Solar phase-change heat collecting and storing tube

A phase change heat storage and solar energy technology, applied in the field of solar phase change heat collection and heat storage tubes, can solve the problems of slow hot start, high installation requirements, large heat capacity, etc., to avoid material denaturation, improve safety performance, heat exchange area big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

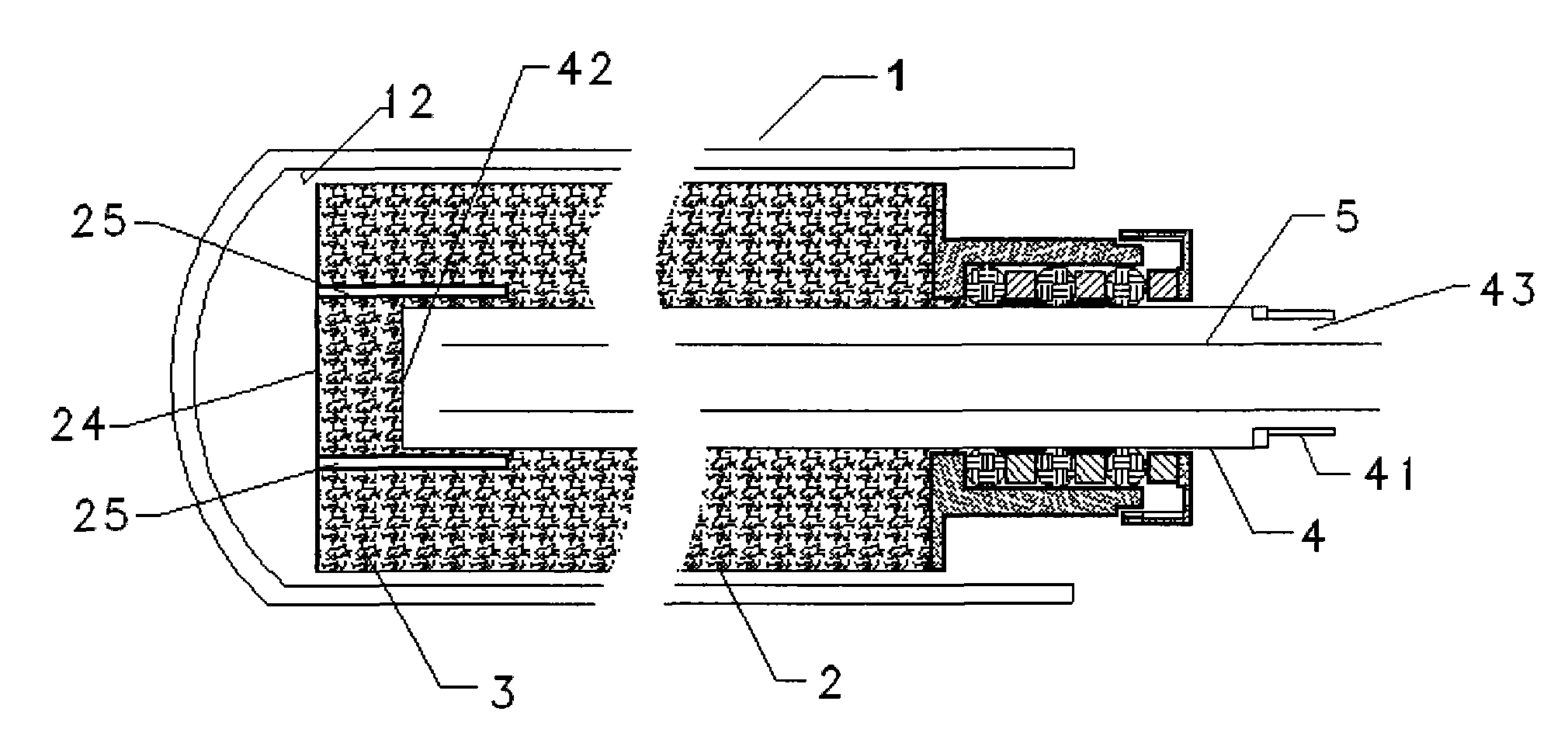

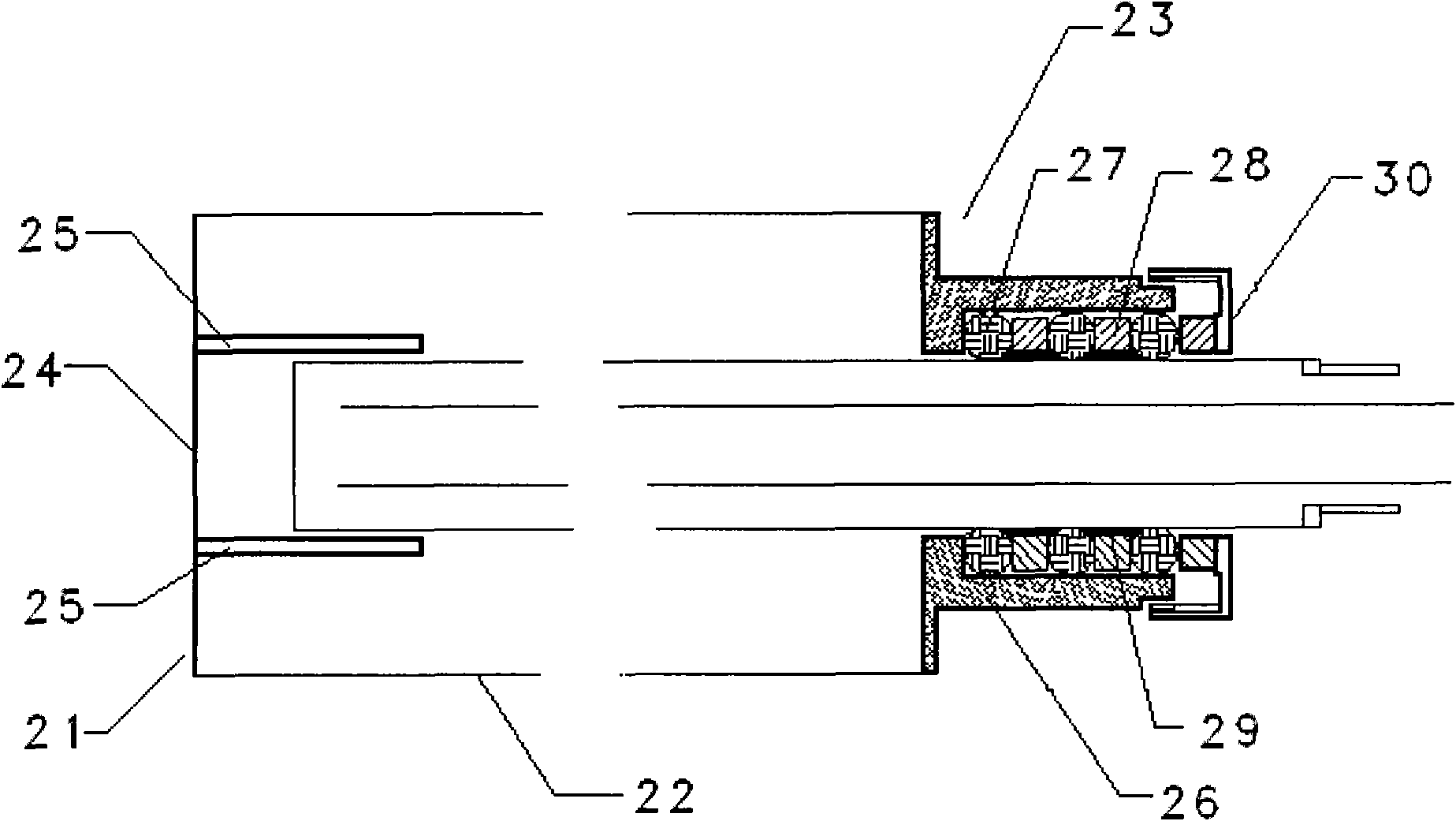

[0030] see figure 1 , a solar phase-change heat-collecting heat-storage tube, including a solar vacuum heat-collecting tube 1, a phase-change heat storage body 2, a phase-change material 3, a heat exchange tube 4 and a flow guide tube 5, and the phase-change heat storage body 2 is arranged on In the solar vacuum heat collection tube 1, the heat exchange tube 4 is placed in the phase change heat storage body 2, the upper part of the heat exchange tube 4 is slidingly connected with the phase change heat storage body 2, and the phase change material 3 is filled in the phase change heat storage body Between the body 2 and the heat exchange tube 4 , the guide tube 5 is inserted into the heat exchange tube 4 .

