Patents

Literature

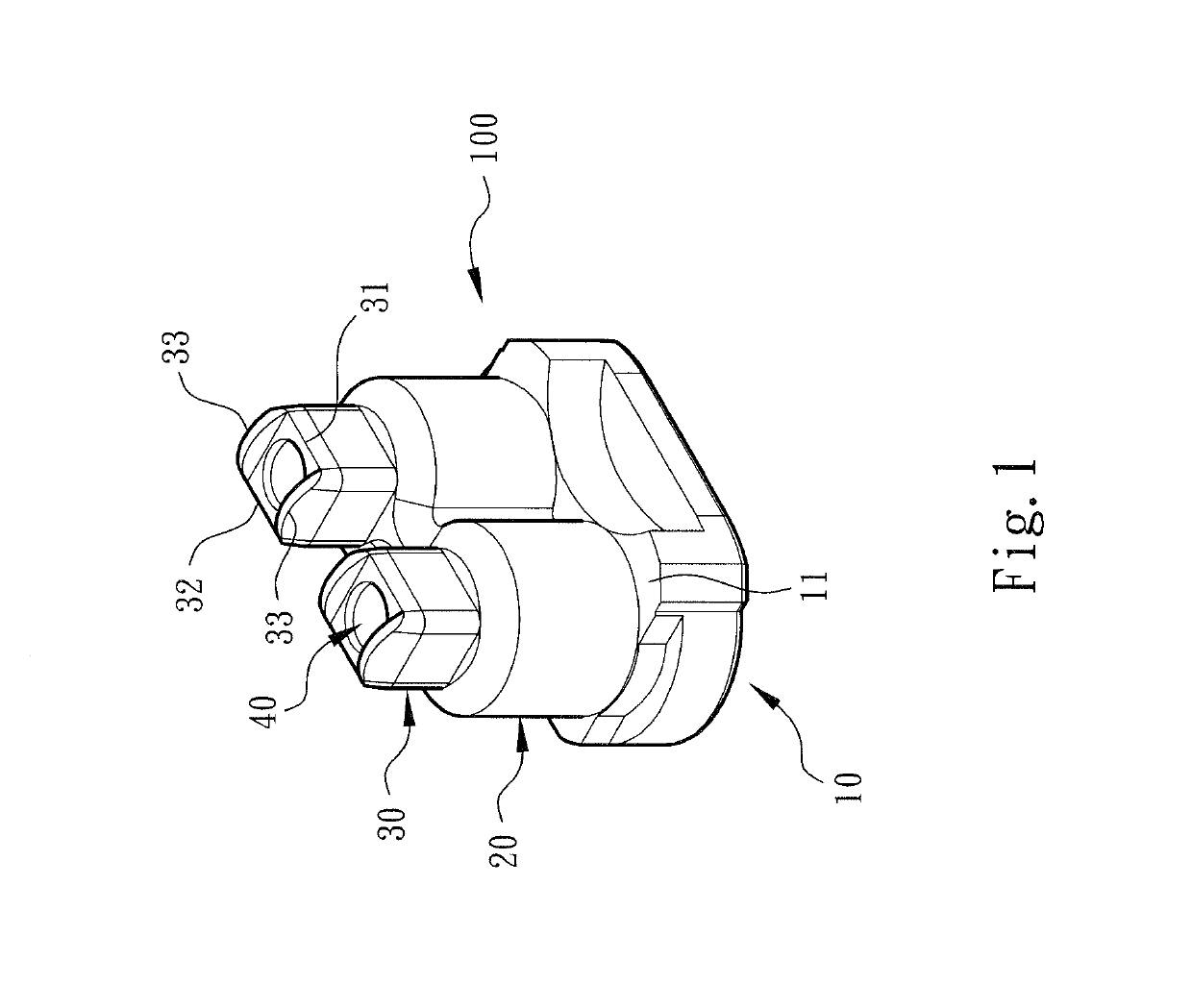

62 results about "Metal leaf" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A metal leaf, also called composition leaf or schlagmetal, is a thin foil used for decoration. Metal leaves can come in many different shades. Some metal leaves may look like gold leaf but does not contain any real gold. This type of metal leaf is often referred to as imitation leaf.

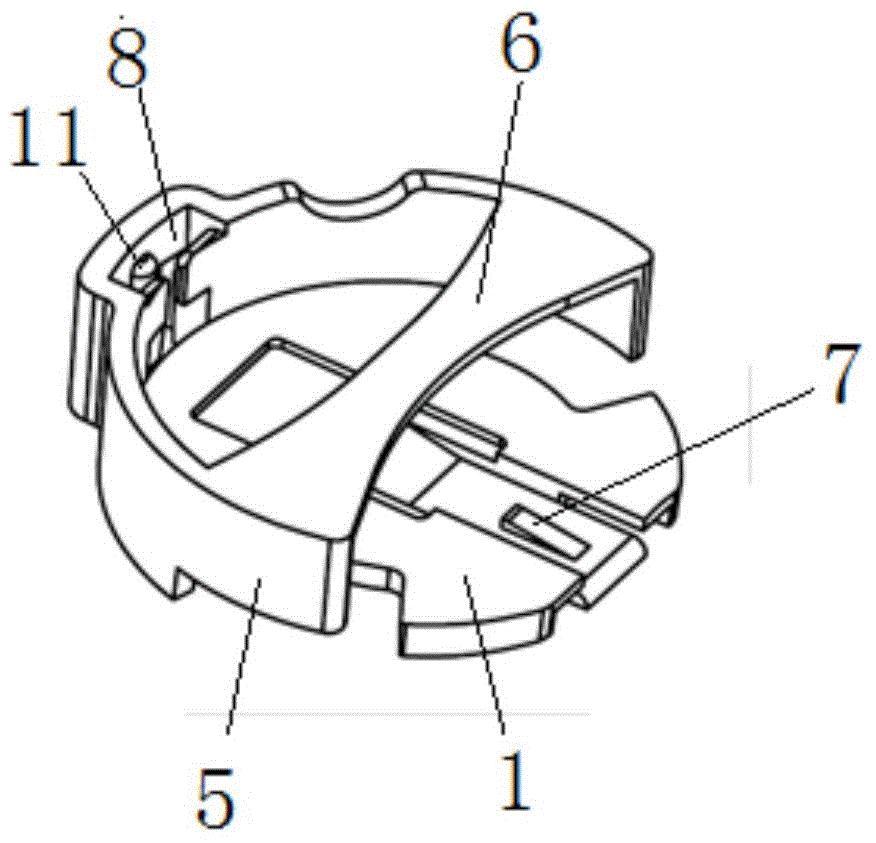

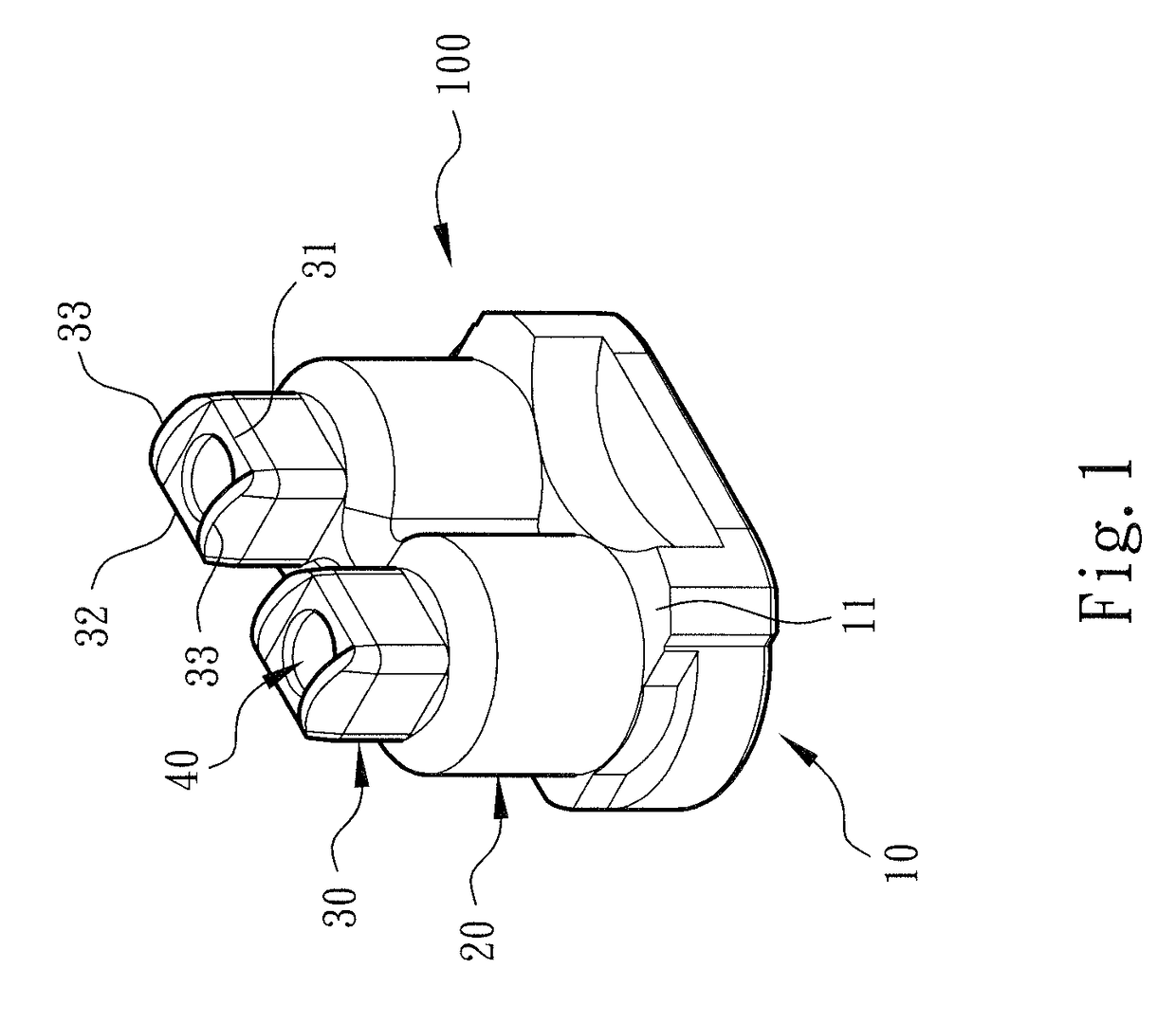

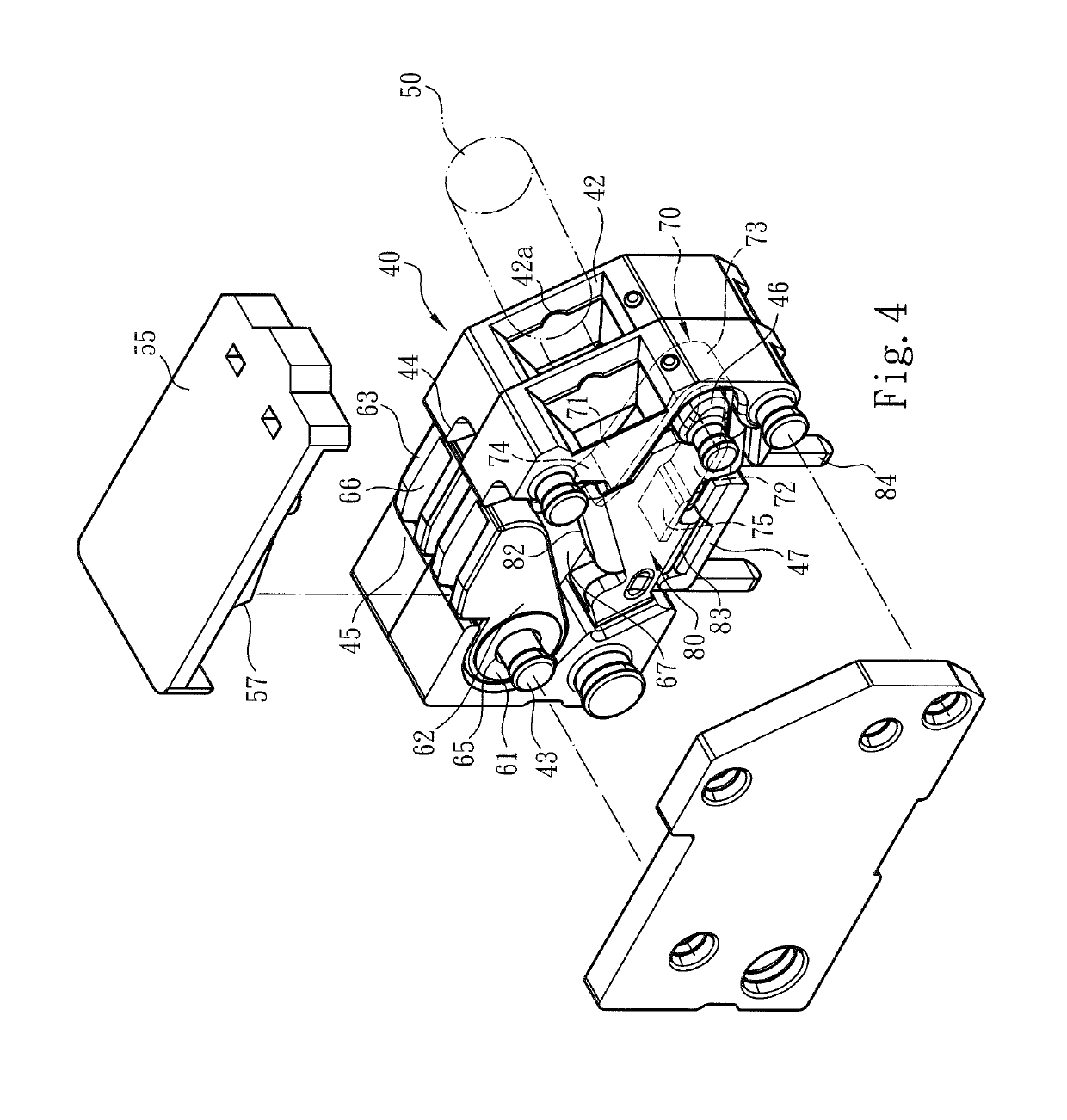

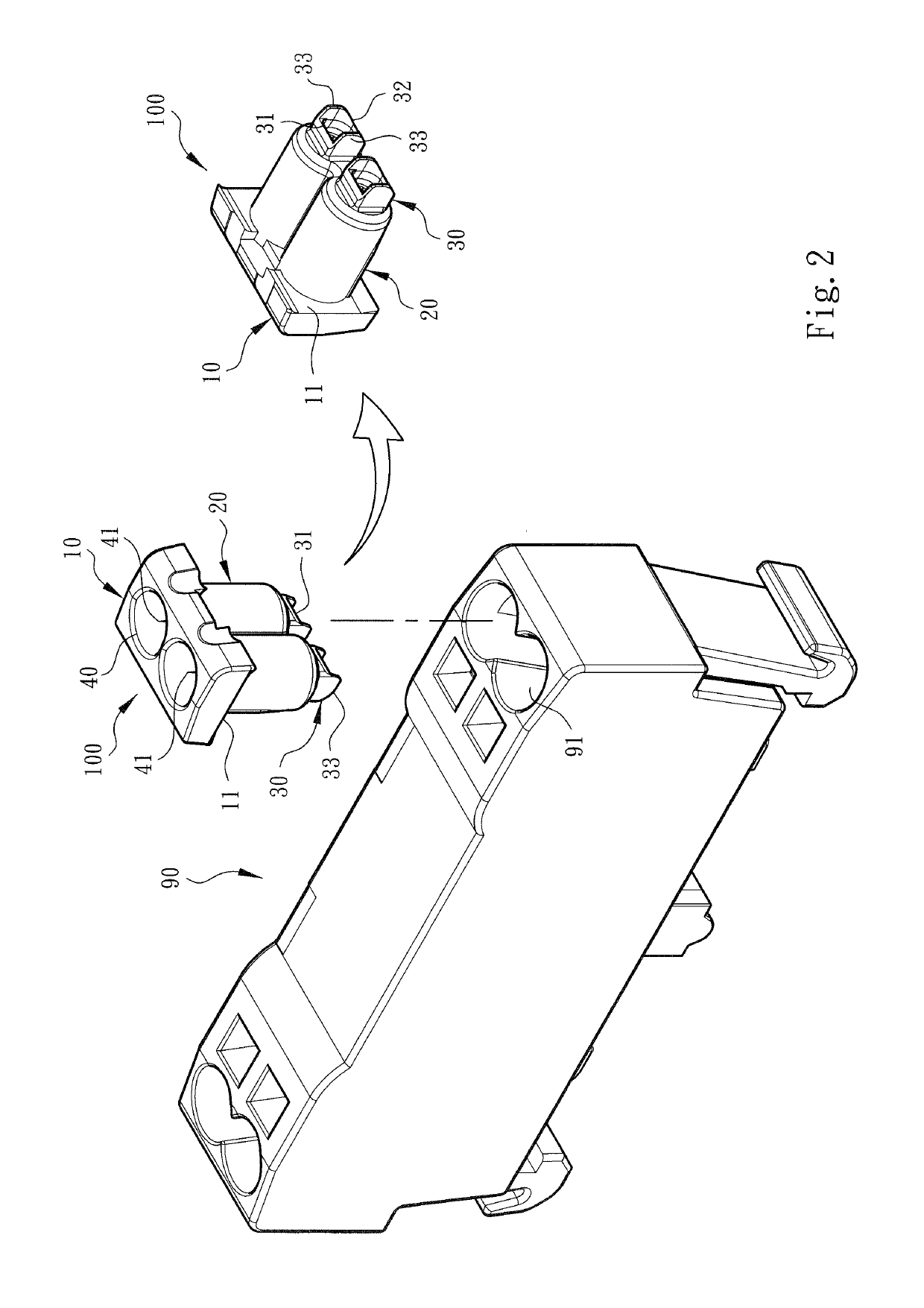

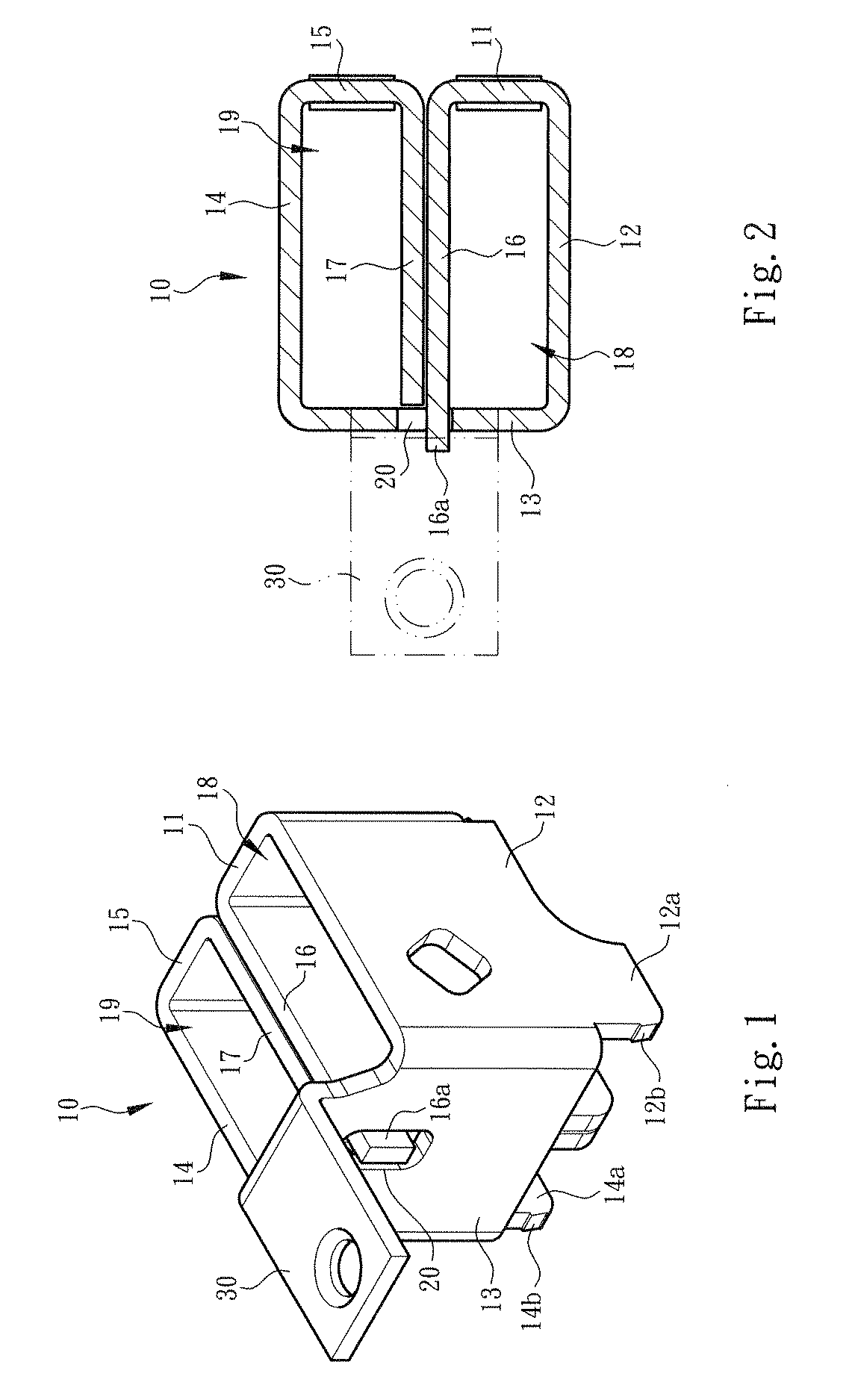

Metal leaf-spring-type connector for electronic cigarette devices

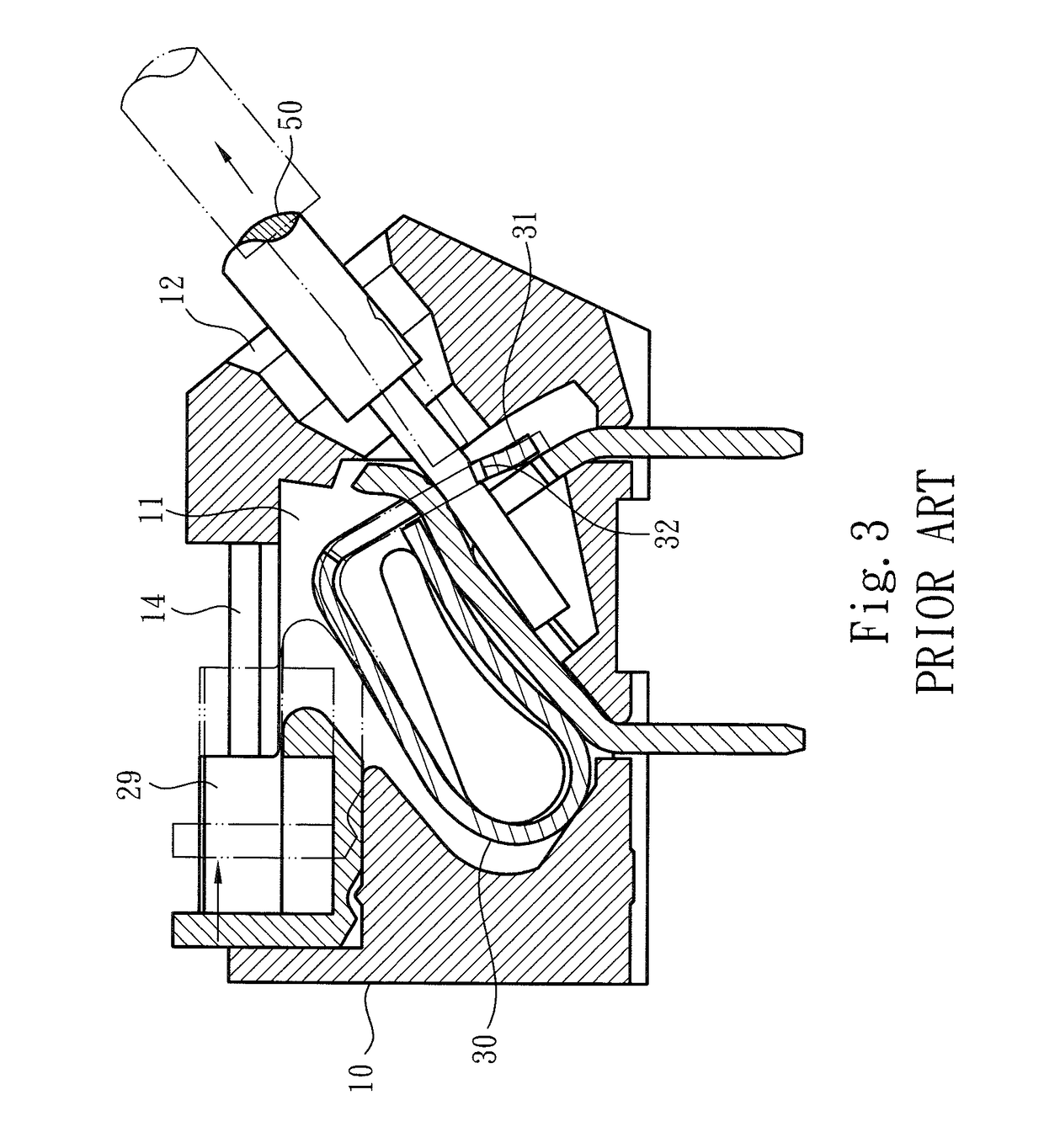

InactiveUS9350102B2Convenient can be dismantled and assembledShorten the timeCoupling contact membersTobacco devicesMetal leafEngineering

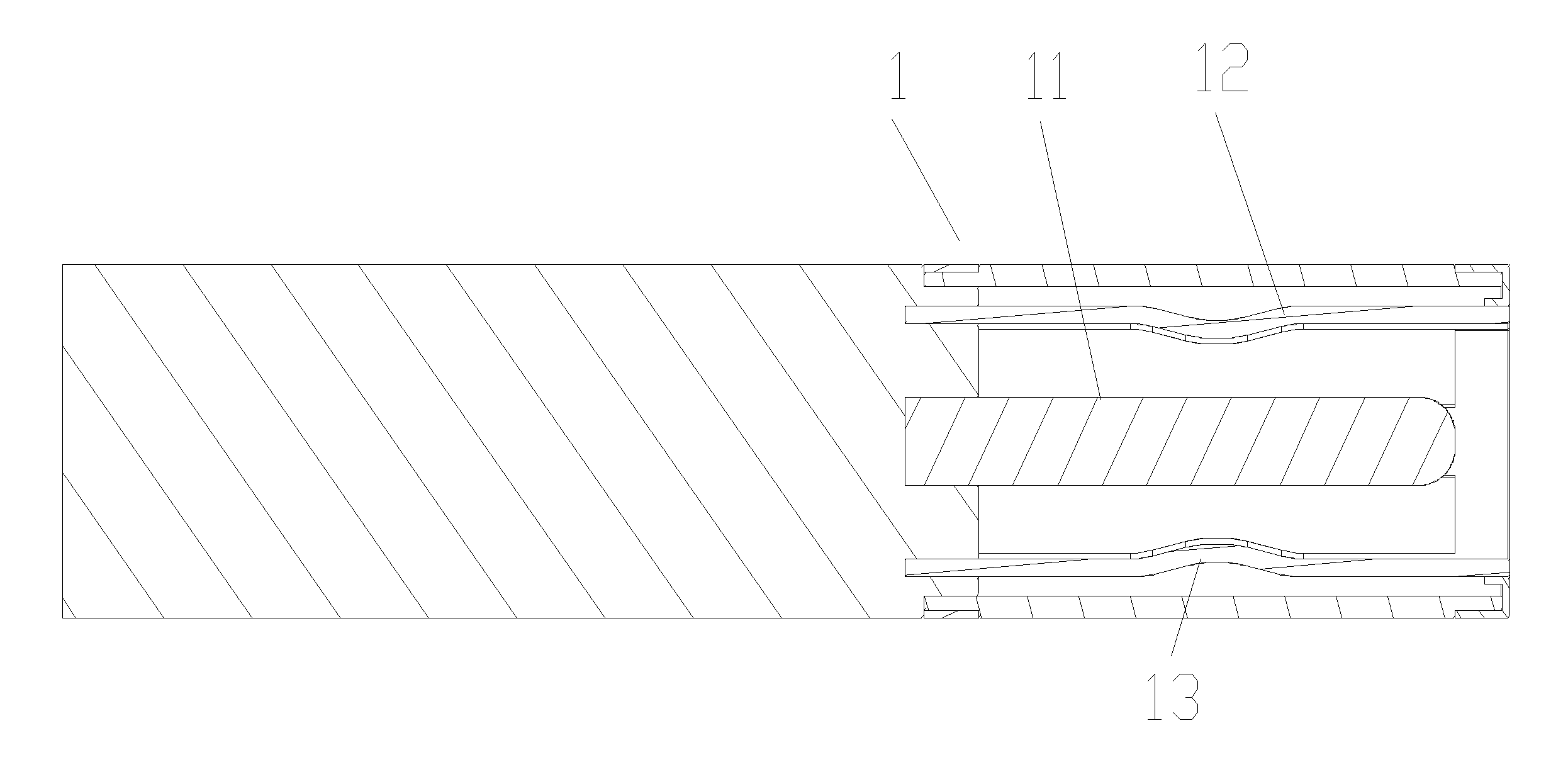

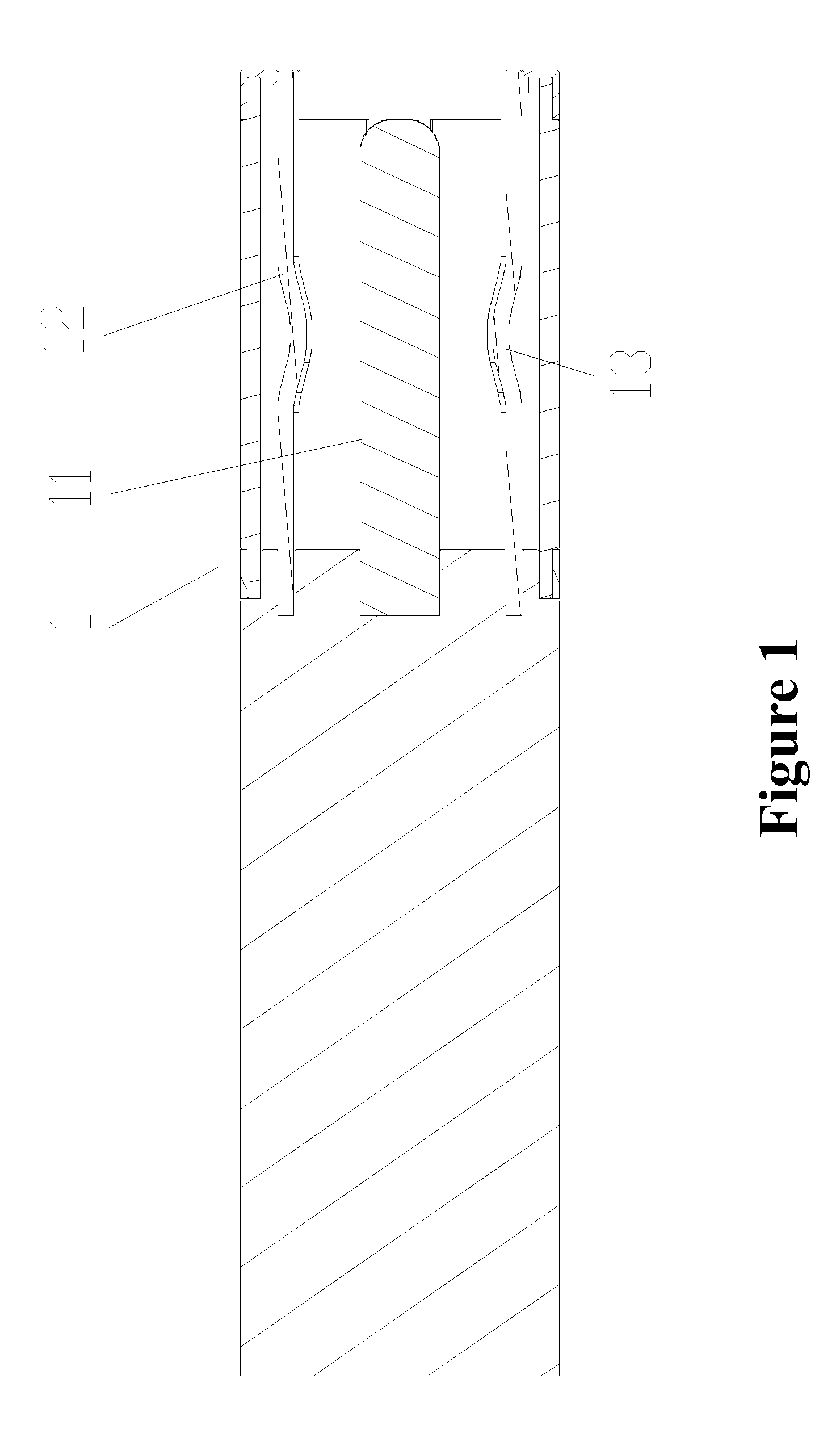

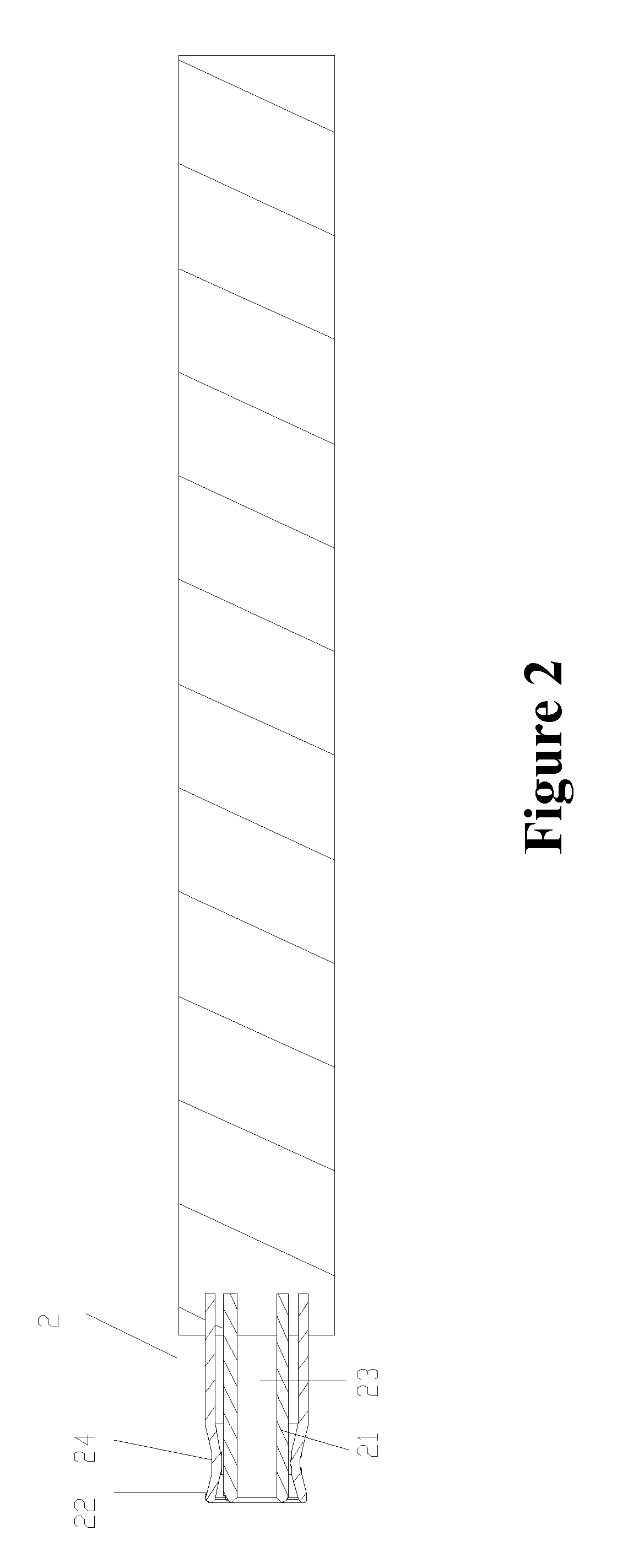

The present invention discloses a metal leaf-spring-type connector used for electronic cigarette devices. The connector comprises a leaf spring component and a connector component. The leaf spring component comprises a central columnar negative electrode leaf spring, and at least one positive electrode leaf spring disposed outside the negative electrode leaf spring. The connector component comprises a hollow central columnar negative electrode connector, and a positive electrode connector disposed outside the negative electrode connector. When the leaf spring component and the connector component are inserted and plugged together, the negative electrode leaf spring is inserted into the circular hole of the negative electrode connector to electrically connect with the negative electrode connector. The positive electrode connector is inserted into a void between the negative electrode leaf spring and the positive electrode leaf spring.

