Patents

Literature

42results about How to "Applicable recycling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Integral recycling method of lithium iron phosphate positive electrode material

ActiveCN108075202AApplicable recyclingAchieve recyclingWaste accumulators reclaimingProcess efficiency improvementElectrical batteryPhosphate

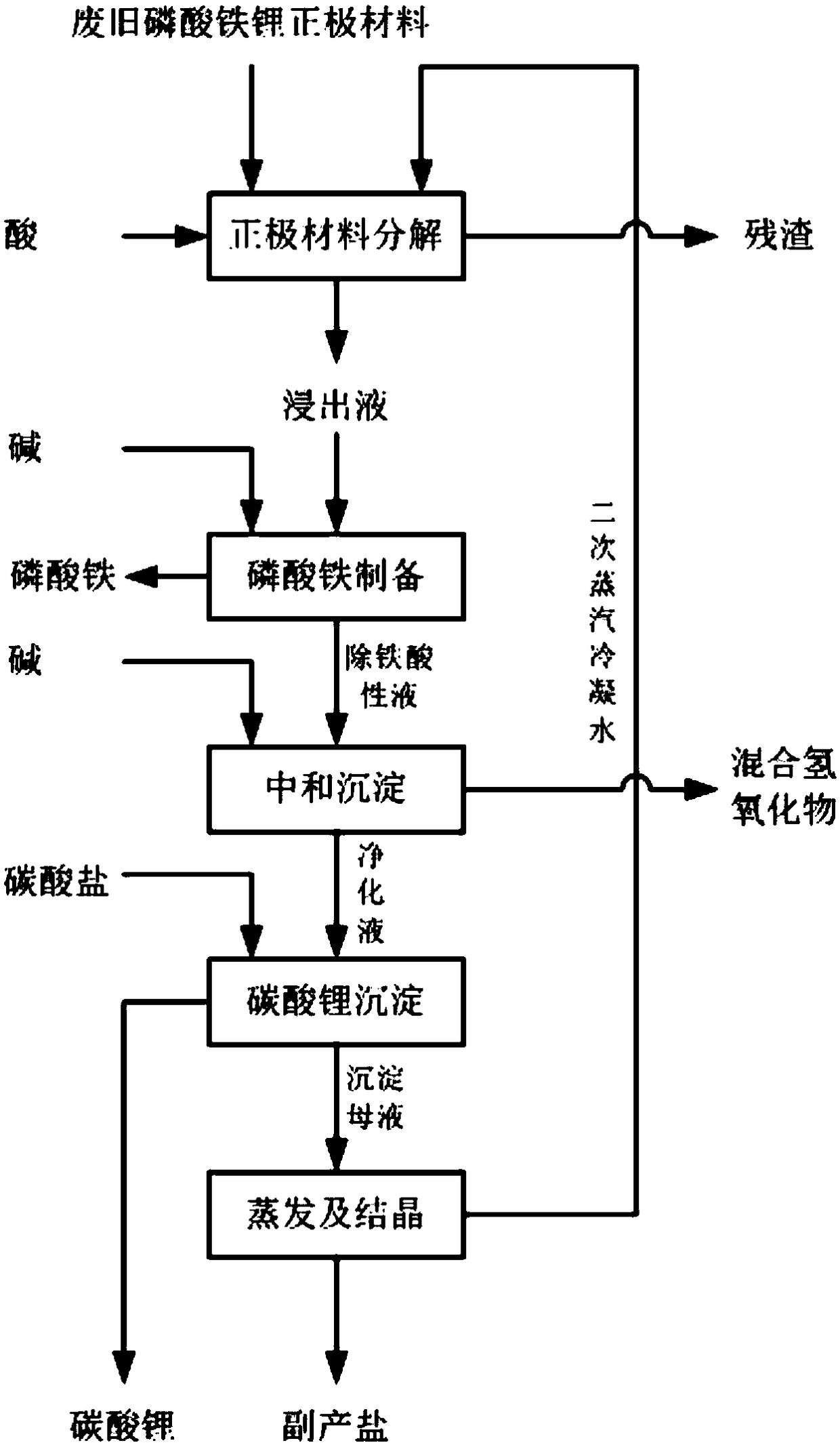

The invention provides an integral recycling method of a lithium iron phosphate positive electrode material. The integral recycling method comprises the steps of (1) preparing paste from the lithium iron phosphate positive electrode material, mixing the paste and an acid for leaching reaction, and performing liquid-solid separation to obtain a leaching liquid and residue; (2) adjusting a pH valueof the leaching liquid to 1.5-3, and performing solid-liquid separation to obtain iron phosphate and a deironing acid liquid; (3) adjusting a pH value of the deironing acid liquid to 5-8, and performing solid-liquid separation to obtain a precipitant of aluminum and iron and a lithium-containing purification liquid; and (4) and performing post-treatment on the purification liquid to obtain a lithium product and a precipitation mother liquid. By the method, the recycling rates of lithium, iron and phosphate all are larger than 95wt%, the purity of the obtained lithium carbonate product is larger than 98.5wt%, the impurity content conforms to the requirement of GB / T11075-2013, the iron phosphate product conforms to the quality requirement (HG / T 4701-2014) of battery-level iron phosphate, theresidue discharging quantity is reduced by 85wt%, the flow is simple, and the process is clean.

Owner:北京中科百特科技有限公司

Preparation method of BPPO and PVA-based organic-inorganic hybrid anion exchange membrane

InactiveCN102698616AGood flexibilityFully quaternizedSemi-permeable membranesChlorobenzenePolyvinyl alcohol

The invention discloses a preparation method of a BPPO (Brominated Polystyrene) and PVA (Polyvinyl Alcohol)-based organic-inorganic hybrid anion exchange membrane. The preparation method comprises the following steps: (1), dissolving the BPPO in chlorobenzene, and adding DMF (Dimethyl Formamide), tertiary amine solution, two micromolecule alkoxy silanes and water so as to obtain BPPO (+) / SiO2 materials; (2) dissolving the obtained BPPO (+) / SiO2 materials into DMF mixed solution so as to BPPO (+) / SiO2 solution; (3) dropping the BPPO (+) / SiO2 solution into PVA solution so as to prepare coating liquid; and (4) coating the coating liquid on a basal body so as to form a diaphragm, and drying the diaphragm to obtain the organic-inorganic hybrid anion exchange membrane. According to the invention, quaternary ammonium BPPO, PVA and micromolecule alkoxy silanes are utilized to prepare the hybrid anion exchange membrane containing the quaternary ammonium group and-OH base, the content of the PVA in the membrane can be controlled, and a cross-linked structure can be formed, so that the stability and mechanical performance of the membrane can be reinforced; and moreover, the -OH base in the PVA can promote the H+ ion to transfer, so that the prepared hybrid anion exchange membrane is particularly suitable for diffusion dialysis process, and can separate and recycle acid waste liquid.

Owner:YANCHENG TEACHERS UNIV

Method for preparing titanium-rich material from titanium-containing slag

InactiveCN101768673AReduce the amount of exhaust gasThe process method is simpleProcess efficiency improvementSlagBall mill

The invention relates to a method for preparing titanium-rich material from titanium-containing slag, comprising the following steps: 1. carrying out ball-milling on titanium-containing slag, then adding Na2CO3 or NaOH and mixing evenly; 2. carrying out calcination on the mixture obtained in step 1, then adding HC1 solution for leaching; 3. filtering the leached solution, concentrating and then recycling the filtrate; 4. calcining the filter residue to obtain titanium-rich material with grade of TiO2 being more than 90%.In the invention, Na2CO3, NaHCO3 or NaOH are added into the titanium-containing slag, then SiO2, Al203 in the slag are converted into NaSiO3 and NaAlO2 which are later leached by HC1 solution, so that SiO2, Al2O3 and MgO which are not converted are leached into the solution and grade of TiO2 in leached slag is improved by a big margin. The technique of the invention features simple method, convenient operation, environmental-friendliness, good economic benefits, high level of resource utilization and adaptability to industrialized production; in addition, the technique is especially suitable for recovering titanium in titanium-containing slag produced by the direct iron process.

Owner:CENT SOUTH UNIV

Method for recycling carbon fiber reinforced resin matrix composites by supercritical mixed fluids

InactiveCN106496631APromote decompositionCapable of dissolving heatPlastic recyclingBulk chemical productionAlcoholCarbon fibers

The invention discloses a method for recycling carbon fiber reinforced resin matrix composites by supercritical mixed fluids. The recycling method includes the steps: 1 cutting the waste carbon fiber reinforced resin matrix composites into composite blocks, placing the composite blocks in a reactor, adding alkali solid catalysts into the reactor and performing temperature programming for the reactor to reach the temperature of 90 DEG C; 2 pumping alcohol and water in fixed proportion into the reactor, continuously heating the reactor to reach the temperature of 310-360 DEG C, enabling alcohol-water binary mixture to reach a supercritical state and transforming the alkali solid catalysts into ionic liquid; 3 cooling the reactor to 80 DEG C after reaction; 4 taking out solid products and drying the solid products at constant temperature. According to the recycling method, composite recycling cost is substantially reduced, recycling efficiency is improved, and the recycling method can be industrially used for the field of recycling and reusing of thermosetting plastics and the carbon fiber reinforced resin matrix composites.

Owner:NANJING INST OF TECH

Method of vegetable fat recycling from spent bleaching clay

ActiveCN106318594ASimple processShort timeFatty-oils/fats refiningFatty-oils/fats productionOil and greaseMicrowave

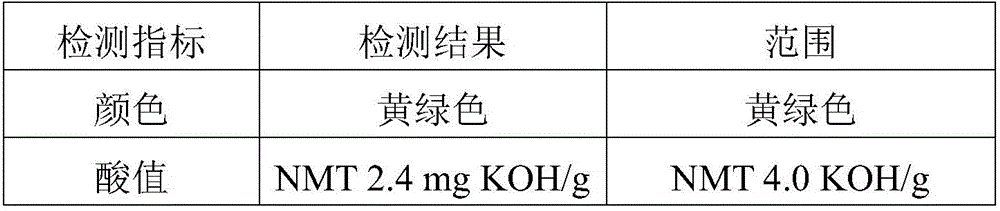

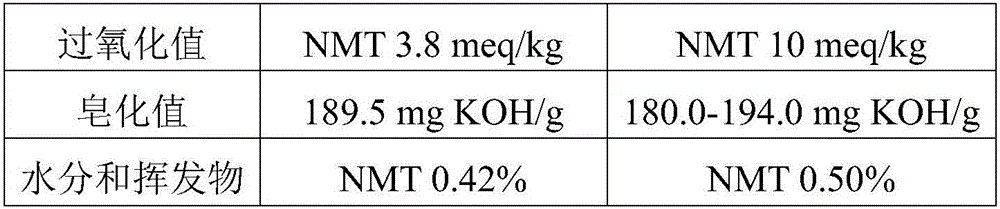

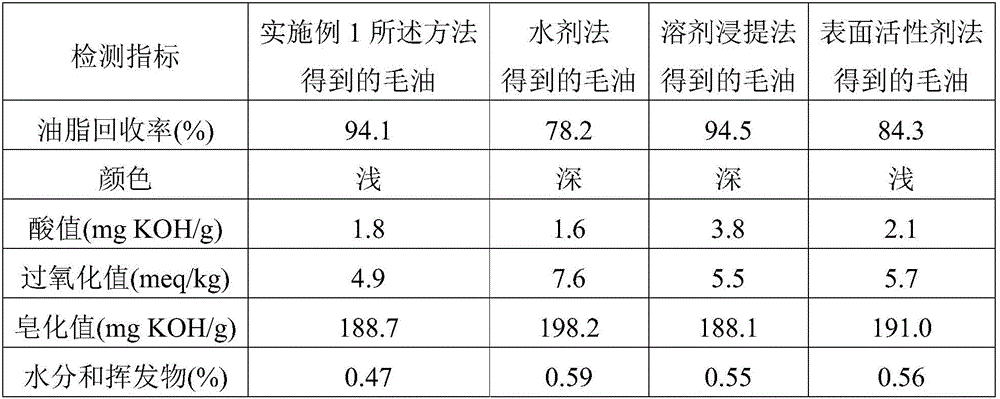

The invention relates to a method of vegetable fat recycling from spent bleaching clay and belongs to the field of vegetable fat processing. Based on spent bleaching clay generated in the vegetable oil refining technique as the raw material, the method comprises the steps of (1) centrifugalizing spent bleaching clay to obtain the centrifugalized spent bleaching clay and liquid I; (2) smashing the centrifugalized spent bleaching clay, adding water, performing ultrasound- microwave, then adding surface active agent, undertaking microwave demulsification after ultrasonic emulsification and recycling supernatant liquid of oil to obtain liquid II; (3) mixing and centrifugalizing liquid I and liquid II, recycling upper grease and filtering to obtain the crude oil. The method mentioned in the invention is characterized by simple technique, short time consumption, high efficiency and low cost.

Owner:SANMARK CORP

Method for recovering triethylamine from aqueous solution

ActiveCN104045567AApplicable recyclingEasy to operateAmino compound purification/separationDistillation purification/separationAlkaline waterDistillation

The invention relates to a method for recovering triethylamine from an aqueous solution. the method comprises the following steps: adjusting pH value of a triethylamine aqueous solution system to 1 by the use of hydrochloric acid, extracting triethylamine by the use of cyclohexane, adjusting pH value to more than 12 by the use of sodium hydroxide, carrying out backflow and water division after division of an alkaline water layer until there is no obvious moisture, carrying out atmospheric distillation, distilling to obtain high-purity triethylamine, and recovering cyclohexane. The method has advantages of simple operation, high efficiency and less environment stress, and is suitable for recovery of a triethylamine aqueous solution with the concentration of 5-50%.

