Patents

Literature

37 results about "Prenol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Prenol, or 3-methyl-2-buten-1-ol, is a natural alcohol. It is one of the most simple terpenoids. It is a clear colorless oil that is reasonably soluble in water and miscible with most common organic solvents. It has a fruity odor and is used occasionally in perfumery.

Method for synthesizing prenol by composite catalyst

ActiveCN102675048ARaw materials are easy to getLow costPreparation by isomerisationButenePtru catalyst

The invention discloses a method for synthesizing prenol by composite catalyst. Generally, rare metals high in price and small in number of application times are used in the existing synthetic methods, and accordingly product cost is increased in industrial production, and product competitiveness is lowered. The method for synthesizing prenol by composite catalyst is characterized by using 3-methl-3-butene-1-ol as raw material, using composite catalyst composed of raney nickel and solid super acid, hydrogenating, and subjecting the 3-methl-3-butene-1-ol double-bond isomerization to synthesize prenol. The composite catalyst is easy to obtain, low in cost, large in number of application times, high in conversion rate and selectivity, low in reaction temperature and the like. Reaction temperature is low, and the method is low in energy consumption and meets the technological requirements on energy conservation and consumption reduction.

Owner:SHANDONG NHU PHARMA +1

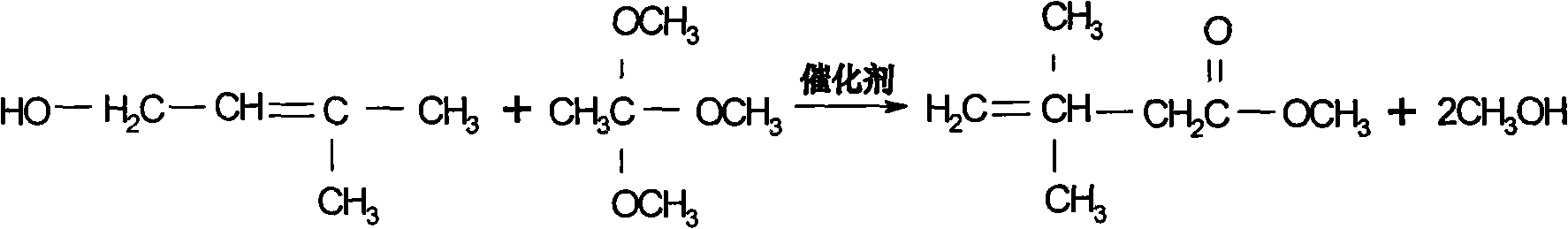

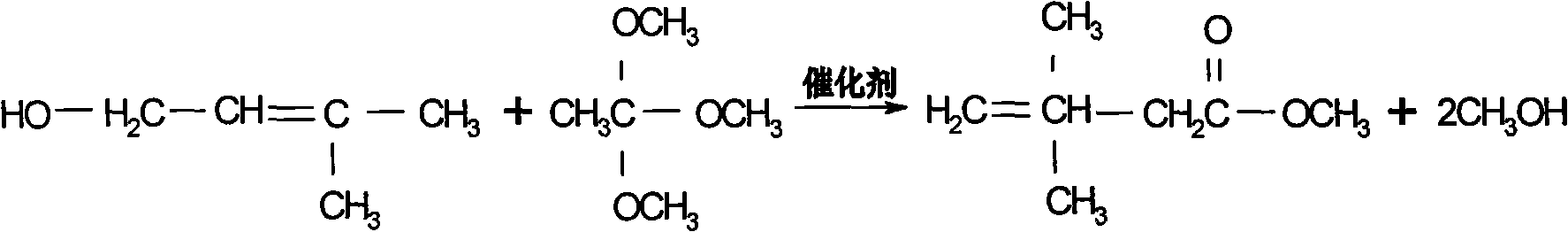

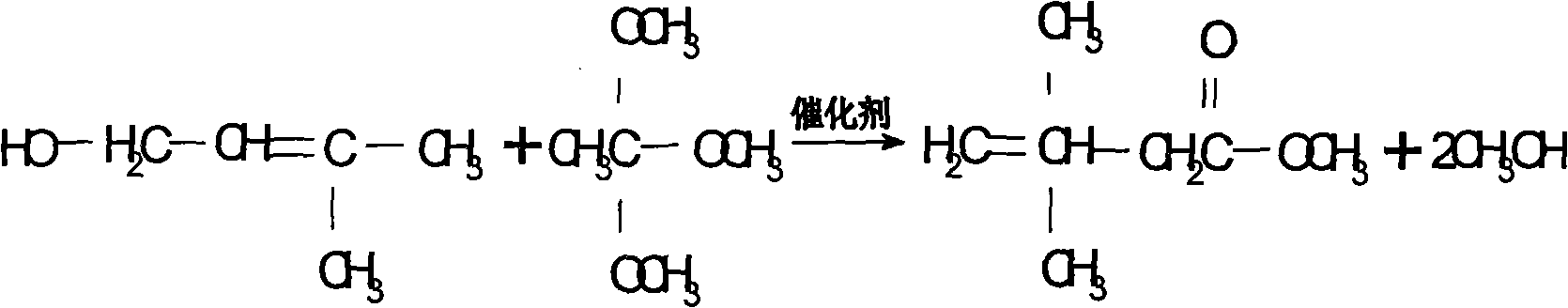

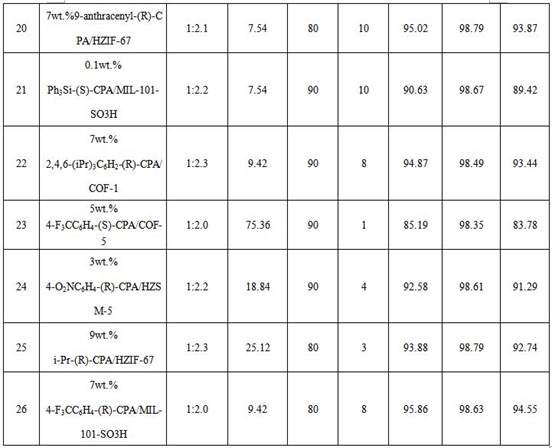

Preparation process of 3,3-dimethyl-4-pentenoic acid methyl ester

InactiveCN101565372AHigh yieldHigh purityPreparation by ester-hydroxy reaction4-pentenoic acidAcetic acid

The invention discloses a preparation process of 3,3-dimethyl-4-pentenoic acid methyl ester, comprising the following steps: heating and reflowing prenol and trimethyl orthoacetate under the existence of a catalyst to obtain methyl alcohol and excessive trimethyl orthoacetate, and the then raising the temperature to produce the 3,3-dimethyl-4-pentenoic acid methyl ester after Clisen rearrangement reaction. The process adopts a novel composite catalyst, improves the yield of the 3,3-dimethyl-4-pentenoic acid methyl ester and has high product purity which is generally over 99 percent.

Owner:NANTONG TENDENCI CHEM

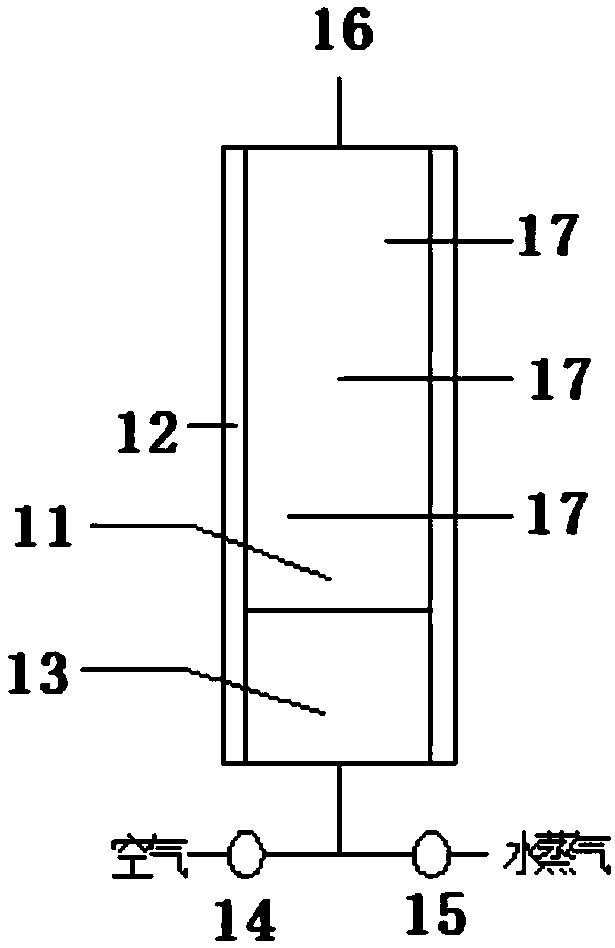

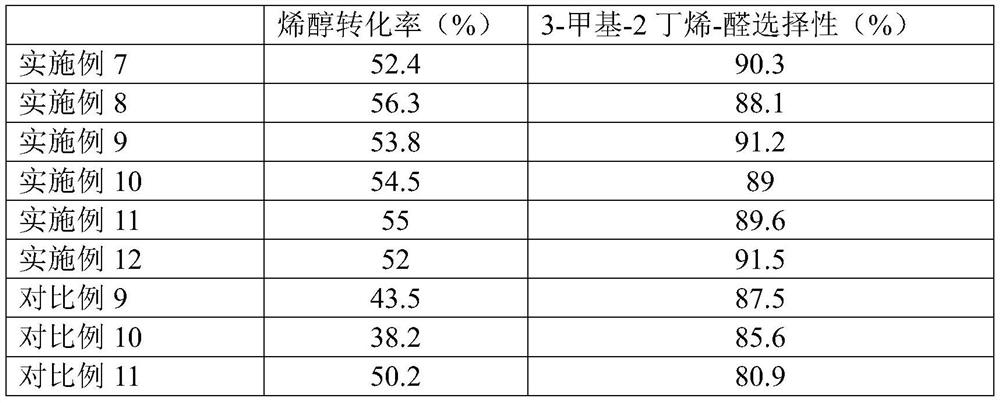

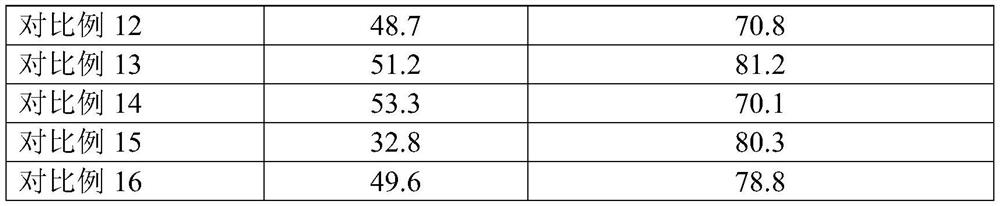

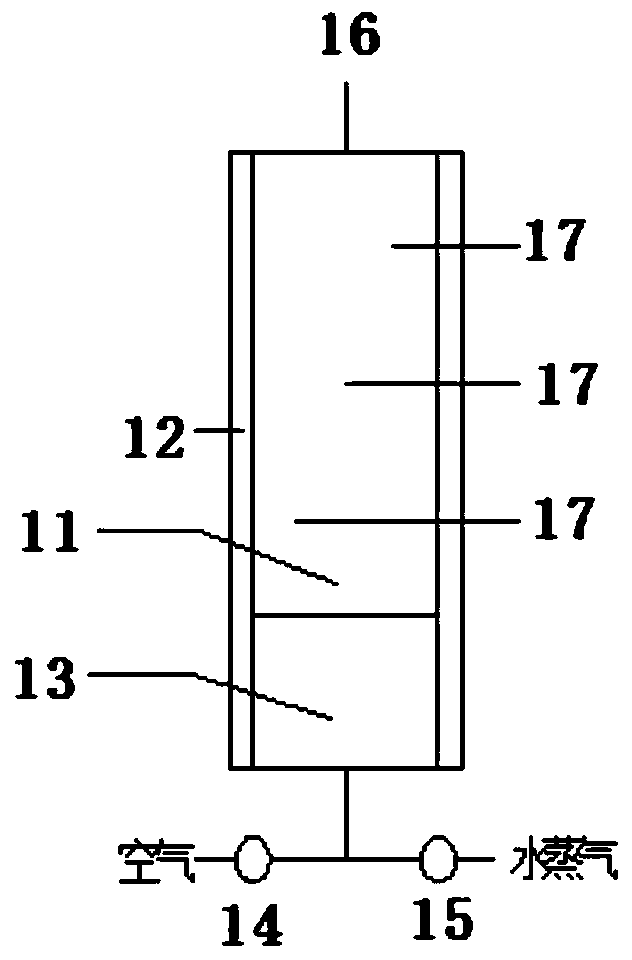

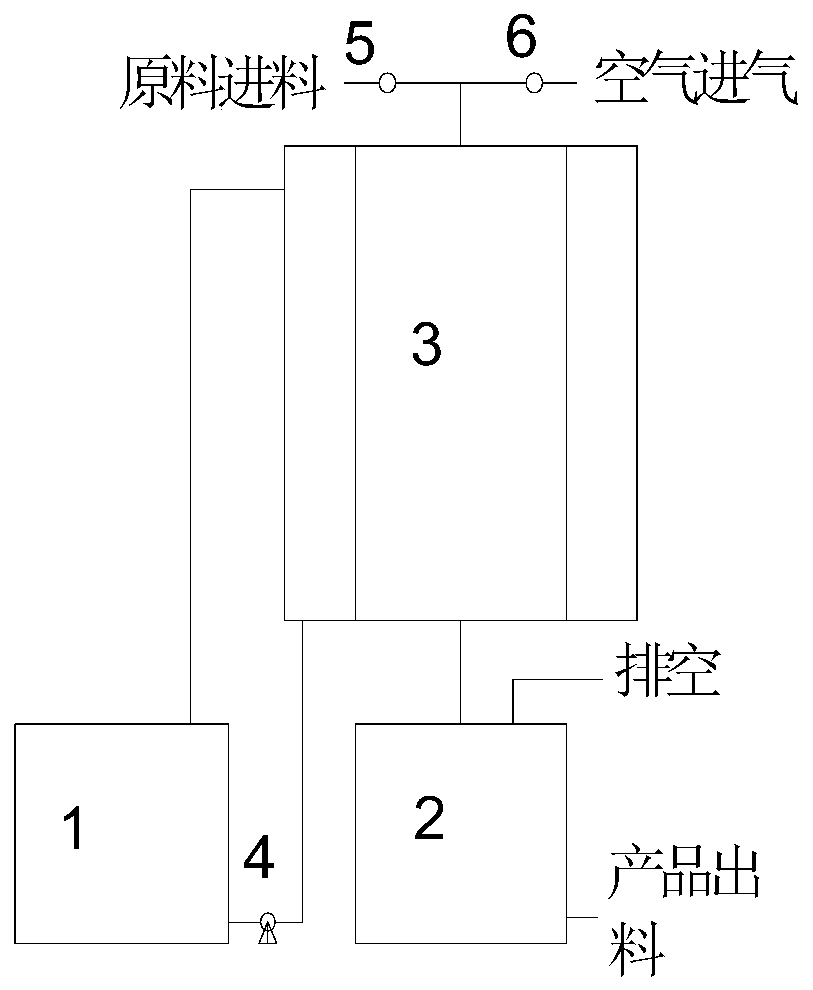

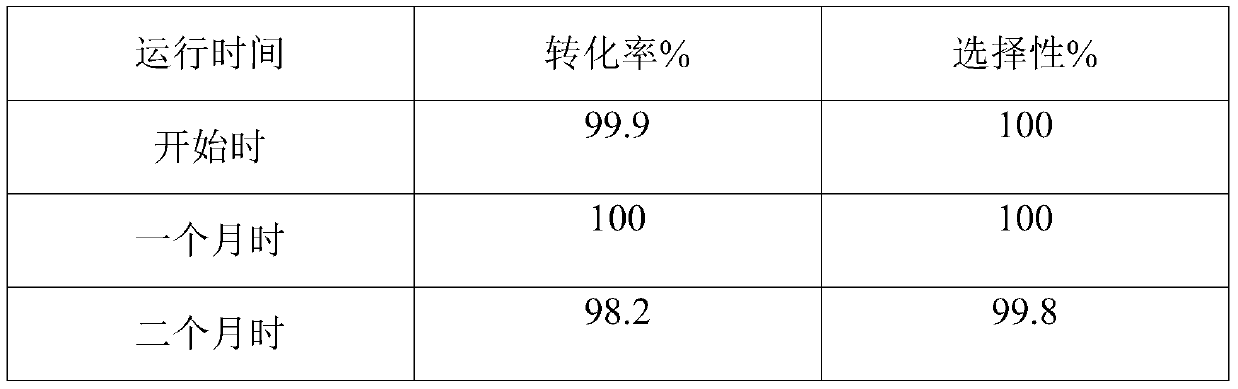

Synthetic method of vanadium-silver-molybdenum phosphate catalyst and method to catalytically prepare prenol and 3-methyl-2-butenal

ActiveCN108404944APreparation by isomerisationPhysical/chemical process catalystsIsobutanolContinuous use

The invention discloses a synthetic method of vanadium-silver-molybdenum phosphate catalyst and a method to catalytically prepare prenol and 3-methyl-2-butenal. The catalyst is prepared by: (1) addingvanadium, silver, molybdenum, phosphorus, benzyl alcohol and isobutanol according to certain molar ratios into a reactor, stirring well, allowing reaction at 100-130 DEG C for 8-10 hours, filtering,and drying filter cake at 150-200 DEG C for 4-5 hours; tableting the solid with a press machine, and activating for 10 hours under the conditions of vapor volume ratio of 70-90%, air volume ratio of 10-30% and temperature of 400-450 DEG C. prenol and 3-methyl-2-butenal are continuously produced at the temperature of 350-450 DEG C from 3-methyl-3-butenyl-ol under the vanadium-silver-molybdenum phosphate catalyst. The vanadium-silver-molybdenum phosphate catalyst is suitable for continuous use for longer than half a year and has unchanged catalytic activity.

