Patents

Literature

54results about "Injection-based meat tenderising" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

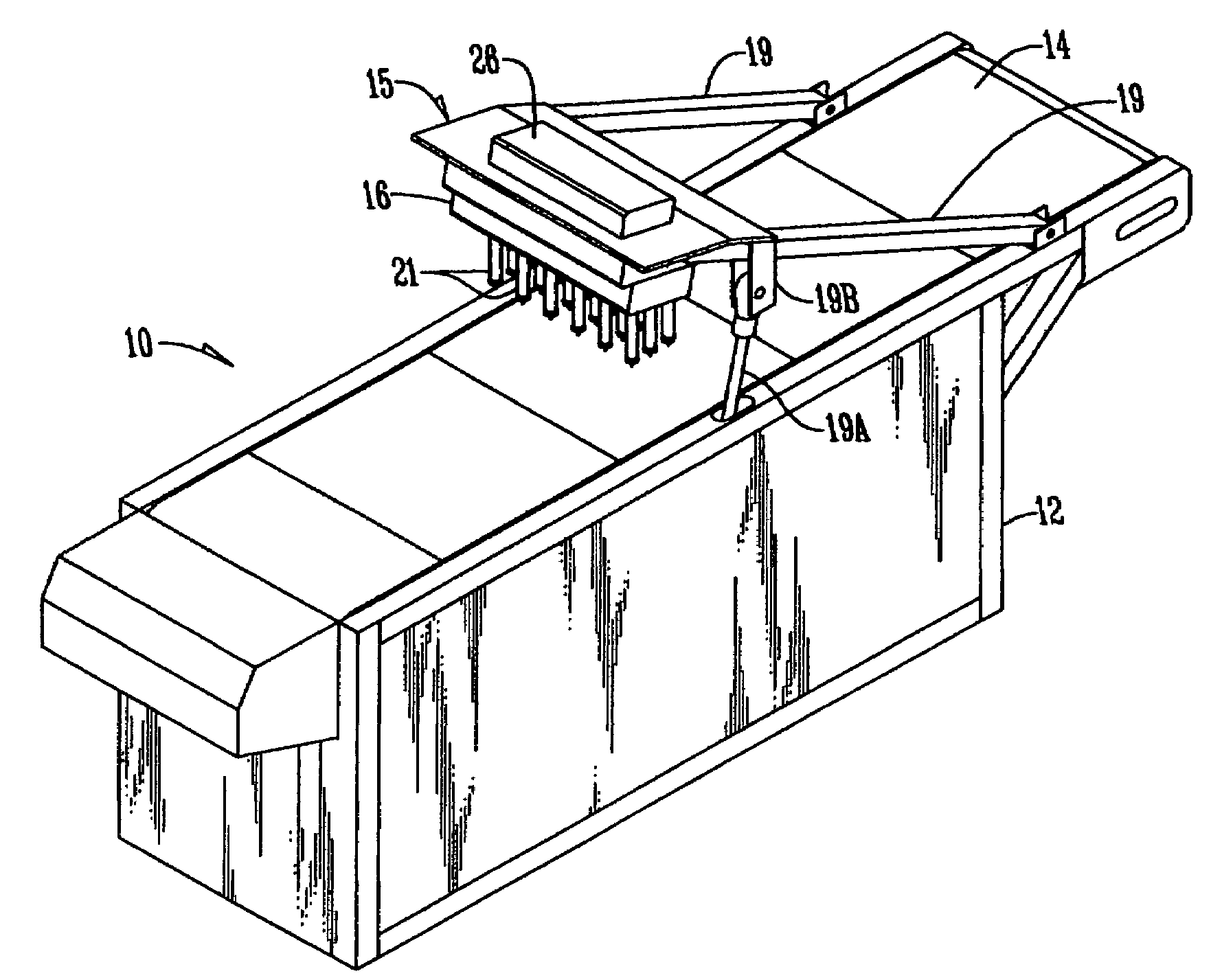

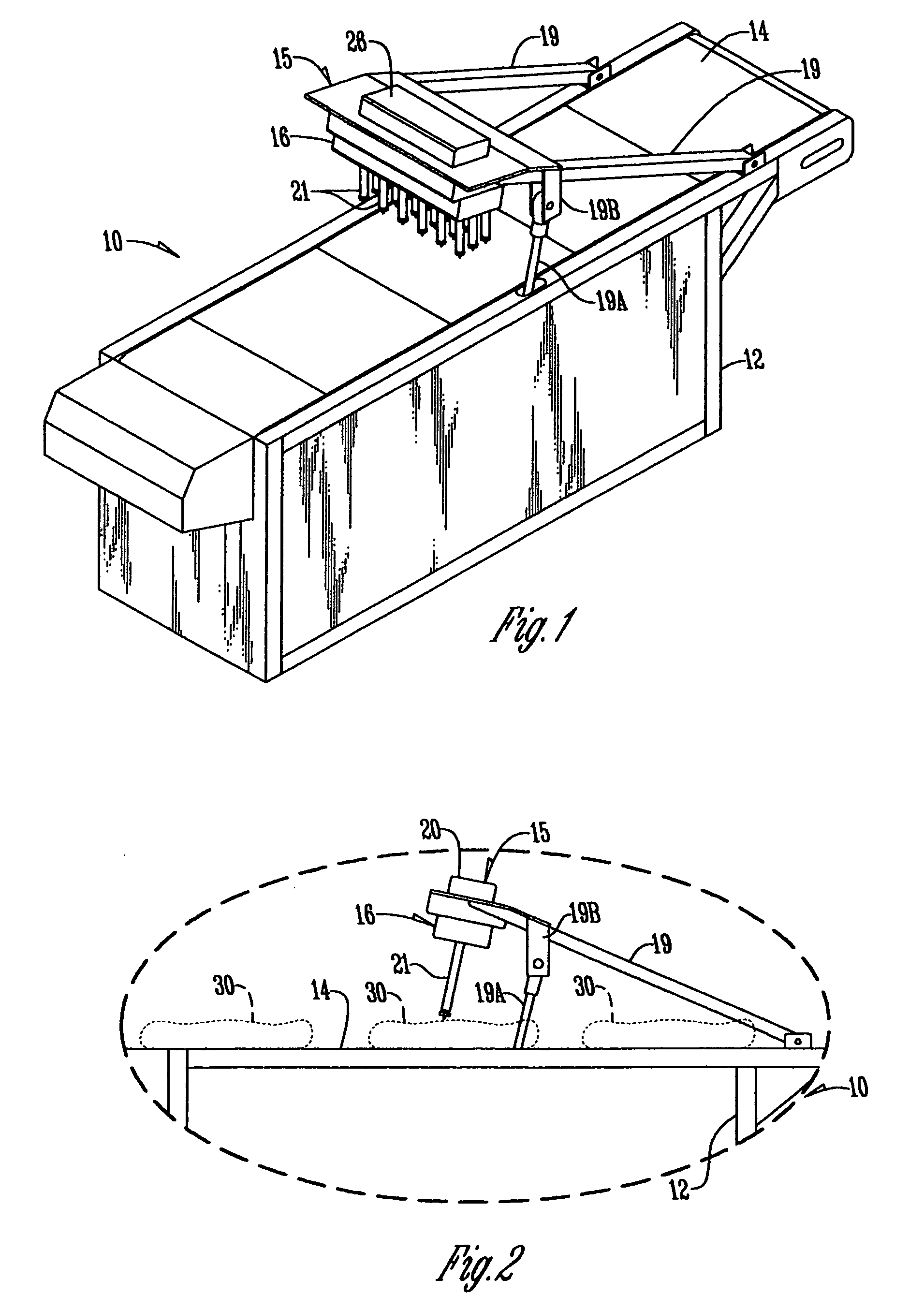

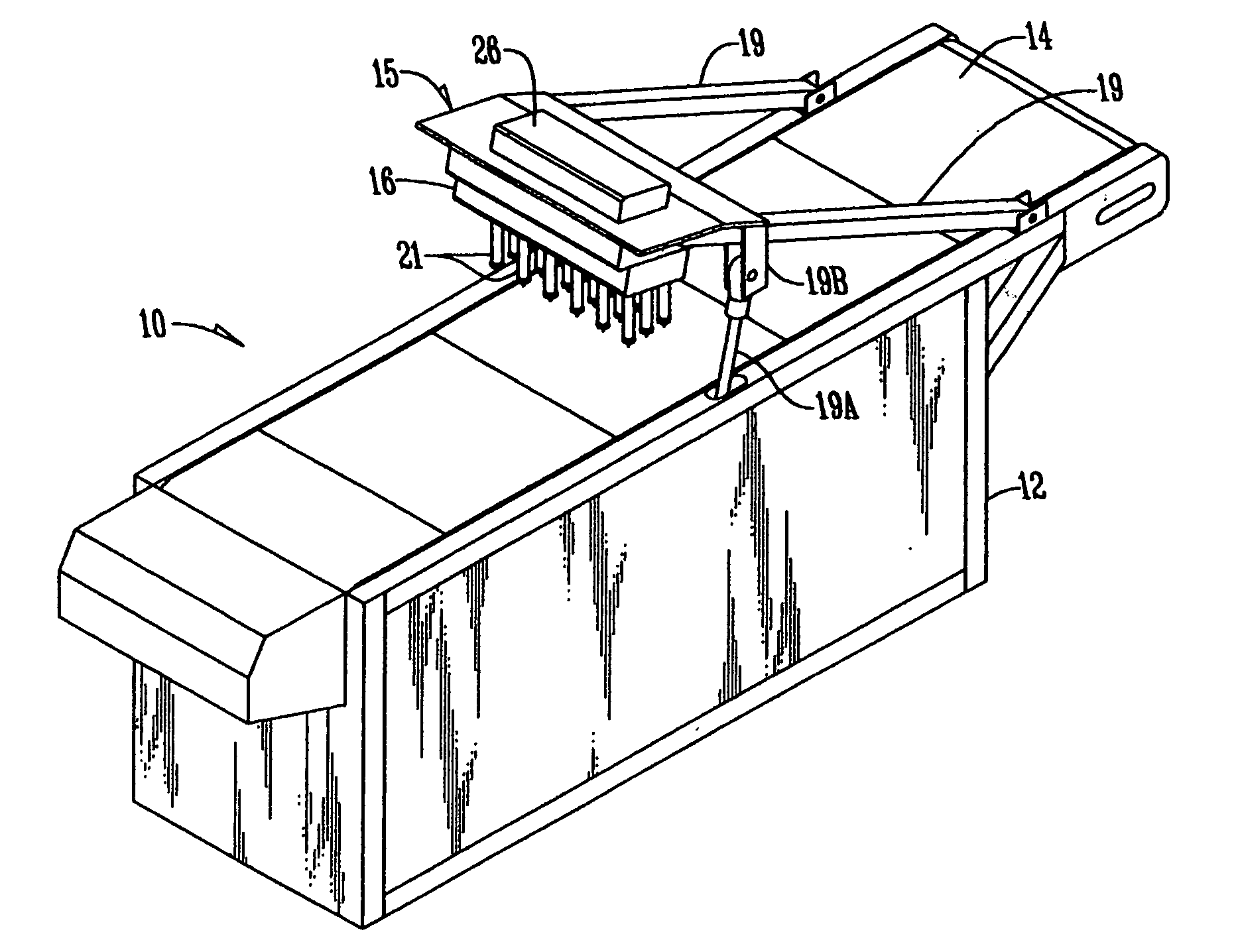

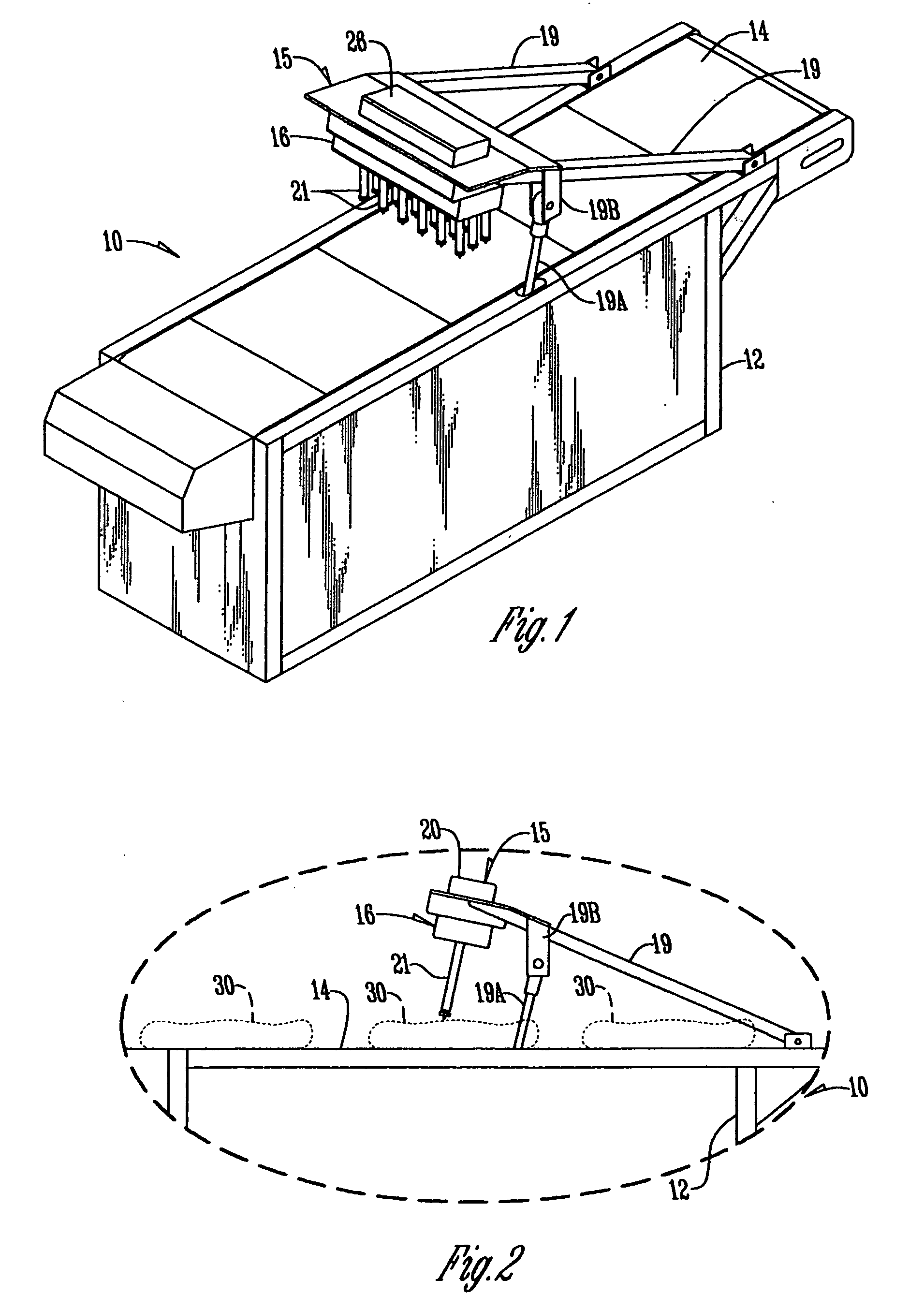

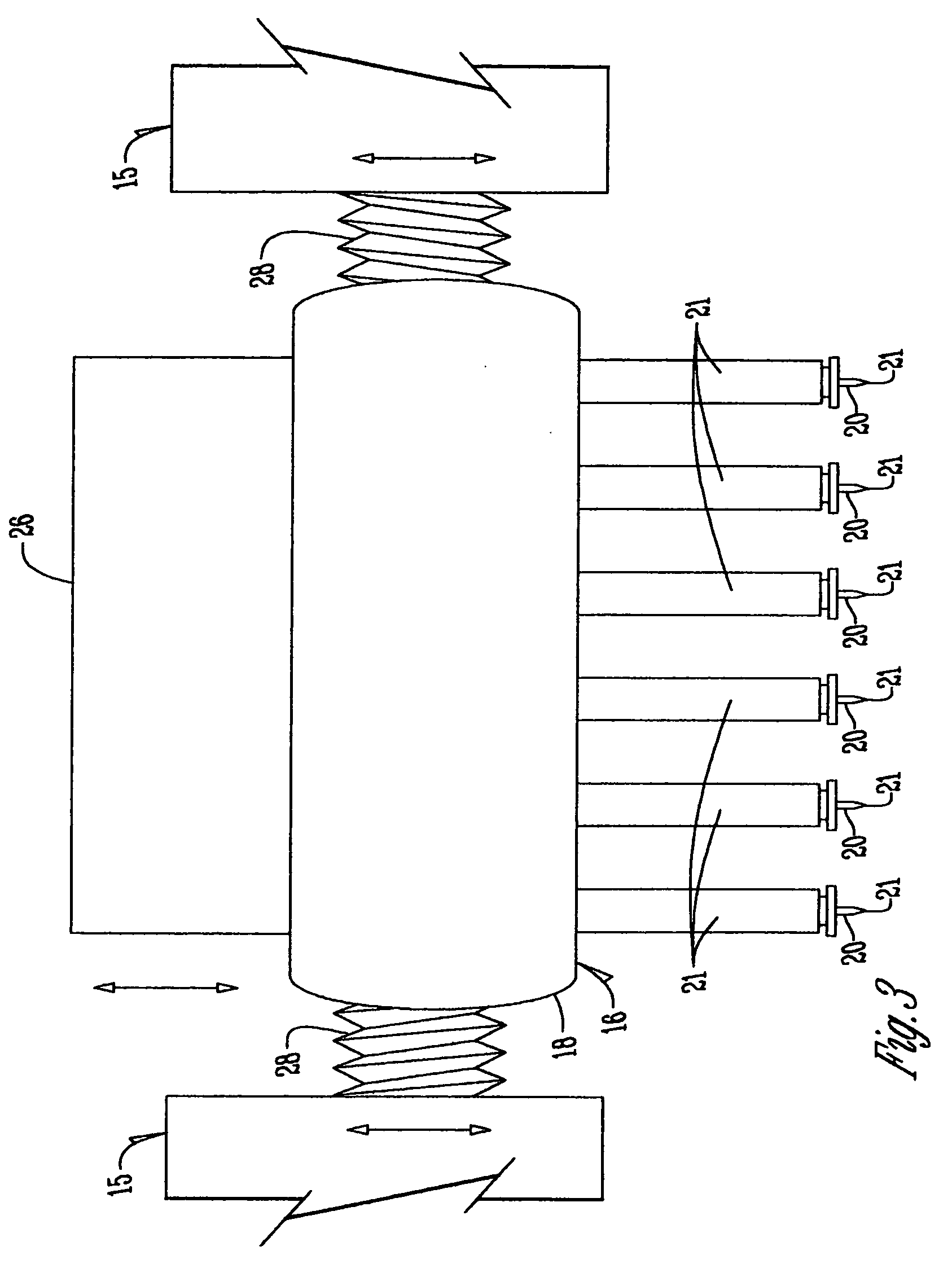

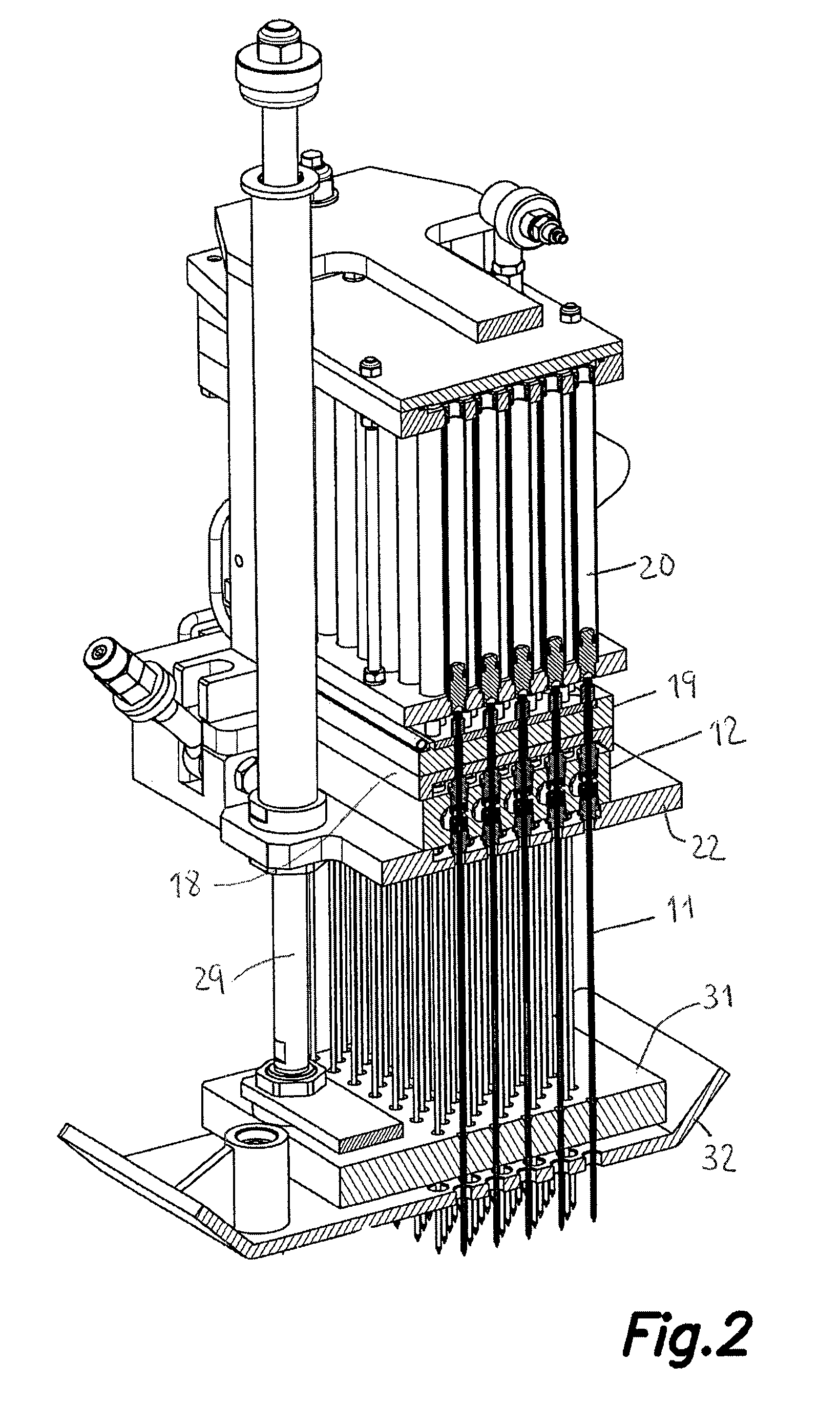

Apparatus for injecting fluid into meat products

InactiveUS7302885B2Easy to disperseIncrease in sizeGrain huskingGrain polishingSyringe needleBiomedical engineering

A method for injecting fluid into meat products comprises taking a plurality of hollow fluid injection needles having sharpened discharge ends, and connecting the needles to a source of pressurized liquid; penetrating the sharpened ends of the needles into the product and thence withdrawing the same while discharging fluid into the product and vibrating the needles for a period of time while they are within the product to enlarge the size of a penetration hole within the product caused by the penetration of the needles to a size greater than the size of the needles to create at least a partial space around the needles to permit fluid from the needles to migrate into the spaces around the needles. The needles have a roughened outside surface.

Owner:STORK TOWNSEND BV

Adding an additive to a meat product

Owner:MAREL STORK POULTRY PROCESSING

Needleless injection device and method of injecting

InactiveUS20080044526A1Enhance market appealBroad possible marketJet injection syringesInjection based meat processingFood additiveNeedle Free Injection

A needleless injection device and method for injecting a food subject is disclosed in which one or more types of liquid food additive are individually and / or simultaneously delivered to a food subject within a sealed injection chamber or compartment. The needleless injection device and method of the present invention utilizes rapid, high pressure injection bursts to completely and uniformly inject the food subject, allowing different food subjects or different food additives to be sequentially injected in an efficient and instant manner. The needleless injection device and method for injecting minimizes contamination by totally enclosing the injection process within a sealed chamber, and by eliminating the need for the injection nozzles to contact, or be placed immediately adjacent to the food subject.

