Patents

Literature

82results about How to "With texture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

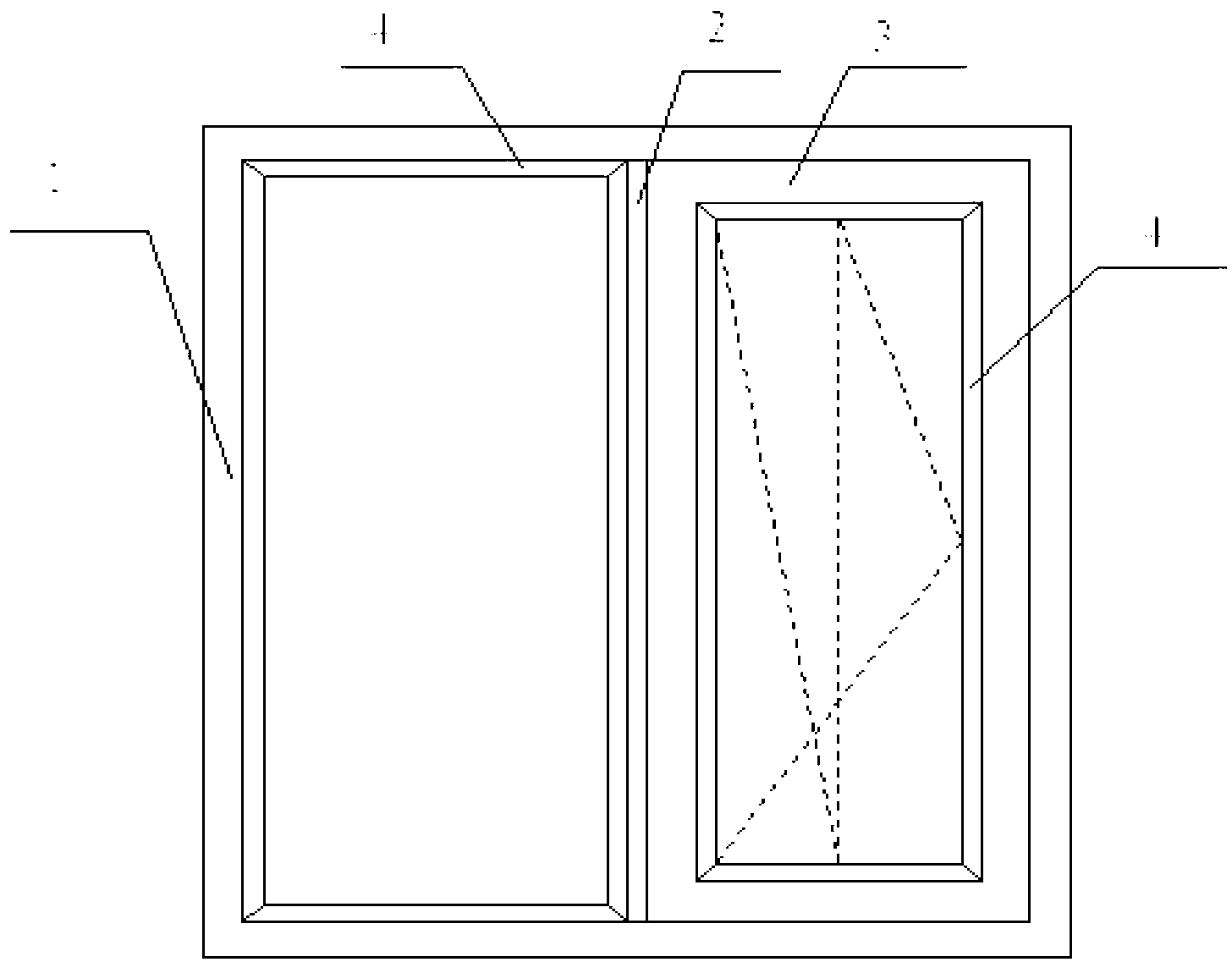

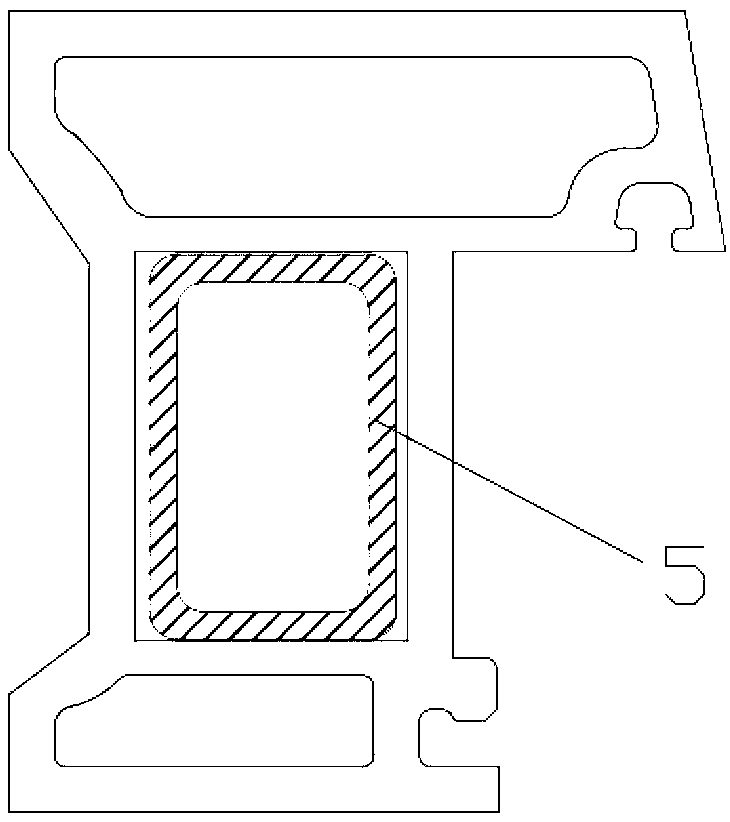

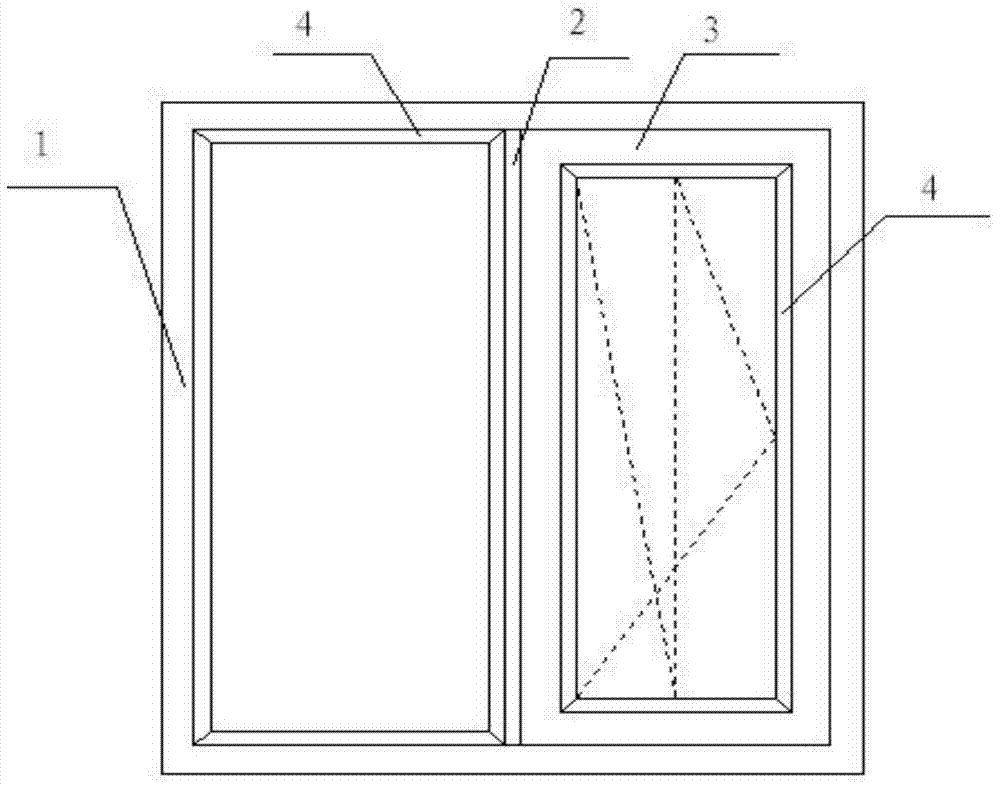

Wood-plastic glazed door and window and preparation method thereof

InactiveCN103225468AIncrease profitWith textureWindow/door framesWing framesEnvironmental resistanceSolid wood

The invention relates to a door and window and a preparation method thereof, in particular to a wood-plastic glazed door and window and a preparation method thereof, and aims to solve the problems that a conventional solid wood door and window has high probability of being rotted and cracked and is high in cost, an aluminium alloy door and window is high in energy consumption during production and has poor thermal insulation performance during use, and an aluminum wood and aluminum-plastic composite door and window is complicated in manufacturing technology. The wood-plastic glazed door and window consists of a hollow wood-plastic profile, glass, fittings and sealing strips. The preparation method comprises the steps of connecting and assembling, mounting the fittings, mounting the glass, the sealing strips and a batten profile and connecting a door and window frame and door and window slashes. The wood-plastic glazed door and window has the advantages of excellent thermal insulation performance, corrosion resistance, water resistance, attractiveness, durability, environmental friendliness, and recyclable material after being scrapped. The preparation method is used for preparing the wood-plastic glazed door and window.

