Mining method of thin minor ore body

A mining method and technology for small ore bodies, which are used in surface mining, earth-moving drilling, underground mining, etc., can solve the problems of subsidence and cracks in surface industrial sites, threatening the safety of surface structures, and high ore loss and dilution rate, so as to reduce ore The effect of loss, reducing ore dilution rate and improving recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

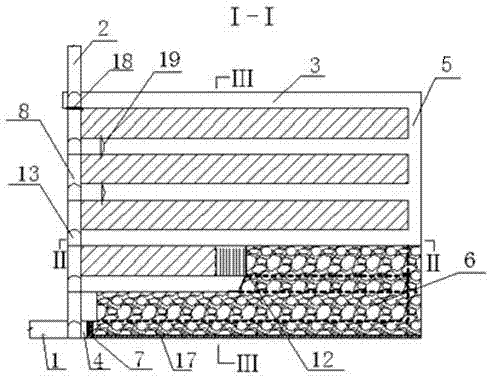

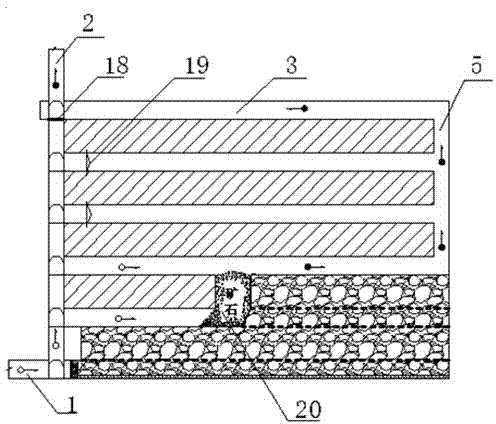

[0032] A method for mining a thin ore body, specifically comprising the following steps;

[0033] 1) Accurate cutting:

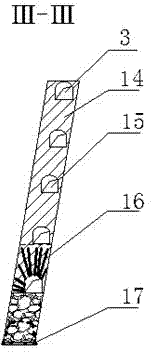

[0034] a. If figure 1 , 2 As shown, the inclined or sharply inclined thin ore body is divided into several mining areas according to the length of the strike. Generally, the length of a mining area is 100m, the height of the stage is 50m, and the height of the segment (layer) is 7m. The manpower shaft 8 also enters the wind shaft, and the ore body footwall is designed to arrange the filling shaft 10 from the surface to the mining area, and the ore chute 9 from the mining area to the next stage, and connects with the mining area through the connecting road 13.

[0035] b. On the top of the mining area, along the ore body, excavate the upper subsection mining transportation roadway 3 and the return air lane in the mining area, and excavate the lower subsection mining transportation tunnel 4, from the lower subsection mining transportation tunnel 4 to the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com