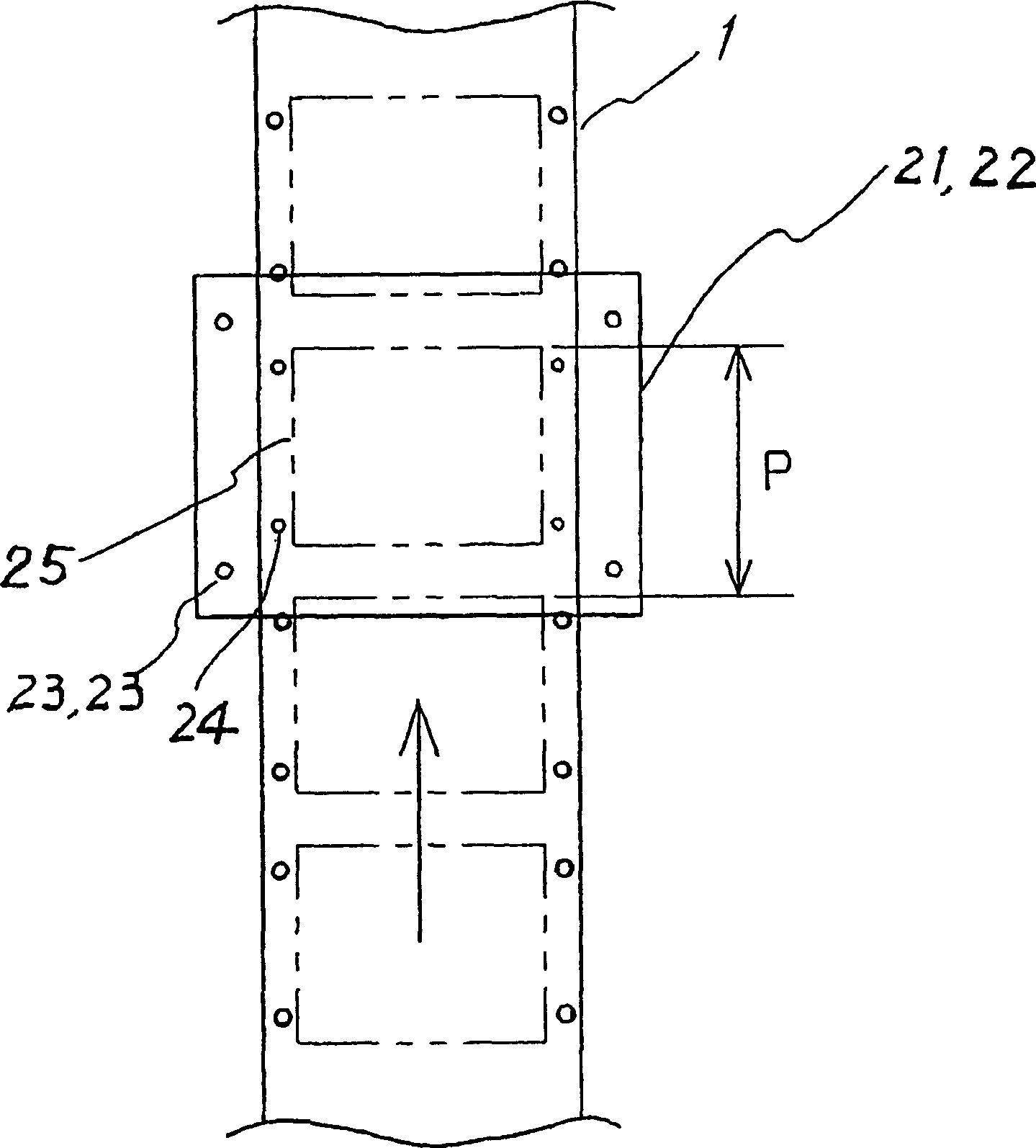

Underwater cable arrangement and coil support arrangement for an underwater cable

InactiveUS6091670ANo bendingProtection from damageRepeater circuitsSeismic signal receiversInterference fitEngineering

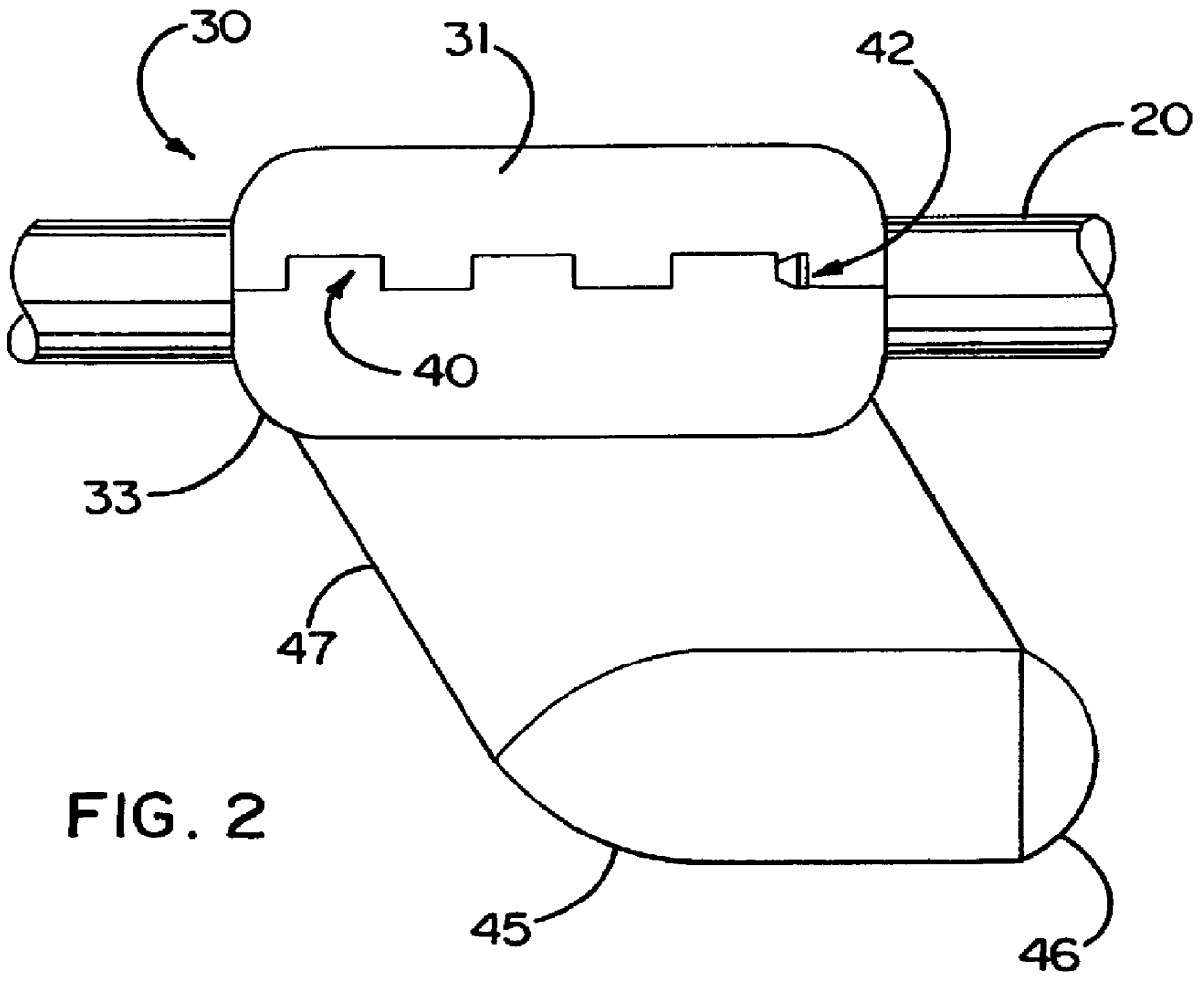

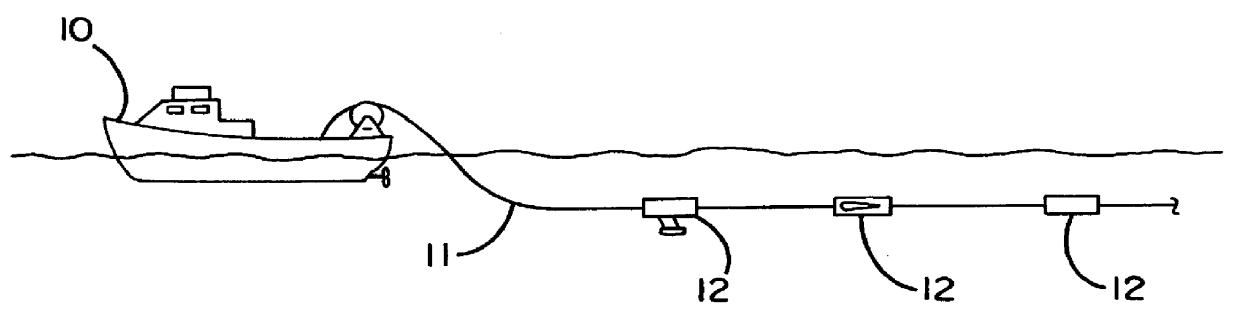

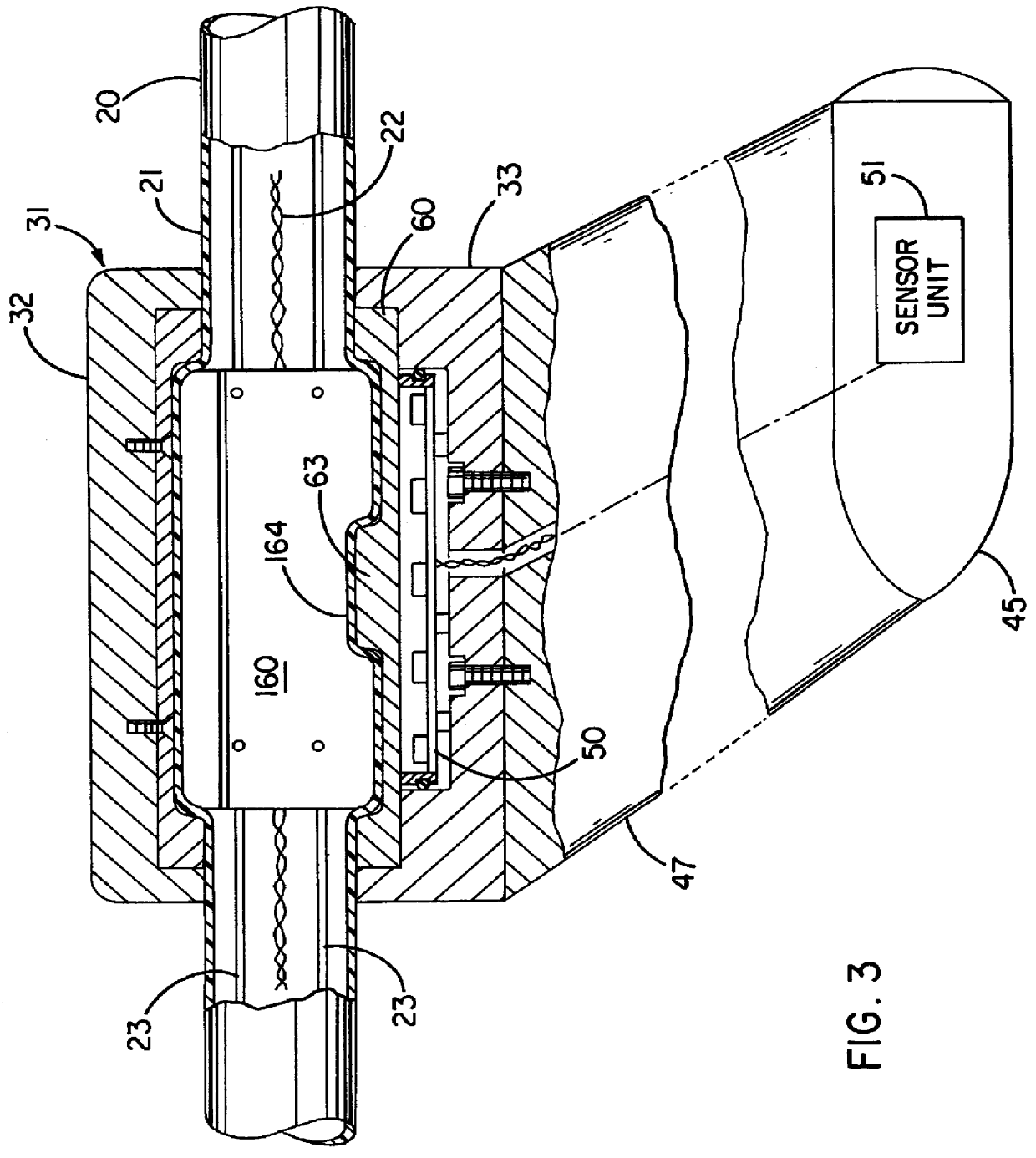

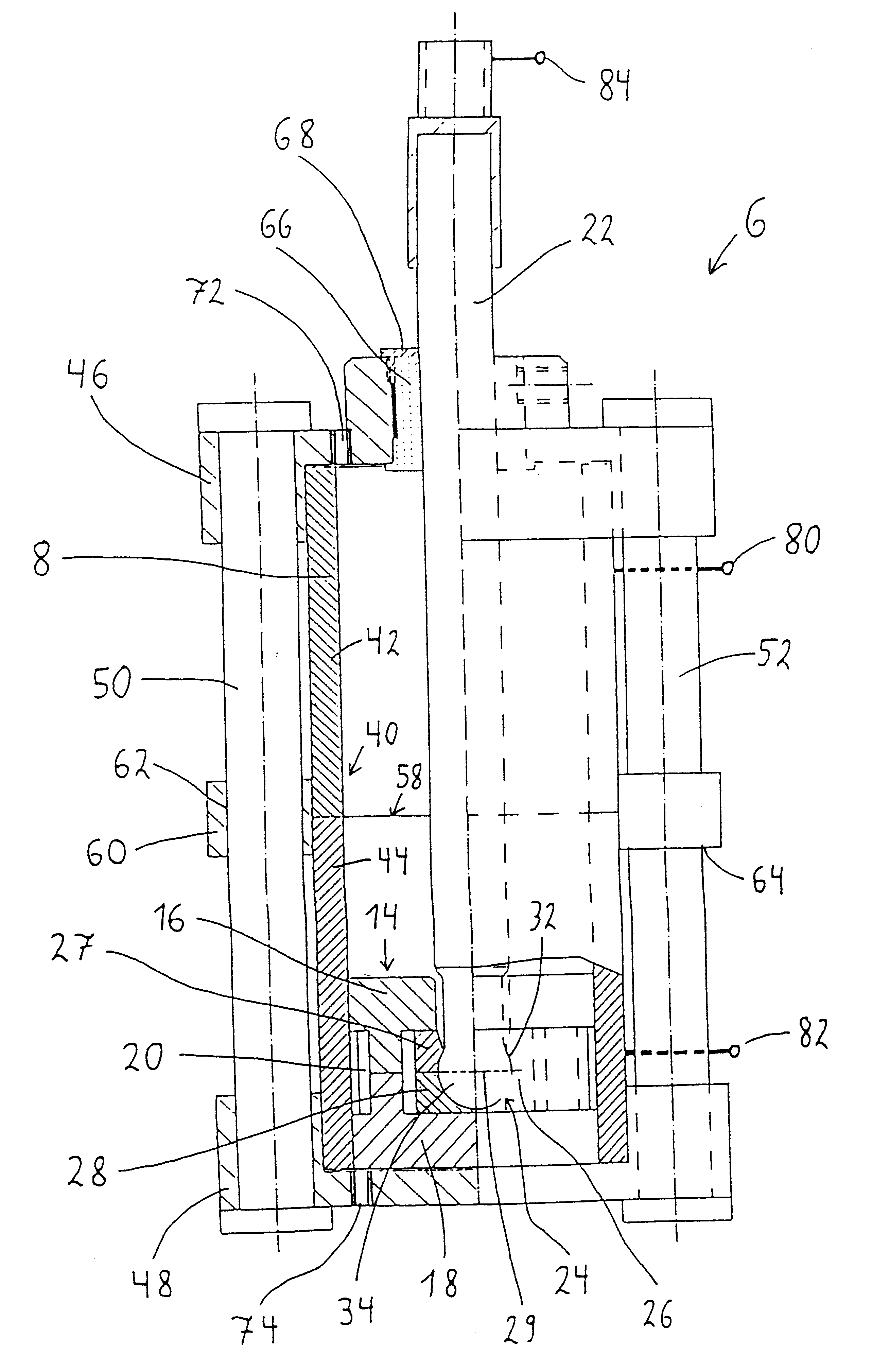

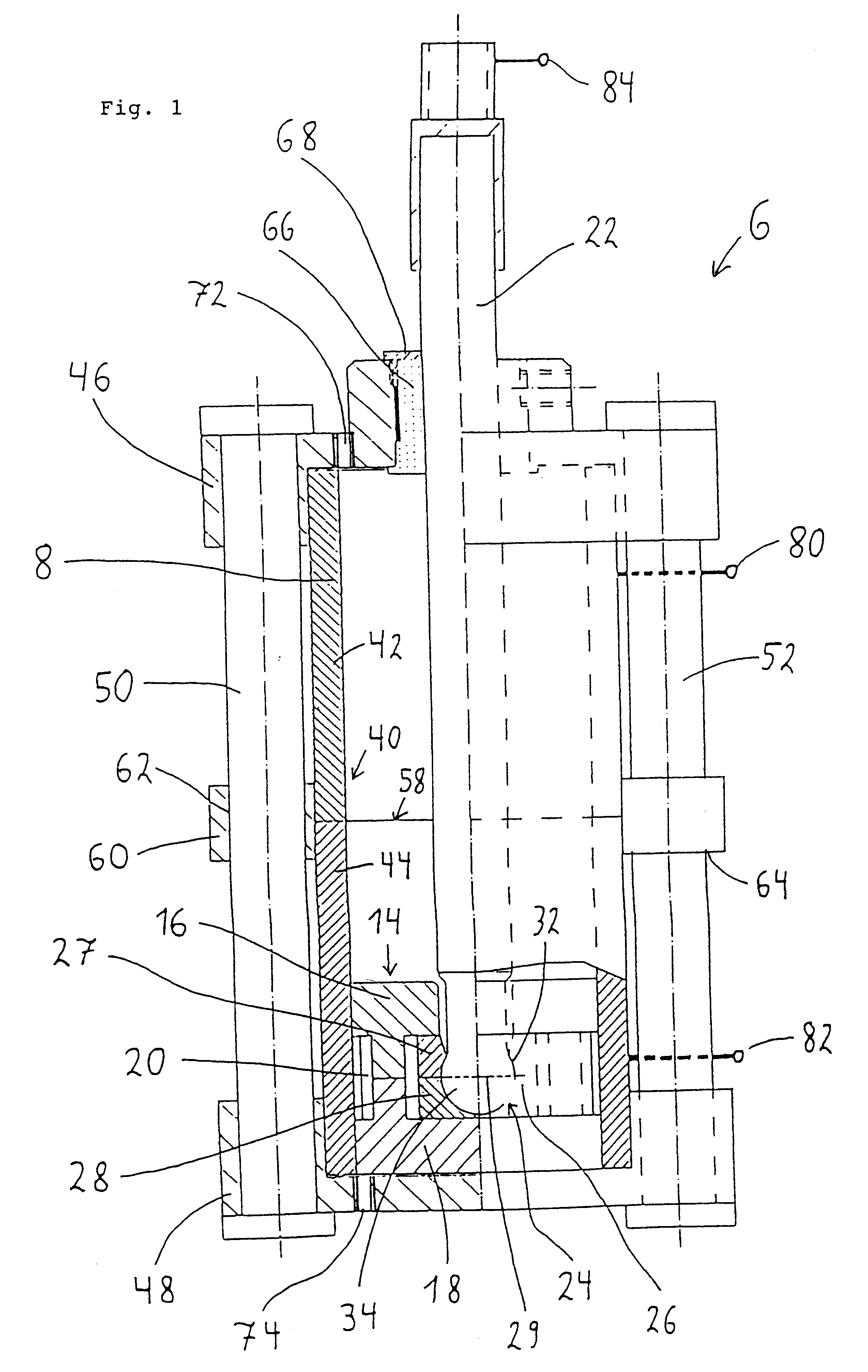

PCT No. PCT / US96 / 15478 Sec. 371 Date Mar. 20, 1998 Sec. 102(e) Date Mar. 20, 1998 PCT Filed Sep. 20, 1996 PCT Pub. No. WO97 / 11395 PCT Pub. Date Mar. 27, 1997An underwater cable arrangement comprises an underwater cable capable of being towed through the water, an external device for mounting on the exterior of the cable, and a coil support device disposed inside the cable for supporting a coil. In some embodiments, the coil support device and the external device have engaging portions which co-act with each other to prevent relative rotation of the coil support device and the external device about the longitudinal axis of the cable. In some embodiments, the underwater cable has a skin and the external device is positioned around the coil support device with the skin of the underwater cable between them. The coil support device and the external device have an interference fit with respect to each other to resist relative movement to the coil support device and the external device in the longitudinal direction of the cable. In some embodiments, the external device and the coil support device are fitted to each other so as to maintain a constant angle between a longitudinal axis of the cable and a longitudinal axis of the external device.

Owner:DIGICOURSE

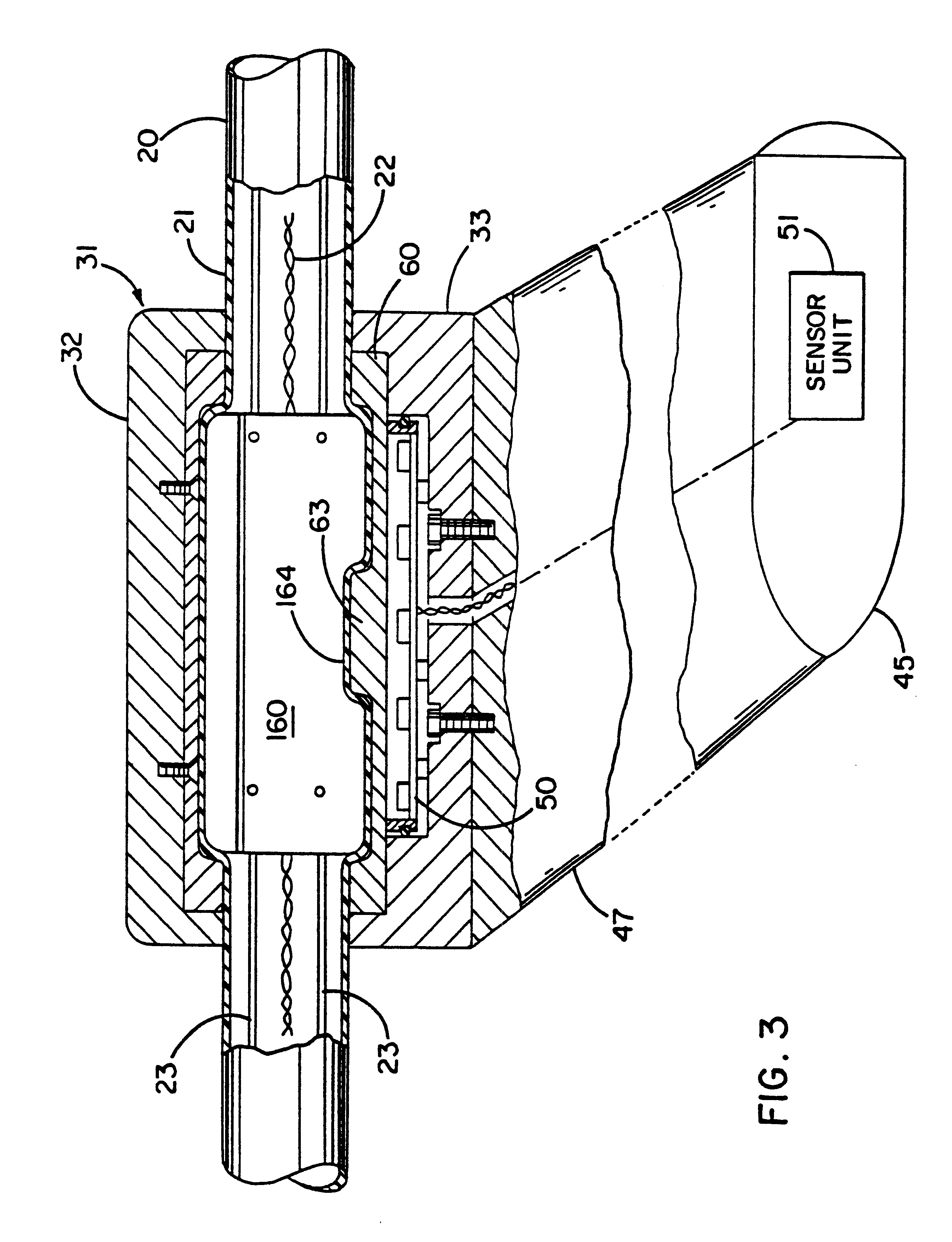

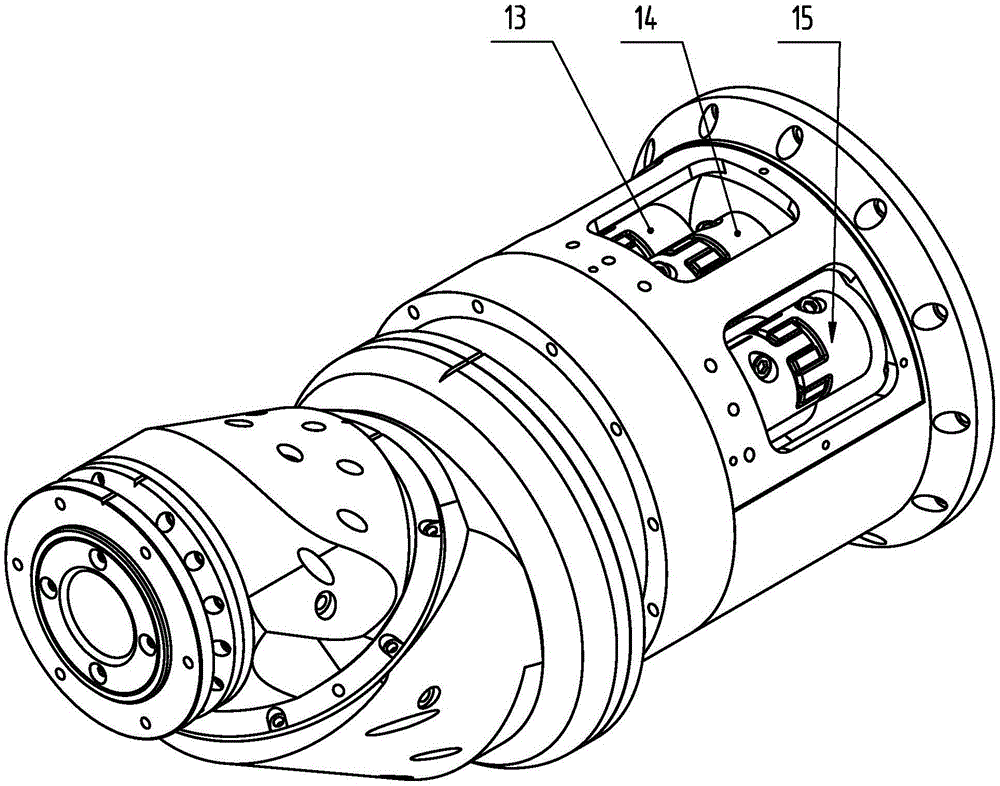

Underwater cable arrangements, internal devices for use in an underwater cable, and methods of connecting and internal device to a stress member of an underwater cable

