Truss type large plate girder system for tower type boiler

A tower boiler and large slab beam technology, which is applied in industrial buildings and other directions, can solve the problems of large slab girder components, large amount of steel used for slab girder, difficulty in materials, fabrication, welding, transportation, installation, and debugging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

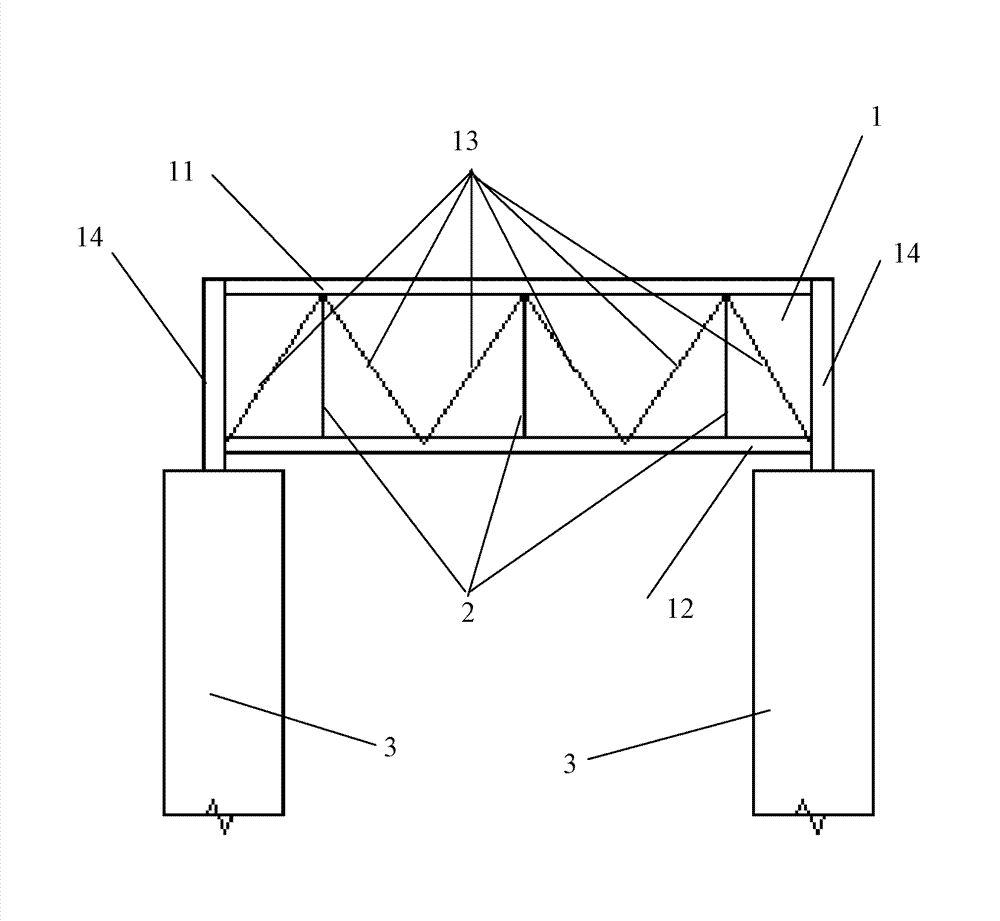

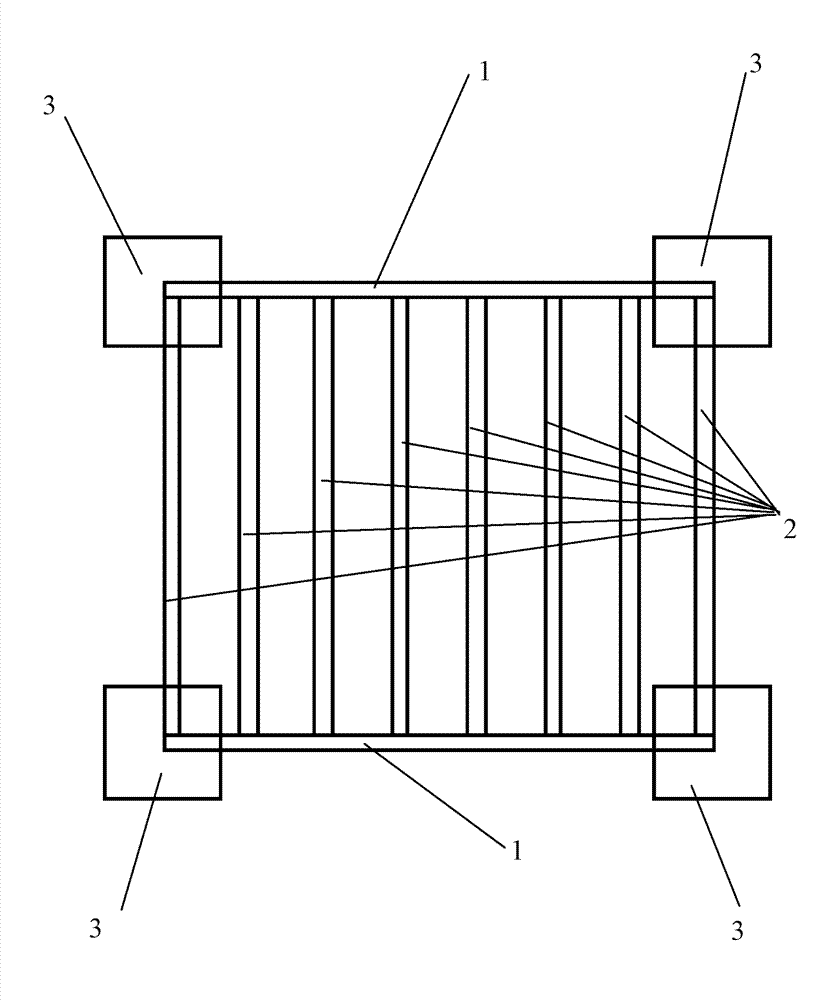

[0032] After long-term in-depth and extensive research, the inventor solved the problem of using a two-product box-shaped superimposed solid-web steel girder as the main girder and a solid-web steel girder as the secondary girder in the existing large plate girder system, which requires a large amount of steel and high welding quality requirements. , transportation difficulties and other defects. Improving the structure of the large plate girder system of the boiler can meet the stress requirements of the large plate girder system while reducing the total steel consumption of the large plate girder system. It has the advantages of good mechanical performance, good vertical rigidity, and convenient installation. The present invention has been accomplished on this basis.

[0033] Unless otherwise defined, all professional and scientific terms used herein have the same meanings as commonly understood by those skilled in the art. In addition, any methods and materials similar or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com