Owner:SHENZHEN SMACO TECHNOLOGY LIMITED

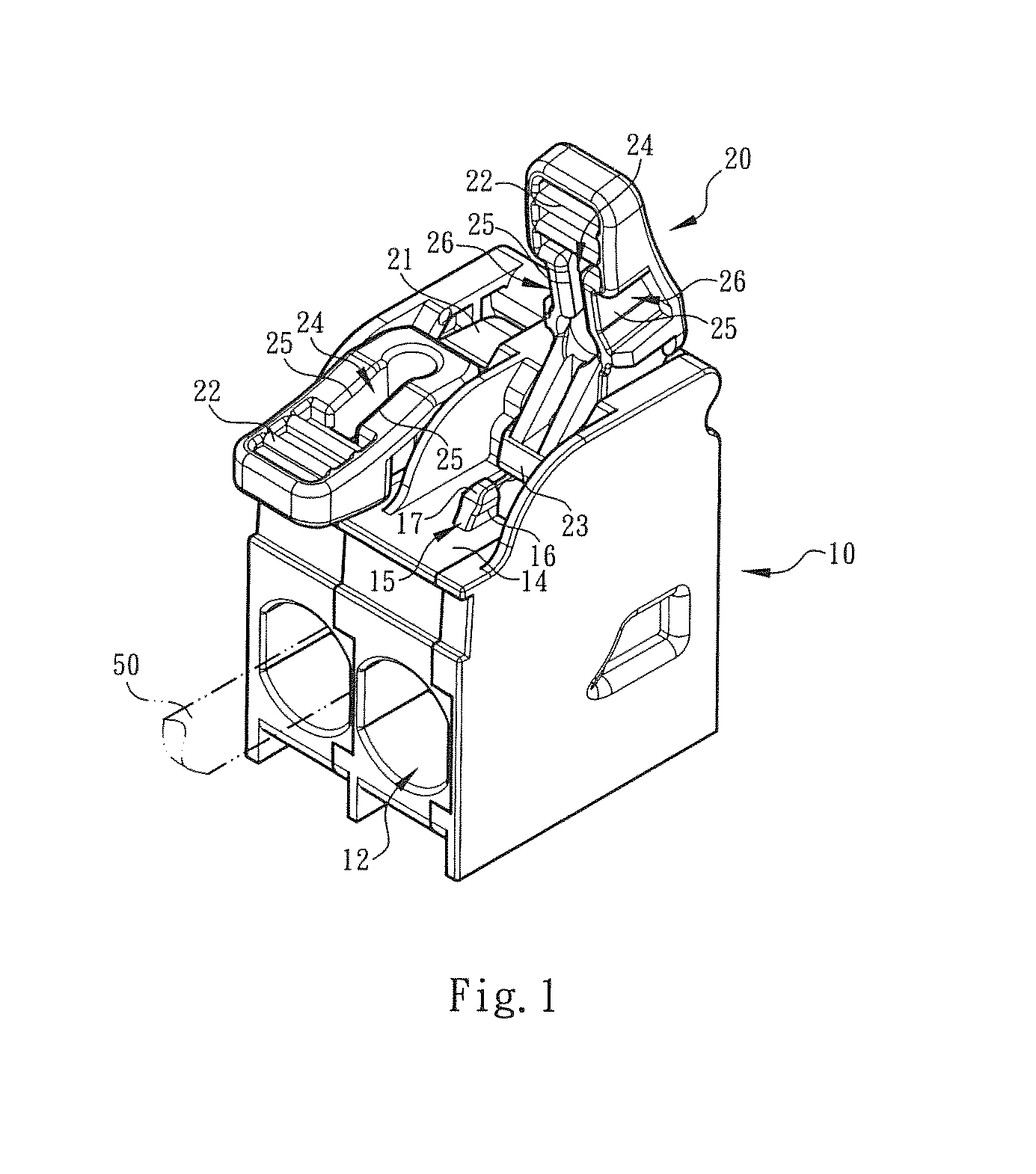

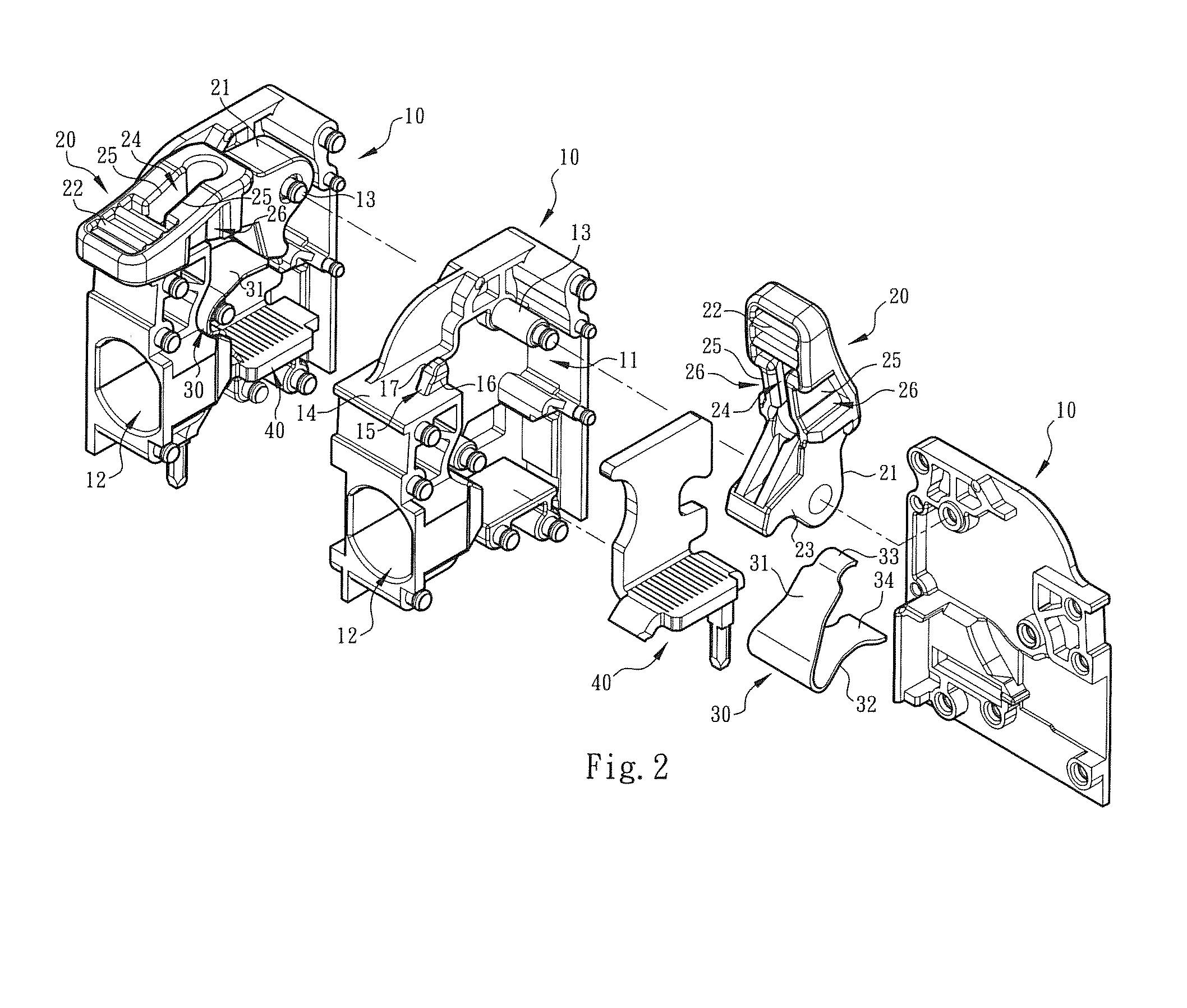

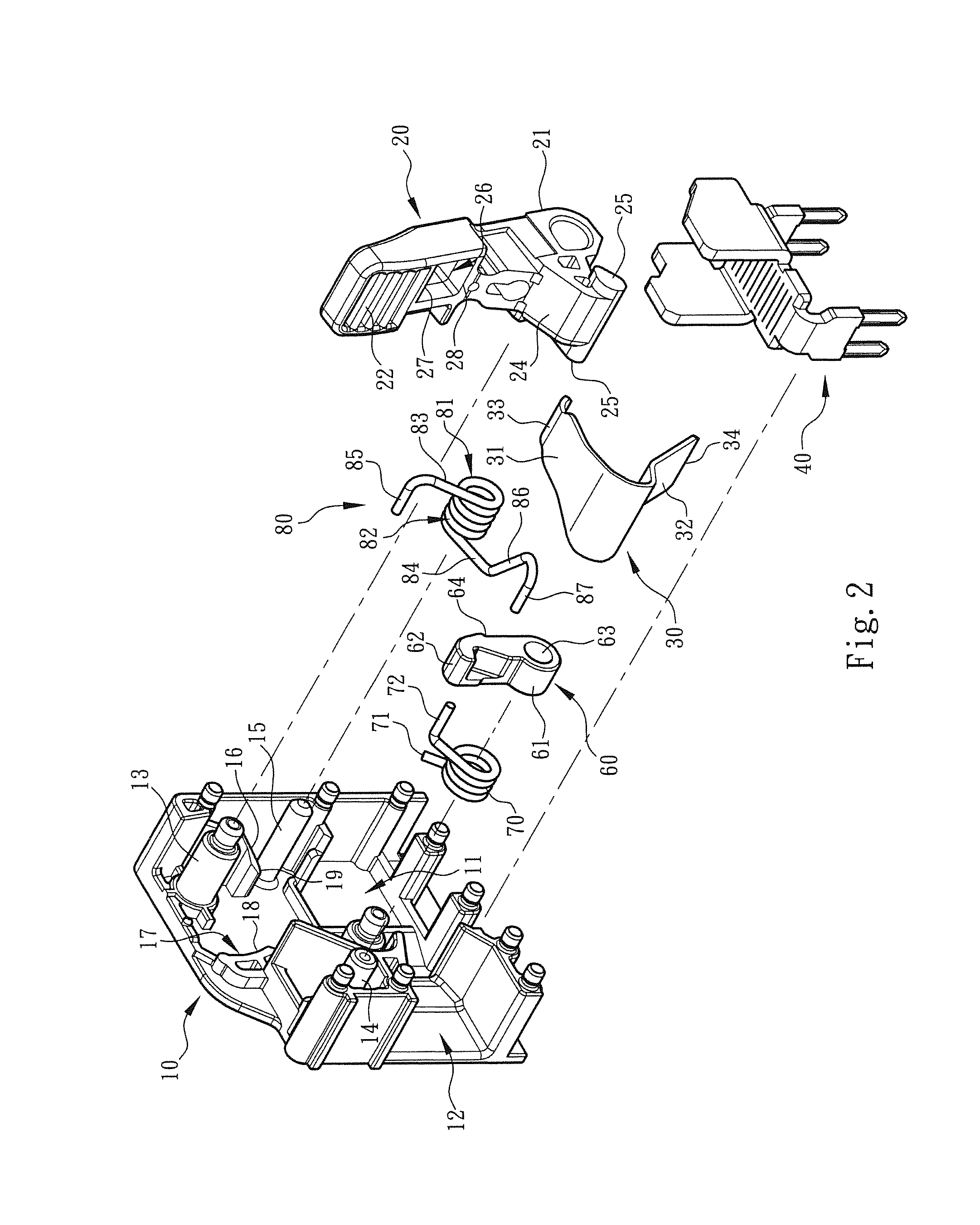

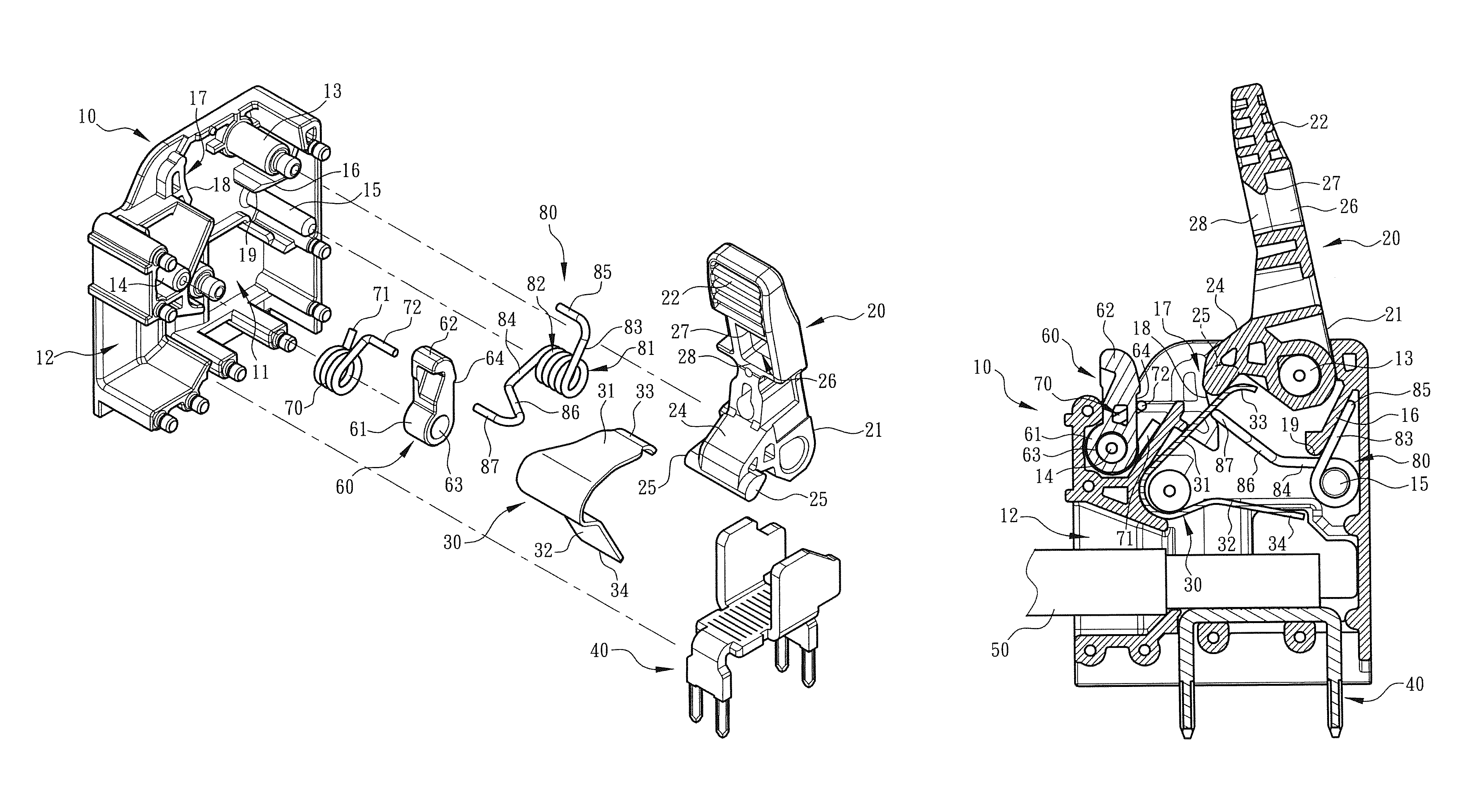

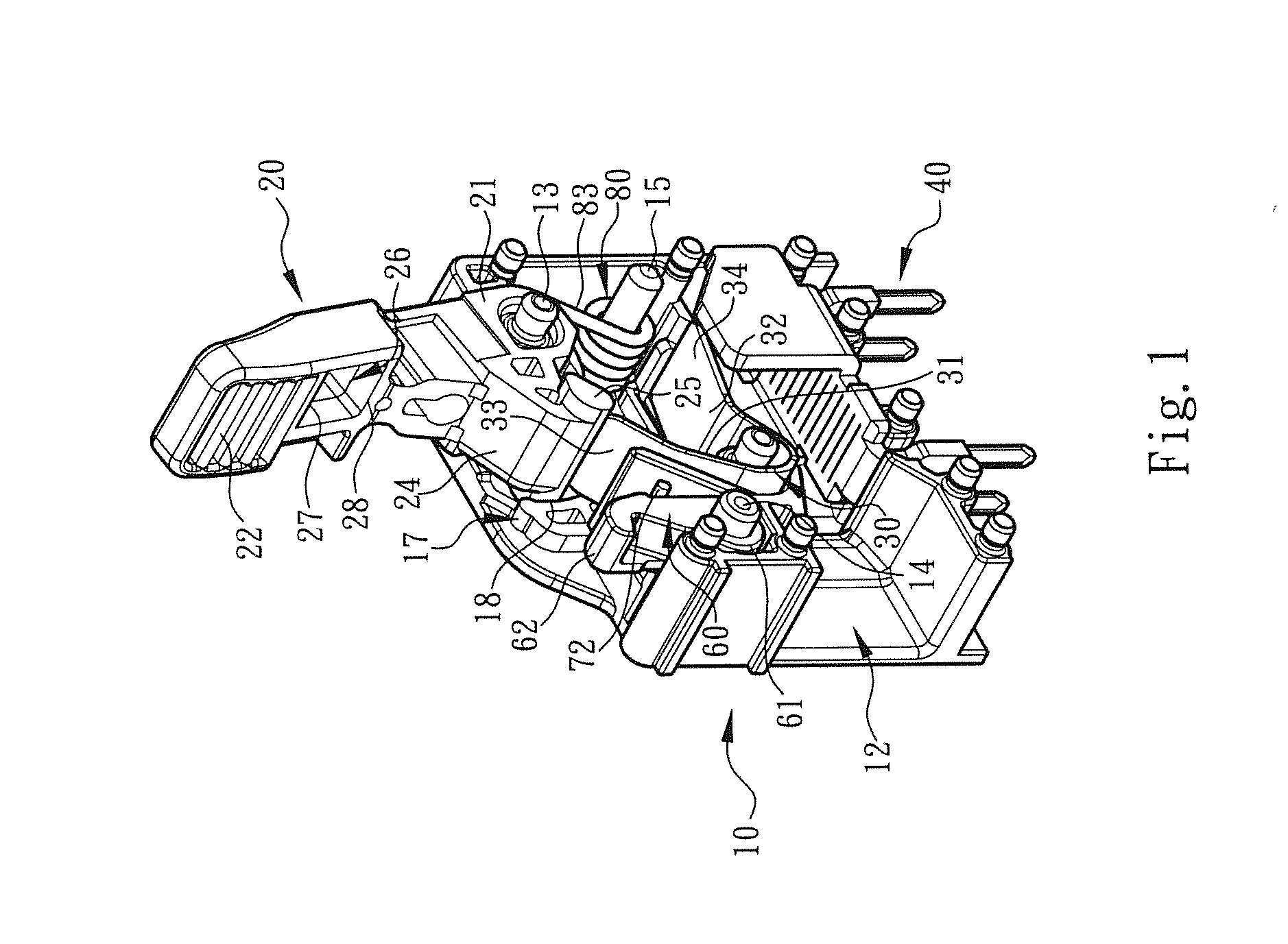

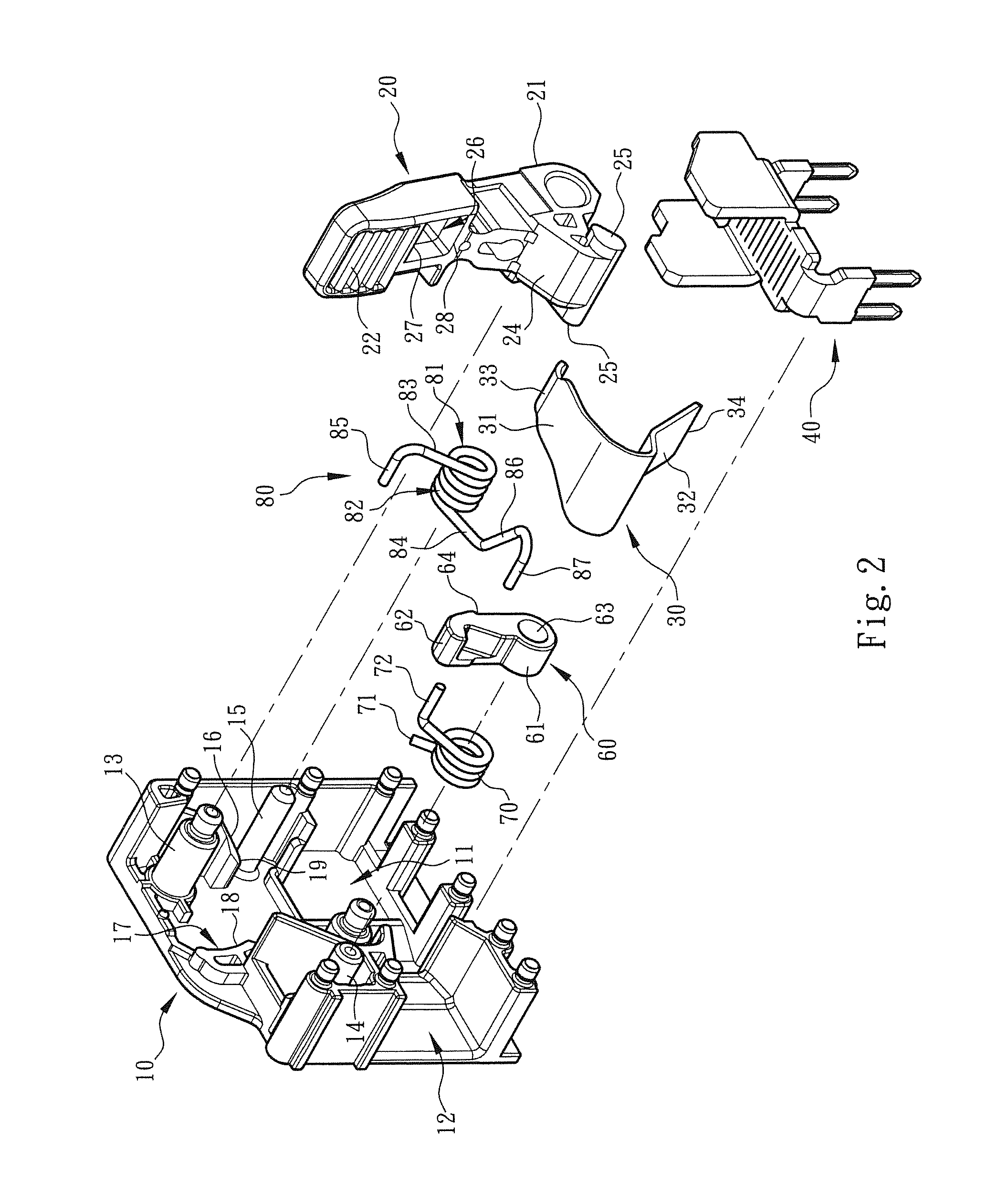

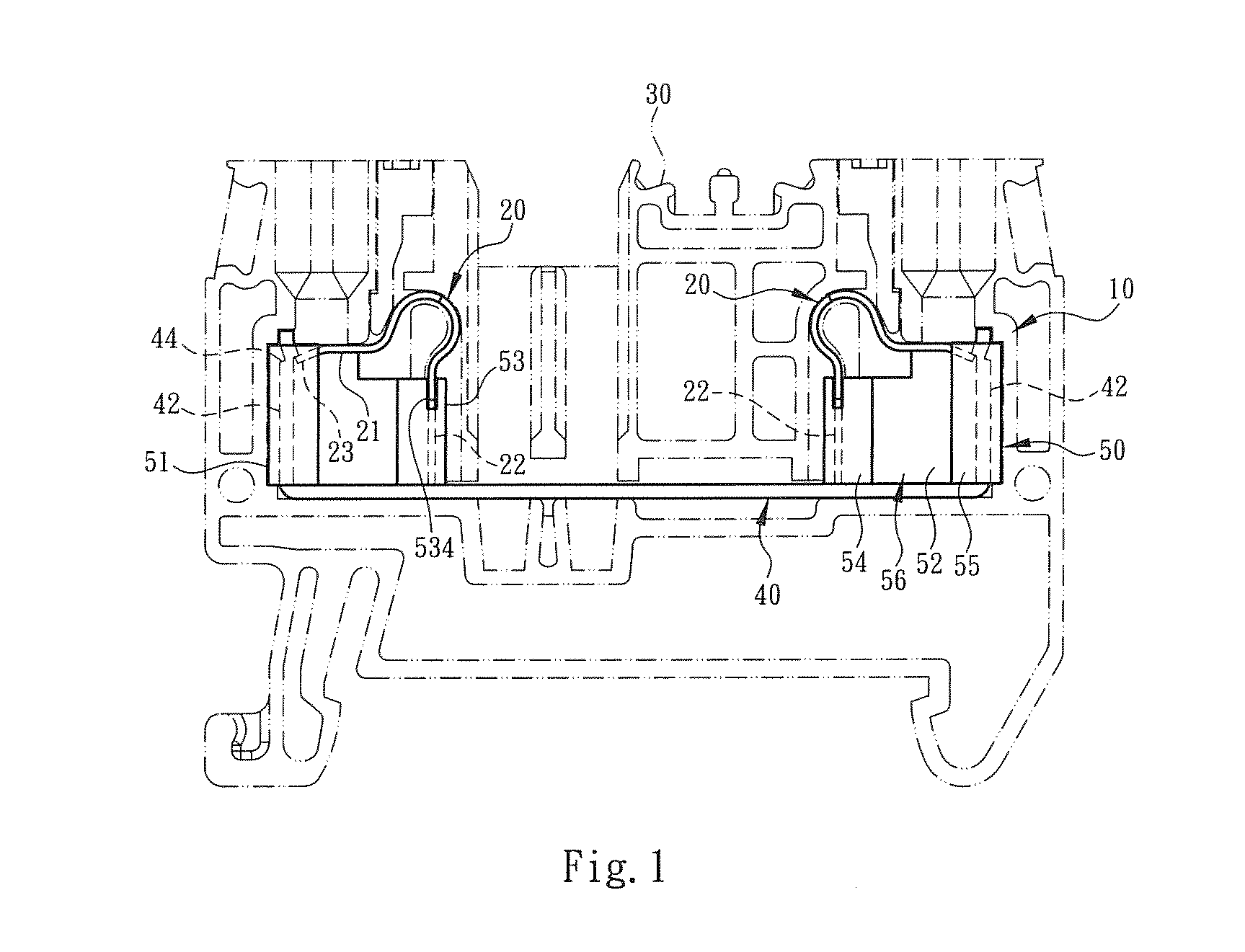

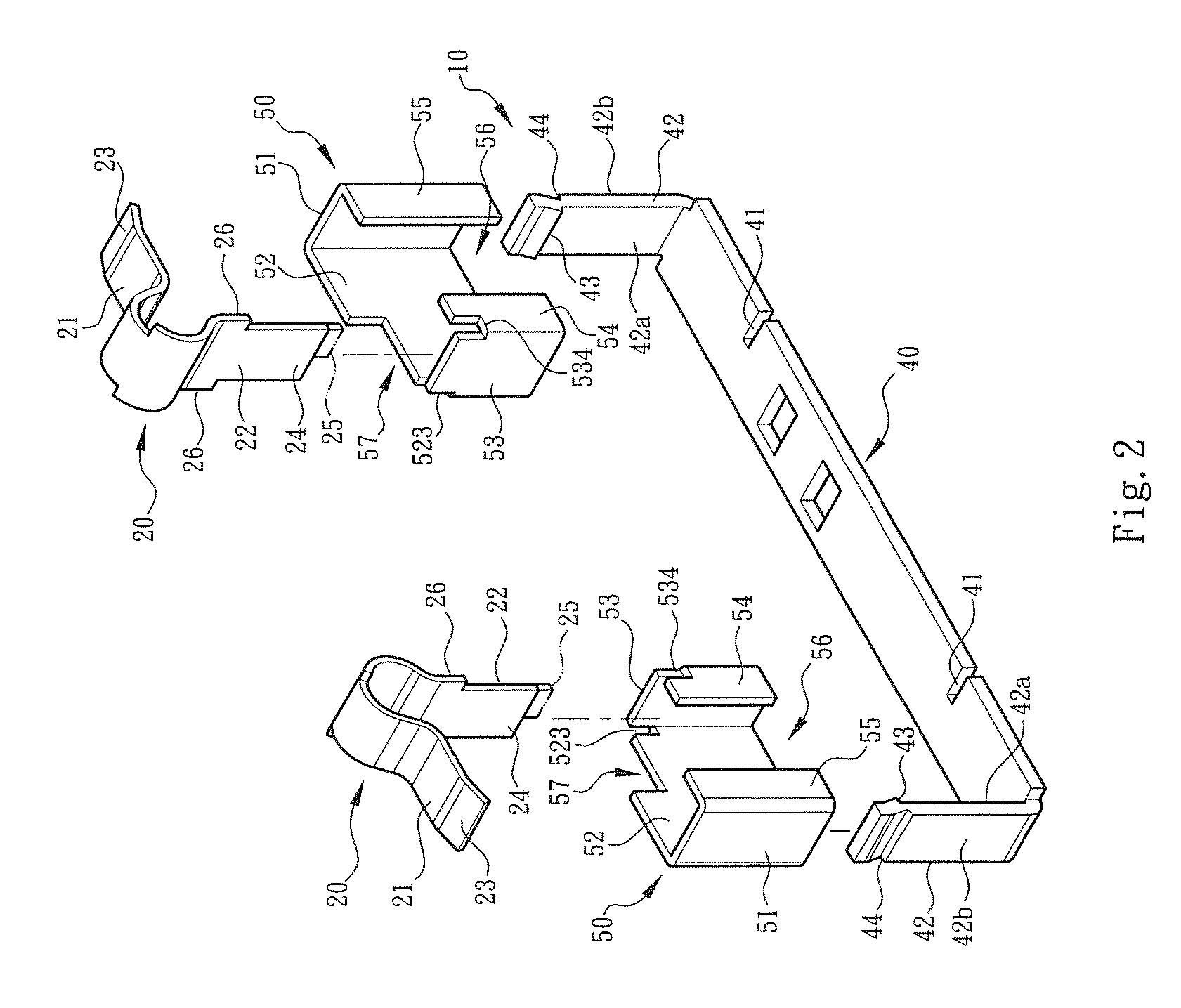

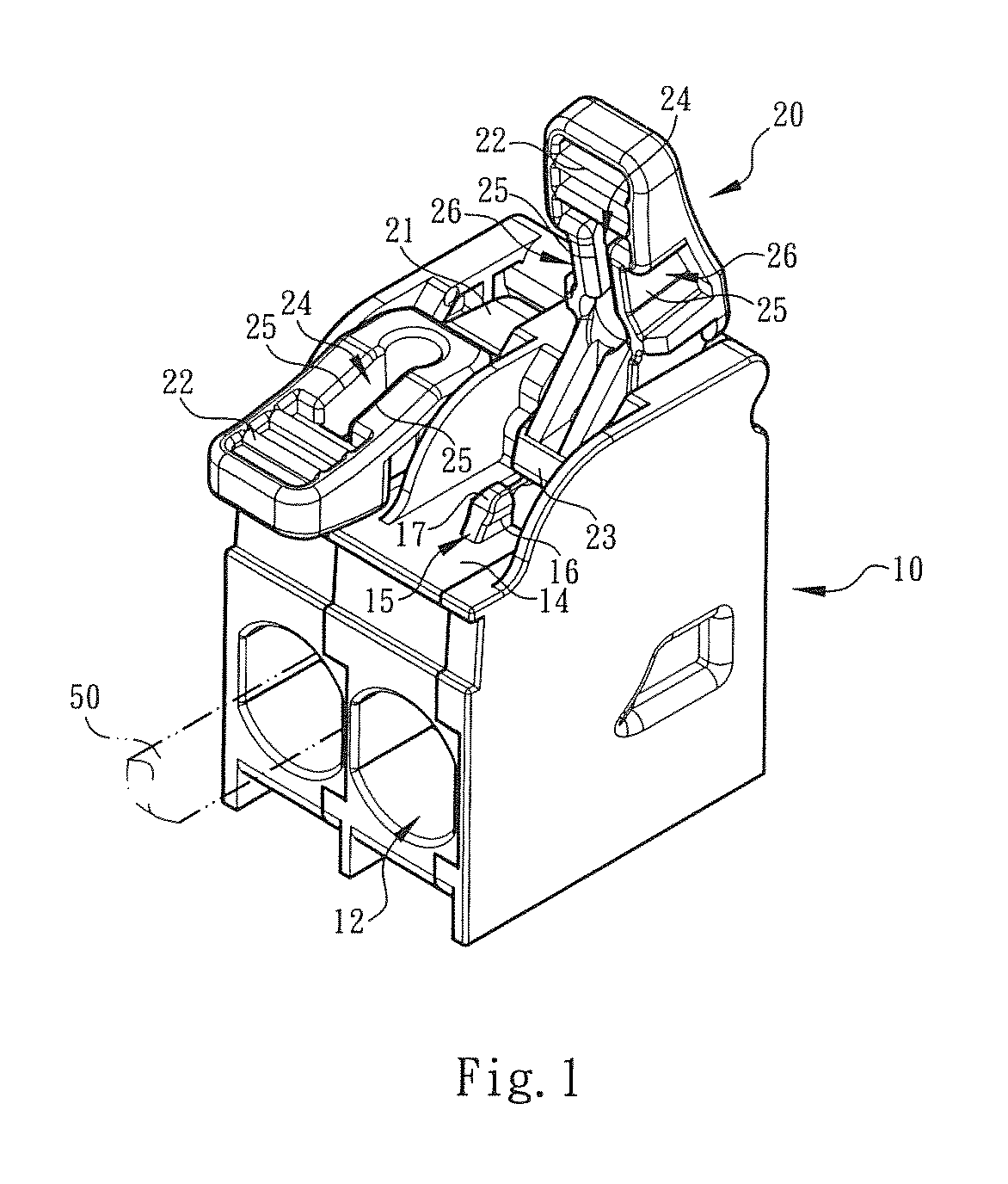

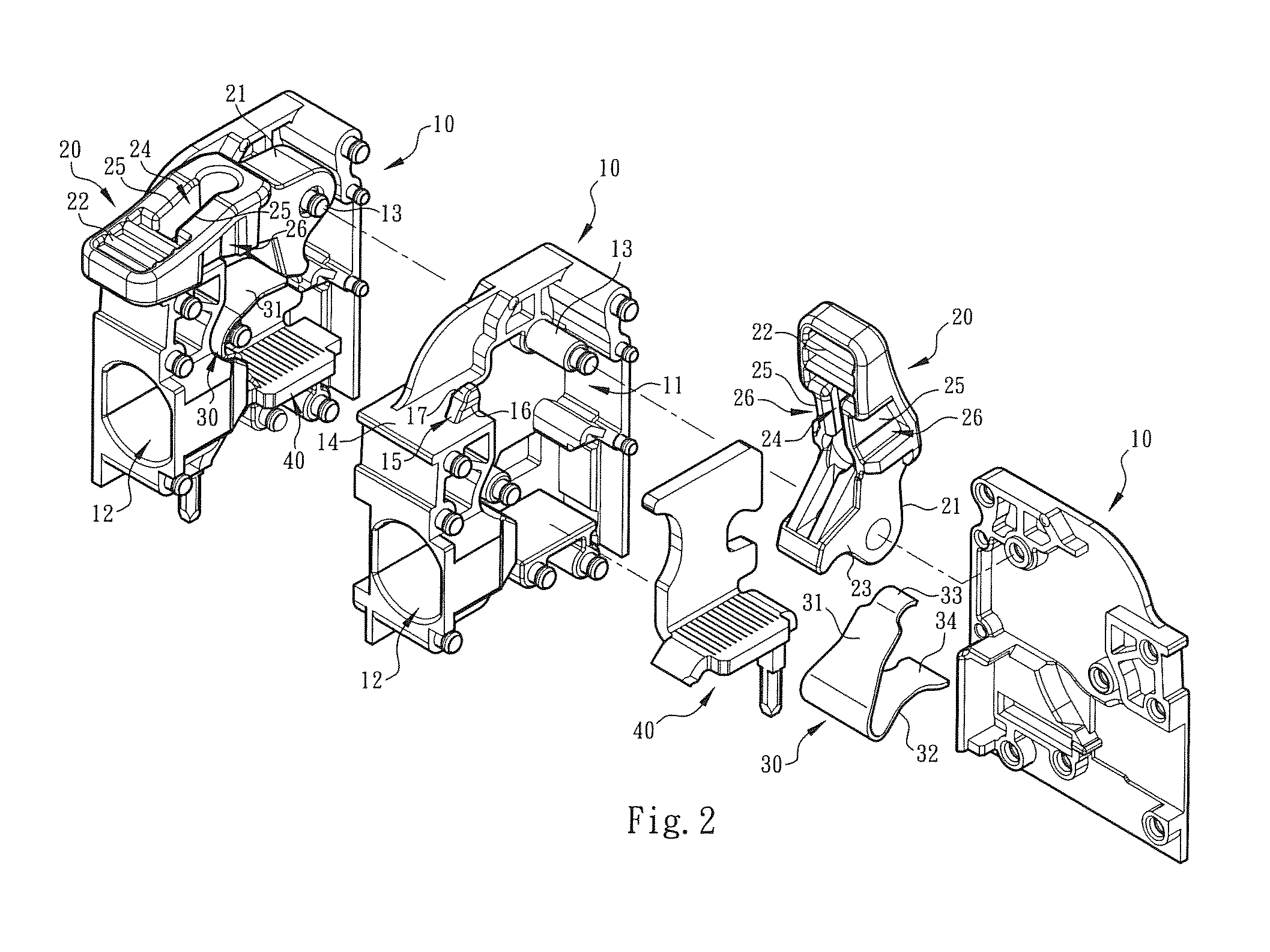

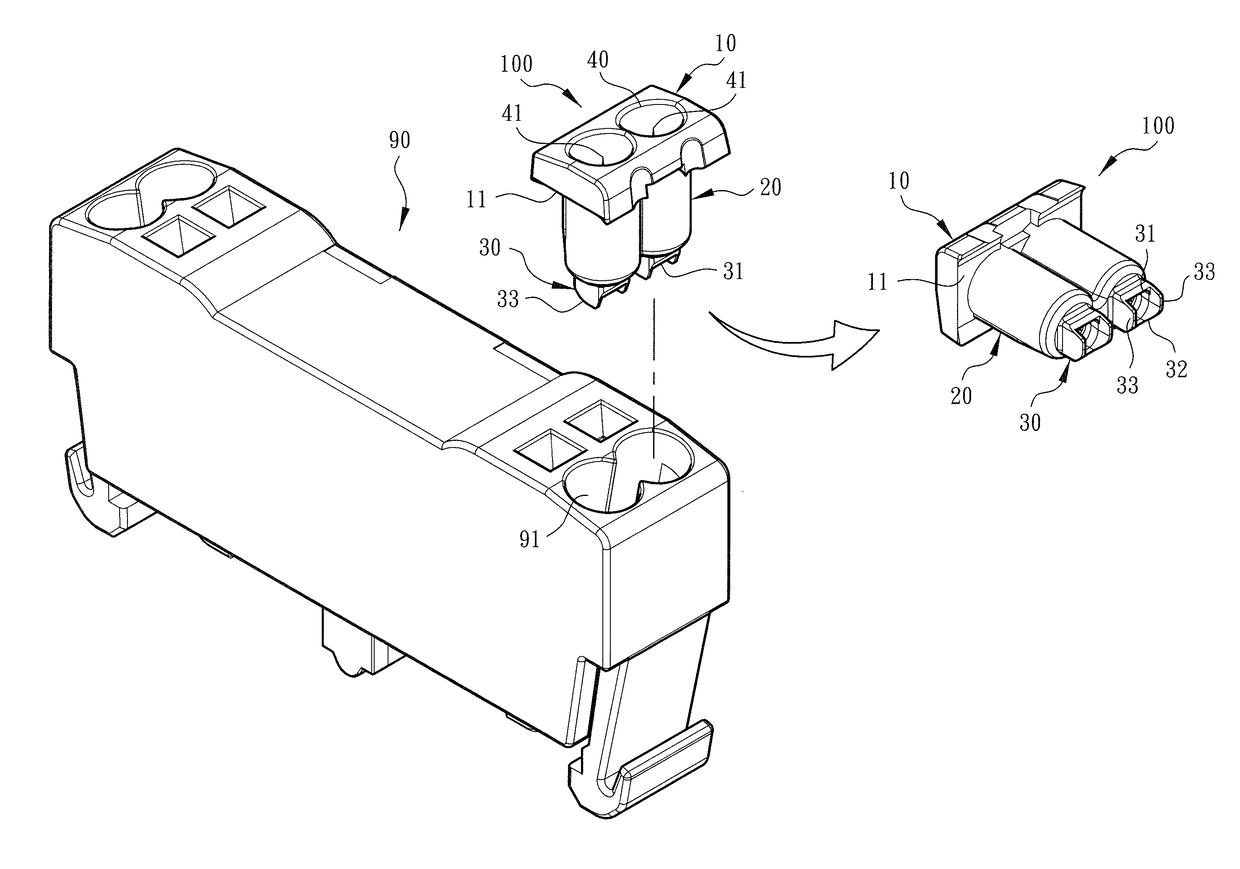

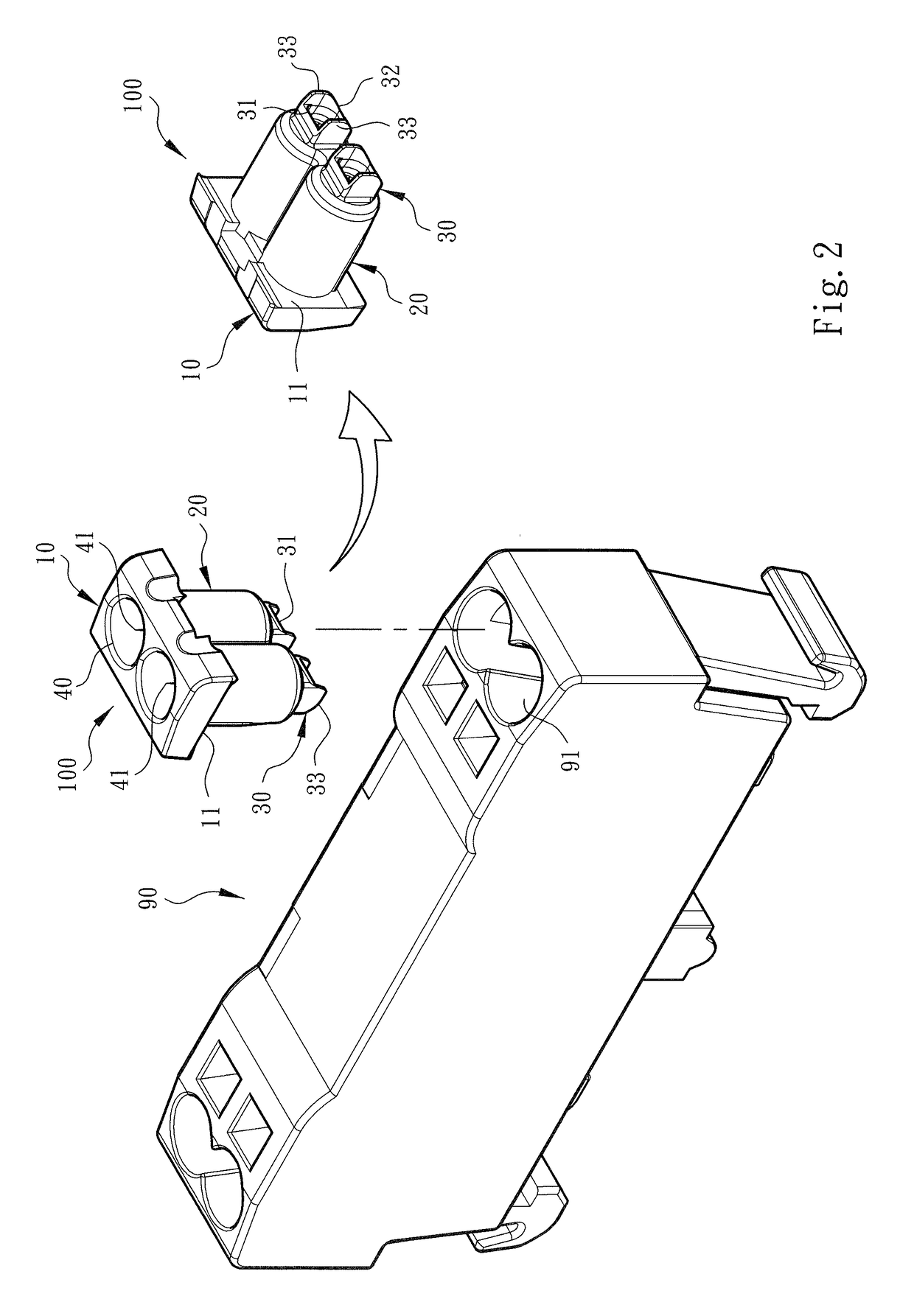

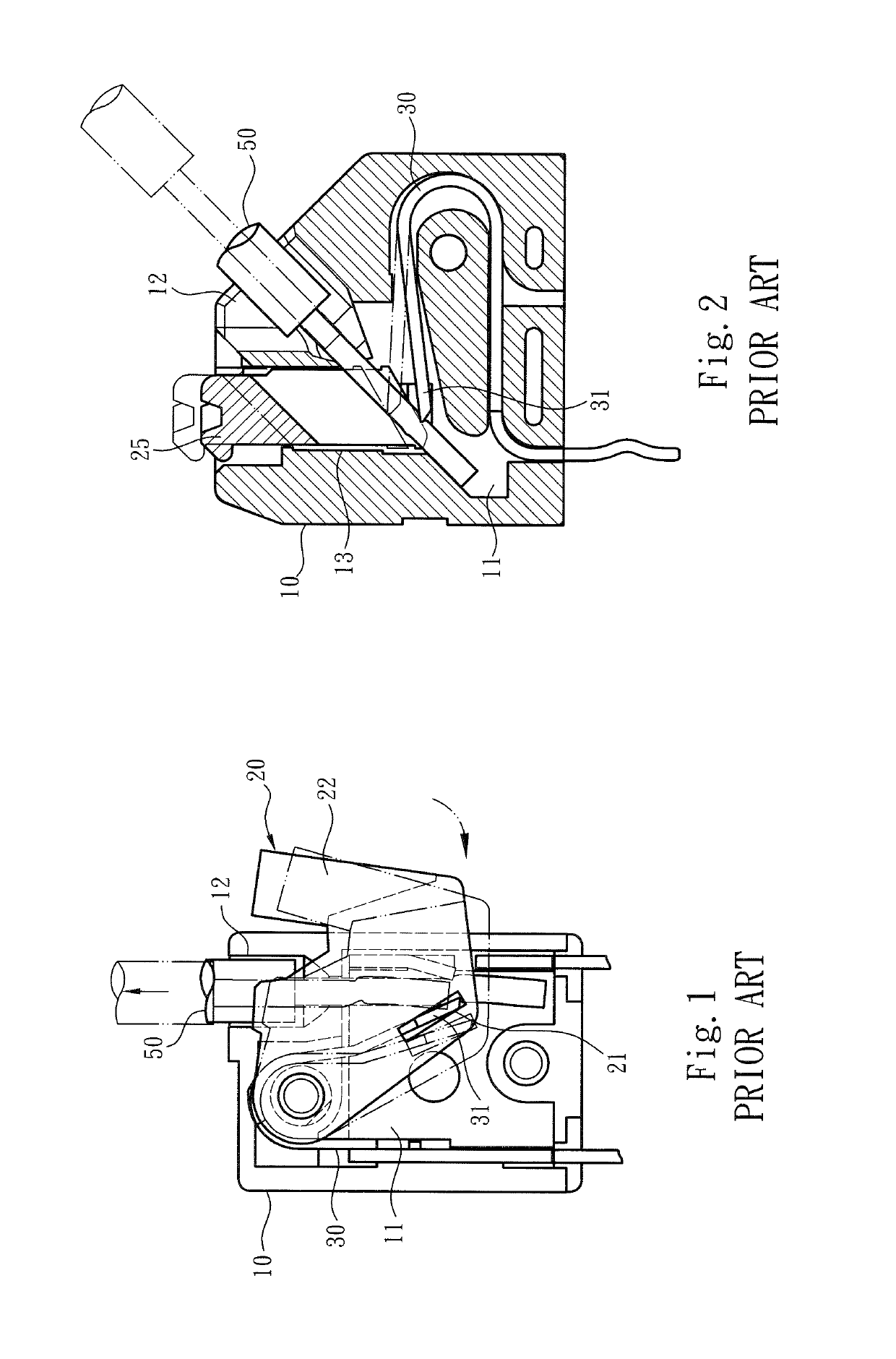

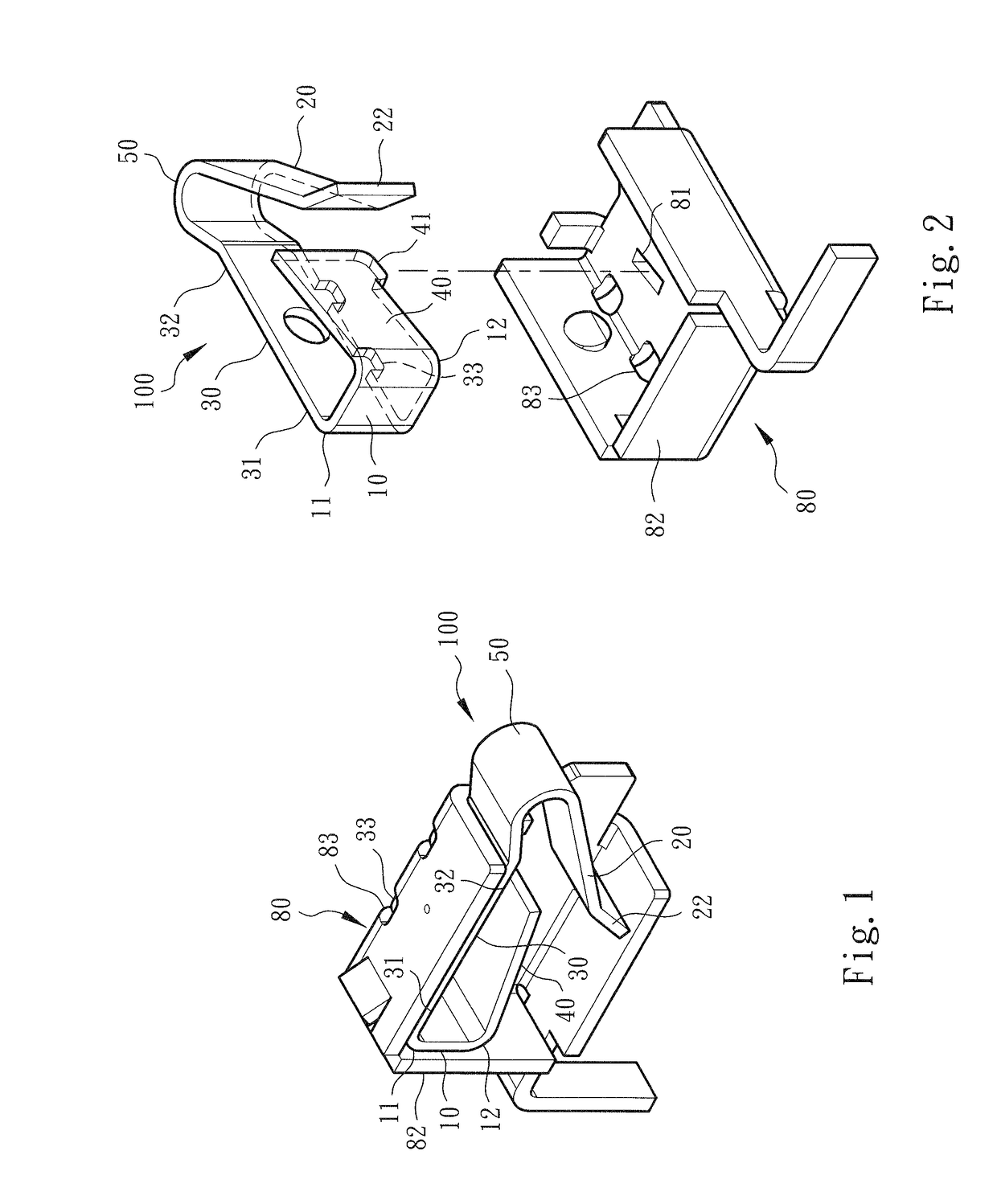

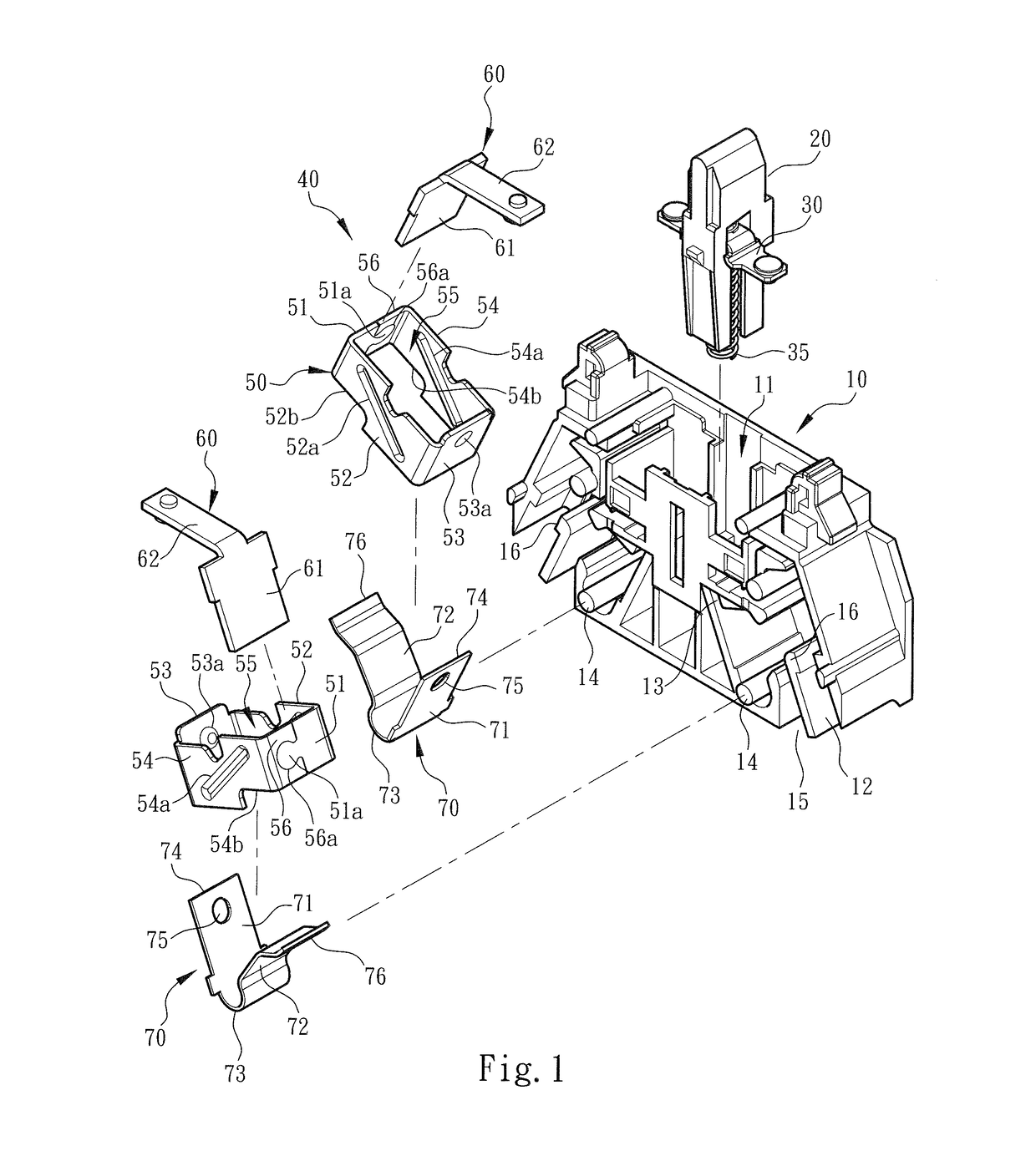

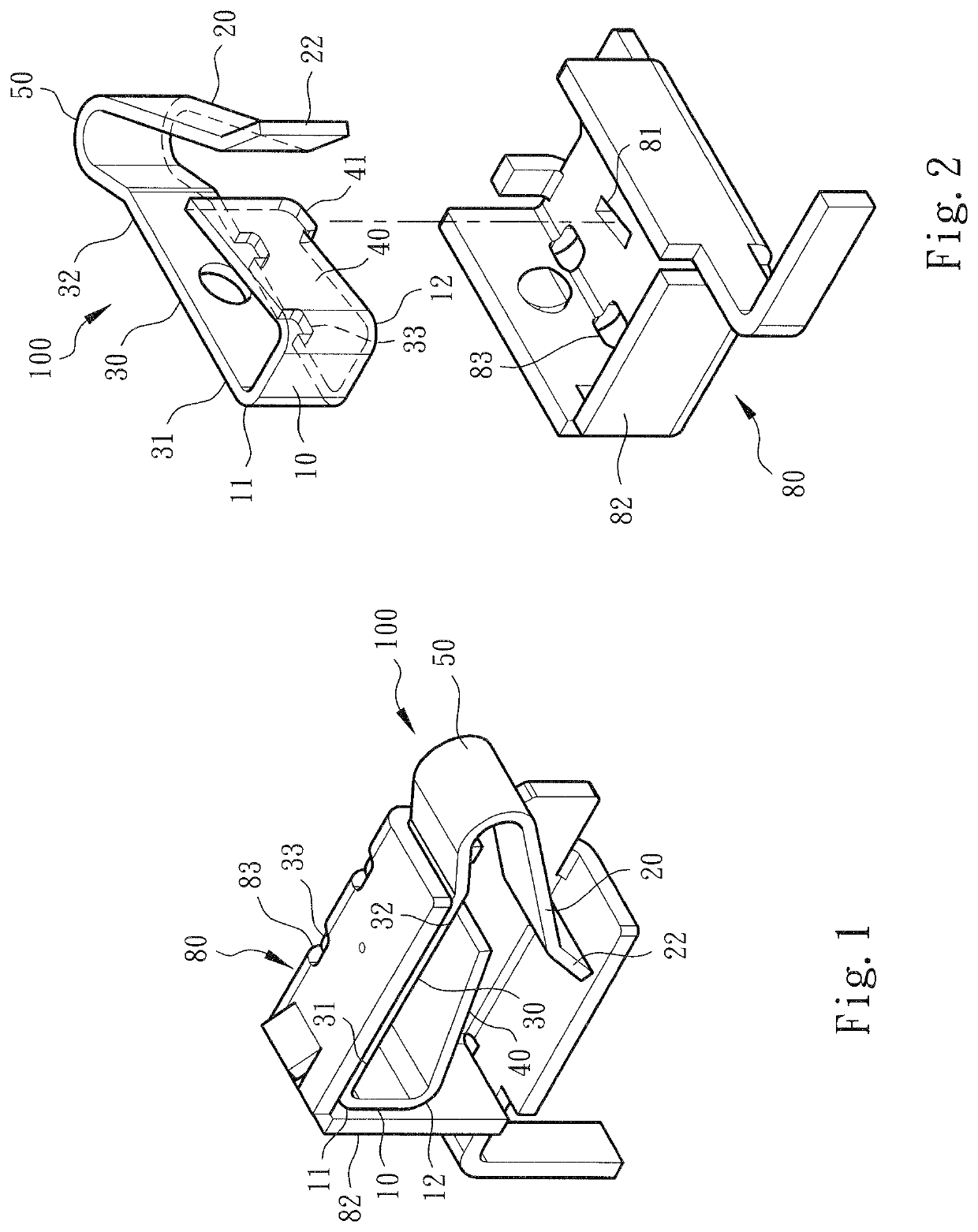

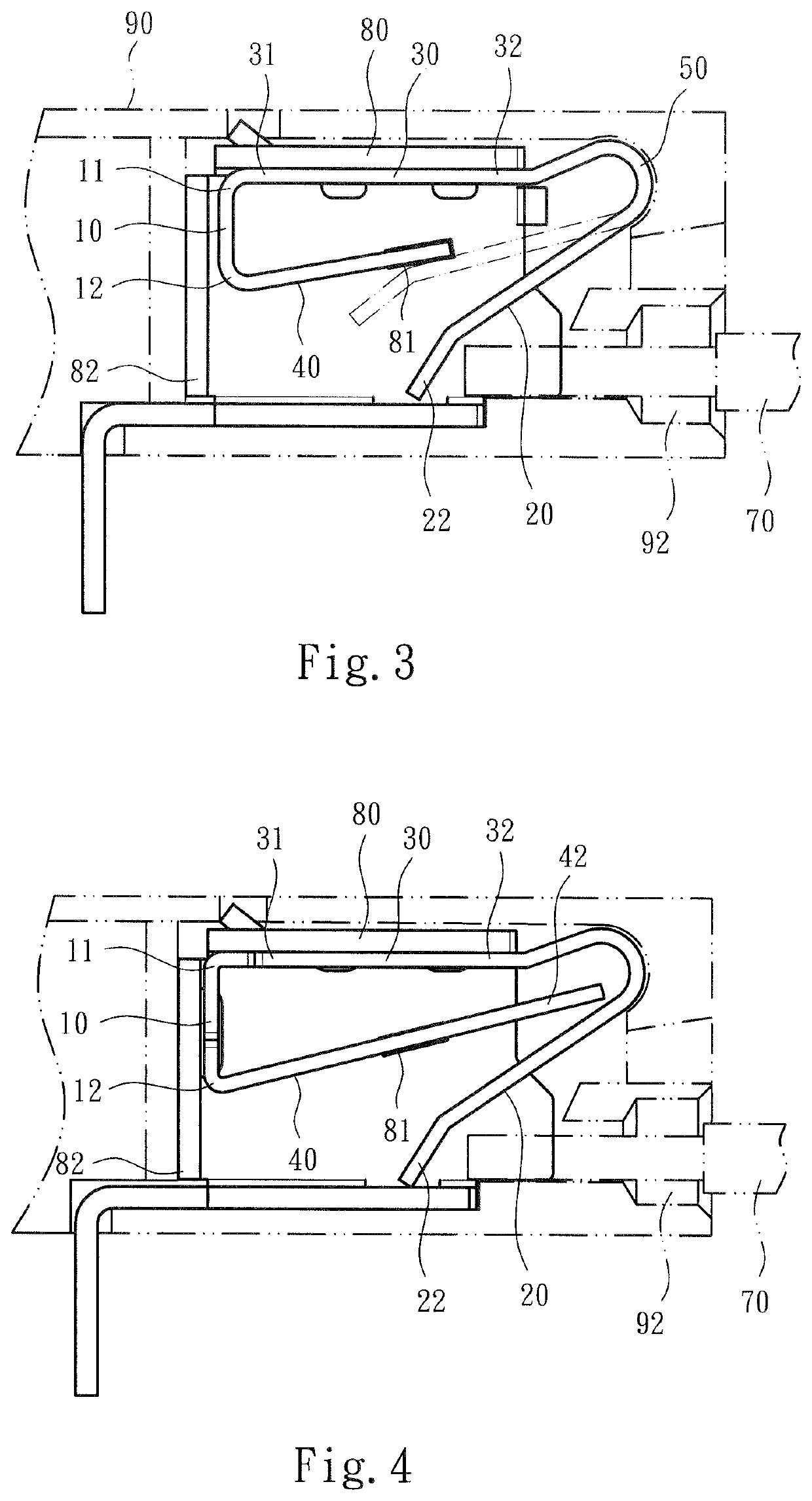

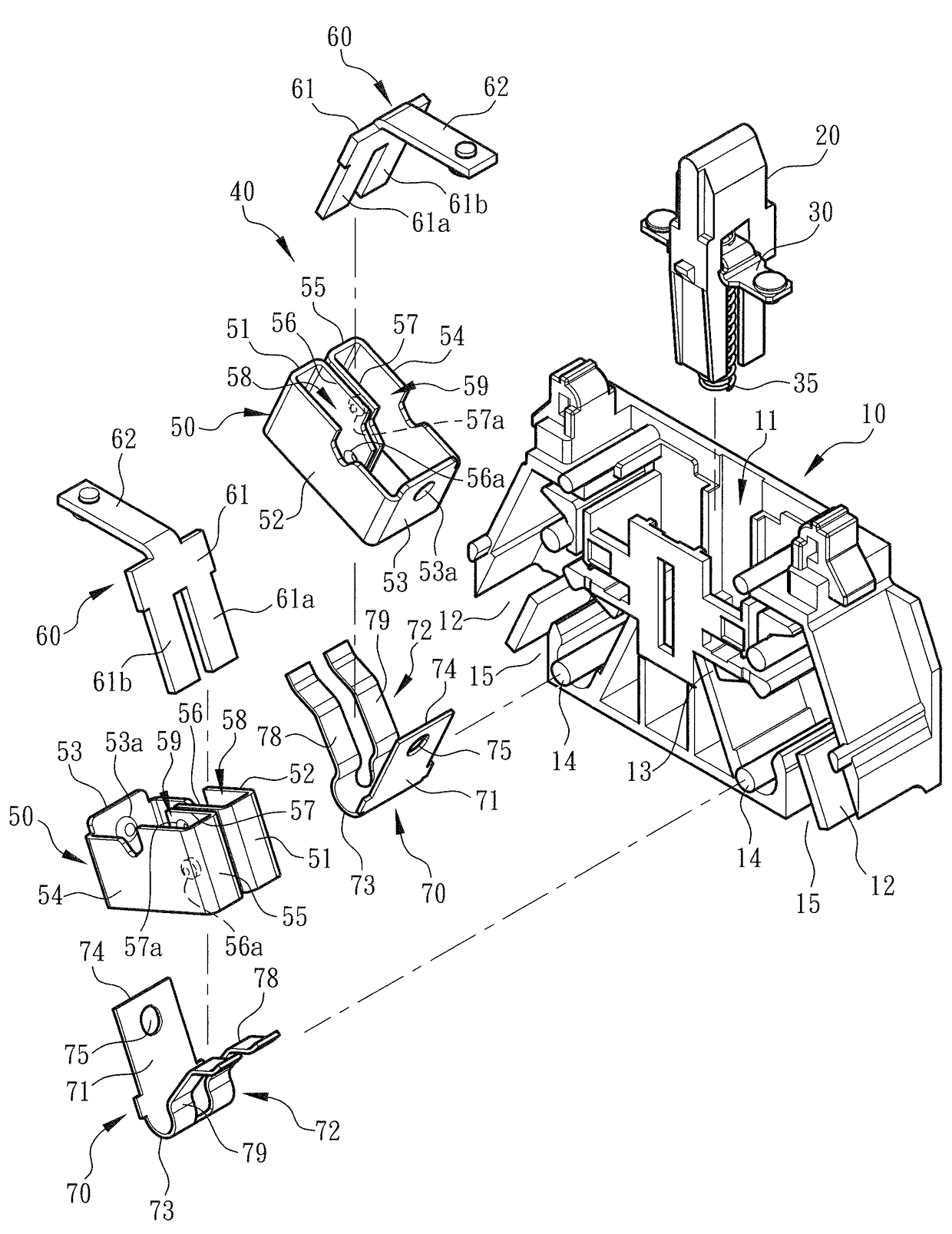

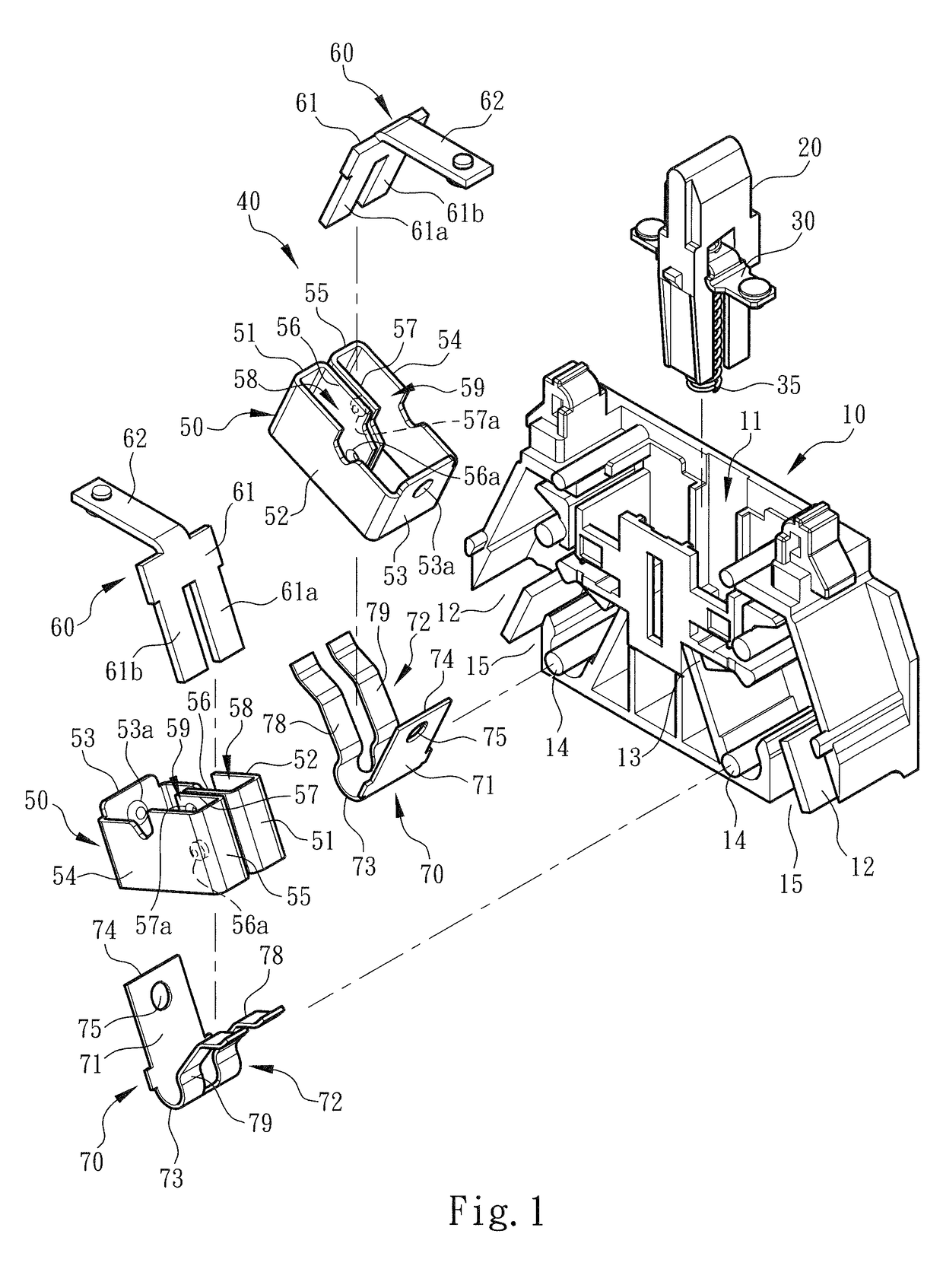

Shift member fixing structure of electrical connection terminal

ActiveUS20160204526A1Improve shortcomingsEasy to operateCoupling device detailsElectric connection basesElectricityElectrical connection

