Patents

Literature

117 results about "Meat fibers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

We often hear talk of muscle fibers and the “grain” of meat. Muscle fibers are long protein fiber strands and the direction of their formation is the grain of the meat (pictured right). Muscle meat of land animals is made up of many bundles of protein fibers. These bundles of protein fibers are called fascicles.

Leisure vegetarian meat based on textured soybean protein

ActiveCN103734454ARich categoryFull of nutritionCheese manufactureVegetable proteins working-upVegetarian dietsMeat fibers

The invention discloses leisure vegetarian meat based on textured soybean protein. The vegetarian meaty food is prepared from the textured soybean protein as a raw material by the procedures of soaking and cleaning to remove beany flavor and peculiar smell, dewatering, surface oiling and sizing, imitating meat to supply flavors, sterilizing at high temperature and the like. The product is free of beany flavor, abundant in nutrient, convenient to carry, high in meat imitating degree, and moderate in saltiness and sweetness, mellow and delicious, strong in sensual appeal, and unique in flavor, has the chewing feeling of a real meat fiber and the flavor of meat, is a novel instant leisure flavor vegetarian product. Not only is the variety of the leisure bean products enriched, but also a new convenient and delicious choice is provided for vegetarian crowd.

Owner:ZUMING BEAN PROD

Pure fish sausage and preparation method thereof

The invention relates to a fish sausage with pieces of fish meat, which is produced by main materials of formed fish meat and auxiliary materials of flavoring. The main materials comprise 8-95% of formed fish meat and 1-49% of minced fish by weight. The sausage can be produced according to conventional technological process by processing the formed fish meat into required blocks, strips, pieces and grains after freezing the fresh fish meat cut by the conventional method and can also be produced by adding minced fish, fruit, preserved fruit, dried fruit or vegetable, accounting for 5-50% of the total weights, after mixing the main materials and the auxiliary materials in a proportion. The inventive product overcomes the disadvantages of process-forming difficulty due to thin fiber and high moisture of the fish meat, maintains the fish original flavor in the sausage furthest, and has a better taste. Therefore, the fish sausage is delicious with pieces of fish meat.

Owner:徐伟

Processing method of instant meat product

ActiveCN104305247AUniform colorReduce lossesClimate change adaptationFood preparationFiberMaillard reaction

The invention relates to a processing method of an instant meat product. The processing method comprises the following steps: selecting fresh meat or frozen meat at first, and pretreating the fresh meat or frozen meat for later use; preparing a maillard reaction solution; crushing and mixing to prepare a spice; cooling the maillard reaction solution to 2-10 DEG C, and uniformly injecting the reaction solution into the meat by using a saline water injection machine, wherein the injection volume is 2-5% of the mass of the meat raw material; standing until the maillard reaction solution is uniformly infiltrated into meat fibers, and cutting the meat into meat particles of 1-2cm<3>; putting the meat particles into a tumbling machine, adding sesame, sugar, edible salt, edible oil, white spirit and the spice, and tumbling to season the meat particles; heating to cure the meat particles in a microwave heating tunnel; and discharging the meat particles, quickly cooling the meat particles in fast-cooling equipment, metering, vacuumizing, packaging, sterilizing by passing through a microwave sterilizing tunnel, and quickly cooling to the normal temperature to obtain the instant meat product. By adopting the processing method disclosed by the invention, the maillard reaction solution is injected into the meat, and reaction is initiated during microwave heating and curing, so that the meat is quickly and uniformly colored, is good in color and luster and has outstanding and lasting meat fragrance; and from microwave sterilization to commercial sterilization, damages to meat fibers are small.

Owner:FARM PROD PROCESSING & NUCLEAR AGRI TECH INST HUBEI ACAD OF AGRI SCI

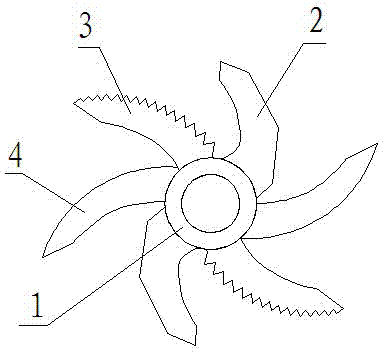

Novel rimer

The invention provides a novel rimer which comprises two sets of blades, wherein each set of blades comprises three blades; the tail ends of the three blades are connected with a central ring; the two sets of blades are uniformly arranged along the circumference of the central ring; each set of blades comprises a fold-type blade, a sawtooth type blade and an arc-shaped blade which are sequentially arranged. When the rimer rotates, the three kinds of blades take turns to cut and divide meat; if a bone is not removed, the cutting edges of the fold-type blades are continuously bent straight lines, and the time that the bone is contacted with different straight lines is different, so that the straight lines bump against the bone discontinuously so as to increase the impact force to the bone and enhance the chopping capacity to the bone; the cutting edges of the sawtooth type blades are sawtooth type and can powerfully cut tendons with stronger tenacity; the arc-shaped blades can cut common meat fiber; the three kinds of blades take turns to cut meat, so that better segmentation and cutting of meat can be realized.

Owner:WUXI YANGGONG MACHINERY MFG

Preparing foodstuffs based on fish flesh, and foodstuffs obtained thereby

InactiveUS6066354AImprove sensory qualityMeat/fish preservation by heatingConfectioneryFood industryModerate extent

The present invention relates mainly to a method of preparing foodstuffs based on fish flesh [i.e. the flesh of fish proper, and / or shellfish], and to foodstuffs obtained by this method. In the method of the invention, the fish flesh is mechanically mixed or kneaded to a moderate extent, i.e. the mechanical action avoids any significant irreversible spoiling of the fiber structure of the flesh, this action taking place in the presence of edible water-retaining compounds, in particular edible hydrocolloids. Mixing and / or kneading is continued until a uniform distribution is obtained in the mass of fish flesh of the water-retaining compounds and any other additives. The present invention is particularly applicable to the food industry. The present invention is mainly applicable to transforming fish proper, as distinct from shellfish.

Owner:NEPTUNE

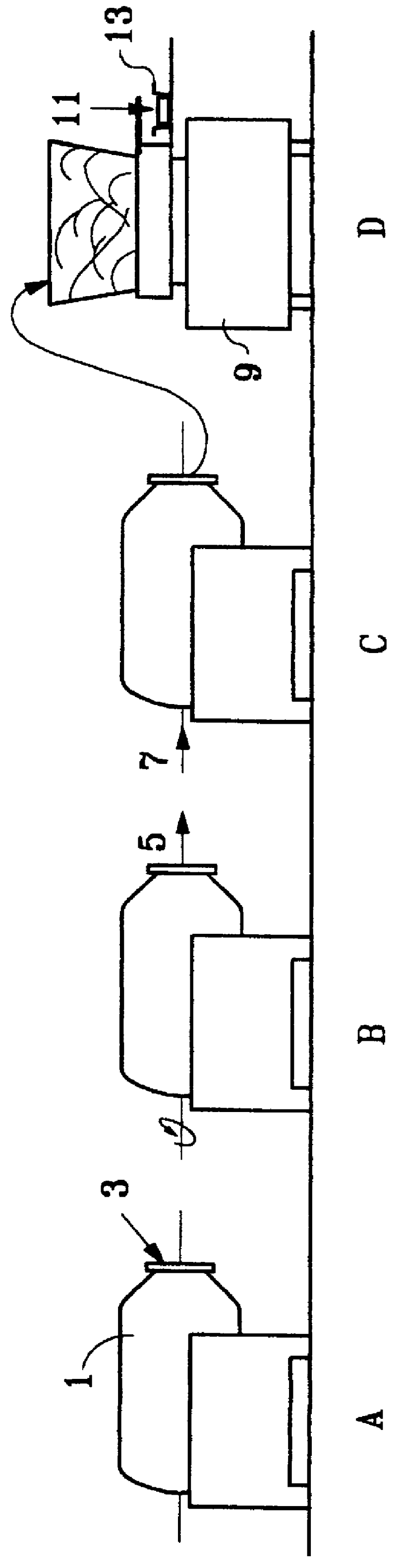

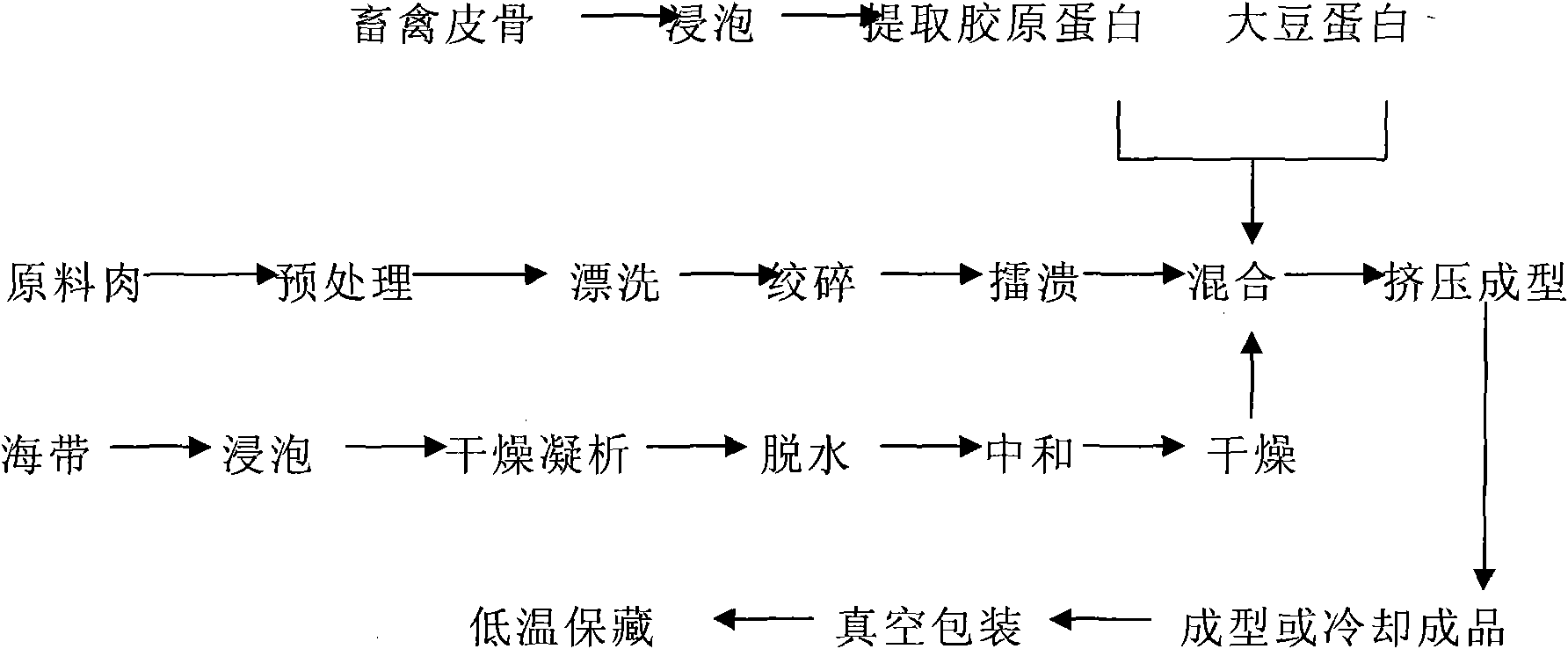

Extrusion production technique for meat simulated fibers

The invention relates to an extrusion production technique for meat simulated fibers, and belongs to the technical field of food science. A low-value meat raw material is used as a main raw material. The technique comprises the following steps of: adding auxiliary materials such as soy protein, animal dermal bone collagen, transglutaminase serving as meat protein coagulation additive, kelp glue serving as kelp extract and the like, performing recombination and cross-linking on multiple proteins and macromolecular polysaccharides by adopting double-screw extrusion technology (the rotational speed of screws is 280 to 450 revolutions per minute, the pressure of a micropore template is 1.7 to 6.0MPa at the temperature of between 150 and 200 DEG C, and the temperature of a cylinder is 170 DEG C), forming meat silk simulated fibers by extrusion, forming cross-linking reaction among meat protein molecules and in molecules, and reshaping micropore formed fibers to obtain recombinant meat food with good color, fragrance, taste and shape. The meat product produced by using the silk muscle simulated fibers produced by the technique is pure natural green food, does not contain chemical substances or preservatives, has the mouthfeel of real meat silks and the specific flavor of meat, has special fragrance and color at the same time, and can be absorbed more easily. Moreover, the added auxiliary materials such as collagen, kelp glue and the like form protein and polysaccharide polymers, so the nutritional components of the product are increased, the quality and structure properties of the product are greatly improved, the water holding property is improved, the problems such as gel cracking and the like are effectively avoided, the quality guarantee period of the product is prolonged, and the social benefit and the economic benefit of the product are increased.