Owner:HANSEN CONLY L +1

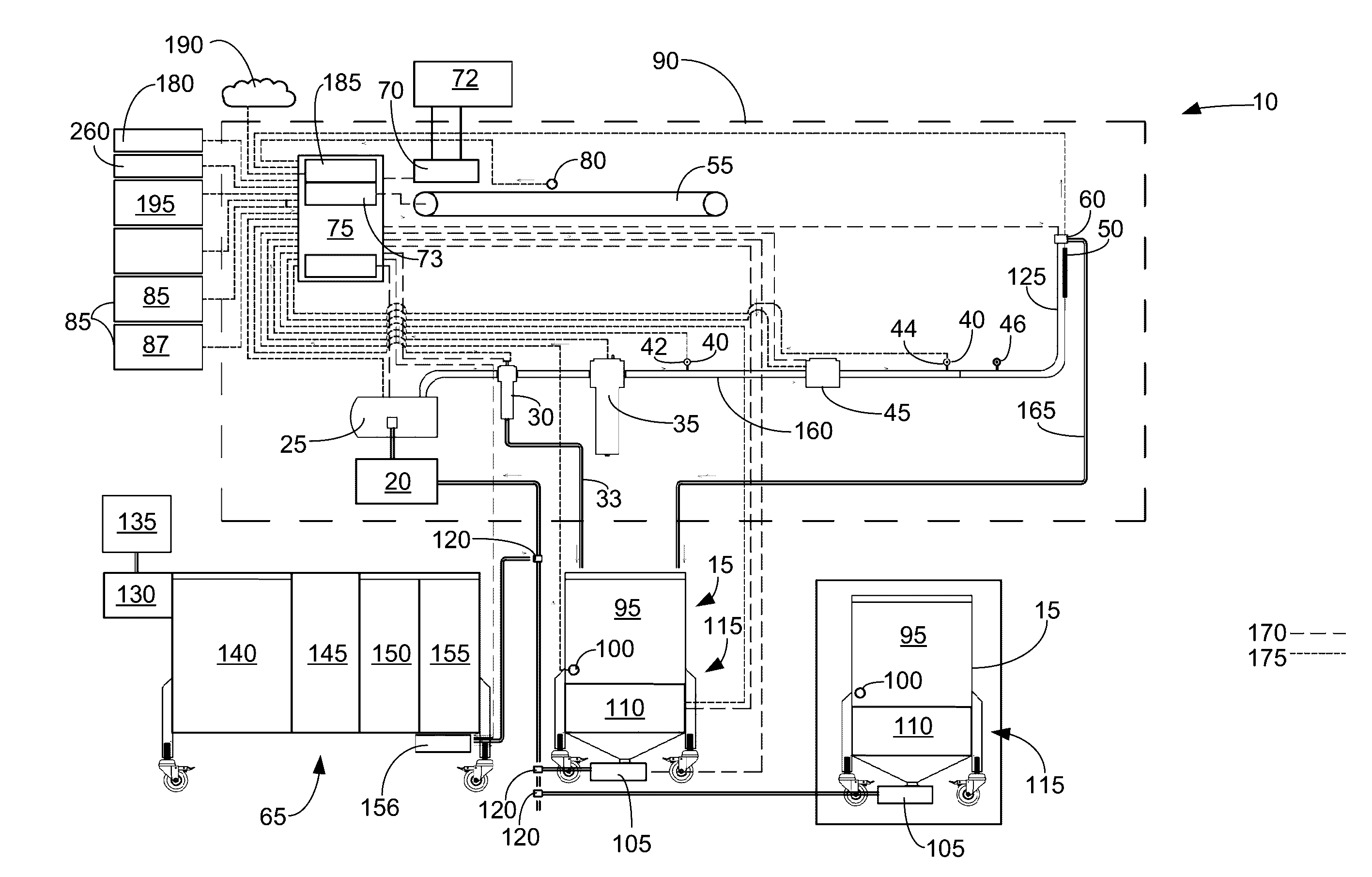

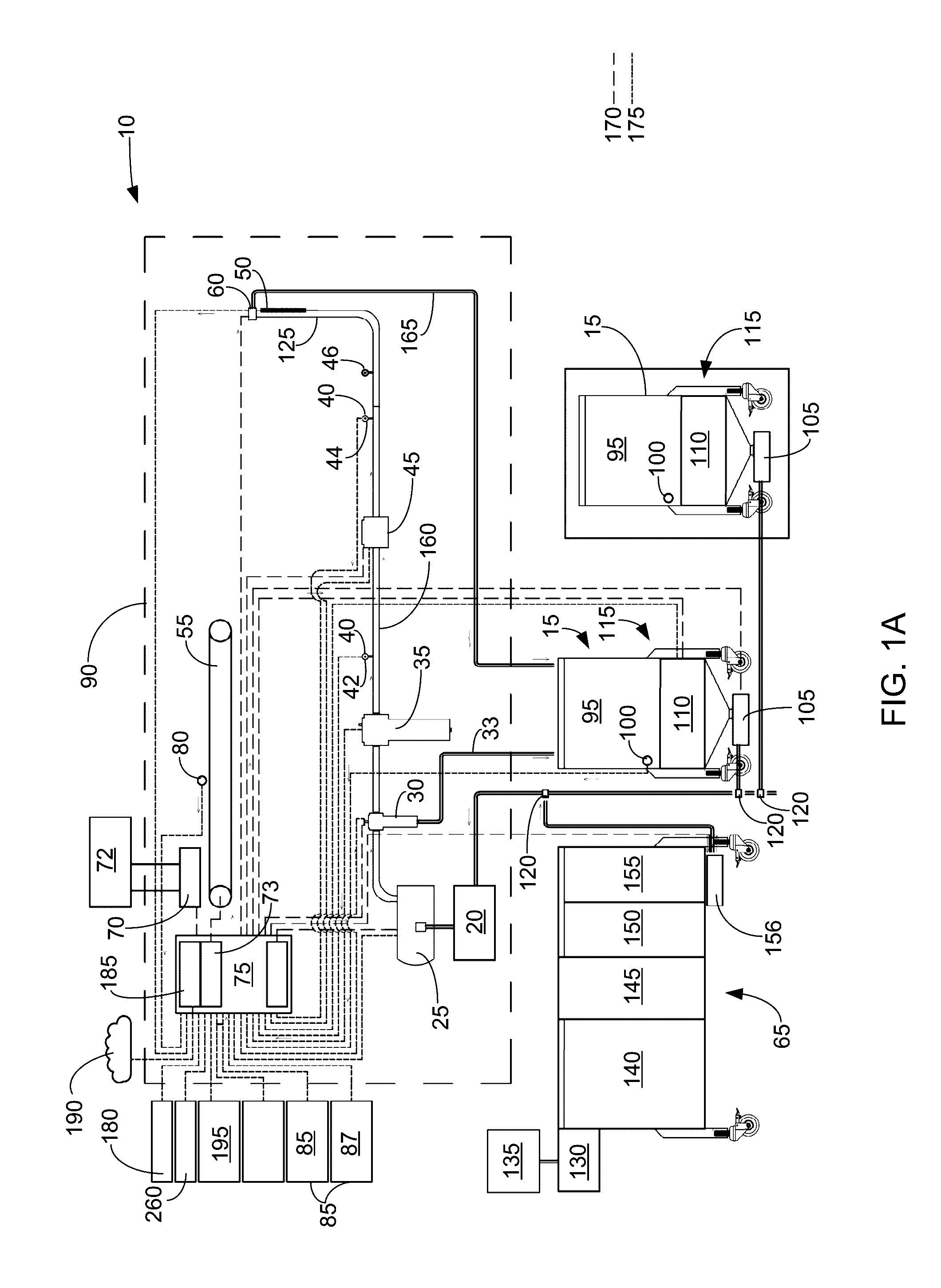

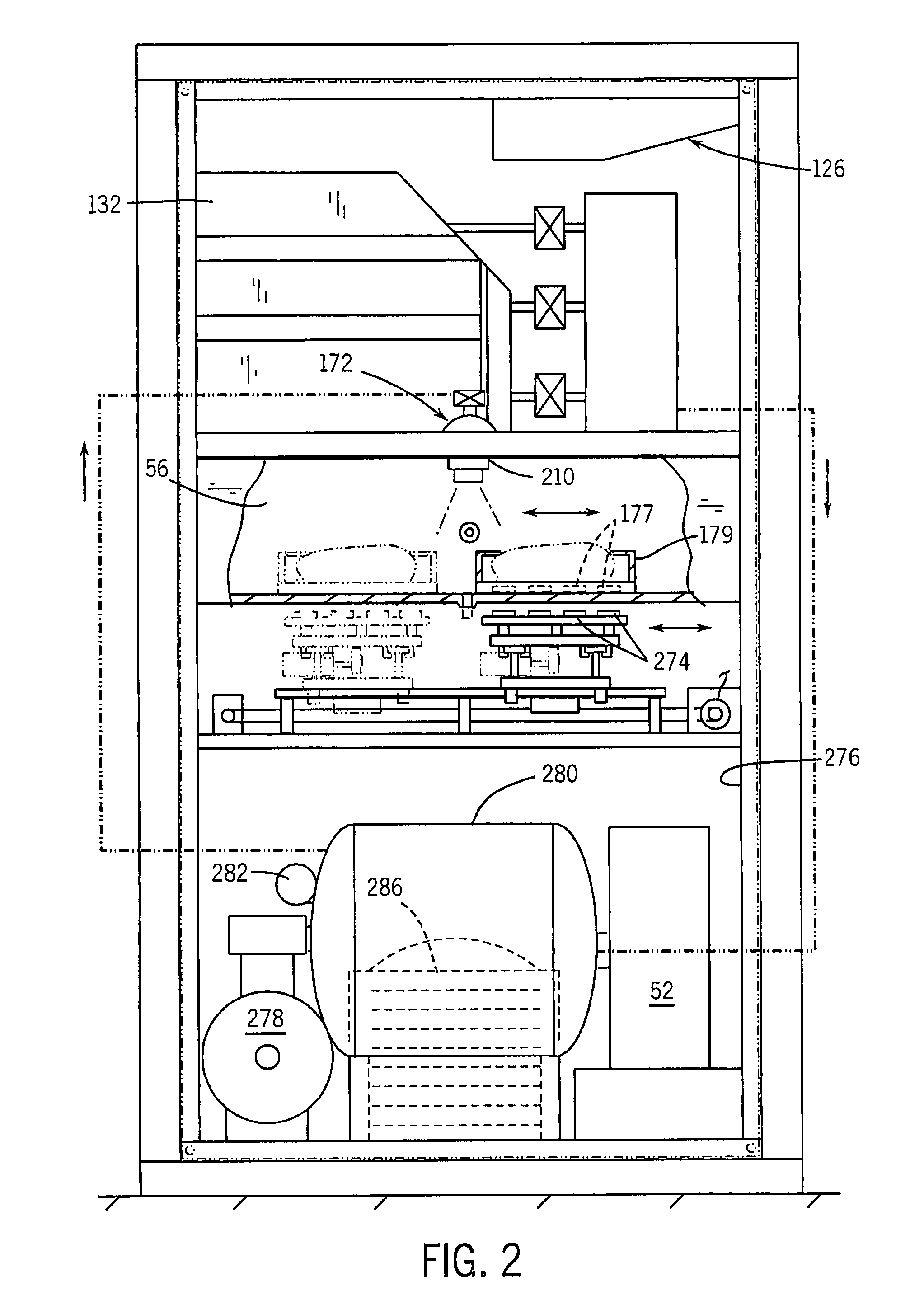

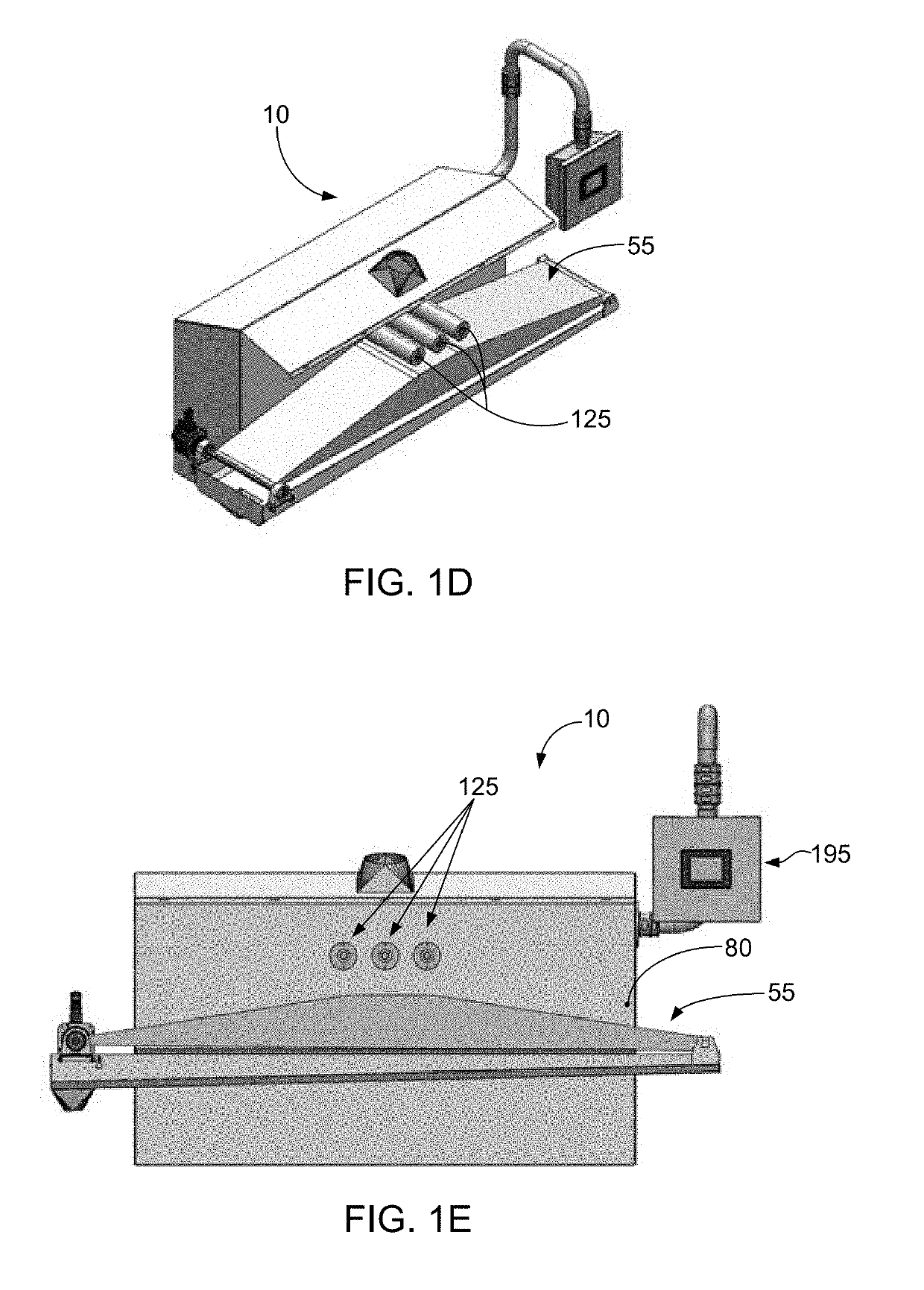

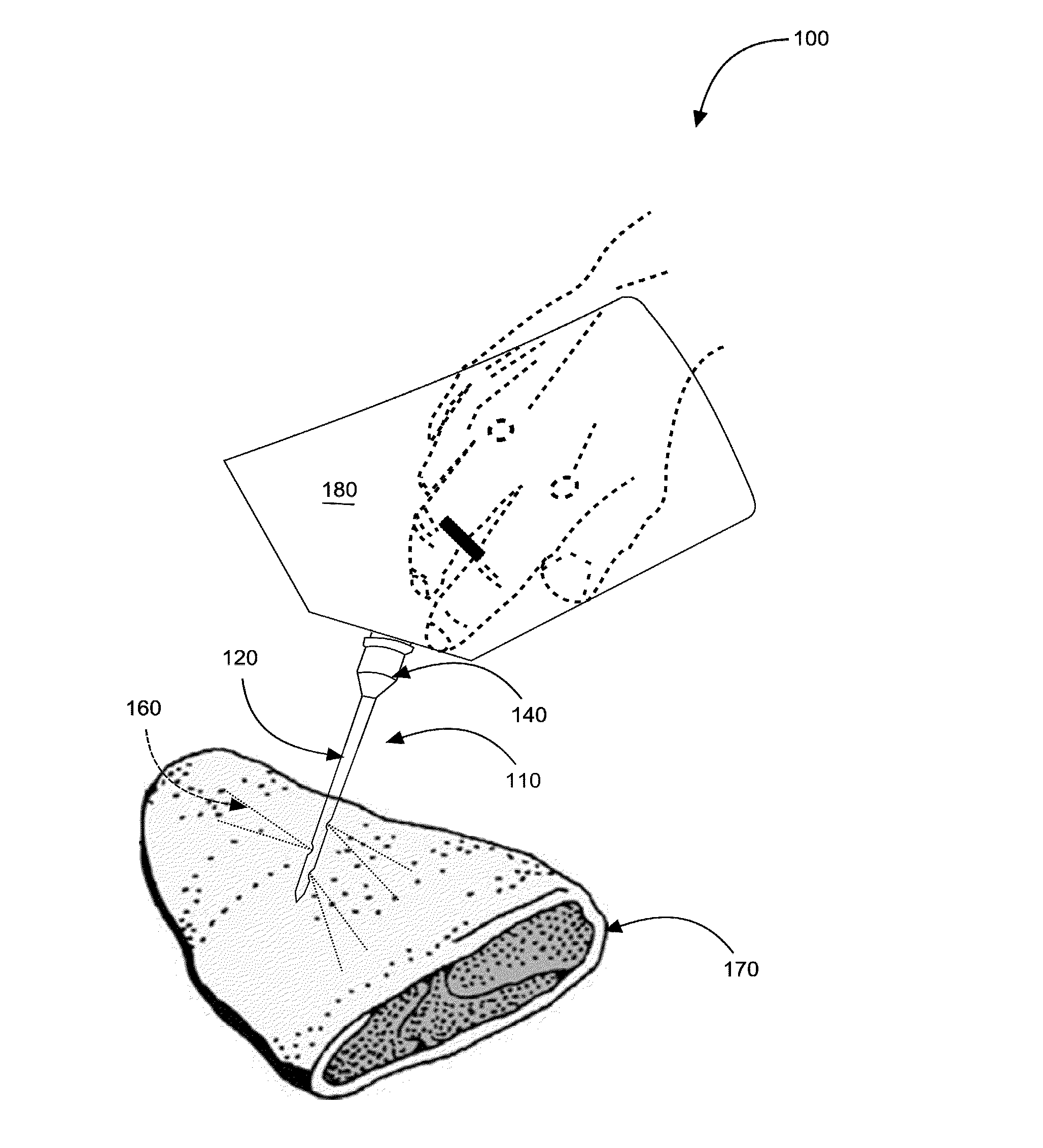

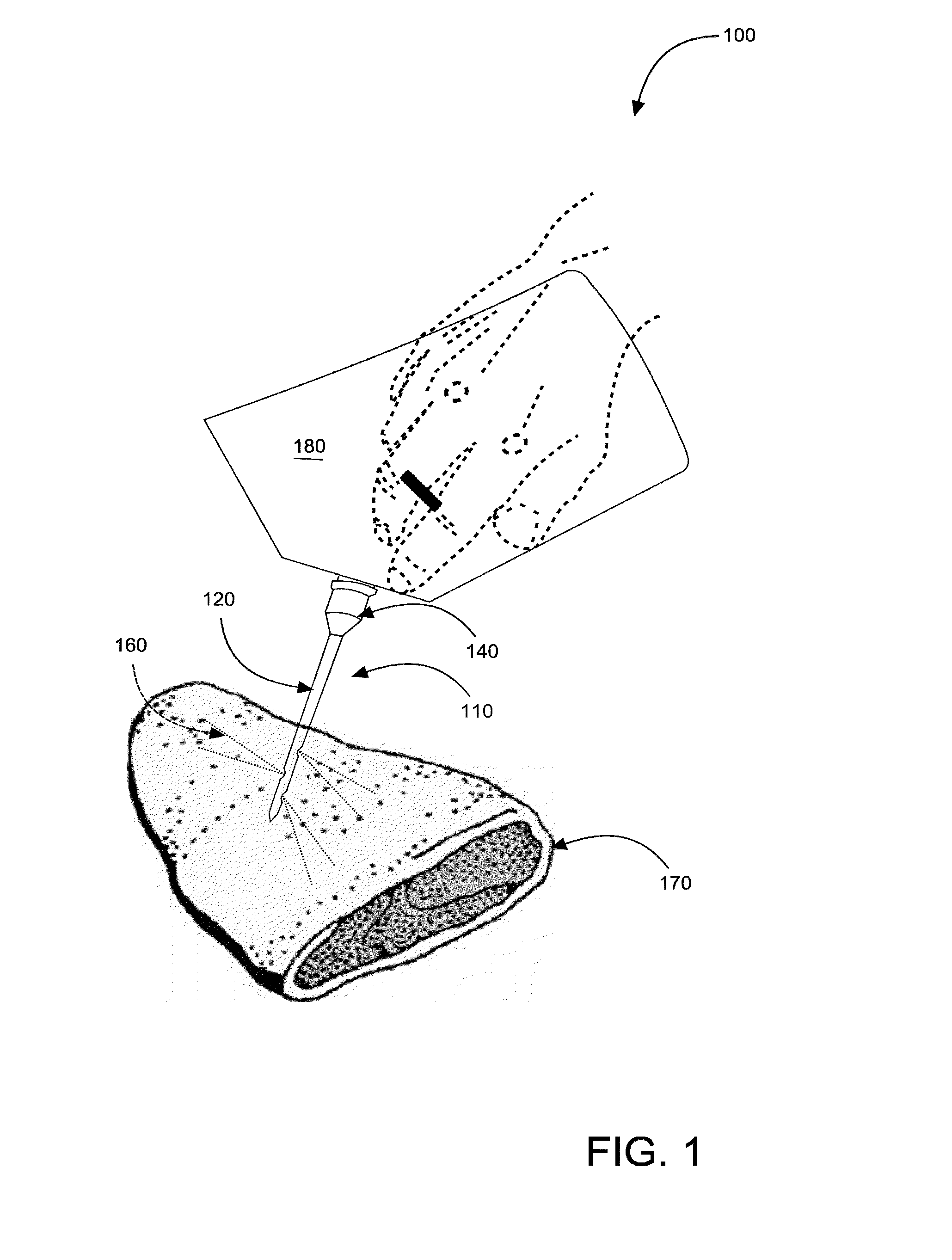

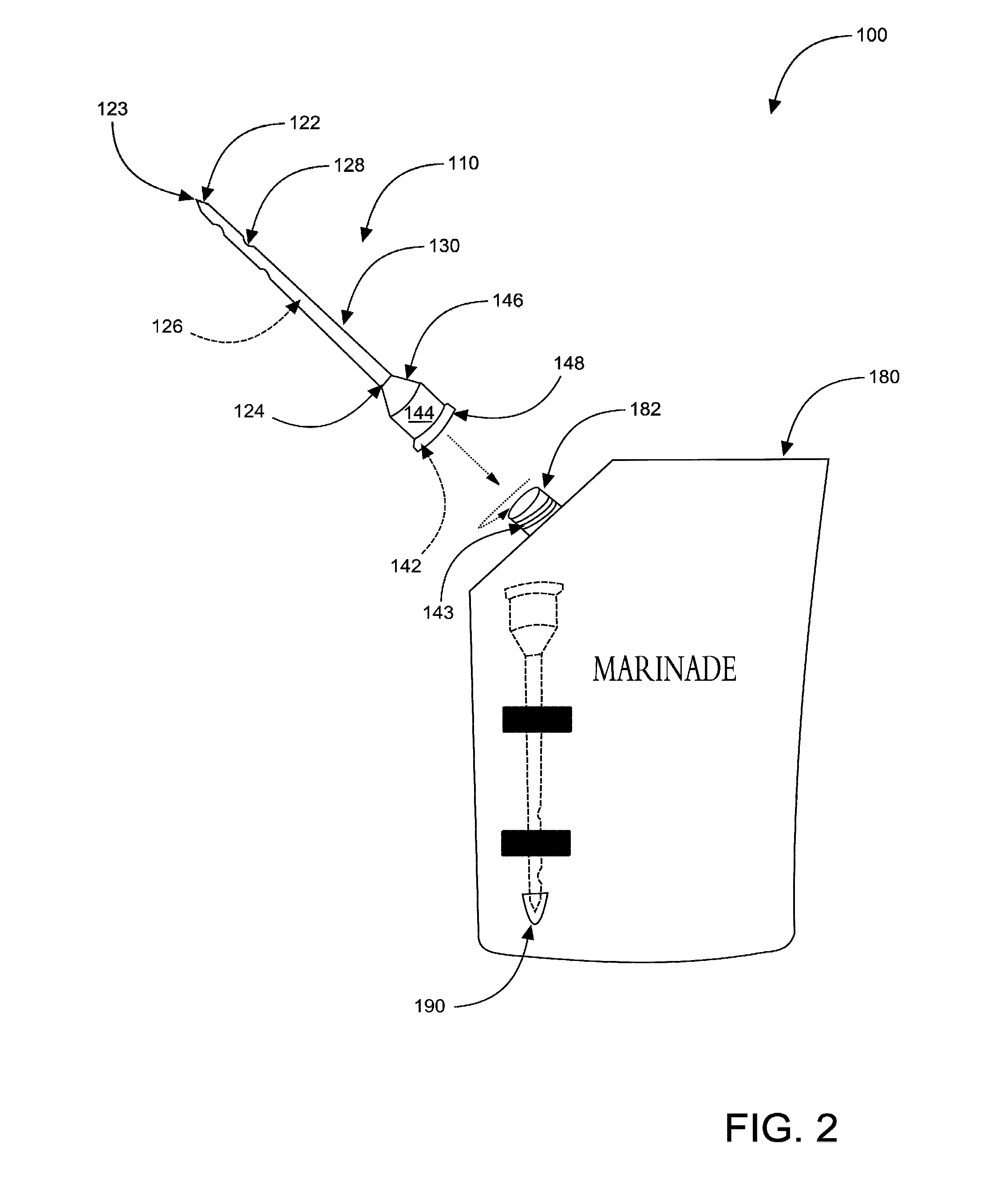

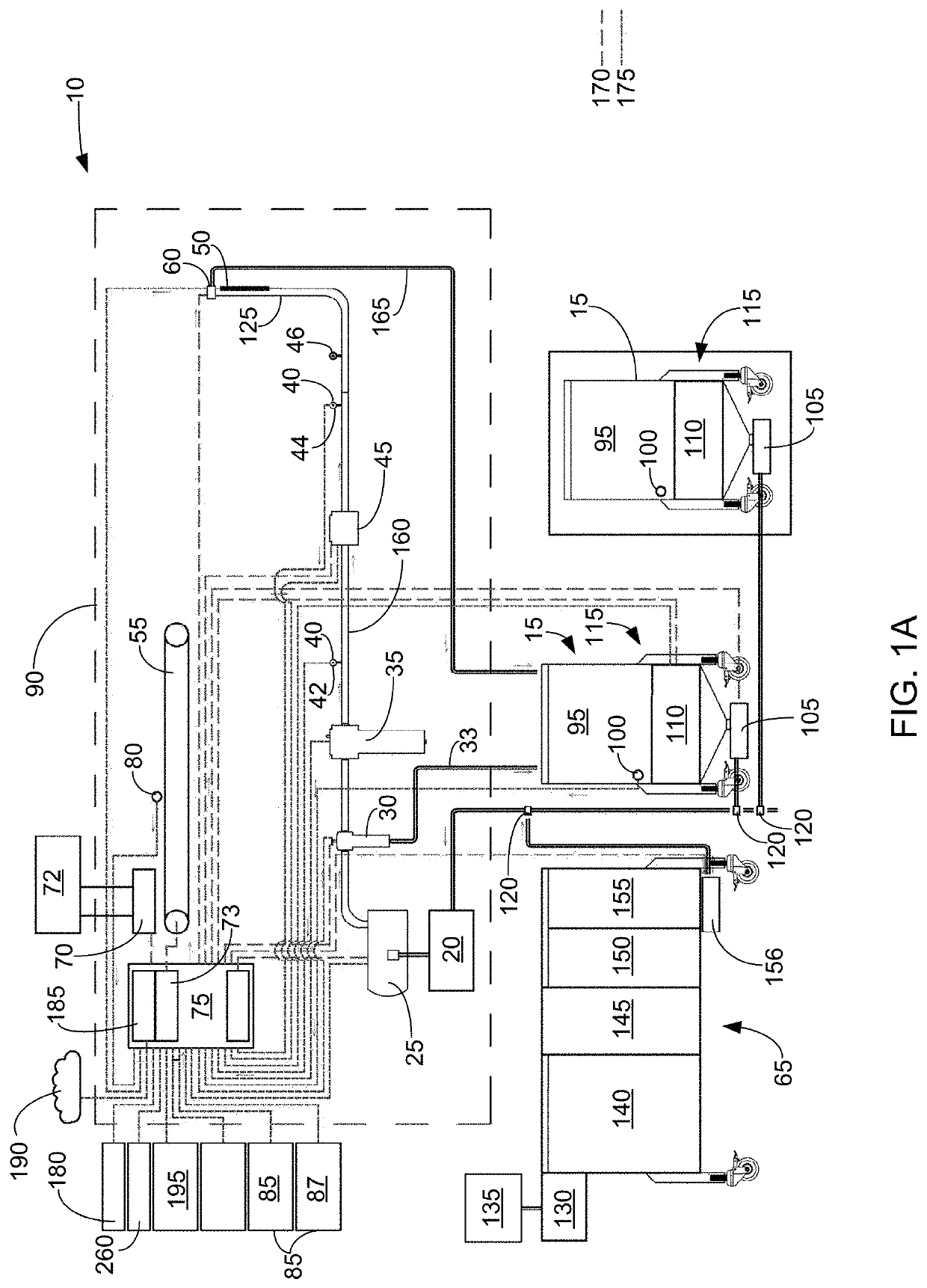

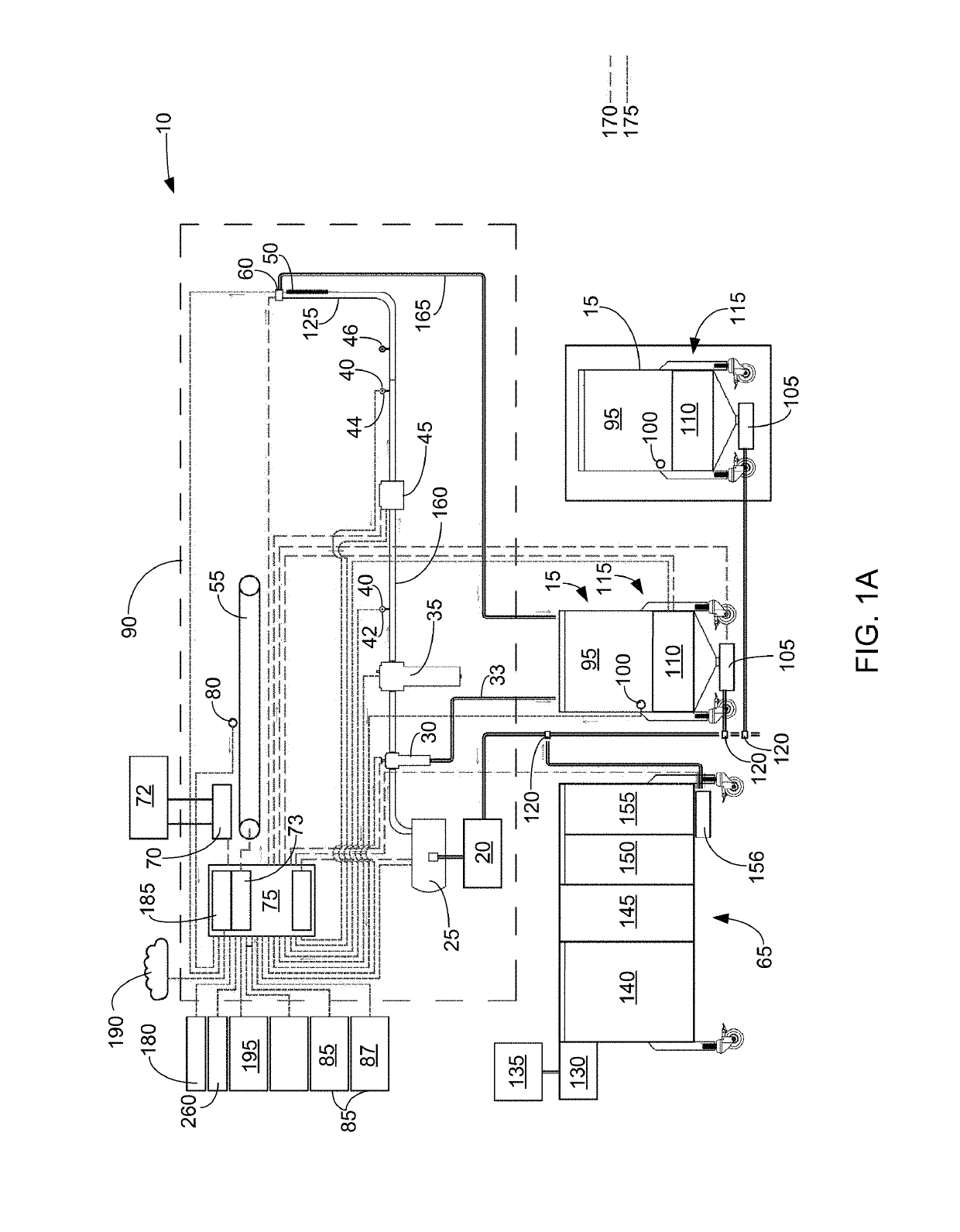

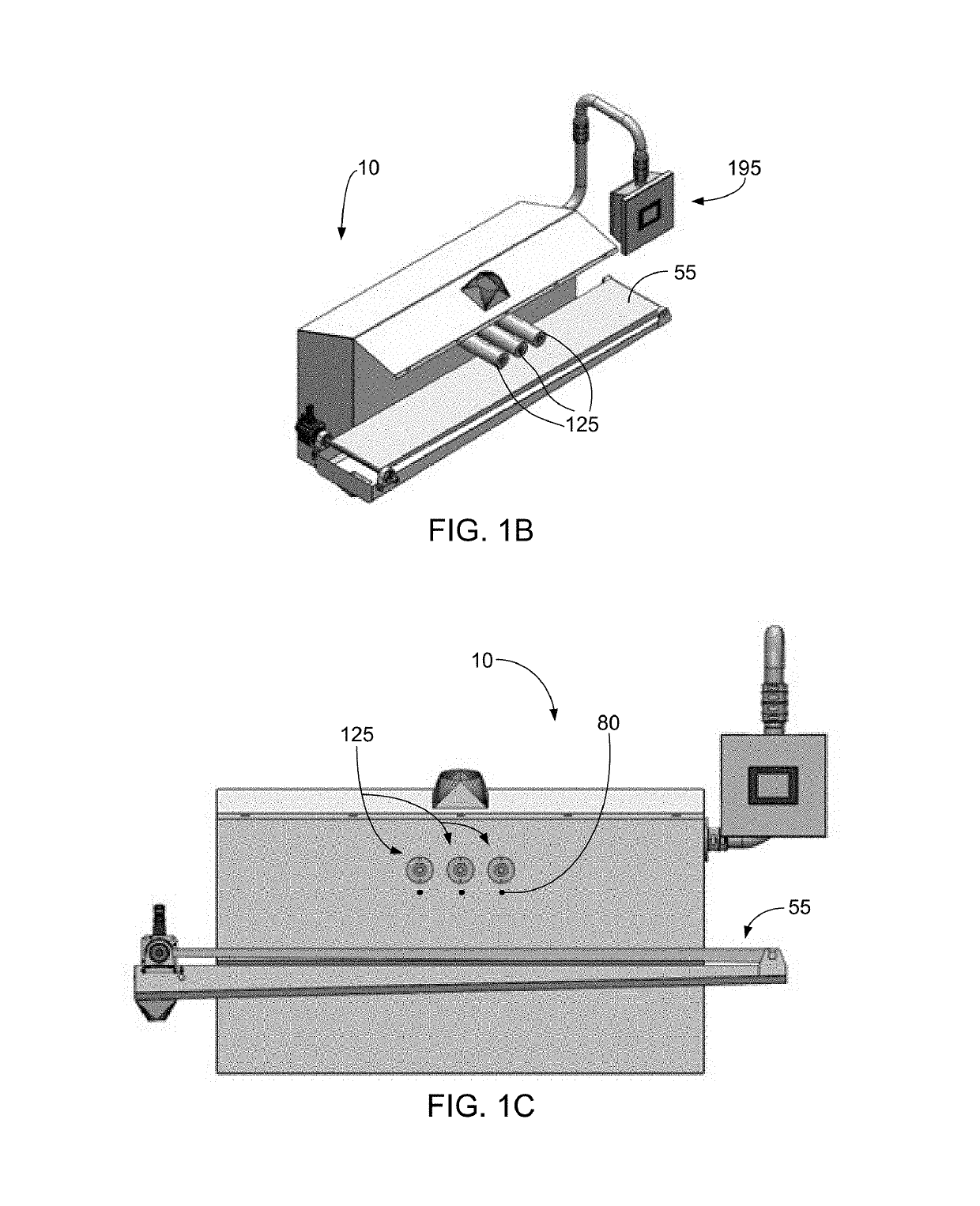

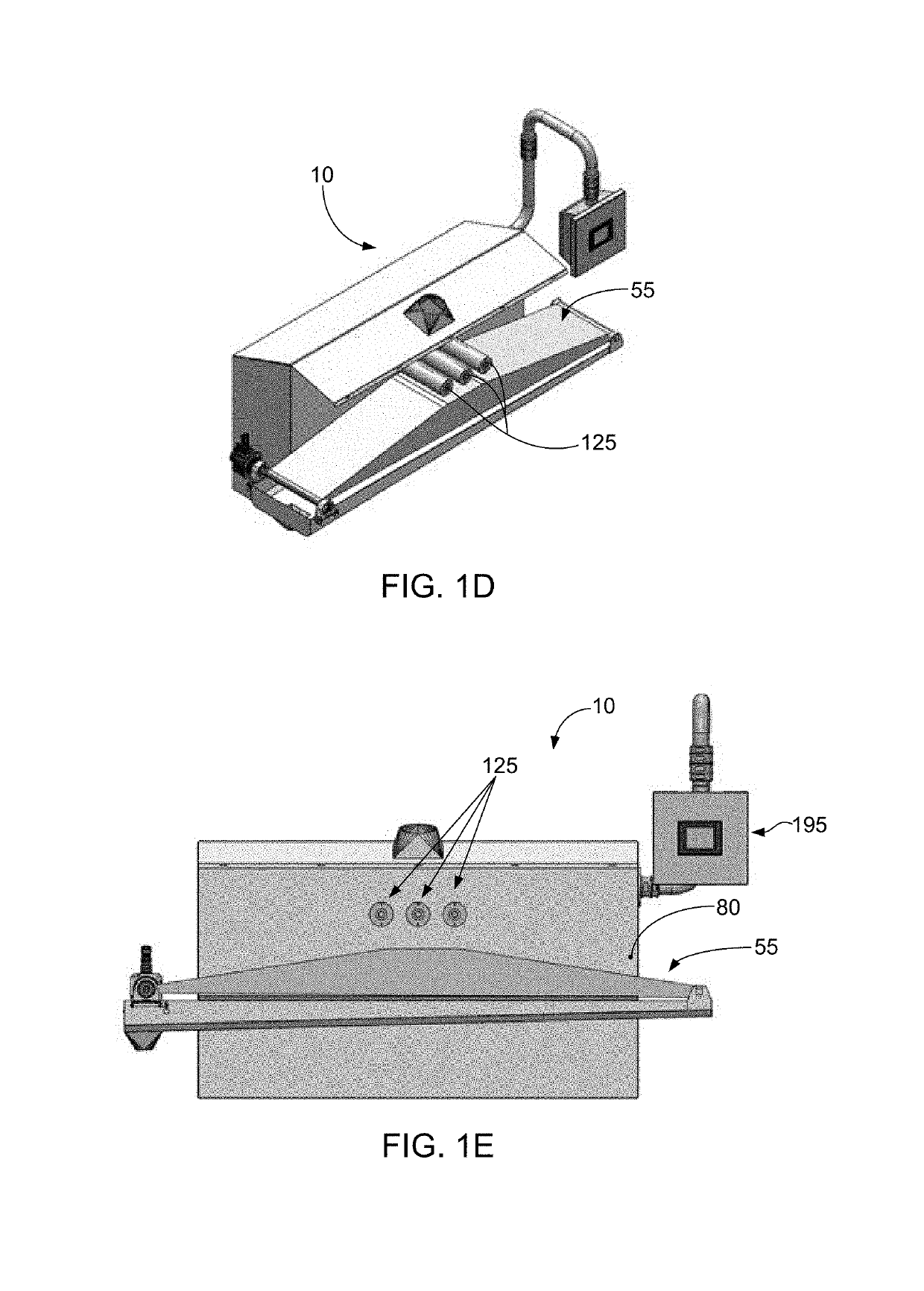

Systems and methods for providing food intervention and tenderization

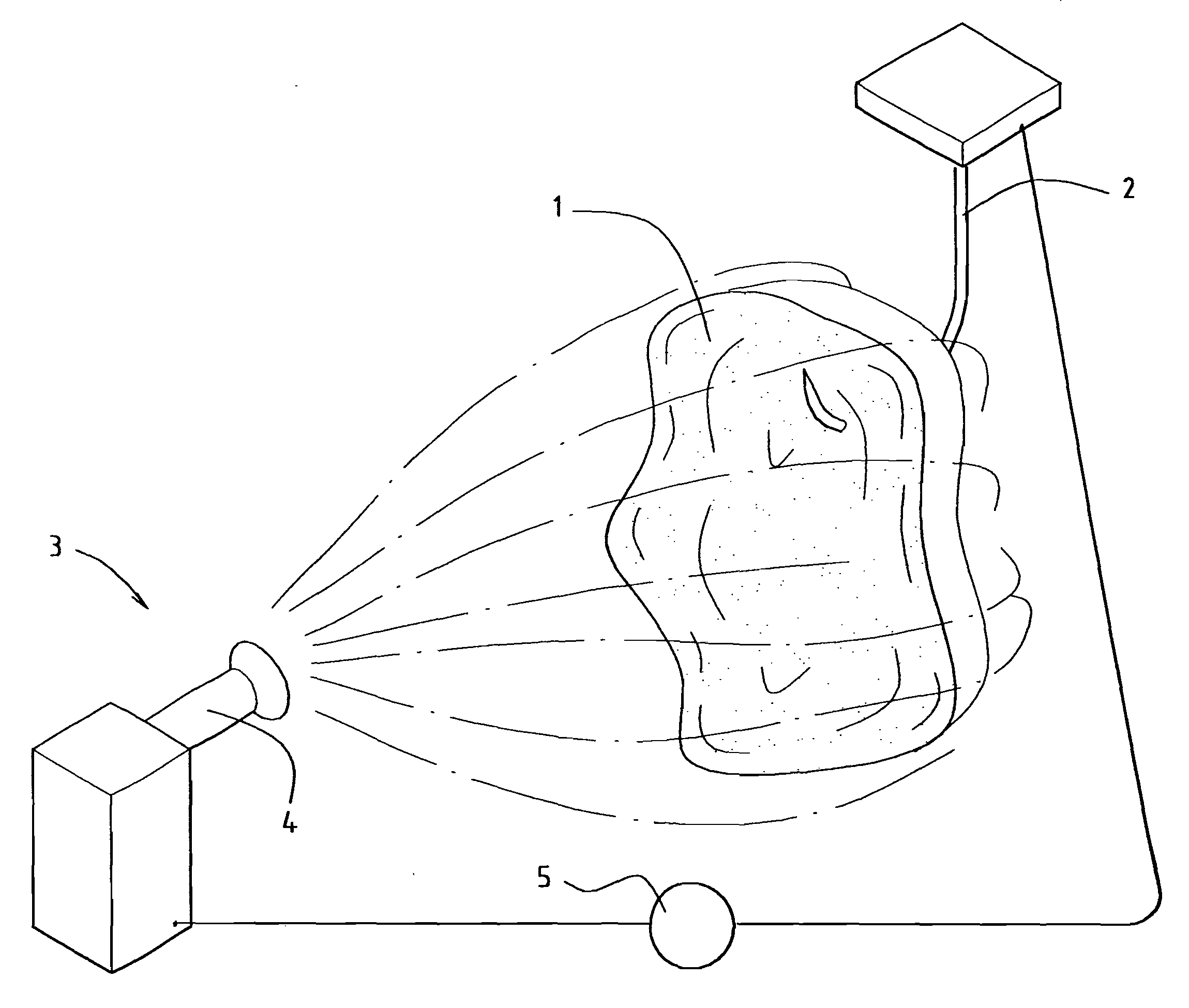

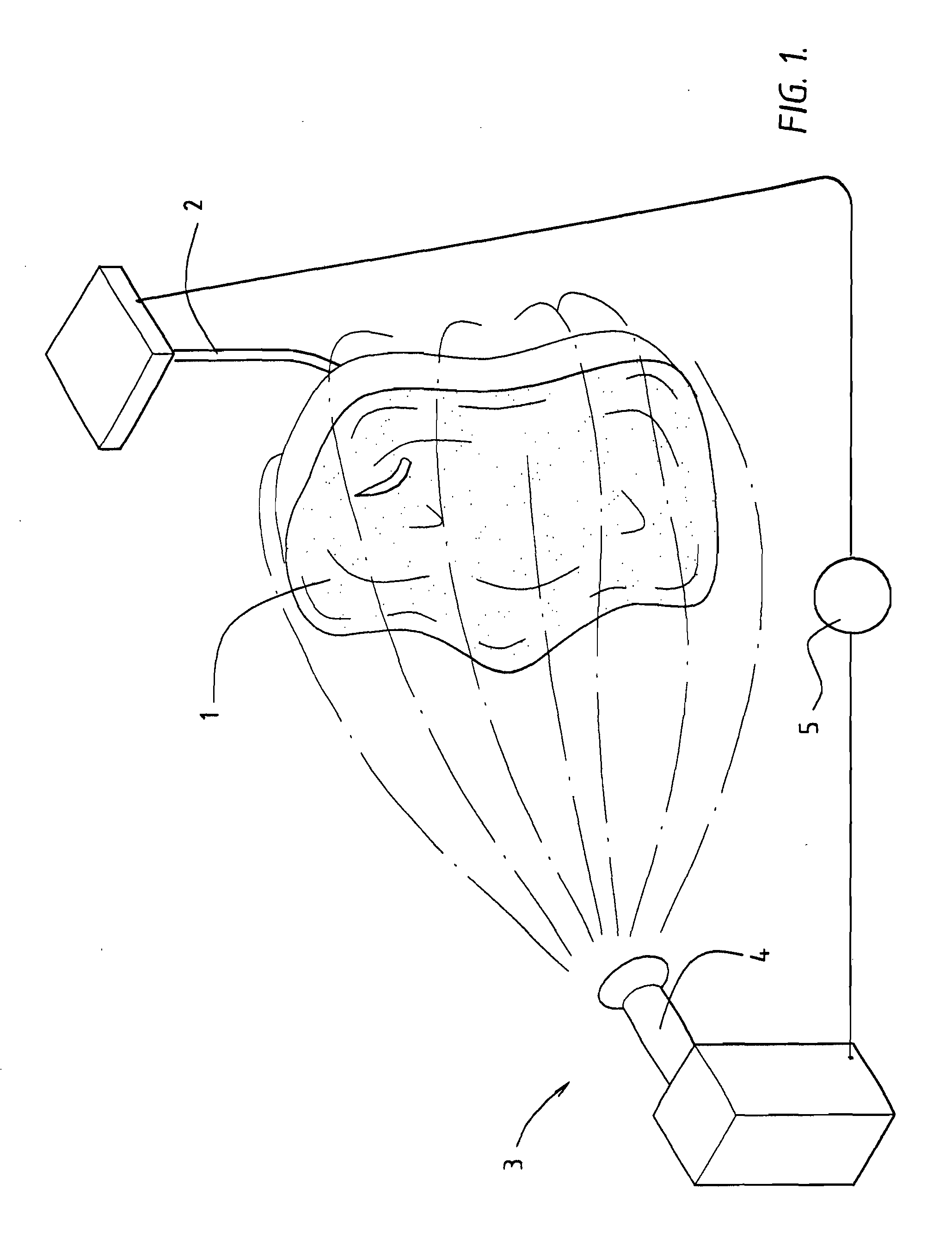

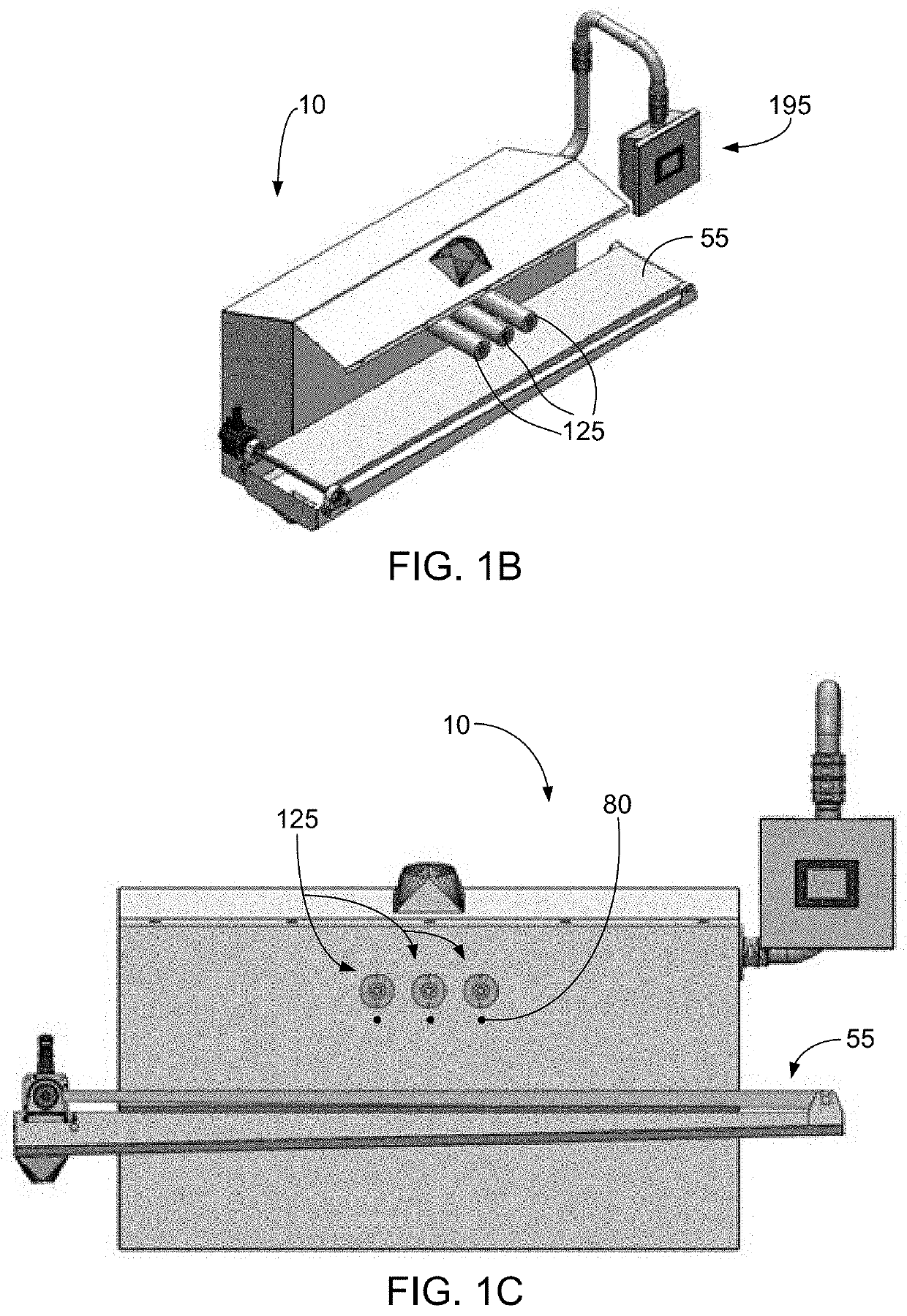

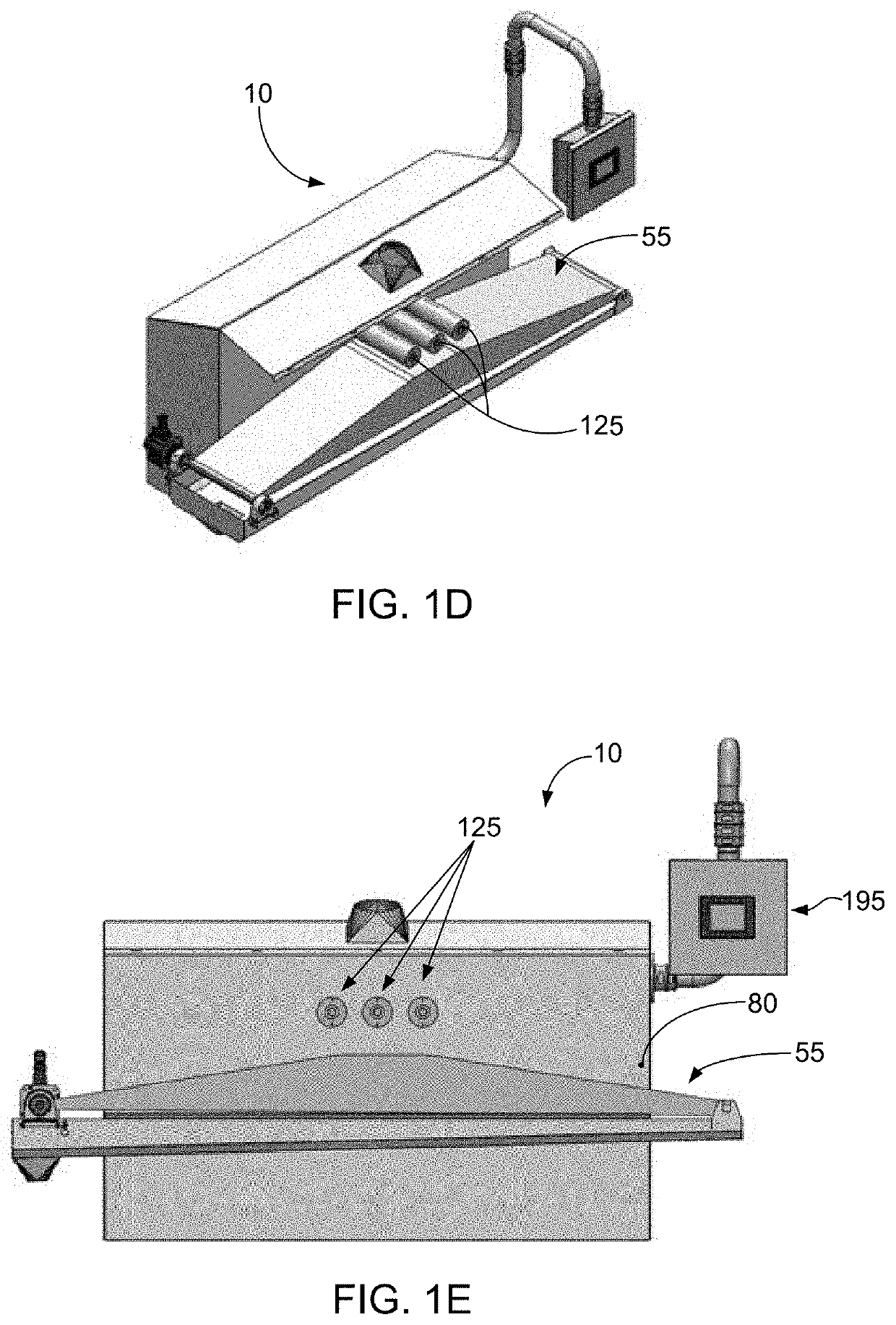

ActiveUS20160338392A1Weight increaseImprove aestheticsFruit and vegetables preservationInjection based meat processingSpray nozzleEngineering

Systems and methods for providing food intervention, pumping up, and tenderization are discussed. While such systems and methods can include any suitable component, in some cases, they include an injectade reservoir, a filter, a first pump configured to force injectade from the injectade reservoir and through the filter, a nozzle configured to inject injectade into a food product without having the nozzle contact the food, and a valve that is configured to selectively open and close to regulate when and how much of the injectade that passes through the filter is forced out of the nozzle. In some cases, the described systems further include a chiller configured to cool injectade in the reservoir, a sensor configured to determine a distance between the nozzle and food item, an actuator configured to move the nozzle, and / or a computer processor that controls an amount of injectade sprayed from the nozzle. Other implementations are described.