Owner:SHANGHAI NEW HUALIAN PHARMA

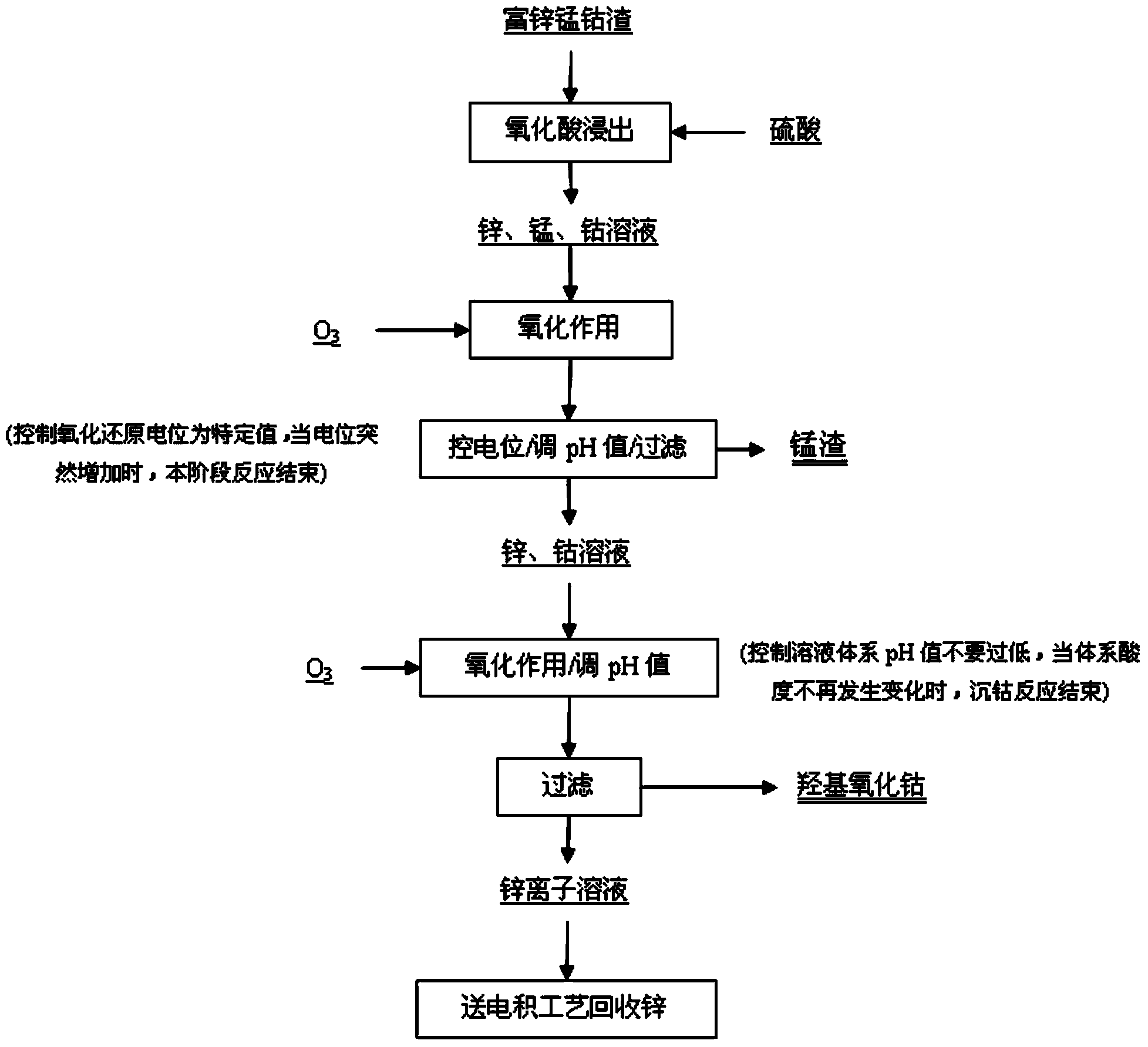

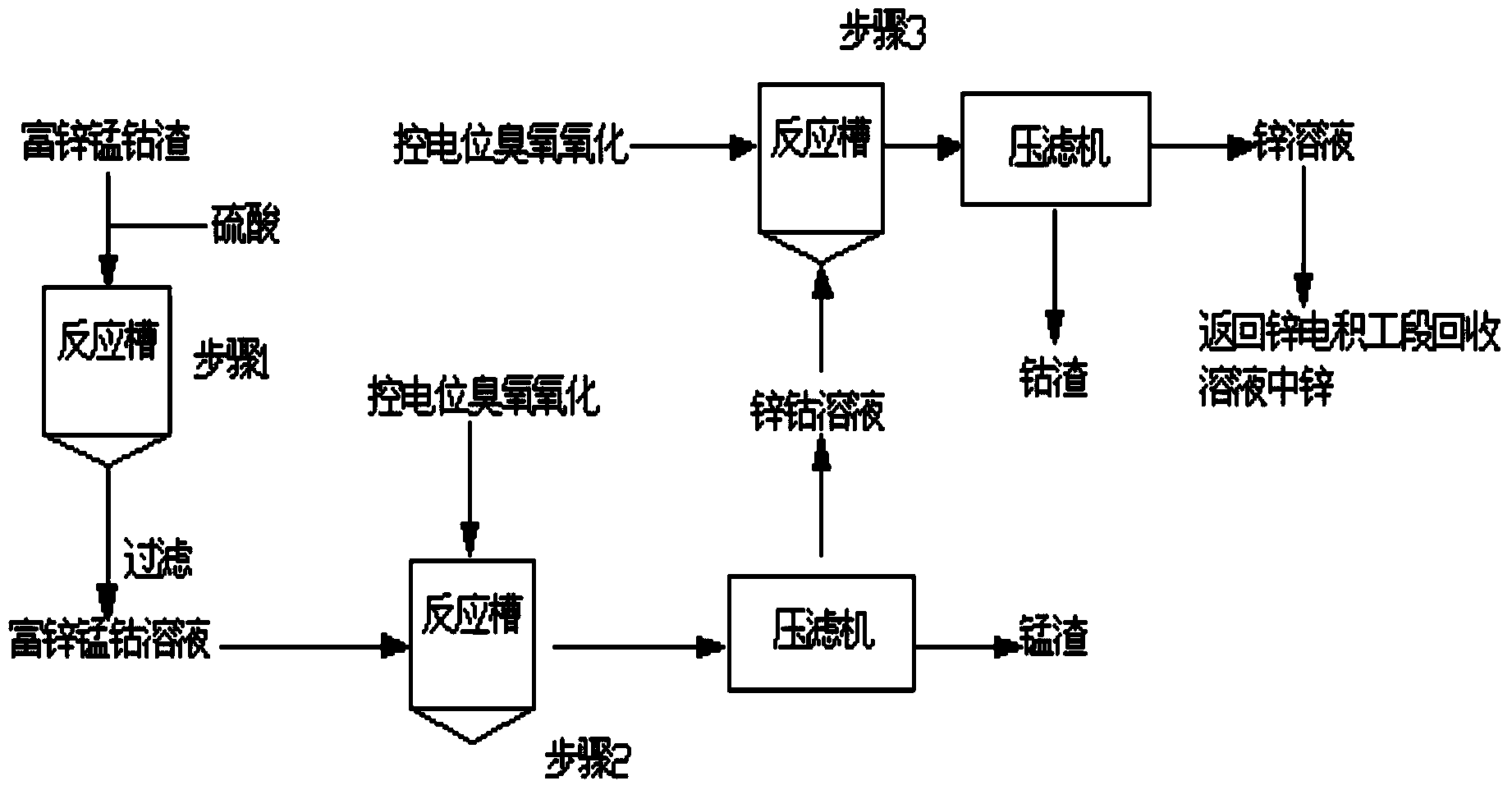

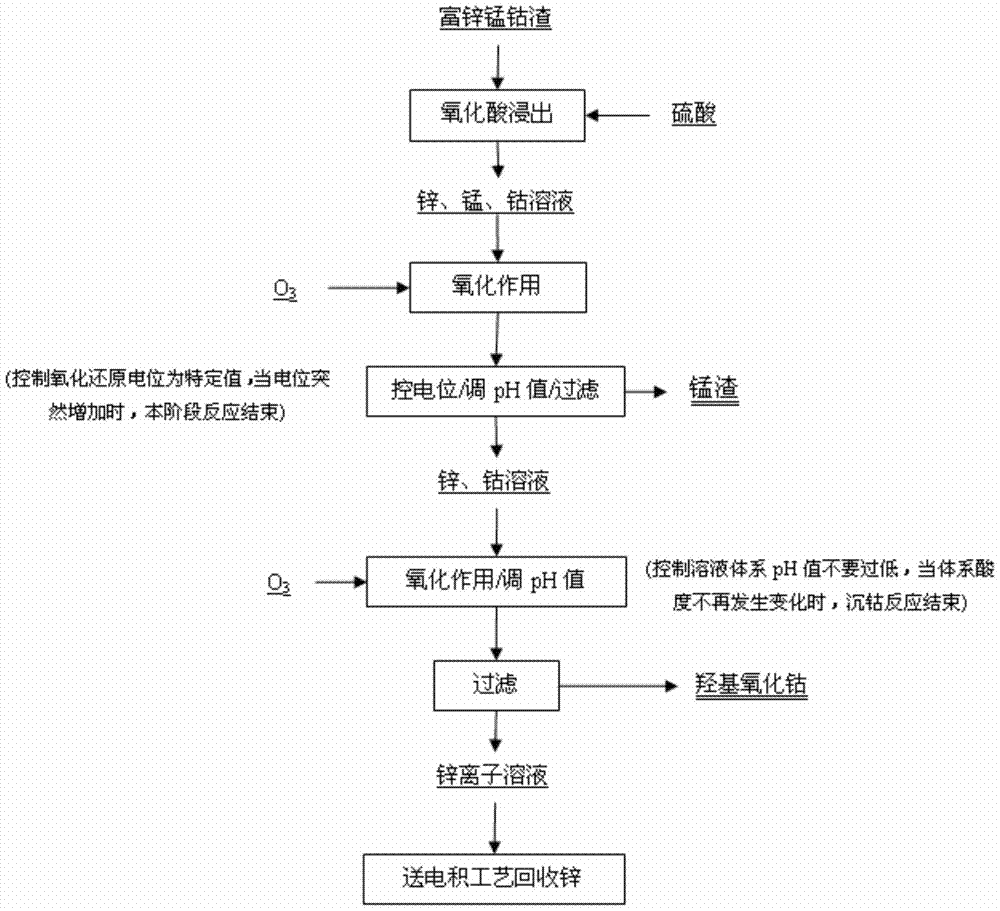

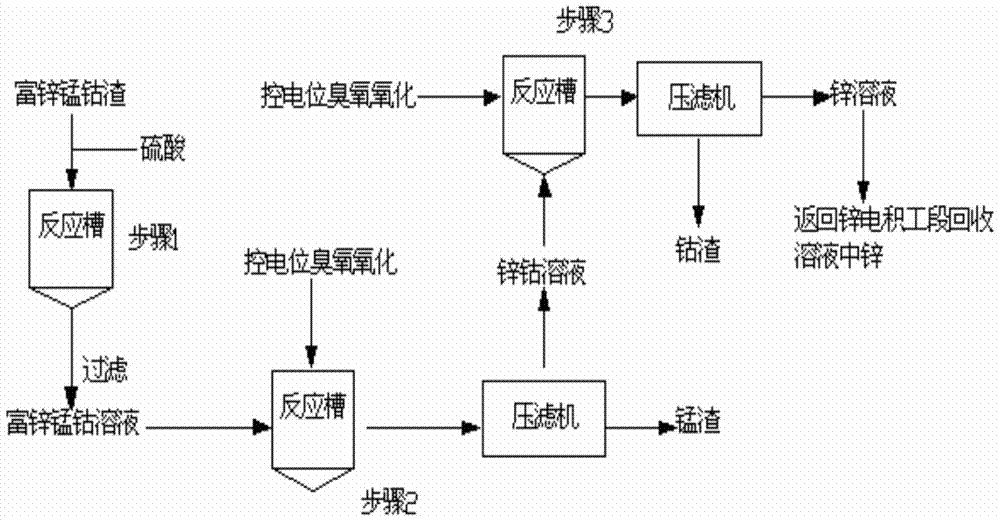

Method for recycling valuable metals step by step from zinc-manganese-cobalt-rich slag in multiplex control manner

ActiveCN103725890AEasy to recycleAvoid pollutionPhotography auxillary processesProcess efficiency improvementSmelting processControl manner

The invention discloses a method for recycling valuable metals step by step from zinc-manganese-cobalt-rich slag in a multiplex control manner. The method comprises the steps of a, processing the zinc-manganese-cobalt-rich slag by utilizing an acid liquor leaching method to obtain multi-metal solution containing manganese, cobalt and zinc; b, introducing ozone gas into the multi-metal solution, previously oxidizing and separating the manganese ions, and filtering the solution to obtain manganese slag and cobalt-zinc-containing solution; c, introducing ozone into the cobalt-zinc-containing solution, oxidizing and separating cobalt ions in the solution, and filtering the solution to obtain the cobalt slag and the zinc-containing solution; d, directly returning the zinc-containing solution to an electrodeposition section so as to directly recycle the zinc ions in the zinc-containing solution. By adopting the method, the smelting process for recycling manganese and cobalt in the multi-metal ions can be simplified, and the separation recycling step of manganese and cobalt can be completed by adopting the same reaction device. The direct recycling rate of manganese and cobalt in the method is high, cleanliness and no pollution can be realized, simplicity in operation can be realized, the equipment investment expense can be saved, and other operating management links can be saved.

Owner:湖南博一环保科技有限公司

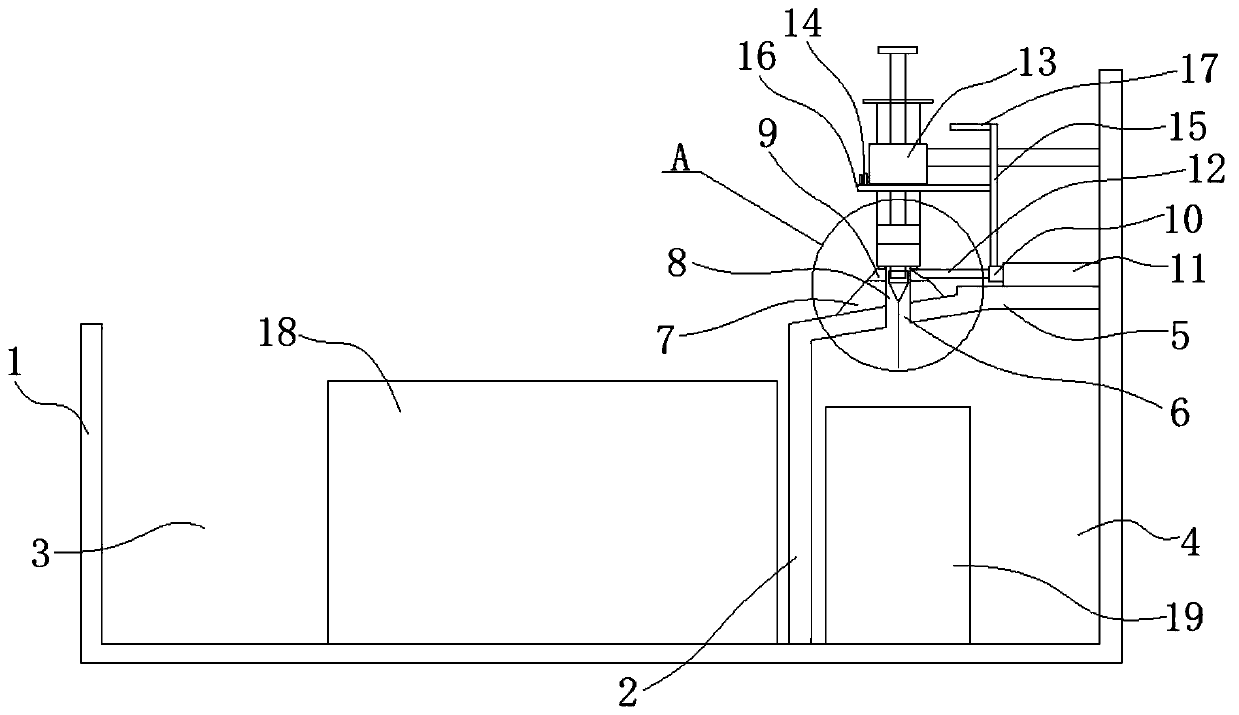

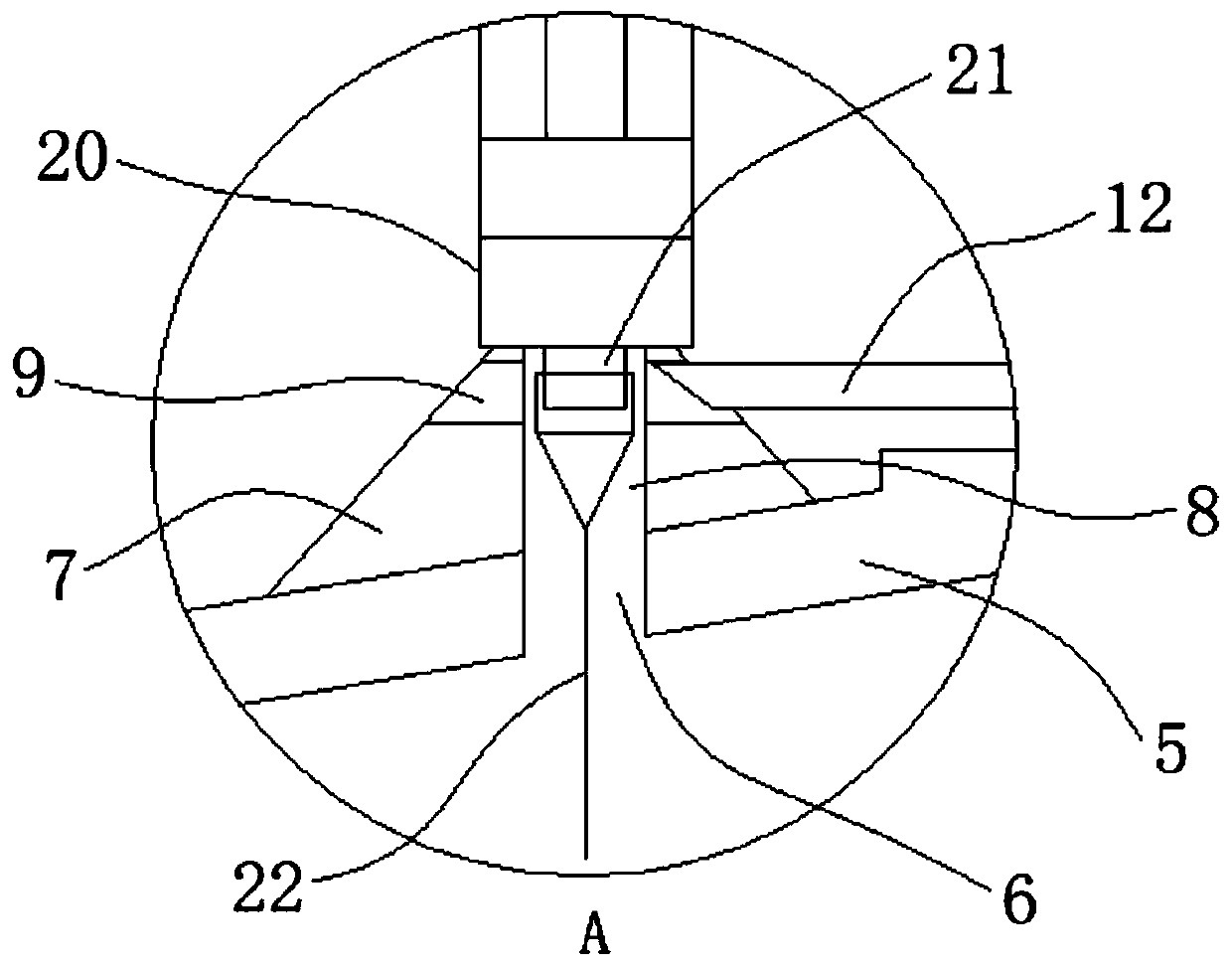

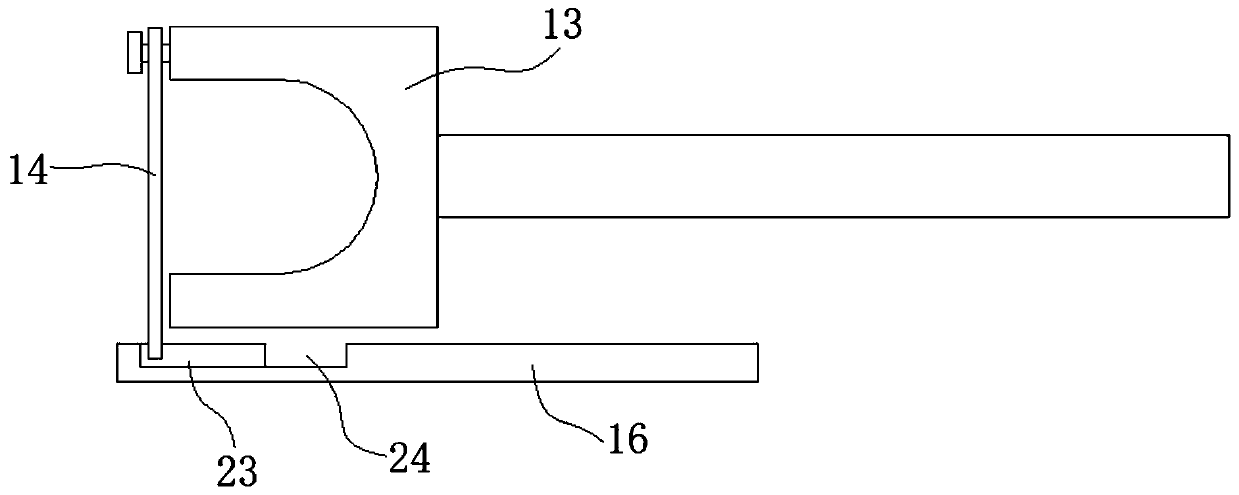

Separating and recovering device for needle and syringe cylinder of injection syringe

The invention discloses a separating and recovering device for a needle and a syringe cylinder of an injection syringe. The device comprises a casing, a supporting plate, a separating base, a pushing base, a separating cutter, a U-shaped positioning sleeve, a baffle rod, a connecting plate, a limiting plate and a pushing rod; a casing cavity of the casing is divided into a syringe cylinder cavity and a needle cavity; the supporting plate is arranged at the upper end of the needle cavity and provided with a guide hole; the separating base is arranged on the supporting plate and provided with a needle hole and a separating hole; the pushing base is arranged on the supporting plate; the separating cutter is arranged at the left end of the pushing base and is exactly opposite to the separating hole; the U-shaped positioning sleeve is located above the separating base; the front end of the baffle rod is hinged to the left end of the front side wall of the U-shaped positioning sleeve; the connecting plate is fixed to the pushing base; the limiting plate is fixed to the connecting plate; the rear end of the baffle rod is supported at the left portion of the limiting plate, and the limiting plate is provided with a falling port; the pushing rod is fixed to the connecting plate and is higher than the U-shaped positioning sleeve. The device can automatically separate the needle of the injection syringe from the syringe cylinder and directly store the needle and the syringe cylinder separately, so that the labor amount of medical staff is reduced, and the safety of the separation process is improved.

Owner:THE FIRST AFFILIATED HOSPITAL OF GUANGXI MEDICAL UNIV

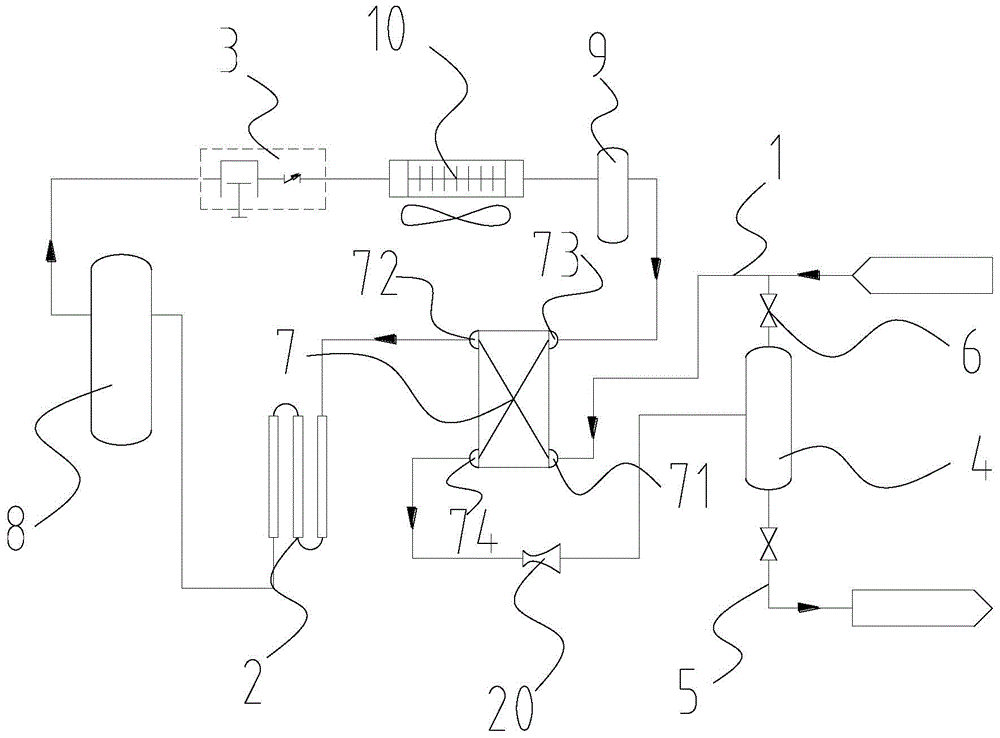

BOG recovery system for LNG (Liquefied Natural Gas) gas station

InactiveCN104806879AAvoid air pollutionAvoid energy wasteContainer filling methodsContainer discharging methodsChillerEngineering

The invention relates to the field of liquefying equipment, and provides a BOG recovery system for an LNG (Liquefied Natural Gas) gas station. The BOG reclaiming system comprises a BOG introduction pipeline, a compressor, a cooler, an ejector and an LNG discharging pipeline, wherein the BOG introduction pipeline, the compressor, the cooler, the ejector and the LNG discharging pipeline are sequentially communicated with one another. The BOG in an LNG storage tank enters the compressor through the BOG introduction pipeline and is pressurized to about 20MPa, the pressurized BOG is cooled by the cooler and enters the ejector to perform ejection liquefaction, and finally, the obtained LNG is introduced into a storage device as products. Through the adoption of the BOG recovery system disclosed by the invention, the BOG generated in the LNG storage tank can be re-liquefied, and the re-liquefied BOG can be introduced into the LNG storage tank or other containers so as to be sufficiently utilized, and the air pollution and the waste of energy sources can be avoided. The BOG recovery system is suitable for LNG gas stations.

Owner:四川金科深冷设备工程有限公司

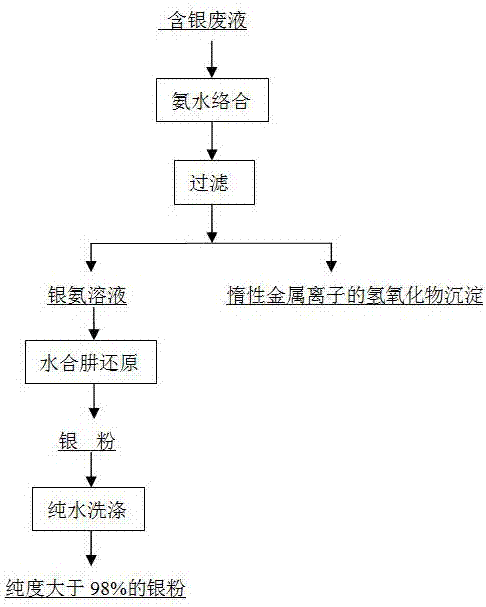

Production method for separating silver from silver waste liquid

The invention discloses a production method for separating silver from silver-containing waste liquid. In the method, firstly, the silver-containing waste liquid is complexed with ammonia water and then filtered, and the hydroxide of inert metal ions is precipitated and removed to obtain silver ammonium solution, and then Use hydrazine hydrate to reduce the silver ammonium solution to obtain silver powder, and finally separate the supernatant, wash the silver powder with pure water several times, filter and dry to obtain silver powder with a purity greater than 98%. The invention only needs a small amount of plastic containers and filter cloth, does not need to invest in complicated equipment, only needs two reagents of ammonia water and hydrazine hydrate, does not need to introduce other base metals, and does not use halides to precipitate silver, and can complete the removal of silver and other metal impurities. Separation, the excess reducing agent added can be removed by washing to obtain higher purity silver powder. The invention has the advantages of low cost, simple operation and high efficiency, and is suitable for recovering and purifying silver in silver-containing waste liquid with a silver concentration greater than 0.1 g / ml, and the separated silver has high purity.