InactiveUS6292436B1Additional movementRelieve pressureSubsonic/sonic/ultrasonic wave measurementSeismic signal receiversMarine engineeringDovetail joint

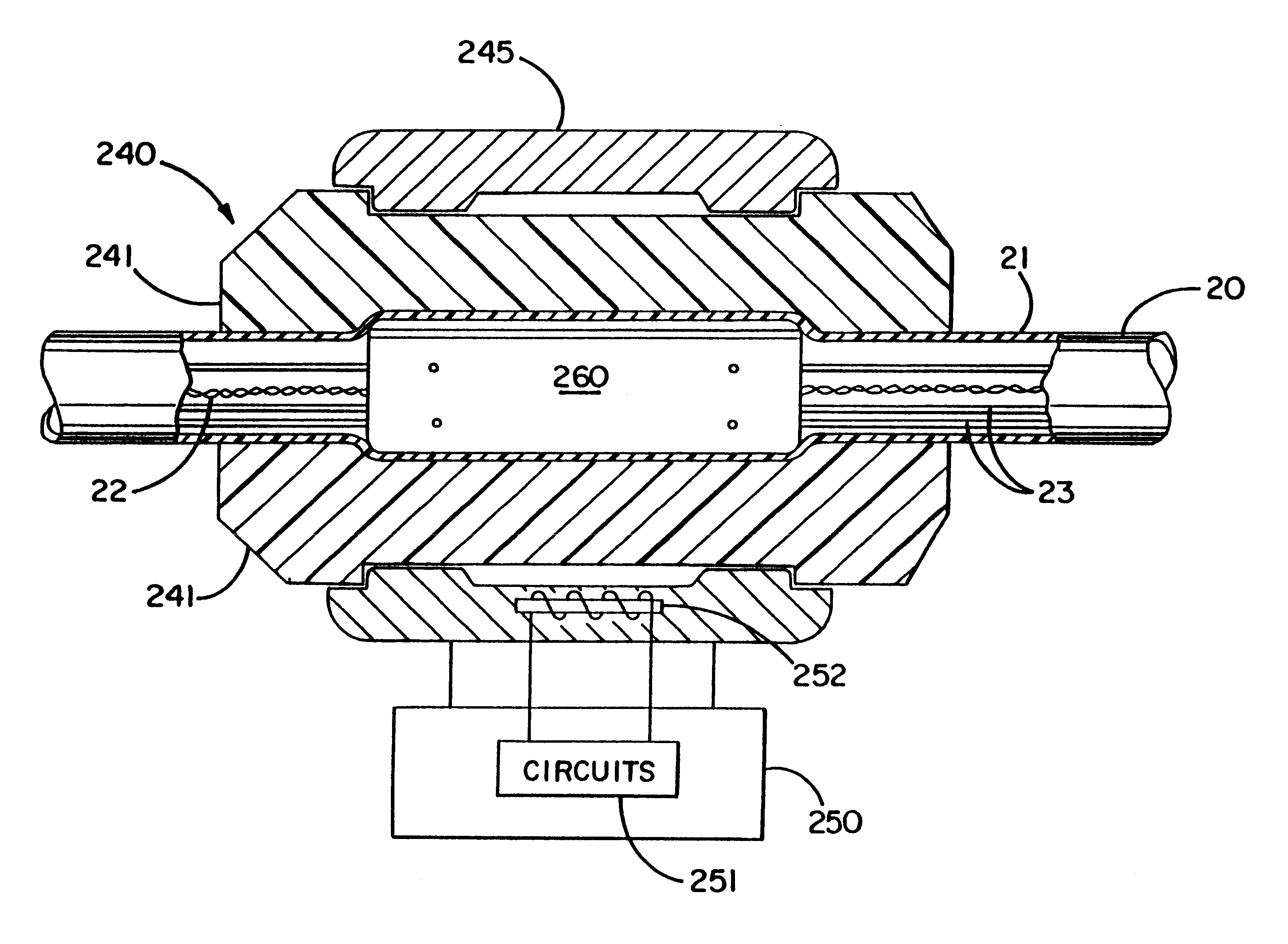

An internal device for use in an underwater cable may comprise a body having an outer periphery, body being mountable inside the cable with the cable surrounding the outer periphery of the body. The body may include a cutaway portion, a slot, or a dovetail joint. An underwater cable arrangement may comprise an underwater cable and an internal device disposed in the cable with the cable surrounding the device. The underwater cable may include a stress member connected to the internal device by an interference fit or the internal device may include a slot for receiving the stress member. A method of connecting a stress member of an under water cable to an internal device includes forming an interference fit between a region of increased diameter of the stress member and the internal device.

Owner:DIGICOURSE

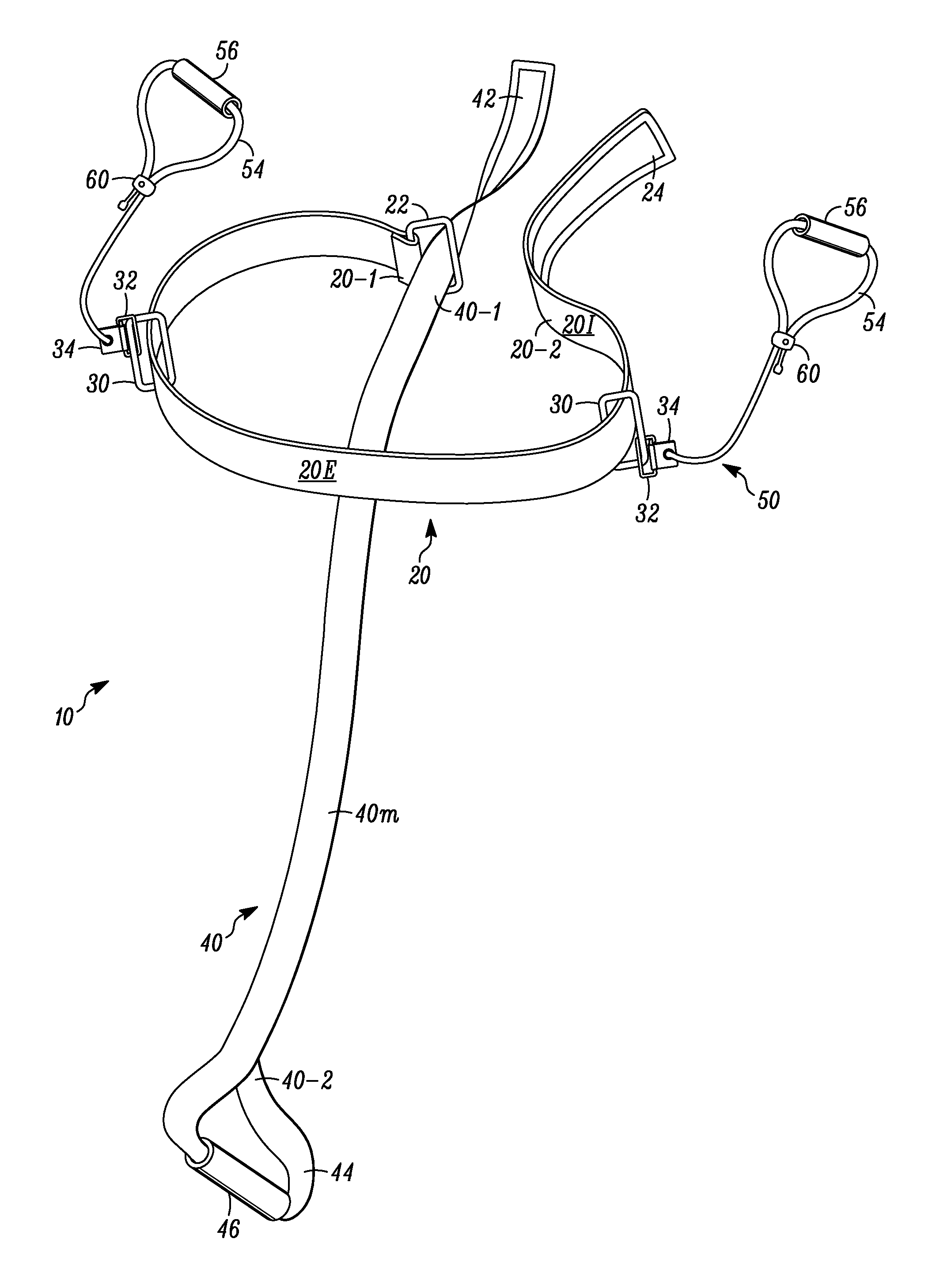

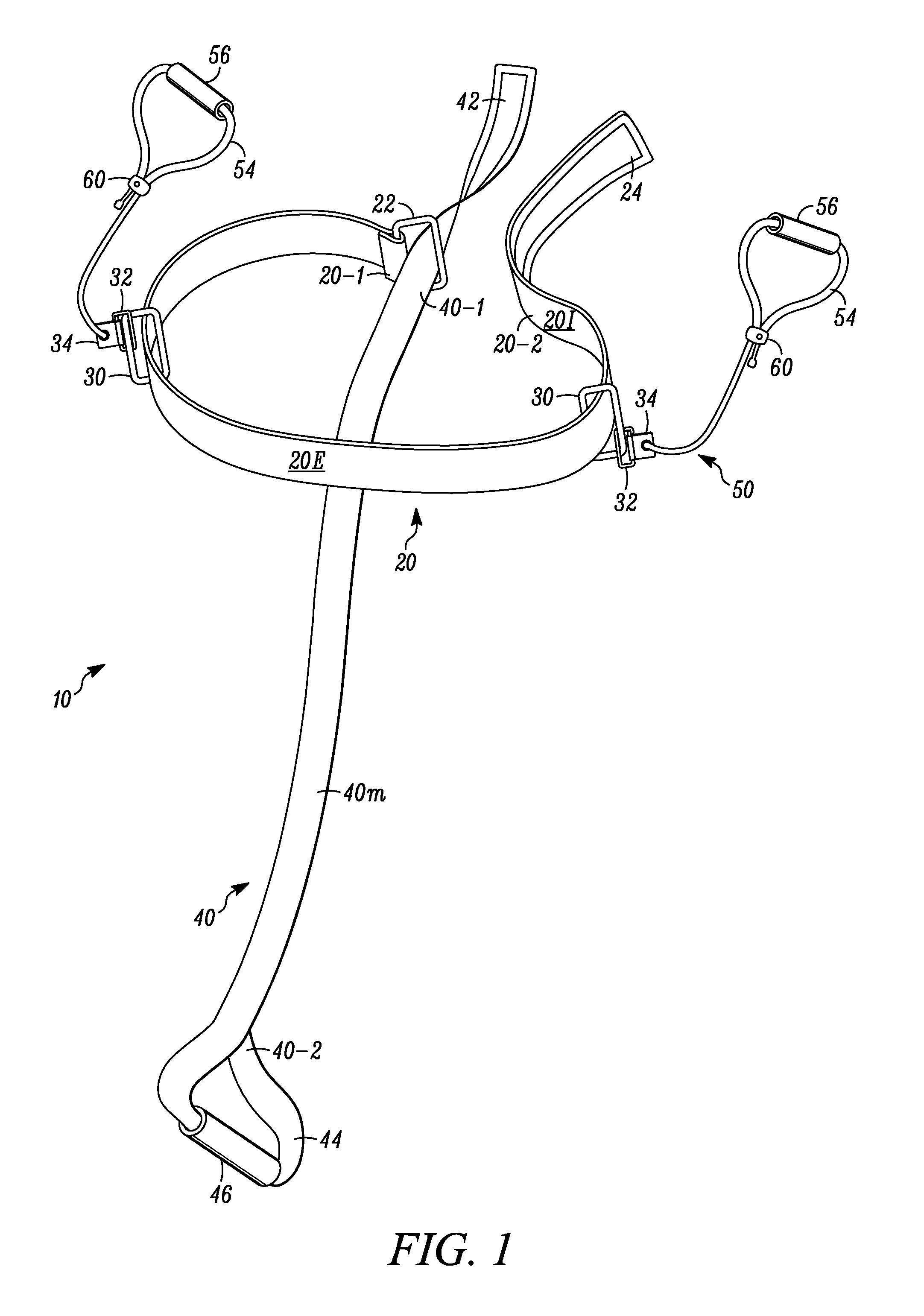

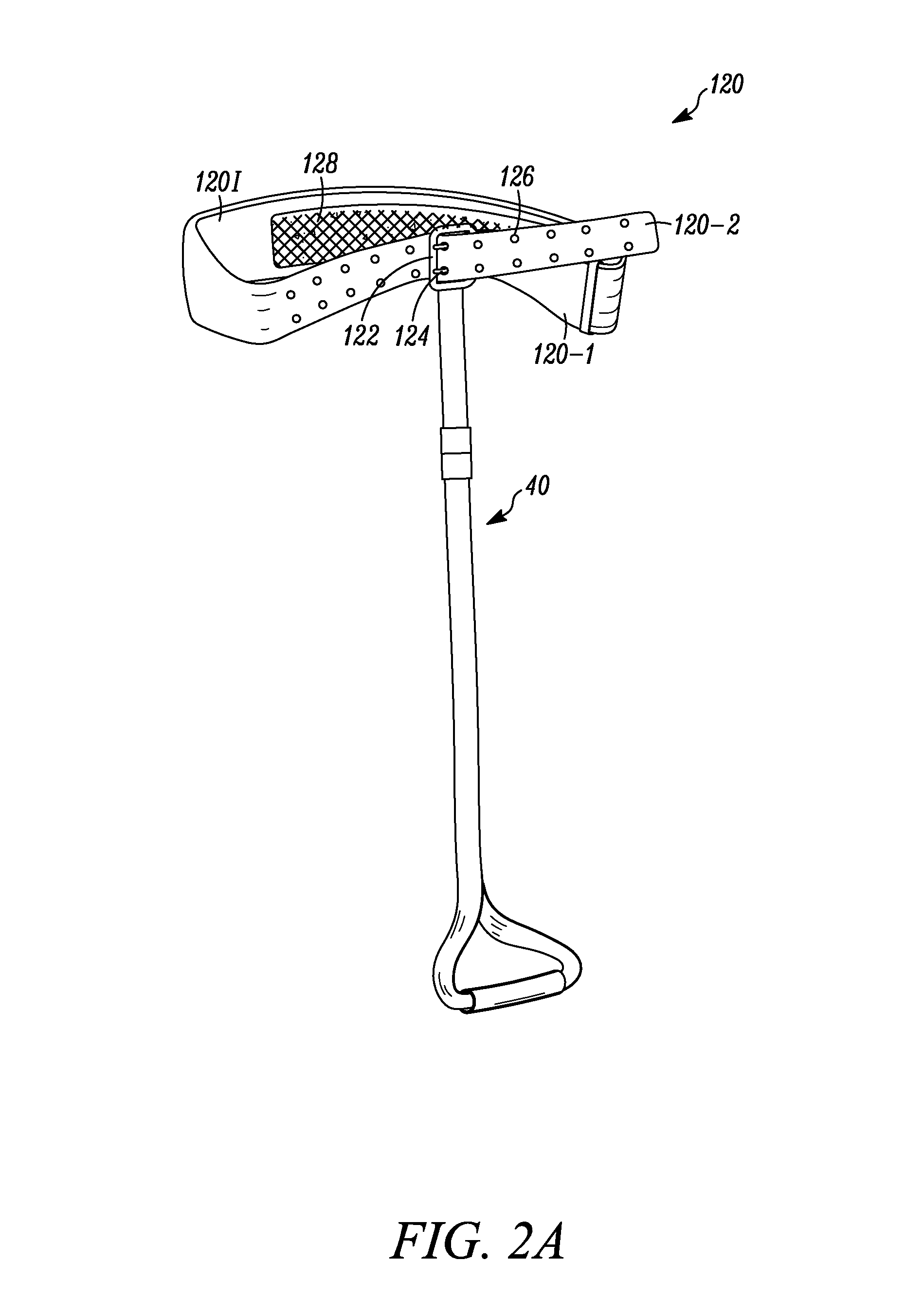

Spinal therapy device

ActiveUS20140200499A1Minimize shearLimited amountFreely-suspended gymnasticsChiropractic devicesAnesthesiaSacroiliac joint

The invention provides a spinal therapy device that can be used by an individual to self-apply overpressure, spinal decompression, spinal joint mobilization or a combination thereof to the spine, as well as methods for using a spinal therapy device to self apply overpressure, spinal decompression, spinal joint mobilization or a combination thereof.