Owner:S2I

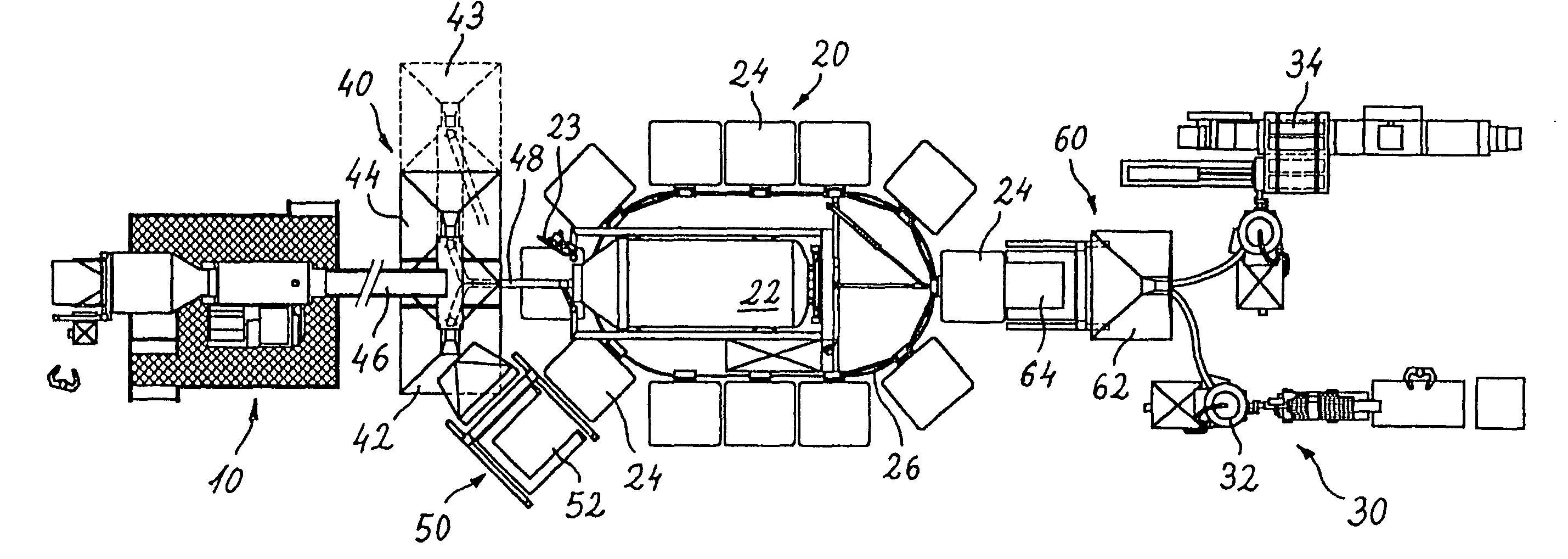

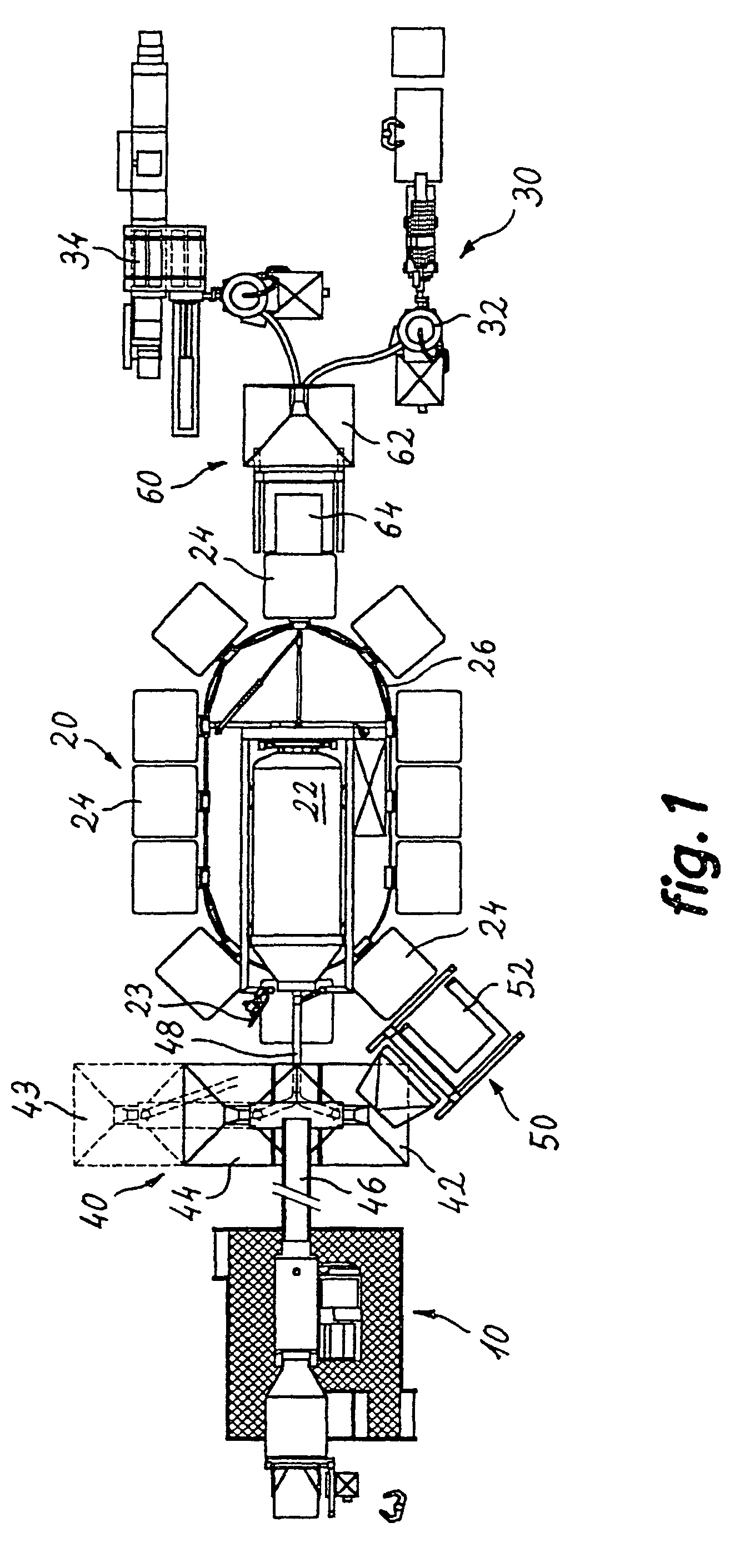

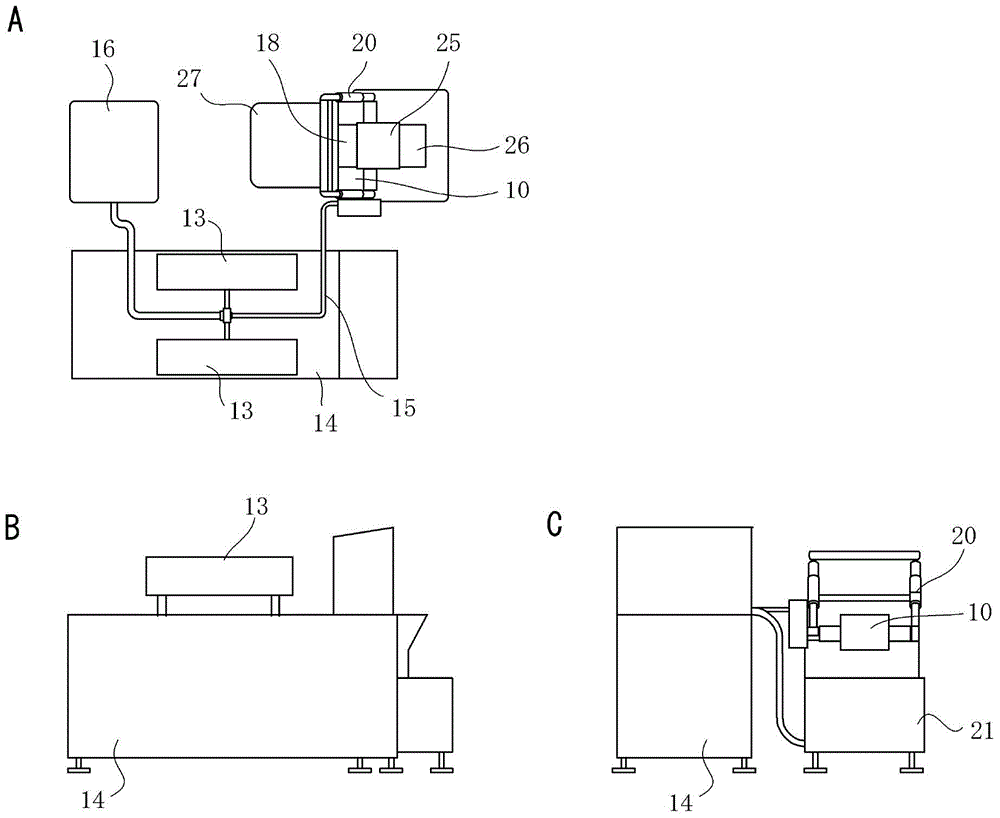

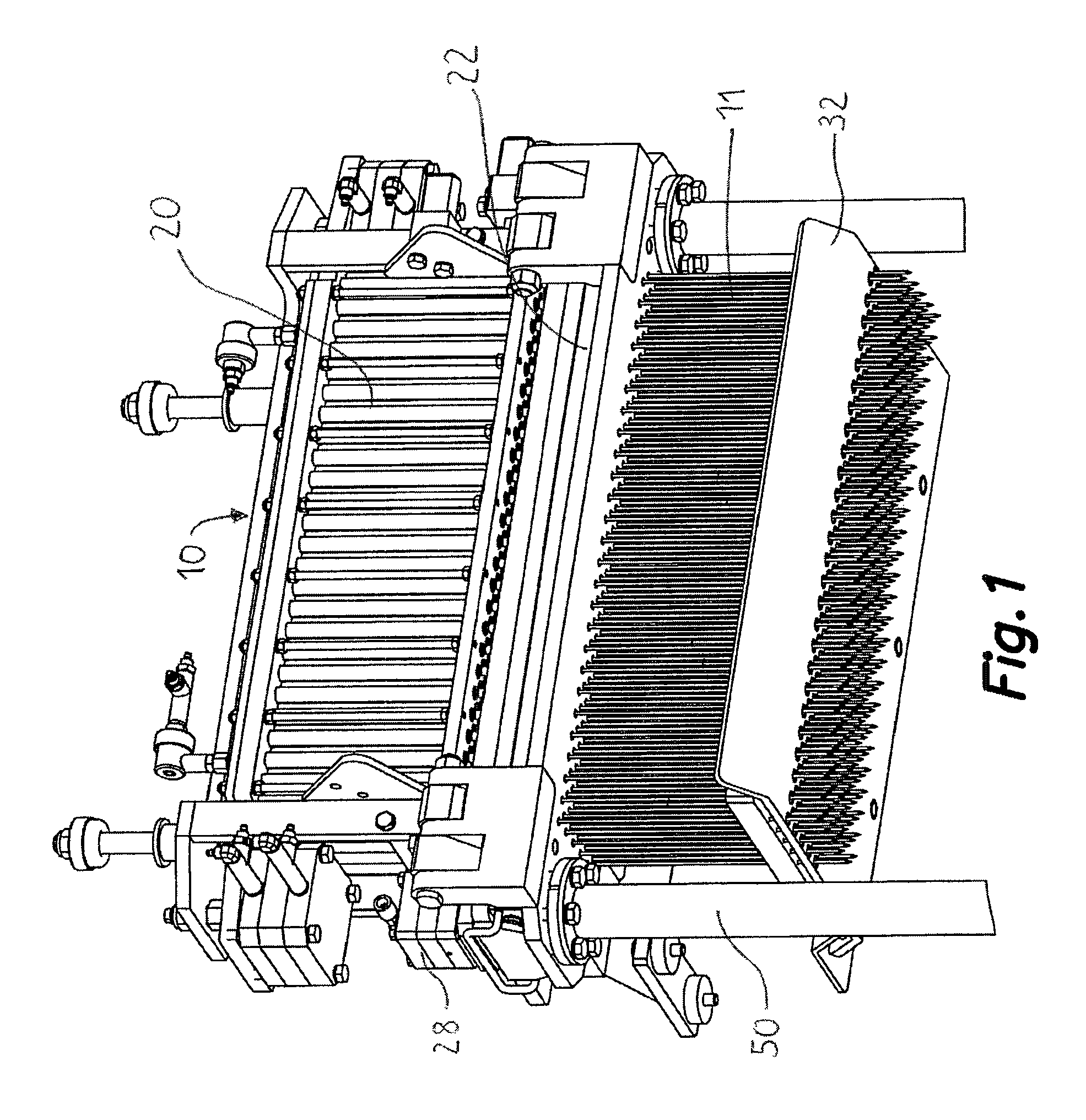

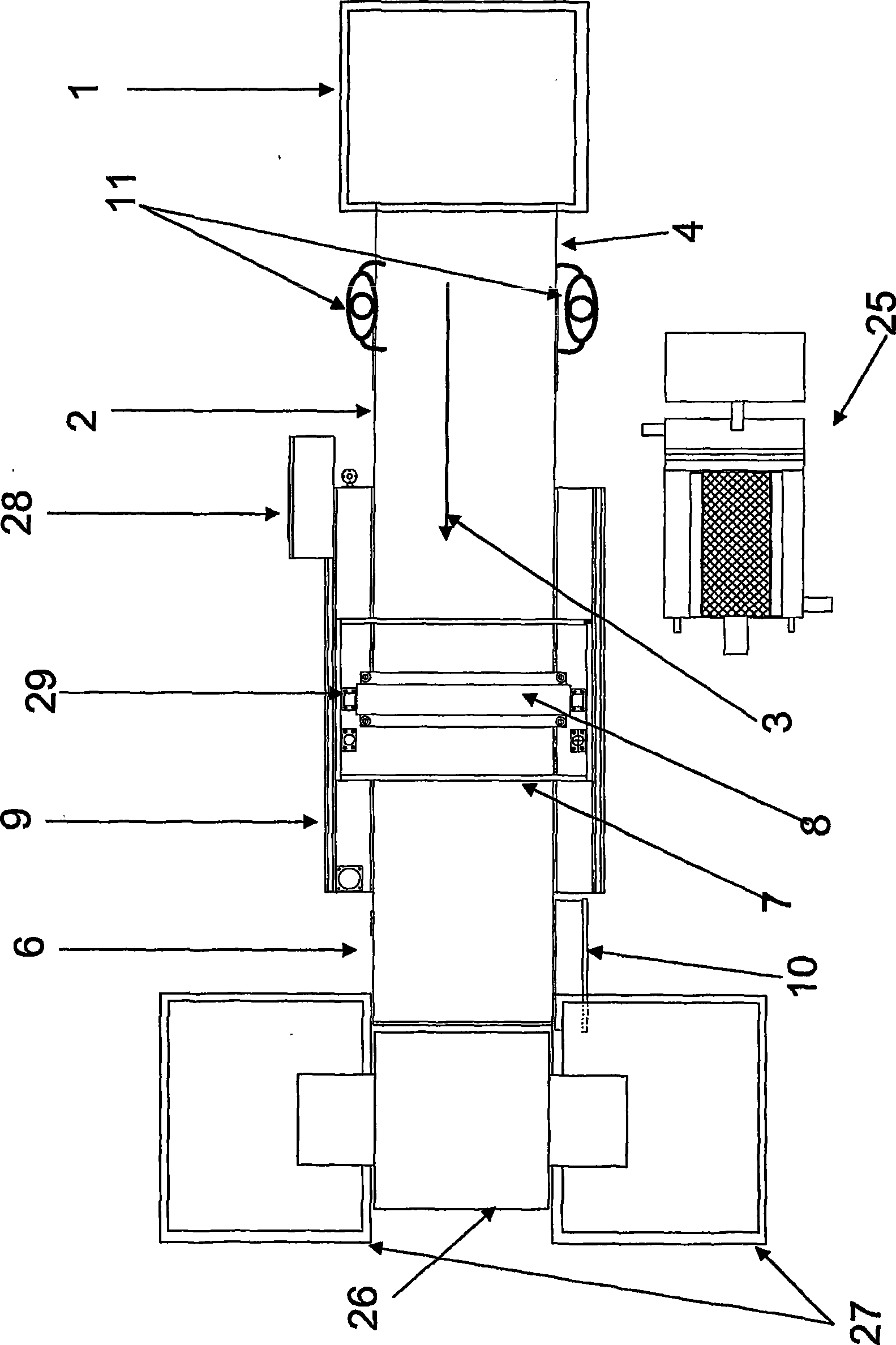

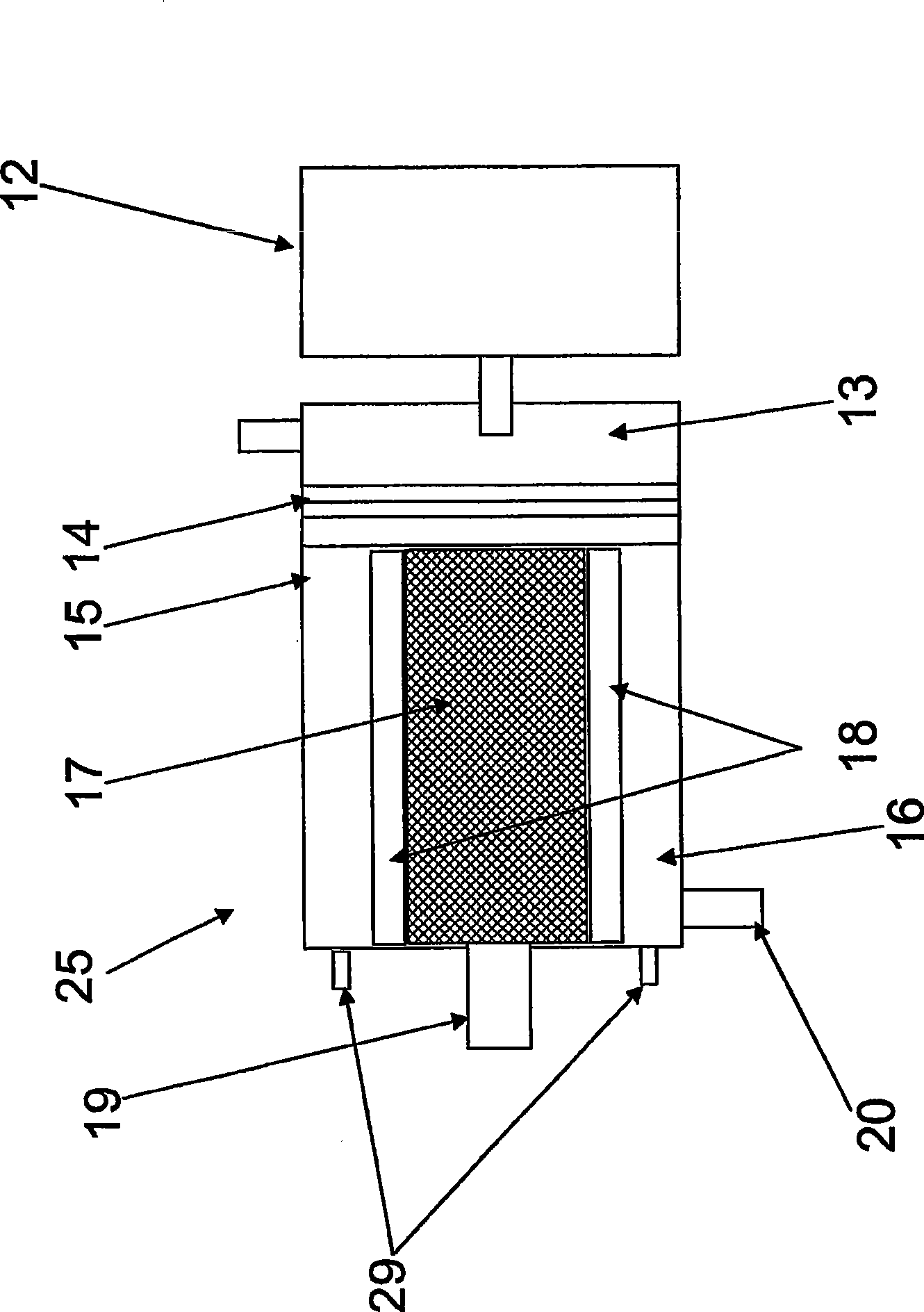

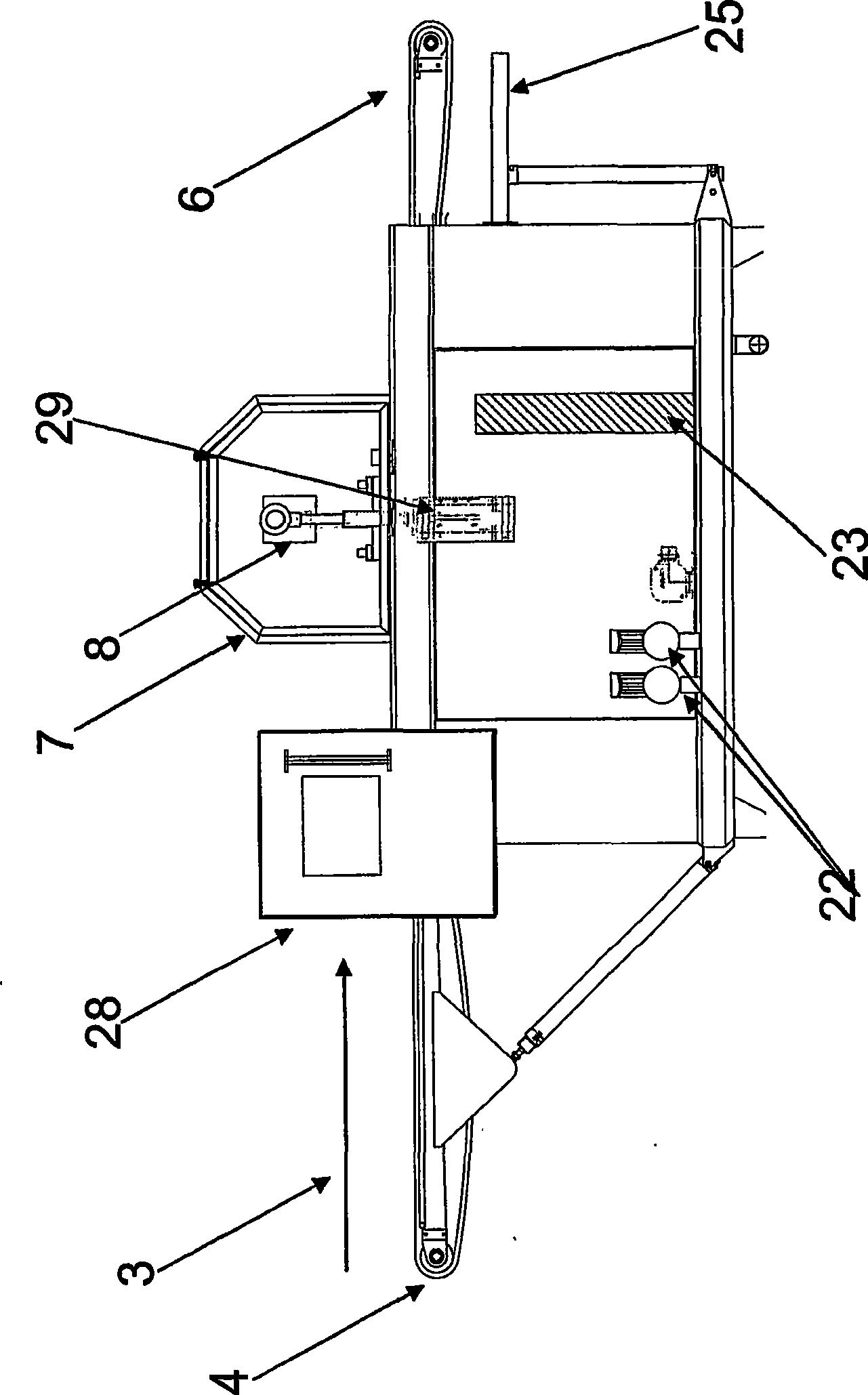

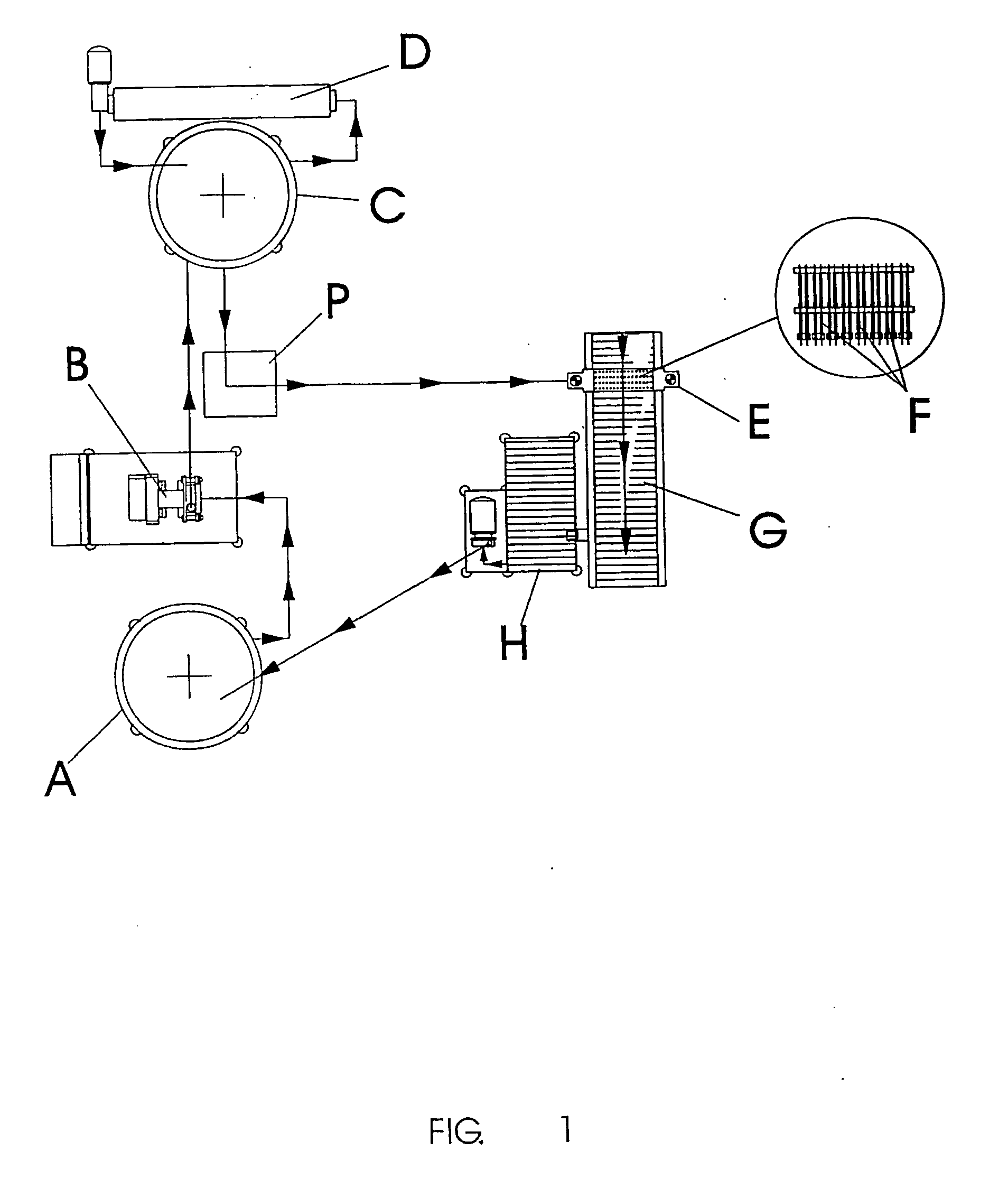

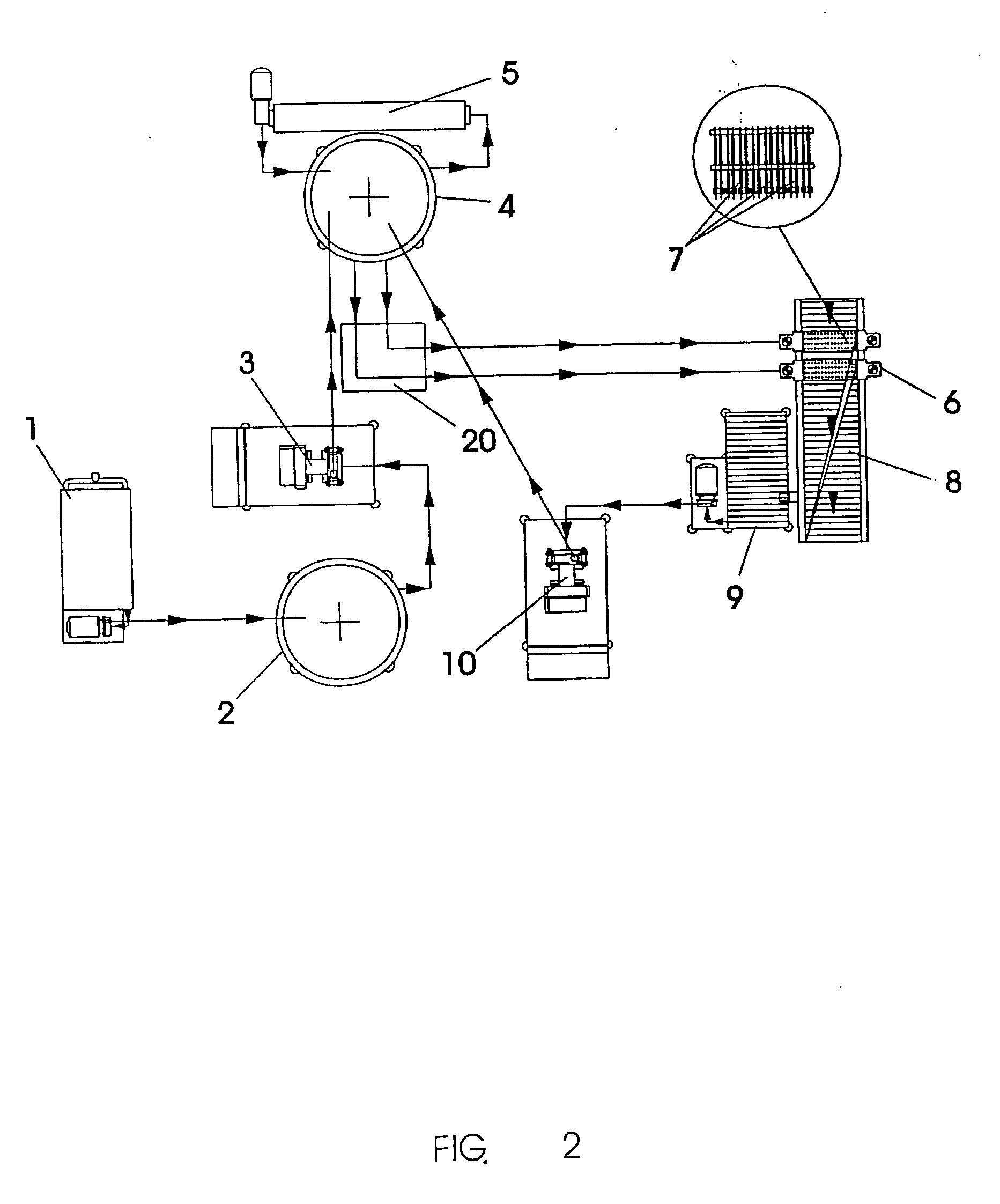

Plant for continuous processing and packing of meat products and method for the implementation thereof

A method and apparatus for a meat processing plant includes an injecting station (10) for injecting meats with brine, a macerating station (20) for massaging the injected meat including movable, plural resting tasks (24) and means (26) for moving these tables with respect to an accumulating and loading station (40) for repeated processing of the injected mean in a rotating drum (22) of the macerating station (20). A packing station (30) can accept treated meat from the resting tanks (24) for final packing in one or more packing machines (32). The method and apparatus can continuously process one or more types of meat products without interruption.

Owner:METALQUIMIA SA

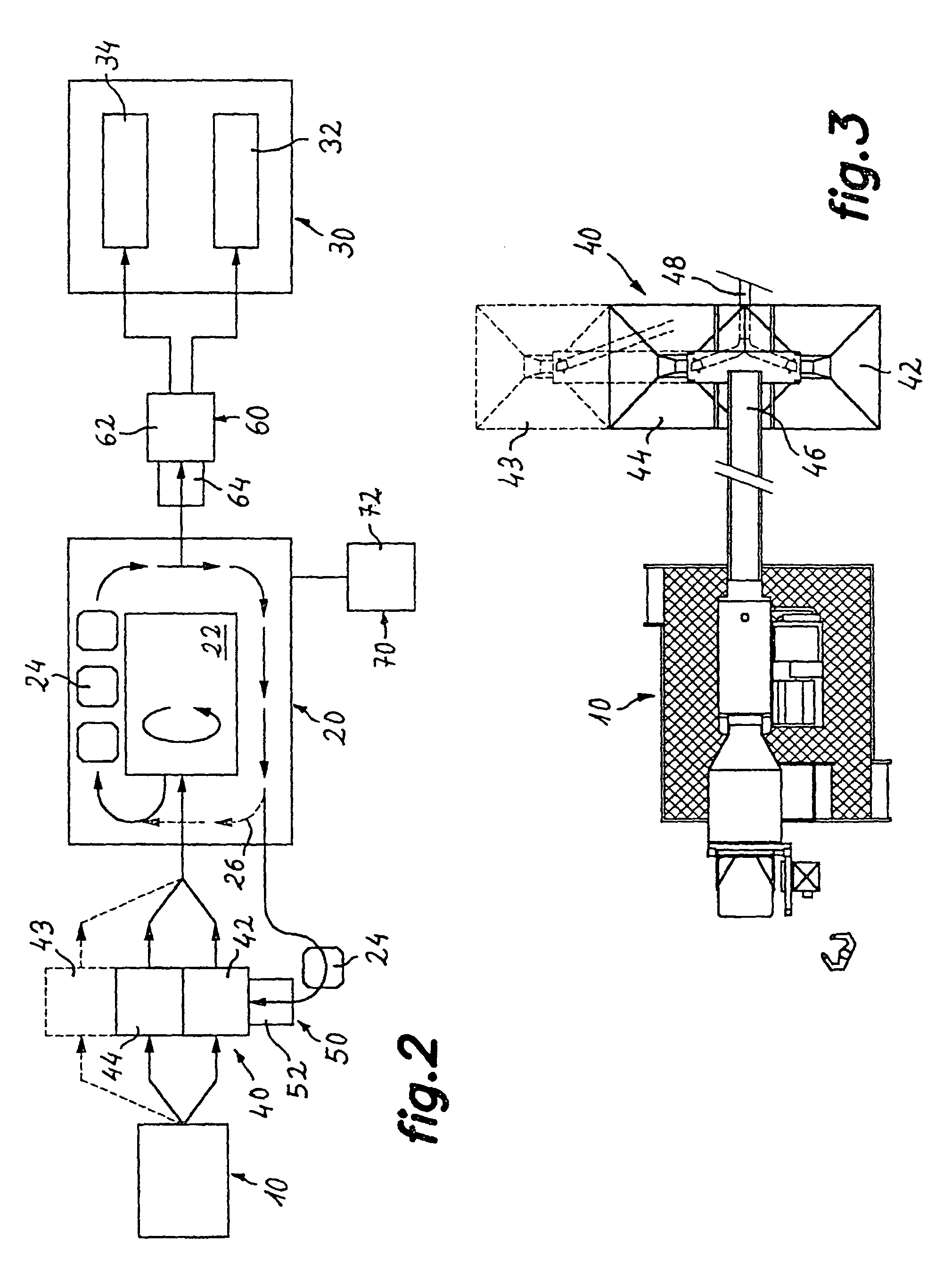

Method of producing salted cod roe

InactiveUS20040258810A1Quality improvementAvoid uneven colorInjection-based meat tenderisingPiercing-based meat tenderisingSaline solutionsState specific

Provided is a method of producing salted cod roe including pickling the roe with a seasoning solution by injecting the seasoning solution into the roe. In the method, frozen roe or fresh roe is washed with saline solution and then the seasoning solution is injected into the roe followed by standing for a predetermined time so that the seasoning solution can migrate into the roe to perform of pickling the roe with the seasoning solution. The method can produce salted roe of a high quality without causing uneven pickling and uneven coloring, achieve uniform migration of the seasoning solution therein in a short time, and maintain the most tasty state specific to salted cod roe. As a result, just-produced, fresh salted cod roe that can be eaten in the most tasty state is produced.

