Auxiliary rubber metal stacking spring for truck and mounting method thereof

A rubber-to-metal truck technology, applied to high internal friction springs, elastic suspensions, vehicle parts, etc., can solve the problems of reduced service life of auxiliary springs, poor use of rubber suspensions, and inability to meet the needs of automobiles, etc., to achieve Ease of loading and unloading, good vibration damping effect, good comfort and passability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

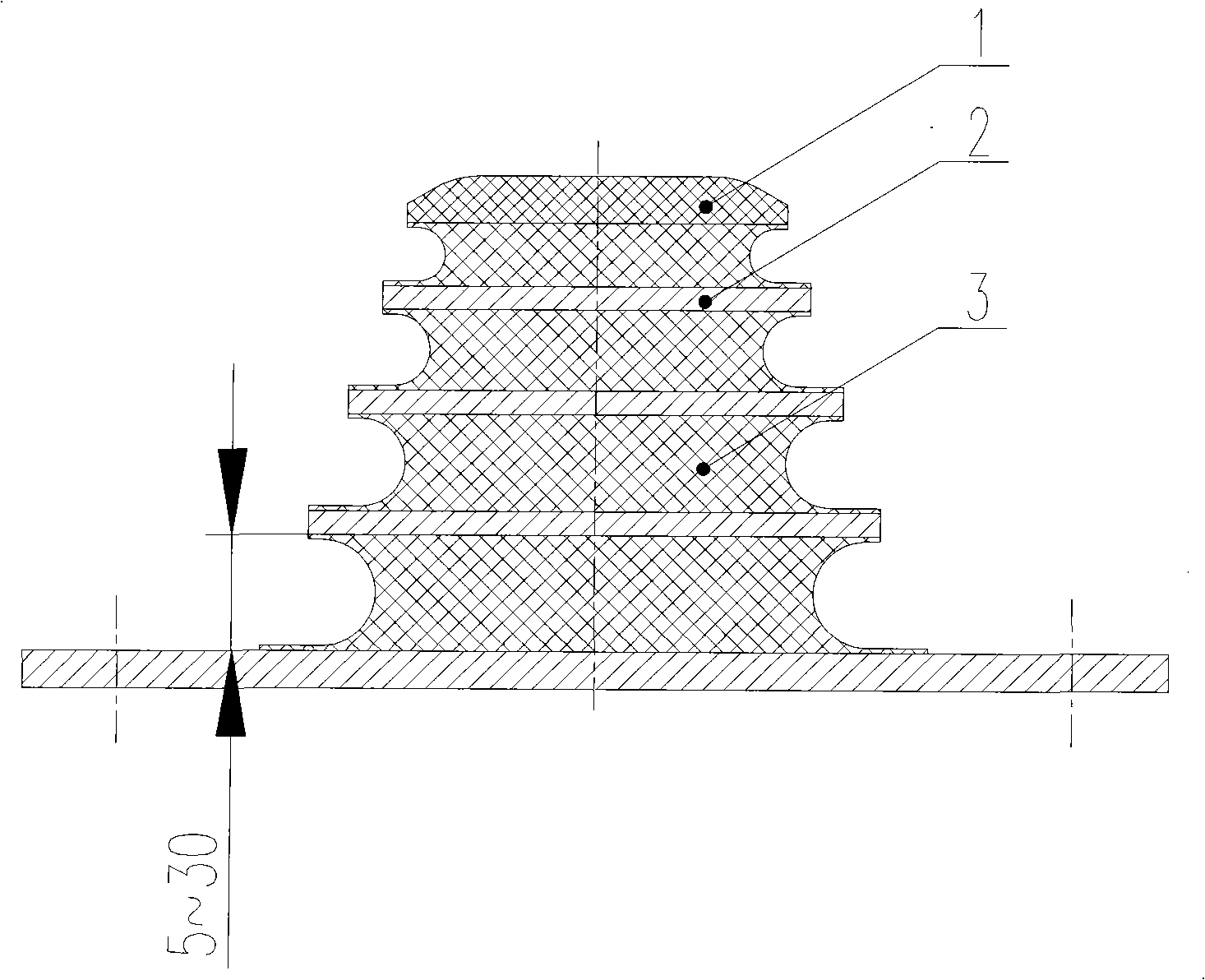