Owner:CHINA CATALYST HLDG CO LTD

Cement kiln castable

The invention aims to overcome defects in the prior art, provides castable which is used for an air duct gate and is resistant to high temperatures, high in abrasion resistance and high in alkali corrosion resistance and aims to provide a preparation method of the castable. According to the technical scheme, the castable is characterized by being prepared from components in percentage by weight as follows: 1% of Taiyuan purple flower waste rock, 15%-25% of zirconium mullite, 10%-20% of silicon carbide, 23%-30% of ferrochrome slag, 5%-10% of zinc ferrite, 5%-8% of magnesium-zirconium olivine, 1%-3% of potassium magnesium titanate, 1%-2% of tri-zirconium nitride aluminide, 3%-5% of clinoenstatite, 5%-10% of alumina micro-powder, 2%-3% of zirconium calcium aluminate and 3%-5% of high-alumina cement; the castable is further prepared from components in percentage by weight as follows: 0.5% of Ti3SiC2, 0.1% of methyl allyl alcohol polyoxyethylene ether, 0.05% of prenol polyoxyethylene ether, 0.1% of aluminum potassium sulfate dodecahydrate and 0.05% of chromium potassium sulfate dodecahydrate.

Owner:张婷

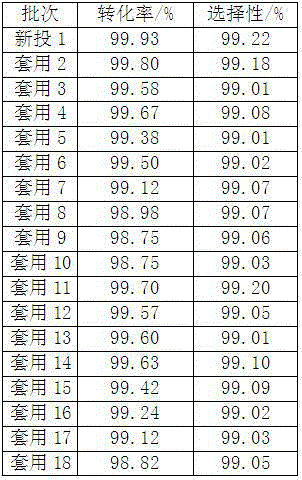

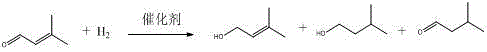

Method for synthesizing prenol employing selective hydrogenation of 3-methylcrotonaldehyde

ActiveCN104387235AEasy to separateSimple and fast operationOrganic compound preparationHydroxy compound preparationHydrogenation reactionNitrogen

The invention discloses a method for synthesizing prenol employing selective hydrogenation of 3-methylcrotonaldehyde. The method comprises the following steps: feeding, nitrogen and hydrogen substitution, hydrogenation reaction, and separation. The used raw materials comprise 1 part of 3-methylcrotonaldehyde, 0.1-10 parts of water and 0.02-0.2 part of a catalyst; and the used catalyst is a water-soluble complex which is formed by a water-soluble salt of the group VIII metal and a water-soluble ligand. The 3-methylcrotonaldehyde conversion ratio and the selectivity of prenol of the synthetic reaction are high; a water phase of the catalyst can be applied repeatedly for over 20 times; the unit consumption of the catalyst is low; the production cost is greatly reduced; and the method is suitable for industrial production.