Owner:TOWA FOODS

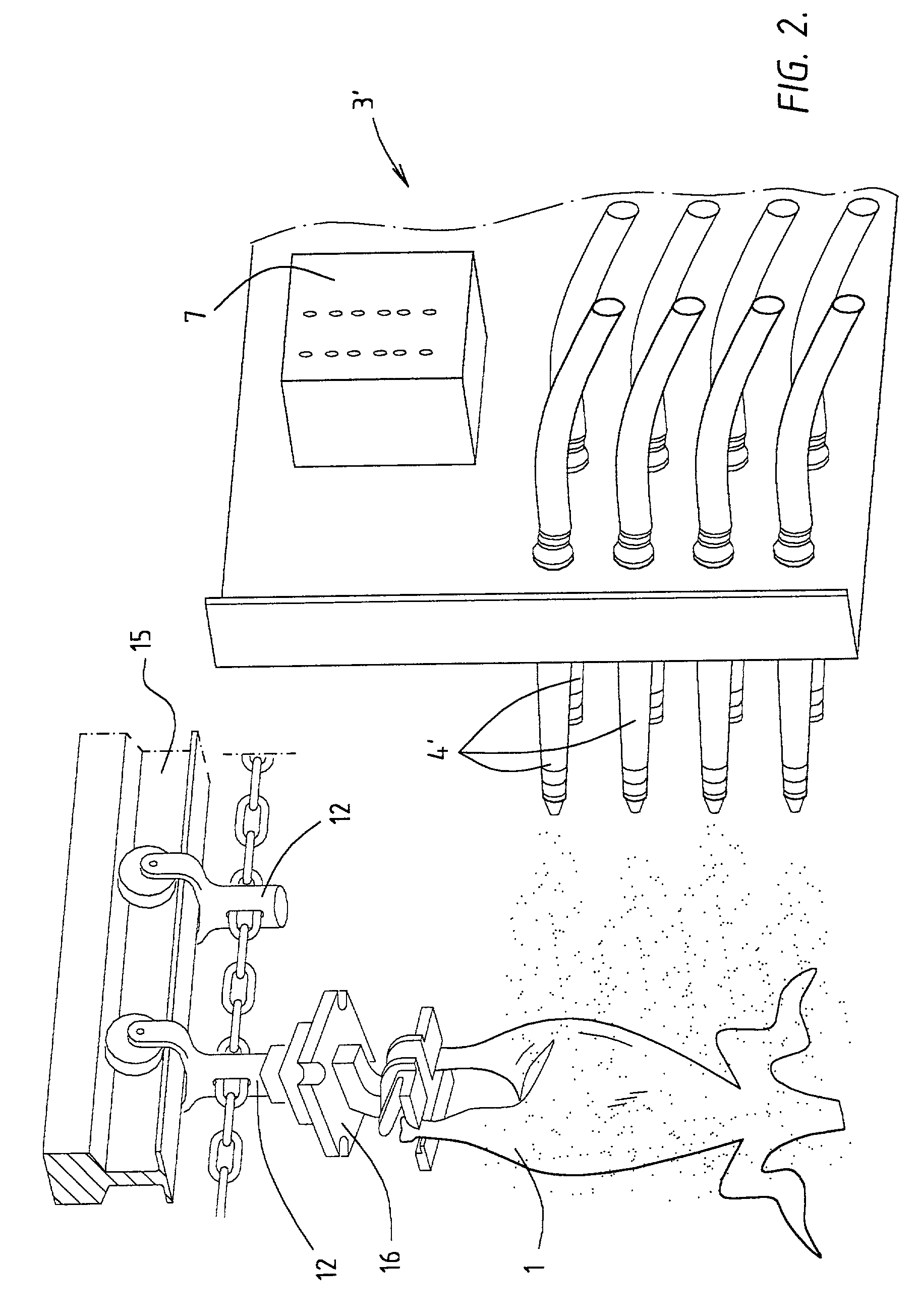

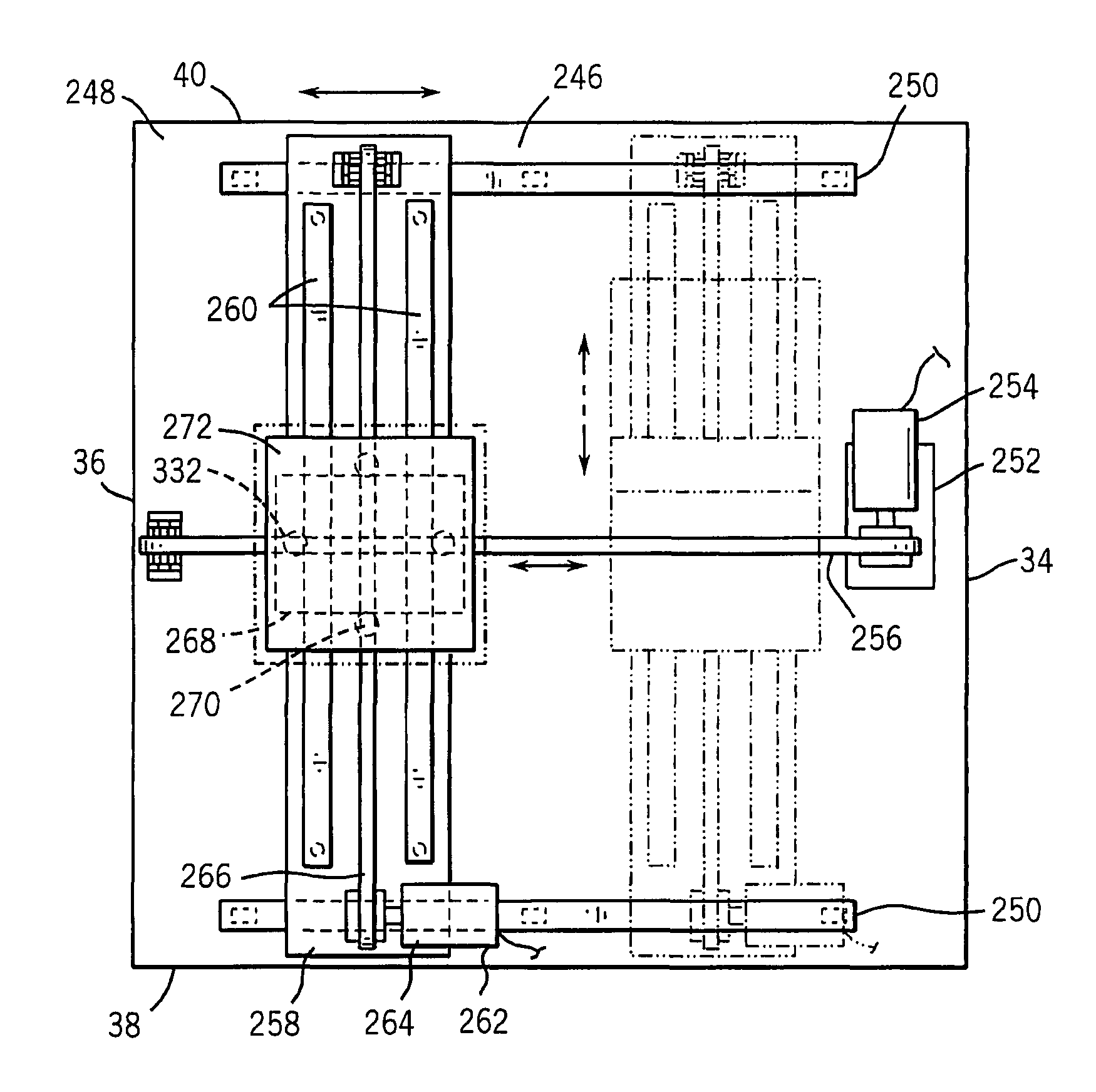

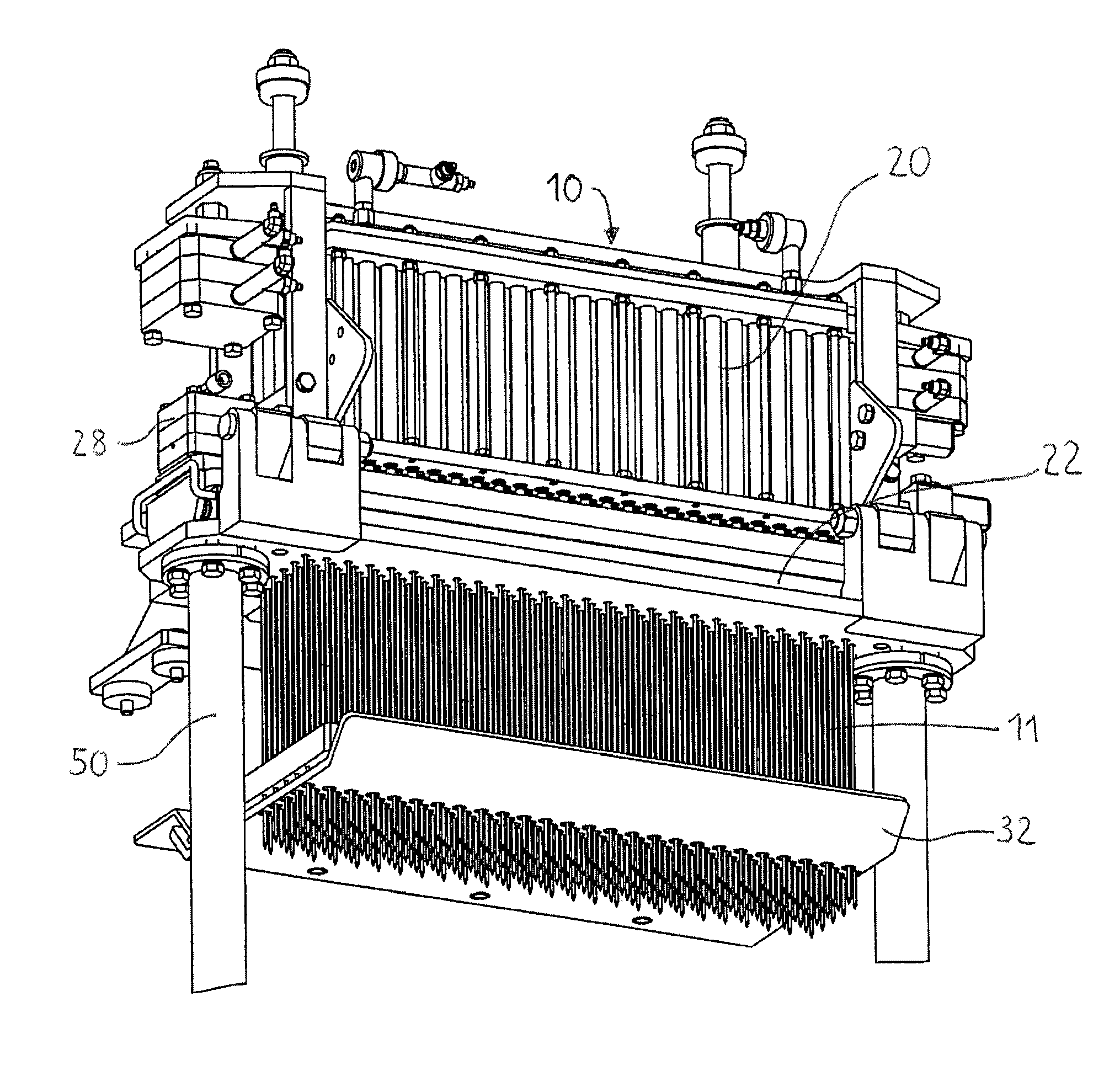

Injecting machine for injecting brine into meat pieces

A machine for injecting brine into meat pieces includes a conveyor having a support surface for conveying meat pieces in a forward step by step movement, each step having a predetermined length, first and second injection heads consecutively arranged over the conveyor relative to the forward direction, each injection head having an array of injection needles covering a whole width of the conveyor support surface. A length of the conveyor support surface corresponds to the predetermined length of the steps of the conveyor step by step movement, head driving device for alternately reciprocating the injection heads between an upper position, enabling the meat pieces to pass under the injection heads, and a lower position, where the injection needles are stuck into the meat pieces located under the injection heads, and brine supplying device supplying brine to the injection needles at least when the injection heads are at their lower position.

Owner:METALQUIMIA SA

Needleless injection device and method of injecting

InactiveUS7968135B2Quickly and easily flavoringEasy to useJet injection syringesInjection based meat processingNeedle Free InjectionFood additive

A needleless injection device and method for injecting a food subject is disclosed in which one or more types of liquid food additive are individually and / or simultaneously delivered to a food subject within a sealed injection chamber or compartment. The needleless injection device and method of the present invention utilizes rapid, high pressure injection bursts to completely and uniformly inject the food subject, allowing different food subjects or different food additives to be sequentially injected in an efficient and instant manner. The needleless injection device and method for injecting minimizes contamination by totally enclosing the injection process within a sealed chamber, and by eliminating the need for the injection nozzles to contact, or be placed immediately adjacent to the food subject.

Owner:HANSEN CONLY L +1

Apparatus for injecting fluid into meat products

InactiveUS20050268796A1Easy to disperseIncrease in sizeGrain huskingGrain polishingNeedle punctureBiomedical engineering

A method for injecting fluid into meat products comprises taking a plurality of hollow fluid injection needles having sharpened discharge ends, and connecting the needles to a source of pressurized liquid; penetrating the sharpened ends of the needles into the product and thence withdrawing the same while discharging fluid into the product and vibrating the needles for a period of time while they are within the product to enlarge the size of a penetration hole within the product caused by the penetration of the needles to a size greater than the size of the needles to create at least a partial space around the needles to permit fluid from the needles to migrate into the spaces around the needles. The needles have a roughened outside surface.

Owner:STORK TOWNSEND BV

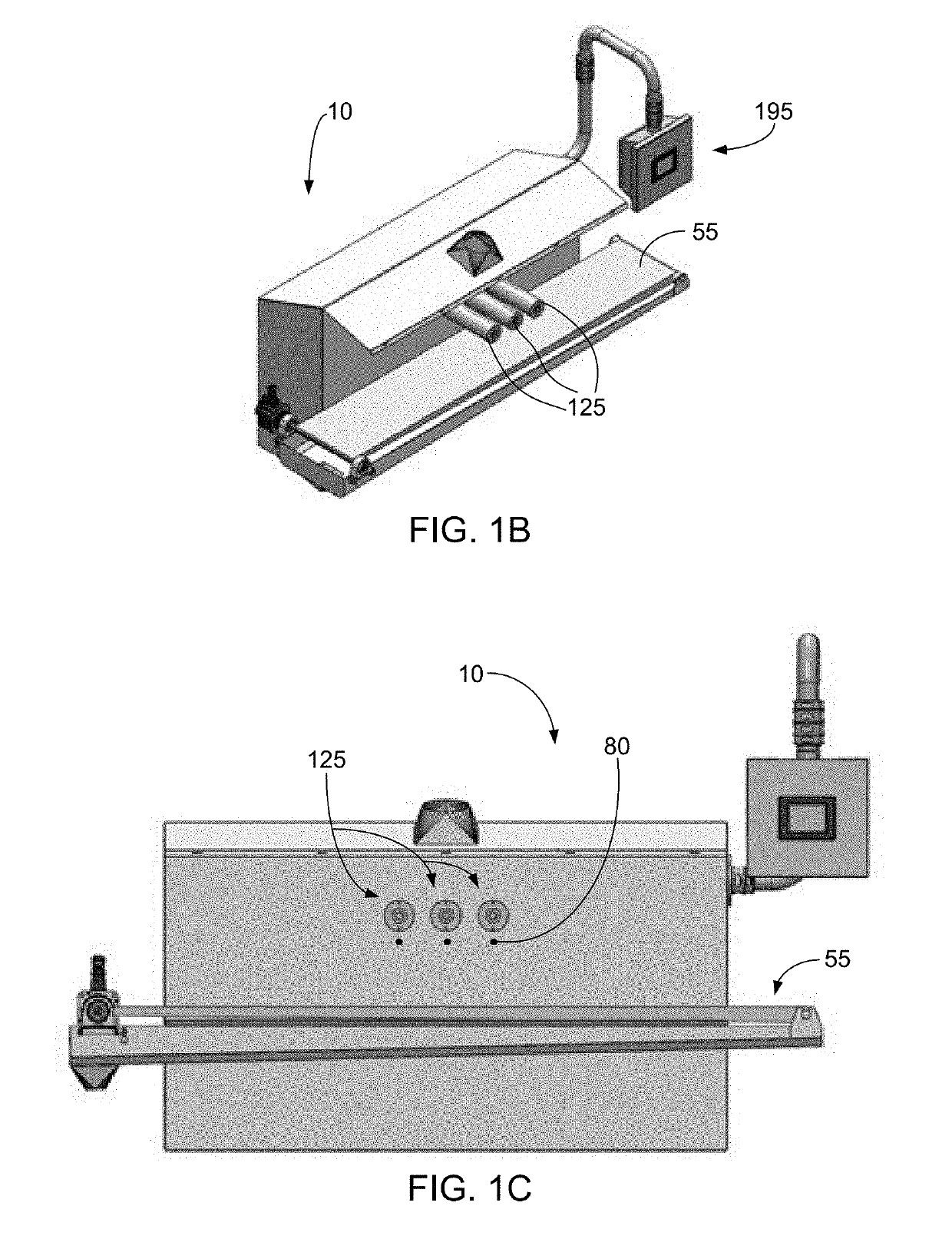

Systems and methods for providing food intervention and tenderization

ActiveUS20190191746A1Improve responseImprove throughputFruit and vegetables preservationInjection based meat processingEngineeringActuator

Systems and methods for providing food intervention, pumping up, and tenderization are discussed. While such systems and methods can include any suitable component, in some cases, they include an injectate reservoir, a filter, a first pump configured to force injectate from the injectate reservoir and through the filter, a nozzle configured to inject injectate into a food product without having the nozzle contact the food, and a valve that is configured to selectively open and close to regulate when and how much of the injectate that passes through the filter is forced out of the nozzle. In some cases, the described systems further include a chiller configured to cool injectate in the reservoir, a sensor configured to determine a distance between the nozzle and food item, an actuator configured to move the nozzle, and / or a computer processor that controls an amount of injectate sprayed from the nozzle. Other implementations are described.

Owner:S2I

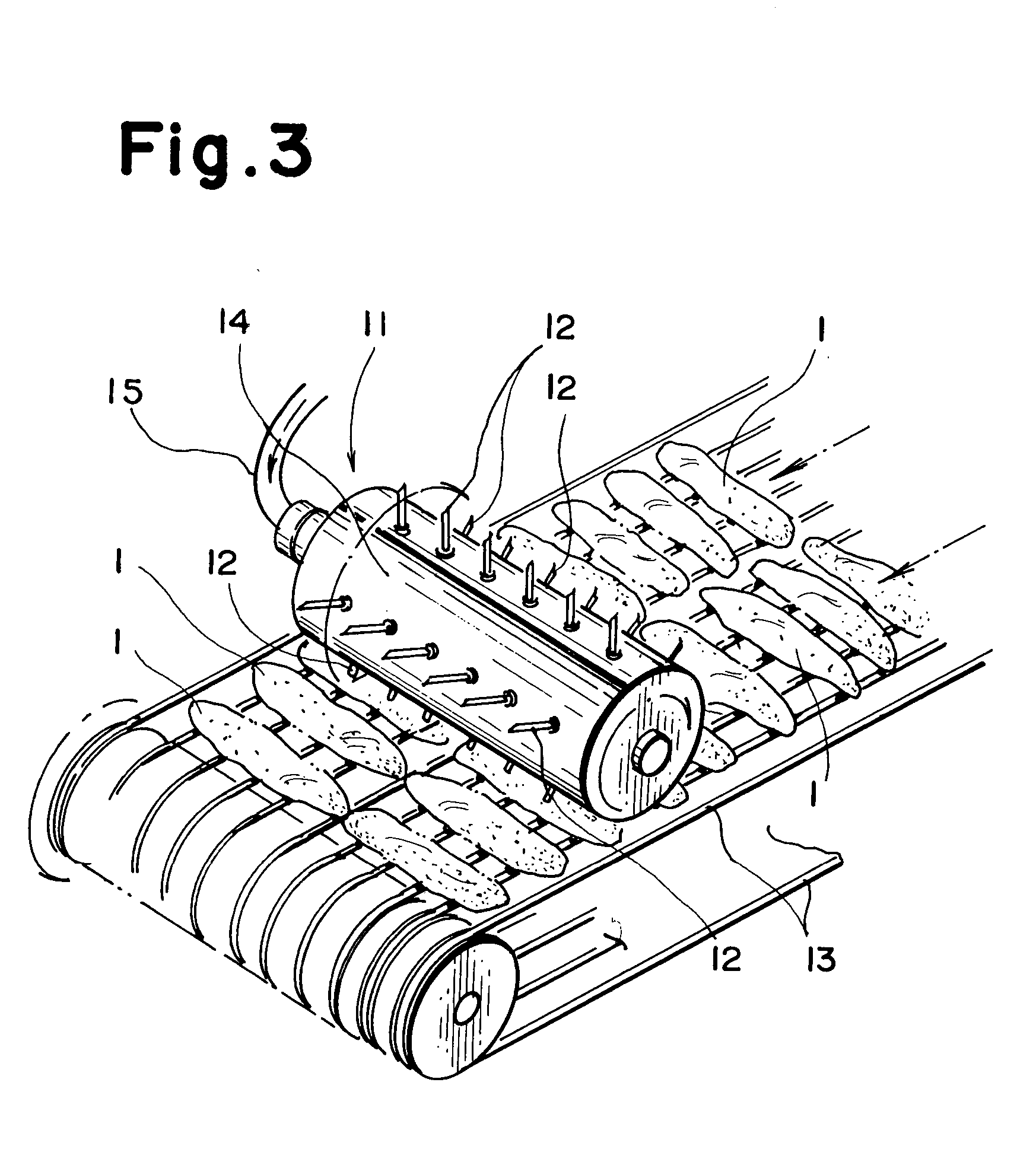

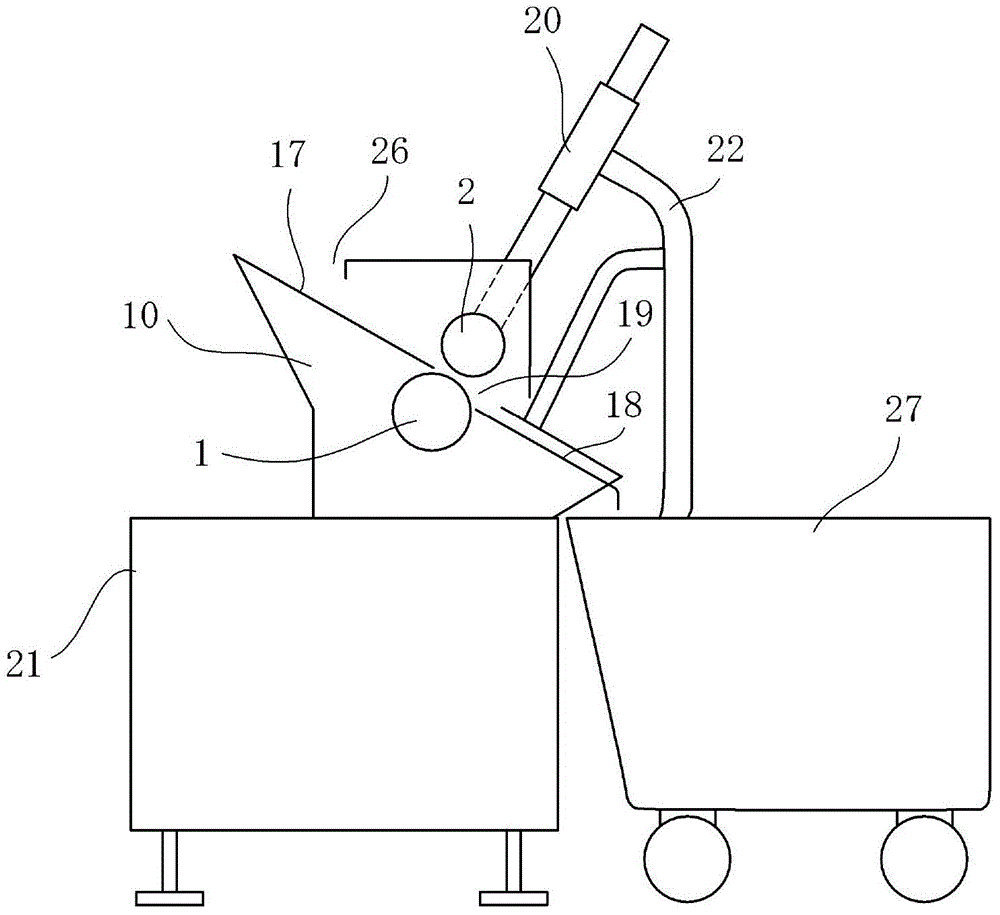

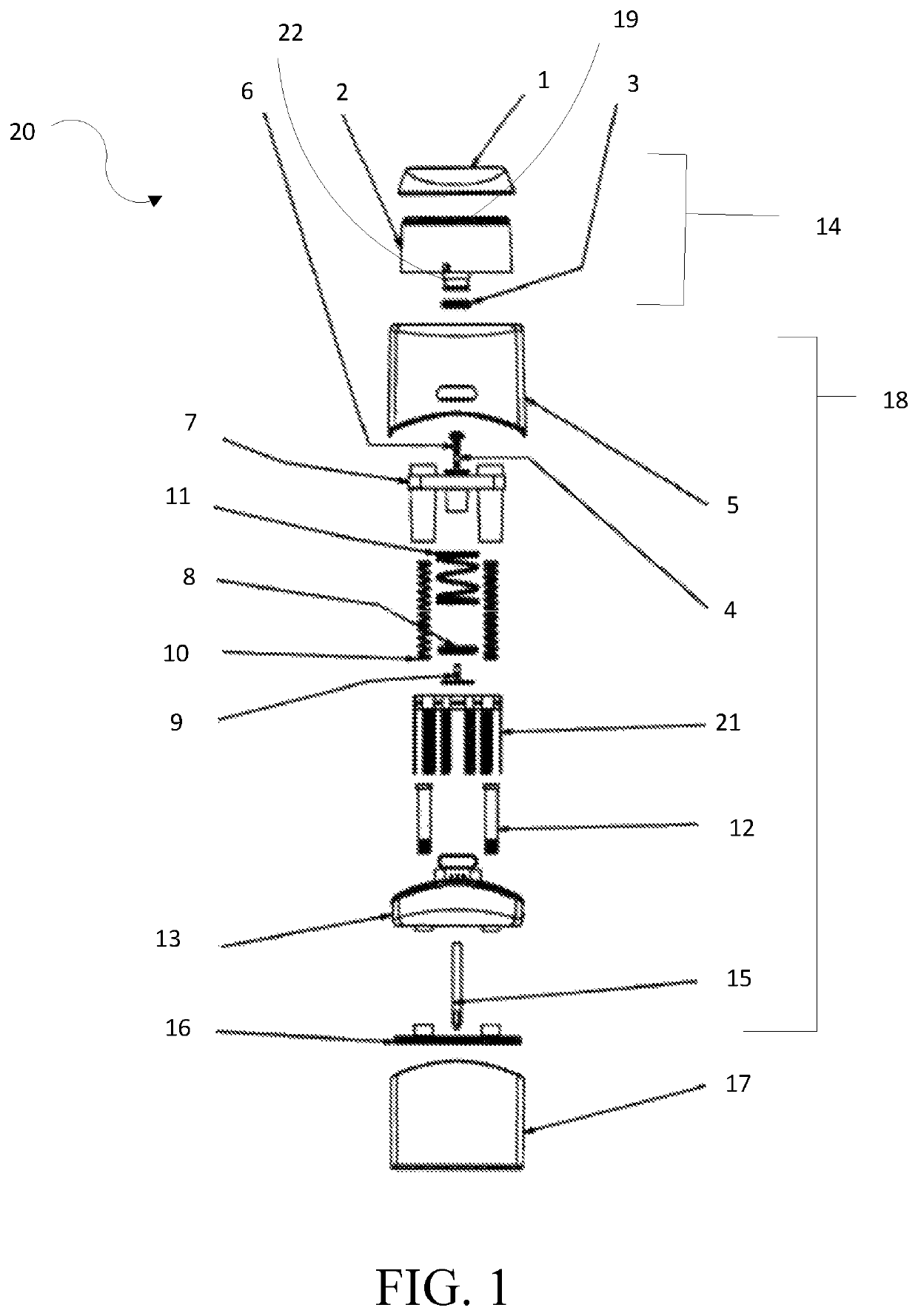

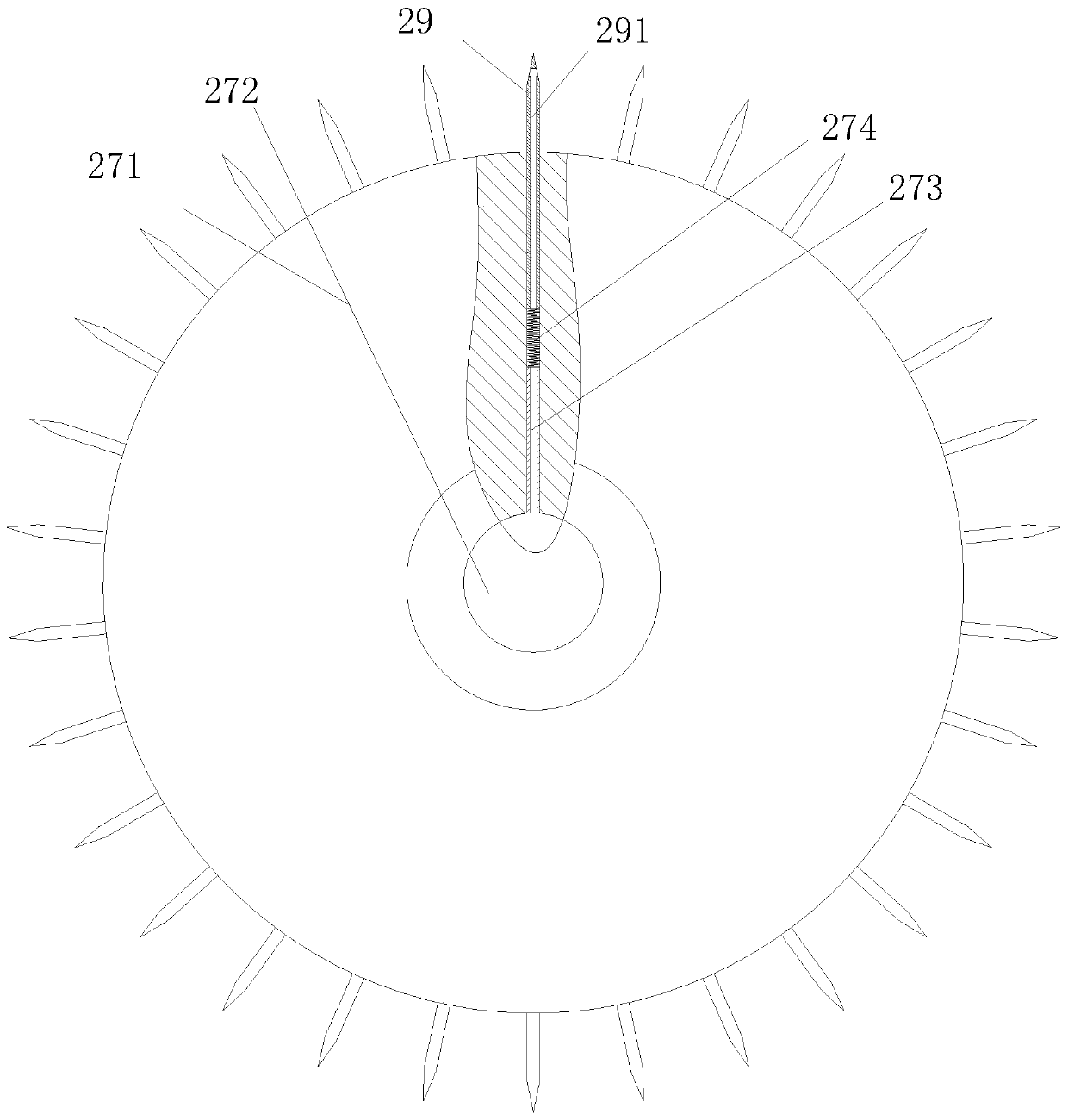

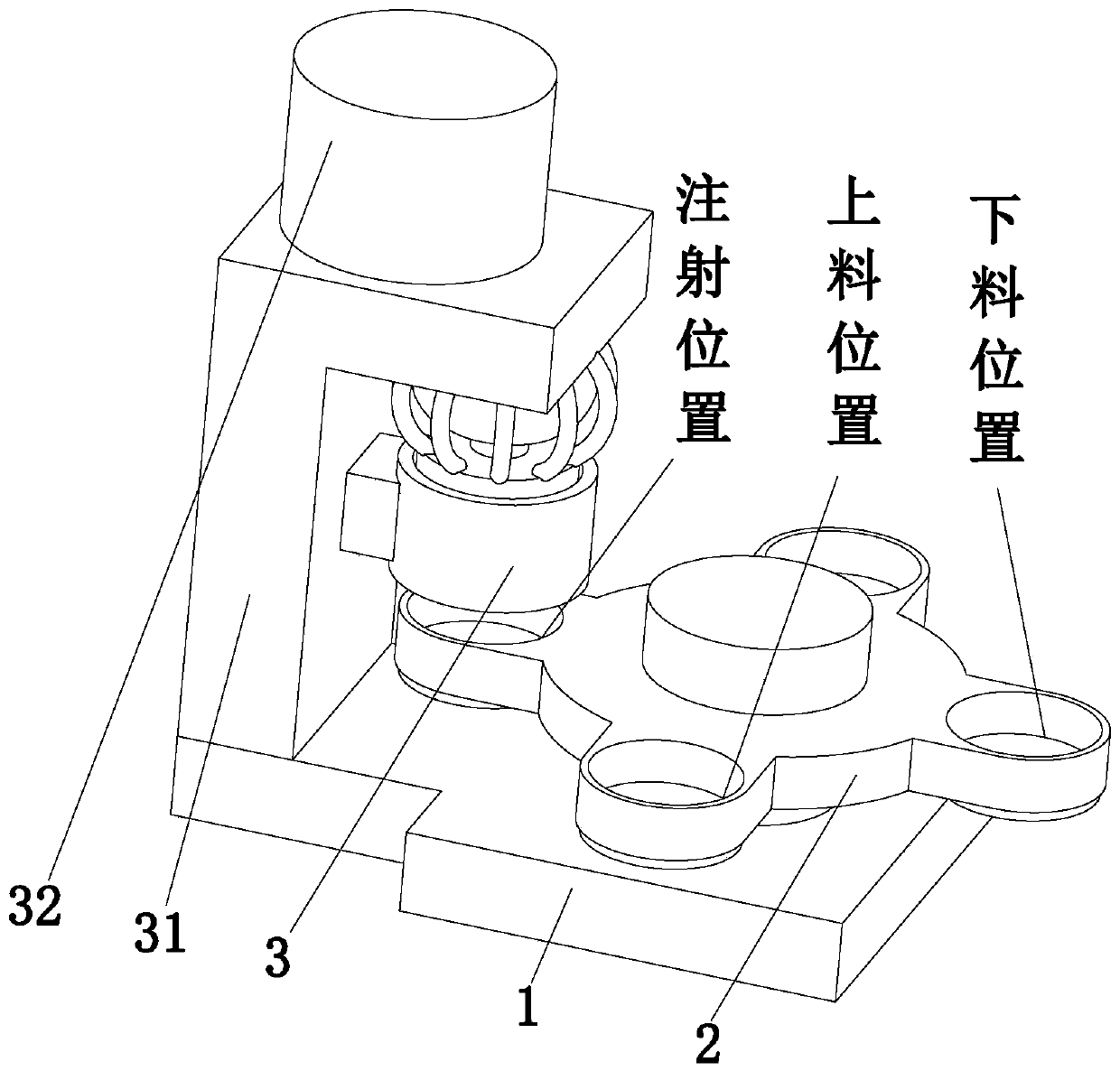

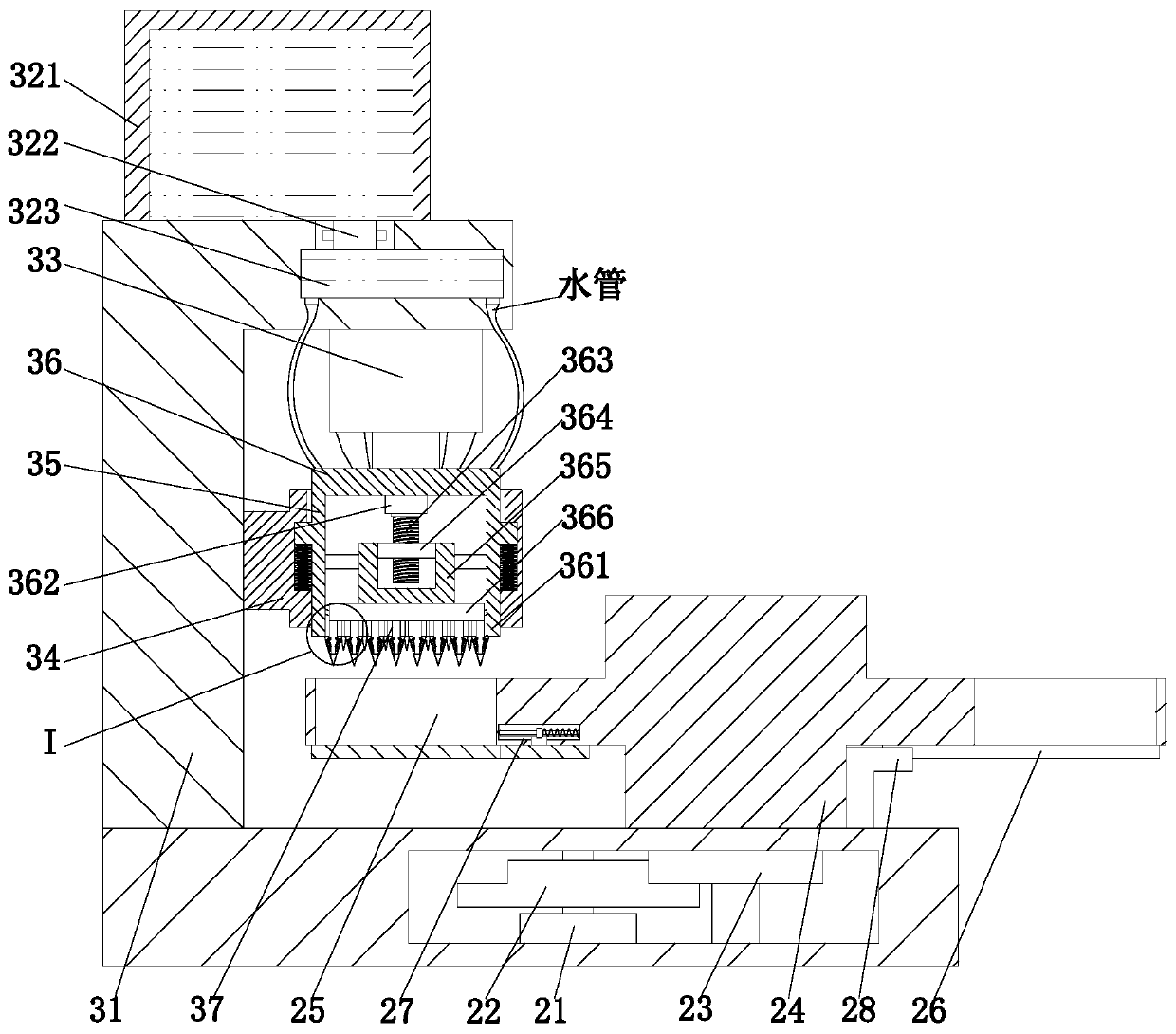

Pickling liquid injector

InactiveCN104938595AInjection based meat processingMeat/fish preservation using liquidsAdditive ingredientEngineering

It is an object of the invention to improve the rotary-type pickling liquid injector so as to inject the pickling liquid into the meat ingredient correctly. A pickling liquid spout roller 1 is combined with an opposed roller 2. A convey mechanism conveys a meat ingredient between the spout and opposed rollers 1 and 2. The meat ingredient is nipped between the spout and opposed rollers 1 and 2, the rotary body 3 is rotated around the fixed body 4, and the opposed roller 2 is rotated around an axis thereof. The pickling liquid is injected into the meat ingredient.

