Patents

Literature

149results about "Beating-based meat tenderising" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

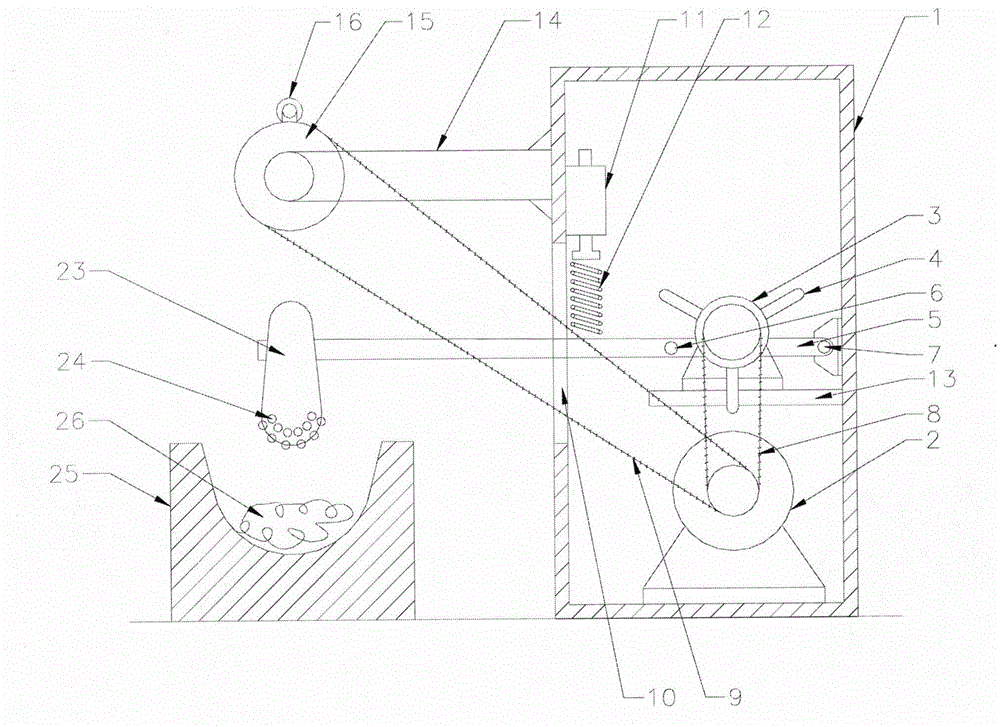

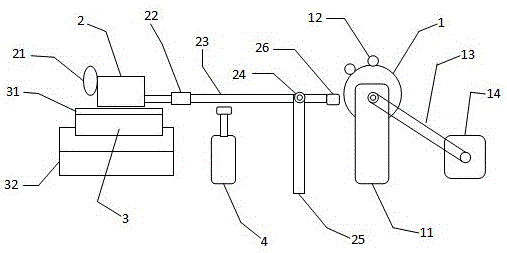

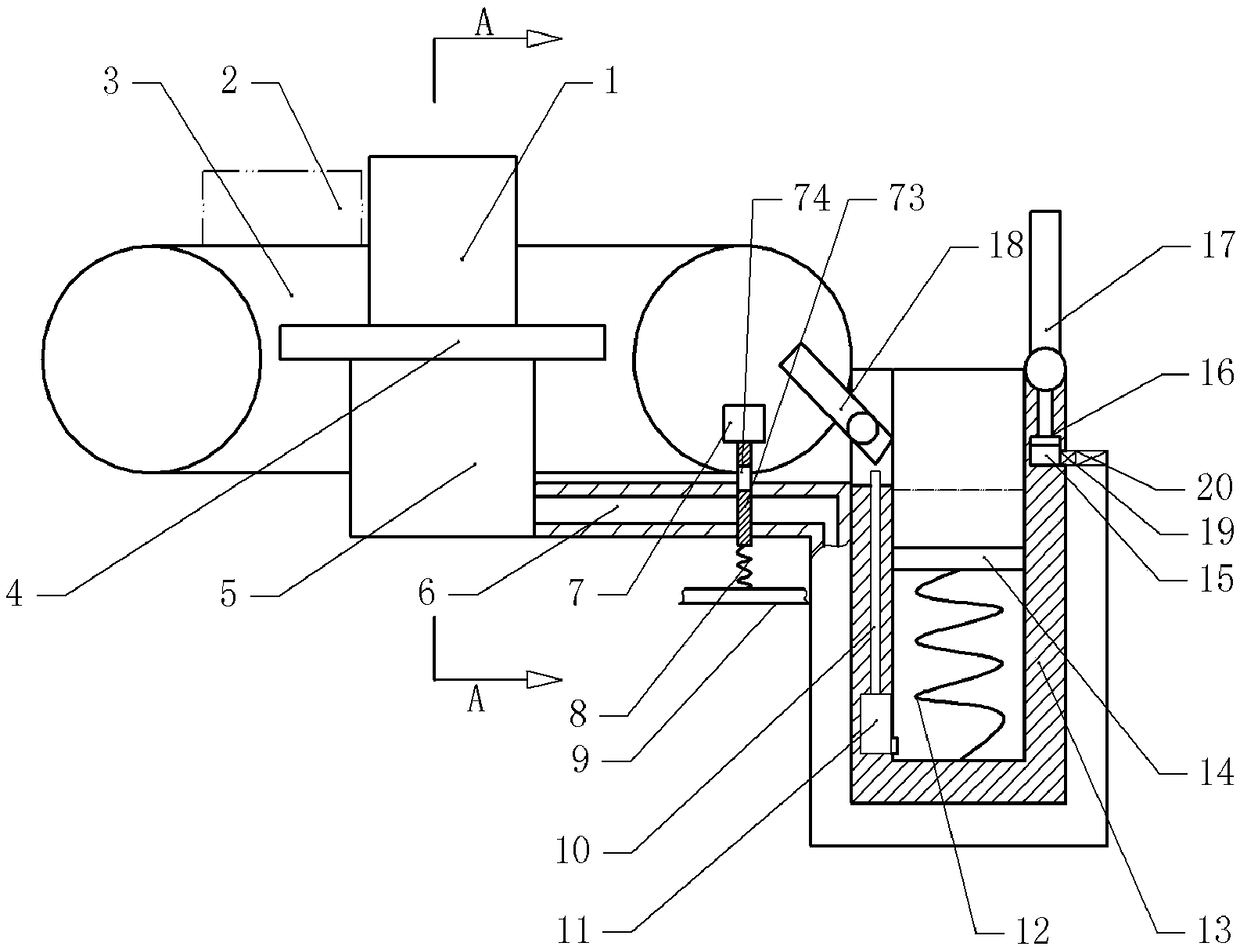

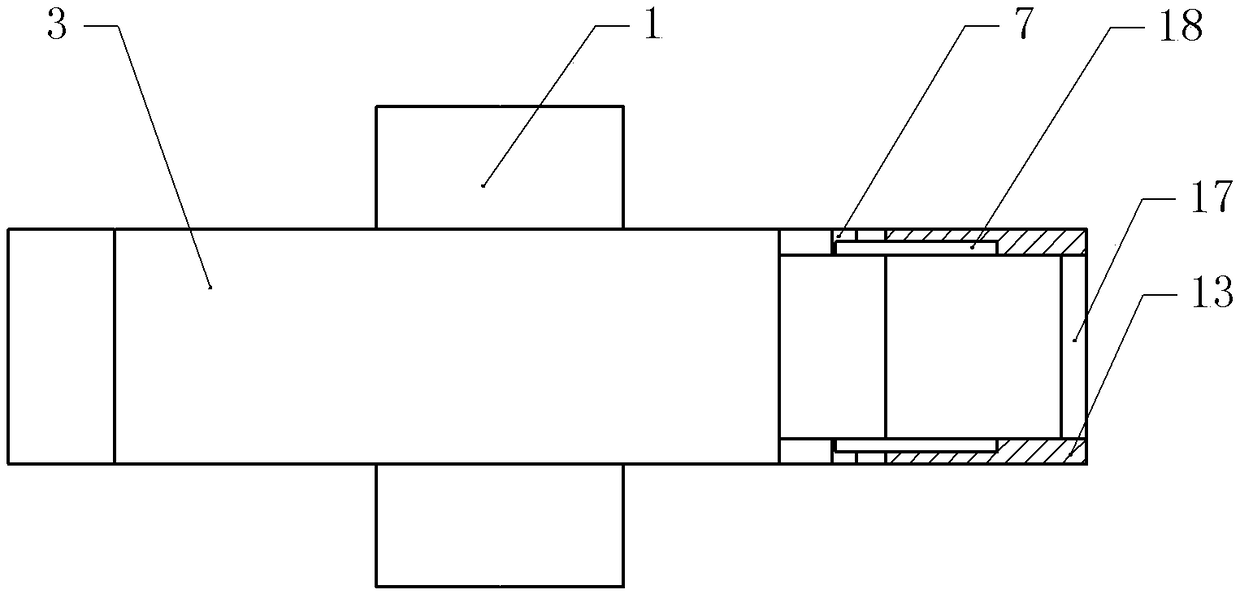

Beef beating and chopping machine

InactiveCN104920571ASave human effortSimple structureBeating-based meat tenderisingAutomatic controlMechanical equipment

The invention mainly relates to mechanical equipment used in a beef beating and chopping process for making beef balls. A beef beating and chopping machine is mainly composed of a motor, a three-fork dial wheel, dial wheel forks, a beef hammer connecting rod, a passive dial wheel handle, a bent axle wheel, a beef pushing rod rotary shaft, a crankshaft, mediad beef pushing rods, elastic tongues, a beef hammer, a beef stable, a linear electric magnet and an adjustment spring. The three-fork dial wheel periodically dials the passive dial wheel handle upward, so that the beef hammer beats beef below the beef hammer. The two mediad beef pushing rods and elastic tongues periodically and alternately gather together beef in the side parts on two sides of the beef stable toward the middle part of the beef stable, and the shaft of the linear electric magnet moves upward or downward, so that the compressing or stretching extent of the adjustment spring changes. By way of automatic control, the force of the beef hammer beating the beef is adjusted. According to the beef beating and chopping machine provided by the invention, the labor force is extremely emancipated and the beef beating operation can be carried out in an unattended condition. The beef beating and chopping machine has the advantages of being simple in structure, low in cost and convenient and easy-to-use.

Owner:范洲卫

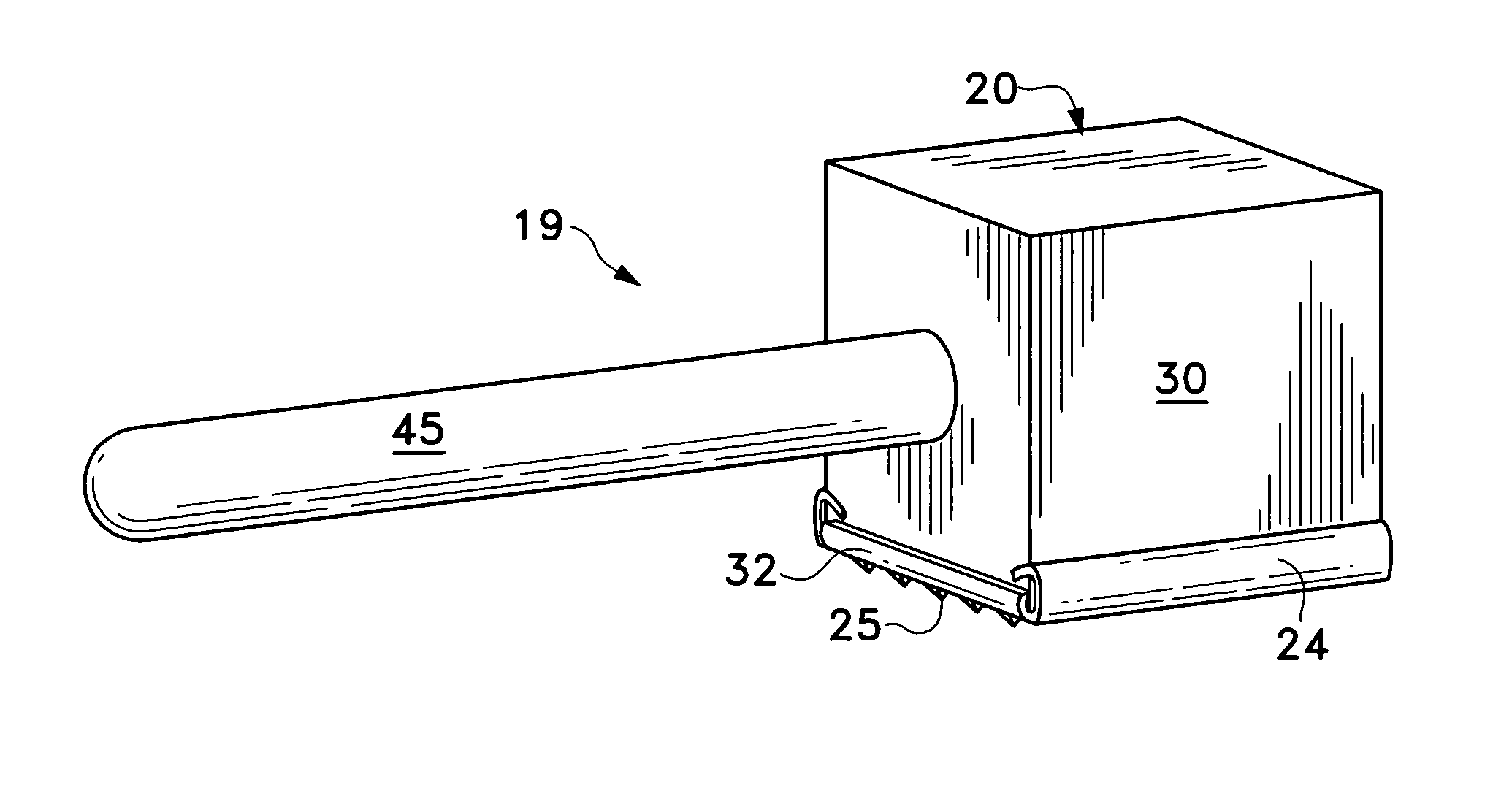

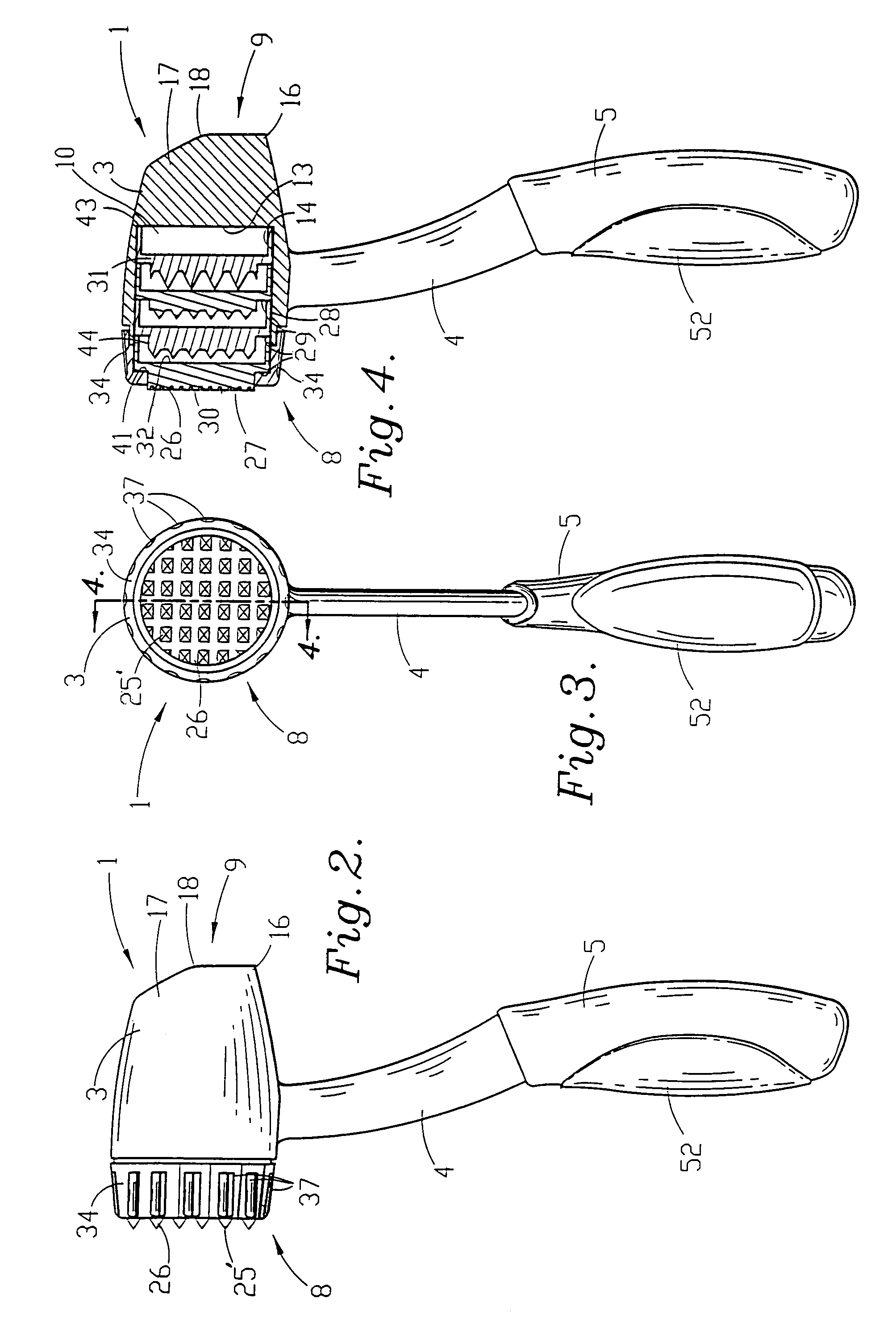

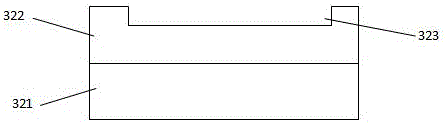

Meat tenderizer with disposable face plates

InactiveUS7862408B1Good adhesionEasy to disassembleFish washing/descalingPoultry plucking mechanismsTime efficientEngineering

A meat tenderizer with disposable face plates requires that a fresh face plate be chosen for each use to prevent cross contamination from one use of the tenderizer to the next. The table or tables of the tenderizer head are flat and accept the face plates which may have a flat tenderizing surface or any of several textured tenderizing surfaces. The face plates are intended for a single use. Once used a face plate is discarded. The user selects the appropriate face plate for the task at hand, attaches it to the tenderizer and removes and discards it after use. Since a clean unused face plate is selected for each use, the tenderizer does not have to be washed between uses thereby saving time for the chef and providing a sanitary tenderizing surface for contact with the meat.