Owner:NORTHEAST FORESTRY UNIVERSITY

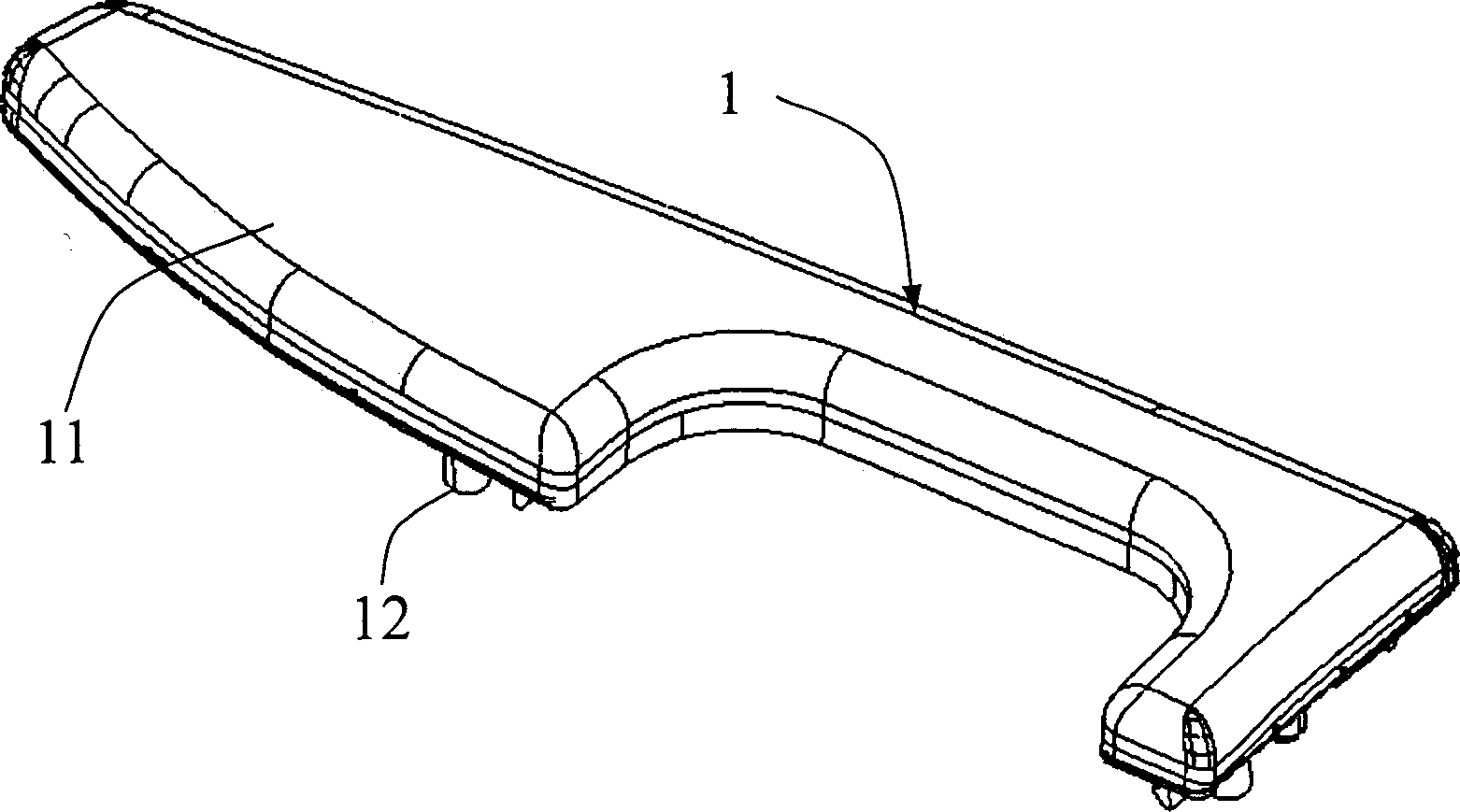

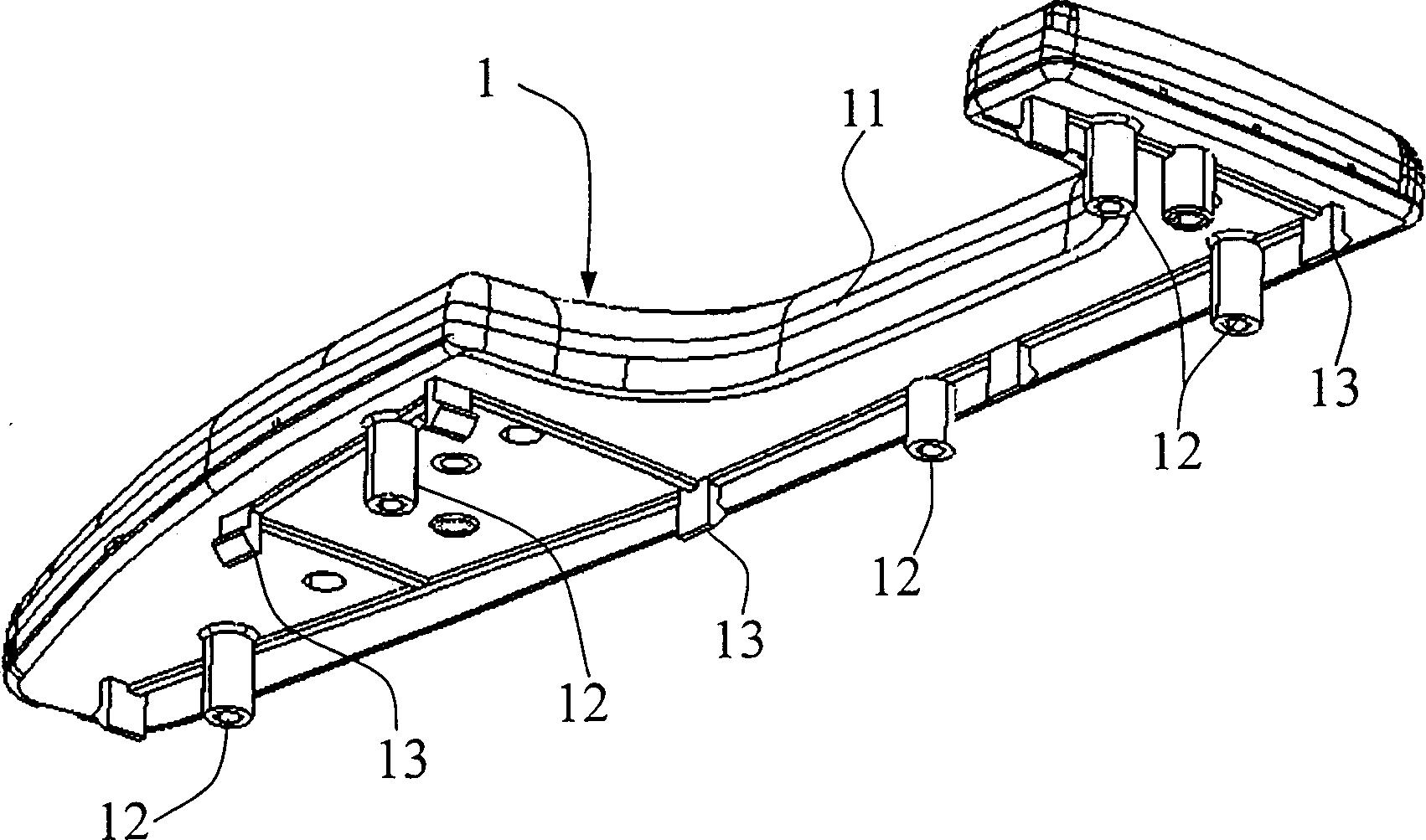

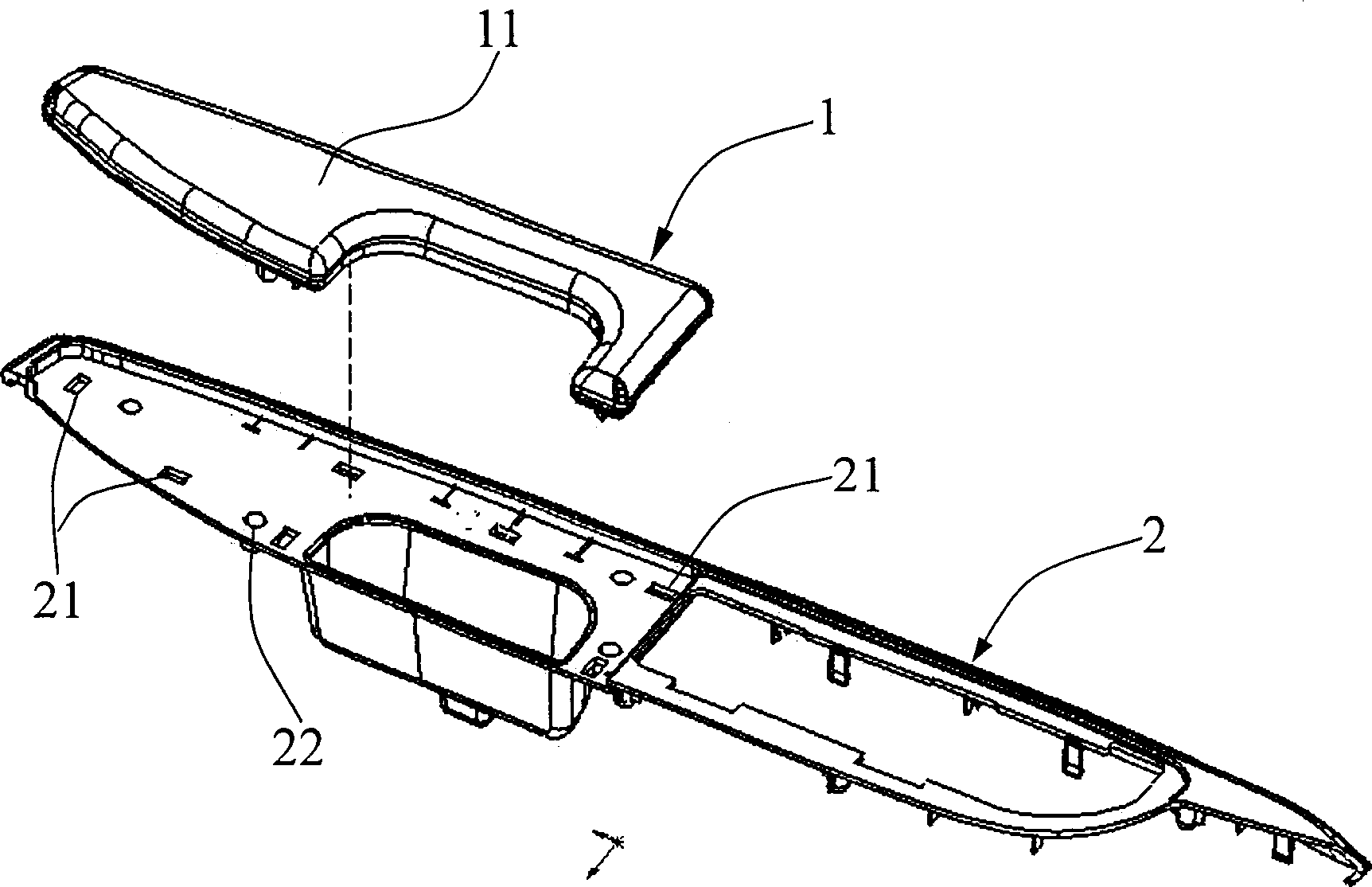

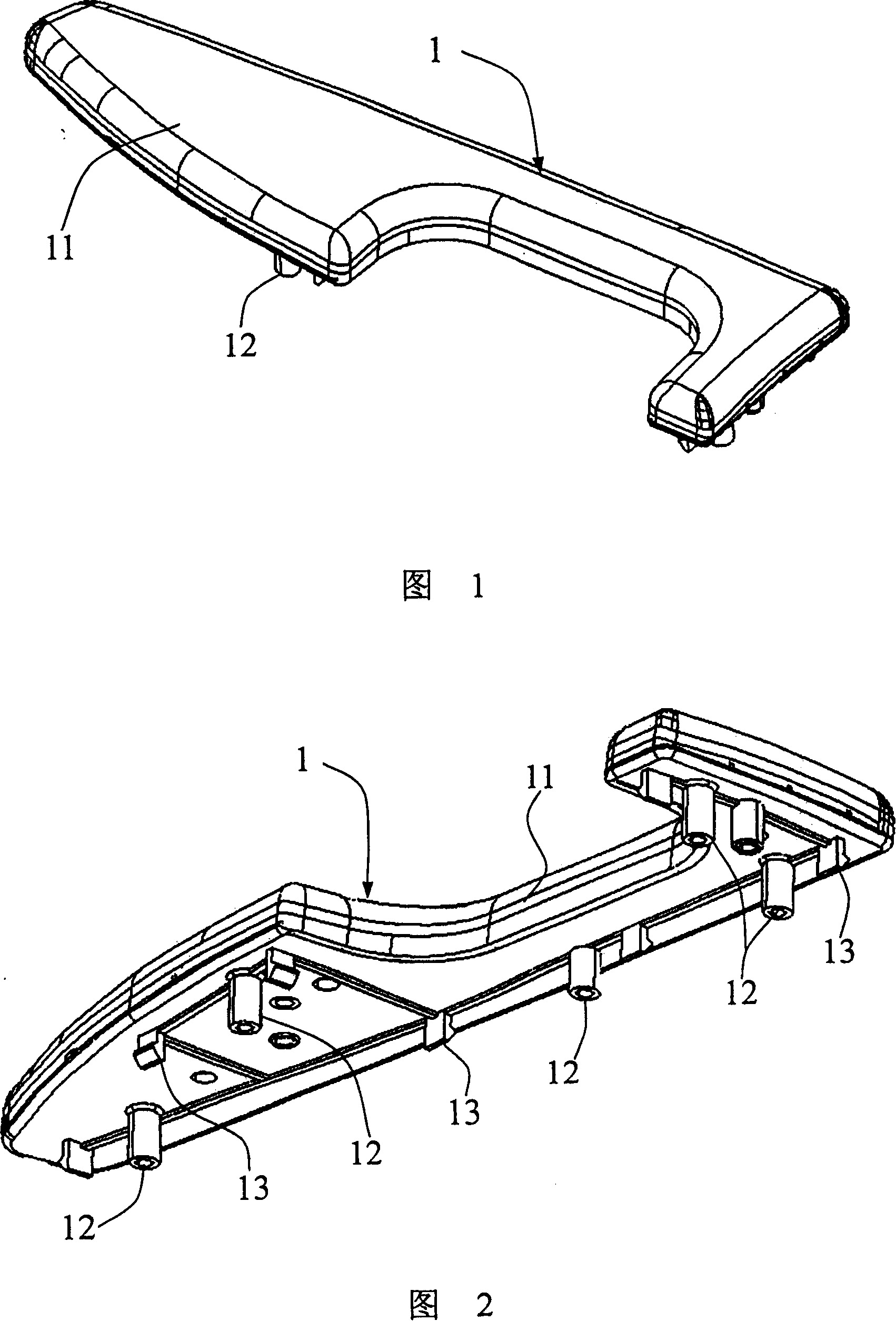

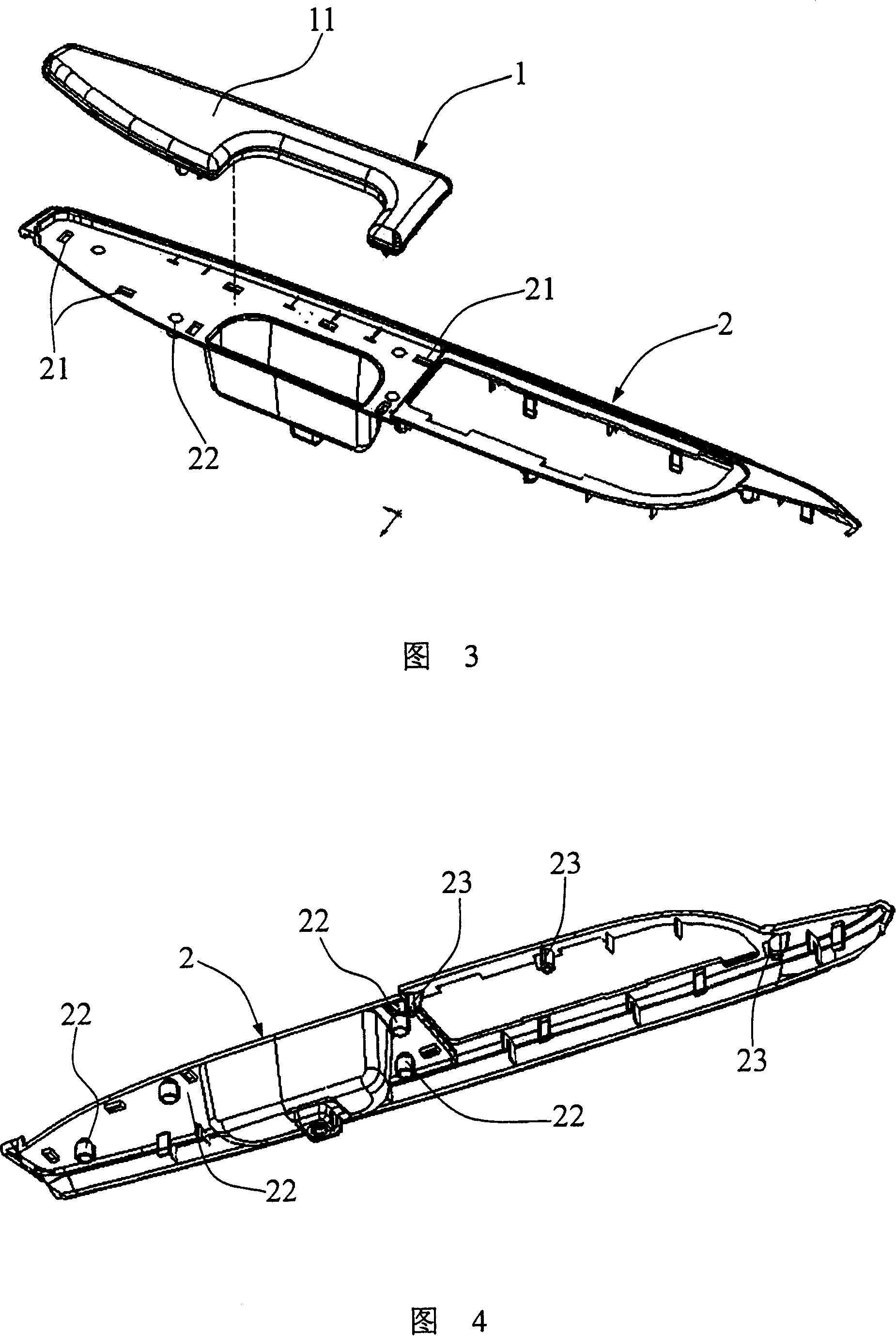

Automobile door plate assembling method with multiple inner decorations

The present invention provides a process of assembling automobile door plate with several inner decorations, including at one handle pad, one wood grain decoration board, one middle board, one upper cover and one lower board. The assembling process includes the following steps: 1. combining the handle pad and the wood grain decoration board integrally with elastic buckles and screws; 2. setting the combined handle pad and wood grain decoration board in the positioning part of the middle board for combining into one integral; 3. setting the upper cover, the lower board and the middle board successively inside the female mold for automobile door plate and connecting with the connecting pins; and 4. welding with a ultrasonic welder to form one integrated automobile door plate.

Owner:全兴工业股份有限公司

Preparation method of spinning hairpiece by human hair and protein acrylic fibre

InactiveCN101037813AWith textureAppearanceWigsConjugated cellulose/protein artificial filamentsMean diameterAcrylic fibre

The invention relates to a preparation method for hairpiece formed by human hair and protein acrylon. The method comprises the following steps: human hairs being crushed into human hair powder at mean diameter of 1-10 micron, wherein the maximum size is not more than 30 micron; the human hair powder uniform distributing in polyacrylonitrile fibre, wherein the content of human hair powder is 1-30%(wt%) and the content of polyacrylonitrile is 70-99%(wt%); using wet-process acrylon spinning technique to finally obtain the protein acrylon hairpiece. The said human hair is crushed, no need of chemical extraction. The operation is simple, the souce of raw materianl is wide and the cost is low. The protein acrylon hairpiece has features of satia plump texture, good hand feeling, reality, similar burning property to human hair.

Owner:DONGHUA UNIV

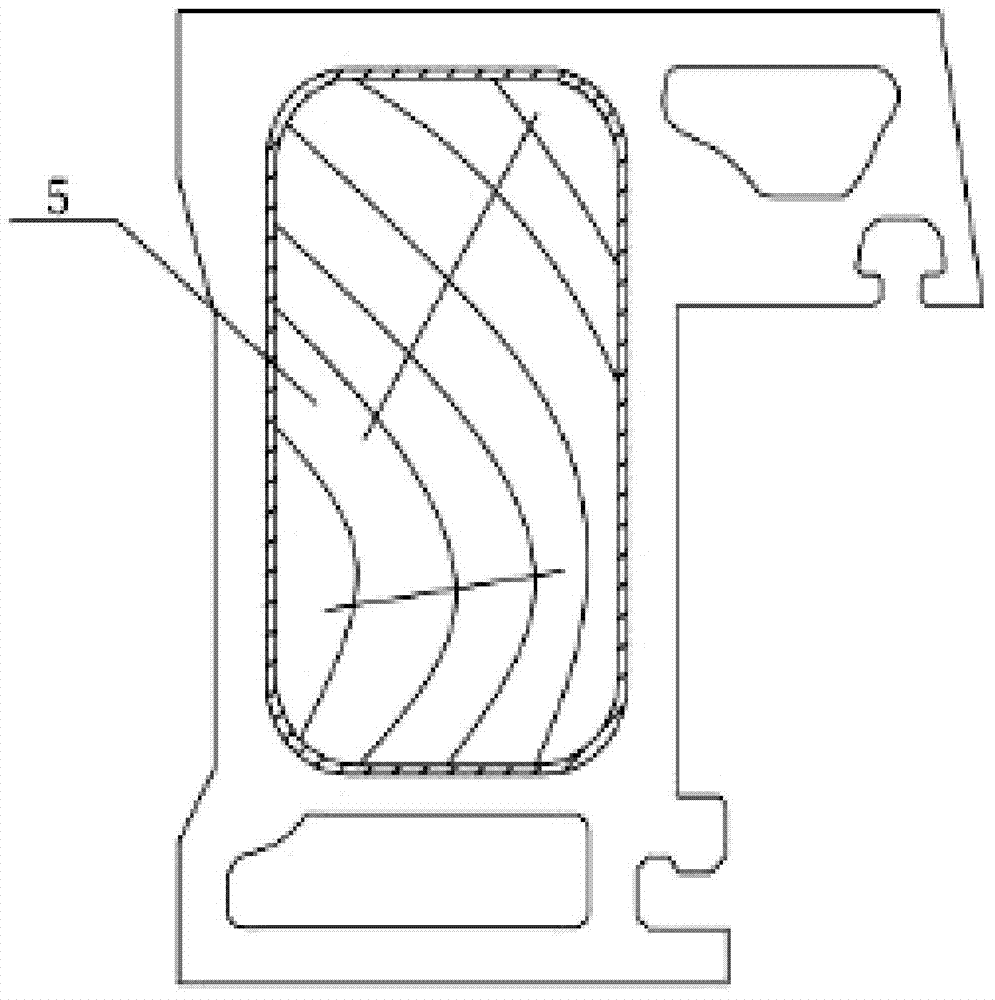

Synthetic-wood solid wood composite door and window and manufacturing method thereof

ActiveCN103498625AIncrease profitWith textureCorner/edge jointsWindow/door framesThermal insulationSolid wood

The invention relates to a door and window and a manufacturing method thereof, in particular to a synthetic-wood solid wood composite door and window and a manufacturing method thereof. The synthetic-wood solid wood composite door and window solves the problems that an existing solid wood door and window is prone to decaying and cracking and high in cost, an aluminum-alloy door and window is large in production energy consumption and poor in thermal insulation in a using process, an aluminum-wood and aluminum-plastic composite door and window is complex in production process, a plastic door and window is prone to deforming and low in quality, and an existing synthetic-wood door and window is complex in process and high in cost. The synthetic-wood solid wood composite door and window is composed of a synthetic-wood solid wood composite section bar, glass, a sealing stripe and a pressing stripe. The manufacturing method comprises the steps of extruding, forming and preparing the synthetic-wood solid wood composite section bar and a synthetic-wood composite pressing stripe section bar, connecting and assembling the section bars, installing accessories, installing the glass, the sealing stripe and the pressing stripe, and connecting a door and window frame and a door and window sash. The synthetic-wood solid wood composite door and window is good in thermal insulation, anticorrosion, mothproof, attractive, durable, green, capable of achieving environmental friendliness and capable of being recycled after being abandoned. The synthetic-wood solid wood composite door and window and the manufacturing method of the synthetic-wood solid wood composite door and window are applied to the field of synthetic-wood solid wood composite doors and windows.

Owner:王清文

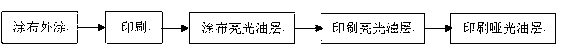

Method of printing high-resistance glossy-matte metal

ActiveCN103317870AThree-dimensionalWith textureOther printing apparatusPrinting after-treatmentHigh resistanceTextile

The invention relates to a method of printing high-resistance glossy-matte metal. The method includes: coating the outer surface of metal, printing, and coating a glossy oil layer. The method is characterized in that a step of printing the glossy oil layer and a step of printing a matte oil layer are used after the step of coating the glossy oil layer, printing plates which are the same need to be independently made for the step of printing the glossy oil layer and the step of printing the matte oil layer, glossy oil and matte oil are transferred to the surface of a product through rubber cloth, the glossy oil and the matte oil are respectively independently solidified and dried by heating at 140-160 DEG C, glossiness of the glossy surface of the finished product is partially larger than or equal to 80 DEG, and glossiness of the matte surface of the finished product is smaller than or equal to 40 DEG. The method has the advantages that metal print with the whole surface which is both glossy and matte can be made by the method and the printed surface is well adhesive, scratch-resistant, good in printing stereoscopic impression and good in texture.