Owner:JINCHUAN GROUP LIMITED

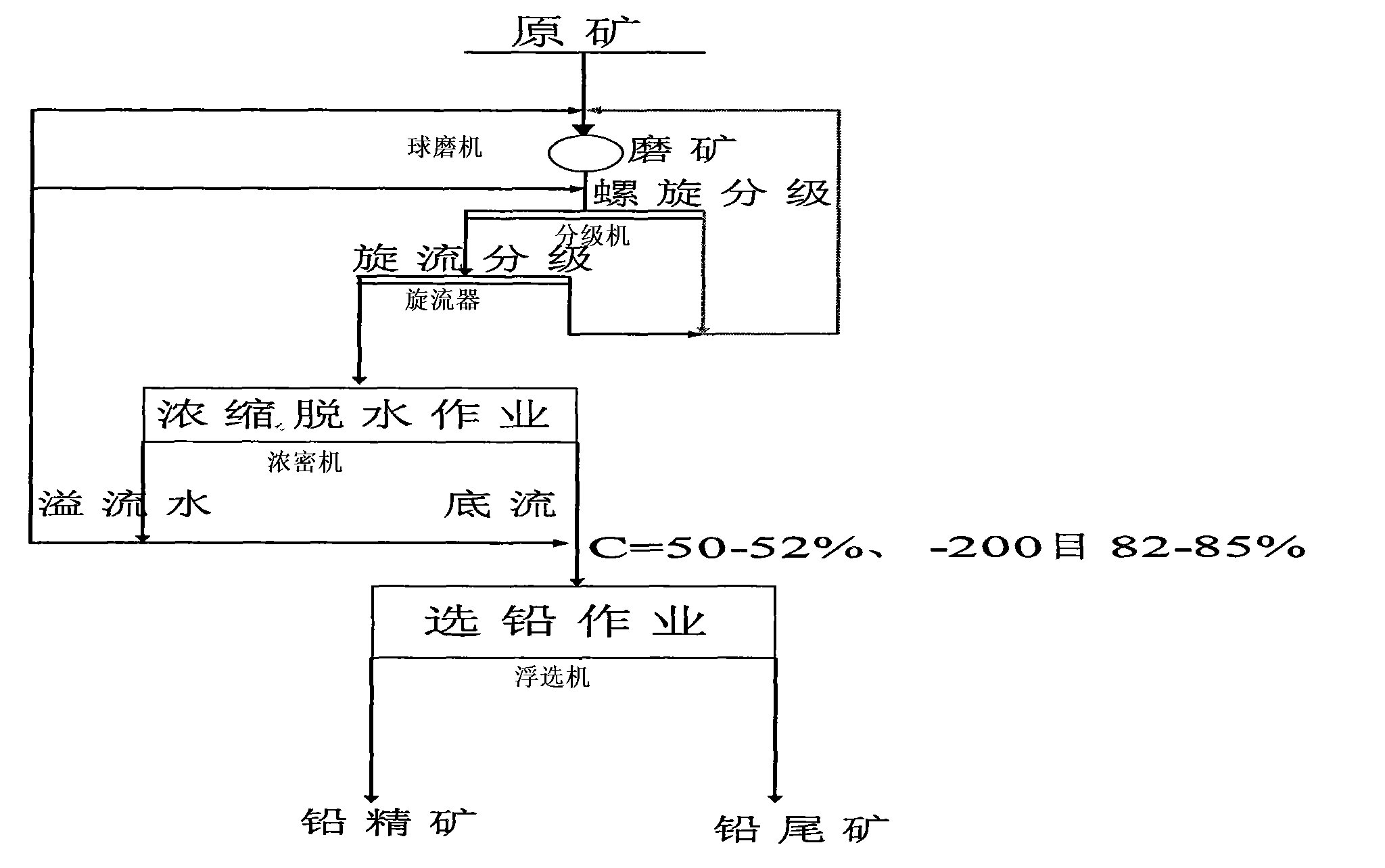

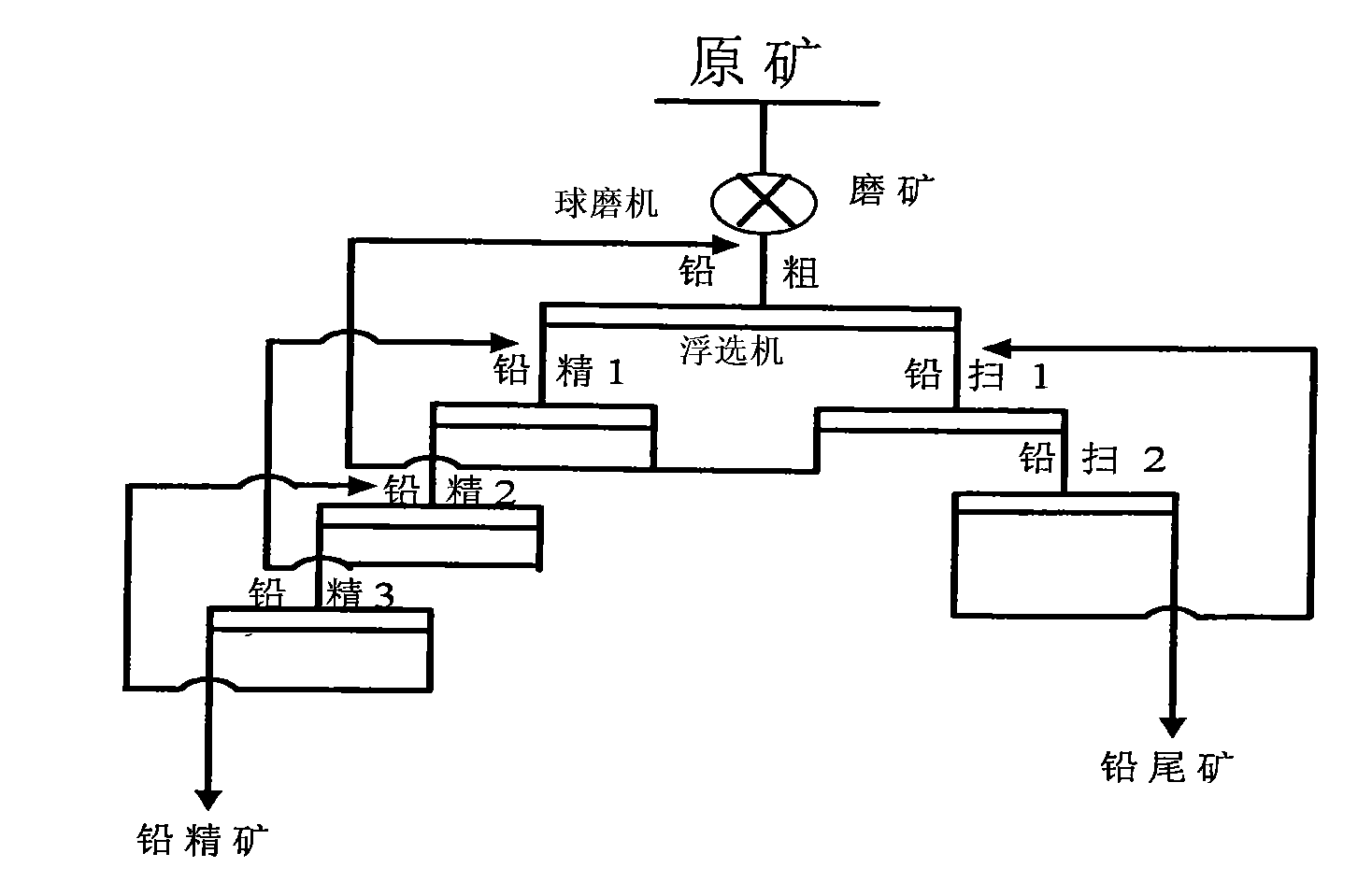

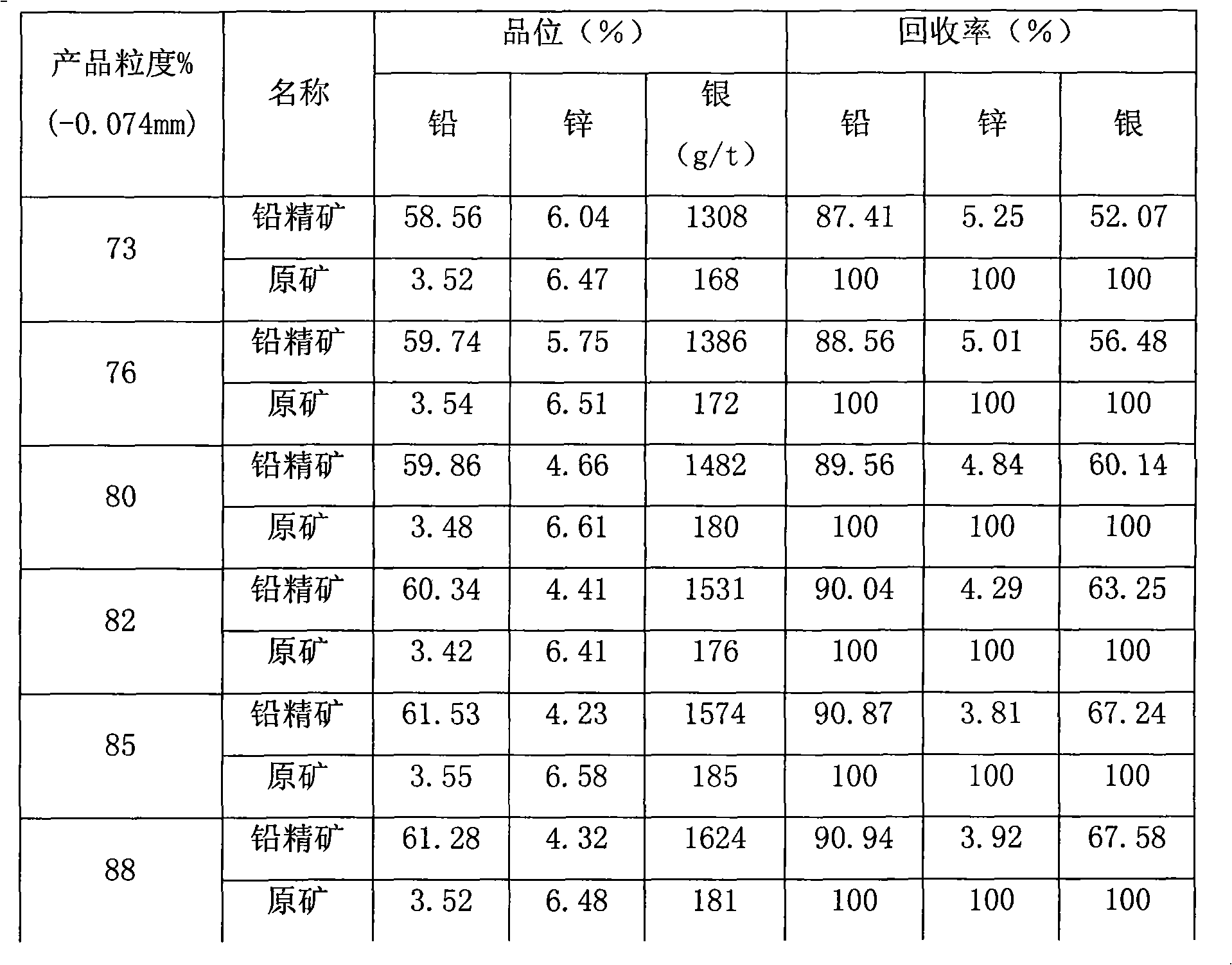

Method for efficiently selecting lead with high-enriched fineness

The invention relates to a method for effectively selecting lead with high-enriched fineness. The method is characterized in that under a condition of one-stage grinding, green ore is sent into a spiral classifier for classification after the green ore is subjected to ball milling through a ball miller; ore slurry overflowing from the spiral classifier is sent into a whirlcone for classifying; the ore slurry with qualified fineness overflowing from the whirlcone is sent into a thickener for concentrating, and is sent into a flotation washer for lead selection. When the method is adopted to carry out floatation on lead-zinc sulphide ore, the recovery rate of lead selection is improved by 2 percentage, the lead concentrate grade is improved by 2 percentage, the recovery rate of silver in lead is improved by 5 percentage, the flotation energy consumption is reduced by 20 percent, and medicaments for lead selection are reduced by 15 percent. The method not only can greatly improve lead dressing index, and save electricity consumption of lead dressing and medicament consumption, but also can realize quick cyclic utilization of lead dressing wastewater and partial lead dressing medicament, prevent pollution to the environment, and finally realize high efficiency separation and clean production of lead dressing. The method is also applicable to multiple-metal reclamation of other sulfide ores.

Owner:南京银茂铅锌矿业有限公司

Method for recovering pyridine from aqueous solution

The invention relates to a method for recovering pyridine from an aqueous solution. The method comprises the following steps: adjusting the pH value of a pyridine aqueous solution system to 1 by using hydrochloric acid; extracting pyridine by using cyclohexane and then adjusting the pH value to more than 12 by using sodium hydroxide; after an alkaline water layer is separated, carrying out reflux and water separation until there is no obvious water and then carrying out normal pressure rectification; and finally, carrying out distillation so as to obtain high-purity pyridine and recovering cyclohexane. The method provided by the invention has the advantages of simple operation, high efficiency, small environment stress and applicability to recovery of an aqueous pyridine solution with a concentration of 5 to 48%.

Owner:SHANGHAI NEW HUALIAN PHARMA

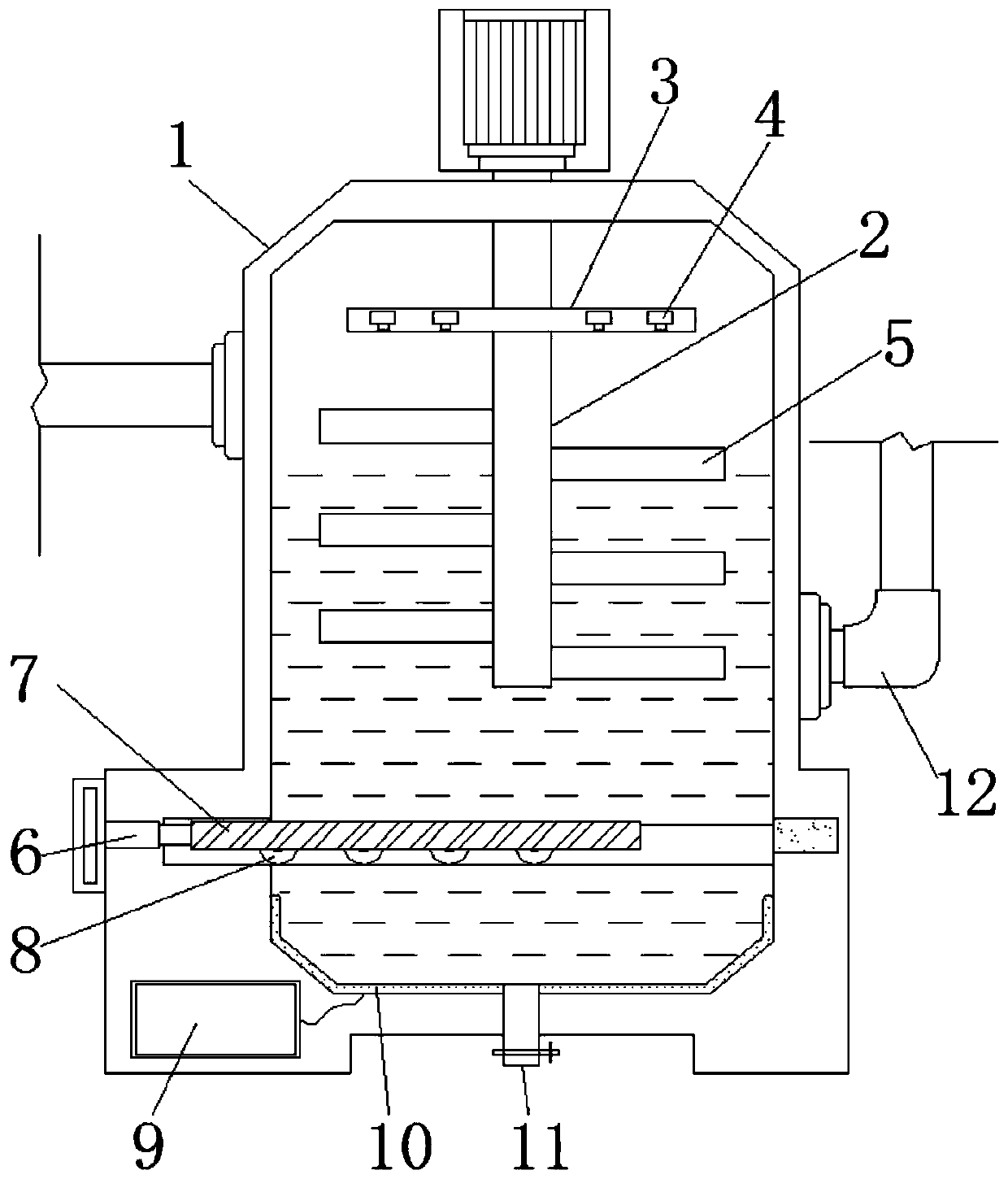

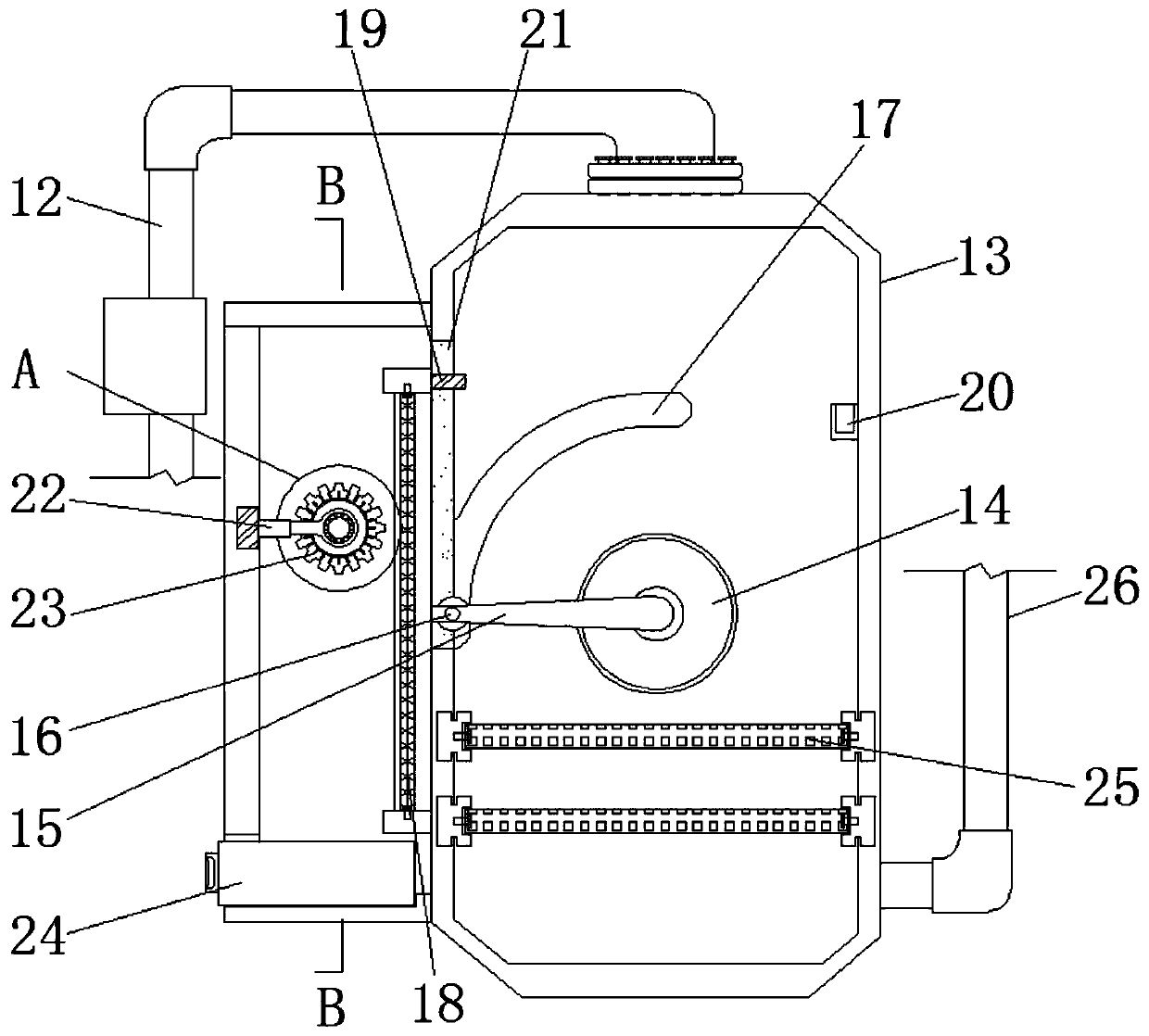

Chemical sewage filtering device with self-cleaning function

InactiveCN109694150AHandle full systemImprove efficiencyWater/sewage treatment by irradiationSpecific water treatment objectivesUltravioletEngineering

The invention discloses a chemical sewage filtering device with a self-cleaning function. The device comprises a first kettle body, a rotating shaft is arranged in the upper end of the first kettle body, ultraviolet lamps are fixedly mounted in a glass plate, rotary stirring blades are connected to the lower end of the rotating shaft in a welding manner, an electric push rod is arranged in the left side of the first kettle body, a water cooler is fixedly arranged in the lower end of the first kettle body, a residue outlet is inserted into the bottom end of the first kettle body, the right endof a first connecting tube is connected with a second kettle body, the middle of a rotating disc is fixedly connected with a movable rod, a first channel is arranged outside a second roller, and one end, away from the rotating disc, of the movable rod is fixedly connected with a filtering plate. The chemical sewage filtering device with the self-cleaning function has the advantages of high efficiency of a sterilization disinfector, high separation efficiency of impurities with large particles in the early stage, and realization of great increase of the filtering efficiency and good filtering effect due to the arrangement of a quick cleaner with the filtering plate, and is suitable for recovering water.