Owner:WEINSTEIN CORI

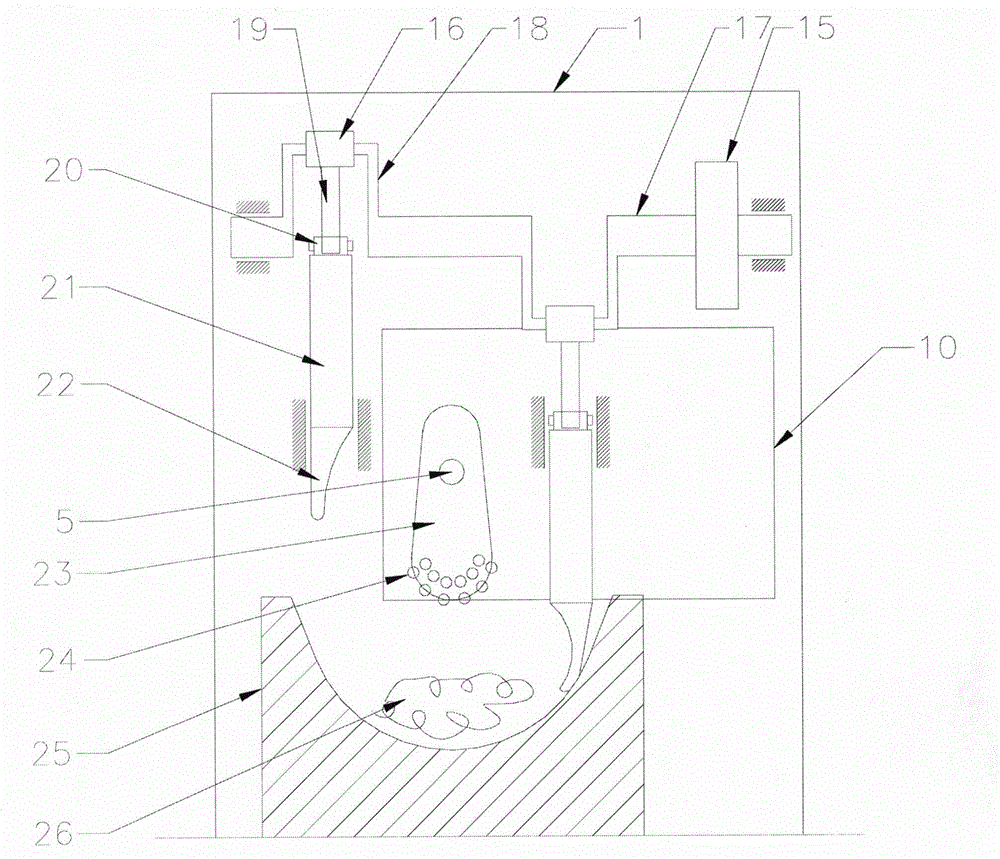

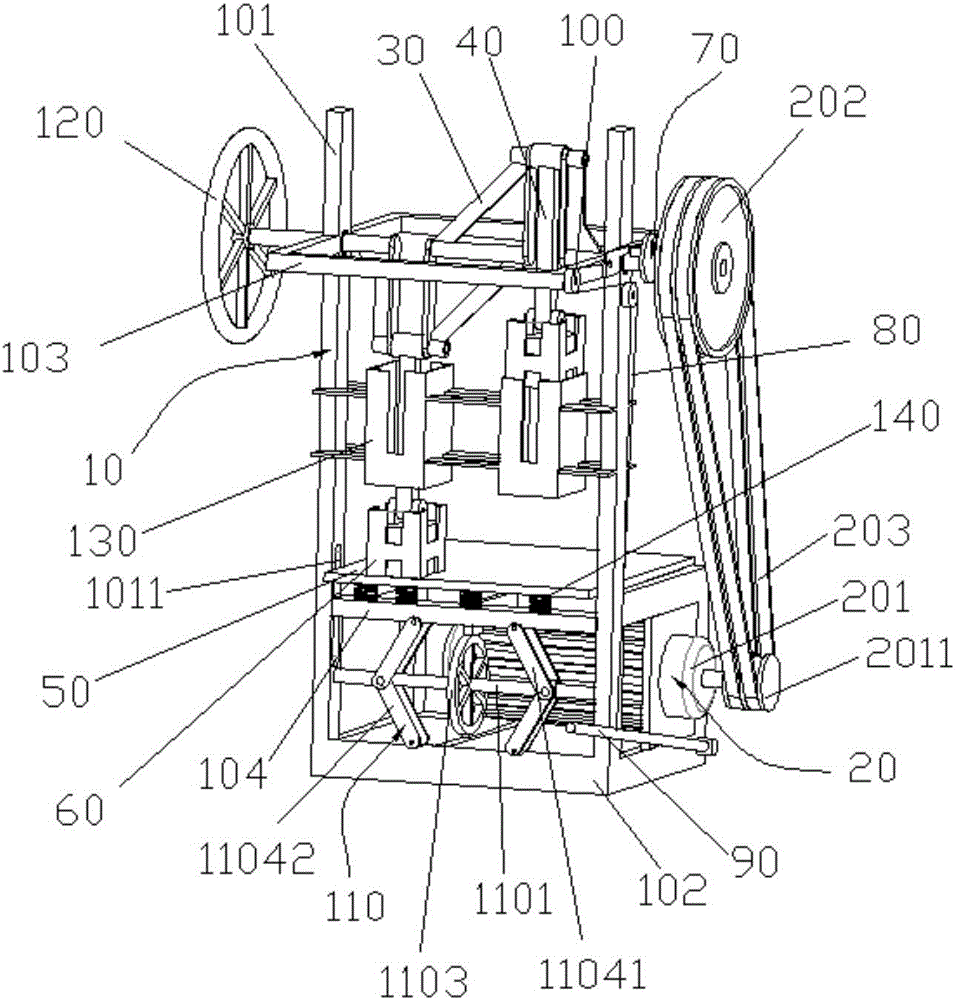

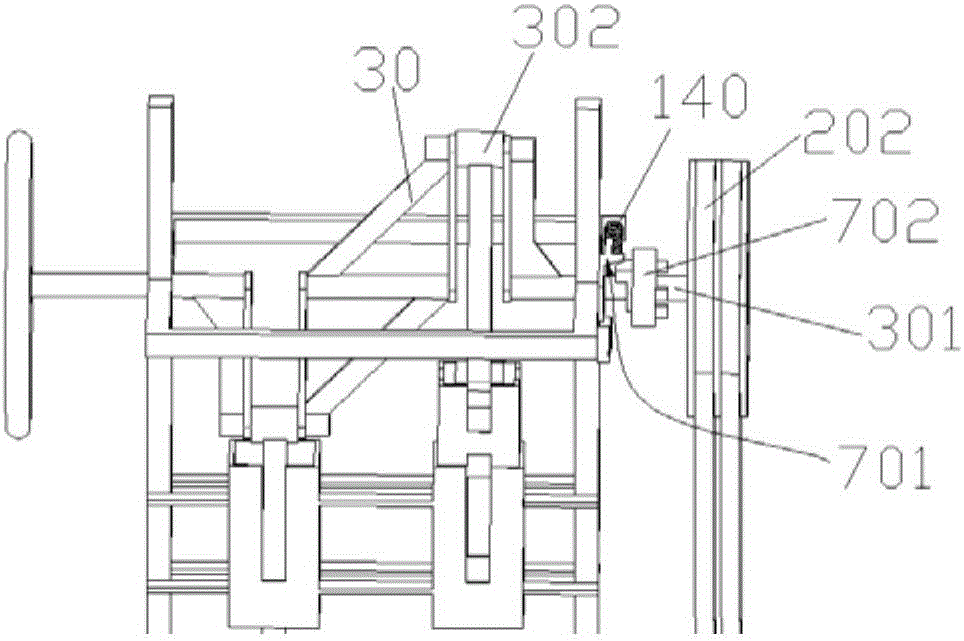

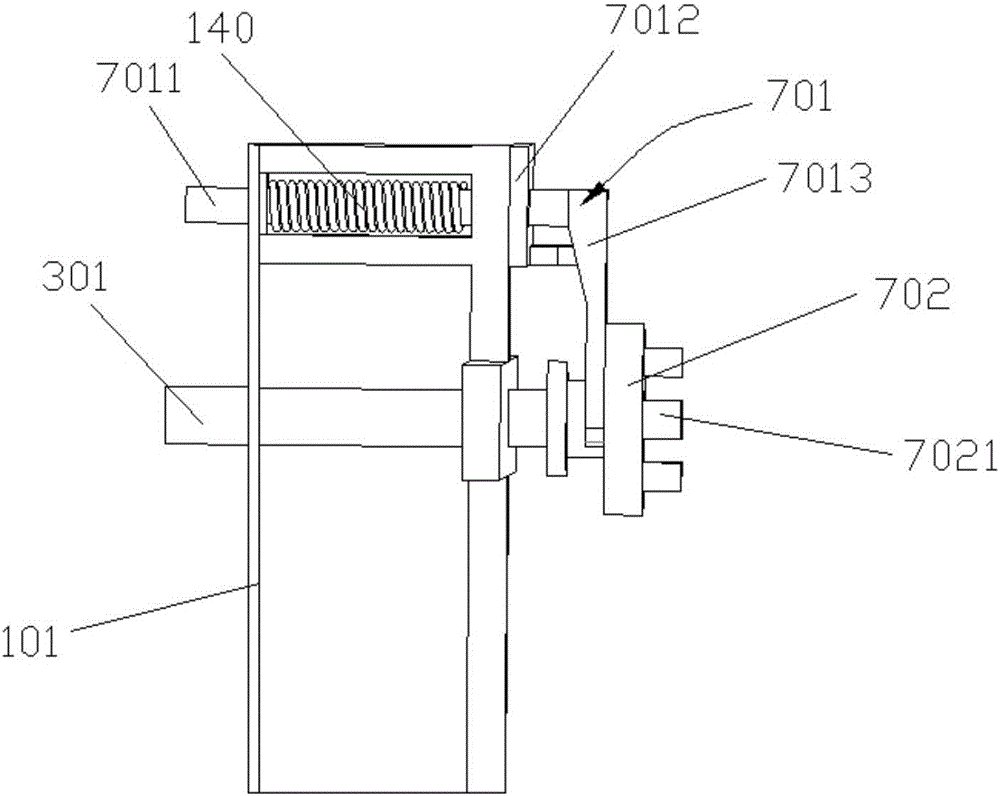

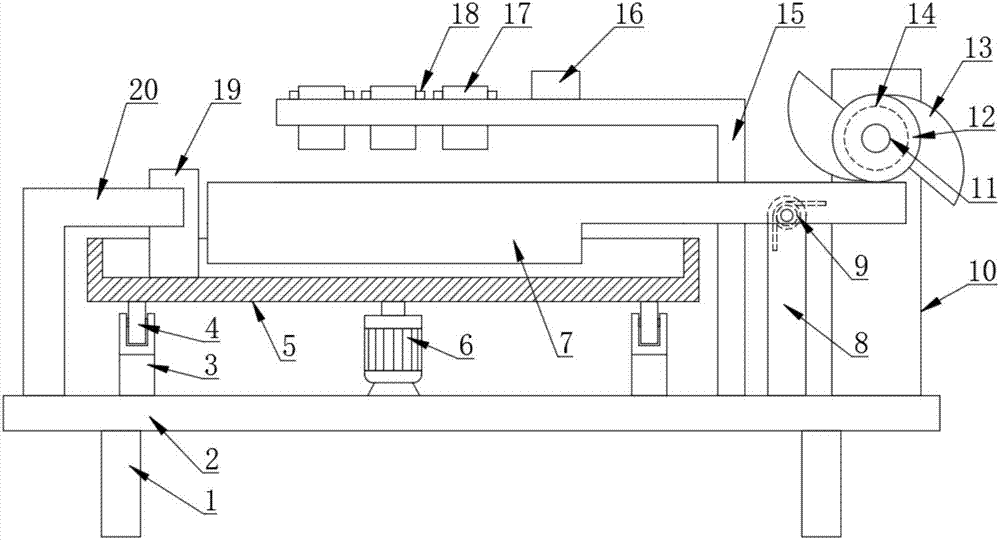

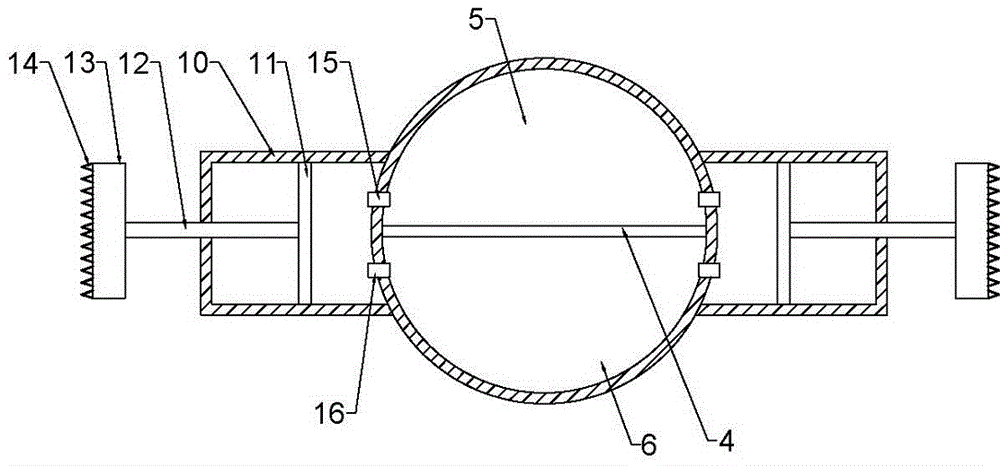

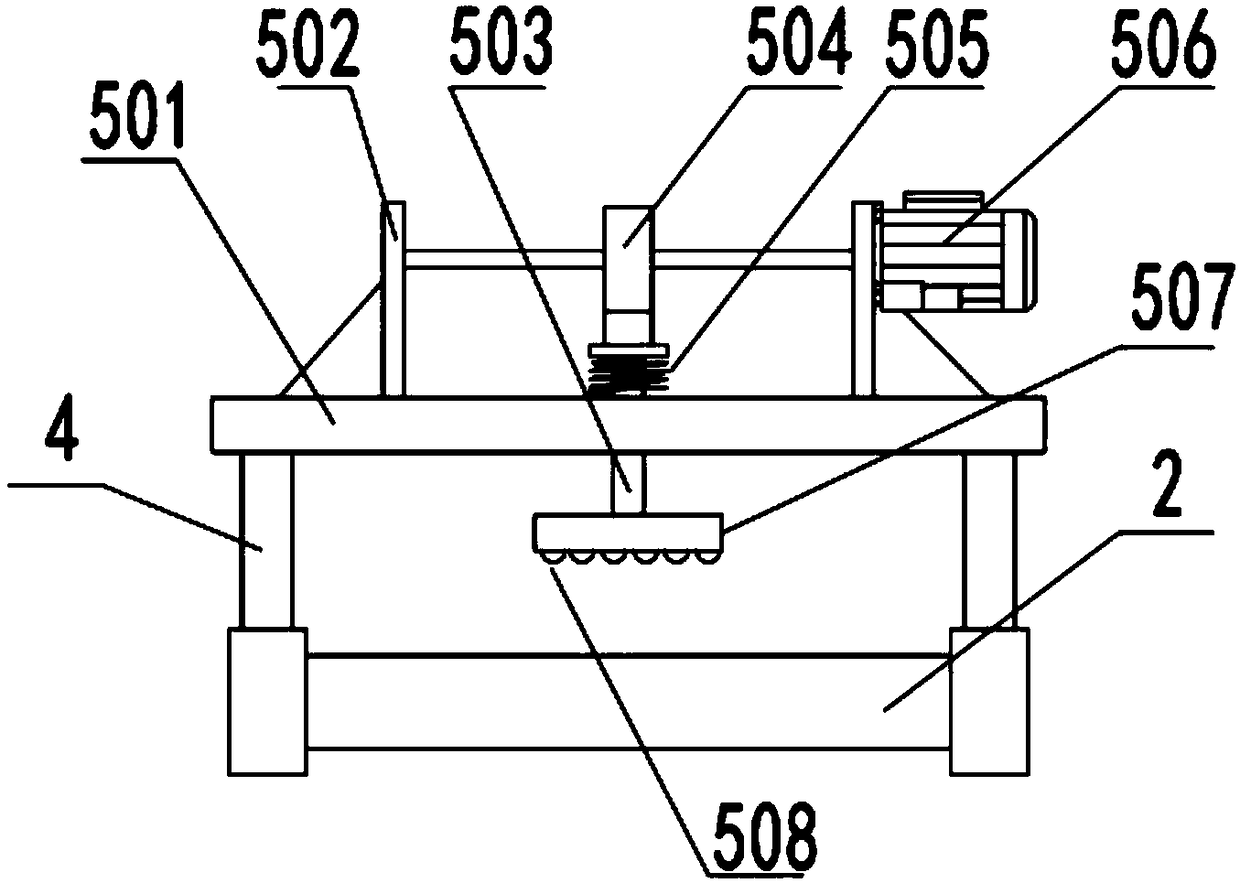

Hammering device

InactiveCN106720140AEasy to operateEasy to useBeating-based meat tenderisingEngineeringProcessing cost

The invention provides a hammering device and relates to the technical field of food processing. The hammering device comprises a frame, a power driving unit, a crankshaft pivoted on the frame, a hammer head connecting rod pivoted on a journal of a connecting rod of the crankshaft at one end and a carrying plate fixedly arranged on the frame in the horizontal direction. A hammer head is pivoted to the other end of the connecting rod of the hammer head, the hammer head is located above the carrying plate, a power output end of the power driving unit is connected to a main journal of the crankshaft, and a clutch for controlling synchronous movements of the crankshaft and the power driving unit sleeves the main journal of the crankshaft. The hammering device provided by the invention alleviates the technical problem that the production efficiency is low and the processing cost is high in the prior art because cured beef which is manually hammered cannot be continuously processed and manufactured and the market demand cannot be met.

Owner:刘正龙

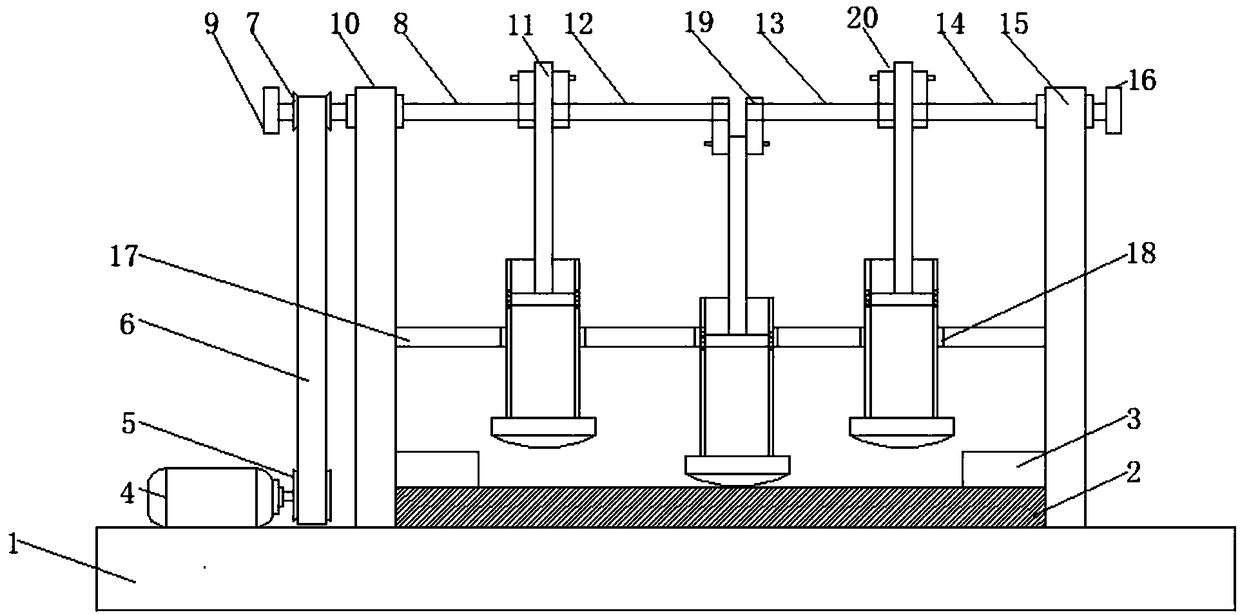

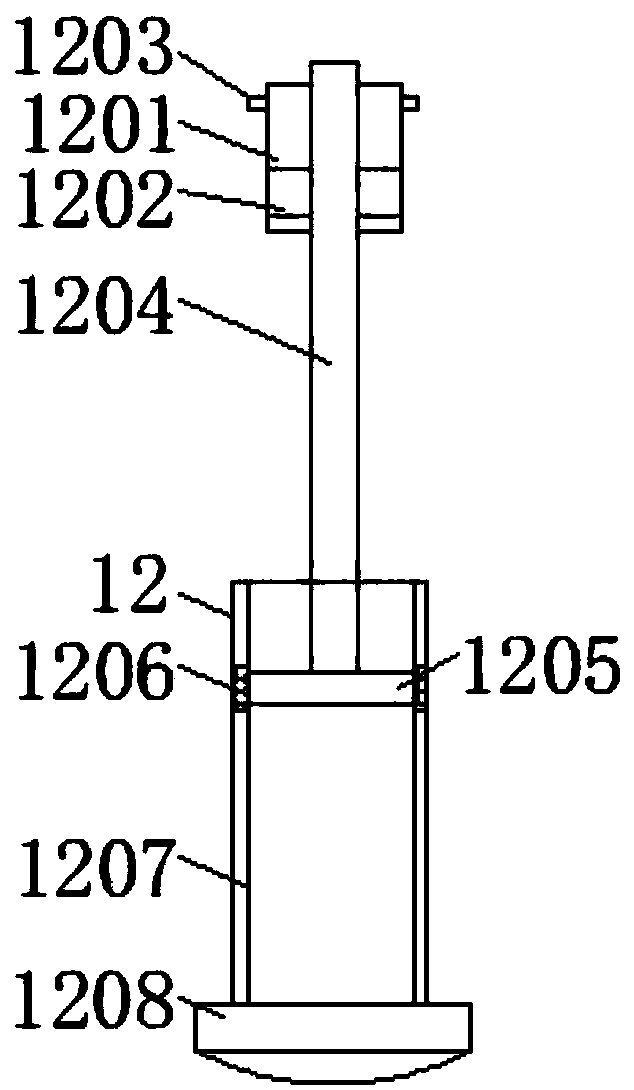

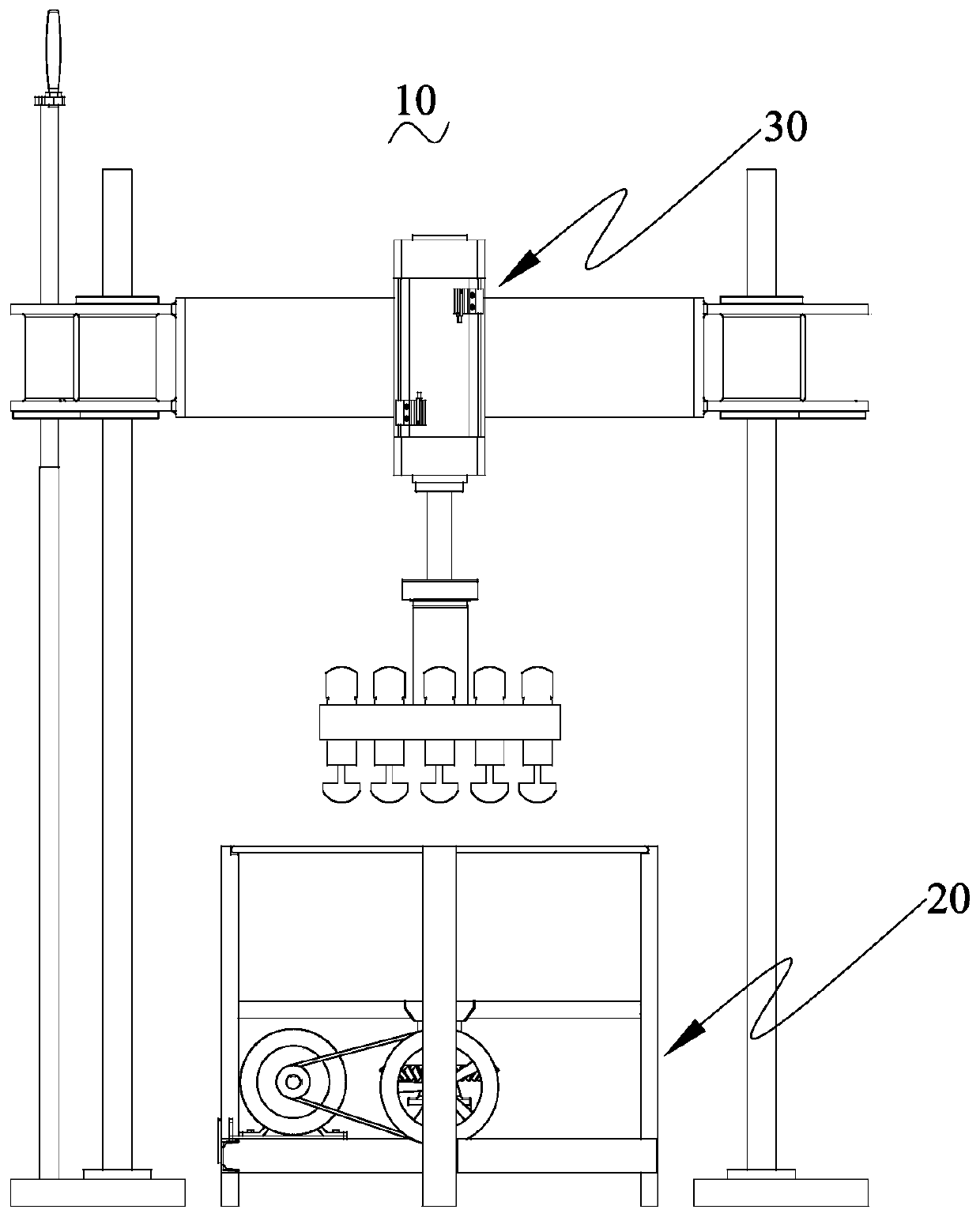

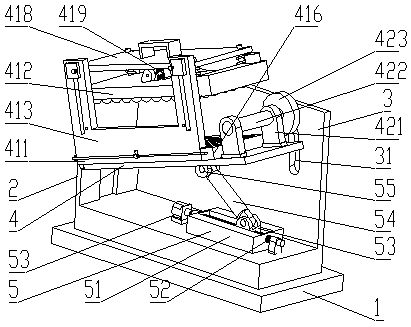

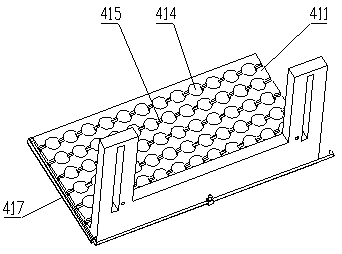

Automatic meat hammering machine imitating handwork

InactiveCN108522612AAvoid spreadingThe effect of hammering is not obviousBeating-based meat tenderisingEngineeringImitation

The invention relates to the technical field of automatic meat hammering machines, in particular to an automatic meat hammering machine imitating handwork. The technical problem to be solved by the invention is that traditional automatic meat hammering machines are equipped with plate-shaped or knife-shaped hammering plates, have heavy damage to meat tissues, and cannot achieve the imitation of manual hammering to a large extent. In order to solve the technical problems, the invention provides the automatic meat hammering machine imitating handwork. The machine includes a bottom plate; both two sides of the top of a placing plate are fixedly connected to meat pushing blocks; two sides of the top of the bottom plate are separately and fixedly connected to a first supporting rod and a secondsupporting rod; the reverse sides of the two meat pushing blocks are separately and fixedly connected to the bottoms of the reverse sides of the first supporting rod and the second supporting rod, respectively. The device is provided with a first meat hammering device, a second meat hammering device and a third meat hammering device, so that the machine can imitate manual hammering to a large extent, and can achieve a better taste effective without damaging meat tissues.

