BOG recovery system for LNG (Liquefied Natural Gas) gas station

A recycling system and gas filling station technology, applied in gas/liquid distribution and storage, container discharge method, container filling method, etc. The effect of preventing energy waste and preventing air pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

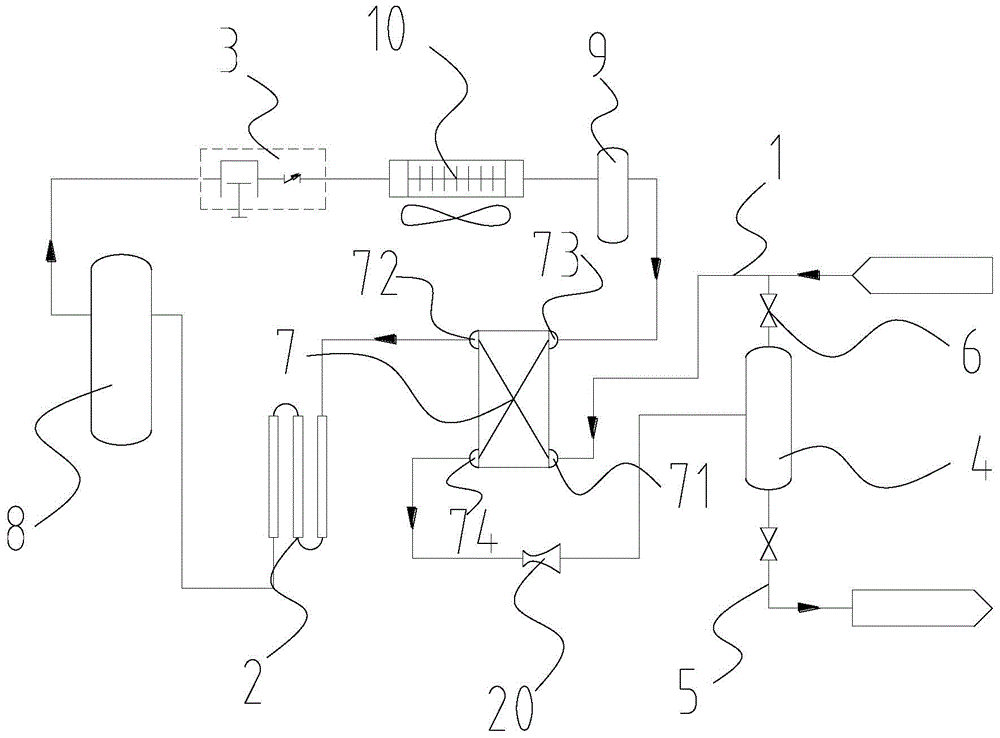

[0015] like figure 1 As shown, the BOG recovery system of the LNG refueling station of the present invention includes a BOG import pipeline 1, a compressor 3, a cooler 10, an injector 20 and an LNG export pipeline 5, and the BOG import pipeline 1, compressor 3 , the cooler 10, the injector 20, and the LNG export pipeline 5 are connected in sequence.

[0016] The BOG from the LNG storage tank passes through the BOG import pipeline 1, enters the compressor 3 and pressurizes to about 20 MPa to obtain high-pressure BOG, which is cooled to a certain temperature by the cooler 10, and then enters the injection part 20 for injection liquefaction, and the obtained LNG is introduced into storage as a product. The present invention adopts the process of pressurized injection, which is easier to realize compared with the traditional expander: if the flow of the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com