Owner:TIANJIN UNIV OF SCI & TECH

Weight systematism flavour fish product and method for producing the same

InactiveCN101194730AAct quicklyShorten the deodorization processing timeFood preparationCalcium in biologyAdditive ingredient

The invention relates to a re-organization flavor fish product and process for preparation, belonging to the technical field of deep processing technology of fresh water fish. The process comprises removing fishy odor of fresh fish, steaming and curing the fish, separating fish bones and fish meat, removing water in fish meat, mixing bone powder which is minced by fish bones with pre-paste granule, table salt, edible sugar powder, pepper powder, sesame seed, glucose syrup, glycerol and flavoring, squeezing into shape, and obtaining the product after procedures such as heated-air drying, microwave processing and the like. The invention solves the problems of hard meat, large production energy-consumption, more fillings, imperfect taste, and low contents of protein, minerals and calcium. The invention has simple production technology, reduces proportioning amount of auxiliary material as a result of filling the bone powder into fish meat, increases nutrient ingredients, and reduces production cost. The invention not only can keep the special flavor of fish meat fiber, but also is rich in protein, minerals and calcium, and has long reservation period, convenient use, free fishy odor and delicious taste, which is suitable for industrialized production.

Owner:FUWA GROUP +1

Flavored recombined fish candy snack food and preparation method thereof

InactiveCN103948049AReduce fishy smellStay nourishedFood ingredientsFood preparationBiotechnologyNutrition

The invention provides a flavored recombined fish candy snack food and a preparation method thereof. The flavored recombined fish candy is a dehydrated snack food which is prepared by comprehensively utilizing fish processing leftover-minced fish or offal fish and scientifically adding textured soybean protein (TSP) by a recombination technique. The preparation method comprises the following steps: defreezing fish, selecting, rinsing, removing fishy smell by biofermentation, rinsing, steaming, separating fish fibers, adding TSP fibers, stir-frying while adding seasonings, adding an exogenous adhesive, mixing, spreading on a tray, forming, drying and packaging to obtain the finished product. The flavored recombined fish candy is a dried recombined fish snack food with the texture, chewiness and nutrition of natural fish fibers, conforms to the new diet concept of nutrition and good taste of consumers, solves the problem in comprehensive utilization of processing byproducts, creates higher economic value for the enterprise, and has practical instruction meanings for enhancing the aquatic product deep processing level.

Owner:FUJIAN AGRI & FORESTRY UNIV

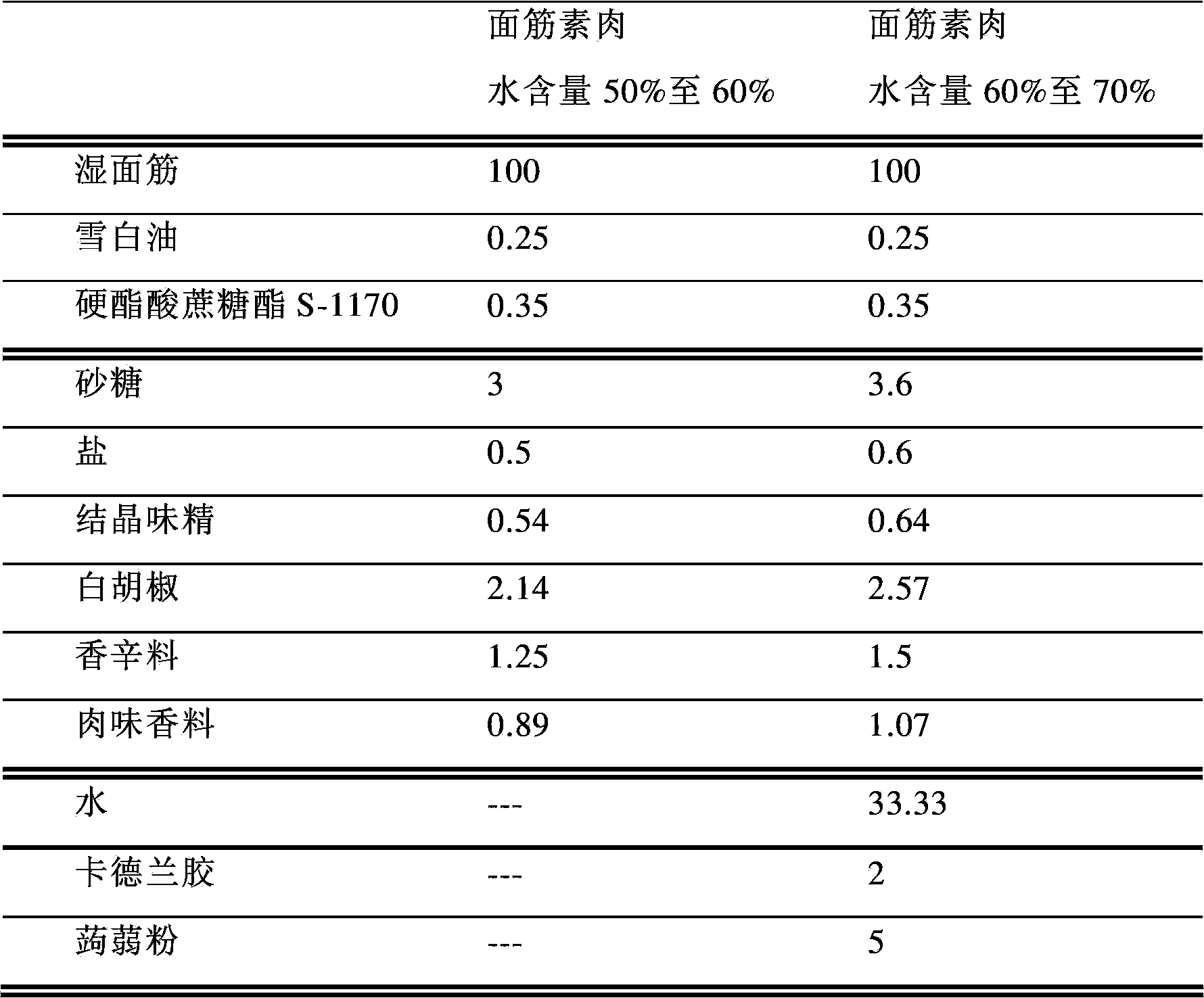

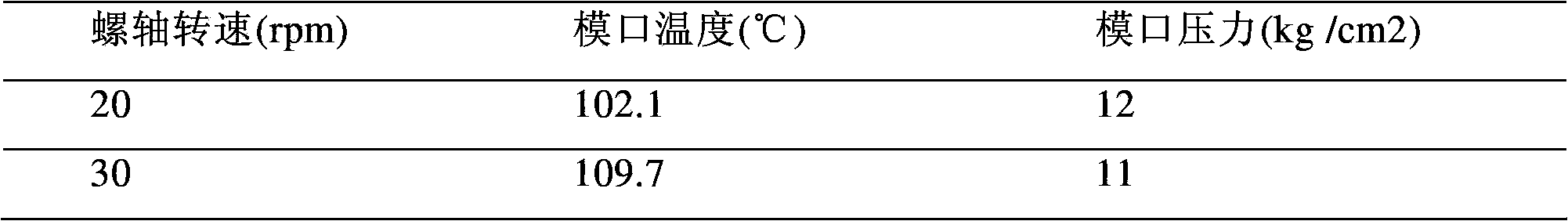

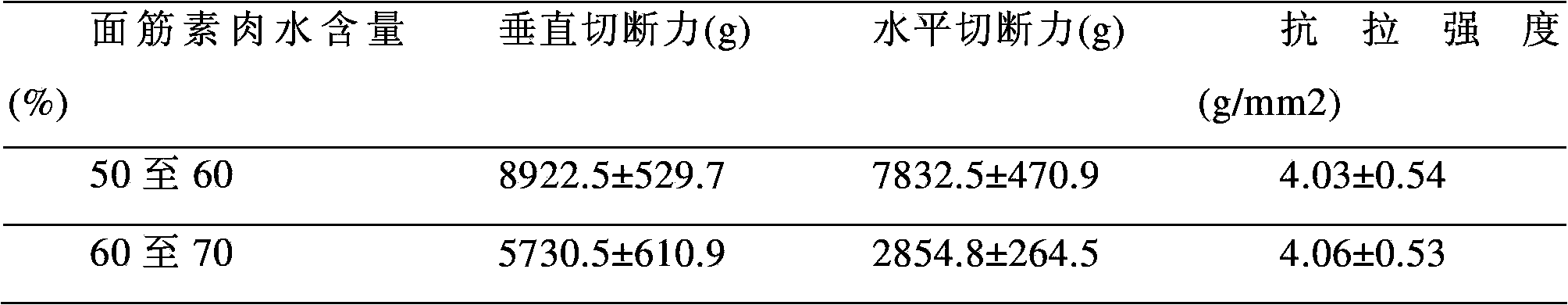

Method for manufacturing vegetarian meat and vegetarian meat

The invention relates to a method for manufacturing vegetarian meat. The method comprises the steps of: (a) stirring for mixing wet gluten and one or more auxiliary raw materials, so as to provide a gluten raw material; (b) subjecting the gluten raw material to segment heating mixing, so as to provide a thermoplastic protein dough; and (c) cooling the thermoplastic protein dough, and then extruding and molding the dough by a mold to obtain the vegetarian meat. The invention also provides the vegetarian meat with chewy mouthfeel of meat fibers.