Owner:李志平

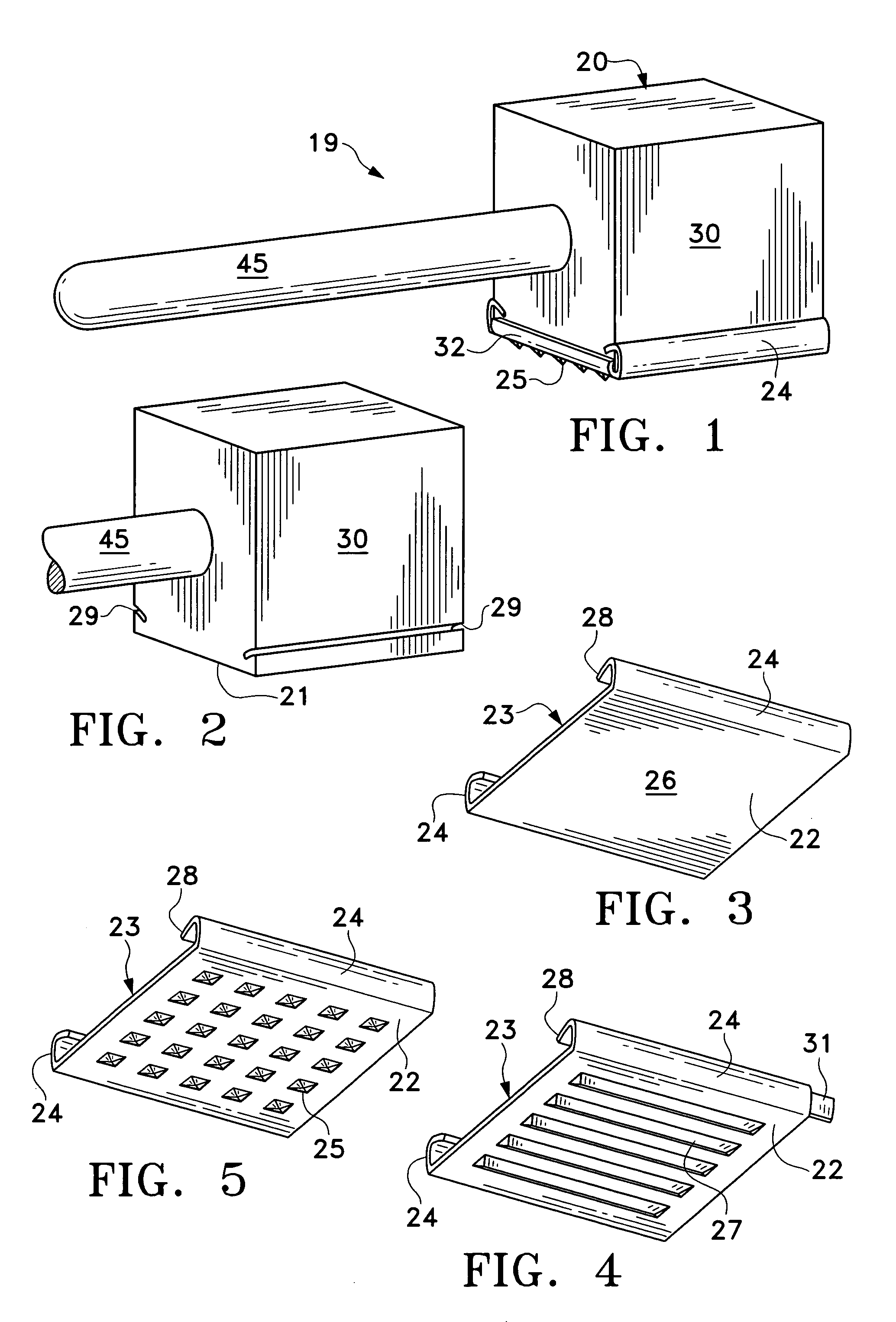

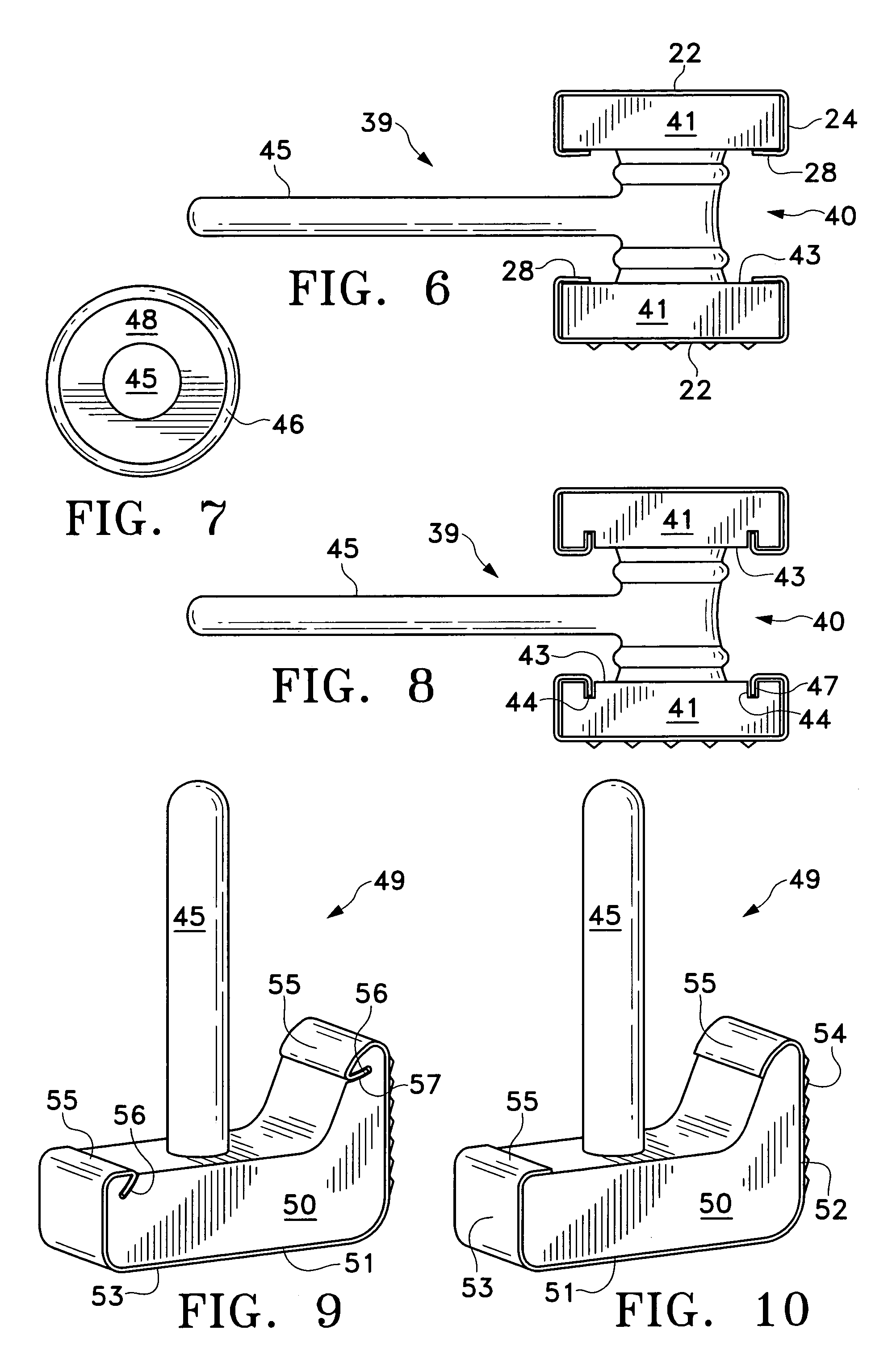

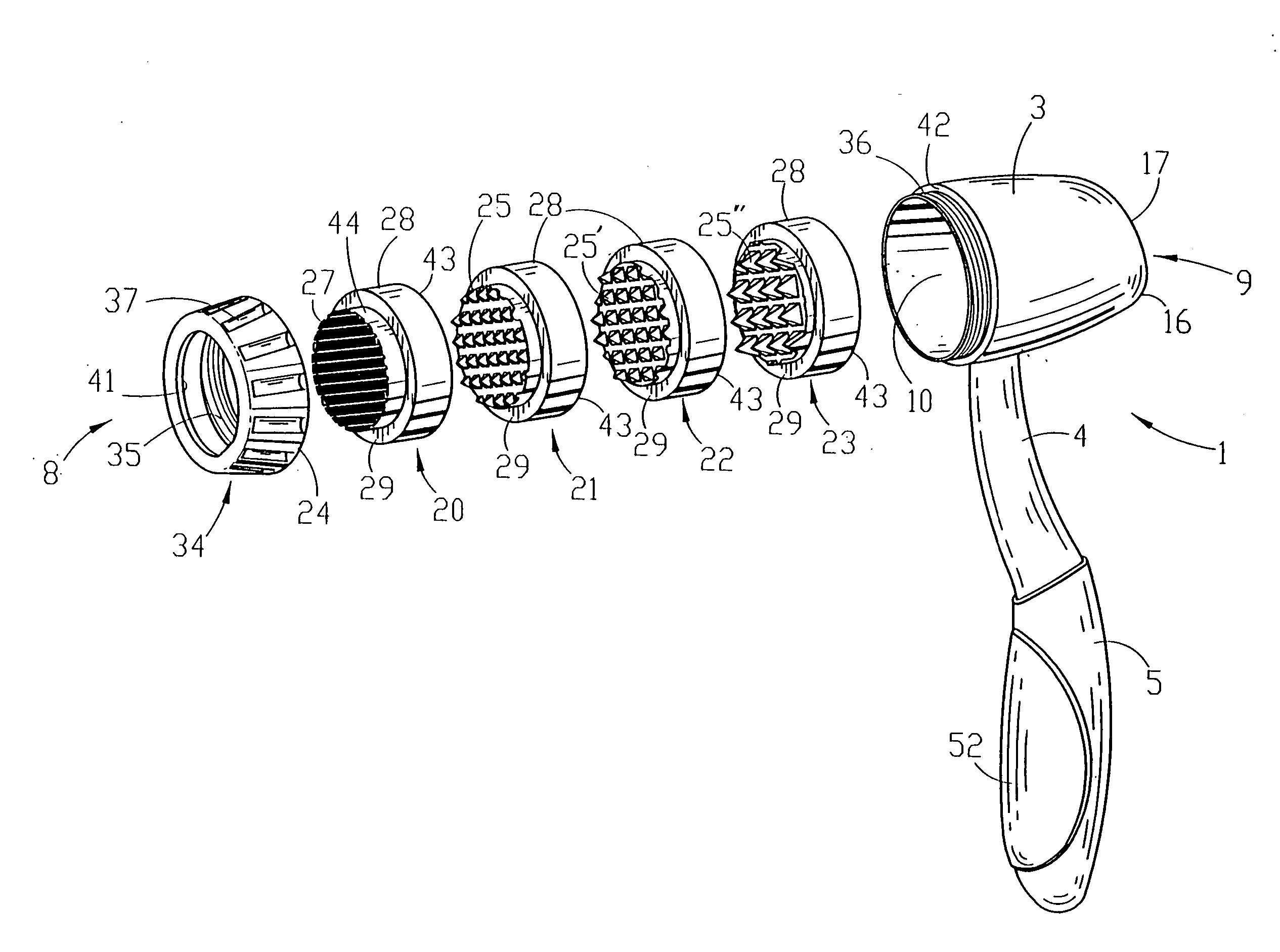

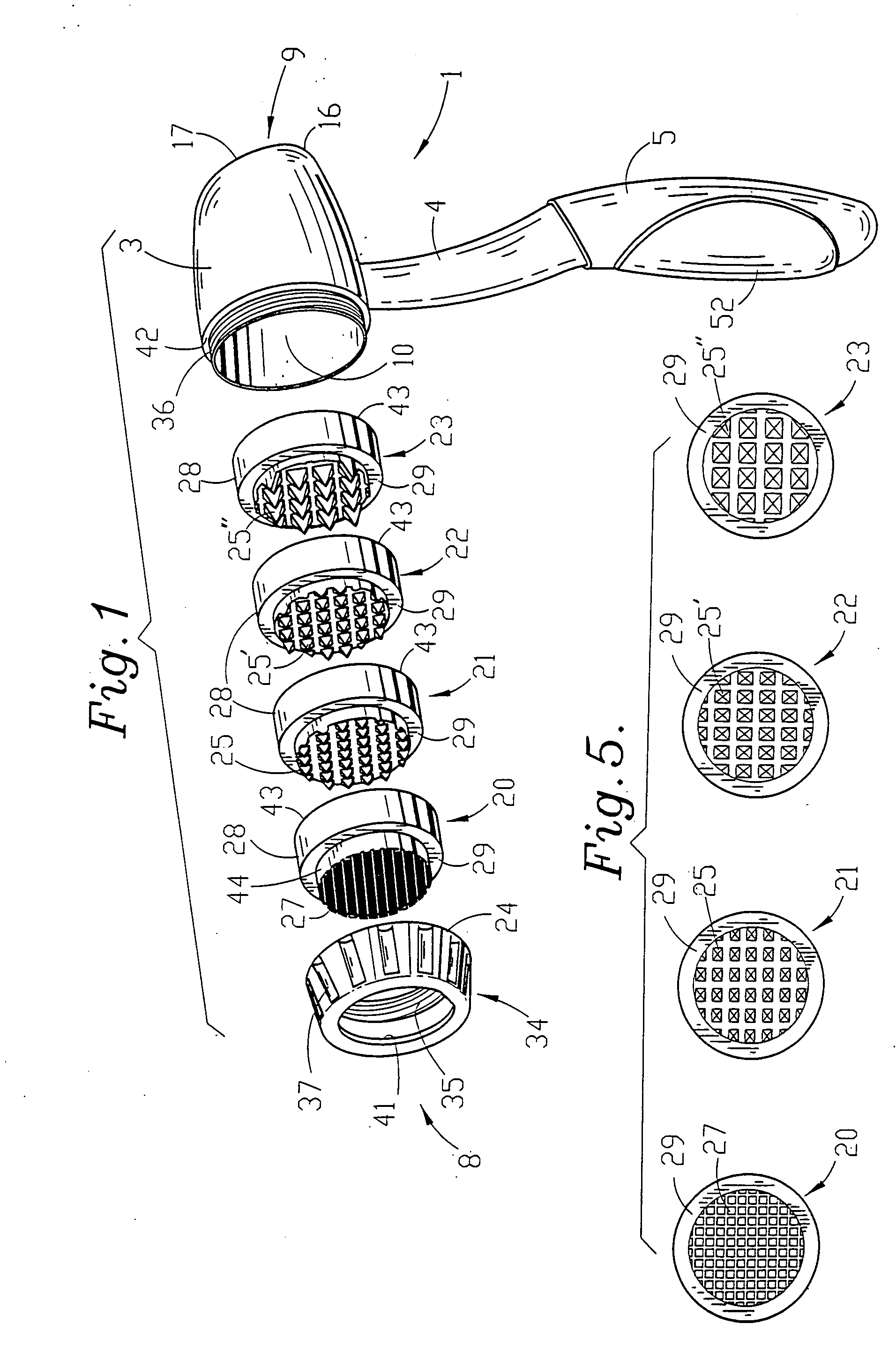

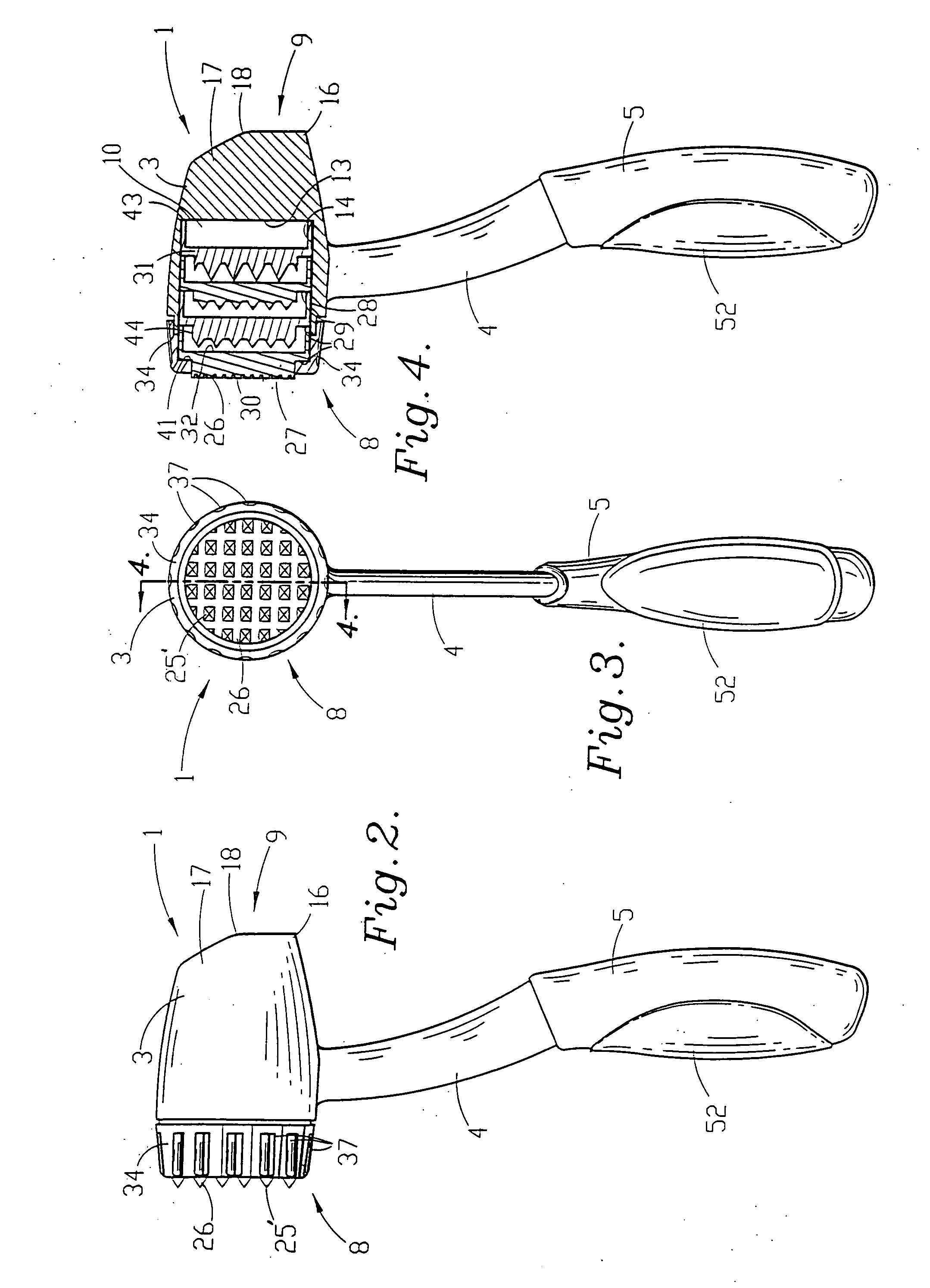

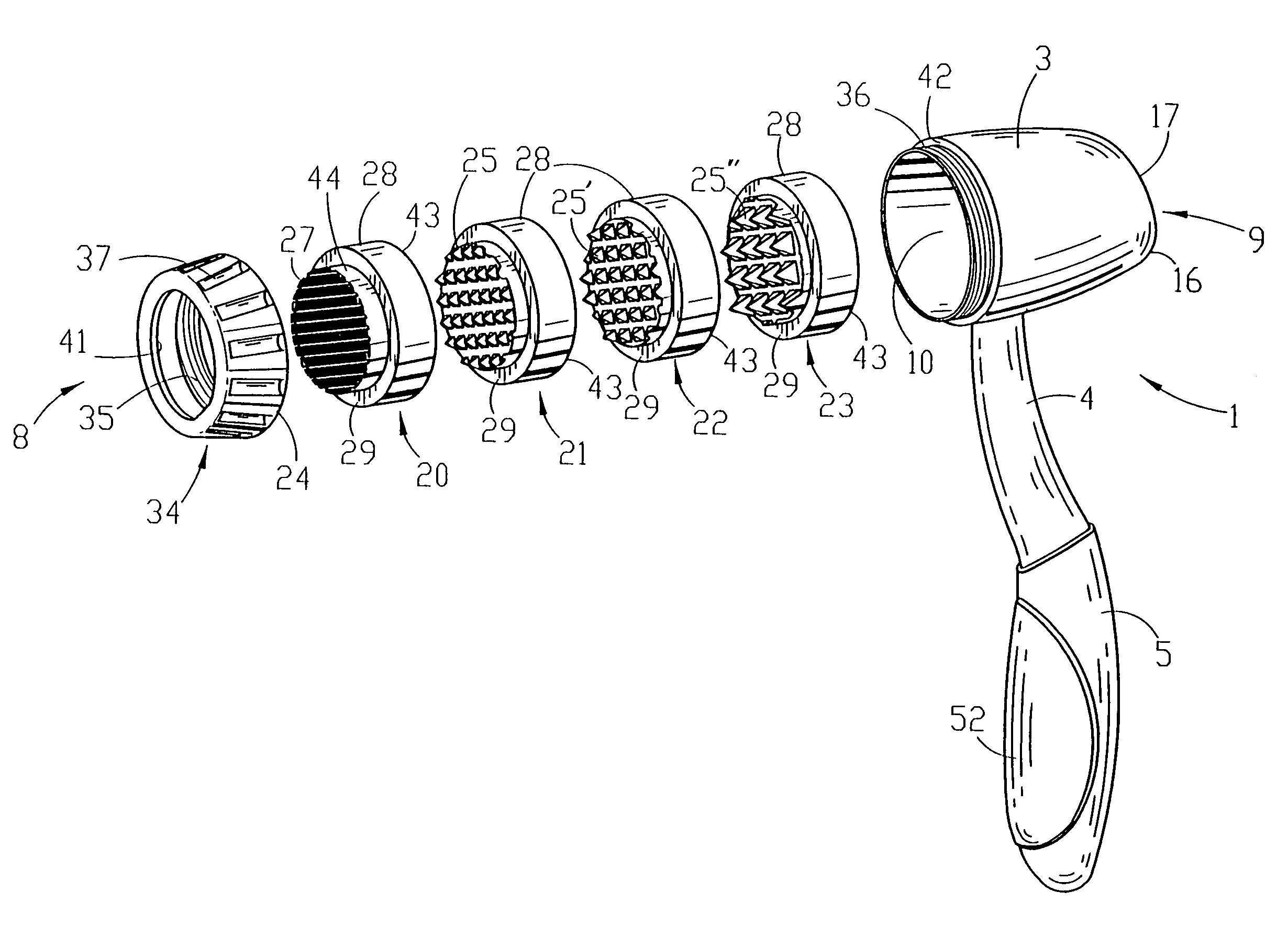

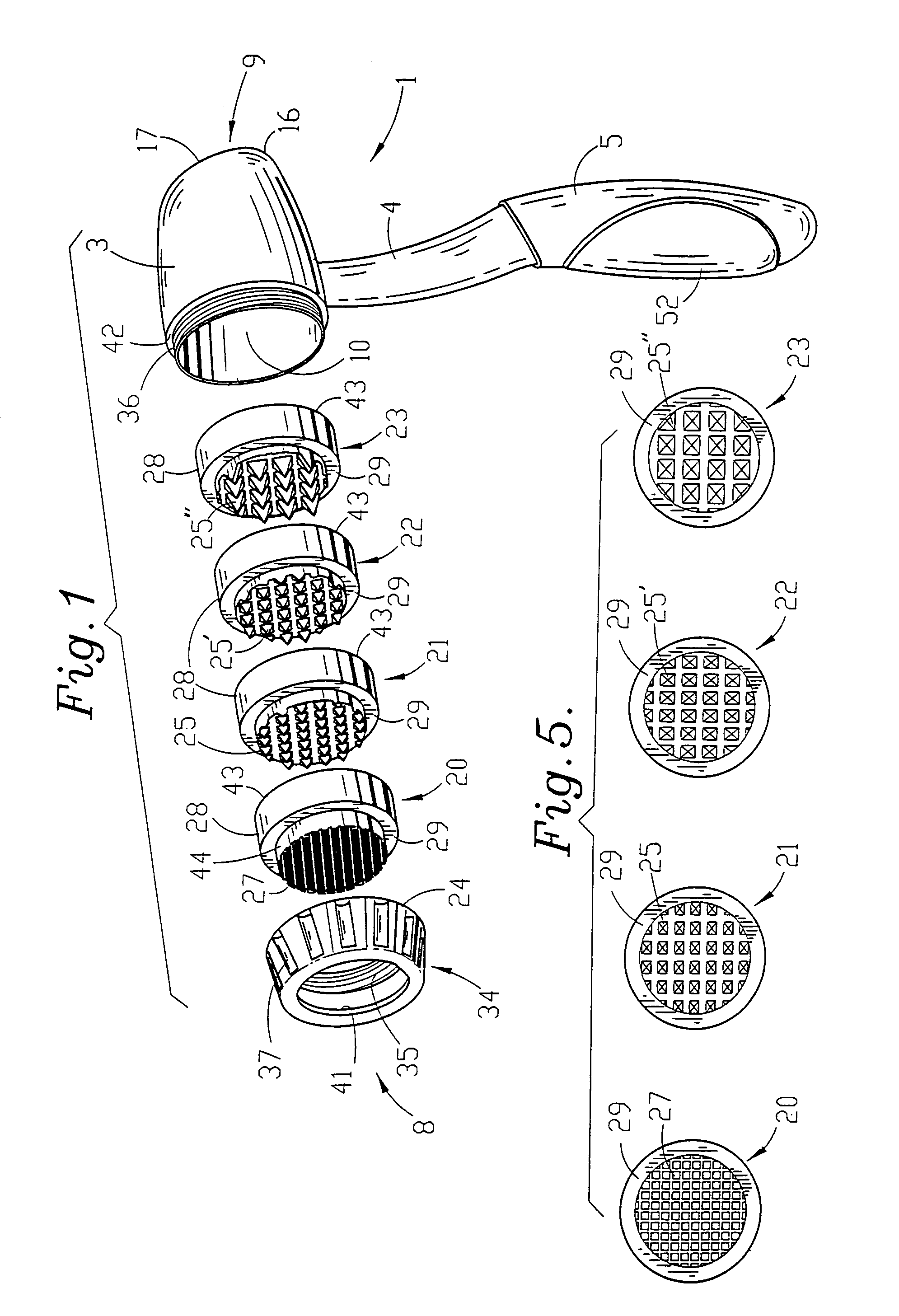

Meat mallet with interchangeable tenderizing surfaces

InactiveUS20060019589A1Reduce manufacturing costLow costFish washing/descalingPoultry plucking mechanismsSupporting systemConnective tissue fiber

A meat mallet for tenderizing and flattening meat with a handle, a neck and a head with interchangeable face plates. The face plates have a meat-engaging surface of varying patterns that can be flat, have outwardly projecting points of different sizes and shapes to accommodate meats having different connective tissues or other suitable tenderizing structure. The head has a partially hollow cavity that opens at a front end and stores the face plates in a nested configuration with the top-most plate being an in-use plate. The face plates have a perimeter support shoulder that facilitates the nesting configuration providing a perimeter support system while protecting the meat engaging surfaces of the face plates. A retainer ring has an inner threaded surface that threadedly engages an outer threaded surface of the front end of the head and allows the meat-engaging surface of the in-use plate to partially extend past the retainer ring to engage the subject meat.

Owner:WANGLER ERIC J +1

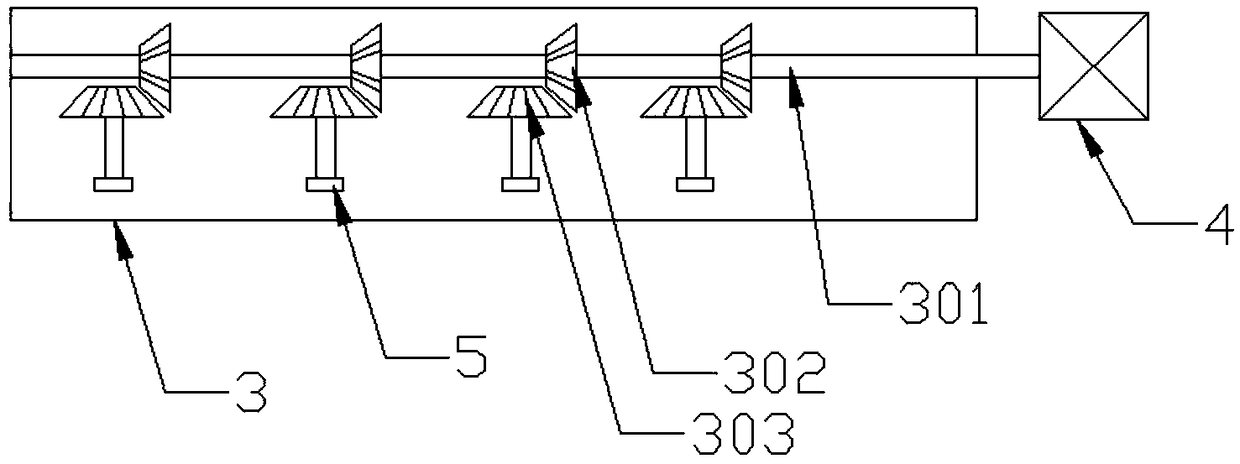

Beef beating device for beef ball preparation

InactiveCN107960441ABeat evenly and fullyBeating without interruptionBeating-based meat tenderisingMeat mixing apparatusEngineeringBlock match

The invention discloses a beef beating device for making beef balls, which comprises a bottom plate, the bottom of the bottom plate is provided with outriggers; the top of the bottom plate is fixedly provided with a first deceleration motor, and the motor shaft at the top of the first deceleration motor is fixedly connected with a beating plate; the top right side of the bottom plate Two second support rods, front and rear, are fixedly installed, and the tops of the second support rods are respectively hinged with square hammer rods; two front and rear support plates are fixedly installed on the right side of the top of the legs, and there is a rotating shaft connected between the front and rear support plates. A rotating roller is fixedly installed, and the left front side and the right rear side of the side wall of the rotating roller are respectively fixedly connected with arc-shaped blocks matching with the front and rear square hammer bars; the left side of the top of the bottom plate is also fixedly equipped with a third pole, and the right end of the third pole top is Fixed connection with scraper. The invention automatically beats the beef through the up and down swing of the square hammering rod, and the beating speed is fast and the efficiency is high; during the beating process, the beating plate rotates, and at the same time cooperates with the scraper to scrape the beef to the middle of the beating plate to ensure that the beef is beaten evenly and fully.

Owner:顾志裕

Meat mallet with interchangeable tenderizing surfaces

Owner:WANGLER ERIC J +1

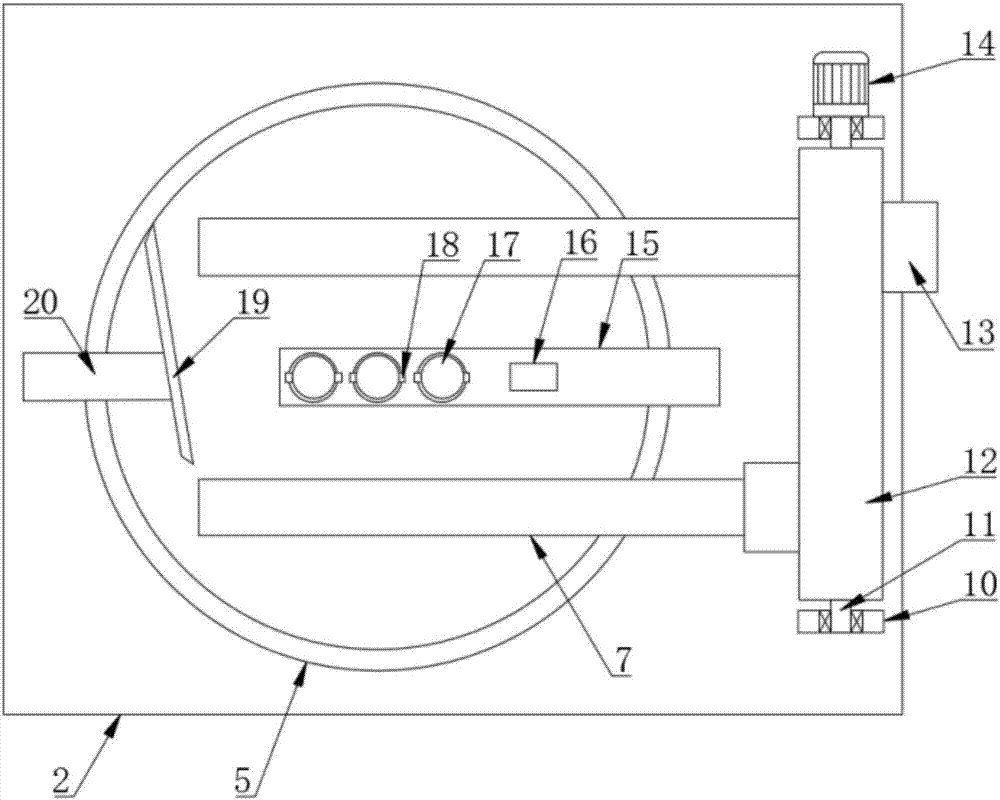

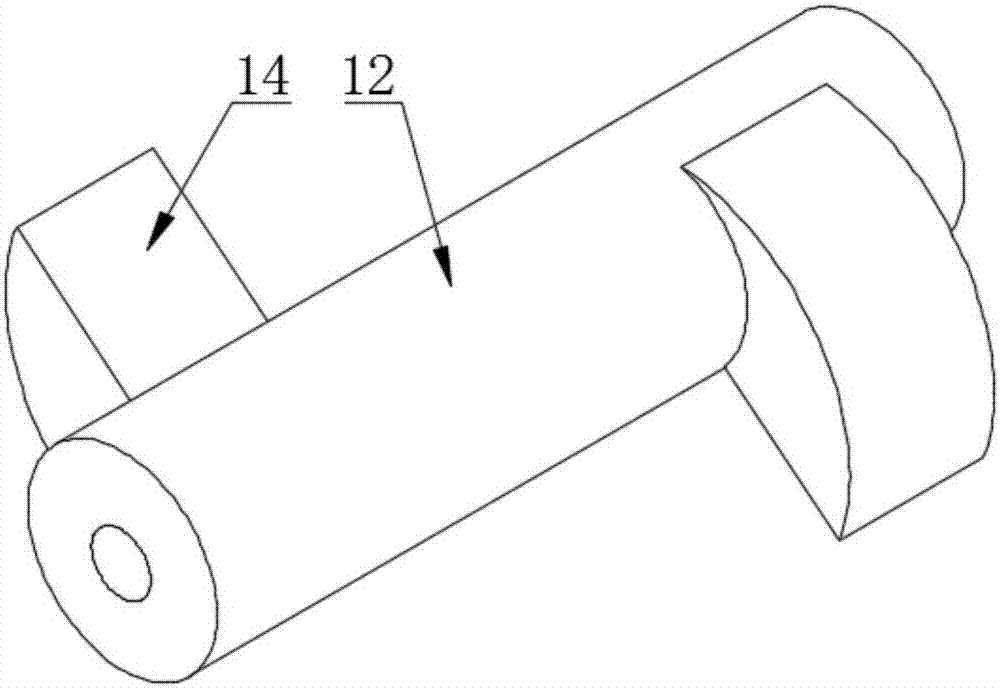

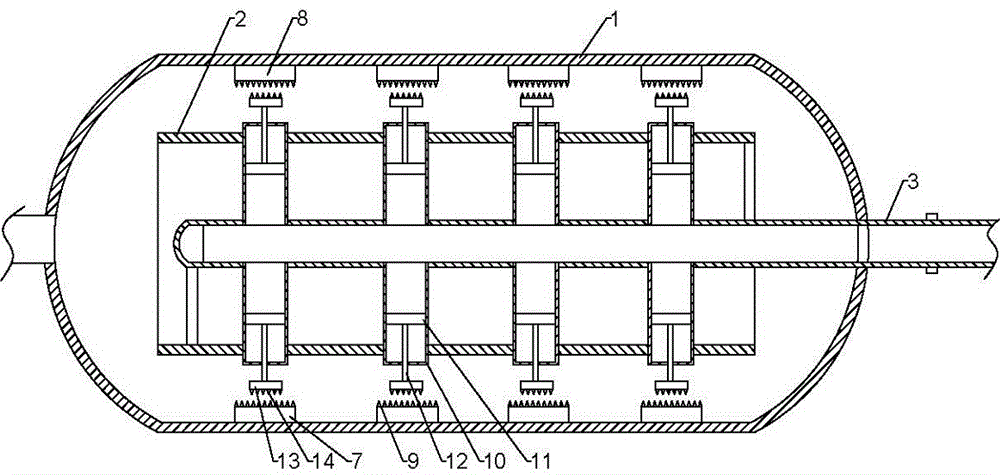

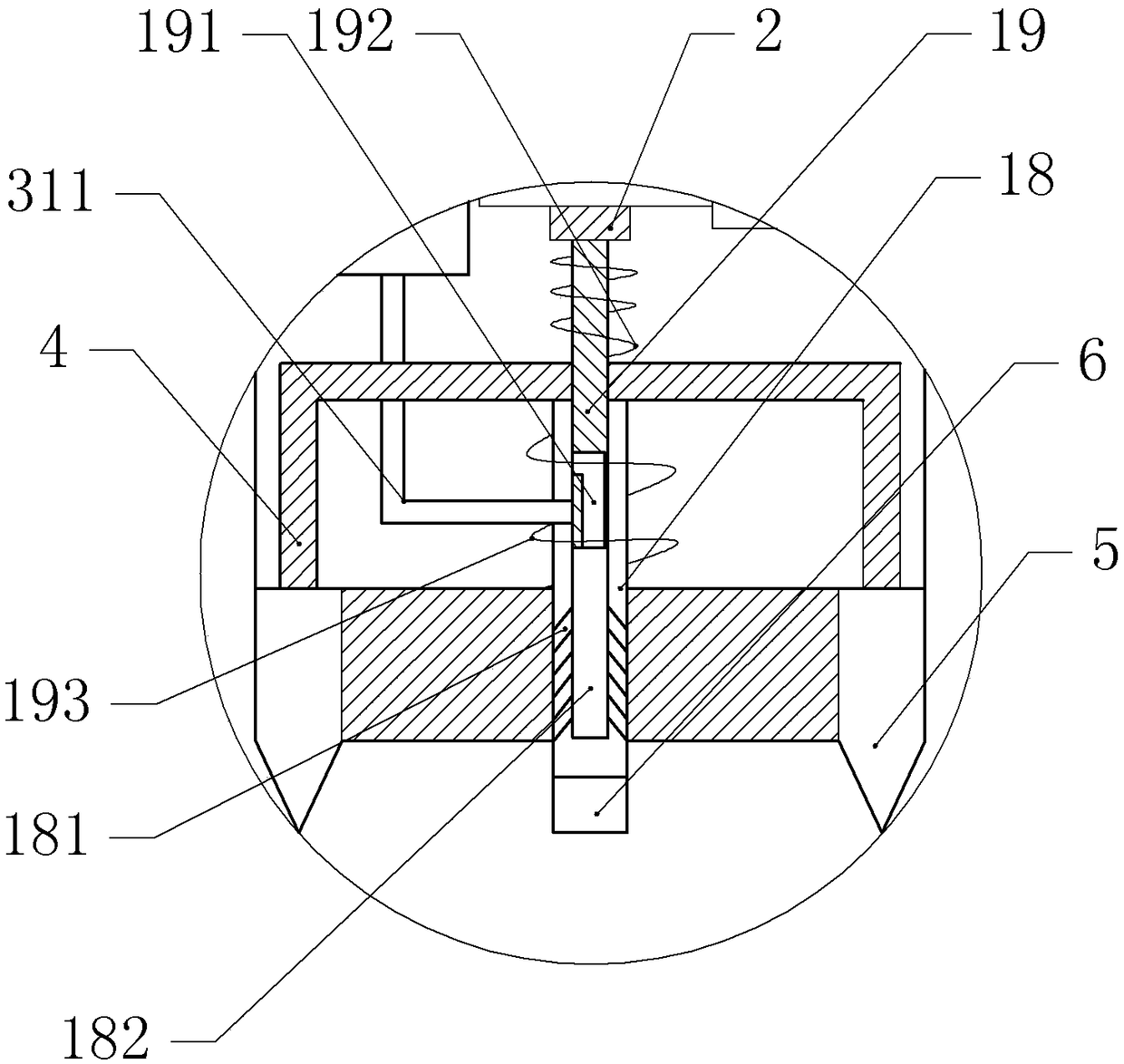

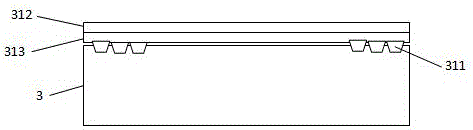

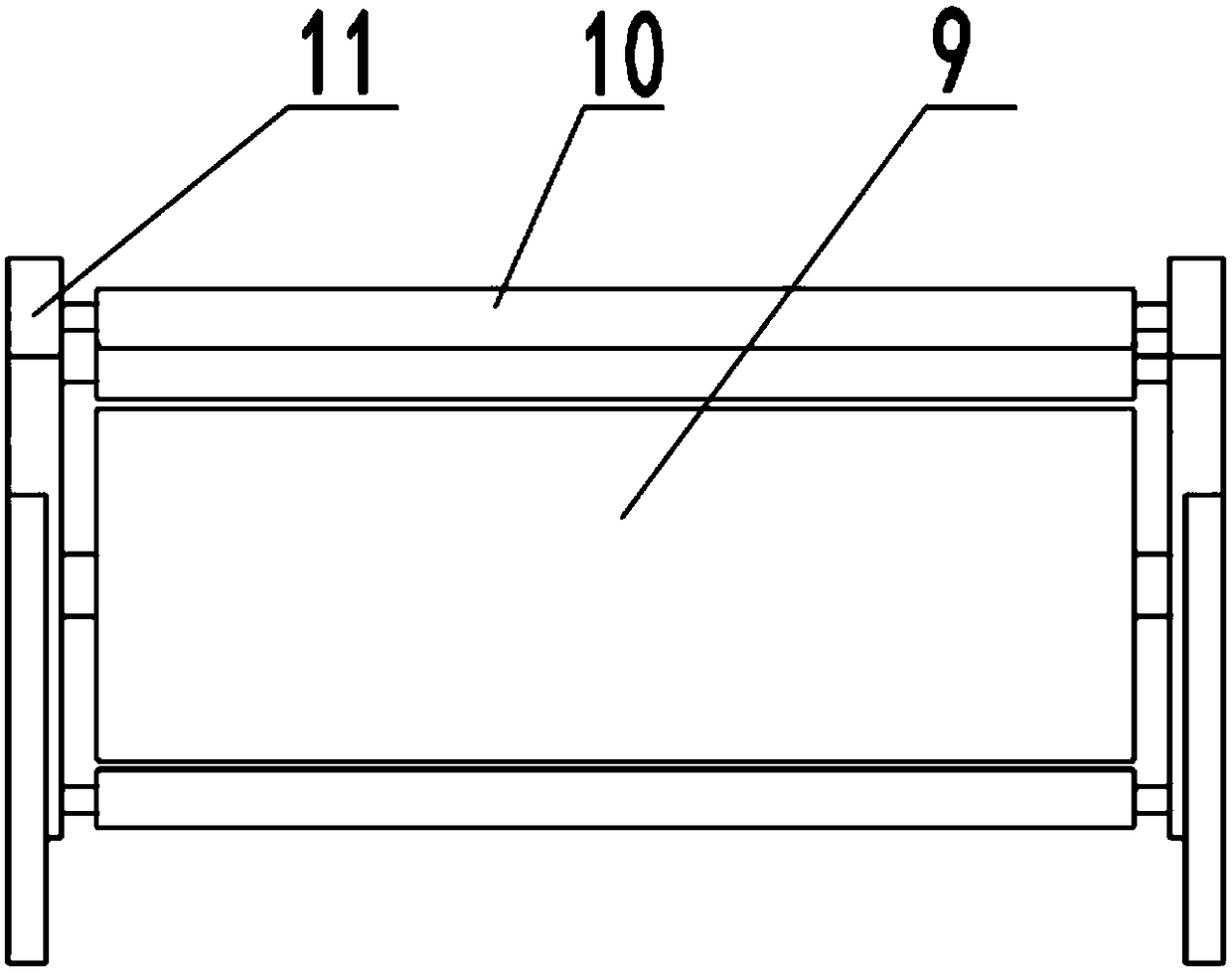

Vacuum refrigeration rolling machine

ActiveCN106819037AMarinate Tumble FastImprove tumbling efficiencyBeating-based meat tenderisingMeat mixing apparatusWater dischargeMagnetic poles

The invention relates to the field of food processing and discloses a vacuum refrigeration rolling machine. The vacuum refrigeration rolling machine comprises a rolling barrel and a hollow rotating shaft, wherein a separating plate is arranged in the rotating shaft; the rotating shaft is separated into a water feeding chamber and a water discharging chamber; the rolling barrel comprises an outer barrel and an inner barrel; a first magnet set and a second magnet set are arranged on the inner wall of the outer barrel; the first magnet set and the second magnet set are both faced to the rotating shaft; the magnetic poles at the ends of the first magnet set and the second magnet set faced to the rotating shaft are opposite to each other; a plurality of striking mechanisms are arranged on the rotating shaft; each striking mechanism comprises a piston barrel; the piston barrel is fixedly connected with the rotating shaft and is communicated with the water feeding chamber and the water discharging chamber; a piston plate is arranged in the piston barrel in a sliding form; a connecting rod is fixedly connected with one end of the piston plate away from the rotating shaft; a third magnet is connected with one end of the connecting rod away from the piston plate; a one-way feeding valve is connected between the piston barrel and the water feeding chamber; and a one-way discharging valve is connected between the piston barrel and the water discharging chamber. Compared with the prior art, the vacuum refrigeration rolling machine has higher rolling efficiency.

