Patents

Literature

213results about How to "Avoid air pollution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

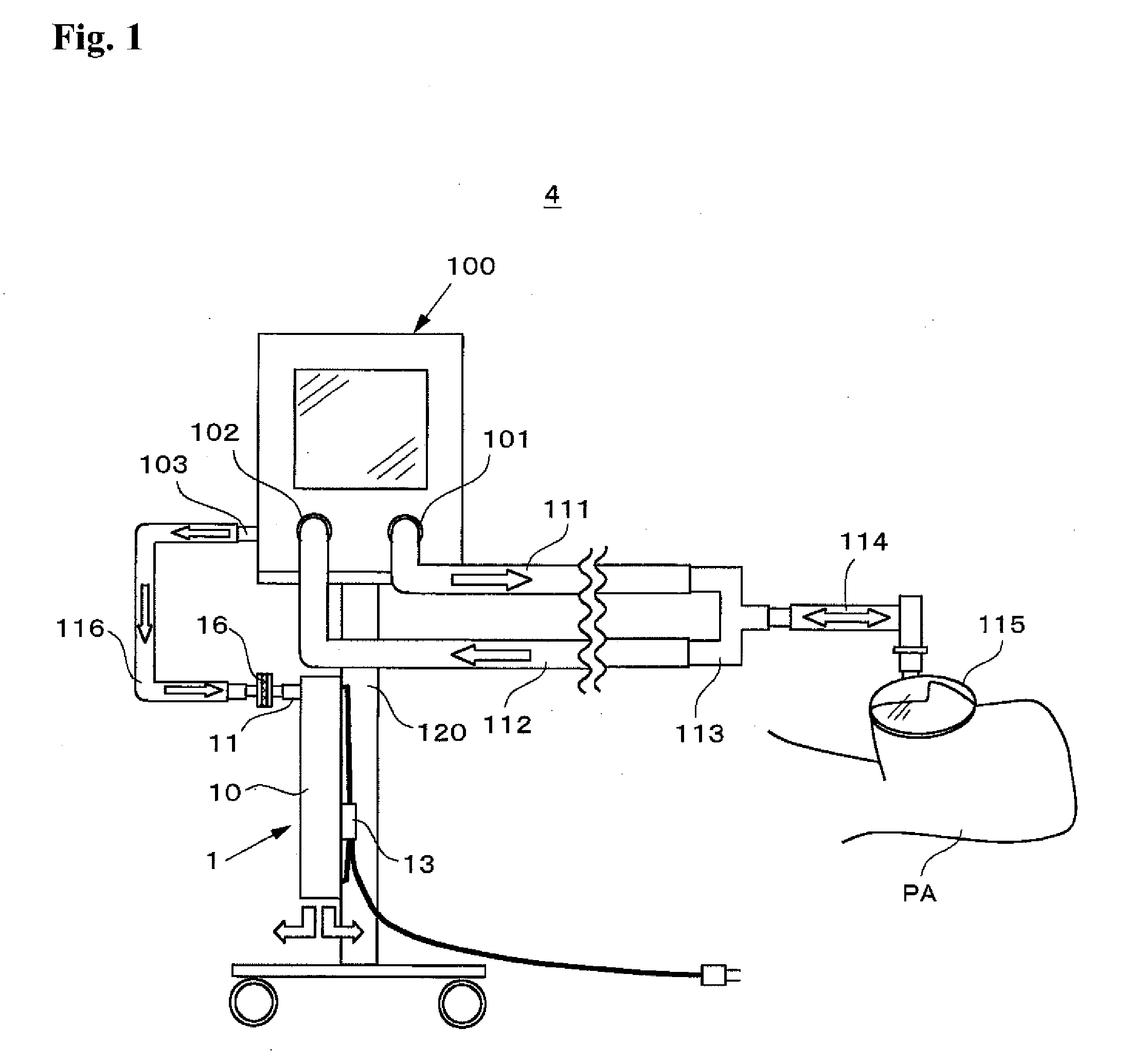

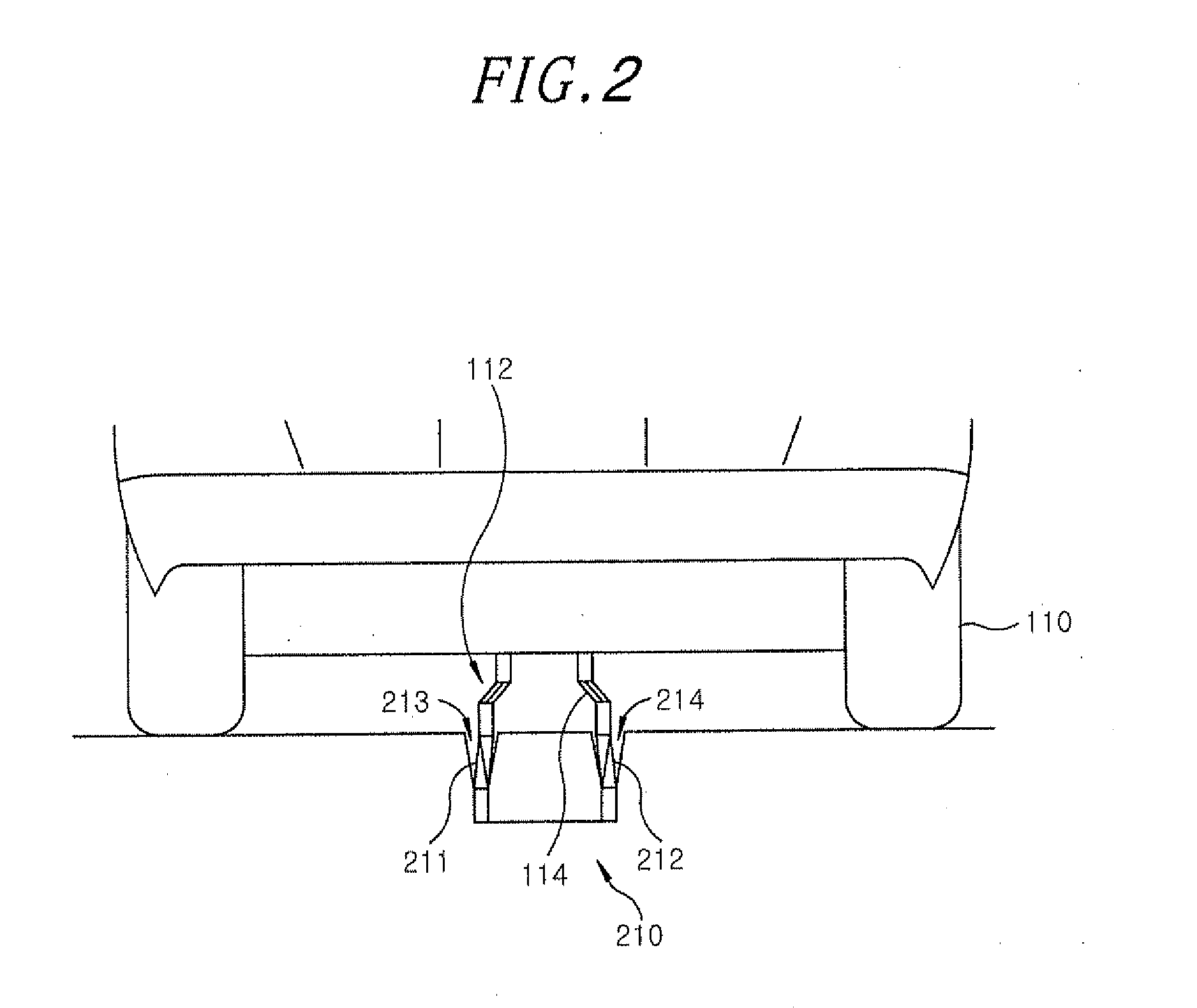

Air disinfection and cleaning device, and exhaled gas disinfection and cleaning device, interior air disinfection and cleaning device, and simplified isolation device using the same

InactiveUS20120285459A1Effective disinfectionHigh disinfection effectRespiratorsMechanical apparatusEngineeringCopper

An air disinfection and cleaning device is provided that includes: a cylindrical reflector having a cylindrical inner surface in which an air flows from an upper end to a lower end and the cylindrical inner surface is subjected to mirror finishing; a rod shaped ultraviolet lamp disposed at the center within the cylindrical reflector parallel to the long side; photocatalytic sheet filters being air permeable photocatalytic sheet filters having a diameter nearly equal to an inner diameter of the cylindrical reflector, provided respectively at one end and the other end in the cylindrical reflector, and being penetrated by the ultraviolet lamp at the center thereof; and a copper sheet filter being an air permeable photocatalytic sheet filter having a diameter nearly equal to an inner diameter of a cylinder member and closing a lower end opening of the cylindrical reflector.

Owner:TKB

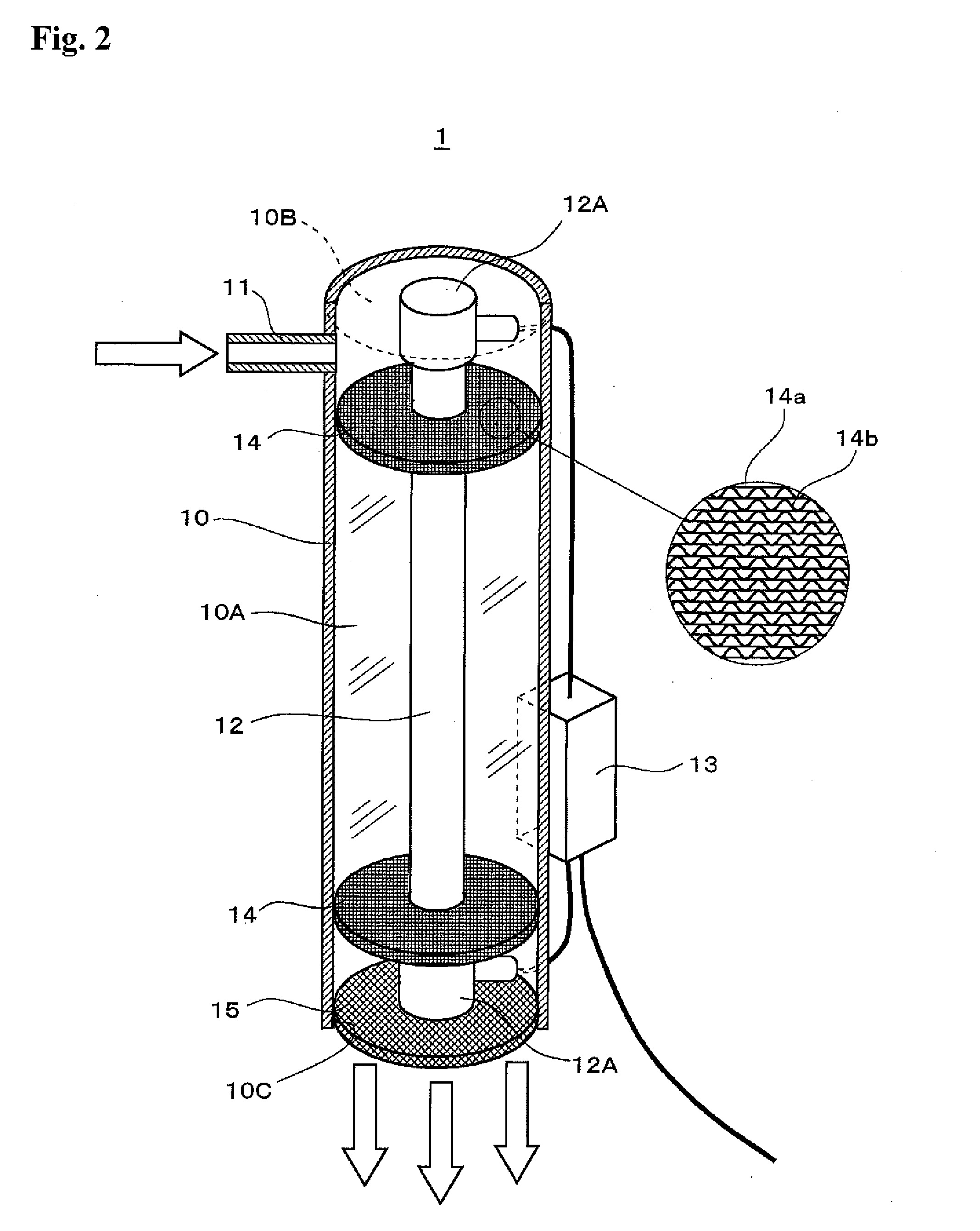

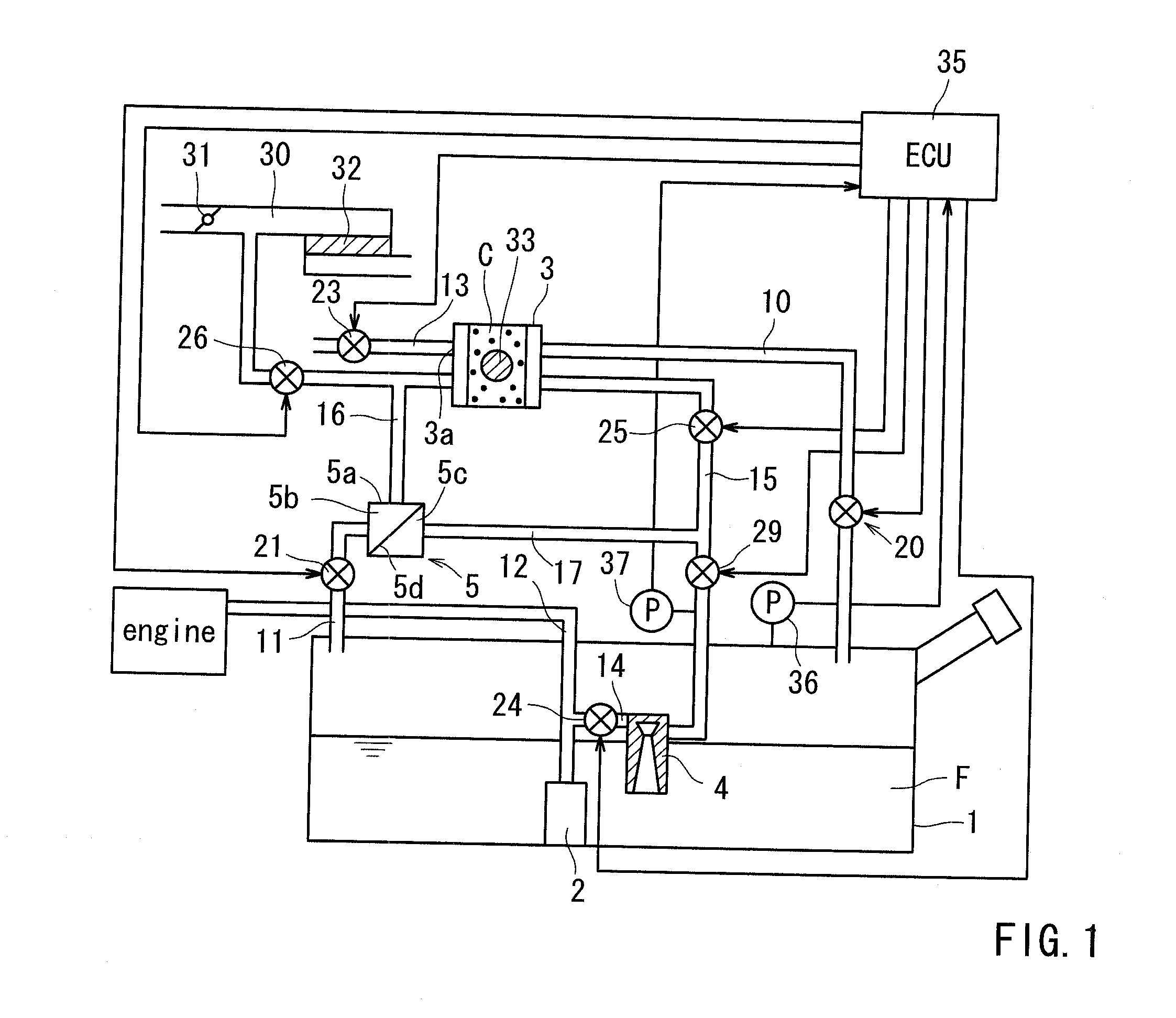

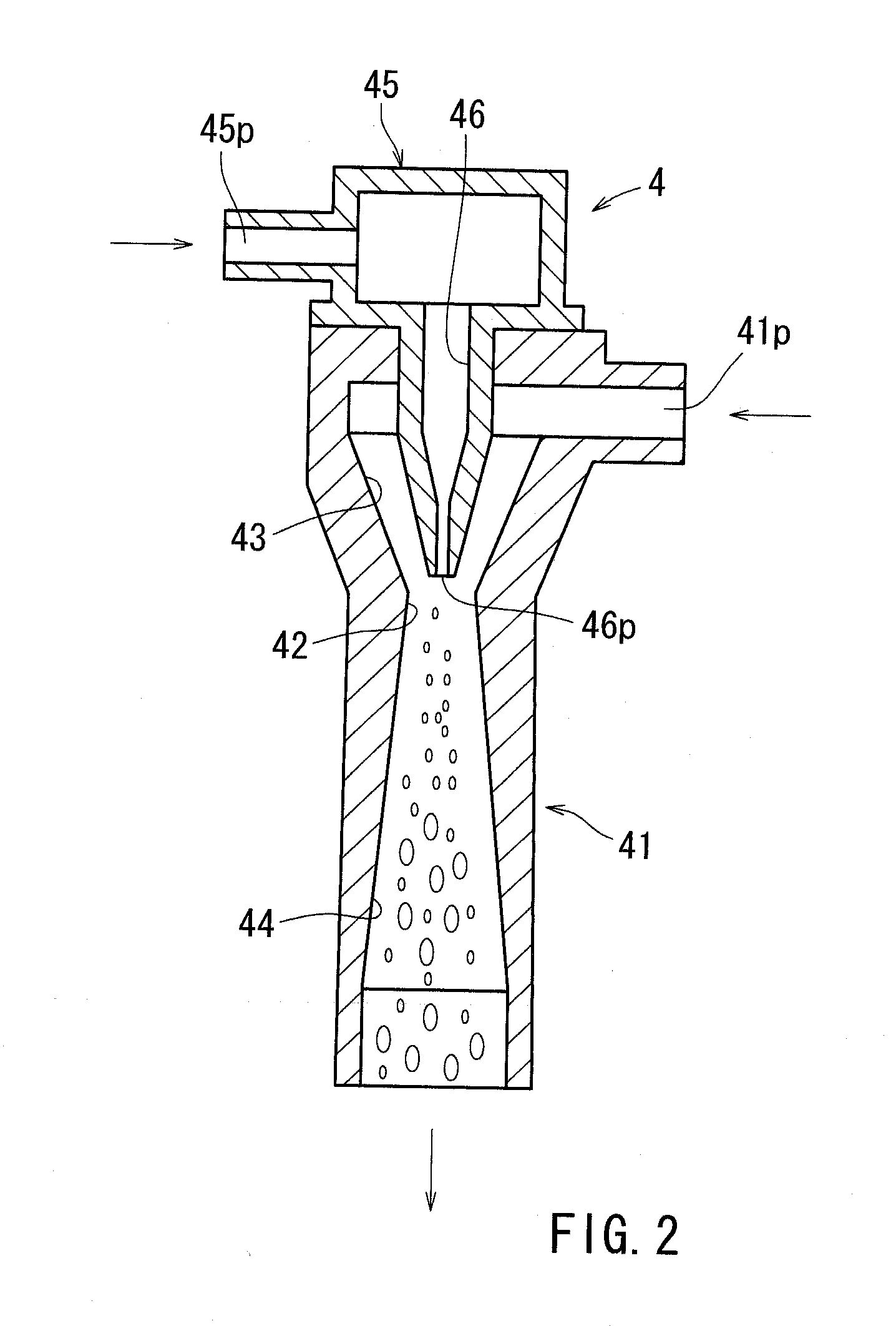

Fuel vapor processors

ActiveUS20110214646A1Avoiding increase in emission contained in exhaustLow densityCombination devicesElectrical controlGas supplyFuel vapor

A fuel vapor processor has a fuel tank configured to reserve fuel, a canister containing adsorbent capable of adsorbing fuel vapor vaporized in the fuel tank, a separator receiving a fuel vapor containing gas from the fuel tank, a regulator controlling the volume of the fuel vapor containing gas supplied to the separator, and a suction unit capable of removing the fuel vapor from the canister. The separator selectively passes the fuel vapor therethrough in order to divide the fuel vapor containing gas into a first gas mainly containing the fuel vapor and a second gas having a fuel vapor density lower than the first gas. The suction unit suctions the first gas from the separator in order to return the first gas into the fuel tank. The second gas is introduced into the canister or is released into the atmosphere.

Owner:AISAN IND CO LTD

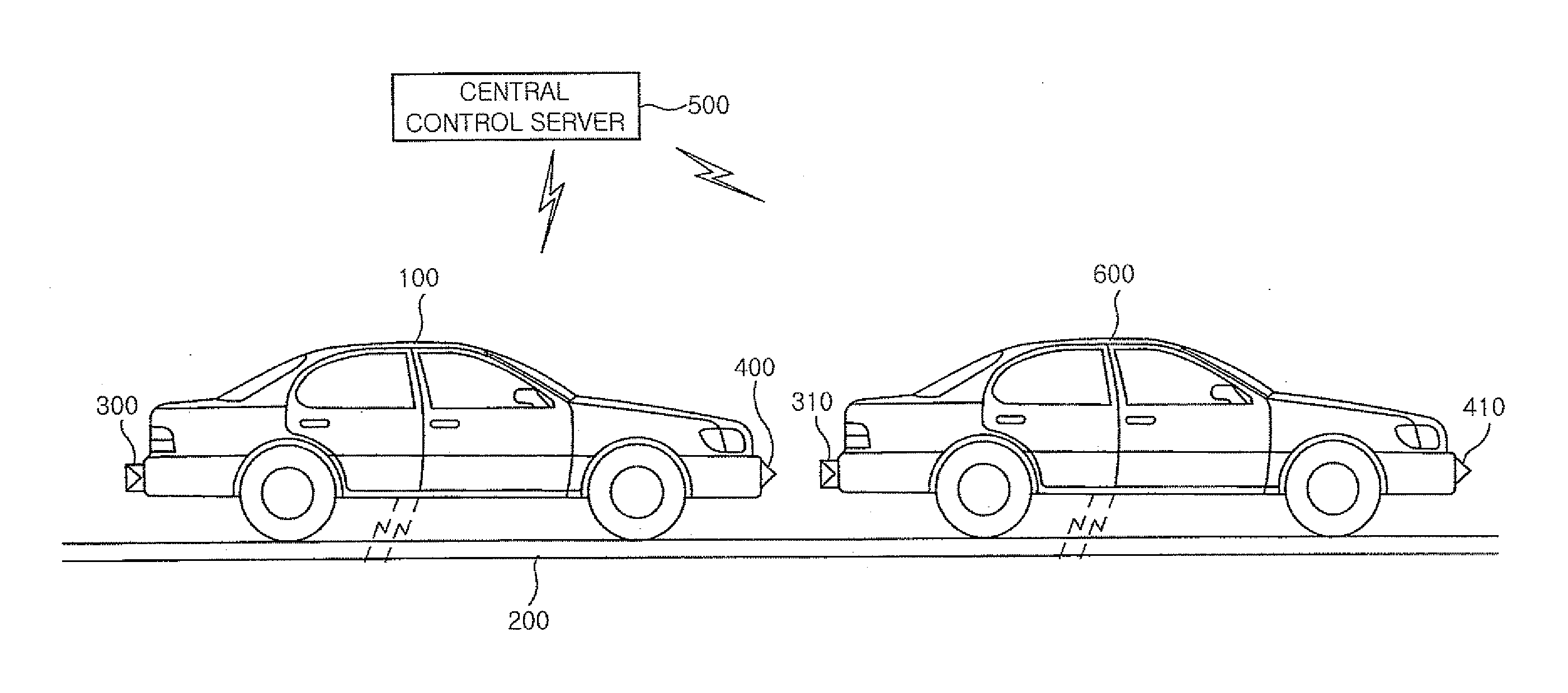

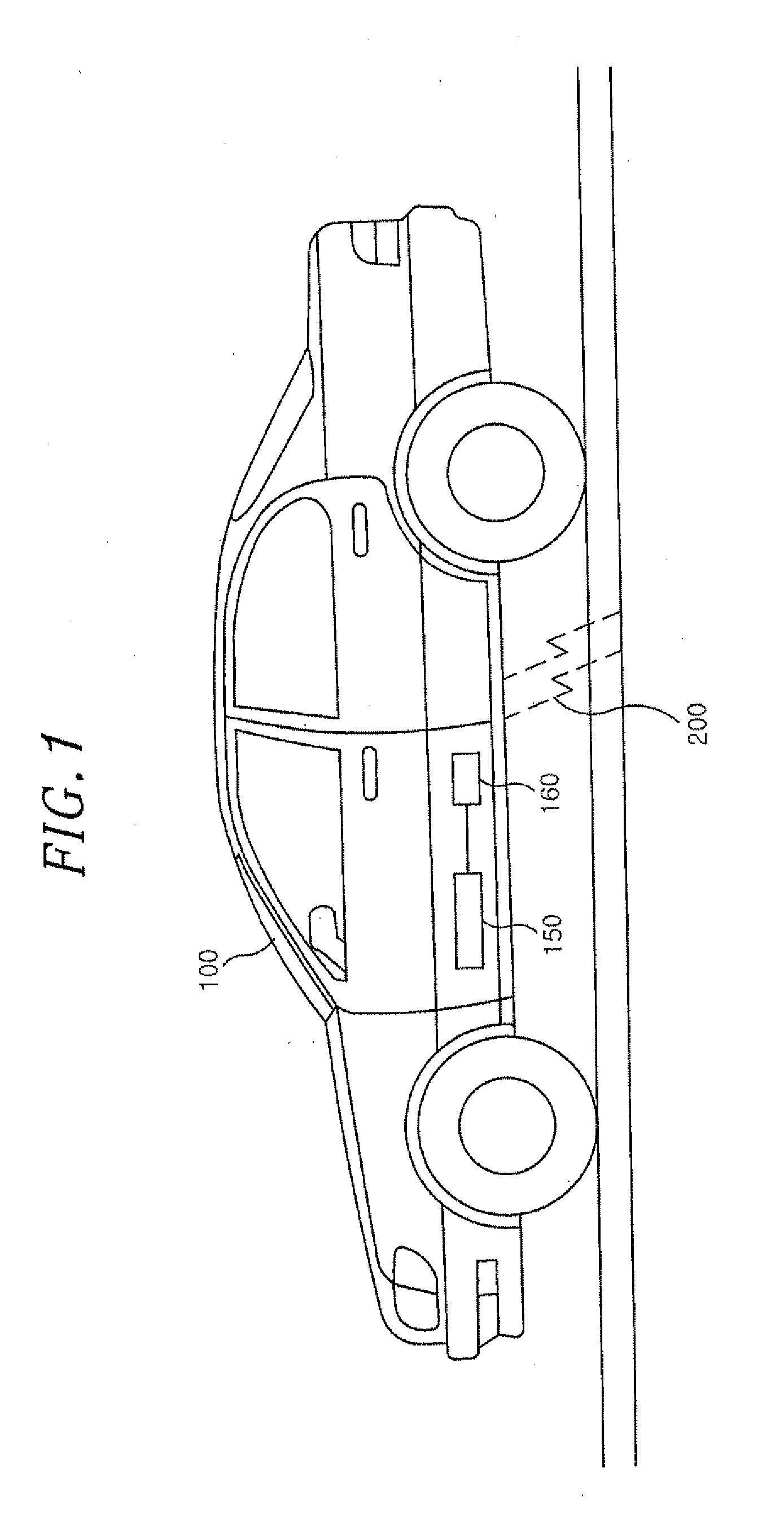

Transportation system using electric automobile

InactiveUS20110153184A1Avoid air pollutionAnalogue computers for vehiclesCharging stationsElectricityElectrical battery

The present invention relates to a transportation system using an electric automobile. The transportation system using the electric automobile comprises the electric automobile and an electricity-supply unit which supplies electricity to the electric automobile. The electric automobile charges a battery included when the electricity is supplied from an external source in motion, using some or all of the electricity and is driven by the electricity of the battery when the electricity supply to the automobile in motion is stopped.

