Flapping type sunflower seed taking-out device

A technology for taking out devices and sunflower seeds, which is applied in threshing equipment, applications, agricultural machinery and tools, etc., can solve the problems of uneven beating and sunflower seeds being taken out in batches, achieve good stress points, high work efficiency, and avoid wandering around splash effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

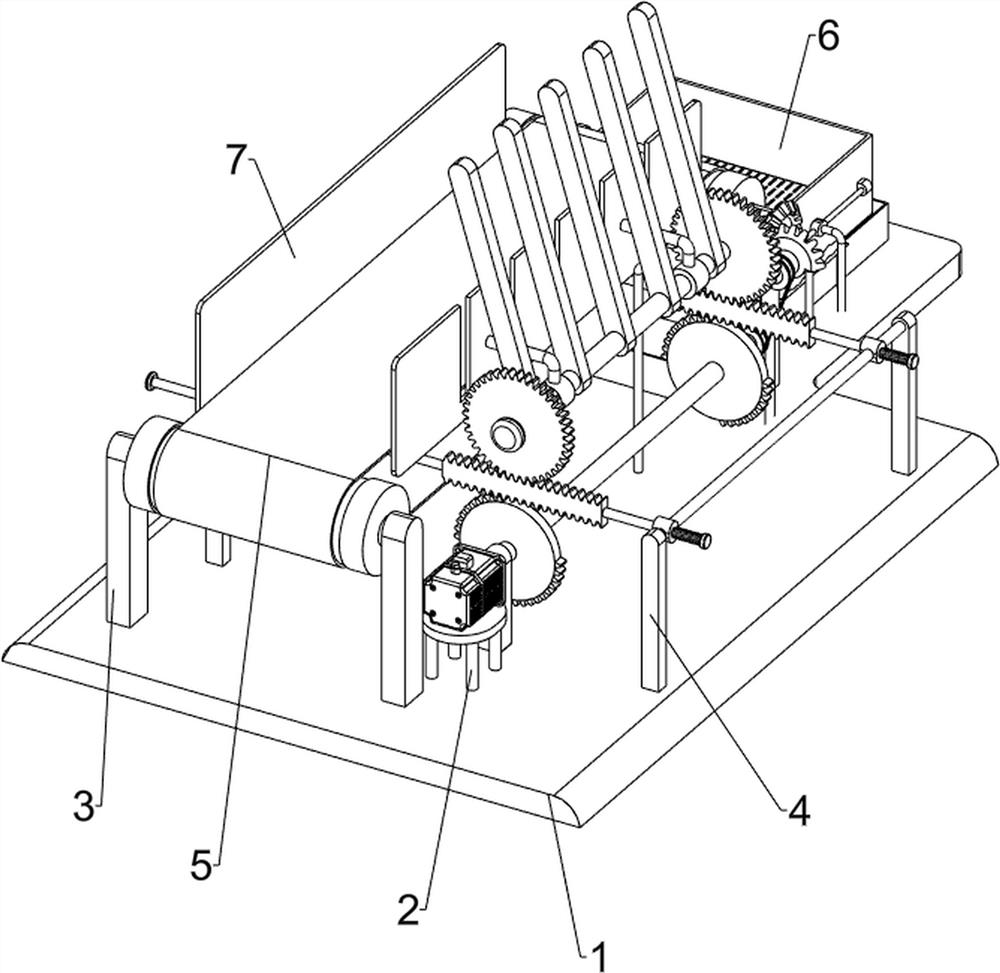

[0051] A flapping sunflower seed removal device, such as figure 1 As shown, it includes a base 1, a mounting base 2, a first bracket 3, a beating mechanism 4 and a transmission mechanism 5. The front side of the top of the base 1 is provided with a mounting base 2, and the left and right sides of the top of the base 1 are all first brackets 3. , the top right side of the base 1 is provided with a beating mechanism 4, and a transmission mechanism 5 is connected between the first brackets 3.

[0052] When the sunflower seeds in the sunflower need to be taken out, the staff can put the sunflower on the parts of the transmission mechanism 5, then start the beating mechanism 4 to work, and the beating mechanism 4 works to pat the sunflower, the sunflower seeds are taken out, and the beating mechanism 4 works Drive transmission mechanism 5 to work simultaneously, and transmission mechanism 5 work drives sunflower to move, and pats more evenly, and sunflower seed can be taken out, an...

Embodiment 2

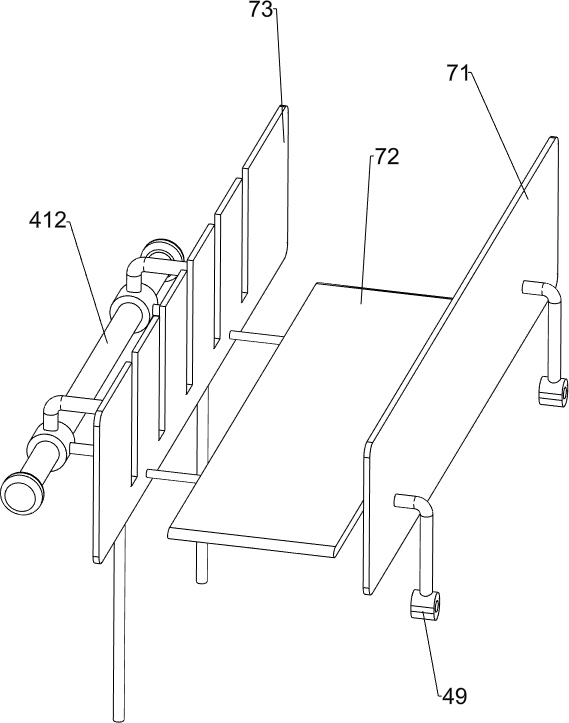

[0054] On the basis of Example 1, such as figure 2 As shown, the beating mechanism 4 includes a support frame 41, a connecting rod 42, a rack bar 43, a spring 44, a first missing tooth gear 45, a second support 46, a motor 47, a first rotating shaft 48, a first sliding sleeve 49, Beating bar 410, full gear 411 and second rotating shaft 412, base 1 top left and right sides all are provided with support frame 41 front and back symmetrically, all are connected with connecting rod 42 between front and rear support frame 41 on the same side, and connecting rod 42 front and rear sides A first sliding sleeve 49 is provided, and a rack bar 43 is connected between the first sliding sleeves 49 on the left and right sides, and a spring 44 is connected between the right end of the first sliding sleeve 49 on the right side and the right side of the rack bar 43, The top of the mounting base 2 is provided with a motor 47, and the base 1 is provided with a second bracket 46 at the front and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com