Owner:THE OAKFORD GRP LLC

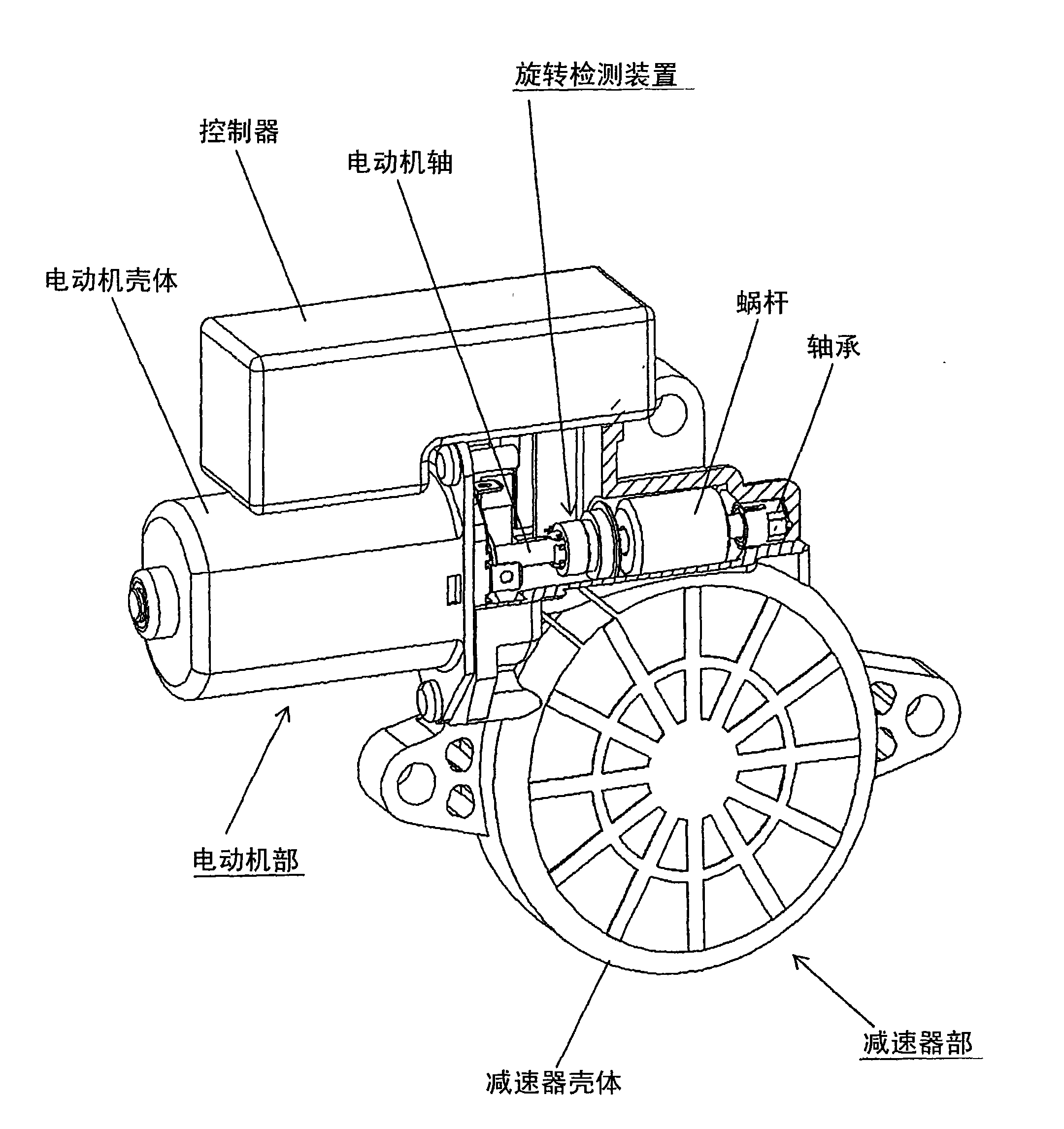

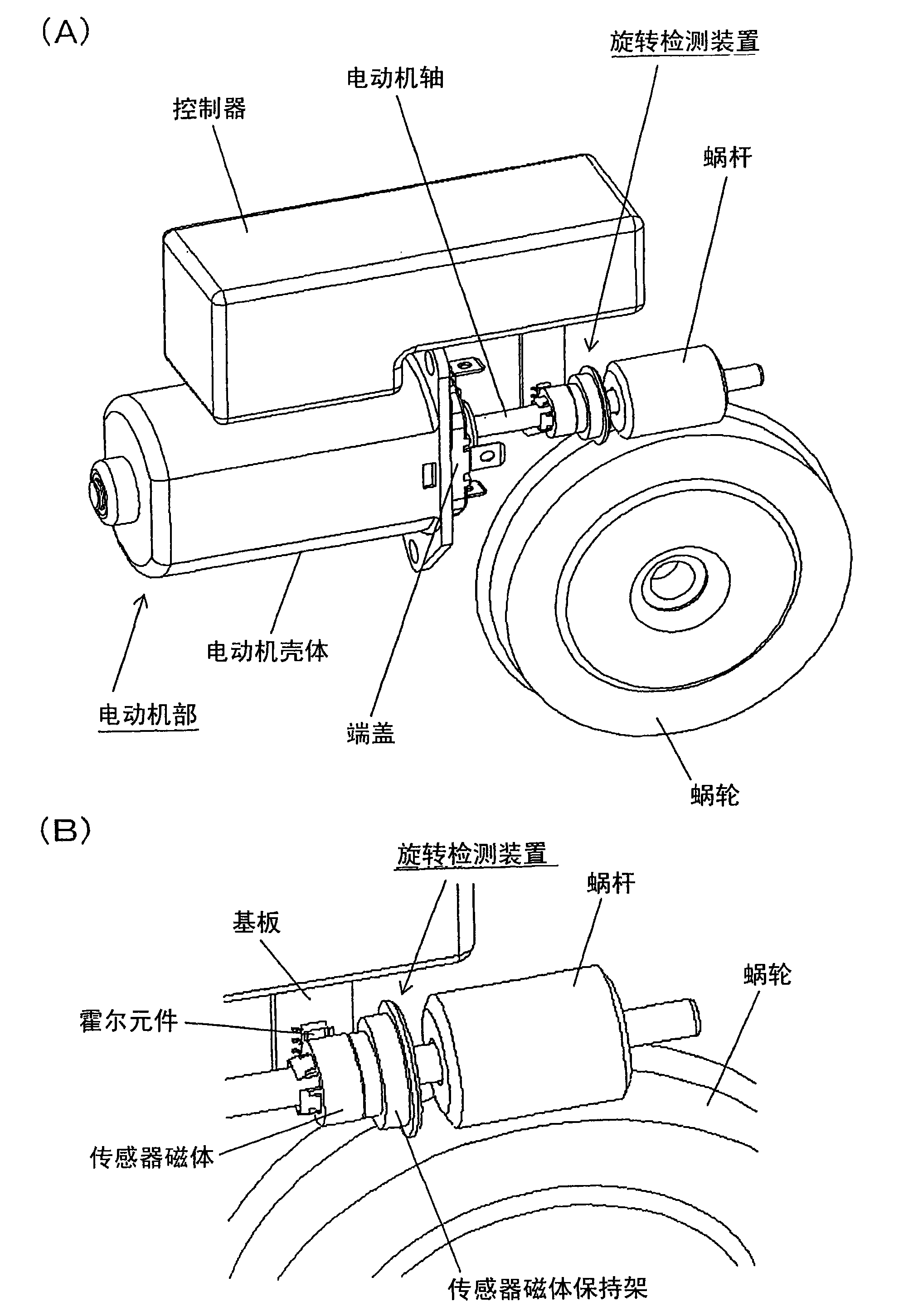

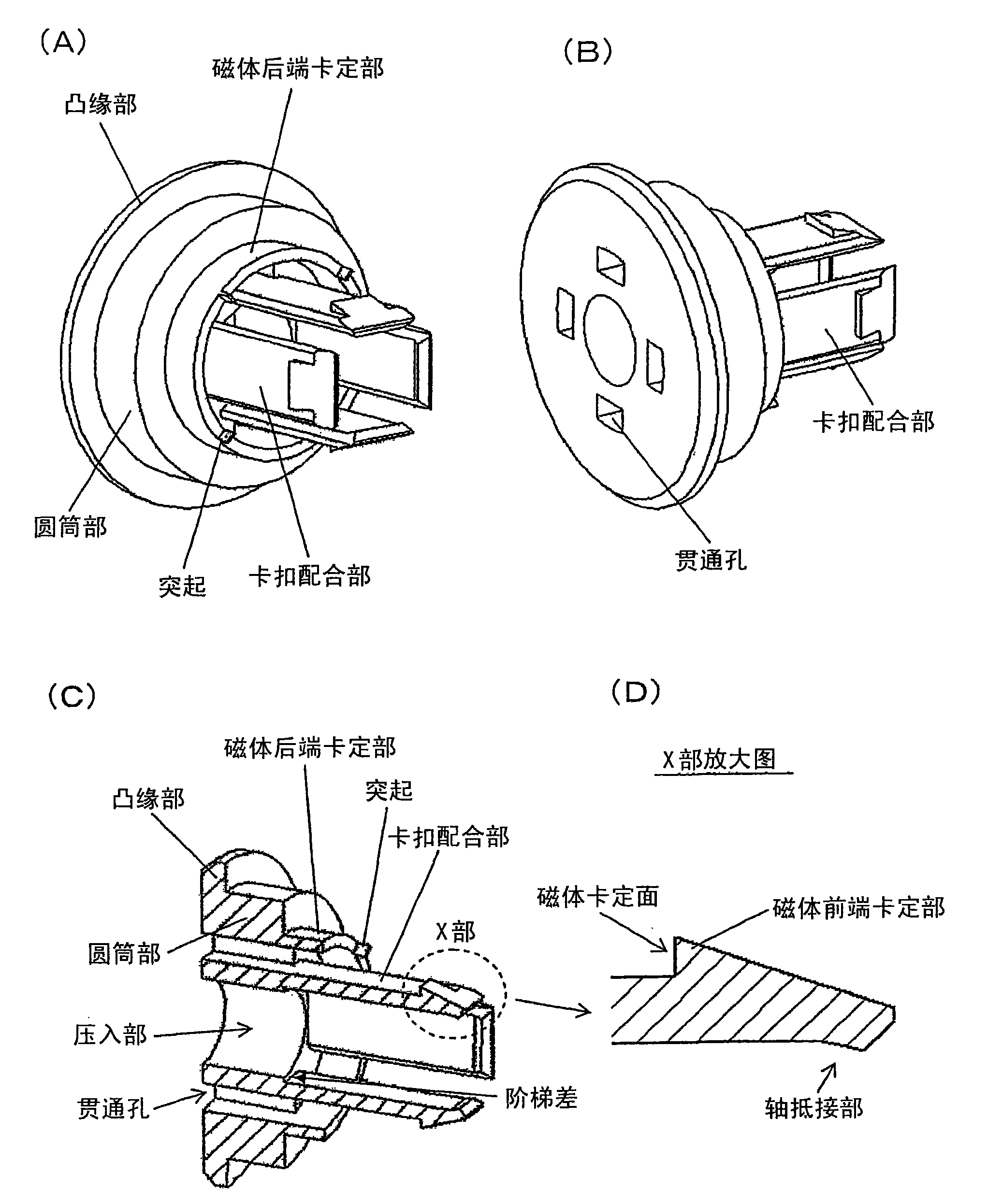

Sensor magnet holder, motor having the holder incorporated therein, and method of manufacturing the motor

ActiveCN101630888AAvoid crackingImprove resistance to movementManufacturing dynamo-electric machinesDC commutatorEngineeringMotor shaft

A sensor magnet holder is formed such that a cylindrical portion, a flange portion formed by increasing the diameter of one end part of the cylindrical portion, a magnet rear-end engagement portion formed at the other end part of the cylindrical portion, and four plate-like snap fit tongues are formed integral with one another. The cylindrical portion including the flange portion has, on its inner diametral side, a press fit portion to be press-fitted to a motor shaft. The four plate-like snap fit tongues have respective magnet front-end engagement portions formed on an outer diametral side of their tip portions. The four snap fit tongues are brought into contact with respective flat inner surfaces of the sensor magnet having four flat inner surfaces, by utilizing elasticity of the snap fit tongues. The sensor magnet is retained between the magnet rear-end engagement portion and the magnet front-end engagement portions.

Owner:MABUCHI MOTOR

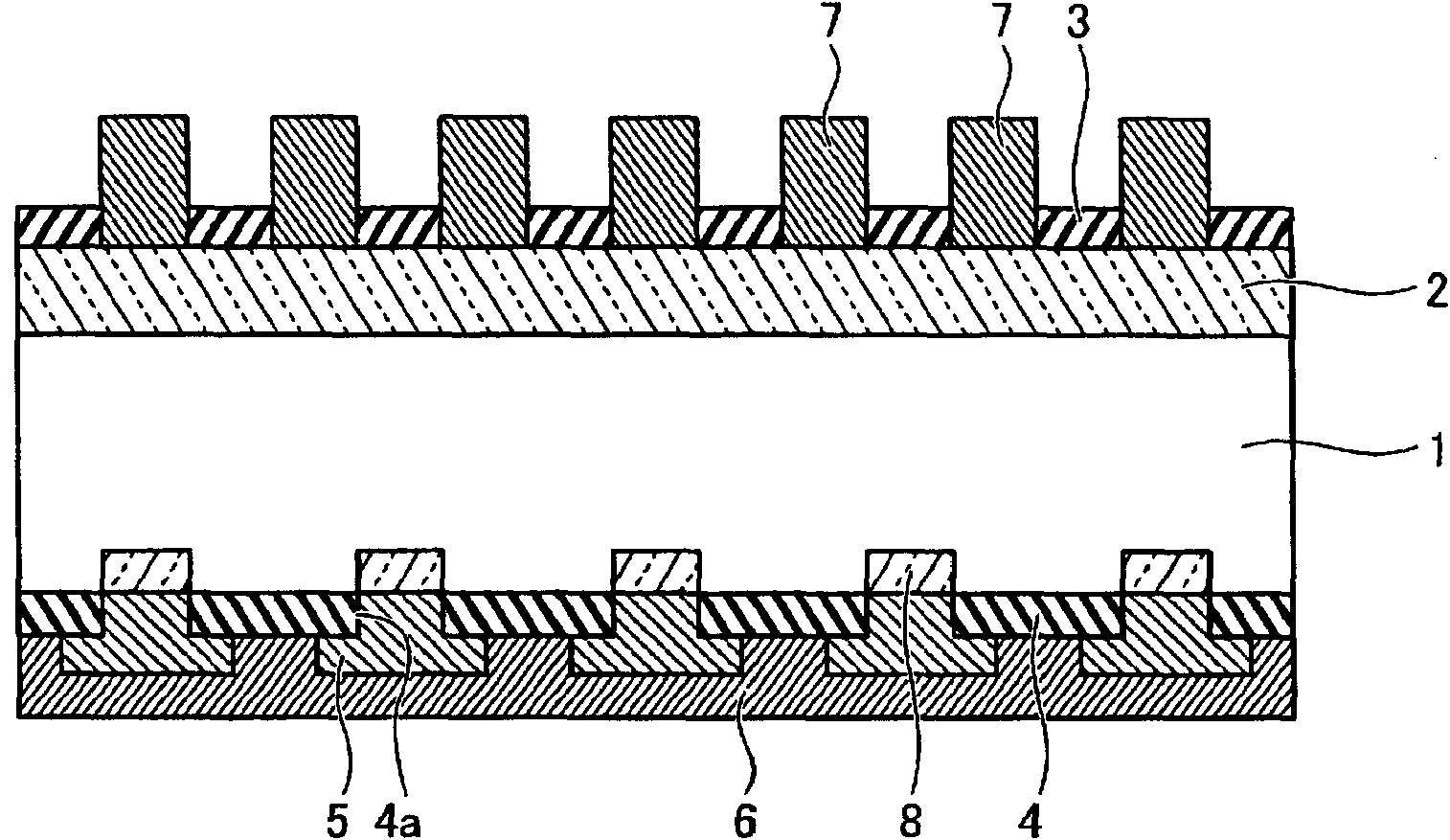

Solar battery cell and process for producing the same

InactiveCN102077359AImprove featuresQuality improvementFinal product manufacturePhotovoltaic energy generationHigh concentrationImpurity diffusion

A second conductivity type impurity diffusion layer and an antireflection film are formed on one side of a first conductivity type semiconductor substrate. A glass-containing first electrode material is coated on the antireflection film. A passivation film is formed on the other side of the semiconductor substrate. A plurality of opening parts, which reaches the other side of the semiconductor substrate, is formed in at least a part of the passivation film. A second electrode material containing the first conductivity type impurity element is coated so as to embed the plurality of opening parts and so as not to come into contact with the second electrode material in the adjacent opening part. A third electrode material is coated onto the passivation film so as to come into contact with the coated whole second electrode material. After coating the first electrode material and the third electrode material, the semiconductor substrate is heated at a predetermined temperature. The above constitution can realize simultaneous formation of a first electrode, which passes through the antireflection film and is electrically connected to the impurity diffusion layer, a high-concentration region, in which, on the other side of the semiconductor substrate, the first conductivity type impurity is diffused in a higher concentration than the other region of the semiconductor substrate, and the second and third electrodes electrically connected to the high-concentration region.

Owner:MITSUBISHI ELECTRIC CORP

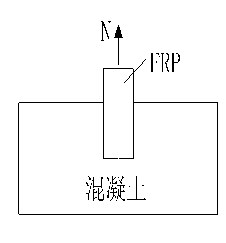

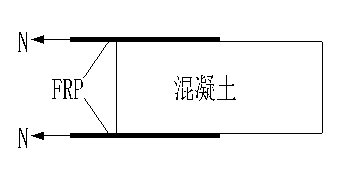

Method for testing interface bond behavior of CFRP (carbon fiber reinforced polymer) cloth-concrete based on beam specimen

InactiveCN103344560ATruly reflect the state of stressEasy to operateUsing mechanical meansMaterial analysisInverted-T shapeEngineering

The invention discloses a method for testing interface bond behavior of CFRP (carbon fiber reinforced polymer) cloth-concrete based on a beam specimen. The method comprises three steps of preparing a test specimen, arranging a test point and loading a test. The test specimen manufactured in the first step is the beam specimen and comprise two concrete test blocks, which are arranged at left and right and symmetric in shape; the two concrete test blocks are inverted T-shaped concrete test blocks; the upper parts in the middle of the two concrete test blocks are connected by a steel hinge; the steel hinge is divided into left and right halves; and the left and right halves are respectively adhered to the concrete test block at the corresponding side, and have the rotation ability. Compared with the traditional double shear test method for testing the interface bond behavior of the CFRP cloth-concrete, the effect of asymmetric loading on the data reliability is avoided; the method has a unique advantage of high accuracy of the test result; and the accuracy and the creditability of the detection result are improved.

Owner:ZHENGZHOU UNIV

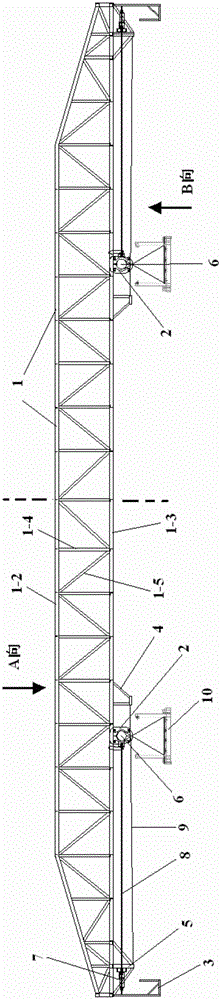

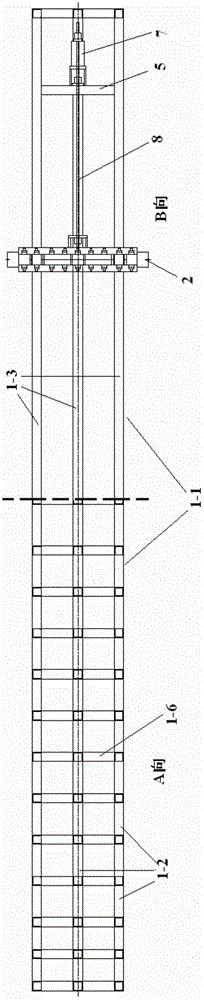

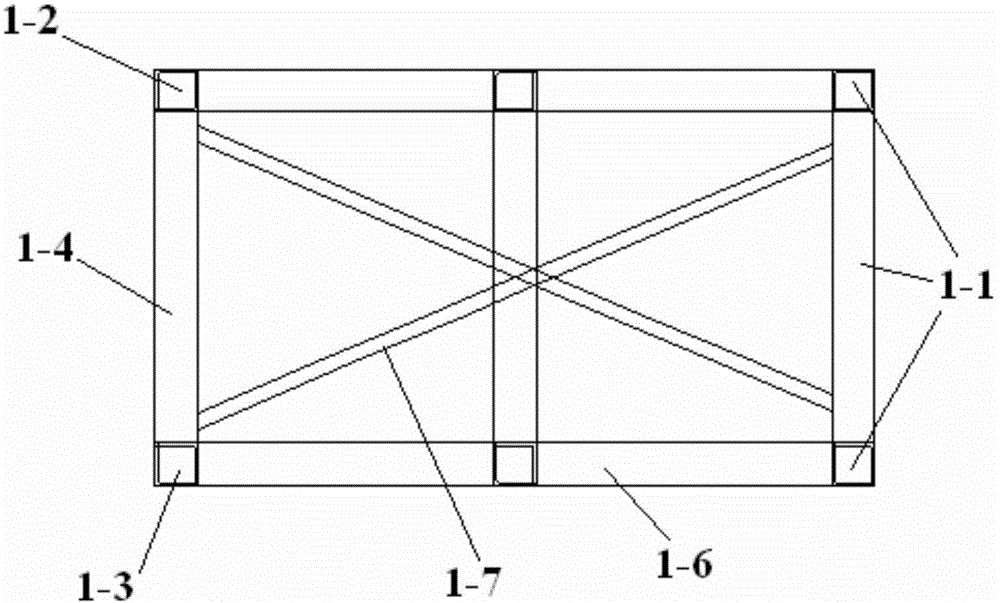

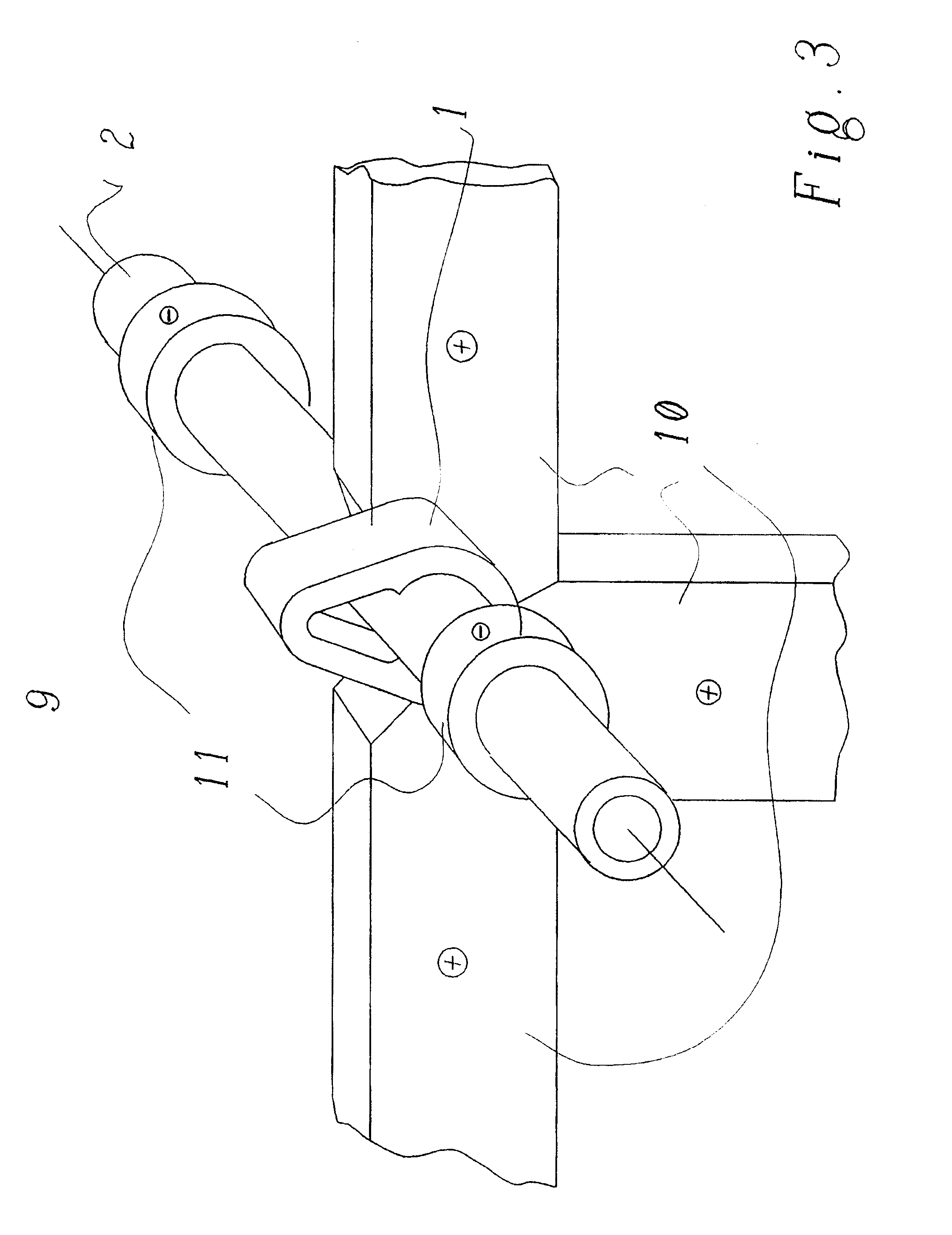

Temporary cross bracing of space cable suspension bridge and lifting-constructing method of temporary cross bracing

InactiveCN104060540AStable structureEasy to set upBridge erection/assemblyEngineeringStructural engineering

The invention provides temporary cross bracings of a space cable suspension bridge and a lifting-constructing method of the temporary cross bracing. The lifting-constructing method comprises the following steps: firstly, mounting a main cable; secondly, mounting trusses at positions of mid-span, one-fourth span, and three-fourths span to form a developed bridge space cable surface for supporting cables; thirdly, mounting cable clamps and suspension cables; finally, lifting and mounting a steel box girder. According to the method of the invention, the constructing method is adopted, that is, the main cable is erected firstly, and then a stiffening girder is lifted and mounted, so that the navigation requirement during a constructing period can be ensured and the disadvantage of erecting a temporary support can be overcome; through arranging truss cross bracings, the main cable is transited from a cable horizontal alignment shape to a developed bridge space cable shape; the cable clamps does not need to be pre-deflected in a horizontal bridge direction; all that is needed is to mount the cable clamps according to the inclined angle formed by that the suspension cables are perpendicular to a down bridge direction under the condition of the developed bridge so as to ensure that the parts between the ear plates of the cable clamps and the ear plates of the suspension cables do not bend during the lifting and mounting process of the steel box girder.

Owner:CHANGAN UNIV

Method for manufacturing wire of bearing steel

A technology for producing steel wire for manufacturing the steel balls of bearing includes such techonlogical steps as hot rolling, spheriodizing, acid washing, phosphorizing, lubricating, drawing, annaling, acid washing, phosphorizing, lubricating and light drawing. Its advantages are high productivity, and high surface hardness of product.

