A kind of synthesis method of vanadium silver molybdenum phosphate catalyst and the method for catalytic preparation of prenyl alcohol and prenyl aldehyde

A synthesis method and catalyst technology, which is applied in the synthesis of vanadium silver molybdenum phosphate catalyst and the catalytic preparation of prenyl alcohol and prenyl aldehyde, which can solve the problems of large equipment investment and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

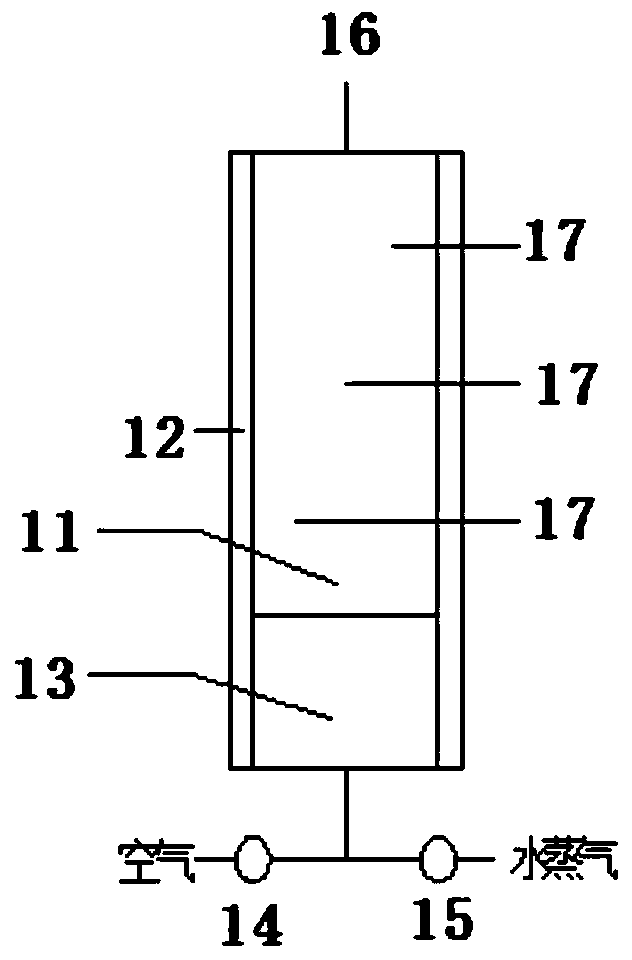

[0017] A catalyst activator for synthesizing prenol and prenaldehyde, the activator is an activator with an electric heating device 12 to control the catalyst activation temperature, and the electric heating device 12 is evenly arranged on the periphery of the activator , the upper part of the activator is a cremation furnace 11, the lower part is a gas distributor 13, the top of the activator is provided with an emptying device 16, and the bottom of the gas distributor 13 is respectively connected to an air feed pipeline and a water vapor inlet pipeline , the water vapor feed pipeline is provided with a water vapor flowmeter 15, and the air intake pipeline is provided with an air flowmeter a14; on the cremation furnace at the top of the activator, according to the order from top to bottom, from left to right, respectively There are 3 temperature measuring points 17 .

[0018] 148 grams of isobutanol, 216 grams of benzyl alcohol, 45 grams of vanadium pentoxide, 0.75 grams of s...

Embodiment 2

[0020] A catalyst activator for synthesizing prenol and prenaldehyde, the activator is an activator with an electric heating device 12 to control the catalyst activation temperature, and the electric heating device 12 is evenly arranged on the periphery of the activator , the upper part of the activator is a cremation furnace 11, the lower part is a gas distributor 13, the top of the activator is provided with an emptying device 16, and the bottom of the gas distributor 13 is respectively connected to an air feed pipeline and a water vapor inlet pipeline , the water vapor feed pipeline is provided with a water vapor flowmeter 15, and the air intake pipeline is provided with an air flowmeter a14; on the cremation furnace at the top of the activator, according to the order from top to bottom, from left to right, respectively There are 3 temperature measuring points 17 .