Owner:KOREA ADVANCED INST OF SCI & TECH

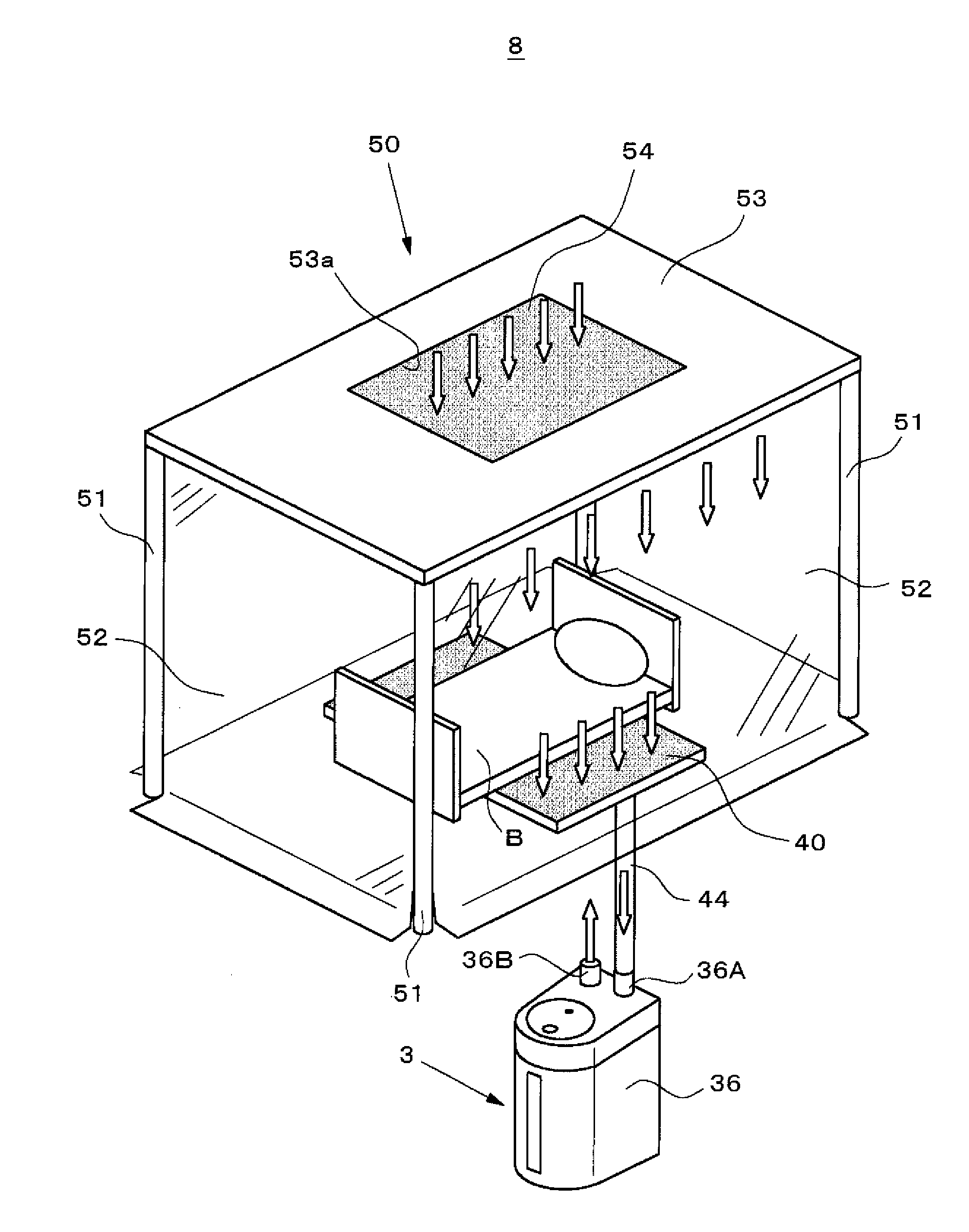

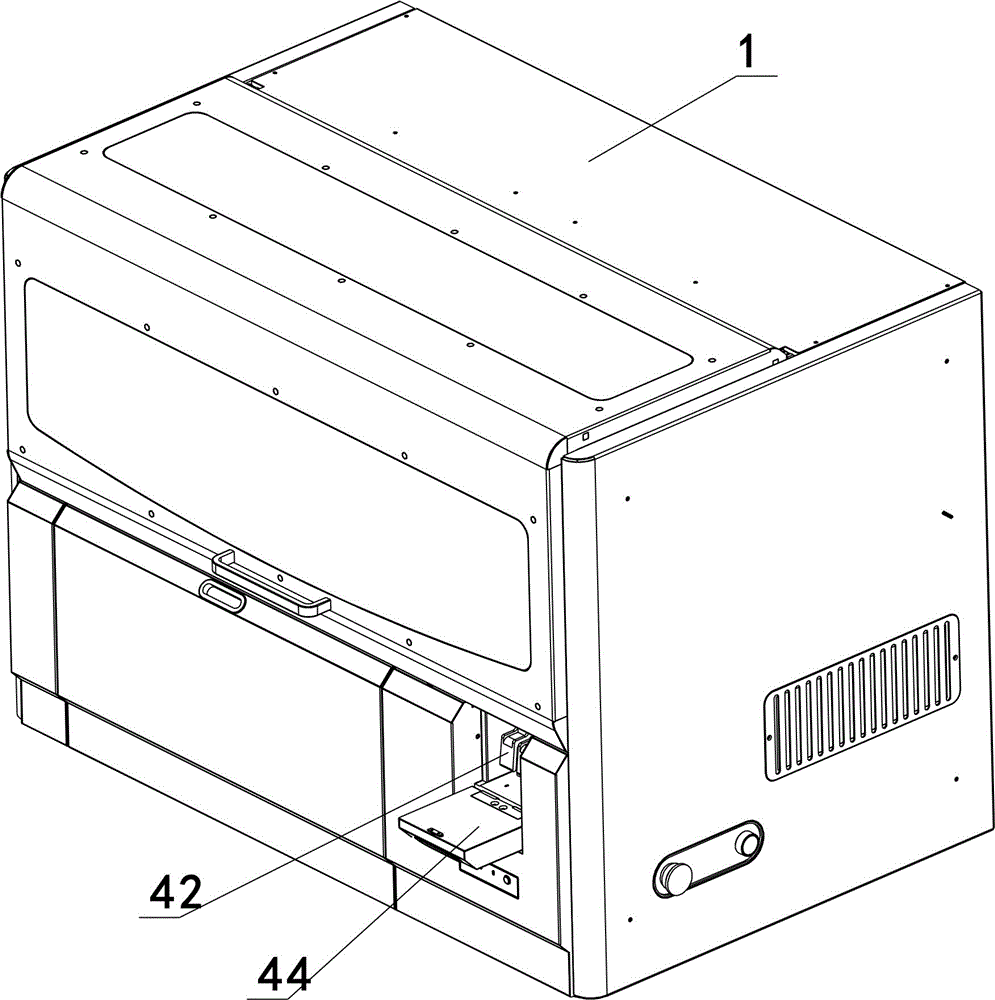

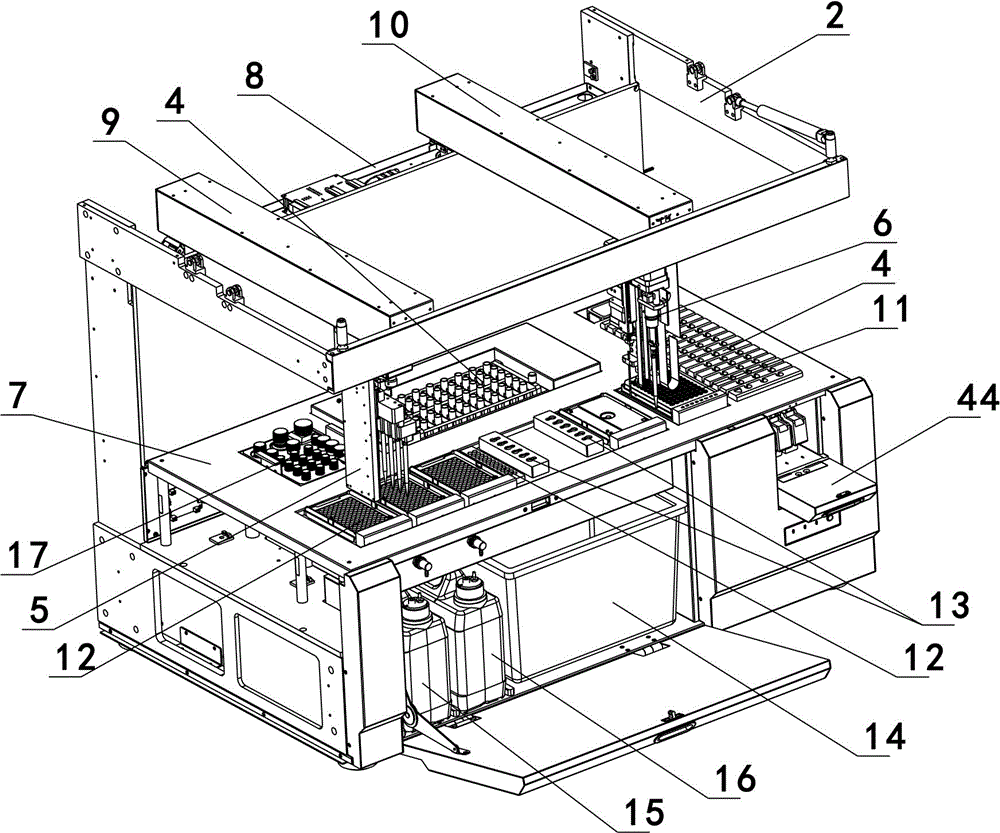

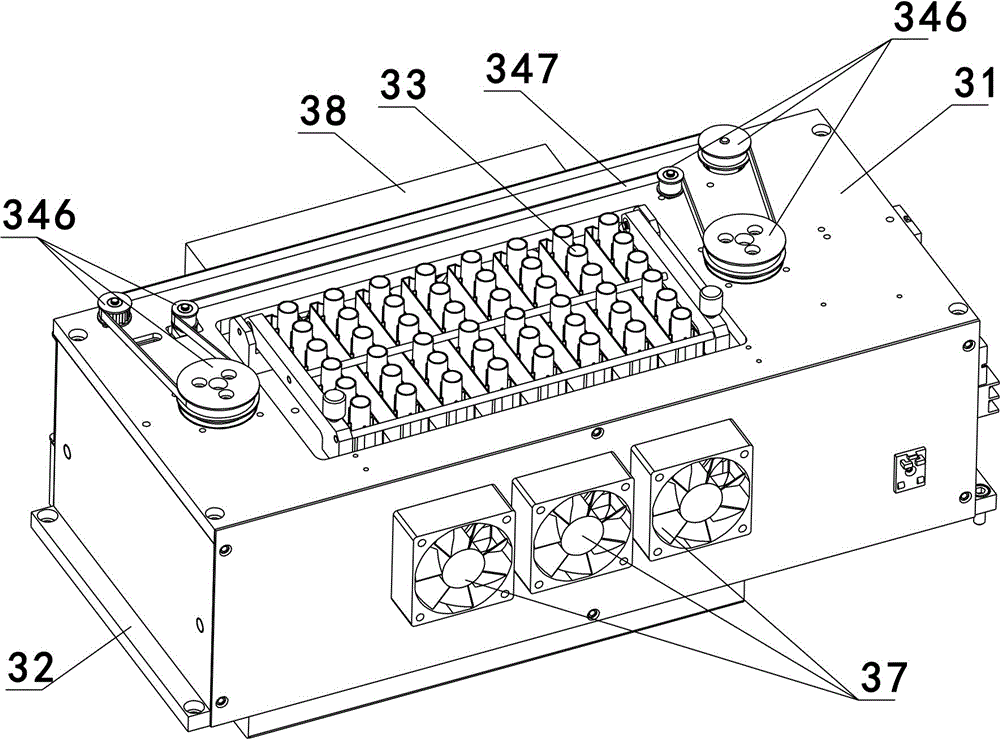

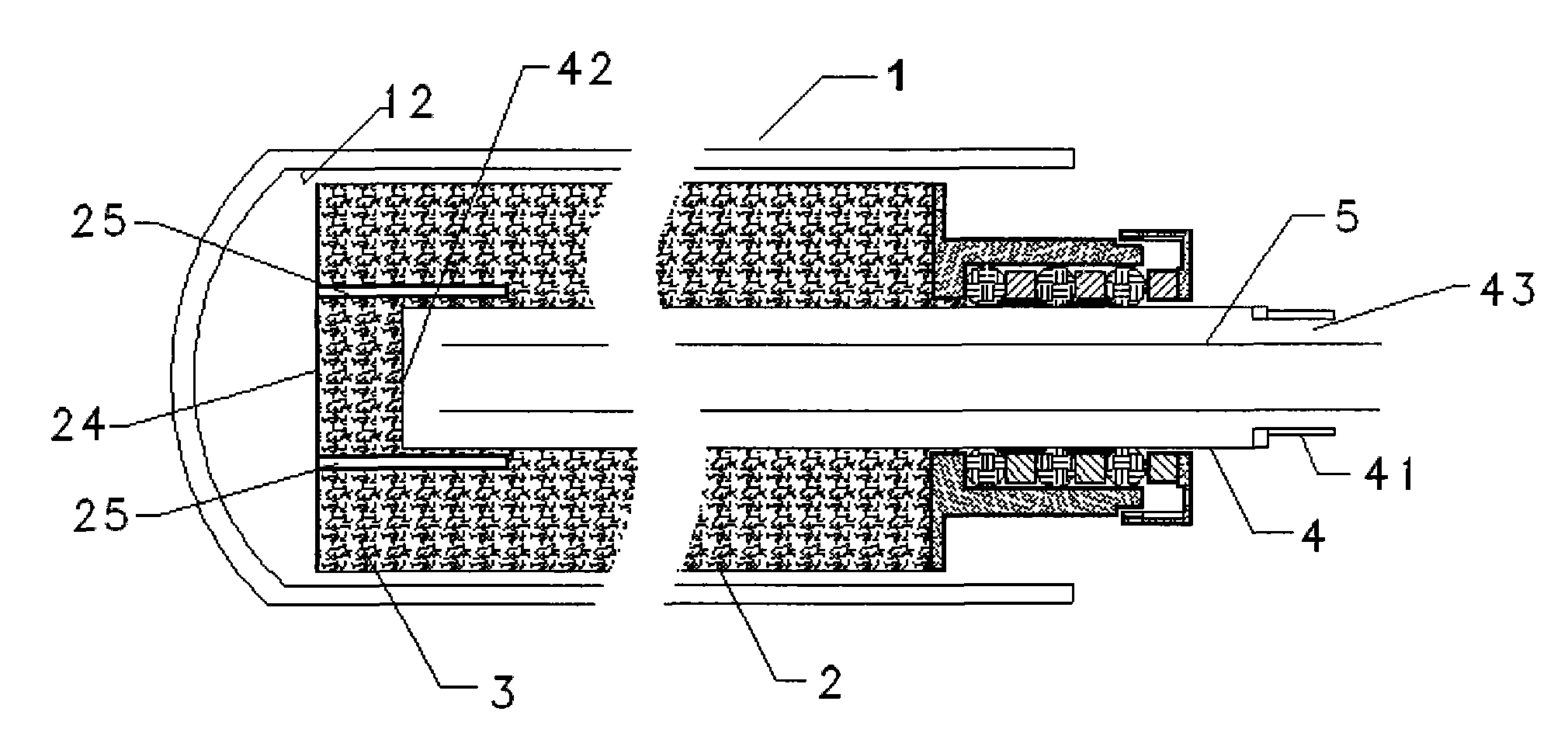

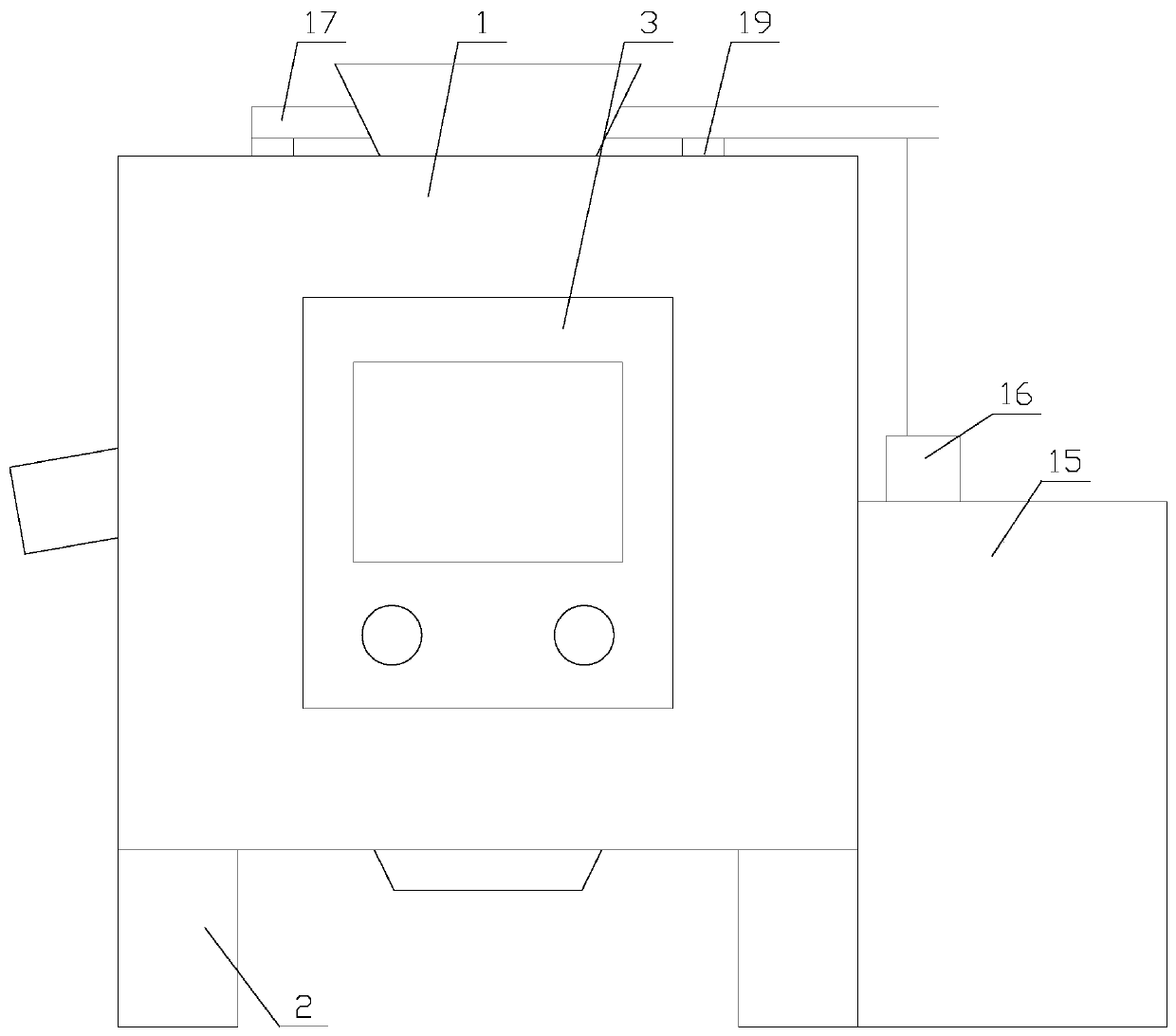

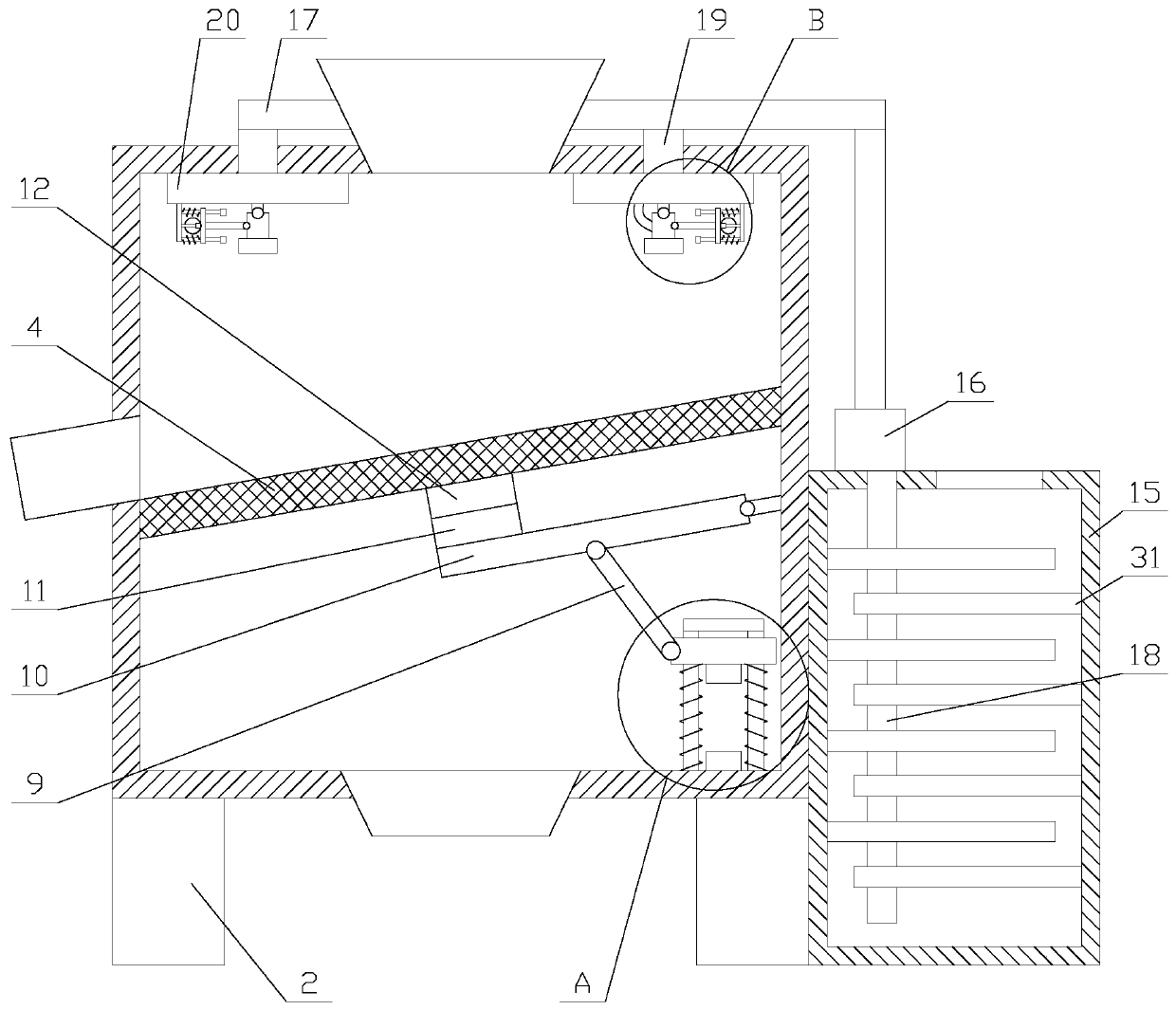

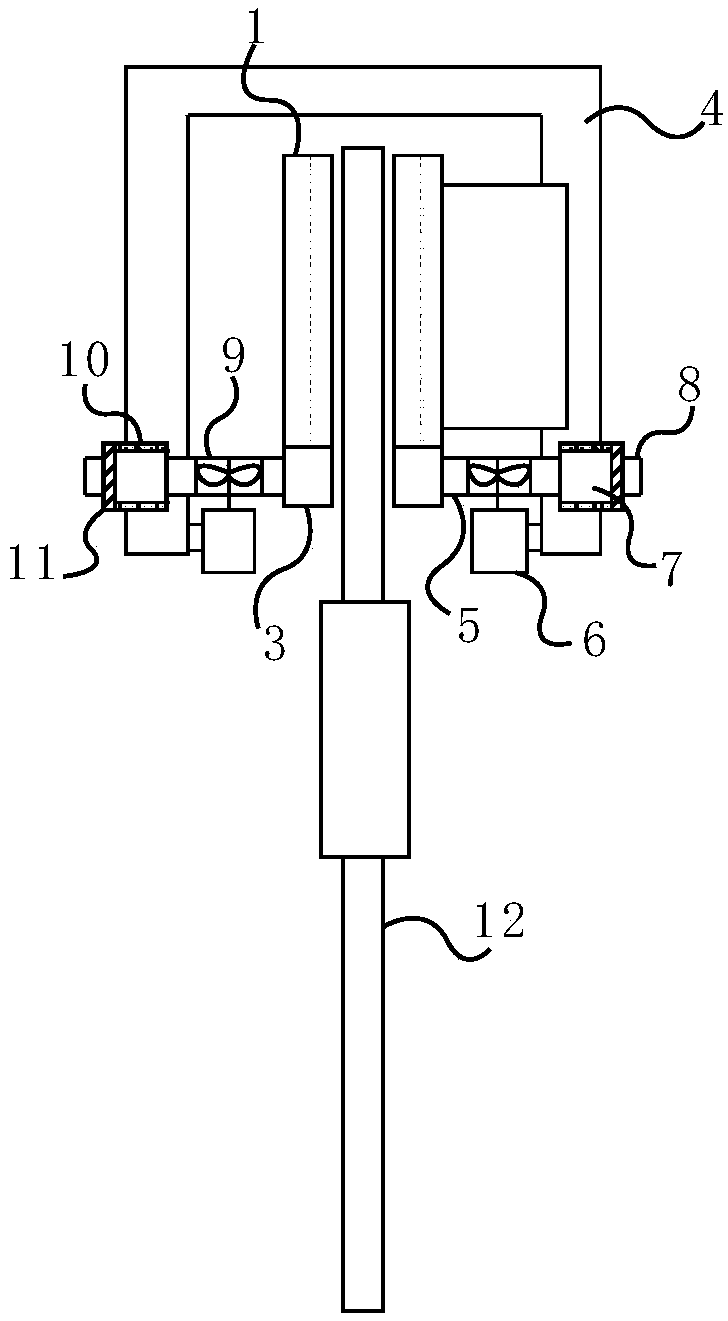

Nucleic acid extractor

ActiveCN104450498AAvoid pollutionAvoid air pollutionBioreactor/fermenter combinationsBiological substance pretreatmentsChemistryPipette

The invention relates to the technical field of medical equipment and particularly relates to a nucleic acid extractor. The nucleic acid extractor comprises a shell, a rack, a nucleic acid extracting module, a sample bin, a reagent region, a multi-pipette module and a single-pipette module, wherein a table board is arranged on the rack; the nucleic acid extracting module, the sample bin and the reagent region are arranged on the table board; the multi-pipette module and the single-pipette module are positioned above the table board; an X arm is arranged on the rack; a multi-pipette Y arm and a single-pipette Y arm are arranged on the X arm; the multi-pipette Y arm and the single-pipette Y arm slide along the X arm; the multi-pipette module is arranged on the multi-pipette Y arm and slides along the multi-pipette Y arm; the single-pipette module is arranged on the single-pipette Y arm and slides along the single-pipette Y arm. The invention provides the nucleic acid extractor which is simple in structure, capable of preventing cross contamination and small in difference.

Owner:JIAXING QUEST LIFE SCI

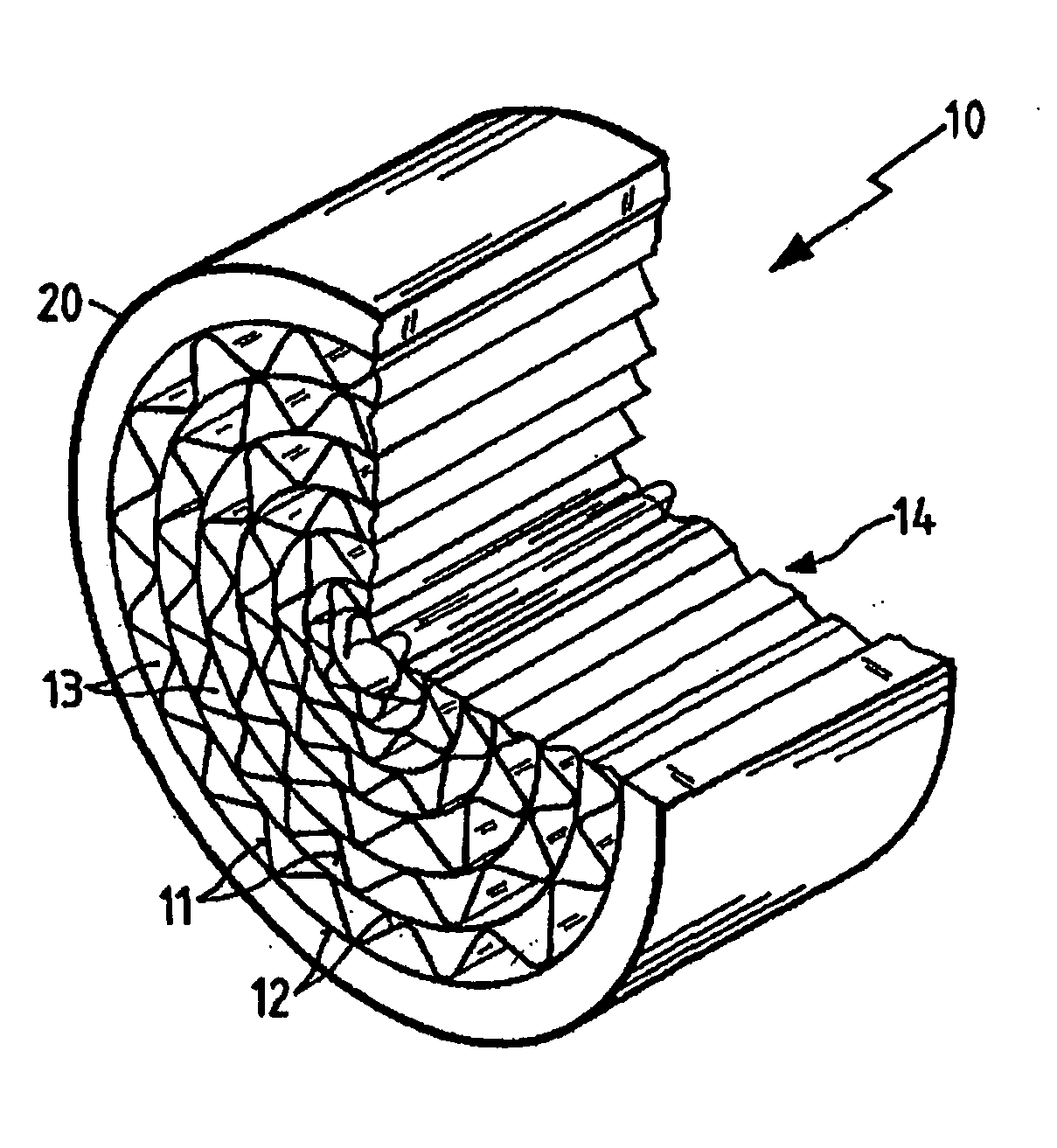

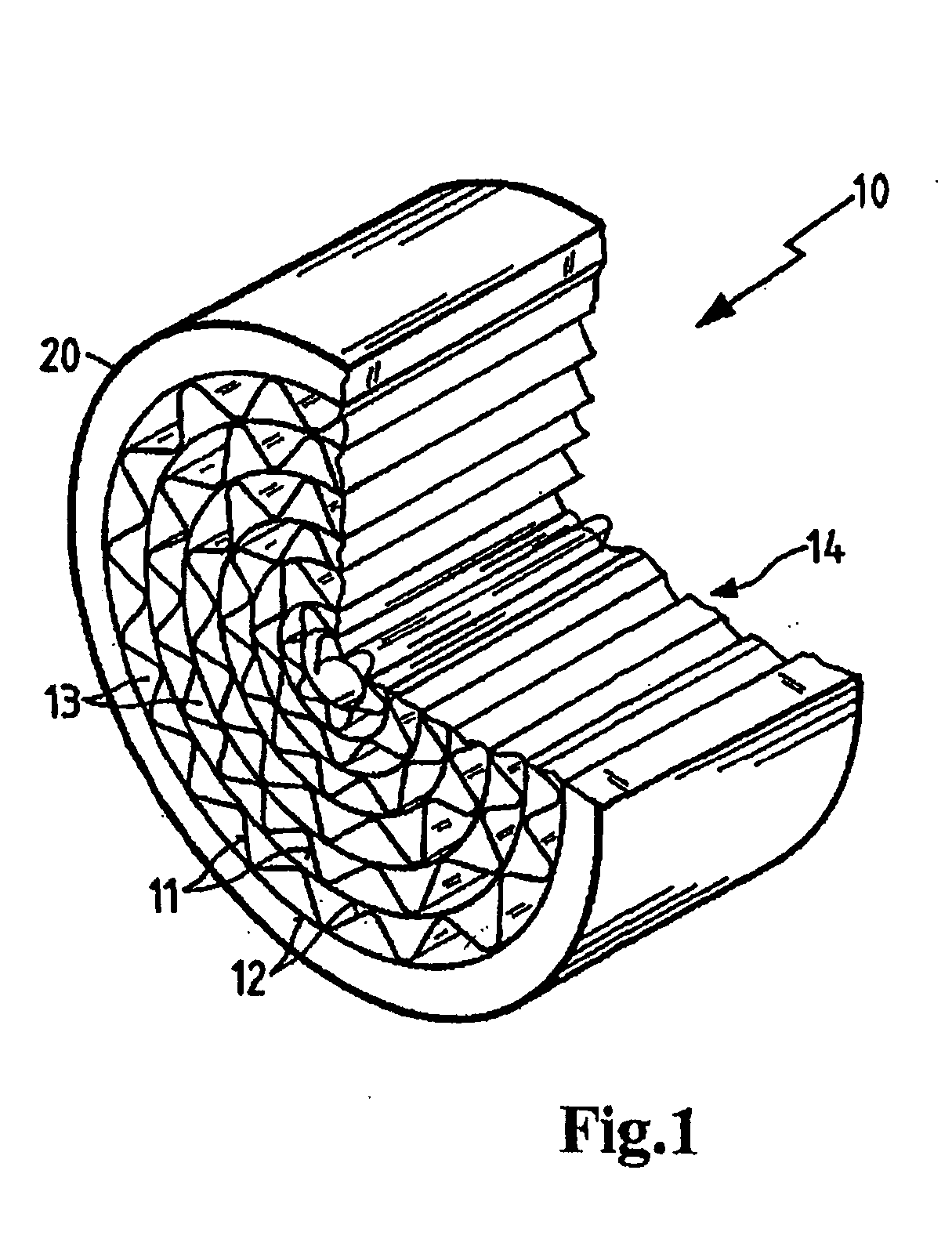

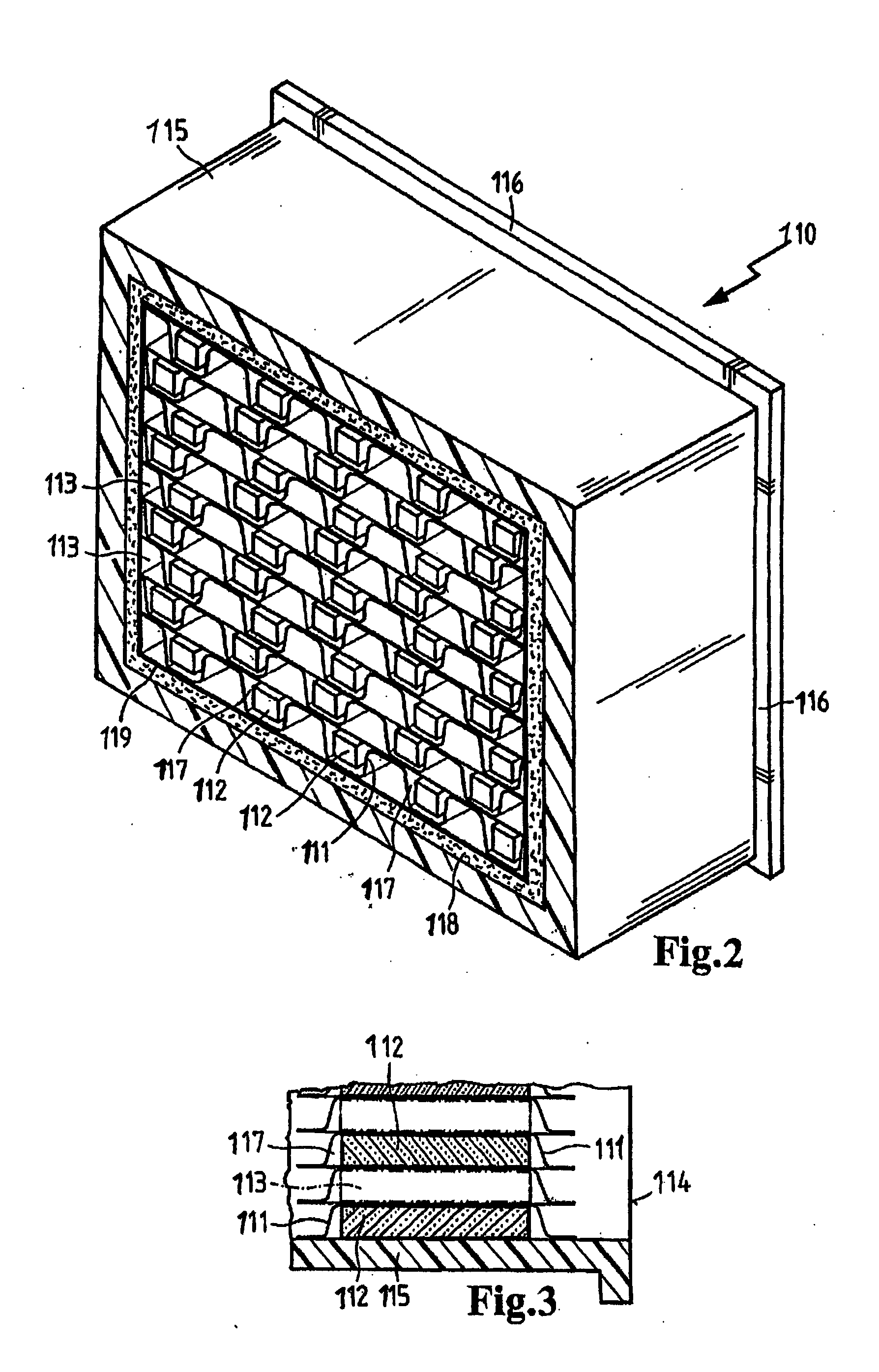

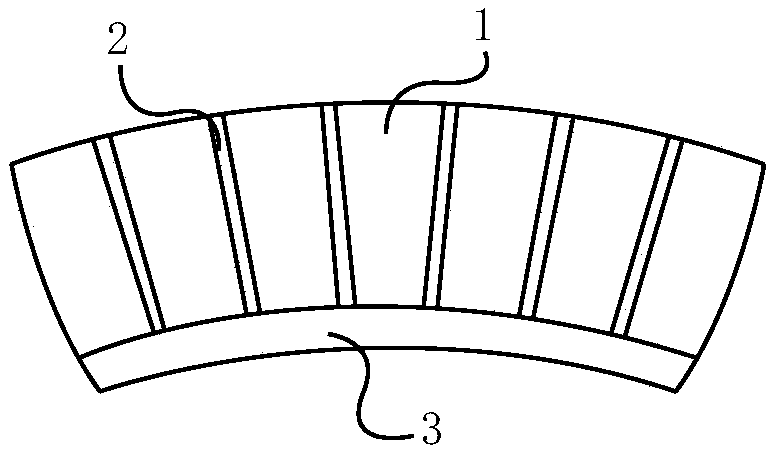

Adsorber for adsorbing hydrocarbon vapors from return flows through an intake tract of an internal combustion engine

InactiveUS20050223894A1Easy to replaceImprove stabilityGas treatmentNon-fuel substance addition to fuelCompound (substance)Internal combustion engine

An adsorption element for adsorbing gases and vapors from the gas atmosphere in a gas stream in an intake tract of an internal combustion engine, in which the gas atmosphere is present in a flow cross section of the intake tract. The adsorption element has free-flow channels through which the gas stream is passed. The adsorption element includes at least one adsorption layer, and the free-flow channels are formed by at least one spacer element, and the spacer element is arranged between adsorption layers.