Owner:HANGZHOU CPMC +1

Method for preparing pure mudar-floss yarns

The invention discloses a method for preparing pure mudar-floss yarns, which comprises the steps of performing cleaning, carding, first drawing and second drawing on mudar-floss fibers, and then carrying out ring spinning, open-end spinning, compact spinning or vortex spinning to spin yarns for textile use. The method is characterized in that the cleaned mudar-floss fibers are tanned with a chemical additive, and then, through carding, first-drawing and second drawing, the mudar-floss fibers are twisted to form the yarns for textile use of the pure mudar-floss fibers. According to the invention, the chemical additive is adopted for tan processing to eliminate the surface flatness of the mudar-floss fibers, so that the friction factor of the surfaces of single fibers is increased, and cohesive force between the mudar-floss fibers and between the mudar-floss fibers and other fibers is enhanced. Therefore, the pure yarn of the mudar-floss fibers or 5% to 95% of mudar-floss fibers can be mixed with cotton, wool, silk, flax, chemical fibers and synthetic fibers so as to spin cloth having the texture of silk, the permeability of pure cotton and comfortable feeling of pashm, and the cloth is novel and environment-friendly fiber textile material and finish products.

Owner:黄惠民 +1

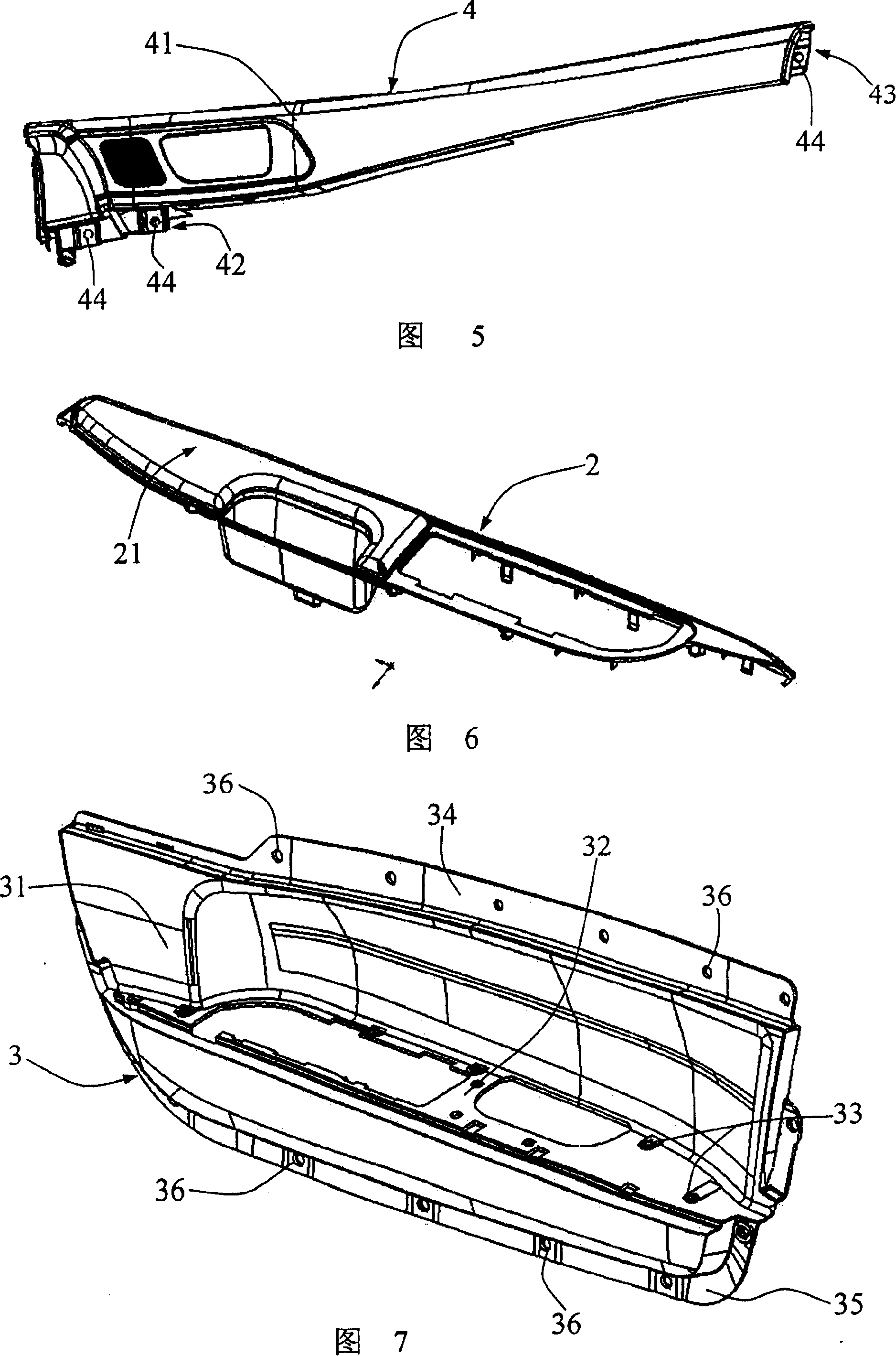

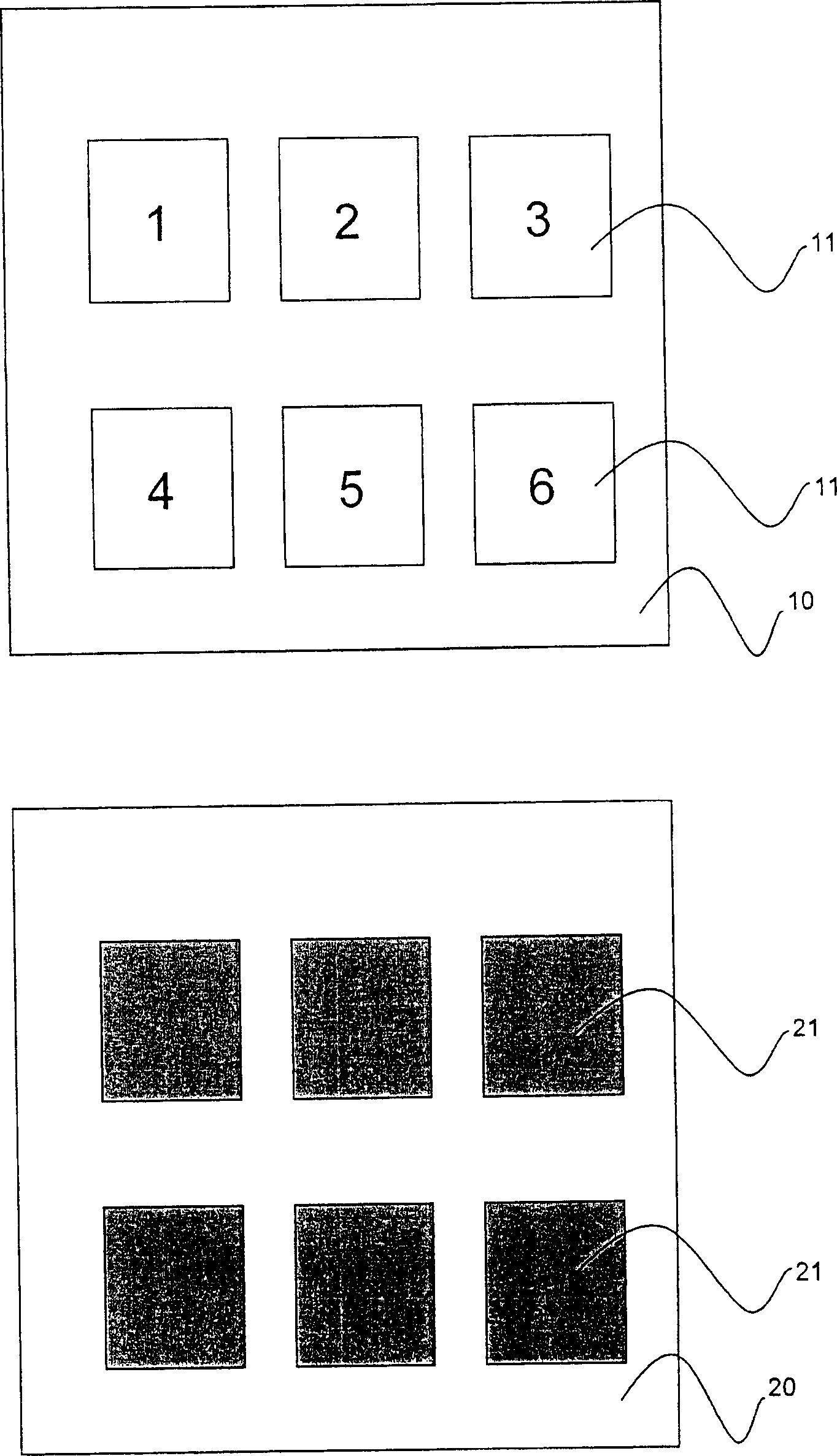

Surface texture structure and a minimized and localized lattice constant and thermal expansion factor mismatching method

This invention refers to a method for solving the problem of mismatching of lattice constant and heat expansion coefficient, which contains 1, preparing superficial makings structure on growth substrate for growing high quality epitaxial layer, 2, preparing superficial makings on said epitaxial layer for growing high quality second epitaxial layer, 3, a method for localizing and minimizing the bad effect resulting from mismatching of lattice constant and heat expansion coefficient, the process of preparing superficial makings can be repeated many times, the semiconductor LED with multi-epitaxial layer can emit white or preset color composite light.

Owner:金芃

Compression molding fibre-reinforced straw plastic combined cabinet slab and preparation method thereof

The invention discloses a compression molding fibre-reinforced straw plastic combined cabinet slab which is prepared from the following raw materials according to parts by weight: 0.2-0.6 part of modified crop straw fibre or straw fibre wood powder thereof, 0.1-0.2 part of PET or nylon waste silk, 0.05-0.2 part of melamine, 0.05-0.2 part of modified talcum powder, 0.01-0.05 part of chemical assistant and 0.3-0.6 part of polyolefin thermoplastic resin. The invention also discloses a preparation method thereof. The cabinet slab of the invention is formaldehyde-free environment-protection material and has wood texture and handling characteristics, and the machinery mechanics strength thereof exceeds that of good-quality solid-wood slabs; and in addition, the cabinet slab does not adsorb water and has the functions of low coefficient of thermal expansion, moisture prevention, mildew prevention, aging prevention, combustion prevention, reuse and the like and is an ideal cabinet slab wood replacing material.