Owner:FOOD IND RES & DEV INST

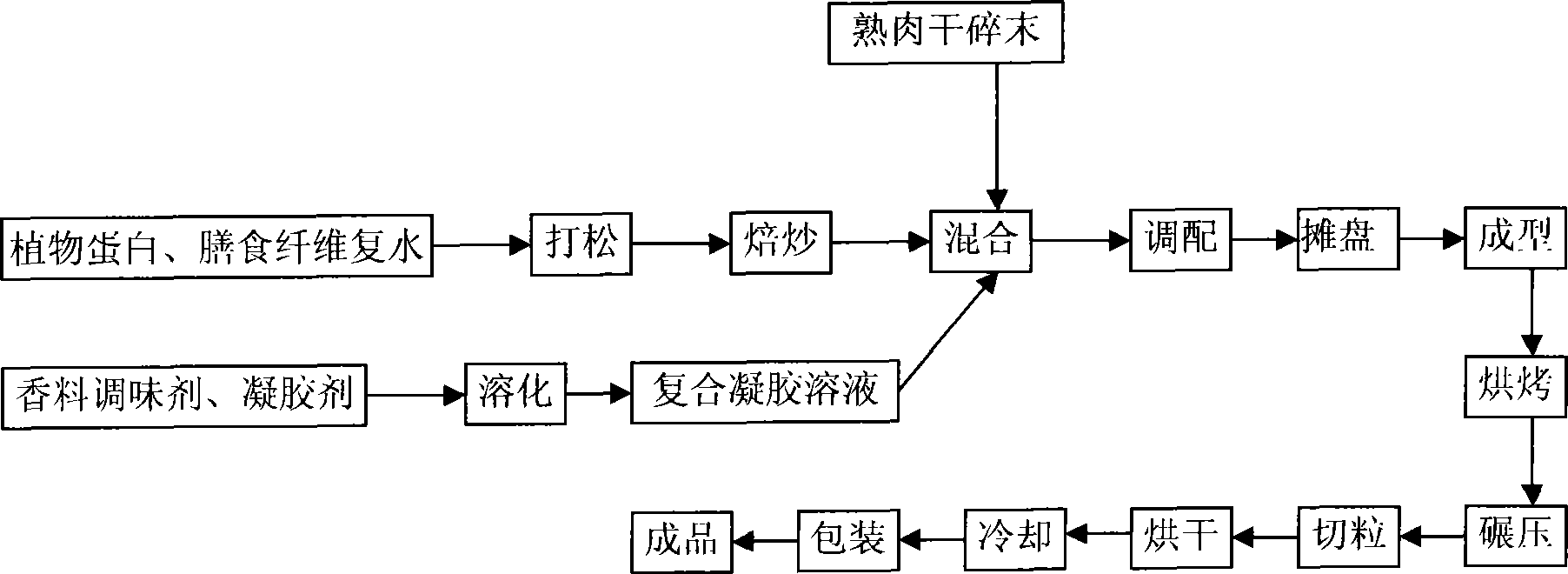

Method for producing assembled bionic dried meat and the products thereof

The invention relates to a method for producing complex bionic dried meat and the relevant product. It takes cooked dried meat powder, textured vegetable protein and edible fiber as main raw material, employs compound gelatin and dietary fatty and meat flavoring agent. The optimal ratio between cooked dried meat and textured vegetable protein and dietary fiber is 6.5: 3.5, the ratio between textured vegetable protein and edible fiber is 2: 1, the optimal amount of compound gelatin and edible fatty is 10% and 8%, and optimal pressure for shaping is 15kN. The invention is characterized by increased nutrition value, reduced cholesterol content, natural meat taste and increased economic benefit.

Owner:FUJIAN AGRI & FORESTRY UNIV

Hot pepper mock meat food and preparing method thereof

ActiveCN103444908ACrispy and spicyRich and mellow tasteCheese manufactureFood scienceHot peppersMeat fibers

The invention discloses hot pepper mock meat food and a preparing method thereof, and belongs to the technical field of extrusion bean products. The preparing method is characterized by comprising the steps that after 10%-14% of oil is squeezed out from soybeans, the soybeans are smashed to the fineness no less than 60 meshes, then bean products which have meat fiber texture structures and meat mouthfeel and are in a particle shape are obtained by extruding and expanding, drying is carried out until moisture content is 8%-10%, after frying, seasoning such as peanuts and hot pepper are added, and the hot pepper mock meat food is prepared. Mock meat which has a meat fiber texture structure and meat mouthfeel is further processed, finished products are crispy and hot, and a new type is created in the field of extrusion bean products.

Owner:SICHUAN NANXI HUIJI FOOD

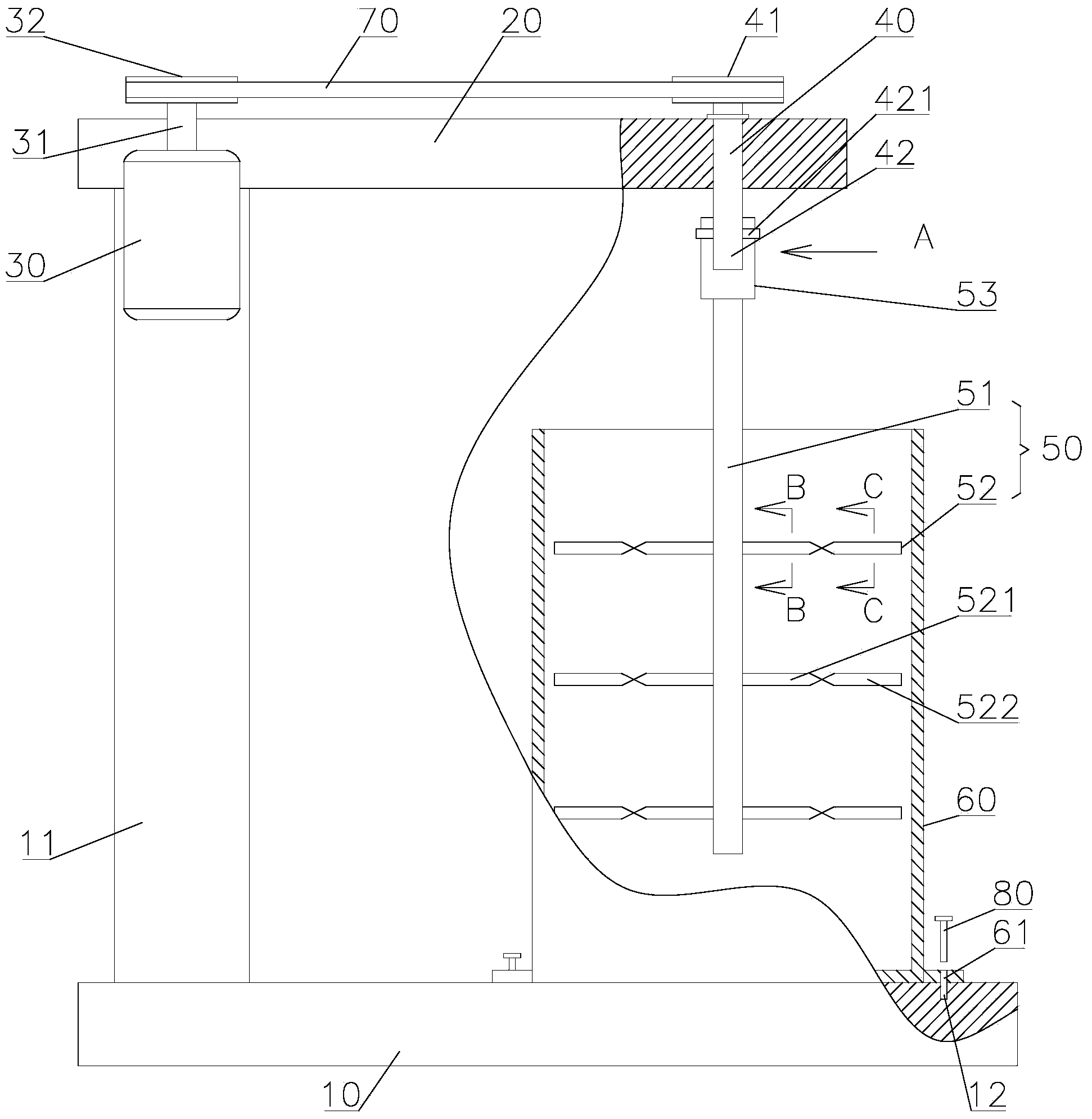

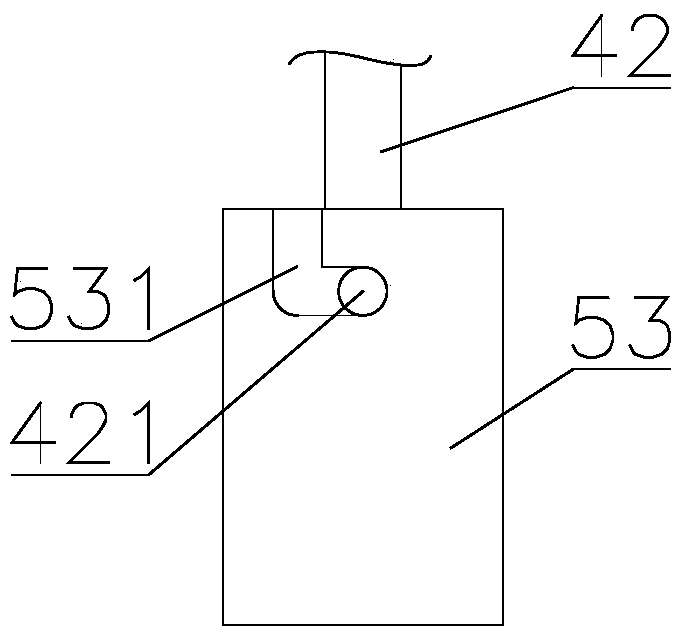

Plant protein type lunch sausage, and preparation method and complete high-temperature sterilization equipment of plant protein type lunch sausage

ActiveCN103876061AStrong meaty fiberAchieve deliciousFood preservationVegan ingredientsBiotechnologyCarrageenan

The invention discloses a plant protein type lunch sausage. The plant protein type lunch sausage contains the following components in parts by weight: 15-20 parts of textured soybean proteins, 3-8 parts of isolated soybean proteins, 10-18 parts of wheat proteins, 10-25 parts of tapioca starch, 5-18 parts of soybean oil, 3-10 parts of carrageenan, 2-8 parts of konjac glucomannan, 35-50 parts of water and 1-8 parts of seasonings. The plant protein type lunch sausage has the advantages that the meat fiber feel is strong and the normal temperature preservation can be realized. The invention also discloses a preparation method of the plant protein type lunch sausage and complete high-temperature sterilization equipment used in the method.