Owner:MANN HUMMEL GMBH

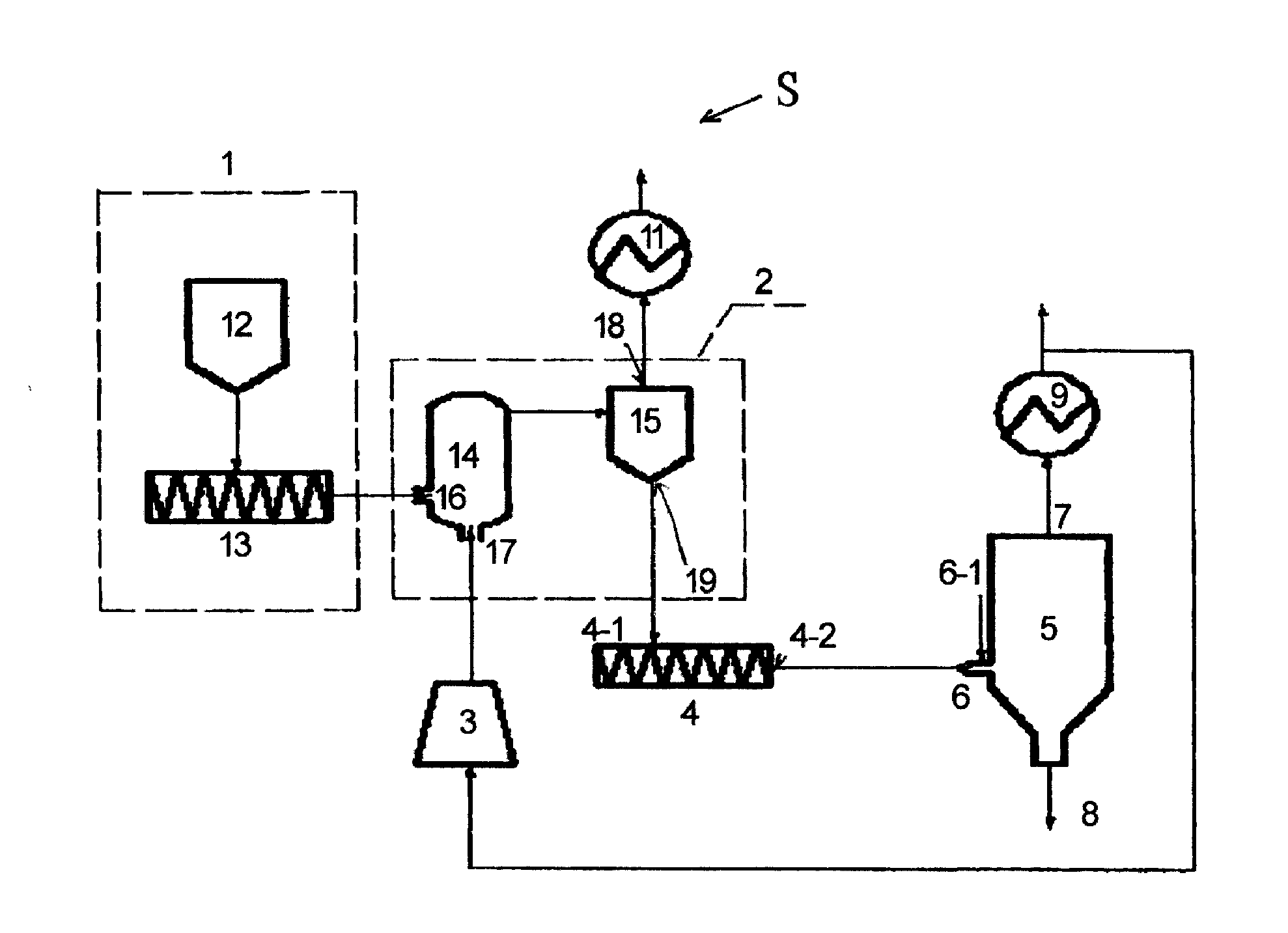

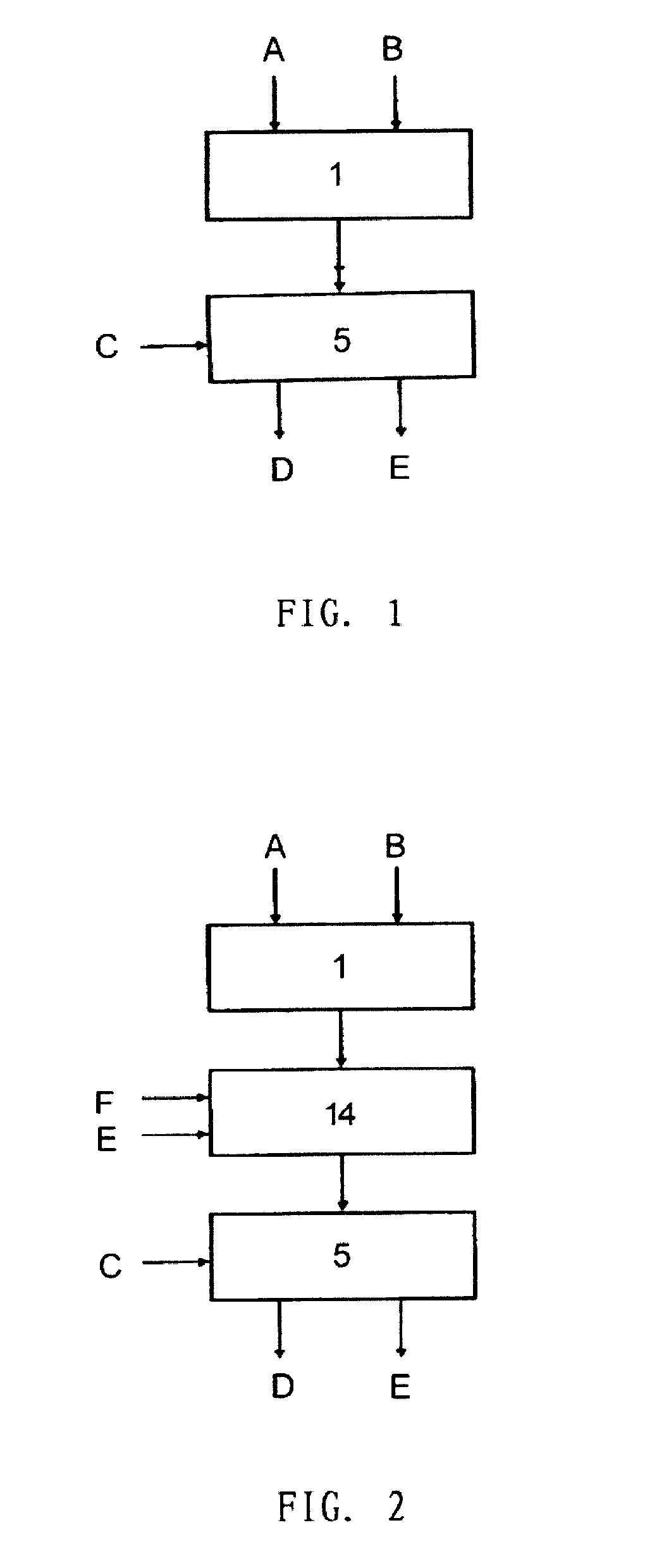

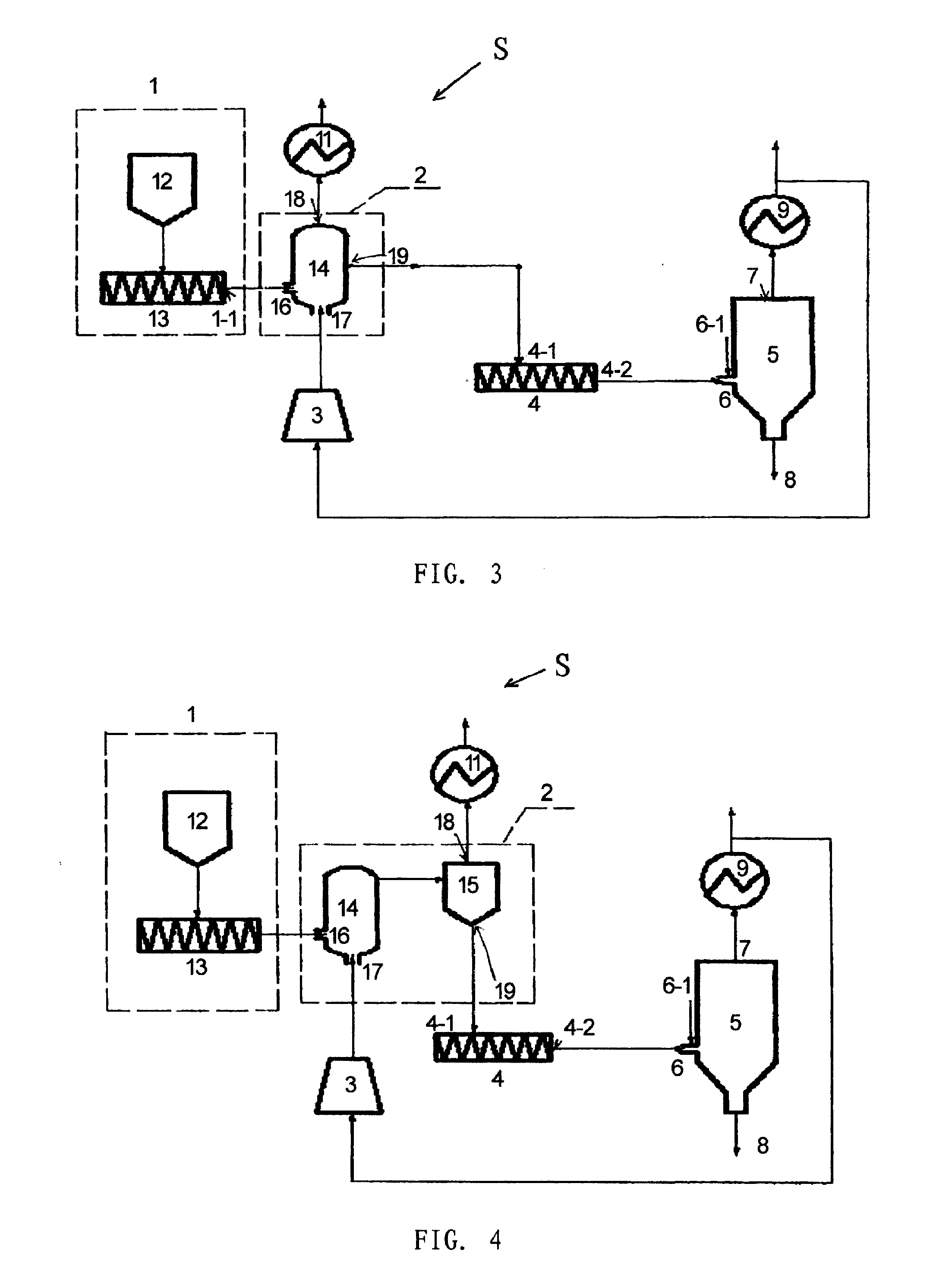

Method and system for producing calcium carbide

InactiveUS20110123428A1Increase response rateLow reaction temperatureEnergy inputCalcium carbideSlagUranium carbide

A method and a system for producing calcium carbide, the method including mixing powdery carbon-containing raw material with powdery calcium-containing raw material, and directly heating the mixture by combusting a part of carbon-containing raw material in an oxygen-containing atmosphere to produce calcium carbide. The carbon-containing raw material can be coal, semi-coke or coke, the calcium-containing raw material can be calcium carbonate, calcium oxide, calcium hydroxide or carbide slag. The system includes a raw material preheating unit, such as a fluidized bed or an entrained flow bed, and a reaction unit such as an entrained flow bed. By combustion of the by-product CO produced during the production of calcium carbide or auxiliary fuel in the air to preheat the raw materials to 500-1500° C., the carbon consumption and the oxygen consumption for the calcium carbide production can be reduced, and thus process energy consumption is further reduced.

Owner:LIU ZHENYU +2

Process for preparing iron oxide red by using sulfuric acid crystal seed mixed acid method and products thereby

InactiveCN1699477AReduce consumptionImprove working environmentInorganic pigment treatmentSulphate IonSlurry

The invention relates to a process for preparing iron oxide red by using sulfuric acid crystal seed mixed acid method, which comprises preparing iron oxide red seed crystal with sulfuric acid process, then washing the iron oxide red seed crystal, lowering the content of sulphate and other impurities in the sulfuric acid process iron oxide red seed crystal, preparing iron oxide red slurry through two-step oxidization, finally dewatering, water scrubbing and drying to obtain the end product.

Owner:SOUTH CHINA UNIV OF TECH

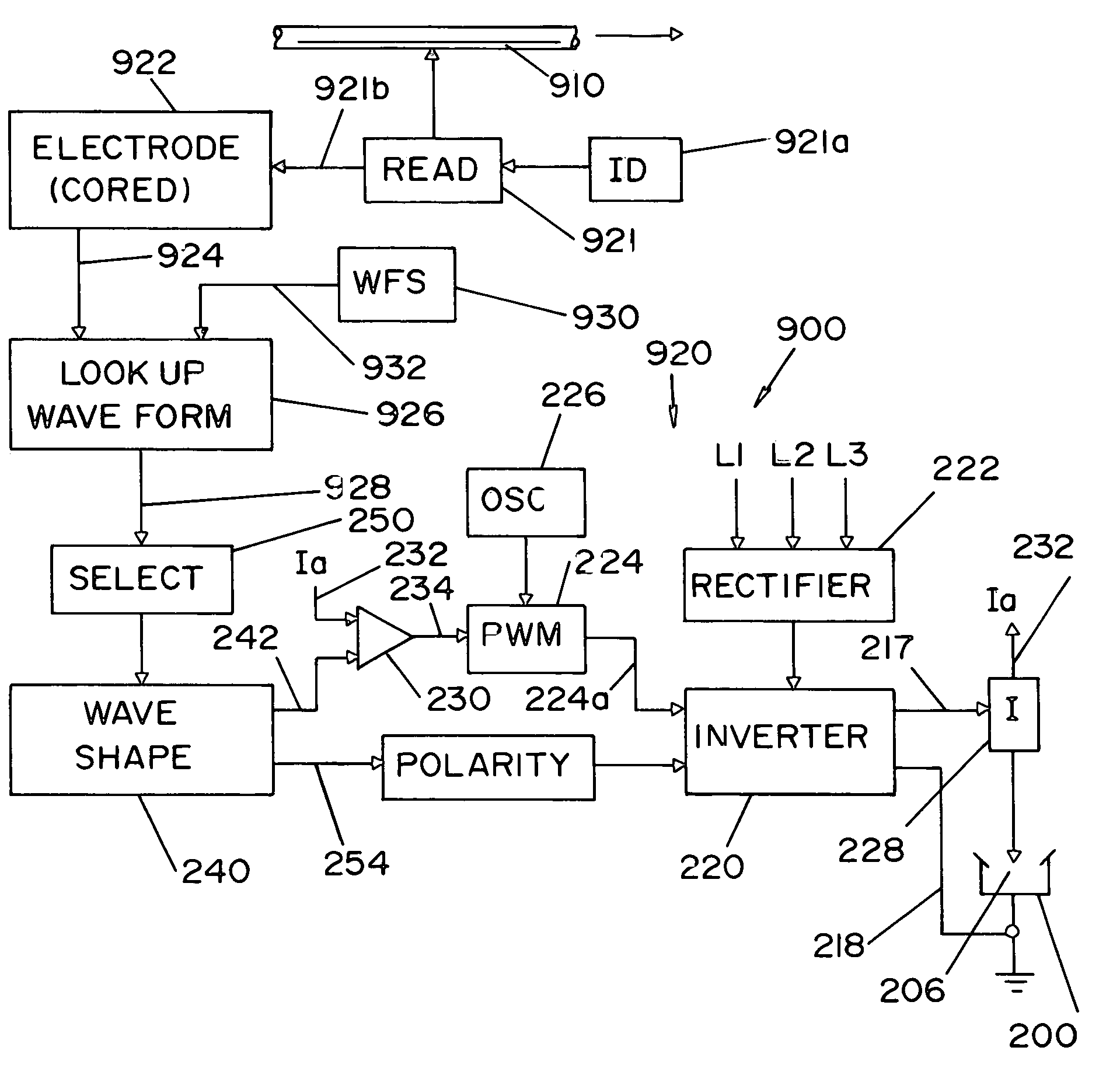

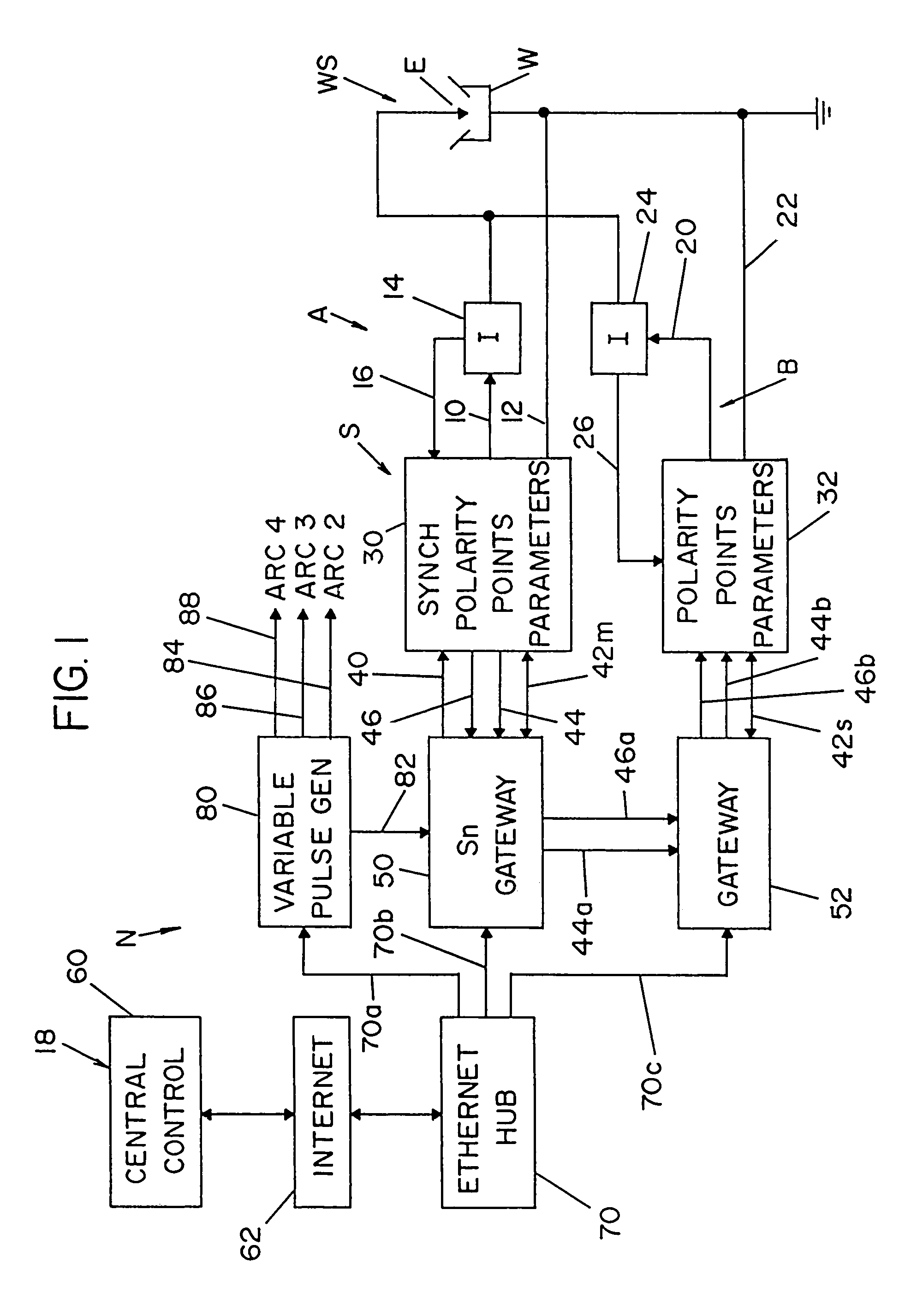

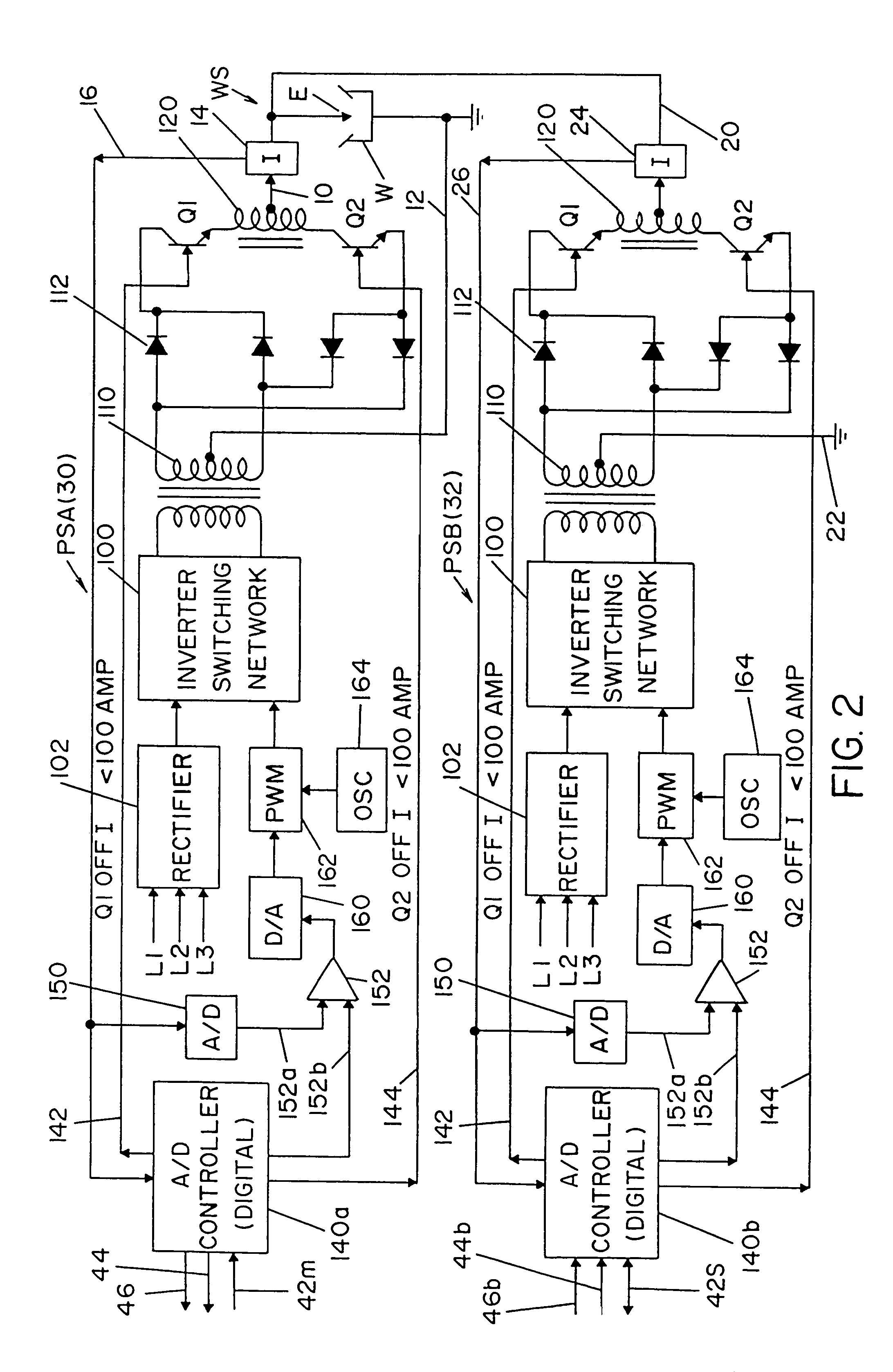

Electric ARC welder system with waveform profile control for cored electrodes

ActiveUS7166817B2Benefit in qualityIncrease productivityArc welding apparatusWaveform shapingEngineering

An electric arc welder for creating a welding process in the form of a succession of AC waveforms between a particular type of cored electrode, with a sheath and core, and a workpiece by a power source comprising an high frequency switching device for creating the individual waveforms in said succession of waveforms, each waveform having a profile is formed by the magnitude of each of a large number of short current pulses generated at a frequency of at least 18 kHz where said profile is determined by the input signal to a wave shaper controlling said short current pulses; a circuit to create a profile signal indicative of said particular type of electrode; and a select circuit to select said input signal based upon said profile signal whereby said wave shaper causes said power source to crate a specific waveform profile for said particular type of cored electrode.