[0021] 148 grams of isobutanol, 216 grams of benzyl alcohol, 50 grams of vanadium pentoxide, 0.5 grams of si...

Embodiment 3

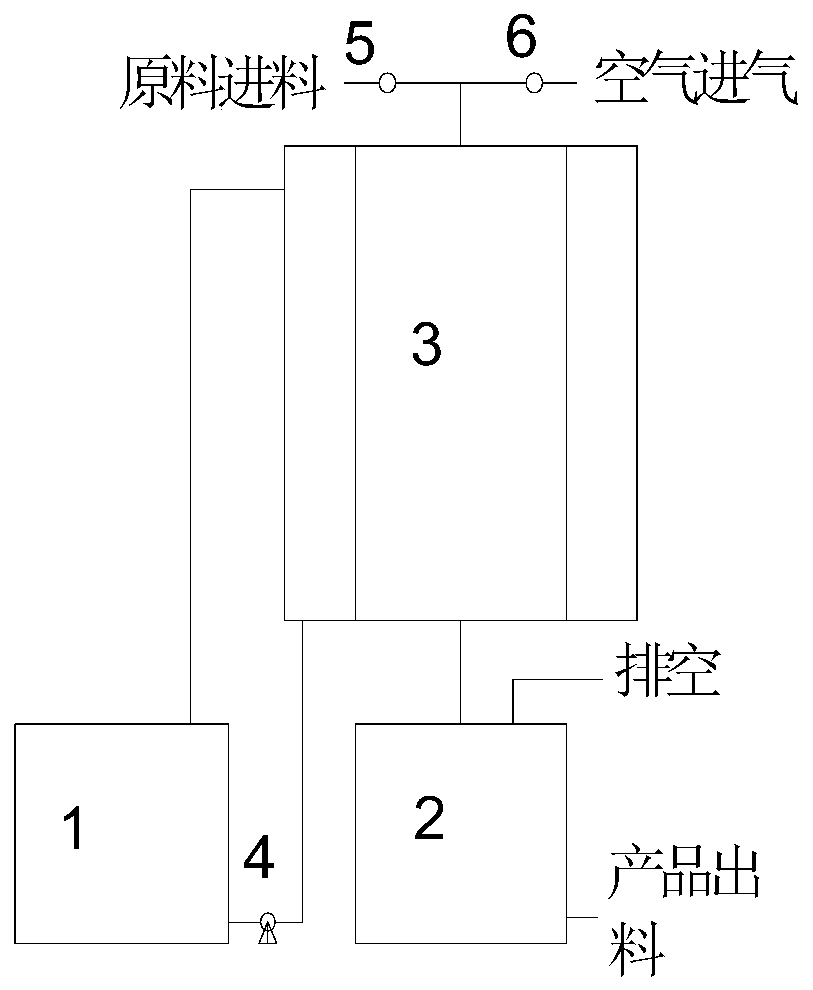

[0023] In reactor 3, add No. 50 grams of catalyst No. 1, when the temperature rises, when the reactor is at ~ 400 DEG C, evenly inject 25 grams of 3-methyl-3-butenyl-1-alcohol per hour with raw material metering pump 5 (content 99%, the content used in the following examples is the same), 25 grams of the product are obtained per hour in the product receiving tank 2, and the product isopentenol content is 98.9% after analysis, and the 3-methyl-3-butenyl-1-alcohol content is 0.1 %. When the feed rate per hour mentions 30 grams, 30 grams of products are obtained per hour, and the product analysis shows that the prenol content is 94.3%, and the 3-methyl-3-butenyl-1-alcohol content is 4.8%. When the feed rate increased to 50 grams per hour, 50 grams of product was obtained per hour, and the product analysis showed that the prenol content was 75.6%, and the 3-methyl-3-butenyl-1-ol content was 23.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com