Owner:宁波市素莲食品有限公司

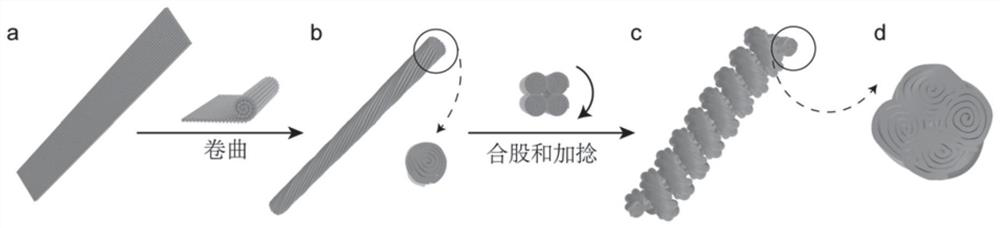

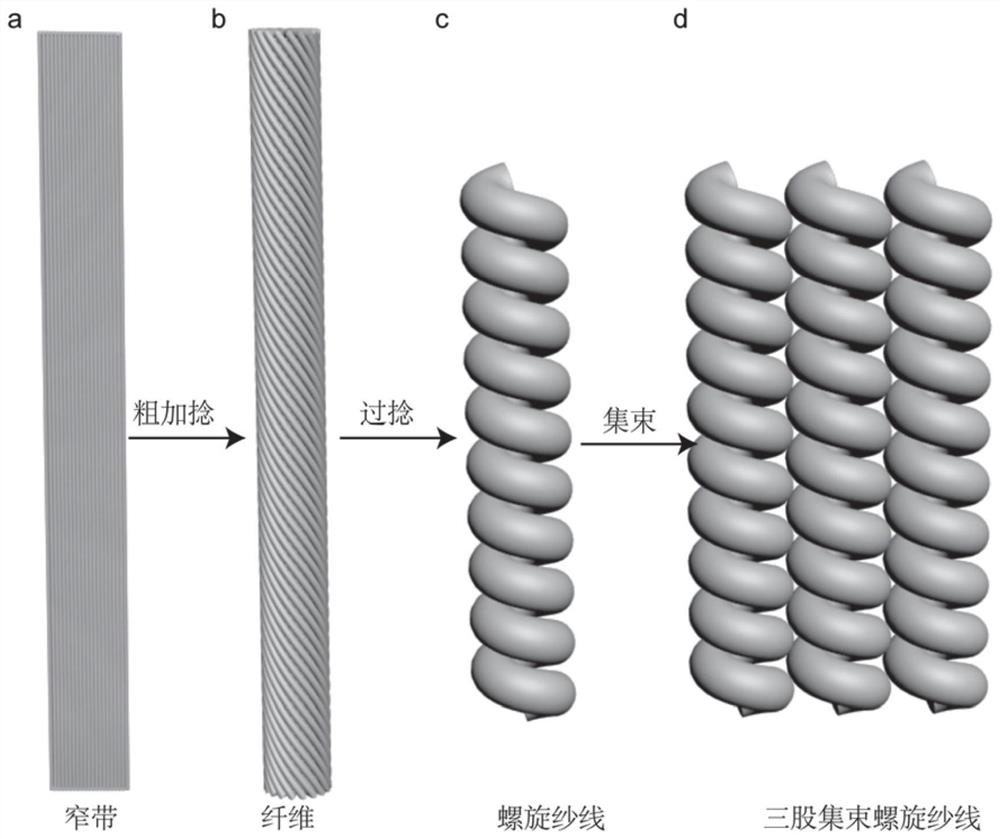

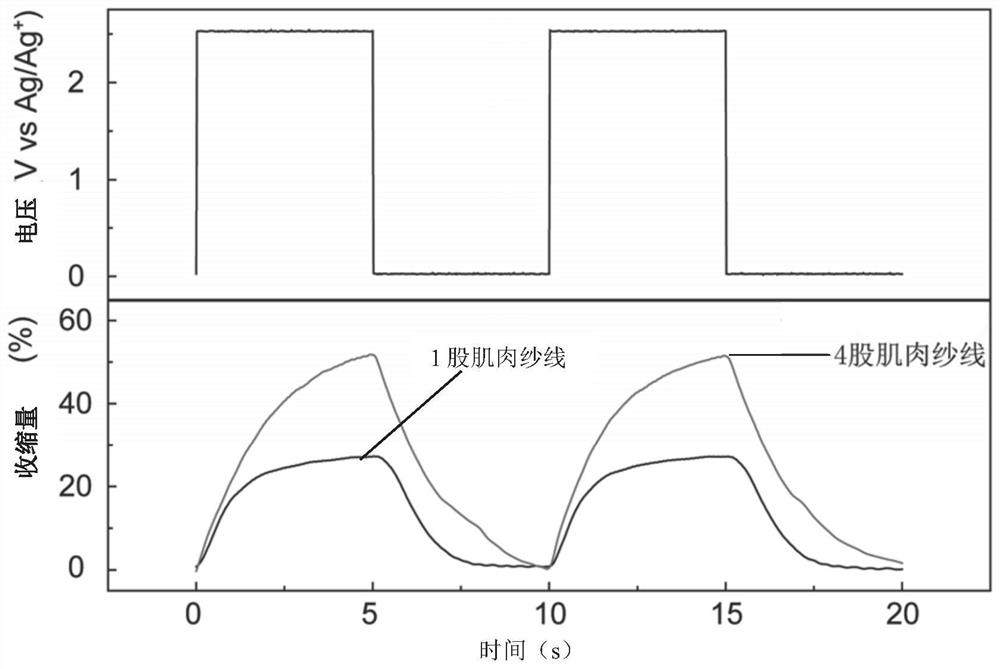

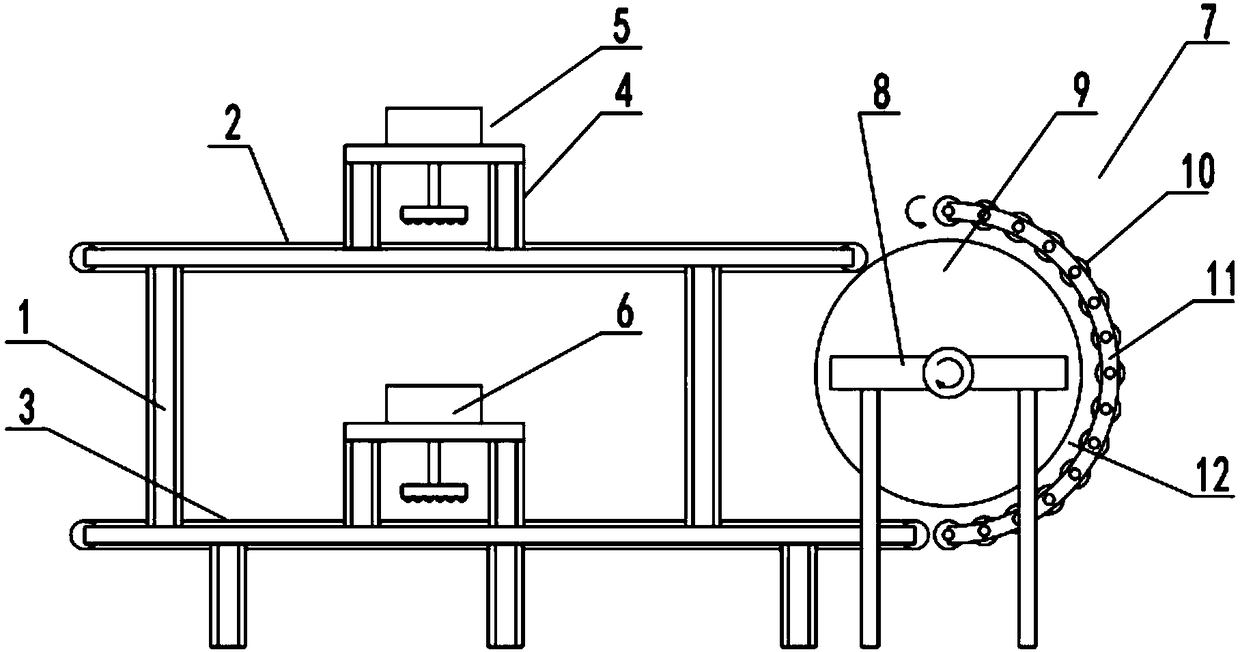

Electrochemically-driven artificial muscle fiber as well as preparation method and application thereof

The invention discloses an electrochemically-driven artificial muscle fiber as well as a preparation method and application thereof. The electrochemically-driven artificial muscle fiber comprises at least one strand of muscle yarn, wherein the muscle yarn is at least obtained by sequentially pre-crimping, stranding and twisting a plurality of carbon nanotube narrow bands until a uniform spiral structure is formed, or the muscle yarn is at least obtained by twisting a single carbon nanotube narrow band until the uniform spiral structure is formed. According to the preparation method of the electrochemically-driven artificial muscle fiber, the plurality of carbon nanotube narrow bands are pre-crimped, stranded and twisted to obtain the muscle yarn, or the carbon nanotube narrow bands are directly twisted to obtain the muscle yarn; the obtained muscle yarn has a spiral or threaded structure, so that the specific surface area of the carbon nanotube narrow bands is increased; a large numberof micro-nano pore passages are introduced into the artificial muscle fiber, and the energy density and the driving stroke of the artificial muscle fiber are improved in a bunching or stranding mode.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

Process for processing plant-based chicken fiber food by using soybean protein isolate

ActiveCN112515034AIncrease moisture contentGreat tasteProteins working-up by texturisingVegetable proteins working-upBiotechnologyProtein molecules

The invention discloses a process for processing a plant-based chicken fiber food by using soybean protein isolate. The plant-based chicken fiber food is obtained by performing twin-screw extrusion processing on the soybean protein isolate, wheat protein, low-temperature soybean meal, corn modified starch and soybean oil according to a specific ratio. Through high-temperature, high-pressure and high-strength shearing and molecular recombination, 2, 3 and 4-level structures of protein molecules are opened, then the protein molecules are crosslinked and recombined with starch and other components and fully fused with water, the chicken-like fiber is obtained, the water content is high, the eating taste is good, the plant-based chicken fiber food can replace chicken to be widely applied to various foods, functional foods and the like, and healthier protein is provided for human beings.

Owner:LINYI SHANSONG BIOLOGICAL PRODS

Method for preparing health-care high-simulation vegetarian meat

The invention provides a method for preparing health-care high-simulation vegetarian meat. The method comprises the following steps of: spraying soluble alginate solution containing soybean protein and transglutaminase (TG) enzyme into aqueous solution containing a soluble calcium salt from a slim hole to prepare calcium alginate vegetarian meat fibers containing the soybean protein and the TG enzyme; wetting the washed vegetarian meat fibers by using low-concentration sodium chloride saline, so that surface layers of the calcium alginate fibers are subjected to calcium-sodium balanced exchange; and adhering slightly among the fibers by utilizing the cohesive property of sodium alginate, extruding appropriately for dehydration, refrigerating, performing enzyme reaction, sizing and stewing to obtain the product. According to the health-care high-simulation vegetarian meat, the soybean protein is degenerated by utilizing the TG enzyme, so that the vegetarian meat offers a tender mouthfeel; and the high-simulation vegetarian meat fibers are prepared by utilizing the gel remodeling of alginates, so that the vegetarian meat fibers are vivid in appearance and have unique functions of blood fat reduction, detoxification and health care.

Owner:青岛喜美克明月海洋科技有限公司

Frozen and recombined fish steak and preparation method thereof

InactiveCN102132899AAchieve scaleRealize industrial productionFood preparationMeat fibersFish processing

The invention provides frozen and recombined fish steak and a preparation method thereof. The frozen and recombined fish steak contains minced fillet and minced fish meat which are added in the weight ratio of 1:1-5. The preparation method comprises the steps of: unfreezing minced fish meat material, selecting, arranging and rinsing; milling a part of the minced fish meat and isolated soy proteinswollen with water in advance into the minced fillet; then mixing the minced fillet and the minced fish meat together,, flavouring and carrying out low-temperature gel forming; packaging and finally freezing at the temperature of 18 DEG C below zero to obtain the frozen and recombined fish steak product. The frozen and recombined fish steak product produced by the method disclosed in the invention is a recombined fish steak product capable of simulating natural fish meat fiber texture. Therefore, the comprehensive development and utilization of side products in fish processing is realized, the additional value of the side products is improved, and the environmental pollution can be reduced. the preparation method of the frozen and recombined fish steak has important realistic significancefor realizing large-scale fish processing and industrial production.

Owner:FUJIAN AGRI & FORESTRY UNIV

Method for prepairing insect albumen powder from sterile maggot and application thereof

The invention discloses a method for preparing insect protein powder by using sterile fly maggot; the sterile fly maggot, which is the larva bred by the fly eggs laid by cultured sterile adult fly, is treated with pressure filtration, decomposition, filtration, adjustment of pH value, precipitation, washing and drying to be prepared into the insect animal protein powder; wherein, pressure filtration is conducted by a frame filter, decomposition is carried out in 1-5% of sodium hydroxide water solution, filtration is implemented with a piece of 200-350 meshes of filter cloth, 1mol / L hydrochloric acid solution is used for adjusting pH value, the protein is precipitated by standing still at room temperature, the precipitated protein is washed to neutrality with water and then prepared into milky white insect protein powder by a high speed centrifugal spray dryer; the content can reach over 90%. The protein powder prepared by the invention is rich in various nutrient components, has low fat, low cholesterin, little meat fiber, reasonable trophic structure and easy absorption, and can improve the immunity of the human body, resist aging, and achieve multiple effects such as disease prevention, nourishment, health care, physical rehabilitation and the alike, thus the insect protein powder has promising application prospect in the field of the medicines and health products for resisting fatigue and improving immunity.

Owner:司忠

Process for processing fresh and tender shredded meat fibers of chicken breast

The invention provides a process for processing fresh and tender shredded meat fibers of chicken breast. The process is characterized by comprising the steps of: (1) using the peeled big breast chicken as a main material for later use, wherein the anadesma on the top of a thick end of the peeled big breast chicken is removed, the fat content is less than or equal to 3%,and the product temperature is 2-5 DEG C; (2) tenderizing a single side of the finished big breast chicken once by a tenderization machine; (3) using a beater, beating the tenderized big breast chicken put into the beater; (4) putting the fibriform shredded meat of the chicken breast into a tumbling solution and stirring uniformly at a high speed by a vacuum tumbling machine; (5) standing and pickling the shredded meat fibers for 8-10h at 0-5 DEG C, and frying to shape the shredded meat fibers; (6) freezing the shredded meat fibers quickly, wherein the centigrade (C.T.) of the product after individual quick freezing is less than or equal to minus 18 DEG C; and (7) packaging the shredded meat fibers and warehousing. The process has the beneficial effects that the shredded meat fibers are kept fully; and meanwhile, by tenderizing and beating to separate out the shredded meat fibers in the raw meat and the big breast chicken, and through the quality improvement and the taste of the rolled and pickled meat, the value and the authenticity of the product are improved greatly.