Owner:绍兴一普塑业有限公司

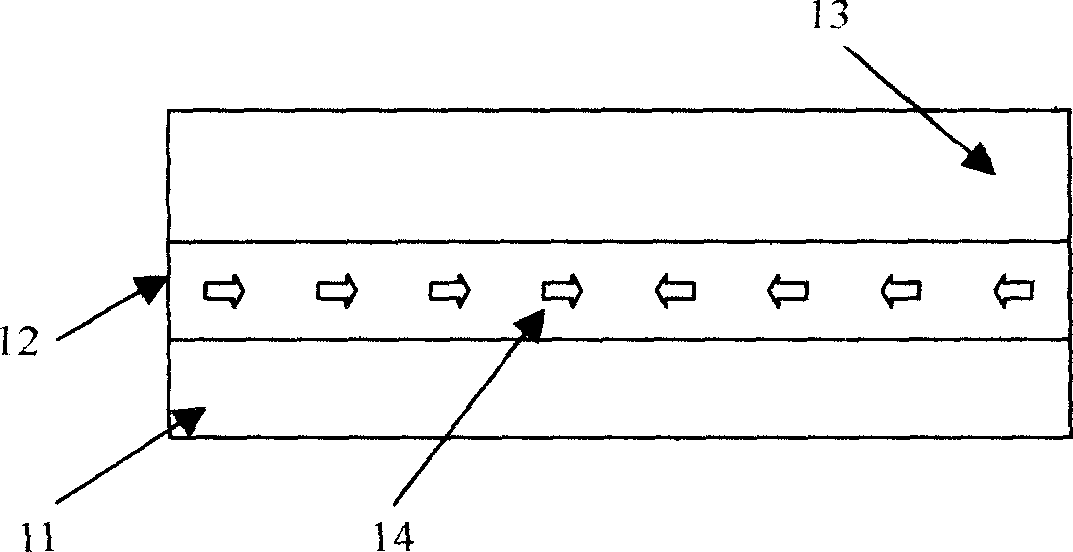

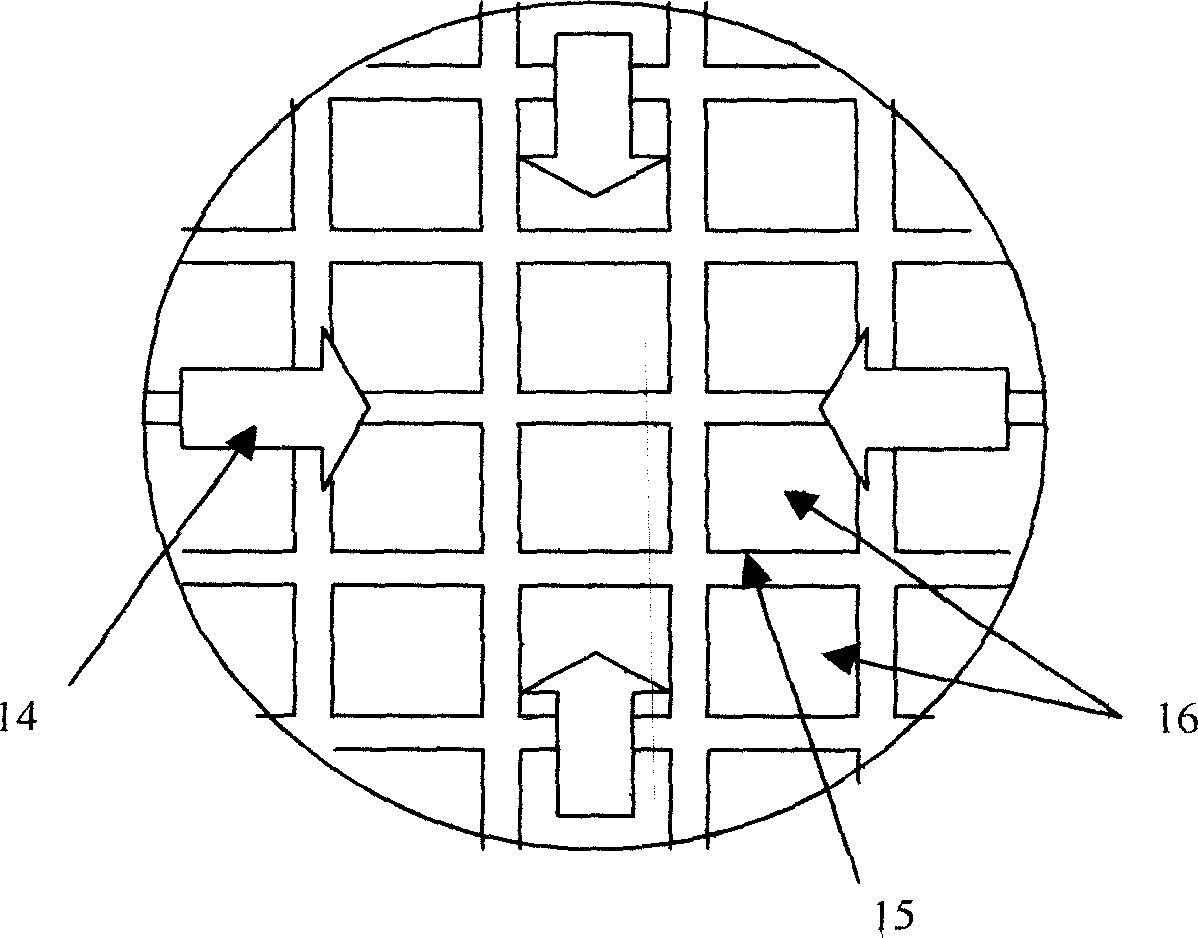

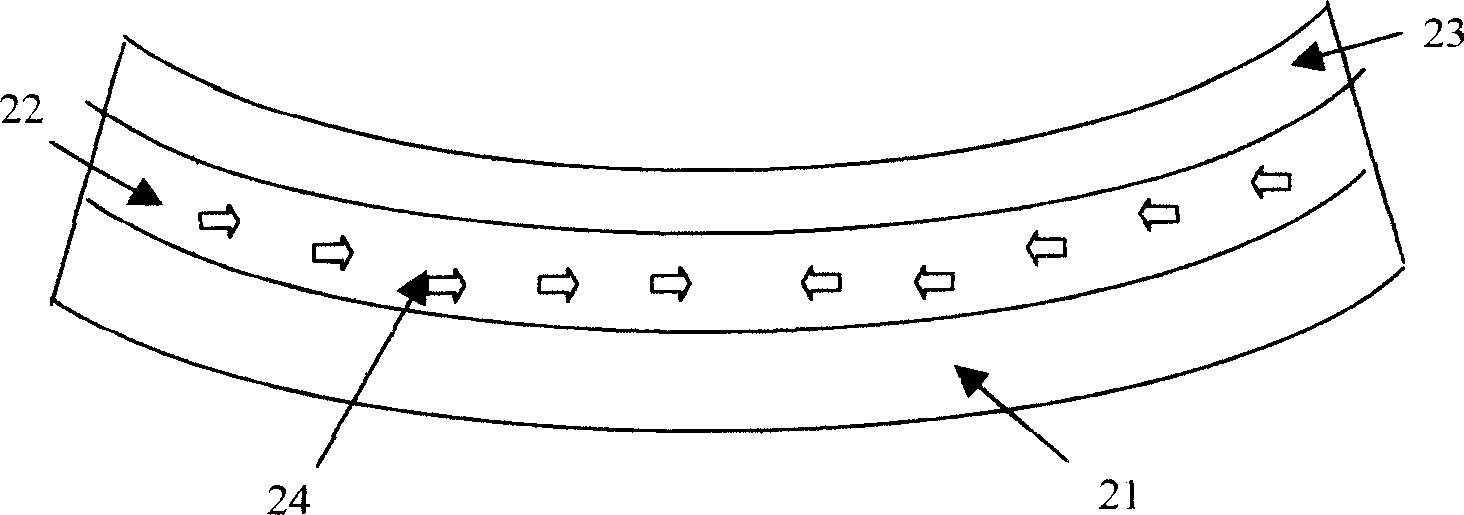

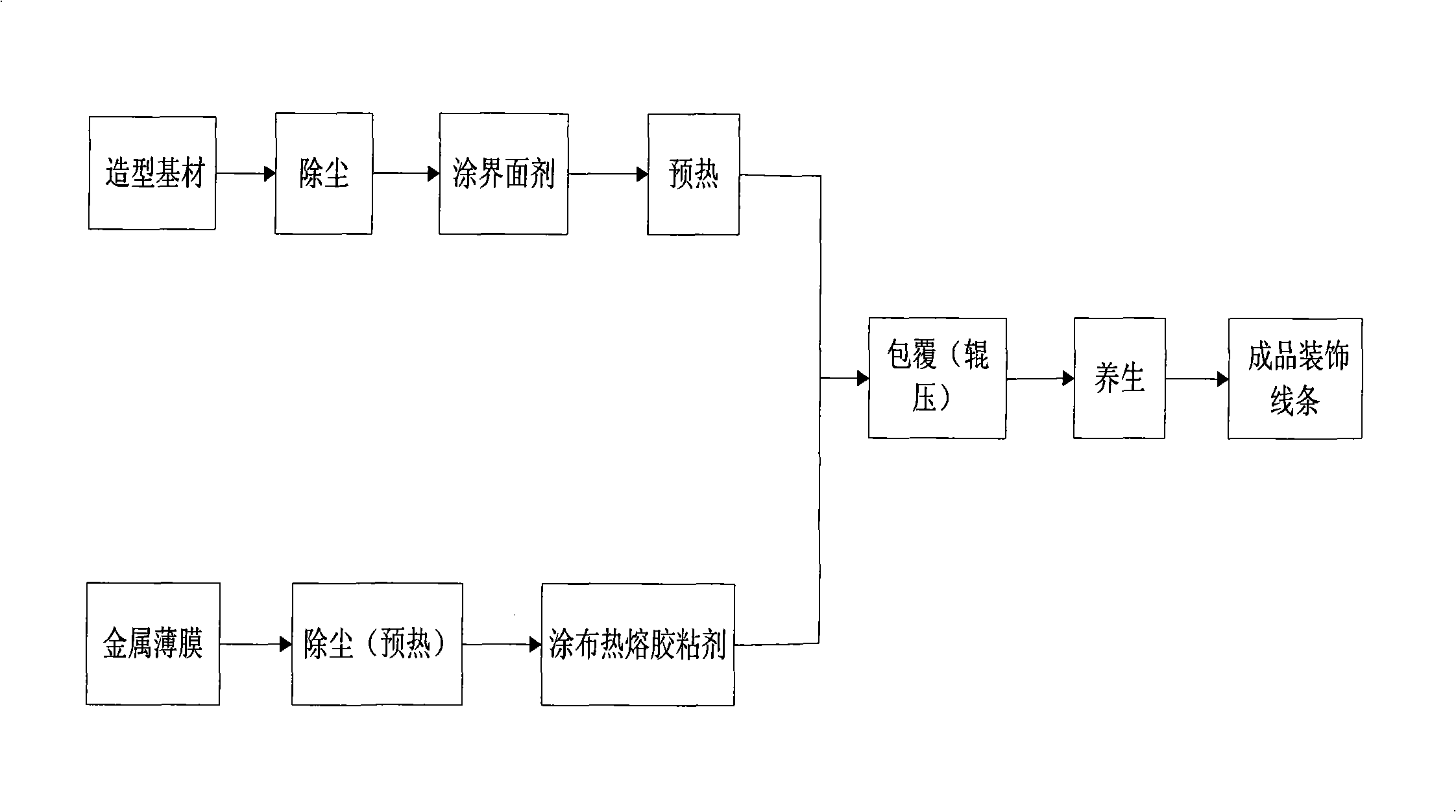

Decorative line covered by metallic film and producing method thereof

InactiveCN101352992AHigh bonding strengthImprove anti-aging propertiesPolyureas/polyurethane adhesivesAdhesive processes with surface pretreatmentWeather resistancePliability

The invention provides a decorative line which coats metal films and a manufacturing method thereof and includes the following steps: a modeling substrate is preheated after being decontaminated and dusted and being coated with a surface affinity agent; a flexible metal film is coated with a hot-melt adhesive after being dusted and preheated; the metal film coated with the adhesive is rolled and coated with a modeling roll wheel on the surface of the modeling substrate on one surface of the surface affinity agent and the health is preserved. The decorative line made with the method is characterized by metal texture, high bonding strength, hydrolysis resistance, non-reversibility, weather resistance, and the like, and improves the texture grades of the decorative line.

Owner:北京市森诺家具材料有限公司

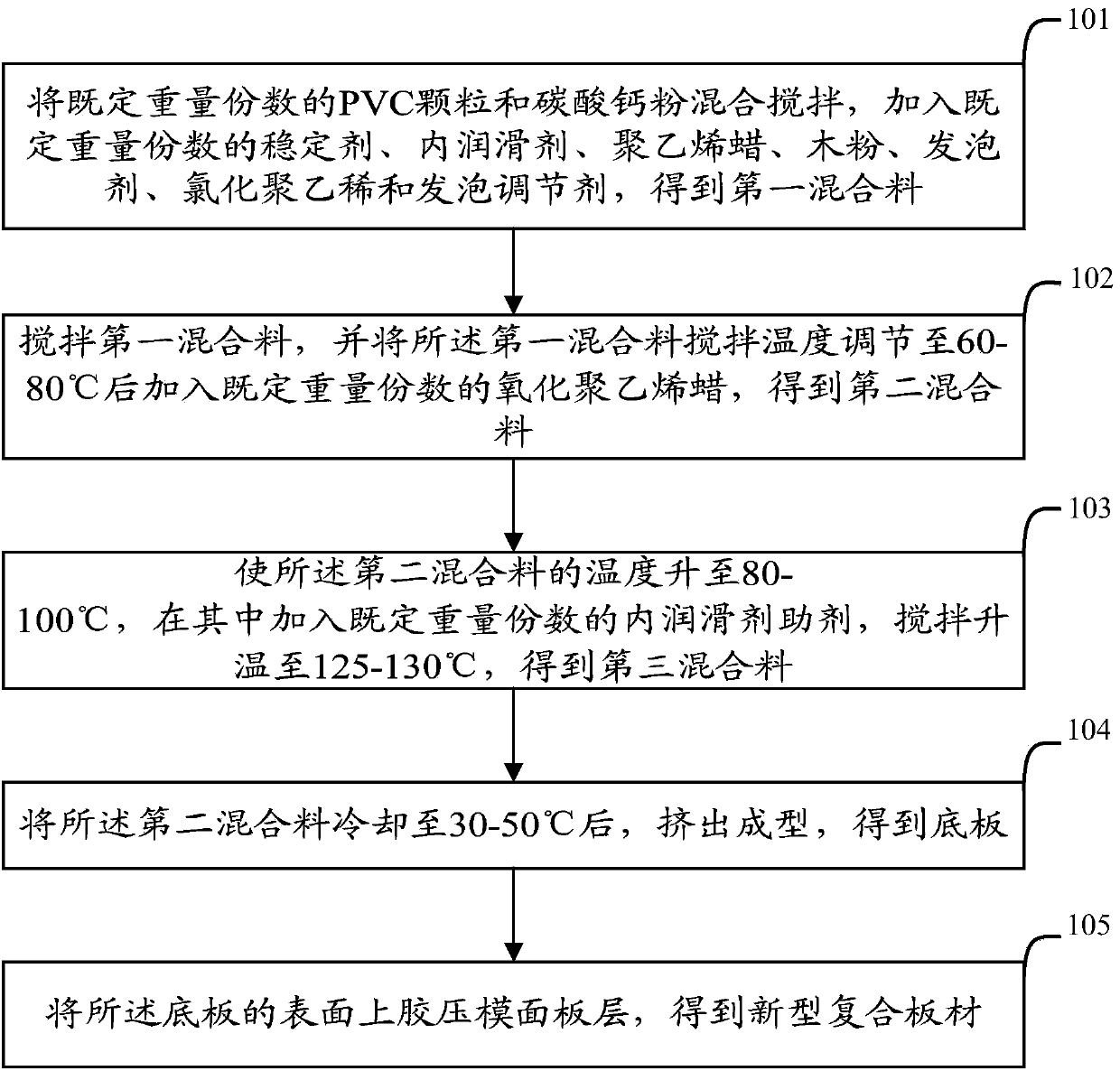

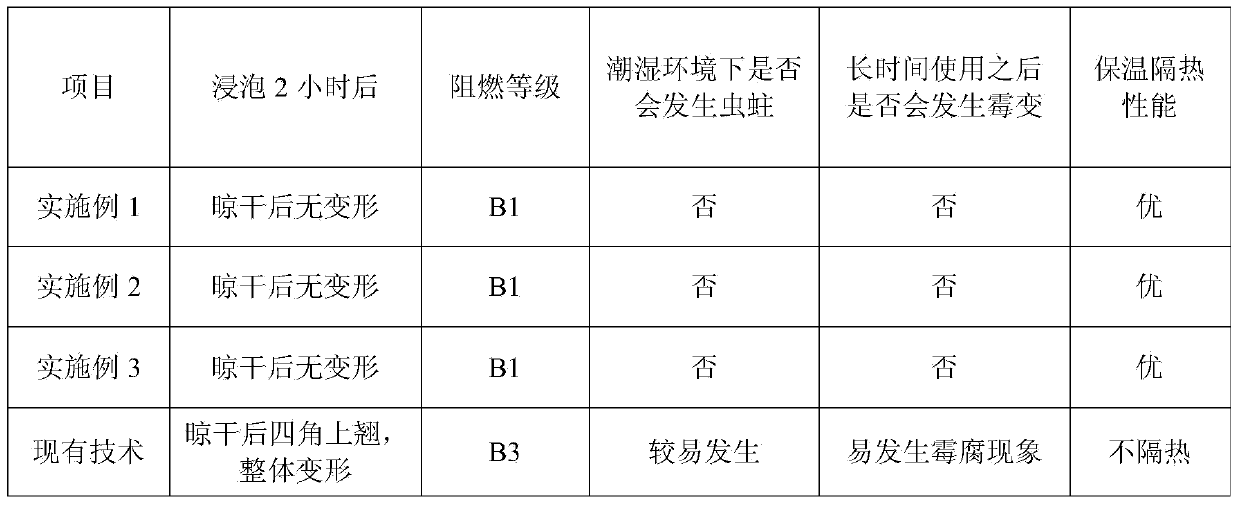

Novel composite board and preparation method thereof

ActiveCN104175660ASave resourcesRaw material environmental protectionSynthetic resin layered productsWood layered productsWaxFoaming agent

The invention relates to the field of building boards and in particular relates to a novel composite board and a preparation method thereof. The novel composite board comprises a bottom board and a panel layer which is stuck on the bottom board, wherein the bottom board comprises the following raw materials in parts by weight: 90-110 parts of PVC particles, 40-60 parts of calcium carbonate powder, 3-6 parts of a stabilizer, 1.0-1.4 parts of a foaming agent, 6-8 parts of a foaming regulator, 0.3-0.5 part of polyethylene wax, 0.3-0.4 part of internal lubricant, 0.2-0.4 part of oxidized polyethylene wax, 4-6 parts of chlorinated polyethylene, 0.5-1.5 parts of an internal lubricant additive and 9-11 parts of wood powder. The novel composite board has the good waterproof and damp-proof effects and solves the problem that common boards in the prior art are soaked by water so as to seriously deform. The novel composite board also has the recycling characteristic and solves the technical problem that a large amount of wood needs to be consumed in wooded boards in the prior art.

Owner:朱青海

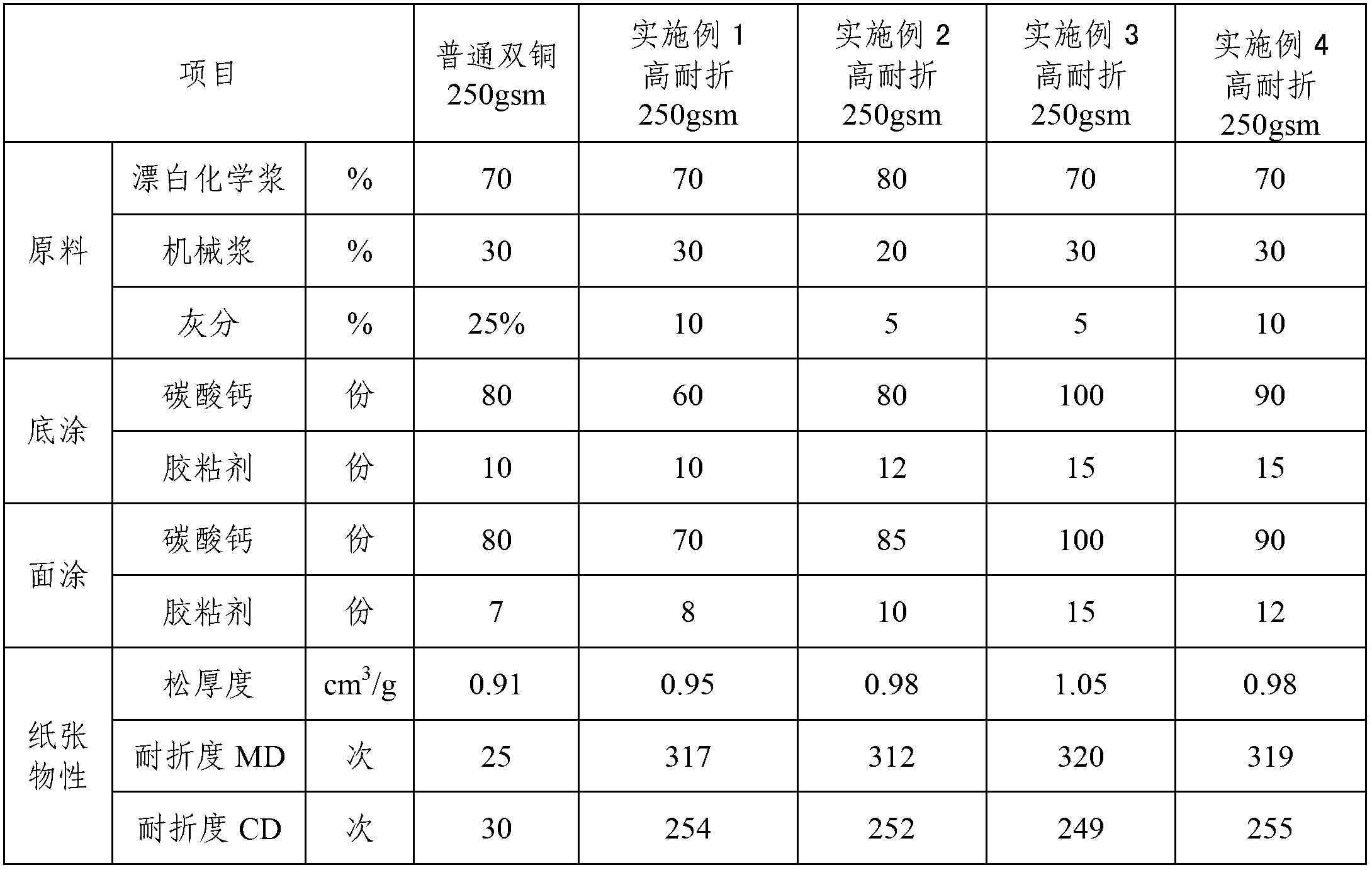

Copper plate card and preparation method thereof

ActiveCN102704321AQuality assuranceWith textureCoatings with pigmentsWater-repelling agents additionNatural resourceFolding endurance

The invention provides a copper plate card, which comprises base paper, a ground coating and a surface coating, wherein the ground coating and the surface coating are coated on both sides of base paper in sequence; the preparation raw material for base paper comprises chemical pulp, mechanical pulp, wet-end chemicals, an inner sizing agent and a surface sizing agent, and the chemical pulp accounts for 20 to 80 parts by weight, and the mechanical pulp accounts for 10 to 30 parts by weight; the ground coating comprises pigment accounting for 60 to 100 parts by weight and an adhesive accounting for 10 to 17 parts by weight; and the surface coating comprises pigment accounting for 70 to 100 parts by weight and an adhesive accounting for 8 to 15 parts by weight. The invention also provides a preparation method of the copper plate card. The copper plate card and the preparation method select and use the mechanical pulp in a suitable proportion, reduce the utilization of the chemical pulp, save natural resources such as forest, water and the like, are beneficial to environmental protection, and ensure the quality; in addition, the bulk of the energy-saving environment-friendly copper plate card with high hard fold quality is controlled within 0.95 to 1.05cm<3> / g, the folding endurance of obtained paper is good, the coating quantity on the both sides are concordant approximately, the remaining effect of printing ink on the paper surface is excellent, and the color of ink is bright.