Owner:重庆汤嫂食品有限公司

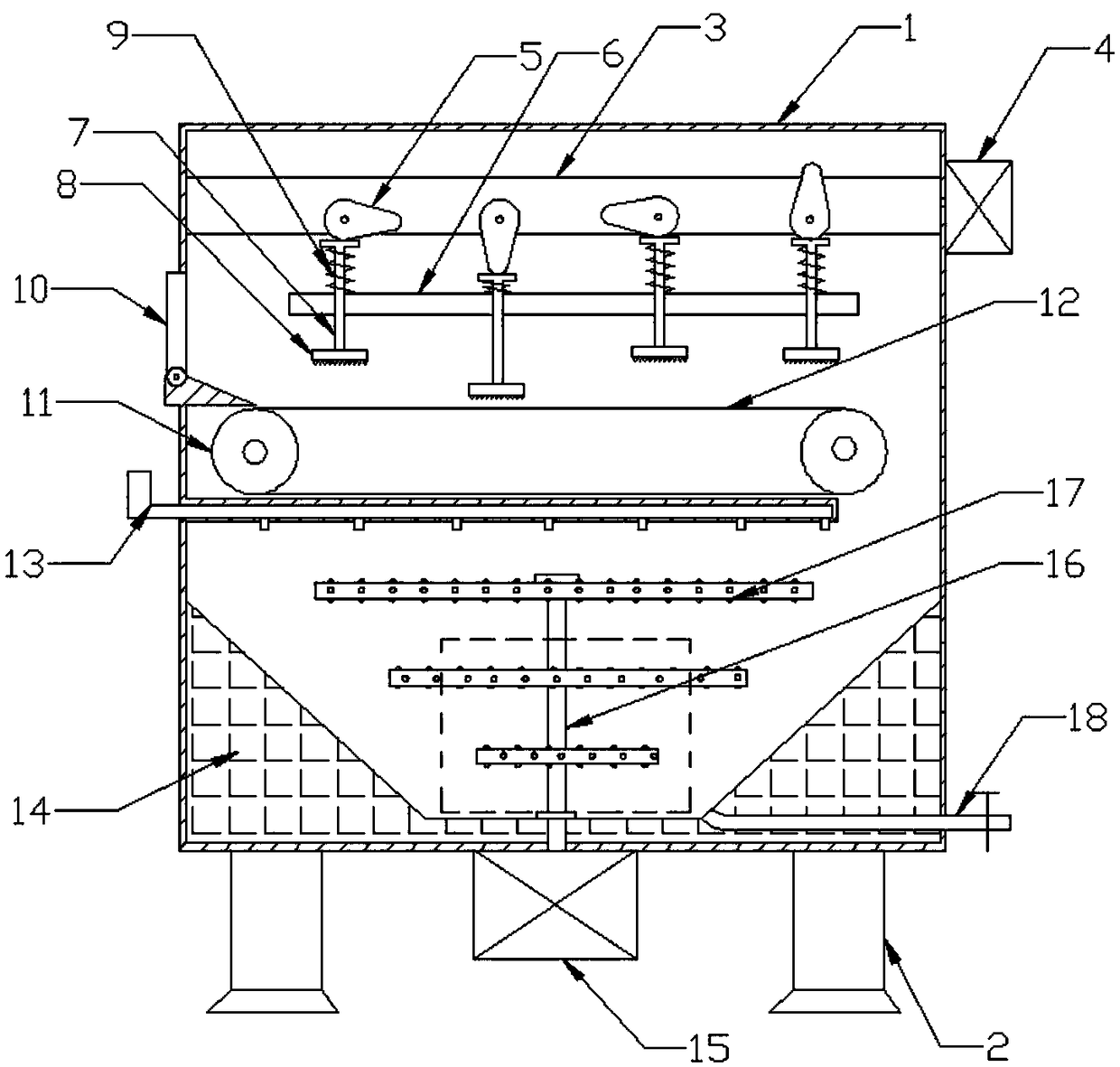

Pickling device for processing of preserved meat

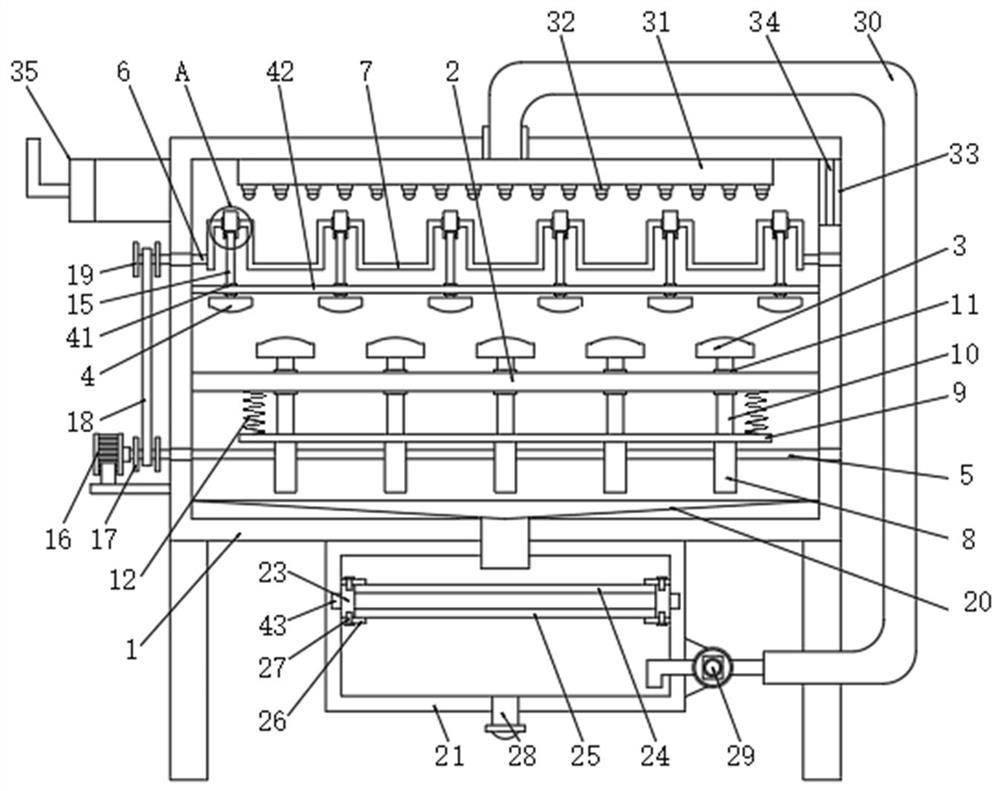

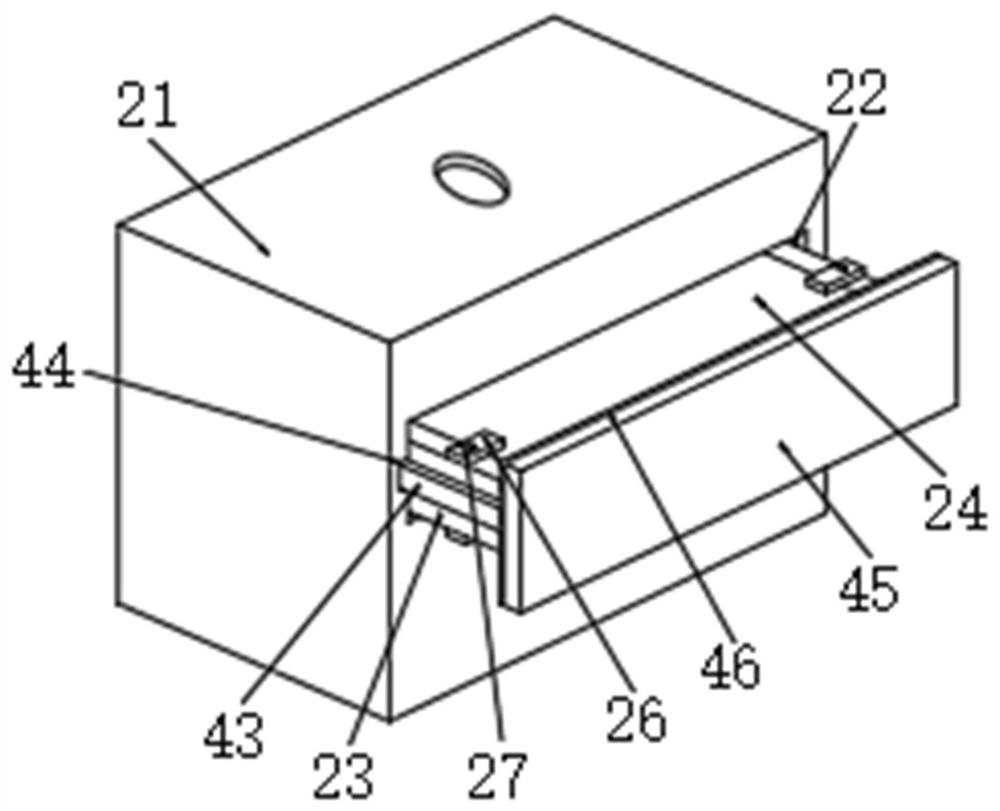

InactiveCN108771145ALoose fiberImprove pickling efficiencyBeating-based meat tenderisingFiberDrive motor

The invention discloses a pickling device for processing of preserved meat. The pickling device comprises a shell. The top of an inner cavity of the shell is provided with a driving box, and the rightside wall of the shell is connected with a driving motor. The front side wall of the driving box is connected with four groups of evenly distributed cams, below which a dead plate is arranged. A motion bar is inserted at the top of the dead plate. A pressure plate is connected at the bottom of the motion bar, the upper end of which is sleeved with a spring. A feed board is hinged to the left sidewall of the shell. Driving rollers are bilaterally symmetrically arranged in the inner cavity of the shell. An infusion tube is plugged in the left side wall of the shell. A stirring motor is connected at the central of the bottom of the shell. The structure of the pickling device is reasonable in design. With the cams pressing the motion bar intermittently, the pressure plate beats the preservedmeat to loosen fibers of the preserved meat, thus facilitating infiltration of seasoning during subsequent pickling. Through the stirring motor for driving a mixer shaft to rotate, a mixing rod stirsa seasoning solution and the preserved meat uniformly, thus facilitating rapid pickling of the preserved meat and greatly improving pickling efficiency of the preserved meat.

Owner:ANHUI HAOZAILAI FOOD

Pork hammering device

InactiveCN107821554AImprove beating efficiencyReduce labor intensityBeating-based meat tenderisingEngineeringUltimate tensile strength

The invention discloses a pork hammering device which includes a machine frame, a circuit controller, a servo motor, a main rotary disk, a plurality of first baffle rods, a plurality of baffle balls,a sub-rotary disk, a secondary baffle rod, a position-limiting groove, an iron hammer, a stone hammer trough, a material trough, a side door, a support frame, an air-cylinder and a pushing plate. Themain rotary disk is rotatably installed on the left end of the machine frame and is connected to an output shaft of the servo motor via a gear. There are eight first baffle rods uniformly arranged onthe side surface of the main rotary disk at equal interval, each first baffle rod being fixedly provided with one baffle ball. The sub-rotary disk is rotatably installed on the right end of the machine frame. A second baffle rod is fixedly installed on the left upper end of the side wall of the sub-rotary disk. The position-limiting groove is formed in the second baffle rod. The iron hammer is fixedly installed on the right lower end of the sub-rotary disk. The pork hammering device is convenient to use, is improved in hammering efficiency and reduces labor intensity of workers.

Owner:ANHUI FURUN MEAT PROCESSING

Auxiliary equipment used for mutton processing

ActiveCN108378118AImprove work efficiencyBeating-based meat tenderisingMeat shaping/cuttingEquipment useEngineering

The invention belongs to the technical field of mutton processing, and discloses auxiliary equipment used for mutton processing. The auxiliary equipment used for mutton processing comprises a machineframe, and a transmission mechanism installed on the machine frame; a knocking mechanism and a cutting mechanism are arranged above the transmission mechanism; the cutting mechanism comprises a reverse-U-shaped rod and cutting blades, wherein the cutting blades are fixed at lower parts of both sides of the reverse-U-shaped rod; a vertical rod in sliding connection with the machine frame is fixed at a middle part of the reverse-U-shaped rod; the knocking mechanism comprises a rotating shaft located above the vertical rod, a first motor fixed on the machine frame and a plurality of convex blocks, wherein the rotting shaft is fixed on an output shaft of the first motor, and the convex blocks are arranged on two sides of the rotating shaft along a direction opposite to the radial direction ofthe rotating shaft; reversed-Y-shaped rods are arranged under the convex blocks, and are in counterbalance with the convex blocks; return springs are arranged at upper parts of the reversed-Y-shaped rods, and are in counterbalance with the machine frame; knocking blocks are connected to lower parts of the reversed-Y-shaped rods in sliding connection; and press spring in counterbalance with the reversed-Y-shaped rods are arranged on the knocking blocks. The auxiliary equipment used for mutton processing is capable of performing regular cutting on mutton, as well as performing knocking on mutton.