Owner:黄澄

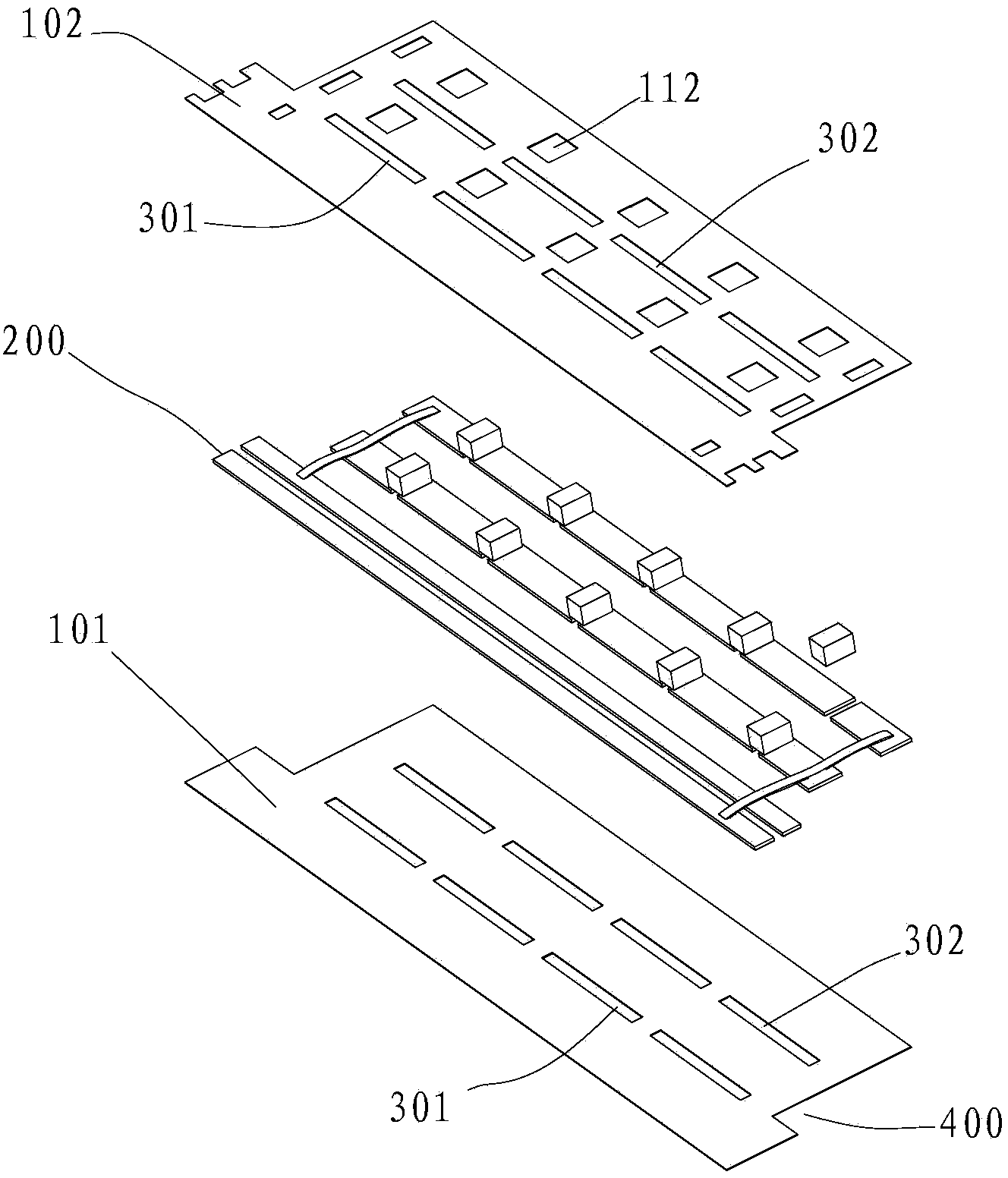

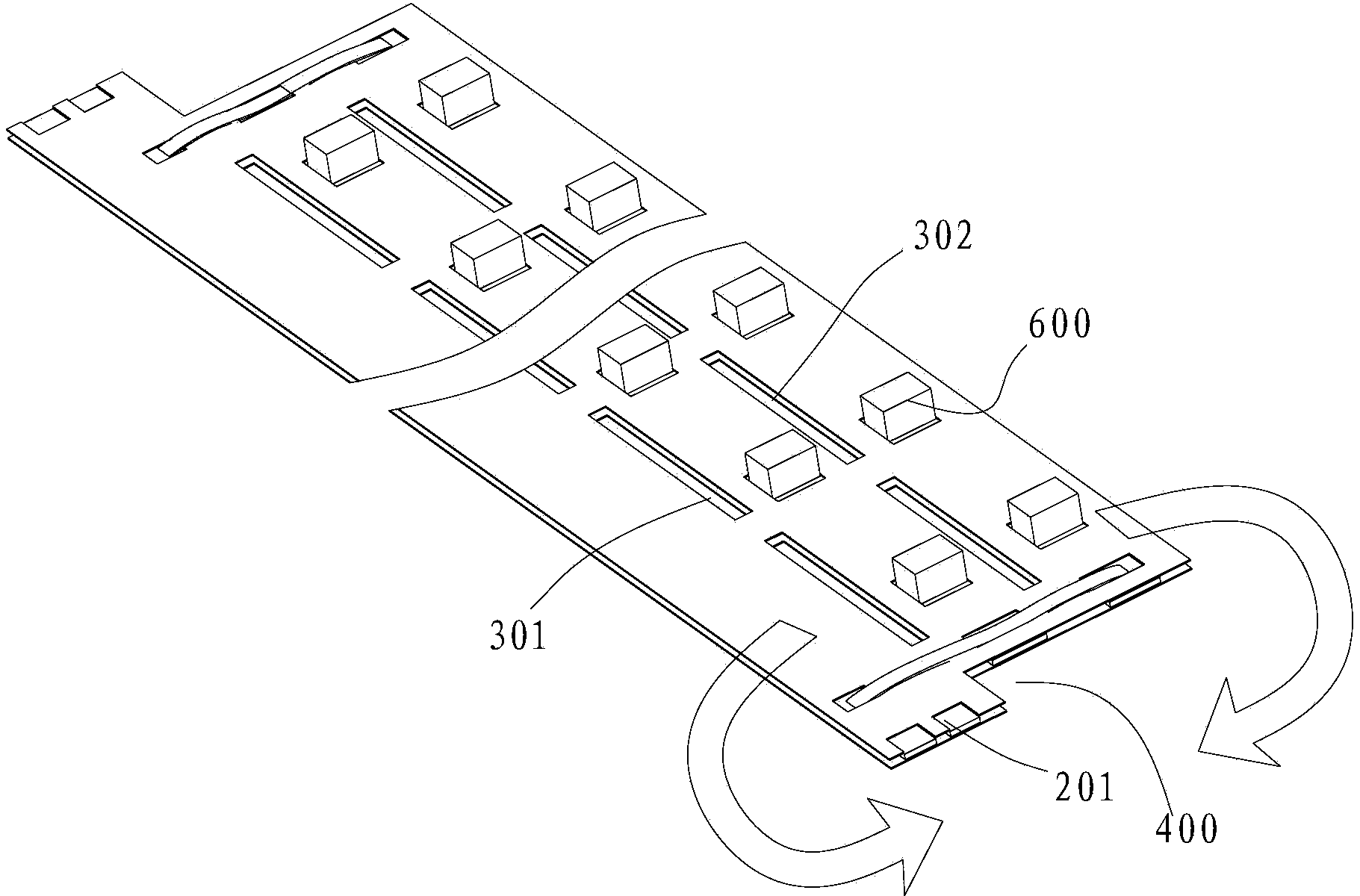

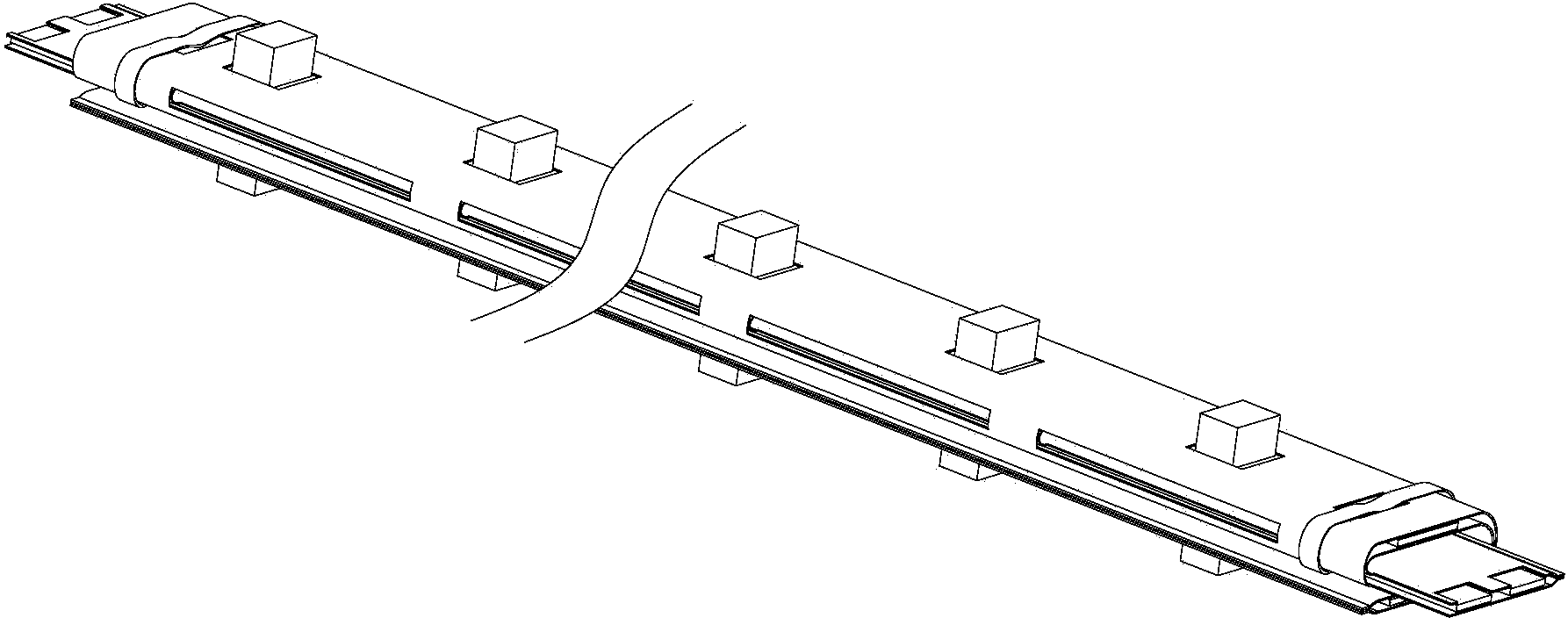

Flexible circuit board, flexible LED lamp bar and manufacturing method of flexible LED lamp bar

ActiveCN103974525AImprove bending performancePrevent mutual liftingPoint-like light sourcePrinted circuit detailsInsulation layerFlexible circuits

The invention discloses a flexible circuit board, a flexible LED lamp bar and a manufacturing method of the flexible LED lamp bar. The flexible circuit board comprises a first insulation layer, a second insulation layer and a circuit layer. The first insulation layer and the second insulation layer are attached to the two sides of the circuit layer respectively. The first insulation layer and the second insulation layer are respectively provided with a folding portion in the length direction. The folding portion of the first insulation layer corresponds to the folding portion of the second insulation layer in position. The circuit layer comprises a set of power lines and at least one light source line. The light source lines and the power lines are arranged on the two sides of the folding portions in a separable mode. The width of the folded flexible circuit board is smaller, so that more occasions where the flexible circuit board with the smaller width is needed are met, and the power lines and the light source lines are not bent when the flexible circuit board is folded. Due to the existence of the folding portions, folding face layers of the power lines and folding face layers of the light source lines can be prevented from tilting up along the folding portions, the folding face layers of the power lines and the folding face layers of the light source lines are easily attached together, and the wrinkling phenomenon is reduced.

Owner:GUANGDONG TONGFANG ILLUMINATIONS CO LTD

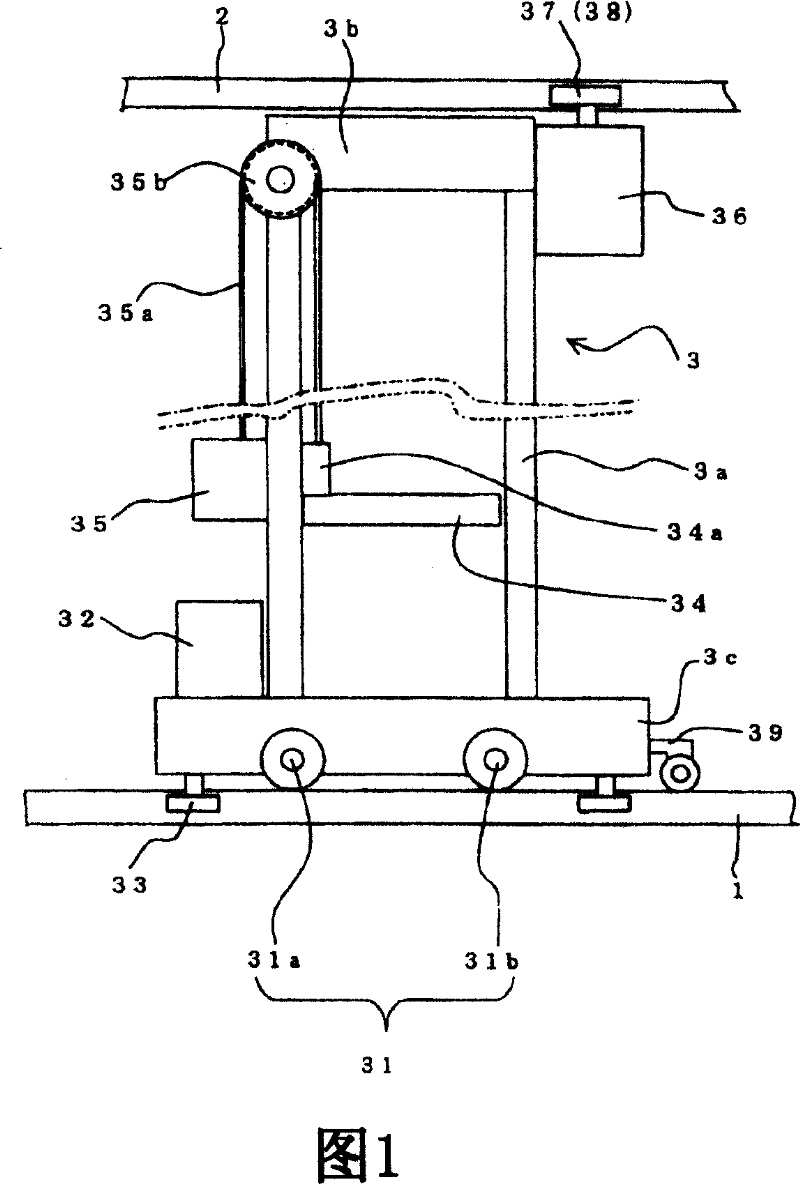

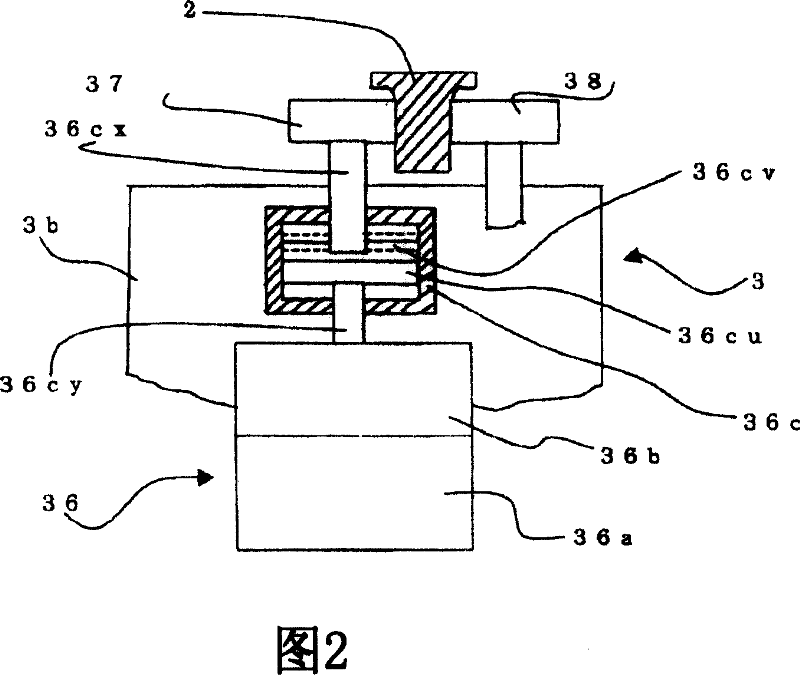

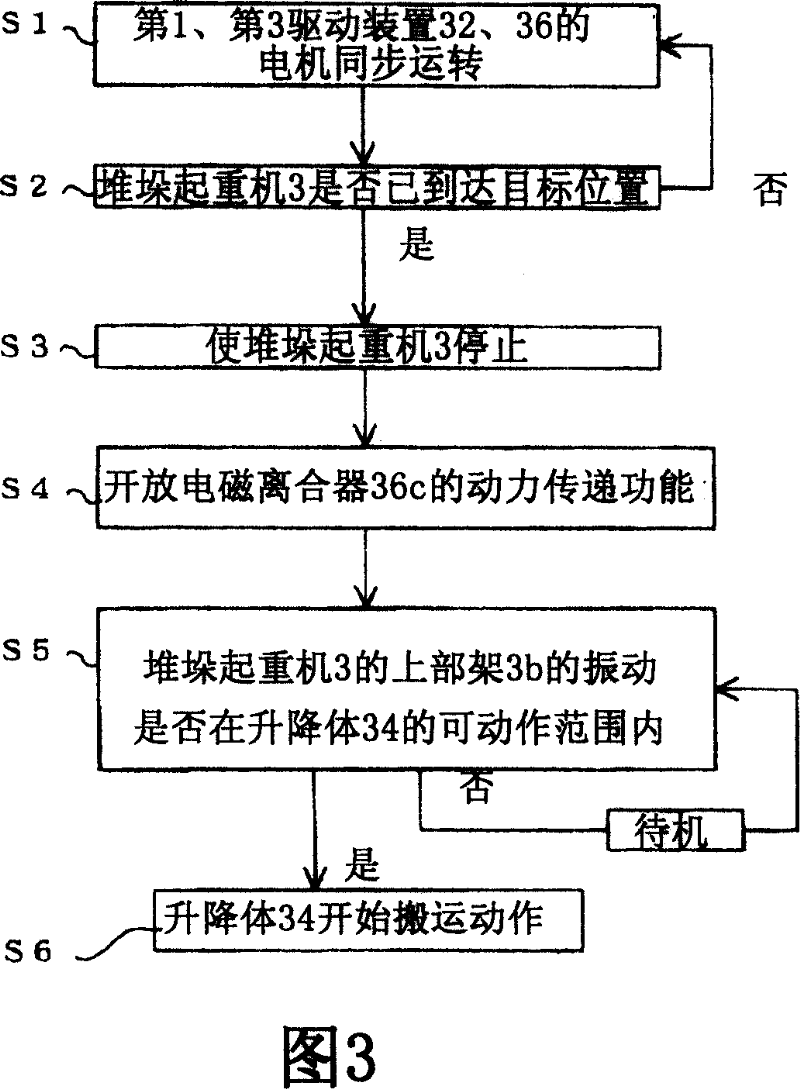

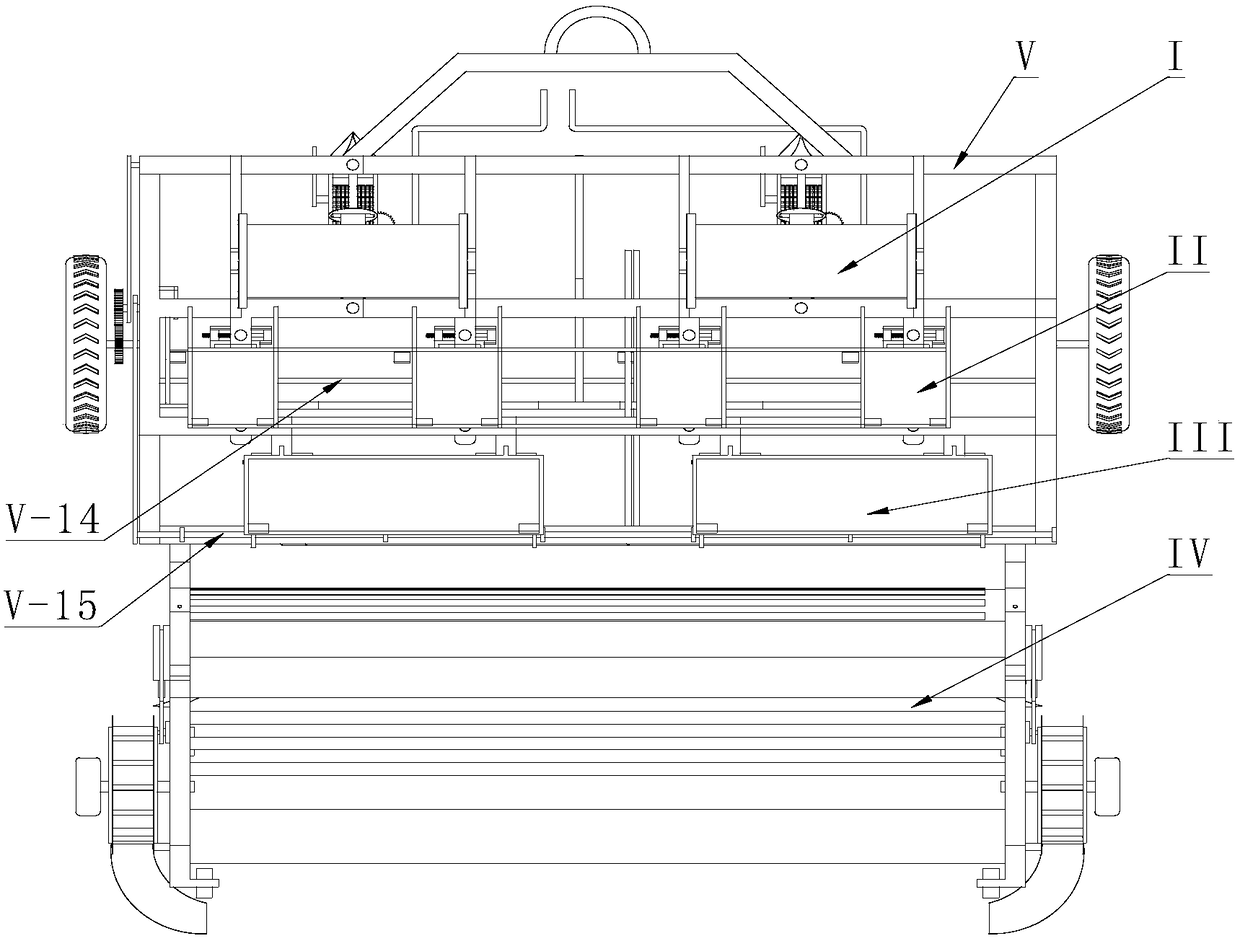

Stack crane and driving control method thereof

ActiveCN101037180AImprove rigidityNo bendingLifting devicesStorage devicesEngineeringMechanical engineering

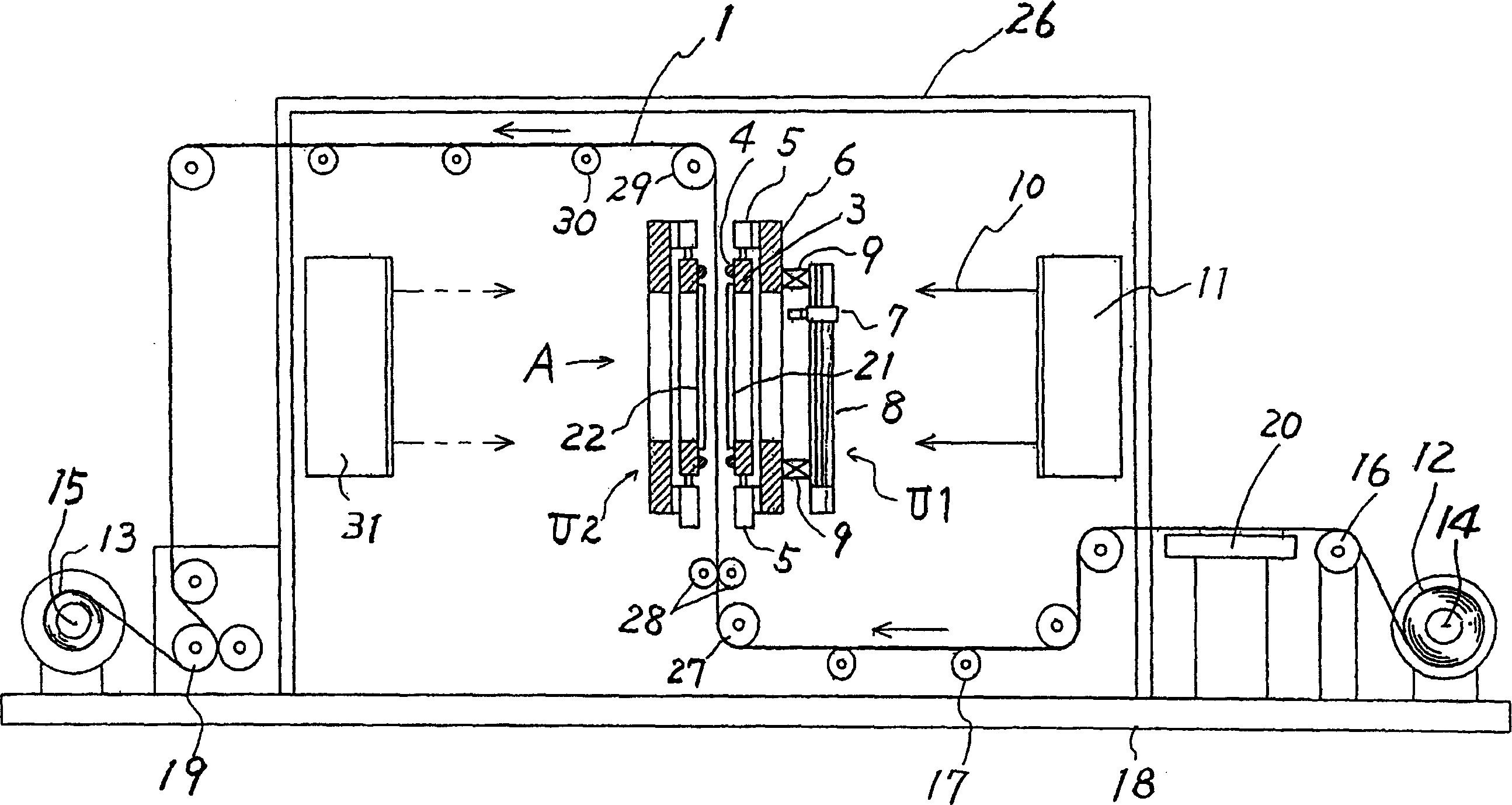

The invention provides a stack chain block and a driving and controlling method thereof. The stack chain block is capable of moving along an upper side guide track and a lower side guide track. An upper portion of a main body is clamped with the upper side guide track and can move relatively to the upper side guide track. A lower portion of a main body is clamped with the lower side guide track and can move relatively to the lower side guide track. A column is extended and provided along a vertical direction, and connects the upper portion and the lower portion of the main body. A lifting body can be moved along the column up and down. An upper side driving device is arranged at the upper portion of the main body, limits the upper portion of the main body relatively to the upper side guide track, and makes the upper portion of the main body move along the upper side guide track. A lower side driving device is arranged at the lower portion of the main body, and makes the lower portion of the main body move along the lower side guide track. A controlling portion inputs a first signal representing a target speed or a target position into the upper side driving device and a lower sidedriving device, so that moving speeds of the upper portion and the lower portion of the main body are equal, the controlling portion inputs a second signal to the upper portion driving device after movement of the upper portion of the main body is finished and during stopping the lifting body, the second signal releases limitation of the upper driving device on the upper side guide track.

