Production method for separating silver from silver waste liquid

A production method and technology of waste liquid, applied in the production field of separating silver, achieving the effect of low cost, high efficiency and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

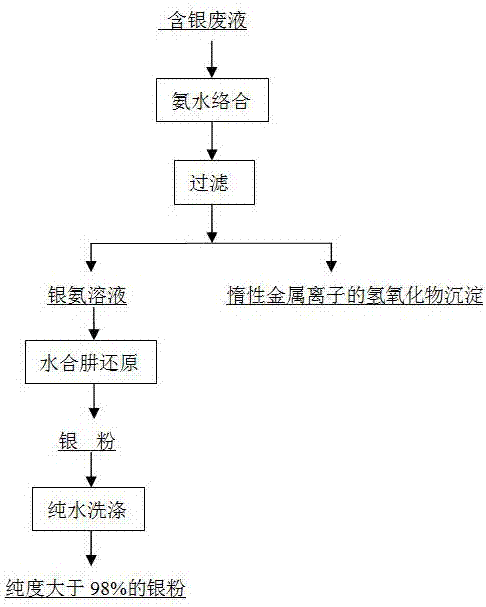

[0019] Such as figure 1 Shown, a kind of production method of separating silver from silver-containing waste liquid, the method may further comprise the steps:

[0020] a) In the silver-containing waste liquid, add ammonia water with a mass concentration of 25% and analytically pure grade, adjust the pH value of the silver-containing waste liquid to 9, and hydrolyze the inert metal ions in the silver-containing waste liquid into hydroxide precipitates, silver The ions generate silver ammonium complex ions, and the hydroxide precipitates of inert metal ions are removed by filtration to obtain silver ammonium solution;

[0021] b) Add excess mass concentration of 80% hydrazine hydrate of analytically pure grade to the silver ammonium solution until no bubbles are produced in the solution, and the silver ions are completely reduced to silver powder;

[0022] c) Separate the supernatant, and wash the silver powder with pure water several times until the pH value of the washing so...

Embodiment 2

[0024] Such as figure 1 Shown, a kind of production method of separating silver from silver-containing waste liquid, the method may further comprise the steps:

[0025] a) In the silver-containing waste liquid, add ammonia water with a mass concentration of 28% and analytically pure grade, adjust the pH value of the silver-containing waste liquid to 10, and hydrolyze the inert metal ions in the silver-containing waste liquid into hydroxide precipitates, silver The ions generate silver ammonium complex ions, and the hydroxide precipitates of inert metal ions are removed by filtration to obtain silver ammonium solution;

[0026] b) Add excess mass concentration of 80% hydrazine hydrate of analytically pure grade to the silver ammonium solution until no bubbles are produced in the solution, and the silver ions are completely reduced to silver powder;

[0027] c) Separate the supernatant, and wash the silver powder with pure water several times until the pH value of the washing s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com