Patents

Literature

254results about How to "Automatic separation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

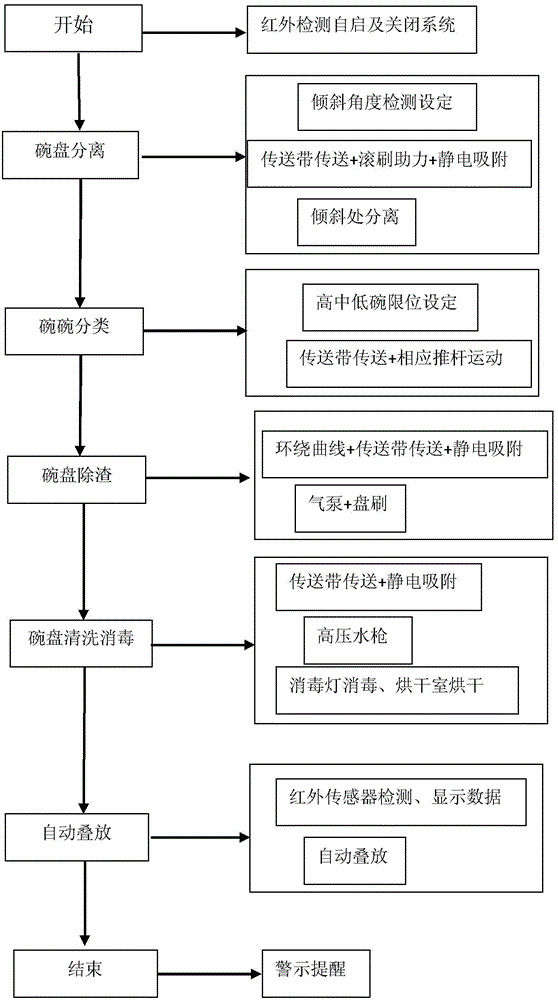

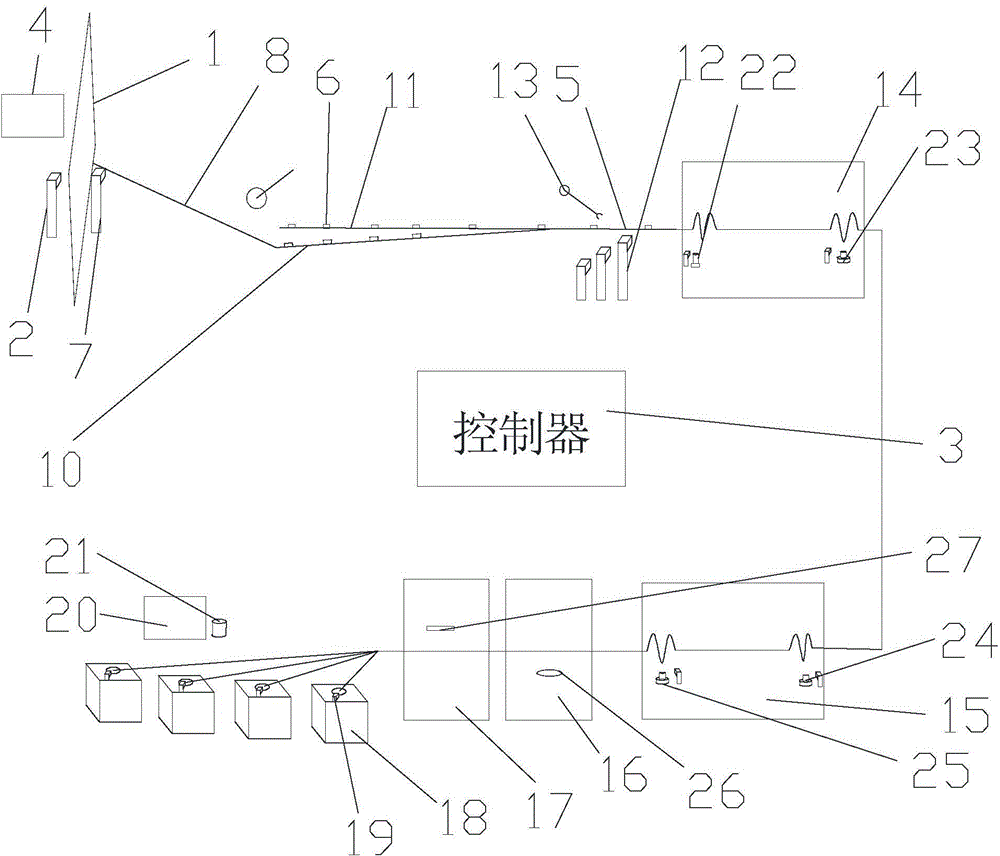

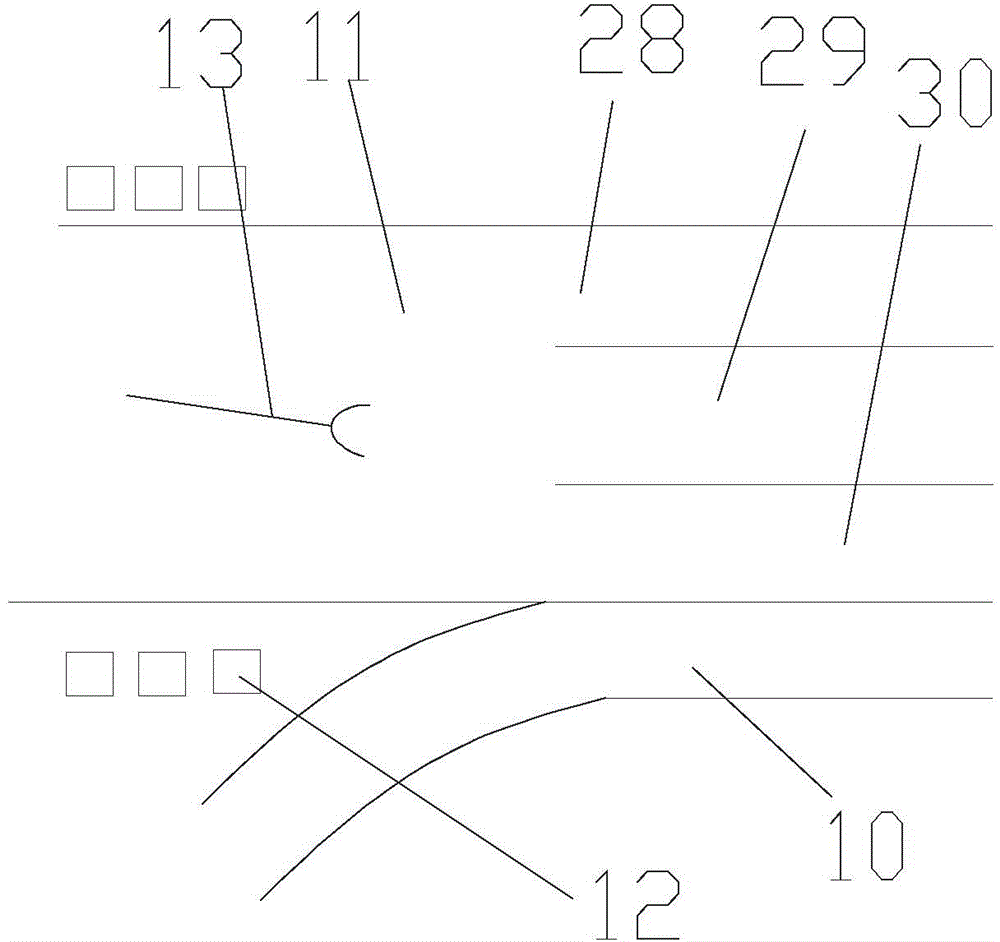

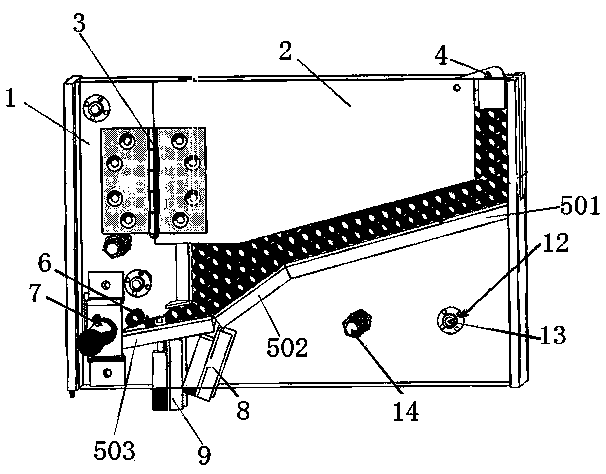

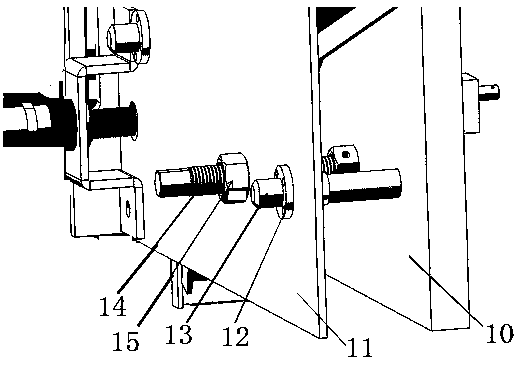

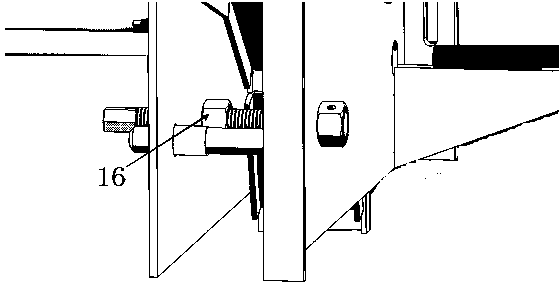

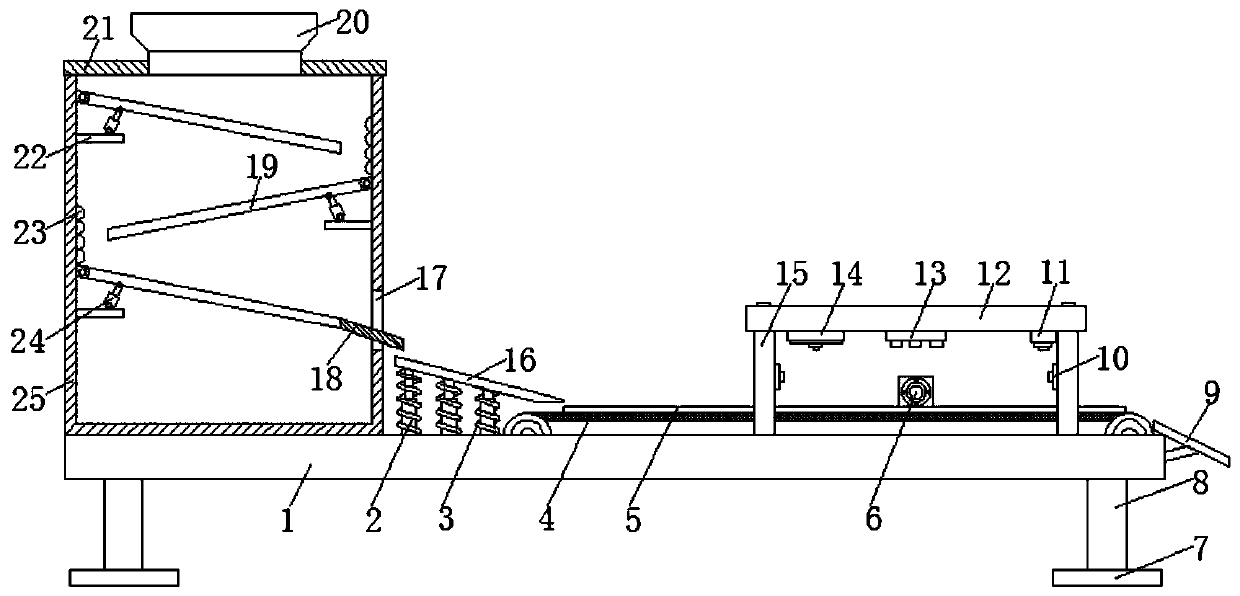

Automatic classifying, residue removing and cleaning system for tableware and using method

ActiveCN104923491AReduce intermediate manual handling stagesReduced manual handling stagesKitchenware cleanersTableware washing/rinsing machinesLife qualityEngineering

The invention discloses an automatic classifying, residue removing and cleaning system for tableware and a using method. By means of a detector, a special track, a display screen, a classifying system and the like, collection, classification, residue processing, washing, disinfection and stacking can be integrated, the classifying link, the residue removing link and the cleaning and disinfecting link of the canteen tableware are combined, and the middle manual carrying link is reduced; bowls and dishes can be automatically separated; the bowls can be automatically classified; the capacity of a bowl box and the capacity of a dish box can be automatically recognized, displayed and prompted. By means of the system and the using method, the work for recycling and cleaning the college canteen tableware can be seamlessly connected with the automation principle, the preliminary requirement of modern people for the living quality and the dietetic hygiene of college canteens is met, meanwhile, the rate for the canteens to utilizing labor force is greatly increased, and the system and the using method adapt to the development tendency of modern science and technology.

Owner:FUJIAN UNIV OF TECH

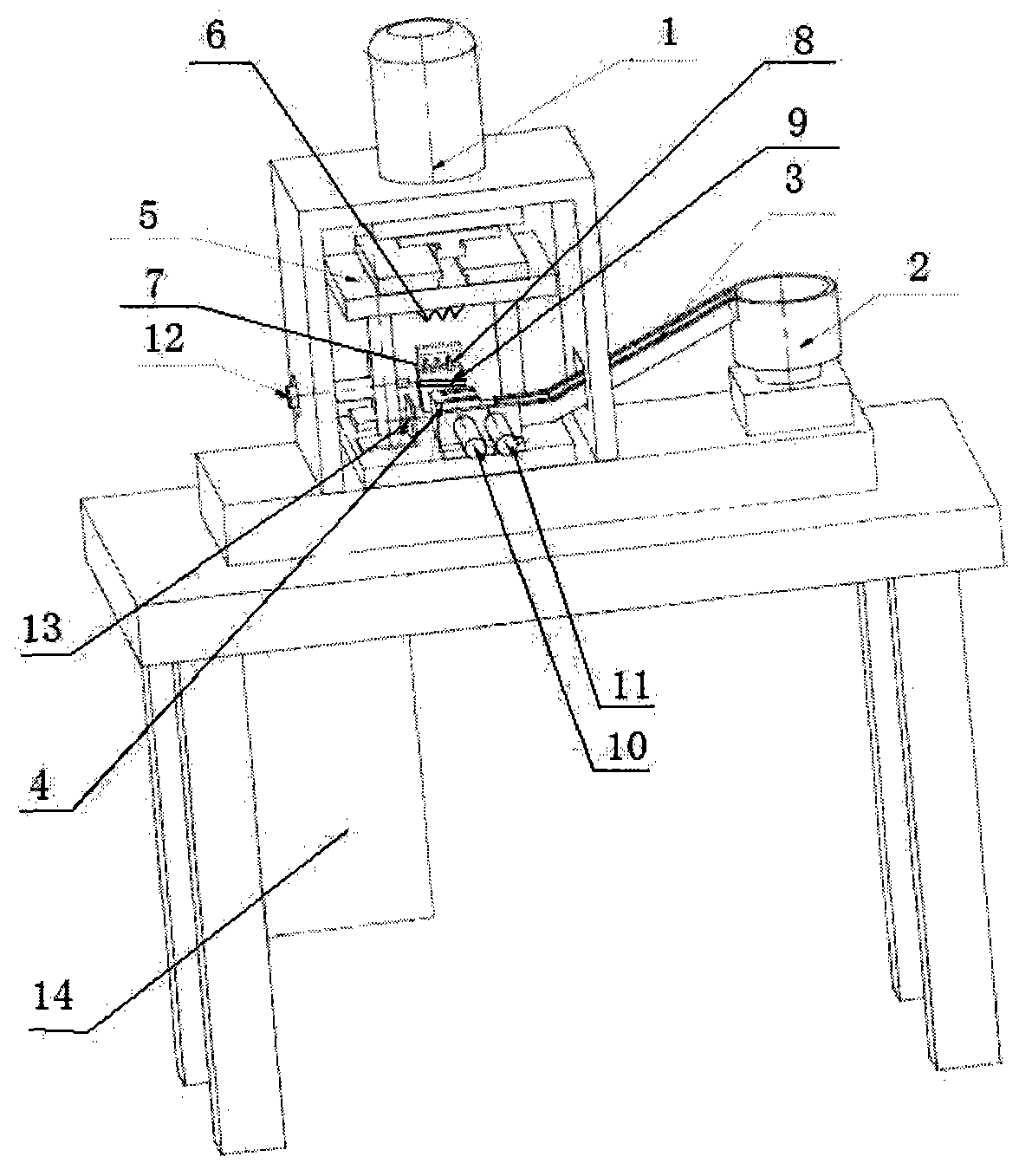

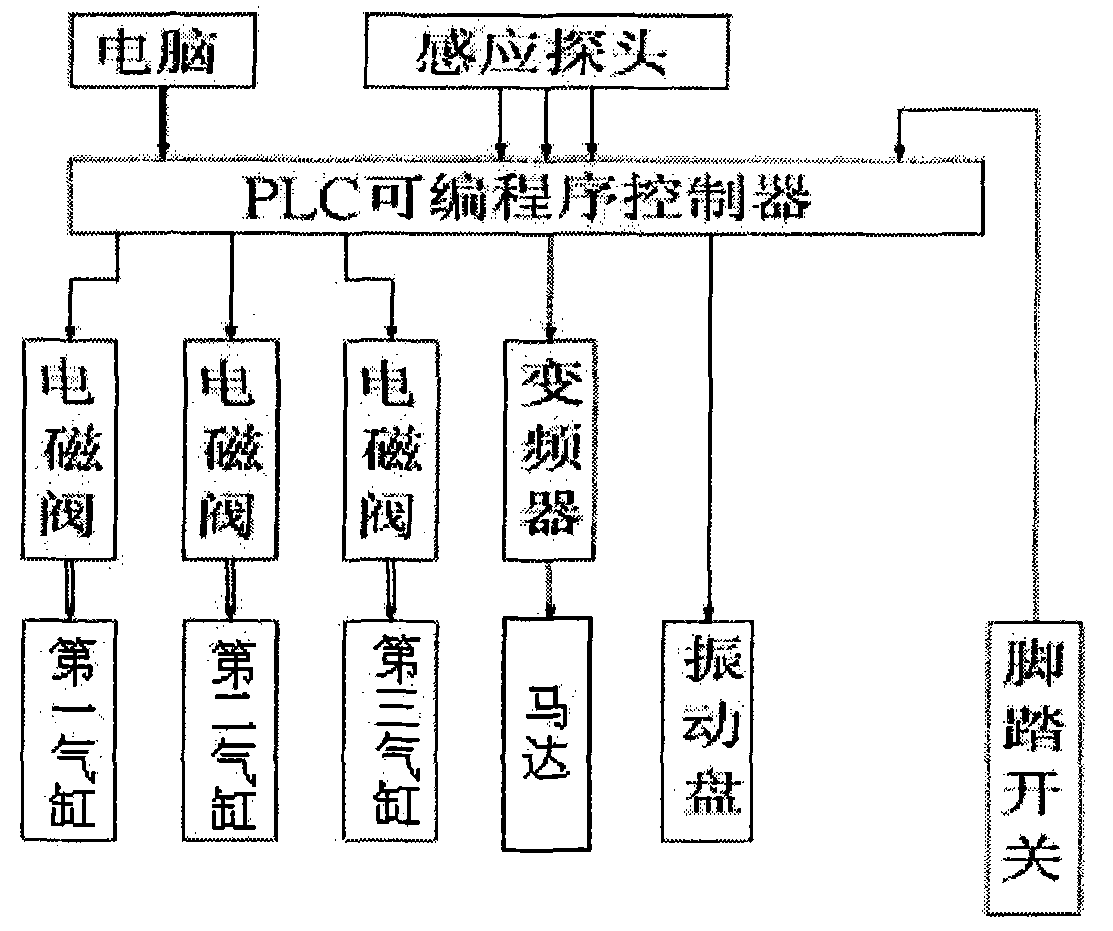

Automatic conveying and riveting device used for power line plug part with plastic body

ActiveCN103972767AIncrease productivityReduce labor costsLine/current collector detailsProgrammable logic controllerEngineering

The invention relates to an automatic conveying and riveting device used for a power line plug part with a plastic body. The automatic conveying and riveting device comprises a terminal machine, a feeding device, a riveting device, an electric device, an inductive probe and a foot switch, wherein the feeding device comprises a vibrating disk, a feeding guide rail and a movable feeding base, the feeding guide rail is connected with a discharge port of the vibrating disk, and the feeding base is connected with the feeding guide rail; the riveting device comprises an upper die base, an upper riveting cutting die base connected with the upper die base, a lower die base, a lower riveting cutting die connected with the lower die base and a stop block connected with the lower riveting cutting die; the electric device comprises a programmable logic controller (PLC), a first air cylinder, a second air cylinder and a third air cylinder, and the first air cylinder, the second air cylinder and the third air cylinder are respectively connected with the PLC. The automatic conveying and riveting device can rivet 15-20 PCS products in one minute, which is equivalent to operation of 2-3 operators through a common terminal machine, moreover, product quality is stable, and safety performance is good.

Owner:HANGZHOU LEROM WIRE & ELECTRIC APPLIANCE

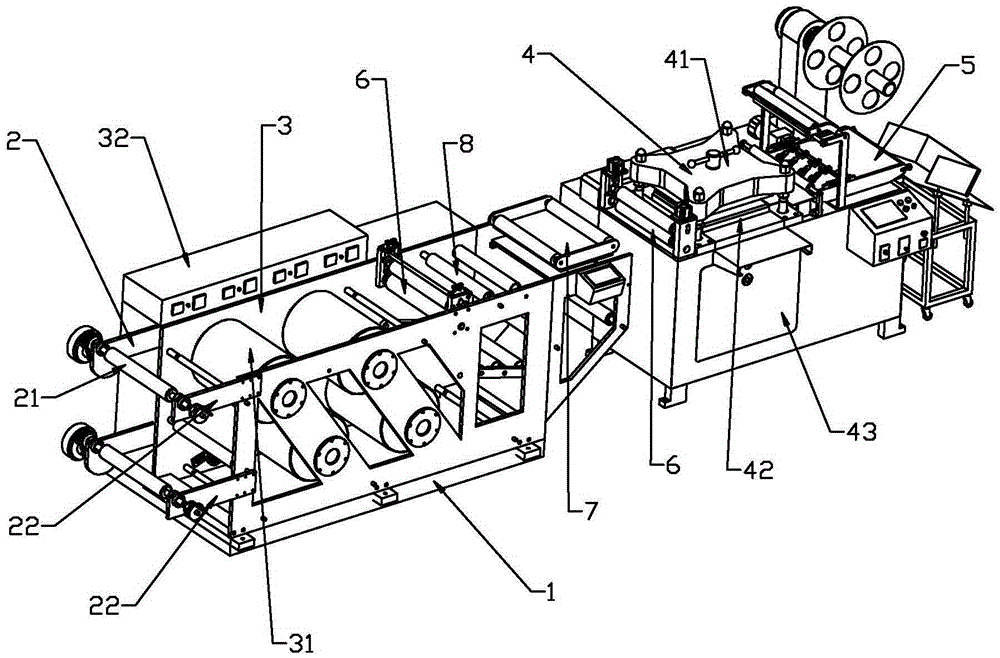

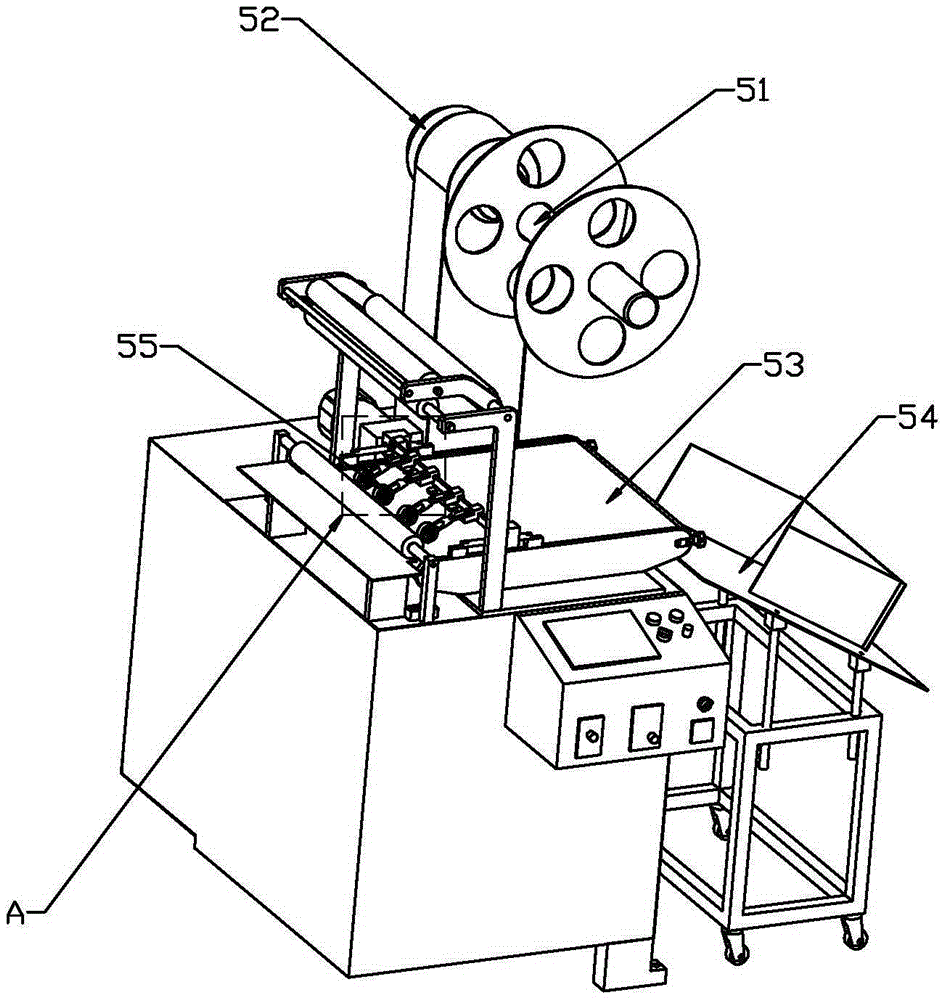

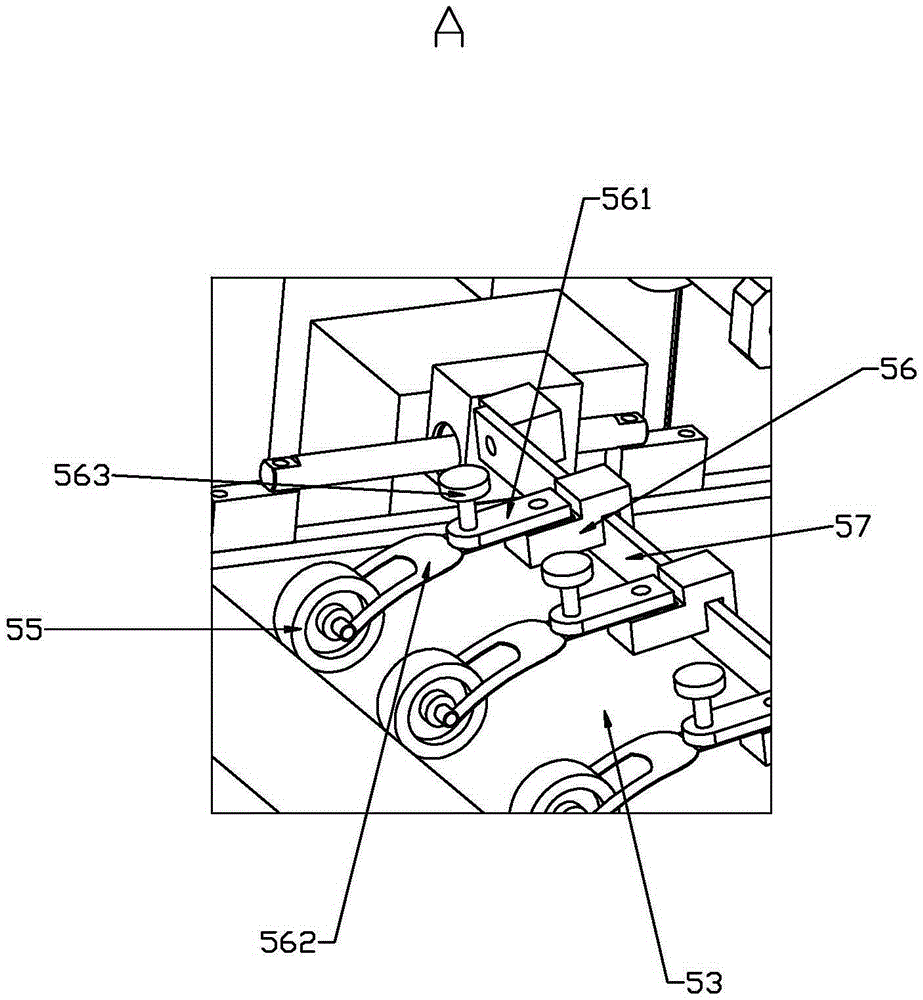

Production line of regenerated spinnable fiber from waste textile of general life clothes

ActiveCN107237011ASolve social stockNo emissionsSolid waste disposalTextile disintegration and recoveryFiberEnvironmental resistance

The invention discloses a production line of regenerated spinnable fiber from waste textile of general life clothes. According to the process, the production line comprises a disinfection device, a sorting device, a cutting device, a button removing device, an opening device and a carding device; the sorting device performs sorting according to colors; the button removing device and the opening device use a steel chain tearing strip and a tearing wheel for mutual tearing; there are multiple choices for the disinfection device, the opening device, the sorting device and the carding device. The invention is suitable for processing recovered regenerated fiber of life clothing, which solves environmental protection problems and livelihood issues in the current society; the production power of each production line reaches 1 to 3 tons and the processing capability is large.