Owner:HIGASHIMOTO KIKAI

Adding an additive to a meat product

InactiveUS20100021618A1Convenient treatmentPoultry cleaning/disinfectionMeat/fish preservation using solidsChemistryCombination Product

Owner:MAREL STORK POULTRY PROCESSING

Machine for injecting fluids into meat or fish products

ActiveUS8336452B2Easy to assembleEasy to handleGrain huskingGrain polishingEngineeringMechanical engineering

Owner:METALQUIMIA SA

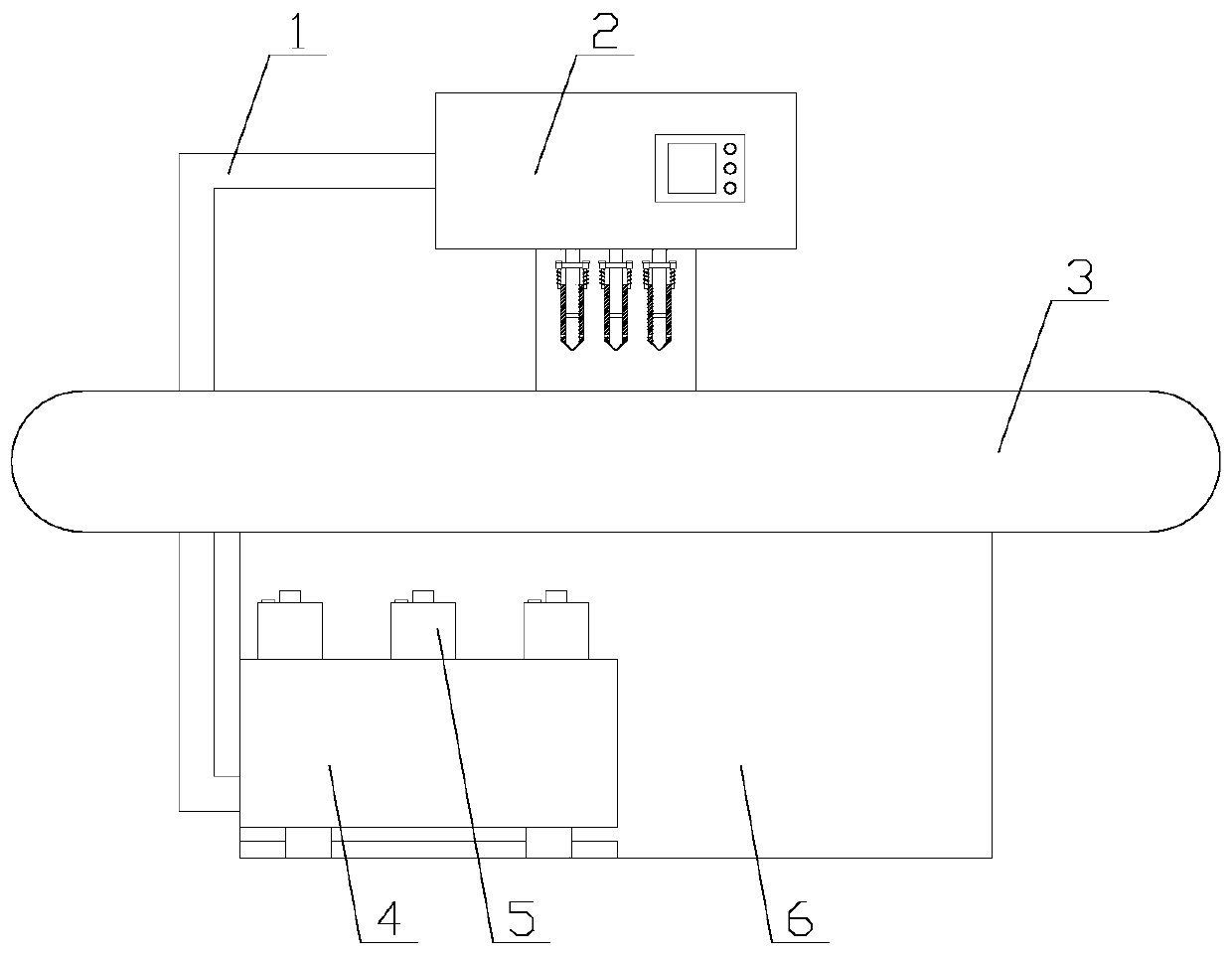

An apparatus for injecting liquid into food objects

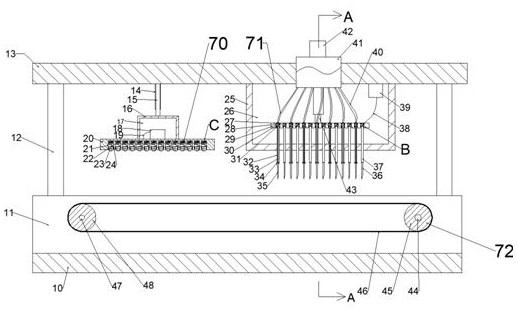

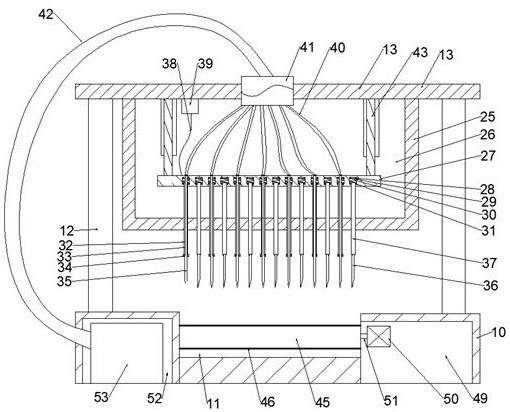

InactiveCN101489398AReduce manual laborReduce processingInjection based meat processingMeat/fish preservation using liquidsEngineeringLiquid based

The present invention discloses an apparatus for injecting liquid into food objects, the apparatus is comprised of a frame, an endless belt, and means for propelling the endless belt to convey the food objects. One or more needle with a passage for penetrating said food objects, a needle holder for holding said one or more needle, and a blending means for blending together substances to create the liquid. A supply means for supplying the liquid to the needles, a means for moving the needle holder, wherein the needles injects the liquid into the food objects while communicating with the food objects, an. Control means, wherein the control means controls the blending means for blending together plurality of substances to create the liquid based on predetermined recipes selected by the control means in response to an input from operator as well as the injection process.

Owner:RAF EHF

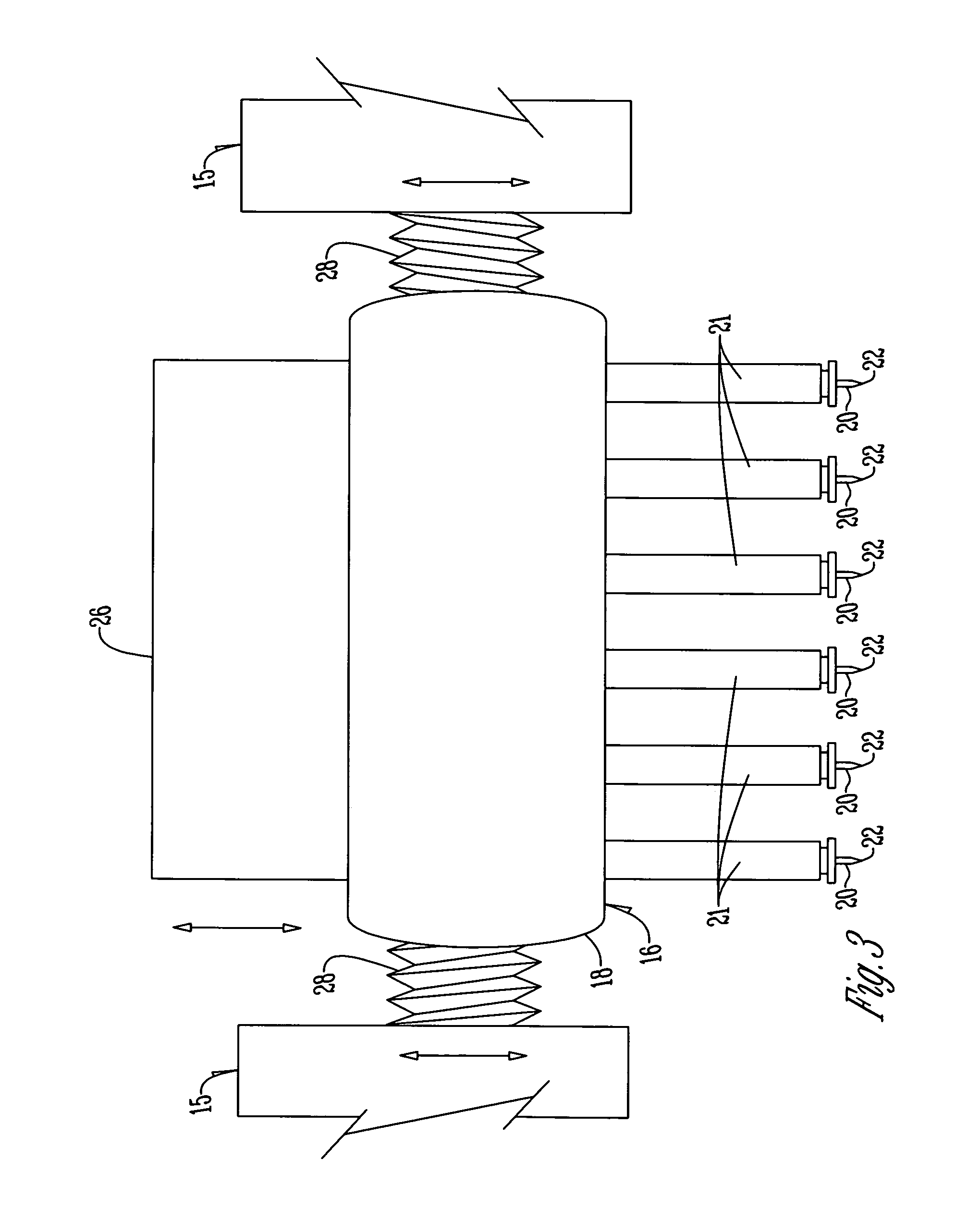

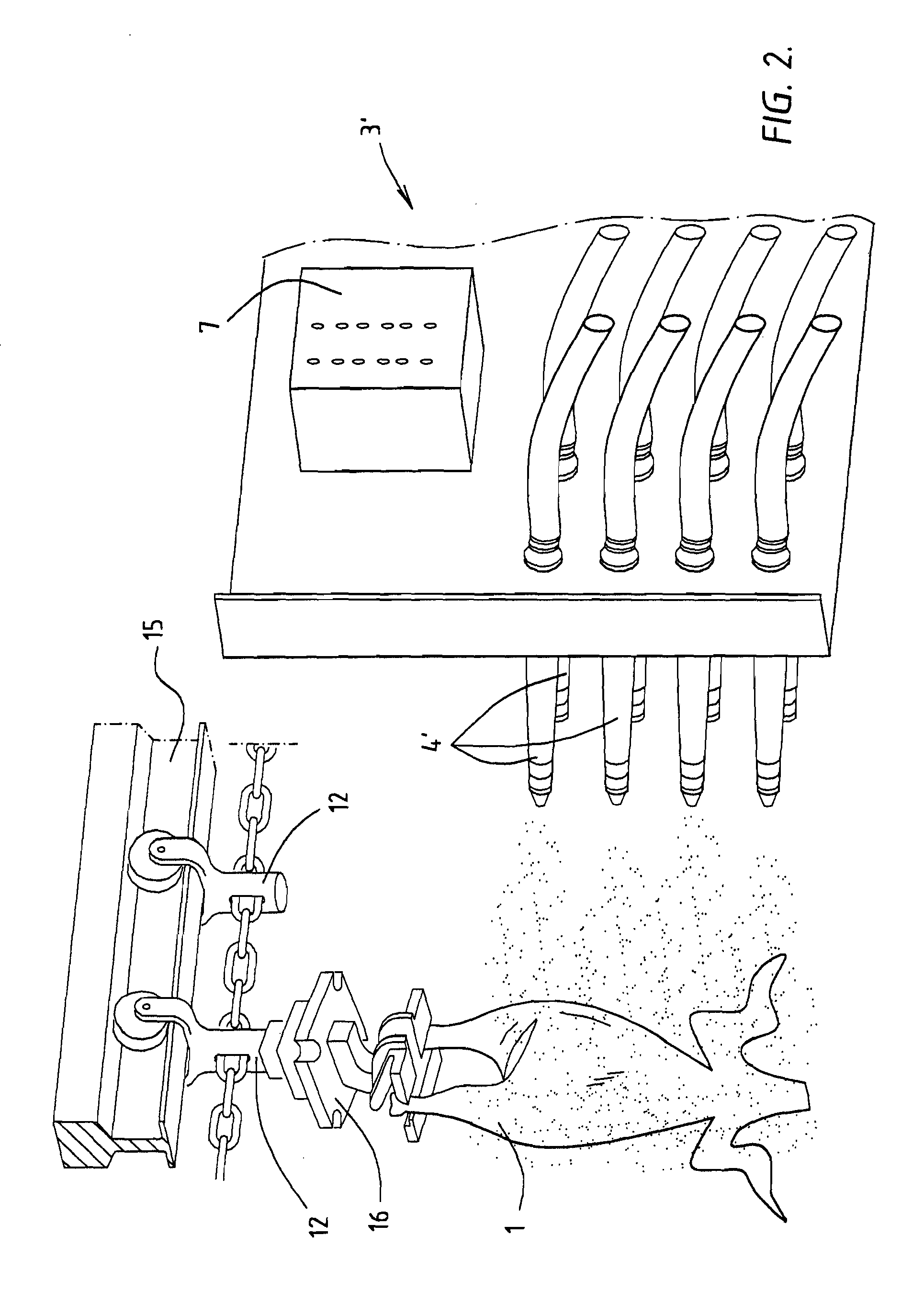

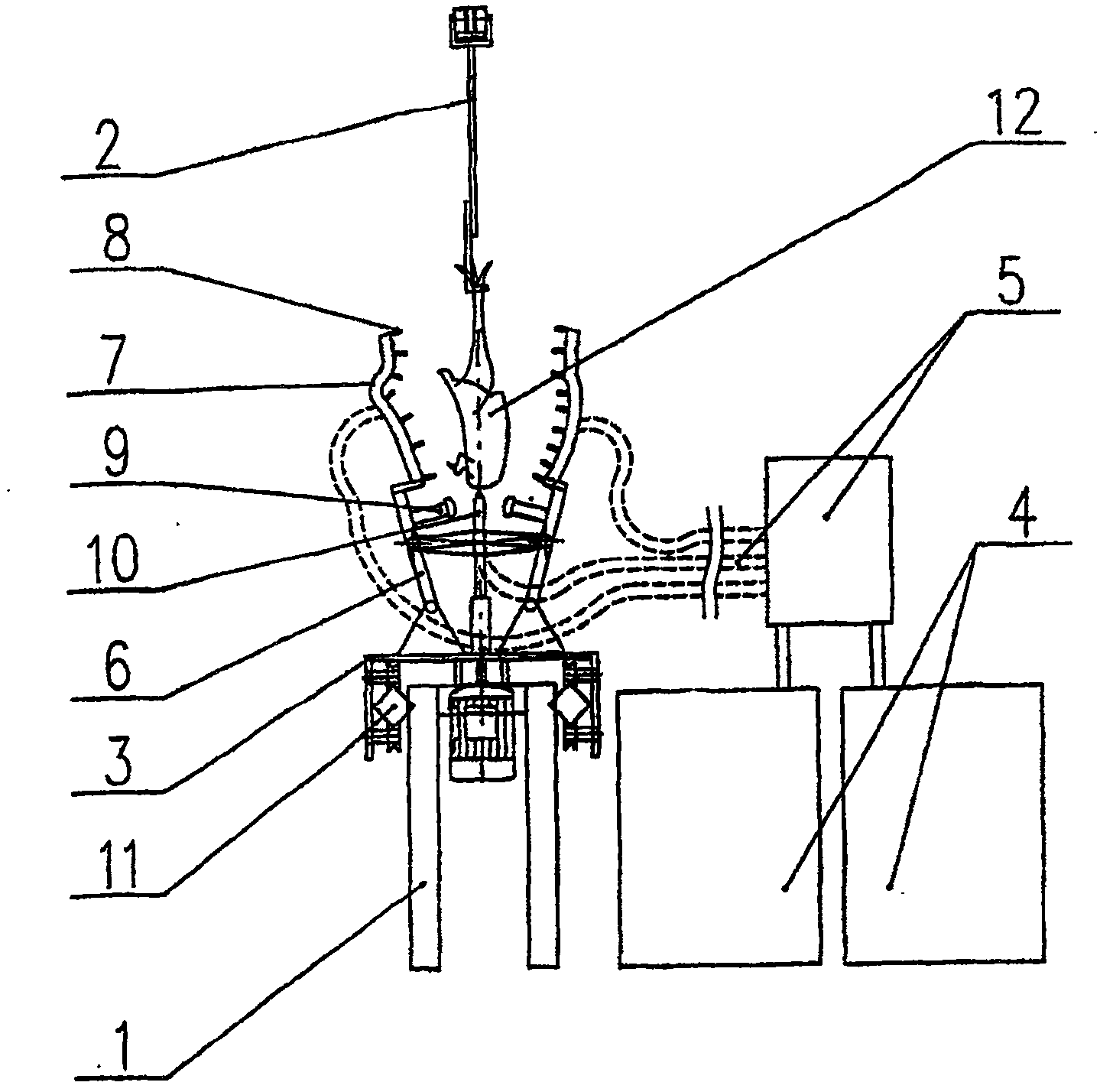

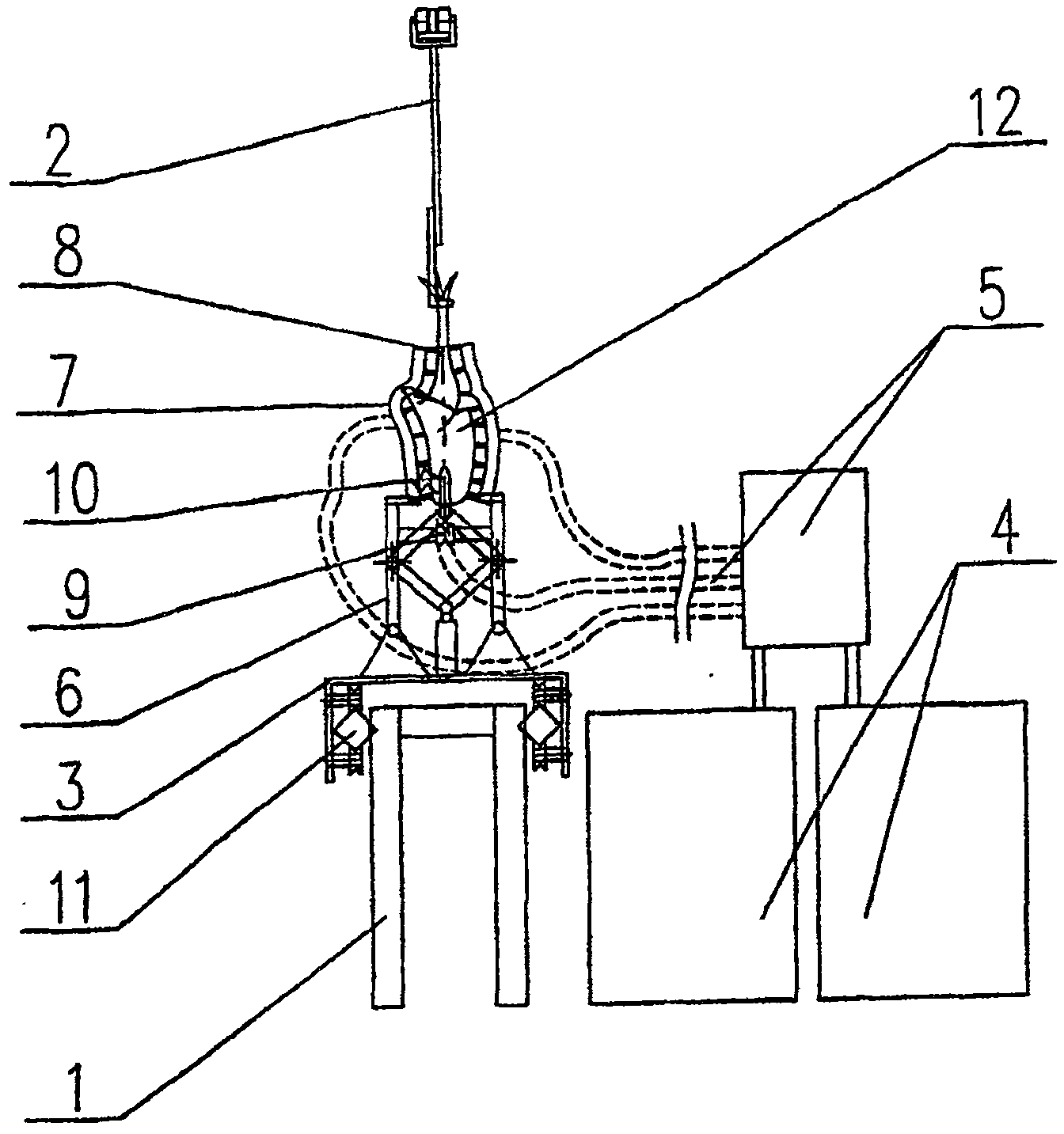

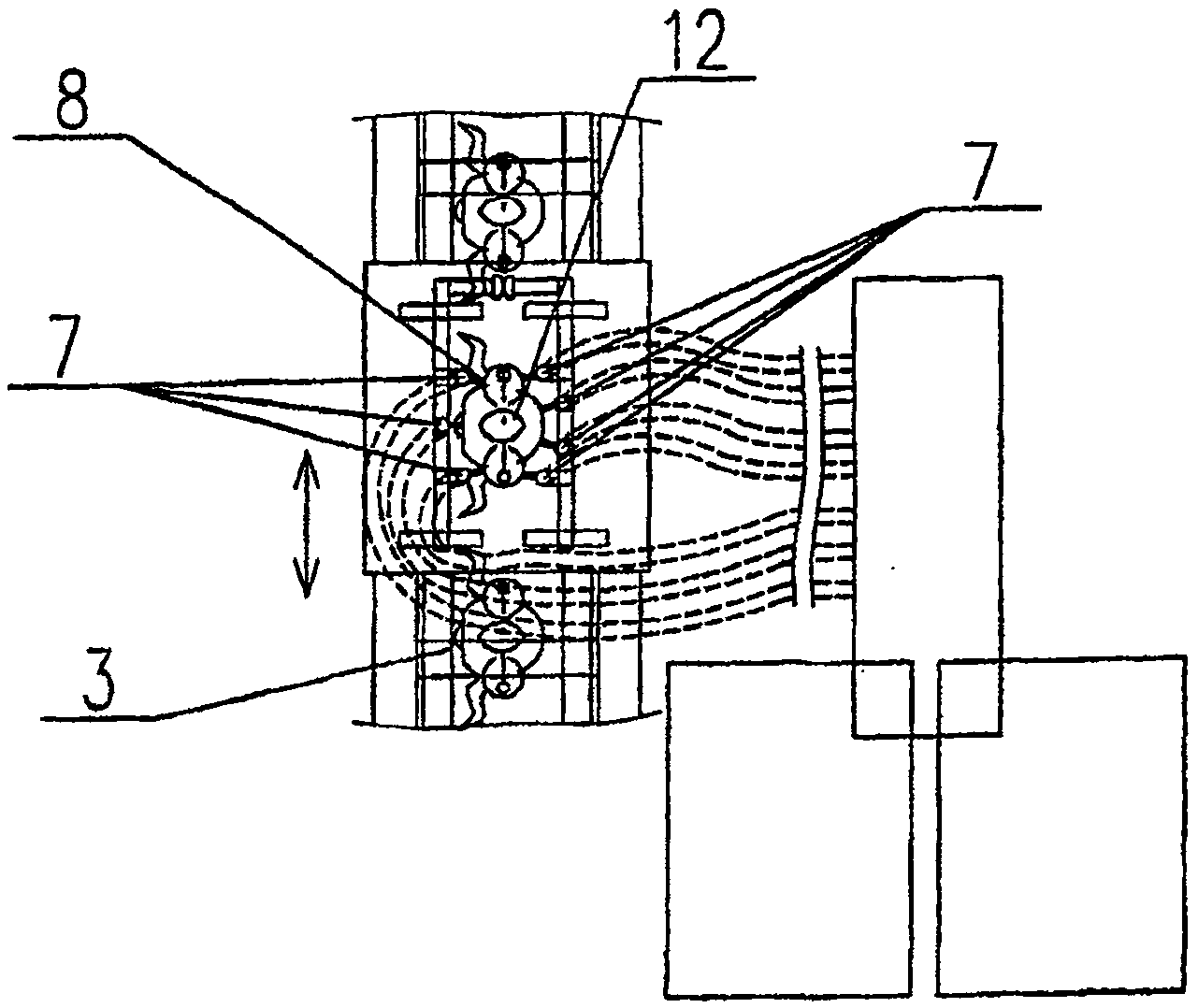

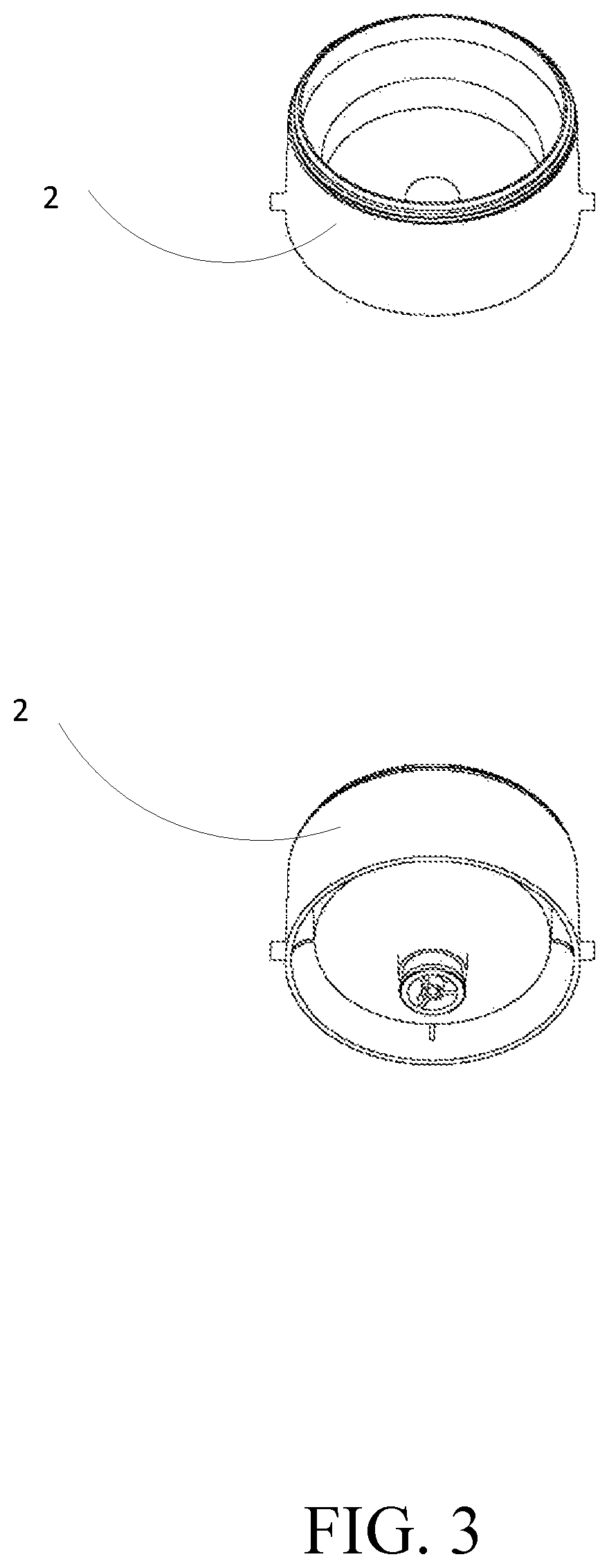

Device and method for introducing liquids into meat

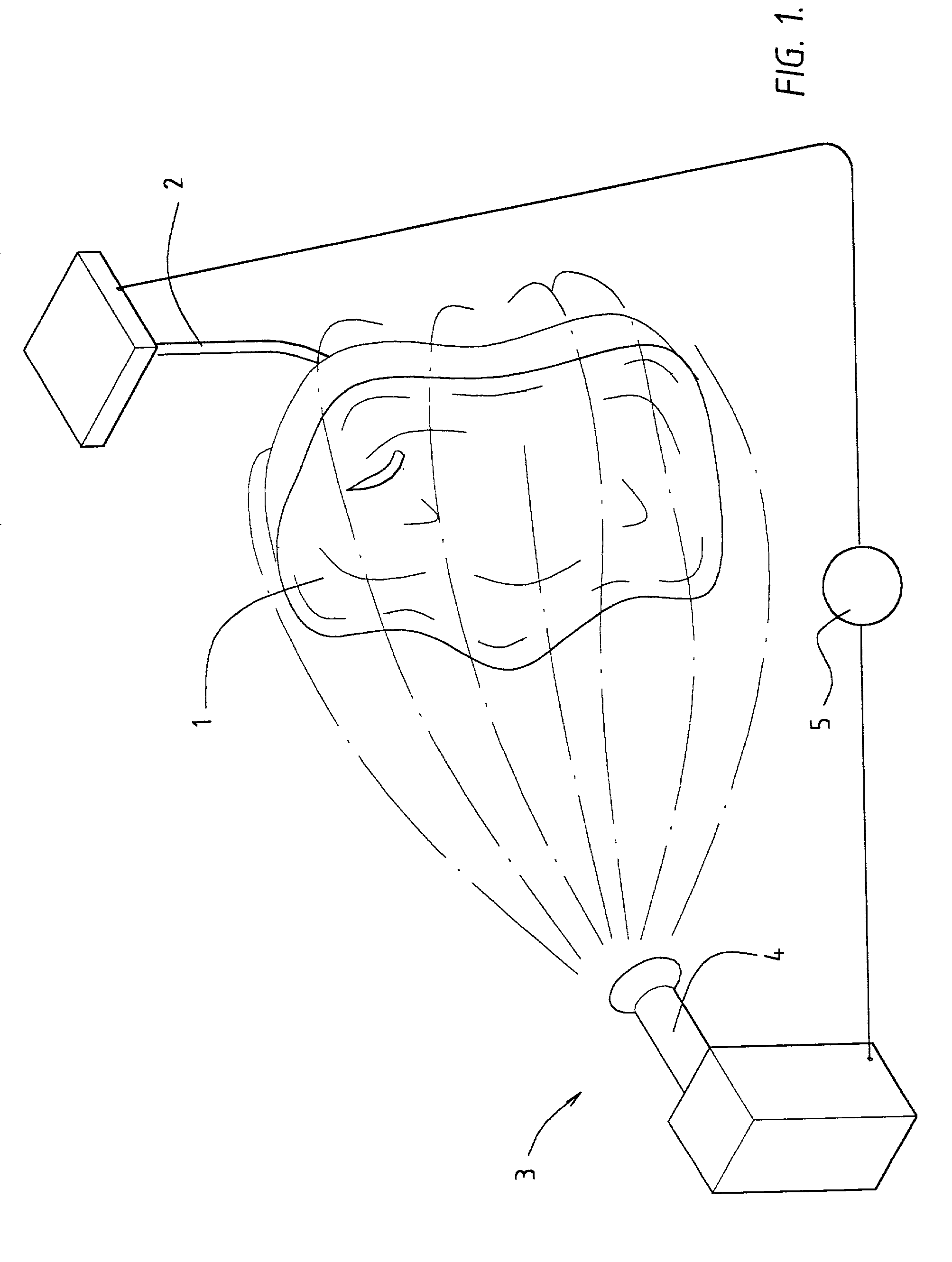

InactiveCN1725955BGuaranteed relative speedHigh speedInjection based meat processingClimate change adaptationNeedle Free InjectionSpray nozzle

Disclosed is a device and a method for introducing liquids into meat containing bones and / or cartilage or connective tissue, e.g. in the slaughtered body of poultry as well as in legs and belly meat, in order to treat, season, and / or preserve said meat. The aim of the invention is to create a device and a method which make it possible to simultaneously introduce exactly defined, even very small quantities of water, brine, preservatives, seasoning liquids, and / or other liquids in a manner that is adapted to the anatomy of the body of the slaughtered animal, even into meat containing bones and / or cartilage or connective tissue, within a very short period of time on almost any conveying unit, even an existing one, and even on a slaughtering conveyor belt, without using any needle while beinghighly effective and highly reliable, having a robust structure, and providing minimal tolerance of the injected quantity. Said aim is achieved by a device for introducing liquids into meat, comprising a base frame (1). Said device is characterized by the fact that one or several machine frame / s (3) is / are arranged in a rigid manner or so as to be movable in a linear direction on the base frame (1) while one / several injection device / s (6) which is / are used for needle-free injection and is / are connected to one / several high pressure unit / s (4) via one / several liquid distribution system / s (5) is / are disposed on the machine frame / s (3), each injection device (6) comprising one or several nozzle pipe / s (7) on which one or several spray nozzle / s (8) is / are arranged and which is / are disposed on the machine frame (3) so as to be deliverable. The inventive method is characterized by the fact that each of the nozzle pipes (7) as well as one / several spray lance / s (6) can be separately impinged upon by an identical and / or different, precisely defined pressure that is applied to different liquids for identical and / or different, exactly defined periods of time.