Owner:SHANDONG NHU PHARMA

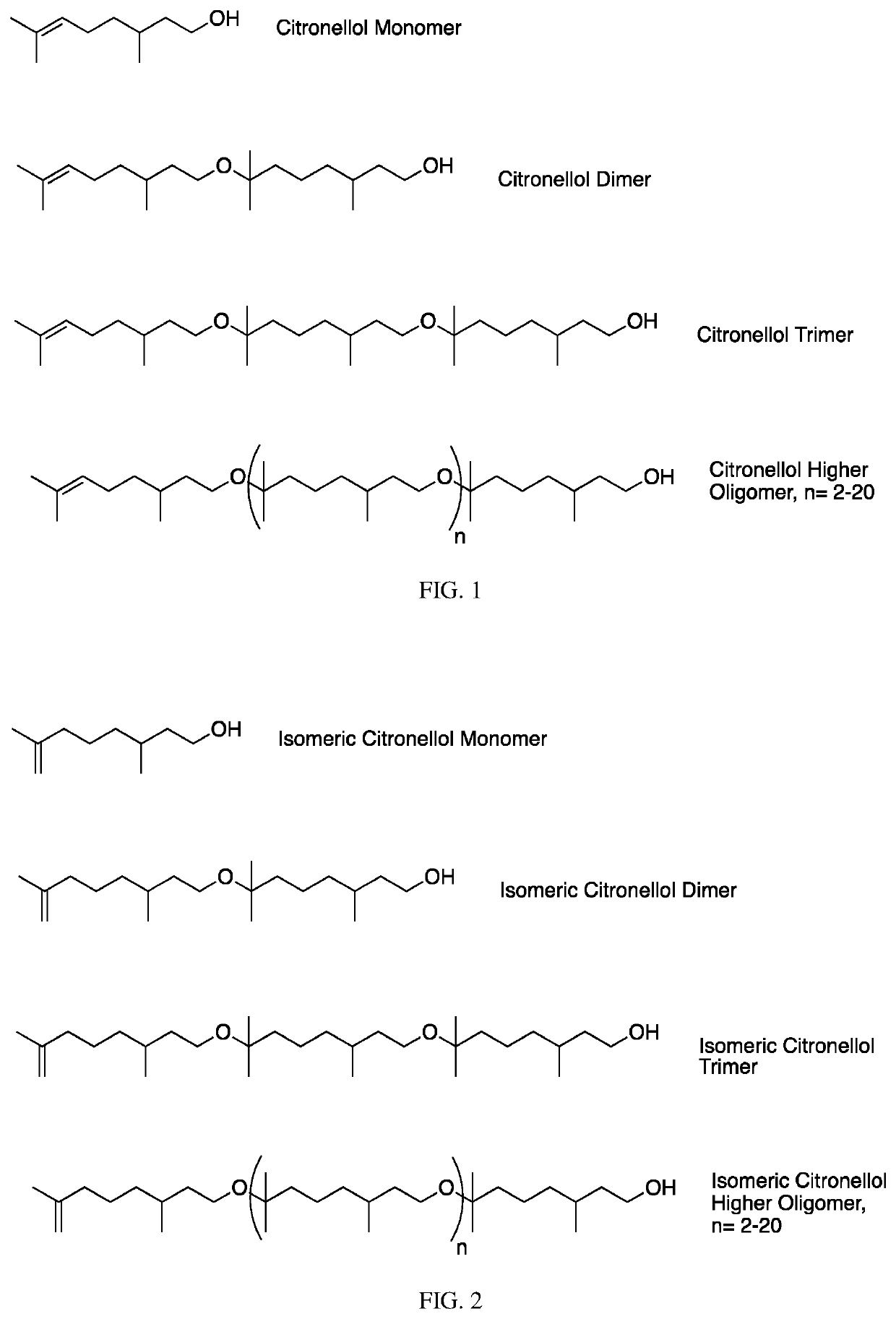

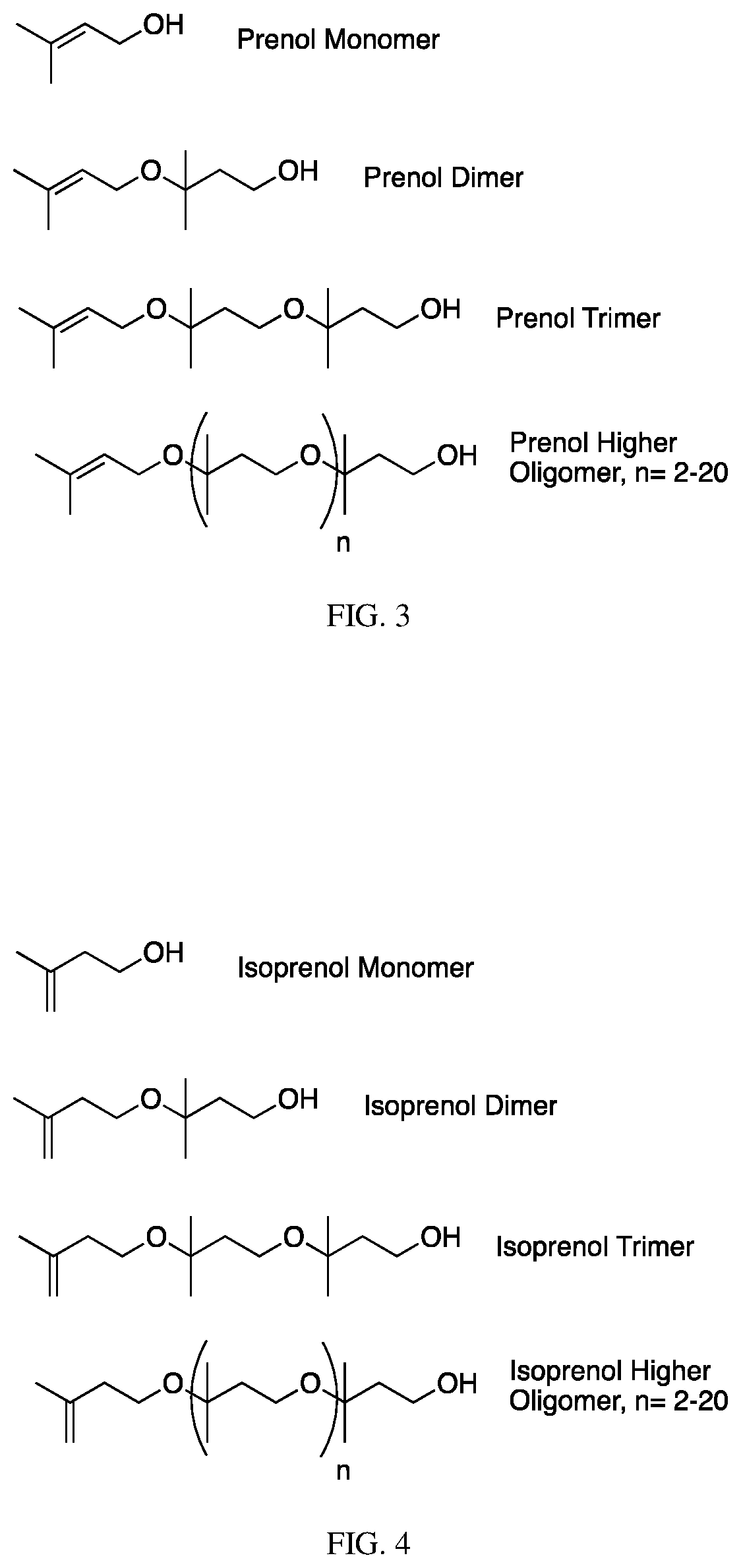

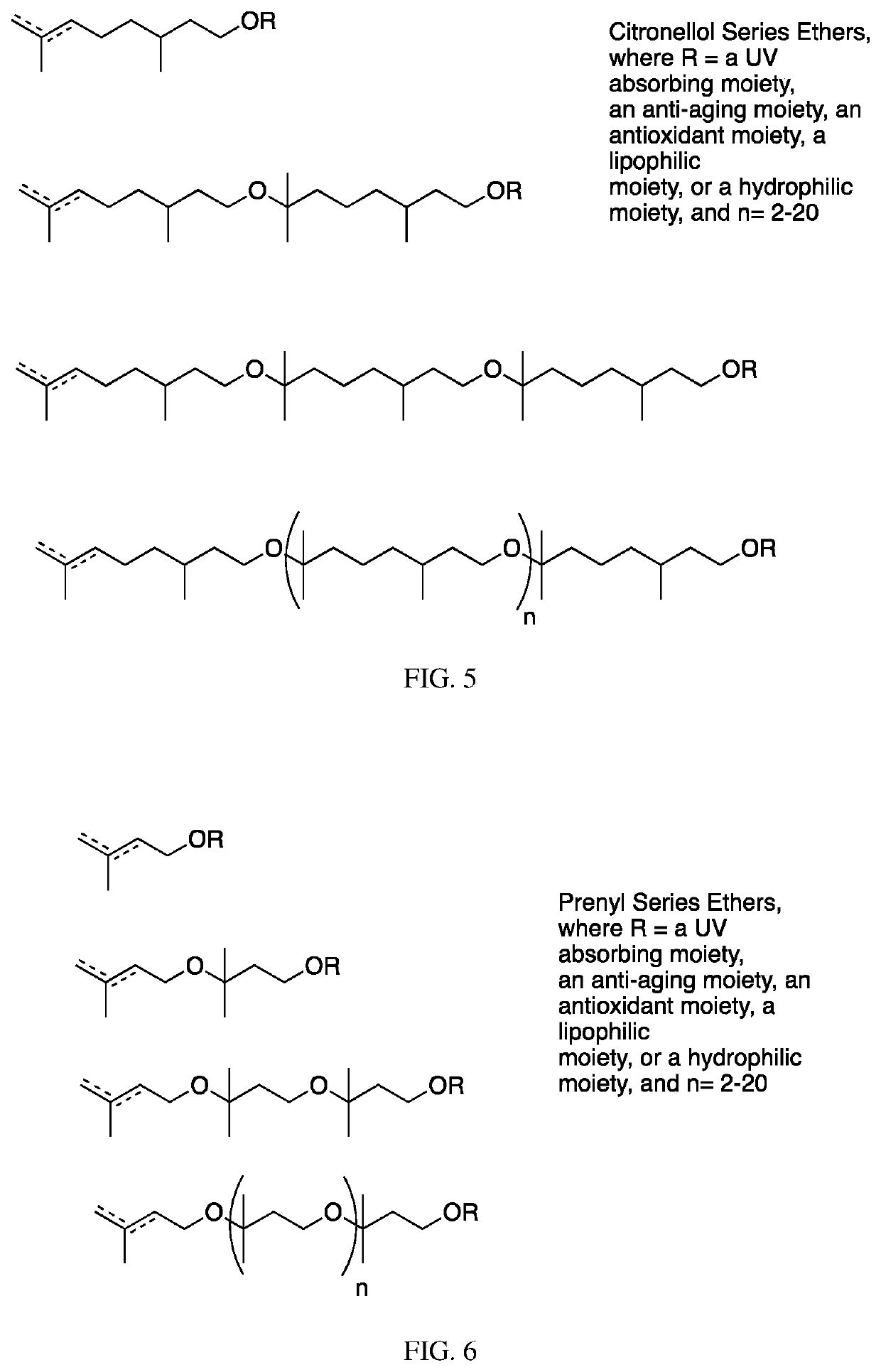

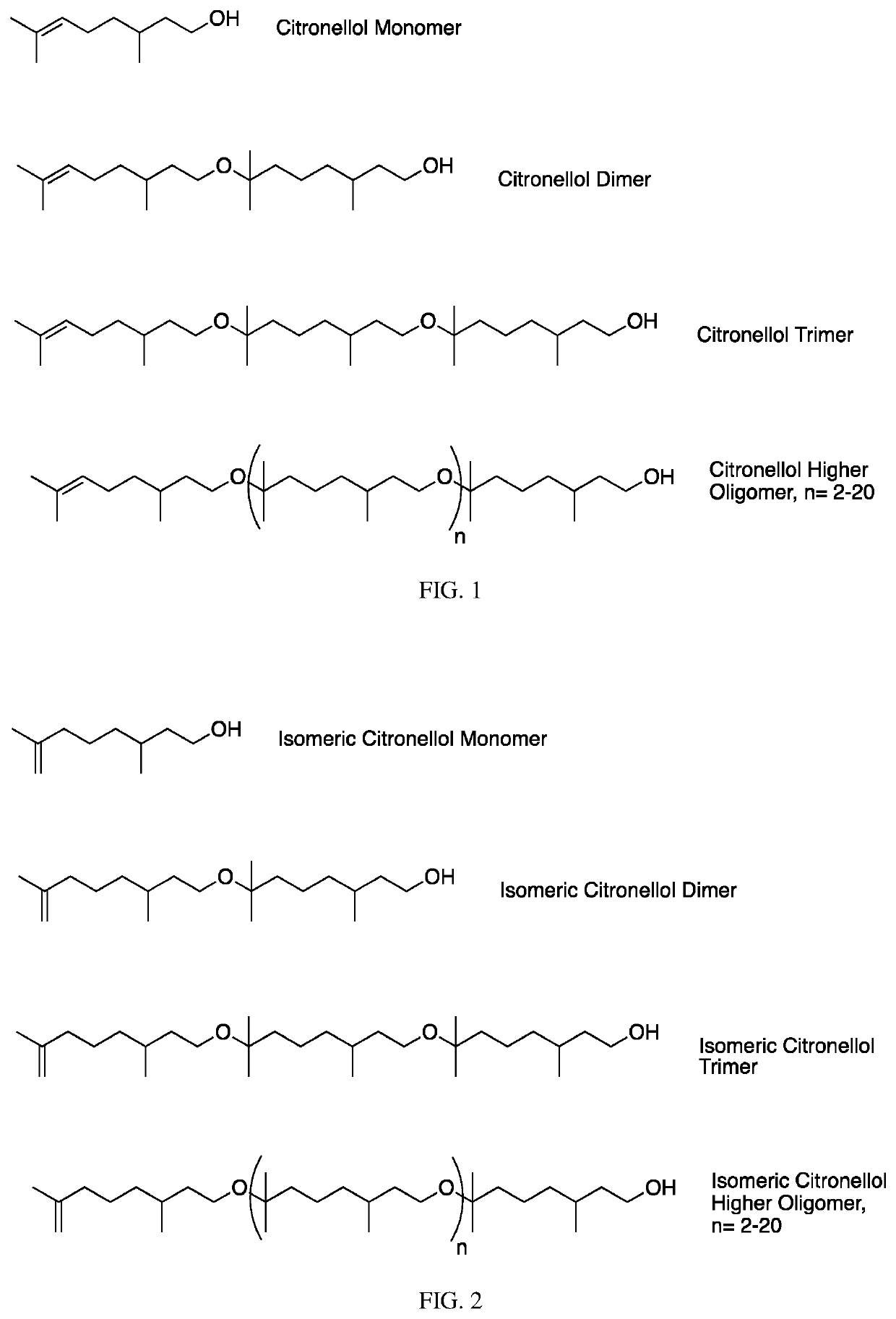

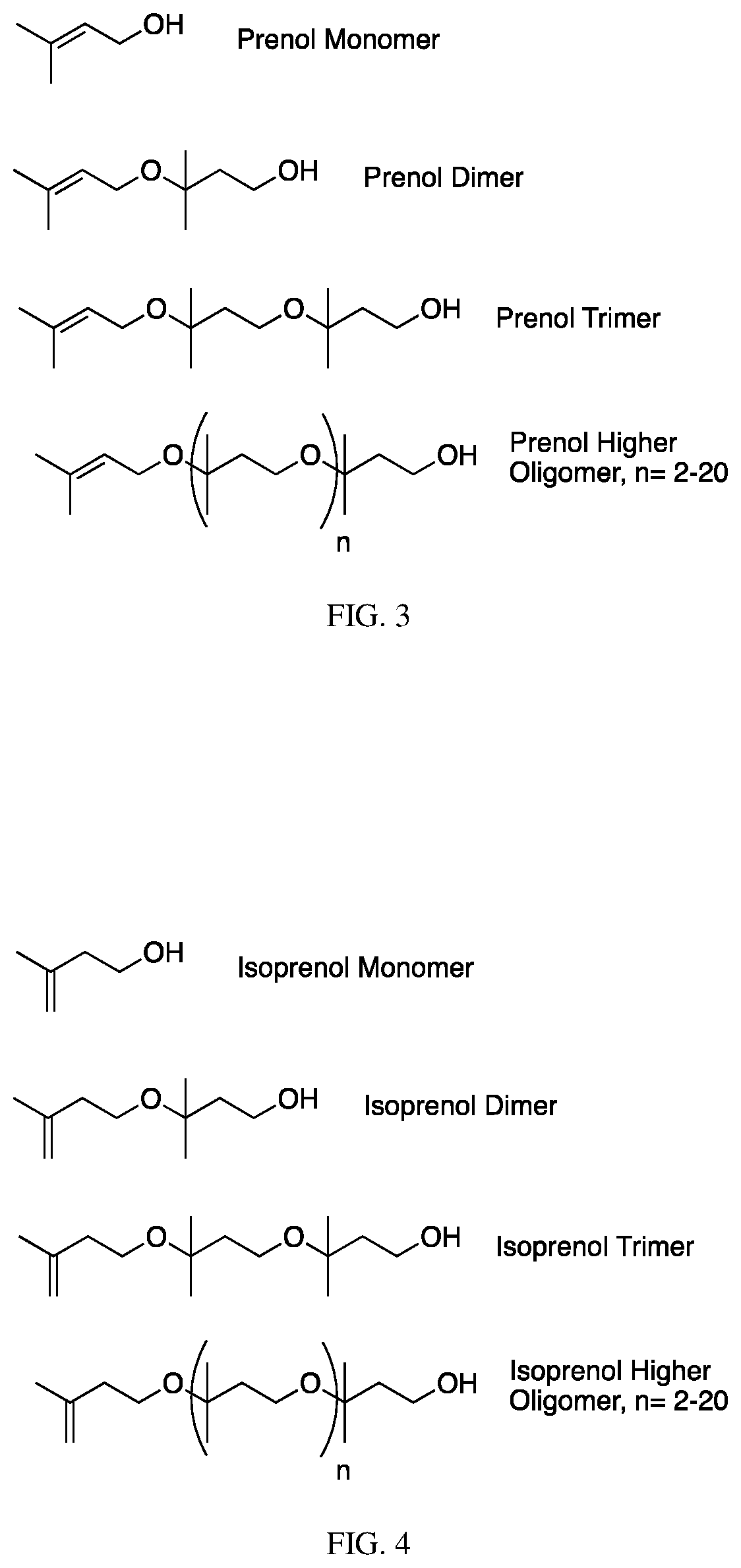

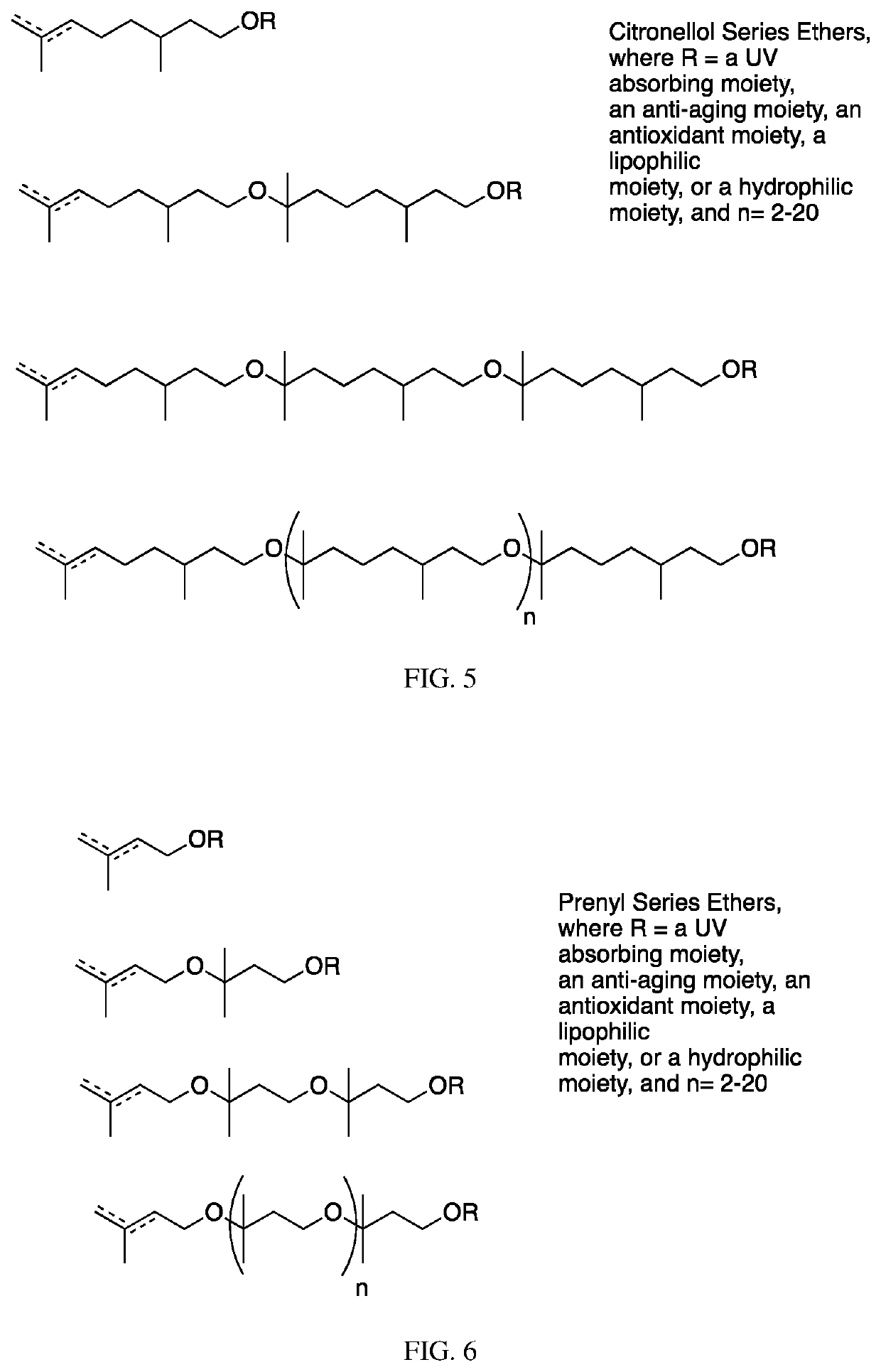

Polyether derivatives, uses, and methods of making the same

The invention contemplates certain polyethers, polyether derivatives, and methods of making and using those same polymers. For example, the starting materials can, e.g., citronellol, prenol, isocitronellol and isoprenol.

