Method for extracting metal solvent

A solvent and metal technology, applied in the field of solvent extraction, can solve problems such as the reduction of extraction capacity, and achieve the effect of improved extraction capacity and great effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

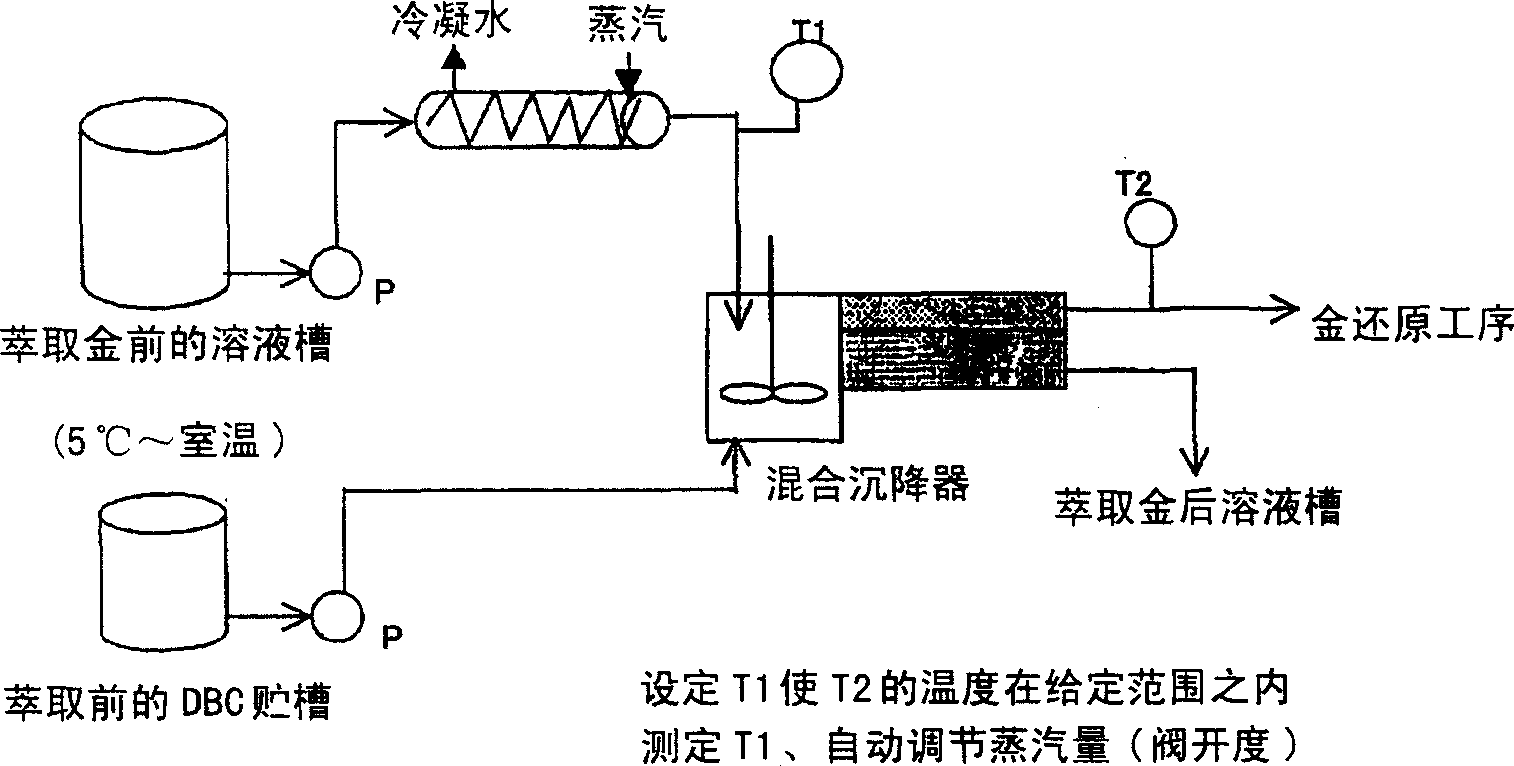

[0044] Follow the figure 1 , to illustrate specific examples.

