Pickling liquid injection system for meat pickling

A technology of injection system and pickling liquid, which is applied in the direction of meat softening, application, and tenderization through injection. The effect of uniform liquid, reducing defective rate and reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

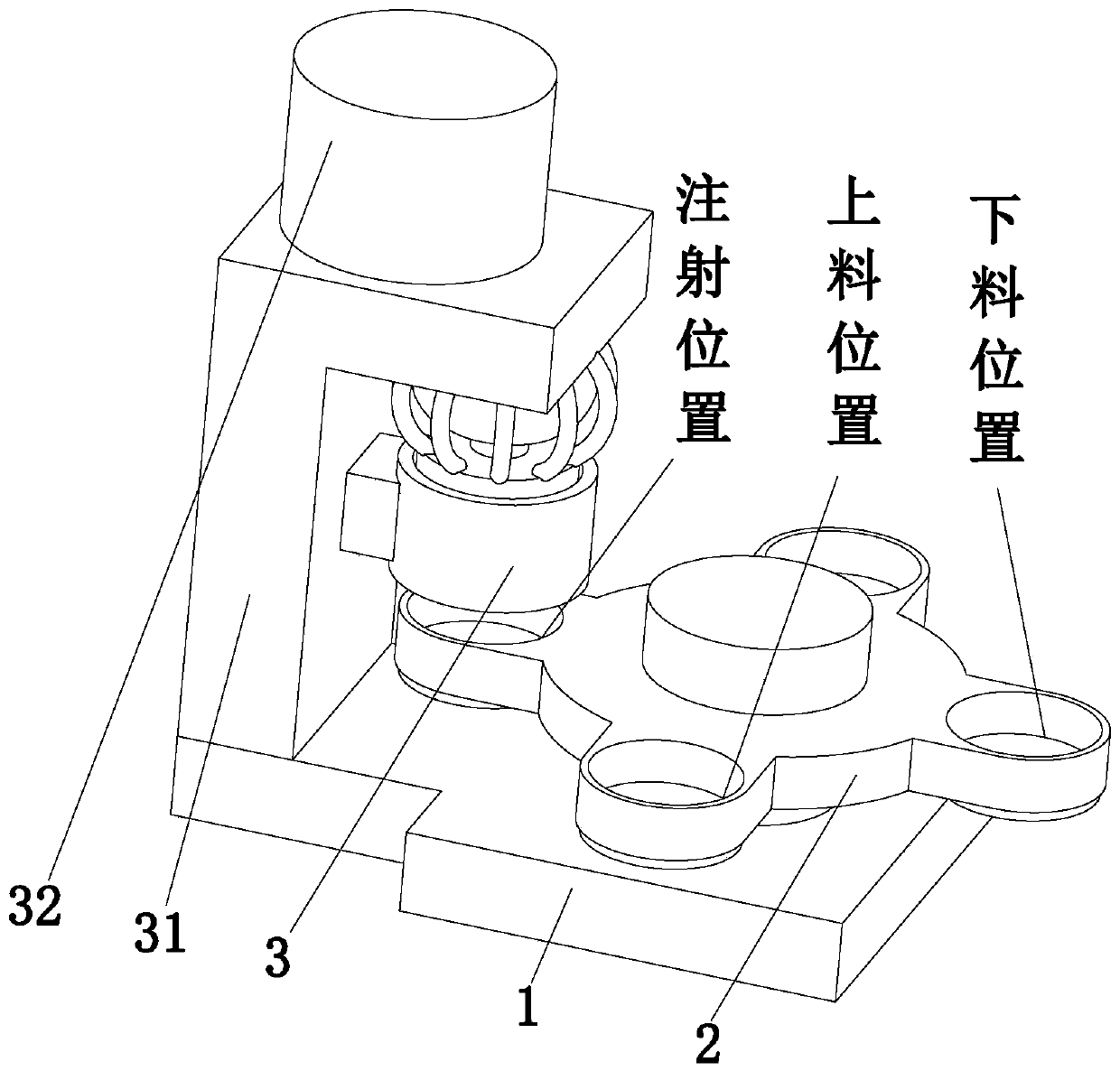

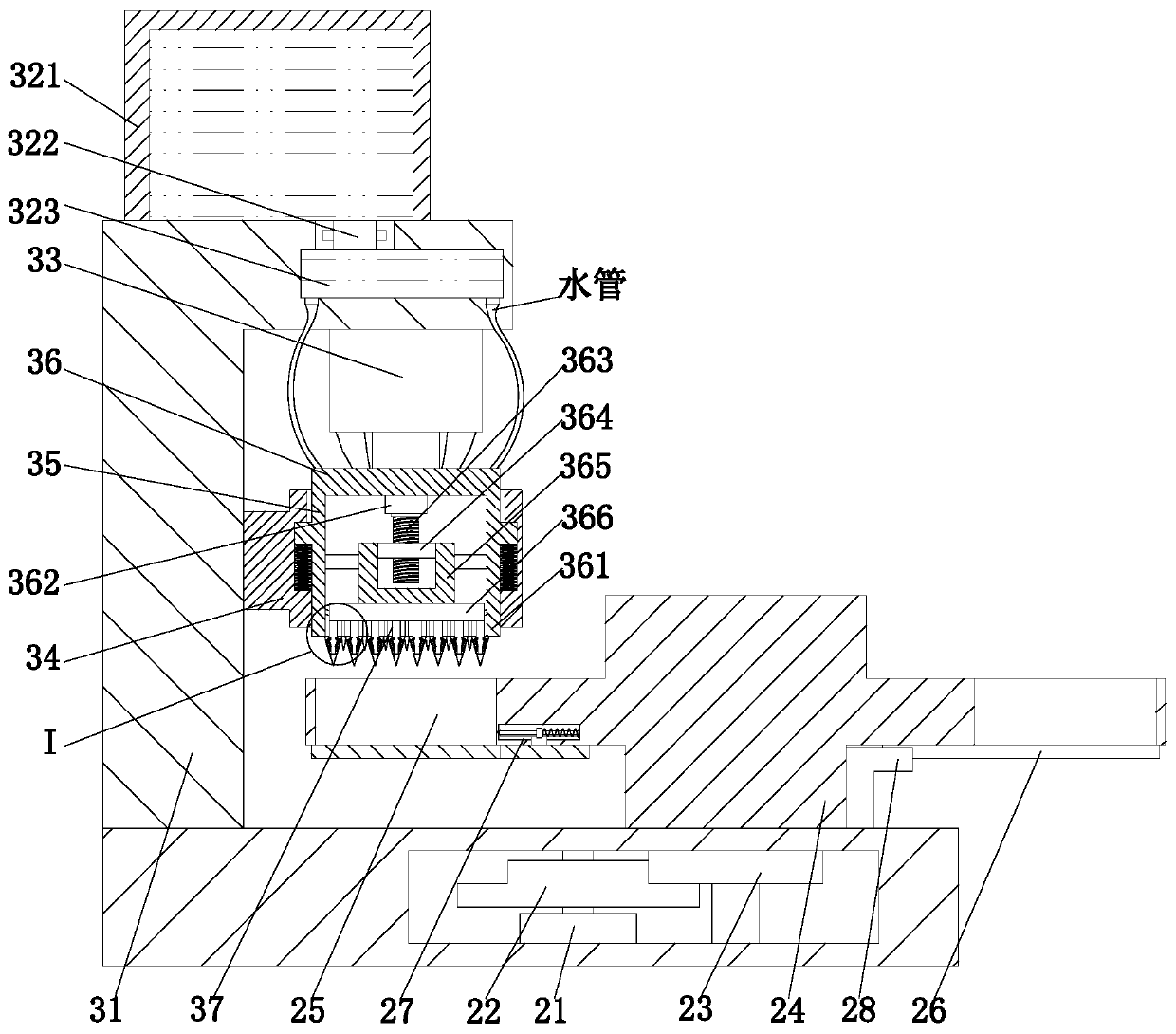