Owner:P2 SCI INC

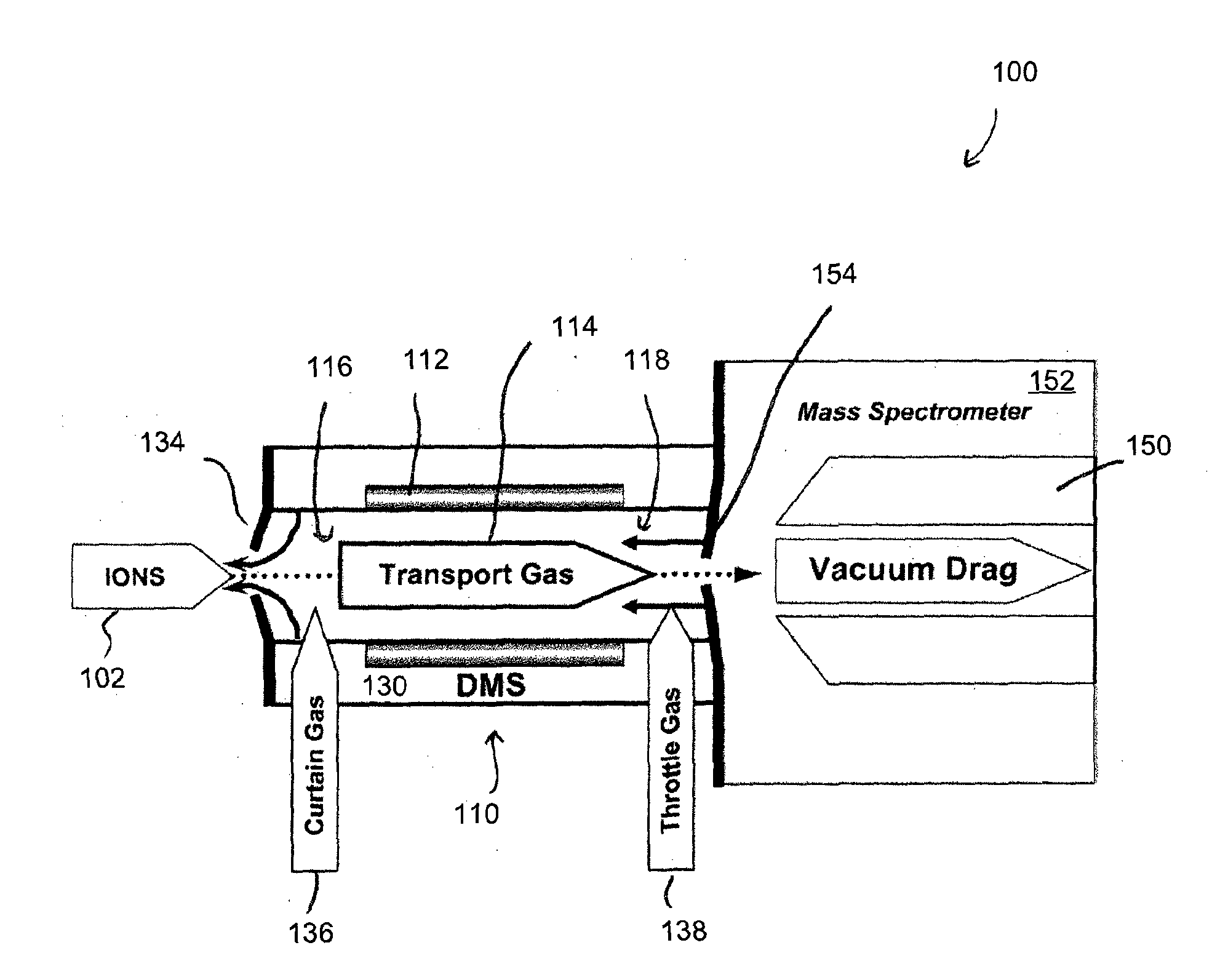

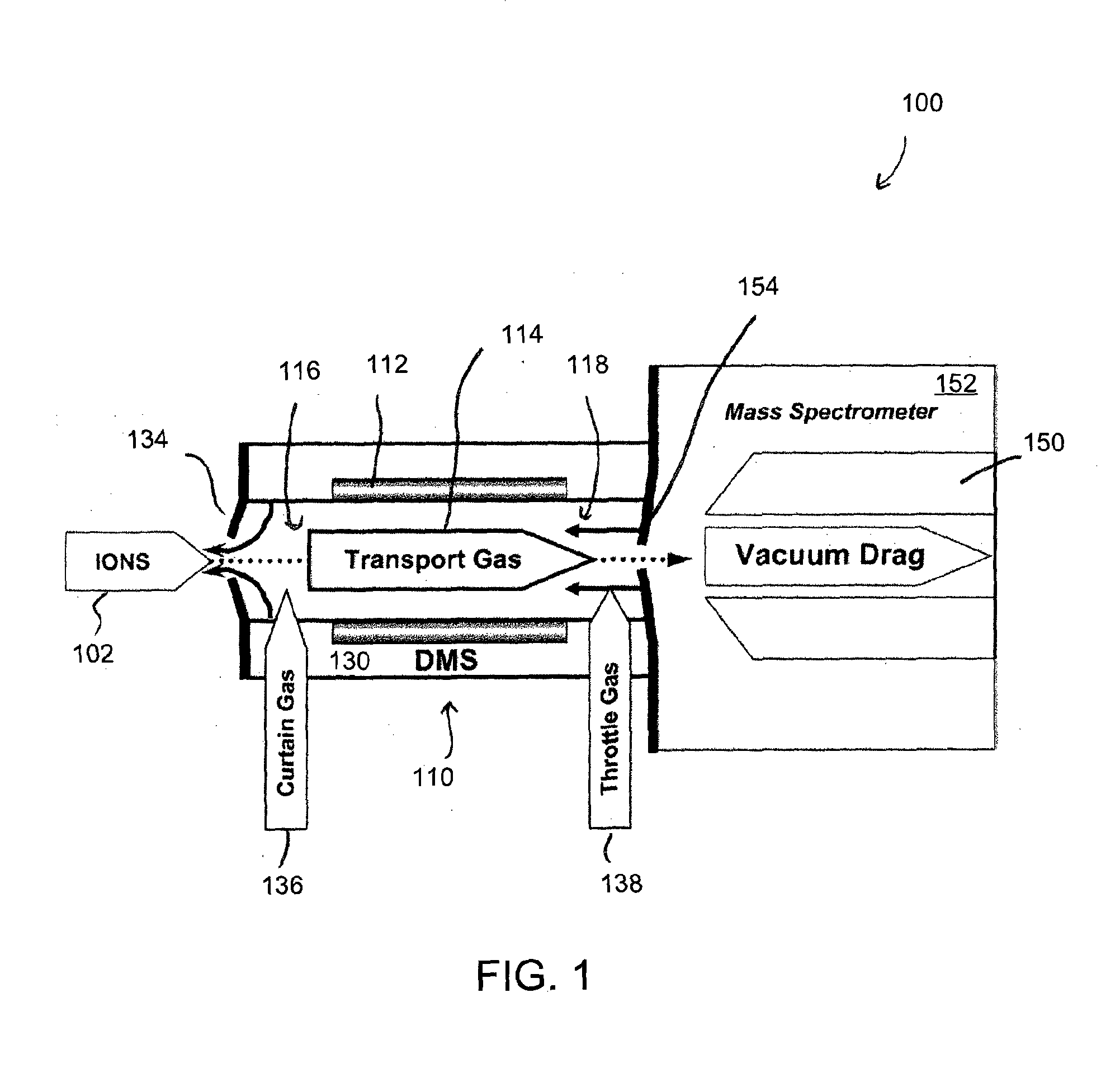

Methods for analysis of isomeric lipids

ActiveUS20150316507A1Allow separationEasy to separateSamples introduction/extractionMaterial analysis by electric/magnetic meansLipid formationPolyketide

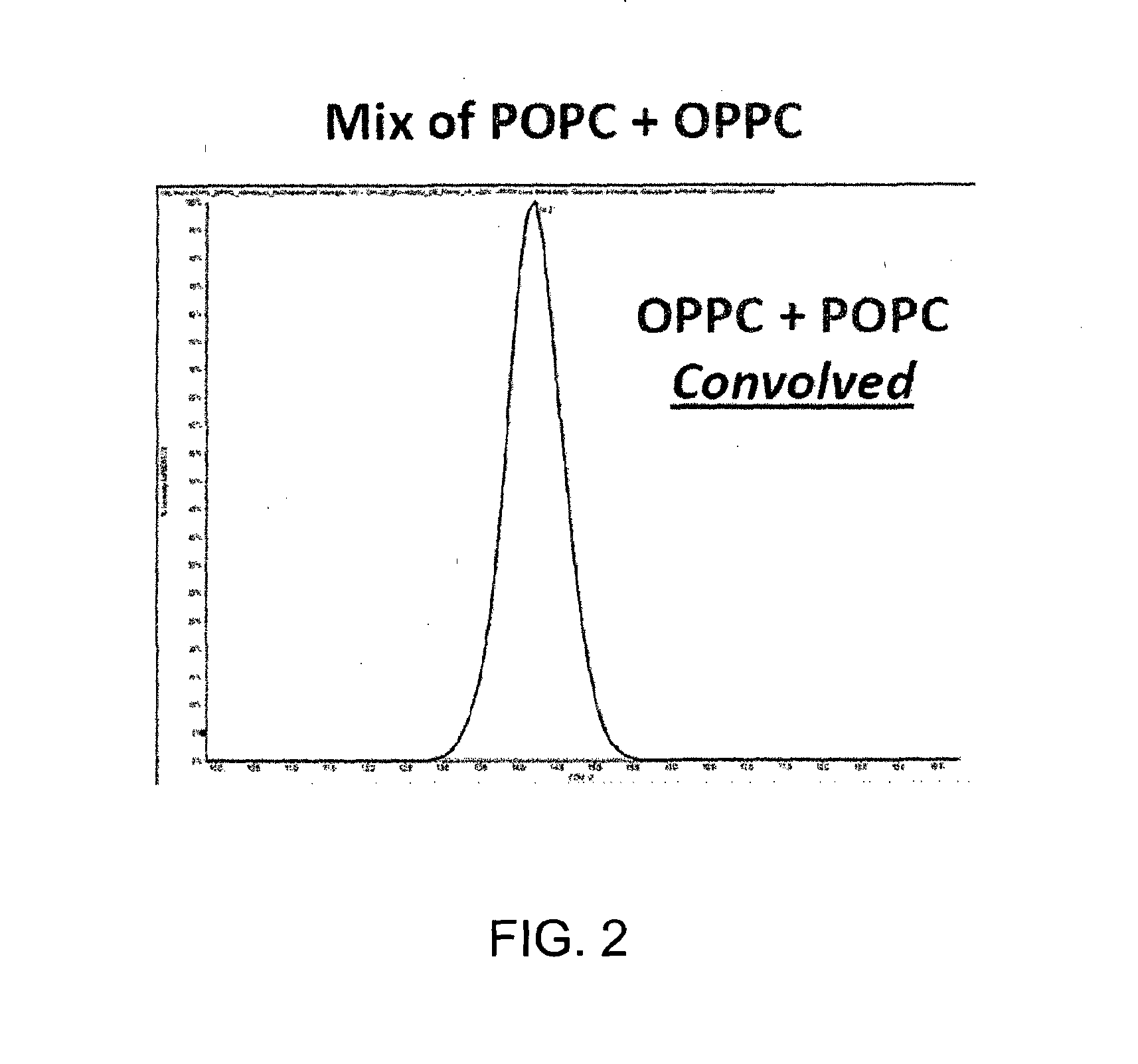

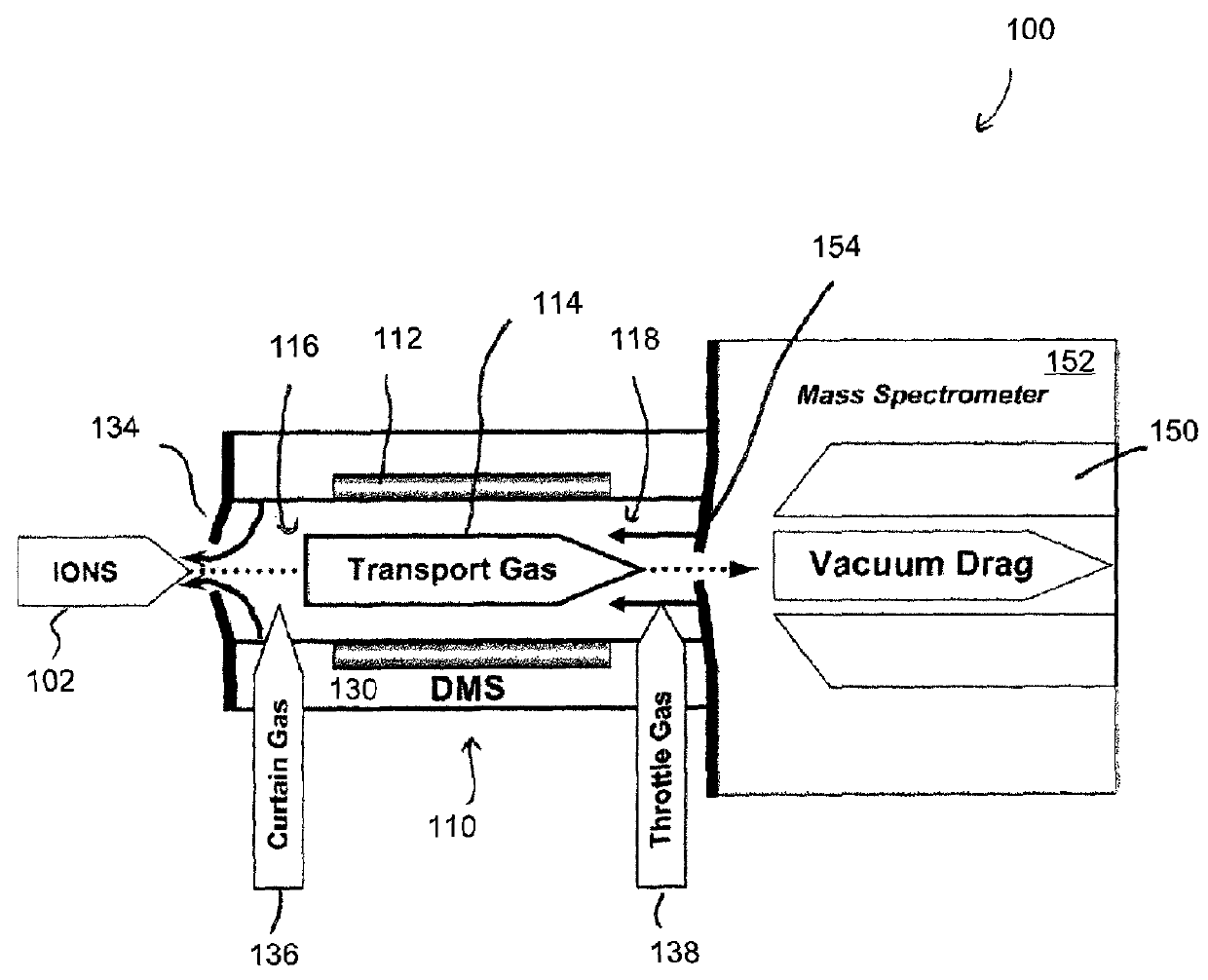

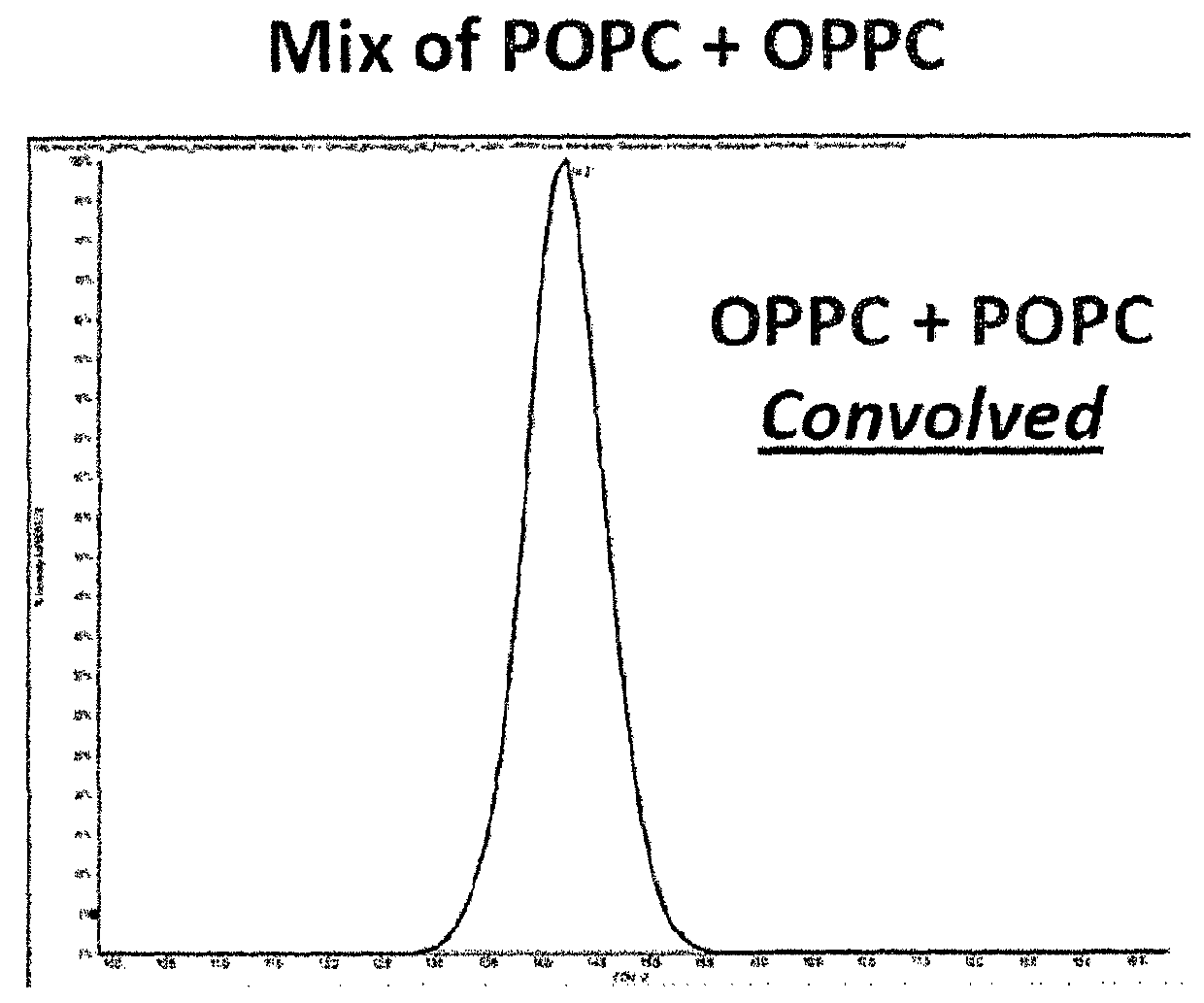

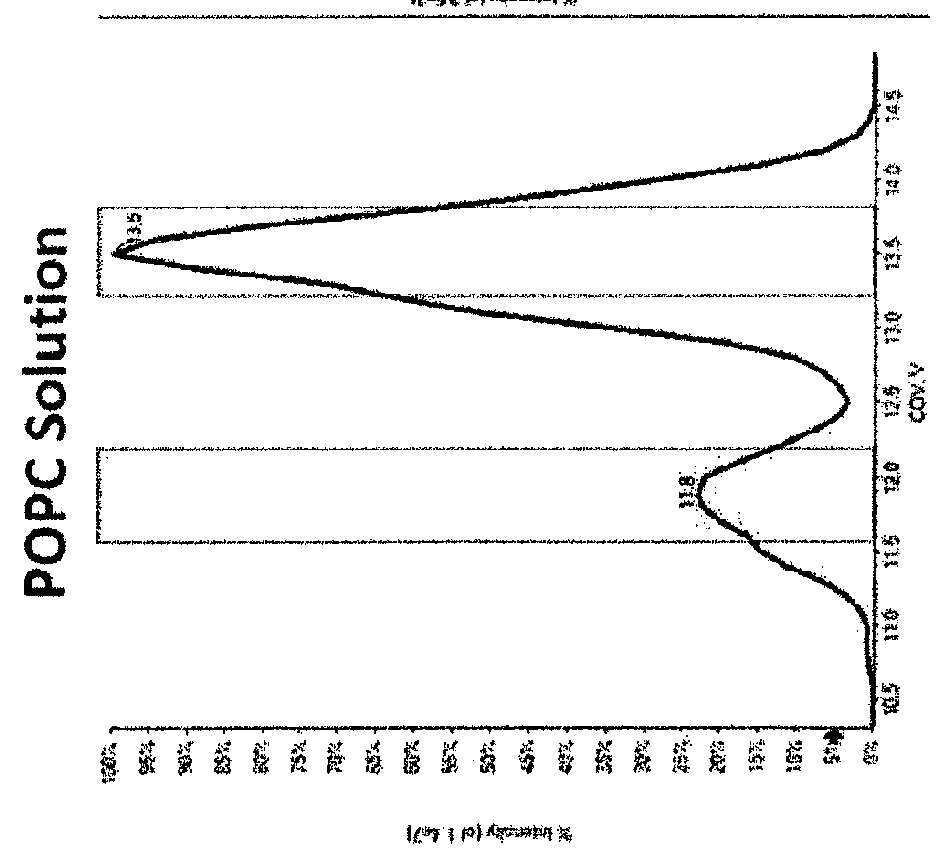

A method for analyzing a sample that contains a plurality of lipid isomers is described that involves forming one or more lipid metal ion adducts and transporting the one or more lipid metal ion adducts through a Mix of POPC+OPPC differential mobility spectrometer to cause separation of the one or more lipid metal ion adducts from each other. The lipid isomers can be chosen, for example, from fatty acids, glycerolipids, glycerophospholipids, sphingolipids, saccharolipids, polyketides, sterol lipids, and prenol lipids. Particular examples include phosphatidylcholine regioisomers such as 1-palmatoyl-2-oleoyl-sn-phosphatidylcholine (POPC) and 1-oleoyl-2-palmatoyl-sn-phosphatidylcholine and triacylglycerols containg palmetic and oleic acid groups. The metal chosen can include a cationization reagent that contains sodium, potassium, silver or lithium.