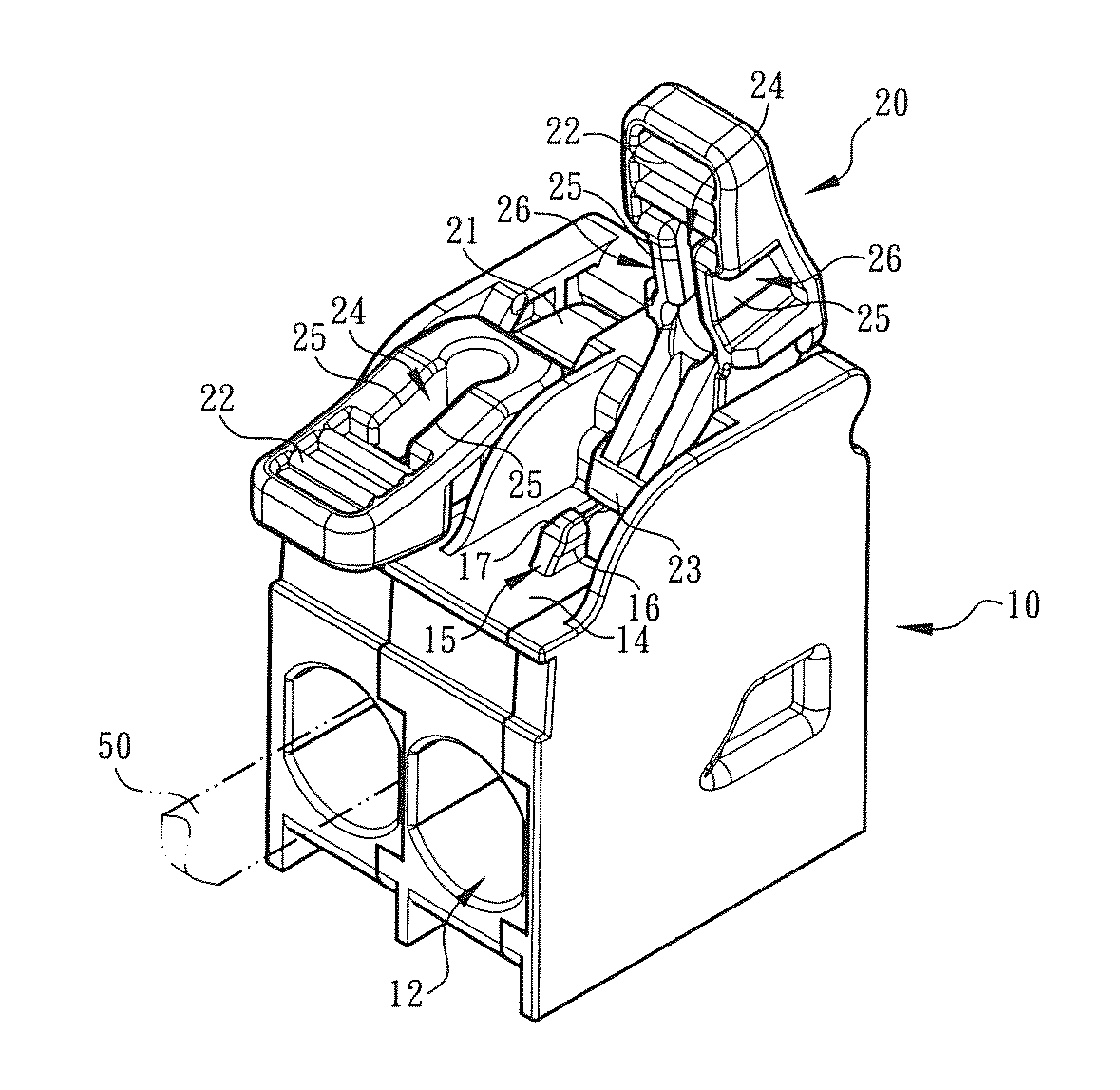

A shift member fixing structure of electrical connection terminal includes an assembly of a terminal and a shift member to improve the shortcoming of the conventional terminal that the structure is complicated and the manufacturing cost is higher. The terminal includes a main body defining a chamber and a metal leaf spring disposed in the chamber for pressing a conductive wire or releasing the conductive wire in response to the operation of the shift member. A predetermined section of the shift member is formed with an insertion section and walls defining the insertion section. A part of the wall is removed to provide elastic effect for the insertion section. The removed part is repositioned on a surface of upper section of the main body to form an interference section. After the shift member is pressed down, the interference section is assembled with the insertion section.