Owner:务川自治县洞家沟农业开发有限公司

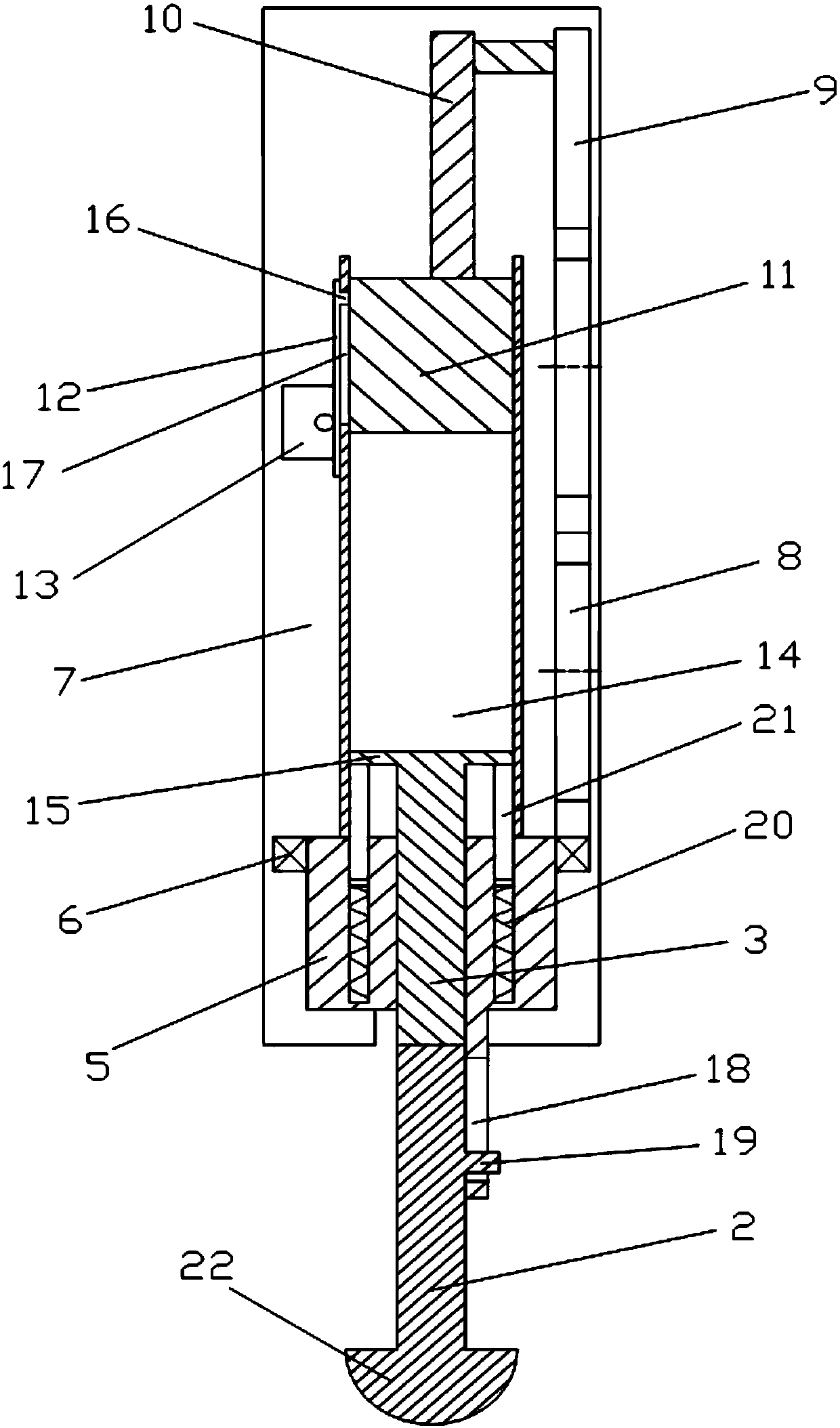

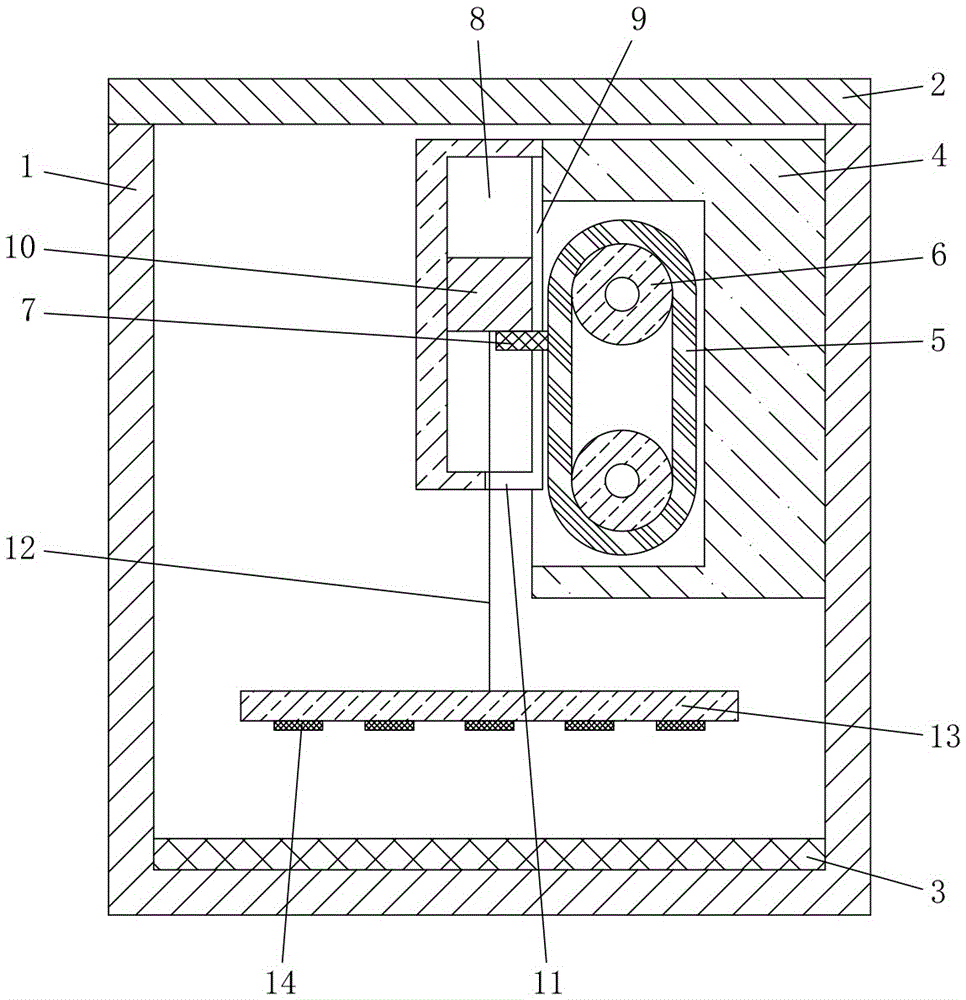

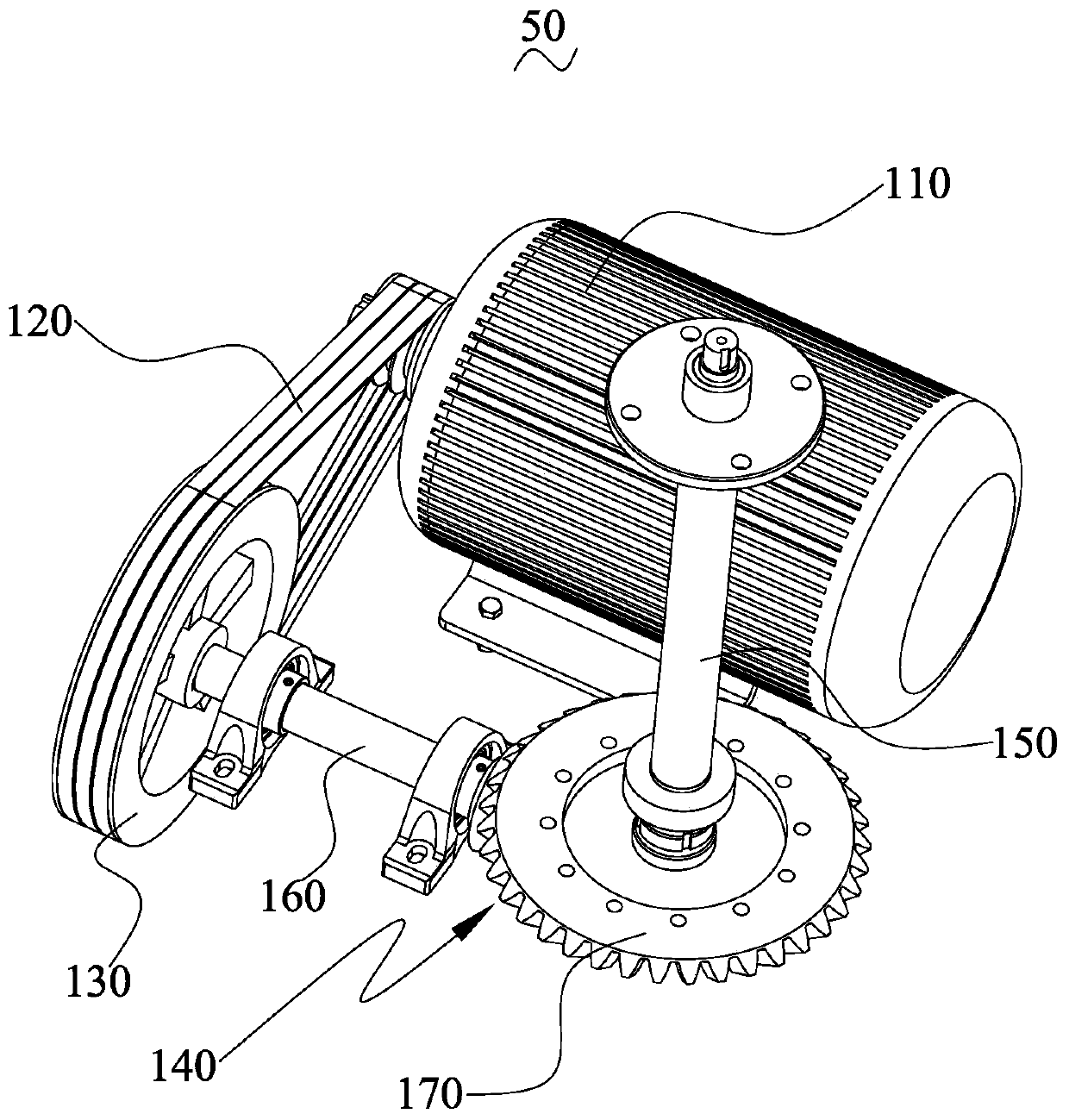

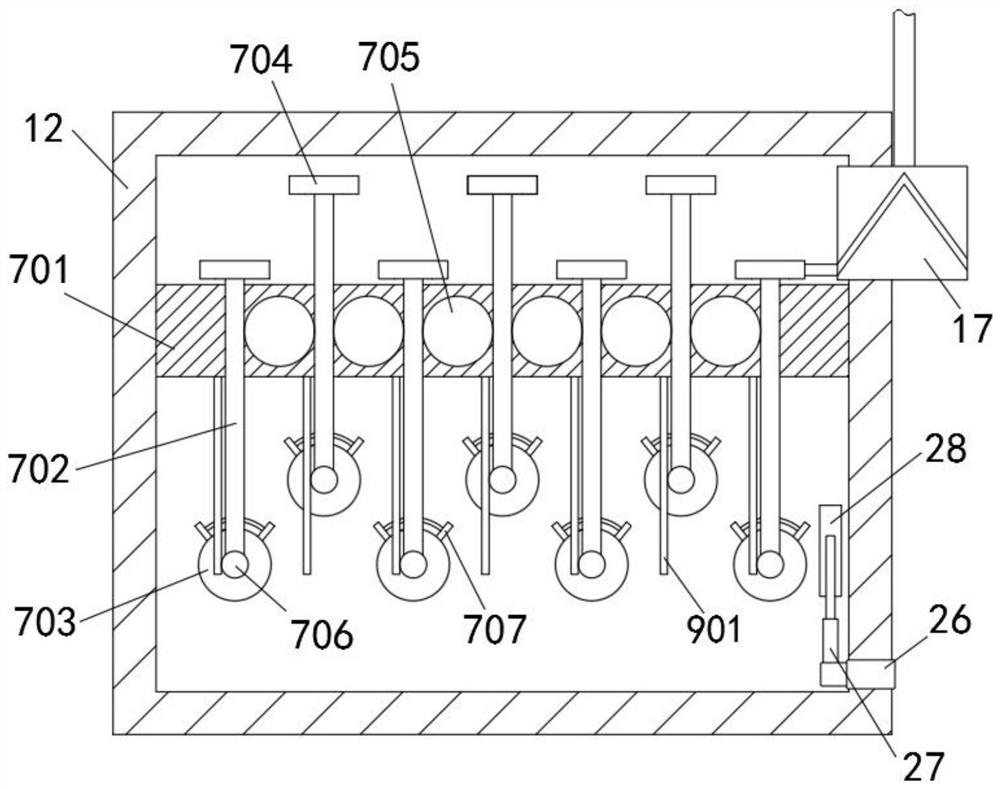

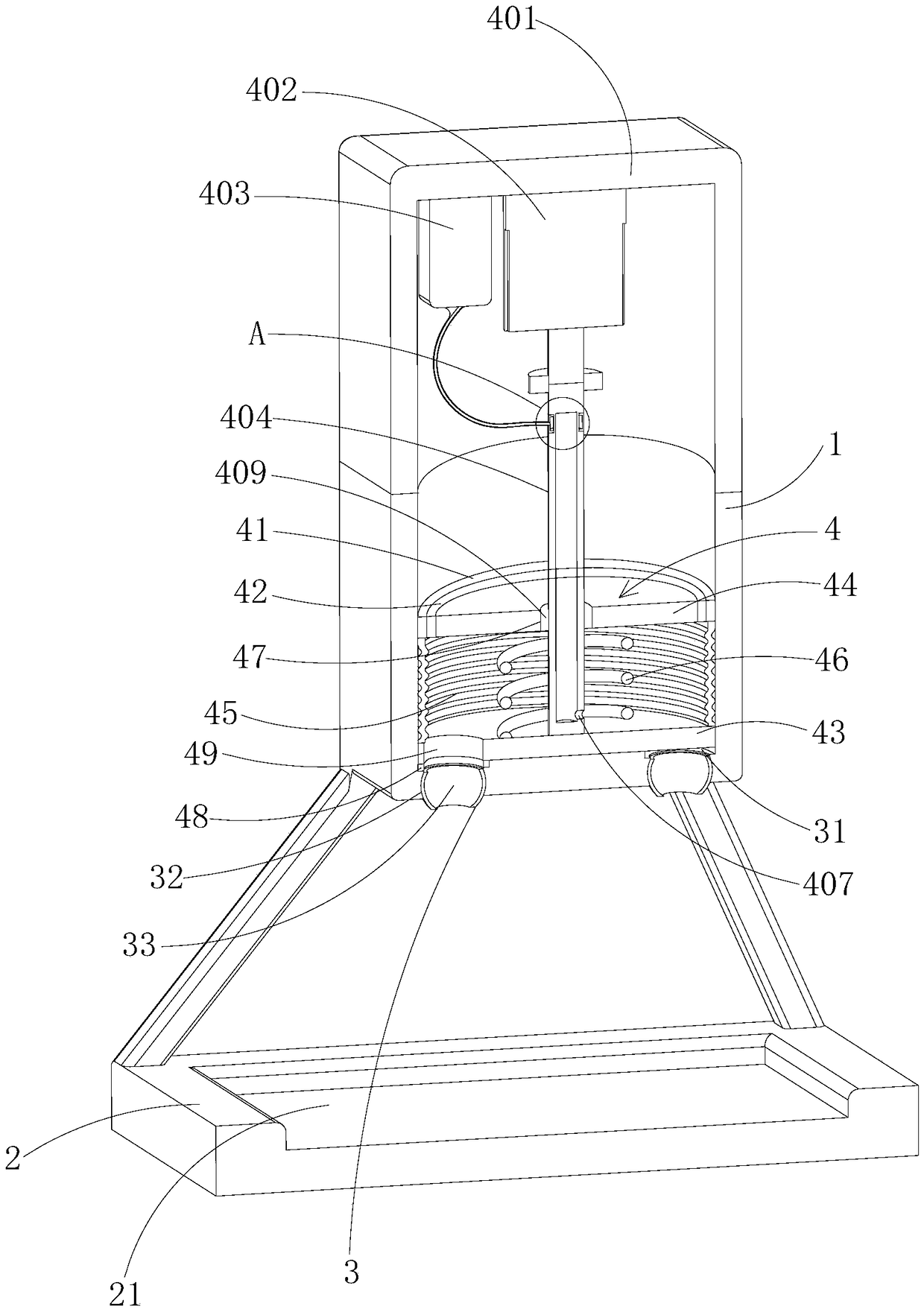

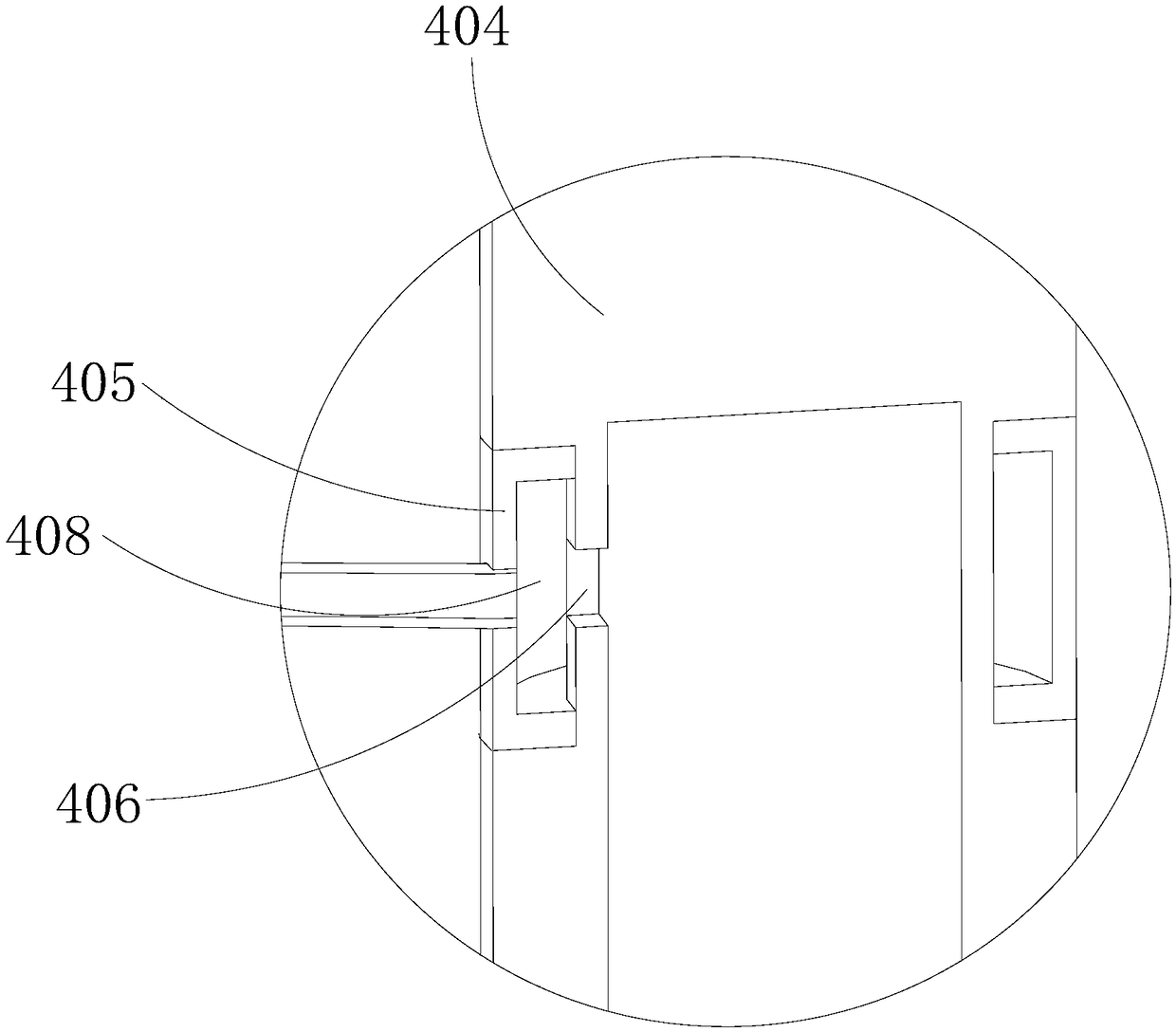

Meat pounding machine of lean meatballs

ActiveCN107668154AThumping all roundHigh frequency of thrashingBeating-based meat tenderisingAdditive ingredientElectric machinery

The invention relates to a stirring and pounding device, in particular to a meat pounding machine of lean meatballs. The meat pounding machine solves the problems of meat food ingredient processing equipment. The meat pounding machine comprises a vessel base for containing raw materials, a hammer body for impacting and pounding materials, an impacting assembly for driving the hammer body to repeatedly pound the materials, a connecting rod through which the hammer body is connected with the impacting assembly, and a fixing base for mounting and fixing the impacting assembly, wherein the impacting assembly comprises an embedded sleeve, worm gears, a shell, a gear, an eccentric wheel, an eccentric rod, a piston, a rack, a motor and the connecting rod; a hollow cavity for allowing the piston to reciprocate is formed in the shell; openings are formed in both ends of the hollow cavity; and the piston is arranged on the inward side, close to the opening, of the hollow cavity. Food ingredientsare repeatedly pounded through the impact force brought by the piston, and besides, the hammer body keeps rotating while pounding the food ingredients, so that the food ingredients are pounded more completely; the design of the structure is fully automated; the pounding frequency is high; the service life of the equipment is long; the meat pounding machine has practicality and economy; and the burden of manpower and material resources is reduced.

Owner:江苏天凤源食品有限公司

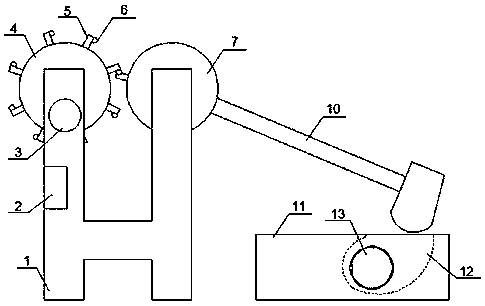

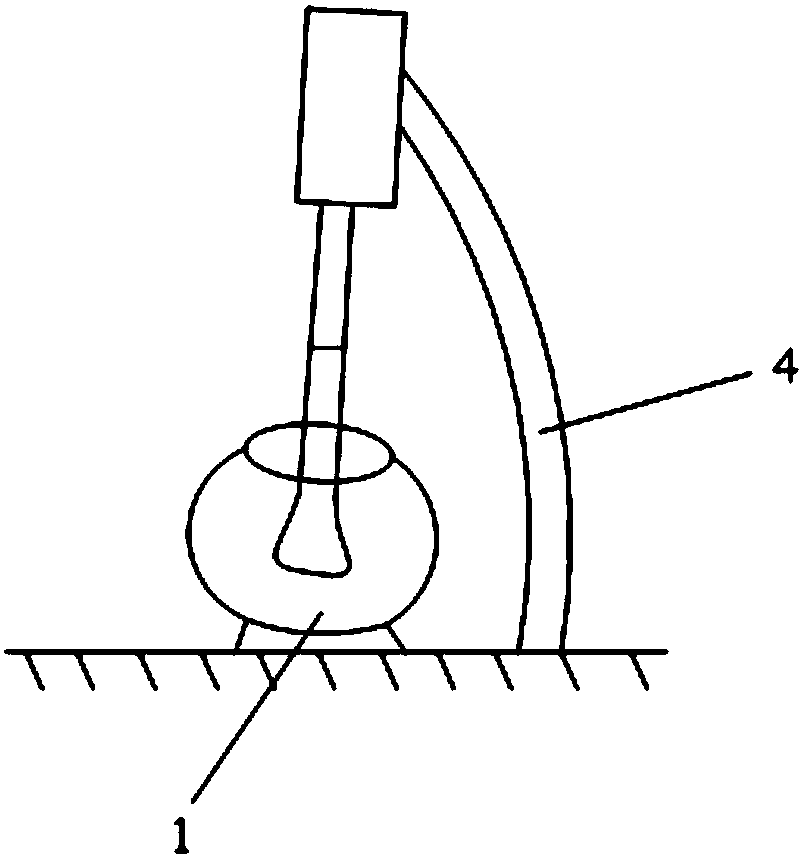

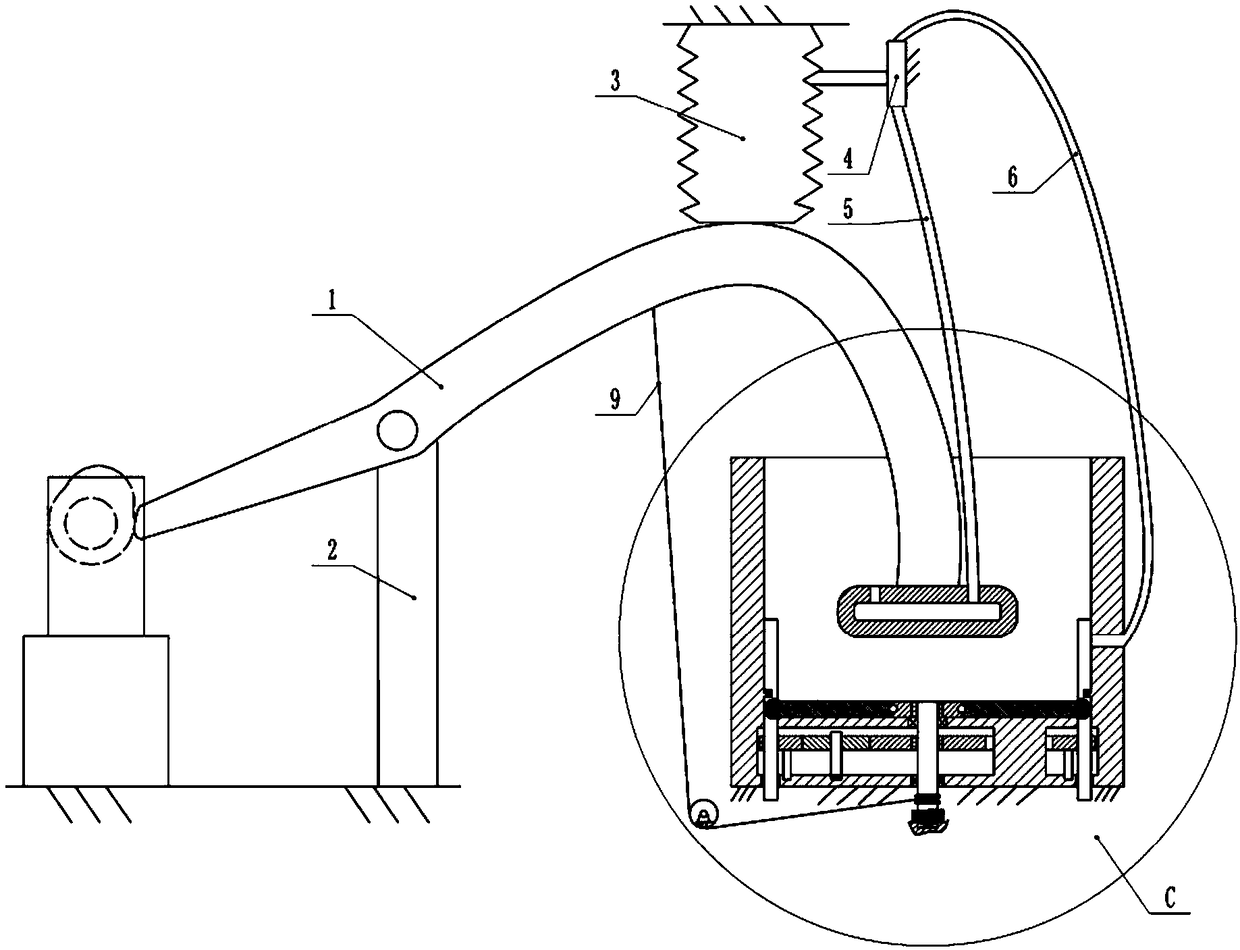

Hand-beating imitated pork meatball dedicated meat-hammering machine

InactiveCN106689316AIncrease elasticityImprove gel clarityBeating-based meat tenderisingFlavorElectric machinery

The invention relates to a muddy meat hammering machine, and especially relates to an hand-beating imitated pork meatball dedicated meat-hammering machine comprising a bone chopping knife and a chopping board; a knife back of the bone chopping knife faces down, the chopping board is arranged below the bone chopping knife, and the tail end of a knife handle of the bone chopping knife is sleevedly connected with a connecting rod through a rubber sleeve; the rear part of the connecting rod is vertically provided with a stand column through a rotating shaft, the tail end of the connecting rod is provided with a scraping block, and the rear of the tail end of the connecting rod is provided with a rotating drum corresponding to the scraping block; the outer surface of the rotating drum is provided with a bulge block corresponding to the scraping block; the rotating drum is connected with a motor through a belt or a chain; the top face of the chopping board is provided with pork skin, the excellent-toughness pork skin is added in the chopping board to block meat bodies and the chopping board, and the mouthfeel is improved; the rubber sleeve is connected between the connecting rod and the bone chopping knife and has the effect similar to that of human wrists, so when the meat bodies are hammered by the bone chopping knife, the meat is beaten with different depths according to the different hardness of meat, so that the flavor of hand-beating meatballs is simulated.

Owner:江先庆

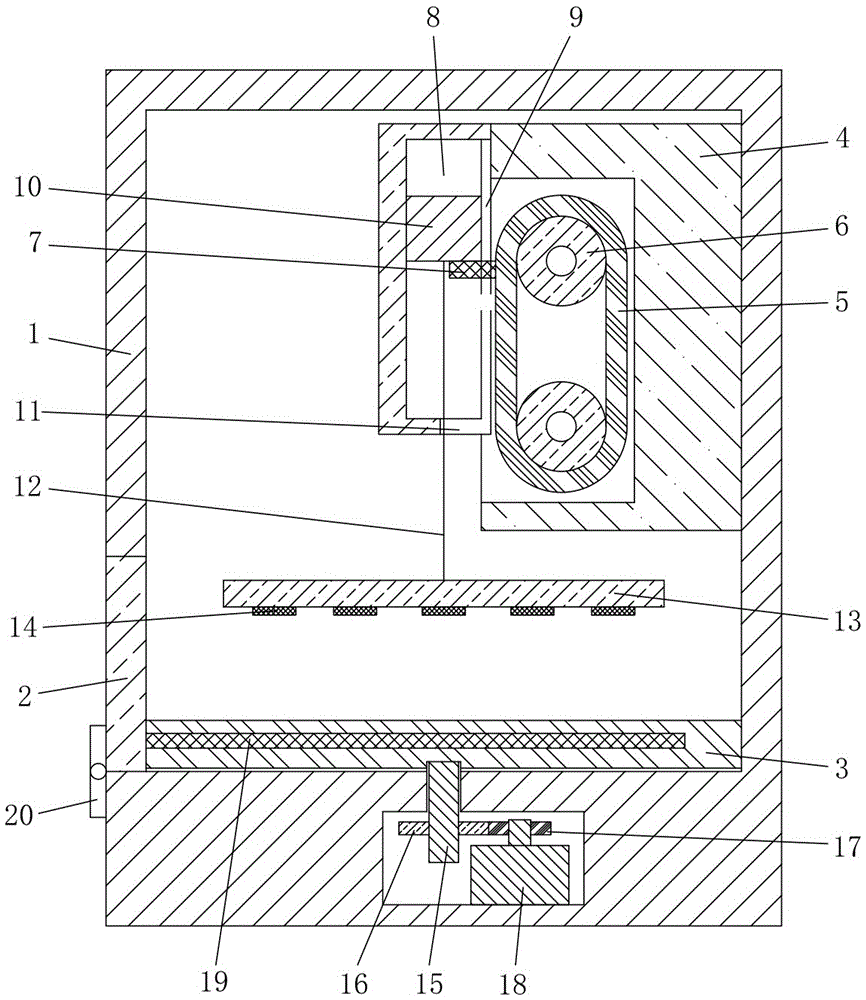

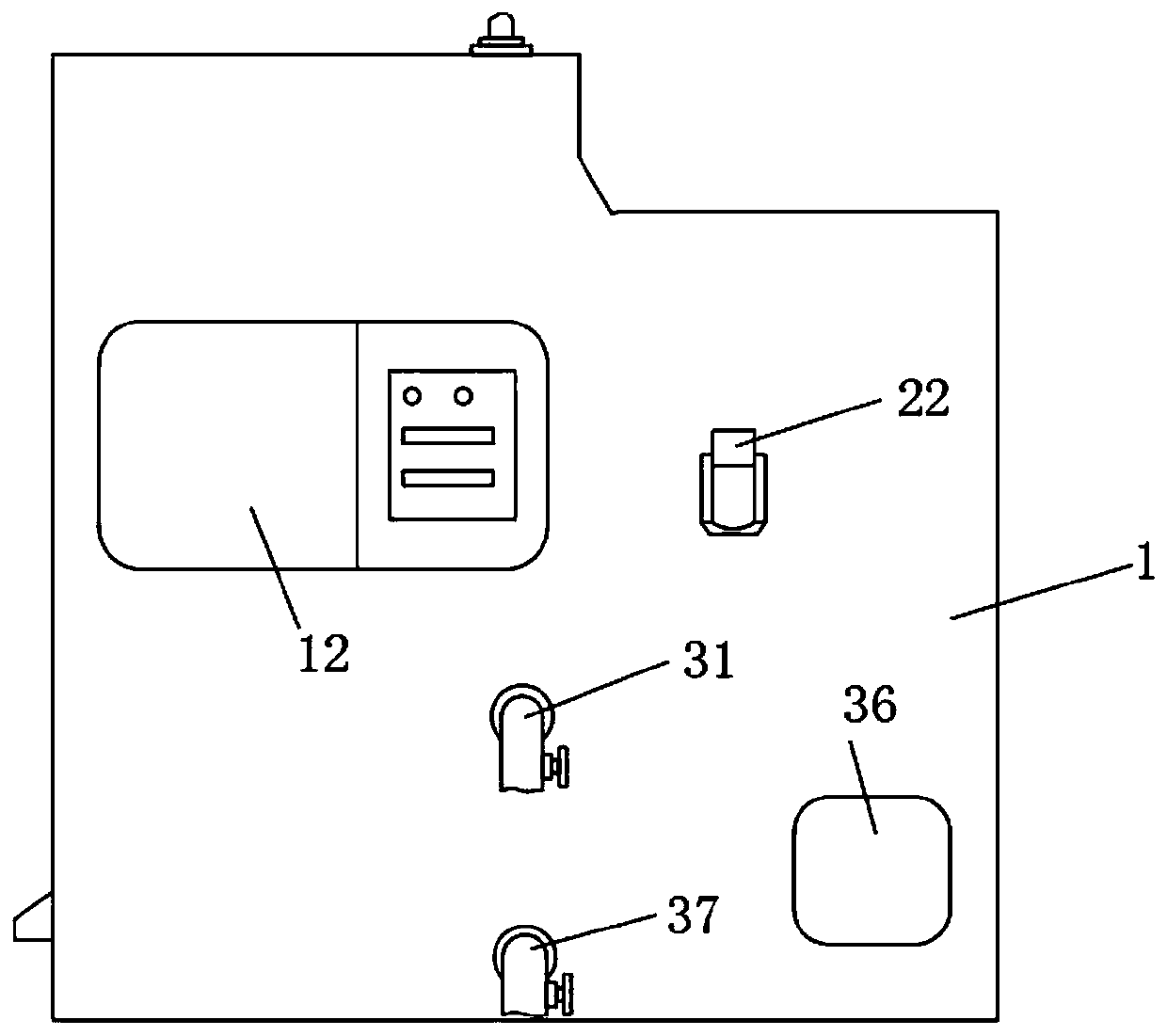

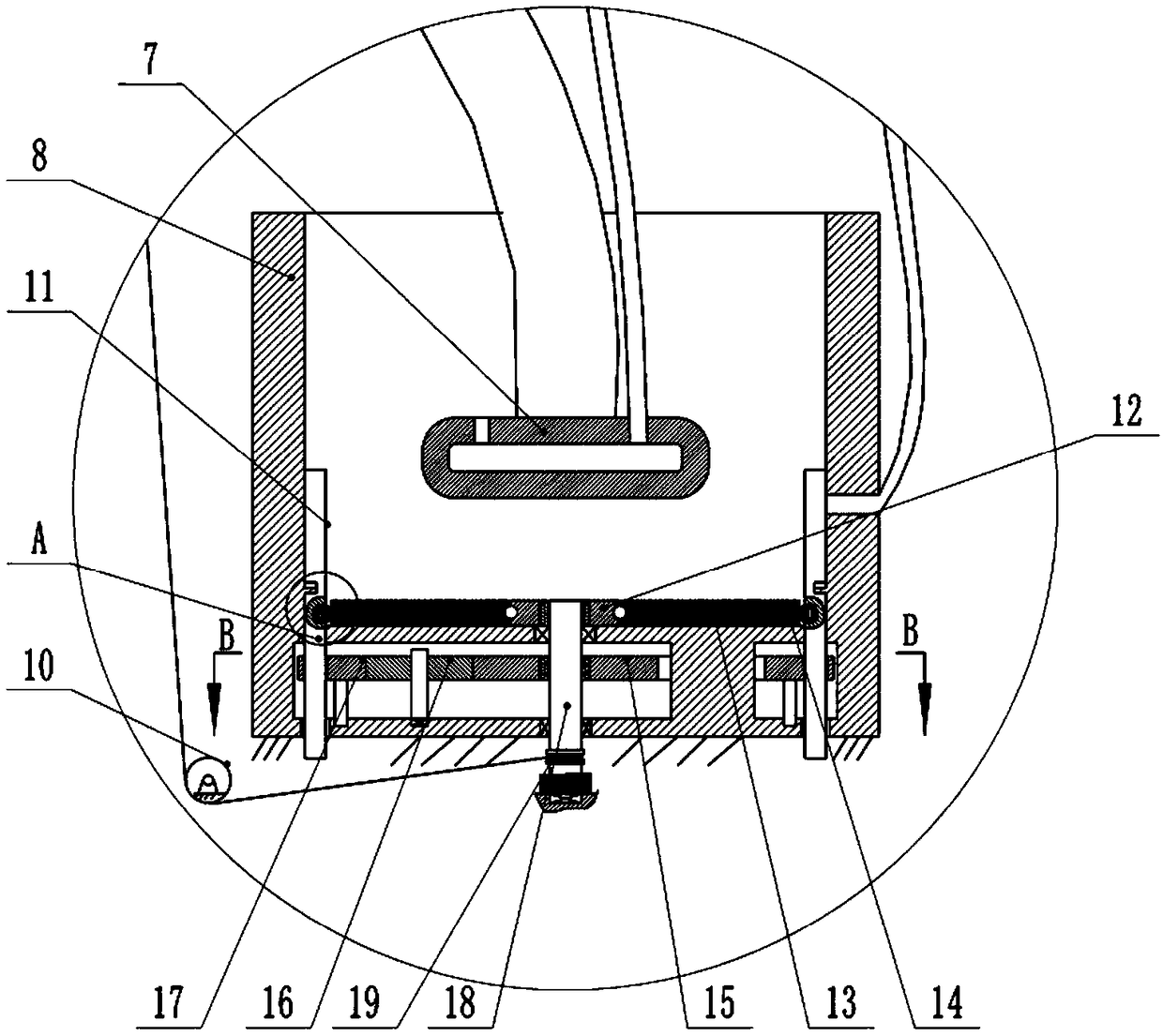

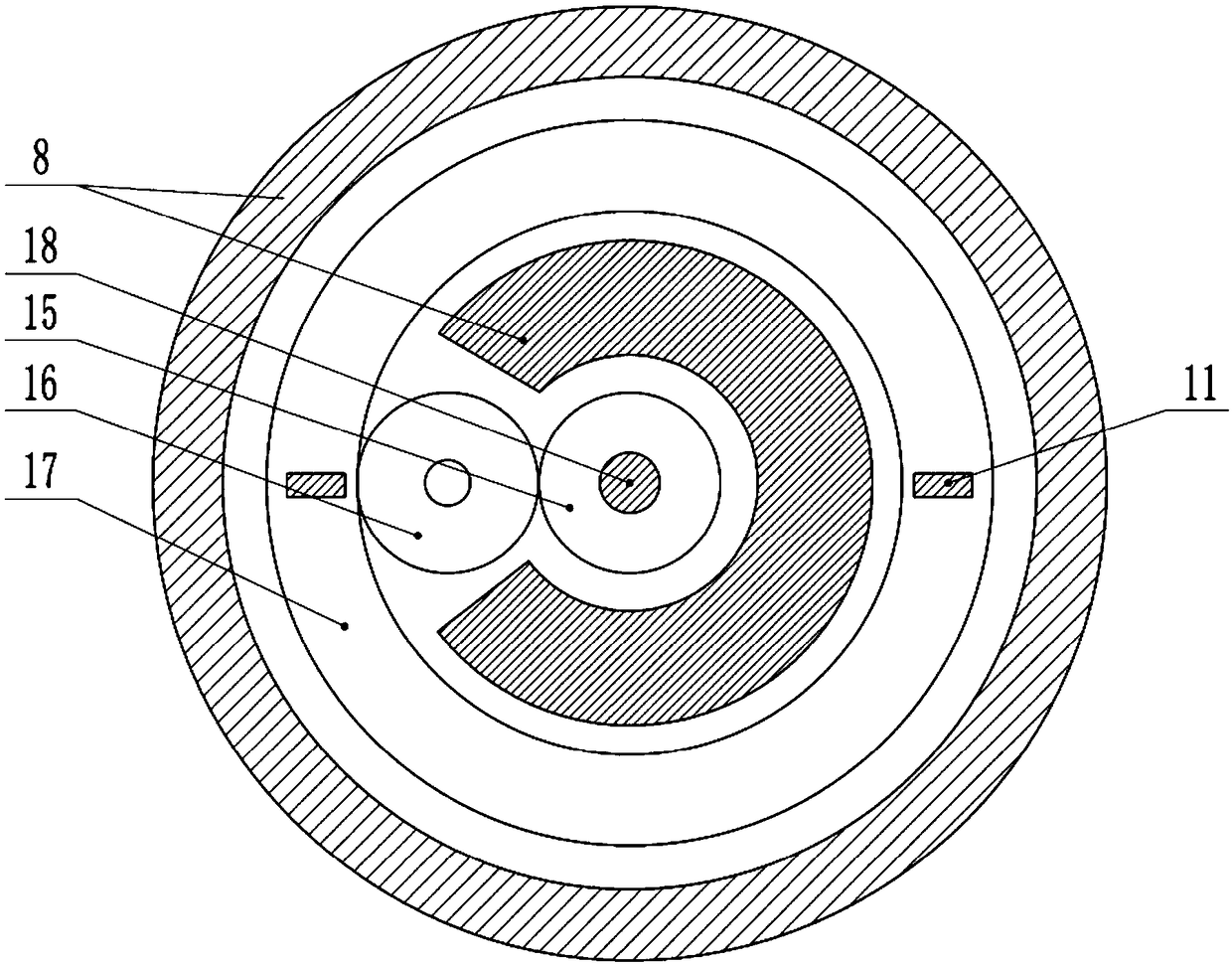

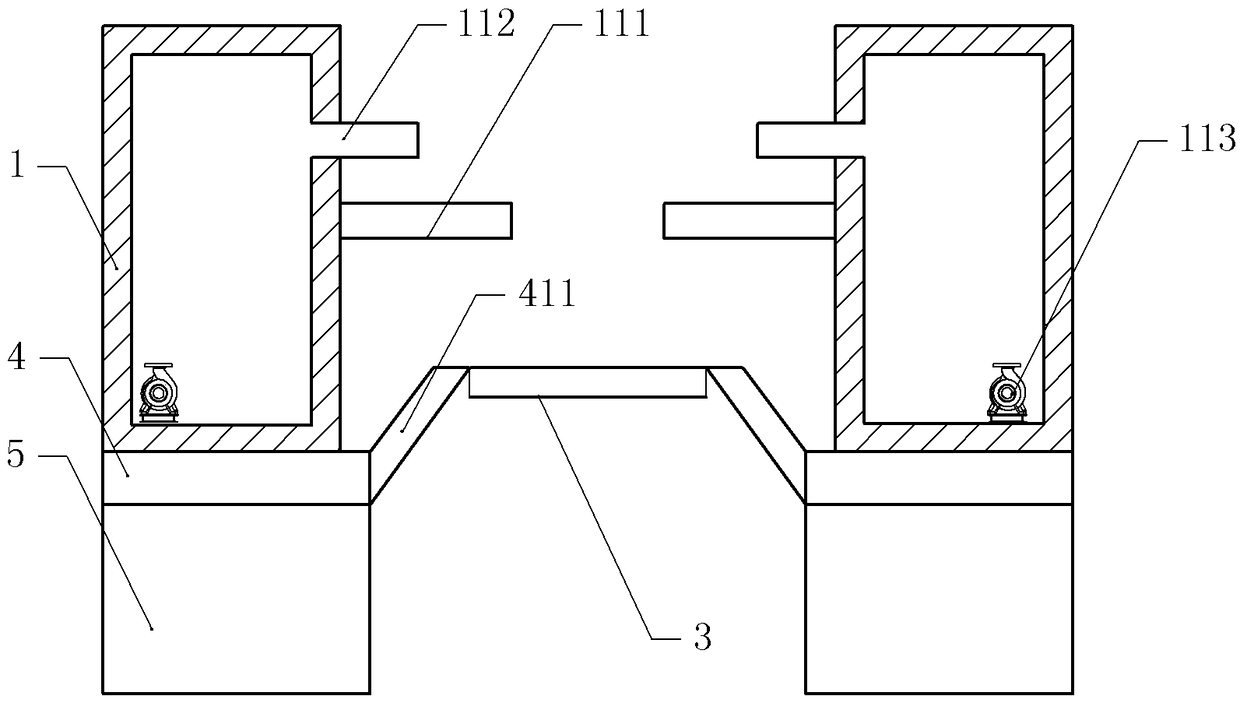

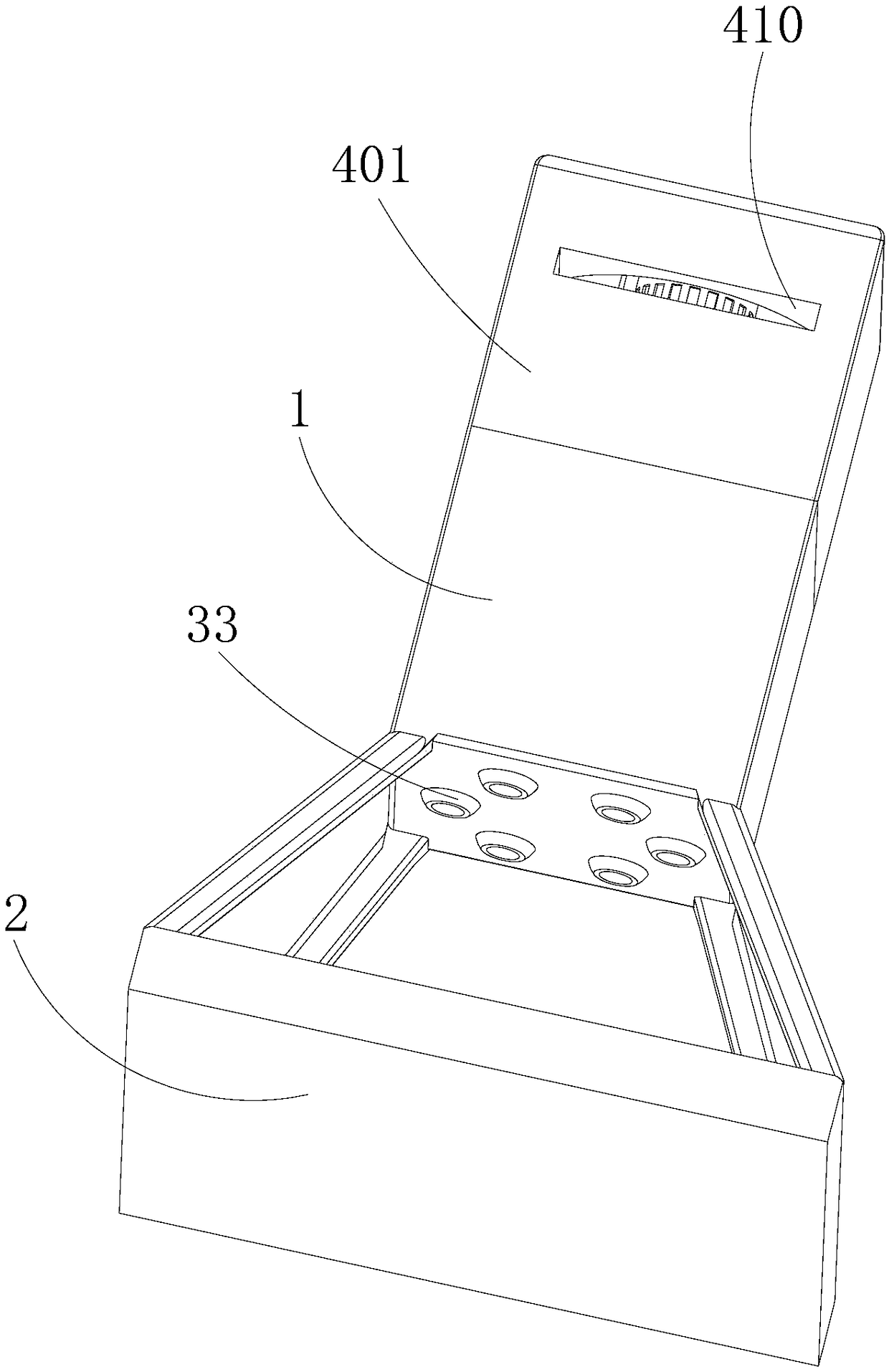

Beef knocking box used for beef barbecue

InactiveCN105557960AHit evenlySolve environmental problemsBeating-based meat tenderisingRaw beefElectric machinery