Owner:QINGDAO CHIA TAI

Boneless fish block and method for making boneless fish block foodstuff

The invention relates to a process for making bone-removed fish blocks comprising the steps of, scaling off domestic fresh water fish, removing internal organs, heads, and main bones, washing, dividing into multiple fish blocks, pickling the fish blocks, first sizing the pickled fish blocks, adding in condiment, charging water into pasty state, charging in fish blocks, deep frying 0.5-4 minutes, removing fish bones, second sizing, coating the fish blocks with dried bread powder, second frying, placing the fish blocks with dried bread powder into fryer of 130-240 deg. C for deep frying till the fish blocks become golden yellow.

Owner:李德一

Edible fungus canned lunch and processing method thereof

Belonging to the technical field of edible fungus processing, the invention in particular relates to an edible fungus canned lunch, which is prepared form the following raw materials by mass: 50-80 parts of edible fungus, 0.5-4 parts of tremella powder, 0-3 parts of edible gum, 0.1-3 parts of a quality improver, 0.5-1.5 parts of salt, 0.1-1 part of a seasoning, and 2-25 parts of water. The product provided by the invention adopts edible fungus as the main raw material, utilizes the gelling forming properties unique to tremella, by means of sterilization, heating and thermal gelation, the product forms a whole, has good visual permeability, good cutting properties, and visible edible fungus material, is not added with meat, also is not added with an edible gelling agent, has the characteristics of rich nutrition, high protein, low fat and low calorie, has a taste close to a meat fiber structure, but also has the unique flavor of edible fungus and good chewing mouthfeel, thus conforming to the diet demands of people for convenience, nutrition and health in today's society.

Owner:HENAN ACAD OF AGRI SCI

Leisure vegetarian meat based on textured soybean protein

ActiveCN103734454BRich categoryNo beany smellCheese manufactureVegetable proteins working-upVegetarian dietsMeat fibers

The invention discloses leisure vegetarian meat based on textured soybean protein. The vegetarian meaty food is prepared from the textured soybean protein as a raw material by the procedures of soaking and cleaning to remove beany flavor and peculiar smell, dewatering, surface oiling and sizing, imitating meat to supply flavors, sterilizing at high temperature and the like. The product is free of beany flavor, abundant in nutrient, convenient to carry, high in meat imitating degree, and moderate in saltiness and sweetness, mellow and delicious, strong in sensual appeal, and unique in flavor, has the chewing feeling of a real meat fiber and the flavor of meat, is a novel instant leisure flavor vegetarian product. Not only is the variety of the leisure bean products enriched, but also a new convenient and delicious choice is provided for vegetarian crowd.

Owner:ZUMING BEAN PROD

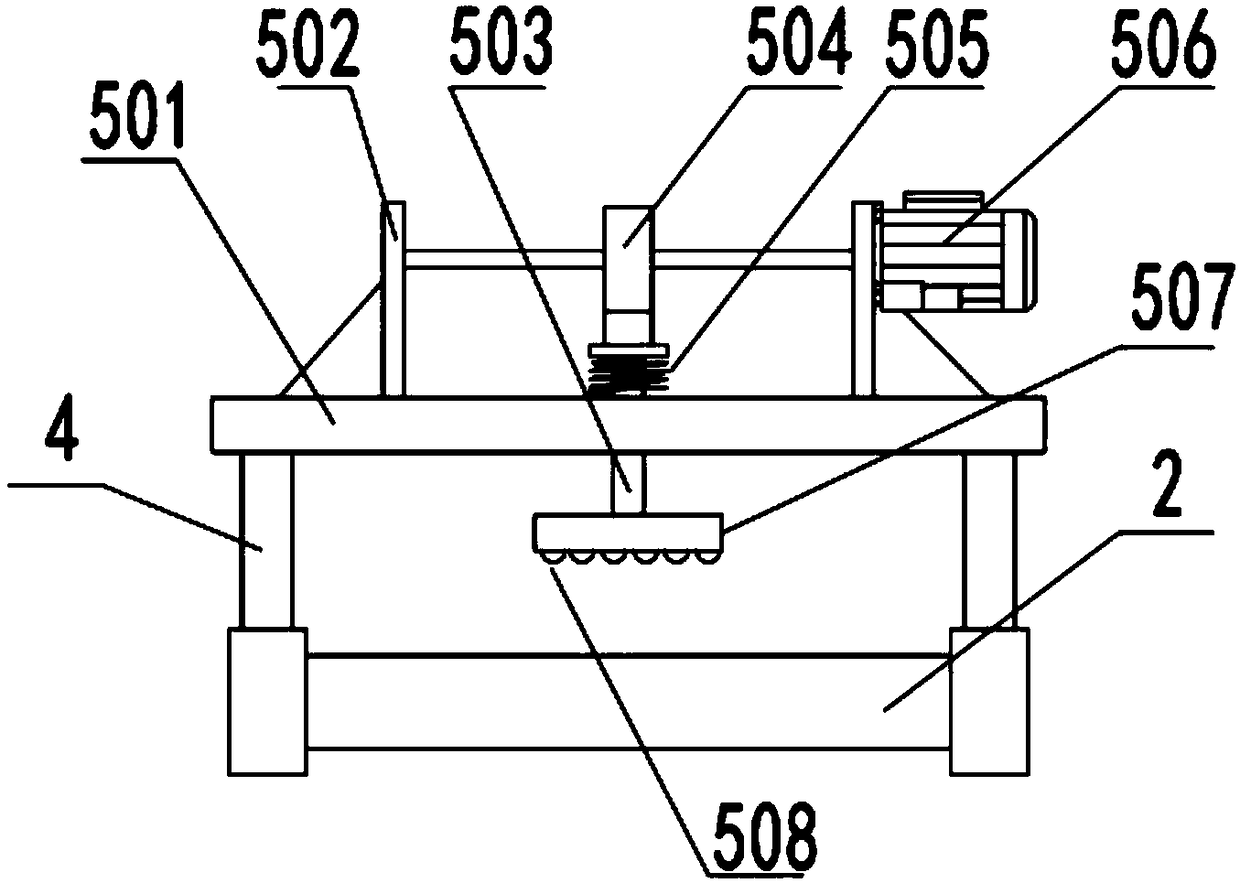

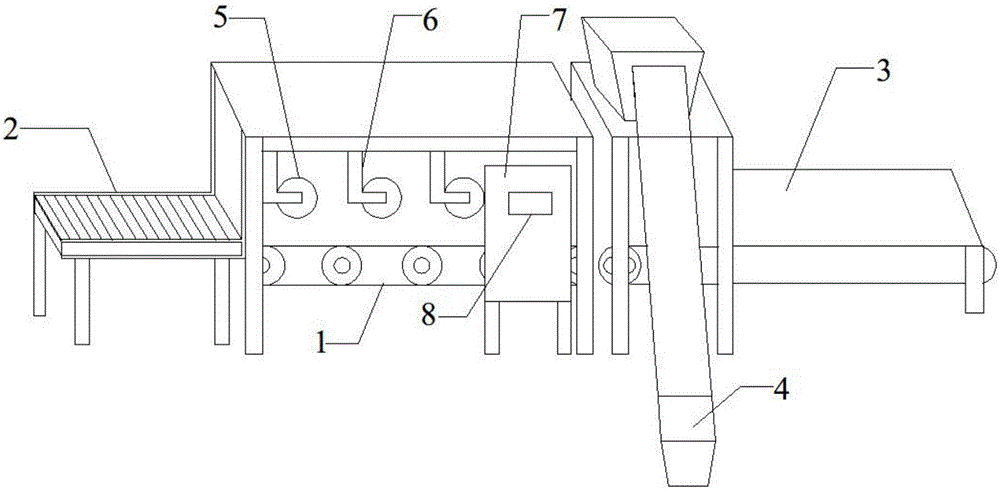

Double-side meat loosening mechanism for processing of pot-stewed steaks

The invention discloses a double-side meat loosening mechanism for processing of pot-stewed steaks. The double-side meat loosening mechanism comprises upper and lower conveyer belts mounted on a frameand used for conveying steaks. The upper and lower conveyer belts are parallel to each other and move oppositely; a hammering rack is fixedly mounted on the frame and is provided with hammering mechanisms I and II correspondingly above the upper and lower conveyer belts and used for hammering steaks; a turnover mechanism is arranged on one side of the upper and lower conveyer belts. The double-side meat loosening mechanism has the advantages that the turnover mechanism helps the hammering mechanisms to effectively knock and hammer the double sides of each steak, meat fibers can be chopped tofacilitate flavoring of condiments, and final taste is improved; the turnover mechanism is simple in structure and can provide automatic turnover, so that labor intensity is greatly reduced for personnel, and meat loosening effect is improved.