Owner:SWITCHLAB +1

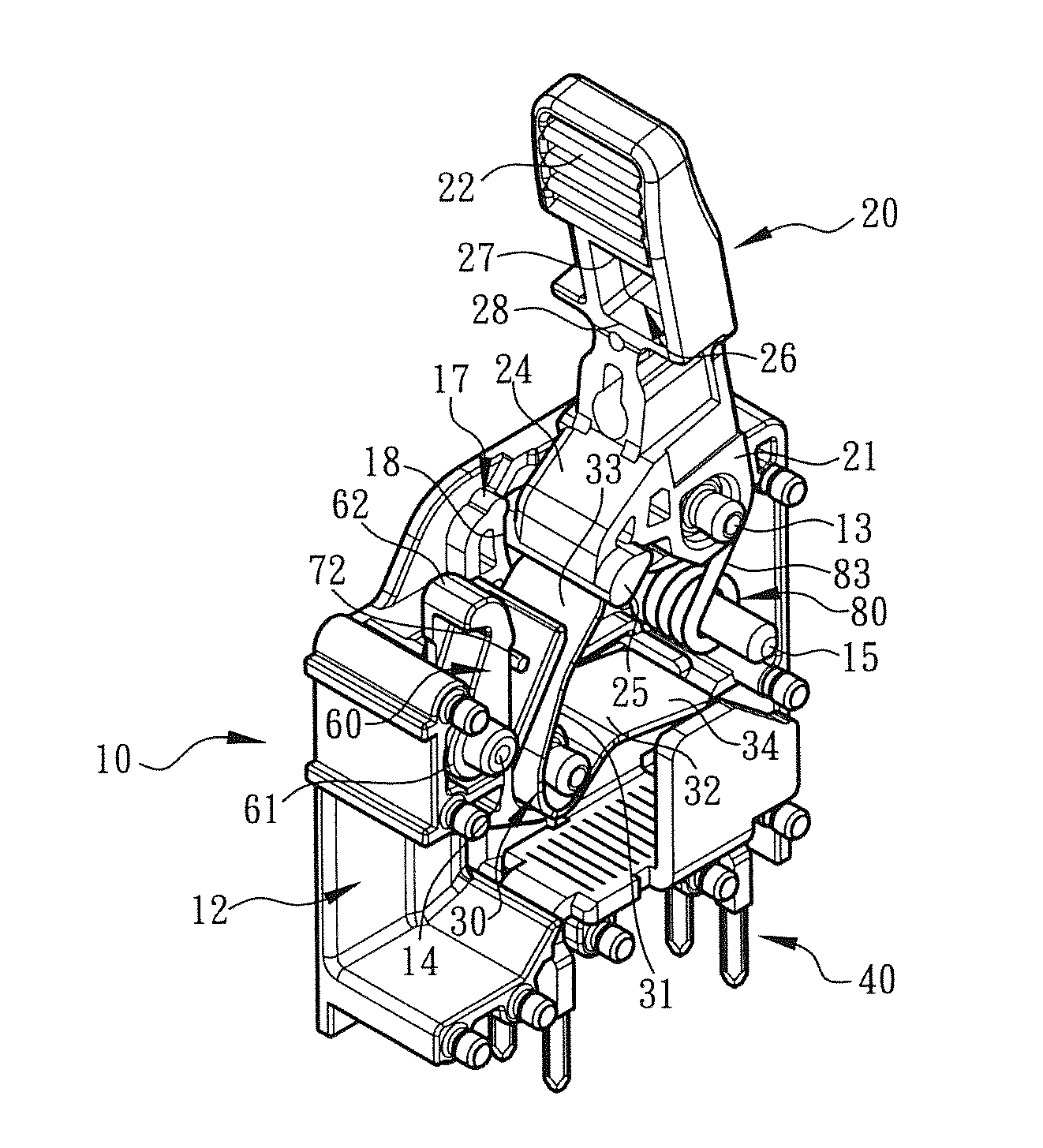

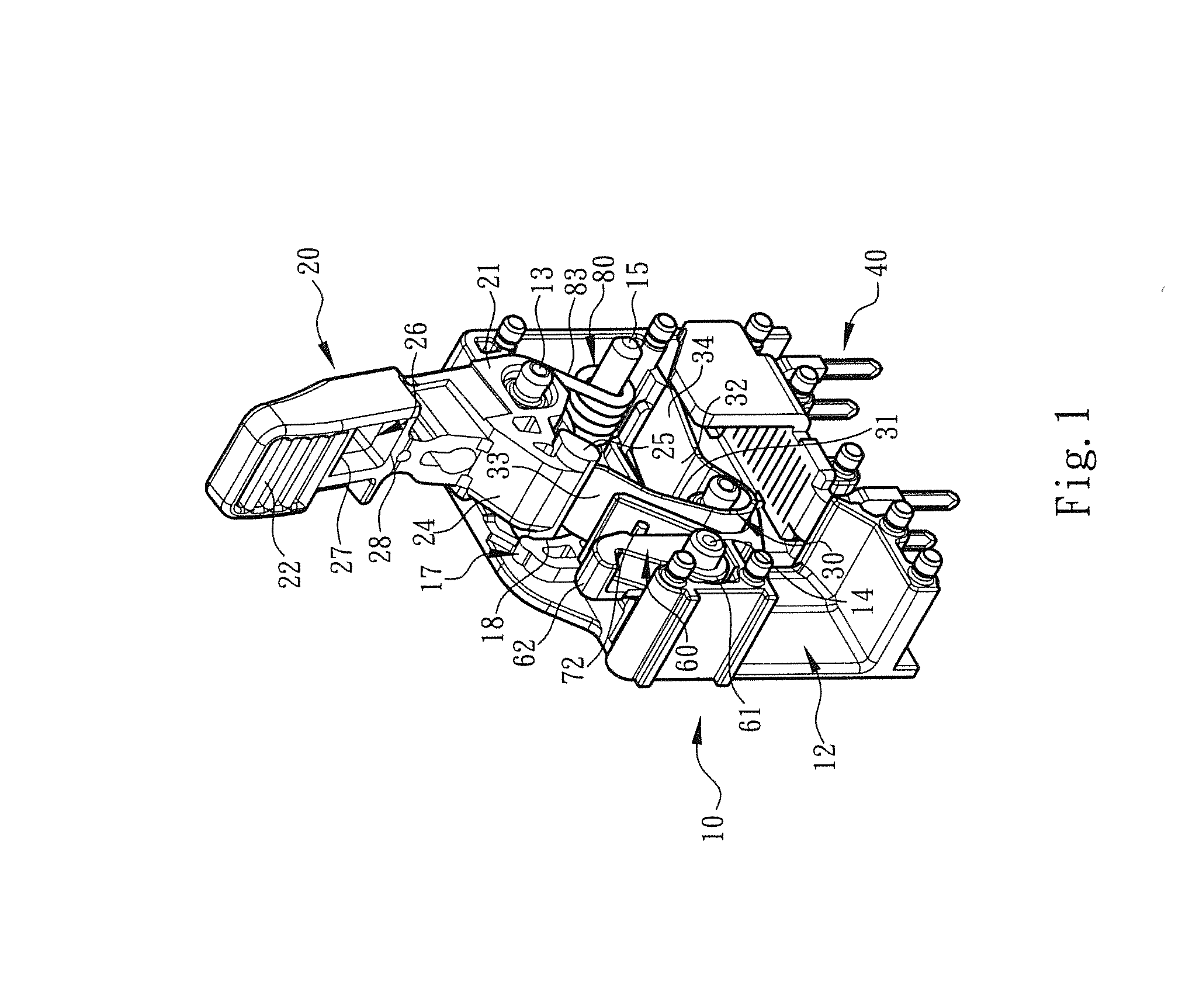

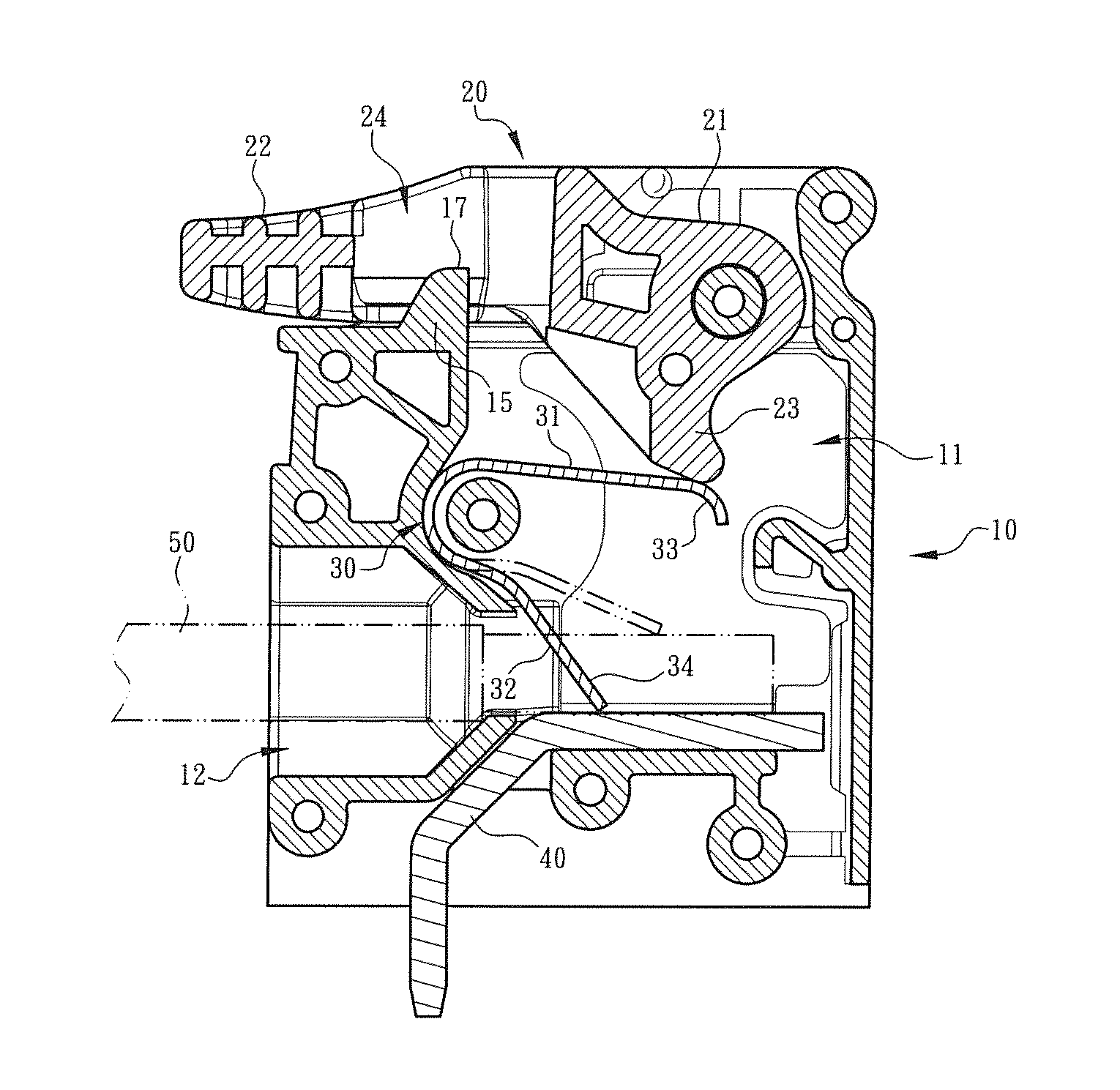

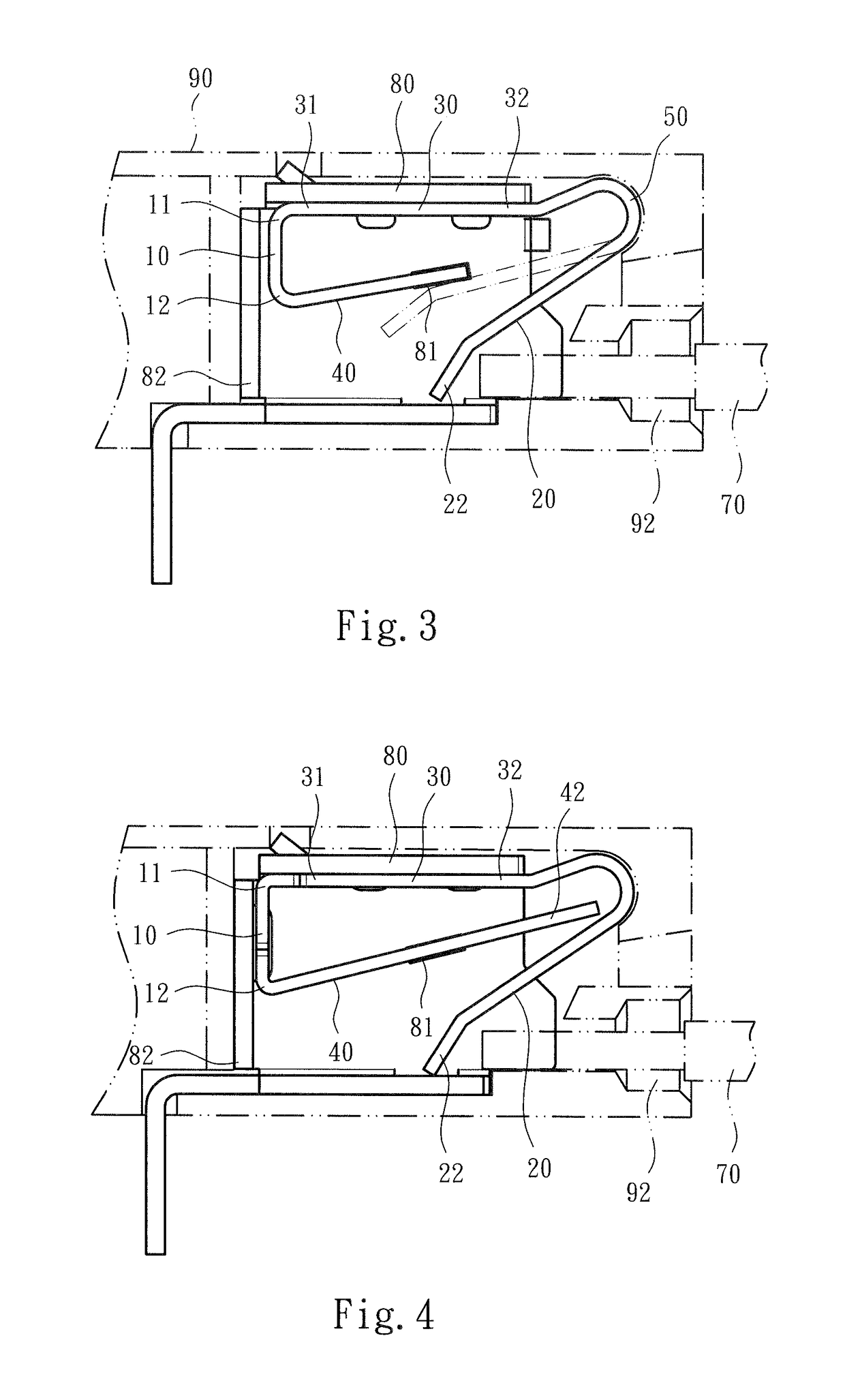

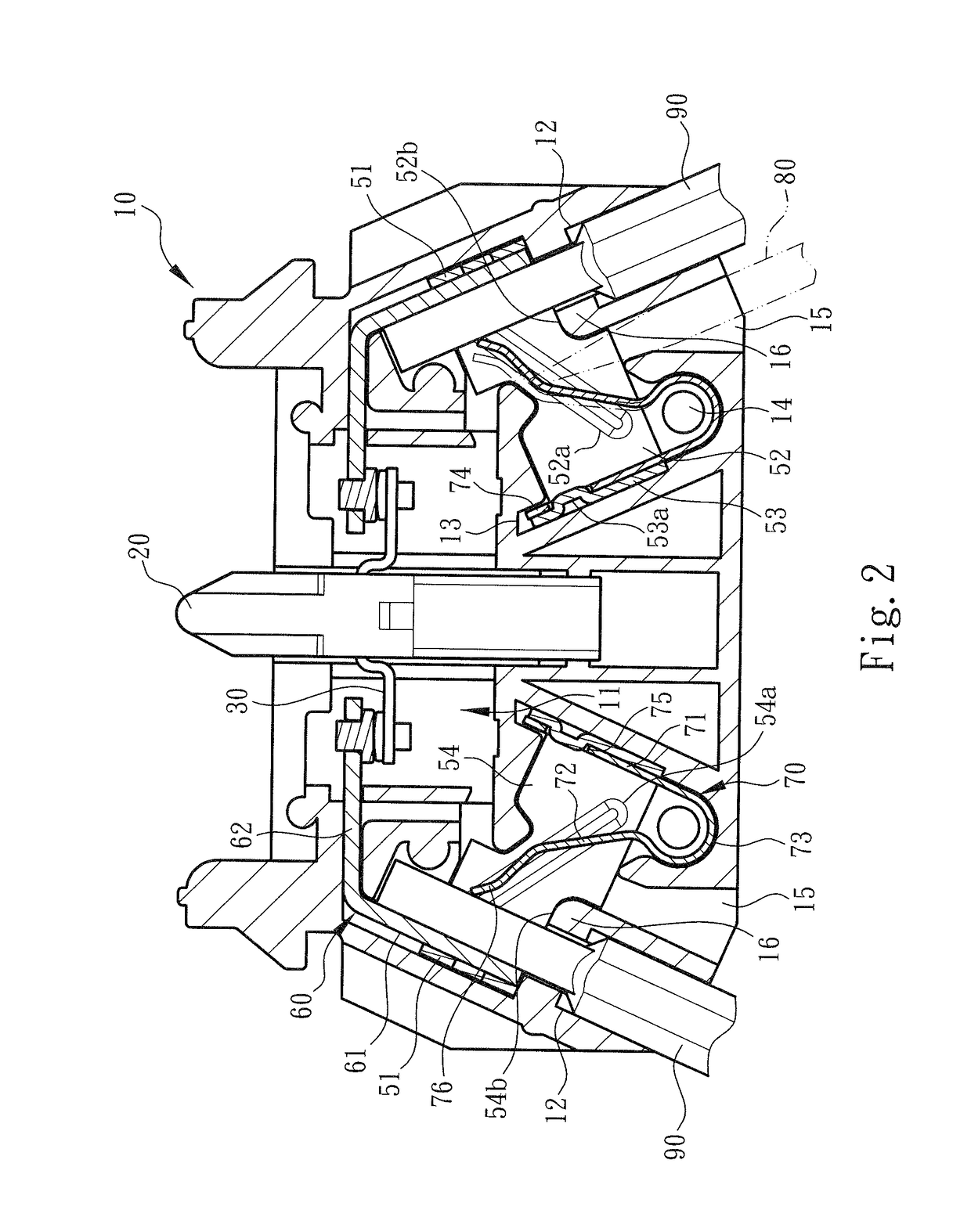

Electrical connection terminal structure

ActiveUS20160190713A1Improve shortcomingsSlowdown speedSecuring/insulating coupling contact membersClamped/spring connectionsElectrical connectionMetal leaf

An electrical connection terminal structure includes: a main body defining a chamber; a metal leaf spring disposed in the chamber, the metal leaf spring being movable with the motion of a shift member to press a conductive wire into electrical connection or release the conductive wire; and an elastic unit mounted in the chamber. When the metal leaf spring is released from the pressing of the shift member to release the conductive wire from the pressing, the elastic unit normally makes the metal leaf spring and the shift member move toward a position where the conductive wire is released. This improves the shortcoming of the conventional electrical connection terminal that when released, the metal leaf spring is apt to interfere with the conductive wire and make it hard to extract the conductive wire out of the main body.

Owner:SWITCHLAB +1

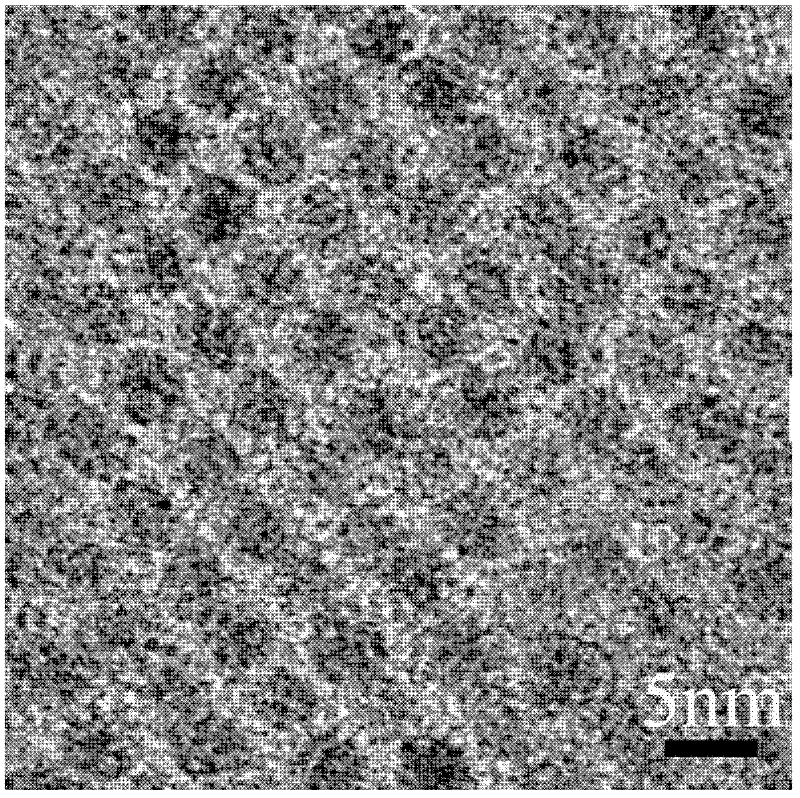

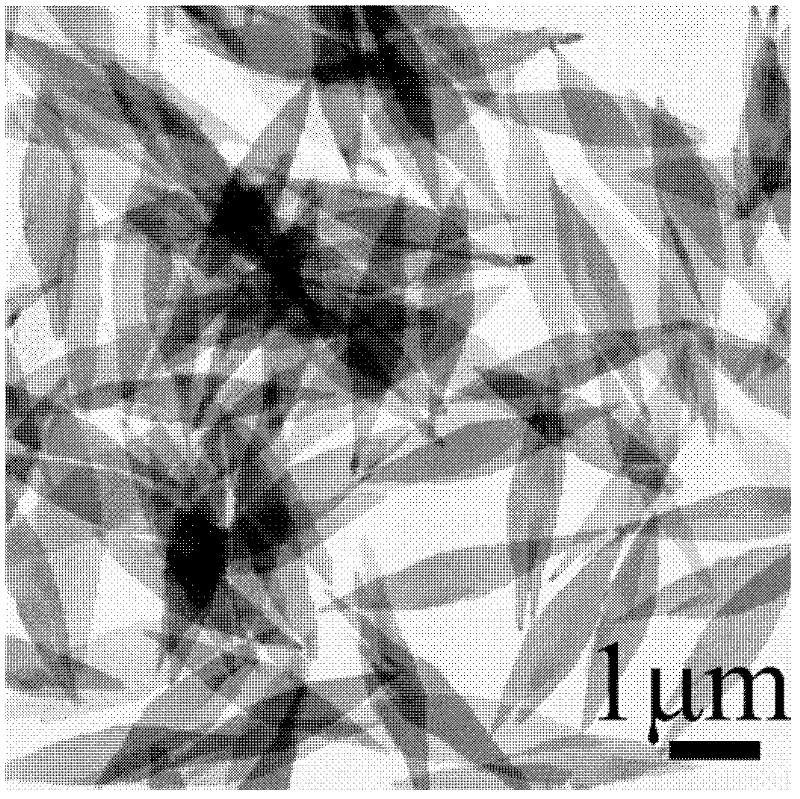

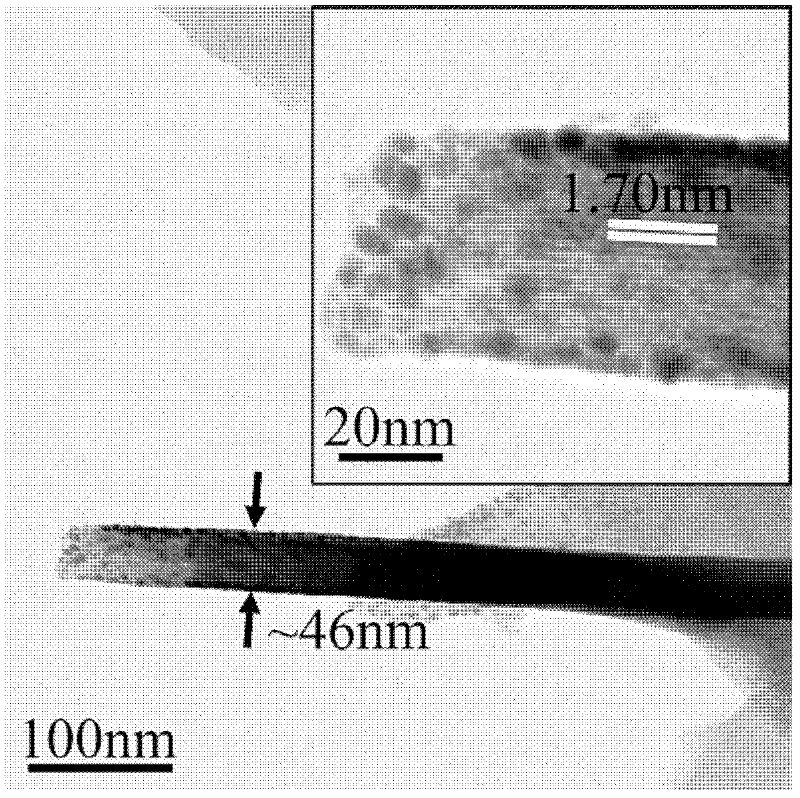

Nano metal leaf and preparation method thereof

InactiveCN102416468ARegulates the growth processUniform sizeMaterial nanotechnologyMetal leafMetal particle

The invention discloses a nano metal leaf and a preparation method thereof. Pure nano metal particles with controllable morphology and size are mixed and reacted at room temperature with a surface modifier which is dispersed in a polar organic solvent and has more than two active functional groups, and the nano metal leaf using the nano metal as a skeleton is obtained after the reaction is finished, wherein the radial size of the nano metal leaf is in several microns, the thickness of the nano metal leaf is in dozens of nanometers, and the nano metal leaf has laminar structure. The nano metalleaf is prepared at room temperature in one step by mixing different polar solvents, adding the specific surface modifier into the mixed polar solvent and adjusting the decomposition and self-assembly processes of the nano metal crystal; the prepared nano metal leaf has the advantages of uniform size, high controllability, high yield and good dispersibility in the polar inorganic solvent; the reaction conditions are easily controlled; and the nano metal leaf can be produced in a large scale.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

Electrical connection terminal having a metal leaf spring actuated by a shift member and an elastic unit

ActiveUS9466894B2Improve shortcomingsSlowdown speedEngagement/disengagement of coupling partsSecuring/insulating coupling contact membersElectrical connectionEngineering

An electrical connection terminal structure includes: a main body defining a chamber; a metal leaf spring disposed in the chamber, the metal leaf spring being movable with the motion of a shift member to press a conductive wire into electrical connection or release the conductive wire; and an elastic unit mounted in the chamber. When the metal leaf spring is released from the pressing of the shift member to release the conductive wire from the pressing, the elastic unit normally makes the metal leaf spring and the shift member move toward a position where the conductive wire is released. This improves the shortcoming of the conventional electrical connection terminal that when released, the metal leaf spring is apt to interfere with the conductive wire and make it hard to extract the conductive wire out of the main body.

Owner:SWITCHLAB +1

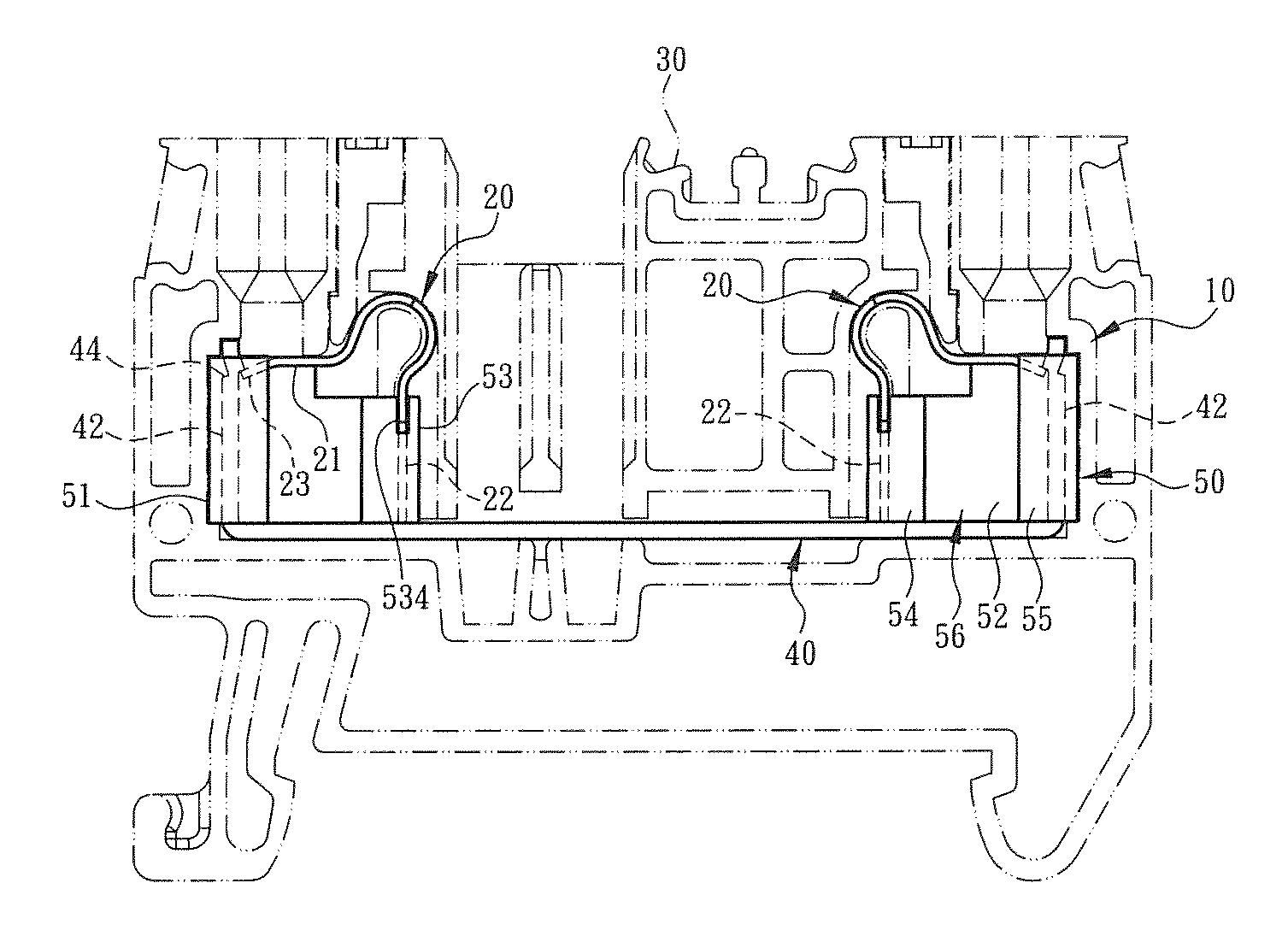

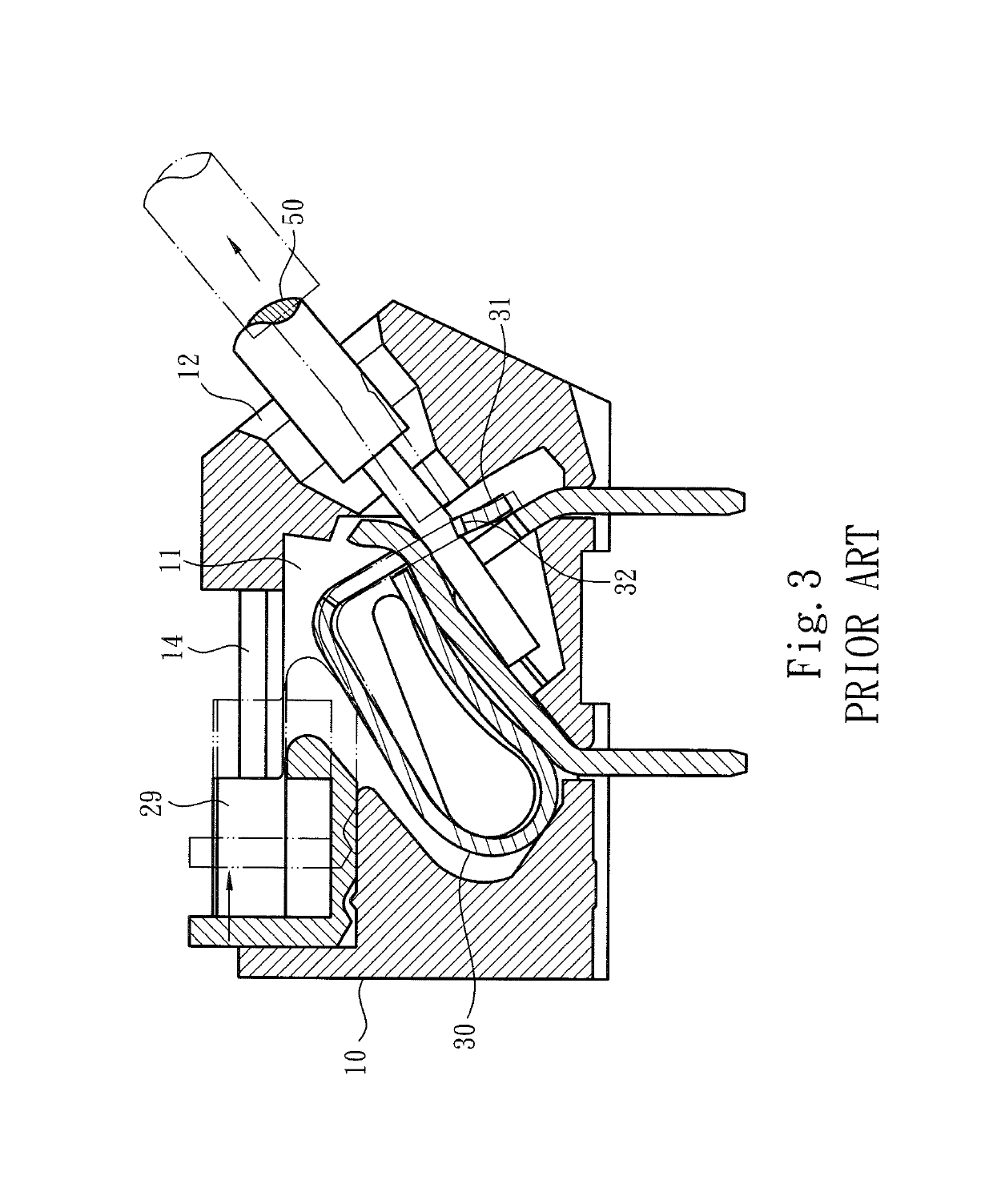

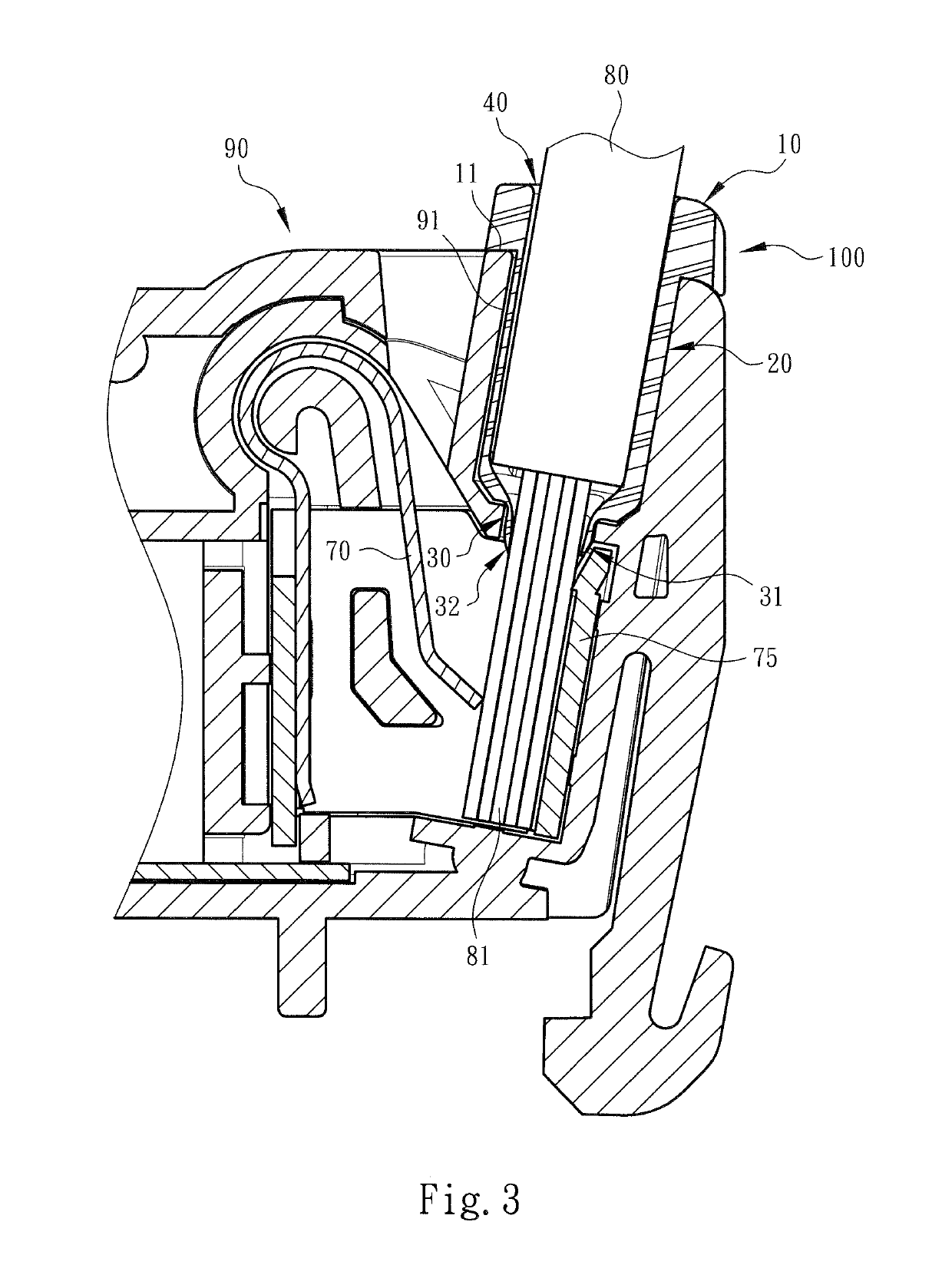

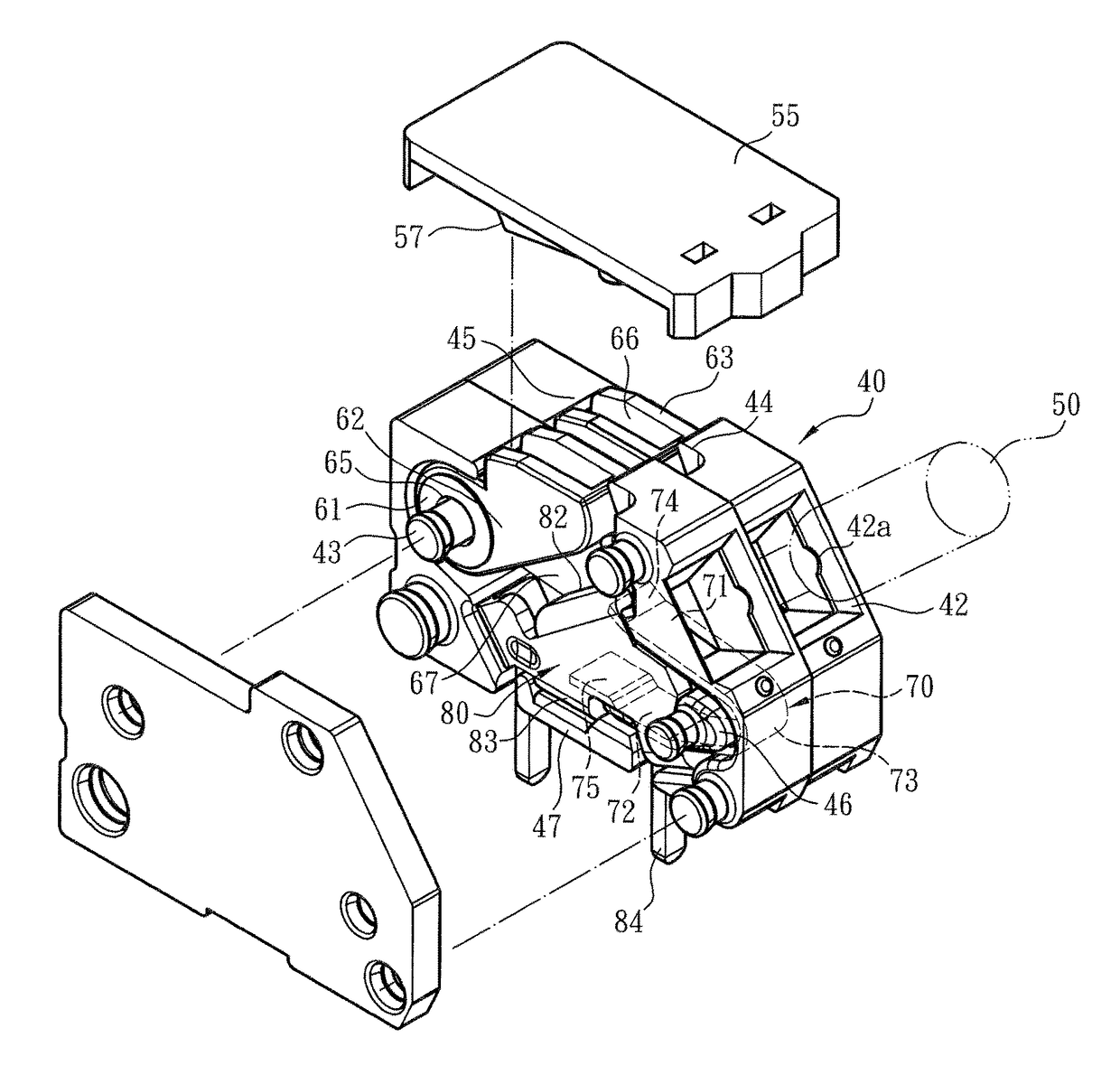

Conductive wire connection structure of rail-type electrical terminal

ActiveUS9525218B2Reduce yieldImprove cooling effectContact members penetrating/cutting insulation/cable strandsClamped/spring connectionsMetal leafEngineering

A conductive wire connection structure of rail-type electrical terminal is able to reduce the yield of waste material in manufacturing, enhance heat dissipation effect and increase operational and motional stability in condition of structural simplification. The conductive wire connection structure includes a conductive support mounted in an insulation case. The conductive support is divided into two parts of a U-shaped support main body and a C-shaped wire connector. The wire connector is assembled with a metal leaf spring and disposed on the support main body together with the metal leaf spring for pivotally connecting with the grounding conductive wire coming from an apparatus. The wire connector and the metal leaf spring are respectively formed with insertion sections for assembling the wire connector with the metal leaf spring to help the support main body to hold the metal leaf spring and prevent the metal leaf spring from deflecting.

