Energy-saving heat-insulating wall body

A technology for thermal insulation walls and thermal insulation wall panels, applied in thermal insulation, walls, building components, etc., can solve the problems of unsolved common quality problems of aerated concrete walls, complex structure of prefabricated walls, and inability to achieve building energy conservation, etc. The effect of reducing greenhouse gas emissions, outstanding shock absorption performance, and reducing maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

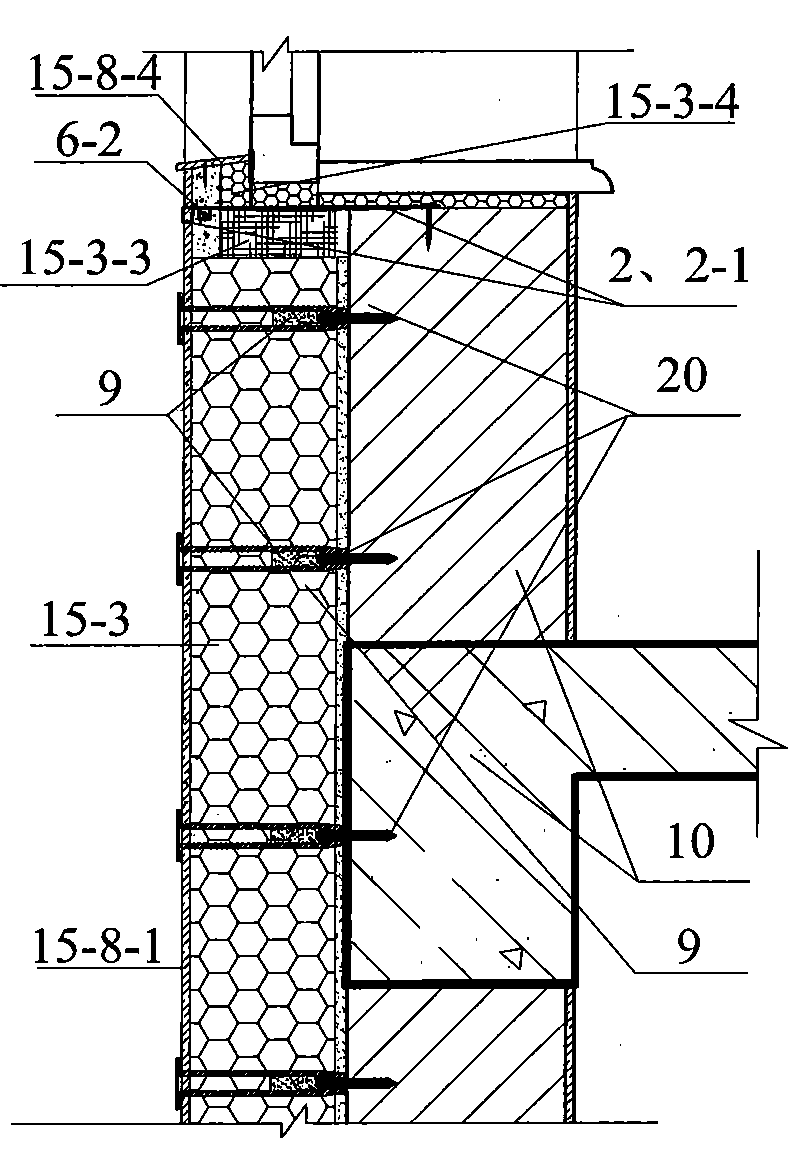

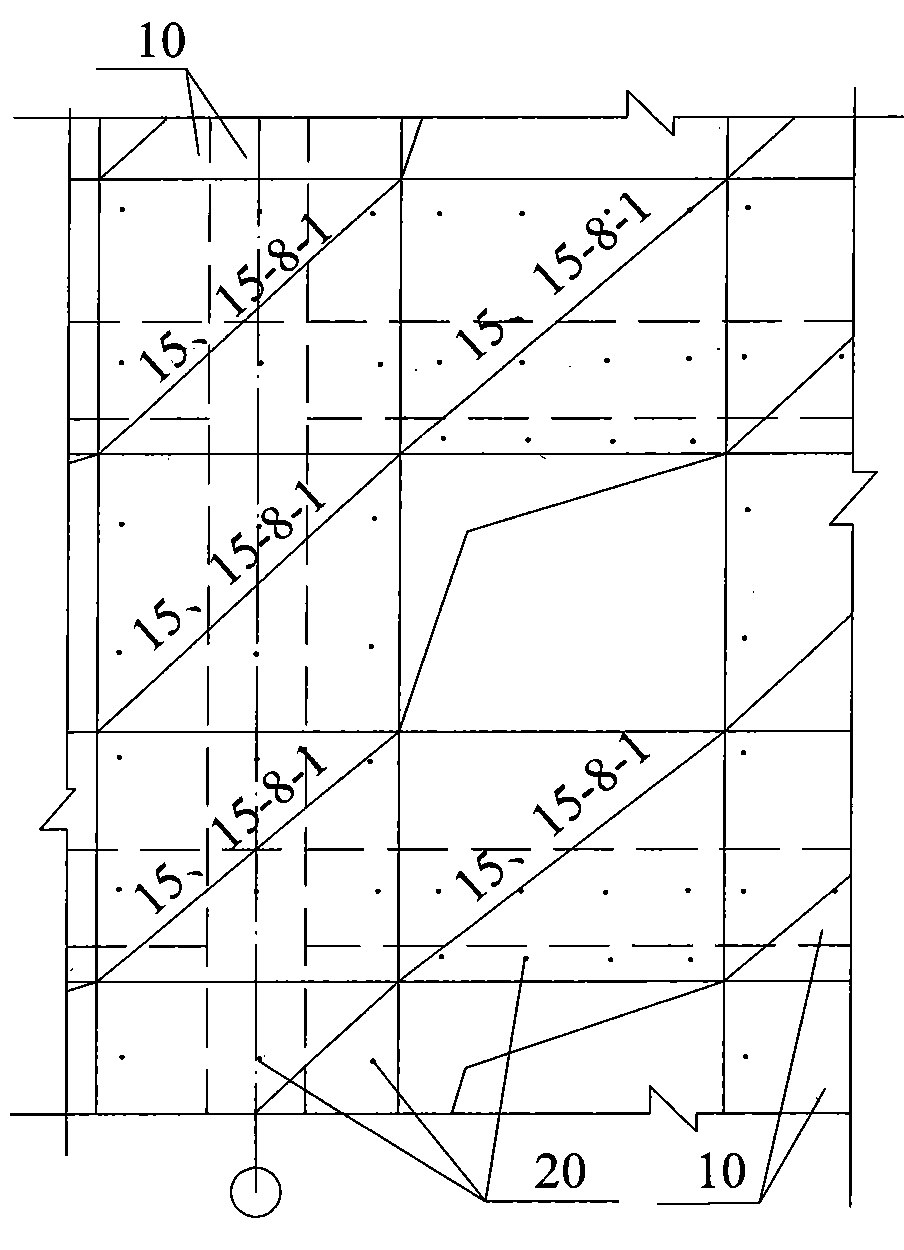

[0096] Implementation mode one: Figure 1 to Figure 4 , an energy-saving thermal insulation wall of the present embodiment, which is composed of a base wall 10, an insulation layer 15-3, an external protective layer 15-8-1, and an anchor bolt 20; the base wall 10 includes a building main body Structure, such as beams and columns of a frame, the base wall 10 is a load-bearing wall or a filled wall of a frame structure; the external protection layer 15-8-1 is a prefabricated protective layer; the prefabricated external protection The layer is a prefabricated plate protective layer, or a prefabricated protective layer formed by plastering;

[0097] The energy-saving and heat-preserving walls are arranged in sequence from the outside to the inside in the following order: the outer protective layer 15-8-1, the insulating layer 15-3, the base wall 10; the anchor bolt 20 passes through the outer protective layer 15-8-1 , thermal insulation layer 15-3, external protective layer 15-8-...