Owner:FEINA

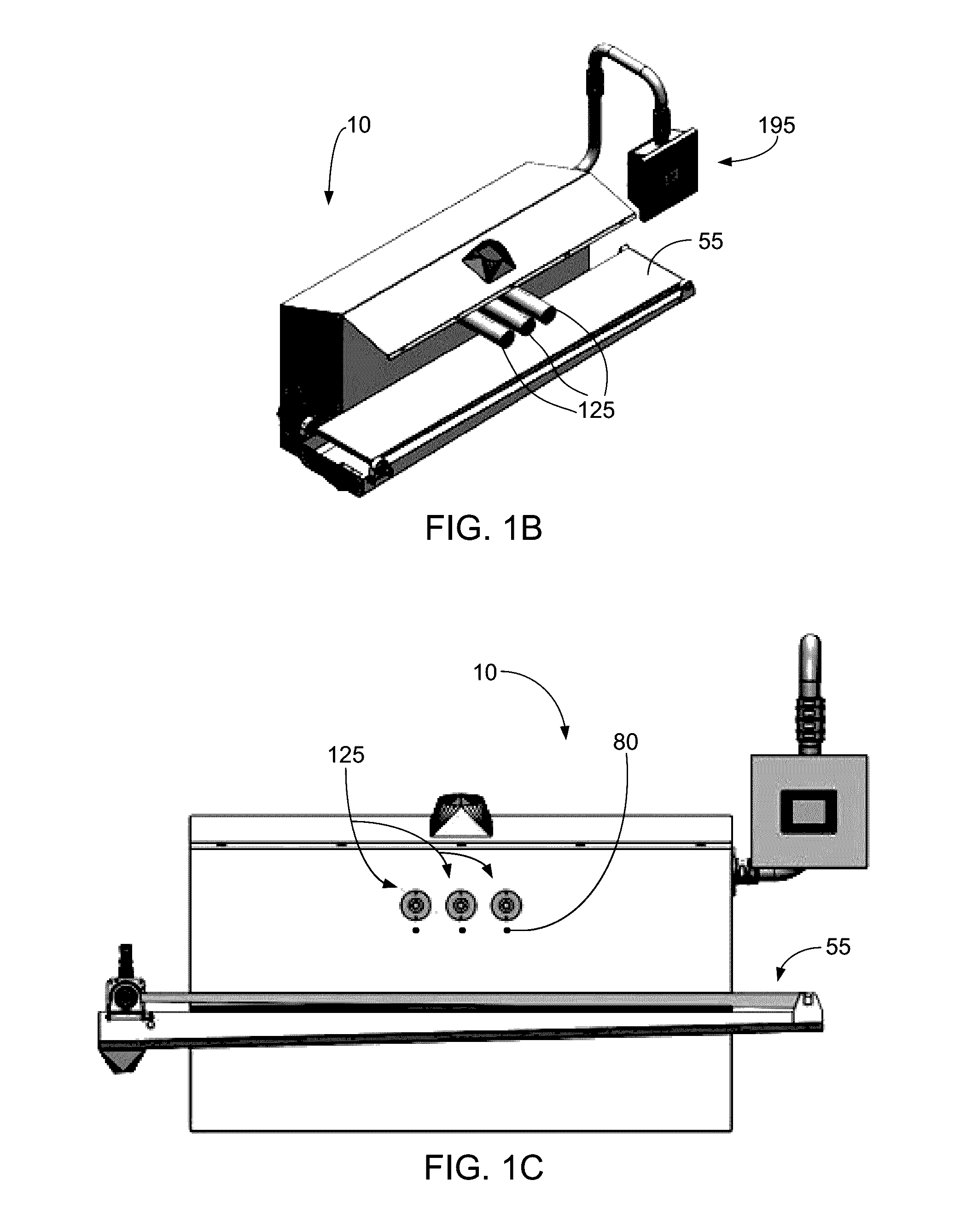

Systems and methods for providing food intervention and tenderization

ActiveUS20190364934A1Improve responseImprove throughputFruit and vegetables preservationInjection based meat processingSpray nozzleFood contact

Systems and methods for providing food intervention, pumping up, and tenderization are discussed. While such systems can include any suitable component, in some cases, they include a needleless spray nozzle head that injects injectade into food without requiring the head to contact the food. In some cases, the head comprises an elongated needleless spray bar that defines multiple internal fluid channels that extend from a first end to a second end of the spray bar. In some cases, the head comprises a manifold system with a first manifold portion at the first end and a second manifold portion at the second end of the spray bar. In some cases, the first manifold portion directs the injectade towards the second end, and the second manifold portion directs the injectade towards the first end of the elongated needleless spray bar. Other implementations are described.

Owner:S2I LLC

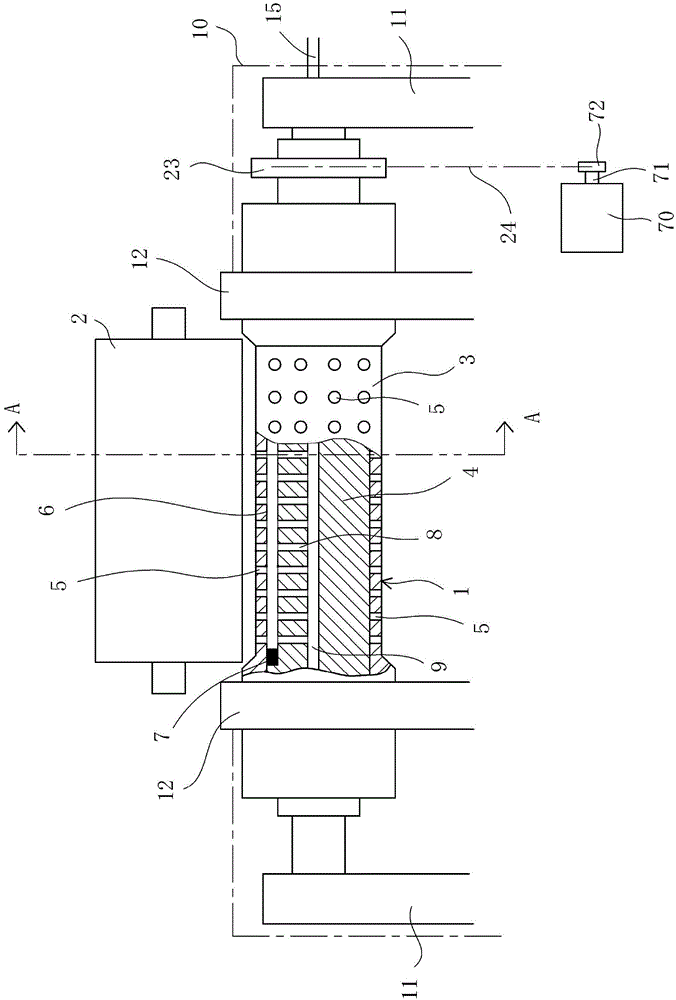

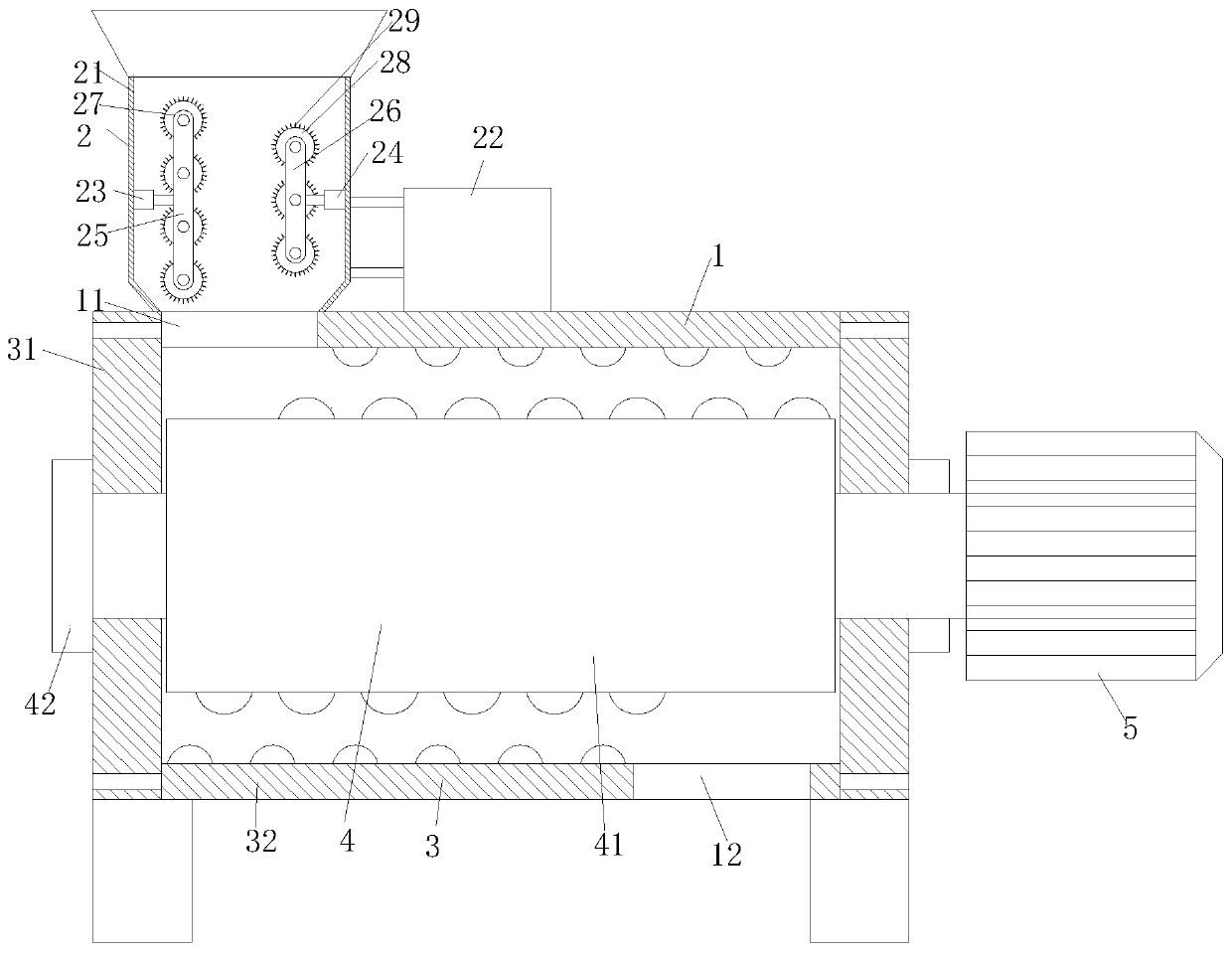

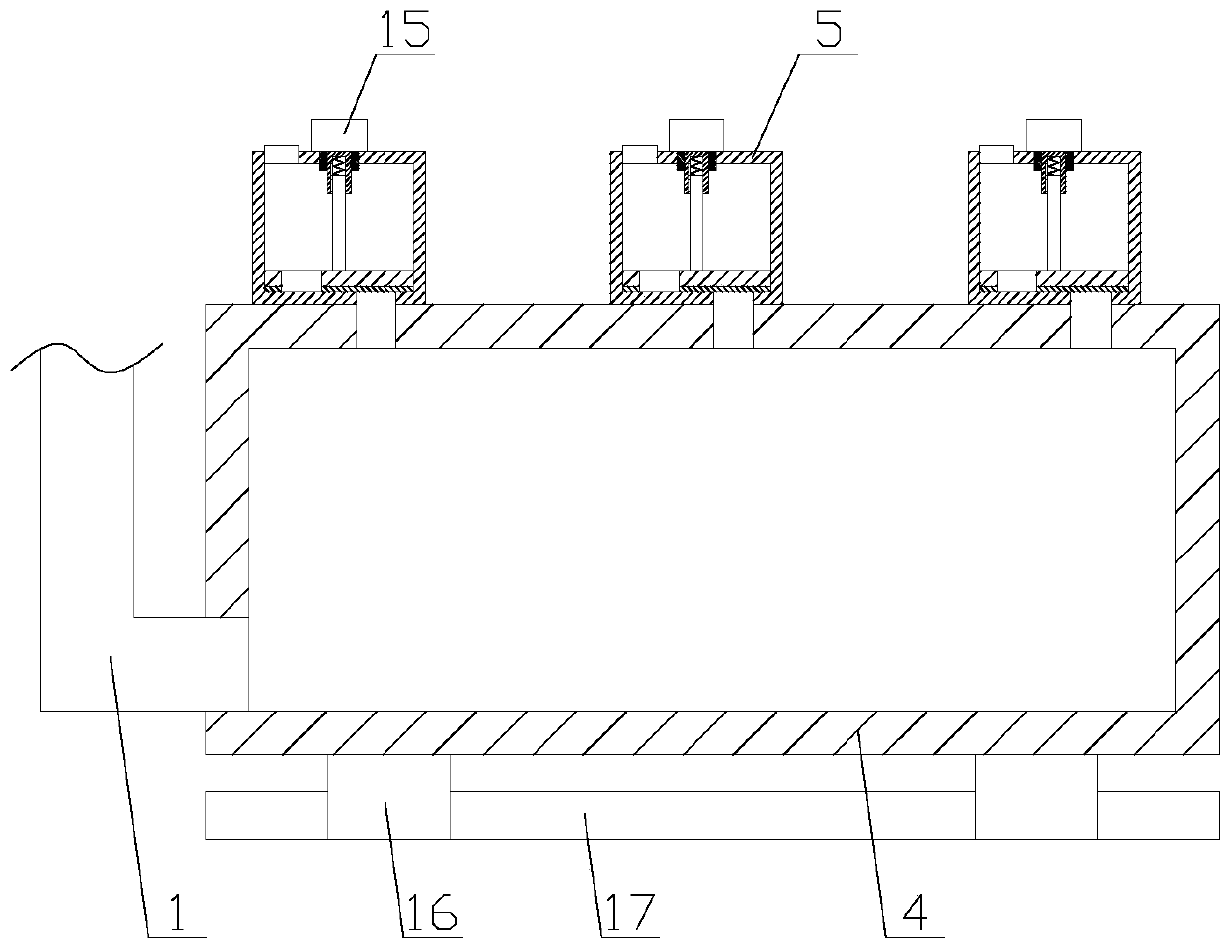

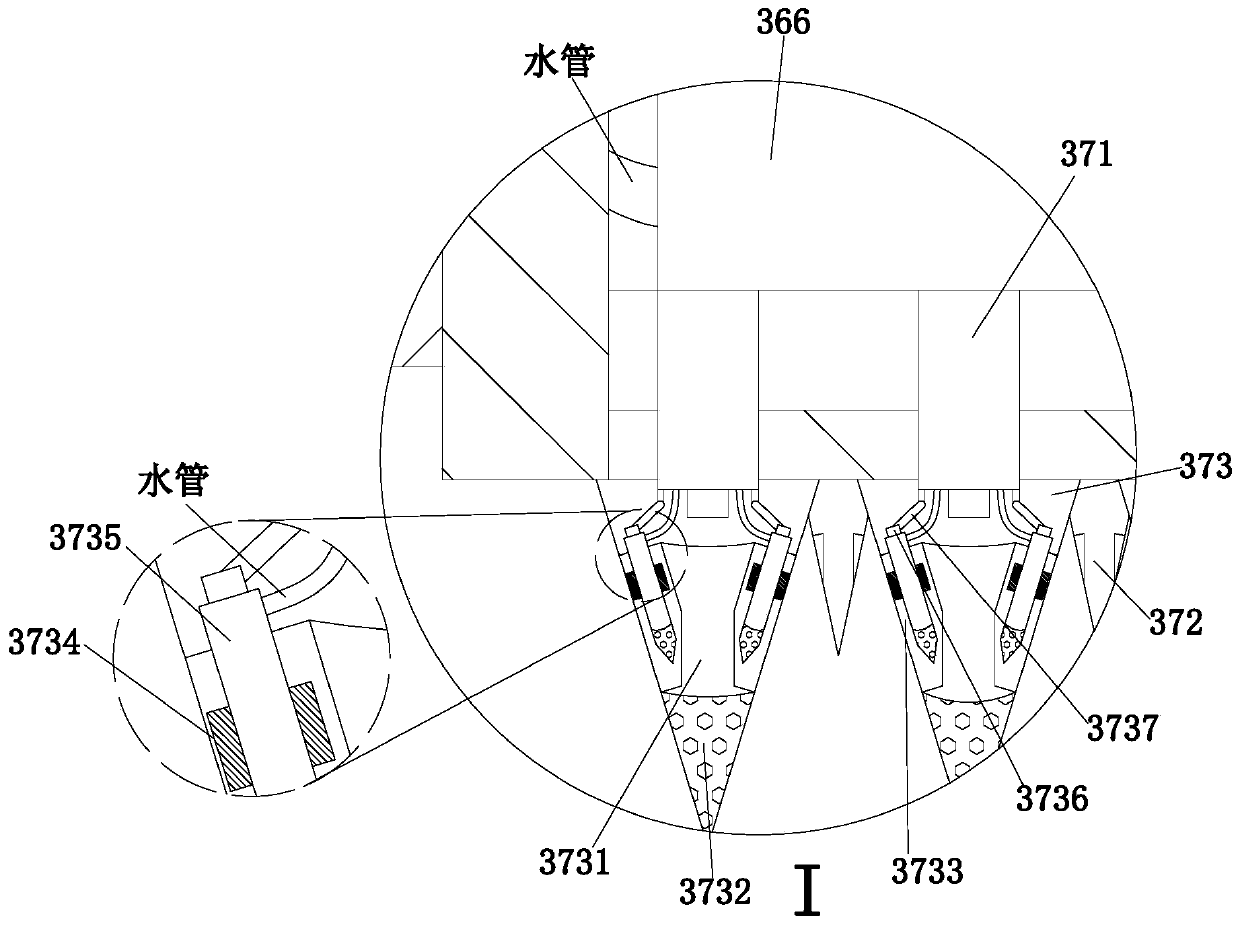

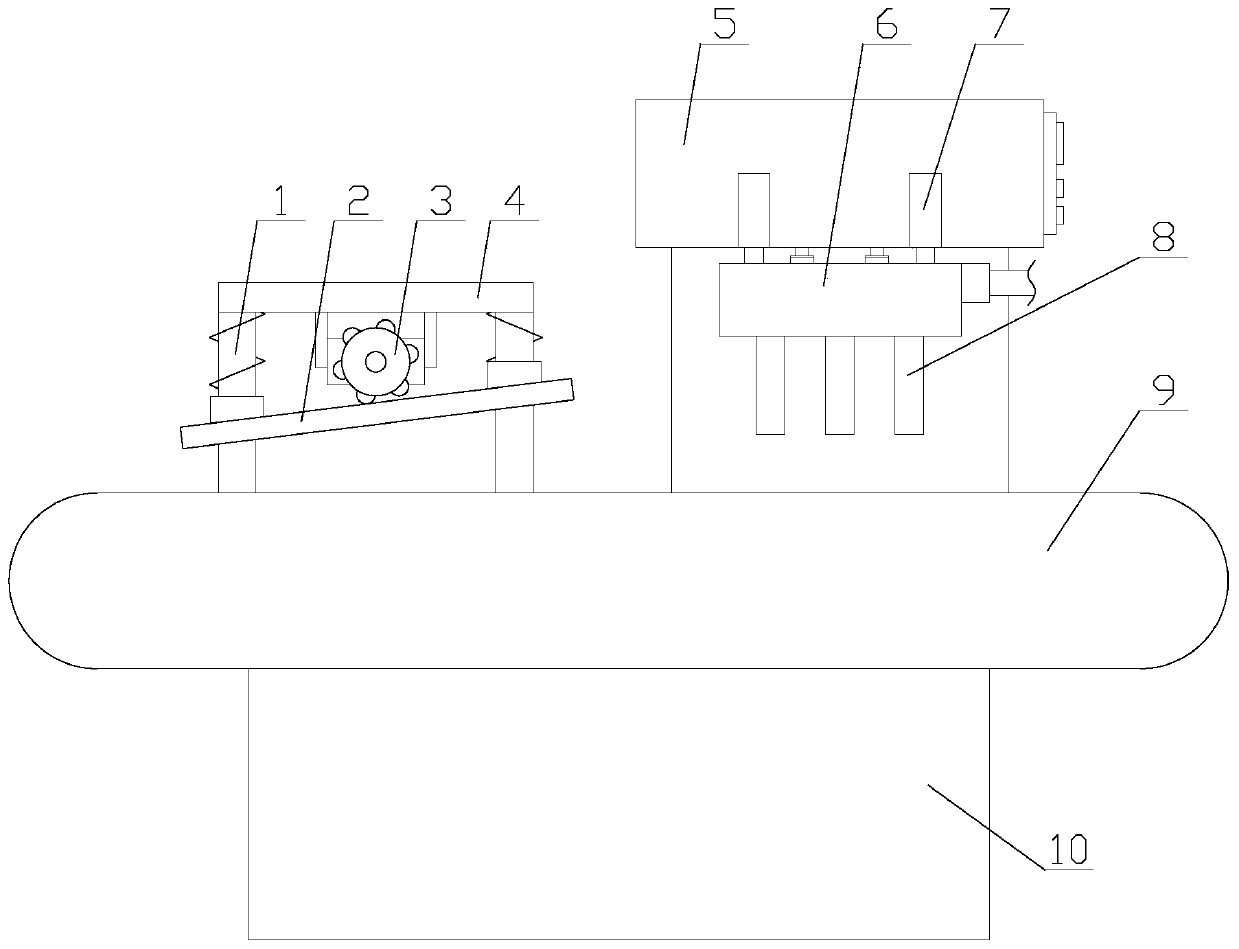

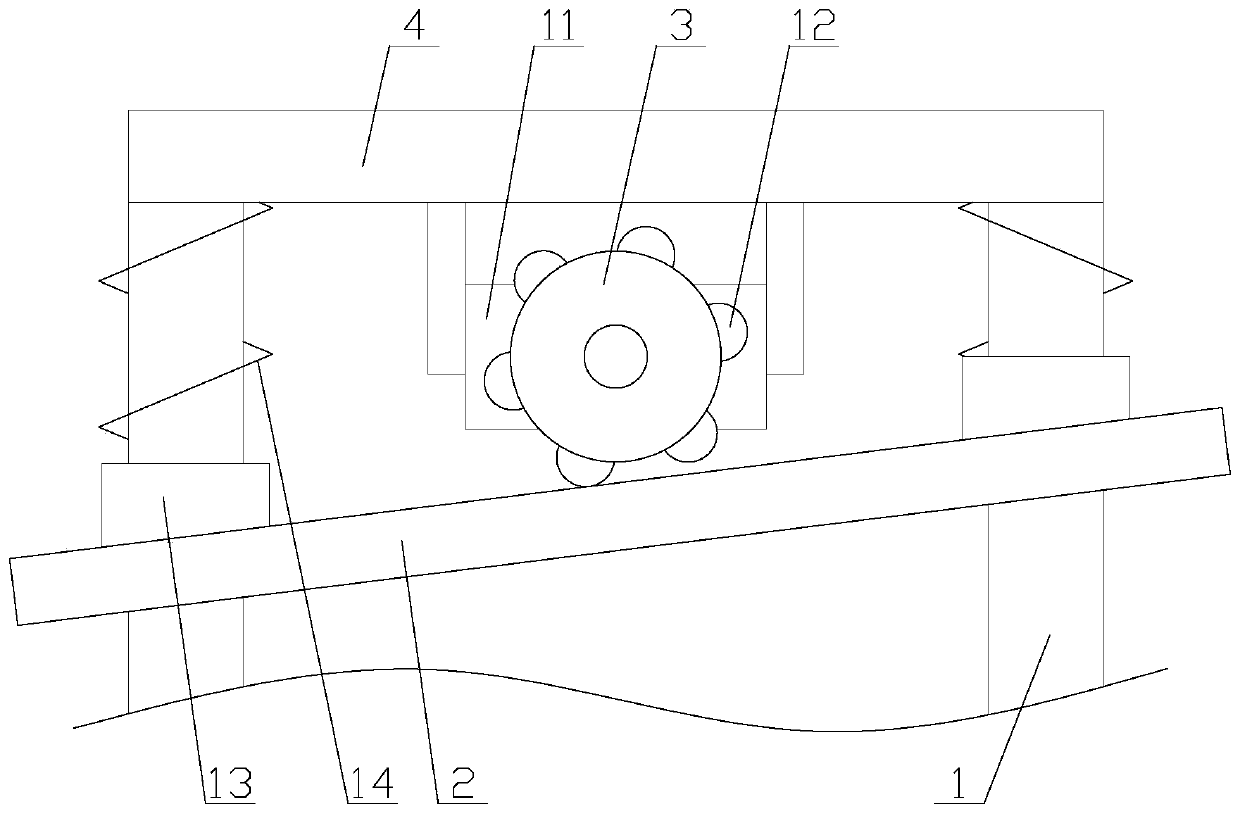

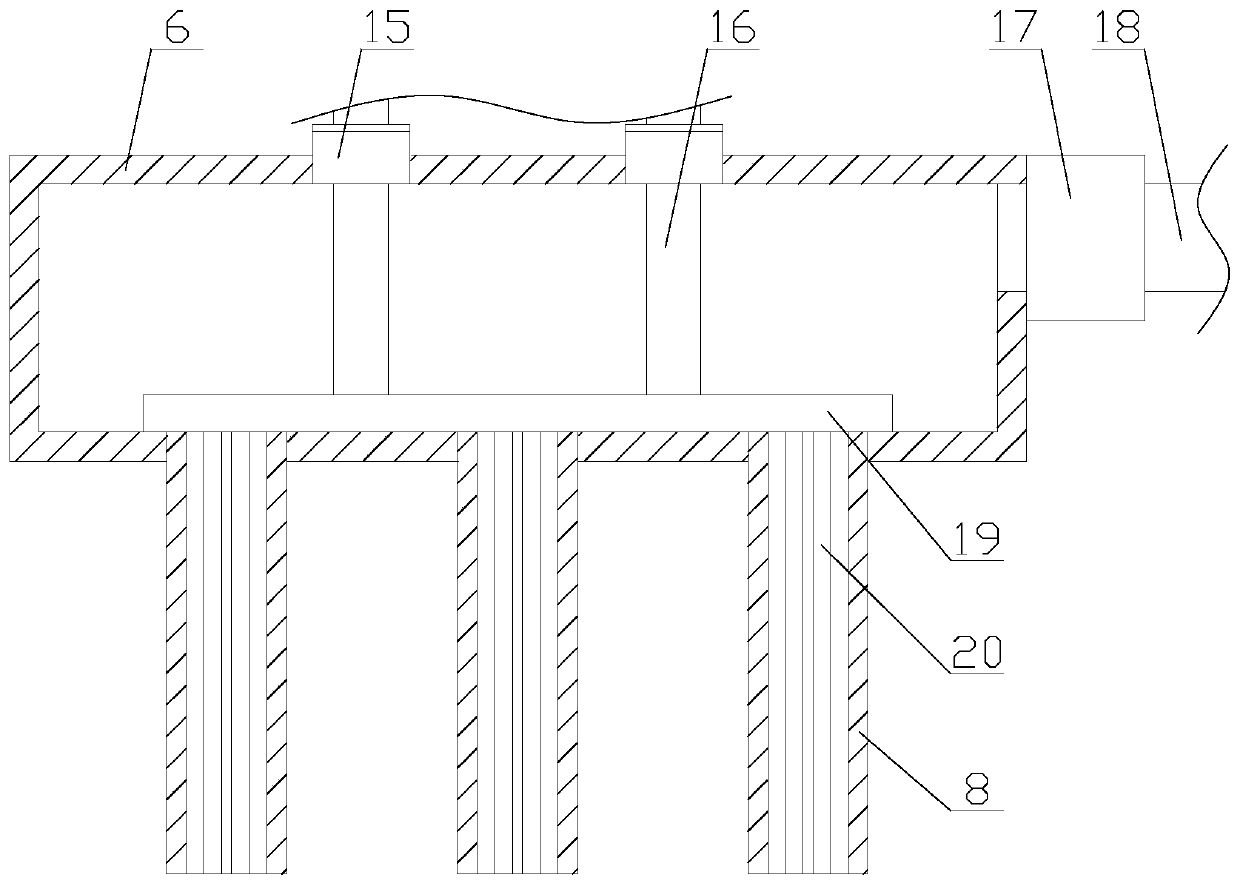

Beefsteak tendon breaking water injection machine

InactiveCN111670936AKeep the tasteEasy to handleInjection-based meat tenderisingApparatus for force/torque/work measurementHydraulic cylinderControl system

The invention discloses a beefsteak tendon breaking water injection machine. The machine comprises a bottom box; four supporting columns are fixedly arranged at the four corners of the upper end faceof the bottom box; an upper cover plate is fixedly arranged on the upper end faces of the four supporting columns; a pressure detection mechanism is arranged on the lower end face of the upper cover plate; the pressure detection mechanism comprises a hydraulic cylinder fixedly connected with the upper cover plate; the lower end of a hydraulic rod controlled by the hydraulic cylinder is fixedly connected with a first placement block; the lower end of the first placement block is fixedly connected with a pressure plate; two hundred and fifty-six pressure cavities with downward openings are evenly distributed in the pressure plate; and spherical pressure blocks connected in a sliding mode are arranged in the pressure cavities. According to the machine, a pressure sensor is used for carrying out pressure induction on beefsteak, the distribution of tendons and meat in the beefsteak is obtained through analysis of a control system, the distribution of a water injection needle and a tendon breaking knife is controlled, a relatively good beefsteak tendon and meat treatment effect is achieved, tendon breaking and water injection of the beefsteak are carried out at the same time, repeated puncture is avoided, and the taste of the beefsteak is retained.