Owner:LINCOLN GLOBAL INC

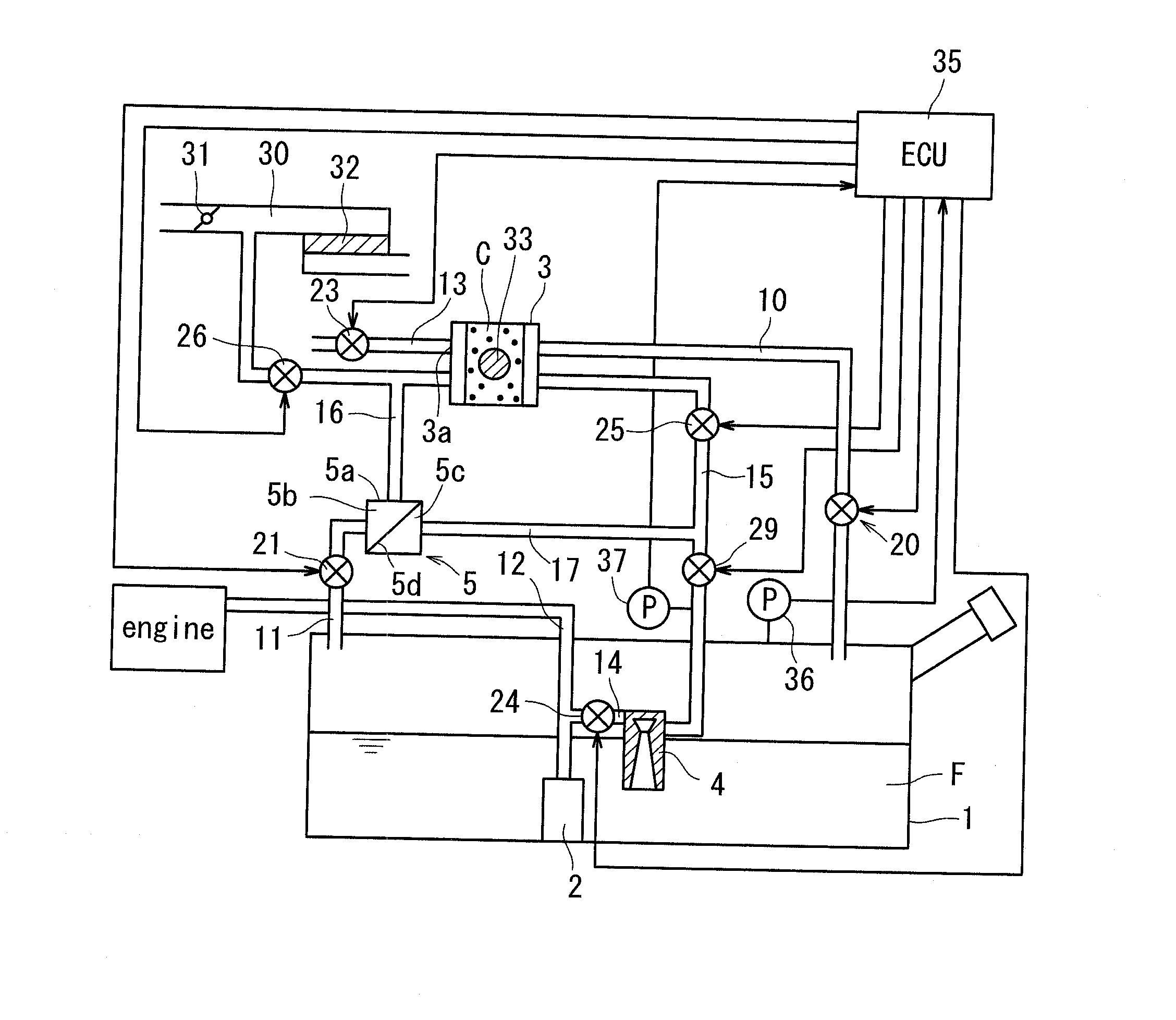

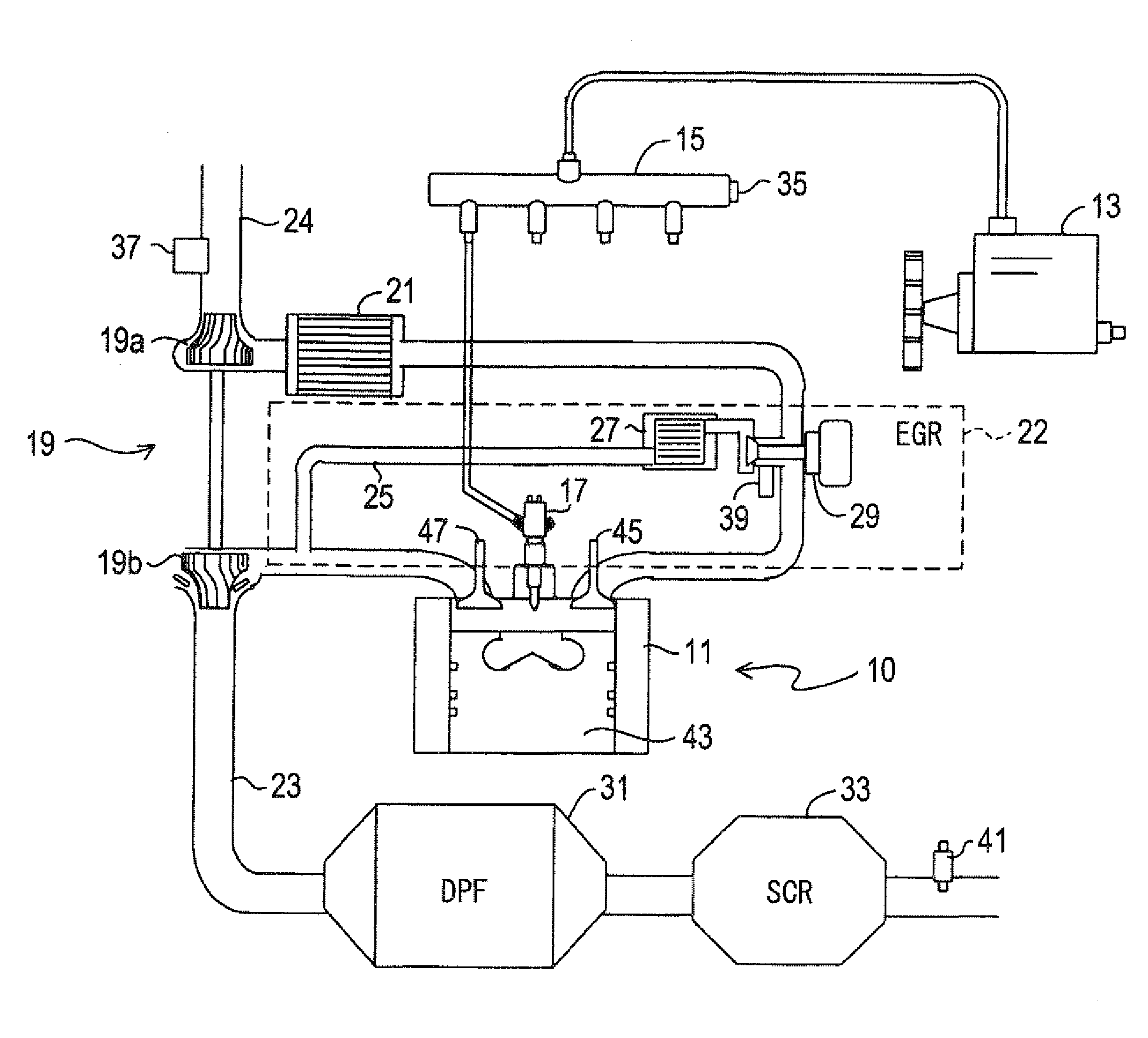

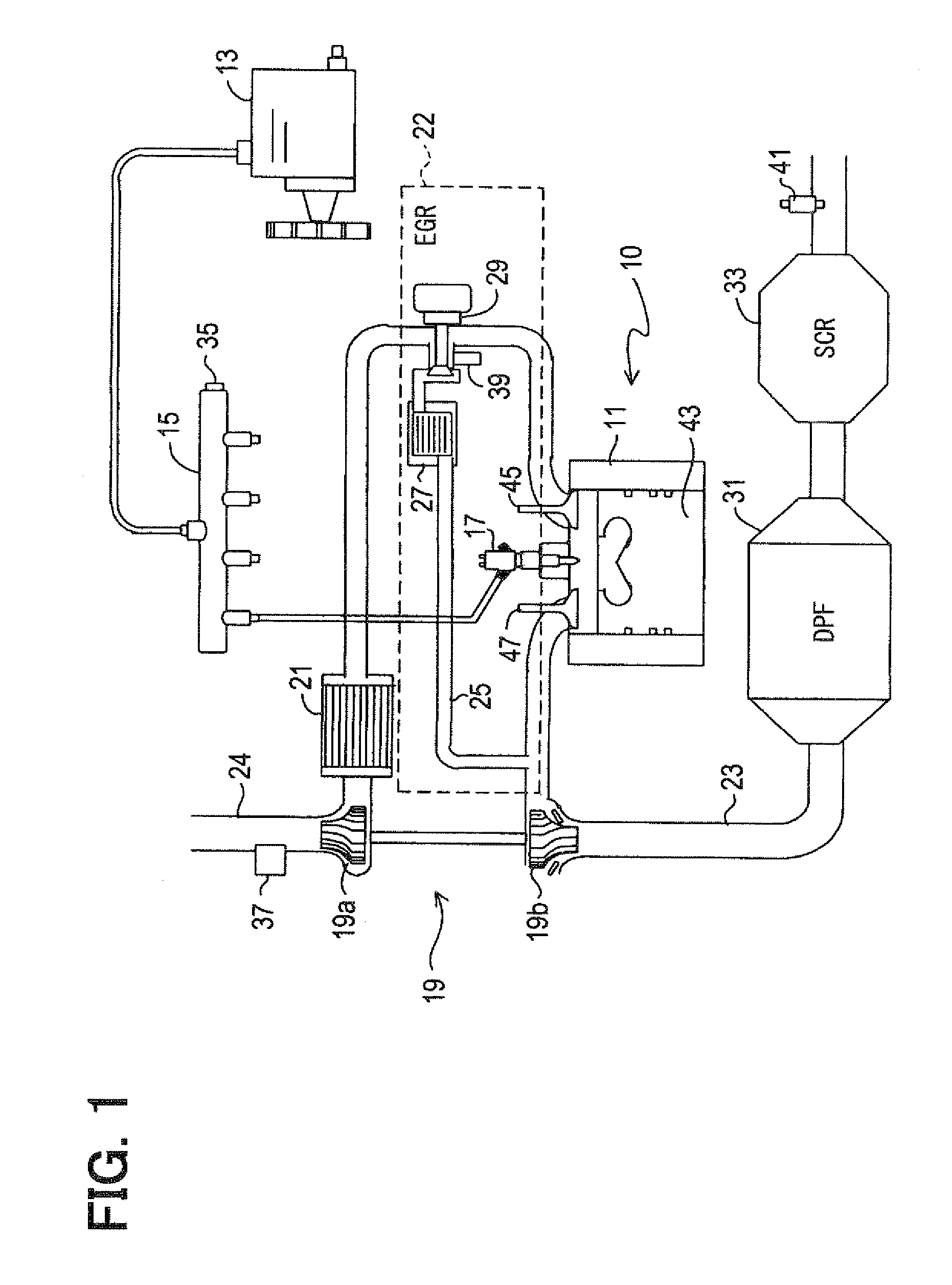

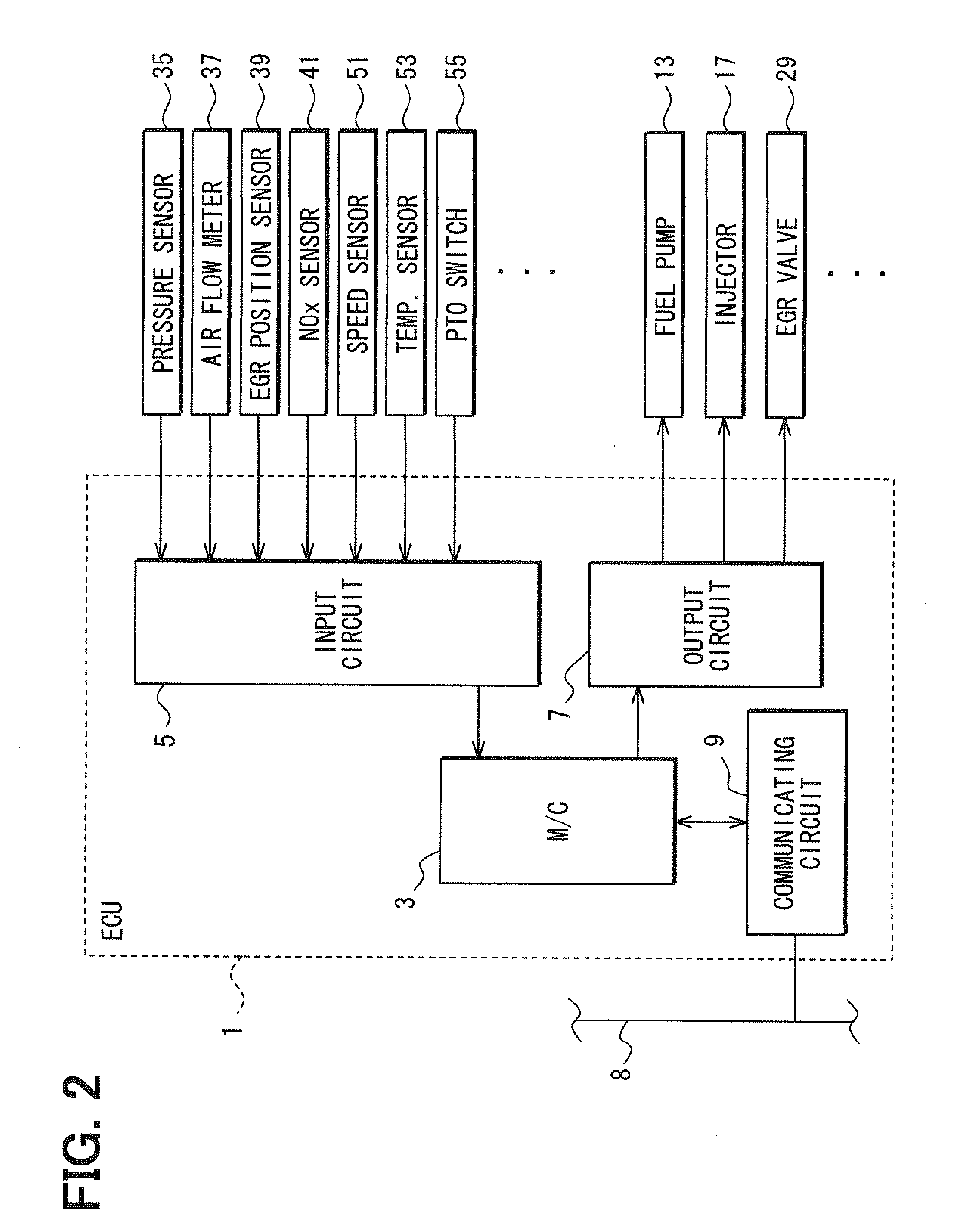

Engine controller

InactiveUS20080294329A1Avoid dischargeAvoid air pollutionAnalogue computers for vehiclesElectrical controlEngine control unitAutomotive engineering

An engine controller for a vehicle equipped with an emission reduction apparatus determines whether the emission reduction apparatus has malfunction. When it is determined that the emission reduction apparatus has malfunction an execution of an idle shutdown control process is permitted. When a predetermined condition is established during an engine idling, the engine is automatically shut down. On the other hand, when it is determined that the emission reduction apparatus has no malfunction, the execution of the idle shutdown control process is prohibited.

Owner:DENSO CORP

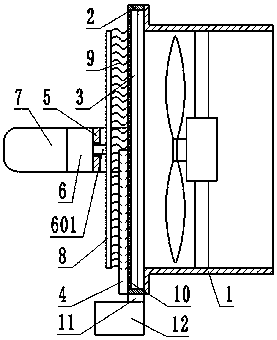

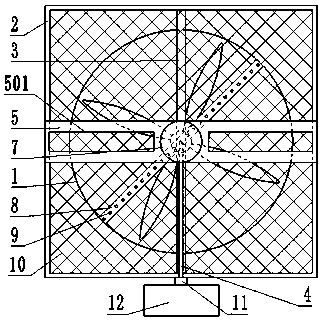

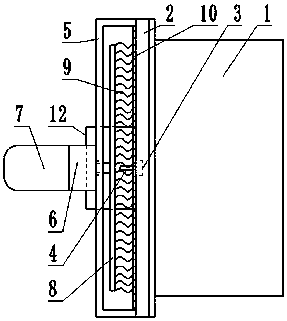

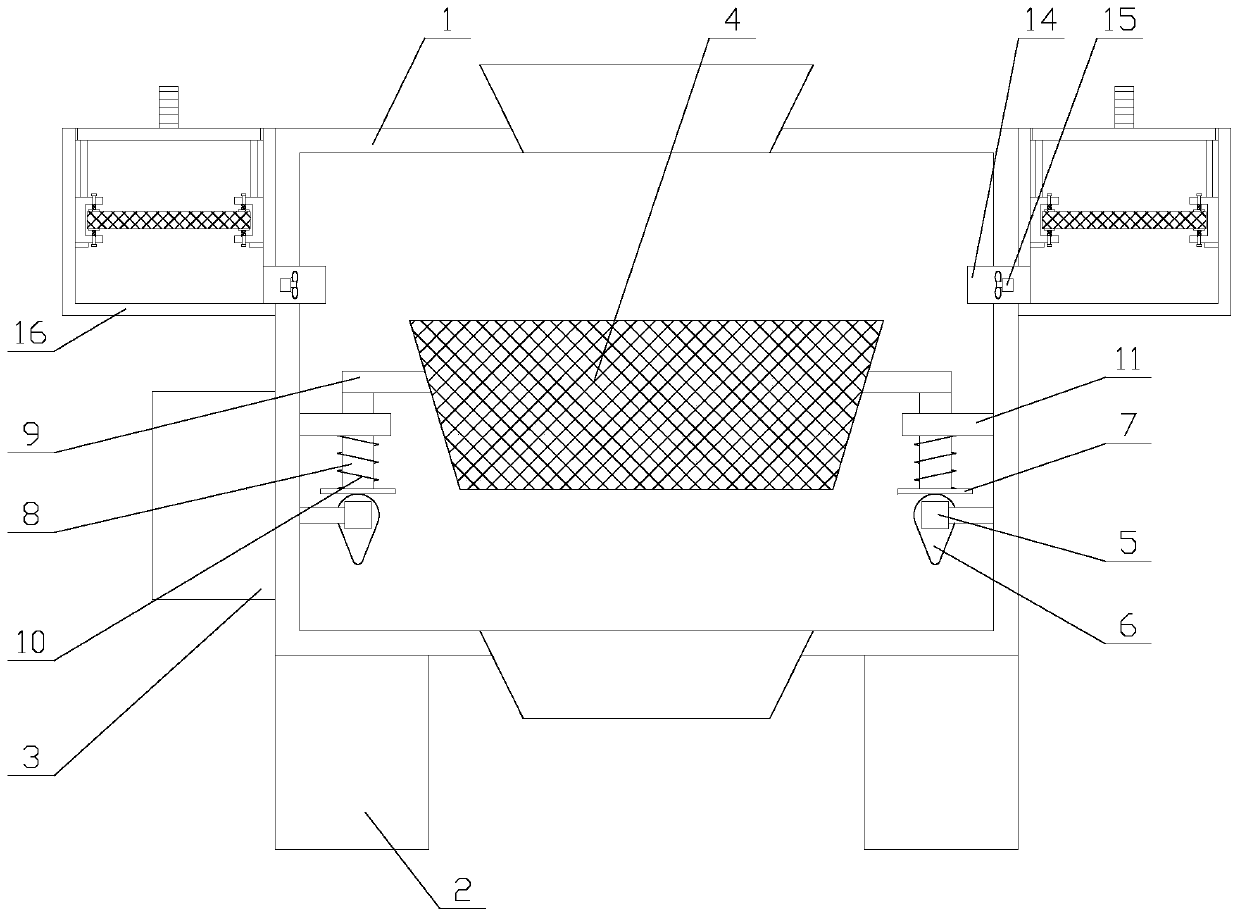

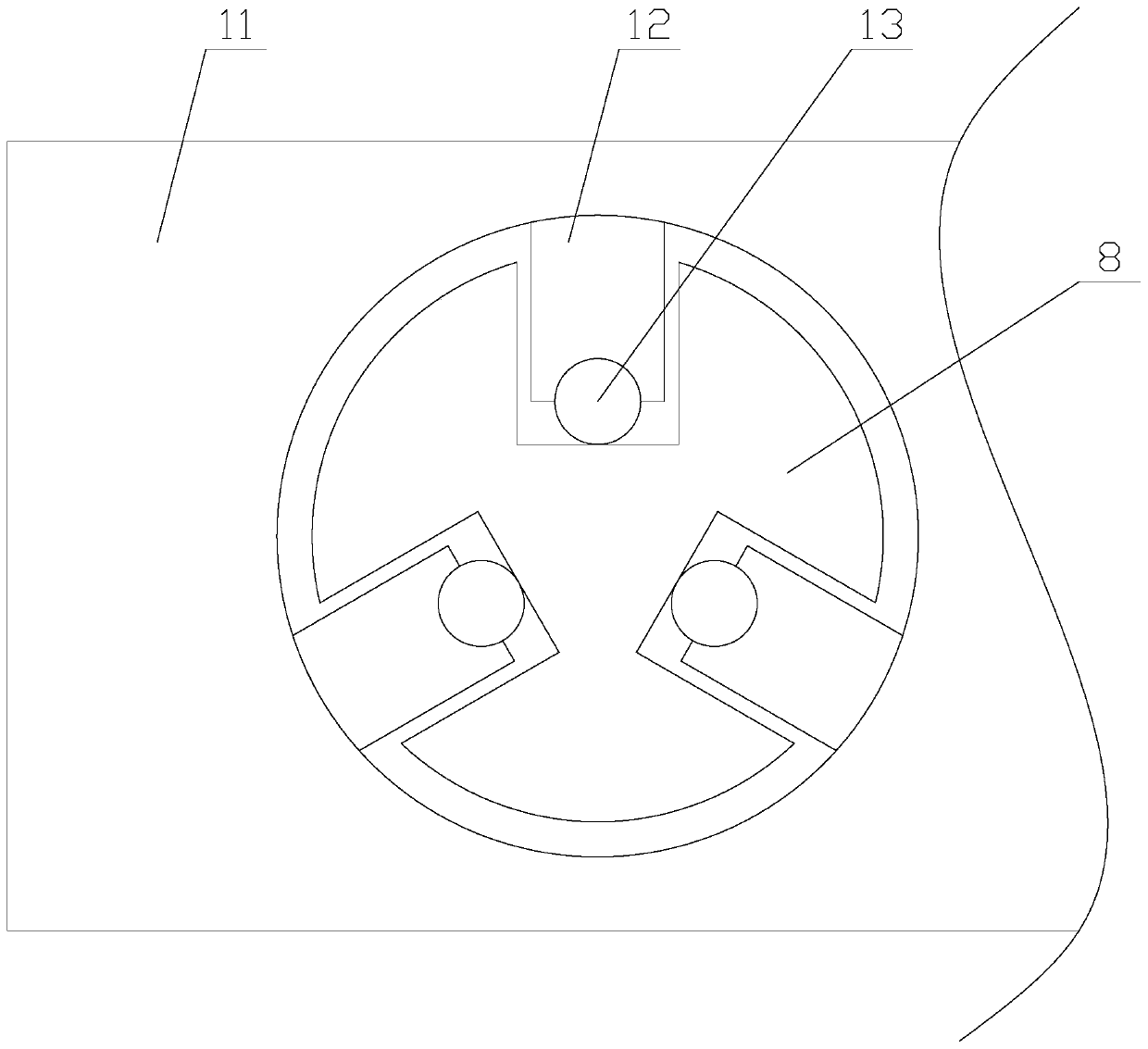

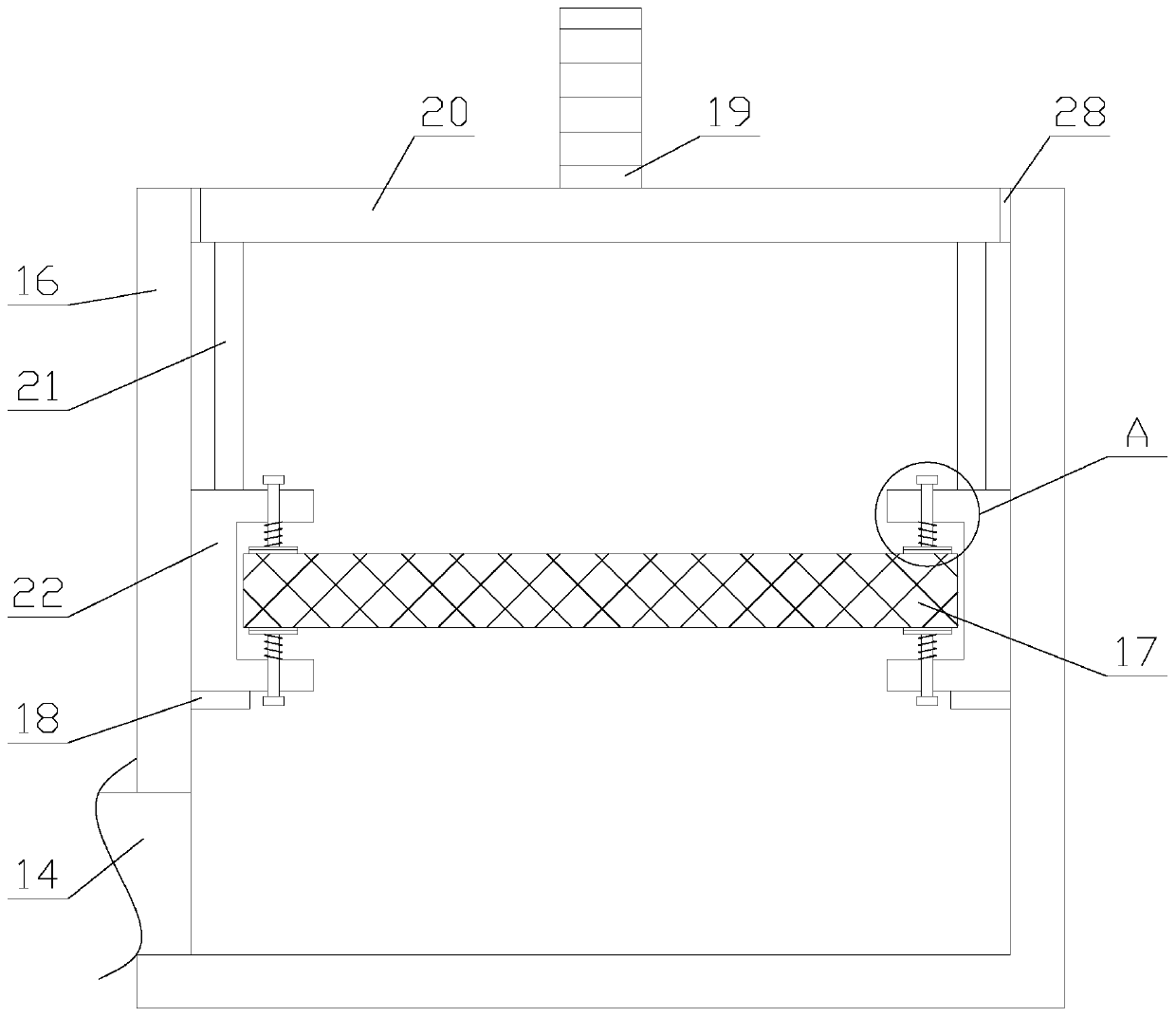

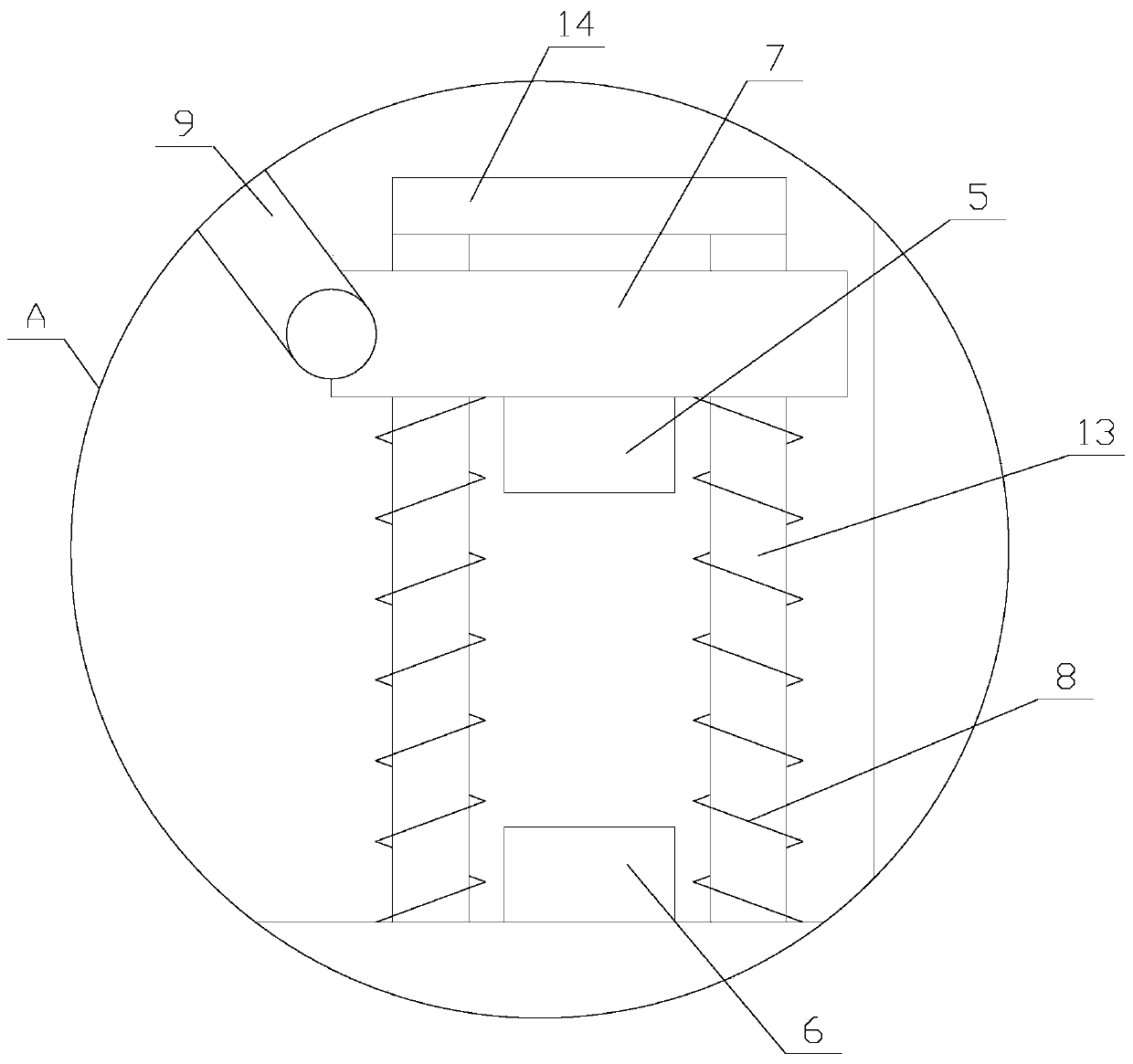

Environment-friendly dust removal device used for textile workshop

PendingCN107899320AAvoid air pollutionReduce pollutionDispersed particle filtrationTransportation and packagingBristleFixed frame

The invention discloses an environment-friendly dust removal device used for a textile workshop. The environment-friendly dust removal device used for the textile workshop comprises a fan, a box, a supporting rod, a dust removal scraper blade, a motor fixing frame, a speed reducer, a motor, a cleaning plate, bristles and a filter screen, wherein the box is fixedly connected with the vertical surface of the left side of the shell of the fan, the supporting rod is vertically and fixedly connected in the middle in the box, the filter screen is arranged at the left side of the supporting rod, theperiphery of the filter screen is fixedly connected with the box, the dust removal scraper blade is arranged at the lower end of the filter screen, the dust removal scraper blade compresses the filterscreen on the supporting rod, and the dust removal scraper blade is fixedly connected with the supporting rod, the motor fixing frame is fixedly connected with the vertical surface of the outer sideof the box in the horizontal direction, the speed reducer is fixedly connected in the middle of the vertical surface of the outer side of the motor fixing frame, and a motor is fixedly connected withthe left side of the speed reducer. The environment-friendly dust removal device used for the textile workshop is scientific and reasonable in structure, good in using effect and low in manufacturingcost, air emission quality of a fan dust removal device is greatly improved, and the environment is effectively protected.