Owner:MURATA MASCH LTD

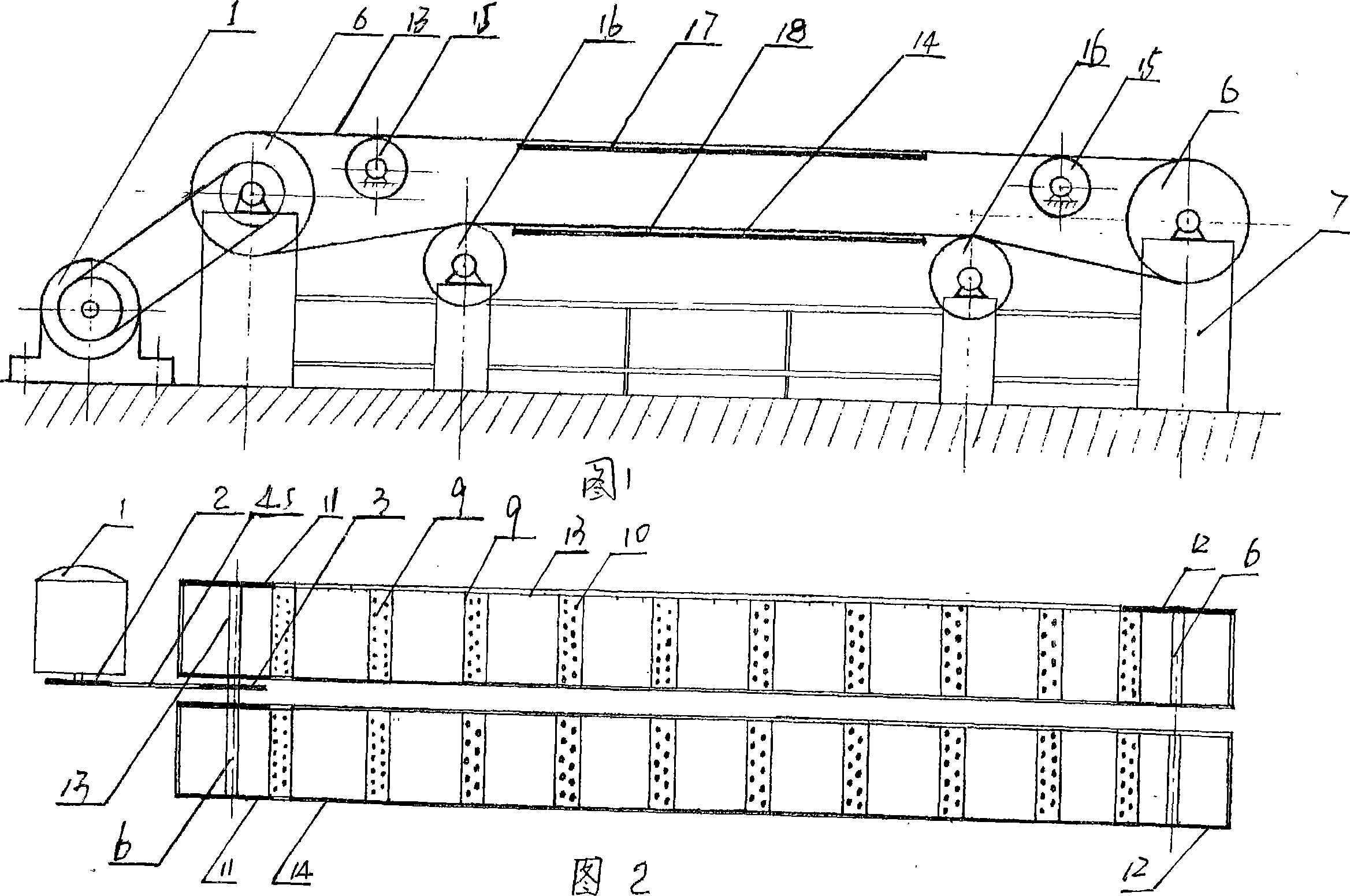

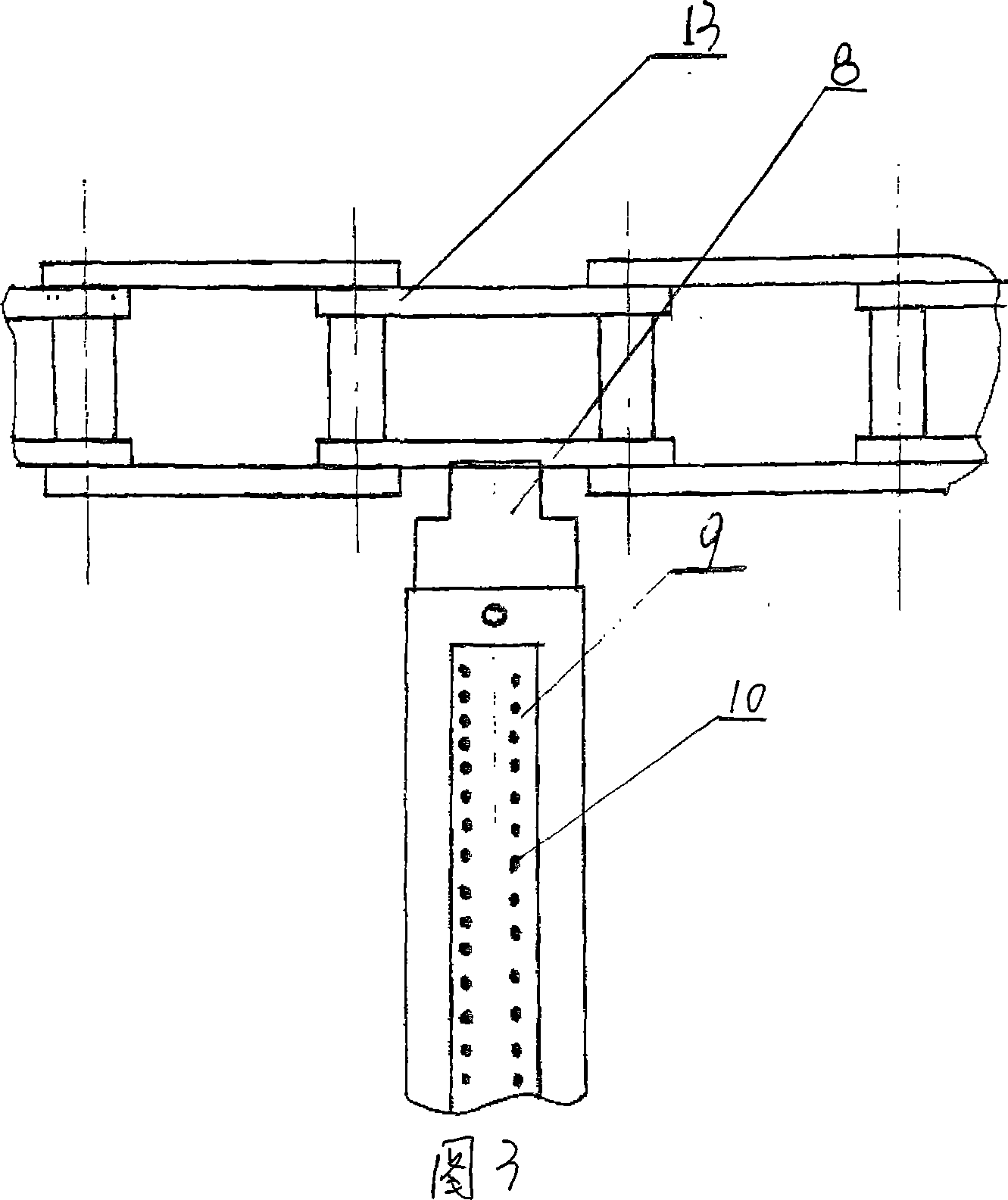

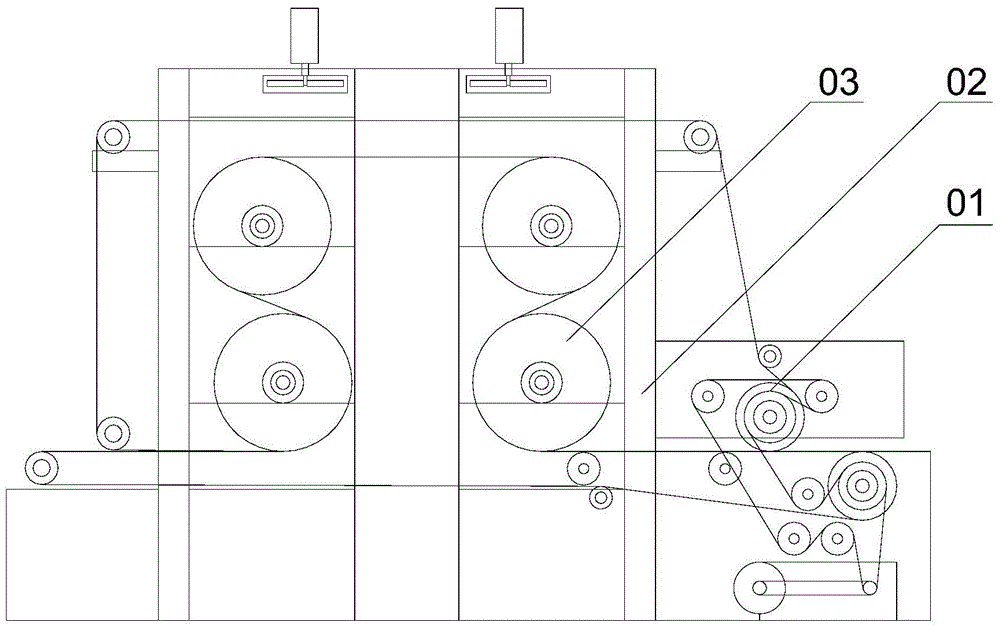

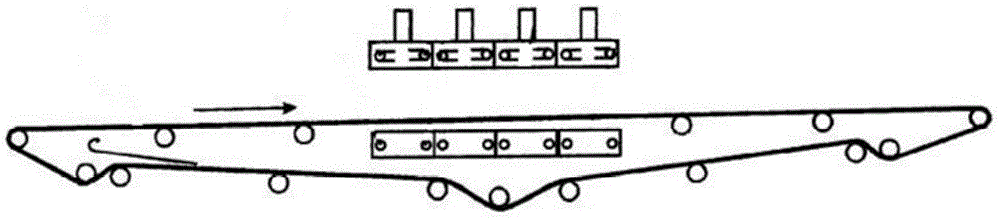

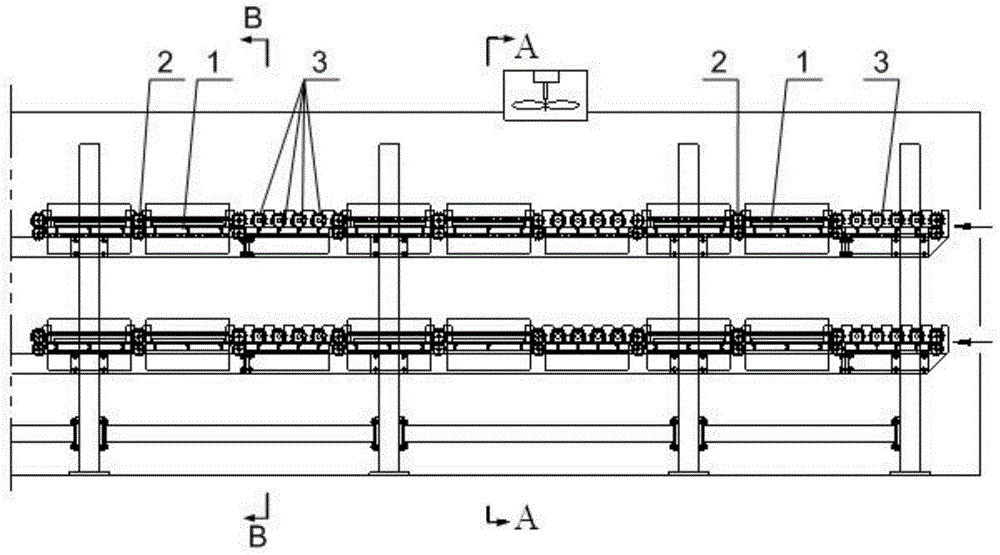

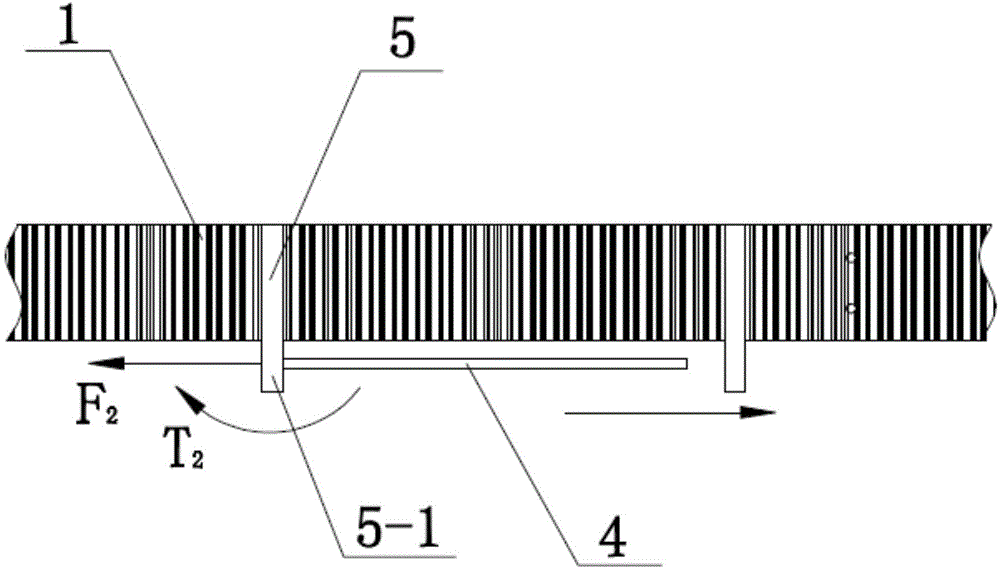

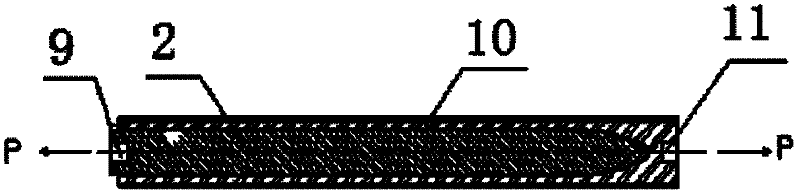

Drying, reforming and transmission device for textile

InactiveCN101054766ASimple structureEasy to operateConveyorsHeating/cooling textile fabricsDrive shaftEngineering

The invention discloses a drying, reforming and transmission device for textile. A transmission shaft (6) is mounted at two ends of a frame (7), transmission chain wheels (11, 12) are equipped on the transmission shaft (6), transmission chains (13) are around the transmission chain wheels (11, 12) to constitute transmission rings, the two transmission rings constitutes a conveying belt, double transmission chain wheels (2, 3) are mounted on a shaft of a motor (1) and the transmission shaft (6), and the double transmission chain wheels (2, 3) are wrapped with transmission chains (4, 5). Characteristic of the invention is that: a set of needle plates (8) are mounted on the two transmission chain (13, 14) alternately, two ends of the needle plates (8) are separately mounted on the transmission chain (13, 14) of the two transmission rings, the needle plates (8) include pallets (9) and positioning needles (10), and the positioning needles (10) are mounted on the pallets (9) to constitute the needle plates (8).Advantages of the invention are: operation is convenient, adjustment is simple, transmission is stable, deforming and bend grain are not generated, application is wide, and product quality is increased.

Owner:刘义涛

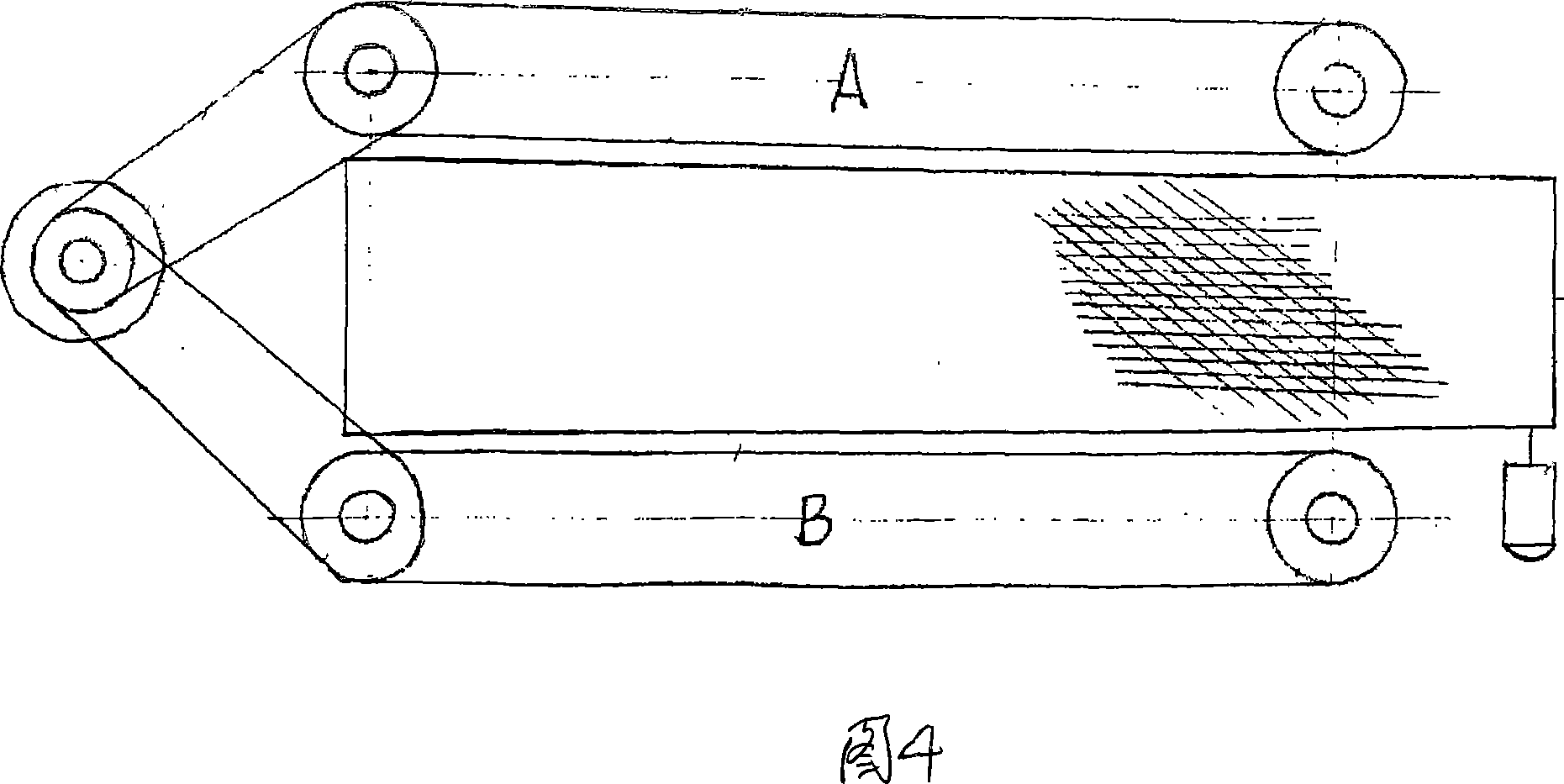

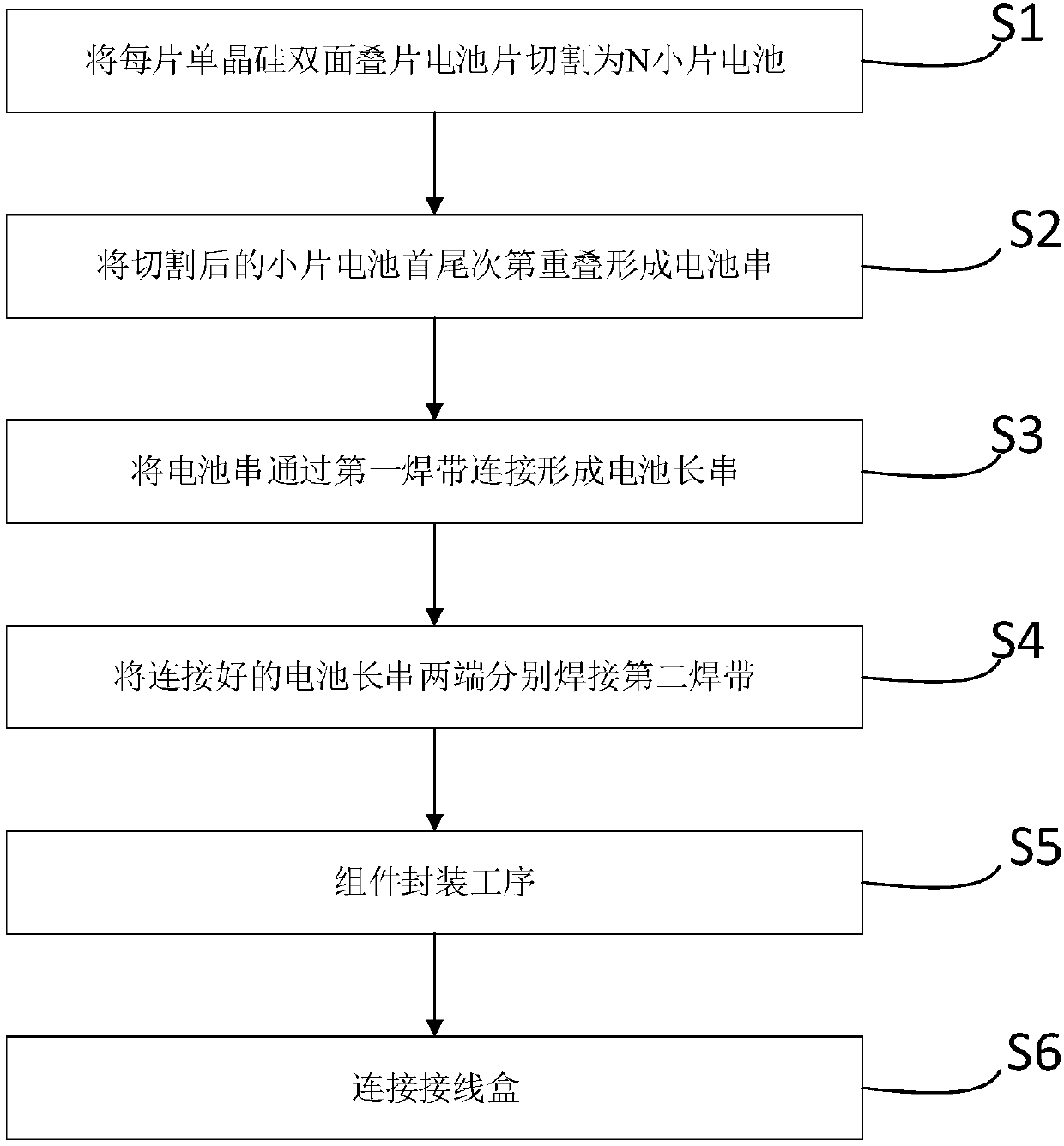

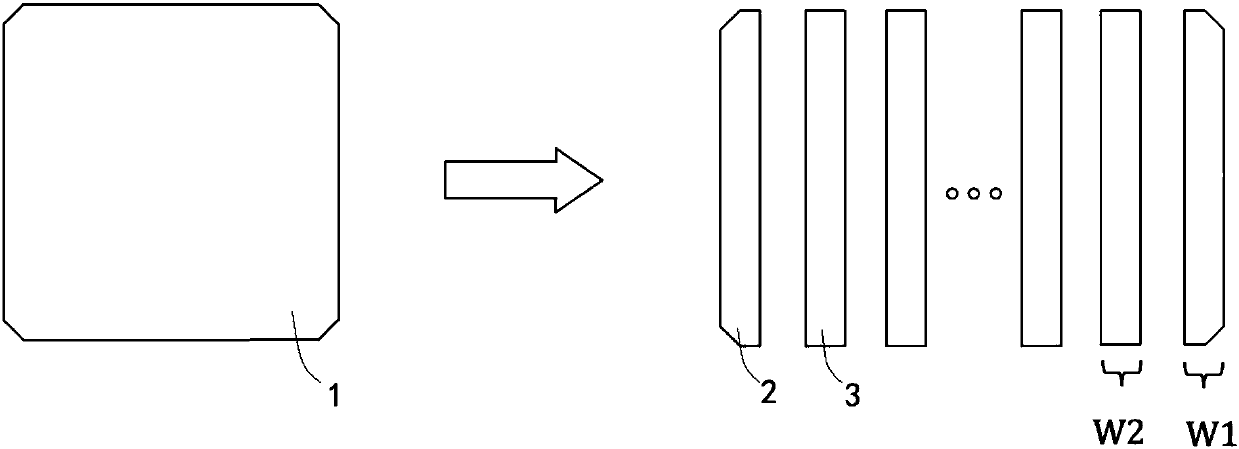

Double-sided monocrystalline laminated photovoltaic module and manufacturing method thereof

ActiveCN107910396AEfficient use ofImprove efficiencyPhotovoltaic energy generationSemiconductor devicesElectrical batteryEngineering

The invention discloses a double-sided monocrystalline laminated photovoltaic module and a manufacturing method thereof. The manufacturing method comprises the steps of S1, cutting each monocrystalline silicon double-sided laminated battery piece 1 into N small battery pieces; S2, sequentially overlapping the cut small battery pieces end to end to form battery strings; S3, connecting the battery strings through a first welding strip to form a long battery string; S4, respectively welding second welding strips to two ends of the connected long battery string; S5, performing a module packaging procedure; and S6, connecting a junction box. According to the invention, one battery piece is cut into two types of small battery pieces, and the small battery pieces are connected according to the shape and specifications to form the battery strings, so that two different types of battery strings are packaged in the same module, and the uniformity of the product appearance is realized.

Owner:LONGI SOLAR TECH (TAIZHOU) CO LTD

Carbon fibre surface energy measurement method

ActiveCN101509864AReduce mistakesReduce distractionsSurface tension analysisSurface energyCapillary action

The invention provides a measuring method for carbon fiber surface energy, which relates to a measuring method for surface energy, which solves the defects that in the existing method for using a seepage instrument to measure the carbon fiber surface energy, as synnema measurement is largely influenced by capillary action, the accuracy of measuring results is low and the carbon fiber surface energy can not be reflected actually. The measuring method comprises the following steps of: (1) drying carbon fiber; (2) preparing sampling by carbon fiber; (3) carrying out detection by using a surface tensiometer; and (4) calculating to obtain the carbon fiber surface energy. As the measuring method of the carbon fiber surface energy reduces the external interference to the measured results to the utmost, the contacting angle measurement of the carbon fiber is more accurate; and the measuring method has high accuracy compared with the existing testing method and can accurate to two digits after the decimal point, thus obtaining the more accurate carbon fiber surface energy.

Owner:HARBIN INST OF TECH

Activated waste slay composite powder and its application in cement, concrete and bake free brick

InactiveCN1493541ANon-proliferationImproved pozzolanic propertiesCement productionBuilding componentsChemical admixtureMineral Sources

An activated composite waste dregs powder used for cement, concrete and non-calcine brick is prepared from acidified zeolite powder, lead or copper dregs, carbonate stone powder, phosphate dregs (ardealite), lime dregs and powdered coal ash as basic materials. Its advantages are high property and low cost.

