Method for reducing leakage of carbon disulfide gas through water seal layer

A technology of carbon disulfide and gas, which is applied in the field of insoluble sulfur production technology, to achieve the effects of reducing pollution and safety hazards, increasing cooling speed, and high recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

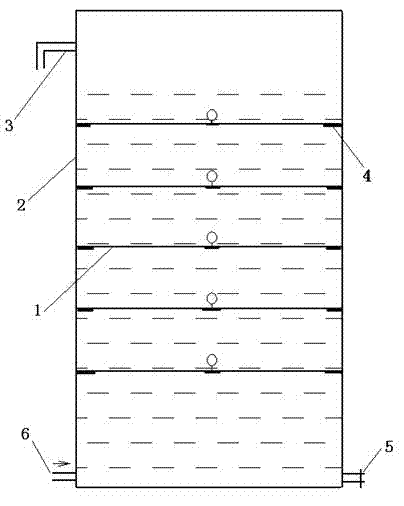

[0021] The specific embodiment of the present invention is as figure 1 shown.

[0022] In this embodiment, five layers of perforated grate plates are installed on the tank wall of the carbon disulfide recovery tank. On the tank wall of the carbon disulfide recovery tank, there are five layers of equal-height mounting brackets for installing porous grate plates; 4 brackets are installed on each layer, and the 4 brackets in the same layer are on the circumference of the recovery tank wall They are distributed at 90° each other.

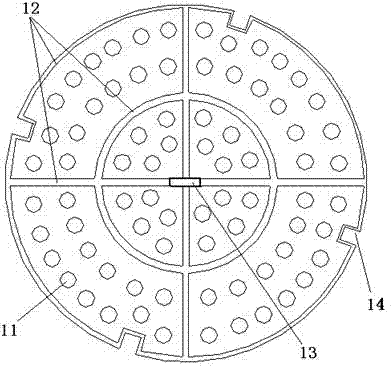

[0023] The porous grate is a circular porous structure made of 1.2mm thick stainless steel sheet. The outer diameter of the porous grate is slightly smaller than the inner diameter of the carbon disulfide recovery tank. Ribs are set in the diameter direction of the two; for the convenience of installation, except for the uppermost porous grate plate, there are 4 installation gaps on the outer edge of each porous grate plate, and the installation gaps...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com