Owner:林雁 +2

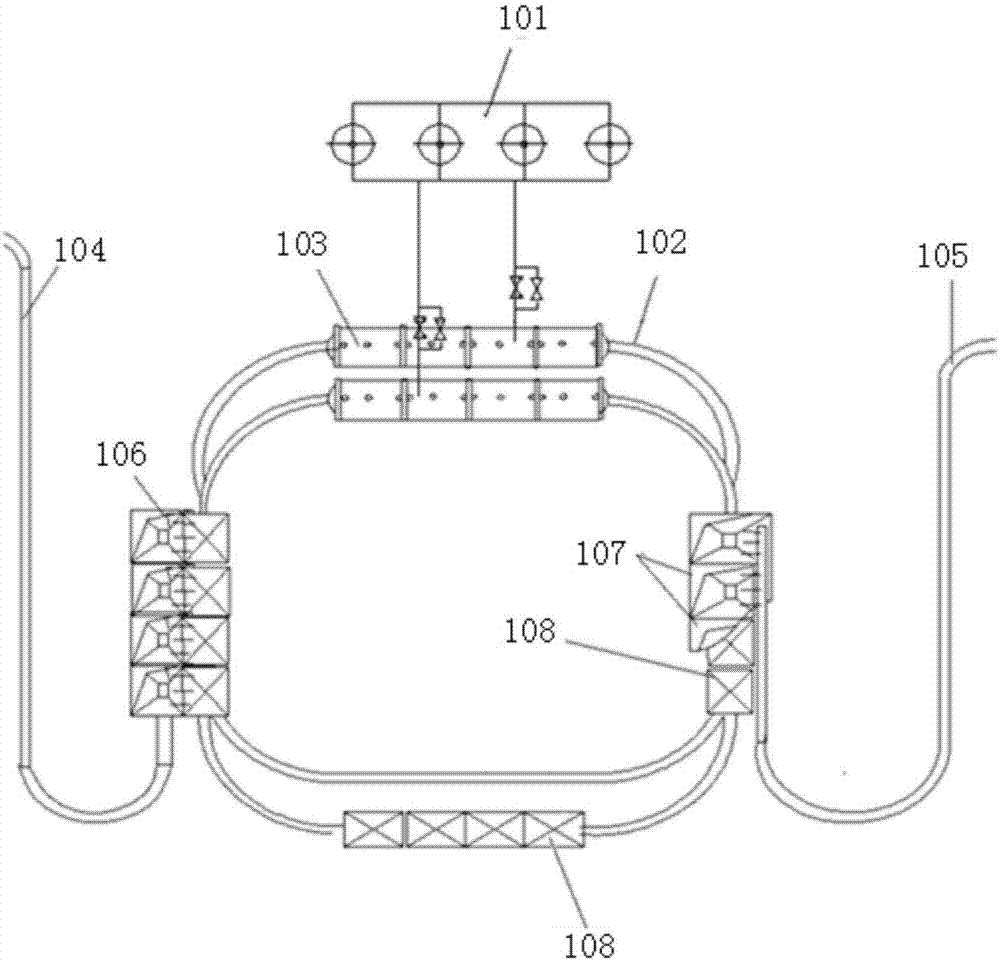

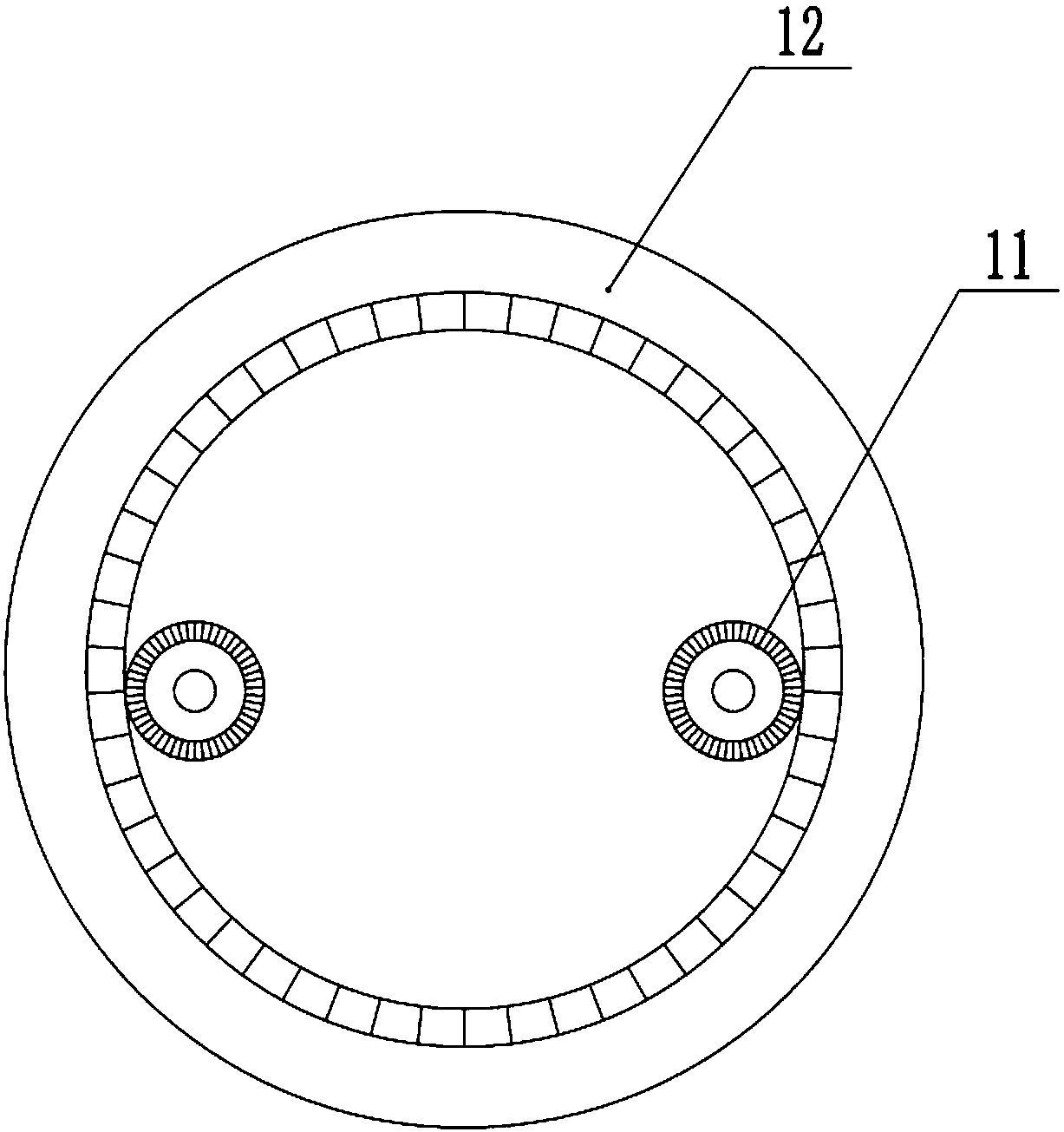

Rotary type ceramic water purifier

ActiveCN101829448AGuaranteed cleanlinessIncrease surface areaMoving filtering element filtersMetallurgyRotation control

The invention discloses a rotary type ceramic water purifier which comprises a shell equipped with a water inlet, a water yielding port and a washing port, a ceramic filtering assembly arranged in the shell and a rotation control and execution mechanism arranged outside the shell, wherein the ceramic filtering assembly is fixed in the shell through a central pipe, and a corrugated ceramic filter disc of the ceramic filtering assembly forms a water inlet area with the shell; the ceramic filter disc is fixed on the central pipe, and one end of the center of the ceramic filter disc is communicated to the upper end of the shell and connected with a motor of the rotation control and execution mechanism, while the other end is connected with a base of the shell; a space formed by the base and the central pipe is a water yielding area; the water inlet port is provided with a flow sensing switch; and the flow sensing switch and the motor form the rotation control and execution mechanism. The rotary type ceramic water purifier increases the surface area of the ceramic filter disc and achieves the purposes of increasing the flow rate and improving the intensity. Meanwhile, during running, the ceramic filter disc rotates under the drive of the motor to realize the automatic removal and separation of impurities and take the effects of filter element self-cleaning and long action and flow rate stabilizing.

Owner:余姚市天沁净水器材有限公司

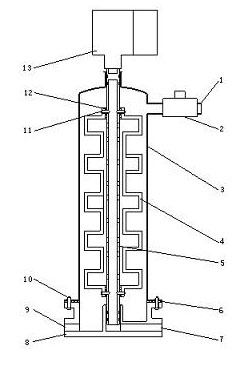

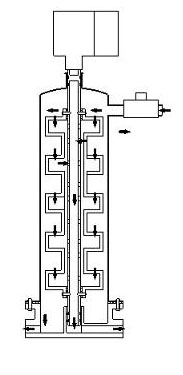

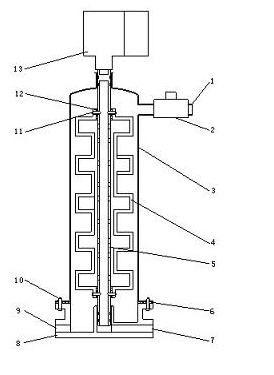

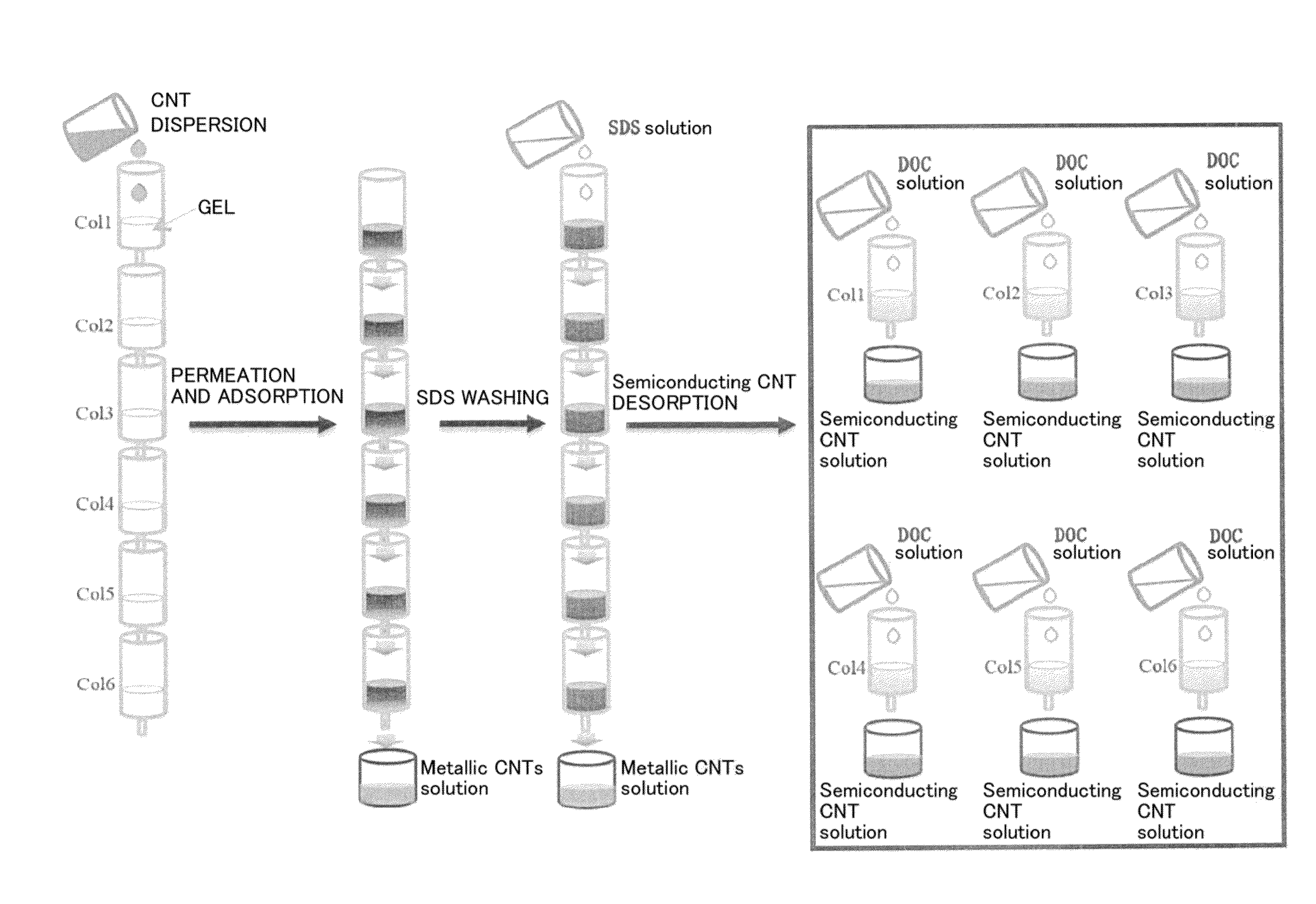

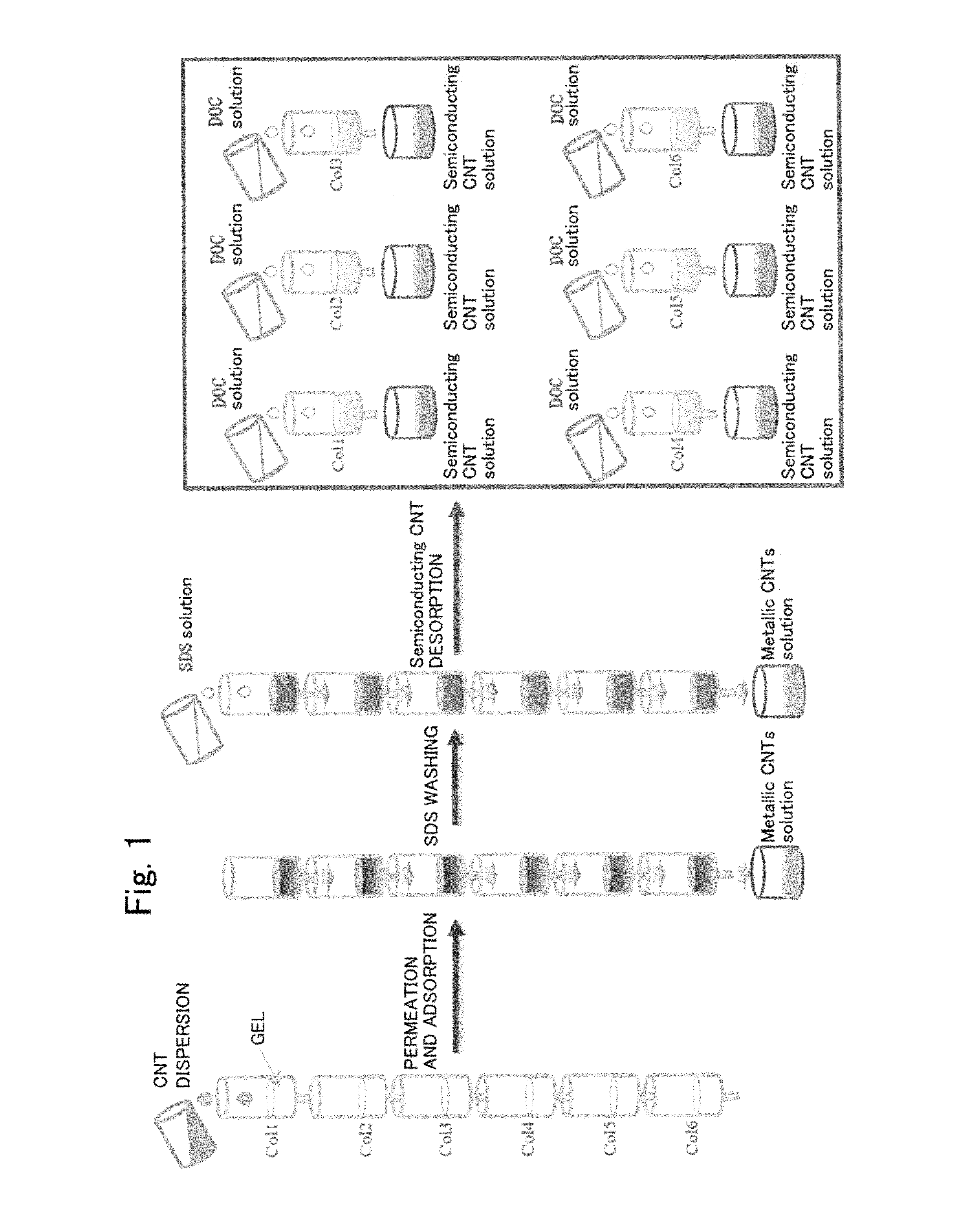

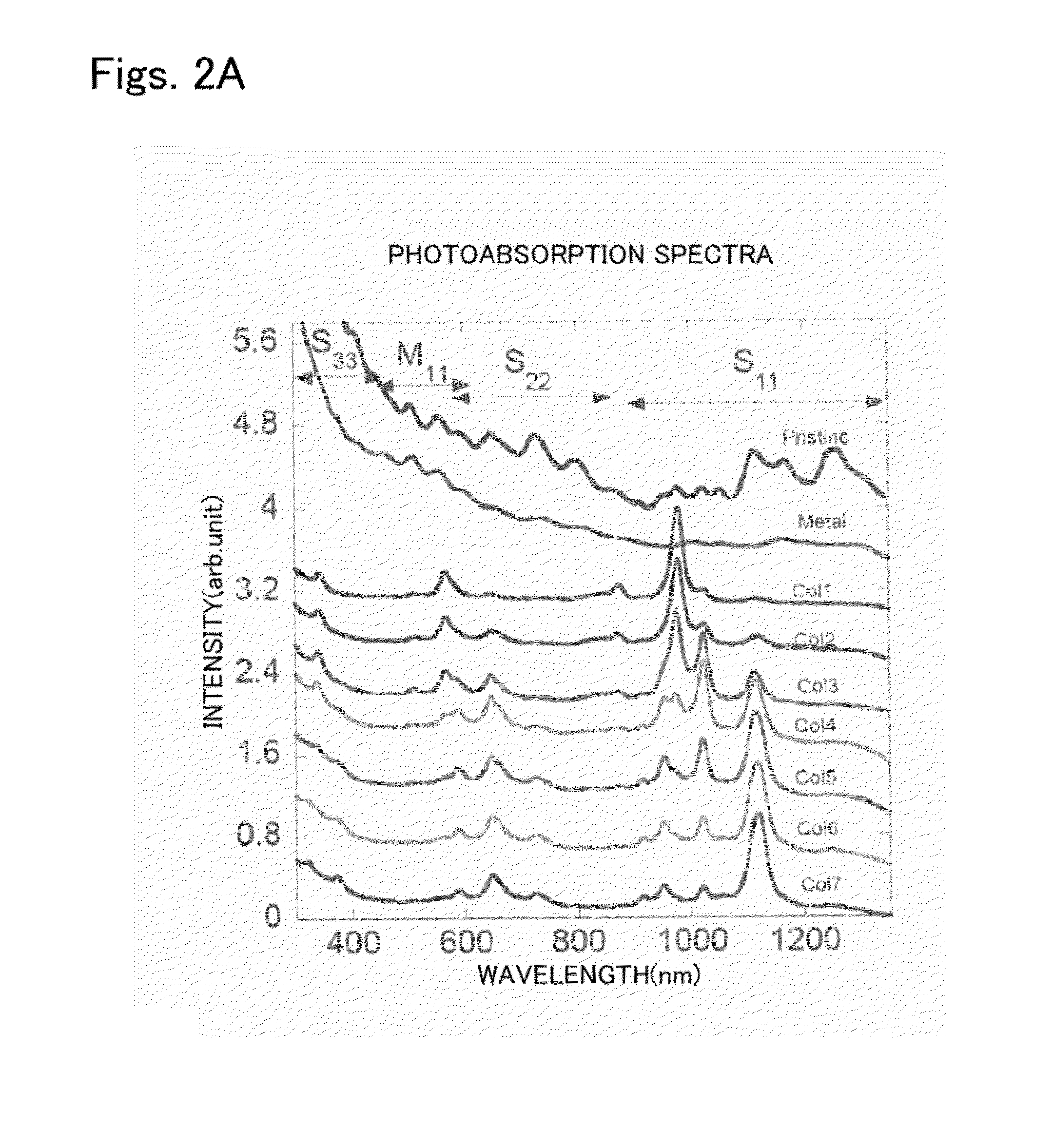

Method for separating and collecting carbon nanotube, and carbon nanotube

InactiveUS8715607B2Improve accuracyAccurate separationIon-exchange process apparatusMaterial nanotechnologyElutionCarbon nanotube

Metallic CNTs and semiconducting CNTs are efficiently separated from a CNT mixture of these CNTs, and semiconducting CNTs are separated by structure by using a method that enables separation in high yield in a short time period while conveniently enabling mass processing and automatic processing with inexpensive equipment.Multiple columns charged with gel are connected in series, and excess amounts of a CNT dispersion is passed through the columns to adsorb only the CNTs of a specific structure on the columns. The CNTs are then eluted with an elution to separate CNTs of different structures with high accuracy. The present technique represents a method that conveniently enables mass processing and automatic processing at high yield in a short time period with inexpensive equipment.

Owner:NAT INST OF ADVANCED IND SCI & TECH

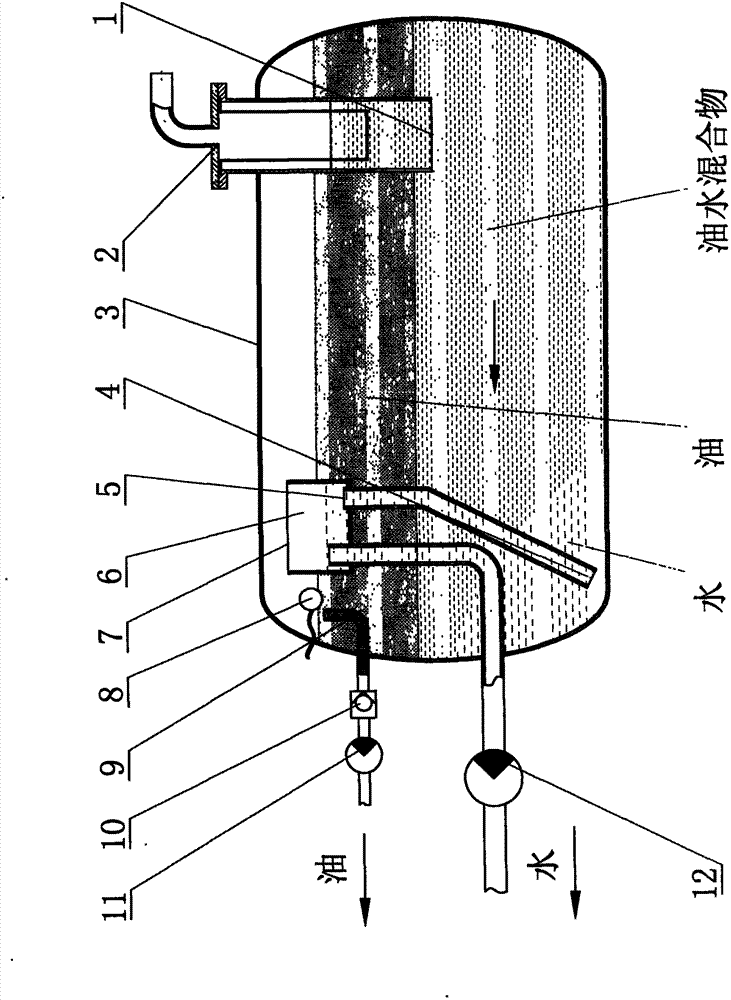

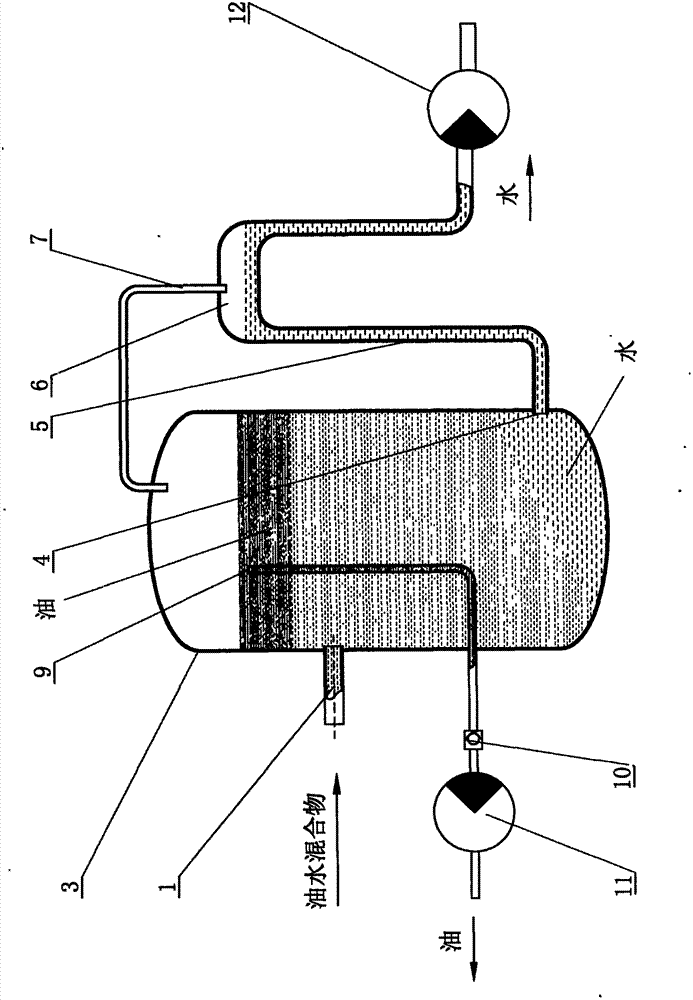

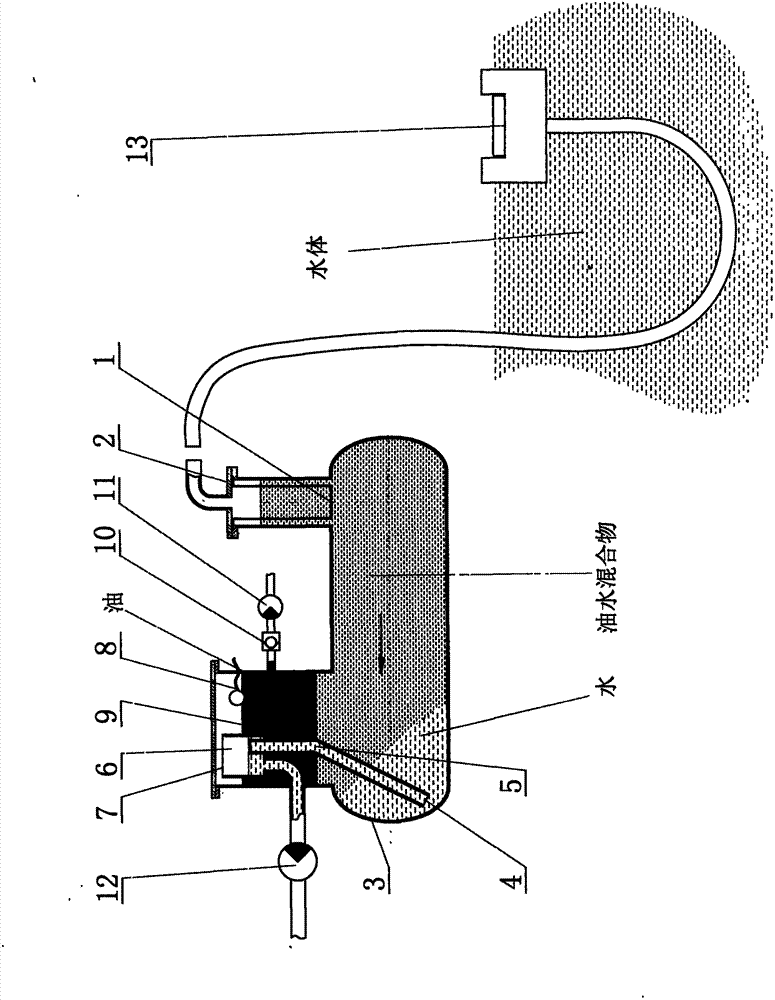

Device for continuously separating oil-water mixture collected from water surface

ActiveCN103028272AHigh stability and reliabilityEasy to clogLiquid separation auxillary apparatusInternal pressureOil water

The invention discloses a device for continuously separating an oil-water mixture collected from a water surface. The device comprises a closed container, a water pumping device and an oil pumping device. The device is provided with an oil-water mixture inlet, a water outlet channel and an oil outlet channel in the closed container, wherein an inlet of the water outlet channel is positioned in a lower container space at the far end relative to the oil-water mixture inlet; the water outlet channel extends upwards to form an overflow zone at the height which corresponds to the upper space of the closed container and reaches to the water pumping device; the inlet of the oil outlet channel is formed in the upper container space; and the thickness of the oil layer is measured through the principle that the external and internal pressures in the overflow zone are equal, and when the oil layer reaches a certain thickness, the oil is pumped through the oil pumping device, the oil and water are rapidly separated in a negative pressure state, the emulsifying and stirring functions of the pump are avoided, the whole device is simple in structure, compact, high-efficiency, stable and reliable, the continuity is realized, and the automatic oil-water separation is realized.