Owner:温州宏量机械科技有限公司

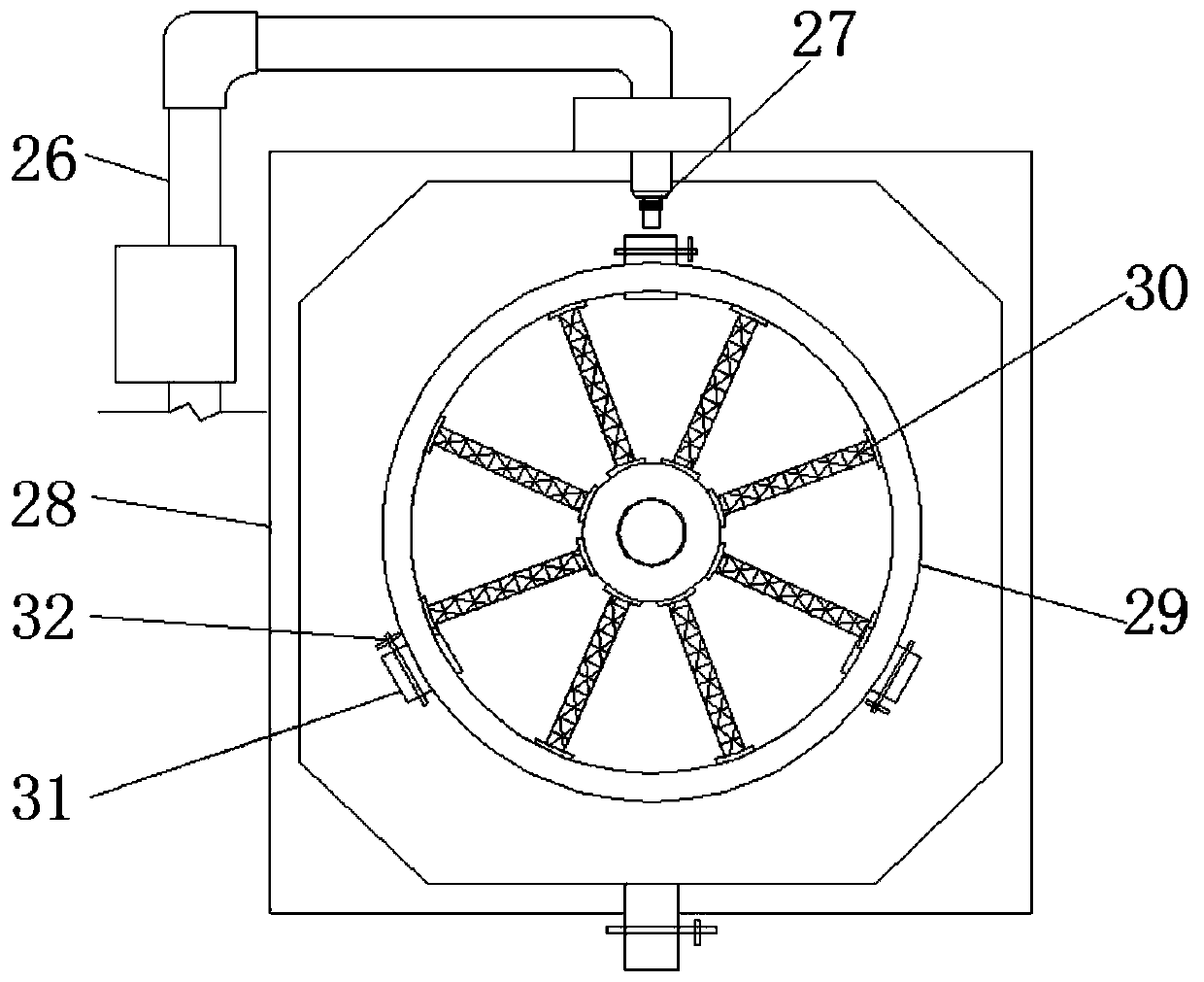

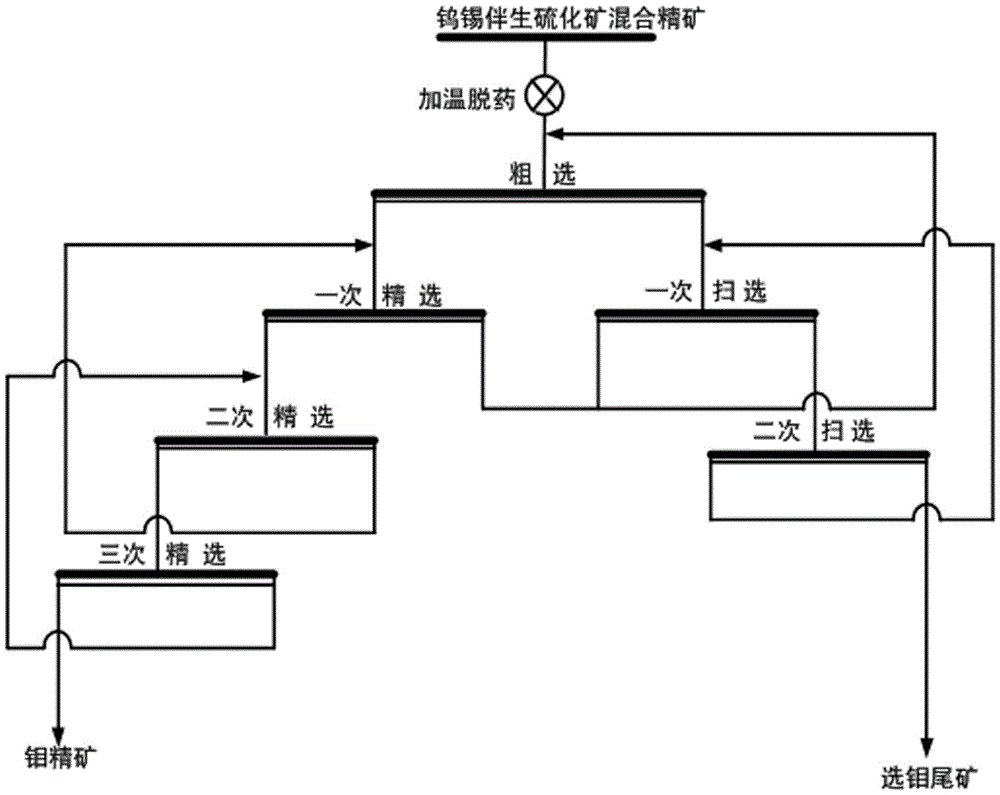

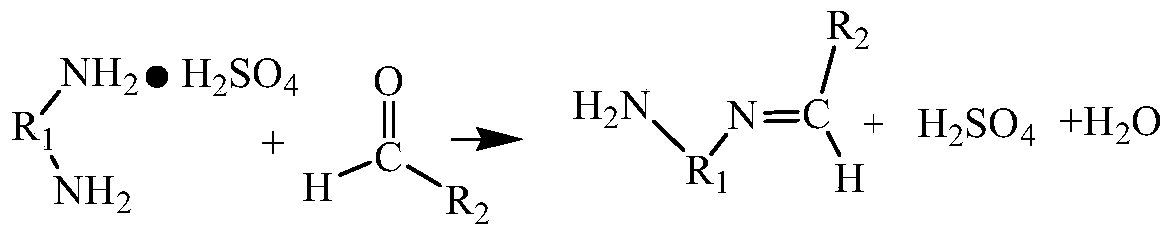

Beneficiation method for recovering molybdenum from tungsten tin associated sulfide ore bulk concentrate

InactiveCN105537005AIncrease floatability differenceGood hydrophobicityFlotationOre concentrateTungsten

The invention discloses a beneficiation method for recovering molybdenum from a tungsten tin associated sulfide ore bulk concentrate. The beneficiation method is characterized by comprising the following steps: after the heating reagent removal is performed for a sulfide ore bulk concentrate obtained from a tungsten tin associated sulfide ore; water is added for mixing pulp; quicklime is added for stirring to adjust the pulp; an inhibitor and a collecting agent are added for primary roughing to obtain a primary roughing concentrate and a primary roughing tailing; the collecting agent is added in the primary roughing tailing for secondary selection to obtain a secondary selection concentrate and a secondary selection tailing; and three times of blank selection are performed for the secondary selection concentrate to obtain a molybdenum concentrate. The method obtains the molybdenum concentrate with a molybdenum grade of 48-52% and a molybdenum recovery rate of 87-93%, reduces the molybdenum selection cost, generates no waste water and other substances harmful to the environment, and is an environment-friendly beneficiation method. The method is suitable for recovering molybdenum from the tungsten tin associated sulfide ore bulk concentrate.

Owner:GUANGZHOU RES INST OF NON FERROUS METALS +1

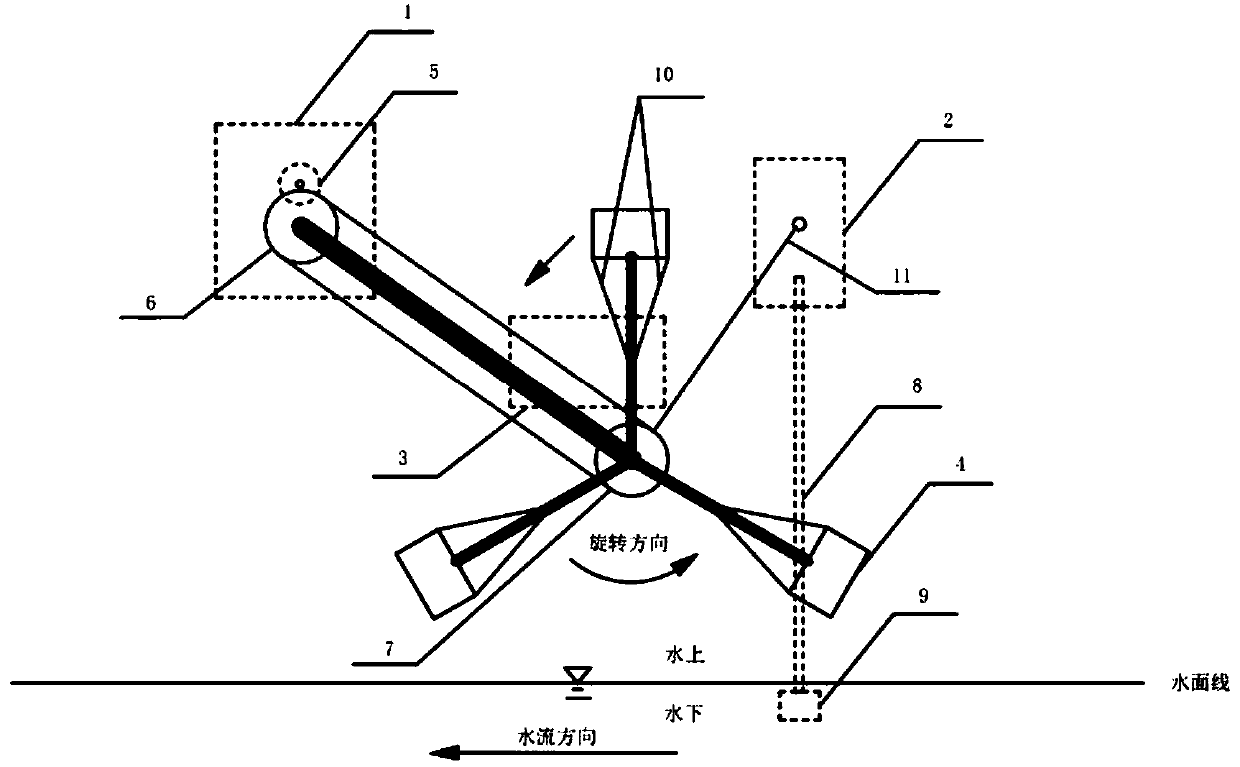

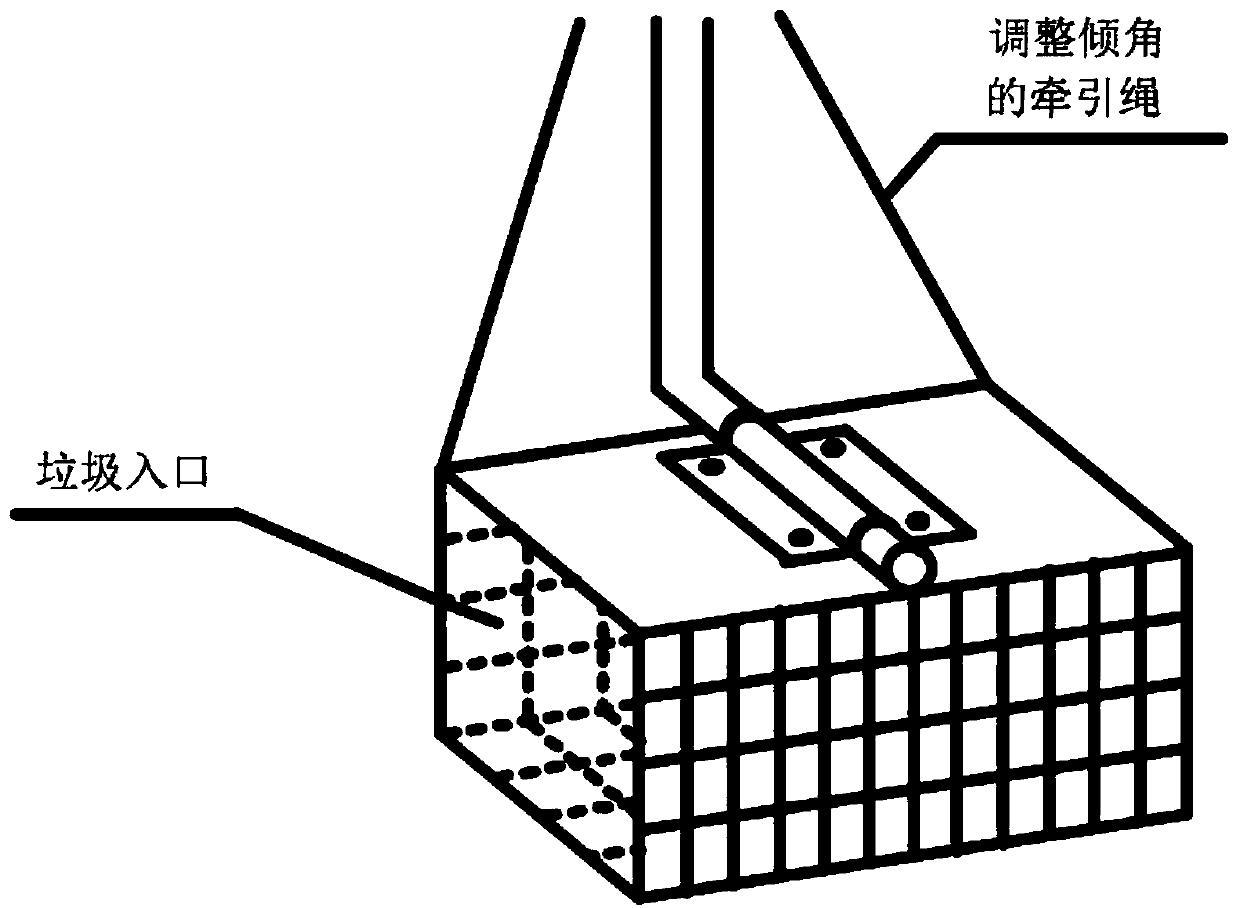

Riverway garbage collection device and method

The invention discloses a riverway garbage collection device and method. The riverway garbage collection device comprises a power device, a transmission device, a garbage collection device and an auxiliary control device; and the garbage collection device comprises a driven wheel, a spoke device, a garbage collector and a garbage temporary storage tank. The riverway garbage collection device is partially fixed to the bank side and partially located on the river side; and the spoke device rotates to collect garbage, and the collected garbage enters the garbage temporary storage tank. The product of the riverway garbage collection device has the characteristics of being efficient, fast and automatic, is wide in applicability and can be used for treatment of most of urban riverway garbage. According to the riverway garbage collection device and method, the situation that the garbage floating on the water surface is cleared manually in the past can be changed, and the collection problem ofthe garbage floating on water is effectively solved. Meanwhile, the auxiliary device is internally provided with a water level gauge and a velocity meter, hydrological data can be recorded and storedin real time, under the background of current big data booming development, the blank of national riverway hydrological data is supplemented, and future scientific research work or commercial behavior is paved.

Owner:ZHEJIANG UNIV

Method of reclaiming tantalum-niobium smelt diluting salt

InactiveCN101058428AIncrease contentLow impurity contentWater/sewage treatmentMultistage water/sewage treatmentRare earthNiobium alloy

The invention discloses a recycling method of smelted dilute salt of tantalum-niobium alloy in the rare earth metal smelting domain, which comprises the following steps: using water to dissolve the composite salt of waste; adding alkaline to adjust pH value more than 11 to remove impurity; evaporating the composite solution over 90 deg. c; insulating when the solution density reaches 1. 318g / cm3-1. 330g / cm3; separating sodium salt from solution; heating the solution continuously to condense; cooling under the temperature less than 30 deg. c; crystallizing KF and KCl; washing through cool water; removing slight residual liquid attached on the surface; drying to obtain KF and KCl; heating to 500-600 deg. c again; insulating not less than 1h; dehydrating completely; obtaining the hyper-pure anhydrous dilute salt. The invention simplifies the technique with the receiving rate of KF and KCl not less than 92%, which reduces impurity content such as Fe, Ni, Cr, Si, Ca, Mg and so on in the dilute salt with the water content of the dilute salt reaching or exceeding anhydrous standard to improve the KF content in the recycled salt.

Owner:NANCHANG UNIV

Reclamation method of hollow and used ink cartridge of ink-jet printer

InactiveCN1803457AImprove recycling efficiencyAvoid print quality degradationPrintingEngineeringHigh pressure

The invention discloses an old- regenerating method of print cartridge in the ink-ejecting printer, which adapts high-pressure hot air to blow and wash the old hollow print cartridge through scouring agent. The method improves the utility of old print cartridge greatly, which possesses high effective economical character.

