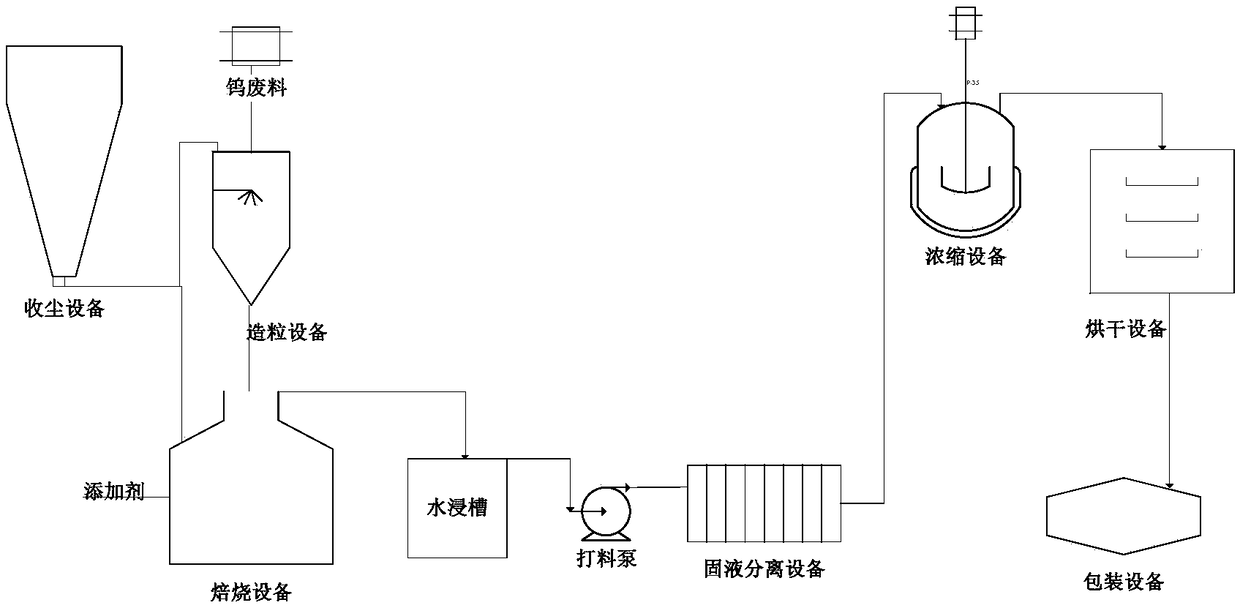

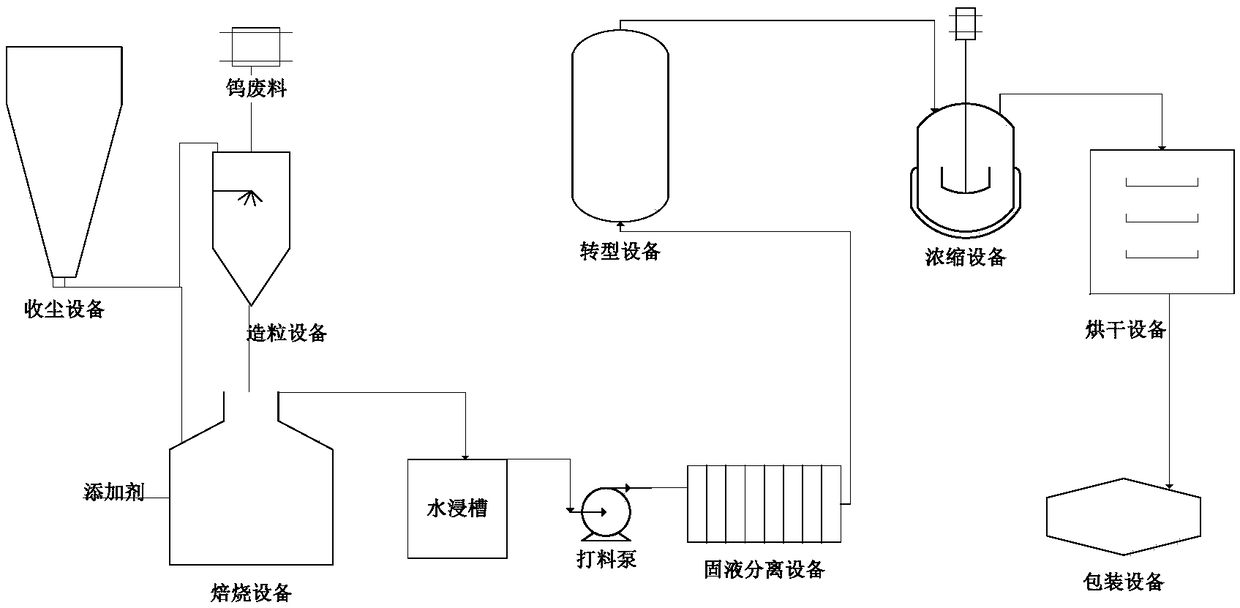

Tungsten-containing waste treating method and device thereof

A treatment method and technology for tungsten waste, applied in the field of recycling and utilization of tungsten-containing waste resources, can solve the problems of strong raw material restrictions, low recovery rate, air pollution, etc., and achieve good raw material adaptability, high recovery rate, and strong applicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The tungsten-containing waste is added to the granulation equipment for granulation, and the particle size of the granular tungsten-containing waste is 5cm; 300Kg of the granular tungsten-containing waste obtained after granulation is sent to the roasting equipment, the roasting temperature is 600 ℃, and the roasting time is 4h. Roasting material; add 15Kg of sodium carbonate, 100Kg of flake soda, and 30Kg of sodium percarbonate to the calcined material while it is still hot, and use the residual temperature of roasting to continue the reaction time for 2h to form a sodium tungstate-containing melt; pour the sodium tungstate-containing melt into Into the water immersion tank, the water immersion time is 0.5h, and the sodium tungstate solution and the cobalt-nickel slag are obtained. The recovery rate of tungsten is 98.0%.

Embodiment 2

[0045] The tungsten-containing waste is added to the granulation equipment for granulation, and the particle size of the granular tungsten-containing waste is 3 cm; 400Kg of the granular tungsten-containing waste obtained after granulation is sent to the roasting equipment, the roasting temperature is 800 ℃, and the roasting time is 3h. Roasting material; add 32Kg of sodium carbonate, 120Kg of caustic soda, and 45Kg of sodium percarbonate to the calcined material while it is still hot, and use the residual temperature of roasting to continue the reaction time for 3h to form a sodium tungstate-containing melt; pour the sodium tungstate-containing melt into Into the water immersion tank, the water immersion time is 0.5h, and the sodium tungstate solution and the cobalt-nickel slag are obtained. The recovery rate of tungsten is 97.5%.

Embodiment 3

[0047] The tungsten-containing waste is added to the granulation equipment for granulation, and the particle size of the granular tungsten-containing waste is 10cm; 250Kg of the granular tungsten-containing waste obtained after granulation is sent to the roasting equipment, the roasting temperature is 550 ° C, and the roasting time is 3h. Roasting material; add 18Kg of sodium carbonate, 75Kg of flake soda, and 12.5Kg of sodium percarbonate to the calcined material while it is still hot, and use the residual temperature of roasting to continue the reaction time for 1h to form a melt containing sodium tungstate; Pour it into a water immersion tank for 1 hour to obtain sodium tungstate solution and cobalt-nickel slag. The recovery rate of tungsten is 97.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com