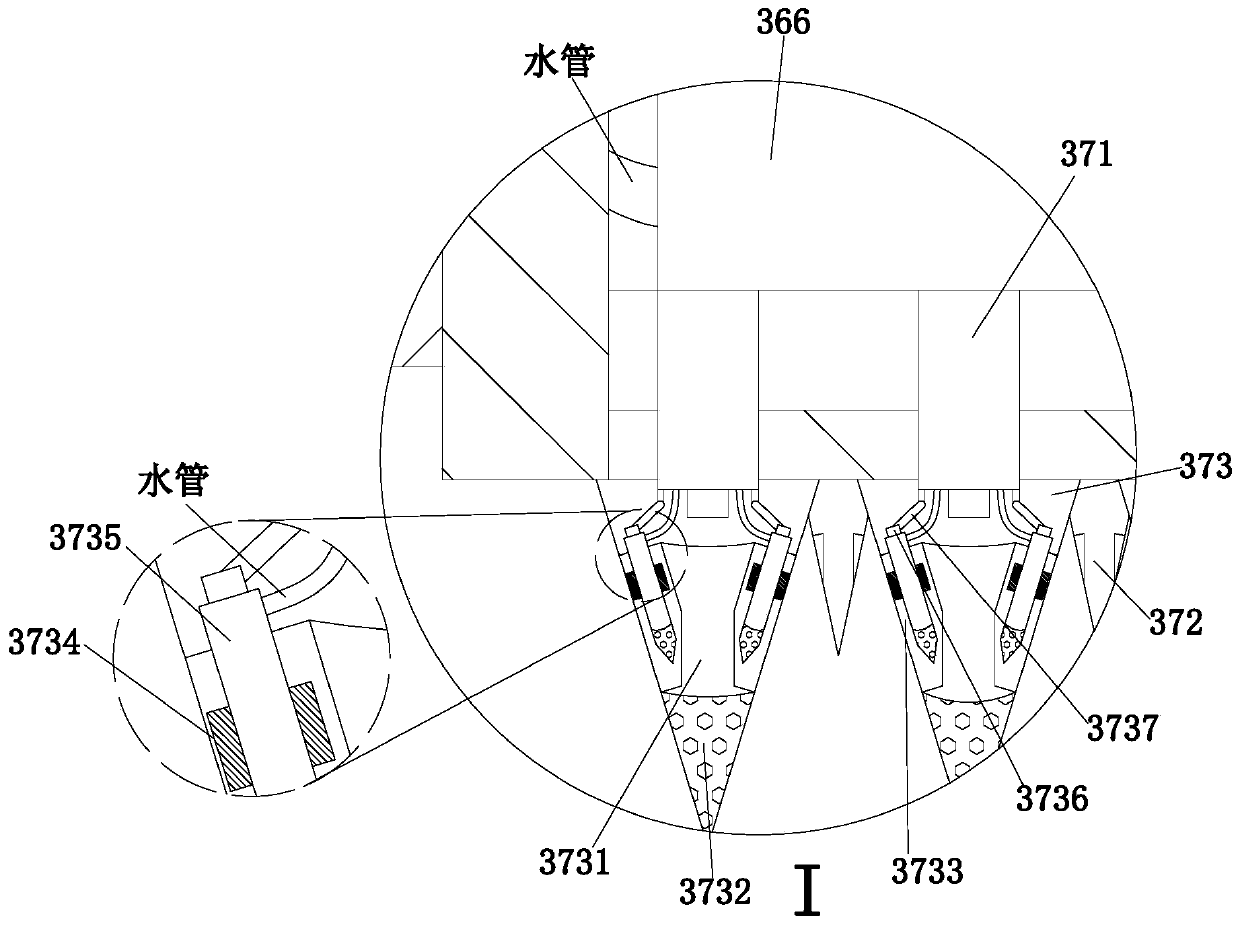

[0027] Such as Figure 1 to Figure 5 As shown, a marinade injection system for marinating meat, including a base 1, a feeding unit 2 and a water injection unit 3, the upper end of the base 1 is equipped with a feeding unit 2 through a bearing, and the upper end of the base 1 is installed on the left side There is a water injection unit 3; the feeding unit 2 carries out feeding, feeding and unloading processes on the meat; the water injection unit 3 injects the pickling solution into the meat to marinate the meat.

[0028] The feeding unit 2 includes a driving motor 21, a mating wheel 22, a sheave 23, a turret 24, a placement groove 25, a sealing plate 26, an opening and closing mechanism 27 and a baffle plate 28, and the driving motor 21 is inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com