Superlift device and crane

A technology of super-lifting device and tensioning device, which is applied to cranes and other directions, can solve problems affecting the lifting stability and safety of telescopic booms and cranes, and achieve the effect of increasing stability and lifting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

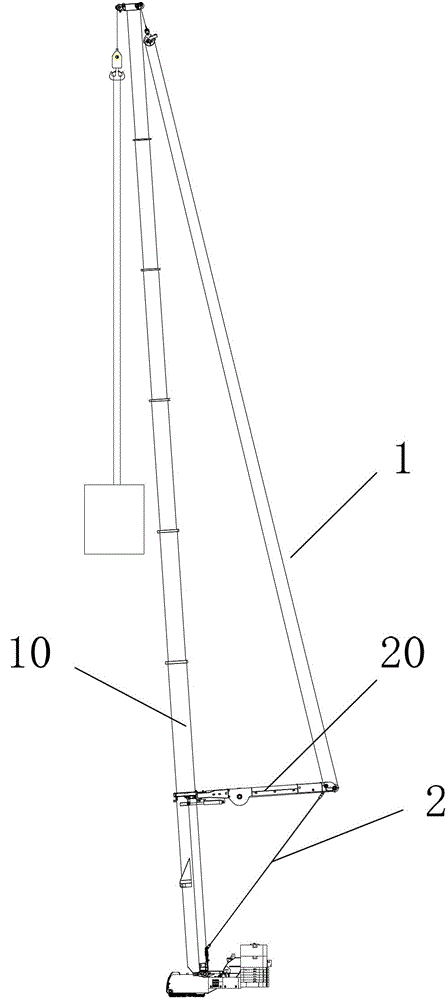

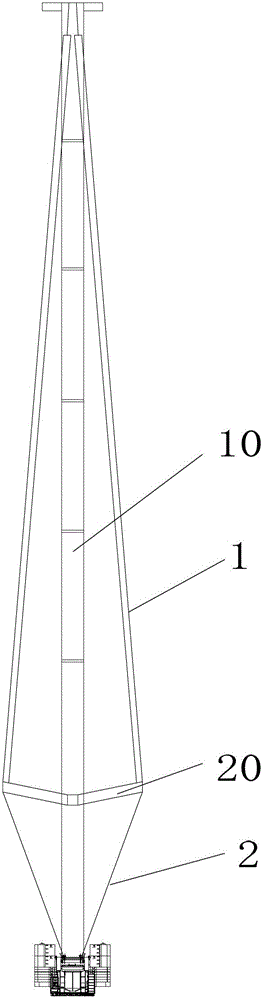

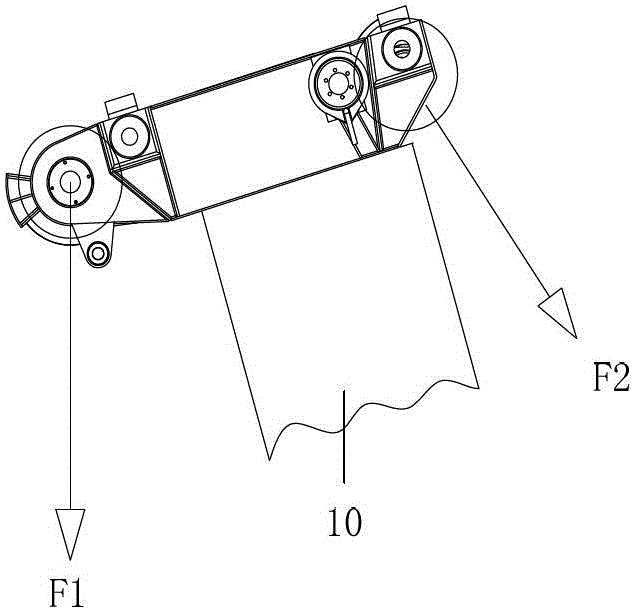

[0040] Such as Figure 6 and Figure 7 As shown, the present invention provides a kind of super lifting device, comprises telescopic arm 10, super lifting bracket 20, first tensioning device 1 and second tensioning device 2, the fixed end of described super lifting bracket 20 is connected with the telescopic The arm 10 is connected, the first tensioning device 1 is arranged between the movable end of the super-lifting bracket 20 and the end of the telescopic arm 10, and the second tensioning device 2 is arranged on the super-lifting bracket Between the active end of 20 and the root of the telescopic arm 10, there is also a third tensioning device 3, one end of the third tensioning device 3 is connected to the telescopic arm 10, and the connection point of the two is located at the Between the end of the telescopic arm 10 and the connection point between the telescopic arm 10 and the fixed end of the super-lifting bracket 20, the other end of the third tensioning device 3 is c...

Embodiment 2

[0057] Another embodiment of the super-lifting device provided by the present invention adopts a hoisting mechanism to replace the ratchet hoisting mechanism and the tensioning oil cylinder provided in the above-mentioned embodiments, that is, the super-lifting bracket 20 is also provided with a guide for guiding the stay rope. The fixed pulley and the hoisting mechanism used for fixing, winding and tensioning of the stay cord, other structures are the same as those of the above-mentioned embodiment 1, and will not be repeated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com