Drying, reforming and transmission device for textile

A conveying device, textile technology, applied in textiles and papermaking, conveyors, transportation and packaging, etc., can solve problems such as affecting operation, reducing output, being torn, etc., to achieve a wide range of application width, improve product quality, operation handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

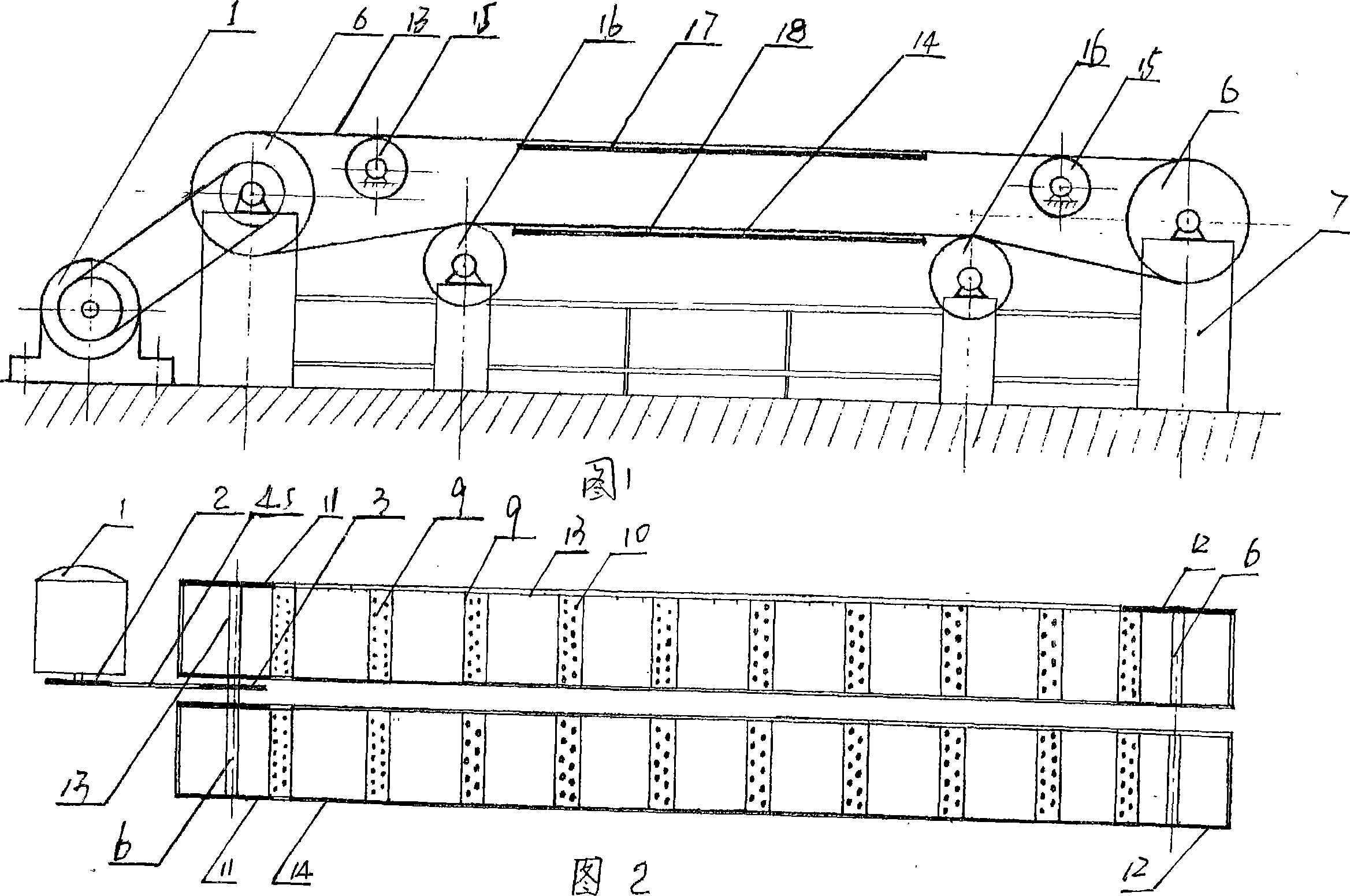

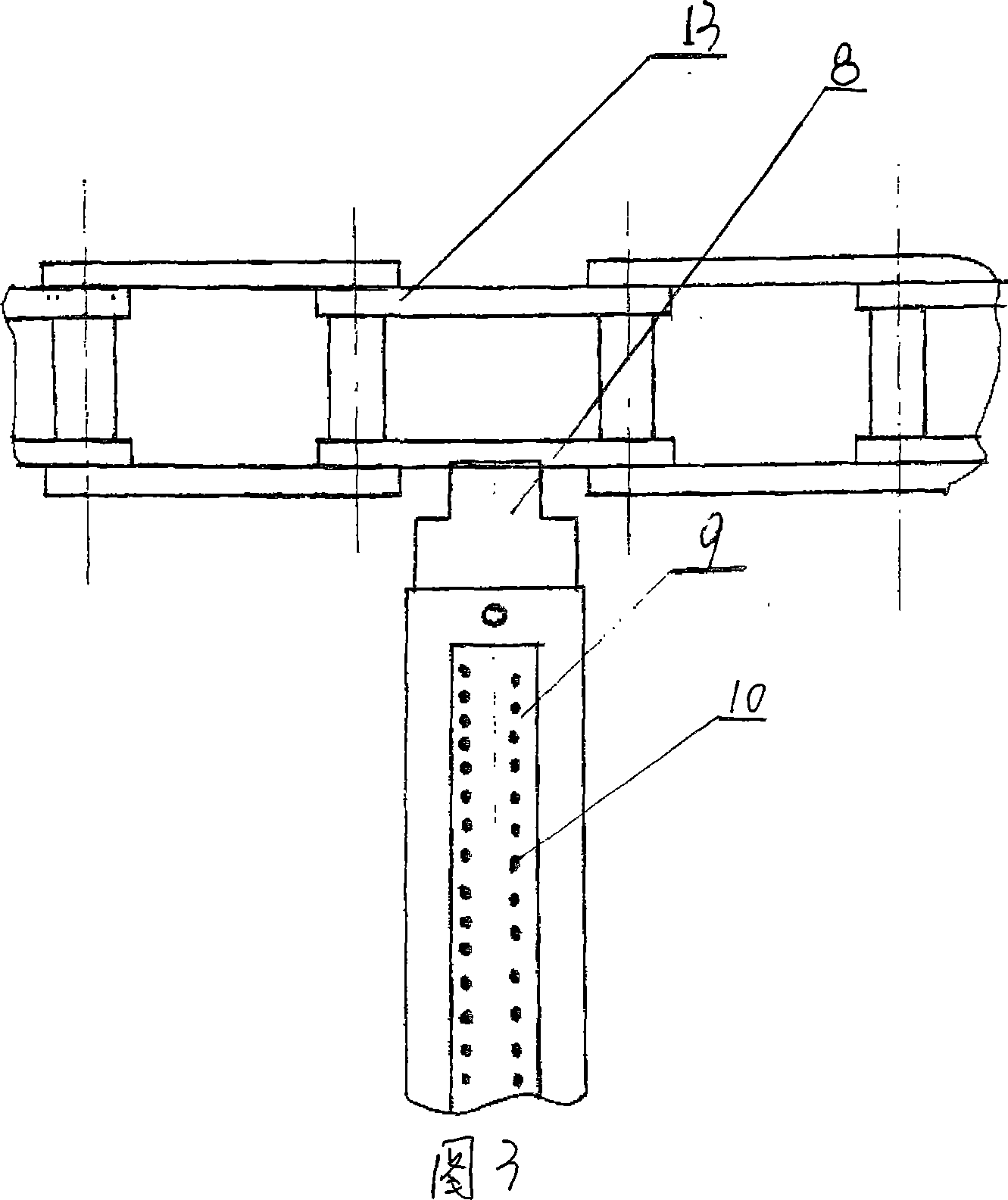

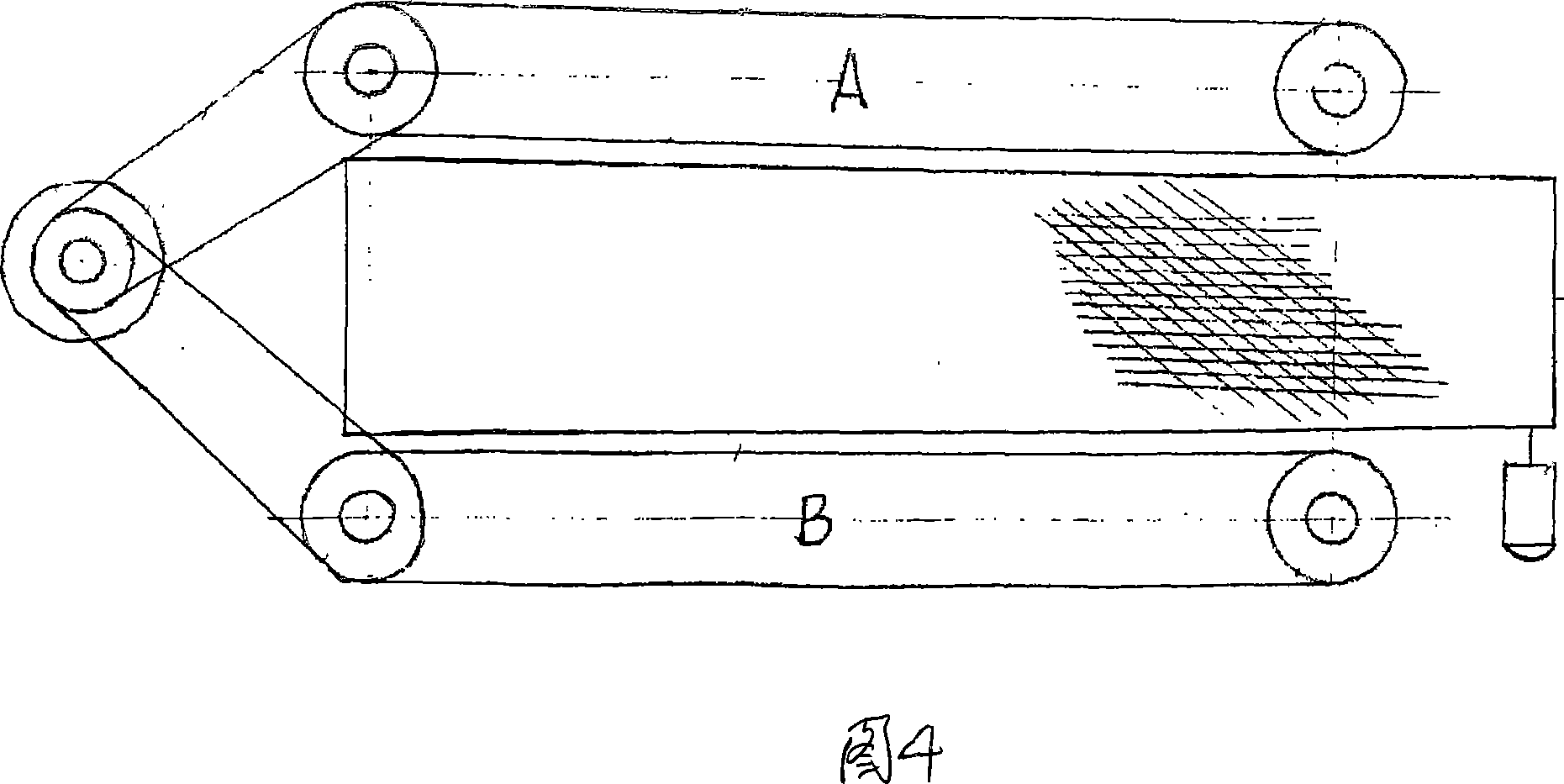

[0014] As shown in Figures 1, 2, and 3, a transmission shaft 6 is installed on both ends of the frame 7, and conveyor sprockets 11, 12 are installed on the transmission shaft 6, and the conveyor chain 13 is wrapped around the conveyor sprockets 11, 12 to form a transmission ring. , the two drive rings installed on the frame form the conveyor belt, the shaft of the motor 1 and the transmission shaft 6 are equipped with double drive sprockets 2, 3, and the double drive sprockets 2, 3 are surrounded by drive chains 4, 5. It is characterized in that a group of needle plates 8 are installed at intervals on the two conveying chains 13 and 14, and the two ends of the needle plates 8 are respectively installed on the conveying chains 13 and 14 of the two transmission rings, wherein the needle plates 8 are supported by Plate 9 and locating pin 10 form, and locating pin 10 is installed on supporting plate 9 to form needle plate 8, and the two ends of supporting plate 9 are installed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com