Owner:DH TECH DEVMENT PTE

Methods for analysis of isomeric lipids

ActiveUS9360455B2Allow separationEasy to separateSamples introduction/extractionMaterial analysis by electric/magnetic meansLipid formationPolyketide

A method for analyzing a sample that contains a plurality of lipid isomers is described that involves forming one or more lipid metal ion adducts and transporting the one or more lipid metal ion adducts through a differential mobility spectrometer to cause separation of the one or more lipid metal ion adducts from each other. The lipid isomers can be chosen, for example, from fatty acids, glycerolipids, glycerophospholipids, sphingolipids, saccharolipids, polyketides, sterol lipids, and prenol lipids. Particular examples include phosphatidylcholine regioisomers such as 1-palmatoyl-2-oleoyl-sn-phosphatidylcholine (POPC) and 1-oleoyl-2-palmatoyl-sn-phosphatidylcholine and triacylglycerols containing palmetic and oleic acid groups. The metal chosen can include a cationization reagent that contains sodium, potassium, silver or lithium.

Owner:DH TECH DEVMENT PTE

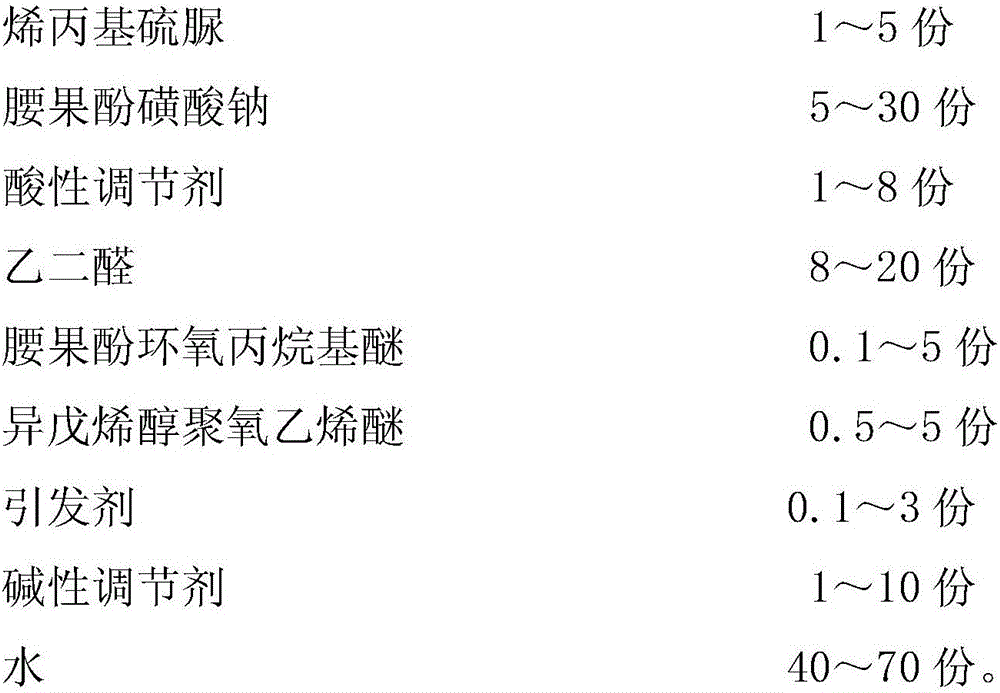

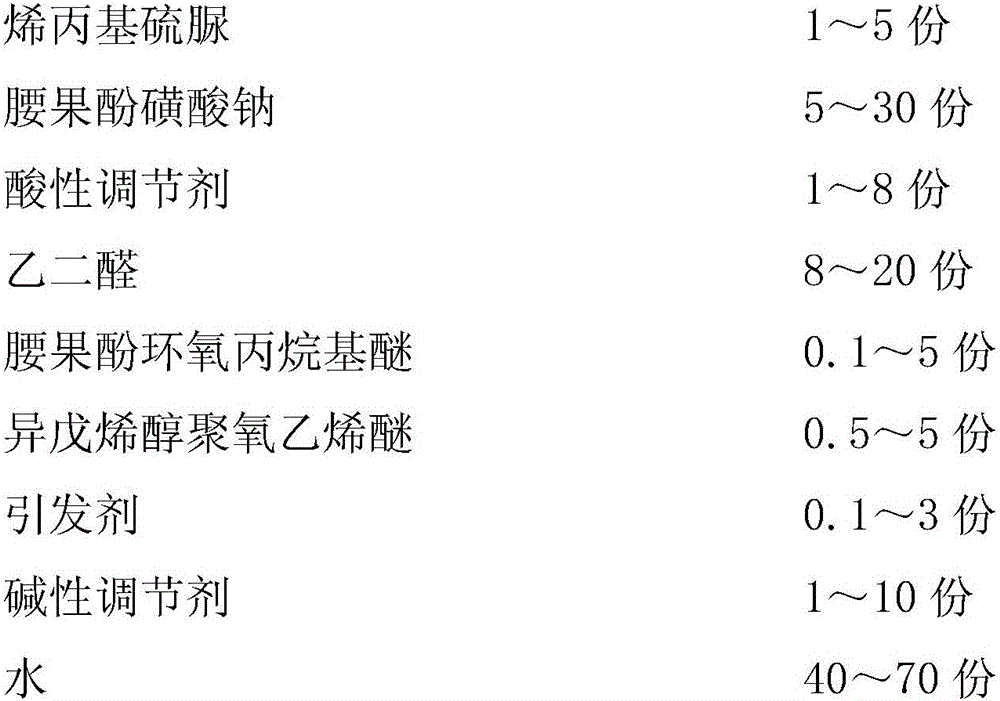

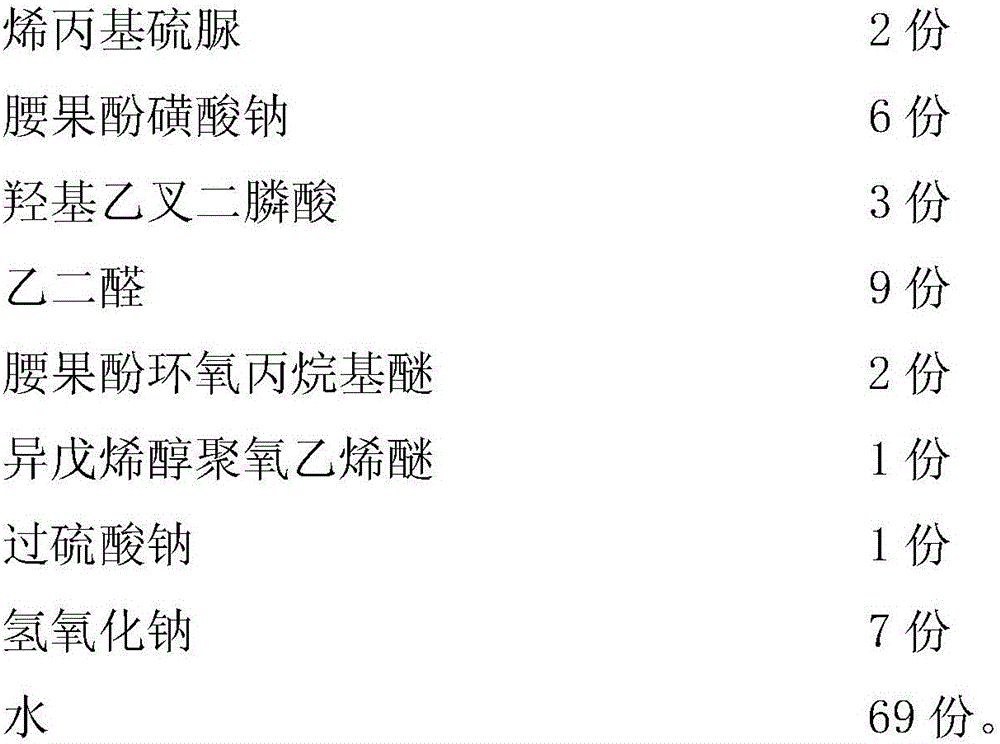

A kind of ceramic dispersant and preparation method thereof

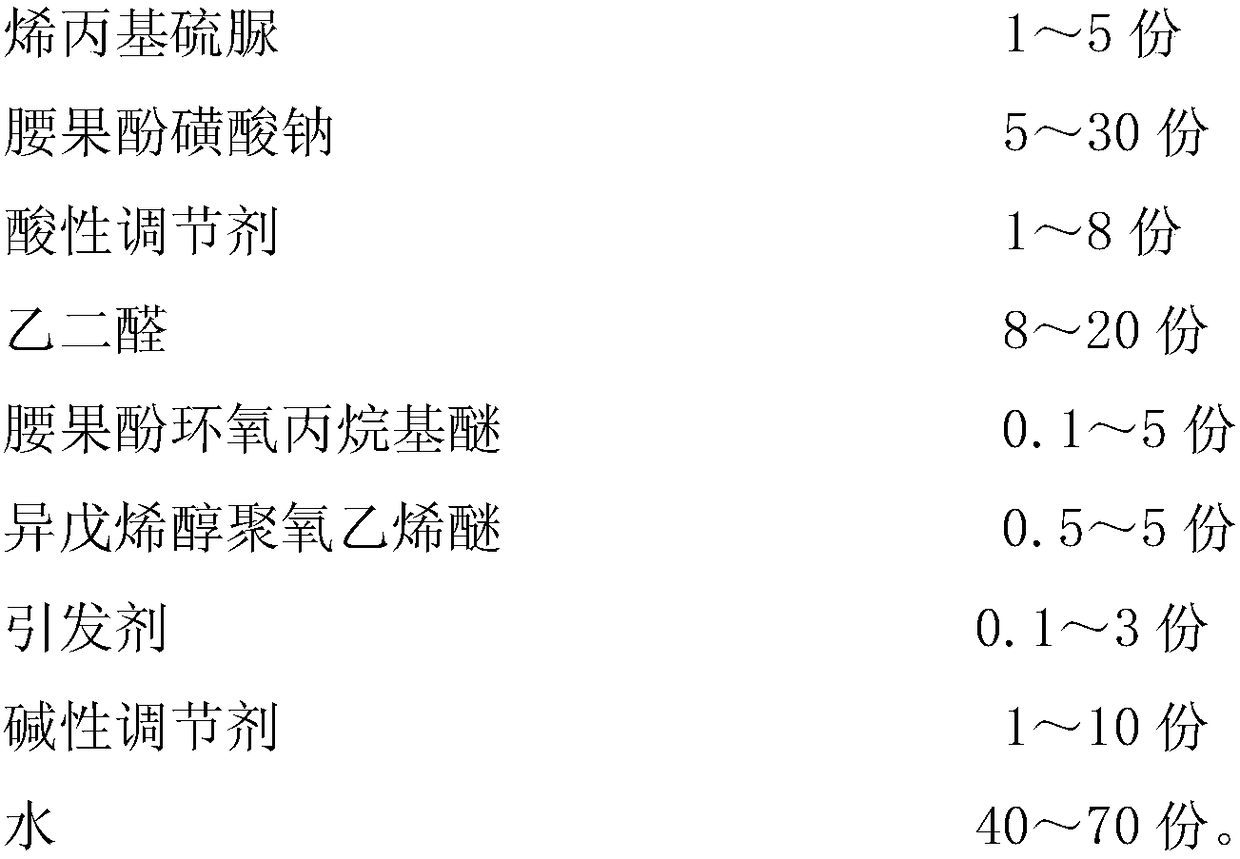

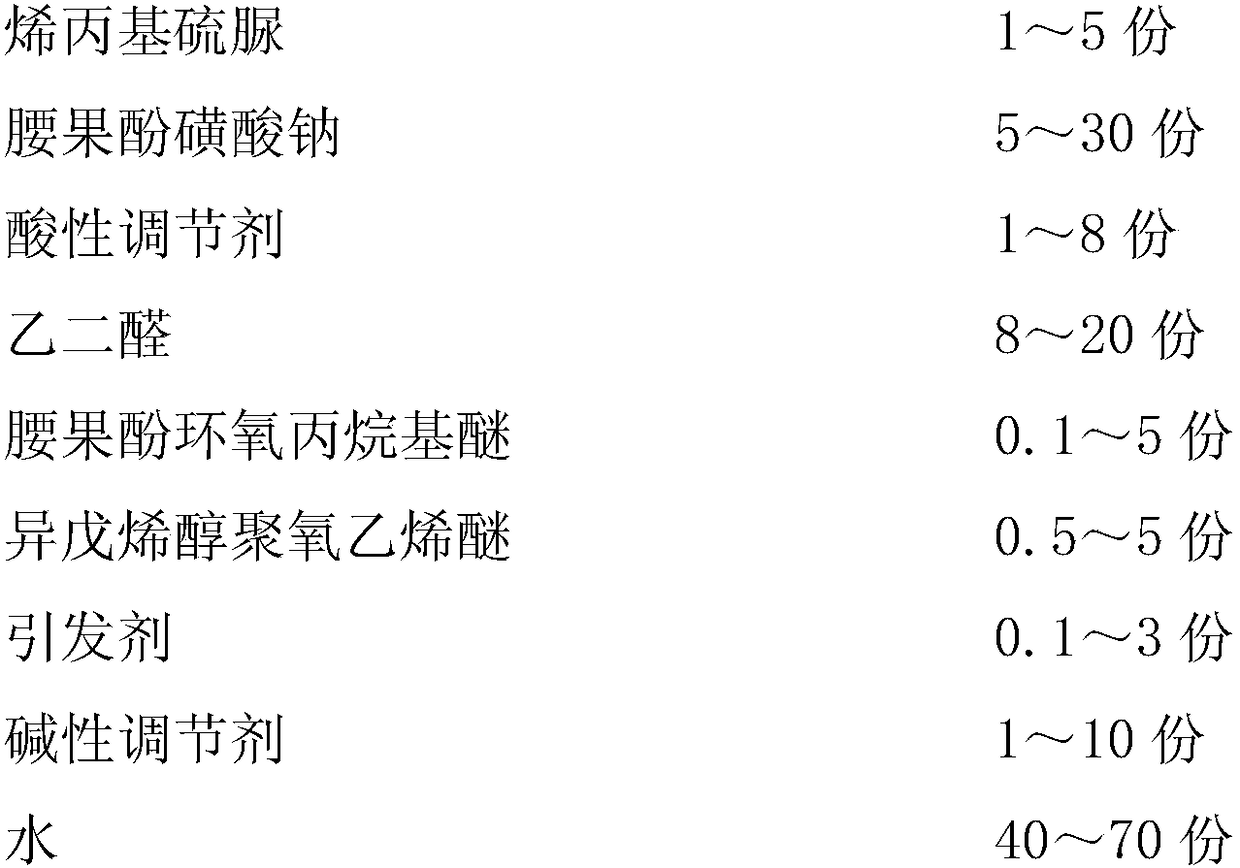

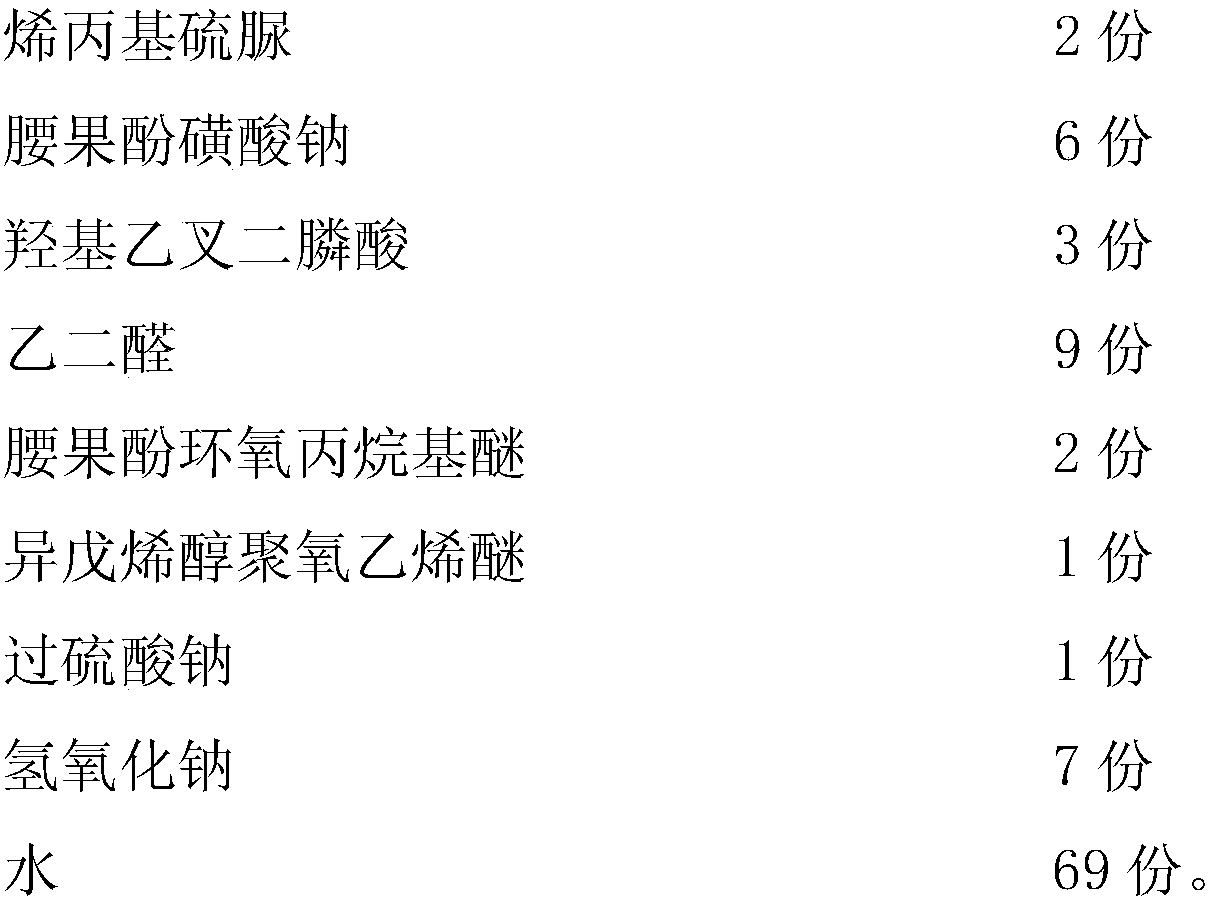

The invention provides a ceramic dispersing agent and a preparation method thereof. The preparation method comprises the following steps that 1, allylthiourea, cardanol sodium sulfonate, an acidity regulating agent and water are added into a reaction kettle, stirring is started, and heating is started to increase the temperature; 2, when the temperature is increased to 100 DEG C-120 DEG C, glyoxal starts to be dropwise added, and the dropwise adding time is 1-5 h; 3, cardanol epoxy propyl ether and prenol polyoxyethylene ether are added into the reaction kettle, and after the materials are stirred to be uniform, an initiator solution with the mass percent concentration of 1%-10% starts to be dropwise added, wherein the initiator solution is prepared from an initiator and part of water, the dropwise adding time is controlled to be 0.5-3 h, and the dropwise adding temperature is controlled to be 95 DEG C-120 DEG C; 4, after dropwise adding is completed, reacting continues to be conducted for 1-4 h by keeping the temperature, an alkalinity regulating agent is added for neutralization, after neutralization is completed, retaining water is added, cooling and discharging are conducted, and then the ceramic dispersing agent is obtained.

Owner:广东枫树陶瓷原料有限公司

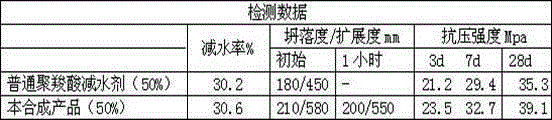

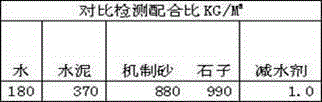

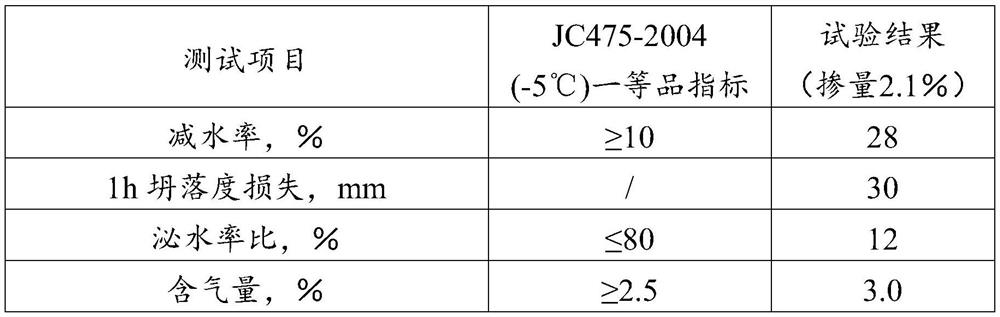

Special water reducing agent for machine-made sand, and synthesis method thereof

The present invention discloses a special water reducing agent for machine-made sand. The special water reducing agent is prepared from the following raw materials: a, prenol polyoxyethylene ether, b, acrylic acid or methacrylic acid, c, allyltrimethylammonium chloride, d, ammonium persulfate, e, sodium hypophosphite, f, mercapto propionic acid or mercapto acetic acid, and g, sodium hydroxide, wherein a mol ratio of a to b to c to g is 1:2-3:0.2-0.3:1-2, the amount of the raw material d is 0.2-0.5% of the total amount of the raw material, the amount of the raw material e is 1-2% of the total amount of the raw material, and the amount of the raw material f is 0.1-0.3% of the total amount of the raw material. The present invention further discloses a synthesis method of the special water reducing agent. According to the present invention, the special water reducing agent product has characteristics of good adaptability to machine-made sand concrete and effective machine-made sand concrete quality improving, and has broad market prospects.

Owner:吉林众鑫化工集团有限公司

Pentenoic acid methylester preparation process