[0045] use figure 1 The device shown in , heats the liquid before extracting gold through a heat exchanger, so that its temperature is 26-39°C.

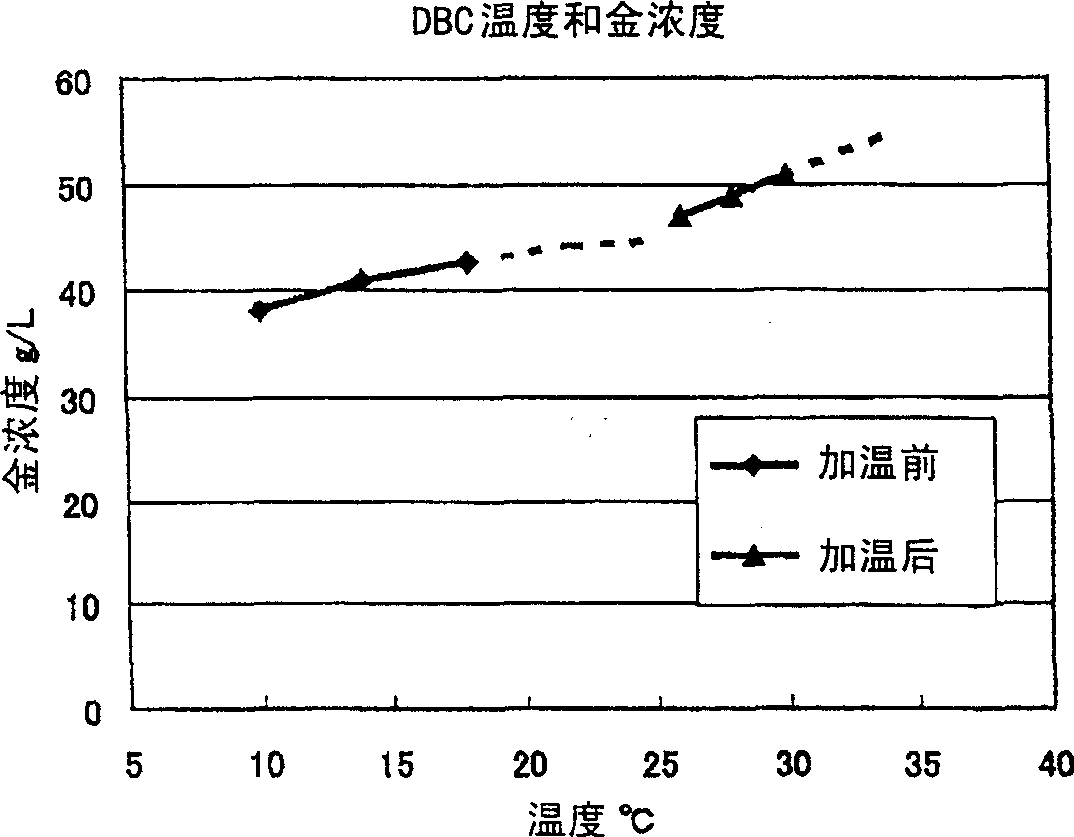

[0046] The results are shown in Table 1. In the mixer-settler, the temperature of the DBC after gold extraction in the liquid to be treated was raised to 26 to 30°C.

[0047] As a result, as shown in Table 1, the extraction amount of gold extracted by DBC was 47 to 51 g / L, and the phase separation property was ensured and the operation was still possible.

[0048] Additionally, according to figure 2 It can be seen that when the temperature of DBC is above 25°C, the optimum gold extraction amount can be guaranteed.

[0049] The temperature of the extracted DBC is measured at T1. For the amount of steam, the temperature T2 of the liquid to be treated is sensed at the outlet of the heat exchanger, and the amount of steam in the heat exchanger is adjusted to achieve a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com