Owner:HAINAN JINHAI PULP & PAPER

Aqueous paint for floor and woodenware

InactiveCN1837308AHigh hardnessGood flexibilityPolyurea/polyurethane coatingsEmulsion paintsWater basedSolid wood

The invention discloses a water-based floor and woodware paint, wherein the water-based paint is stired by water-based polyurethane, nanometer strengthening agent, water-based oil and water-based adjuvant according to certain dispense, which possesses paint film property, high hardness, good abrasive-proof property and easy construction. The invention can replace solvent-pattern paint with lower price than import paint, which can satisfies kinds of places and environments.

Owner:周正根

Shoes with diamante heels

InactiveCN103734992ANon-slip withWith textureSolesShoemaking devicesMechanical engineeringIndustrial engineering

The invention discloses shoes with diamante heels. The shoes comprise shoe uppers, the heels, shoe soles and slugged bottoms. The shoes with the diamante heels are manufactured by adopting the real-leather covered heel and diamond embedding technology of the heels, the design of the slugged bottoms and the antiskid technology of the shoe soles, and the shoes have the functions of preventing skidding, being textured, attractive and comfortable and the like.

Owner:QINGDAO HENGDA CO LTD +2

Automobile door plate assembling method with multiple inner decorations

The present invention provides a process of assembling automobile door plate with several inner decorations, including at one handle pad, one wood grain decoration board, one middle board, one upper cover and one lower board. The assembling process includes the following steps: 1. combining the handle pad and the wood grain decoration board integrally with elastic buckles and screws; 2. setting the combined handle pad and wood grain decoration board in the positioning part of the middle board for combining into one integral; 3. setting the upper cover, the lower board and the middle board successively inside the female mold for automobile door plate and connecting with the connecting pins; and 4. welding with a ultrasonic welder to form one integrated automobile door plate.

Owner:全兴工业股份有限公司

Metal coating panel with touch control induction isolation zone and its producing method

ActiveCN1900898AWith textureImprove qualityInput/output processes for data processingMetal coatingCapacitance

The metal coating panel with touch induction isolating area is set over one printed circuit board with capacitance touch control switches. It has at least one isolating unit without metal coating and for separating the below capacitance touch control switch from other touch control switches. When some block of the metal coating panel is touched by the finger of the user, the corresponding capacitance touch control switch is induced to start while the other capacitance touch control switches are not affected. The metal coating panel may be used through matching with capacitance touch control switches, and this can raise the quality of panel.

Owner:MICRO-STAR INTERNATIONAL

Environment-friendly cork compound material, adhesion agent and preparation method for products thereof

InactiveCN103072177AAntioxidantUsableWood working apparatusDomestic articlesPlant fibrePulp and paper industry

The invention discloses an environment-friendly cork compound material, an adhesion agent and a preparation method for products thereof. After the adhesion agent for the environment-friendly cork compound material is prepared, the adhesion agent is applied to the cork compound material and the products thereof. The environment-friendly cork compound material comprises a cork waste material, a natural plant fiber, the adhesion agent and an essence, wherein the cork waste material is a red wine cork recycling material. The preparation method for the products of the environment-friendly cork compound material comprises the following steps: a, crushing a red wine cork; b, mixing all the raw materials of the compound material; c, split-charging the fully mixed raw materials; and d, completely pouring the mixed raw materials in an utensil into a cavity of a mould for the required products, and hotly pressing and shaping. The products made of the cork compound material are environment-friendly and non-toxic, has the effects of antibiosis, mildew resistance, anti-oxidation, and the like, and meanwhile has an excellent mechanical property.

Owner:杨鸿雨 +1

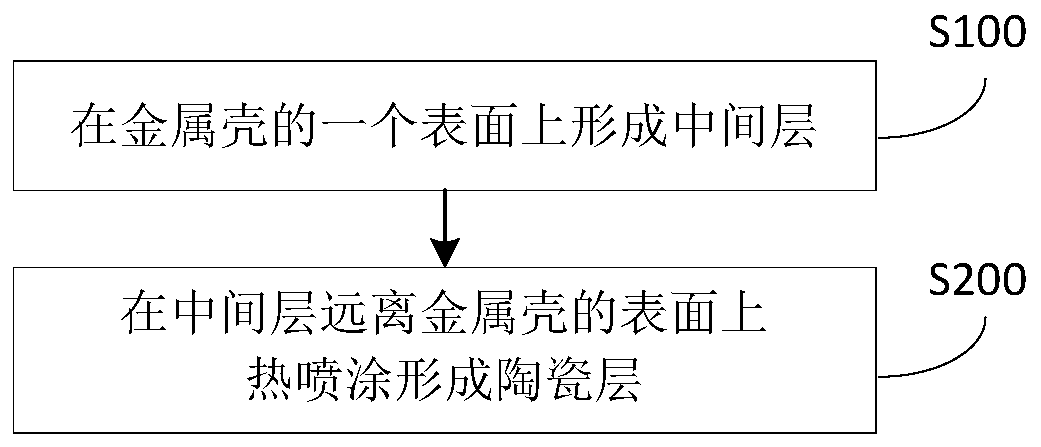

Electronic equipment shell, manufacturing method thereof and electronic equipment

The invention provides an electronic equipment shell, a manufacturing method thereof and electronic equipment. The electronic equipment shell comprises a metal layer, a middle layer and a ceramic layer, wherein the middle layer is arranged on one surface of the metal layer and is formed by a metal alloy; and the ceramic layer is arranged on the surface, far away from the metal layer, of the middlelayer. According to the electronic equipment shell, the middle layer of the metal alloy is additionally arranged between the metal layer and the ceramic layer, so that the bonding force between the metal layer and the ceramic layer can be effectively increased, the metal layer has the appearance, the texture, the high hardness and the wear resistance of ceramic, and meanwhile, the electronic equipment shell has higher anti-falling performance.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

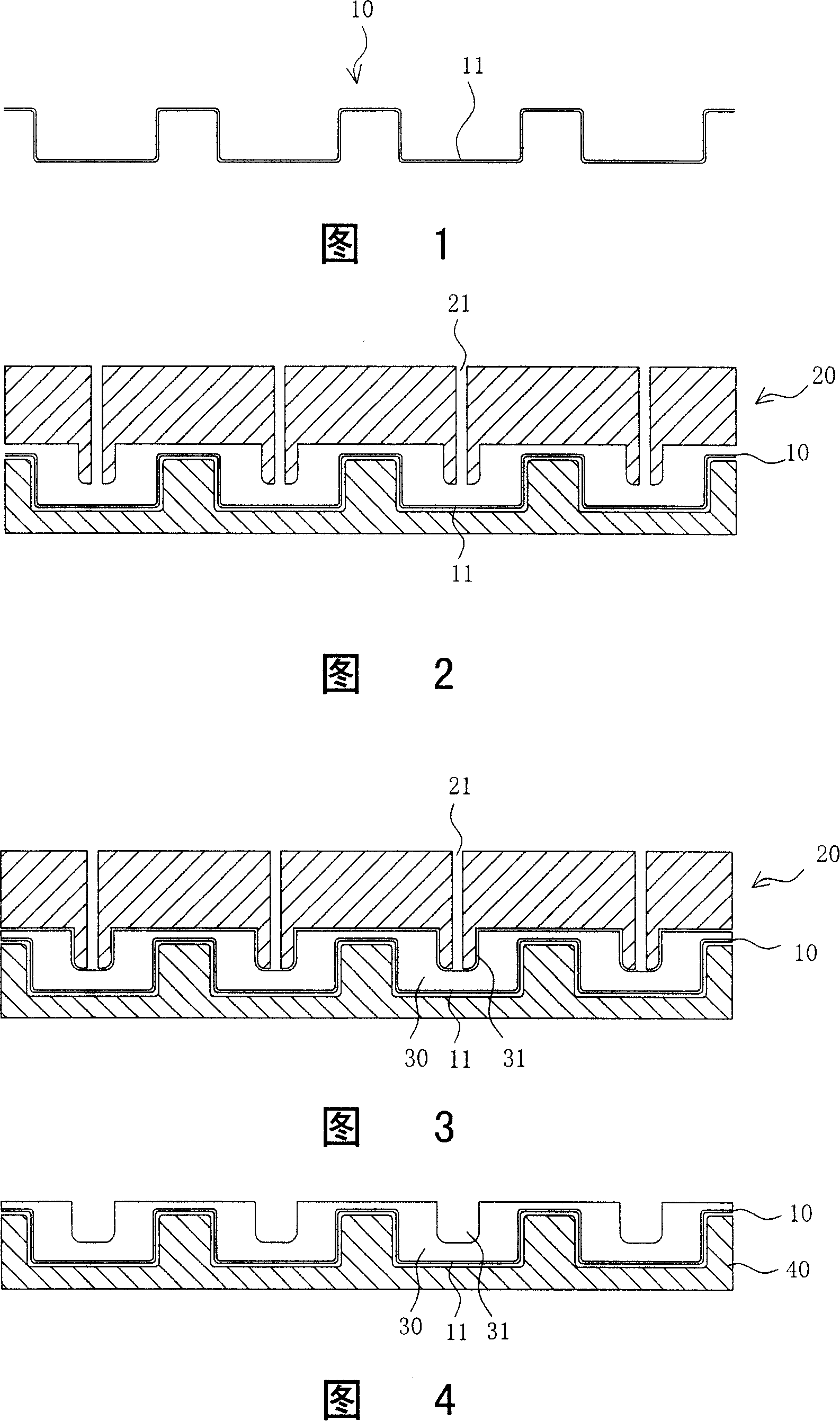

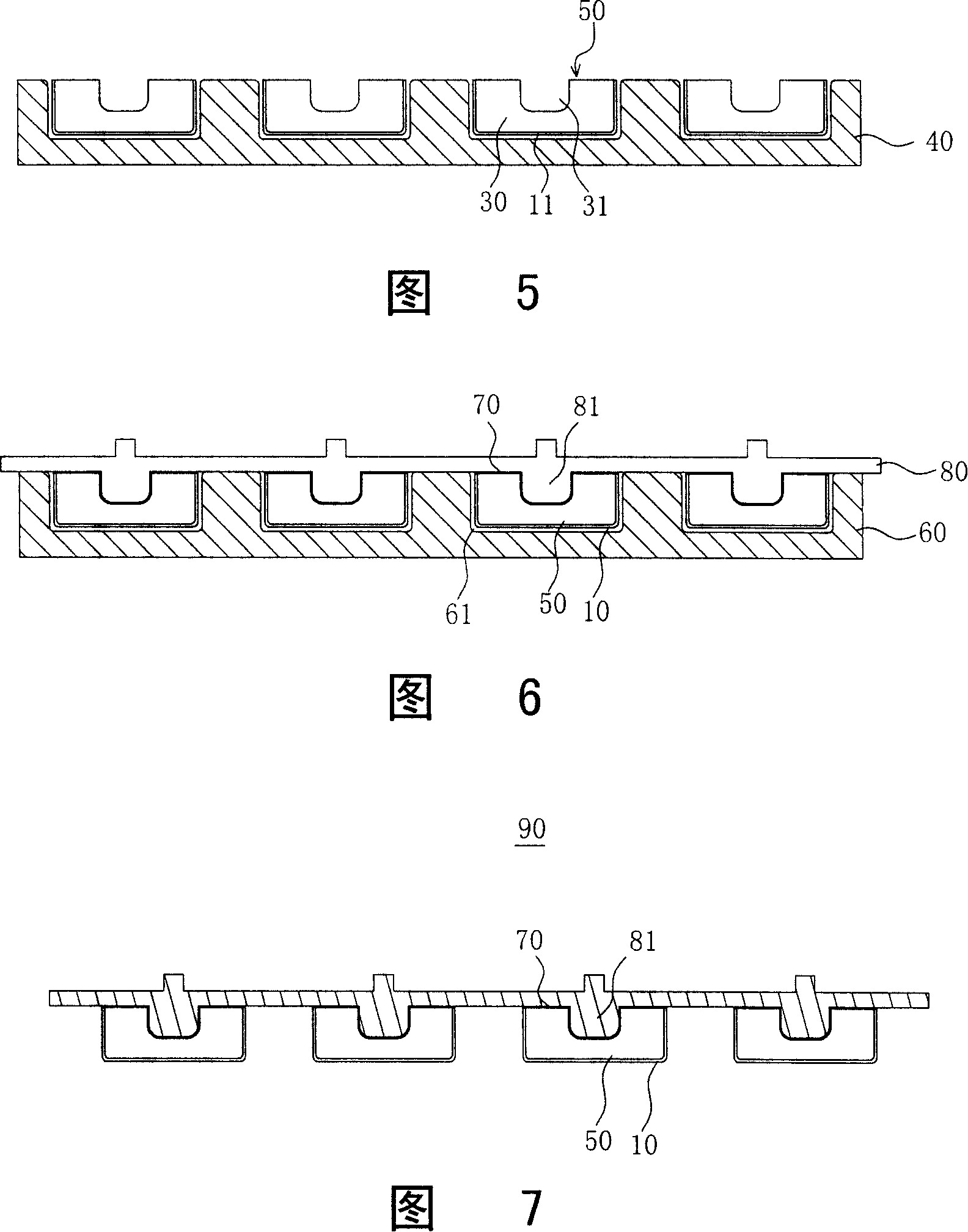

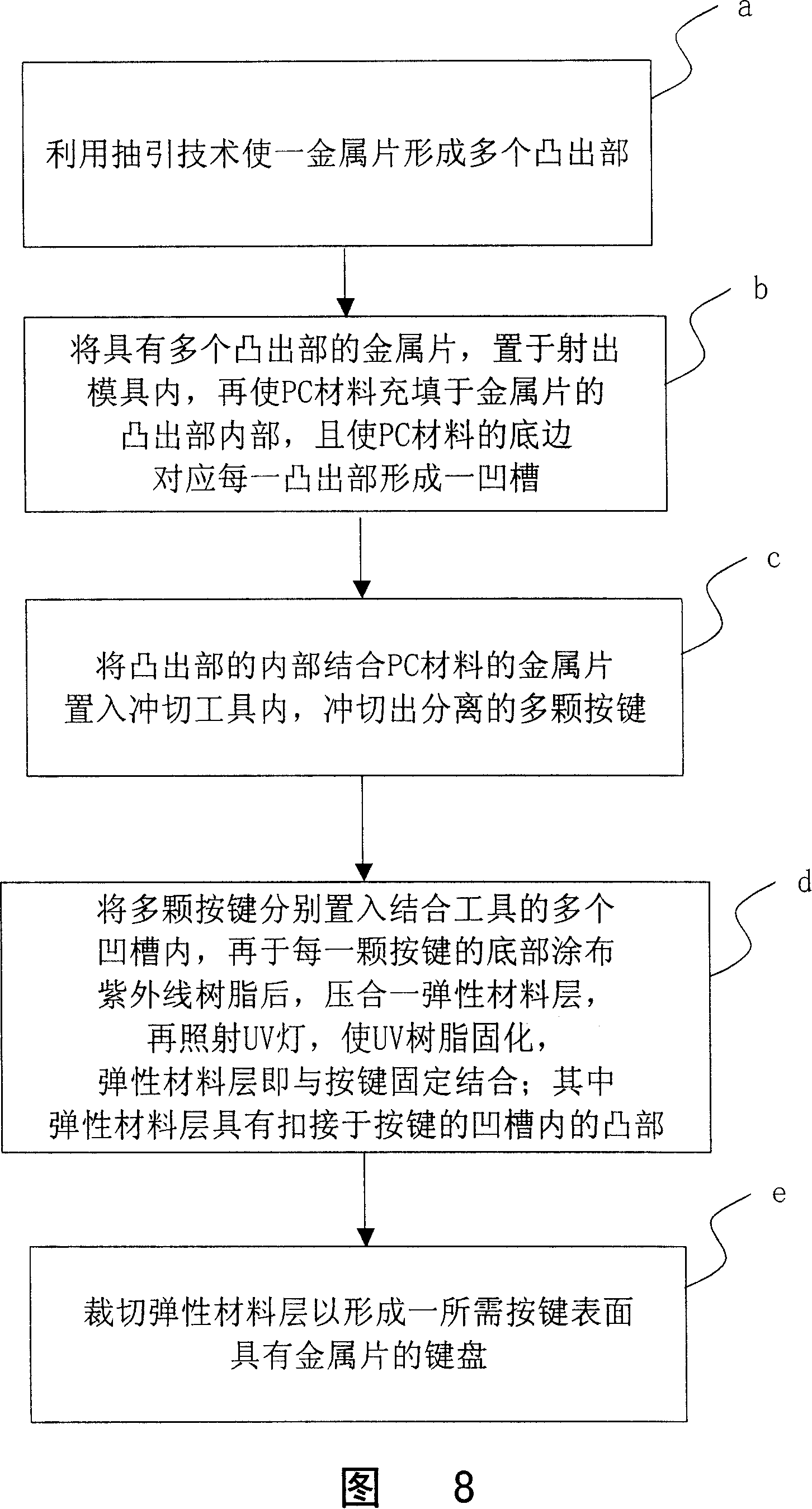

Method for making keyboard with metal leaf mould ejection push-button and keyboard thereof

The present invention discloses a method of making a keyboard by a key-press emitted from the internal mould of a sheet metal and the keyboard. The keyboard consists of a drawing moulding sheet metal, a key-press which is made by the emitting technology and the surface thereof is provided with a sheet metal and an elastic material layer which is combined with the hemline of the key-press groove; the surface of the keyboard has a metallic layer. The keyboard is a metallic keyboard with high texture which is capable of satisfying the requirement of the customer.