Owner:黄海峰

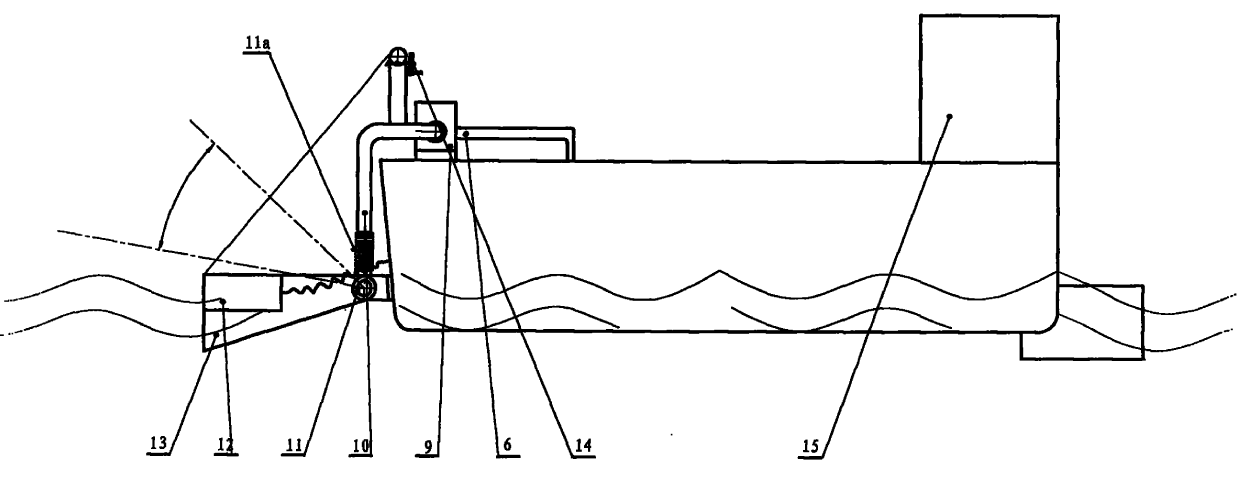

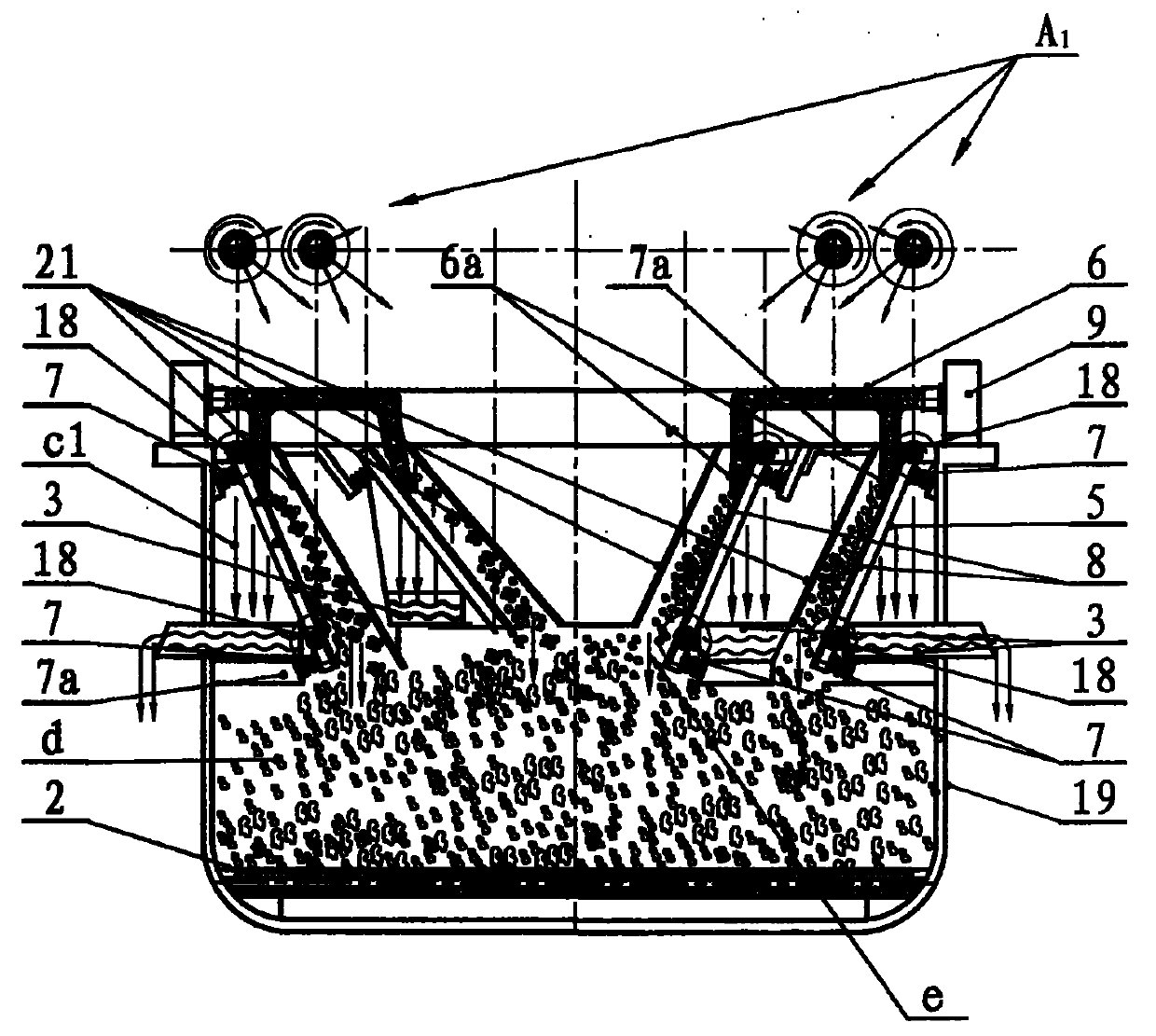

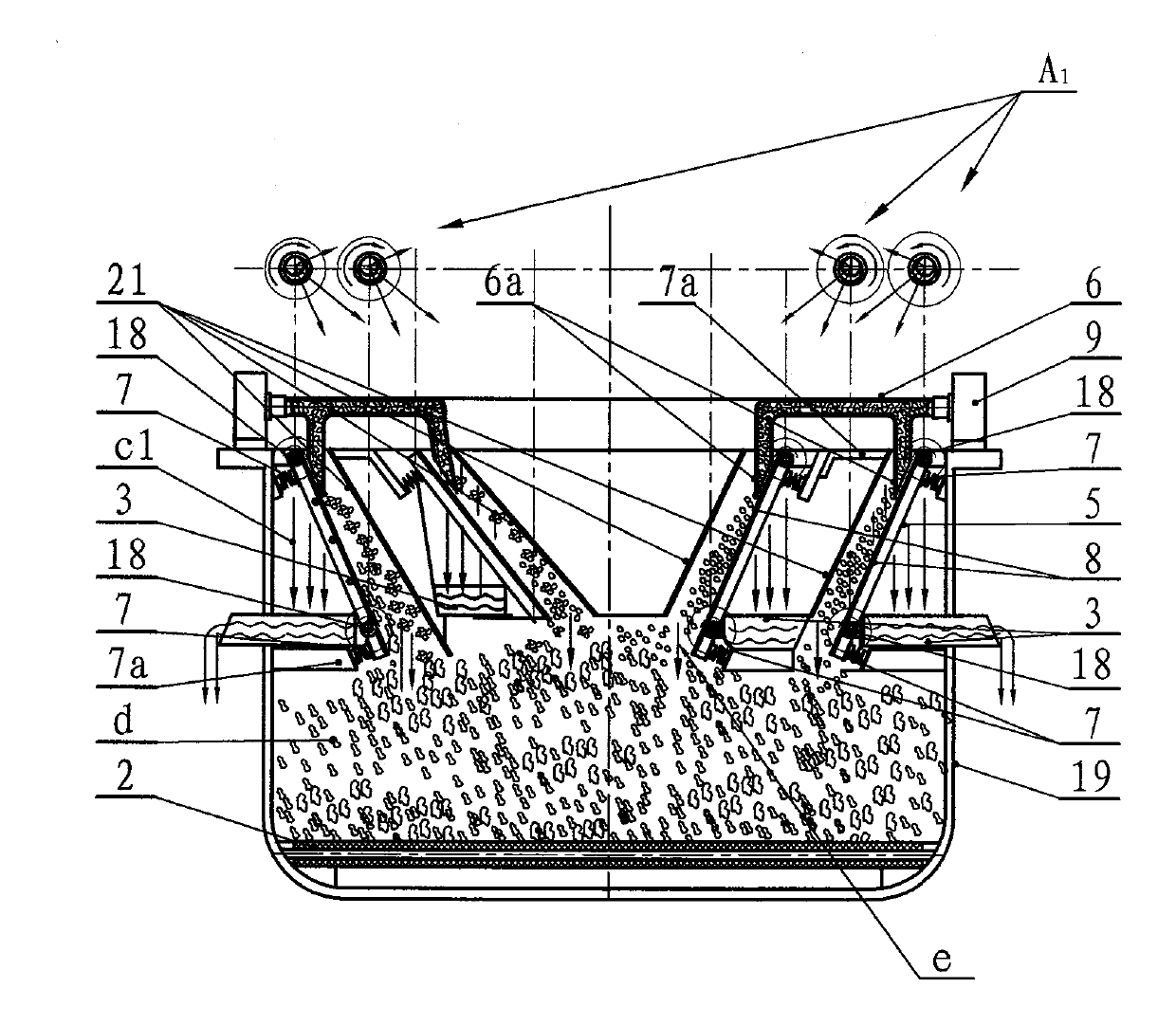

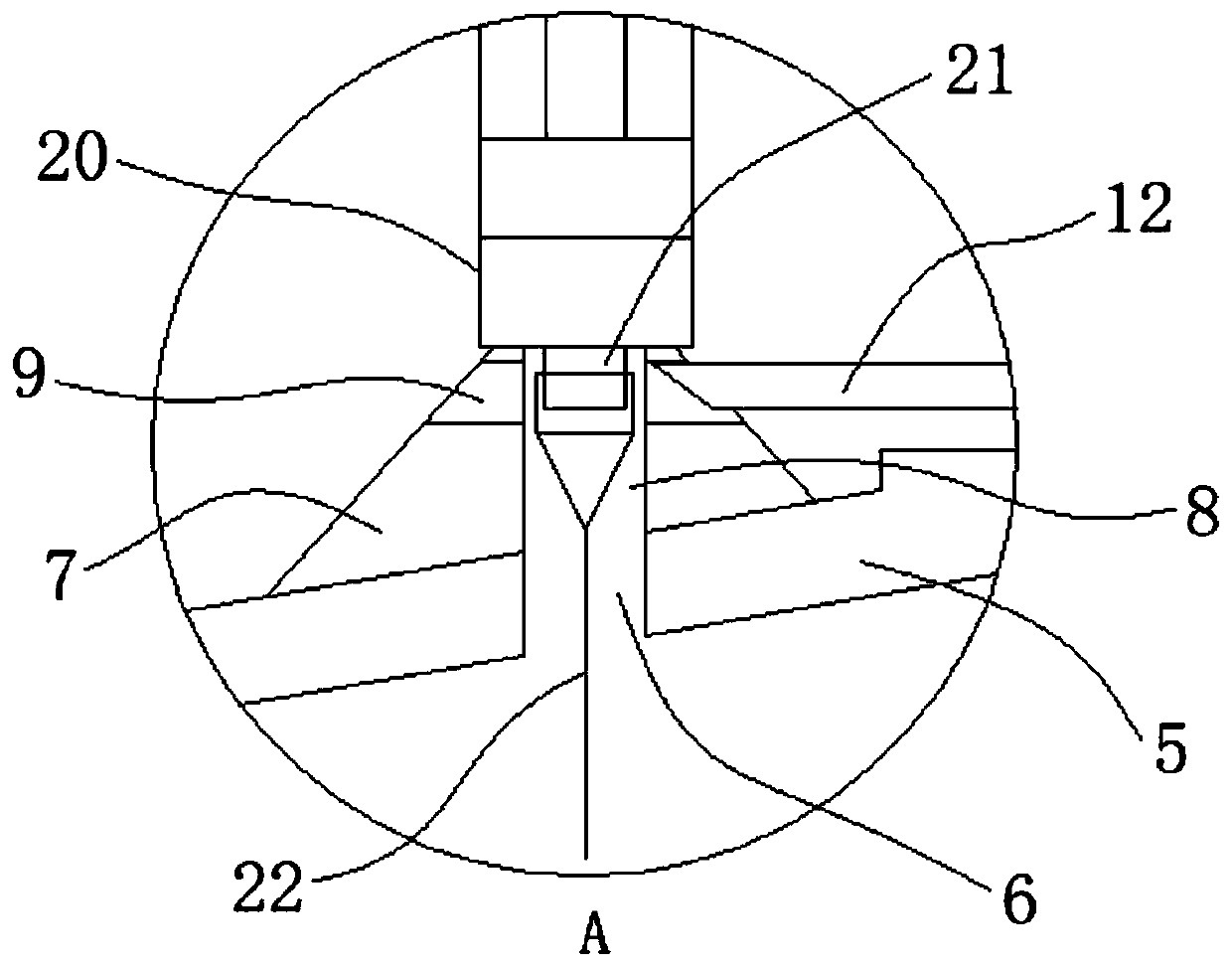

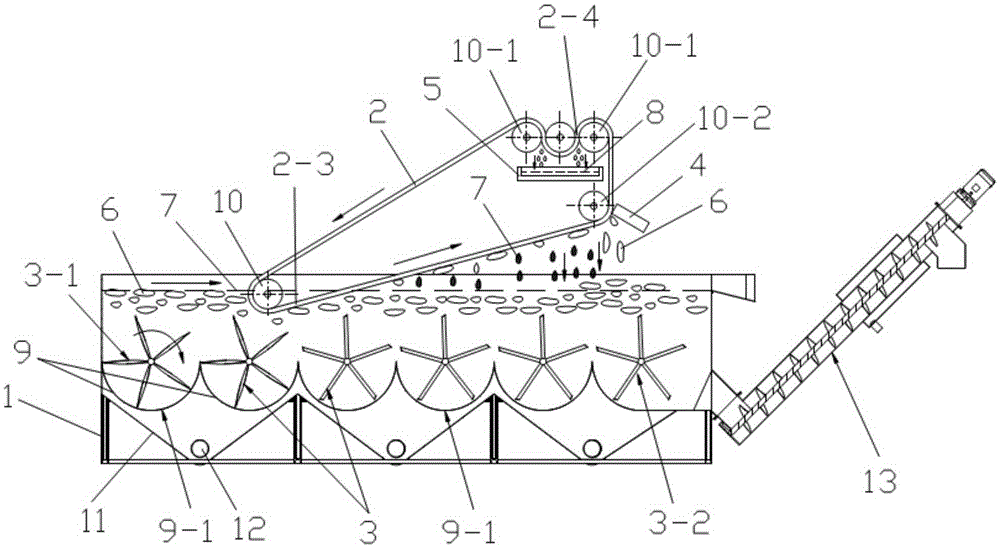

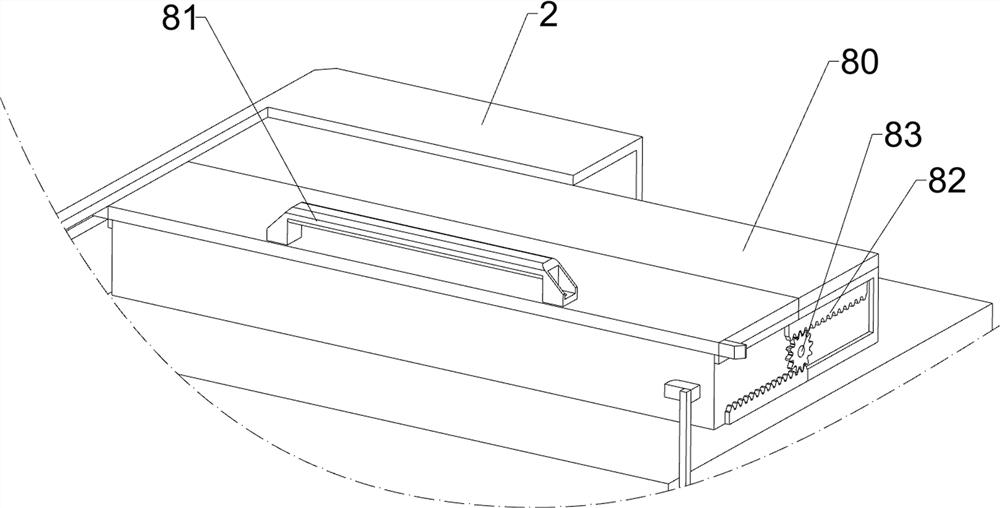

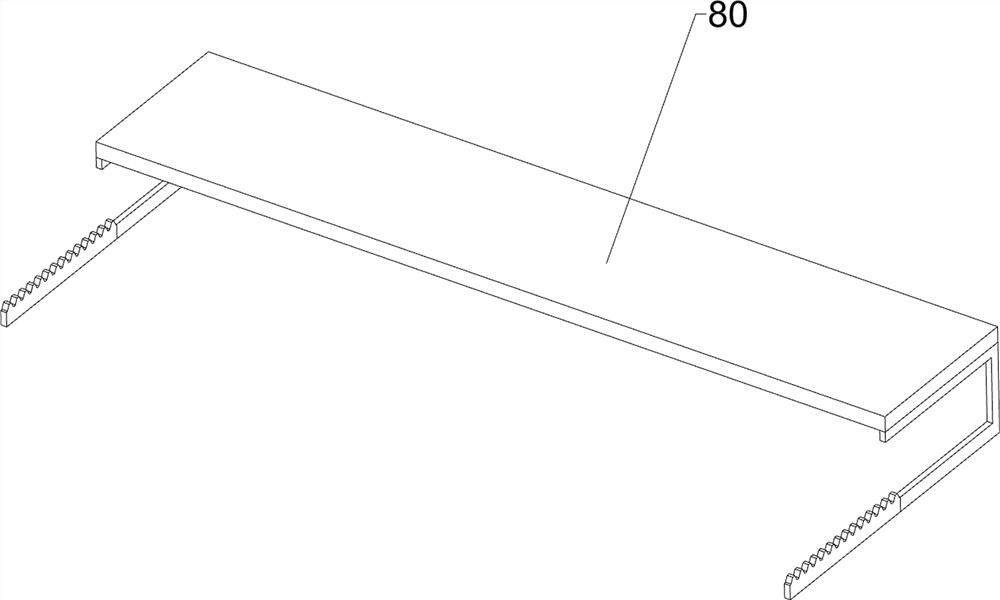

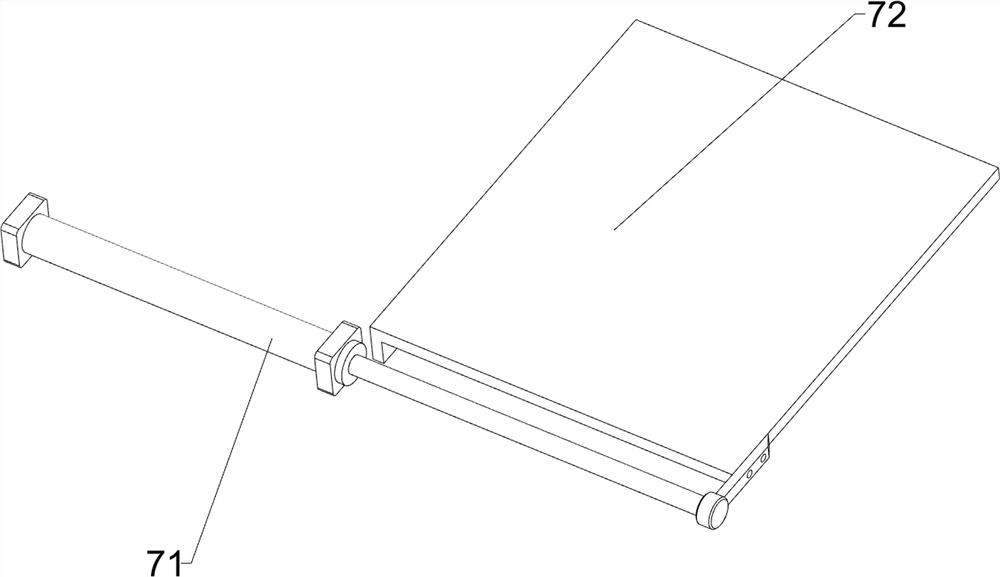

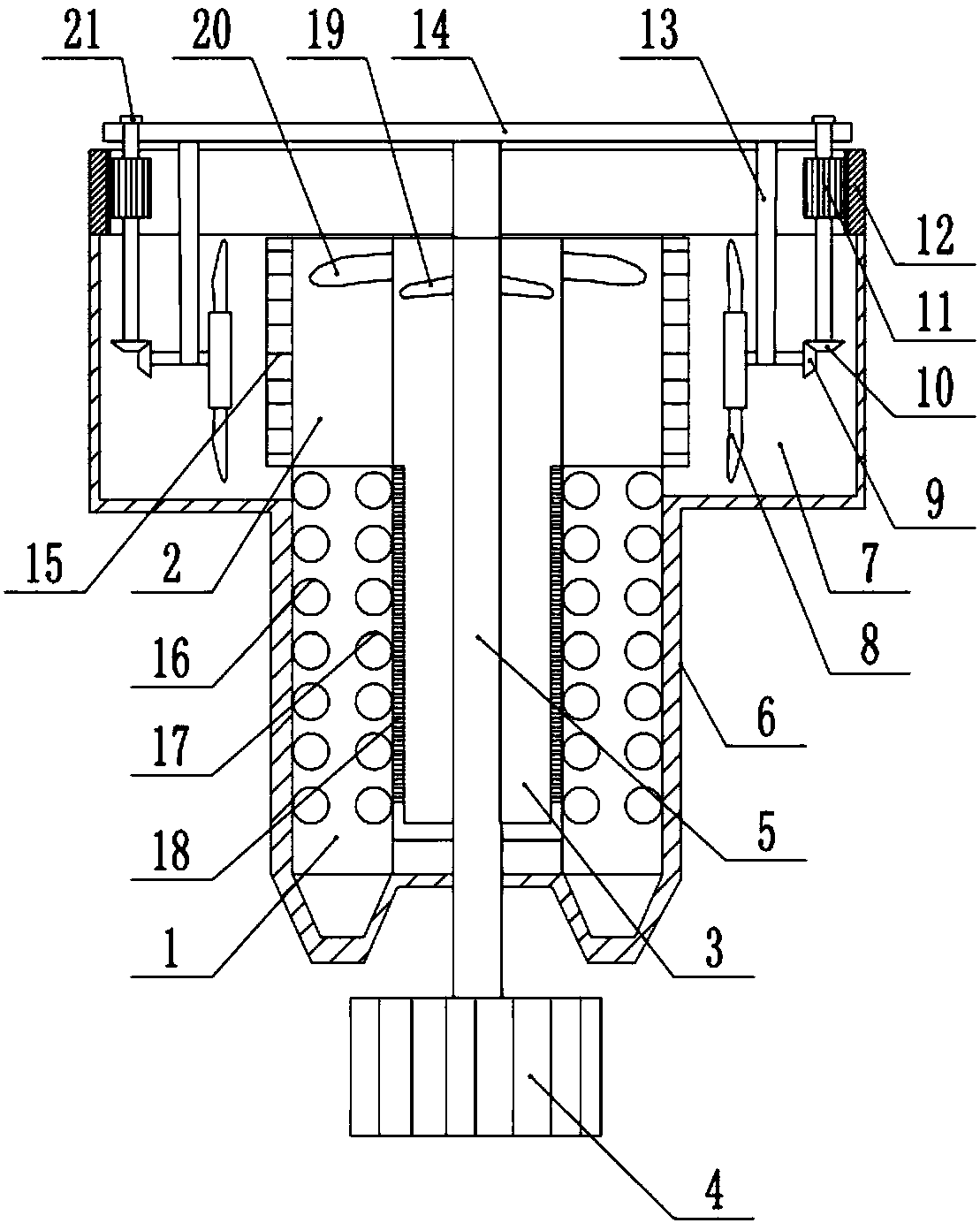

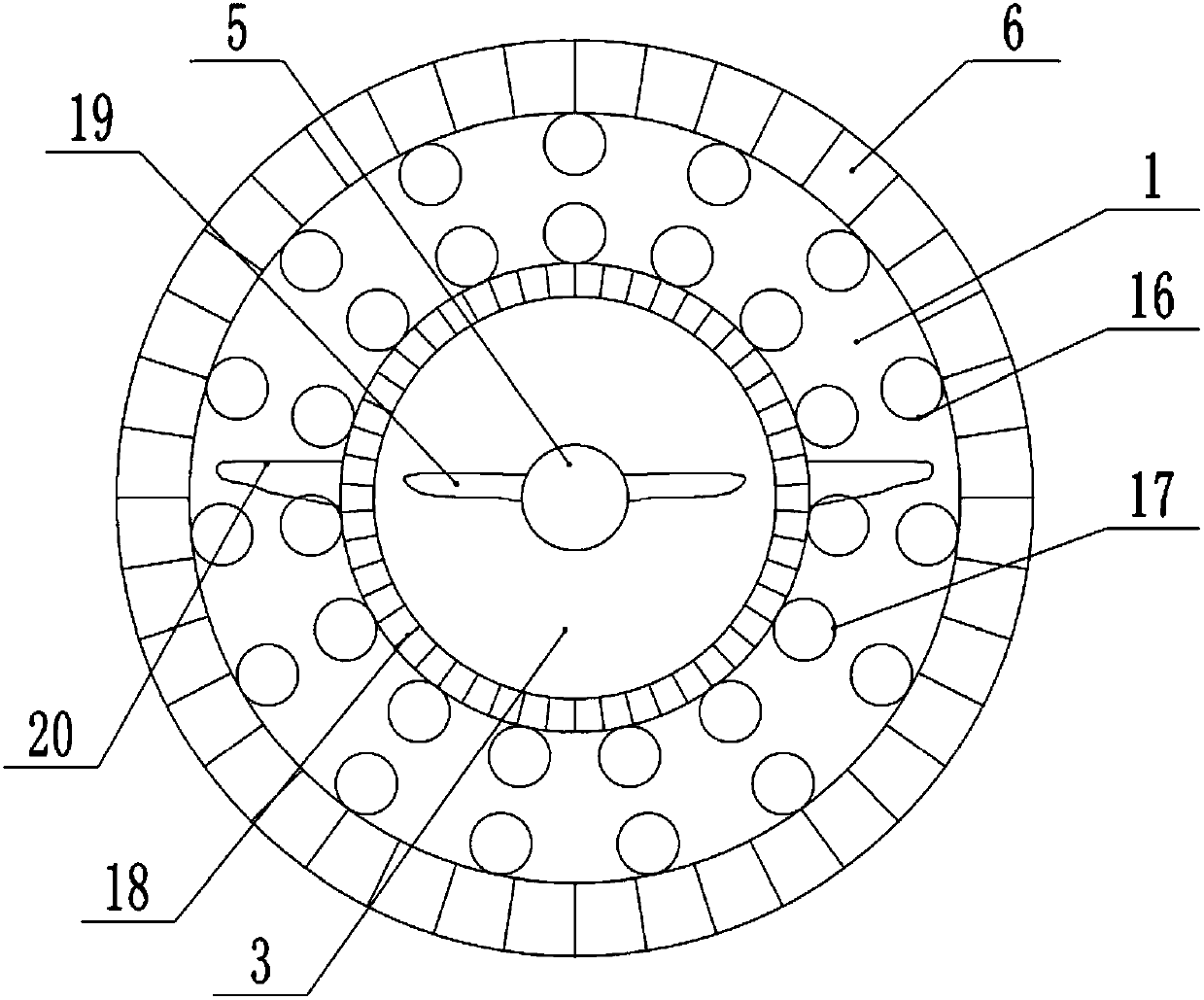

Automatic blue-green algae finishing boat

The invention discloses an automatic blue-green algae finishing boat, which mainly comprises a suction head A, an algae-water separation device B and a drive device C. The suction head A is provided with a buoy, a water pump and a prolate nozzle; the algae-water separation device B is provided with a filtering net, a net frame, an eccentric shaft and a bearing; and the drive device C is provided with a motor (or small internal-combustion engine), a transmission wheel belt, a motor boat and a water outlet pipe groove; the algae-rich water flowing out of the prolate nozzle 6 rushes into the filtering net 8, and under the effect of vibration force, the water can flow through the net holes and falls into the water outlet pipe groove 3, while the algae is blocked by the net holes and thrown toward the direction of vibration resultant force to fall into the boat; and a baffle 20 can block sporadic algae. As the eccentricity of the eccentric shaft is relatively small and the speed can be regulated according to the strength of the algae-rich water, the energy-save measures such as mechanical kinetics are comprehensively used, the power consumption during the use is relatively low, and the problem of blocking the net holes during suction is solved; moreover, automatic and fast algae-water separation is realized during the algae collection, the product is small, the efficiency is high, the operation is simple, the labor is saved and the cost is greatly reduced, and therefore the automatic blue-green algae finishing boat is blue-green algae finishing equipment with reasonable and scientific comprehensive performance.