Owner:吴发辉

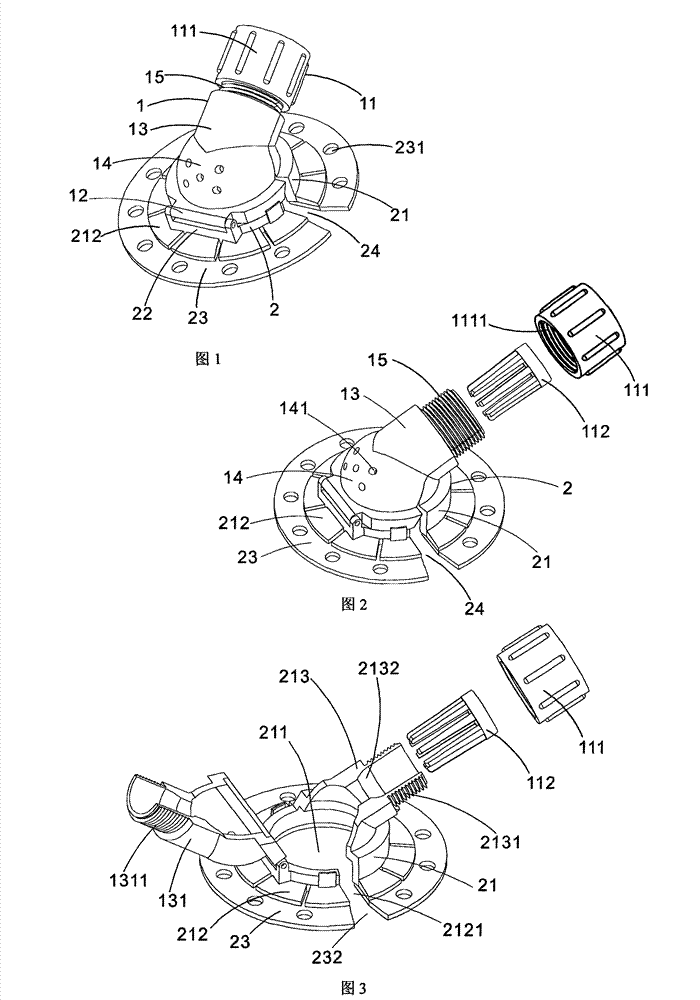

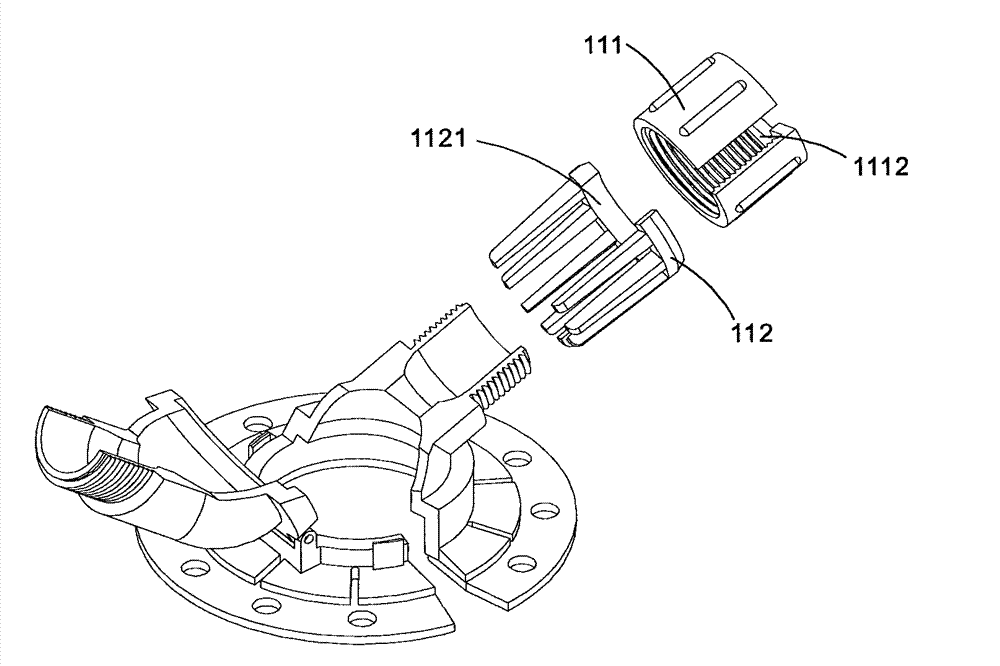

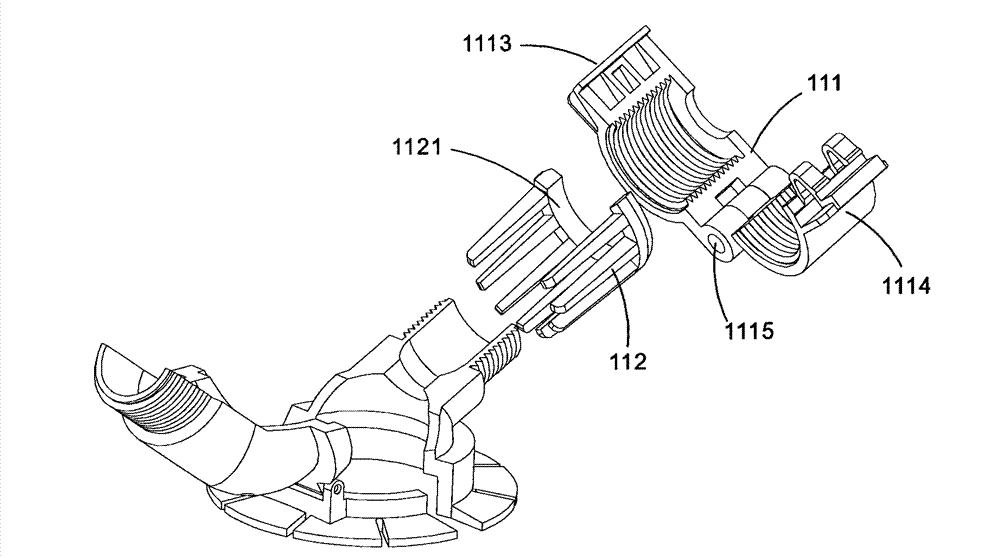

Device for fixing drainage tube

A drainage tube fixing assembly which is used for supporting and fixing a drainage tube and a body surface fixing component are connected and the flip-type structure which can be opened and locked is combined with the integrated design of a tube imbedding opening and a screwing ring, thus the drainage tube is easy to imbed without pressing peripheral muscle of the wound, the drainage tube is prevented from bending and winding and the wound can be observed and nursed at any time.

Owner:李林风

High-power LED (Light-Emitting Diode) heat dissipation ceramic substrate

The invention belongs to the technical field of ceramic substrates, and particularly relates to a high-power LED (Light-Emitting Diode) heat dissipation ceramic substrate. The ceramic substrate comprises the following materials in percentage by mass: 70-80 percent of alumina powder, 3-8 percent of melamine, 3-6 percent of hydroxymethyl cellulose, 6-10 percent of deionized water and 5-10 percent of composite sintering aid, wherein the composite sintering aid comprises the following materials in percentage by mass: 40-60 percent of silicon powder, 5-10 percent of aluminum powder, 20-30 percent of kaolin powder and 10-30 percent of calcium fluoride. The ceramic substrate has the advantages of high heat conductivity coefficient, excellent heat resistance, high bending strength and avoidance of the phenomena of bending, wrapping and the like. Through adoption of an appropriate sintering method and selection of an appropriate sintering aid, denseness of an alumina ceramic sintered body is realized, and the heat conductivity of alumina ceramics is increased greatly.

Owner:SUZHOU ZHIRUI PHOTOELECTRIC MATERIAL TECH CO LTD

Veneer dryer

ActiveCN104697308AHigh surface flatnessNo bendingDrying machines with progressive movementsDrying solid materialsEngineeringUtilization rate

The invention discloses a veneer dryer which comprises a plurality of heating plate groups and a plurality of transmission drum groups that are arranged in a planar continuous alternation manner; each heating plate group comprises an upper heating plate and a lower heating plate; a distance between each upper heating plate and each lower heating plate is greater than the thickness of veneers; each transmission drum group comprises an upper drum and a lower drum that are arranged relatively vertically, are opposite in rotation direction and are used for clamping and conveying the veneers; and a center distance between every two adjacent transmission drum groups is less than the length of the side, parallel to a conveying direction, of each veneer. According to the veneer dryer, the upper heating plates and the lower heating plates dry the veneers from the upper sides and the lower sides; since the upper heating plates and the lower heating plates are fixed, no air flows; a heat utilization rate is increased; the drying efficiency is high; the veneers is extruded by the upper drums and the lower drums; the evenness of the veneers is improved; since the heating plate groups and the transmission drum groups are arranged in a planar manner, the veneers cannot be bent; and a proportion of the broken veneers is decreased.

Owner:快乐木业集团有限公司

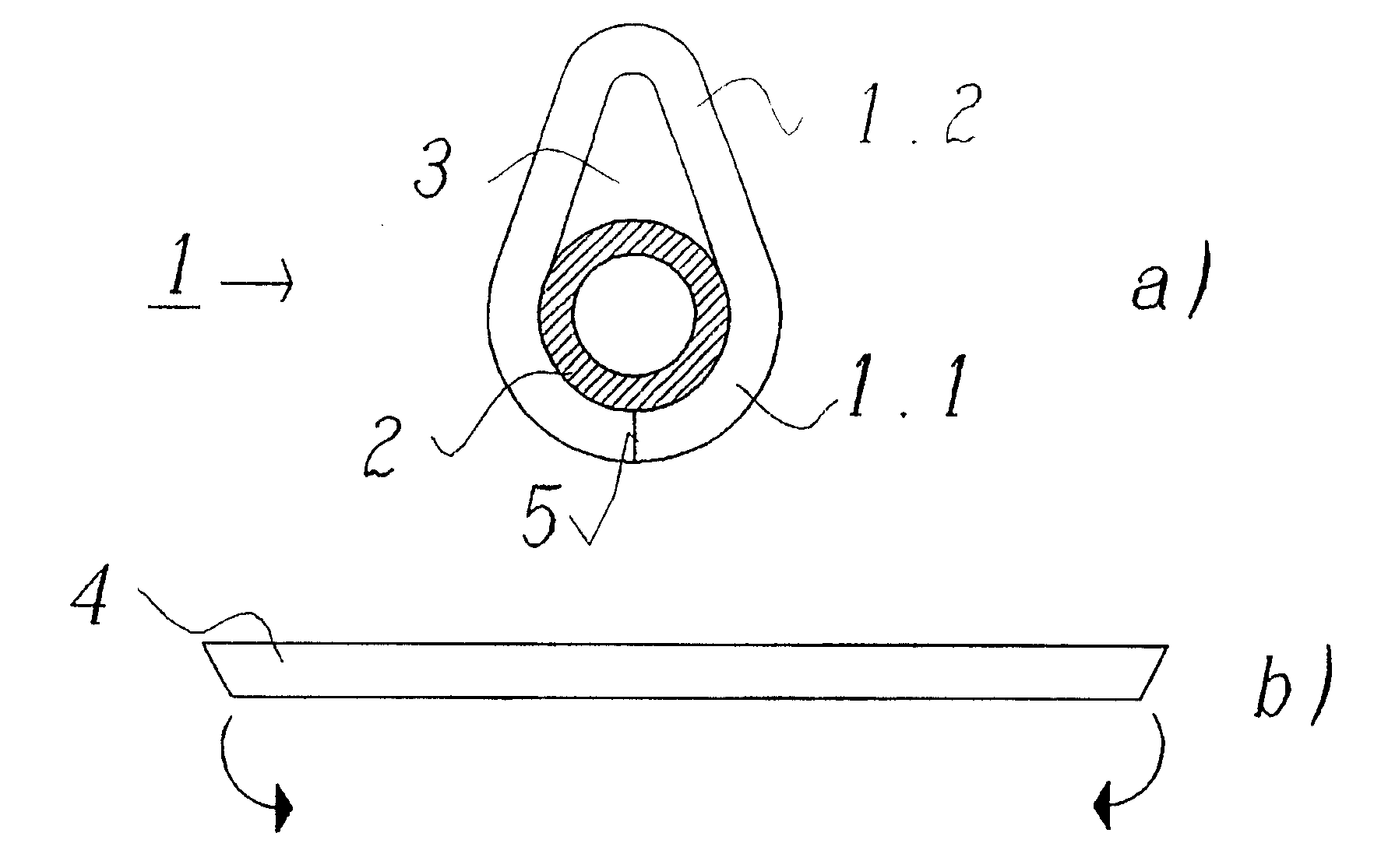

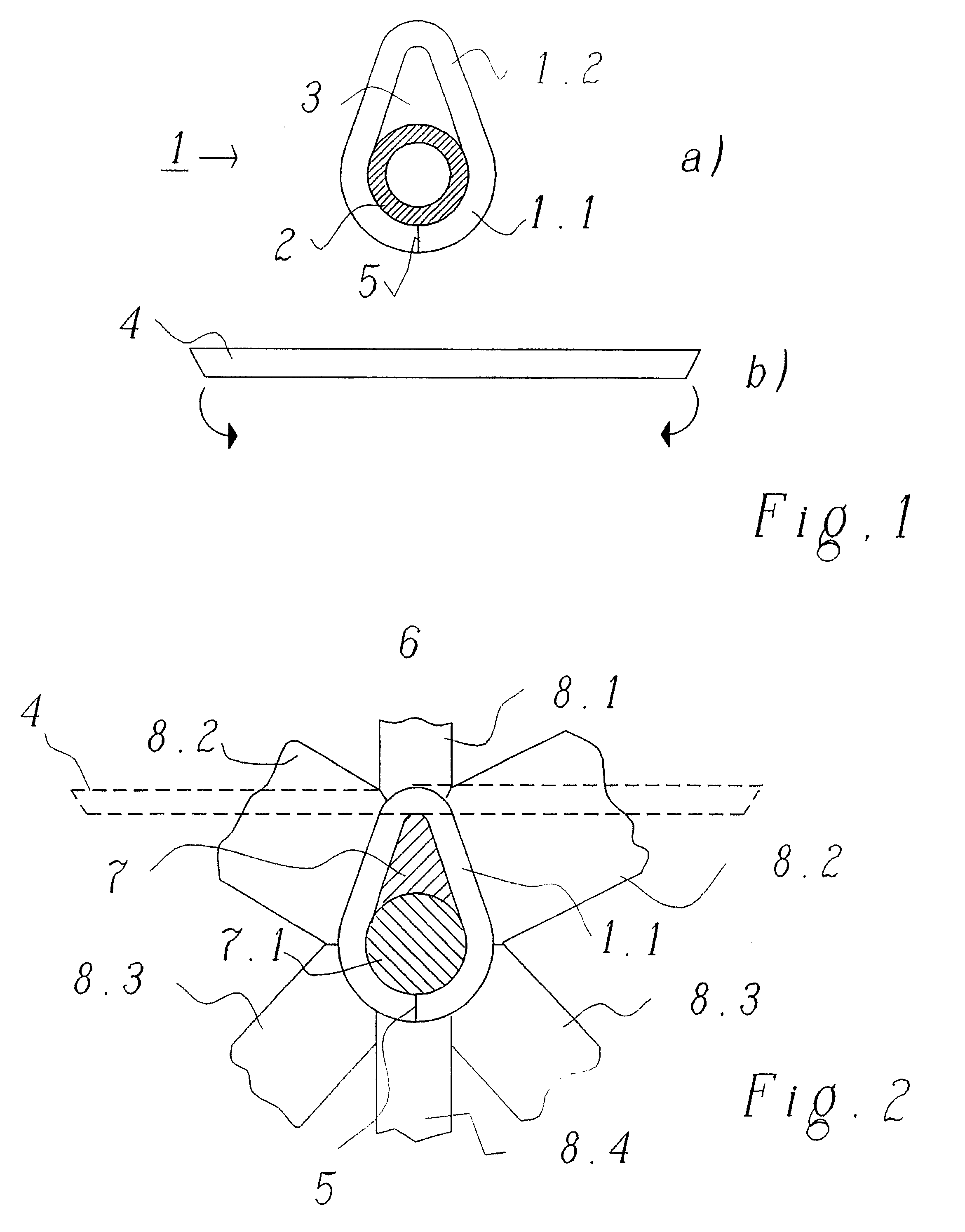

Method for producing a cam for a camshaft

InactiveUS7020962B2Simple and efficient and quick and economicalShorten the lengthCamsValve drivesCamElectric resistance welding

The invention relates to a method for producing cams (1) for a camshaft. The cams are produced by bending together the ends of long profile strips (4) or by bending and putting together several pieces of profile strips in a circumferential direction. Cams produced in such a way are preferably welded onto the shaft. The invention also relates to suitable welding methods such as resistance welding, laser-beam or electron-beam welding and corresponding devices.

Owner:MERZ KARL

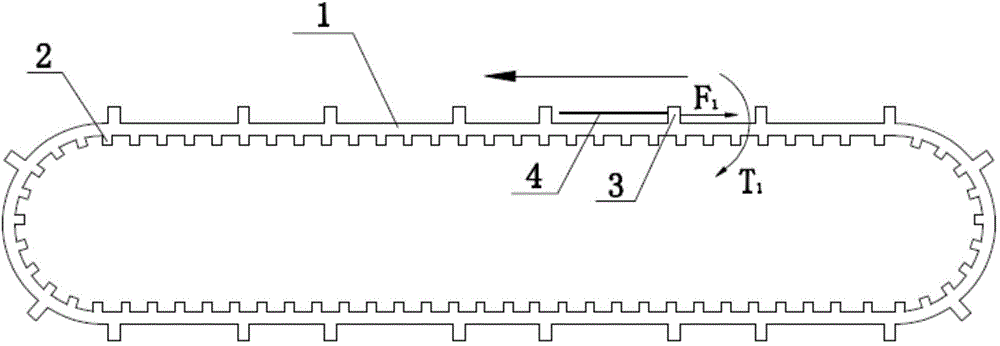

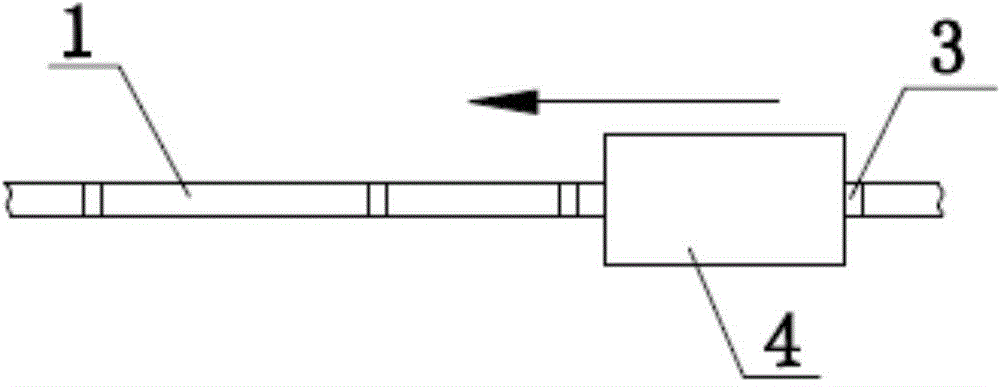

Smart card conveyer belt and smart card conveying mechanism

The invention discloses a smart card conveyer belt and a smart card conveying mechanism. The smart card conveyer belt comprises a conveyer belt body, the conveyer belt body is provided with a plurality of rigid shifting teeth, the shifting teeth extend in the height direction of the conveyer belt body to extend out of the lower edge of the conveyer belt body, and a card pushing part for pushing cards is formed by the extending-out part. The smart card conveying mechanism comprises the conveyer belt and a power mechanism, the power mechanism comprises a motor and at least two synchronization belts, synchronization teeth of the conveyer belt are meshed with tooth grooves in synchronization belt wheels, and one synchronization belt wheel is driven by the motor. By means of the smart card conveyer belt, the shifting teeth cannot be bent and deformed when the cards are pushed to conduct code printing, and it is guaranteed that the positions of printed characters on the cards are accurate.

Owner:GUANGZHOU MINGSEN TECH CO LTD

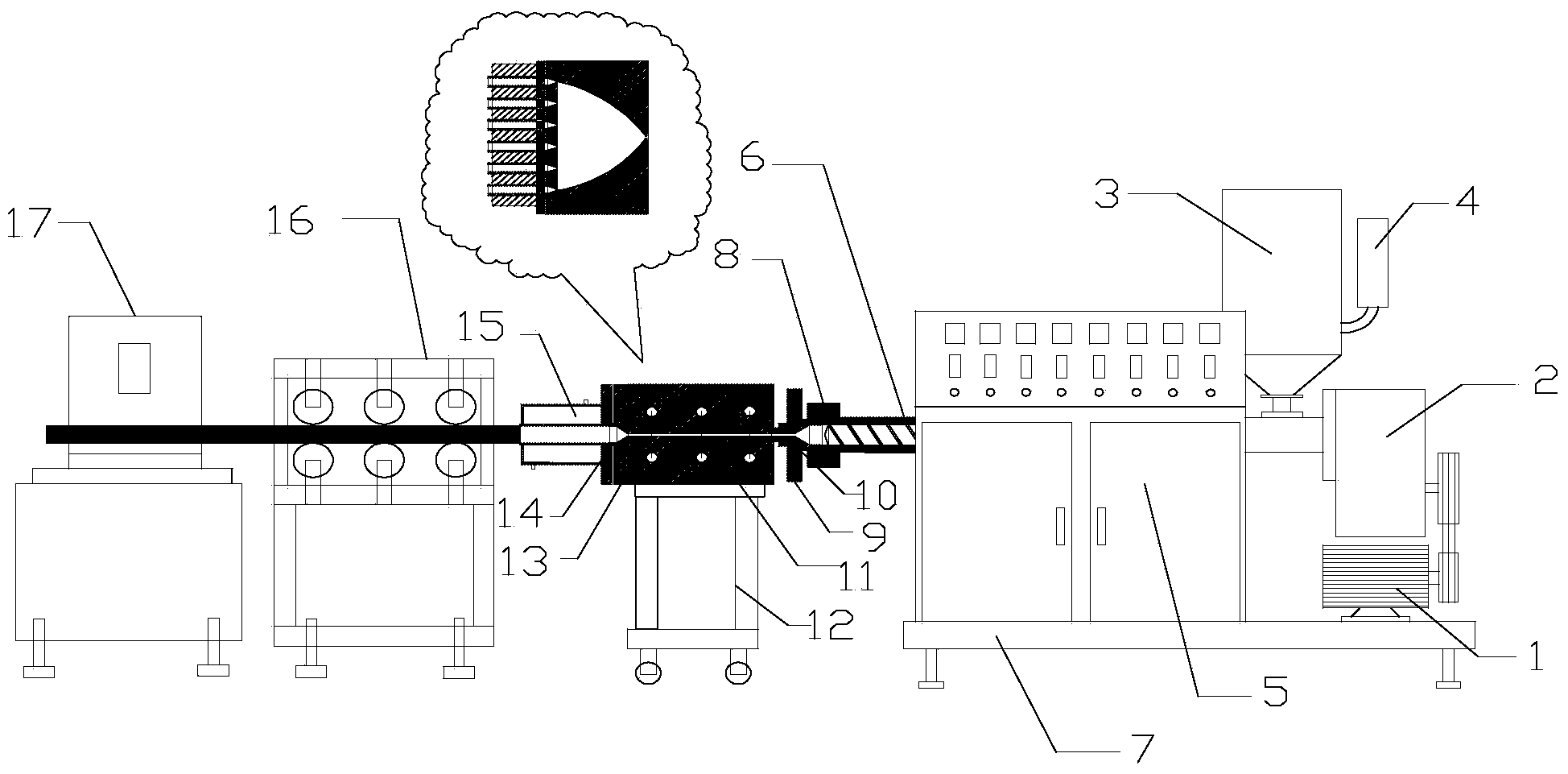

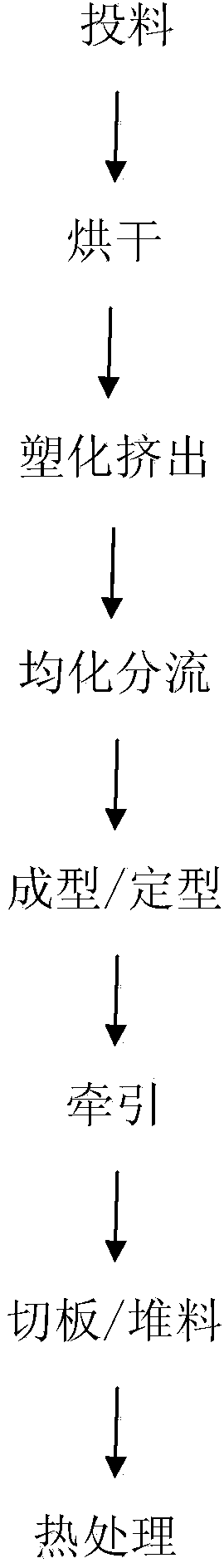

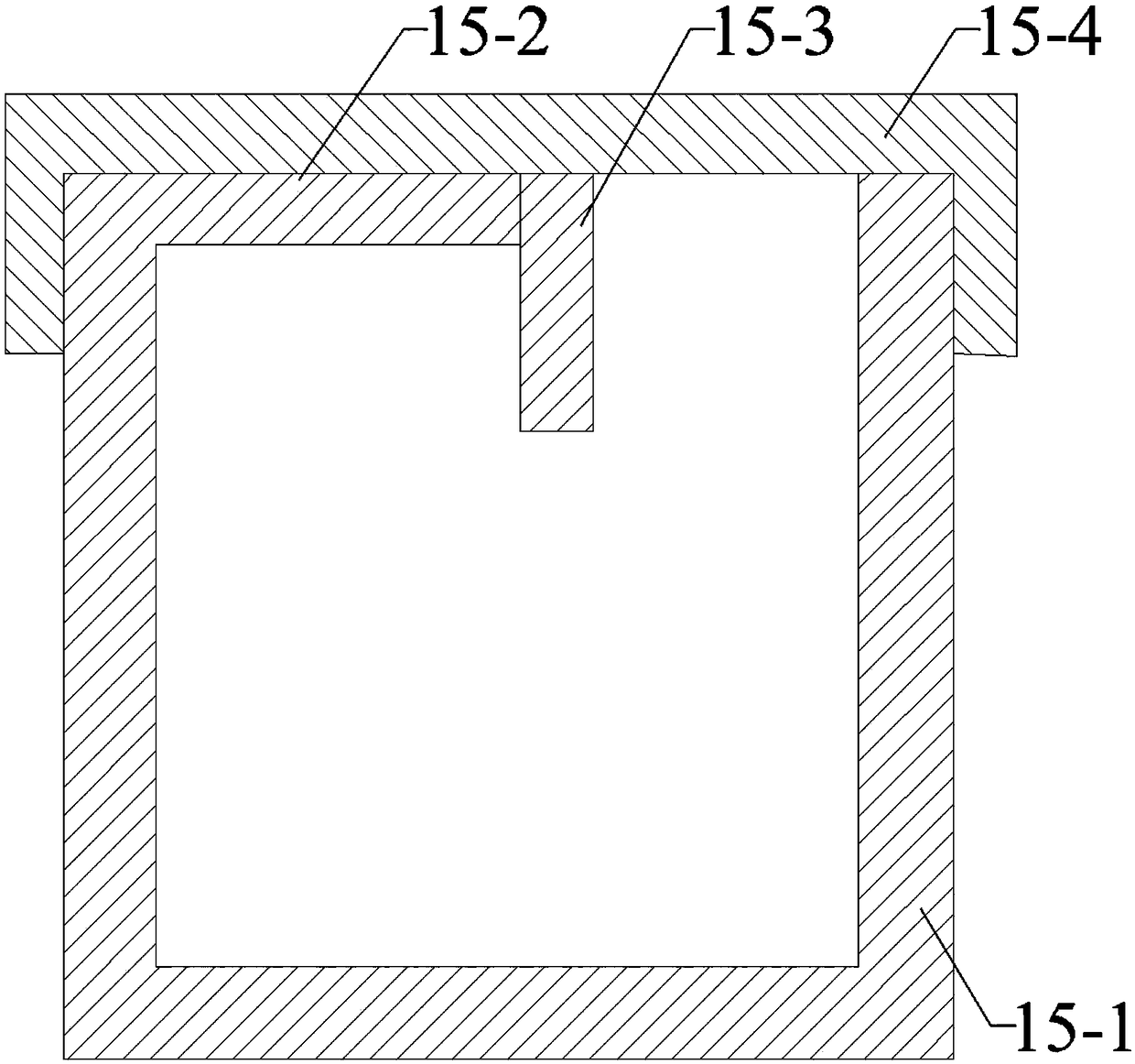

PEEK plastic rod production device and process

InactiveCN103722718AReduced flow marks and scratchesMeet the mechanical propertiesPolyether ether ketoneCompression device

The invention discloses a PEEK plastic rod production device and process. The PEEK plastic rod production device comprises a main machine and an auxiliary machine. The main machine is an extruder and comprises an extruding system, a rotating system and a control system, wherein the extruding system is a gun barrel screw; the rotating system comprises a motor and a reduction box; the control system comprises an electric appliance instrument and an actuating mechanism; the auxiliary machine comprises a mold, a traction machine, an oil temperature machine, a cutting machine and an oven; the mold comprises a main mold, a guide plate, a heat insulation ring, a forming shaping barrel and a cooling water tank; the oil temperature machine is installed on a shaping section of a forming pipe; the traction machine mainly comprises a transmission device, a roller compression device and a brake device, and is installed behind a heat preserving device; the cutting machine is installed behind an outlet of the mold; the oven is a closed box body. The process comprises the steps of charging, drying, plasticizing extruding, homogenizing distributing, forming / shaping, pulling, cutting / stacking and thermal processing.