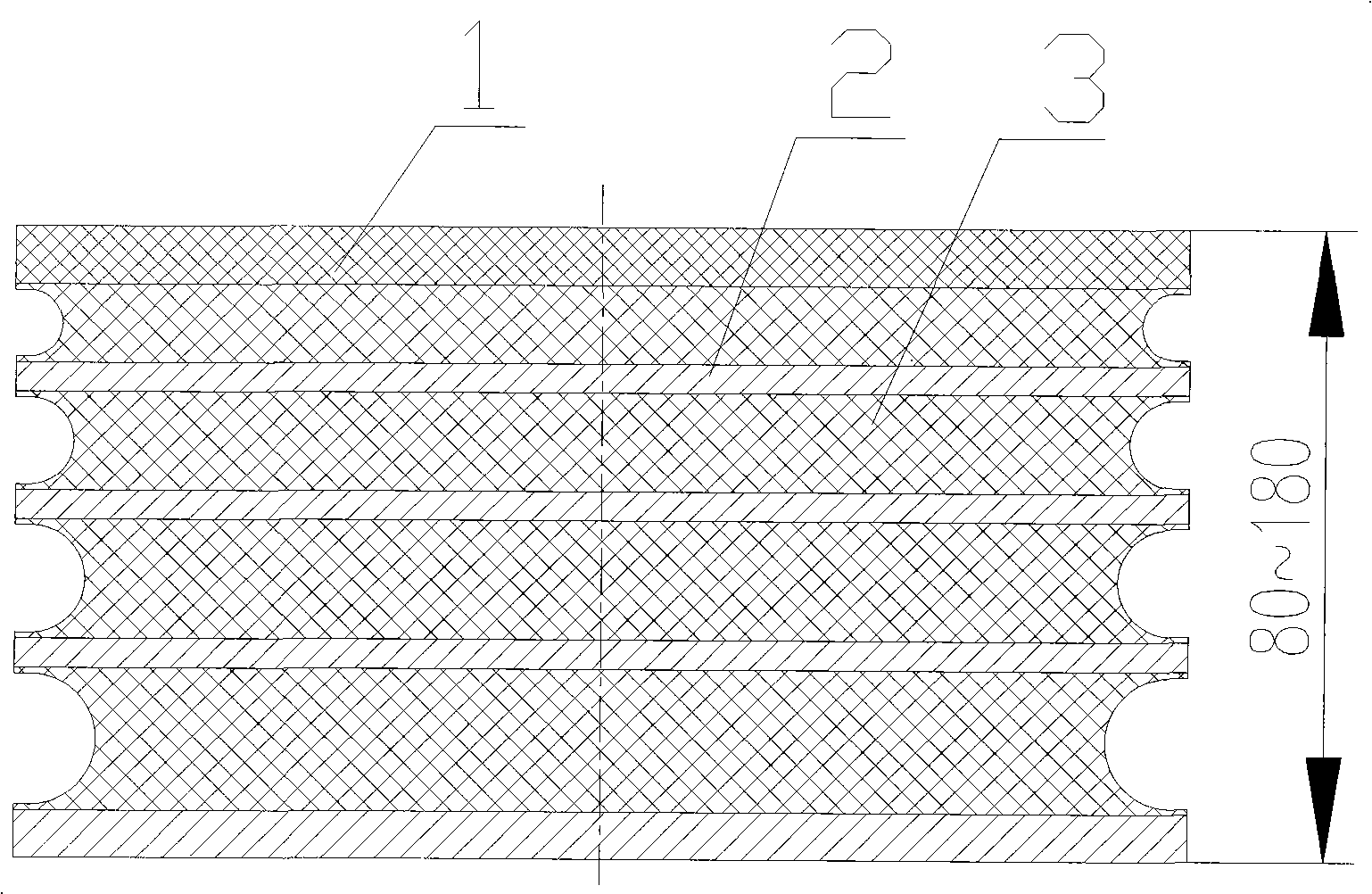

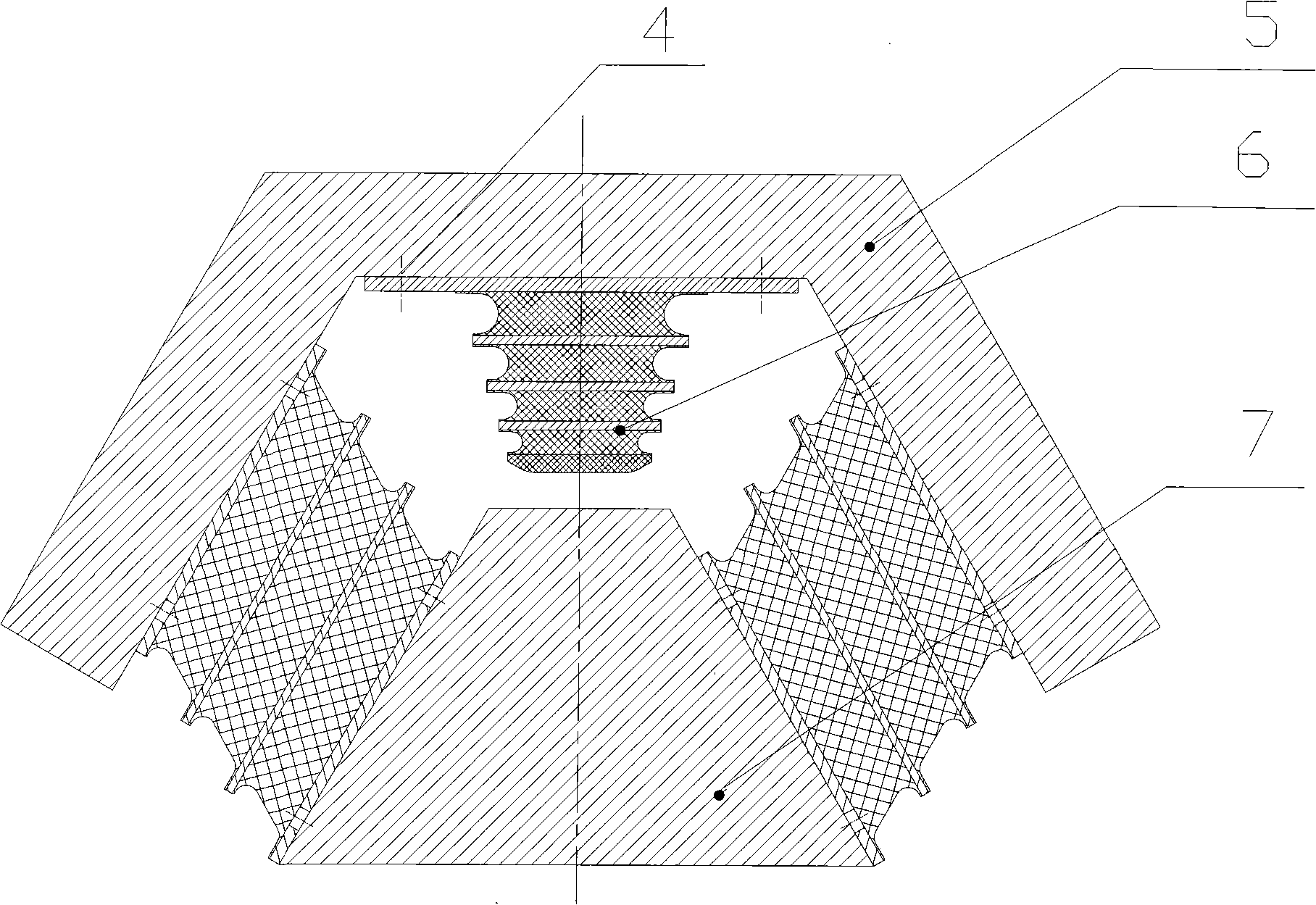

[0016] The accompanying drawings show an embodiment of the present invention, and the present invention will be further described below in conjunction with the accompanying drawings.

[0017] It can be seen from the accompanying drawings that the present invention is an auxiliary rubber-metal laminated spring for trucks, which is mainly used on the rubber suspension of trucks. It is an assembly of laminated rubber-metal springs formed by compounding rubber and metal. The metal spring structure is composed of multi-layer elastic rubber layer 3 and multi-layer metal spacer 2 to form a composite elastic rubber metal body, and the multi-layer elastic rubber layer 3 and multi-layer metal spacer 2 are arranged in a tapered structure, ranging from Elastic combination of elastic force; the multi-layer elastic rubber layer 2 can be composed of 2-9 layers of rubber layers, and the multi-layer metal spacer is 3-9 layers; on the top layer of the composite elastic rubber-metal body Attache...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com