Owner:潘忠勋

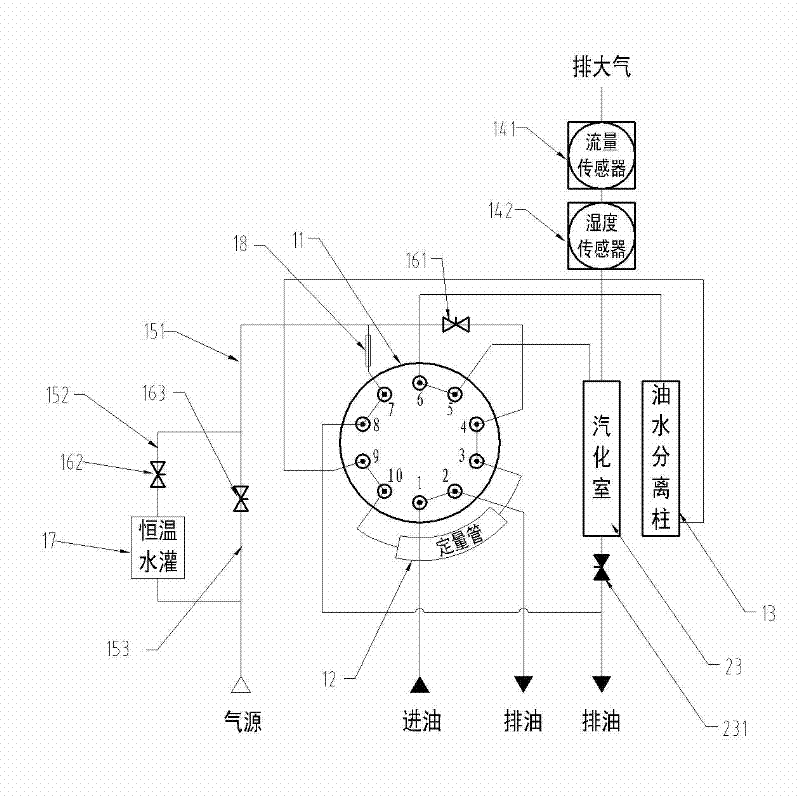

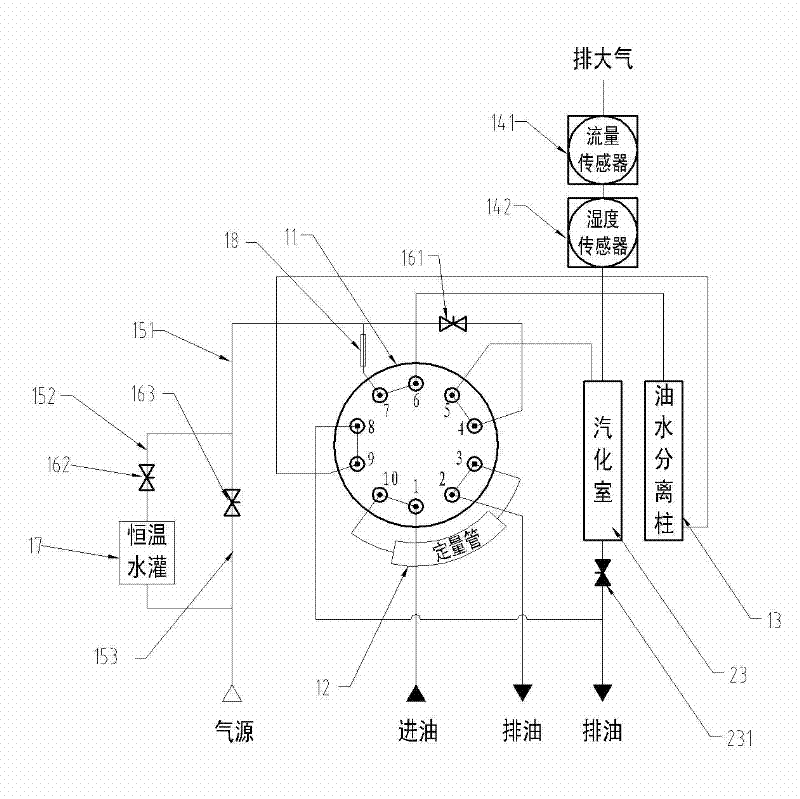

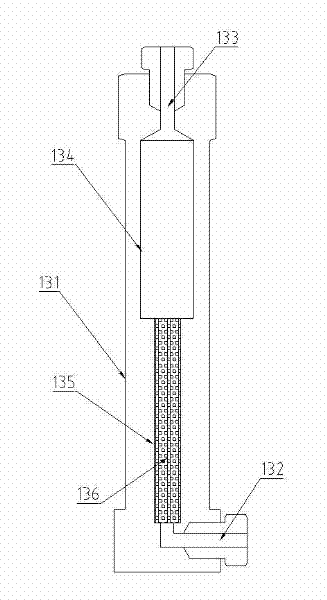

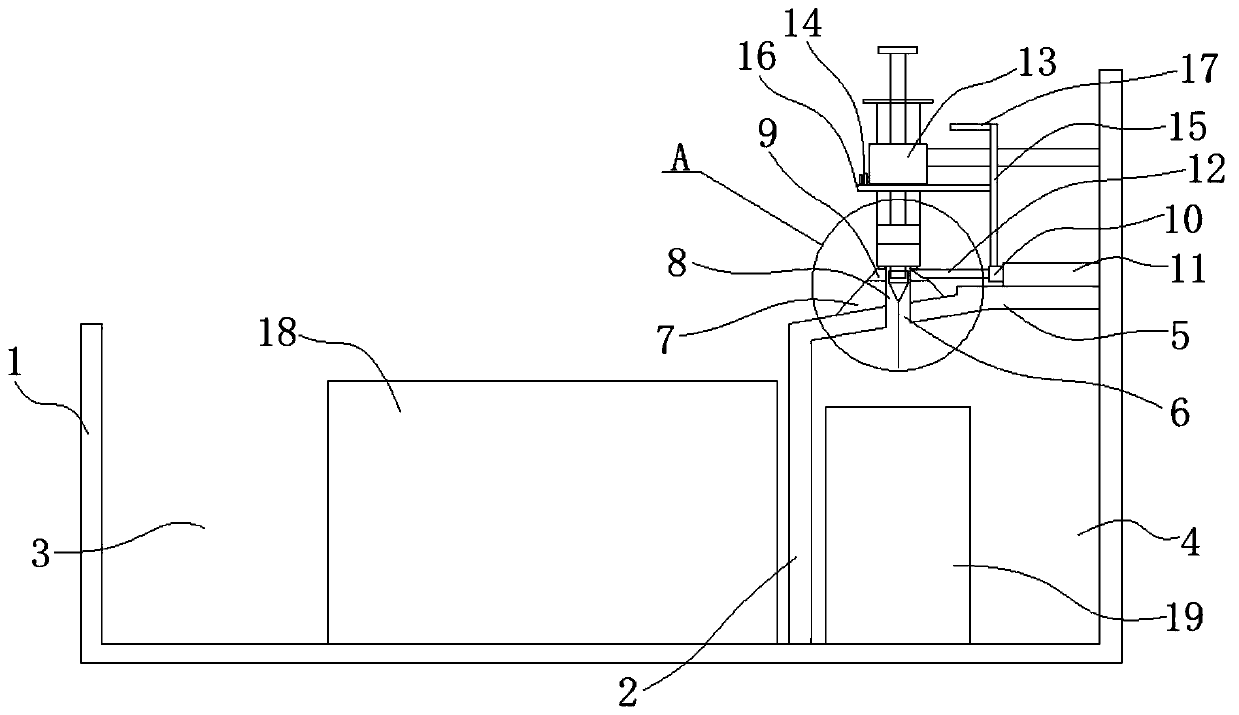

Measuring instrument for trace moisture in oil

ActiveCN102411045ANon-toxicNo pollution in the processMaterial testing goodsChemical reactionMeasuring instrument

The invention relates to a measuring instrument for trace moisture in oil. The measuring instrument for trace moisture in oil adopts a physical measuring method to measure trace moisture in oil, and has no need for chemical reagent, no chemical reaction, no toxic hazard to operation staff, no environmental pollution, and low operation cost, thus realizing a whole measuring process of green environmental protection. The measuring instrument of the invention has simple operation and no need for preparing and storing chemical reagents, and can automatically realize quantitative sampling, oil-moisture separation, moisture vaporization, moisture measuring, as well as trace moisture content calculation.

Owner:GL TECH CO LTD

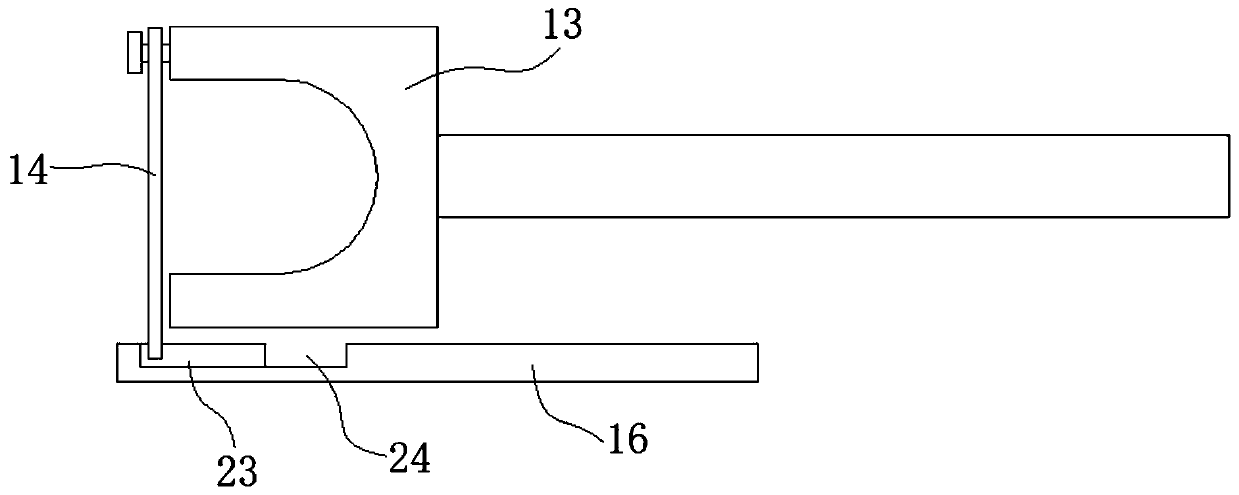

Separating and recovering device for needle and syringe cylinder of injection syringe

The invention discloses a separating and recovering device for a needle and a syringe cylinder of an injection syringe. The device comprises a casing, a supporting plate, a separating base, a pushing base, a separating cutter, a U-shaped positioning sleeve, a baffle rod, a connecting plate, a limiting plate and a pushing rod; a casing cavity of the casing is divided into a syringe cylinder cavity and a needle cavity; the supporting plate is arranged at the upper end of the needle cavity and provided with a guide hole; the separating base is arranged on the supporting plate and provided with a needle hole and a separating hole; the pushing base is arranged on the supporting plate; the separating cutter is arranged at the left end of the pushing base and is exactly opposite to the separating hole; the U-shaped positioning sleeve is located above the separating base; the front end of the baffle rod is hinged to the left end of the front side wall of the U-shaped positioning sleeve; the connecting plate is fixed to the pushing base; the limiting plate is fixed to the connecting plate; the rear end of the baffle rod is supported at the left portion of the limiting plate, and the limiting plate is provided with a falling port; the pushing rod is fixed to the connecting plate and is higher than the U-shaped positioning sleeve. The device can automatically separate the needle of the injection syringe from the syringe cylinder and directly store the needle and the syringe cylinder separately, so that the labor amount of medical staff is reduced, and the safety of the separation process is improved.

Owner:THE FIRST AFFILIATED HOSPITAL OF GUANGXI MEDICAL UNIV

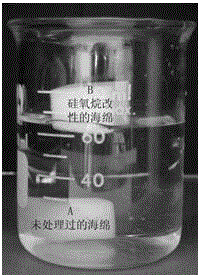

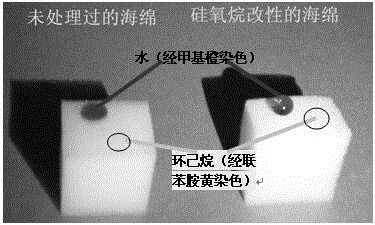

Method for preparing efficient oil-water separation sponge

ActiveCN105688846AEfficient separationAutomatic separationFatty/oily/floating substances removal devicesOther chemical processesSuperhydrophobeEcological environment

The invention discloses a method for preparing efficient oil-water separation sponge. Porous sponge sold on the market is adopted as a base body, an addition reaction of polymethylhydrosiloxane (PHMS) and tetravinyl tetramethylcyclotetrasiloxane (Vid4) is adopted, an organosiloxane coating is established on the surface of the sponge, that is, an organic silicone hydrophobic material is obtained, and thus the efficient oil-water separation sponge with a high superhydrophobicity characteristic and a super-oleophilicity characteristic is prepared. The method is simple in operation, raw materials are cheap and easy to obtain, the prepared efficient oil-water separation sponge can separate oil / water mixtures in a layered mode efficiently and automatically and can be recycled, and a new thought is provided for developing an intelligent oil-water separation material and relieving huge pressure of the ecological environment.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

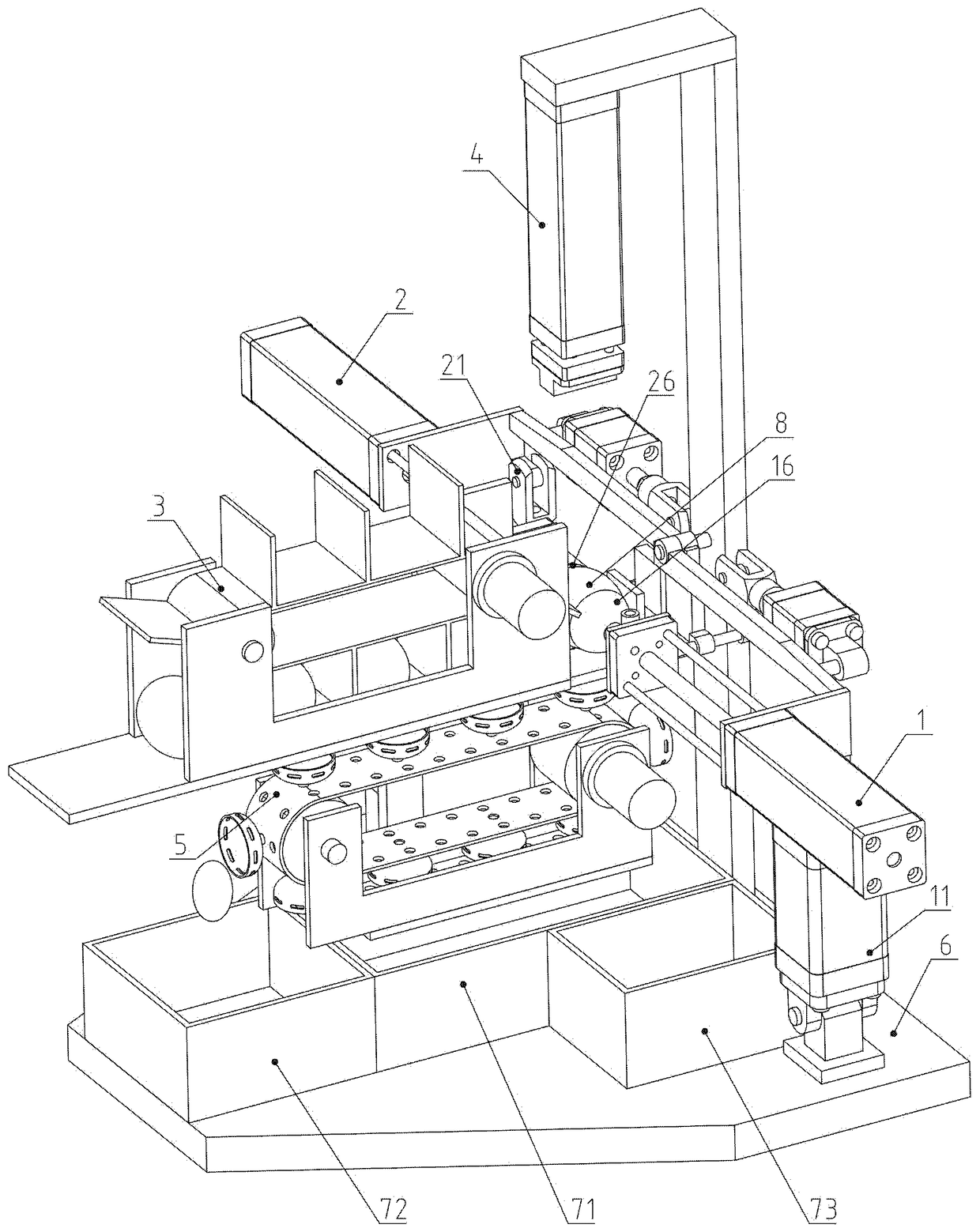

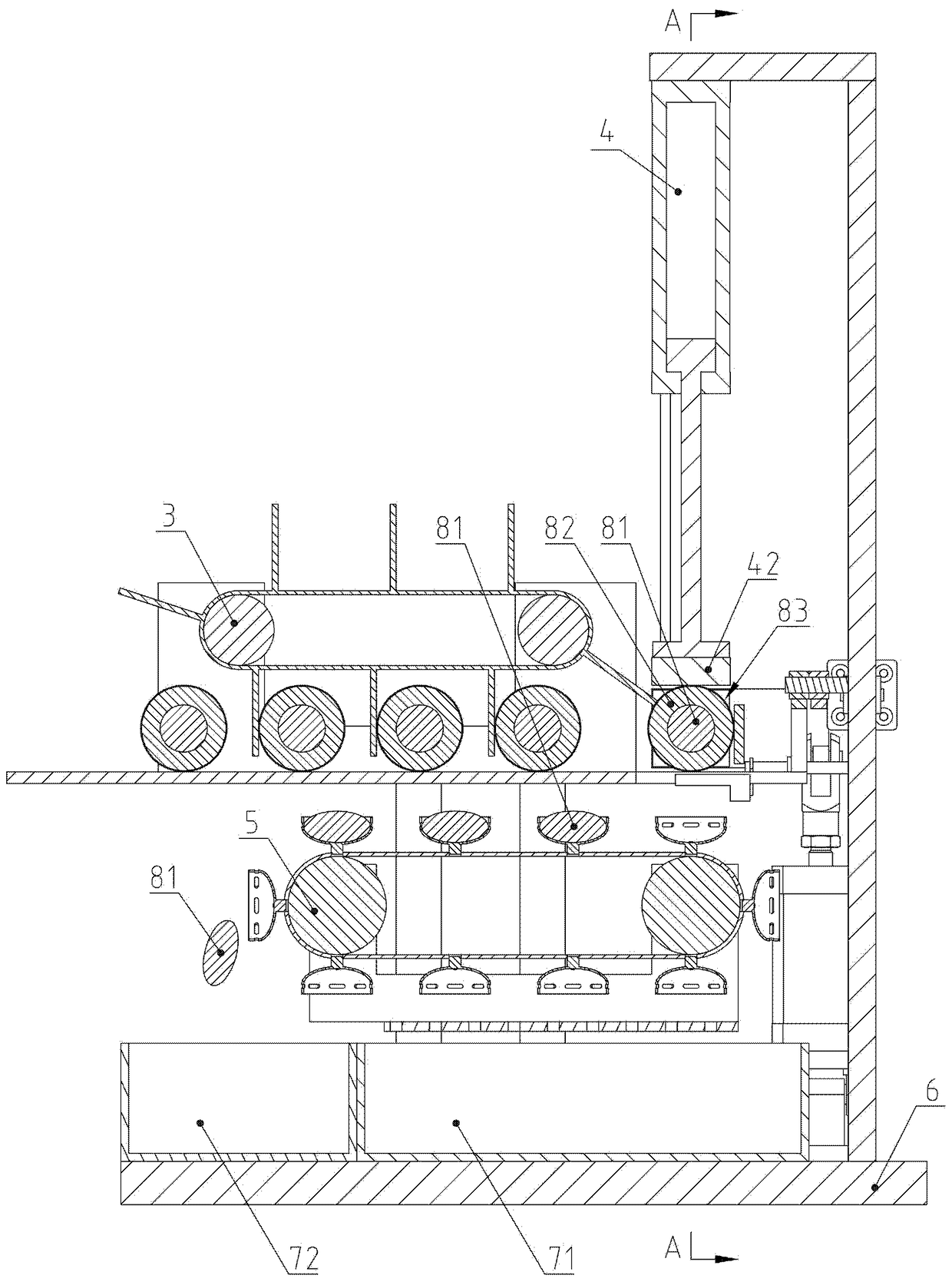

Multifunctional automatic tube sorting machine

InactiveCN103662471AGuaranteed uptimeAutomatic separationLarge containersChutesProduction lineStops device

The invention discloses a multifunctional automatic tube sorting machine which comprises a body, a bin gate, a bin gate clamping device used for locking the bin gate, a tube sliding way arranged in an inclined mode, a stopping device located at the tail end of the tube sliding way and a tube moving device. A tube supporting device is arranged below the tube sliding way so that after tubes are supported, the tubes can pass through the stopping device. The tube sliding way comprises a first sliding way, a second sliding way and a third sliding way. A stopping structure is arranged in the inlet position of the third sliding way so that the tubes can enter the third sliding way in a single layer. The multifunctional automatic tube sorting machine has the advantages that the circular tubes can be automatically and efficiently separated and the multifunctional automatic tube sorting machine has the blocking-resistant function and guarantees continuous operation, so that the stability of a production line is guaranteed, the work efficiency is improved, and the production cost is reduced; in addition, the tube sorting machine can be flexibly applied to the tubes of different lengths through a length adjusting device.

Owner:昆山三众汽车部件制造有限公司

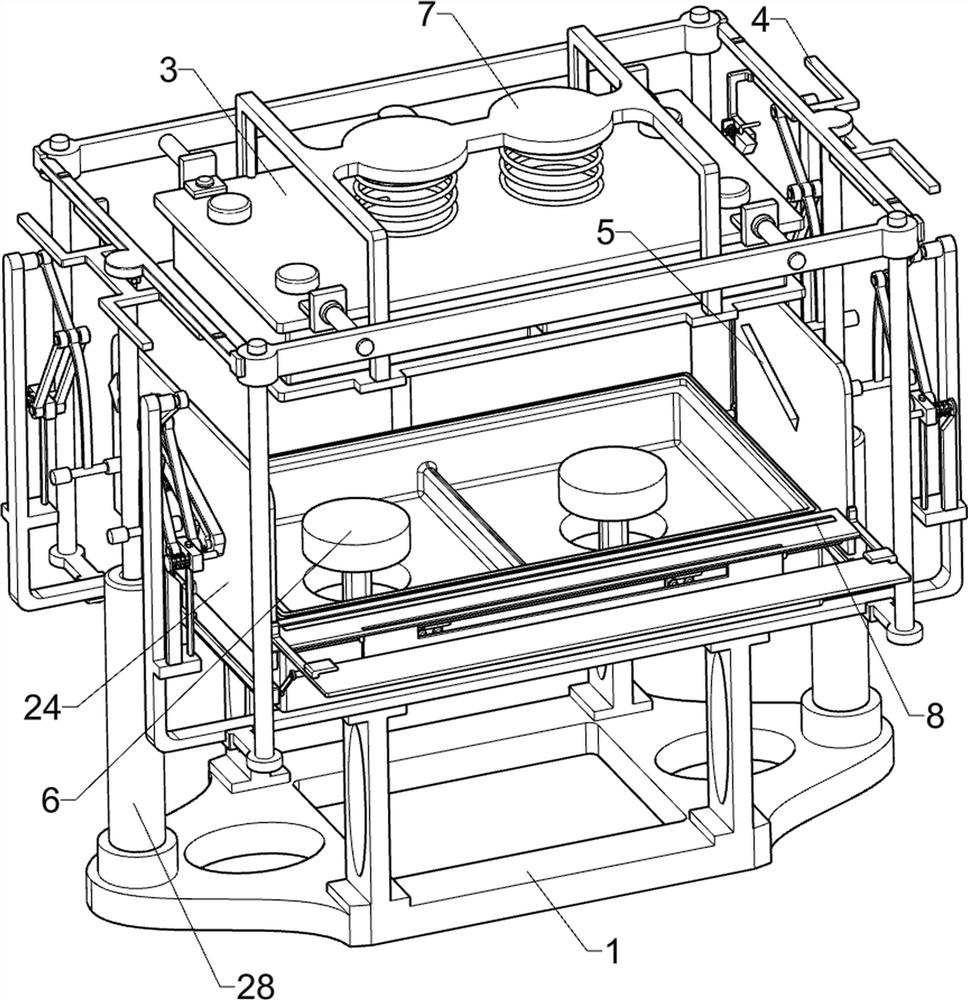

Automatic boxing machine for detecting completeness and maturity of apples

PendingCN109941502AImprove efficiency and qualityOvercome manual selection of unqualified applesPackagingSortingIndustrial engineeringConveyor belt

The invention relates to the technical field of automatic boxing, in particular to an automatic boxing machine for detecting completeness and maturity of apples. The machine comprises a bottom plate,wherein support legs are fixedly arranged at four corners of the lower bottom surface of the bottom plate, a plurality of blanking speed control mechanisms are fixedly arranged in a feeding box, an inclined plate is fixedly arranged on one side, close to the feeding box, of the upper surface of the bottom plate through a plurality of buffering mechanisms, and slideway is fixedly installed in the middle of one side, away from the feeding box, of the upper surface of the inclined plate, a conveyor belt is fixedly installed on the upper surface of the bottom plate, a track is fixedly installed inthe middle of the upper surface of the conveyor belt, one end of the conveyor belt is positioned under the inclined plate, a push-out device is fixedly installed on one side of the conveyor belt, a detection mechanism is fixedly installed on one side, away from the feeding box, of the upper surface of the bottom plate, and a guide plate is fixedly installed at one end, away from the feeding box,of the bottom plate. According to the automatic boxing machine for detecting the completeness and maturity of the apples, incomplete and immature apples can be automatically removed, the speed in thefeeding process is controllable, and the boxing efficiency is high.