Owner:PRINT RITE UNICORN IMAGE PROD CO LTD

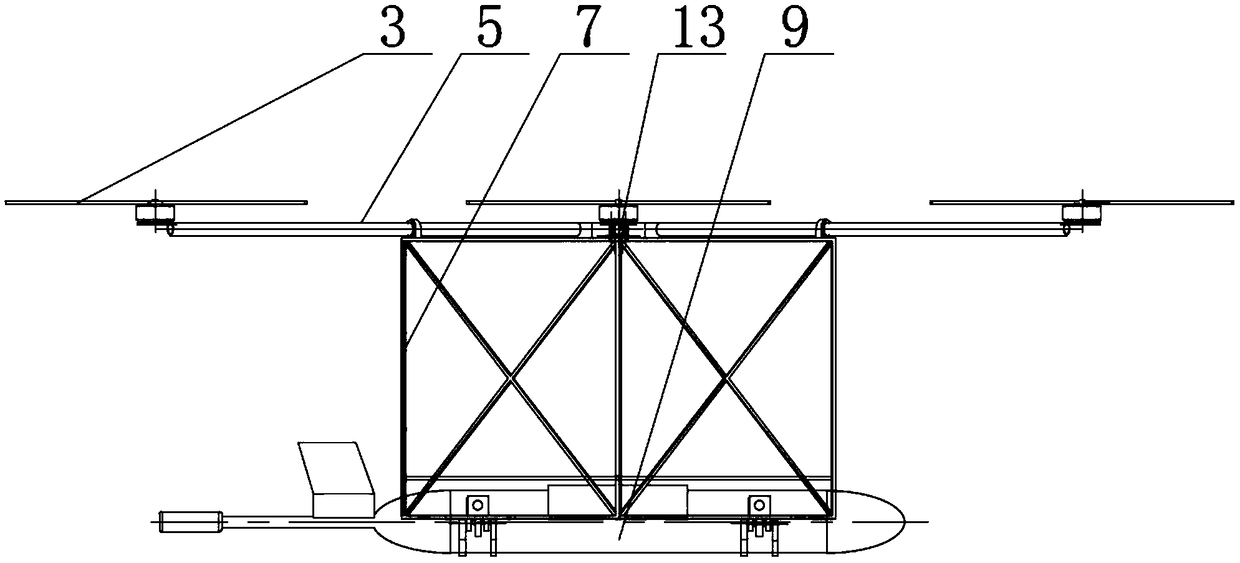

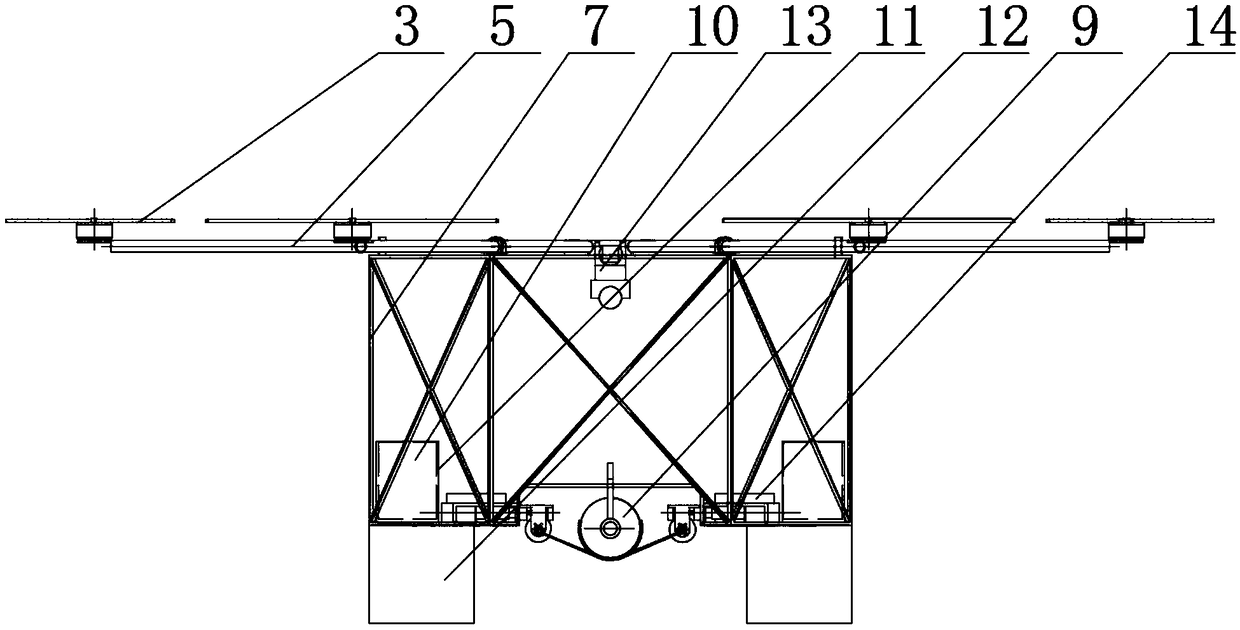

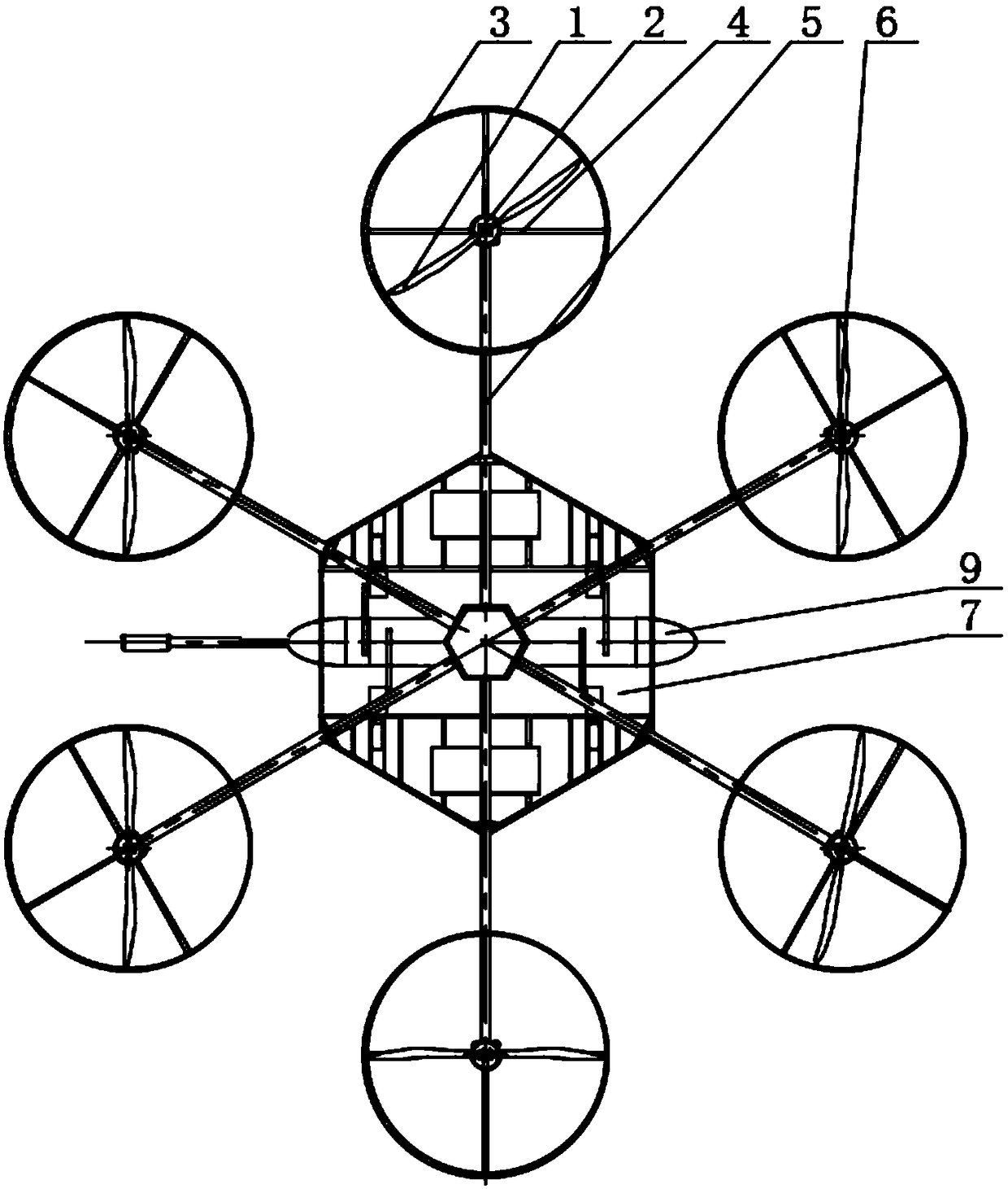

Deployment and recovery device of a flight suspension type underwater glider

ActiveCN109250037AImprove the safety of deployment and recoveryImprove deployment and recovery efficiencyLifeboat handlingAircraft convertible vehiclesElectric machinePropeller

A deployment and recovery device of a flight suspension type underwater glider comprises a frame structure. A controller is mounted in the middle of the top surface of the rack, a camera is mounted under the controller, a plurality of motor folding brackets are uniformly spaced apart from each other in the circumferential direction of the outer ring of the controller, the head of each electric motor folding support frame is fixed with a rotating electric machine, the output end of the rotating electric machine is installed with a propeller fixing plate, the propeller is installed on the propeller fixing plate, the head of each electric motor folding support frame is also fixed with a cross-shaped conduit fixing frame, and a circular conduit is installed on the outside of the conduit fixingframe; a battery box fixing seat is also installed on the inner side of the rack, a battery is installed on the inner side of the battery box fixing seat, a self-clamping catch device is symmetrically installed on the bottom of the rack, and two self-clamping catch devices grasp the glider; air bags are installed at both ends of the bottom of the frame. The device is flexible and reliable to use.

Owner:CHINA SHIP SCIENTIFIC RESEARCH CENTER (THE 702 INSTITUTE OF CHINA SHIPBUILDING INDUSTRY CORPORATION)