Embodiment approach 2

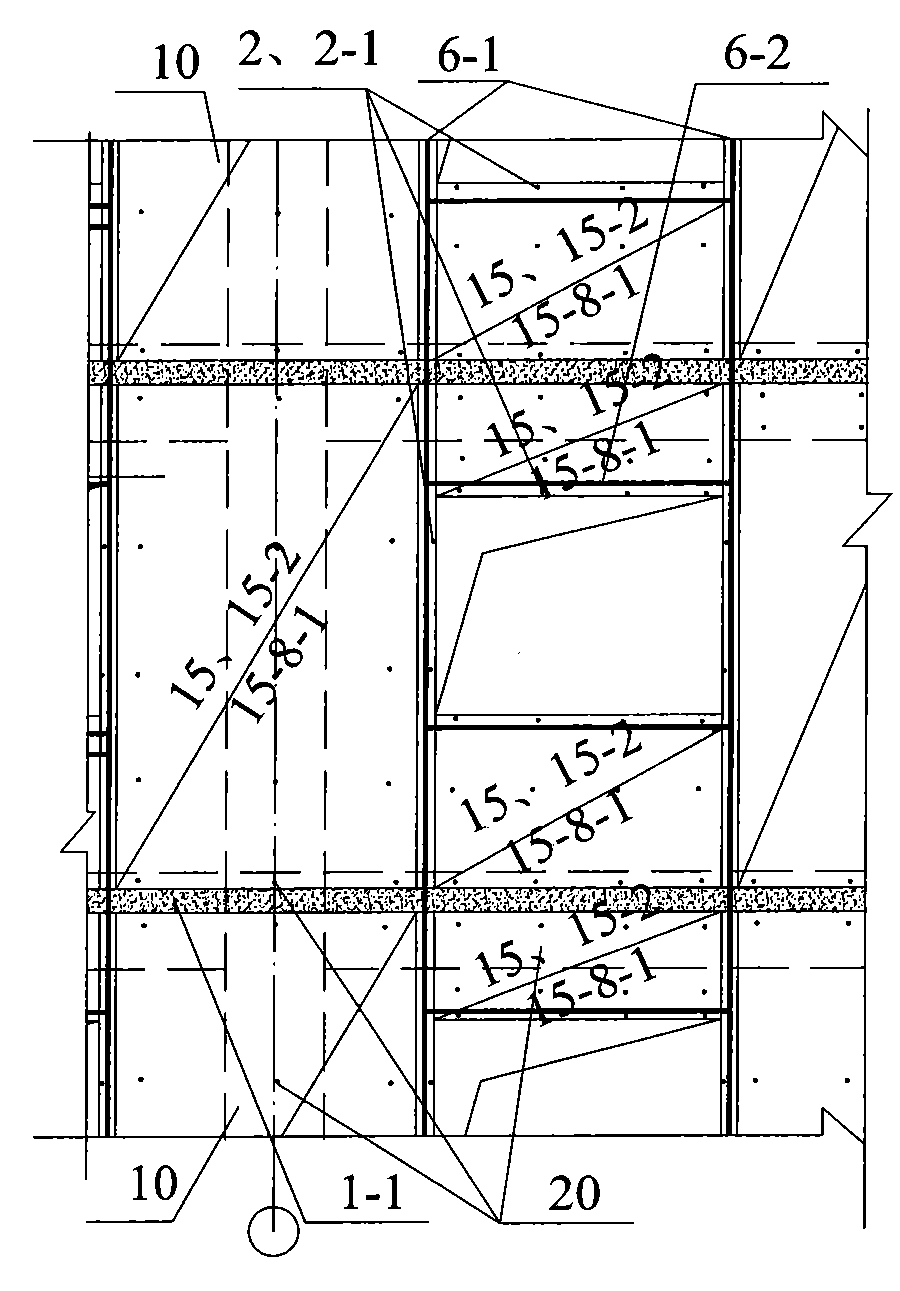

[0139] Implementation mode two: figure 1 , image 3 , Figure 4 , Figure 7 , the difference between this embodiment and Embodiment 1 is that this embodiment adds a structural support 1-1; the structural support 1-1 is arranged on the side of the main structure of the building in the base wall 10, and the structure The supporting part 1-1 is the extension of the main structure of the building in the base wall 10 in the horizontal direction.

[0140] The structural supporting part 1-1 supports the external protective layer 15-8-1, or supports the prefabricated thermal insulation board 15 composed of the external protective layer 15-8-1 and the thermal insulation layer 15-3; it mainly supports the wall between the windows and the external protective layer 15-8-1 and the prefabricated thermal insulation board 15 at the place without opening; The prefabricated thermal insulation board 15 of the lower wall can be squeezed and pasted together with the prefabricated thermal insu...

Embodiment approach 3

[0157] Implementation mode three: image 3 , Figure 4 , Figure 7 , Figure 8 , Figure 12 , Figure 13 , Figure 16 The difference between this embodiment and embodiment one or two is that this embodiment also adds an internal protective layer 15-8-2 inside the prefabricated thermal insulation board 15, and the internal protective layer 15-8-2 and the thermal insulation layer 15-3 connected to form a prefabricated thermal insulation wallboard 15-2; the inner protective layer 15-8-2 is a prefabricated protective layer;

[0158] The prefabricated protective layer is a prefabricated plate protective layer, or a prefabricated protective layer formed by plastering;

[0159] The prefabricated thermal insulation wall panels 15-2 of this embodiment can be prefabricated thermal insulation wall panels of various structures: including light prefabricated thermal insulation wall panels, heavy prefabricated thermal insulation wall panels, steel wire grid cement sandwich panels; ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com