Owner:梁永江

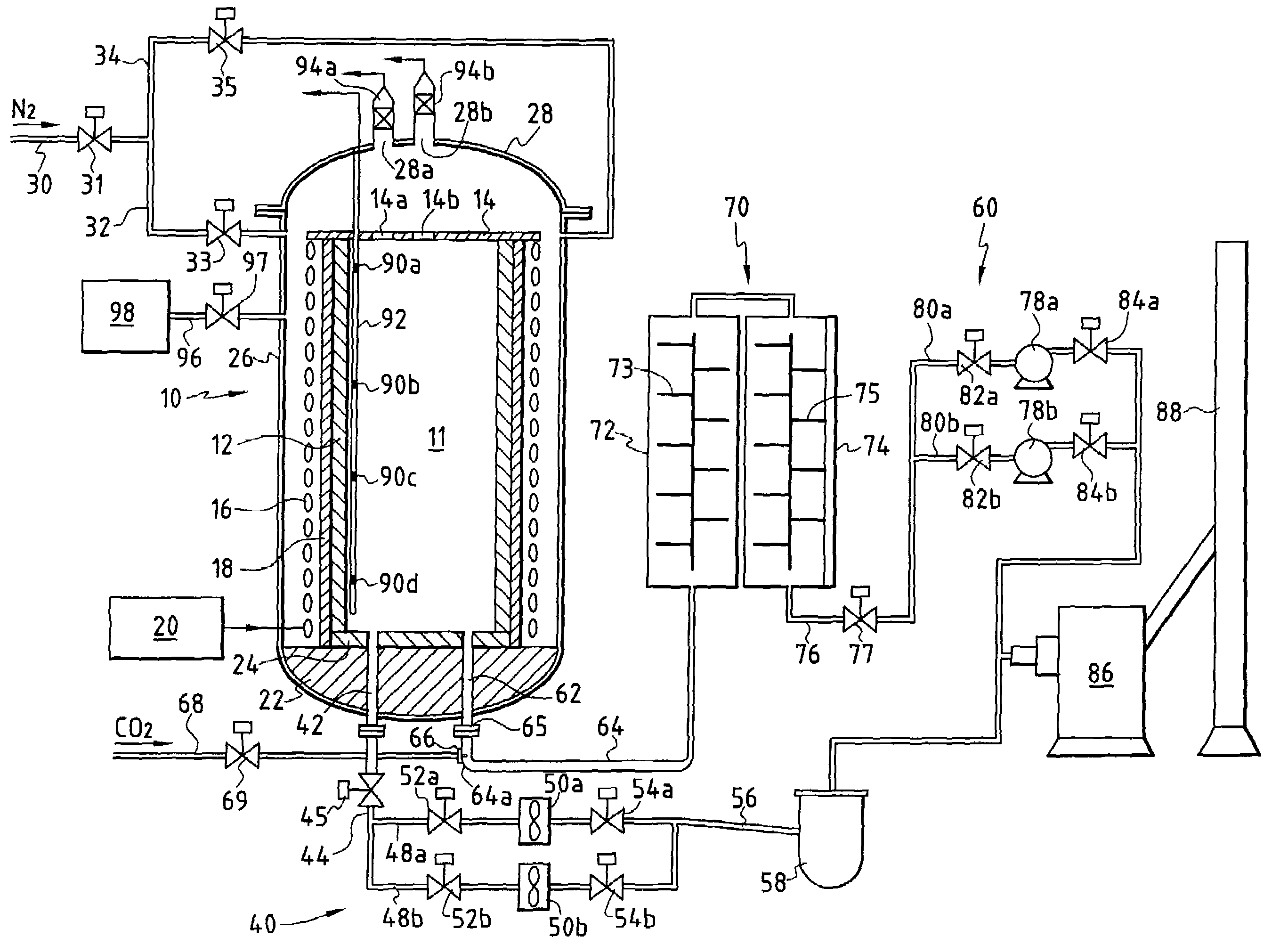

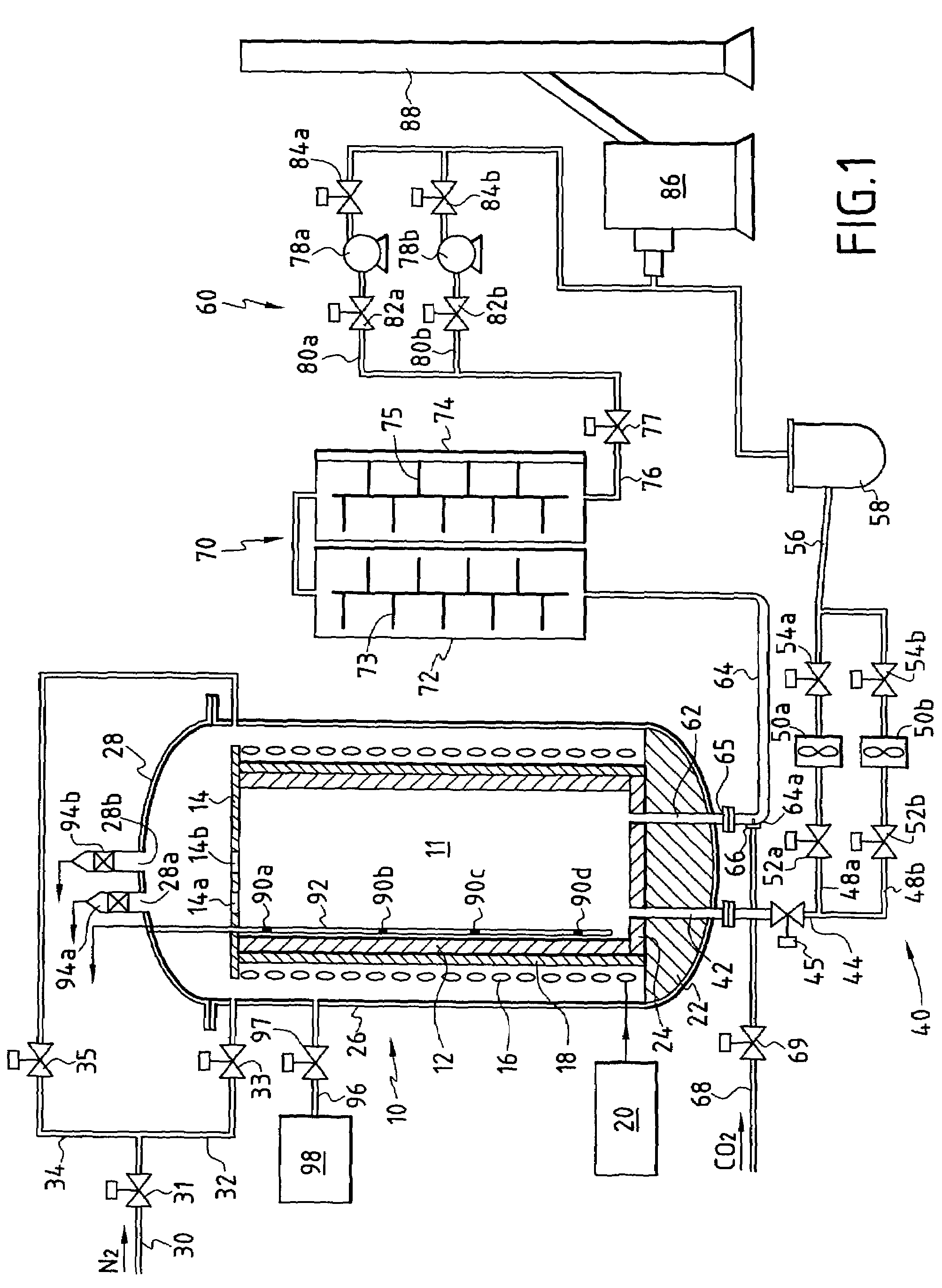

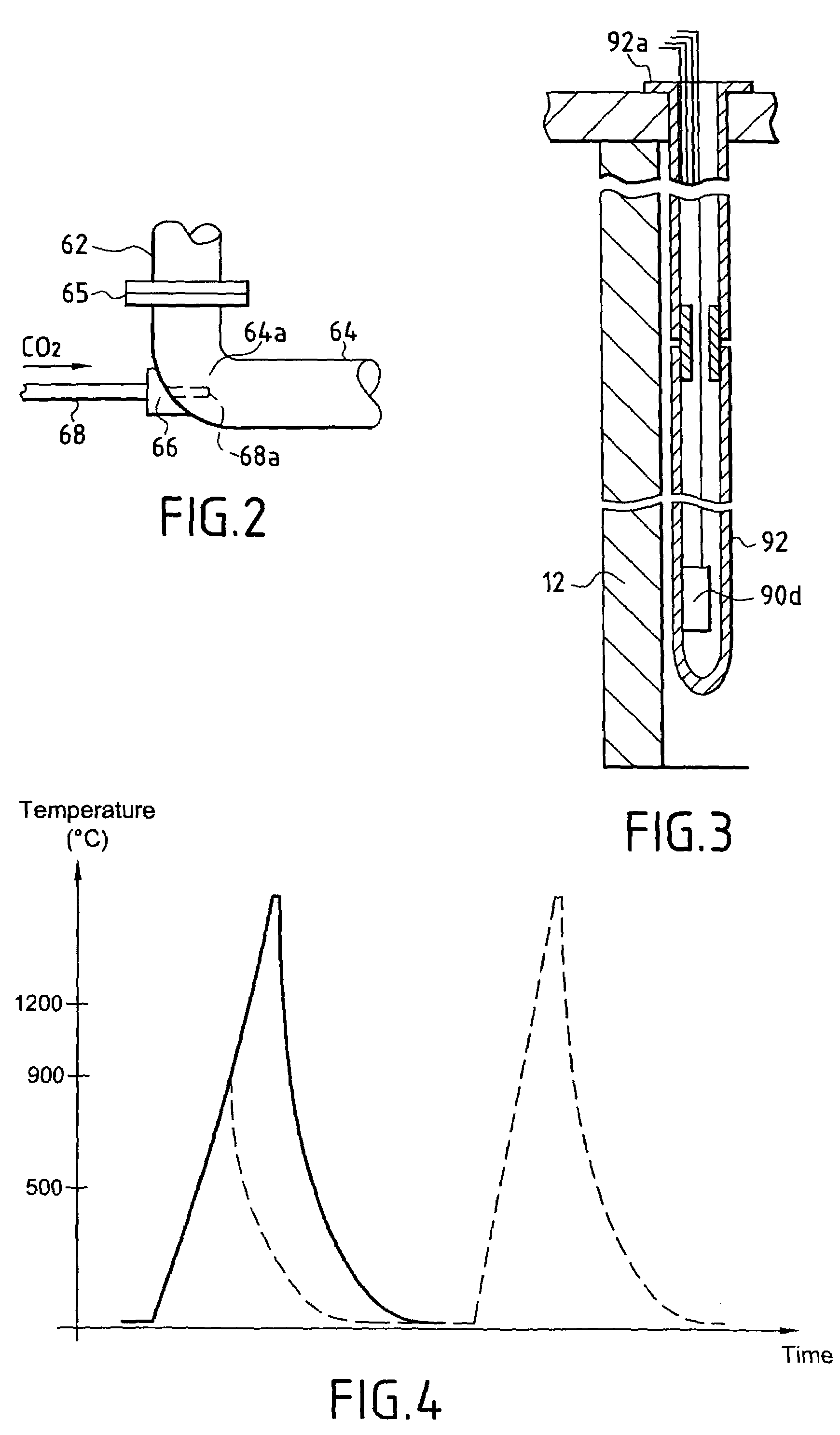

Method and an installation for obtaining carbon bodies from carbon-precursor bodies

ActiveUS7410630B2Significant in of costSignificant in of durationPigmenting treatmentFibre chemical featuresEngineeringProcess engineering

The method comprises a first stage of transforming carbon precursor material into carbon by heating, with the resulting gaseous effluent being extracted continuously, and a second stage of high temperature heat treatment under low pressure with the resulting gaseous effluent being extracted continuously. The first and second stages are performed one after the other in the same oven by proceeding, after the end of the first stage, with the steps of switching the gaseous effluent outlet from the oven to interrupt a connection with a first extractor device and to establish a connection with a second extractor device, of adjusting the pressure inside the oven to the value required for the second stage, and of adjusting the heating temperature of the oven starting from the temperature reached at the end of the first stage. It is also possible to switch temperature measurement from at least one first sensor to at least one second sensor different from the first. During the second stage, any alkali metal such as sodium contained in sublimed form in the gaseous effluent coming from the oven can be neutralized, e.g. by injecting CO2 into an effluent exhaust pipe.

Owner:MESSIER BUGATTI INC +1

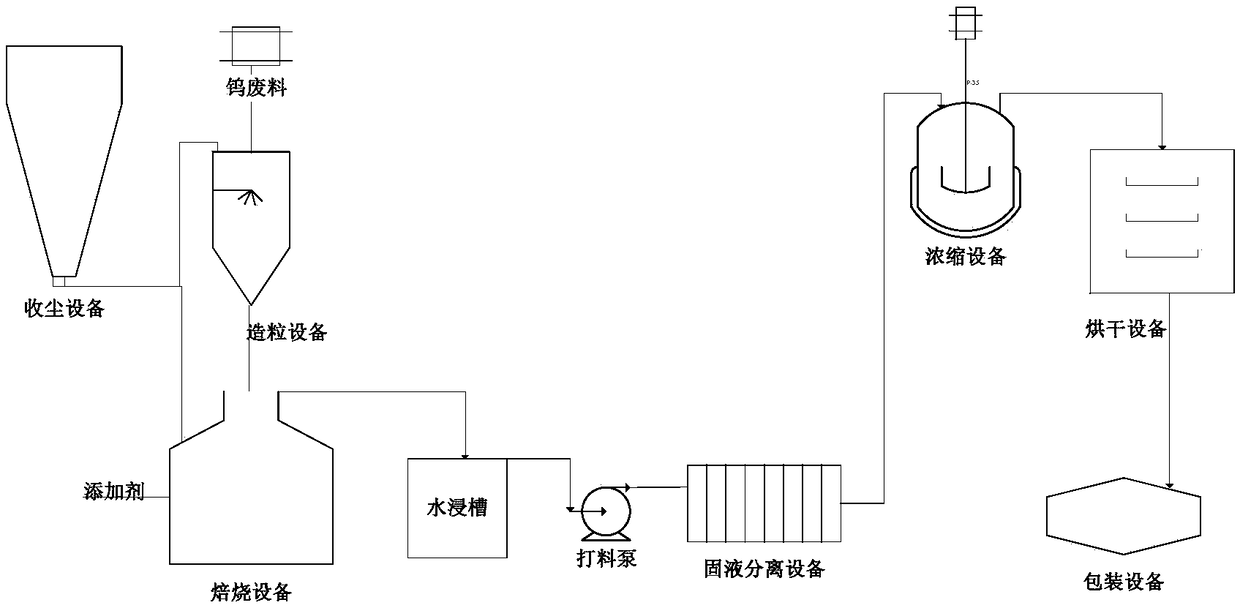

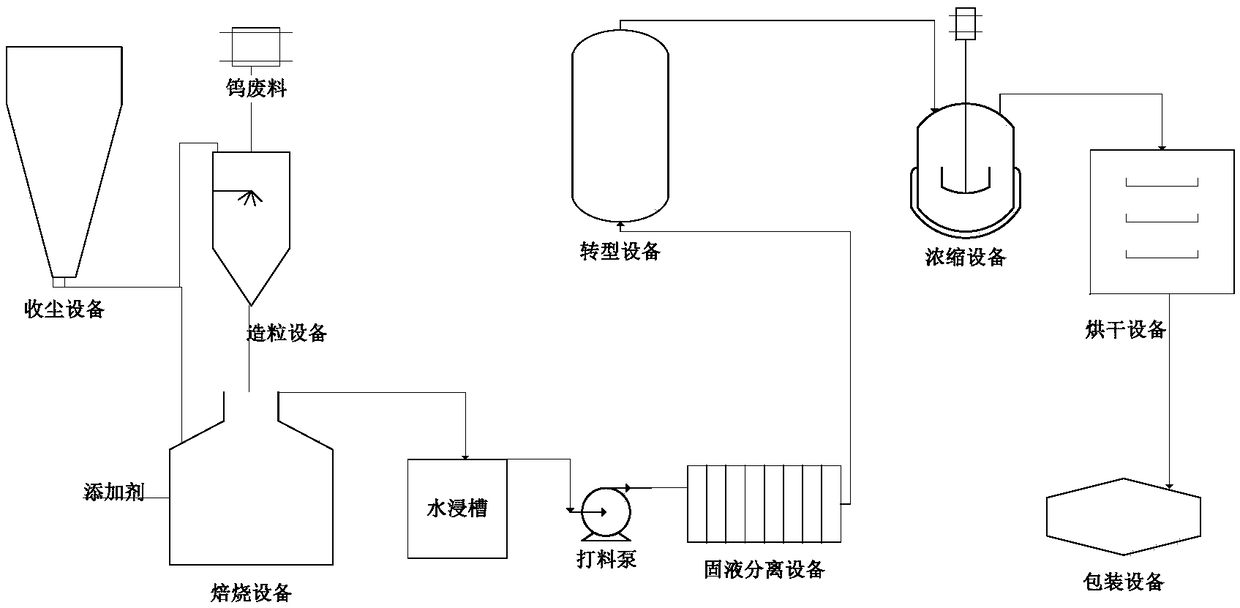

Tungsten-containing waste treating method and device thereof

The invention relates to a tungsten-containing waste treating method and device thereof. The method comprises the following steps: pelletizing tungsten-containing wastes to obtain granular tungsten-containing wastes; roasting the granular tungsten-containing wastes obtained in step 1 to obtain a roasted material; adding an additive into the hot roasted material obtained in step 2; and reacting through the afterheat after roasting to obtain a melt; and dipping the melt obtained in step 3 into water to obtain a solution and a solid. The device comprises a pelletizing device, a roasting device, adust collecting device, a water dipping tank, a conveying pump, a solid-liquid separation device, a concentrating device, a drying device and a packing device. The method is short in process and highin recovering rate; special limitation to the content of impurity elements in the tungsten-containing wastes is avoided; the raw material adaptability is high; and the method is a green and environmentally-friendly treatment method.

Owner:XIAMEN TUNGSTEN +1

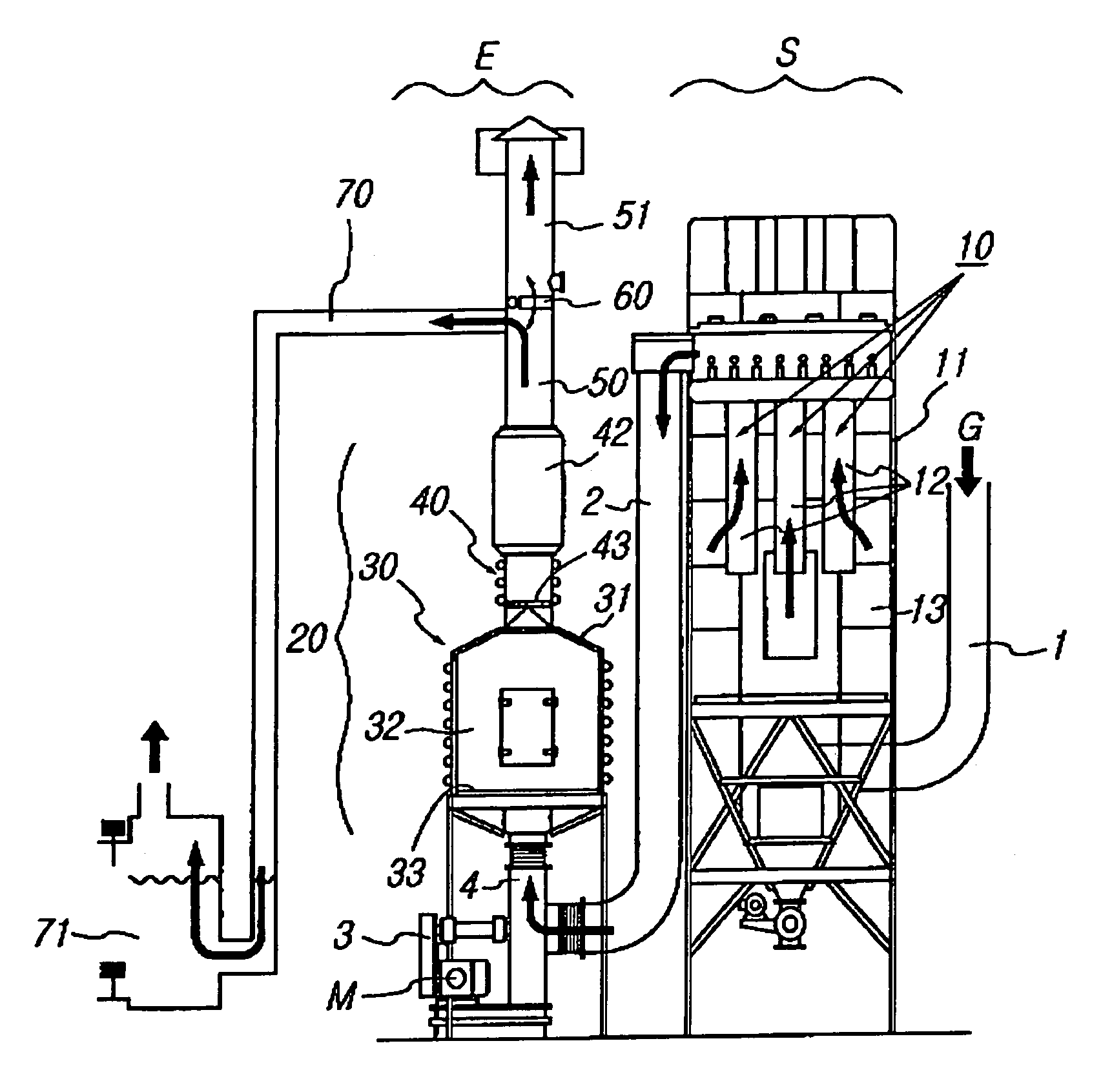

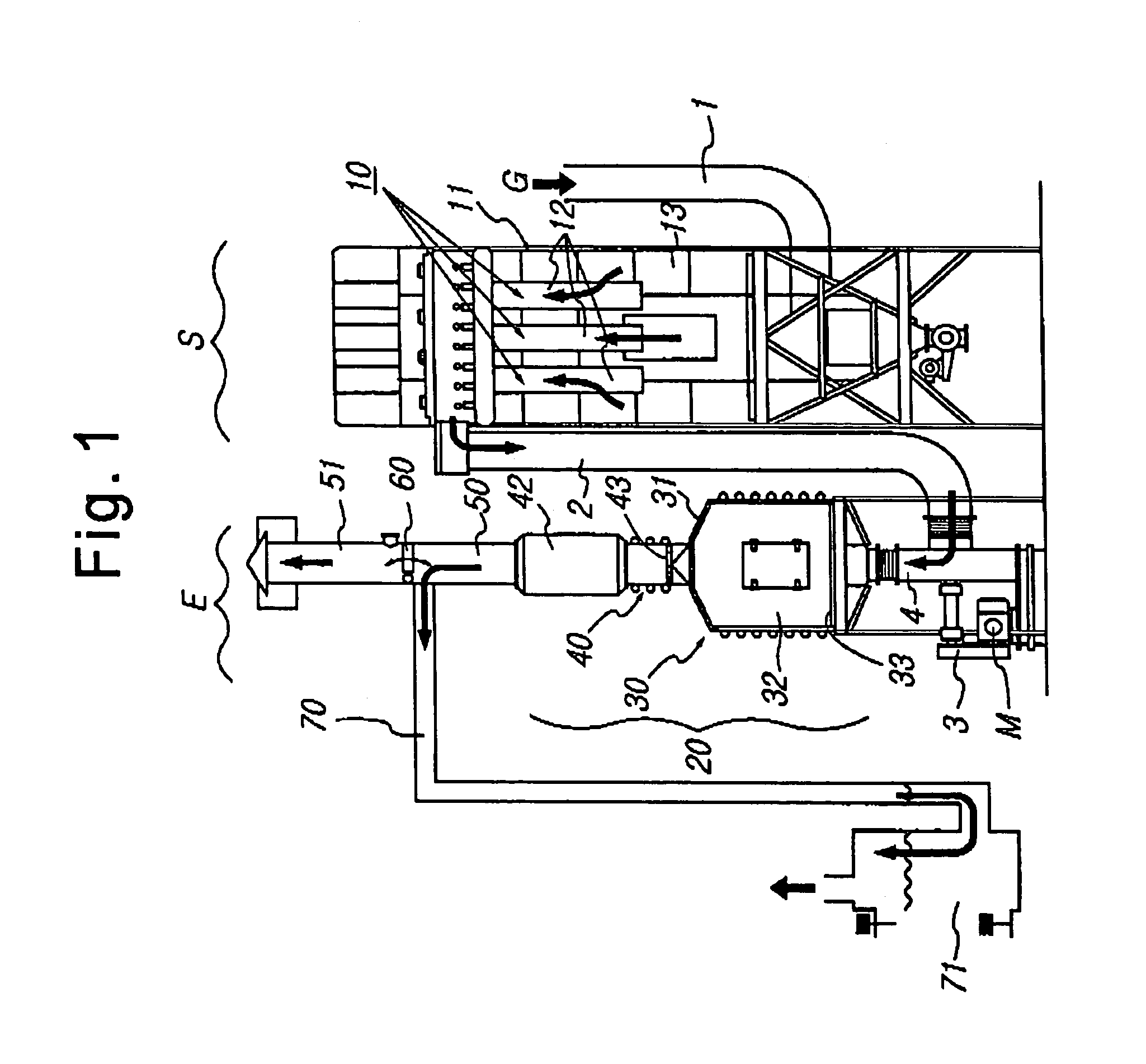

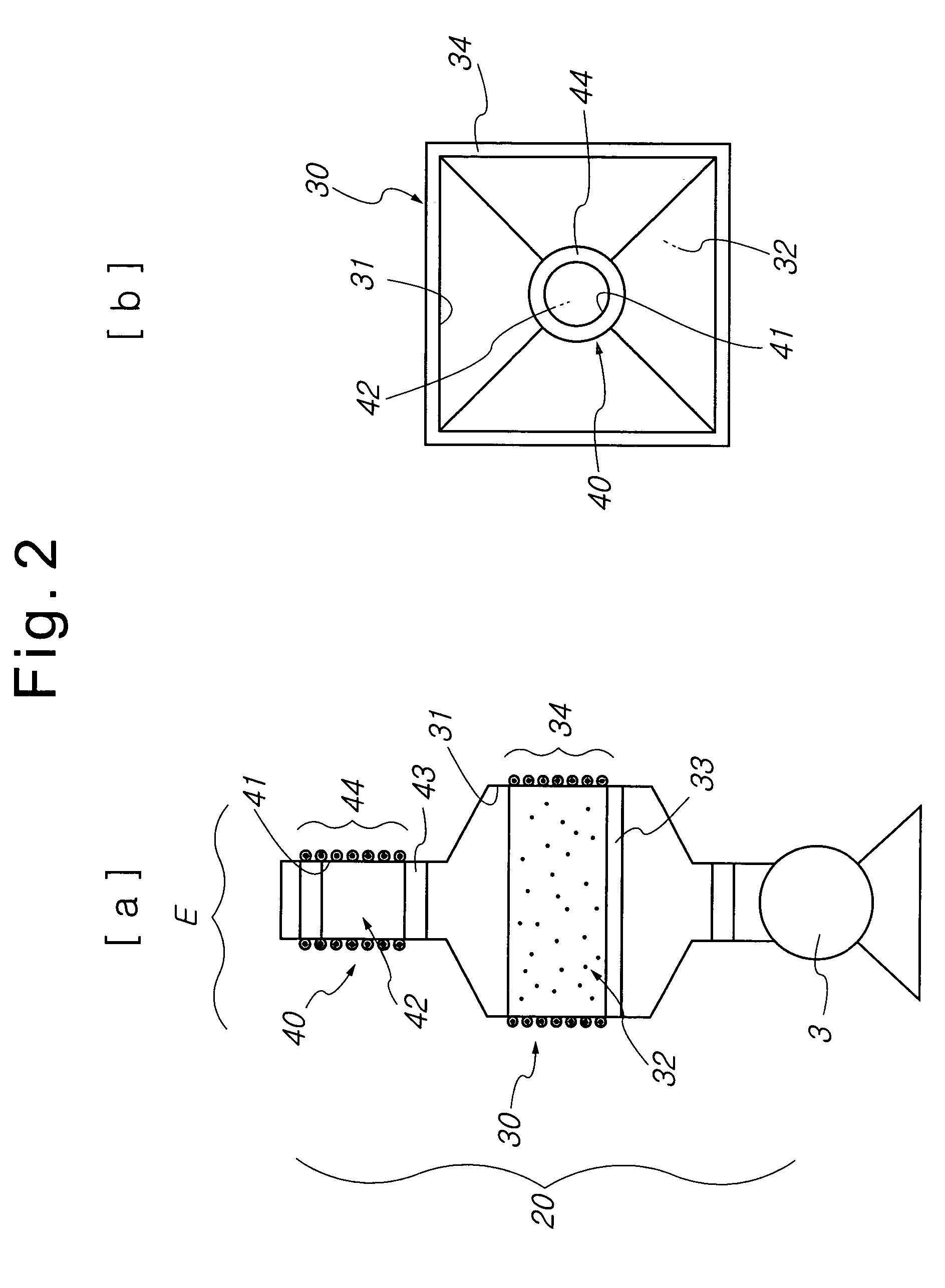

System for simultaneously removing dust and volatile toxic organic compounds

InactiveUS6962621B2Remove obstaclesImprove working environmentCombination devicesGas treatmentEngineeringOrganic compound

Disclosed herein is a system for simultaneously removing dust and volatile toxic organic compounds. The system comprises a dust collecting unit disposed between an inlet duct and an outlet duct for removing dust, an organic compound removing unit disposed between the inlet duct and the outlet duct for removing volatile toxic organic compounds, and an inlet blower disposed between the dust collecting unit and the organic compound removing unit. The dust collecting unit is made up of a bag filter, which comprises a housing formed in the shape of a box and connected to the inlet duct, a plurality of filtering members, such as cloth or felt, arranged in the housing, and dust collecting layers defined between the housing and the filtering members. The organic compound removing unit comprises an absorbing apparatus for absorbing the volatile toxic organic compounds, and regenerating heaters attached on the outer circumference of the absorbing apparatus.

Owner:RES COOPERATION FOUND OF YEUNGNAM UNIV

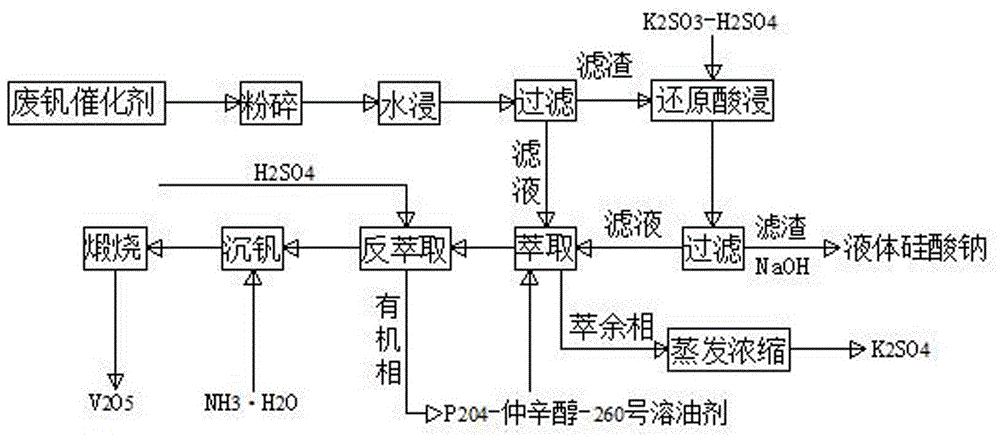

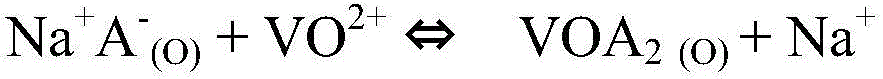

Comprehensive recovery and utilization method for waste vanadium catalyst

ActiveCN107177737AHigh purityQuality improvementAlkali metal silicatesChemical recyclingEvaporationRaffinate

The invention discloses a comprehensive recovery and utilization method for a waste vanadium catalyst. The method comprises the steps that water leaching and reductive acid leaching are sequentially conducted on the waste vanadium catalyst; silicon is separated and recycled by being prepared into sodium silicate through alkaline leaching in a residue leaching mode; single-stage extraction is conducted on leachate through saponification P204, vanadium and potassium are extracted and separated through vanadium extraction technologies of tail liquid concentration and separate re-extraction, potassium is separated by preparing potassium sulphate from raffinate through evaporation and concentration, and vanadium is recycled by preparing vanadium pentoxide from an extraction phase through the processes of back extraction, vanadium precipitation, calcination and the like. Through the extremely high selection characteristic of the saponification P204, not only are the extraction capacity, the utilization rate and the vanadium extraction rate increased, but also influences of iron, phosphorus and arsenic on V2O5 purity are effectively avoided, vanadium precipitation can be directly conducted after back extraction, a high-purity vanadium product is prepared, and the phenomenon that chlorine is released in the oxidization process to pollute the environment is avoided. The method has the advantages that the extraction stages and part of the processes are reduced, the technological process is simplified, the cost is reduced, the economic benefit is increased, and the double effects of making the best use of everything and protecting the environment are achieved.

Owner:KAIFENG UNIV

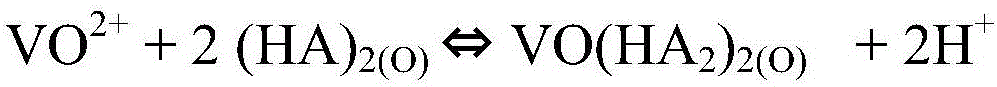

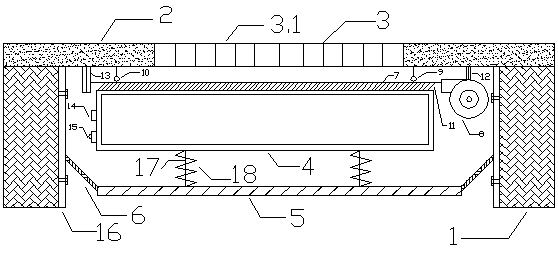

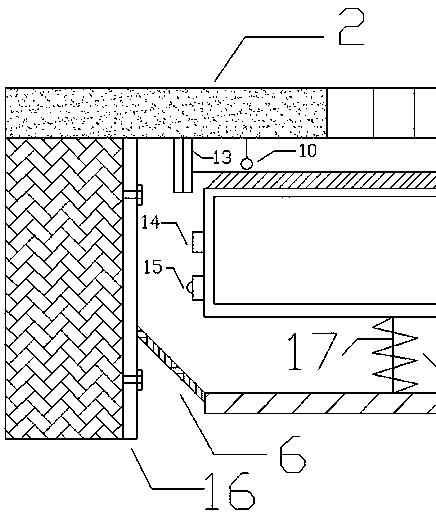

Expansion joint dust collecting device and construction method thereof

ActiveCN108487055AAvoid air pollutionAvoid safety hazardsFouling preventionBridge structural detailsExpansion jointBridge deck

The invention relates to an expansion joint dust collecting device and a construction method thereof. The expansion joint dust collecting device comprises a bridge body, a bridge deck and an expansionjoint cover plate and is characterized in that a dust collecting box is arranged below the expansion joint cover plate, a dust receiving plate is arranged at the top of the dust collecting box, and tiny gravels, dust and other sundries fall downwardly through the gaps of the expansion joint cover plate onto the dust receiving plate and are guided into the dust collecting box through the dust receiving plate; when the dust quantity in the dust collecting box reaches a preset value, an alarm lamp flickers to give out an alarm to remind maintenance staff to clean the dust collecting box. The expansion joint dust collecting device has the advantages that by arranging the dust collecting box below the expansion joint cover plate, the fallen tiny gravels, dust and other sundries can be completely collected in the dust collecting box, atmospheric pollution is avoided, risks caused by the fact that the tiny gravels, dust and other sundries fall off the bridge deck, and bridge safety is increased.