Owner:SWITCHLAB +1

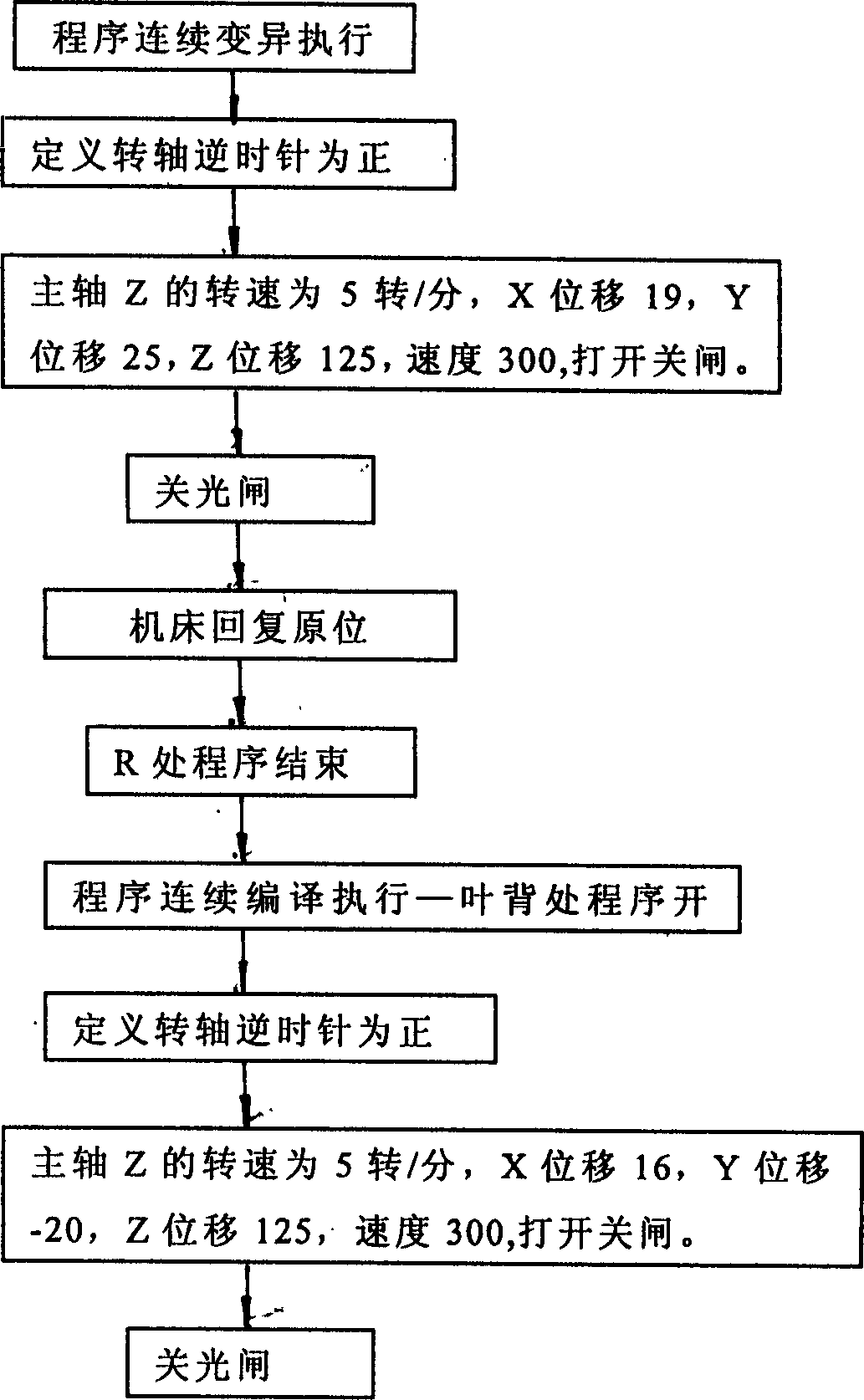

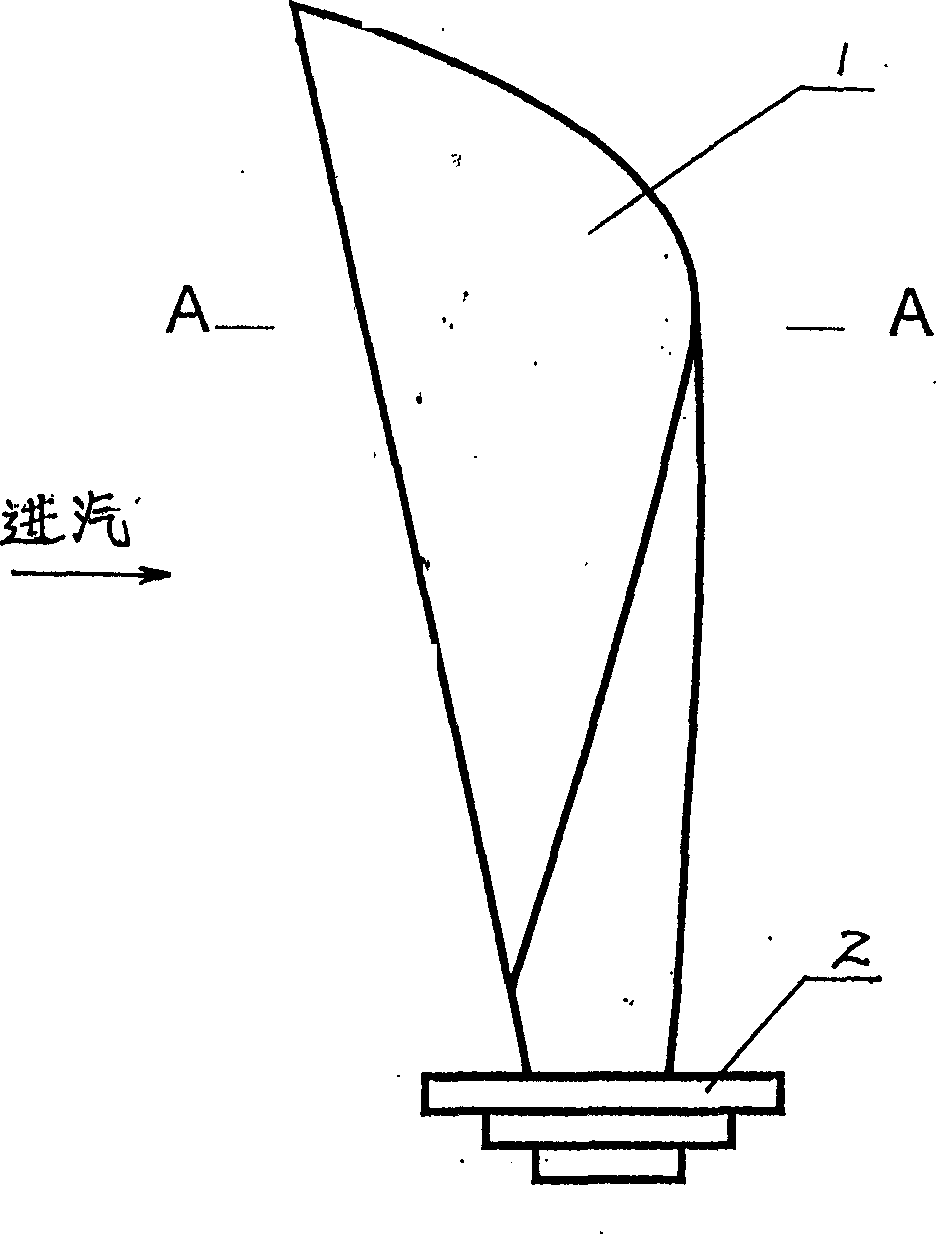

Laser strengthening process for metal leaf

ActiveCN1603052AAvoid deformationRealize automatic processing and productionLaser beam welding apparatusExtinctionAlloy

The invention relates to a metal leaf laser strengthening technology. After the surface of the metal required processing area is coated alloy extinction coating, the light beam with certain facula selected by the processed area is practiced laser processing. The laser location and moving in the processed area are realized the light beam three-dimensional motion by the digital control programming of the leaf local processed area shaped conductor. At the same time, the inert gases are used to protect the action area, and the average hardness of the local hardened layer reaches from HV four hundred and fifty to HV six hundred and fifty. And it is reduced with gradient from the outer to inner. The depth of the single side hardened layer is more than 0.25 millimeter. The width of the hardened band is adjustable, and it has no processed crack, deformation. The invention solves the deformation problem when the metal blaze is practiced induction hardening. And the hardness is higher than from ten percent to twenty percent of the induction hardening.

Owner:ZHEJIANG UNIV OF TECH

Dynamic alloy wire valve for a multimedia linked scent delivery system

InactiveUS6371165B1Rapidly change from one scentMinimum amount of air flowOperating means/releasing devices for valvesStage arrangementsMetal leafEngineering

A dynamic alloy wire valve for a multimedia linked scent delivery system consists of a hollow body with one flapper valve inlet which comes directly from a compressor and multiple flapper outlets, each of which feeds a separate fragrance air inlet. Inside the hollow body there is gang of flapper valves, which are arranged radially around a center spindle. At the other end of the flapper valve is valve tip, which fits snugly into a flapper valve seat. The flat metal leaf that forms the body of this flapper valve has an inherent spring tension much like a leaf spring. This spring tension normally keeps the valve tip pressed snugly against the valve seat, in the normally closed position. On the other side of the valve tip, there is attached a valve opener made from a dynamic alloy wire.

Owner:MANNE JOSEPH S

Shift member fixing structure of electrical connection terminal

ActiveUS9525216B2Improve shortcomingsEasy to operateCoupling device detailsContact members penetrating/cutting insulation/cable strandsElectricityElectrical connection

A shift member fixing structure of electrical connection terminal includes an assembly of a terminal and a shift member to improve the shortcoming of the conventional terminal that the structure is complicated and the manufacturing cost is higher. The terminal includes a main body defining a chamber and a metal leaf spring disposed in the chamber for pressing a conductive wire or releasing the conductive wire in response to the operation of the shift member. A predetermined section of the shift member is formed with an insertion section and walls defining the insertion section. A part of the wall is removed to provide elastic effect for the insertion section. The removed part is repositioned on a surface of upper section of the main body to form an interference section. After the shift member is pressed down, the interference section is assembled with the insertion section.

Owner:SWITCHLAB +1

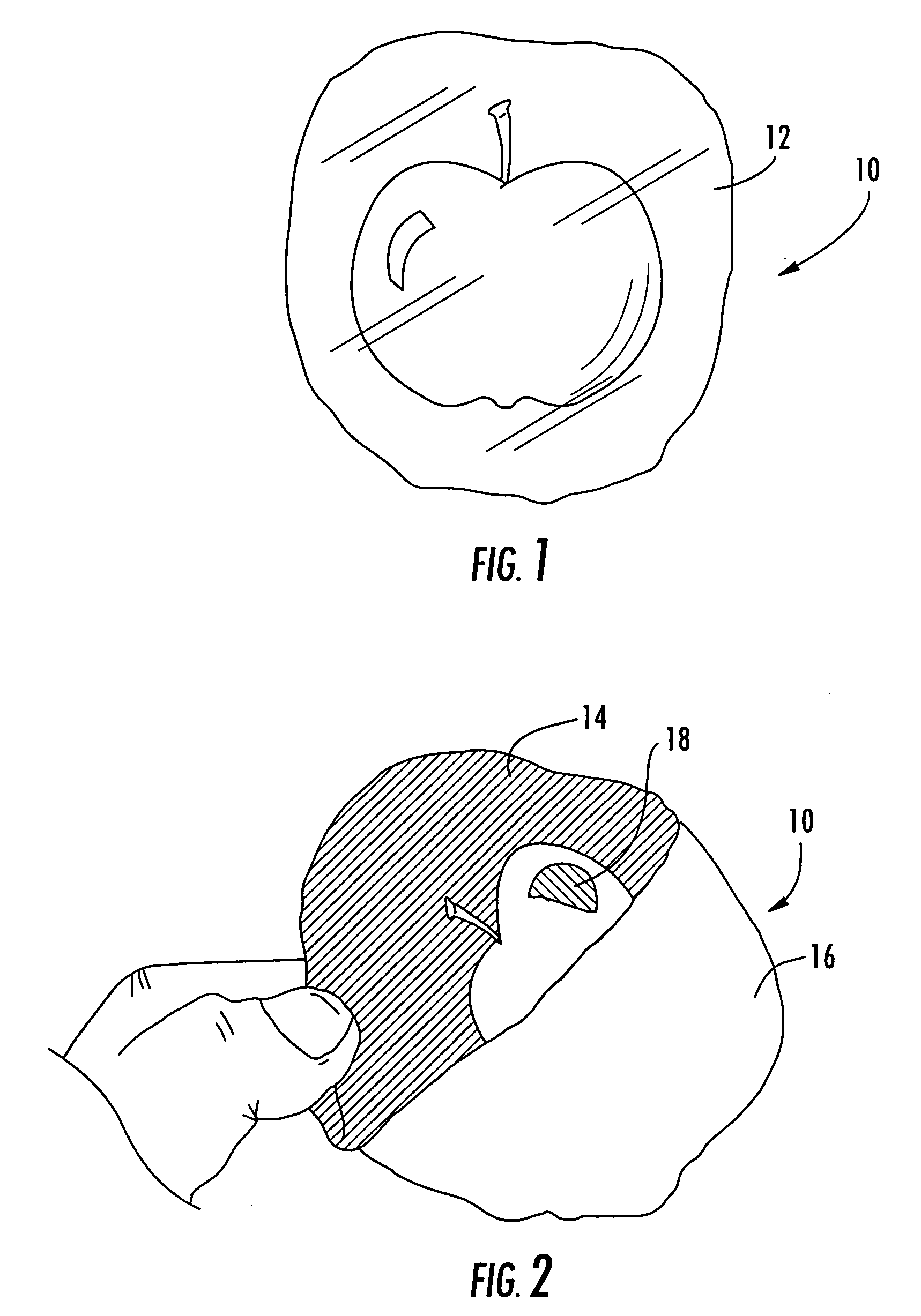

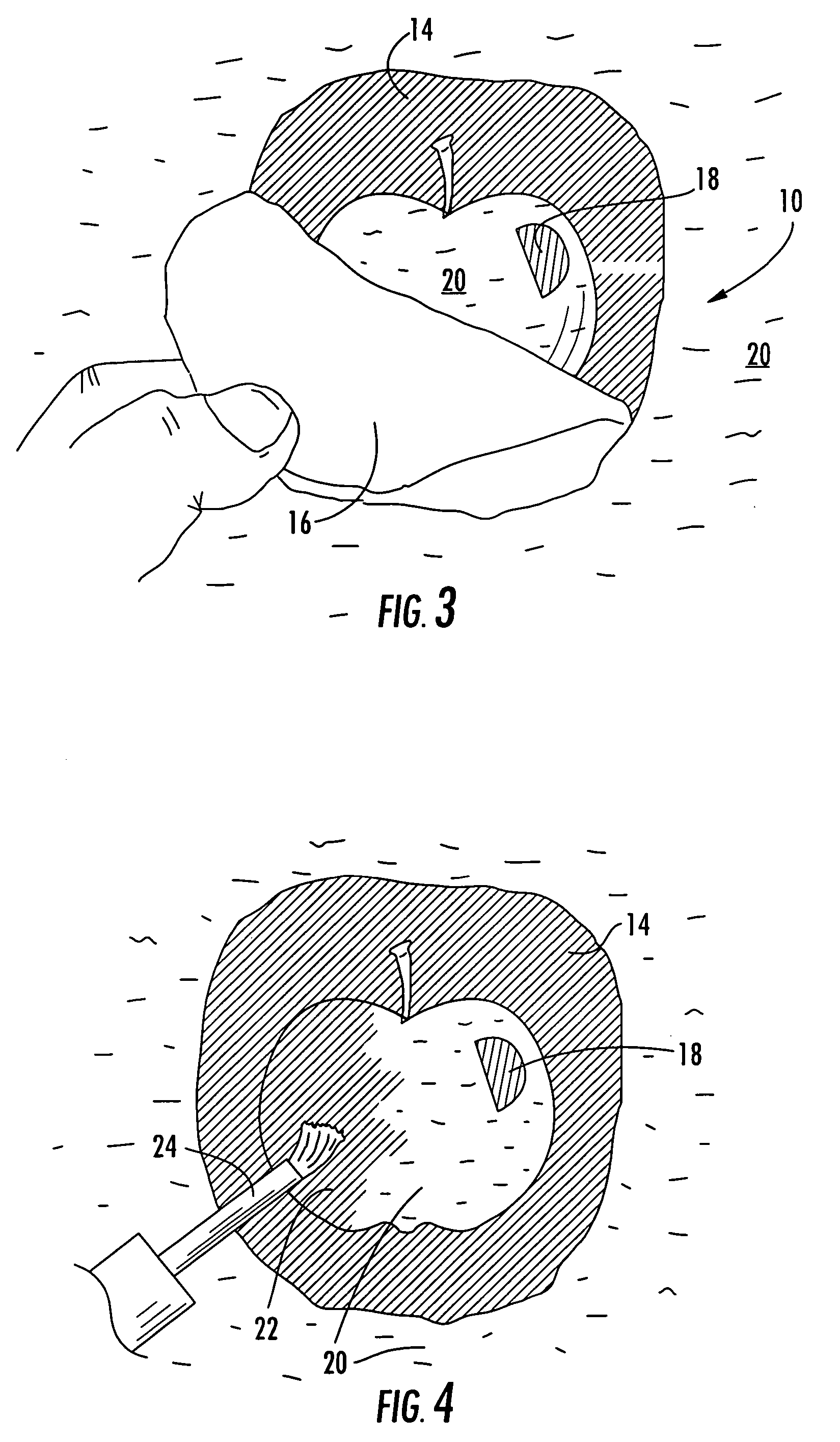

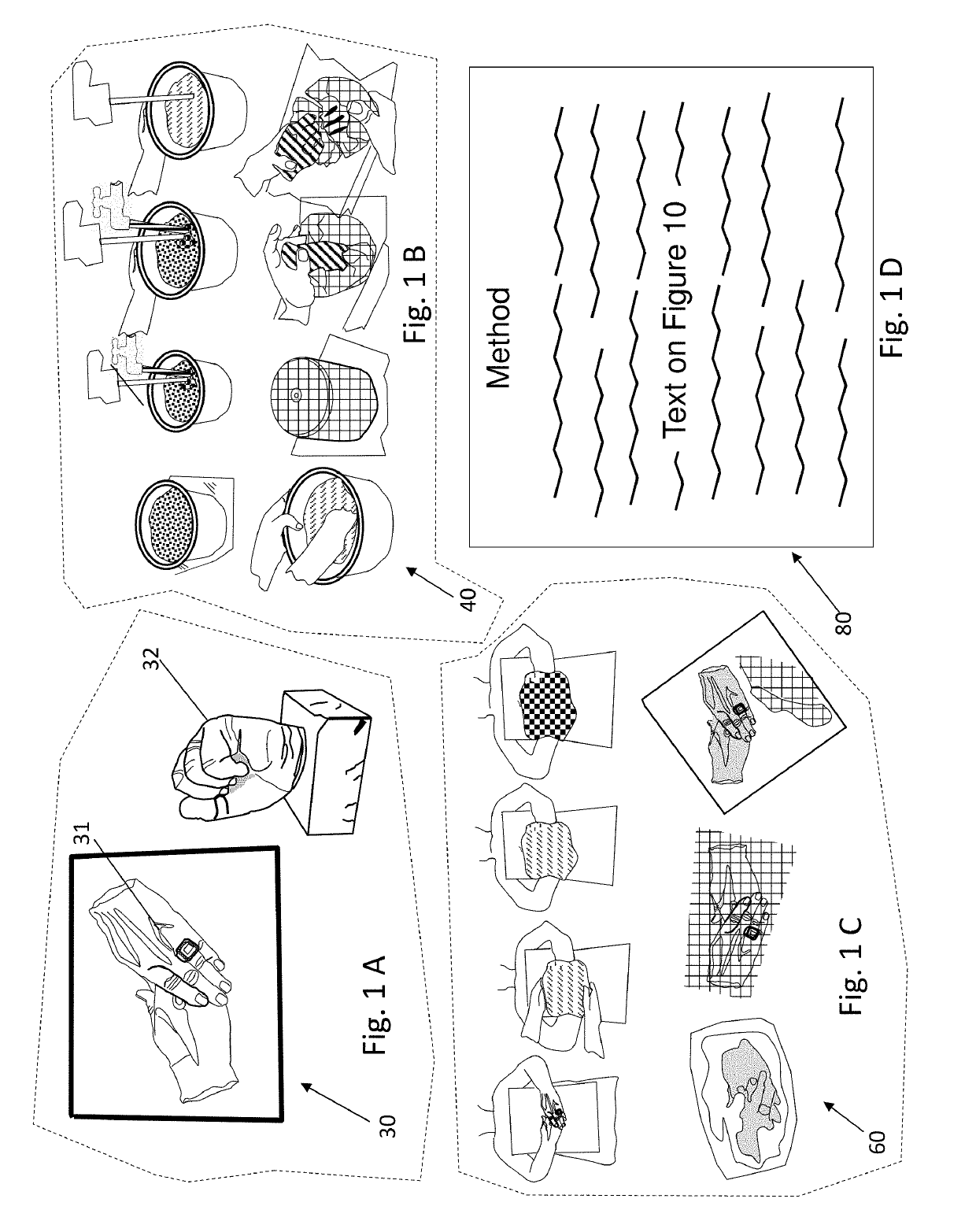

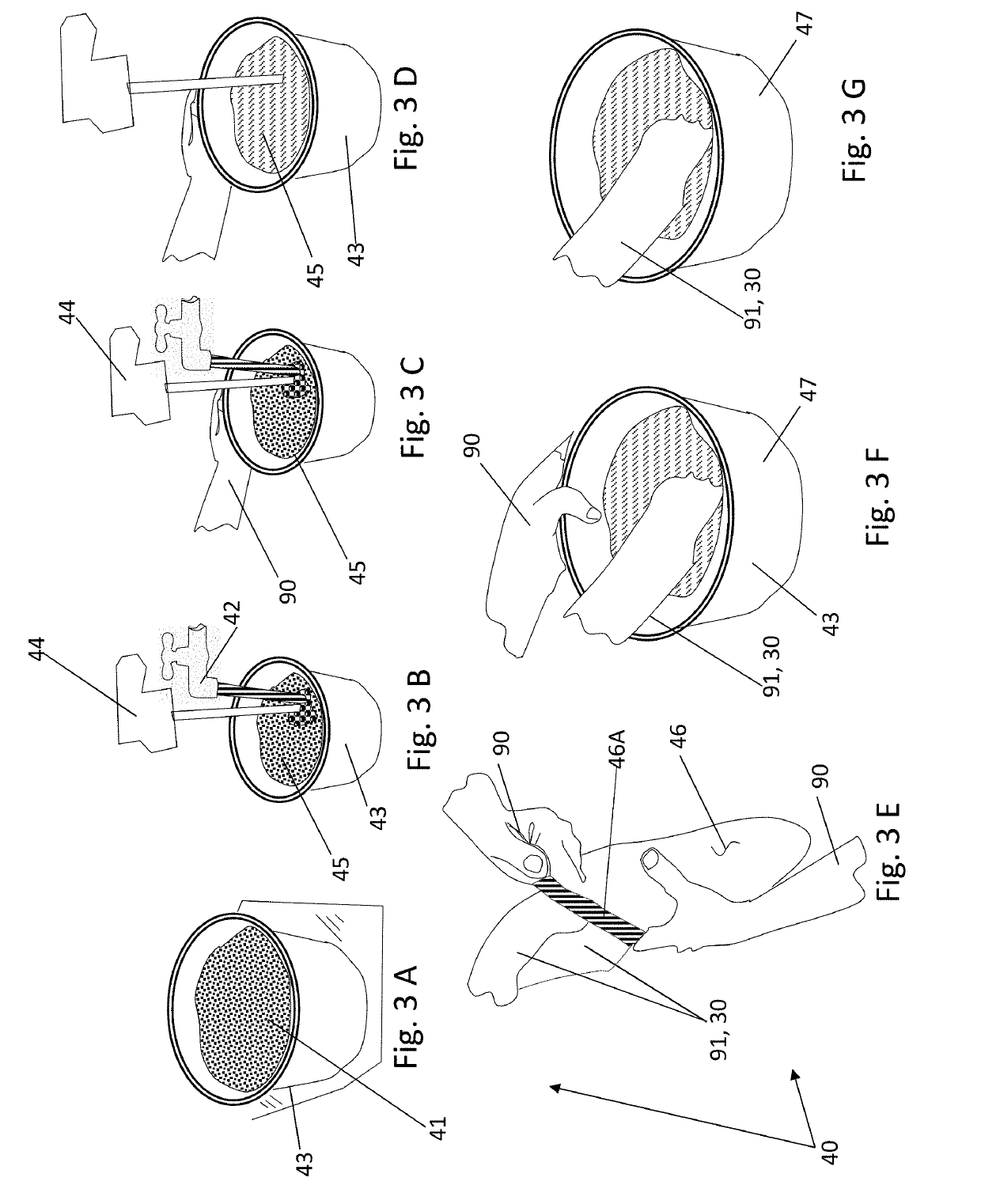

Method for producing a metallic temporary tattoo

A method of creating a temporary tattoo is described. The method includes creating a template for the temporary tattoo, which may be formed of vinyl. The template is applied to the skin of a person. Skin safe adhesive is applied to the skin within the template, and metal leaf is applied to the adhesive layer on the skin within the template. The template is removed to reveal a metal leaf tattoo on the skin. The metal leaf may be platinum, gold, silver, copper, aluminum or colored metal leaf.

Owner:WILLIAMS THOMAS D

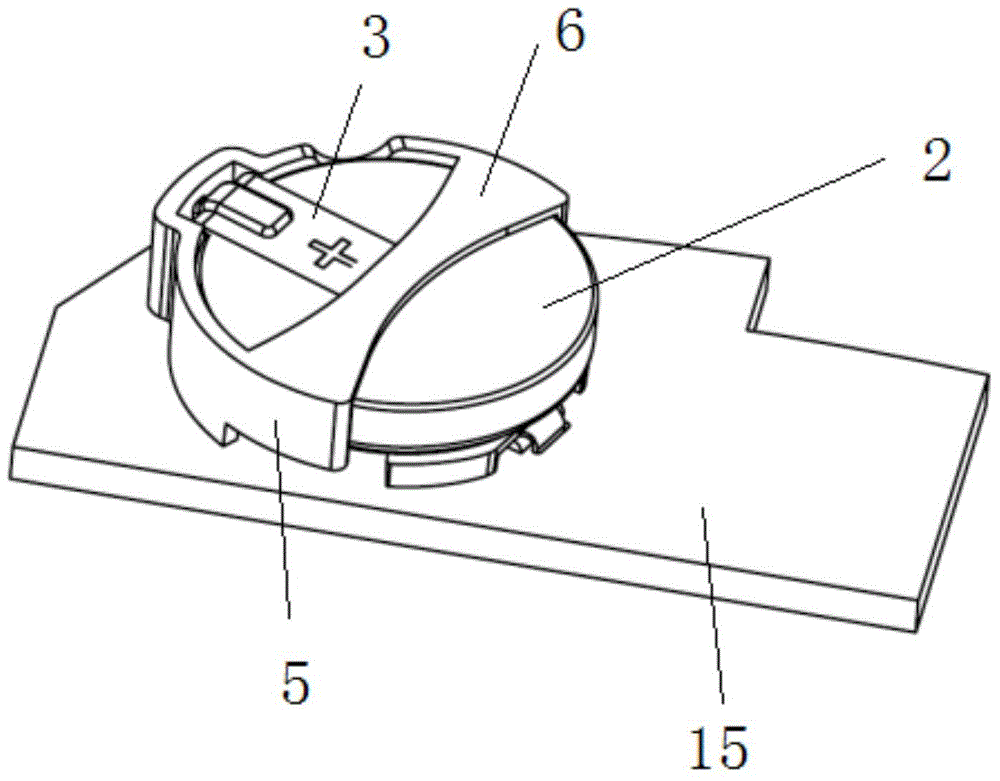

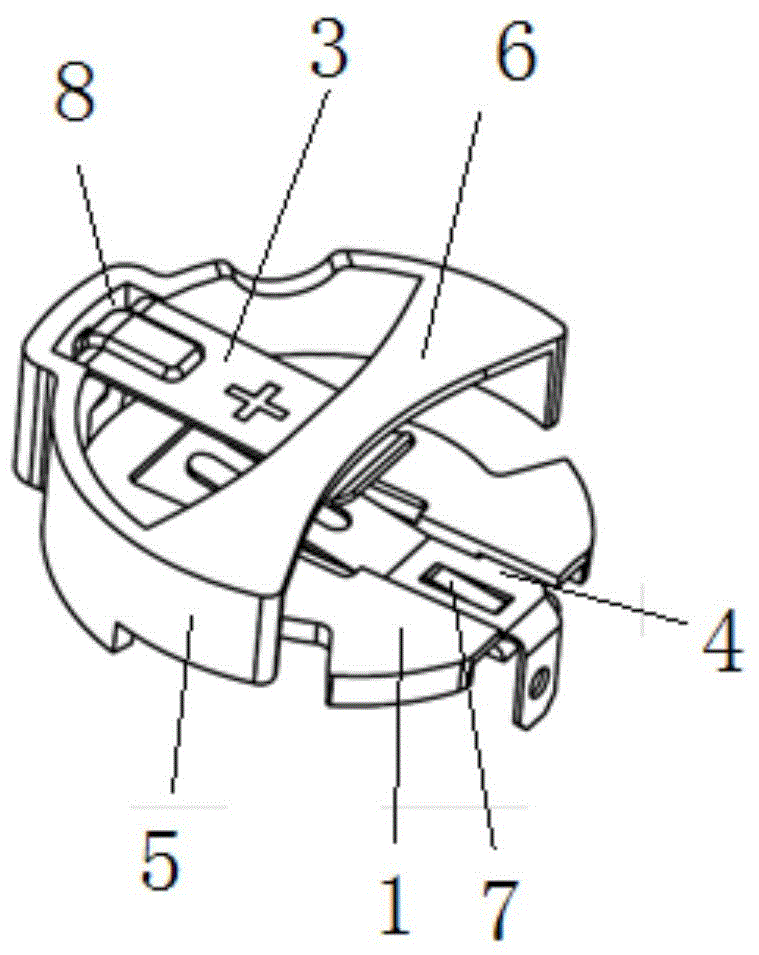

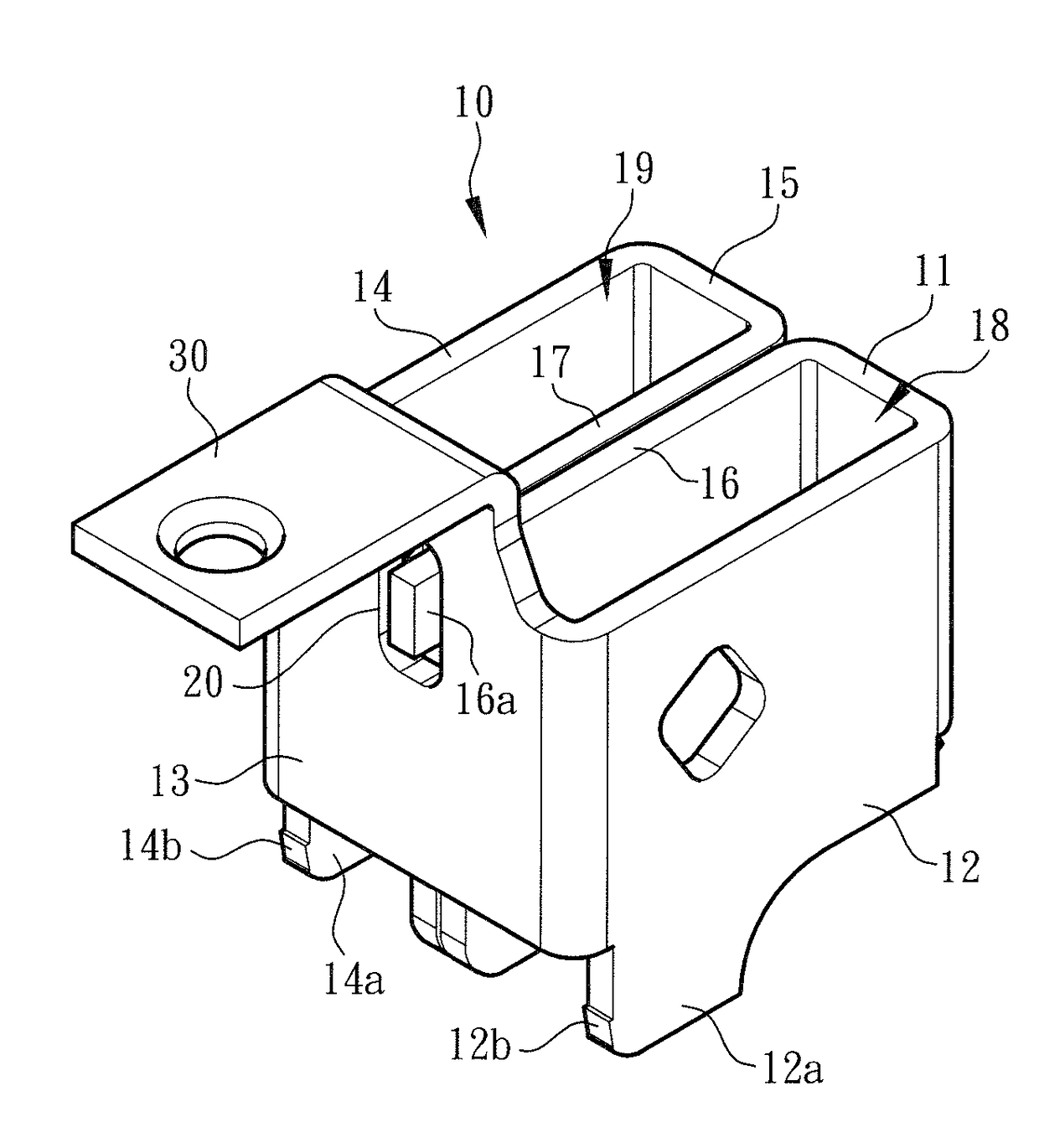

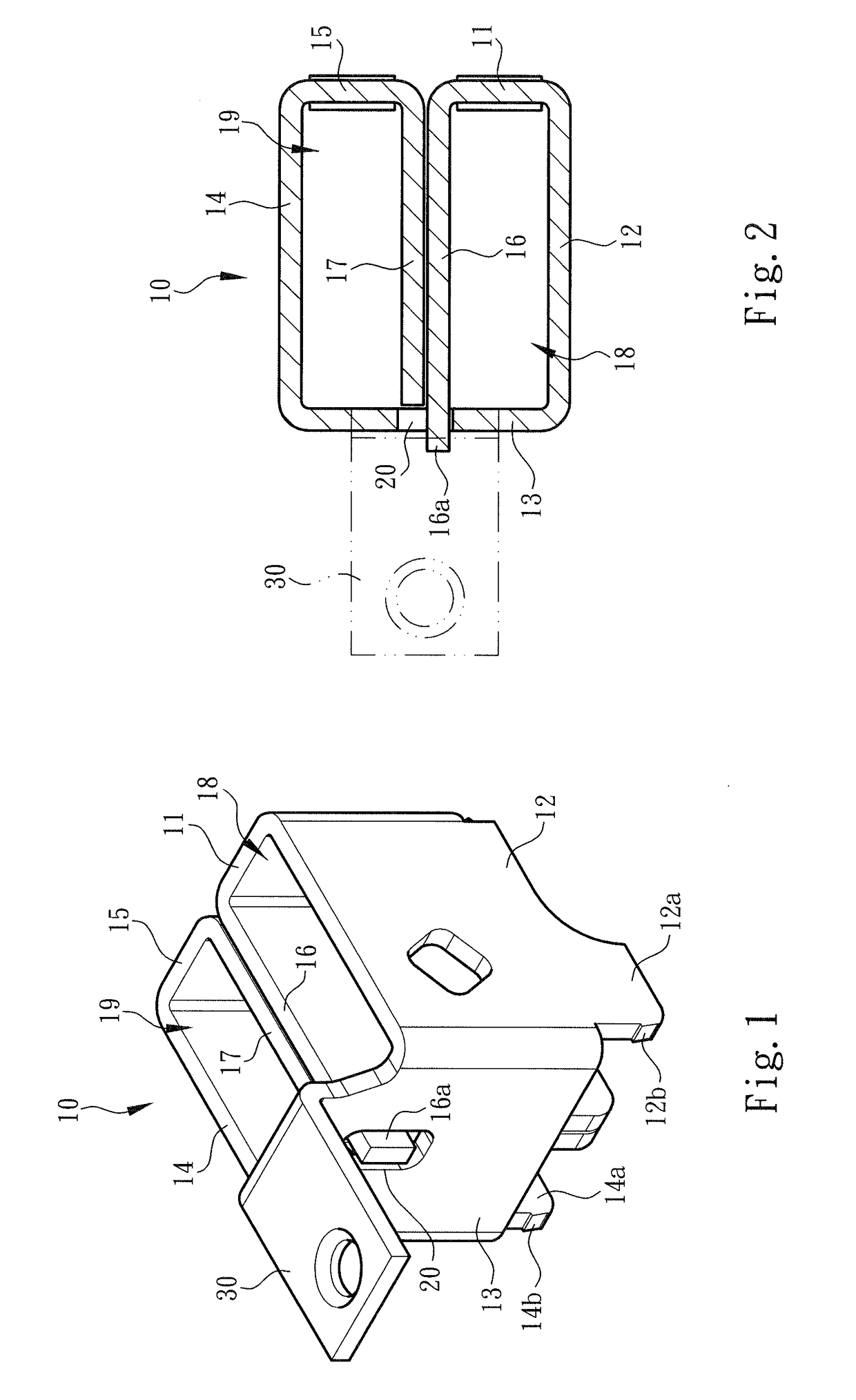

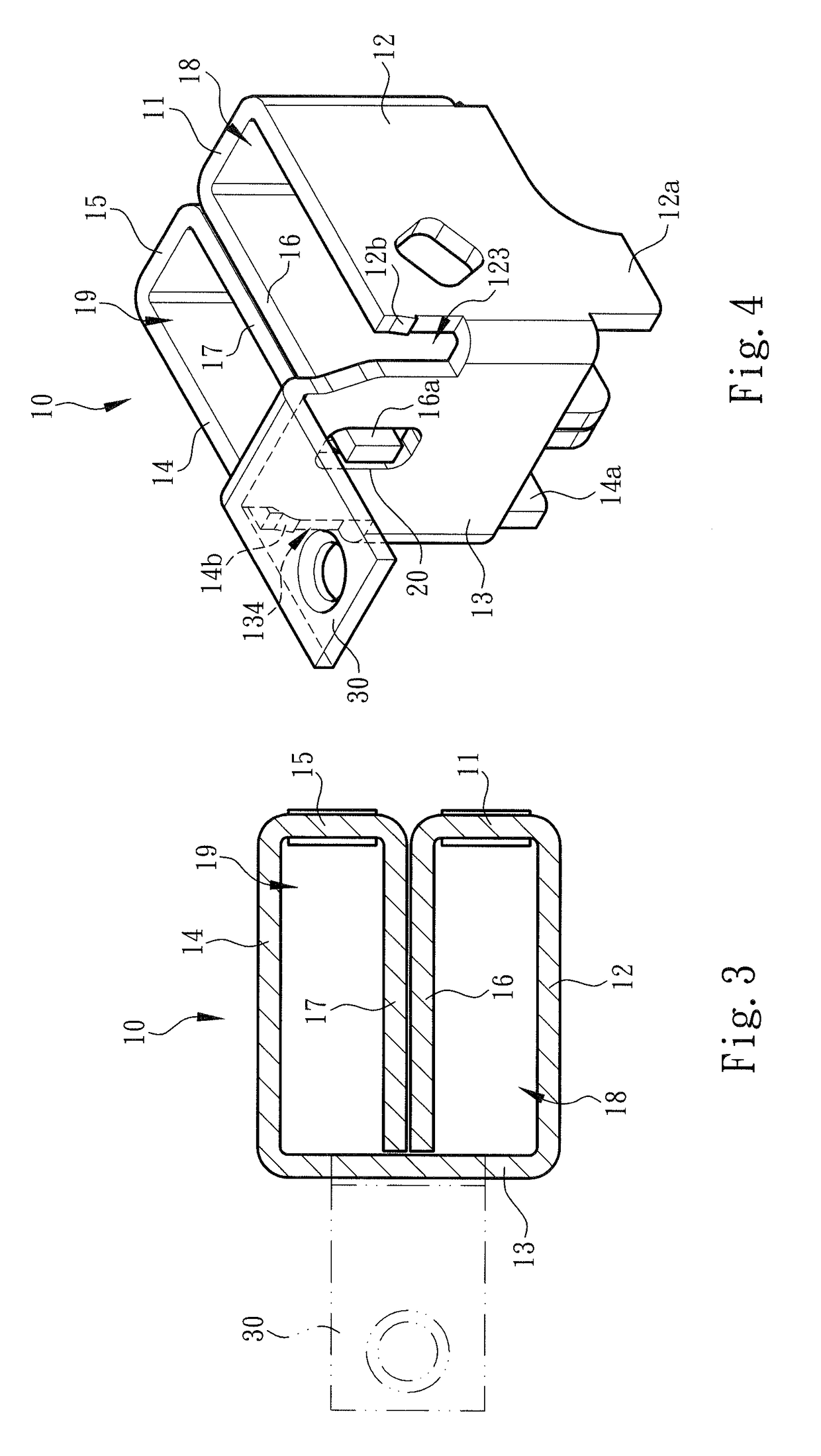

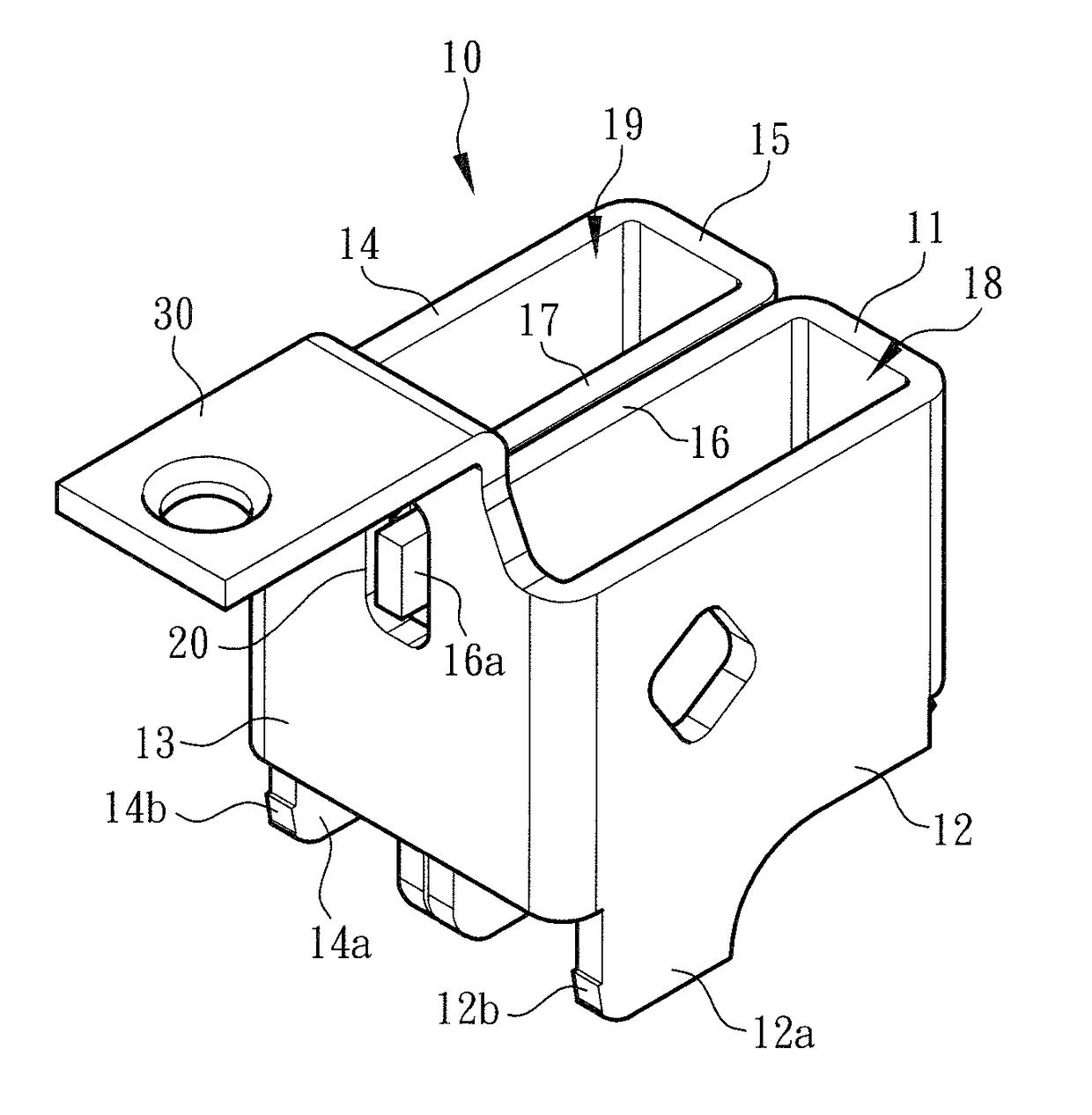

Car key battery assembly

ActiveCN104466056AFixedSolve the phenomenon of poor weldingElectric connector introductionPortable system fuel cellsMetal leafElectrical and Electronics engineering

The invention discloses a car key battery assembly which comprises a battery fixing housing, wherein the car key battery structure further comprises a metal leaf spring and a battery; the metal leaf spring comprises a positive electrode plate and a negative electrode plate; the battery fixing housing comprises a bottom plate, wherein an arc-shaped side wall is arranged along the edge of the bottom plate, the two ends of an upper end edge of the arc-shaped side wall are connected through a limiting arm; the bottom plate, the arc-shaped side wall and the limiting arm form a battery insertion slot structure for placing a battery; a sunken surface is further arranged on the upper end surface of the bottom plate; a limiting lug is arranged on the sunken surface; a limiting slot hole sleeved on the limiting lug is arranged on the negative electrode plate; one end of the negative electrode plate is a battery clamping end, the other end of the negative electrode plate is extended with an insertion sheet; and an insertion slot is formed in the arc-shaped side wall. By adopting the structure, the car key battery assembly has the advantages of good elasticity, high conductive performance, a long service life, capacity of relieving the oxidization of a contact point of the spring leaf and the battery, and simple assembling.

