Method for making keyboard with metal leaf mould ejection push-button and keyboard thereof

A technology of in-mold injection and metal sheet, which is applied in the direction of electrical components, electric switches, circuits, etc., can solve the problems of time-consuming and inferior quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

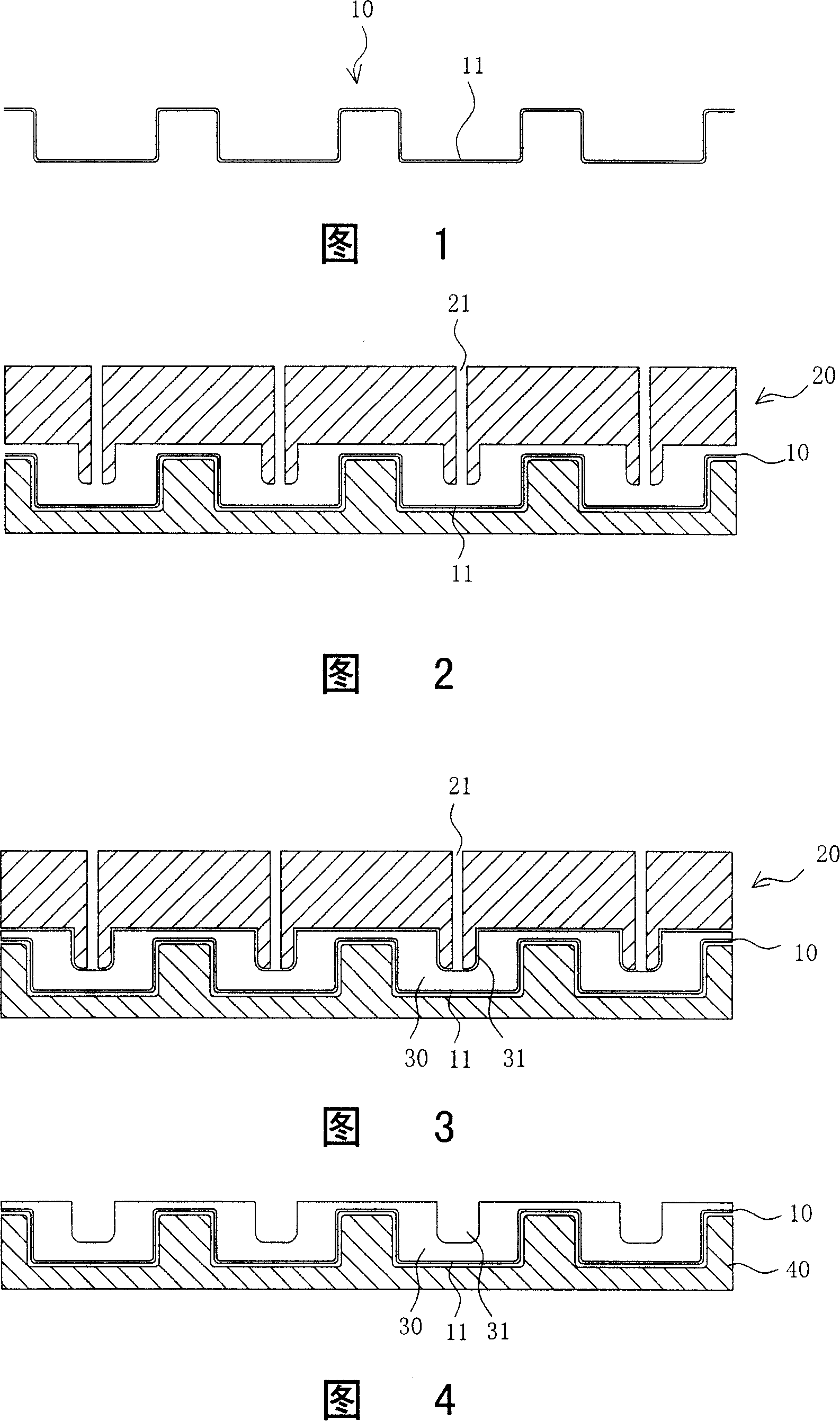

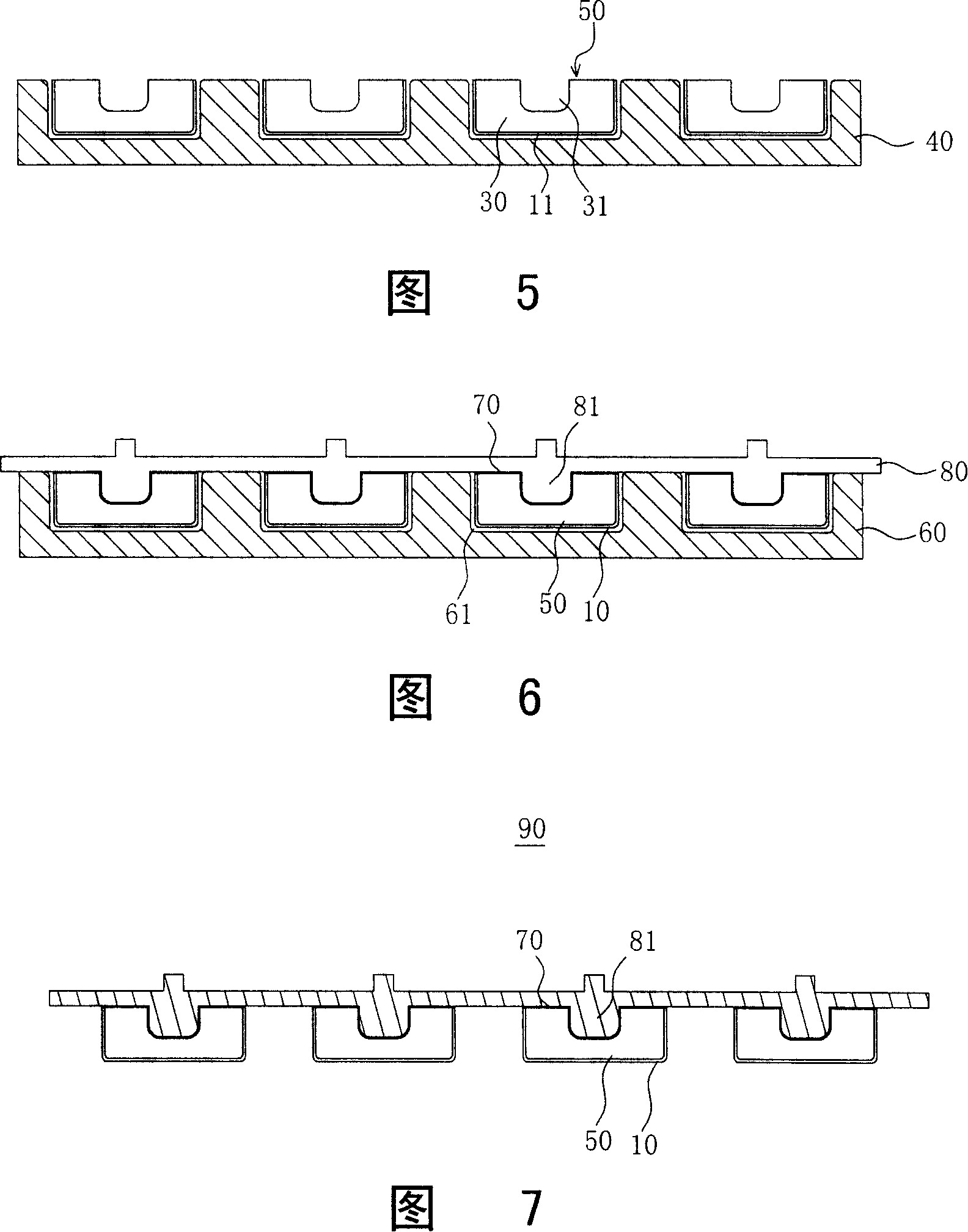

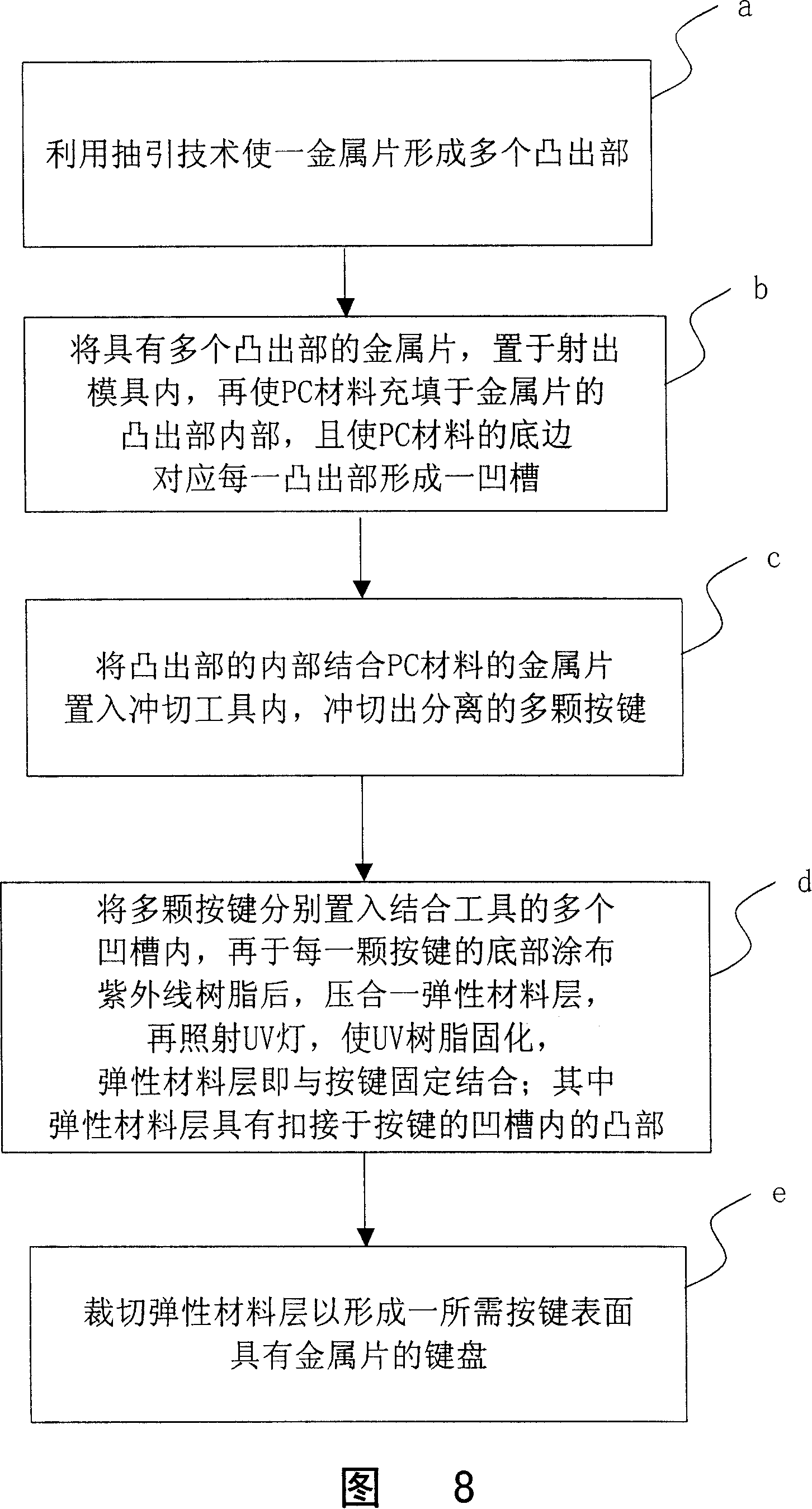

[0038] Please refer to Figure 1-8. In the present invention, the method for making a keyboard by injecting keys in a metal sheet mold is to form the metal sheet on the surface of the key, so that the keyboard with the metal key is more textured. Embodiments of the method of the present invention include the following steps:

[0039] Step a utilizes drawing technology to make a metal sheet 10 form a plurality of protrusions 11, as shown in Figure 1; before being drawn, the metal sheet 10 is printed with numbers and symbols of required colors;

[0040] In step b, the metal sheet 10 having a plurality of protruding parts 11 is placed in the injection mold 20, as shown in FIG. part 11, and make the bottom edge of PC material 30 correspond to each protruding part 11 to form a groove 31, as shown in Figures 3 and 4;

[0041] In step c, put the metal sheet 10 combined with the PC material 30 inside the protruding part 11 into the punching tool 40, as shown in FIG. 4, and punch out a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com