The invention mainly discloses a pentenoic acid methylester preparation method, which is characterized in that prenol and trimethyl orthoacetate are in pressurized reaction in the existence of catalysts, and the by-product methanol is recovered by rectifying, so that pentenoic acid methylester is prepared. The pentenoic acid methylester preparation process has the advantages that reaction time is only 12-15 hours by means of pressurizing and catalyst synthesis, and the content of the prepared pentenoic acid methylester is higher than 99.8%.

Owner:NANTONG TENDENCI CHEM

Ceramic dispersing agent and preparation method thereof

The invention provides a ceramic dispersing agent and a preparation method thereof. The preparation method comprises the following steps that 1, allylthiourea, cardanol sodium sulfonate, an acidity regulating agent and water are added into a reaction kettle, stirring is started, and heating is started to increase the temperature; 2, when the temperature is increased to 100 DEG C-120 DEG C, glyoxal starts to be dropwise added, and the dropwise adding time is 1-5 h; 3, cardanol epoxy propyl ether and prenol polyoxyethylene ether are added into the reaction kettle, and after the materials are stirred to be uniform, an initiator solution with the mass percent concentration of 1%-10% starts to be dropwise added, wherein the initiator solution is prepared from an initiator and part of water, the dropwise adding time is controlled to be 0.5-3 h, and the dropwise adding temperature is controlled to be 95 DEG C-120 DEG C; 4, after dropwise adding is completed, reacting continues to be conducted for 1-4 h by keeping the temperature, an alkalinity regulating agent is added for neutralization, after neutralization is completed, retaining water is added, cooling and discharging are conducted, and then the ceramic dispersing agent is obtained.

Owner:广东枫树陶瓷原料有限公司

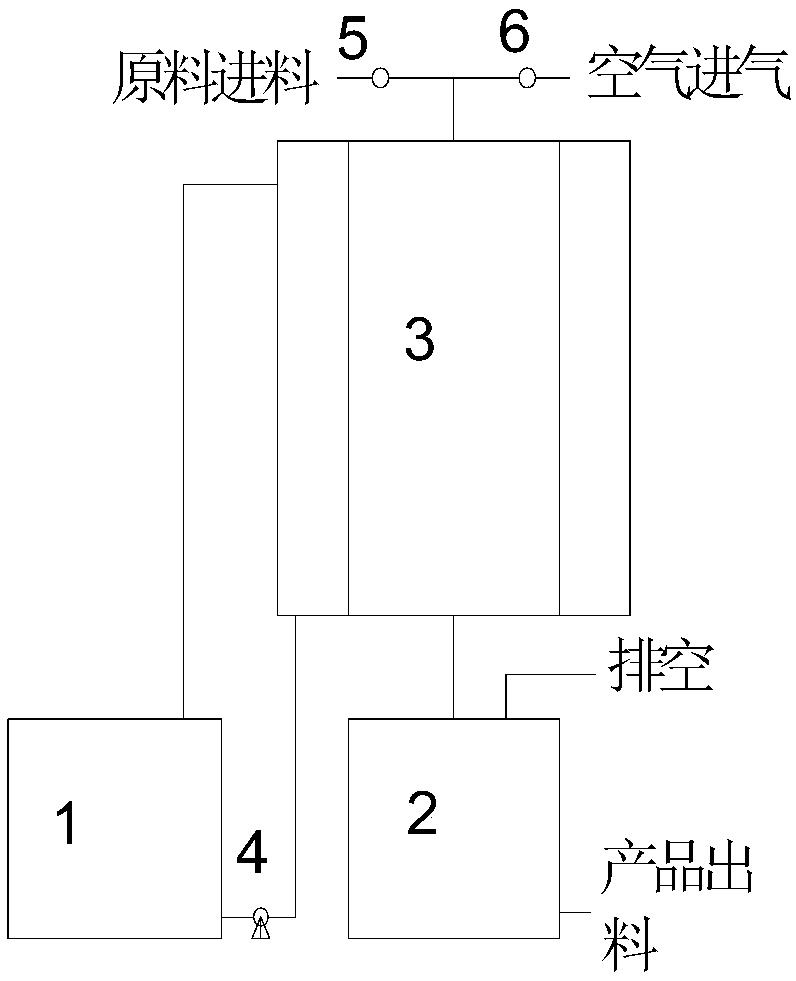

Process for producing prenol and prenal from isoprenol

ActiveUS20190077736A1High reactivityHigh selectivityPreparation by isomerisationOrganic compound preparationIsomerizationDehydrogenation

The present invention relates to a process for preparing 3-methyl-2-butenol (prenol) and 3-methyl-2-butenal (prenal) from 3-methyl-3-butenol (isoprenol), in which 3-methyl-3-butenol is subjected to a catalytic isomerization over a carbon-supported Pd catalyst in the presence of a gas mixture comprising 1% to 15% by volume of oxygen to obtain a first product mixture, and the first product mixture is subjected to an oxidative dehydrogenation over a Pd catalyst comprising SiO2 and / or Al2O3 as support material, or over a carbon-supported Pd / Au catalyst in the presence of a gas mixture comprising 5% to 25% by volume of oxygen.

Owner:BASF AG

Polyether derivatives, uses, and methods of making the same

The invention contemplates certain polyethers, polyether derivatives, and methods of making and using those same polymers. For example, the starting materials can, e.g., citronellol, prenol, isocitronellol and isoprenol.

Owner:P2 SCI INC

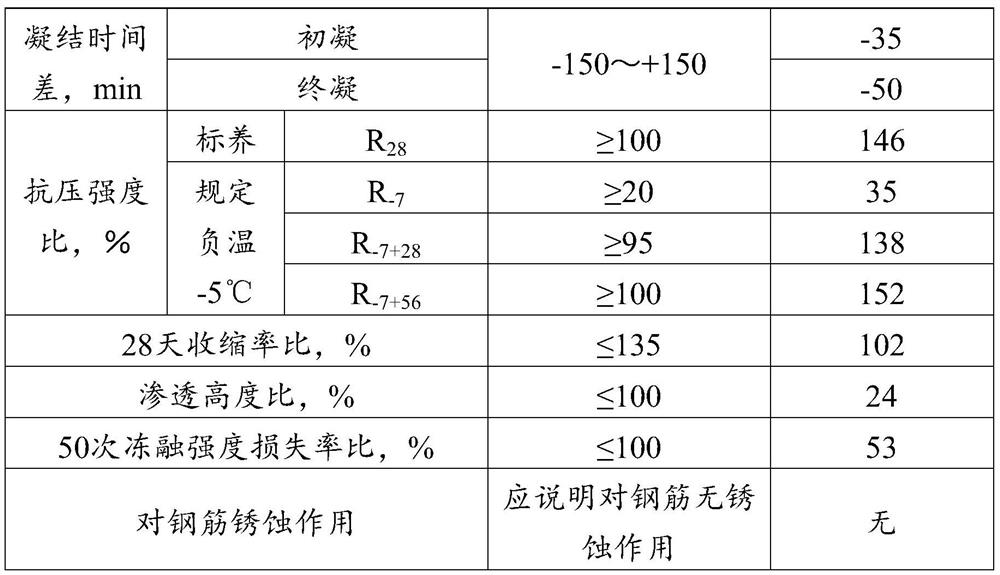

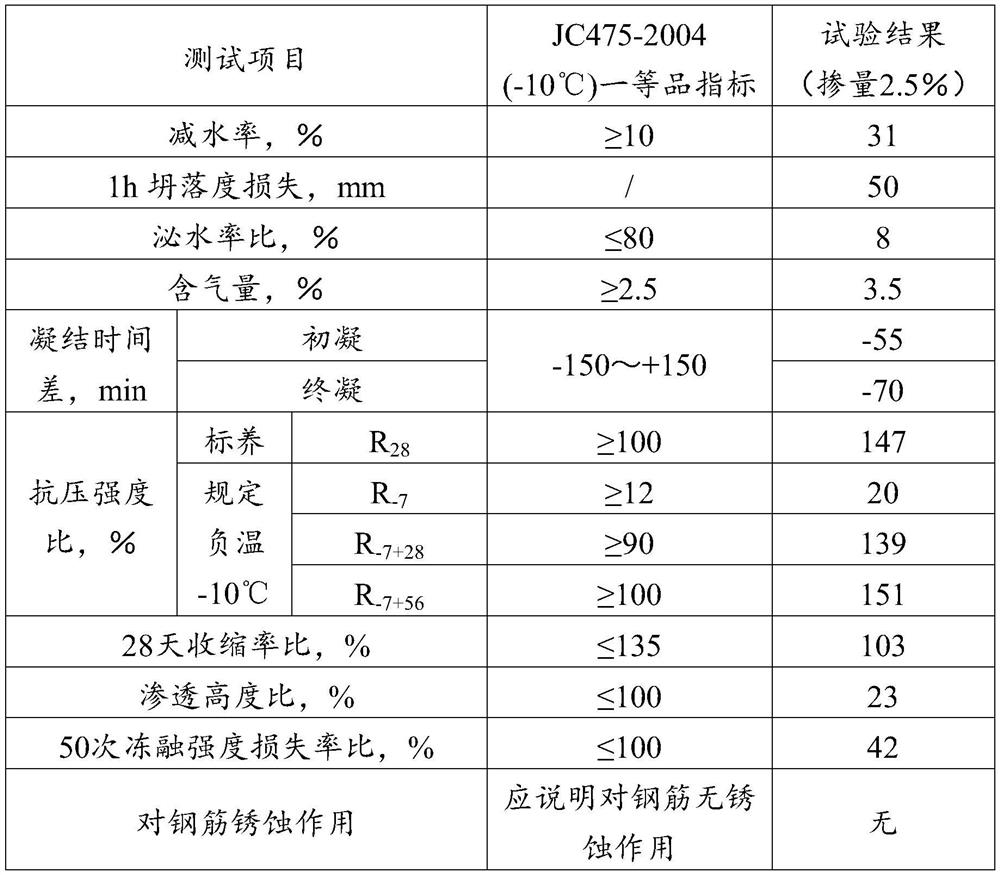

Water reducing agent and preparation method thereof, antifreeze agent and use thereof, and concrete

The invention provides a water reducing agent and a preparation method thereof, an antifreeze agent and its use, and concrete, and relates to the technical field of antifreeze. The water reducing agent includes the following raw materials: prenol polyoxyethylene ether and allyl alcohol polyoxyethylene ether, and at least one of acrylic acid and maleic anhydride, wherein the prenol polyoxyethylene ether and the The molar ratio of the allyl alcohol polyoxyethylene ether is 1:(0.5-1). Antifreezes include the aforementioned water reducers and non-oxidizing salts. In the water reducing agent, isoprenol polyoxyethylene ether and allyl alcohol polyoxyethylene ether are used to synthesize the water reducing agent. Workability, when the water reducer is used in antifreeze, because the water reducer has strong early strength properties, it can effectively reduce the use of antifreeze early strength components in antifreeze; antifreeze is safe and conducive to Reducing the alkali content in concrete can effectively reduce the risk of concrete bleeding.

