Automatic cleaning device for evaporating pot heat exchange tube

A technology for automatic cleaning and heat exchange tubes, which is applied in the direction of cleaning heat transfer devices, flushing, lighting and heating equipment, etc. It can solve the problems of complex structure and limited cleaning range, and achieve the effect of expanding the use range and improving the stress situation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

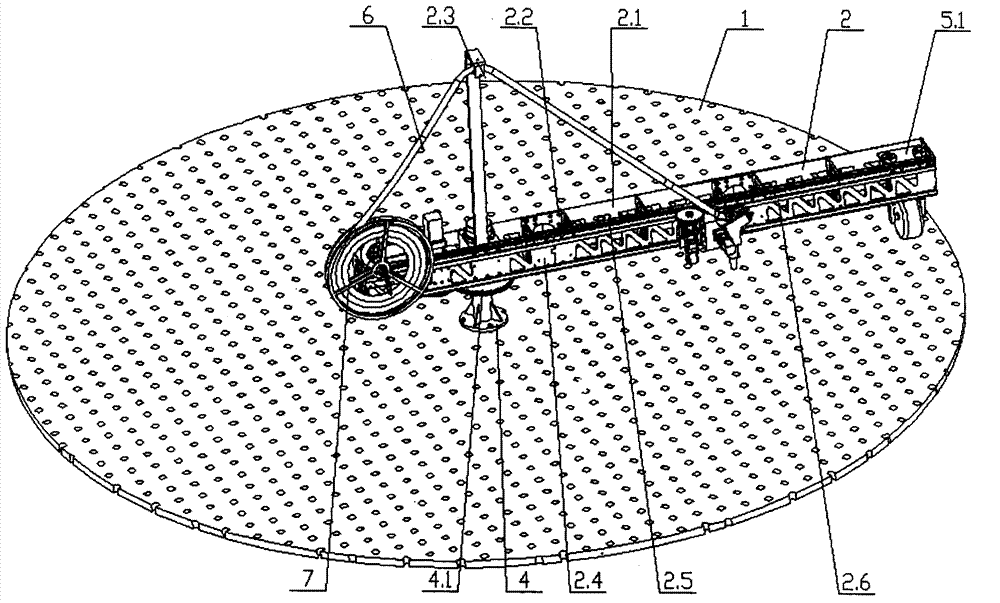

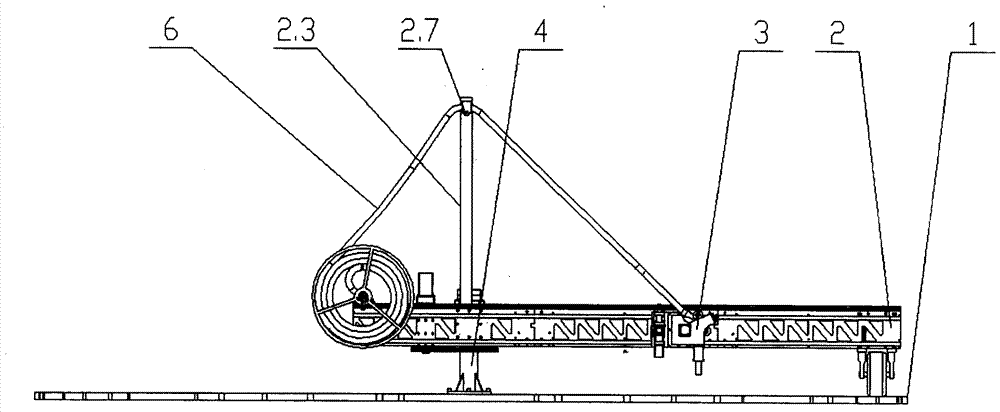

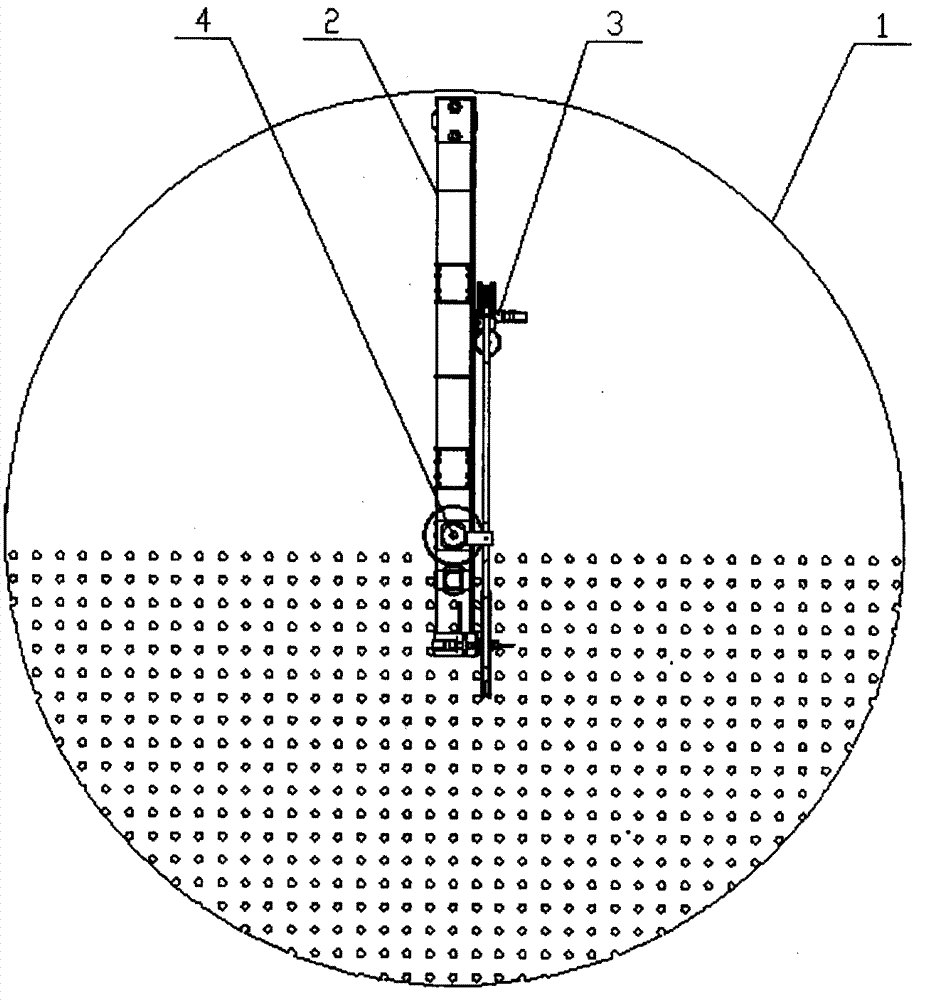

[0027] The automatic cleaning device for the heat exchange tube of the evaporation tank of the present invention, such as figure 1 , figure 2 and image 3 shown, where figure 1 The top surface of the medium evaporator 1 is all nozzles with heat exchange tubes distributed therein. For clarity, image 3 Only half of it is represented by ellipsis. The front frame rotating table 2.8 of the frame part is installed on the front frame 2.4 and is hinged with the center column 4, and the center column 4 is installed in the center of the evaporation tank 1 under the working state; the end of the rear frame 2 is connected with the frame wheel part Positioning connection, frame wheel 5.5 walks on evaporation tank 1, this part is as follows Figure 4 Shown; Cleaning machine head 3 is housed on the frame part; Guide wheel frame 2.3 is equippe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com