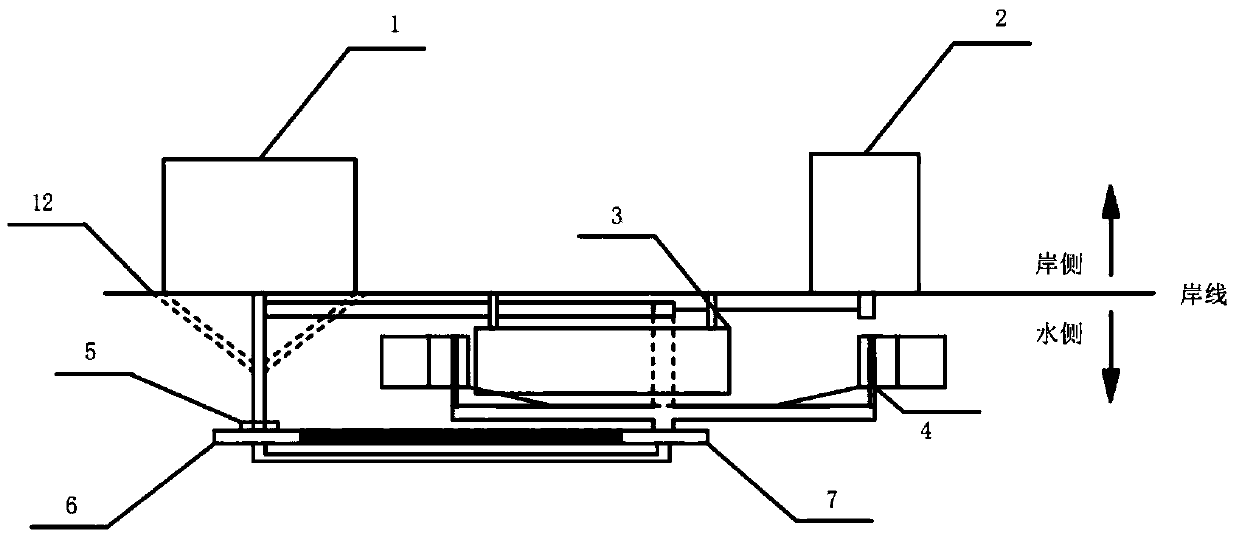

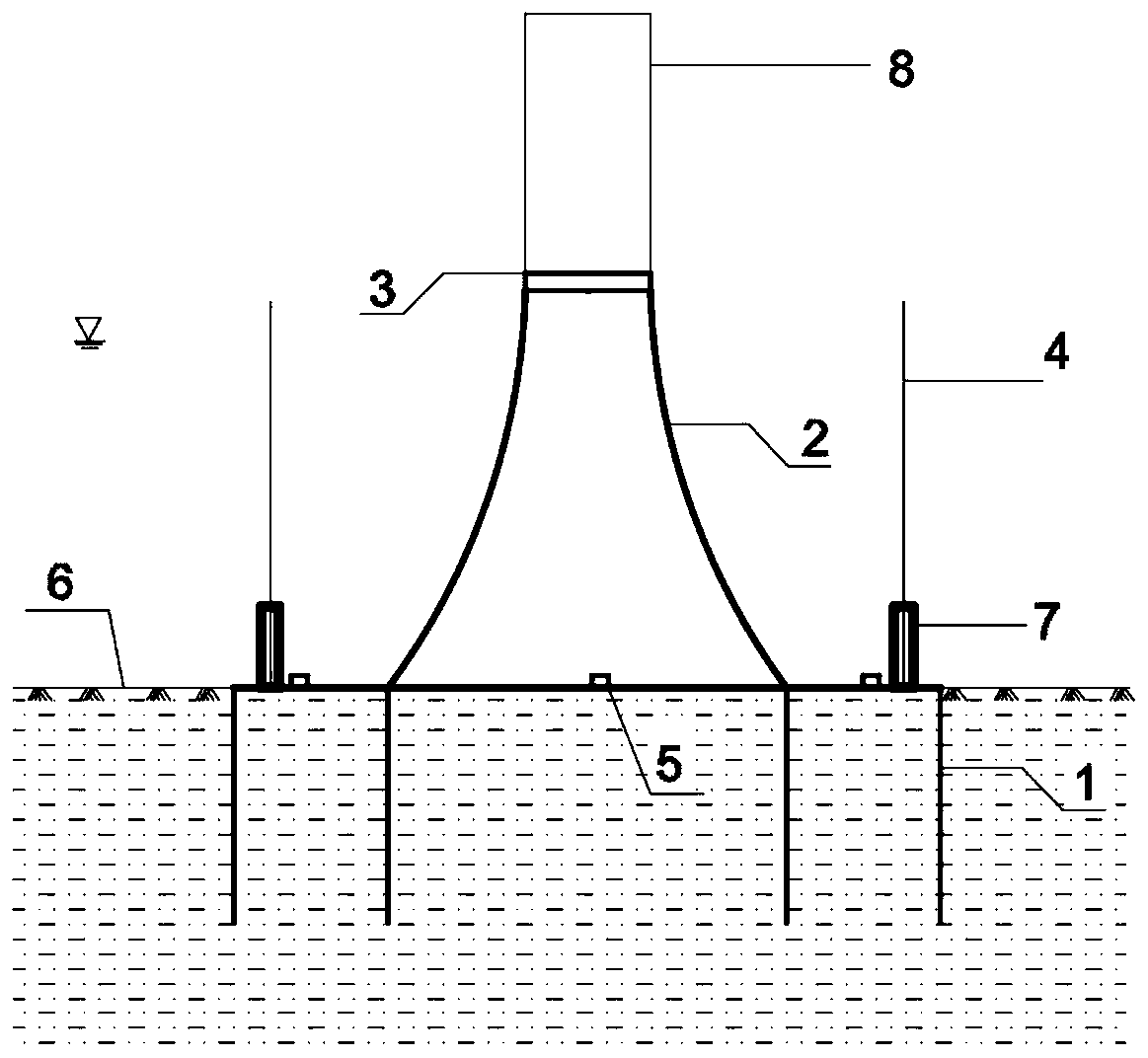

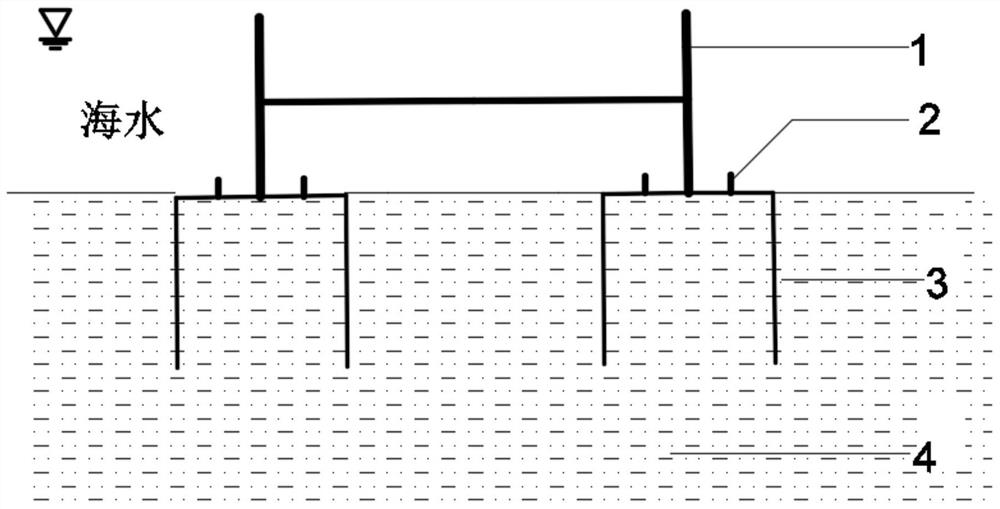

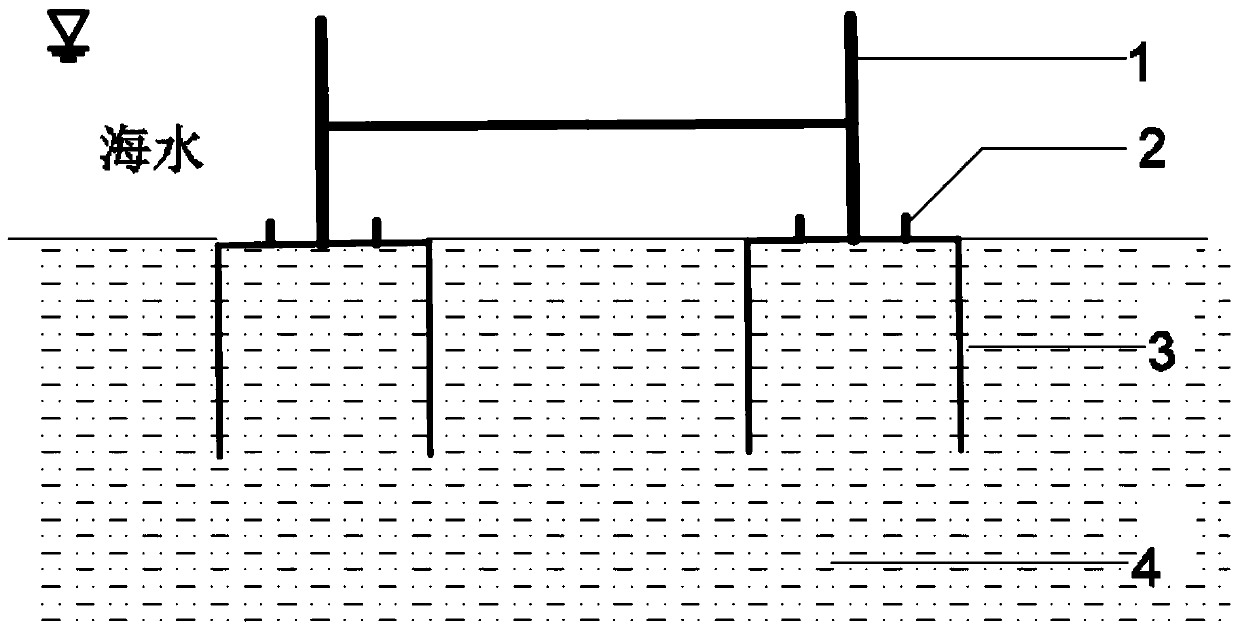

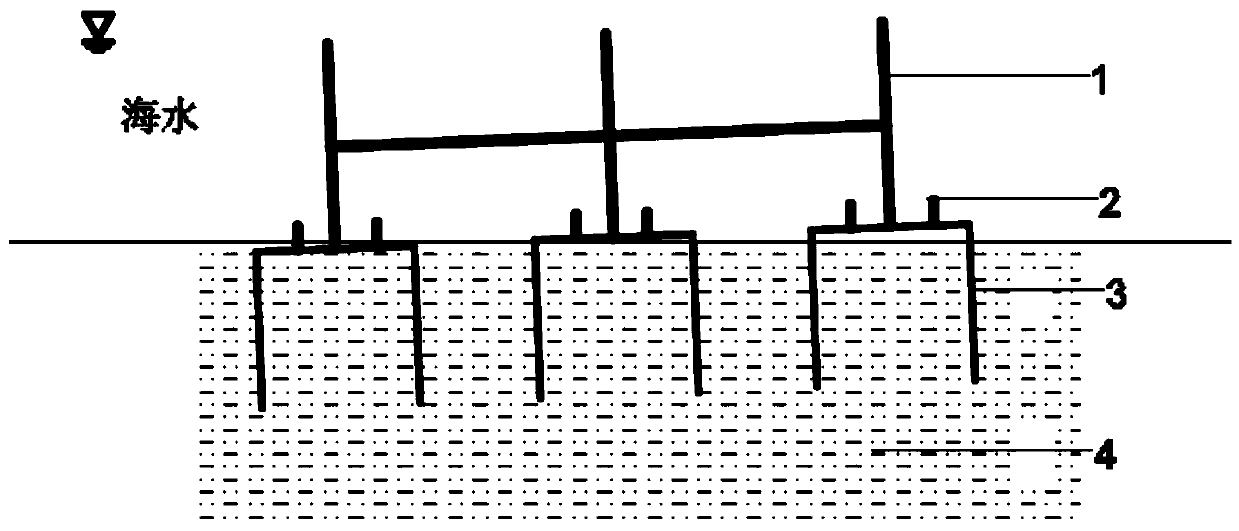

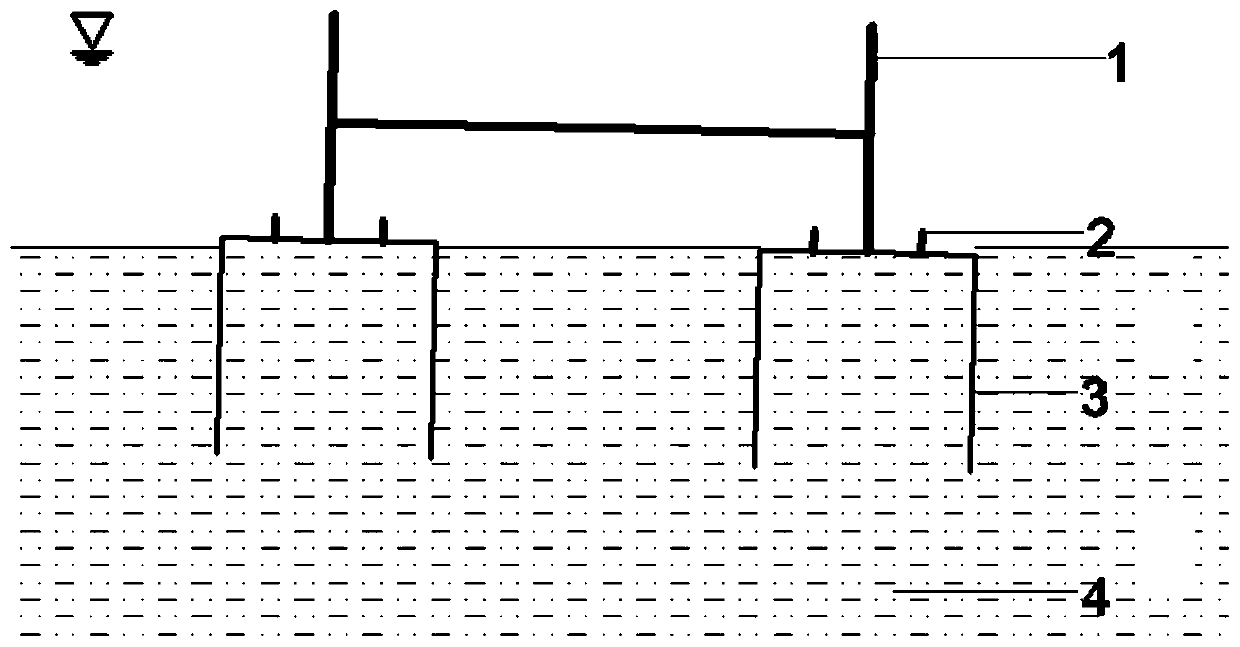

Construction method for recovery of offshore wind-power bucket foundation

InactiveCN110172993ARealize integrated recyclingReduce resistanceFoundation engineeringElectricityArchitectural engineering

The invention belongs to the technical field of recovery of offshore wind-power foundations, and discloses a construction method for recovery of an offshore wind-power bucket foundation. The construction method for recovery of the offshore wind-power bucket foundation comprises a water-injection jacking stage, an inflation jacking stage, a mooring rope-assisted up-pulling stage and a self-floatingstabilization stage. Specifically, water is injected into a steel cylinder through a drain pipe at first to make the bucket foundation move vertically, a mooring rope is used for assisting the bucketfoundation in rising, water injection is stopped when the bucket foundation rises to a certain height, the steel cylinder is inflated through the drain pipe till the bucket foundation moves upwards,and the up-pulling force of the mooring rope is adjusted to guarantee constant-speed rising of the bucket foundation; and when a top cover of the steel cylinder reaches the water surface, the steel cylinder continues to be inflated till the up-pulling force of the mooring rope is decreased to zero, and then the bucket foundation floats automatically to rise so as to be recovered. According to theconstruction method for recovery of the offshore wind-power bucket foundation, water-injection jacking is adopted at the early stage, so that the soil around the whole bucket foundation is sheared tobe damaged, and accordingly, the jacking resistance is reduced; then water-injection and inflation jacking is adopted, so that large construction equipment is not used; and the construction economicalefficiency is good, and the construction period is short.

Owner:TIANJIN UNIV

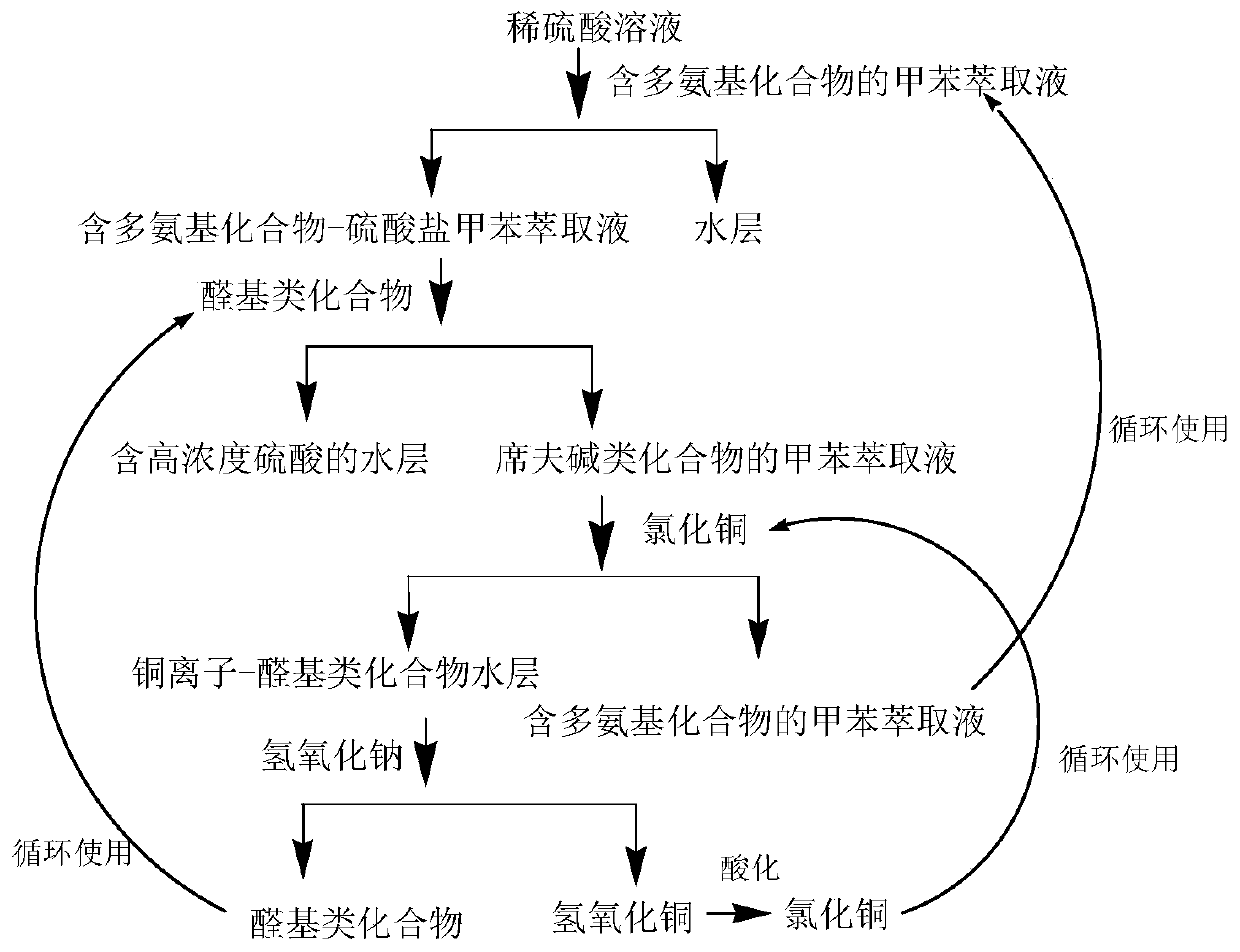

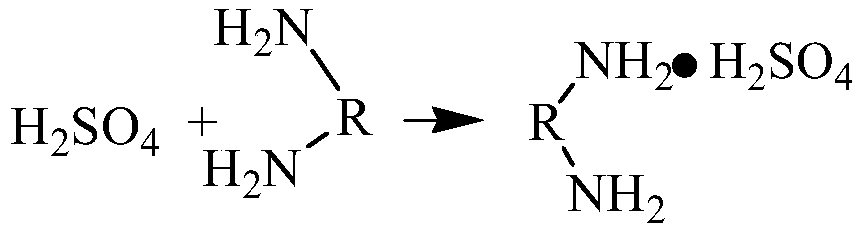

Recovery process of dilute sulfuric acid in industrial wastewater

ActiveCN110697661AAvoid side effectsEasy equipmentSulfur-trioxide/sulfuric-acidCopper chlorideSchiff base

The invention discloses a recovery process of dilute sulfuric acid in industrial wastewater. The process comprises the steps: adding a polyamino compound-containing toluene extract to the dilute sulfuric acid-containing industrial wastewater, performing stirring and still standing, separating the toluene extract, adding an aldehyde group-containing compound and deionized water to the separated toluene extract, performing stirring and still standing, performing separation so as to obtain a Schiff base compound-containing toluene solution and a sulfuric acid aqueous solution, and then recyclingintermediate products by using copper chloride, deionized water, sodium hydroxide and other substances. The recovery process has large universality for to-be-treated dilute sulfuric acid solutions andconcentrations of the to-be-treated dilute sulfuric acid solutions, and is suitable for general recovery of sulfuric acid in wastewater which contains dilute sulfuric acid with different concentrations; and the adopted reagents and the generated by-products in the entire process can be recycled basically, sulfuric acid is precipitated through a room-temperature reaction between the aldehyde group-containing compound and the polyamino compound-containing sulfate solution so that side effects caused by high-temperature reactions can be avoided, and no easy damage to equipment and high safety are achieved.

Owner:MINNAN NORMAL UNIV

A kind of beneficiation method for recovering molybdenum from tungsten-tin associated sulfide ore mixed concentrate

InactiveCN105537005BMineral processing method to solve recoveryIncrease floatability differenceFlotationWastewaterTungsten

The invention discloses a beneficiation method for recovering molybdenum from a tungsten tin associated sulfide ore bulk concentrate. The beneficiation method is characterized by comprising the following steps: after the heating reagent removal is performed for a sulfide ore bulk concentrate obtained from a tungsten tin associated sulfide ore; water is added for mixing pulp; quicklime is added for stirring to adjust the pulp; an inhibitor and a collecting agent are added for primary roughing to obtain a primary roughing concentrate and a primary roughing tailing; the collecting agent is added in the primary roughing tailing for secondary selection to obtain a secondary selection concentrate and a secondary selection tailing; and three times of blank selection are performed for the secondary selection concentrate to obtain a molybdenum concentrate. The method obtains the molybdenum concentrate with a molybdenum grade of 48-52% and a molybdenum recovery rate of 87-93%, reduces the molybdenum selection cost, generates no waste water and other substances harmful to the environment, and is an environment-friendly beneficiation method. The method is suitable for recovering molybdenum from the tungsten tin associated sulfide ore bulk concentrate.

Owner:GUANGZHOU RES INST OF NON FERROUS METALS +1

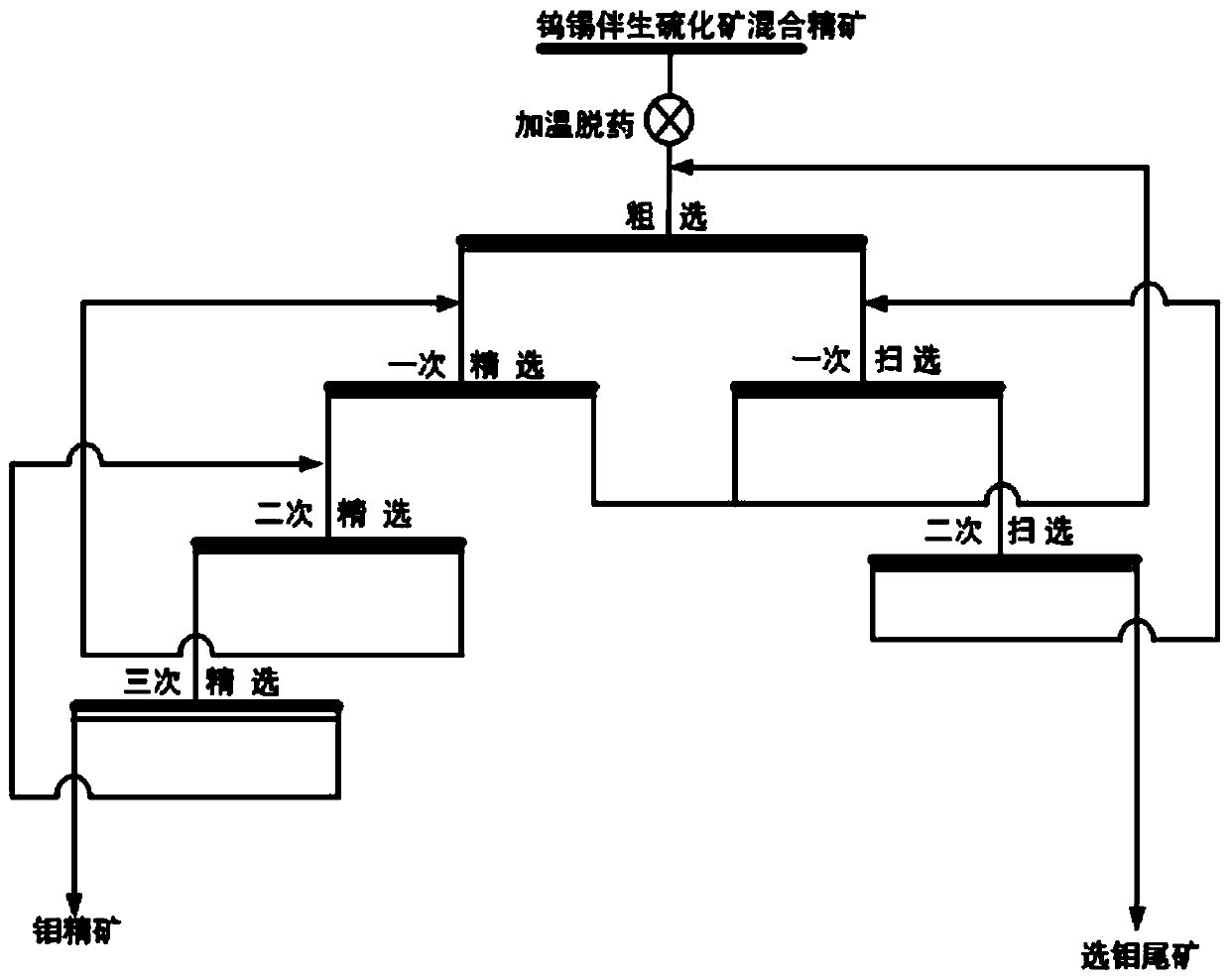

Method for recovering valuable metals from tungsten rough concentrate containing sulfide ore

The invention discloses a method for recovering valuable metal from a sulfide ore-contained tungsten rough concentrate. The method is characterized by comprising the following steps: after an ore is grinded, water is added to mix slurry; quicklime is added to stir; the pH is adjusted; a capturing agent is added for roughing, scavenging and selecting to obtain a copper concentrate; a scavenged copper tailing is added with an adjusting agent, an activating agent and a capturing agent for roughing, scavenging and selecting to obtain a bismuth concentrate; a scavenged bismuth tailing is added with an activating agent and a capturing agent for roughing, scavenging and selecting to obtain a sulfur concentrate; and a scavenged sulfur tailing is reselected by a shaker to obtain a tungsten concentrate. The obtained copper concentrate has the copper grade of 17-26% and the recovery rate of 85-93%; the bismuth concentrate has the bismuth grade of 16-23% and the recovery rate of 83-91%; the sulfur concentrate has the sulfur grade of 38-46% and the recovery rate of 68-78%; and the tungsten concentrate has the tungsten grade of 52-62% and the recovery rate of 87-95%. The valuable metal recovery method, provided by the invention, is excellent in separation effect, high in recovery rate and low in sulfur content in the tungsten concentrate, and is suitable for recovering the valuable metal from the sulfide ore-contained tungsten rough concentrate.

