Extraction vanadium recovery process

An extraction and process technology, applied in the field of vanadium extraction process, can solve the problems of low efficiency of single-stage extraction, cumbersome multi-stage extraction, and large loss of extraction agent, so as to reduce the number of extraction stages and oxidation processes, increase extraction capacity, and reduce price. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

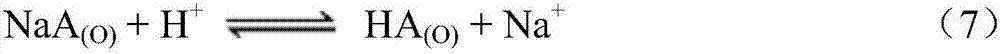

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1: extraction vanadium extraction process comprises the following steps:

[0042] 1) Obtain the original extract

[0043] a. Grind the particle size of the spent vanadium catalyst to less than 375 μm, immerse in water at a temperature of 100°C and leaching for 1.5 hours, filter to obtain the water leaching filtrate and water leaching filter residue, and wash the water leaching filter residue with water until neutral Obtain water immersion residue, water immersion filtrate, and washing liquid are combined to obtain water immersion liquid, and water immersion residue and water immersion liquid are respectively collected for subsequent use;

[0044] b. to the water leaching slag obtained in step a at a liquid-solid ratio of 2ml:1g, H 2 SO 4 Adding the reducing agent potassium sulfite under the condition that the mass percent concentration is 12%, performing reducing acid leaching, filtering to obtain the reducing acid leaching solution and reducing acid leachi...

Embodiment 2

[0049] Embodiment 2: extraction process for vanadium extraction, comprising the following steps:

[0050] 1) Obtain the original extract

[0051] a. Grind the particle size of the spent vanadium catalyst to less than 375 μm, immerse in water at a temperature of 100°C and leaching for 1.5 hours, filter to obtain the water leaching filtrate and water leaching filter residue, and wash the water leaching filter residue with water until neutral Obtain water immersion residue, water immersion filtrate, and washing liquid are combined to obtain water immersion liquid, and water immersion residue and water immersion liquid are respectively collected for subsequent use;

[0052] b. to the water leaching slag obtained in step a at a liquid-solid ratio of 2ml:1g, H 2 SO 4 Adding the reducing agent potassium sulfite under the condition that the mass percent concentration is 12%, performing reducing acid leaching, filtering to obtain the reducing acid leaching solution and reducing acid ...

Embodiment 3

[0057] Embodiment 3: extract vanadium extraction process, comprise the following steps:

[0058] 1) Obtain the original extract

[0059] a. Grind the particle size of the spent vanadium catalyst to less than 375 μm, immerse in water at a temperature of 100°C and leaching for 1.5 hours, filter to obtain the water leaching filtrate and water leaching filter residue, and wash the water leaching filter residue with water until neutral Obtain water immersion residue, water immersion filtrate, and washing liquid are combined to obtain water immersion liquid, and water immersion residue and water immersion liquid are respectively collected for subsequent use;

[0060] b. to the water leaching slag obtained in step a at a liquid-solid ratio of 2ml:1g, H 2 SO 4 Adding the reducing agent potassium sulfite under the condition that the mass percent concentration is 12%, performing reducing acid leaching, filtering to obtain the reducing acid leaching solution and reducing acid leaching ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| extraction efficiency | aaaaa | aaaaa |

| extraction efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com