Seamless bridge deck expansion joint structure for road engineering

A technology of road engineering and expansion joints, which is applied in the direction of bridges, bridge construction, bridge parts, etc., can solve the problems of driving comfort, appearance, and poor installation quality, so as to improve driving comfort, high structural safety, and convenience. The effect of replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

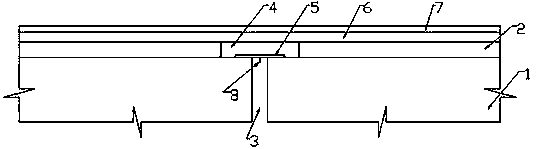

[0037] A seamless bridge deck expansion joint structure for road engineering includes a beam body 1 and an expansion joint. The beam body 1 is provided with a concrete paving layer 2, and a reserved slot is formed between two adjacent concrete paving layers. There is a gap 3 between the two adjacent beams or between the beam and the abutment, which also includes an elastic plastic body 4 and a backing plate 5. The backing plate 5 is located on the bottom surface of the reserved slot to close the gap 3, and the backing plate 5 is set on the elastic Under the plastic body 4, the elastic plastic body 4 is located in the reserved slot to form an elastic plastic body expansion joint, and an asphalt concrete layer is laid through the concrete paving layer 2 and the elastic plastic body expansion joint.

[0038] A preferred embodiment of the present invention is that the asphalt concrete layer includes a lower asphalt concrete layer 6 and an upper asphalt concrete layer 7 on the lower as...

Embodiment 2

[0047] This embodiment is basically the same as the foregoing embodiment, with the difference that: the limiting member 8 is a steel bar with a diameter of 12 mm and a length of 6 cm. The backing plate 5 is a steel plate with a thickness of 1.6 cm, a width of 55 cm, and a length of 35 cm. The elastic plastic body expansion joint has a width of 55 cm and a thickness of 12 cm. The thickness of the lower asphalt concrete layer 6 is 7 cm, and the thickness of the upper asphalt concrete layer 7 is 5 cm.

[0048] In the construction process, when the expansion joint is constructed and the upper asphalt concrete pavement is constructed, the daily average temperature shall be 12℃. The highest temperature on the day of construction shall not exceed 20℃, the daily average temperature shall not exceed 15℃, and the asphalt concrete pavement temperature shall not exceed Below 0°C. The elastomer mixture is a mixture of binder and aggregate, and the amount of binder in the elastomer mixture p...

Embodiment 3

[0050] This embodiment is basically the same as the foregoing embodiment, with the difference that: the limiting member 8 is a steel bar with a diameter of 10 mm and a length of 5 cm. The backing plate 5 is a steel plate with a thickness of 1.4 cm, a width of 50 cm, and a length of 30 cm. The elastic plastic body expansion joint has a width of 50 cm and a thickness of 10 cm. The thickness of the lower asphalt concrete layer 6 is 6 cm, and the thickness of the upper asphalt concrete layer 7 is 4 cm.

[0051] In the construction process, when the expansion joint is constructed and the upper asphalt concrete pavement is constructed, the daily average temperature shall be 10℃. The highest temperature on the day of construction shall not exceed 20℃, the daily average temperature shall not exceed 15℃, and the asphalt concrete pavement temperature shall not exceed Below 0°C. The elastomer mixture is a mixture of binder and aggregate, and the amount of binder in the elastomer mixture p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com