Owner:GUANGZHOU FENGE FOOD TECH CO LTD

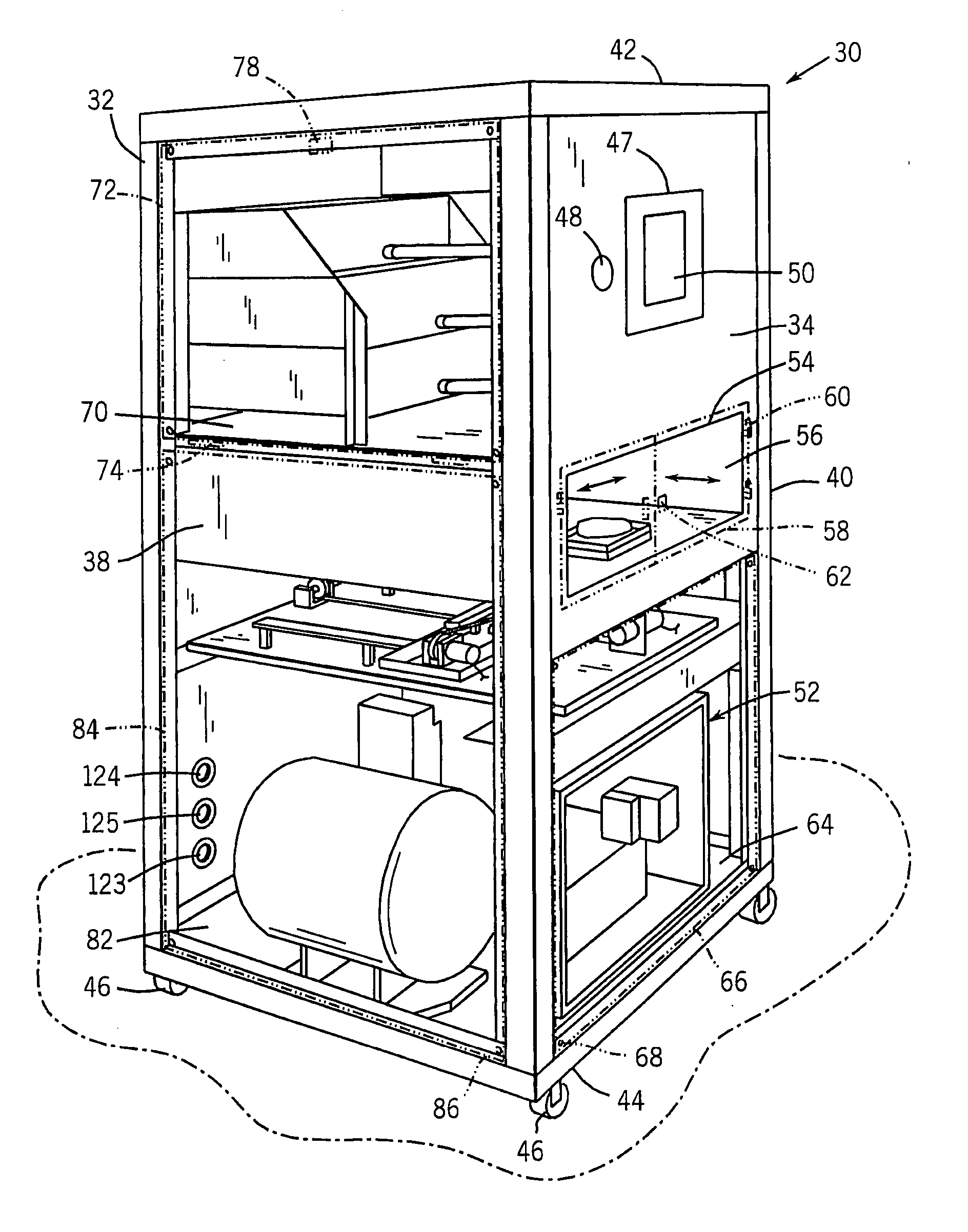

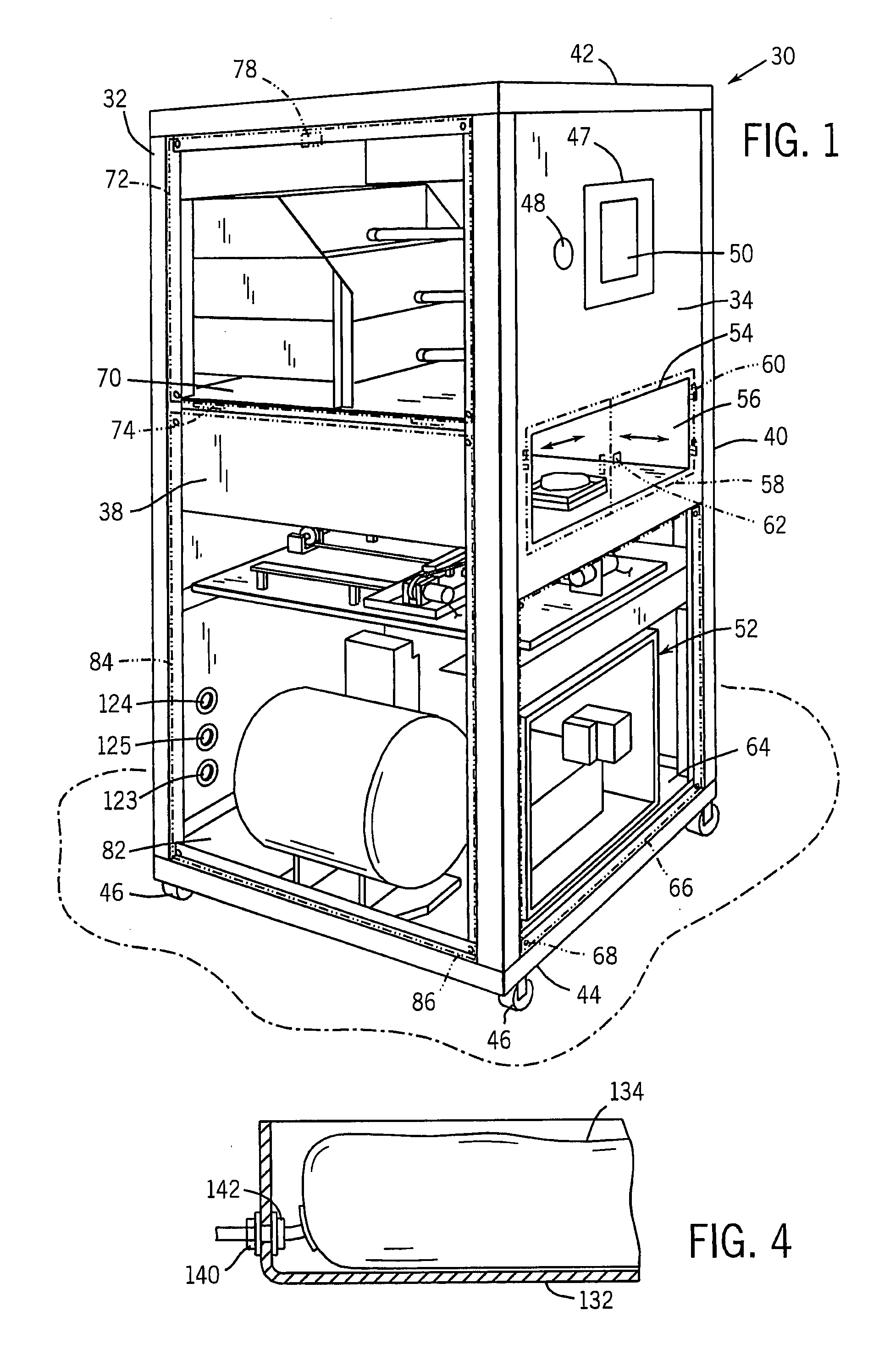

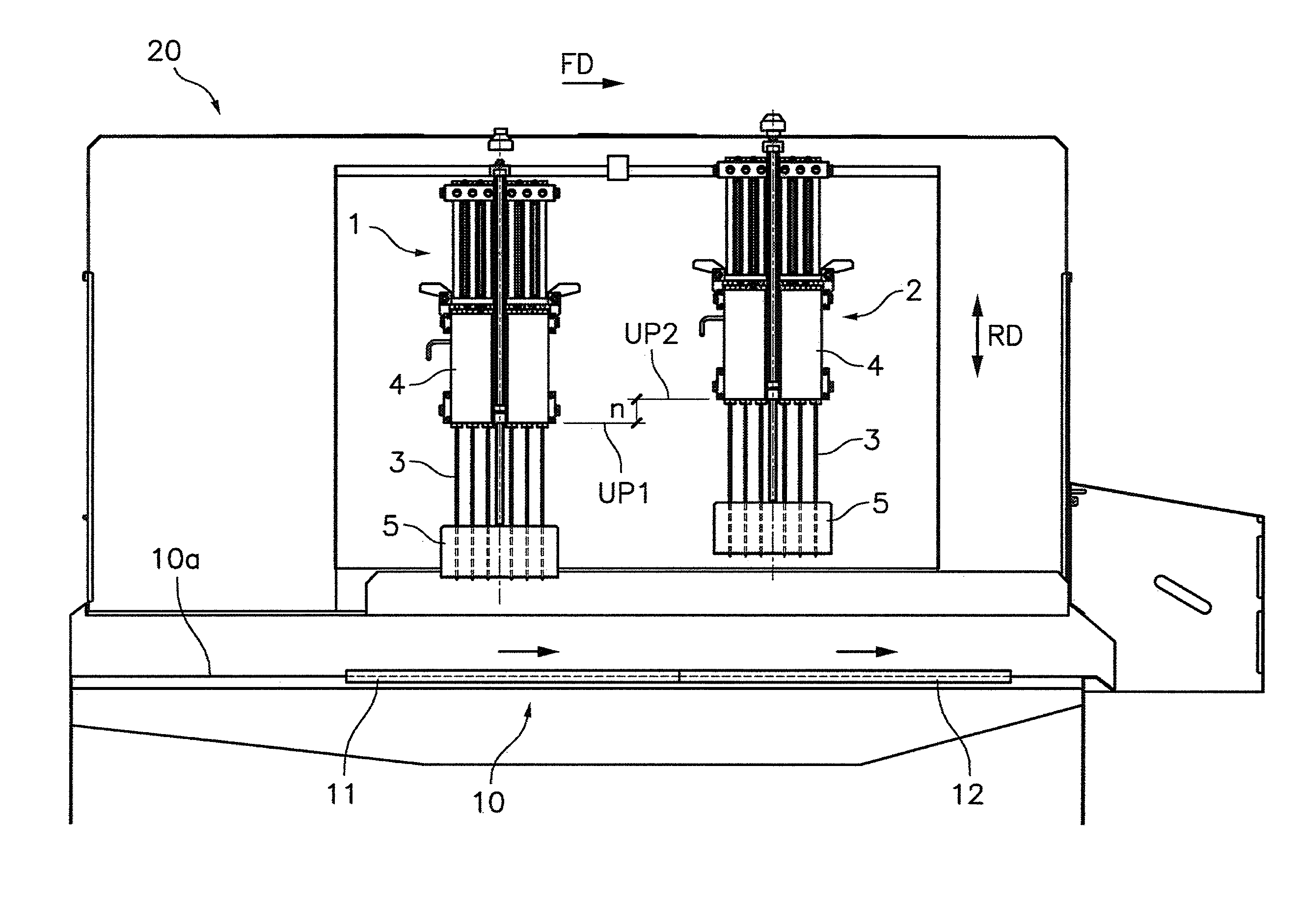

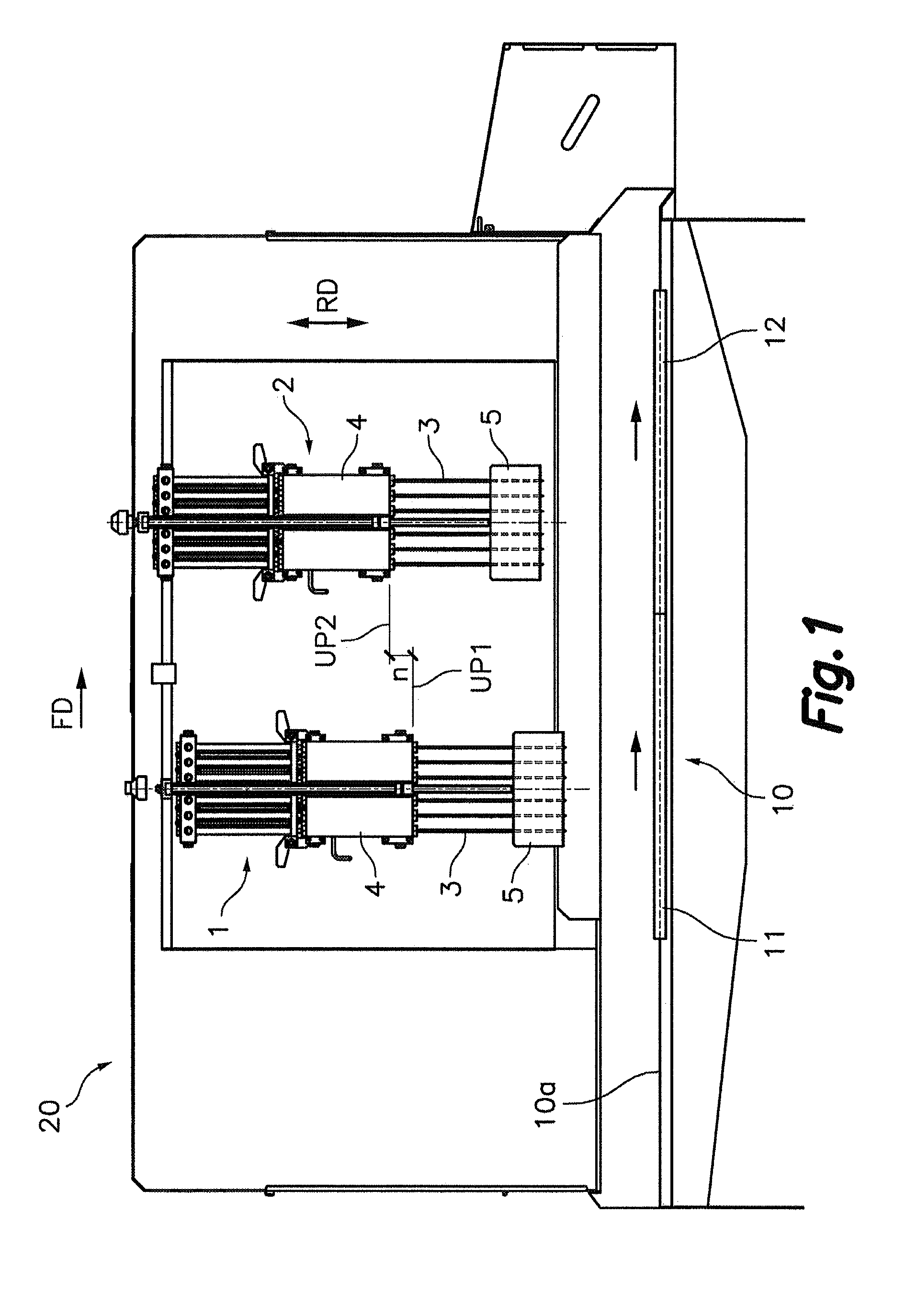

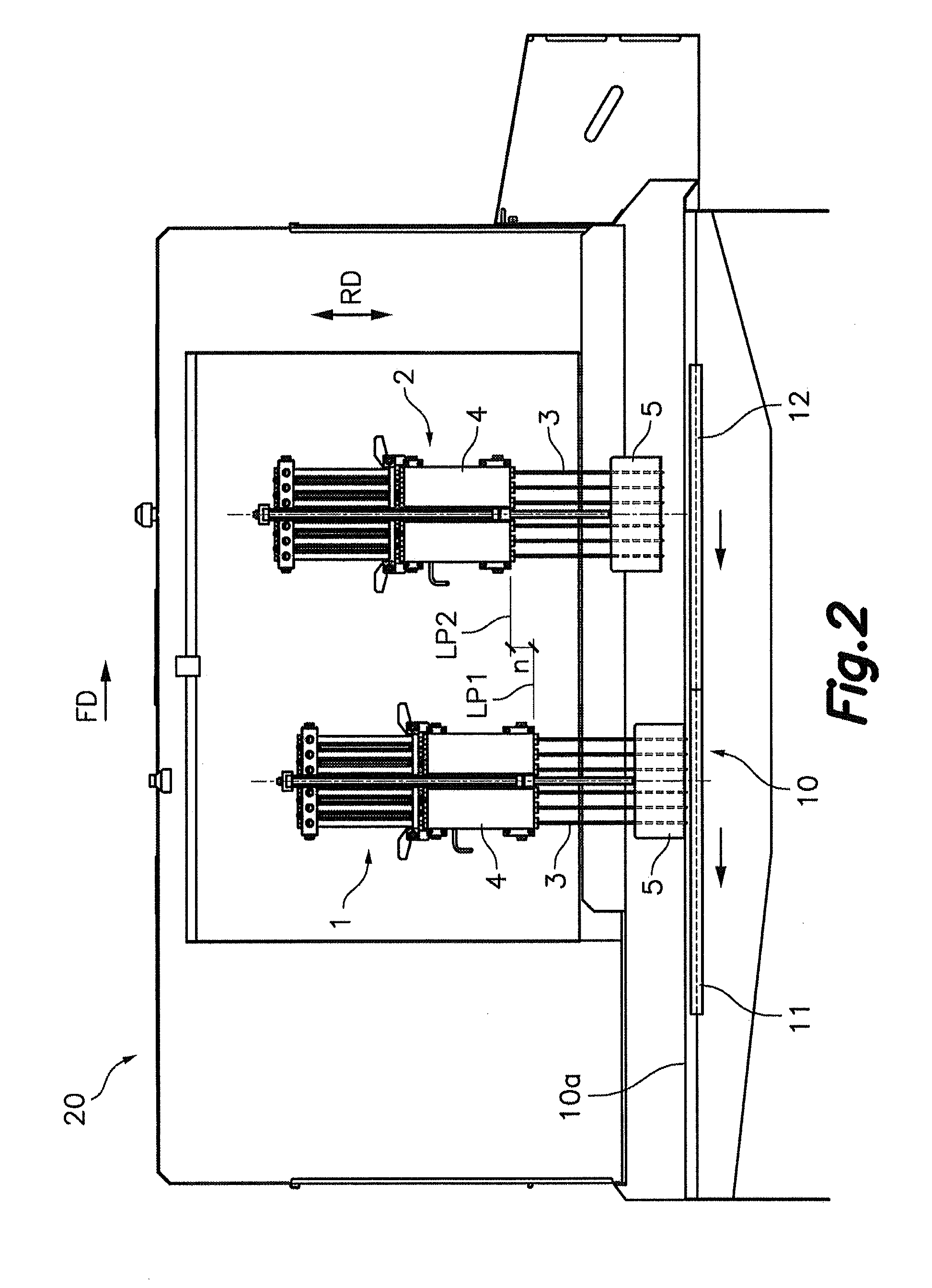

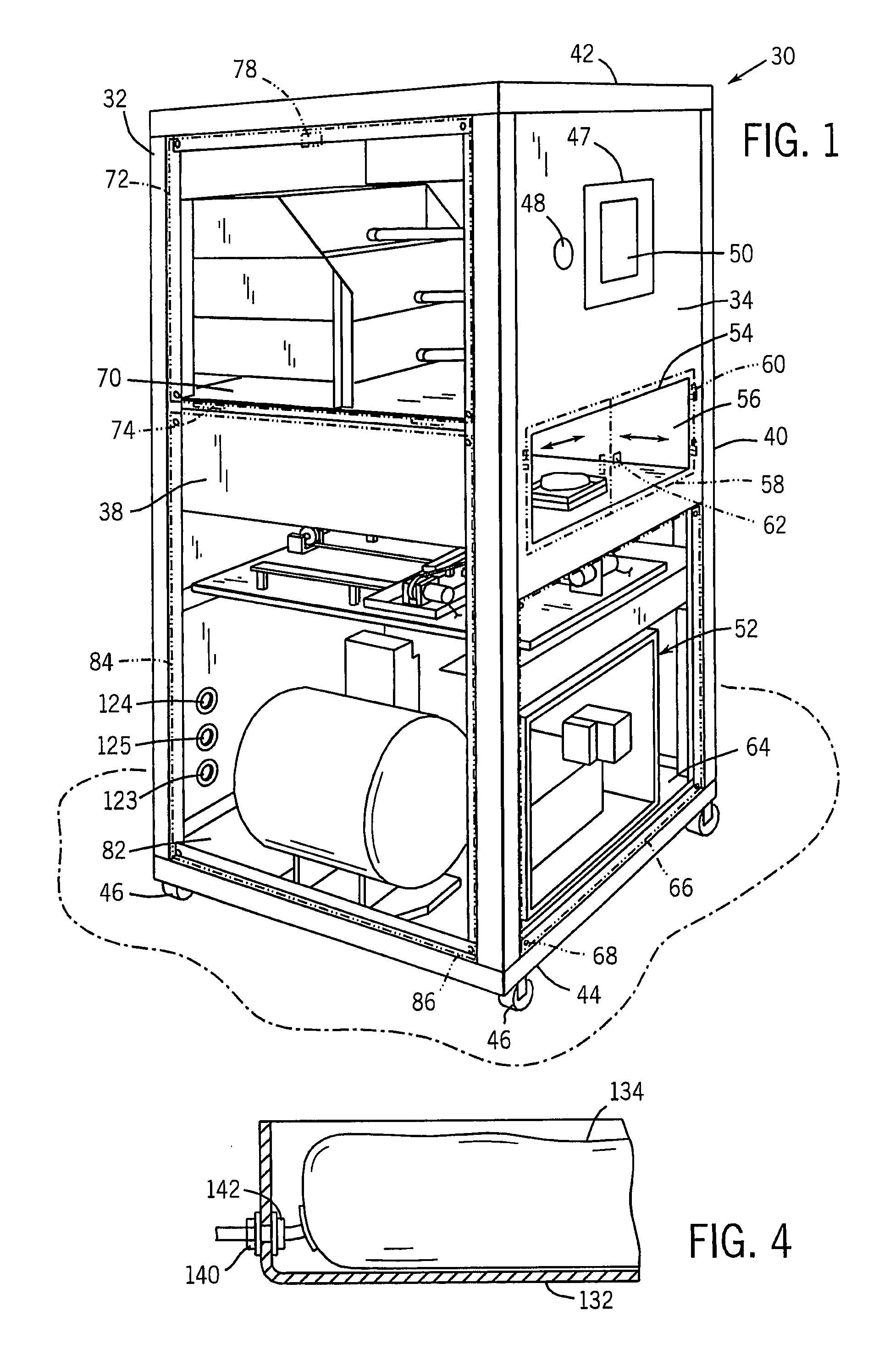

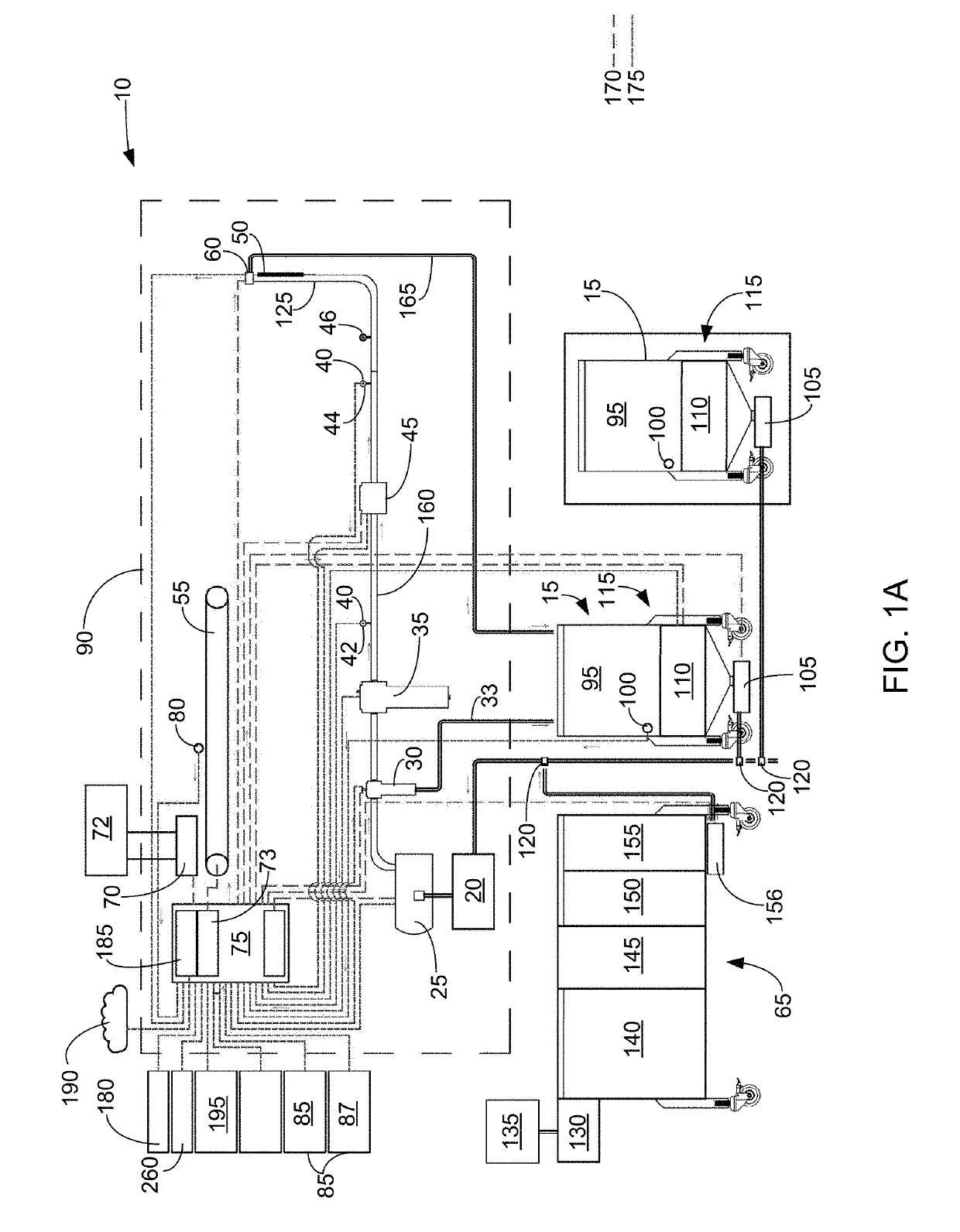

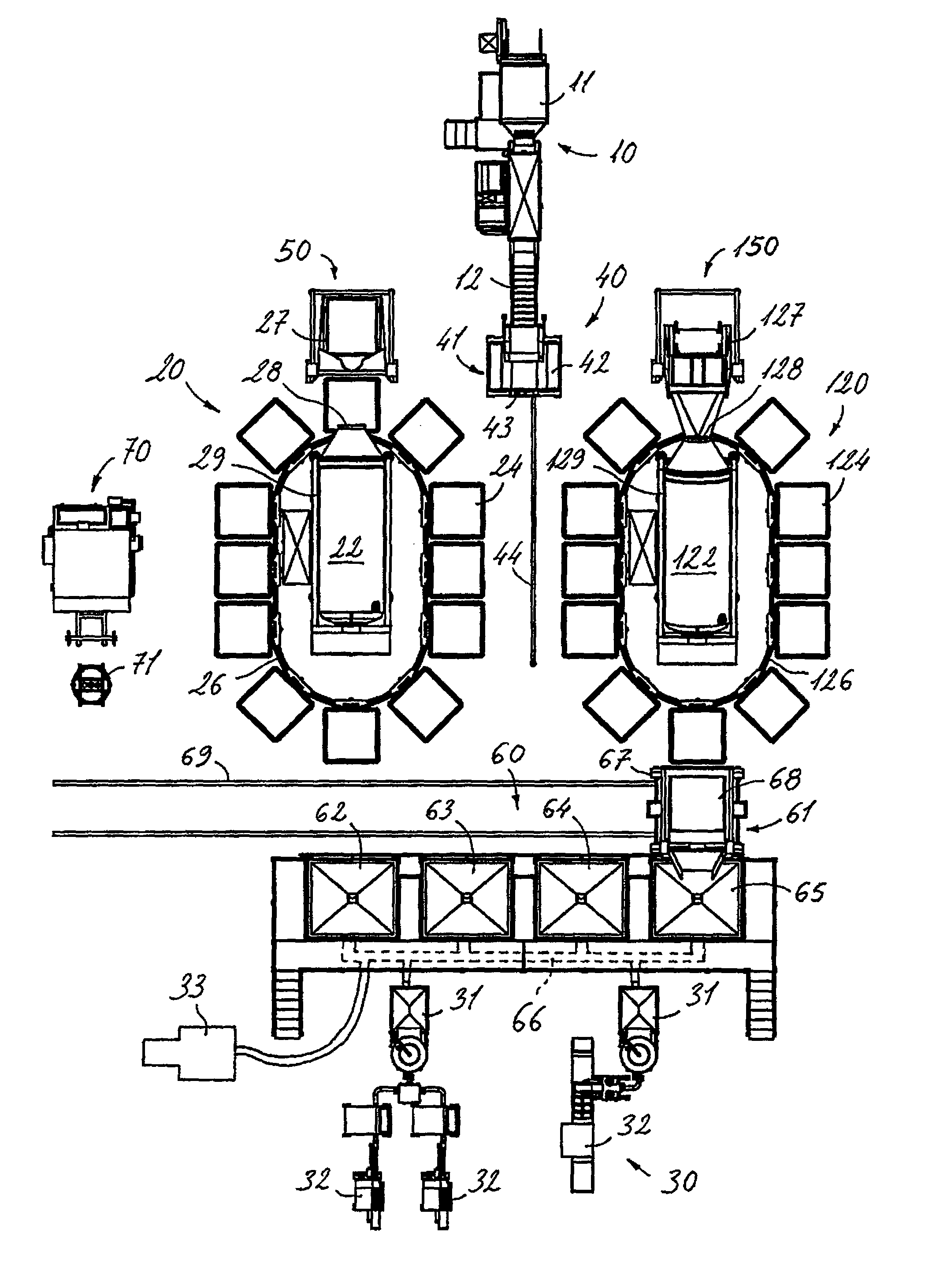

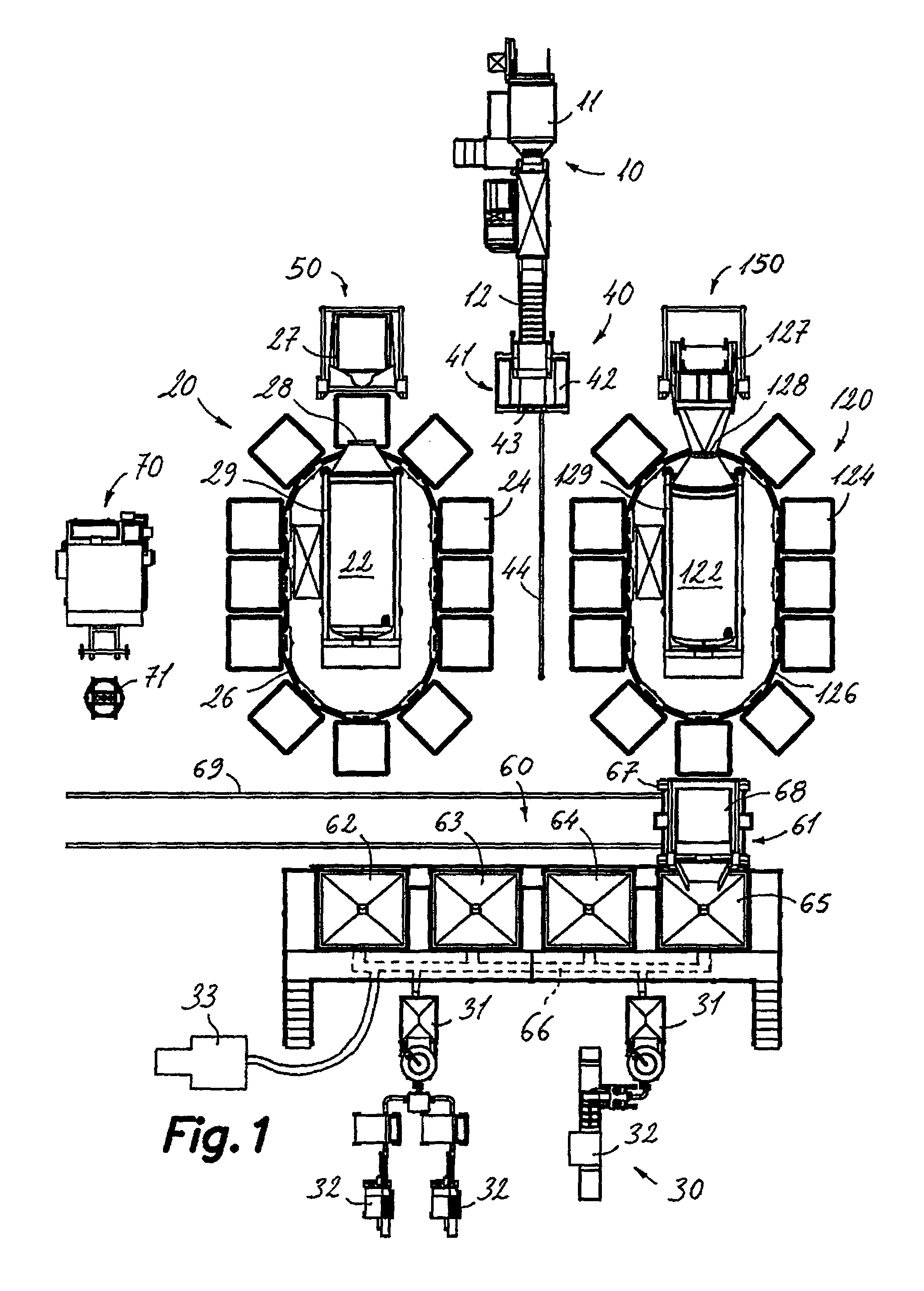

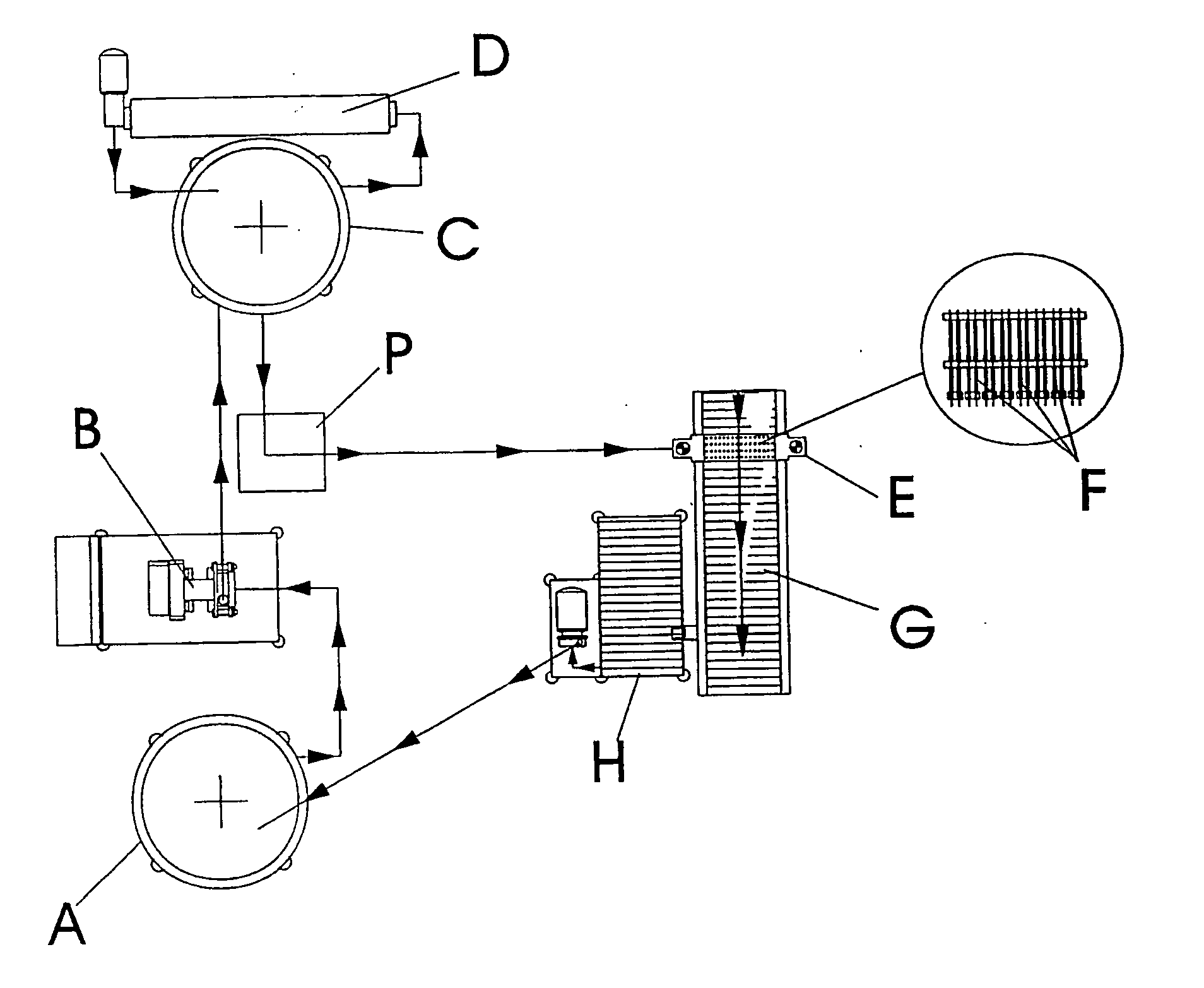

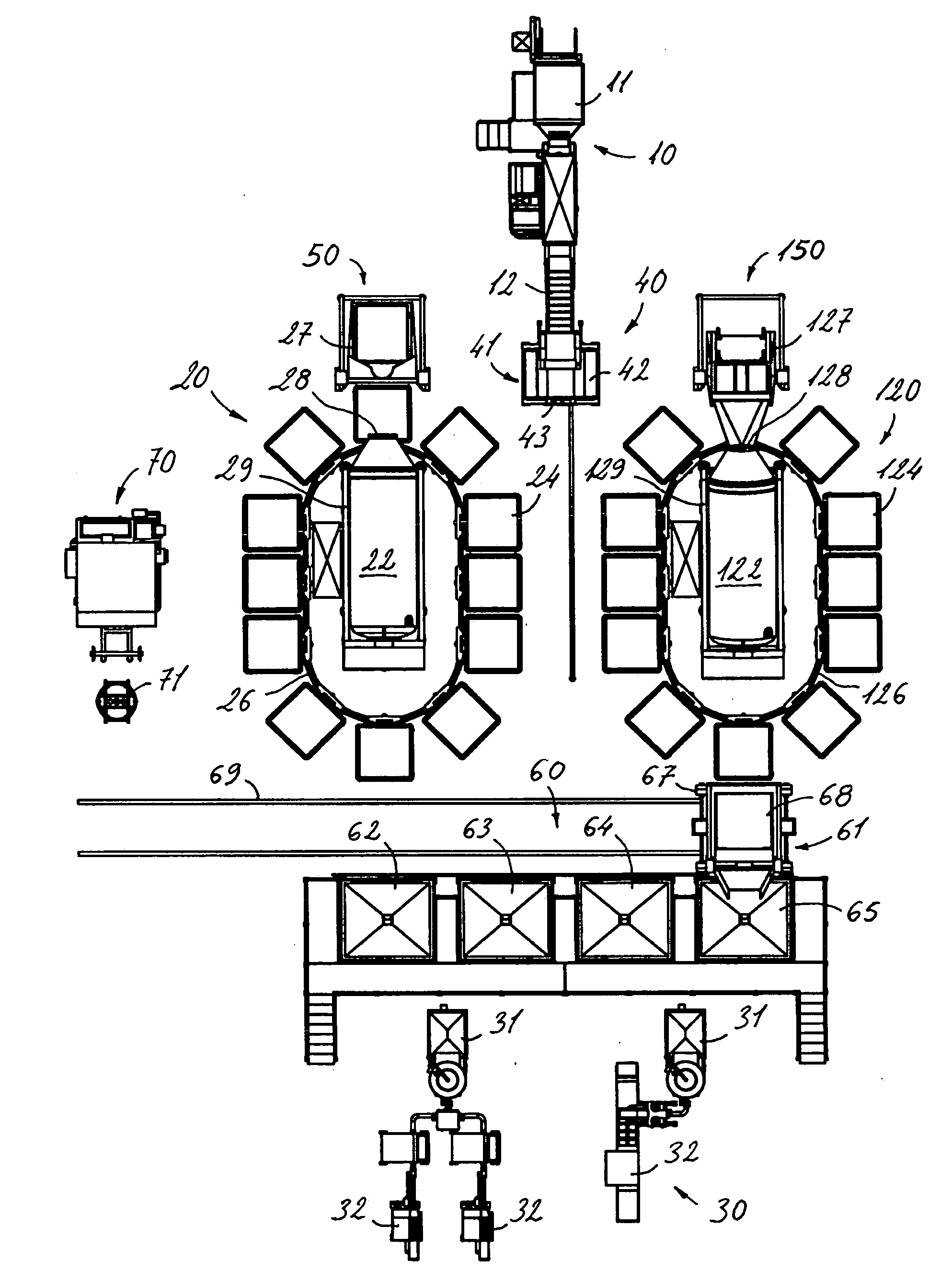

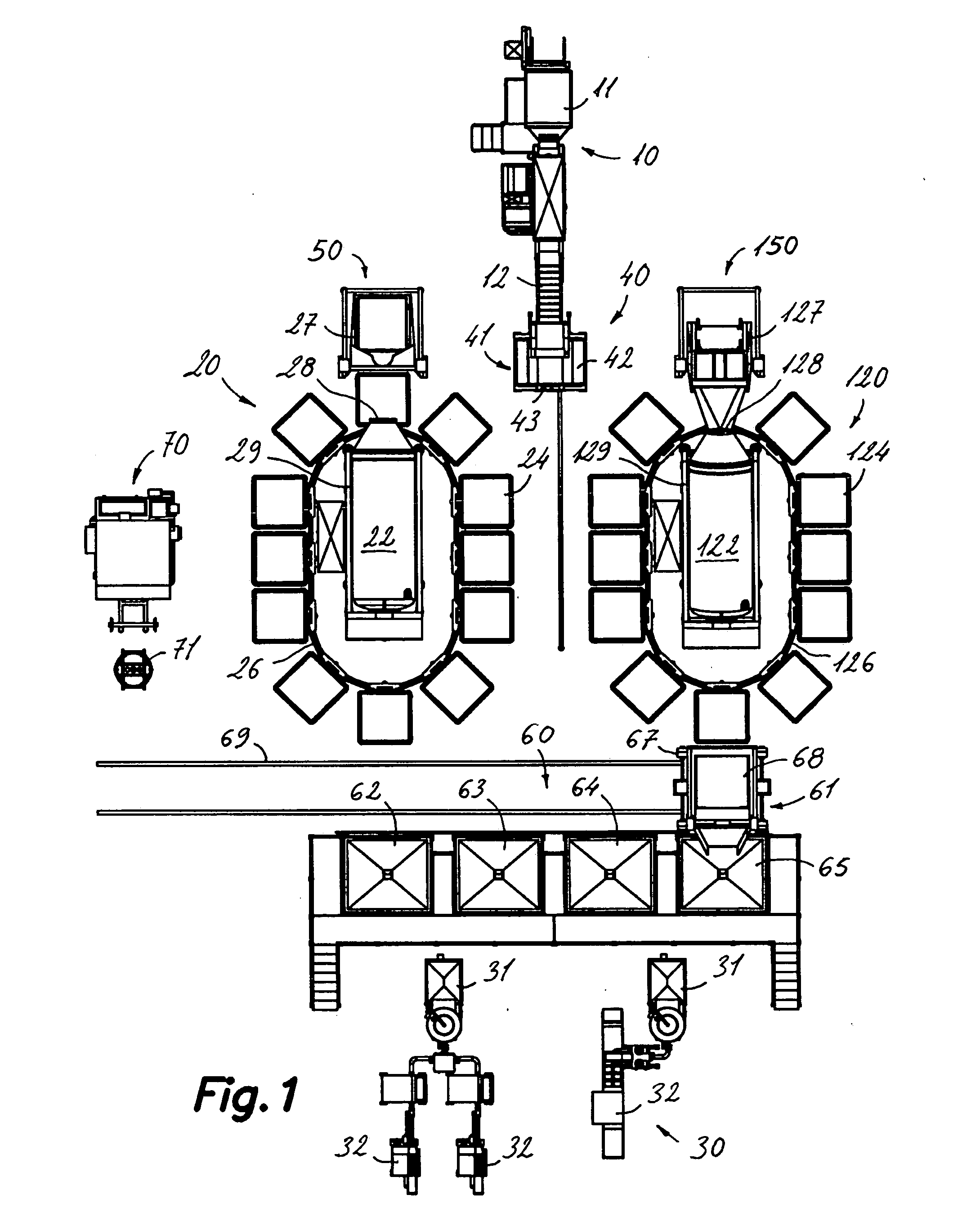

Automatic plant for the treatment and packing of meat product

An automatic plant for the treatment and packing of meat product, including an injection station for injecting brine into a meat product, first and second maceration stations for macerating the injected meat product, and a packing station for packing the treated meat product. The injection station is connected to the first and second maceration stations by an accumulating and loading unit for accumulating meat product coming from the injection station and selectively loading it into the first and second maceration stations which are connected to the packing station by a transfer unit adapted for transferring the meat product from the first and second maceration stations to feed hoppers for feeding the packing station. The plant is controlled by computerized control.