Owner:北京金隅节能科技有限公司 +1

A water-reducing agent with high cement compatibility

ActiveCN111943559BGood compatibilityReduced hydration rateO-Phosphoric Acid(Hydroxyethyl)methacrylate

The invention discloses a water reducing agent with high cement compatibility, which comprises component A and component B, and the raw materials of component A are: isopentenol polyoxyethylene ether, reducing agent, acrylic acid, hydroxyethyl methacrylate, Chain transfer agent, polyethylene glycol diacrylate, oxidizing agent and water; the preparation method of component B is: (1) ball mill the mixed powder of calcium aluminum silicate and calcium sulfate, and sieve; (2) configure sodium borate, phosphoric acid Sodium aqueous solution, heat the sieved powder to 1200-1250°C, keep it warm for 1-2h, then immerse it in the solution and water-cool it to room temperature, take it out after cooling, repeat the heating and keeping warm, soaking process twice; finally solid-phase washing, drying, Obtain solid phase A; (3) configure the aqueous solution of maleic acid and N,N-dimethylformamide in the container, soak solid phase A wherein, heat, keep warm, air-cool, filter, wash, dry, obtain Component B. The invention improves the compatibility between the concrete and the water reducing agent, reduces the hydration speed, improves the fluidity, and has very good use effect.

Owner:ZHUZHOU HONGXIN TECH DEV CO LTD

A kind of method for continuously preparing isopentenol

ActiveCN109721470BReduction of regeneration linksLow costPreparation by isomerisationPtru catalystPrenol

The invention discloses a method for continuously preparing isopentenol. The method is as follows: using 3-methyl-3-butene-1-alcohol as a raw material, dissolving a catalyst in the raw material, and adding a solvent according to the proportion , under a certain pressure and temperature, use a plunger pump to pump the raw materials into the reaction tube for reaction, collect the reaction solution after cooling, and rectify to obtain pure prenol, the product purity is greater than 99%. The method of the invention is prepared in a continuous manner, and the operation is simple and convenient, and the reaction is carried out in a non-hydrogen-facing state. The catalyst used does not need to be prepared in advance and does not use noble metals such as palladium, cerium, and tellurium, and the production cost is low.

Owner:CHINA CATALYST HLDG CO LTD

A kind of synthetic method of 3-methyl-2-butene-1-aldehyde diisopentenyl acetal

ActiveCN112299962BDelay inactivationImprove stabilityOrganic chemistryOrganic compound preparationPtru catalystHigh activity

The invention provides a synthesis method of 3-methyl-2-butene-1-aldehyde diprenyl acetal, in the presence of a supported catalyst, prenyl aldehyde and prenol undergo aldol condensation Synthesis of 3-methyl-2-butene-1-aldehyde di-isopentenyl acetal with high reaction activity and high selectivity. The catalyst of the present invention improves the activity of reactants and the selectivity of products, can obtain higher yields, avoids the problem of equipment corrosion, prolongs the service life of equipment, has remarkable environmental protection benefits, is environmentally friendly, and is beneficial to large-scale industrial production .

Owner:SHANDONG NHU PHARMA

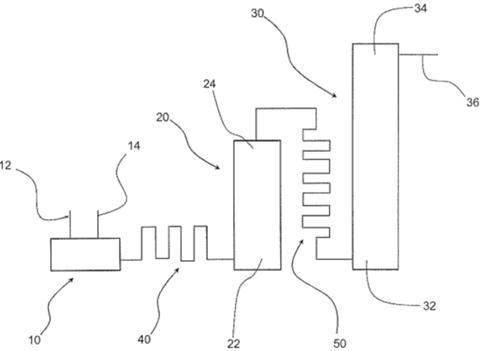

Method for continuously preparing prenol

The invention discloses a method for continuously preparing prenol. The method comprises the following steps: taking 3-methyl-3-butene-1-ol as a raw material, dissolving a catalyst in the raw material, adding a solvent according to a ratio, pumping the raw material into a reaction tube through a plunger pump under a certain pressure and temperature, carrying out a reaction, cooling the reaction liquid, then collecting the reaction liquid, and carrying out rectifying to obtain a prenol pure product, wherein the purity of the product is greater than 99%. According to the method disclosed by theinvention, preparation is carried out in a continuous mode, and operation is simple and convenient; the preparation is carried out in a non-hydrogen state, the adopted catalyst does not need to be prepared in advance, and precious metals such as palladium, cerium and tellurium are not used, so that production cost is low.

Owner:CHINA CATALYST HLDG CO LTD

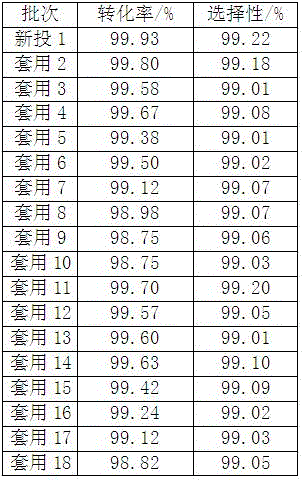

A kind of method that catalyzes prenyl alcohol to prepare prenyl aldehyde

ActiveCN109422632BEfficient oxidation productionStable oxidation productionOrganic compound preparationCarbonyl compound preparationButenePtru catalyst

The invention provides a method for preparing prenal by catalyzing the oxidation of prenol by a supported gold catalyst. The catalyst is a gold catalyst supported by Al2O3 or a bimetallic catalyst composed of gold and cheap metals. The alumina carrier of the catalyst is modified by alkali metals such as Na, Mg, K, and Cs, and one or two of gold, palladium, silver, and copper are loaded as active components. Among them, gold is the main active component, and its loading percentage is 0.1%-5%, and the secondary active components such as silver and copper are loaded at 0.1%-2%. Catalyst is used for the reaction of 3-methyl-2-butene-1-aldehyde (prenyl aldehyde) by oxidative dehydrogenation of 3-methyl-2-butene-alcohol (prenyl alcohol), at lower temperature The oxidative dehydrogenation of 3-methyl-2-buten-alcohol can be realized under the following conditions, and the selectivity of its product prenaldehyde is as high as 98%.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

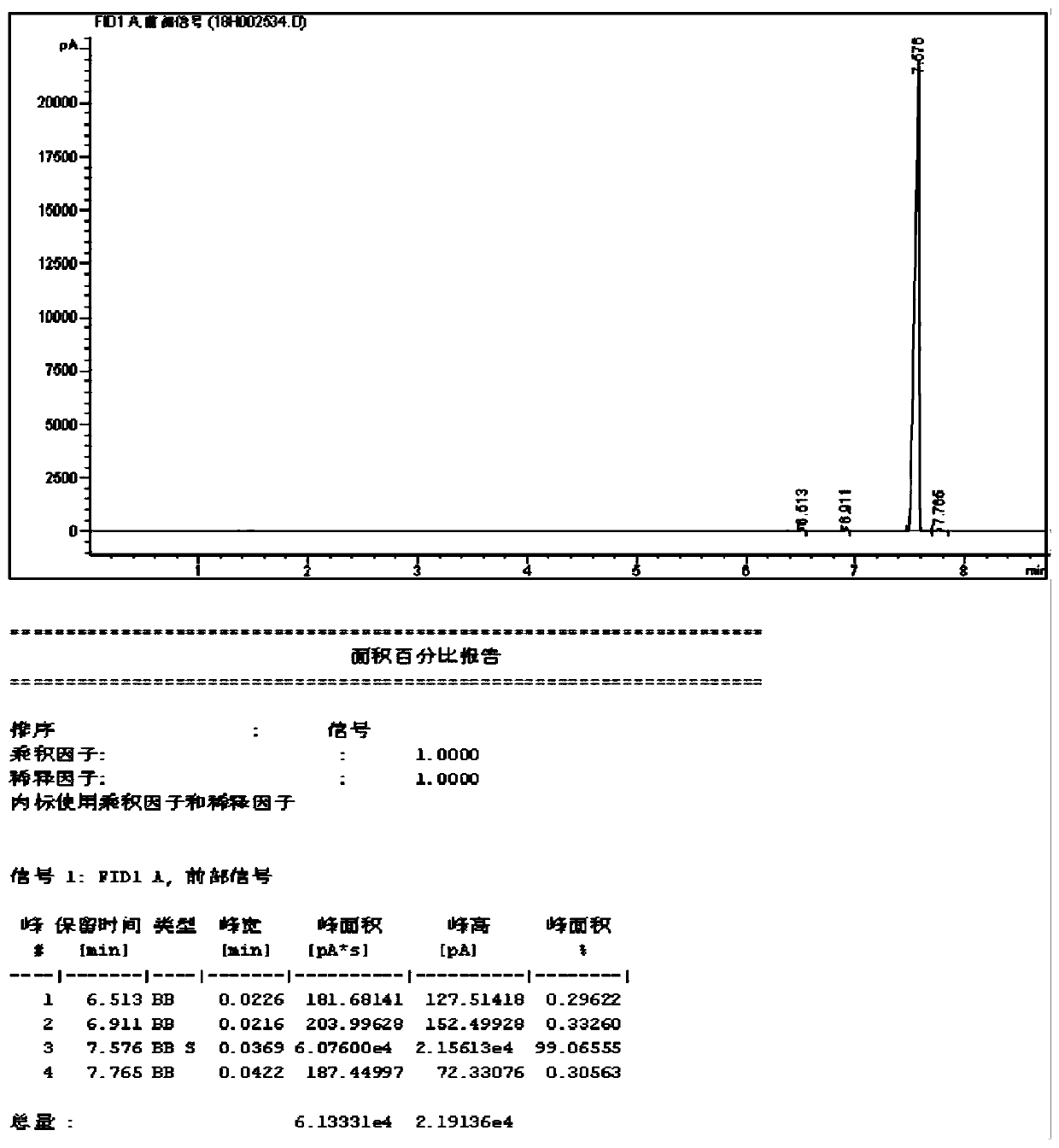

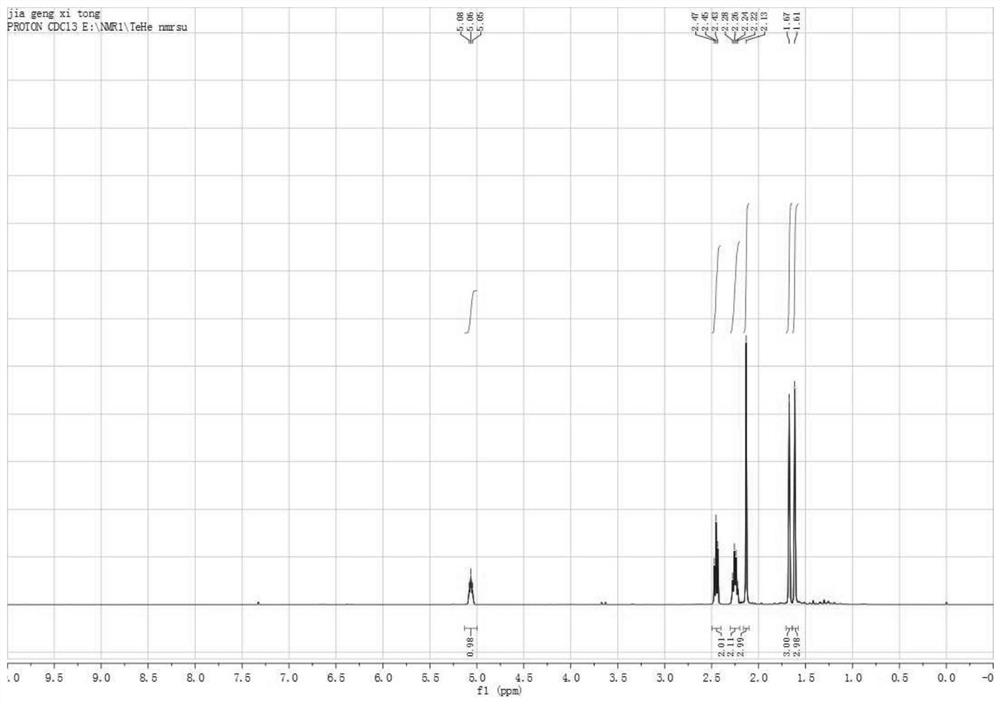

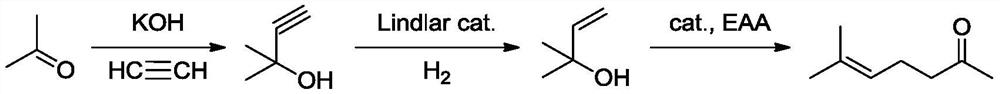

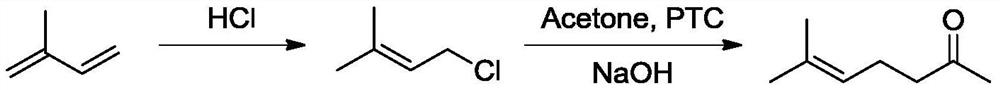

A method for synthesizing methylheptenone by isopentenol

ActiveCN109232212BLow costEasy to operateOrganic compound preparationCarbonyl compound preparationPtru catalystDistillation

The invention provides a method for efficiently synthesizing methyl heptenone from prenol. The method comprises: (1) prenol is reacted with concentrated hydrochloric acid under the action of catalyst A, the reaction liquid is phase-separated after the reaction, and the organic phase is distilled after washing to obtain 1-chloro-3-methyl-2-butene and A chlorinated mixture of 3-chloro-3-methyl-1-butene; (2) the above-mentioned chlorinated mixture is directly condensed with acetone under the action of catalyst B to obtain a single product, methyl heptenone. The present invention adopts metal inorganic salt as a catalyst and concentrated hydrochloric acid as a chlorination agent to efficiently realize the chlorination of prenyl alcohol; the chlorination reaction liquid is separated and simply distilled to obtain a chlorinated mixture without the need for isomerization conversion and purification. Operation steps such as distillation and purification; use N,N-dimethylformamide as the condensation reaction solvent, which promotes the dissolution of the base, does not need to add a phase transfer catalyst, reduces the condensation reaction time, and improves the reaction yield.