Owner:INST OF RESOURCES UTILIZATION & RARE EARTH DEV GUANGDONG ACAD OF SCI

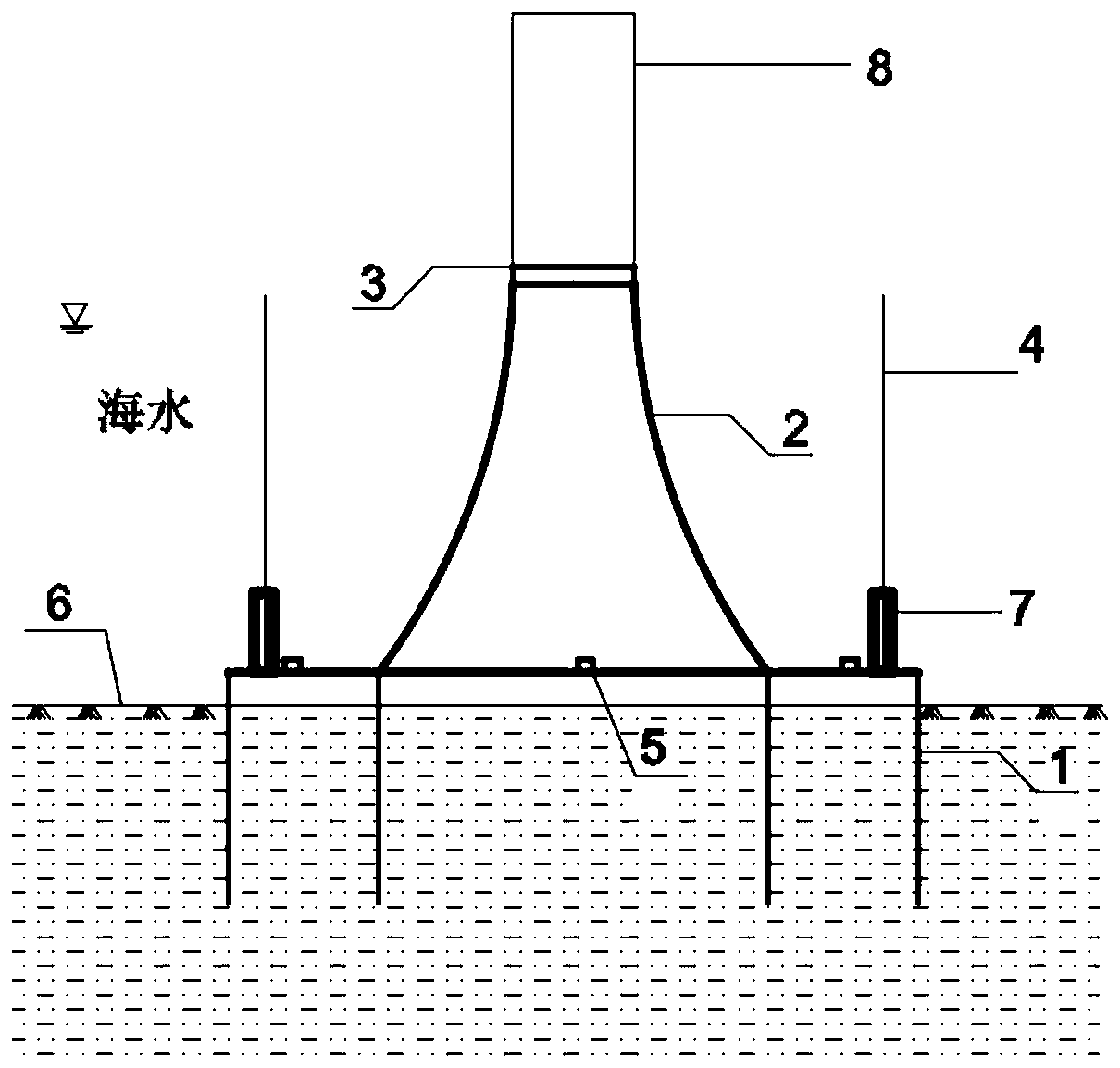

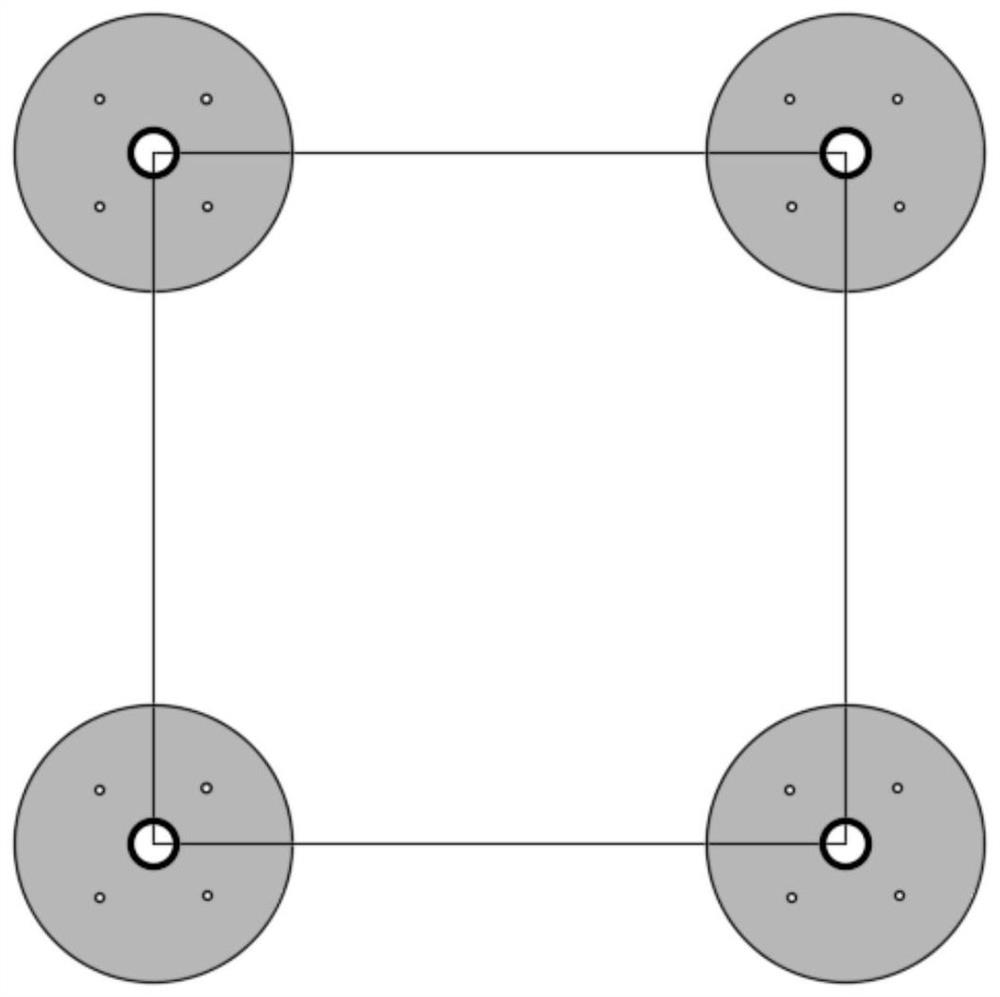

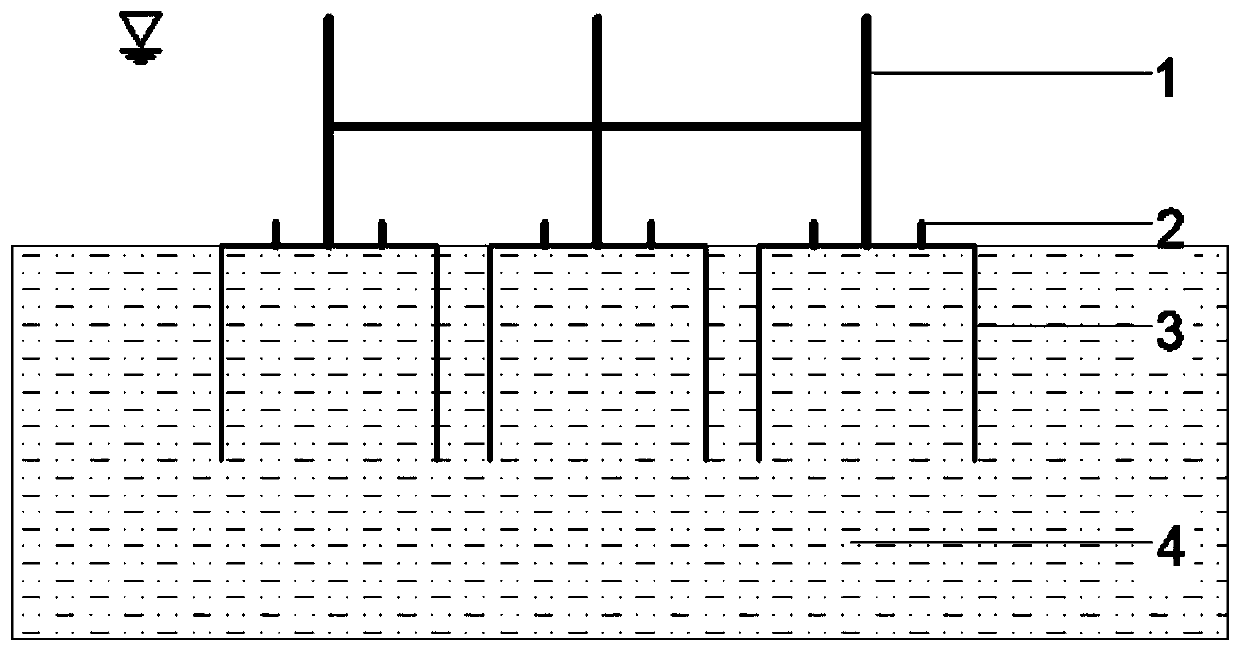

A recovery construction method for the foundation of a four-barrel fan

InactiveCN110172992BRealize integrated recyclingReduce resistanceFoundation engineeringArchitectural engineeringStructural engineering

The invention belongs to the technical field of offshore wind power foundation recycling, and discloses a construction method for recovering the foundation of a four-cylinder wind turbine. Firstly, the entire fan foundation is tilted to the direction of another single cylinder by injecting water into three single cylinders, and then released The water pressure of the three single cylinders is repeated in this way to make the four single cylinders incline in turn, and then inject water into the four single cylinders at the same time to make the cylindrical foundation rise; after the rising height of the cylindrical foundation from the initial height reaches a certain requirement, Stop water injection, and pump air to the four single cylinders at the same time to make the cylindrical foundation continue to rise; after the air pumping volume meets the design requirements, if the cylindrical foundation continues to rise, wait until the cylindrical foundation rises to the water surface; if the cylindrical foundation is no longer If it continues to rise, the cylindrical foundation will rise to the water surface through the pulling force of the suspension rope, thus completing the recovery work of the four-cylinder fan foundation. The invention realizes the integrated recovery of the foundation and the fan, does not require large-scale construction equipment, and has good construction economy and short construction period.

Owner:TIANJIN UNIV

Four-drum fan foundation recovery construction method

InactiveCN110172992ARealize integrated recyclingReduce resistanceFoundation engineeringElectricityOffshore wind power

the invention belongs to the technical field of offshore wind power foundation recovery and discloses a four-drum fan foundation recovery construction method. The method comprises the steps of injecting water into and pressurizing three drums to allow a whole fan foundation to be inclined to another drum, releasing water pressure of the three drums, repeating the operation to allow the four drumsto be inclined sequentially, injecting the water into and pressurizing the four drums simultaneously to raise the drum foundation, stopping water injection after the drum foundation rises to certain required height from the initial height, inflating the four drums simultaneously to continue raising the drum foundation, after an inflating amount meets a design requirement, waiting the drum foundation to rise to the water surface if the drum foundation continues rising, raising the drum foundation to the water surface through an uplift force of a lifting rope if the drum foundation does not continue rising, and accomplishing recovery work of the four-drum fan foundation. The method achieves integrated recovery of the foundation and a fan, and is high in construction economical efficiency andshort in construction period, and large construction equipment is not required.

Owner:TIANJIN UNIV

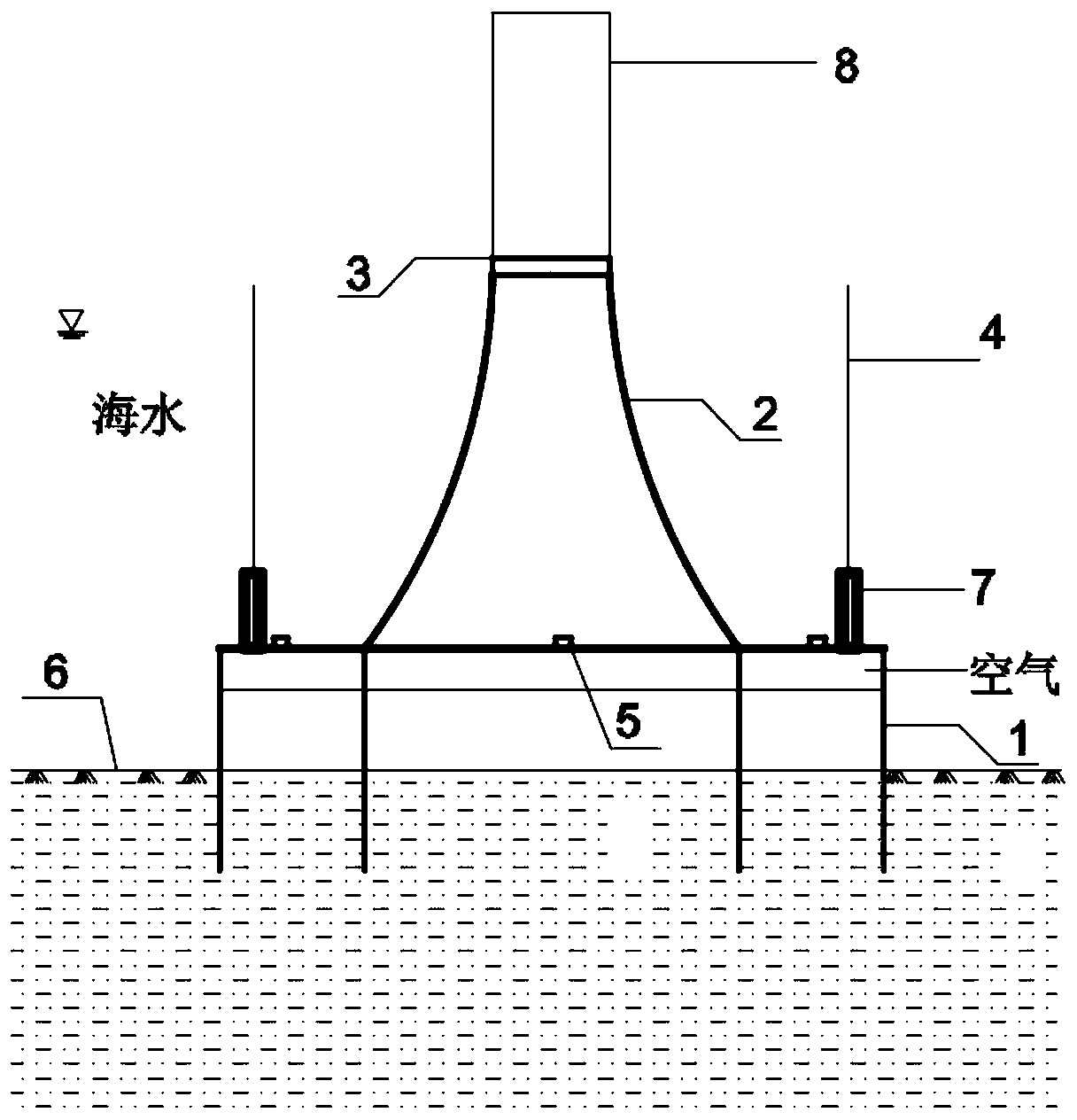

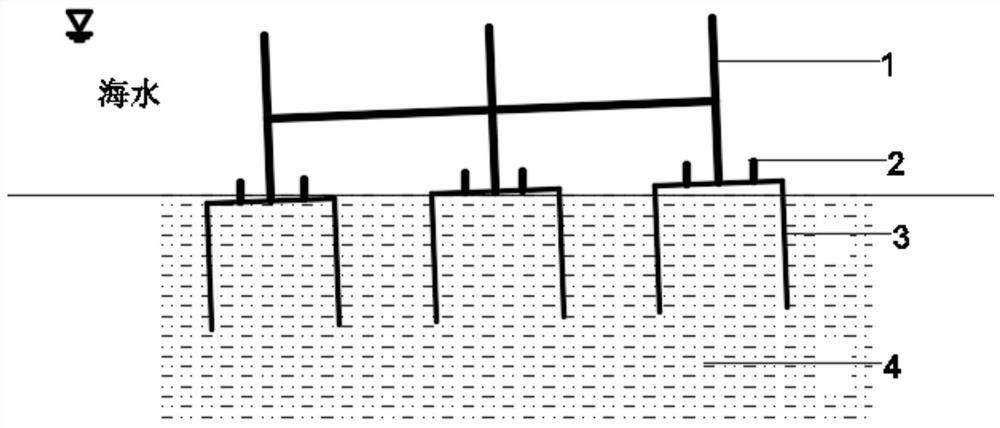

Three-cylinder fan foundation recycling construction method

InactiveCN110172991ARealize integrated recyclingReduce resistanceFoundation engineeringElectricityPull force

The invention belongs to the technical field of offshore wind power foundation recycling, and discloses a three-cylinder fan foundation recycling construction method. The method comprises the steps that the manner of conducting water injection pressurization on two single cylinders is adopted to enable a whole fan foundation to incline to the direction of another single cylinder, and then water pressure of the two single cylinders is released; the first is repeatedly conducted till the three single cylinders incline sequentially, water is simultaneously injected into the three single cylindersfor pressurization, and then the cylinder-type foundation is lifted; after the cylinder-type foundation is lifted to a certain height from the initial height, water injection is stopped, and air inflation is simultaneously conducted on the three single cylinders to enable the cylinder-type foundation is continuously lifted; after the air inflation amount meets the design requirement, if the cylinder-type foundation is kept lifting continuously, and then the cylinder-type foundation is lifted to the water surface; and if the cylinder-type foundation does not continuously lift, the cylinder-type foundation is lifted to the water surface through the up-pulling force of lifting ropes, and then recycling work of the three-cylinder fan foundation is completed. According to the three-cylinder fan foundation recycling construction method, integrated recycling of the foundation and a fan is achieved, and large construction equipment is not needed; and meanwhile, the construction economic efficiency is good, and the construction period is short.

Owner:TIANJIN UNIV

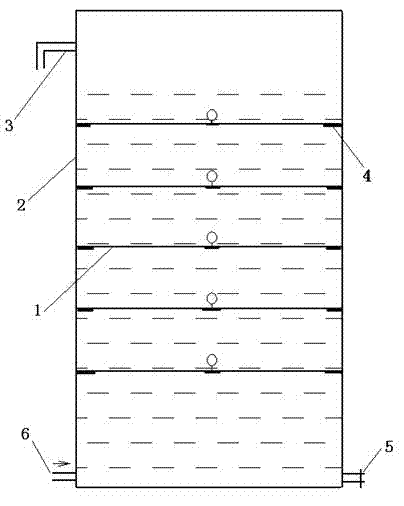

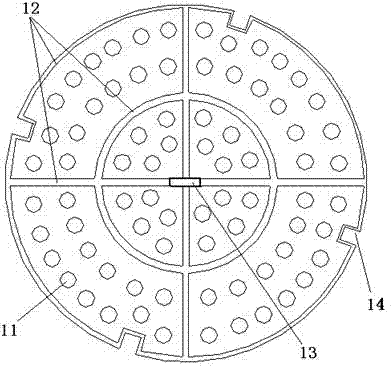

Method for reducing leakage of carbon disulfide gas through water seal layer

InactiveCN104326444AImprove recovery rateIncrease surface areaSulfur preparation/purificationLiquid statePhysical chemistry

The invention relates to a method for reducing leakage of carbon disulfide gas through a water seal layer, which is characterized in that on pot wall of a carbon disulfide recovery pot (2), multilayer porous grid plates (1) which are perpendicular to the pot wall are arranged; each layer of the porous grid plate is placed on a lug (4) which has equal height with each layer of pot wall of the carbon disulfide recovery pot, carbon disulfide gas passes through the multi-layer porous grids, delay cooling time of carbon disulfide in water is increased, bubbles of carbon disulfide formed in water are fragmented layer by layer during a rising process and are getting smaller for being liquefied, carbon disulfide gas leakage amount can be greatly reduced. According to the invention, multilayer porous grid plates are added in the water seal layer of the recovery pot, the total superficial area for contacting carbon disulfide gas and water can be greatly increased through bubbles fragmentation, cooling speed of the carbon disulfide gas is increased, conversion proportion of gaseous state carbon disulfide to liquid state carbon disulfide can be increased, carbon disulfide gas leakage can be greatly reduced, recovery rate of carbon disulfide is high, and pollution and hidden trouble due to carbon disulfide leakage can be reduced.

Owner:江西恒兴源化工有限公司

A method for stepwise recovery of valuable metals from zinc-manganese-cobalt-rich slag with multiple controls

ActiveCN103725890BEasy to recycleAvoid pollutionPhotography auxillary processesProcess efficiency improvementSmelting processControl manner

The invention discloses a method for recycling valuable metals step by step from zinc-manganese-cobalt-rich slag in a multiplex control manner. The method comprises the steps of a, processing the zinc-manganese-cobalt-rich slag by utilizing an acid liquor leaching method to obtain multi-metal solution containing manganese, cobalt and zinc; b, introducing ozone gas into the multi-metal solution, previously oxidizing and separating the manganese ions, and filtering the solution to obtain manganese slag and cobalt-zinc-containing solution; c, introducing ozone into the cobalt-zinc-containing solution, oxidizing and separating cobalt ions in the solution, and filtering the solution to obtain the cobalt slag and the zinc-containing solution; d, directly returning the zinc-containing solution to an electrodeposition section so as to directly recycle the zinc ions in the zinc-containing solution. By adopting the method, the smelting process for recycling manganese and cobalt in the multi-metal ions can be simplified, and the separation recycling step of manganese and cobalt can be completed by adopting the same reaction device. The direct recycling rate of manganese and cobalt in the method is high, cleanliness and no pollution can be realized, simplicity in operation can be realized, the equipment investment expense can be saved, and other operating management links can be saved.