Owner:ATECH AUTOMOTIVE WUHU

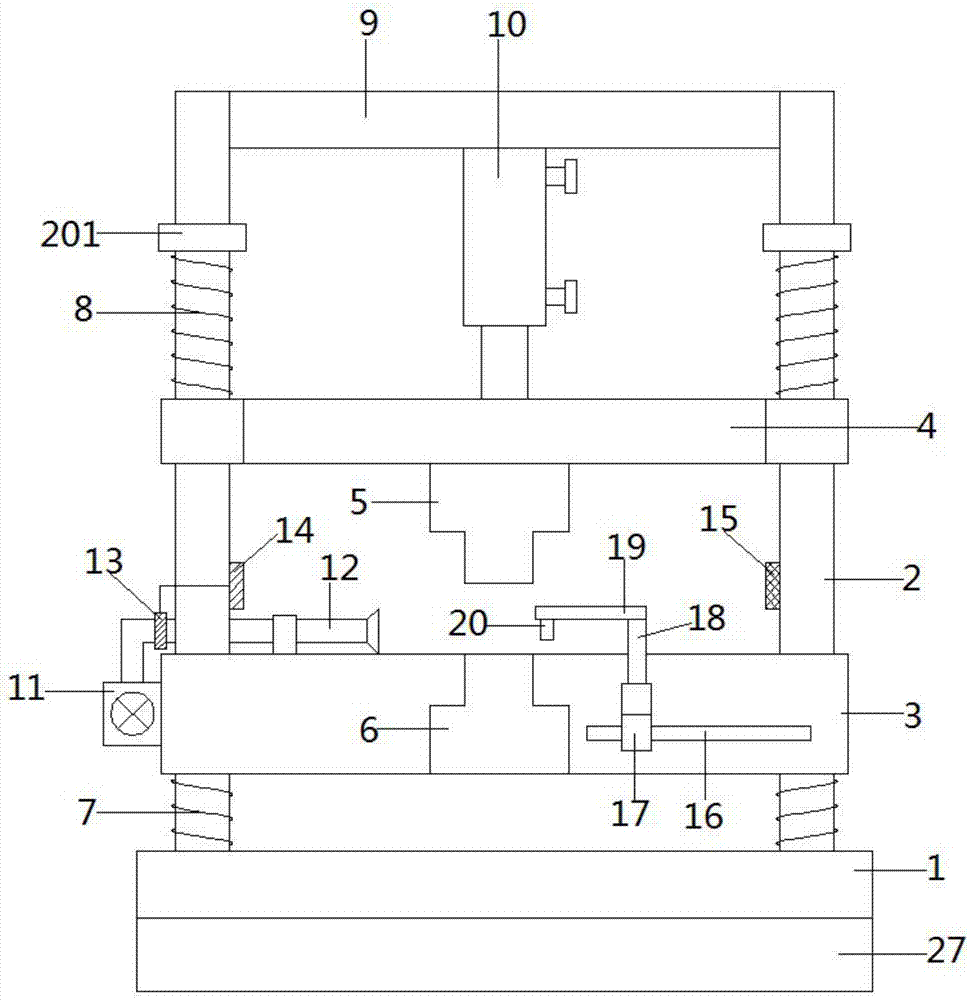

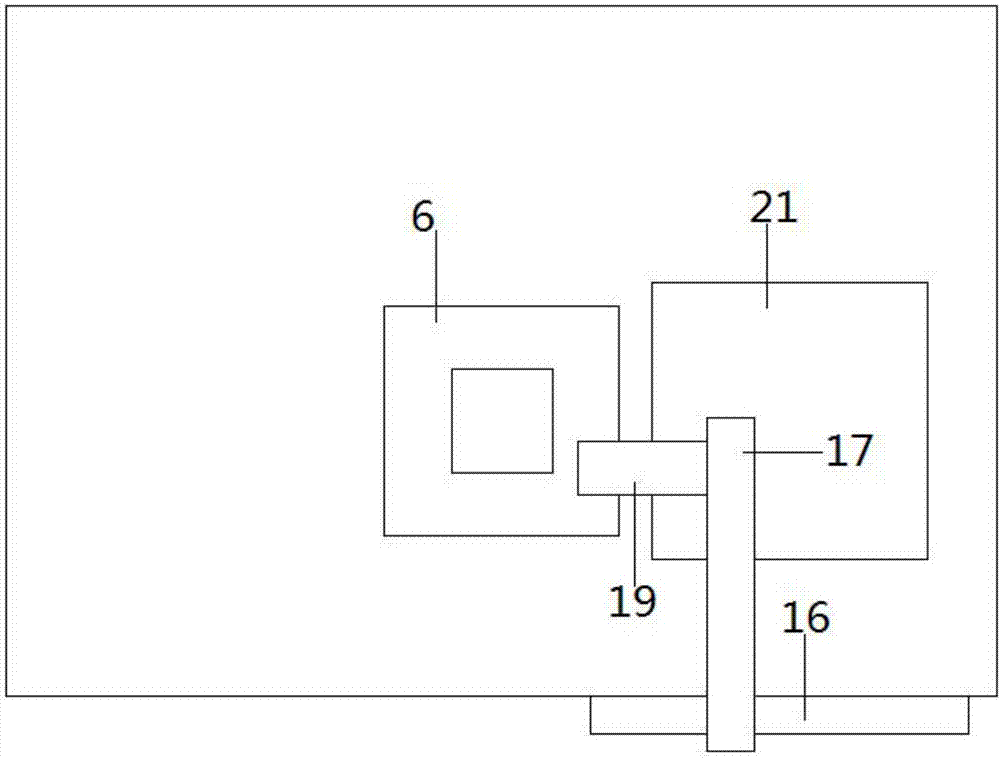

Stamping device for LED lamp production

InactiveCN107470425AImprove work efficiencyImprove securityShaping toolsNon-rotating vibration suppressionVulcanizationMetal leaf

The present invention discloses a stamping device for LED lamp production. The stamping device comprises a supporting base. Guide rods are arranged in parallel at both left and right ends of the upper side of the supporting base. A lower die supporting plate and an upper die supporting plate are arranged between the guide rods. Two sides of each of the lower die supporting plate and the upper die supporting plate sleeve the guide rods. A lower die is arranged in the middle of the upper side of the lower die supporting plate. A damping device is arranged at the lower side of the supporting base, which comprises a vulcanization-bonding layer, a metal leaf spring, a stabilizer, a pedestal and a damping layer. The upper surface of the vulcanization-bonding layer is vulcanization-bonded with the bottom of the supporting base. The stamping device for LED lamp production of the present invention allows for effective protection for the device and the ground, can achieve automatic discharge and can effectively blow away leftover materials from machining in the stamping process. With no need for manual operation, the working efficiency of the stamping machine and the safety are improved. In addition, effective damping can be achieved so that the stability of the device is effectively improved.

Owner:芜湖晶鑫光电照明有限公司

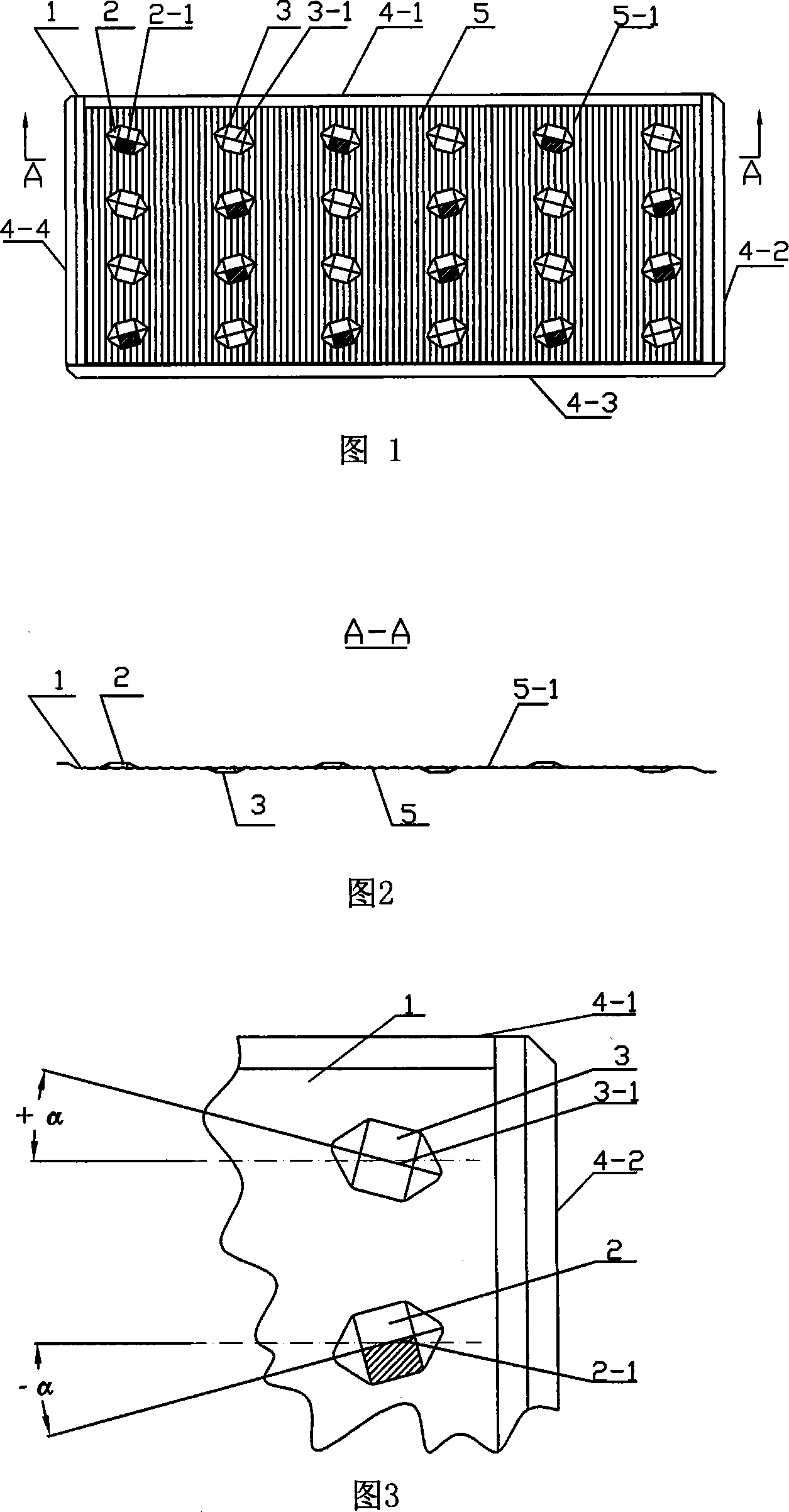

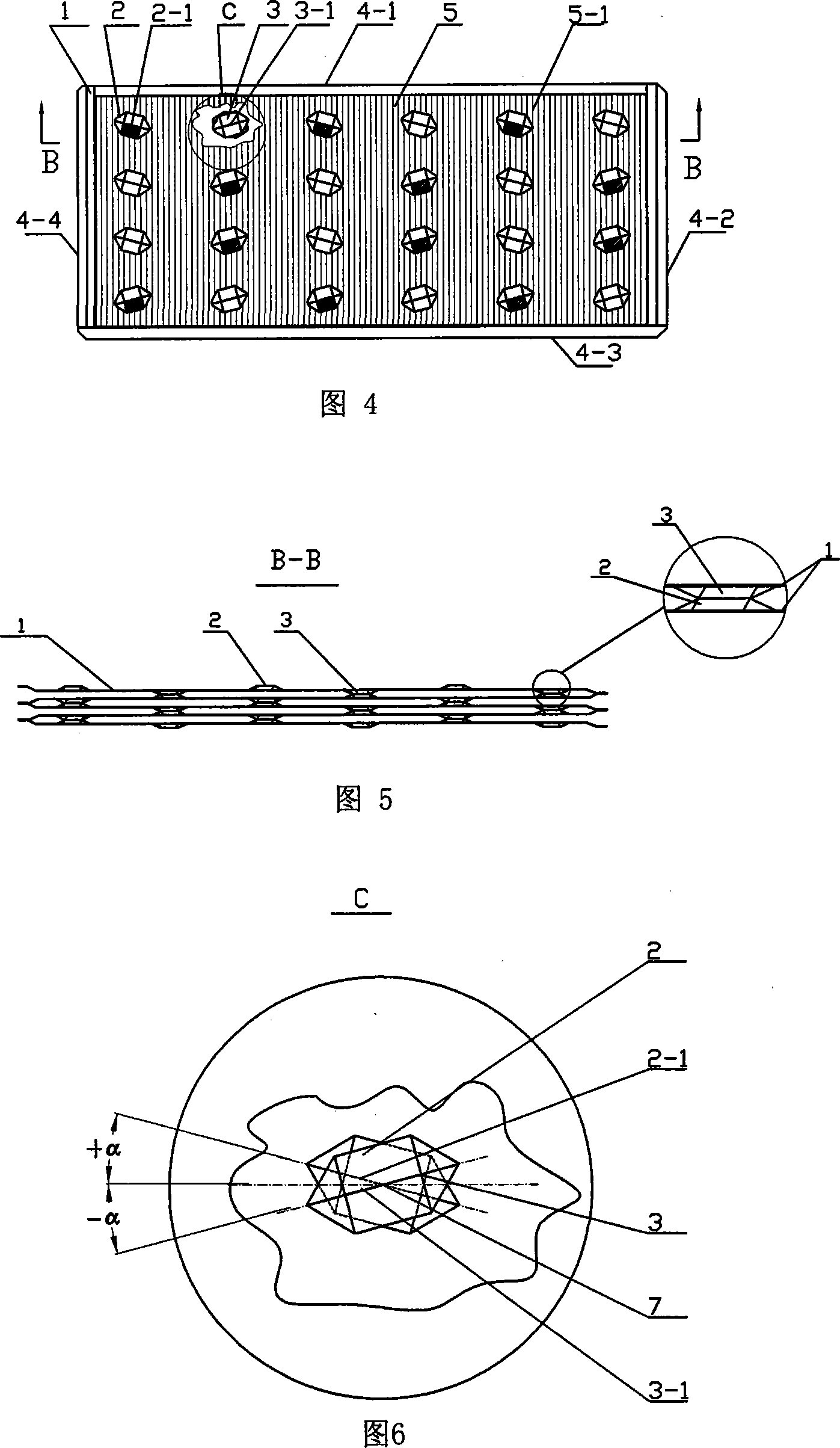

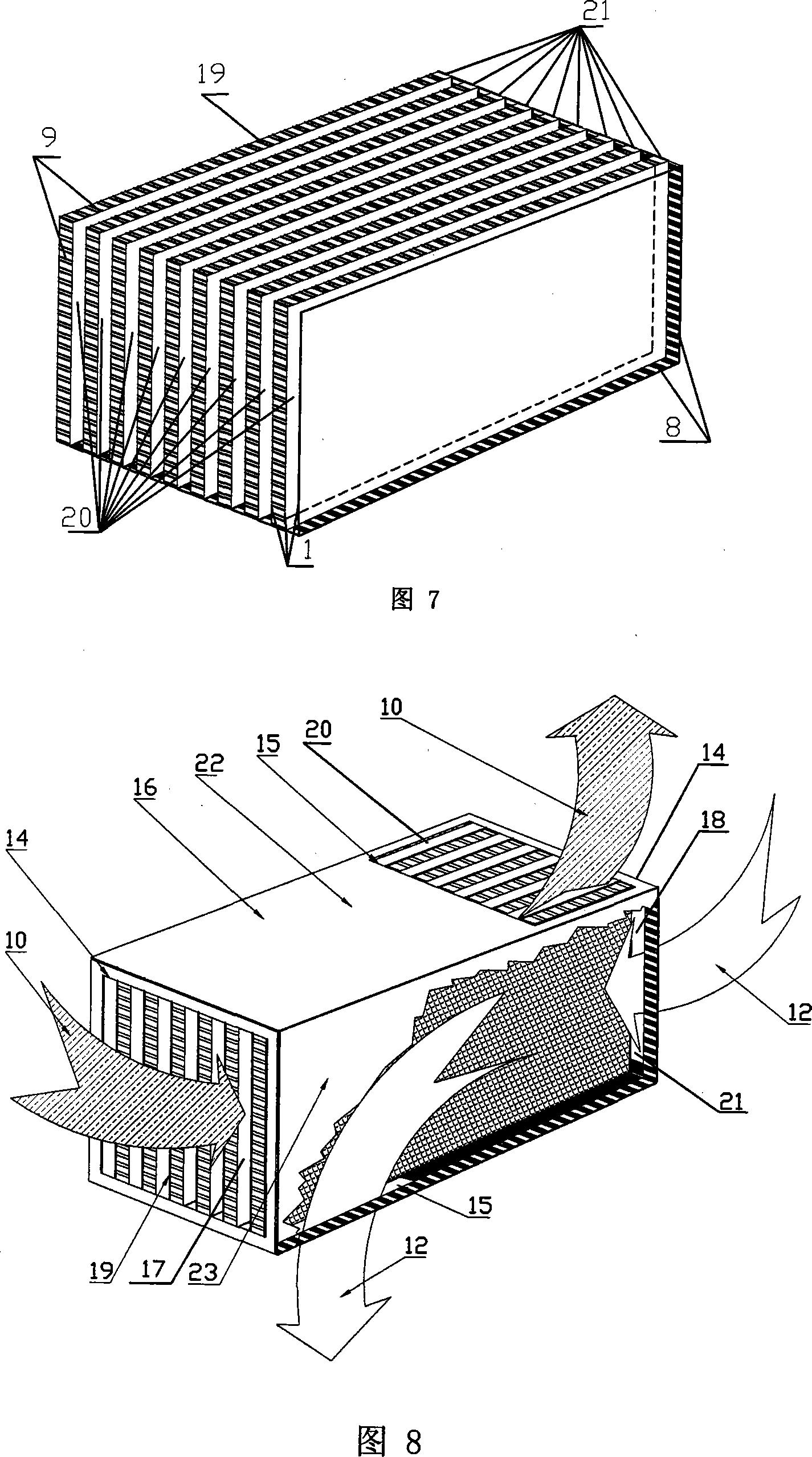

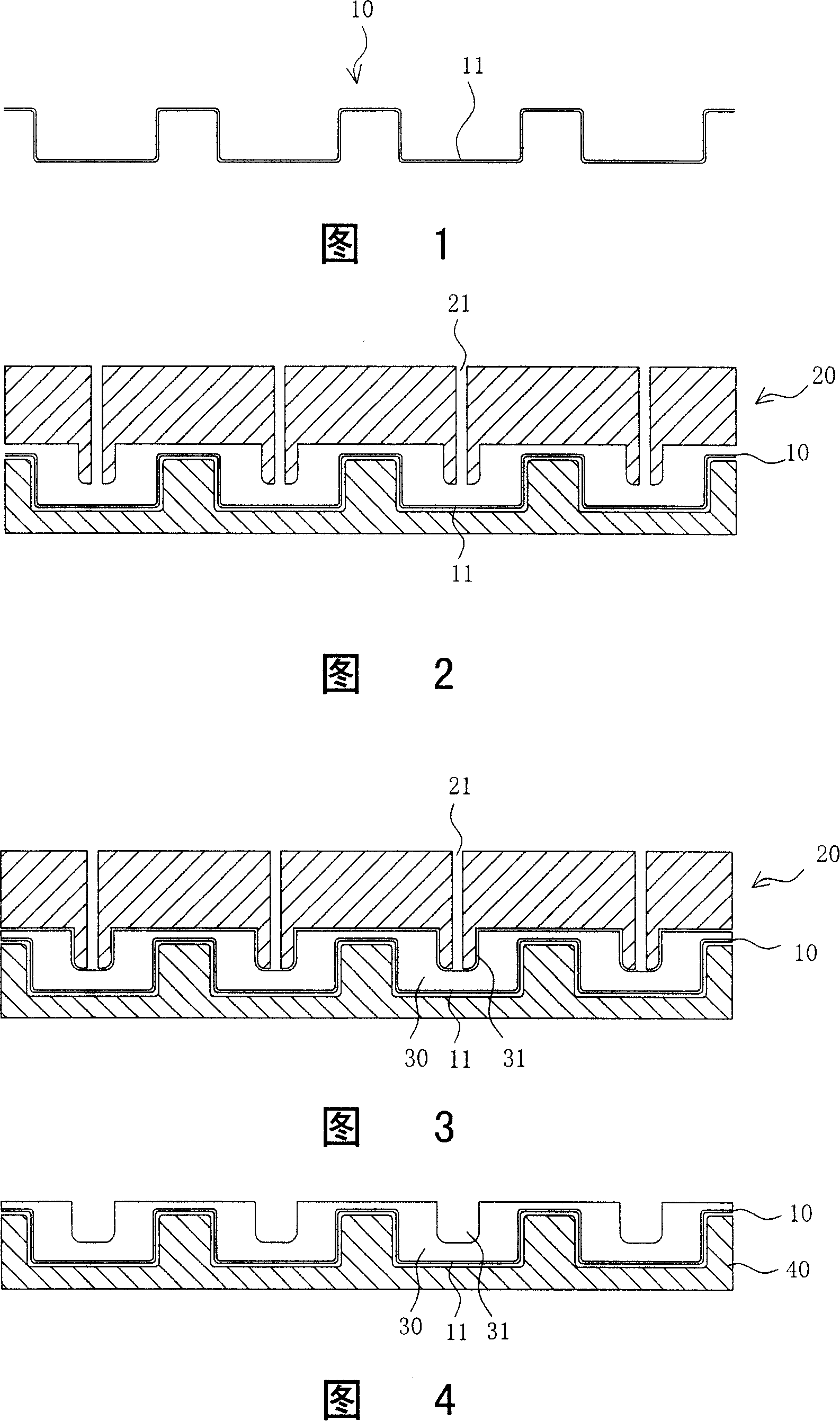

Heat exchange piece and piece type air heat exchanger using same

InactiveCN101118132AEfficient use ofAvoid harmLaminated elementsStationary plate conduit assembliesMetal foilEngineering

The present invention relates to a heat exchange chip and a chip type air heat exchanger, the heat exchange chip which adopts a metal foil mold compressed piece consists of a base chip and a metal leaf die pressing element arranged vertically, horizontally and crosswise, and composed of a plurality of convex and concave casing type units. The present invention is characterized in that the convex and concave casing type units are convex and a concave multi-surface casings being symmetrical to a central ridge, the included angle between the central ridge and the side of the heat exchange chip parallel to the air intake direction is plus Alpha or minus Alpha, the value of the Alpha is 10 degrees to 45 degrees; the chip type air heat exchanger is characterized in that the heat exchange chip is adopted, a plurality layers of heat exchange chips are folded and arranged in rows through the central ridge of the convex and the concave multi-surface casing between two adjacent layers, and one side connecting edge corresponding the two adjacent layers or the other symmetrical side connecting edge are consecutively and orderly connected, to form a heat exchanger core; a guide flow fixing box is suited at the outer part of the heat exchanger core. The present invention has the advantages of large amount of wind flow, high efficiency of heat exchanging, good protection performance, severe structure, small size and light weight, and the present invention is suitable for outdoor electrical cabinet.

Owner:天津市研翔电子科技有限公司

Wire plug-in aid sleeve structure for wire connection terminal

ActiveUS20180337472A1Improve securityImprove shortcomingsRelieving strain on wire connectionTwo-part coupling devicesMetal leafElectrical and Electronics engineering

A wire plug-in aid sleeve structure for wire connection terminal is assembled in a wire plug-in hole of the terminal. The aid sleeve includes a head section, a belly section connected with the head section and a tail section connected with the belly section. The head section, the belly section and the tail section together define a guide hole for the conductive wire to plug in. The tail section has a first side and a second side positioned on a peripheral section of the guide hole. After the conductive wire passes through the guide hole into the terminal, the metal leaf spring disposed in the terminal is facilitated to press the conductive wire toward the first side or second side.

Owner:SWITCHLAB +1

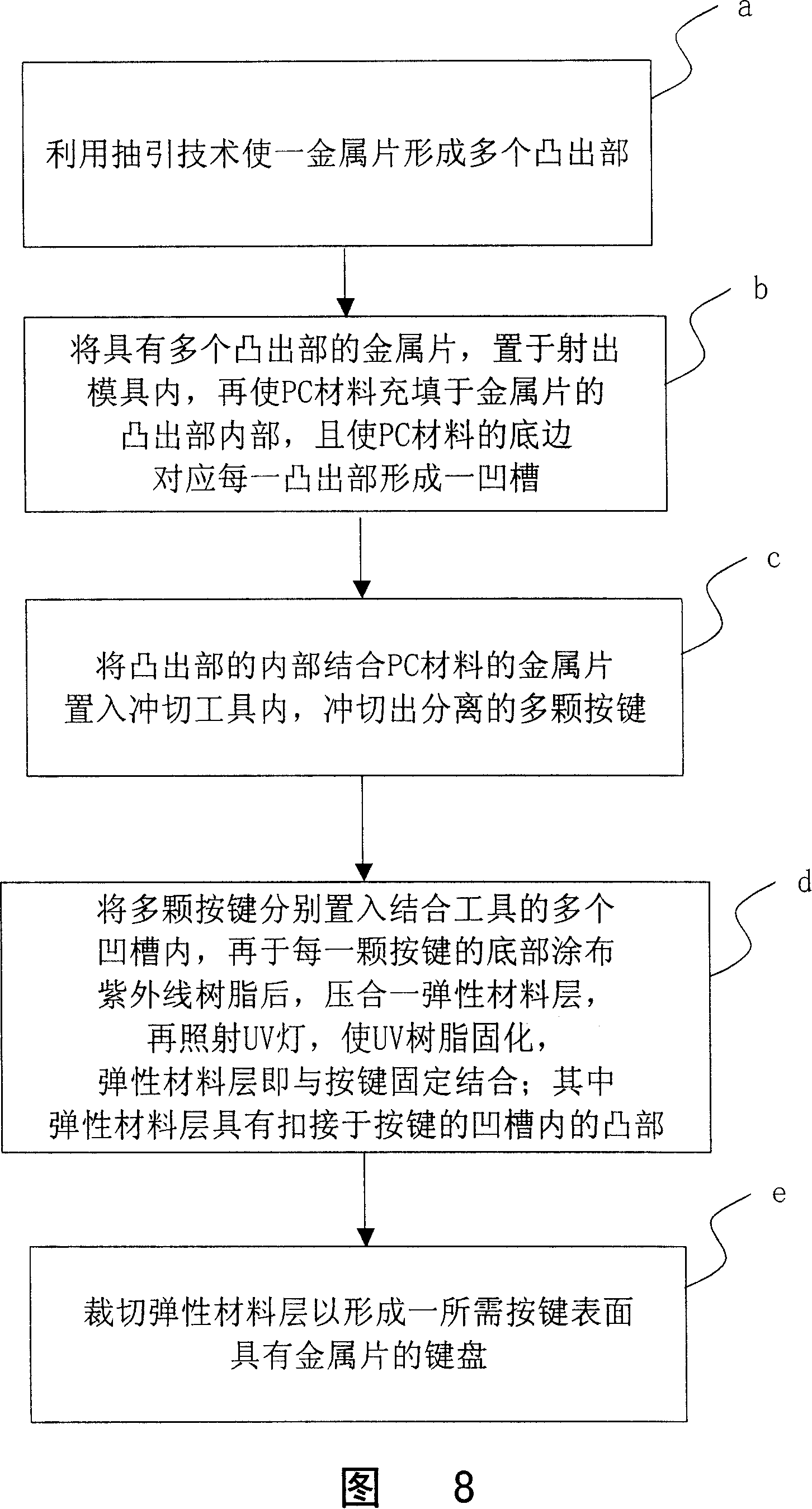

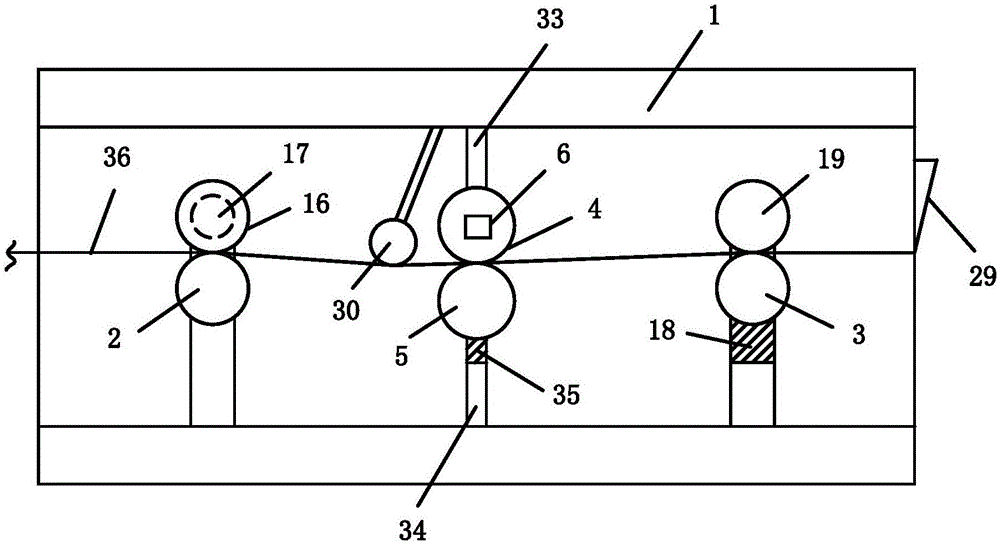

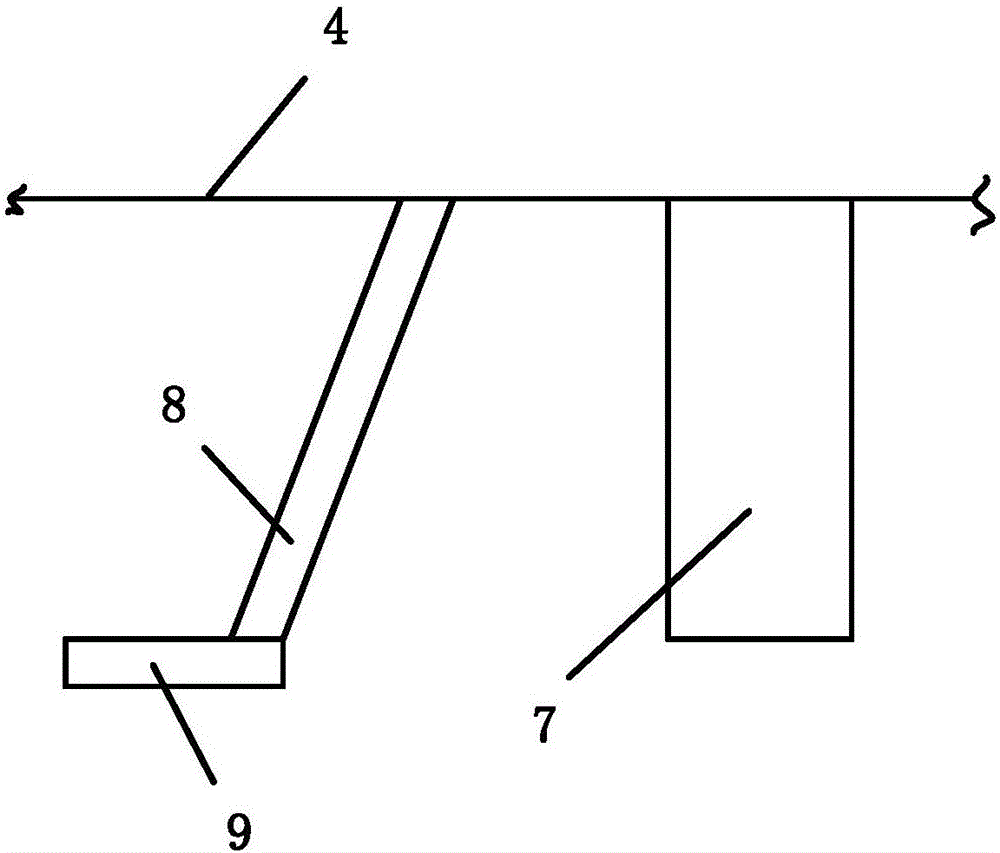

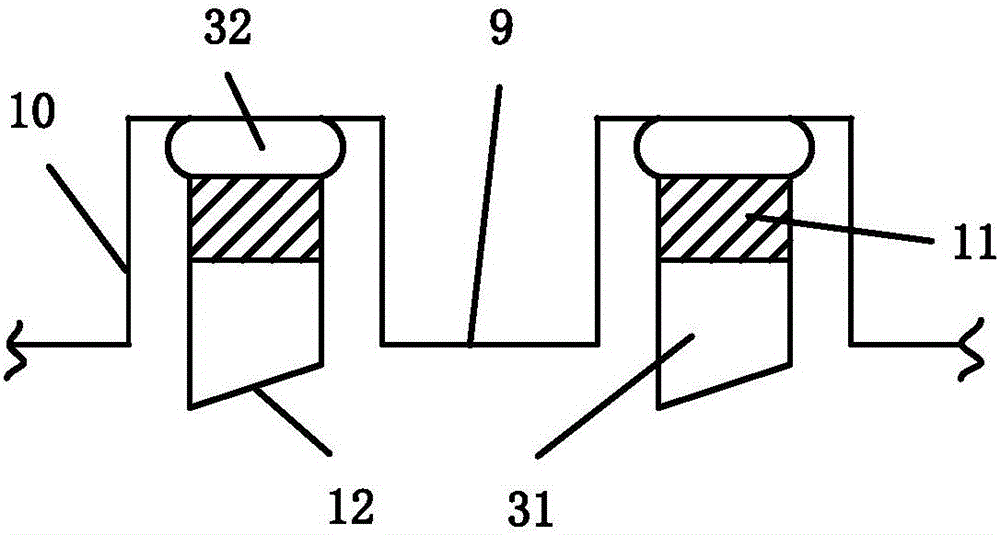

Method for making keyboard with metal leaf mould ejection push-button and keyboard thereof

The present invention discloses a method of making a keyboard by a key-press emitted from the internal mould of a sheet metal and the keyboard. The keyboard consists of a drawing moulding sheet metal, a key-press which is made by the emitting technology and the surface thereof is provided with a sheet metal and an elastic material layer which is combined with the hemline of the key-press groove; the surface of the keyboard has a metallic layer. The keyboard is a metallic keyboard with high texture which is capable of satisfying the requirement of the customer.

Owner:WISTRON CORP

Embossing and slicing integrated machine for aluminum foil production

ActiveCN106695910AReduce vibration disturbanceAvoid twisting and bendingMechanical working/deformationMetal working apparatusRubber ringMetal leaf

The invention discloses an embossing and slicing integrated machine for aluminum foil production. The embossing and slicing integrated machine comprises a machine frame. A feeding roller and a discharging roller are arranged at the two ends of the machine frame correspondingly. An embossing roller is arranged between the feeding roller and the discharging roller. A cutter is arranged on the outer side of the discharging roller. A rubber lifting roller is arranged below the embossing roller. The embossing roller is connected with a driving motor. Annular rubber rings are arranged at the two ends of the embossing roller. Metal leaf springs are arranged on the outer sides of the annular rubber rings. The radial included angle between the metal leaf springs and the annular rubber rings is 15-30 degrees. The bottoms of the metal leaf springs are provided with rubber pressing plates. The rubber pressing plates are parallel to the annular rubber rings in the axial direction. The bottom faces of the rubber pressing plates are provided with a plurality of first grooves. Pressing columns are connected with the interiors of the first grooves through first spring bodies. The bottoms of the pressing columns are provided with inclined face portions. The defects in the prior art can be overcome, the embossing roller is in charge of both embossing and driving, and embossing control precision is kept.

