Method for solid-phase synthesis of polycarboxylate water reducer by virtue of microwave assistance

A microwave-assisted, solid-phase synthesis technology, which is applied in the field of concrete admixtures, can solve the problems of high investment and operation costs, and reduced water-reducing performance of products, and achieves the effects of good adaptability, small equipment investment, and simple synthesis.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

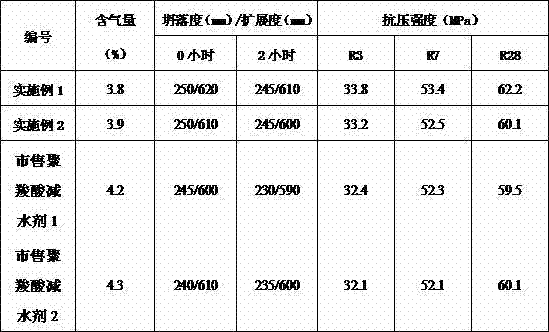

Embodiment 1

[0022] Weigh each component according to the ratio of raw materials, fully mix 15g of acrylic acid, 0.3g of vitamin C, 0.2g of thioglycolic acid and 15g of water, and fully mix the mixed liquid with 100g of prenol polyoxyethylene ether and 1g of ammonium persulfate Mix to get a paste. Spread the paste evenly on a flat pan, adjust the power of the microwave oven to 0.8 kilowatts, and react for 40 minutes to obtain a solid product of polycarboxylate superplasticizer with a water content of 5.22%.

Embodiment 2

[0024] The first step of material preparation: Weigh each component according to the ratio of raw materials, fully mix 16g methacrylic acid, 0.3g hanging white block, 0.2g mercaptoacetic acid and 16g water, and mix the mixed liquid with 100g isobutylene alcohol polyoxyethylene ether , 0.5g of hydrogen peroxide and fully mixed to obtain a paste. Spread the paste evenly on a flat pan, adjust the power of the microwave oven to 1.0 kilowatts, and react for 30 minutes to obtain a solid product of polycarboxylate superplasticizer with a water content of 3.82%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com