Owner:深圳市恩欣龙特种材料股份有限公司

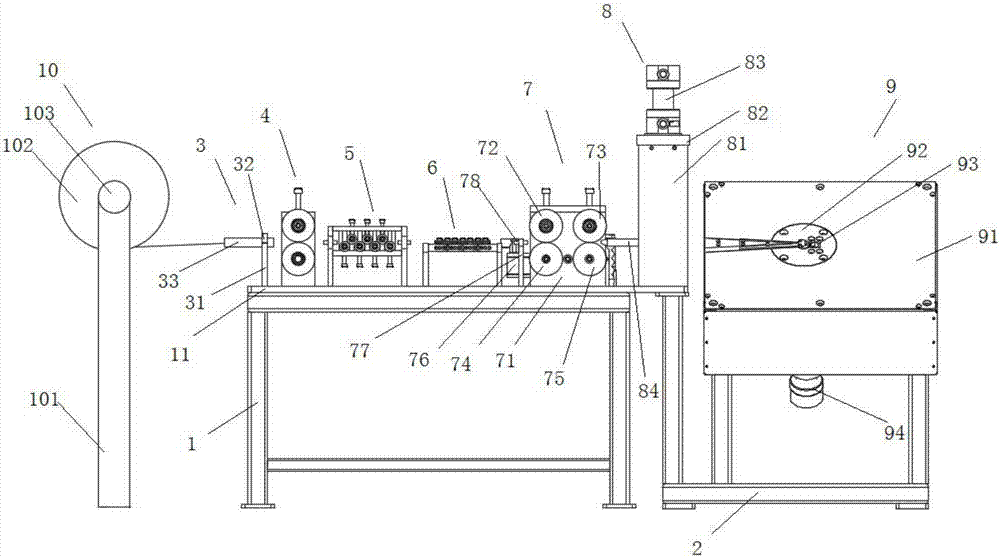

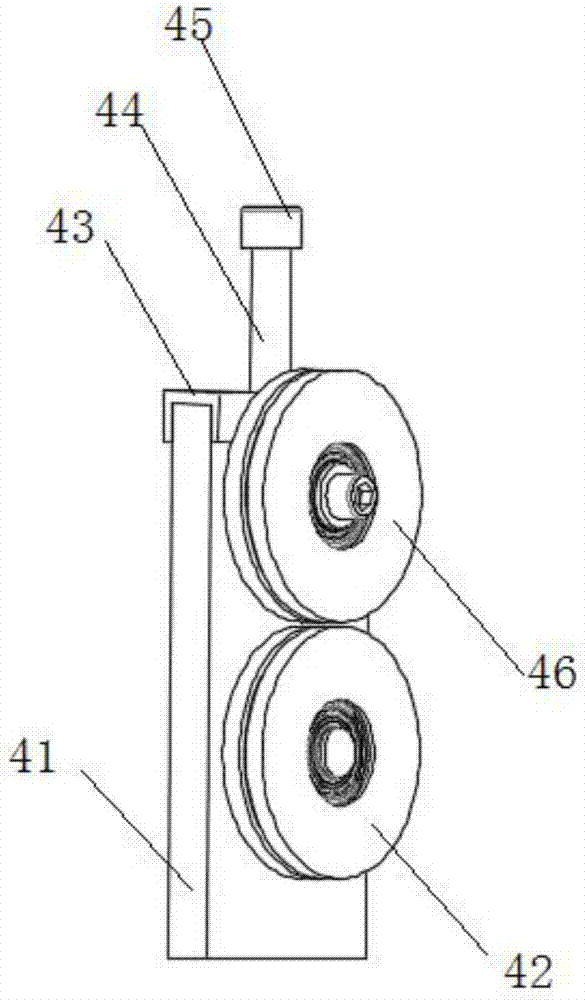

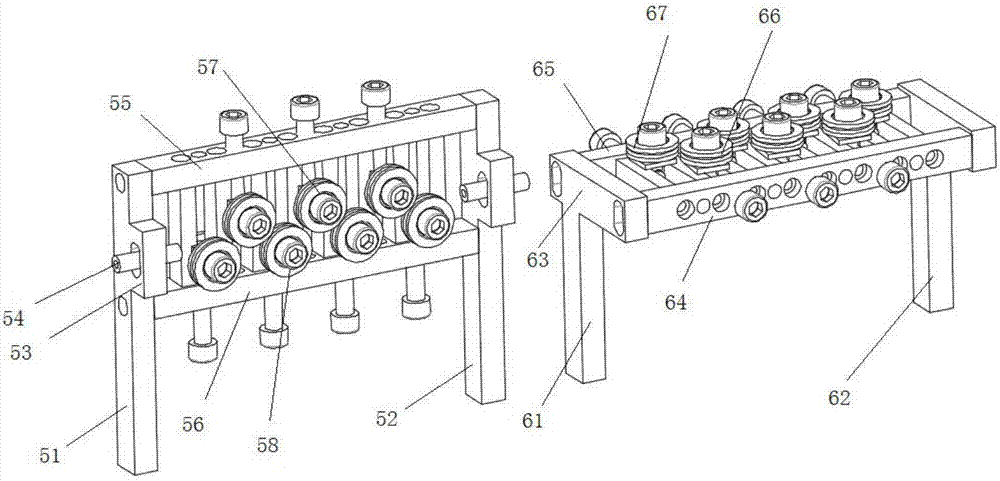

Wire bending device with straightening function

The present invention proposes a wire bending device with straightening function, which includes a first frame and a second frame, the first frame is arranged at the left end of the second frame, and the surface of the first frame is fixed There is a working platform board, and the working platform board is equipped with a wire feeding assembly, a straightening assembly, a straightening assembly, a straightening assembly, a straightening assembly, a straightening assembly and a wire discharge positioning assembly from left to right. Assemblies, a wire bending assembly is fixed at the second frame, and a wire reel is also provided on the left side of the first frame. This kind of wire bending device with straightening function is beneficial to increase production capacity through automatic straightening and bending, and the bending component with high automation integration can improve bending efficiency and significantly improve product quality.

Owner:嘉善中正电子科技有限公司

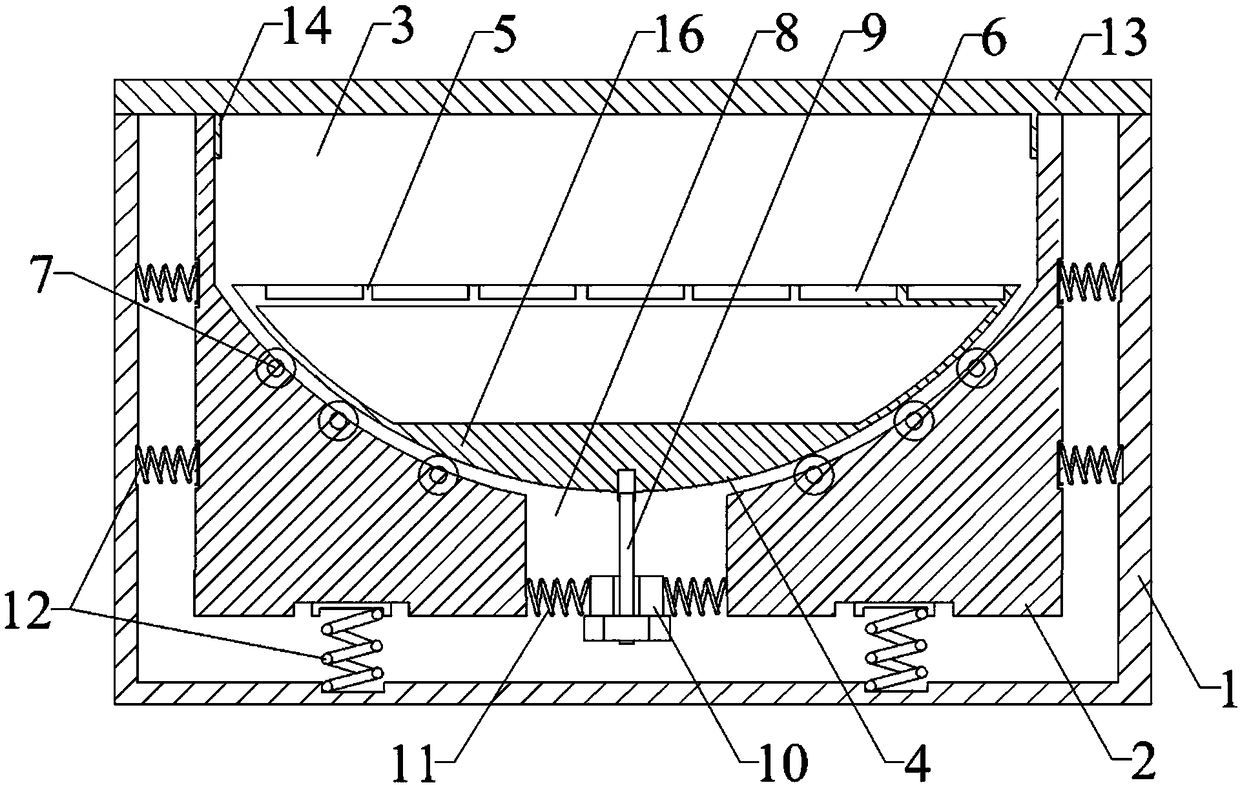

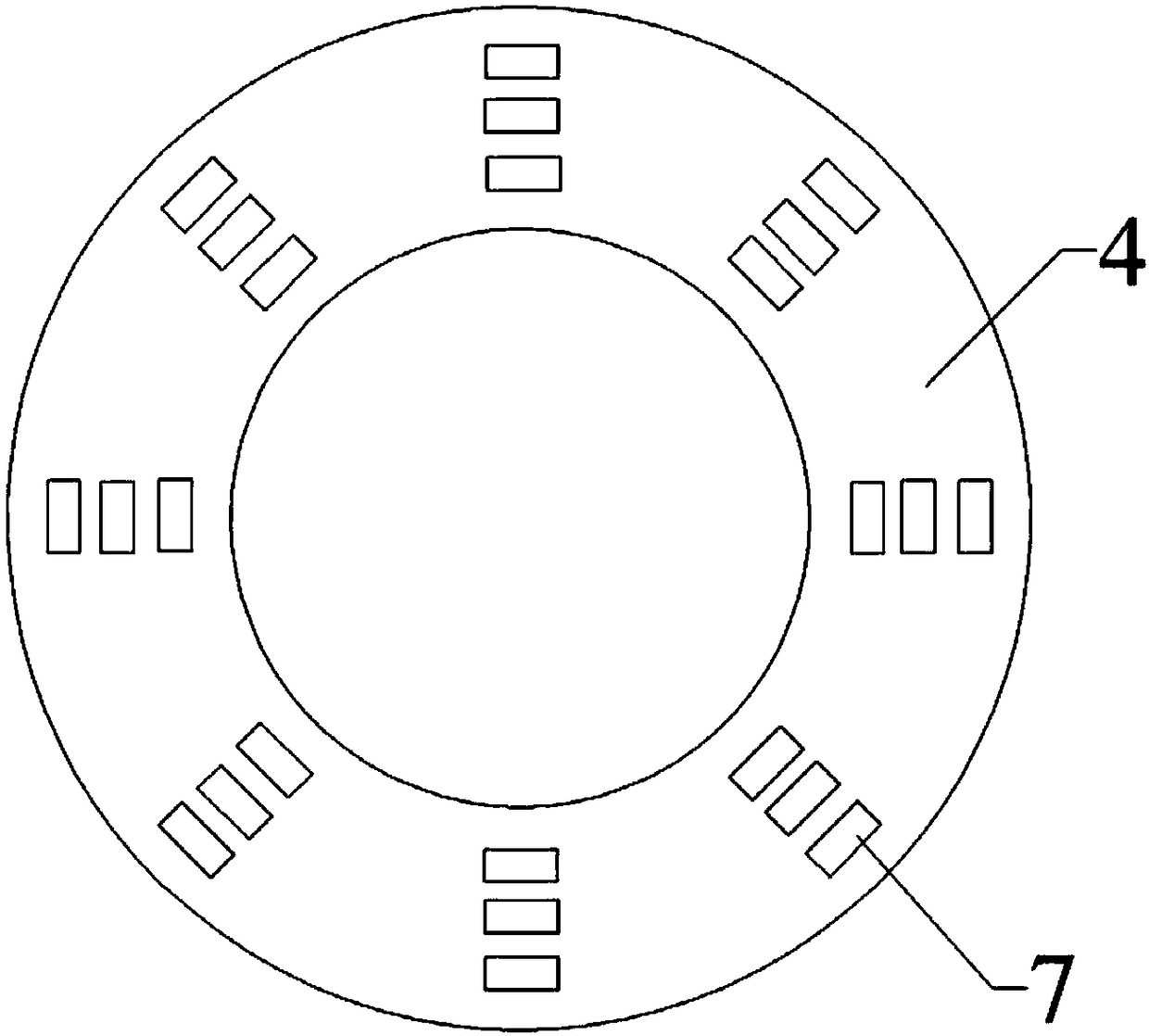

Vibration-absorbing self-balancing anti-spilling transporting device

ActiveCN108382731AExtend the impact timeReduce shockContainers to prevent mechanical damageInternal fittingsEngineeringInertia

The invention relates to a vibration-absorbing self-balancing anti-spilling transporting device. The vibration-absorbing self-balancing anti-spilling transporting device comprises a housing, a vibration absorbing spring, a cover plate, a spilling preventing device and a spilling preventing soup box which is used in a matching manner. The spilling preventing device comprises a shake supporting roller and a buffer spring. When the overall device meets shake or sudden speed reduction, the inner bottom slides at the internal surface of a vibration absorbing seat through the shake supporting roller; the buffer spring and the vibration absorbing spring stretch or is compressed to reduce the impact degree and reduce the shake transmitted to the vibration absorbing seat from the corresponding position and direction; besides, the cover plate can be used for making the vibration absorbing spring at the bottom of the vibration absorbing seat only generate stretch and retraction and generate no bending and twisting; and the spilling preventing soup box can further reduce spilling of liquid or powdery materials. The vibration-absorbing self-balancing anti-spilling transporting device provided by the invention solves the problems that in the prior art spilling is prevented by chiefly controlling the inertia of a conveying carrier and adopting a relatively low conveying speed in a manual conveying process, and improves the conveying efficiency and safety of the liquid or powdery materials.

Owner:CHANGAN UNIV

Production method of high-performance titanium alloy blind pipe

The invention discloses a production method of a high-performance titanium alloy blind pipe. The production method comprises the following steps of: (a) coating a graphite coating on the surface of a core bar; (b) placing the core bar in a sheath cylinder and clamping the core bar at the centre of the sheath cylinder by using a core bar positioning tool; fixing the bottom end of the core bar on asheath bottom cover, and welding the sheath bottom cover at the bottom end of the sheath cylinder; and then filling titanium alloy powder into a cavity which is formed by the sheath cylinder and the core bar; (c) welding a sheath top cover at the top of the sheath cylinder, reserving a space for placing a degasification pipeline, and vacuumizing the sheath cylinder; (d) fixing both ends of a sheath in a sheath hot isostatic pressing tool, and carrying out a thermal isostatic pressing process; (e) taking out the sheath, fixing both ends of the sheath on a hydraulic machine, and drawing out thecore bar in the sheath; and (f) machining the core bar to obtain the titanium alloy blind pipe. According to the production method provided by the invention, because the core bar can be rapidly removed, the final size of the prepared high-performance thin and long titanium alloy blind pipe can be reached without machining an inner cavity, therefore, the production period is short, the yield is high, and the product performance and the internal quality are stable and reliable.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

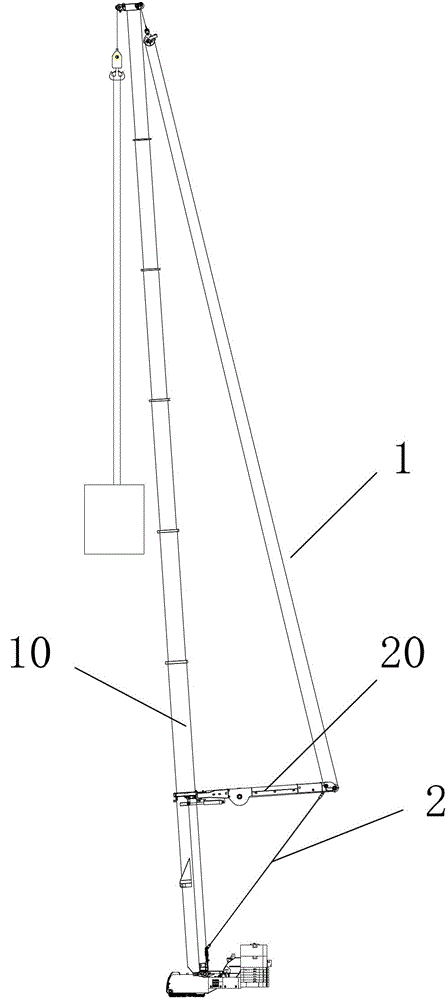

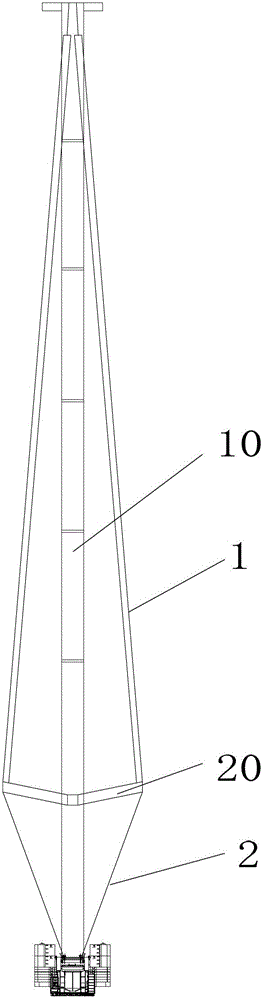

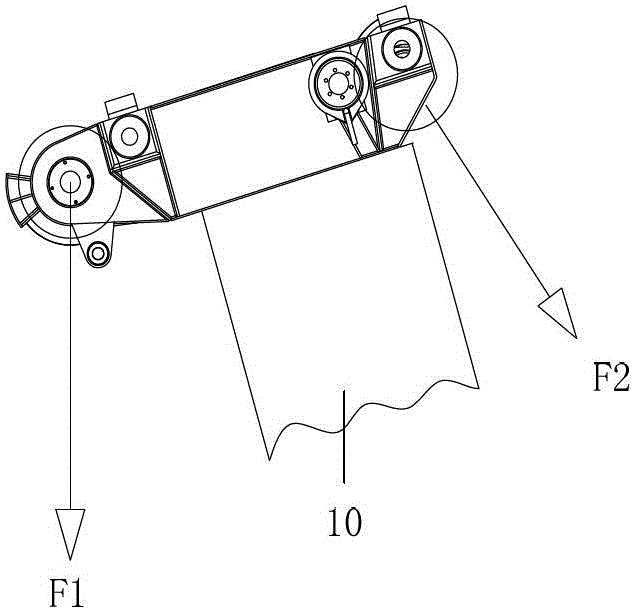

Superlift device and crane

Owner:SANY AUTOMOBILE HOISTING MACHINERY

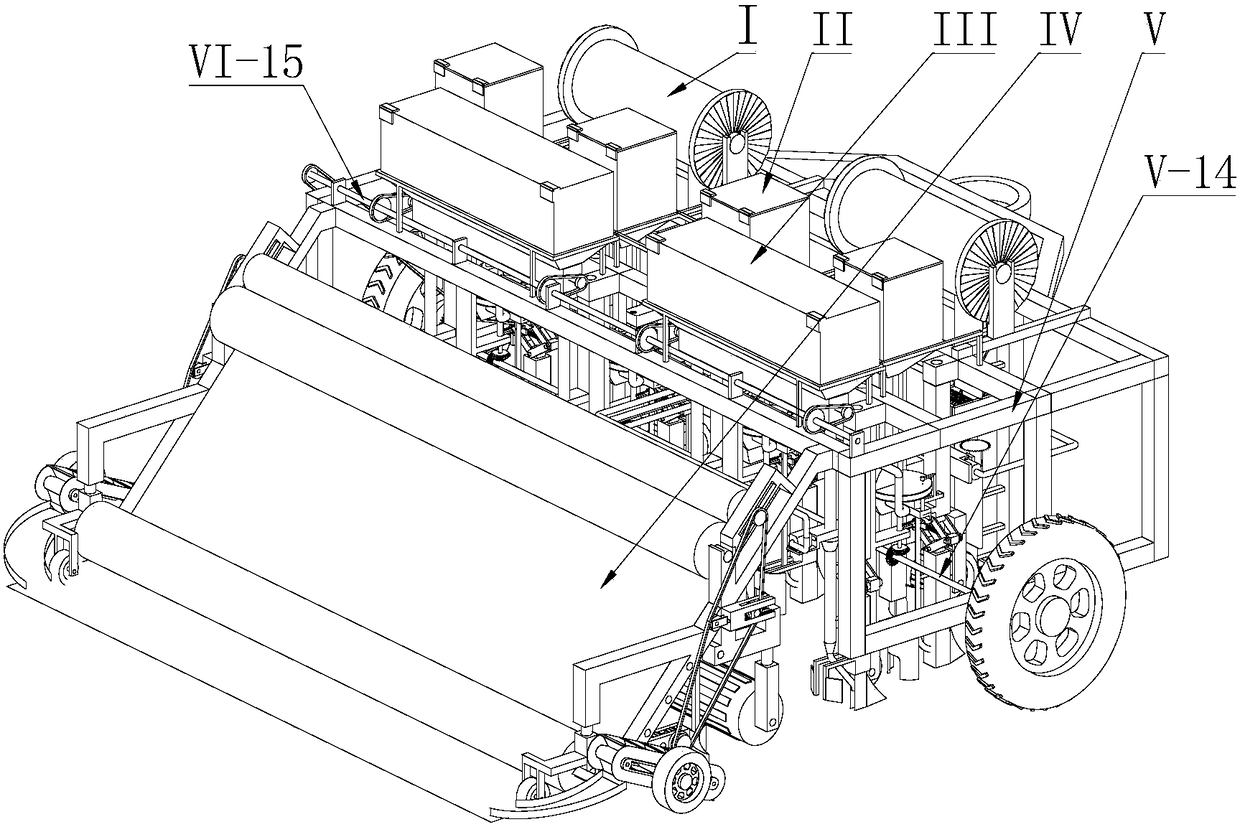

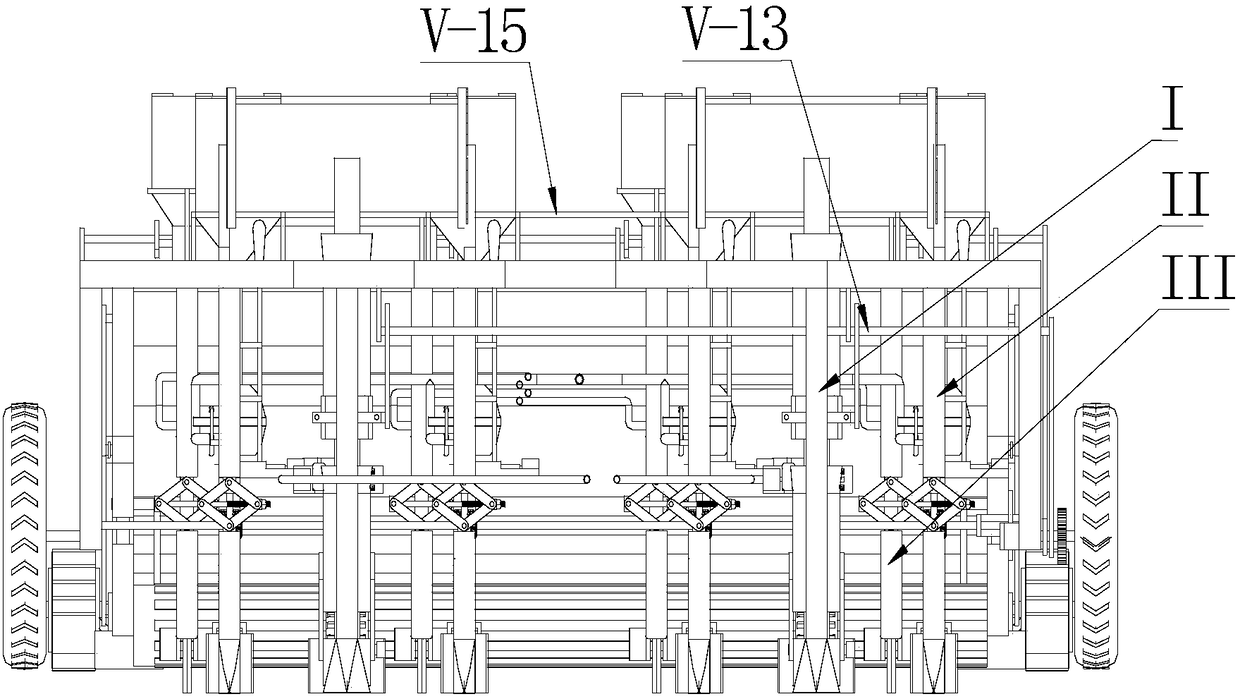

Agricultural machinery equipment integrated with simultaneous precision sowing and fertilization, shallow-buried drip irrigation pipe laying and mulching and method