Owner:ZHUOZHOU HAOYUAN FOIL IND

Wire connection terminal device

ActiveUS10333232B2Improve shortcomingsBig spaceClamped/spring connectionsElectricityTerminal equipment

A wire connection terminal device includes a main body and a pressing / moving unit assembled with the main body. The pressing / moving unit has a shafted section, a cam section connected with the shafted section and a force application section formed on the cam section and a press section formed on the cam section. The cam section can freely rotate or swing within a chamber defined by the main body. A metal leaf spring is disposed in the chamber of the main body for pressing and electrically connecting with a conductive wire. The metal leaf spring is responsive to the motion of the pressing / moving unit to release the conductive wire. The wire connection terminal device improves the shortcomings of the conventional structure that the volume of the case and the operational space are larger and the motional travel is longer.

Owner:SWITCHLAB +1

Wire plug-in aid sleeve structure for wire connection terminal

ActiveUS10297933B2Improve securityImprove shortcomingsRelieving strain on wire connectionTwo-part coupling devicesEngineeringMetal leaf

Owner:SWITCHLAB +1

Memorial object for preserving cremains and methods to produce

This device is a memorial product manufactured with cremation remains encased in various non-glass materials. A is the making of a special impression molding device from an original form of a person, pet or special object, alive or deceased, and processing this form as a memorial and a vessel made from cremation ashes. The final restoration can be accurate and well adapted from the initial impression. Then a cementitious or plaster of Paris mix is used for the purposes of making the memorial product from the impressions. A ratio of water to cementitious material and other additives are suitable. The mix flows well into the pits, fissures and undercuts. It shows impeccable details. If desired, a finish seal, paint, electro-plate, or metal leaf can be utilized as a finish.

Owner:ALLISON CHRISTINA +1

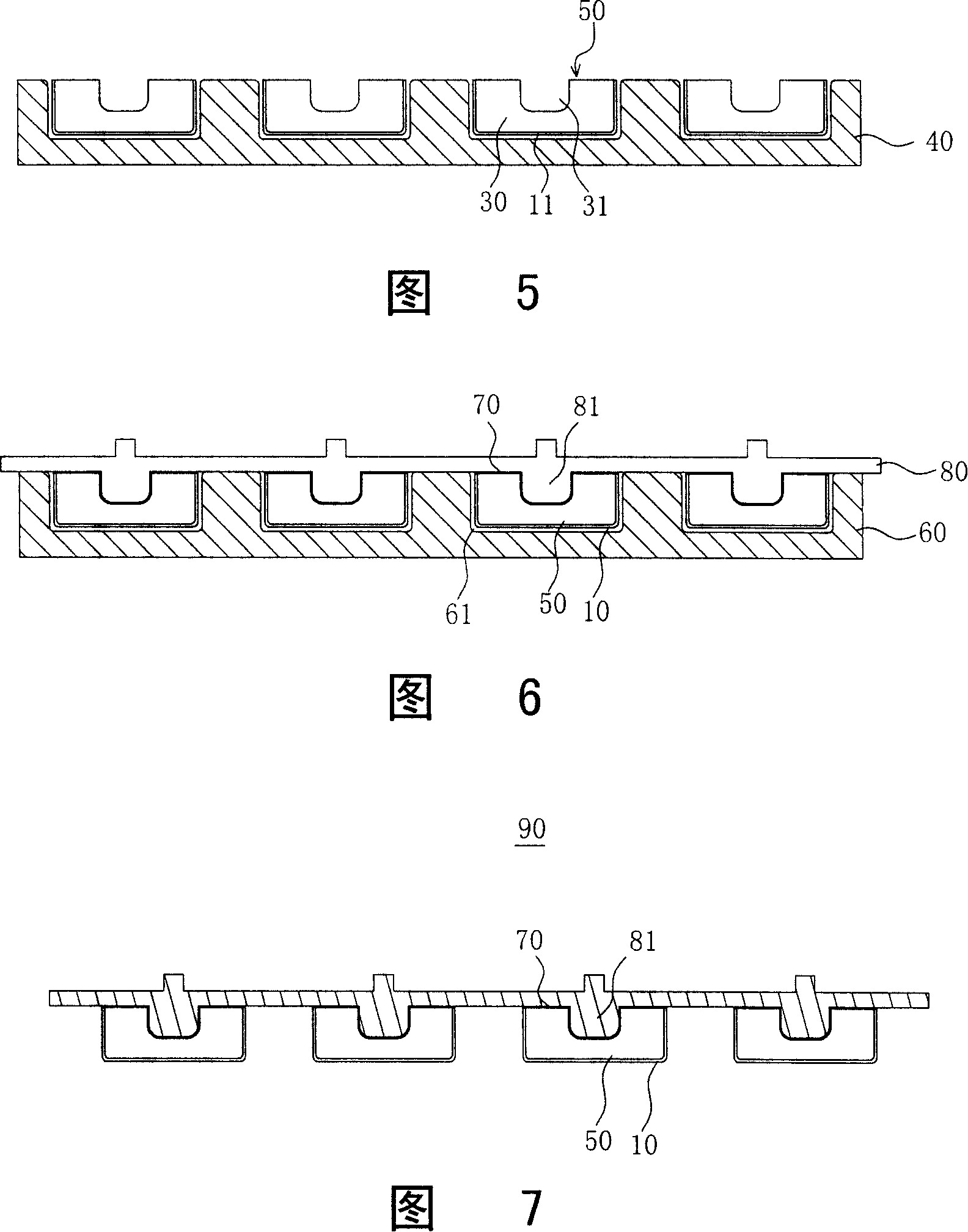

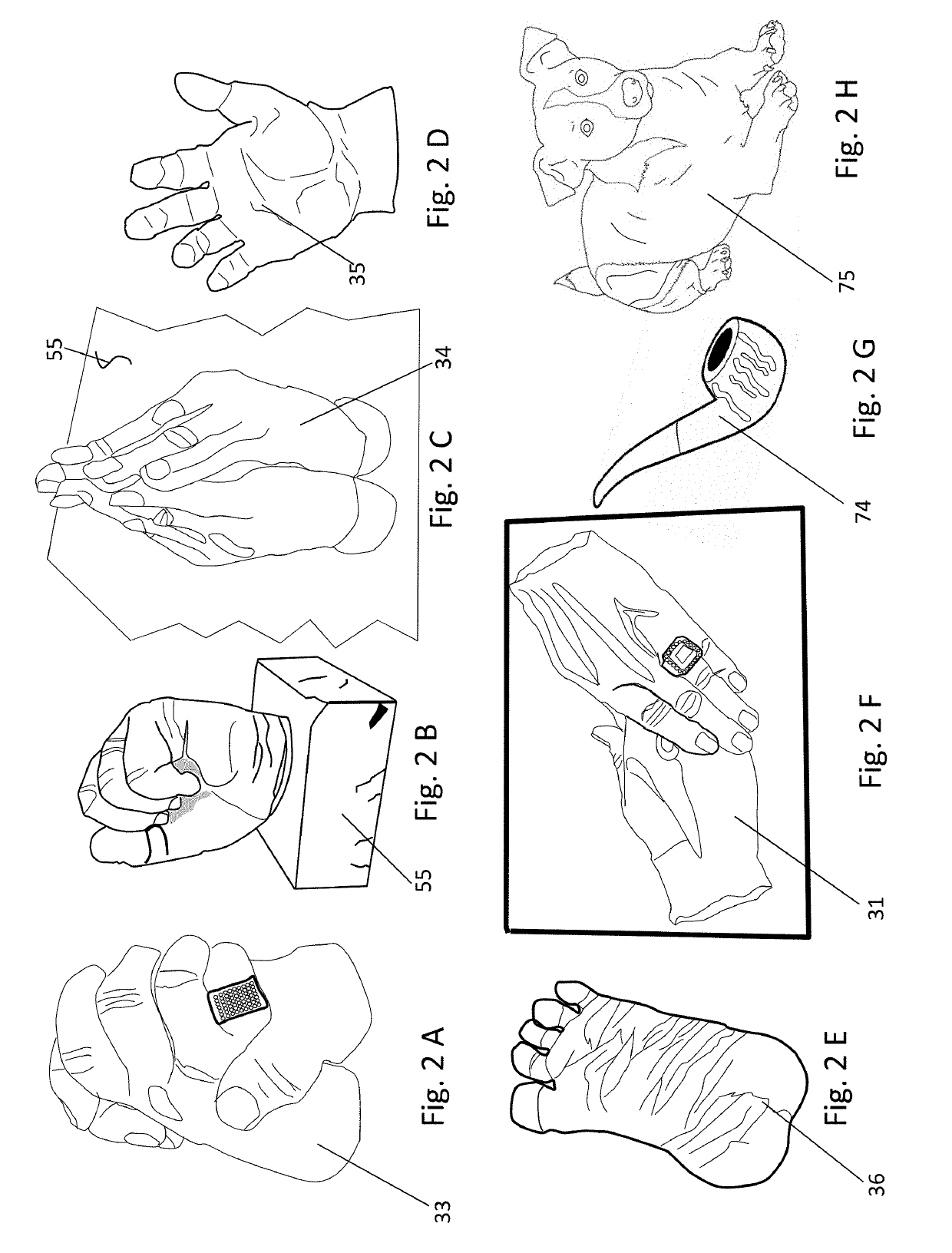

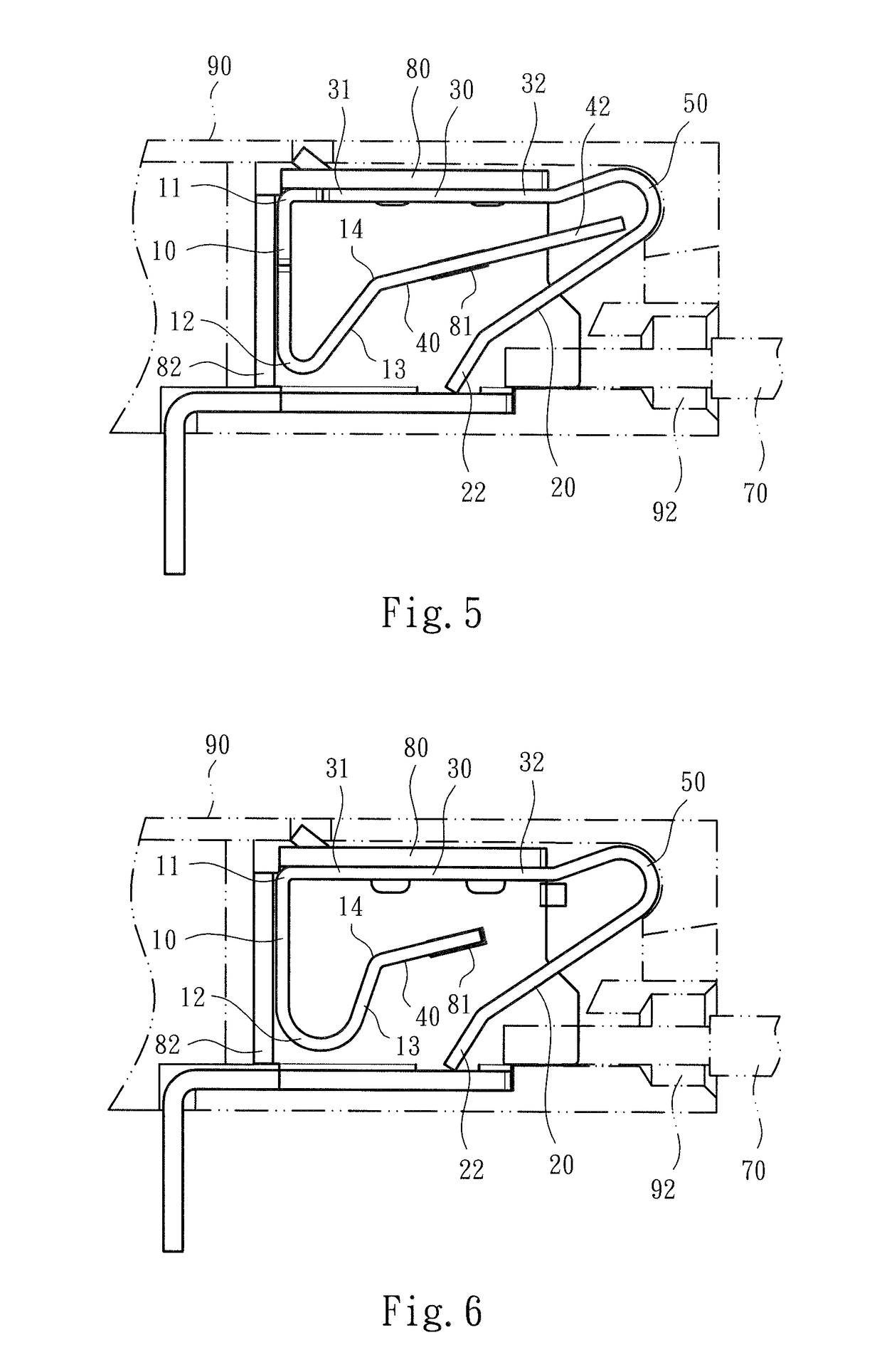

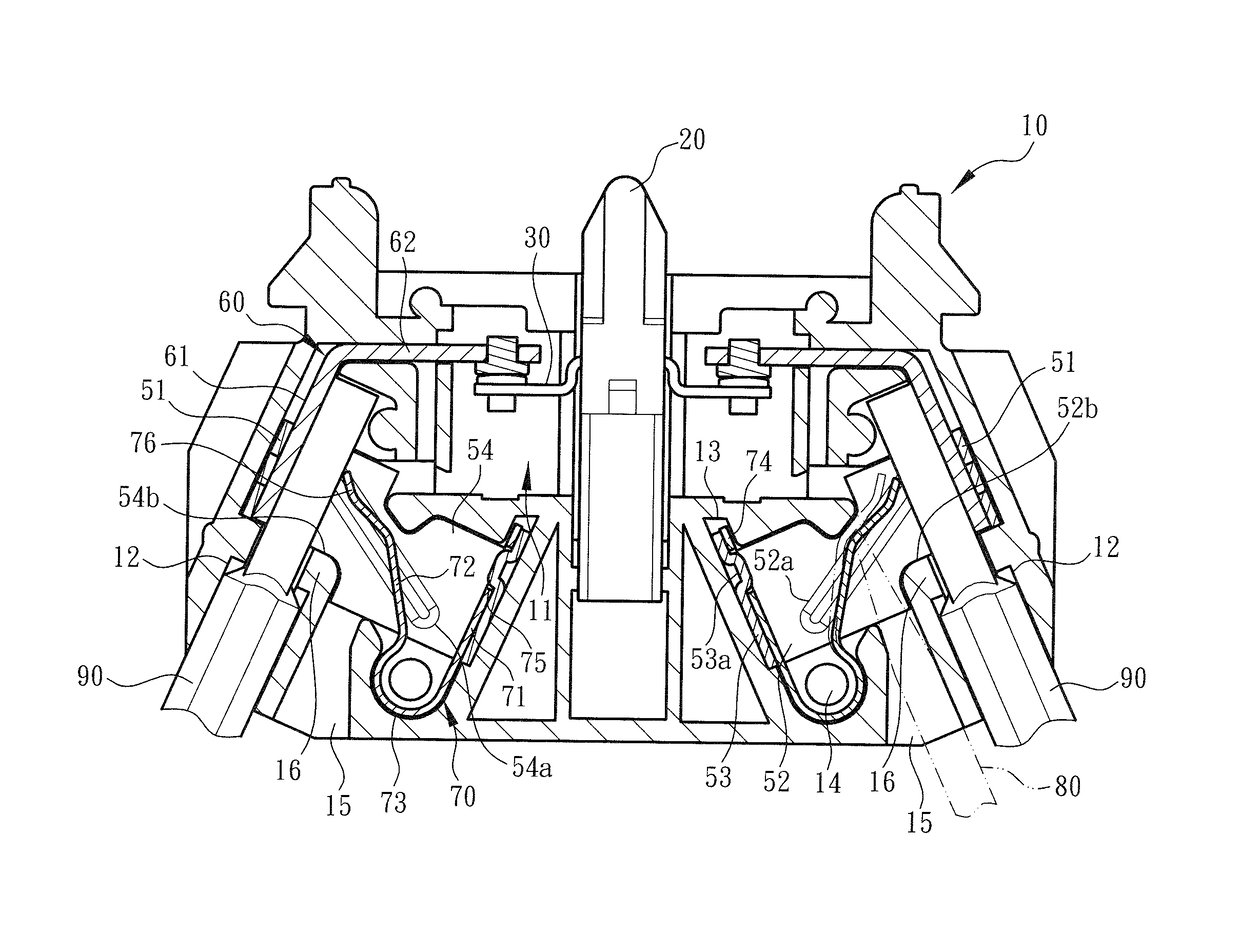

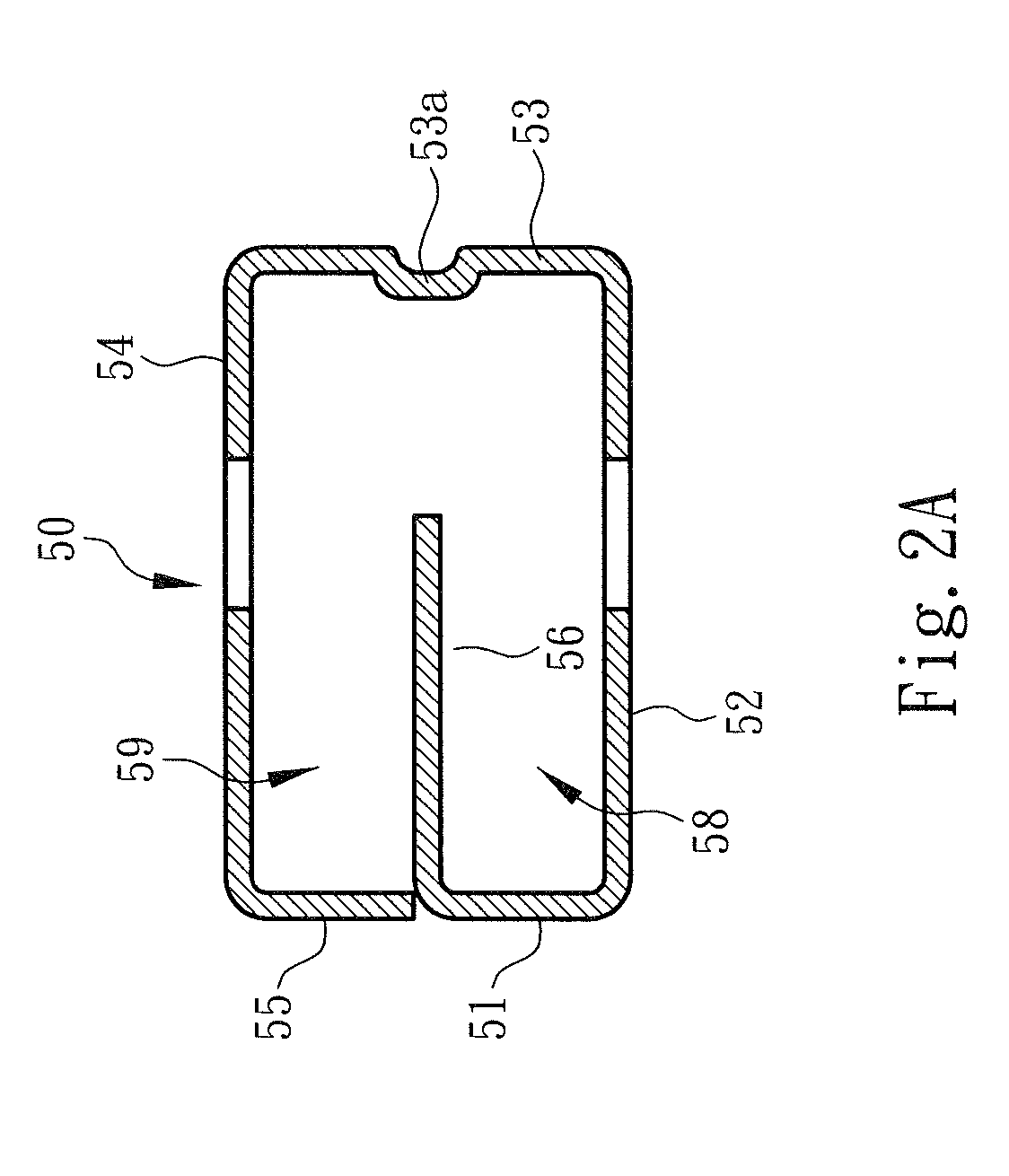

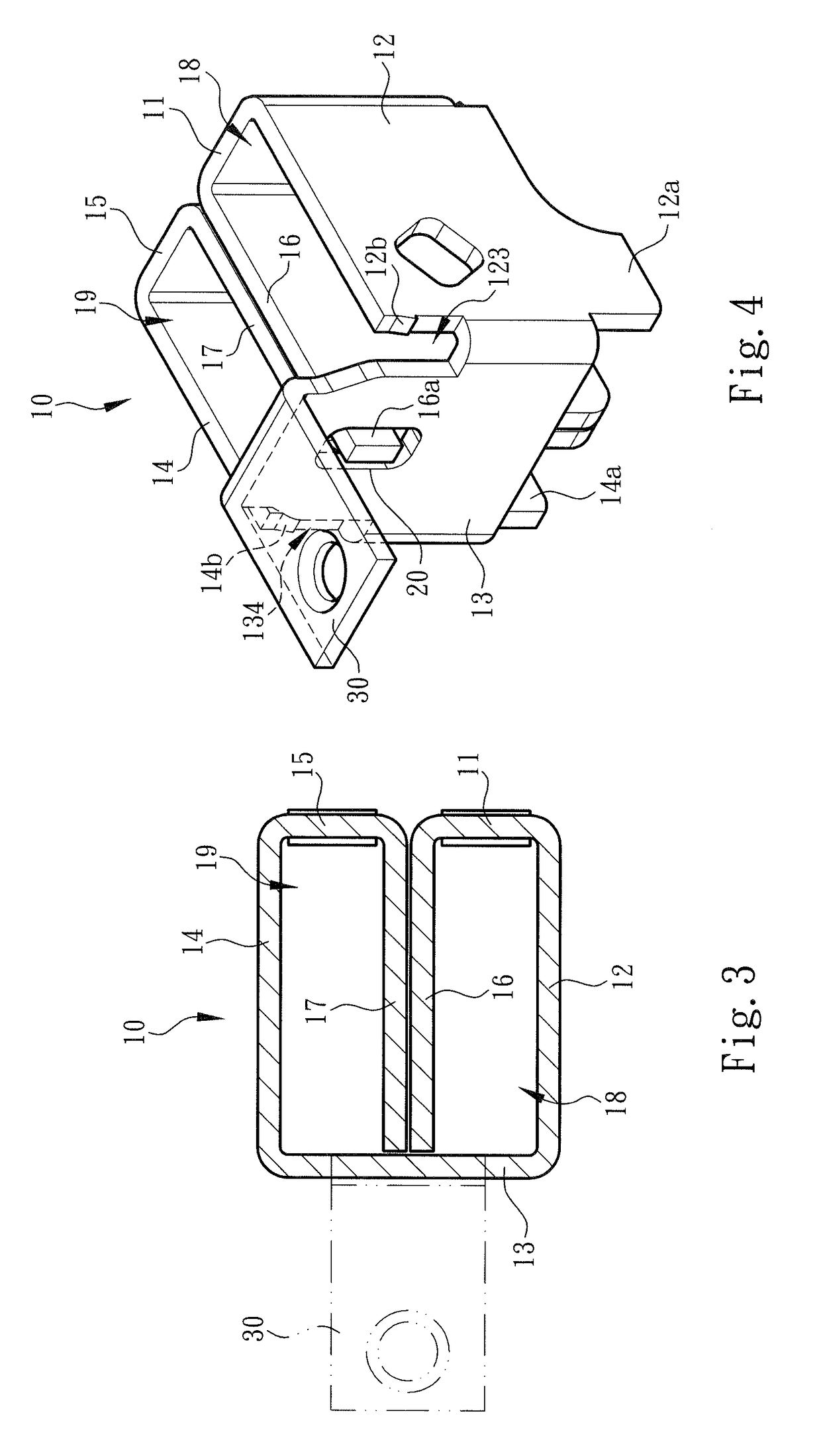

Metal leaf spring structure of electrical connection terminal

ActiveUS20180342817A1Improve shortcomingsFixed connectionsClamped/spring connectionsElectrical connectionEngineering

A metal leaf spring structure of electrical connection terminal includes a main body. The main body has a base section defined with a first end and a second end. The first end is connected with a first section and a locating section. The second end is connected with a bight section and a reciprocally movable second section. The locating section is positioned in the reciprocally moving path of the second section to setup a moving endpoint of the second section. The metal leaf spring structure of electrical connection terminal improves the shortcomings of the conventional metal leaf spring that the conductive wire cannot be plugged into the terminal by a precise angle so that the metal leaf spring is over-bent to affect the pressing and securing effect.

Owner:SWITCHLAB +1

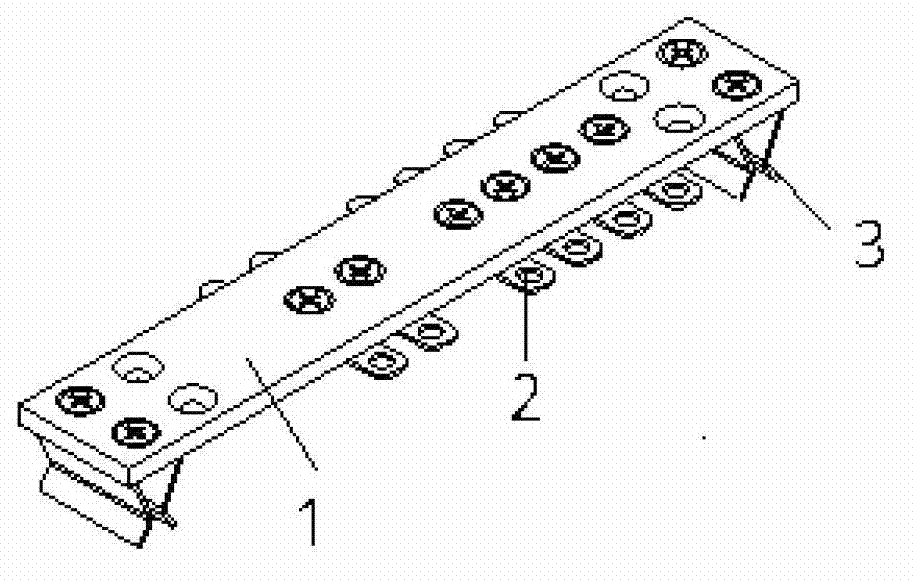

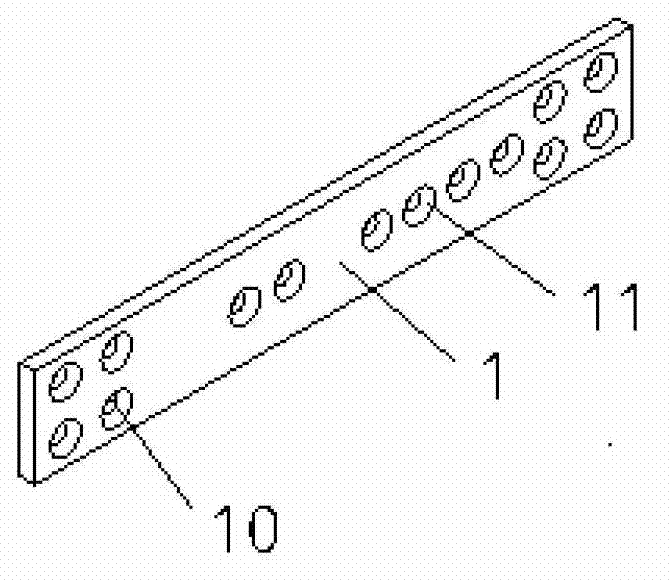

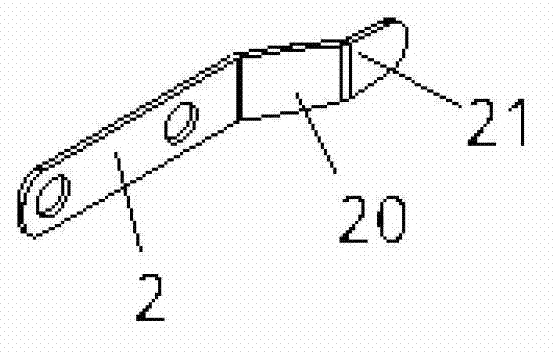

Intelligent energy meter auxiliary terminal leaf-spring-type wire connector

InactiveCN103048504ANo need to locateRealize automatic positioningTime integral measurementMetal leafEngineering

The invention discloses an intelligent energy meter auxiliary terminal leaf-spring-type wire connector, which comprises an insulation fixed plate, wherein two ends of the insulation fixed plate are respectively fixedly provided with an elastic tightening clamp, and the middle part of the insulation fixed plate is provided with a row of metal leaf springs. The insulation fixed plate is a rectangular insulation plastic fixed plate, and the insulation fixed plate is provided with threaded fixed holes to be in thread connection with the elastic tightening clamp and the metal leaf springs. The elastic tightening clamp comprises a soleplate and clamping plates which are arranged on two sides of the soleplate, and the waist positions of the clamping plate are retracted so as to enable the upper ends of the two clamping plates to form a V-shaped opening structure. One end of each metal leaf spring is provided with a 20-DEG slope, and the top end of the slope is connected with a platform. The wire connector is simple in structure, low in cost and capable of improving the meter calibration quality and efficiency.