The invention discloses a beef knocking box used for a beef barbecue. The beef knocking box comprises a closed cylindrical box body; the side wall of the cylinder box body is provided with a movable openable and closeable door; the movable openable and closeable door is connected with the cylindrical box body through a hinge; a round turntable used for carrying raw beef is arranged in the cylindrical box body; a round cavity is formed in the round turntable; the side edge of the round turntable is provided with a rectangular cavity window; the round cavity is connected with outside through the cavity window; a length size of the cavity window is equal to a diameter size of the round cavity; ice is held in the round cavity; a knocking mechanism is arranged above the round turntable; the knocking mechanism comprises a support fixed on the inner wall face of the cylinder box body; the support is provided with a chain, chain wheels and a motor, wherein the chain wheels are connected with the chain, and the motor is used for driving the chain wheels; the chain is provided with a stopper. A beef knocking problem under a field environment is solved by the beef knocking box used for a beef barbecue provided by the invention.

Owner:重庆市老川牛食品有限公司

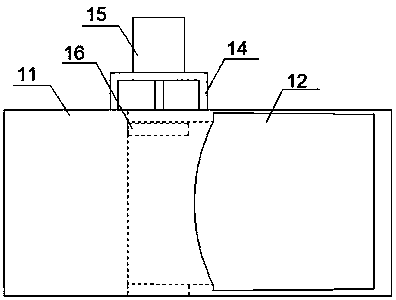

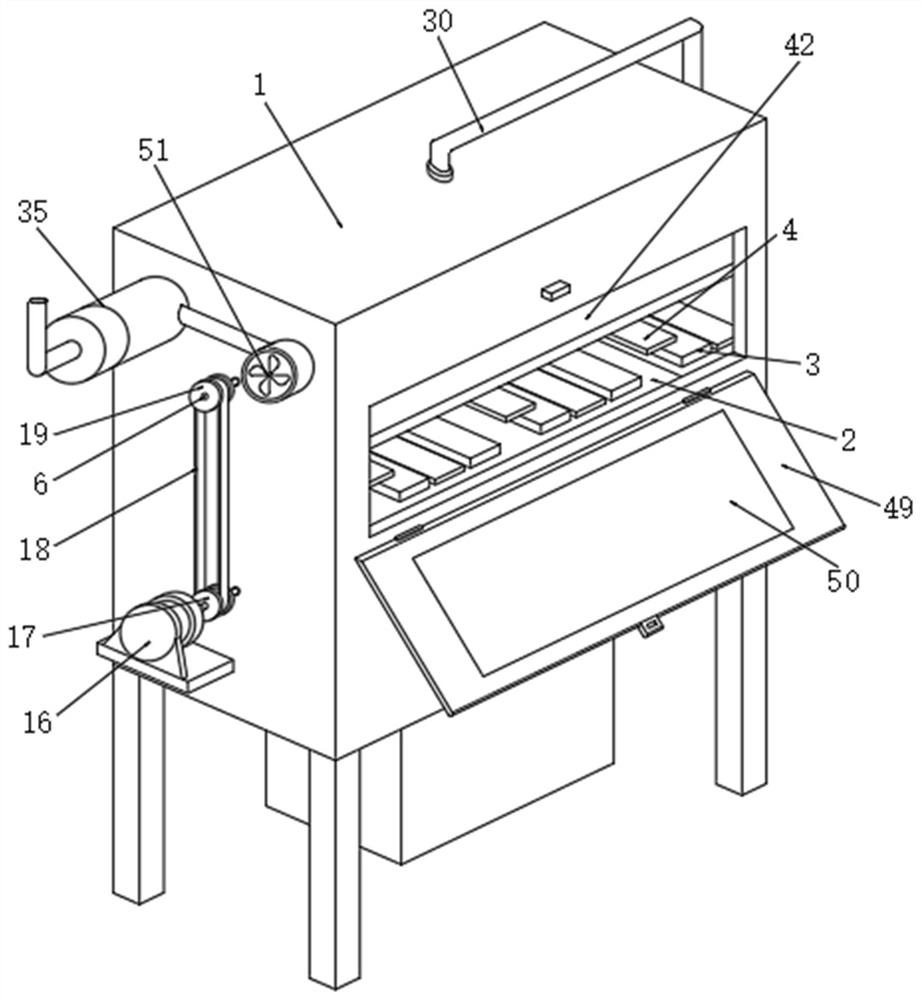

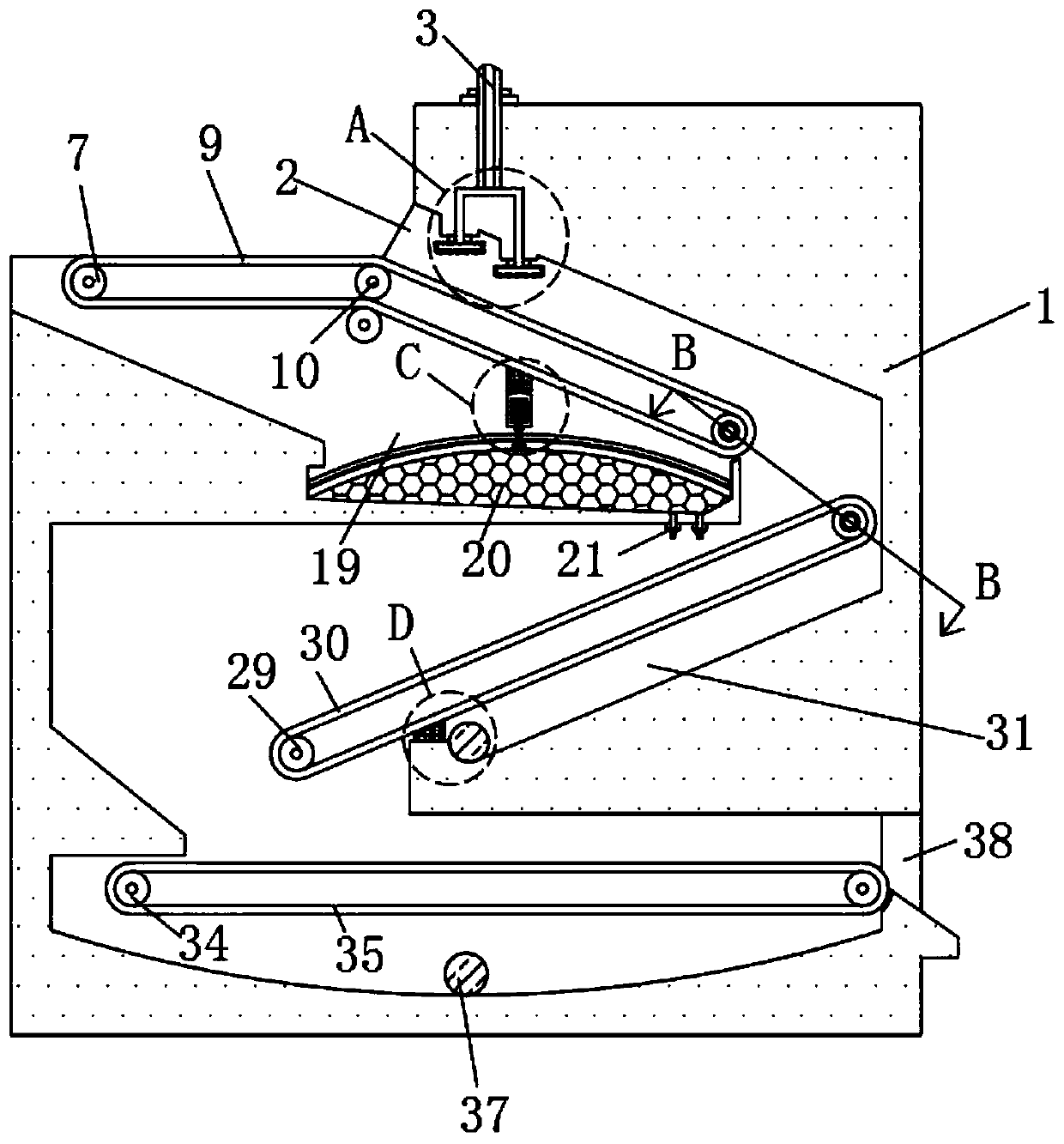

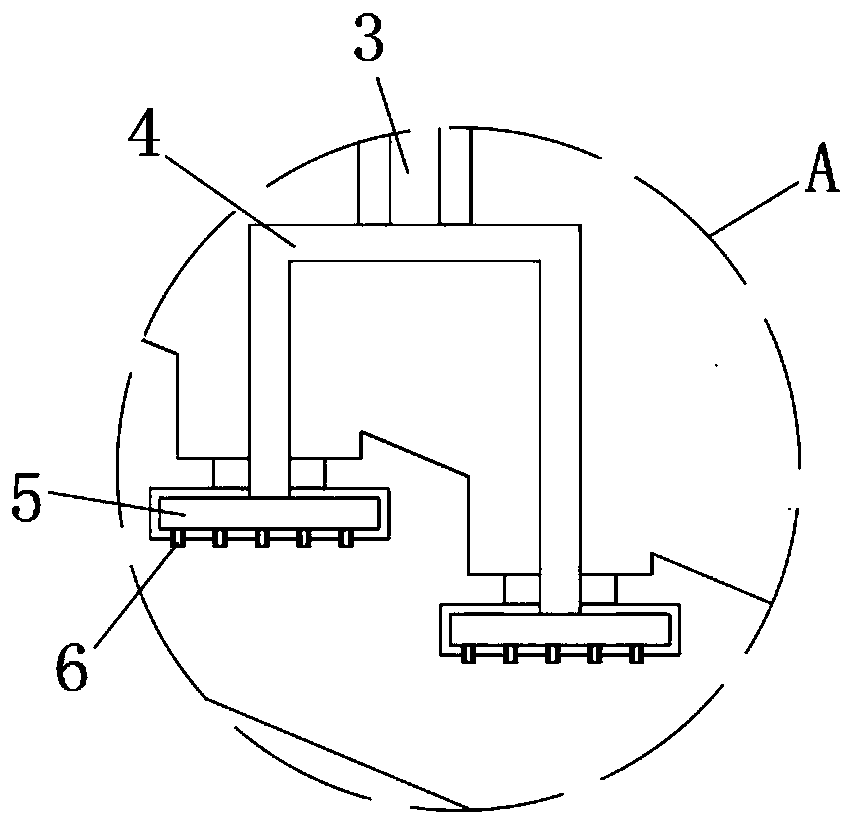

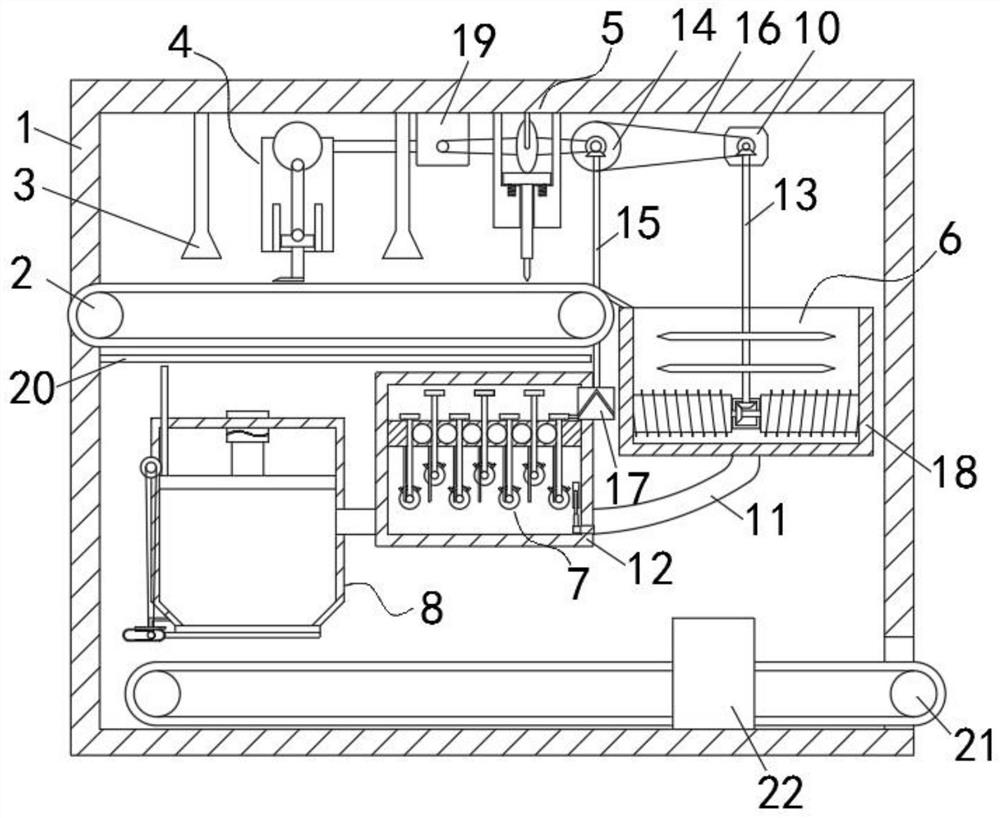

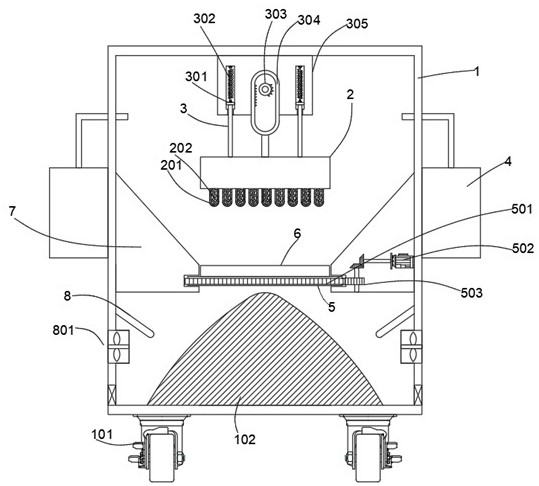

Cleaning equipment used before beefsteak processing and using method thereof

InactiveCN112544674AAvoid wastingGuaranteed recyclingGas treatmentFatty/oily/floating substances removal devicesOil and greaseRinse water

The invention discloses cleaning equipment used before beefsteak processing, and belongs to the technical field of beefsteak processing. The cleaning equipment comprises a cleaning box body and a sealing door; the surface of the sealing door is provided with a transparent window, and the sealing door is hinged to the cleaning box body; a containing plate is horizontally arranged inside the cleaning box body; a plurality of first beating hammers and second beating hammers are arranged above the containing plate in a staggered mode; and a driving assembly used for driving the first beating hammers and the second beating hammers to move relatively is installed on the cleaning box body, so that beef can be beaten and the good toughness of the beef can be guaranteed. Water in a water tank is pumped by a water pump and sprayed out through a spray head to be cleaned, the flushing water is received by a water receiving cover and flows back into the water tank, and impurities and grease are filtered out through a first filter screen and a grease filter membrane on a mounting frame, so that the water can be treated, recycling is guaranteed, and water resource waste is avoided; and a drawingplate is matched with a sealing gasket, so that the mounting frame can be conveniently pulled out to clean and replace the first filter screen and the grease filter membrane, the structure is simple,and the operation is convenient.

Owner:安徽荷金来农业发展股份有限公司

Automatic turnover-type device for uniformly smearing sauce for batch processing of cooked meat

ActiveCN110800791AAccelerate the speed of penetration into the jerkyHigh speedBeating-based meat tenderisingElectric machineryCooked meat

The invention discloses an automatic turnover-type device for uniformly smearing sauce for batch processing of cooked meat. The device comprises a device body, a first motor, a second motor and a third motor; a feed inlet is formed in the upper side of the device body; a sauce input pipe is inserted into the upper end of the device body; the lower end of the sauce input pipe communicates with an opening at the upper end of a sauce branch pipe; and two groups of openings at the lower end of the sauce branch pipe are fixedly connected with openings at the upper ends of two groups of splitting bins respectively. When a transmission shaft rotates to drive a second conveying roller to work, a sleeve block can be driven to rotate, then springs on the sleeve block drive collision balls to knock aconnecting rod, and shock generated during collision is transmitted to the second conveying roller through the connecting rod, so that a first conveying belt on the second conveying roller vibrates,and therefore, dried meat slices on the first conveying belt resonate. Sauce smeared on the dried meat slices can be flattened on the surfaces of the dried meat slices due to vibration, the speed of penetration into the dried meat slices can be accelerated, so that the interior of the dried meat slices can be tasty.

Owner:湖南亲零嘴食品有限公司

Meat beating and mincing device

InactiveCN109349325AGreat tasteSimple structureBeating-based meat tenderisingGrain treatmentsReciprocating motionEngineering

The invention relates to the technical field of food processing equipment and discloses a meat beating and mincing device. The meat beating and mincing device comprises a device outer shell, a meat inlet and a meat outlet, the upper portion and the lower portion of the device outer shell are provided with the meat inlet and the meat outlet respectively, a beating frame supported by the bottom of the device outer shell is arranged in the device outer shell, and a first motor is fixedly arranged on the inner wall of the device outer shell. A crankshaft is arranged in the beating frame and underthe meat inlet, a guide sleeve rod is arranged below the crankshaft, and one end of the crankshaft penetrates the beating frame to connect with the first motor while the other end of the crankshaft isin movable connection with the beating frame. The crankshaft is provided with a plurality of minced meat beating plates in vertical reciprocating motion through the guide sleeve rod, and a filter plate is arranged on the inner wall of the device outer shell and under the minced meat beating plates connected with the crankshaft. The meat beating and mincing device has advantages of simple structure, energy saving and high elasticity of meat.

Owner:胡园园

Beef beating box for beef barbecue

The invention discloses a beef beating box for beef barbecue.The beef beating box for beef barbecue comprises a closed square box body, a door openable and closeable freely is arranged on the upper portion of the square box body, a beef containing disk is arranged in the square box body and contains raw beef, and a beating mechanism is arranged above the beef containing disk and comprises a support which is fixed on the inner wall surface of the square box body and is provided with a passage.A chain, chain wheels connected with the chain and a motor driving the chain wheels are arranged on the support, a stopper is arranged on the chain, the chain is perpendicularly erected beside the passage and clings to the passage, an elongated window is formed in a position, facing the chain direction, of the passage wall, the stopper passes through the elongated window to extend into the passage, a bearing block is arranged in the passage, a flexible cord is connected at the lower end of the bearing block and penetrates through a small window, an oblate heavy block is fixed at the other end of the flexible cord, and a plurality of projecting transverse bars are arranged on the lower surface of the heavy block.The beef beating box for beef barbecue solves the problem of beef beating in a field environment.

Owner:中山市骏佳电器有限公司

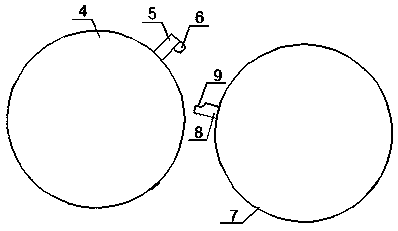

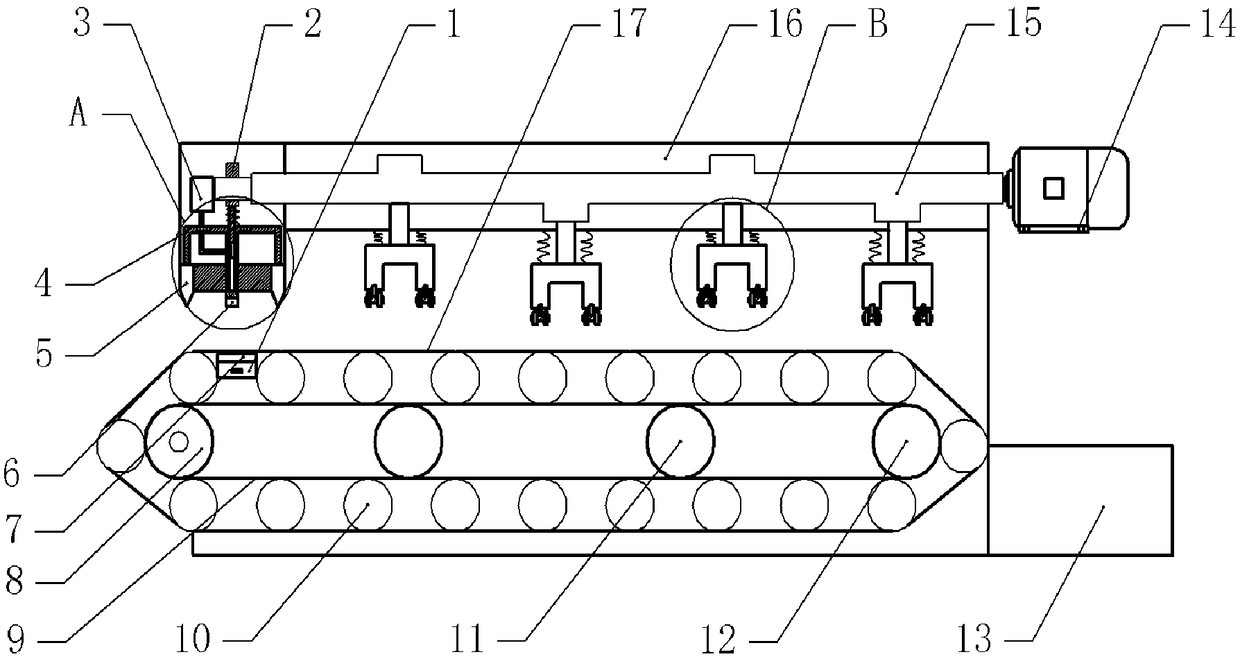

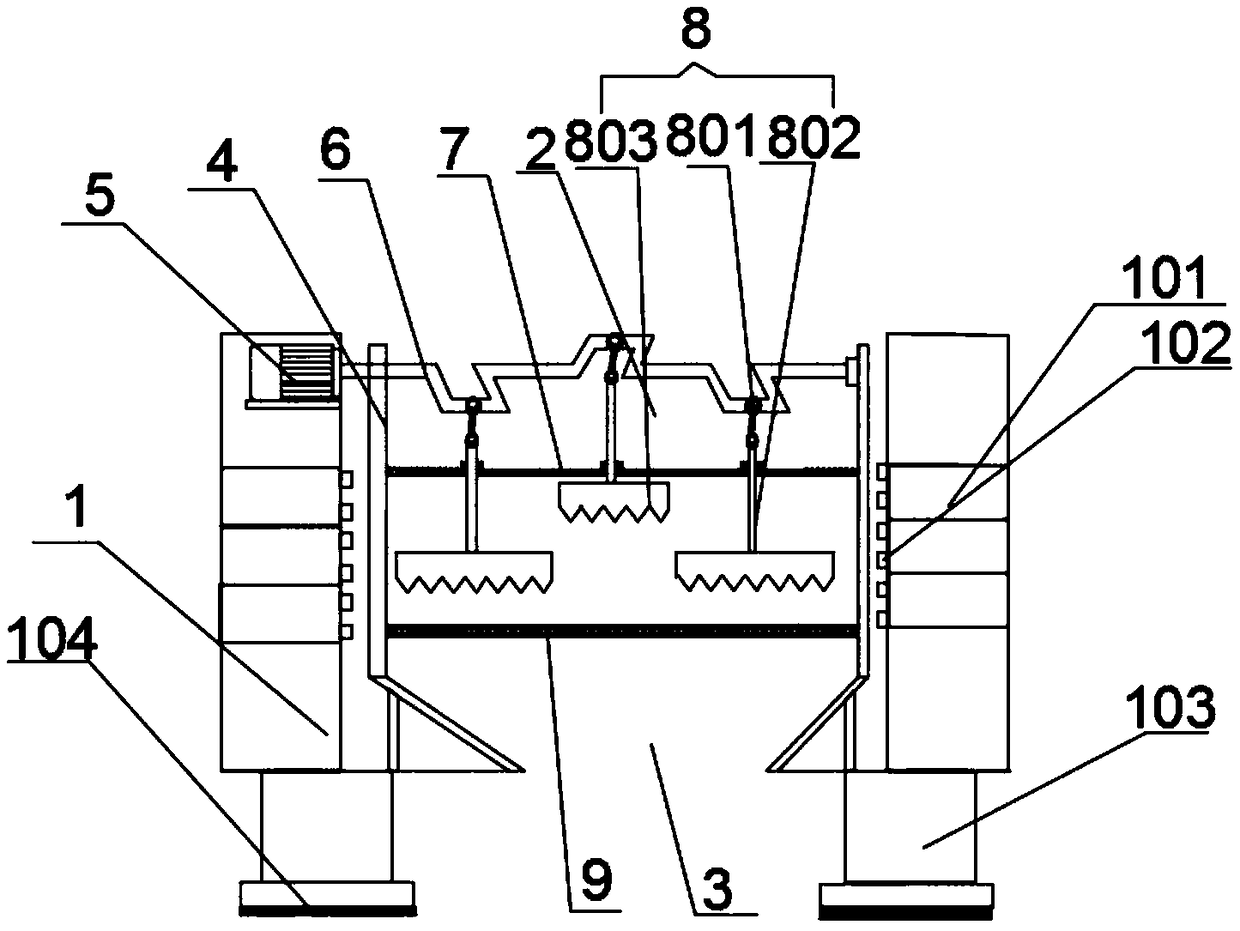

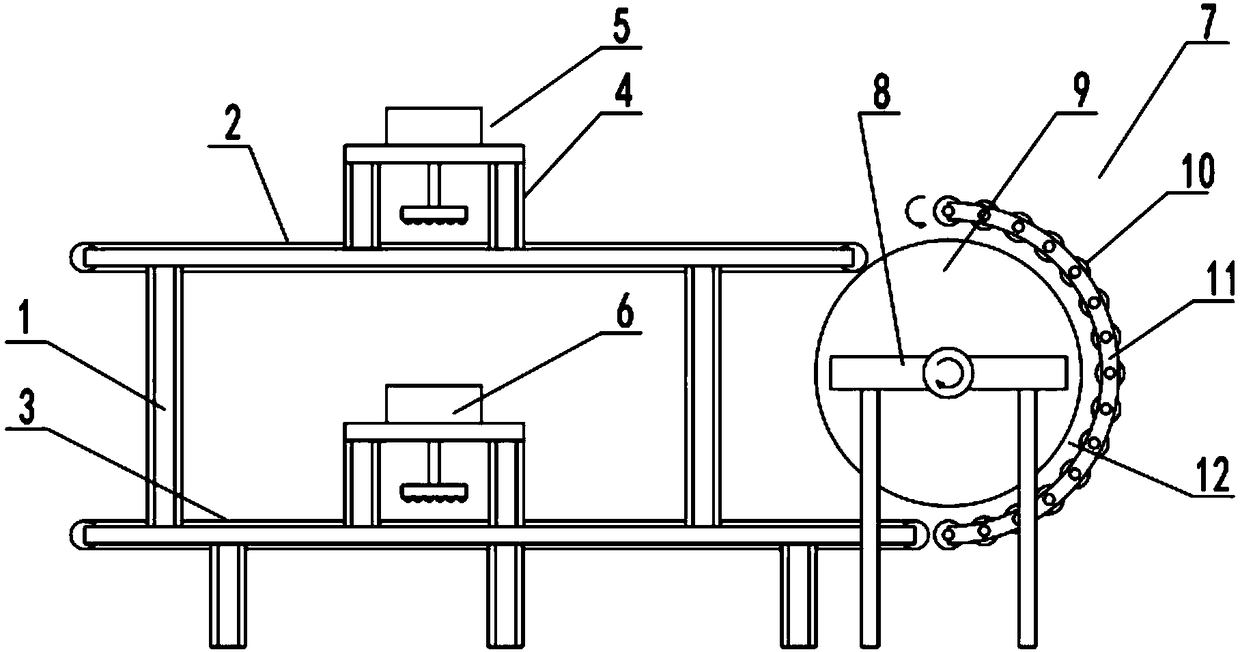

Double-side meat loosening mechanism for processing of pot-stewed steaks

The invention discloses a double-side meat loosening mechanism for processing of pot-stewed steaks. The double-side meat loosening mechanism comprises upper and lower conveyer belts mounted on a frameand used for conveying steaks. The upper and lower conveyer belts are parallel to each other and move oppositely; a hammering rack is fixedly mounted on the frame and is provided with hammering mechanisms I and II correspondingly above the upper and lower conveyer belts and used for hammering steaks; a turnover mechanism is arranged on one side of the upper and lower conveyer belts. The double-side meat loosening mechanism has the advantages that the turnover mechanism helps the hammering mechanisms to effectively knock and hammer the double sides of each steak, meat fibers can be chopped tofacilitate flavoring of condiments, and final taste is improved; the turnover mechanism is simple in structure and can provide automatic turnover, so that labor intensity is greatly reduced for personnel, and meat loosening effect is improved.