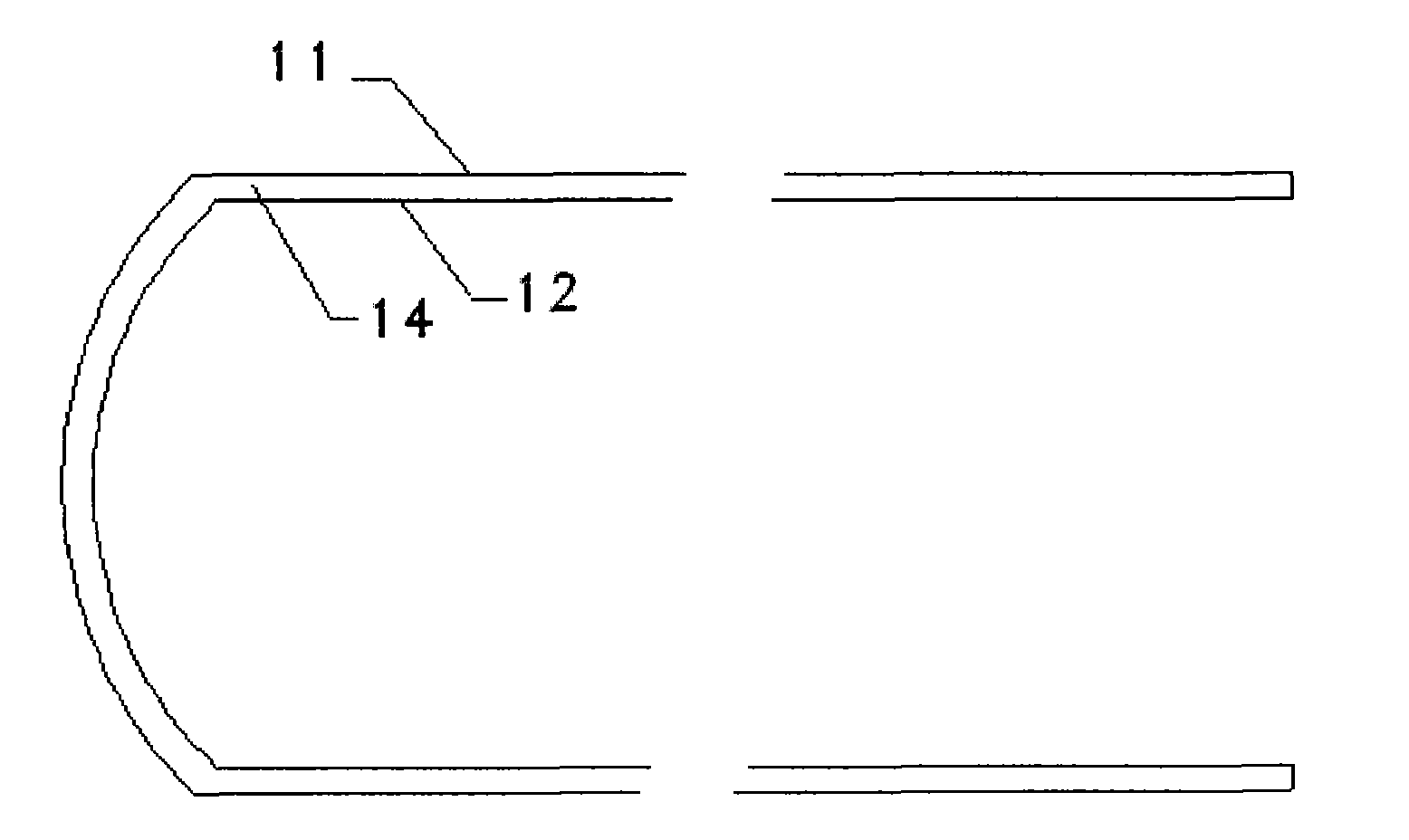

[0031] see figure 2 , the solar vacuum heat collector tube 1 is composed of an outer glass tube 11 and an inner glass tube 12, the outer glass tube 11 and the inner glass tube 12 are closed at one end and open at the other end, and the inner and outer glass tubes 12 and 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com