Owner:安徽谦源项目管理有限公司

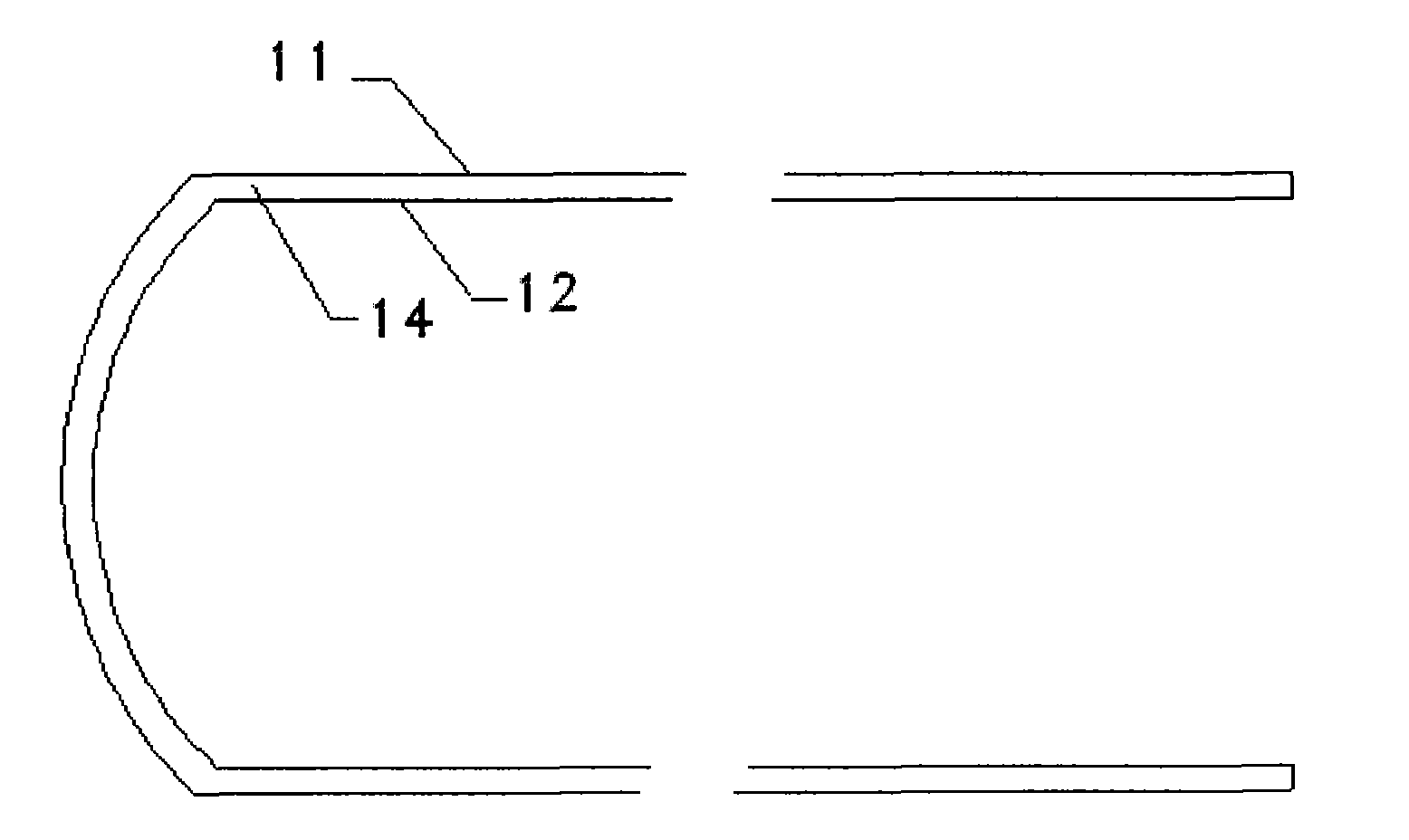

Solar phase-change heat collecting and storing tube

InactiveCN101846398AImprove securityOverheating will notSolar heating energySolar heat devicesEngineeringHigh pressure

The invention relates to a solar phase-change heat collecting and storing tube, which comprises a solar vacuum heat collecting tube, a heat exchange tube, a phase-change material, a phase-change heat accumulator and a draft tube. The phase-change heat accumulator is arranged in the solar vacuum heat collecting tube; the heat exchange tube is embedded in the phase-change heat accumulator, and the upper part of the heat exchange tube is slidably connected with the phase-change heat accumulator; the phase-change material is filled between the phase-change heat accumulator and the heat exchange tube; and the draft tube is inserted into the heat exchange tube. In the solar phase-change heat collecting and storing tube, the fastening end cover of the phase-change heat accumulator is provided with sealing grease, so the heat exchange tube is slidably connected with the phase-change heat accumulator; when the phase-change material is overheated, high pressure in the tube body of the phase-change heat accumulator can push the heat exchange tube to move outwards to release high pressure so as to complete overheated unloading, so the safety performance when the heat collecting tube is overheated is greatly improved and the phase-change material is ensured not to be overheated.

Owner:皇明太阳能(上海)有限公司

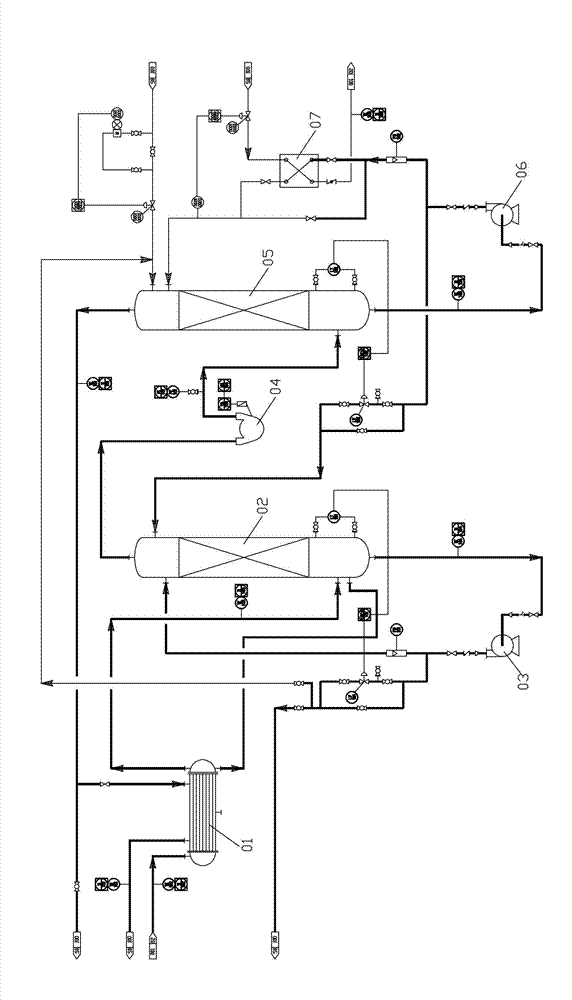

High-efficiency spraying solvent recovery system and process thereof

ActiveCN103084043AAvoid air pollutionImprove environmental benefitsDispersed particle separationChemical industrySolvent

The invention discloses a high-efficiency spraying solvent recovery system and a process thereof. An absorption tower model of the chemical industry is adopted to absorb an NMP solvent in gas by water. The NMP solvent-containing gas discharged by a coating or drying device can achieve solvent recycling through a gas-gas heat exchanger and a secondary cooling absorption tower of the recovery system. By means of complete recycling of the solvent, the circumstance of air pollution caused by redundant exhaust gas emission can be avoided really, so that the benefits of environmental protection can be further improved effectively. The system and process provided in the invention have the notable advantages of: 1. low operation energy consumption, less than 23kw.h of power consumption for treating every ten thousand standard cubic gas; 2. low NMP content in tail gas, about less than 30ppm; 3. no reflux of liquid and no pipeline leak; 4. less running equipment and reduced maintenance cost; and 5. full utilization of thermal energy in hot wind.

Owner:福建玮士迈科技有限公司

Anti-blocking screening device with dedusting function and for mineral separation

ActiveCN110252649AImprove convenienceAvoid affecting the screening effectSievingDispersed particle filtrationScreening effectEngineering

The invention relates to an anti-blocking screening device with a dedusting function and for mineral separation. The anti-blocking screening device with the dedusting function and for the mineral separation comprises a main body, a screen barrel and two supports, and further comprises two dust removal mechanisms and two vibration mechanisms, wherein each vibration mechanism comprises a cam, a connection rod, a moving rod, a moving plate, a limiting ring, a motor, a first spring and a fixed rod, and each dust removal mechanism comprises a connection pipe, a dust removal box, a filter net, an air fan, a seal cover, a handle, two fixed plates and two replacement assemblies, and each replacement assembly comprises a fixed block, a support rod and two replacement units. The anti-blocking screening device with the dedusting function and for the mineral separation can perform up-down shaking operation on mineral aggregate in the screen barrel, prevents the mineral aggregate from blocking the screen barrel so as to prevent the mineral aggregate from influencing screening effect when the screen barrel performs screening work, can perform impurity removal and purification work on dust in the main body through the dust removal mechanisms, and prevents the dust from scattering in all directions so as to prevent the dust from influencing surrounding air environment.

Owner:肇庆市华楠环保建材有限公司

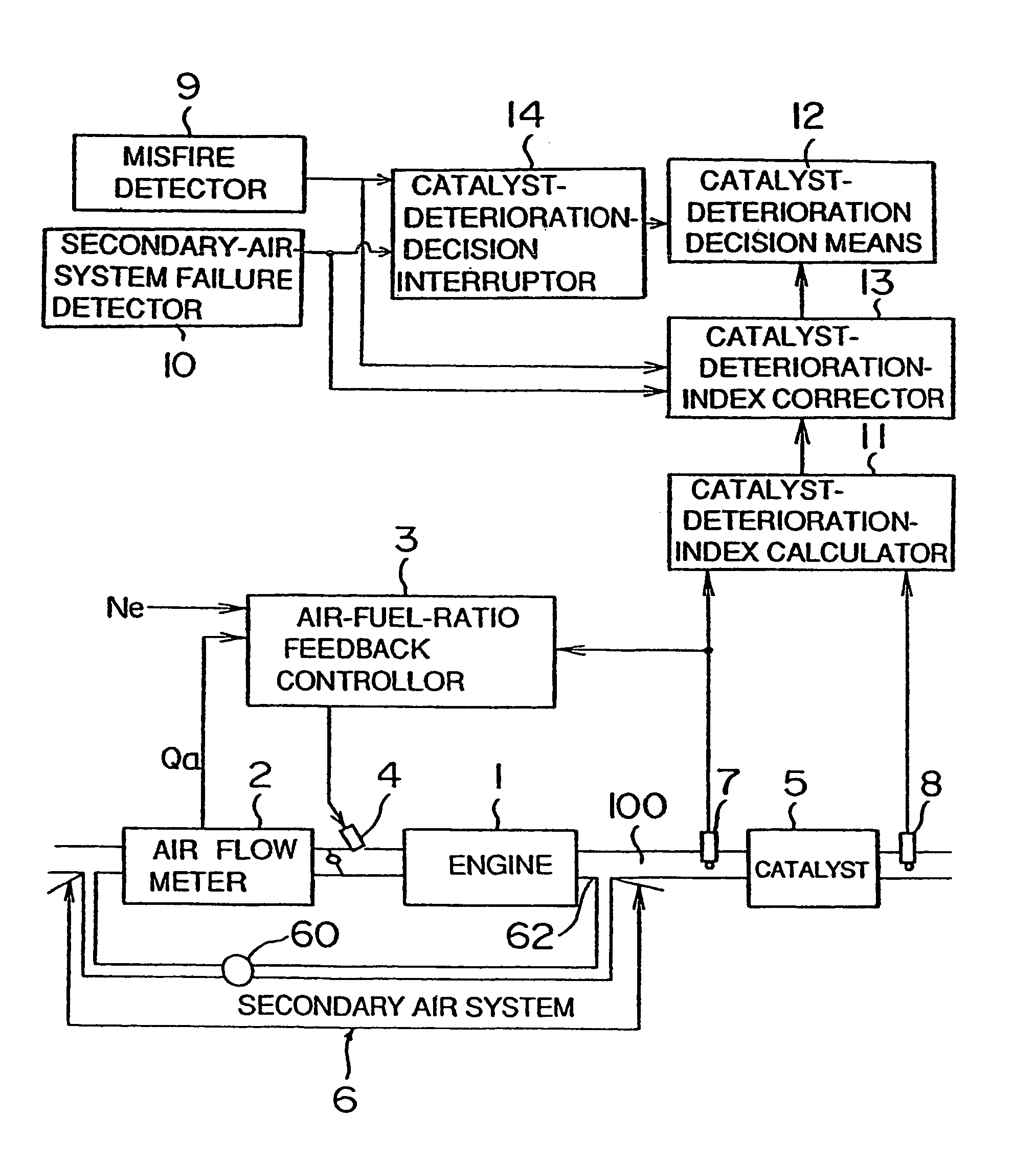

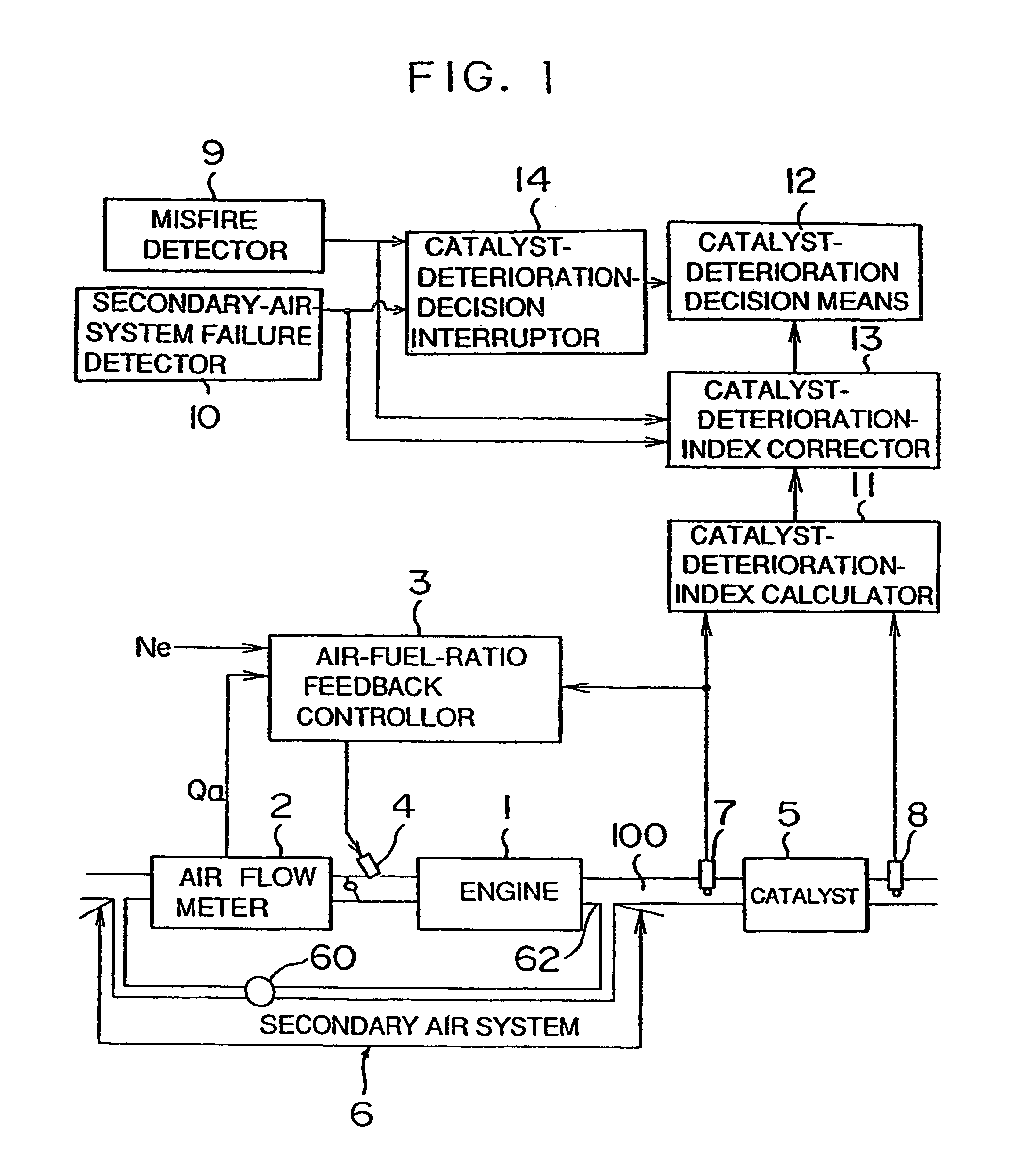

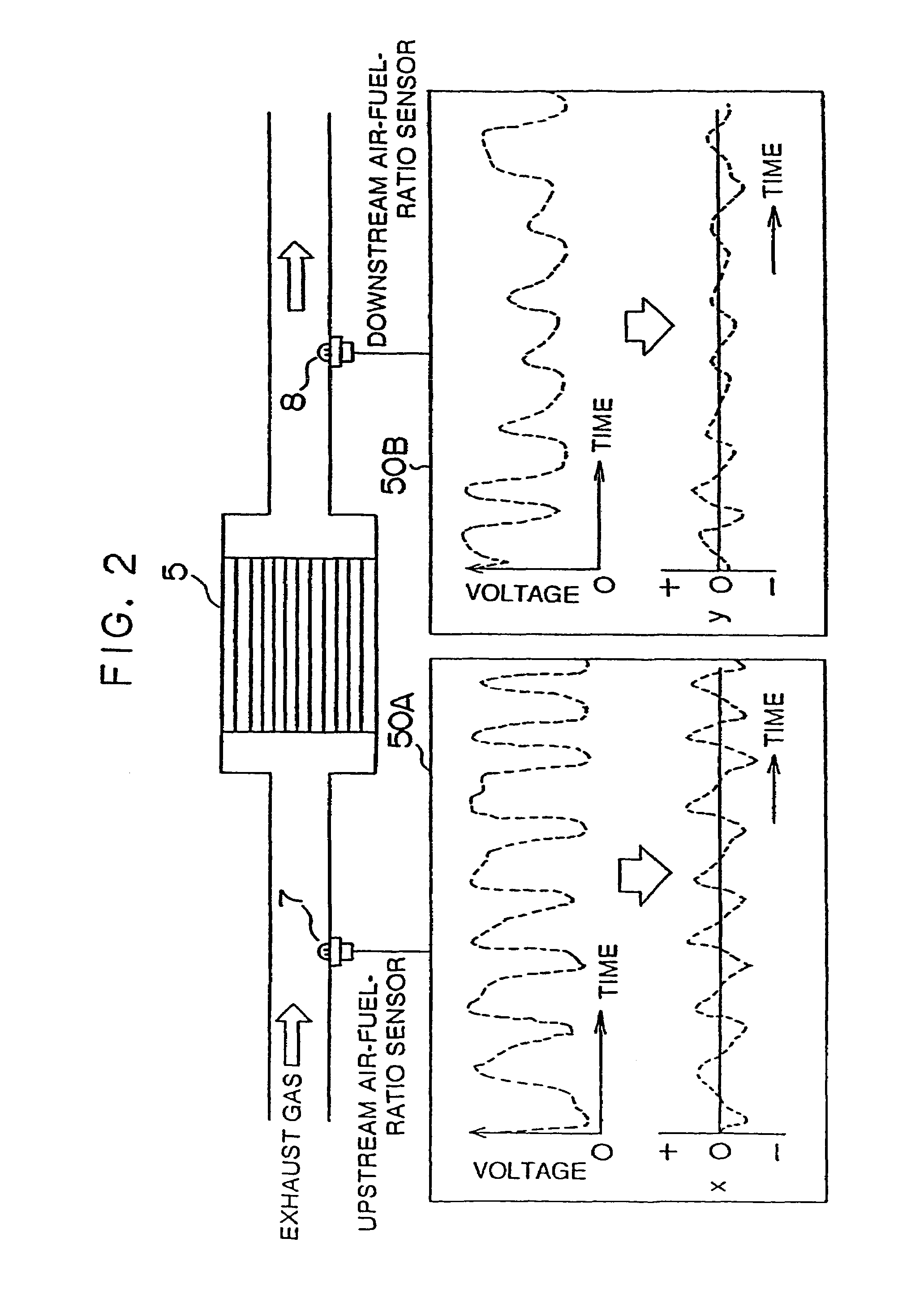

Diagnostic equipment for an exhaust gas cleaning apparatus

InactiveUS7117664B2Wasted expenseAvoid air pollutionElectrical controlInternal combustion piston enginesExhaust fumesSystem failure

A diagnostic equipment for an exhaust gas cleaning apparatus installed for an engine, comprising a misfire detector which detects the misfire of the engine, and a secondary-air-system failure detector which detects the failure of a secondary air system. An index corrector corrects a deterioration index calculated by a deterioration-index calculator, in accordance with the detected result of the detector. A deterioration decision unit decides if the diagnostic equipment has failed, by the use of the corrected deterioration index. In a case where the extent of the misfire or the like is severe, a decision interrupter interrupts the decision of the deterioration decision unit. Thus, even when the misfire of the engine or the failure of the secondary air system has occurred, the detection of the deterioration of a catalyst does not err. It is therefore avoided to erroneously replace the catalyst which has not deteriorated yet, or to run the engine in spite of the deterioration of the catalyst.

