Mono-active center Ziegler-Natta catalyst for olefinic polymerization

A single-site, olefin polymerization technology, applied in the field of new single-site Ziegler-Natta olefin polymerization catalysts, can solve problems such as synthesis difficulties, development and application limitations, and a large number of cocatalysts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

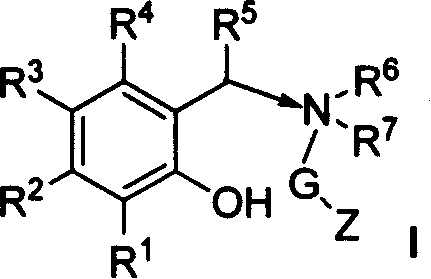

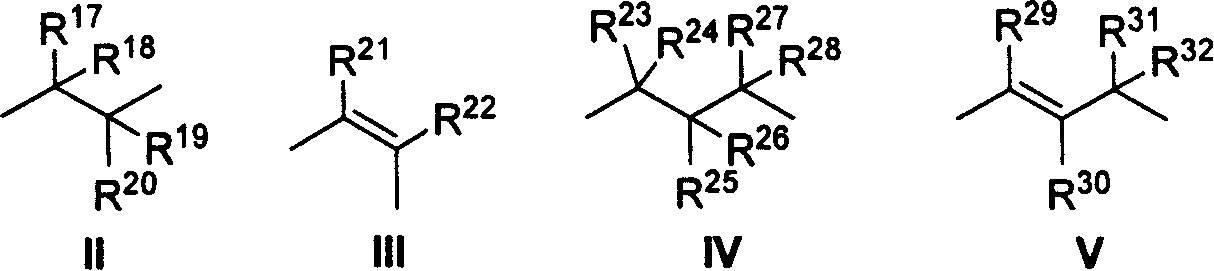

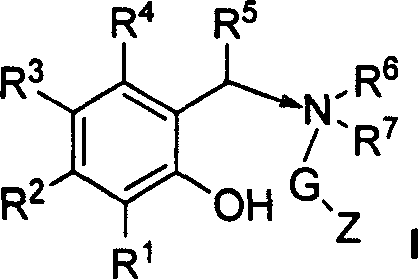

Method used

Image

Examples

Embodiment 1

[0060] The preparation of embodiment 1 catalyst 1:

[0061] The electron donor is:

[0062]

[0063] (1) Heat treatment of the carrier

[0064] Take ES70 type silica gel (product of Ineos Company) and bake it under nitrogen atmosphere. The calcination conditions are: treat at 200°C for 2h, then raise the temperature to 400°C for 4h, and cool naturally under nitrogen atmosphere. Denoted as ES70 vector.

[0065] (2) Preparation of Catalyst 1

[0066] Add 1.0g of anhydrous magnesium chloride to 40mL of tetrahydrofuran (hereinafter referred to as THF), stir at 60°C for 2h; add dropwise 3.4mmol of TiCl4 , reacted at 60°C for 4h, then added 1.0g of ES70 carrier after heat treatment, reacted at 60°C for 4h; finally added 4.0mmol of electron donor L1 prepared above, reacted at 60°C for 12h. After the reaction, the solvent was evaporated under reduced pressure, and the product was washed with hexane (3×20 mL), and then dried under reduced pressure to obtain ...

Embodiment 2

[0067] The preparation of embodiment 2 catalyst 2:

[0068] Add 1.0g of anhydrous magnesium chloride to 40mL of tetrahydrofuran (hereinafter referred to as THF), stir at 60°C for 2h; add 15mmol of TiCl dropwise 4 , reacted at 60°C for 4h, then added 1.0g of ES70 carrier after heat treatment, reacted at 60°C for 4h; finally added 4.0mmol of electron donor L1 prepared above, reacted at 60°C for 12h. After the reaction, the solvent was evaporated under reduced pressure, and the product was washed with hexane (3×20 mL), and then dried under reduced pressure to obtain catalyst 2. Ti content: 5.23wt-%

Embodiment 3

[0069] The preparation of embodiment 3 catalyst 3:

[0070] Add 1.0g of anhydrous magnesium chloride to 40mL of tetrahydrofuran (hereinafter referred to as THF), stir at 60°C for 2h; add dropwise 3.4mmol of TiCl 4 , reacted at 60°C for 4h, then added 1.0g of the heat-treated ES757 carrier, reacted at 60°C for 4h; finally added 10mmol of the electron donor L1 prepared above, and reacted at 60°C for 12h. After the reaction, the solvent was evaporated under reduced pressure, and the product was washed with hexane (3×20 mL), and then dried under reduced pressure to obtain catalyst 3. Ti content: 2.60wt-%

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com