Owner:JINHUA ELECTRIC POWER BUREAU +1

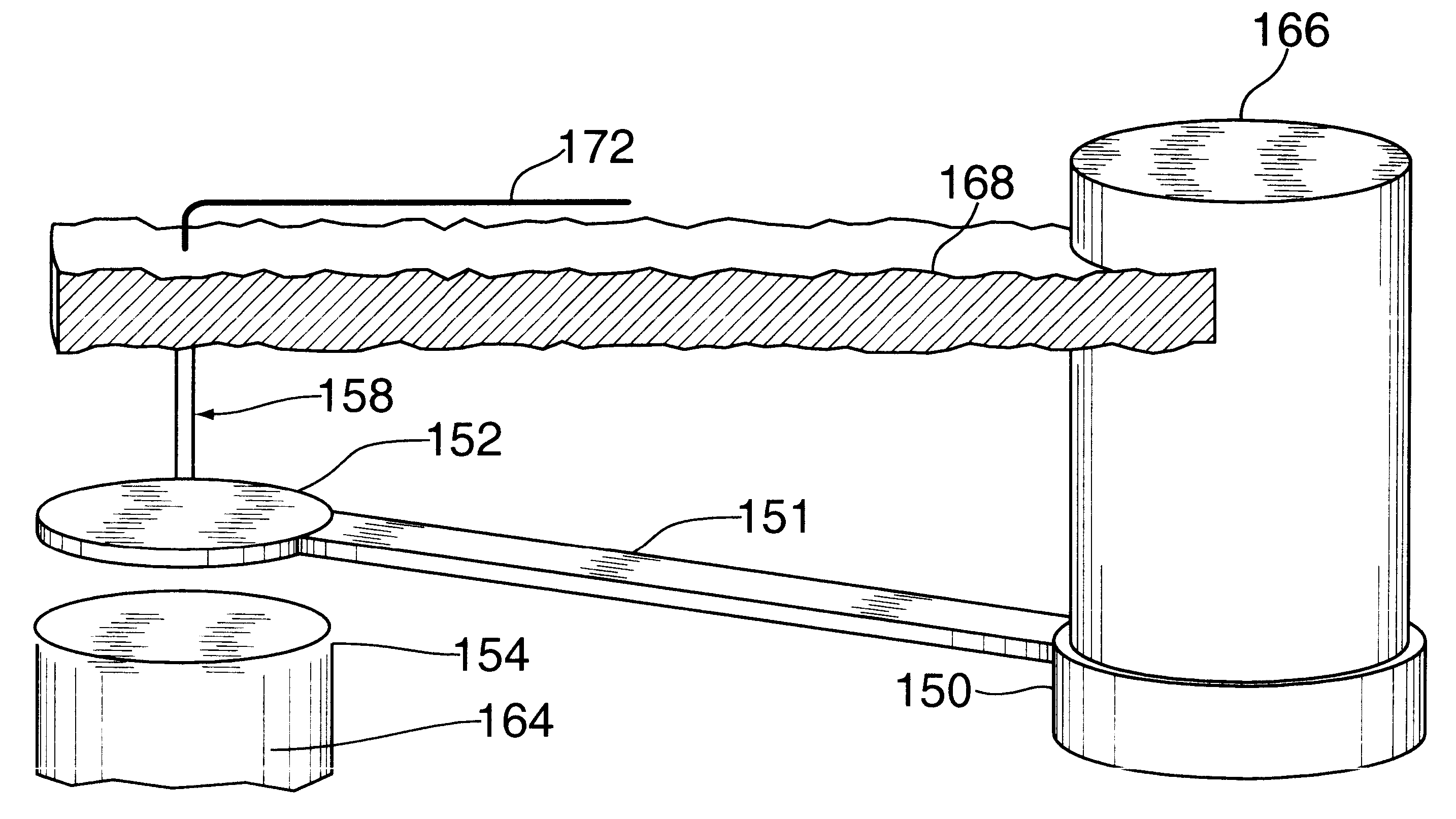

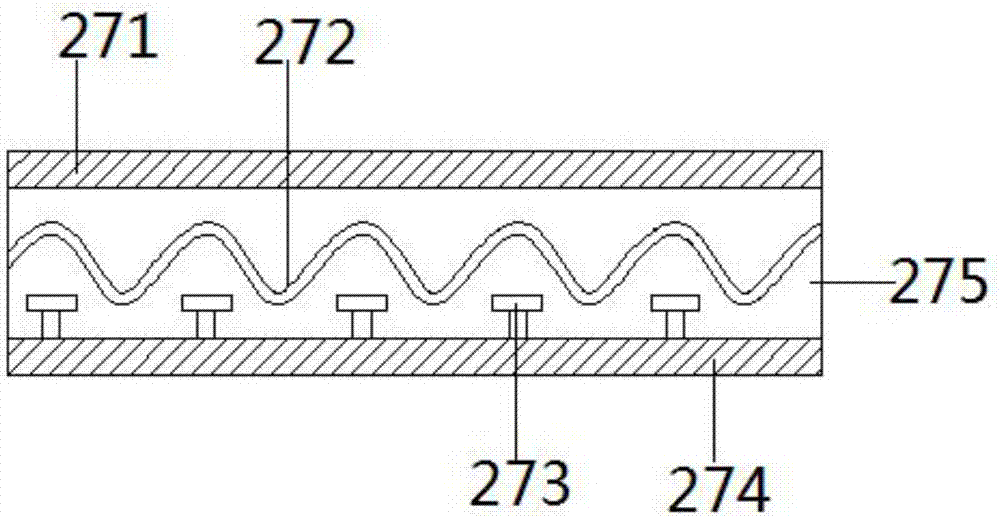

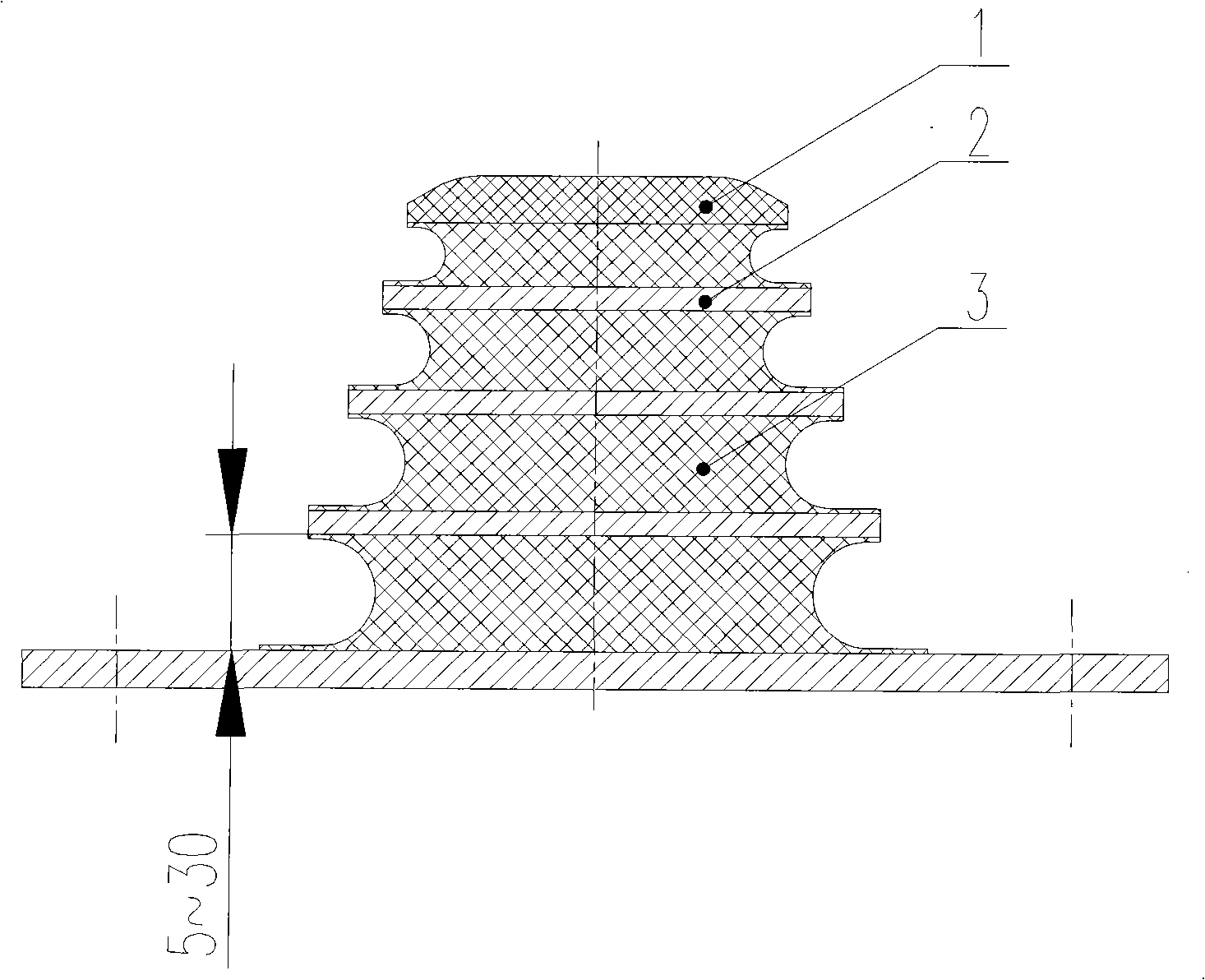

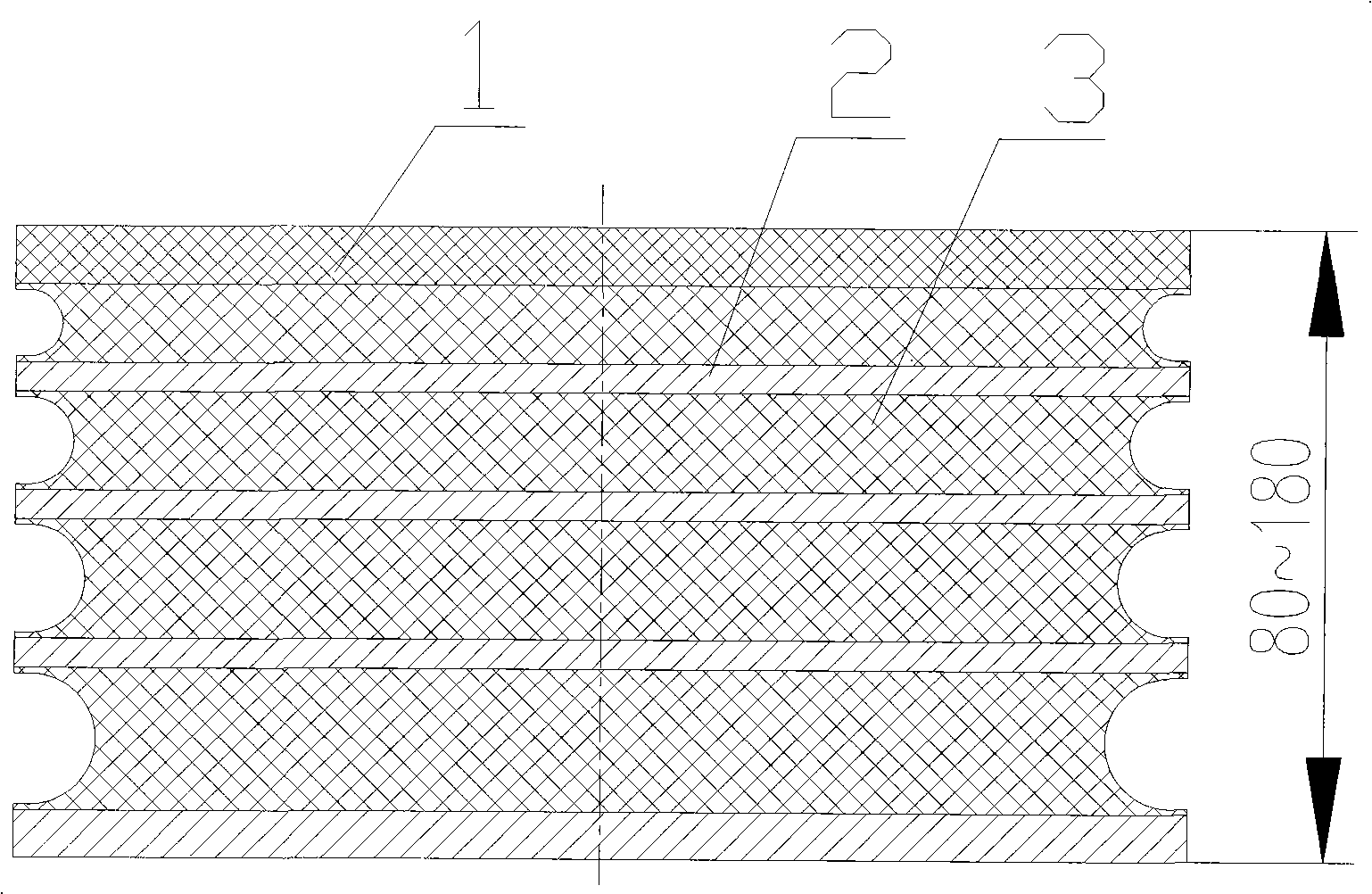

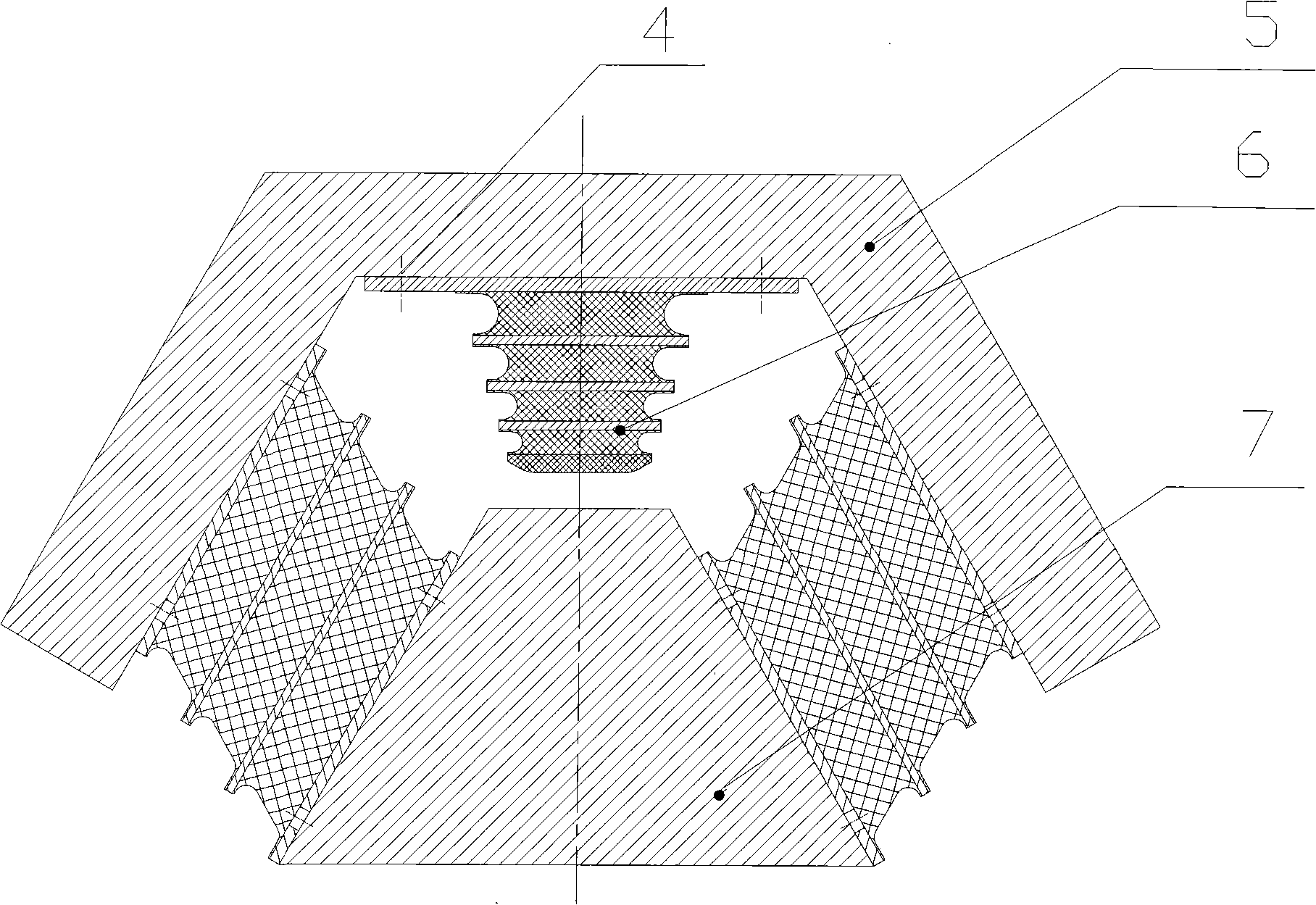

Auxiliary rubber metal stacking spring for truck and mounting method thereof

ActiveCN101328945AGood vertical stiffnessStrong rigidityHigh internal friction springsResilient suspensionsVehicle frameMetal leaf

The invention provides an auxiliary rubber-metal leaf spring used in a cargo truck and an installation method thereof. The auxiliary rubber-metal leaf spring is a composite elastic rubber-metal body which adopts a leaf rubber-metal spring structure, and is combined by a plurality of elastic rubber layers and metal spacers, and the elastic rubber layers and the metal spacers are arranged by adopting a conical structure, which is an elastic body combination with unequal elasticity; the elastic rubber layers can be 2 to 9 rubber layers, and the metal spacers can be 3 to 9 layers; a layer of nylon plate is attached on the top layer of the composite elastic rubber metal body, and is on the top end of the auxiliary rubber-metal leaf spring. The auxiliary rubber-metal spring is reversely vertically arranged on a truck frame through a bolt, and maintains a certain clearance with an axle when the truck is in idle load. When the cargo truck does not have goods, the auxiliary rubber-metal leaf spring is not contacted with the axle; when load increases, the nylon plate of the auxiliary rubber-metal leaf spring starts to be contacted with the axle to play a role in decreasing vibration.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

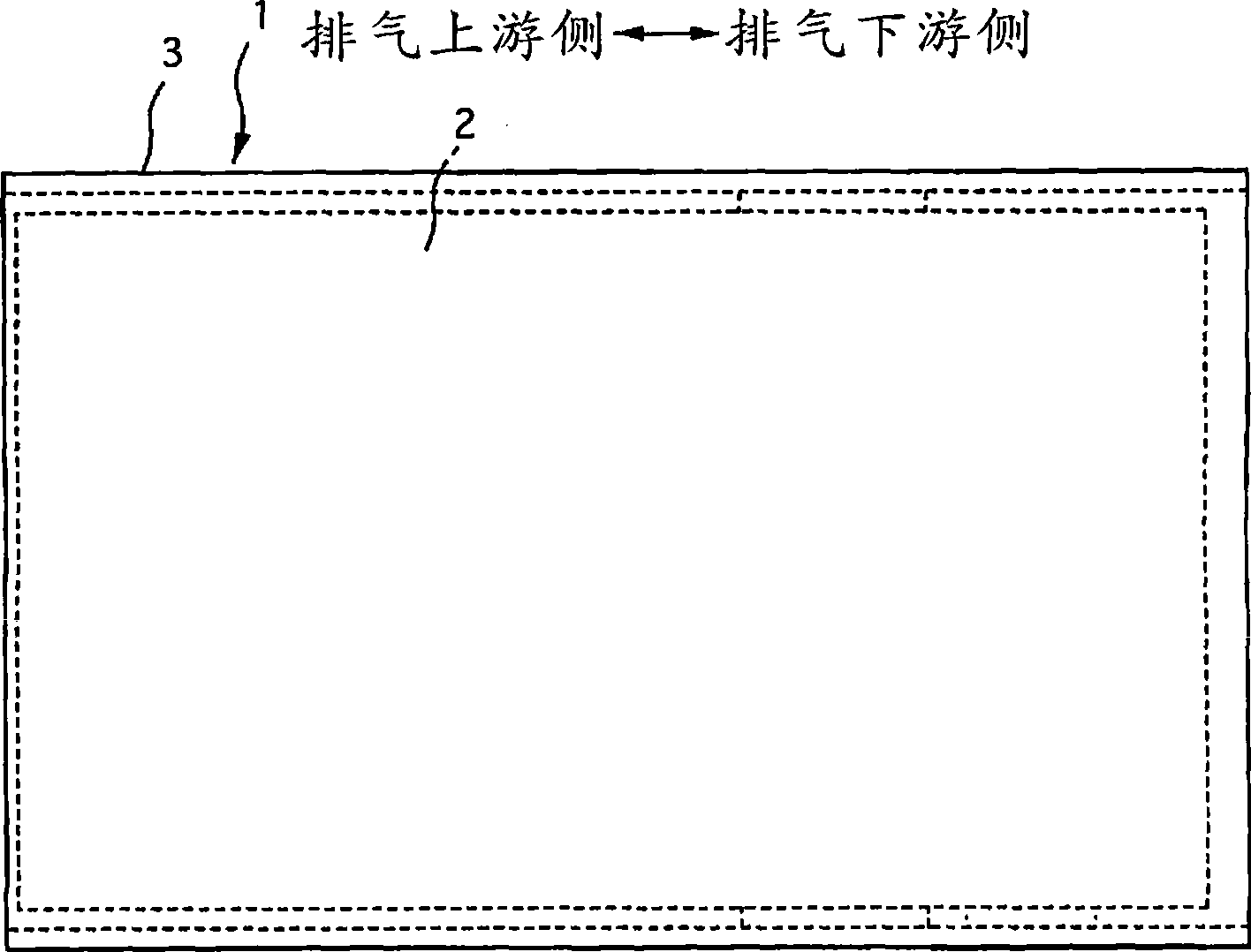

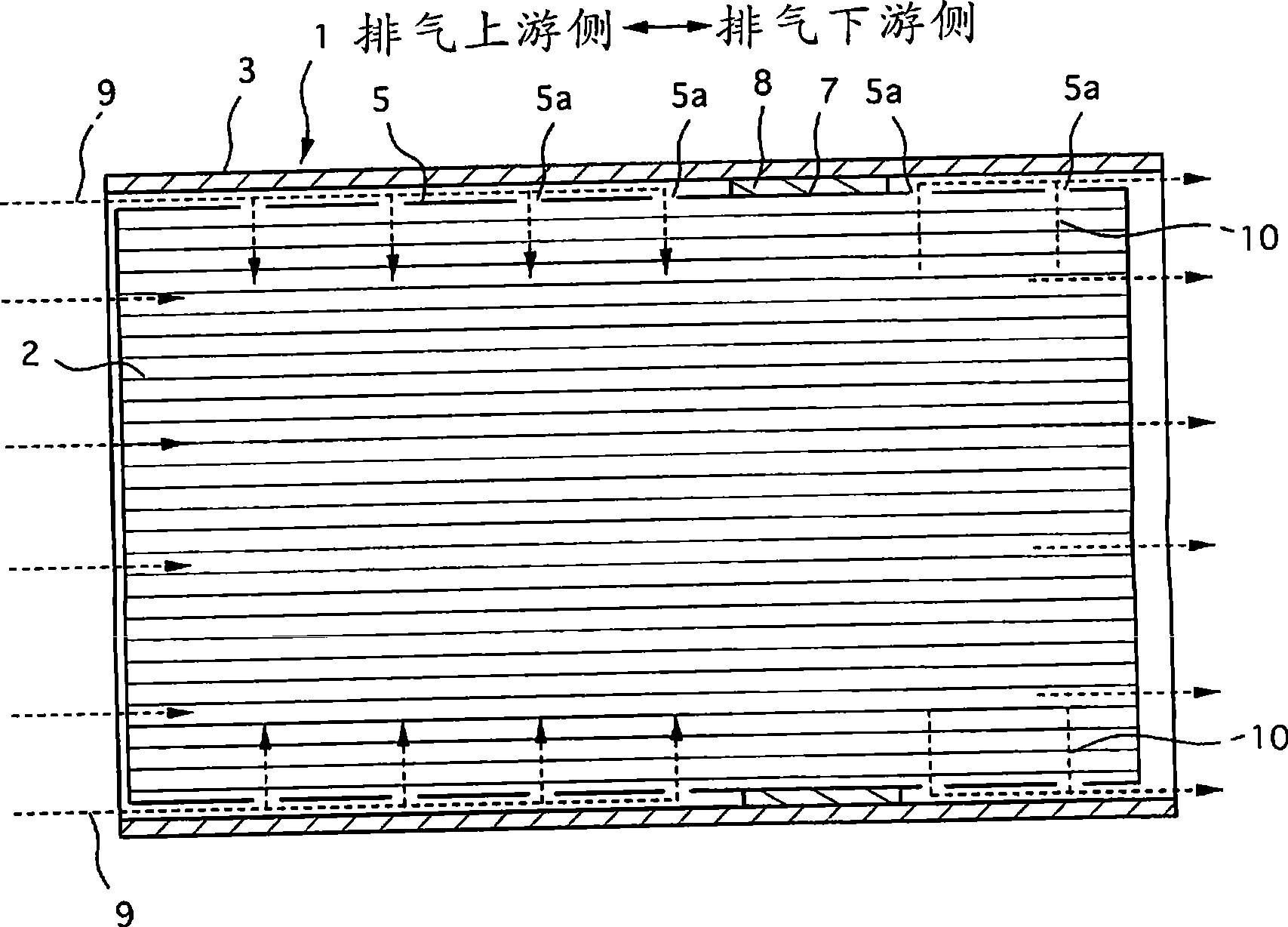

Metallic catalyst support with slit pore

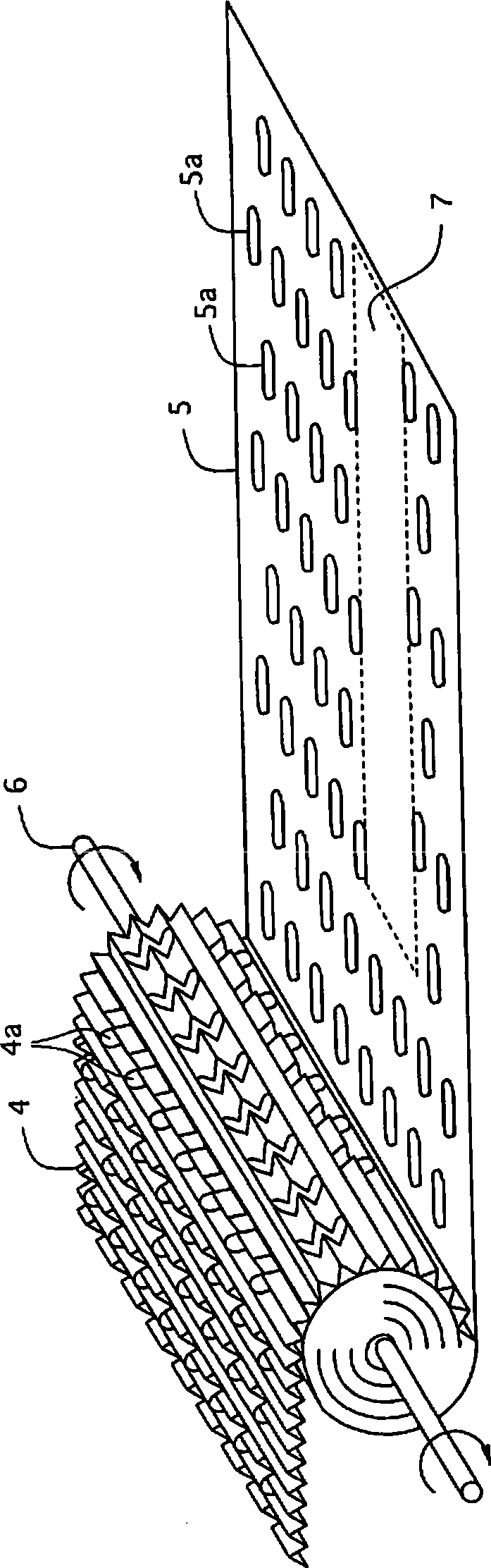

The invention provides a metal catalyst carrier having slit pore capable of obtaining effect of spreading the exhaust gas generated by slit pore of metal leaf at outermost periphery, while preventing the metal leaf from tearing along the heat expansion and heat contraction of the honeycomb ceramics, thereby improving durability. The metal catalyst carrier comprises a roller honeycomb ceramic (2) and a barrel-shaped outer cylinder (3) for containing the honeycomb ceramic (2); the honeycomb ceramic (2) is formed by winding undulatory metal leaf (4) and tabulate metal leaf (5) into a plurality of layer under the condition of overlapping the same; the slit pores (4a, 5a) are provided on theundulatory metal leaf (4) and tabulate metal leaf (5); by aid of brazing filler metal (brazing foil (8)), a part of periphery (7) of the honeycomb ceramic (2) and the outer cylinder (3) are fixed; the slit pore (5a) at the metal leaf (5) at outermost periphery of the honeycomb ceramic (2) is arranged at the position except from the part of periphery (7).

Owner:CALSONIC KANSEI CORP

Switch wire connection device

ActiveUS20170110267A1Simple structureEasy to operateElectrically conductive connectionsContact electric connectionMetal leafOperational stability

A switch wire connection device has a simplified structure and is easy to operate with enhanced stability of operation. The switch wire connection device includes a conductive component mounted in an insulation case, a switch pushbutton assembled with the conductive component and an electrical contact. The electrical contact has a restriction unit and a contact plate connected with the restriction unit. By means of operating the pushbutton, the conductive component is driven to selectively electrically contact or separate from the contact plate. The restriction unit defines a space, in which a metal leaf spring is assembled. The wiring circuit or conductive wire of a machine or equipment can be easily directly plugged into the space of the restriction unit and held by the metal leaf spring. The metal leaf spring is prevented from deflecting in the operation process.

Owner:SWITCHLAB +1

Metal leaf spring structure of electrical connection terminal

ActiveUS10622730B2Improve shortcomingsFixed connectionsClamped/spring connectionsElectrical connectionEngineering

A metal leaf spring structure of electrical connection terminal includes a main body. The main body has a base section defined with a first end and a second end. The first end is connected with a first section and a locating section. The second end is connected with a bight section and a reciprocally movable second section. The locating section is positioned in the reciprocally moving path of the second section to setup a moving endpoint of the second section. The metal leaf spring structure of electrical connection terminal improves the shortcomings of the conventional metal leaf spring that the conductive wire cannot be plugged into the terminal by a precise angle so that the metal leaf spring is over-bent to affect the pressing and securing effect.

Owner:SWITCHLAB +1

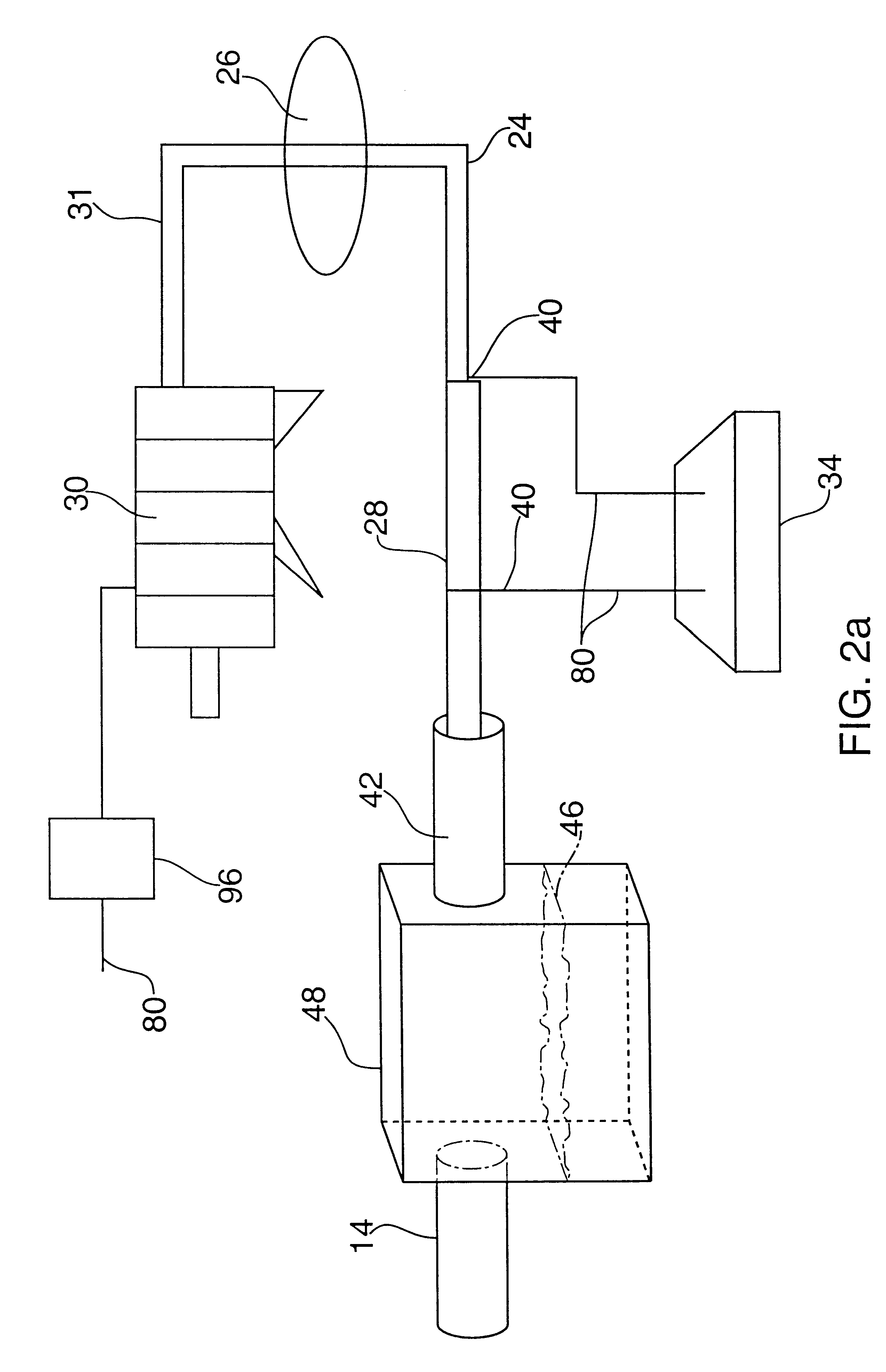

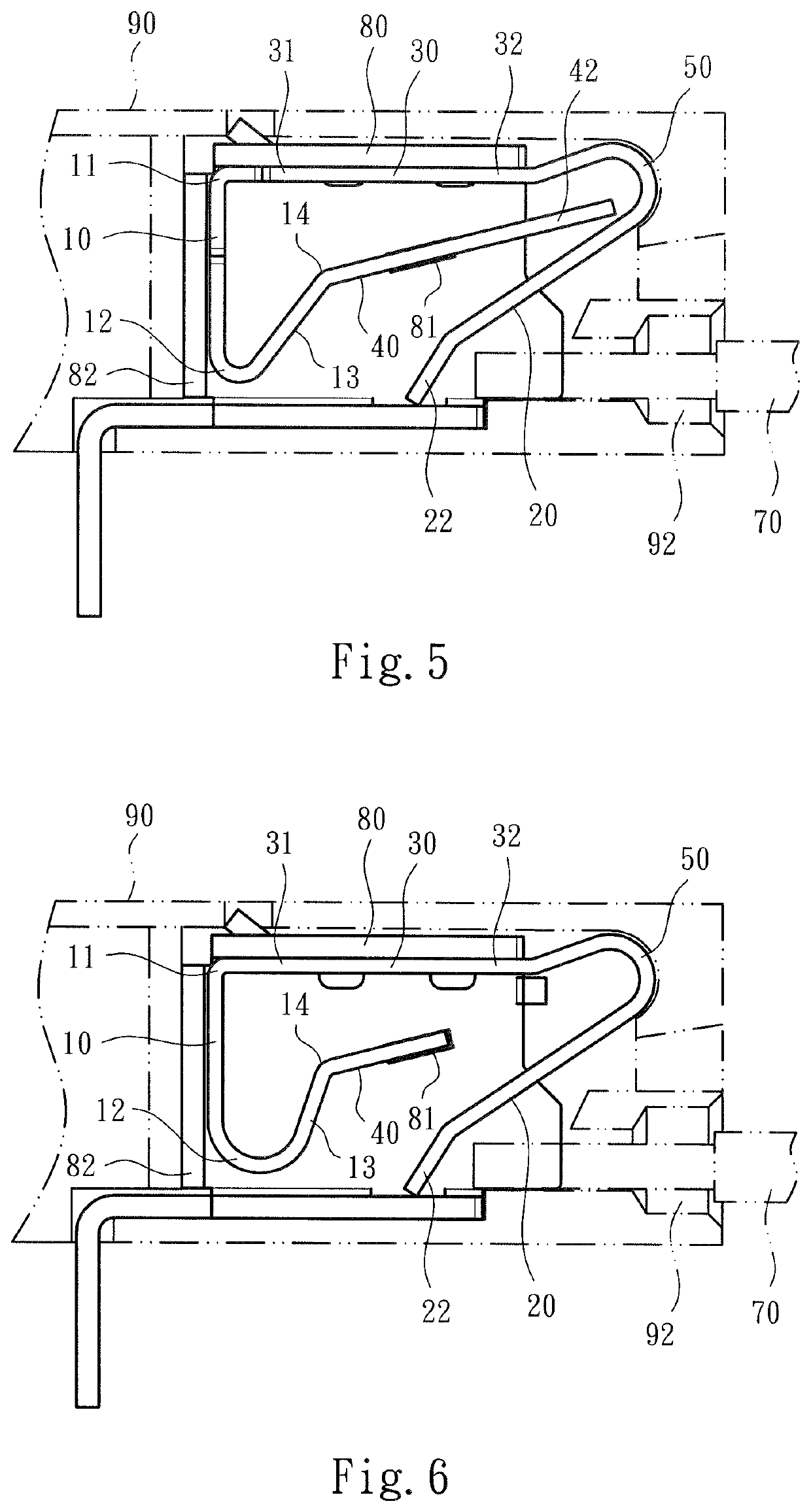

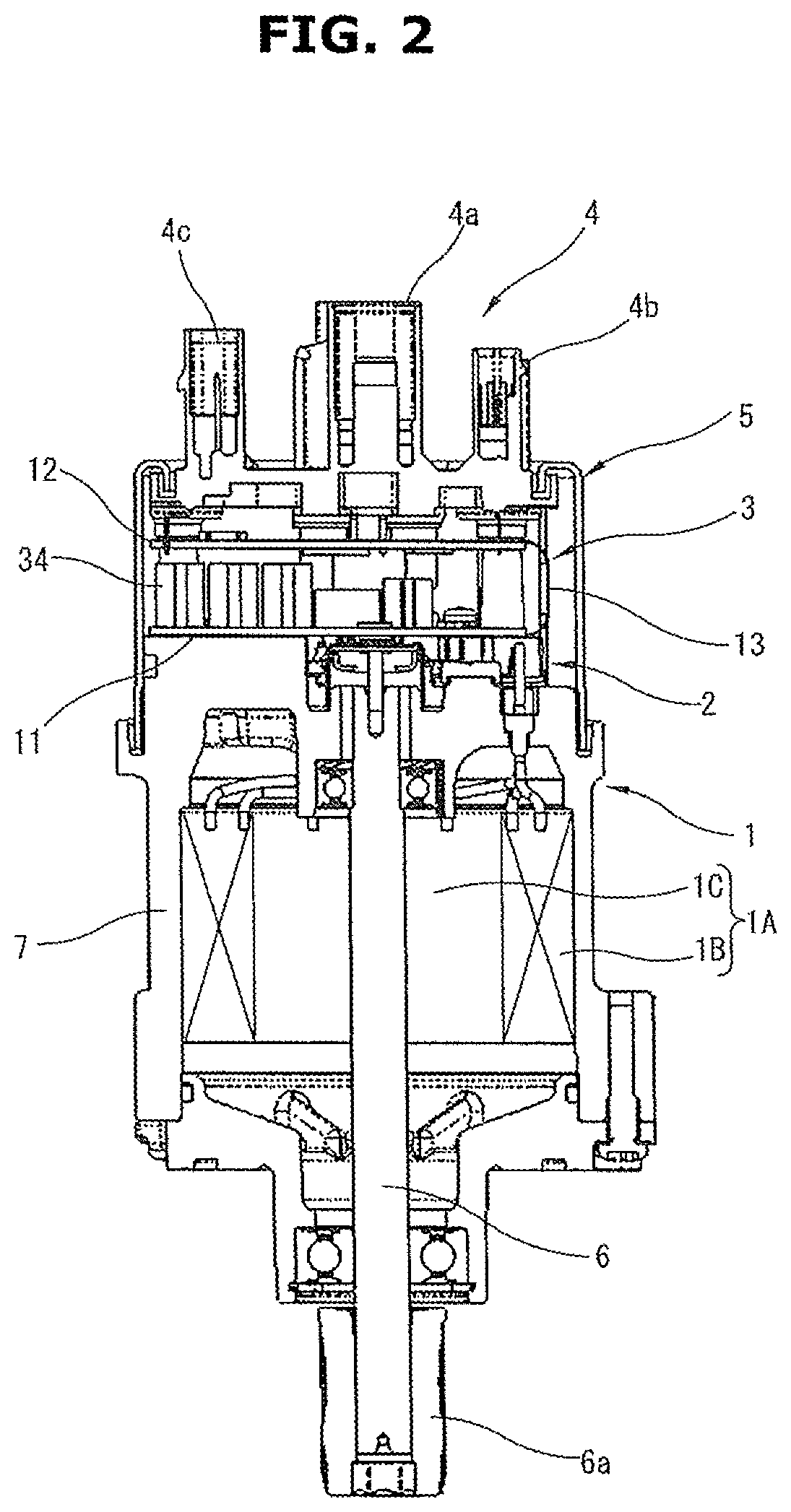

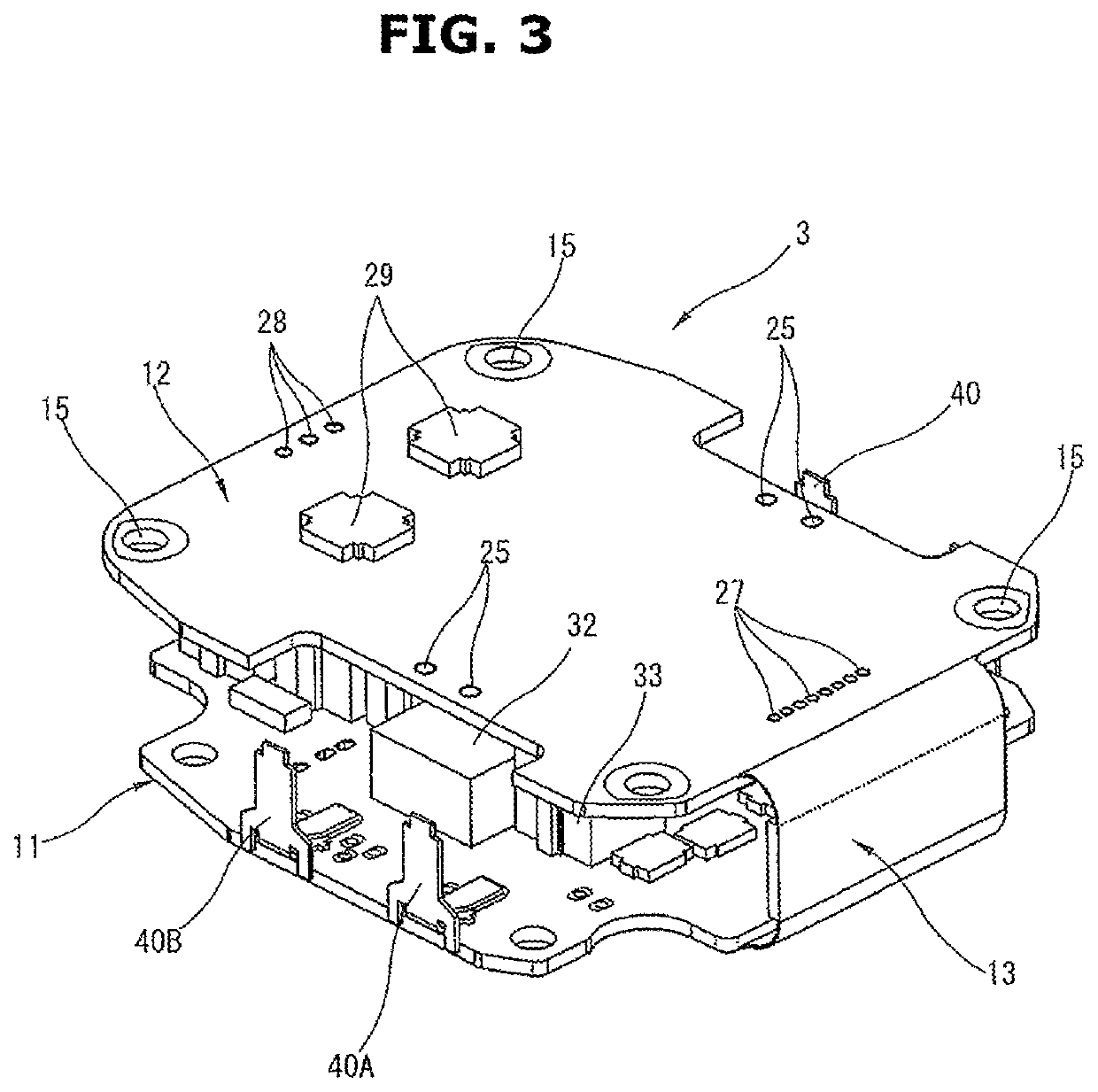

Electronic control device

ActiveUS20200321839A1Reduce the numberThin thicknessCircuit bendability/stretchabilityAssociation with control/drive circuitsCapacitanceDriver circuit

A wiring board (3) has first and second rigid sections (11, 12) each having six metal leaf layers, and a flexible section (13) having two metal leaf layers that connect the both rigid sections (11, 12). A capacitor unit (34) and a filter unit 31, which supplies power to an inverter, are mounted on the first rigid section (11), and a CPU (21) and a pre-driver circuit element (22) are mounted on the second rigid section (12). Mutually-independent two control systems are arranged so as to be symmetrical about a board center line (M). Detection signal lines (51) of rotation sensors (37, 38) located at the middle of the first rigid section (11) extend along the board center line (M) on the flexible section (13). Each of the two control systems is configured along a wiring direction of the detection signal lines (51).

Owner:HITACHI ASTEMO LTD

Wire connection terminal device

ActiveUS20170331201A1Improve shortcomingsBig spaceClamped/spring connectionsElectricityTerminal equipment

A wire connection terminal device includes a main body and a pressing / moving unit assembled with the main body. The pressing / moving unit has a shafted section, a cam section connected with the shafted section and a force application section formed on the cam section and a press section formed on the cam section. The cam section can freely rotate or swing within a chamber defined by the main body. A metal leaf spring is disposed in the chamber of the main body for pressing and electrically connecting with a conductive wire. The metal leaf spring is responsive to the motion of the pressing / moving unit to release the conductive wire. The wire connection terminal device improves the shortcomings of the conventional structure that the volume of the case and the operational space are larger and the motional travel is longer.

Owner:SWITCHLAB +1

Switch wire connection device

ActiveUS9922778B2Simple structureEasy to operateElectrically conductive connectionsContact electric connectionMetal leafOperational stability

A switch wire connection device has a simplified structure and is easy to operate with enhanced stability of operation. The switch wire connection device includes a conductive component mounted in an insulation case, a switch pushbutton assembled with the conductive component and an electrical contact. The electrical contact has a restriction unit and a contact plate connected with the restriction unit. By means of operating the pushbutton, the conductive component is driven to selectively electrically contact or separate from the contact plate. The restriction unit is divided into a first space and a second space, in which a first leg section and a second leg section of a metal leaf spring are respectively assembled. The wiring circuits or conductive wires can be easily directly plugged into the first and second spaces of the restriction unit and held by the first and second leg sections.

Owner:SWITCHLAB +1

Electrical connector limiter structure of wire connection terminal

ActiveUS20170264027A1Increase relative motionEasy to operateClamped/spring connectionsMetal leafEngineering

An electrical connector limiter structure of wire connection terminal is easily operable to enhance the stability of the operation and motion of metal leaf springs. The wire connection terminal includes conductive components mounted in the insulation case and electrical connector assembled with the conductive components. The electrical connector has a limiter for receiving the metal leaf springs and restricting moving path thereof. The limiter is partitioned to define a first space and a second space with fully closed peripheries, in which the metal leaf springs are mounted. The wiring circuits or conductive wires coming from an apparatus can be easily directly plugged into the first and second spaces of the limiter to insert with the metal leaf springs. The limiter serves to prevent the metal leaf springs from deflecting in operation.

Owner:SWITCHLAB +1

Electrical connector limiter structure of wire connection terminal

ActiveUS9899751B2Enhance stability of operation and motionAvoid skewClamped/spring connectionsMetal leafElectrical connector

An electrical connector limiter structure of wire connection terminal is easily operable to enhance the stability of the operation and motion of metal leaf springs. The wire connection terminal includes conductive components mounted in the insulation case and electrical connector assembled with the conductive components. The electrical connector has a limiter for receiving the metal leaf springs and restricting moving path thereof. The limiter is partitioned to define a first space and a second space with fully closed peripheries, in which the metal leaf springs are mounted. The wiring circuits or conductive wires coming from an apparatus can be easily directly plugged into the first and second spaces of the limiter to insert with the metal leaf springs. The limiter serves to prevent the metal leaf springs from deflecting in operation.

Owner:SWITCHLAB +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com