Owner:宁夏弘兴达果业有限公司

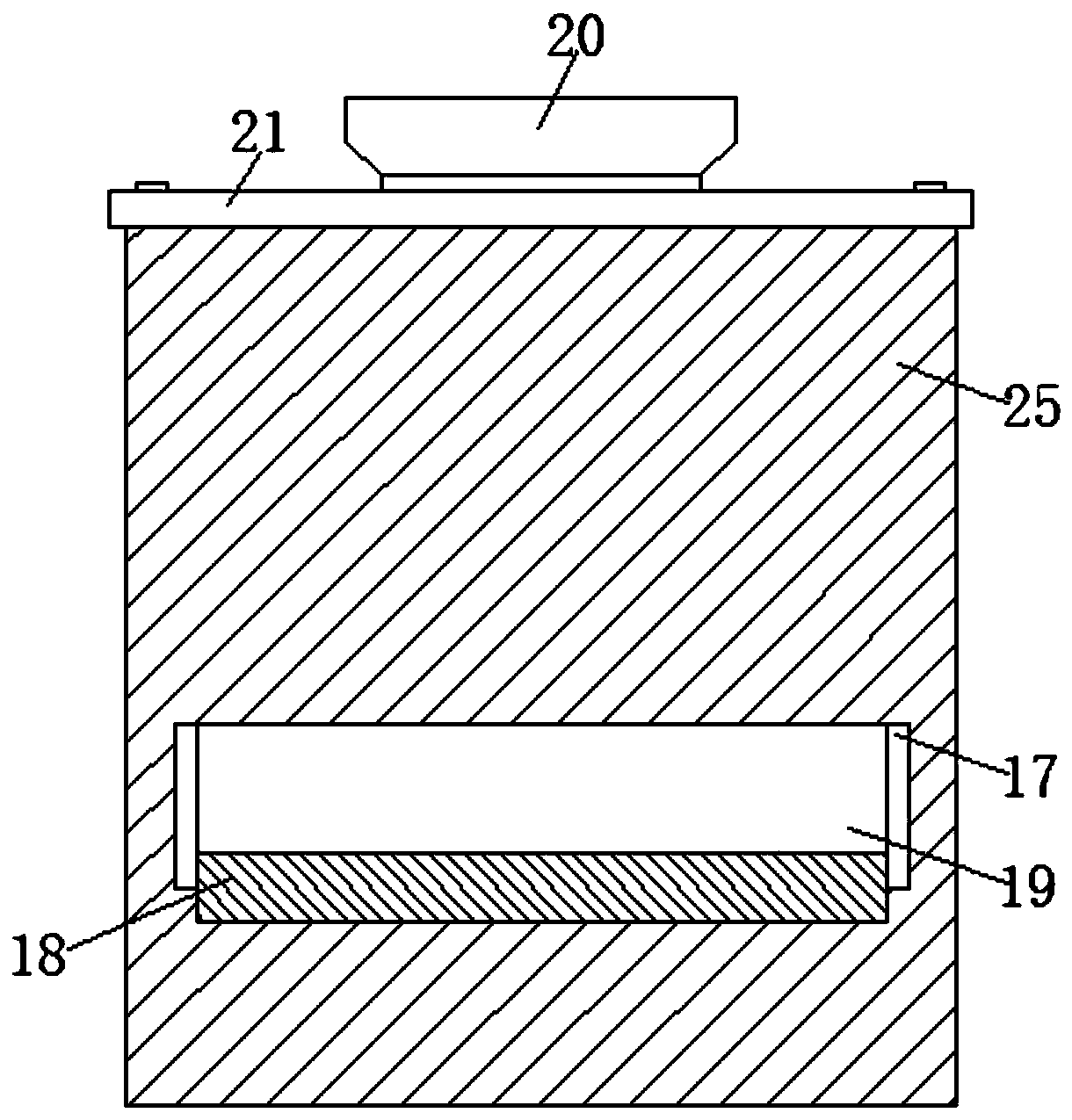

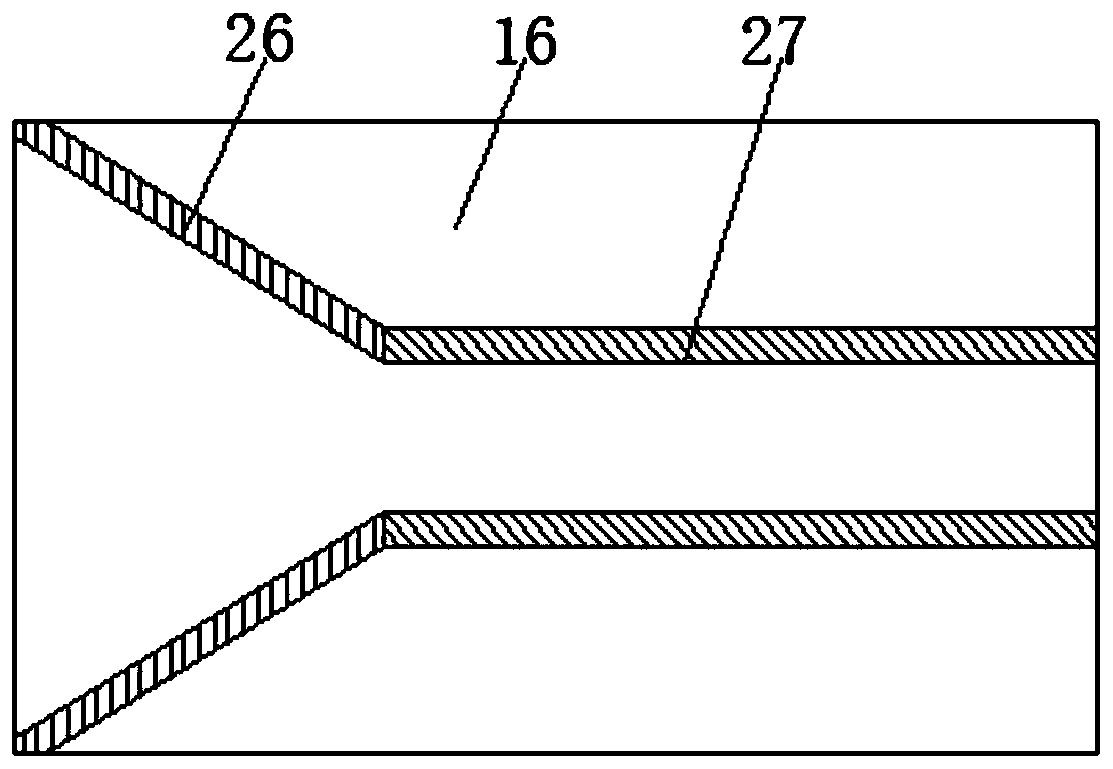

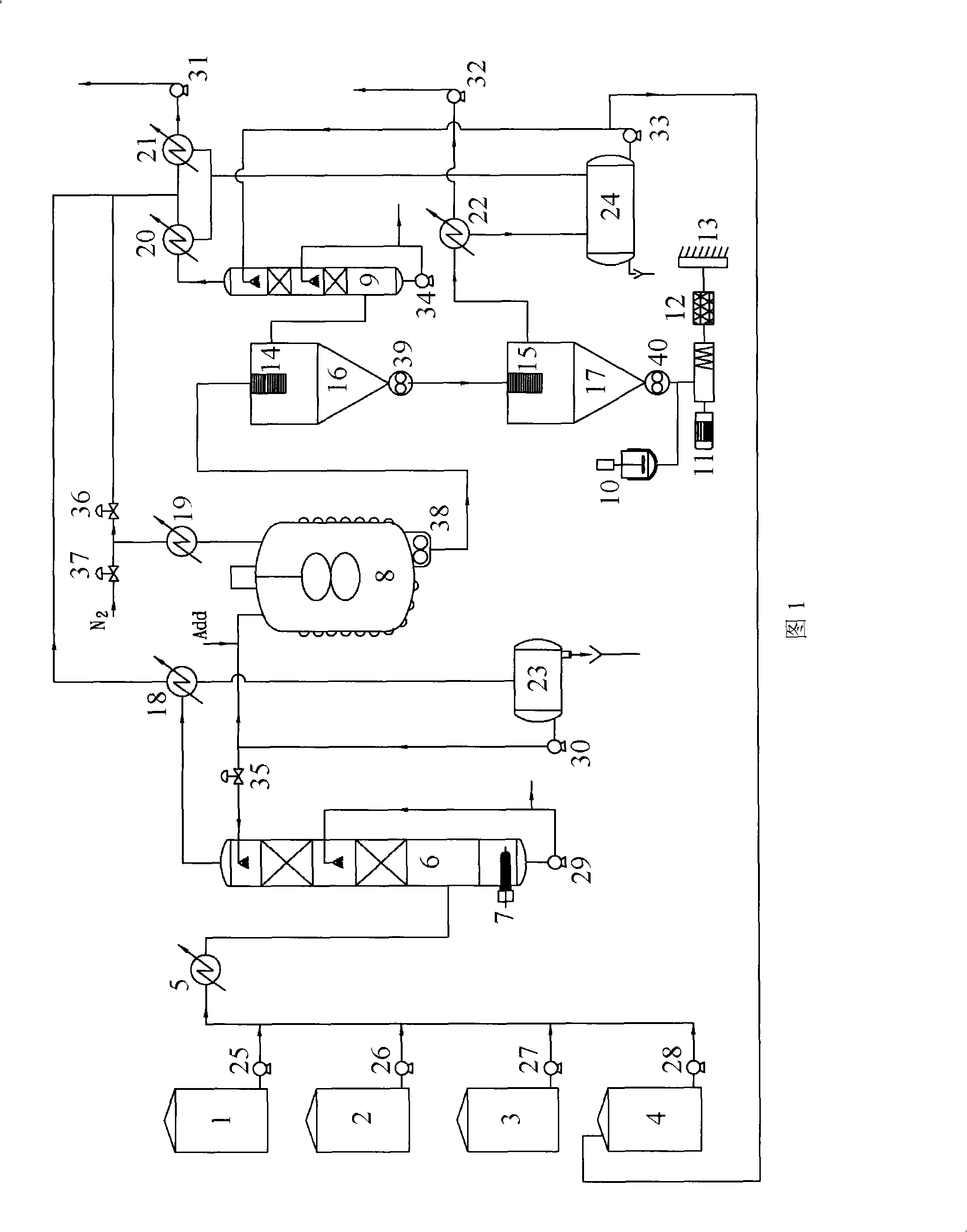

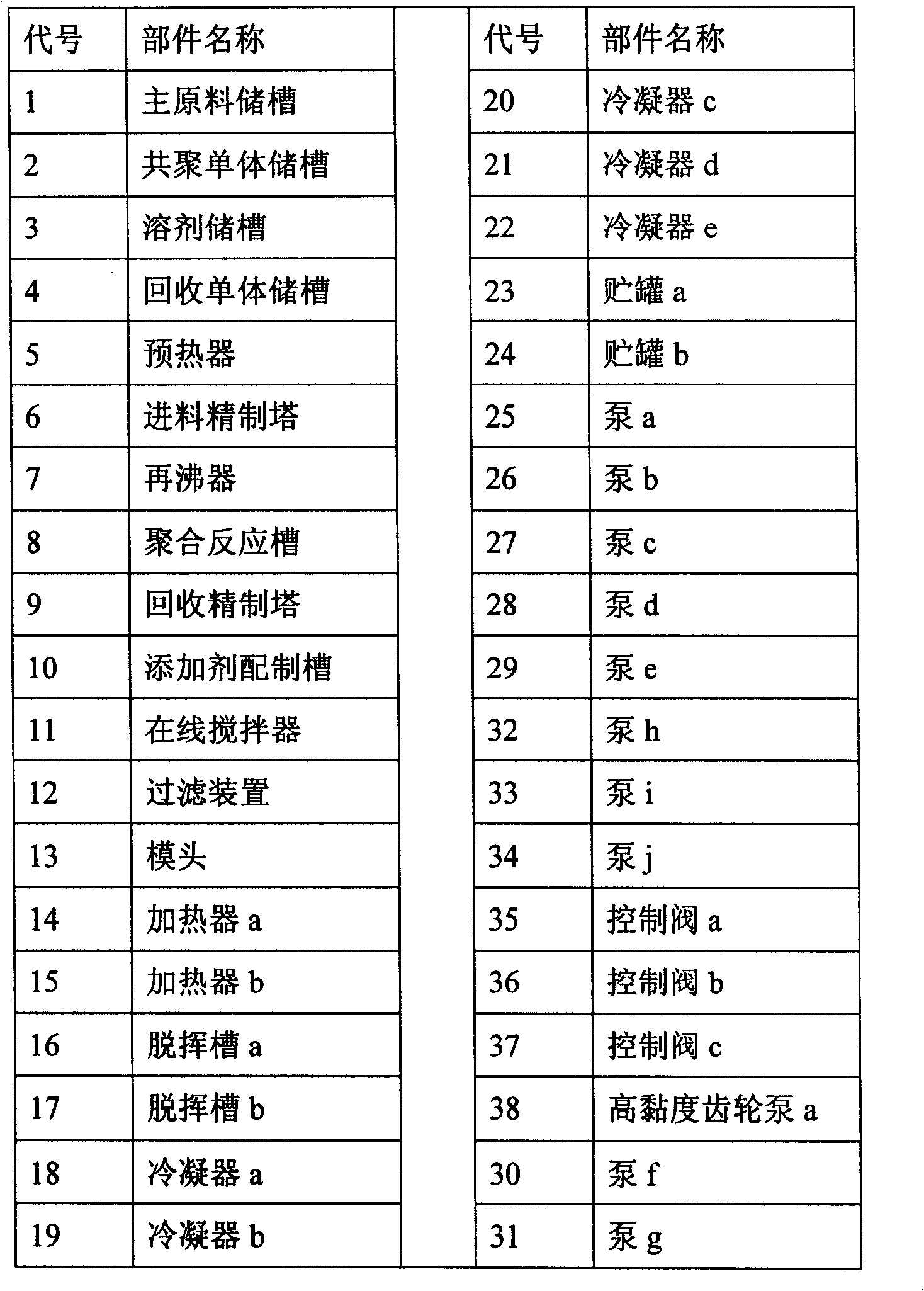

Optical-grade polymethylmethacrylate continuous solution polymerization process and equipment thereof

The invention relates to the preparation method of a polymer compound and a plant used therefor, in particular to a continuous solution polymerization process of optical-grade poly(methyl methacrylate) and the plant used therefor. The plant used for the continuous solution polymerization process of optical-grade poly(methyl methacrylate) comprises a refining and distillation device, a polymerization reaction device, a two-stage devolatilization device, and a wire-drawing and granulation device connected with each other in series, and specifically comprises a feed refining tower, a polymerization reaction groove, a recovering and refining tower, heaters a and b, and devolatilization tanks a and b. The continuous solution polymerization process can prepare optical-grade poly(methyl methacrylate) from monomers, a copolymer, a stabilizing agent, a molecular weight regulator, an initiator and a solvent according to the following four steps: (1) refining and distillation, (2) polymerization reaction, (3) flash devotilization and (4) wire drawing and granulation. The PMAA produced by the process has the advantages of high safety, no gel accumulation, improved physical properties and color of the produt, low energy consumption, environmental protection, clean production, good weathering resistance of the product, anhydrous polymerization, no black spots on the product, etc.

Owner:SHANGHAI JINGQI POLYMER MATERIAL

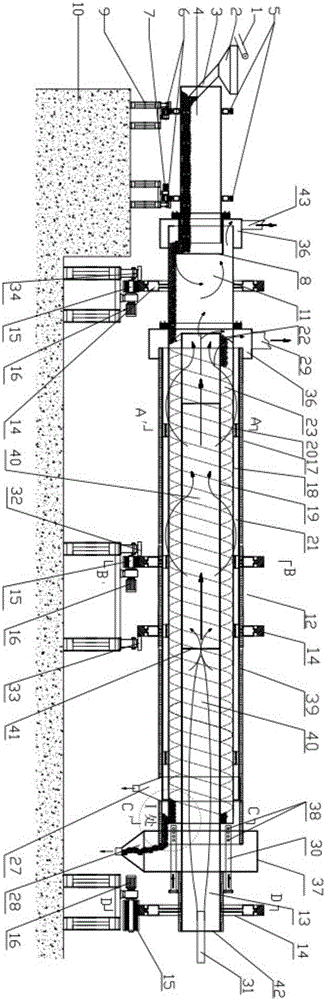

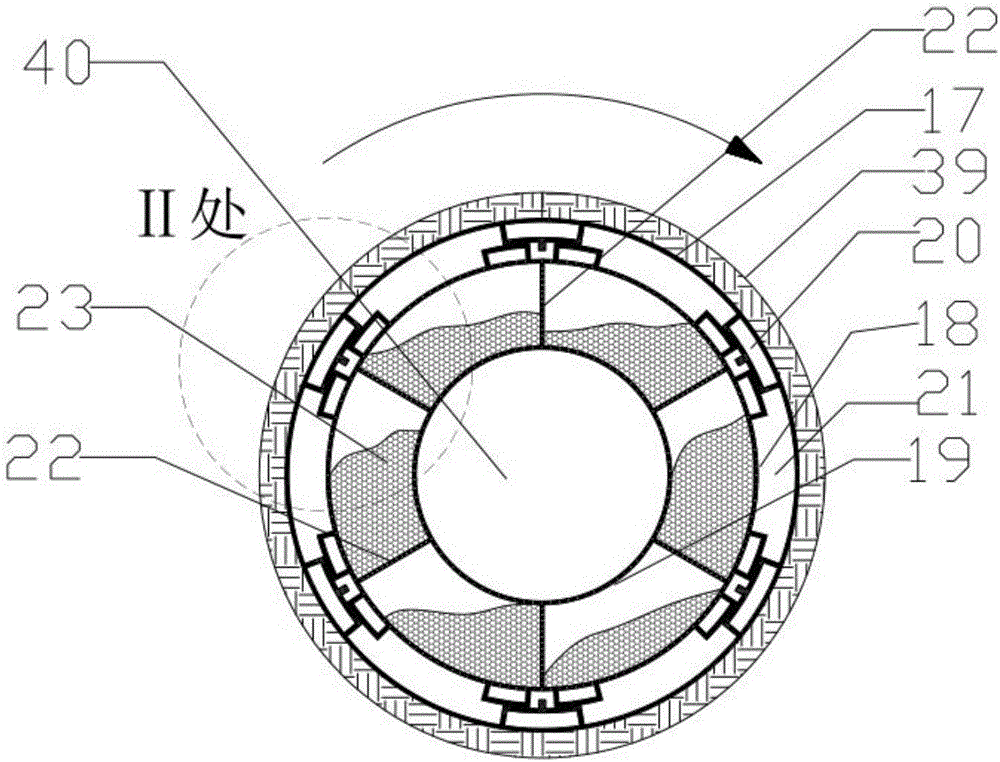

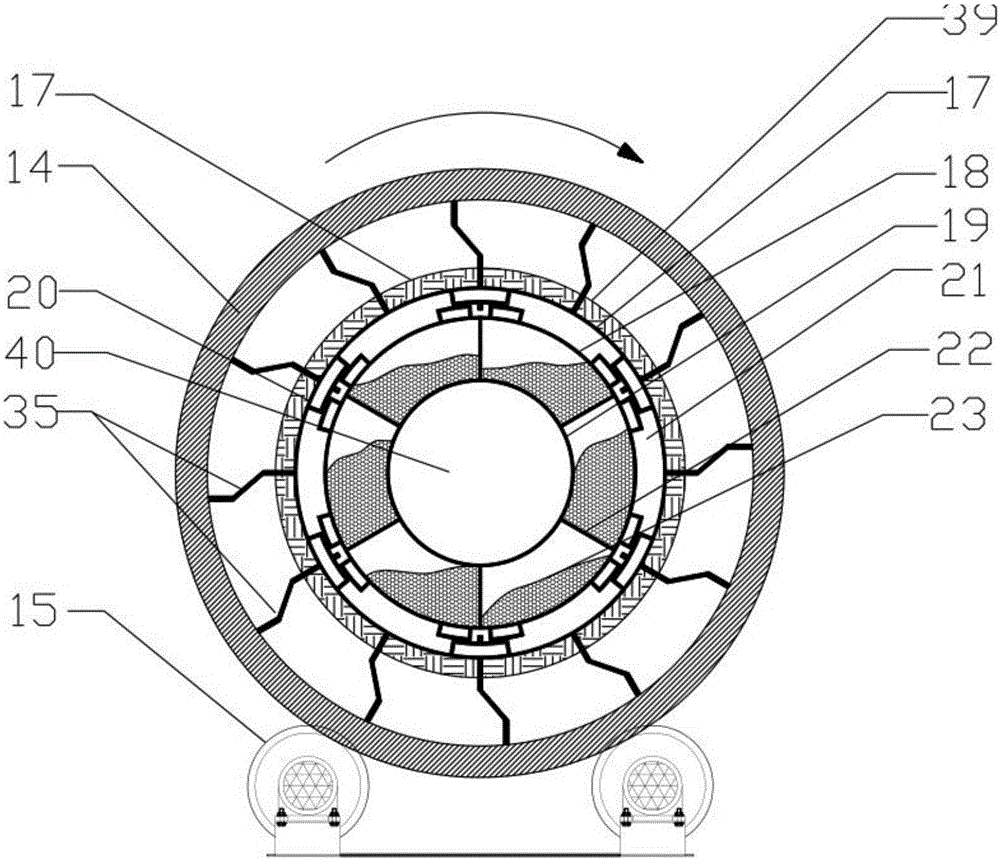

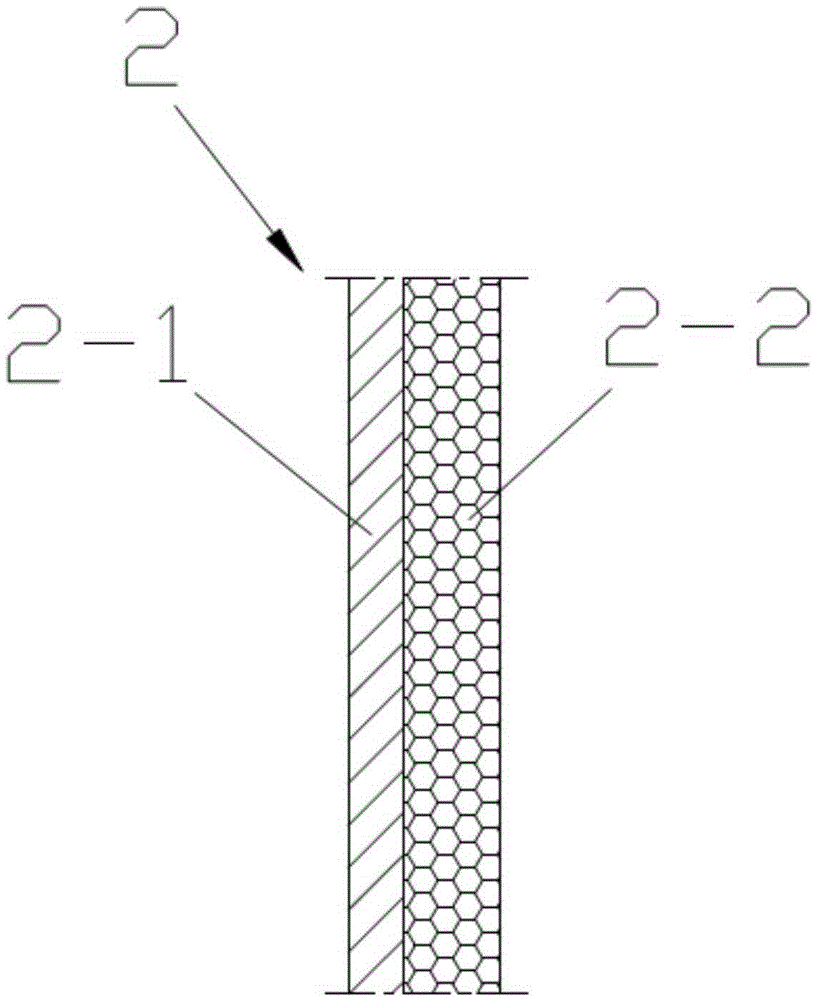

Roller type drying and sintering or roasting device

InactiveCN106679366AAutomatic separationEven heat absorptionRotary drum furnacesDrying gas arrangementsEngineeringNet shape

The invention relates to a roller type drying and sintering or roasting device which comprises a kiln body and a drive device. A drying roller comprises a kiln body outer shell, a net-shaped outer sleeve and a net-shaped inner sleeve from outside to inside in the radial direction of the drying roller. The inner wall of the kiln body outer shell and the outer wall of the net-shaped outer sleeve are connected through a plurality of sliding drive shifting blocks evenly distributed in the circumferential direction, and rotary drive is carried out. A powder chamber is formed by a space between the kiln body outer shell and the net-shaped outer sleeve. The net-shaped outer sleeve and the net-shaped inner sleeve are connected through a plurality of net-shaped partitions spirally extending in the length direction of the kiln body. A space between the net-shaped outer sleeve and the net-shaped inner sleeve is divided by the partitions into a plurality of drying or roasting (sintering) material chambers distributed in the circumferential direction. An inner sleeve air chamber is formed by a space in the inner sleeve. The device has the beneficial effects that material drying is even, thorough and fast; the manmade pellet (spherical block) damage rate is low; the device investment is reduced; the productivity is greatly improved; and energy saving and emission reduction are realized.

Owner:唐竹胜

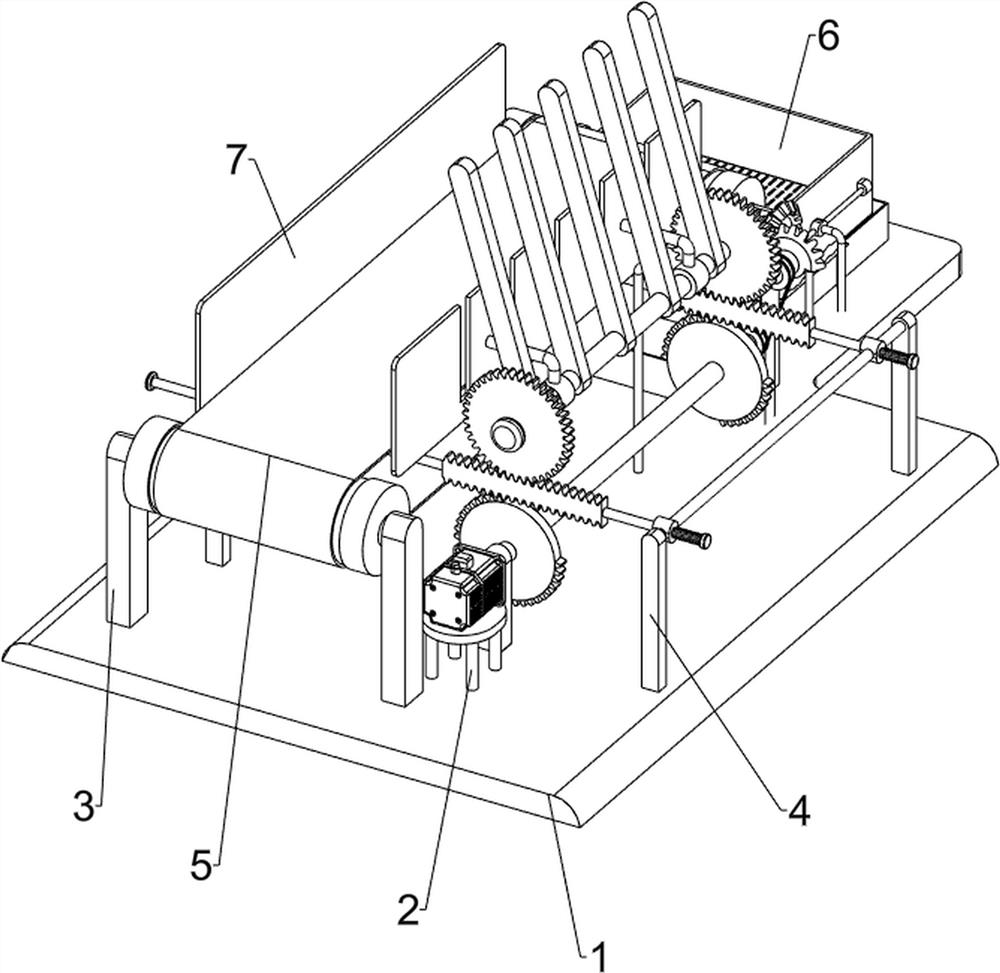

Flapping type sunflower seed taking-out device

The invention relates to a taking-out device, in particular to a flapping type sunflower seed taking-out device. The flapping type sunflower seed taking-out device can automatically flap sunflowers, is uniform in flapping and can also automatically separate sunflower seeds from the sunflowers. The flapping type sunflower seed taking-out device comprises a mounting seat, first brackets, a flappingmechanism and a transmission mechanism. The mounting seat is mounted at one side of the top of a base, the first brackets are arranged on the periphery of the top of the base, the flapping mechanism is arranged at the position, close to one side of the mounting seat, of the top of the base, and the transmission mechanism is connected between the first brackets. The sunflowers can be beaten intermittently through cooperation of a full gear and a rack rod, meanwhile, the sunflowers can be transmitted intermittently through an arranged roller and an arranged belt, flapping is more uniform, a screening frame drives a through hole block to move left and right, under cooperation of a special-shaped rod and a convex block, the convex block can be driven to shake up and down, the sunflower seeds and the sunflowers are automatically separated, and the working efficiency is high.

Owner:合肥市航拯工业设计有限公司

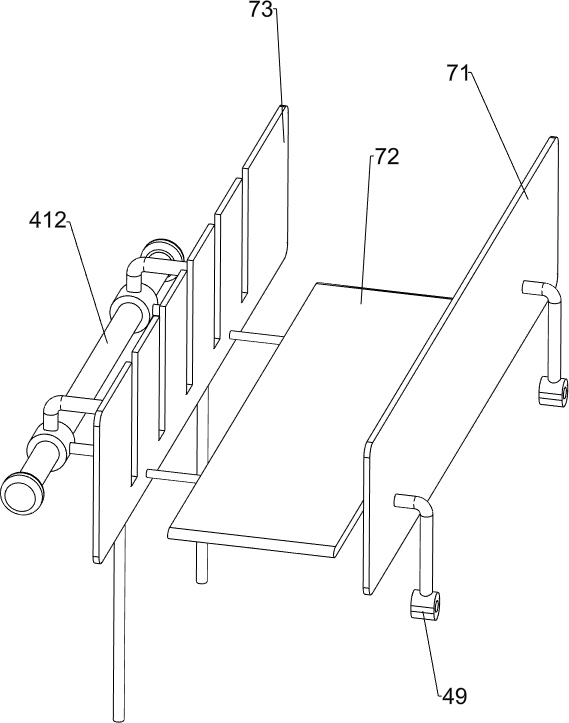

Device for automatically breaking egg shell, shelling eggs and separating egg white from egg yolk

The invention belongs to the technical field of food machinery or medical machinery, and relates to an egg pretreatment device, in particular to a device for automatically breaking egg shell, shellingeggs and separating egg white from egg yolk. A conveyor belt prodding plate intermittently prods eggs to roll forward to the upper platform surfaces of a right swing platform and a left swing platform, the eggs stop at a front limit plate, a right suction disc and a left suction disc suck the two ends of each egg, a lower pressing plate presses the upper surface of the egg, a right knife edge and a left knife edge are attached together, the lower surface of the egg is cut and cracks, a right swinging component and a left swinging component swing in the separating direction, the eggshell is divided into haves: a right eggshell and a left eggshell, the egg yolk falls into a egg yolk receiving bowl which is arranged directly below and then is transferred to an egg yolk receiving container,the egg white flows into an egg white receiving container below, and the right eggshell and the left eggshell are placed in an eggshell receiving container. The device can automatically separate eggshells, egg white and egg yolk, is high in efficiency and complete in separation, saves manpower, and reduces the production cost of the enterprise.

Owner:杜宗英

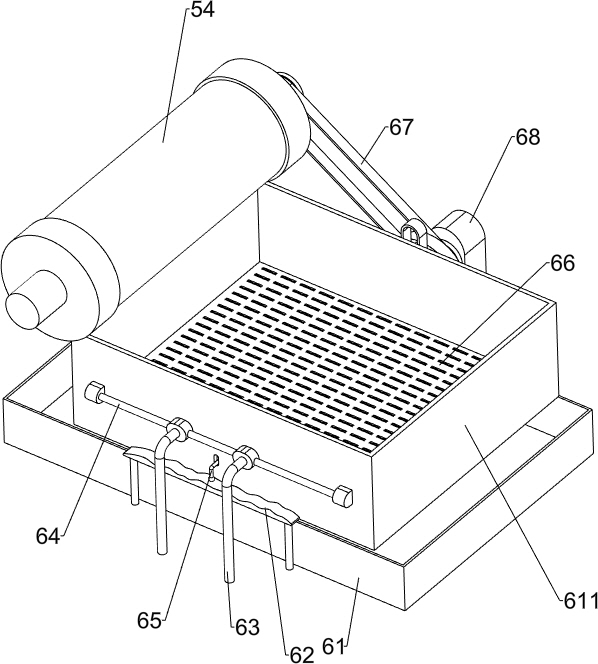

Cleaning device and method for fragments with grease

ActiveCN105312273AExtrusion will notRealize continuous operationCleaning using toolsCleaning using liquidsOil and greasePetroleum engineering

The invention discloses a cleaning device and a cleaning method for fragments with grease. The cleaning device comprises a rinsing tank, wherein a grease removing mechanism is arranged on the upper part of the rinsing tank; the grease removing mechanism comprises a plurality of tensioning wheels, an oil absorbing belt encircling the tensioning wheels, a power mechanism connected with the tensioning wheels, a fragment scraping plate and an oil absorbing tank; the oil absorbing belt consists of a stress layer and an oil absorbing layer; the oil absorbing belt is provided with an oil absorbing part which stretches below the level of the rinsing tank; at least one of the tensioning wheels comprises a group of oil extrusion tensioning wheels; each group of oil extrusion tensioning wheels comprises two oil extrusion tensioning wheels; an oil extrusion gap which is smaller than the thickness of the oil absorbing belt is formed between the two oil extrusion tensioning wheels; the oil absorbing belt passes the oil extrusion gap to form an oil extrusion part; and the fragment scraping plate is arranged on the outer side of the oil absorbing belt. The grease in the fragments can be effectively removed by the cleaning device for fragments with grease. The cleaning device has the advantages that the production efficiency is high; the grease separating effect is good; the shapes of the fragments are maintained as much as possible in the cleaning process; the degree of automation is high and the like.

