Staggered spoke type stretchable tool for friction stir welding and adjusting method of tool

A friction stir welding and spoke-type technology, which is applied in auxiliary devices, manufacturing tools, welding equipment, etc., can solve problems such as unstable friction stir welding process, imperfect friction stir welding tooling, and small application range of tooling, so as to improve welding The effect of good quality, good adaptability and simple processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

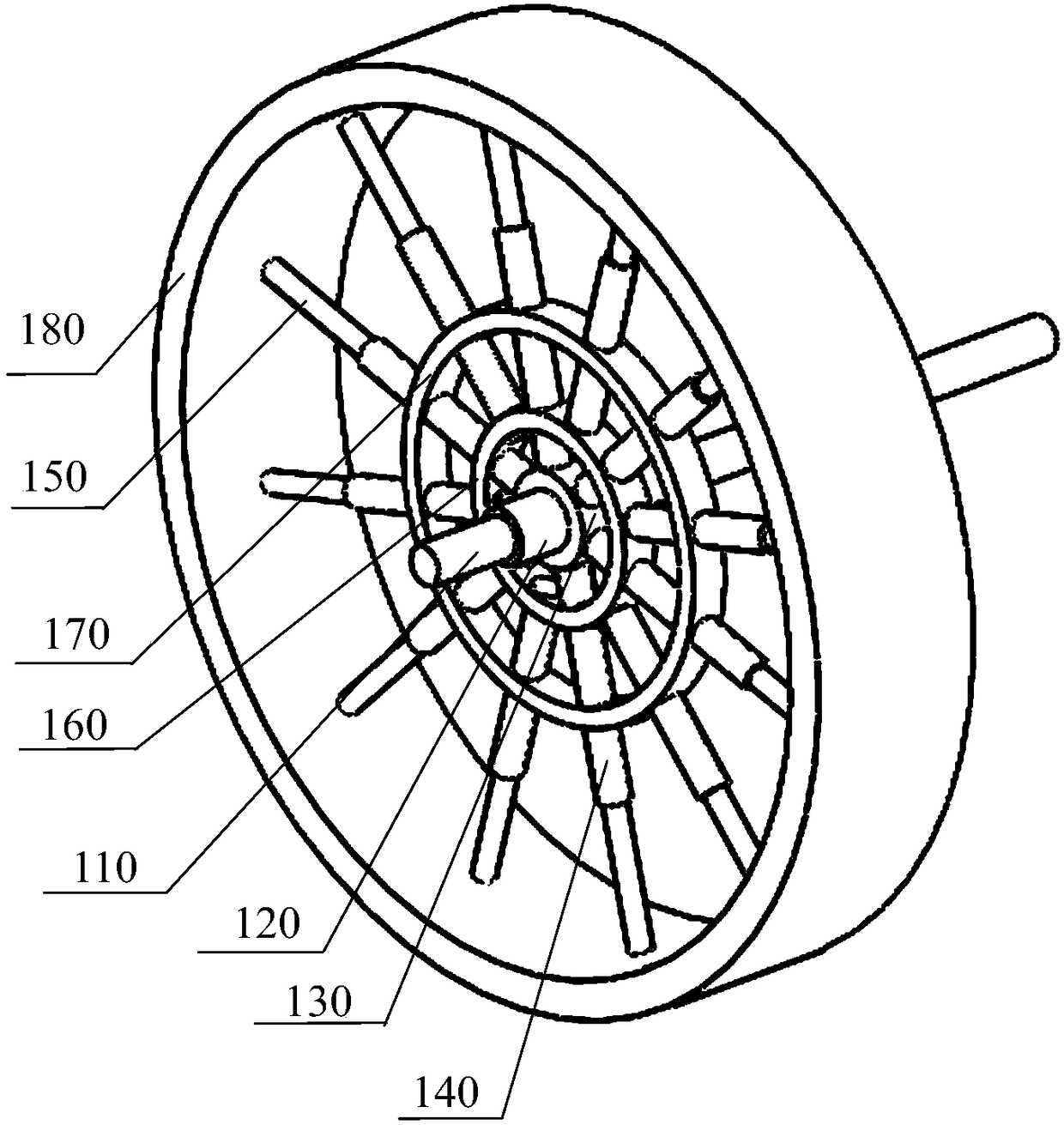

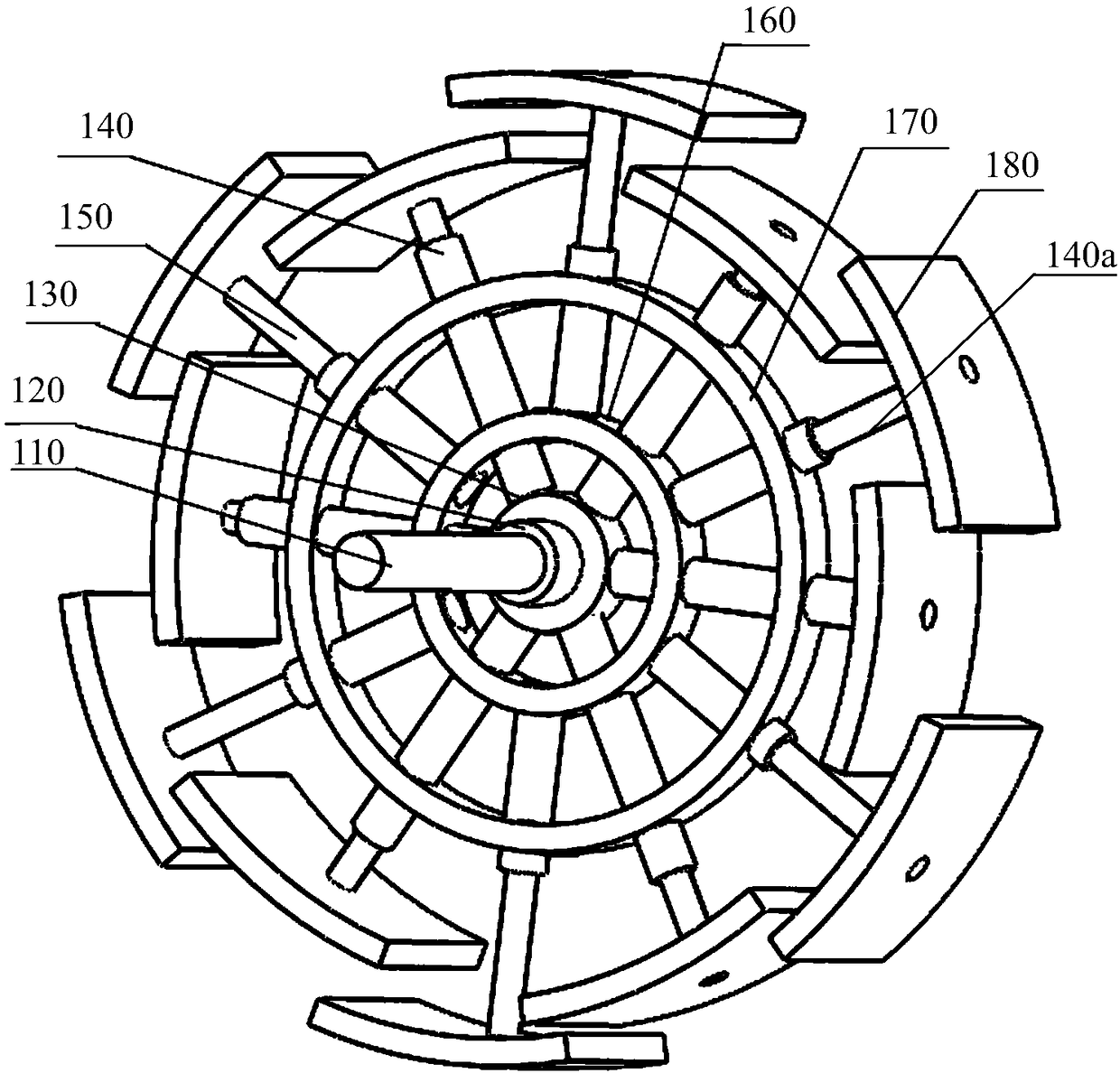

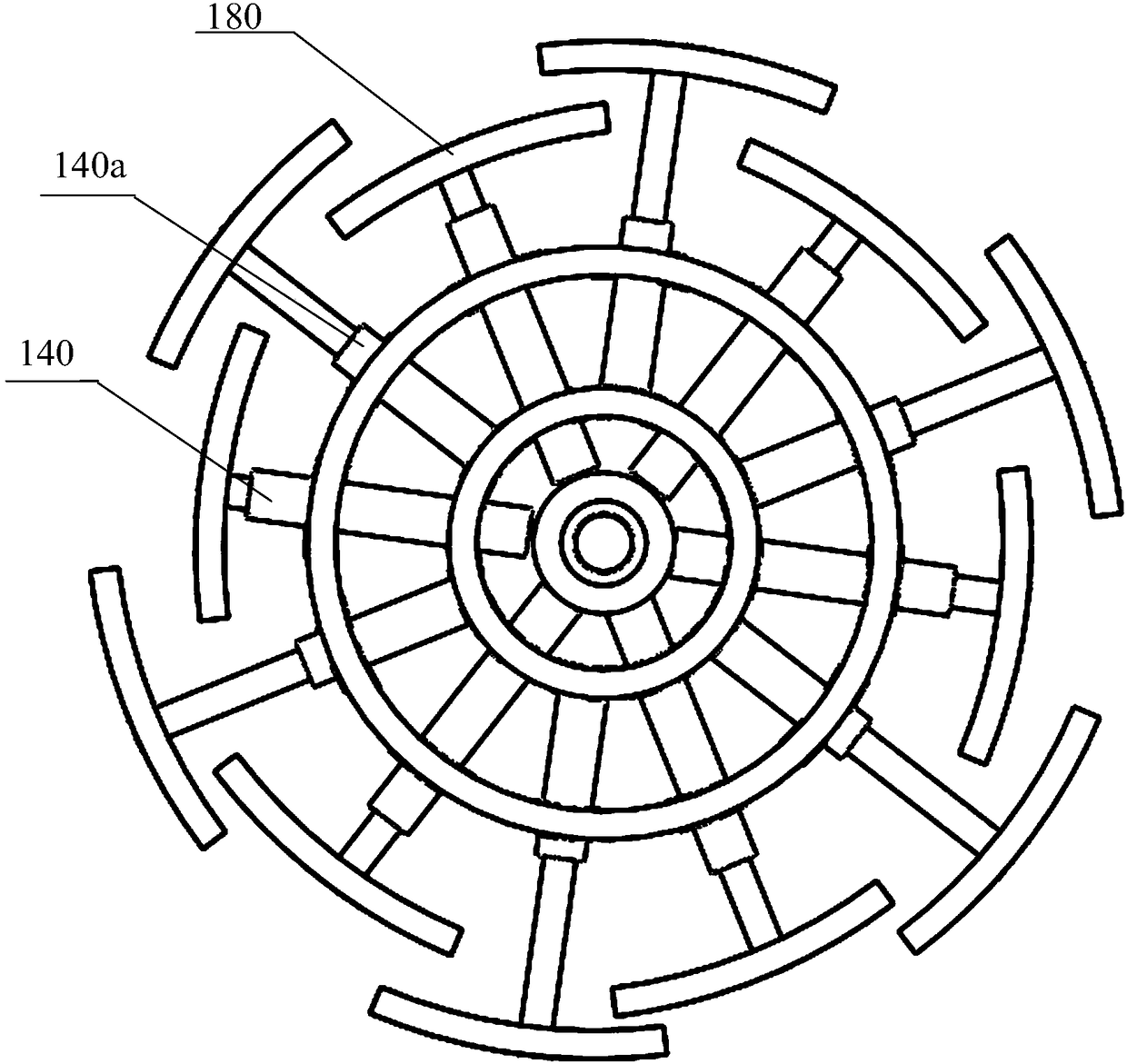

[0054] Such as figure 1 As shown, the staggered spoke type telescopic tooling for friction stir welding provided by the present invention includes:

[0055]Bearing 110 and bearing sleeve 120, wherein the bearing sleeve 120 is set on the bearing 110, and is used to connect the spoke tooling and the cross manipulator type positioner; during friction stir welding, the position of the welding head remains unchanged, and the barrel section follows the positioner Rotate, at this time, the spoke tooling rotates with the barrel joint, and the bearing is fixed on the cross manipulator type positioner.

[0056] The first support ring 130 is located outside the bearing sleeve, the inner ring of the first bearing ring 130 is connected to the bearing sleeve 120, and can rotate with the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com