Owner:WISTRON CORP

Ceramic plate with starlight effect and preparation method thereof

The invention discloses a ceramic plate with a starlight effect and a preparation method thereof. The ceramic tile comprises a blank layer and a decorative layer located on the surface of the blank layer, and the decorative layer comprises a covering layer, a basic colored layer and a surface soft light colored layer which are sequentially arranged from bottom to top. Both the basic colored layerand the surface soft light colored layer comprise ceramic pigment which is silver gray after being fired; the covering layer, the basic colored layer and the surface soft light colored layer are all formed by firing glaze, and glaze raw materials of the surface soft light colored layer comprise starlight dry particles and ignition loss dry particles; the surface soft light colored layer is provided with concave holes with different sizes, the concave holes are formed by burning loss dry particles, and the burning loss dry particles are composed of 10-mesh dry particles, 20-mesh dry particles,60-mesh dry particles and 100-mesh dry particles. The plate has a soft light effect with starlight, is glittering but not dazzling, shows an inverted image effect in combination with the light reflection effect of the small pits, and overcomes the defect of dark surface color.

Owner:FOSHAN PINWEIXIAN CERAMICS CO LTD

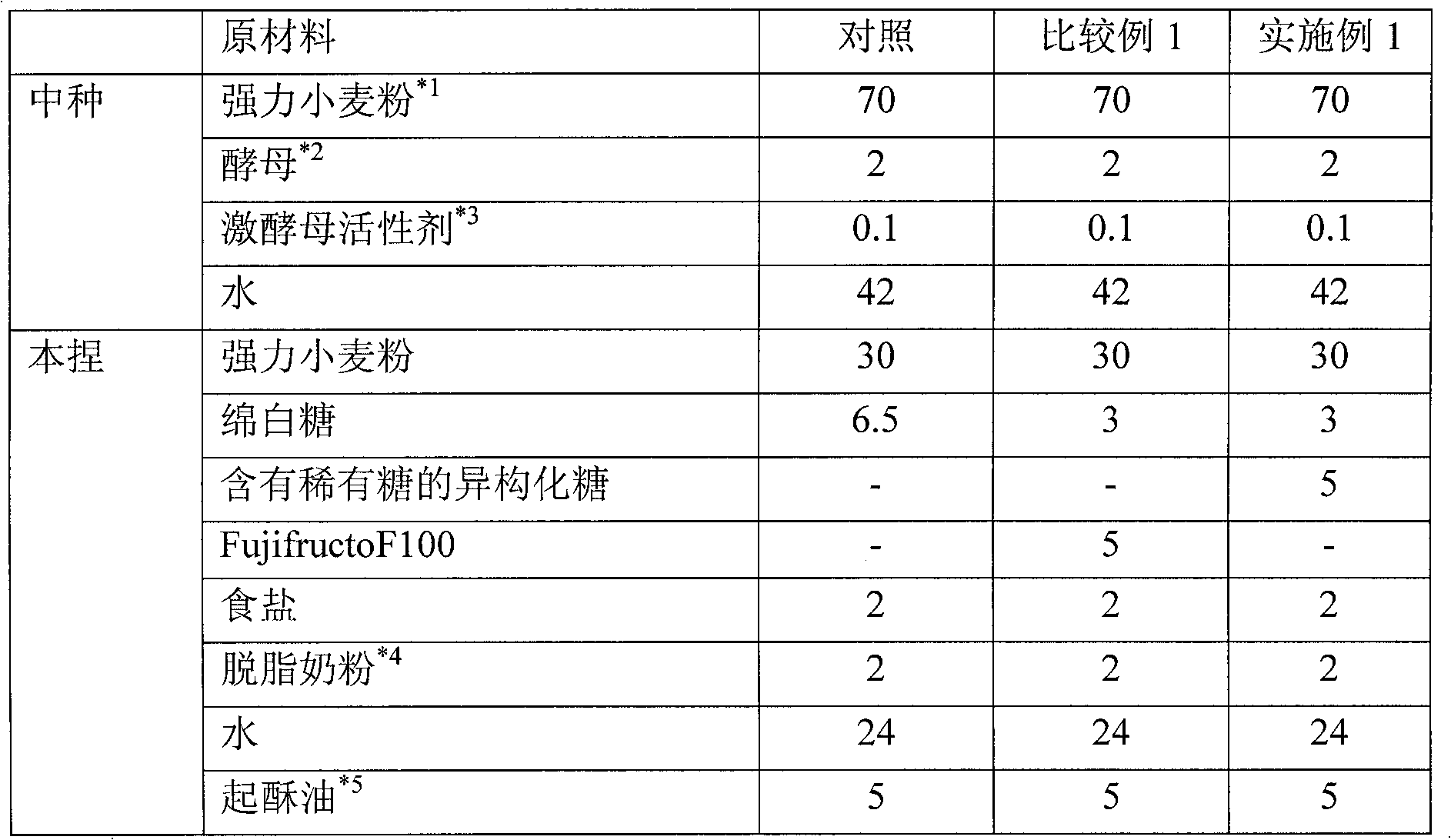

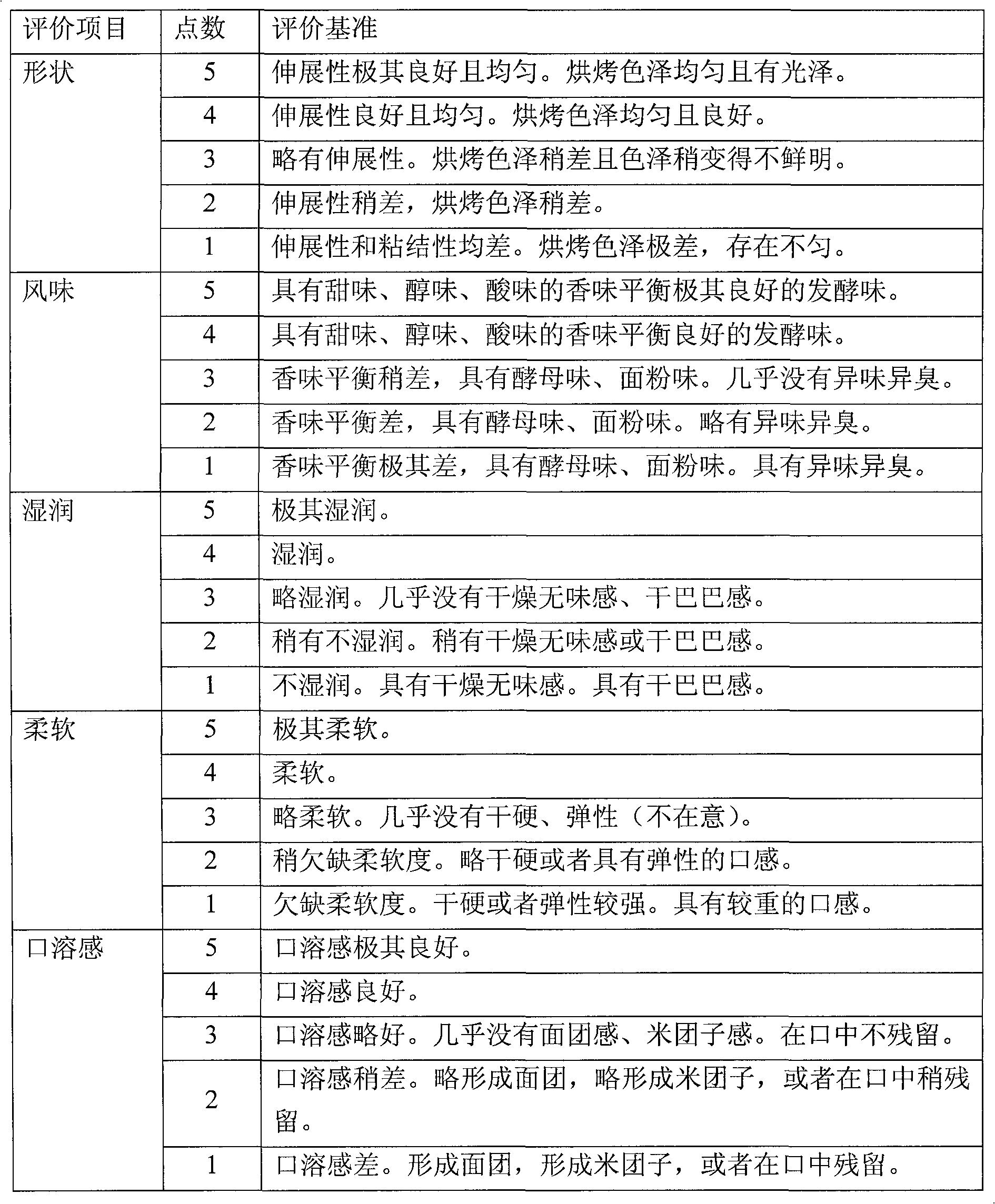

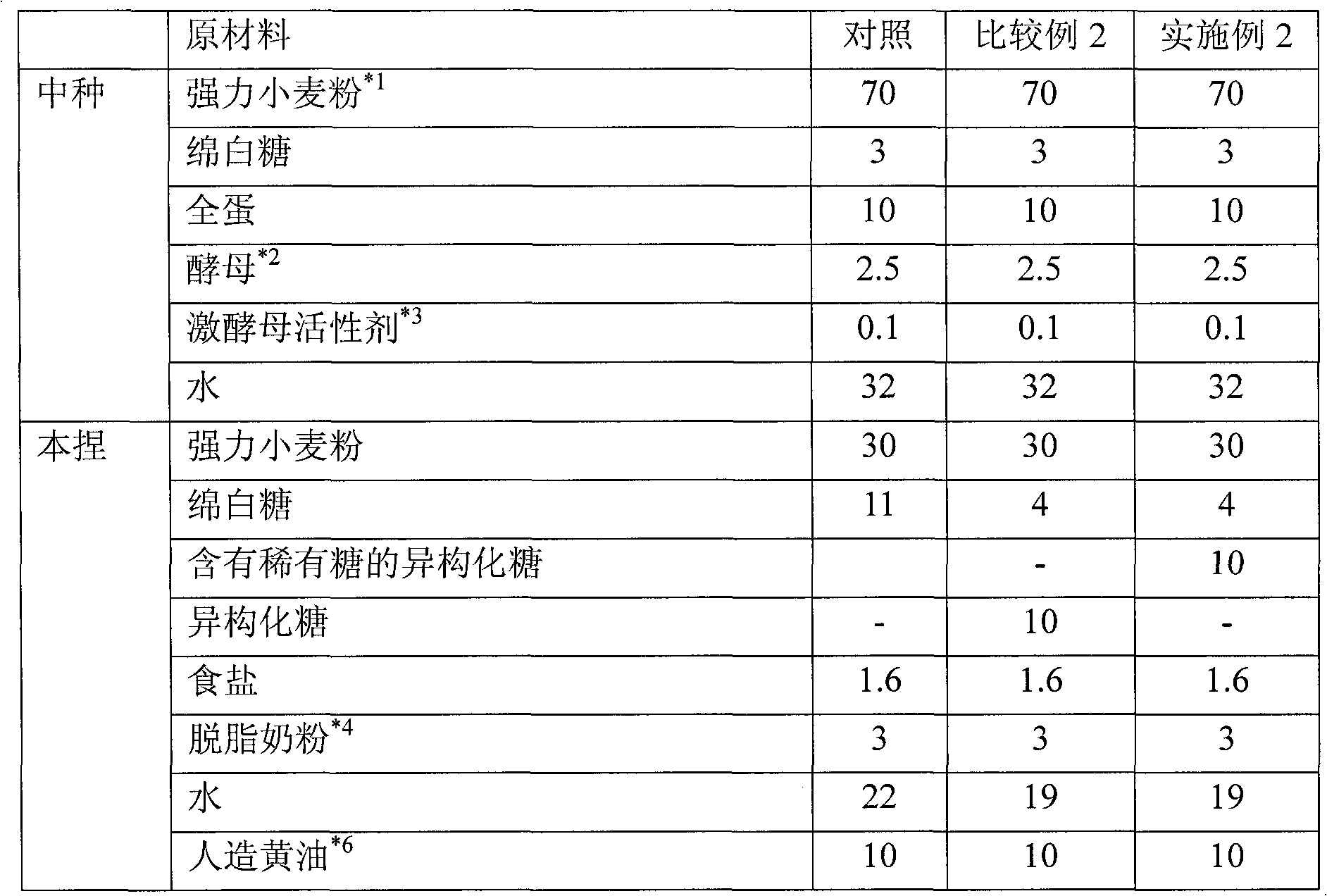

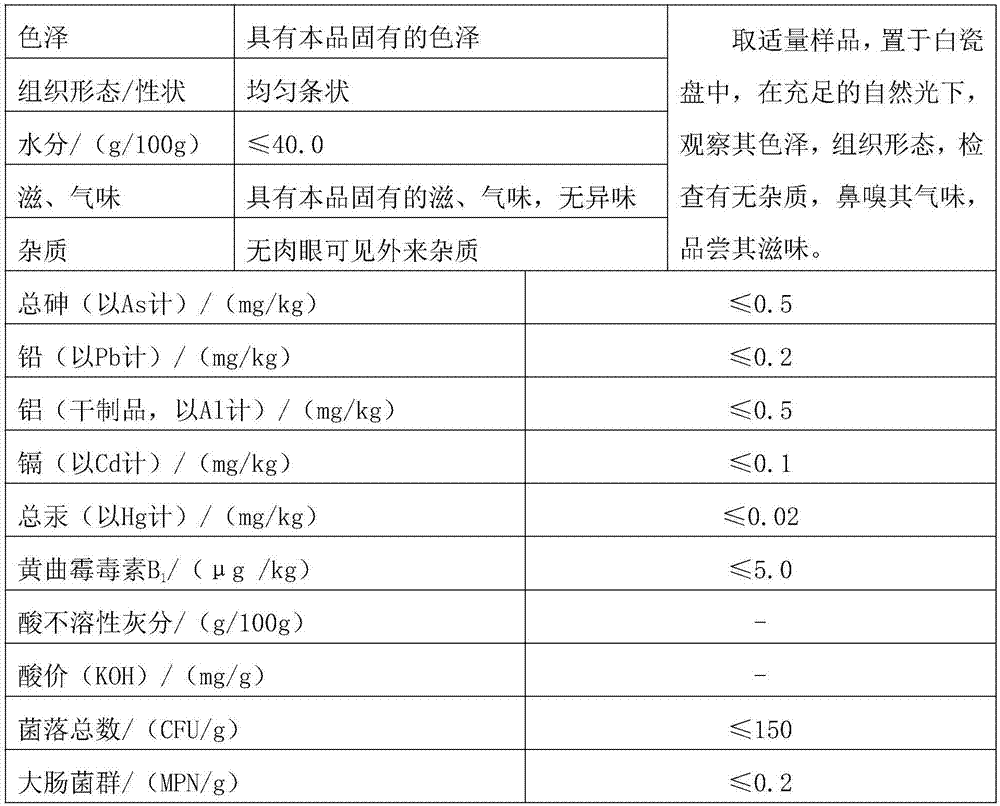

Bakery product having excellent texture and taste and method of producing the same

ActiveCN102428982ASoft and moist mouthfeelGood melt in the mouthDough treatmentPre-baking dough treatmentRare sugarFlavor

An object of the present invention is to provide a bakery product which has a soft and moist texture, sweetly dissolves in the mouth, has a favorable flavor, and is well risen and a method of producing the same. Another object of the present invention is to provide a method of producing the same. By using raw material flour obtained by blending a rare sugar-containing isomerized sugar syrup or a rare sugar in wheat flour as a main raw material in the production of a bakery product, a bakery product to which softness, moistness, and a property of sweetly dissolving in the mouth is imparted is produced.

Owner:MATSUTANI CHEM INDS CO LTD

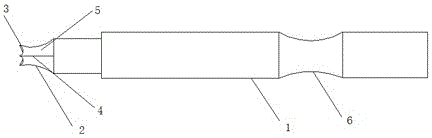

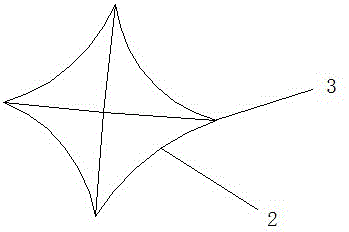

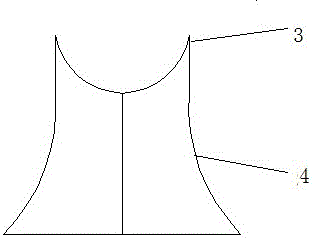

Novel tool bit for numerical-control machining tool special for non-metallic materials

Owner:SUZHOU YASIKE PRECISION CNC CO LTD

Making method of instant fresh noodles and instant fresh noodles made by method

ActiveCN106923178AKeep healthyRestoring the tasteFood preservationFood ingredient as taste affecting agentWater bathsCooking & baking

The invention relates to a making method of instant fresh noodles and the instant fresh noodles made by the method. The making method comprises the following making steps of adding flour, starch, vital wheat gluten, table salt, edible oil, sodium alginate, ice water and lactic acid into a vacuum dough mixer in proportion, and making dough; then performing high-temperature high-pressure shaping to obtain noodles, cooking the noodles, and sterilizing the cooked noodles; performing shaping to obtain cakes, and performing quick baking until noodle crusts are quickly dehydrated, dried and crisp and noodle core parts maintain wet and soft; then performing cooling until the outer surfaces of the noodles are 70 DEG C or below; loading the cooled noodles into packaging bags, and performing vacuumizing; performing water bath sterilization; putting the sterilized noodles into a freezer, and performing quick cooling; and performing matching with seasoning bags so as to obtain finished products. In the process of making the instant fresh noodles, the noodles are all in a machine cavity and are not in contact with the outside. The invention provides the making method of the instant fresh noodles, and the noodles made by the method. According to the method, deep-frying is not performed, in later-stage preservation, preservatives are not used, and the instant fresh noodles are rich in nutrition, have palatable taste and texture of domestic noodles, and are quite convenient noodles the same as present instant noodles when being eaten.