Owner:WANHUA CHEM GRP CO LTD

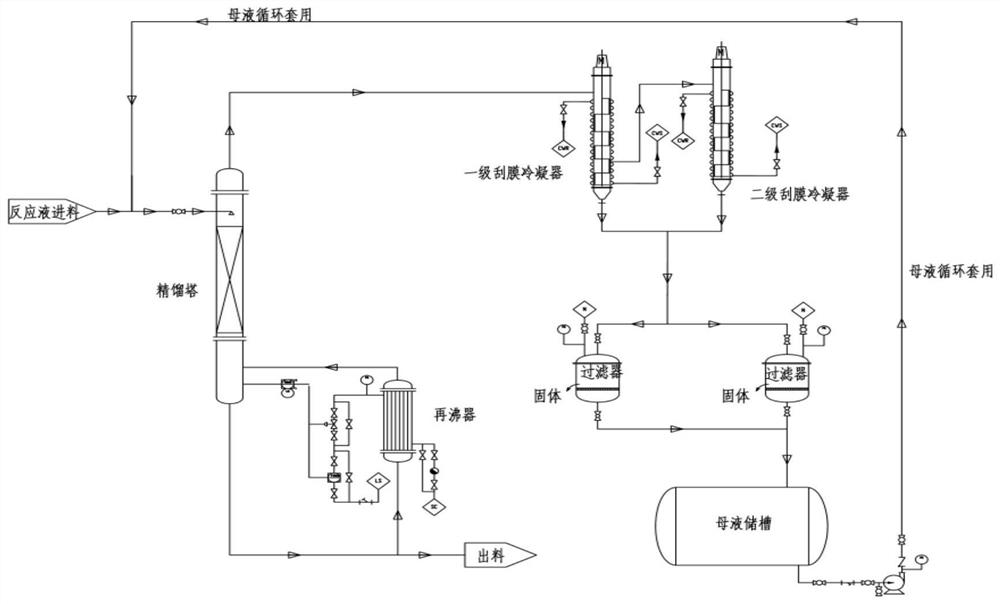

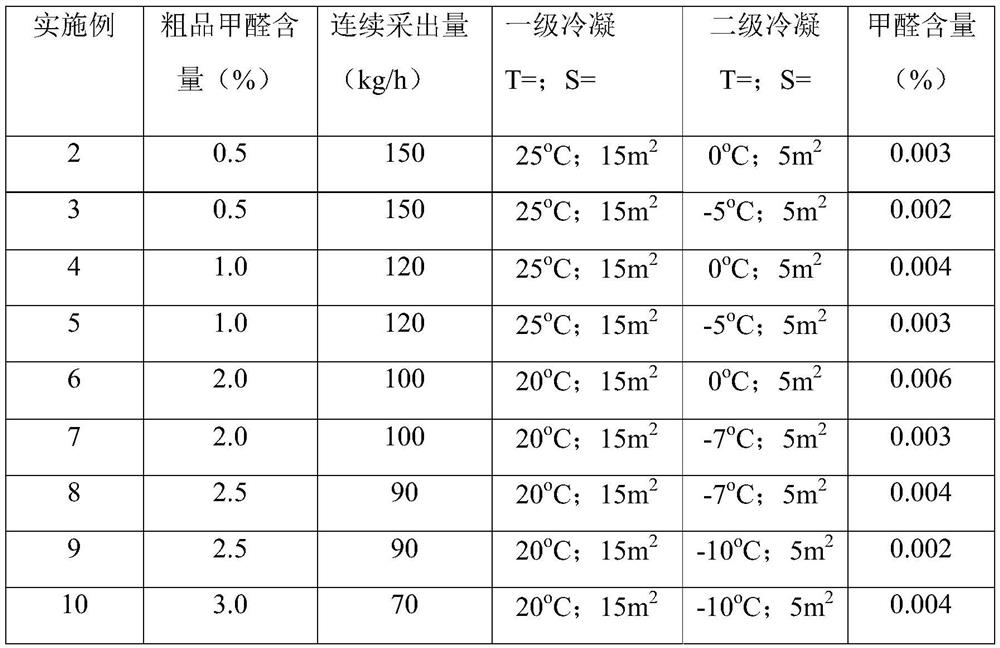

A kind of recovery method of formaldehyde in prenol system synthesized by supercritical method

ActiveCN107188783BOrganic compound preparationHydroxy compound separation/purificationAlcoholAlcohol synthesis

The invention discloses a method of recovering formaldehyde from a supercritical method prenyl alcohol synthesis system. According to the method, formaldehyde-containing 3-alcohol crude product which is obtained by supercritical reactions is subjected to continuous rectification under a normal pressure; formaldehyde and a little of 3-alcohol are directly produced from the tower top; formaldehyde is enriched continuously and carries out self-polymerization to form polymer (solid) adhered on the internal wall of a condenser; then the formaldehyde polymer is separated by a scraper and a cold filtering method; and 3-alcohol obtained by tower top filtering and 3-alcohol in the tower bottom are dehydrated, weight-reduced, and rectified to carry out purification. By adopting the method, the formaldehyde content of 3-alcohol crude product can be reduced to less than 0.01%, the product becomes qualified, at the same time, the recovered formaldehyde polymer can be used as a raw material, and the waste is converted into valuable resource. The technology can remove formaldehyde without adding any alkaline chemical reagent, the cost is saved, and the discharged wastewater is greatly reduced. The method is green and environmentally-friendly, has a lower cost, and can be widely used in industry.

Owner:ZHEJIANG NHU CO LTD +2

A kind of eggshell silver catalyst and its preparation method and application

ActiveCN111229216BImprove performanceImprove utilization efficiencyOrganic compound preparationCatalyst activation/preparationAlkaline earth metalPtru catalyst

The invention provides an eggshell-type silver catalyst and a preparation method and application thereof. The steps of the preparation method include: mixing a silver-containing solution, an alkali metal or alkaline earth metal-containing auxiliary agent and a dispersant, adding a carrier and immersing it for 20-60 minutes under normal pressure. , dried to obtain the first impregnated substance; the first impregnated substance was added to the precipitant solution, firstly impregnated under vacuum for 30-60 min, then released the vacuum, continued to impregnate for 30-60 min, and dried to obtain the second impregnated substance; the second impregnation After calcination and reduction, the eggshell silver catalyst was obtained. The preparation method of the invention has the advantages of simple process and mild conditions, the prepared eggshell-shaped silver catalyst in which the silver particles are evenly distributed on the surface of the carrier, realizes the technical effect that the loading amount and the thickness of the eggshell can be controlled at the same time, and has excellent catalytic performance and good catalyst life. , suitable for the oxidative dehydrogenation of alcohols to aldehydes and epoxidation reactions, especially the reaction of catalyzing the oxidative dehydrogenation of prenol to prepare prenaldehyde.

Owner:WANHUA CHEM GRP CO LTD

Composition for cleaning paint film

The invention discloses a composition for cleaning paint coating films, which is composed of the following components in weight percent: 45-55% of diglycolamine, 20-30% of isopentenol, and 5-10% of trifluoroethylene ether , hexamethyldisiloxane 6‑13%, hexaalkylphenoxy polyethoxybutanol 2‑8%, powdered sodium hydroxide 2‑5%, the sum of each component is 100%, can Quickly and easily remove the coating film on the substrate.

Owner:HAIAN GASOLINEEUM SCI RES INSTR

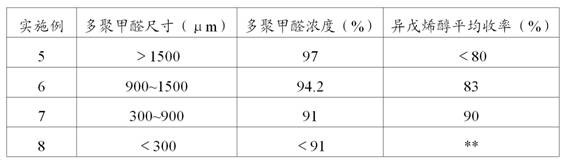

A kind of production technology of industrialized isopentenol

ActiveCN112430178BHigh selectivityHigh yieldOrganic compound preparationHydroxy compound preparationPrins reactionPrenol

The invention provides a production process of industrialized prenyl alcohol, comprising the following steps: A) depolymerizing paraformaldehyde to generate free formaldehyde; B) contacting the free formaldehyde with alkaline isobutylene, and carrying out Prince react to obtain isopentenol; the basic isobutene includes isobutene and an alkaline medium, and the pH value of the basic isobutene is 7.4 to 7.8. The raw material of the present invention is basic isobutene, and the alkali in basic isobutene can neutralize the formic acid generated by the disproportionation of formaldehyde in the addition reaction, and effectively prevent the side reaction of isobutene dimerization to generate dimethylhexene and trimethylcyclopentane ; Thereby improving the chromaticity of prenyl alcohol product, obtains colorless and transparent prenyl alcohol.

Owner:TIAN JIN AN DE SHENG SCI -TECH SERVICE CO LTD

A kind of catalyst and application thereof of isopentenyl acetate transesterification to prepare prenyl alcohol

ActiveCN108927171BSolve problems such as difficult separationHigh selectivityPreparation by ester-hydroxy reactionOrganic compound preparationPtru catalystSolid acid

The invention relates to a catalyst for preparing isopentenol through transesterification of isopentenyl acetate and a reaction process thereof. The method uses isopentenyl acetate and normal alcohol as reaction raw materials, and under the action of a solid acid as a catalyst, isopentenyl alcohol and certain acetate are transesterified. The normal alcohols include methanol, ethanol, propanol and butanol, and the corresponding certain acetates are methyl acetate, ethyl acetate, propyl acetate and butyl acetate. Described this solid acid catalyst adopts IrFe / CeO 2 / SiO 2 as a catalyst system. It is particularly pointed out that an important reaction process step to obtain a high-yield target product (≥90%) is to first feed H in the reaction process. 2 for a period of time, and then switch to N 2 . The invention has the obvious advantages of low economic and environmental costs, easy separation of products, simple post-treatment, etc., and has good application prospects.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

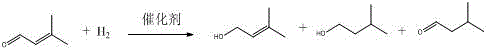

A method for the selective hydrogenation of prenyl aldehyde to synthesize prenol

ActiveCN104387235BEasy to separateSimple and fast operationOrganic compound preparationHydroxy compound preparationHydrogenation reactionNitrogen

The invention discloses a method for synthesizing prenol employing selective hydrogenation of 3-methylcrotonaldehyde. The method comprises the following steps: feeding, nitrogen and hydrogen substitution, hydrogenation reaction, and separation. The used raw materials comprise 1 part of 3-methylcrotonaldehyde, 0.1-10 parts of water and 0.02-0.2 part of a catalyst; and the used catalyst is a water-soluble complex which is formed by a water-soluble salt of the group VIII metal and a water-soluble ligand. The 3-methylcrotonaldehyde conversion ratio and the selectivity of prenol of the synthetic reaction are high; a water phase of the catalyst can be applied repeatedly for over 20 times; the unit consumption of the catalyst is low; the production cost is greatly reduced; and the method is suitable for industrial production.

Owner:SHANDONG NHU PHARMA

A kind of synthesis method of vanadium silver molybdenum phosphate catalyst and the method for catalytic preparation of prenyl alcohol and prenyl aldehyde

ActiveCN108404944BPreparation by isomerisationPhysical/chemical process catalystsPtru catalystPhosphate

The invention discloses a synthesis method of a vanadium silver molybdenum phosphate catalyst and a method for catalytically preparing prenyl alcohol and prenyl aldehyde. The catalyst is prepared according to (1) vanadium, silver, molybdenum, phosphorus, benzyl alcohol, and isobutanol put it into the reactor and stir evenly, react at 100-130°C for 8-10 hours, filter, and dry the filter cake at 150-200°C for 4-5 hours; The steam volume ratio accounts for 70-90%, the air volume ratio accounts for 10-30%, and the temperature is 400-450°C for 10 hours. Using 3-methyl-3-butenyl-1-alcohol as raw material under the vanadium-silver molybdophosphate catalyst to continuously produce prenol and prenal in the range of 350-450°C. The catalyst can be used continuously for more than half a year without changing the catalytic activity.

Owner:CHINA CATALYST HLDG CO LTD

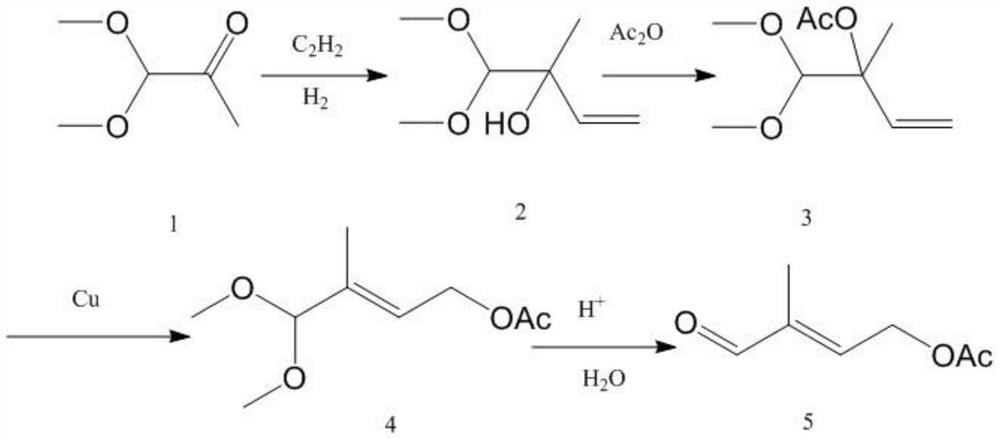

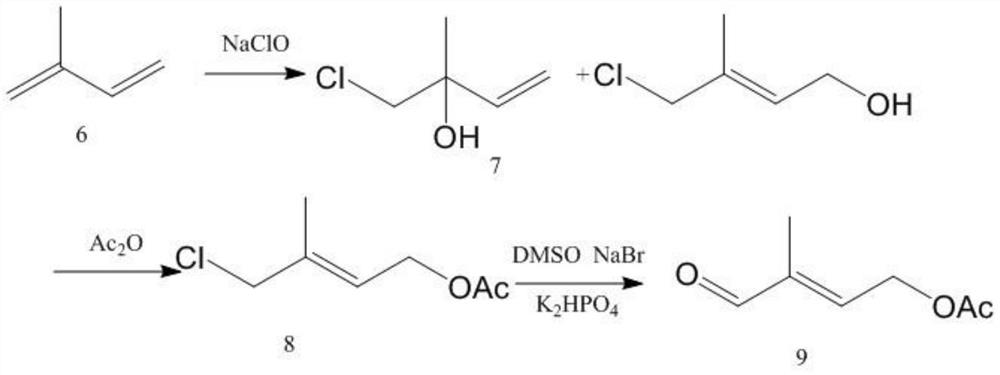

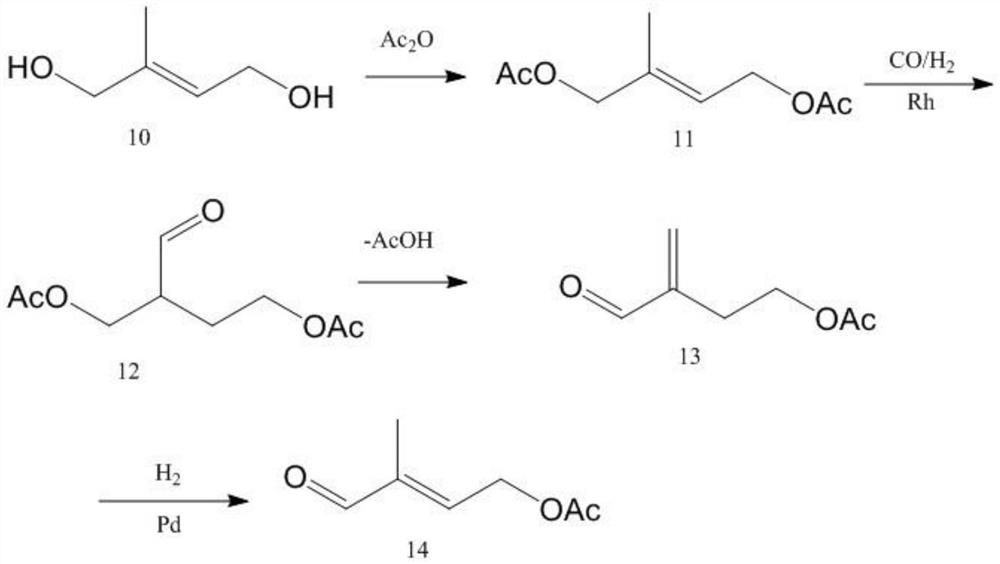

A kind of preparation method of 4-acetoxy-2-methyl-2-butenal

ActiveCN108997112BSimple processEasy to operateOrganic compound preparationCarboxylic acid esters preparationPtru catalystEthylic acid

The invention discloses a preparation method of 4-acetoxy-2-methyl-2-butenal. The method comprises the following steps: (1) under the catalysis of a phase-transfer catalyst, the chlorinated isopentene reacts with acetate to generate prenol acetate; (2) under the catalysis of selenium dioxide, the step (1) Oxidation of prenol acetate obtained to obtain 4-acetoxy-2-methyl-2-butenal. The method uses chlorinated isopentene as a starting material, which is a common fine chemical intermediate, is cheap and easy to obtain, does not need to use noble metal catalysts in the reaction process, has low cost, short synthetic route, simple operation, and little environmental pollution . It is an effective synthetic route.

Owner:WANHUA CHEM GRP CO LTD

Method for synthesizing prenol by composite catalyst

ActiveCN102675048BRaw materials are easy to getLow costPreparation by isomerisationButenePtru catalyst

Owner:SHANDONG NHU PHARMA +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com