Owner:冯愚斌

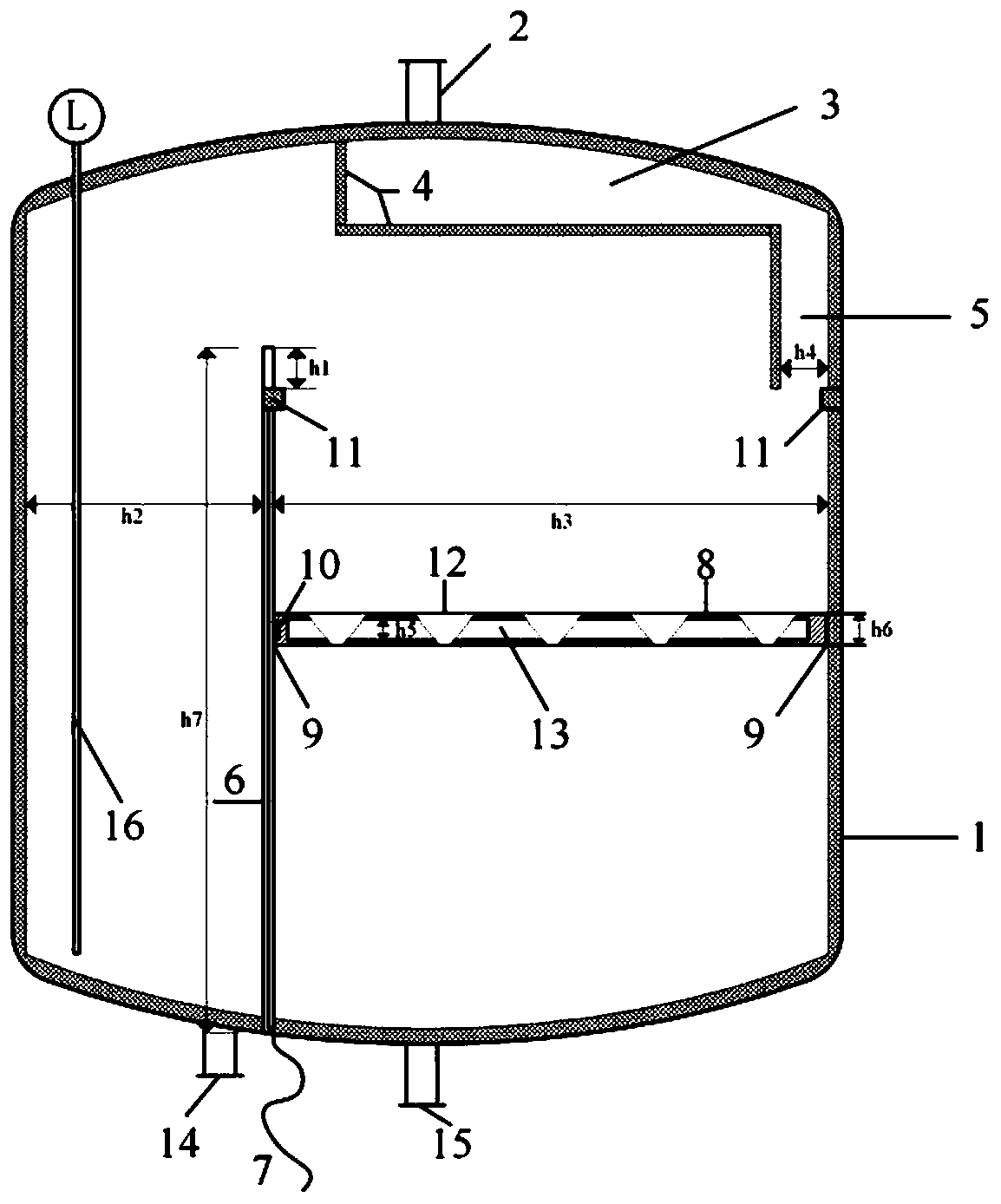

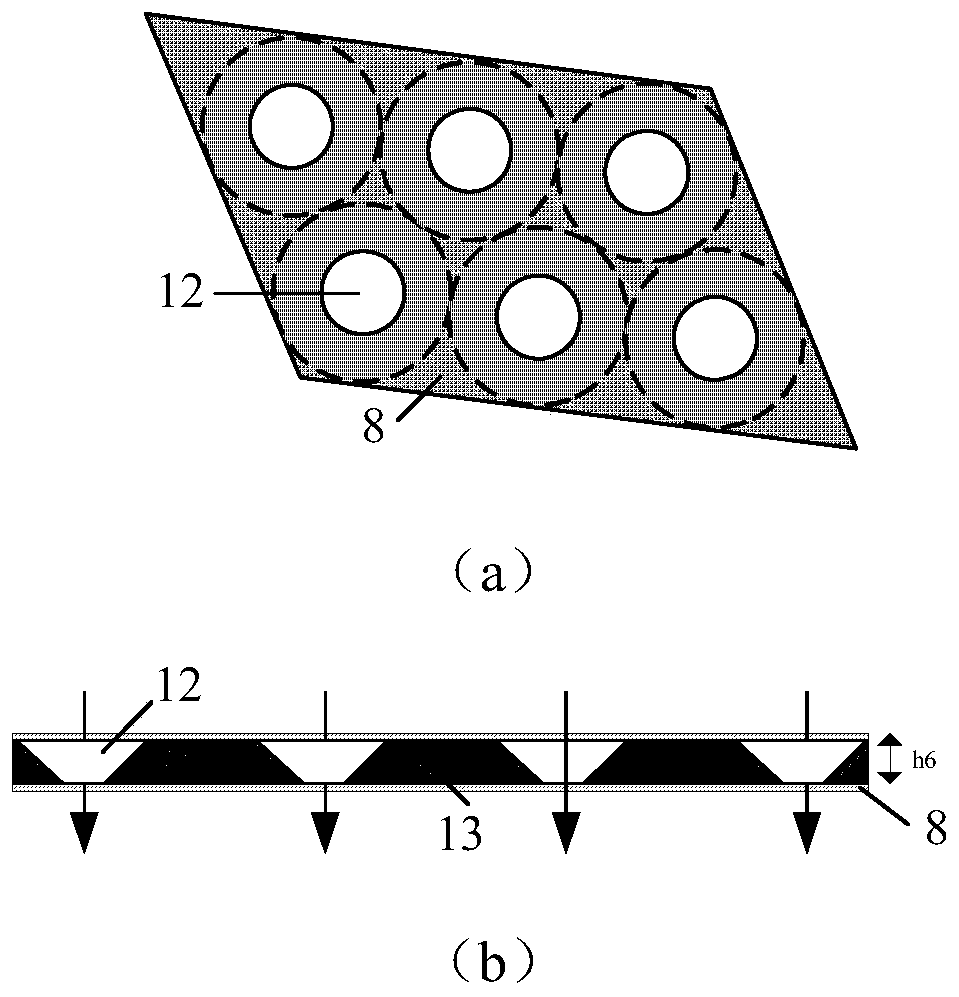

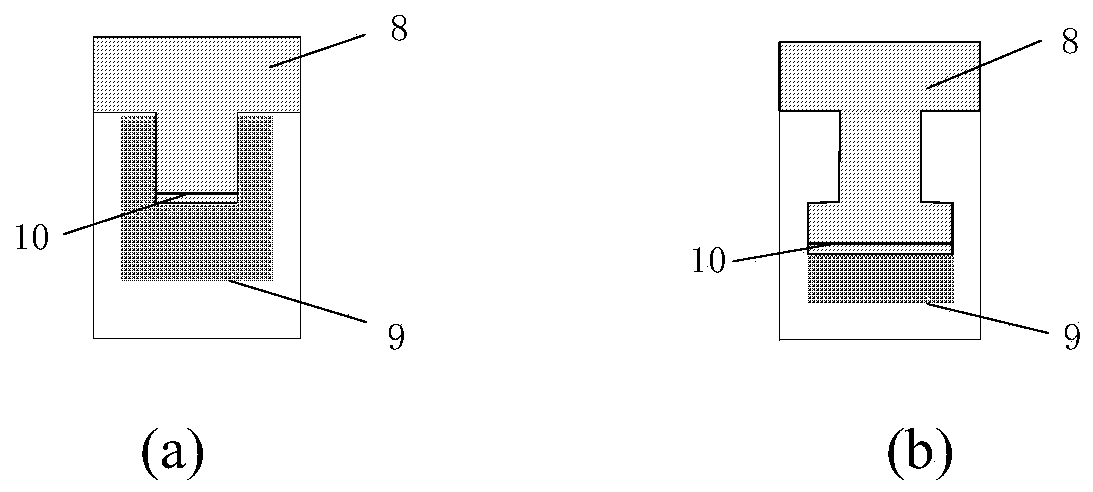

Oil-water separator and separation system

PendingCN110215741AAchieve separationAutomatic separationNon-miscible liquid separationChemical industryVolumetric Mass Density

The invention discloses an oil-water separator for chemical industry and an oil-water separation system. The oil-water separator is of a tank-type hollow structure and is internally provided with a separation channel coated with a hydrophobic membrane, a physical partition plate and a novel liquid level floating plate; and an oil phase discharging hole and a water phase discharging hole are respectively formed in a tank bottom. Due to the arrangement of a hydrophobic membrane layer, the rapid separation of oil and water is realized in the separation channel, and the oil-water separation time is shortened; the density-adjustable oil-water separation liquid level floating plate is designed by adopting a novel air sac floating plate, so that the separation of an oil phase and a water phase isefficiently accelerated; and meanwhile, due to the adoption of a magnetic induction device at a liquid level floating plate end, phase interface positions of the two phases including the oil phase and the water phase can be monitored in real time, the yield of the water phase is directed to be controlled, an effective liquid level monitoring means is provided for a chemical oil-water separation process, and the oil-water separator is suitable for traditional chemical oil-water separation controlled a DCS.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

FPC (flexible printed circuit) turnover machine

ActiveCN108112163AAutomatic separationGood adhesionPrinted circuit detailsPrinted circuit aspectsEngineeringMechanical engineering

The invention discloses an FPC (flexible printed circuit) turnover machine, which comprises a test table, a jig, a circuit board pushing and ejecting device, a film tearing device, a turnover device and a laminating device. The jig is fixed on the test table and is located on one side of the test table. The circuit board pushing and ejecting device, the film tearing device, the turnover device andthe laminating device are arranged corresponding to the jig respectively. The jig comprises a jig plate. A product placement area is arranged on one side, away from the test table, of the jig plate.A product fixing structure is arranged on the product placement area. The circuit board pushing and ejecting device is located on one side, close to the test table, of the jig plate. A through hole used for allowing the circuit board pushing and ejecting device to penetrate through is formed in the jig plate. According to the invention, the automatic turnover and forming of an FPC is realized without the manual operation. Therefore, the manual cost is reduced, and the turnover precision is further improved.

Owner:INTERFACE TECH CHENGDU CO LTD +2

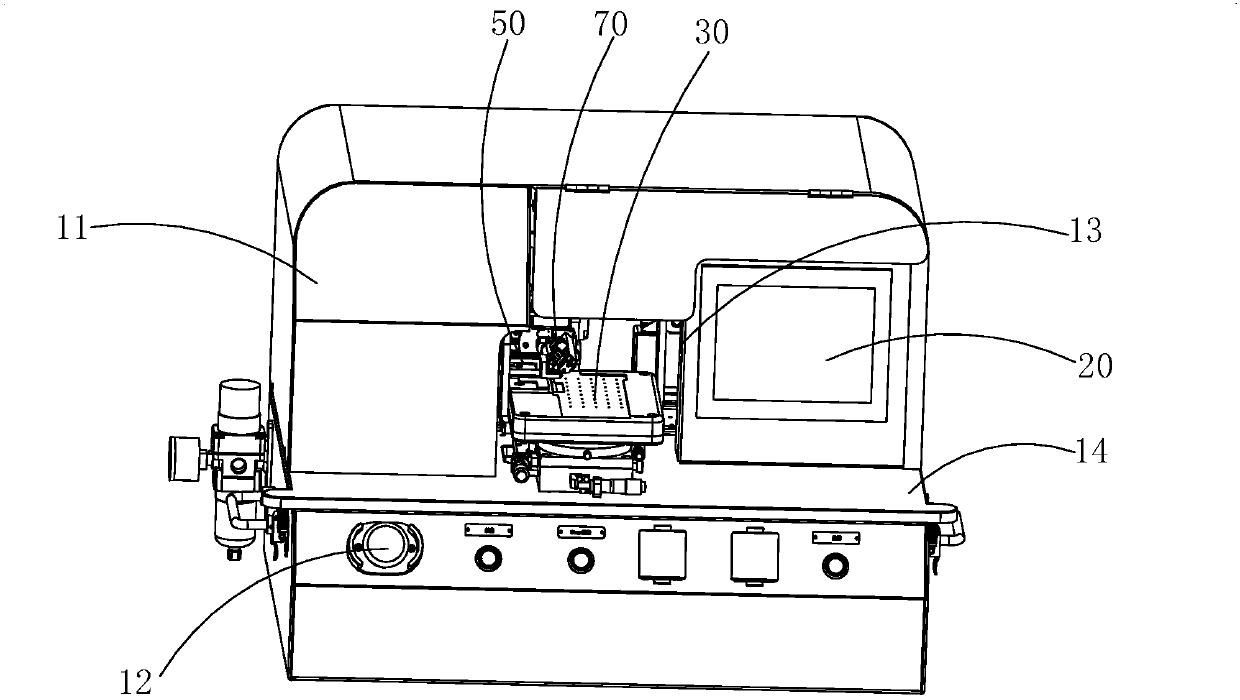

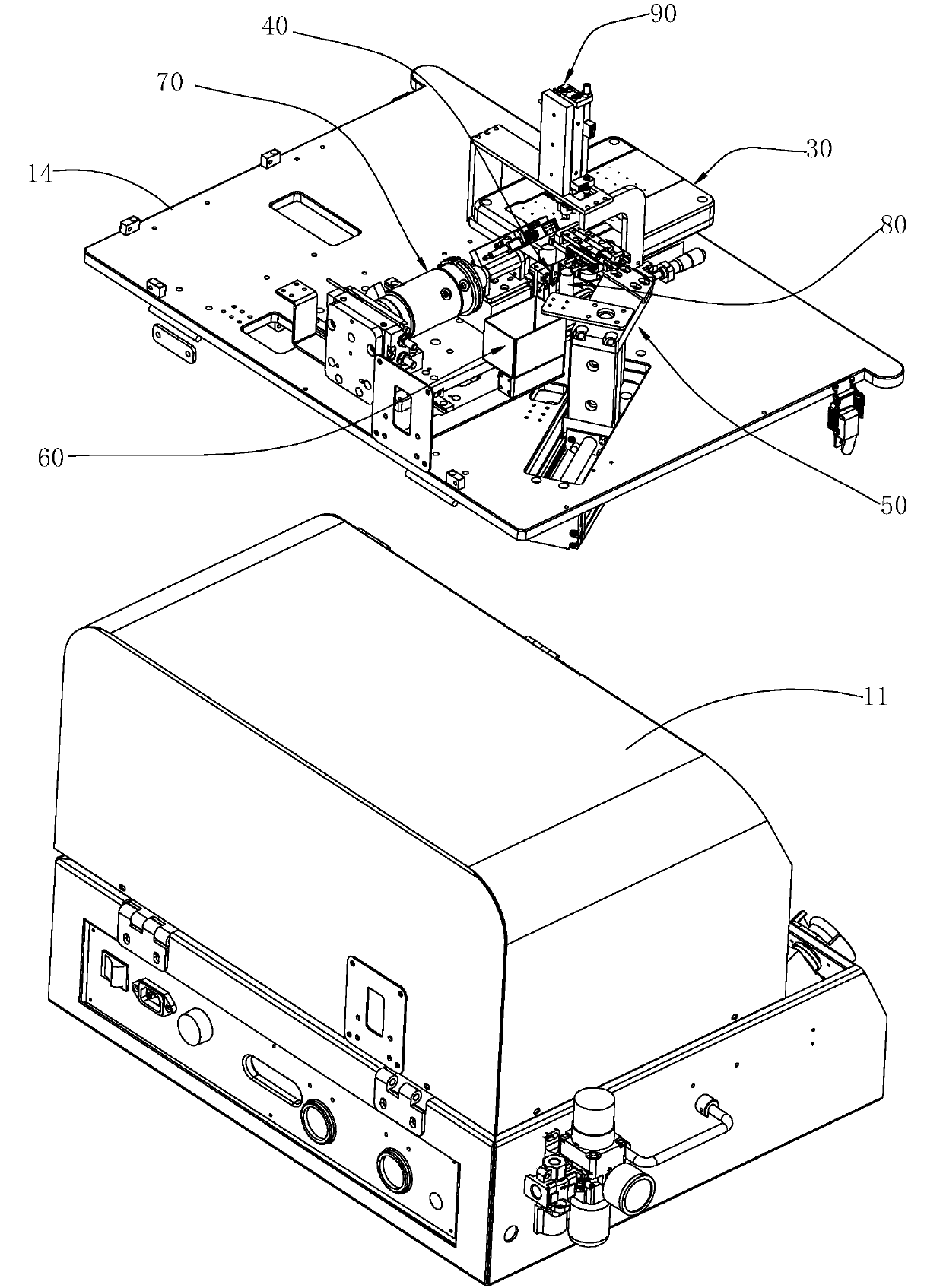

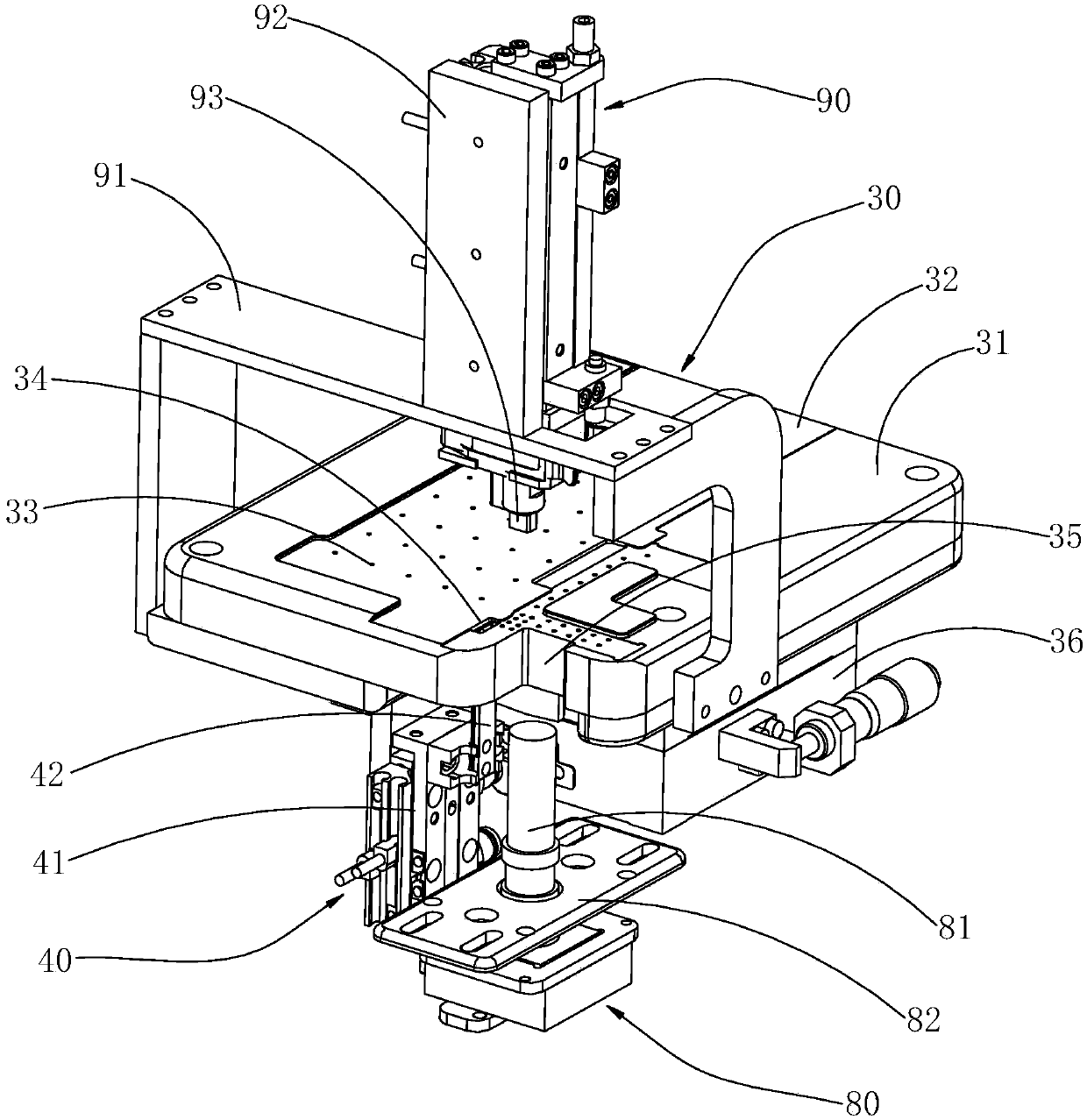

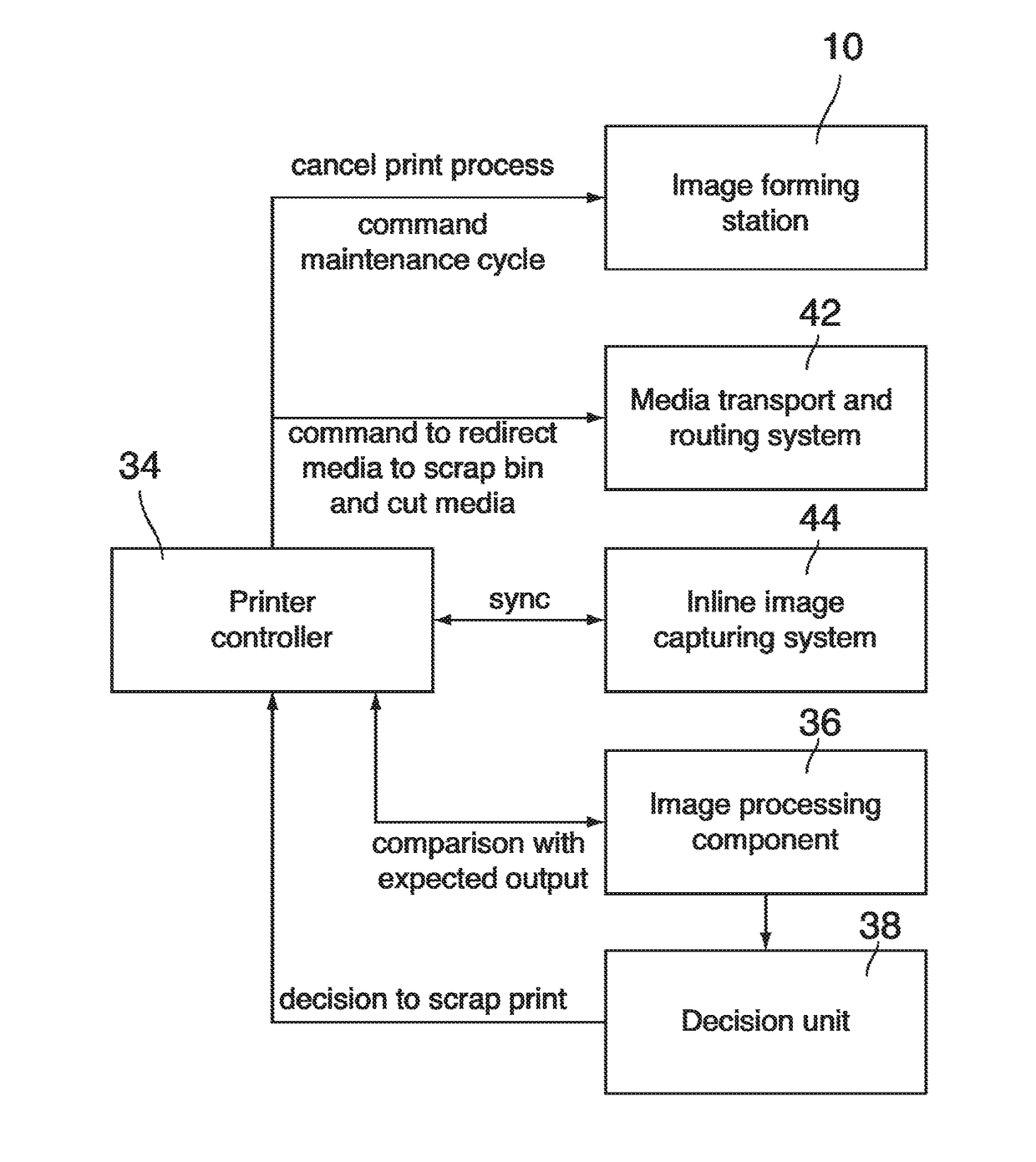

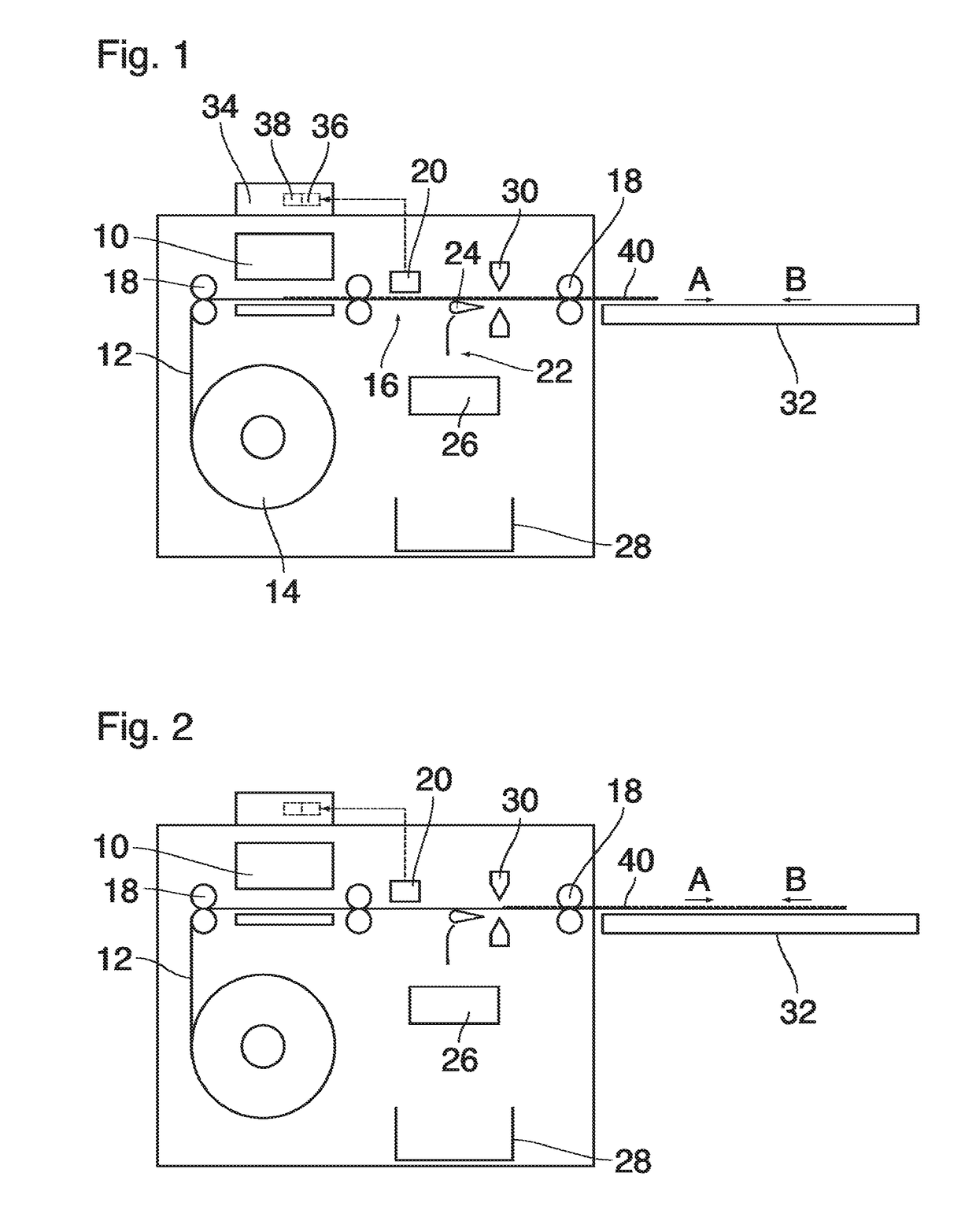

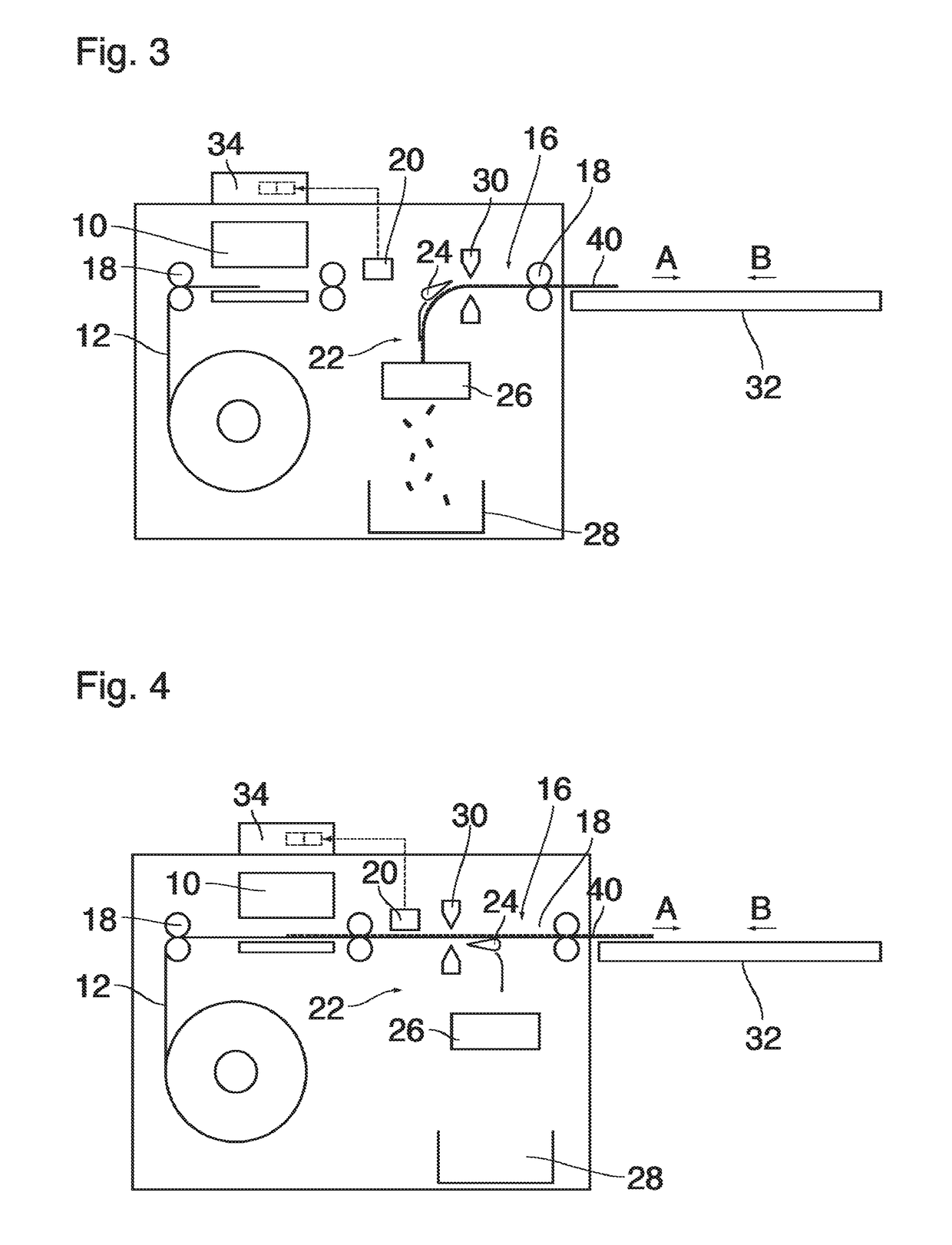

Printer with image inspection device

InactiveUS20180170077A1Compact designAutomatic separationElectrographic process apparatusOther printing apparatusImage InspectionComputer printing

A printer includes an image forming station; a first media transport path arranged to convey printed media from the image forming station to an output port; a second media transport path branching off from the first media transport path and arranged to convey printed media to a reject port; a switch for directing printed media into the second media transport path; an image inspection device for inspecting images printed onto the media; and a decision unit arranged to decide, on the basis of an inspection result obtained from the image inspection device, whether a printed image shall be rejected, and arranged to control the switch. The printer is a roll-to-sheet printer having a roll from which the media are supplied into the first media support path in the form of an endless web. The printer includes a cutting device for cutting the web; and the decision unit is arranged to cause a reversal of the transport direction of the media in the first media transport path, thereby to move an edge of the printed media to the position of the switch.