Owner:孙平建

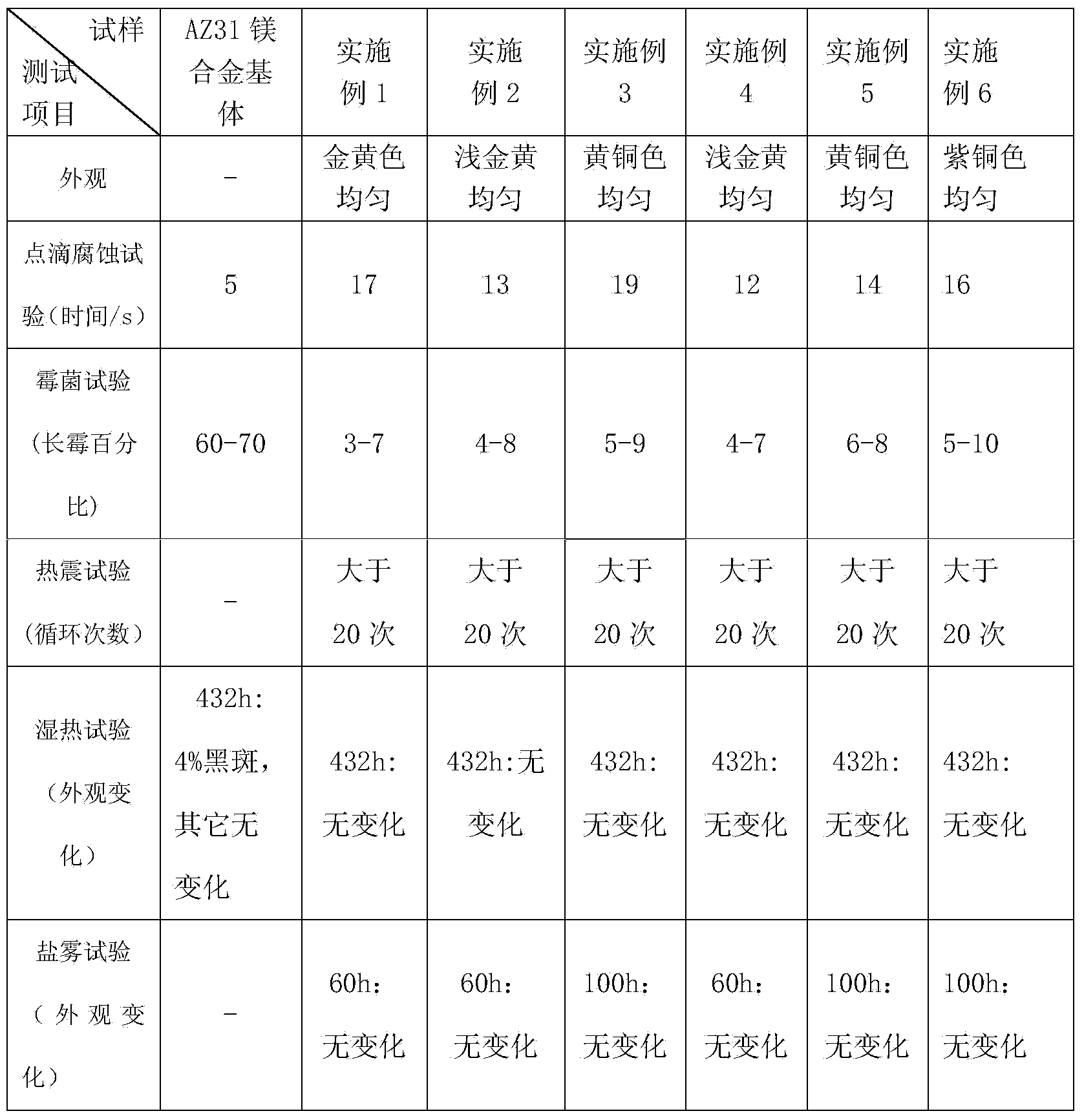

Technical method for imitating copper and gold on surface of magnesium alloy

InactiveCN103924232AReasonable process designSimple processMetallic material coating processesCopperAqueous solution

The invention discloses a technical method for imitating copper and gold on the surface of magnesium alloy. The technical method comprises the steps of soaking ground, polished or wiredrawn magnesium alloy into a passivating solution to passivate and color, wherein the passivating solution is water or a water solution containing at least one orthophosphate; keeping the temperature at 80-100 DEG C for 2-10h, and then, sealing a hole by using colorless and transparent waterborne resin; next, baking at the temperature of 120-260 DEG C. The magnesium alloy obtained by the invention finally has the gloss or texture of copper or gold and is relatively good in corrosion and mildew resistance. The technical method disclosed by the invention is reasonable in process, simple in process flow, low in cost, safe in production process, high in efficiency, free of acidic waste liquid discharge and special equipment and environmental friendly in process; the passivating and coloring solution is pollution-free and nontoxic; in addition, the obtained product has the gloss and texture of metal, is attractive in appearance and relatively high in corrosion and mildew resistance, and has a favorable application prospect.

Owner:CENT SOUTH UNIV

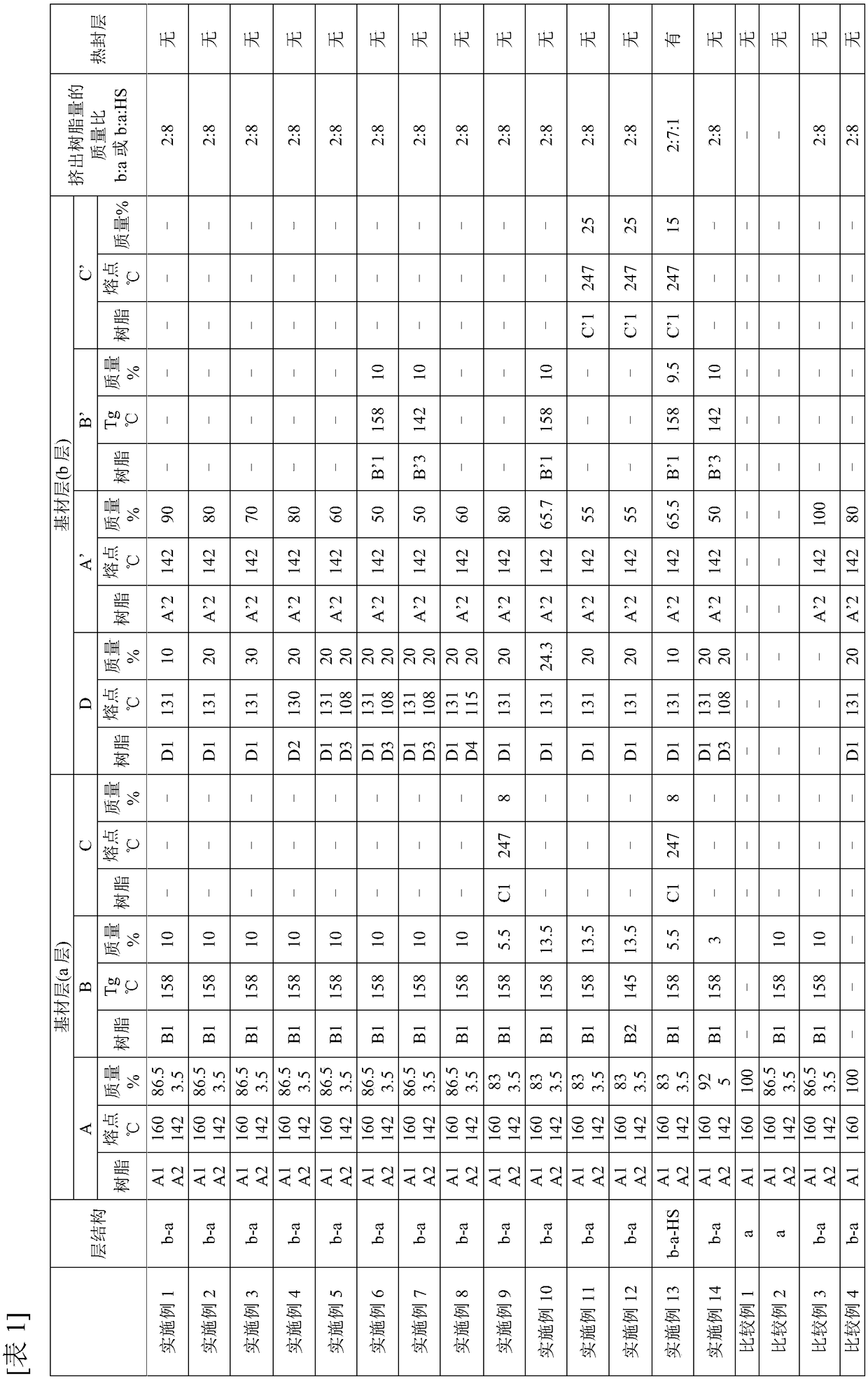

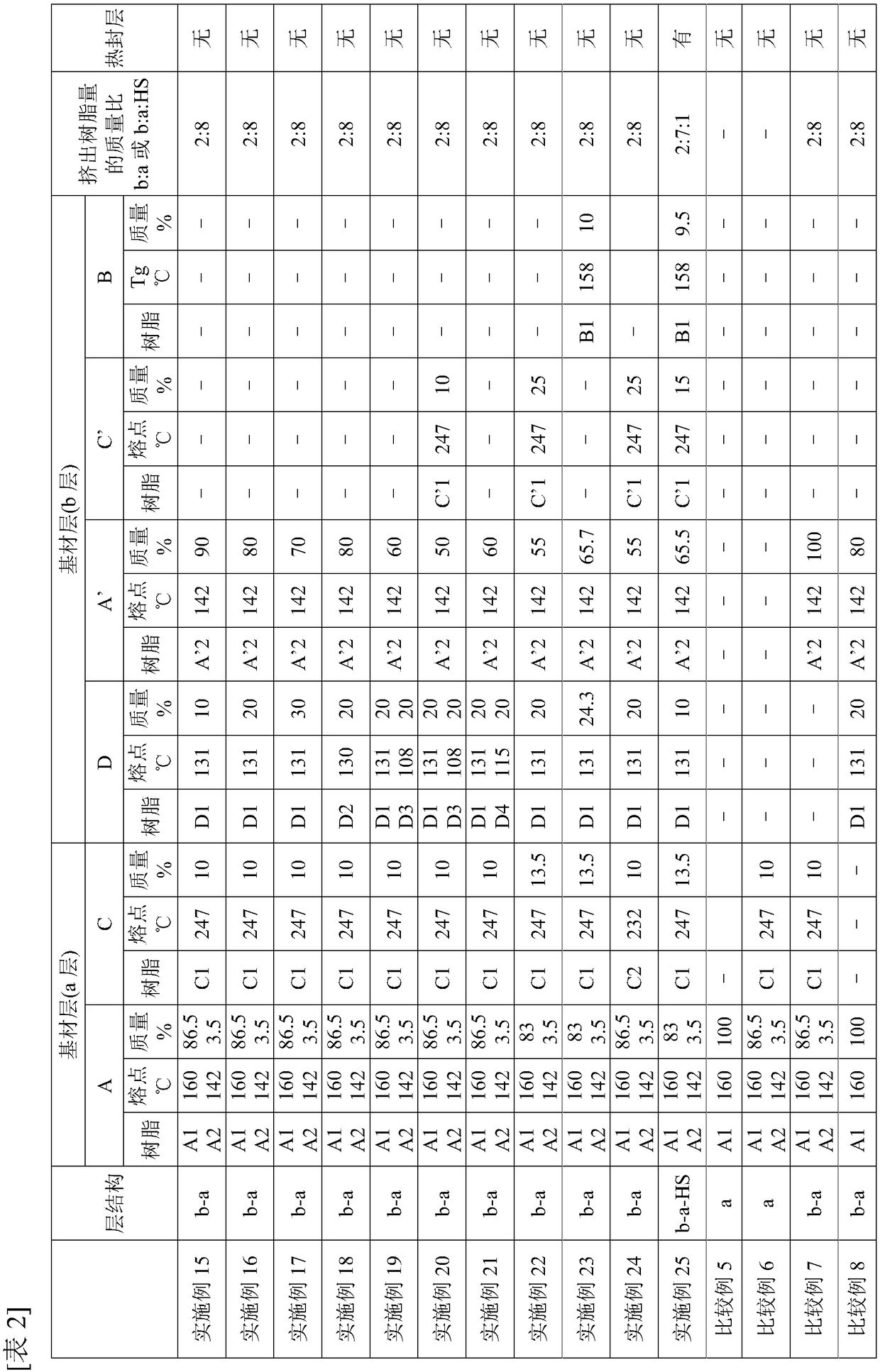

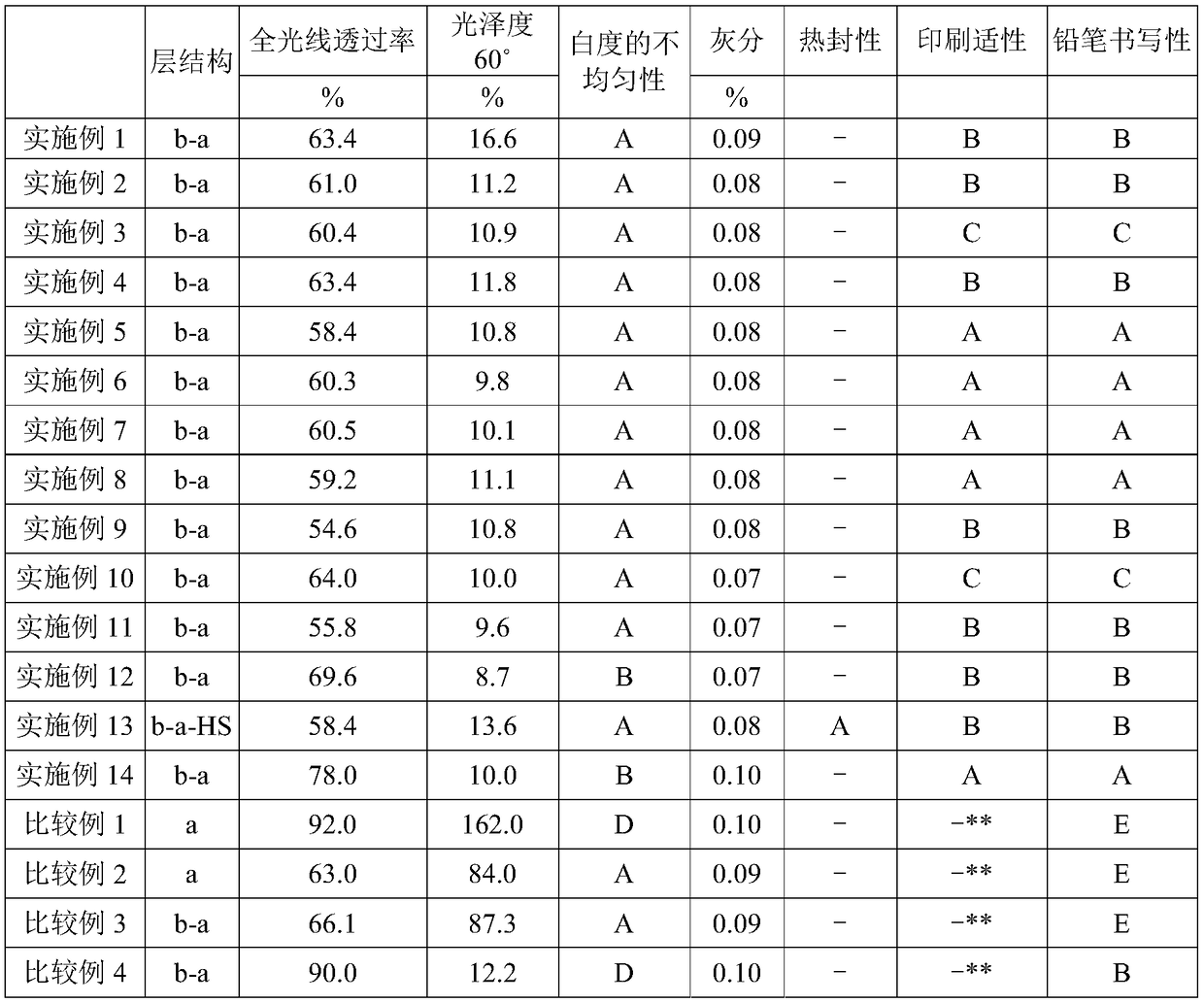

Translucent stretched film

ActiveCN109070556AGood water resistanceGood oil resistanceSynthetic resin layered productsFlat articlesThermoplasticTransmittance

The present invention provides: a translucent stretched film having a matte appearance; and a translucent stretched film which preferably has excellent printability and heat sealability, while having,if desired, pencil writability. More specifically, the present invention relates to a translucent stretched film which comprises at least a base layer and a surface layer, and wherein: the base layercomprises one or more layers that contain, as resin components, at least a crystalline thermoplastic resin A having a melting point of 120-175 DEG C and an amorphous thermoplastic resin B; the surface layer contains, as a resin component, at least a crystalline thermoplastic resin D having a melt mass flow rate of 0.02-2 g / 10 min at 190 DEG C under a load of 2.16 kg; and the total light transmittance is 35-85%.