Owner:临泉县生产力促进中心

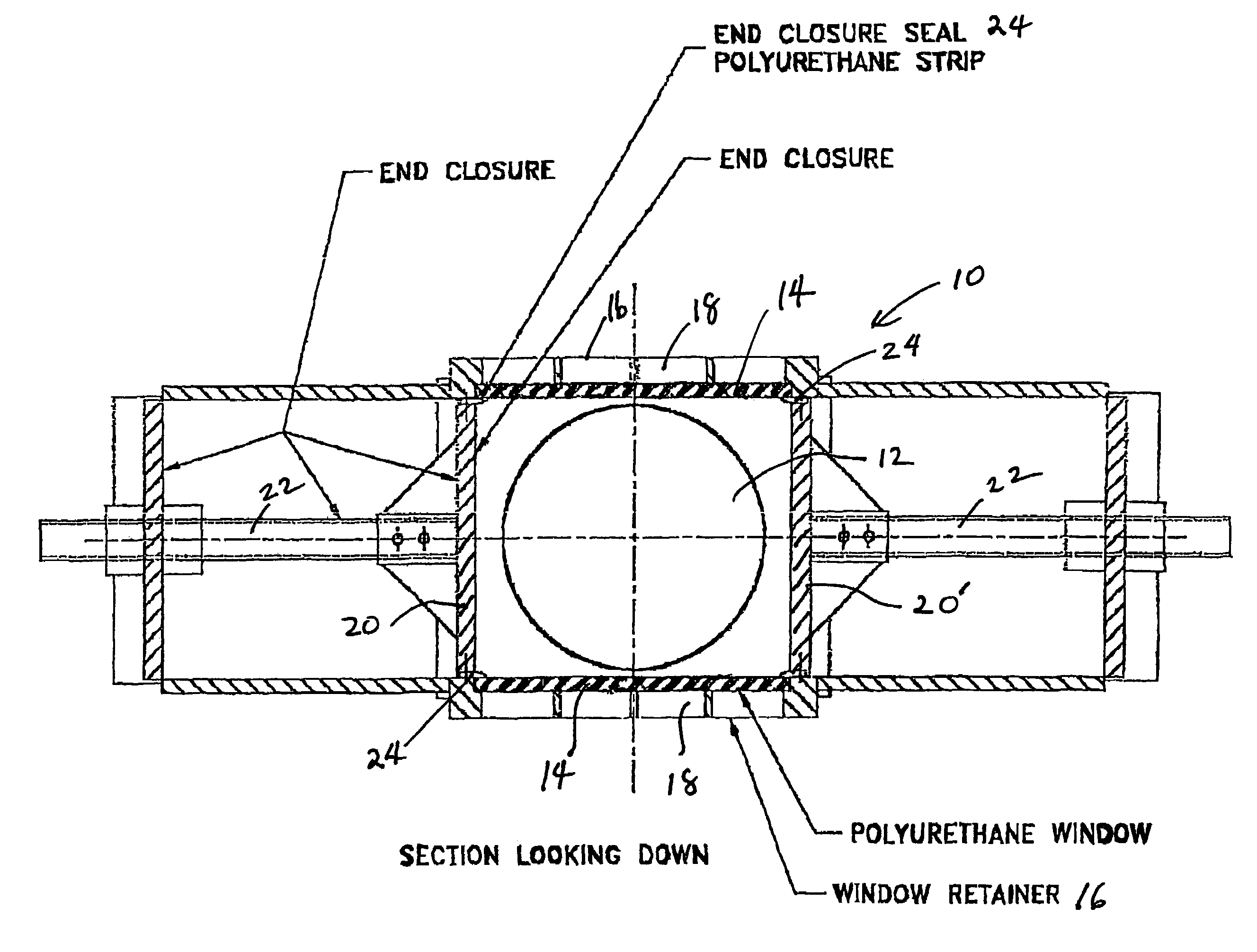

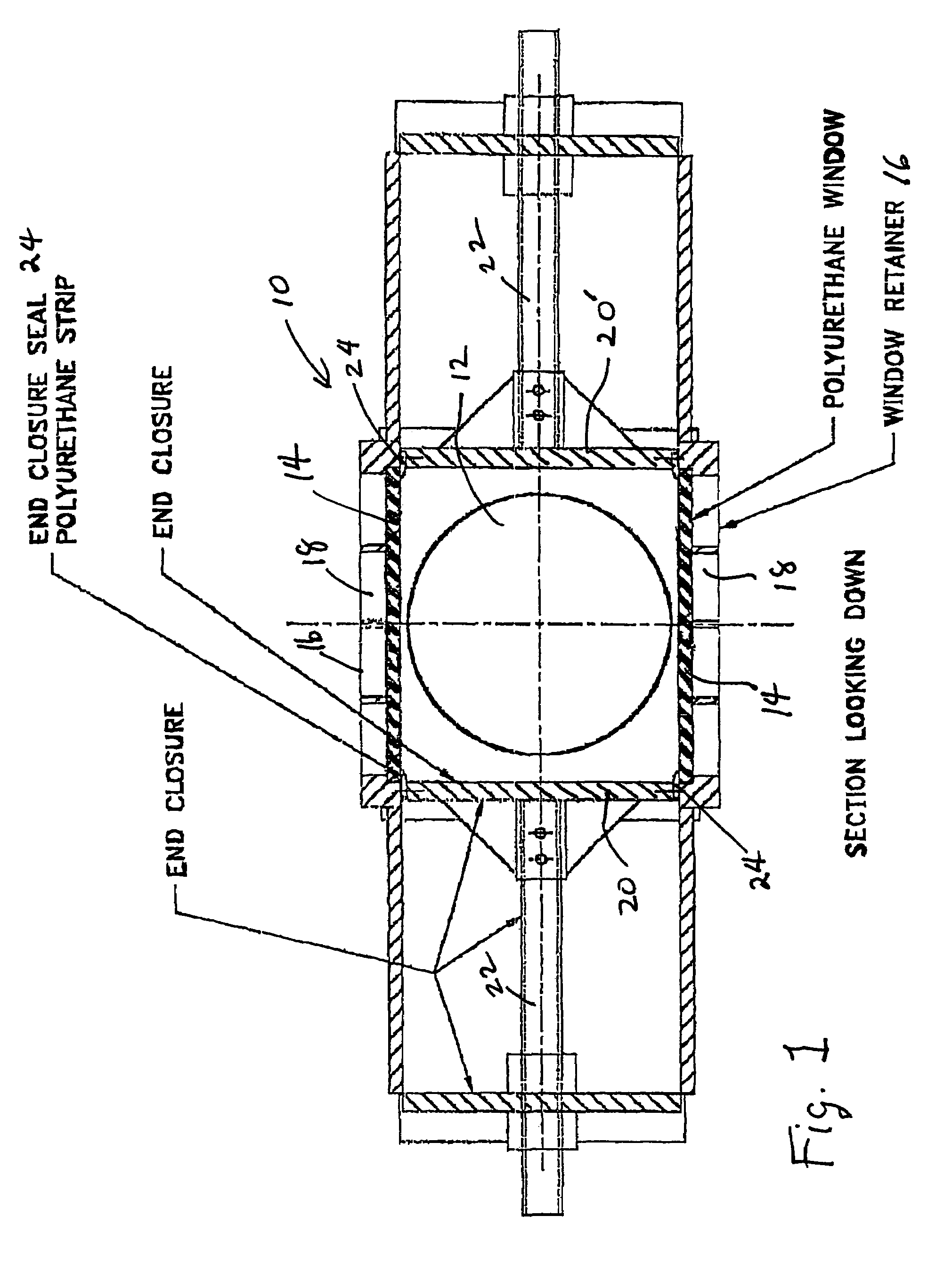

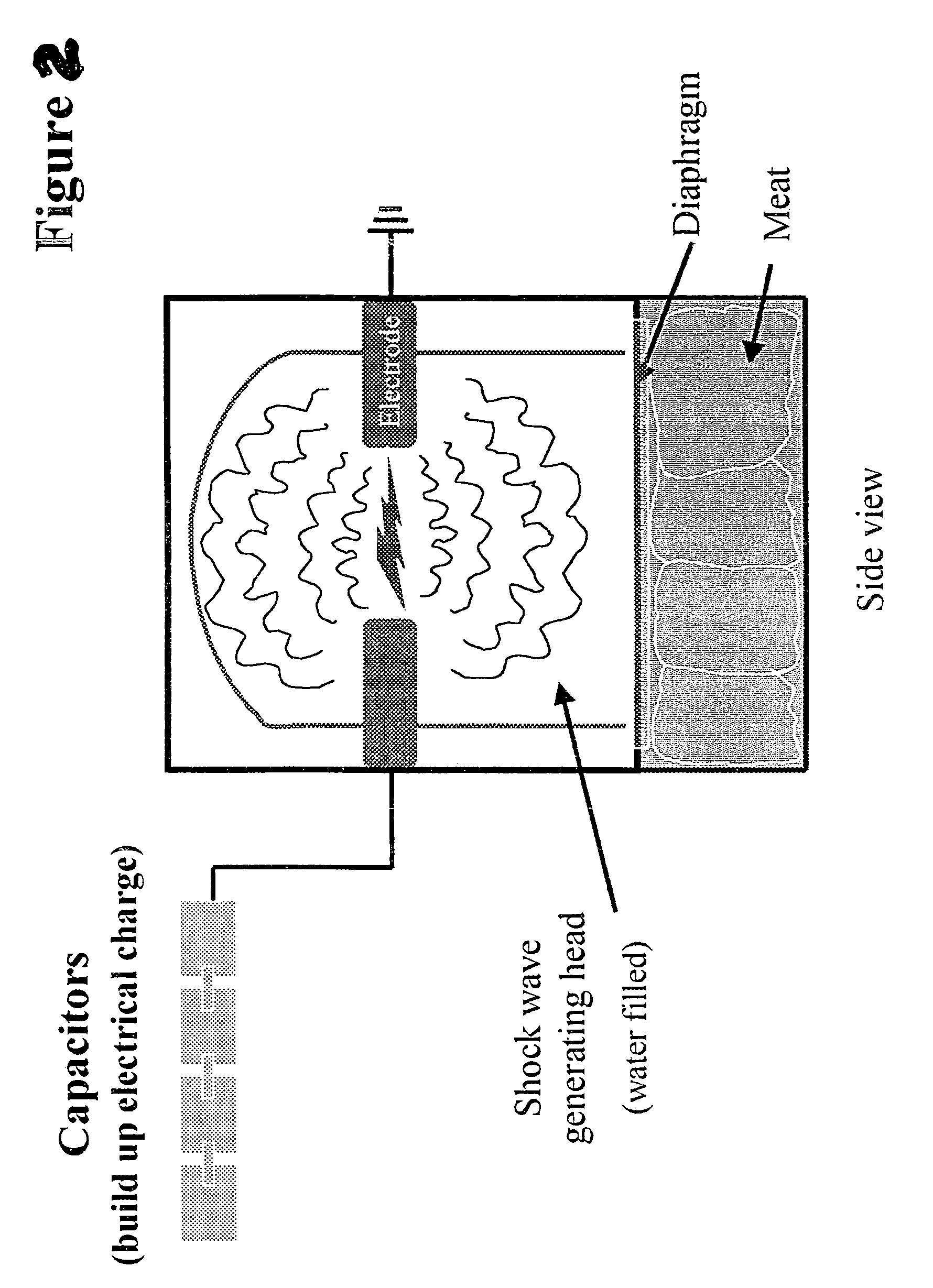

Shock wave treatment of meat

ActiveUS7244459B2Eliminate air pocketPromote resultsMilk preparationMilk preservationShock waveAcoustics

A system for treating meat by the application of a shock wave to the meat while the meat is in contact with a diaphragm which is substantially transparent to the shockwave, confines the meat within a tunnel. In addition, the diaphragm and shock wave generating chamber are preferably disposed above the meat.

Owner:HYDRODYNE INC

Rapid meat pickling device and method

InactiveCN110236133AFull of flavorImprove pickling qualityBeating-based meat tenderisingEngineeringExtrusion

The invention discloses a rapid meat pickling device and method. The device comprises a base, wherein the base is internally provided with a pickling liquid sealing compartment, the end, away from the base, of an extrusion pump is fixedly provided with an injection plate, injection needles are communicated with injection channels, the base is also fixedly provided with a pickling box, wheel shafts of driven belt wheels are fixedly connected with translation screw rods respectively, a discharging port is internally and movably provided with a discharging rotary table, the bottom of the discharging port is fixedly provided with a pickling material uniform distribution plate; a telescopic connecting rod is movably inserted in a telescopic sleeve, a spring seat is fixedly arranged on the telescopic connecting rod, the two side of a rotating shaft are fixedly provided with protective wheels, and the middle of the rotating shaft is fixedly provided with an extrusion cooperation roller. The rapid meat pickling device and method have the advantages that a pickling method that a pickling material is applied on the surface of meat and pickling liquid is injected in the meat is adopted, the surface of the meat is extruded and coated to ensure fully tasty pickled meat, the structure is simple, the installation cost is low, and the device and method are suitable for enterprises of various scales.