Owner:HITACHI LTD

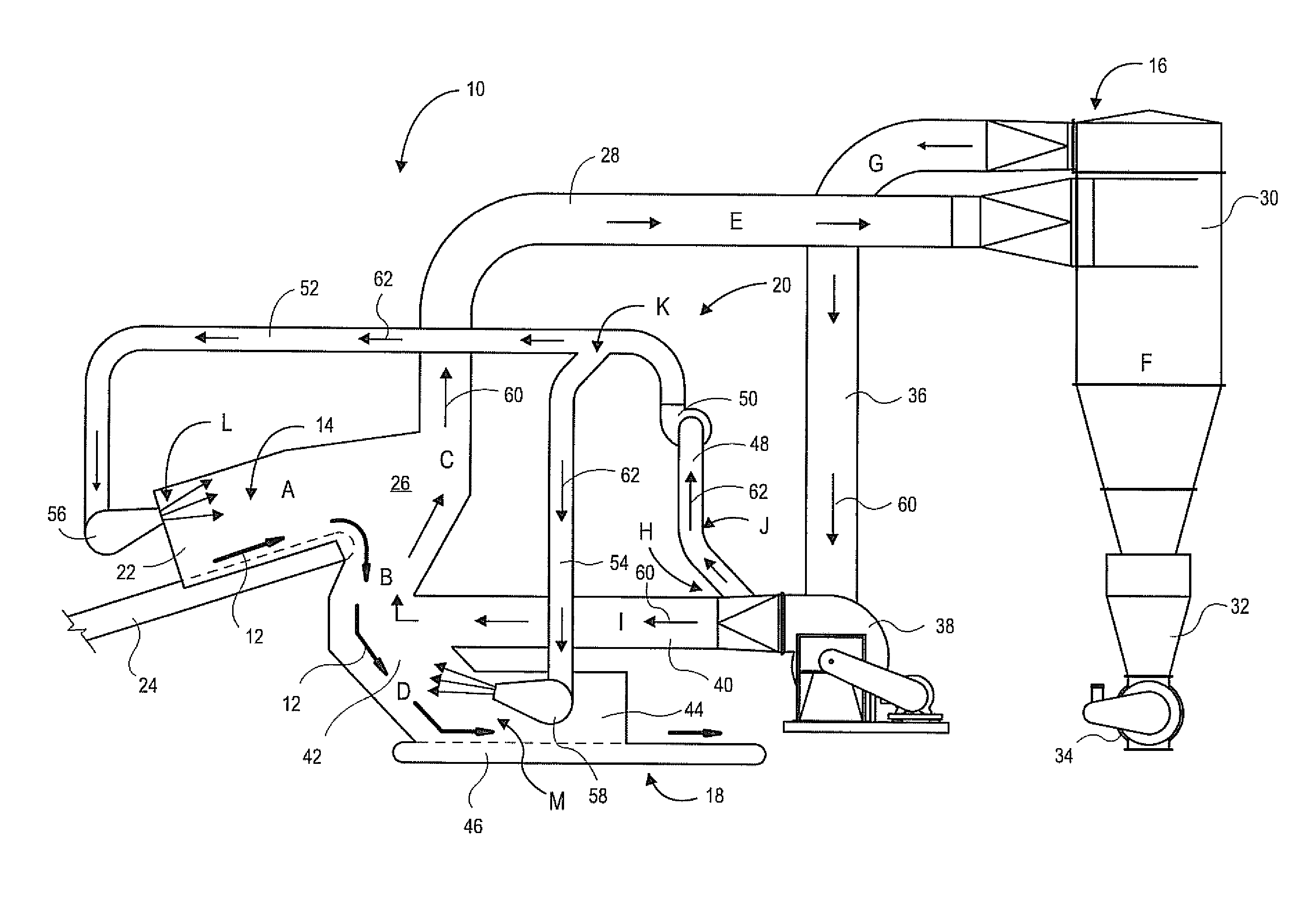

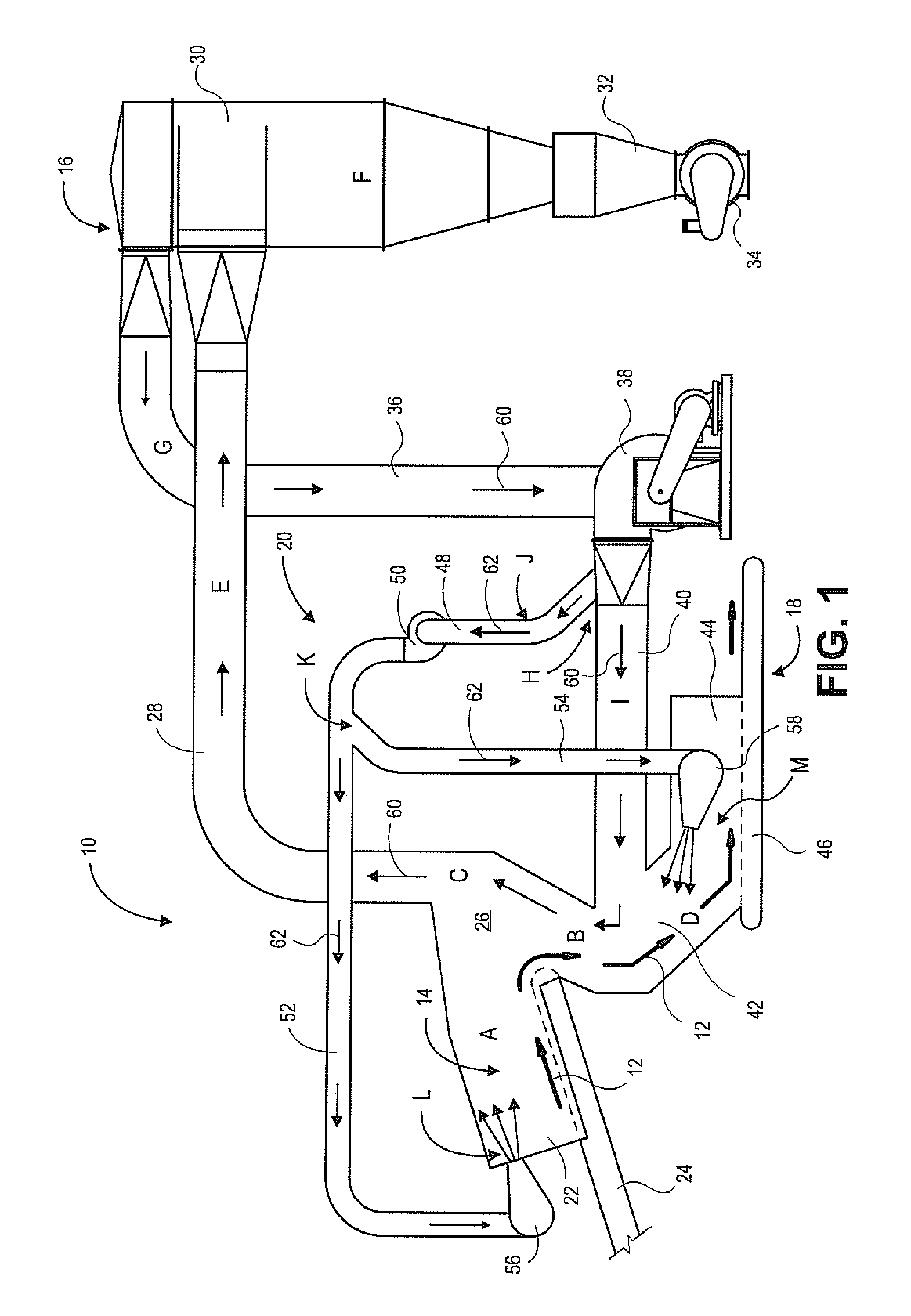

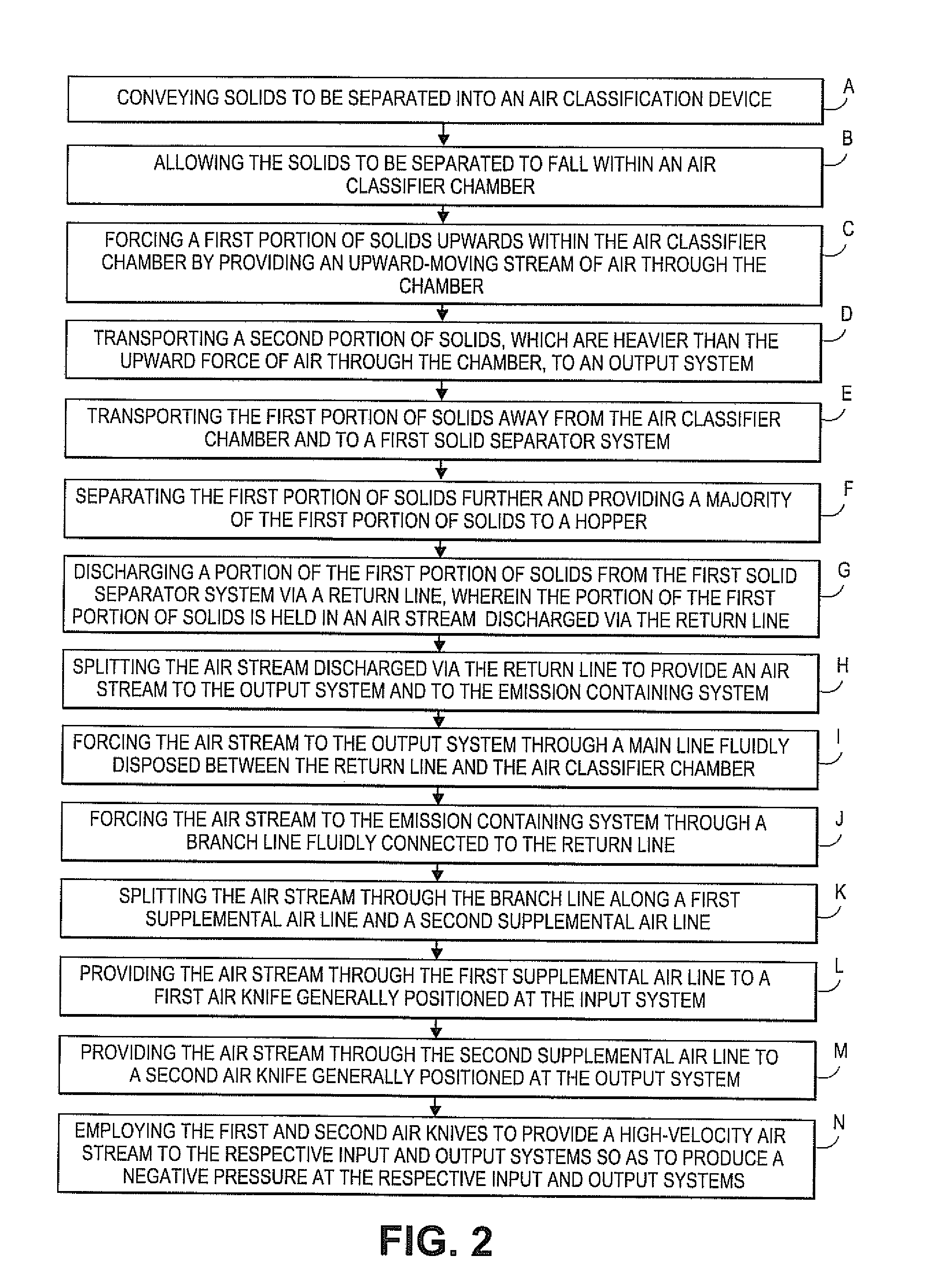

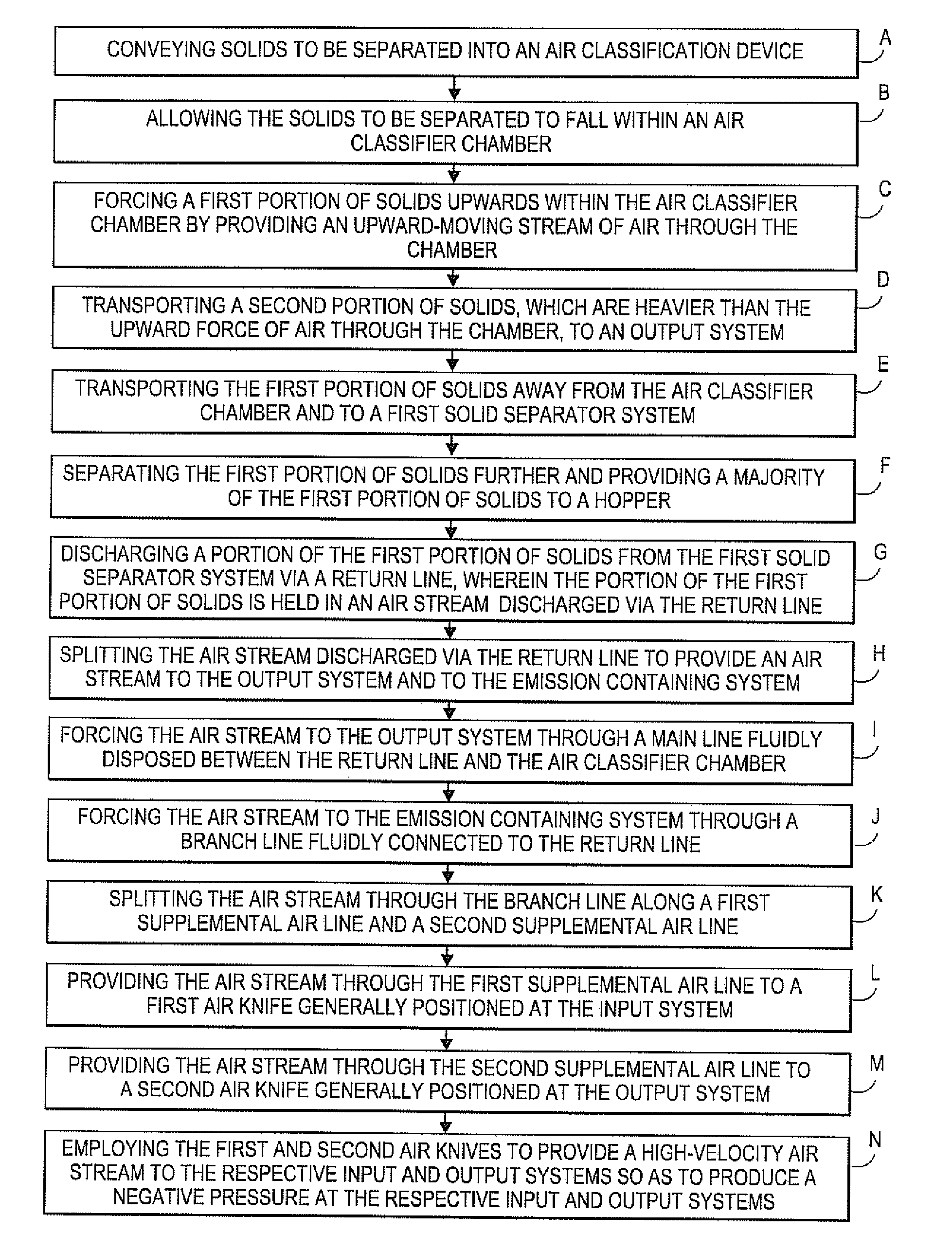

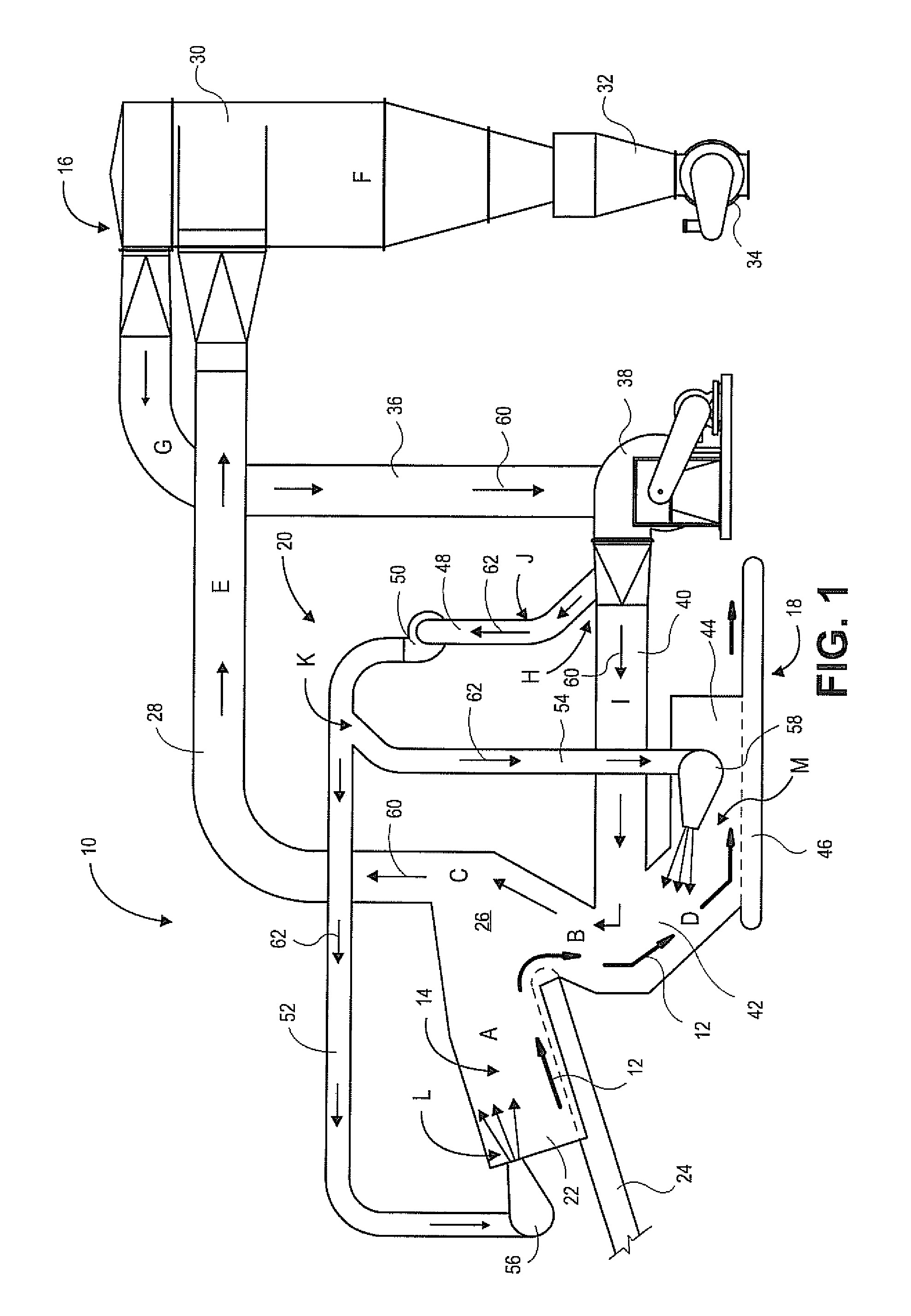

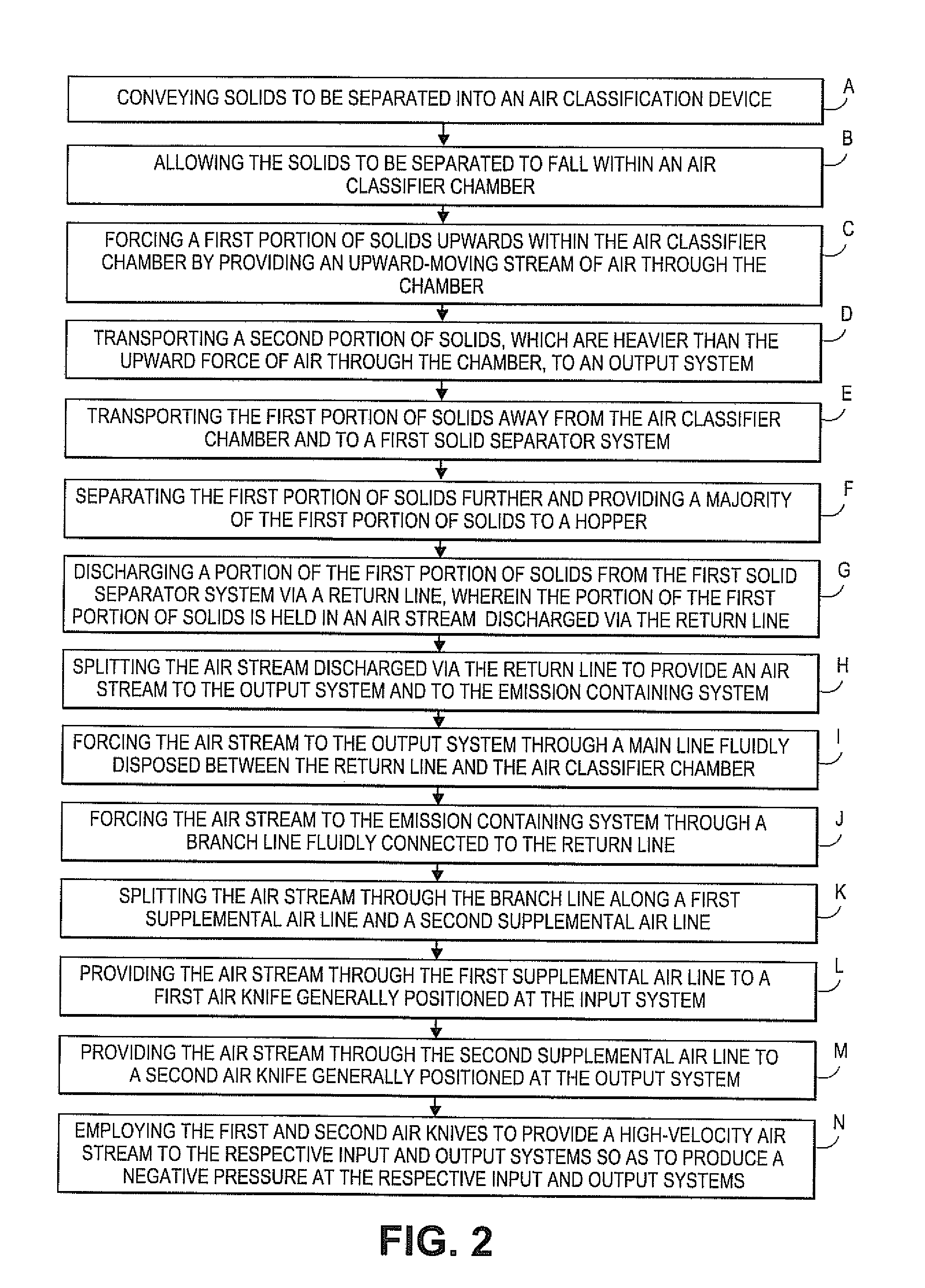

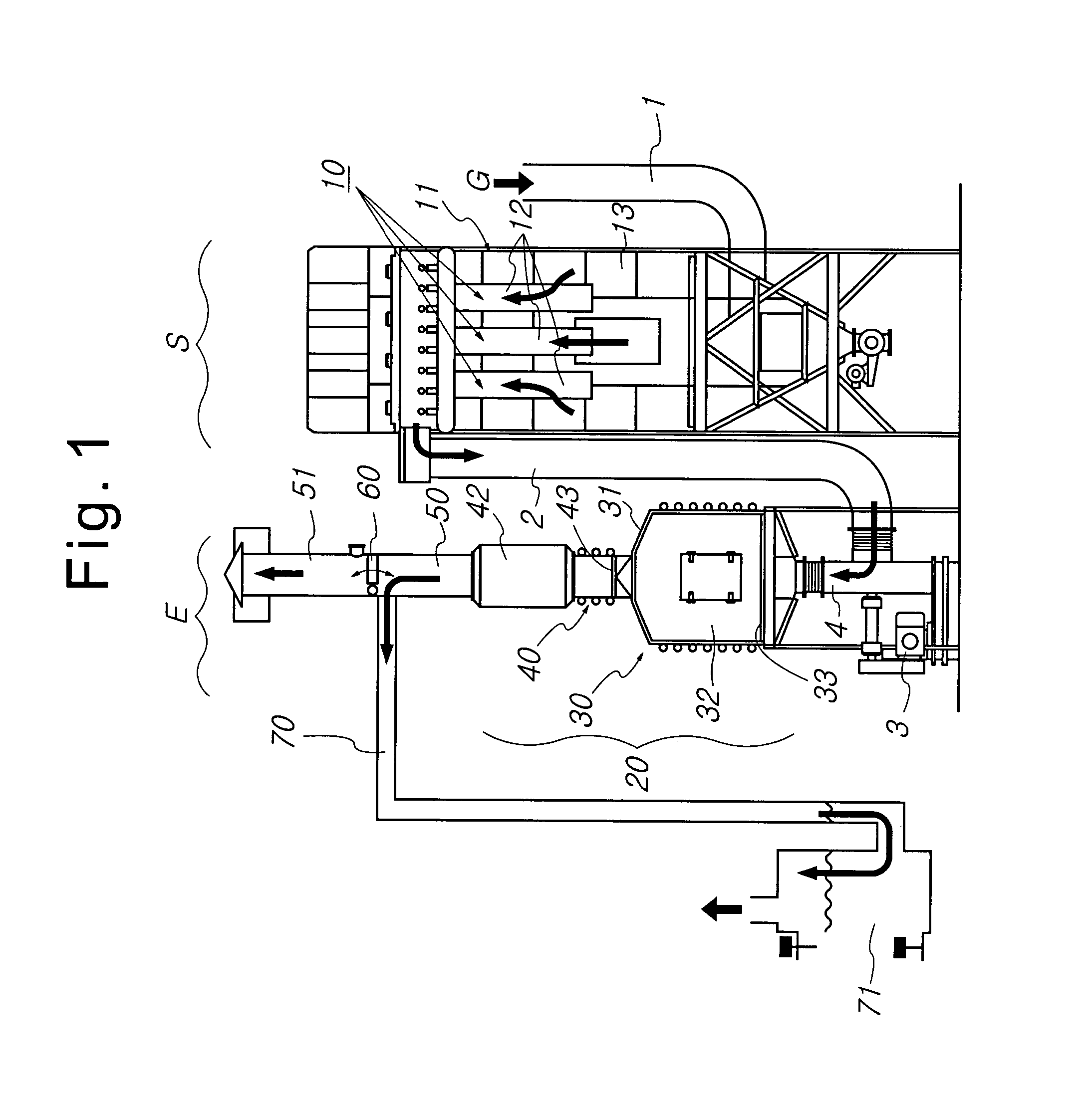

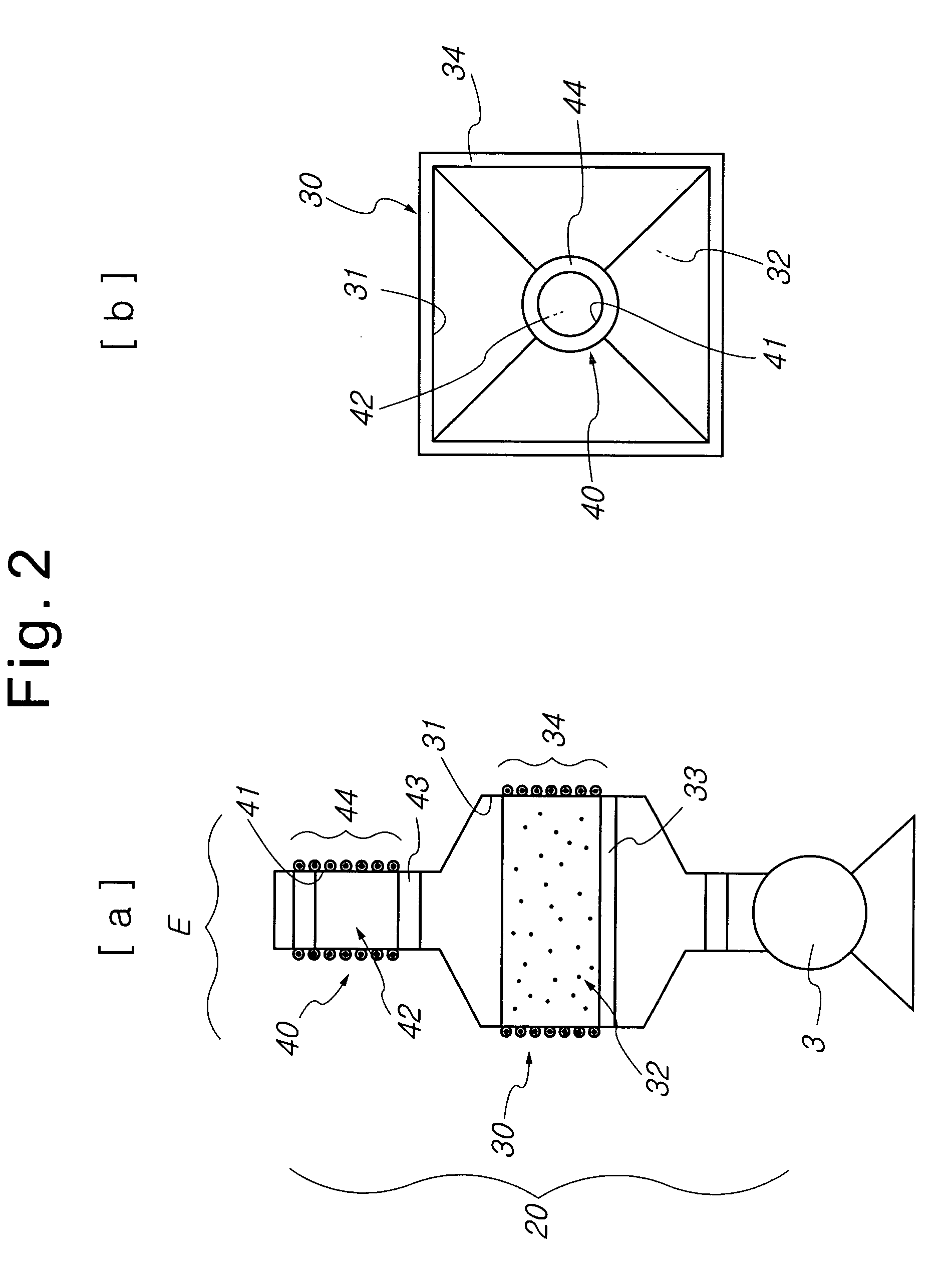

System and method for eliminating emissions from an air classification device

InactiveUS8016117B2Eliminating undesired emissionEliminate emissionsGas current separationSortingEngineeringAtmospheric pressure

An air classification device for separation of solids comprising an input system, a first solid separator system, an output system, and an emission containing system. The emission containing system employs supplemental air lines, a supplemental air source, and high-velocity air knives to create negative air pressure at any opening in the device. The negative air pressure induces air to move into the device and prevents polluted air from escaping the device at the openings.

Owner:SCHENCK PROCESS LLC

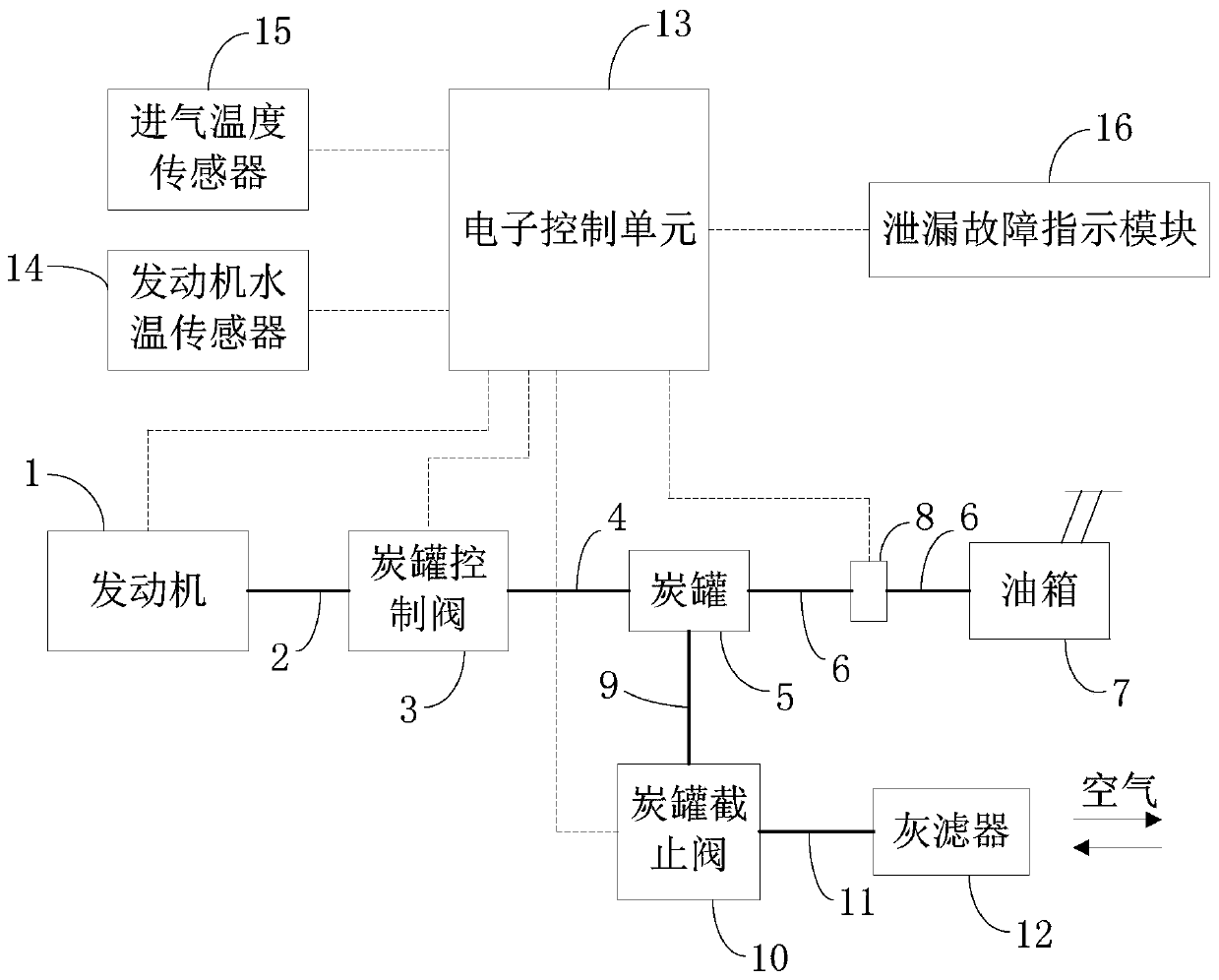

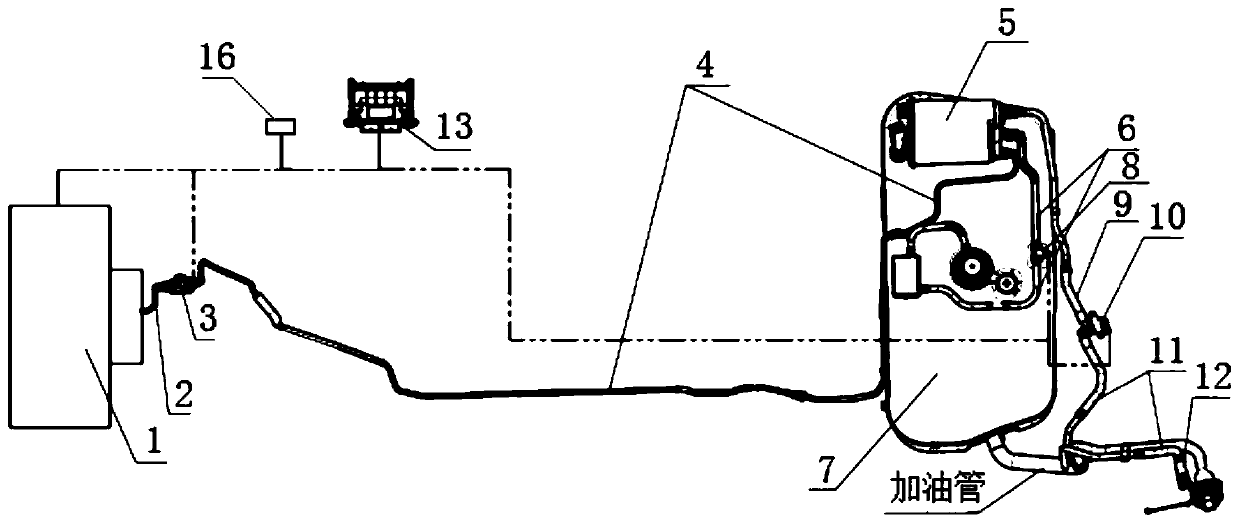

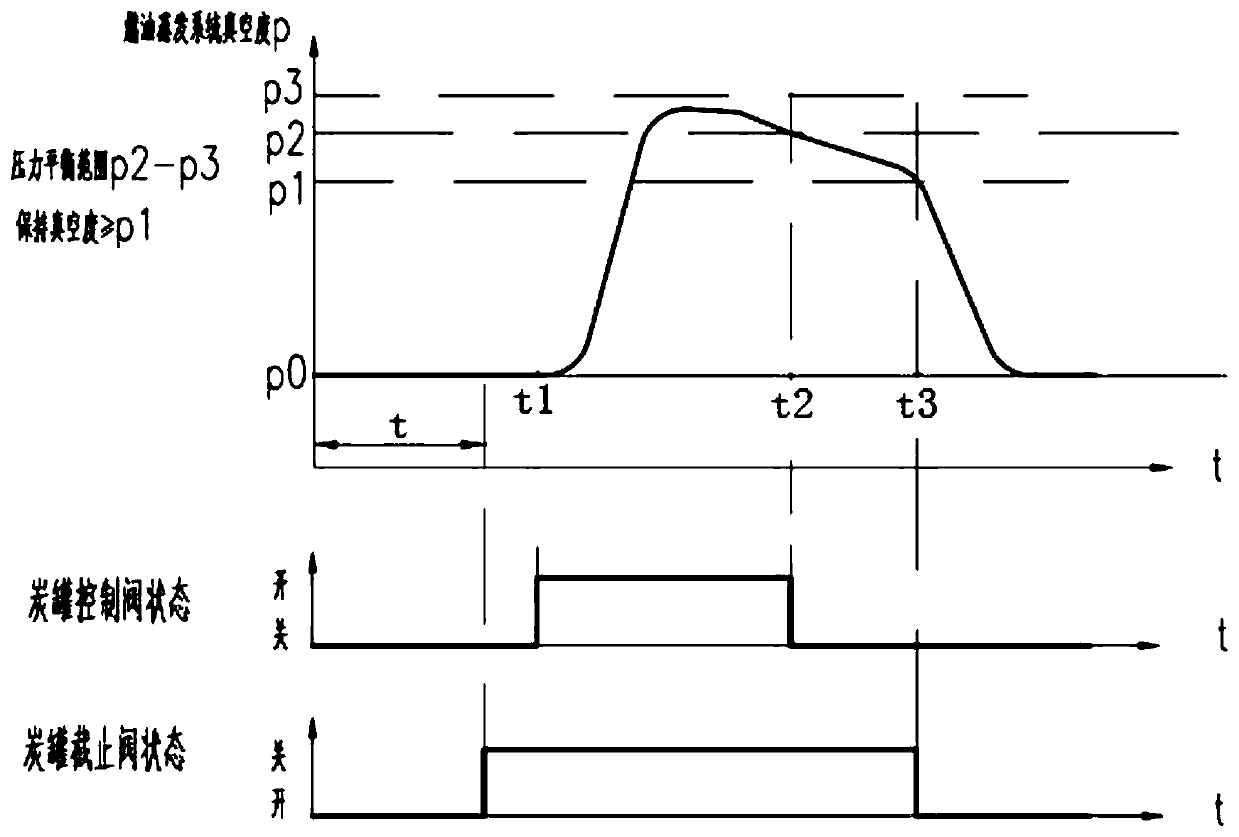

Detection device and detection method of sealing performance of automobile fuel evaporation system

InactiveCN110044556AAvoid air pollutionReduce hardware costsMeasurement of fluid loss/gain rateNon-fuel substance addition to fuelElectronic control unitElectricity

The invention discloses a detection device and a detection method of sealing performance of an automobile fuel evaporation system. The detection device comprises an engine, a carbon canister control valve, a carbon canister, a fuel tank, an ash filter, an electronic control unit, an engine water temperature sensor and an intake air temperature sensor, wherein the detection device further comprisesa pressure sensor, a carbon canister stop valve and a leakage fault indication module, the pressure sensor is installed on a connecting pipe of the carbon canister and the fuel tank, the carbon canister stop valve is connected with the carbon canister and the ash filter, and the pressure sensor, the carbon canister stop valve and the leakage fault indication module are electrically connected withthe electronic control unit; and the detection method comprises the following steps: firstly detecting whether the carbon canister stop valve has leakage under the condition that a detection condition is satisfied, then detecting whether the fuel evaporation system has large leakage, and finally detecting whether the fuel evaporation system has small leakage. By adoption of the detection device and the detection method disclosed by the invention, whether the fuel evaporation system has leakage can be detected in time during the operation of the engine so as to better avoid the air pollution caused by fuel vapor leakage.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

System and method for eliminating emissions from an air classification device

InactiveUS20110024334A1Eliminating undesired emissionEliminate emissionsGas current separationSortingEngineeringAtmospheric pressure

An air classification device for separation of solids comprising an input system, a first solid separator system, an output system, and an emission containing system. The emission containing system employs supplemental air lines, a supplemental air source, and high-velocity air knives to create negative air pressure at any opening in the device. The negative air pressure induces air to move into the device and prevents polluted air from escaping the device at the openings.