Owner:OJI HLDG CORP

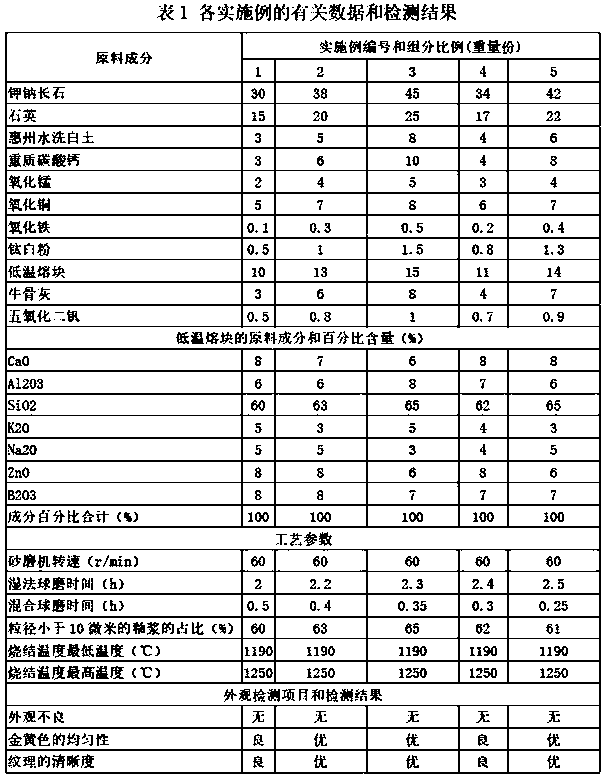

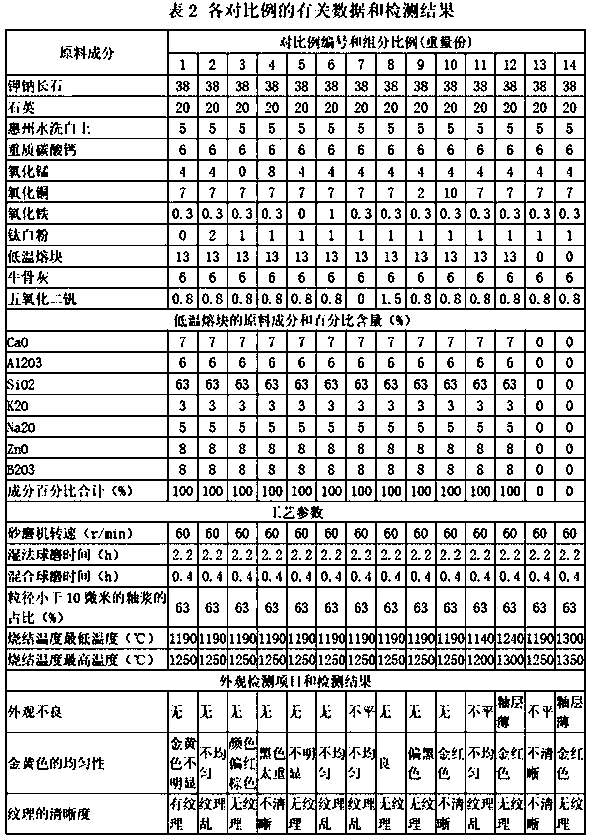

Sanitary ceramic glaze with golden yellow texture and sanitary ceramic preparation method thereof

The invention discloses sanitary ceramic glaze with golden yellow textures which includes following raw materials, in parts by weight: 30-45 parts of potassium-sodium feldspar, 15-25 parts of quartz,3-8 parts of Huizhou washed carclazyte, 3-10 parts of ground calcium carbonate, 2-5 parts of manganese oxide, 5-8 parts of copper oxide, 0.1-0.5 part of iron oxide, 0.5-1.5 parts of titanium dioxide,10-15 parts of low-temperature frit, 3-8 parts of bovine bone ash and 0.5-1.0 part of vanadium pentoxide. A CuMn2O4 spinel structure is generated in the firing process of the glaze, wherein golden metallic luster is generated through the light reflection effect, so that no crystallization area is connected to form a black line, and the golden yellow texture effect composed of golden yellow crystallization glaze and the black line is formed. The invention also provides a preparation method of the sanitary ceramic glaze with the golden yellow texture, and the prepared glaze does not contain leadand chromium, consists of yellow metal glaze and unique black lines, and has a good market prospect.

Owner:FOSHAN DONGPENG CERAMIC +1

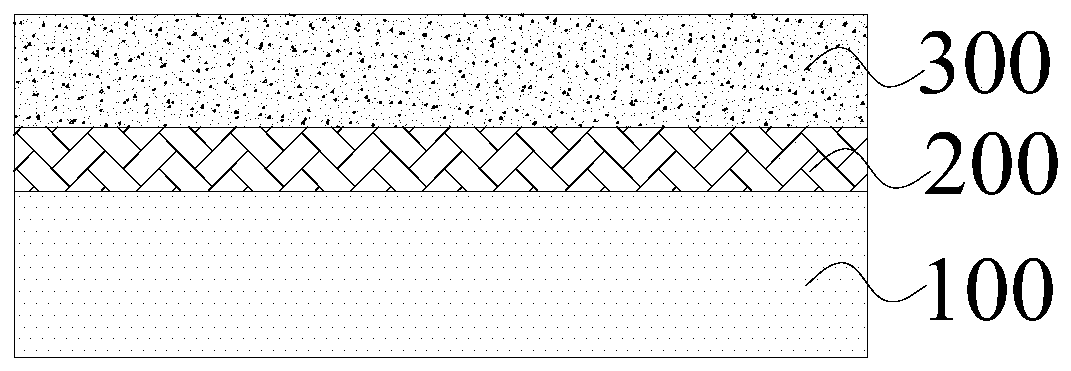

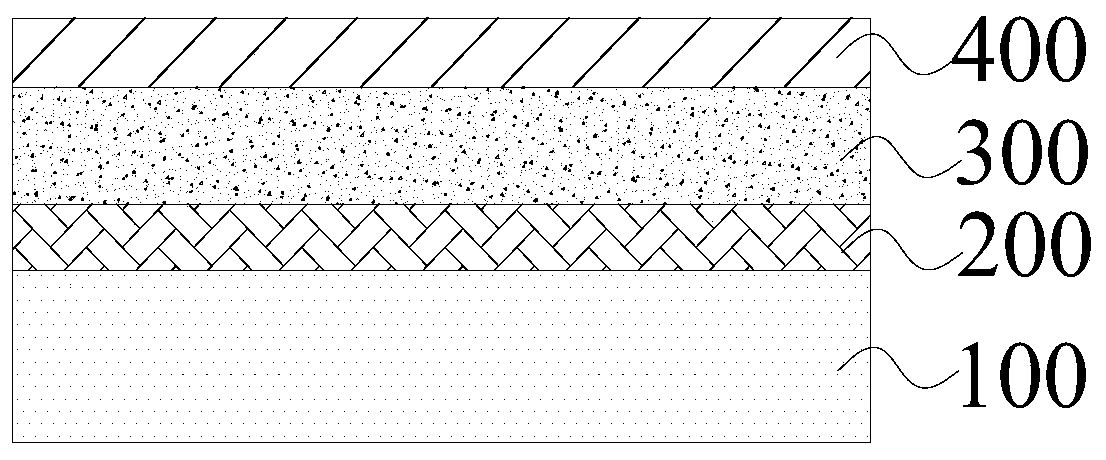

SPC solid wood composite floor

InactiveCN108019028ARaw materials are easy to obtainNot easy to crack and deformFlooringSolid woodWax

The invention provides an SPC solid wood composite floor comprising a PVC board and a solid wood board skin. The PVC board and the solid wood board skin are glued and fixed into a whole; the PVC boardcomprises, by weight, 80-130 parts of PVC resin, 260-350 parts of calcium carbonate powder, 1-1.5 parts of PE wax, 5.5-8 parts of a calcium and zinc stabilizer, 6-12 parts of ACR-401, and 3-4.5 partsof stearic acid. The SPC solid wood composite floor is attractive and generous, safe and environmentally friendly, and not only are the natural wood grain, texture, and foot feeling of solid wood floor obtained, but also the SPC solid wood composite floor has suitable elasticity and is not prone to being deformed and cracked, and has excellent performance in water and moisture resistance, impactresistance, corrosion resistance, and anti-skid and wear-resistance.

Owner:ANHUI TIANRUN PLASTIC IND

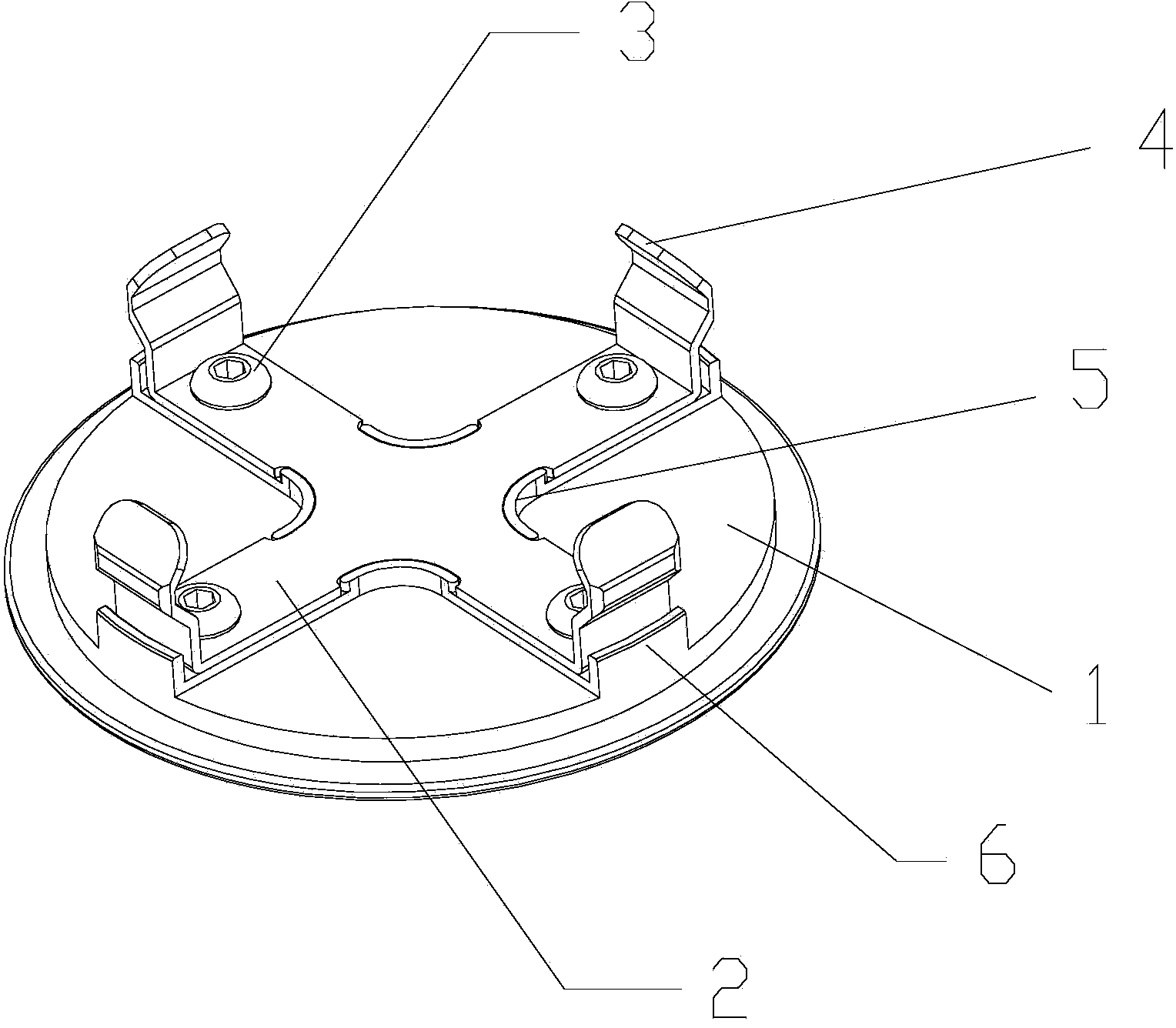

Wheel hub cover

InactiveCN103770564AHigh temperature resistantThree-dimensionalWheel protectionCircular discEngineering

The invention provides a wheel hub cover, which comprises a circular disc-shaped main body piece, a fixing piece and screws, wherein the circular disc-shaped main body piece is provided with a label, the fixing piece is connected with a wheel hub, and adopts a cross elastic sheet, each top end of the elastic sheet is provided with a clamping claw which is bent with 90 degrees to one direction, the elastic sheet is in contact with the back side of the main body piece and is fixed by the screws, and the main body piece and the elastic sheet are respectively made of aluminum alloy. Compared with the traditional plastic product, the aluminum alloy hub cover has more outstanding mechanical properties (particularly elastic limit, strength limit and yield ratio), anti-elastic properties (namely elasticity-expanding and retraction-reducing properties, also known as anti-loosening property), fatigue-resistant property, high temperature-resistant property and the like, and the service life is longer.

Owner:李春柏

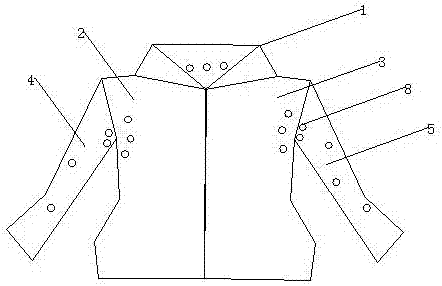

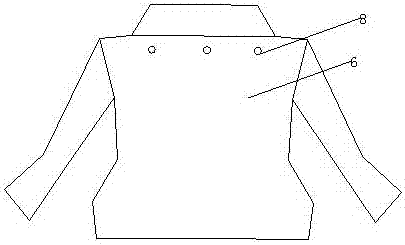

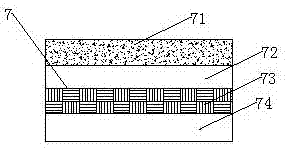

Heat dissipation coat

InactiveCN107114829AWith textureNo delaminationIlluminated signsProtective garmentComputer engineering

The invention belongs to the technical field of coats, and provides a heat dissipation coat. The heat dissipation coat comprises a collar, a right front part, a left front part, a right sleeve, a left sleeve and a back part, wherein 3-5 through poles are evenly formed in the collar; three through holes are formed in the portion, close to the axilla portion of the coat, of the right front part; three through holes are formed in the portion, close to the axilla portion of the coat, of the left front part; two through holes are formed in the portion, close to the axilla portion of the coat, of the left sleeve, and 2-4 through holes are formed in the rest parts; two through holes are formed in the portion, close to the axilla portion of the coat, of the right sleeve, and 2-4 through holes are formed in the rest parts; 2-3 through holes are horizontally formed in the portion, close to the neck portion, of the back part. The invention aims at providing the heat dissipation coat. According to the heat dissipation coat, a plurality of through holes are formed in a plurality of parts of the coat respectively, and when sweat is discharged after people exercise, the sweat can be excreted to the outside of the body from the through holes at any time. The situation that people have a cold is effectively avoided, the design is simple and reasonable, the practicability is high, and the coat is suitable for wide popularization.

Owner:HEFEI YUANKE GARMENT DESIGN CO LTD

Method for manufacturing composite marble-imitated coating based on elastic multicolor paint

InactiveCN111484780AExtend your lifeAchieve decorative effectPaints with biocidesPolyurea/polyurethane coatingsSpray coatingVarnish

The invention relates to a method for manufacturing a composite marble-imitated coating based on elastic multicolor paint, which comprises the following steps: a, forming a putty layer on a wall body,and applying an alkali-penetration-resistant primer by roll coating to form an alkali-penetration-resistant primer layer; b, spraying middle coating paint once to form a middle coating layer; c, after drying, applying an elastic multicolor paint by spray coating or roll coating to form a multicolor layer; and d, applying varnish once or multiple times by brushing or roll coating to form a finishing layer, wherein the multicolor layer is used as a marble-imitated main color layer, and the elastic multicolor paint comprises the following components in parts by weight: 50 parts of a pigment component, 20 parts of a dispersion medium and 30 parts of varnish. The elastic multicolor paint is adopted to form marble texture and marble veins, so that the service life of a building is prolonged while the decorative effect of the building is achieved. Meanwhile, the elastic multicolor paint has elasticity at normal temperature through emulsion type selection and an emulsion blending modificationtechnology, and the risks of cracking and peeling of the outer wall can be reduced.

Owner:上海磐彩环保科技股份有限公司

Preparation method for novel porcelain tire body inorganic repairing material and porcelain product repaired by inorganic repairing material

ActiveCN106747216AThe production method is scientific and reasonableDoes not affect scientific informationRepair materialUltimate tensile strength

The invention discloses a preparation method for a novel porcelain tire body inorganic repairing material and a porcelain product repaired by the inorganic repairing material. Kaolin and commercially pure chemical raw materials are adopted. The novel porcelain tire body inorganic repairing material is prepared from the following raw materials in percentage by weight: 55 to 62 percent of kaolin, 10 to 15 percent of sodium hydroxide, 6 to 9 parts of sodium silicate, 8 to 10 percent of beta-semi-hydrated gypsum and 10 to 17 percent of deionized water. The inorganic repairing material is obtained by calcining, ball milling, drying and stirring the raw materials. By adopting the preparation method, the defects of sparse structure, low strength, high water absorption and lack in porcelain quality due to repair of a porcelain tire body with gypsum are overcome; moreover, the novel inorganic repairing material is scientific and reasonable in production method, is easy to implement, and has a wide market prospect.

Owner:JINGDEZHEN CERAMIC INSTITUTE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com