Owner:METALQUIMIA SA

Tenderization of meat

Owner:HYDRODYNE INC

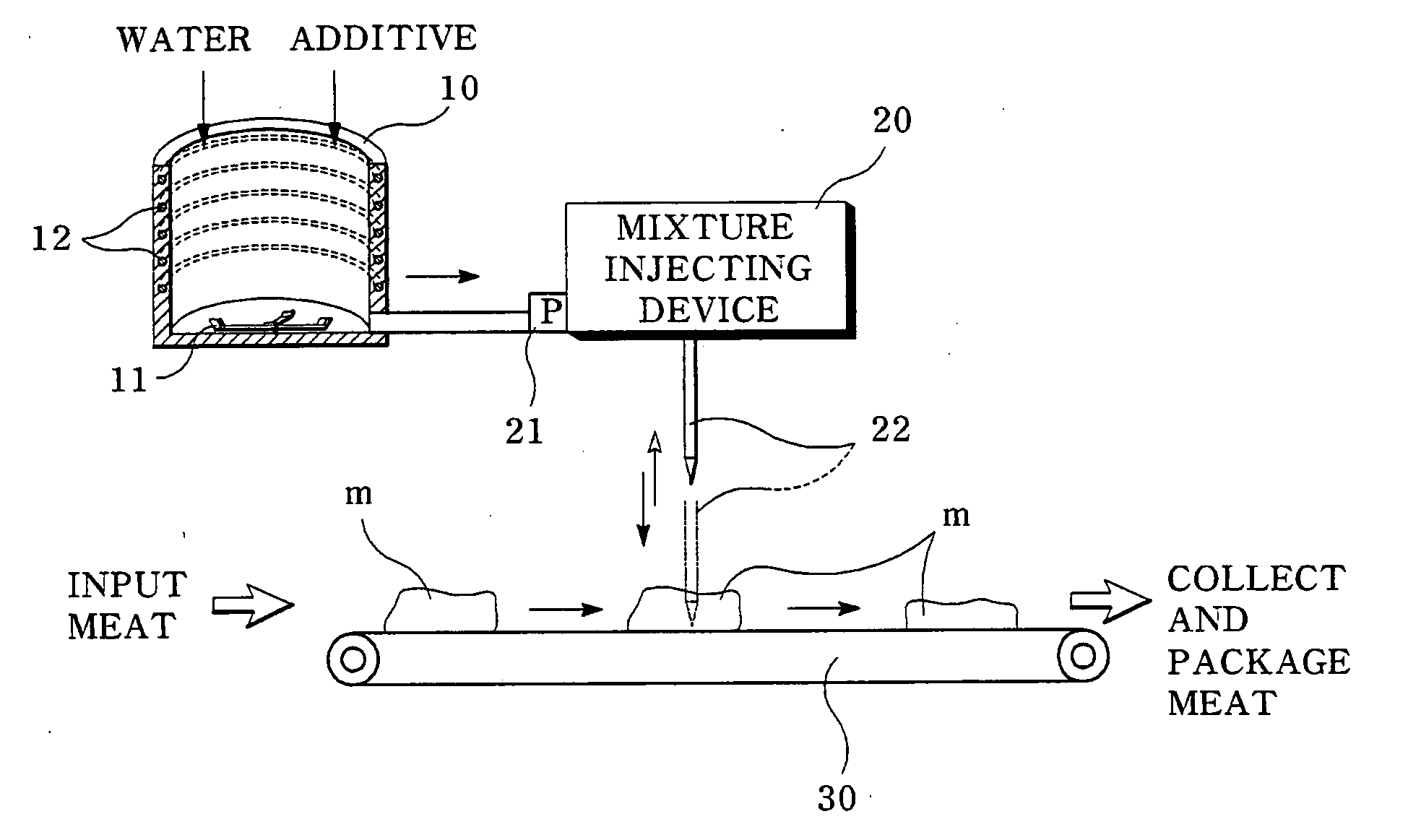

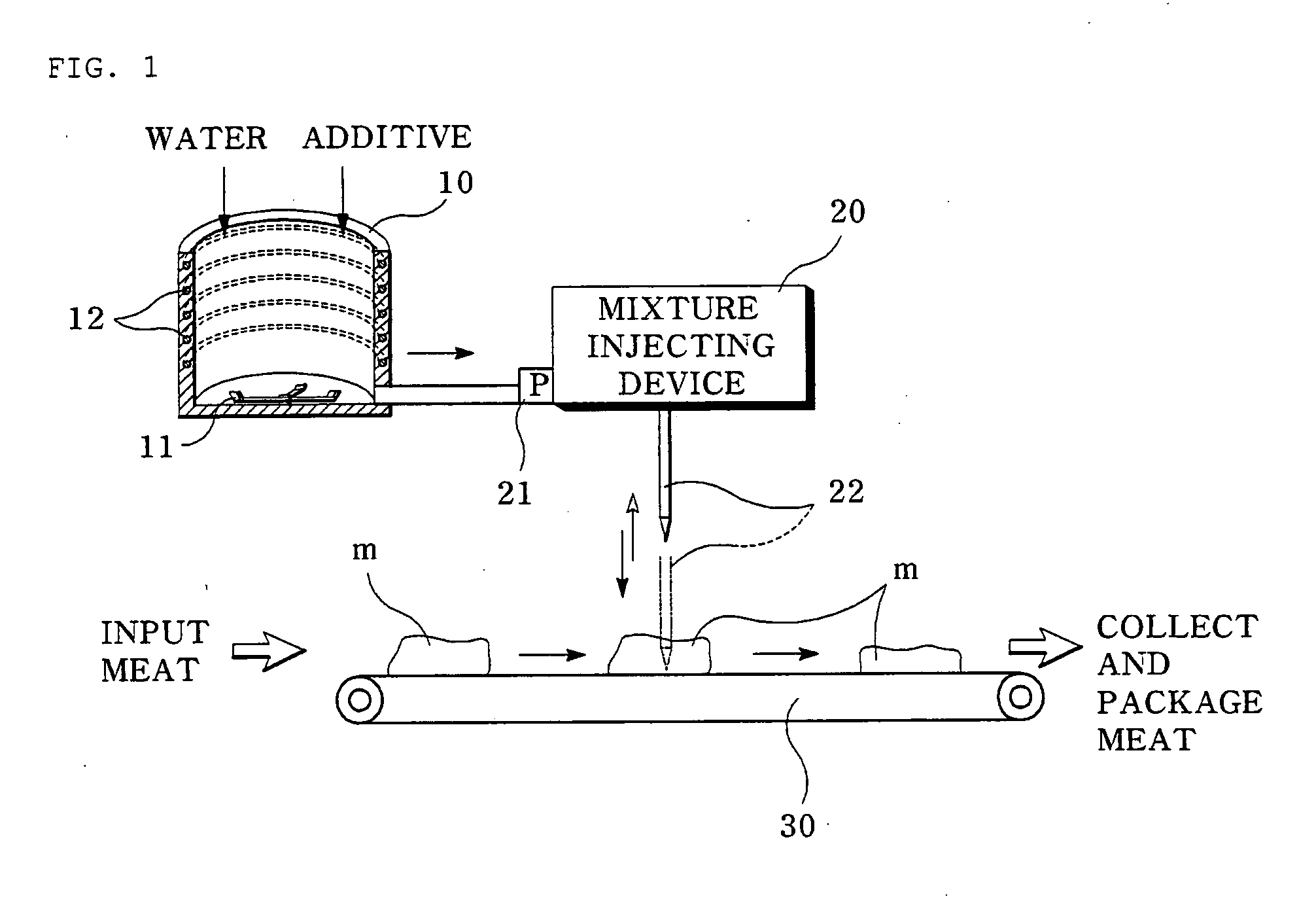

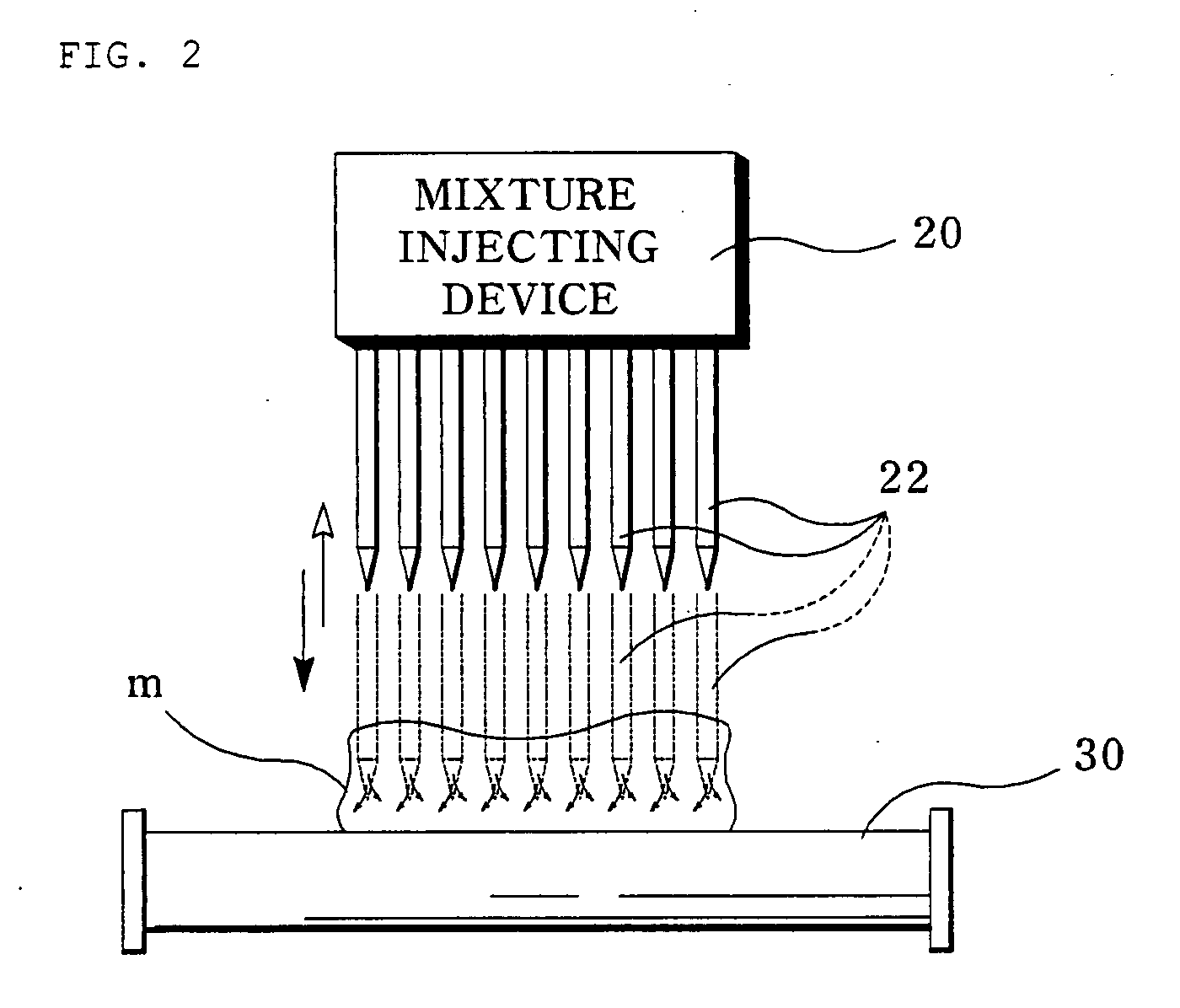

Method for processing meat

InactiveUS20080118616A1Improve preferenceRemove the stenchInjection-based meat tenderisingMeat mixing apparatusMaterials scienceProcessed meat

A method for processing meat is provided. The method includes the steps of: putting an additive and water into a mixer at a weight ratio of about 0.01-1.5:1; producing an additive mixture by forcedly mixing the additive and water in the mixer for about 5 to 20 minutes within a temperature range of about 4 to 85° C.; collecting the produced additive mixture from the mixer into a mixture injecting device; conveying meat m loaded on a conveyer disposed under the mixture injecting device; injecting about 2 to 10 parts by weight of the additive mixture into about 100 parts by weight of the meat by driving the mixture injecting device; and collecting the additive mixture added meat m and packaging the collected meat at a rear end of the conveyer.

Owner:YOO BYOUNG JOO

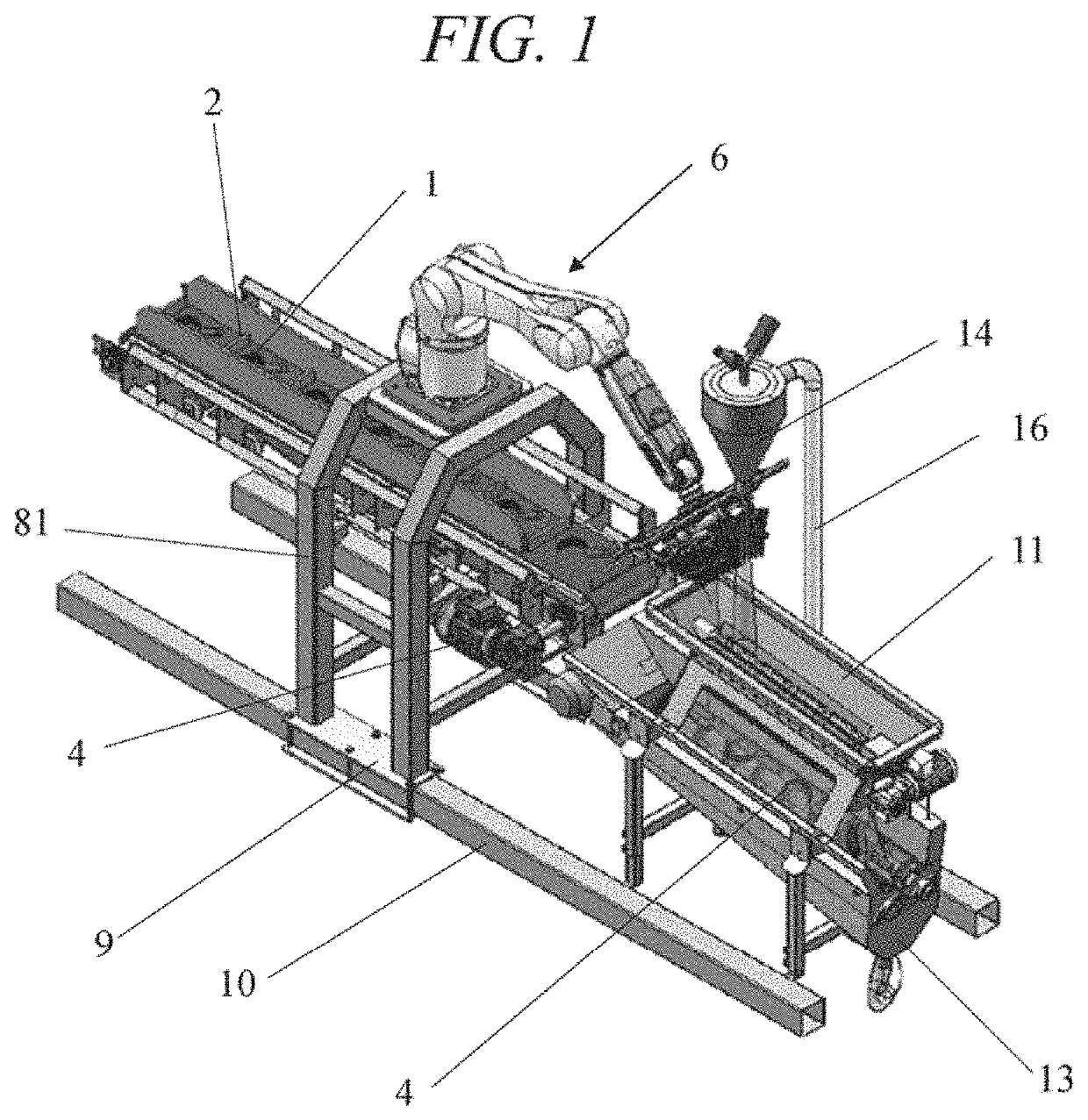

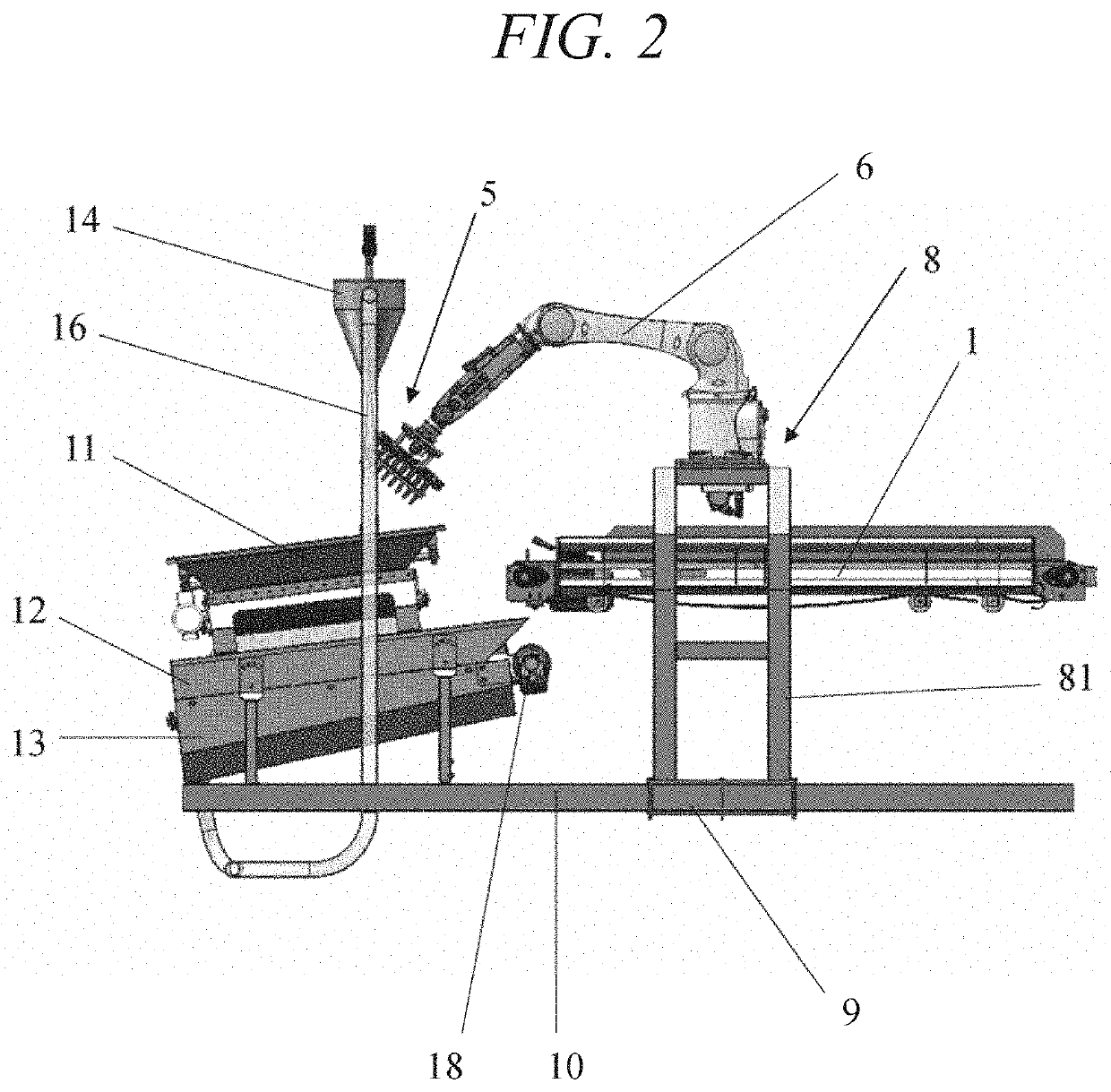

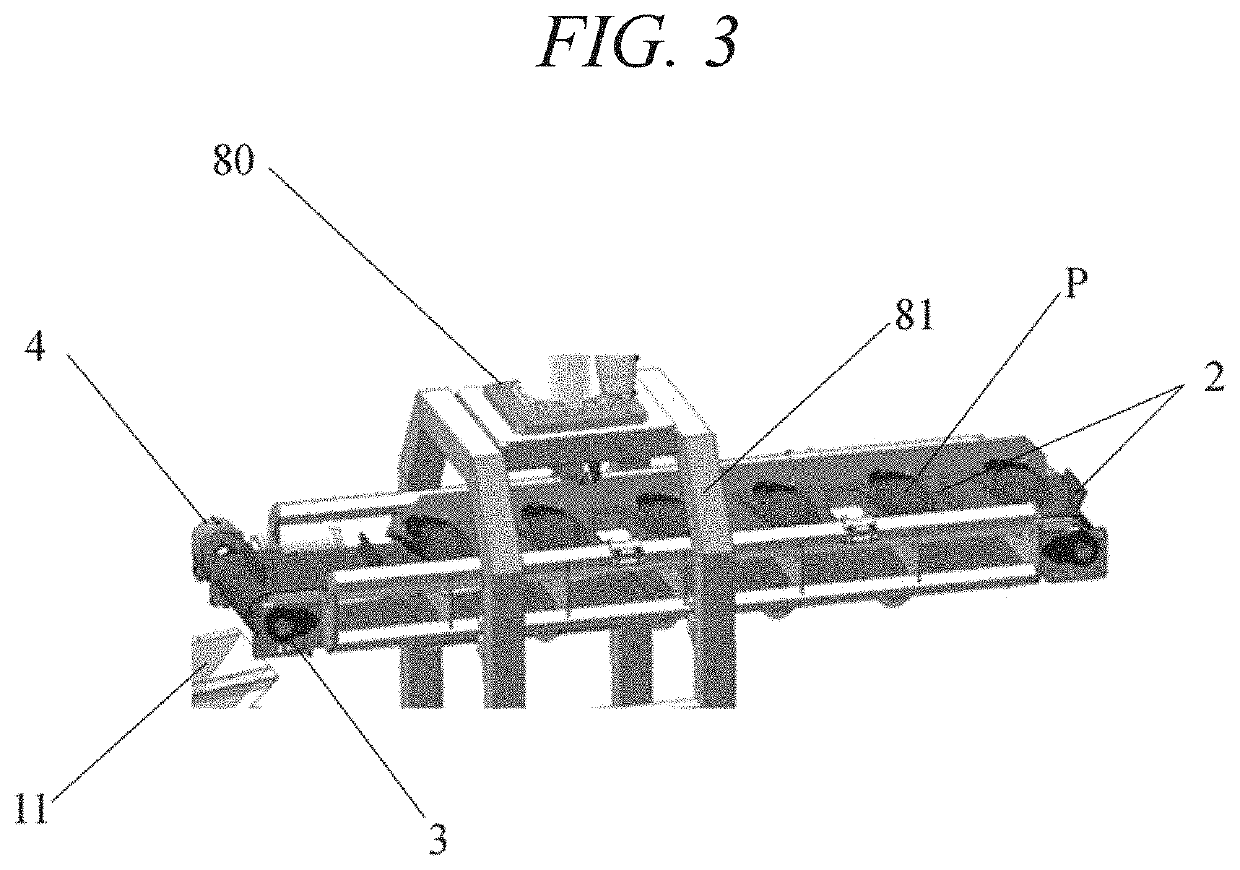

Automated station for salting meat pieces and operating method thereof

PendingUS20210244038A1Promotes downward movementMinimising the possible pathologies sufferedProgramme-controlled manipulatorInjection based meat processingEngineeringProcess engineering

The invention relates to an automated station for salting meat pieces in a predetermined manner, enabling a method for salting poultry meat pieces to be automated, thus increasing productivity and thereby improving safety conditions. The station comprises motorised supply means for supplying meat pieces (P) in a forward direction, handling means for handling meat pieces in order to handle the meat piece coming from the supply means, salt supply means configured to provide salt on an inner and outer area of the meat piece (P), as well as a retrieval system for retrieving salt coming from the salt supply means.

Owner:DISENO Y CONSTR DE MAQUINARIA AUTOMATIZADA

Tenderizing apparatus with fluid reservoir

ActiveUS10779549B1Easy to storeEasy to cleanClimate change adaptationInjection-based meat tenderisingLiquid storage tankLiquid tank

A system comprising a tenderizing apparatus with a fluid reservoir provides users an efficient way to simultaneously tenderize and marinate food. The tenderizer with a fluid reservoir generally includes a fluid outlet or valve and a tensioning element. A fluid reservoir receives marinade. Activation of the system by applying downward pressure releases marinade into an injector. The injector is inserted into the target food. Substantially simultaneously, activation results in at least one projection penetrating the surface of the target food. When downward pressure is released, the injector and projection retract. A first portion and a second portion are separated for easy cleaning. A removably attached first portion cover and third cover provide easy storage.

Owner:HAMMAD RANDOLPH OMAR WALEED

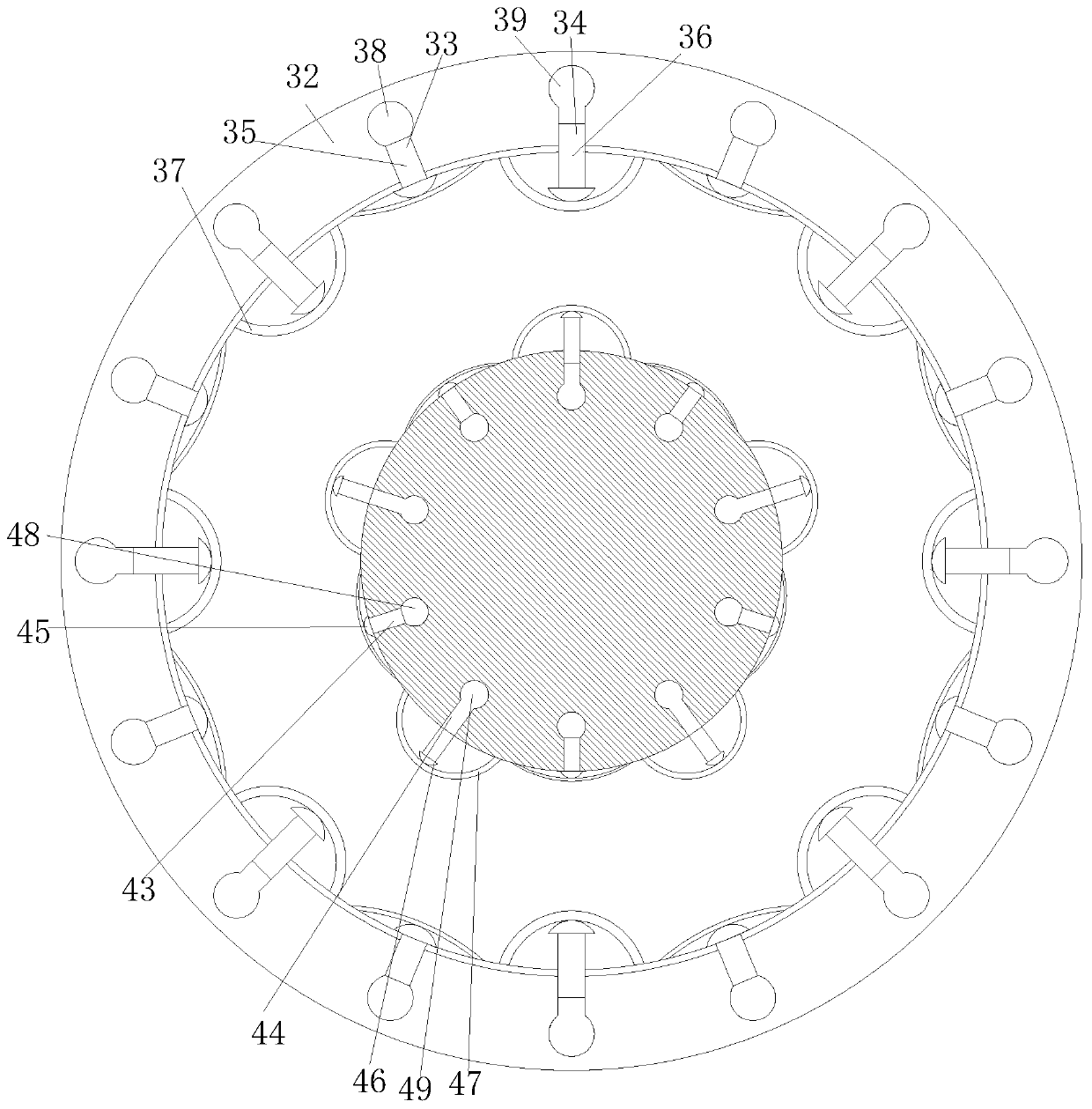

Polypeptide adding device for preparing stewed meat

InactiveCN110915866AFully absorbedHigh yieldInjection-based meat tenderisingMassaging-based meat tenderisingBiotechnologyEngineering

The invention discloses a polypeptide adding device for preparing stewed meat. The device comprises a box body, a material inlet is arranged in the upper part of the box body, an injection component is installed at the material inlet, and a material outlet is arranged in the lower part of the box body; and a tumbling cavity is arranged in the box body, a tumbling component is rotatably installed in the middle of the box body, a main motor for driving the tumbling component to rotate is installed on one side of the tumbling component, and the tumbling component cooperates with the tumbling cavity for work. According to the device, the injection component is arranged, polypeptide is injected and added into the stewed meat through the injection component, the obtained stewed meat is added into the box body through the material inlet, the main motor drives the tumbling component to work, through the combination with the tumbling component and the tumbling cavity, the polypeptide in the stewed meat can be fully absorbed into the stewed meat, so that the production rate of the stewed meat product can be improved.

Owner:安徽匠桥财务咨询服务有限公司

Process for injection of particles in food

ActiveUS20050095327A1Improve performanceEliminate inconvenienceGrain huskingGrain polishingSuspended particlesFood industry

The present invention relates to a process for injection of refrigerated suspended particles into food products and the products resulting from such process. The present invention applies to the food industry in the field of meat products, and reveals those characteristics which are relevant for the process of preparation of said meat products suspension, to be later aggregated on larger sized meat products, as well as those characteristics which are relevant for said injection process. The main object of the present invention is to increase the final product green weight without incurring loss of flavor, shortening of shelf life, nutritional value or texture, making feasible the incorporation of smaller size pieces to a product featuring a higher commercial value. The term meat products is herein used meaning those products extracted from poultry, fish, cattle, pork, sheep, etc., both with and without fat either in the shape of meat cut or shred, ground meat, frozen meat, semi-frozen meat or refrigerated meat.

Owner:COZZINI DO BRASIL LTDA

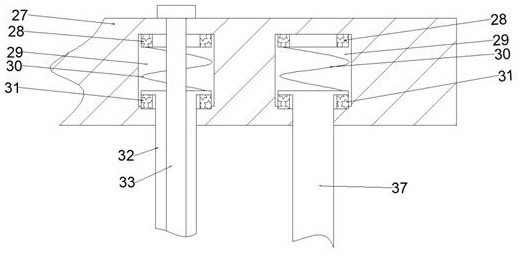

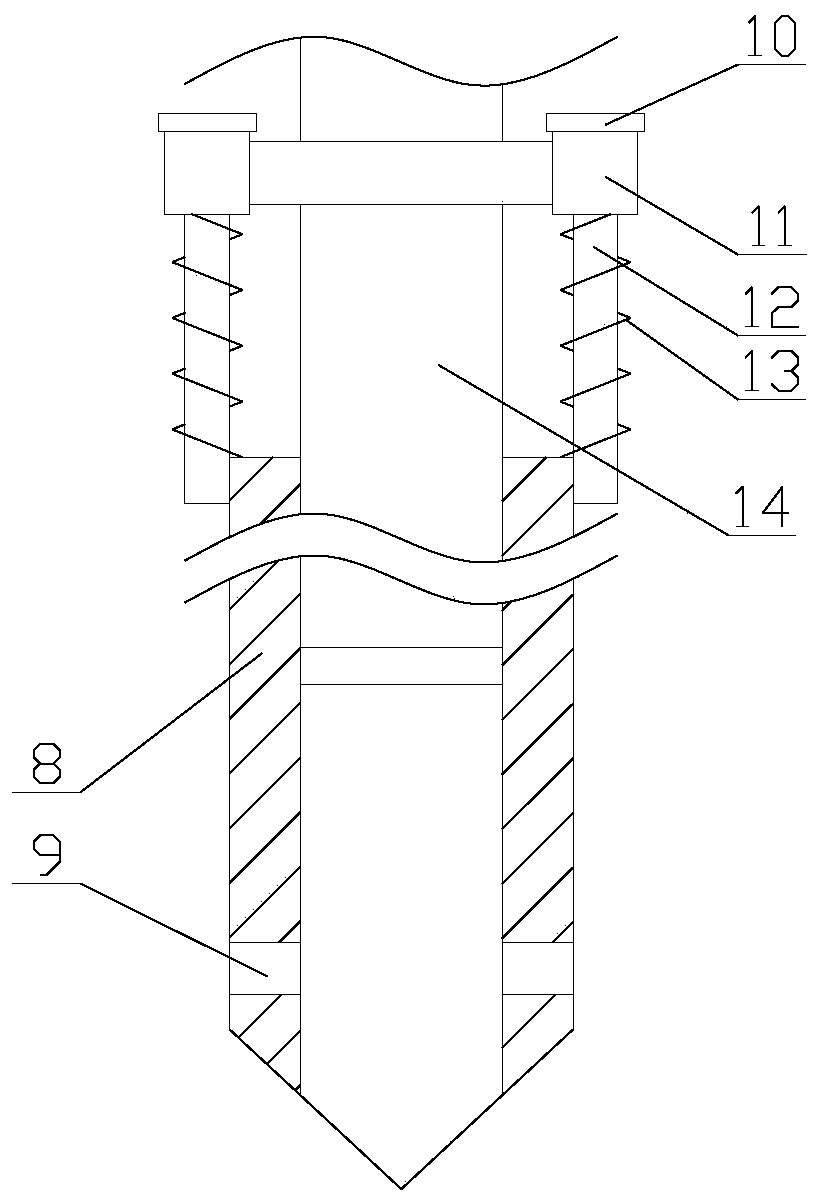

Saline water injection machine with automatic preparation and needle protection functions

InactiveCN110583745ALow failure rateReduce preparation timeInjection-based meat tenderisingSaline waterEngineering

The invention relates to a saline water injection machine with automatic preparation and needle protection functions. The saline water injection machine comprises a base, a conveying device and a power device, and also comprises a preparation mechanism and at least two injection mechanisms, wherein each injection mechanism comprises a second needle tubing, a first needle tubing, at least two through holes and at least two support assemblies; each support assembly comprises a support rod, a support casing, a limiting block and a first spring; the preparation mechanism comprises a mixing box, abottom plate, a conveying pipe, a pressure sensor and at least two quantification assemblies; and each quantification assembly comprises a storage box, a feeding pipe, a discharging pipe, a rotating disc, a drive shaft, a drive pipe, a motor, a limit unit, a second spring and a mounting bearing. In the saline water injection machine with automatic preparation and needle protection functions, the self-buffer function of the injection mechanism reduces the probability of damage to the mechanism due to collision with bone and reduces the fault rate of the saline water injection machine, saline water can be prepared automatically, and the working efficiency of the saline water injection machine is improved.

Owner:张宇

Automatic Plant for the Treatment and Packing of Meat Product

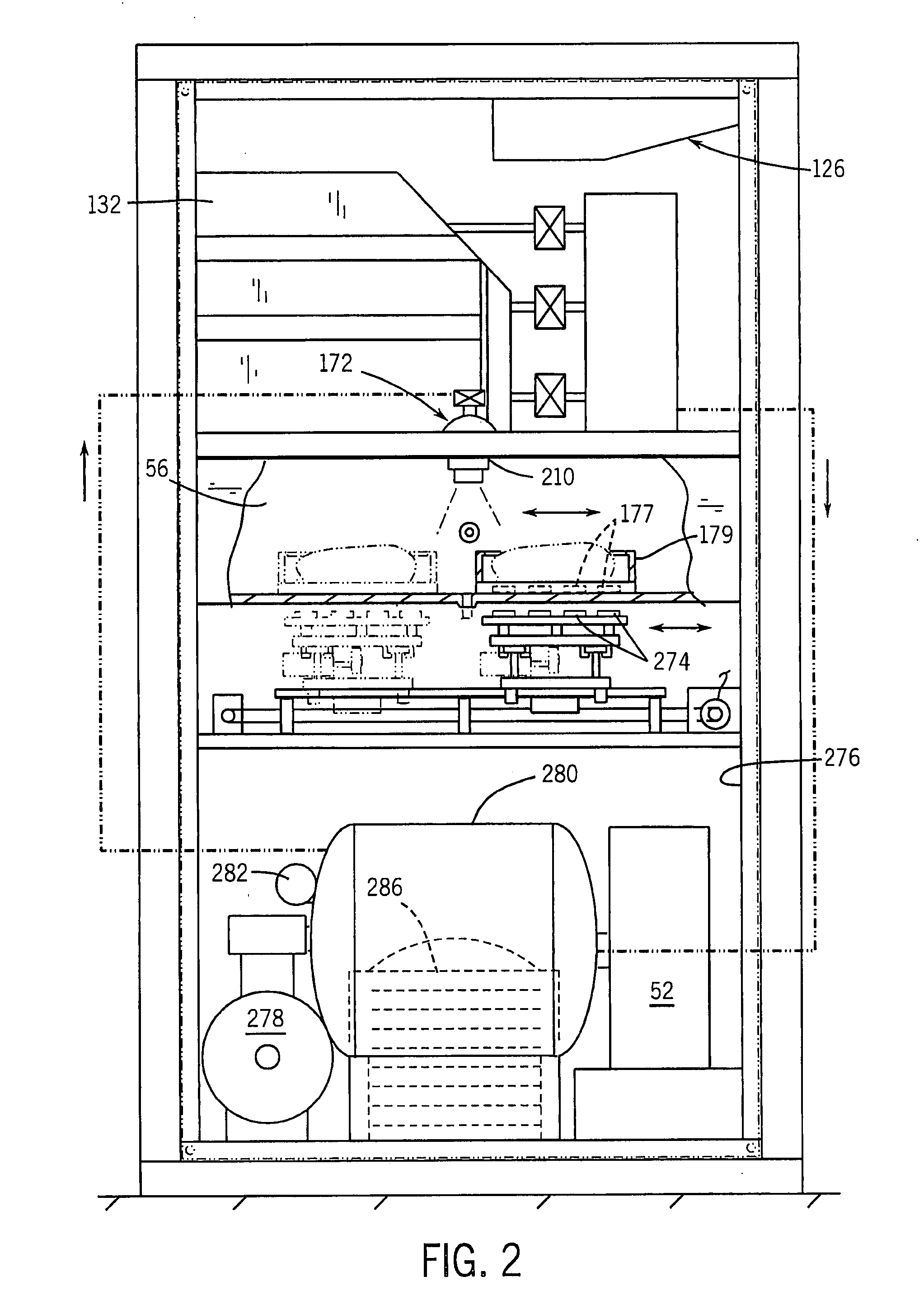

InactiveUS20080065250A1Satisfies needImprove productivityGrain huskingGrain polishingWaste managementComputer control

The invention relates to an automatic plant for the treatment and packing of meat product, comprising an injection station for injecting brine into a meat product, first and second maceration stations for macerating the injected meat product, and a packing station for packing the treated meat product. The injection station is connected to said first and second maceration stations by an accumulating and loading unit for accumulating meat product coming from the injection station and selectively loading it into the first and second maceration stations which are connected to the packing station by means of a transfer unit adapted for transferring the meat product from the first and second maceration stations to feed hoppers for feeding the packing station. The plant is controlled by computerized control.

Owner:METALQUIMIA SA

Systems and methods for providing food intervention and tenderization

ActiveUS10375977B2Fruit and vegetables preservationInjection based meat processingSpray nozzleEngineering

Systems and methods for providing food intervention, pumping up, and tenderization are discussed. While such systems and methods can include any suitable component, in some cases, they include an injectade reservoir, a filter, a first pump configured to force injectade from the injectade reservoir and through the filter, a nozzle configured to inject injectade into a food product without having the nozzle contact the food, and a valve that is configured to selectively open and close to regulate when and how much of the injectade that passes through the filter is forced out of the nozzle. In some cases, the described systems further include a chiller configured to cool injectade in the reservoir, a sensor configured to determine a distance between the nozzle and food item, an actuator configured to move the nozzle, and / or a computer processor that controls an amount of injectade sprayed from the nozzle. Other implementations are described.

Owner:S2I LLC

Pickling liquid injection system for meat pickling

ActiveCN110973211APrecise positioningReduce defective rateMeat/fish preservation using liquidsInjection-based meat tenderisingBiotechnologyEngineering

The invention relates to a pickling liquid injection system for meat pickling. The pickling liquid injection comprises a base, a feeding unit and a water injection unit; the feeding unit is arranged at the upper end of the base through a bearing; and the water injection unit is arranged at the left side of the upper end of the base. According to the invention, meat blocks are fed in an intermittent feeding mode, so that the meat blocks are easy to position and are automatically fed to an injection position; and meanwhile, through a sealing cylinder formed between a placing groove and a sealingplate, loss of pickling liquid is reduced, and manufacturing cost of an enterprise is reduced. Uniform treatment of pickling liquid injection is finished by increasing the contact area between an injection end and meat blocks, so that the meat blocks are in more uniform contact with the pickling liquid, and the defective percentage of the meat blocks is reduced.

Owner:ANHUI GUANGZHENG FOOD

Even-injection saline injection machine with anti-blocking function

InactiveCN110537562AWith anti-clogging functionEvenly dispersedInjection-based meat tenderisingBeating-based meat tenderisingSaline injectionEngineering

The invention relates to an even-injection saline injection machine with an anti-blocking function. The even-injection saline injection machine comprises a base, a delivering device and a bracket andfurther comprises an injection mechanism and a patting mechanism, the injection mechanism comprises a lifting assembly, a medicine delivering tank, a cover plate, a power pump, a delivering pipe, twoconnecting rods, two fixed sleeves, at least two needle tubes and at least two push rods, the patting mechanism comprises a supporting rod, a driving assembly, an extruding plate, two sliding rods, two springs and two lifting sleeves, the lifting assembly comprises two air cylinders, and the driving assembly comprises a motor, a rotating disc and at least two knocking blocks. According to the even-injection saline injection machine with the anti-blocking function, saline can be injected into meat products through the injection mechanism, meanwhile, the probability that the mechanism is blockedis decreased, and the patting mechanism can pat the meat products injected with the saline, so that the saline is evenly dispersed to everywhere inside the meat products, and the quality of the meatproducts is improved.

Owner:GUANGZHOU DANJUE COMM TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com