Smashed straw quantitative ditch-buried and returning-to-field device

A straw and trench burial technology, applied in plant protection covers, crop processors, cutters, etc., can solve the problems of inability to adjust the amount of crushed straw buried, difficult to guarantee the buried quality, unfavorable for continuous operation, etc., to achieve simple and convenient adjustment and adaptability. Good performance and the effect of reducing the amount of ground breaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

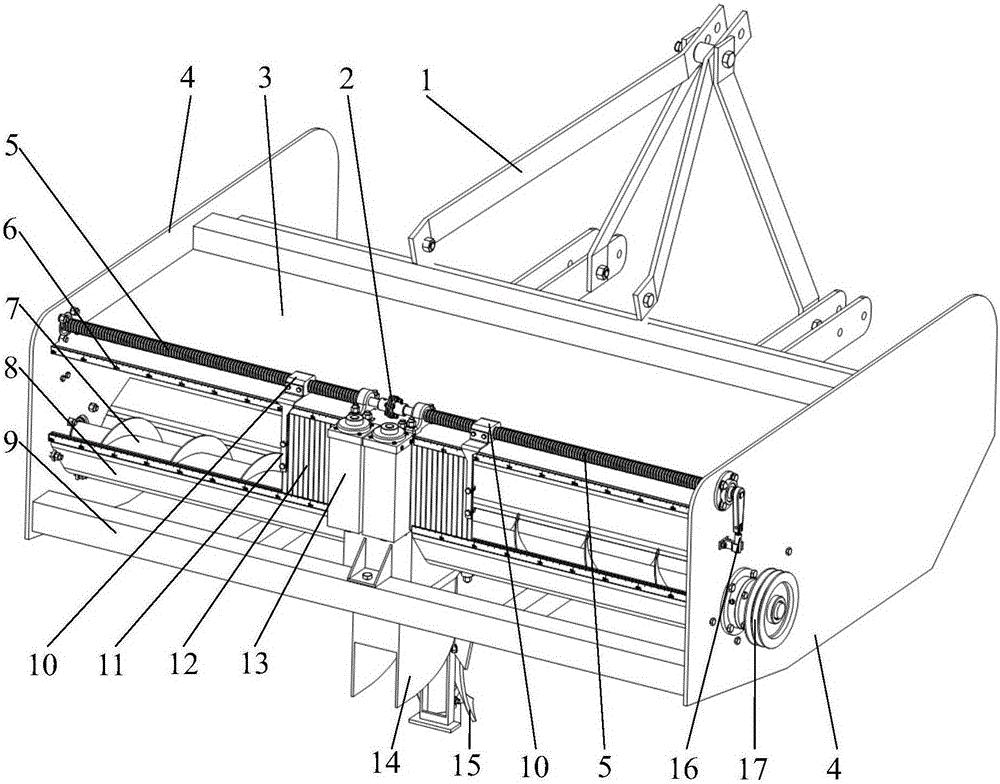

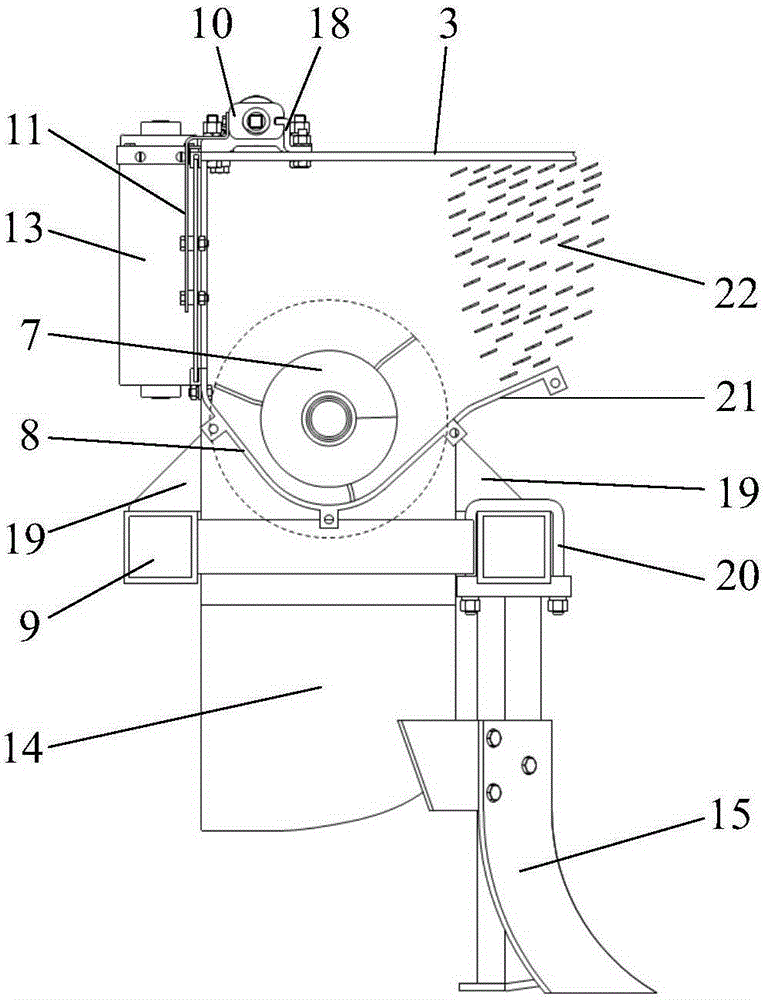

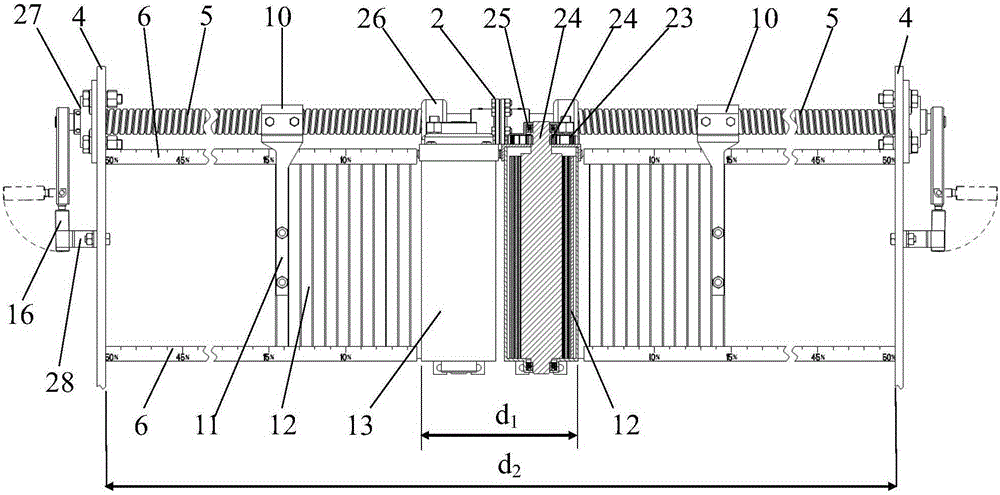

[0028] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 7As shown, a variable-variable ditch burying and returning device for crushed straw of the present invention includes a rolling shutter driving mechanism, a coupling 2, a rolling shutter mechanism, a screw conveying mechanism 7, a screw conveying housing 8, a grass bearing plate 21, and a straw guiding housing 14, beam frame 9 and double-sided furrowing plow 15. The device is assembled on the horizontal straw crushing and field returning machine through the traction frame 1 .

[0029] The beam frame 9 is horizontally arranged on the lower side of the device, such as Figure 5 As shown, the beam frame 9 includes a pair of cros...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com