Owner:BENGBU COLLEGE

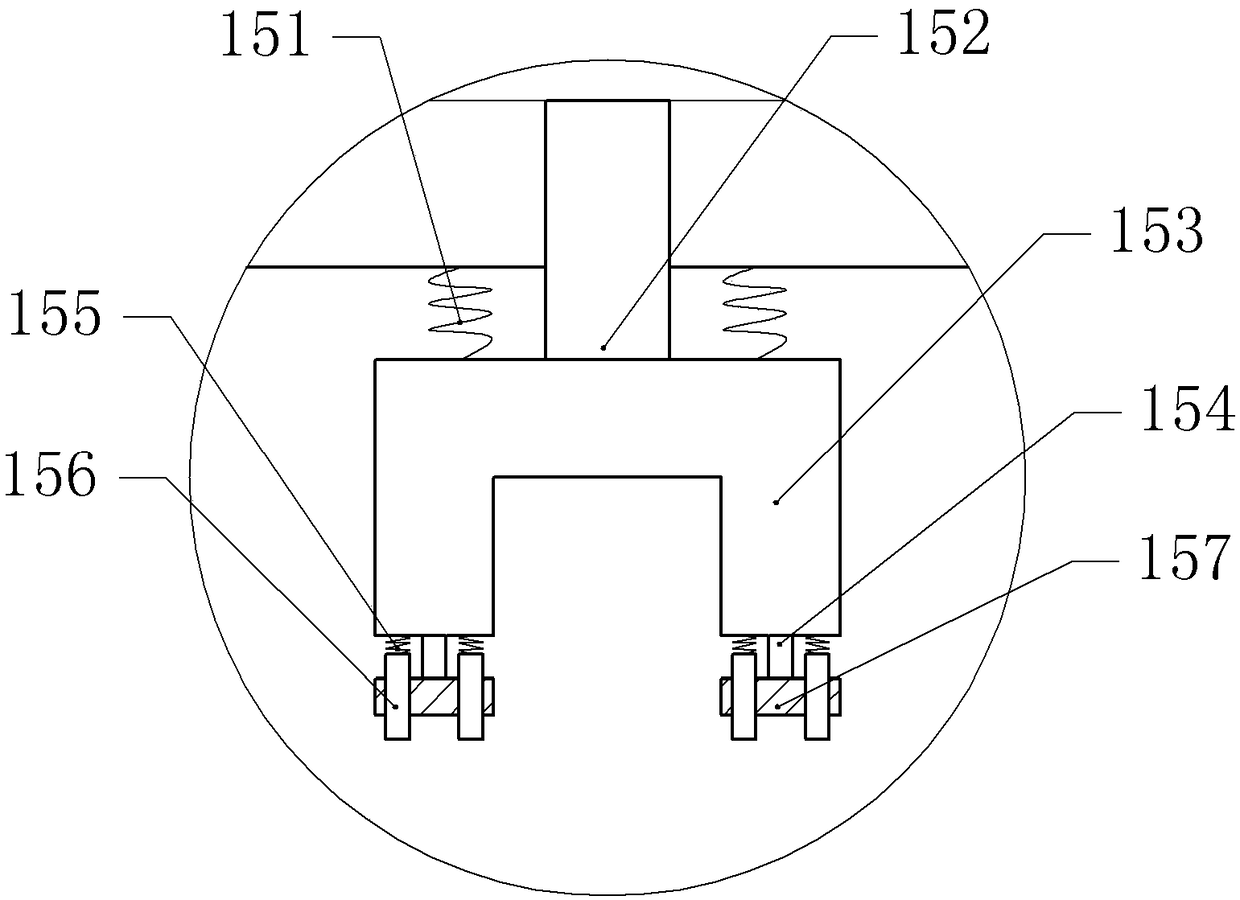

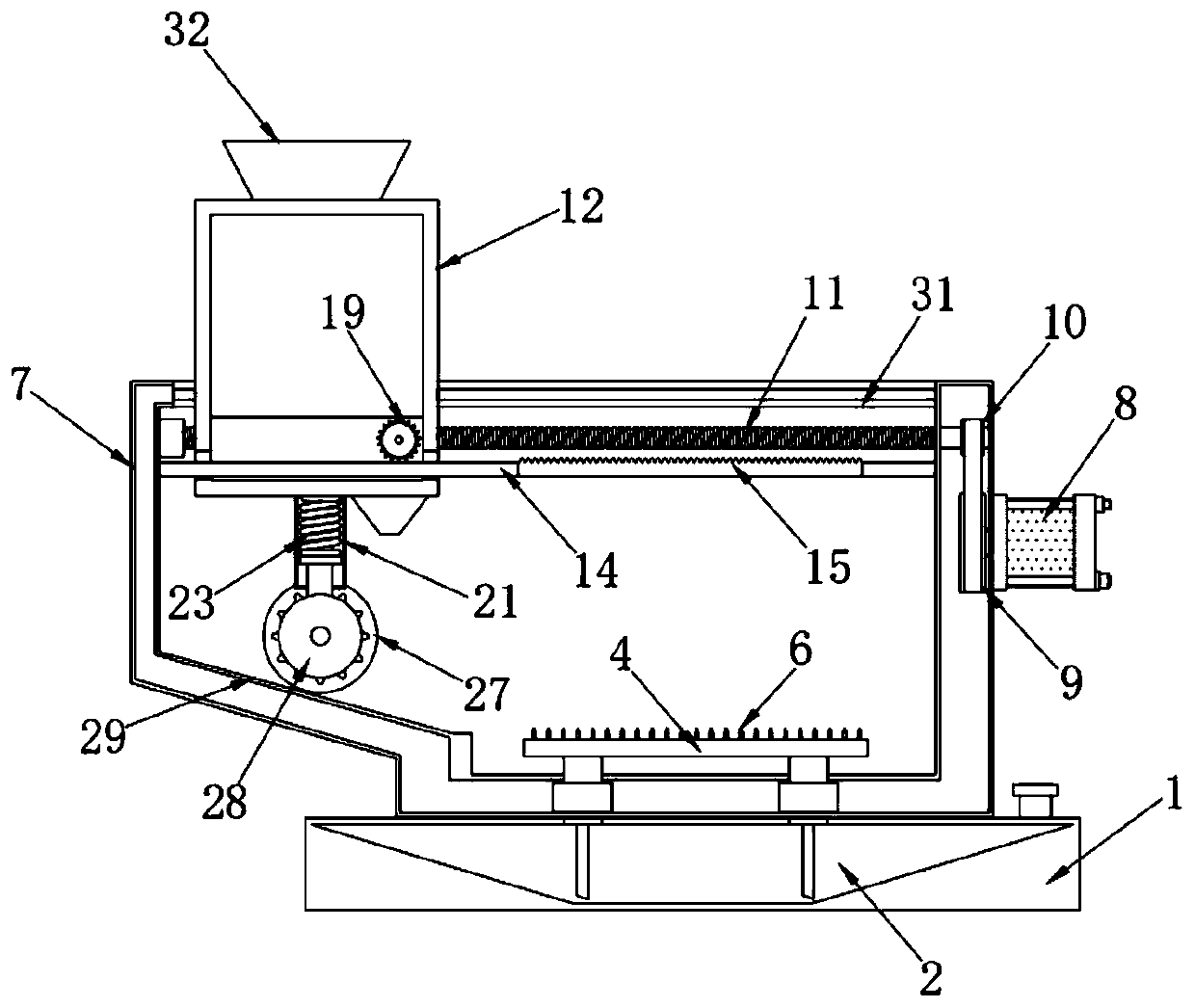

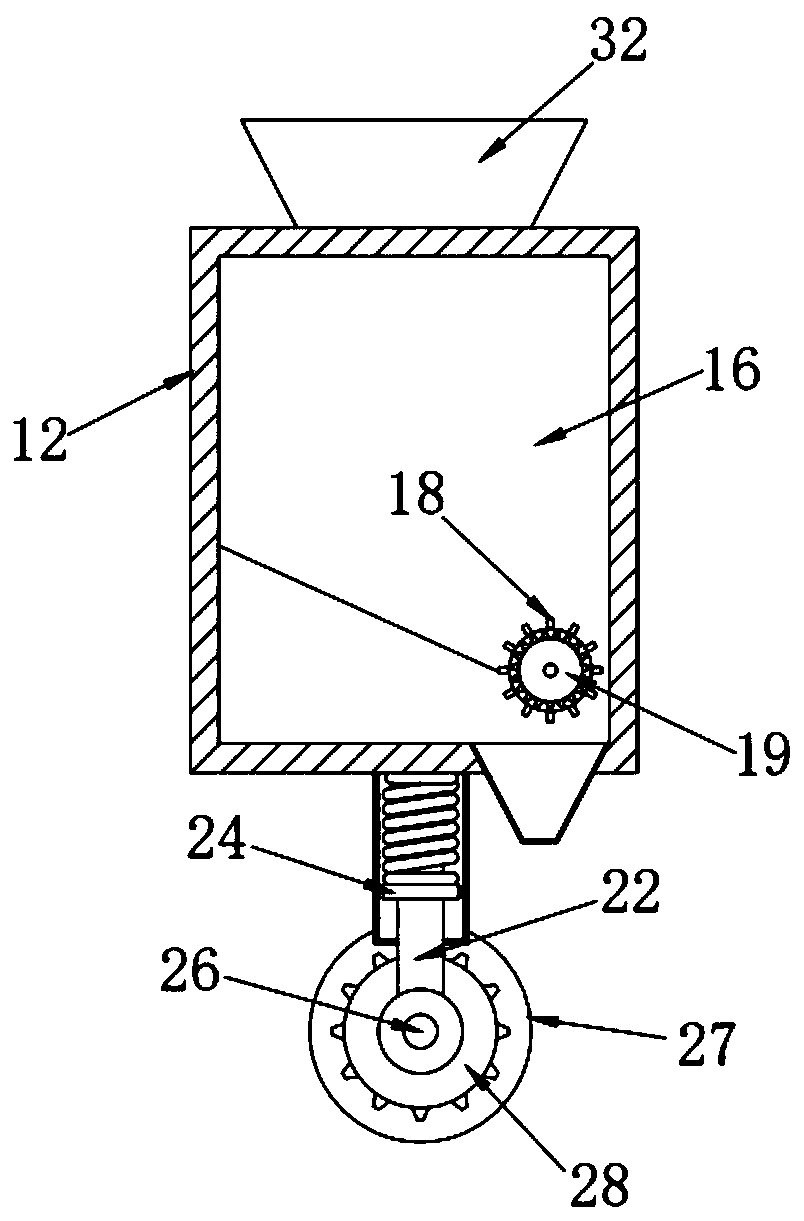

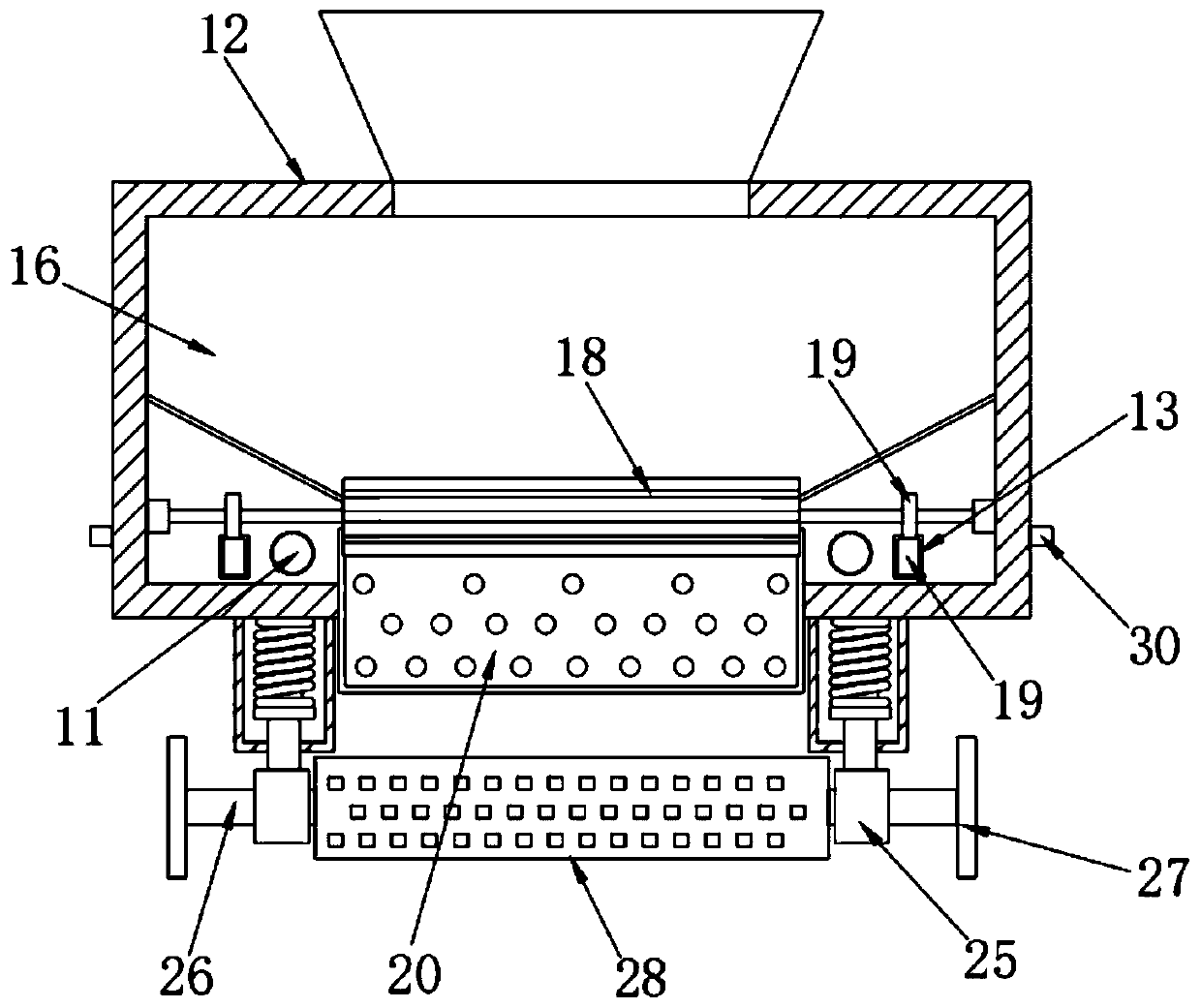

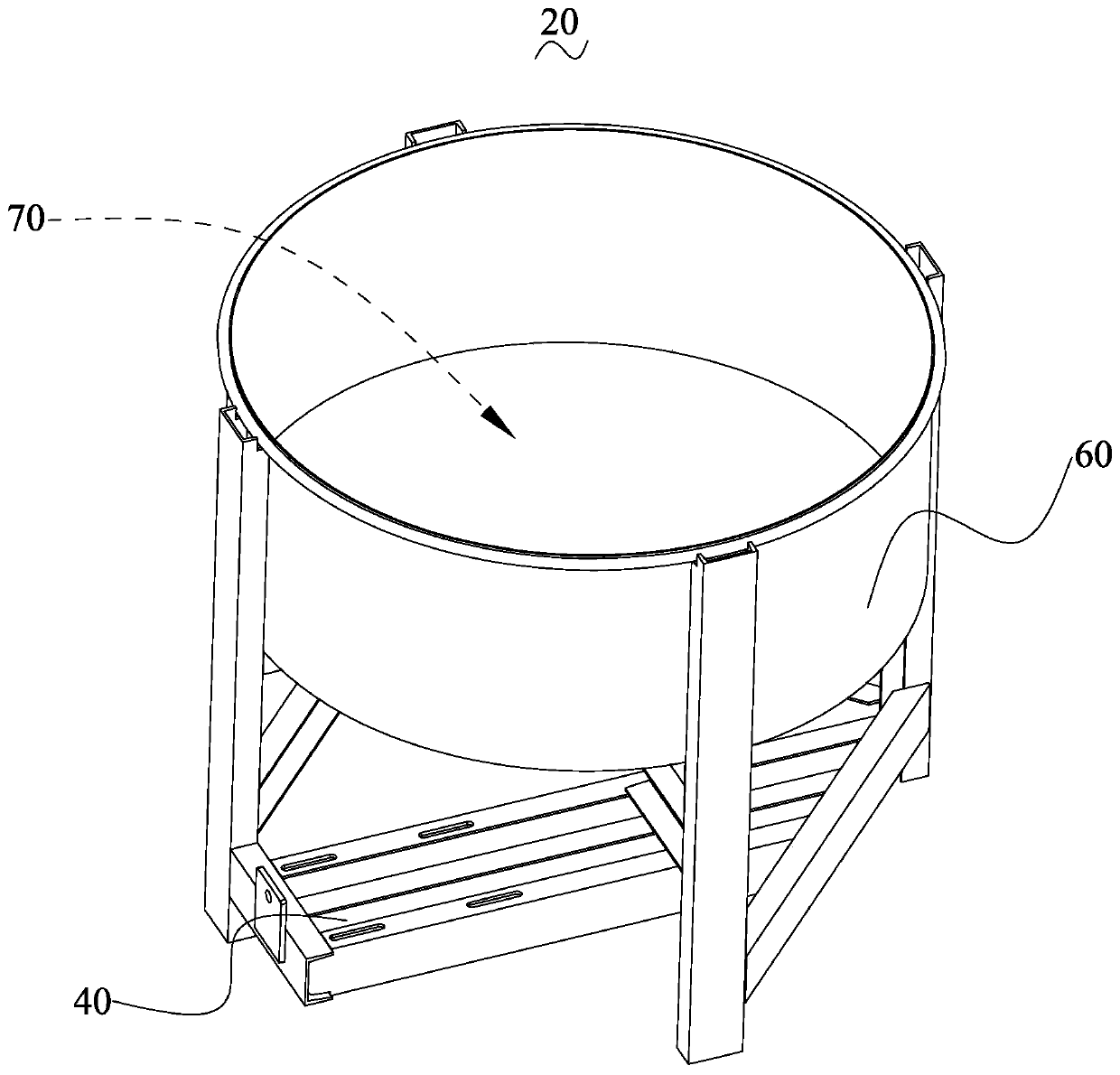

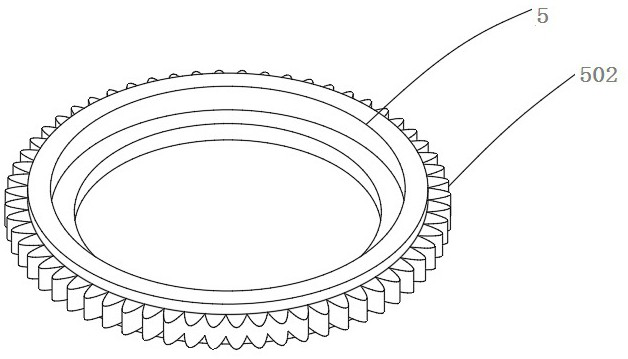

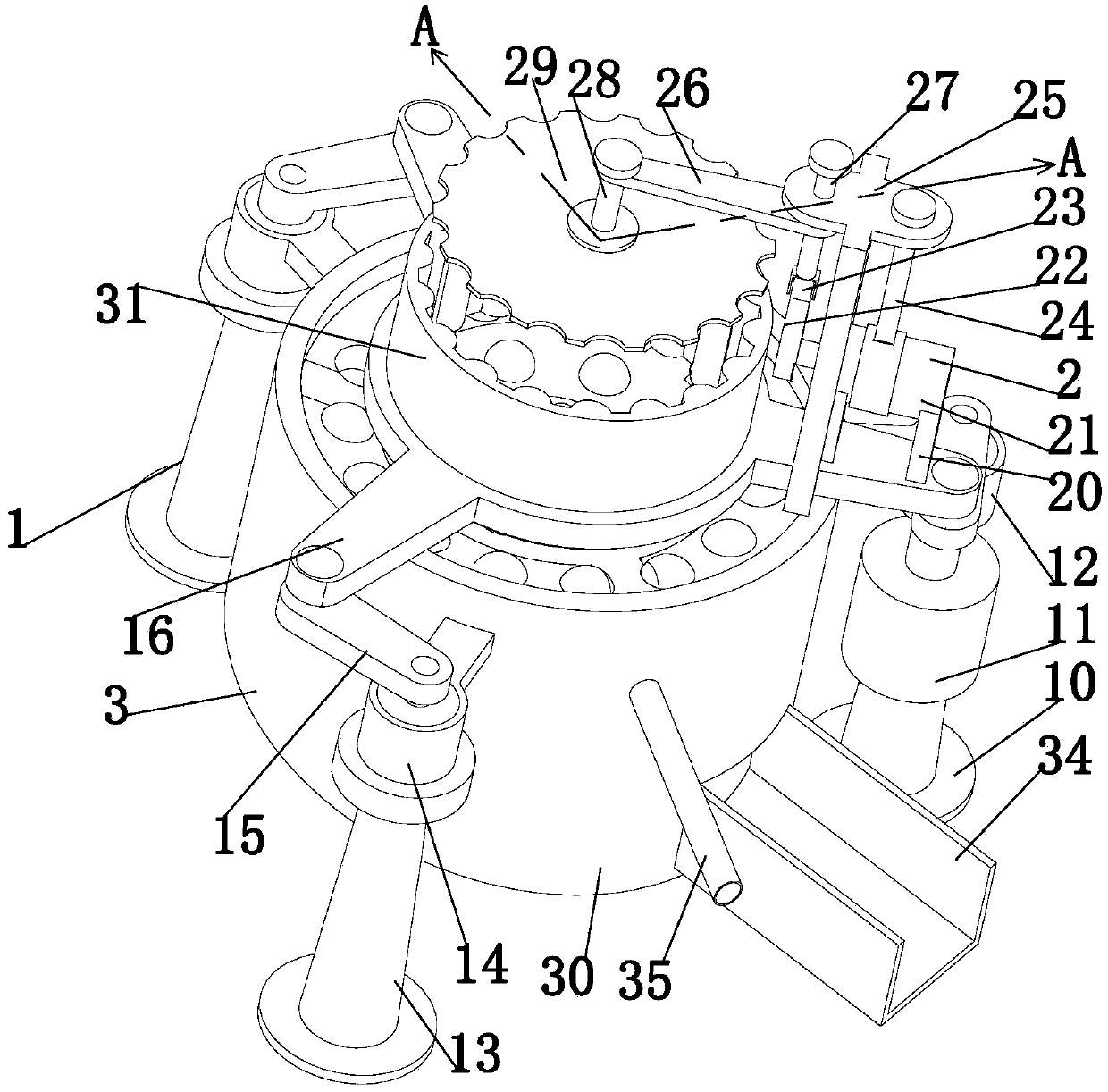

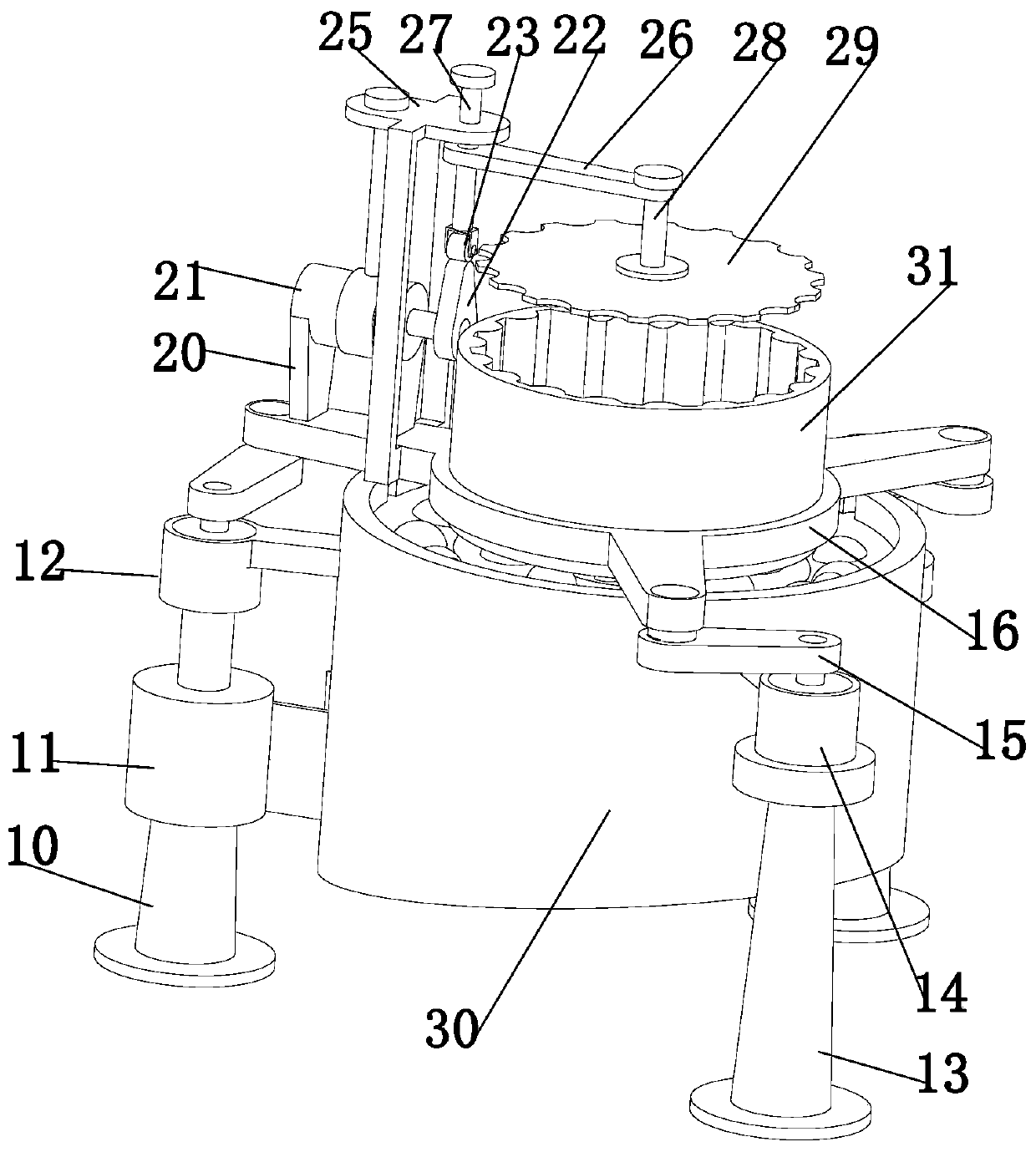

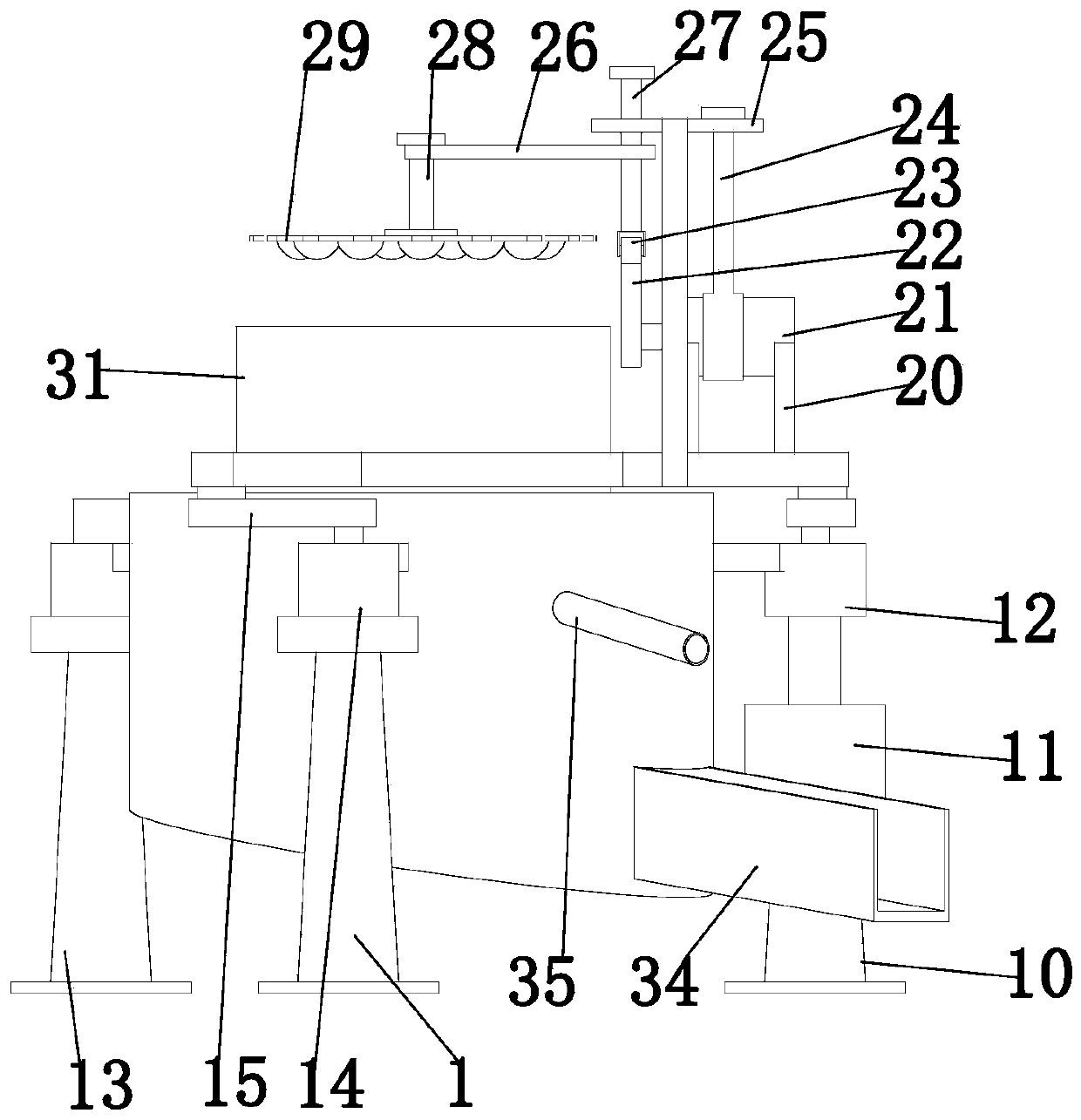

Meatball production equipment with rotary drum and production method thereof

ActiveCN111227012AGreat tasteBeat evenlyBeating-based meat tenderisingEngineeringMechanical engineering

Owner:深圳市华峰食品有限公司

Meat hammering device

ActiveCN108713580ARealize automatic flippingGuaranteed uniformityBeating-based meat tenderisingEngineeringMechanical engineering

The invention belongs to the technical field of edible meat processing equipment and particularly discloses a meat hammering device. The device comprises a hammering barrel, a hammering head, a powersource, a transmission mechanism and a stirring mechanism. The power source drives the hammering head to perform repeated hammering in the hammering barrel through the transmission mechanism; the stirring mechanism comprises a rotating disk at the bottom of the hammering barrel; the rotating disk comprises a middle fixed plate and two movable plates articulated with the two sides of the fixed plate; a rotating shaft is fixedly arranged at the lower end of the fixed plate; a central gear is arranged on the rotating shaft; a transmission gear and a gear ring are rotationally connected below therotating disk; scrapers are connected with the left side and the right side of the gear ring in a sliding manner; first sliding cavities and second sliding cavities are arranged on the two sides of the two scrapers; two arc sliding rails are arranged on an inner wall of the hammering barrel; the second sliding cavities of the two scrapers are connected onto the two sliding rails in a sliding manner; one side, close to the inner wall of the hammering barrel, of each scraper is adhered to the inner wall of the hammering barrel; and the two movable plates are connected into the two first slidingcavities in a sliding manner. The device automatically hammers meat, achieves automatic stirring of the meat at the same time and improves working efficiency.

Owner:重庆登娃食品开发有限公司

Food processing detection device based on big data cloud platform and use method of device

InactiveCN111802431ARefreshing and smoothAvoid hammeringBeating-based meat tenderisingCleaning using toolsMeat pasteEngineering

The invention relates to the technical field of food processing, in particular to a food processing detection device based on a big data cloud platform and a use method of the device. The food processing detection device based on the big data cloud platform comprises a processing detection box, a first conveying belt is arranged on the left side of the top of the processing detection box, a turnover assembly and a pre-dicing assembly are arranged on the top of the first conveying belt, beating assemblies are arranged at the bottom, a cutting stirring assembly is arranged on the right side of the first conveying belt, and a meatball forming assembly is arranged on the left sides of the beating assemblies. According to the beating assemblies, the beating assemblies alternately move downwardsto beat minced meat, and the minced meat is beaten, so that made meat balls are elastic and more refreshing, tender and smooth in taste; beating wheels can be driven to rotate in the process of moving up and down after beating is completed, so that a scraping blade can effectively scrape the surface of the beating wheels to clean the beating wheels, and meat paste residues are prevented from being left on the surface of the beating wheels.

Owner:安徽野虎数据科技有限公司

Beef loosing device

PendingCN109548840AIncrease frictionPrevent fallingBeating-based meat tenderisingGear wheelEngineering

The scheme of the invention discloses a beef loosing device, and relates to the technical field of beef processing. The beef loosing device comprises a dual-shaft motor, a rotating mechanism, an expanding and contracting mechanism and a base, wherein a fixing plate is fixed on the base; the dual-shaft motor is fixed on the fixing plate; the rotating mechanism comprises a rotating rod and a processing earthen bowl, wherein the processing earthen bowl is rotatably connected to the base; a plurality of grooves are formed in the outer surface of the processing earthen bowl; a sliding rod is fixedly connected to the rotating rod, and is located in the grooves; the expanding and contracting mechanism comprises a fixing rod, a swinging rod and a worm, wherein a turbine is meshed to the worm; a connecting rod is rotatably connected to the turbine; the connecting rod is rotatably connected to the swinging rod; a segment gear is fixed on the swinging rod; the fixing rod is fixed on the fixing plate; a beating pipe is arranged outside the fixing rod in a sliding and sleeving manner; a beating plate is arranged at the bottom of the beating pipe; a rack which is meshed with the segment gear isarranged on the side wall of the bearing pipe; the dual-shaft motor is fixed on the fixing plate; and the rotating rod and the worm are separately and fixedly connected to two output ends of the dual-shaft motor. The beef loosing device disclosed by the invention can loosen beef tissue, so that the beef subjected to subsequent pickling is more tasteful.

Owner:遵义溯源科技有限公司

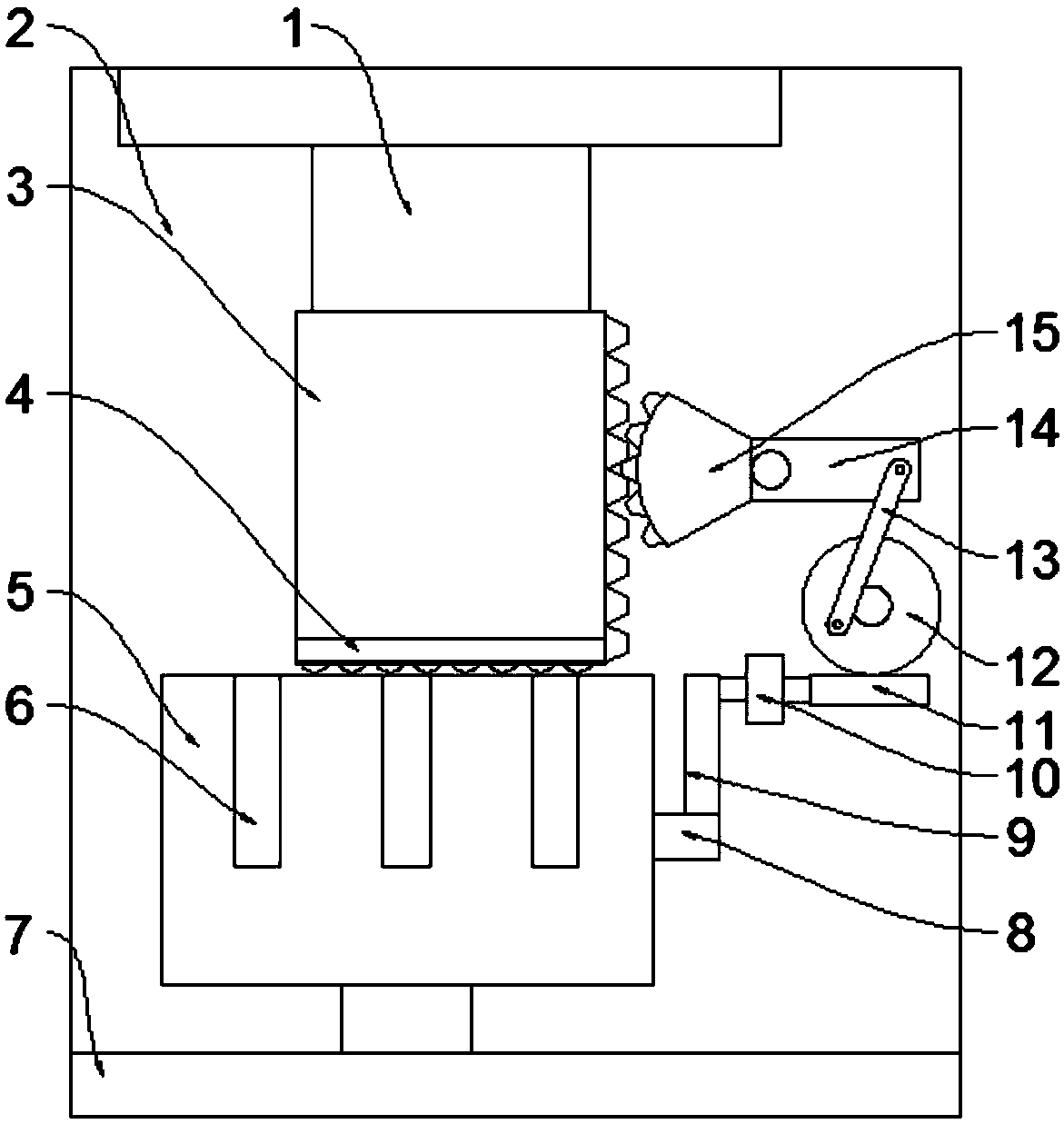

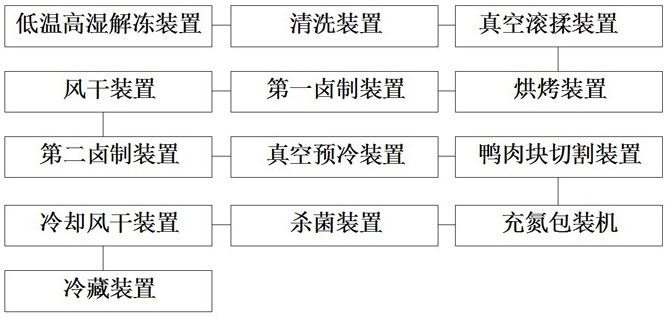

Novel special production line for duck meat products

PendingCN112244231AProduction Process AutomationEasy to thawPoultry cleaning/disinfectionBaking ovenProcess engineeringProduction automation

The invention discloses a novel special production line for duck meat products. The novel special production line comprises a low-temperature high-humidity unfreezing device, a cleaning device, a vacuum rolling device, a baking device, a first marinating device, an air drying device, a second marinating device, a vacuum pre-cooling device, a duck meat block cutting device, a nitrogen-filled packaging machine, a sterilizing device, a cooling and air drying device and a refrigerating device which are sequentially connected through a conveying belt. The novel special production line for the duckmeat products can realize production automation of the novel duck meat block products, and the novel duck meat block products meeting requirements are produced.

Owner:郴州舜华鱼业有限责任公司 +1

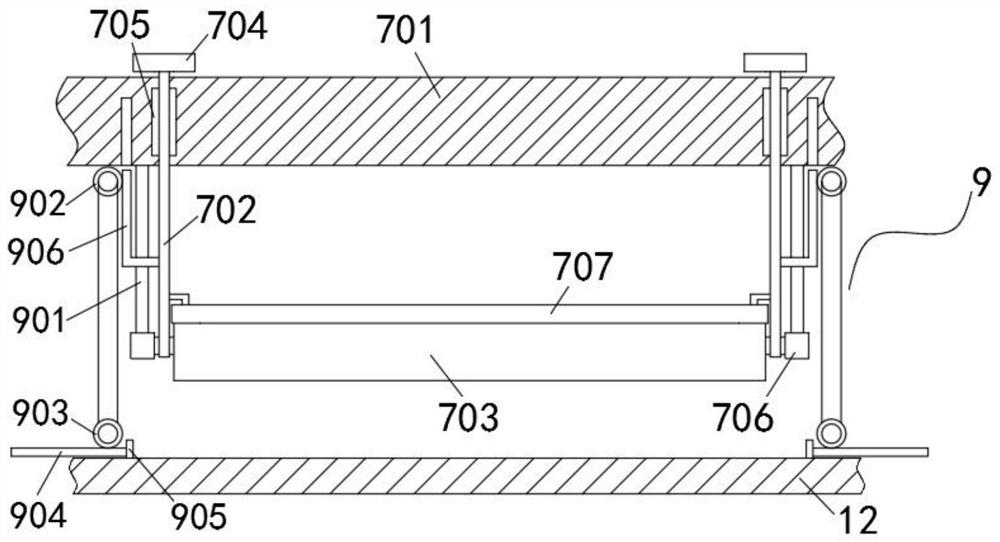

Tumbling device for pickling products

InactiveCN111000158AEvenly absorb pickleImprove knot strengthBeating-based meat tenderisingMassaging-based meat tenderisingIndustrial engineeringFood science

The invention provides a tumbling device for pickling products. The device comprises an actuating mechanism, a cam mechanism and a tumbling mechanism. The cam mechanism is mounted above the actuatingmechanism. The tumbling mechanism is arranged in the middle of the actuating mechanism. The tumbling mechanism is movably connected with the cam mechanism. According to the tumbling device provided by the invention, the problems that in the process of processing a meat product into pickled finished products, the meat product needs to be cleaned and diced firstly, and then beaten and loosened to relax fibers thereof, and more convenience is brought to follow-up flavoring work; a traditional meat beating and loosening process is manually carried out by workers; a large amount of time and a large amount of manpower are consumed in the whole process; the workers often lower the working requirements due to working fatigue; and customer complaints are caused due to the fact that the follow-up flavoring work of the meat product cannot meet expected requirements are solved.

Owner:ANHUI GUANGZHENG FOOD

Making method and device of puff beef steak

InactiveCN109363091AEasy to makeHigh-grade material selectionClimate change adaptationBeating-based meat tenderisingChemistry

The invention discloses a puff beef steak, and relates to the field of food technical equipment. The technical scheme of the invention lies in that the puff beef steak comprises a puff, a sandwiched sauce and a beef sirloin steak which are sequentially coated from outside to inside, wherein the sandwiched sauce is applied on the outer surface of the beef steak obtained in S2, the beef steak on which the sauce is applied is placed in the middle part of the puff, then peripheral puff is folded to coat the beef steak; and the treated beef steak is preheated in an oven to 200 DEG C, and after baking is performed for 30 minutes, the puff beef steak can be eaten. The puff beef steak disclosed by the invention has the beneficial effects of providing a novel beef steak product for a consumer market; to high-grade shops and supermarkets, a beef steak product which is convenient to make, has certain shelf life and has certain popularity is provided; and according to interview of some of the high-grade shops and supermarkets, no similar product is found.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

Mutton processing device

ActiveCN108633980AClean upSoft meatMeat packaging/handling/transportingBeating-based meat tenderisingSpray nozzleEngineering

The present invention relates to the technical field of mutton processing and discloses a mutton processing device. The mutton processing device comprises a machine frame and a conveying mechanism arranged on the machine frame; the conveying mechanism comprises a conveyor belt, a driving roller and a driven roller; a washing mechanism is arranged on both sides along a conveyor belt width direction; the washing mechanism comprises washing boxes and waste water boxes; the waste water box is provided with a drainage board; the drainage board is located on both sides of the conveyor belt width direction; one side of the washing box is fixed with elastic members and spraying nozzles; water pumps are fixed in the washing boxes; positioning blocks are arranged on both sides of the driven roller along the conveyor belt width direction; the positioning block is provided with a groove; the groove is slidably connected with a wedge piece; a friction piece is fixed on the wedge piece; a collectingbox is arranged at the end of the conveying direction of the conveyor belt; the upper part of the collection box is hingedly connected with a limiting plate by a torsion spring; the lower side of thelimiting plate is provided with a sliding rod; the lower side of the sliding rod is connected with air bags; the collecting box is slidably connected with a piston plate; and the lower part of the piston plate is provided with a spring. The mutton processing device is simple in structure, and convenient for collection of mutton and convenient for the washing of the mutton.

Owner:务川自治县洞家沟农业开发有限公司

Low-pollution air meat beating equipment

ActiveCN109349326AReduce reaction forceEliminate pollutionBeating-based meat tenderisingFiberEngineering

Owner:浙江欧托电气有限公司

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com