Metallic catalyst support with slit pore

A technology of catalyst carrier and porous metal, which is applied in the direction of catalyst carrier, physical/chemical process catalyst, chemical instrument and method, etc., can solve the problems of durability reduction, honeycomb body tearing, etc., and achieve the effect of improving durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1 will be described below.

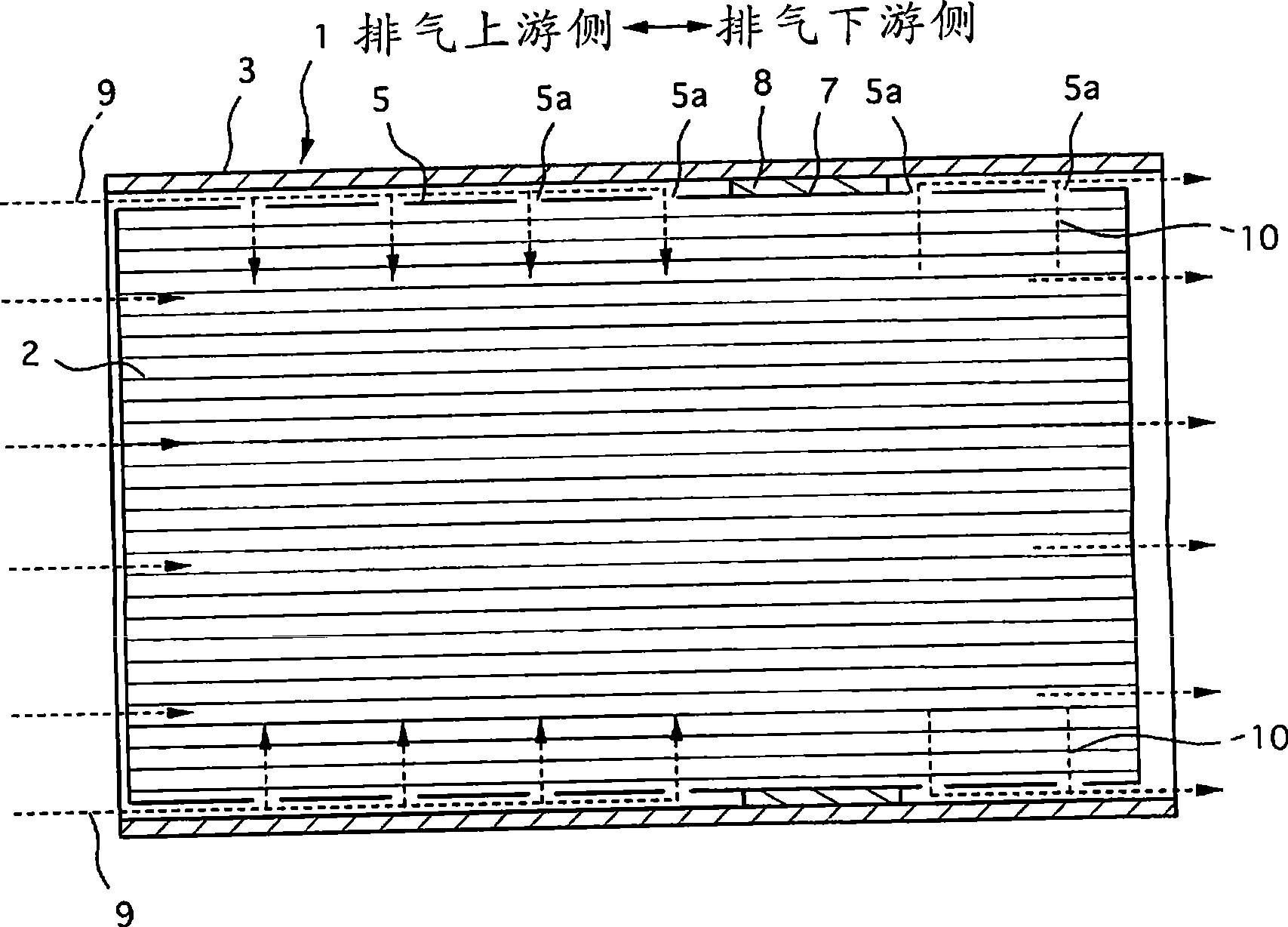

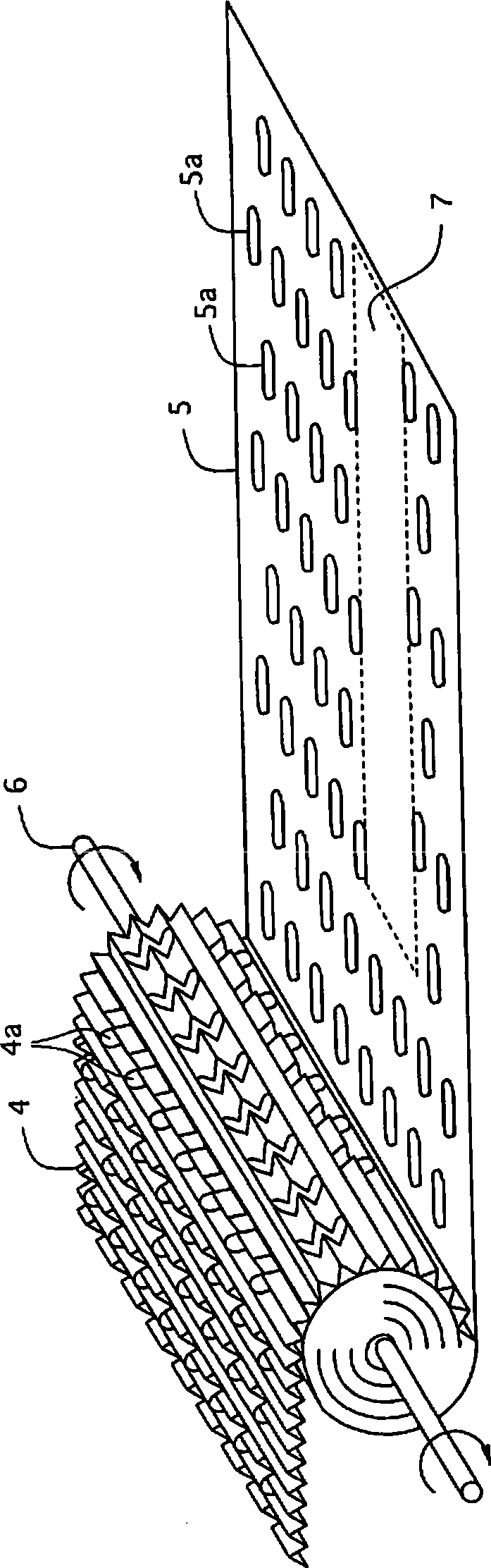

[0019] figure 1 is a side view of the metal catalyst carrier of Example 1, figure 2 is a side sectional view of the metal catalyst carrier, image 3 is a diagram illustrating the manufacture of the honeycomb body of Example 1, Figure 4 is a perspective view of the honeycomb body of Example 1, Figure 5 It is a perspective view of the honeycomb body of Example 1 in which foil-shaped brazing filler metal is provided.

[0020] First, the overall structure will be described.

[0021] Such as figure 1 , 2 As shown, the metal catalyst carrier 1 of Example 1 is composed of a metal cylindrical honeycomb body 2, a metal cylindrical outer cylinder 3 for accommodating the honeycomb body 2, and the like.

[0022] Such as image 3 As shown, the honeycomb body 2 is made by fixing the respective starting ends of the corrugated metal foil 4 and the flat metal foil 5 on the reel 6 of the winding machine, and then wrapping the two metal f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com