Owner:临泉县生产力促进中心

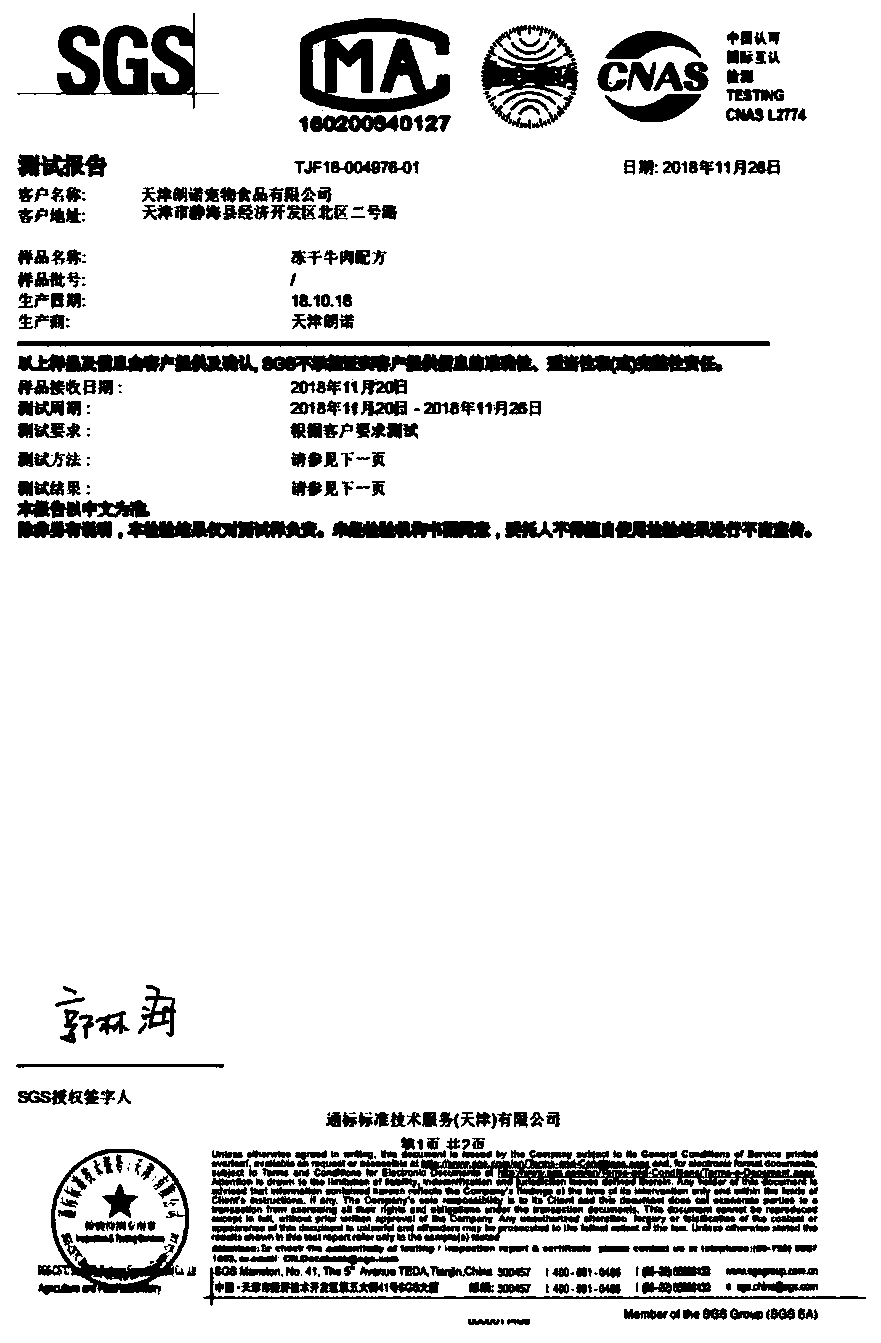

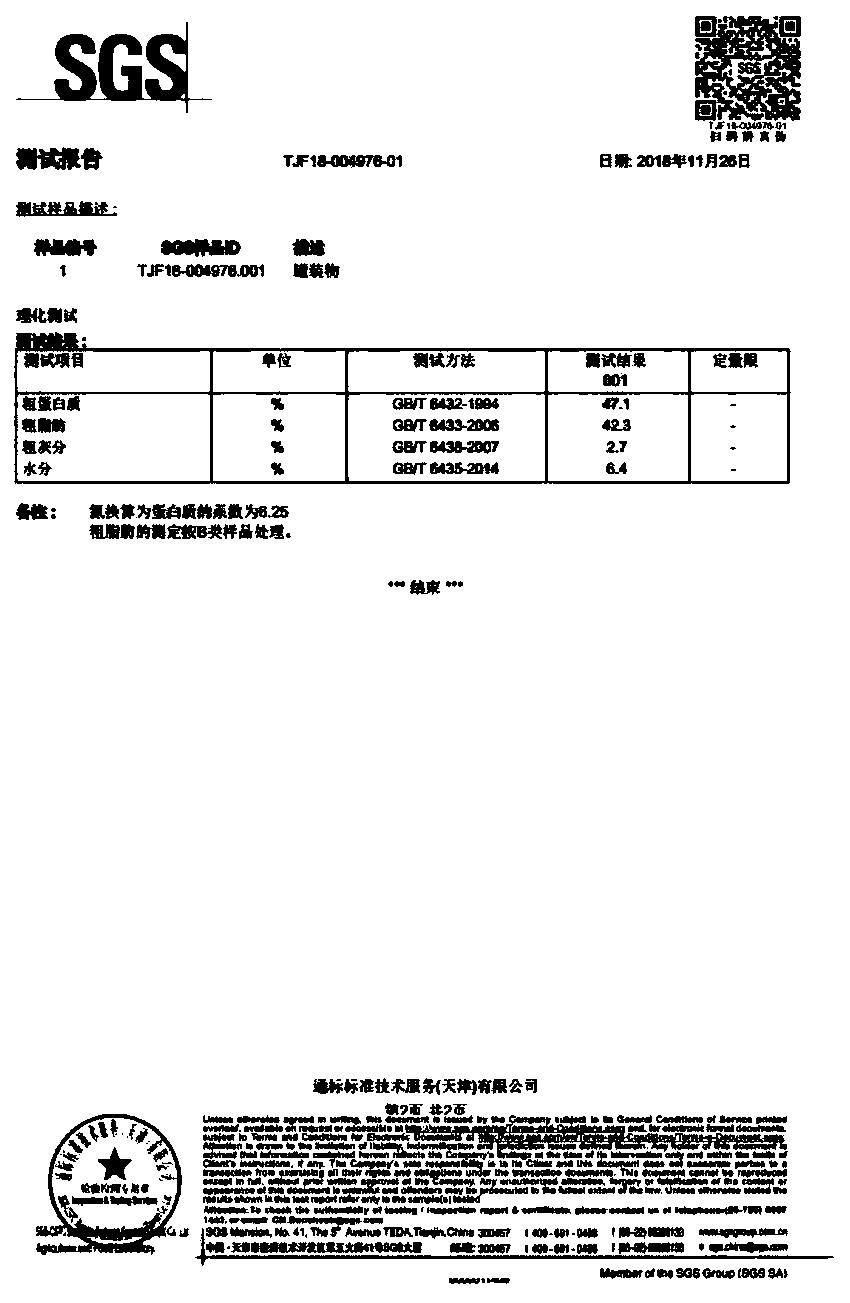

Freeze-dried pet food and preparation process thereof

PendingCN110037168ASoft touchGreat tasteAnimal feeding stuffAccessory food factorsBiotechnologyFreeze-drying

The invention relates to the technical field of pet food and discloses freeze-dried pet food. The freeze-dried pet food comprises, in parts by weight, 45-90 parts of a main material, 15-50 parts of ingredients and 0.01-0.5 part of auxiliary materials; the main material is mixed meat of one or two or more of livestock and poultry meat and fish meat; and the livestock and poultry meat is mixed meatone or more of chicken, duck meat, mutton and mutton. The freeze-dried pet food contains no preservative or artificial essence and contains no gluten; the pet food is in a form of flocculent meat fiber after being twisted with hand and touches soft; vacuum freeze drying treatment instead of cooking is adopted, and a large number of nutrients such as vitamins which are lost easily at high temperature in raw materials are retained; livestock and poultry meat, fish meat and animal liver are combined to be used as the raw materials of the pet food, so that the freeze-dried pet food has more comprehensive nutrients than freeze-dried pet food produced from single meat material, conforms to rules of ingestion of cats and dogs under the natural condition and is closer to habits in the wild growthstate; and a preparation process of the freeze-dried pet food is provided.

Owner:TIANJIN RANOVA PET FOOD

Rolling and kneading equipment for pickling ham

The invention discloses rolling and kneading equipment for pickling ham. The rolling and kneading equipment comprises a rolling and kneading machine, wherein a conveying roller path is arranged on one side of the rolling and kneading machine; the rolling and kneading machine is in driving connection with a driving mechanism; the rolling and kneading machine is provided with a plurality of rollers for pressing the ham; the rollers are respectively connected with a bracket in match and are horizontally mounted inside the rolling and kneading machine; a conveyer belt is arranged on the other side of the rolling and kneading machine; the conveyer belt is used for feeding the pressed harm into a salting funnel for adding salt on the harm. By adopting the rolling and kneading equipment disclosed by the invention, meat pieces are mutually extruded and abraded because of the rollers inside the rolling and kneading machine so that massage and pickling functions can be achieved, meat fiber is rapidly fused with the added salt, salt-soluble protein can be rapidly and completely leached out, and the rolling and kneading equipment is simple to operate and good in rolling and kneading effect; the rolling and kneading machine can be controlled to perform intermittent rolling and kneading operation through a rolling and kneading switch inside a control box, and thus the energy consumption can be reduced.

Owner:JIANGSU CHANGSHOU GRP CO LTD

Functional snack for pet dogs and preparation method thereof

InactiveCN106666085AImprove absorption rateImprove the degree of decompositionFood processingAnimal feeding stuffDiseaseGlycerol

The invention discloses a functional snack for pet dogs and a preparation method thereof. The functional snack for pet dogs comprises the following components in parts by weight: 20-50 parts of cattle bone, 1-4 parts of seaweed meal, 10-30 parts of peanut albumen powder, 0.5-2 parts of deep sea fish oil, 10-30 parts of chicken breast, 2-5 parts of soybean protein isolate, 2-5 parts of wheat flour, 2-5 parts of corn starch, 0.1-0.5 part of composite bacteria for fermentation, 2-5 parts of serum protein powder, 0.1-0.2 part of green tea powder, 0.1-0.5 part of glycerol and 0.1-0.5 part of potassium sorbate. The functional snack for pet dogs can solve the problems by improving the intestinal tract absorptivity and raw material decomposition degree; and the meat fibers which can not be digested and absorbed in the raw materials are subjected to in-vitro chopping, stirring and emulsification by the preparation technique to achieve the in-vitro predigestion effect, thereby promoting the development and response capacity of the organism immunological cells, and achieving the goals of nutrition and disease resistance.

Owner:青岛嘉远宠物食品有限公司

Flavor rabbit meat ball and preparation method thereof

The invention relates to a flavor rabbit meat ball, which belongs to the technical field of the food processing. The rabbit meat ball is prepared from 40-60 parts of rabbit meat, 1-3 parts of table salt, 1-2 parts of white granulated sugar, 0.1-0.2 part of white pepper powder, 8-15 parts of starch, 3-5 parts of protein powder, 0.1-0.2 part of ginger powder, 0.1-0.2 part of garlic powder, 0.3-0.8 part of monosodium glutamate, 3-5 parts of cooking wine, 0.3-0.5 part of five spice powder, 3-5 parts of egg white and 20-30 parts of cold water. The preparation method comprises the following steps: chopping thawed and rabbit meat, the table salt, the white granulated sugar, the white pepper powder, the ginger powder, the garlic powder, the monosodium glutamate, the cooking wine, the five spice powder and half of cold water for 2-3 minutes; then, adding the starch, the protein powder, the egg white and the other half of cold water; chopping for 2-3 minutes; adding into a ball forming machine to regulate the size of the ball; boiling the shaped ball for two times, and cooling; and finally quickly freezing to obtain the flavor rabbit meat ball. The flavor rabbit meat ball is free from the preservative so as to prevent from damaging meat fiber. The flavor rabbit meat ball contains high protein and low fat, is flexible and crisp and soft taste, is not greasy, is convenient to eat, can be cooked into any mode, has the advantages of reasonable formula and simple manufacture method and is suitable for mass production.