Owner:湖南博一环保科技有限公司

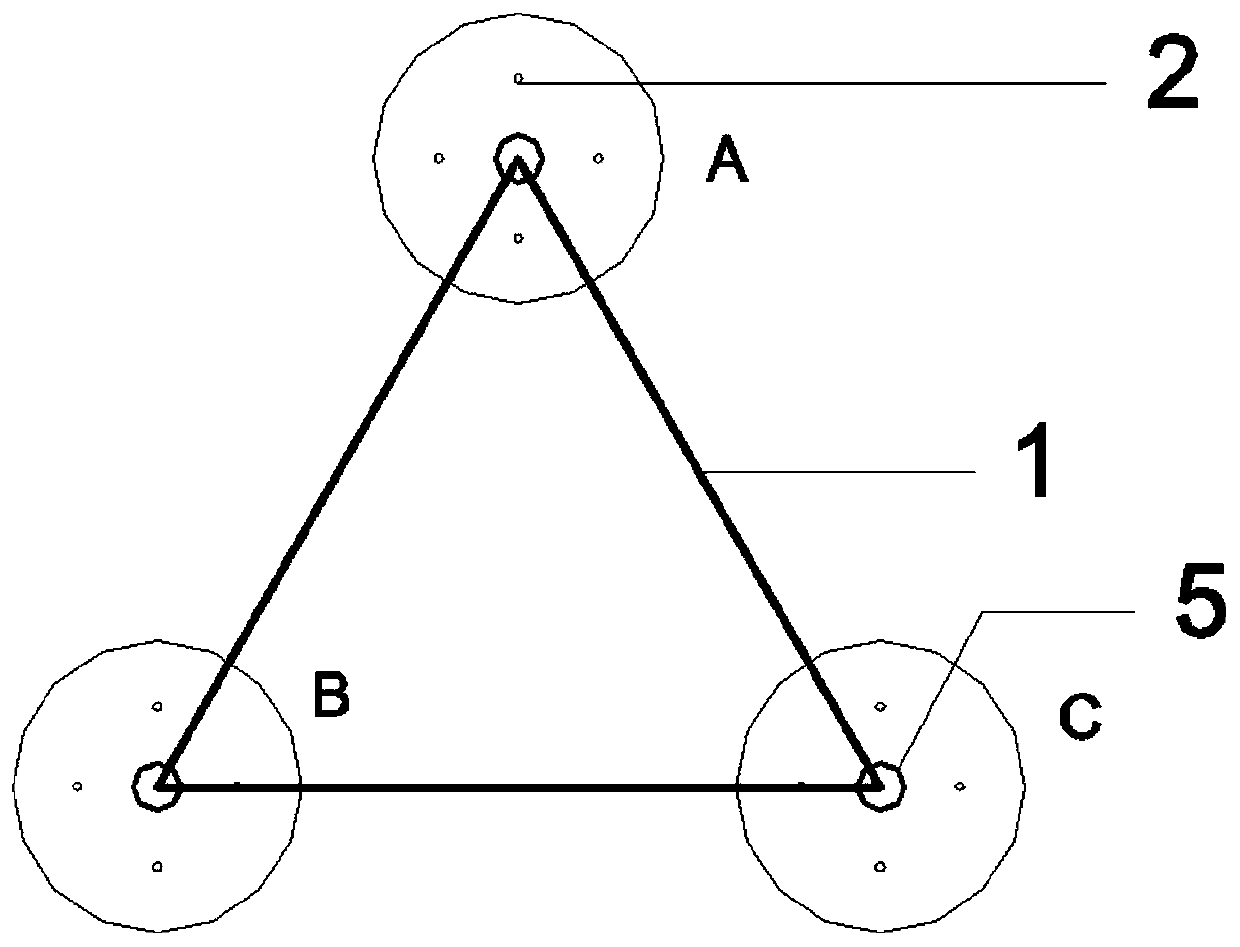

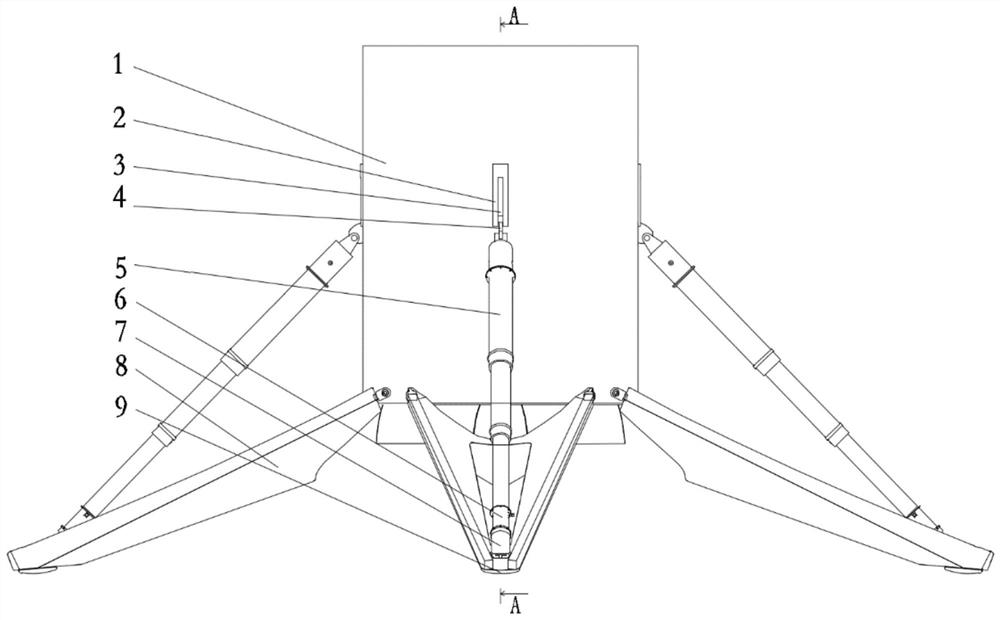

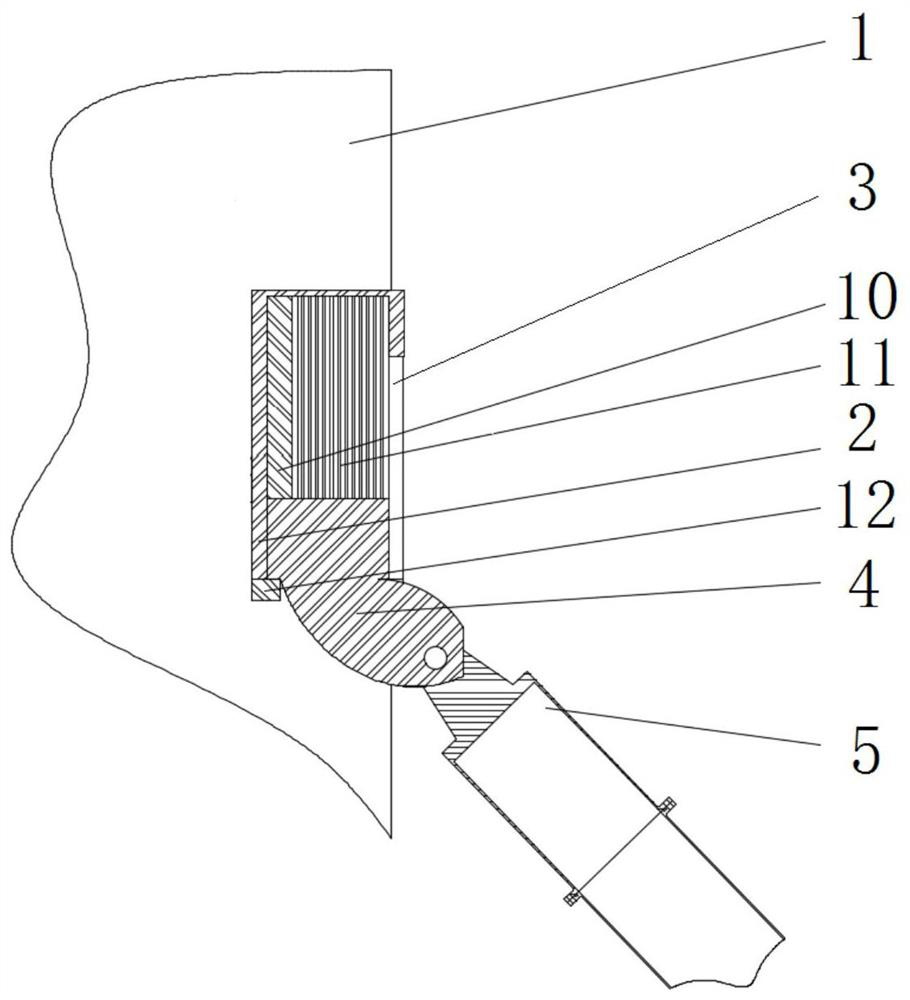

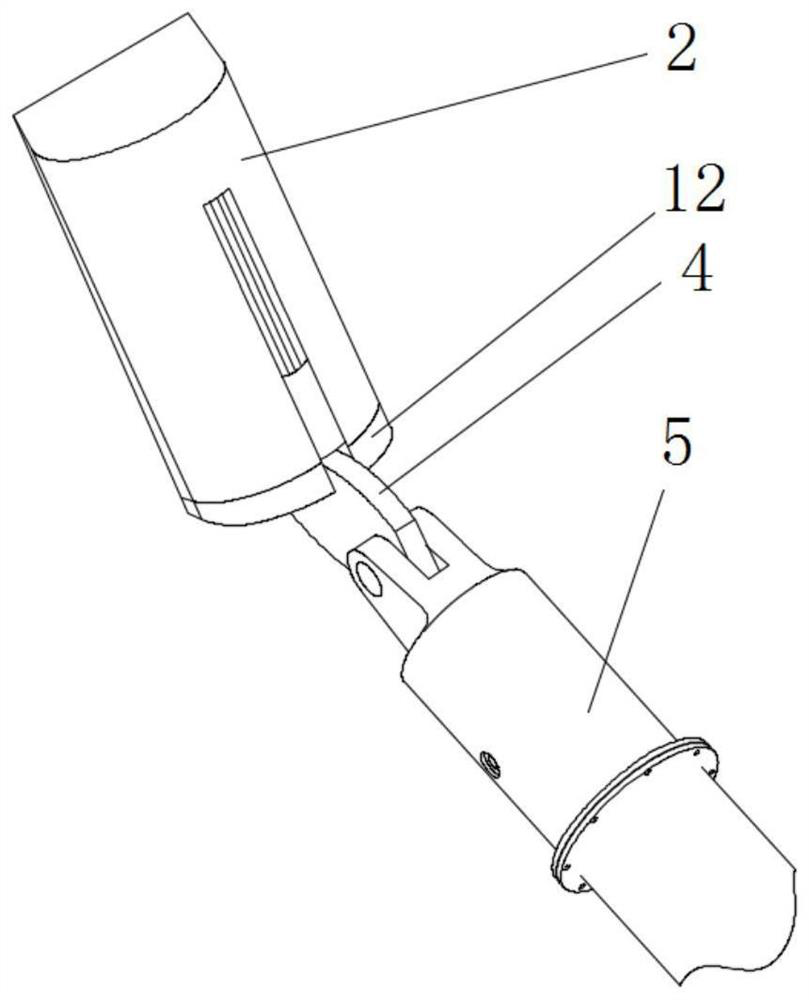

Carrier landing mechanism and method based on oil-gas buffer and anti-crash device

ActiveCN109533297BEnable safe recyclingShorten the lengthUndercarriagesStructural engineeringMechanical engineering

The invention discloses a carrier landing mechanism based on an oil-gas buffer and anti-crash device and a method thereof. The carrier landing mechanism includes at least three landing brackets uniformly arranged on the side wall of the carrier in the circumferential direction; the landing bracket includes an anti-crash device. device, retractable strut, oil and gas buffer device and auxiliary casing; the anti-crash device is fixed on the outer wall of the carrier, and its piston is hinged through the connecting rod and one end of the retractable strut, the other end of the retractable strut and the oil and gas buffer device One end is coaxially fixed; the auxiliary shell is triangular, two corners are hinged with the lower end of the side wall of the carrier respectively, and the other end of the other corner is hinged with the oil-gas buffer device. The invention can not only realize the repeated use of the large dead-weight carrier under normal working conditions, but also realize the safe recovery under dangerous working conditions, and at the same time realize the lightweight and compact structure.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

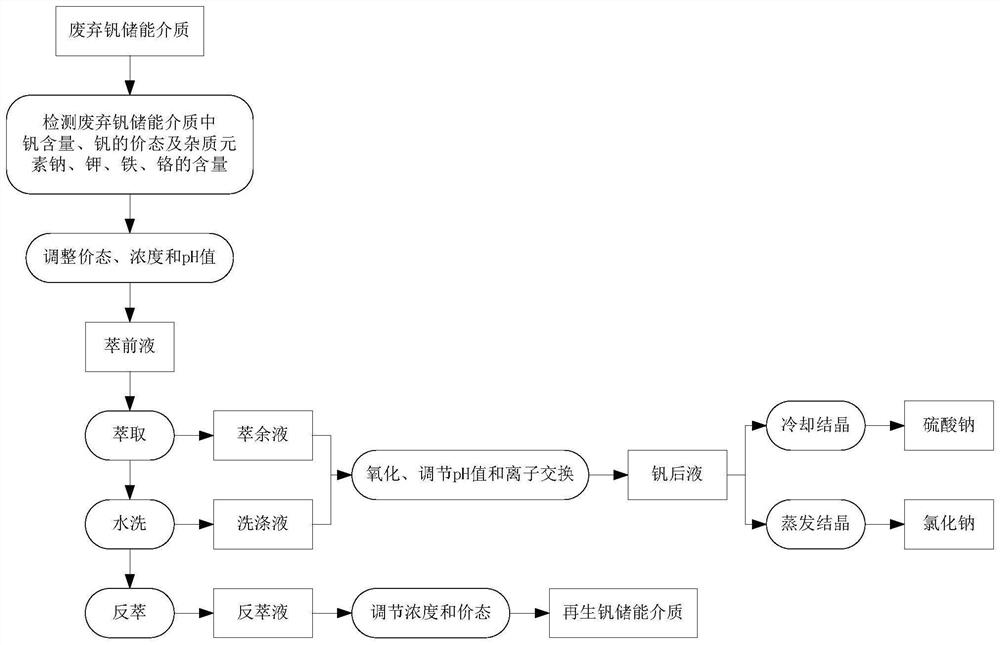

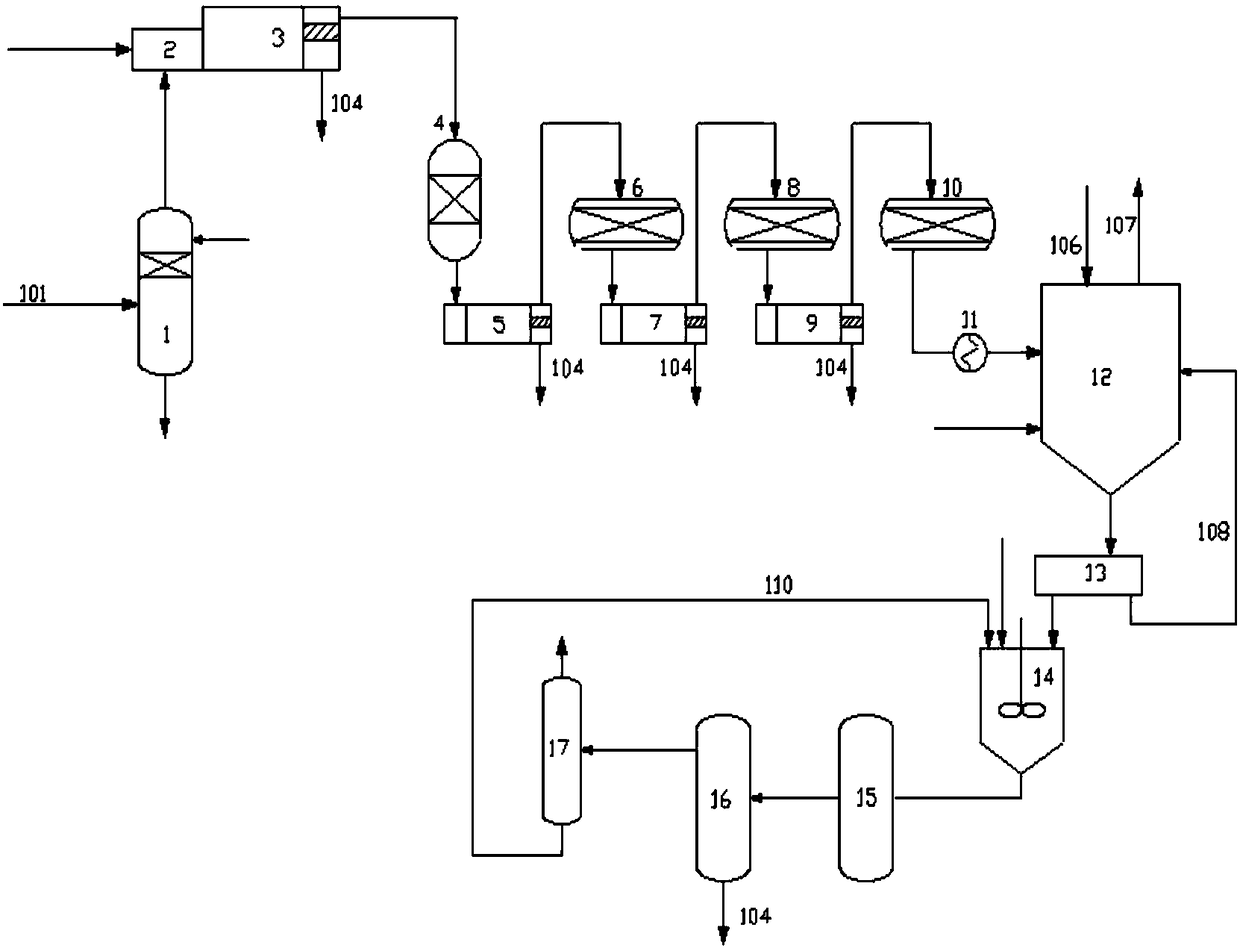

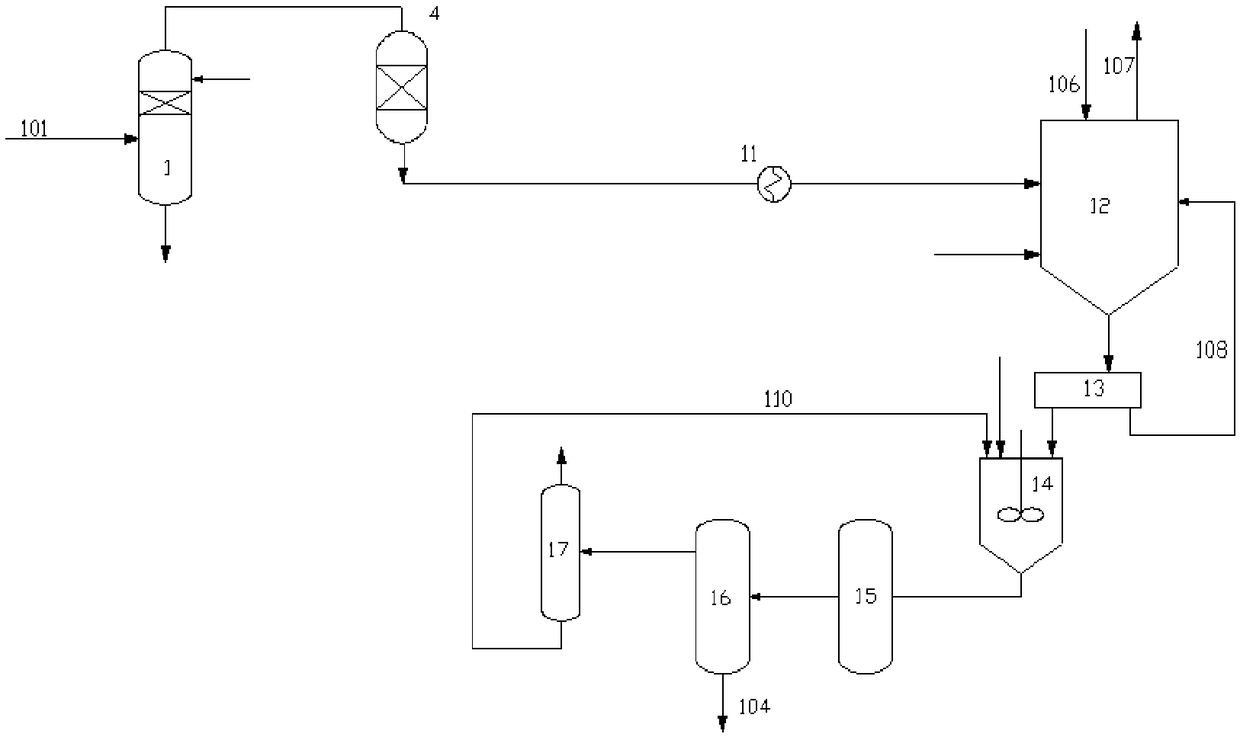

Regeneration method of waste vanadium energy storage medium

PendingCN114243041ASimple recycling processApplicable recyclingFuel cells disposal/recyclingRegenerative fuel cellsElectrolysisIon exchange

The invention provides a regeneration method of a waste vanadium energy storage medium. The regeneration method comprises the following steps: detecting the content of elements in the waste vanadium energy storage medium; the valence state of vanadium is adjusted to 3.98-4.02 valence, and a vanadium solution is obtained; adding pure water or mother liquor to dilute the vanadium solution, and adjusting the pH value of the vanadium solution to obtain a pre-extraction solution; performing counter-current extraction, counter-current washing and counter-current reverse extraction to obtain raffinate, washing liquid and high-purity reverse extraction liquid; the high-purity strip liquor is adjusted to the standard concentration of the vanadium energy storage medium, the valence state is adjusted through electrolysis, and the regenerated vanadium energy storage medium is obtained; adjusting the pH values of the raffinate and the water washing liquid, adding an oxidizing agent or oxidizing tetravalent vanadium into pentavalent vanadium by adopting electrolytic oxidation, carrying out ion exchange through resin, and recovering vanadium in the raffinate and the water washing liquid to obtain vanadium post-liquid; and crystallizing the post-vanadium liquid to obtain mother liquor and crystals. According to the method, impurity elements in the vanadium energy storage medium can be separated, and the purpose of regeneration is achieved.

Owner:DALIAN RONGKE ENERGY STORAGE GRP CO LTD

A new process for treating acid gas containing ammonia, carbonyl sulfide and hydrogen sulfide and recovering sulfur

ActiveCN106395756BImprove qualityReduce sulfur contentGas treatmentDispersed particle separationCombustionHydrogenation reaction

The present invention discloses a novel method for processing ammonia, carbonyl sulfide and hydrogen sulfide-containing acid gases, and recycling the sulfur. According to the method, the measures of washing to remove ammonia, Claus combustion, hydrolysis reaction, Claus reaction, hydrogenation reaction, absorption and oxidation reaction, and sulfur refining are combined. According to the composition of acid gases, the technological process is flexibly selected, and the heat of acid gases is recovered. Therefore, the purposes of energy saving and emission reduction are realized. The method can be used for purifying acid gases of different compositions. After being processed, the tail gas can be discharged directly. Meanwhile, the high-quality sulfur can be recovered, and the sulfur recovery rate is more than 99.95%.

Owner:HUALU ENG & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com