Owner:SCHENCK PROCESS LLC

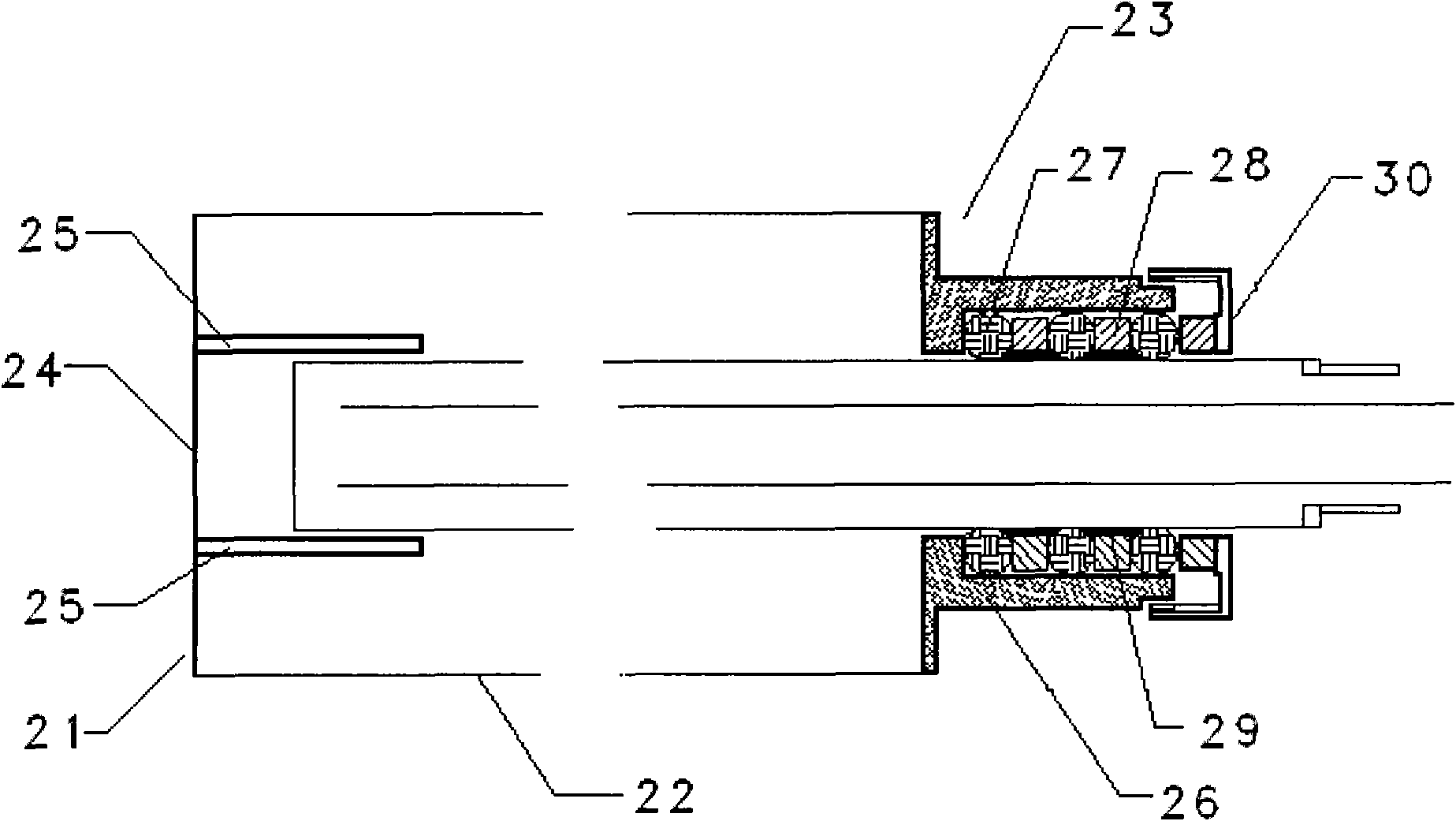

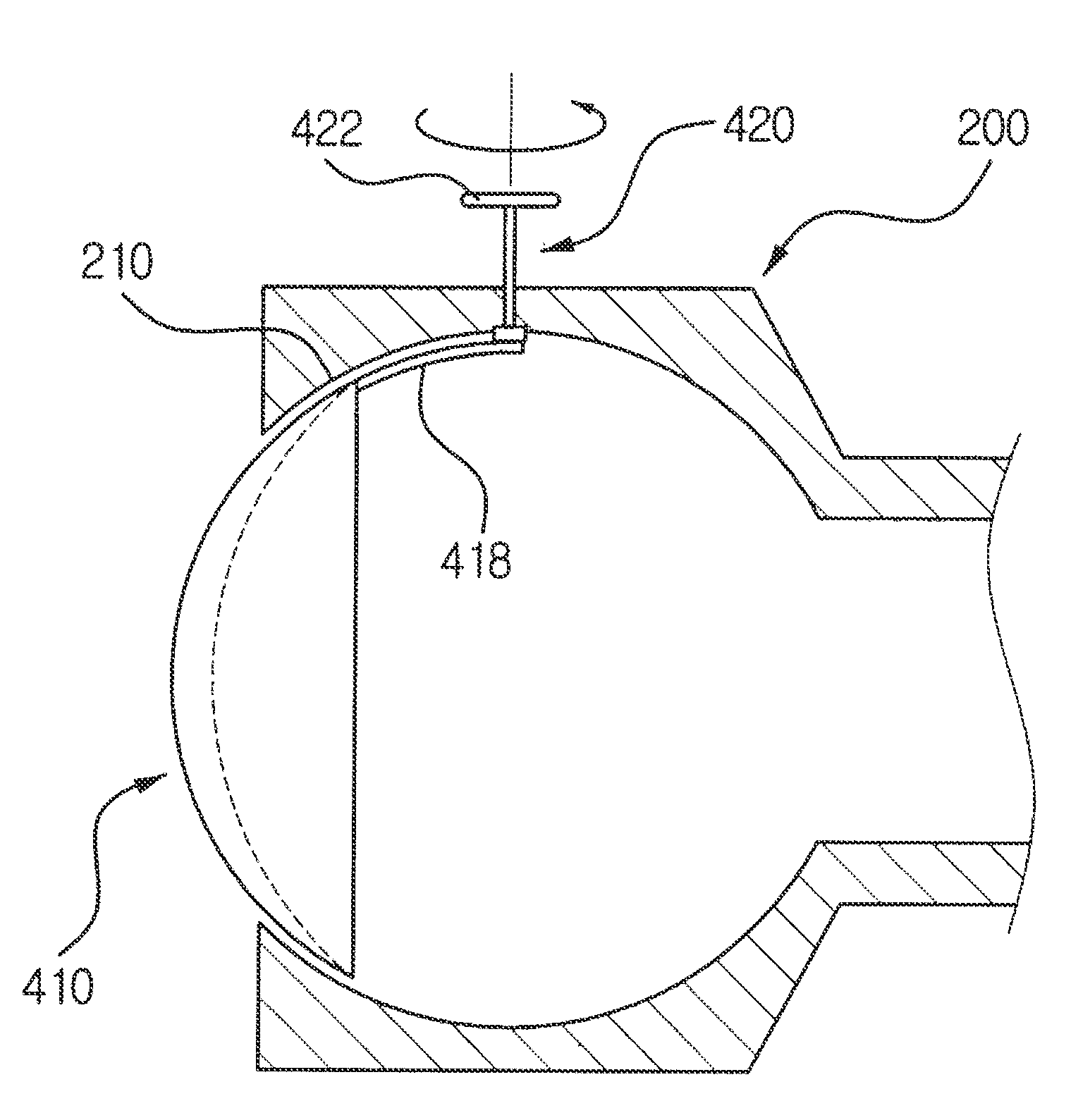

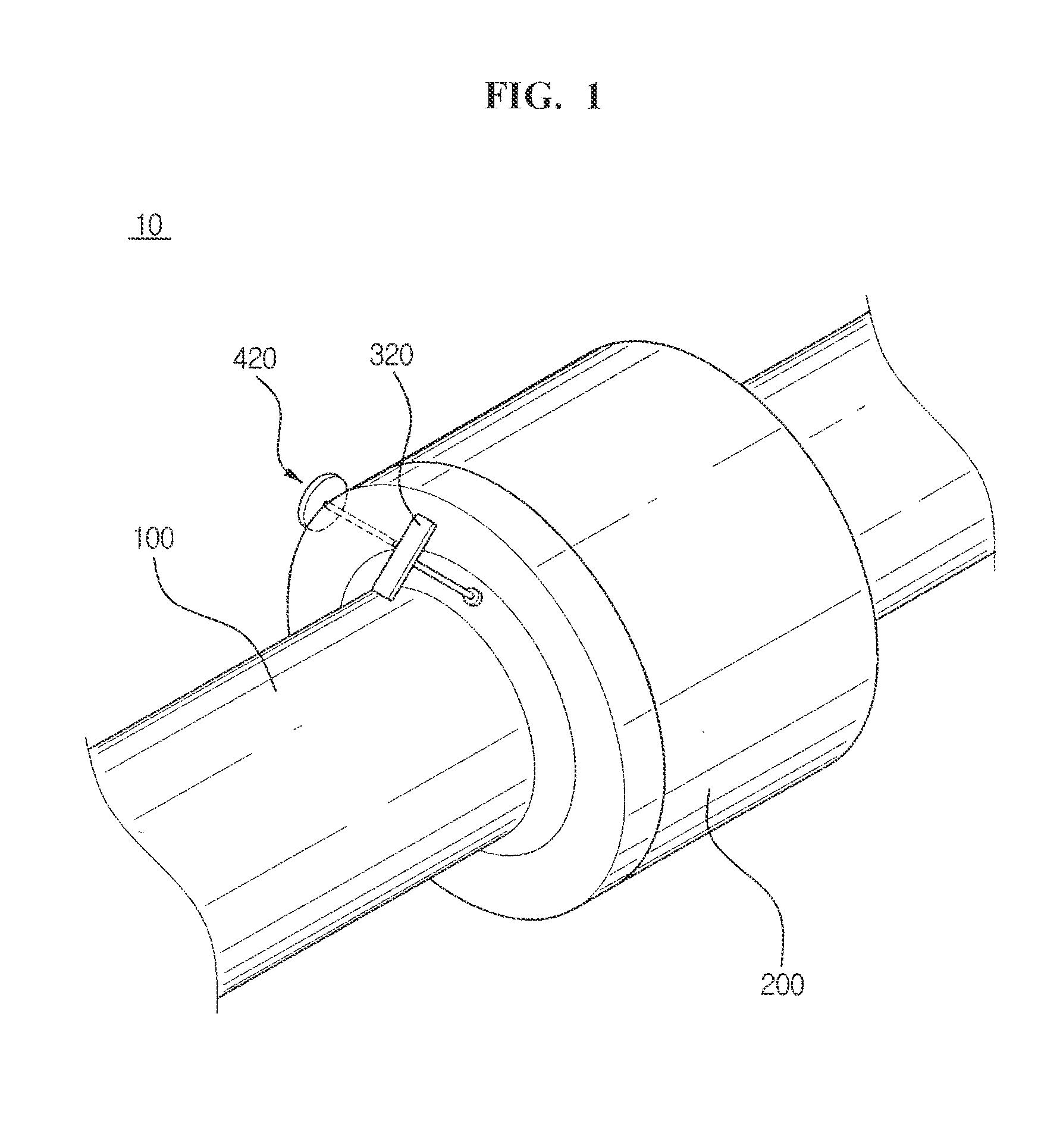

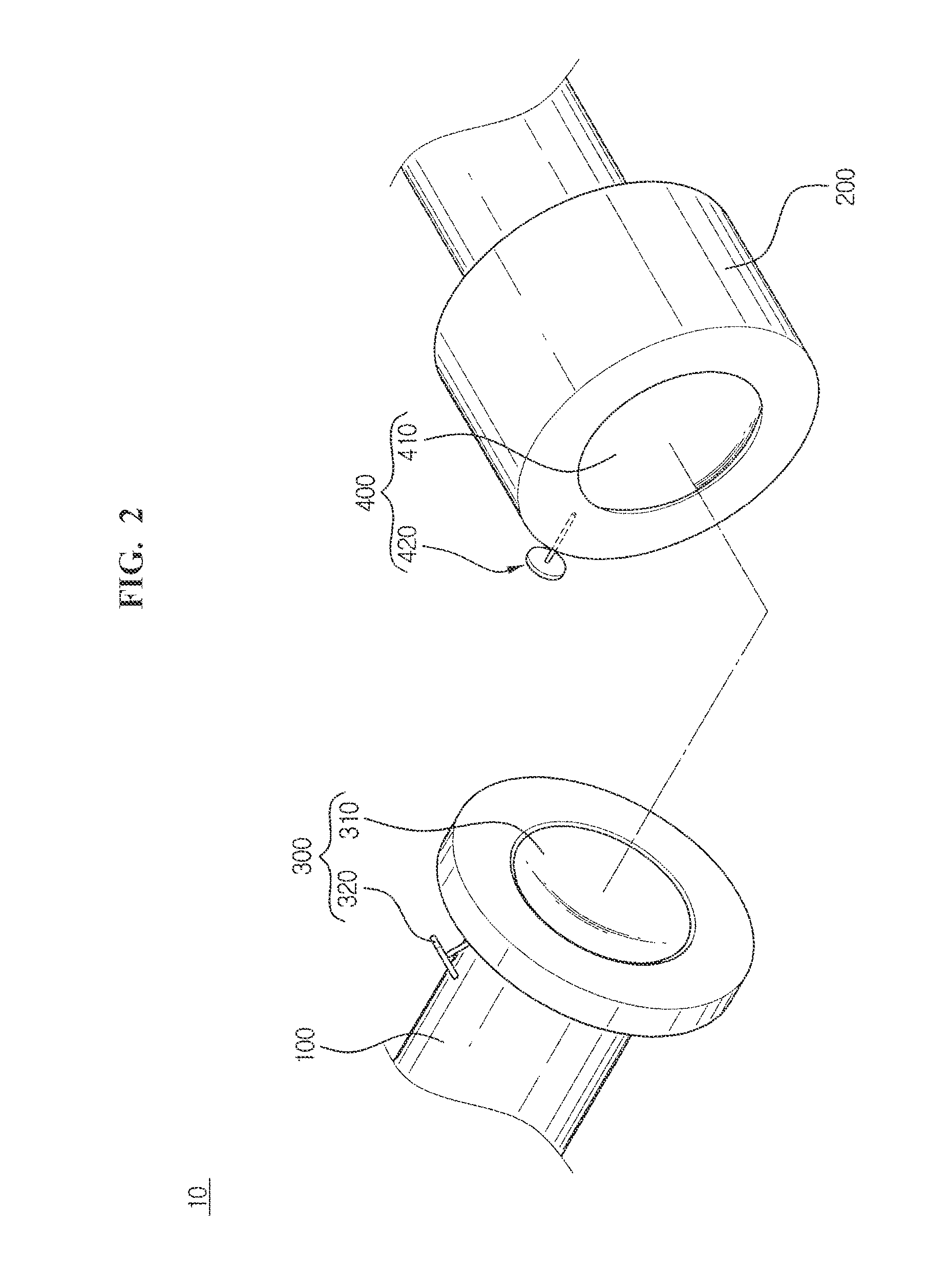

Coupling and decoupling assembly of pipe having double valve

InactiveUS20080001397A1Avoid air pollutionPrevent disastrous accidentPipe elementsCouplingsCouplingEngineering

A coupling / decoupling assembly of a pipe which can selectively open / close a flow channel of the pipe is provided. In the coupling / decoupling assembly of the pipe, a first valve and a second valve are respectively joined with each end of a first pipe and a second pipe. A first driving axis and a second driving axis are respectively joined with each end of the first valve and the second valve. An outer surface and an inner surface of the first and second valves are formed in a spherical body, and the inner surface of the first valve and the outer surface of the second valve are overlapped with each other to close the flow channel of the pipe, and the inner surface of the first valve and the outer surface of the second valve having an identical radius of a curvature.

Owner:KOREA ATOMIC ENERGY RES INST +1

Artificial leather additive and preparation method thereof

The invention relates to an artificial leather additive and a preparation method thereof. The invention relates to a field of artificial leather additive processing. According to the invention, the additive is composed of crushed tree branches, hydrogen peroxide accounting for 5-15% of the total weight of the crushed tree branches, ultramarine blue accounting for 0.05-1% of the total weight of the crushed tree branches, glass water accounting for 3-13% of the total weight of the crushed tree branches, a whitening agent accounting for 0.5-3% of the total weight of the crushed tree branches, caustic soda flake accounting for 0.5-2% of the total weight of the crushed tree branches, and sodium sulfide nonahydrate accounting for 1-5% of the total weight of the crushed tree branches. Through steps of stirring, sun-drying, pulverizing, powder sieving, quality inspection, sterilization, and bagging, finished products are obtained. According to the invention, the artificial leather additive is manufactured by using tree branches as a raw material, such that atmosphere pollution caused by a traditional preparation method using plastic is avoided, and resource is greatly saved. As it is known to all, wood is a renewable resource. With the circulated utilization method, harmful gas caused by plastic production is greatly reduced. Also, the cost of wood is low, and the additive production method is simple.

Owner:ANHUI BODA CELLULOSE TECH

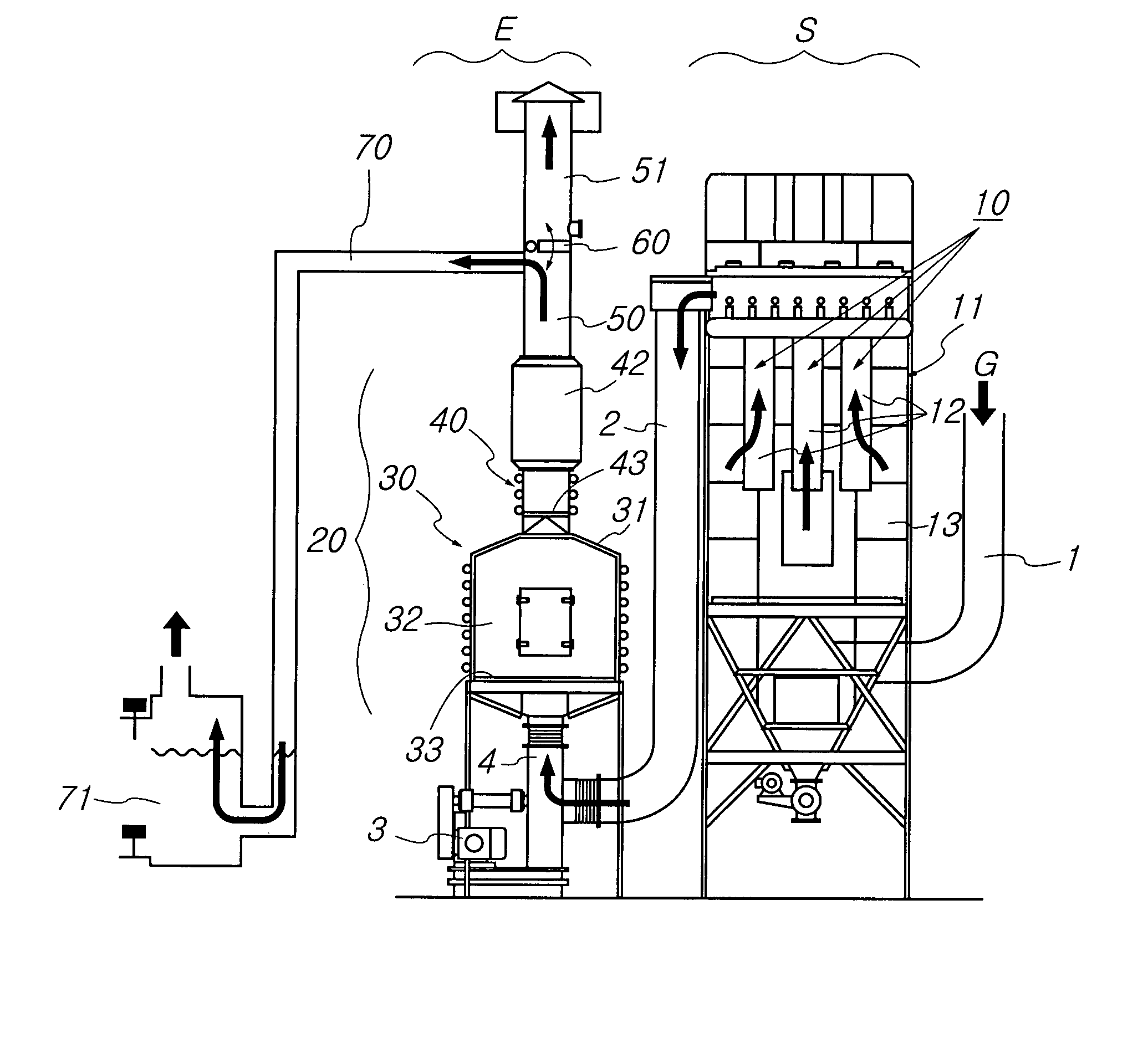

System for simultaneously removing dust and volatile toxic organic compounds

InactiveUS20050011361A1Improve working environmentAvoid air pollutionCombination devicesGas treatmentSimple Organic CompoundsEngineering

Disclosed herein is a system for simultaneously removing dust and volatile toxic organic compounds. The system comprises a dust collecting unit disposed between an inlet duct and an outlet duct for removing dust, an organic compound removing unit disposed between the inlet duct and the outlet duct for removing volatile toxic organic compounds, and an inlet blower disposed between the dust collecting unit and the organic compound removing unit. The dust collecting unit is made up of a bag filter, which comprises a housing formed in the shape of a box and connected to the inlet duct, a plurality of filtering members, such as cloth or felt, arranged in the housing, and dust collecting layers defined between the housing and the filtering members. The organic compound removing unit comprises an absorbing apparatus for absorbing the volatile toxic organic compounds, and regenerating heaters attached on the outer circumference of the absorbing apparatus.

Owner:RES COOPERATION FOUND OF YEUNGNAM UNIV

Mineral separation anti-blockage screening equipment having dedusting function

InactiveCN110152987AExpand the scope of absorptionAvoid affecting the screening effectSievingScreeningScreening effectEngineering

The invention relates to mineral separation anti-blockage screening equipment having the dedusting function. The mineral separation anti-blockage screening equipment comprises a main body, a screeningnet and four support feet and further comprises a dedusting mechanism and a vibrating mechanism. The vibrating mechanism comprises a vibrating block, a beating block, a beating plate, a support shaft, an adjustment rod and a driving assembly. The dedusting mechanism comprises a water tank, an air exhaust assembly and two dedusting assemblies. Each dedusting assembly comprises a connecting pipe, ahose, a connecting box, a suction nozzle, a fixing rod and a power unit. According to the mineral separation anti-blockage screening equipment having the dedusting function, the screening net can vibrate through the vibrating mechanism, and the problem that the screening effect is affected due to the fact that dust on the screening net blocks the screening net is avoided; and by means of the dedusting mechanism, the dedustiong work of the interior of the main body can be conducted, and the problem that the dust is scattered in all directions to affect the air environment is avoided.

Owner:GUANGZHOU DANJUE COMM TECH CO LTD

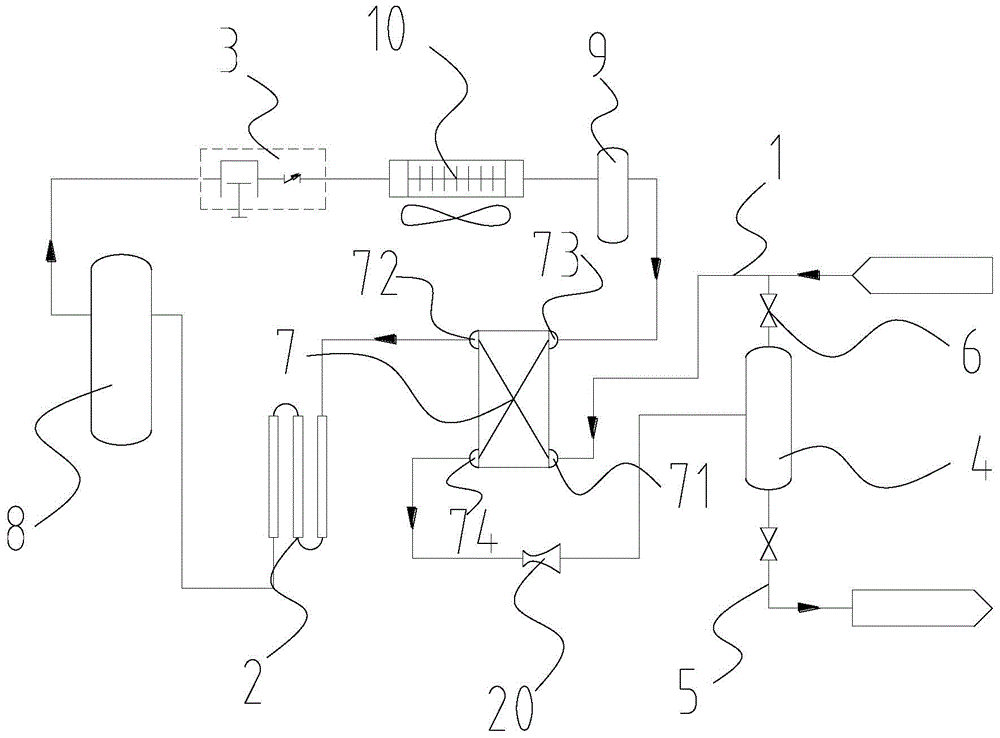

BOG recovery system for LNG (Liquefied Natural Gas) gas station

InactiveCN104806879AAvoid air pollutionAvoid energy wasteContainer filling methodsContainer discharging methodsChillerEngineering

The invention relates to the field of liquefying equipment, and provides a BOG recovery system for an LNG (Liquefied Natural Gas) gas station. The BOG reclaiming system comprises a BOG introduction pipeline, a compressor, a cooler, an ejector and an LNG discharging pipeline, wherein the BOG introduction pipeline, the compressor, the cooler, the ejector and the LNG discharging pipeline are sequentially communicated with one another. The BOG in an LNG storage tank enters the compressor through the BOG introduction pipeline and is pressurized to about 20MPa, the pressurized BOG is cooled by the cooler and enters the ejector to perform ejection liquefaction, and finally, the obtained LNG is introduced into a storage device as products. Through the adoption of the BOG recovery system disclosed by the invention, the BOG generated in the LNG storage tank can be re-liquefied, and the re-liquefied BOG can be introduced into the LNG storage tank or other containers so as to be sufficiently utilized, and the air pollution and the waste of energy sources can be avoided. The BOG recovery system is suitable for LNG gas stations.

Owner:四川金科深冷设备工程有限公司

Brake pad with dust filter structure

InactiveCN109307029AAvoid air pollutionAvoid accumulationBraking membersFriction liningAdverse effectEngineering

The invention relates to a brake pad with a dust filter structure. The brake pad with the dust filter structure comprises a brake pad body, a dust collection part, a dust filter box and an air inducing mechanism, wherein a dust discharge groove is formed in the brake pad body; the lower end of the dust discharge groove communicates with the dust collection part; and a filter screen is fixedly connected to the inner wall of the dust filter box in a direction vertical to a dust discharge channel. In the case that lots of dust is generated due to continuous wear between the brake pad body and a brake disc, the dust can be discharged into the dust collection part through the dust discharge groove, the air inducing mechanism discharges the dust in the dust collection part into the filter box, and the dust is prevented from being accumulated on working surfaces of the brake pad body and the brake disc to cause adverse effects to a brake force of a brake system; and in addition, through the arrangement for the filter box, the dust generated in a brake process can be filtered, clean air is discharged into the atmosphere, and the dust is effectively prevented from being directly dischargedinto air, so that air pollution is avoided.

Owner:盐城市天驰汽配有限公司

Extraction vanadium recovery process

ActiveCN107245586AImprove extraction capacityIncrease profitProcess efficiency improvementAir quality improvementVanadium oxideImpurity

The invention discloses an extraction vanadium recovery process. Spent vanadium catalysts are subjected to water leaching and reductive acid leaching treatment to obtain VOSO4-containing extracted raw liquid, the raw liquid is subjected to the single-stage extraction, tail liquid concentration, separate reextraction and back extraction vanadium recovery process, vanadium precipitation is carried out with ammonium hydroxide, and roasting is conducted to produce vanadium pentoxide. Saponified P204 is adopted as a main extraction agent, it is ensured that the pH value of the whole system is within the optimal pH value range in the extraction process, the extraction system can maintain a stable pH value, and the single-stage extraction rate of vanadium is greatly improved to above 96.4%; tetravalent vanadium obtained through extraction can be directly subjected to vanadium precipitation without oxidation, a high-purity vanadium product is produced, the technological process is simplified, and atmosphere pollution caused by chlorine generated by chlorate vanadium oxide is avoided; meanwhile, the selectivity characteristic of the saponified P204 is utilized, the influences of iron, phosphorus and arsenic on purity of extracted vanadium are effectively avoided, a part of impurity removal work is reduced, raw material consumption is reduced, enterprise cost is reduced, and economic benefits are remarkable.

Owner:KAIFENG UNIV

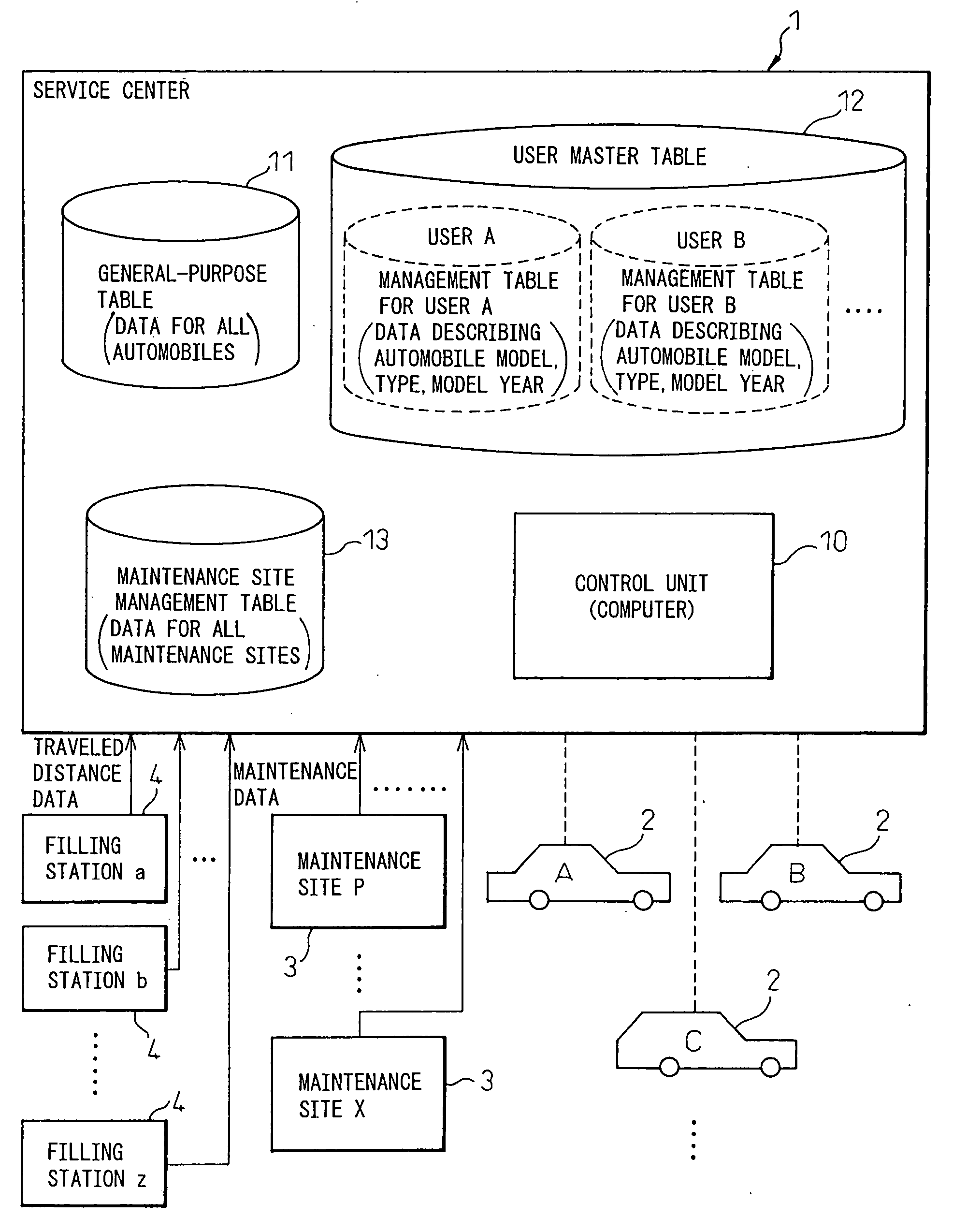

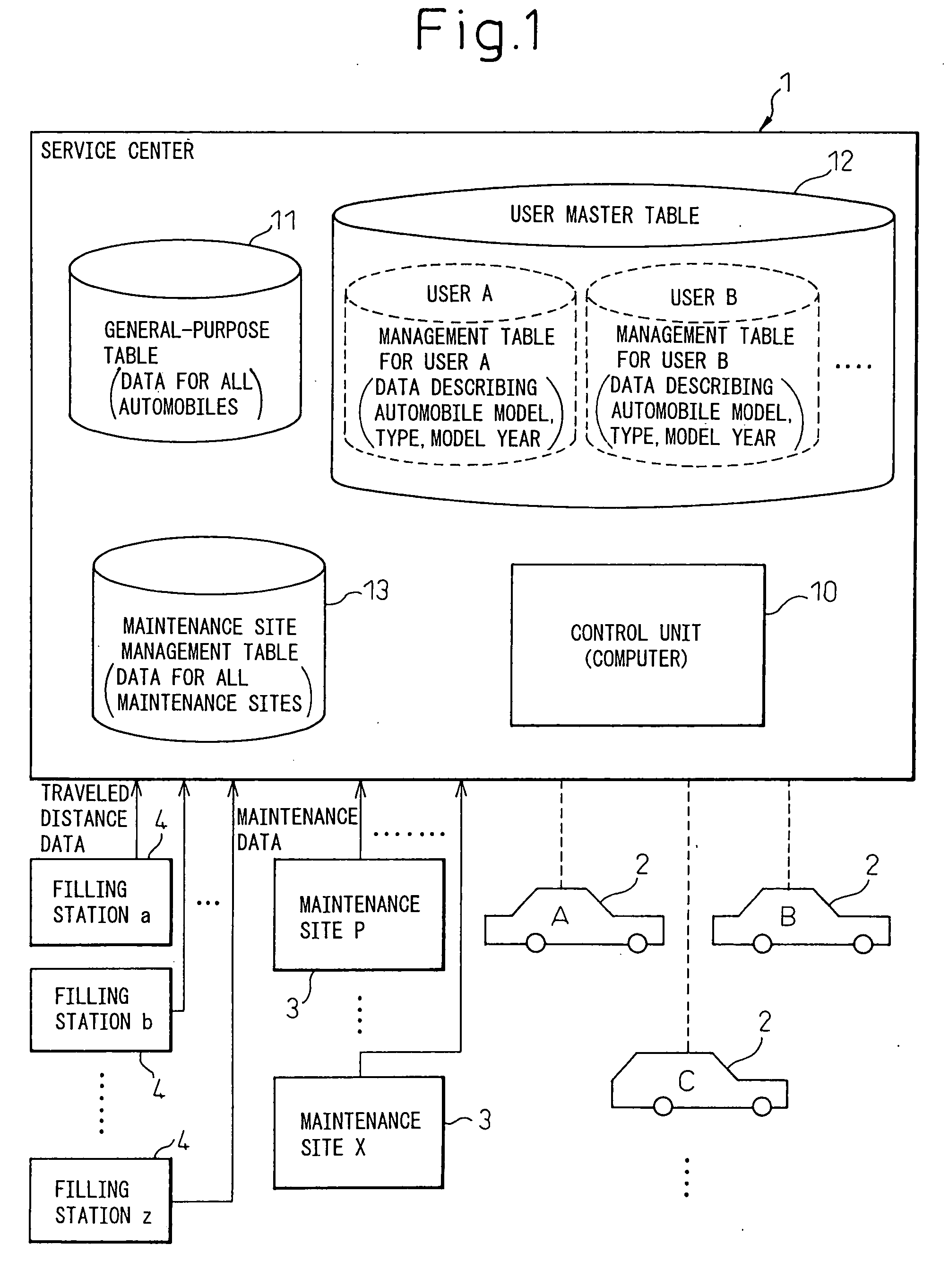

Automobile failure prevention support method and system

InactiveUS20050049895A1Effective and economical utilizationPreventing a public nuisanceTechnology managementResourcesFailure preventionGeneral purpose

An automobile failure prevention support service method for providing support for prevention of automobile failures to registered users, wherein: the degrees of deterioration of items such as expendables and oils and automotive parts designated as periodic automobile inspection items are stored for all automobiles in a general-purpose table in corresponding relationship to traveled distance thereof; for each user, data about items such as expendables and oils and automotive parts to be inspected on the user's automobile is stored in an automobile management table, along with maintenance and repair history thereof; each time the user's automobile travels a predetermined distance or each time the automobile undergoes maintenance or inspection at a service factory, the total distance so far traveled by the automobile is input and data thereof is stored in the automobile management table; a determining device searches the automobile management table based on the stored traveled-distance information and determines whether or not there is any part that needs checking or any item that needs servicing or replacing and, if there is any part that needs checking or any item that needs servicing or replacing, the automobile user is notified accordingly.

Owner:FUJITSU LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com