Owner:翁桦

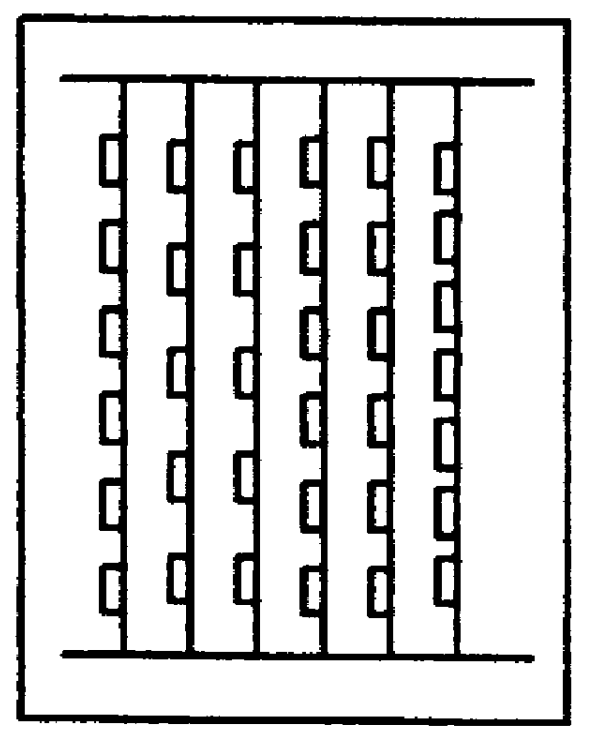

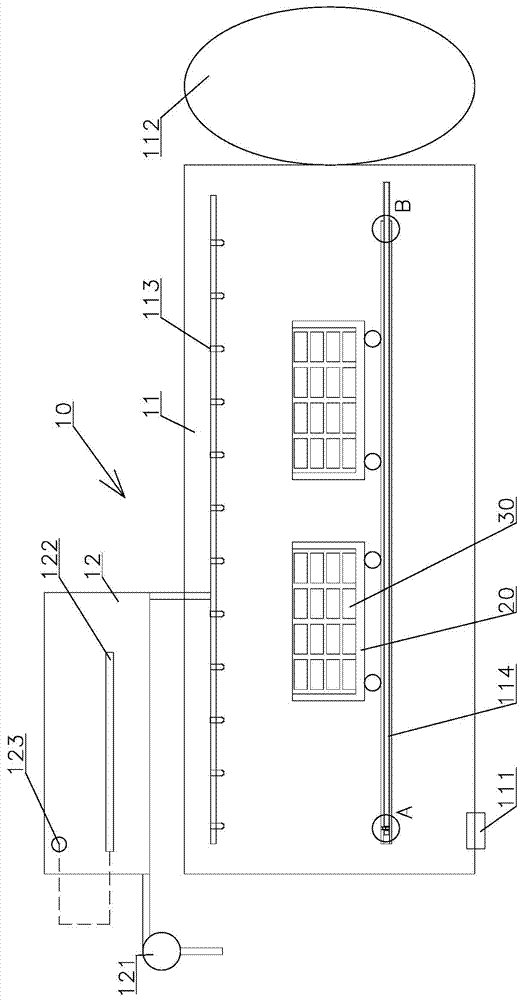

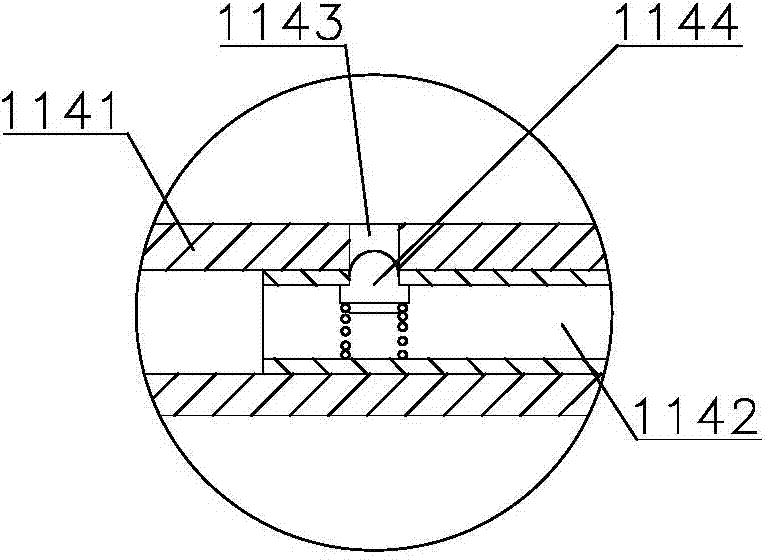

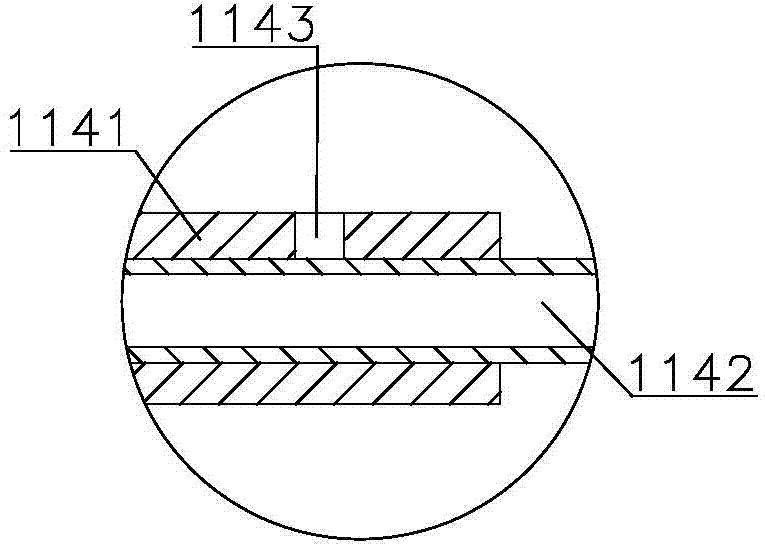

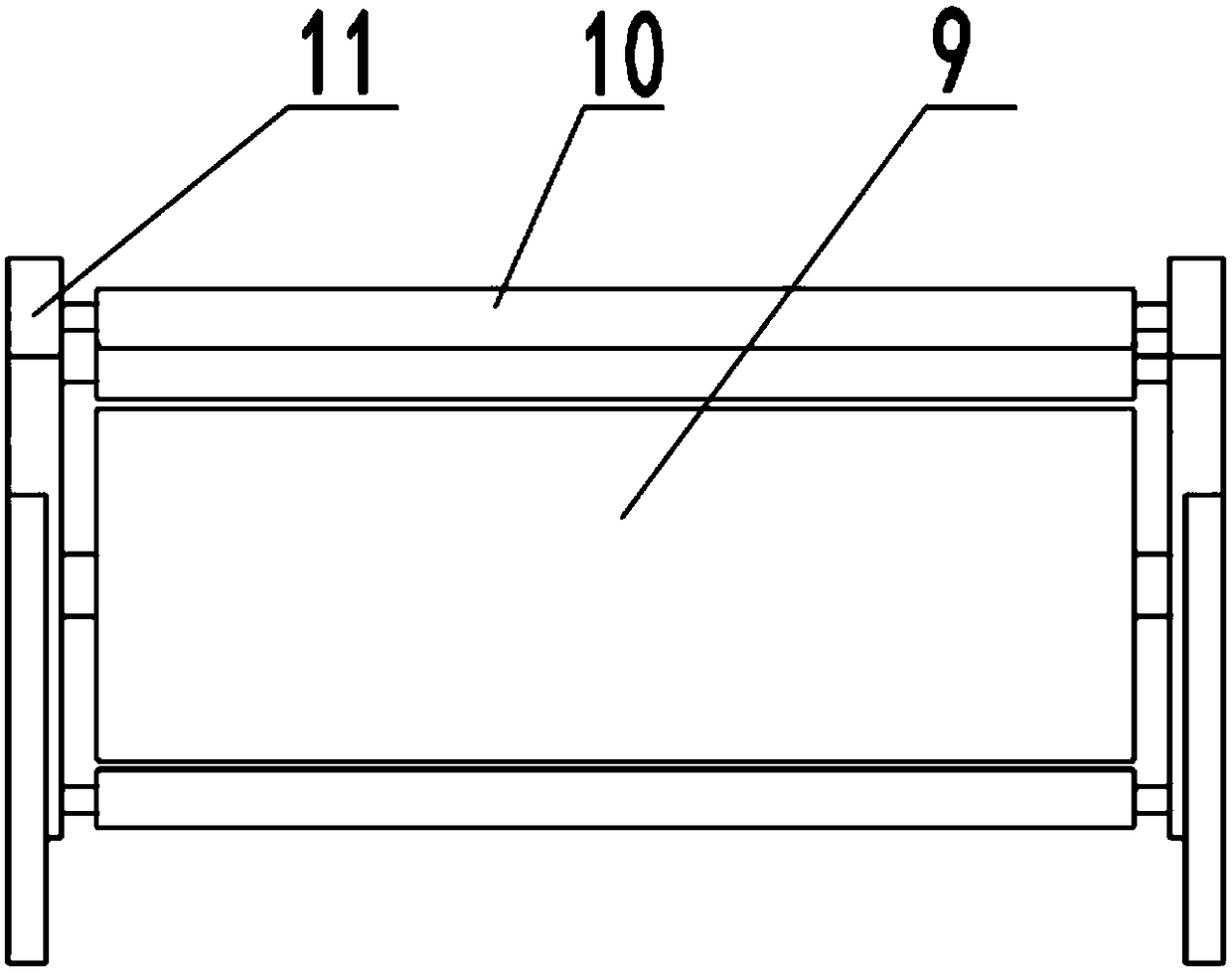

Vegetarian meat floss, preparation method of vegetarian meat floss, and two fiber fluffing machines used in method

ActiveCN104041812ASensory fibers are slenderTaste meaty and fibrousFood ingredientsFood shapingFiberSesamum

The invention discloses vegetarian meat floss. The vegetarian meat floss comprises the following ingredients in parts by weight: 30 to 45 parts of textured soybean protein, 20 to 30 parts of soybean flour, 10 to 20 parts of corn starch, 15 to 25 parts of soybean vegetable oil, 10 to 15 parts of white granulated sugar, 2 to 5 parts of sesames, 2 to 5 parts of nori and 5 to 10 parts of seasonings. The vegetarian meat floss has the advantages that fibers are slender, the taste is strong in meat fiber, the floss does not taste like powder and is not sticky and greasy, and the floss is crisp, chewable and capable of being stored at normal temperature. The invention also discloses a preparation method of the vegetarian meat floss and two fiber fluffing machines used in the method.

Owner:宁波市素莲食品有限公司

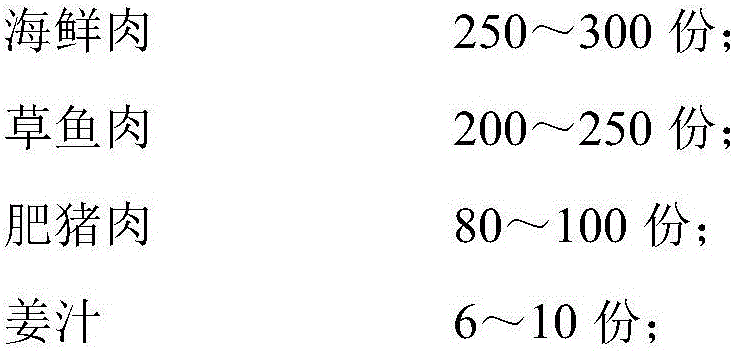

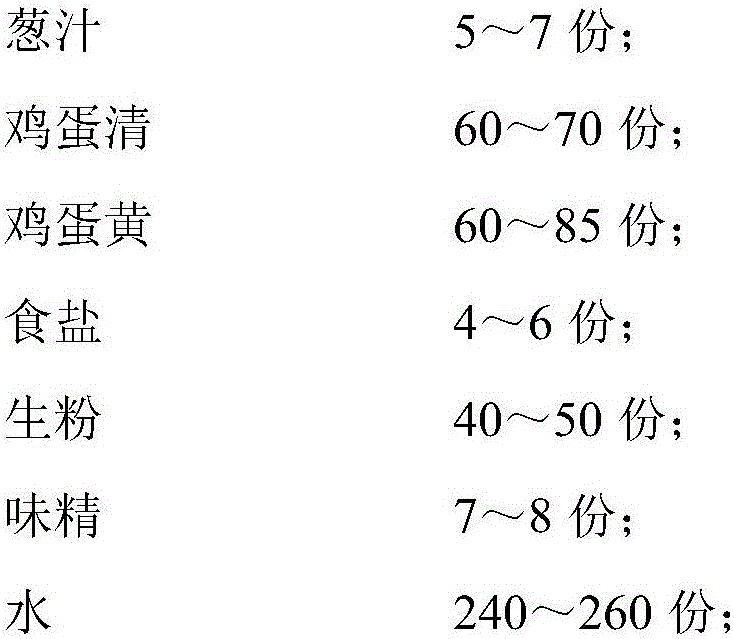

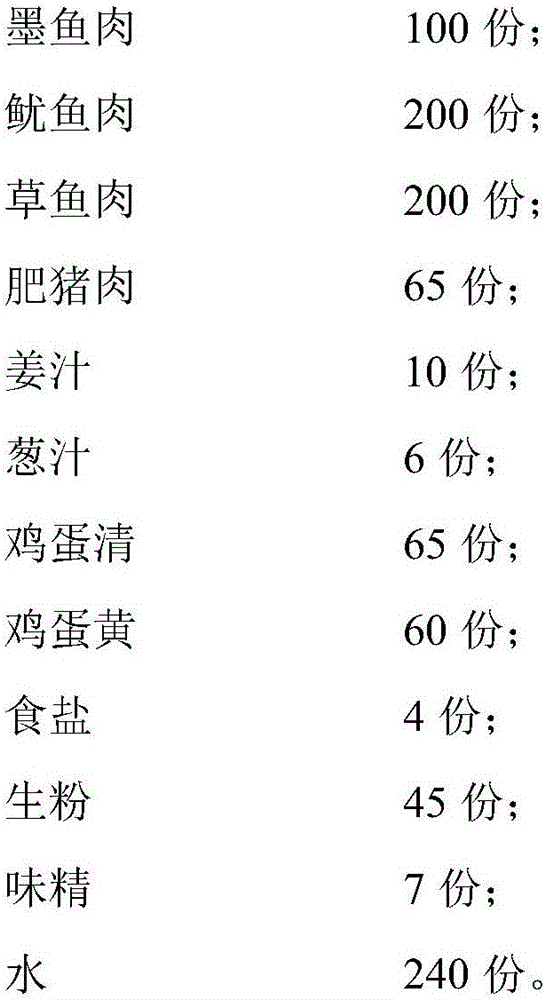

Double-seafood fish ball and preparation method thereof

InactiveCN105942293AImprove food valueImprove economyFood ingredient as taste affecting agentFood ingredient as mouthfeel improving agentFlavorFood additive