Owner:OCE HLDG BV

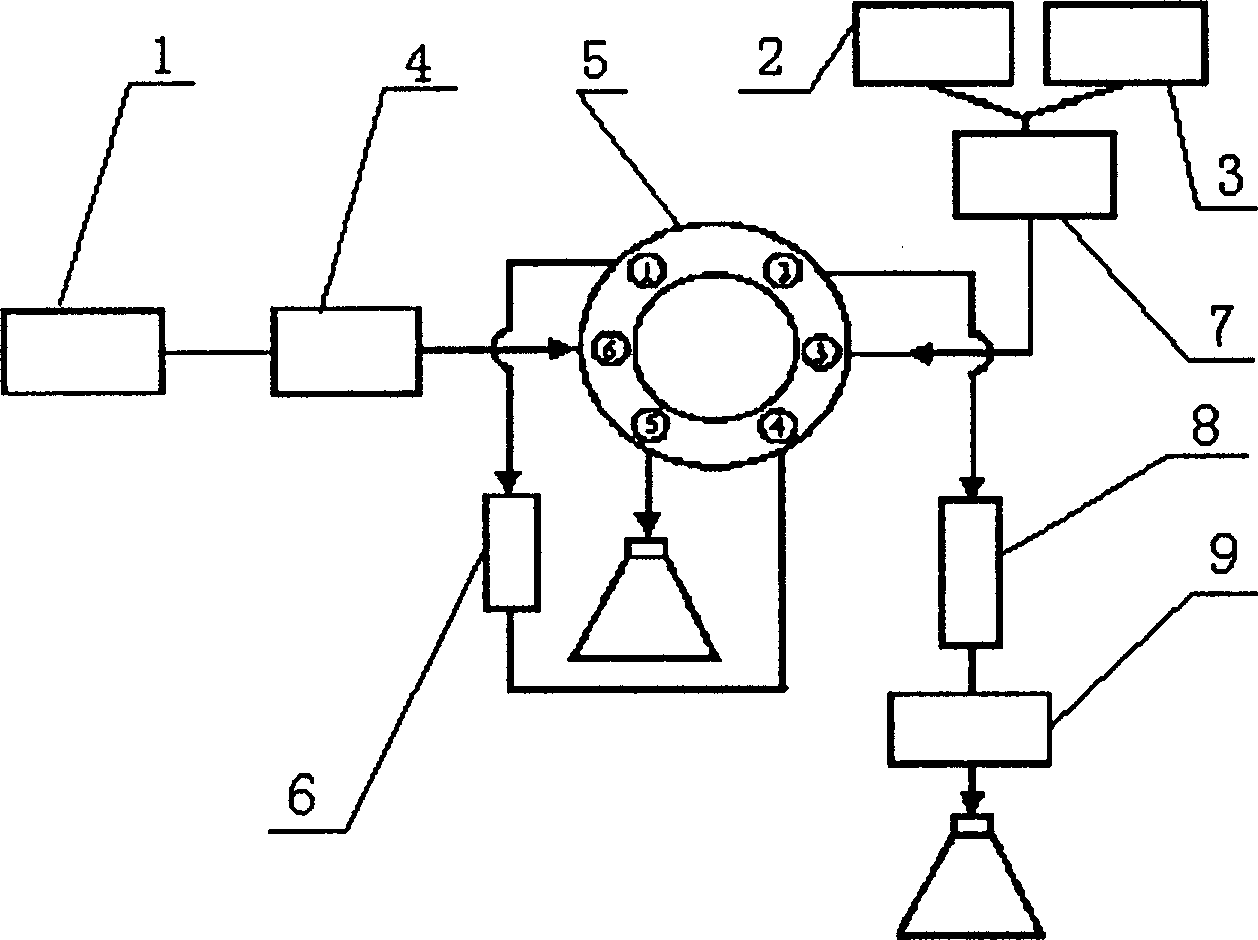

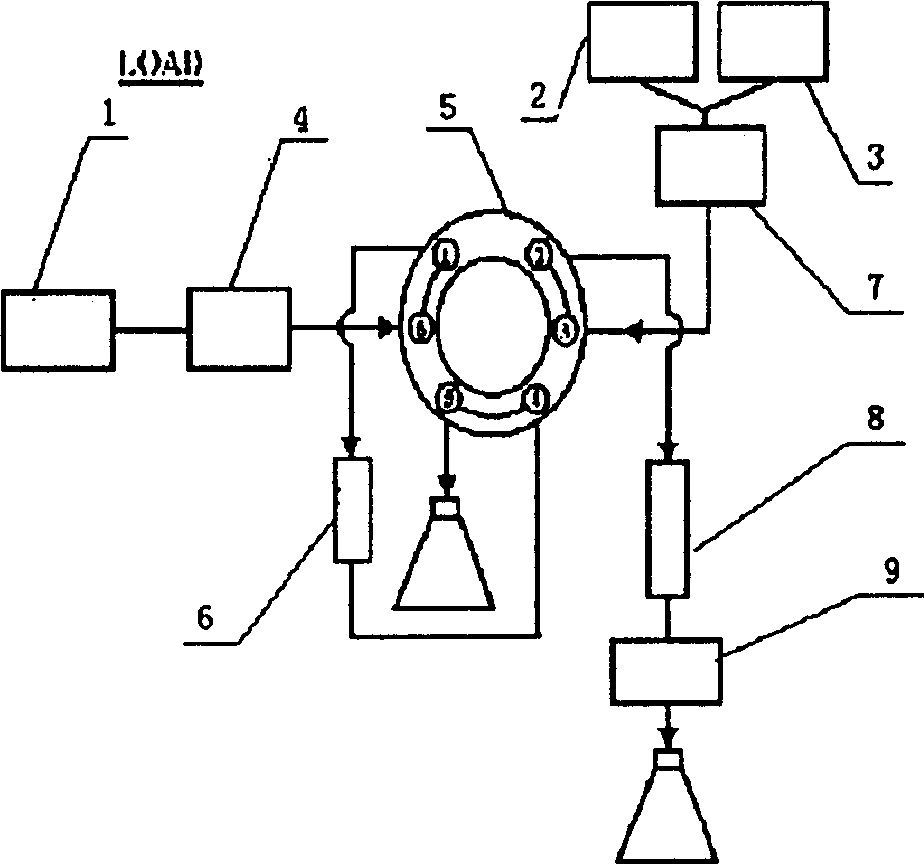

New type automatic malignent fumour auxiliary diagnostic instrument

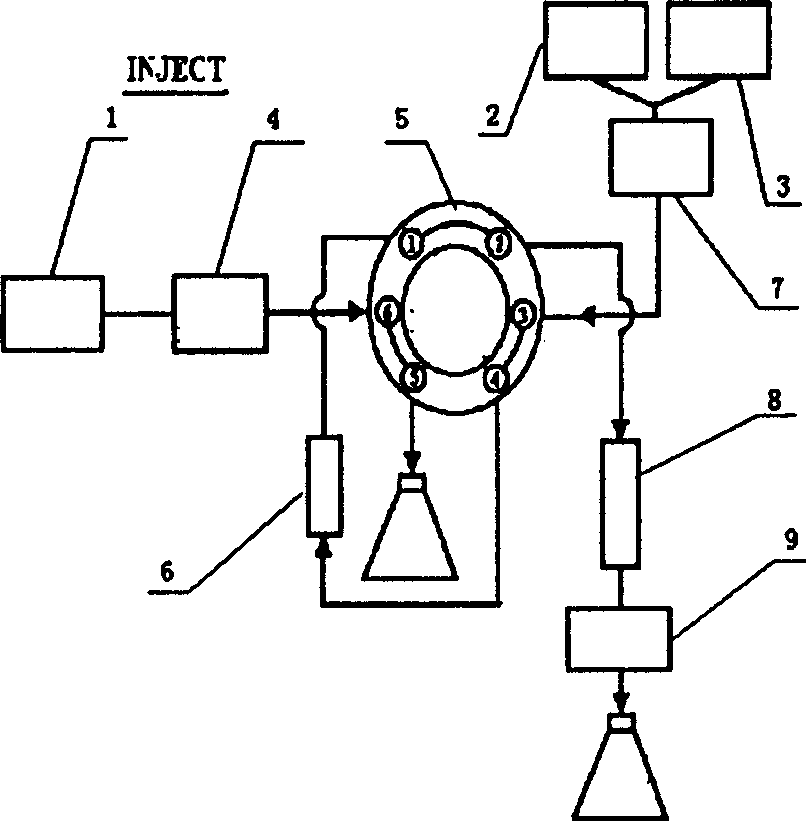

InactiveCN1534291APreprocessing steps to avoidHigh precisionComponent separationAutosamplerData treatment

An automatic auxiliary diagnosing instrument for cancer is composed of high-pressure pumps A, B and C, automatic specimen feeder, 6-way valve, affinity chromatographic column, mixer, analyzing column, and ultraviolet-visual light tester. It can automatically separate the nucleoside from urine and analyze it for diagnosing cancers. Its advantages are high accuracy, less needed speciment and high speed.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

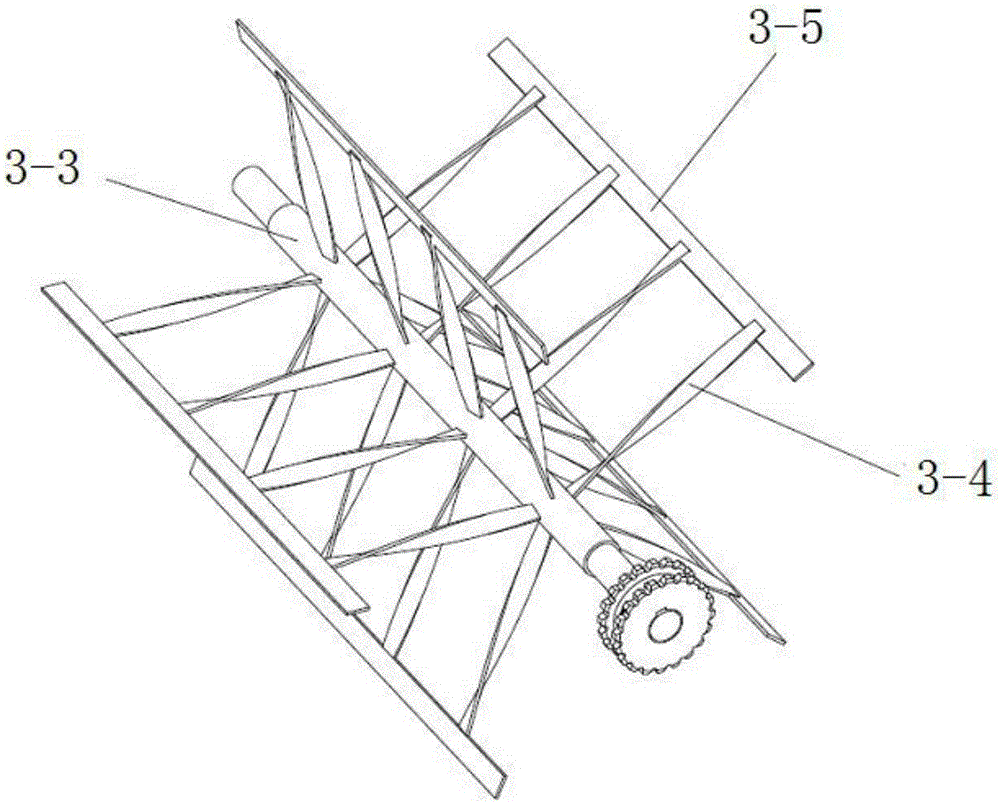

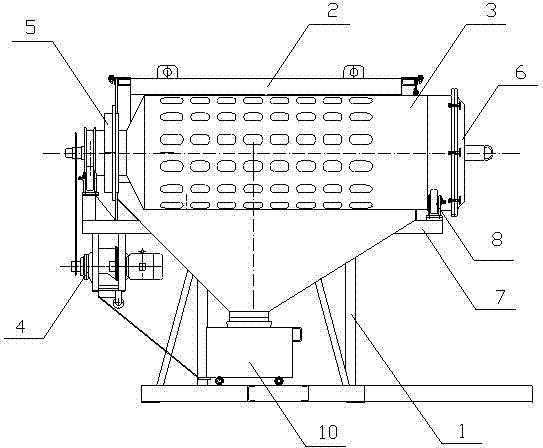

Automatic separating and recovering device for zinc-nickel permeated layer permeating agent

The invention discloses an automatic separating and recovering device for a zinc-nickel permeated layer permeating agent, which comprises a turning machine frame, an ash tank, an ash sieving tank, an ash sieving tank driving device and an ash receiving trolley, wherein the ash tank is a tank body with openings at two ends; the ash sieving tank is a tank body with one end closed and the other end opening and sieve pores on the side wall, the tank body is positioned in the ash tank, the two ends of the ash sieving tank extends out from the openings at the two ends of the ash tank; supporting plates are arranged under the parts, which extend out from the two open ends of the ash tank, of the ash sieving tank; roller devices for supporting the ash sieving tank is arranged between the supporting plates and the ash sieving tank; the ash sieving tank deriving device is connected with the closed end of the ash sieving tank; the ash tank is rotationally connected with the turning machine frame; and a turbine reducer is arranged on the turning machine frame. The device can quickly, efficiently and automatically separate permeating agent powder adhered on the surface of a permeated workpiece, and can fully recover the permeating agent powder.

Owner:CHONGQING DAYOU SURFACE TECH

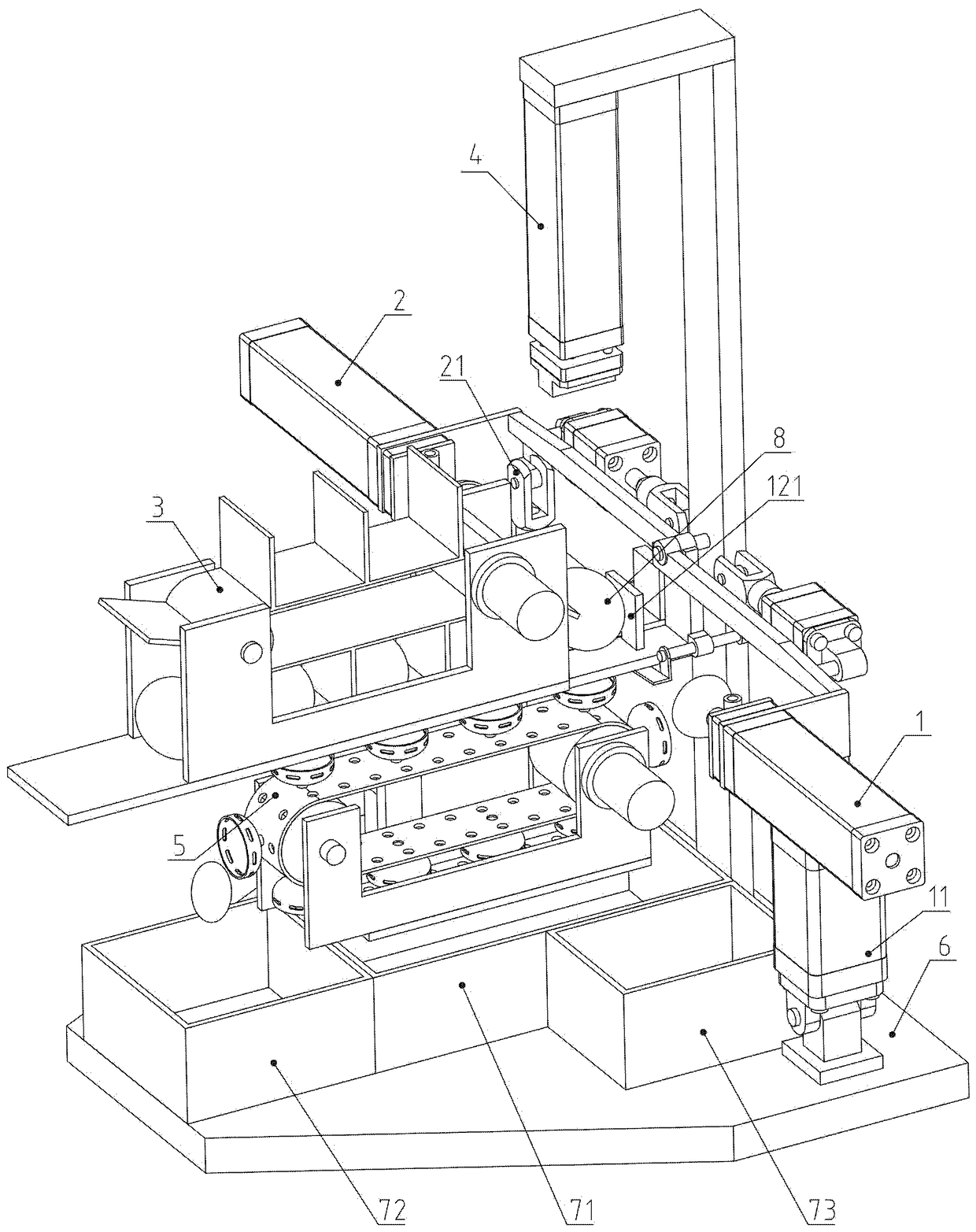

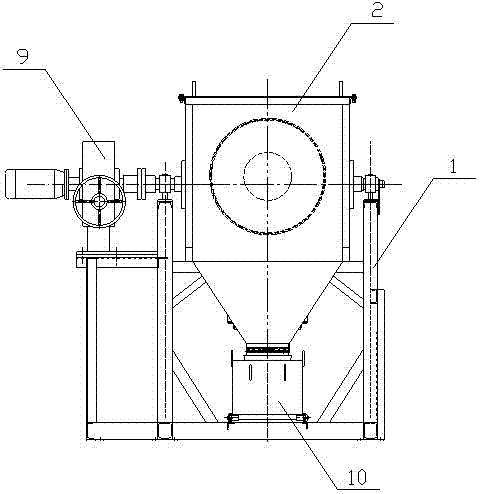

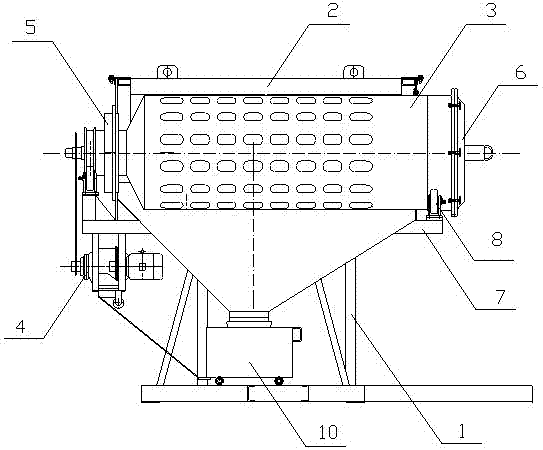

Impurity separation treatment equipment for building waste

InactiveCN113304812AAutomatic separationUnified collectionSievingScreeningArchitectural engineeringWaste material

The invention relates to treatment equipment, in particular to impurity separation treatment equipment for building waste. According to the impurity separation treatment equipment for the building waste, the building waste can be automatically separated and screened. The impurity separation treatment equipment for the building waste comprises a supporting frame, a shell, a screen, a smashing mechanism, a screening mechanism, a conveying mechanism and a pushing mechanism, the shell is arranged at the top of the supporting frame, the screen is arranged on one side in the shell in a sliding mode, the smashing mechanism is arranged on the side, close to the screen, of the shell, the screening mechanism is arranged between the screen and the smashing mechanism, the conveying mechanism is arranged on the shell, and the pushing mechanism is arranged on the rear side of the shell. Broken stones screened by the screen can fall down on a crawler belt, the crawler belt rotates, and under the action of a limiting block, the crawler belt can convey the broken stones to the left side to an opening of the shell, so that the broken stones can be collected and cleaned in a unified manner.

Owner:深圳市信誉鑫环保科技有限公司

Rice processing equipment

ActiveCN108043491APrevent containingKeep the relative position unchangedGrain huskingGrain polishingTransverse planeBroken rice

The invention relates to rice processing equipment. The rice processing equipment comprises an outer cylinder and an inner cylinder, and an annular cavity is formed between the inner cylinder and theouter cylinder; a transverse filter plate is inserted in the cavity; a first cavity body is formed above the filter plate and internally provided with a first negative pressure fan connected to the outer wall of the inner cylinder, and a bran shell recycling box is arranged on the outer side of the first cavity body; a second cavity body is formed below the filter plate, a discharging opening is formed in the bottom of the second cavity body, and inner polishing pellets and outer polishing pellets are arranged in the second cavity body; a third cavity body is formed in the inner cylinder, anda vertical rod penetrates through the interior of the third cavity body; the bottom end of the vertical rod is connected with a motor, and the top end of the vertical rod is connected with a transverse plate; the vertical rod is connected with a second negative pressure fan; an inner gear ring is arranged between the transverse plate and the outer cylinder, and a vertical rotating shaft is rotatably arranged on the transverse plate; the rotating shaft is connected with a straight gear engaged with the inner gear ring, and the bottom of the rotating shaft is rotatably connected with a transverse shaft; and one end of the transverse shaft is connected with a third negative pressure fan. According to the scheme, both bran shells and broken rice are prevented from entering the bran shell recycling box, and thus the bran shells and the broken rice are separated.

Owner:重庆市合川区云天食品科技有限公司

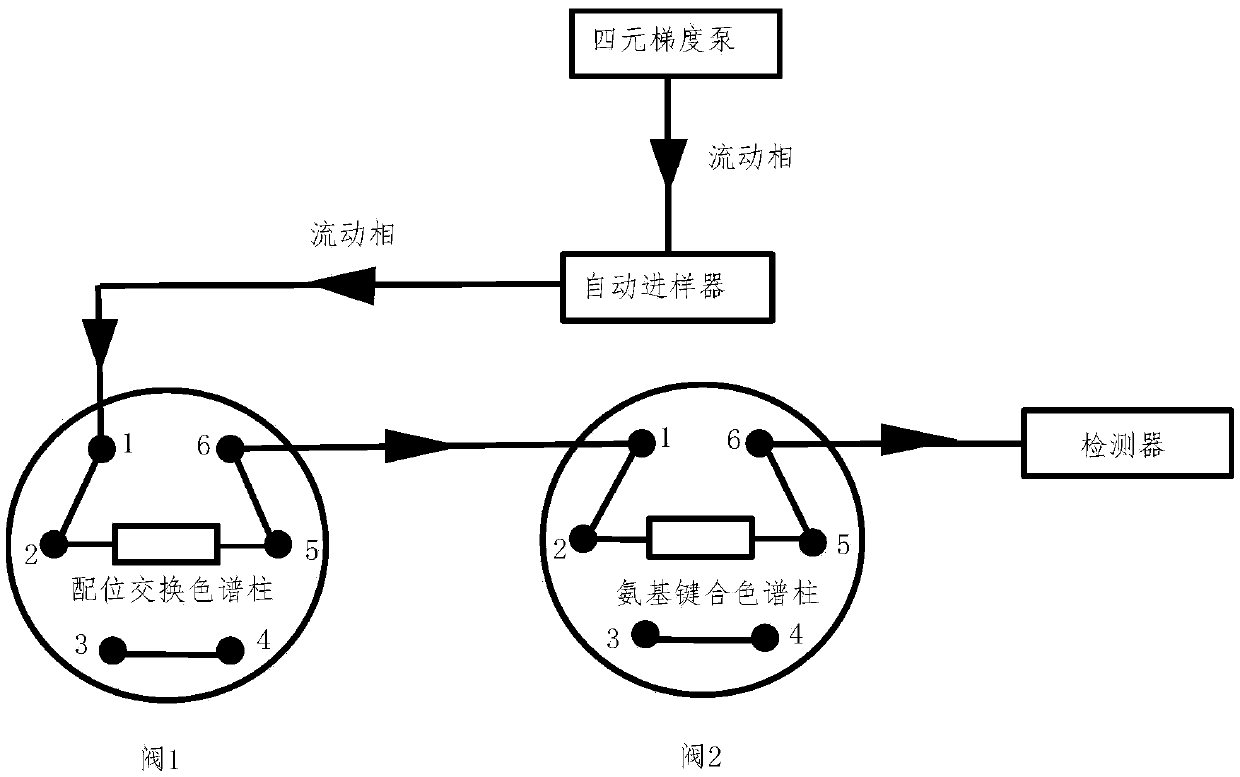

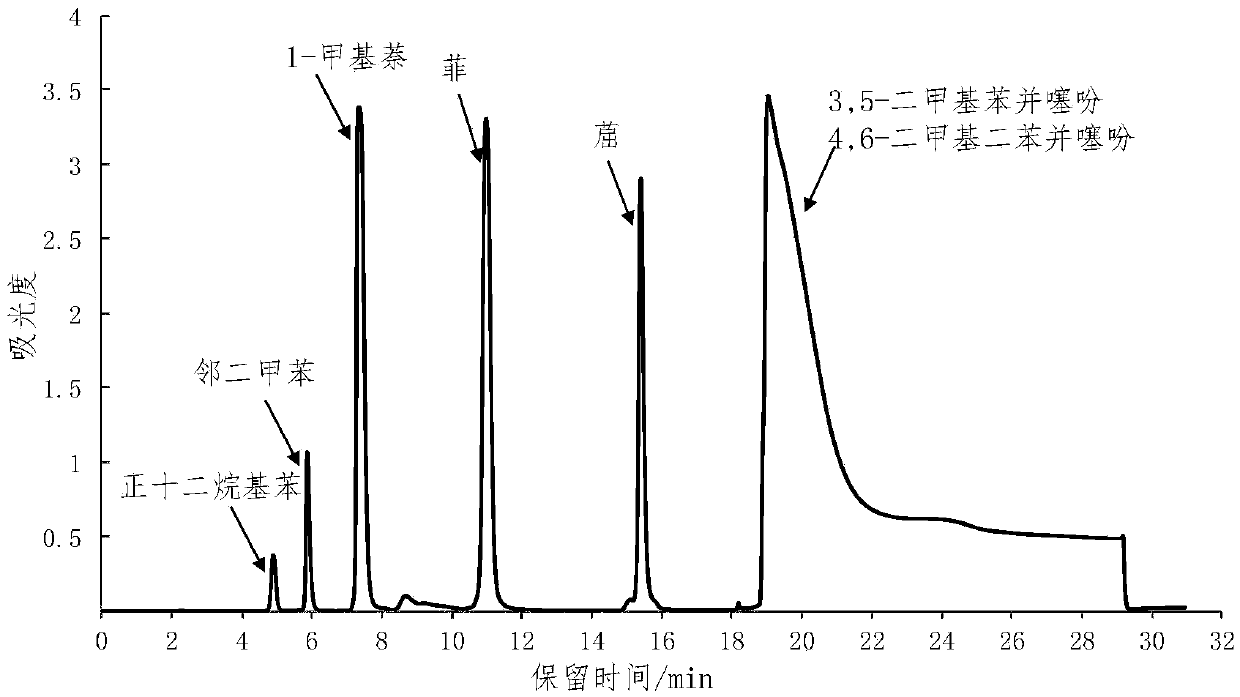

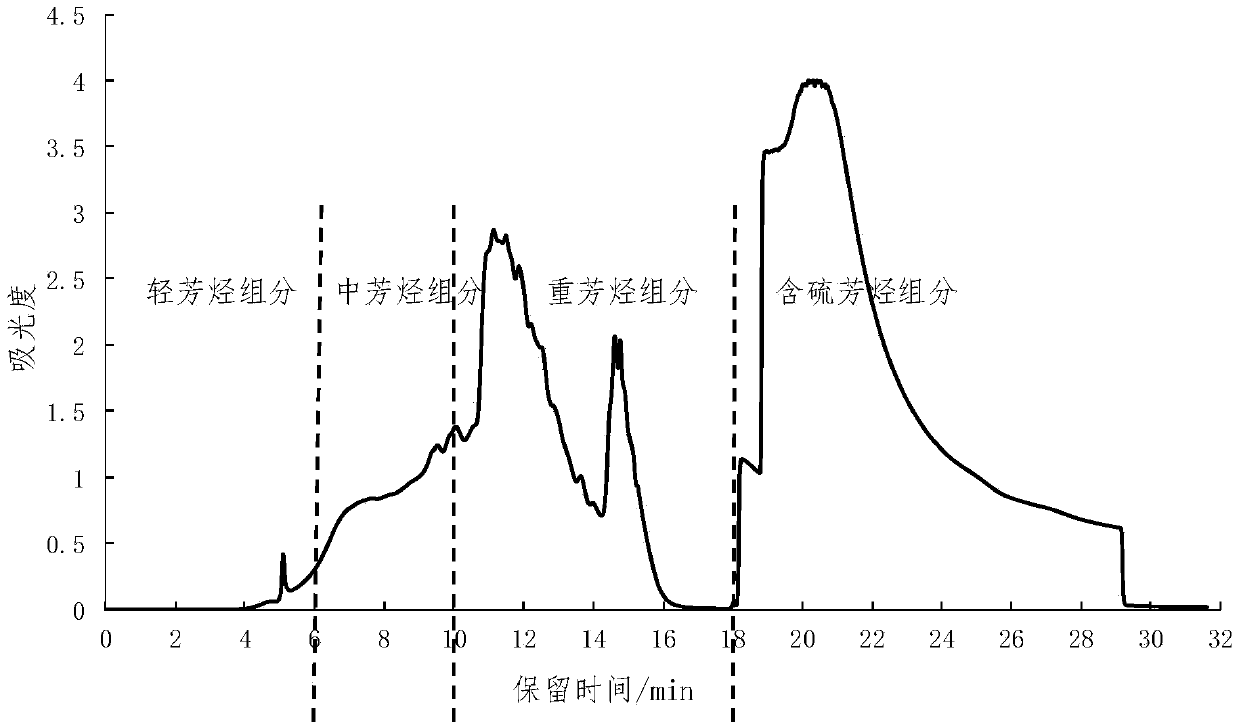

Separation and characterization methods for heavy oil aromatic hydrocarbon components, two-dimensional liquid chromatography, and device

ActiveCN110870985AHigh content of monocyclic aromatic hydrocarbonsHigh bicyclic aromatic contentComponent separationSolid sorbent liquid separationStationary phaseFluid phase

The invention relates to separation and characterization methods for heavy oil aromatic hydrocarbon components, two-dimensional liquid chromatography, and a device. The separation method includes: 1)dissolving the aromatic hydrocarbon components, and loading the sample to a coordination exchange chromatographic column of the two-dimensional liquid chromatography, the two-dimensional liquid chromatography further including a normal-phase chromatographic column at the downstream of the coordination exchange chromatographic column; 2) successively washing a first stationary phase of the coordination exchange chromatographic column and a second stationary phase of the normal-phase chromatographic column by means of a first moving phase, and bypassing the coordination exchange chromatographiccolumn, continuously washing the second stationary phase by means of the moving phase; 3) connecting the coordination exchange chromatographic column and bypassing the normal-phase chromatographic column, and washing the first stationary phase, in which sulfur-containing aromatic hydrocarbon, by using a second moving phase. By means of the separation method, light aromatic hydrocarbon components,medium aromatic hydrocarbon components, heavy aromatic hydrocarbon components and sulfur-containing aromatic hydrocarbons in heavy oil aromatic hydrocarbon components are separated high-effectively. The characterization method and device are high in speed and are high in automation degree.