InactiveCN108738540ANo bendingPrevent situationPlantingClimate change adaptationFertilizerFarm machine

The invention discloses an agricultural machinery equipment integrated with simultaneous precision sowing and fertilization, shallow-buried drip irrigation pipe laying and mulching and a method. The agricultural machinery equipment comprises an integrated chassis, a system power wheel is mounted on the integrated chassis, a gear is fixedly connected to the axle of the system power wheel, the gearis meshed with a reverse gear, and thereby power is respectively transmitted to a shallow-buried drip irrigation pipe laying system, an air suction type precision sowing system, a quantitative and positioned seed and fertilizer spiral conveying system and a mulching film covering and earthing system; and a control system is respectively connected to the shallow-buried drip irrigation pipe laying system, the air suction type precision sowing system, the quantitative and positioned seed and fertilizer spiral conveying system and the mulching film covering and earthing system, and is used for controlling the operation of each system. The agricultural machine disclosed by the application can simultaneously carry out four-row sowing and two-row pipe laying operations, and can be adapted to therequirement of row spacings and plant spacings of different crops and the requirement of fertilization pipe laying positions according to actual requirements of agricultural production. Intelligentized high-efficient sowing, fertilization, irrigation and mulching are realized, and the adaptability of the machine and the working efficiency of agricultural cultivation are greatly increased.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY +1

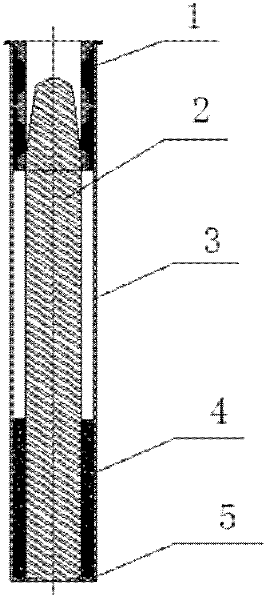

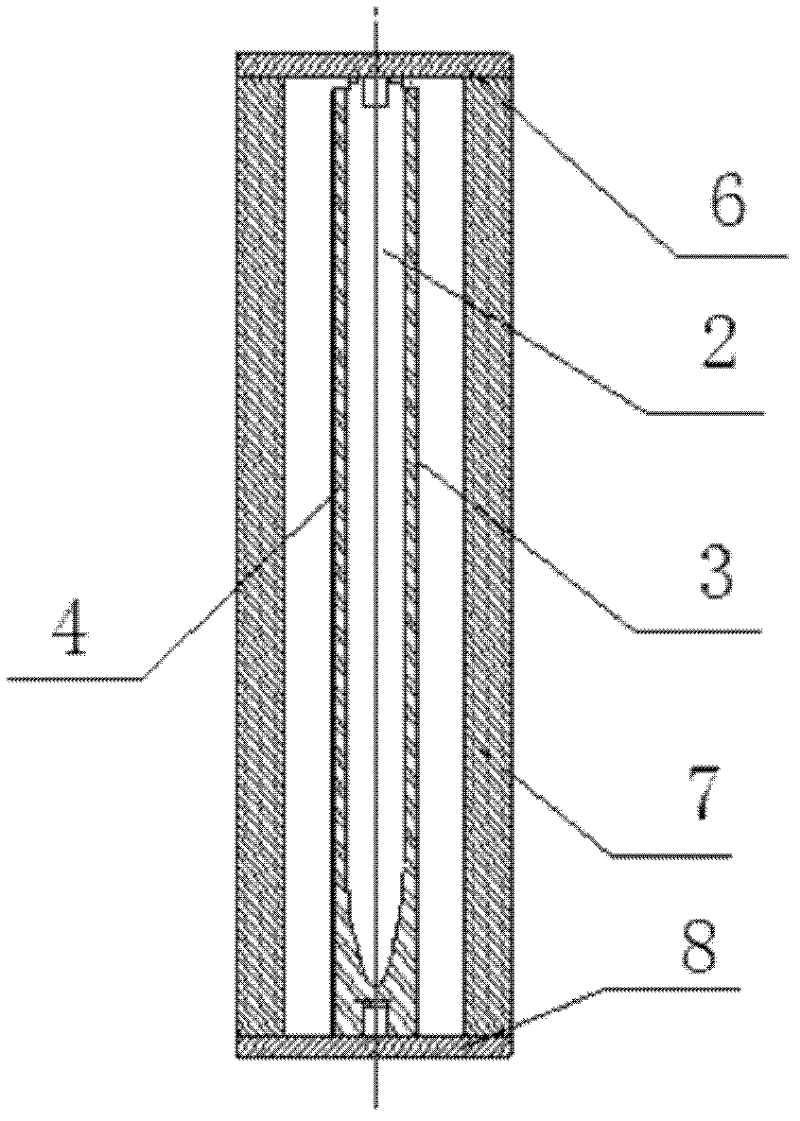

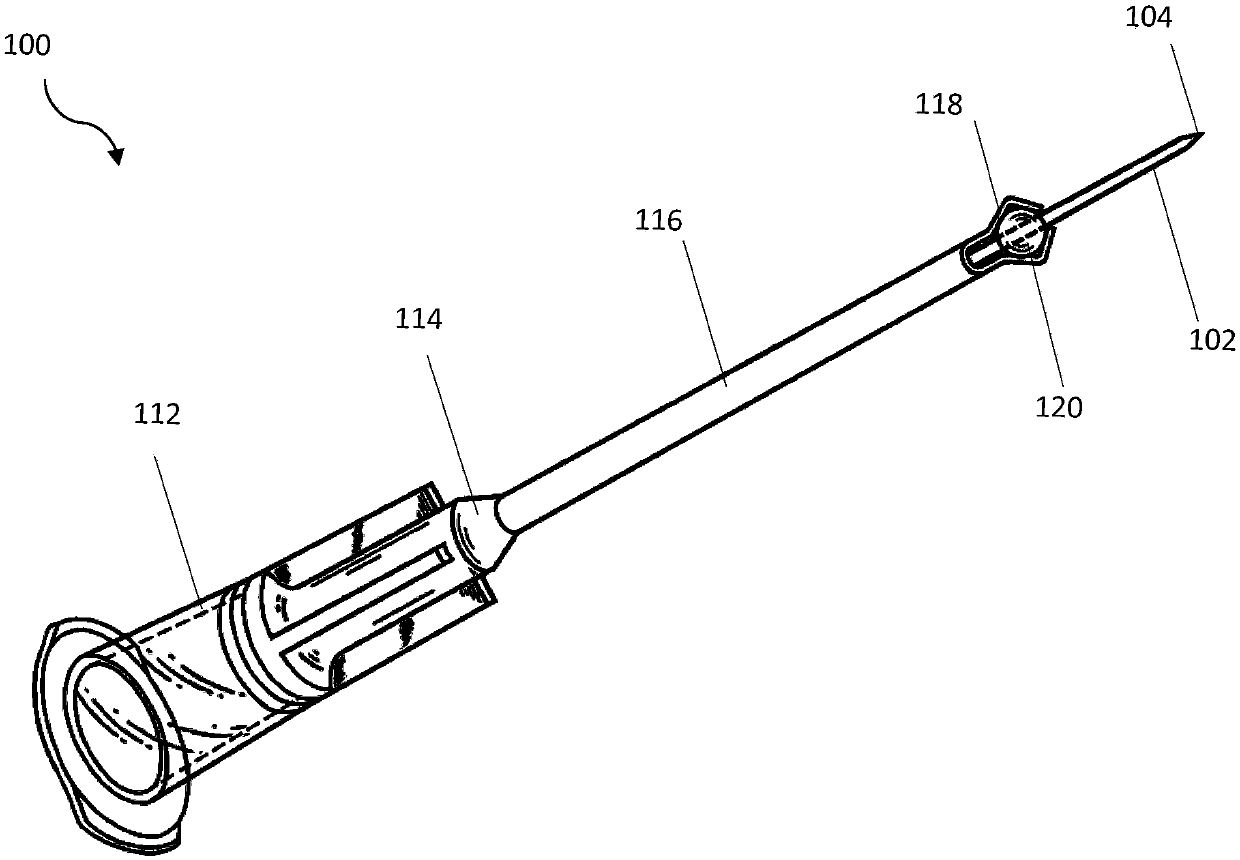

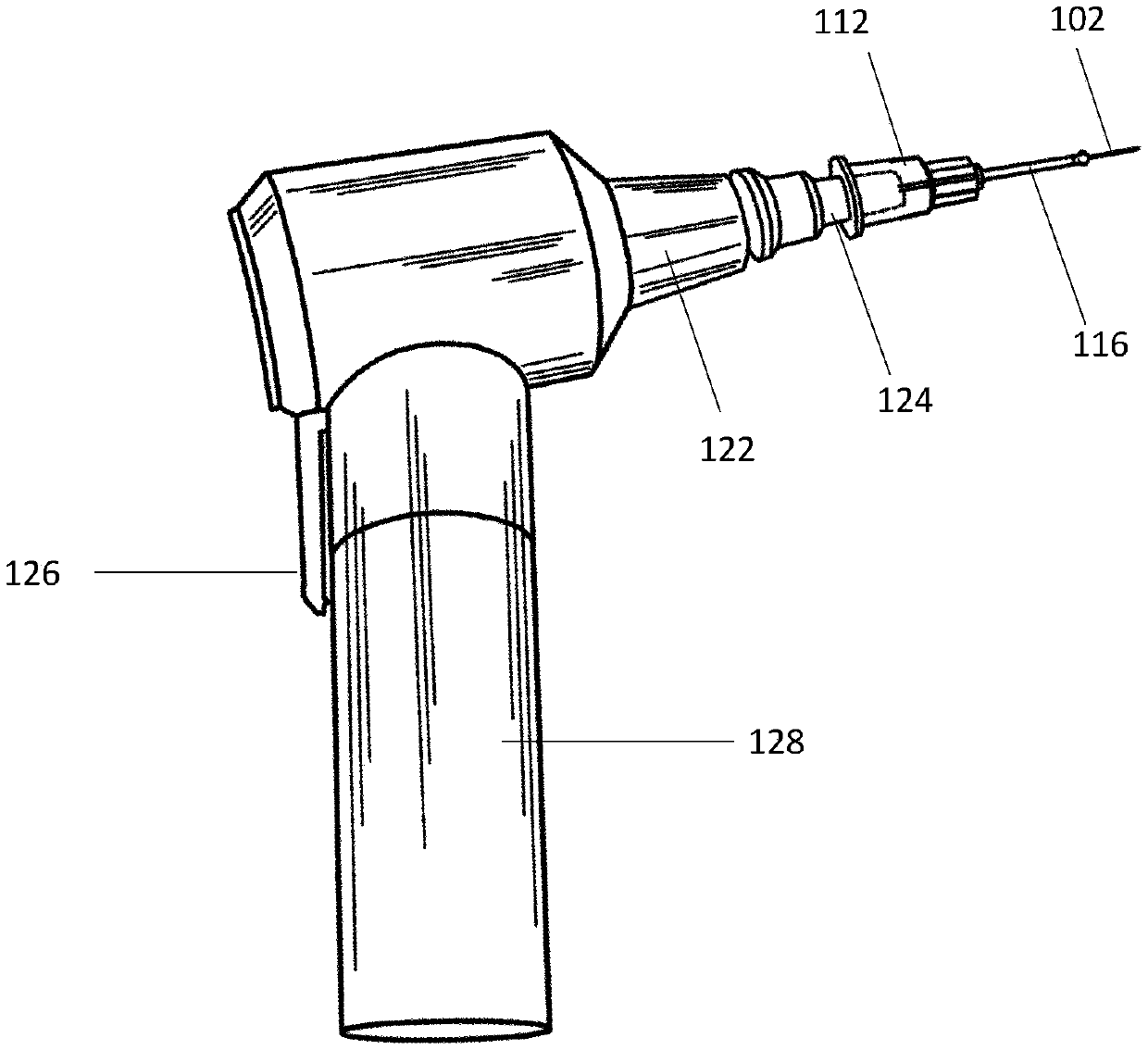

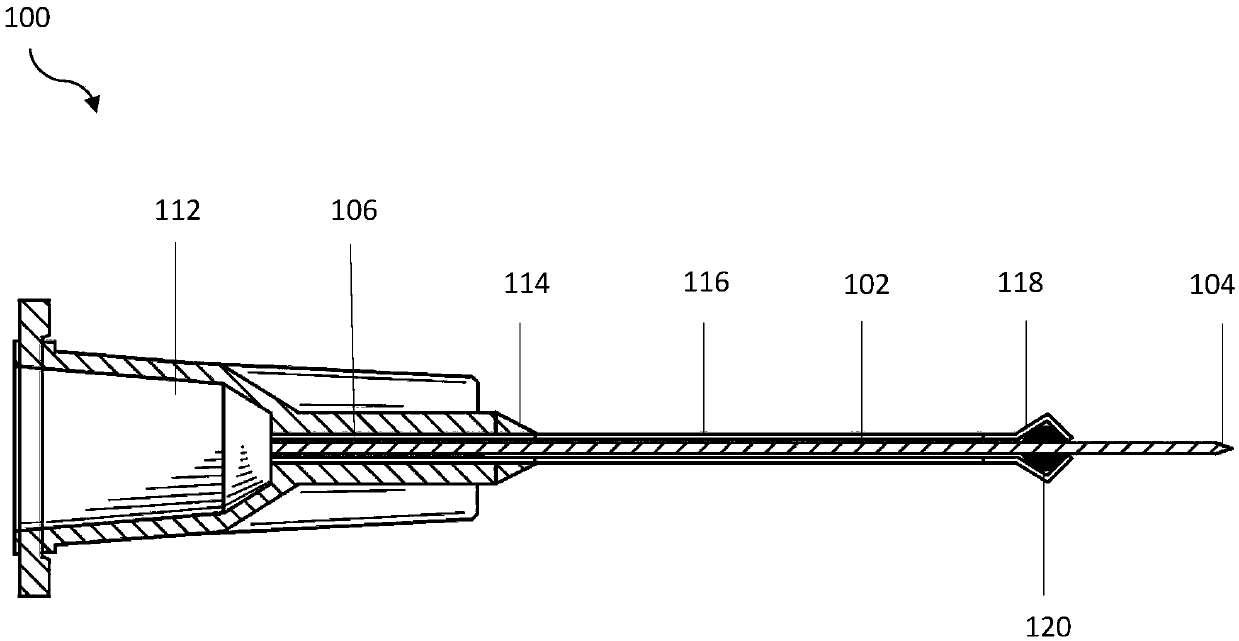

Sleeve-type superfine diameter osteofixation needle

ActiveCN109692055AStrong maneuverabilityWide range of indicationsSurgerySurgical veterinaryForcepsEngineering

A sleeve-type superfine diameter osteofixation needle comprises a power assisting sleeve and a superfine diameter osteofixation needle disposed in the power assisting sleeve, one end of the power assisting sleeve being provided with an adapter seat to connect to a rotor of a drive electric motor, and another end is provided with a detachable rigid connection apparatus. The power assisting sleeve is fixed to the osteofixation needle by means of the rigid connection apparatus, and the rigid connection apparatus limiting extension of a needle tip of the osteofixation needle from the power assisting sleeve to a set length. Starting the electric motor can cause the electrically driven osteofixation needle to enter a bone by means of percutaneous self-tapping drilling, and after the needle tip of the osteofixation needle extending from the power assistance sleeve penetrates a target bone, detaching the rigid connection apparatus from a distal end of the power assistance sleeve, removing thepower assistance sleeve from the osteofixation needle; finally, screwing into an anchor bone matrix by means of needle-holding forceps gripping a screw thread section of a back part of the osteofixation needle. Feasibility of percutaneous anchor needle puncturing is realized for small animal bone fracture and bone malformation models and clinical osteofixation of small bone breaks in specific parts, including hand and foot; the method is simple and convenient, time-saving and efficient, causes little surgical trauma, and needle anchoring stability is reliable.

Owner:王力平

Exposure unit

ActiveCN1703137ANo bendingSufficient planarityPhotomechanical exposure apparatusMicrolithography exposure apparatusEngineeringHigh dimensional

Owner:SANEI GIKEN

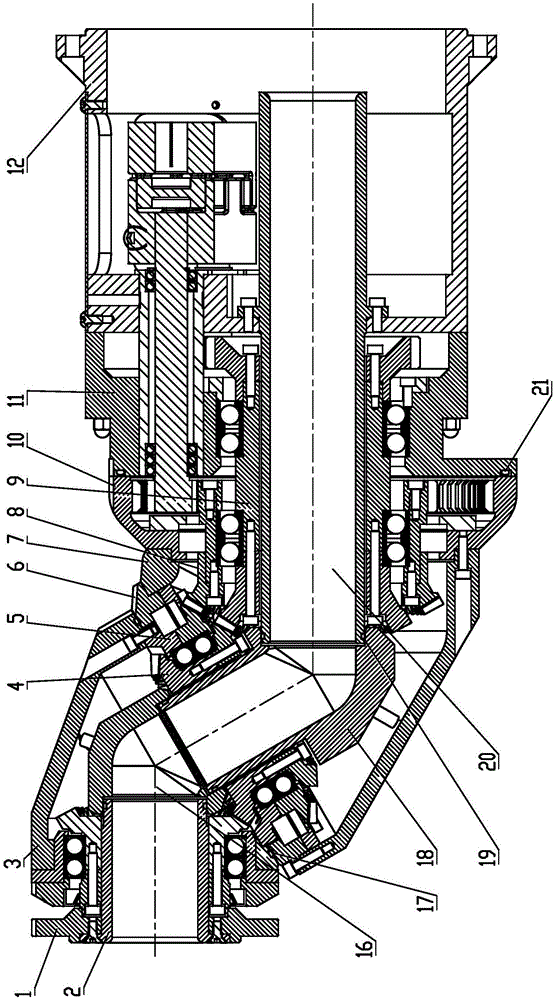

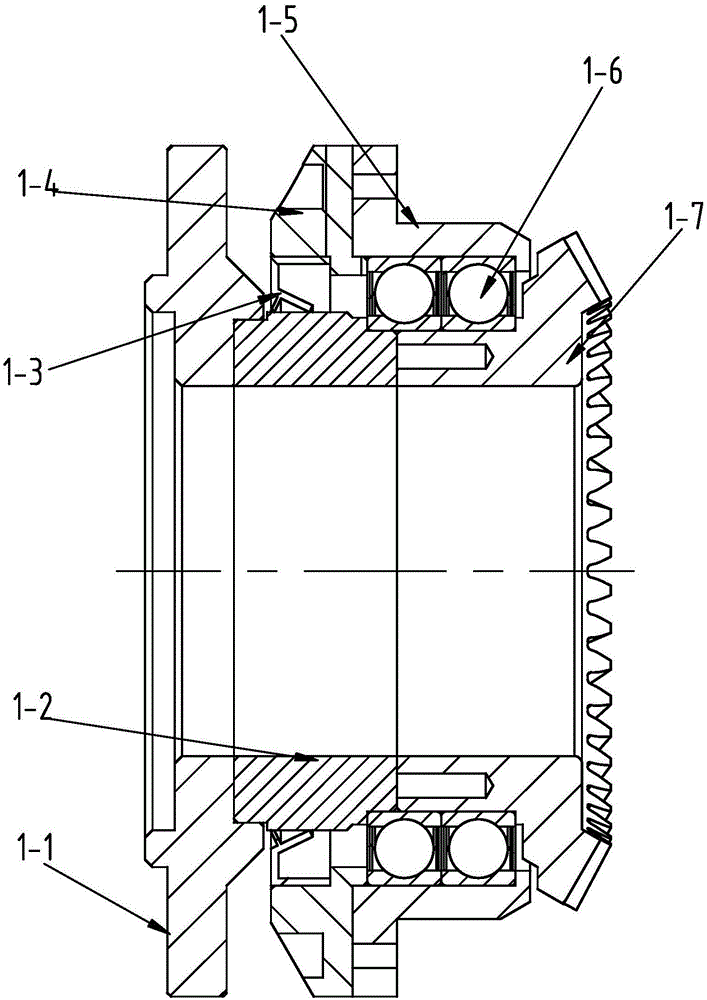

Hollow bias structure of wrist of industrial robot

The invention relates to a hollow bias structure of a wrist of an industrial robot. The hollow bias structure comprises a tail end output assembly, a first inner sheath, a sixth-axis wrist body, a first sixth-axis transition transmission assembly, a fifth-axis output assembly, a fifth-axis crossed roller bearing locking flange, a fourth-axis wrist body, a fifth-axis transition transmission assembly, a second sixth-axis transition transmission assembly, a fourth-axis output assembly, a first wrist connecting piece, a second wrist connecting piece, a fourth-axis input assembly, a fifth-axis input assembly, a sixth-axis input assembly, a second inner sheath, a first O-type sealing ring, a third inner sheath, a first O-type sealing ring, a fourth inner sheath and a second O-type sealing ring. The left side of the fourth inner sheath is sleeved with the second sixth-axis transition transmission assembly, and the right side of the fourth inner sheath is sleeved with the second wrist connecting piece. A servo motor is used for controlling, the wrist is driven to run through a speed reducer and a series of transmission manners, a fifth axis can rotate without limitations, the takt can be increased, efficiency can be improved, and the requirements of the spraying technology can be met.

Owner:希美埃(芜湖)机器人技术有限公司

High thermal conductivity C/C composite and preparation method

A high thermal conductivity C / C composite comprises carbon fiber base bodies, nano carbon pipes, and pyrolytic carbons, wherein the nano carbon pipes are vertically distributed on the surfaces of the carbon fiber base bodies; the pyrolytic carbons are deposited on the surfaces of the carbon fibers and the nano carbon pipes in a 'three-dimensional' manner to form a high-texture CNT / PyC interface transitional layer. The preparation method comprises the following steps: laminating unidirectlonal weftless cloth to form unidirectional long carbon fibers base bodies, soaking in a nickel nitrate solution, drying and calcining; introducing H2 for reduction; after in-situ growth of nano carbon pipes, performing CVD deposition and graphitization processing to obtain the C / C composite. The composite is reasonable in structure, high in thermal conductivity, simple in process, and convenient in operation; the nano carbon pipes are vertically distributed on the surfaces of the carbon fibers; the high-texture CNT / PyC interface transitional layer is formed between the carbon fibers and the base body carbons through the processes of CVD deposition and graphitization processing, so that the heat conduction efficiency of the base bodies and the transitional layer is greatly improved. Therefore, the composite is suitable for industrialized production.

Owner:CENT SOUTH UNIV

Actuator

Owner:FESTO AG & CO KG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com