The invention relates to the technical field of food manufacturing, and discloses a double-seafood fish ball and a preparation method thereof. Based on an idea of healthy diet, the invention provides the double-seafood fish ball developed by taking two types of seafood meat and grass carp meat as main materials, taking lard, egg white and egg yolk as auxiliary materials, and taking ginger juice, fistular onion juice and the like as seasoners under the condition of completely abandoning food additives. The selected seafood meat is coarse in meat fiber, insufficient in viscidity and low in economic value; through technology processing, the mouthfeel and the taste of the seafood meat are improved, and the edibleness and the economic value of seafood are increased; by continuous exploratory experiments of the applicant, recipe parameters of the double-seafood fish ball are accurately optimized, and the double-seafood fish ball is formed by being processed with a simple and stable technology; the obtained double-seafood fish ball is bright and clean in color, fine and tender in mouthfeel, and full in elasticity; meanwhile, the original flavor and nutrition of the product raw materials are furthest reserved, the eating needs of different people in various age stages can be met, and good popularization and market values are achieved.

Owner:LINGNAN NORMAL UNIV

Salted meat and preparation method thereof

InactiveCN107811224AUnique flavorFull of nutritionFood ingredient as taste affecting agentFood ingredient as flavour affecting agentFiberMeat fibers

The invention relates to salted meat and a preparation method thereof and belongs to the technical field of food processing. The salted meat is prepared from the following food raw materials in partsby weight: 1000-1500 parts of fresh meat, 50-100 parts of radish leaves or pumpkin leaves, 3-5 parts of dried orange peel, 1-2 parts of amomum fruits, 5-8 parts of ginger, 0.5-1 part of aniseed, 0.2-0.5 part of fennel, 15-30 parts of table salt, 1-2 parts of vinegar, 50-100 parts of sweet wine liquid, 300-500 parts of oil and 50-150 parts of sugarcane juice. The preparation method comprises the steps: (1) cleaning, (2) boiling in water, (3) frying in oil, (4) pickling, and (5) vacuum packaging. The salted meat provided by the invention is unique in flavor, fat but not greasy, soft and tender in meat fibers, digestible, red in color, salty and sweet in mouthfeel, crisp, soft, delicious, fragrant, delicate, smooth, juicy, chewy and strong in fragrance, the flavor leaves in the mouth and on the lips for a long time after the salted meat is eaten and the salted meat has a lingering aftertaste.

Owner:施俊

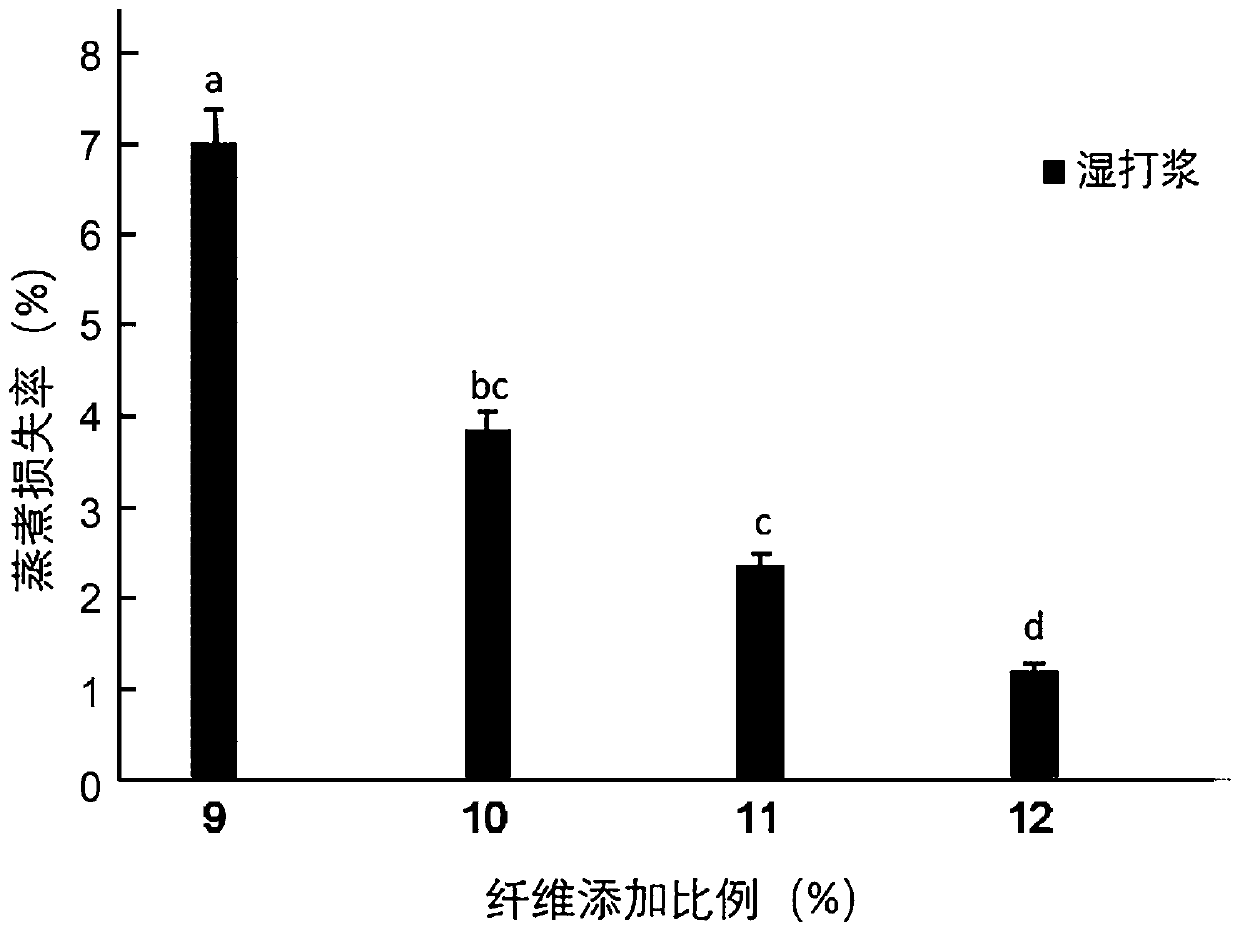

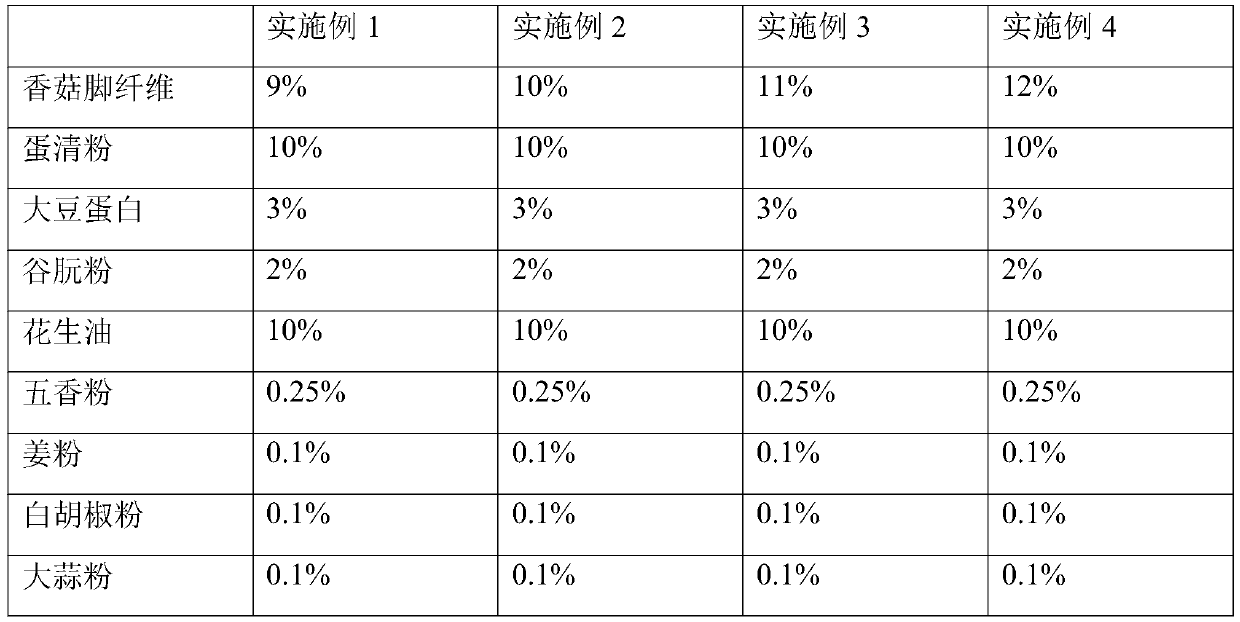

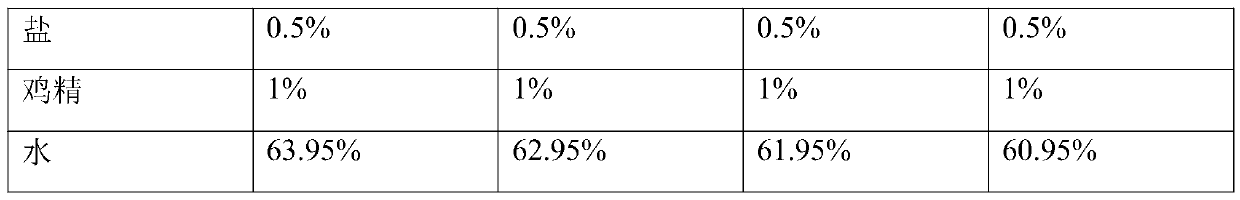

Meat-like sausage based on lentinus edodes root fibers and preparation method thereof

PendingCN111466557AEfficient use ofReduce waste of resourcesFood coatingFood ingredient functionsBiotechnologyMeat fibers

The invention discloses a meat-like sausage based on lentinus edodes root fibers. The meat-like sausage comprises the following components in percentage by weight: 5-15% of shiitake mushroom root fibers, 8-12% of egg white powder, 3-5% of soybean protein, 2-3% of vital gluten, 10% of peanut oil, 0.25% of five spice powder, 0.1% of ginger powder, 0.1% of white pepper powder, 0.1% of garlic powder,0.5% of salt, 1% of chicken essence and 53-69% of water. The meat-like sausage is prepared by mixing the components in proportion, and performing stirring, filling and cooking. The prepared meat-likesausage can achieve chewing feeling of animal meat fiber tissues, is proper in viscoelasticity and hardness, good in taste and high in dietary fiber content, is suitable for people of all ages, and meets the requirements of people for healthy food.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com