Owner:CHINA PETROLEUM & CHEM CORP +1

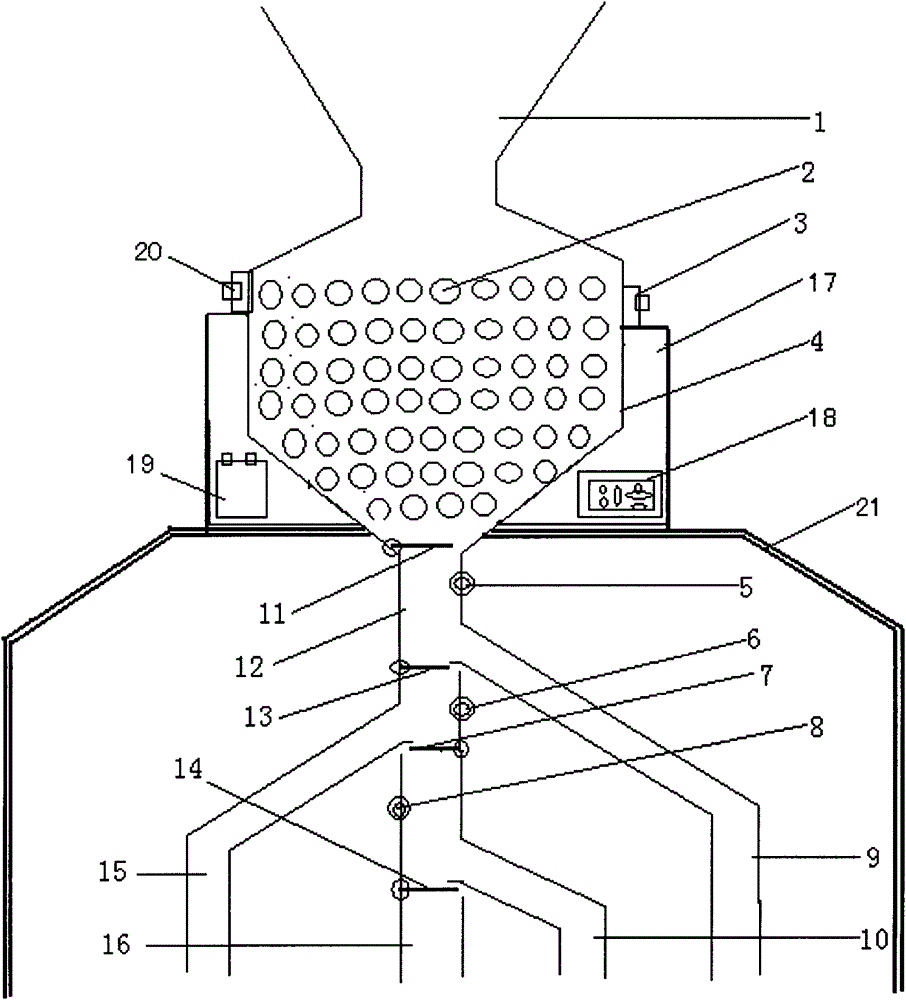

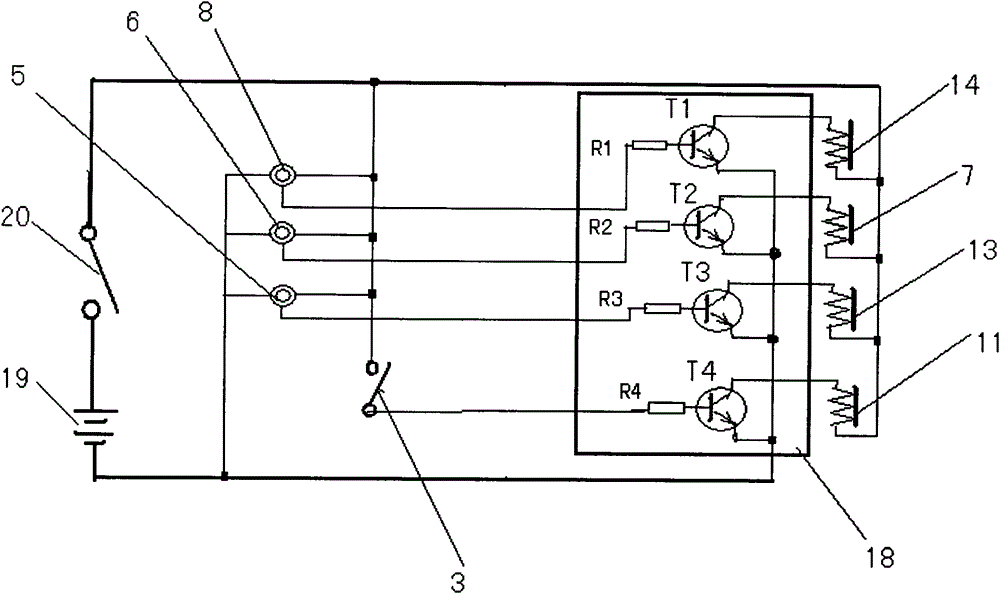

Automatic mixed bean sorting device

The invention discloses an automatic mixed bean sorting device which comprises a case and a stander, wherein a bean box, a storage battery and a circuit board are arranged in the case; a flared mouth is formed on the top of the bean box; a power switch and a starting switch are arranged on the shell of the bean box; the bottom of the bean box is connected to a main pipeline. Firstly, mixed soybeans, red beans, black beans and mung beans are poured into the bean box, the power switch and the starting switch are pressed in sequence, and a main electromagnetic valve in the main pipeline is started, so that the mixed beans can be automatically separated. If red beans drop first, a red sensor on the inner wall of the pipeline transmits a signal and a red bean electromagnetic valve in the pipeline is turned off, so that the red beans only can drop along a red bean pipeline beside; if beans in other colors drop first, the red sensor fails to transmit the signal and the red bean electromagnetic valve is not turned off, so that the beans in other colors directly drop along the pipelines, deduced by analogy, four trays are arranged at outlets of the four pipelines to receive beans in the four colors. The automatic sorting device disclosed by the invention is small and exquisite, and capable of rapidly and easily separating the mixed beans.

Owner:KUNSHAN CITY YUSHAN TOWN SHILONG DESIGN STUDIO

New energy automobile power battery pack shell stamping device

InactiveCN113770221AIncrease punch pressureStamping fully efficientShaping toolsMetal-working feeding devicesPower batteryNew energy

The invention provides a new energy automobile power battery pack shell stamping device. The device comprises a supporting base, a special-shaped supporting frame, a mold supporting frame, a lower mold frame, grooving limiting plates and the like. The special-shaped supporting frame is fixedly connected to the top of the supporting base, the mold supporting frame is fixedly connected to the top of the special-shaped supporting frame, the lower mold frame is fixedly connected into the mold supporting frame, and the grooving limiting plates are fixedly connected to the left side and the right side of the mold supporting frame. In the stamping process, a push-out frame can move downwards, when stamping is completed, the push-out frame can move upwards and push out stamped new energy automobile power battery pack shells, an automatic demolding effect is achieved, other equipment can conveniently take out the new energy automobile power battery pack shells, the stamped new energy automobile power battery pack shells can be prevented from deforming, and the aim of automatically demolding the stamped new energy automobile power battery pack shells is achieved.

Owner:杭州巍枫减速机械有限公司

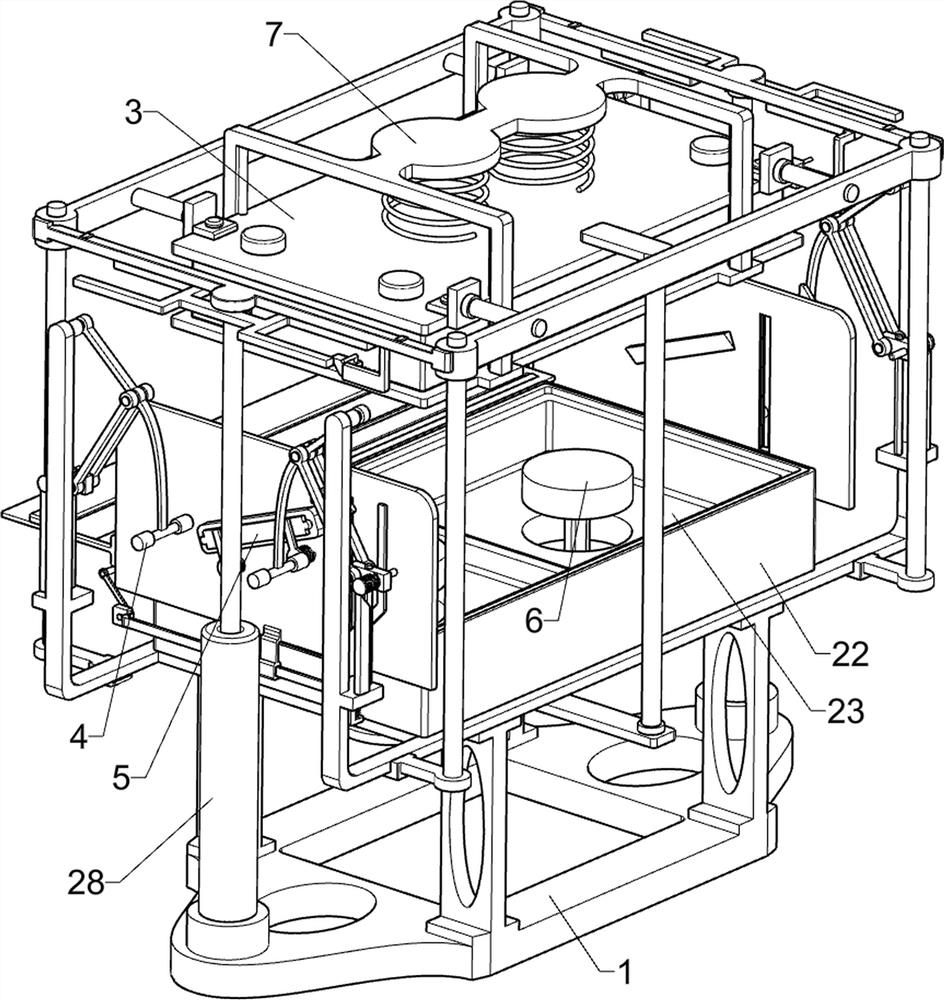

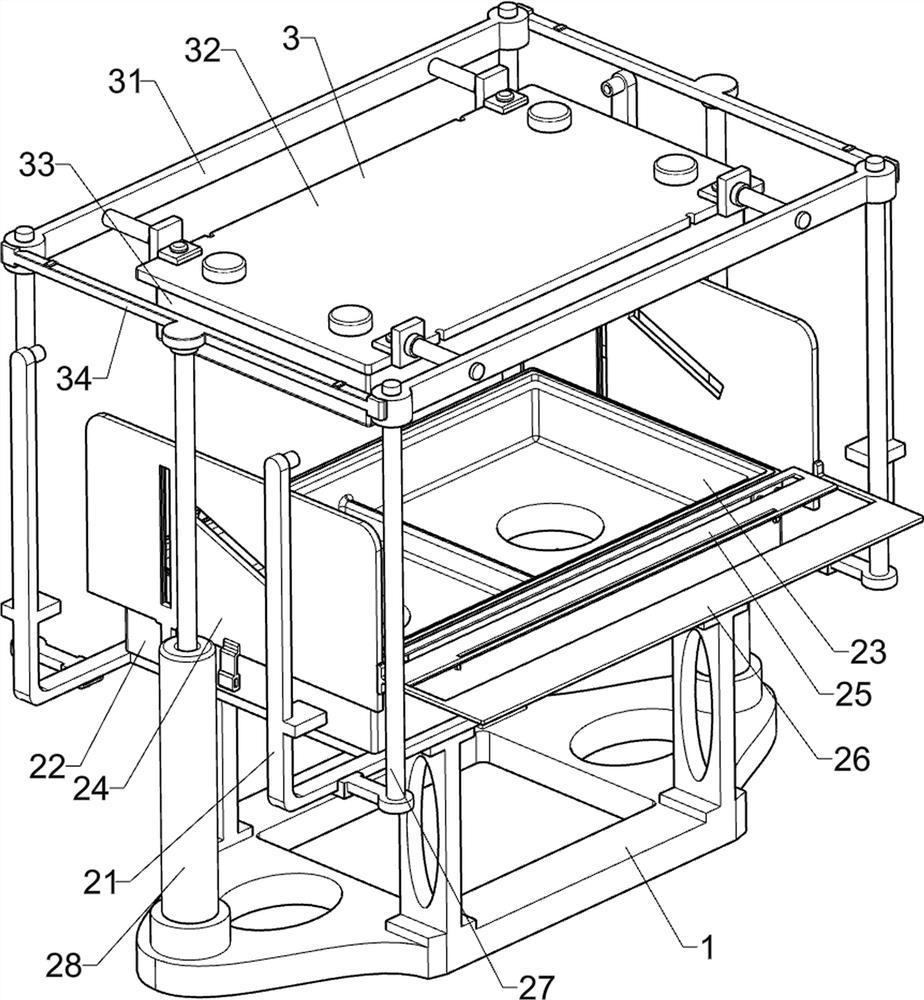

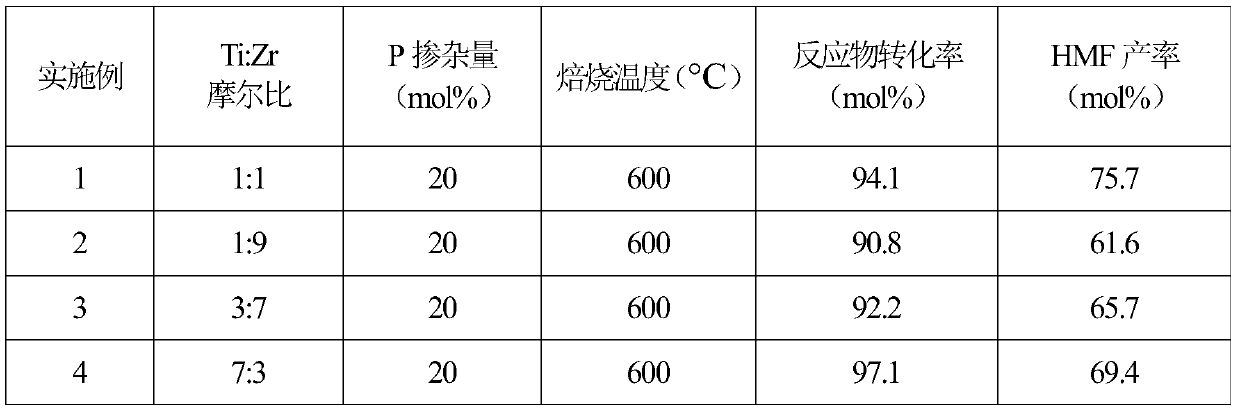

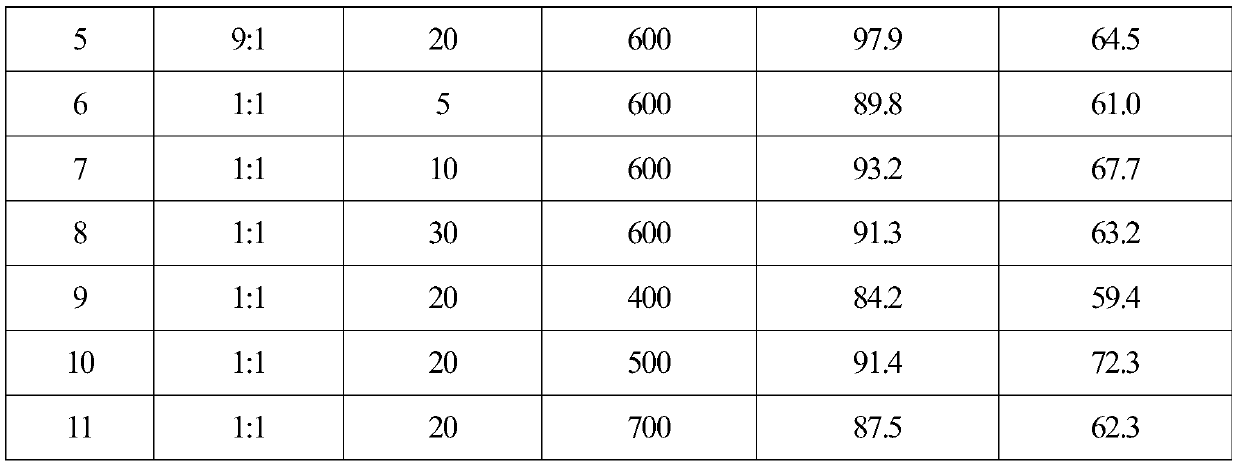

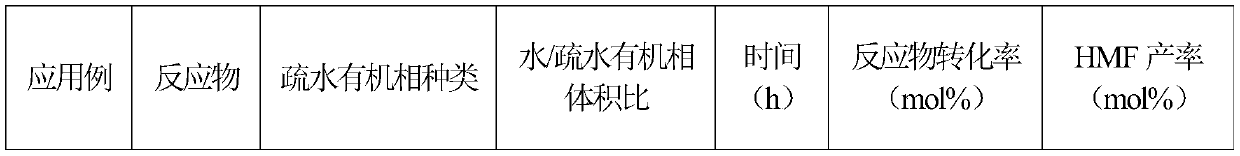

Method for preparing 5-hydroxymethylfurfural, catalyst thereof and preparation method of catalyst

InactiveCN111229264AImprove catalytic performanceNot easy to inactivateOrganic chemistryCatalyst activation/preparationChemical synthesisPtru catalyst

The invention relates to the field of chemical synthesis, and discloses a method for preparing 5-hydroxymethylfurfural, a catalyst thereof and a preparation method of the catalyst, the catalyst is a phosphorylated composite metal oxide, and the doping amount of phosphorus is 5-30% of the total mole number of metal elements in the catalyst; the composite metal oxide is a compound of titanium oxideand zirconium oxide; wherein the molar ratio of titanium to zirconium in the catalyst is 1: 9-9: 1. The catalyst is obtained by the following steps: dissolving titanium salt and zirconium salt, addingphosphoric acid, stirring to obtain gel and roasting. Under the condition of 150-200 DEG C, the catalyst is used for catalyzing carbohydrate in a two-phase solvent to generate 5-hydroxymethylfurfural, and under the catalytic action of the catalyst, high raw material conversion rate and HMF yield can be obtained. The catalyst has the advantages of simple preparation process, high dispersion degreeof each active component element, strong hydrothermal stability, no substantial reduction of the catalytic performance after repeated recycling, and extremely good economy and environmental protection property.

Owner:ZHEJIANG UNIV

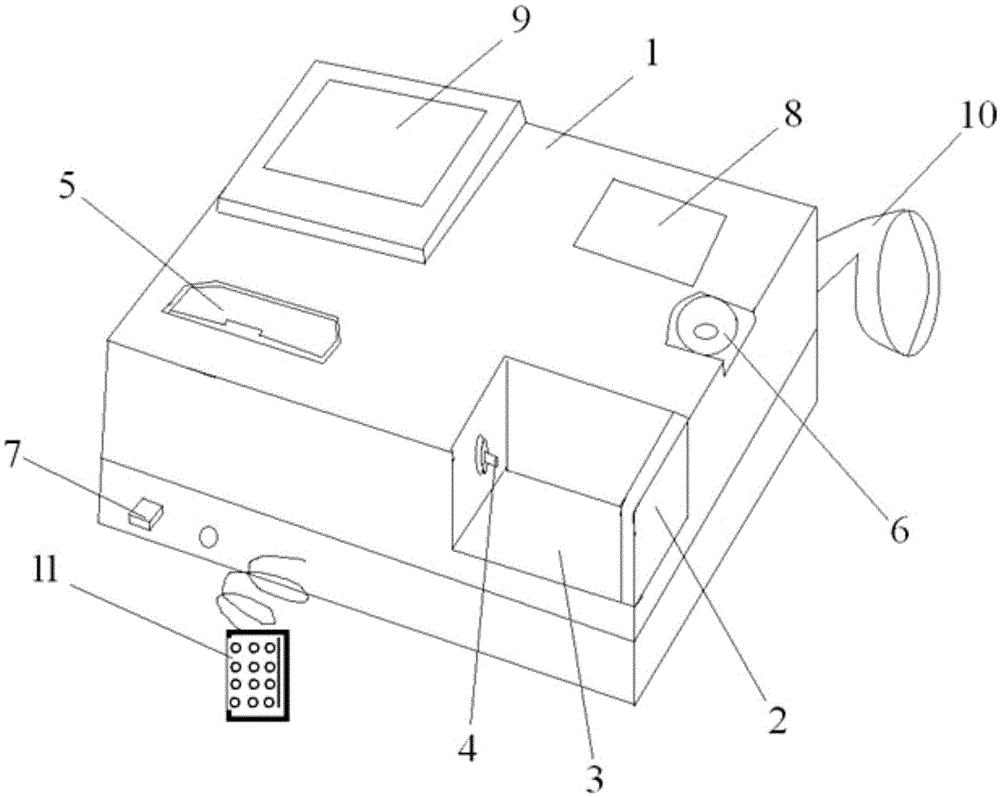

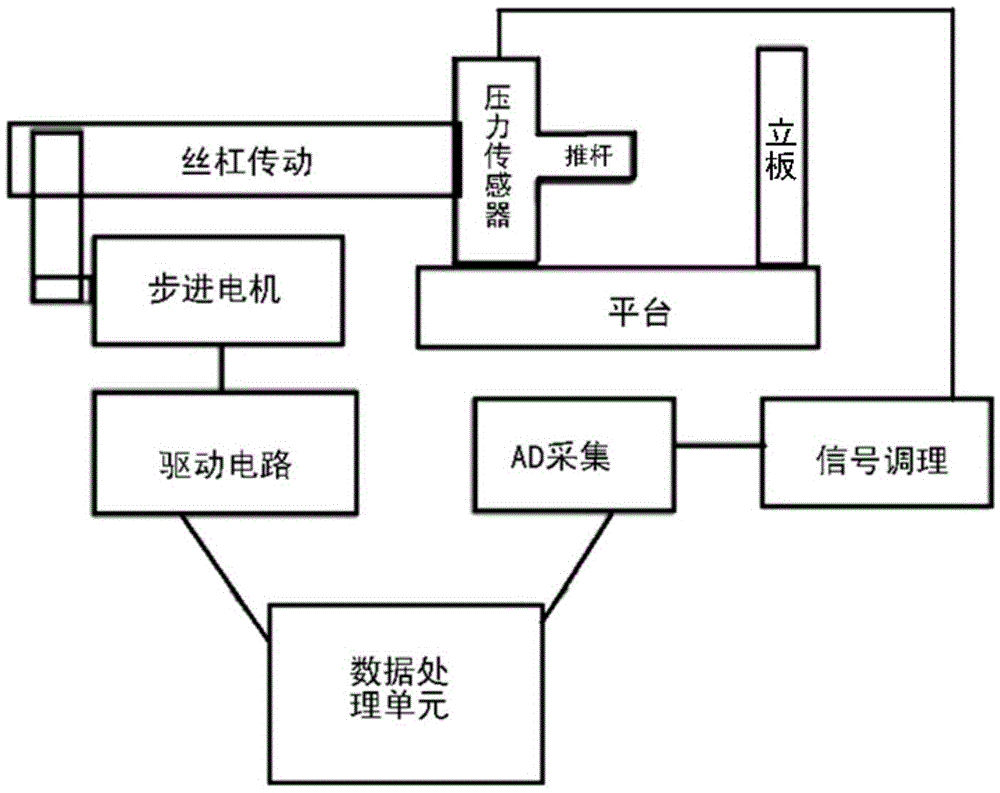

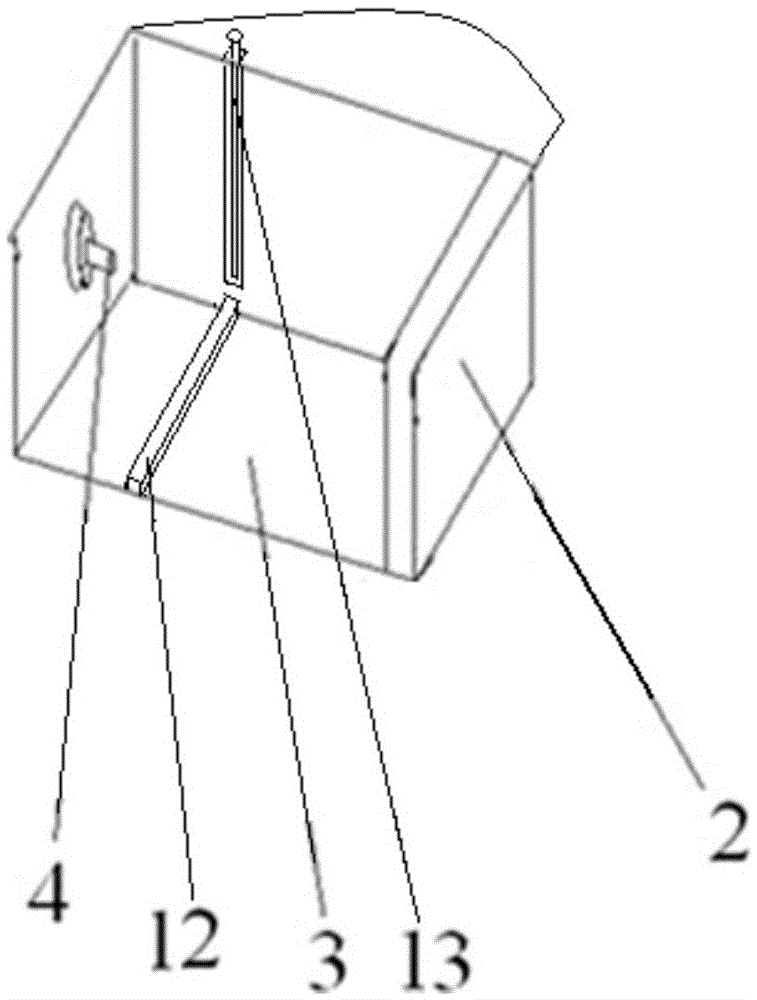

Fruit quality fast detector

The present invention provides a fruit quality fast detector including a housing, a fruit quality detection unit, a display and a central data processing unit, the display is arranged on the housing, the fruit quality detection unit includes a hardness testing module, the hardness testing module includes a fruit placement platform arranged on the housing and a vertical plate arranged on the fruit placement platform, the vertical plate is opposite to a pushing rod which is arranged on the housing and can stretch out and draw back along the horizontal direction, the pushing rod is provided with a pressure sensor, and the pressure sensor and the display are connected with the central data processing unit respectively. The hardness testing module is fast and easy to operate, short in detection time, and can effectively improve the detection efficiency.

Owner:XIAN VISION INFORMATION TECH CO LTD

Automatic film cutting and forming equipment

ActiveCN105345876AAutomatic separationGuaranteed machining accuracyMetal working apparatusTransfer mechanismEngineering

The invention relates to automatic film cutting and forming equipment which comprises a rack, wherein an unfolding mechanism, a heating mechanism, a cutting mechanism, a material receiving mechanism and a transferring mechanism are orderly arranged on the rack; the unfolding mechanism is used for unfolding a volumed film, and the heating mechanism is used for heating the unfolded film; the cutting mechanism is used for cutting the heated film to the required shape, and the material receiving mechanism is used for collecting the cut finished product; the transferring mechanism is used for transferring the film among the unfolding mechanism, the heating mechanism, the cutting mechanism and the material receiving mechanism; the material receiving mechanism comprises a waste receiving mechanism and a finished product receiving mechanism which are vertically arranged; the waste receiving mechanism comprises a waste roller and a waste rotating component for driving the waste roller to rotate, and the waste receiving mechanism further comprises a conveying belt component, a clamping roller and a material receiving frame; the conveying belt component is positioned at the tail end of the cutting mechanism, the clamping roller is rotationally arranged above the conveying belt component, and the material receiving frame is positioned at the tail end of the conveying belt component. According to the scheme, the invention provides the automatic film cutting and forming equipment with multi-step continuous processing.

Owner:ZHEJIANG HANGAO MACHINERY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com